Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

141results about How to "With acid and alkali resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

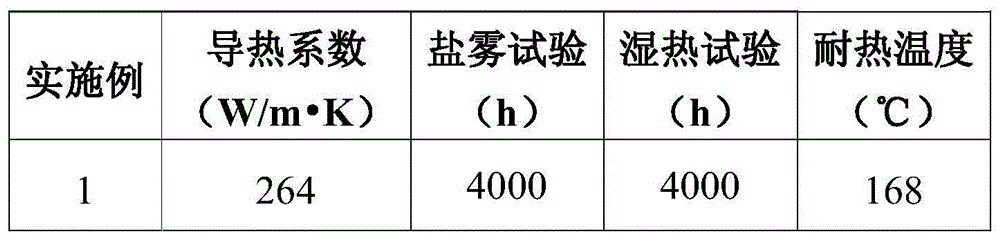

Fluororesin radiating paint and preparation method thereof

ActiveCN103131274AReduce thermal contact resistanceHigh thermal conductivityCoatingsCarbon nanotubeElectron transfer

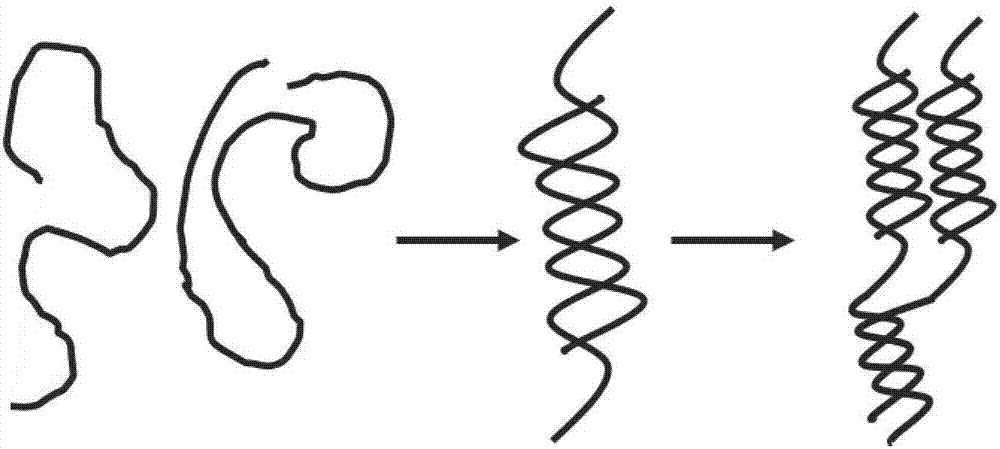

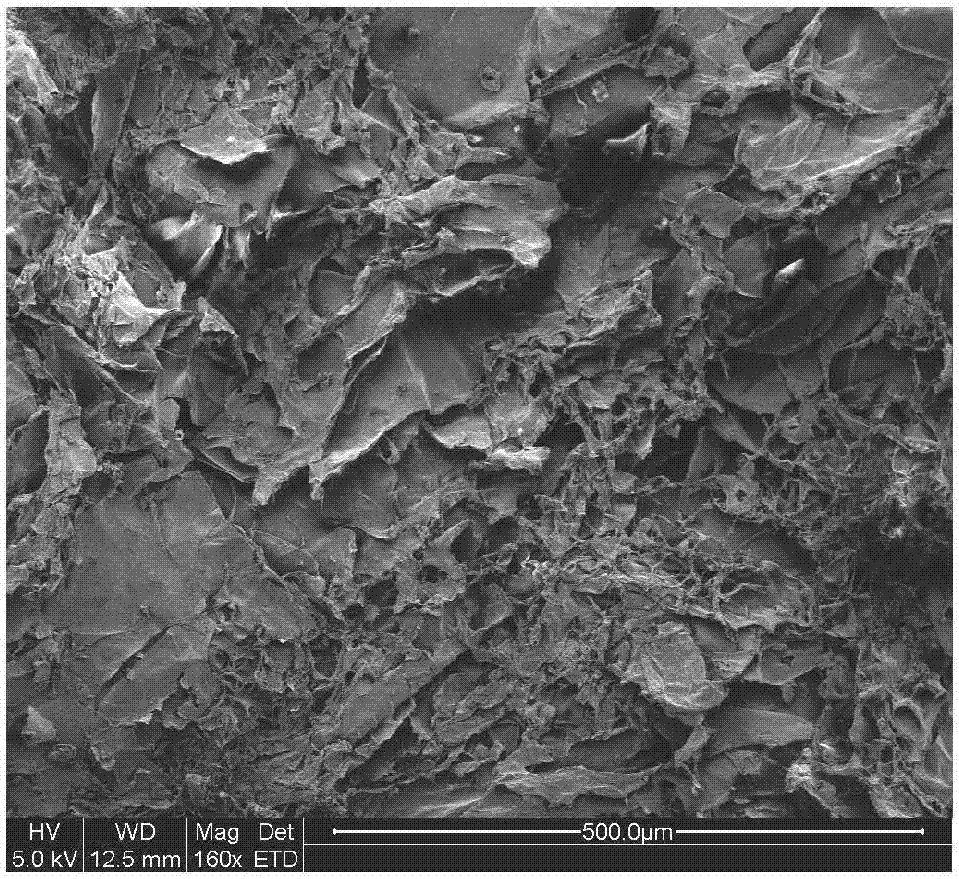

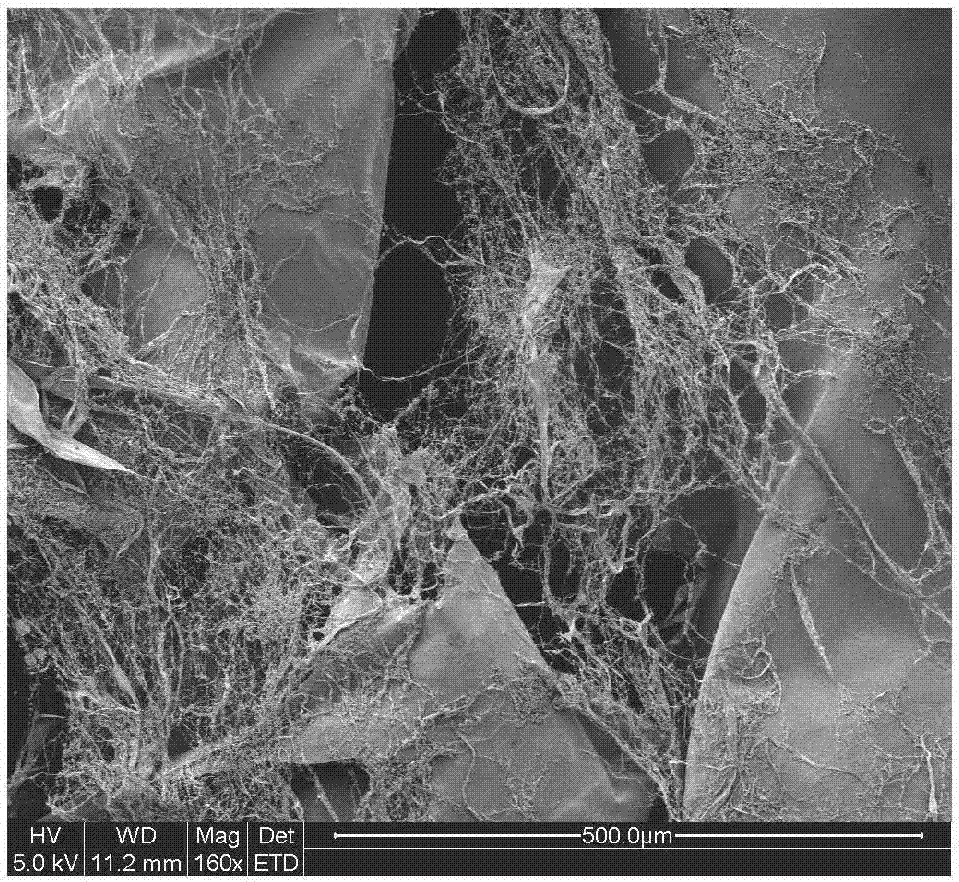

The invention discloses fluororesin radiating paint and a preparation method thereof. The paint mainly comprises an electron transfer type organic compound, graphene, a carbon nanotube, titanium white, other additives and fluororesin, wherein the fluororesin is a paint brand having the highest comprehensive property at present; the electron transfer type organic compound can greatly enhance the thermal radiation rate of the paint; the graphene and the carbon nanotube can further accelerate thermal conduction; and the electron transfer type organic compound, the carbon nanotube and the graphene finally form a full three-dimensional network distribution of granules (electron transfer type organic compound), wires (carbon nanotube) and planes (graphene) in a fluid. The fluororesin radiating paint disclosed by the invention has high thermal radiation rate, high thermal conductivity and low thermal resistance, can realize radiation cooling, and simultaneously has the effects of self cleaning, acid / alkali resistance and super high insulativity, thereby having high practical value.

Owner:明朔(北京)电子科技有限公司

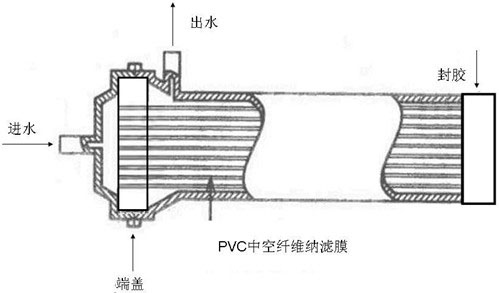

Positively charged polyvinyl chloride hollow fiber nanofiltration membrane and preparation method thereof

ActiveCN102210979ABacteria resistantWith acid and alkali resistanceSemi-permeable membranesFiberPolyvinyl chloride

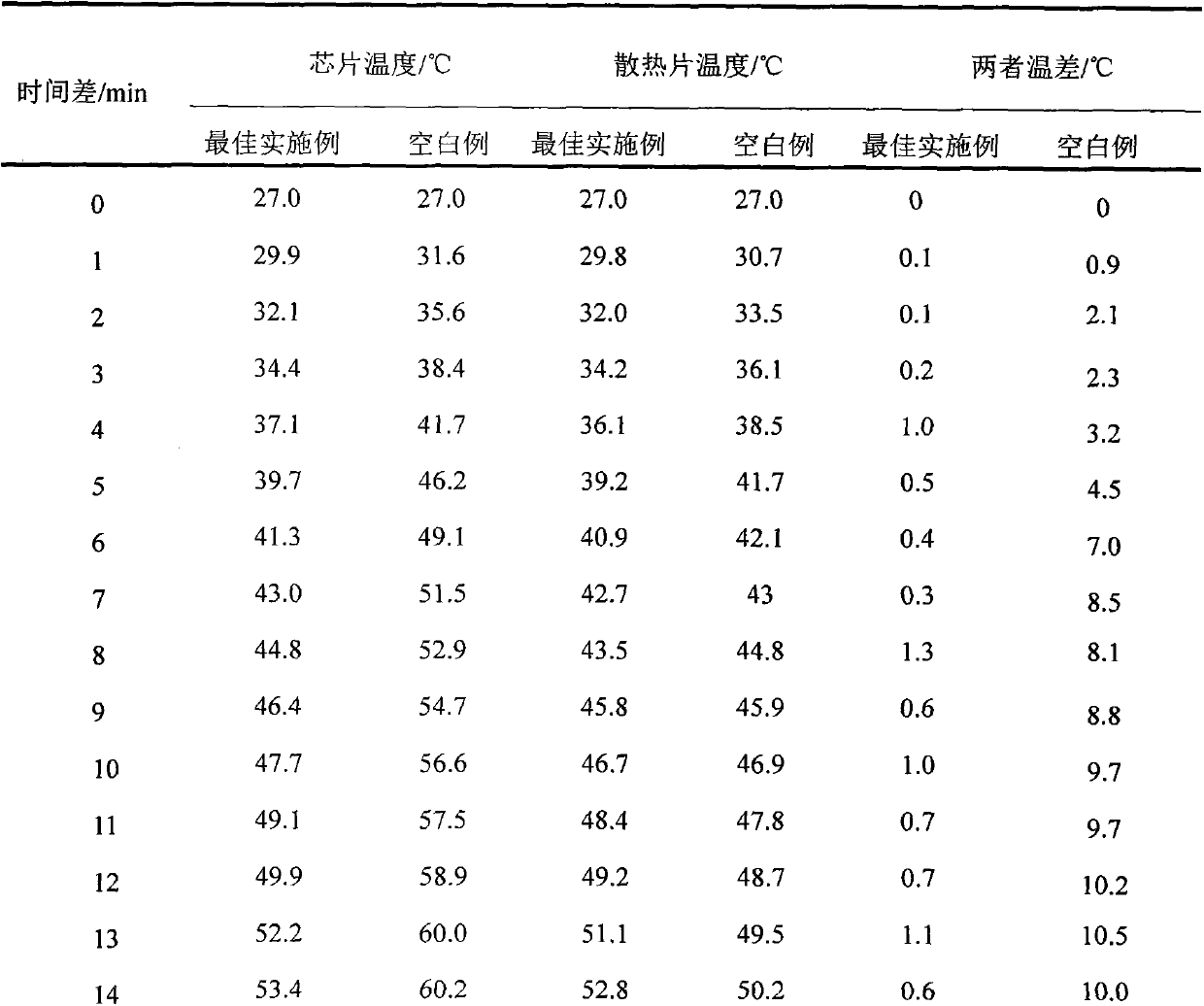

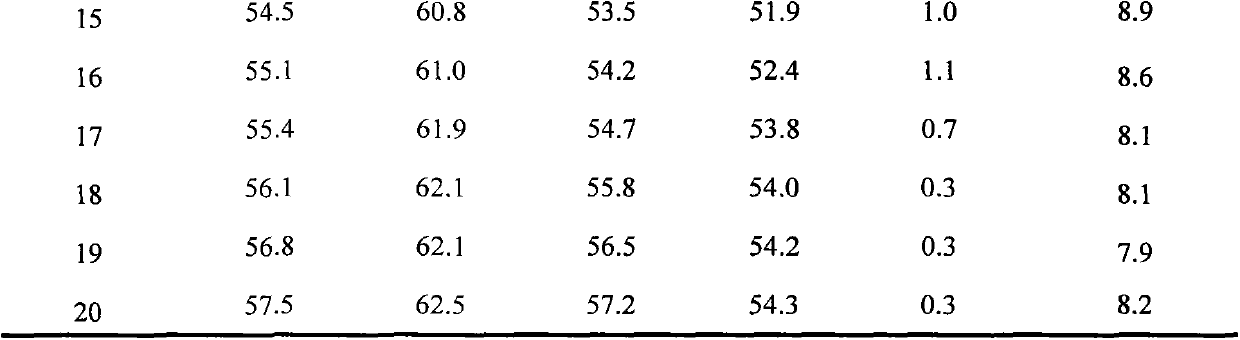

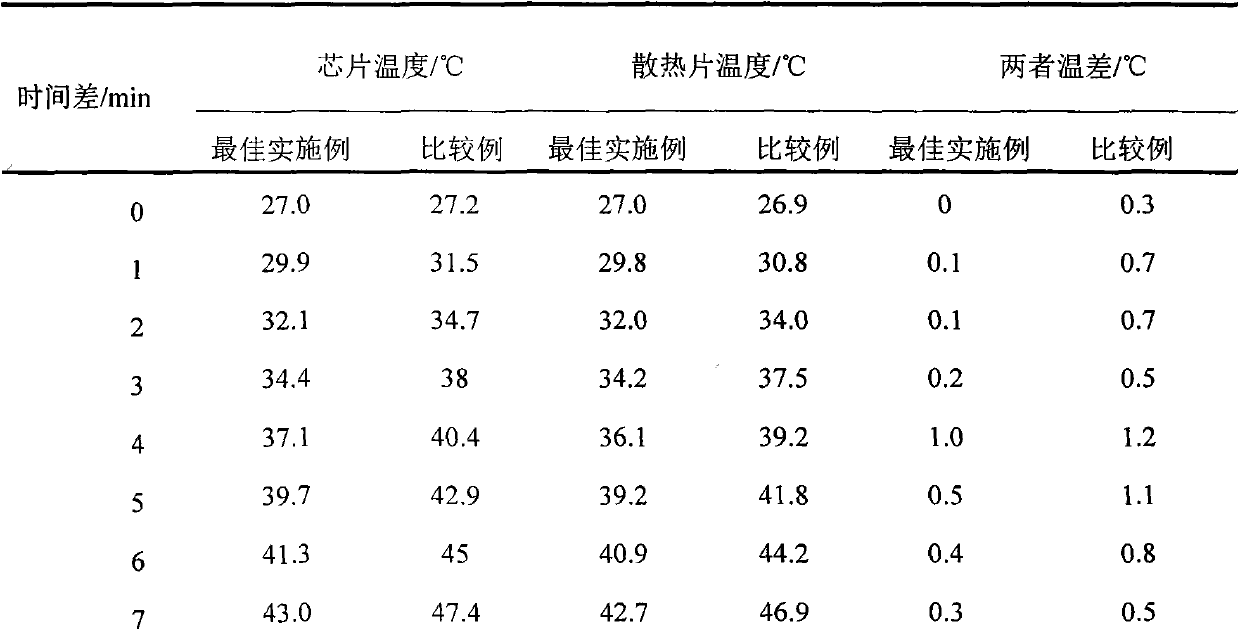

The invention discloses a method for preparing a positively charged polyvinyl chloride (PVC) hollow fiber nanofiltration membrane. The positively charged PVC hollow fiber nanofiltration membrane has a two-layer structure consisting of a positively charged compact skin layer and an electrically neutral porous support layer; the pore diameter of micropores of the compact skin layer is 1-5nm, and the pore diameter of micropores of the porous support layer is 10-100nm; and the outer diameter of the membrane is 1.5-3.0mm, and the inner diameter of the membrane is 0.5-2mm, wherein the positively charged compact skin layer comprises main components of polyvinyl chloride and cationic copolymer; and the electrically neutral porous support layer comprises main components of polyvinyl chloride and an inorganic filler. The method for preparing the positively charged PVC hollow fiber nanofiltration membrane comprises the following steps of: co-extruding positively charged compact skin layer membrane preparing liquid and electrically neutral porous support layer membrane preparing liquid in a two-layer ring shape; and curing and forming hollow fibers by using a dry-wet spinning process. The prepared hollow fiber nanofiltration membrane has the advantages of easily controlled interception property, high strength, simple preparation process and the like, and is a high-performance, low-cost and long-life nanofiltration membrane material for water treatment.

Owner:HAINAN LITREE PURIFYING TECH CO LTD

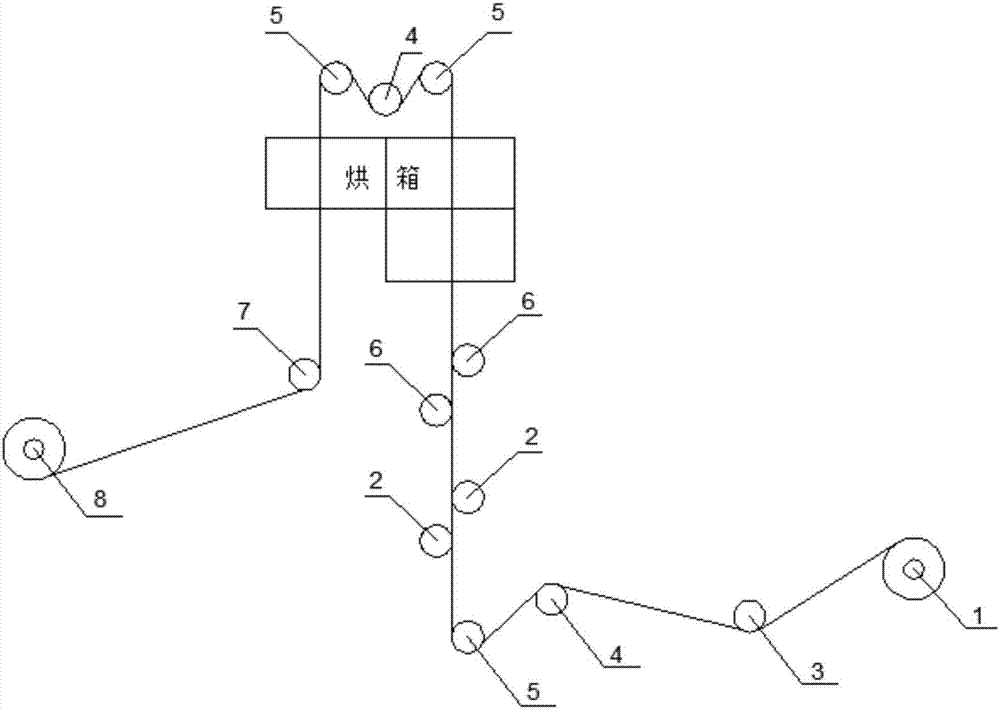

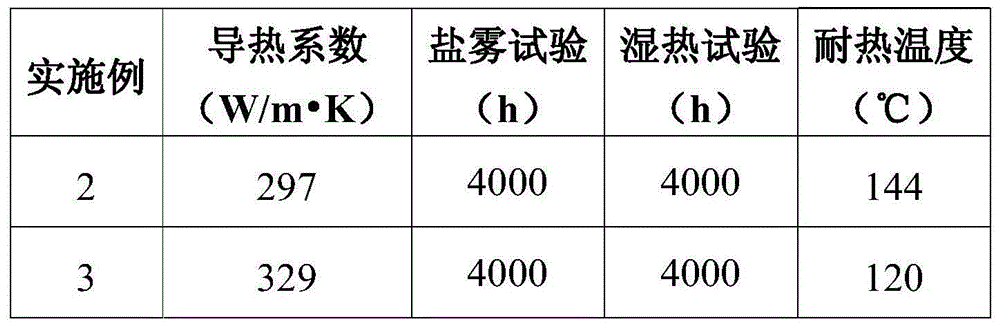

High-temperature-resistant water-based aramid coating lithium ion battery diaphragm and preparation method thereof

ActiveCN107118599AHigh degree of automationImprove qualityFireproof paintsCell component detailsWater basedElectrical battery

The invention relates to a high-temperature-resistant water-based aramid coating lithium ion battery diaphragm, and belongs to the technical field of a battery diaphragm. The high-temperature-resistant water-based aramid coating lithium ion battery diaphragm comprises a base diaphragm, wherein coating slurry is attached onto the diaphragm surfaces of one side or two sides of the base diaphragm; the coating slurry is prepared from the following ingredients in percentage by mass: 5 to 25 percent of nanometer aramid fiber powder, 3 to 10 percent of acrylic adhesives, 1 to 5 percent of fluorocarbon surfactants and cellulose ether type dispersing agents, 0.02 to 0.05 percent of agaroidin, 0.03 to 0.1 percent of dibutyl phthalate, 0.03 to 0.1 percent of trimethylolpropane tripropionate and the balance deionized water. The invention also provides a preparation method of the high-temperature-resistant water-based aramid coating lithium ion battery diaphragm. The high-temperature-resistant water-based aramid coating lithium ion battery diaphragm has high safety of ceramic coating diaphragm on the battery and also achieves the high-temperature resistant performance; the shrinkage rate of the diaphragm under the high-temperature condition is reduced; the whole service life of the battery is prolonged. The preparation method provides a mature efficient process for the preparation of the high-temperature-resistant water-based aramid coating lithium ion battery diaphragm.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

Preparation method of ceramic plate decorative painting through colored engraving

The invention relates to a preparation method of a ceramic plate decorative painting through colored engraving. The method comprises the following steps: 1), a protective film is attached to the surface of a ceramic plate; 2), sidelines of a specified figure are engraved on the surface of the ceramic plate by a laser engraving machine; 3), the protective film at a to-be-etched part is removed so as to expose an engraving surface; 4), the surface of the ceramic plate is eroded by an abrasive material at a high flow rate, so that an uncolored solid figure is formed through engraving on the ceramic surface with the protective film removed, the pressure is 1-10 kg / m<3>, and the flow is 5-20 m<3> / min; 5), sand blasting is at least performed on a to-be-colored part of the surface of the ceramic plate so as to at least remove a glaze layer of the to-be-colored part and form a frosted surface, the sand blasting pressure is 1-10 kg / m<3>, and the flow is 5-20 m<3> / min; 6), the frosted surface of the ceramic plate prepared in the step 5) is cleaned and dried, a pattern is spray-printed and drawn, and a protective glaze layer is spray-printed; 7), the ceramic plate prepared in the step 6) is sintered rapidly.

Owner:MONALISA GRP CO LTD

High-strength high-flexibility flame-retardant cable sheath rubber and preparation method thereof

InactiveCN102250427AEasy to processHigh strengthInsulated cablesInsulated conductorsEpoxyPlasticizer

The invention discloses a high-strength high-flexibility flame-retardant cable sheath rubber and a preparation method thereof. The sheath rubber comprises 100 parts of chlorosulfonated polyethylene, 15-25 parts of plasticizer, 3-7 parts of compound stabilizer, 40-60 parts of thermal decomposition process carbon black, 15-25 parts of active calcium carbonate, 3-6 parts of antimony trioxide, 2-4 parts of vaseline, 1.5-4.5 parts of antioxidant, 8-10 parts of magnesium oxide and 10-15 parts of epoxy resin. In the cable sheath rubber disclosed by the invention, through the optimal combination of chlorosulfonated polyethylene and other components, the material has the characteristics of high strength, high flexibility and flame retardancy, and at the same time, the material has the advantages of oil resistance, heat resistance, fire resistance, weathering resistance, ozone resistance, acid and base resistance, chemical resistance and the like.

Owner:WUXI MINGZHU CABLE

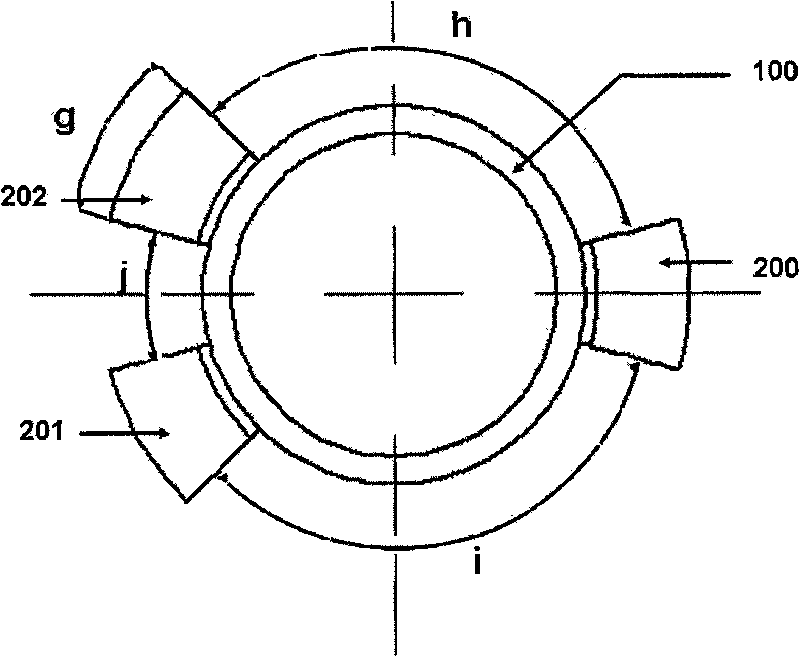

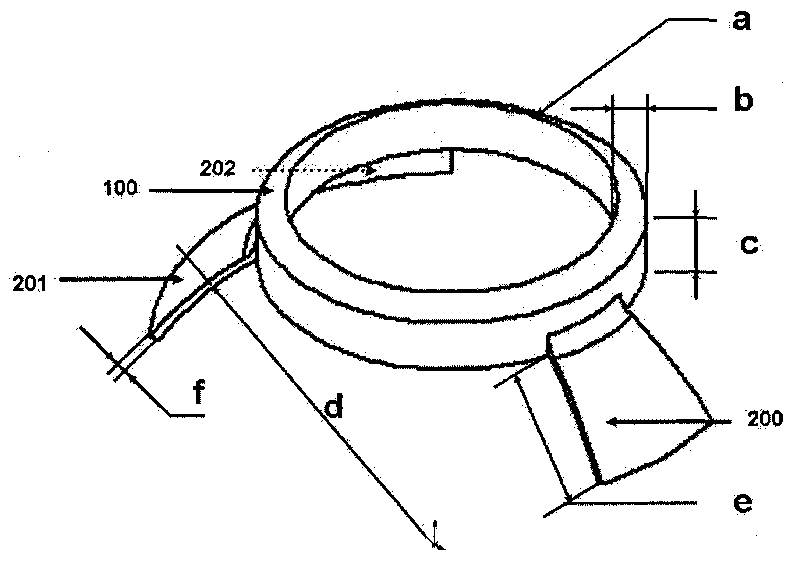

Stitch-free silicon rubber corneal arcus for use in vitreous body resection operation using needle with casing pipes

InactiveCN101695460AAvoid getting in the wayOvercome stabilityEye implantsEye surgeryMedicineSpherical shaped

The invention discloses a stitch-free silicon rubber corneal arcus for use in a vitreous body resection operation using a needle with casing pipes, which consists of a medical silicon rubber ring, wherein the surface between the upper and lower two ends of the ring have a spherical shape having a curvature similar to that of eye balls; the periphery of the bottom surface of the ring is provided with first sectorial thin claw, second sectorial thin claw and third sectorial thin claw which have the same structure at the positions corresponding to three casting pipes respectively; the inside diameter a of the ring is more than or equal to 10 millimeters and less than or equal to 12 millimeters, the thickness b is more than or equal to 1 millimeter and less than or equal to 2 millimeters, and the height c is more than or equal to 1 millimeter and less than or equal to 3 millimeters; the length e of the sectorial thin claws is more than or equal to 3 millimeters and less than or equal to 8 millimeters, the thickness f is more than or equal to 0.1 millimeter and less than or equal to 1.5 millimeters and the radian g of the sectors is more than or equal to 20 DEG and less than or equal to 90 DEG; and the coplanar curvature d of the bottom surface of the ring and the first, second and third sectorial thin claws ranges from 10 millimeters to 14 millimeters. The stitch-free silicon rubber corneal arcus has the advantages of simple structure, convenient operation, stable supporting effect and suitability for various vitreous body resection operation systems using the needle with casing pipes.

Owner:吴建国

Anticorrosive heat dissipation coating and production method thereof

InactiveCN104861821AWith acid and alkali resistanceHigh temperature resistantAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyAlcohol

The invention relates to anticorrosive heat dissipation coating. The anticorrosive heat dissipation coating is produced through the following raw materials of, by weight, 30 to 60 parts of epoxy resin, 10 to 20 parts of polyurethane resin, 15 to 30 parts of inorganic filler, 2 to 4 parts of carbon black, 0.5 to 2.5 parts of modified imidazole and 50 to 96 parts of alcohol diluent. A production method for producing the anticorrosive heat dissipation coating comprises the steps of step 1, accurately weighing the epoxy resin, the polyurethane resin and the diluent to be uniformly mixed to form a resin solution; step 2, taking the all mass of resin solution in the step 1 to be mixed with the carbon black and the inorganic filler to be poured into a grinding machine to be ground and dispersed and uniformly stirring at the speed of 800 to 1000 revolutions every minute at room temperature; step 3, enabling coating and the modified imidazole in the step 2 to be mixed with each other, uniformly stirring at the speed of 800 to 1000 revolutions every minute at room temperature and obtaining the target coating after stabilization.

Owner:FOSHAN HECAI TECH SERVICE

High-elasticity thin film and preparation method thereof

The invention provides a high-elasticity thin film which includes 90-110 parts of PVC resin, 20-50 parts of rubber powder, 10-90 parts of a filling material, 0.5-8 parts of a stabilizer, 55-120 parts of a plasticizer and 0-2 parts of a pigment. The rubber powder includes nitrile butadiene rubber powder and butyl rubber powder according to the mass ratio of (4-6):(1-3). The invention also provides a preparation method of the high-elasticity thin film. By means of optimization on component proportion, the thin film is high in elasticity, high in hardness, high in tensile strength and good in rebound property, has the performances of being insulating and anti-static, being good in sealing performance and weather resistance, and being resistant against acid, alkali and high temperature. The thin film not only can be used in electronic products but also has great application prospect in the fields of machinery and aerospace technology. The high-elasticity thin film is greatly reduced in cost, breaks technical monopoly of foreign products, and filling the technical blank of domestic high-strength and high-elasticity thin films.

Owner:孙宝林

Newly packed naloxone hydrochloride injection and its producing method

InactiveCN1748702AAvoid pollutionStable and reliable productionOrganic active ingredientsAntipyreticBottleNaloxone Hydrochloride

The process of producing naloxone hydrochloride injection in new package includes the following steps: preparing naloxone hydrochloride injection intermediate; bacteria-free filtering the intermediate to obtain filtrate; bacteria-free packing the filtrate in Schering bottle; and sterilizing with flowing steam. While bacteria-free filtering, the insoluble particles in the medicine liquid are also eliminated, and this can greatly reduce the phlebitis attacking probability. The product is safe and reliable.

Owner:BEIJING KAWIN TECH SHARE HLDG

Preparation method for decorative picture of thousand-layer carved ceramic plate

The present invention relates to a preparation method for a decorative picture of a thousand-layer carved ceramic plate. The method comprises: 1) covering a layer of protective film on a surface of a ceramic plate; 2) using a laser carving machine to carve edge lines of a predetermined pattern on the surface of the ceramic plate, wherein the pattern comprises a plurality of parts; 3) removing the protective film gradually from each part of the pattern, and carving with sandblast until a complete multi-layer carved pattern is formed, wherein a sandblasting pressure adopted in the sandblasting carving is 1-10 kg / m<3>, and a flow rate is 5-20 m<3> / min; 4) sandblasting the surface of the ceramic plate to remove a glazed layer on the surface of the ceramic plate and form a frosted surface, wherein the sandblasting pressure is 1-10 kg / m<3>, and the flow rate is 5-20 m<3> / min; 5) after the frosted surface of the ceramic plate prepared in the step 4) is cleaned and dried, jet printing and drawing the pattern, and then jet printing a protective glazed layer; and 6) sintering the ceramic plate prepared in the step 5) rapidly.

Owner:MONALISA GRP CO LTD

Antibacterial gel and preparation method thereof

ActiveCN107233226AIncrease profitAvoid the influence of steric hindranceCosmetic preparationsToilet preparationsMorpholineBiological activation

The invention discloses antibacterial gel and a preparation method thereof, and belongs to the field of gel preparation. The antibacterial gel comprises deacylation gellan gum, nisin, 2-(N-morpholine) ethanesulfonic acid, 1-(3-dimethylamino propyl)-3-ethyl carbodi-imide hydrochloride, N-hydroxy succinimide thiosulfate and deionized water. The preparation method includes the steps: resin pretreatment; solution preparation; activation; acylation; dialysis; gel forming. The deacylation gellan gum is covalently grafted to the nisin to form the antibacterial gel, so that the antibacterial gel has the advantages the antibacterial gel is high in grafting ratio, low in cost, easy to form, easily formed, thermally reversible, free from toxicity and the like, and the antibacterial gel is suitable for preparation of antibacterial washing gel.

Owner:JIANGNAN UNIV +1

Composite fire-proof paint

InactiveCN1621463AHigh mechanical strengthStrong adhesionFireproof paintsPolymer scienceWater soluble

The present invention is one kind of water soluble fireproof composite inorganic / organic polymer filming paint. The present invention has excellent fireproof performance, can bear the effect of flame, and has fireproof foamed layer with high heat isolating performance, high mechanical strength, less chap and falling out, good decoration property, low cost and other advantages.

Owner:长春百乐施建筑装饰设计院

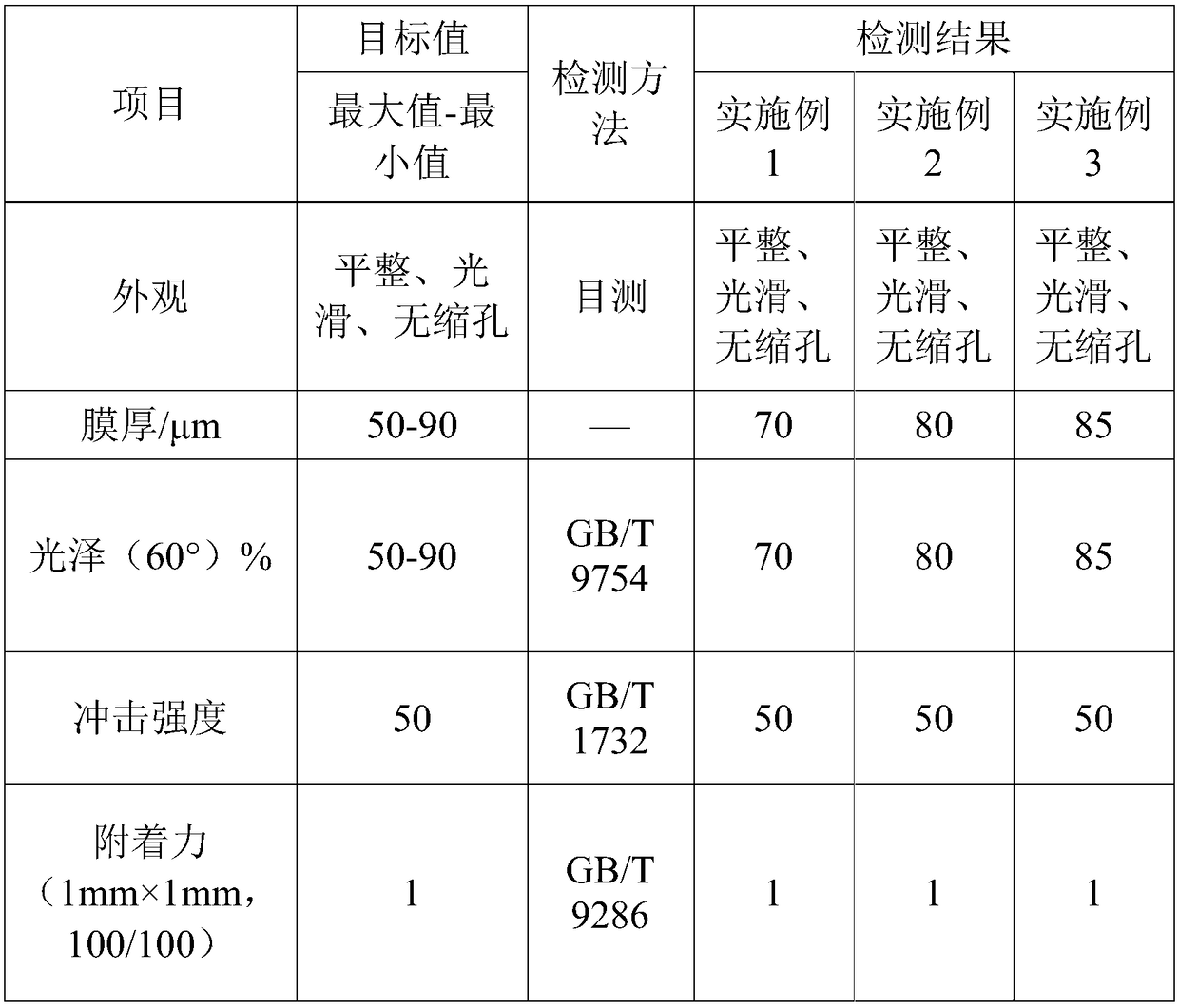

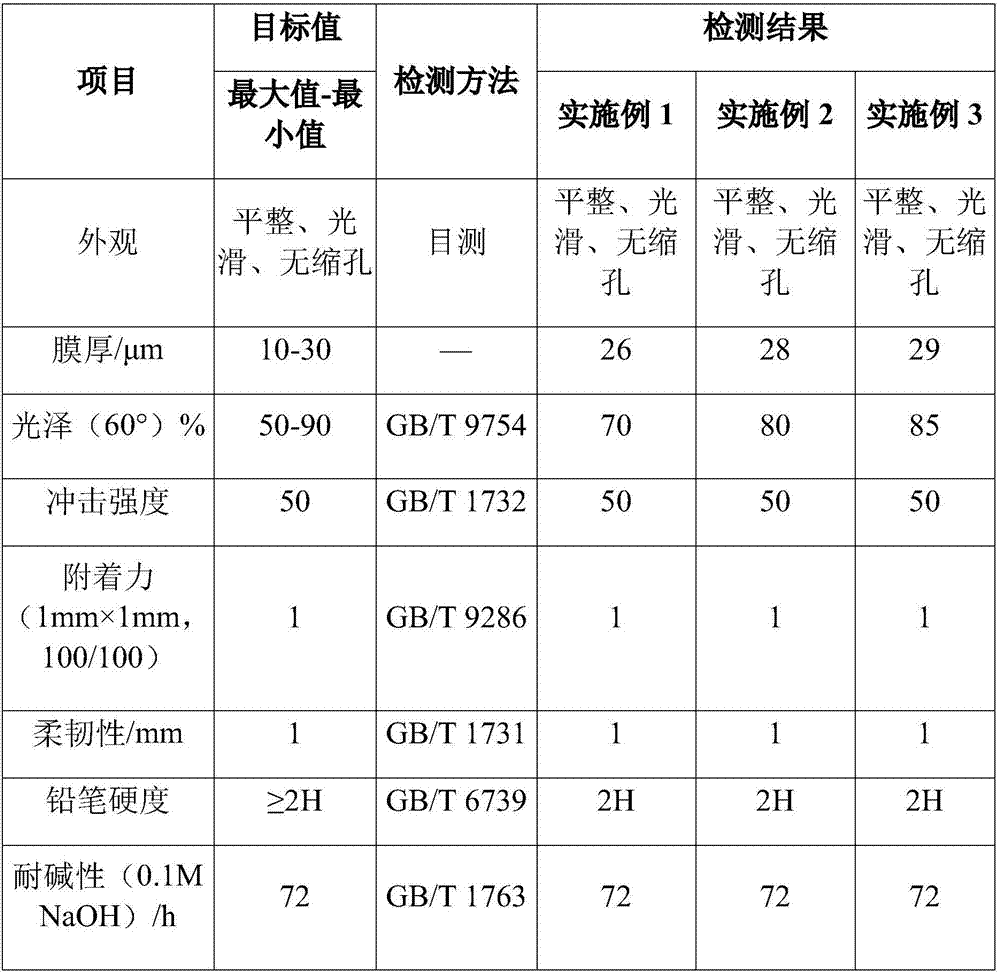

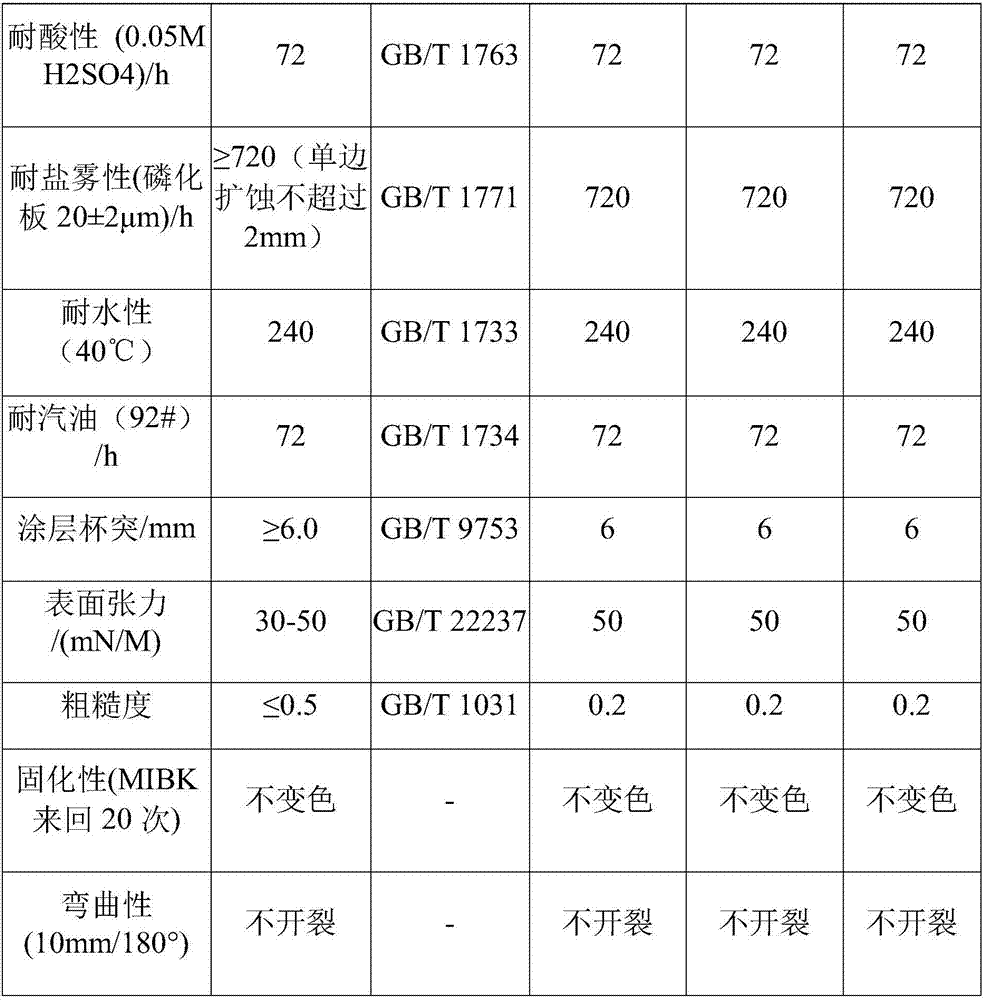

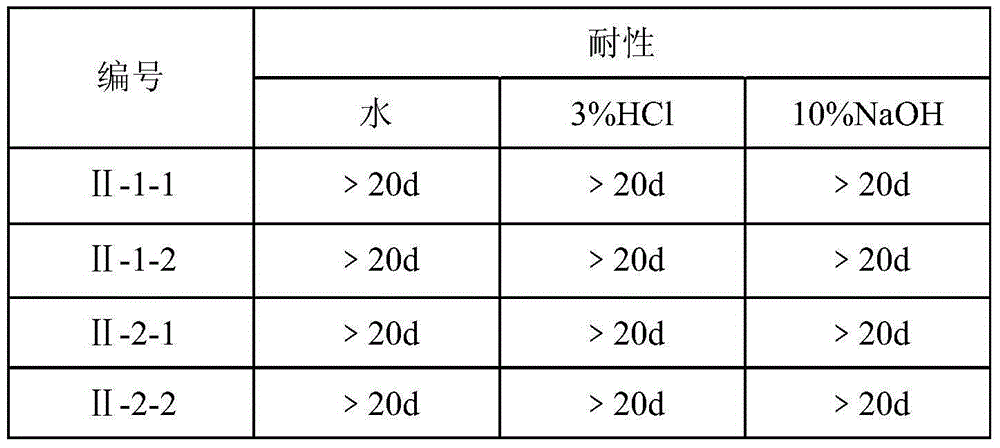

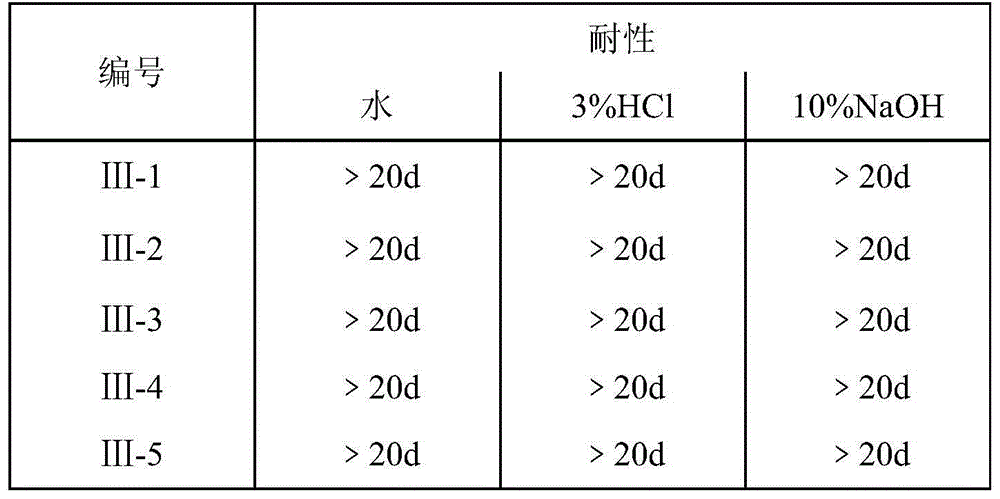

Cathodic electrophoretic coating and preparation method thereof

InactiveCN108727958AWater and oil resistanceWith acid and alkali resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsEmulsionHardness

The invention relates to the technical field of coatings and particularly discloses a cathodic electrophoretic coating and a preparation method thereof. The coating comprises components in parts by weight as follows: 10-20 parts of color paste, 30-60 parts of an emulsion and 40-60 parts of deionized water. The color paste comprises components in parts by weight as follows: 18-35 parts of modifiedresin, 5-15 parts of an environment-friendly cosolvent, 1-6 parts of a neutralizer, 0.1-0.5 parts of a surfactant, 30-40 parts of deionized water and 20-30 parts of pigment and filler. The emulsion comprises components in parts by weight as follows: 35-50 parts of modified resin, 2-8 parts of an emulsifier, 1-8 parts of a neutralizer and 30-50 deionized water. The cathodic electrophoretic coatinghas good gloss and high hardness and adhesion and has excellent impact resistance, corrosion resistance, acid resistance, base resistance and the like.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

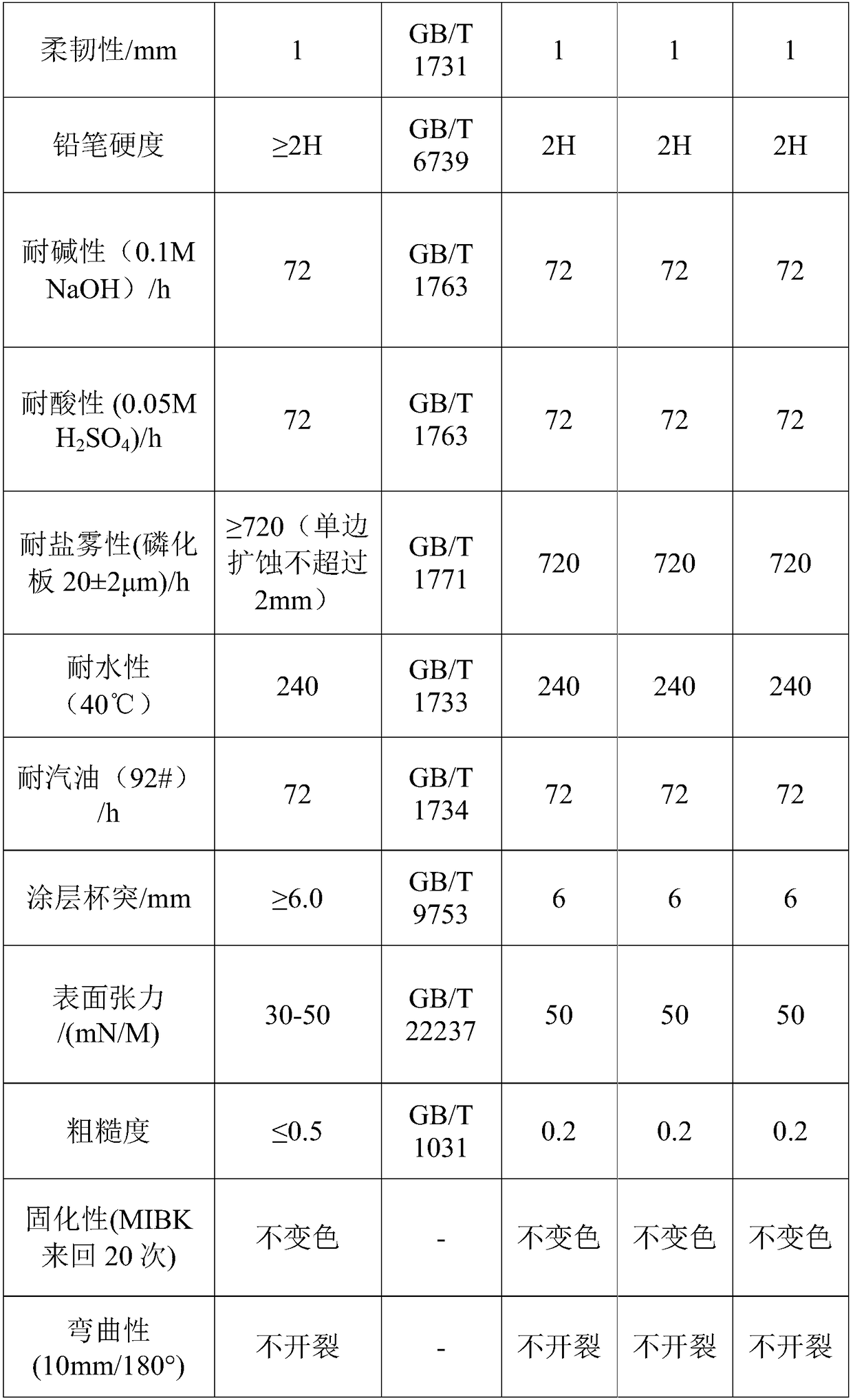

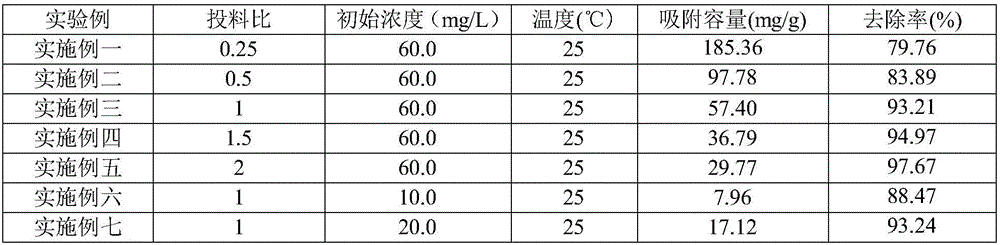

Method for removing antibiotic-sulfadiazine in water through activated carbon fiber adsorbent

InactiveCN105948158AStable removalHigh removal rateWater contaminantsWater/sewage treatment by sorptionFiberActivated carbon

The invention discloses a method for removing antibiotic-sulfadiazine in water through activated carbon fiber adsorbent. The method comprises the steps that the activated carbon fiber adsorbent is placed into water containing antibiotic-sulfadiazine according to the certain placing amount, vibration adsorption is carried out at set temperature, the treated water is filtered after vibration adsorption is finished, activated carbon fiber adsorbing antibiotic-sulfadiazine is separated from the treated water, and therefore the antibiotic-sulfadiazine in the water is removed. The method can effectively remove antibiotic-sulfadiazine in water, and meanwhile has the advantages of being high in removal efficiency, resistant to corrosion and heat, beneficial to separation and the like. The absorbent preparation process is simple, low in cost, low in energy consumption and quite good in application prospect. The method for removing sulfadiazine through the activated carbon fiber is low in energy consumption, economic and environmentally friendly, has the certain industrial development potential and provides a new thought for removing sulfadiazine.

Owner:SHANGHAI UNIV

Terylene, vinylon and cotton fiber blended yarn preparation method

The invention provides a terylene, vinylon and cotton fiber blended yarn preparation method. The blended yarn is formed by the following raw materials in parts by weight: 20-100 parts of terylene fibers, 10-30 parts of vinylon fibers and 10-50 parts of long stapled cotton fibers. The preparation method comprises the following steps: cotton cleaning, cotton carding, drawing, roving, fine spinning and winding. The terylene, vinylon and cotton fiber blended yarn has good advantages of terylene, vinylon and cotton fibers simultaneously, and eliminates defects of the terylene, vinylon and cotton fibers respectively.

Owner:安徽创星实业有限公司

RFID label and preparation method

PendingCN107451639AGuaranteed stabilityGuaranteed reliabilityRecord carriers used with machinesEngineeringComputational physics

The invention discloses an RFID label and preparation method. According to the scheme, a polyimide covering film covers a flexible substrate antenna layer, and a chip and an antenna are welded, thereby ensuring stability, reliability, alkaline washing resistance, high temperature resistance and durability of performance in label application. The scheme can be applied to high frequency band labels, ultrahigh frequency band labels or dual-band labels of the above two frequencies. The RFID label adopts a mature and simple process, and is suitable for volume production.

Owner:上海奕尔达科技有限公司

Cathode electrophoretic coating applicable to grooved pipe fittings and preparation method of cathode electrophoretic coating

InactiveCN107573836AWater and chemical resistanceStrong swimming powerPolyurea/polyurethane coatingsPaints for electrolytic applicationsEpoxyCorrosion

The invention relates to the technical field of coatings, and particularly discloses a cathode electrophoretic coating applicable to grooved pipe fittings. The cathode electrophoretic coating is prepared from the following components in parts by weight: 10 to 20 parts of color paste, 30 to 60 parts of emulsion and 40 to 60 parts of pure water; the color paste is prepared from the following components in parts by weight: 10 to 35 parts of acrylate polyurethane modified epoxy resin, 5 to 15 parts of environmentally-friendly cosolvent, 1 to 6 parts of a neutralizer, 0.1 to 0.5 part of a surfactant, 25 to 40 parts of deionized water, 5 to 30 parts of kaolin and 3 to 23 parts of a pigment; the emulsion is prepared from the following components in parts by mass: 30 to 40 parts of acrylate polyurethane modified epoxy resin, 2 to 8 parts of an emulsifier, 1 to 8 parts of a neutralizer and 30 to 50 parts of pure water. The cathode electrophoretic coating provided by the invention is high in hardness, and is excellent in corrosion resistance, acid resistance, alkali resistance and the like.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Preparation method of hydrophilic porous formed activated carbon

The invention relates to the field of functional materials, and especially relates to a preparation method of hydrophilic porous formed activated carbon. The preparation method of the hydrophilic porous formed activated carbon comprises the following steps: preparing a proper concentration of an aqueous solution of a water-soluble hydroxy polymer; weighing a certain amount of the water-soluble hydroxy polymer, dissolving the certain amount of the water-soluble hydroxy polymer in distilled water, swelling and dissolving, and cooling; adding 2wt% of an aqueous solution of NaOH to alkalize, and adding a proper amount of activated carbon into the above obtained glue system; adding a proper amount of a cross-linking agent chloropropylene oxide, and controlling a mass ratio of the water-soluble hydroxy polymer to chloropropylene oxide; adding a foaming agent ammonium bicarbonate, and uniformly stirring; reacting under stirring in a warm water bath, and neutralizing after the reaction to make the pH be 7; and pouring the above obtained activated carbon mixed solution into a die, and drying in a 110DEG C oven. The preparation method has the advantages of simple process and convenient operation, and the formed activated carbon obtained in the invention has the advantages of water resistance, acid and alkali resistance, and high cost performance.

Owner:QUFU TIANBO CRYSTALLIZED CARBON TECH CO LTD

Graphene modified organosilicone liquid defoaming agent

InactiveCN107469412AWith high temperature resistanceWith acid and alkali resistanceFoam dispersion/preventionHydrolysateAlkylphenol

Disclosed is a graphene modified organosilicone liquid defoaming agent. The agent is prepared from, by weight, 50-70 parts of organosilicone active matter, 20-30 parts of emulgator, 2-5 parts of graphene, 1-1.5 parts of thickening agent and 1-1.5 parts of coupling agent. The organosilicone active matter is formed by compounding one or more of methyl silicone oil, methyl phenyl silicone oil, ethyl silicone oil, polyether modified silicone oil and dimethyl siloxane hydrolysate; the emulgator is a non-ionic surface active agent and is formed by compounding one or more of alkylphenol polyoxyethylene ether, polyoxyethylene ether and fatty alcohol-polyoxyethylene ether; the thickening agent is formed by compounding one or more of hydroxymethyl cellulose, hydroxyethyl cellulose and hydroxypropyl cellulose. The defoaming agent has the performance of high temperature resistance, acid and alkali resistance and hydrophile of oxidized graphene, the defoaming performance of the defoaming agent can be enhanced, and the foam generating performance is inhibited. The invention further provides a preparation method of the defoaming agent.

Owner:徐州中泰能源科技有限公司

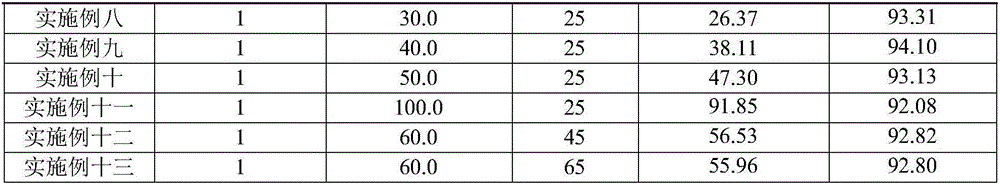

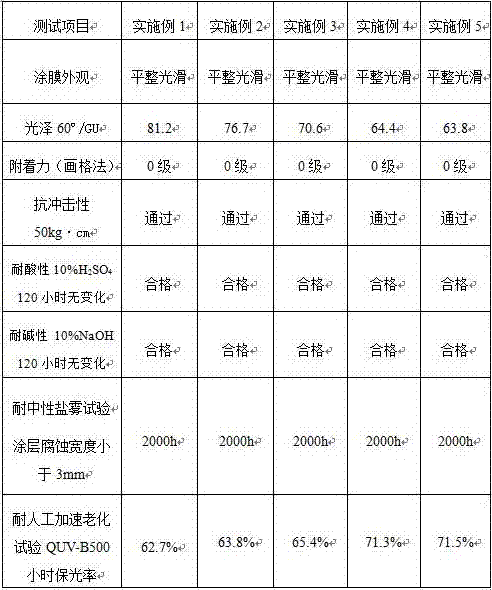

Polyurethane-fluorocarbon composite powder coating suitable for humid and hot marine climatic environment and preparation method of polyurethane-fluorocarbon composite powder coating

InactiveCN107974183AThe recipe is simpleHas super weather resistanceFireproof paintsPolyurea/polyurethane coatingsSalt resistanceHigh humidity

The invention discloses a fluorocarbon-polyurethane composite powder coating suitable for a humid and hot marine climatic environment. The fluorocarbon-polyurethane composite powder coating comprises,in parts by weight, 100-160 parts of polyurethane resin, 40-100 parts of fluorocarbon resin, 20-80 parts of isocyanate resin, 0-5 parts of accelerator, 30-100 parts of filler, 0.5-3 parts of a levelling agent, 0.5-2 parts of defoamer and 0.5-5 parts of pigment. The invention also discloses a preparation method of the polyurethane-fluorocarbon composite powder coating. The powder coating has the characteristics of a simple process formula, super weatherability, acid and alkali resistance, heavy salt resistance, high humidity and heat resistance and other excellent performance, and is suitablefor a protective coating in the humid and hot marine climatic environment, the coating has a long service life, and the comprehensive cost of maintenance is low.

Owner:GUANGZHOU KINTE IND

Halogen-free flame-retardant silicone rubber wire and cable material and preparation method thereof

InactiveCN103665883AHeat radiation resistantSimple processRubber insulatorsPolymer scienceAging resistance

The invention provides a halogen-free flame-retardant silicone rubber wire and cable material and a preparation method thereof. The halogen-free flame-retardant silicone rubber wire and cable material comprises the following components in parts by weight: 30-40 parts of aluminum hydroxide, 5-8 parts of aluminum hydroxide surface modifier, 4-6 parts of a mixture of multiple halogen-free flame retardants and 90-120 parts of high-temperature-resistant silicone rubber compound, wherein the mixture of multiple halogen-free flame retardants contains no aluminum hydroxide. The halogen-free flame-retardant silicone rubber wire and cable material has excellent flame retardance and excellent insulativity, mechanical property, aging resistance and environmental protection property; and the preparation method of the halogen-free flame-retardant silicone rubber wire and cable material is simple in process, easy to operate, high in production efficiency and low in cost.

Owner:东莞新东方科技有限公司

Method for preparing foam ceramic by using industrial and mining, building and sludge residue as raw materials

PendingCN107892583AReduce energy consumptionEfficient recyclingCeramic materials productionCeramicwareTunnel kilnSludge

The invention particularly relates to a method for preparing a foam ceramic by using industrial and mining, building and sludge residue as raw materials, and belongs to the technical field of environmental-protection foam ceramics, wherein protein foaming agent preparing, foam slurry preparing, molding and curing, high-temperature sintering, and detecting and packaging are performed to prepare thefoam ceramic. According to the present invention, the molded and cured foam slurry is conveyed to the tunnel kiln using liquefied petroleum gas as the fuel, and then enters the high temperature section through the sintering device, such that the two composite heating modes are innovatively connected in series so as to save the energy consumption or the fuel cost by 15-30%, and the technical problem that heavy metals, dioxins, and other organic pollutants cannot be completely removed during the combustion of industrial and mining, building and sludge residue is fundamentally solved; and the foam ceramic prepared through the method is the novel building material, and can have excellent performances of hydrophobicity, fire resistance, sound resistance, heat insulation, high compressive strength, acid resistance, alkali resistance, no aging, less deformation and the like according to the opened and closed gaps of the foam.

Owner:FUJIAN FUYONGDE ENVIRONMENTAL TECH CO LTD

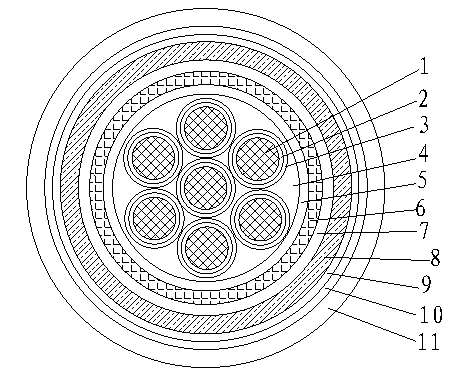

Watertight tractive load-bearing control cable

InactiveCN104143388ASecurityGood flexibilityClimate change adaptationSubmarine cablesElectric power transmissionCopper wire

The invention discloses a watertight tractive load-bearing control cable. The watertight tractive load-bearing control cable comprises a copper conductor formed by bundling a plurality of strands of copper wires. A sealing layer I is formed by coating the copper conductor with a sealant. An insulated cable core is formed by extruding a TPV elastic body insulating layer outside the sealing layer I. A waterproof layer is formed by filling gaps among the cable cores with waterproof glue when a finished cable is formed by stranding the cable cores. Waterproof wrapping tape is wound around the finished cable. An armor aramid fiber tensile enhancement layer is wound around the waterproof wrapping tape, waterproof wrapping tape I is wound around the aramid fiber tensile enhancement layer. A polyurethane inner sheath is extruded outside the wound waterproof wrapping tape I. A shielding layer is formed outside the inner sheath by weaving tinning annealed copper wires and is coated with a sealant so that a sealing layer II can be formed. A polyurethane outer sheath is extruded outside the sealing layer II. The watertight tractive load-bearing control cable is reliable in longitudinal watertightness performance, good in flexibility, light in weight, resistant to wear and bending, good in tension resistance, and can normally maintain reliability of electric transmission and control signal transmission under certain water pressure.

Owner:安徽宏源特种电缆集团有限公司

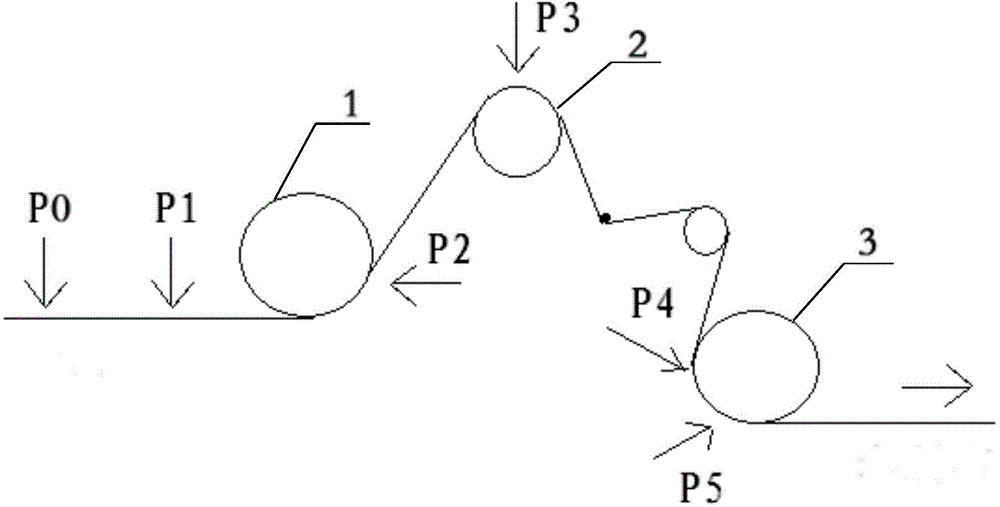

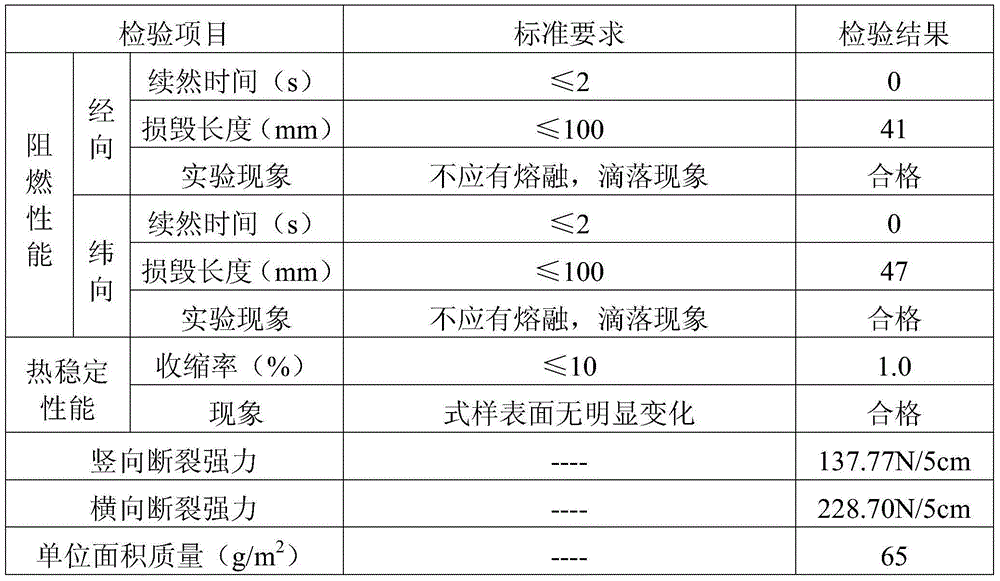

Papermaking rubber roller with high-strength non-woven and production process

ActiveCN103603137AMeet the use requirementsHigh strengthNon-woven fabricsNonwoven fabricHigh pressure

The invention disclose a papermaking rubber roller with high-strength non-woven and the production process which is made by aramid fiber through spunlaced process. The production process comprises the following steps: A. Opening; B. Combing; C. Lapping: putting fiber web into lapping machine and crosswise lying are called lapping; D. Drafting: the lapping is slowly dragged trough drafting machine to reduce vertical and horizontal force ratio difference of drafting; E. Spunlace: lapping which is finished by drafting does spunlaced reinforcement by using spunlace machine. Since aramid fiber has the excellent performances of super strength, high modulus and heat resistance, acid alkali resistance, light weight, insulation, aging resistance and long life cycle and the like. The high-strength non-woven which is made by adopting the above-mentioned technical proposal has the advantages of heat and high voltage resistance, good anti-aging performance and long service life and can meet operating requirements of the papermaking rubber of high speed paper machine.

Owner:SHAOXING HENGRUI NONWOVEN TECH

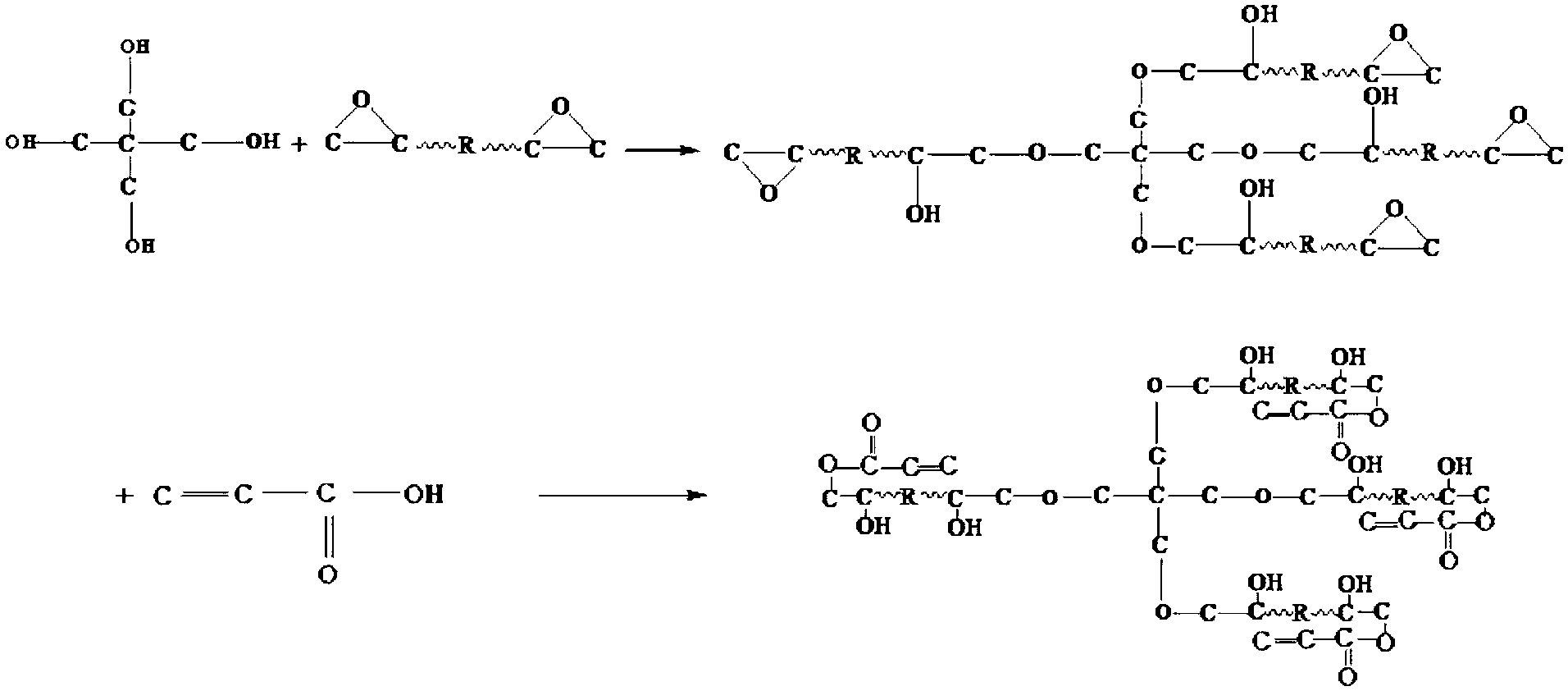

Low-viscosity epoxy acrylate paint for inner wall of food can and preparation method thereof

The invention relates to a low-viscosity epoxy acrylate paint for an inner wall of a food can and a preparation method thereof. The preparation method comprises the following steps: 1) preparation of low-viscosity epoxy acrylate resin: adding bisphenols A epoxy resin and a catalyst into a reaction vessel, stirring and heating, adding pentaerythritol, keeping the temperature and carrying out reflux condensation so as to prepare pentaerythritol epoxy ester; cooling, dropwisely adding a mixture of the catalyst, a polymerization inhibitor and acrylic acid, carrying out a thermostatic reaction, cooling and discharging so as to prepare low-viscosity epoxy acrylate resin; adding a leveling agent and an antifoaming agent, stirring and uniformly mixing so as to obtain the low-viscosity epoxy acrylate paint for the inner wall of the food can. The invention has the following beneficial effects: pentaerythritol epoxy acrylate has a hyper-branched characteristic, has advantages of high degree of unsaturation, low viscosity and good adhesive force, is suitable for electron beam curing, and is non-toxic; and a cured film has properties such as high crosslinking density, excellent glossiness, flexibility, hardness, acid resistance, alkali resistance, water resistance and the like.

Owner:武汉工大科技园发展有限公司

Supported nano zinc oxide as well as preparation and application thereof

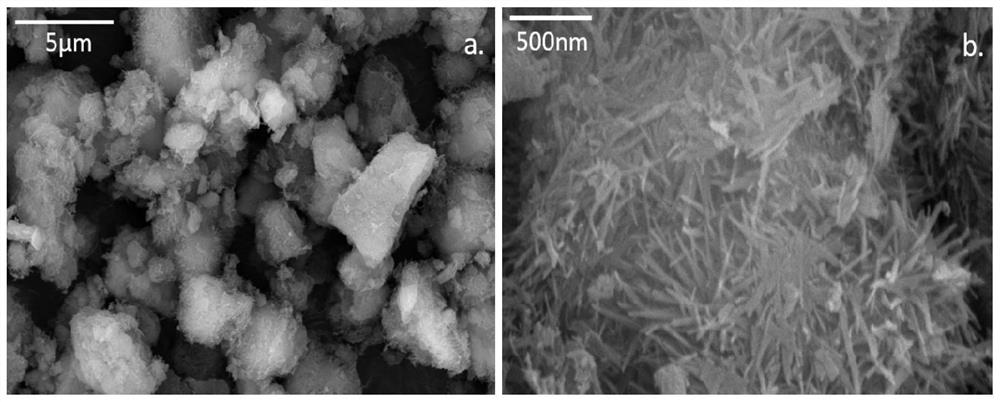

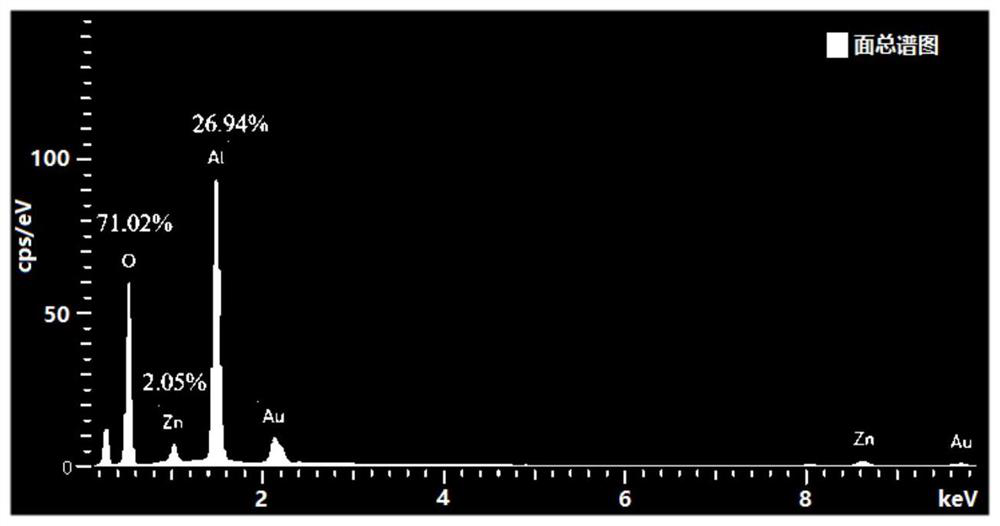

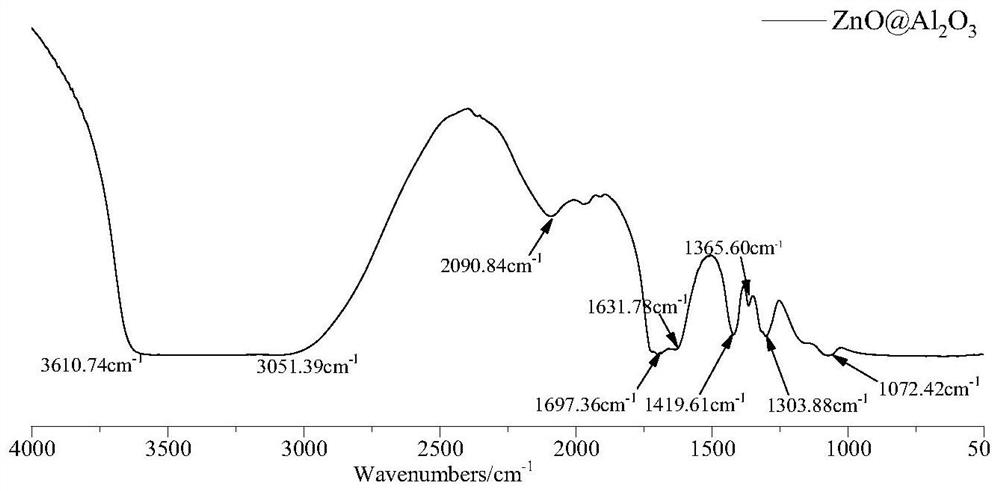

ActiveCN111729664ALarge specific surface areaSimple preparation processBiocideWater/sewage treatment by irradiationNanoparticleAntibiotic drug

The invention provides supported nano-zinc oxide as well as a preparation method and application thereof. A carrier of the supported nano zinc oxide is aluminum oxide, wherein ZnO accounts for 9%-11%of the total mass; the particle size of the ZnO@Al2O3 particles is 3-5 [mu] m, and the surface of the ZnO-coated Al2O3 particles is needle-like zinc oxide with the length of 400-500 nm. The hydrothermal method is simple in process. The supported nano-zinc oxide has the effects of killing bacteria, inactivating antibiotic resistance genes and inhibiting repair under visible light. The supported nano-zinc oxide is convenient to recycle, agglomeration can be avoided, dispersion is facilitated, and more importantly, nano-particles cannot enter aquatic organisms to generate toxic action. ZnO and Al2O3 under ultraviolet irradiation are used as a sterilization system, and the sterilization temperature is 5-40 DEG C; wherein the ultraviolet irradiation time is 3 to 240 minutes, and the concentration of ZnO@Al2O3 is 10 to 250 mg / L. The effectiveness and durability of sterilization are improved. Meanwhile, a model is established for a mechanism of killing antibiotic-resistant bacteria and inactivating antibiotic-resistant genes by the supported nano-zinc oxide, so that theoretical support is provided for practical application of zinc oxide in the aspect of sterilization.

Owner:JILIN UNIV

Preparation method of halogen-free low-smoke flame retardant crosslinked polyolefin insulation material for photovoltaic cable

InactiveCN106432871AEvenly dispersedEnhancer acid resistancePlastic/resin/waxes insulatorsPolyolefinPolymer science

The invention discloses a preparation method of a halogen-free low-smoke flame retardant crosslinked polyolefin insulation material for a photovoltaic cable. The halogen-free low-smoke flame retardant crosslinked polyolefin insulation material for the photovoltaic cable is prepared by carrying out processes including pretreatment, internal mixing, twin-screw extrusion, single-screw extrusion pelleting, air cooling and packaging on resin, an inorganic flame retardant, a liquid flame retardant, a liquid crosslinking agent, nano-scale ceramics, white carbon black and a processing aid. According to the preparation method, the volume resistivity of a product is larger than that required in standard requirement by one order of magnitude; and the product has acid resistance and alkali resistance, and the performance of the product meets the performance of 125 DEG C halogen-free low-smoke flame retardant crosslinked polyolefin insulation material.

Owner:高团结

High-performance adsorption film used for removing VOC exhaust gas

InactiveCN106861620AHigh densityLarge adsorption capacityGas treatmentOther chemical processesActivated carbonFiltration membrane

The invention is suitable for the field of protective articles, and provides high-performance adsorption film used for removing VOC exhaust gas. The film includes activated carbon fiber-type nonwoven fabric membranes and adsorbent particles. The adsorbent particles are clamped between the activated carbon fiber-type nonwoven fabric membranes and are fixed to the activated carbon fiber-type nonwoven fabric membranes through adhesive particles. The particle size of the adsorbent particles is 200-500 [mu]m. The particle size of the adhesive is one fourth to one third of the particle size of the adsorbent particles. In the film, the activated carbon fiber-type nonwoven fabric membranes are adopted as substrate filtration membranes, and activated carbon fibers when compared with activated carbon have higher adsorption capacity and higher adsorption-desorption speeds and have acid-resistant and alkali-resistant properties.

Owner:布和

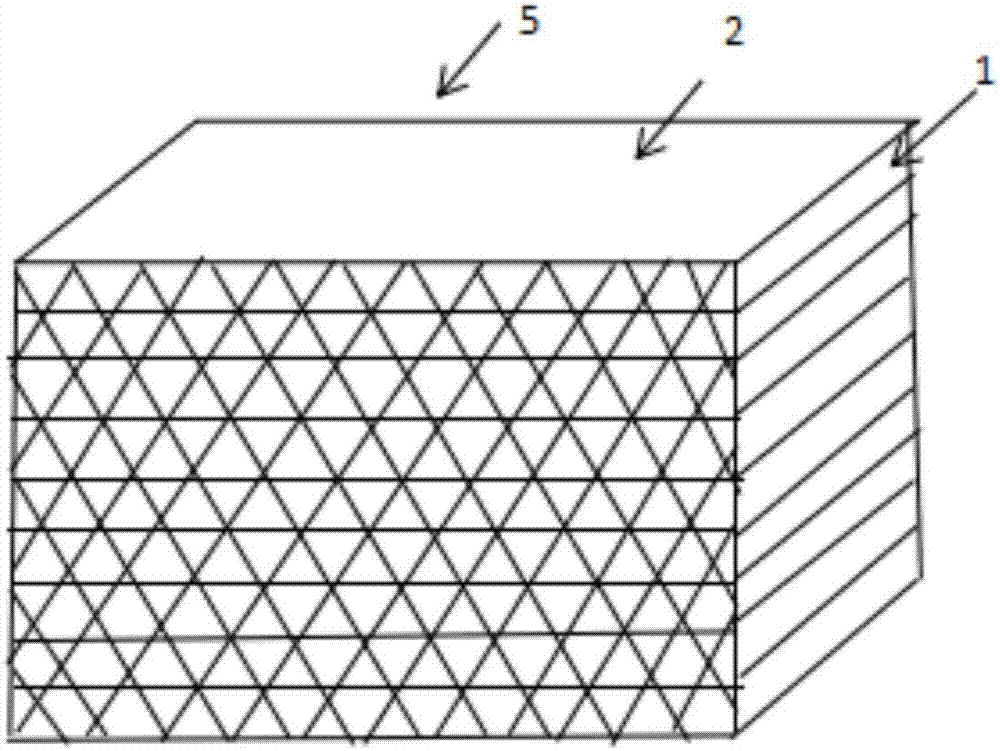

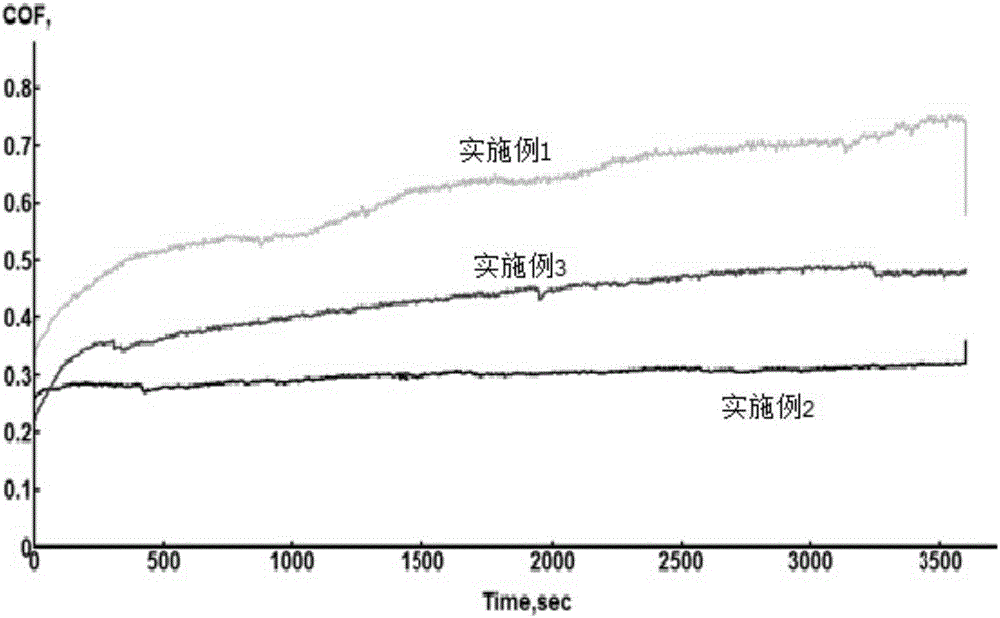

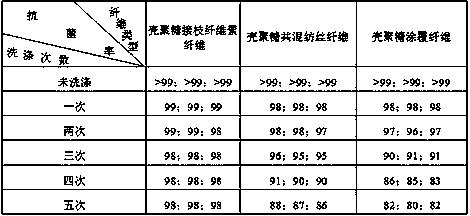

2.5-dimensional carbon fiber/aramid fiber woven perform reinforced cashew nut shell oil modified phenolic resin-based friction material

InactiveCN105697624AImprove integrityImprove carrying capacityOther chemical processesFriction liningCarbon fibersHeavy load

The invention discloses a 2.5-dimensional carbon fiber / aramid fiber woven perform reinforced cashew nut shell oil modified phenolic resin-based friction material. According to the friction material, a 2.5-dimensional carbon fiber / aramid fiber woven perform formed by weaving carbon fibers and aramid fibers in a mixed mode is adopted as a reinforcing structure and is subjected to composite solidification with a cashew nut shell oil modified phenolic resin glue solution to obtain the friction material. The friction material can be completely used under extreme operating conditions such as heavy loads and high speeds. The friction material has high mechanical performance and can bear large impact force, resist abrasion at high speeds, transfer heat in the friction material out in time and protect a brake disc well, and the service life of a brake pad is prolonged due to abrasion resistance.

Owner:JIANGNAN UNIV

Preparation process for novel chitosan antibacterial fiber

InactiveCN108774888ATo achieve the purpose of antibacterialHigh grafting rateBiochemical fibre treatmentVegetal fibresAfter treatmentSilanes

The invention relates to a preparation process for novel chitosan antibacterial fiber, which comprises the following steps: A. preparation of raw materials, B. preparation of a silane coupling agent kh560 grafted fiber, C. preparation of the novel chitosan antibacterial fiber. The preparation process adopts grafting technique, chitosan and cellulose fiber are effectively connected, the grafted chitosan fiber has acid and base resistance, and can ensure that the fiber has good antibacterial performance after treatment including dyeing, washing, drying, etc. The grafting rate of chitosan and cellulose is high, waste of raw materials is less, and production cost is low.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com