Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

324 results about "Air bridge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

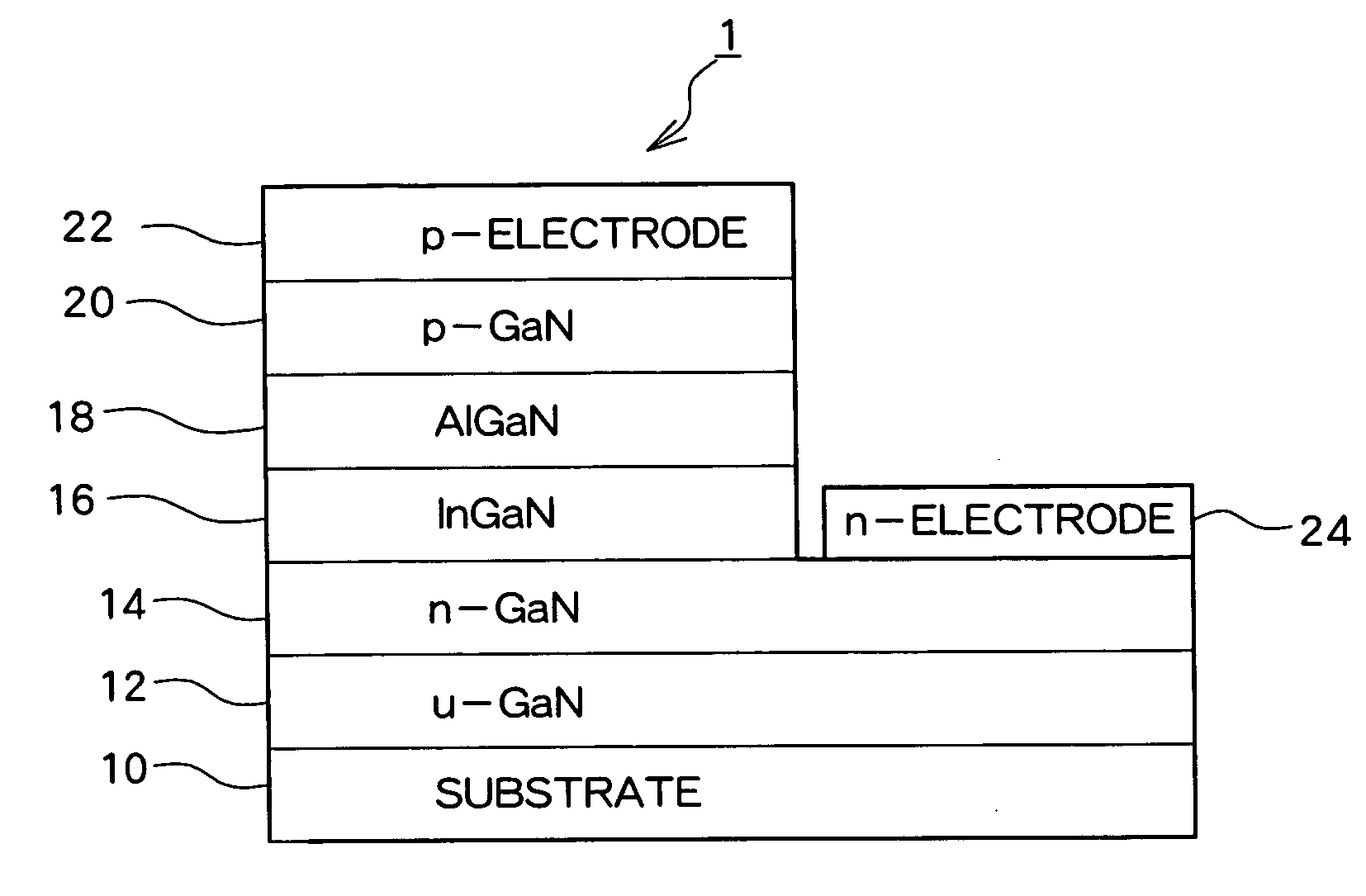

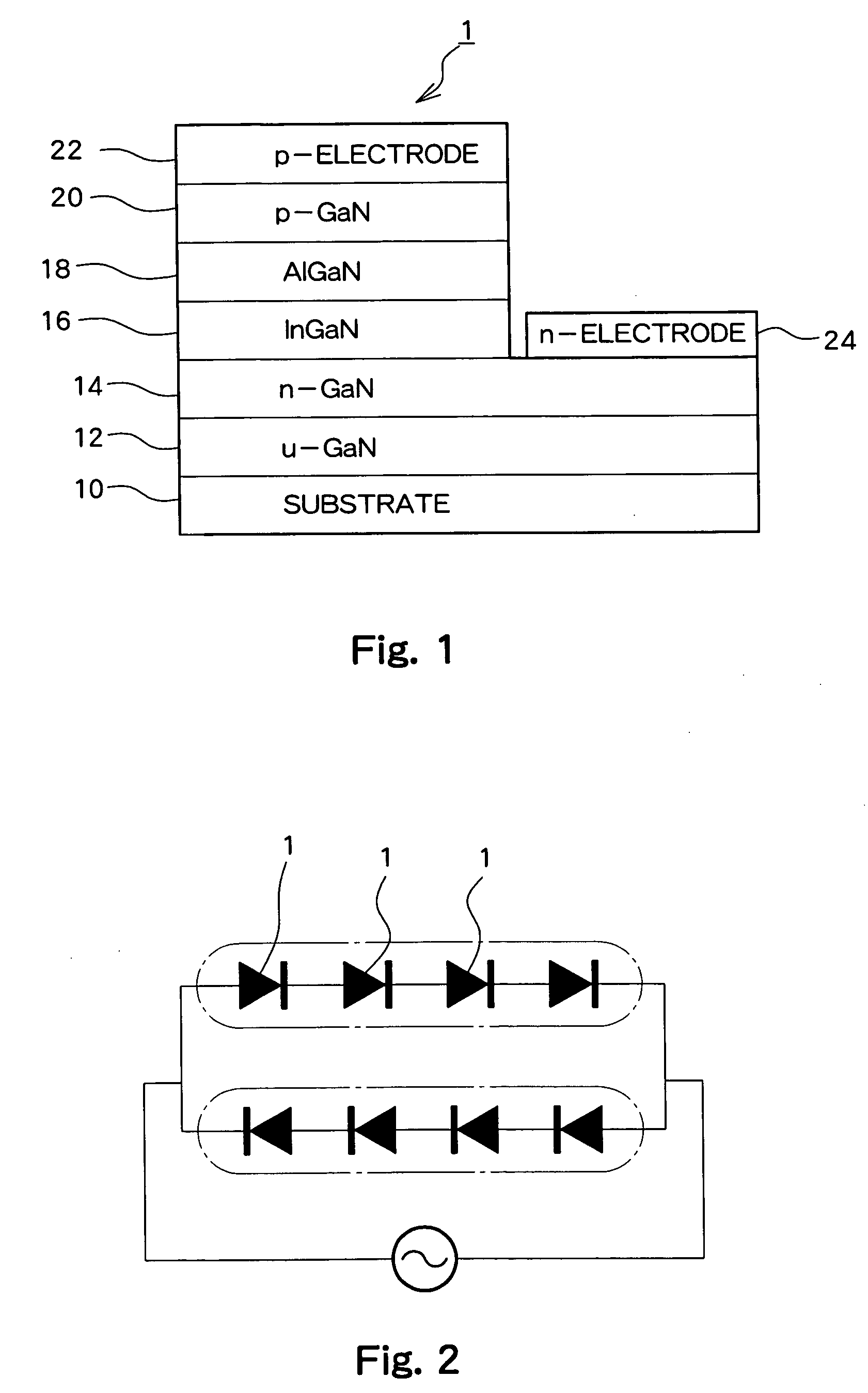

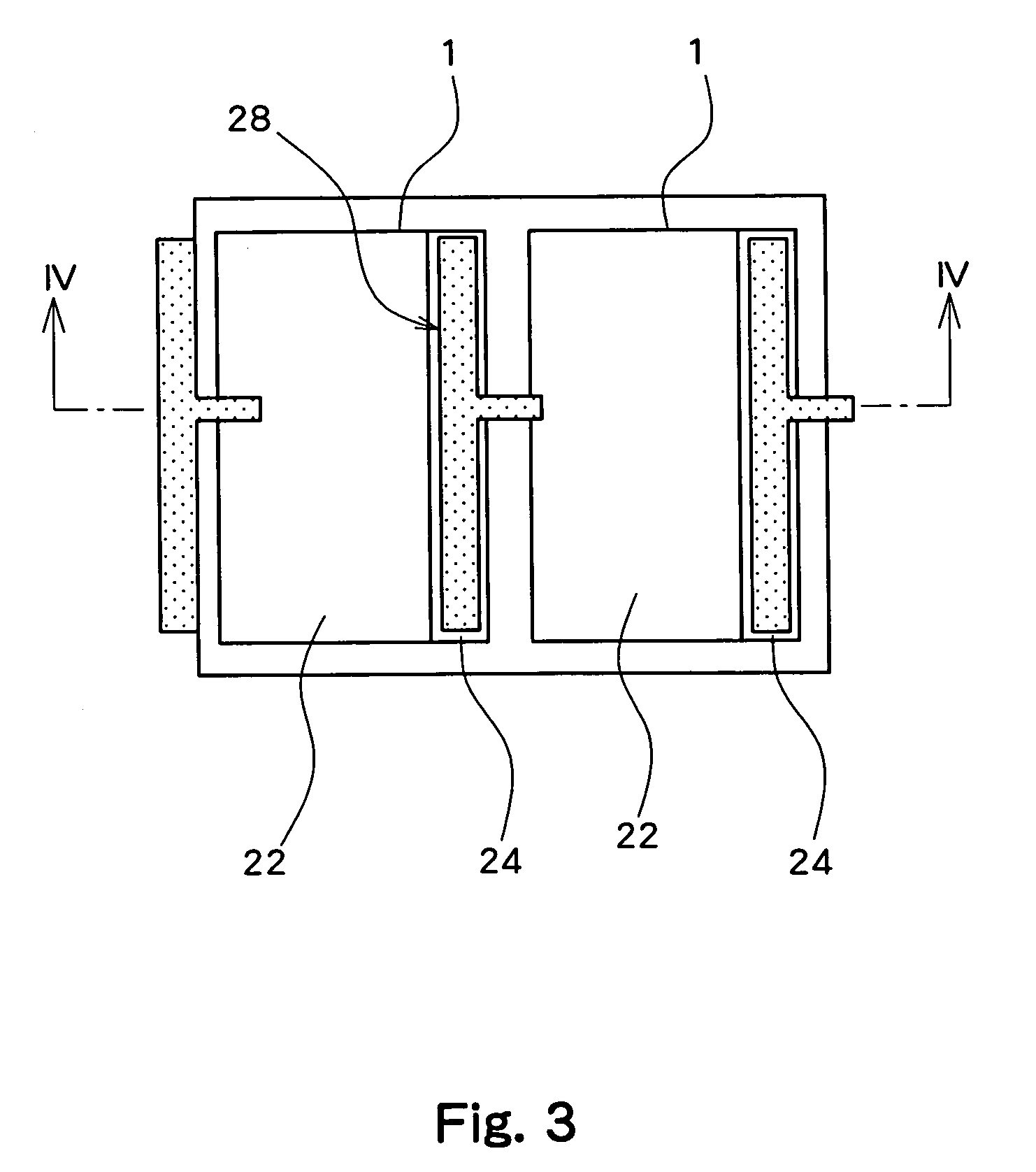

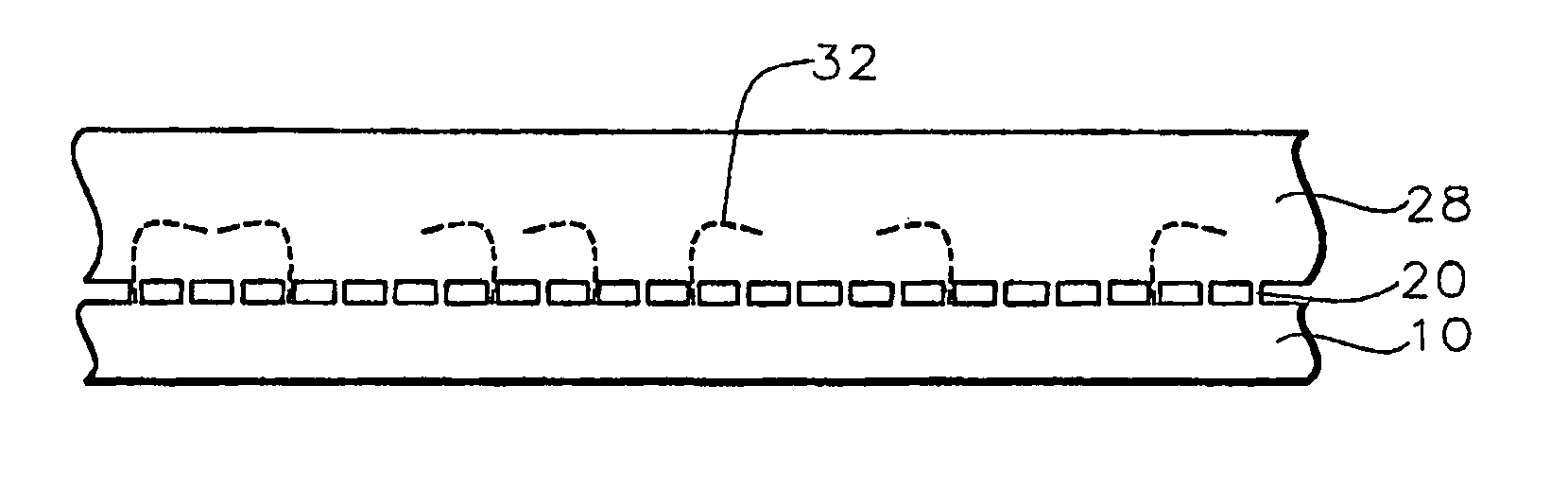

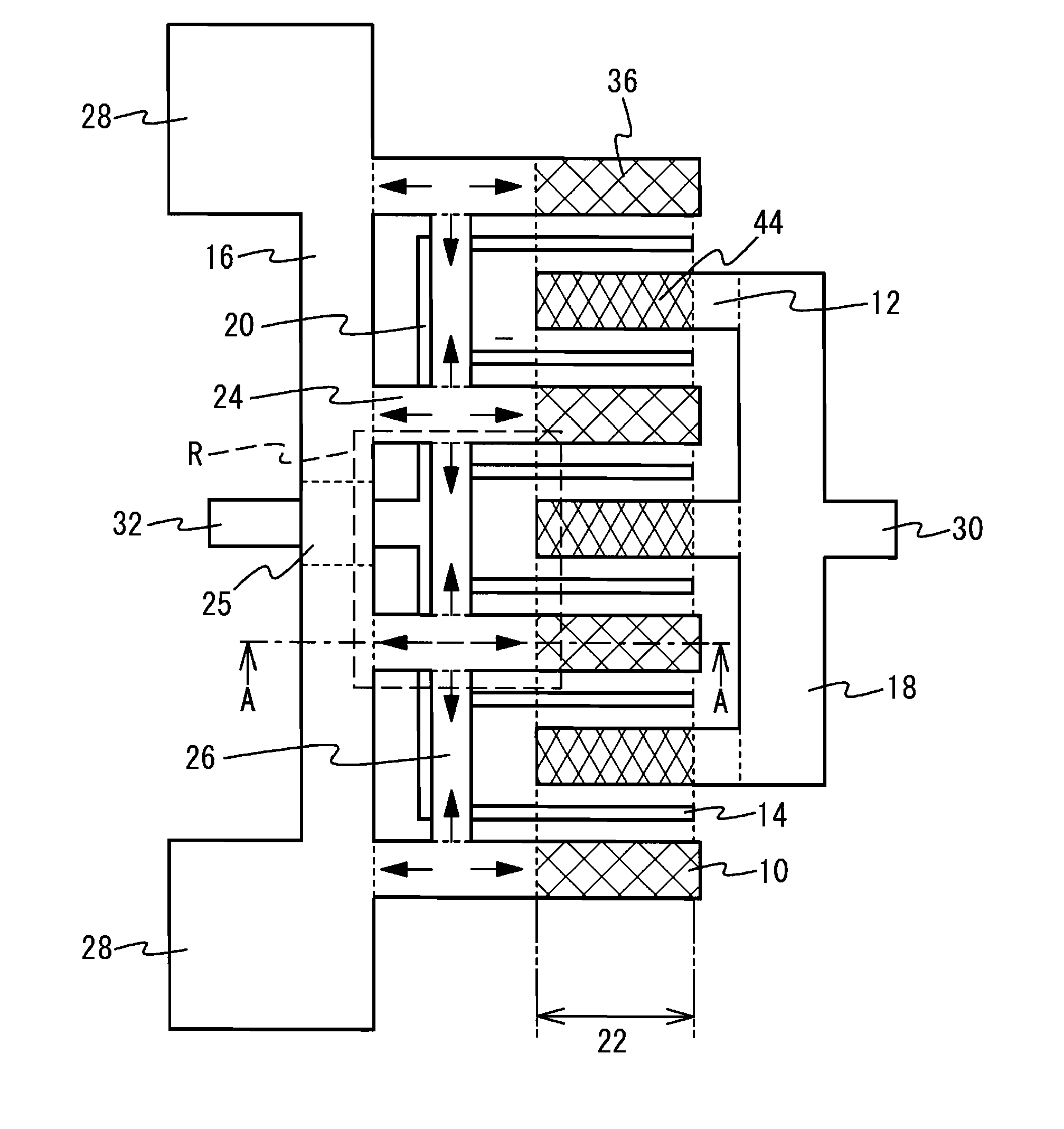

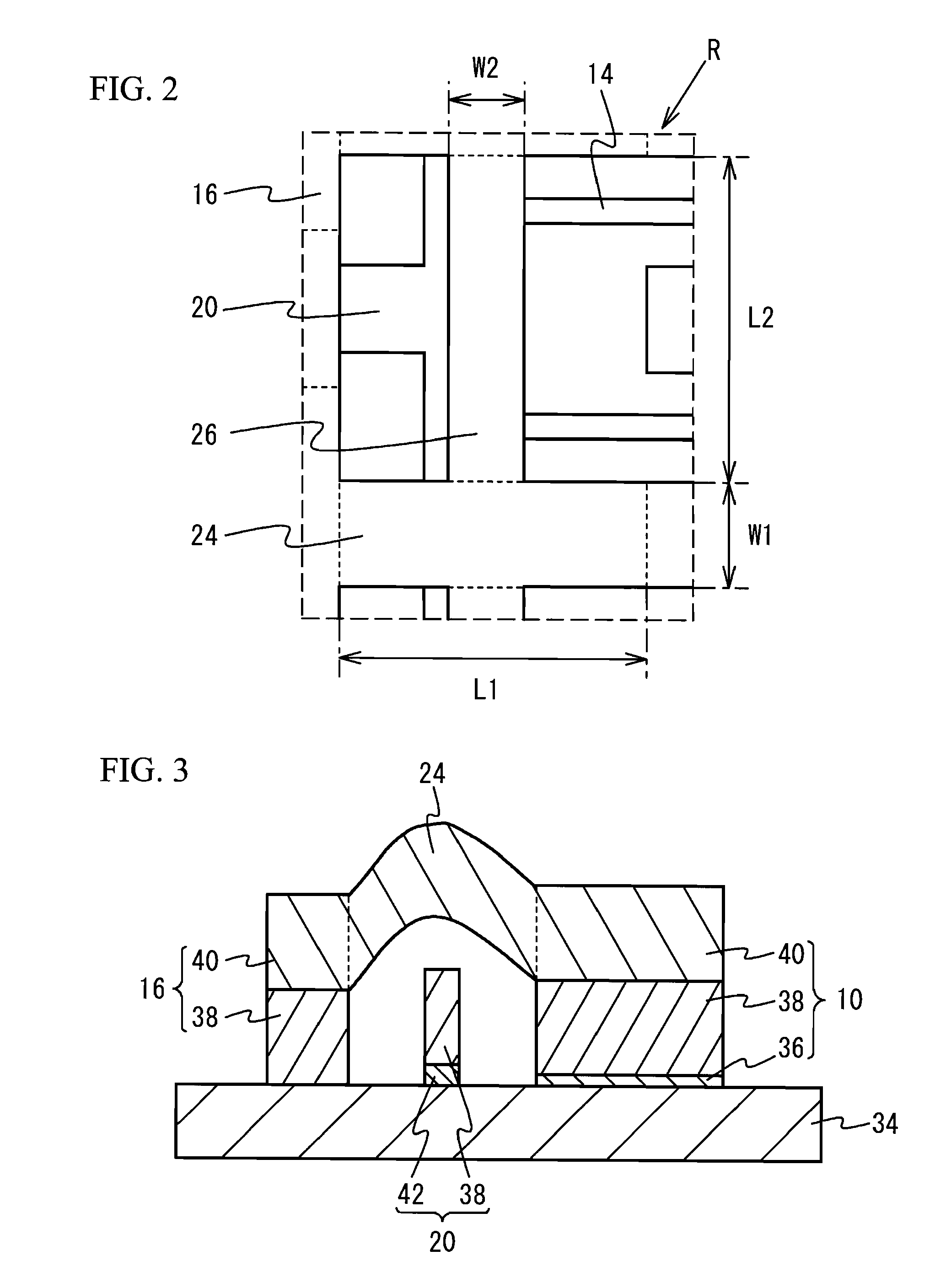

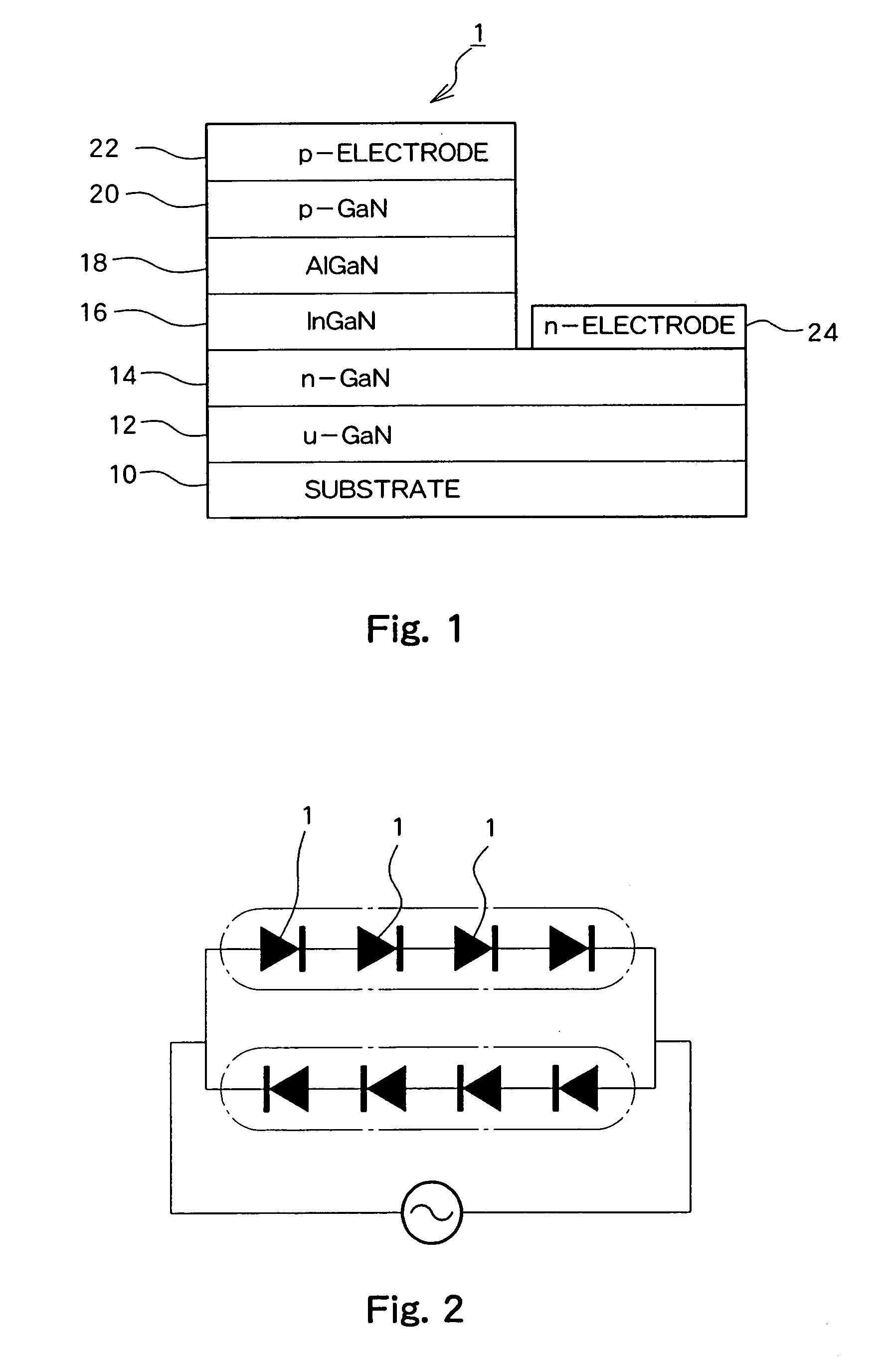

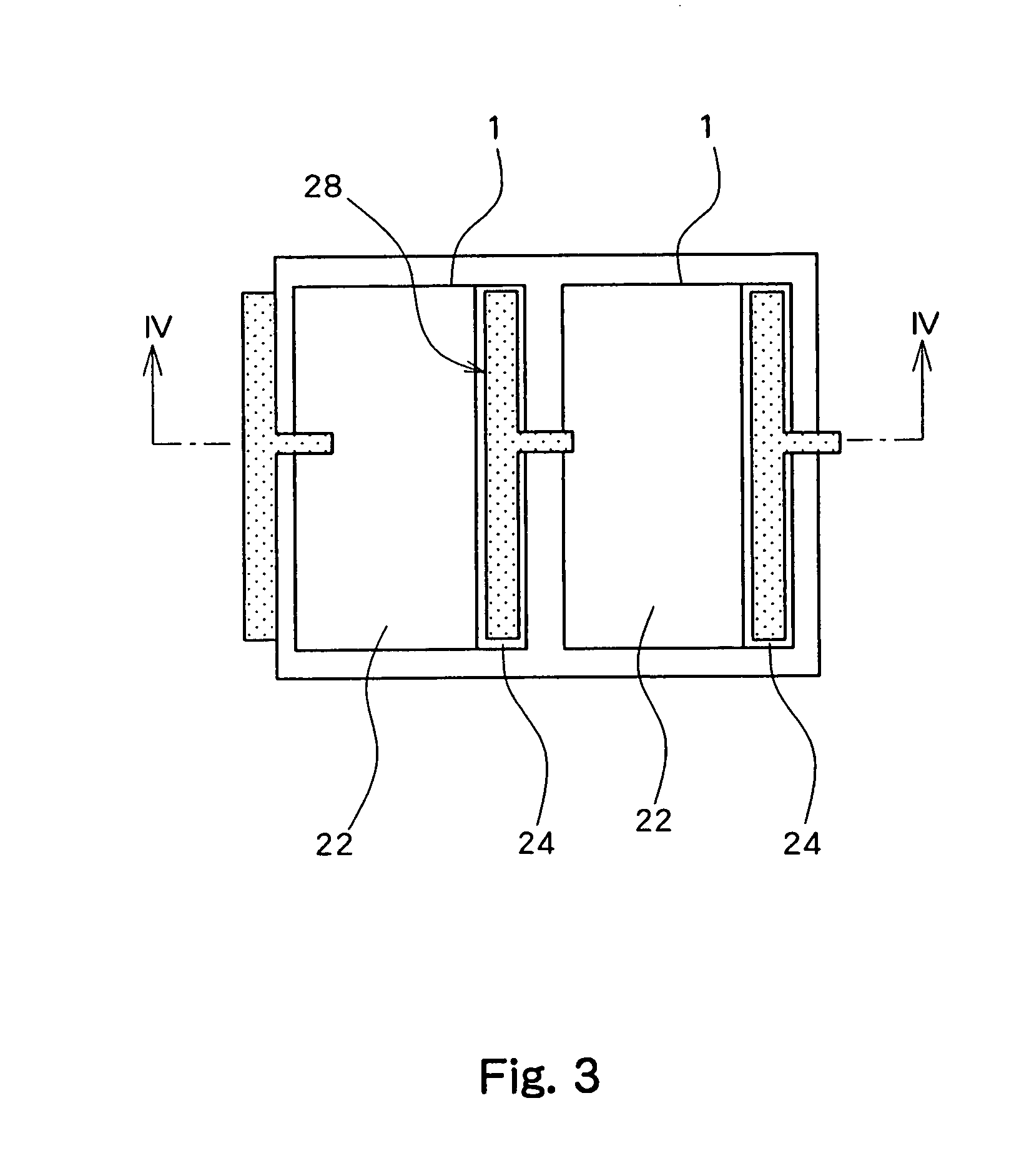

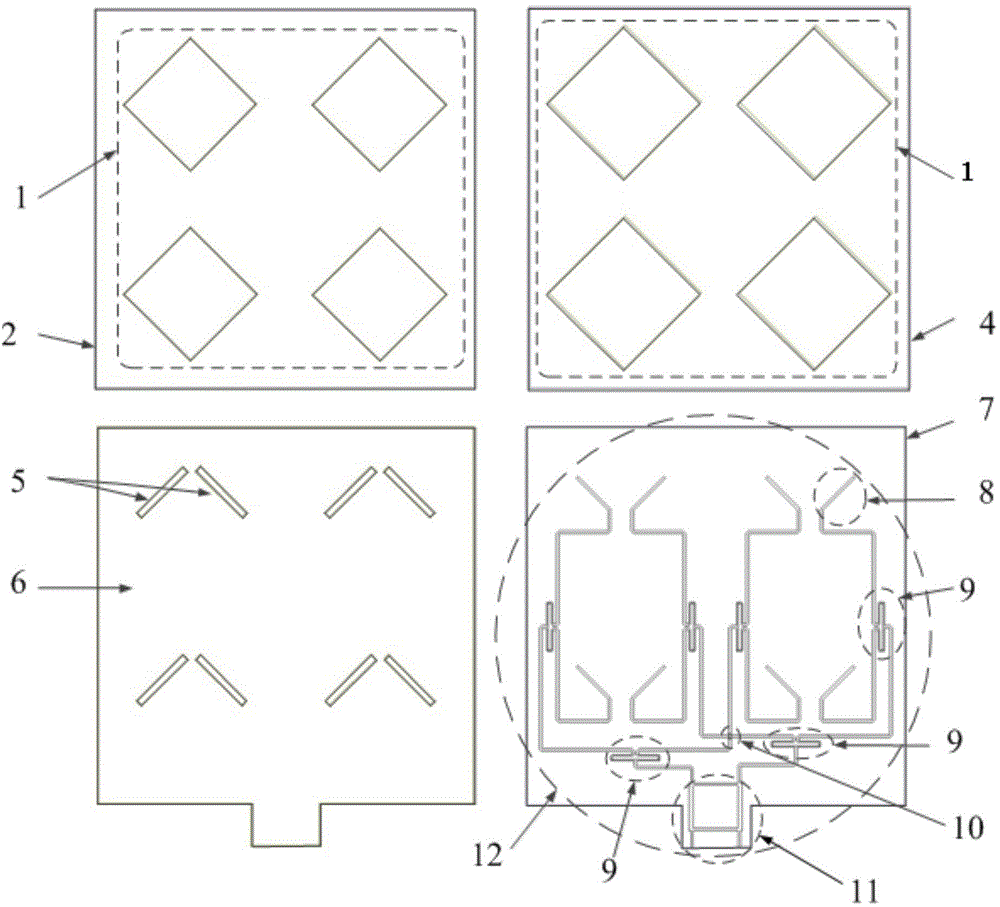

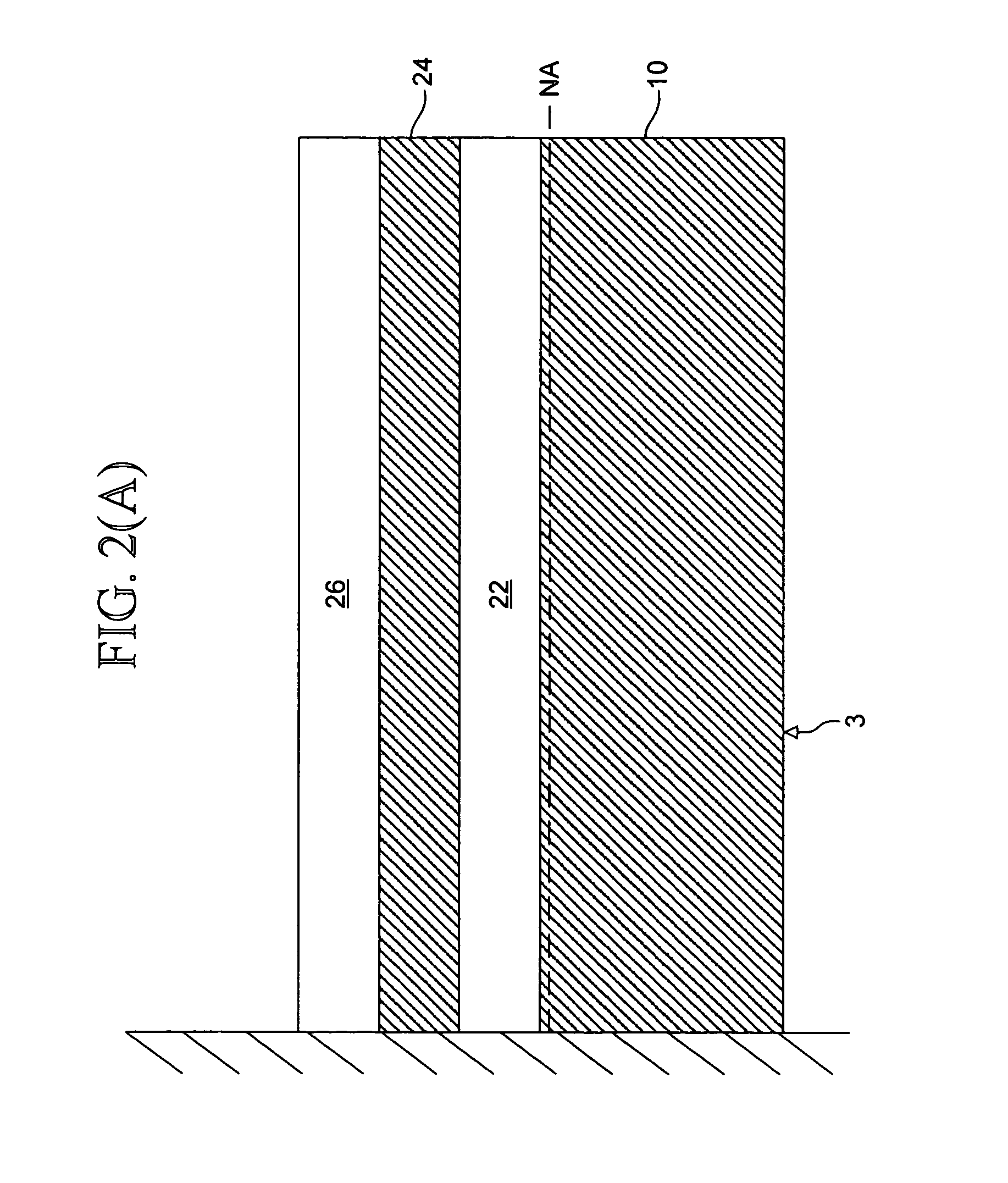

Light-emitting device having light-emitting elements

InactiveUS20050253151A1Increase the driving voltageEfficient use ofSolid-state devicesSemiconductor devicesDriving currentAir bridge

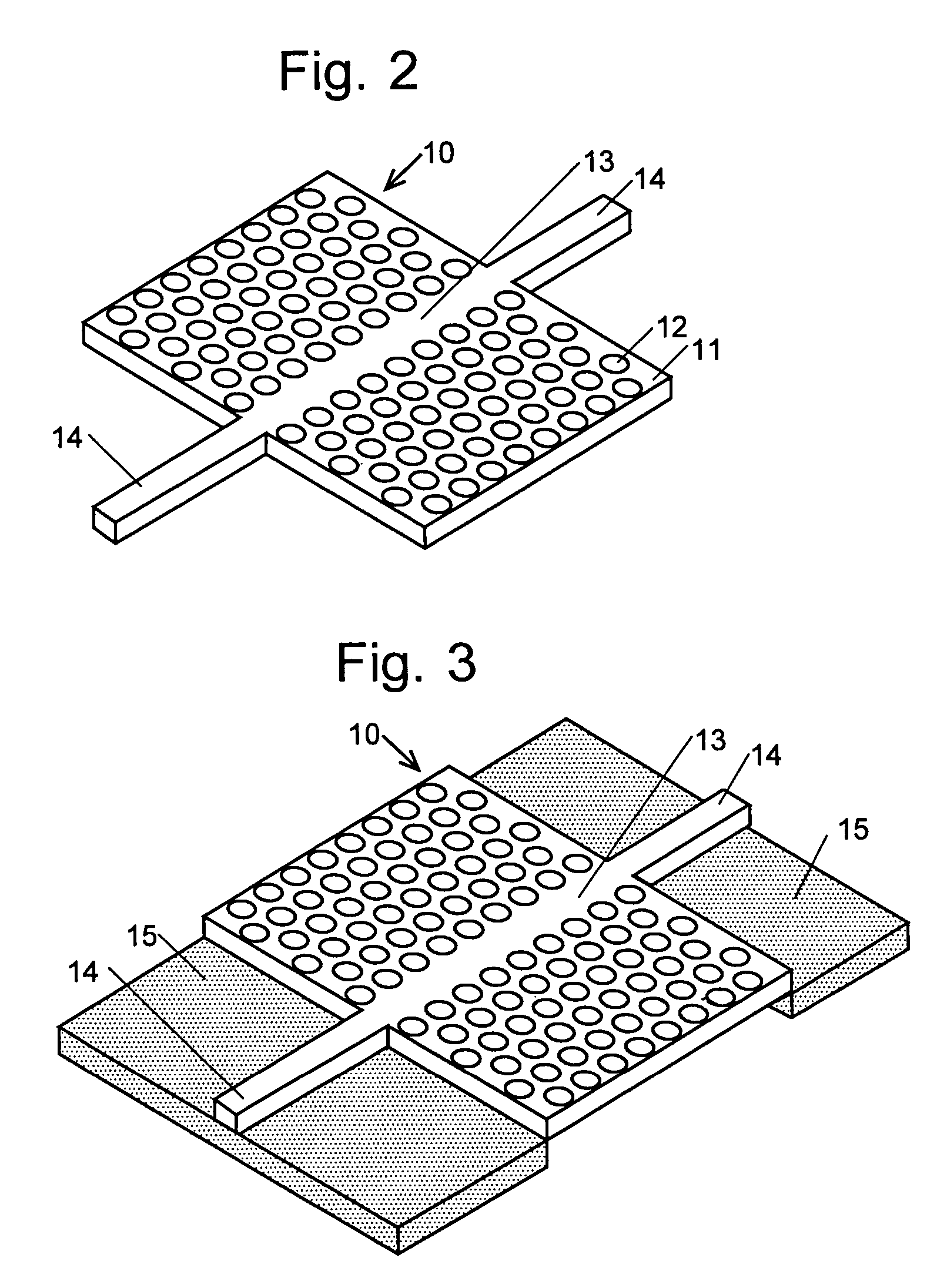

A light-emitting device operating on a high drive voltage and a small drive current. LEDs (1) are two-dimensionally formed on an insulating substrate (10) of e.g., sapphire monolithically and connected in series to form an LED array. Two such LED arrays are connected to electrodes (32) in inverse parallel. Air-bridge wiring (28) is formed between the LEDs (1) and between the LEDs (1) and electrodes (32). The LED arrays are arranged zigzag to form a plurality of LEDs (1) to produce a high drive voltage and a small drive current. Two LED arrays are connected in inverse parallel, and therefore an AC power supply can be used as the power supply.

Owner:SEOUL SEMICONDUCTOR

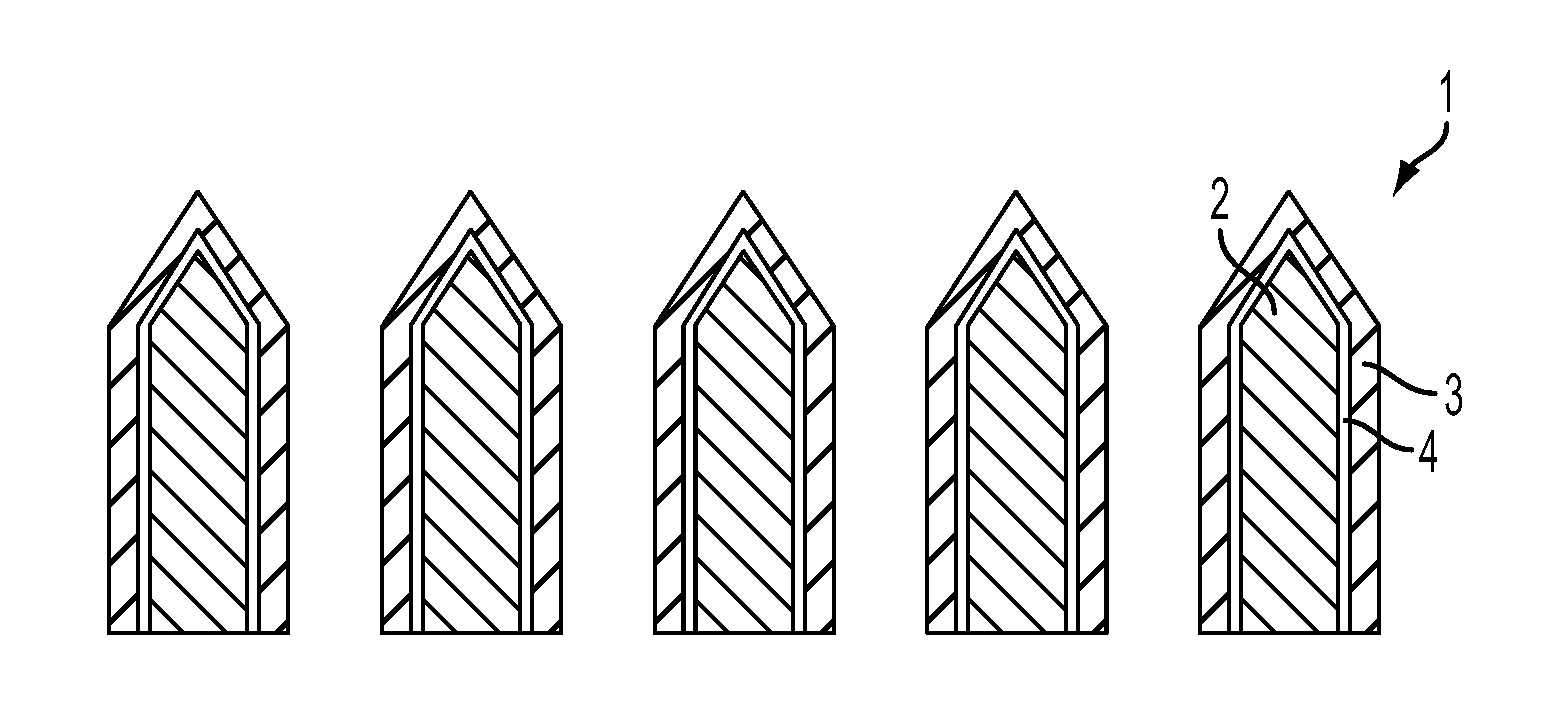

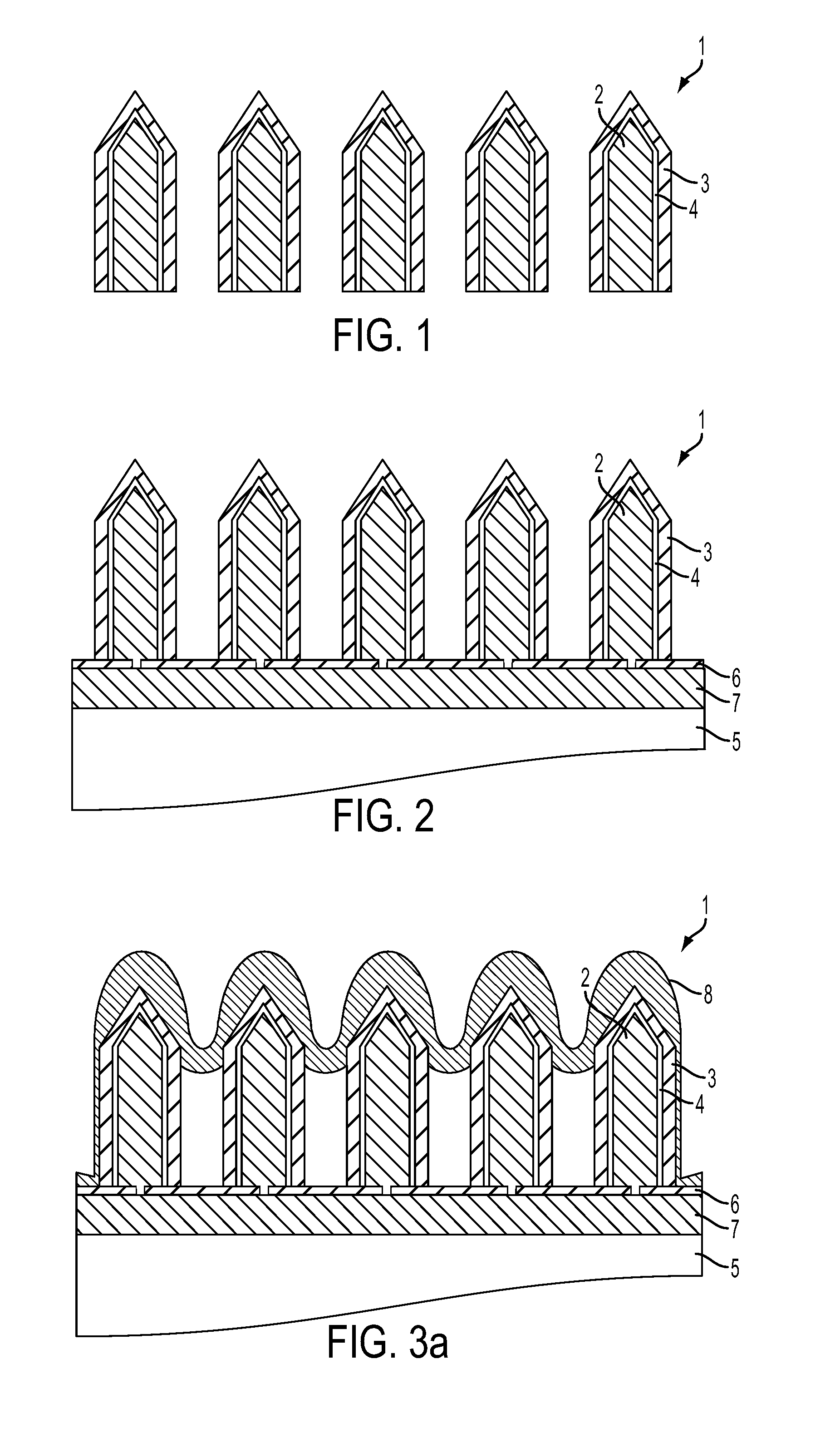

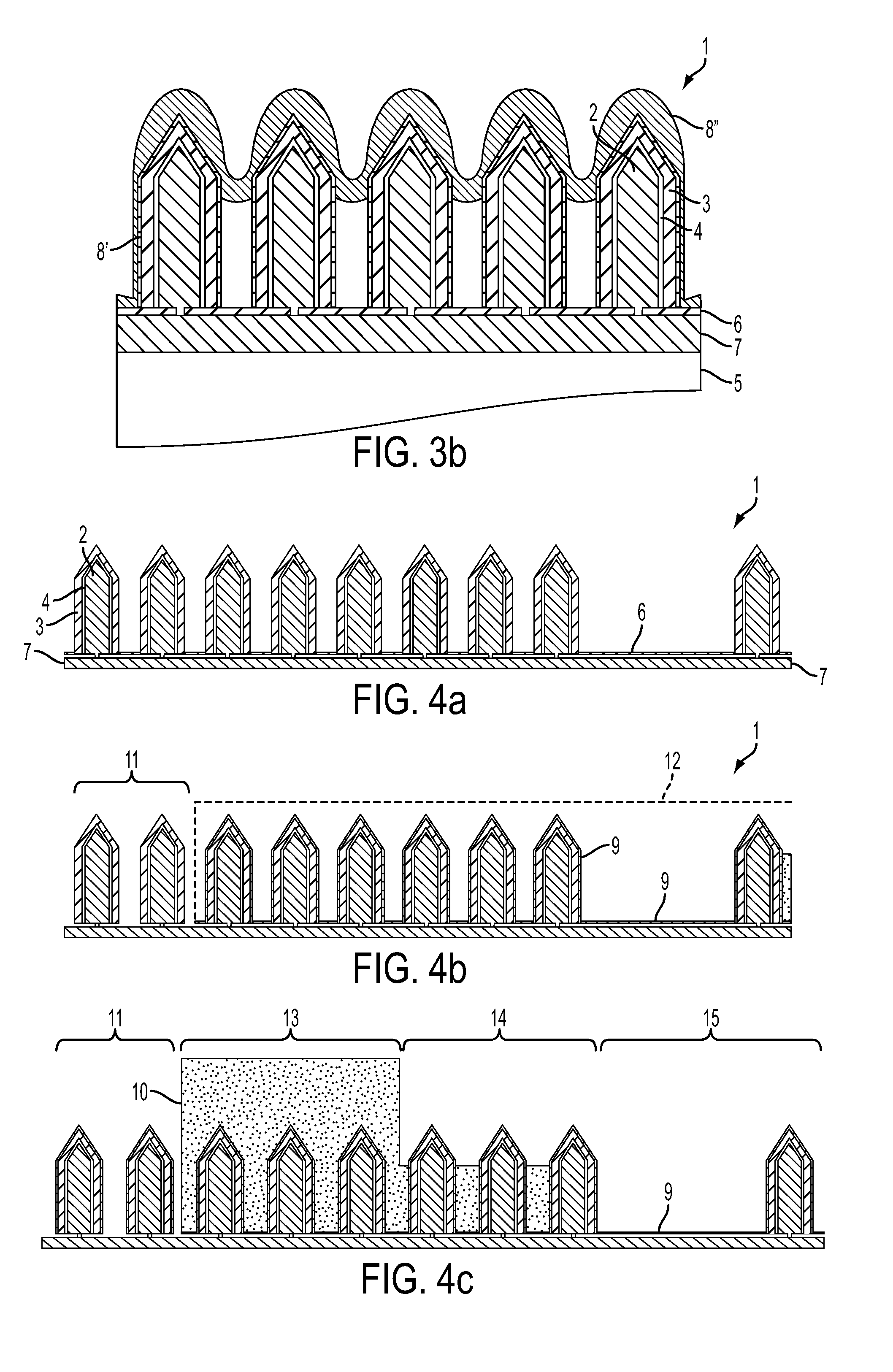

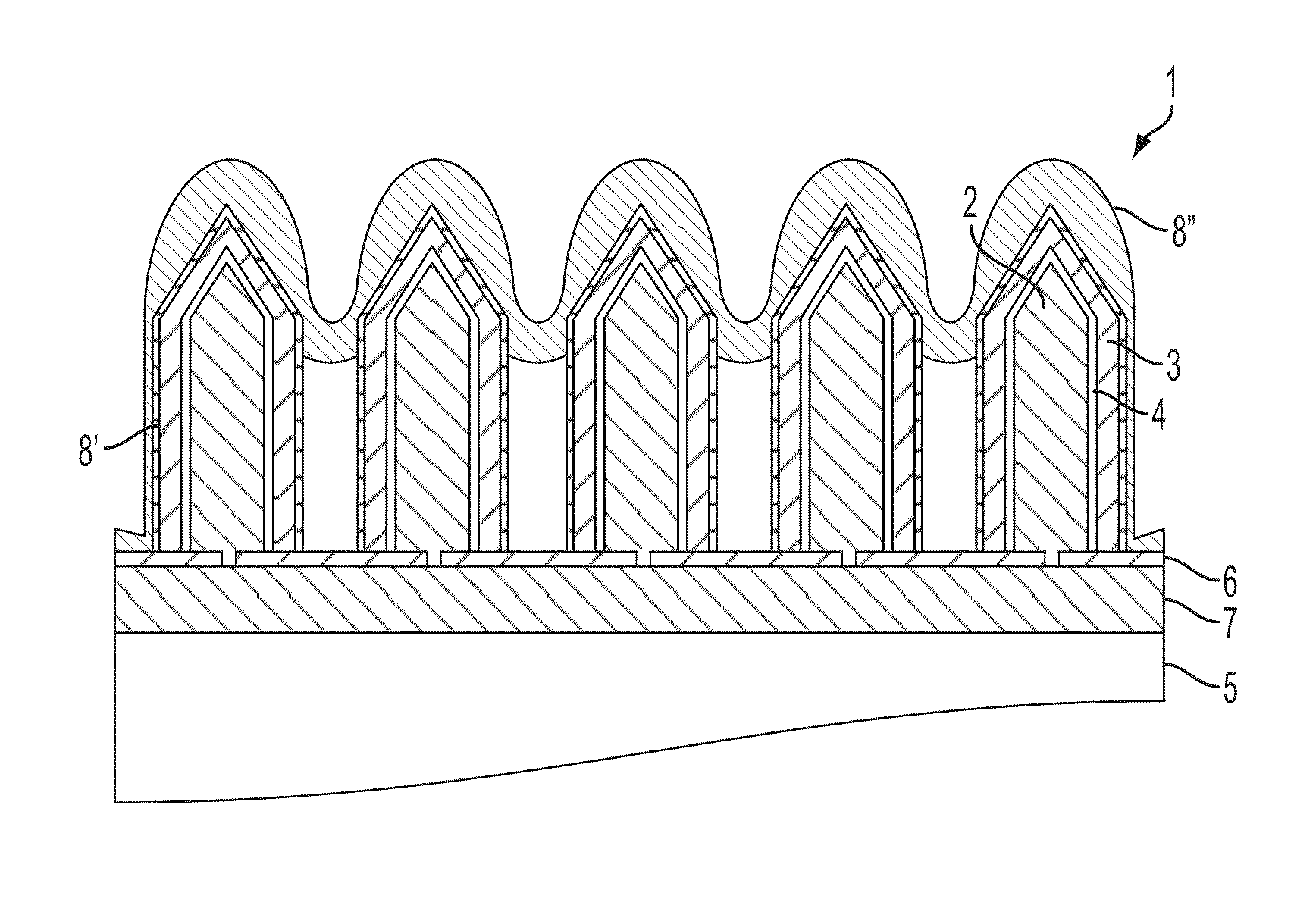

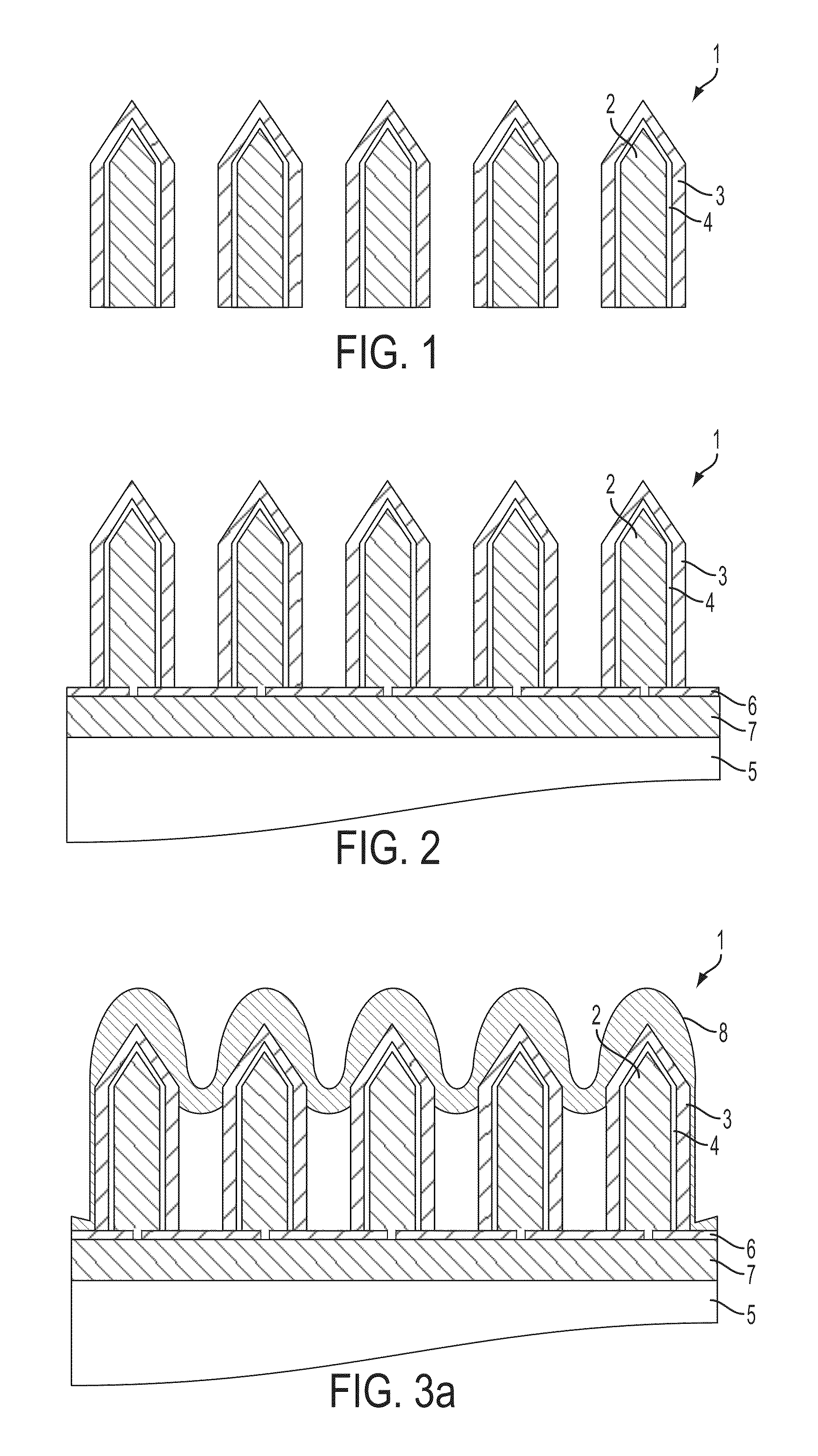

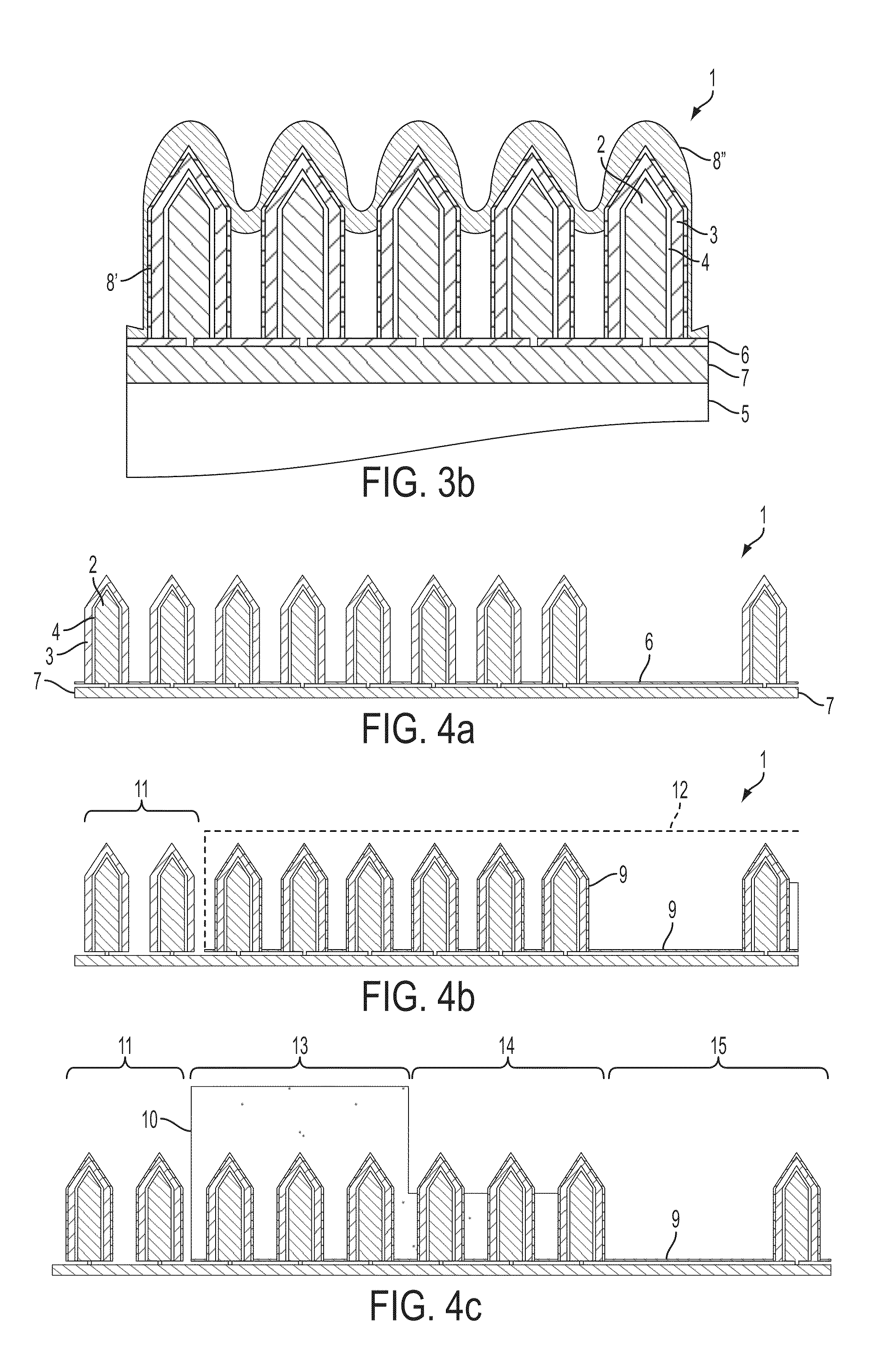

Nanowire LED structure and method for manufacturing the same

ActiveUS20110309382A1Discontinuity is reduced and eliminatedEasy to spreadSolid-state devicesSemiconductor/solid-state device manufacturingElectricityAir bridge

A light emitting diode (LED) structure includes a plurality of devices arranged side by side on a support layer. Each device includes a first conductivity type semiconductor nanowire core and an enclosing second conductivity type semiconductor shell for forming a pn or pin junction that in operation provides an active region for light generation. A first electrode layer extends over the plurality of devices and is in electrical contact with at least a top portion of the devices to connect to the shell. The first electrode layer is at least partly air-bridged between the devices.

Owner:NANOSYS INC

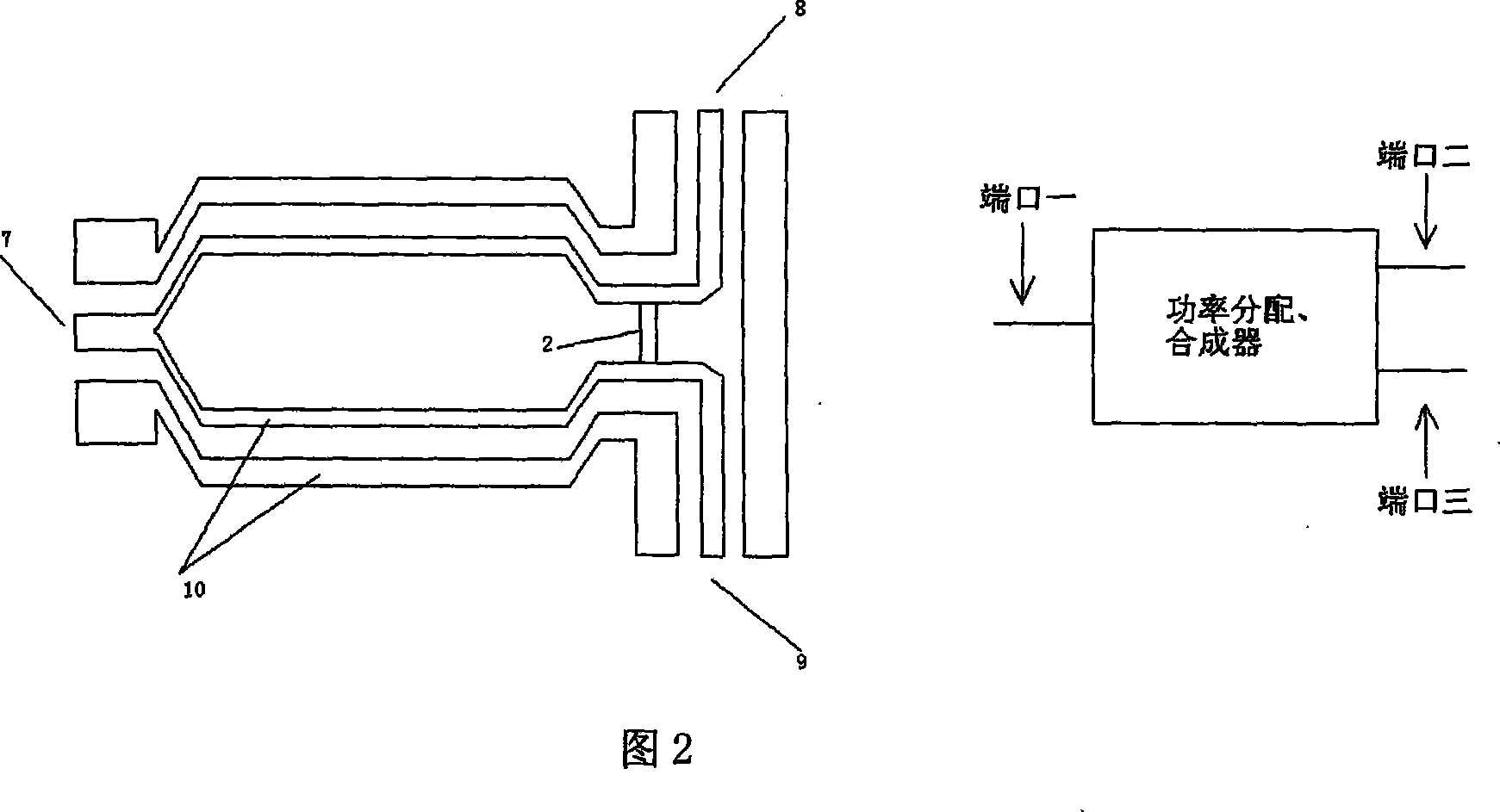

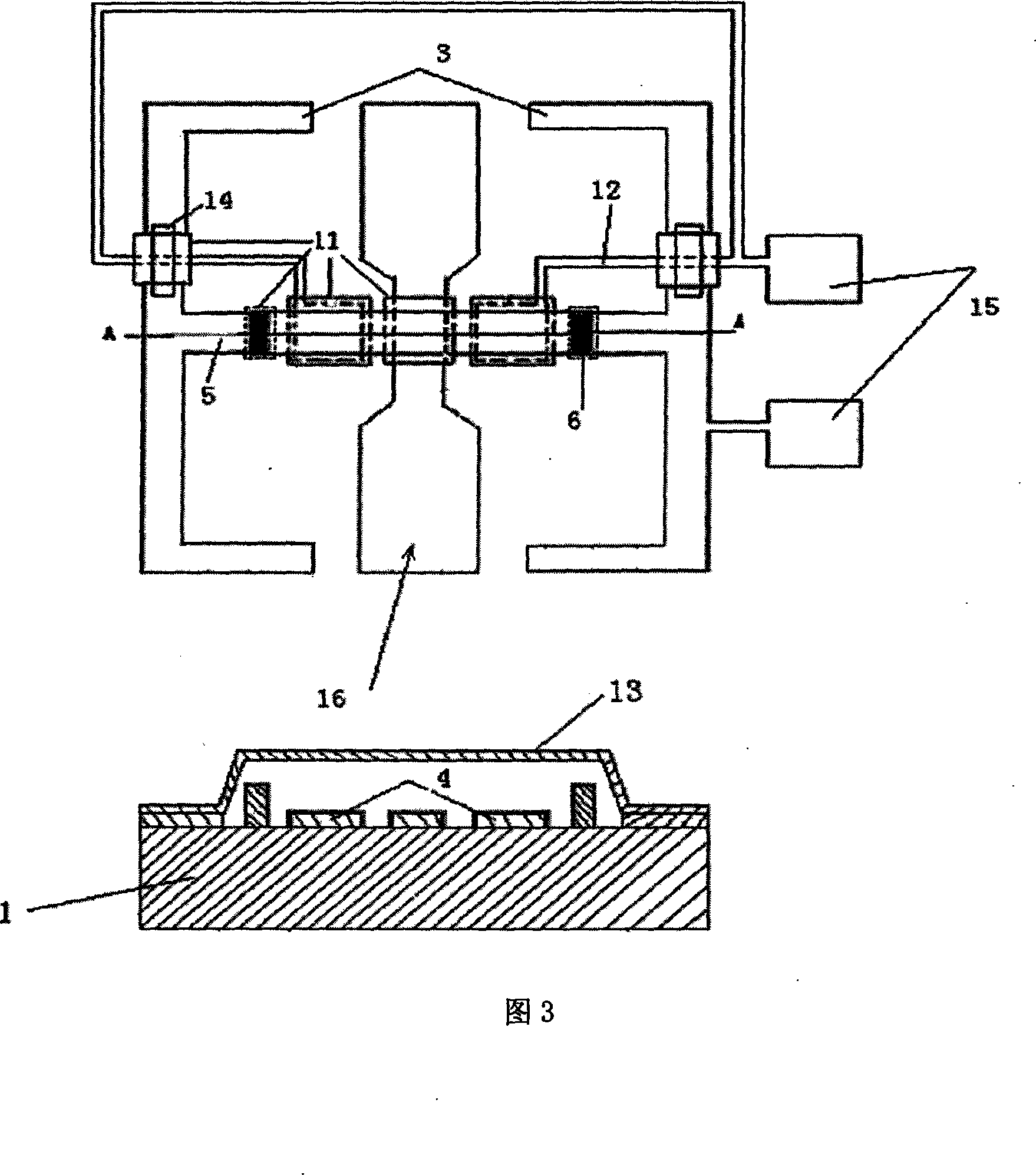

Microelectronic machinery orthogonal double channels microwave phase online detector and manufacturing method therefor

InactiveCN101034122AIncreaseIncreased bandwidthElectromagentic field characteristicsCapacitancePower combiner

this invention relates to power in direct-current circuits. The invention takes gallium arsenide as foundation (1). On the foundation has power divider, power synthesizer, 90deg phaser, solid beam structure. Power divider and power synthesizer composed by port one (7), port two(8), port three(8), dissymmetry coplane band line(10), nitride tantalum electric resistance. Solid beam structure includes signal input port(16), pier(5), solid beam(13), pedestal structure(6), sensing electrode(4), sensing electrode leader(12), capacitance detecting port(15), air bridge(14). There are nitriding silicon medium layer on the transmission line, pedestal structure and sensing electrode under solid beam, and sensing electrode leader under Air Bridge.

Owner:SOUTHEAST UNIV

Method for producing a semiconductor device and resulting device

ActiveUS20060205161A1Easy to integrateCompact structureSemiconductor/solid-state device detailsSolid-state devicesAir bridgeDevice material

The present invention is related to a method of producing a semiconductor device and the resulting device. The method is suitable in the first place for producing high power devices, such as High Electron Mobility Transistors (HEMT), in particular HEMT-devices with multiples source-gate-drain groups or multiple base bipolar transistors. According to the method, the interconnect between the source contacts is not produced by air bridge structures, but by etching vias through the semiconductor layer directly to the ohmic contacts and applying a contact layer on the backside of the device.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

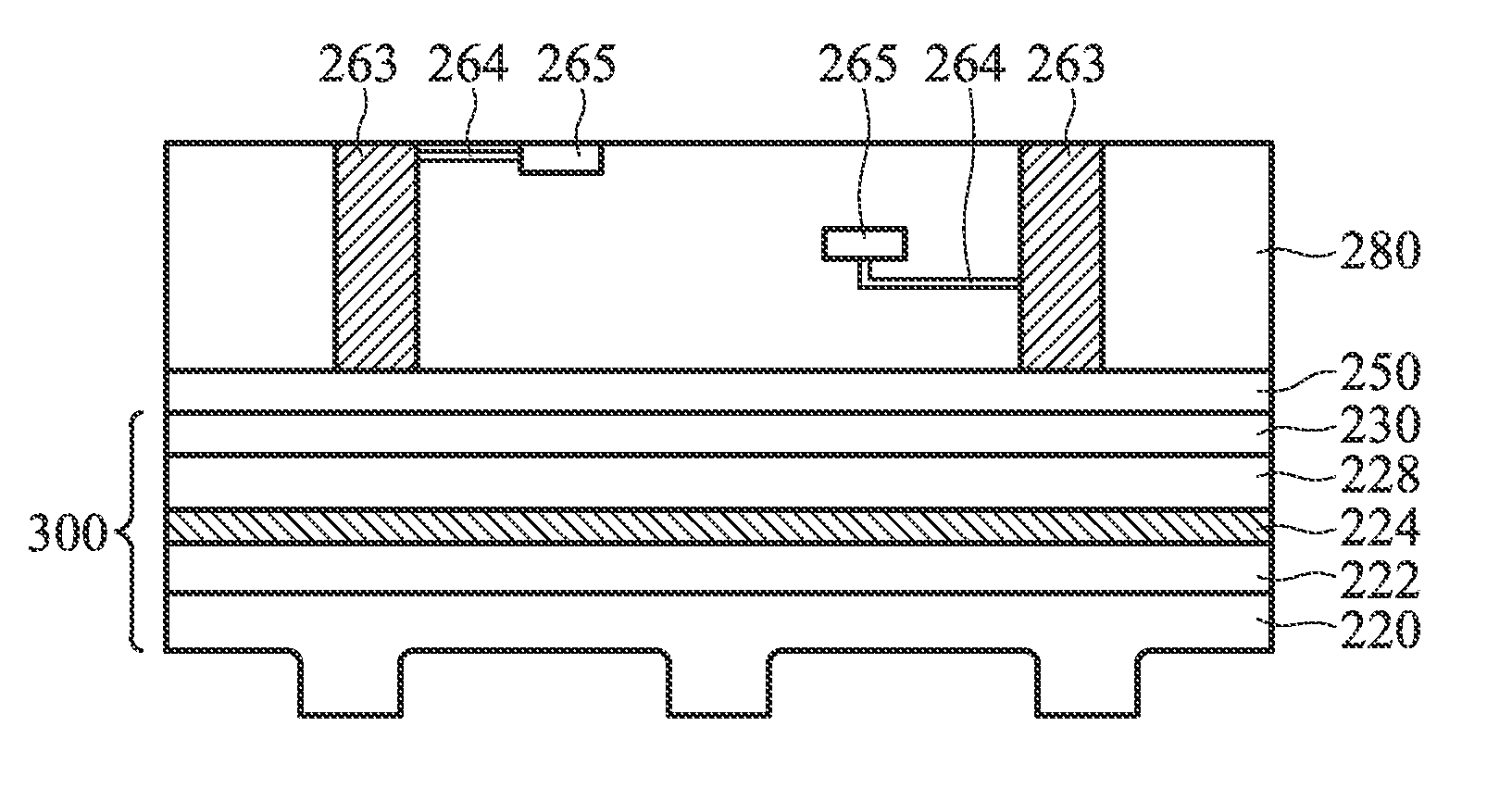

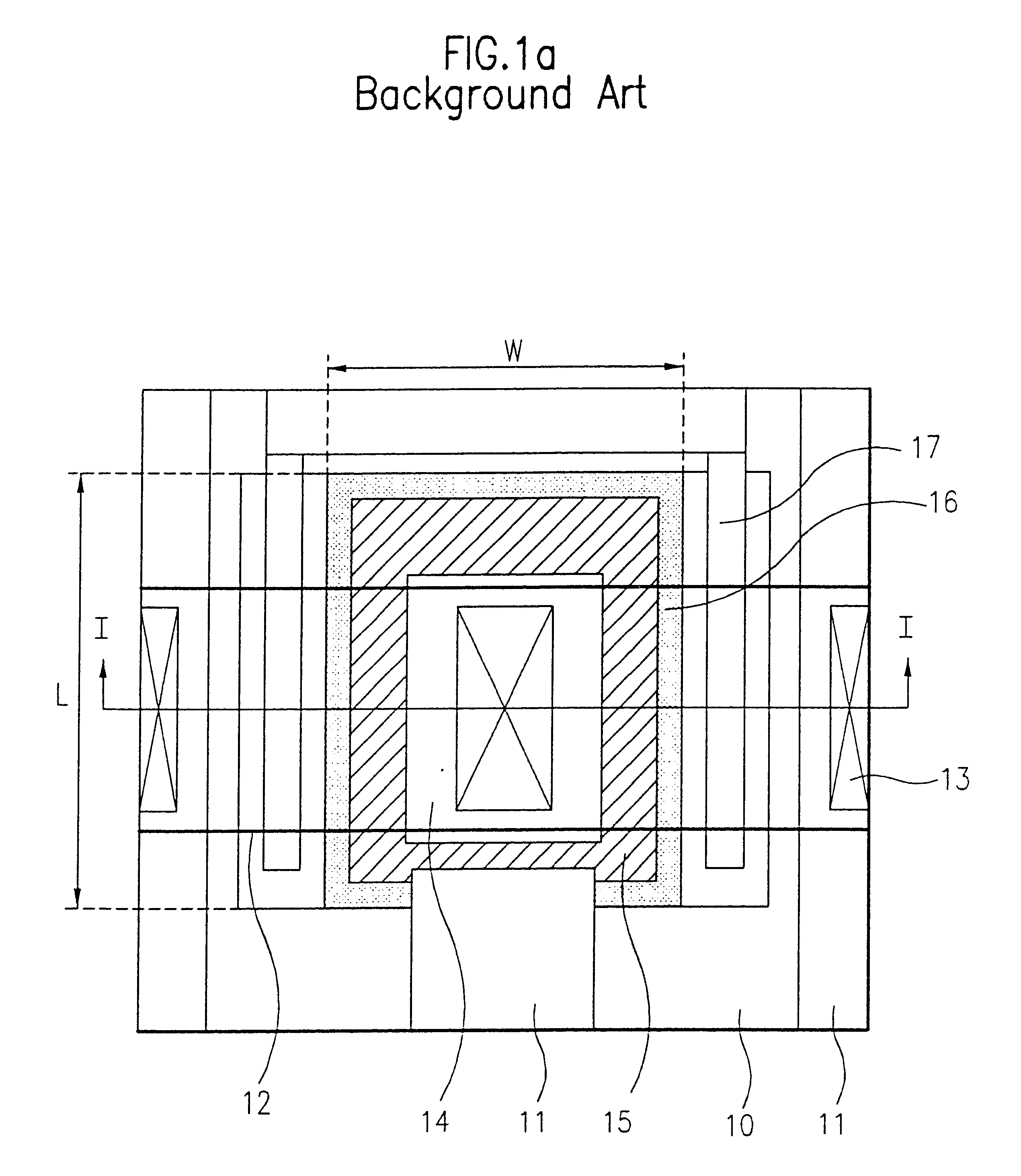

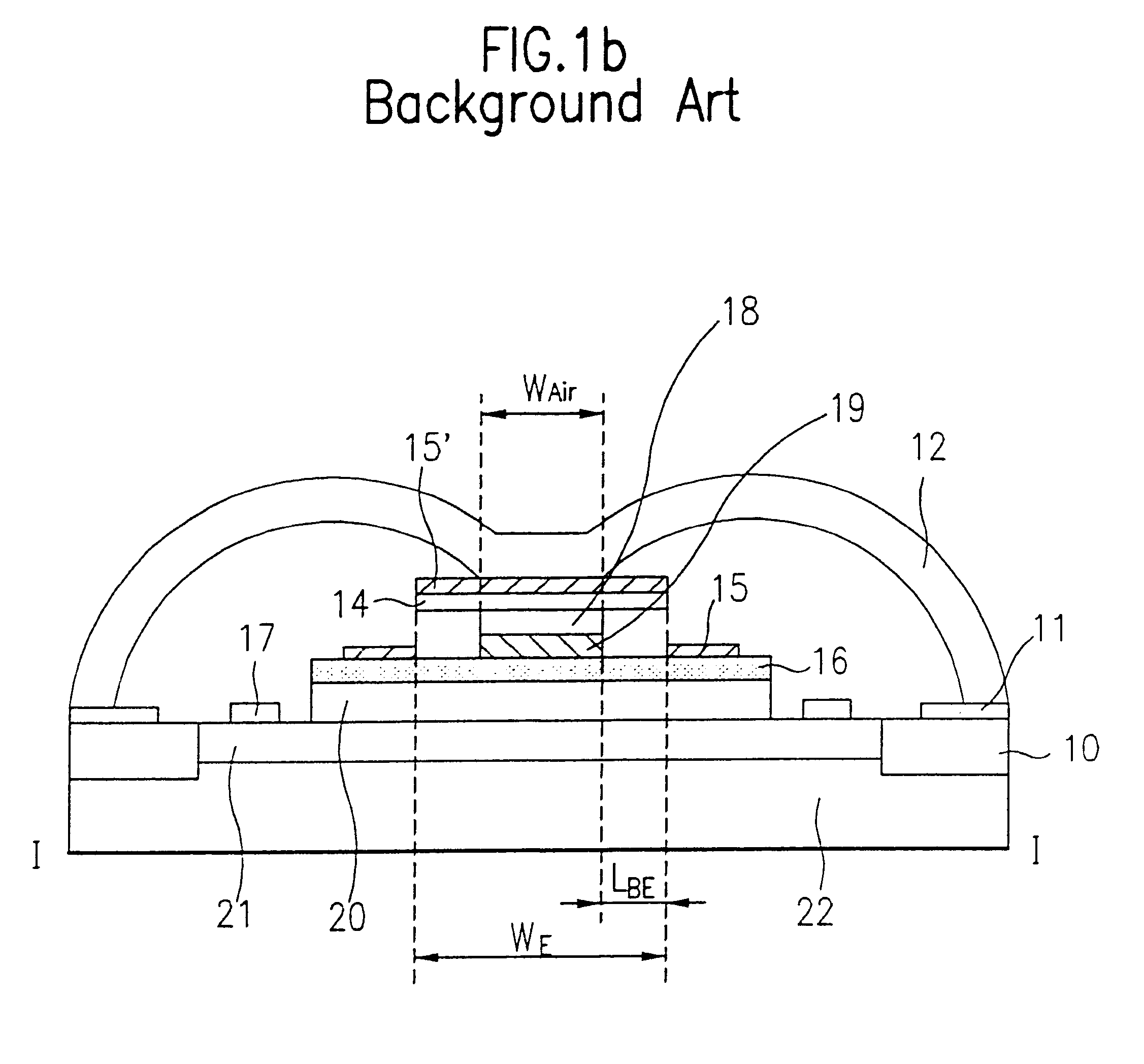

Thin film bulk acoustic wave resonator and production method of the same

InactiveUS7129806B2Improve concentrationComposition is stablePiezoelectric/electrostrictive device manufacture/assemblyImpedence networksThin-film bulk acoustic resonatorAir bridge

Owner:SONY CORP

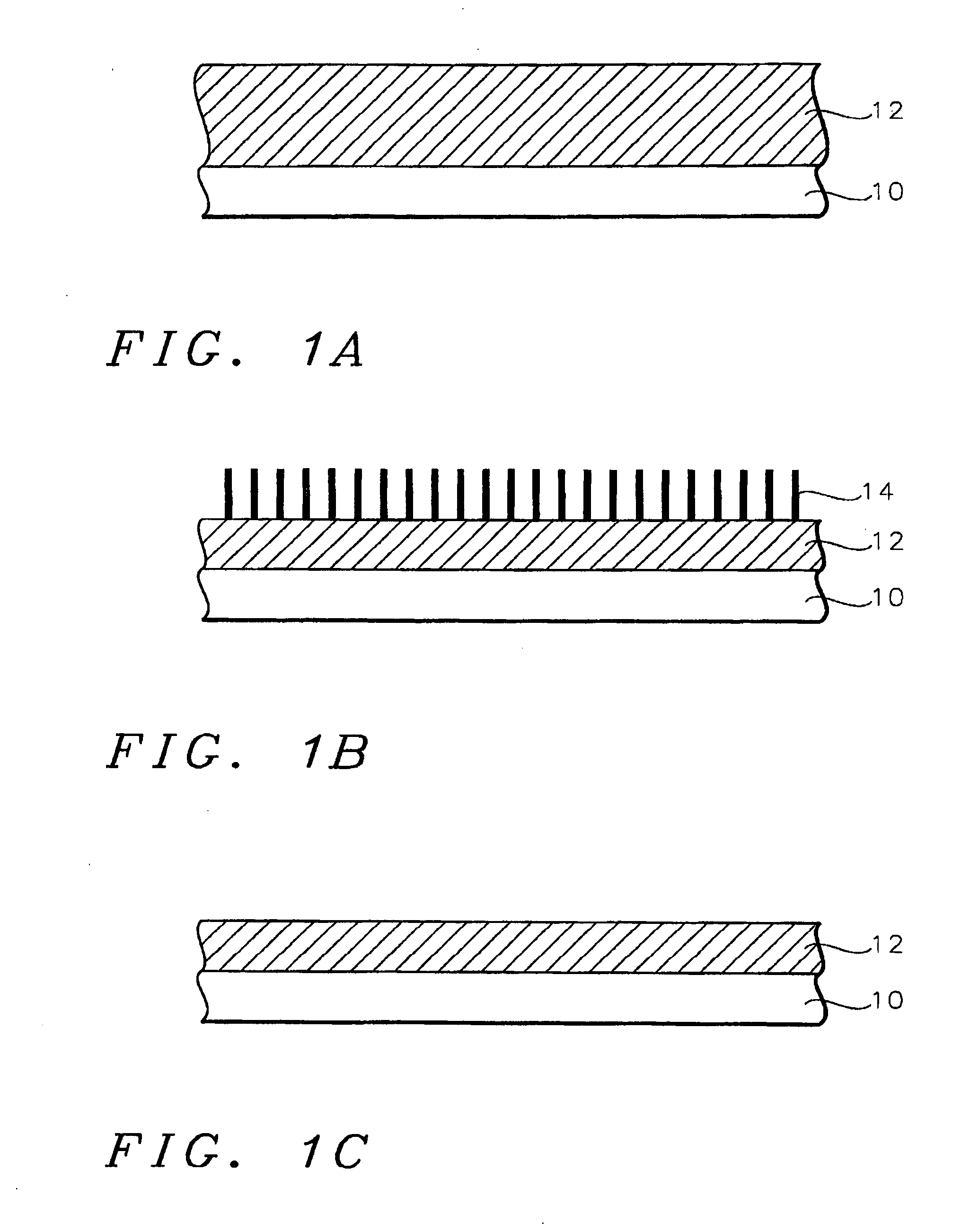

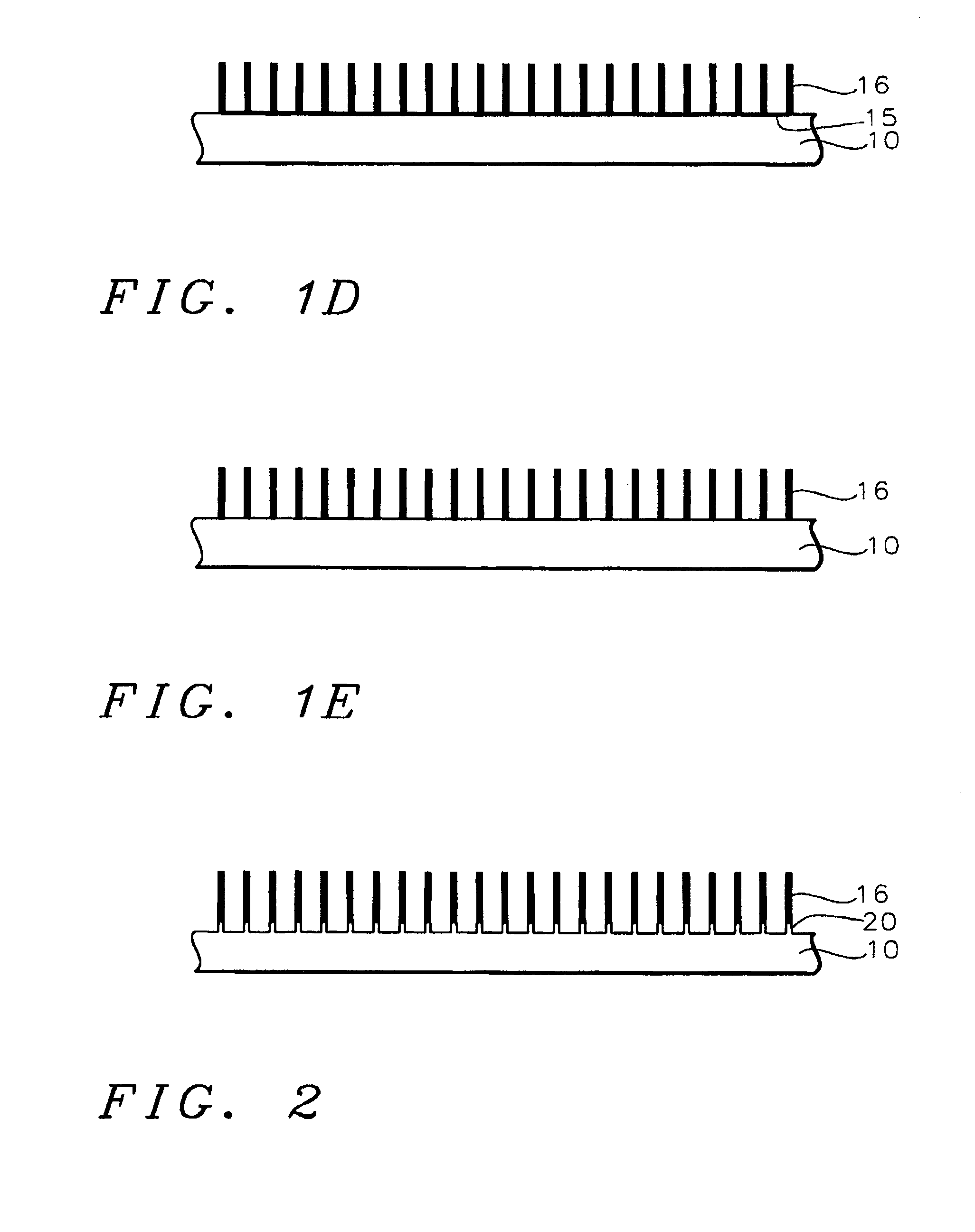

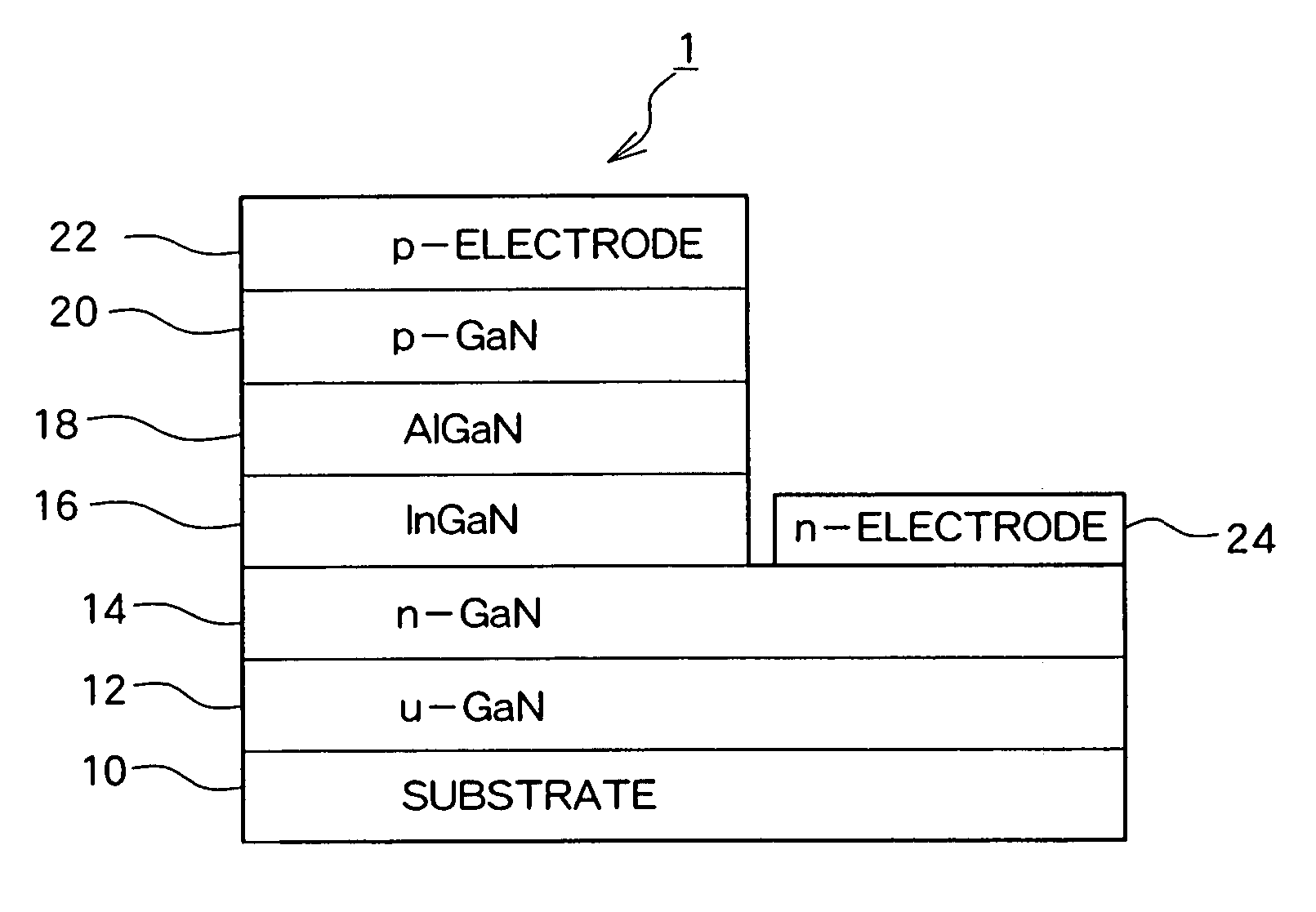

Nano-air-bridged lateral overgrowth of GaN semiconductor layer

InactiveUS20060270201A1Reduces dislocation density and stressRadiative recombination efficiency in the epitaxial layer is improvedPolycrystalline material growthSemiconductor/solid-state device manufacturingAir bridgeLateral overgrowth

A technique for growing a high quality gallium nitride layer on a uniform nano-patterned substrate is described. The invented technique is based on the transfer of ordered nano-patterns from a nano-template to the substrate, followed by the growth of gallium nitride on the nano-patterned substrate. The nano-patterned substrate serves as a buffer layer to reduce the stress and dislocations.

Owner:NAT UNIV OF SINGAPORE

Thin device and method of fabrication

InactiveUS20060017352A1Improve performanceEasily etched awayImpedence networksPiezoelectric/electrostriction/magnetostriction machinesAir bridgeAcoustic wave

A method of fabricating air-bridge type FBAR devices provides for a piezoelectric material sandwiched between two electrodes with an air / crystal interface on each electrode to trap sound waves within the film structure. Copper is used as a sacrificial material deposited in cavities in the substrate. Following deposition of the electrodes and piezoelectric material, the copper is etched away leaving the bottom electrode suspended over a cavity void.

Owner:TOKO JAPANESE

Pyroelectric sensor

ActiveUS20070108385A1Environmentally friendlyEnvironmentally robustMaterial analysis by optical meansPyrometry using electric radation detectorsHysteresisEngineering

A ferroelectric / pyroelectric sensor employs a technique for determining a charge output of a ferroelectric scene element of the sensor by measuring the hysteresis loop output of the scene element several times during a particular time frame for the same temperature. An external AC signal is applied to the ferroelectric scene element to cause the hysteresis loop output from the element to switch polarization. Charge integration circuitry, such as a combination output capacitor and operational amplifier, is employed to measure the charge from the scene element. Preferably, the ferroelectric of the scene element is made of an economical and responsive strontium bismuth tantalate, SBT, or derivative thereof, disposed directly between top and bottom electrodes. Because of the frequency characteristics of the sensor, created by the external AC signal, the element need not be thermally isolated from the silicon substrate by a traditional air bridge, which is difficult to manufacture, and instead is preferably thermally isolated by spin-on-glass, SOG. To prevent saturation of an output signal voltage of the sensor by excessive charge accumulation in an output capacitor, the sensor preferably has a reference element configured electrically in parallel with the scene element. When the voltage of the AC signal is negative the output capacitor is discharged by flowing current through the reference element thus interrogating the polarization of the reference element which is compared to and subtracted from the polarization of the scene element for each cycle. The polarization difference measured for each cycle over a set time period are summed by an integrating amplifier to produce a signal output voltage.

Owner:APTIV TECH LTD +1

Semiconductor device

ActiveUS20120267795A1Semiconductor/solid-state device detailsSolid-state devicesAir bridgeEngineering

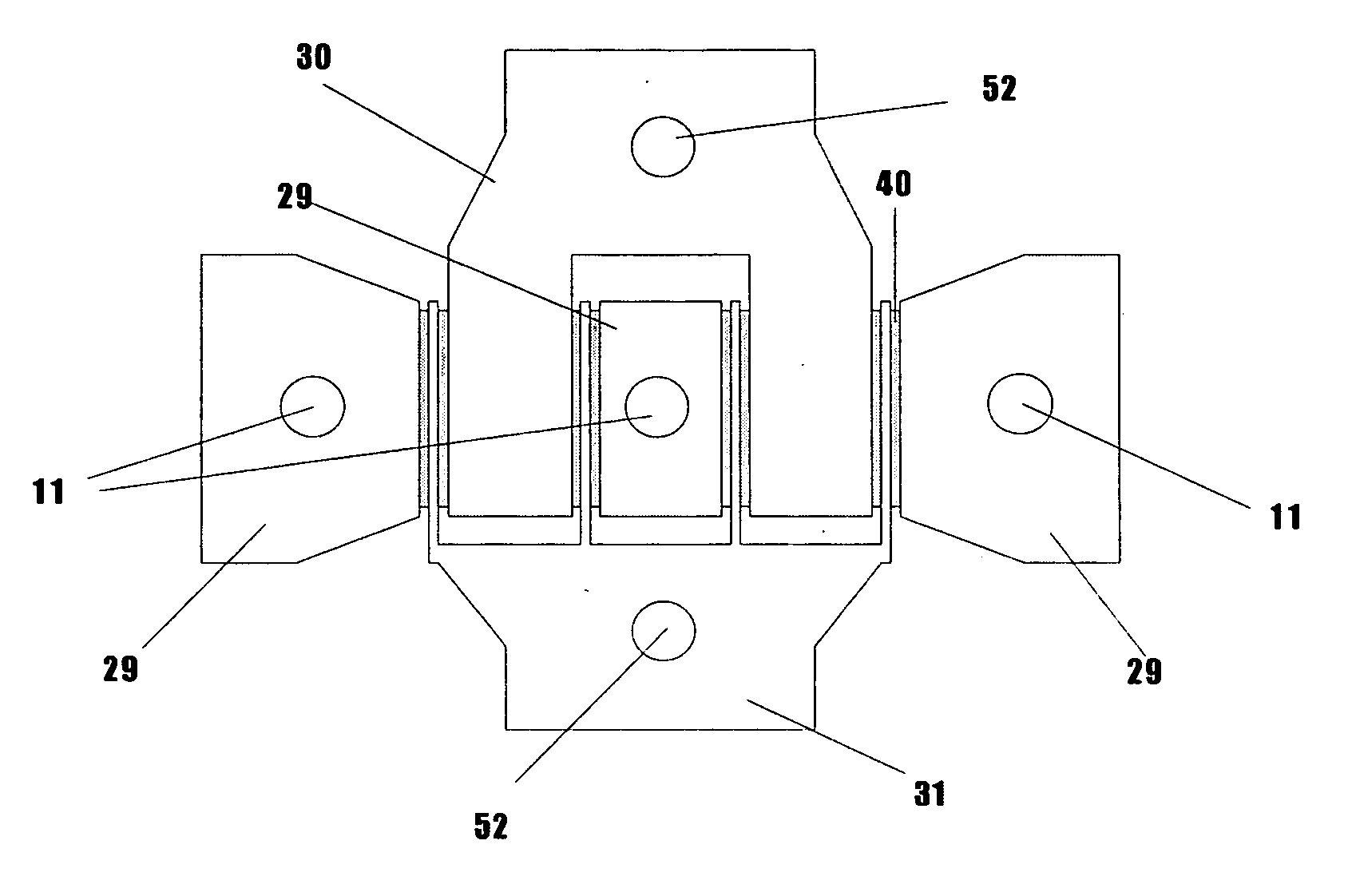

A semiconductor device includes a semiconductor layer, an active region defined in the semiconductor layer, first fingers provided on the active region and arranged in parallel with respect to a first direction, second fingers provided on the active region and interleaved with the first fingers, a bus line that is provided on an outside of the active region and interconnects the first fingers, first air bridges that are provided on the outside of the active region and are extended over the bus line, and that are connected to the second fingers, and second air bridges that are provided on the outside of the active region and are arranged in a second direction which crosses to the first direction, and that interconnect the first air bridges.

Owner:SUMITOMO ELECTRIC DEVICE INNOVATIONS

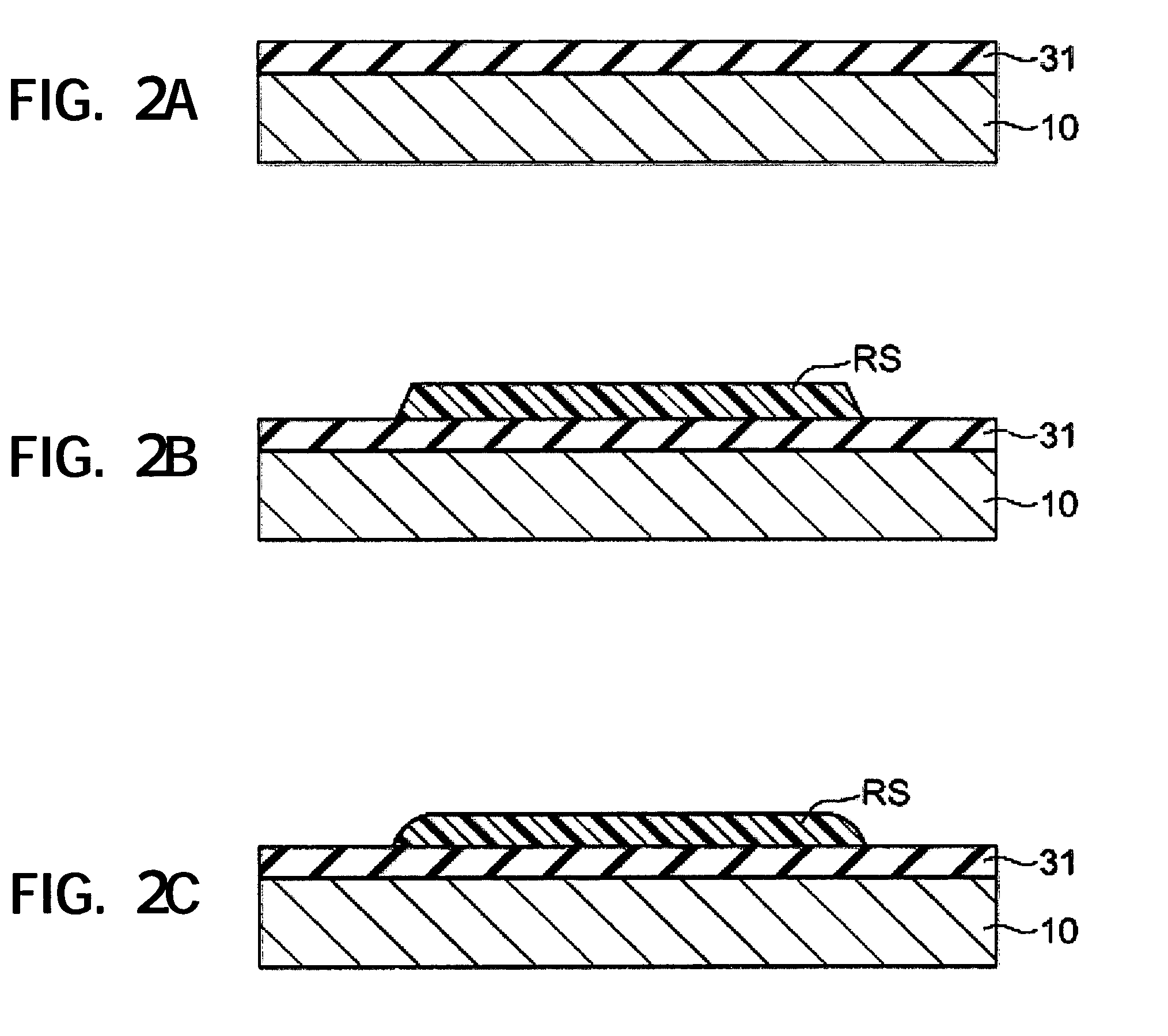

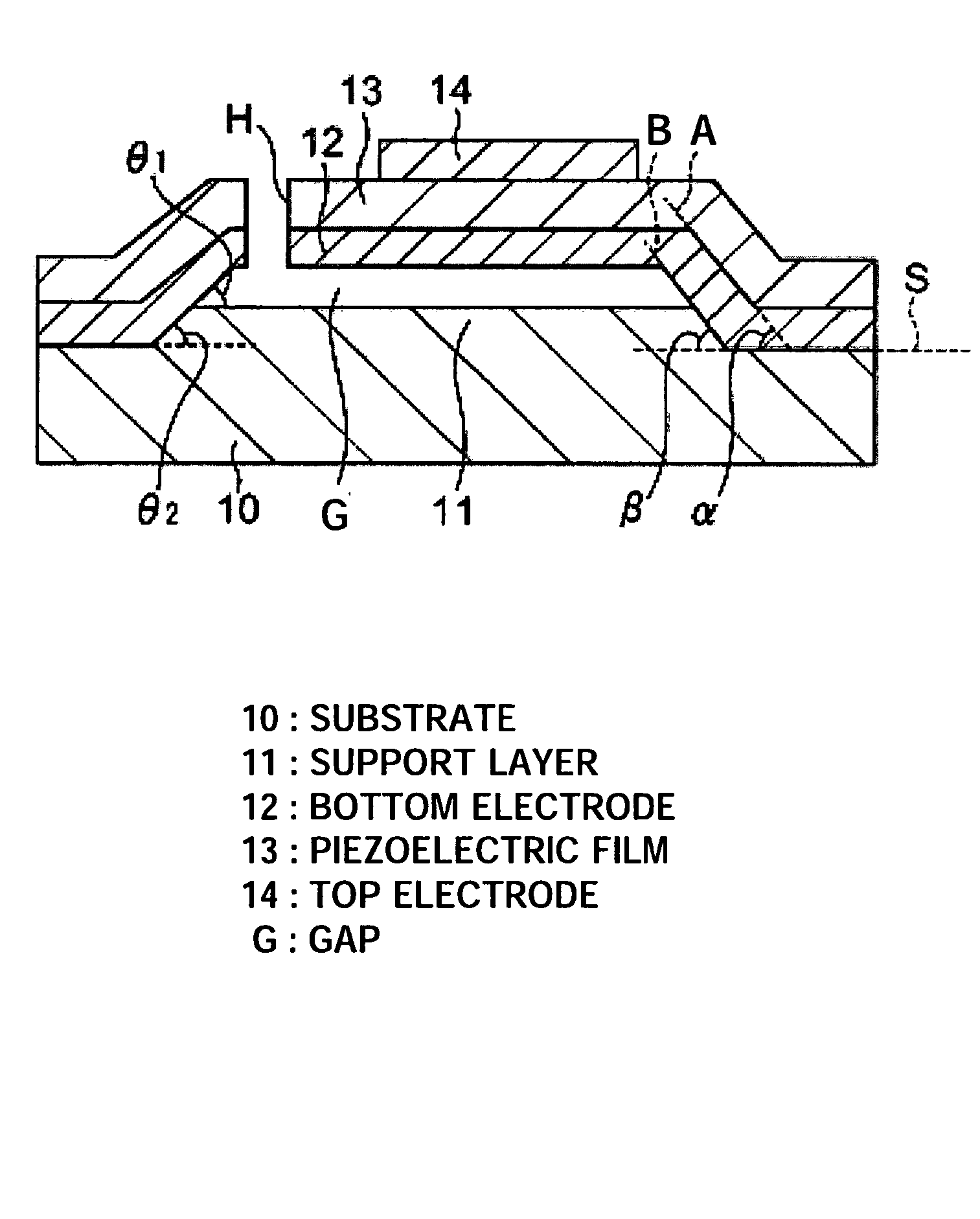

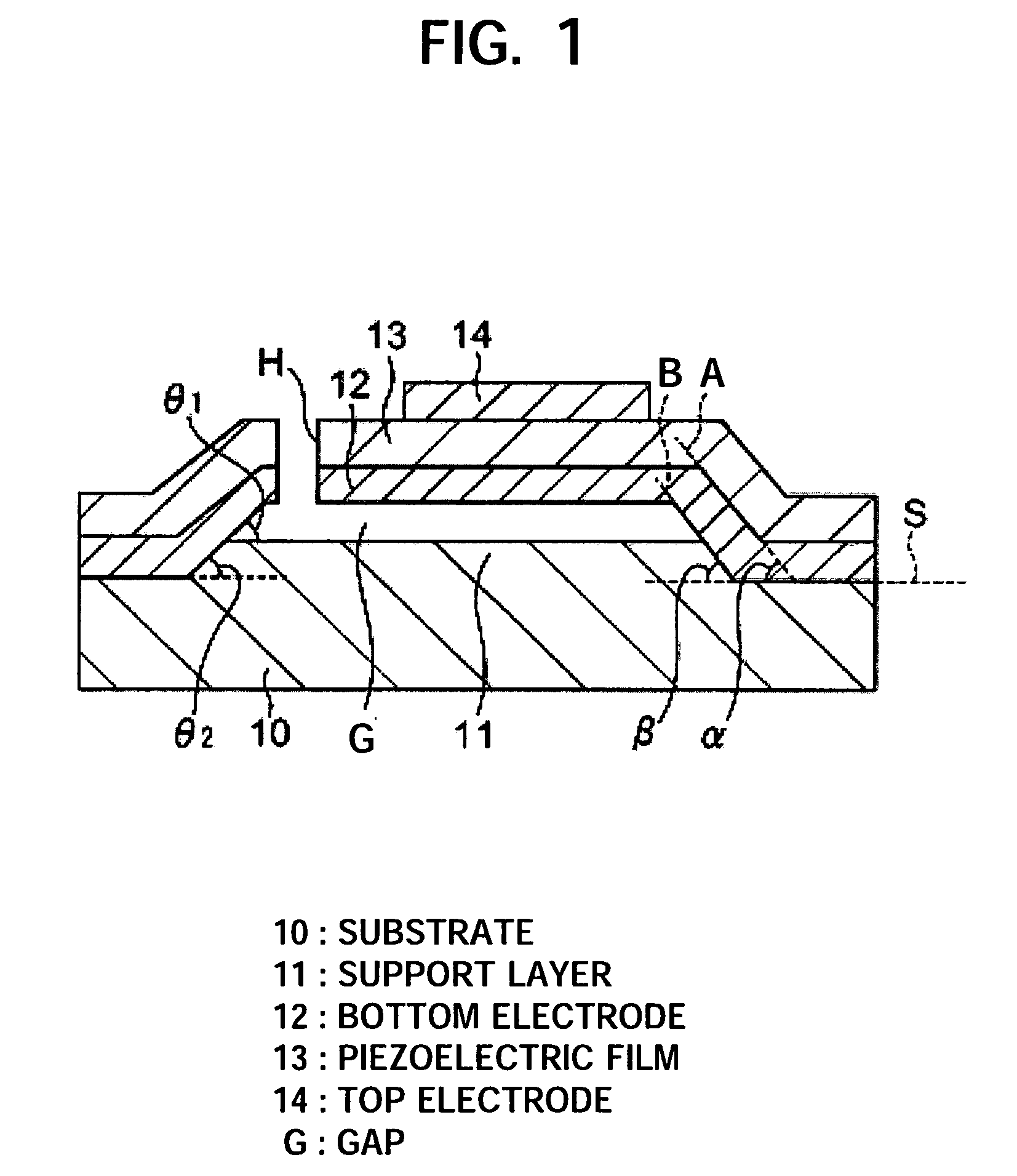

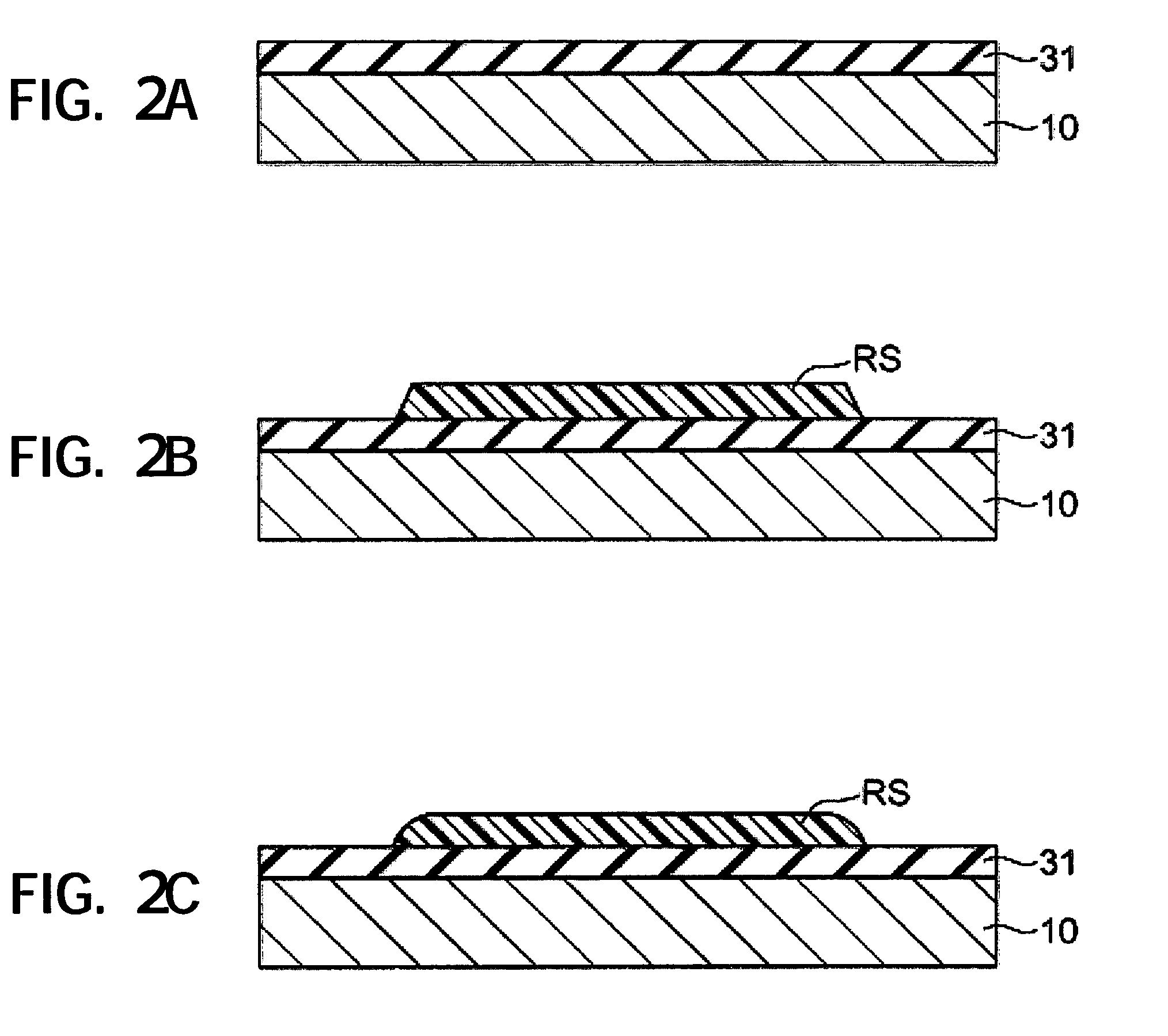

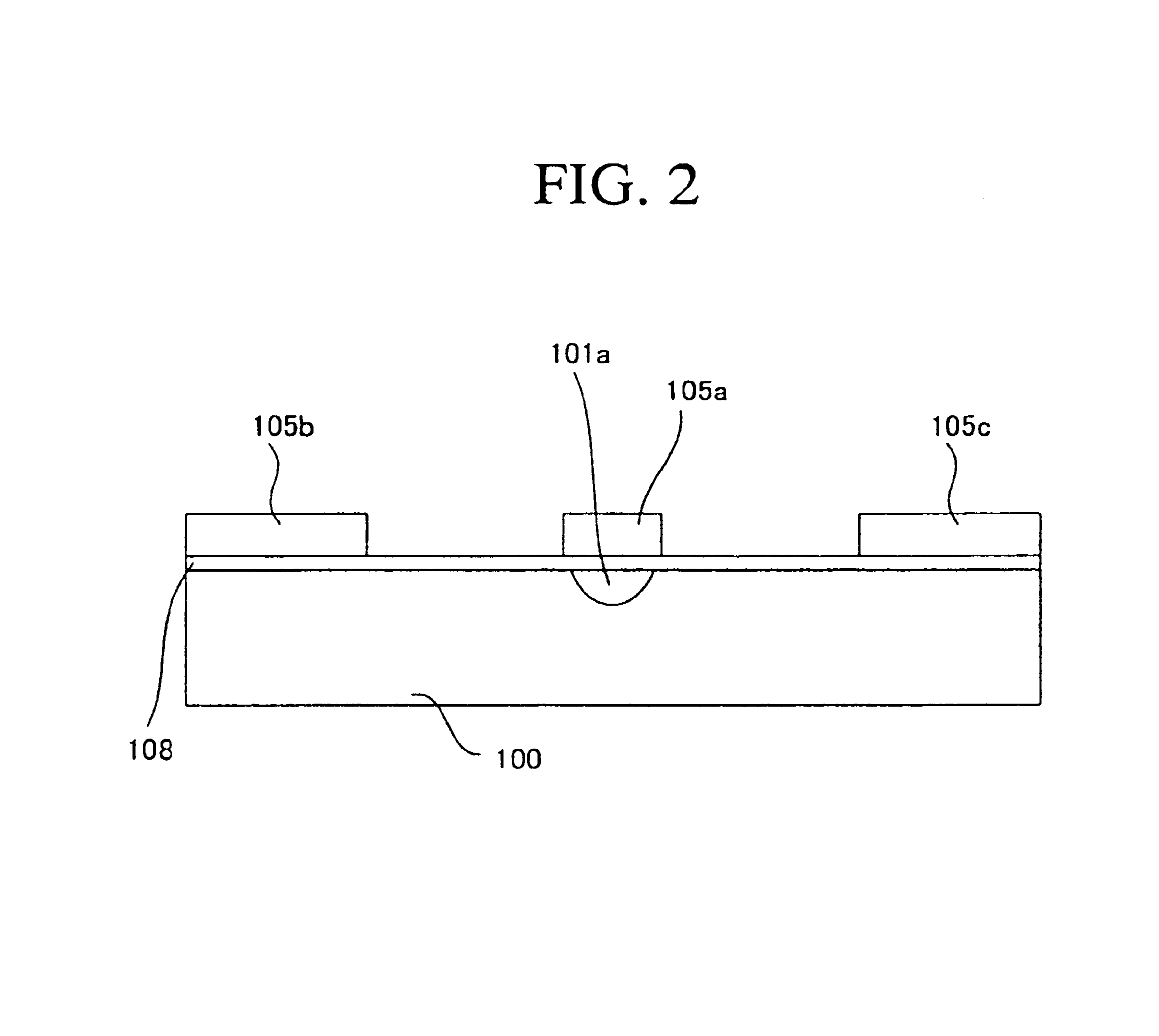

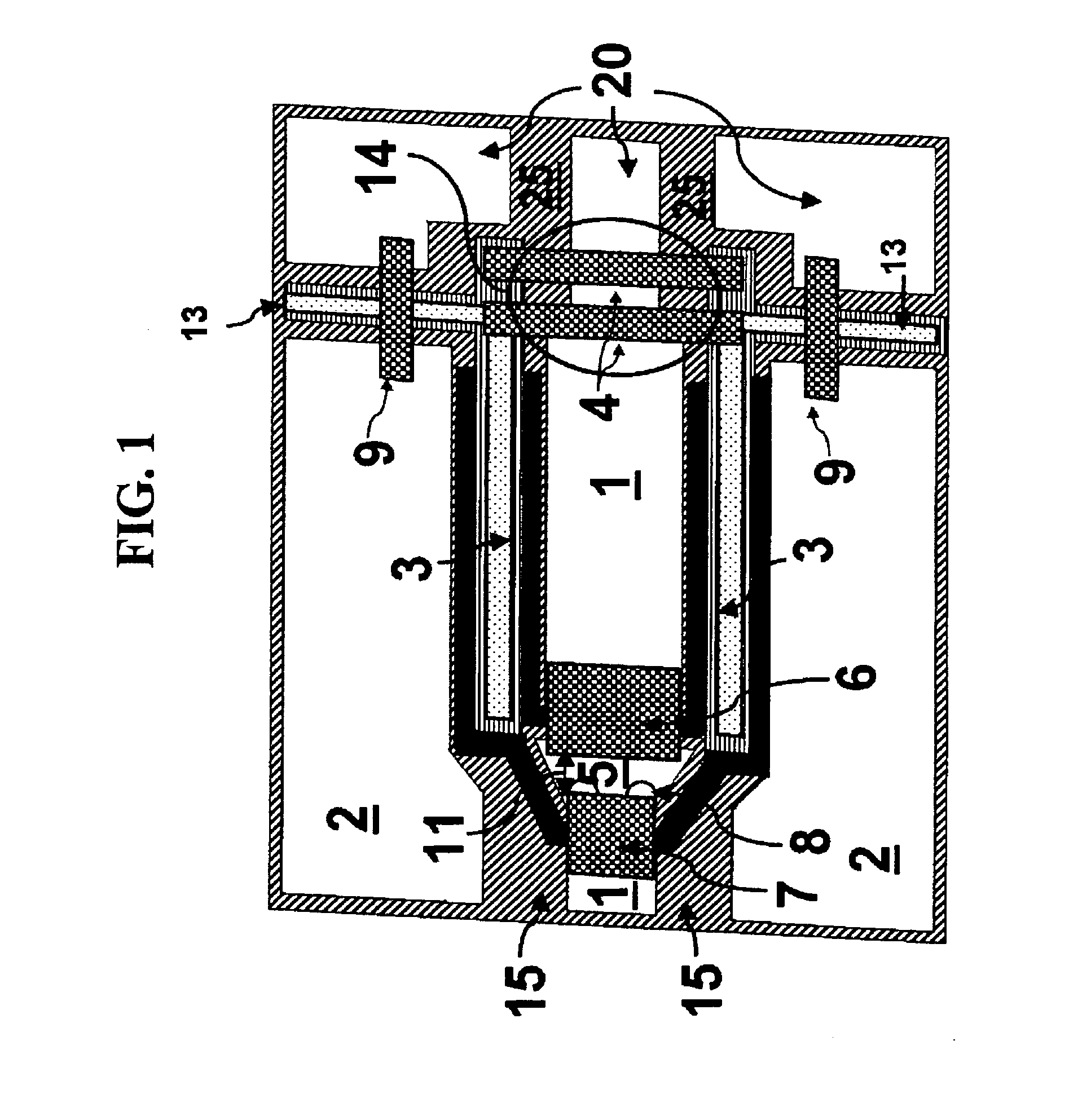

Thin film bulk acoustic wave resonator and production method of the same

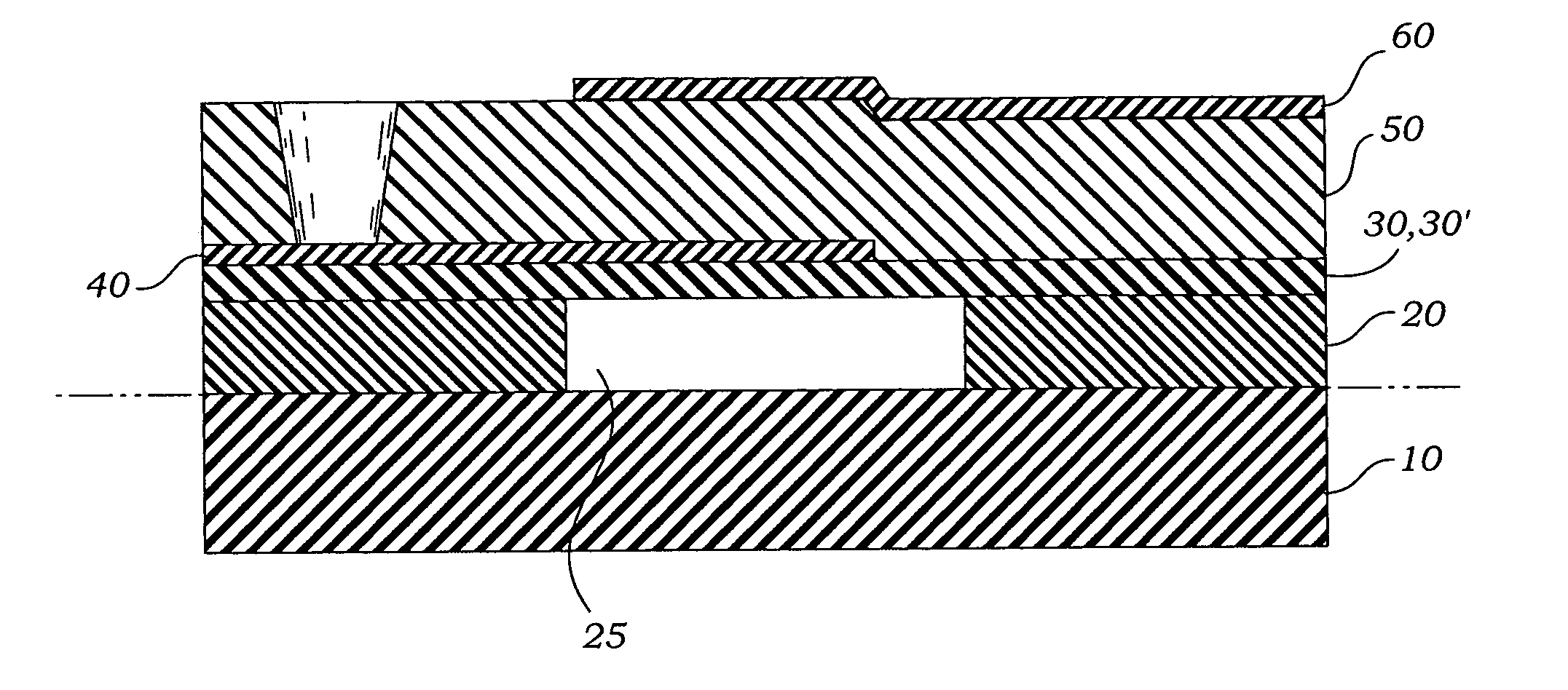

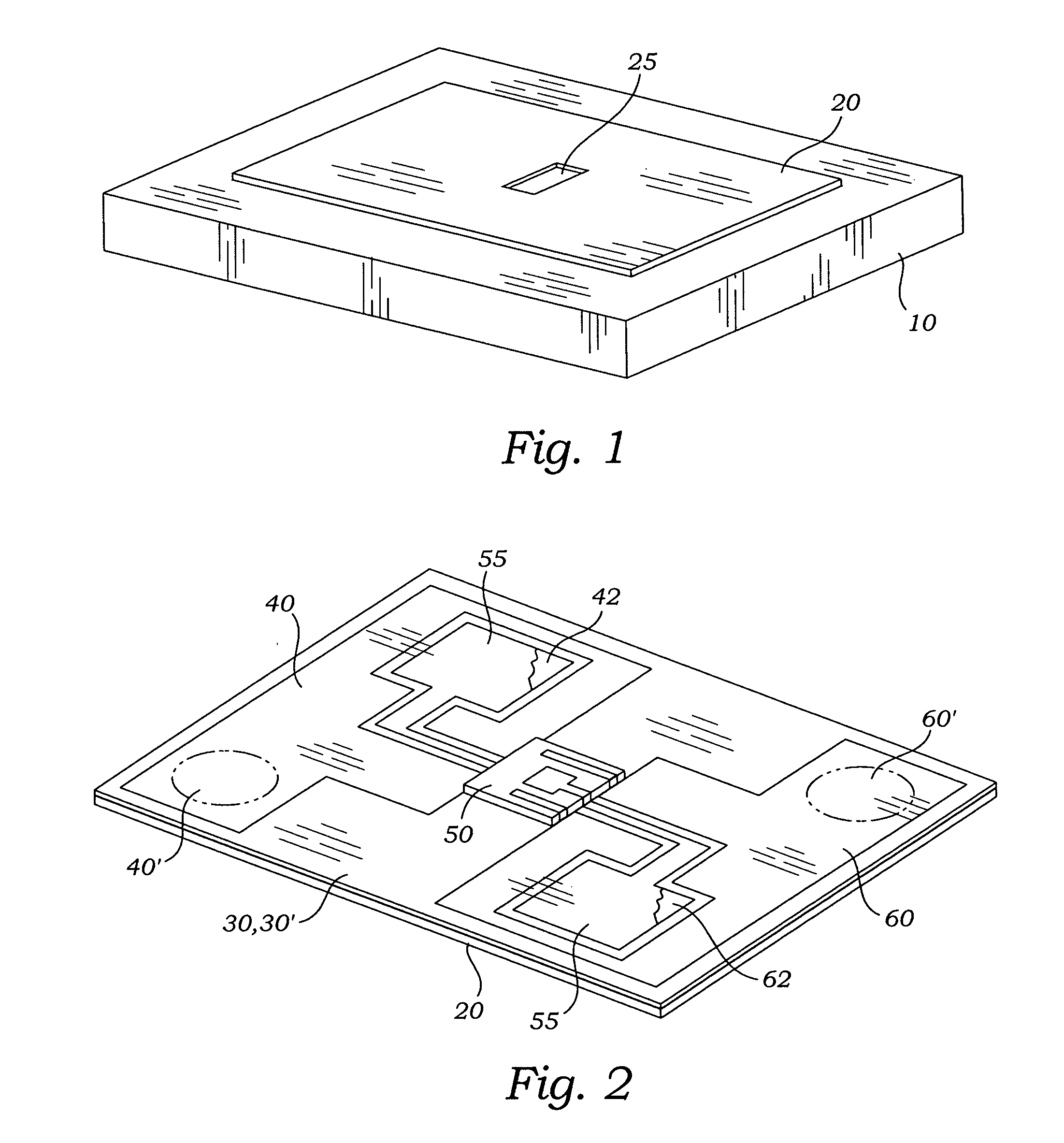

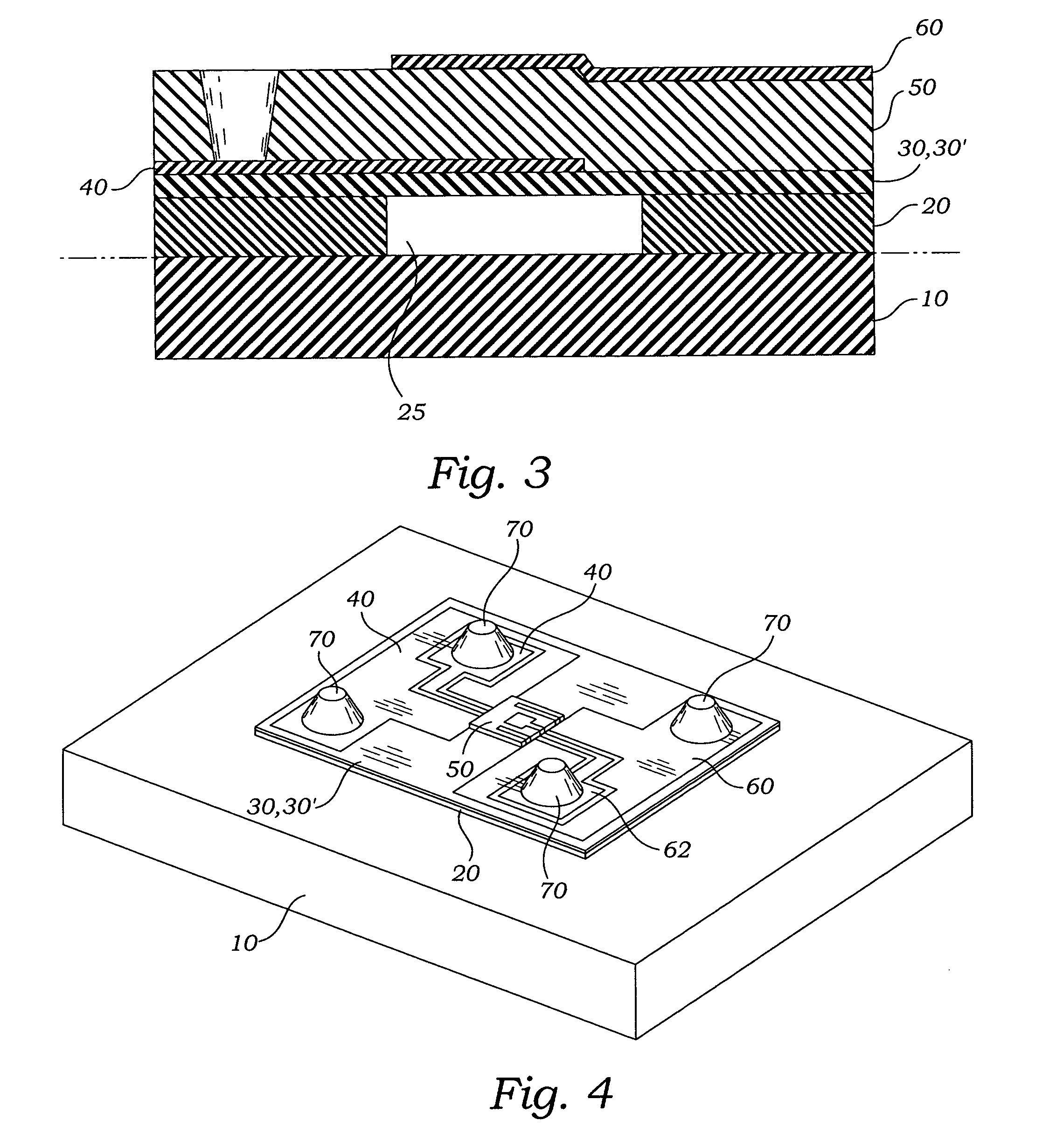

InactiveUS20050179508A1Improve concentrationComposition is stablePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesThin-film bulk acoustic resonatorProduction rate

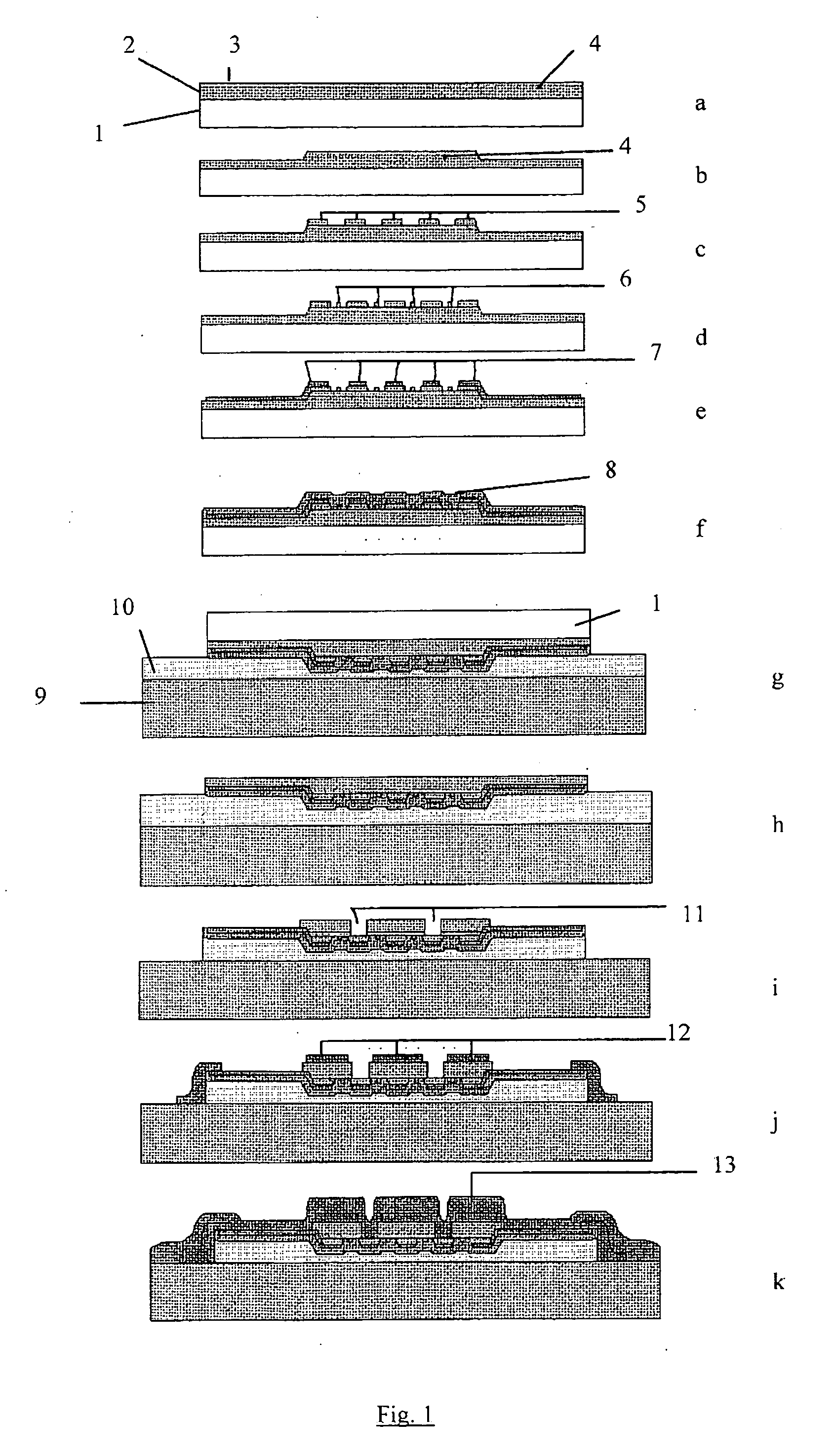

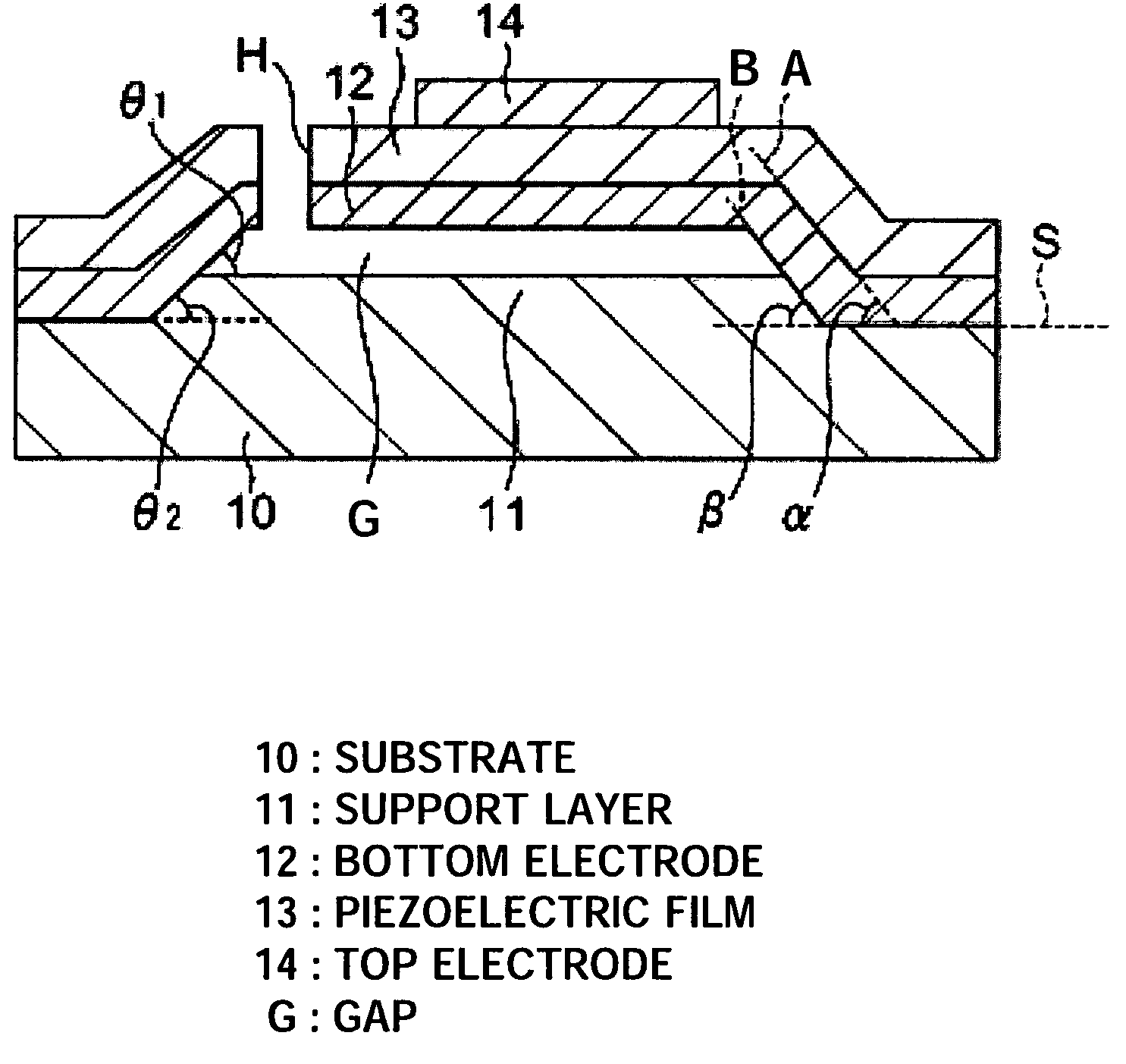

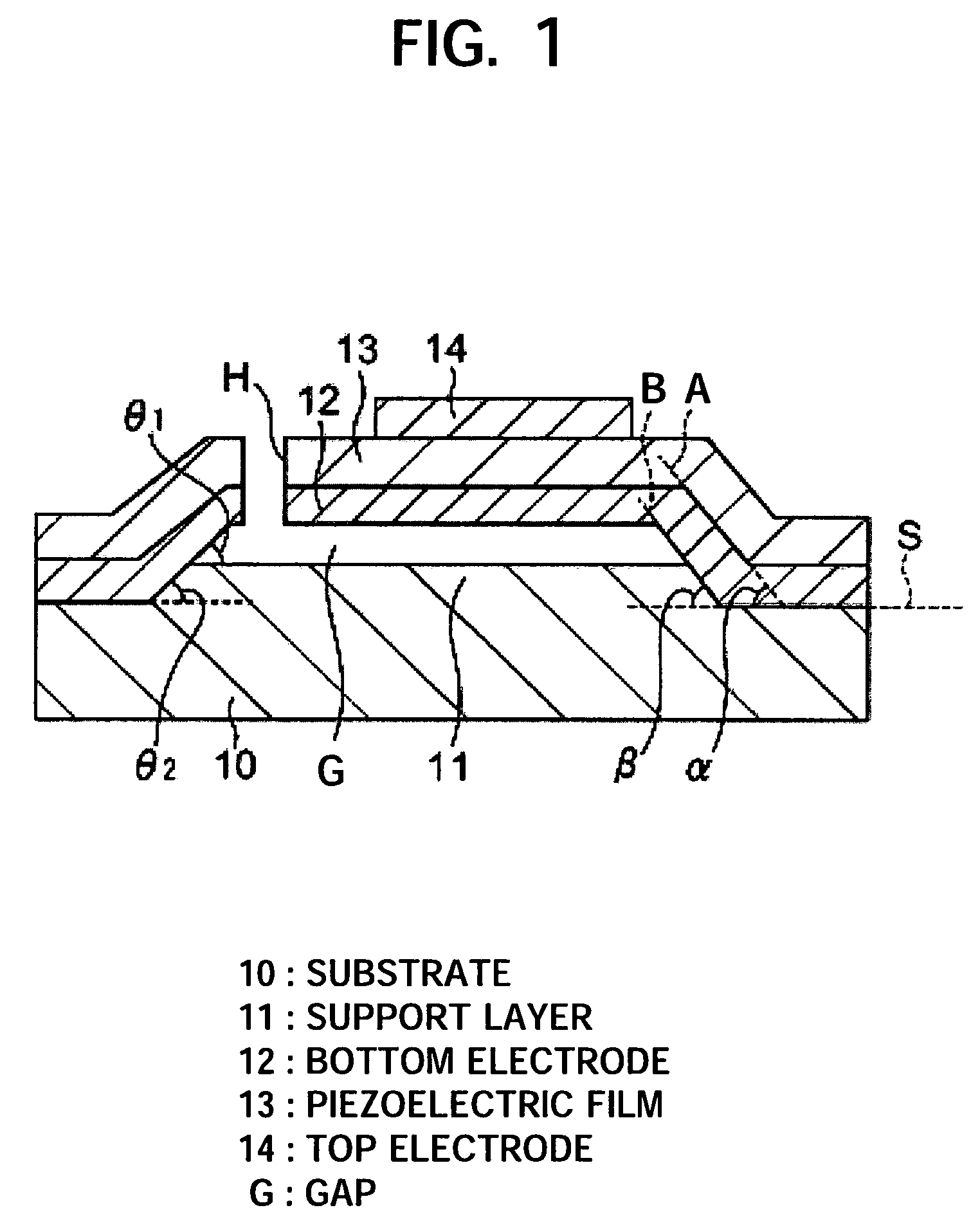

A thin film bulk acoustic wave resonator and method of producing same are provided. The thin film bulk acoustic wave resonator has a superior resonance characteristic (e.g., highly-orientation and densification of a piezoelectric film), wherein the thin film bulk acoustic wave resonator that a local stress to a piezoelectric film is relaxed and improvement of productivity due to a stable structure causing a crack of the piezoelectric film and high yield and a corresponding cost-reduction are realized, and the production method of the same, such as in an air bridge type thin film bulk acoustic wave resonator. A region including a substrate, a support layer formed convexly on the substrate and a gap upper than the support layer has a laminate of a bottom electrode, a piezoelectric film and an upper layer, where the laminate is formed on the substrate and the support layer. The gap is formed between the support layer and the bottom electrode so that at least a portion of it is located upper than a surface of the support layer, and is composed a resonance region. For example, the support layer has a height of 20% or more of the maximum height from the support layer surface to the top of the gap.

Owner:SONY CORP

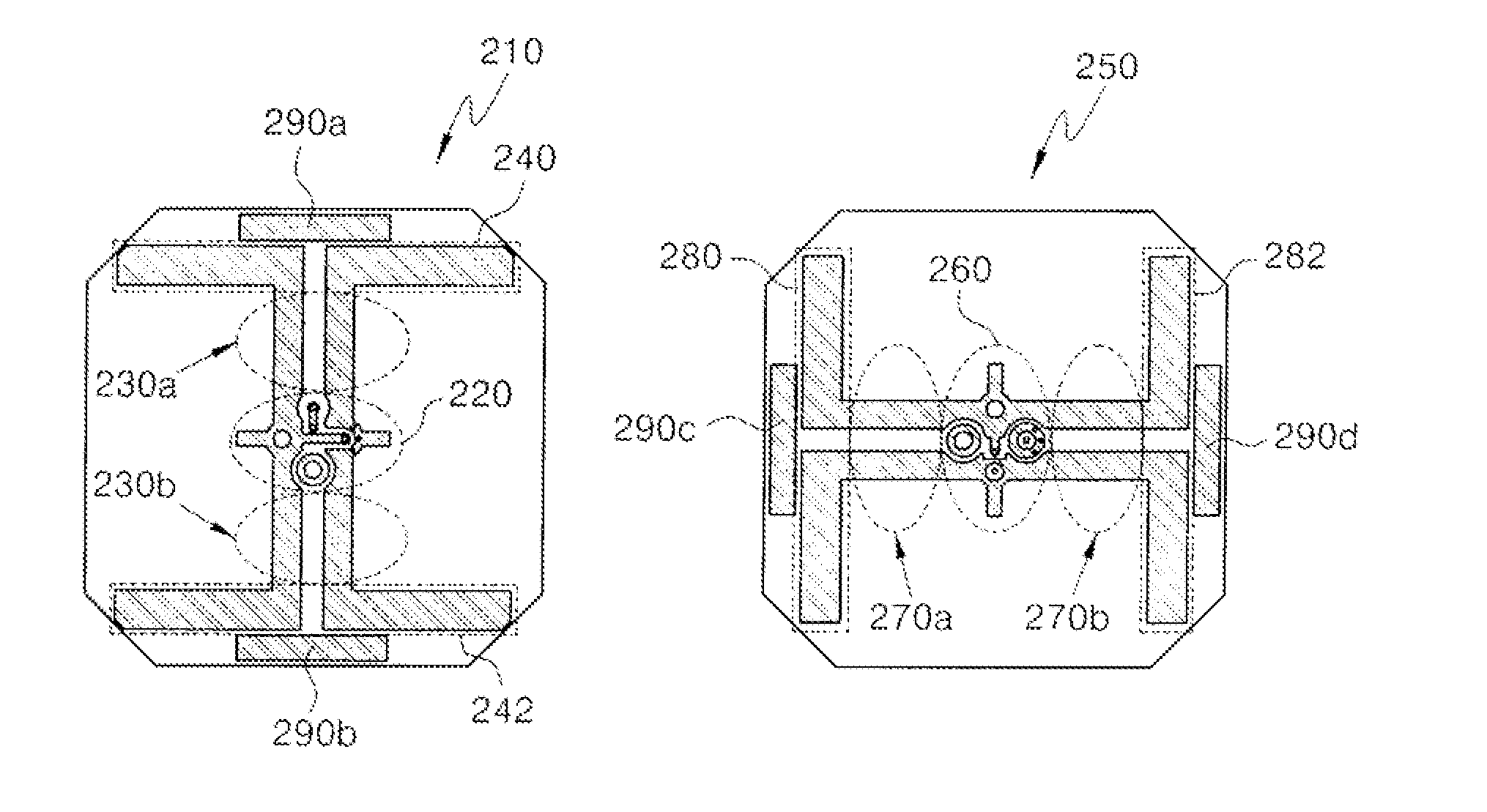

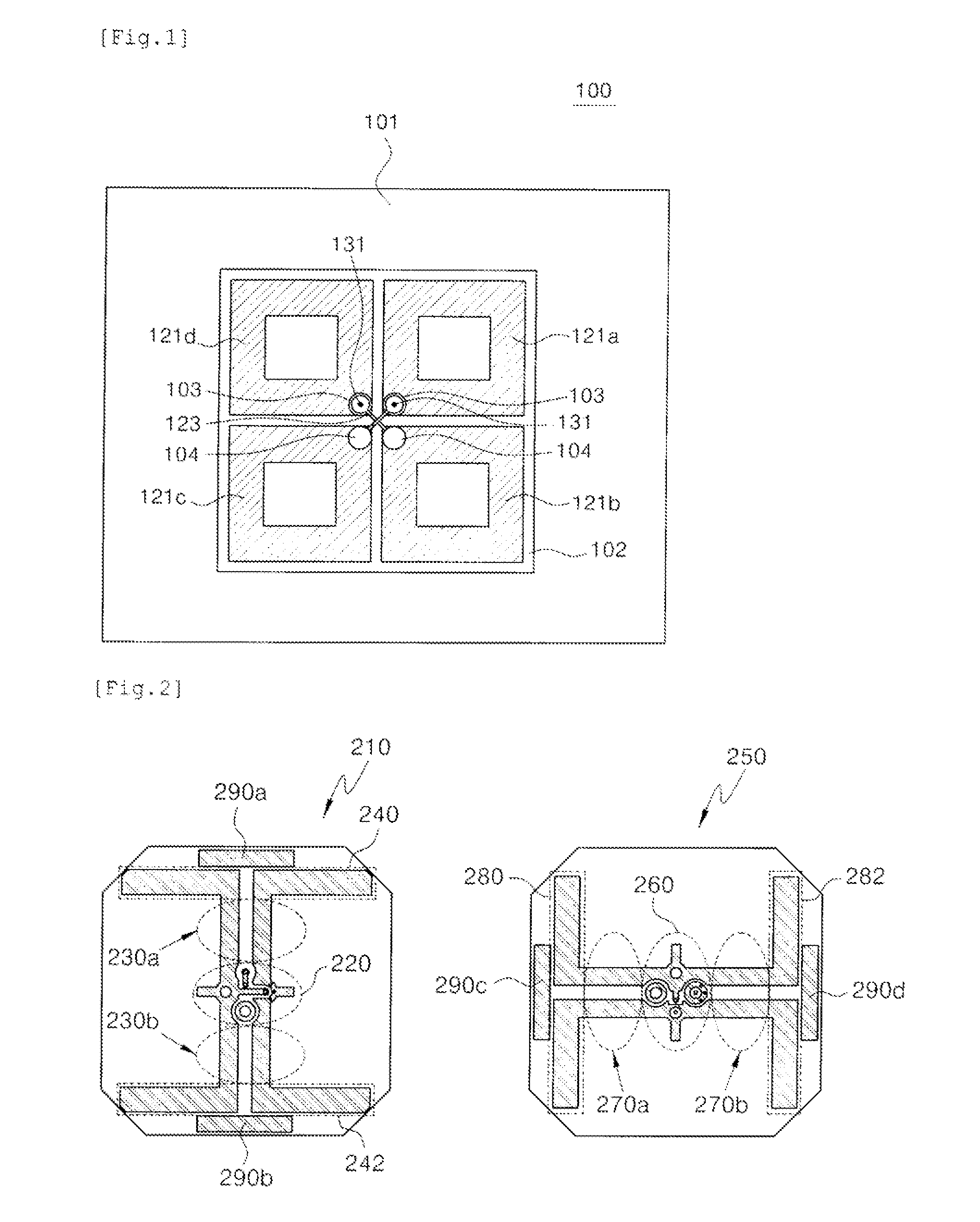

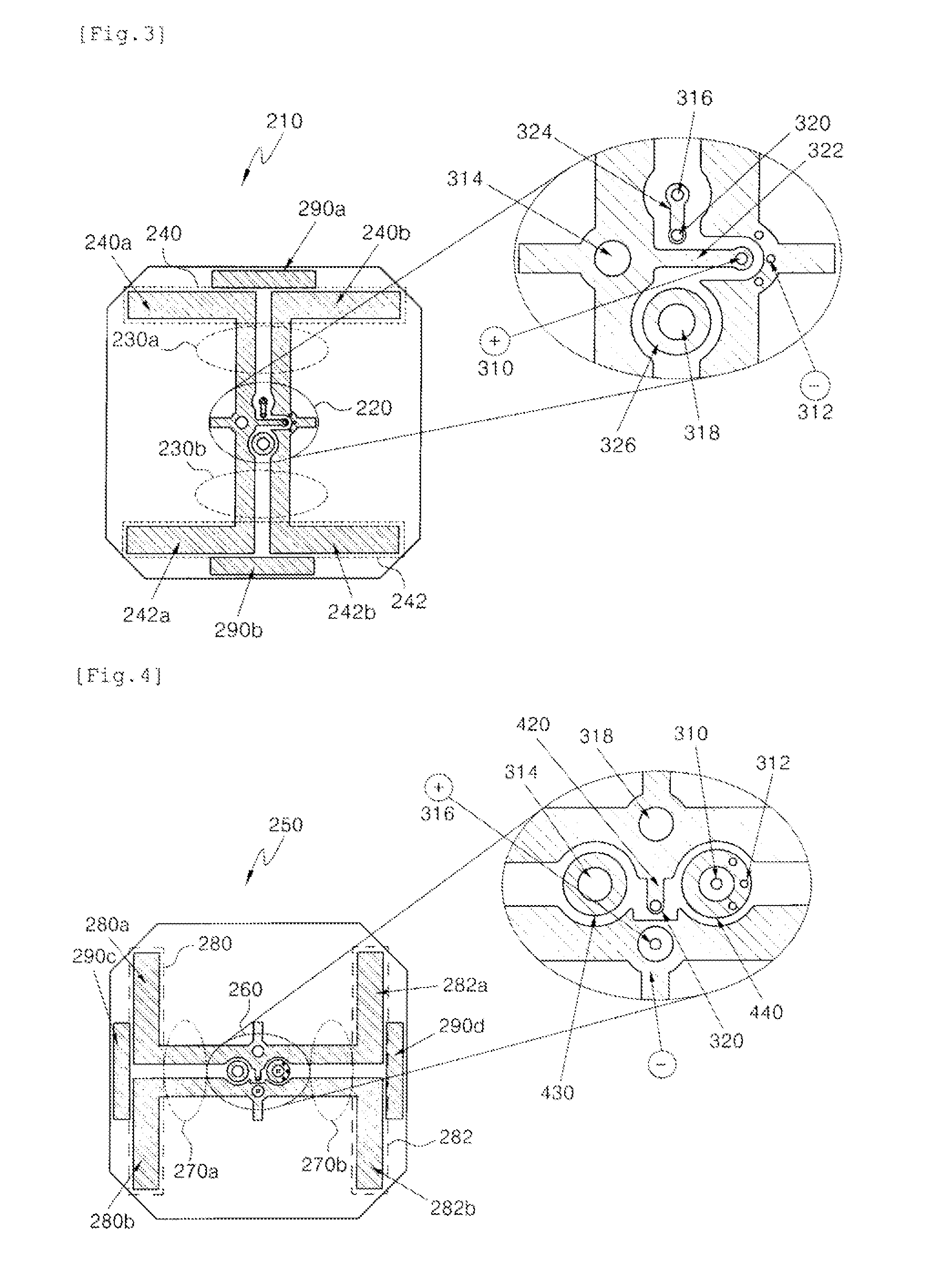

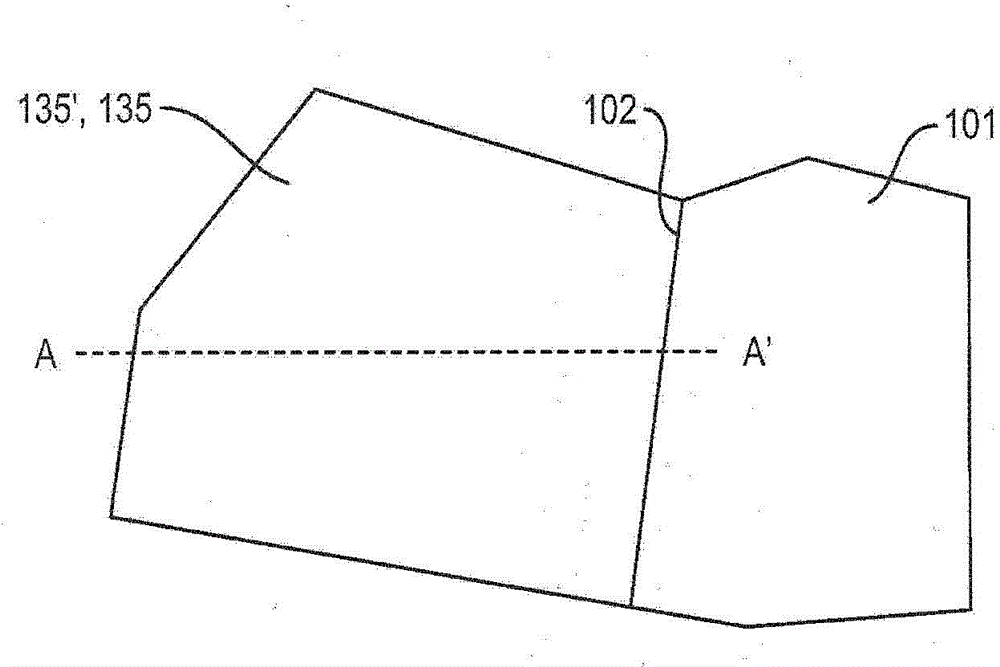

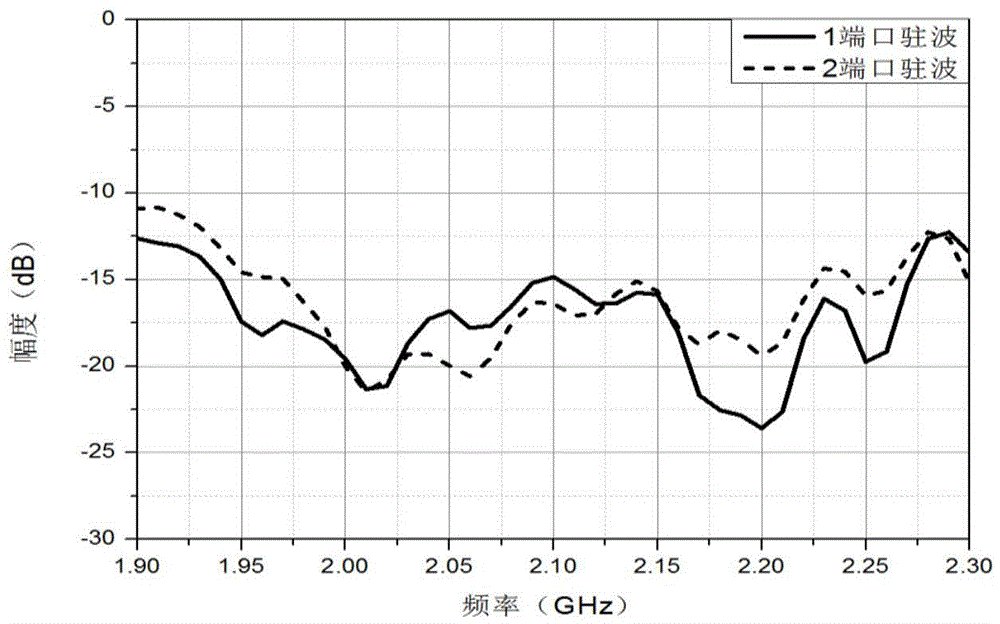

Board-shaped wideband dual polarization antenna

InactiveUS20110043424A1Simple feed structureWideband characteristicIndividually energised antenna arraysPolarised antenna unit combinationsDipole antennaPrinted circuit board

This invention relates to a board-shaped wideband dual polarization antenna whose feeding structure is simplified. Dipole antennas are prepared on both front and rear surfaces of a printed circuit board, and an electric signal is fed to the dipole antennas through via holes at the same time. Through the dipole antennas, the dual polarization antenna radiates dual polarized waves whose radiation emissions have perpendicular directions to each other. The wideband characteristics of the dual polarization antenna are improved through parasitic elements. The disclosed printed circuit board comprises: a first line hole into which a first core line (+) of a first electric cable transmitting a first electric signal is inserted; a first ground via hole through which a first ground line (−) of the first electric cable passes; a first balun hole into which a first balun cable is inserted; a second line hole into which a second core line (+) of a second electric line is inserted; is second balun hole into which a second balun cable is inserted; and a connection via-hole through which both the second core line (+) and the second balun cable pass. The first and second balun cables make a pair with the first and second electric cables respectively by being parallel to those electric cables respectively in order so perform the function of a balun. According to the invention, the dual polarization antenna is able to radiate, through the dipole antennas on both surfaces of the printed circuit boards, dual polarized waves whose radiation emissions have perpendicular directions to each other. In addition, the feeding structure can be simplified and a complex three-dimensional air-bridge structure does not need to be used in the dual polarization antenna since an electric signal is fed to the dipole antennas on both surfaces of the printed circuit board at the same time.

Owner:GAMMA NU

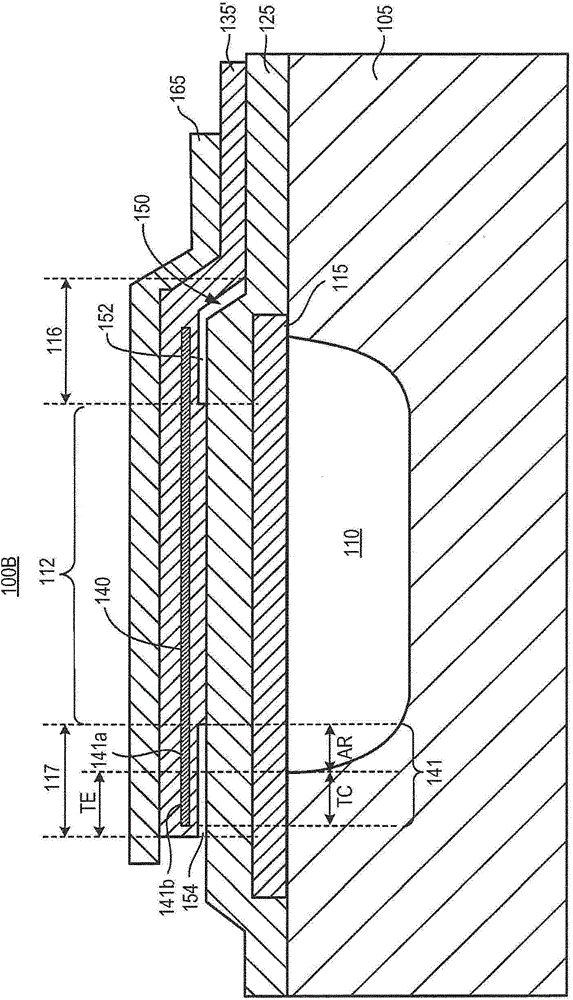

Acoustic resonator device with air-ring and temperature compensating layer

A bulk acoustic wave (BAW) resonator device includes a substrate defining a cavity, a bottom electrode formed over the substrate and at least a portion of the cavity, a piezoelectric layer formed on the bottom electrode, and a top electrode formed on the piezoelectric layer. An air-wing and an air-bridge are formed between the piezoelectric layer and the top electrode, the air-wing having an inner edge that defines an outer boundary of an active region of the BAW resonator device. The BAW resonator device further includes a temperature compensation feature having positive temperature coefficient for offsetting at least a portion of a negative temperature coefficient of the piezoelectric layer. The temperature compensation feature extends outside the active region by a predetermined length.

Owner:AVAGO TECH INT SALES PTE LTD

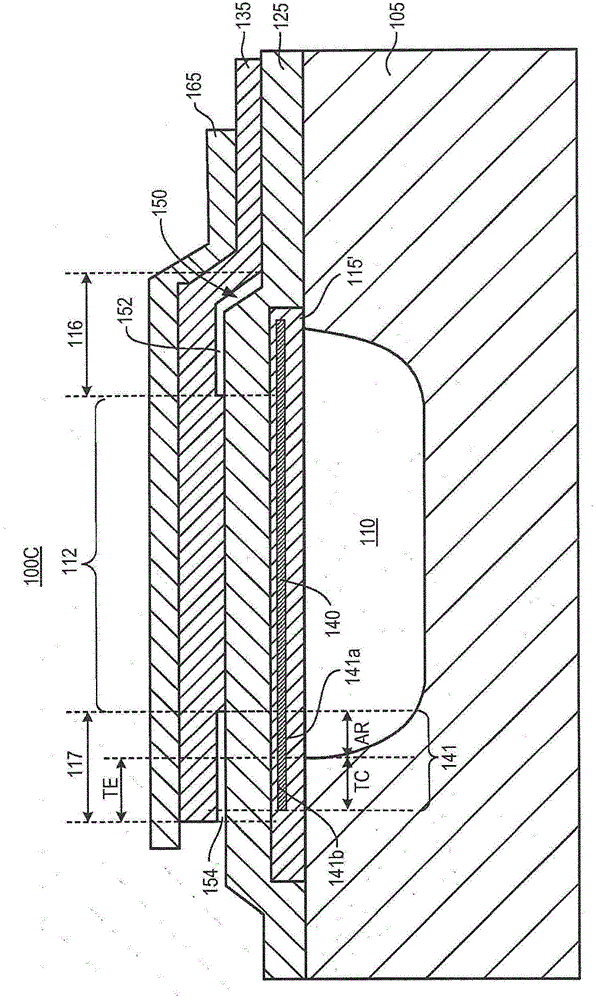

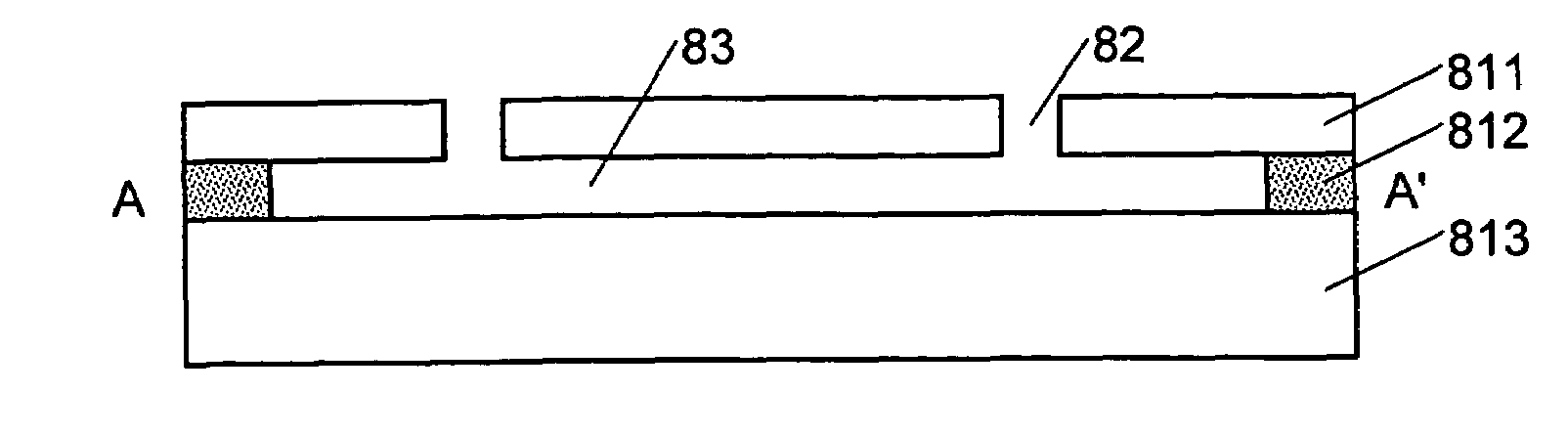

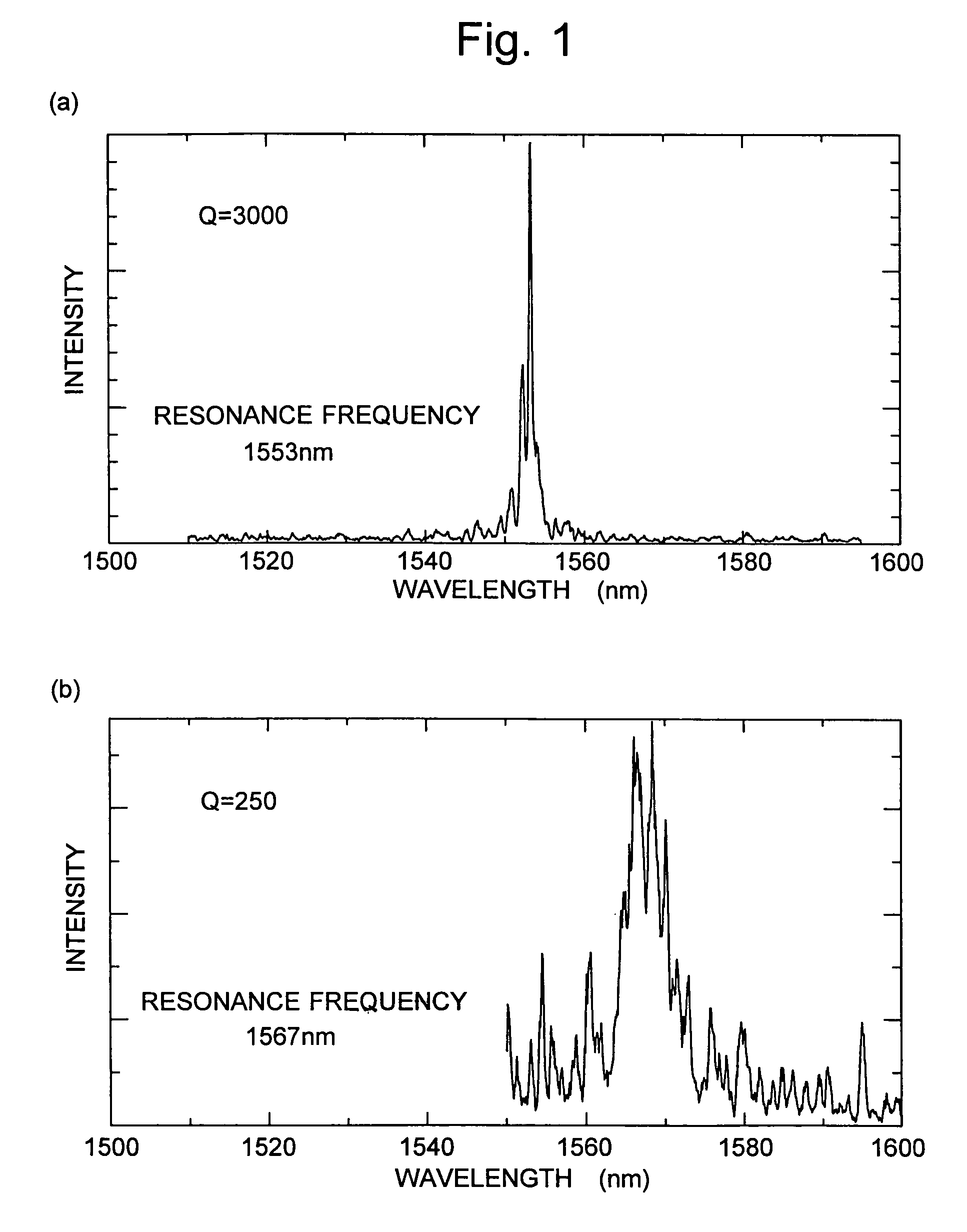

Two-dimensional photonic crystal having air-bridge structure and method for manufacturing such a crystal

The present invention intends to provide a two-dimensional photonic crystal having a high level of mechanical strength and functioning as a high-efficiency resonator. The two-dimensional photonic crystal according to the present invention includes a slab layer 31 under which a clad layer 32 is located. In the slab layer 31, areas 35 having a refractive index different from that of the slab layer 31 are cyclically arranged to create a two-dimensional photonic crystal. A portion of the cyclic arrangement of the areas 35 are omitted to form a point-like defect 36. This defect 36 functions as a resonator at which a specific wavelength of light resonates. An air-bridge cavity 37 facing the point-like defect 36 is formed over a predetermined range of the clad layer 32. In this construction, the clad layer 32 supports the slab layer 31 except for the range over which the air-bridge space 37 is formed. Therefore, the two-dimensional photonic crystal has a high level of mechanical strength. The presence of the air-bridge space 37 under the point-like defect 36 makes it easy to confine light at the point-like defect 36 by the difference in the refractive index between the slab layer 31 and the air. Thus, the point-like defect 36 functions as a high-performance resonator.

Owner:KYOTO UNIV

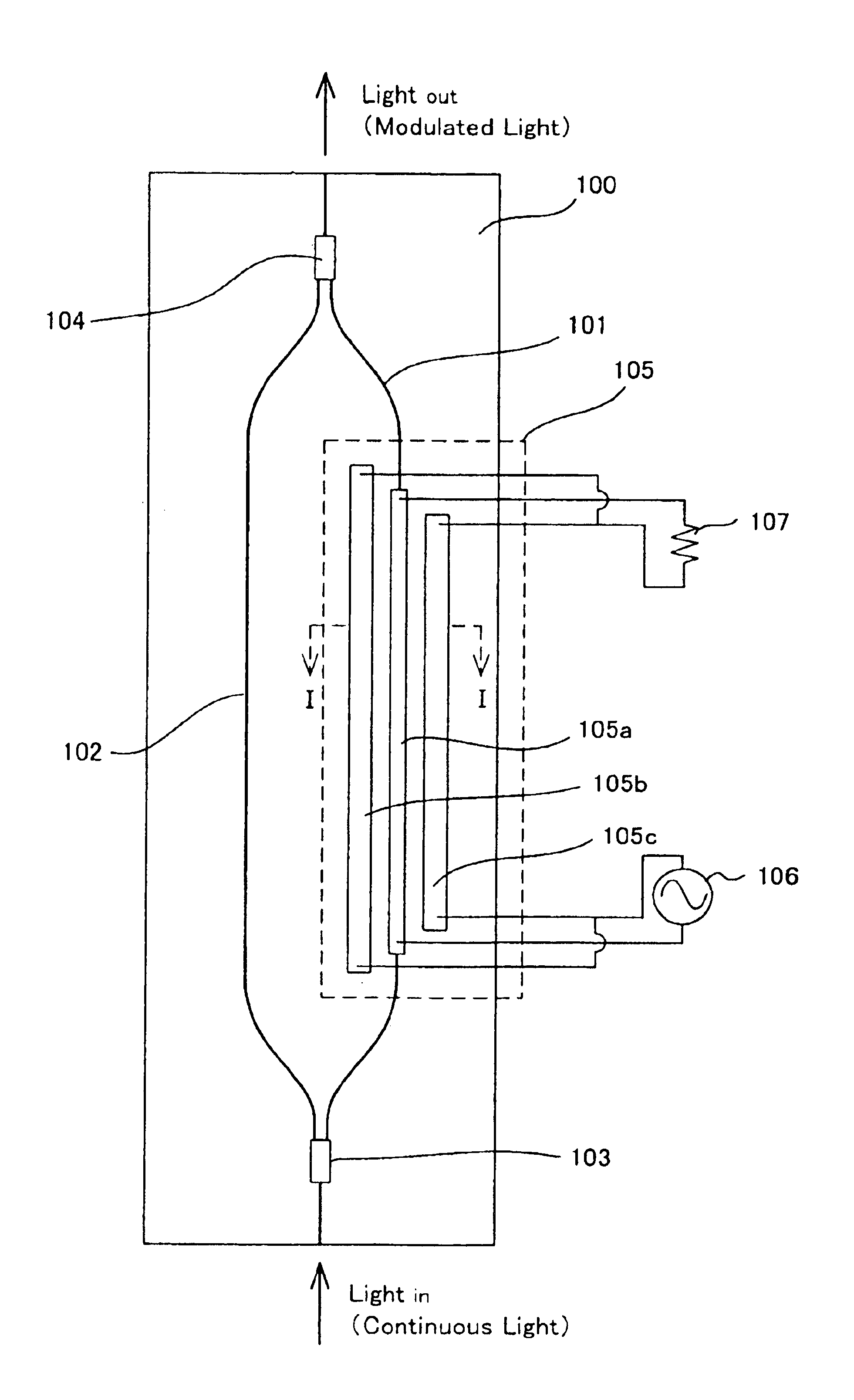

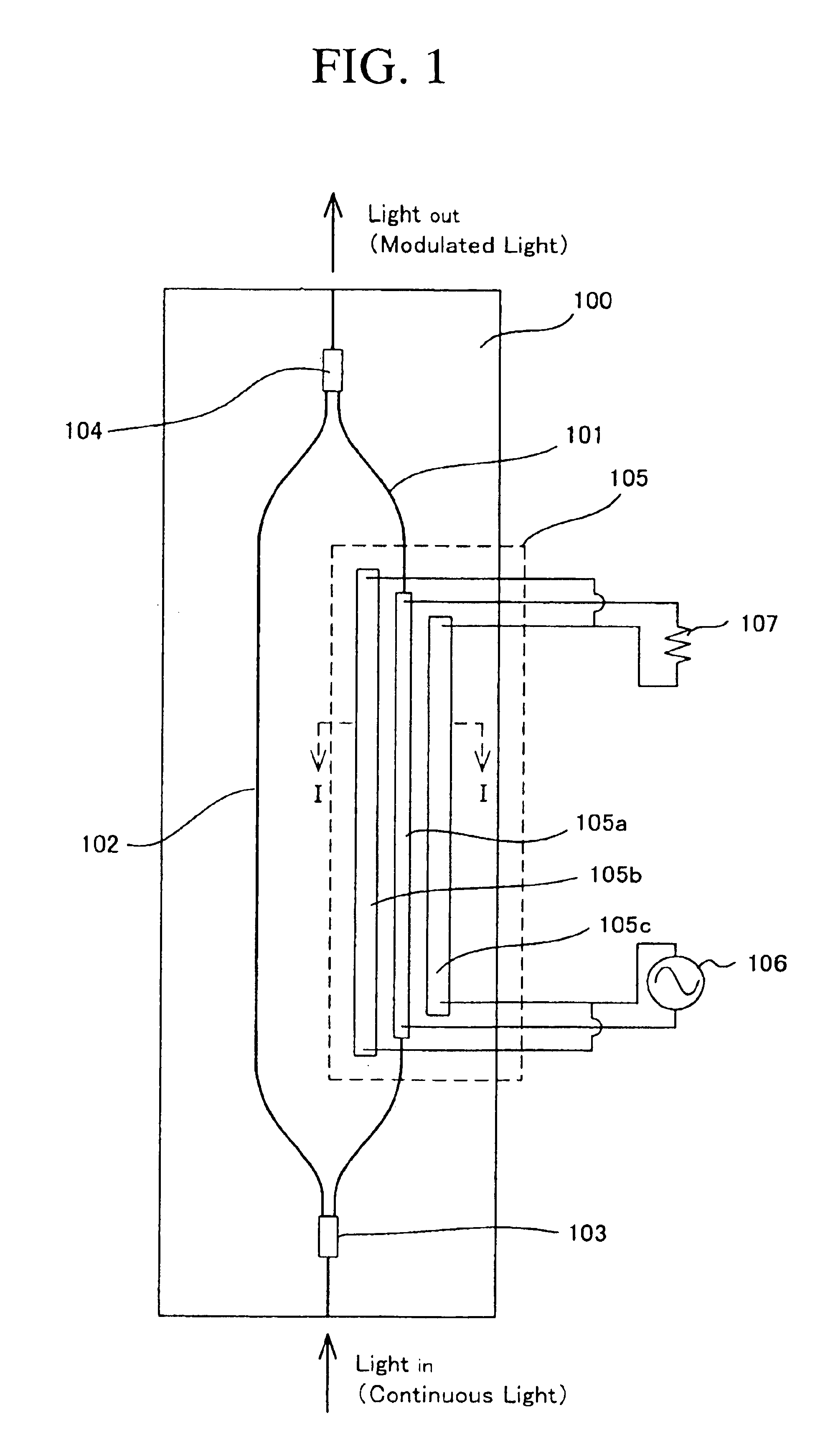

Optical semiconductor device

InactiveUS6872966B2Easy to manufactureReduce signalingLaser detailsLaser optical resonator constructionAir bridgeWaveguide

There are provided first and second optical waveguides formed on a semiconductor substrate and having upper clad layers and core layers that are separated mutually respectively, first and second phase modulation electrodes formed on the first and second optical waveguides respectively, and first and second slot-line electrodes formed on the semiconductor substrate on both sides of the first and second optical waveguides and connected to the first and second phase modulation electrodes via air-bridge wirings separately respectively.

Owner:FUJITSU LTD

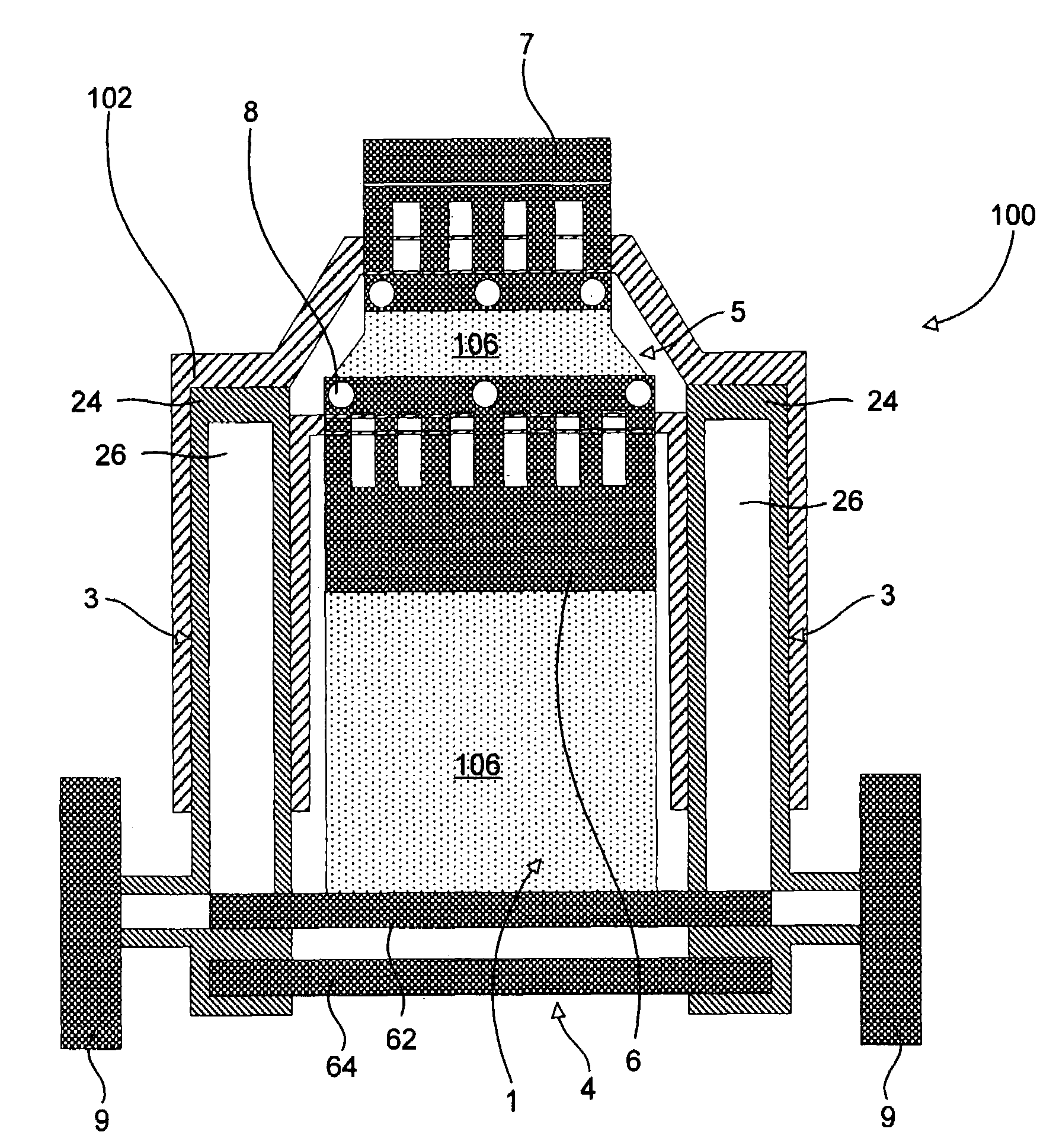

Device used for realizing microwave chip eutectic pressurization and pressurization method

InactiveCN105789071AAvoid damageAvoid tensionSolid-state devicesSemiconductor/solid-state device manufacturingAir bridgeMicrowave chips

The invention relates to the microwave chip eutectic technology and discloses a device used for realizing microwave chip eutectic pressurization. The device specifically comprises a substrate limiter, a chip limiter and a point contact press block, wherein the chip limiter is provided with a chip limit hole, the dimension of the chip limit hole is in matching with the dimension of a chip and is used for limiting the chip, the lower surface of the chip contacts with an upper surface of a substrate through a welding tab, the bottom board of the point contact press block is provided with micro supporting columns, the quantity of the micro supporting columns is smaller than or equal to the quantity of welding pads on the upper surface of the chip, positions of the micro supporting columns and positions of the welding pads on the upper surface of the chip are in mirror symmetric relationship, and the micro supporting columns on the point contact press block contact with the welding pads on the upper surface of the chip. When the chip and the substrate are in an eutectic state, on the point contact press block, only the micro supporting columns and the welding pads on the surface of the chip mutually contact, so a special structure such as an air bridge on the surface of the microwave chip can be prevented from being damaged. The invention further discloses a microwave chip eutectic pressurization method.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

Nanowire LED structure and method for manufacturing the same

ActiveUS8669125B2Discontinuity is reduced and eliminatedEasy to spreadSolid-state devicesSemiconductor/solid-state device manufacturingAir bridgeNanowire

Owner:GLO TECH LLC

Light-emitting device having light-emitting elements

InactiveUS20070138500A1Increase the driving voltageEfficient use ofSolid-state devicesSemiconductor devicesDriving currentAir bridge

Owner:SEOUL SEMICONDUCTOR

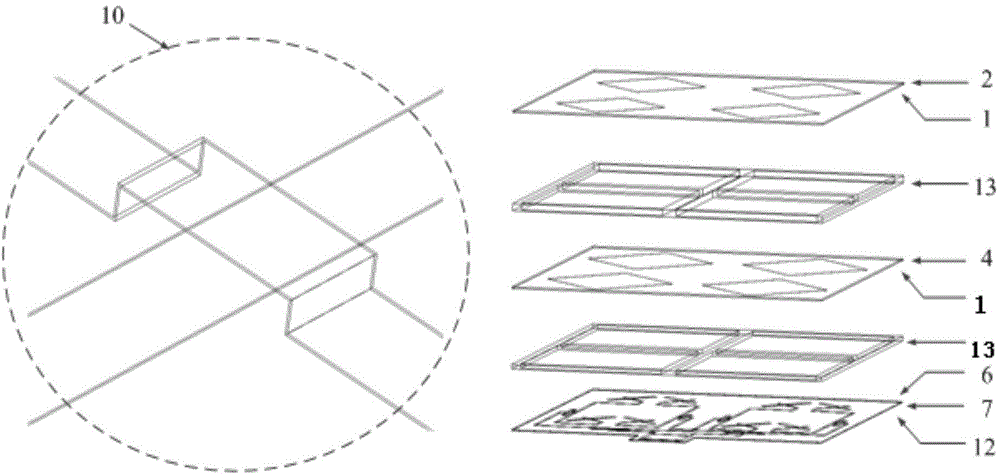

Broadband high-gain double-circle polarized patch antenna

ActiveCN104600425AHigh gainDual Circular Polarization ConvenienceAntenna supports/mountingsRadiating elements structural formsPatch arrayCircularly polarized antenna

The invention discloses a broadband high-gain double-circle polarized patch antenna. The broadband high-gain double-circle polarized patch antenna comprises a floor layer, a feed network, square patch arrays, an upper dielectric substrate, a middle dielectric substrate and a lower dielectric substrate, wherein the upper dielectric substrate, the middle dielectric substrate and the lower dielectric substrate are sequentially arranged from top to bottom and are supported separably through dielectric frames. The square patch arrays are adhered to the lower surfaces of the upper dielectric substrate and the middle dielectric substrate. Each square patch array comprises four square units in two-row two-column arrangement. The floor layer is positioned on the upper surface of the lower dielectric substrate. The feed network is etched on the lower surface of the lower dielectric substrate. Eight radiant gaps are etched on the floor layer. The feed network comprises a directional coupler, six power dividers and an air bridge. The feed network divides an input signal into eight channels of signals, feeds the signals into the radiant gaps and feeds electricity upwardly to the square patch arrays through the radiant gaps, and finally, an antenna radiation effect is achieved through middle and upper radiation. The broadband high-gain double-circle polarized antenna is achieved by the aid of a printed circuit process.

Owner:SOUTHEAST UNIV

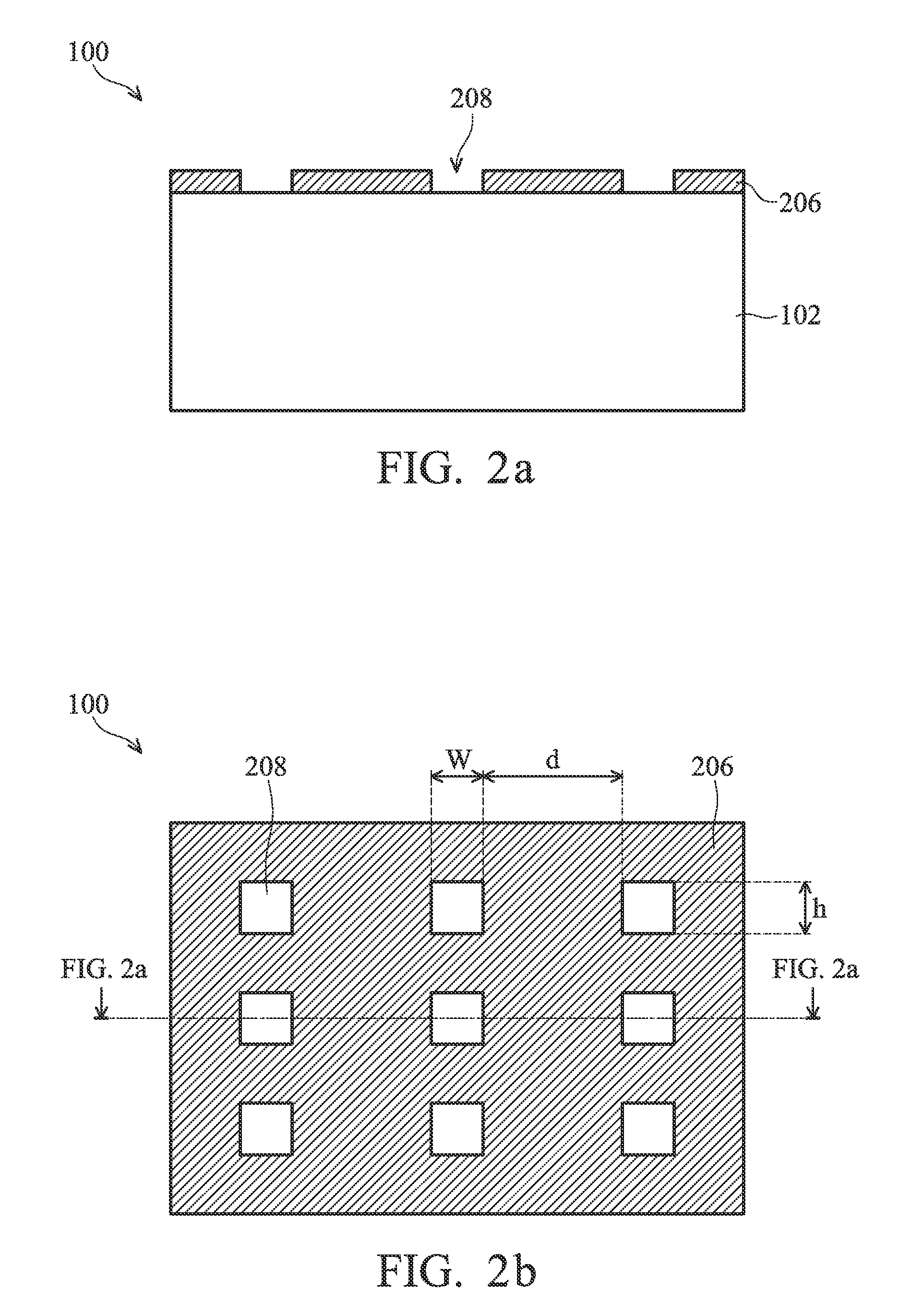

Method of Separating Light-Emitting Diode from a Growth Substrate

A method of forming a light-emitting diode (LED) device and separating the LED device from a growth substrate is provided. The LED device is formed by forming an LED structure over a growth substrate. The method includes forming and patterning a mask layer on the growth substrate. A first contact layer is formed over the patterned mask layer with an air bridge between the first contact layer and the patterned mask layer. The first contact layer may be a contact layer of the LED structure. After the formation of the LED structure, the growth substrate is detached from the LED structure along the air bridge.

Owner:EPISTAR CORP

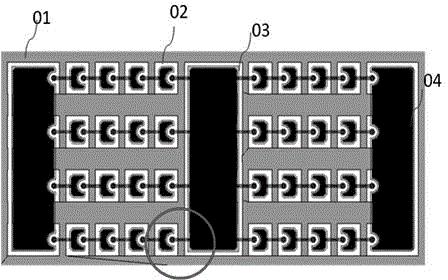

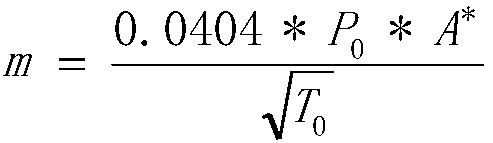

Terahertz low-frequency GaAs based high-power schottky frequency multiplication diode

ActiveCN104867968AHigh power inputNot easy to damageSemiconductor devicesAir bridgeManufacturing technology

The invention discloses a terahertz low-frequency GaAs based high-power schottky frequency multiplication diode. The terahertz low-frequency GaAs based high-power schottky frequency multiplication diode comprises 40 schottky anode junctions and is of a four-row structure; each row structurally comprises 10 schottky junctions, and radio frequency concurrent parallel connection and direct-current reverse serial connection are adopted for each row of the structure; a semi-insulation GaAs substrate is adopted for the frequency multiplication diode, and is provided with a heavy doped GaAs layer and a passivation layer; the heavy doped GaAs layer is provided with a low-doped GaAs layer and an Ohm contact metal layer; the low-doped GaAs layer is provided with a schottky contact metal layer and a silicon dioxide layer; the Ohm contact metal layer is provided with a metal thickening layer which is connected with the schottky contact metal layer via an air bridge, so that the frequency multiplication diode can bear relatively high power input and is less prone to damage; the high-power schottky frequency multiplication diode is relatively high in application frequency; the manufacturing technology is compatible with existing technology; the high-power schottky frequency multiplication diode is high in practicability, and has the technical effects of being applied to secondary frequency multiplication and third-time frequency multiplication simultaneously.

Owner:四川众为创通科技有限公司

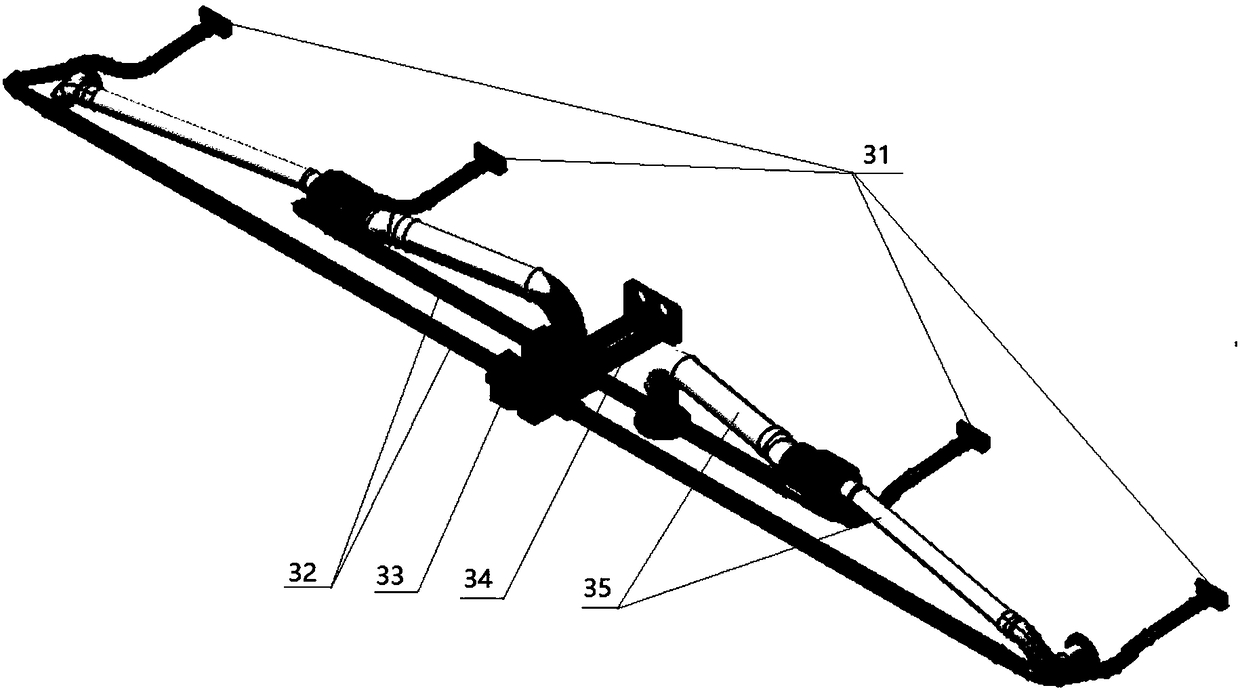

Calibration method of balance with air bridge of wind tunnel strain considering pressure influence

ActiveCN108507752AShorten the calibration cycleImprove R&D efficiencyAerodynamic testingAir bridgeAerodynamic load

The present invention provides a calibration method of a wind tunnel strain balance with an air bridge considering pressure influence. Working formulas, with a limited quantity, of a balance with an air bridge in different pressure states are employed to perform fitting and generate a general balance working formula suitable for a pressure range required by a test, and the general balance workingformula comprises pressure parameters. The pressure parameters are added into the general balance working formula of the balance with the air bridge, and when wind tunnel test is performed, an actually measurement pressure value and electrical signal increment value of each component of the balance are substituted into the general balance working formula to calculate and obtain accurate aerodynamic loading. Compared to the calculation result of a traditional balance formula, the general balance working formula can obtain more accurate aerodynamic loading so as to facilitate improvement of accuracy of the type of the wind tunnel test.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

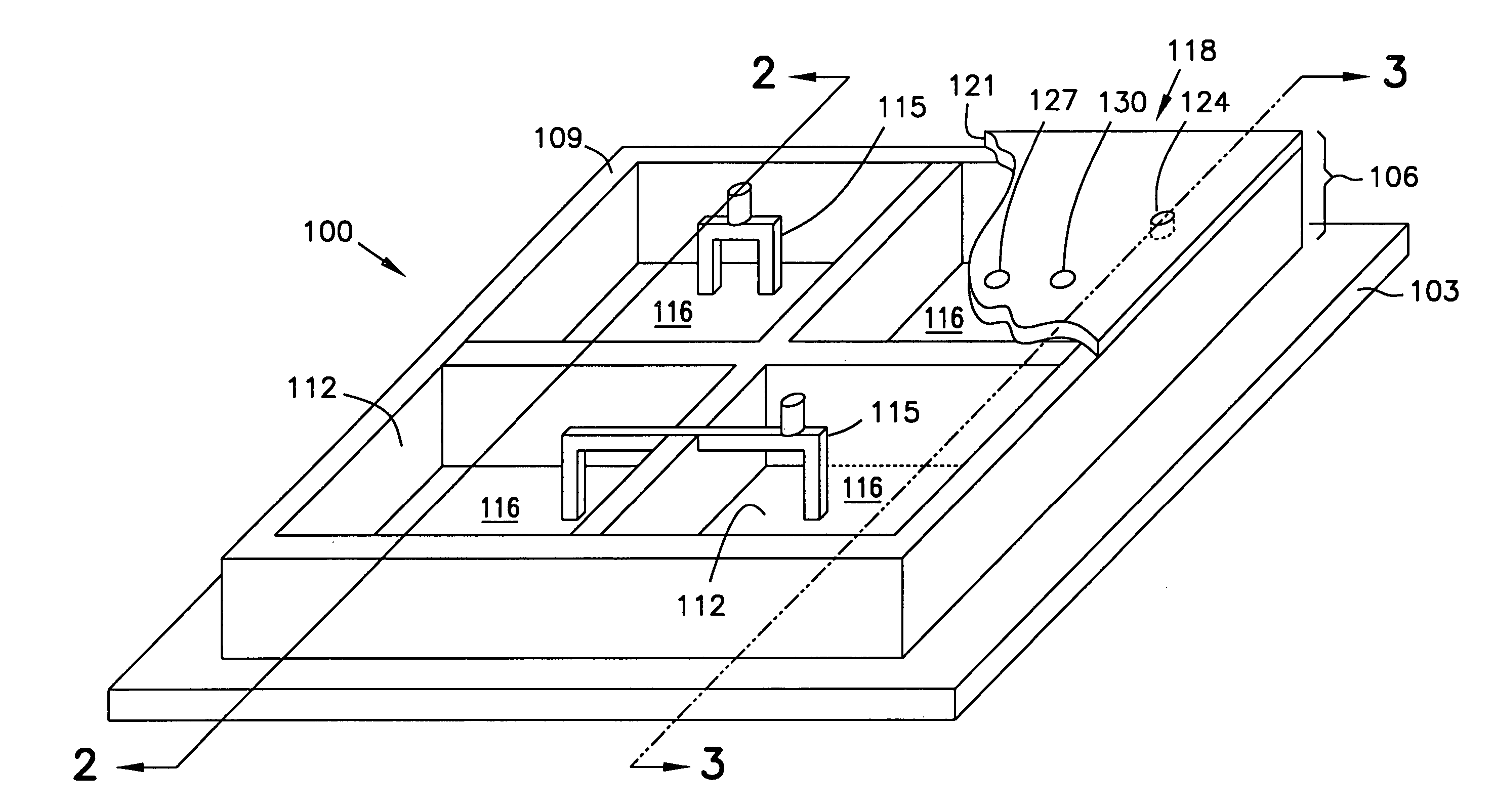

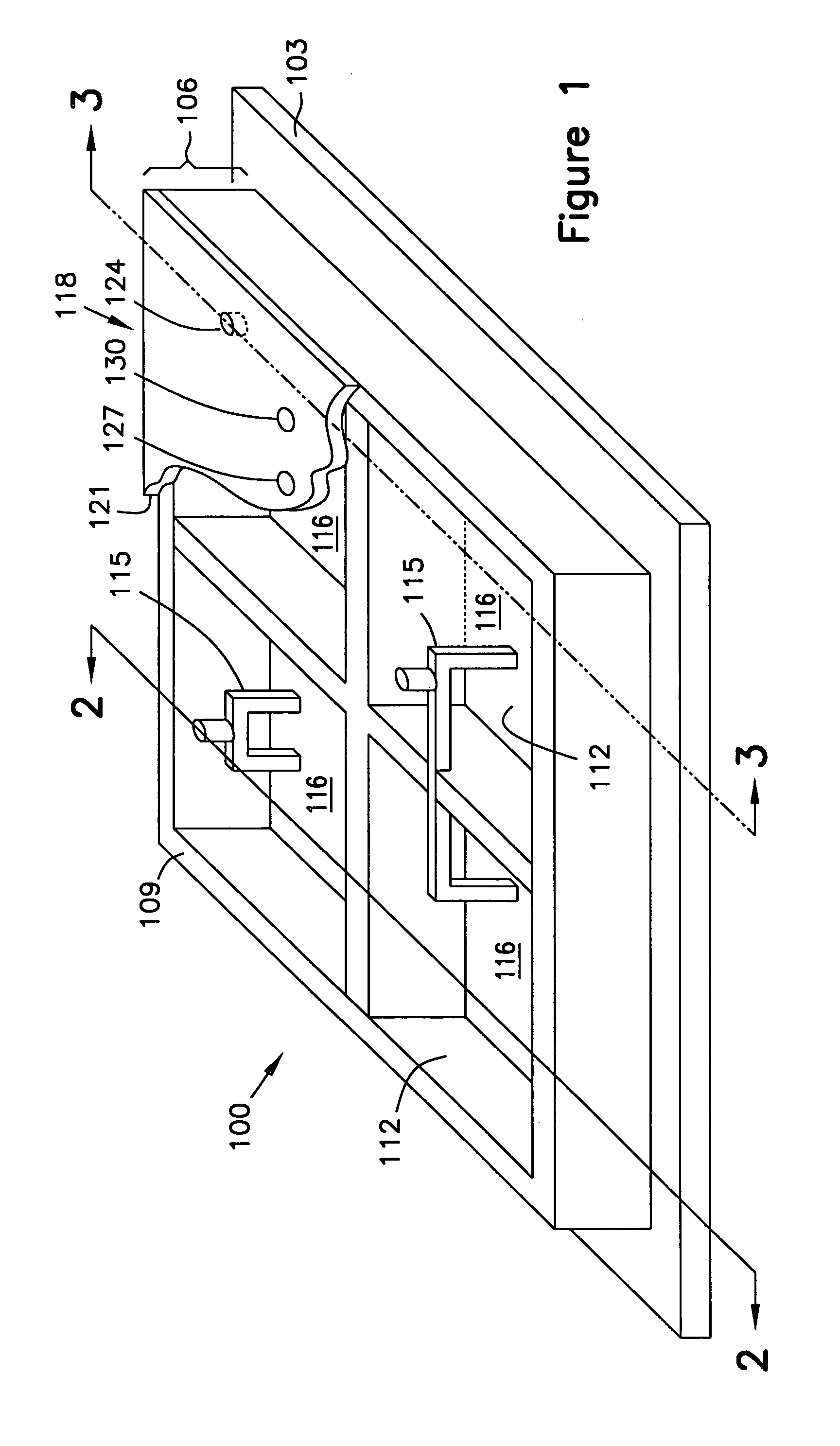

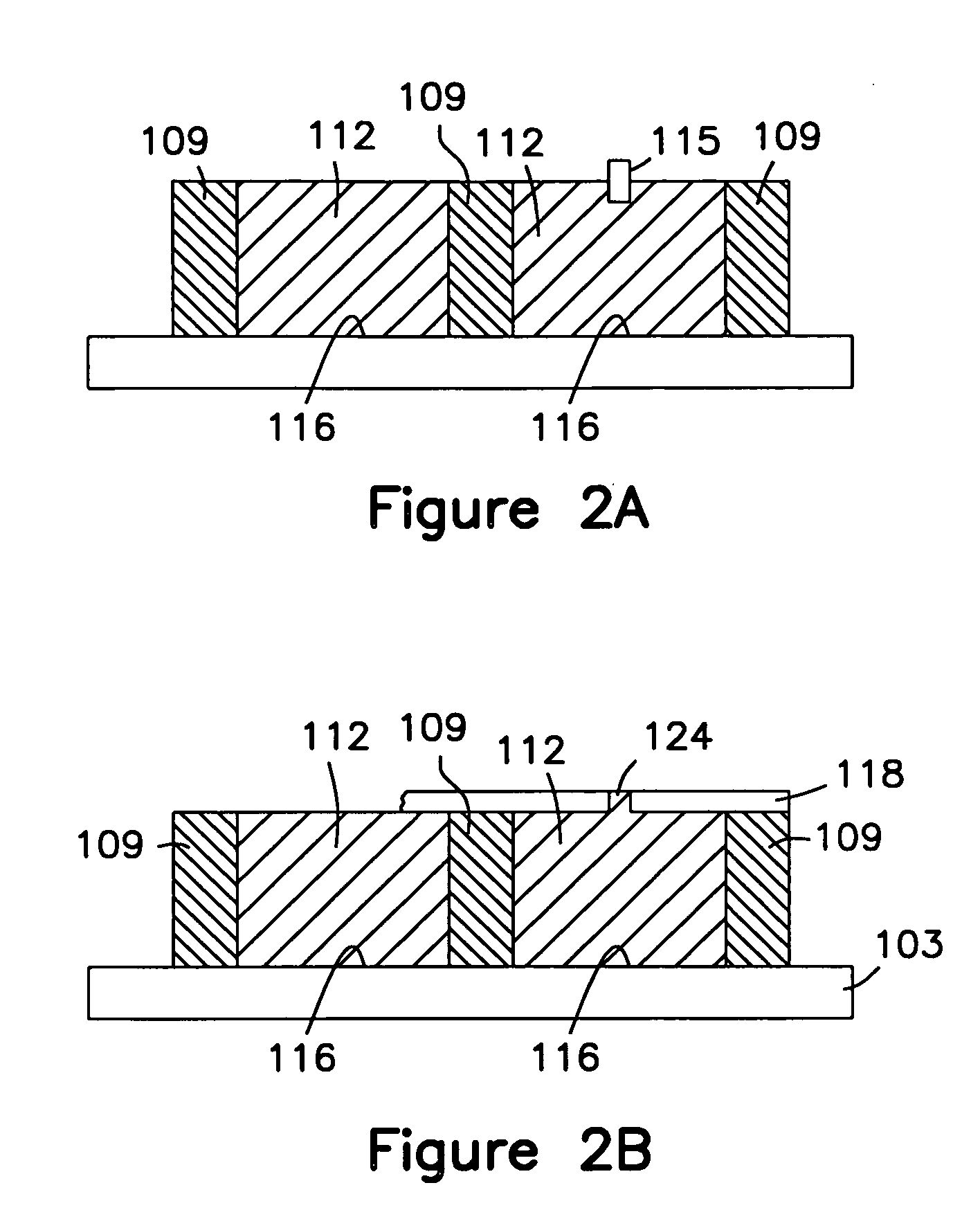

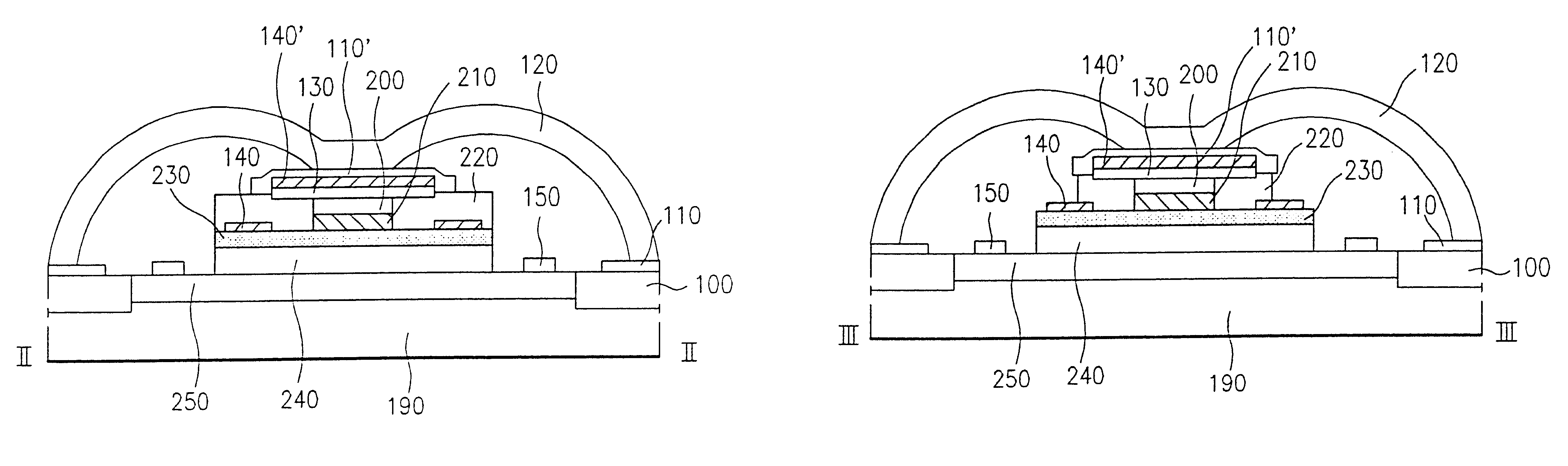

Packaging of electronic chips with air-bridge structures

InactiveUS20050285220A1Semiconductor/solid-state device detailsSolid-state devicesMulti materialAir bridge

A circuit assembly for fabricating an air bridge structure and a method of fabricating an integrated circuit package capable of supporting a circuit assembly including an air bridge structure. A circuit assembly comprises an electronic chip and a conductive structure embedded in a plurality of materials having a plurality of vaporization temperatures. The plurality of materials is formed on the electronic chip and the conductive structure is coupled to the electronic chip. To fabricate the circuit assembly, a support structure, including interstices, is formed on an electronic chip. The interstices of the support structure are filled with a material having a vaporization temperature that is less than the vaporization temperature of the support structure. Conductive structures are embedded in the support structure and the material, and a connective structure is mounted on the support structure. Finally, the material is removed from the interstices by heating the circuit assembly.

Owner:MICRON TECH INC

Method for producing air bridge of compound semiconductor microwave high power device

InactiveCN101097860AReduce widthReduce difficultySemiconductor/solid-state device manufacturingSemiconductor devicesState of artCyanide

Owner:XIDIAN UNIV

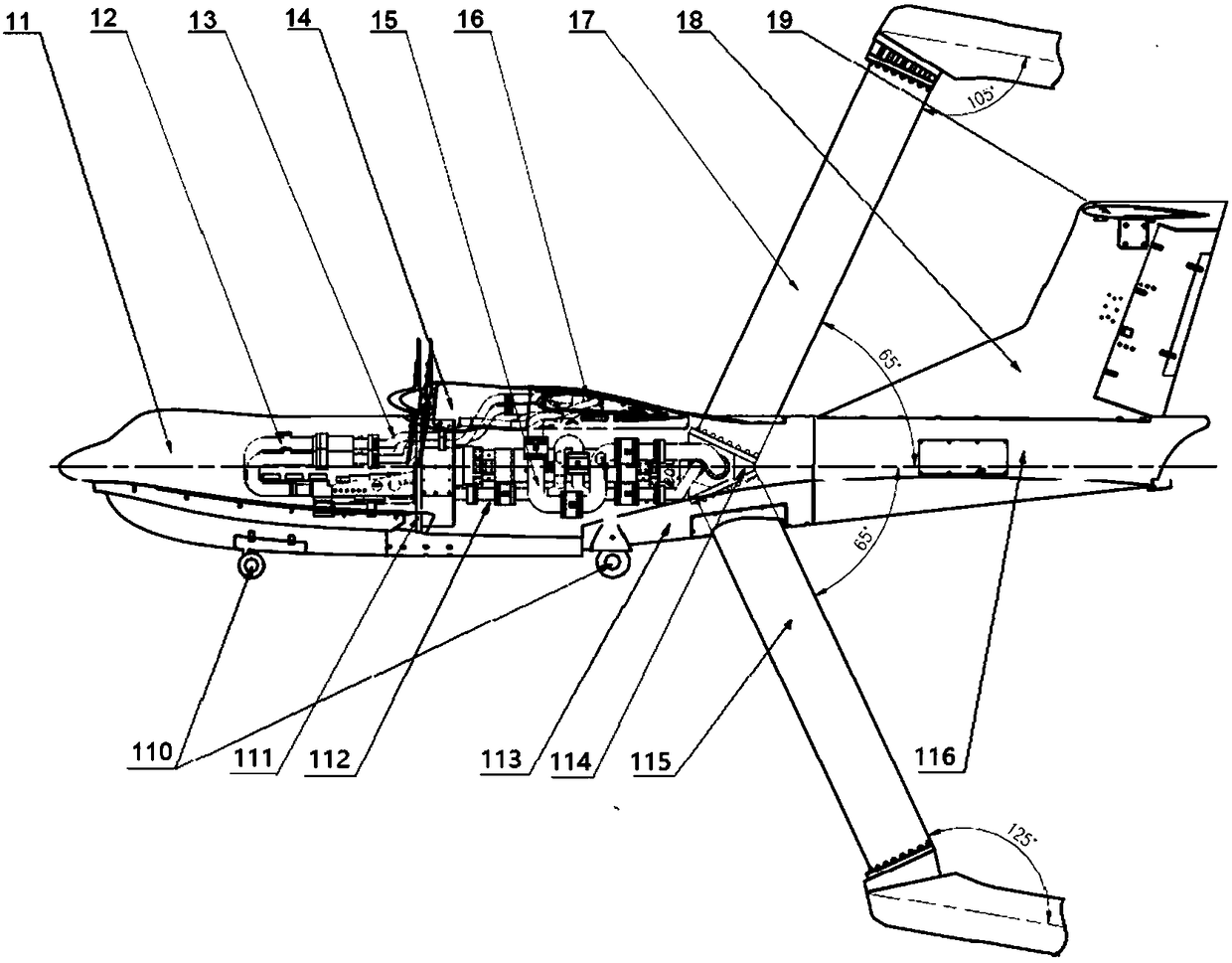

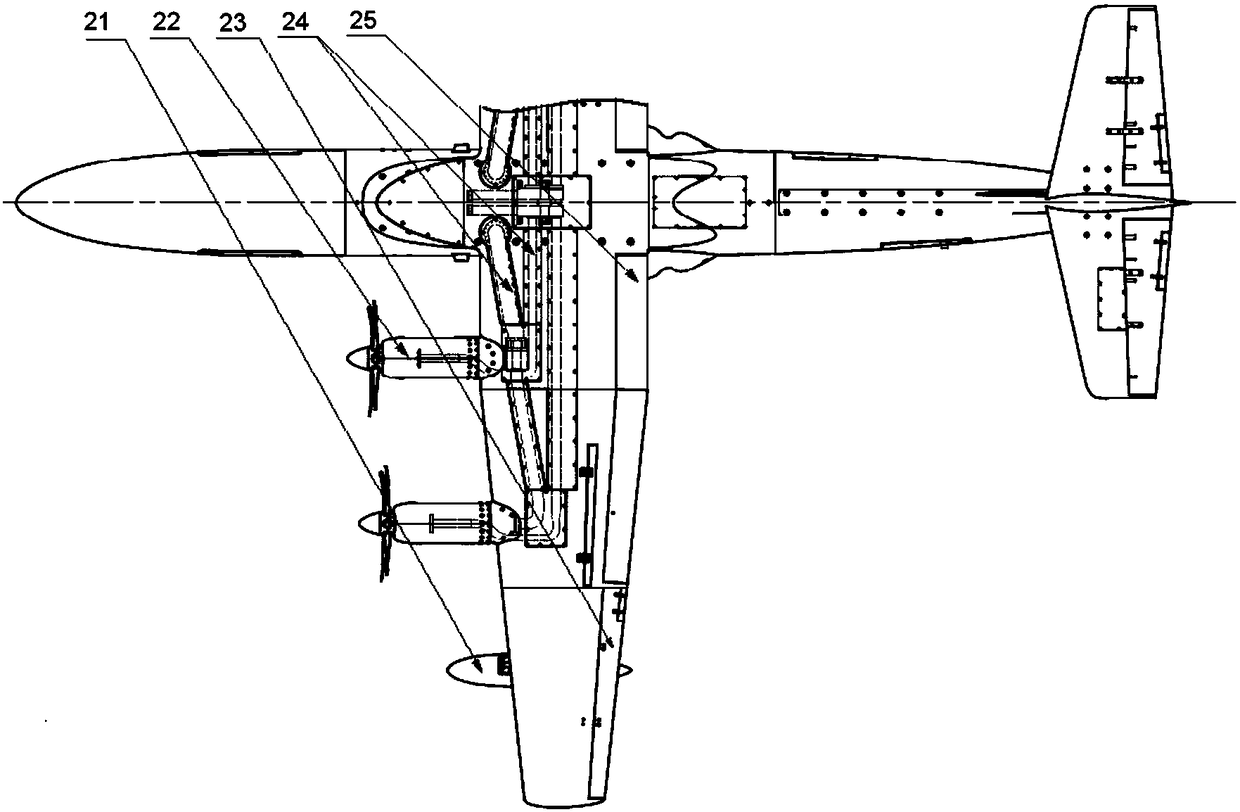

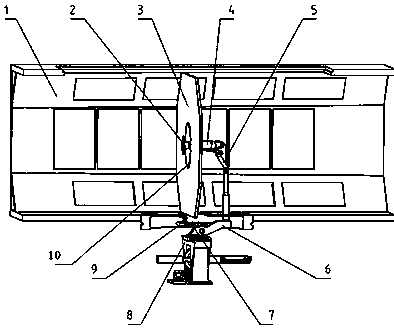

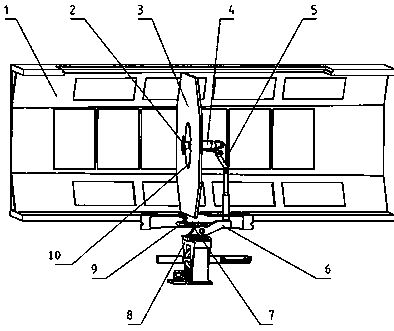

Four-engine propeller aircraft wind tunnel test model based on air motors

ActiveCN108106814AImprove accuracyGuarantee the sameAerodynamic testingAircraft components testingAir bridgePropeller

The invention discloses a four-engine propeller aircraft wind tunnel test model based on air motors. One end of a supporting member is fixedly connected with a wind tunnel balance rack, and the otherend is connected to a main balance by means of a supporting rod connection member and an air bridge. Empennage and aerofoil assemblies are installed on an aircraft body, the middle section of the aircraft body is fixedly connected to balance connection members, the other end of each balance connection member is fixedly connected to the main balance, and a whole aircraft acting force is transmittedonto the main balance by means of the balance connection members. Flaps and ailerons are connected with an aerofoil stabilizing plane by means of respective angle changing pieces. A force and momentof a propeller are measured in real time by means of a rotating shaft balance during a wind tunnel test. A flow control device is installed in the aircraft body, and controls output power of the air motors by controlling gas flow. The invention provides a design method of the wind tunnel test model using the air motors for simulating power of the propellers, the flow field similarity degree in thepropeller power simulation tests is improved, and the data precision of wind tunnel tests is effectively improved.

Owner:中航通飞华南飞机工业有限公司

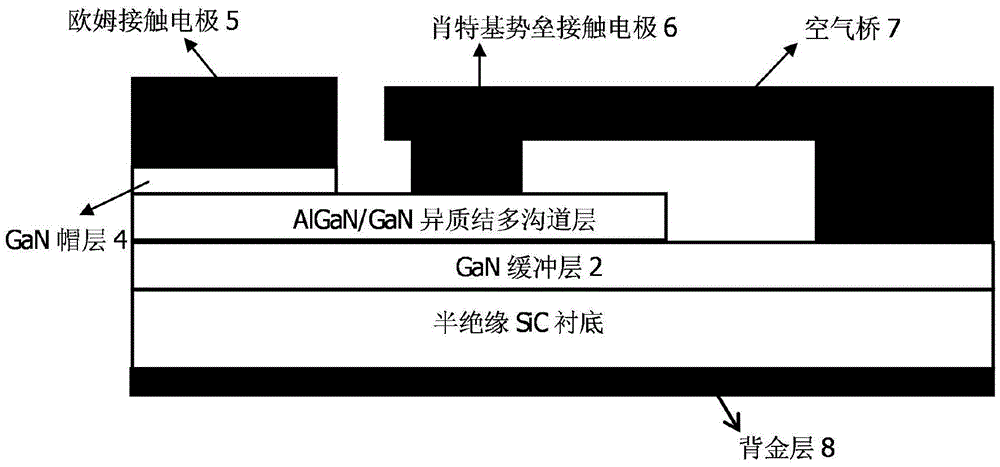

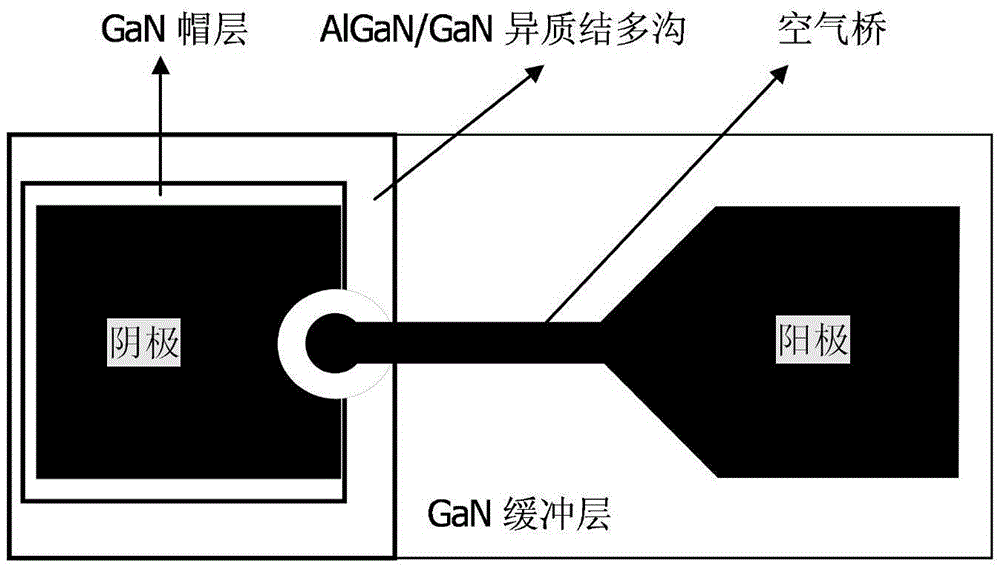

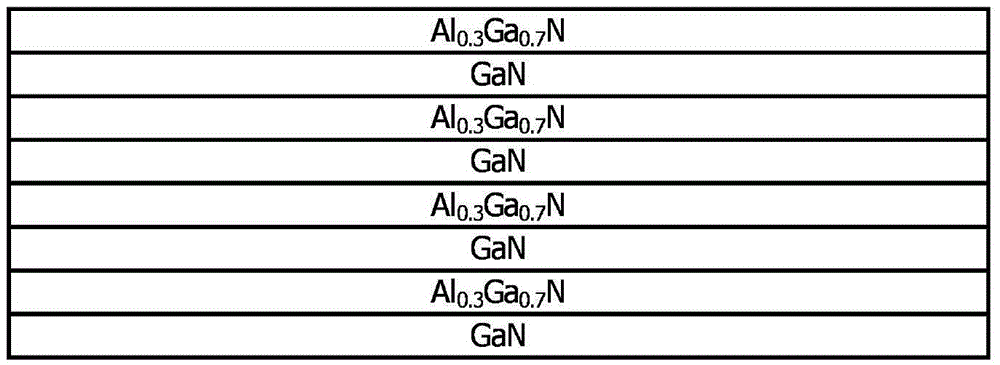

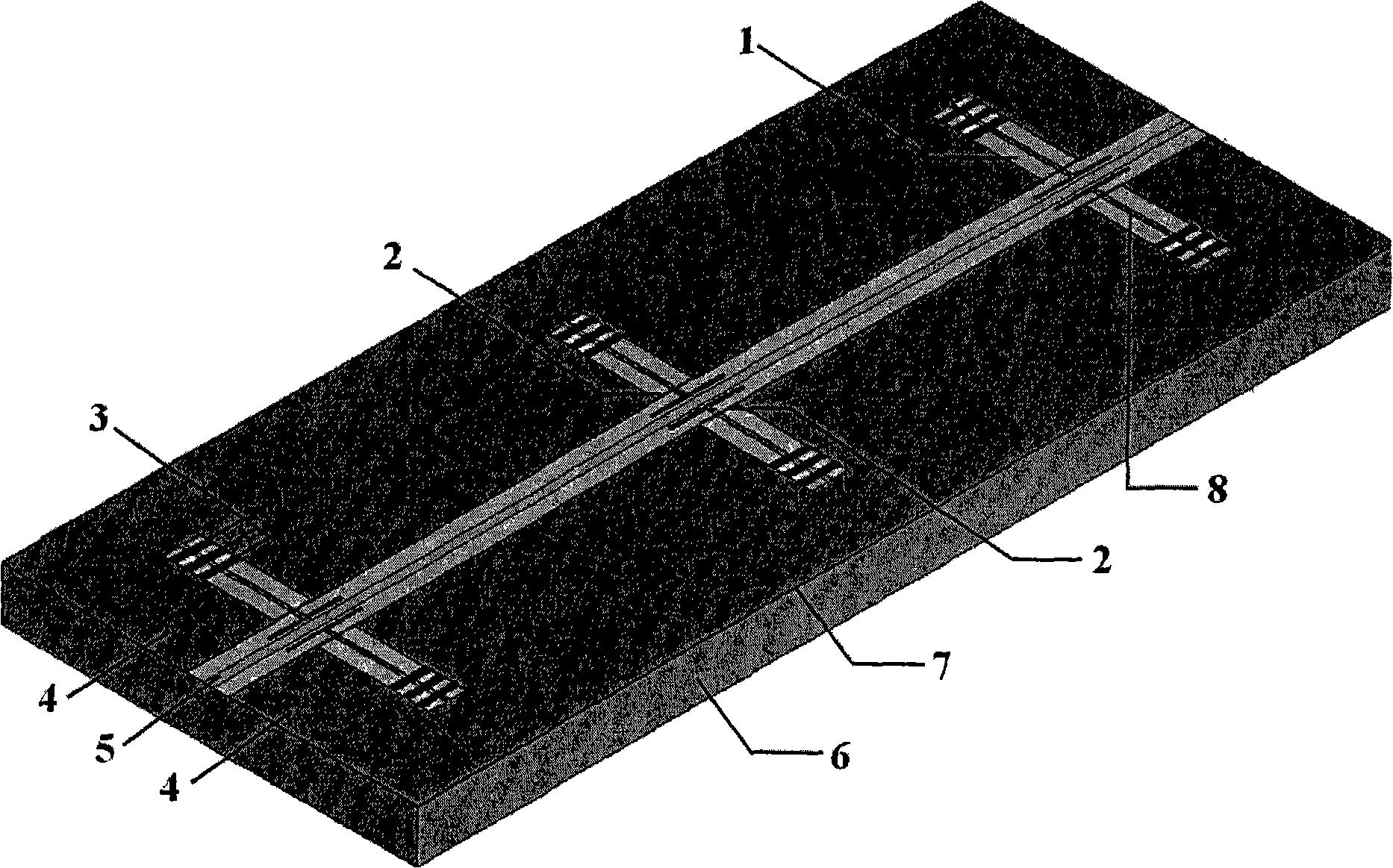

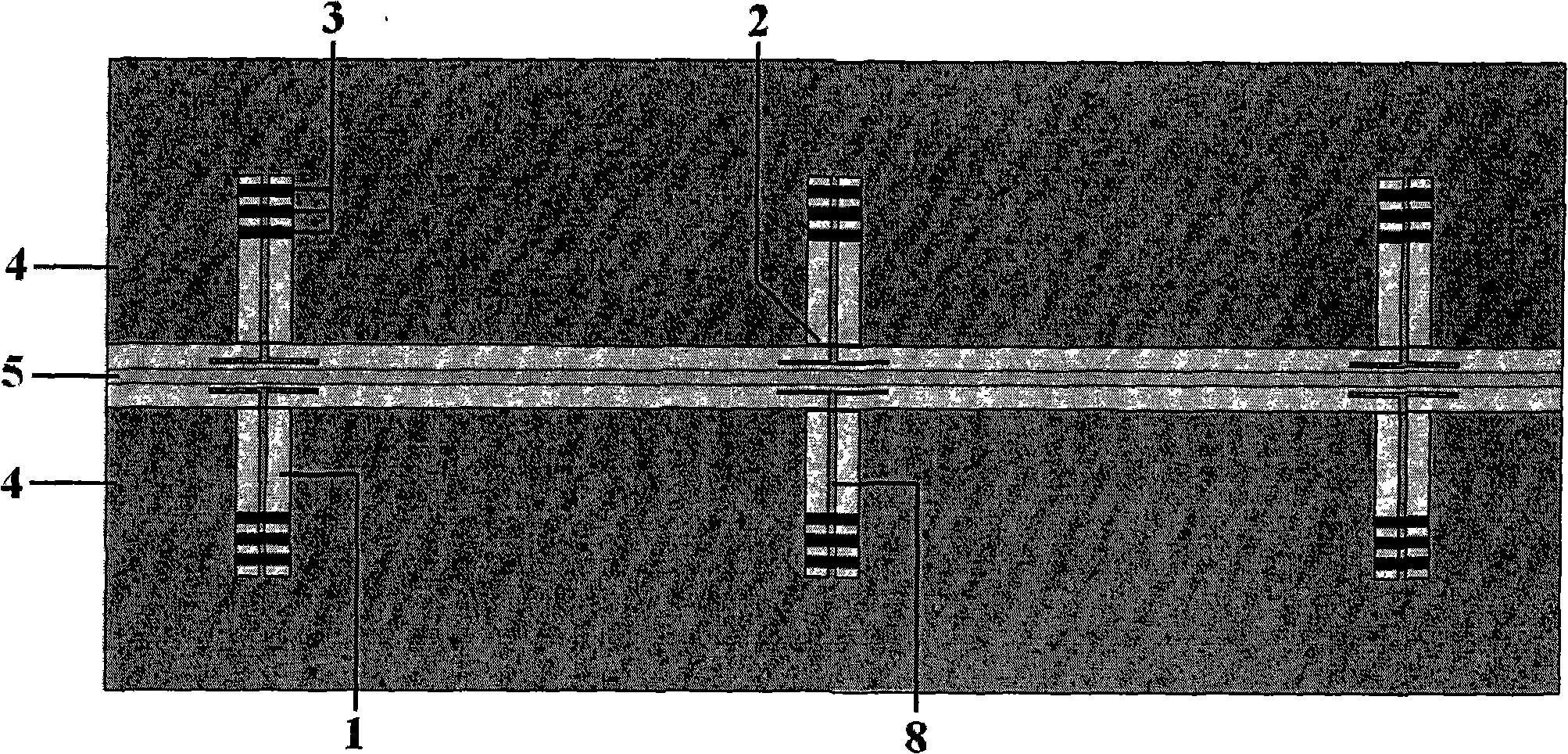

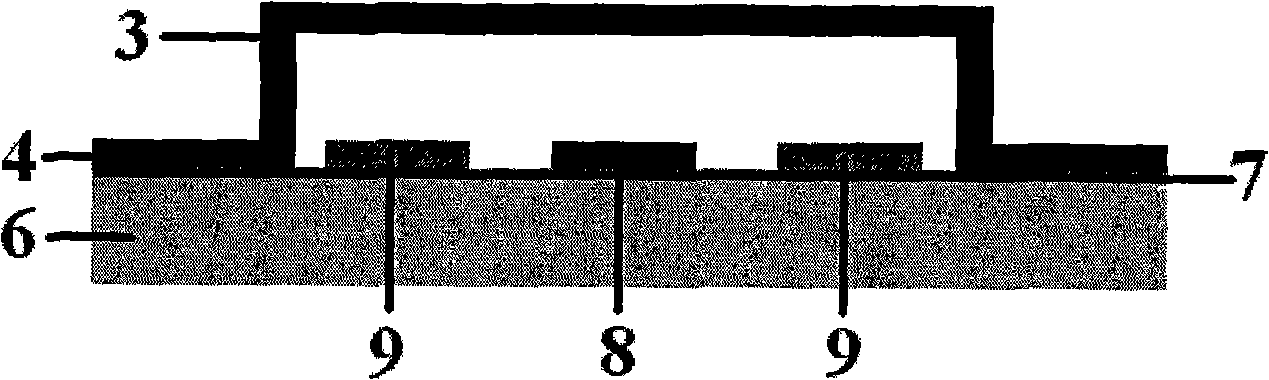

AlGaN/GaN heterojunction multi-channel structure based terahertz schottky diode and manufacturing method therefor

ActiveCN105679838AImprove mobilityRaise the cutoff frequencySemiconductor/solid-state device manufacturingDiodeHeterojunctionSchottky barrier

The invention discloses an AlGaN / GaN heterojunction multi-channel structure based terahertz schottky diode and a manufacturing method therefor, and mainly aims to solve the problem of low doping mobility ratio, high series resistance and low cut-off frequency of the existing GaN schottky diode. The AlGaN / GaN heterojunction multi-channel structure based terahertz schottky diode comprises a main body part and an auxiliary body part, wherein the main body part comprises (1) a semi-insulating SiC substrate, (2) a GaN buffer layer, (3) an AlGaN / GaN heterojunction multi-channel layer, and (4) a GaN cap layer from the bottom up; the auxiliary body part comprises (5) an ohmic contact electrode (negative electrode), (6) a schottky barrier contact electrode (positive electrode), (7) an air bridge and (8) a back gold layer, wherein the AlGaN / GaN heterojunction multi-channel layer adopts an AlGaN / GaN type superlattice structure; the superlattice has 2-6 periods; and the thicknesses of the GaN layer and the AlGaN layer are both 10-20nm in each period, and the Al component accounts for 30% of the AlGaN layer. According to the terahertz schottky diode provided by the invention, the conventional n type doping process can be avoided; the multi-layer two-dimensional electron gas channels formed by polarization are adopted, so that the electron mobility is improved, the series resistance is lowered, and the cut-off frequency is improved, so that the AlGaN / GaN heterojunction multi-channel structure based terahertz schottky diode is applicable to operations under terahertz frequency bands.

Owner:XIDIAN UNIV

MEMS electromagnetic band gap adjustable band-elimination filter applied to K wave band

InactiveCN101359760AChange the resonant frequencyChanging the resonant inductanceWaveguide type devicesAir bridgeCoplanar waveguide

Disclosed is an MEMS electromagnetic band gap tunable band-stop filter used in K wave band, wherein a coplanar waveguide center transmission line is arranged on a vertical center line of a coplanar waveguide ground plane, both of which are disposed on a substrate, and carved grooves are arranged in the direction which is vertical to the coplanar waveguide center transmission line; the horizontal ends of a pair of T-shaped lines are respectively parallel to the coplanar waveguide center transmission line and are symmetrically distributed on both sides thereof, and the vertical ends are respectively arranged in the carved grooves on both sides of the coplanar waveguide center transmission line; two ends of a pair of air-bridge span over the opening of the edge of the carved groove which is near the coplanar waveguide center transmission line; two ends of a pair of MEMS direct-contact switching group span across two tail ends of the carved groove which is along the direction of keeping away from the coplanar waveguide center transmission line; the unit resonant circuits formed by the foregoing structure are collocated cyclically along the direction of the coplanar waveguide center transmission line to form the MEMS electromagnetic band gap tunable band-stop filter used in K wave band; and the invention adopts an MEMS switch to achieve wide-range tuning of the filter center frequency, and introduce the electromagnetic band gap structure to achieve good isolation performance within the stop band.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

RF MEMS series switch using piezoelectric actuation and method of fabrication

A microelectromechanical system (MEMS) switch comprising a radio frequency (RF) transmission line; a structurally discontinuous RF conductor adjacent to the RF transmission line; a pair of cantilevered piezoelectric actuators flanking the RF conductor; a contact pad connected to the pair of cantilevered piezoelectric actuators; a pair of cantilevered structures connected to the RF conductor; a plurality of air bridges connected to the pair of cantilevered piezoelectric actuators; and a plurality of contact dimples on the contact pad. Preferably, the RF transmission line comprises a pair of co-planar waveguide ground planes flanking the RF conductor; and a plurality of ground straps connected to the pair of co-planar waveguide ground planes, wherein the RF transmission line is operable to provide a path along which RF signals propagate.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Heterojunction bipolar transistor and its fabrication method

A heterojunction bipolar transistor and its fabrication method is disclosed. The heterojunction bipolar transistor includes a substrate; a collector layer formed to have a ledge or MESA on the substrate; a collector electrode formed on the collector layer surrounding the ledge; a base layer formed on the ledge of the collector layer; an ohmic cap layer on the emitter layer; an emitter layer formed in the center of the base layer; an emitter electrode formed on the ohmic cap layer; a base electrode formed on the base layer surrounding the emitter electrode; an insulating layer formed to cover the base electrode and to overlay on the insulating layer; a metal wire formed to cover the emitter electrode; and an air bridge brought in contact with the metal wire and electrically connected to an external pad lying on an ion-implanted isolation region.

Owner:LG ELECTRONICS INC

TPS reverse thrust nacelle thrust calibration test method

PendingCN110031181AReduce the impactImprove securityAerodynamic testingEngine testingAir bridgeNacelle

The invention discloses a TPS reverse thrust nacelle thrust calibration test method comprising a partition, a bell mouth, a rectifying device, a ventilation strut, a support base, an air bridge, an intake steel pipe, a thrust balance and a measuring system. In the thrust calibration test, the thrust balance measures the thrust generated by the TPS reverse thrust nacelle, the actual thrust of the nacelle is obtained after the air bridge and the labyrinth seal influence are corrected, and the ratio of the theoretical thrust and the actual thrust is calculated to obtain a thrust calibration coefficient of the corresponding state. The method provided by the invention has high precision of thrust calibration by measuring the thrust generated by the TPS reverse thrust nacelle through the thrustbalance, improves the accuracy of balance measurement by reducing the influence of high pressure air pipeline on balance measurement through the air bridge, and improves the safety and reliability ofthe reverse thrust calibration test by preventing the reverse tail jet of the TPS reverse thrust nacelle from the re-inhalation of the nacelle air intake through the partition.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

Method for preparing air bridge using photosensitive subbing

InactiveCN101276778AEasy to operateImprove controllabilitySemiconductor/solid-state device manufacturingAir bridgeEtching

The invention is related to a semiconductor device and the technical field of integrated circuit manufacturing process, and discloses a method for utilizing a photosensitive glue layer to manufacture air bridge, comprising the steps of: A, coating a sacrificed glue layer on a substrate to cover metal on the substrate, photo-etching, exposing and developing the coated sacrificed glue layer to form the air bridge support; B, baking the substrate which forms the air bridge support in order to smooth and solidify the edge corners f the sacrificed glue layer; C, coating secondary photo-etching glue on the substrate, photo-etching, exposing and developing the coated secondary photo-etching glue to form bridge surface; D, evaporating, sputtering and plating a layer of metal material on the substrate; E, peeling off the photo-etching glue on the substrate to form the air bridge. Usage of the invention can simplify the manufacturing process, improve controllability and precision of manufacturing, avoid the using of virulent reagent, and lessen damages of the device in the manufacturing process.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com