Exploring Polysilane for High-Performance Coatings

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane Coatings Background and Objectives

Polysilanes have emerged as a promising class of materials for high-performance coatings, attracting significant attention in both academic research and industrial applications. The development of polysilane coatings can be traced back to the 1980s when researchers first recognized their unique optical and electronic properties. Since then, the field has witnessed substantial growth, driven by the increasing demand for advanced coating materials with superior performance characteristics.

The evolution of polysilane technology has been marked by several key milestones. Initially, the focus was on understanding the fundamental properties of these silicon-based polymers, including their molecular structure, synthesis methods, and basic physical characteristics. As research progressed, scientists began to explore the potential applications of polysilanes in various fields, with coatings emerging as a particularly promising area.

One of the primary drivers behind the interest in polysilane coatings is their exceptional combination of properties. These materials exhibit high thermal stability, excellent optical transparency, and remarkable resistance to environmental degradation. Additionally, polysilanes possess unique electronic properties due to their σ-conjugated backbone, which allows for efficient charge transport and energy transfer along the polymer chain.

The current technological landscape for polysilane coatings is characterized by ongoing efforts to optimize their performance and expand their range of applications. Researchers are actively working on improving synthesis techniques to achieve better control over molecular weight, polydispersity, and side-group functionalization. These advancements aim to enhance the processability and tailor the properties of polysilane coatings for specific end-use requirements.

The objectives of exploring polysilanes for high-performance coatings are multifaceted. Firstly, there is a strong focus on developing coatings with enhanced durability and longevity, particularly in harsh environments. This includes improving resistance to UV radiation, chemical exposure, and mechanical stress. Secondly, researchers are investigating ways to leverage the unique electronic properties of polysilanes to create smart coatings with responsive or self-healing capabilities.

Another key objective is to expand the application range of polysilane coatings. While they have already shown promise in areas such as optical coatings, protective layers for electronics, and anti-corrosion coatings, there is significant potential for their use in emerging fields like flexible electronics, photovoltaics, and biomedical devices. Achieving these goals requires a comprehensive understanding of structure-property relationships and the development of novel processing techniques.

The evolution of polysilane technology has been marked by several key milestones. Initially, the focus was on understanding the fundamental properties of these silicon-based polymers, including their molecular structure, synthesis methods, and basic physical characteristics. As research progressed, scientists began to explore the potential applications of polysilanes in various fields, with coatings emerging as a particularly promising area.

One of the primary drivers behind the interest in polysilane coatings is their exceptional combination of properties. These materials exhibit high thermal stability, excellent optical transparency, and remarkable resistance to environmental degradation. Additionally, polysilanes possess unique electronic properties due to their σ-conjugated backbone, which allows for efficient charge transport and energy transfer along the polymer chain.

The current technological landscape for polysilane coatings is characterized by ongoing efforts to optimize their performance and expand their range of applications. Researchers are actively working on improving synthesis techniques to achieve better control over molecular weight, polydispersity, and side-group functionalization. These advancements aim to enhance the processability and tailor the properties of polysilane coatings for specific end-use requirements.

The objectives of exploring polysilanes for high-performance coatings are multifaceted. Firstly, there is a strong focus on developing coatings with enhanced durability and longevity, particularly in harsh environments. This includes improving resistance to UV radiation, chemical exposure, and mechanical stress. Secondly, researchers are investigating ways to leverage the unique electronic properties of polysilanes to create smart coatings with responsive or self-healing capabilities.

Another key objective is to expand the application range of polysilane coatings. While they have already shown promise in areas such as optical coatings, protective layers for electronics, and anti-corrosion coatings, there is significant potential for their use in emerging fields like flexible electronics, photovoltaics, and biomedical devices. Achieving these goals requires a comprehensive understanding of structure-property relationships and the development of novel processing techniques.

Market Analysis for High-Performance Coatings

The high-performance coatings market has been experiencing significant growth in recent years, driven by increasing demand across various industries such as automotive, aerospace, construction, and industrial manufacturing. The global market for high-performance coatings was valued at approximately $80 billion in 2020 and is projected to reach $105 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.5%.

The automotive sector remains a key driver of demand for high-performance coatings, as manufacturers seek innovative solutions to enhance vehicle aesthetics, durability, and fuel efficiency. The aerospace industry also contributes substantially to market growth, with a rising need for coatings that can withstand extreme temperatures and harsh environmental conditions.

In the construction industry, there is a growing trend towards sustainable and energy-efficient buildings, leading to increased adoption of high-performance coatings that offer thermal insulation and weather resistance properties. The industrial sector, including oil and gas, marine, and power generation, continues to drive demand for coatings that provide corrosion protection and extend the lifespan of equipment and infrastructure.

Geographically, Asia-Pacific dominates the high-performance coatings market, accounting for over 40% of global market share. This is primarily due to rapid industrialization, urbanization, and infrastructure development in countries like China and India. North America and Europe follow closely, with mature markets characterized by stringent environmental regulations and a focus on technological advancements.

The market for polysilane-based high-performance coatings is still in its nascent stage but shows promising growth potential. Polysilanes offer unique properties such as high thermal stability, excellent adhesion, and superior UV resistance, making them attractive for various applications. The automotive and electronics industries are particularly interested in polysilane coatings for their potential to enhance product performance and durability.

Key market trends include a shift towards environmentally friendly and low-VOC (volatile organic compound) coatings, driven by stringent regulations and growing consumer awareness. This trend aligns well with the development of polysilane-based coatings, which can potentially offer improved environmental profiles compared to traditional coating technologies.

Another significant trend is the increasing focus on smart coatings with self-healing, self-cleaning, or sensing capabilities. While polysilane coatings are not yet widely commercialized in this segment, ongoing research suggests potential applications in developing such advanced functionalities.

The automotive sector remains a key driver of demand for high-performance coatings, as manufacturers seek innovative solutions to enhance vehicle aesthetics, durability, and fuel efficiency. The aerospace industry also contributes substantially to market growth, with a rising need for coatings that can withstand extreme temperatures and harsh environmental conditions.

In the construction industry, there is a growing trend towards sustainable and energy-efficient buildings, leading to increased adoption of high-performance coatings that offer thermal insulation and weather resistance properties. The industrial sector, including oil and gas, marine, and power generation, continues to drive demand for coatings that provide corrosion protection and extend the lifespan of equipment and infrastructure.

Geographically, Asia-Pacific dominates the high-performance coatings market, accounting for over 40% of global market share. This is primarily due to rapid industrialization, urbanization, and infrastructure development in countries like China and India. North America and Europe follow closely, with mature markets characterized by stringent environmental regulations and a focus on technological advancements.

The market for polysilane-based high-performance coatings is still in its nascent stage but shows promising growth potential. Polysilanes offer unique properties such as high thermal stability, excellent adhesion, and superior UV resistance, making them attractive for various applications. The automotive and electronics industries are particularly interested in polysilane coatings for their potential to enhance product performance and durability.

Key market trends include a shift towards environmentally friendly and low-VOC (volatile organic compound) coatings, driven by stringent regulations and growing consumer awareness. This trend aligns well with the development of polysilane-based coatings, which can potentially offer improved environmental profiles compared to traditional coating technologies.

Another significant trend is the increasing focus on smart coatings with self-healing, self-cleaning, or sensing capabilities. While polysilane coatings are not yet widely commercialized in this segment, ongoing research suggests potential applications in developing such advanced functionalities.

Polysilane Technology Status and Challenges

Polysilane technology has made significant strides in recent years, particularly in the field of high-performance coatings. However, several challenges remain that hinder its widespread adoption and full potential realization. The current status of polysilane technology is characterized by a mix of promising advancements and persistent obstacles.

One of the primary challenges facing polysilane technology is the complexity of synthesis and processing. While researchers have developed various methods for polysilane production, including Wurtz-type coupling reactions and catalytic dehydrogenative coupling, these processes often involve harsh conditions and yield products with limited molecular weight control. This lack of precise control over molecular structure and weight distribution can lead to inconsistent performance in coating applications.

Another significant hurdle is the stability of polysilanes under ambient conditions. Many polysilane structures are susceptible to oxidation and photodegradation, which can compromise their long-term performance as coatings. This sensitivity to environmental factors necessitates the development of more robust polysilane architectures or the incorporation of stabilizing additives, both of which present their own technical challenges.

The scalability of polysilane production remains a concern for industrial applications. Current synthesis methods are often limited to laboratory-scale production, and scaling up these processes while maintaining product quality and cost-effectiveness is a major challenge. This limitation has restricted the availability of polysilanes for large-scale coating applications and hindered their commercial viability.

Despite these challenges, polysilane technology has shown remarkable potential in several areas. The unique electronic properties of polysilanes, stemming from their σ-conjugated backbone, make them excellent candidates for optoelectronic applications. In the context of high-performance coatings, polysilanes have demonstrated promising characteristics such as high thermal stability, excellent adhesion to various substrates, and tunable optical properties.

Recent research has focused on addressing the stability issues of polysilanes through the development of novel molecular designs. For instance, the incorporation of bulky side groups or the creation of hybrid organic-inorganic structures has shown promise in enhancing the environmental stability of polysilane-based coatings. Additionally, advances in controlled polymerization techniques are gradually improving the ability to tailor polysilane molecular weights and architectures.

The global distribution of polysilane technology research is concentrated in a few key regions, with Japan, the United States, and several European countries leading the way. This geographical concentration of expertise presents both opportunities for collaboration and challenges in terms of technology transfer and global adoption.

In conclusion, while polysilane technology for high-performance coatings faces several significant challenges, ongoing research and development efforts are steadily addressing these issues. The field remains dynamic, with potential breakthroughs in synthesis, stability, and scalability on the horizon, promising to unlock the full potential of polysilanes in advanced coating applications.

One of the primary challenges facing polysilane technology is the complexity of synthesis and processing. While researchers have developed various methods for polysilane production, including Wurtz-type coupling reactions and catalytic dehydrogenative coupling, these processes often involve harsh conditions and yield products with limited molecular weight control. This lack of precise control over molecular structure and weight distribution can lead to inconsistent performance in coating applications.

Another significant hurdle is the stability of polysilanes under ambient conditions. Many polysilane structures are susceptible to oxidation and photodegradation, which can compromise their long-term performance as coatings. This sensitivity to environmental factors necessitates the development of more robust polysilane architectures or the incorporation of stabilizing additives, both of which present their own technical challenges.

The scalability of polysilane production remains a concern for industrial applications. Current synthesis methods are often limited to laboratory-scale production, and scaling up these processes while maintaining product quality and cost-effectiveness is a major challenge. This limitation has restricted the availability of polysilanes for large-scale coating applications and hindered their commercial viability.

Despite these challenges, polysilane technology has shown remarkable potential in several areas. The unique electronic properties of polysilanes, stemming from their σ-conjugated backbone, make them excellent candidates for optoelectronic applications. In the context of high-performance coatings, polysilanes have demonstrated promising characteristics such as high thermal stability, excellent adhesion to various substrates, and tunable optical properties.

Recent research has focused on addressing the stability issues of polysilanes through the development of novel molecular designs. For instance, the incorporation of bulky side groups or the creation of hybrid organic-inorganic structures has shown promise in enhancing the environmental stability of polysilane-based coatings. Additionally, advances in controlled polymerization techniques are gradually improving the ability to tailor polysilane molecular weights and architectures.

The global distribution of polysilane technology research is concentrated in a few key regions, with Japan, the United States, and several European countries leading the way. This geographical concentration of expertise presents both opportunities for collaboration and challenges in terms of technology transfer and global adoption.

In conclusion, while polysilane technology for high-performance coatings faces several significant challenges, ongoing research and development efforts are steadily addressing these issues. The field remains dynamic, with potential breakthroughs in synthesis, stability, and scalability on the horizon, promising to unlock the full potential of polysilanes in advanced coating applications.

Current Polysilane Coating Solutions

01 Optical and electronic properties of polysilanes

Polysilanes exhibit unique optical and electronic properties, making them suitable for various applications. They possess high photosensitivity, good charge transport capabilities, and can be used as photoresists or in optoelectronic devices. The performance of polysilanes can be tuned by modifying their molecular structure and composition.- Optical and electronic properties of polysilanes: Polysilanes exhibit unique optical and electronic properties, making them suitable for various applications. They possess high photosensitivity, good charge transport capabilities, and can be used as photoresists or in optoelectronic devices. The performance of polysilanes can be tuned by modifying their molecular structure and composition.

- Polysilane synthesis and processing methods: Various methods for synthesizing and processing polysilanes have been developed to enhance their performance. These include novel polymerization techniques, purification processes, and methods for controlling molecular weight and distribution. Improved synthesis and processing methods can lead to polysilanes with superior properties and performance characteristics.

- Applications of polysilanes in coatings and films: Polysilanes have shown promising performance in coating and film applications. They can be used to create protective coatings, barrier films, and functional layers in various industries. The unique properties of polysilanes, such as their thermal stability and optical characteristics, make them suitable for specialized coating applications.

- Polysilane-based photoresists and lithography: Polysilanes have demonstrated excellent performance as photoresist materials in lithography processes. Their high photosensitivity and good etching resistance make them suitable for use in semiconductor manufacturing and other microfabrication applications. The development of novel polysilane-based photoresists has led to improvements in resolution and pattern transfer.

- Functionalization and modification of polysilanes: The performance of polysilanes can be enhanced through functionalization and modification of their chemical structure. This includes the incorporation of various functional groups, copolymerization with other monomers, and the creation of hybrid materials. These modifications can lead to improved thermal stability, mechanical properties, and tailored electronic characteristics.

02 Synthesis and processing of polysilanes

Various methods for synthesizing and processing polysilanes have been developed to enhance their performance. These include novel polymerization techniques, purification processes, and methods for controlling molecular weight and distribution. Improved synthesis and processing techniques can lead to polysilanes with enhanced thermal stability, solubility, and film-forming properties.Expand Specific Solutions03 Polysilane-based composites and blends

Combining polysilanes with other materials to form composites or blends can enhance their overall performance. These combinations can improve mechanical properties, thermal stability, and processability. Polysilane-based composites and blends find applications in areas such as coatings, adhesives, and high-performance materials.Expand Specific Solutions04 Polysilanes in photolithography and semiconductor applications

Polysilanes have shown promising performance in photolithography and semiconductor applications. They can be used as photoresists, offering high resolution and sensitivity. Additionally, polysilanes can serve as precursors for silicon-based materials in semiconductor manufacturing, providing unique properties and processing advantages.Expand Specific Solutions05 Functionalization and modification of polysilanes

The performance of polysilanes can be further enhanced through functionalization and modification. This includes the incorporation of various functional groups, side-chain modifications, and copolymerization with other monomers. These modifications can improve solubility, thermal stability, and introduce new properties such as increased reactivity or specific interactions with other materials.Expand Specific Solutions

Key Players in Polysilane Coating Industry

The polysilane high-performance coatings market is in an early growth stage, with increasing interest from various industries due to the material's unique properties. The global market size is estimated to be relatively small but growing rapidly, driven by demand for advanced coating solutions in electronics, automotive, and aerospace sectors. Technologically, polysilane coatings are still evolving, with ongoing research to optimize performance and scalability. Key players like PPG Industries, Shin-Etsu Chemical, and 3M are investing in R&D to develop proprietary formulations and application methods. Smaller specialized firms like Ecosil Technologies are also contributing to innovation in this niche field. As the technology matures, we can expect increased competition and market expansion in the coming years.

Evonik Operations GmbH

Technical Solution: Evonik has made significant strides in polysilane technology for high-performance coatings. Their research focuses on developing hybrid organic-inorganic coatings using polysilanes as key components. Evonik's polysilane-based coatings exhibit exceptional hardness, abrasion resistance, and chemical resistance[7]. The company has successfully incorporated polysilanes into sol-gel coating systems, resulting in improved durability and thermal stability. Evonik's polysilane coatings also demonstrate excellent optical properties, including high transparency and tunable refractive indices[8]. They have developed specialized polysilane formulations for electronics and semiconductor applications, providing protection against moisture and contaminants[9].

Strengths: Strong R&D capabilities, diverse product portfolio, and expertise in specialty chemicals. Weaknesses: Potential scalability challenges for some specialized polysilane formulations, competition from established coating technologies.

PPG Industries Ohio, Inc.

Technical Solution: PPG Industries has developed innovative polysilane-based coatings for various industrial applications. Their research focuses on incorporating polysilanes into existing coating systems to enhance performance. PPG's polysilane coatings exhibit improved scratch resistance, weatherability, and chemical resistance compared to conventional coatings[4]. The company has successfully applied these coatings in automotive, aerospace, and marine industries. PPG's polysilane coatings also demonstrate self-healing properties, allowing minor scratches to repair themselves over time[5]. Additionally, they have developed polysilane-based primers that significantly improve adhesion and corrosion resistance on metal substrates[6].

Strengths: Extensive experience in coating formulations, global distribution network, and strong presence in multiple industries. Weaknesses: Potential higher costs associated with polysilane incorporation, need for customer education on new technology.

Core Innovations in Polysilane Synthesis

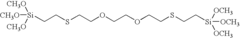

Sulfur modified silanes for the elaboration of high refractive index materials

PatentWO2009138853A1

Innovation

- A process involving the mixing of a polythiol and an alkenyl silane, followed by thiol-ene addition under UV radiation or heat, to produce polysulfide polysilanes with refractive indices ranging from 1.47 to 1.55, which can be further hydrolyzed to form high refractive index coatings and bulk materials with improved mechanical properties.

Sulfur modified silanes for the elaboration of high refractive index materials

PatentActiveUS7867577B2

Innovation

- A polysulfide polysilane is synthesized through a thiol-ene addition process, which can be hydrolyzed to form a high refractive index coating or bulk material, optionally combined with other silanes like Glymo and infused with inorganic nanoparticles, and then processed through a sol-gel method for enhanced mechanical and optical properties.

Environmental Impact of Polysilane Coatings

The environmental impact of polysilane coatings is a critical consideration in their development and application. These coatings, while offering high-performance characteristics, also present potential environmental concerns that must be carefully evaluated.

One of the primary environmental advantages of polysilane coatings is their potential for improved durability and longevity compared to traditional coating materials. This increased lifespan can lead to reduced waste generation and resource consumption over time, as fewer reapplications are necessary. Additionally, some polysilane formulations have demonstrated enhanced resistance to weathering and chemical degradation, which may further extend their useful life and minimize the need for frequent replacements.

However, the production process of polysilane coatings raises several environmental concerns. The synthesis of polysilanes often involves energy-intensive processes and the use of potentially hazardous chemicals. These factors contribute to increased carbon emissions and the risk of environmental contamination if proper safety measures are not implemented. Furthermore, the disposal of waste products from polysilane manufacturing requires careful management to prevent soil and water pollution.

The application of polysilane coatings also presents environmental challenges. Many formulations contain volatile organic compounds (VOCs) that can be released into the atmosphere during application and curing. These emissions contribute to air pollution and may have adverse effects on both human health and the environment. Efforts are ongoing to develop low-VOC and VOC-free polysilane coating alternatives to mitigate these issues.

End-of-life considerations for polysilane coatings are another important aspect of their environmental impact. The disposal or recycling of materials coated with polysilanes may present challenges due to the complex chemical nature of these coatings. Proper recycling techniques and disposal methods need to be developed to ensure that these materials do not contribute to long-term environmental pollution.

On the positive side, some polysilane coatings have shown potential for enhancing the energy efficiency of buildings and vehicles. By improving thermal insulation and reducing heat transfer, these coatings can contribute to lower energy consumption and reduced greenhouse gas emissions over the lifetime of the coated products.

Research is ongoing to develop more environmentally friendly polysilane coatings. This includes exploring bio-based precursors, improving production efficiency to reduce energy consumption, and investigating methods for recycling and reusing polysilane materials. These efforts aim to balance the high-performance characteristics of polysilane coatings with reduced environmental impact, aligning with global sustainability goals.

One of the primary environmental advantages of polysilane coatings is their potential for improved durability and longevity compared to traditional coating materials. This increased lifespan can lead to reduced waste generation and resource consumption over time, as fewer reapplications are necessary. Additionally, some polysilane formulations have demonstrated enhanced resistance to weathering and chemical degradation, which may further extend their useful life and minimize the need for frequent replacements.

However, the production process of polysilane coatings raises several environmental concerns. The synthesis of polysilanes often involves energy-intensive processes and the use of potentially hazardous chemicals. These factors contribute to increased carbon emissions and the risk of environmental contamination if proper safety measures are not implemented. Furthermore, the disposal of waste products from polysilane manufacturing requires careful management to prevent soil and water pollution.

The application of polysilane coatings also presents environmental challenges. Many formulations contain volatile organic compounds (VOCs) that can be released into the atmosphere during application and curing. These emissions contribute to air pollution and may have adverse effects on both human health and the environment. Efforts are ongoing to develop low-VOC and VOC-free polysilane coating alternatives to mitigate these issues.

End-of-life considerations for polysilane coatings are another important aspect of their environmental impact. The disposal or recycling of materials coated with polysilanes may present challenges due to the complex chemical nature of these coatings. Proper recycling techniques and disposal methods need to be developed to ensure that these materials do not contribute to long-term environmental pollution.

On the positive side, some polysilane coatings have shown potential for enhancing the energy efficiency of buildings and vehicles. By improving thermal insulation and reducing heat transfer, these coatings can contribute to lower energy consumption and reduced greenhouse gas emissions over the lifetime of the coated products.

Research is ongoing to develop more environmentally friendly polysilane coatings. This includes exploring bio-based precursors, improving production efficiency to reduce energy consumption, and investigating methods for recycling and reusing polysilane materials. These efforts aim to balance the high-performance characteristics of polysilane coatings with reduced environmental impact, aligning with global sustainability goals.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for polysilane-based high-performance coatings present both challenges and opportunities. As the demand for these advanced materials grows, it becomes crucial to develop efficient and cost-effective production methods that can be scaled up to meet industrial requirements.

One of the primary challenges in scaling up polysilane production is the complexity of the synthesis process. Traditional methods often involve the use of expensive catalysts and require precise control over reaction conditions. To address this, researchers are exploring novel synthetic routes that utilize more readily available precursors and employ less demanding reaction conditions. These efforts aim to simplify the manufacturing process and reduce production costs, making large-scale production more feasible.

Another critical aspect of scalability is the development of continuous flow processes. Batch production, while suitable for small-scale synthesis, can be inefficient and inconsistent when scaled up. Continuous flow reactors offer several advantages, including improved heat and mass transfer, better control over reaction parameters, and the potential for automation. Implementing such systems for polysilane synthesis could significantly enhance production efficiency and product quality.

The choice of solvents and reagents also plays a crucial role in the scalability of polysilane manufacturing. Environmentally friendly and recyclable solvents are being investigated to reduce waste and improve the sustainability of the production process. Additionally, the use of less hazardous reagents can simplify handling procedures and reduce safety concerns in large-scale manufacturing settings.

Quality control and characterization techniques must be adapted for high-volume production. In-line monitoring systems and rapid analytical methods are being developed to ensure consistent product quality without compromising production speed. These advancements are essential for maintaining the high performance of polysilane coatings in industrial applications.

The integration of polysilane coating processes into existing manufacturing lines presents another challenge. Compatibility with current coating equipment and techniques is crucial for widespread adoption. Research is ongoing to optimize coating formulations and application methods that can be seamlessly incorporated into established production workflows.

As the technology matures, considerations for end-of-life management and recycling of polysilane coatings become increasingly important. Developing efficient recycling processes and exploring biodegradable alternatives can enhance the overall sustainability of these high-performance materials.

In conclusion, while challenges exist in scaling up polysilane production for high-performance coatings, ongoing research and technological advancements are paving the way for more efficient and sustainable manufacturing processes. The successful implementation of these strategies will be crucial in realizing the full potential of polysilane coatings in various industrial applications.

One of the primary challenges in scaling up polysilane production is the complexity of the synthesis process. Traditional methods often involve the use of expensive catalysts and require precise control over reaction conditions. To address this, researchers are exploring novel synthetic routes that utilize more readily available precursors and employ less demanding reaction conditions. These efforts aim to simplify the manufacturing process and reduce production costs, making large-scale production more feasible.

Another critical aspect of scalability is the development of continuous flow processes. Batch production, while suitable for small-scale synthesis, can be inefficient and inconsistent when scaled up. Continuous flow reactors offer several advantages, including improved heat and mass transfer, better control over reaction parameters, and the potential for automation. Implementing such systems for polysilane synthesis could significantly enhance production efficiency and product quality.

The choice of solvents and reagents also plays a crucial role in the scalability of polysilane manufacturing. Environmentally friendly and recyclable solvents are being investigated to reduce waste and improve the sustainability of the production process. Additionally, the use of less hazardous reagents can simplify handling procedures and reduce safety concerns in large-scale manufacturing settings.

Quality control and characterization techniques must be adapted for high-volume production. In-line monitoring systems and rapid analytical methods are being developed to ensure consistent product quality without compromising production speed. These advancements are essential for maintaining the high performance of polysilane coatings in industrial applications.

The integration of polysilane coating processes into existing manufacturing lines presents another challenge. Compatibility with current coating equipment and techniques is crucial for widespread adoption. Research is ongoing to optimize coating formulations and application methods that can be seamlessly incorporated into established production workflows.

As the technology matures, considerations for end-of-life management and recycling of polysilane coatings become increasingly important. Developing efficient recycling processes and exploring biodegradable alternatives can enhance the overall sustainability of these high-performance materials.

In conclusion, while challenges exist in scaling up polysilane production for high-performance coatings, ongoing research and technological advancements are paving the way for more efficient and sustainable manufacturing processes. The successful implementation of these strategies will be crucial in realizing the full potential of polysilane coatings in various industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!