Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60 results about "Butylamines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Isomeric amines of butane, where an amino group replaces a hydrogen on one of the four carbons. They include isobutylamine, n-Butylamine, sec-Butylamine, and tert-Butylamine.

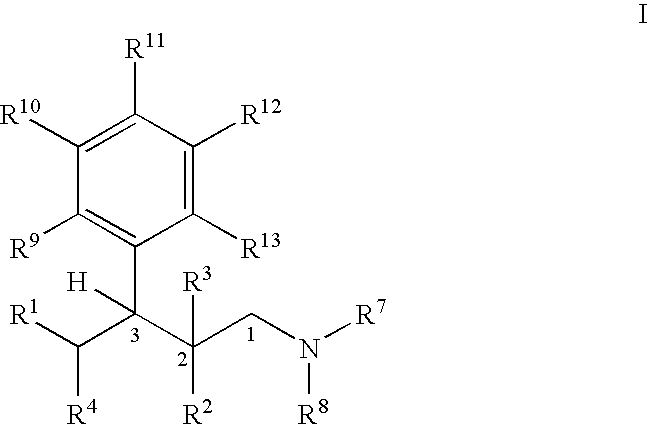

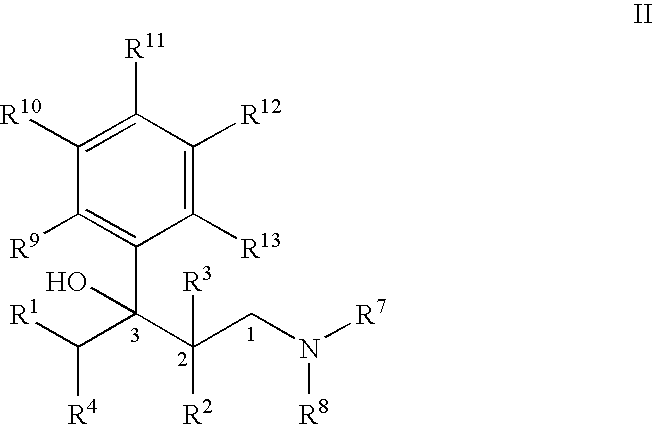

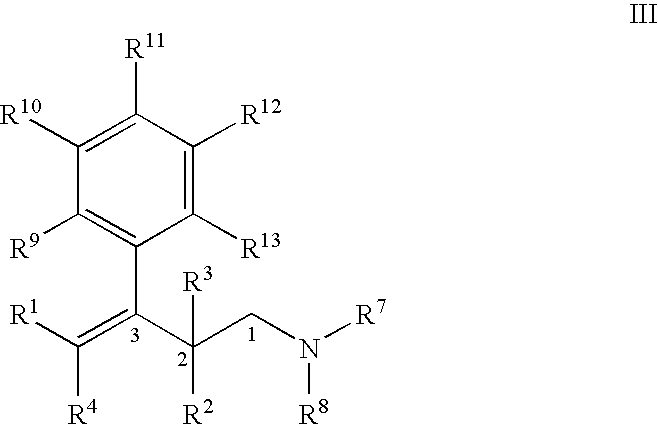

Process for the preparation of substitued 3-aryl-butylamine compounds

Methods for the dehydration of substituted 1-amino-3-aryl-butan-3-ol compounds for the preparation of substituted 3-aryl-butyl-amine compounds.

Owner:GRUNENTHAL GMBH

Process for the preparation of substituted 3-aryl-butylamine compounds

ActiveUS7417170B2High yieldImprove environmental friendlinessOrganic compound preparationAmino compound preparationArylAlcohol

Methods for the dehydration of substituted 1-amino-3-aryl-butan-3-ol compounds for the preparation of substituted 3-aryl-butyl-amine compounds.

Owner:GRUNENTHAL GMBH

Method for synthesizing core-shell type zeolite molecular sieve

ActiveCN101723402APromote formationEvenly dispersedMolecular sieve catalystsPentasil aluminosilicate zeoliteSoluble glassPropylamine

The invention relates to a method for synthesizing ZSM-5 / ZSM-5 core-shell type zeolite molecular sieve, mainly solving the technical problems of expensive used raw materials, great environment pollution of template agent, high difficulty of industrial amplification and synthesis, difficult industrial production and the like of the core-shell type zeolite molecular sieve in the prior art. The invention adopts the following technical scheme: the core-shell zeolite molecular sieve is prepared by adopting ZSM-5 core phase molecular sieve with a relatively low silica alumina ratio as a seed crystal, using at least one of soluble glass, silica solution, sodium silicate, white carbon black or atlapulgite which are cheap and easily obtained as a silicon source, and taking at least one organic amine from ethylamine, ethanediamine, propylamine and butylamine or the mixture of the organic amine and inorganic amine as a template agent so as to better solve the above technical problems. The invention can be used in industrialized synthetic production of core-shell type molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

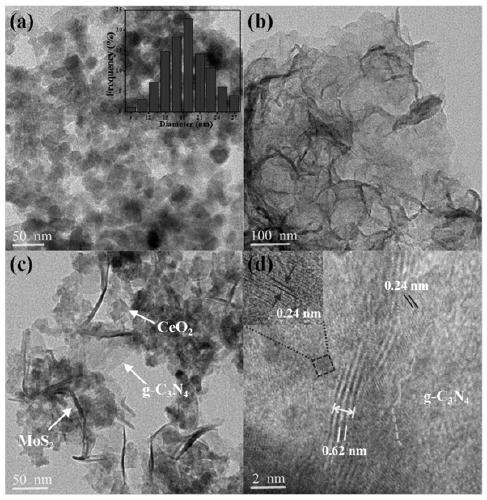

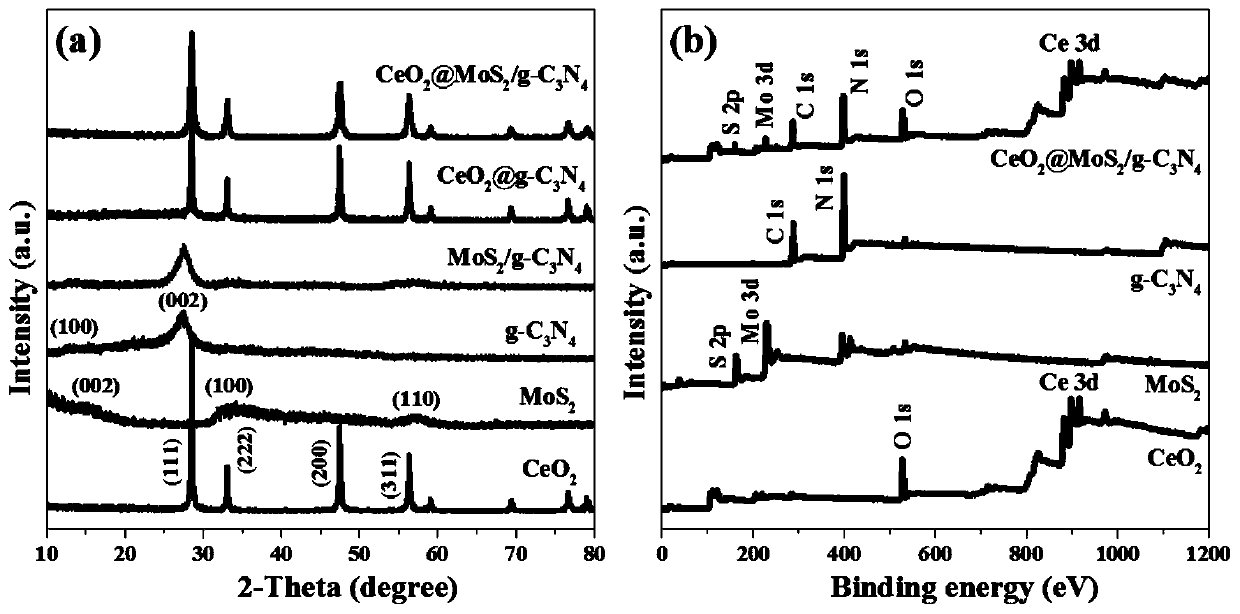

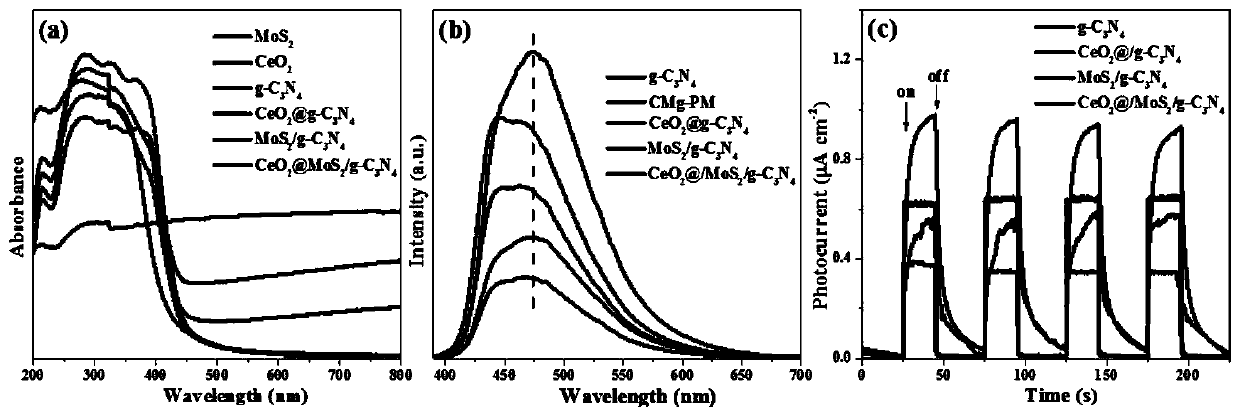

CeO2@MoS2/g-C3N4 ternary composite photocatalyst and preparation method thereof

ActiveCN110152711AImprove light responsivenessUnique two-dimensional nanostructureMaterial nanotechnologyWater/sewage treatment by irradiationNitrogen gasControllability

The invention belongs to the field of nano-material preparation, and discloses a CeO2@MoS2 / g-C3N4 composite photocatalysis material and a preparation method thereof. The preparation method comprises the following steps: (1) adding cerium oxide hexahydrate to a mixed solution of butylamine and toluene, carrying out hydrothermal treatment on the obtained mixed solution, and calcining the obtained reaction product to obtain CeO2 nanocrystals; (2) ultrasonically dispersing sodium molybdate dihydrate and g-C3N4 nanosheets in a mixed solution of L-cysteine and dimethyl sulfoxide, and carrying outhydrothermal treatment on the obtained mixed solution to obtain MoS2 / g-C3N4 nanosheets; (3) ultrasonically dispersing the CeO2 nanocrystals and MoS2 / g-C3N4 in a methanol solution, volatilizing the methanol, and collecting the obtained product to obtain a CeO2-MoS2 / g-C3N4 composite material; and (4) placing the CeO2-MoS2 / g-C3N4 composite material in a tubular furnace, and calcining in a nitrogen atmosphere to obtain the CeO2@MoS2 / g-C3N4 ternary composite photocatalyst. The preparation method of the invention is simple and has strong controllability, and the obtained composite photocatalyst hasan excellent photocatalytic degradation performance.

Owner:NANJING UNIV +1

Beneficiation method for low-grade copper sulphide ore

The invention relates to a beneficiation method for low-grade copper sulphide ore. The method comprises the technology steps and conditions that ore grinding is carried out, and water, lime and butylamine dithiophosphate are added; flash flotation is carried out, the pH value is adjusted, and MIBC is added; roughing I and roughing II are carried out, and modified butylamine dithiophosphate and MIBC are added in flash flotation tailings; ore grinding is carried out through roughing concentrate obtained through two times of roughing; sifting I is carried out, lime is added in re-ground ore grain powder B pulp to adjust the pH value, and water glass is added; sifting II is carried out, and no additive is added; scavenging I is carried out, and sodium sulphide, butylamine dithiophosphate and MIBC are added in roughing II tailings; and scavenging II is carried out, and butylamine dithiophosphate and MIBC are added in scavenging I tailings. The beneficiation method has the beneficial effects that the flotation efficiency of the objective mineral is high, the mineral which is good in floatability and is separated in a monomer manner is preferably recycled, the phenomena of enrichment and excessive crushing of associated noble metal in a loop can be avoided, the comprehensive mineral recovery rate is high, and the flotation pulp environment is good; and the rough ore and concentrate yield is high, the separated mineral is preferably recycled, copper mineral and connected growing bodies hard to separate are effectively recycled, and the associated noble metal is efficiently recovered. The beneficiation method is applicable for processing noble metal containing copper sulphide ore not even in dissemination size.

Owner:ZIJIN MINING GROUP

Synthesizing method of N,N-diisopropyl butylamine

InactiveCN101638370ARaw materials are cheap and easy to getReduce manufacturing costAmino preparation by functional substitutionReaction temperatureDiisopropylamine

The invention discloses a synthesizing method of N,N-diisopropyl butylamine, which comprises the following steps: using diisopropylamine and 1-chlorobutane as raw materials to carry out a reaction in a high-pressure kettle under reaction pressure of 1.05-2.0Mpa and a reaction temperature of 150-250 DEG C for 4-10 hours in a molar ratio of the diisopropylamine to the 1-chlorobutane of 2-5:1; regulating the pH of the resulting reaction solution to be 12.5-13.5; and then separating out an organic phase to rectify so as to obtain the N,N-diisopropyl butylamine. The N,N-diisopropyl butylamine synthesized by the method has the characteristics of low production cost, simple process, high yield, and the like.

Owner:ZHEJIANG UNIV

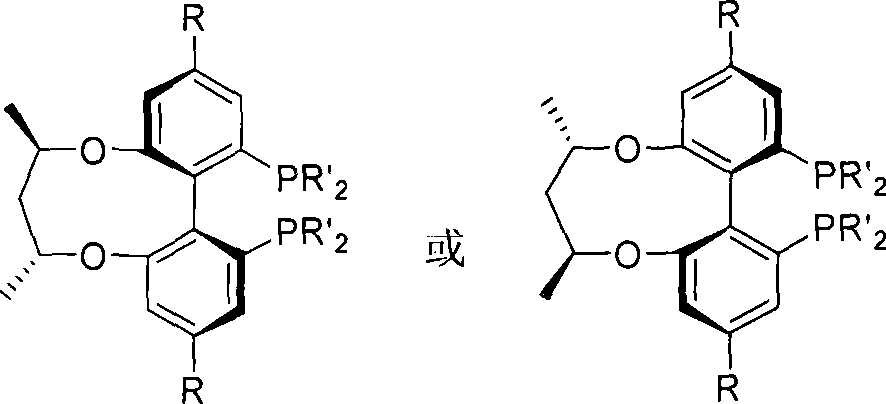

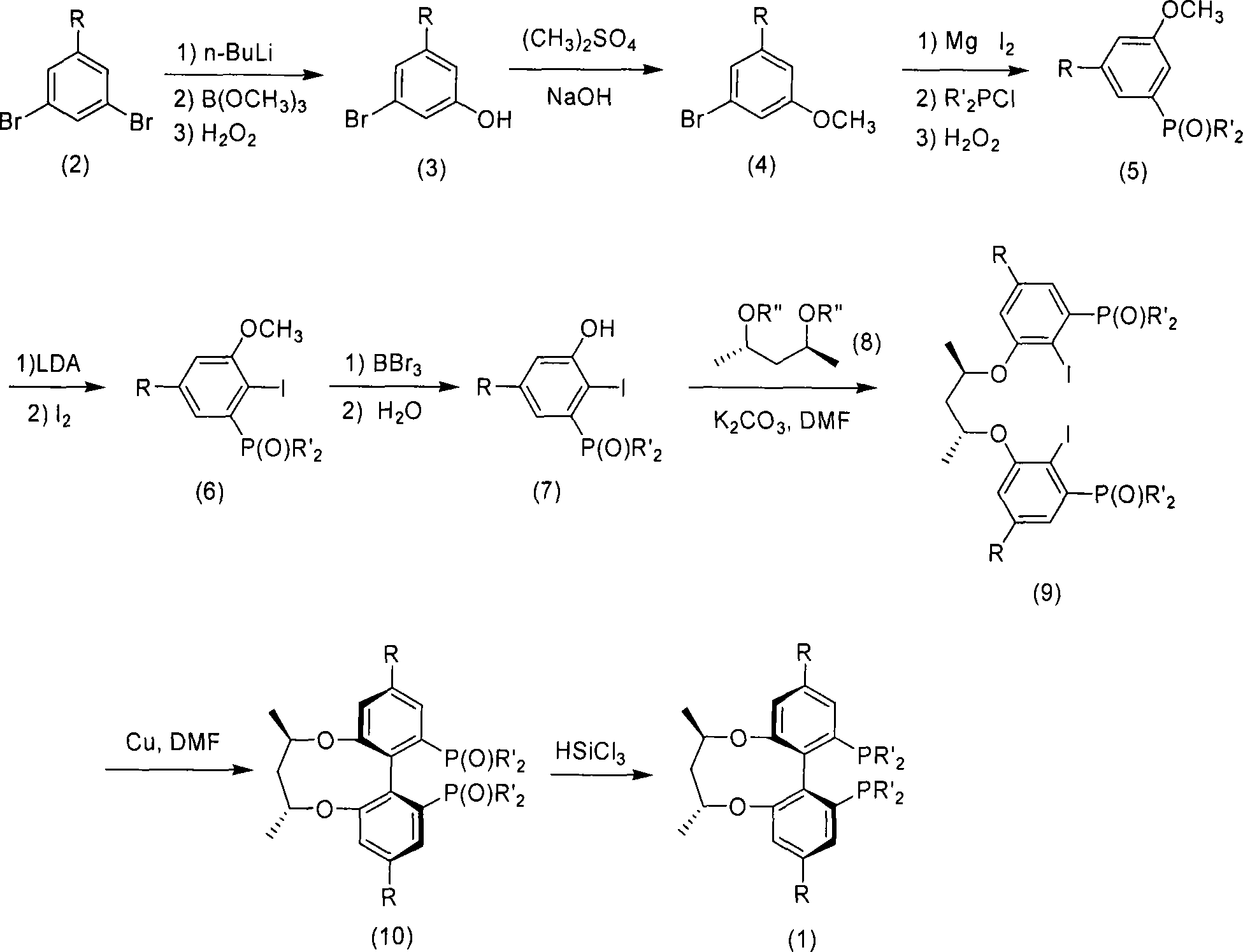

Central chirality induced axial chirality diphosphine ligand and method for synthesizing same

InactiveCN101230075AAvoid splittingEasy to synthesizeGroup 5/15 element organic compoundsDiphosphinesStructural formula

The invention relates to central chiral induced axial chiral diphosphine ligand, which adopts the structural formula that in the formula, R1 is benzyl or substituted benzyl; R is tertiary butyl or trifluoromethyl. The invention adopts the preparation method that 1-R-3, 5-dibromo benzene is used as the raw material, to produce 3-R-5- bromophenol; and then methylation is performed to obtain 1-R-3- bromine -5- anisole; after lithium realization of 3-dihydro pjosphinyl-5-R methyl phenoxide which reacts with dihydro phosphonic chloride and is obtained through oxidation, the product of the reaction with iodine reacts with boron tribromide, 2-iodine-3-dihydro pjosphinyl-5-R phenol obtained through demethylation and then reacts with central chiral 2, 4- pentanediol derivative, to obtain 2, 4-di (2-iodine-3- dihydro pjosphinyl-5- substituent phenoxy oxygen) pentane; <6, 61 -(2, 4- pentanediol oxygen)>-(4, 41)- disubstituent -(2, 21)-di (dialkyl pjosphinyl)-(1, 11)- biphenyl is produced through coupling, and finally reaction is performed with tri-butylamine and trichlorosilane, to obtain the diphosphine ligand.

Owner:WUHAN UNIV

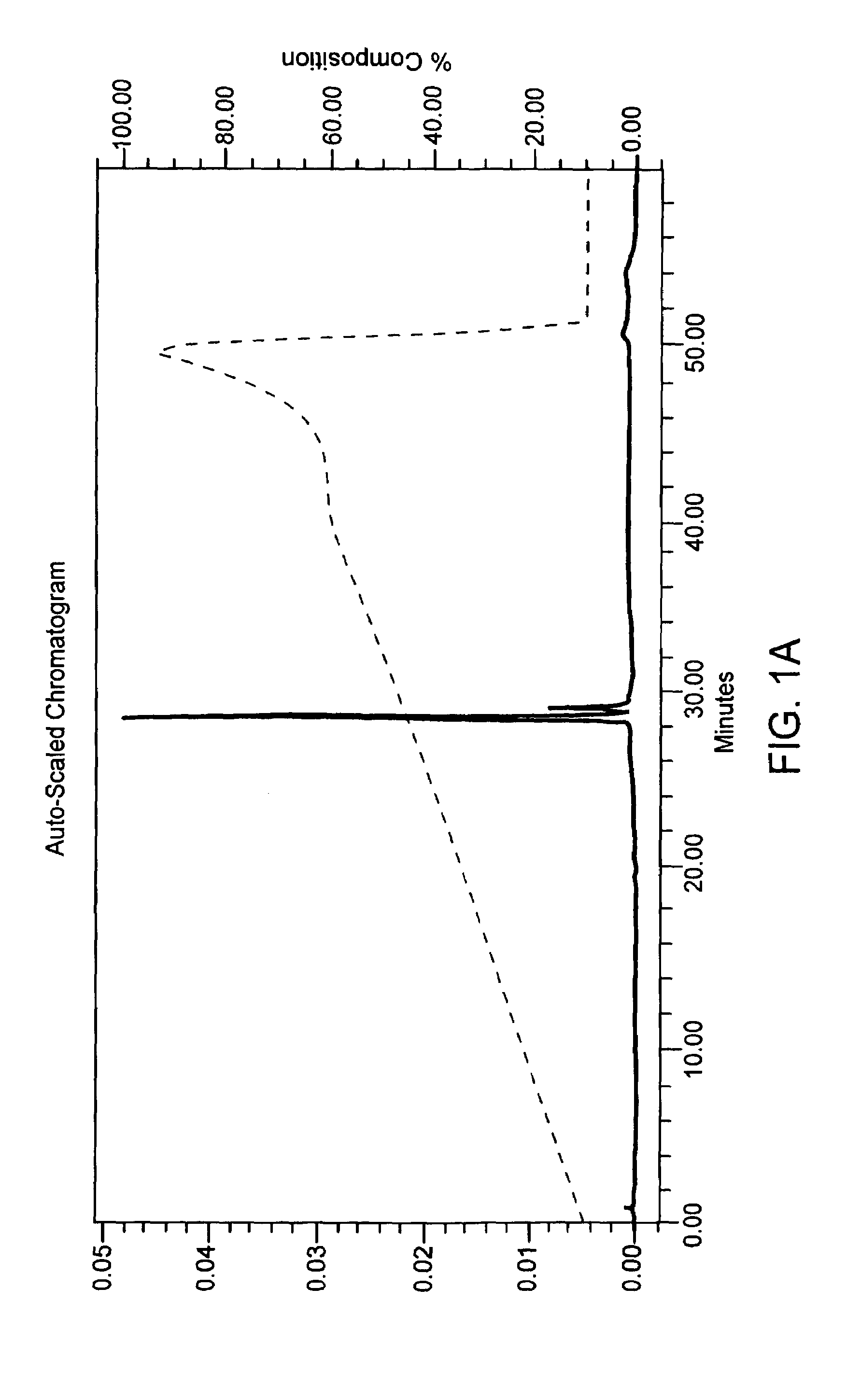

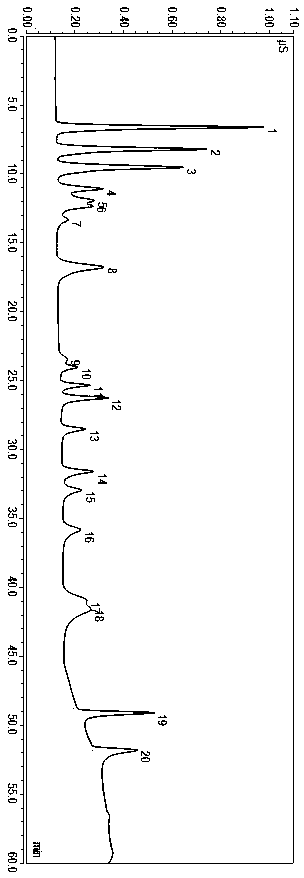

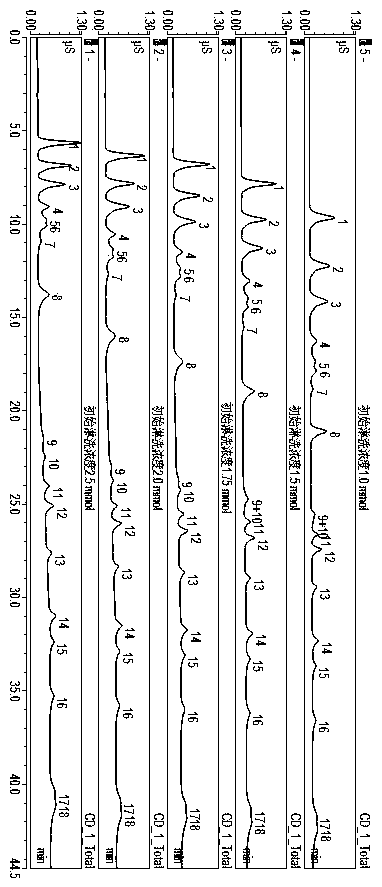

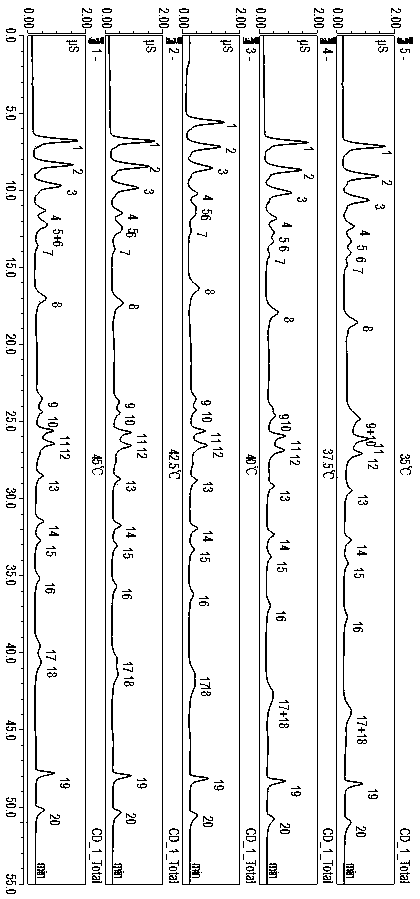

Method for simultaneously determining 20 organic amines, biogenic amines and cations in fruit juice beverage

ActiveCN110261530AImprove detection efficiencyEfficient separationComponent separationFruit juiceIon chromatography

The invention discloses a method for simultaneously determining 20 organic amines, biogenic amines and cations in a fruit juice beverage, belonging to the field of analytical chemistry. In the method, a conductivity inhibition-ion chromatography method is adopted, and under the condition of multi-stage gradient elution, the experimental determination conditions are optimized by researching a plurality of experimental influence factors, so that the method for simultaneously determining 20 organic amines, biogenic amines and cations (methylamine, dimethylamine, trimethylamine, diethanolamine, butylamine, histamine, cadaverine, putrescine, agmatine, heptanediamine, spermidine, spermine, Li+, Na+, NH4+, K+, Mg2+, Ca2+, Sr2+ and Ba2+) in the fruit juice beverage is established. The method is rapid, simple and convenient, high in high in sensitivity and good in stability, and achieves the aims of rapid analysis, green analysis and multi-component simultaneous analysis.

Owner:日照海关综合技术服务中心

The production method of accelerator n-tert-butyl-2-benzothiazole sulfenamide

The present invention relates to the production method of promotor N-tert-butyl-2-benzothiazole sulfenamide, 32.5g promotor M is added in 100ml water, add 2 milliliters concentration again and be 7% and add dispersing agent total 125ml, make up water Or mother liquor to 125ml to make accelerator M slurry, put it in a container for standby; put 100ml of sodium hypochlorite with 18.4-18.6g / 100ml of available chlorine and 0.8-1g / 100ml of free alkali into the container for standby; put tert-butylamine into a 300ml reaction container , the molar ratio of the total amount of tert-butylamine to the total amount of accelerator M is 1.06:1, stir and heat up to 43-45°C; add 5ml of accelerator M slurry as a base material, and then add the accelerator M slurry in step 1) and the sodium hypochlorite in step 2) are added dropwise in a volume ratio of 5:3, and the dropwise addition needs to be completed within 45-55 minutes, and the temperature during the dropping process cannot be higher than 45°C. The invention does not need mother liquor recovery and distillation, reduces waste water discharge, lowers costs, is economical and environmentally friendly, and all technical indicators of the product meet national standards.

Owner:KEMAI CHEM

Method for recovering associated sulphide copper-zinc ore from cyaniding slag of gold-silver concentrate

The invention discloses a method for recovering associated sulphide copper-zinc ore from cyaniding slag of gold-silver concentrate and belongs to the technical field of flotation recovery of valuable metals in the gold smelting industry. The method comprises the steps of preparing pulp: preparing the cyaniding slag of the silver concentrate into the pulp with the concentration of 30-35% under the condition of the roughing concentration of ore flotation and injecting into a flotation machine, activating with LGY-01 as an activator for the floatation of sulphide copper-zinc ore, and obtaining copper-zinc mixed concentrate via single roughing and single scavenging by taking a combination of butyl xanthate and butylamine dithiophosphate at a weight ratio of 3:2 as a collecting agent and 2# oil as a foaming agent, wherein the activator LGY-01 is prepared from sodium pyrosulfite and sodium hydrosulfite at a weight ratio of 5:1. The method is a floatation technology for floatation recovery of the sulphide copper-zinc concentrate from the gold-silver cyaniding slag, increases a resource utilization rate, reduces environmental pollution and increases economic benefits of an enterprise.

Owner:JIANGXI UNIV OF SCI & TECH

Method for combining tributylamine and used catalyst

ActiveCN102614893AModerate reaction conditionsHigh selectivityMetal/metal-oxides/metal-hydroxide catalystsAmino compound preparation by disproportionationPlatinumHydrogen

The invention discloses a load type catalyst, which utilizes roasted gama-alumina as a carrier. An active component is loaded on the carrier to obtain the load type catalyst. The active component is composed of nickel, copper, iron and platinum. The weight sum of the nickel, the copper, the iron, the platinum and the roasted gama-alumina is the total weight. The nickel occupies 15% to 25% of the total weight, the copper occupies 5% to 12% of the total weight, the iron occupies 0.5% to 1% of the total weight, and the platinum occupies 0.5% to 1% of the total weight. A preparation method of the load type catalyst and a method for preparing tributylamine by using the load type catalyst are further disclosed. Butylamine and dibutylamine are mixed in a mixed cylinder to obtain mixed liquid, the mixed liquid is gasified and then passes through a fixed bed reactor containing an activated load type catalyst, catalyst reaction is conducted under the hydrogen condition, and a product is collected after condensation to obtain the tributylamine.

Owner:ZHEJIANG JIANYE CHEM

Low-temperature mechanical alloying method for preparing sulphur selenide submicro powder material

InactiveCN102616753AAvoid introducingReaction raw materials are readily availableSelenium/tellurium compundsIsobutanolEthylenediamine

The invention discloses a low-temperature mechanical alloying method for preparing a sulphur selenide submicro powder material. Simple substance metal powder and simple substance non-metal powder are added into a ball mill tank and ball milled according to rated ball material ratio and set rotating speed with alcohol and amine mixing liquid serving as a process control agent, and ball mill products are washed centrifugally and dried to obtain target products. The simple substance metal powder is one of Zn powder, Sn powder and Cu powder. The simple substance non-metal powder is S powder or Sepowder. The process control agent is mixture of alcohol and amine with volume ratio as 1-20:1, the alcohol is one of ethanol, glycol, n-butyl alcohol, isobutanol, isoamylol, tert-amyl alcohol and glycerol, and the amine is one of ethylenediamine, iso-butylamine, diisopropylamine, hexamethylenediamine and triethylamine. The raw material is easy to obtain, products are pure, energy consumption is low, product appearance is easy to control, technology is simple, and the method is suitable for industrial production.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Flotation technology of micro-fine particle inbuilt state copper ore

InactiveCN107138270AGuaranteed RecoveryGuaranteed gradeFlotationGrain treatmentsFoaming agentResource development

The invention discloses a flotation technology of micro-fine particle inbuilt state copper ore. A staged grinding and separation process is adopted, rapid selection and re-grinding selection are adopted to treat and recycle copper ore in different dissociated states, lime serves as a slurry pH adjusting agent, sodium n-butylxanthate and butylamine dithiophosphate serve as a collecting agent, MIBC serves as a foaming agent, the lime and part of the collecting agent are added in a grinding machine, within the proper basicity range caused by the lime, through the selective collecting effect of the collecting agent on the copper, the recycling rate and the grade of the copper are ensured, and the silicon content of concentrates is limited. The technology is particularly suitable for treating copper sulphide ore with the fine inbuilt granularity and with the complex inbuilt relation with the silicate gangue. The reliable beneficiation technical guarantee is provided for the copper ore resource development, and efficient development and utilization can be promoted.

Owner:厦门紫金矿冶技术有限公司

Method for preparing 4-amino-N-[(2R,3S)-3-amino-2-hydroxy-4-benzene butyl]-N-isobutyl benzsulfamide

ActiveCN104387299ALow costImprove stabilitySulfonic acid amide preparationP-nitrobenzenesulfonyl chlorideNitro reduction

The invention discloses a method for preparing 4-amino-N-[(2R,3S)-3-amino-2-hydroxy-4-benzene butyl]-N-isobutyl benzsulfamide. The method comprises the following steps: S1: enabling L-phenylalanine and diazomethane to react to obtain a diazo methyl ketone intermediate product, and enabling the diazo methyl ketone intermediate product and haloid acid to react to obtain a compound A; S2, conducting carbonyl deoxidation on the compound A to obtain a compound B; S3, under the existence of iso-butylamine, conducting cyclization reaction and ring-opening reaction on the compound B in sequence to obtain a compound C; S4, enabling the compound C and nitrobenzenesulfonyl chloride to react to obtain a compound D; S5, conducting nitro reduction on the compound D to obtain the 4-amino-N-[(2R,3S)-3-amino-2-hydroxy-4-benzene butyl]-N-isobutyl benzsulfamide. The method is simple in course, low in cost, mild in condition, and higher in intermediate product stability, and is beneficial for industrial application.

Owner:ASYMCHEM LAB TIANJIN +4

Flotation method for separating silver from high leaching residues

The invention discloses a flotation method for separating silver from high leaching residues. The flotation method comprises the steps of performing processes of silver rough flotation, silver scavenging and silver fine flotation on the high leaching residues. The process of silver rough flotation comprises the following steps: (a) adding sodium hexametaphosphate into high leaching residue slurry and stirring the mixture for 5-10 minutes, wherein 100-140 grams of sodium hexametaphosphate is added in one ton of high leaching residues; (b) adding activated carbon into a flotation tank and stirring the mixture for 4-6 minutes, wherein 2000-4000 grams of activated carbon is added in one ton of high leaching residues; and (c) adding a collecting agent and a foaming agent into the flotation tank, wherein Z-200 and D amine black medicine are taken as the collecting agent, flotation oil No.2 is taken as the foaming agent, and 50-150 grams of Z-200, 400-800 grams of butylamine aerofloat and 8-15 grams of flotation oil No.2 are added in one ton of high leaching residues. By using the flotation method provided by the invention, the silver recovery rate can reach 60-80%. Besides, the flotation method has the advantages of simple process, less chemical agent consumption and low cost.

Owner:赤峰中色库博红烨锌业有限公司

Flotation technology for efficiently recycling complex copper oxide ore

The invention discloses a flotation technology for efficiently recycling complex copper oxide ore. The principles of stage agent addition, rapid flotation and early and fast recycling are adopted for all selection and scavenging in the technological process. The flotation technology comprises the steps that ore grinding is carried out at first, ore slime is dispersed through sodium fluosilicate after ore is ground to have the qualified granularity, gangue is restrained, sodium sulphide is used as an activating agent for activating copper oxide ore, amyl xanthate and butylamine aerofloat are used as a composite collecting agent, 2# oil is used as a foaming agent, rapid flotation is carried out, and first high-grade copper concentrate is obtained; and first-time scavenging is carried out to obtain high-grade middlings, first-time selection is carried out to obtain second concentrate, second-time scavenging, third-time scavenging and fourth-time scavenging are carried out to obtain low-grade middlings and second selection concentrate, the obtained middlings are combined with third concentrate obtained through second-time selection, and concentrate in high grade, intermediate grade and low grade is produced. The flotation technology is applicable to raw ore with the copper element mass fraction being 5-6%, and mixed copper concentrate with the grade being 23-25% and the recycling rate being 77% can be obtained.

Owner:厦门紫金矿冶技术有限公司

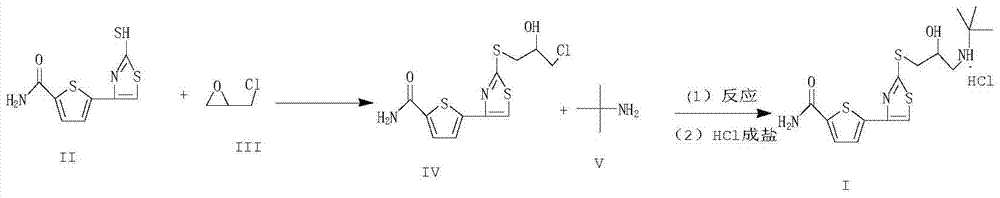

A new method for the preparation of alololol hydrochloride

Owner:JIANGXI BAISHEN PHARMA

Reinforced composite polyethylene pipe and preparation method thereof

The invention provides a reinforced polyethylene composite pipe and a preparation method thereof, and relates to the technical field of polymer materials. The reinforced polyethylene composite pipe of the present invention is made of the following raw materials: polypropylene, acrylate, tert-butylamine, nano-carbon fiber, filler, glass beads, white oil, ethanol, antistatic masterbatch, flame retardant, antioxidant, coupler joint agent. The enhanced polyethylene composite pipe of the present invention has high surface hardness, is not easy to be oxidized, has high mechanical strength, and has good impact resistance, so that the pipe is not easy to crack when it directly contacts with sharp stones, thereby increasing the pipe material in non-opening applications. The safety in digging and laying also greatly prolongs the service life of the pipe.

Owner:ANHUI DADI ENG PIPELINE

Preparation process of tetrabutyl urea

InactiveCN107868022AImprove product qualityRaw materials are cheap and easy to getUrea derivatives preparationOrganic compound preparationOrganic solventReaction rate

The invention provides a preparation process for synthesizing tetrabutylurea by using the phosgene method, using di-n-butylamine and phosgene as the main ingredients in an alkaline organic solvent, and the process steps are as follows: (1) in a reaction vessel according to the composition than adding di-n-butylamine, carbonyl chloride and an organic solvent; (2) adjust the acylation reaction temperature, control the acylation reaction time, and obtain the crude product of tetrabutylurea; (3) the crude product of tetrabutylurea is subjected to standing, separation, Distillation and purification to obtain the final product of tetrabutylurea. The preparation method of the invention has simple and convenient operation steps, cheap and easy-to-obtain raw materials, good product quality, a reaction yield of more than 90 percent, and a purity of more than 99 percent.

Owner:青岛九洲千和机械有限公司

Process for producing tertiary butylamine ethoxy ethyl alcohol with space steric effect

InactiveCN1623978AHigh boiling pointReduce use costOrganic compound preparationAmino-hyroxy compound preparationAlcoholTert-Butylamine

A process for preparing the tert-butylamino ethoxyethanol as the selective desulfurizing solvent with sterical hindering effect includes such steps as putting tert-butylamine, 2-chloroethyoxy ethanol and reaction medium in reactor, heating while reaction, alkali neutralizing, condensing to recover excessive tert-butylamine, filtering, distilling, and rectifying. Its advantages are high selectivity and absorptivity to H2S, high boilding point and high purification.

Owner:四川省精细化工研究设计院

Method for synthesizing core-shell type zeolite molecular sieve

The invention relates to a method for synthesizing ZSM-5 / ZSM-5 core-shell type zeolite molecular sieve, mainly solving the technical problems of expensive used raw materials, great environment pollution of template agent, high difficulty of industrial amplification and synthesis, difficult industrial production and the like of the core-shell type zeolite molecular sieve in the prior art. The invention adopts the following technical scheme: the core-shell zeolite molecular sieve is prepared by adopting ZSM-5 core phase molecular sieve with a relatively low silica alumina ratio as a seed crystal, using at least one of soluble glass, silica solution, sodium silicate, white carbon black or atlapulgite which are cheap and easily obtained as a silicon source, and taking at least one organic amine from ethylamine, ethanediamine, propylamine and butylamine or the mixture of the organic amine and inorganic amine as a template agent so as to better solve the above technical problems. The invention can be used in industrialized synthetic production of core-shell type molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

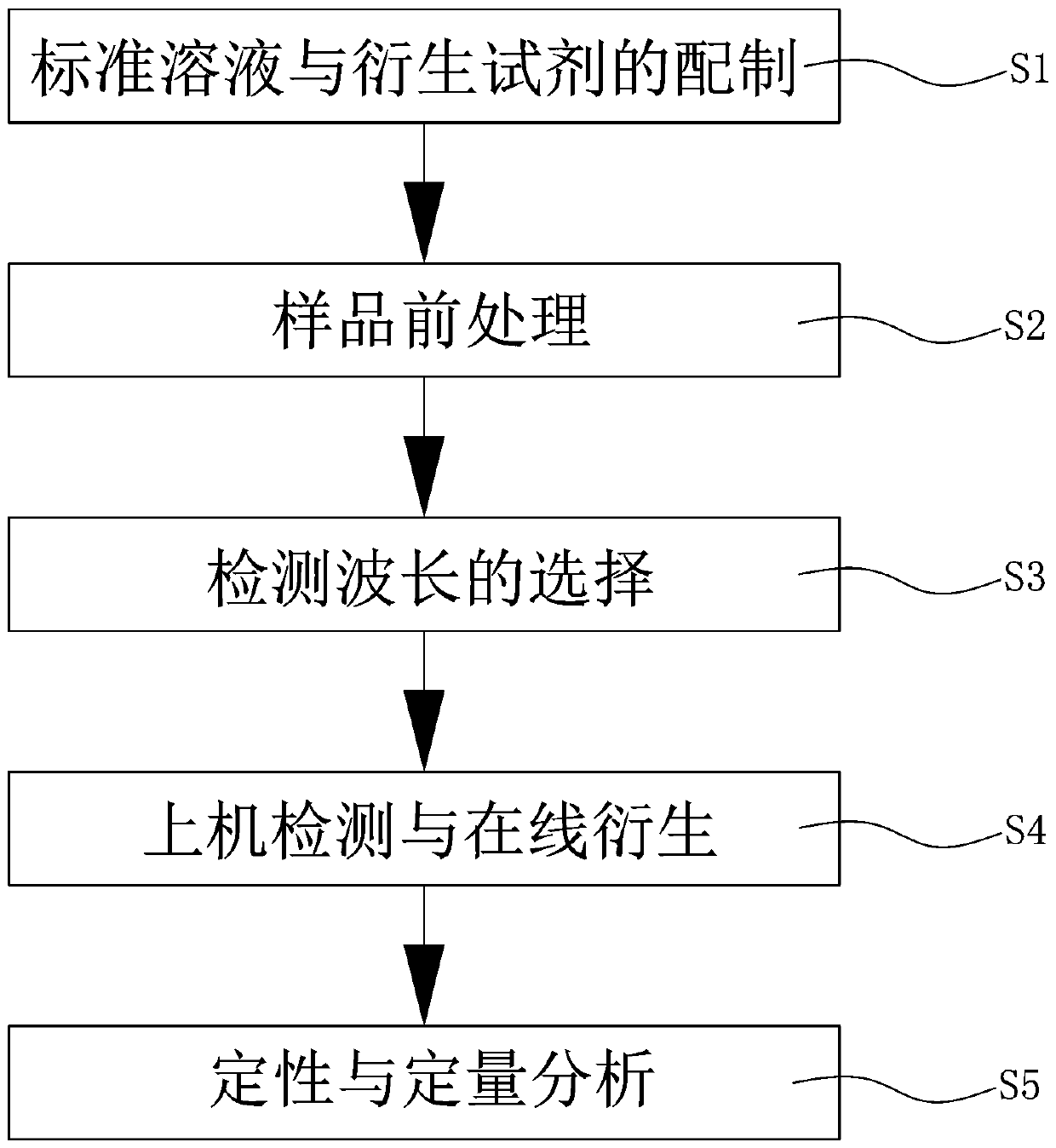

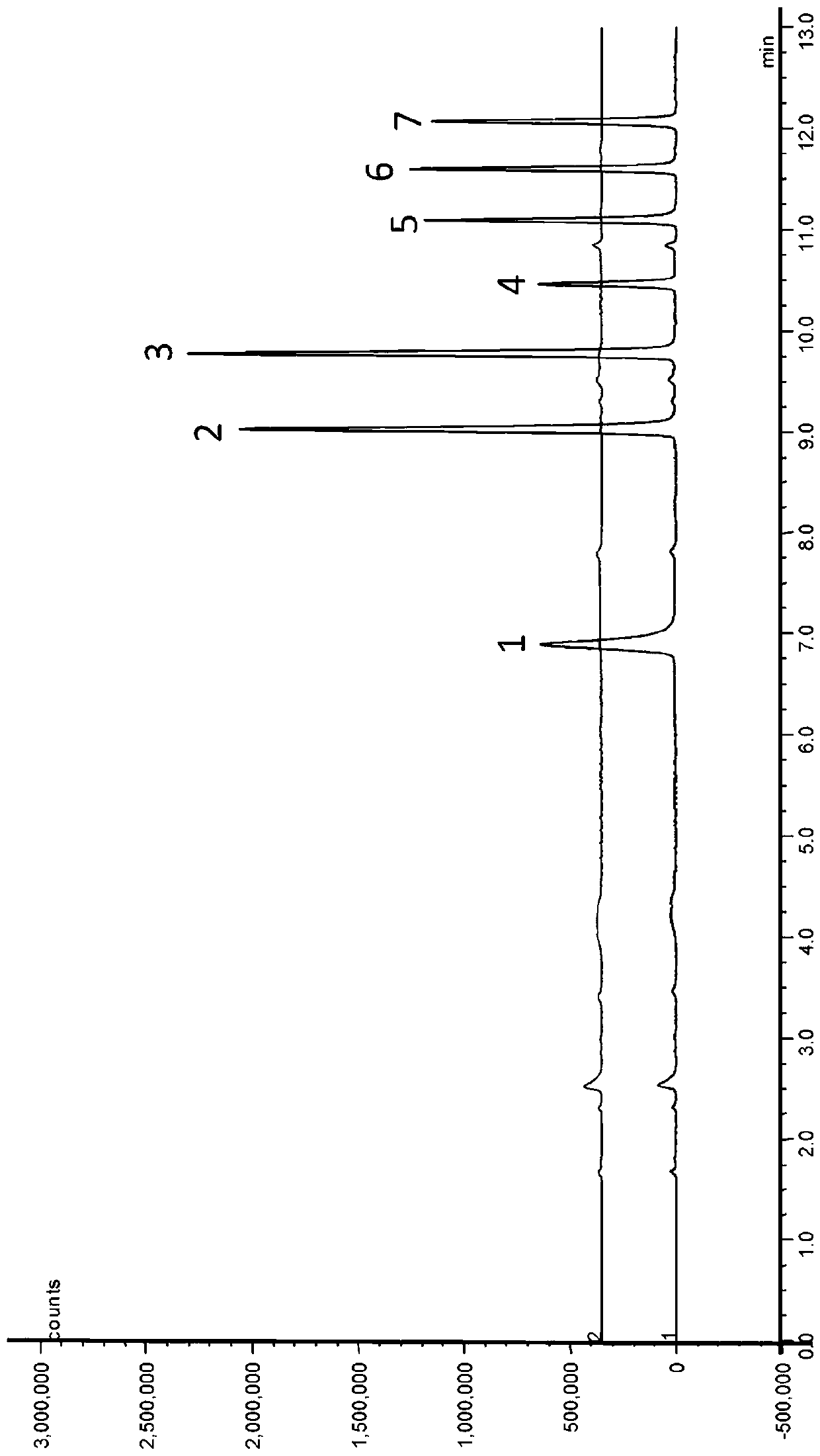

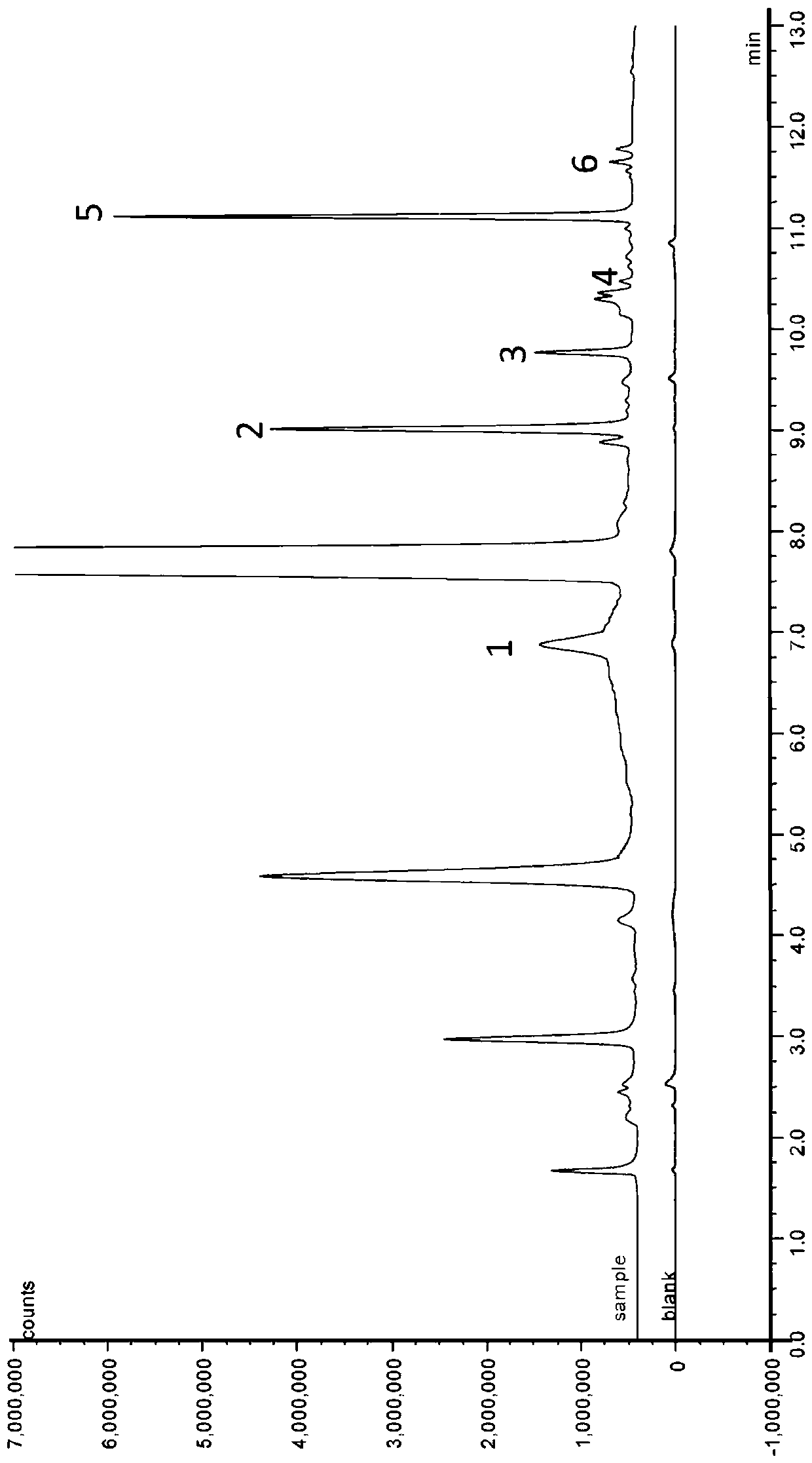

Method for determination of trace organic amine in atmospheric particulate matters

ActiveCN107703222ANo need to worry about stabilityHigh sensitivityComponent separationParticulatesPropylamine

The invention discloses a method for determination of trace organic amine in atmospheric particulate matters, wherein the method comprises the steps: S1, preparation of a standard solution and a derivatization reagent; S2, sample pretreatment; S3, detection wavelength selection; S4, on-machine detection and on-line derivatization; and S5, qualitative and quantitative analysis. Under conditions without tedious offline derivatization at present, the method sensitively and accurately determines seven organic amines of ethanol amine, methylamine, ethylamine, propylamine, butylamine, pentylamine and hexylamine in the atmospheric particulate matters.

Owner:厦门鉴科检测技术有限公司

N,O-double ligand metal catalyst with stereo structure and preparation method

InactiveCN102504056AGood light transmissionHigh glass transition temperatureFatty amineIsopropylamine

An N,O-double ligand metal catalyst with a stereo structure and a preparation method. The catalyst has the following general formula; M is a nickel, palladium, cobalt, iron or copper central metal atom; R1 is bromine, chlorine, iodine, methyl, propyl, butyl, phenyl, naphthyl, methoxyl or ethyoxyl; when R2 is aromatic amine or aliphatic amine, R2 is ethylamine, propylanmine, isopropylamine, butylamine, tert-butylamine, hexylamine, or cyclohexylamine. The catalyst of the invention has high light transmittance, a high glass-transition temperature, good thermal stability, oxidation stability, low hygroscopicity, a low dielectric constant, and good processing performance, dissolving performance and adhesion performance.

Owner:江西耀泰铜业有限公司

Method for directly synthesizing rubber vulcanization accelerator TBBS from resin in waste water

InactiveCN109180605ASave the process of dissolution and sedimentationReduce pollutionOrganic chemistryVulcanizationDissolution

The invention belongs to the field of wastewater treatment and particularly relates to a method for directly synthesizing a rubber vulcanization accelerator TBBS from resin in waste water. The methodcomprises: 1) mixing resin and an aqueous solution of NaOH under stirring at a normal temperature to obtain an M-Na salt solution, 2) adding 1.5 to 3 parts by weight of t-butylamine and 2 to 3 parts by weight of water into a reactor and carrying out uniform stirring to obtain a t-butylamine aqueous solution, 3) mixing the M-Na salt and acid obtained in the step 1), and an oxidant, and adding the mixture into the reactor in the step 2), and 4) carrying out setting layering on the reaction product for 0.5-1h and carrying out centrifugation spin-drying on the lower layer material to obtain a product. The method is free of a high temperature solvent dissolution and sedimentation process and is simple and easy to operate. The method is free of heating, can selectively use a solvent, reduces energy source consumption, reduces the environmental pollution caused by the volatilization of the solvent and has a target product TBBS yield of more than 99.0% (on the basis of MBT content).

Owner:KEMAI CHEM

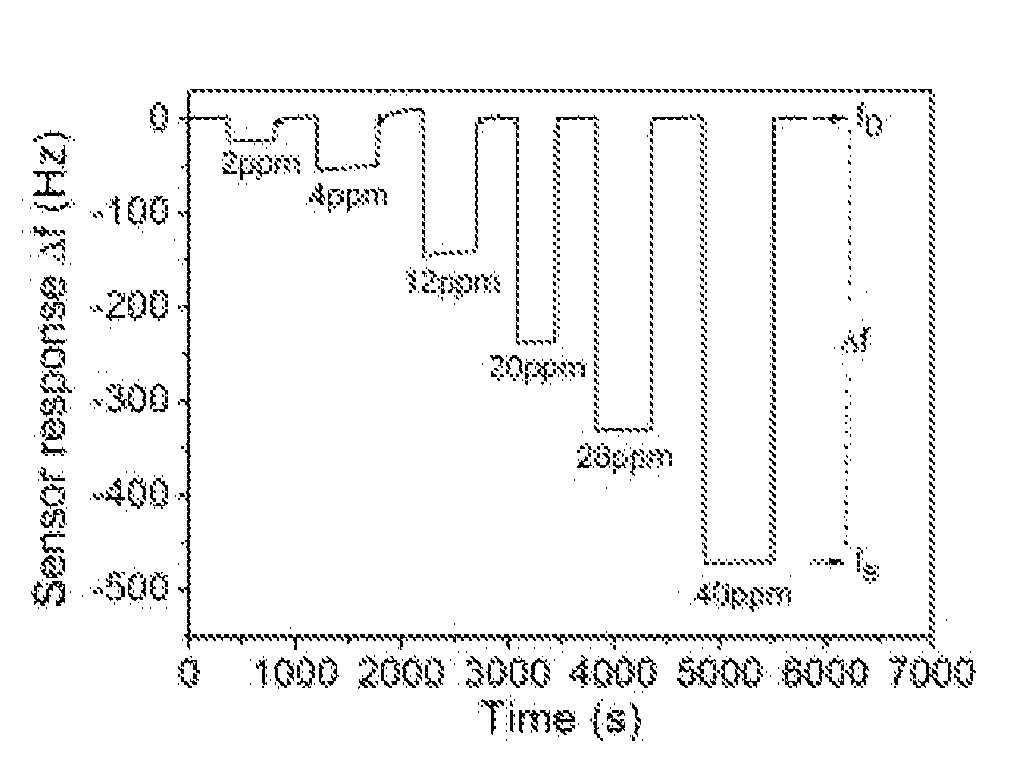

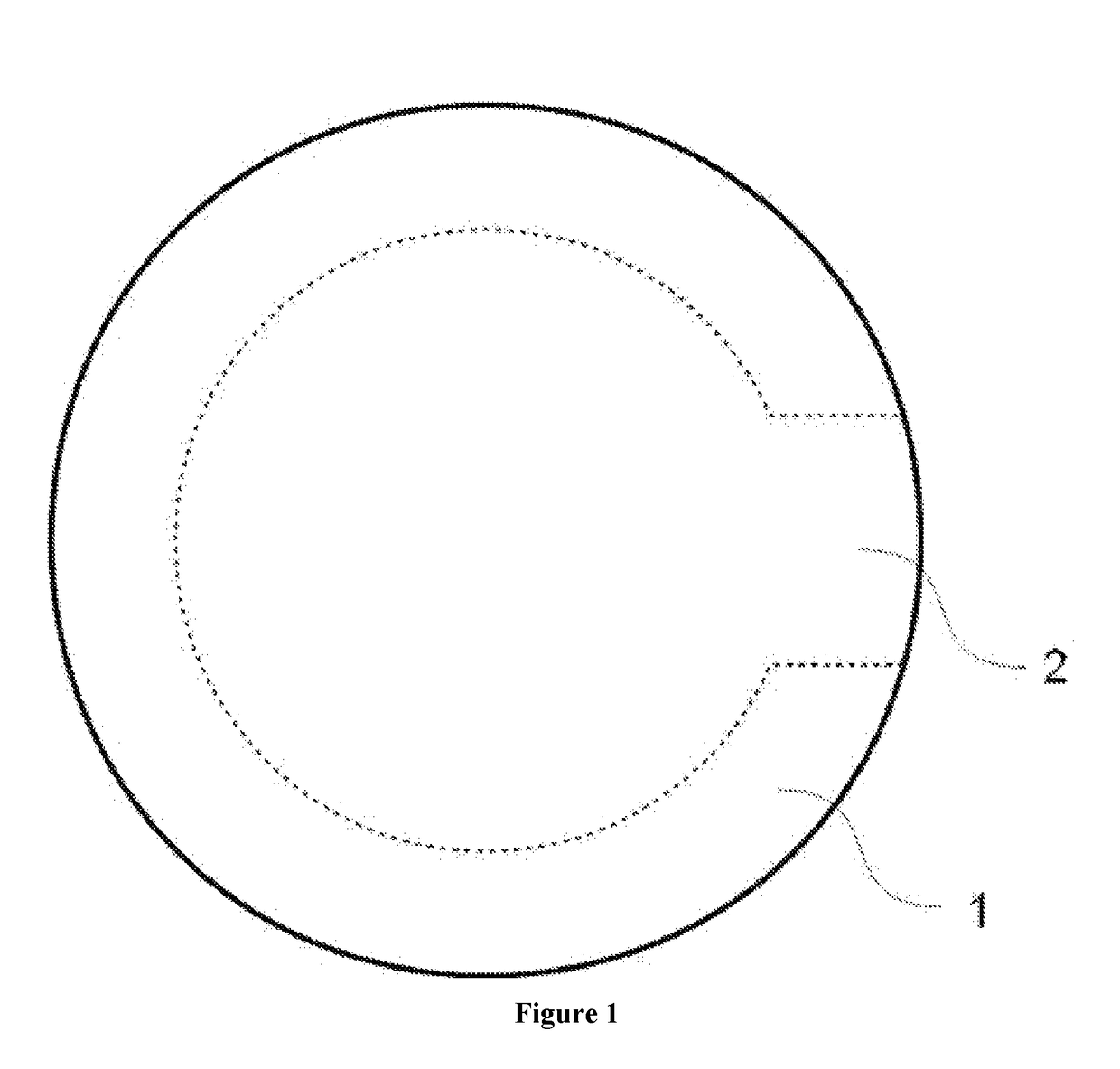

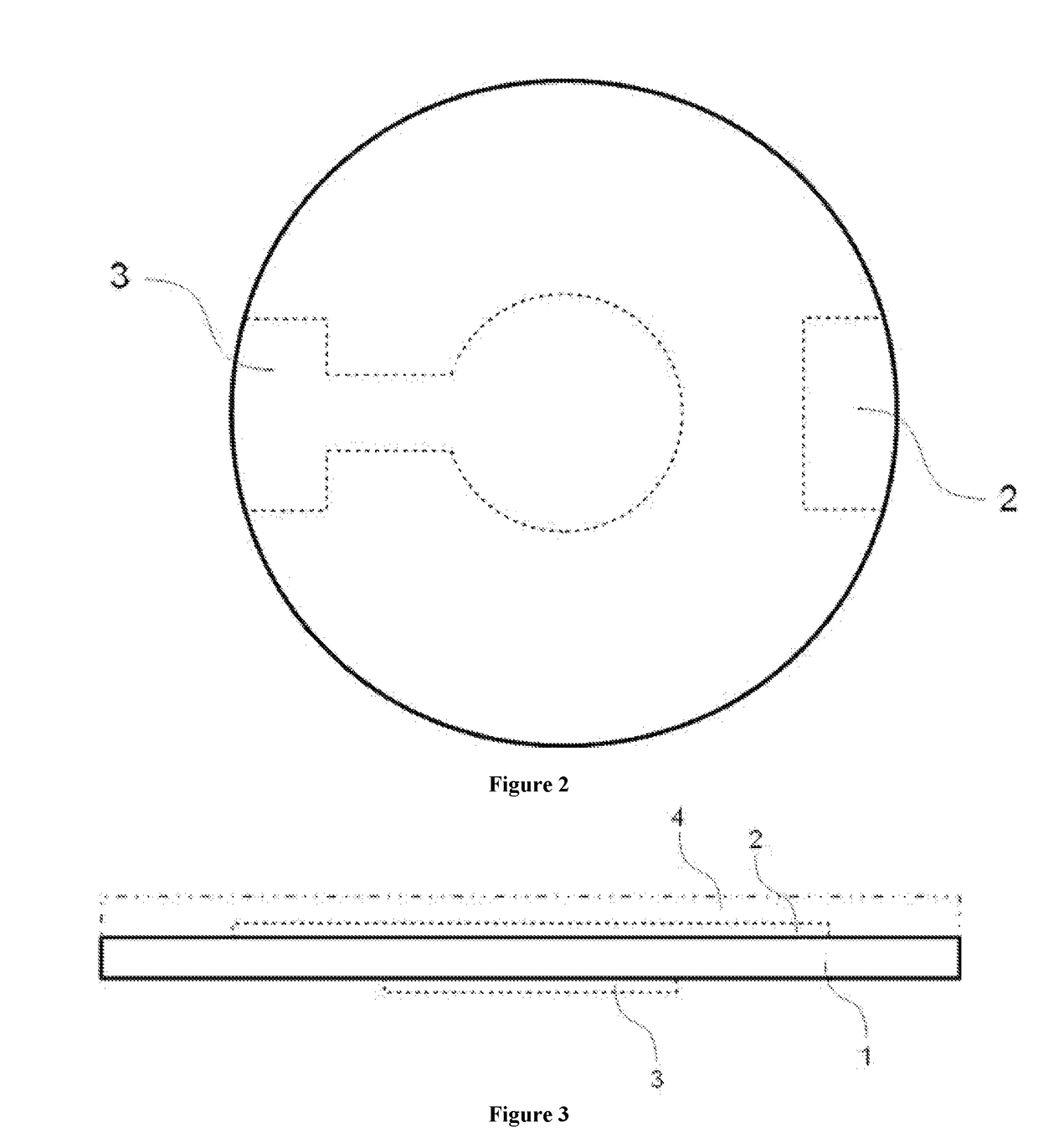

Use of piezoelectric transducers modified with metal oxide-based thin films for direct detection of amine derivatives in liquid media

InactiveUS20180080902A1High sensitivityHighly capableAnalysing fluids using sonic/ultrasonic/infrasonic wavesTesting organic contamination in waterLiquid mediumChloramine

The invention discloses a chemical sensor device including a sensitive material formed as a thin film on the active side of a transducer substrate. The sensor uses vanadium oxide (V2O5) as a sensing material to detect amine and amine derivatives directly in liquid media. The developed sensor has been tested against selected amines as target analytes (such as triethylamine, butylamine, hexylamine and chloramine-T), organic chlorinated, non-chlorinated compounds, phenols, and a variety of pesticides which can be found in water and act as interferences. The sensor has exhibited sensitivity values of 12 Hz / ppm against chloramine-T and in the range of 1-2 Hz / ppm for the amines. The detection limit is 80 ppb for chloramine-T and below 1 ppm for the amines. The developed sensor does not respond to potentially interfering compounds.

Owner:TUBITAK

Method for synthesizing N-butyl-glucosamine

InactiveCN1611484AMild reaction conditionsImprove responseOrganic compound preparationAmino-hyroxy compound preparationPolymer scienceHydrogen pressure

The invention relates to a kind of synthesizing method of midbody N- butyl- glucosamine, a medicine to therapy Gaucher I disease. The existing method has harsh requirement of reaction condition, low product yield, many by-product, and bad quality, so it is difficult to realize industrialization production. The reaction steps of the invention are as follows: A) Stuff casting: in autoclave, add D-glucose and ortho-butylamine according to molar ratio of D-glucose / ortho-butylamine with 1 / 1.05-1.10; then add 70-95% alcohols solvent with 5-10 times weight of glucose; and after nitrogen displace, add activity nickel catalyst with 5-10% weight of glucose; inject high purity hydrogen, keep hydrogen pressure to 2-3Mpa, and then intensify the temperature slowly; B) Reaction: control reaction temperature in 35-45deg.C, hydrogen pressure in 2-4Mpa, and reaction by 10-15 hours; C) Get white pulverous solid by after-treatment. The synthesizing method of the invention can make the reaction easy to take, and it generates by-product and other impurity badly, and also it has high conversion rate, more than or equal to 98% purity, high quality of product generated, so it adapts to industrialization production.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

Improved production process for repaglinide

InactiveCN105175361AChange the status quo of low puritySimplified synthesis stepsOrganic chemistry methodsPhenyl acetic acidButylamines

The invention provides an improved production process for repaglinide. The process is characterized by comprising the following steps: with (S,S')-3-methyl-1-(2-(1-piperidinyl)phenyl)butylamine, N-acetyl-glutamate as a main material, adding ammonia water to prepare chiral amine (S)-(+)-3-methyl-1-(2-piperidinyl-phenyl)butyl amine; then adding triethylamine and adding a mixed liquid of pivaloyl chloride and toluene drop by drop; subjecting a product obtained in the previous step and 3-ethoxy-4-ethoxycarbonyl phenyl acetic acid to a condensation reaction so as to prepare a compound (S)-2-ethoxy-4[2-[3-methyl-1-[2-(1-piperidinyl)-phenyl]-butyl]-amino]-2-carbonylehtyl ethyl benzoate; hydrolyzing the compound in ethanol and a sodium hydroxide solution so as to obtain a crude repaglinide product; and dissolving the obtained crude repaglinide product in a mixed solution of ethanol and water for purification so as to prepare a refined repaglinide product. The improved production process provided by the invention further simplifies synthesis and purification steps, has the advantages of high efficiency, low toxicity, low danger, easy operation, etc. and has the characteristics of simplicity and easiness in control and industrial production.

Owner:TIANJIN PHARMA GROUP GENCOM PHARMA

Method of preventing modification of synthetic oligonucleotides

InactiveUS7038027B2High recovery rateReduce the amount requiredSugar derivativesSugar derivatives preparationScavengerSufficient time

The present invention relates to a method of preventing modification of a synthetic oligonucleotide or oligonucleotide analog during removal of at least one β-cyanoethyl protecting group from the oligonucleotide or oligonucleotide analog. The method involves contacting the oligonucleotide or oligonucleotide analog with a basic solution having at least one acrylonitrile scavenger, such as t-butylamine, at a sufficient temperature and for a sufficient period of time to remove at least one β-cyanoethyl protecting group. The present invention also relates to a method of producing a synthetic oligonucleotide or oligonucleotide analog.

Owner:AVECIA BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for preparing 4-amino-N-[(2R,3S)-3-amino-2-hydroxy-4-benzene butyl]-N-isobutyl benzsulfamide Method for preparing 4-amino-N-[(2R,3S)-3-amino-2-hydroxy-4-benzene butyl]-N-isobutyl benzsulfamide](https://images-eureka-patsnap-com.sutd.idm.oclc.org/patent_img/a8d980e4-fe1e-488c-8f1b-65059c0e6bf2/HDA0000592763380000011.PNG)

![Method for preparing 4-amino-N-[(2R,3S)-3-amino-2-hydroxy-4-benzene butyl]-N-isobutyl benzsulfamide Method for preparing 4-amino-N-[(2R,3S)-3-amino-2-hydroxy-4-benzene butyl]-N-isobutyl benzsulfamide](https://images-eureka-patsnap-com.sutd.idm.oclc.org/patent_img/a8d980e4-fe1e-488c-8f1b-65059c0e6bf2/HDA0000592763380000021.PNG)

![Method for preparing 4-amino-N-[(2R,3S)-3-amino-2-hydroxy-4-benzene butyl]-N-isobutyl benzsulfamide Method for preparing 4-amino-N-[(2R,3S)-3-amino-2-hydroxy-4-benzene butyl]-N-isobutyl benzsulfamide](https://images-eureka-patsnap-com.sutd.idm.oclc.org/patent_img/a8d980e4-fe1e-488c-8f1b-65059c0e6bf2/HDA0000592763380000031.PNG)