Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Poor wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

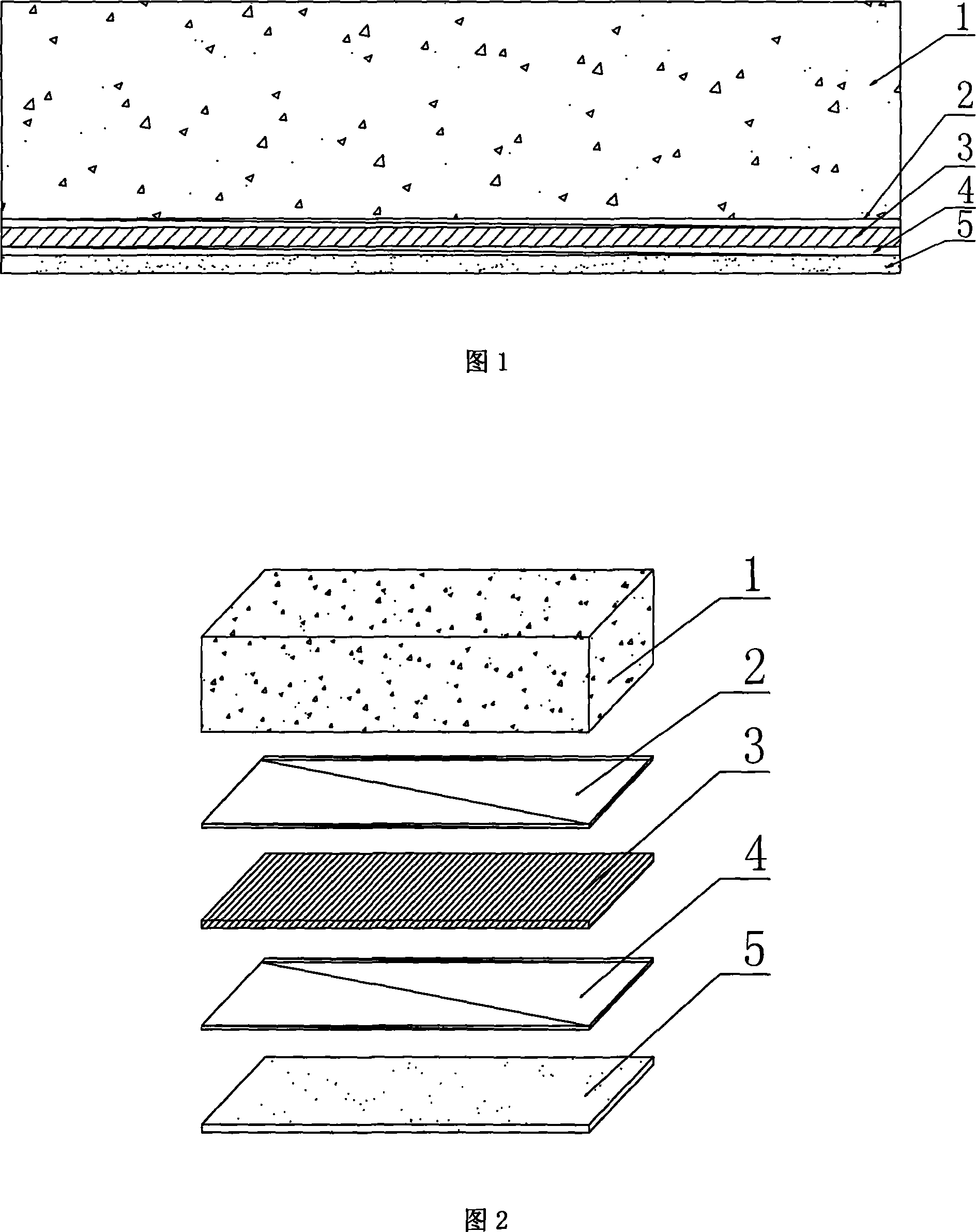

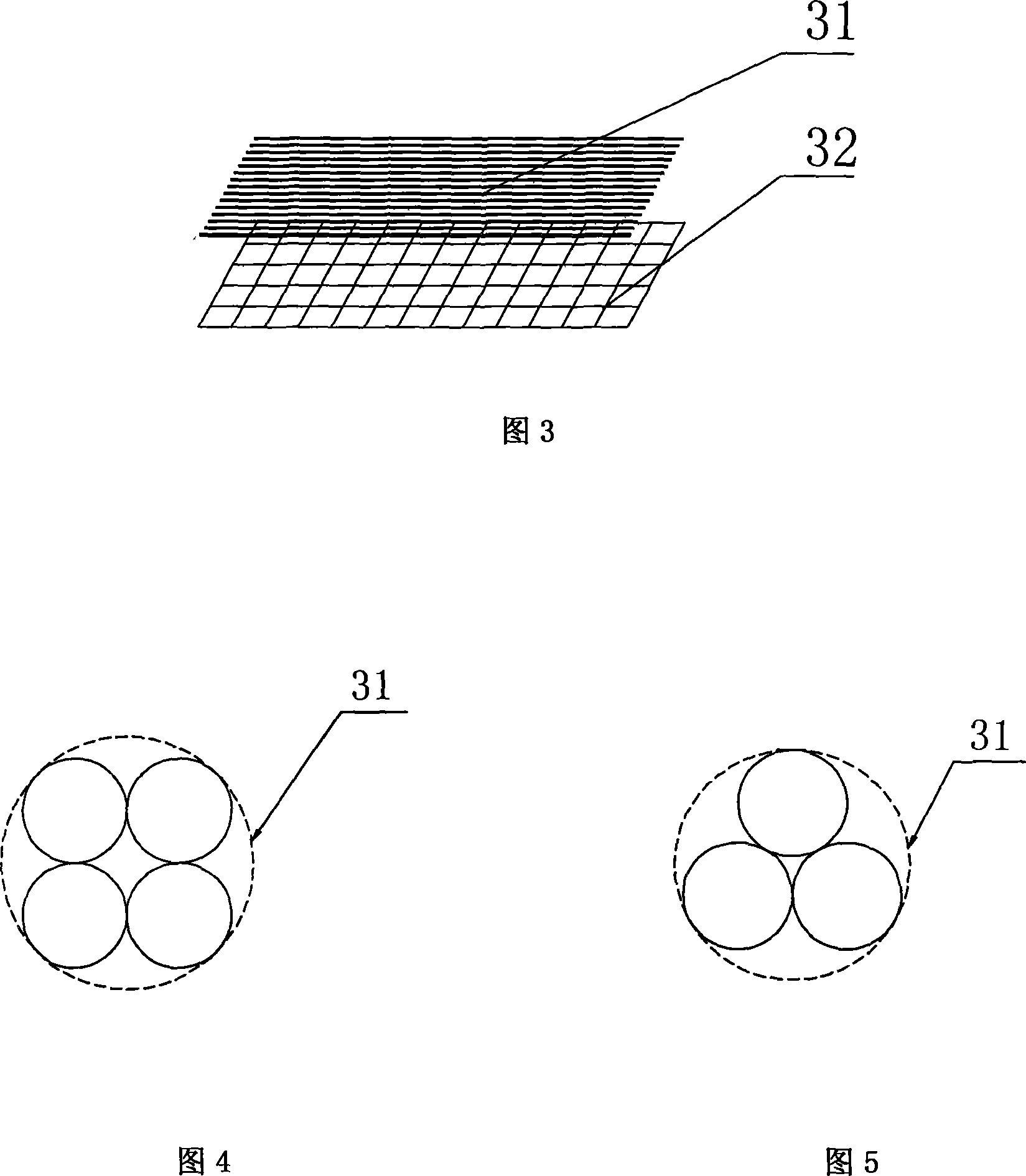

Reinforcement method for concrete structure

InactiveCN101100905AChange durabilityChange fire resistanceBuilding repairsHigh intensityFiber orientation

A reinforcing method for concrete structure follows the steps as: surface treatment to the concrete structure to reveal structure sheaf and smooth and dust clean; preset super strength steel micro fiber on web texture in the same direction to form a steel micro fiber tape; spray coat on the concrete structure with a layer of high strength polymer mortar or resin mortar; stick the steel micro fiber tape to the surface; spray coat on the steel fiber tape with a layer of high strength polymer mortar or resin mortar and roll on along the fiber direction to form a close grained layer; finally spray coat protection layer to it.

Owner:上海维固工程实业有限公司 +1

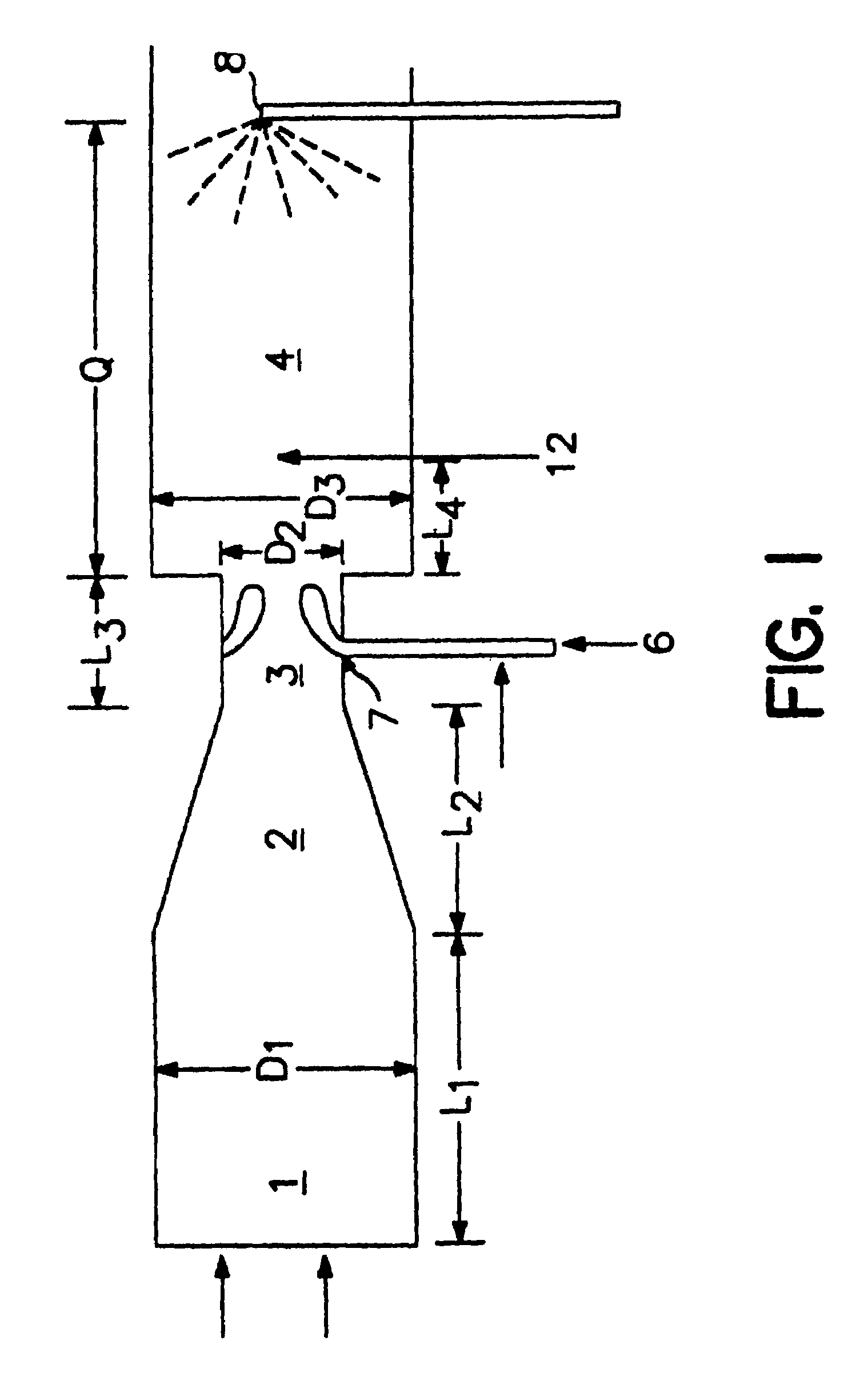

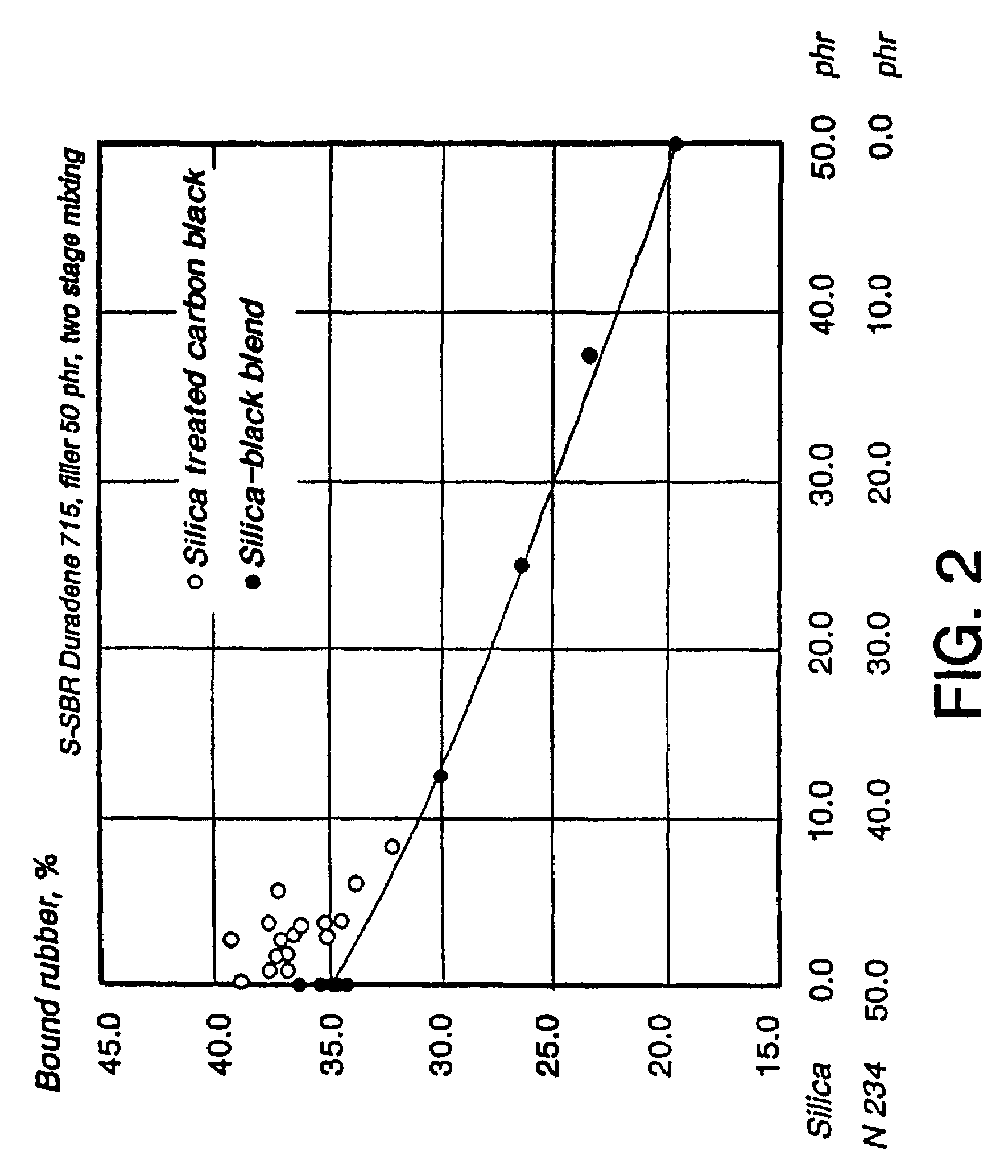

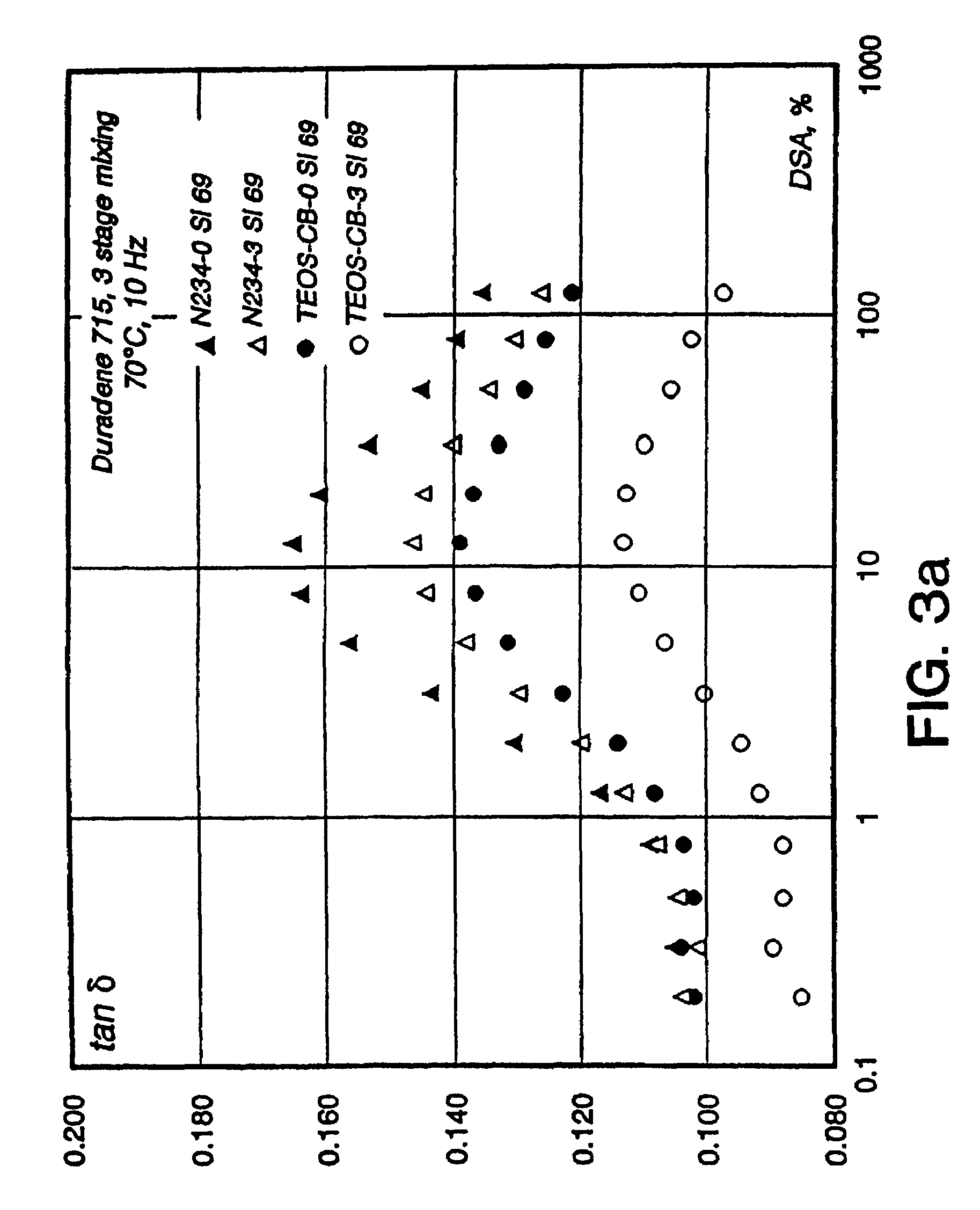

Elastomeric compounds incorporating silicon-treated carbon blacks

InactiveUS7199176B2Poor wear resistanceReduce hysteresisPigmenting treatmentSpecial tyresCarbon blackHysteresis

Disclosed are elastomeric compounds including an elastomer and a silicon-treated carbon black, and optionally including a coupling agent. The elastomeric compound exhibits poorer abrasion resistance in the absence of a coupling agent, lower hysteresis at high temperature and comparable or increased hysteresis at low temperature compared to an elastomer containing an untreated carbon black. A variety of elastomers and formulations employing such elastomers are contemplated and disclosed. Elastomeric compounds incorporating an elastomer and an oxidized, silicon-treated carbon black are also disclosed. Also disclosed are methods for preparing elastomers compounded with the treated carbon black.

Owner:CABOT CORP

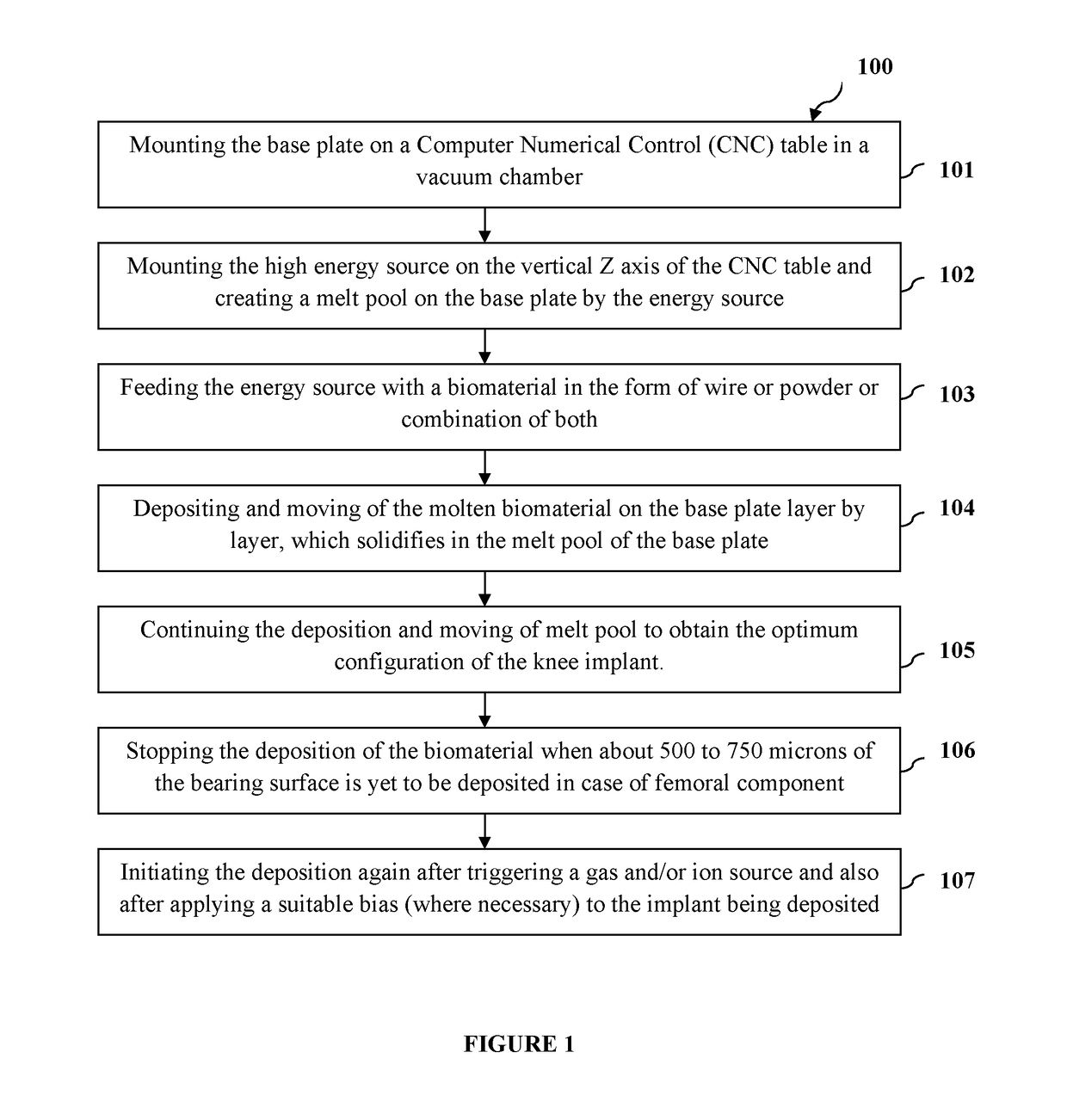

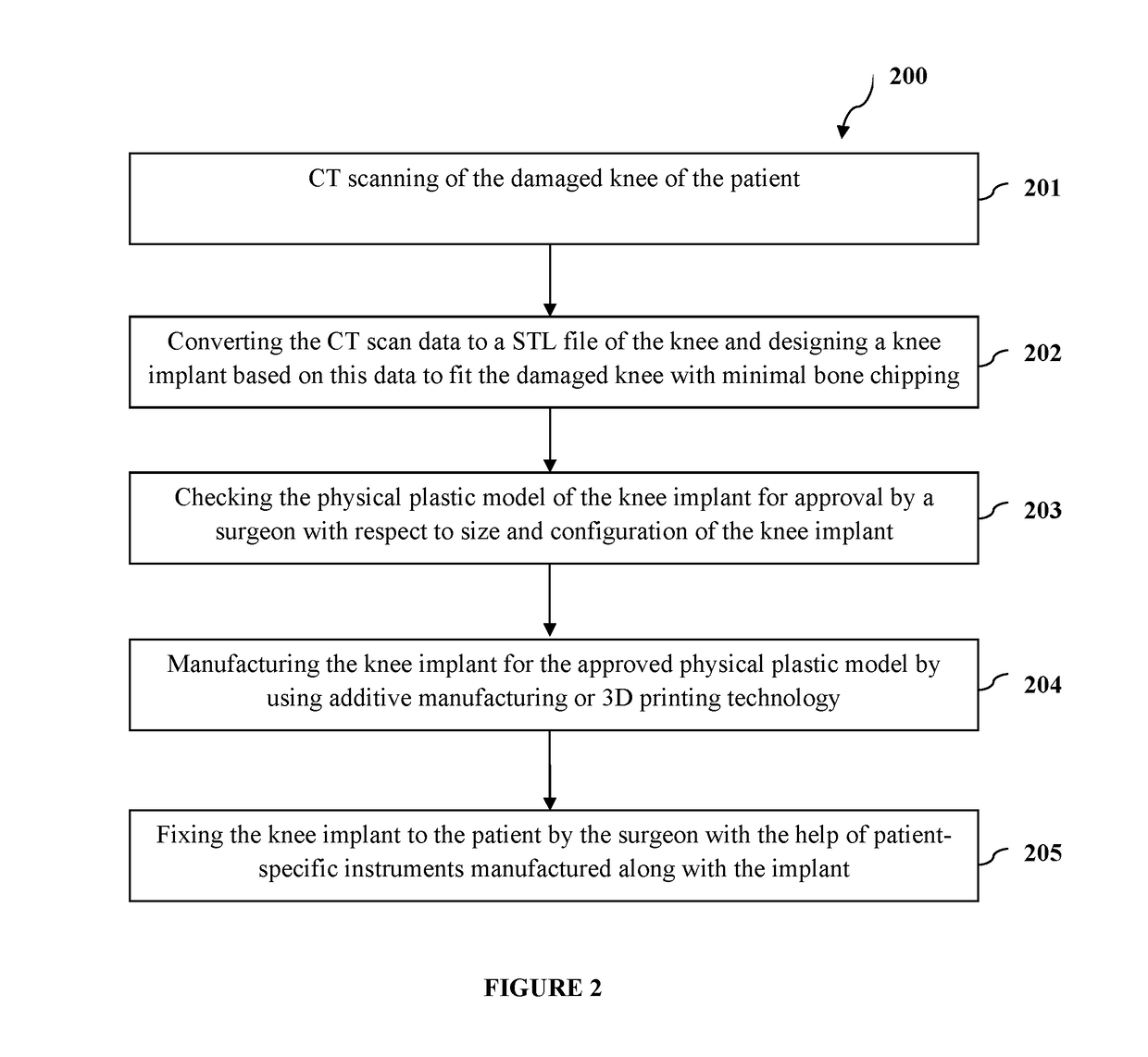

Composition of orthopedic knee implant and the method for manufacture thereof

InactiveUS20170071744A1Reduce coefficient of frictionImprove contactPharmaceutical delivery mechanismJoint implantsPatient specificBiomedical engineering

The present invention discloses a composition of a knee implant comprising biomaterials such as combination of Ti—Nb—Zr alloy and tantalum to support osseointegration. The present invention further discloses a method of manufacturing customized patient-specific knee implant using 3D printing technology to suit the patient. The method involves the use of high energy source such as fiber laser or electron-beam. The base plate is mounted on the CNC. The energy source creates a melt pool on the base plate and the energy source is fed with a biomaterial in the form of wire or powder. The biomaterial is deposited on the base plate layer by layer, which solidifies in the melt pool of the base plate. The knee implant thus fabricated suits the elastic modulus of the bone and is useful as customized implant in patient undergoing replacement surgery.

Owner:BALI SULZHAN +1

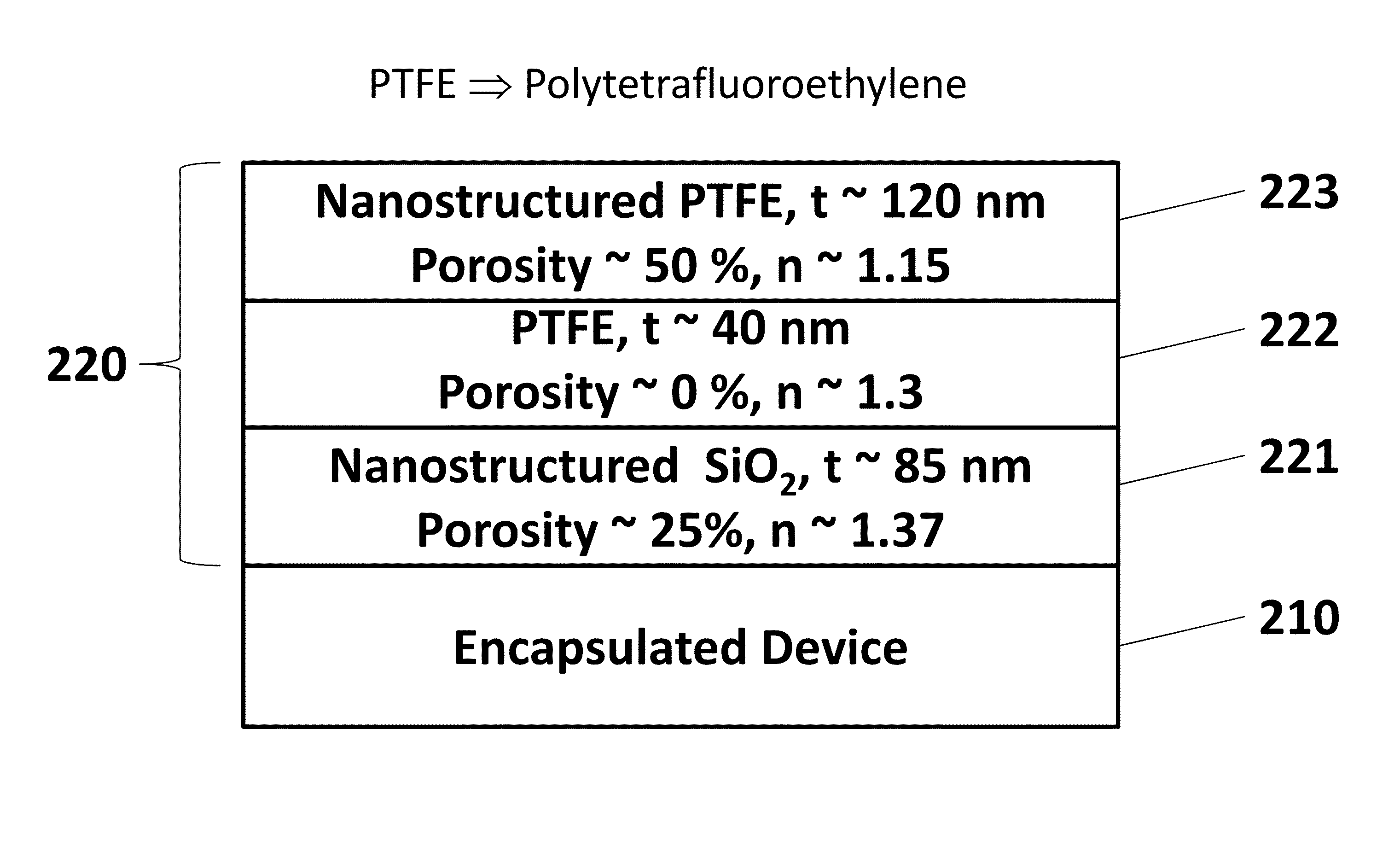

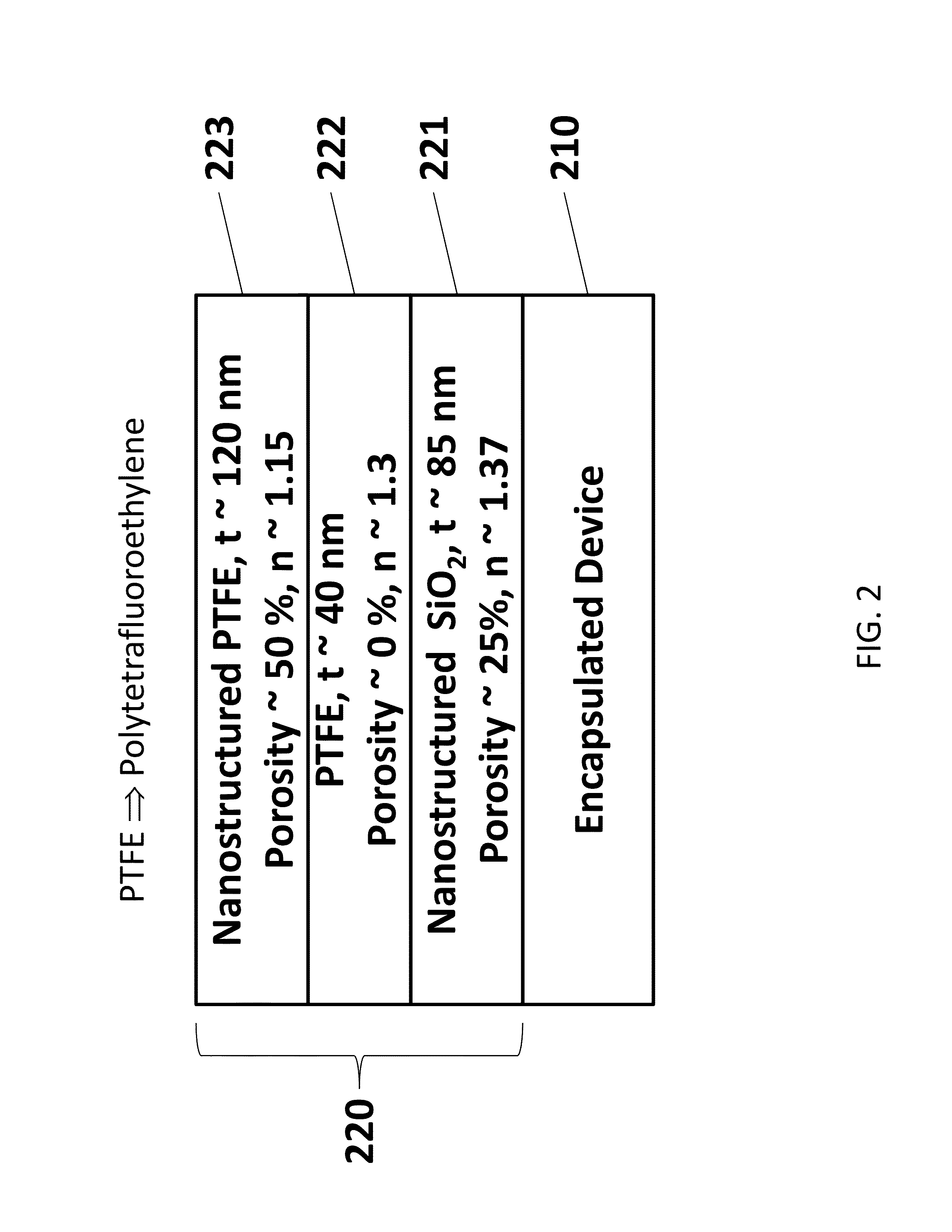

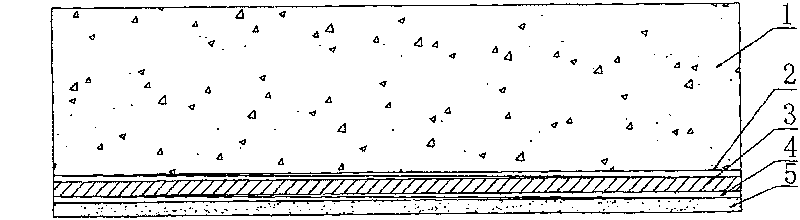

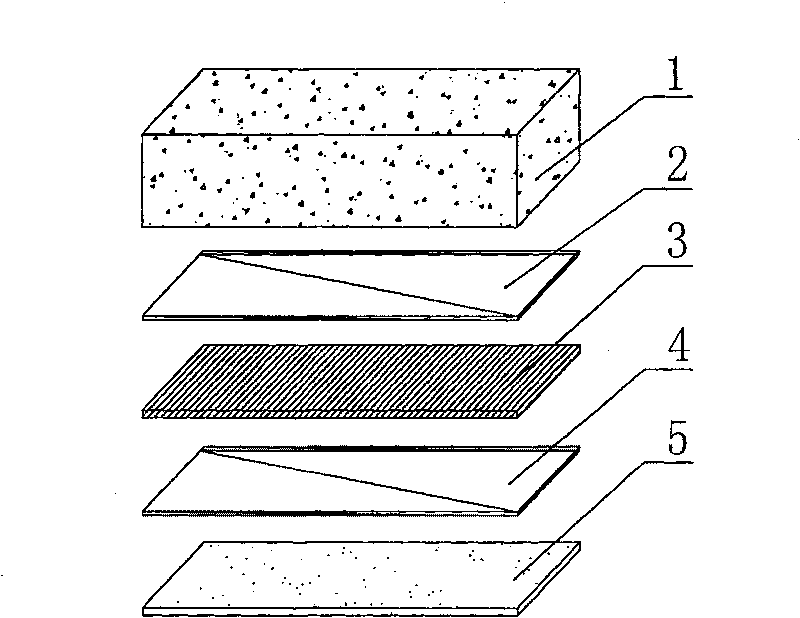

Highly durable hydrophobic antireflection structures and method of manufacturing the same

ActiveUS9400343B1Minimize reflection lossGood broadbandCoatingsPhotovoltaic energy generationReflection lossRefractive index

Durable hydrophobic antireflection structures for optical elements, optical windows, and front sheets of encapsulated photovoltaic and photonic devices are disclosed which can minimize reflection losses over the entire accessible portion of the solar spectrum simultaneously provide self-cleaning and finger-print-free surface. Reduced reflectance and self-cleaning surfaces are resulted from coating the front sheet of encapsulated device with combination of nonporous and porous nanostructured materials such as silicon dioxide nanorods and PTFE. Step-graded antireflection structures can exhibit excellent omnidirectional performance, significantly outperforming conventional quarter wavelength and low-high-low refractive index coatings. Methods of constructing nanostructured durable optical coatings with hydrophobic surfaces are disclosed that can cover large-area ridged and flexible substrates.

Owner:MAGNOLIA OPTICAL TECH

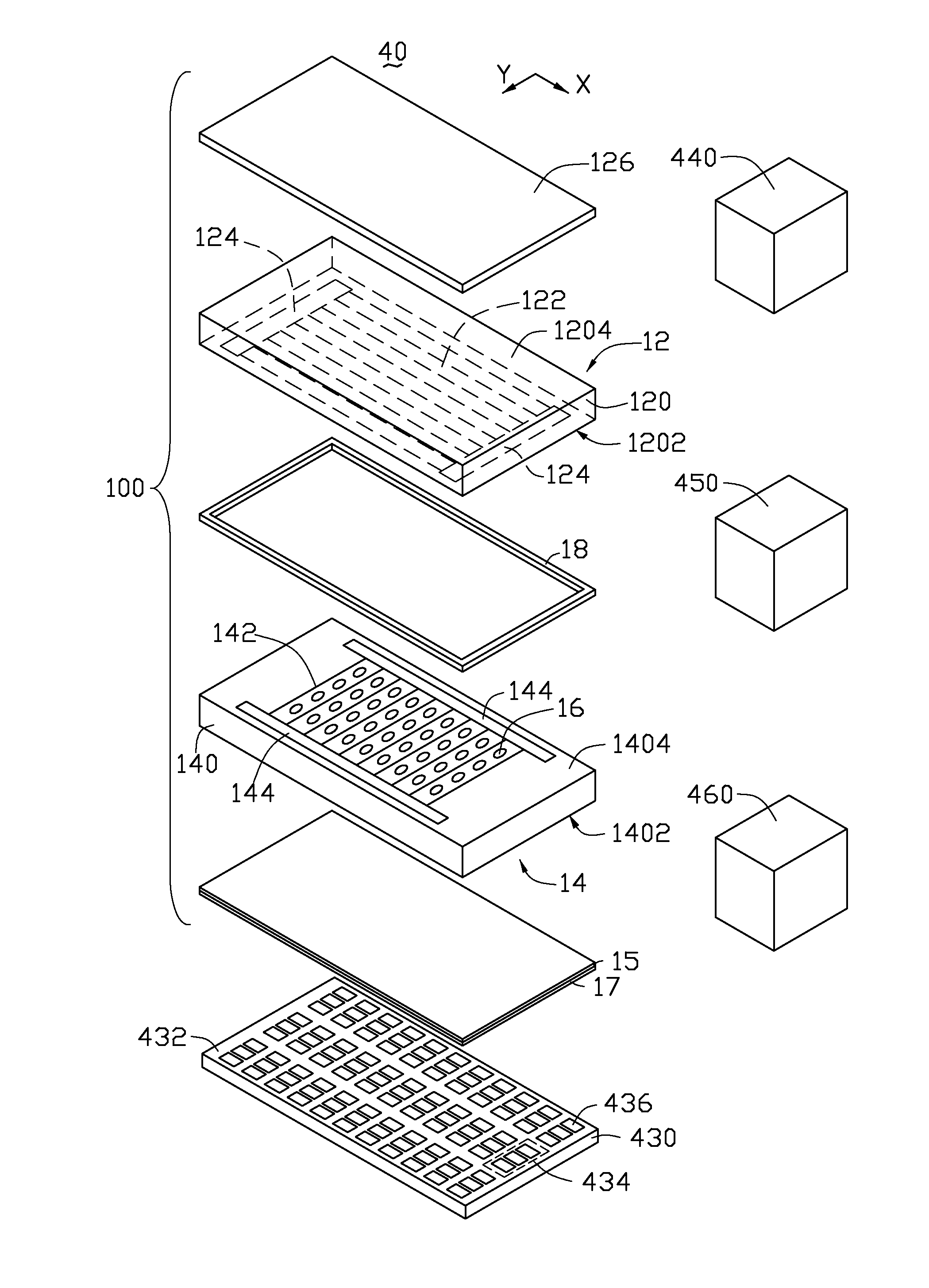

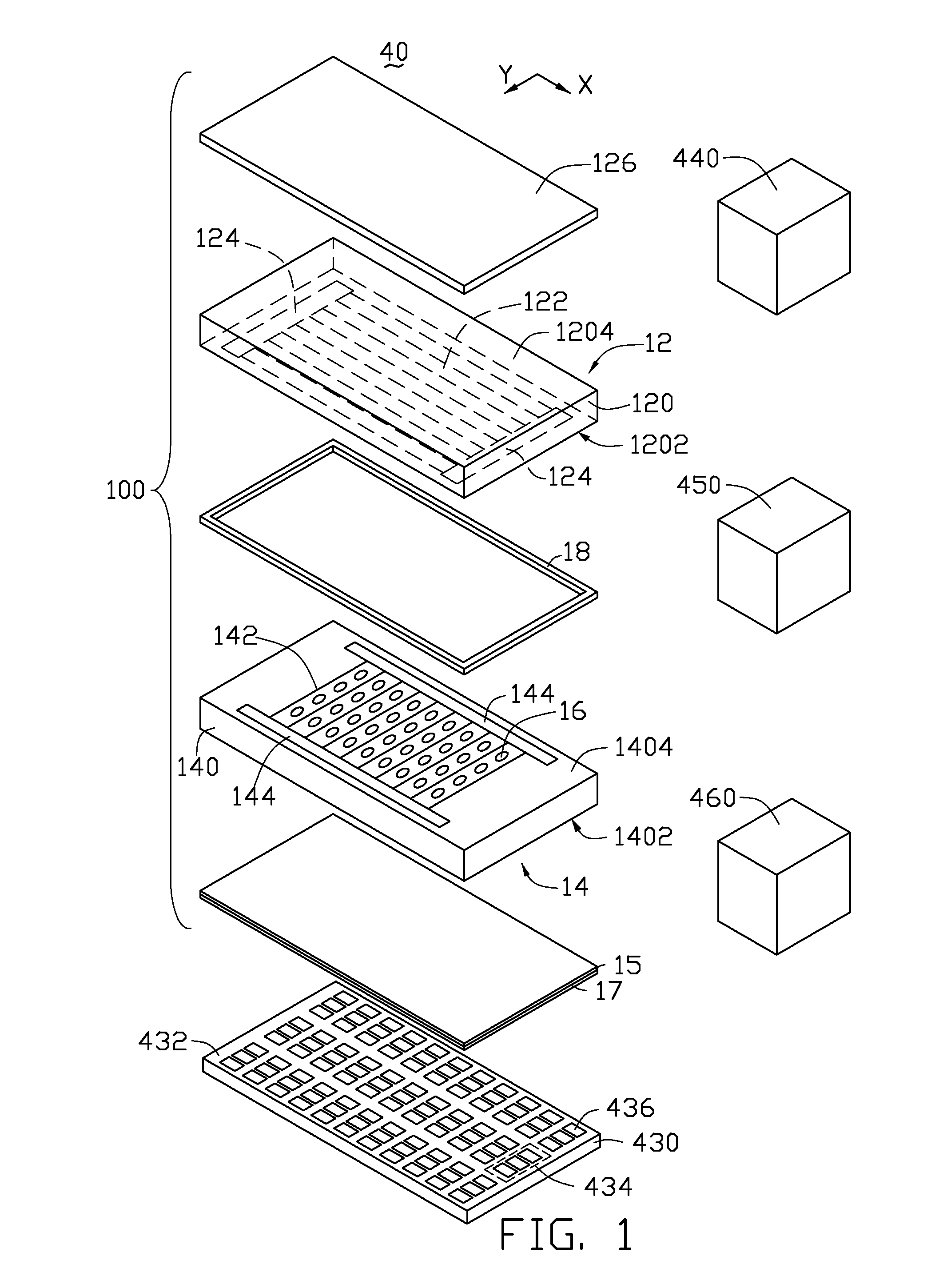

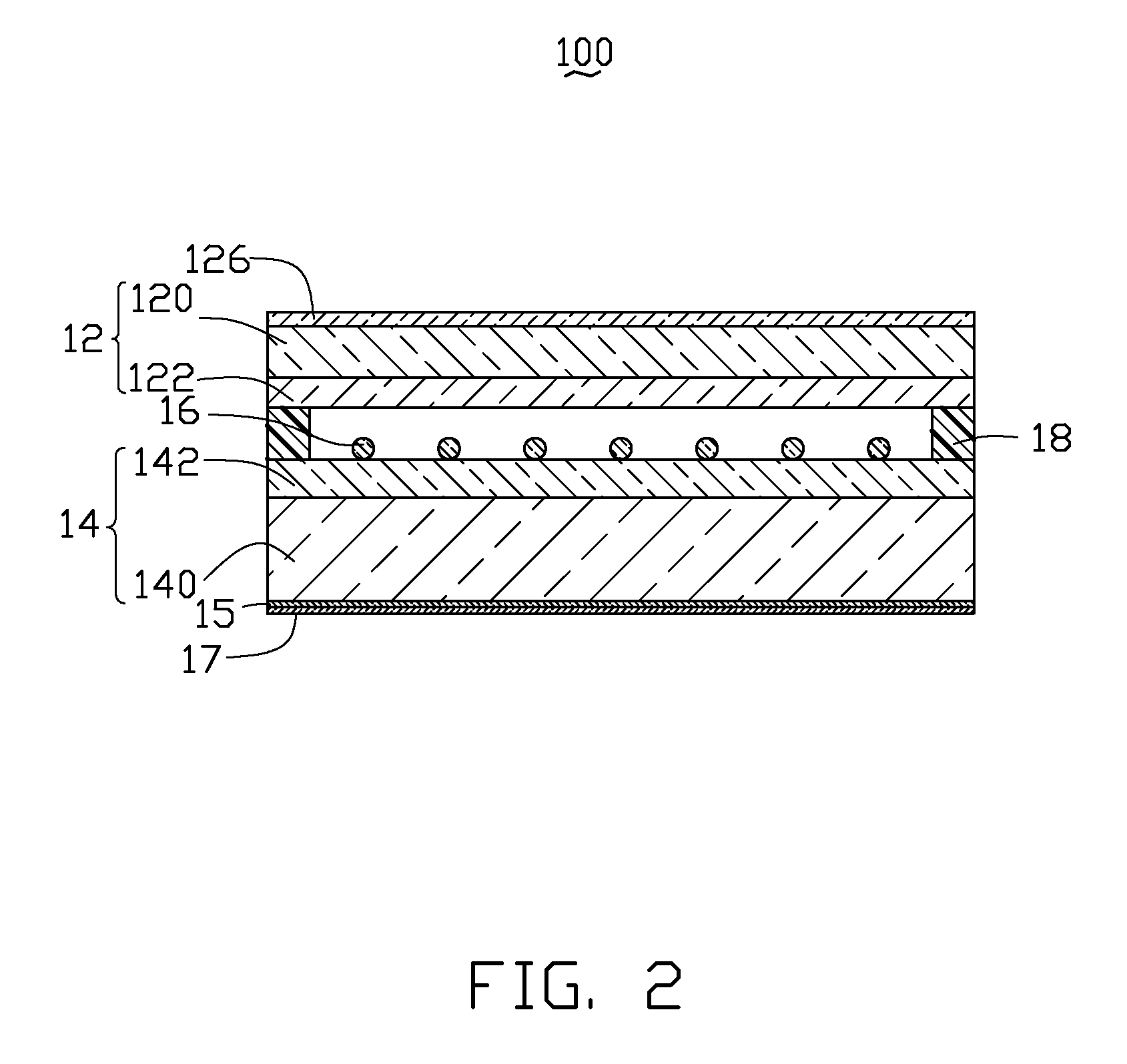

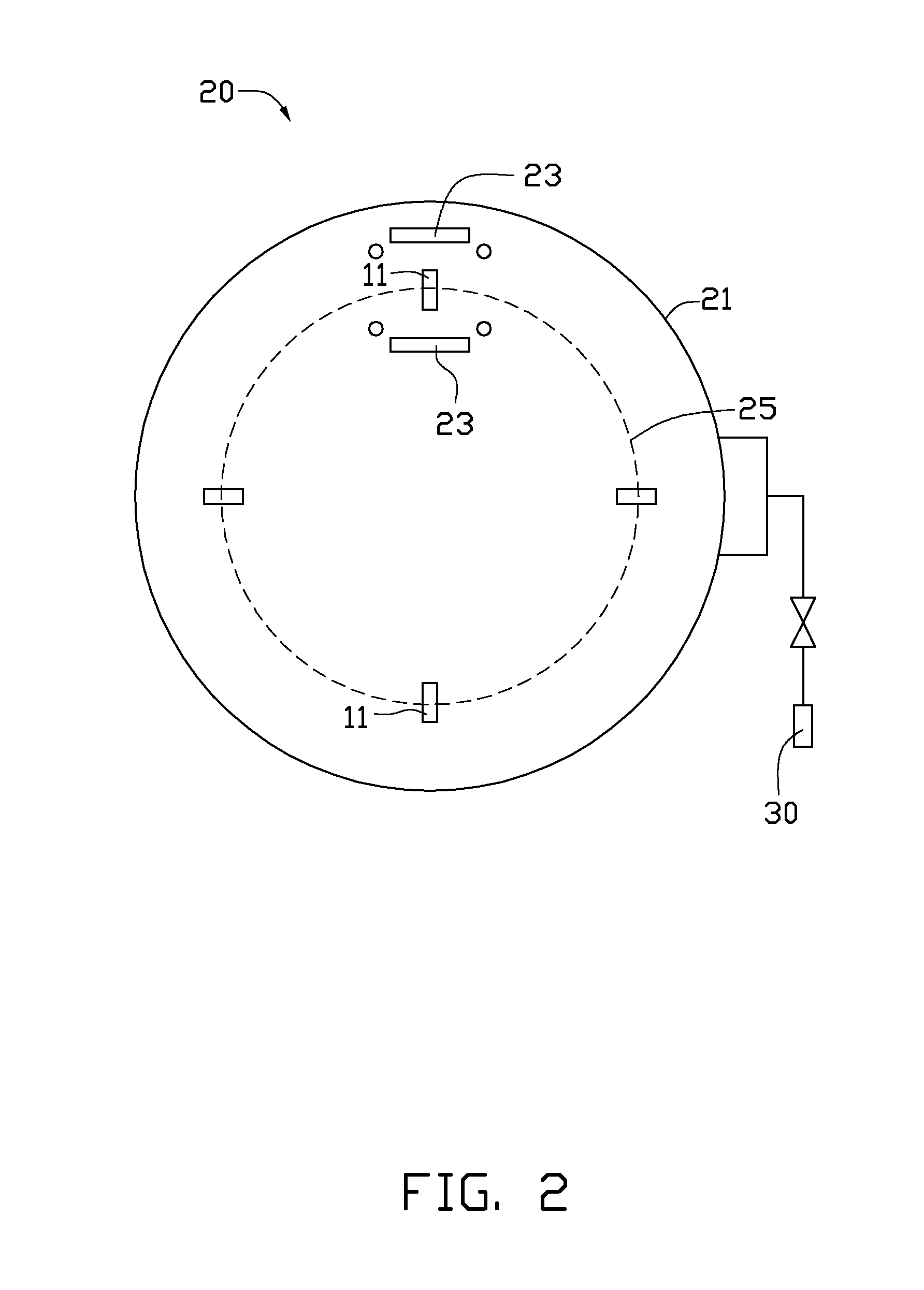

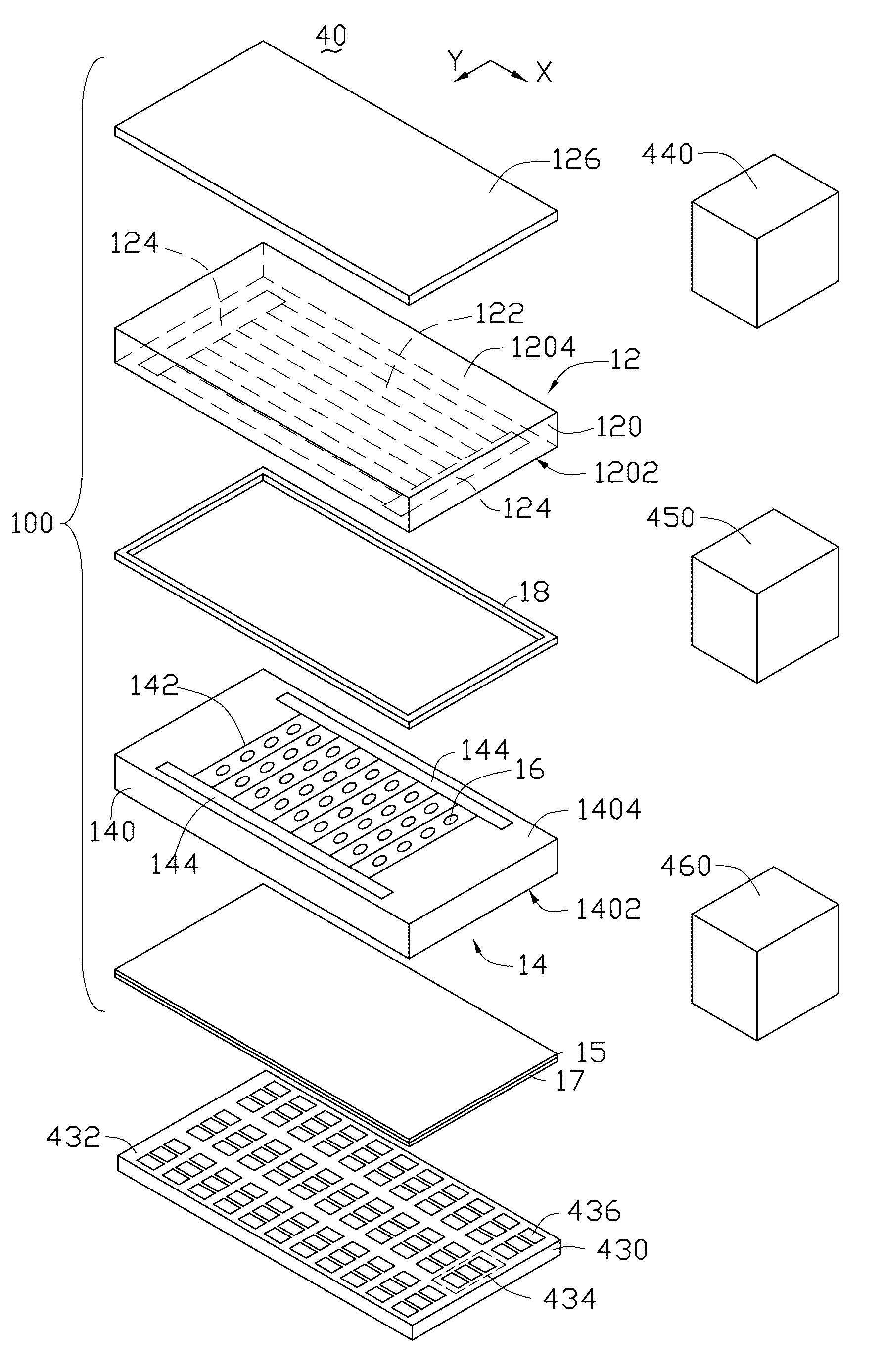

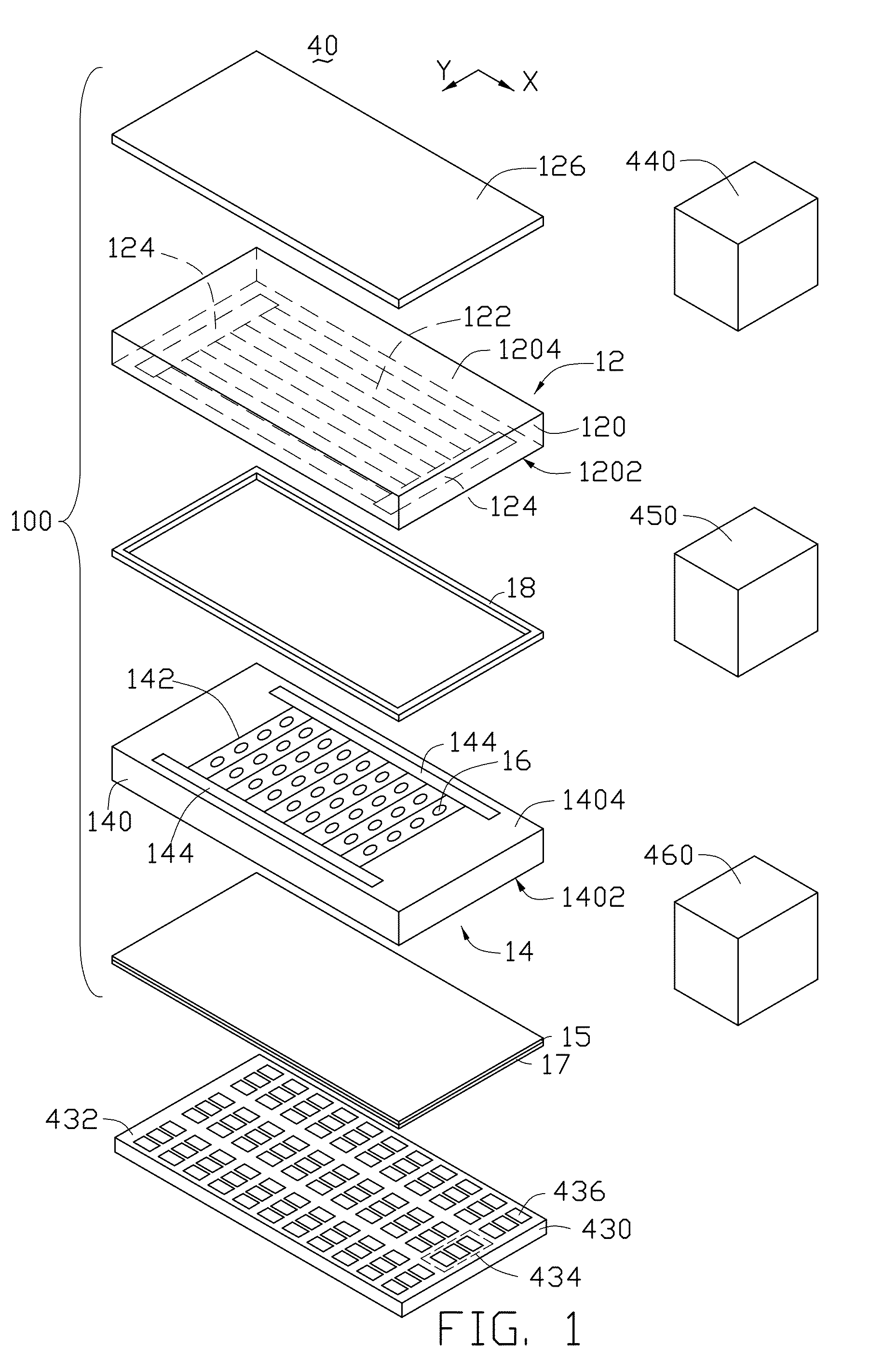

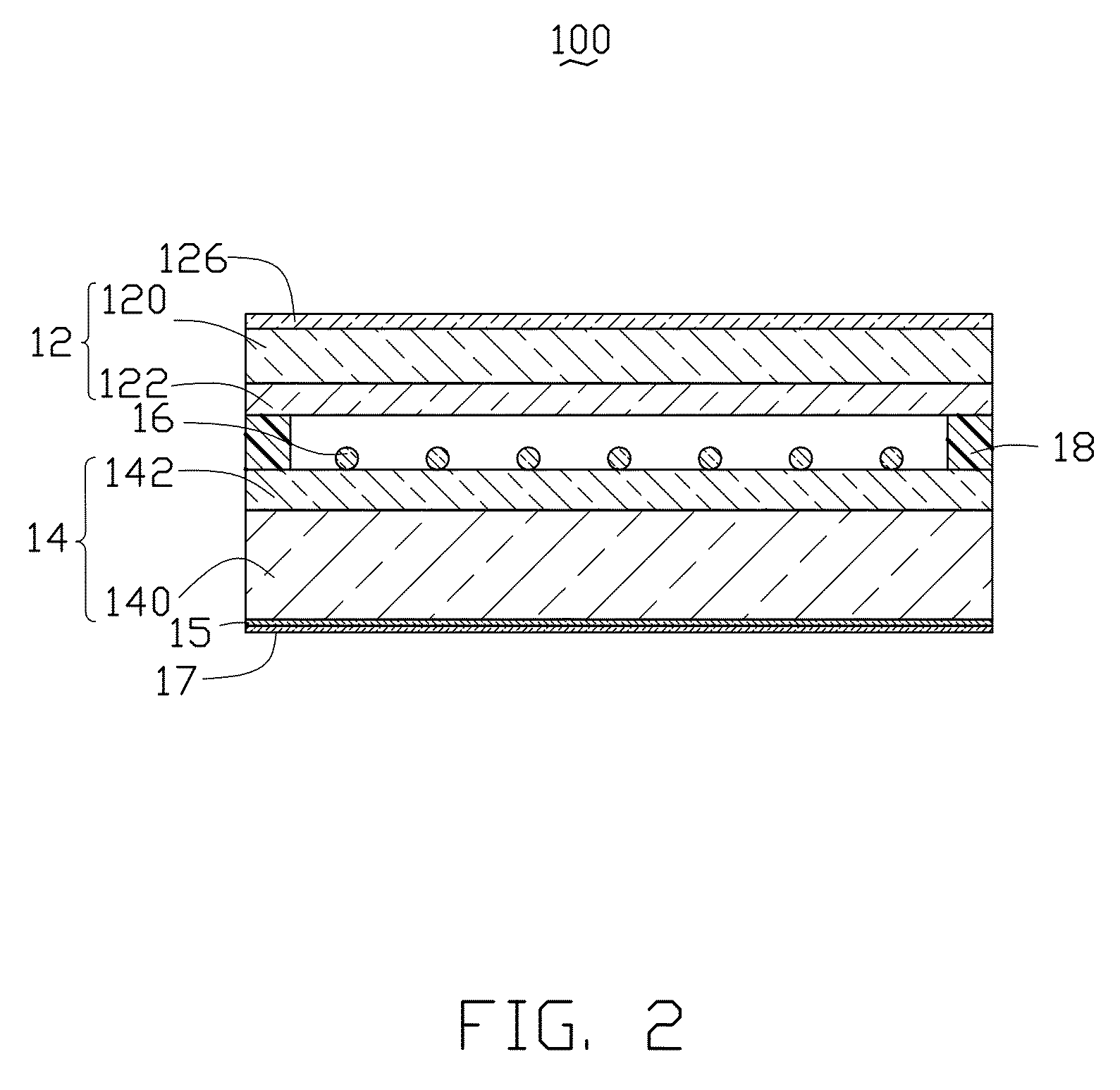

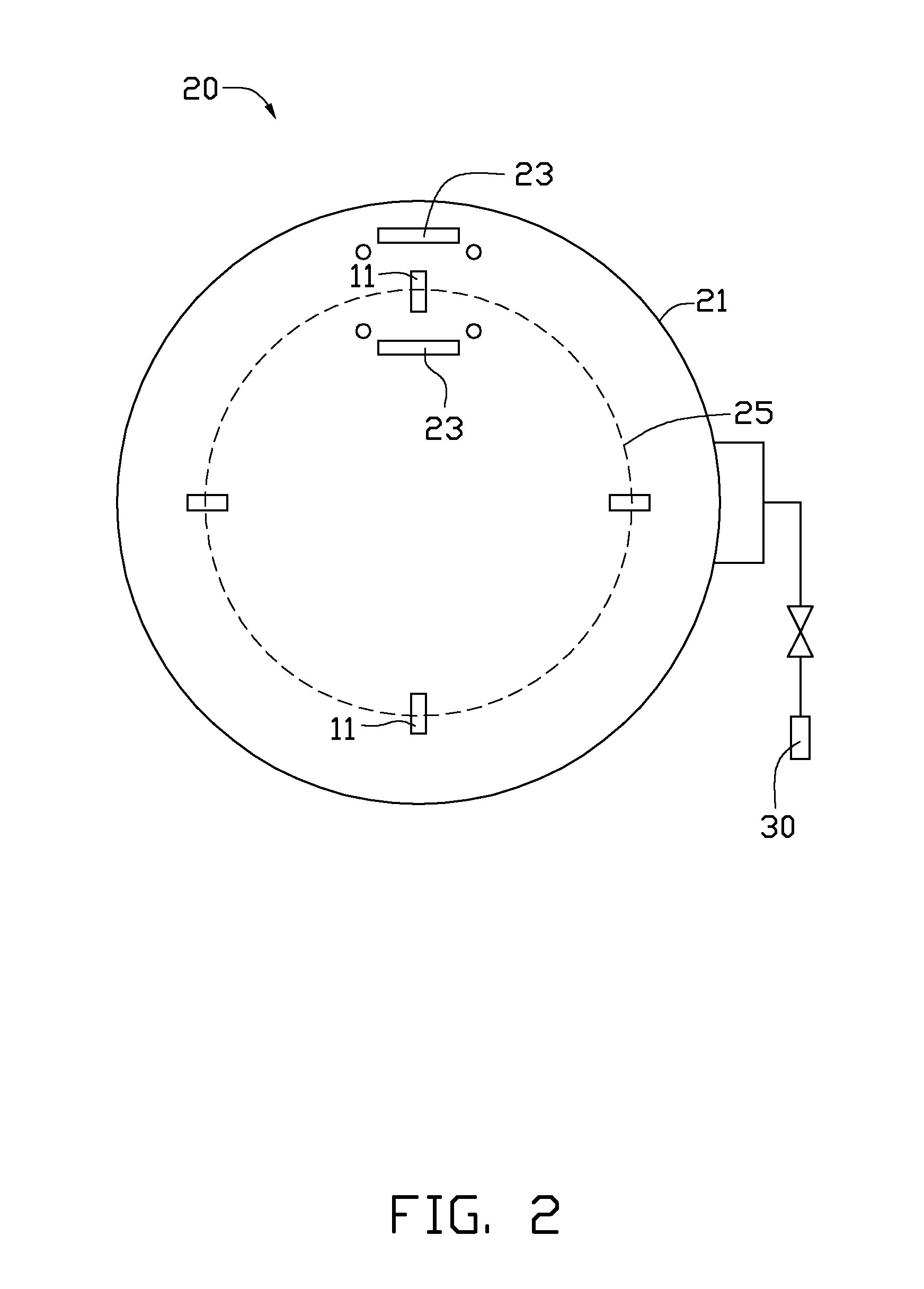

Display device and touch panel

ActiveUS20110242046A1Poor wear resistanceLow chemical enduranceDischarge tube luminescnet screensLamp detailsDisplay deviceCarbon nanotube

A display device includes a touch panel. The touch panel includes at least one transparent conductive layer. The at least one transparent conductive layer is a carbon nanotube layer including a plurality of carbon nanotubes, and the plurality of carbon nanotubes are substantially arranged along the same axis, and the density of the carbon nanotube layer is not constant.

Owner:BEIJING FUNATE INNOVATION TECH

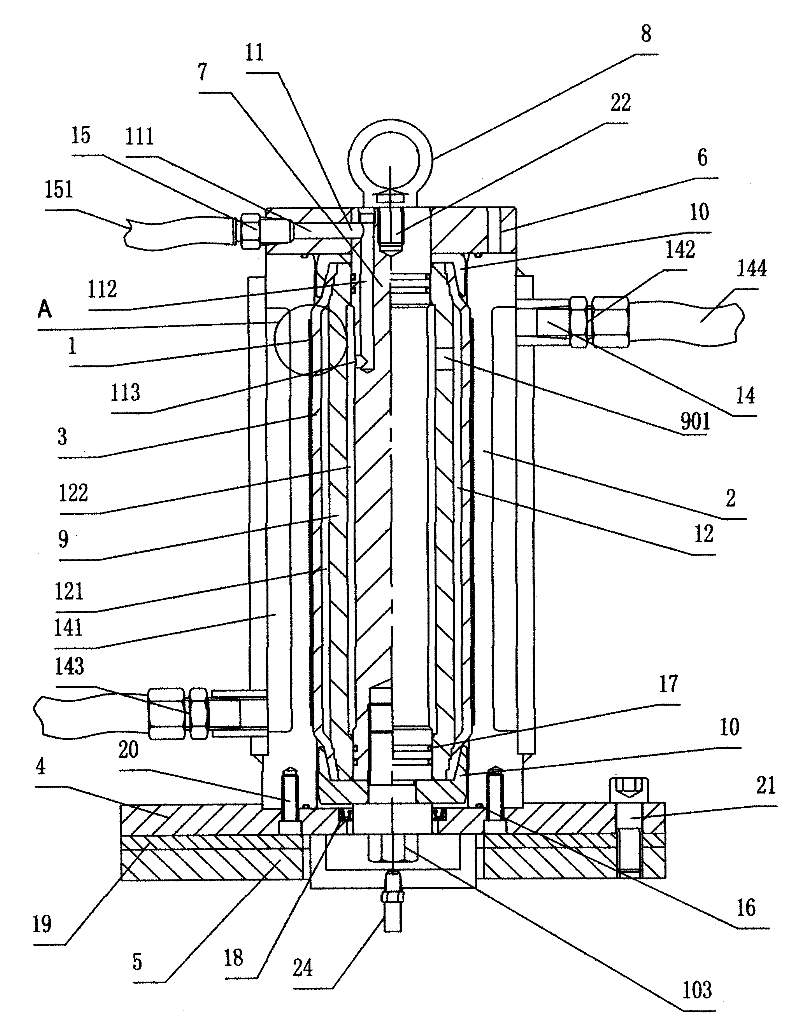

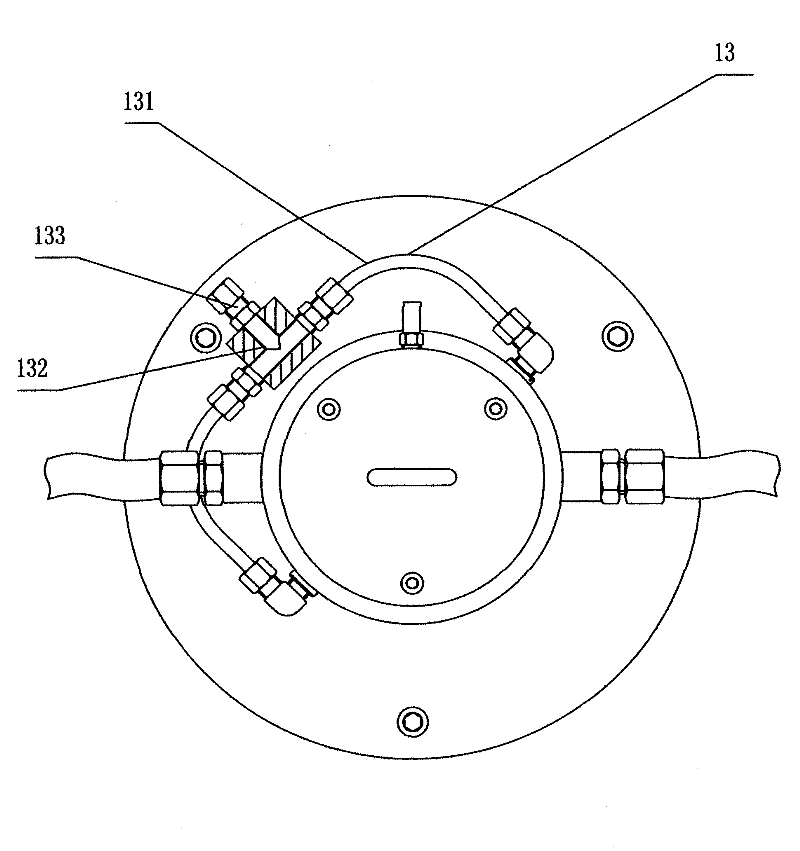

Preparation method of high-performance molded elastic multi-wedge belt and mold device therefor

The invention relates to the field of driving belts, and discloses a preparation method of a high-performance molded elastic multi-wedge belt and a mold device therefor. The preparation method solves the problems that the existing multi-wedge belt preparation technology usually adopts a production mode of preparing a wedge by a profiling grinding wheel, and thus in production, raw material consumption and energy consumption are high and in multi-wedge belt running, large noise and wedge wearing can be produced easily. The preparation method of the high-performance molded elastic multi-wedge belt comprises the following steps of A, preparing a rubber sleeve, B, carrying out pretreatment on a rubber sheet, C, rolling the pretreated rubber sheet, D, pasting the rolled rubber sheet to obtain a belt cylinder, E, vulcanizing the belt cylinder, and F, cooling and cutting to obtain a finished product. The preparation method of the high-performance molded elastic multi-wedge belt has the advantages of low raw material consumption, low energy consumption and excellent product quality.

Owner:NINGBO GUL TZ RUBBER BELT

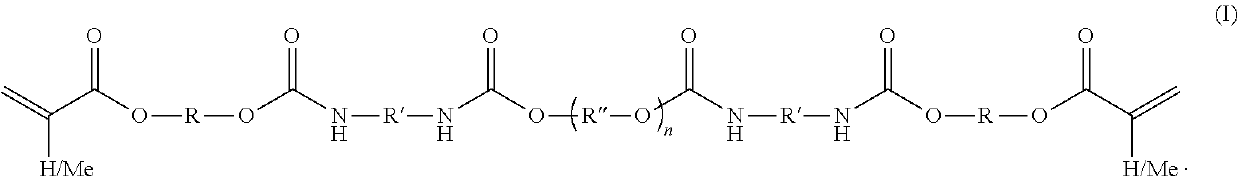

Uv-curing acrylic resin compositions for thermoformable hard coat applications

InactiveUS20190185602A1Flexibility and hardnessPoor impact resistanceCoatingsMonomer compositionMeth-

The present invention provides ultraviolet (UV) curing acrylic compositions for use in making thermoformable hard coats for curved optical displays comprising: (a) one or more multifunctional (meth)acrylate diluents chosen from (a1) an aliphatic trifunctional (meth)acrylate monomer; (a2) an aliphatic tetrafunctional (meth)acrylate monomer; or (a3) an aliphatic pentafunctional (meth)acrylate monomer; (b) from 3 to 30 wt. %, based on the total weight of monomer solids, of one or more one (meth)acrylate monomer containing an isocyanurate group; (c) from 5 to 40 wt. %, based on the total weight of monomer solids, of one or more aliphatic urethane (meth)acrylate functional oligomer having from 6 to 12 (meth)acrylate groups; (d) from 2 to 10 wt. %, based on total monomer solids, of one or more UV radical initiators; and (e) one or more organic solvents for the monomer composition. The composition has a viscosity measured by Anton Parr ASVM 3001 digital viscometer at 50 wt. % solids of from 10 to 200 centipoise (cPs).

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Preparation method of Anti-bacterial coating on plastic surface

InactiveUS20120193232A1Good effectImprove timelinessElectrolysis componentsVolume/mass flow measurementBiotechnologySpray coating

The present invention is a preparation method of an anti-bacterial coating on a plastic surface. A preparation method of an anti-bacterial coating on a plastic surface with a better anti-bacterial effect is provided and comprises putting a plastic substrate into a PVD vacuum device; coating an anti-bacterial metallic layer on the plastic surface; and spray coating an anti-bacterial middle coating on the sample coated with anti-bacterial metallic coating. Utilizing PVD to coat antibacterial layer offsets timeliness of bacterial activity of the organic anti-bacterial coating, which allows the products with double bacterial layers have excellent anti-bacterial and bacteria-inhibited effects during their life spans. The anti-bacterial effect can not only be lasted for a long time, but also achieve high anti-bacterial efficiency (antibacterial rate is more than 99%). The product has excellent function and superior appearance, which is suitable for bath products, electronic devices, domestic appliances, cars and other industries.

Owner:XIAMEN RUNNER IND CORP

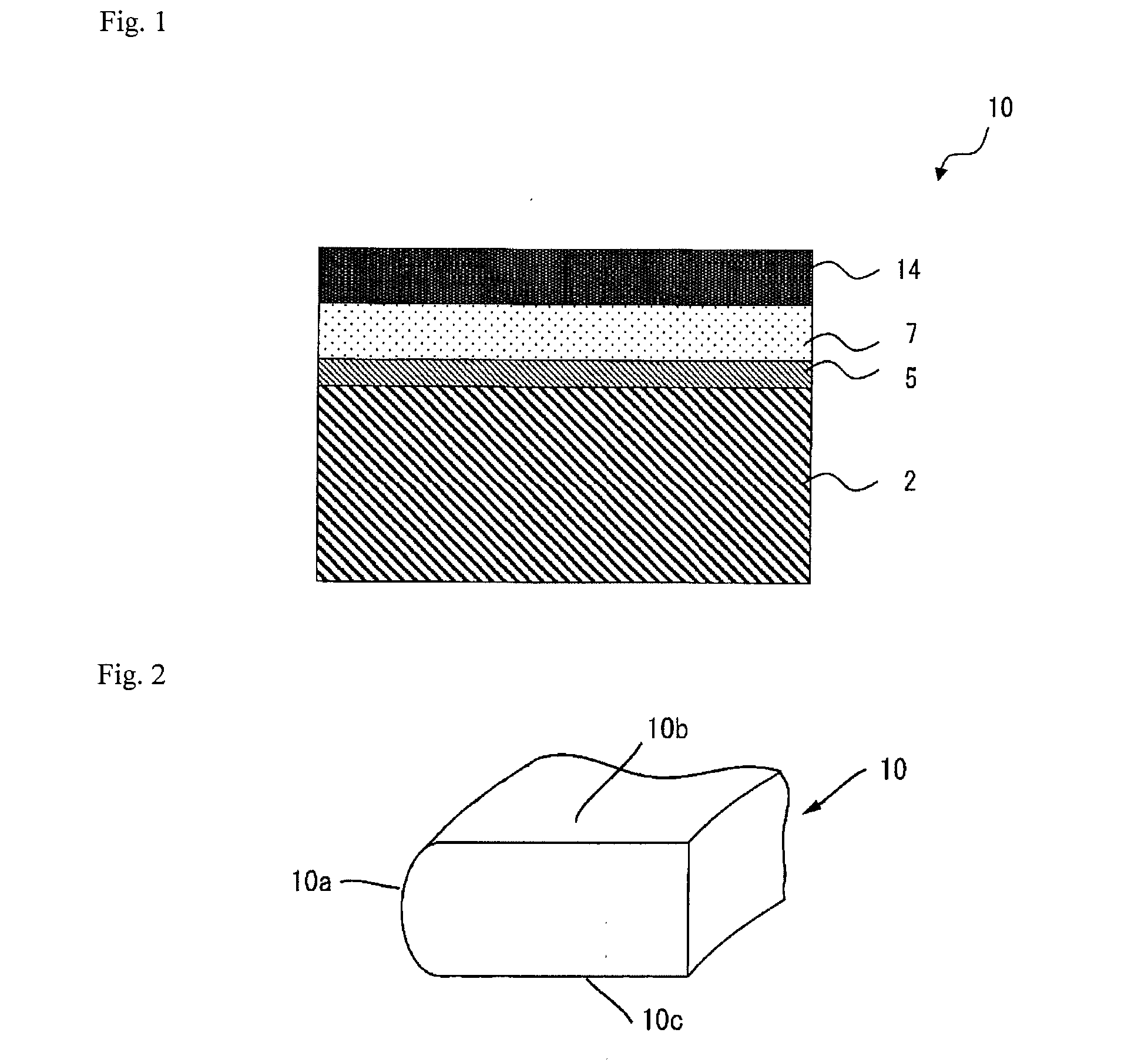

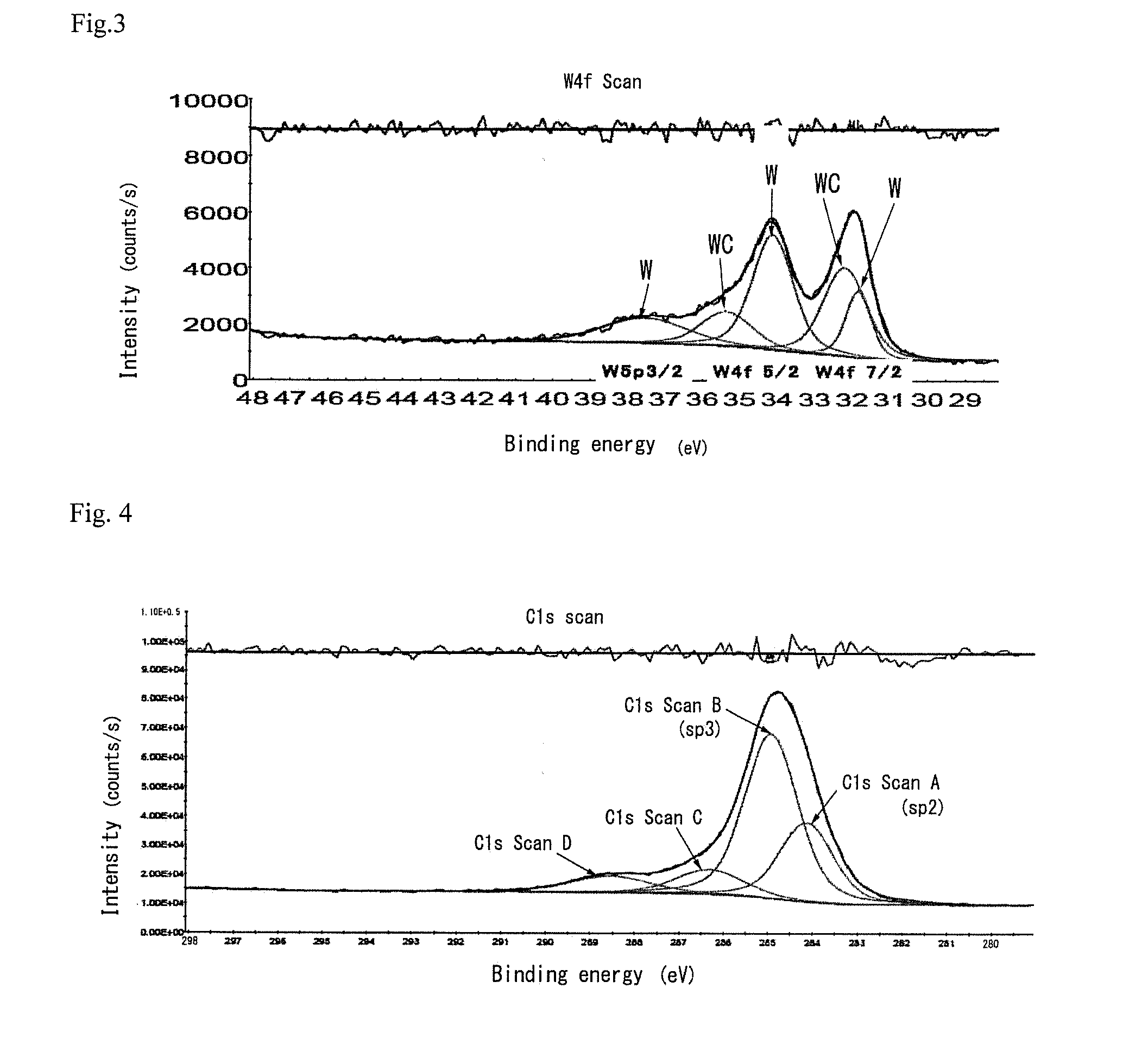

Piston ring

ActiveUS20160245407A1Improve wear resistanceReduce wearPiston ringsVacuum evaporation coatingCarbon coatingPiston ring

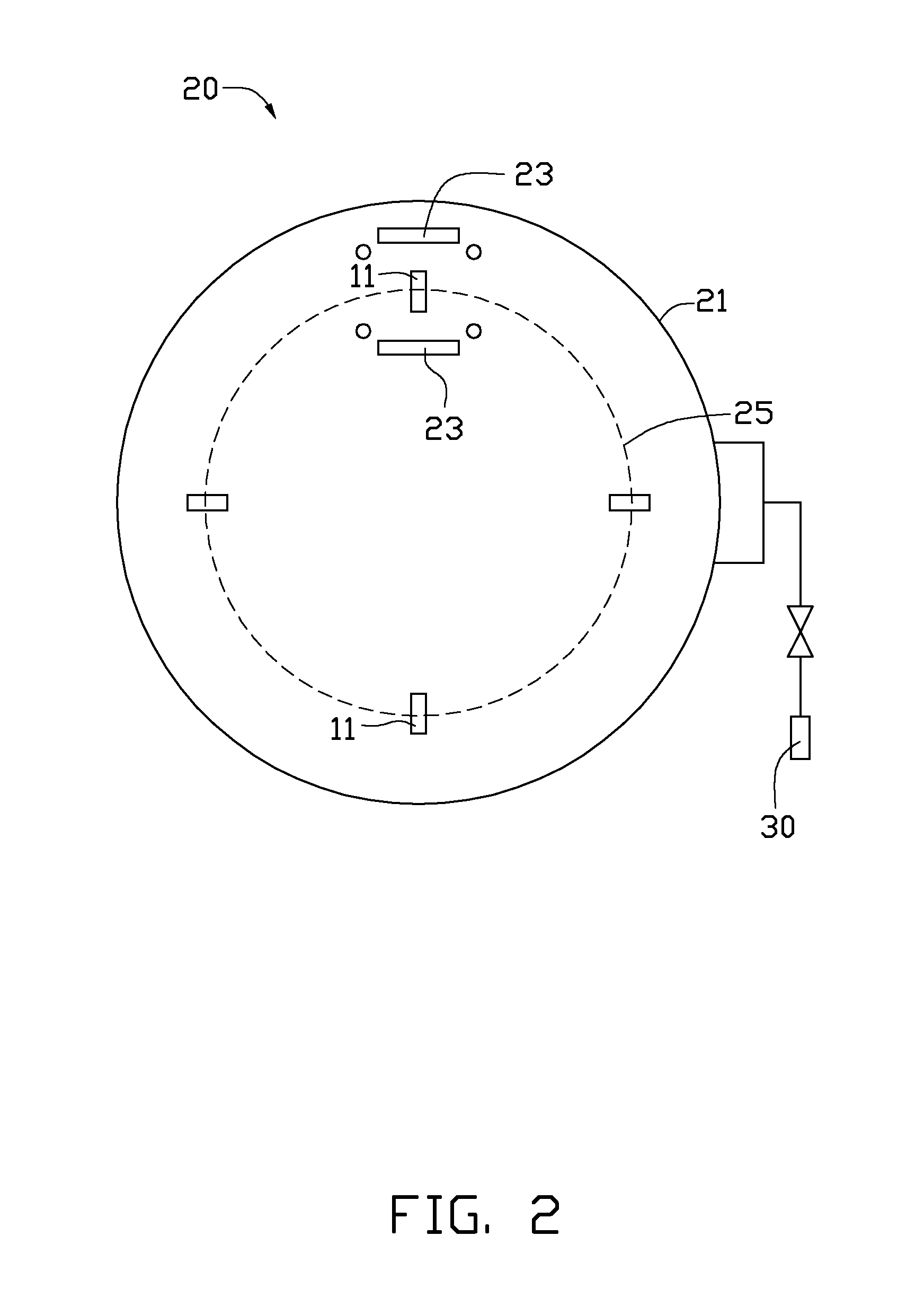

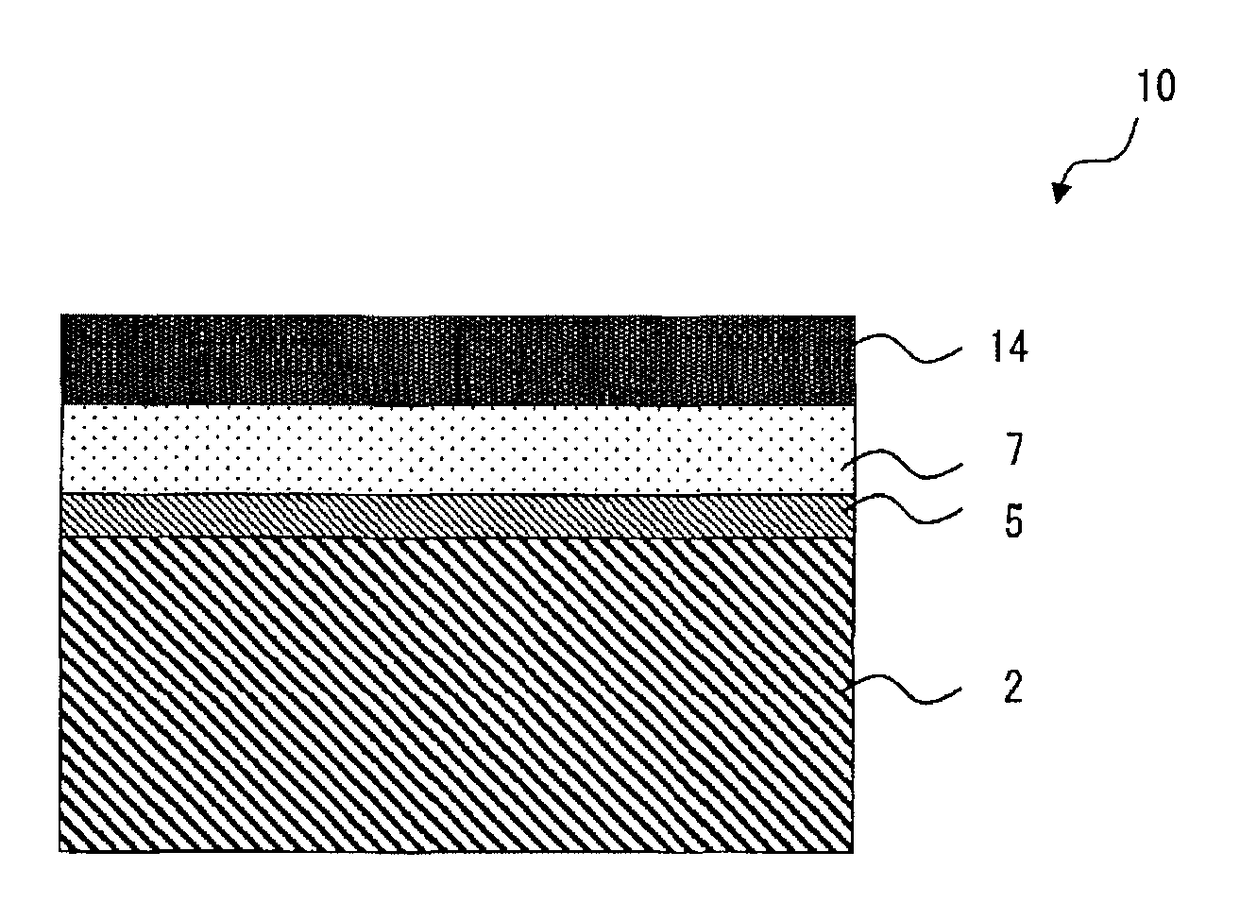

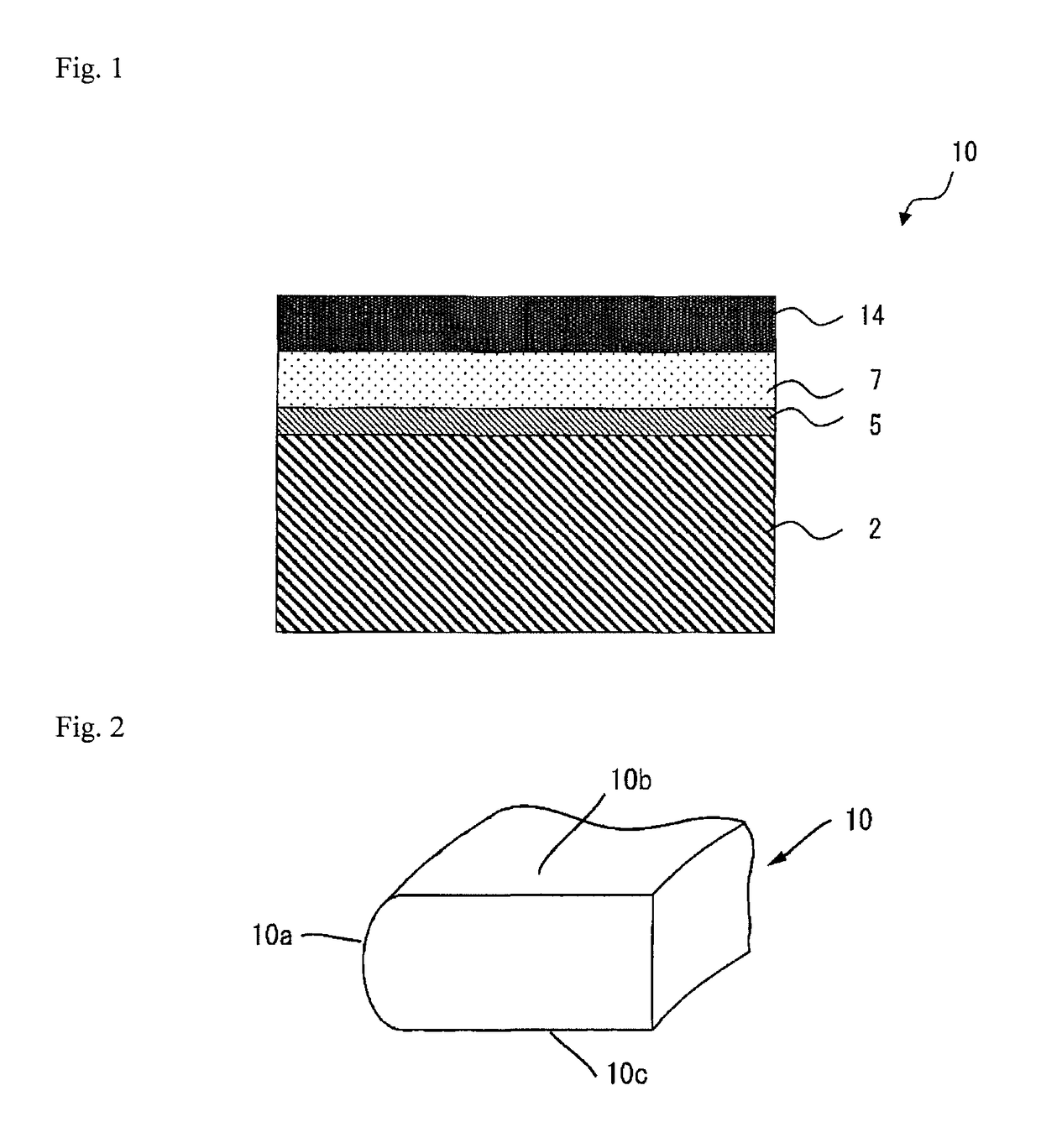

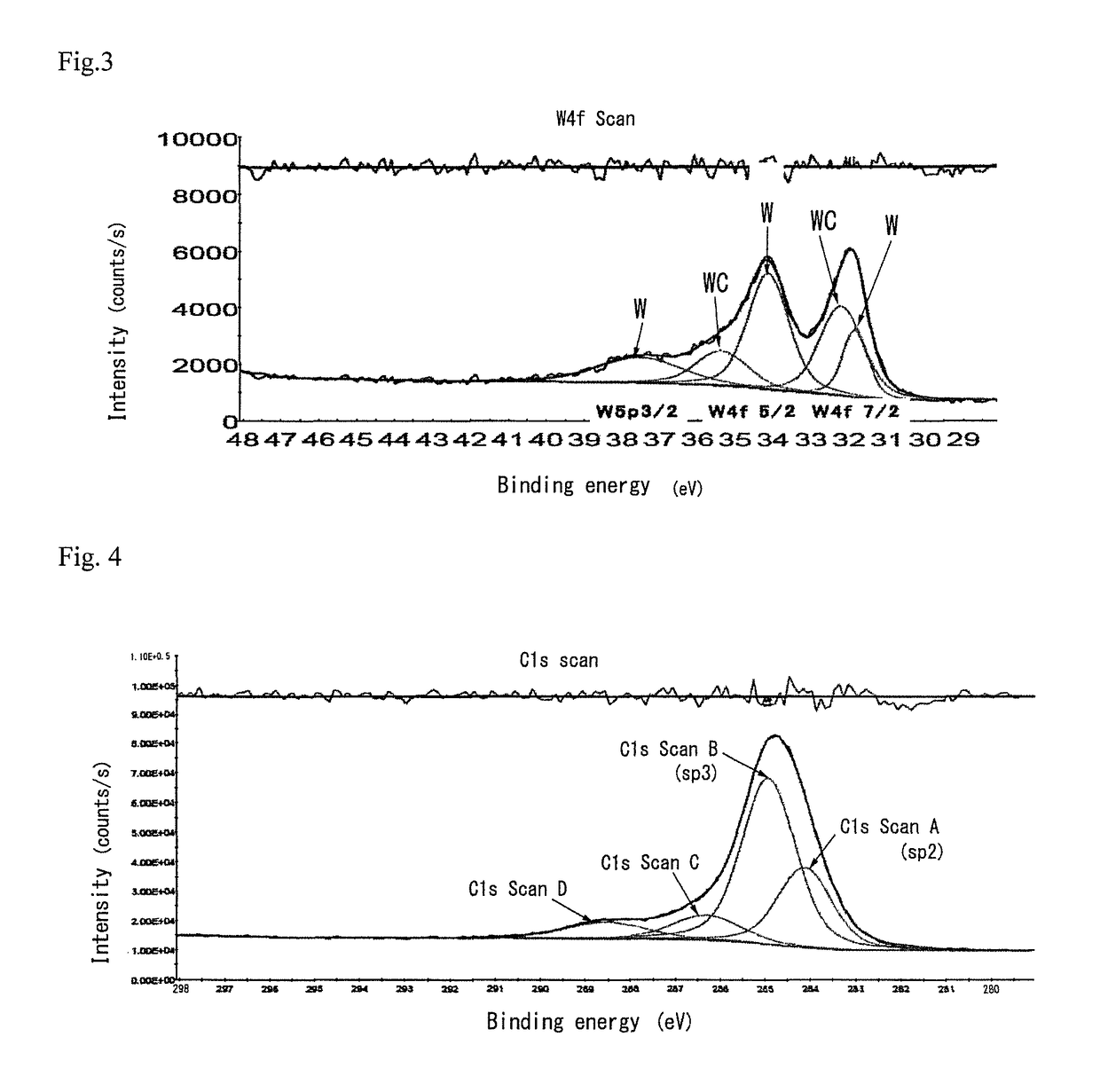

The present invention provides a piston ring having excellent abrasion resistance to an aluminum alloy cylinder or cylinder liner formed of a mating material and is therefore capable of decreasing abrasion of the mating material. An exemplary piston ring has a hard carbon coating formed on an outer peripheral surface, and the hard carbon coating contains 0.5 atom % or more to less than 5 atom % of tungsten (W).

Owner:RIKEN CO LTD

Matte ink composition and method of use

InactiveUS6245136B1Improve adhesionSuperior matte-gloss contrast finishInksPolymer chemistryContrast ratio

A matte ink composition and method for using the composition to produce a superior matte-gloss contrast finish. The matte ink composition comprises (1) an oleoresinous component, (2) a matte agent to impart a matte finish, (3) a cobalt catalyst to accelerate drying of the composition, and (4) an etching agent to condition a gloss surface to promote adherence of the ink composition to the gloss surface. To prepare a matte-gloss finish according to the present invention, a printing substrate is first coated with a gloss film lamination and, after the gloss coating has adequately dried, the matte ink composition of the present invention is lithography printed onto the gloss surface. This novel matte ink composition provides a superior matte-gloss contrast finish without the need for specialized UV equipment and procedures. Further, the matte ink composition of the present invention and its method of use allow substantially finer matte-gloss contrast detailing than attainable by presently used UV ink compositions and methods for forming a matte-gloss finish.

Owner:COMML PRINTING

Ai base alloy excellent in heat resistance, workability and rigidity

Disclosed is a lightweight aluminum based alloy that is high in strength and elongation properties at high temperatures of around 200° C. to 300° C. and has excellent workability in hot working. Disclosed also is a heat-resistant aluminum based alloy excellent in wear resistance and rigidity. Specifically, an aluminum based alloy contains, in terms of percent by mass, 5% to 10% of Mn; 0.5% to 5% of V; 0.5% to 5% of Cr; 0.5% to 5% of Fe; 1% to 8% of Si; 0.5% to 5% of Ni, with the balance being aluminum and inevitable impurities. The aluminum based alloy has a structure including 35 to 80 percent by volume of an intermetallic compound phase with the balance being an aluminum metal matrix.

Owner:KOBE STEEL LTD

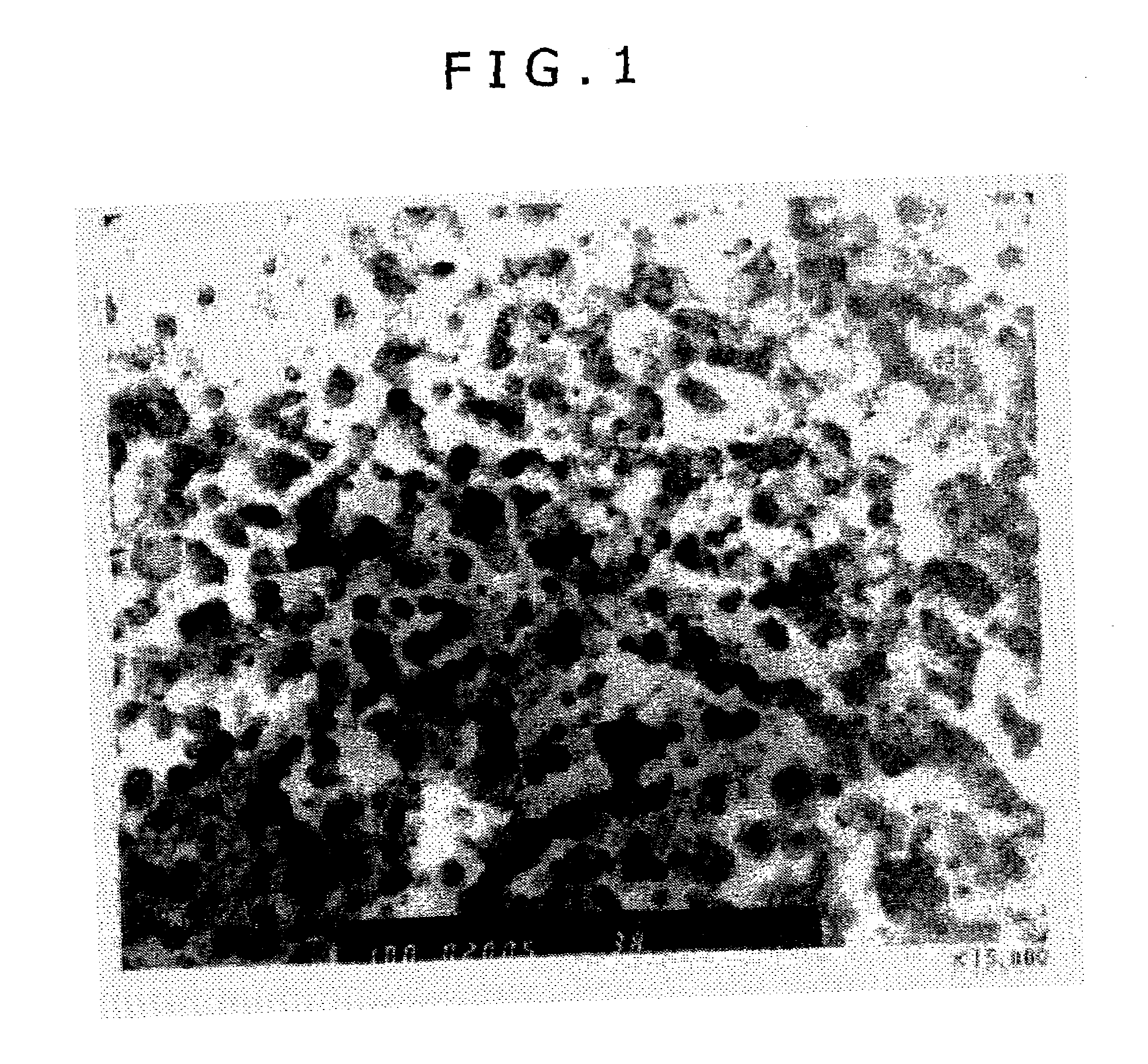

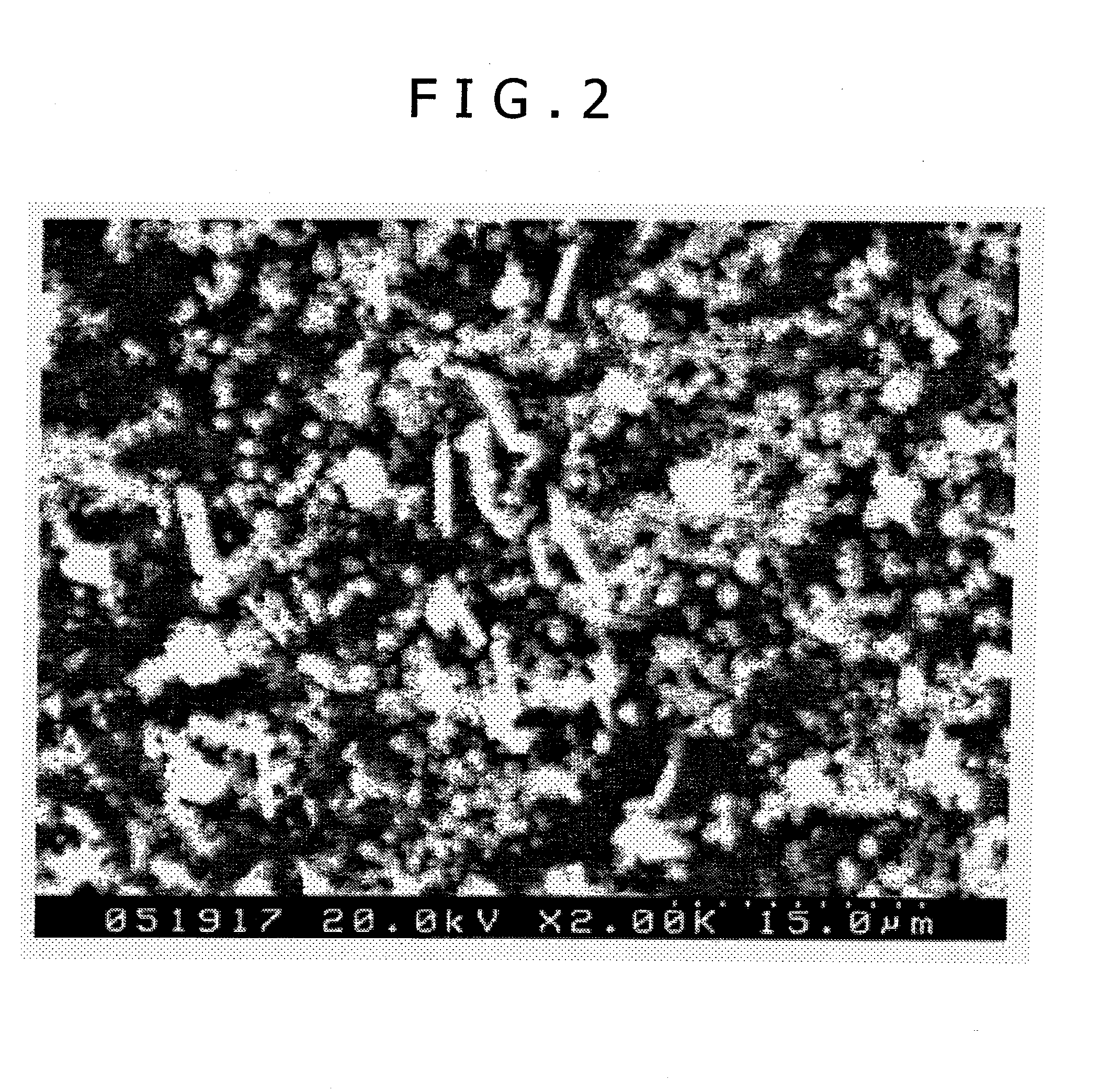

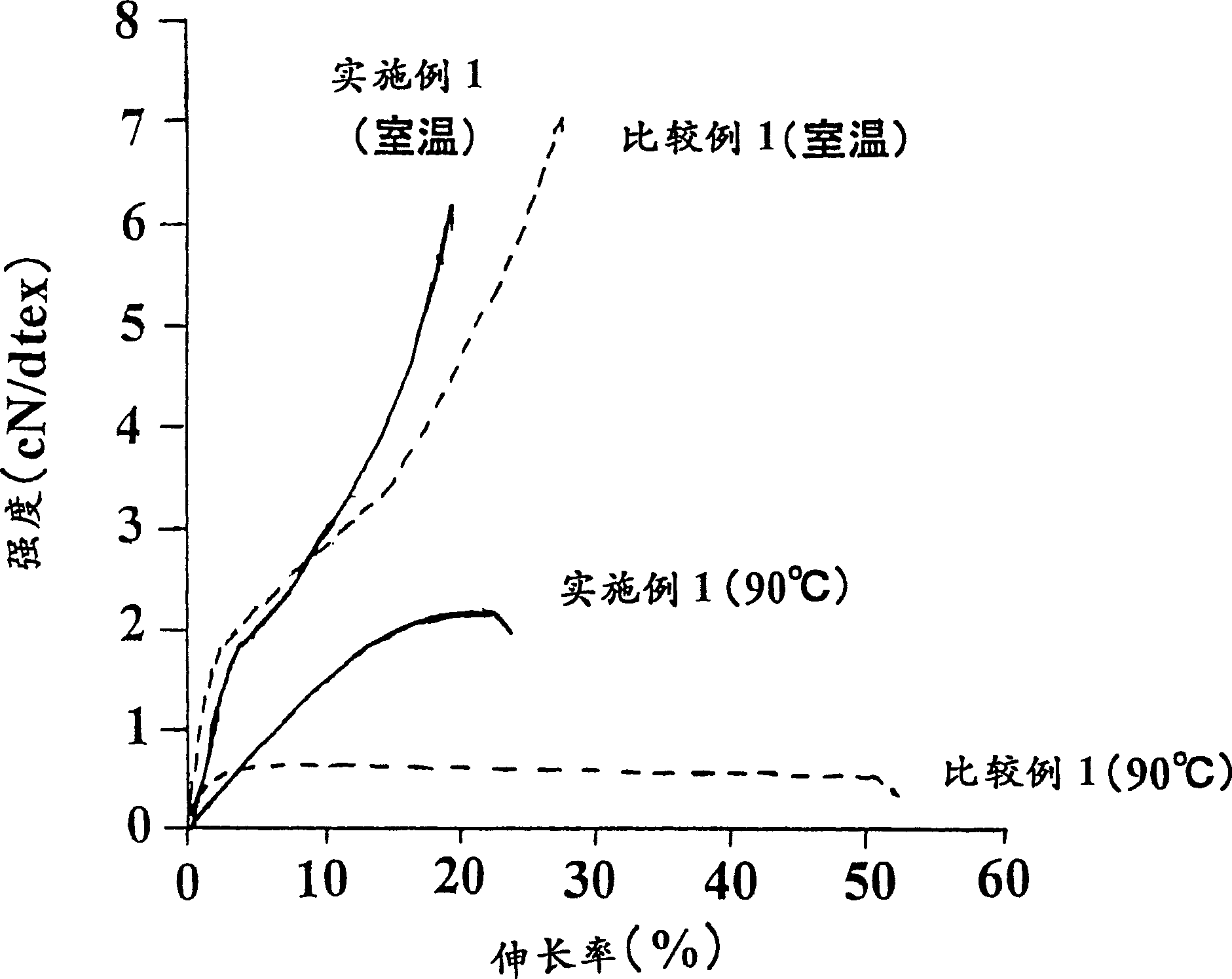

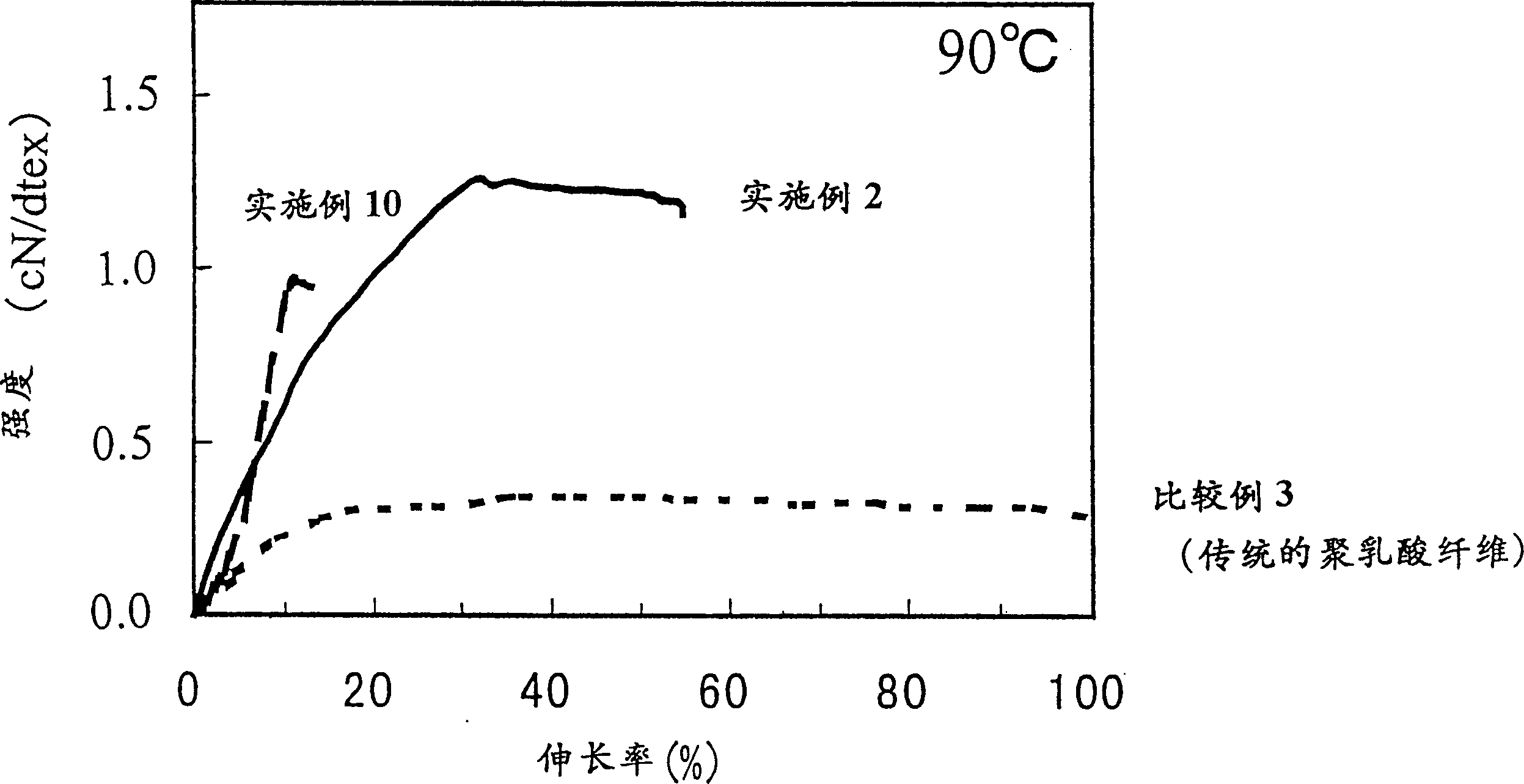

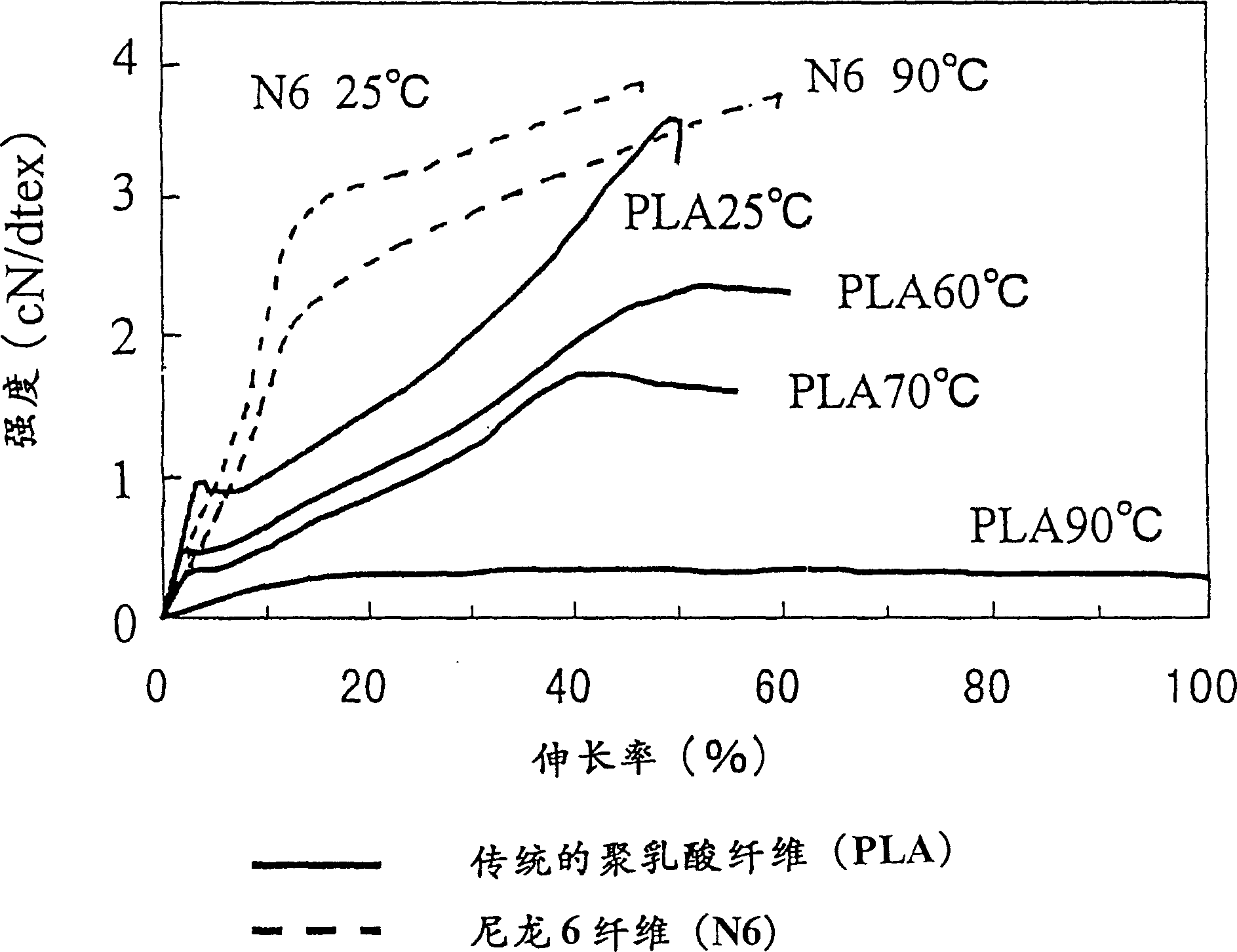

Polylactate fiber

InactiveCN1217040CIntense fluffingPoor wear resistanceFilament/thread formingWoven fabricsFiberPolymer science

A poly(lactic acid) fiber has a strength at 90 DEG C of equal to or more than 0.8 cN / dtex and exhibits significantly satisfactory mechanical properties at high temperatures as compared with conventional poly(lactic acid) fibers.

Owner:TORAY IND INC

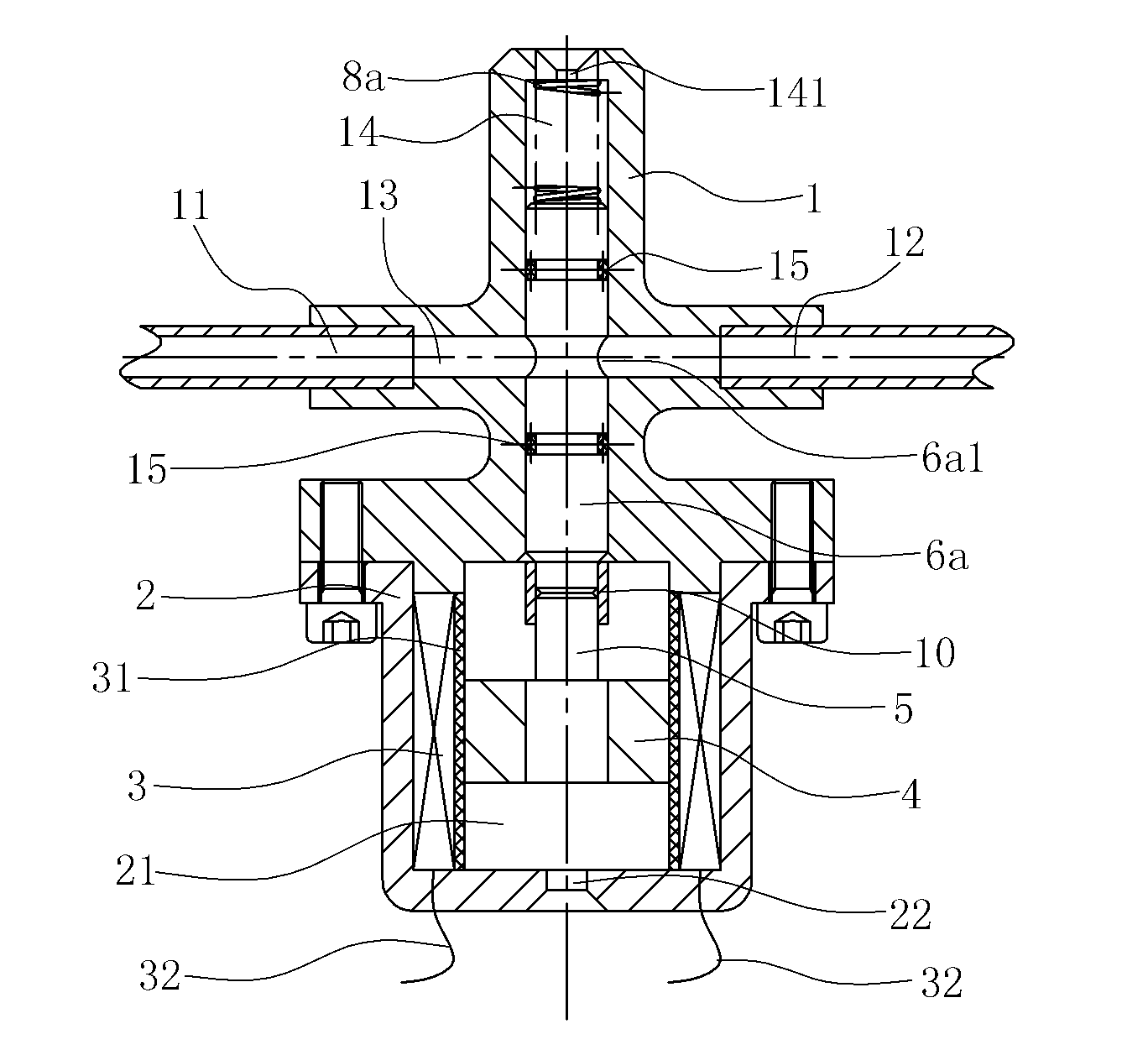

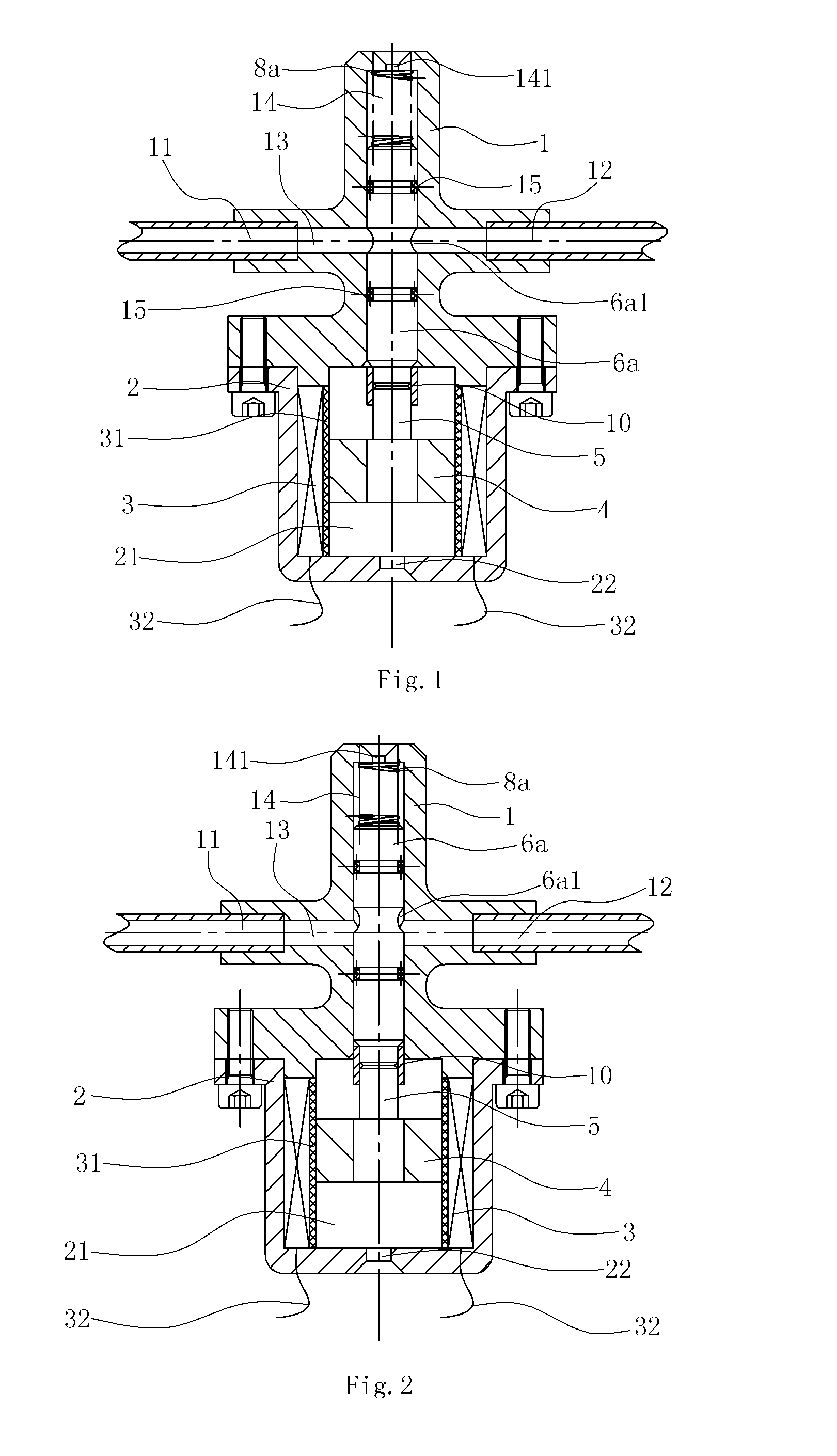

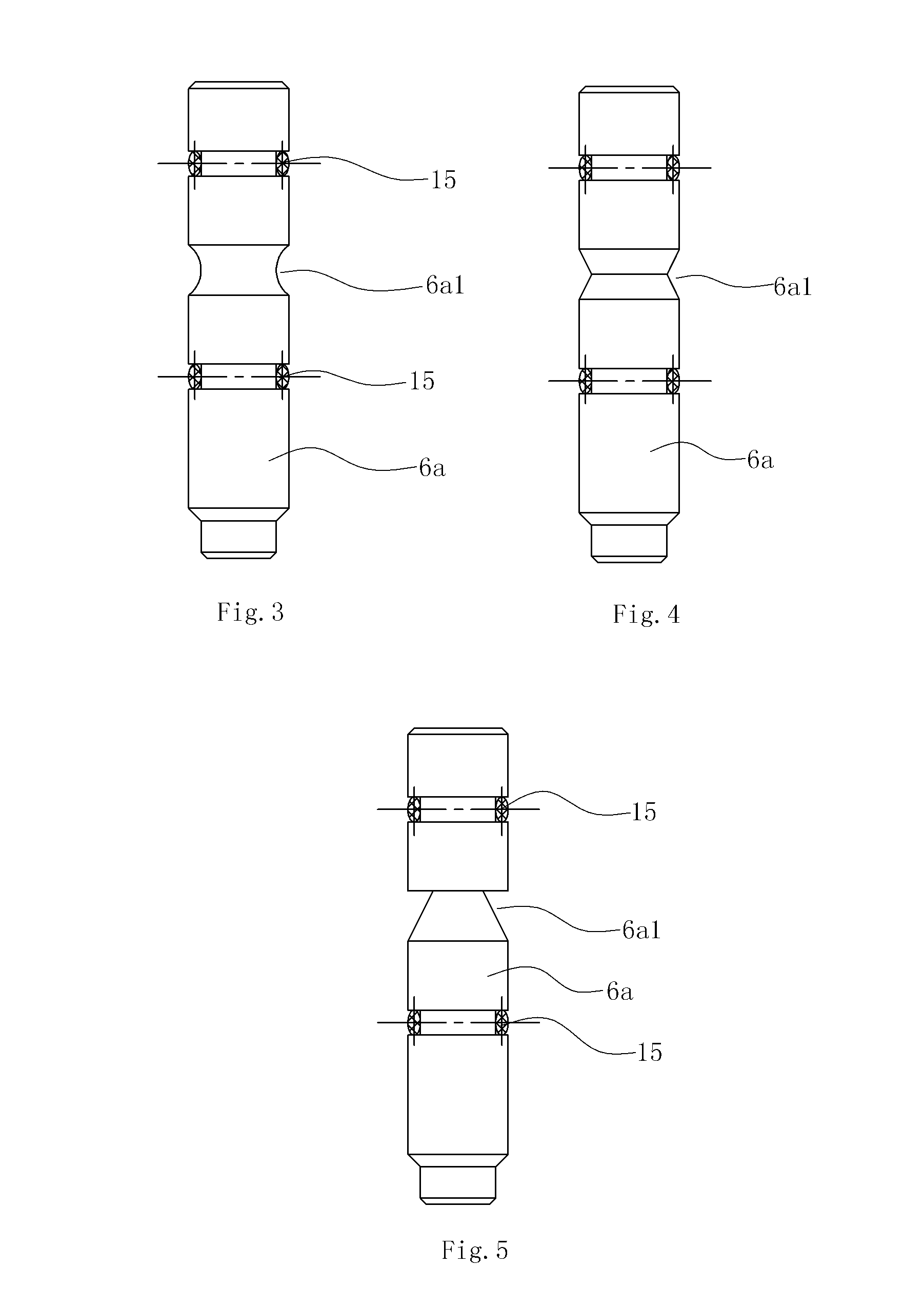

Throttle Valve

InactiveUS20110297858A1Simple structureLight weightOperating means/releasing devices for valvesEfficient regulation technologiesEngineeringThrottle

A throttle valve comprises a valve body (1) provided with a flow passage (13) and a mounting hole (14), a valve core movably inserted inside the mounting hole (14) and a driving mechanism for the valve core disposed out of the valve body (1) and connected with the valve body (1); the driving mechanism directly drives the valve core to slide axially, said driving mechanism includes a valve seat (2) with a cavity (21) inside, a coil (3) disposed in said cavity (21), a magnetic element (4) surrounded by said coil (3), which can be driven to slide relatively to said coil (3) by the electromagnetic force, an iron core (5) connected with said valve core and said magnetic element (4), and an elastic part acting on said valve core. The damping force of the elastic part to said valve core resists the electromagnetic force of said coil (3) to said magnetic element (4). The throttle valve of the present invention has simple structure, low cost and light weight

Owner:NINGBO ALLKO AUTOMOBILE AIR CONDITIONERS

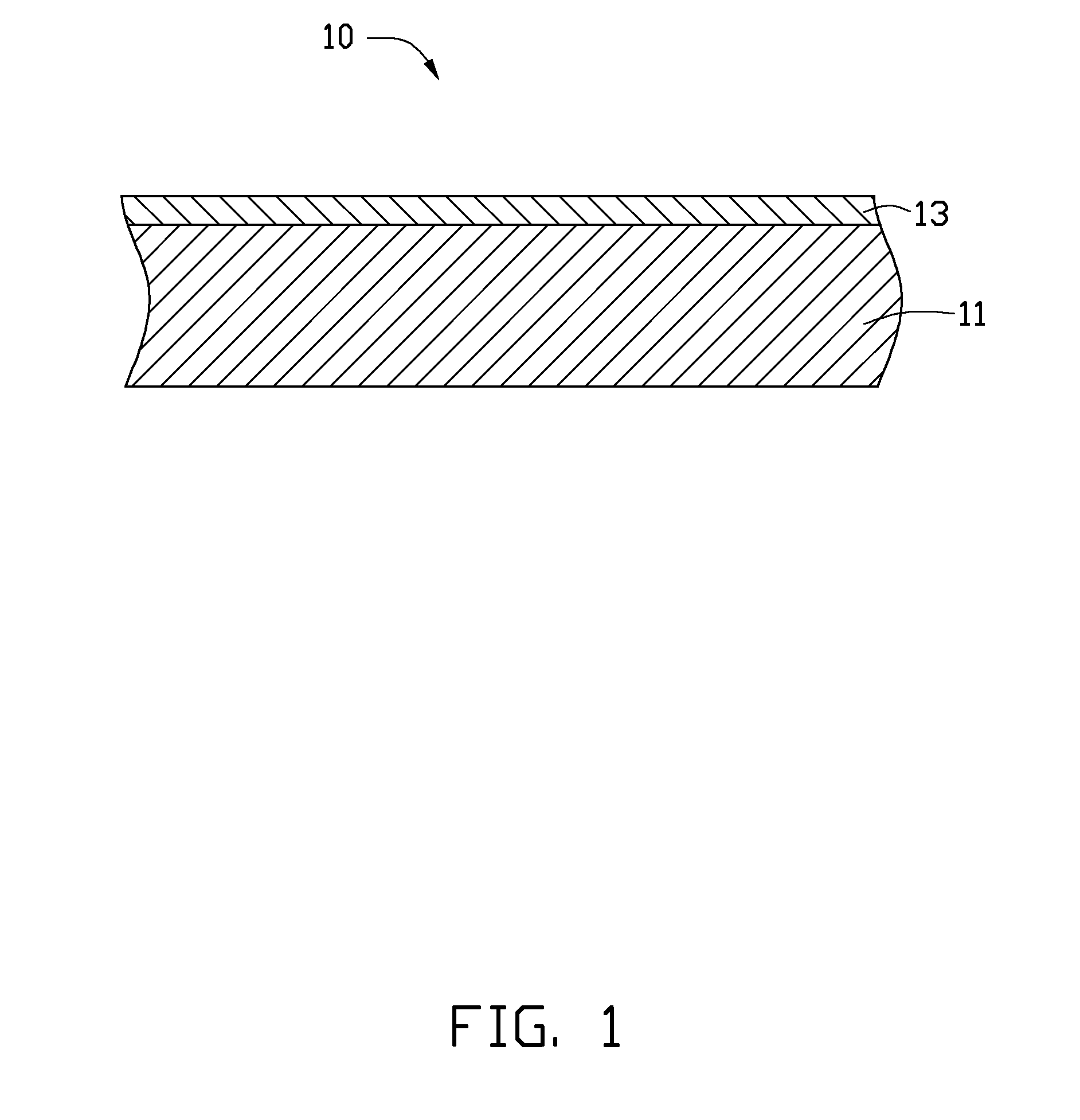

Coated article and method for making same

InactiveUS20120171474A1Improve wettabilityReduce hardnessVacuum evaporation coatingSputtering coatingWear resistanceChemical stability

A coated article is provided. The coated article includes a substrate, a hydrophobic layer formed on the substrate. The hydrophobic layer includes a first layer portion formed on the substrate and a second layer portion formed on the first layer portion, the first layer portion is a CNy layer, the second layer portion is a CNxFz layer, wherein 1≦y≦3, 1≦x≦3, 1≦z≦4. The water contact angle of the hydrophobic layer is more than 110°. The hydrophobic layer has a good chemical stability, high-temperature resistance and a good abrasion resistance, which effectively extends the use time of the coated article. A method for making the coated article is also described there.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

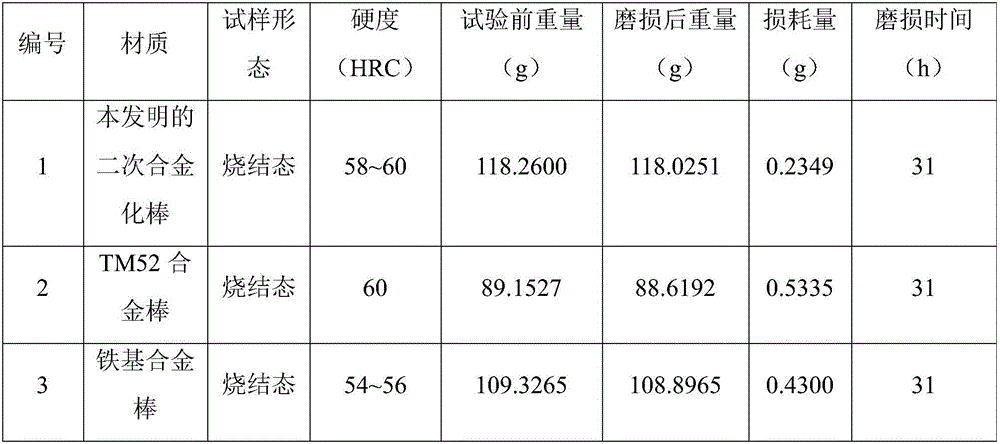

Method for preparing high-hardness high-strength-and-toughness iron-based wear resistant material through secondary alloying

The invention discloses a method for preparing a high-hardness high-strength-and-toughness iron-based wear resistant material through secondary alloying. The method comprises the following steps: (1) smelting raw materials, and then preparing alloy powder A through a water mist method, wherein the alloy powder A contains the following elements in percentage by mass: 18-23% of Cr, 0.8-1.8% of Mo, 0.6-1.5% of Ni, 0.3-0.8% of Ti, 0.4-1.0% of Si, 0.6-1.2% of V, 2.4-2.9% of C and the balance of Fe; and (2) performing ball milling on 7-10 parts by mass of powder B and 90-93 parts by mass of alloy powder A, mixing, adding a forming agent to prepare a blank, and sintering to obtain the iron-based wear resistant material, wherein the powder B comprises the following components in percentage by mass: 12-24% of Cu, 12-20% of Ni, 9-15% of Mo, 6-12% of Mn, 15-25% of TiC and the balance of Fe. The iron-based wear resistant material disclosed by the invention has favorable physical and mechanical properties, and reaches the technical standard of a corresponding designation of an industrial steel bond hard alloy.

Owner:嘉禾县飞恒合金铸造有限公司

Fiber reinforced hose

ActiveUS6994119B2High tensile strengthImprove heat resistanceClosuresClosure using stoppersYarnHeat resistance

A flexible fiber inforced hose comprises an inner rubber layer, an outer rubber layer, and a fiber reinforced layer provided between the inner rubber layer and the outer rubber layer, wherein the fiber reinforced layer is constructed by using a reinforcing fiber of at least one raw yarn, which is a spanized yarn consisting of monofilaments made of a para aromatic polyamide material. Such a fiber reinforced hose has excellent heat resistance, tensile strength, and adhesiveness with the rubber layers, as well as durability against repetitive pressurizations.

Owner:SUMITOMO RIKO CO LTD

Production technology of wear-resistant offset ink

ActiveCN105440776AImprove wear resistanceLarge total specific surface areaInksProcess engineeringMaterials science

The invention relates to the technical field of ink production, in particular to a production technology of wear-resistant offset ink. The production technology of the wear-resistant offset ink comprises steps as follows: Step 1, base ink is heated to a certain temperature; Step 2, then wax powder is added to the base ink at the certain temperature, the adding speed of the wax powder is controlled, low-speed stirring is required in the whole process when the wax powder is added to the base ink, and a mixture is obtained after addition of the wax powder; Step 3, after addition of the wax powder, the temperature of the mixture is controlled continuously, then the mixture is stirred at the high speed for a period, and the wear-resistant offset ink is obtained. The production technology of the wear-resistant offset ink has the advantages of simple production technology and low equipment energy consumption, the dispersion degree of the wax powder in the base ink can be increased, and the wear resistance of the prepared wear-resistant offset ink is better.

Owner:茂名阪田油墨有限公司

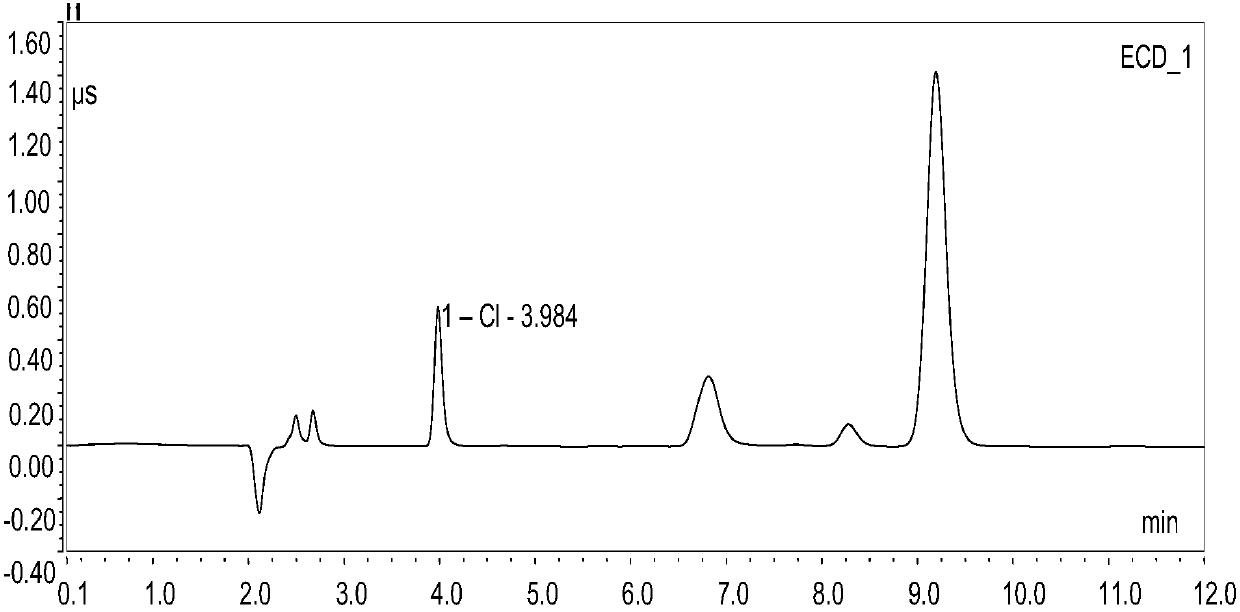

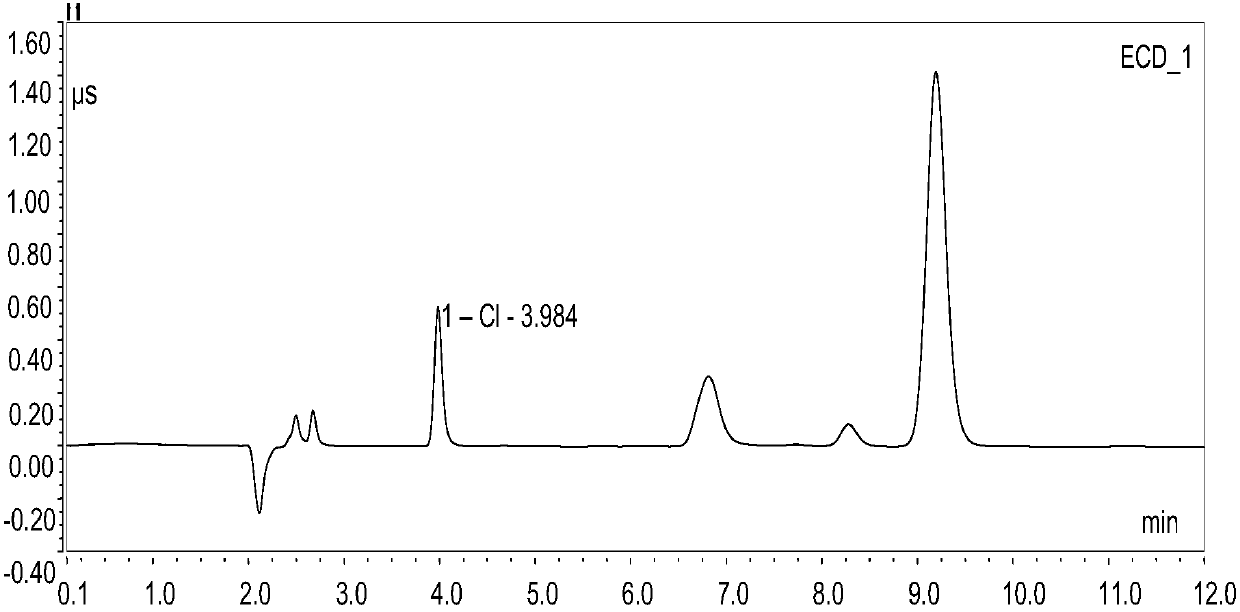

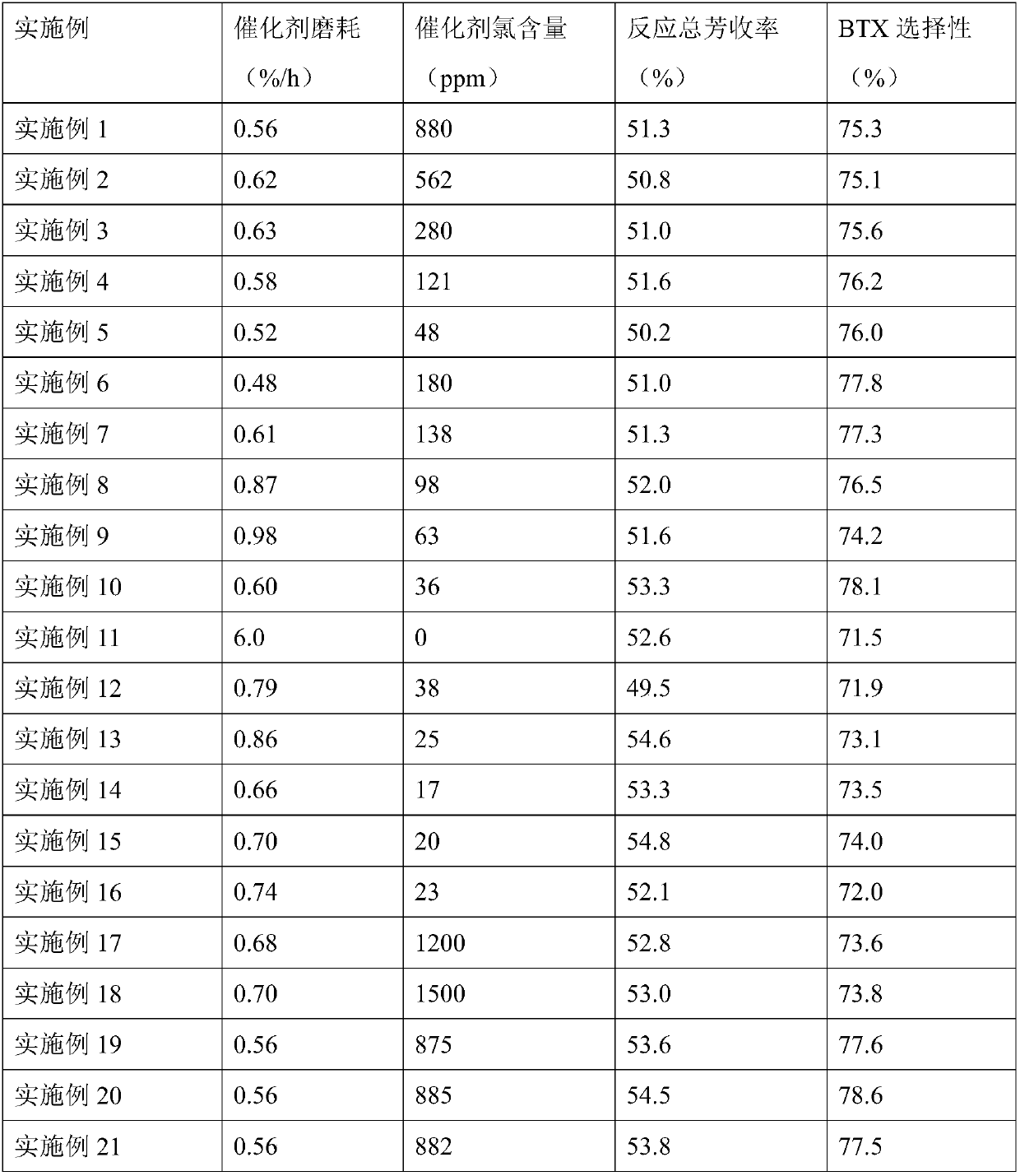

Fluidized bed catalyst for preparing aromatic hydrocarbons from methanol

ActiveCN109701622APoor wear resistanceImprove wear resistanceMolecular sieve catalystsCatalyst activation/preparationAluminium chlorideMolecular sieve

The invention provides a fluidized bed catalyst for preparing aromatic hydrocarbons from methanol. The catalyst provided by the invention is good in wear resistance, low in chlorine content and low inequipment corrosion. The catalyst provided by the invention adopts hydroxyl aluminium chloride with a good binding property or a mixture of the hydroxyl aluminium chloride and an acidic silica sol asa forming binder, a molecular sieve, the binder and a structure enhancer are mixed and subjected to spraying molding and then impregnation with an active metal to obtain the fluidized bed catalyst for preparing the aromatic hydrocarbons from the methanol. Before the catalyst is used, the catalyst and 300-680 DEG c high-temperature water vapor are subjected to contact treatment for a certain timefor washing off of a large amount of chlorine elements residual in the catalyst, the corrosion risk of the catalyst to reaction equipment is reduced, and the good technical effect is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

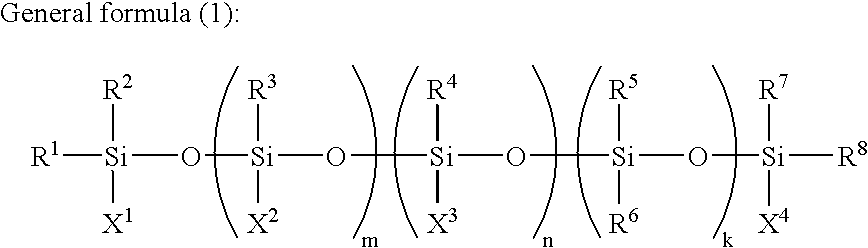

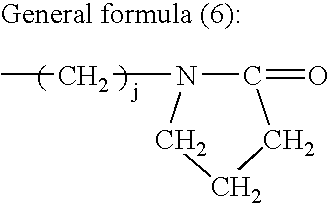

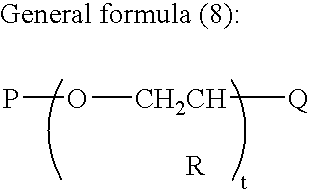

Conjugated diene rubber, process for producing the same, and rubber composition

InactiveUS7241842B2Poor wear resistanceReduce heat buildupSpecial tyresPolymer scienceConjugated diene

A conjugated diene rubber obtained by a process wherein active conjugated diene polymer chains each having an active metal at a polymer chain terminal, which have been obtained by polymerizing a conjugated diene monomer alone, or a conjugated diene monomer and an aromatic vinyl monomer with the aid of an organic active metal in an inert solvent, are allowed to react with a specific polyorganosiloxane capable of reacting with the active metal bonded to the polymer chain terminal. The conjugated diene rubber contains at least 5% by weight of a structure comprising at least three conjugated diene polymer chains bonded through a polyorganosiloxane. The conjugated diene rubber gives, when silica is incorporated therein, a rubber composition having good processability and giving a crosslinked rubber having reduced heat build-up, good wet grip performance and good abrasion resistance.

Owner:ZEON CORP

Display device and touch panel

ActiveUS8519976B2Poor wear resistanceLow chemical enduranceDischarge tube luminescnet screensLamp detailsDisplay deviceCarbon nanotube

A display device includes a touch panel. The touch panel includes at least one transparent conductive layer. The at least one transparent conductive layer is a carbon nanotube layer including a plurality of carbon nanotubes, and the plurality of carbon nanotubes are substantially arranged along the same axis, and the density of the carbon nanotube layer is not constant.

Owner:BEIJING FUNATE INNOVATION TECH

Reinforcement method for concrete structure

A reinforcing method for concrete structure follows the steps as: surface treatment to the concrete structure to reveal structure sheaf and smooth and dust clean; preset super strength steel micro fiber on web texture in the same direction to form a steel micro fiber tape; spray coat on the concrete structure with a layer of high strength polymer mortar or resin mortar; stick the steel micro fibertape to the surface; spray coat on the steel fiber tape with a layer of high strength polymer mortar or resin mortar and roll on along the fiber direction to form a close grained layer; finally spraycoat protection layer to it.

Owner:上海维固工程实业有限公司 +1

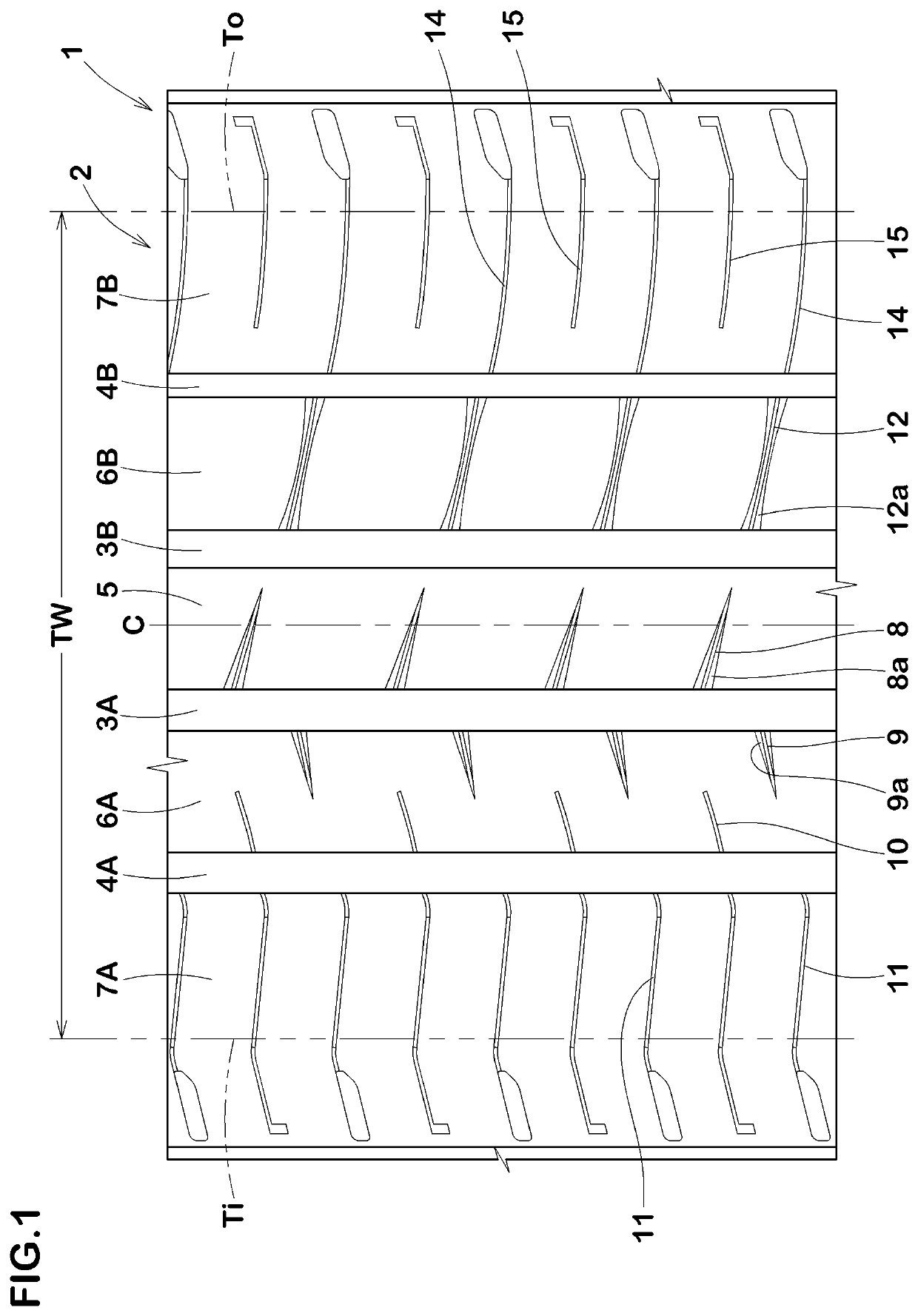

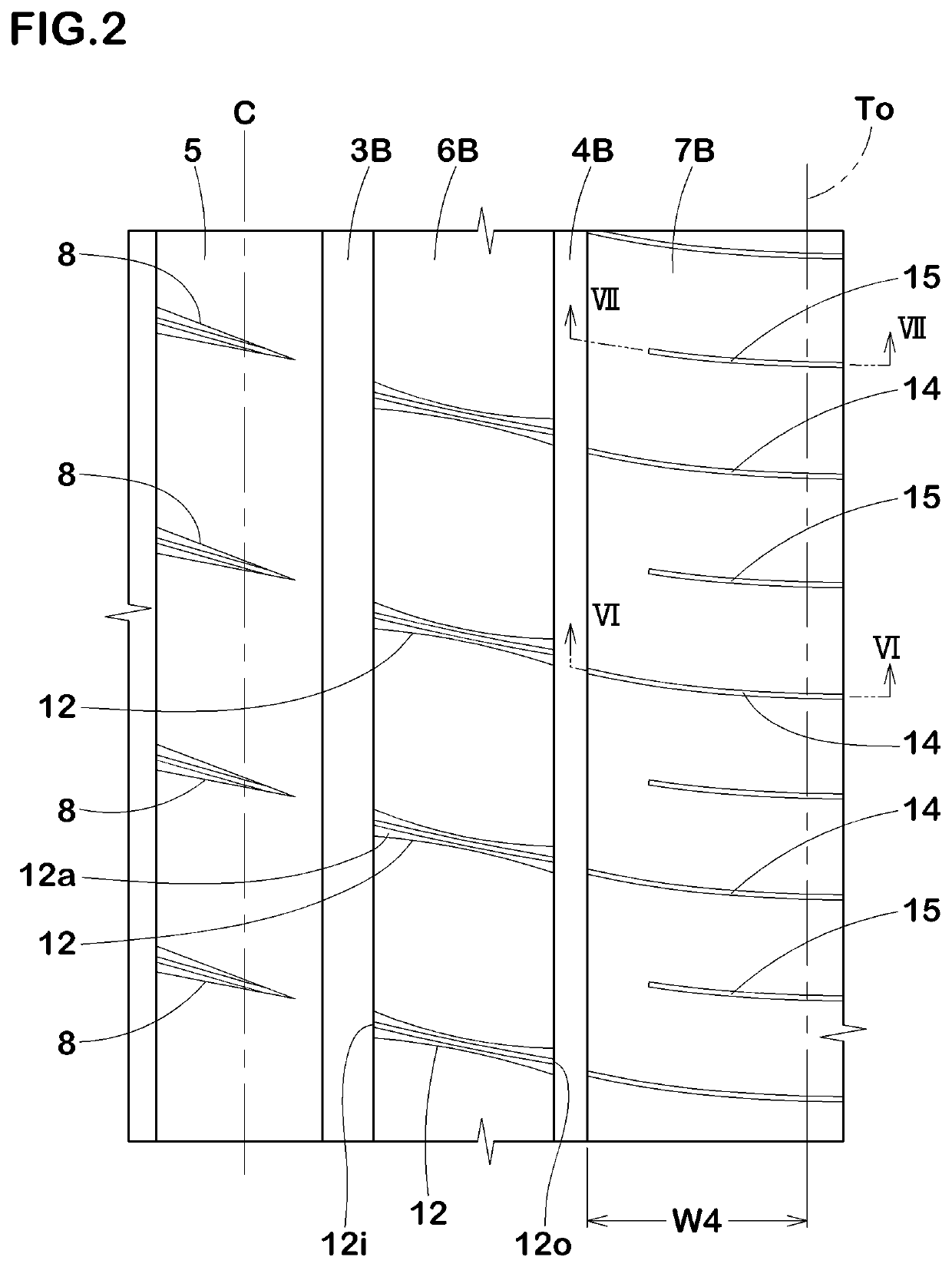

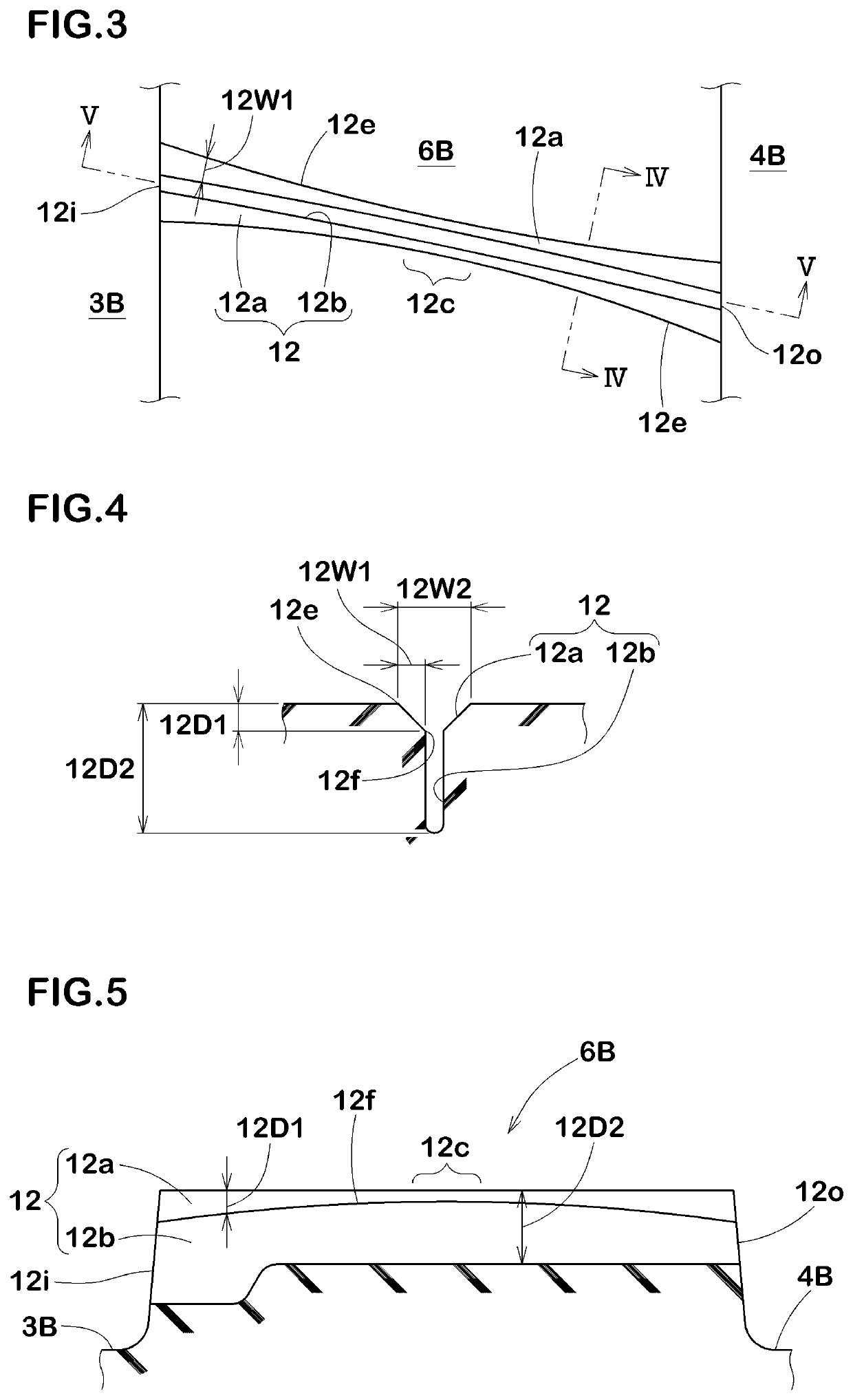

Tyre

PendingUS20210197622A1Poor wear resistanceImproving ride comfort and wear resistanceTyre tread bands/patternsMining engineeringStructural engineering

Owner:SUMITOMO RUBBER IND LTD

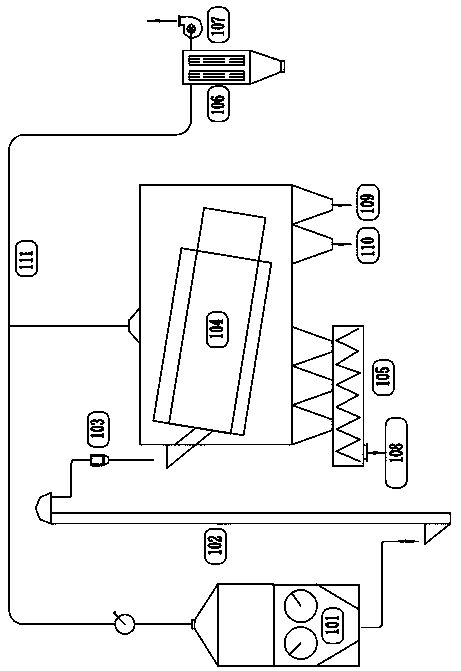

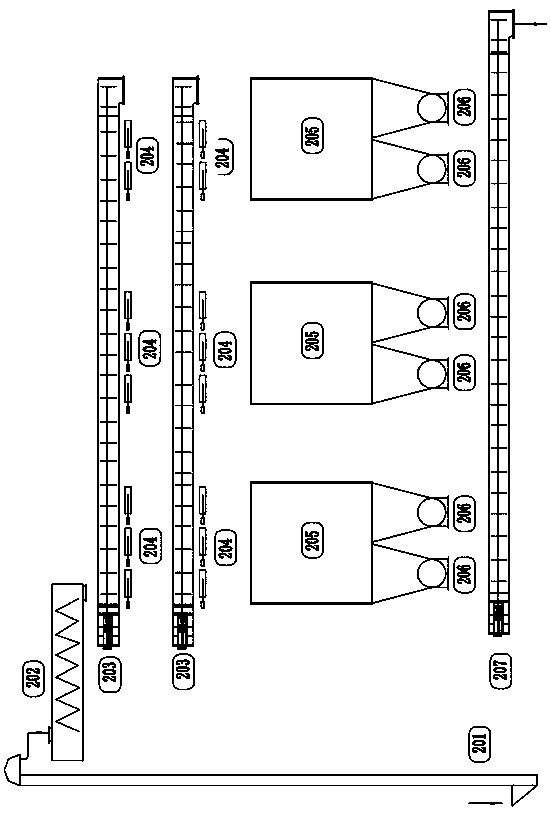

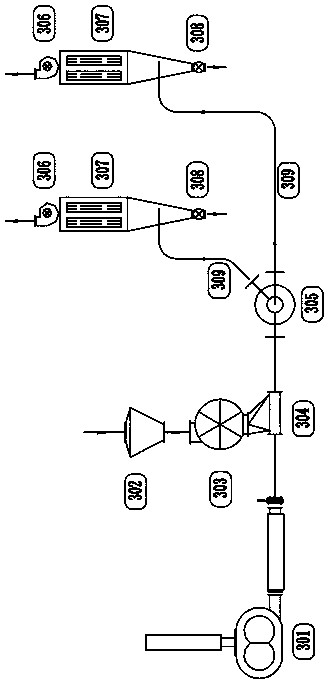

Rice husk cleaning, warehousing and conveying production line

PendingCN109626014AEasy to cleanImprove working environmentBulk conveyorsMagnetic separationProduction lineHusk

A rice husk cleaning, warehousing and conveying production line comprises a cleaning classification work section, a storage work section and a wind power conveying work section, all of which are sequentially arranged. The cleaning classification work section comprises a double-screw feeder, a first elevator, a permanent magnetic drum, a double-barrel rotation screen and a light impurity gatheringscrew conveyor. The storage work section comprises a second elevator, a both-way screw conveyor, a bin feeding scraper conveyor, a pneumatic gate valve, a rice husk bin, a bin bottom screw conveyor and a bin discharging scraper conveyor. The wind power conveying work section comprises positive-pressure conveying equipment or negative-pressure conveying equipment, and a feeding port of the positive-pressure conveying equipment or negative-pressure conveying equipment is connected with a discharging port of the bin discharging scraper conveyor. The rice husk cleaning, warehousing and conveying production line is complete in function, and the three major functions of rice husk cleaning, storing and wind power conveying can be finished. The rice husk cleaning, warehousing and conveying production line can be used for comprehensive rice husk cleaning, moulding is avoided in the storage process, bridging / arching of rice husks in the bin is not likely to happen, bin discharging is more reliable, positive-pressure and negative-pressure wind power conveying is adopted according to the conveying distance, stability and reliability are achieved, and energy saving and environment friendlinessare achieved.

Owner:三门峡高新机械有限公司

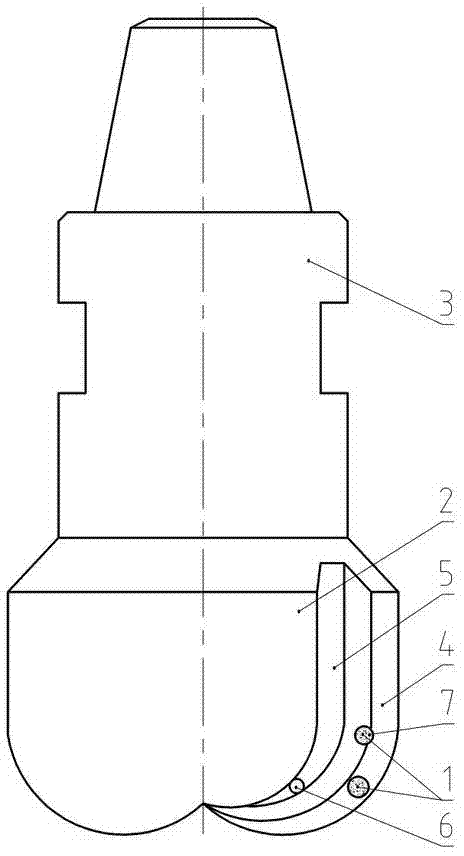

Steel body type diamond-impregnated bit

The invention relates to a steel body type diamond-impregnated bit, and belongs to the field of boring tools. The steel body type diamond-impregnated bit is composed of an impregnated body, a bit body and a joint, wherein the bit body is a steel body type bit body; a blade, a nozzle and a flow channel are processed on the steel body type bit body, and the impregnated body is arranged on the blade and exposed; the steel body type diamond-impregnated bit is characterized in that the impregnated body and a cutting material have dual rock breaking functions of shearing fracture and plough cutting; the whole intensity of the steel body type bit body is high, the steel body type bit body is beneficial to developing the large-size steel body type diamond-impregnated bit, designing a long blade and a deep chip groove and increasing the height of the impregnated body; the wearability of the steel body type bit body is poor, the impregnated body is easy to expose, the mechanical drilling speed and drilling footage are increased, the cost of the steel body type bit body is lower than that of a fetal body, and the bit cost is greatly reduced; the impregnated body is manufactured through a hot pressing agglomeration technology, the quality is better, the drilling footage is improved, and the cost is reduced through serialization; and an impregnated body and steel body type bit body fission type structure is beneficial to form an industry group and accelerating research and development and the updating speed.

Owner:CHINA PETROLEUM & CHEM CORP +1

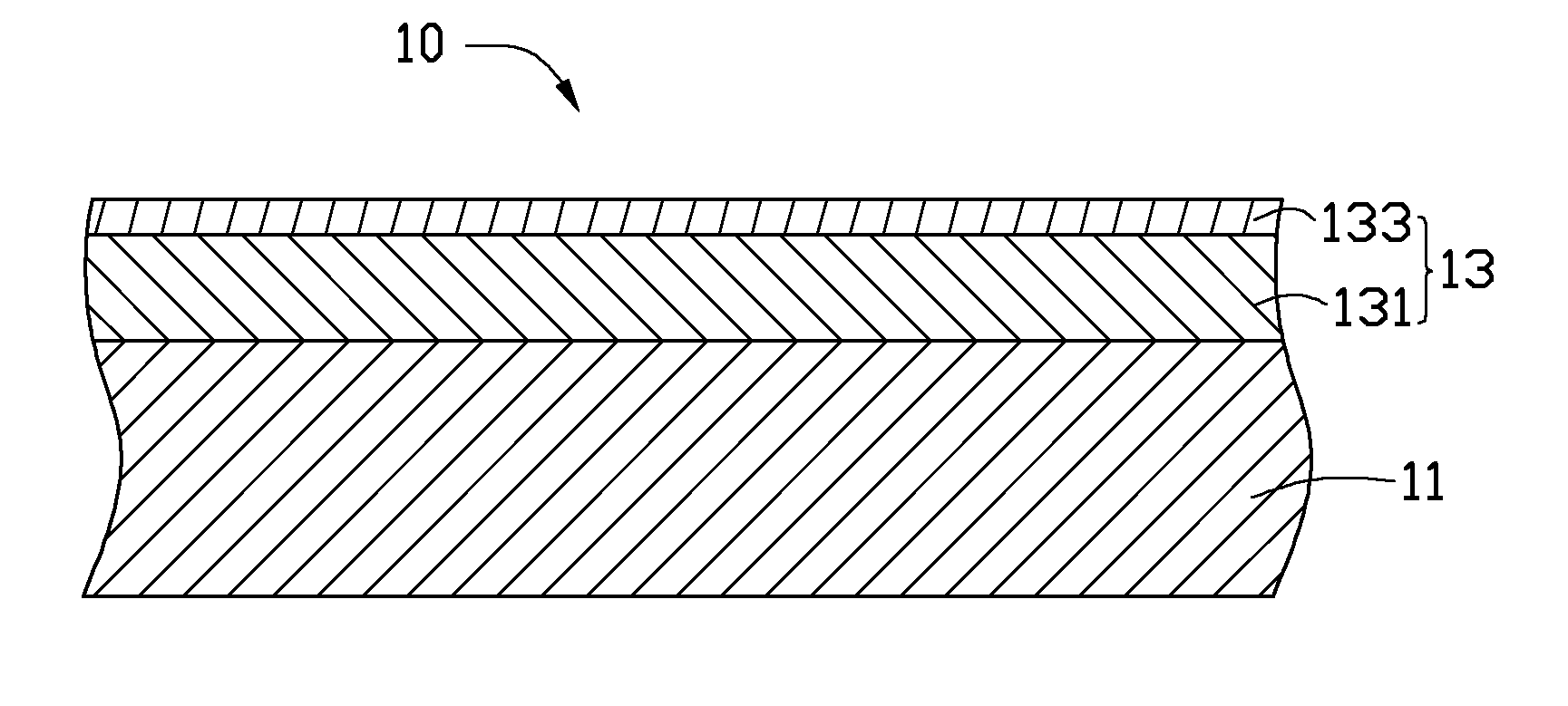

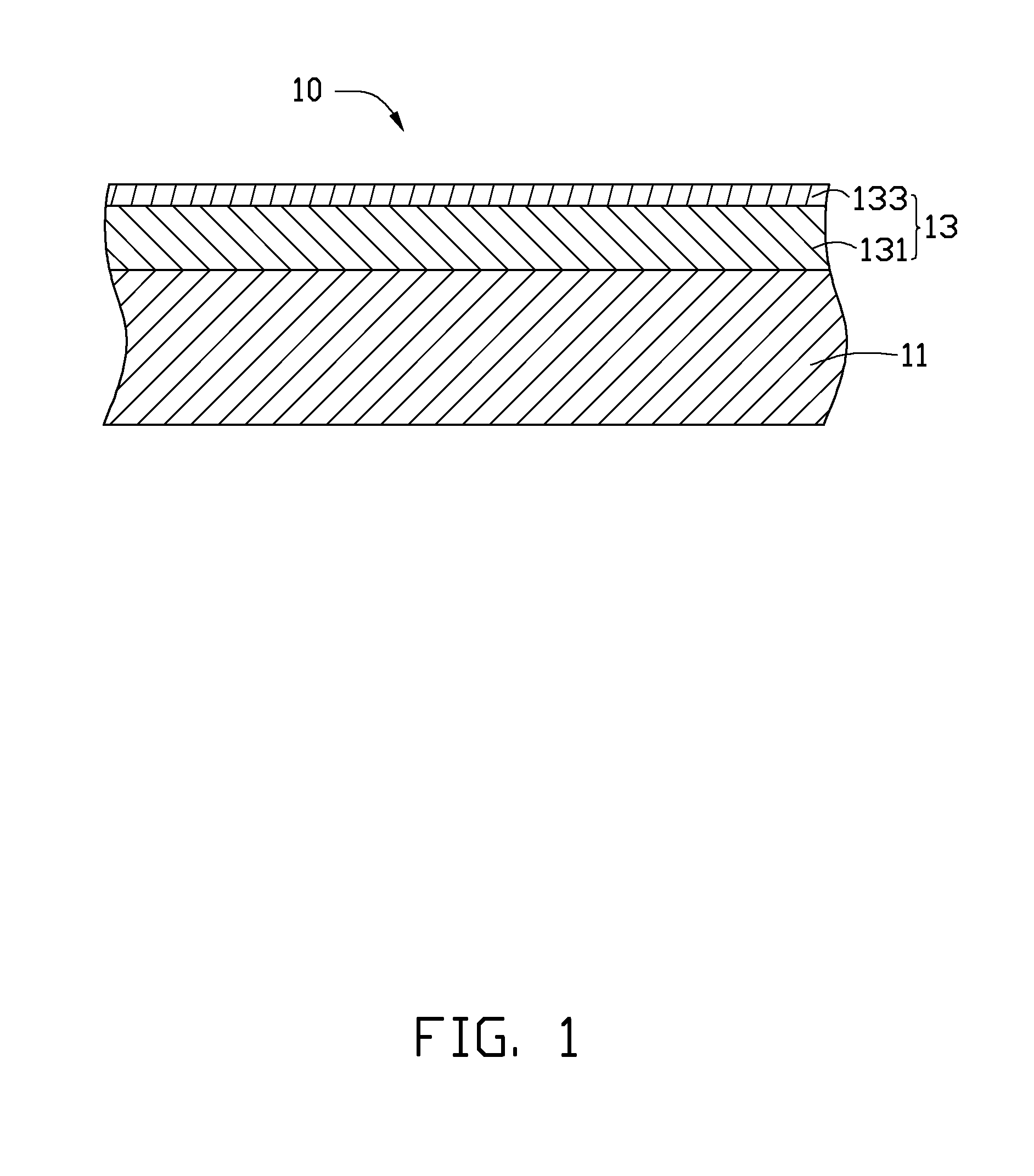

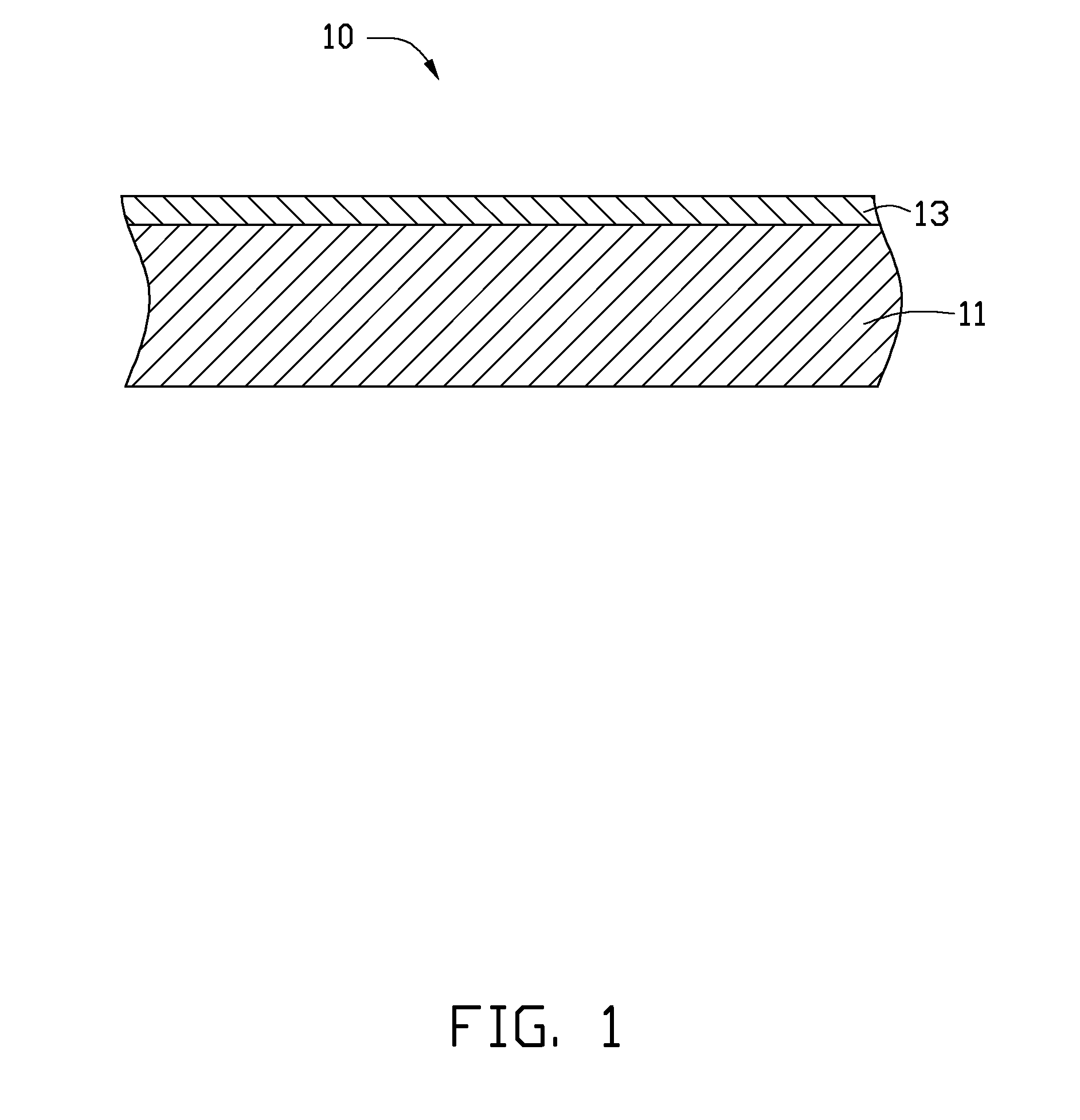

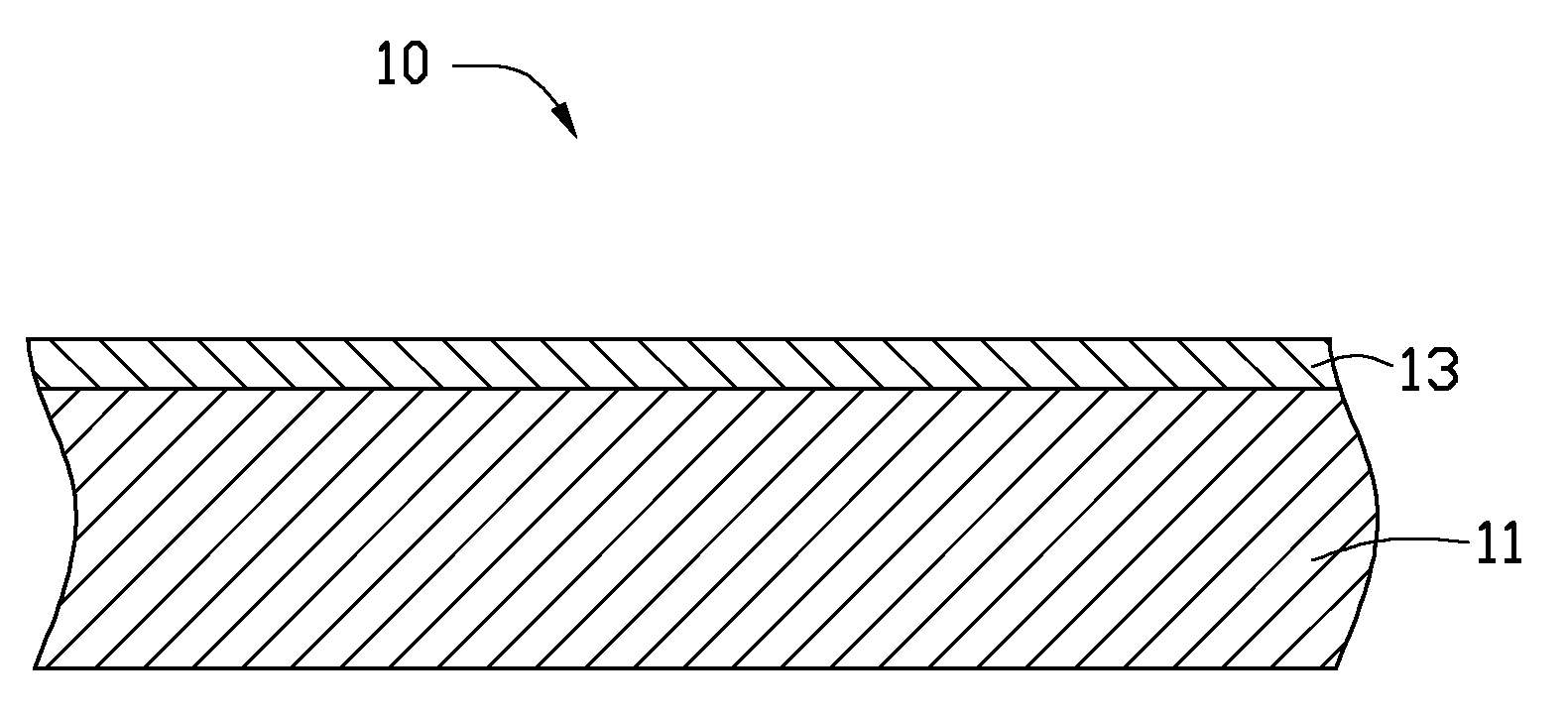

Coated article and method for making same

InactiveUS20120171473A1Improve wettabilityReduce hardnessVacuum evaporation coatingSputtering coatingTemperature resistanceWear resistance

A coated article is provided. The coated article includes a substrate, a hydrophobic layer formed on the substrate. The hydrophobic layer is an amorphous carbon nitride layer which is defined as CNy, wherein y is in a range of from about 1 to about 3. The water contact angle of the hydrophobic layer 13 is about 100° to about 110°. The hydrophobic layer has a good chemical stability, high-temperature resistance and a good abrasion resistance, which effectively extends the use time of the coated article. A method for making the coated article is also described therein.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

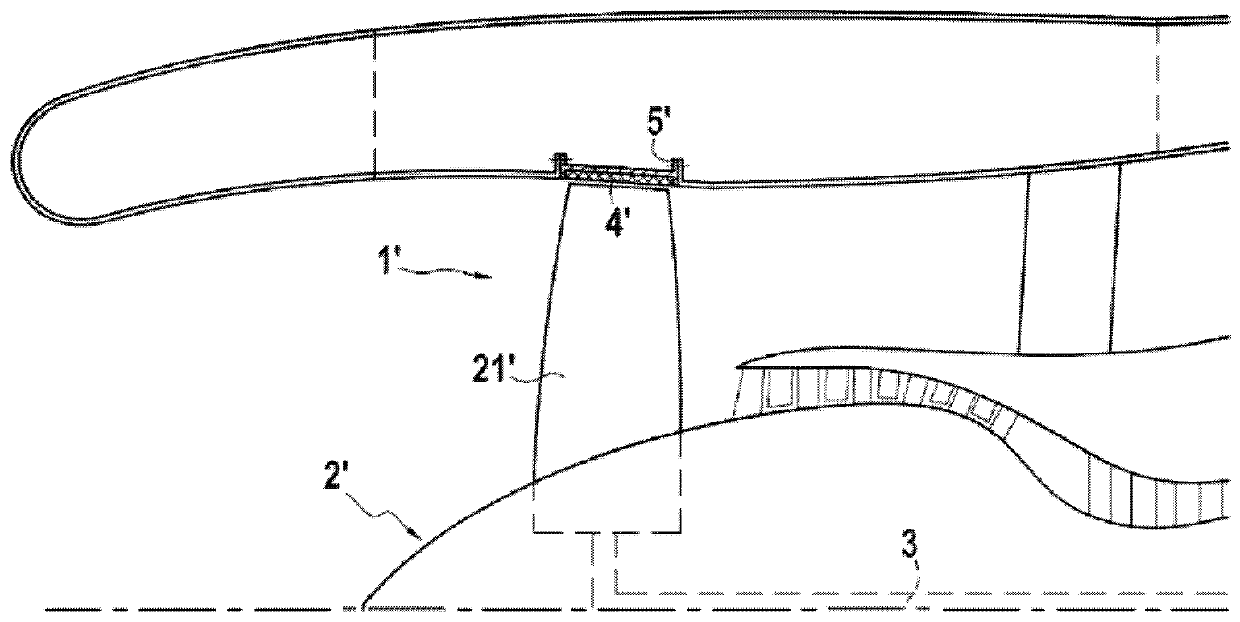

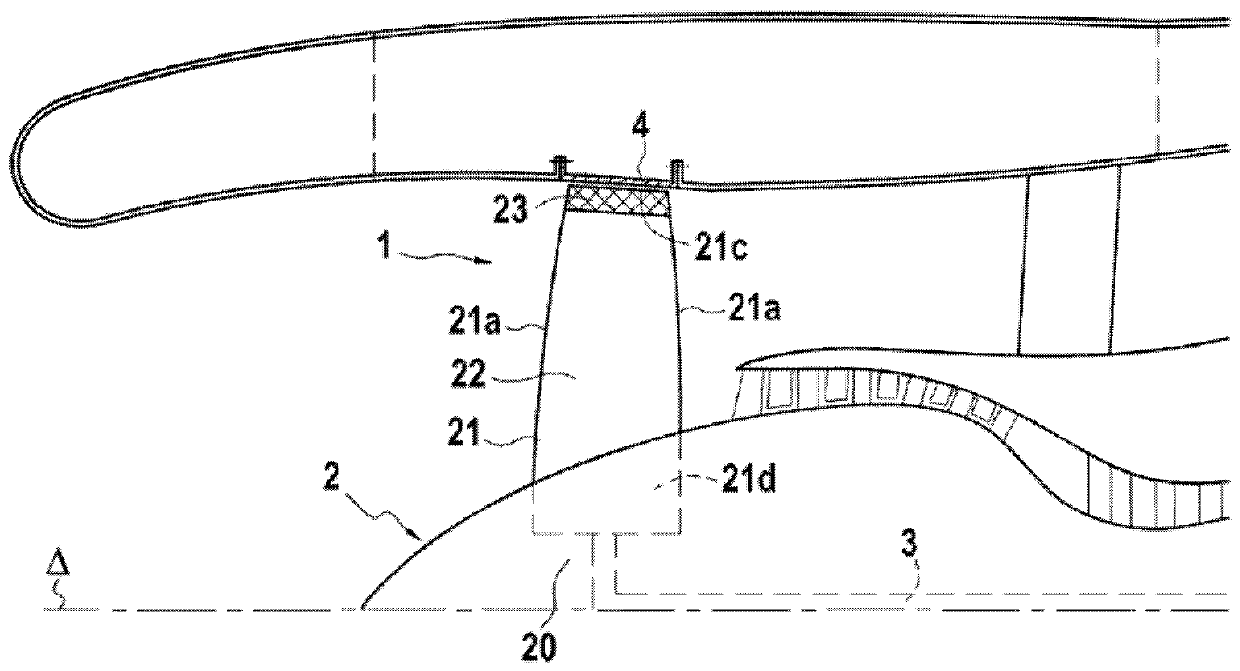

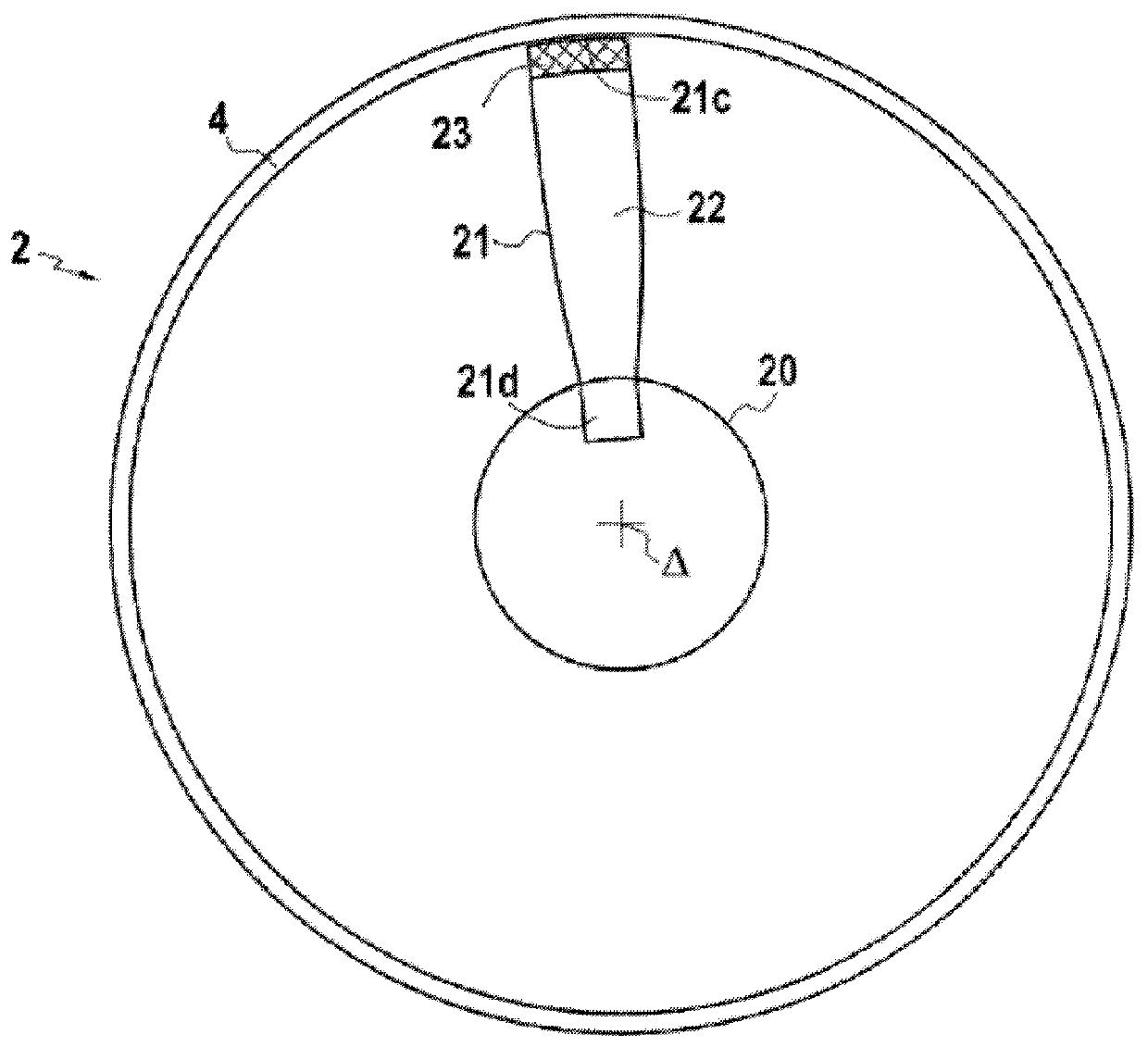

Composite material fan blade integrating large clearance

PendingCN110566505AQuick wearHigh mechanical strengthPump componentsEngine fuctionsEngineeringFan blade

The invention provides a composite material blade (21) for a fan (2) of a turbine engine (1). The blade (21) is characterized by including a first portion (22) that extends to the root (21d) of the blade (21) and that is made of a first material including first fiber reinforcement densified by a first matrix, the blade (21) also including a second portion (23) that extends to the tip (21c) of theblade (21) and that is made of a second material that is different from the first material and that includes second fiber reinforcement densified by a second matrix, the second material possessing abrasion resistance that is less than that of the first material.

Owner:SAFRAN AIRCRAFT ENGINES SAS

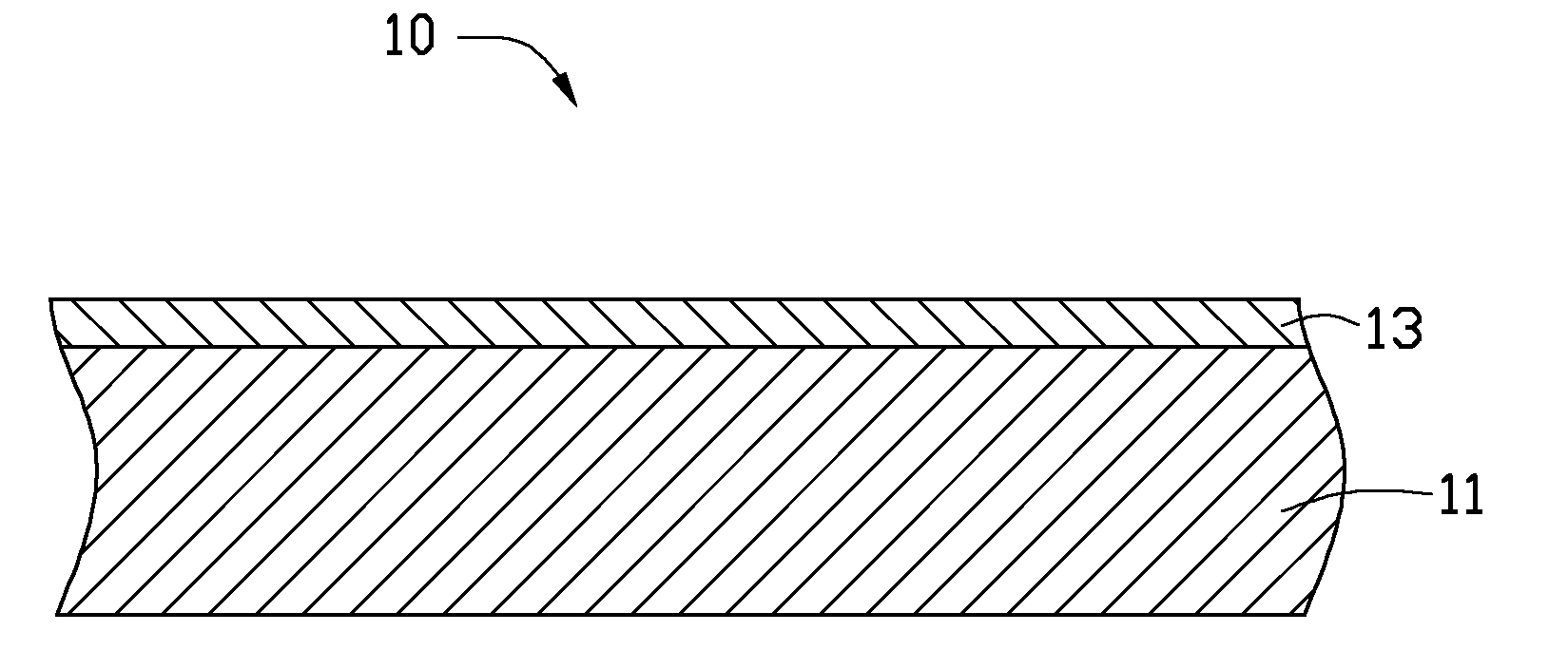

Coated article and method for making same

InactiveUS8614012B2Improve wettabilityReduce hardnessVacuum evaporation coatingSputtering coatingTemperature resistanceWear resistance

A coated article is provided. The coated article includes a substrate, a hydrophobic layer formed on the substrate. The hydrophobic layer is an amorphous carbon nitride layer which is defined as CNy, wherein y is in a range of from about 1 to about 3. The water contact angle of the hydrophobic layer 13 is about 100° to about 110°. The hydrophobic layer has a good chemical stability, high-temperature resistance and a good abrasion resistance, which effectively extends the use time of the coated article. A method for making the coated article is also described therein.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Piston ring

ActiveUS10100929B2Improve wear resistanceReduce wearPiston ringsVacuum evaporation coatingCarbon coatingPiston ring

The present invention provides a piston ring having excellent abrasion resistance to an aluminum alloy cylinder or cylinder liner formed of a mating material and is therefore capable of decreasing abrasion of the mating material. An exemplary piston ring has a hard carbon coating formed on an outer peripheral surface, and the hard carbon coating contains 0.5 atom % or more to less than 5 atom % of tungsten (W).

Owner:RIKEN CO LTD

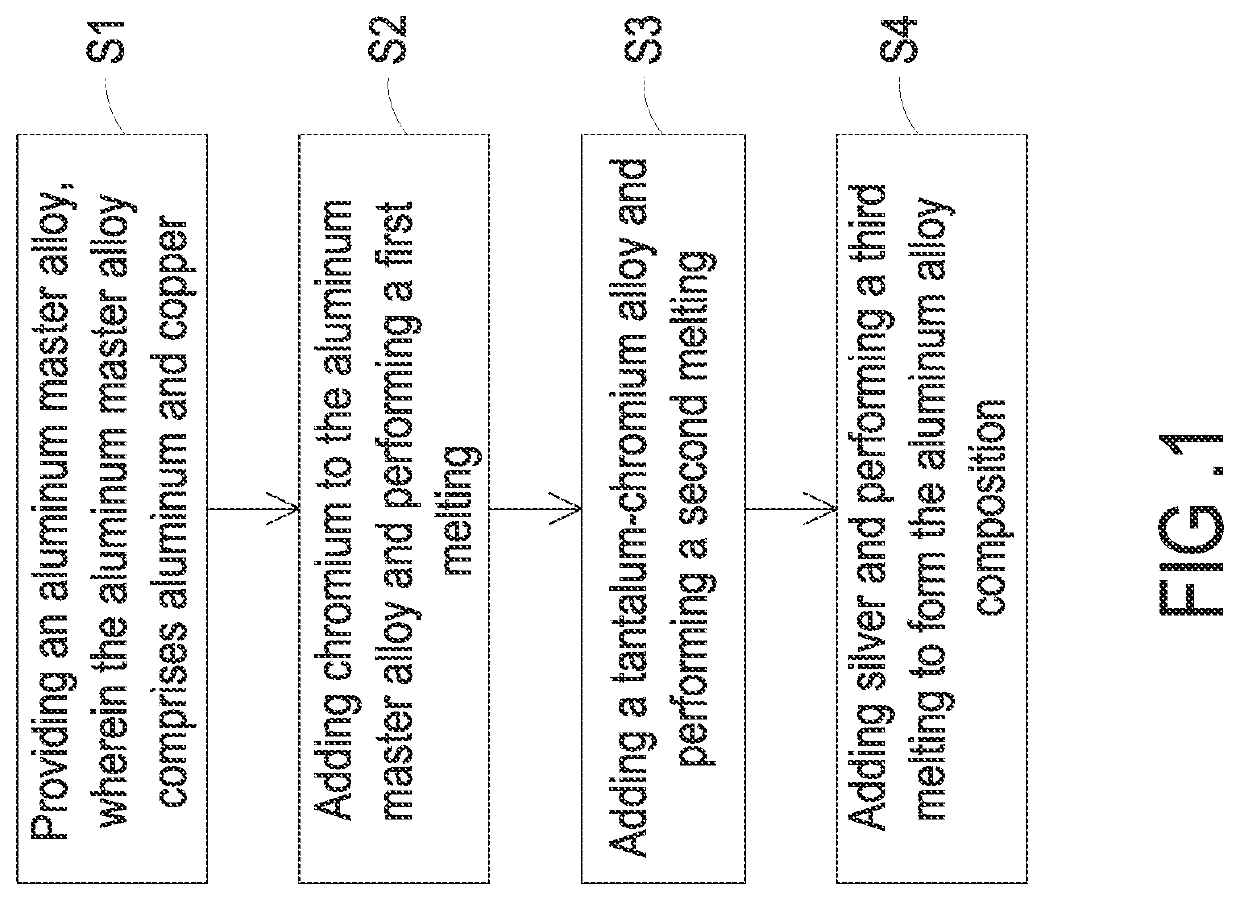

Aluminum alloy composition and manufacturing method thereof

The present disclosure provides a manufacturing method of an aluminum alloy composition. The manufacturing method includes the following steps in the sequence set forth: (S1) providing an aluminum master alloy, wherein the aluminum master alloy comprises aluminum and copper; (S2) adding chromium to the aluminum master alloy and performing a first melting; (S3) adding a tantalum-chromium alloy and performing a second melting; and (S4) adding silver and performing a third melting to form the aluminum alloy composition.

Owner:DELTA ELECTRONICS INC

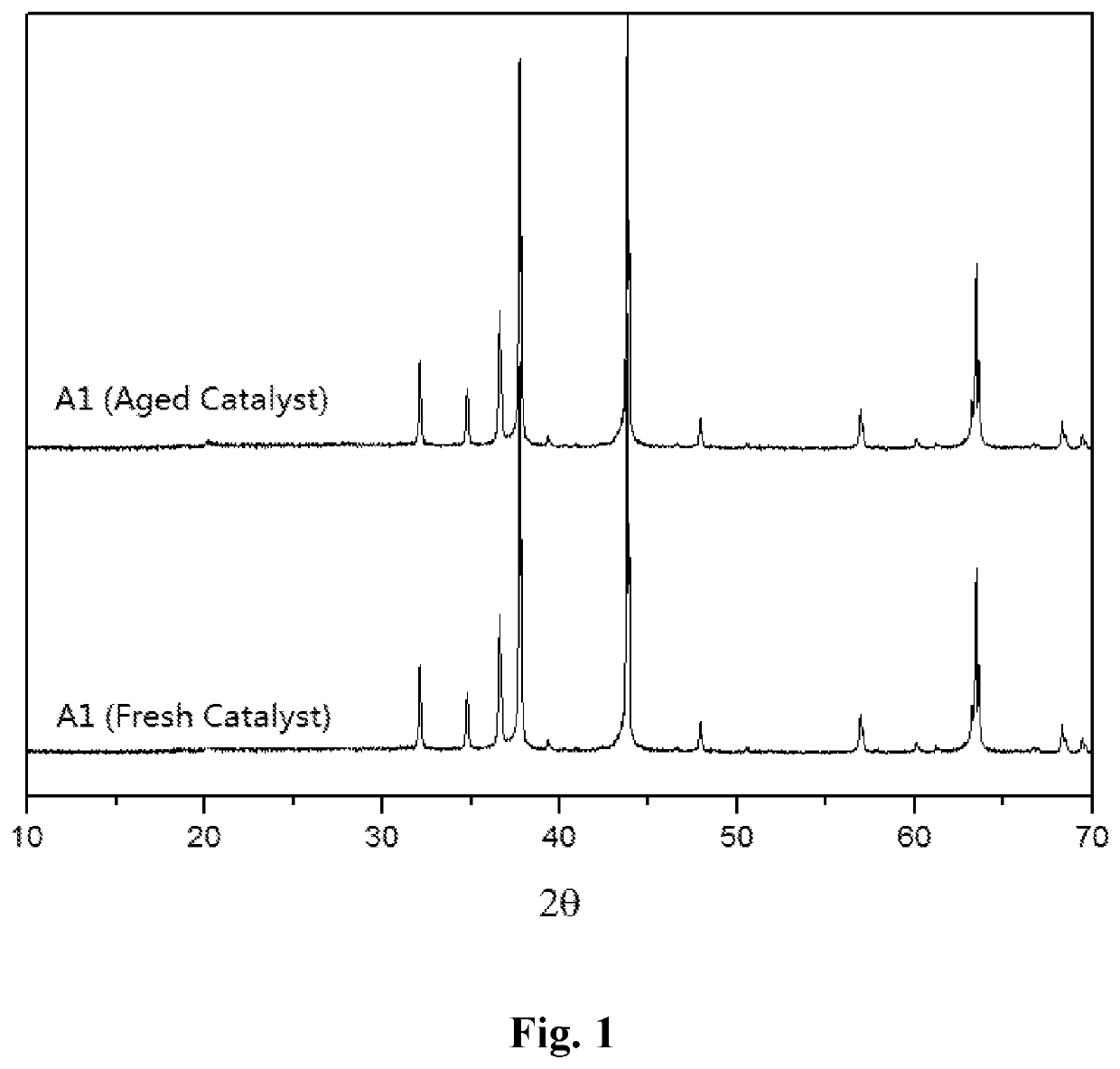

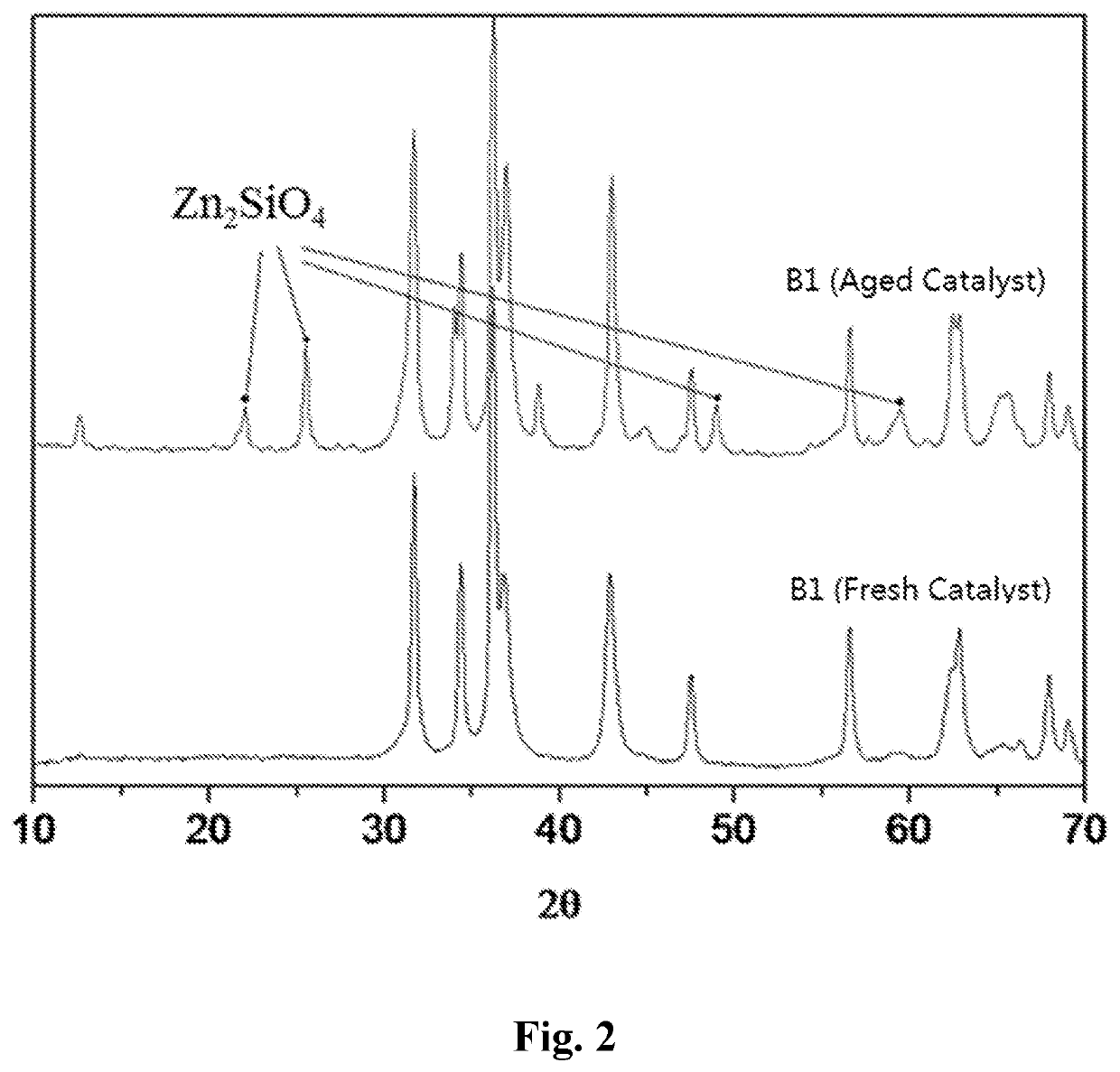

Desulfurization catalyst for hydrocarbon oils, its preparation, and use thereof

ActiveUS10717939B2Reduced activityLow structural stabilityMolecular sieve catalystsZinc oxides/hydroxidesPtru catalystManganese

Disclosed is a desulfurization catalyst for hydrocarbon oils, comprising a support and at least one metal promoter selected from the group consisting of cobalt, nickel, iron and manganese, the support comprising at least one metal oxide selected from the group consisting of oxides of Group IIB, Group VB and Group VIB metals and a refractory inorganic oxide, wherein the support further comprises at least about 5% by weight of vanadium carbide, based on the total weight of the desulfurization catalyst for hydrocarbon oils. The desulfurization catalyst for hydrocarbon oils shows a good stability, a high desulfurization activity, an excellent abrasion resistance, and a long service life. Also disclosed is a process for preparing the desulfurization catalyst for hydrocarbon oils, and use of the catalyst in the desulfurization of sulfur-containing hydrocarbon oils.

Owner:RES INST OF PETROLEUM PROCESSING SINOPEC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com