How to Innovate Kevlar-Based Smart Fabrics for Health Monitoring?

JUL 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar Smart Fabrics: Background and Objectives

Kevlar, a high-strength synthetic fiber developed by DuPont in the 1960s, has long been renowned for its exceptional durability and heat resistance. Initially utilized in military and aerospace applications, Kevlar's potential has expanded significantly over the years. The evolution of smart fabrics has opened new avenues for integrating advanced functionalities into textiles, presenting an opportunity to merge Kevlar's robust properties with cutting-edge health monitoring capabilities.

The primary objective of innovating Kevlar-based smart fabrics for health monitoring is to create a new generation of wearable technology that combines the strength and reliability of Kevlar with sophisticated sensing and data collection features. This fusion aims to address the growing demand for non-invasive, continuous health monitoring solutions in various sectors, including healthcare, sports, and occupational safety.

The development of such smart fabrics is driven by several key factors. Firstly, there is an increasing need for real-time health data collection and analysis, particularly in remote or challenging environments where traditional monitoring methods may be impractical. Secondly, the rise of personalized medicine and preventive healthcare strategies has created a market for wearable devices that can provide continuous, accurate physiological data.

Kevlar's unique properties make it an ideal candidate for this innovation. Its high tensile strength-to-weight ratio ensures durability in demanding conditions, while its flexibility allows for comfortable, form-fitting wearables. Moreover, Kevlar's resistance to chemicals and extreme temperatures provides a stable platform for integrating sensitive electronic components and sensors.

The technical goals for this innovation encompass several critical areas. These include developing methods to seamlessly integrate sensors and conductive materials into Kevlar fibers without compromising their structural integrity, creating power-efficient systems for continuous operation, and designing data processing algorithms capable of extracting meaningful health insights from the collected information.

Furthermore, the objectives extend to enhancing the fabric's ability to monitor a wide range of physiological parameters, such as heart rate, respiratory rate, body temperature, and even biochemical markers through sweat analysis. The ultimate aim is to create a versatile, robust platform that can be adapted for various applications, from monitoring athletes' performance to assessing the health status of workers in hazardous environments.

As we explore the potential of Kevlar-based smart fabrics for health monitoring, it is crucial to consider the interdisciplinary nature of this endeavor. Success in this field will require collaboration between materials scientists, electronic engineers, data analysts, and healthcare professionals. The convergence of these diverse expertise areas will be key to overcoming the technical challenges and realizing the full potential of this innovative technology.

The primary objective of innovating Kevlar-based smart fabrics for health monitoring is to create a new generation of wearable technology that combines the strength and reliability of Kevlar with sophisticated sensing and data collection features. This fusion aims to address the growing demand for non-invasive, continuous health monitoring solutions in various sectors, including healthcare, sports, and occupational safety.

The development of such smart fabrics is driven by several key factors. Firstly, there is an increasing need for real-time health data collection and analysis, particularly in remote or challenging environments where traditional monitoring methods may be impractical. Secondly, the rise of personalized medicine and preventive healthcare strategies has created a market for wearable devices that can provide continuous, accurate physiological data.

Kevlar's unique properties make it an ideal candidate for this innovation. Its high tensile strength-to-weight ratio ensures durability in demanding conditions, while its flexibility allows for comfortable, form-fitting wearables. Moreover, Kevlar's resistance to chemicals and extreme temperatures provides a stable platform for integrating sensitive electronic components and sensors.

The technical goals for this innovation encompass several critical areas. These include developing methods to seamlessly integrate sensors and conductive materials into Kevlar fibers without compromising their structural integrity, creating power-efficient systems for continuous operation, and designing data processing algorithms capable of extracting meaningful health insights from the collected information.

Furthermore, the objectives extend to enhancing the fabric's ability to monitor a wide range of physiological parameters, such as heart rate, respiratory rate, body temperature, and even biochemical markers through sweat analysis. The ultimate aim is to create a versatile, robust platform that can be adapted for various applications, from monitoring athletes' performance to assessing the health status of workers in hazardous environments.

As we explore the potential of Kevlar-based smart fabrics for health monitoring, it is crucial to consider the interdisciplinary nature of this endeavor. Success in this field will require collaboration between materials scientists, electronic engineers, data analysts, and healthcare professionals. The convergence of these diverse expertise areas will be key to overcoming the technical challenges and realizing the full potential of this innovative technology.

Health Monitoring Market Analysis

The health monitoring market has experienced significant growth in recent years, driven by increasing health consciousness, aging populations, and advancements in wearable technology. The global market for health monitoring devices is projected to reach $30 billion by 2025, with a compound annual growth rate of 8.9% from 2020 to 2025. This growth is particularly evident in the smart fabric sector, where innovations in materials like Kevlar-based textiles are opening new possibilities for integrated health monitoring solutions.

The demand for non-invasive, continuous health monitoring has surged, especially in the wake of the COVID-19 pandemic. Consumers are increasingly seeking ways to track their vital signs, physical activity, and overall well-being without the need for frequent hospital visits. This trend has created a fertile ground for the development of smart fabrics that can seamlessly integrate health monitoring capabilities into everyday clothing and accessories.

Kevlar-based smart fabrics for health monitoring are positioned at the intersection of two rapidly growing markets: smart textiles and wearable health devices. The smart textile market is expected to reach $5.5 billion by 2025, with health monitoring applications accounting for a significant portion of this growth. The unique properties of Kevlar, including its strength, durability, and potential for sensor integration, make it an ideal candidate for developing advanced health monitoring fabrics.

Key market segments for Kevlar-based smart fabrics include sports and fitness, medical and healthcare, military and defense, and occupational safety. In the sports and fitness sector, there is a growing demand for performance-enhancing garments that can monitor heart rate, respiration, and muscle activity. The medical and healthcare segment is particularly promising, with applications ranging from remote patient monitoring to early detection of health issues in at-risk populations.

The aging population in developed countries is a significant driver for the health monitoring market. As the number of elderly individuals increases, so does the need for continuous health monitoring solutions that can detect falls, monitor vital signs, and alert caregivers to potential health issues. Kevlar-based smart fabrics could play a crucial role in developing comfortable, durable, and effective monitoring solutions for this demographic.

Emerging economies present substantial growth opportunities for the health monitoring market. As healthcare infrastructure improves and disposable incomes rise in countries like China and India, the demand for advanced health monitoring solutions is expected to increase. This presents an opportunity for Kevlar-based smart fabrics to gain market share in these rapidly expanding economies.

However, the market also faces challenges, including concerns about data privacy, the need for regulatory approvals, and competition from established wearable device manufacturers. Successful innovation in Kevlar-based smart fabrics for health monitoring will require addressing these challenges while leveraging the unique properties of Kevlar to create differentiated, high-value products that meet the evolving needs of consumers and healthcare providers.

The demand for non-invasive, continuous health monitoring has surged, especially in the wake of the COVID-19 pandemic. Consumers are increasingly seeking ways to track their vital signs, physical activity, and overall well-being without the need for frequent hospital visits. This trend has created a fertile ground for the development of smart fabrics that can seamlessly integrate health monitoring capabilities into everyday clothing and accessories.

Kevlar-based smart fabrics for health monitoring are positioned at the intersection of two rapidly growing markets: smart textiles and wearable health devices. The smart textile market is expected to reach $5.5 billion by 2025, with health monitoring applications accounting for a significant portion of this growth. The unique properties of Kevlar, including its strength, durability, and potential for sensor integration, make it an ideal candidate for developing advanced health monitoring fabrics.

Key market segments for Kevlar-based smart fabrics include sports and fitness, medical and healthcare, military and defense, and occupational safety. In the sports and fitness sector, there is a growing demand for performance-enhancing garments that can monitor heart rate, respiration, and muscle activity. The medical and healthcare segment is particularly promising, with applications ranging from remote patient monitoring to early detection of health issues in at-risk populations.

The aging population in developed countries is a significant driver for the health monitoring market. As the number of elderly individuals increases, so does the need for continuous health monitoring solutions that can detect falls, monitor vital signs, and alert caregivers to potential health issues. Kevlar-based smart fabrics could play a crucial role in developing comfortable, durable, and effective monitoring solutions for this demographic.

Emerging economies present substantial growth opportunities for the health monitoring market. As healthcare infrastructure improves and disposable incomes rise in countries like China and India, the demand for advanced health monitoring solutions is expected to increase. This presents an opportunity for Kevlar-based smart fabrics to gain market share in these rapidly expanding economies.

However, the market also faces challenges, including concerns about data privacy, the need for regulatory approvals, and competition from established wearable device manufacturers. Successful innovation in Kevlar-based smart fabrics for health monitoring will require addressing these challenges while leveraging the unique properties of Kevlar to create differentiated, high-value products that meet the evolving needs of consumers and healthcare providers.

Smart Fabric Technology Landscape

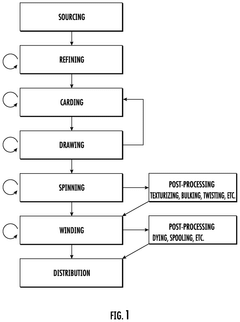

Smart fabrics, also known as e-textiles or intelligent textiles, represent a rapidly evolving field at the intersection of textile engineering, electronics, and materials science. These innovative fabrics incorporate advanced technologies to provide functionalities beyond traditional textiles, such as sensing, data processing, and communication capabilities. The landscape of smart fabric technology has been shaped by advancements in conductive materials, miniaturized electronics, and flexible sensors.

The evolution of smart fabrics can be traced back to the late 20th century, with early experiments in integrating electronic components into textiles. However, the field has gained significant momentum in the past decade due to breakthroughs in nanotechnology, flexible electronics, and wireless communication. The current smart fabric technology landscape is characterized by a diverse range of applications, including health monitoring, sports performance tracking, military applications, and interactive fashion.

In the context of health monitoring, smart fabrics offer unique advantages over traditional wearable devices. They provide a more comfortable and unobtrusive way to continuously monitor vital signs and physiological parameters. The integration of sensors directly into the fabric allows for more accurate and comprehensive data collection, as the sensors maintain consistent contact with the skin.

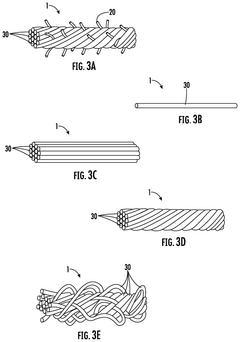

Key technologies driving the smart fabric landscape include conductive yarns and threads, printed electronics, flexible sensors, and energy harvesting systems. Conductive materials enable the creation of electrical pathways within the fabric, while flexible sensors allow for the detection of various physiological signals. Printed electronics techniques facilitate the integration of complex circuitry onto textile substrates, and energy harvesting systems, such as piezoelectric fibers, provide power for embedded electronics.

The smart fabric market is experiencing rapid growth, with major players from both the textile and technology sectors investing in research and development. Companies like Google, Nike, and Under Armour have launched smart fabric products, while startups are continuously emerging with innovative solutions. The healthcare sector, in particular, has shown significant interest in smart fabrics for remote patient monitoring and preventive care.

Challenges in the smart fabric landscape include durability, washability, and scalability of production. Ensuring that electronic components can withstand repeated washing and wear remains a key focus area. Additionally, standardization of smart fabric technologies and interoperability between different systems are ongoing concerns that the industry is addressing.

Looking ahead, the smart fabric technology landscape is poised for further innovation. Emerging trends include the development of self-healing fabrics, integration of artificial intelligence for real-time data analysis, and the use of biodegradable materials for more sustainable smart textiles. As the technology matures, we can expect to see more seamless integration of smart fabrics into everyday clothing and an expansion of their capabilities in health monitoring and beyond.

The evolution of smart fabrics can be traced back to the late 20th century, with early experiments in integrating electronic components into textiles. However, the field has gained significant momentum in the past decade due to breakthroughs in nanotechnology, flexible electronics, and wireless communication. The current smart fabric technology landscape is characterized by a diverse range of applications, including health monitoring, sports performance tracking, military applications, and interactive fashion.

In the context of health monitoring, smart fabrics offer unique advantages over traditional wearable devices. They provide a more comfortable and unobtrusive way to continuously monitor vital signs and physiological parameters. The integration of sensors directly into the fabric allows for more accurate and comprehensive data collection, as the sensors maintain consistent contact with the skin.

Key technologies driving the smart fabric landscape include conductive yarns and threads, printed electronics, flexible sensors, and energy harvesting systems. Conductive materials enable the creation of electrical pathways within the fabric, while flexible sensors allow for the detection of various physiological signals. Printed electronics techniques facilitate the integration of complex circuitry onto textile substrates, and energy harvesting systems, such as piezoelectric fibers, provide power for embedded electronics.

The smart fabric market is experiencing rapid growth, with major players from both the textile and technology sectors investing in research and development. Companies like Google, Nike, and Under Armour have launched smart fabric products, while startups are continuously emerging with innovative solutions. The healthcare sector, in particular, has shown significant interest in smart fabrics for remote patient monitoring and preventive care.

Challenges in the smart fabric landscape include durability, washability, and scalability of production. Ensuring that electronic components can withstand repeated washing and wear remains a key focus area. Additionally, standardization of smart fabric technologies and interoperability between different systems are ongoing concerns that the industry is addressing.

Looking ahead, the smart fabric technology landscape is poised for further innovation. Emerging trends include the development of self-healing fabrics, integration of artificial intelligence for real-time data analysis, and the use of biodegradable materials for more sustainable smart textiles. As the technology matures, we can expect to see more seamless integration of smart fabrics into everyday clothing and an expansion of their capabilities in health monitoring and beyond.

Current Kevlar Smart Fabric Solutions

01 Kevlar-based smart fabrics for health monitoring

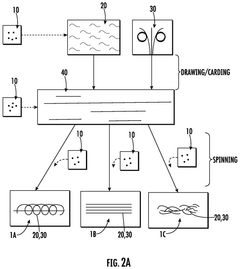

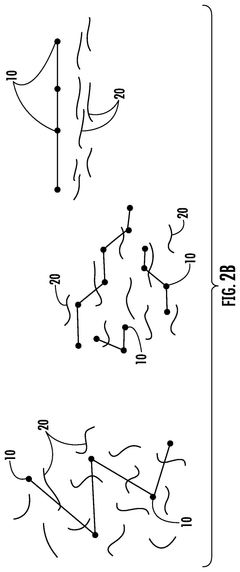

Integration of Kevlar fibers with sensors and conductive materials to create smart fabrics capable of monitoring various health parameters. These fabrics can measure vital signs, track physical activity, and detect physiological changes while maintaining the strength and durability of Kevlar.- Kevlar-based smart fabrics for health monitoring: Integration of Kevlar fibers with sensors and electronic components to create smart fabrics capable of monitoring various health parameters. These fabrics combine the strength and durability of Kevlar with advanced sensing technologies to provide real-time health data.

- Wearable health monitoring devices using Kevlar-reinforced materials: Development of wearable devices that incorporate Kevlar-reinforced materials to enhance durability and flexibility. These devices can monitor vital signs, physical activity, and other health-related metrics while withstanding harsh conditions and frequent use.

- Integration of nanosensors in Kevlar-based fabrics: Incorporation of nanosensors into Kevlar-based fabrics to enhance their health monitoring capabilities. These nanosensors can detect various biomarkers, environmental factors, and physiological changes, providing comprehensive health data.

- Data processing and transmission systems for Kevlar-based smart fabrics: Development of advanced data processing and transmission systems specifically designed for Kevlar-based smart fabrics. These systems enable efficient collection, analysis, and secure transmission of health data gathered by the smart fabrics.

- Kevlar-based smart fabrics for specific medical applications: Customization of Kevlar-based smart fabrics for specific medical applications, such as monitoring chronic conditions, post-operative care, or athletic performance. These specialized fabrics are designed to meet the unique requirements of different healthcare scenarios.

02 Wearable health monitoring devices using Kevlar composites

Development of wearable devices incorporating Kevlar composites for enhanced durability and flexibility. These devices can be integrated into clothing or accessories to continuously monitor health metrics such as heart rate, blood pressure, and body temperature.Expand Specific Solutions03 Kevlar-based smart textiles with embedded biosensors

Creation of smart textiles using Kevlar fibers with embedded biosensors for real-time health monitoring. These textiles can detect and analyze biomarkers in sweat or other bodily fluids, providing valuable health information to users and healthcare professionals.Expand Specific Solutions04 Kevlar-reinforced electronic skin for health monitoring

Development of flexible, Kevlar-reinforced electronic skin that can be applied directly to the body for continuous health monitoring. This electronic skin can measure various physiological parameters and transmit data wirelessly to connected devices for analysis and tracking.Expand Specific Solutions05 Integration of Kevlar-based smart fabrics with IoT for remote health monitoring

Incorporation of Kevlar-based smart fabrics into Internet of Things (IoT) ecosystems for remote health monitoring applications. This integration allows for real-time data collection, analysis, and transmission to healthcare providers, enabling early detection of health issues and personalized care.Expand Specific Solutions

Key Players in Smart Textile Industry

The innovation of Kevlar-based smart fabrics for health monitoring is in an early development stage, with a growing market potential driven by increasing demand for wearable health technologies. The market size is expanding, attracting diverse players from academia and industry. While the technology is still evolving, companies like Nanowear, Myant, and BioSerenity are making significant strides in integrating nanosensors and AI into fabrics. Universities such as Drexel, Northwestern, and Donghua are contributing to research advancements. Established players like Philips and Adidas are also exploring this field, indicating its potential for mainstream adoption. The technology's maturity varies, with some companies already offering commercial products while others focus on R&D.

Nanowear, Inc.

Technical Solution: Nanowear has developed a proprietary cloth-based nanosensor technology that can be integrated into Kevlar-based fabrics for health monitoring. Their smart fabric platform utilizes conductive nanomaterials to create a network of sensors capable of capturing and transmitting various physiological signals. The company's technology enables continuous, real-time monitoring of vital signs such as heart rate, respiratory rate, and body temperature[1]. Nanowear's smart fabrics are designed to be washable, durable, and comfortable, making them suitable for long-term wear in various applications, including military and first responder gear[2].

Strengths: Highly sensitive nanosensor technology, washable and durable fabric, continuous real-time monitoring. Weaknesses: May require specialized manufacturing processes, potential high cost of production.

Myant, Corp.

Technical Solution: Myant has developed SKIIN, a platform for Kevlar-based smart textiles that incorporates a range of sensors and actuators. Their technology uses conductive fibers seamlessly knitted into fabrics to create a distributed sensor network. SKIIN can monitor various health parameters, including ECG, EMG, temperature, and hydration levels[3]. Myant's innovation lies in their ability to integrate these sensors without compromising the protective properties of Kevlar. The company has also developed advanced algorithms for data analysis and interpretation, enabling real-time health insights and predictive analytics[4].

Strengths: Comprehensive health monitoring capabilities, seamless integration with Kevlar, advanced data analytics. Weaknesses: Complexity of manufacturing process, potential high cost of end products.

Core Innovations in Kevlar Integration

Smart knitted fabrics

PatentPendingUS20160000374A1

Innovation

- Incorporating conductive yarns into knitted fabric structures using advanced knitting machines and CAD systems to integrate electronics directly into garments, eliminating the need for adhesives and enabling versatile design solutions for sensing, communication, and tactile interaction.

Electrically conductive yarn and fabric-based, noise-cancelling, multimodal electrodes for physiological measurements

PatentPendingUS20250057458A1

Innovation

- Development of flexible, fabric-based, noise-cancelling, and multimodal electrodes made from electrically conductive yarns that can be integrated into clothing, allowing for reliable detection and measurement of physiological signals from any desired location on the body, along with an in-garment connector strategy and a CPU capable of differentiating between various measurement modes.

Durability and Washability Challenges

The integration of Kevlar-based smart fabrics for health monitoring presents significant challenges in terms of durability and washability. Kevlar, known for its exceptional strength-to-weight ratio, must maintain its structural integrity while accommodating embedded sensors and conductive elements. The primary durability concern lies in preserving the fabric's performance under repeated stress, bending, and stretching during regular wear. Smart fabrics must withstand daily activities without compromising their sensing capabilities or physical properties.

Washability poses a unique set of challenges for Kevlar-based smart textiles. Traditional washing methods can potentially damage or degrade the embedded electronic components and sensors. Water exposure, detergents, and mechanical agitation in washing machines may lead to short circuits, sensor malfunction, or degradation of conductive pathways. Moreover, the adhesion between Kevlar fibers and electronic elements must remain intact throughout multiple wash cycles.

To address these challenges, researchers are exploring various approaches. One promising avenue involves the development of waterproof coatings that encapsulate electronic components without affecting the fabric's breathability or flexibility. These coatings must be durable enough to withstand repeated washing while maintaining their protective properties. Another approach focuses on creating modular designs where electronic components can be easily removed before washing and reinserted afterward.

The integration of nanoparticles into Kevlar fibers is being investigated to enhance both durability and washability. These nanoparticles can potentially improve the fabric's resistance to abrasion, chemicals, and moisture while maintaining its lightweight properties. Additionally, researchers are exploring the use of conductive inks and printable electronics that can be more seamlessly integrated into the fabric structure, potentially improving their resilience to washing and wear.

Developing standardized testing protocols for smart fabrics is crucial to ensure consistent performance and reliability. These protocols must evaluate not only the physical durability of the fabric but also the longevity of its sensing capabilities under various conditions. Accelerated aging tests, simulating multiple wash cycles and wear patterns, are being designed to predict the long-term performance of Kevlar-based smart fabrics.

The challenge of power supply for embedded sensors also intersects with durability and washability concerns. Innovative solutions such as flexible, washable batteries or energy harvesting technologies that can withstand washing processes are being explored. These power sources must be seamlessly integrated into the fabric structure without compromising its flexibility or comfort.

Washability poses a unique set of challenges for Kevlar-based smart textiles. Traditional washing methods can potentially damage or degrade the embedded electronic components and sensors. Water exposure, detergents, and mechanical agitation in washing machines may lead to short circuits, sensor malfunction, or degradation of conductive pathways. Moreover, the adhesion between Kevlar fibers and electronic elements must remain intact throughout multiple wash cycles.

To address these challenges, researchers are exploring various approaches. One promising avenue involves the development of waterproof coatings that encapsulate electronic components without affecting the fabric's breathability or flexibility. These coatings must be durable enough to withstand repeated washing while maintaining their protective properties. Another approach focuses on creating modular designs where electronic components can be easily removed before washing and reinserted afterward.

The integration of nanoparticles into Kevlar fibers is being investigated to enhance both durability and washability. These nanoparticles can potentially improve the fabric's resistance to abrasion, chemicals, and moisture while maintaining its lightweight properties. Additionally, researchers are exploring the use of conductive inks and printable electronics that can be more seamlessly integrated into the fabric structure, potentially improving their resilience to washing and wear.

Developing standardized testing protocols for smart fabrics is crucial to ensure consistent performance and reliability. These protocols must evaluate not only the physical durability of the fabric but also the longevity of its sensing capabilities under various conditions. Accelerated aging tests, simulating multiple wash cycles and wear patterns, are being designed to predict the long-term performance of Kevlar-based smart fabrics.

The challenge of power supply for embedded sensors also intersects with durability and washability concerns. Innovative solutions such as flexible, washable batteries or energy harvesting technologies that can withstand washing processes are being explored. These power sources must be seamlessly integrated into the fabric structure without compromising its flexibility or comfort.

Biocompatibility and Safety Considerations

The integration of Kevlar-based smart fabrics for health monitoring necessitates a thorough examination of biocompatibility and safety considerations. Kevlar, known for its exceptional strength and durability, must be carefully evaluated for its interaction with human skin and potential long-term effects on the body. The primary concern is ensuring that the fabric does not cause irritation, allergic reactions, or other adverse effects when in prolonged contact with the skin.

One crucial aspect is the potential leaching of chemicals from the Kevlar fibers or any additional components used in the smart fabric construction. Rigorous testing protocols must be established to assess the release of any substances that could be absorbed through the skin or inhaled. This includes evaluating the stability of the Kevlar fibers under various conditions, such as exposure to sweat, different pH levels, and temperature fluctuations typically encountered during wear.

The incorporation of electronic components for health monitoring introduces additional safety considerations. These components must be seamlessly integrated into the fabric structure without compromising the material's integrity or creating potential hazards. Careful attention must be paid to the insulation of electronic elements to prevent any electrical risks to the wearer, especially in scenarios involving moisture or physical stress on the fabric.

Electromagnetic radiation emitted by the smart fabric's sensors and communication systems is another critical factor to address. While the levels are typically low in wearable devices, the cumulative effect of prolonged exposure must be thoroughly investigated. Compliance with international standards for electromagnetic radiation exposure in wearable technology is essential to ensure user safety.

The durability and degradation characteristics of Kevlar-based smart fabrics over time also warrant careful consideration. As the fabric undergoes repeated use, washing, and exposure to environmental factors, it is crucial to monitor any changes in its physical properties or the potential release of microfibers. The environmental impact of these microfibers, if shed, must be assessed to ensure the fabric's sustainability and safety for both users and ecosystems.

Furthermore, the biocompatibility of any coatings or treatments applied to enhance the fabric's functionality or durability must be rigorously tested. These additives should not compromise the skin's natural barrier function or disrupt the skin microbiome. Long-term studies on the effects of prolonged skin contact with these materials are essential to validate their safety for continuous wear in health monitoring applications.

Lastly, the development of appropriate cleaning and maintenance protocols is crucial for ensuring the ongoing safety and effectiveness of Kevlar-based smart fabrics. These protocols must effectively sanitize the fabric without degrading its structural integrity or compromising the functionality of integrated electronic components. Clear guidelines for users on proper care and handling of the smart fabric will be essential to maintain its safety profile throughout its lifecycle.

One crucial aspect is the potential leaching of chemicals from the Kevlar fibers or any additional components used in the smart fabric construction. Rigorous testing protocols must be established to assess the release of any substances that could be absorbed through the skin or inhaled. This includes evaluating the stability of the Kevlar fibers under various conditions, such as exposure to sweat, different pH levels, and temperature fluctuations typically encountered during wear.

The incorporation of electronic components for health monitoring introduces additional safety considerations. These components must be seamlessly integrated into the fabric structure without compromising the material's integrity or creating potential hazards. Careful attention must be paid to the insulation of electronic elements to prevent any electrical risks to the wearer, especially in scenarios involving moisture or physical stress on the fabric.

Electromagnetic radiation emitted by the smart fabric's sensors and communication systems is another critical factor to address. While the levels are typically low in wearable devices, the cumulative effect of prolonged exposure must be thoroughly investigated. Compliance with international standards for electromagnetic radiation exposure in wearable technology is essential to ensure user safety.

The durability and degradation characteristics of Kevlar-based smart fabrics over time also warrant careful consideration. As the fabric undergoes repeated use, washing, and exposure to environmental factors, it is crucial to monitor any changes in its physical properties or the potential release of microfibers. The environmental impact of these microfibers, if shed, must be assessed to ensure the fabric's sustainability and safety for both users and ecosystems.

Furthermore, the biocompatibility of any coatings or treatments applied to enhance the fabric's functionality or durability must be rigorously tested. These additives should not compromise the skin's natural barrier function or disrupt the skin microbiome. Long-term studies on the effects of prolonged skin contact with these materials are essential to validate their safety for continuous wear in health monitoring applications.

Lastly, the development of appropriate cleaning and maintenance protocols is crucial for ensuring the ongoing safety and effectiveness of Kevlar-based smart fabrics. These protocols must effectively sanitize the fabric without degrading its structural integrity or compromising the functionality of integrated electronic components. Clear guidelines for users on proper care and handling of the smart fabric will be essential to maintain its safety profile throughout its lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!