Polysilane Development: Key Breakthroughs and Insights

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane Evolution

Polysilanes have undergone a remarkable evolution since their initial discovery in the mid-20th century. The journey of these unique silicon-based polymers began with the groundbreaking work of Kipping and colleagues in the 1920s, who first synthesized and characterized organosilicon compounds. However, it wasn't until the 1960s that significant progress was made in the field of polysilanes.

The 1970s marked a pivotal era in polysilane development, with researchers like Yajima and West making substantial contributions. Yajima's work on the thermal conversion of polysilanes to silicon carbide fibers opened up new avenues for high-performance materials. Concurrently, West's investigations into the electronic properties of polysilanes laid the foundation for their potential use in optoelectronic applications.

The 1980s witnessed a surge in polysilane research, driven by the discovery of their unique σ-conjugation and associated optical and electronic properties. This period saw the development of various synthetic methods, including Wurtz coupling and catalytic dehydrogenative coupling, which greatly expanded the range of accessible polysilane structures.

In the 1990s and early 2000s, the focus shifted towards understanding and manipulating the relationship between polysilane structure and properties. Researchers explored the effects of side-group substitution, molecular weight, and polymer architecture on optical and electronic characteristics. This era also saw the emergence of polysilanes as potential photoresists for microlithography and as precursors for silicon-based materials.

The past two decades have been characterized by a more application-oriented approach to polysilane research. Advances in controlled polymerization techniques have enabled the synthesis of well-defined polysilane architectures, including block copolymers and hyperbranched structures. These developments have paved the way for novel applications in areas such as photonics, energy storage, and nanomaterials.

Recent years have seen a renewed interest in polysilanes as precursors for silicon-based nanomaterials. The controlled thermal decomposition of polysilanes has been utilized to produce silicon nanoparticles, nanowires, and porous silicon structures with tailored properties. This approach has shown promise in fields ranging from photovoltaics to biomedical imaging.

The evolution of polysilane chemistry has also been marked by significant improvements in characterization techniques. Advanced spectroscopic methods, such as solid-state NMR and synchrotron-based X-ray techniques, have provided deeper insights into polysilane structure and dynamics, enabling more precise structure-property correlations.

Looking ahead, the future of polysilane development appears bright, with emerging opportunities in fields like quantum computing, flexible electronics, and sustainable materials. As researchers continue to explore new synthetic strategies and applications, polysilanes are poised to play an increasingly important role in advanced materials science and technology.

The 1970s marked a pivotal era in polysilane development, with researchers like Yajima and West making substantial contributions. Yajima's work on the thermal conversion of polysilanes to silicon carbide fibers opened up new avenues for high-performance materials. Concurrently, West's investigations into the electronic properties of polysilanes laid the foundation for their potential use in optoelectronic applications.

The 1980s witnessed a surge in polysilane research, driven by the discovery of their unique σ-conjugation and associated optical and electronic properties. This period saw the development of various synthetic methods, including Wurtz coupling and catalytic dehydrogenative coupling, which greatly expanded the range of accessible polysilane structures.

In the 1990s and early 2000s, the focus shifted towards understanding and manipulating the relationship between polysilane structure and properties. Researchers explored the effects of side-group substitution, molecular weight, and polymer architecture on optical and electronic characteristics. This era also saw the emergence of polysilanes as potential photoresists for microlithography and as precursors for silicon-based materials.

The past two decades have been characterized by a more application-oriented approach to polysilane research. Advances in controlled polymerization techniques have enabled the synthesis of well-defined polysilane architectures, including block copolymers and hyperbranched structures. These developments have paved the way for novel applications in areas such as photonics, energy storage, and nanomaterials.

Recent years have seen a renewed interest in polysilanes as precursors for silicon-based nanomaterials. The controlled thermal decomposition of polysilanes has been utilized to produce silicon nanoparticles, nanowires, and porous silicon structures with tailored properties. This approach has shown promise in fields ranging from photovoltaics to biomedical imaging.

The evolution of polysilane chemistry has also been marked by significant improvements in characterization techniques. Advanced spectroscopic methods, such as solid-state NMR and synchrotron-based X-ray techniques, have provided deeper insights into polysilane structure and dynamics, enabling more precise structure-property correlations.

Looking ahead, the future of polysilane development appears bright, with emerging opportunities in fields like quantum computing, flexible electronics, and sustainable materials. As researchers continue to explore new synthetic strategies and applications, polysilanes are poised to play an increasingly important role in advanced materials science and technology.

Market Applications

Polysilanes have emerged as versatile materials with a wide range of potential market applications across various industries. In the electronics sector, these silicon-based polymers show promise as photoresists for semiconductor manufacturing, offering high resolution and sensitivity in lithography processes. Their unique optical and electronic properties make them suitable for use in organic light-emitting diodes (OLEDs) and photovoltaic devices, potentially enhancing the efficiency and performance of next-generation display technologies and solar cells.

The aerospace and automotive industries are exploring polysilanes as precursors for silicon carbide ceramics, which are valued for their high temperature resistance and mechanical strength. These materials could lead to the development of more durable and lightweight components for aircraft and vehicles, contributing to improved fuel efficiency and overall performance.

In the field of nanotechnology, polysilanes serve as building blocks for the synthesis of silicon nanoparticles and nanowires. These nanostructures have potential applications in quantum computing, advanced sensors, and high-performance batteries, opening up new possibilities for miniaturization and enhanced functionality in electronic devices.

The biomedical sector is investigating polysilanes for drug delivery systems and tissue engineering scaffolds. Their biocompatibility and ability to be functionalized with various bioactive molecules make them attractive candidates for controlled release formulations and regenerative medicine applications.

In the coatings industry, polysilanes are being developed as high-performance protective coatings for metals and other surfaces. Their excellent adhesion properties, chemical resistance, and ability to form thin, uniform films make them suitable for corrosion protection in harsh environments, as well as for anti-fouling coatings in marine applications.

The energy storage sector is exploring polysilanes as potential anode materials for lithium-ion batteries. Their unique structure and properties could lead to improved battery capacity, faster charging rates, and longer cycle life, addressing key challenges in the development of next-generation energy storage solutions.

As environmental concerns grow, polysilanes are being investigated for their potential in water treatment applications. Their ability to form porous networks and interact with various contaminants makes them promising materials for advanced filtration systems and environmental remediation technologies.

The aerospace and automotive industries are exploring polysilanes as precursors for silicon carbide ceramics, which are valued for their high temperature resistance and mechanical strength. These materials could lead to the development of more durable and lightweight components for aircraft and vehicles, contributing to improved fuel efficiency and overall performance.

In the field of nanotechnology, polysilanes serve as building blocks for the synthesis of silicon nanoparticles and nanowires. These nanostructures have potential applications in quantum computing, advanced sensors, and high-performance batteries, opening up new possibilities for miniaturization and enhanced functionality in electronic devices.

The biomedical sector is investigating polysilanes for drug delivery systems and tissue engineering scaffolds. Their biocompatibility and ability to be functionalized with various bioactive molecules make them attractive candidates for controlled release formulations and regenerative medicine applications.

In the coatings industry, polysilanes are being developed as high-performance protective coatings for metals and other surfaces. Their excellent adhesion properties, chemical resistance, and ability to form thin, uniform films make them suitable for corrosion protection in harsh environments, as well as for anti-fouling coatings in marine applications.

The energy storage sector is exploring polysilanes as potential anode materials for lithium-ion batteries. Their unique structure and properties could lead to improved battery capacity, faster charging rates, and longer cycle life, addressing key challenges in the development of next-generation energy storage solutions.

As environmental concerns grow, polysilanes are being investigated for their potential in water treatment applications. Their ability to form porous networks and interact with various contaminants makes them promising materials for advanced filtration systems and environmental remediation technologies.

Technical Challenges

The development of polysilanes faces several significant technical challenges that have hindered their widespread adoption and commercialization. One of the primary obstacles is the difficulty in synthesizing high molecular weight polysilanes with controlled structures. Traditional methods often result in low molecular weight polymers or a broad distribution of molecular weights, limiting their potential applications.

Another major challenge lies in the stability of polysilanes. These materials are highly sensitive to oxidation and photodegradation, which can lead to rapid deterioration of their properties when exposed to air or light. This instability poses significant hurdles for their use in long-term applications and necessitates the development of effective protection strategies.

The processability of polysilanes presents another technical hurdle. Many polysilanes exhibit poor solubility in common organic solvents, making it challenging to process them into thin films or other desired forms. This limitation restricts their potential use in various applications, particularly in the field of electronics and optoelectronics.

Furthermore, controlling the electronic properties of polysilanes remains a complex task. The σ-conjugation along the silicon backbone, which is responsible for many of the unique properties of polysilanes, is highly sensitive to structural variations. Achieving precise control over the electronic band structure and charge transport properties requires sophisticated synthetic approaches and molecular engineering techniques.

The scalability of polysilane production is another significant challenge. Current synthesis methods are often limited to small-scale laboratory production, and scaling up these processes for industrial applications presents numerous technical and economic obstacles. This includes issues related to reaction control, purification, and cost-effectiveness at larger scales.

Additionally, the characterization of polysilanes poses unique challenges. Traditional polymer characterization techniques may not always be suitable or sufficient for accurately determining the structure, molecular weight, and properties of polysilanes. This necessitates the development of specialized analytical methods and tools tailored to these silicon-based polymers.

Lastly, the integration of polysilanes into functional devices and systems remains a significant technical challenge. While polysilanes show promise in various applications, such as photoresists, sensors, and optoelectronic devices, translating their unique properties into practical, reliable, and high-performance devices requires overcoming numerous engineering and materials science challenges. This includes addressing issues of interface compatibility, device stability, and performance optimization in real-world conditions.

Another major challenge lies in the stability of polysilanes. These materials are highly sensitive to oxidation and photodegradation, which can lead to rapid deterioration of their properties when exposed to air or light. This instability poses significant hurdles for their use in long-term applications and necessitates the development of effective protection strategies.

The processability of polysilanes presents another technical hurdle. Many polysilanes exhibit poor solubility in common organic solvents, making it challenging to process them into thin films or other desired forms. This limitation restricts their potential use in various applications, particularly in the field of electronics and optoelectronics.

Furthermore, controlling the electronic properties of polysilanes remains a complex task. The σ-conjugation along the silicon backbone, which is responsible for many of the unique properties of polysilanes, is highly sensitive to structural variations. Achieving precise control over the electronic band structure and charge transport properties requires sophisticated synthetic approaches and molecular engineering techniques.

The scalability of polysilane production is another significant challenge. Current synthesis methods are often limited to small-scale laboratory production, and scaling up these processes for industrial applications presents numerous technical and economic obstacles. This includes issues related to reaction control, purification, and cost-effectiveness at larger scales.

Additionally, the characterization of polysilanes poses unique challenges. Traditional polymer characterization techniques may not always be suitable or sufficient for accurately determining the structure, molecular weight, and properties of polysilanes. This necessitates the development of specialized analytical methods and tools tailored to these silicon-based polymers.

Lastly, the integration of polysilanes into functional devices and systems remains a significant technical challenge. While polysilanes show promise in various applications, such as photoresists, sensors, and optoelectronic devices, translating their unique properties into practical, reliable, and high-performance devices requires overcoming numerous engineering and materials science challenges. This includes addressing issues of interface compatibility, device stability, and performance optimization in real-world conditions.

Current Methodologies

01 Synthesis and properties of polysilanes

Polysilanes are synthesized through various methods and exhibit unique properties. These silicon-based polymers have applications in electronics, optics, and materials science due to their electronic and optical characteristics. The synthesis methods and resulting properties can be tailored for specific applications.- Synthesis and properties of polysilanes: Polysilanes are silicon-based polymers with a Si-Si backbone. They can be synthesized through various methods and exhibit unique optical and electronic properties. These polymers have applications in photoresists, semiconductors, and optoelectronic devices due to their σ-conjugation along the silicon backbone.

- Polysilane-based coatings and films: Polysilanes can be used to create thin films and coatings with specific properties. These films can be applied to various substrates and may exhibit characteristics such as improved adhesion, thermal stability, or optical properties. The processing methods for creating these films often involve solution-based techniques or vapor deposition.

- Functionalization and modification of polysilanes: Polysilanes can be functionalized or modified to enhance their properties or introduce new functionalities. This can involve the incorporation of various organic groups, crosslinking agents, or other elements into the polymer structure. Such modifications can lead to improved thermal stability, solubility, or specific reactivity for targeted applications.

- Polysilanes in photolithography and semiconductor applications: Polysilanes have found applications in photolithography and semiconductor manufacturing. They can be used as photoresists or as precursors for silicon-based materials in microelectronics. The photosensitivity of certain polysilanes allows for their use in patterning and etching processes in the fabrication of integrated circuits and other electronic devices.

- Polysilane-based composite materials: Polysilanes can be incorporated into composite materials to impart specific properties or functionalities. These composites may combine polysilanes with other polymers, inorganic materials, or nanoparticles. The resulting materials can exhibit enhanced mechanical, thermal, or electrical properties, making them suitable for various applications in aerospace, automotive, or electronics industries.

02 Polysilane-based coatings and films

Polysilanes are used to create coatings and films with specific properties. These coatings can be applied to various substrates and may exhibit characteristics such as improved adhesion, thermal stability, or optical properties. The composition and processing of polysilane-based coatings can be optimized for different applications.Expand Specific Solutions03 Polysilanes in photoresist and lithography applications

Polysilanes are utilized in photoresist formulations and lithography processes. Their unique electronic properties make them suitable for use in semiconductor manufacturing and other microfabrication techniques. The photosensitivity and patterning capabilities of polysilanes can be exploited for creating fine structures.Expand Specific Solutions04 Functionalization and modification of polysilanes

Polysilanes can be functionalized or modified to enhance their properties or introduce new functionalities. This includes the incorporation of various side groups, crosslinking, or combining polysilanes with other materials to create hybrid structures. These modifications can lead to improved performance in specific applications.Expand Specific Solutions05 Polysilanes in energy and electronic applications

Polysilanes have potential applications in energy-related fields and electronic devices. Their unique electronic properties make them suitable for use in solar cells, light-emitting diodes, and other optoelectronic devices. Research is ongoing to optimize polysilane structures and compositions for these applications.Expand Specific Solutions

Industry Leaders

The development of polysilane technology is currently in an emerging phase, with significant potential for growth across various industries. The market size is expanding as research progresses, though it remains relatively niche compared to established polymer markets. Technological maturity is advancing, with key players like JSR Corp., Wacker Chemie AG, and Momentive Performance Materials leading innovations. These companies are investing in R&D to improve polysilane synthesis, properties, and applications. Academic institutions such as Hangzhou Normal University and South China Normal University are also contributing to fundamental research. While polysilane technology shows promise, further advancements are needed to achieve widespread commercial adoption and realize its full potential in areas like electronics, photonics, and advanced materials.

JSR Corp.

Technical Solution: JSR Corp. has made significant strides in polysilane development, focusing on improving the material's optical and electronic properties. Their approach involves synthesizing novel polysilane structures with controlled molecular weight and distribution[1]. JSR's research has led to the development of polysilanes with enhanced photosensitivity and charge carrier mobility, making them suitable for advanced optoelectronic applications[2]. The company has also explored the use of polysilanes as precursors for silicon carbide ceramics, demonstrating improved thermal stability and conversion efficiency[3]. JSR's polysilane materials have shown promise in photoresist applications, offering high resolution and sensitivity for next-generation lithography processes[4].

Strengths: Advanced synthesis techniques, improved optoelectronic properties, and versatile applications in electronics and ceramics. Weaknesses: Potential challenges in scaling up production and competing with established materials in some applications.

Wacker Chemie AG

Technical Solution: Wacker Chemie AG has been at the forefront of polysilane research, focusing on developing novel synthesis methods and applications. Their approach involves the use of catalytic dehydrocoupling reactions to produce high-molecular-weight polysilanes with controlled structures[5]. Wacker has successfully developed polysilanes with improved thermal stability and processability, making them suitable for use in high-performance coatings and composites[6]. The company has also explored the potential of polysilanes as precursors for silicon-based ceramics, demonstrating enhanced conversion efficiency and mechanical properties[7]. Wacker's research has led to the development of UV-curable polysilane resins, which offer rapid curing and excellent adhesion properties for various industrial applications[8].

Strengths: Innovative synthesis methods, diverse range of applications, and improved material properties. Weaknesses: Potential cost constraints for large-scale production and competition from alternative materials in some sectors.

Key Patents Analysis

Polysilane and resin composition containing polysilane

PatentInactiveEP1958979A1

Innovation

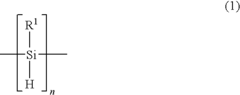

- Introducing a Si-H group into the polysilane main chain and bonding a hydrosilylatable compound with functional groups such as hydroxyl, carboxyl, or epoxy groups, allowing for controlled hydrosilylation to enhance solubility and reactivity without complex steps or special apparatus.

Polysilane and polysilane-containing resin composition

PatentInactiveUS20090156775A1

Innovation

- Introducing a Si—H group into the polysilane main chain and bonding a hydrosilylatable compound with functional groups, such as hydroxyl or carboxyl groups, to enhance solubility and reactivity, allowing for controlled functionality and solubility adjustments through hydrosilylation.

Environmental Impact

The development of polysilanes has significant environmental implications that warrant careful consideration. As these materials gain prominence in various applications, their potential impact on ecosystems and human health becomes increasingly important.

One of the primary environmental concerns associated with polysilanes is their production process. The synthesis of these materials often involves the use of chlorosilanes, which can be highly reactive and potentially harmful if released into the environment. Proper containment and handling procedures are crucial to prevent accidental spills or emissions that could contaminate soil, water, or air.

The disposal of polysilane-containing products at the end of their lifecycle presents another environmental challenge. While some polysilanes are biodegradable, others may persist in the environment for extended periods. Research into the development of more environmentally friendly polysilane formulations is ongoing, with a focus on enhancing biodegradability and reducing potential toxicity.

On the positive side, polysilanes have shown promise in various environmental applications. Their unique optical and electronic properties make them suitable for use in solar cells and other renewable energy technologies. By improving the efficiency of solar energy conversion, polysilanes could contribute to reducing reliance on fossil fuels and mitigating climate change.

Furthermore, polysilanes have potential applications in water treatment and environmental sensing. Their ability to form thin films and their sensitivity to certain chemicals make them valuable in developing advanced filtration systems and environmental monitoring devices. These applications could lead to improved water quality and more effective detection of pollutants.

The use of polysilanes in electronic devices also has indirect environmental implications. As these materials enable the development of more efficient and compact electronics, they could contribute to reducing energy consumption and electronic waste. However, this potential benefit must be balanced against the environmental impact of their production and disposal.

As research in polysilane technology progresses, there is a growing emphasis on green chemistry principles. Scientists are exploring alternative synthesis methods that use less hazardous reagents and reduce waste generation. Additionally, efforts are being made to develop polysilanes from renewable resources, further enhancing their environmental credentials.

In conclusion, the environmental impact of polysilanes is multifaceted, presenting both challenges and opportunities. As the field advances, it is crucial to prioritize sustainable practices in their production, use, and disposal to maximize their potential benefits while minimizing negative environmental consequences.

One of the primary environmental concerns associated with polysilanes is their production process. The synthesis of these materials often involves the use of chlorosilanes, which can be highly reactive and potentially harmful if released into the environment. Proper containment and handling procedures are crucial to prevent accidental spills or emissions that could contaminate soil, water, or air.

The disposal of polysilane-containing products at the end of their lifecycle presents another environmental challenge. While some polysilanes are biodegradable, others may persist in the environment for extended periods. Research into the development of more environmentally friendly polysilane formulations is ongoing, with a focus on enhancing biodegradability and reducing potential toxicity.

On the positive side, polysilanes have shown promise in various environmental applications. Their unique optical and electronic properties make them suitable for use in solar cells and other renewable energy technologies. By improving the efficiency of solar energy conversion, polysilanes could contribute to reducing reliance on fossil fuels and mitigating climate change.

Furthermore, polysilanes have potential applications in water treatment and environmental sensing. Their ability to form thin films and their sensitivity to certain chemicals make them valuable in developing advanced filtration systems and environmental monitoring devices. These applications could lead to improved water quality and more effective detection of pollutants.

The use of polysilanes in electronic devices also has indirect environmental implications. As these materials enable the development of more efficient and compact electronics, they could contribute to reducing energy consumption and electronic waste. However, this potential benefit must be balanced against the environmental impact of their production and disposal.

As research in polysilane technology progresses, there is a growing emphasis on green chemistry principles. Scientists are exploring alternative synthesis methods that use less hazardous reagents and reduce waste generation. Additionally, efforts are being made to develop polysilanes from renewable resources, further enhancing their environmental credentials.

In conclusion, the environmental impact of polysilanes is multifaceted, presenting both challenges and opportunities. As the field advances, it is crucial to prioritize sustainable practices in their production, use, and disposal to maximize their potential benefits while minimizing negative environmental consequences.

Regulatory Framework

The regulatory framework surrounding polysilane development plays a crucial role in shaping the industry's growth and ensuring safety standards. As polysilanes find increasing applications in various sectors, governments and regulatory bodies have been adapting their policies to address the unique challenges posed by these materials.

At the international level, organizations such as the International Organization for Standardization (ISO) and the Organisation for Economic Co-operation and Development (OECD) have been working on developing guidelines for the safe handling and use of polysilanes. These efforts aim to establish a harmonized approach to risk assessment and management across different countries.

In the United States, the Environmental Protection Agency (EPA) has taken steps to regulate polysilanes under the Toxic Substances Control Act (TSCA). The agency has implemented specific reporting requirements for manufacturers and importers of polysilanes, focusing on potential environmental and health impacts. Additionally, the Occupational Safety and Health Administration (OSHA) has issued guidelines for workplace safety when handling polysilanes.

The European Union has incorporated polysilanes into its REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation. This comprehensive framework requires companies to register polysilane substances and provide detailed information on their properties, potential risks, and safe use. The European Chemicals Agency (ECHA) plays a central role in overseeing compliance and disseminating information to stakeholders.

In Asia, countries like Japan and South Korea have also established regulatory frameworks for polysilanes. The Japanese Ministry of Economy, Trade and Industry (METI) has implemented specific guidelines for the manufacture and use of polysilanes, particularly in the semiconductor industry. Similarly, South Korea's Ministry of Environment has incorporated polysilanes into its chemical management regulations.

As the field of polysilane development continues to evolve, regulatory bodies are faced with the challenge of keeping pace with technological advancements. This has led to increased collaboration between industry stakeholders and regulators to ensure that policies remain relevant and effective. Many countries are now adopting a risk-based approach to regulation, focusing on the specific properties and applications of different polysilane compounds.

The regulatory landscape also reflects growing environmental concerns. Policies are increasingly emphasizing the need for sustainable production methods and end-of-life management for polysilane-based products. This has spurred research into recyclable and biodegradable polysilanes, aligning with broader sustainability goals.

At the international level, organizations such as the International Organization for Standardization (ISO) and the Organisation for Economic Co-operation and Development (OECD) have been working on developing guidelines for the safe handling and use of polysilanes. These efforts aim to establish a harmonized approach to risk assessment and management across different countries.

In the United States, the Environmental Protection Agency (EPA) has taken steps to regulate polysilanes under the Toxic Substances Control Act (TSCA). The agency has implemented specific reporting requirements for manufacturers and importers of polysilanes, focusing on potential environmental and health impacts. Additionally, the Occupational Safety and Health Administration (OSHA) has issued guidelines for workplace safety when handling polysilanes.

The European Union has incorporated polysilanes into its REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation. This comprehensive framework requires companies to register polysilane substances and provide detailed information on their properties, potential risks, and safe use. The European Chemicals Agency (ECHA) plays a central role in overseeing compliance and disseminating information to stakeholders.

In Asia, countries like Japan and South Korea have also established regulatory frameworks for polysilanes. The Japanese Ministry of Economy, Trade and Industry (METI) has implemented specific guidelines for the manufacture and use of polysilanes, particularly in the semiconductor industry. Similarly, South Korea's Ministry of Environment has incorporated polysilanes into its chemical management regulations.

As the field of polysilane development continues to evolve, regulatory bodies are faced with the challenge of keeping pace with technological advancements. This has led to increased collaboration between industry stakeholders and regulators to ensure that policies remain relevant and effective. Many countries are now adopting a risk-based approach to regulation, focusing on the specific properties and applications of different polysilane compounds.

The regulatory landscape also reflects growing environmental concerns. Policies are increasingly emphasizing the need for sustainable production methods and end-of-life management for polysilane-based products. This has spurred research into recyclable and biodegradable polysilanes, aligning with broader sustainability goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!