Preparation method and application of UV (Ultraviolet) photocatalysis-based unsaturated vegetable oil D-A (Diels-Alder) reaction product

A reaction product, unsaturated technology, applied in the direction of organic chemistry, can solve the problems of complex post-processing, high energy consumption, high energy consumption, etc., and achieve the effect of optimizing UV reactivity and curing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

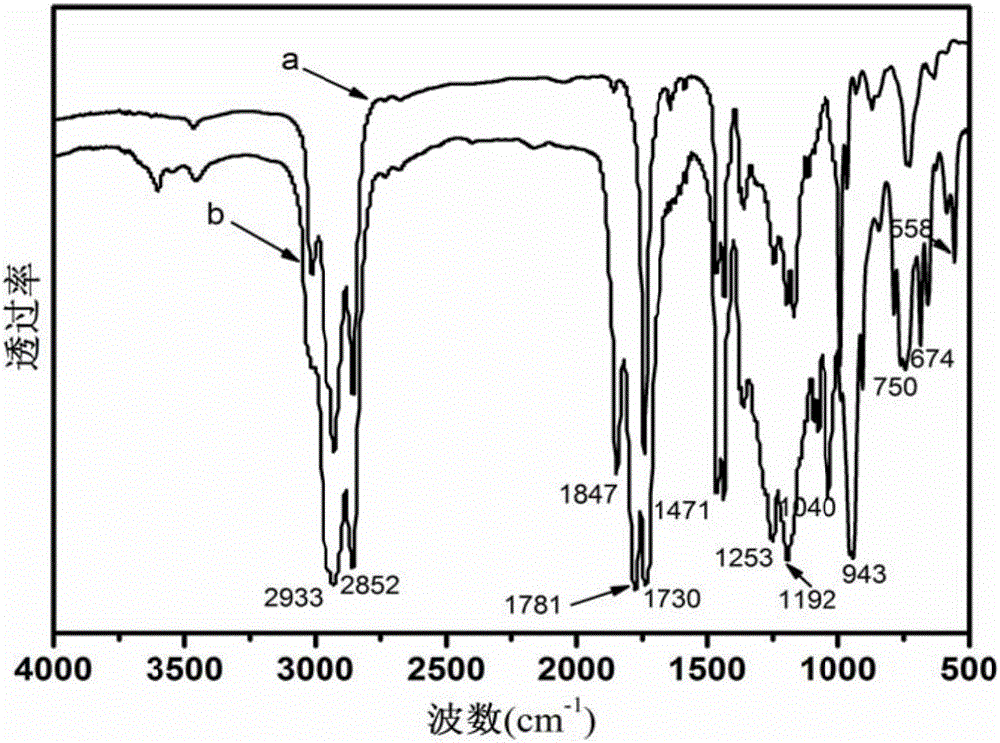

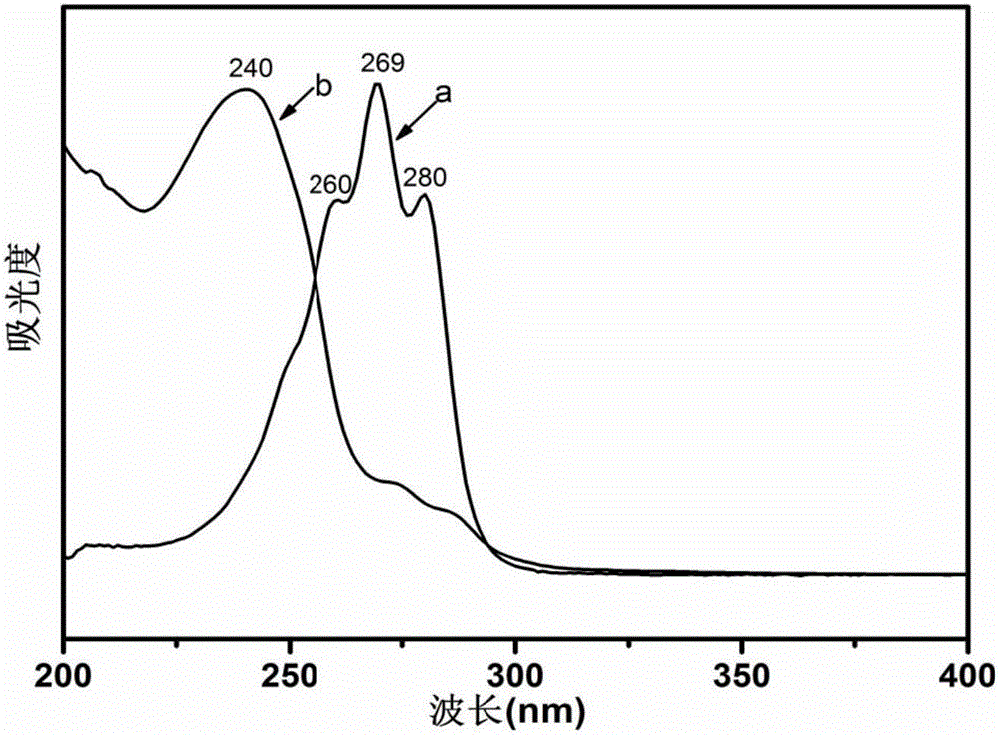

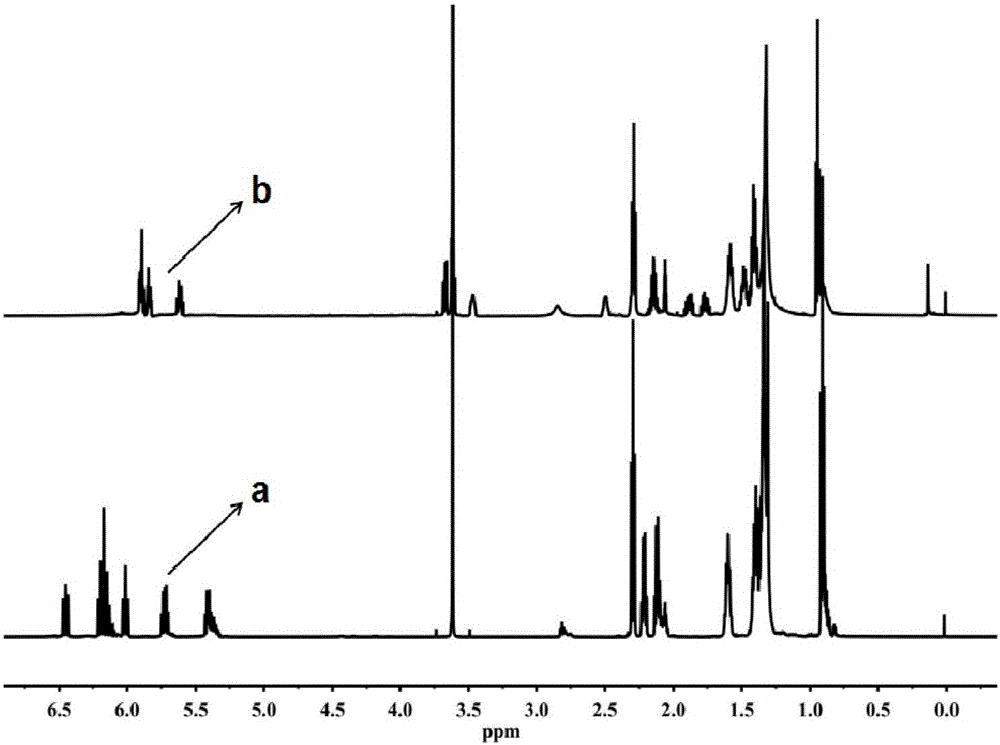

[0038] Embodiment 1UV photocatalytic lycate D-A reaction product MEMAA compound

[0039] (1) Synthesis and separation and purification of methyl trophic acid: Add 87.2 g of tung oil (0.10 mol, tung oil is calculated as glyceryl citric acid ester (872)) into a 250 mL three-neck flask, install a condensing reflux device, and heat the constant temperature water bath to 70 °C Afterwards, add the NaOH / methanol solution (0.872g / 19.2g) that prepares, wherein methyl alcohol: tung oil=6:1 (mol / mol), methyl alcohol 0.6mol (19.2g); NaOH is 1% (0.872g) of tung oil quality ); turn on the magnetic stirring, and stop the reaction after reacting for about 1 hour; add an appropriate amount of phosphoric acid to neutralize, transfer the reaction solution to a separatory funnel while it is hot, let it stand, and separate the glycerin layer (lower layer); wash the upper layer of liquid with hot distilled water 3 to 4 times, remove the water phase in the lower layer, distill under reduced pressure...

Embodiment 2

[0052] Embodiment 2UV photocatalysis linoleic acid ester D-A reaction product

[0053] (1) Synthesis and separation and purification of methyl linolenate: Add 87.2g linseed oil (0.10mol, linseed oil is calculated as linolenic acid glyceride (872)) in a 250mL three-necked flask, install a condensing reflux device, and heat the constant temperature water bath to After 60°C, add the prepared KOH / methanol solution, wherein methanol: tung oil = 5:1 (mol / mol), methanol 0.50mol; KOH is 2% of the mass of linseed oil; turn on the magnetic stirring, and stop after about 80min of reaction Reaction; add an appropriate amount of phosphoric acid for neutralization, transfer the reaction solution to a separatory funnel while it is hot, let it stand, and separate the glycerin layer (lower layer); wash the upper layer of liquid with hot distilled water for 3 to 4 times, remove the lower layer of water phase, and remove Pressure distillation to remove methanol and most of the water, etc., and d...

Embodiment 3

[0056] Embodiment 3UV photocatalysis soybean oleic acid ester D-A reaction product

[0057](1) Synthesis and separation and purification of soybean oil ester: Add 87.2g soybean oil (0.10mol, soybean oil is calculated as linoleic acid glyceride 878) in a 250mL three-necked flask, install a condensing reflux device, and heat the constant temperature water bath to After 80°C, add the prepared KOH / methanol solution, wherein methanol: tung oil = 8:1 (mol / mol), methanol 0.8mol; KOH is 2% of the mass of soybean oil; turn on magnetic stirring, react for about 50 minutes, stop Reaction; add an appropriate amount of phosphoric acid for neutralization, transfer the reaction solution to a separatory funnel while it is hot, let it stand, and separate the glycerin layer (lower layer); wash the upper layer of liquid with hot distilled water for 3 to 4 times, remove the lower layer of water phase, and remove Pressure distillation to remove methanol and most of the water, etc., and dry with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com