Developing Surface Plasmon Resonance Sensors Using Sulphanilic Acid

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SPR Sensor Development Background and Objectives

Surface Plasmon Resonance (SPR) sensors have emerged as a powerful tool in various fields, including biochemistry, environmental monitoring, and medical diagnostics. The development of SPR sensors using sulphanilic acid represents a significant advancement in this technology, offering potential improvements in sensitivity, selectivity, and cost-effectiveness.

The evolution of SPR sensor technology can be traced back to the early 1980s when it was first applied to biosensing applications. Since then, continuous research and development efforts have led to substantial improvements in sensor design, materials, and detection methodologies. The integration of sulphanilic acid into SPR sensors marks a new chapter in this technological progression, aiming to address some of the limitations of conventional SPR systems.

Sulphanilic acid, an organic compound with unique chemical properties, has shown promise in enhancing the performance of SPR sensors. Its ability to form stable monolayers on metal surfaces and interact with various analytes makes it an attractive candidate for sensor development. The incorporation of sulphanilic acid is expected to improve the sensor's surface chemistry, potentially leading to increased sensitivity and broader applicability.

The primary objectives of developing SPR sensors using sulphanilic acid are multifaceted. Firstly, researchers aim to enhance the sensor's detection limit, enabling the identification of analytes at lower concentrations. This improvement could significantly impact areas such as early disease diagnosis and environmental pollutant detection. Secondly, there is a focus on increasing the sensor's specificity, reducing false positives and improving overall reliability.

Another key goal is to expand the range of detectable analytes. Traditional SPR sensors have limitations in detecting small molecules or low molecular weight compounds. By leveraging the unique properties of sulphanilic acid, developers hope to overcome these constraints, broadening the sensor's applicability across various industries and research fields.

Cost-effectiveness and scalability are also crucial objectives in this development process. By utilizing sulphanilic acid, which is relatively inexpensive and readily available, researchers aim to create more affordable SPR sensor systems. This could potentially democratize access to this advanced technology, making it more accessible to smaller laboratories and developing countries.

The development of these sensors also aligns with the broader trend of miniaturization and portability in analytical devices. There is a growing demand for compact, field-deployable SPR sensors that can provide rapid, on-site analysis. The integration of sulphanilic acid could contribute to the realization of such portable systems, opening up new possibilities for real-time monitoring in various applications.

As research in this area progresses, it is anticipated that SPR sensors using sulphanilic acid will play a crucial role in advancing analytical capabilities across multiple disciplines. The success of this technology could pave the way for more sensitive, versatile, and accessible sensing platforms, contributing significantly to scientific research, healthcare, and environmental protection efforts.

The evolution of SPR sensor technology can be traced back to the early 1980s when it was first applied to biosensing applications. Since then, continuous research and development efforts have led to substantial improvements in sensor design, materials, and detection methodologies. The integration of sulphanilic acid into SPR sensors marks a new chapter in this technological progression, aiming to address some of the limitations of conventional SPR systems.

Sulphanilic acid, an organic compound with unique chemical properties, has shown promise in enhancing the performance of SPR sensors. Its ability to form stable monolayers on metal surfaces and interact with various analytes makes it an attractive candidate for sensor development. The incorporation of sulphanilic acid is expected to improve the sensor's surface chemistry, potentially leading to increased sensitivity and broader applicability.

The primary objectives of developing SPR sensors using sulphanilic acid are multifaceted. Firstly, researchers aim to enhance the sensor's detection limit, enabling the identification of analytes at lower concentrations. This improvement could significantly impact areas such as early disease diagnosis and environmental pollutant detection. Secondly, there is a focus on increasing the sensor's specificity, reducing false positives and improving overall reliability.

Another key goal is to expand the range of detectable analytes. Traditional SPR sensors have limitations in detecting small molecules or low molecular weight compounds. By leveraging the unique properties of sulphanilic acid, developers hope to overcome these constraints, broadening the sensor's applicability across various industries and research fields.

Cost-effectiveness and scalability are also crucial objectives in this development process. By utilizing sulphanilic acid, which is relatively inexpensive and readily available, researchers aim to create more affordable SPR sensor systems. This could potentially democratize access to this advanced technology, making it more accessible to smaller laboratories and developing countries.

The development of these sensors also aligns with the broader trend of miniaturization and portability in analytical devices. There is a growing demand for compact, field-deployable SPR sensors that can provide rapid, on-site analysis. The integration of sulphanilic acid could contribute to the realization of such portable systems, opening up new possibilities for real-time monitoring in various applications.

As research in this area progresses, it is anticipated that SPR sensors using sulphanilic acid will play a crucial role in advancing analytical capabilities across multiple disciplines. The success of this technology could pave the way for more sensitive, versatile, and accessible sensing platforms, contributing significantly to scientific research, healthcare, and environmental protection efforts.

Market Analysis for SPR Biosensors

The global market for Surface Plasmon Resonance (SPR) biosensors has been experiencing significant growth, driven by increasing demand in pharmaceutical research, environmental monitoring, and food safety applications. The integration of sulphanilic acid in SPR sensor development represents a promising avenue for enhancing sensor performance and expanding market opportunities.

In the pharmaceutical sector, SPR biosensors are widely used for drug discovery and development processes, offering real-time, label-free detection of biomolecular interactions. The market for SPR biosensors in this segment is expected to grow steadily as pharmaceutical companies continue to invest in research and development activities. The potential for sulphanilic acid-based SPR sensors to improve sensitivity and specificity could further accelerate adoption in this sector.

Environmental monitoring applications present another substantial market opportunity for SPR biosensors. With increasing concerns about water and air quality, there is a growing need for rapid, on-site detection of pollutants and contaminants. Sulphanilic acid-based SPR sensors could offer improved detection capabilities for specific environmental toxins, potentially expanding the market reach in this segment.

The food safety industry is another key market driver for SPR biosensors. As food safety regulations become more stringent globally, the demand for rapid and accurate detection methods for pathogens, allergens, and contaminants is rising. The development of SPR sensors using sulphanilic acid could enhance detection limits and reduce false positives, addressing critical needs in this market segment.

In the healthcare sector, point-of-care diagnostics represent a rapidly growing application area for SPR biosensors. The potential for sulphanilic acid-based sensors to offer improved performance in detecting biomarkers could open new opportunities in clinical diagnostics and personalized medicine.

The Asia-Pacific region is expected to witness the fastest growth in the SPR biosensor market, driven by increasing research and development activities, growing awareness about food safety, and rising healthcare expenditure. North America and Europe continue to be significant markets, with established research infrastructure and stringent regulatory standards driving adoption.

Key market players in the SPR biosensor industry include GE Healthcare, Bio-Rad Laboratories, and HORIBA. These companies are likely to show interest in sulphanilic acid-based SPR sensor technology if it demonstrates significant performance improvements. Smaller, specialized companies focusing on novel SPR sensor development may also emerge as important players in commercializing this technology.

While the market potential for SPR biosensors using sulphanilic acid is promising, challenges such as cost considerations, regulatory approval processes, and competition from other sensing technologies need to be addressed. The success of this technology in the market will depend on its ability to offer clear advantages in terms of sensitivity, specificity, and reliability compared to existing solutions.

In the pharmaceutical sector, SPR biosensors are widely used for drug discovery and development processes, offering real-time, label-free detection of biomolecular interactions. The market for SPR biosensors in this segment is expected to grow steadily as pharmaceutical companies continue to invest in research and development activities. The potential for sulphanilic acid-based SPR sensors to improve sensitivity and specificity could further accelerate adoption in this sector.

Environmental monitoring applications present another substantial market opportunity for SPR biosensors. With increasing concerns about water and air quality, there is a growing need for rapid, on-site detection of pollutants and contaminants. Sulphanilic acid-based SPR sensors could offer improved detection capabilities for specific environmental toxins, potentially expanding the market reach in this segment.

The food safety industry is another key market driver for SPR biosensors. As food safety regulations become more stringent globally, the demand for rapid and accurate detection methods for pathogens, allergens, and contaminants is rising. The development of SPR sensors using sulphanilic acid could enhance detection limits and reduce false positives, addressing critical needs in this market segment.

In the healthcare sector, point-of-care diagnostics represent a rapidly growing application area for SPR biosensors. The potential for sulphanilic acid-based sensors to offer improved performance in detecting biomarkers could open new opportunities in clinical diagnostics and personalized medicine.

The Asia-Pacific region is expected to witness the fastest growth in the SPR biosensor market, driven by increasing research and development activities, growing awareness about food safety, and rising healthcare expenditure. North America and Europe continue to be significant markets, with established research infrastructure and stringent regulatory standards driving adoption.

Key market players in the SPR biosensor industry include GE Healthcare, Bio-Rad Laboratories, and HORIBA. These companies are likely to show interest in sulphanilic acid-based SPR sensor technology if it demonstrates significant performance improvements. Smaller, specialized companies focusing on novel SPR sensor development may also emerge as important players in commercializing this technology.

While the market potential for SPR biosensors using sulphanilic acid is promising, challenges such as cost considerations, regulatory approval processes, and competition from other sensing technologies need to be addressed. The success of this technology in the market will depend on its ability to offer clear advantages in terms of sensitivity, specificity, and reliability compared to existing solutions.

Current Challenges in SPR Sensor Technology

Surface Plasmon Resonance (SPR) sensor technology has made significant strides in recent years, yet several challenges persist in its development and application, particularly when using sulphanilic acid as a key component. One of the primary obstacles is achieving optimal sensitivity and selectivity. While SPR sensors offer high sensitivity, further improvements are needed to detect trace amounts of analytes in complex matrices, especially in environmental and biomedical applications.

The stability of the sensor surface remains a critical issue. Sulphanilic acid-based coatings can degrade over time, affecting the long-term reliability and reproducibility of measurements. Researchers are grappling with ways to enhance the durability of these coatings without compromising their sensing capabilities. Additionally, non-specific binding continues to be a significant challenge, leading to false positives and reduced accuracy in analyte detection.

Miniaturization and integration of SPR sensors into portable devices present another set of hurdles. While there is a growing demand for on-site and real-time monitoring in various fields, reducing the size of SPR systems without sacrificing performance proves to be technically challenging. The integration of microfluidics with SPR sensors using sulphanilic acid also requires further optimization to ensure efficient sample handling and analysis.

The cost-effectiveness of SPR sensor production and operation is an ongoing concern. Current fabrication processes for high-quality SPR sensors, especially those incorporating sulphanilic acid, can be expensive and complex. Developing more economical manufacturing methods while maintaining sensor performance is crucial for widespread adoption of this technology.

Another significant challenge lies in the development of multiplexing capabilities. The ability to simultaneously detect multiple analytes using a single SPR sensor array is highly desirable but technically demanding. Researchers are exploring ways to functionalize different areas of the sensor surface with sulphanilic acid derivatives to enable multi-analyte detection without cross-reactivity.

Data interpretation and signal processing present additional challenges. As SPR sensors become more sensitive and are applied to more complex samples, the need for advanced algorithms to process and interpret the data becomes increasingly important. Developing robust data analysis methods that can handle noise, drift, and matrix effects is essential for reliable sensor performance.

Lastly, the standardization of SPR sensor technology, particularly for sulphanilic acid-based systems, remains an ongoing challenge. The lack of universally accepted protocols for sensor fabrication, calibration, and data reporting hinders the comparison of results across different studies and laboratories. Establishing standardized methods is crucial for the wider acceptance and implementation of SPR sensor technology in various applications.

The stability of the sensor surface remains a critical issue. Sulphanilic acid-based coatings can degrade over time, affecting the long-term reliability and reproducibility of measurements. Researchers are grappling with ways to enhance the durability of these coatings without compromising their sensing capabilities. Additionally, non-specific binding continues to be a significant challenge, leading to false positives and reduced accuracy in analyte detection.

Miniaturization and integration of SPR sensors into portable devices present another set of hurdles. While there is a growing demand for on-site and real-time monitoring in various fields, reducing the size of SPR systems without sacrificing performance proves to be technically challenging. The integration of microfluidics with SPR sensors using sulphanilic acid also requires further optimization to ensure efficient sample handling and analysis.

The cost-effectiveness of SPR sensor production and operation is an ongoing concern. Current fabrication processes for high-quality SPR sensors, especially those incorporating sulphanilic acid, can be expensive and complex. Developing more economical manufacturing methods while maintaining sensor performance is crucial for widespread adoption of this technology.

Another significant challenge lies in the development of multiplexing capabilities. The ability to simultaneously detect multiple analytes using a single SPR sensor array is highly desirable but technically demanding. Researchers are exploring ways to functionalize different areas of the sensor surface with sulphanilic acid derivatives to enable multi-analyte detection without cross-reactivity.

Data interpretation and signal processing present additional challenges. As SPR sensors become more sensitive and are applied to more complex samples, the need for advanced algorithms to process and interpret the data becomes increasingly important. Developing robust data analysis methods that can handle noise, drift, and matrix effects is essential for reliable sensor performance.

Lastly, the standardization of SPR sensor technology, particularly for sulphanilic acid-based systems, remains an ongoing challenge. The lack of universally accepted protocols for sensor fabrication, calibration, and data reporting hinders the comparison of results across different studies and laboratories. Establishing standardized methods is crucial for the wider acceptance and implementation of SPR sensor technology in various applications.

Sulphanilic Acid-based SPR Sensor Solutions

01 Nanostructure-enhanced sensitivity

Utilizing nanostructures, such as nanoparticles or nanopatterned surfaces, can significantly enhance the sensitivity of surface plasmon resonance (SPR) sensors. These nanostructures increase the surface area and localize electromagnetic fields, leading to improved detection limits and overall sensor performance.- Nanostructure-based SPR sensors: Utilizing nanostructures such as nanoparticles, nanorods, or nanoarrays to enhance the sensitivity of Surface Plasmon Resonance (SPR) sensors. These nanostructures can increase the surface area and localize electromagnetic fields, leading to improved detection limits and overall sensor performance.

- Multi-channel SPR sensing systems: Developing SPR sensors with multiple channels or detection areas to enable simultaneous measurement of multiple analytes or to improve the signal-to-noise ratio. This approach can enhance sensitivity by allowing for real-time reference measurements and reducing environmental interferences.

- Novel optical configurations: Implementing innovative optical setups, such as phase-sensitive detection methods or wavelength interrogation techniques, to improve the sensitivity of SPR sensors. These configurations can enhance the detection of small refractive index changes and minimize noise.

- Surface functionalization techniques: Developing advanced surface modification methods to improve the binding efficiency and specificity of target analytes to the sensor surface. This can include the use of self-assembled monolayers, polymer brushes, or biomolecular recognition elements to enhance sensitivity and reduce non-specific binding.

- Signal processing and data analysis: Implementing advanced signal processing algorithms and data analysis techniques to extract meaningful information from SPR sensor responses. This can include machine learning approaches, noise reduction methods, and pattern recognition algorithms to improve sensitivity and detection limits.

02 Multi-channel SPR sensing

Implementing multi-channel SPR sensing systems allows for simultaneous detection of multiple analytes or improved signal-to-noise ratios. This approach can enhance sensitivity by providing comparative measurements and reducing environmental interferences.Expand Specific Solutions03 Advanced signal processing techniques

Employing sophisticated signal processing algorithms and data analysis methods can improve the sensitivity of SPR sensors. These techniques may include noise reduction, signal amplification, and advanced curve fitting to extract more information from the sensor response.Expand Specific Solutions04 Novel plasmonic materials and structures

Exploring alternative plasmonic materials and structures, such as graphene or metamaterials, can lead to enhanced sensitivity in SPR sensors. These materials may offer unique optical properties or improved surface chemistry for analyte binding.Expand Specific Solutions05 Temperature control and compensation

Implementing precise temperature control and compensation mechanisms can significantly improve the sensitivity and stability of SPR sensors. This approach minimizes thermal drift and allows for more accurate measurements of small refractive index changes.Expand Specific Solutions

Key Players in SPR Sensor Industry

The development of Surface Plasmon Resonance (SPR) sensors using sulphanilic acid is in a nascent stage, with significant potential for growth. The market for SPR sensors is expanding, driven by applications in healthcare, environmental monitoring, and biotechnology. While the technology is still evolving, several key players are advancing research and development efforts. Companies like Seiko Epson Corp., ROHM Co., Ltd., and OMRON Corp. are leveraging their expertise in electronics and sensing technologies to explore SPR applications. Academic institutions such as Hangzhou Dianzi University and Jilin University are contributing to fundamental research. The involvement of diverse stakeholders, including both industry leaders and research organizations, indicates a competitive landscape with opportunities for innovation and commercialization in this emerging field.

Cytiva Sweden AB

Technical Solution: Cytiva Sweden AB has developed advanced surface plasmon resonance (SPR) sensors using sulphanilic acid for enhanced biosensing applications. Their approach involves modifying gold surfaces with sulphanilic acid to create a stable and sensitive platform for biomolecule detection. The company utilizes a proprietary surface chemistry that allows for covalent immobilization of sulphanilic acid on gold, resulting in a highly reproducible and robust sensing surface[1]. This modified surface exhibits excellent stability in various buffer conditions and provides a wide dynamic range for analyte detection. Cytiva's SPR sensors incorporating sulphanilic acid demonstrate improved sensitivity, with reported detection limits in the sub-nanomolar range for various protein biomarkers[3]. The company has also developed multiplexed SPR systems that can simultaneously analyze multiple analytes using sulphanilic acid-modified sensor chips, increasing throughput and reducing sample consumption[5].

Strengths: High sensitivity, excellent stability, wide dynamic range, and multiplexing capabilities. Weaknesses: Potential cross-reactivity with certain biomolecules, limited selectivity in complex biological samples.

Revvity Health Sciences, Inc.

Technical Solution: Revvity Health Sciences, Inc. has pioneered the development of SPR sensors using sulphanilic acid for high-throughput drug discovery and biomolecular interaction analysis. Their approach involves a novel surface functionalization technique that incorporates sulphanilic acid as a linker molecule between the gold surface and capture ligands. This method enhances the sensor's sensitivity and specificity for a wide range of analytes, including small molecules and large proteins[2]. Revvity's SPR platform utilizes advanced microfluidics and automated sample handling systems, allowing for rapid and precise measurements of binding kinetics and affinity constants. The company has reported a significant improvement in signal-to-noise ratio compared to conventional SPR sensors, with detection limits reaching the picomolar range for certain biomolecules[4]. Additionally, Revvity has developed proprietary data analysis software that leverages machine learning algorithms to interpret complex SPR sensorgrams, enabling more accurate and reliable characterization of molecular interactions[6].

Strengths: High-throughput capabilities, improved sensitivity and specificity, advanced data analysis tools. Weaknesses: Higher cost compared to traditional SPR systems, potential limitations in analyzing very large biomolecules.

Innovations in Sulphanilic Acid SPR Sensing

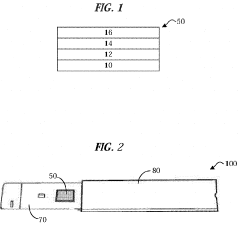

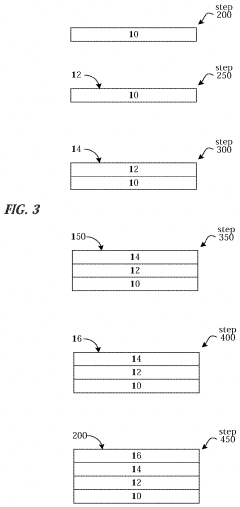

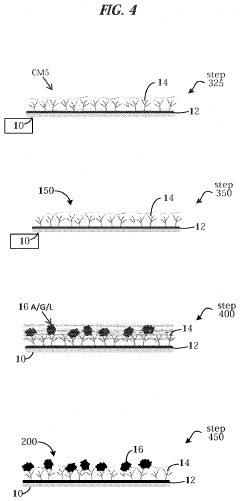

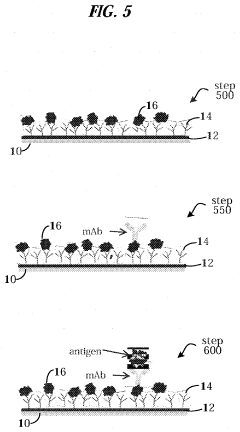

Surface plasmon resonance sensor chip having sensor surface capable of capturing multiple species of antibodies and method of making

PatentPendingUS20220170925A1

Innovation

- A sensor surface comprising a substrate, a metal layer, a protective surface layer, and a protein layer of A/G/L fusion proteins, which allows for the capture of any antibody species by leveraging the combined IgG binding profiles of Protein A, Protein G, and Protein L, enabling broad antibody capture and characterization.

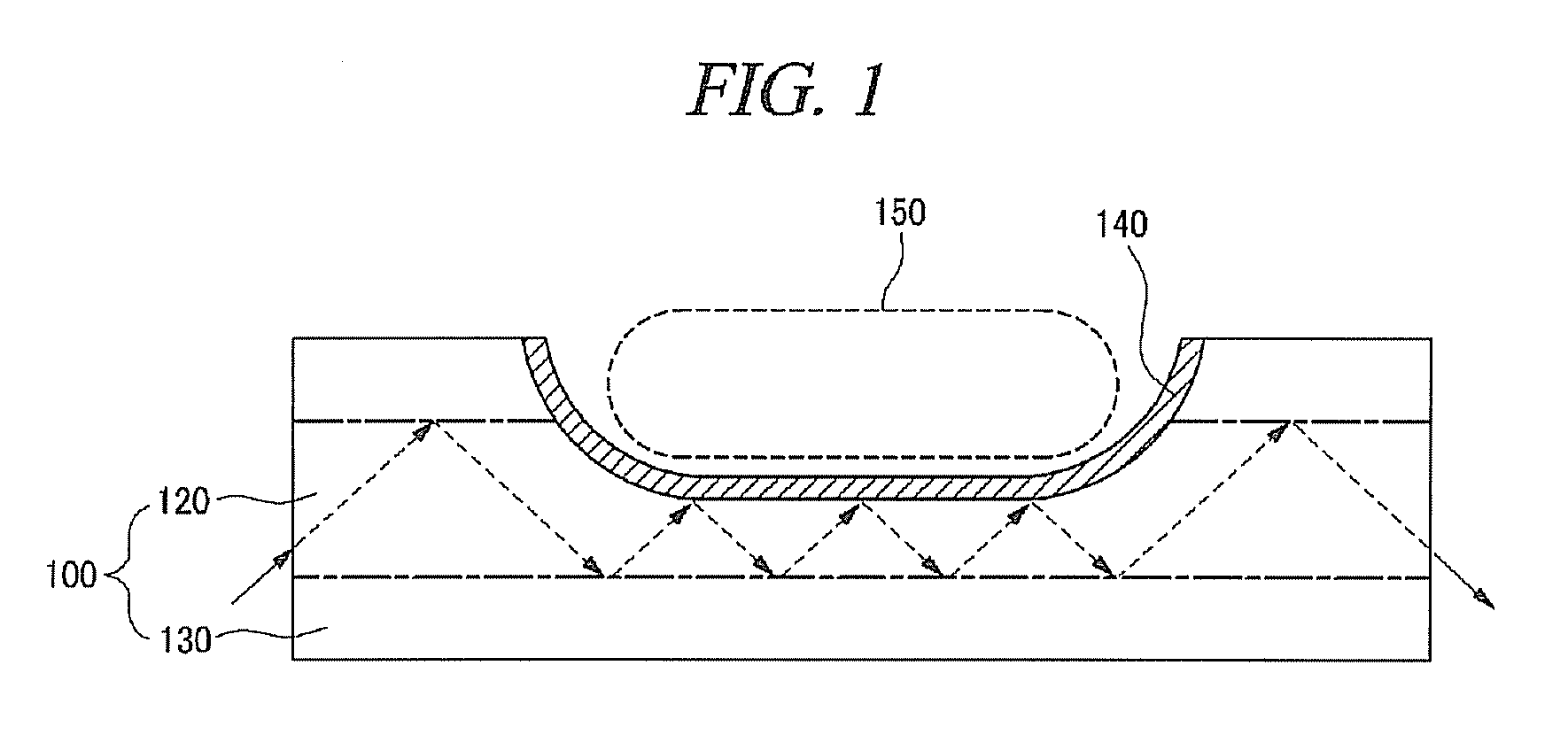

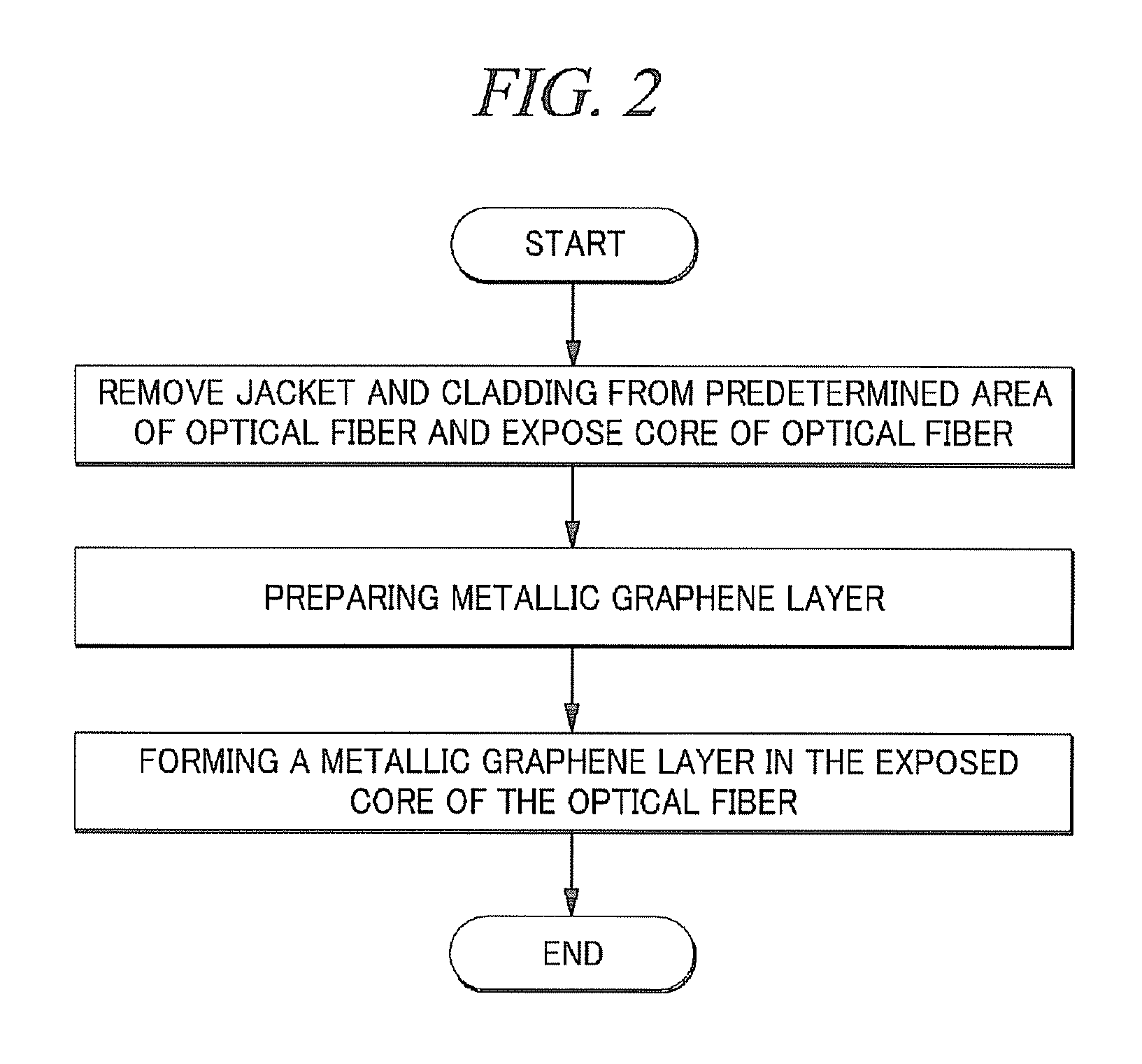

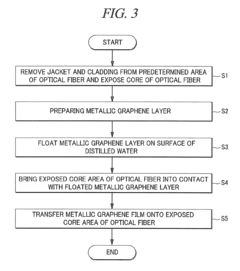

Surface plasmon resonance sensor using metallic graphene, preparing method of the same, and surface plasmon resonance sensor system

PatentActiveUS9075009B2

Innovation

- A surface plasmon resonance sensor system utilizing a metallic graphene layer formed on the core of an optical fiber from which the jacket and cladding are removed, enhancing sensitivity and mechanical strength, and eliminating the need for a buffer layer by incorporating various cladding modes that inherently excite surface plasmon waves.

Environmental Impact of SPR Sensor Materials

The development of Surface Plasmon Resonance (SPR) sensors using sulphanilic acid brings forth important considerations regarding the environmental impact of the materials involved. As these sensors gain prominence in various applications, it becomes crucial to assess their ecological footprint throughout their lifecycle.

Sulphanilic acid, a key component in these SPR sensors, is an organic compound with potential environmental implications. Its production process involves chemical synthesis, which may generate waste products and consume energy resources. However, the relatively small quantities required for sensor fabrication mitigate some of these concerns.

The substrate materials used in SPR sensors, typically gold or silver thin films, also warrant attention from an environmental perspective. While these precious metals are used in minute amounts, their extraction and processing can have significant ecological consequences, including habitat disruption and energy-intensive refining processes.

The disposal and end-of-life management of SPR sensors present another environmental challenge. The composite nature of these devices, combining organic compounds and metallic elements, complicates recycling efforts. Proper disposal protocols must be established to prevent the release of potentially harmful substances into ecosystems.

On a positive note, the high sensitivity and reusability of SPR sensors contribute to their environmental sustainability. These characteristics allow for reduced sample volumes and extended sensor lifespans, potentially decreasing overall material consumption and waste generation in analytical processes.

The miniaturization trend in SPR sensor development further enhances their eco-friendliness. Smaller sensors require less material input and energy during production, while also minimizing waste at the end of their lifecycle. This aligns with broader sustainability goals in the field of analytical instrumentation.

When comparing SPR sensors to alternative analytical techniques, their environmental profile often proves favorable. Many traditional methods require larger sample volumes, more extensive sample preparation, and generate more waste. The real-time, label-free nature of SPR sensing can significantly reduce the use of reagents and auxiliary chemicals.

To fully address the environmental impact of SPR sensor materials, ongoing research focuses on developing more sustainable alternatives. This includes exploring bio-based substrates, investigating recyclable sensor components, and optimizing production processes to minimize resource consumption and waste generation.

In conclusion, while the environmental impact of SPR sensor materials warrants careful consideration, the technology's inherent efficiency and ongoing sustainability efforts position it as a relatively eco-friendly analytical tool. Continued research and development in this field should prioritize further reducing its ecological footprint, ensuring that the benefits of SPR sensing extend beyond analytical performance to environmental stewardship.

Sulphanilic acid, a key component in these SPR sensors, is an organic compound with potential environmental implications. Its production process involves chemical synthesis, which may generate waste products and consume energy resources. However, the relatively small quantities required for sensor fabrication mitigate some of these concerns.

The substrate materials used in SPR sensors, typically gold or silver thin films, also warrant attention from an environmental perspective. While these precious metals are used in minute amounts, their extraction and processing can have significant ecological consequences, including habitat disruption and energy-intensive refining processes.

The disposal and end-of-life management of SPR sensors present another environmental challenge. The composite nature of these devices, combining organic compounds and metallic elements, complicates recycling efforts. Proper disposal protocols must be established to prevent the release of potentially harmful substances into ecosystems.

On a positive note, the high sensitivity and reusability of SPR sensors contribute to their environmental sustainability. These characteristics allow for reduced sample volumes and extended sensor lifespans, potentially decreasing overall material consumption and waste generation in analytical processes.

The miniaturization trend in SPR sensor development further enhances their eco-friendliness. Smaller sensors require less material input and energy during production, while also minimizing waste at the end of their lifecycle. This aligns with broader sustainability goals in the field of analytical instrumentation.

When comparing SPR sensors to alternative analytical techniques, their environmental profile often proves favorable. Many traditional methods require larger sample volumes, more extensive sample preparation, and generate more waste. The real-time, label-free nature of SPR sensing can significantly reduce the use of reagents and auxiliary chemicals.

To fully address the environmental impact of SPR sensor materials, ongoing research focuses on developing more sustainable alternatives. This includes exploring bio-based substrates, investigating recyclable sensor components, and optimizing production processes to minimize resource consumption and waste generation.

In conclusion, while the environmental impact of SPR sensor materials warrants careful consideration, the technology's inherent efficiency and ongoing sustainability efforts position it as a relatively eco-friendly analytical tool. Continued research and development in this field should prioritize further reducing its ecological footprint, ensuring that the benefits of SPR sensing extend beyond analytical performance to environmental stewardship.

Standardization and Quality Control in SPR Sensing

Standardization and quality control are critical aspects in the development and application of Surface Plasmon Resonance (SPR) sensors using sulphanilic acid. These processes ensure consistent performance, reliability, and reproducibility of results across different laboratories and experimental setups.

One of the primary challenges in SPR sensing is the variability in sensor chip preparation. To address this, standardized protocols for the functionalization of gold surfaces with sulphanilic acid must be established. These protocols should specify precise concentrations, reaction times, and environmental conditions to ensure uniform surface coverage and optimal sensor performance.

Quality control measures for SPR sensors begin with the characterization of the gold surface before and after functionalization. Techniques such as atomic force microscopy (AFM) and X-ray photoelectron spectroscopy (XPS) can be employed to verify surface roughness, thickness, and chemical composition. Establishing acceptable ranges for these parameters is crucial for maintaining sensor quality.

The sensitivity and specificity of SPR sensors are key performance indicators that require standardization. Reference analytes with known binding affinities to sulphanilic acid-functionalized surfaces should be identified and used to calibrate sensors across different batches and laboratories. This approach allows for the development of standardized sensitivity metrics and detection limits.

Reproducibility is another critical aspect of quality control in SPR sensing. Inter-laboratory comparisons and round-robin tests can help identify sources of variability and establish best practices. These exercises should include the preparation of sensor chips, sample handling, and data analysis to ensure consistency across different research groups and applications.

Data analysis and interpretation present additional challenges in SPR sensing standardization. Developing standardized algorithms for signal processing, baseline correction, and kinetic analysis is essential for comparing results across different studies. Open-source software platforms can facilitate the adoption of these standardized analysis methods within the research community.

Long-term stability and shelf-life of sulphanilic acid-functionalized SPR sensors must also be addressed through quality control measures. Accelerated aging studies and periodic performance checks can help establish storage conditions and expiration dates for sensor chips, ensuring reliable performance over time.

Finally, the development of certified reference materials (CRMs) for SPR sensing using sulphanilic acid would greatly enhance standardization efforts. These CRMs could serve as benchmarks for sensor performance and aid in the validation of new sensor designs and functionalization methods.

One of the primary challenges in SPR sensing is the variability in sensor chip preparation. To address this, standardized protocols for the functionalization of gold surfaces with sulphanilic acid must be established. These protocols should specify precise concentrations, reaction times, and environmental conditions to ensure uniform surface coverage and optimal sensor performance.

Quality control measures for SPR sensors begin with the characterization of the gold surface before and after functionalization. Techniques such as atomic force microscopy (AFM) and X-ray photoelectron spectroscopy (XPS) can be employed to verify surface roughness, thickness, and chemical composition. Establishing acceptable ranges for these parameters is crucial for maintaining sensor quality.

The sensitivity and specificity of SPR sensors are key performance indicators that require standardization. Reference analytes with known binding affinities to sulphanilic acid-functionalized surfaces should be identified and used to calibrate sensors across different batches and laboratories. This approach allows for the development of standardized sensitivity metrics and detection limits.

Reproducibility is another critical aspect of quality control in SPR sensing. Inter-laboratory comparisons and round-robin tests can help identify sources of variability and establish best practices. These exercises should include the preparation of sensor chips, sample handling, and data analysis to ensure consistency across different research groups and applications.

Data analysis and interpretation present additional challenges in SPR sensing standardization. Developing standardized algorithms for signal processing, baseline correction, and kinetic analysis is essential for comparing results across different studies. Open-source software platforms can facilitate the adoption of these standardized analysis methods within the research community.

Long-term stability and shelf-life of sulphanilic acid-functionalized SPR sensors must also be addressed through quality control measures. Accelerated aging studies and periodic performance checks can help establish storage conditions and expiration dates for sensor chips, ensuring reliable performance over time.

Finally, the development of certified reference materials (CRMs) for SPR sensing using sulphanilic acid would greatly enhance standardization efforts. These CRMs could serve as benchmarks for sensor performance and aid in the validation of new sensor designs and functionalization methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!