Flex-panel AMOLED applications in nautical technology.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AMOLED Flex-panel Evolution

The evolution of AMOLED flex-panel technology has been a significant driver in the advancement of display technologies, particularly in the context of nautical applications. This journey began with the introduction of basic OLED displays in the early 2000s, which offered improved contrast and power efficiency compared to traditional LCD screens. However, these early iterations were rigid and unsuitable for the demanding marine environment.

The breakthrough came with the development of flexible AMOLED panels in the mid-2010s. This innovation allowed for curved displays that could better conform to the contours of ship consoles and instrument panels. The flexibility not only enhanced ergonomics but also improved visibility in various lighting conditions, a crucial factor in maritime operations.

As the technology progressed, manufacturers focused on increasing the durability and water resistance of flex-panel AMOLEDs. This was particularly important for nautical applications, where displays are exposed to harsh environmental conditions, including saltwater spray and intense sunlight. The introduction of advanced encapsulation techniques and protective coatings marked a significant milestone in making these displays suitable for marine use.

The next phase of evolution saw the integration of touch functionality into flexible AMOLED panels. This development allowed for the creation of intuitive, multi-touch interfaces that could replace traditional button-based controls on nautical instruments. The ability to interact directly with curved displays revolutionized the design of navigation systems and radar displays, enhancing user experience and operational efficiency.

Recent advancements have focused on improving the resolution and color accuracy of flex-panel AMOLEDs. High-resolution displays are crucial for detailed nautical charts and real-time data visualization. Enhanced color accuracy ensures that critical information, such as depth readings and weather patterns, is displayed with precision, reducing the risk of misinterpretation.

The latest iterations of flex-panel AMOLED technology have also addressed power consumption concerns, a critical factor in marine applications where energy efficiency is paramount. Low-power modes and adaptive brightness features have been developed to extend battery life and reduce the overall power demands of onboard systems.

Looking ahead, the evolution of flex-panel AMOLEDs in nautical technology is expected to continue with a focus on larger, seamless displays that can cover entire control panels. Research is also underway to develop transparent and semi-transparent flexible AMOLEDs, which could revolutionize heads-up displays and augmented reality applications in maritime navigation and operations.

The breakthrough came with the development of flexible AMOLED panels in the mid-2010s. This innovation allowed for curved displays that could better conform to the contours of ship consoles and instrument panels. The flexibility not only enhanced ergonomics but also improved visibility in various lighting conditions, a crucial factor in maritime operations.

As the technology progressed, manufacturers focused on increasing the durability and water resistance of flex-panel AMOLEDs. This was particularly important for nautical applications, where displays are exposed to harsh environmental conditions, including saltwater spray and intense sunlight. The introduction of advanced encapsulation techniques and protective coatings marked a significant milestone in making these displays suitable for marine use.

The next phase of evolution saw the integration of touch functionality into flexible AMOLED panels. This development allowed for the creation of intuitive, multi-touch interfaces that could replace traditional button-based controls on nautical instruments. The ability to interact directly with curved displays revolutionized the design of navigation systems and radar displays, enhancing user experience and operational efficiency.

Recent advancements have focused on improving the resolution and color accuracy of flex-panel AMOLEDs. High-resolution displays are crucial for detailed nautical charts and real-time data visualization. Enhanced color accuracy ensures that critical information, such as depth readings and weather patterns, is displayed with precision, reducing the risk of misinterpretation.

The latest iterations of flex-panel AMOLED technology have also addressed power consumption concerns, a critical factor in marine applications where energy efficiency is paramount. Low-power modes and adaptive brightness features have been developed to extend battery life and reduce the overall power demands of onboard systems.

Looking ahead, the evolution of flex-panel AMOLEDs in nautical technology is expected to continue with a focus on larger, seamless displays that can cover entire control panels. Research is also underway to develop transparent and semi-transparent flexible AMOLEDs, which could revolutionize heads-up displays and augmented reality applications in maritime navigation and operations.

Nautical Market Analysis

The nautical market has been experiencing significant growth and transformation in recent years, driven by technological advancements and increasing demand for sophisticated marine electronics. The integration of Flex-panel AMOLED technology into nautical applications represents a promising opportunity to revolutionize marine navigation and communication systems.

The global marine electronics market, which encompasses a wide range of devices including display systems, is projected to expand substantially over the coming years. This growth is fueled by the rising adoption of advanced technologies in commercial vessels, recreational boats, and naval fleets. The demand for more efficient, durable, and user-friendly display systems in marine environments has created a fertile ground for innovative solutions like Flex-panel AMOLED displays.

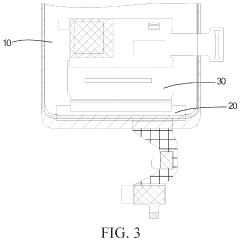

One of the key drivers for the adoption of Flex-panel AMOLED technology in the nautical sector is the increasing focus on enhancing situational awareness and safety at sea. Traditional display systems often struggle with visibility issues in varying light conditions, a challenge that AMOLED technology can effectively address with its superior contrast ratios and brightness levels. Moreover, the flexibility of these panels allows for curved or non-traditional form factors, which can be particularly advantageous in the confined spaces typical of marine vessels.

The recreational boating segment presents a particularly lucrative market for Flex-panel AMOLED applications. As consumers seek more luxurious and technologically advanced yachts and pleasure crafts, there is a growing demand for sleek, modern display systems that can provide both functionality and aesthetic appeal. The ability of Flex-panel AMOLED displays to conform to various surfaces and integrate seamlessly into boat designs makes them an attractive option for manufacturers looking to differentiate their products in a competitive market.

In the commercial maritime sector, the potential for Flex-panel AMOLED technology is equally promising. Large vessels such as cargo ships and cruise liners require extensive monitoring and control systems. The implementation of flexible, high-quality displays could significantly improve the efficiency of bridge operations and enhance the overall user experience for crew members. Additionally, the durability and energy efficiency of AMOLED technology align well with the industry's push towards more sustainable and long-lasting marine equipment.

The naval and defense sector also represents a significant market opportunity for Flex-panel AMOLED applications. Military vessels demand cutting-edge technology that can withstand harsh environmental conditions while providing critical information with utmost clarity. The adaptability of flexible displays to various installation scenarios and their potential for reduced power consumption make them an attractive option for naval applications.

However, the adoption of Flex-panel AMOLED technology in the nautical market is not without challenges. Concerns about the long-term durability of flexible displays in marine environments, particularly their resistance to saltwater exposure and extreme temperatures, need to be addressed. Additionally, the initial cost of implementing this technology may be a barrier for some segments of the market, particularly smaller vessels or budget-conscious operators.

The global marine electronics market, which encompasses a wide range of devices including display systems, is projected to expand substantially over the coming years. This growth is fueled by the rising adoption of advanced technologies in commercial vessels, recreational boats, and naval fleets. The demand for more efficient, durable, and user-friendly display systems in marine environments has created a fertile ground for innovative solutions like Flex-panel AMOLED displays.

One of the key drivers for the adoption of Flex-panel AMOLED technology in the nautical sector is the increasing focus on enhancing situational awareness and safety at sea. Traditional display systems often struggle with visibility issues in varying light conditions, a challenge that AMOLED technology can effectively address with its superior contrast ratios and brightness levels. Moreover, the flexibility of these panels allows for curved or non-traditional form factors, which can be particularly advantageous in the confined spaces typical of marine vessels.

The recreational boating segment presents a particularly lucrative market for Flex-panel AMOLED applications. As consumers seek more luxurious and technologically advanced yachts and pleasure crafts, there is a growing demand for sleek, modern display systems that can provide both functionality and aesthetic appeal. The ability of Flex-panel AMOLED displays to conform to various surfaces and integrate seamlessly into boat designs makes them an attractive option for manufacturers looking to differentiate their products in a competitive market.

In the commercial maritime sector, the potential for Flex-panel AMOLED technology is equally promising. Large vessels such as cargo ships and cruise liners require extensive monitoring and control systems. The implementation of flexible, high-quality displays could significantly improve the efficiency of bridge operations and enhance the overall user experience for crew members. Additionally, the durability and energy efficiency of AMOLED technology align well with the industry's push towards more sustainable and long-lasting marine equipment.

The naval and defense sector also represents a significant market opportunity for Flex-panel AMOLED applications. Military vessels demand cutting-edge technology that can withstand harsh environmental conditions while providing critical information with utmost clarity. The adaptability of flexible displays to various installation scenarios and their potential for reduced power consumption make them an attractive option for naval applications.

However, the adoption of Flex-panel AMOLED technology in the nautical market is not without challenges. Concerns about the long-term durability of flexible displays in marine environments, particularly their resistance to saltwater exposure and extreme temperatures, need to be addressed. Additionally, the initial cost of implementing this technology may be a barrier for some segments of the market, particularly smaller vessels or budget-conscious operators.

Technical Challenges

The application of flex-panel AMOLED technology in nautical environments presents several significant technical challenges. One of the primary obstacles is ensuring the durability and reliability of flexible displays in harsh marine conditions. Saltwater exposure, high humidity, and extreme temperature fluctuations can severely impact the performance and longevity of AMOLED panels, necessitating advanced protective measures and materials.

Another critical challenge lies in maintaining display visibility and readability in varying light conditions. Nautical applications often require displays to be clearly visible in both bright sunlight and low-light situations, which demands sophisticated brightness control and anti-glare technologies. The flexible nature of these displays further complicates this issue, as bending or flexing can affect light distribution and viewing angles.

Power efficiency is a crucial concern in nautical applications, where energy resources may be limited. While AMOLED technology is generally known for its energy efficiency, the additional power requirements for flexible panels and the need for increased brightness in outdoor settings can strain power systems. Developing more efficient power management solutions specifically tailored for flex-panel AMOLEDs in marine environments is essential.

The integration of touch functionality in flexible AMOLED displays for nautical use presents another set of challenges. Ensuring accurate touch response on a curved or flexible surface, especially when exposed to water or when operated with gloved hands, requires advanced touch sensing technologies and algorithms.

Mechanical stress and repeated flexing of the display can lead to degradation of the OLED materials and the thin-film transistor (TFT) backplane. This necessitates the development of more robust materials and structural designs that can withstand the physical demands of nautical applications without compromising display quality or lifespan.

Color accuracy and stability under various environmental conditions pose additional challenges. The marine environment's unique lighting conditions and the potential for display curvature can affect color reproduction, requiring advanced color management systems and calibration techniques.

Finally, the manufacturing process for flex-panel AMOLEDs suitable for nautical use faces its own set of challenges. Producing displays that meet the stringent requirements for durability, water resistance, and performance consistency at scale requires significant advancements in manufacturing technologies and quality control processes.

Another critical challenge lies in maintaining display visibility and readability in varying light conditions. Nautical applications often require displays to be clearly visible in both bright sunlight and low-light situations, which demands sophisticated brightness control and anti-glare technologies. The flexible nature of these displays further complicates this issue, as bending or flexing can affect light distribution and viewing angles.

Power efficiency is a crucial concern in nautical applications, where energy resources may be limited. While AMOLED technology is generally known for its energy efficiency, the additional power requirements for flexible panels and the need for increased brightness in outdoor settings can strain power systems. Developing more efficient power management solutions specifically tailored for flex-panel AMOLEDs in marine environments is essential.

The integration of touch functionality in flexible AMOLED displays for nautical use presents another set of challenges. Ensuring accurate touch response on a curved or flexible surface, especially when exposed to water or when operated with gloved hands, requires advanced touch sensing technologies and algorithms.

Mechanical stress and repeated flexing of the display can lead to degradation of the OLED materials and the thin-film transistor (TFT) backplane. This necessitates the development of more robust materials and structural designs that can withstand the physical demands of nautical applications without compromising display quality or lifespan.

Color accuracy and stability under various environmental conditions pose additional challenges. The marine environment's unique lighting conditions and the potential for display curvature can affect color reproduction, requiring advanced color management systems and calibration techniques.

Finally, the manufacturing process for flex-panel AMOLEDs suitable for nautical use faces its own set of challenges. Producing displays that meet the stringent requirements for durability, water resistance, and performance consistency at scale requires significant advancements in manufacturing technologies and quality control processes.

Current Nautical Solutions

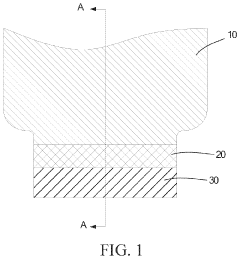

01 Flexible AMOLED panel structure

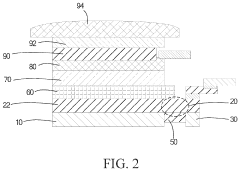

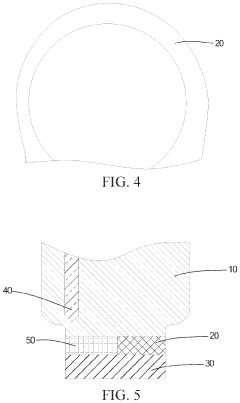

Flex-panel AMOLED displays incorporate flexible substrates and specialized layering techniques to achieve bendable or foldable screens. These structures often include thin-film transistors (TFTs) on a flexible base, with organic light-emitting diodes (OLEDs) arranged in an active matrix configuration. The design allows for curved or rollable displays while maintaining high image quality and responsiveness.- Flexible AMOLED panel structure: Flex-panel AMOLED displays incorporate flexible substrates and thin-film encapsulation to achieve bendable or foldable screens. These panels use organic light-emitting materials and active-matrix backplanes to create vibrant, energy-efficient displays that can conform to various shapes and form factors.

- Pixel circuit design for flexible displays: Specialized pixel circuits are developed for flex-panel AMOLEDs to maintain display performance during bending. These circuits often include compensation mechanisms for stress-induced variations and can adapt to different curvatures, ensuring consistent image quality across the flexible panel.

- Flexible touch sensor integration: Integrating touch sensors into flex-panel AMOLEDs requires innovative approaches to maintain touch functionality while allowing for bending. This may involve using flexible transparent conductive materials or novel sensor patterns that can withstand repeated flexing without degradation in performance.

- Stress management and durability enhancement: Techniques are developed to manage mechanical stress in flex-panel AMOLEDs and enhance their durability. This includes the use of stress-relief structures, optimized layer compositions, and protective films to prevent damage during bending and to extend the lifespan of flexible displays.

- Driving methods for flexible AMOLED panels: Specialized driving methods are implemented to address the unique challenges of flex-panel AMOLEDs. These methods may include adaptive refresh rates, compensation for non-uniform current distribution, and techniques to minimize image distortion when the display is bent or folded.

02 Pixel circuit design for flexible displays

Advanced pixel circuits are crucial for flex-panel AMOLEDs to ensure uniform brightness and color accuracy across the curved or bent surface. These circuits often incorporate compensation mechanisms to address potential issues caused by bending stress, such as threshold voltage shifts in TFTs. Innovative driving schemes and pixel architectures are employed to maintain display performance in various flex configurations.Expand Specific Solutions03 Encapsulation and protection methods

Flex-panel AMOLEDs require specialized encapsulation techniques to protect the sensitive organic materials from moisture and oxygen while maintaining flexibility. Thin-film encapsulation (TFE) methods, multi-layer barrier films, and hybrid inorganic-organic structures are commonly used. These protection methods aim to extend the lifespan of flexible displays and ensure consistent performance under various bending conditions.Expand Specific Solutions04 Touch integration in flexible AMOLED panels

Integrating touch functionality into flex-panel AMOLEDs presents unique challenges due to the bendable nature of the display. Advanced touch sensor designs, such as in-cell or on-cell touch solutions, are developed to maintain touch accuracy and responsiveness across curved surfaces. These integrated touch systems often utilize specialized materials and manufacturing processes to ensure compatibility with flexible display structures.Expand Specific Solutions05 Stress management and durability enhancement

Ensuring the longevity and reliability of flex-panel AMOLEDs requires innovative approaches to manage mechanical stress and enhance durability. This includes the development of stress-resistant materials, optimized layer structures, and novel folding mechanisms. Techniques such as neutral plane design, stress-relief patterns, and dynamic stress distribution are employed to minimize damage from repeated bending or folding actions.Expand Specific Solutions

Key Industry Players

The research on Flex-panel AMOLED applications in nautical technology is in an emerging stage, with a growing market potential as maritime industries seek advanced display solutions. The technology's maturity is progressing, with key players like BOE Technology, Samsung Electronics, and LG Display leading development efforts. These companies are leveraging their expertise in AMOLED technology to create flexible, durable displays suitable for harsh marine environments. While the market size is currently limited, it is expected to expand as the technology becomes more robust and cost-effective for nautical applications.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed flexible AMOLED panels specifically tailored for nautical applications. Their technology incorporates water-resistant and anti-corrosion features to withstand harsh marine environments[1]. The panels utilize low-temperature polycrystalline silicon (LTPS) backplanes for improved electron mobility and power efficiency[2]. BOE's flexible AMOLED displays for nautical use offer high brightness levels (up to 1000 nits) for clear visibility in bright sunlight conditions often encountered at sea[3]. The company has also implemented advanced touch sensitivity features that work even when the screen is wet, addressing a common challenge in marine environments[4].

Strengths: Specialized marine-grade durability, high brightness for outdoor visibility, wet-touch functionality. Weaknesses: Potentially higher cost due to specialized features, limited production capacity for niche marine market.

Everdisplay Optronics (Shanghai) Co., Ltd.

Technical Solution: Everdisplay has developed flexible AMOLED technology for nautical applications, focusing on customization and integration capabilities. Their marine-grade flexible displays feature a ruggedized design with reinforced corners to withstand impact and vibration common in marine environments[13]. Everdisplay's panels incorporate a specialized anti-reflective coating to minimize glare from sunlight and water reflections, enhancing readability in various maritime conditions[14]. The company has also implemented a unique thermal management system to ensure stable performance across a wide range of temperatures encountered at sea[15]. Everdisplay's flexible AMOLED displays for nautical use support seamless integration with existing marine electronics and navigation systems[16].

Strengths: Highly customizable for specific marine applications, advanced anti-reflective technology, robust thermal management. Weaknesses: Smaller production scale compared to larger competitors, potentially longer lead times for customized solutions.

Core AMOLED Innovations

Active matrix organic light emitting diode panel

PatentInactiveUS20200185645A1

Innovation

- An AMOLED panel design featuring a hydrogel layer coated between two backing plates at the bent portion, which is then solidified with ultraviolet light, providing structural strength and toughness to the fillet formed when the panel is folded, thereby preventing deformation and breakage.

Active matrix organic light emitting diode display panel structure

PatentActiveUS10181505B2

Innovation

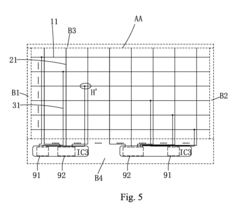

- The AMOLED display panel structure features ultra-narrow border frames by relocating row and column driving circuits to the lower border frame region, using vertically extending switching lines coupled to horizontally extending scan lines, and employing thin film packaging in the left, right, and upper border frames for packaging only, with a substrate and layers optimized for efficient signal transmission.

Environmental Considerations

The application of Flex-panel AMOLED technology in nautical environments presents unique environmental considerations that must be carefully addressed. The marine setting exposes electronic devices to harsh conditions, including high humidity, saltwater exposure, extreme temperatures, and intense sunlight. These factors can significantly impact the performance and longevity of display technologies.

Flex-panel AMOLED displays offer several advantages in this context. Their flexibility allows for better integration into curved surfaces of marine vessels, potentially improving ergonomics and space utilization. The thin and lightweight nature of these displays can contribute to overall weight reduction in nautical equipment, which is crucial for fuel efficiency and vessel performance.

However, the environmental challenges in marine applications require specific adaptations. Waterproofing and salt resistance are paramount. Manufacturers must develop robust encapsulation techniques to protect the sensitive organic materials in AMOLED displays from moisture ingress and corrosive salt spray. This may involve advanced sealing methods and the use of hydrophobic coatings.

Temperature fluctuations pose another significant challenge. AMOLED displays must maintain consistent performance across a wide temperature range, from the freezing conditions of arctic waters to the scorching heat of tropical climates. This necessitates the development of temperature-resistant materials and adaptive brightness controls to ensure readability in varying conditions.

UV radiation from prolonged exposure to sunlight is a critical concern for AMOLED displays in nautical applications. The organic materials in these displays are susceptible to degradation from UV light, potentially leading to color shifts and reduced lifespan. Implementing UV-filtering layers and developing more UV-resistant organic compounds are essential areas of research to enhance the durability of Flex-panel AMOLEDs in marine environments.

Energy efficiency is another crucial environmental consideration. Marine vessels often operate on limited power resources, making the low power consumption of AMOLED technology particularly attractive. However, researchers must focus on optimizing power usage while maintaining visibility in bright outdoor conditions, potentially through the development of adaptive power management systems.

Lastly, the environmental impact of manufacturing and disposing of Flex-panel AMOLED displays must be considered. As the maritime industry increasingly focuses on sustainability, there is a growing need for eco-friendly production processes and recyclable materials. Researchers should explore ways to reduce the use of rare earth elements and develop end-of-life recycling solutions for these specialized displays.

Flex-panel AMOLED displays offer several advantages in this context. Their flexibility allows for better integration into curved surfaces of marine vessels, potentially improving ergonomics and space utilization. The thin and lightweight nature of these displays can contribute to overall weight reduction in nautical equipment, which is crucial for fuel efficiency and vessel performance.

However, the environmental challenges in marine applications require specific adaptations. Waterproofing and salt resistance are paramount. Manufacturers must develop robust encapsulation techniques to protect the sensitive organic materials in AMOLED displays from moisture ingress and corrosive salt spray. This may involve advanced sealing methods and the use of hydrophobic coatings.

Temperature fluctuations pose another significant challenge. AMOLED displays must maintain consistent performance across a wide temperature range, from the freezing conditions of arctic waters to the scorching heat of tropical climates. This necessitates the development of temperature-resistant materials and adaptive brightness controls to ensure readability in varying conditions.

UV radiation from prolonged exposure to sunlight is a critical concern for AMOLED displays in nautical applications. The organic materials in these displays are susceptible to degradation from UV light, potentially leading to color shifts and reduced lifespan. Implementing UV-filtering layers and developing more UV-resistant organic compounds are essential areas of research to enhance the durability of Flex-panel AMOLEDs in marine environments.

Energy efficiency is another crucial environmental consideration. Marine vessels often operate on limited power resources, making the low power consumption of AMOLED technology particularly attractive. However, researchers must focus on optimizing power usage while maintaining visibility in bright outdoor conditions, potentially through the development of adaptive power management systems.

Lastly, the environmental impact of manufacturing and disposing of Flex-panel AMOLED displays must be considered. As the maritime industry increasingly focuses on sustainability, there is a growing need for eco-friendly production processes and recyclable materials. Researchers should explore ways to reduce the use of rare earth elements and develop end-of-life recycling solutions for these specialized displays.

Regulatory Framework

The regulatory framework surrounding flex-panel AMOLED applications in nautical technology is complex and multifaceted, involving various international and national bodies. The International Maritime Organization (IMO) plays a crucial role in setting global standards for maritime safety and environmental protection. Its regulations, particularly those related to electronic chart display and information systems (ECDIS), have significant implications for the adoption of flex-panel AMOLED displays in nautical applications.

National maritime authorities also contribute to the regulatory landscape. In the United States, the Coast Guard and the Federal Communications Commission (FCC) oversee the certification of marine electronics. The European Union's Marine Equipment Directive (MED) sets standards for equipment used on EU-flagged vessels. These regulations often require rigorous testing and certification processes to ensure the reliability and durability of electronic displays in harsh marine environments.

Environmental considerations are increasingly important in maritime regulations. The IMO's MARPOL convention addresses pollution prevention, which may influence the materials and manufacturing processes used in flex-panel AMOLED production. Additionally, regulations on electronic waste disposal and recycling, such as the EU's Waste Electrical and Electronic Equipment (WEEE) Directive, may impact the entire lifecycle of these displays.

Safety standards specific to marine electronics, such as those set by the International Electrotechnical Commission (IEC), are critical for flex-panel AMOLED applications. These standards address issues like electromagnetic compatibility, vibration resistance, and waterproofing, all of which are essential for nautical use.

The regulatory framework also extends to data protection and cybersecurity. As flex-panel AMOLEDs may be integrated into navigation and communication systems, they must comply with regulations like the IMO's Guidelines on Maritime Cyber Risk Management and the EU's Network and Information Security (NIS) Directive.

Intellectual property regulations play a significant role in the development and deployment of flex-panel AMOLED technology. Patent laws and licensing agreements can influence the availability and cost of implementing these advanced displays in nautical equipment.

As the technology evolves, regulatory bodies are likely to update their frameworks to address new capabilities and potential risks associated with flex-panel AMOLEDs. This may include regulations on the use of augmented reality features or the integration of artificial intelligence in display systems. Manufacturers and developers must stay abreast of these evolving regulations to ensure compliance and market access for their nautical applications.

National maritime authorities also contribute to the regulatory landscape. In the United States, the Coast Guard and the Federal Communications Commission (FCC) oversee the certification of marine electronics. The European Union's Marine Equipment Directive (MED) sets standards for equipment used on EU-flagged vessels. These regulations often require rigorous testing and certification processes to ensure the reliability and durability of electronic displays in harsh marine environments.

Environmental considerations are increasingly important in maritime regulations. The IMO's MARPOL convention addresses pollution prevention, which may influence the materials and manufacturing processes used in flex-panel AMOLED production. Additionally, regulations on electronic waste disposal and recycling, such as the EU's Waste Electrical and Electronic Equipment (WEEE) Directive, may impact the entire lifecycle of these displays.

Safety standards specific to marine electronics, such as those set by the International Electrotechnical Commission (IEC), are critical for flex-panel AMOLED applications. These standards address issues like electromagnetic compatibility, vibration resistance, and waterproofing, all of which are essential for nautical use.

The regulatory framework also extends to data protection and cybersecurity. As flex-panel AMOLEDs may be integrated into navigation and communication systems, they must comply with regulations like the IMO's Guidelines on Maritime Cyber Risk Management and the EU's Network and Information Security (NIS) Directive.

Intellectual property regulations play a significant role in the development and deployment of flex-panel AMOLED technology. Patent laws and licensing agreements can influence the availability and cost of implementing these advanced displays in nautical equipment.

As the technology evolves, regulatory bodies are likely to update their frameworks to address new capabilities and potential risks associated with flex-panel AMOLEDs. This may include regulations on the use of augmented reality features or the integration of artificial intelligence in display systems. Manufacturers and developers must stay abreast of these evolving regulations to ensure compliance and market access for their nautical applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!