Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2099results about How to "Prevent spillage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

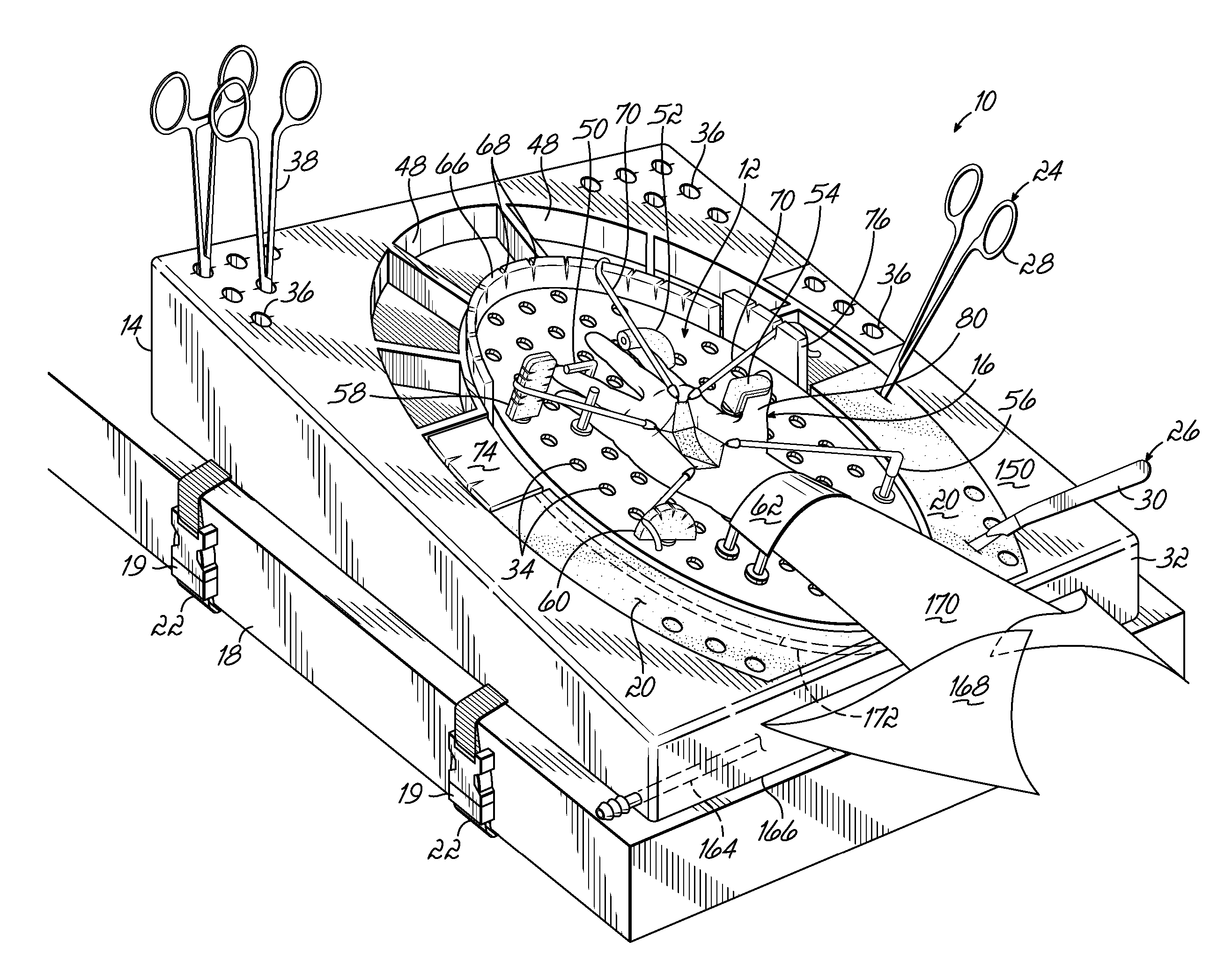

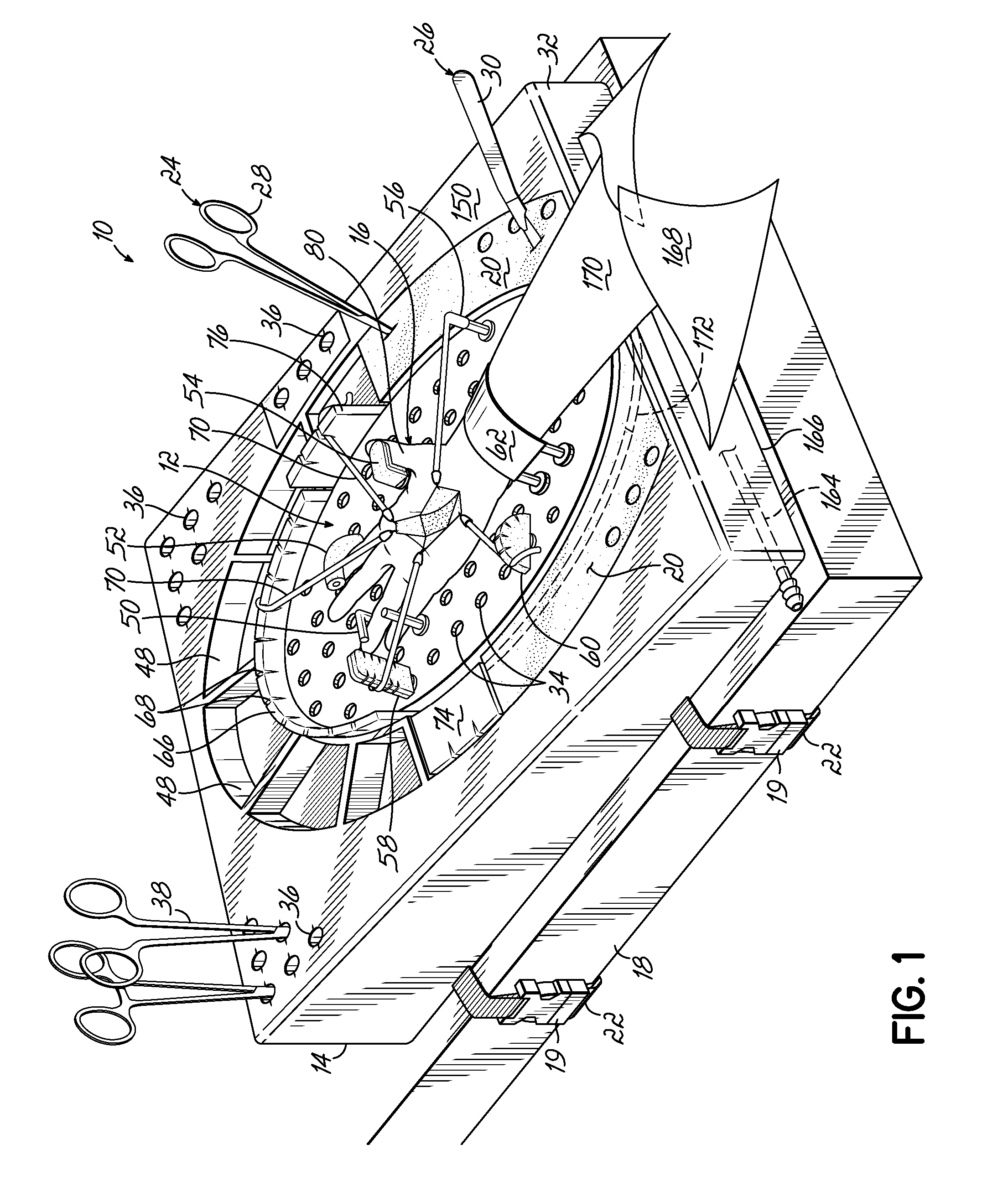

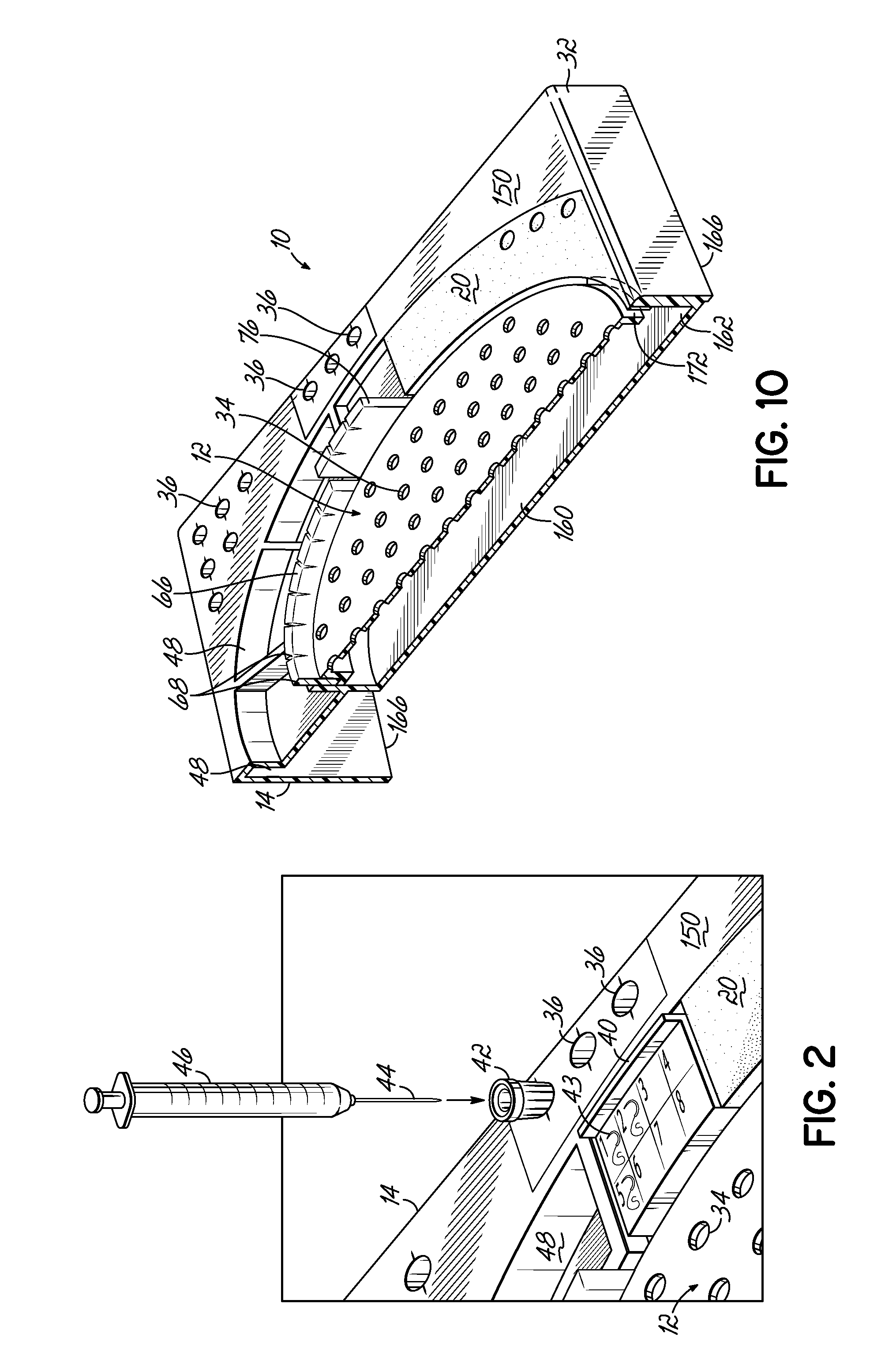

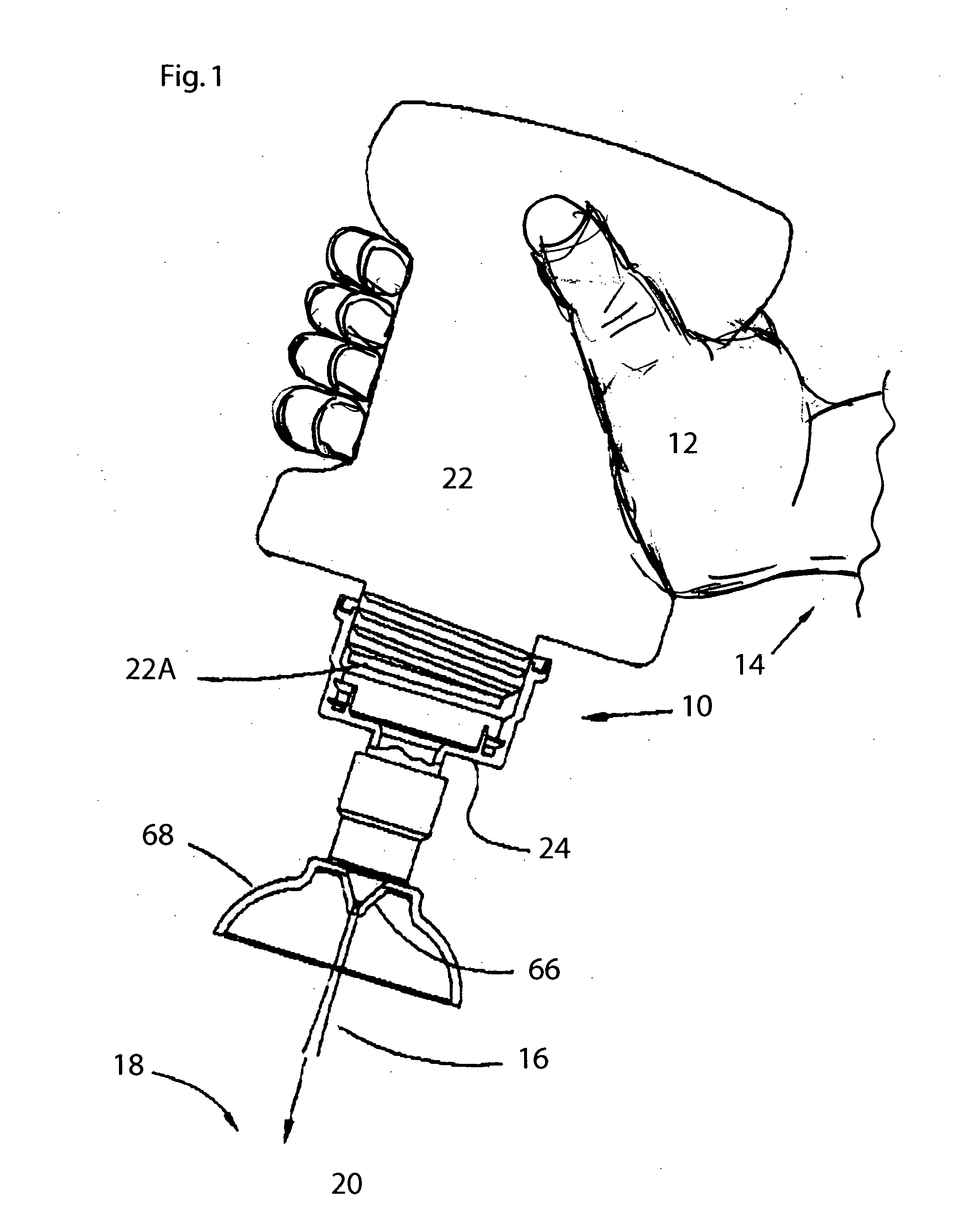

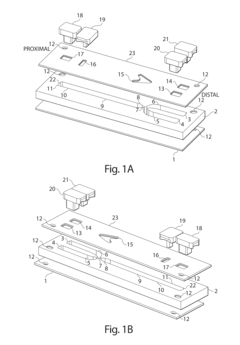

Surgical Tray

InactiveUS20060272979A1Prevent spillageReduce needSurgical furnitureDiagnosticsEngineeringSurgical trays

A surgical tray for operations on a patient's limb or extremity generally comprises a surgical site board adapted to support a portion of the patient's body. The site board includes a plurality of apertures. A retention device or retraction device is removably securable in at least one of the apertures and configured to retain a portion of the extremity being operated upon or retract tissue from the intended surgical site.

Owner:LUBBERS LAWRENCE M

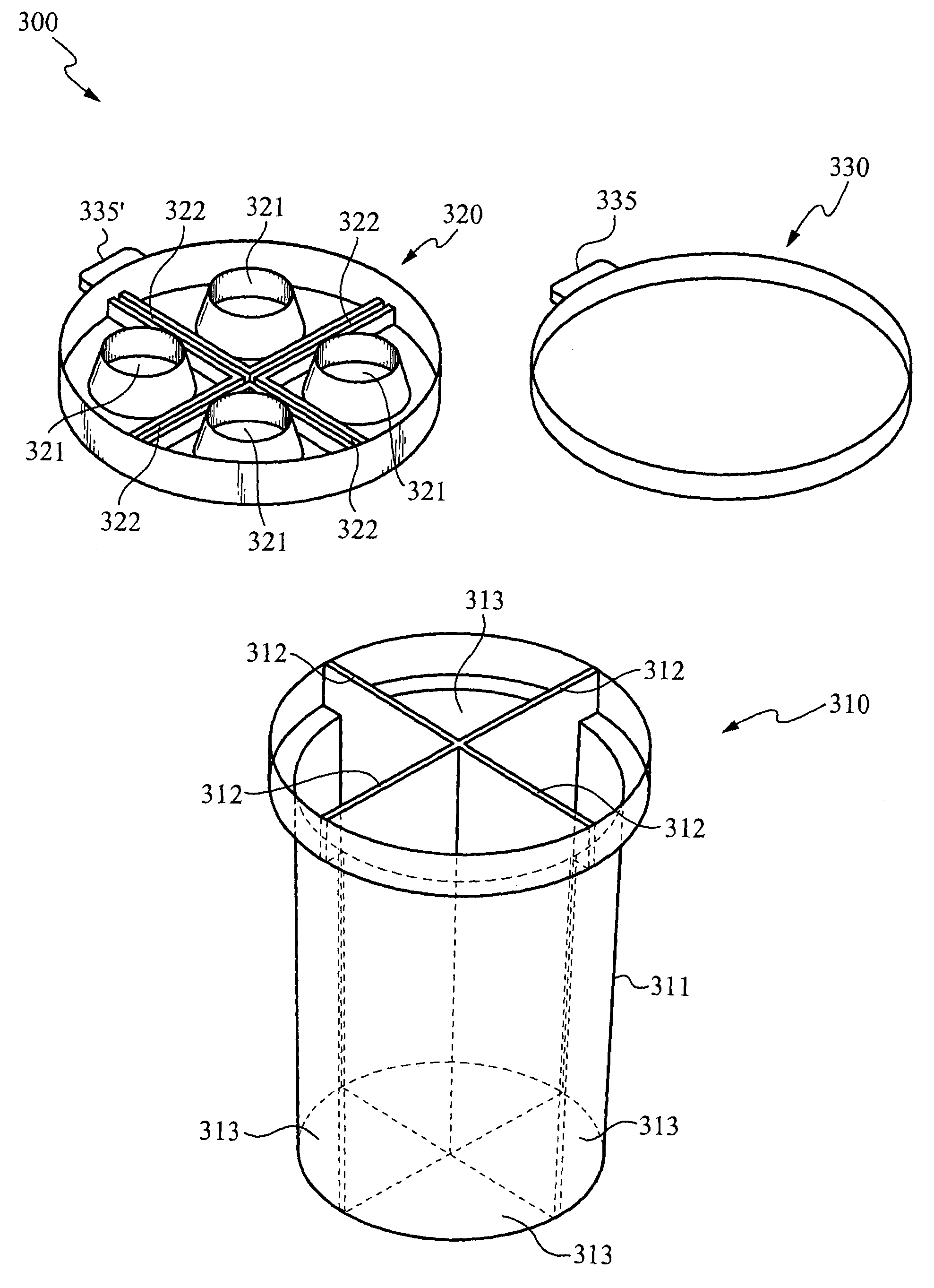

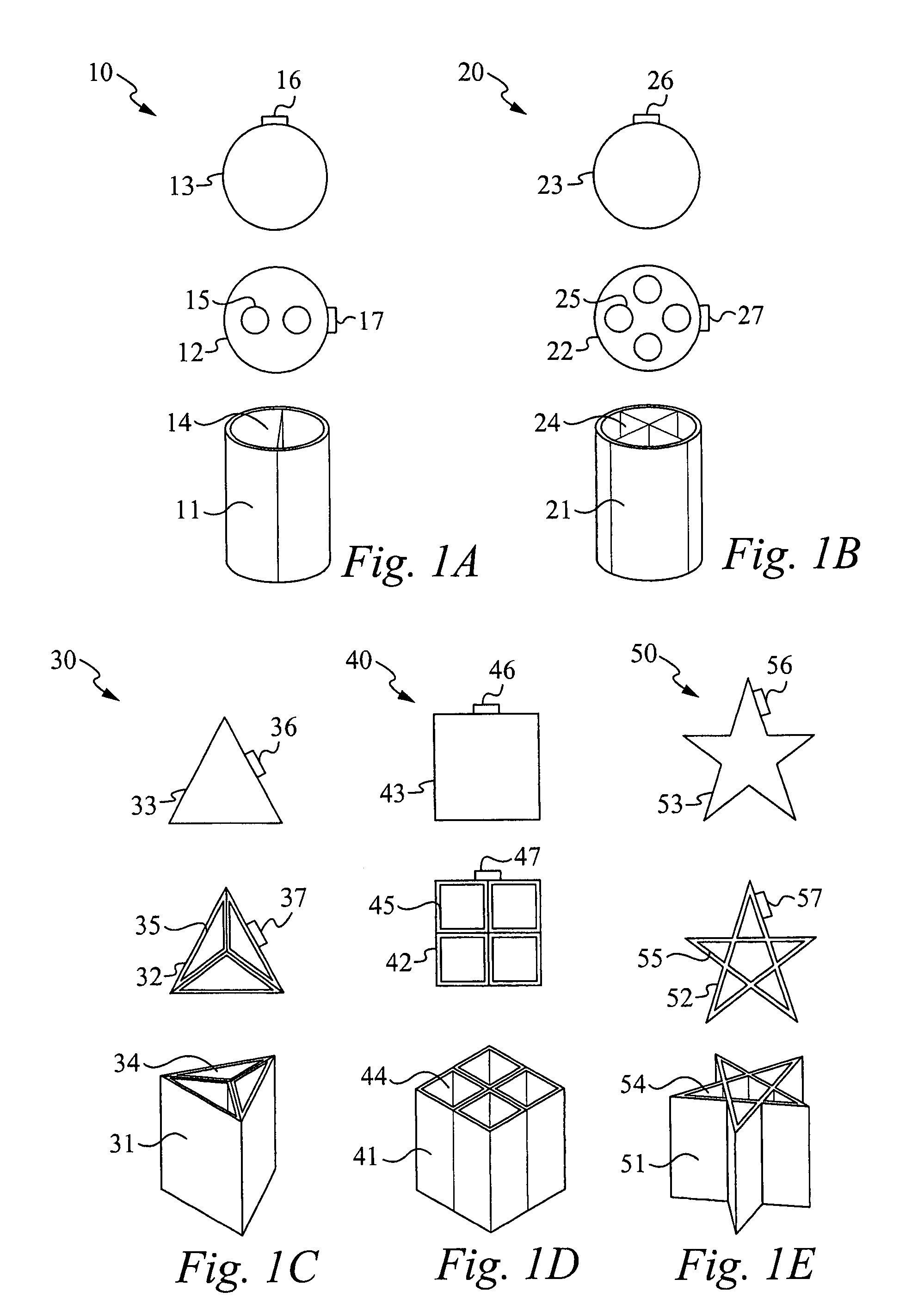

Divided paint storage apparatus

InactiveUS7090072B1Easy accessPrevent spillageDispensing apparatusCosmetic containersBiomedical engineering

A paint storage apparatus comprising a cap, a container divided into a plurality of chambers, and a lid having a plurality of orifices is disclosed. The apparatus is preferably substantially cylindrical and is uniformly formed from a homogenous material. When the lid is fixed on the container, the orifices are aligned over the chambers, with one of the plurality of orifices over each of the plurality of chambers. Further, when the lid and the container are mated, the plurality of chambers in the container are sealed such that paint cannot be interchanged between the chambers. The cap is configured to detachably couple to the lid and prevent spillage and spoilage of paint stored within the container. In addition, the cap and the lid preferably each further comprise tabs configured to facilitate removal of the lid from the container and to facilitate removal of the cap from the lid.

Owner:EXCELLIGENCE LEARNING CORP

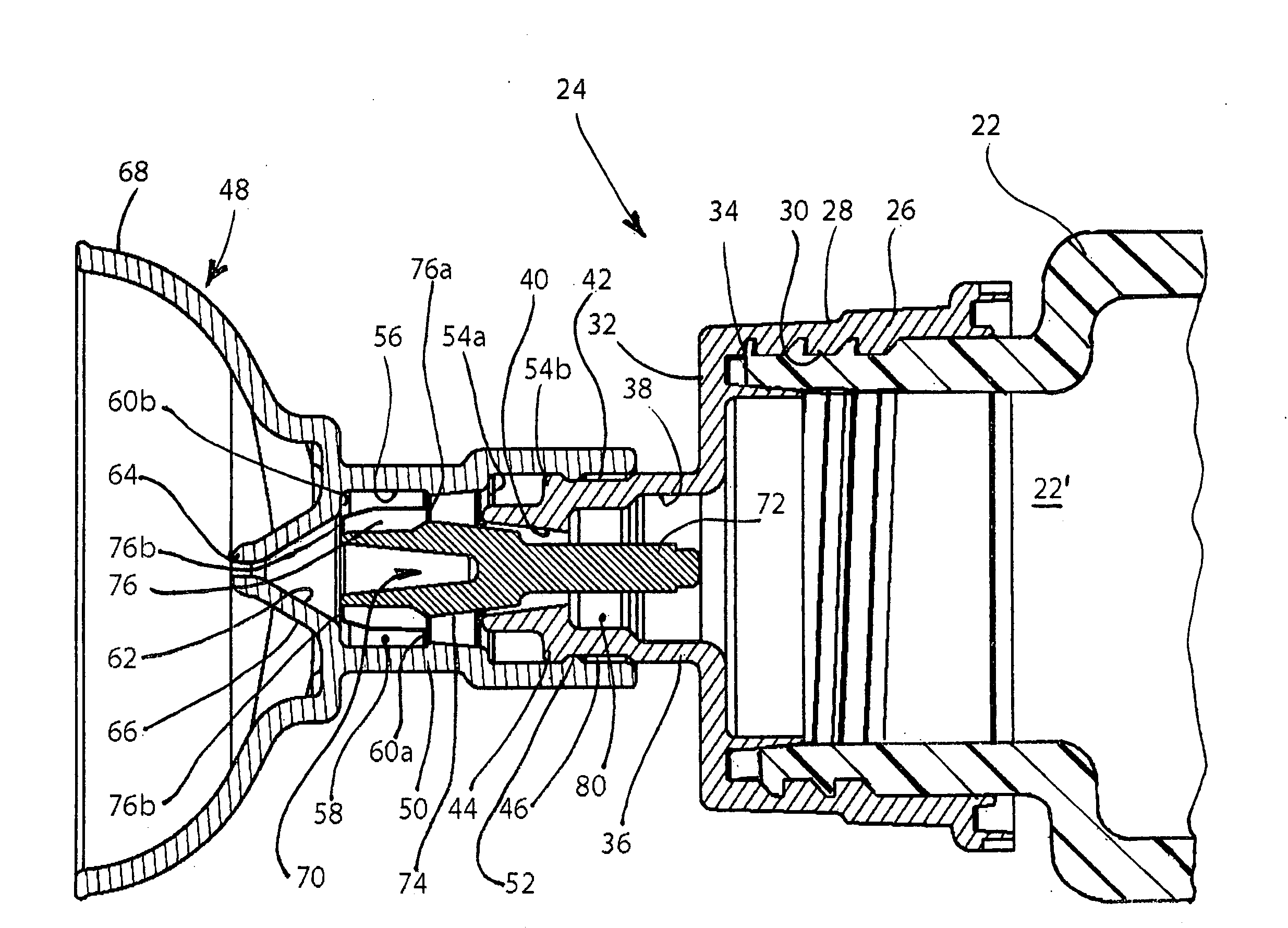

Wound irrigation apparatus and method

InactiveUS20050124946A1Efficient removalProtect the woundEnemata/irrigatorsSuction devicesJet flowEngineering

A dispenser cap for combination with a standard flexible irrigation solution bottle to make a portable wound irrigation dispenser includes a collar threadably engageable with the irrigation bottle, and closed at one end by a wall defining a tubular neck. The tubular neck forms a flow path from the bottle to a splash shield including a nozzle for directing irrigation solution. A valve is disposed in the flow path for opening and closing this flow path. A combination apparatus includes the flexible irrigation solution bottle, which may be inverted and squeezed in order to direct a jet of cleansing liquid into a wound. A single use version of the apparatus includes a valve which is closed in a storage and shipping configuration of the apparatus, and an indicator which is freed within the transparent or translucent flexible bottle when the valve is opened, thus irreversibly indicating that the apparatus has been used. An alternative embodiment of the apparatus includes a safety valve which also prevents misuse of the apparatus without the splash shield installed.

Owner:LANDAU SERGIO +1

Air freshener and combination container and lid

InactiveUS20070051826A1Not pronePrevent spillageTobacco devicesGaseous substancesConductive materialsAir purifier

An air freshener and combination container and lid for forming an air freshener. The air freshener includes a scented wax solid, a container, a lid, and an attachment for attaching the container to a surface. The container is manufactured of a thermally conductive material and has a bottom and at least one sidewall defining an interior, an exterior, and an open top. The interior of the container is dimensioned such that scented wax solid fits within the interior. The lid is removably attached to the open top of the container and includes a seal and a plurality of vent openings disposed therethrough. The air freshener prevents liquid wax from escaping through the vent openings when the container is moved in a direction parallel to the bottom of the container.

Owner:SCHOFIELD JOSHUA

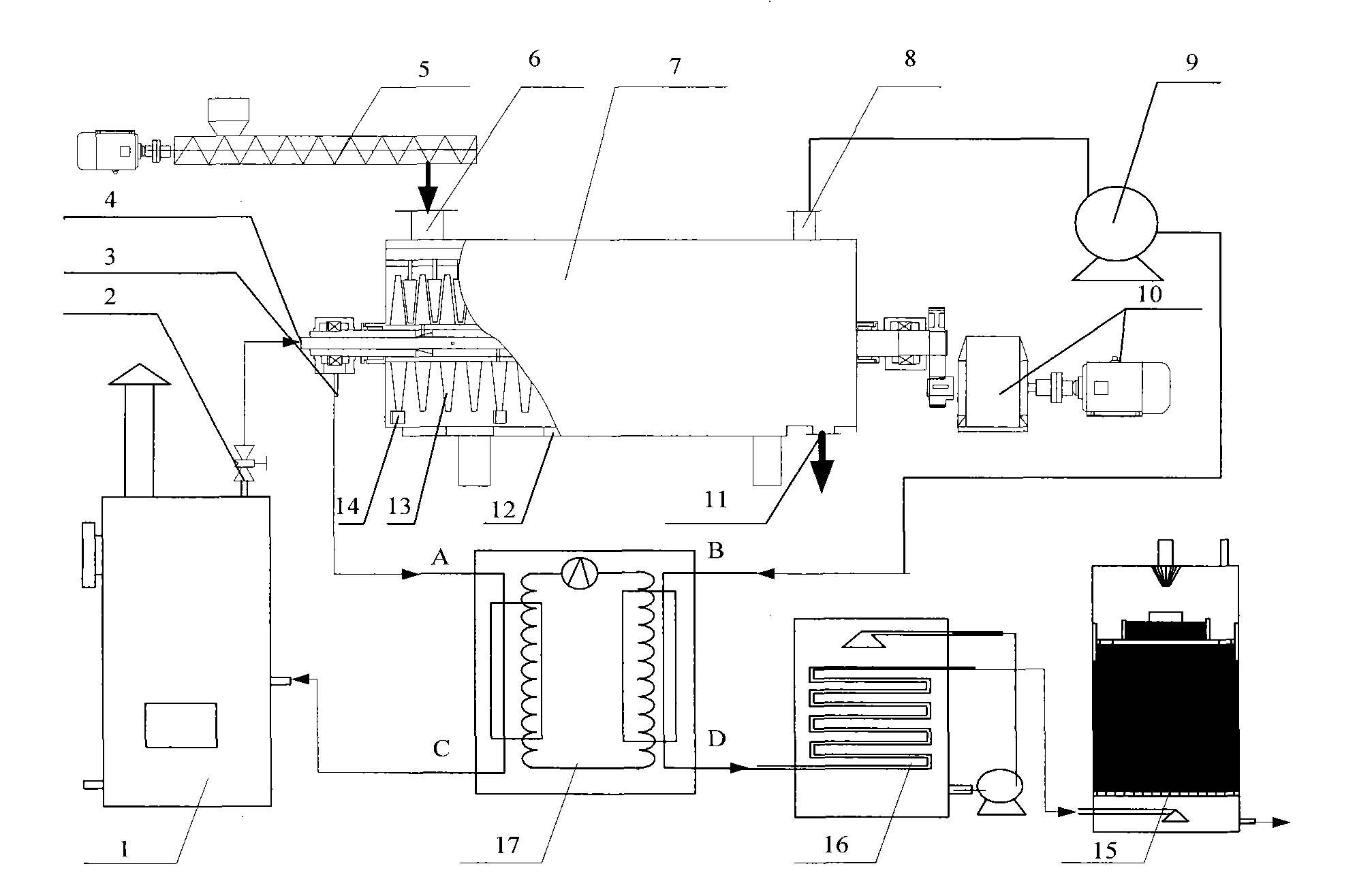

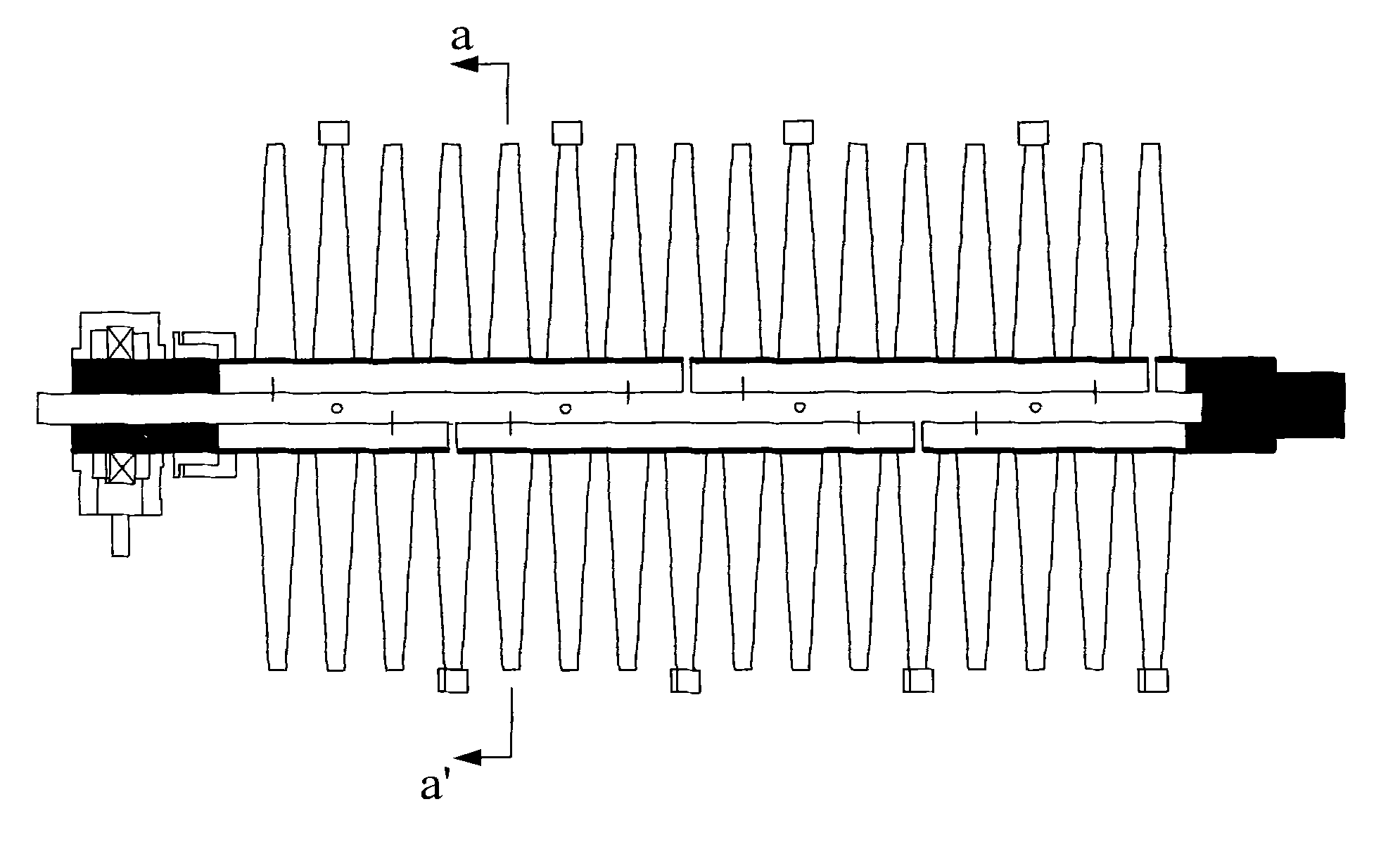

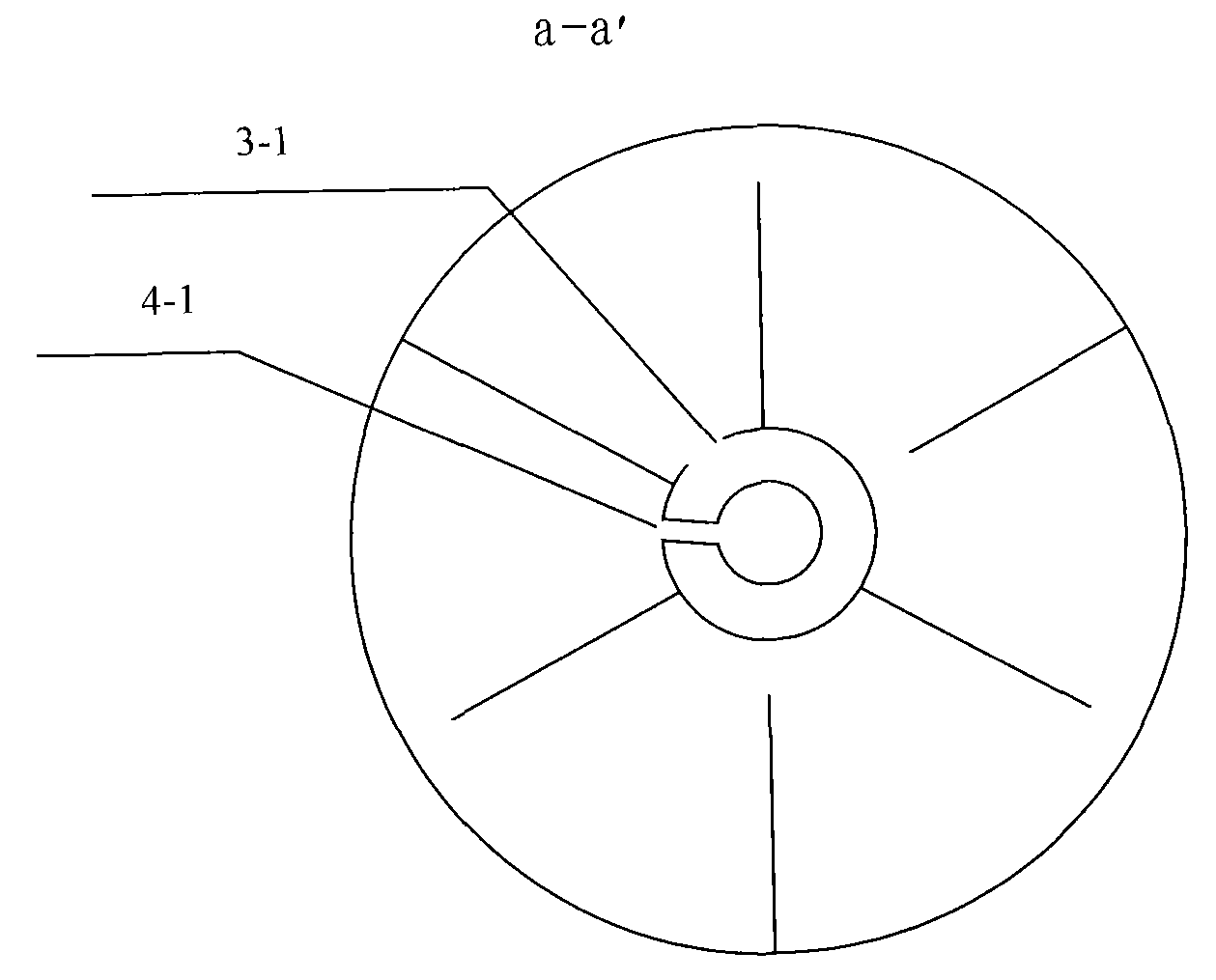

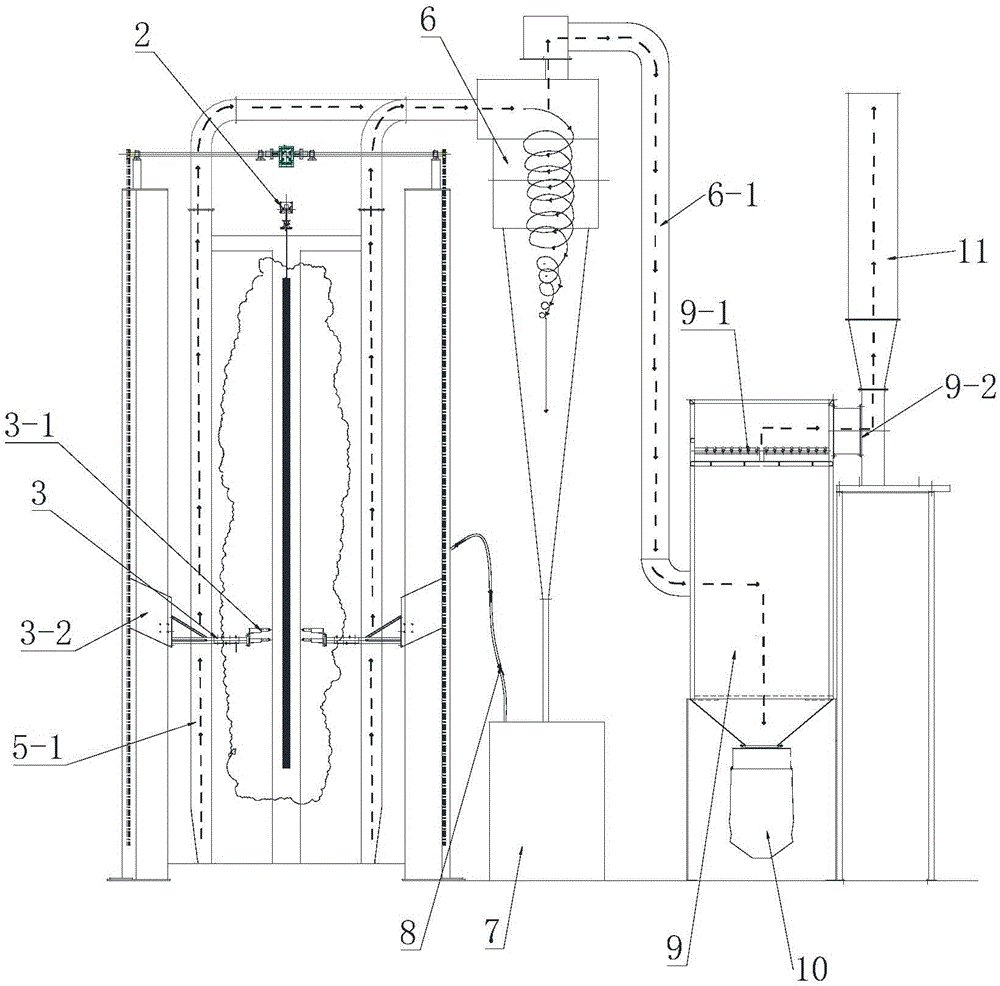

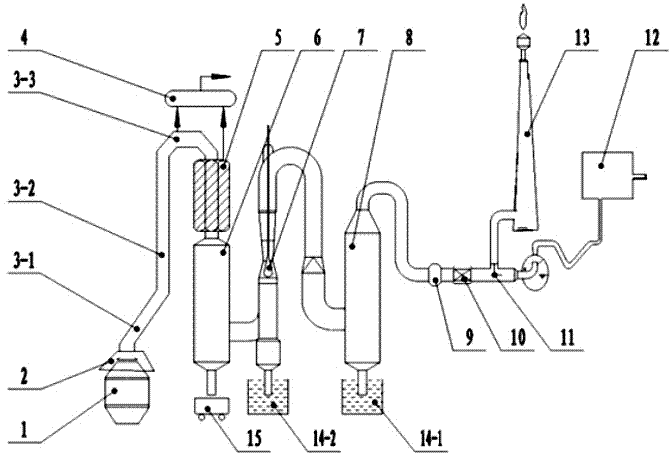

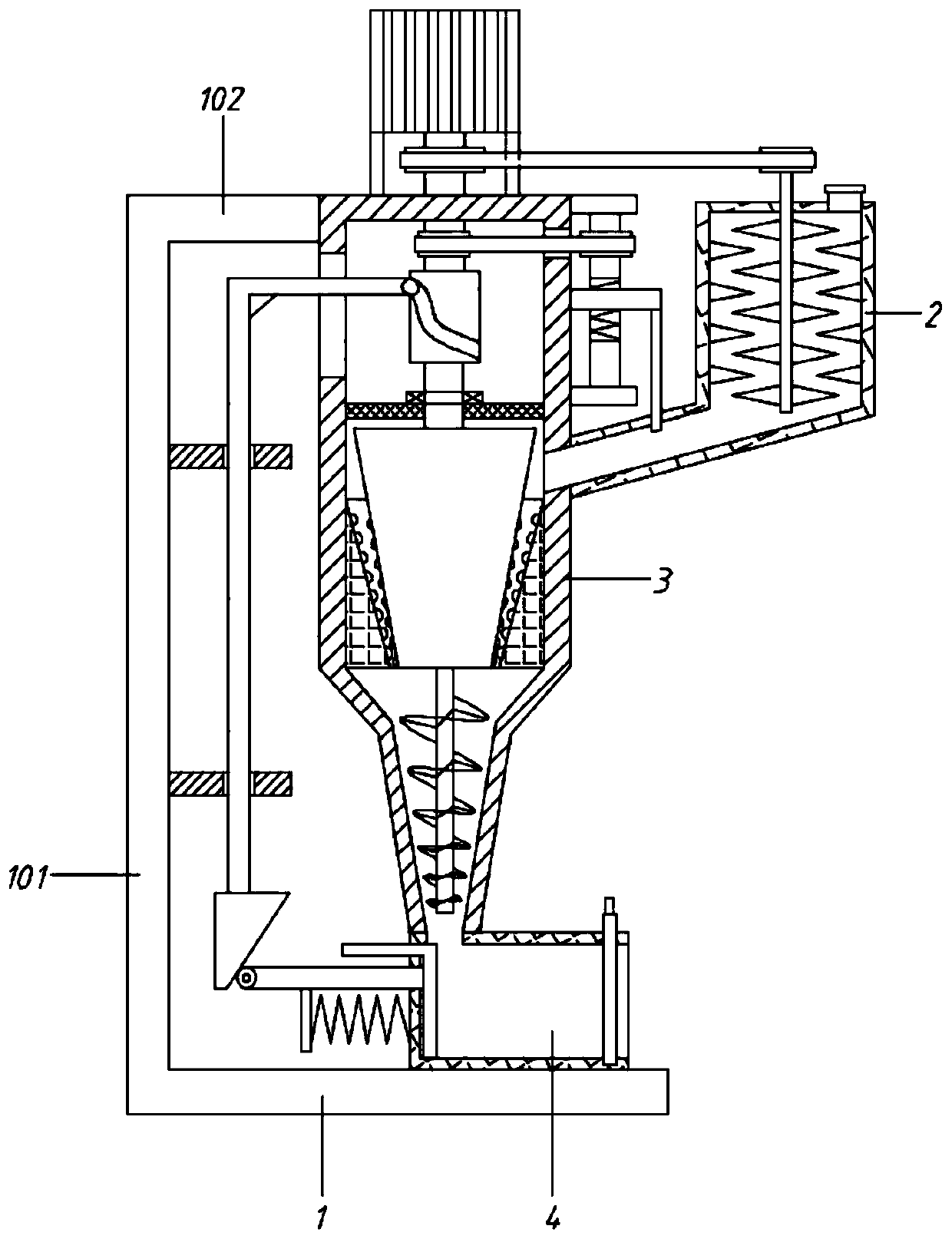

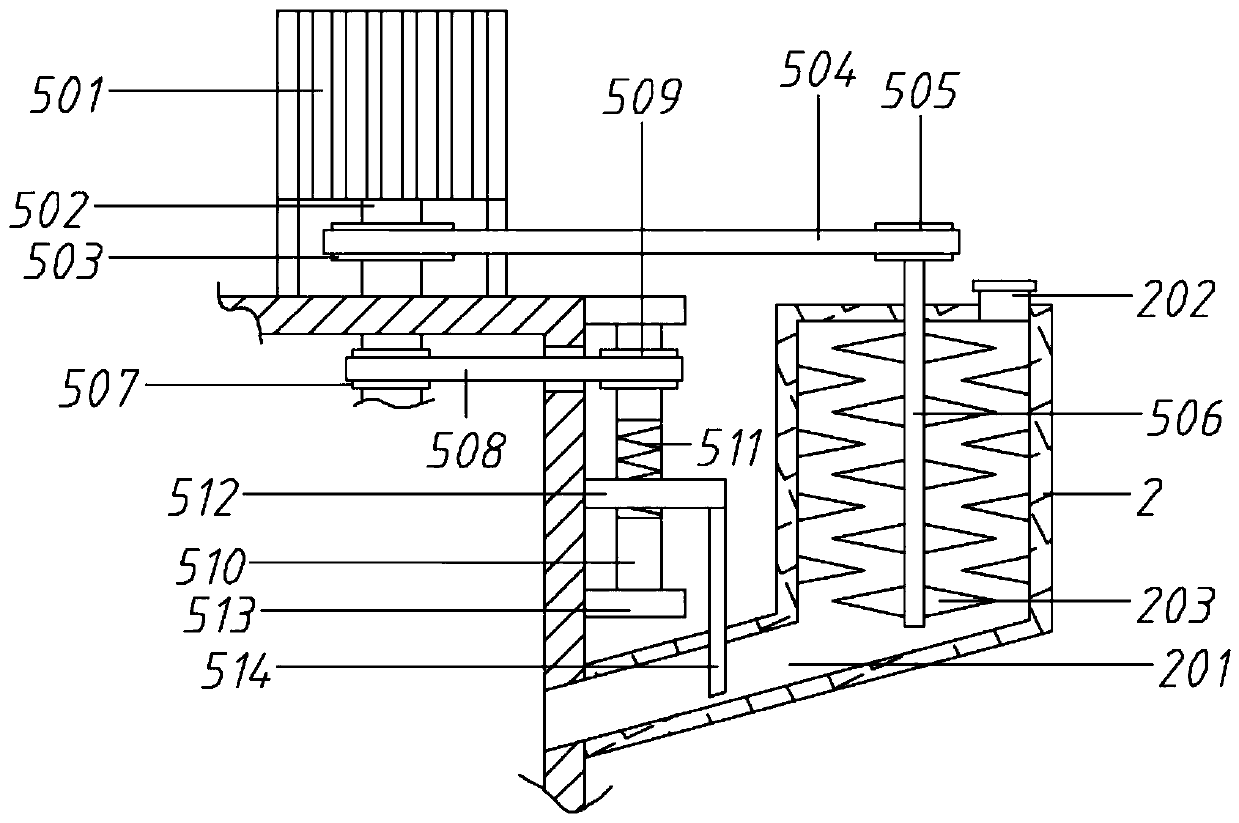

Latent heat recoverable multi-phase change sludge drying method and device

ActiveCN101774743AReduce drying costsEnergy balanceSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningThermal energyBrick

The invention discloses a latent heat recoverable multi-phase change sludge drying method and a latent heat recoverable multi-phase change sludge drying device, which are designed for solving the technical problems that the energy consumption is high, the latent heat of the sludge vapor cannot be recovered and reused, the dried tail gas pollutes the environment, the operating cost is high and the like in the conventional sludge drying technology. Due to the combination of a low-temperature vapor turntable dryer, a sludge waste vapor latent heat recover heat pump and a tail gas purification device, and the use of indirect phase change heat exchange for low-temperature vapor, the heat exchange is improved, and the loss of organic components of the sludge is low. The latent heat of the sludge drying tail gas is recovered by using the latent heat recover heat pump, and the recovered heat energy is reused for sludge drying. Therefore, the heat efficiency is improved, the operating cost is reduced, and the problems that the heat utilization ratio is low, the operating cost is high and the like in the sludge drying process are better solved. The dried products meet the requirement of baking light and energy-saving bricks and producing cement laminated products, and over 90 percent of heat value of the original sludge is maintained. Therefore, the resource utilization value of the sludge is maximized.

Owner:SHENYANG INST OF AERONAUTICAL ENG

Multichannel preparative electrophoresis system

ActiveUS20100126862A1Prevent spillagePrevent overflowSludge treatmentVolume/mass flow measurementElectrophoretic mobilitiesSingle application

The invention provides an electrophoresis cassette, methods for making the electrophoresis cassette, and method of fractionating analytes from a sample based upon electrophoretic mobility in a single application of the sample to an electrophoretic system.

Owner:SAGE SCI

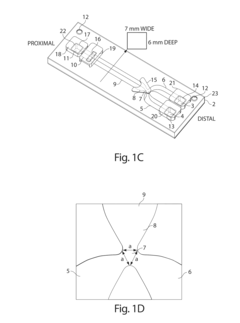

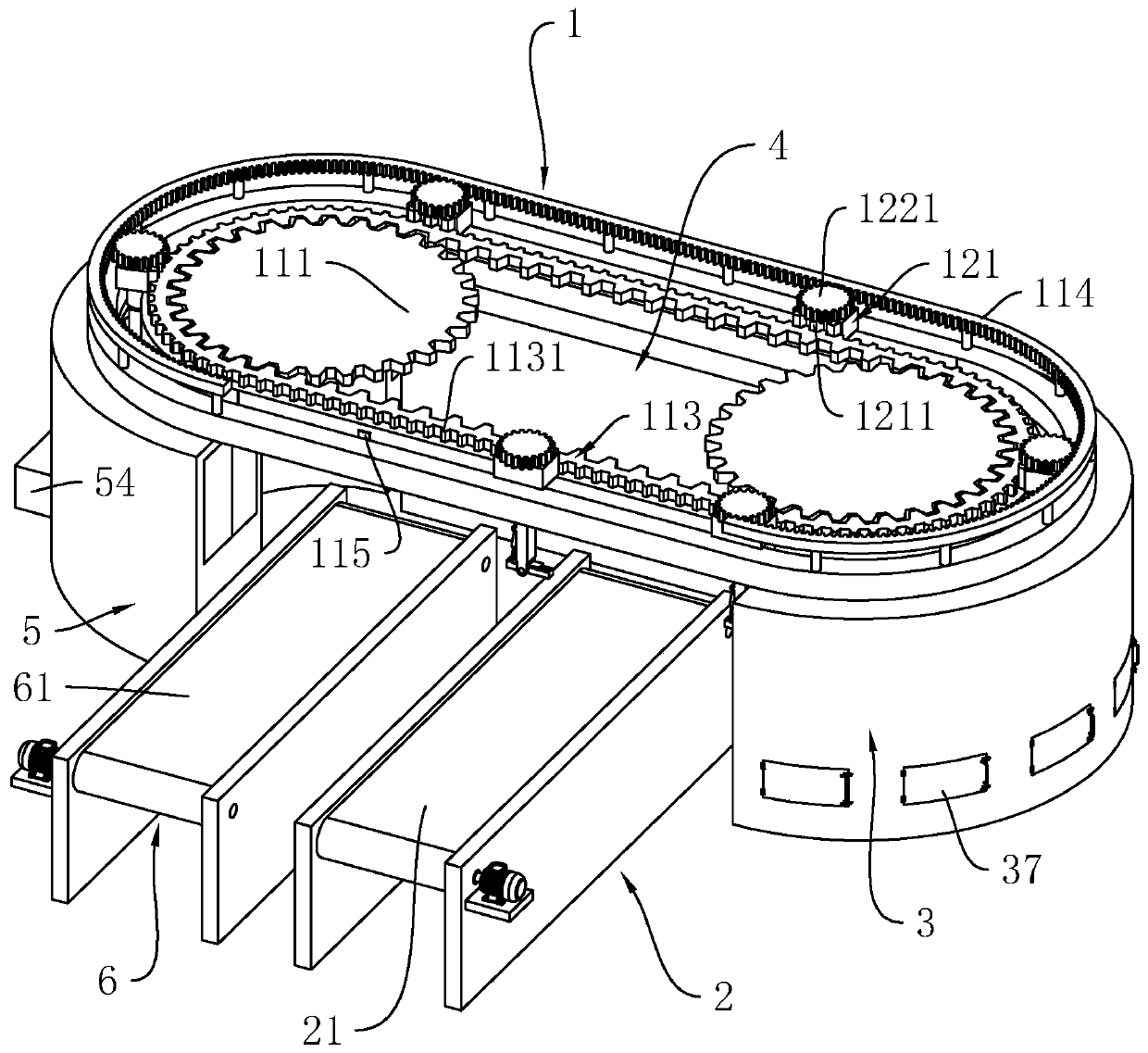

Workpiece lifting spraying production line

The invention relates to a workpiece lifting spraying production line which comprises a lifting conveying device, a feeding station, a spray cleaning station, a spraying station, a drying station anda discharging station. The lifting conveying device comprises a conveying rail in the shape of a kidney-shaped ring, and multiple lifting frames arranged on the lower side of the conveying rail. The spray cleaning station comprises a spray cleaning box, and a first through groove for the lower ends of the lifting frames to be inserted into the spray cleaning box conveniently is formed in the upperside of the spray cleaning box. Multiple gas spraying guns capable of spraying gases to workpieces are arranged at the positions, corresponding to the lifting frame conveying track, of the two sidesof the spray cleaning box. A blanking groove is fixedly connected to the position, corresponding to the lower side of the lifting frame, of the spray cleaning box along the movement track of the lifting frame, and a cloth bag dust collecting bag with an opening formed in the upper end is arranged on the lower side of the blanking groove. A draught fan is fixedly connected to the position, corresponding to the lower side of the cloth bag dust collecting bag, of the spray cleaning box. First flexible dust blocking curtains are further fixedly connected to the two ends of the spray cleaning box.The workpiece lifting spraying production line has the beneficial effects that the workpieces can be automatically cleaned, the labor intensity is lowered, and the work efficiency is improved.

Owner:青岛欧轩机械有限公司

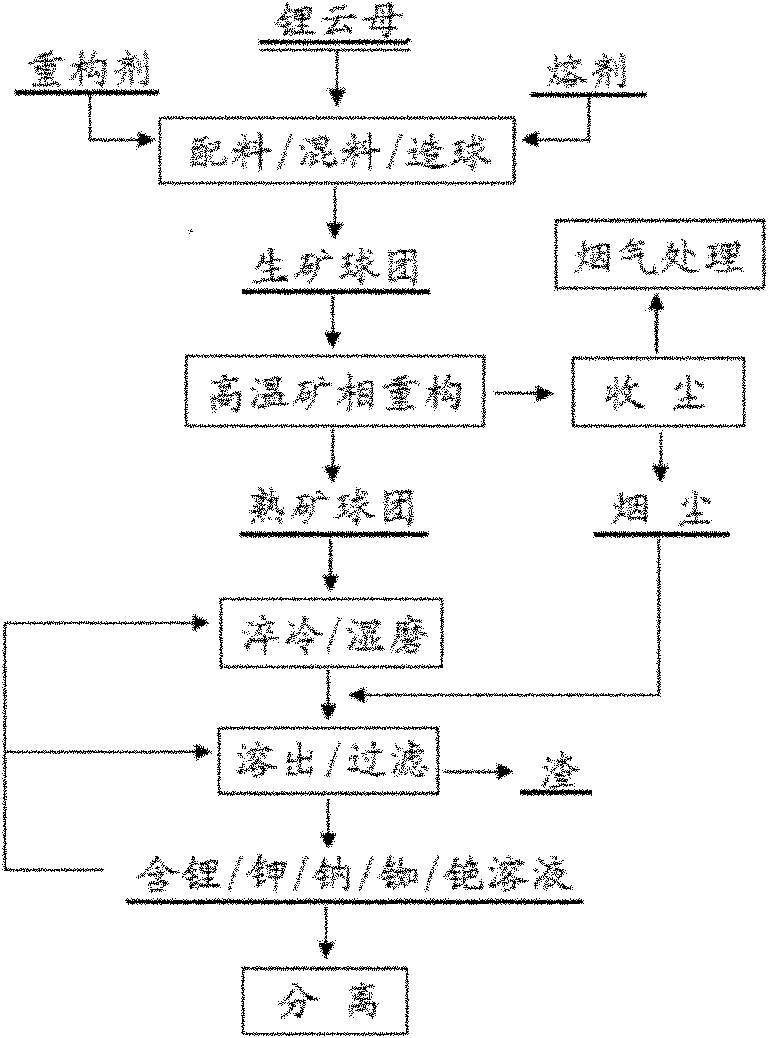

Method for extracting lithium and other alkali metal elements from lepidolite mineral

InactiveCN101974678AEfficient extractionEasy to optimizeProcess efficiency improvementRubidiumPotassium

The invention discloses a high-temperature mineral phase reconstruction method for extracting lithium and other alkali metal elements from lepidolite mineral, comprising the following steps: mixing raw materials, pelletizing, calcining at high temperature, water quenching, ball milling, dissolving out, producing compounds and the like. The invention teaks raw mineral component composition to design target reconstruction mineral and composition to obtain the purpose of optimizing processes, lowering energy consumption and cost of treatment process and efficiently extracting lithium, potassium, rubidium, caesium and the like. Silicon and aluminum in lepidolite can enter anorthite type mineral phase (CaO.Al2O3.2SiO2, (Ca, Na)O. (Al, Si)2O3.2SiO2) and calcium ash quarry phase (CaO.SiO2) after mineral phase reconstruction, and do not dissolve in water and aqueous solution. After mineral phase reconstruction reaction, fluorine in lepidolite enters calcium fluoride mineral phase and does not dissolve in water and aqueous solution. Lithium and other alkali metal elements in lepidolite enter salt (chloride, sulfate) or alkali (hydroxide) phase of lithium and other alkali metal elements after mineral phase reconstruction reaction and can be dissolved in water and aqueous solution.

Owner:CENT SOUTH UNIV

Environment-friendly type bottom filter process blast furnace slag treatment device and treatment method

The invention discloses an environment-friendly blast furnace slag treatment device based on bottom filter process and a treatment method thereof. The treatment device comprises a water slag granulation pool. The water slag granulation pool comprises a granulation pool entrance unit and a granulation pool exit unit. The granulation pool entrance unit is provided thereon with a granulator. The water slag granulation pool is provided inside with a granulation pool condensation / spray device. The granulation pool exit unit is connected with a filter tank. The downstream of the filter tank is connected with a cooling tower via an upper tower pump. The invention realizes energy conversation, discharge reduction and safe production, overcomes the problem of large occupied area of the conventional bottom filter process, and reduces the costs for construction and operation.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

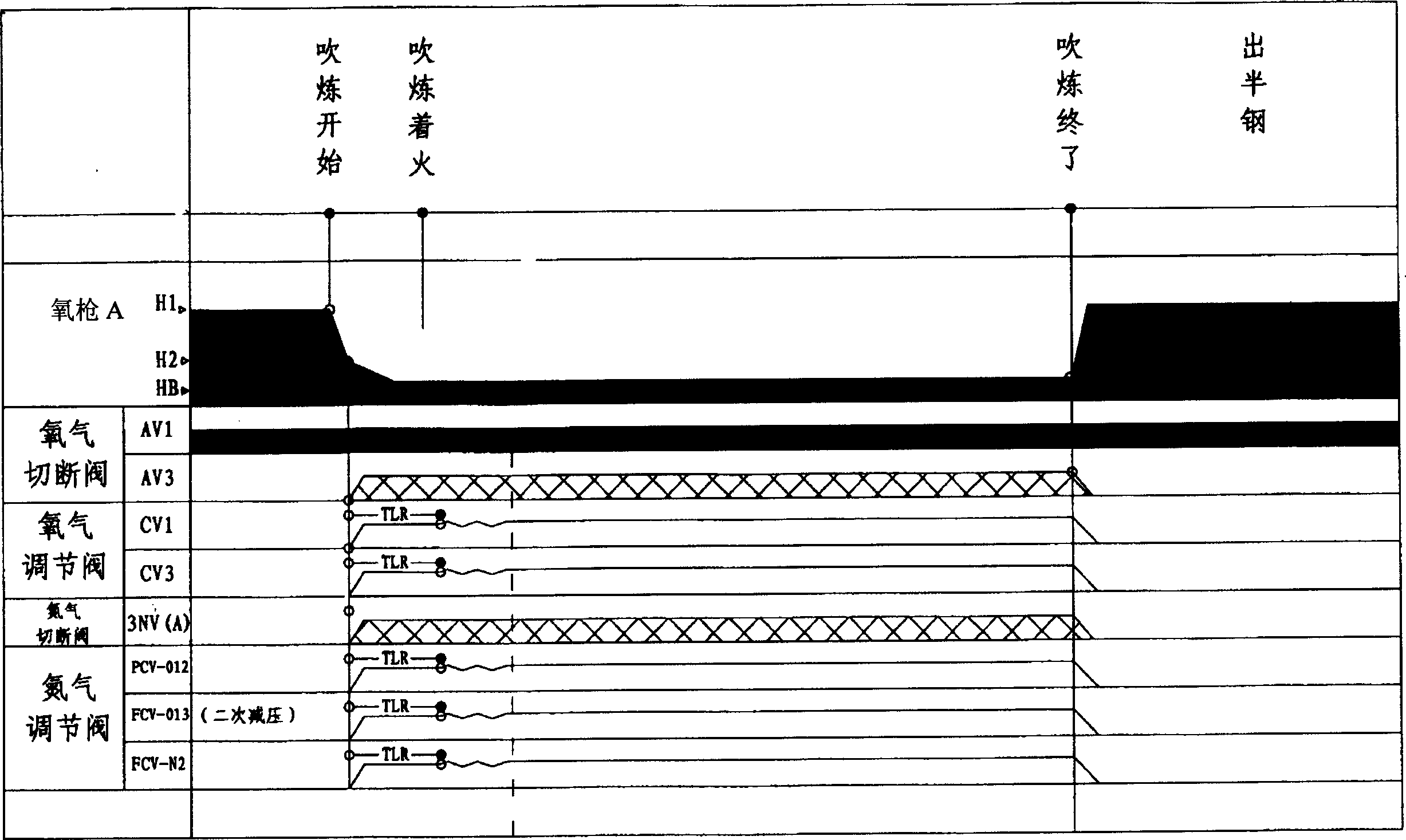

Converter oxide and nitrogen top-blown dephosphorizing method

InactiveCN1552919AHigh carbon contentInhibition of decarburization reactionsManufacturing convertersSputteringSlag

An oxygen-nitrogen top blowing converter process for desulfurization is carried out by blowing oxygen-nitrogen at its top while blowing nitrogen or inertial gases at its bottom to desulfurise. Its top blowpipe controls oxygen blowing to desulfurise in two modes, with mixed gases at some ratio or with pure oxygen switched with pure nitrogen, in order to inhibit sputtering and to enhance stirring in smelting pool when sputter occurs by excessive oxidation, so that balance of (P) / [P] in dynamics is improved. It desulfurises better when bottom blowing is weak, can inhibit decarbonise reaction effectively with >70% recovery of Mn in molten iron, also, strengthen blowing at top to stir strongly and shorten pre-treat time, increase rate of desulfurization, control slag elimination in procedure effectively to prevent sputtering, and increase stability and security.

Owner:BAOSHAN IRON & STEEL CO LTD

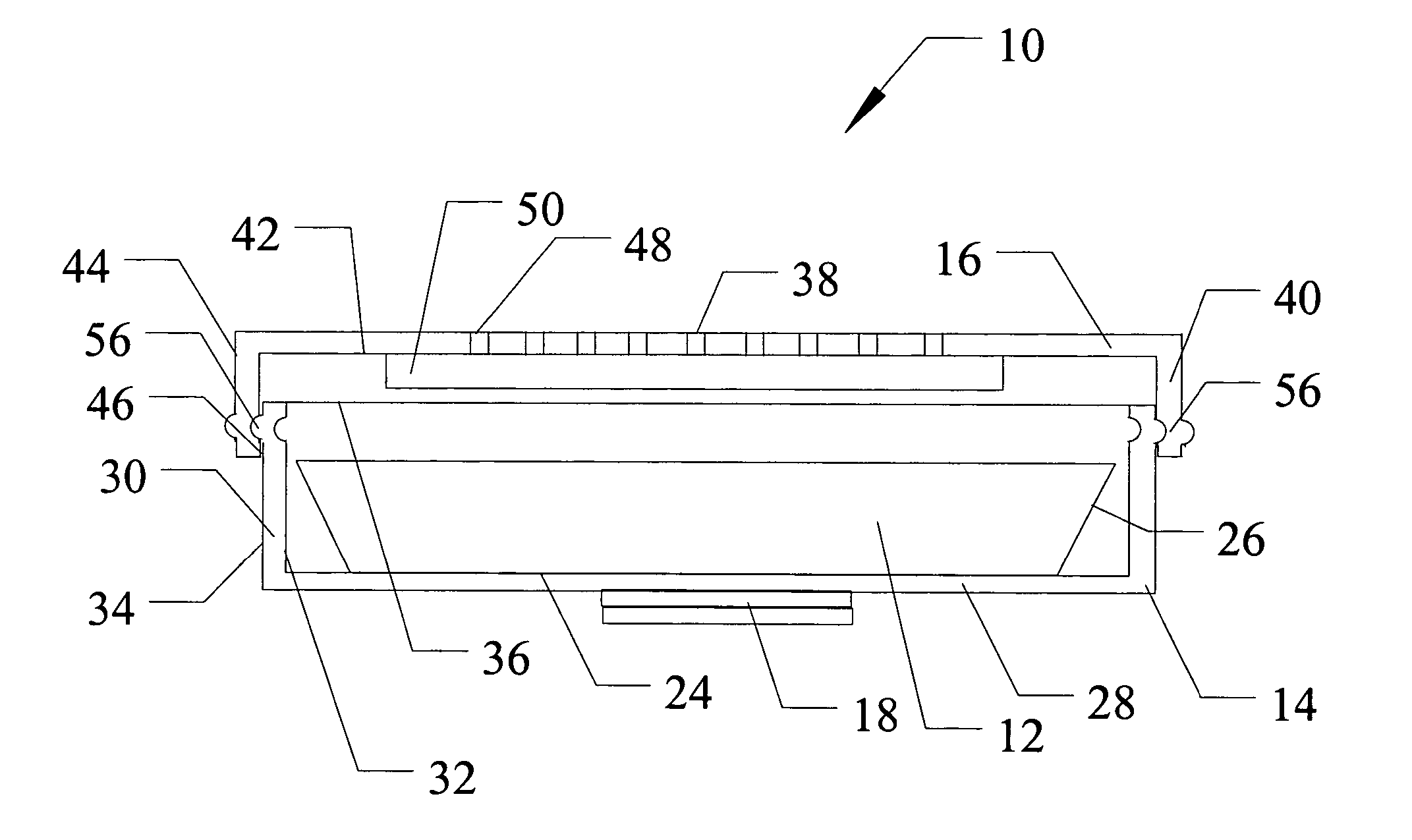

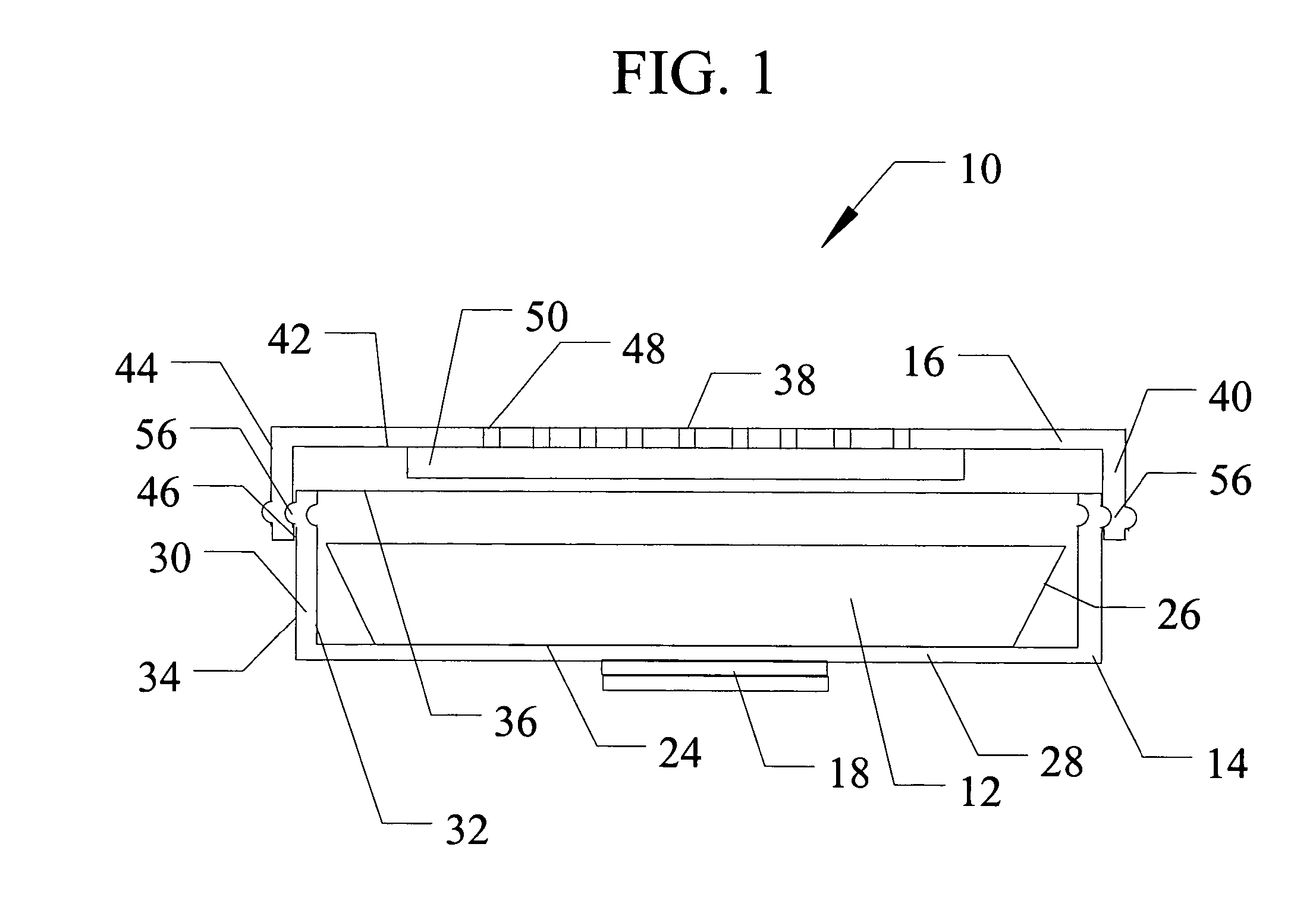

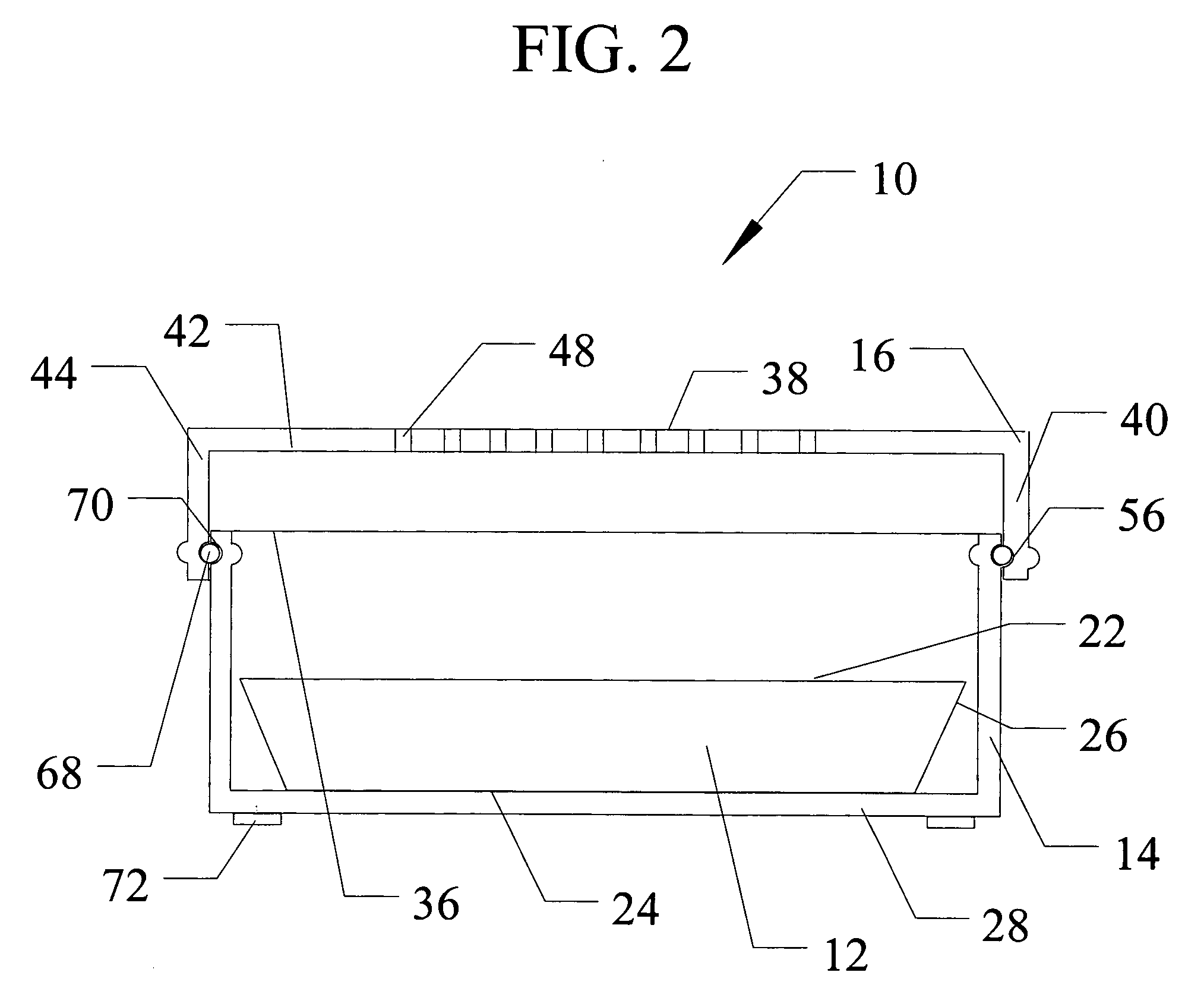

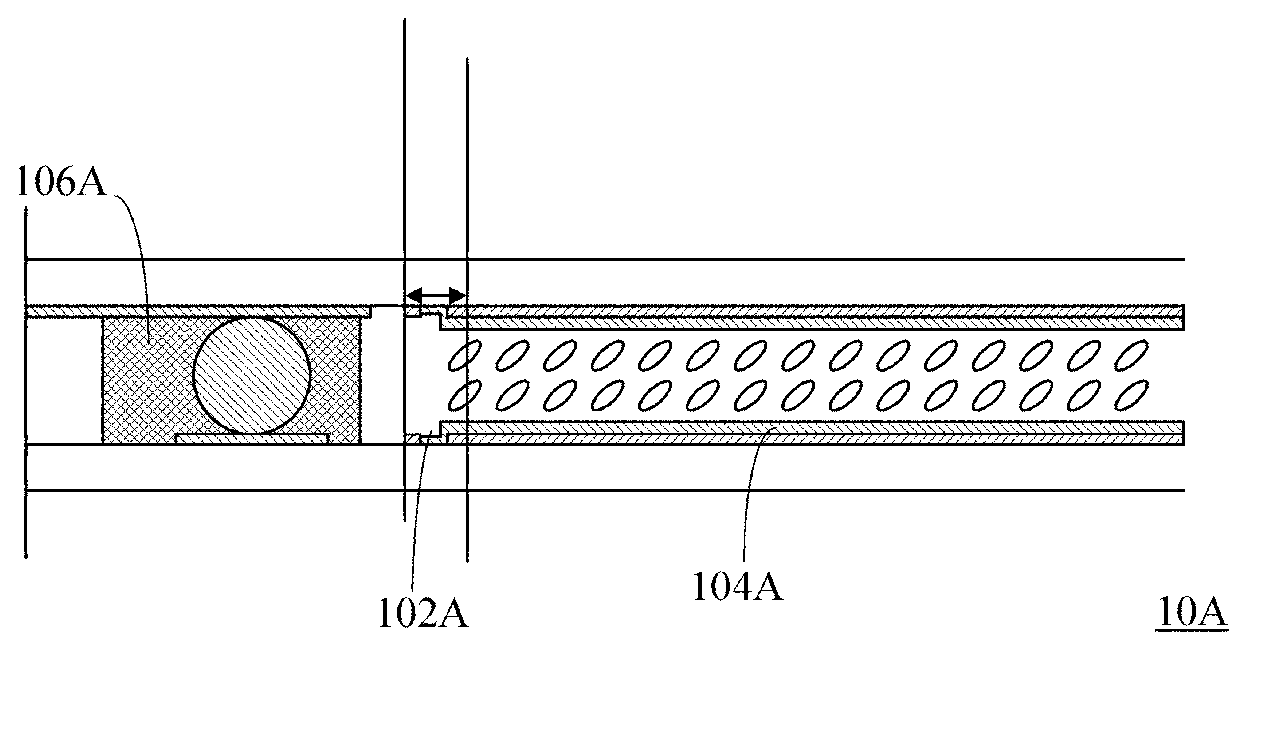

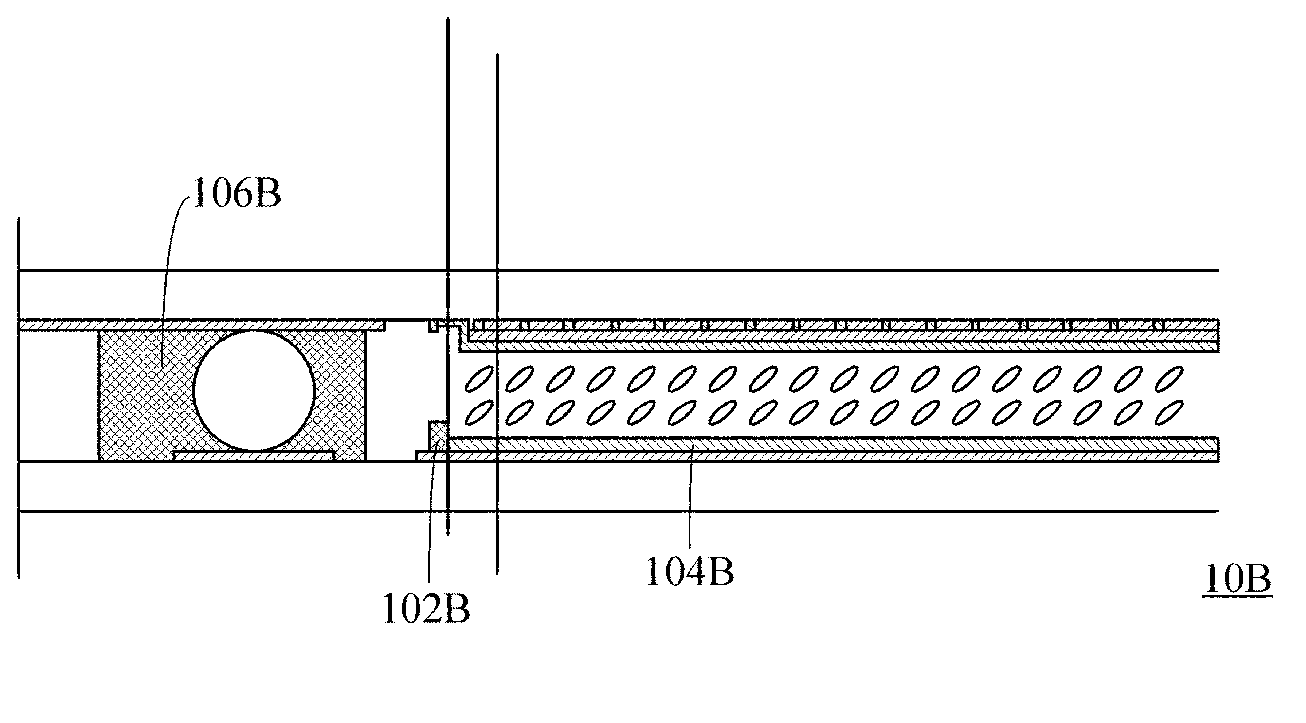

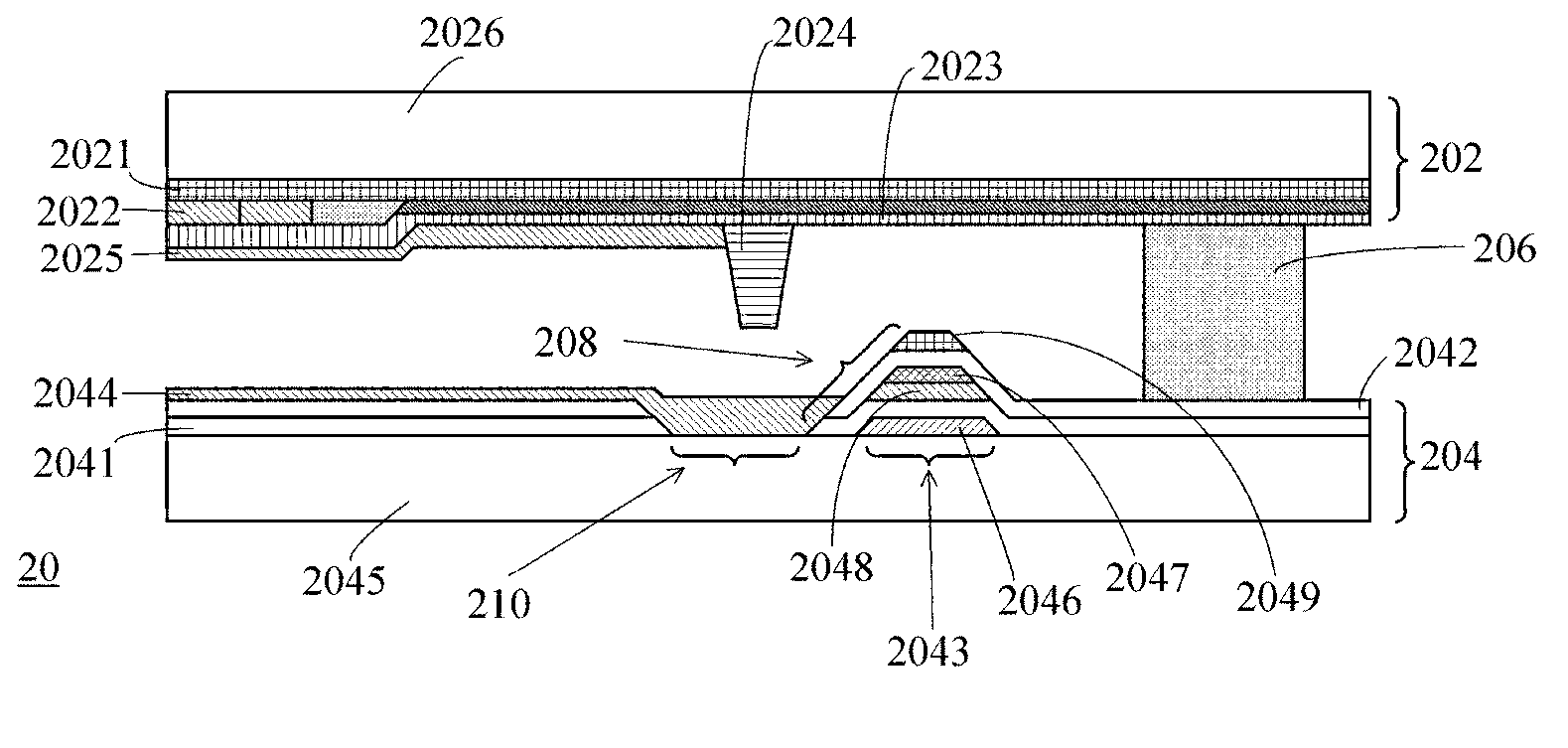

Liquid crystal panel and manufacturing method thereof

The invention provides a liquid crystal panel, which comprises an upper substrate, a lower substrate and frame glue, wherein the lower substrate comprises a display area, a non-display area, a first limiting component and a second limiting component; the non-display area is adjacent to the display area; and the frame glue is arranged on the non-display area; the first limiting component is located at edge of the non-display area; the second limiting component is located between the display area and the first limiting component. By virtue of combination of the first limiting component and the second limiting component, when an alignment film is coated on the lower substrate, the alignment film is not expanded to the non-display area.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

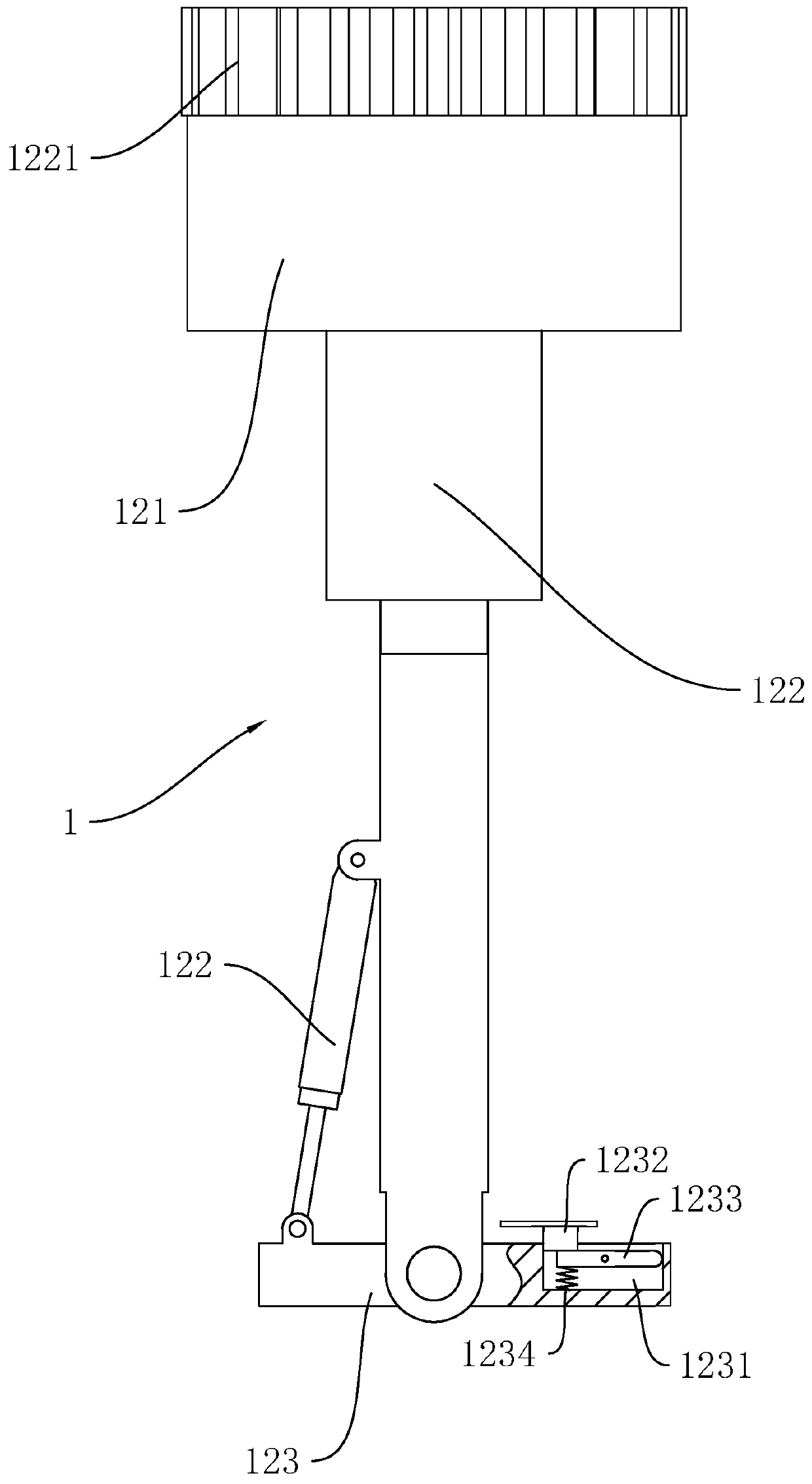

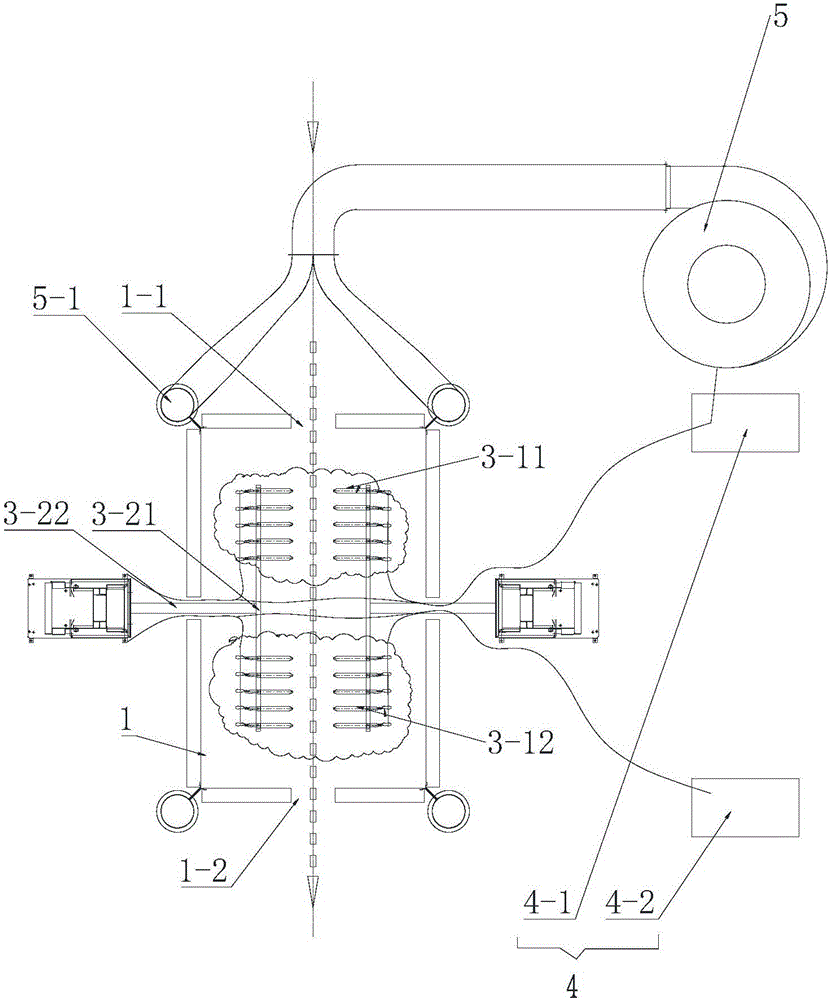

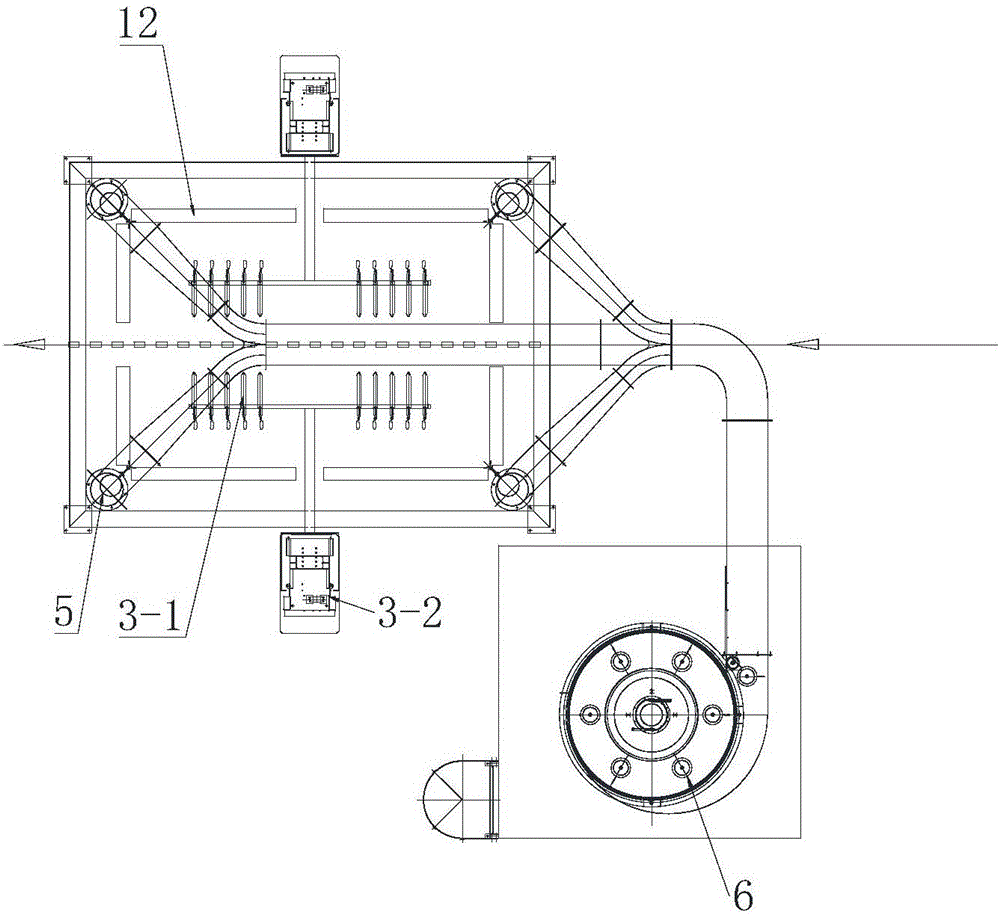

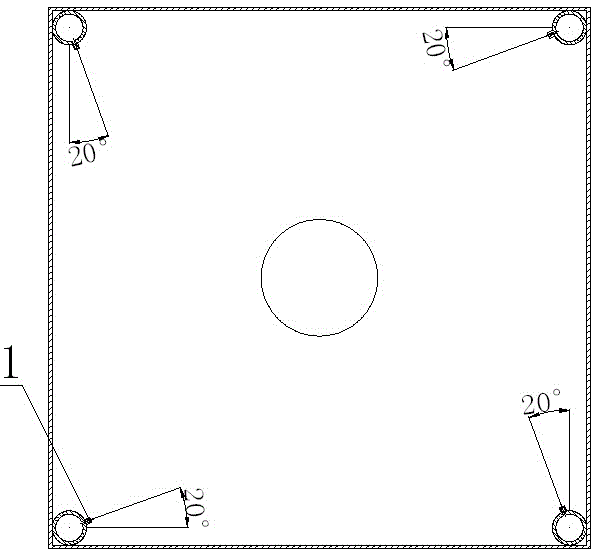

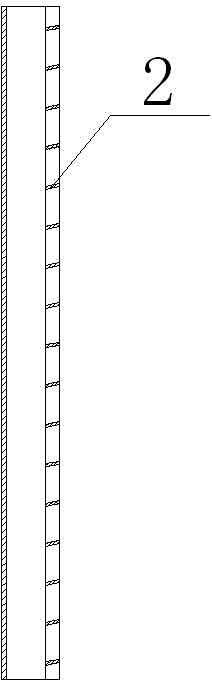

Electrostatic powder vertical type spraying device

ActiveCN105964435AEasy to closePrevent spillageLiquid spraying plantsLiquid surface applicatorsMetallurgyExhaust pipe

The invention discloses an electrostatic powder vertical type spraying device. The electrostatic powder vertical type spraying device comprises a powder spraying house, a conveying device for conveying workpieces, a powder spraying device, a powder supplying device and a powder recycling device. The powder spraying house is provided with a workpiece input port and a workpiece output port both of which correspond to the conveying device. The electrostatic powder vertical type spraying device is characterized in that the powder recycling device comprises exhaust pipes arranged at the four corners of the powder spraying house respectively, and each exhaust pipe is provided with a gap for exhausting air from bottom to top, so that air flow in the powder spraying house is uniform and the negative pressure of air needing to be exhausted is reduced; the powder spraying device comprises electrostatic spray gun sets oppositely arranged on the two sides of the conveying device and a lifting device driving the electrostatic spray guns on the two sides to synchronously ascend and descend. The electrostatic powder vertical type spraying device is simple in structure and convenient to use and install; in the powder spraying production process, powder consumption is low, the one-time powder coating rate is high, the time taken to clean the powder house and the time taken to change powder are shortened, electric energy is saved, fewer operating workers are needed, and the production cost is greatly reduced.

Owner:佛山市安邦得机械设备有限公司

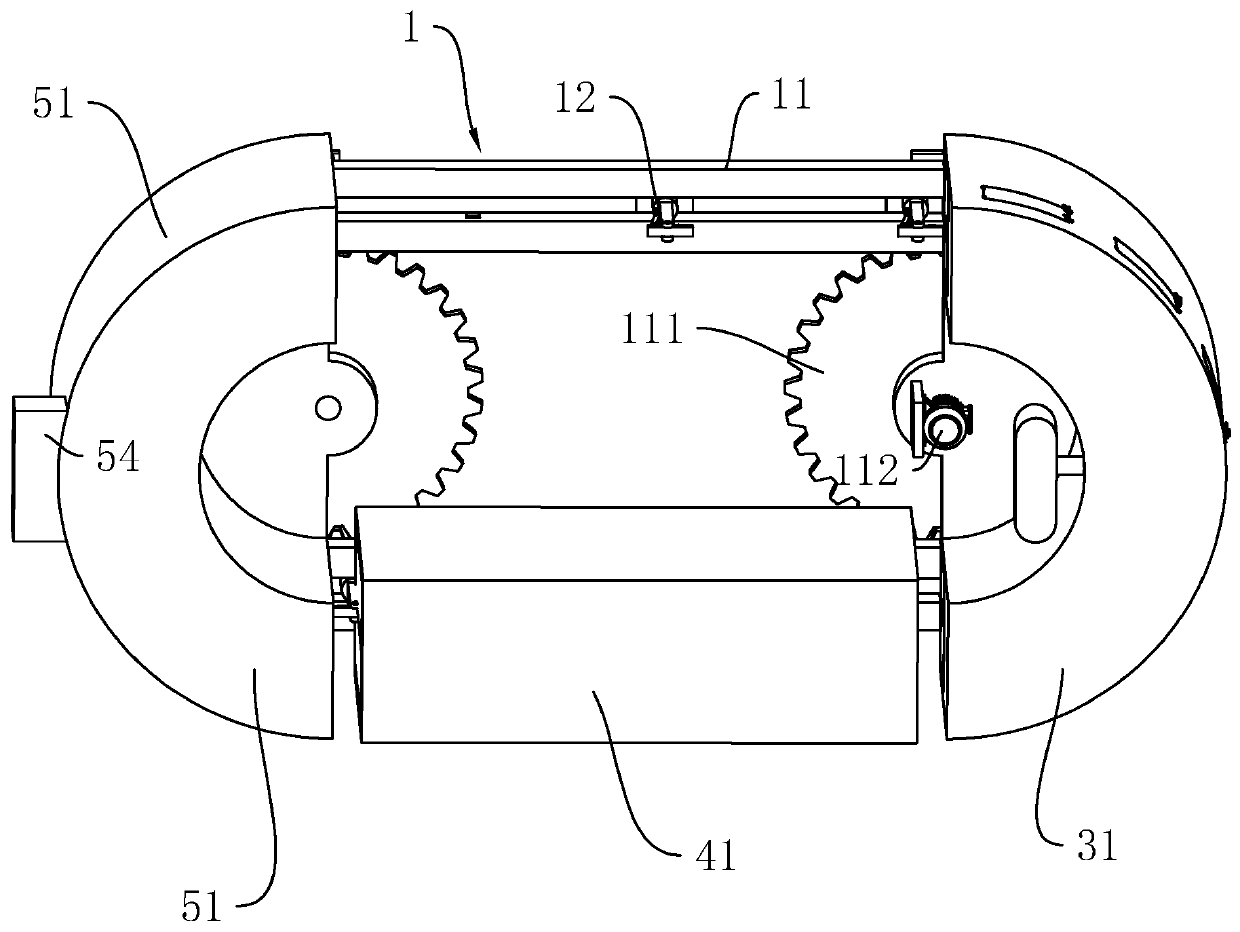

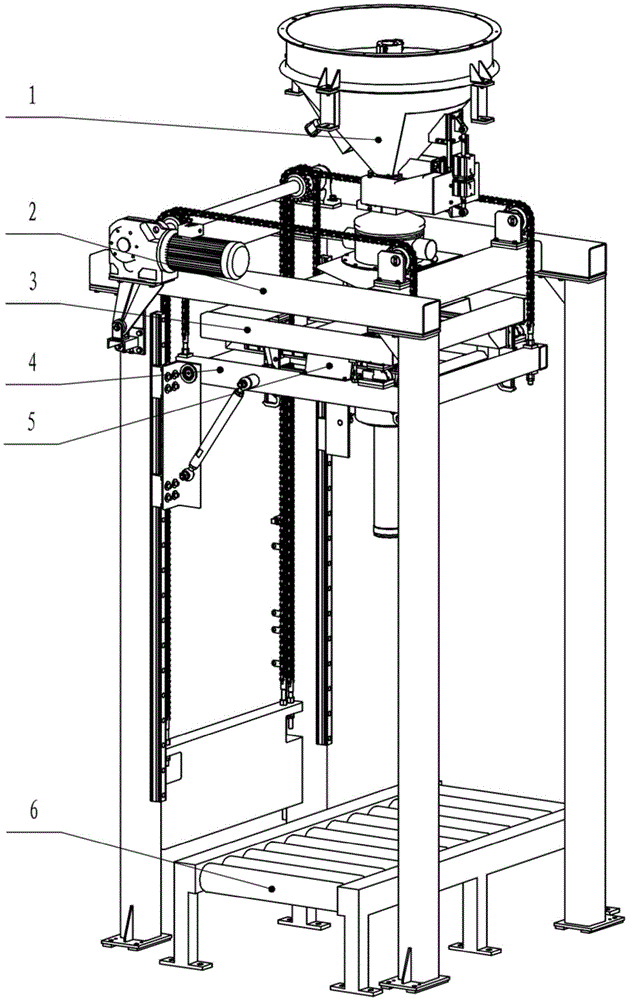

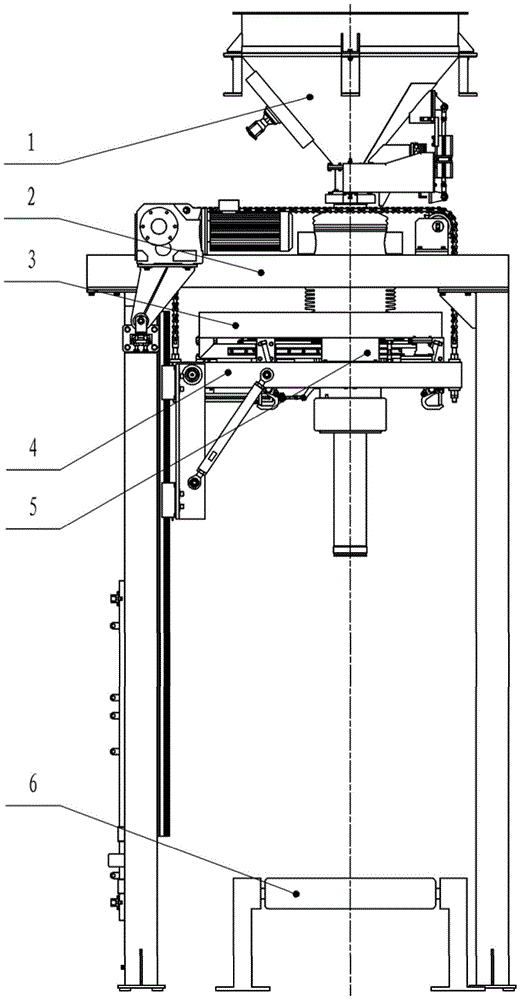

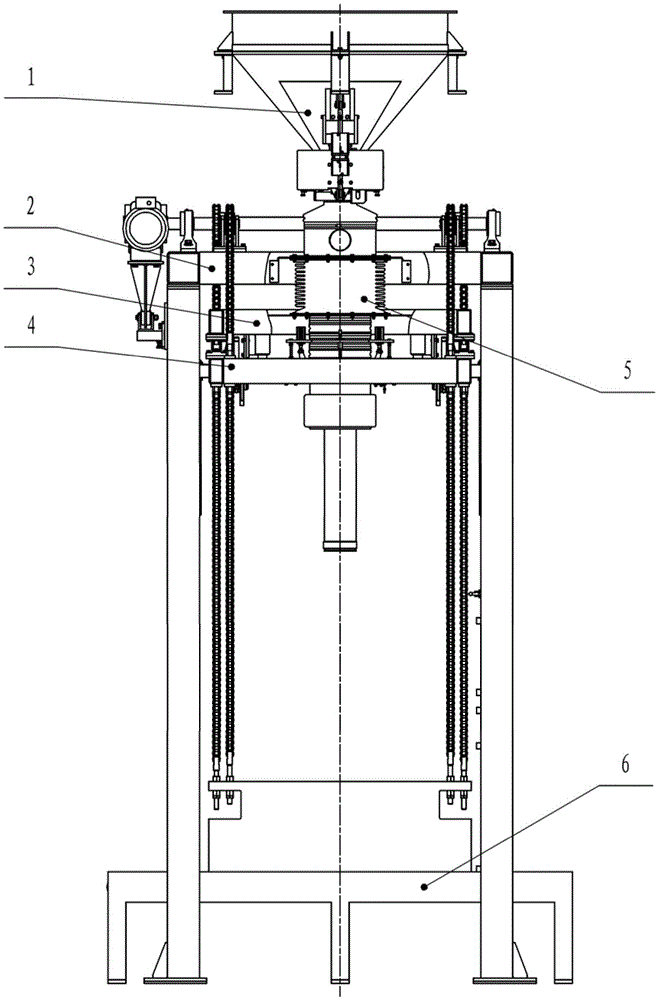

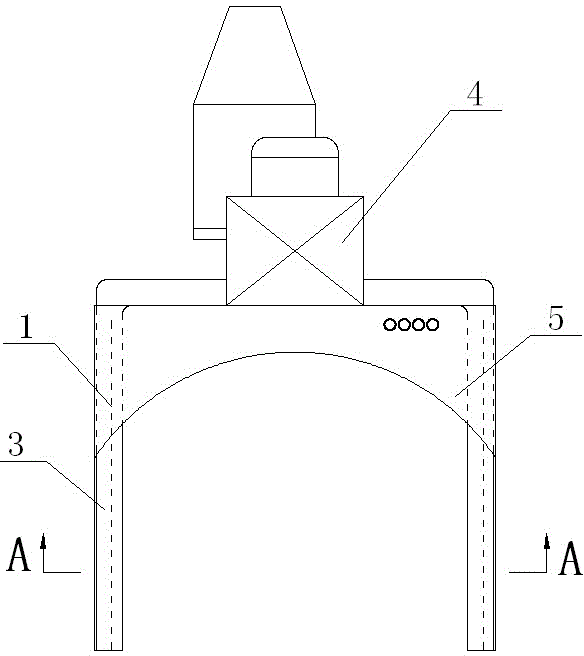

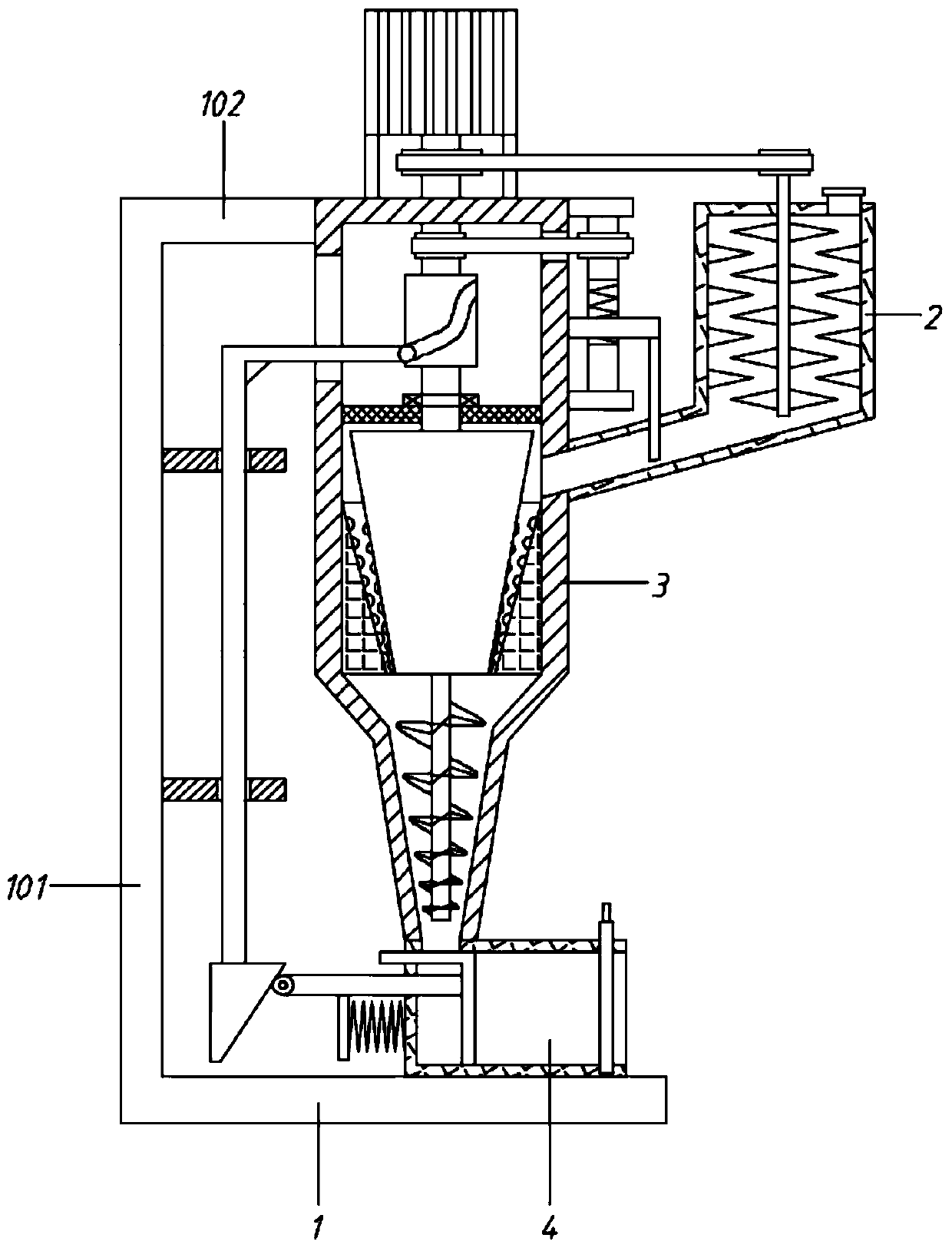

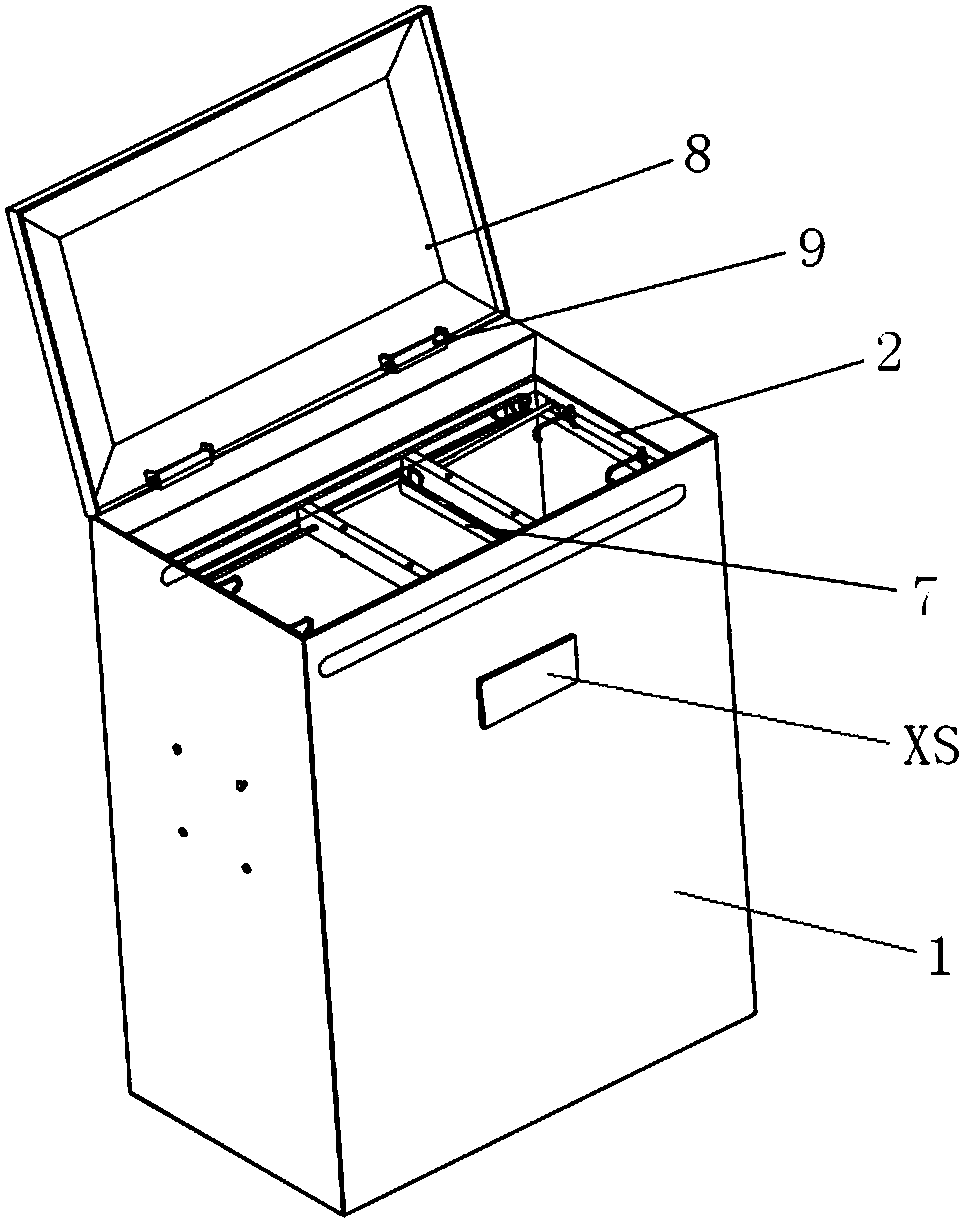

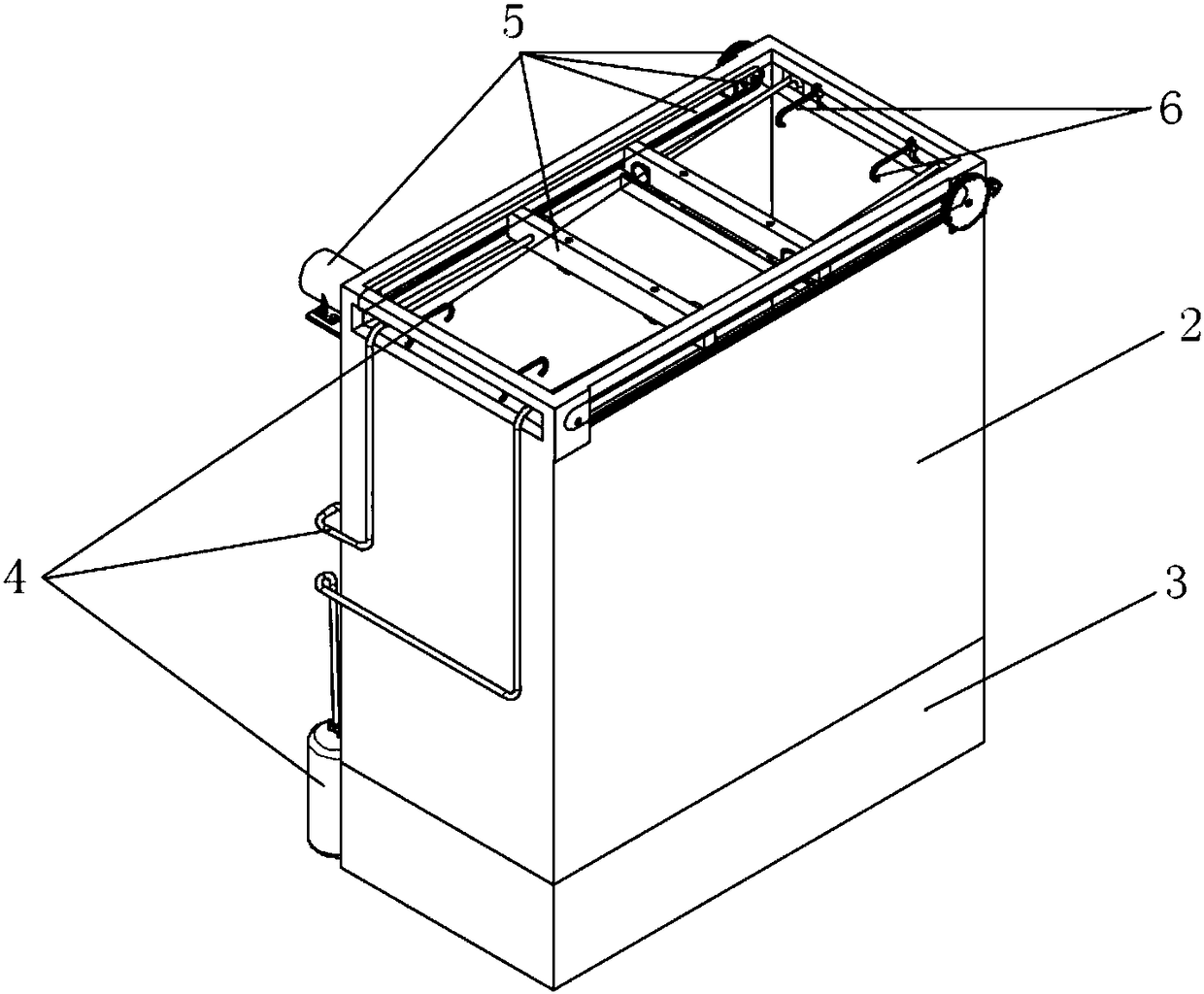

Automatic ton bag packing device suitable for fine powder

The invention discloses an automatic ton bag packing device suitable for fine powder. The device comprises a feeder 1, a frame 2, a bag clamping device 3, a lifting frame 4, an inflation dust removing pipeline 5 and a conveyor 6, wherein the feeder 1 is positioned at the upper part of the center of the frame 2; a chain lifting mechanism arranged at the upper end of the frame 2 drives the lifting frame 4 to move up and down; three weighing sensors 42 are arranged on the lifting frame 4, and are connected with the bag clamping device 3; the bag clamping device 3 is provided with a bag hanging mechanism 32, a bag opening expanding mechanism 33 and a butt joint mechanism 34; the butt joint mechanism 34 includes a butt joint soft cylinder 343; the upper end of the butt joint soft cylinder 343 is connected with a lower mounting plate 54 of the inflation dust removing pipeline 5; the lower mounting plate 54 is fixed on the lifting frame 4; the upper end of the inflation dust removing pipeline 5 is flexibly and tightly connected with an outer cylinder of the feeder 1; and the conveyor 6 is arranged at the lower part of the frame 2. The automatic ton bag packing device suitable for fine powder can satisfy the production requirements of packing the fine powder in ton bags, reduces the generation of dust, improves the operation environment, and improves the equipment productivity.

Owner:HARBIN BOSHI AUTOMATION

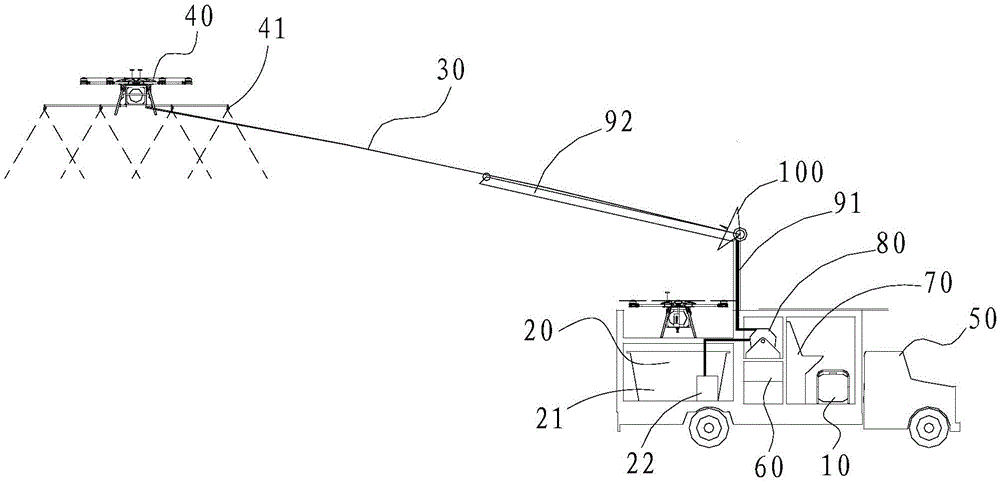

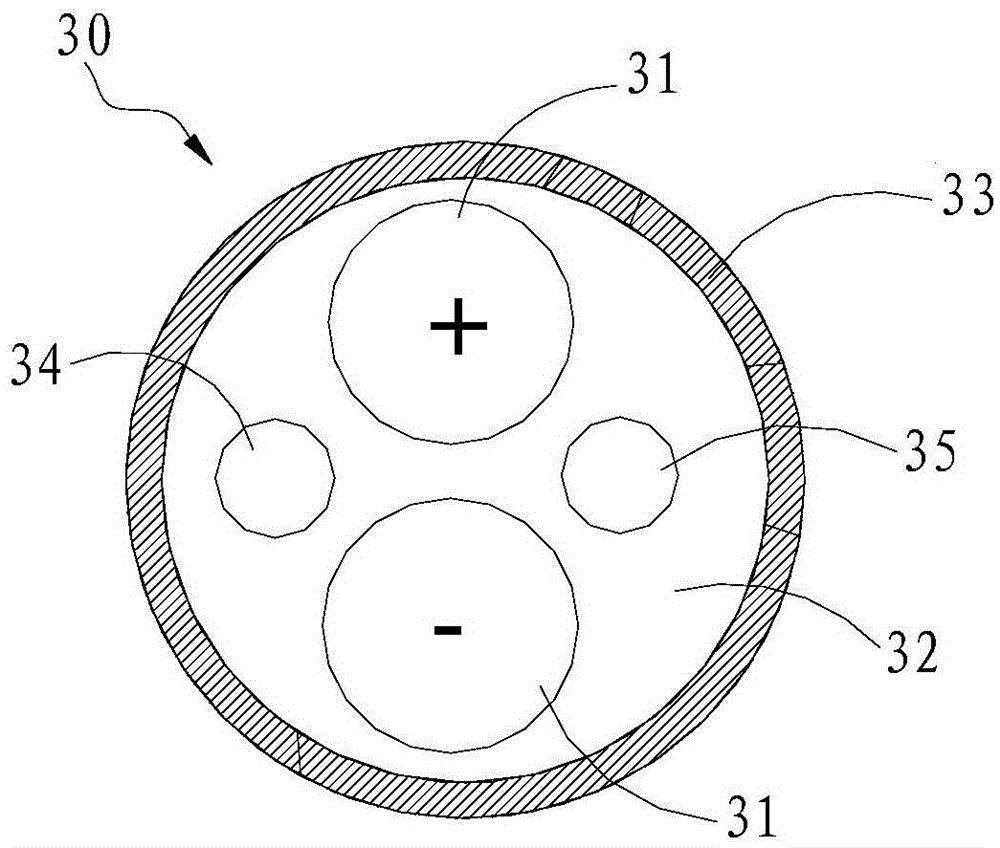

Fluid and power supply system of unmanned aerial vehicle

ActiveCN105599916AReduce loadReduce energy consumptionPower installationsGround installationsFuel tankMooring line

The invention discloses a fluid and power supply system of an unmanned aerial vehicle. The fluid and power supply system comprises a ground power supply device, a ground fluid supply device, a mooring line and the unmanned aerial vehicle. The mooring line comprises a power supply wire and a fluid supply pipeline. The two ends of the power supply wire are electrically connected with the ground power supply device and the unmanned aerial vehicle respectively, and the two ends of the fluid supply pipeline are connected with the ground fluid supply device and a spray head of the unmanned aerial vehicle. According to the fluid and power supply system of the unmanned aerial vehicle, the ground power supply device and the ground fluid supply device continuously supply the electric energy and pesticide to the unmanned aerial vehicle through the mooring line, and the unmanned aerial vehicle can spray the pesticide onto farmland for a longer time according to the electric energy and the pesticide which are supplied by the ground power supply device and the ground fluid supply device. A fluid storage case and an oil storage caste are not needed for the unmanned aerial vehicle, the load of the unmanned aerial vehicle is reduced, and the energy consumption is greatly reduced.

Owner:浙江空行飞行器技术有限公司

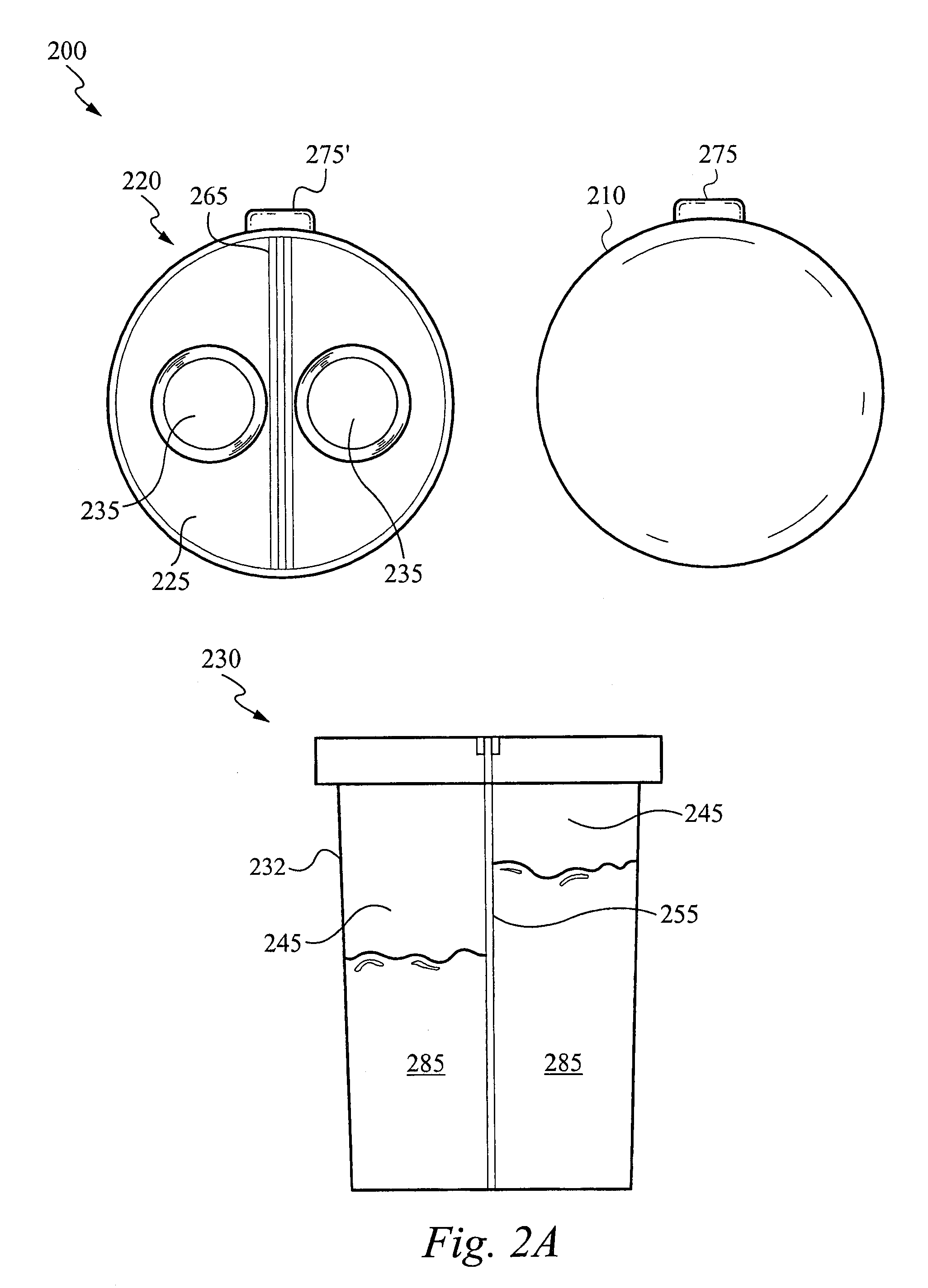

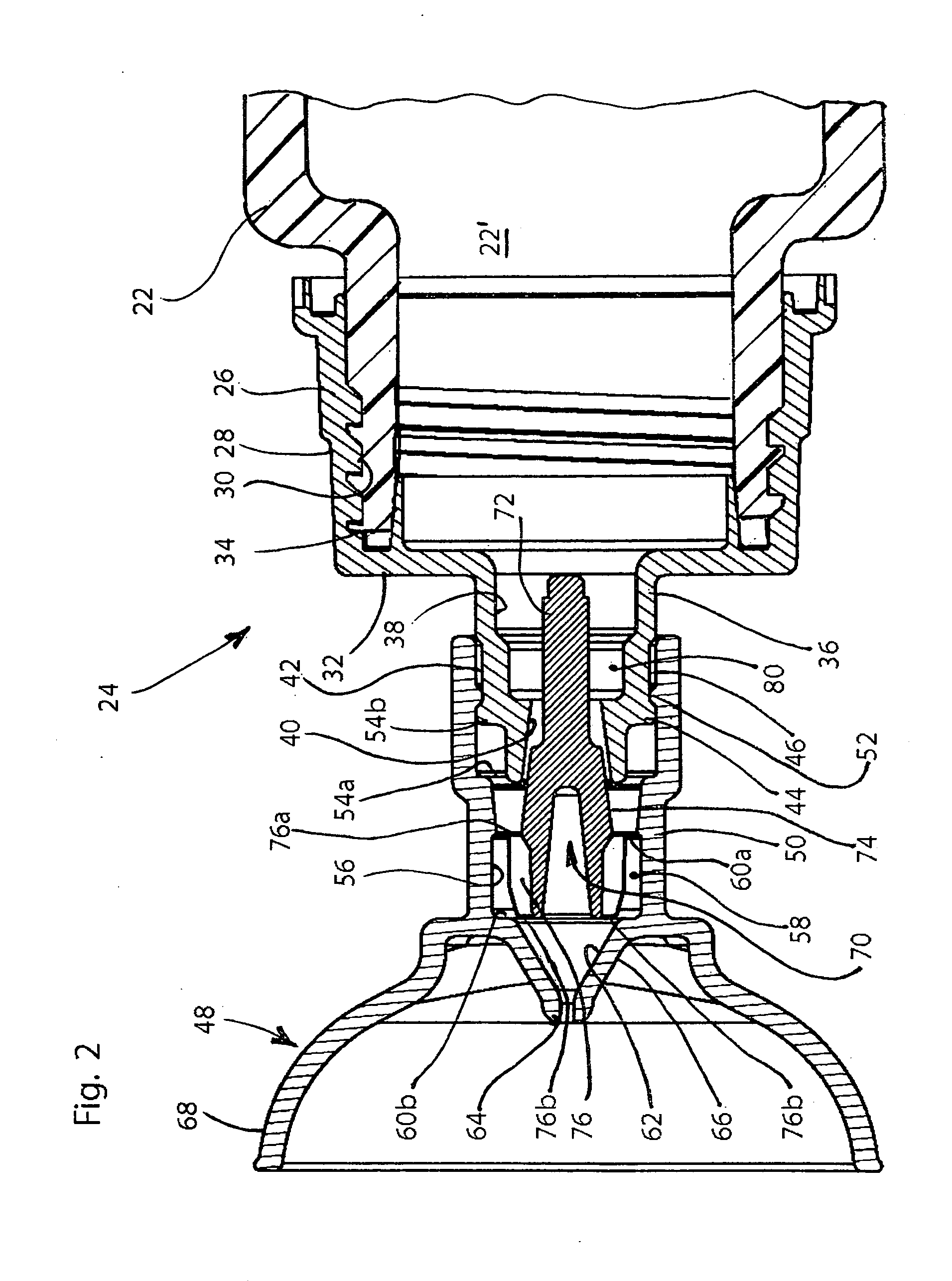

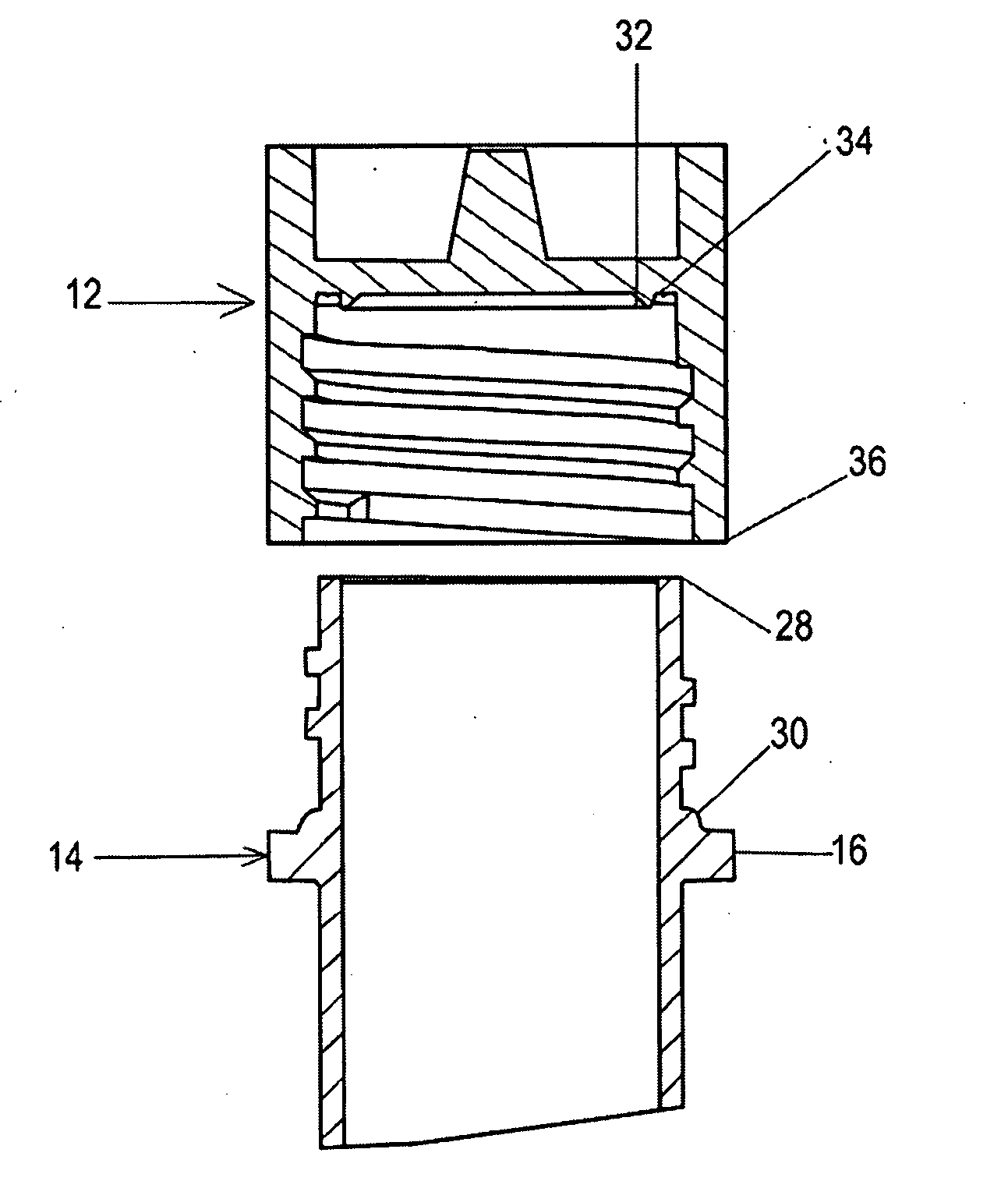

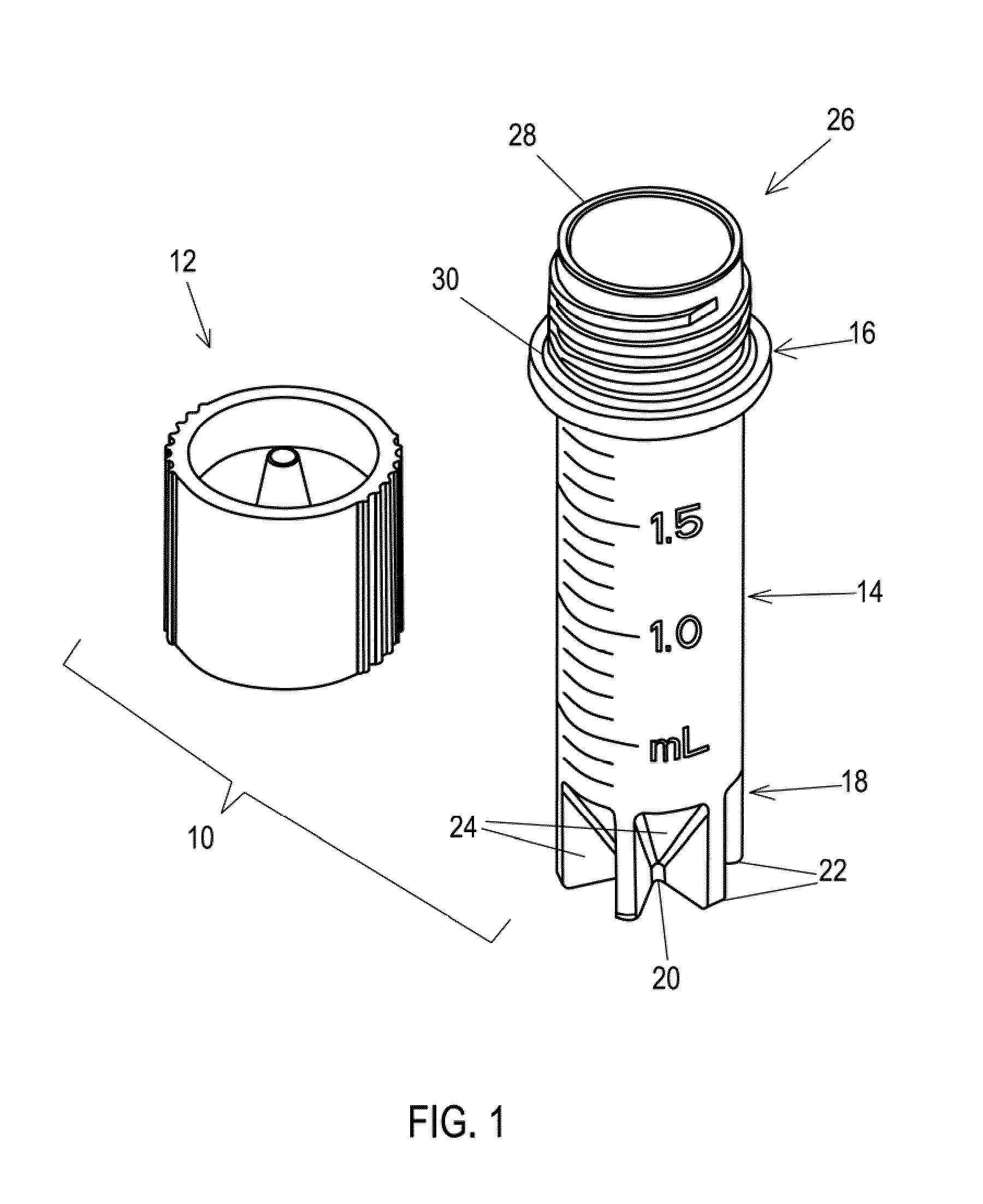

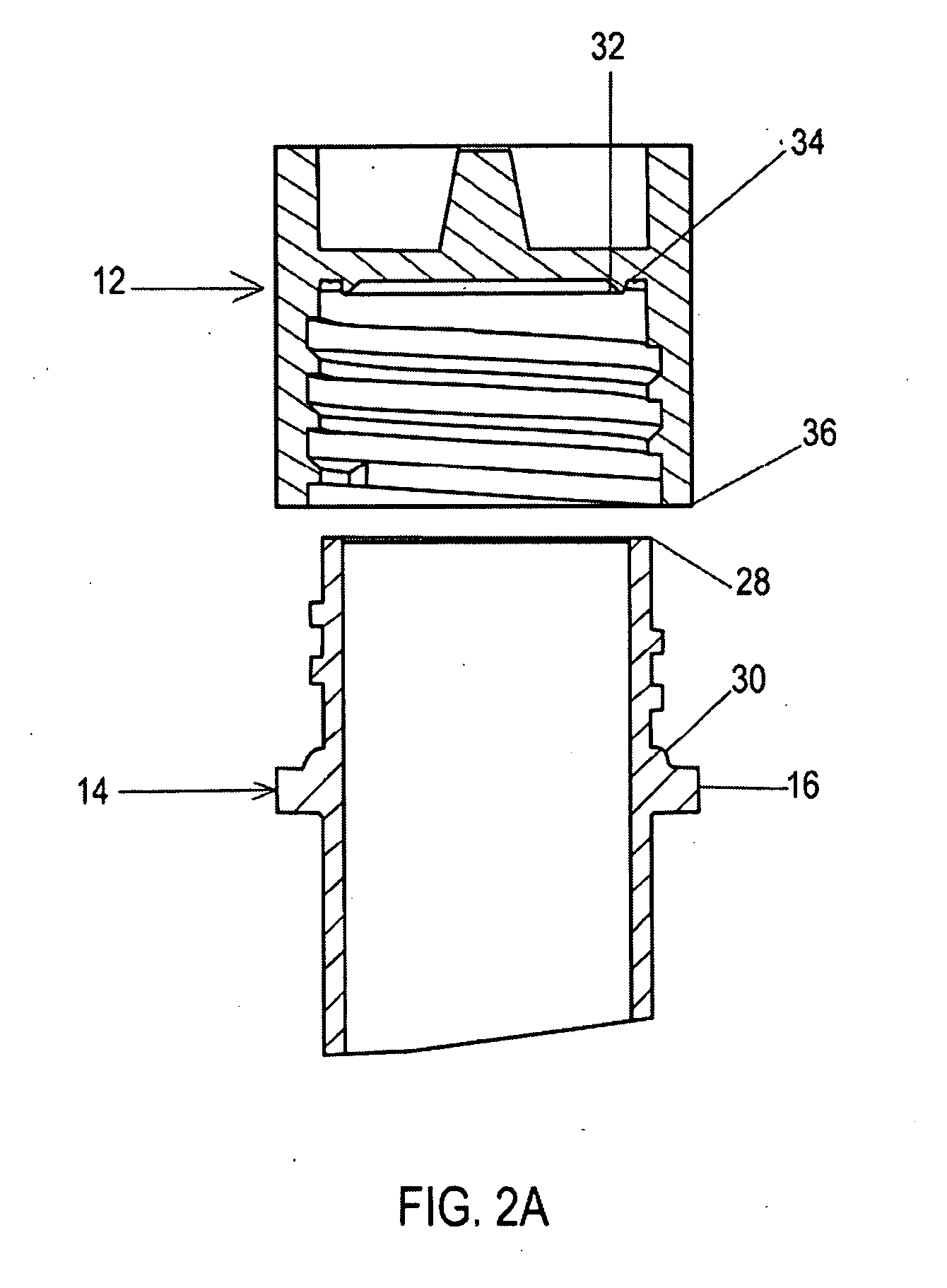

Cryogenic storage container

InactiveUS20090255938A1Prevent spillageAvoid contaminationCapsContainer filling methodsWarming rateCryopreservation

A cryopreservation storage and processing container for cryogenic material is disclosed. In one embodiment, the container can be used to cryopreserve and store biological specimens at cryogenic temperature but also can be used directly in centrifuges or microcentrifuges to process biological materials. It incorporates the functions of both storage container and centrifuge tubes, provides self-sealing mechanism, and accommodates higher cooling / warming rates. The storage container includes both a vessel body 14 and a cap 12.

Owner:FUJA TANNIN J

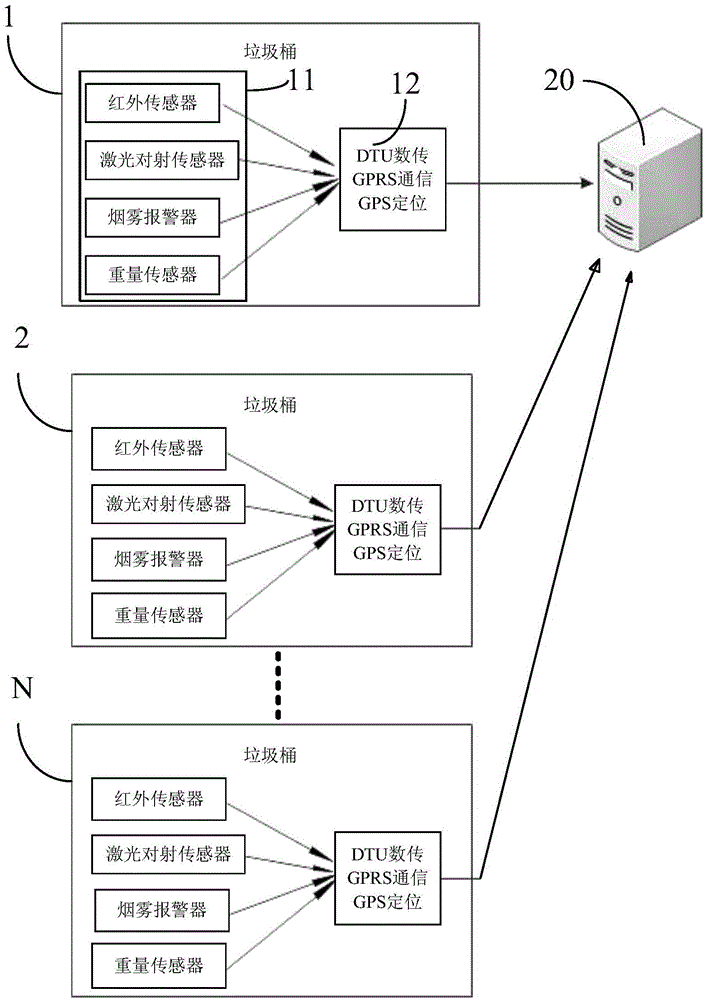

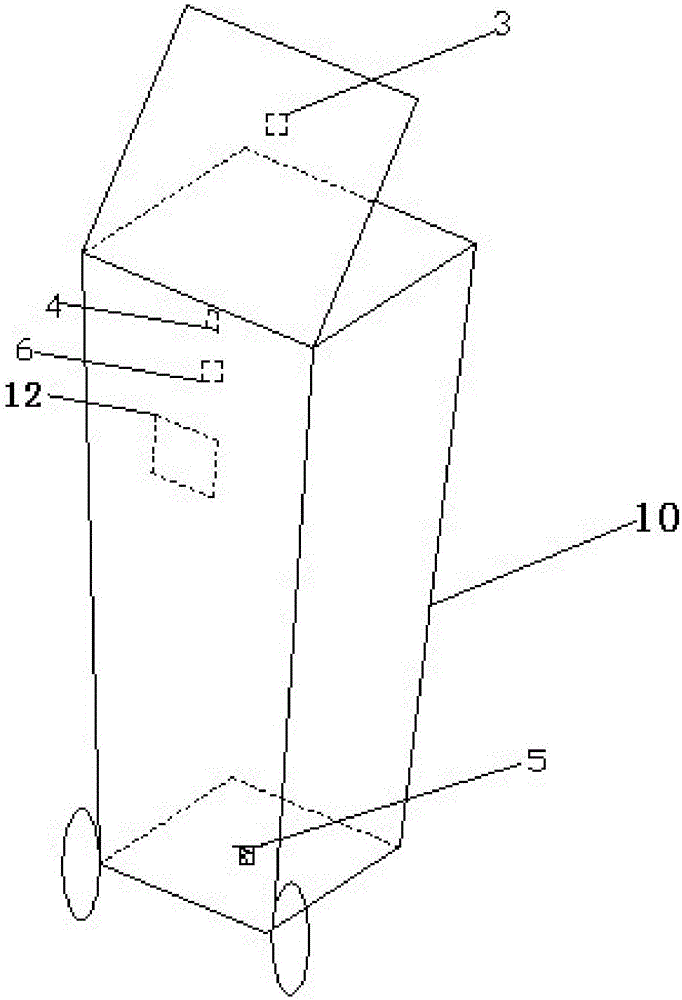

Internet of Things management system for district intelligent dustbins

InactiveCN105046403ATimely processingAvoid the problem of poor environment in the communityResourcesTransmissionComputer moduleManagement system

The invention discloses an Internet of Things (IOT) management system for district intelligent dustbins. The IOT management system comprises at least one dustbin and a management server. Each dustbin is provided with a sensor assembly and an information receiving transmission module. The sensor assembly is in communication connection with the information receiving transmission module and may acquire dustbin state information and sends the dustbin state information via the information receiving transmission module. The management server is provided with an information receiving module. The information receiving module is in communication connection with the information receiving transmission module of each dustbin, receives the dustbin state information sent by the information receiving transmission module of each dustbin, and gives prompt information about the real-time state of each dustbin according to the dustbin state information. The IOT management system may timely transmit the real-time states of the dustbins to the management server in order that a district property management worker timely and reasonably sends for a transfer station worker to clear the garbage, thereby achieving a purpose of saving environmental sanitation management cost to the utmost extent.

Owner:启迪城市环境服务集团有限公司

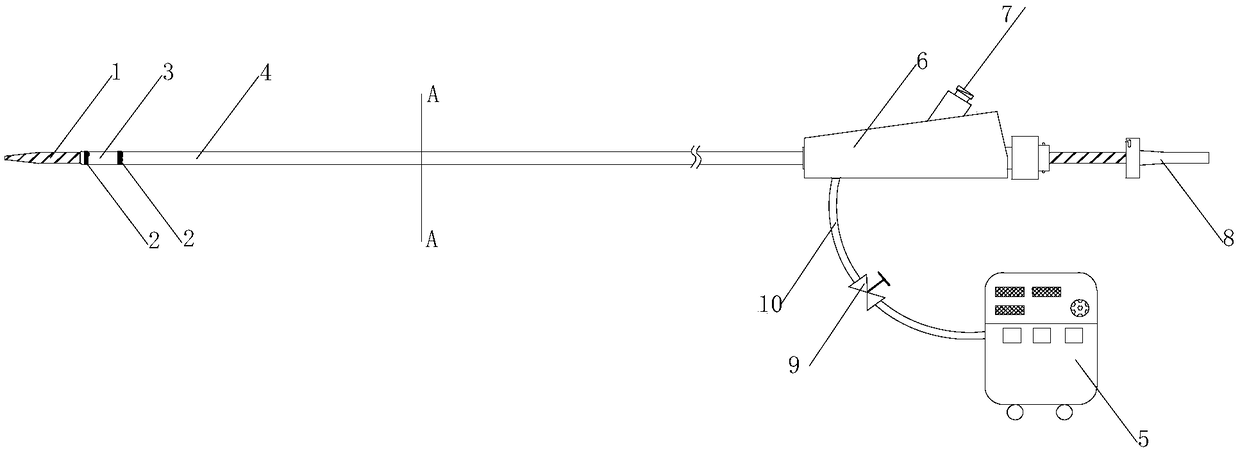

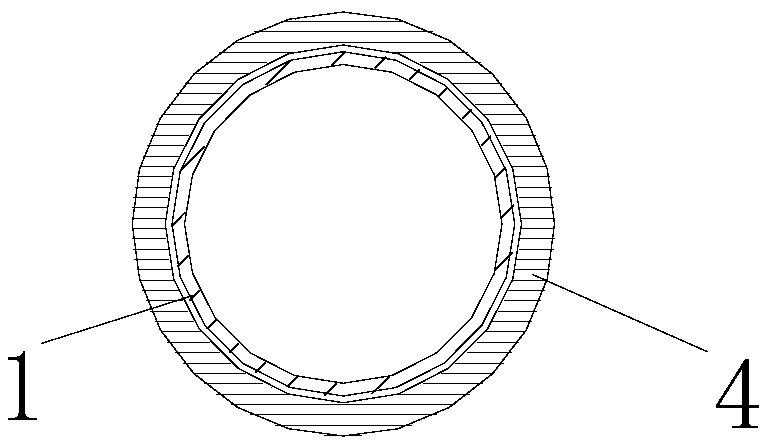

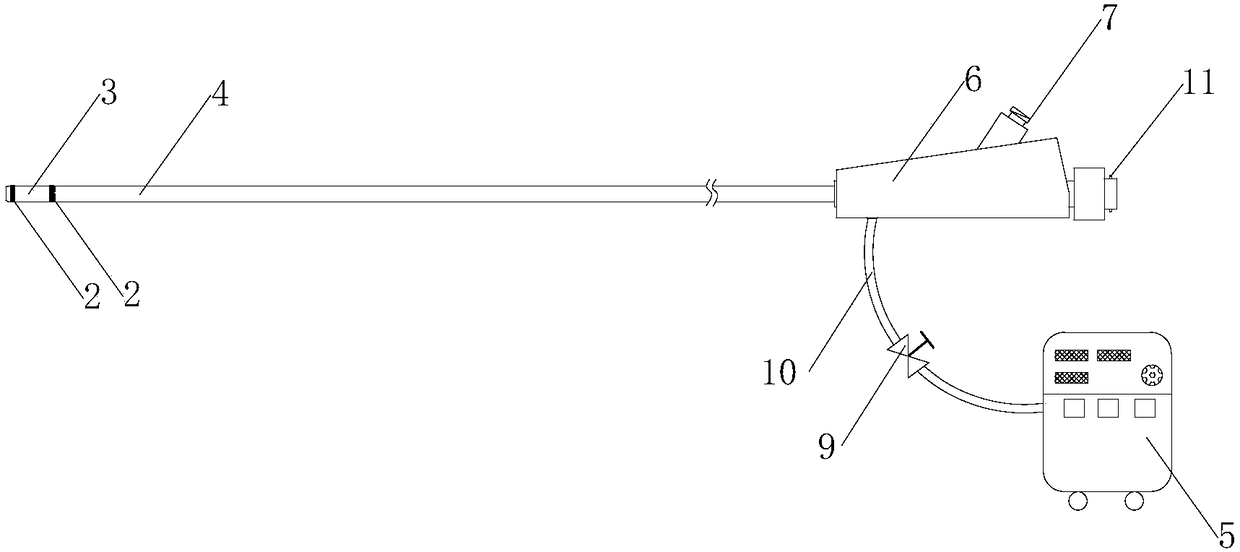

Thrombus taking catheter and thrombus taking device for same

The invention provides a thrombus taking catheter. The thrombus taking catheter comprises a blocking sheath and a thrombus taking device, wherein the blocking sheath comprises a sheathing canal; a ball bag is arranged at a far end of the sheathing canal; a handle is arranged at a near end of the sheathing canal in a connected manner; at least two cavities are formed in the sheathing canal; a cavity of the ball bag communicates with a ball bag filling joint on the handle by the first cavity; a developing mark is arranged on the sheathing canal on the ball bag side; the near end of the second cavity communicates with a negative-pressure suction device arranged on the handle in a connected manner; an opening portion which communicates with the second cavity in an axial direction is further formed in the handle; an expander can extend into the second cavity of the sheathing canal from the opening portion of the handle; the thrombus taking device can extend into the second cavity from the opening portion of the handle and comprises an outer tube, an inner tube and a dense net shaped thrombus taking piece; the outer tube and the inner tube are arranged in a sleeving manner coaxially; oneend of the dense net shaped thrombus taking piece is connected with a far end of the inner tube; the other end of the dense net shaped thrombus taking piece is connected with the far end of the outertube, and the inner tube is pulled so that the dense net shaped thrombus taking piece is expanded or loose. By the thrombus taking catheter, the thrombus removal rate can be increased effectively, and the blood loss is reduced.

Owner:上海唯域医疗科技有限公司

Rotary air curtain rang hood with oil fume filter device

ActiveCN102913970AStop oil fume from spillingHigh smoke collection efficiencyDomestic stoves or rangesLighting and heating apparatusAirflowComing out

The invention provides a rotary air curtain rang hood with an oil fume filter device. The rotary air curtain rang hood comprises an engine cover, a fan, a suction pipe and an oil fume separation device, wherein a first flow divider and a second flow divider are respectively mounted on an outlet of the fan; the outlet of the second flow divider is respectively connected with a plurality of air supply ducts; a plurality of air supply columns communicated with the air supply ducts are mounted in the engine cover; each air supply column is provided with a strip-shaped nozzle; the airflow forms a rotary air curtain in the engine cover after coming out of the strip-shaped nozzles; one end of the suction pipe is connected with the oil fume separation device, while the other end of the suction pipe is arranged above the rotary air curtain; and an ejector pipe is connected on the outlet of the first flow divider and extends into the suction pipe. According to the rotary air curtain rang hood with an oil fume filter device, the rotary air curtain is formed in the engine cover, so that the spillover diffusion of oil fume can be effectively avoided in the cooking process, and the extracting rate of the oil fume is increased.

Owner:HANGZHOU DE&E ELECTRICAL CO LTD

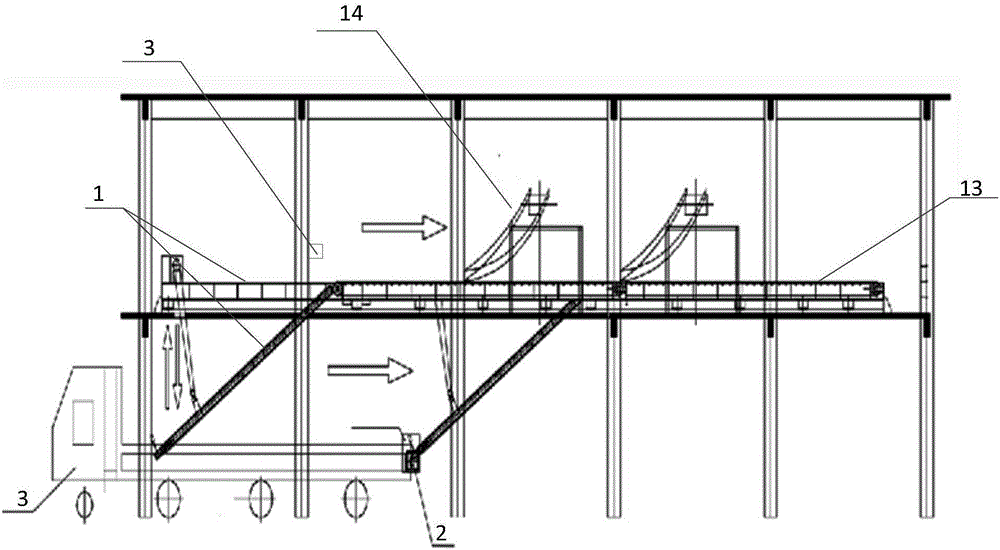

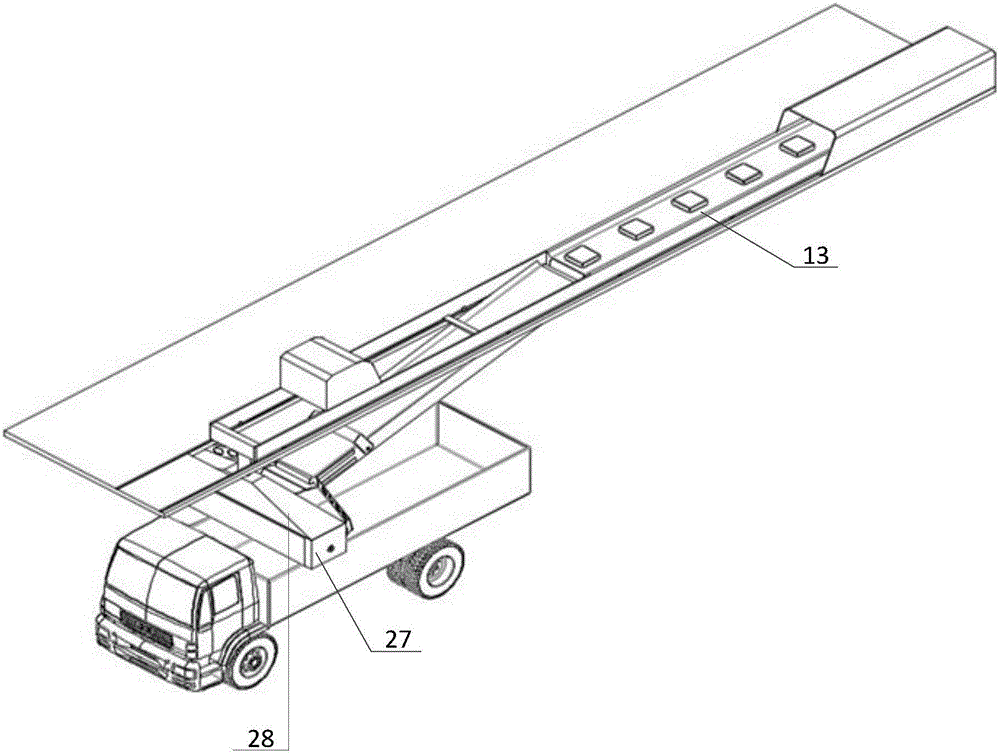

Automatic loading device applicable to bagged materials and application method of automatic loading device

ActiveCN106516799AReduce labor intensityImprove loading speedLoading/unloadingEngineeringSocial benefits

The invention discloses an automatic loading device applicable to bagged materials. The automatic loading device comprises a material conveying unit, a material turning unit and a control terminal, wherein the material turning unit comprises a conveying section and a swerving power mechanism arranged at one end of the conveying section to enable the conveying section to deflect in a preset direction by a preset angle; the control terminal is connected with the material conveying unit and the material turning unit in a communication manner; and the conveying section comprises at least one set of conveyor belts which can carry out conveying by a preset distance in the preset direction, and the material turning unit is further connected with the material conveying unit through a support assembly. The automatic loading device applicable to the bagged materials solves the problems that the loading efficiency is low, an existing loading device cannot adapt to various transport cart types, the manual uncontrollable factors are too large, the labor force amount is large and the dust pollution is serious and other problems; and the automatic loading device is also applicable to loading of other bagged materials, and has wide market prospects and good economic and social benefits.

Owner:绵阳钢猫科技有限公司

Plane button type packing technology of integrated circuit or discrete component and its packing structure

ActiveCN1725460ASmooth productionImprove yieldSolid-state devicesSemiconductor/solid-state device manufacturingIntegrated circuitEngineering

This invention relates to a plane salient point encapsulation technology and its structure of IC or discrete components, among which, the technology includes: taking a base plate, dry-film layers are pasted to the front and back side of the base plate, removing part of the upper layer for the preparation of forming a basic island and pins, plating metal layers on the front, removing the rest dry film on the upper layer of the base plate, semi-etching it, removing the dry film on the back, implanting the chip, wiring, packaging with plastic capsule, pasting a dry film on the back of the base plate again, etching the dry film at the back and the rest of the metal of the semi-etched zone again so as to enable the back of the basic island and the pin projecting over the plastic capsule, removing the rest dry film, plating metal layers on the surface, pasting film on the front of the plastic capsule then cutting.

Owner:长电科技管理有限公司

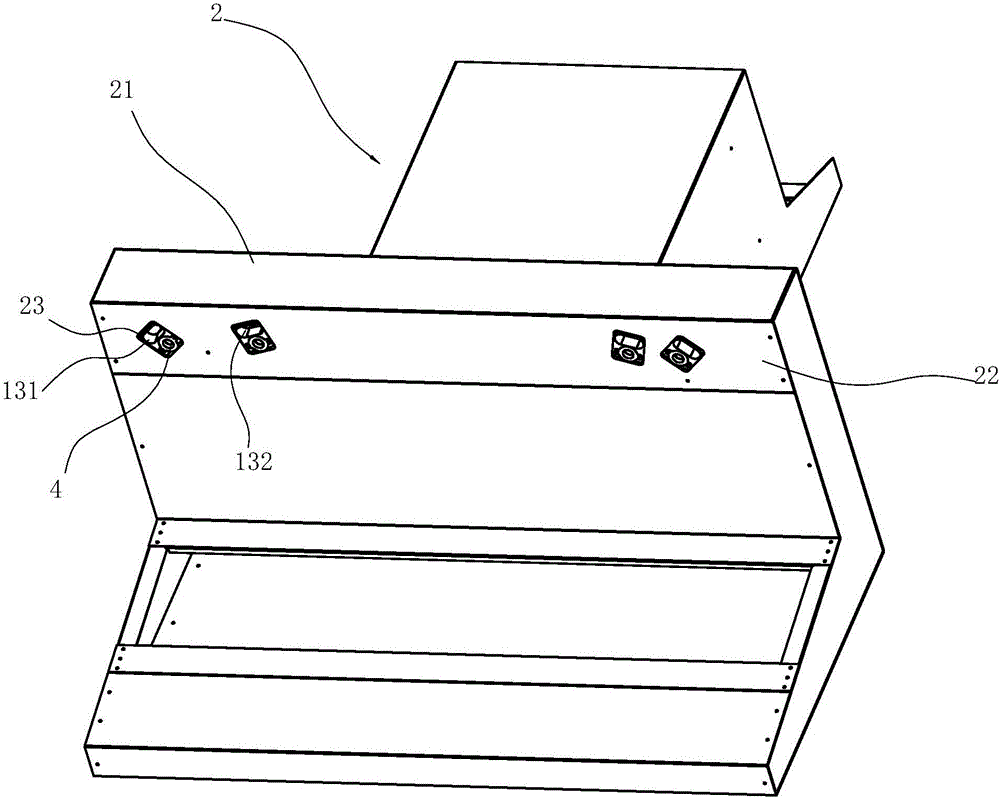

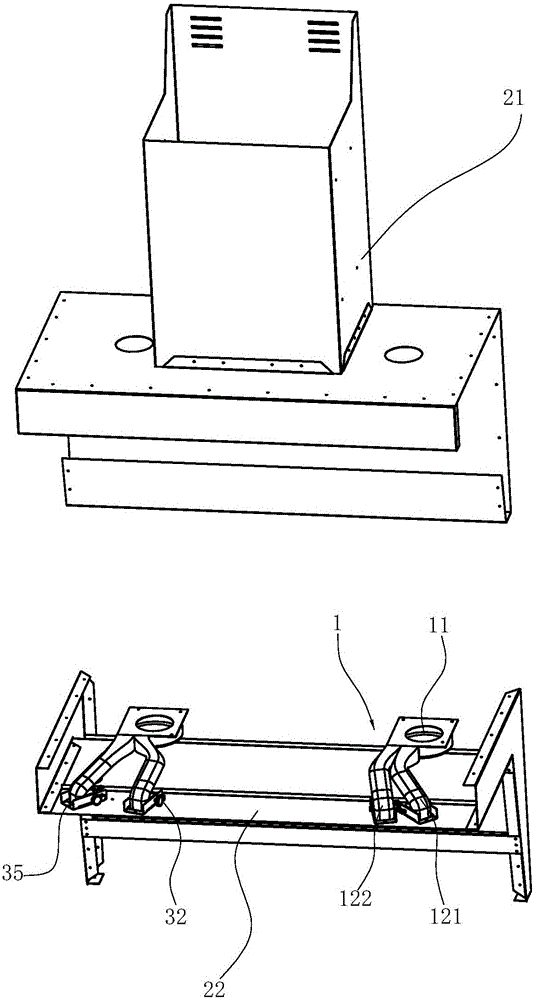

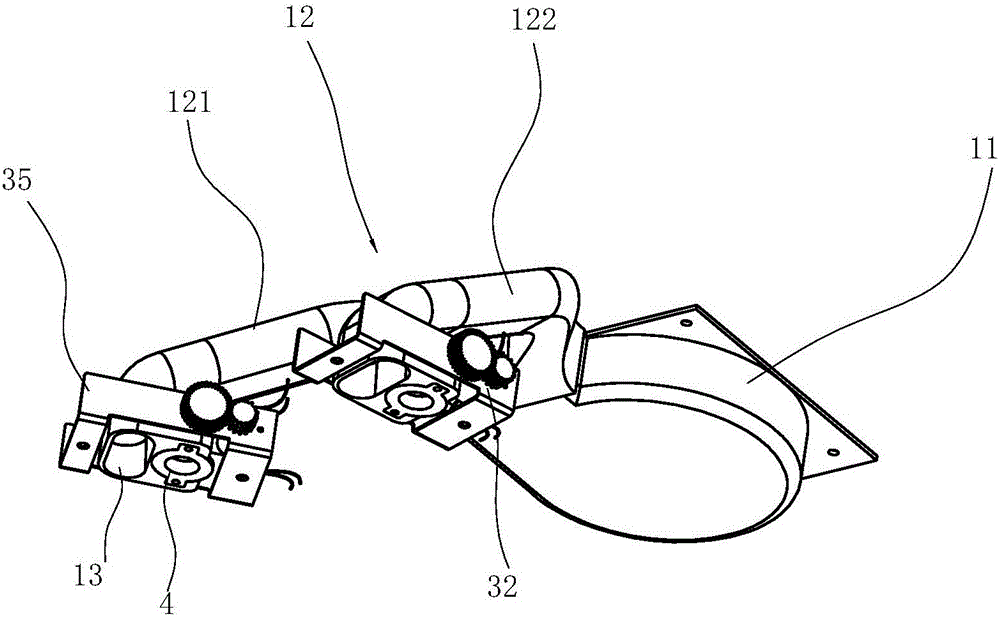

Extractor hood with absorption assisting device and method for pumping and absorbing oil fume

ActiveCN105783064ALow powerWill not be stainedDomestic stoves or rangesLighting and heating apparatusCentrifugal fanWaste management

The invention relates to an extractor hood with an absorption assisting device and a method for pumping and absorbing oil fume. The extractor hood comprises an extractor hood main body and air supply devices arranged on the extractor hood main body, and is characterized by further comprising driving devices, detectors used for detecting the position of cookware, and a control device; each air supply device comprises a centrifugal fan, the exhaust port of the centrifugal fan is connected with an air duct, the air duct is provided with at least one air outlet, and the air outlet is downward or obliquely downward; the driving devices are connected with the air supply devices in a driving way and used for changing the direction of airflow output by the air supply devices; and the driving devices and the detectors are both connected with the control device. The air supply airflow of the extractor hood with an absorption assisting device directly blows into the cookware, and can propel the oil fume to gather to the exhaust opening of the extractor hood at the beginning of generation of the oil fume, thus thoroughly avoiding overflow of the oil fume in rising.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

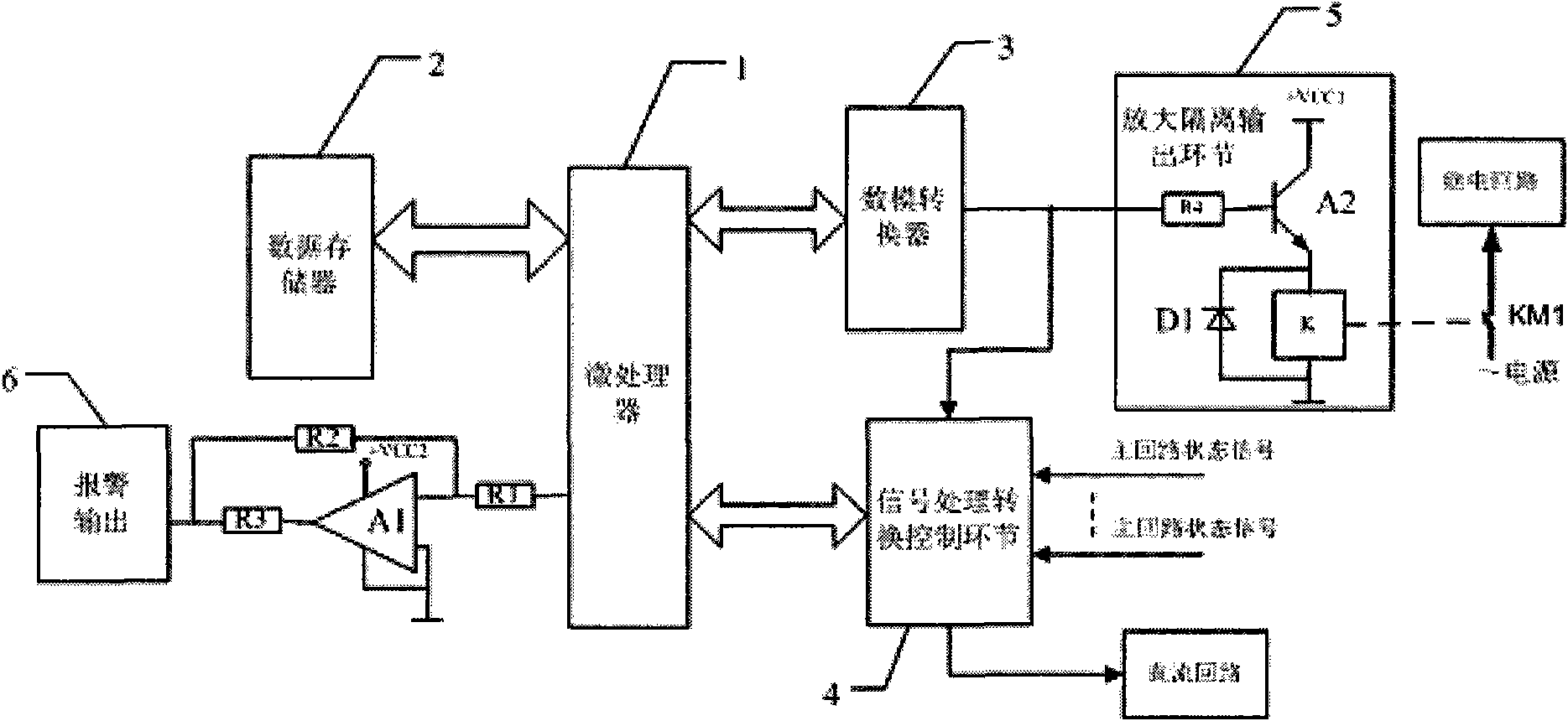

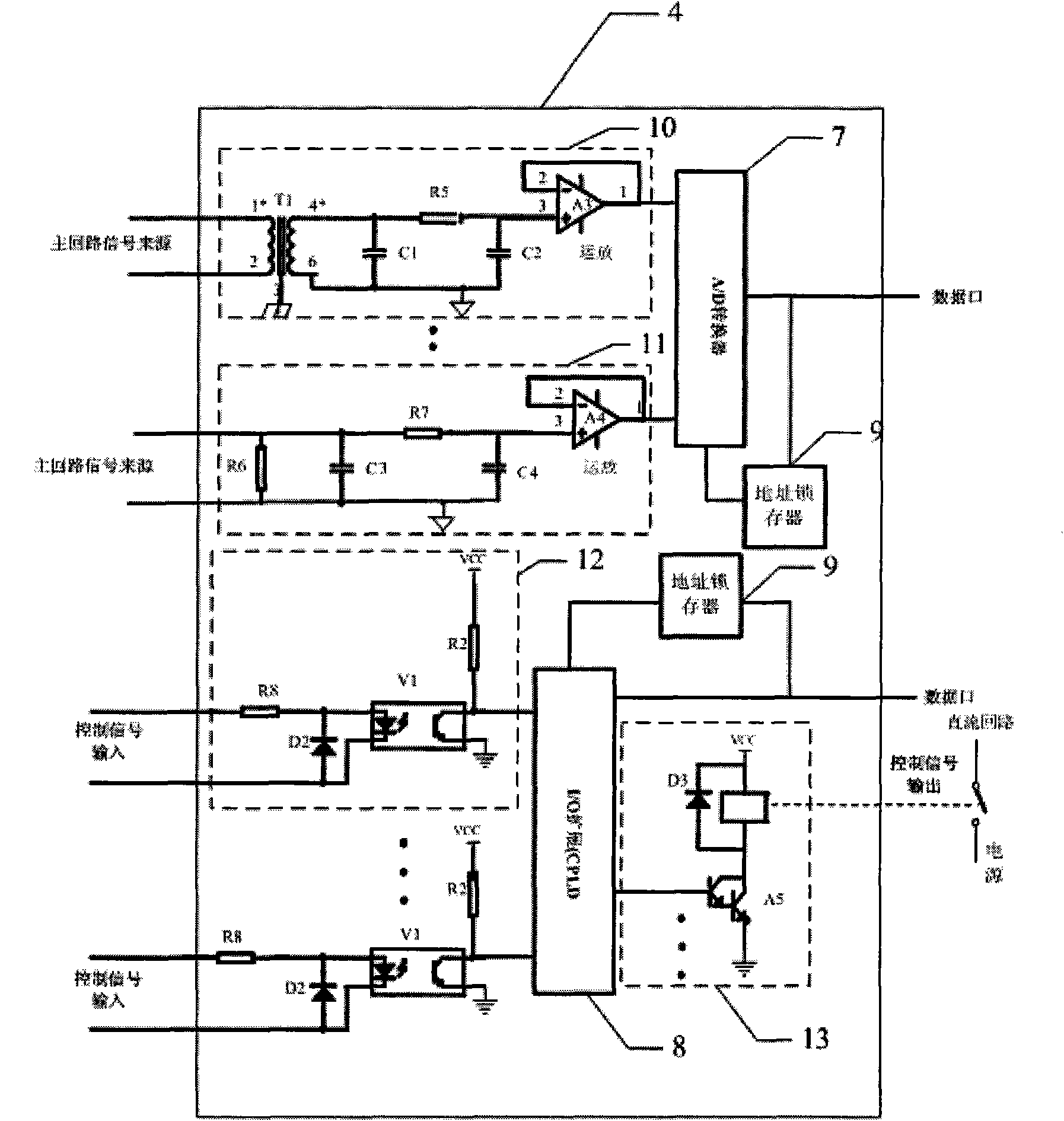

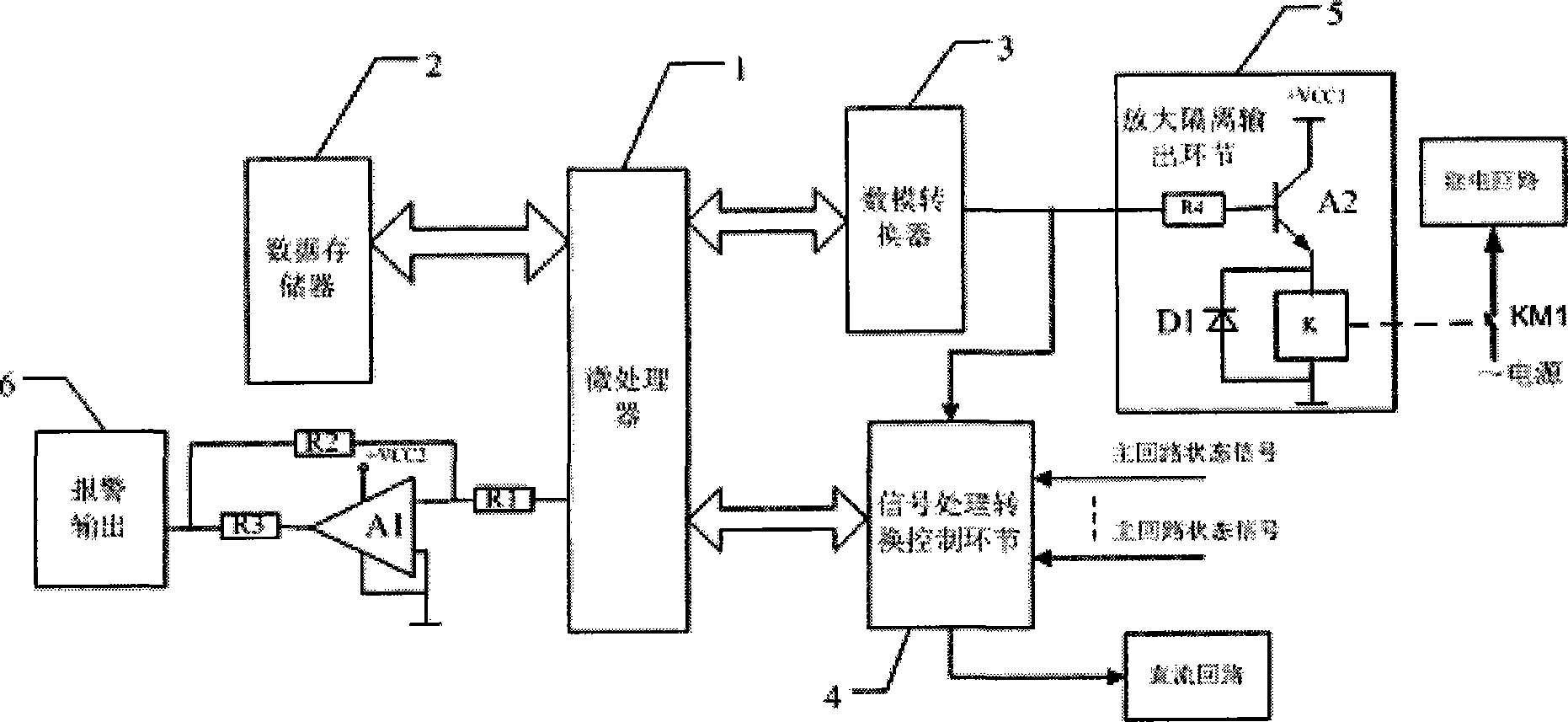

Sewage level sensor fault instant diagnosing, alarming and switching device

InactiveCN101776916APrevent spillageEffective early warning of automatic control dysfunctionTesting/calibration apparatusElectric testing/monitoringAutomatic controlAudio power amplifier

The invention discloses a sewage level sensor fault instant diagnosing, alarming and switching device. The device comprises a microprocessor, a data memory and a D / A converter, a signal processing and switching link, an amplifying and isolated outputting link and an alarm output, wherein the I / O data port of the microprocessor is connected with the serial port of the data memory, the data port of the D / A converter is connected with the data port of the signal processing and switching link, the I / O output port of the microprocessor is connected with the alarm output through an amplifier A, and the analog output port of the D / A converter is connected with the input end of the amplifying and isolated outputting link and the control signal input end of the signal processing and switching link. The device can be used to perform instant diagnosing and alarming to the sewage level sensor fault, effectively predict the fault, namely automatic control function disorder, caused by sewage level sensor fault and abnormal operation, of a pump station discharging system, perform switching control, avoid sewage leakage caused by the fault and the accident occurrences such as the damage of a pump and facilitate the fault to be instantly removed.

Owner:杭州华孚环境工程技术有限公司

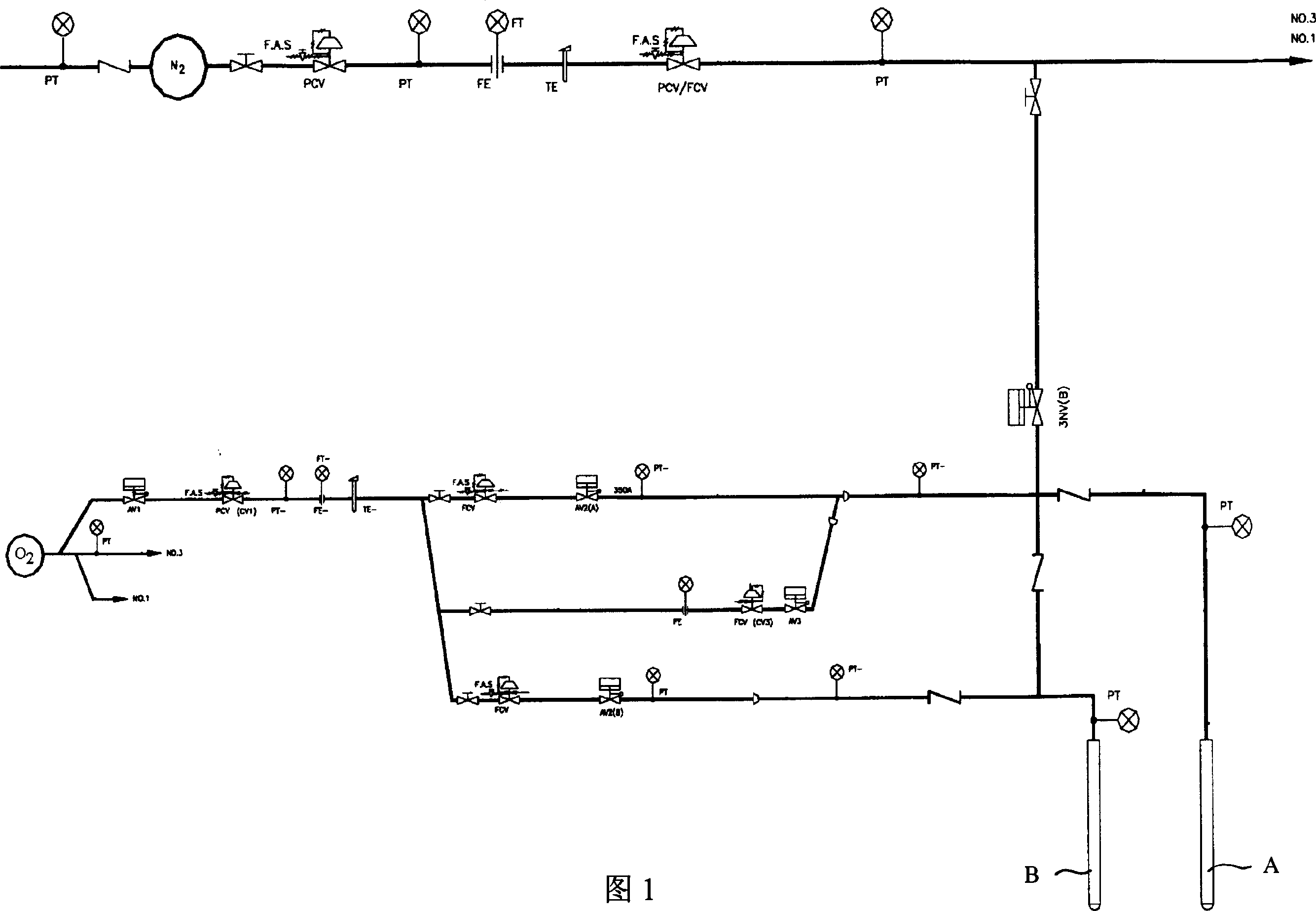

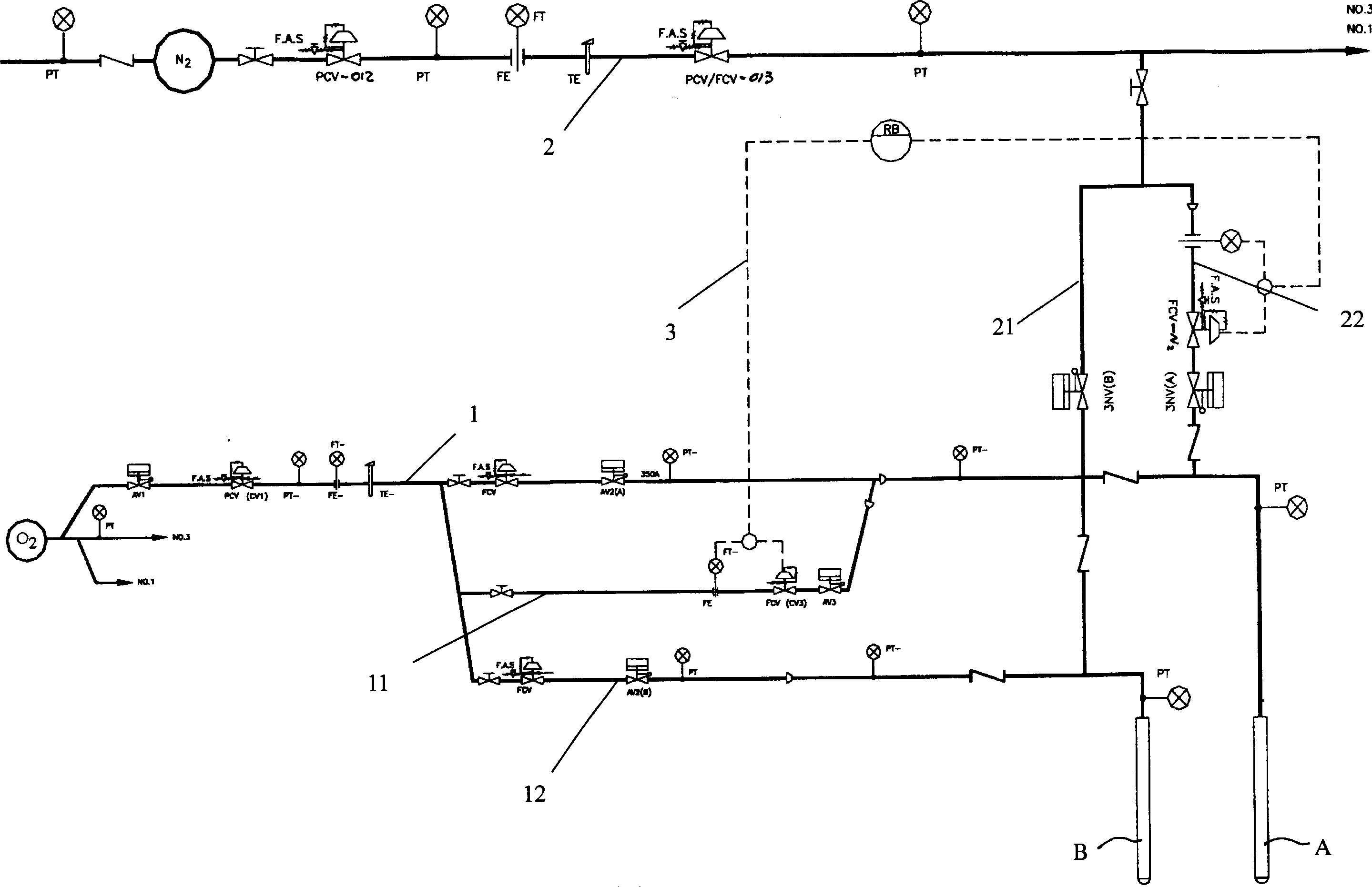

System and method for treating converter flue gas

InactiveCN102899444AEasy to controlEasy to operateIncreasing energy efficiencyManufacturing convertersEvaporative coolerDust control

The invention relates to an environmental-friendly device of an iron and steel enterprise and a dust removal method, that is to say, a system and a method for treating converter flue gas. The system comprises a furnace mouth nitrogen injection sealing petticoat pipe, a segmental evaporation cooling flue, a high-temperature heat pipe steam generator, a spray evaporation cooler, a long neck adjustable throat venturi tube, an impeller type composite dehydrator, a fan, an automatic continuous coal gas detector and a three-way switching valve, which are connected in sequence, wherein the three-way switching valve is connected with a gas chamber; or the three-way switching valve is communicated with a chimney. The method comprises the following steps of: forming a soft sealing screen between a furnace mouth and a petticoat pipe, after segmentally vaporizing and cooling the flue gas, and cooling in a high-temperature heat pipe; after carrying out spray evaporation, cooling and rough dust removal through a dry method, carrying out fine dust removal and cooling by a venturi tube through a wet method, dehydrating the flue gas, and entering into a coal gas recycling stage lastly. According to the invention, the wet method and the dry method are combined, waste heat recovery, coal gas recovery, sewage treatment and dust removal can be planned in a flue gas treatment and utilization system as a whole and the combination action of the device is fully exerted.

Owner:北京五一环保科技股份有限公司

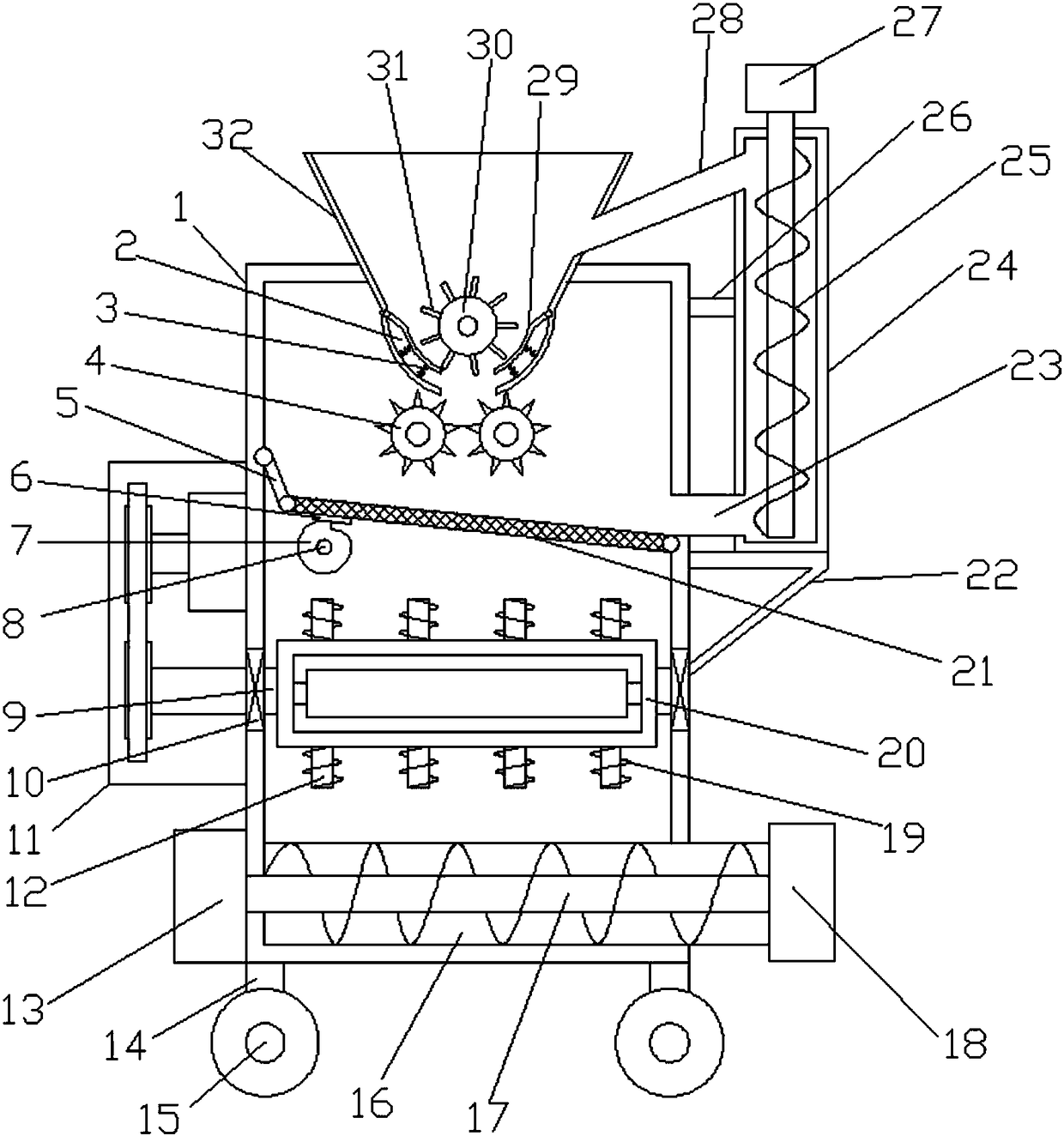

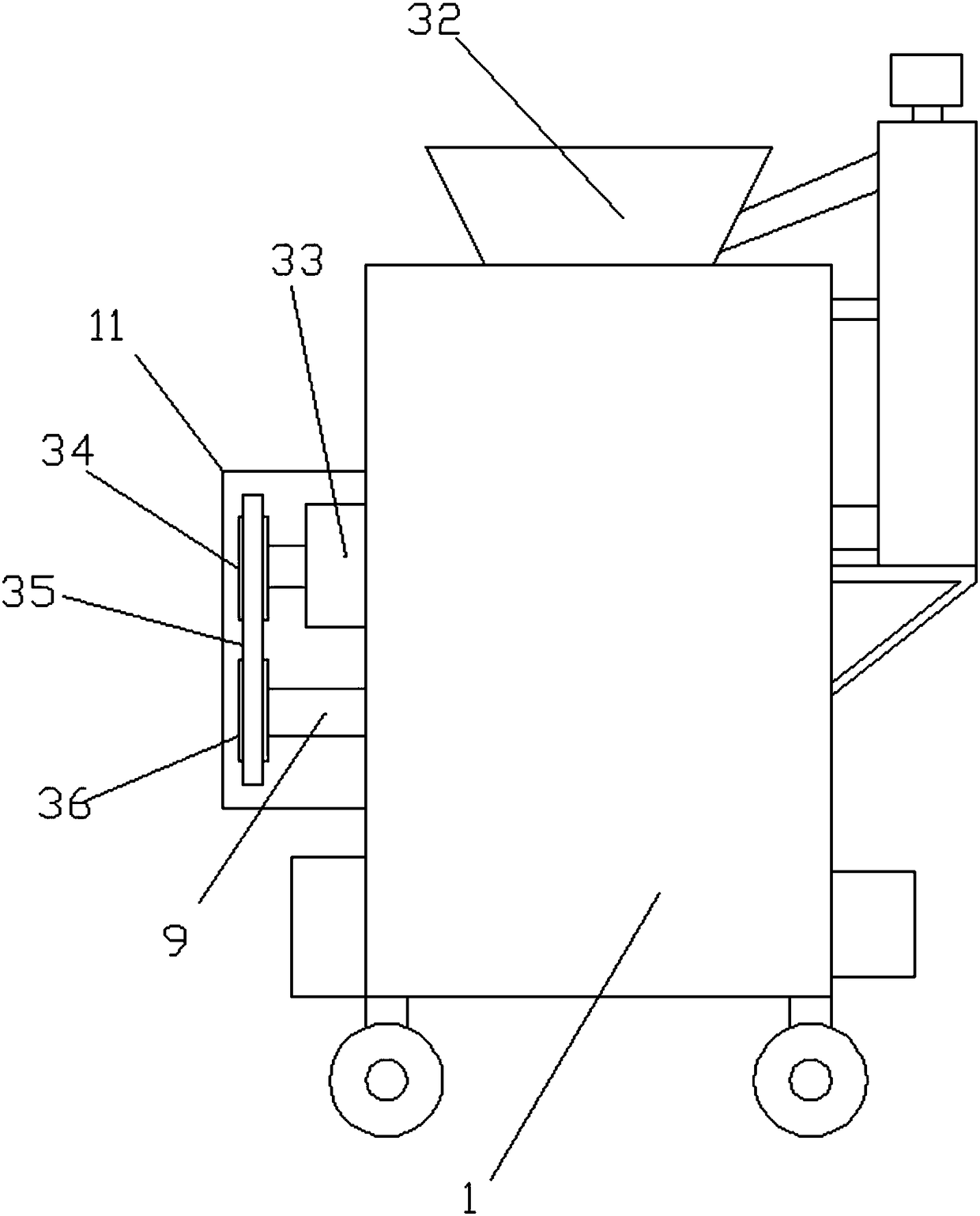

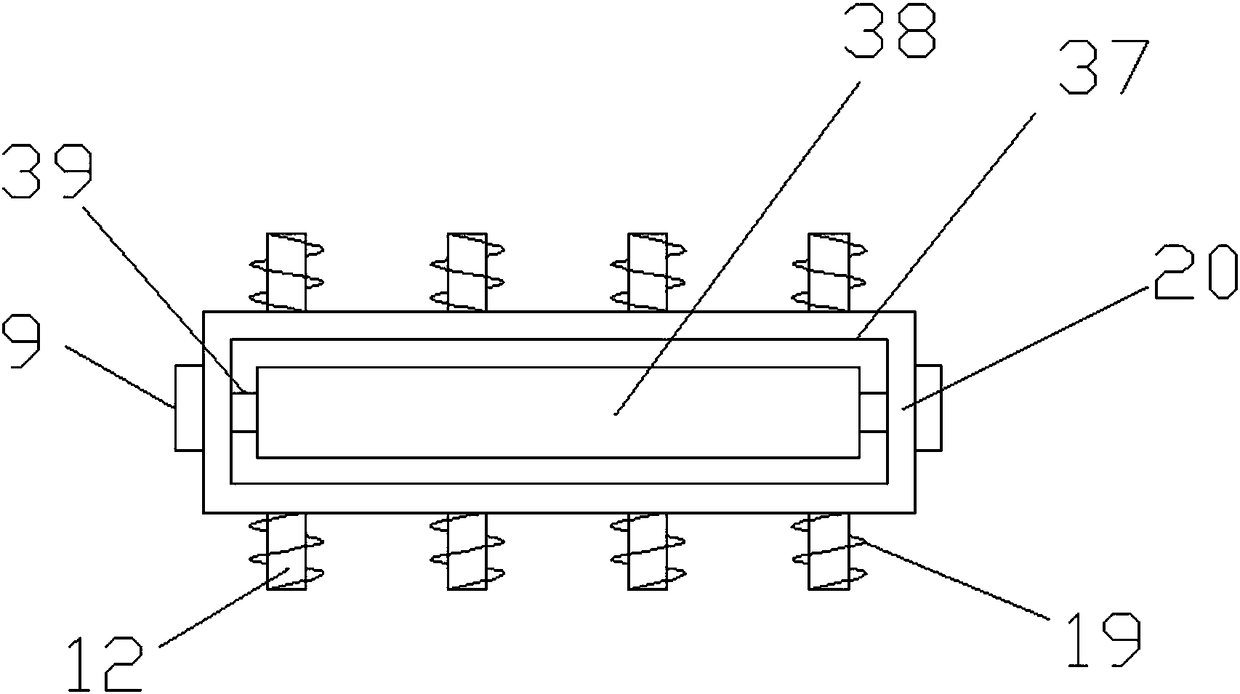

Efficient coal multi-stage crushing equipment for coal mine exploitation

InactiveCN111036376ARealize multi-stage crushingImprove crushing effectGrain treatmentsCoalMining engineering

The invention relates to the technical field of coal crushing equipment, in particular to efficient coal multi-stage crushing equipment for coal mine exploitation. A first rotating shaft is driven bya servo motor to rotate, on one hand, the first rotating shaft drives a second d rotating shaft to rotate through a transmission belt, crushing cutters interact, and coal in a feeding hopper is crushed; on the other hand, the first rotating shaft directly drives a grinding end to grind coal falling into a grinding channel through a feeding pipe, and therefore multi-stage crushing is achieved, andthe crushing effect and efficiency are improved; the first rotating shaft further drives a third rotating shaft to rotate through the transmission belt, a moving block moves up and down in the axial direction, a baffle is driven to move, the feeding pipe is intermittently opened or sealed, and intermittent feeding is achieved; and a push-pull assembly is arranged, a cylinder cam rotates along withthe first rotating shaft, a wedge block is driven by a connecting rod to move up and down, a push-pull rod drives a blocking plate to work in cooperation with a spring, and blocking and material pushing are completed.

Owner:安徽信典网络科技有限公司

Multifunctional intelligent garbage can

The invention discloses a multifunctional intelligent garbage can. The multifunctional intelligent garbage can comprises an outer can, an inner can, a garbage bag opening and closing device and an intelligent controller, wherein the inner can is sleeved with the outer can, the garbage bag opening and closing device comprises a grabbing device and an opening and closing mechanism, the opening and closing mechanism comprises two parallel push rods and a push rod driving mechanism, the two ends of each push rod correspond to the upper edges of the front and rear walls of the inner can respectively, the grabbing device comprises vacuum pumps and multiple suckers, and the suckers are distributed and installed on the opposite surfaces of the two push rods and connected with the vacuum pumps through flexible air pipes. According to the multifunctional intelligent garbage can, a garbage can body is internally provided with the garbage bag opening and closing device controlled by the intelligent controller, so that automation of garbage bag opening and closing is achieved, not only are replacement and sealing of garbage bags convenient and fast, but also there is no need for a user to touchgarbage directly, and thus the life quality of the user is greatly improved; the garbage can is low in production cost and suitable for application and popularization.

Owner:TANGSHAN COLLEGE

Construction structure and method for plugging water and sand gushing from foundation pit base

The invention provides a construction structure for plugging water and sand gushing from a foundation pit base. The construction structure comprises a steel sleeve, a concrete cover plate, a groutingreinforcing layer placed below the concrete cover, a concrete bottom plate and a concrete backfill layer of the bottom plate; the concrete construction method specifically comprises the following steps that the steel sleeve is installed with a water and sand gushing point as the circle center, and the bottom of the steel sleeve extends to the position 1m below the foundation pit base; waterstop ring plates are installed on the middle part and the upper part of the steel sleeve; high-grade early-strength concrete is poured into the steel sleeve to form the concrete cover plate, and after the final setting of the concrete, and grouting reinforcement of a disturbed soil layer is carried out within the range of the depth range of 1.0 m below the bottom of the cover plate within the scope of the cover plate of the concrete cover plate in the periphery of the steel sleeve; then a drain valve in the side wall of the steel sleeve is opened, and a sleeve opening of the steel sleeve is plugged through a sealing flange steel cover plate; and finally, the drain valve in the side wall of the steel sleeve is closed, and grouting into the steel sleeve is carried out for plugging the water gushingthrough a grouting pipe reserved in the steel cover plate. According to the construction structure and method for plugging the water and sand gushing from the foundation pit base, the plugging speedis high, the effect is good, the cost is low, and the control effect of a water gushing range is remarkable.

Owner:URBAN MASS TRANSIT ENG CO LTD OF CHINA RAILWAY 11TH BUREAU GRP

Efficient harmless treatment device for medical waste

InactiveCN108405054ACleverly structuredReasonable arrangementMedical waste disposalGrain treatmentsMedical wasteEngineering

The invention discloses an efficient harmless treatment device for medical waste. The efficient harmless treatment device comprises a shell; a feeding hopper is arranged at the top of the shell; an arc-shaped groove is formed in the bottom of the feeding hopper; a rotating roller is arranged at the circle center position of the arc-shaped groove; scraping plates are arranged on the rotating roller; supporting plates are arranged in the arc-shaped groove in bilateral symmetry; the top ends of the supporting plates are hinged to the left inner wall and the right inner wall of the arc-shaped groove; the lower sides of the supporting plates are supported on the inner wall of the arc-shaped groove through a plurality of compression springs; the supporting plates are connected to the scraping plates on the two sides of the rotating roller in an abutting mode to seal the feeding hopper; a pair of crushing rollers are arranged at the position, corresponding to the position below the feeding hopper, in the shell; crushing teeth are uniformly arranged on the crushing rollers; and a screen is arranged at the position, corresponding to the position below the crushing rollers, in the shell andis obliquely arranged in a downward sloping mode. The efficient harmless treatment device for the medical waste has the advantages that the structure set is ingenious, the layout is reasonable, harmless treatment of animals can be realized, the discharging effect is good, and the efficiency is high.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

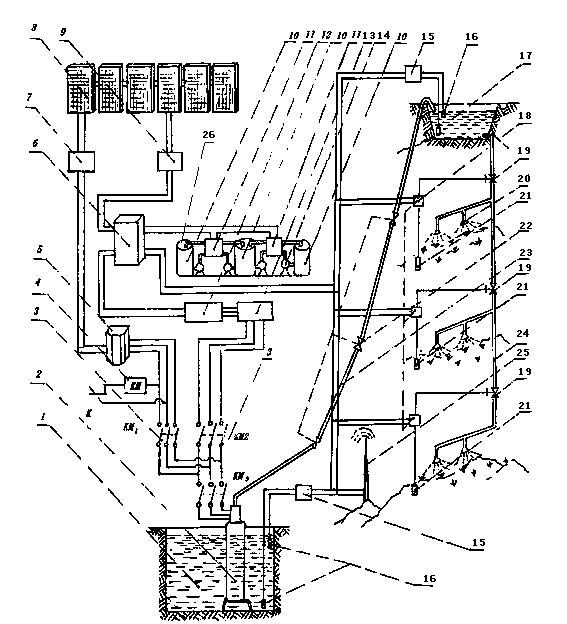

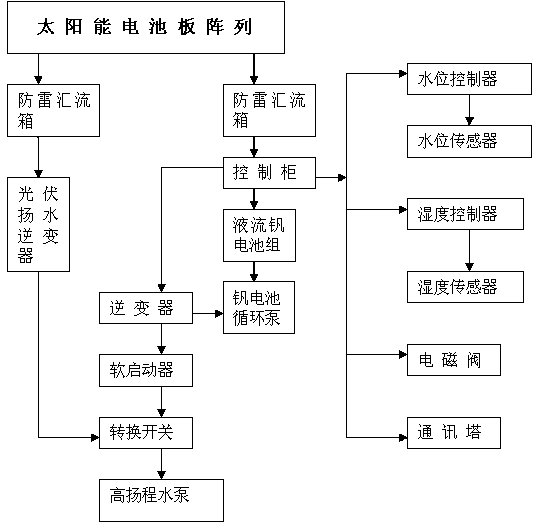

Solar pumping irrigation system

InactiveCN103348898ALarge energy storage capacityGood deep discharge performanceWatering devicesRenewable energy machinesElectricityEngineering

The invention relates to a solar pumping irrigation system. The solar pumping irrigation system is characterized by comprising a solar panel array, a control cabinet, a vanadium battery pack, an inverter, a soft starter, a solar pumping inverter, a control device, a high-lift water pump, an impounding reservoir, and a sprinkler plant, wherein the solar panel array is connected with the solar pumping inverter, a change-over switch and the high-lift water pump in series; meanwhile, the solar panel array is connected with the control cabinet, the vanadium battery pack, the inverter, the starter, the change-over switch and the high-lift water pump in series; the high-lift water pump is connected to a mountain reservoir through an upper water pipe and a check valve, and then connected with a sprinkler gun through a lower water pipe. The solar pumping irrigation system is suitable for being popularized and applied to villages in remote and mountain areas and power shortage areas.

Owner:攀枝花市银江金勇工贸有限责任公司

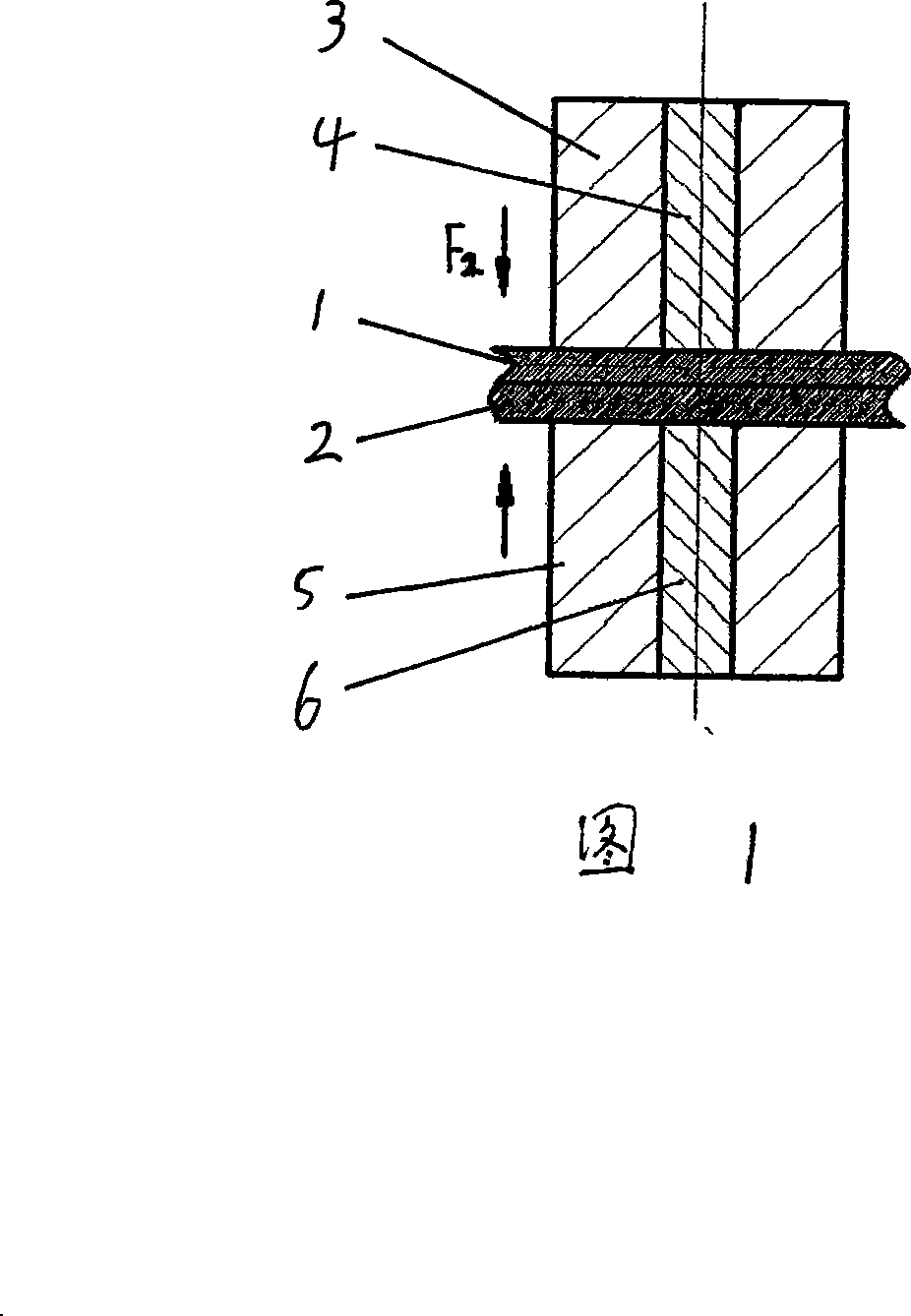

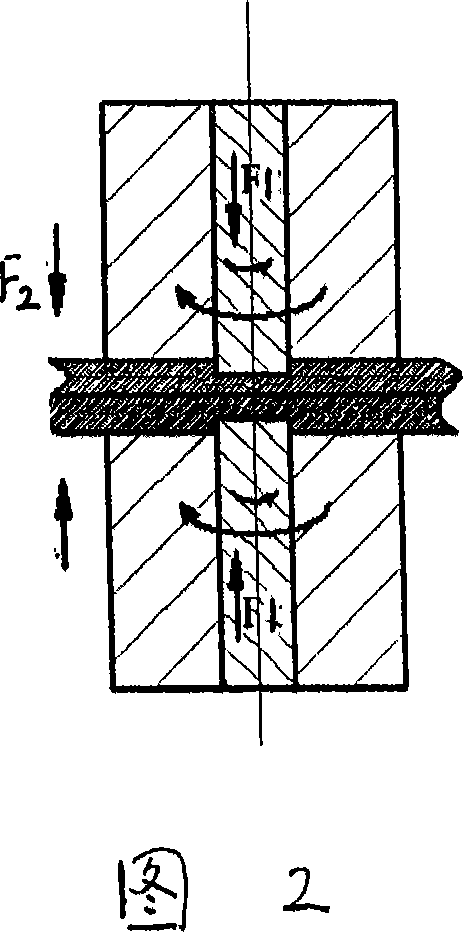

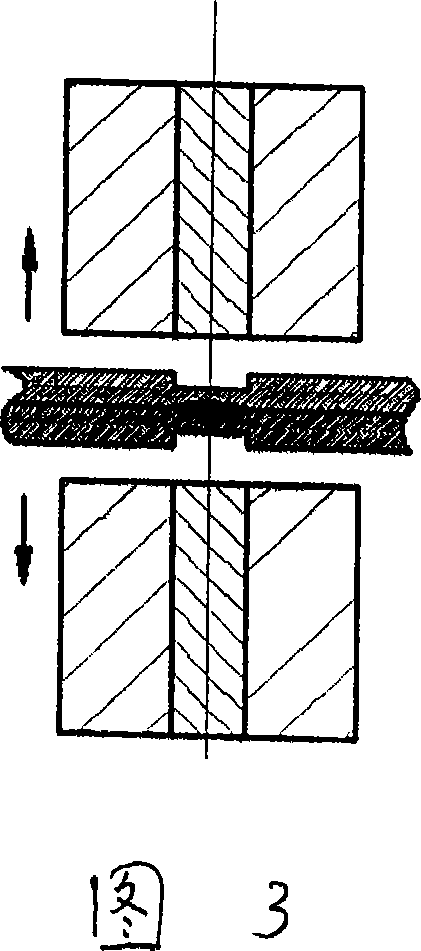

Stirring friction spot welding technology

InactiveCN101053923APrevent spillageReduce workloadNon-electric welding apparatusProduction rateFree rotation

A stir friction spot welding technology adopts stir heads, and the spot welding can be carried out by agitating and rubbing from both faces simultaneously. The welding application part of the invention mainly includes four parts, that is an upper and a lower stir heads and an upper and a lower fillets. Friction heat and plastic deformation energy of the double-face friction spot welding process are produced from the upper and the lower faces; the freely rotating fillets are provided surrounding the upper and the lower stir heads in the double-face friction spot welding process, wherein the rotating of the fillets can complement defect of heat of the stir heads generated in the double-face friction spot welding process. Just because of the above characteristics, the invention can not only reduce pressure concave and extrudate of the welding surface by a half but also can increase heat generated in the welding process by one time, thus the double-face friction spot welding process can overcome defect of the friction spot welding process with single face as well as improve production efficiency.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

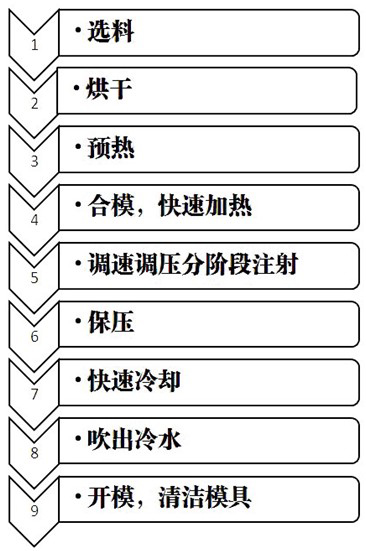

Steam type highlight and traceless injection-molding and forming process for complex precise product

The invention discloses a steam type highlight and traceless injection-molding and forming process for a complex precise product. The process sequentially comprises the following steps of: selecting raw materials, baking, pre-heating, combining a die, then quickly heating, adjusting speed and pressure, injecting in sections, maintaining the pressure, cooling quickly, blowing out cold air, opening the die and cleaning the die. An advanced pressure-regulation and speed-regulation staging injection process and an automatic blowing and impurity-removing technology are adopted in the invention. A special heating and cooling technology is that the shapes, the widths and the arrangement density of water passages are designed according to nonuniform heat and cold of the complex precise product in the injection-molding and forming course and the overall shape variation of the product. The steam type highlight and traceless injection-molding and forming process for the complex precise product has the advantages that the residual stress of the product is effectively decreased, various defects generated in the course of producing the plastic product are greatly reduced, the surface quality and the precision of the product are remarkably improved, and the life of the product is remarkably prolonged at the same time because the special process ensures heating and cooling rates of each part of the complex product in the injection-molding and forming course tend to be consistent.

Owner:海门市创豪工业设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com