Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

132results about How to "No waste of water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for ecological breeding of crawfish in rice field

InactiveCN107047411AEasy plantingEasy to manageFood processingClimate change adaptationAdditive ingredientPrawn

The invention belongs to the technical field of aquaculture, in particular to a method for ecological breeding of crawfish in the rice field. The method for ecological breeding of crawfish in the rice field has the following beneficial effects: excavating groined field ditches after rice harvesting, arranging an anti-escape net and aeration equipment around the rice field to obtain an aquatic breeding farm for crawfish; scattering quicklime to disinfect and planting waterweeds to measure water temperature and throwing parent shrimps; throwing mixed feeds to the field ditches per day, scattering farmyard manures to the field ditches after breeding for some time and planting fresh water plants, marketing crawfish after growing up, finally, throwing young crawfish after transplanting seedlings of rice and throwing mixed feeds, completely catching adult crawfish before rice harvesting, and keeping crawfish that are not caught as seed crawfish in a pond for natural reproduction and carrying out rotation planting in a circular manner. The method for ecological breeding of crawfish in the rice field has the following beneficial effects: the method can be used for dual purposes in one field so that income is raised; meanwhile, artificial feed and medicament are not used so that nutritional ingredients of crawfish are improved; and no environmental contamination of aquatic water is caused.

Owner:刘滨

Intelligent irrigation system

InactiveCN107258485AMeet growth needsFertilize evenlyWatering devicesPressurised distribution of liquid fertiliserSubsurface irrigationWater storage tank

The invention provides an intelligent irrigation system. The intelligent irrigation system comprises a water storage tank, a medicament mixing tank, a fertilizer mixing tank, a spraying system and an underground irrigation system, wherein one path of passage is formed by the water storage tank, the medicament mixing tank and the spraying system; one path of passage is formed by the water storage tank, the fertilizer mixing tank and the underground irrigation system; the spraying system and the underground irrigation system are arranged respectively and can both be used for irrigating; when pesticide needs to be sprayed to crops, a medicament can be added into the medicament mixing tank and the pesticide is sprayed while irrigation is carried out through the spraying system; when fertilizer needs to be applied to the crops, the fertilizer can be added into the fertilizer mixing tank and the fertilizer can be applied while the irrigation is carried out through the underground irrigation system; uniform application of the pesticide and the fertilizer can be ensured; a humidity sensor is arranged and can be used for detecting moisture content of soil; and the irrigation can be carried out or stopped according to moisture content conditions, so that growth requirements of plants can be met, the yield is improved and water resources are not wasted.

Owner:佛山杰致信息科技有限公司

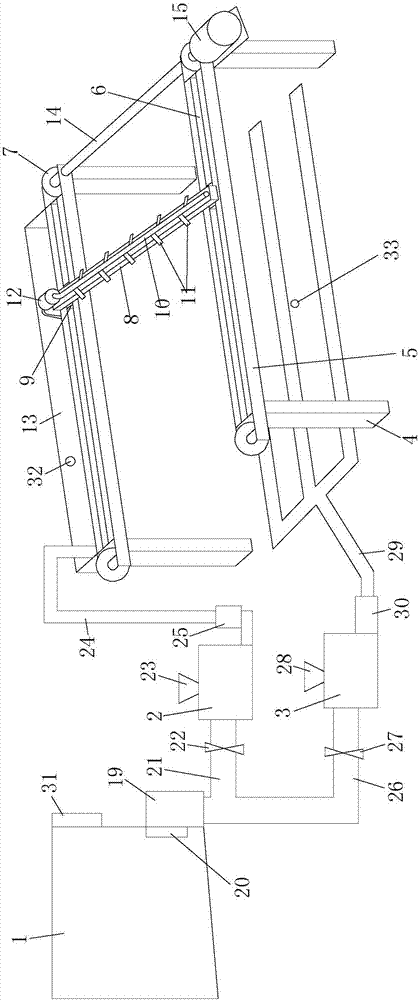

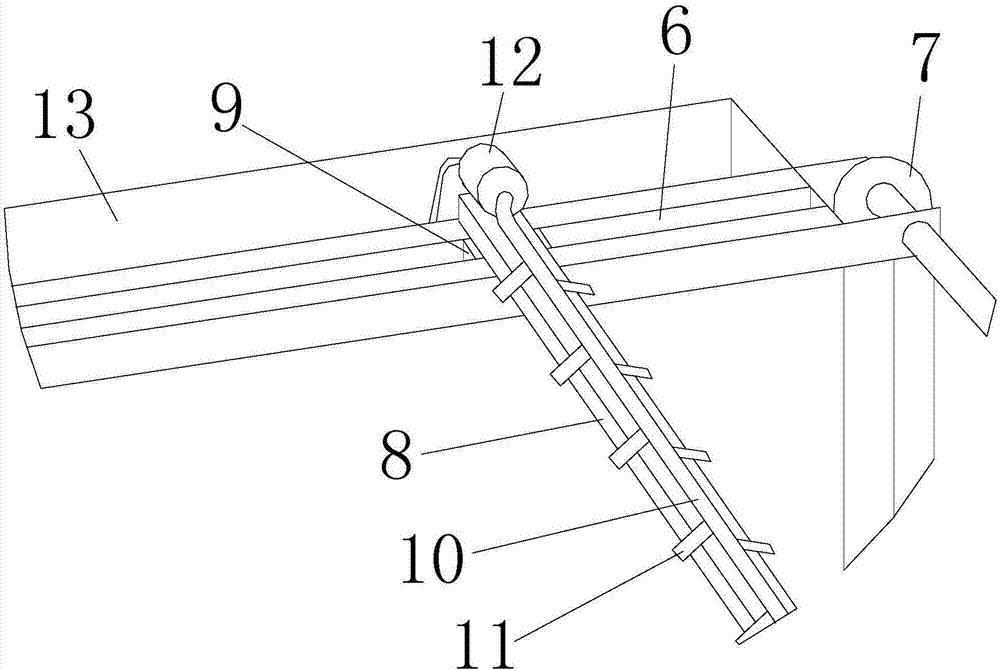

Automatic water feeding robot for trains

Provided is an automatic water feeding robot for trains. The movable end of a horizontal movement device is connected with one end of a first telescopic arm through a rotary shaft. A rotation driving device is arranged between the horizontal movement device and the first telescopic arm. The rotation driving device can drive the first telescopic arm to rotate around the rotary shaft. An adsorption device is arranged at the other end of the first telescopic arm, and the first telescopic arm is connected with the adsorption device through a traction device. The traction device can drive the adsorption device to move. A second telescopic arm is installed at the fixed end of the first telescopic arm. The first telescopic arm and the second telescopic arm are each internally provided with a telescopic drive device, and the telescopic drive devices can drive the first telescopic arm and the second telescopic arms to be telescopic correspondingly. According to the automatic water feeding robot for the trains, manual operation is not needed at all, water addition to the trains is wholly controlled through programs, the water addition speed is high, no water resource is wasted, the telescopic arms can determine the three-dimension space position through horizontal movement, rotation and telescoping, and the trains stopped on the two sides of a water feeding channel can both be fed with water automatically by installing the automatic water feeding robot on the water feeding channel of a station.

Owner:王雨坤

Learning writing brush cleaning device for students

The invention relates to a learning cleaning device for students, in particular to a learning writing brush cleaning device for students. The learning writing brush cleaning device for the students comprises a bottom plate, legs, a cleaning frame, a water outlet pipe, a valve, a water tank, a water pump, a water inlet pipe and the like. The legs are arranged on the top of the bottom plate, the cleaning frame is connected with the tops of the legs, the water outlet pipe is connected with the lower portion of the right side of the cleaning frame and is communicate with the inside of the cleaning frame, the valve is arranged on the water outlet pipe, and the water tank is mounted on the left side of the top of the bottom plate in a bolted connection mode. The learning writing brush cleaning device for the students has the advantages that the time and labor can be saved, a plurality of writing brushes can be simultaneously cleaned, and accordingly the learning writing brush cleaning device is high in efficiency; the quantity demand on water can be regulated by the aid of a water quantity regulating device according to the quantity of the writing brushes, and accordingly waste of water resources can be prevented; ink on the writing brushes can be quickly spilled out by the aid of fixing blocks mounted in the cleaning frame.

Owner:同码信息科技(常州)有限公司

Rainproof window for high-altitude building

ActiveCN110924807AAvoid inconvenienceShorten the timeWing fastenersPower-operated mechanismWater resourcesStructural engineering

The invention discloses a rainproof window for a high-altitude building. The rainproof window comprises a wall body, wherein a window frame is arranged on the wall body, a wind support is arranged onthe side wall of the window frame, an installation frame is fixedly connected to the side wall of the wind support, a glass window is fixedly connected to the inner wall of the installation frame, a switch mechanism is jointly arranged on the wall body and the window frame, the switch mechanism comprises a first sliding groove arranged in the side wall of the window frame, a first magnetic slidingblock is slidably arranged in the first sliding groove, the rotating part of the wind support is fixedly connected with the side wall of the first magnetic sliding block, a water pipe is arranged inthe wall body, both ends of the water pipe communicate with the outside, the side wall of the wall body is provided with a first water guide plate, the inner wall of the water pipe is fixedly connected with a spiral baffle, and a rotating shaft is rotatably inserted in the water pipe. The window can be automatically closed on rainy days, and the glass window can be automatically cleaned, so that time and energy of people are greatly saved, and water resources are not wasted.

Owner:绍兴盛坤机械科技有限公司

Pipelining emergent repairing method of prestressing steel cylinder concrete pipe

The invention relates to a pipelining emergent repairing method of an underground prestressing steel cylinder concrete pipe (hereinafter referred as to PCCP), in particular to an emergent repairing method for PCCP pipeling damaged by external force. According to the technical solution of the invention, a lining plate is arranged in the inner wall of a pipeline which corresponds to a damaged opening; a screw is arranged on the lining plate; a cover plate which covers the damaged opening is arranged on the external surface of the pipeline which corresponds to an exposed steel cylinder at the damaged opening; a rubber ring is arranged between the cover plate and the steel cylinder; the cover plate and the lining plate are mutually connected; a hollow cavity between the cover plate and the lining plate is filled with concrete; a steel plate which is connected with a sample plate is arranged above the cover plate; and the hollow cavities among the steel plate, the cover plate and a top plate are filled with fine stone concrete. The method can solve the problem that the usual repairing method takes much time, has great waste, high cost, etc.

Owner:无锡华毅管道有限公司

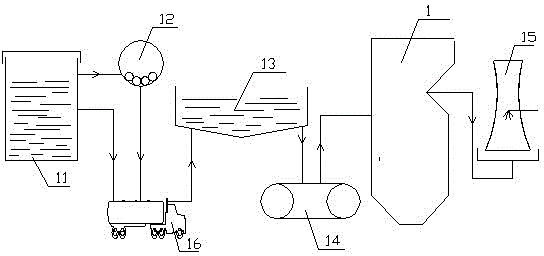

Sludge drying incineration system based on thermal power plant

ActiveCN104628237ALow costImprove operabilityCombination devicesSludge treatment by de-watering/drying/thickeningPollutantThermal power station

The invention discloses a sludge drying incineration system based on a thermal power plant. The system comprises a sludge drying system and a sludge mixing incineration system, wherein the sludge drying system comprises a heat supply system, a feeding system, a paddle type sludge dryer, a dead steam treating system, a dead steam recycling system and a dried sludge collecting and handling system; and the sludge mixing incineration system comprises a dried sludge mixing system and a dried sludge incineration system. According to the sludge drying incineration system based on the thermal power plant, sludge is dried through high-temperature steam produced by a boiler of the thermal power plant; the dried sludge is incinerated and the resulting heat is used for producing steam; the whole process is free of pollutant; therefore, an effective way is actually developed for recycling the wastes and treating wastes with the wastes, the social and environmental benefits are obvious, and a feasible way is provided for harmless handling, reducing handling and recycling of sludge.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Dry cleaning and screening method and equipment system for bauxite

InactiveCN105149071AAvoid stickingObvious sticking phenomenonSievingScreeningSeparation processEngineering

The invention provides a dry cleaning and screening method and equipment system for bauxite, belonging to the technical field of a mining and mineral separation process. The method comprises the following steps: drying the bauxite into dry ore, breaking and separating the dry ore into ore and muddy silt, screening and separating the ore and the muddy silt to remove the muddy silt, and thus obtaining net bauxite. The structure of the dry cleaning and screening equipment system for the bauxite is as follows: an ore hopper is connected with a bauxite feeding opening of a drying roller through a conveying belt, and a discharging opening of the drying roller is connected with a feeding opening of an ore-mud separator; a coarse ore discharging opening of the ore-mud separator is connected with a crusher, and a discharging opening of the crusher is connected to the feeding opening of the ore-mud separator through a conveying belt. The method can realize the separation of ore and mud without water washing, so that the water resource is not wasted, sewage is not generated, and facilities for sewage treatment and tailings maintenance and preservation are not needed. The mud after ore washing can be completely recycled.

Owner:德保县新德誉选矿有限公司

Industrial wastewater physicochemical treatment agent and application thereof

ActiveCN103896464AOvercome the chromaticity that exceeds the standard by a large marginHigh use valueMultistage water/sewage treatmentTreatment effectElectrolysis

The invention relates to an industrial wastewater physicochemical treatment agent and an application thereof. A physicochemical treatment material HB-F001, a physicochemical treatment oxidizing and adsorbing agent HB-F002 and a physicochemical treatment solid-liquid separating agent HB-F003 are applied to industrial wastewater treatment through stirring, adsorbing, reacting, separating, circulating and the like. The industrial wastewater physicochemical treatment agent solves the problems that the iron-carbon bed hardening subsequent treatment efficiency is low, electricity consumption is high, more materials are consumed and more solid wastes are generated during electrolysis, secondary pollution is caused by plenty of salt generated by repeatedly adjusting the Fenton treatment pH value, the application ranges of photocatalysis and ultrasonic waves are limited, ozone is high in electricity consumption and high in investment, ozone is generated unstably and the treatment effects are unstable, and solves the problems of high treatment cost of a wet oxidation process and safety. The industrial wastewater physicochemical treatment agent substantially increases the wastewater pollutant control and pollution factor removal rate, satisfies reuse water biochemical treatment conditions and treatment cost, is sustainable and stable, avoids secondary pollution, is low in cost, has quite high application values, and really achieves the effect of environmental protection.

Owner:NANJING HUHANG ENVIRONMENTAL PROTECTION

Instantaneous water heater

The invention relates to an instantaneous water heater. The instantaneous water heater comprises a water inlet pipe, a heating barrel, a water outlet pipe and a water outlet switch, wherein a one-wayvalve I is arranged on the water inlet pipe; the water outlet pipe is a coaxial two-channel water pipe and comprises an outer pipe and an inner pipe; the outer pipe is communicated with the heating barrel and the water outlet switch; one end of the inner pipe is a free end and stops at the water outlet switch; the other end of the inner pipe runs out of the outer pipe at the heating barrel to be connected with the water inlet pipe and the connection is located between the one-way valve I and the heating barrel; and a water pump and a one-way valve II are arranged on the pipeline, of the innerpipe, which is connected to the water outlet pipe and the water inlet pipe, and used for coordinately controlling water to flow back from the water outlet pipe to the water inlet pipe. When used, theinstantaneous water heater achieves the effect that when the water outlet switch is turned on, water flowing out is hot water, so that waiting is not needed and the water waste is reduced.

Owner:盐城市旺科电子技术有限公司

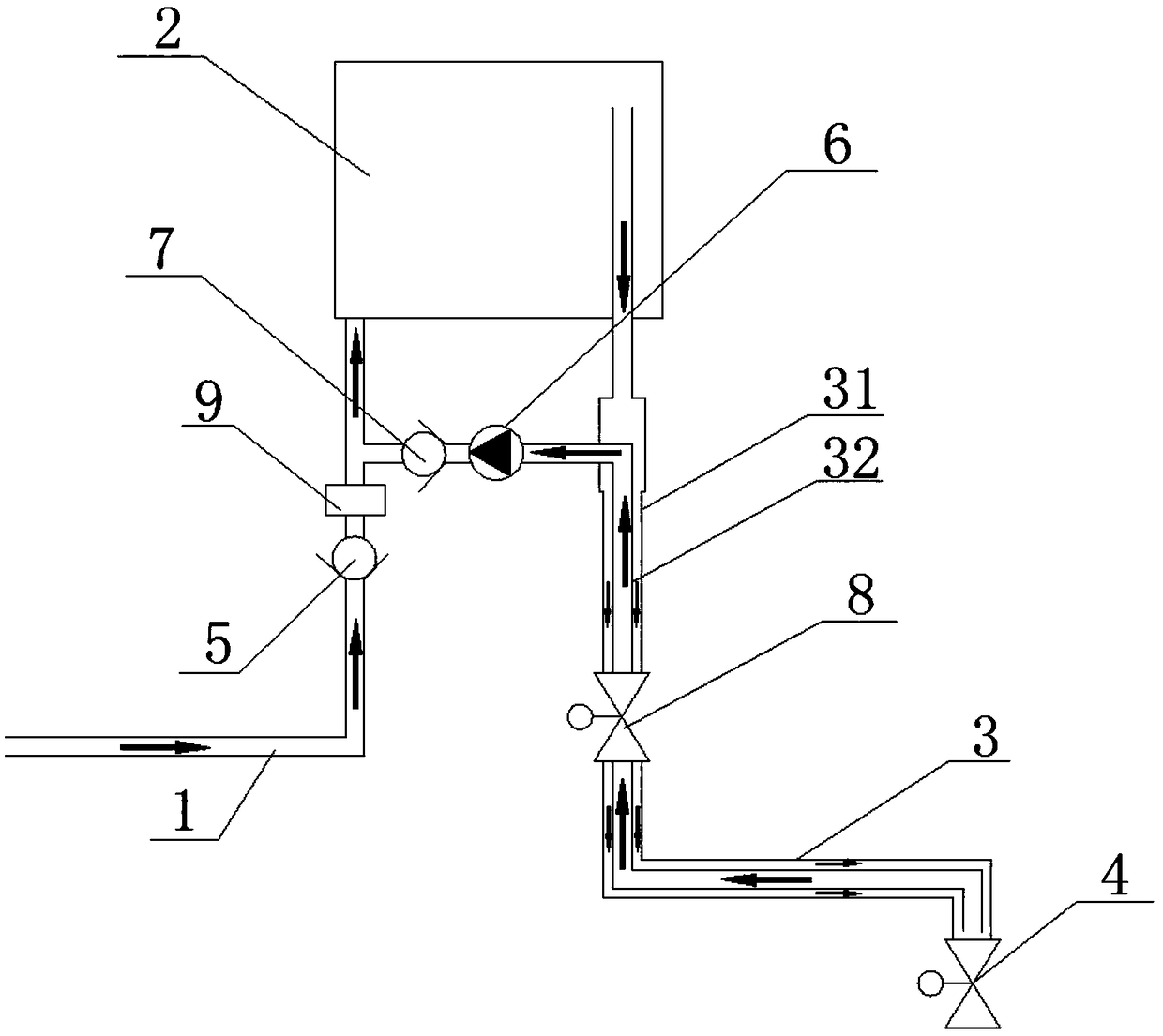

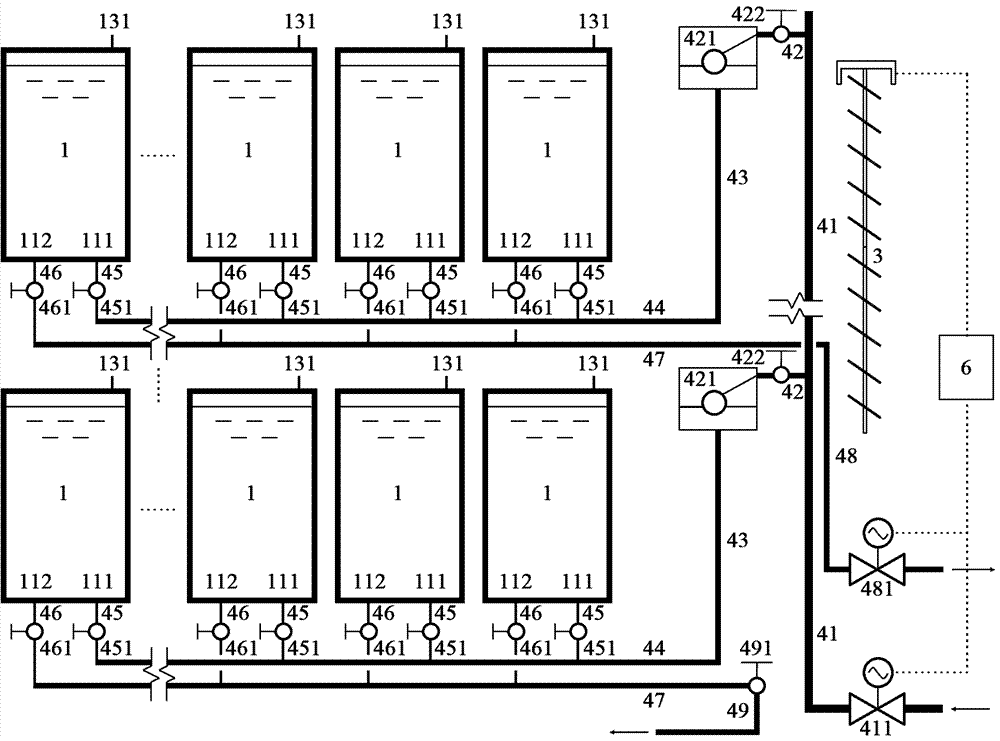

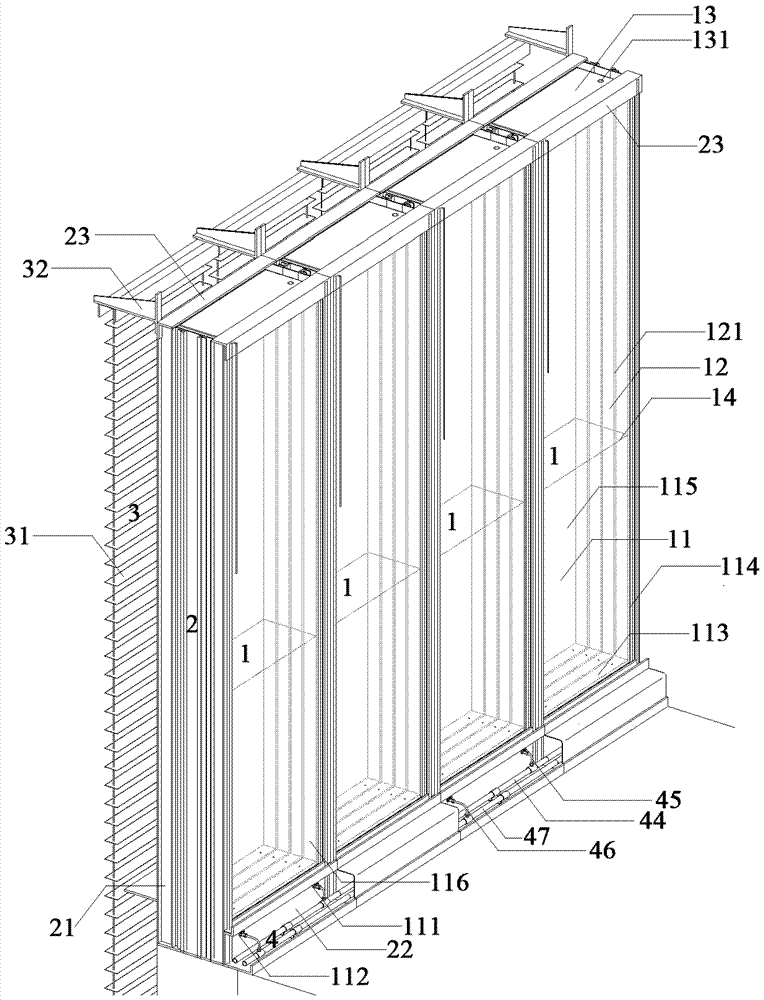

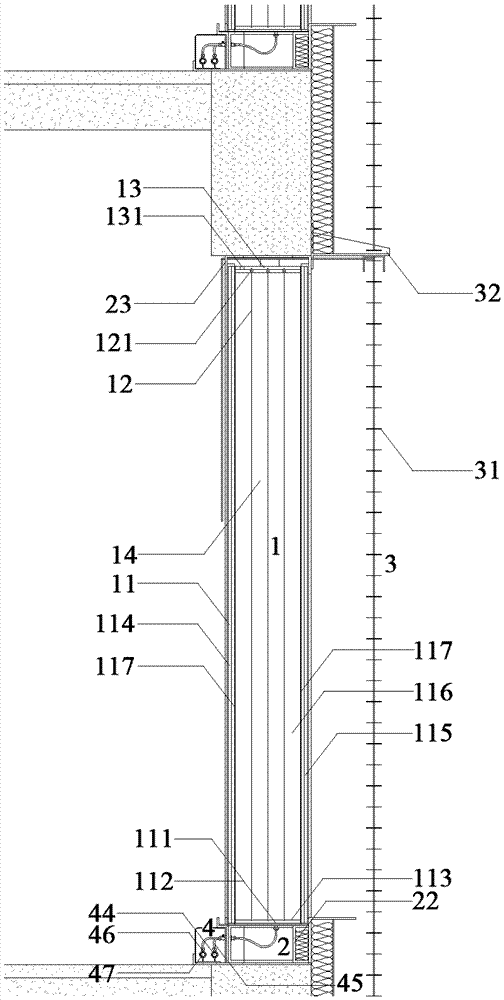

Climate adaptability transparent water storage enclosing structure for low-energy-consumption building and operation method

InactiveCN107476473AImprove thermal stabilityEfficient heat dissipationLighting and heating apparatusWallsWater storageAutomatic control

The invention provides a climate adaptability transparent water storage enclosing structure for a low-energy-consumption building and an operation method and relates to the technical field of building energy saving and building enclosing structures. According to the transparent water storage enclosing structure for the low-energy-consumption building, the problems that as for an current building with a plurality of transparent enclosing structures, the comfort in summer and winter is poor, and energy consumption is high are solved. The transparent water storage enclosing structure for the low-energy-consumption building comprises transparent water storage modules, supporting connecting frames of the transparent water storage modules, an adjustable shading device, a water system pipeline, an outer layer transparent enclosing structure and an automatic control system, wherein the adjustable shading device and the water system pipeline are arranged on the outdoor sides, and the outer layer transparent enclosing structure and the automatic control system can be additionally arranged. The climate adaptability transparent water storage enclosing structure is mainly characterized in that the transparent water storage modules are used for water filling, and thus the thermal inertia and thermal storage property of the enclosing structure are strengthened; a flow resisting layer is used for restraining convection to enhance the thermotechnical efficiency of the transparent water storage modules; meanwhile, relying on simple adjustment of the adjustable shading device in summer and winter, when stored water is overheated in summer, the water is discharged and heat is dissipated, and in the extreme low temperature in winter, the water is discharged to form an air layer for heat preservation; and through reusing of returned water generated by gravity self-flowing and natural daylighting, the indoor thermal comfort is kept, and building energy consumption is reduced.

Owner:刘向峰

Production process of environment-friendly cattle hide mattress

InactiveCN105316437AFeel comfortableGood elasticityTanning treatmentPre-tanning chemical treatmentContinuous useEnzyme

The invention discloses a production process of environment-friendly cattle hide mattress. The production process includes the following steps: primary tanning, finely cutting, shaping and drying, mill-softening, spray-scalding, cutting, splicing, quality inspection, and storage in storerooms to obtain a real leather mattress finish product. Compared with the prior art, the production process is safe and environment-friendly and is free of pollution. The prepared leather is free of heavy metal and formaldehyde and satisfies environment requirement. By means of a bio-enzyme preparation for degrading and dissolving materials, an aqueous solution for dissolving the materials can be recycled without water resource waste. The prepared leather has a good hand feel, is excellent in elasticity, smoothness and extensibility. The mattress is safe to use and is free of damage on human body.

Owner:YIBIN HAOYU LEATHER CO LTD

Water resource rationally utilized centralized dual water supply system

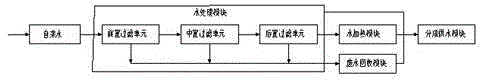

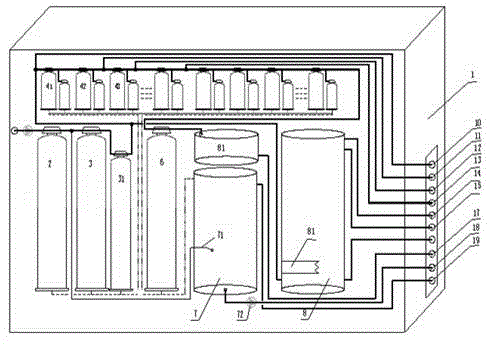

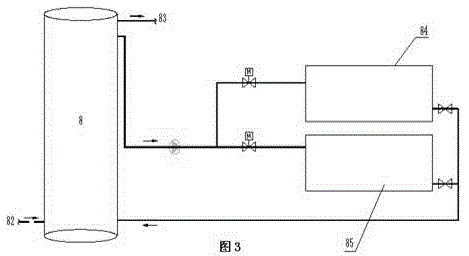

InactiveCN103603410AMeet the needs of healthy waterConserve waterGeneral water supply conservationIndustrial water supply conservationWater useTap water

Disclosed is a water resource rationally utilized centralized dual water supply system. A case is provided with a water treatment module and also provided with a waste water recycling module, a water heating module and a dual water supply module; the water treatment module is connected with the external tap water; the waste water recycling module is connected with the water treatment module; the dual water supply module is connected with the water treatment module. According to the water resource rationally utilized centralized dual water supply system, the filtering is performed with the tap water as the raw water, every treatment unit of the water treatment module is fully utilized to achieve the dual water supply of families, the waste water recycling module is utilized to achieve the recycling of the waste water, and accordingly the rational utilization of every drop of water is achieved.

Owner:广东汉子电器有限公司

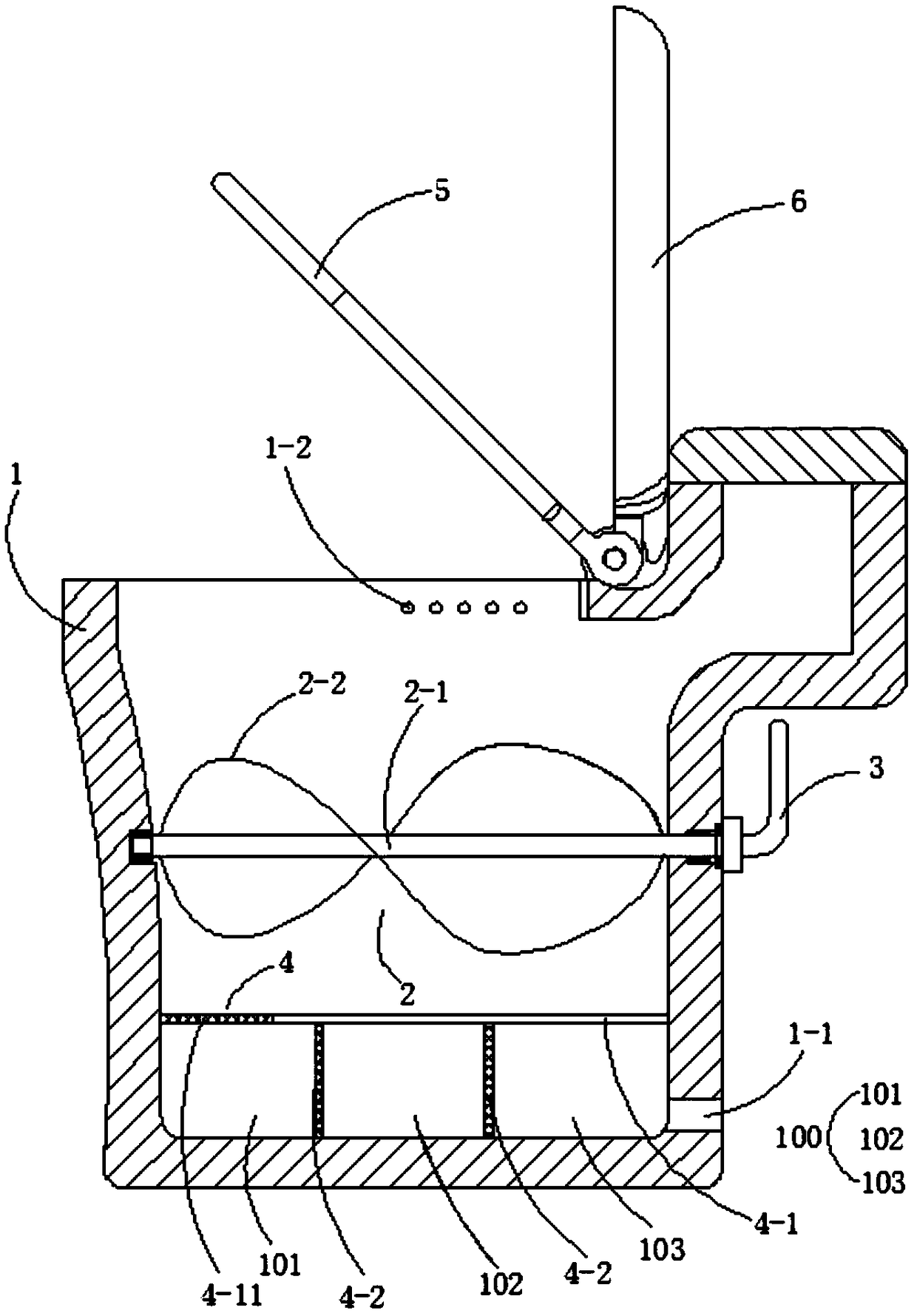

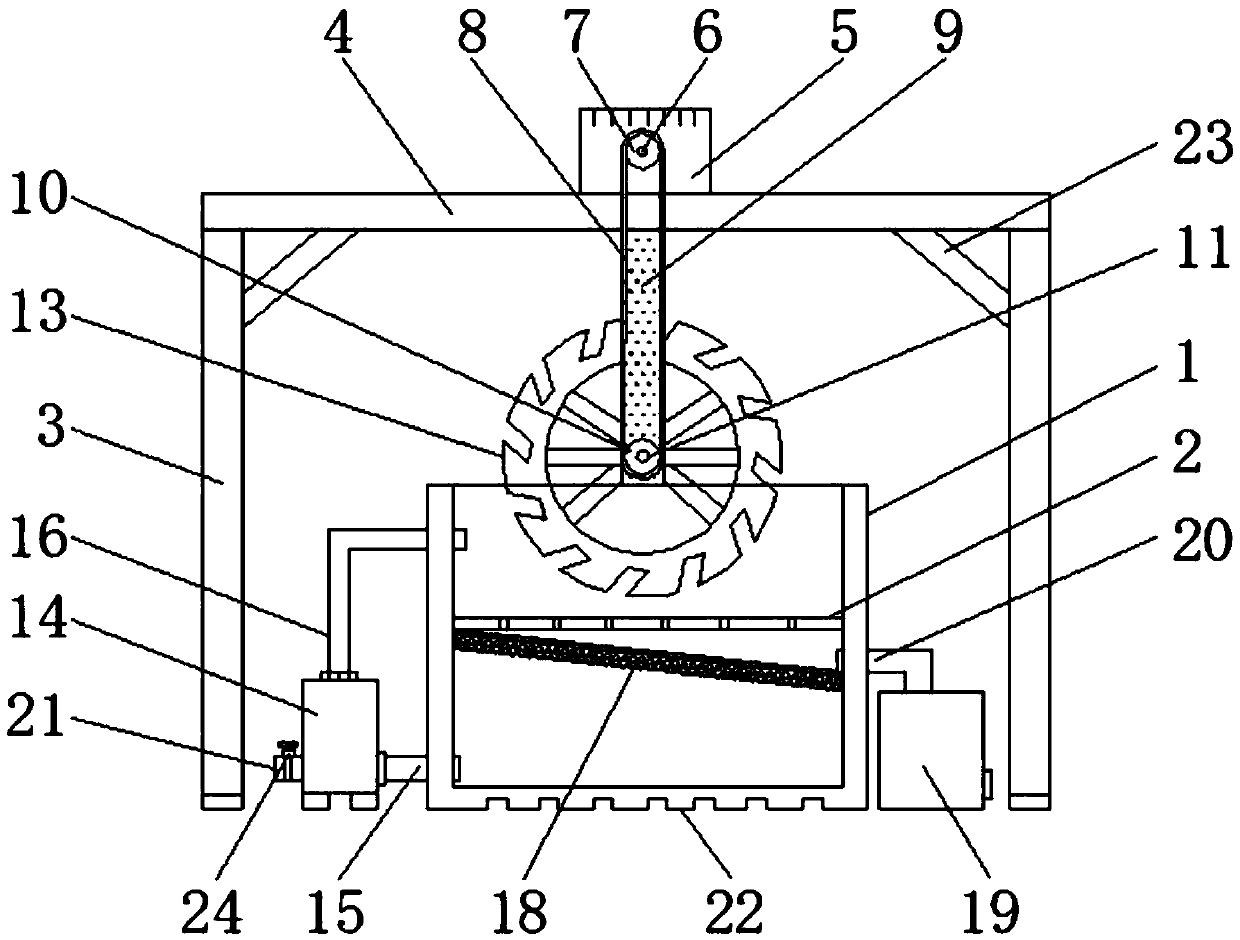

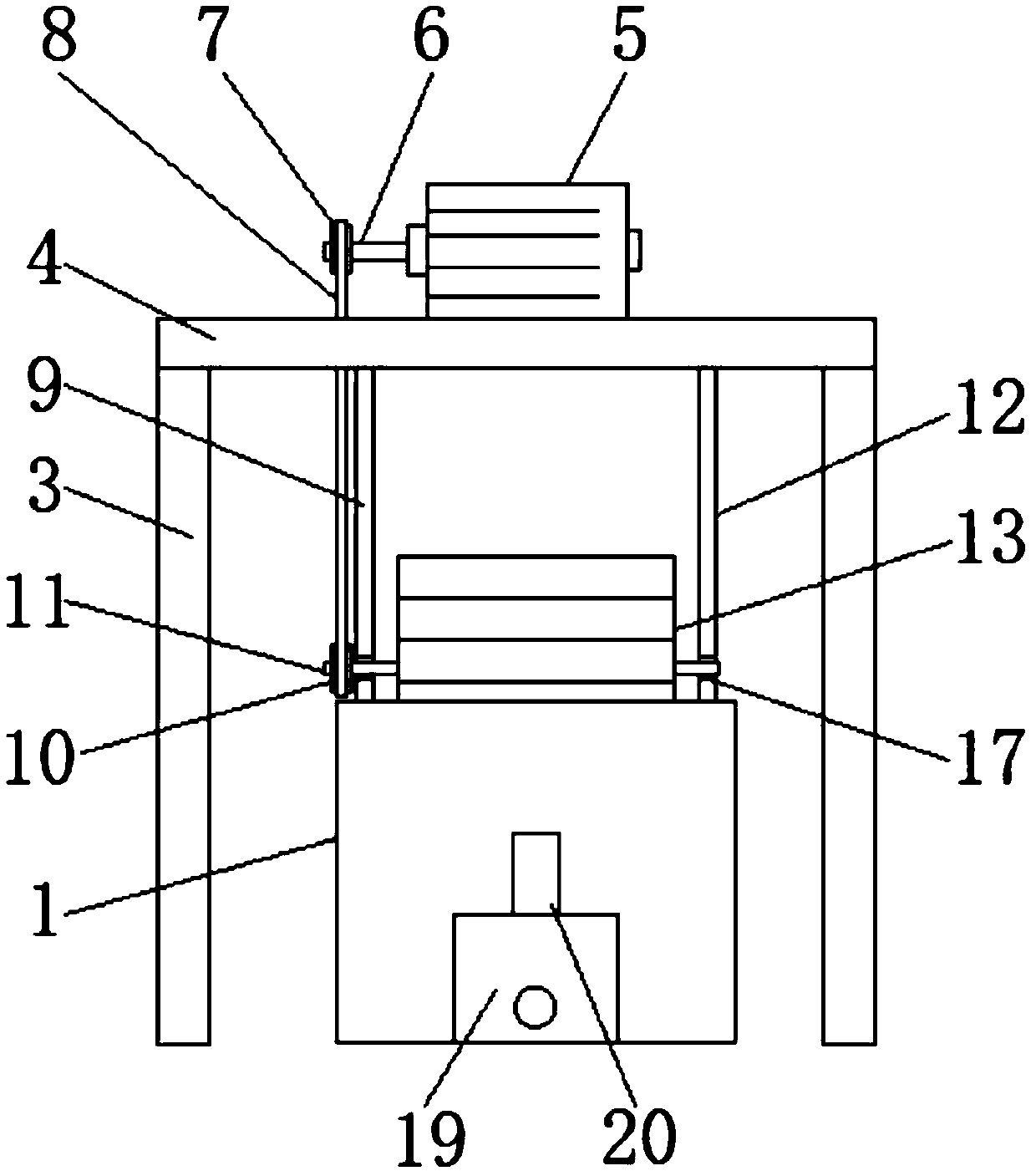

Flushing-free manure water separated biodegradable bio-toilet

PendingCN108729519AStir wellSolve the problem of difficult toiletTreatment involving filtrationBathroom coversFecesToilet

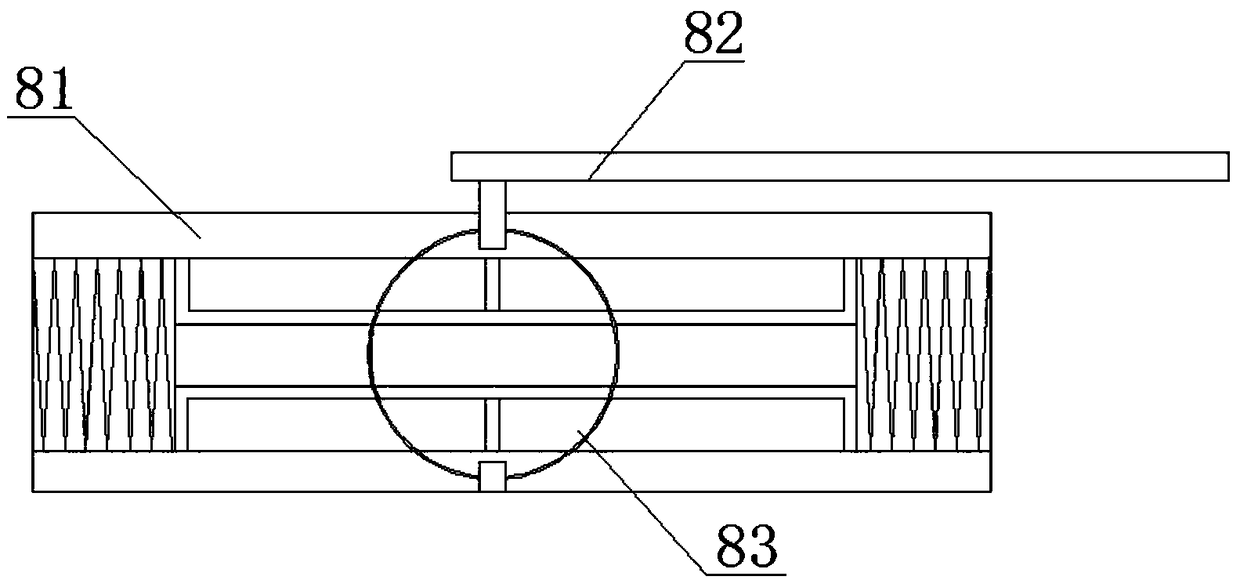

The invention relates to a flushing-free manure water separated biodegradable bio-toilet. The bio-toilet comprises a tank body, a stirring device, a driving device and a filtering device, wherein thestirring device is arranged in the tank body; the driving device is arranged on the outer side wall of the tank body and connected with the stirring device; the filtering device comprises a partitionplate and a filter layer; the partition plate is positioned below the stirring device and transversely detachably connected onto the inner side wall of the tank body; a straight slot is formed in thepartition plate; a filtering net is arranged at the straight slot on the partition plate; the partition plate and the bottom of the tank body are encircled into a containing cavity; the filter layer is vertically arranged in the containing cavity; a water outlet is formed in the containing cavity on the tank body. The stirring device is driven to rotate by adopting an electric manner and a manualmanner, so that various requirements of users are met. Manure inside the tank body is fully stirrer by utilizing a stirring head of an 8 shape, an S shape or a spiral structure, so that the manure isuniformly fermented and degraded. Urine is filtered and discharged by the filtering device.

Owner:QINGDAO DINGLI ECOLOGICAL AGRI TECH DEV CO LTD

Low-energy-consumption hot ore crushing device

The invention relates to a low-energy-consumption hot ore crushing device. The low-energy-consumption hot ore crushing device comprises a preparation cavity, a heating cavity, a crushing cavity, a grinding cavity and a conveying cavity. Through the overall design and transformation on the aspects of circulating water cooling and waste heat utilization and reasonable arrangement of the crushing cavity, the preparation cavity and the grinding cavity, the environmental friendliness of the production environment is greatly improved, the overall energy consumption is effectively reduced, and the production efficiency is improved.

Owner:北京安康科创节能环保科技有限公司 +1

Bridge bearing grouting material and preparation method thereof

InactiveCN108164231AAchieving self-compacting propertiesHas self-compacting propertiesAcid waterWater reducer

The invention discloses a bridge bearing grouting material and a preparation method thereof, and belongs to the technical field of building materials. The grouting material comprises the following materials: 350-500 parts of a cementing material, 500-800 parts of fine aggregates, 20-60 parts of an expanding agent, 50-110 parts of fly ash and 7-25 parts of admixtures, wherein the cementing materialis a mixture of sulphoaluminate and ordinary Portland cement at a mixing mass ratio of 5: (3-1); the fine aggregates are quartz sand, wherein the particle size of the quartz sand is 0.1-4 mm; and theadmixtures comprise at least a water reducing agent and an early strength agent, wherein the water reducing agent is a polycarboxylic acid water reducing agent. The grouting material provided by theinvention has advantages of fast hardening and high strength.

Owner:湖北恒利建材科技有限公司

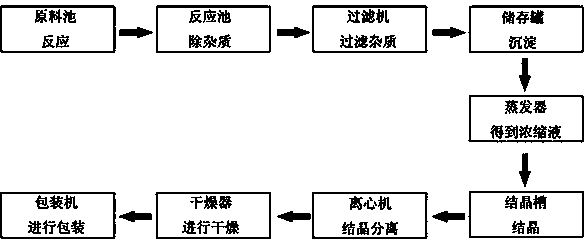

Process for preparing zinc sulfate

The invention provides a process for preparing zinc sulfate and the process is simple in step, low in energy consumption, high in production efficiency and high in product purity. The process comprises the following steps: putting secondary zinc oxide and zinc oxide in waste residues produced in zinc preparation in a raw material tank filled with dilute sulfuric acid, reacting to generate a zinc sulfate solution, guiding the zinc sulfate solution into a reaction tank, removing impurities such as iron, cobalt and copper in the reaction tank, filtering the impurities through a filtering machine, guiding the zinc sulfate solution into a storage tank for precipitation, evaporating the zinc sulfate solution in an evaporator to obtain a concentrated solution, crystallizing in a crystallizing tank, carrying out crystal separation in a centrifugal machine, cooling to obtain zinc sulfate containing crystal water and drying in a dryer to obtain the zinc sulfate. According to the process, the zinc sulfate solution is concentrated in the way of pouring hot oil and circularly heating, so that the heating temperature is higher, the heating material can be recycled, the energy consumption is little and the cost is reduced. The process for preparing the zinc sulfate is simple and clear in processing step, energy-saving, friendly to the environment and convenient to operate.

Owner:TIANJIN XINXIN CHEM FACTORY

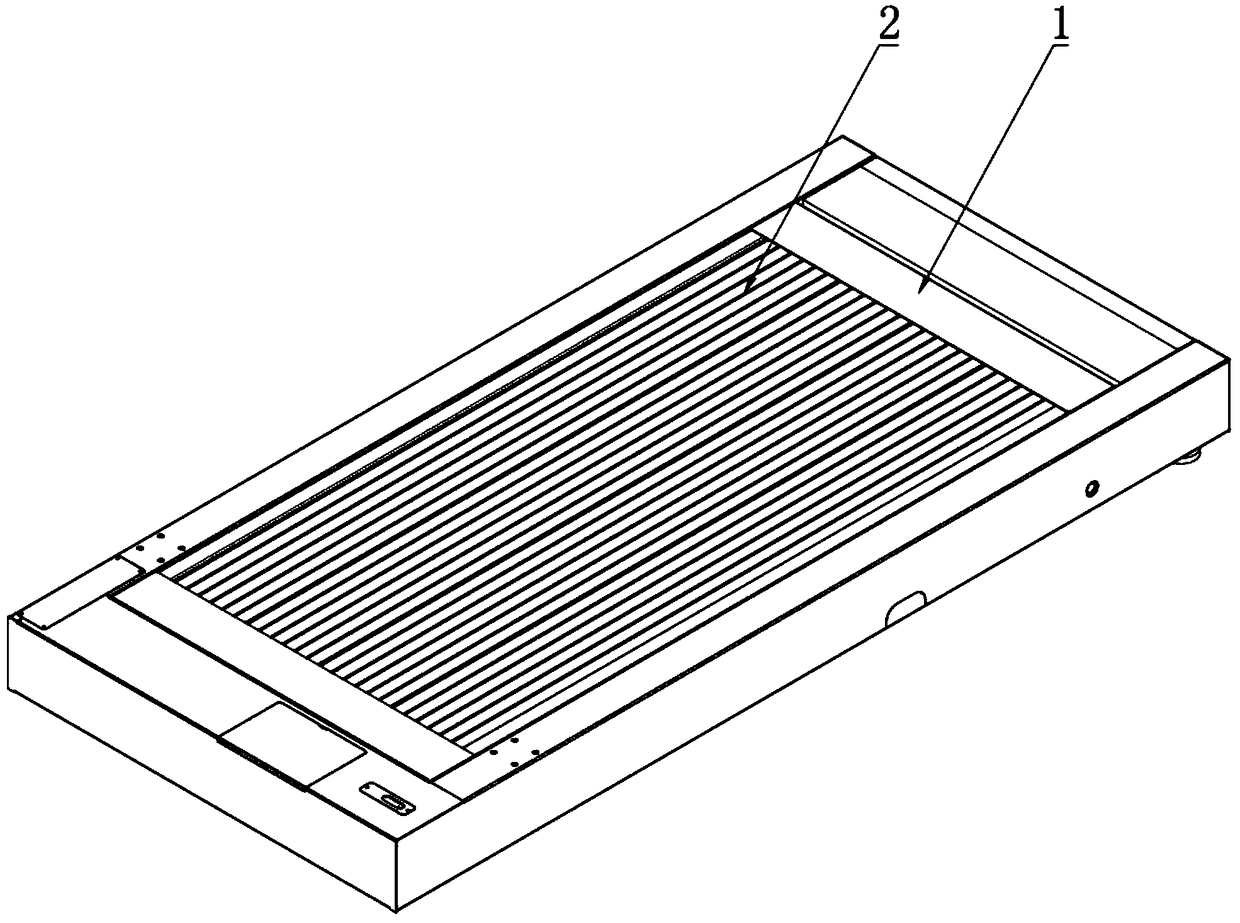

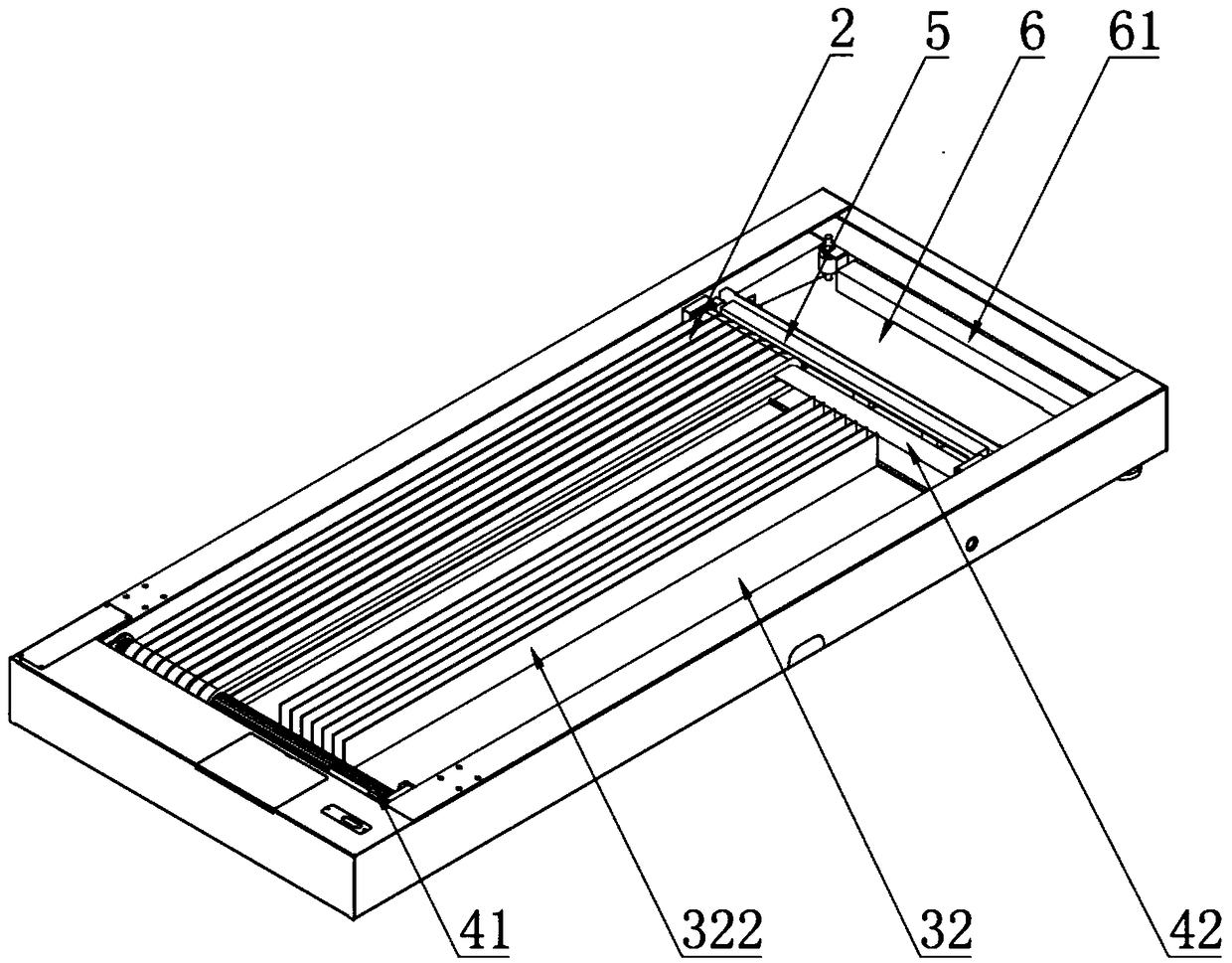

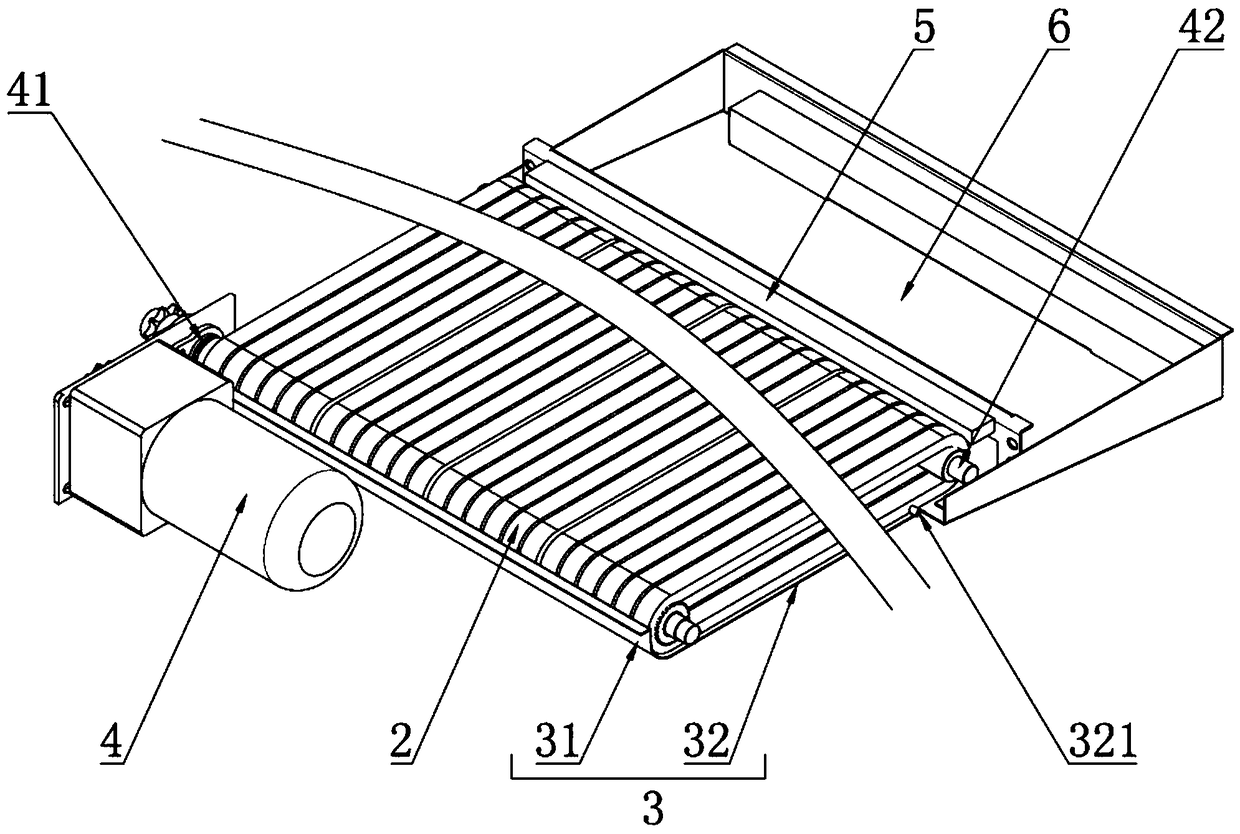

Folding clothes dryer

PendingCN111851018ASmall footprintEasy to replaceTextiles and paperLaundry driersWater circulationStructural engineering

Owner:李国文

Environment-friendly fur tanning method

InactiveCN103320551AFeel comfortableIncrease elasticityTanning treatmentPre-tanning chemical treatmentFood gradeWater resources

The invention belongs to the field of processing of fur, and discloses an environment-friendly fur tanning method. The method comprises the following steps of: soaking the fur, degreasing, pickling, tanning, neutralizing, drying, kicking oil and softening. The materials adopted by the method are in food grade, safe and environment-friendly, and free of pollution; and the prepared fur does not contain heavy metals and formaldehyde, and accords with the environment-friendly requirements. A chemical material is degraded by a biological enzyme preparation, so that the solution of the chemical material and water is continuously used; water resource is not wasted; and the fur prepared by the method is thin and soft, and comfortable in hand handle, and has good elasticity, smoothness and extensibility.

Owner:GUCHENG DAHUA HAOYE FUR TANNAGE

Cooling energy-saving device for evaporative condenser in refrigeration and air-conditioning system

InactiveCN102322711ANo pollution in the processSimple structureDomestic cooling apparatusEvaporators/condensersWater storageHigh energy

The invention discloses a cooling energy-saving device for an evaporative condenser in a refrigeration and air-conditioning system, which belongs to the technical field of refrigeration and air-conditioning devices and aims at solving the problems of poor condensing effect, high energy consumption and water resource waste of the existing evaporative condenser in the refrigeration and air-conditioning system. The cooling energy-saving device is provided with an evaporative condenser, a cooling coil pipe, a water pump, a water source well water conveying pipe, a recharge well water conveying pipe, water valves, a water source well and a recharge well, wherein the water source well and the recharge well are respectively connected with the water conveying pipes, the water pump is arranged on the water source well conveying pipe, the water valves respectively arranged on the water source well water conveying pipe and the recharge well water conveying pipe are connected with the water inlet end and the water outlet end of the cooling coil pipe, and the cooling coil pipe is arranged in the water storage groove of the evaporative condenser. The structure is simple and practical, and the cooling energy-saving device is applicable to various kinds of evaporative condensers.

Owner:强福悦

Automatic switchover integrated type outer-door-free air conditioner having double-cold-source refrigeration function

ActiveCN103542477AHigh energy efficiency ratio of cooling workEasy to installSpace heating and ventilation safety systemsLighting and heating apparatusControl engineeringHigh pressure

The invention discloses an automotive switchover integrated type outer-door-free air conditioner having a double-cold-source refrigeration function. A pumping pipe is arranged on a right bottom side of a machine body; a water pump is arranged on a left side of the pumping pipe; a water inlet pipe is arranged at the upper end of the water pump; a water fluorine double-evaporator is arranged on the upper end of the water inlet pipe; a suction ventilator is arranged on the left side of the water fluorine double-evaporator; a compressor is arranged on the left side of the water pump; a condenser is arranged on the inner side of the compressor; a high pressure pipe is arranged at the upper end of the compressor; the inner end of the high pressure pipe is connected to an air inlet of the condenser; a low pressure air returning pipe is arranged at the left end of the compressor; the upper end of the low pressure air returning pipe is connected to a connecting opening of the water fluorine double-evaporator; a filter is arranged at the right upper end of the condenser; a capillary pipe is arranged at the upper end of the filter; the upper end of the capillary pipe is connected to the connecting opening of the condenser; a cool air outlet is formed in the upper end of the machine body; a cabinet door is arranged at the front end of the machine body; a display screen is arranged on the upper end of the cabinet door.

Owner:临泉县少华制冷设备有限公司

Adjustable dish-washing machine bracket

PendingCN107582005AAvoid damageWash thoroughlyTableware washing/rinsing machine detailsEngineeringMechanical engineering

The invention discloses an adjustable dish-washing machine bracket which comprises a baffle, a fixing rod and a limiting rod, wherein the interior of the fixing rod is connected with a sliding rod through a chute in a sliding manner; the interior of the sliding rod is connected with the baffle through the chute in a sliding manner; a water outlet is formed inside the baffle; one side of the wateroutlet is connected with a water pipe through a hose; a handle is arranged on one side of the sliding rod; the top of the fixing rod is connected with the limiting rod through a connecting rod. According to the adjustable dish-washing machine bracket disclosed by the invention, a fixing ring is arranged on the outer part of the limiting rod in a sleeving manner, and one side of the fixing ring isrotationally connected with a limiting block used for fixing the baffle, so that a user can perform adjustment according to sizes of bowls while placing the bowls and dishes, and the bowls are fixed by the limiting block. Therefore, the arrangement can be applied to bowls of different sizes, and tableware can be fixed and is prevented from toppling and falling to be damaged due to an extremely high water pressure.

Owner:KEPURUITIANJIN KITCHEN EQUIP CO LTD

Improved ultra-high pressure stopped foot pedal control valve

InactiveCN101424359ANo waste of waterImprove sealingOperating means/releasing devices for valvesFluid-delivery valvesUltra high pressureWater resources

The invention provides an improved ultrahigh pressure cutoff foot control valve, which is well sealed, saves labor in treading, saves water resources because water returns back to a water tank through a water return hole when a treadle is loosened, and has a wide use range. The improved ultrahigh pressure cutoff foot control valve comprises a bottom plate, a protecting hood, the treadle, a valve body, a liquid outlet and a liquid inlet, wherein the front of the bottom plate is provided with the valve body; the treadle is arranged on the valve body through two cylindrical pins; the protecting hood covers the outside of the treadle and is arranged on the bottom plate; and a valve core is arranged inside the valve body. The improved ultrahigh pressure cutoff foot control valve is characterized in that one end of the treadle facing to the valve core is provided with a controlling device; an inner cavity of the valve body is provided with a guide sleeve and a valve seat in turn; the valve core is sleeved on the inner walls of the guide sleeve and the valve seat; the valve seat is compressed and fixed on the valve body by a threaded sleeve; and a spring on the other end of the valve core is connected with the inner wall of the threaded sleeve.

Owner:无锡威顺煤矿机械有限公司

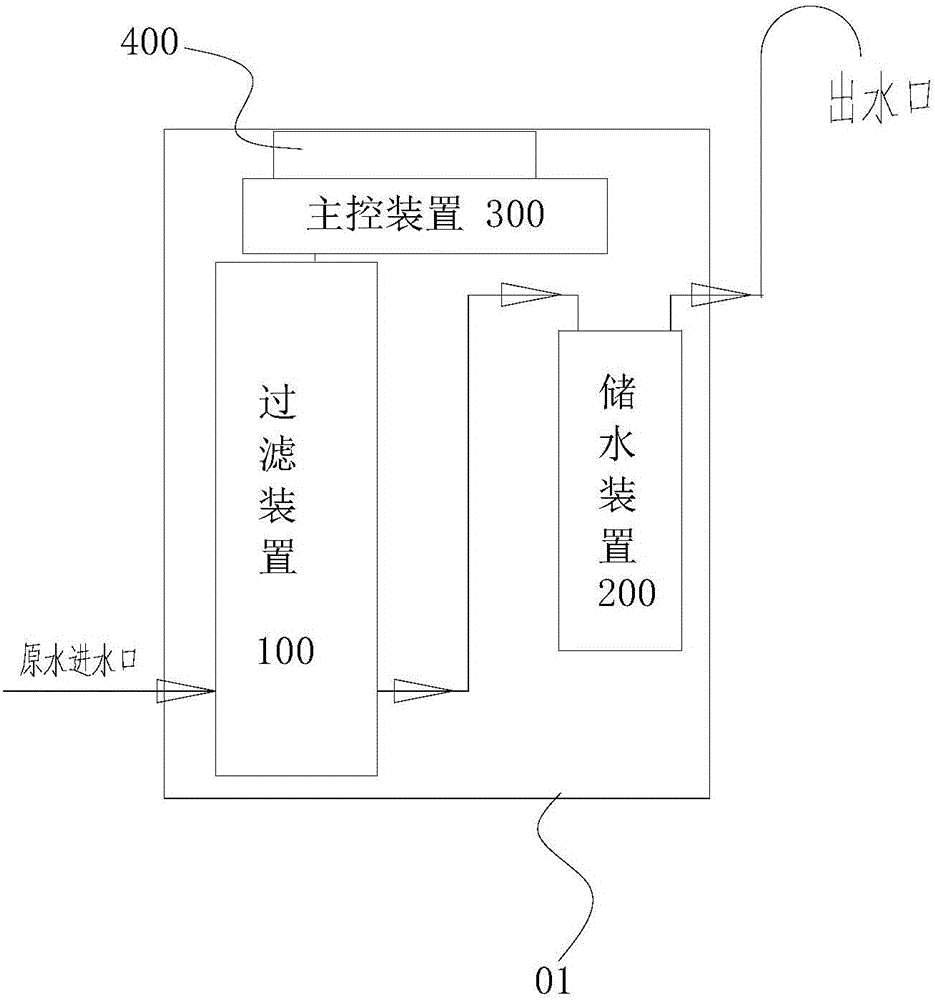

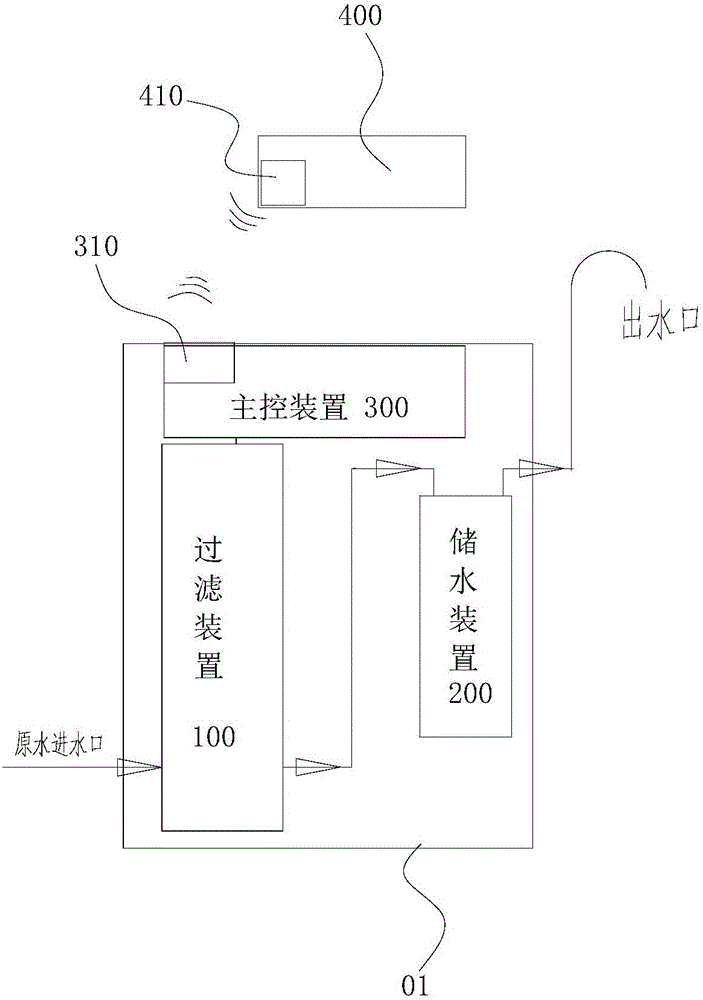

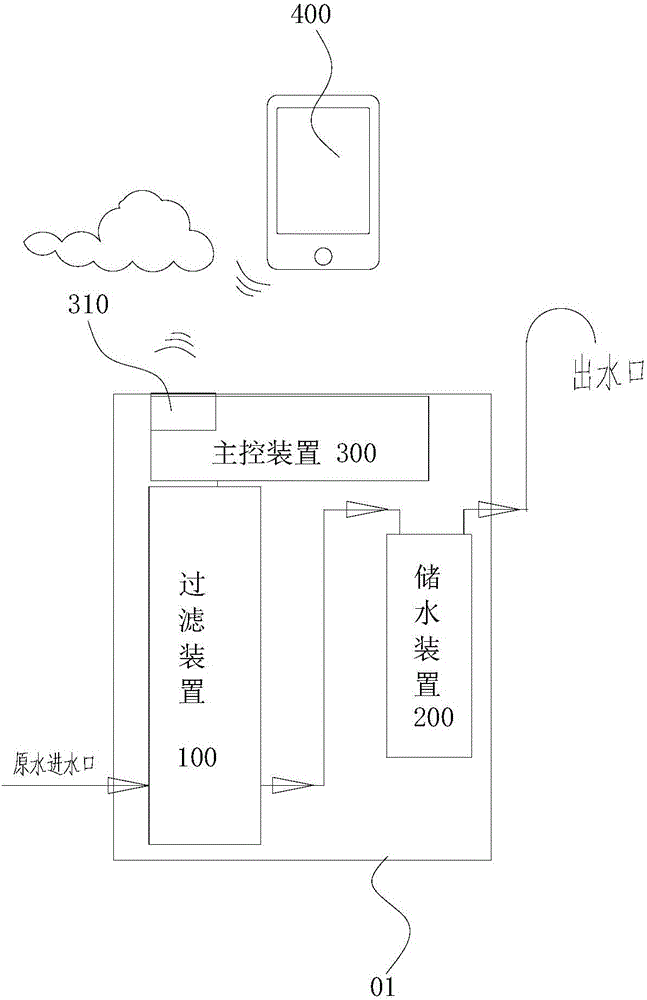

Water production controllable water purification equipment

PendingCN106006794AFresh waterNo waste of waterTreatment involving filtrationTreatment control/steeringRaw waterProduced water

The invention relates to the technical field of water purification, in particular to water production controllable water purification equipment, which is provided with a body, a filtering device, a master control device and a user interface device, wherein the filtering device and the master control device are arranged on the body respectively; the filtering device is used for filtering raw water to obtain purified water; the master control device is in signal connection with the user interface device; the user interface device is used for setting daily water consumption information and sending the daily water consumption information to the master control device; the master control device is used for controlling the water production of the filtering device according to the received daily water consumption information; the water consumption information set by the user interface device is a daily consumption person number and / or daily water production; the user interface device is arranged on the body, or is of a split structure. According to the production controllable water purification equipment, the water production can be controlled according to the number of consumption persons, the produced water is fresh, and waste is avoided.

Owner:GUANGDONG LIZI TECH CO LTD

Straw slices purifying machine

InactiveCN1730158AImprove puritySimple structureWet separationWater resourcesEnvironmental engineering

The invention discloses a de-burring machine used to process weed, which is characterized in water tank containing water in it, debonding unit locating at the rear of water tank to separate water with weed, capitation locating under the debonding unit, weed gathering device collecting weed from debonding unit, said capitation connecting with water tank via pipes, and circulating pump being equipped on said pipes to transport water in capitation to water tank. The invention makes use of buoyant force of water and gravity to separate weed and impurity. The invention has the advantages of simple structure, saving water and improving purity of the forage fodder.

Owner:李风宁

Crawler-type sole cleaning machine

The invention discloses a crawler-type sole cleaning machine. The machine comprises a machine body, multiple continuous tracks, a self-cleaning plate and a cleaning pipe. A driving mechanism, the self-cleaning plate, the cleaning pipe and the continuous tracks are arranged in the machine body; the continuous tracks are provided with hairbrushes for cleaning soles; the continuous tracks are embedded in the machine body and driven by the driving mechanism to rotate circularly; the self-cleaning plate is arranged below the continuous tracks and wraps the cleaning initial ends and lower portions of the continuous tracks, and the hairbrushes of the continuous tracks abut against the self-cleaning plate; the cleaning pipe is arranged at the cleaning tail end and sprays water to the continuous tracks and the hairbrushes of the continuous tracks. According to the crawler-type sole cleaning machine, the self-cleaning plate is further arranged below the continuous tracks and covers and shields partial continuous tracks, and the hairbrushes of the continuous tracks abut against the self-cleaning plate. In the extrusion process, the deformed hairbrushes can shake out dust and the like, the elasticity of the hairbrushes can be restored at last, and cleaning work continues. Through the cleanliness of the hairbrushes, the cleanliness of sole cleaning is guaranteed, and cleaning is efficient.

Owner:惠州市柯林沃德科技有限公司

Self-cleaning dog cage and implementing method thereof

The invention discloses a self-cleaning dog cage and implementing method thereof, and comprises a dog cage with a manure treatment device located at the lower portion. The manure treatment device comprises cleaning water pipes and a sewage treatment trough. The sewage treatment trough is connected with the bottom of the dog cage through an elastic connection part. One end of the sewage treatment trough is provided with a discharge hole. The cleaning water pipes are fixed to four sides of sewage the treatment trough. Water discharge holes are formed at the sides of the cleaning water pipes, which faces the sewage treatment trough. The cleaning water pipes are connected with a water source through a solenoid valve. The solenoid valve is connected with a controller. The controller is connected with a power supply, a weight sensor and a time delayer which are both located at the bottom of the sewage treatment trough. By checking the change of the weight of the sewage treatment trough, cleaning treatment is conducted to the sewage treatment trough. The self-cleaning dog cage and implementing method thereof has the advantages of being simple in structure, obvious in effect, capable of timely rinsing off the canine feces, completely improving the living environment of the caged canines, effectively guaranteeing the air freshness, hugely enhancing the life comfort, supplying water on demands, effectively saving water, and making sure that no water resources are wasted.

Owner:董明明

Polishing device with cooling system

InactiveCN108058091APlay an instant cooling effectNo waste of waterGrinding carriagesPolishing machinesWater storage tankSmall hole

The invention relates to a polishing device with a cooling system. The polishing device comprises a polishing assembly, a workbench and the cooling system, wherein the polishing assembly is used for polishing a workpiece; the workbench is used for overturning the workpiece; and the cooling system is used for cooling the workpiece in the polishing process. The workbench comprises a support seat andtwo overturning assemblies, wherein the two overturning assemblies drive the workpiece to be overturned. The cooling system comprises a water storage tank and two water suction devices, wherein the two water suction devices are placed in the water storage tank. Each water suction device comprises a water suction pump, a cooling spray pipe and a spray head. A sunken flow guiding groove is formed in the middle of the support seat. A flow guiding channel is formed in the middle of the flow guiding groove and communicates with the water storage tank. One end of each cooling spray pipe is connected to the corresponding water suction pump, and the other end of each cooling spray pipe penetrates the support seat; and each spray head is mounted at the end of the corresponding cooling spray pipe.Each spray head is in a disc shape and provided with multiple water outlet small holes.

Owner:佛山市鼎翘五金有限公司

Water purification device with user-defined capacity

InactiveCN106094595AFlexible capacity settingFresh waterTreatment involving filtrationProgramme control in sequence/logic controllersWater storageFresh water

The invention relates to the technical field of water purification technologies and specifically relates to a water purification device with user-defined capacity. The water purification device with user-defined capacity is provided with a device body, a filtering device, a water storage device, a main control device and a user interface device, wherein the filtering device, the water storage device and the main control device are respectively arranged in the machine body; the filtering device is used for filtering original water, then purified water is stored in the water storage device, the main control device is in signal connection with the user interface device, capacity of the water storage device is set via the user interface device, information of the set capacity of the water storage device is sent to the main control device, and the main control device controls the filtering device to produce water according to the set capacity. The water purification device with user-defined capacity is capable of flexibly setting the capacity of the water storage device, water can be produced according to the set capacity, fresh water can be produced, and the water can be prevented from being wasted. The water purification device with user-defined capacity is capable of controlling a water quantity according to the number of users, the fresh water can be produced, and the water can be prevented from being wasted.

Owner:FOSHAN VIOMI ELECTRICAL TECH +1

Sand washer used for water conservancy equipment production

InactiveCN107755080AEnhance friction strengthImprove overall stabilityWet separationHydraulic equipmentEquipment use

The invention discloses a sand washing machine for the production of water conservancy equipment, which comprises a cleaning box, a sand washing plate is arranged inside the cleaning box, fixing rods are arranged on both sides of the cleaning box, and a support frame is fixedly connected to the top of the fixing rod , the top of the support frame is fixedly connected with a motor, the output end of the motor is fixedly connected with a rotating rod, the end of the rotating rod away from the motor is fixedly connected with a first gear, the outer surface of the first gear is provided with a rack, and the inner wall of the rack is connected to the second gear. The outer surface of a gear meshes, and the end of the rack away from the first gear runs through the top of the support frame and extends to the outside of the support frame. The top of the cleaning box is fixedly connected with a first fixed plate and a second fixed plate, and the first fixed plate Both the top and the top of the second fixing plate are fixedly connected with the bottom of the support frame, and a second gear is provided on one side of the first fixing plate. The sand washing machine used in the production of water conservancy equipment has the advantages of simple structure, high work efficiency and no waste of water resources.

Owner:江苏天康光电缆仪表有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com