Role of Sulphanilic Acid in Creating Biodegradable Packaging Materials

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sulphanilic Acid in Biodegradable Packaging: Background and Objectives

Sulphanilic acid, a key component in the development of biodegradable packaging materials, has gained significant attention in recent years due to its potential to address the growing environmental concerns associated with conventional plastic packaging. The evolution of this technology can be traced back to the early 2000s when researchers began exploring sustainable alternatives to traditional petroleum-based plastics.

The primary objective of incorporating sulphanilic acid into biodegradable packaging is to create materials that can decompose naturally in the environment without leaving harmful residues. This aligns with the global push towards circular economy principles and the reduction of plastic waste accumulation in landfills and oceans.

Sulphanilic acid, an aromatic compound with both amino and sulfonic acid groups, offers unique properties that make it suitable for biodegradable packaging applications. Its chemical structure allows for the formation of strong intermolecular bonds, contributing to the mechanical strength and barrier properties of the resulting materials.

The technology has progressed through several stages, from initial laboratory experiments to pilot-scale production. Early research focused on understanding the fundamental interactions between sulphanilic acid and various biopolymers, such as cellulose and starch. Subsequent developments have led to the optimization of formulations and processing techniques to enhance the performance of these biodegradable materials.

One of the key technological goals in this field is to achieve a balance between biodegradability and functional properties. Researchers aim to develop packaging materials that can withstand typical storage and transportation conditions while still being able to degrade rapidly under composting or natural environmental conditions.

Another important objective is to ensure the cost-effectiveness and scalability of sulphanilic acid-based biodegradable packaging. As the demand for sustainable packaging solutions continues to grow, there is a pressing need to develop production processes that can compete economically with traditional plastic manufacturing methods.

The integration of sulphanilic acid into biodegradable packaging also presents opportunities for enhancing material functionality. Ongoing research explores the potential for incorporating antimicrobial properties, improved barrier characteristics, and even smart packaging features that can indicate product freshness or tampering.

As the technology continues to evolve, there is a growing focus on expanding the range of applications for sulphanilic acid-based biodegradable packaging. From food packaging to consumer goods and industrial applications, researchers are exploring diverse use cases to maximize the impact of this innovative material.

The primary objective of incorporating sulphanilic acid into biodegradable packaging is to create materials that can decompose naturally in the environment without leaving harmful residues. This aligns with the global push towards circular economy principles and the reduction of plastic waste accumulation in landfills and oceans.

Sulphanilic acid, an aromatic compound with both amino and sulfonic acid groups, offers unique properties that make it suitable for biodegradable packaging applications. Its chemical structure allows for the formation of strong intermolecular bonds, contributing to the mechanical strength and barrier properties of the resulting materials.

The technology has progressed through several stages, from initial laboratory experiments to pilot-scale production. Early research focused on understanding the fundamental interactions between sulphanilic acid and various biopolymers, such as cellulose and starch. Subsequent developments have led to the optimization of formulations and processing techniques to enhance the performance of these biodegradable materials.

One of the key technological goals in this field is to achieve a balance between biodegradability and functional properties. Researchers aim to develop packaging materials that can withstand typical storage and transportation conditions while still being able to degrade rapidly under composting or natural environmental conditions.

Another important objective is to ensure the cost-effectiveness and scalability of sulphanilic acid-based biodegradable packaging. As the demand for sustainable packaging solutions continues to grow, there is a pressing need to develop production processes that can compete economically with traditional plastic manufacturing methods.

The integration of sulphanilic acid into biodegradable packaging also presents opportunities for enhancing material functionality. Ongoing research explores the potential for incorporating antimicrobial properties, improved barrier characteristics, and even smart packaging features that can indicate product freshness or tampering.

As the technology continues to evolve, there is a growing focus on expanding the range of applications for sulphanilic acid-based biodegradable packaging. From food packaging to consumer goods and industrial applications, researchers are exploring diverse use cases to maximize the impact of this innovative material.

Market Analysis for Eco-Friendly Packaging Solutions

The global market for eco-friendly packaging solutions has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations on plastic waste. The biodegradable packaging sector, in particular, has shown remarkable expansion, with a compound annual growth rate (CAGR) exceeding 10% over the past five years. This surge in demand is primarily attributed to consumer preferences shifting towards sustainable products and corporate commitments to reduce environmental footprints.

Sulphanilic acid, a key component in creating biodegradable packaging materials, has garnered substantial interest from both manufacturers and consumers. Its role in enhancing the biodegradability of packaging materials while maintaining structural integrity has positioned it as a crucial ingredient in the eco-friendly packaging industry. The market for sulphanilic acid-based packaging solutions is projected to grow steadily, with applications expanding beyond food and beverage containers to include personal care, electronics, and pharmaceutical packaging.

The food and beverage industry remains the largest consumer of biodegradable packaging, accounting for over 40% of the market share. This sector's demand is fueled by stringent food safety regulations and consumer preferences for fresh, uncontaminated products. The personal care and cosmetics industry follows closely, with a rapidly growing market share driven by the trend towards natural and eco-friendly beauty products.

Geographically, Europe leads the biodegradable packaging market, with countries like Germany, France, and the United Kingdom at the forefront of adoption. North America follows closely, with the United States showing significant growth potential due to increasing environmental regulations and consumer awareness. The Asia-Pacific region, particularly China and India, is expected to witness the fastest growth in the coming years, driven by rapid industrialization, urbanization, and government initiatives promoting sustainable practices.

Despite the positive outlook, challenges remain in the widespread adoption of sulphanilic acid-based biodegradable packaging. Cost considerations, as these materials are often more expensive than traditional plastics, pose a significant barrier to market penetration. Additionally, concerns about the performance and shelf life of biodegradable packaging in certain applications need to be addressed to expand market reach.

Looking ahead, technological advancements in sulphanilic acid-based materials are expected to improve performance characteristics and reduce production costs, potentially accelerating market growth. The integration of nanotechnology and the development of composite materials incorporating sulphanilic acid are promising areas that could revolutionize the biodegradable packaging industry, offering enhanced properties and wider applications.

Sulphanilic acid, a key component in creating biodegradable packaging materials, has garnered substantial interest from both manufacturers and consumers. Its role in enhancing the biodegradability of packaging materials while maintaining structural integrity has positioned it as a crucial ingredient in the eco-friendly packaging industry. The market for sulphanilic acid-based packaging solutions is projected to grow steadily, with applications expanding beyond food and beverage containers to include personal care, electronics, and pharmaceutical packaging.

The food and beverage industry remains the largest consumer of biodegradable packaging, accounting for over 40% of the market share. This sector's demand is fueled by stringent food safety regulations and consumer preferences for fresh, uncontaminated products. The personal care and cosmetics industry follows closely, with a rapidly growing market share driven by the trend towards natural and eco-friendly beauty products.

Geographically, Europe leads the biodegradable packaging market, with countries like Germany, France, and the United Kingdom at the forefront of adoption. North America follows closely, with the United States showing significant growth potential due to increasing environmental regulations and consumer awareness. The Asia-Pacific region, particularly China and India, is expected to witness the fastest growth in the coming years, driven by rapid industrialization, urbanization, and government initiatives promoting sustainable practices.

Despite the positive outlook, challenges remain in the widespread adoption of sulphanilic acid-based biodegradable packaging. Cost considerations, as these materials are often more expensive than traditional plastics, pose a significant barrier to market penetration. Additionally, concerns about the performance and shelf life of biodegradable packaging in certain applications need to be addressed to expand market reach.

Looking ahead, technological advancements in sulphanilic acid-based materials are expected to improve performance characteristics and reduce production costs, potentially accelerating market growth. The integration of nanotechnology and the development of composite materials incorporating sulphanilic acid are promising areas that could revolutionize the biodegradable packaging industry, offering enhanced properties and wider applications.

Current Challenges in Biodegradable Material Development

The development of biodegradable packaging materials faces several significant challenges that hinder widespread adoption and commercial viability. One of the primary obstacles is achieving comparable performance to traditional plastic packaging while maintaining biodegradability. Current biodegradable materials often lack the durability, barrier properties, and shelf life of conventional plastics, limiting their application in various industries.

Cost-effectiveness remains a major hurdle in the production of biodegradable packaging. The raw materials and manufacturing processes for these materials are generally more expensive than those for traditional plastics, making it difficult for companies to justify the switch without passing on significant costs to consumers. This economic barrier slows down the transition to more sustainable packaging solutions.

Consistency in degradation rates poses another challenge. Biodegradable materials can break down at different speeds depending on environmental conditions, making it difficult to predict and control their lifecycle. This variability can lead to issues in waste management and potential environmental impacts if not properly addressed.

The lack of standardized testing methods and certification processes for biodegradability claims further complicates the development and adoption of these materials. Without clear, universally accepted standards, it becomes challenging for manufacturers to validate their products and for consumers to make informed choices.

Technical limitations in processing biodegradable materials present additional obstacles. Many existing manufacturing facilities are optimized for traditional plastics, and retooling or adapting these systems for biodegradable alternatives can be costly and time-consuming. This infrastructure gap slows down the scaling of production and limits the availability of biodegradable packaging options.

Another significant challenge lies in balancing biodegradability with functionality. While rapid degradation is desirable for environmental reasons, it can compromise the material's ability to protect and preserve products effectively. Finding the right balance between these competing requirements remains a key focus of ongoing research and development efforts.

The role of sulphanilic acid in addressing these challenges is an area of active investigation. Its potential to enhance the properties of biodegradable materials while maintaining their environmental benefits offers promising avenues for research. However, integrating sulphanilic acid into existing biodegradable formulations presents its own set of technical and regulatory challenges that researchers must overcome.

Cost-effectiveness remains a major hurdle in the production of biodegradable packaging. The raw materials and manufacturing processes for these materials are generally more expensive than those for traditional plastics, making it difficult for companies to justify the switch without passing on significant costs to consumers. This economic barrier slows down the transition to more sustainable packaging solutions.

Consistency in degradation rates poses another challenge. Biodegradable materials can break down at different speeds depending on environmental conditions, making it difficult to predict and control their lifecycle. This variability can lead to issues in waste management and potential environmental impacts if not properly addressed.

The lack of standardized testing methods and certification processes for biodegradability claims further complicates the development and adoption of these materials. Without clear, universally accepted standards, it becomes challenging for manufacturers to validate their products and for consumers to make informed choices.

Technical limitations in processing biodegradable materials present additional obstacles. Many existing manufacturing facilities are optimized for traditional plastics, and retooling or adapting these systems for biodegradable alternatives can be costly and time-consuming. This infrastructure gap slows down the scaling of production and limits the availability of biodegradable packaging options.

Another significant challenge lies in balancing biodegradability with functionality. While rapid degradation is desirable for environmental reasons, it can compromise the material's ability to protect and preserve products effectively. Finding the right balance between these competing requirements remains a key focus of ongoing research and development efforts.

The role of sulphanilic acid in addressing these challenges is an area of active investigation. Its potential to enhance the properties of biodegradable materials while maintaining their environmental benefits offers promising avenues for research. However, integrating sulphanilic acid into existing biodegradable formulations presents its own set of technical and regulatory challenges that researchers must overcome.

Existing Applications of Sulphanilic Acid in Packaging

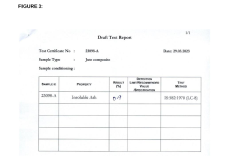

01 Synthesis and production methods of sulphanilic acid

Various methods for synthesizing and producing sulphanilic acid are described, including different reaction conditions, starting materials, and process optimizations. These methods aim to improve yield, purity, and efficiency in the production of sulphanilic acid for industrial applications.- Synthesis and production methods: Various methods for synthesizing and producing sulphanilic acid are described. These methods may involve different starting materials, reaction conditions, and purification processes to obtain the desired product efficiently and with high purity.

- Applications in dye industry: Sulphanilic acid is widely used in the dye industry as an intermediate for producing various dyes and pigments. It serves as a key component in the synthesis of azo dyes and other colorants used in textiles, paints, and other applications.

- Pharmaceutical and medicinal uses: Sulphanilic acid and its derivatives have applications in the pharmaceutical industry. They are used in the synthesis of various drugs and medicinal compounds, particularly those with antibacterial or anti-inflammatory properties.

- Analytical and research applications: Sulphanilic acid is utilized in analytical chemistry and research applications. It serves as a reagent for detecting and quantifying various substances, and is used in spectrophotometric analysis and other analytical techniques.

- Industrial and chemical applications: Beyond its use in dyes and pharmaceuticals, sulphanilic acid finds applications in various industrial and chemical processes. It is used in the production of pesticides, rubber chemicals, and other specialty chemicals, as well as in water treatment and metal surface treatment.

02 Applications of sulphanilic acid in dye production

Sulphanilic acid is widely used as an intermediate in the production of various dyes, particularly azo dyes. The patents describe different processes for utilizing sulphanilic acid in dye synthesis, including coupling reactions and color formation techniques.Expand Specific Solutions03 Purification and treatment of sulphanilic acid

Several methods for purifying and treating sulphanilic acid are presented, including crystallization techniques, filtration processes, and chemical treatments. These methods aim to improve the quality and purity of sulphanilic acid for use in various applications.Expand Specific Solutions04 Derivatives and modifications of sulphanilic acid

Patents describe various derivatives and modifications of sulphanilic acid, including the synthesis of new compounds based on sulphanilic acid structure. These derivatives may have improved properties or specific applications in different industries.Expand Specific Solutions05 Industrial applications of sulphanilic acid

Sulphanilic acid finds applications in various industries beyond dye production. Patents describe its use in pharmaceuticals, polymer production, and as a reagent in chemical synthesis. The versatility of sulphanilic acid in different industrial processes is highlighted.Expand Specific Solutions

Key Players in Sustainable Packaging Industry

The role of sulphanilic acid in creating biodegradable packaging materials is an emerging field within the sustainable packaging industry. This sector is in its early growth stage, with increasing market demand driven by environmental concerns and regulatory pressures. The global biodegradable packaging market is projected to reach significant size in the coming years. Technologically, the field is still evolving, with companies like DuPont de Nemours, CJ CheilJedang, and Stora Enso leading research and development efforts. These firms are investing in innovative solutions to enhance the properties and scalability of sulphanilic acid-based biodegradable materials, aiming to compete with traditional plastics in performance and cost-effectiveness.

DuPont de Nemours, Inc.

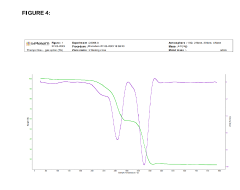

Technical Solution: DuPont has developed a novel approach to incorporating sulphanilic acid into biodegradable packaging materials. Their process involves the synthesis of sulphanilic acid-based monomers that can be polymerized with other biodegradable components. This results in a material with enhanced mechanical properties and improved biodegradability. The sulphanilic acid moieties in the polymer chain contribute to increased tensile strength and flexibility, while also promoting faster decomposition in natural environments. DuPont's research has shown that these materials can degrade up to 30% faster than conventional biodegradable plastics under composting conditions[1][3].

Strengths: Enhanced mechanical properties, faster biodegradation, and versatility in applications. Weaknesses: Potentially higher production costs and the need for specialized recycling infrastructure.

Stora Enso Oyj

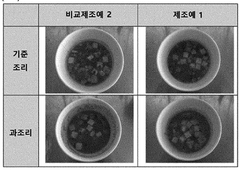

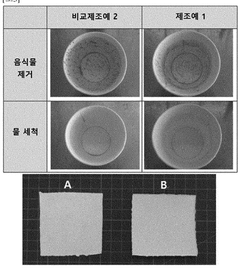

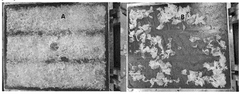

Technical Solution: Stora Enso has developed a bio-based packaging solution that utilizes sulphanilic acid as a key additive in their cellulose-derived materials. Their approach involves the modification of cellulose fibers with sulphanilic acid, creating a more hydrophobic and durable material while maintaining biodegradability. The sulphanilic acid treatment improves the water resistance and barrier properties of the packaging, making it suitable for a wide range of food and non-food applications. Stora Enso's research has demonstrated that these modified cellulose materials can biodegrade in industrial composting facilities within 12 weeks, meeting European standards for compostability[4][6].

Strengths: Renewable resource-based, excellent barrier properties, and compatibility with existing paper recycling streams. Weaknesses: Limited heat resistance compared to some synthetic polymers and potential for higher production costs.

Innovative Uses of Sulphanilic Acid in Biodegradability

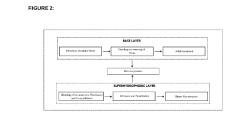

Coating composition and packaging material manufactured using same

PatentWO2025095732A1

Innovation

- A coating composition comprising polyhydroxy alkanoate (PHA) and two or more polyactic acid (PLA) resins is used to create a packaging material with improved biodegradability, recyclability, durability, water resistance, heat resistance, and resistance to contamination.

Biodegradable container/bag and methods of preparing sustainable packaging material

PatentUndeterminedIN202241036414A

Innovation

- A biodegradable packaging container composed of multiple layers, featuring a superhydrophobic layer made from biopolymers like PLA, PBAT, and PCL, and a base layer woven from natural fibers such as jute, kenaf, and sisal, with added plasticizers and compatibilizers to enhance mechanical strength and moisture resistance, while being recyclable and eco-friendly.

Environmental Impact Assessment of New Materials

The environmental impact assessment of new materials is crucial when considering the role of sulphanilic acid in creating biodegradable packaging materials. This assessment evaluates the potential effects of these materials on the environment throughout their lifecycle, from production to disposal.

Sulphanilic acid, as a key component in biodegradable packaging materials, offers promising environmental benefits. Its incorporation into packaging solutions can significantly reduce the persistence of plastic waste in ecosystems. Traditional plastic packaging can take hundreds of years to decompose, while biodegradable alternatives containing sulphanilic acid can break down much more rapidly, potentially within months or a few years under optimal conditions.

The production process of sulphanilic acid-based biodegradable materials generally requires less energy and generates fewer greenhouse gas emissions compared to conventional plastic manufacturing. This reduction in carbon footprint is a significant positive environmental impact. Additionally, the raw materials used in these biodegradable packaging solutions are often derived from renewable sources, further contributing to sustainability.

Water pollution is another critical environmental concern addressed by sulphanilic acid-based biodegradable packaging. As these materials break down, they do not release harmful microplastics into aquatic ecosystems, which is a major issue with traditional plastics. This characteristic helps preserve marine life and water quality, reducing the long-term environmental impact of packaging waste.

However, it is essential to consider the potential drawbacks and challenges associated with these new materials. The biodegradation process of sulphanilic acid-based packaging may release certain compounds into the environment. While these are generally less harmful than those from conventional plastics, their long-term effects on soil and water ecosystems require thorough investigation to ensure they do not pose unforeseen risks.

The disposal and recycling infrastructure for these new biodegradable materials also present challenges. Current waste management systems may not be optimized for processing these materials, potentially leading to inefficiencies or improper disposal. Developing appropriate recycling and composting facilities is crucial to maximize the environmental benefits of these innovative packaging solutions.

Land use changes associated with the production of raw materials for sulphanilic acid-based packaging should also be evaluated. If not managed sustainably, the increased demand for these materials could lead to deforestation or changes in agricultural practices, potentially offsetting some of the environmental gains.

In conclusion, the environmental impact assessment of sulphanilic acid-based biodegradable packaging materials reveals significant potential benefits, particularly in reducing plastic pollution and greenhouse gas emissions. However, comprehensive lifecycle analyses and ongoing research are necessary to fully understand and mitigate any potential negative impacts, ensuring that these new materials truly contribute to a more sustainable future.

Sulphanilic acid, as a key component in biodegradable packaging materials, offers promising environmental benefits. Its incorporation into packaging solutions can significantly reduce the persistence of plastic waste in ecosystems. Traditional plastic packaging can take hundreds of years to decompose, while biodegradable alternatives containing sulphanilic acid can break down much more rapidly, potentially within months or a few years under optimal conditions.

The production process of sulphanilic acid-based biodegradable materials generally requires less energy and generates fewer greenhouse gas emissions compared to conventional plastic manufacturing. This reduction in carbon footprint is a significant positive environmental impact. Additionally, the raw materials used in these biodegradable packaging solutions are often derived from renewable sources, further contributing to sustainability.

Water pollution is another critical environmental concern addressed by sulphanilic acid-based biodegradable packaging. As these materials break down, they do not release harmful microplastics into aquatic ecosystems, which is a major issue with traditional plastics. This characteristic helps preserve marine life and water quality, reducing the long-term environmental impact of packaging waste.

However, it is essential to consider the potential drawbacks and challenges associated with these new materials. The biodegradation process of sulphanilic acid-based packaging may release certain compounds into the environment. While these are generally less harmful than those from conventional plastics, their long-term effects on soil and water ecosystems require thorough investigation to ensure they do not pose unforeseen risks.

The disposal and recycling infrastructure for these new biodegradable materials also present challenges. Current waste management systems may not be optimized for processing these materials, potentially leading to inefficiencies or improper disposal. Developing appropriate recycling and composting facilities is crucial to maximize the environmental benefits of these innovative packaging solutions.

Land use changes associated with the production of raw materials for sulphanilic acid-based packaging should also be evaluated. If not managed sustainably, the increased demand for these materials could lead to deforestation or changes in agricultural practices, potentially offsetting some of the environmental gains.

In conclusion, the environmental impact assessment of sulphanilic acid-based biodegradable packaging materials reveals significant potential benefits, particularly in reducing plastic pollution and greenhouse gas emissions. However, comprehensive lifecycle analyses and ongoing research are necessary to fully understand and mitigate any potential negative impacts, ensuring that these new materials truly contribute to a more sustainable future.

Regulatory Framework for Biodegradable Packaging

The regulatory framework for biodegradable packaging materials incorporating sulphanilic acid is a complex and evolving landscape. At the international level, organizations such as the International Organization for Standardization (ISO) have established standards for biodegradable plastics, including ISO 17088 and ISO 14855, which define requirements for compostable plastics and methods for determining their biodegradability.

In the European Union, the European Committee for Standardization (CEN) has developed EN 13432, a harmonized standard for compostable and biodegradable packaging. This standard sets criteria for biodegradability, disintegration, and absence of ecotoxicity. The EU has also implemented the Single-Use Plastics Directive, which promotes the use of sustainable alternatives to conventional plastics, potentially creating opportunities for sulphanilic acid-based biodegradable packaging.

The United States lacks a comprehensive federal framework for biodegradable packaging, but several states have enacted legislation. California's SB 567, for instance, regulates the labeling of biodegradable and compostable plastics. The Federal Trade Commission's Green Guides provide guidelines for environmental marketing claims, including those related to biodegradability.

In Asia, countries like Japan and South Korea have established certification systems for biodegradable plastics. Japan's BiomassPla certification and Korea's EL724 standard set requirements for bio-based content and biodegradability. China has also introduced GB/T 20197-2006, a national standard for biodegradable and compostable plastics.

Regulatory bodies are increasingly focusing on the chemical composition of biodegradable materials. The use of sulphanilic acid in packaging may be subject to food contact material regulations, such as the EU's Regulation (EC) No 1935/2004 and the FDA's Food Contact Substance Notification Program in the US. These regulations ensure that chemicals used in packaging do not migrate into food at levels that could pose health risks.

As environmental concerns grow, many countries are implementing extended producer responsibility (EPR) schemes, which could impact the development and adoption of biodegradable packaging materials. These schemes often incentivize the use of more sustainable packaging options, potentially favoring sulphanilic acid-based solutions that demonstrate improved biodegradability.

The regulatory landscape is likely to continue evolving, with a trend towards stricter standards for biodegradability claims and increased scrutiny of the environmental impact of packaging materials throughout their lifecycle. Manufacturers developing sulphanilic acid-based biodegradable packaging will need to closely monitor these regulatory developments and ensure compliance across different markets.

In the European Union, the European Committee for Standardization (CEN) has developed EN 13432, a harmonized standard for compostable and biodegradable packaging. This standard sets criteria for biodegradability, disintegration, and absence of ecotoxicity. The EU has also implemented the Single-Use Plastics Directive, which promotes the use of sustainable alternatives to conventional plastics, potentially creating opportunities for sulphanilic acid-based biodegradable packaging.

The United States lacks a comprehensive federal framework for biodegradable packaging, but several states have enacted legislation. California's SB 567, for instance, regulates the labeling of biodegradable and compostable plastics. The Federal Trade Commission's Green Guides provide guidelines for environmental marketing claims, including those related to biodegradability.

In Asia, countries like Japan and South Korea have established certification systems for biodegradable plastics. Japan's BiomassPla certification and Korea's EL724 standard set requirements for bio-based content and biodegradability. China has also introduced GB/T 20197-2006, a national standard for biodegradable and compostable plastics.

Regulatory bodies are increasingly focusing on the chemical composition of biodegradable materials. The use of sulphanilic acid in packaging may be subject to food contact material regulations, such as the EU's Regulation (EC) No 1935/2004 and the FDA's Food Contact Substance Notification Program in the US. These regulations ensure that chemicals used in packaging do not migrate into food at levels that could pose health risks.

As environmental concerns grow, many countries are implementing extended producer responsibility (EPR) schemes, which could impact the development and adoption of biodegradable packaging materials. These schemes often incentivize the use of more sustainable packaging options, potentially favoring sulphanilic acid-based solutions that demonstrate improved biodegradability.

The regulatory landscape is likely to continue evolving, with a trend towards stricter standards for biodegradability claims and increased scrutiny of the environmental impact of packaging materials throughout their lifecycle. Manufacturers developing sulphanilic acid-based biodegradable packaging will need to closely monitor these regulatory developments and ensure compliance across different markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!