Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1173 results about "Selenide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A selenide is a chemical compound containing a selenium anion with oxidation number of −2 (Se²⁻), much as sulfur does in a sulfide. The chemistry of the selenides and sulfides is similar. Similar to sulfide, in aqueous solution, the selenide ion, Se²⁻, is prevalent only in very basic conditions. In neutral conditions, hydrogen selenide ion, HSe⁻, is most common. In acid conditions, hydrogen selenide, H₂Se, is formed.

Zinc Ion-Exchanging Energy Storage Device

ActiveUS20160301096A1Quick releaseRapid depositionHybrid capacitor electrolytesAlkaline accumulatorsChemical treatmentZinc metal

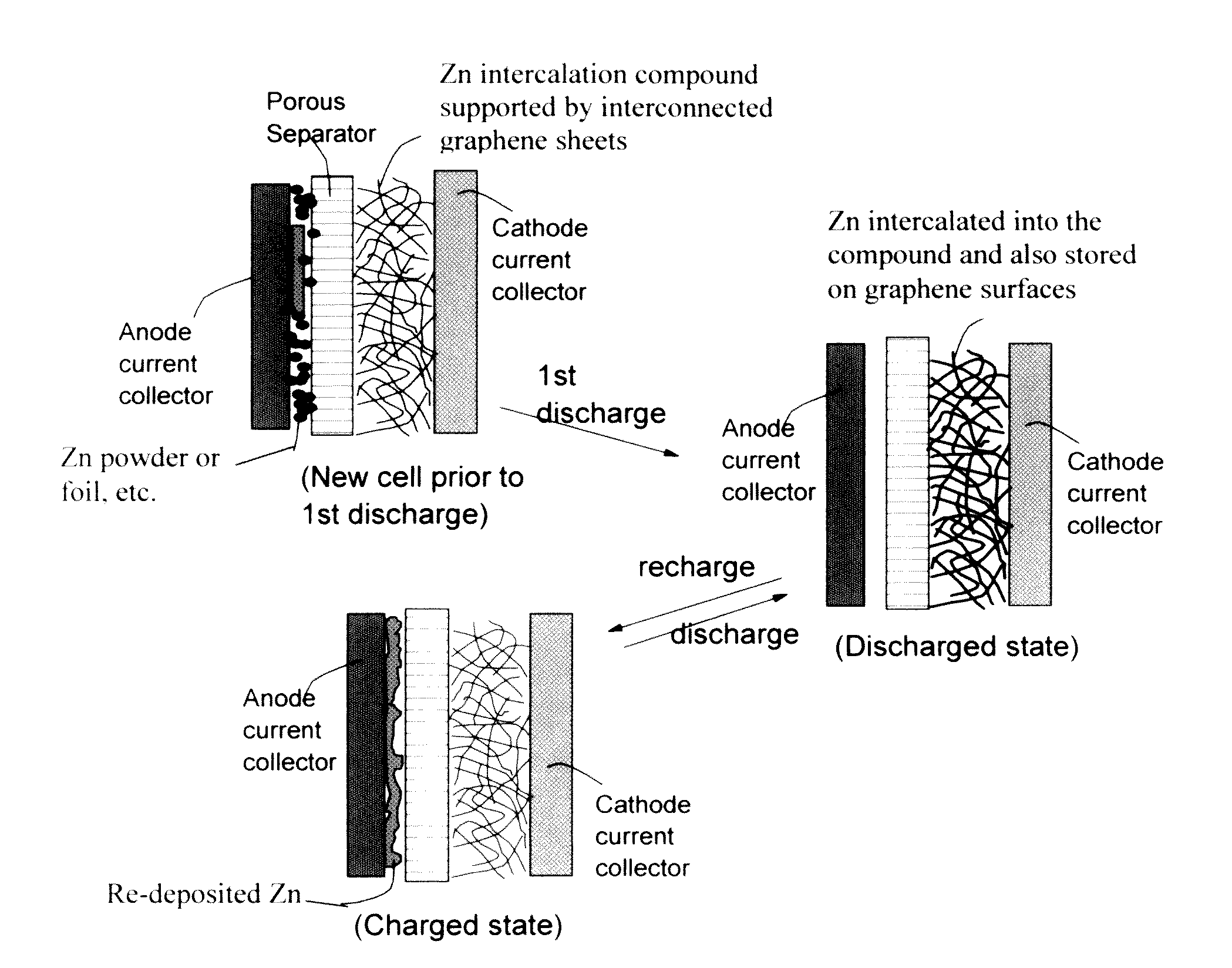

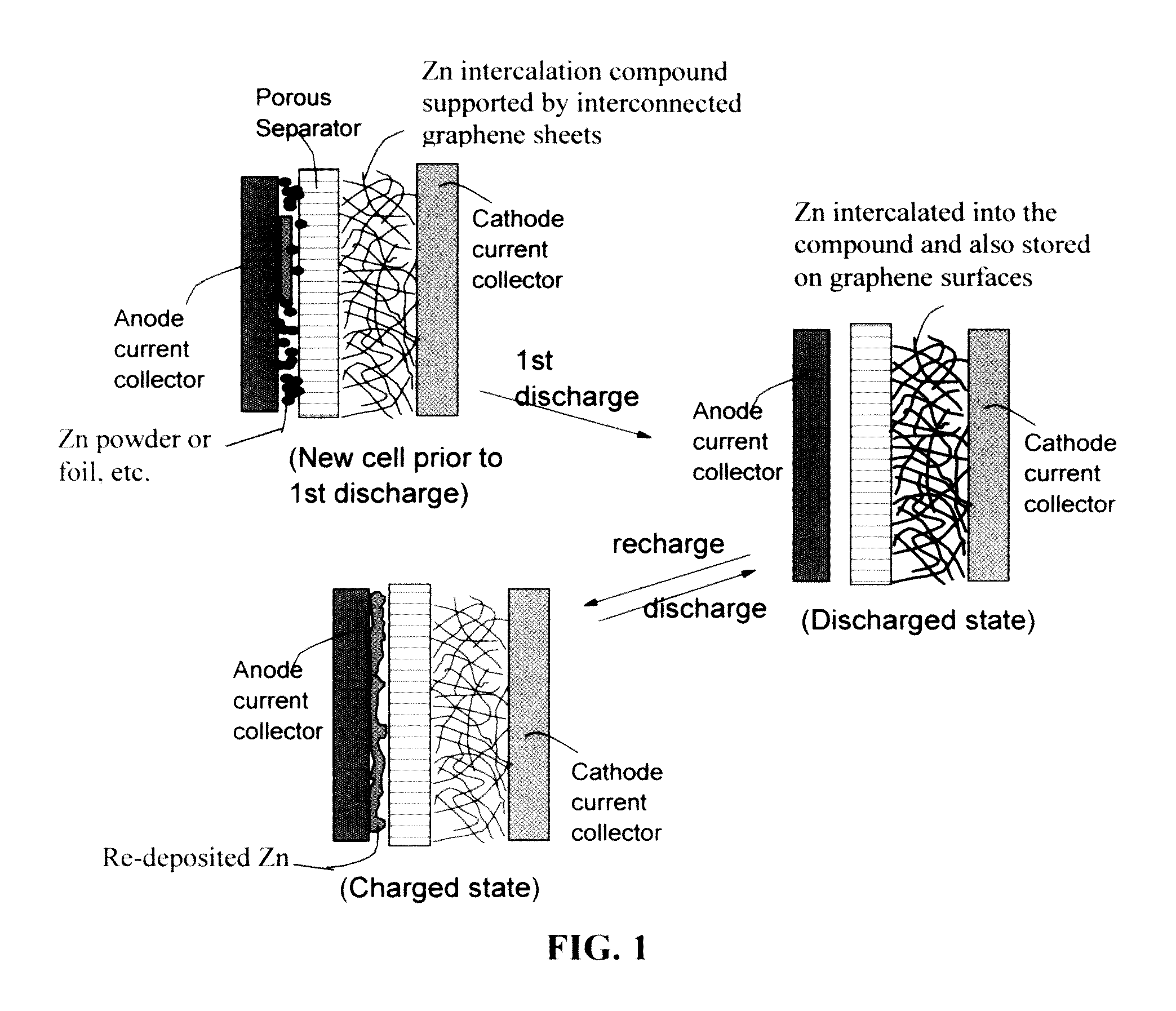

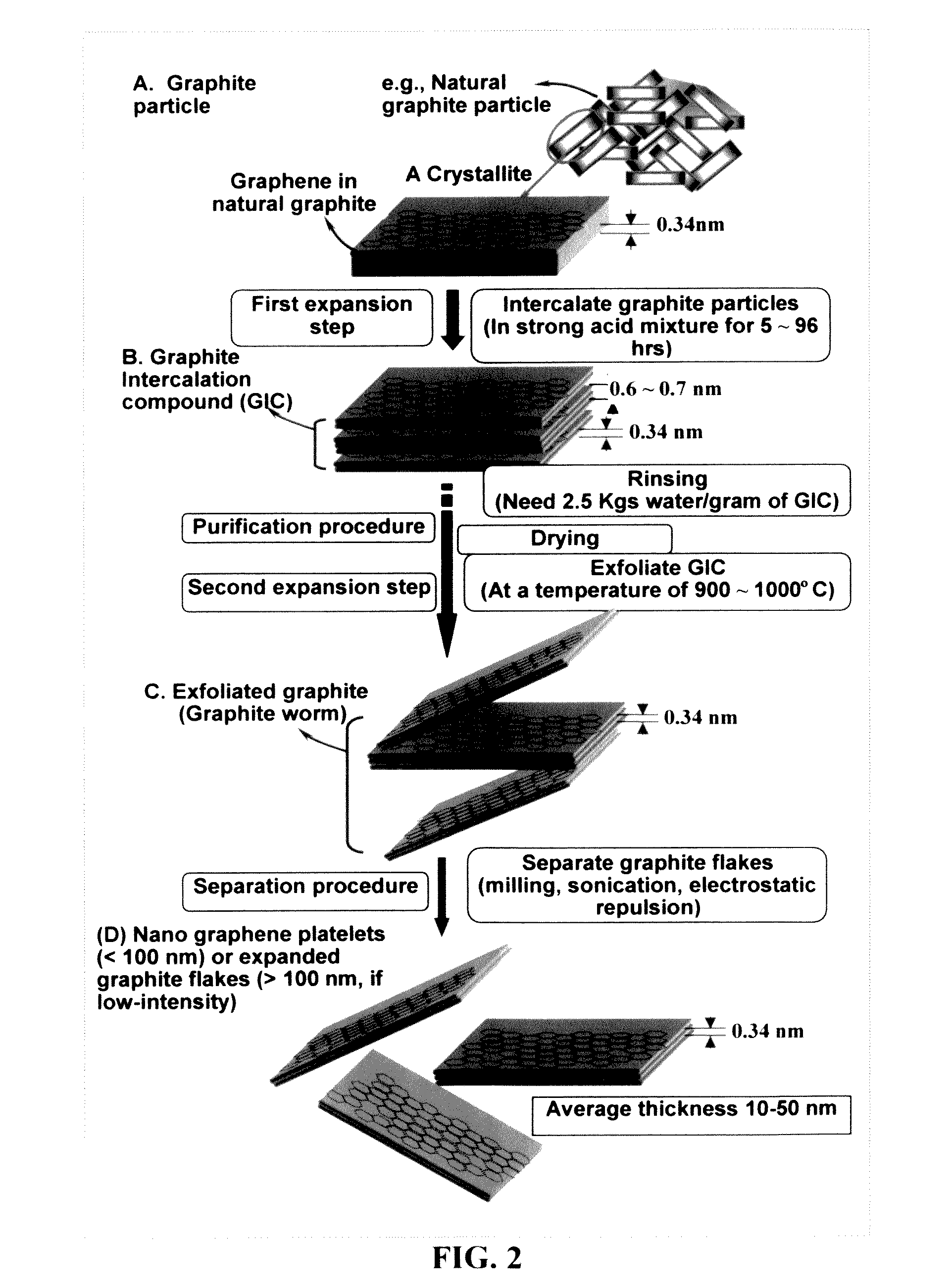

A zinc ion-exchanging battery device comprising: (A) a cathode comprising two cathode active materials (a zinc ion intercalation compound and a surface-mediating material); (B) an anode containing zinc metal or zinc alloy; (C) a porous separator disposed between the cathode and the anode; and (D) an electrolyte containing zinc ions that are exchanged between the cathode and the anode during battery charge / discharge. The zinc ion intercalation compound is selected from chemically treated carbon or graphite material having an expanded inter-graphene spacing d002 of at least 0.5 nm, or an oxide, carbide, dichalcogenide, trichalcogenide, sulfide, selenide, or telluride of niobium, zirconium, molybdenum, hafnium, tantalum, tungsten, titanium, vanadium, chromium, cobalt, manganese, iron, nickel, or a combination thereof. The surface-mediating material contains exfoliated graphite or multiple single-layer sheets or multi-layer platelets of a graphene material.

Owner:GLOBAL GRAPHENE GRP INC

Metal amides of cyclic amines

ActiveUS20160152649A1Improve thermal stabilityImprove conductivityIron group organic compounds without C-metal linkagesNickel organic compoundsGermanideMetal silicide

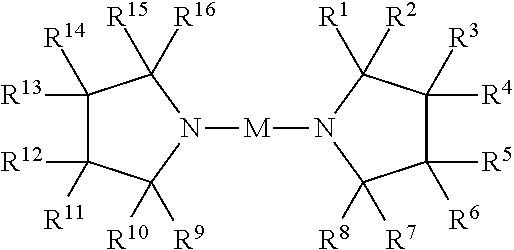

Compounds, and oligomers of the compounds, are synthesized with cyclic amine ligands attached to a metal atom. These compounds are useful for the synthesis of materials containing metals. Examples include pure metals, metal alloys, metal oxides, metal nitrides, metal phosphides, metal sulfides, metal selenides, metal tellurides, metal borides, metal carbides, metal silicides and metal germanides. Techniques for materials synthesis include vapor deposition (chemical vapor deposition and atomic layer deposition), liquid solution methods (sol-gel and precipitation) and solid-state pyrolysis. Suitable applications include electrical interconnects in microelectronics and magnetoresistant layers in magnetic information storage devices. The films have very uniform thickness and high step coverage in narrow holes.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Method and composition to reduce cancer incidence

InactiveUS6090414AReduce distractionsInhibition formationBiocideTetrapeptide ingredientsHydroxybenzoate EthersS oxidation

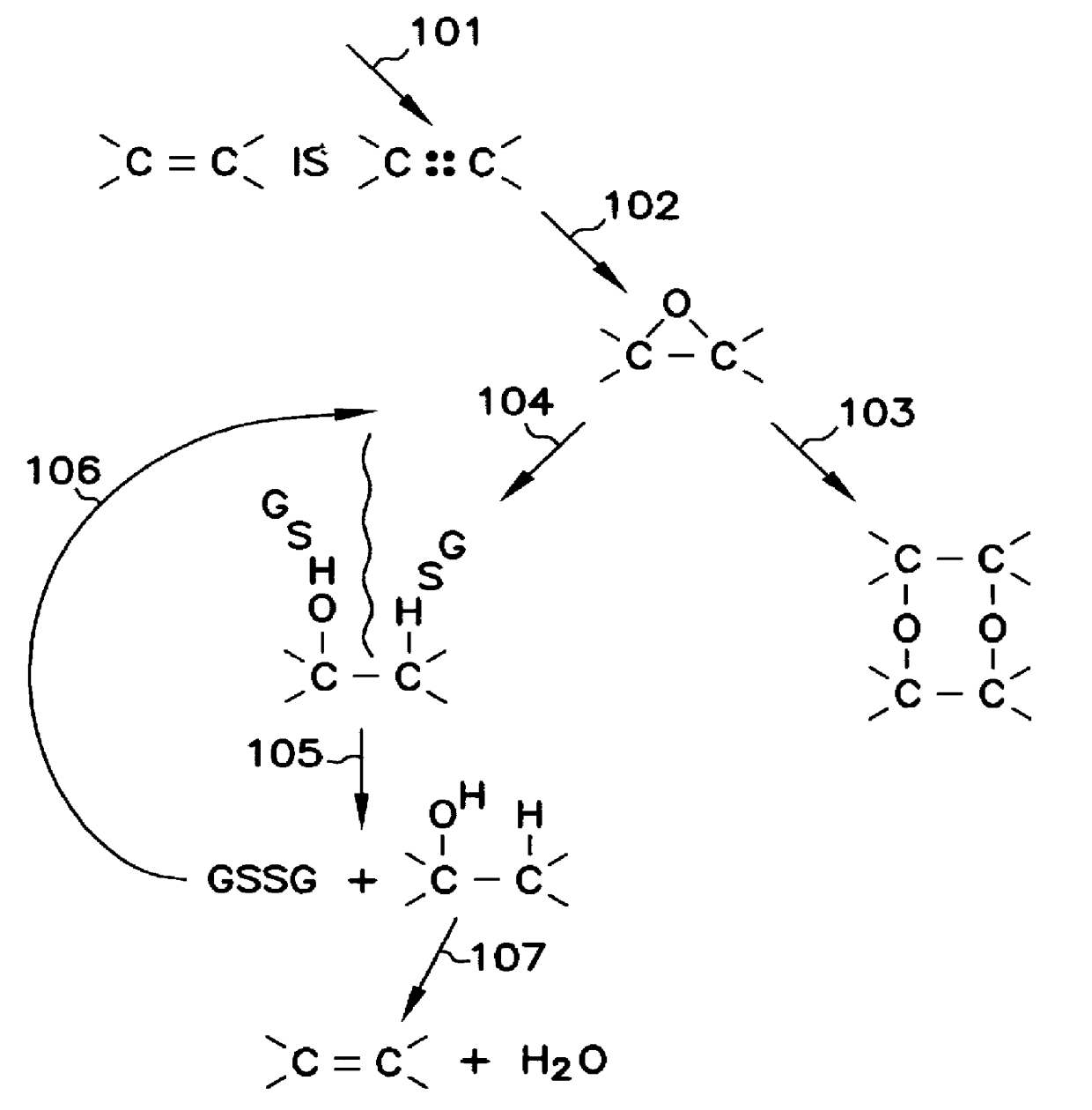

The five component composition consisting essentially of: (1) Water soluble antioxidant vitamin C or ascorbic acid, or any of its forms or derivatives, or mixtures thereof. (2) Oil soluble antioxidant vitamin E or Alpha-tocophorol, or any of its forms or derivatives, or mixtures thereof. (3) The element selenium, or a chemical (or composition) containing it, or mixtures thereof. The most preferred chemical containing selenium is dimethyl selenide and mixtures thereof. The words "dimethyl selenide" here and hereinafter mean dimethyl selenide and / or it's oxidation products, including dimethyl selenoxide. (4) A sulfur amino acid, in any form, or a sulfur peptide, or a sulfur protein, or any of their derivatives, or mixtures thereof. The mixture of methionine and cysteine, which contains as impurities some seleno-methionine and some selenocysteine, is preferred,-the tripeptide glutathione containing cysteine is also preferred. (5) Another antioxidant, other than vitamin C and other than vitamin E, which is synthetic or natural and water soluble or oil soluble, or a mixture of such antioxidants, or a combination of such forms thereof. The mixtures of butylated hydroxyanisole and ethoxyquin is preferred.

Owner:LIFE SCI LAB

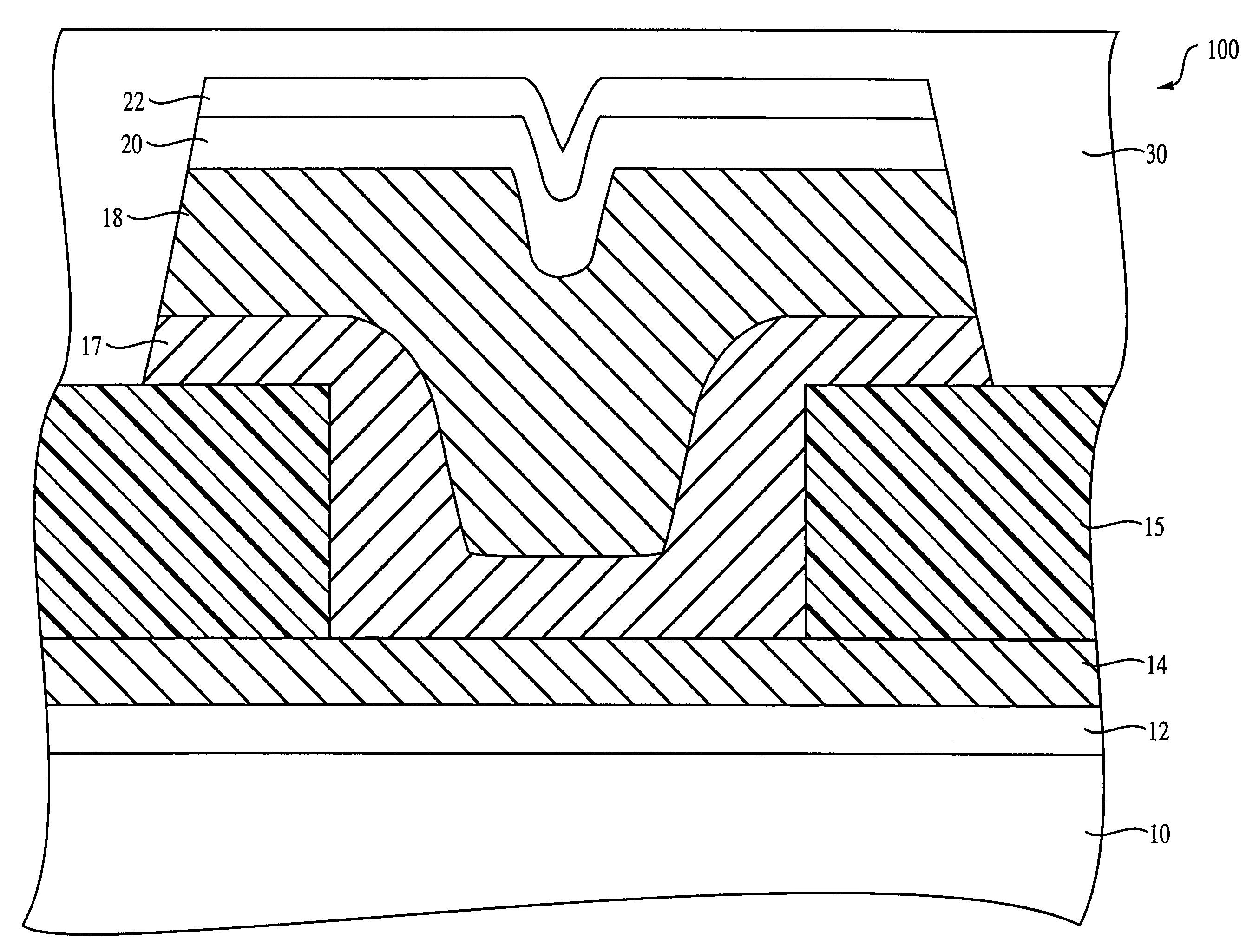

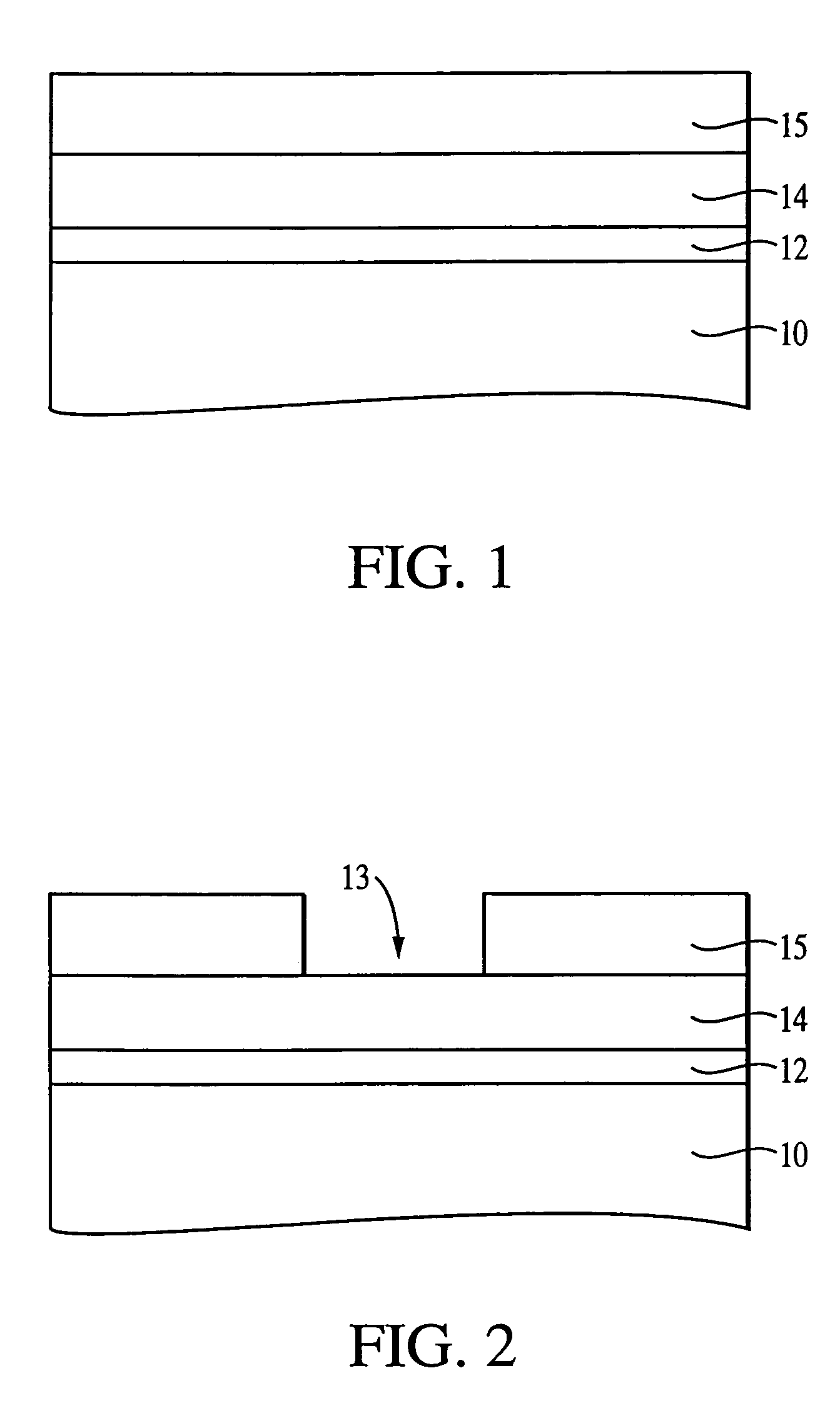

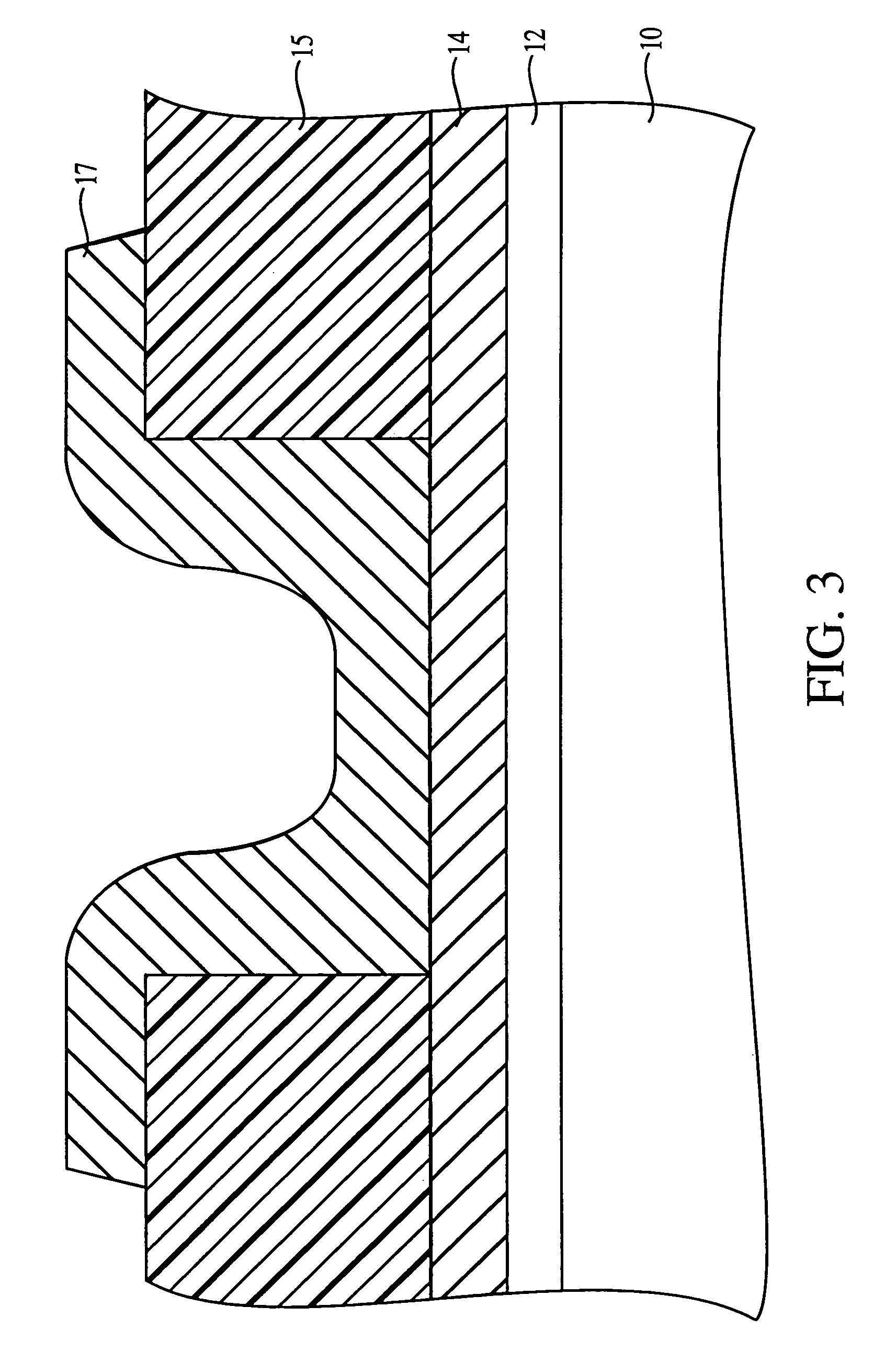

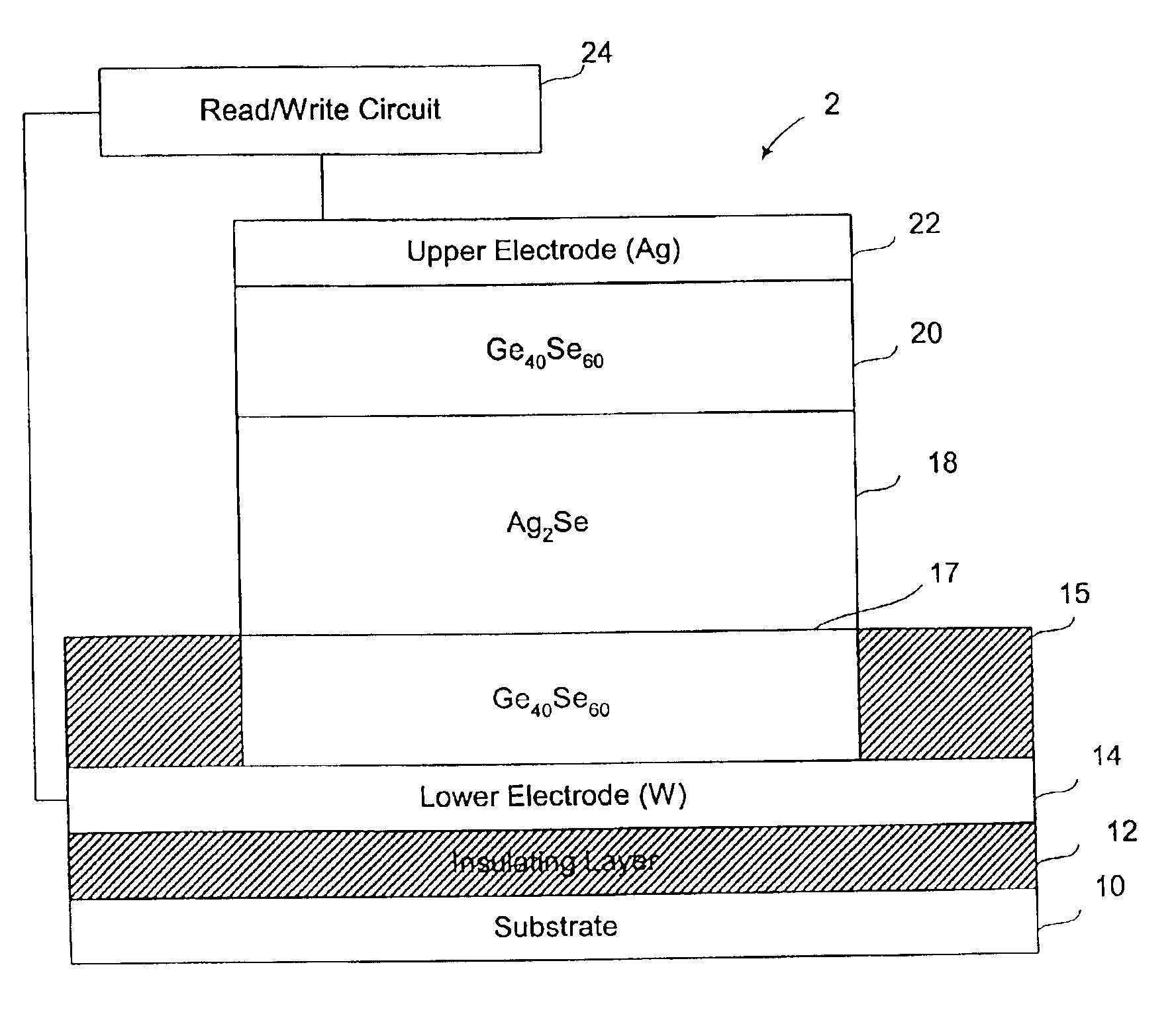

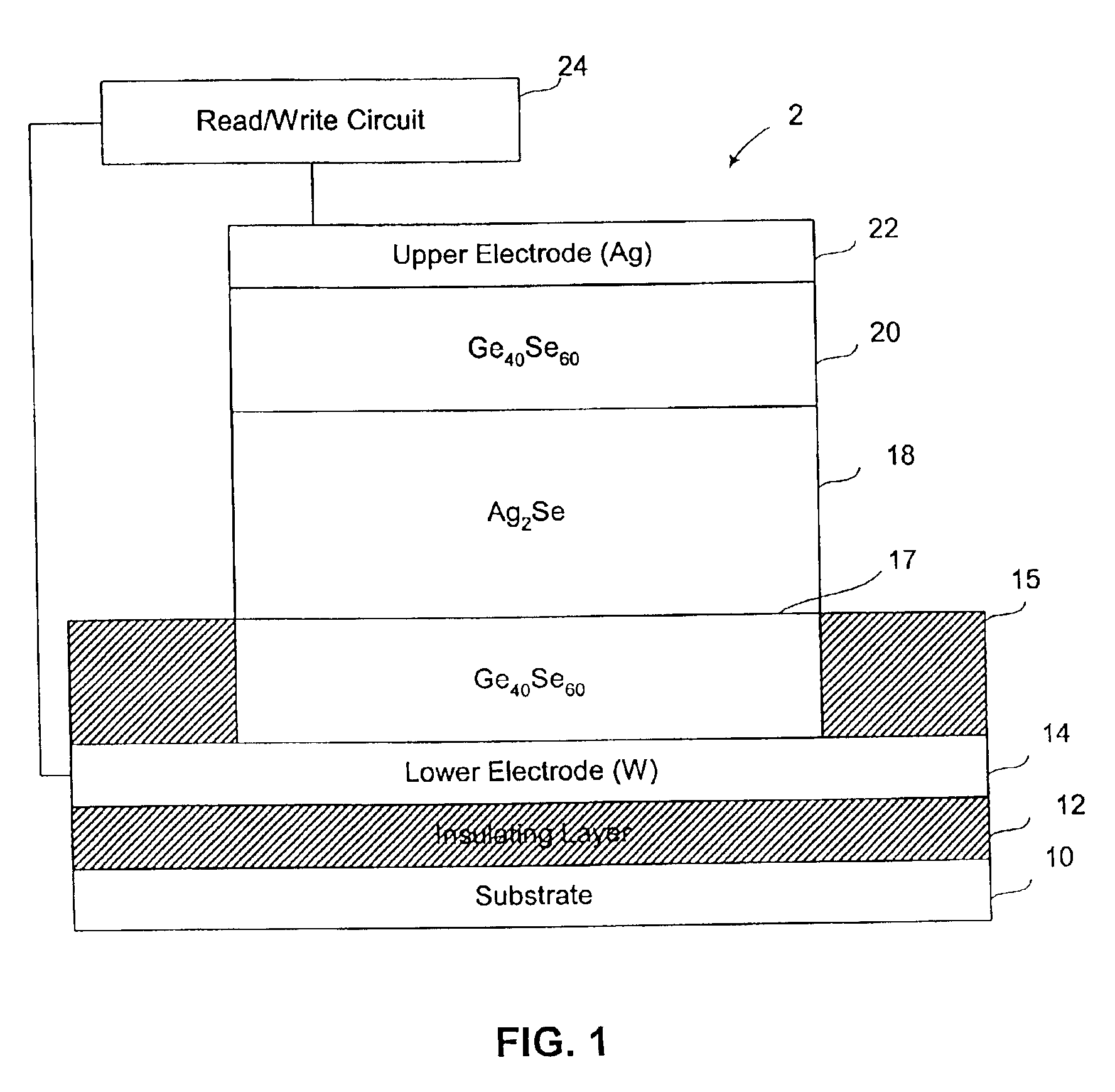

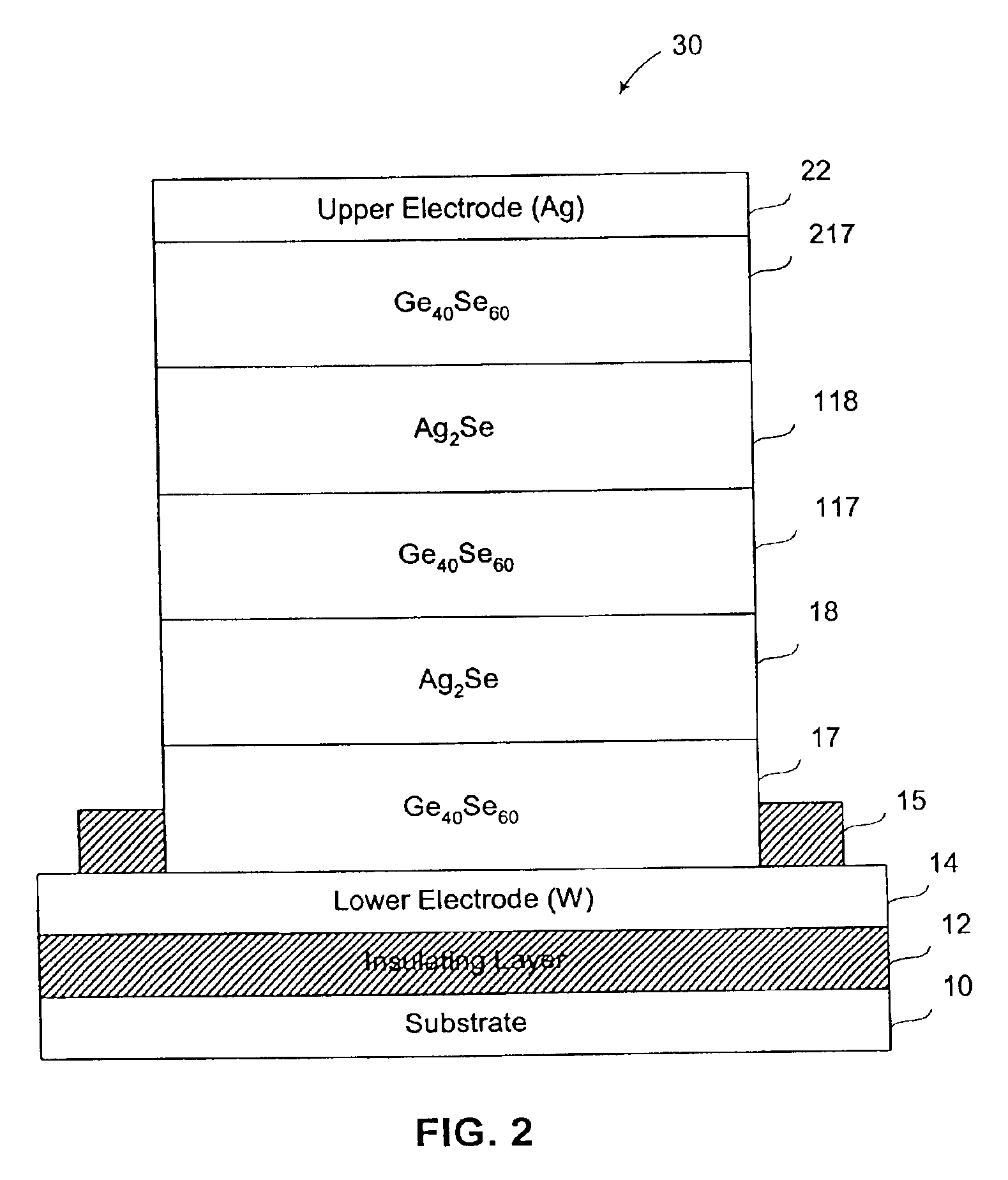

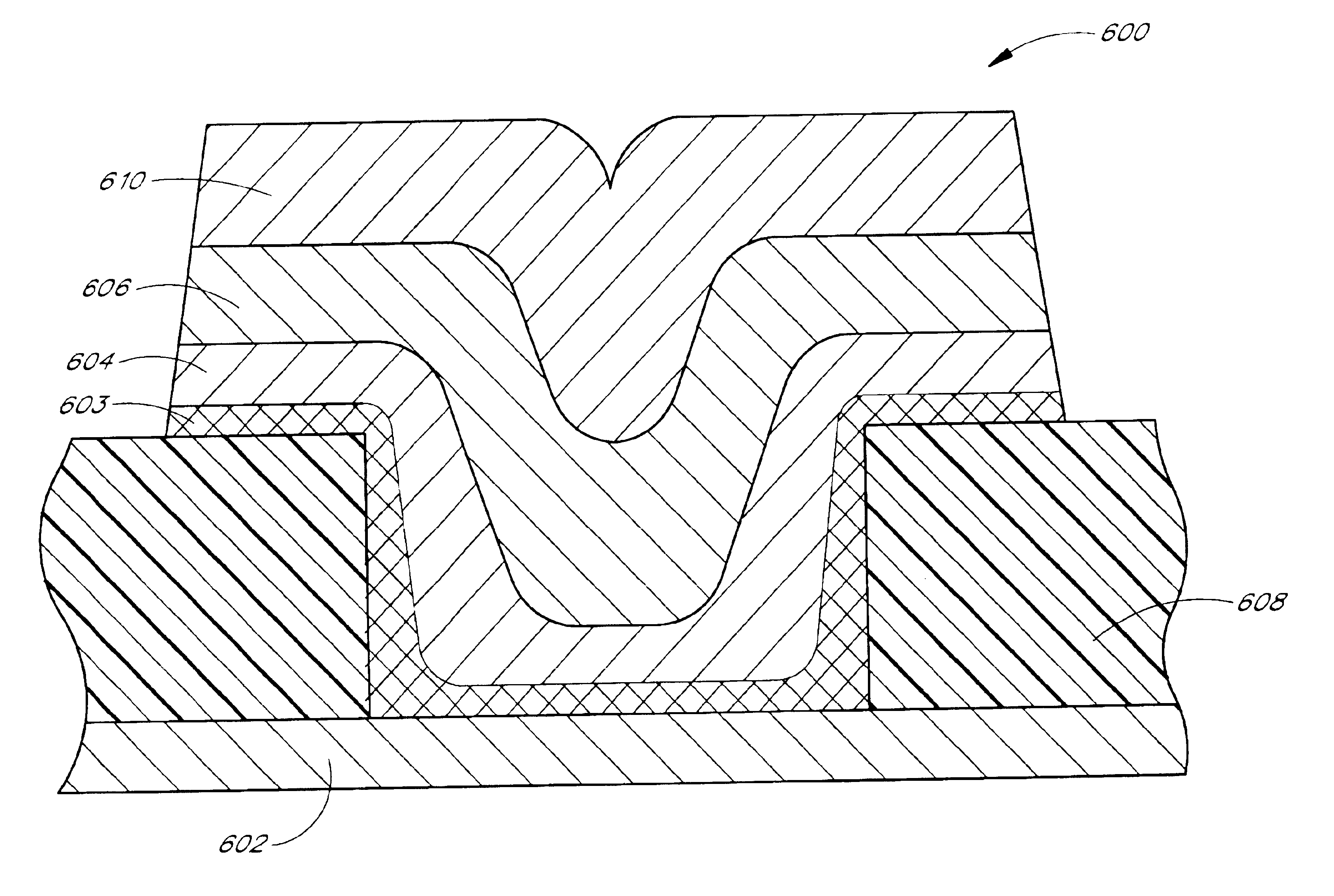

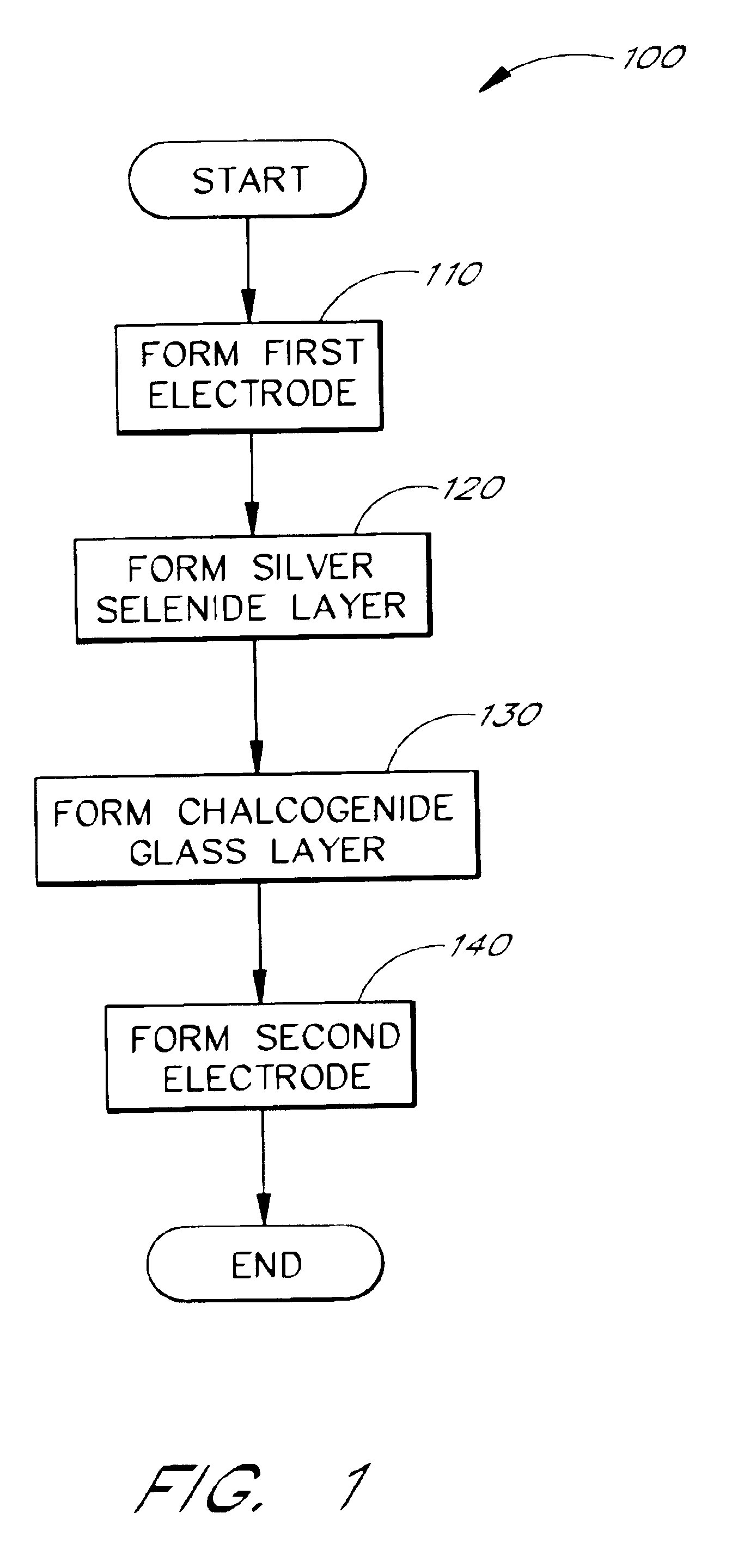

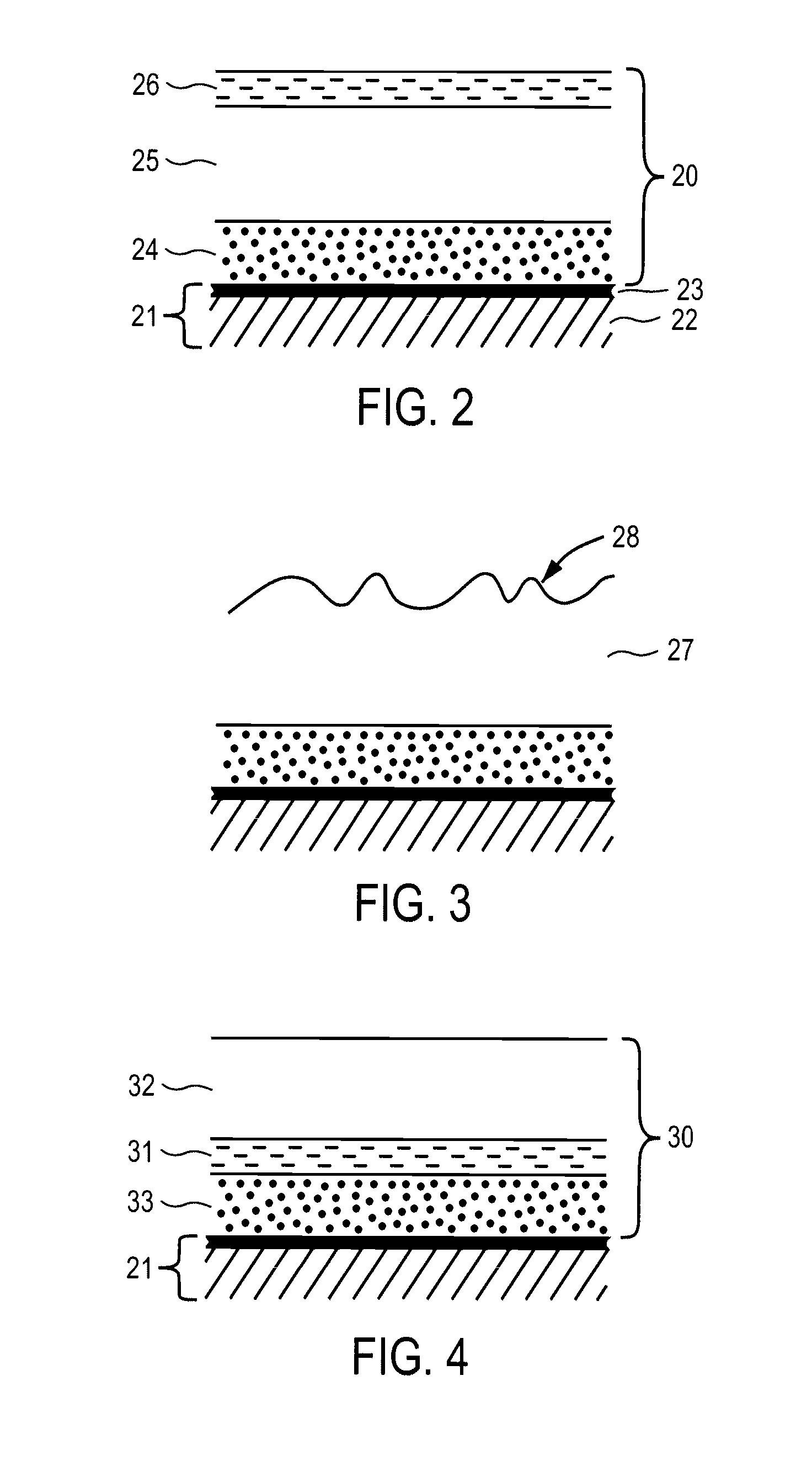

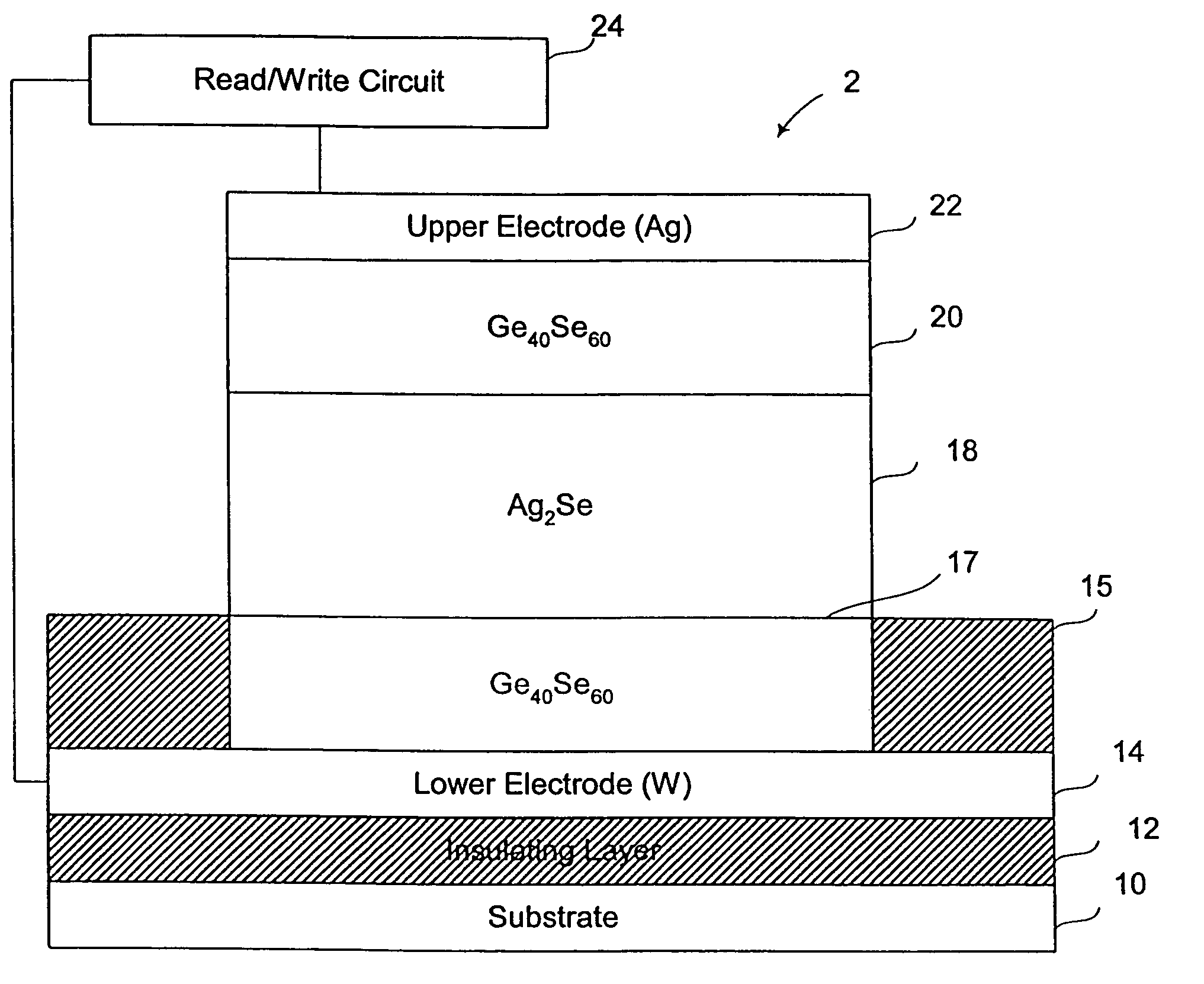

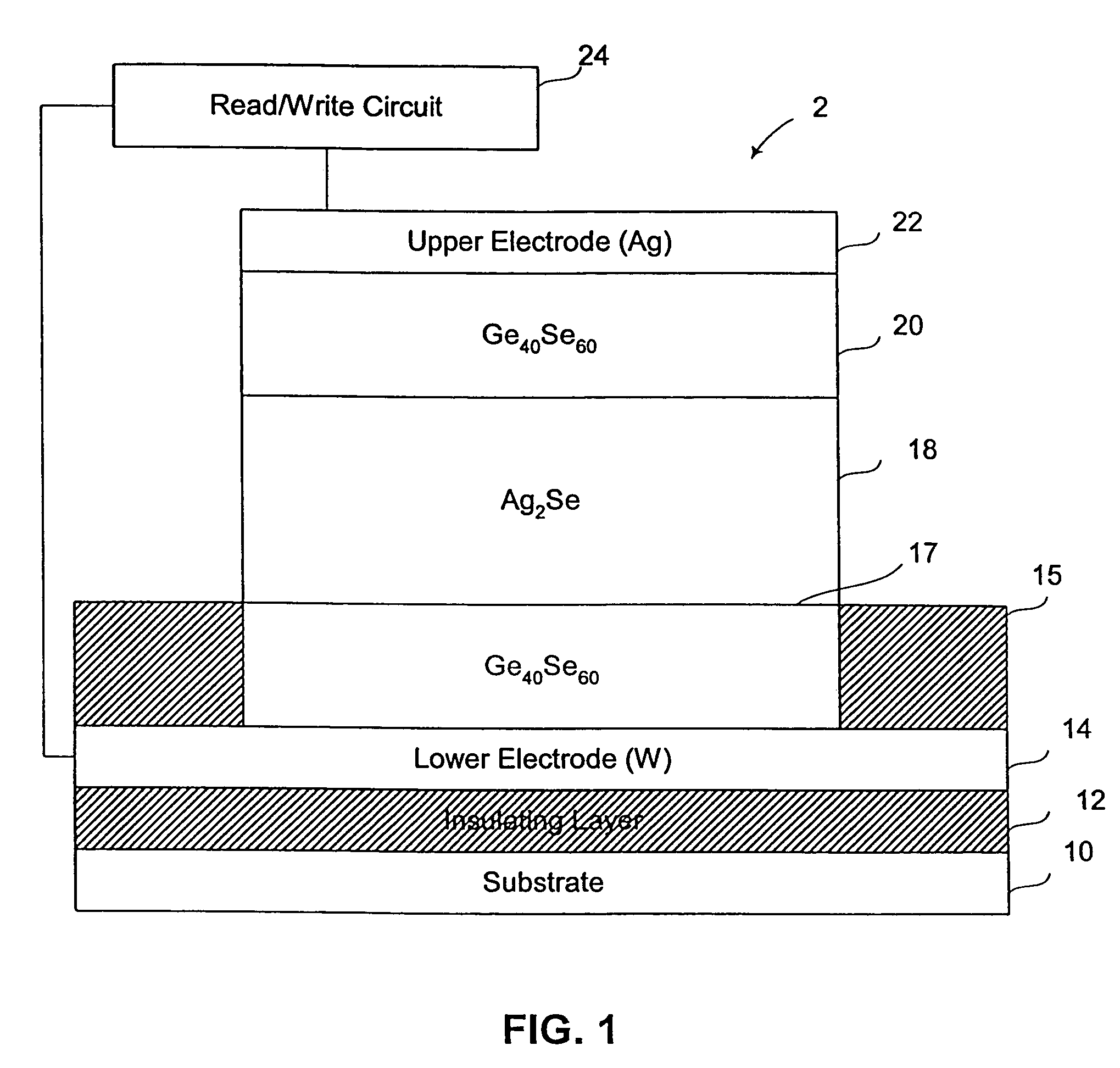

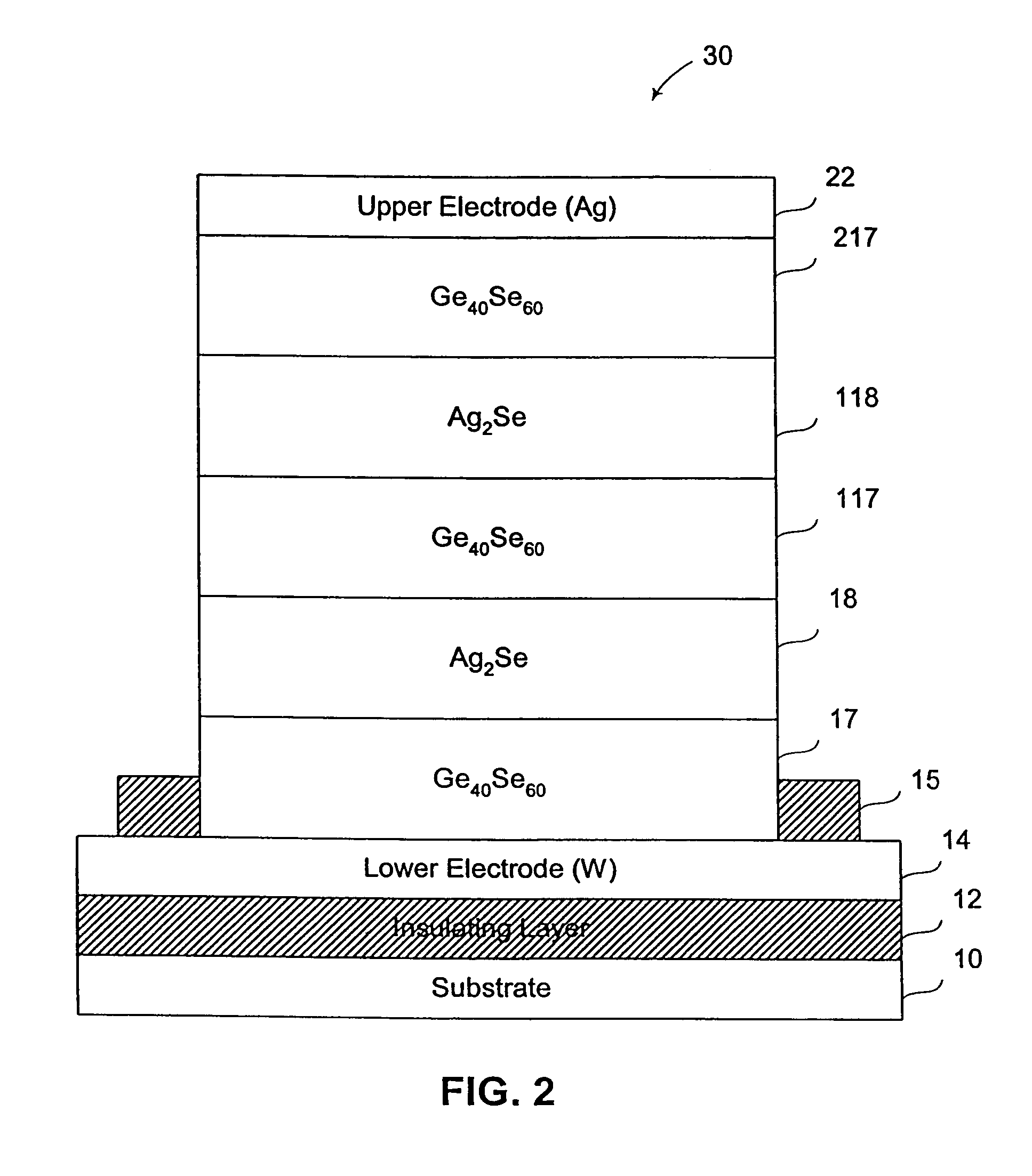

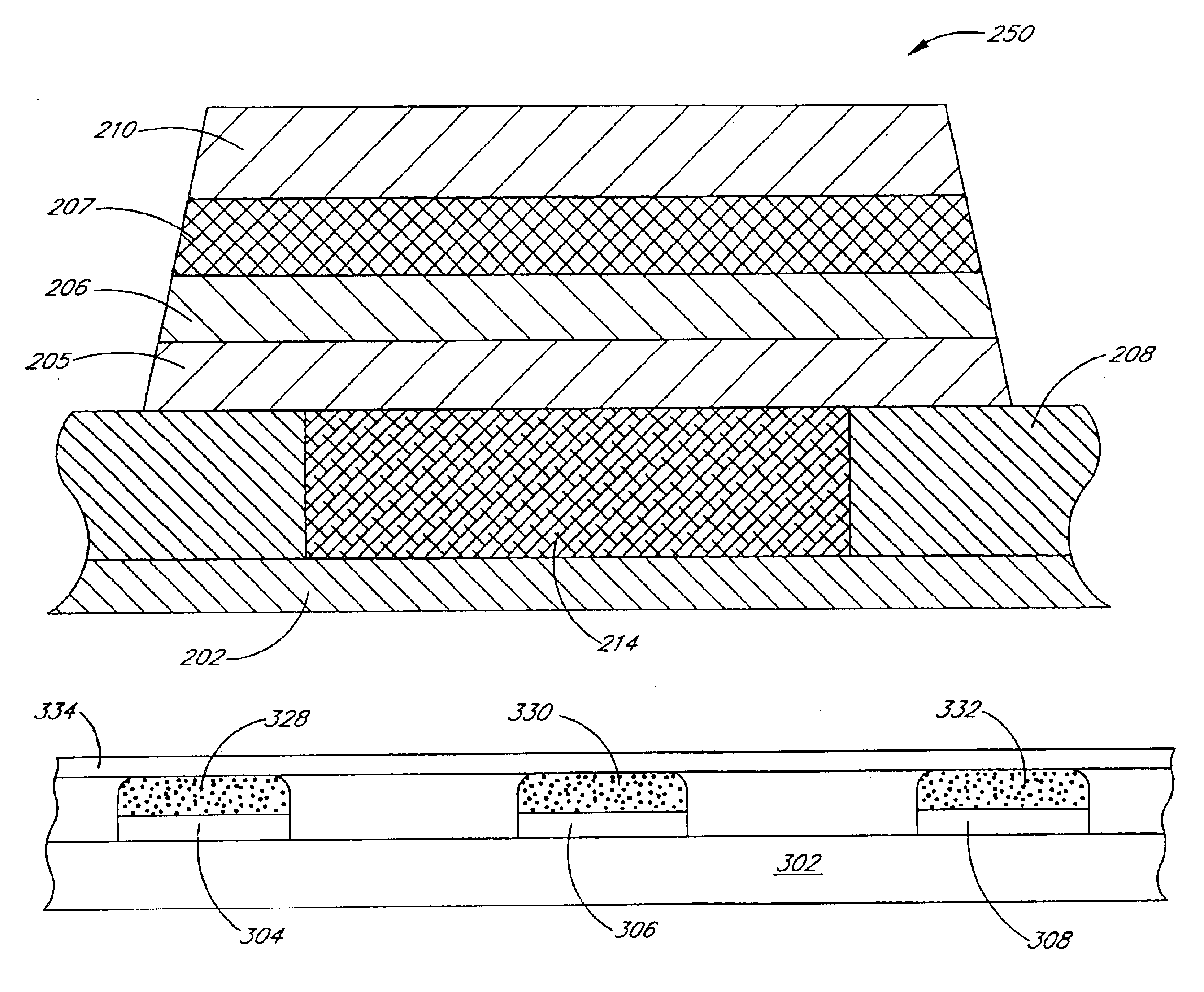

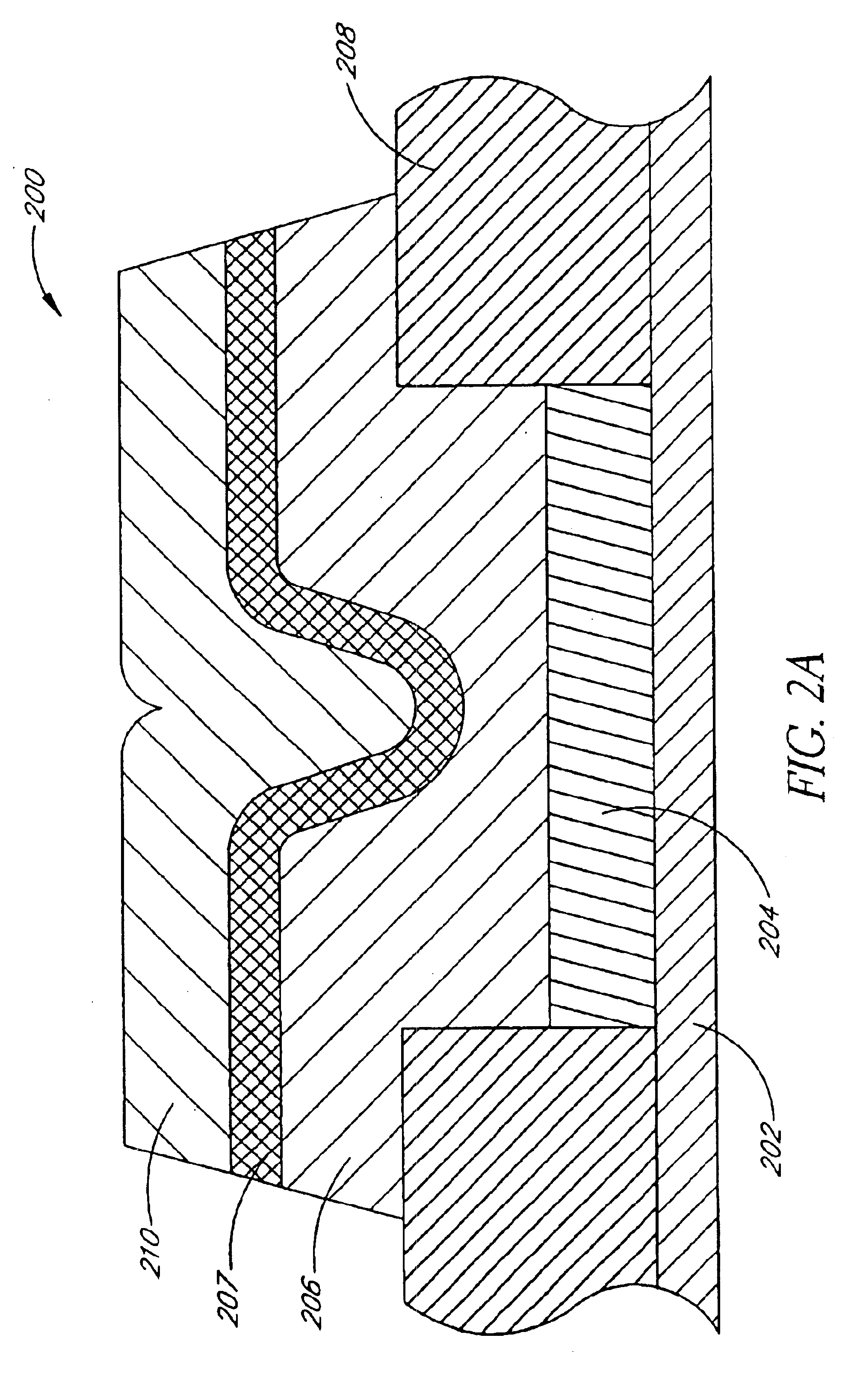

Silver-selenide/chalcogenide glass stack for resistance variable memory

InactiveUS7151273B2Solid-state devicesSemiconductor/solid-state device manufacturingComputer hardwareSulfur

The invention is related to methods and apparatus for providing a resistance variable memory element with improved data retention and switching characteristics. According to an embodiment of the invention a resistance variable memory element is provided having at least one silver-selenide layer in between glass layers, wherein at least one of the glass layers is a chalcogenide glass, preferably having a GexSe100−x composition.

Owner:MICRON TECH INC

Single-polarity programmable resistance-variable memory element

A resistance variable memory element with improved data retention and switching characteristics switched between resistance memory states upon the application of write pulses having the same polarity. The resistance variable memory element can be provided having at least one silver-selenide layer in between glass layers, the glass layers are a chalcogenide glass having a GexSe100−x composition.

Owner:OVONYX MEMORY TECH LLC

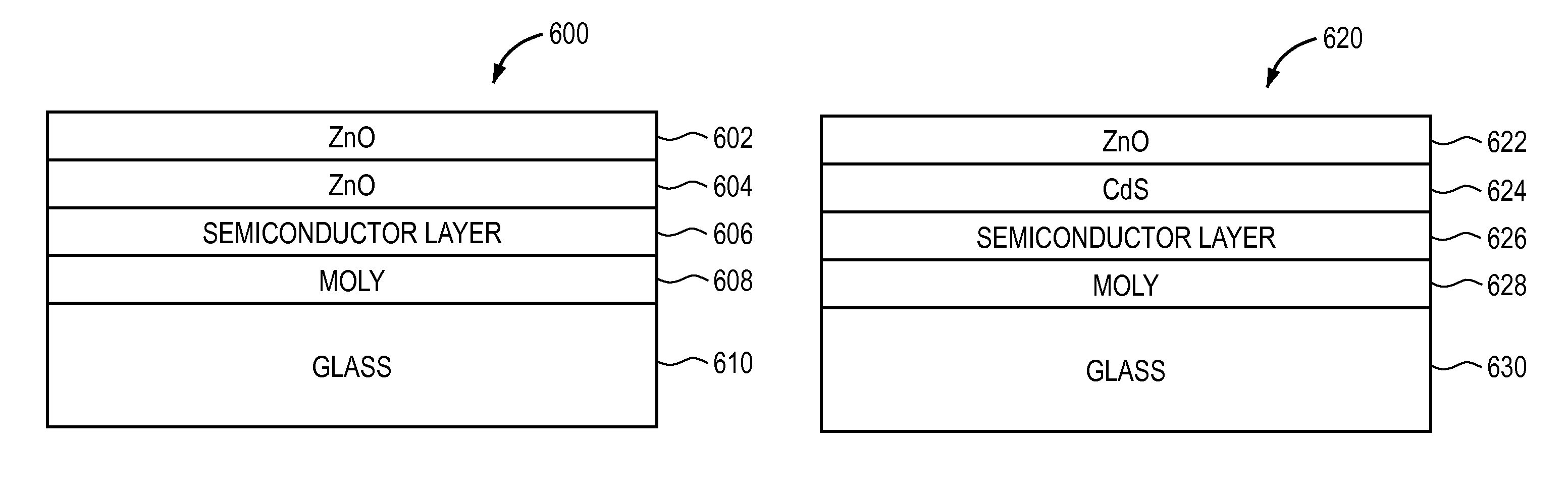

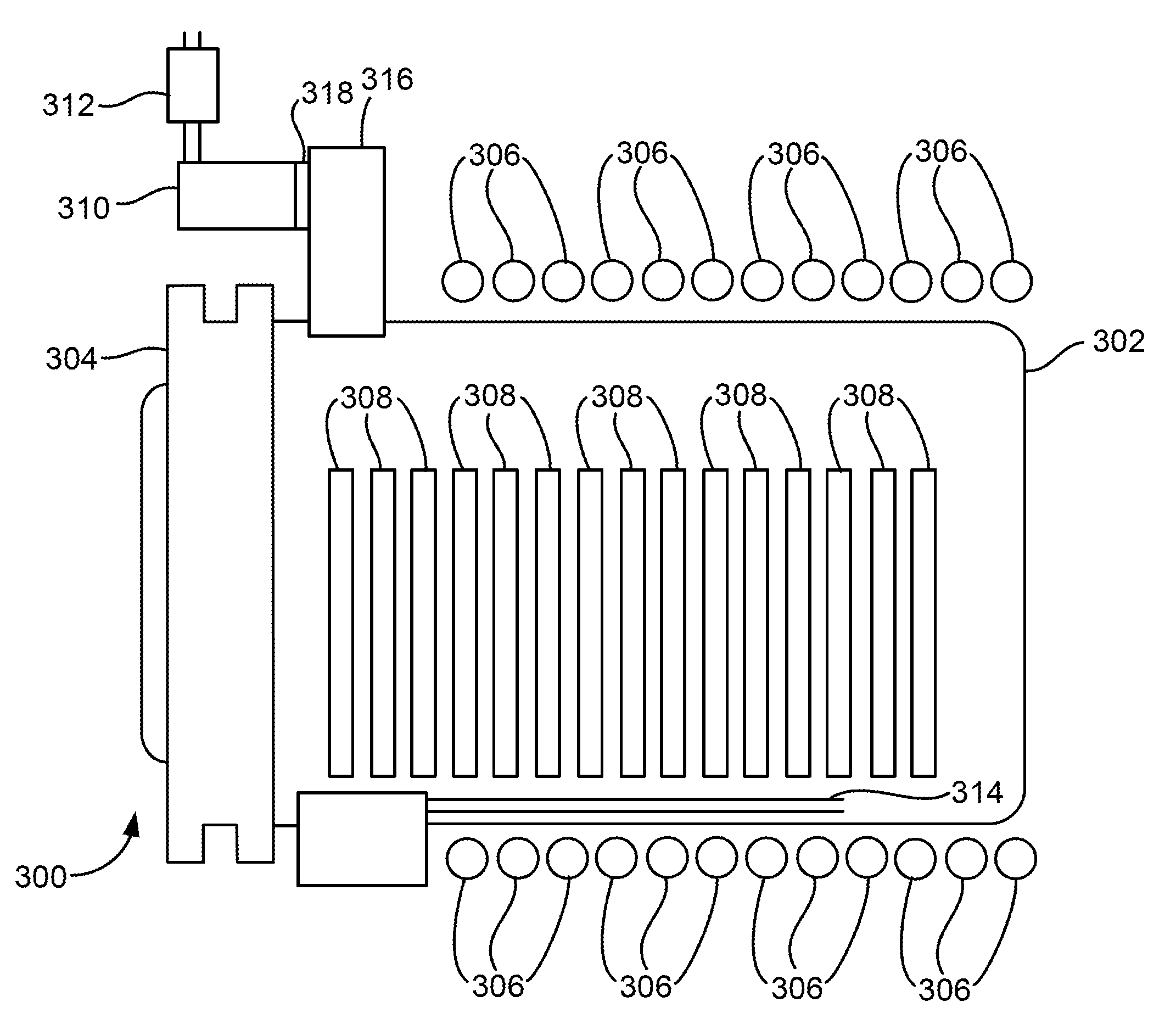

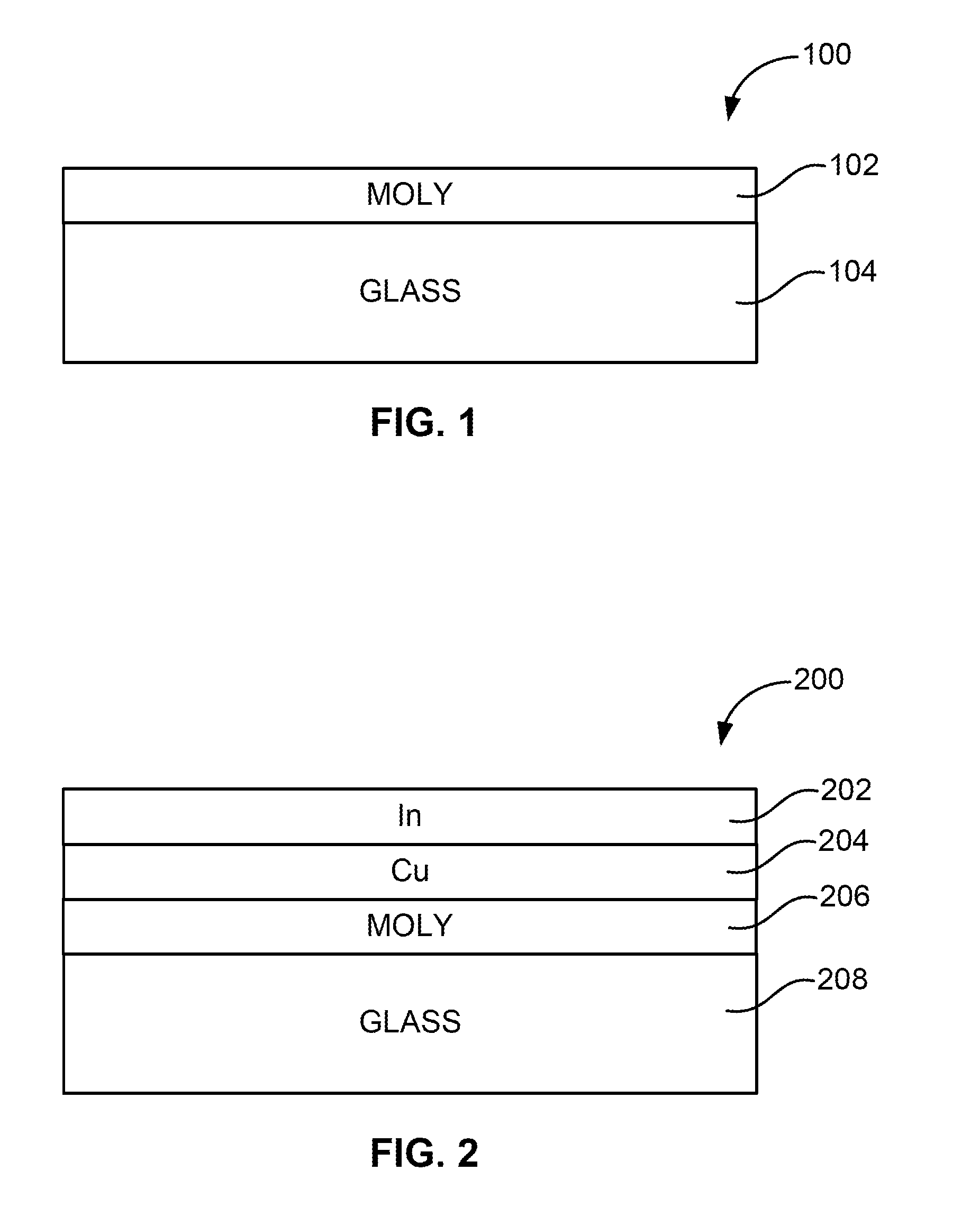

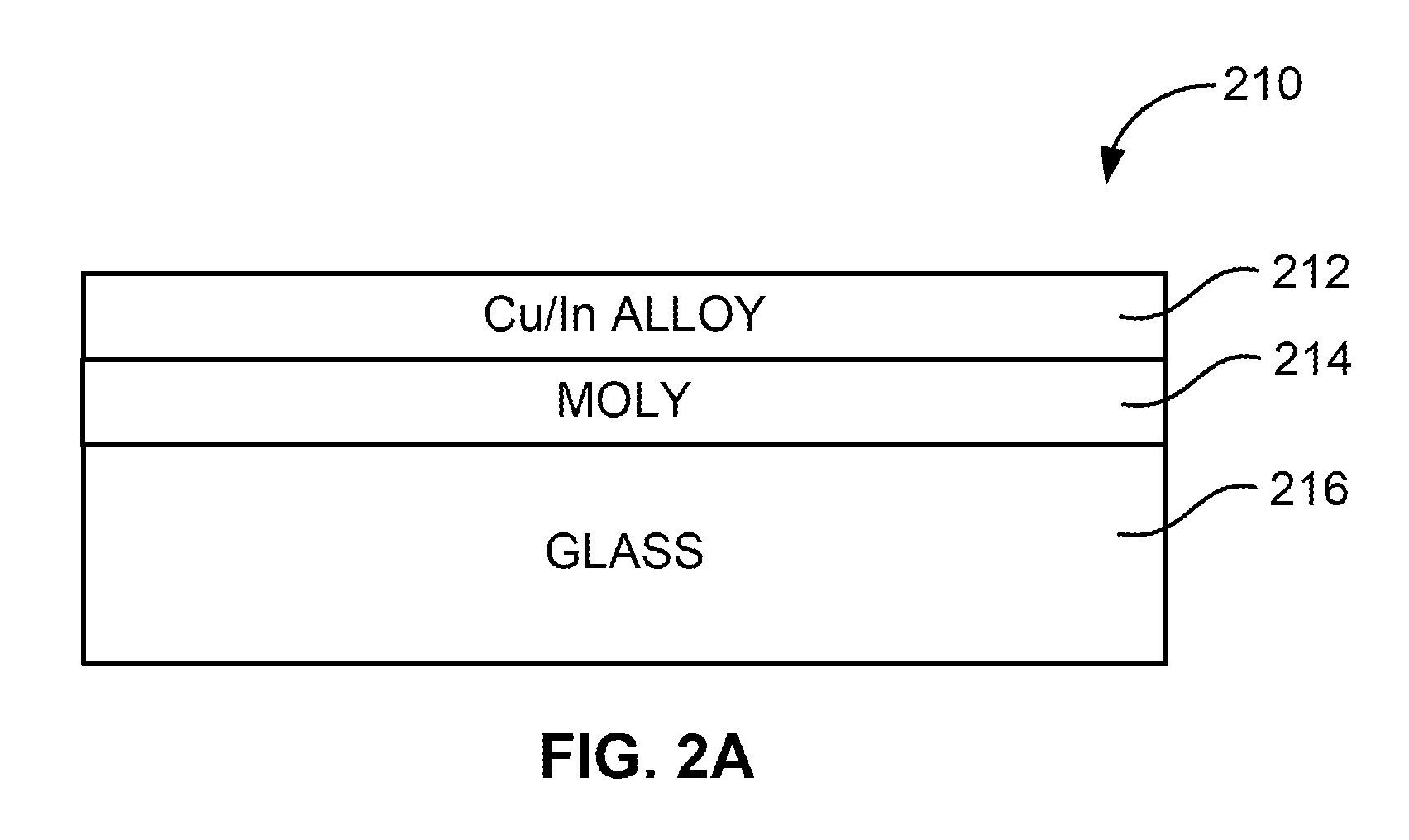

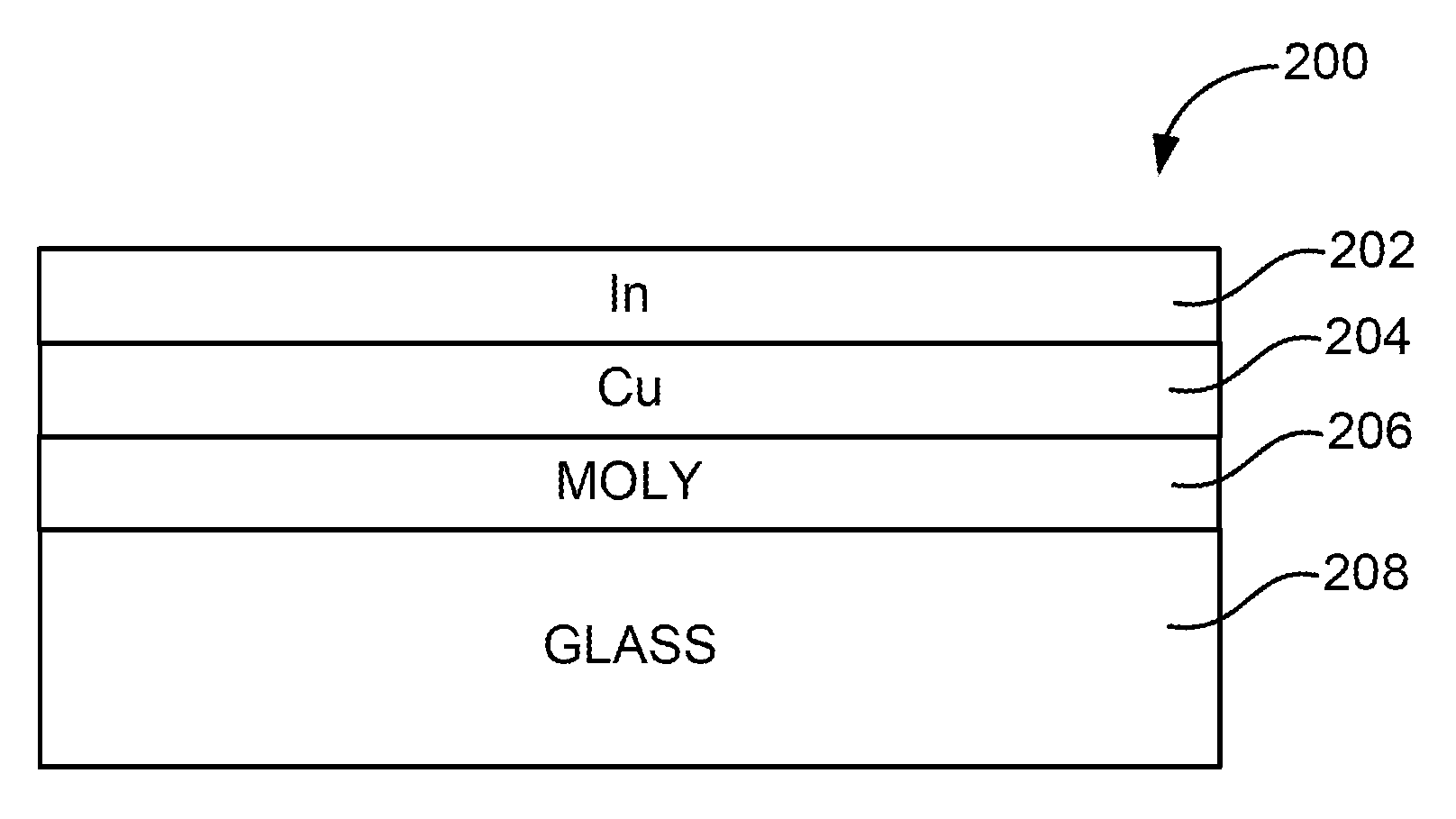

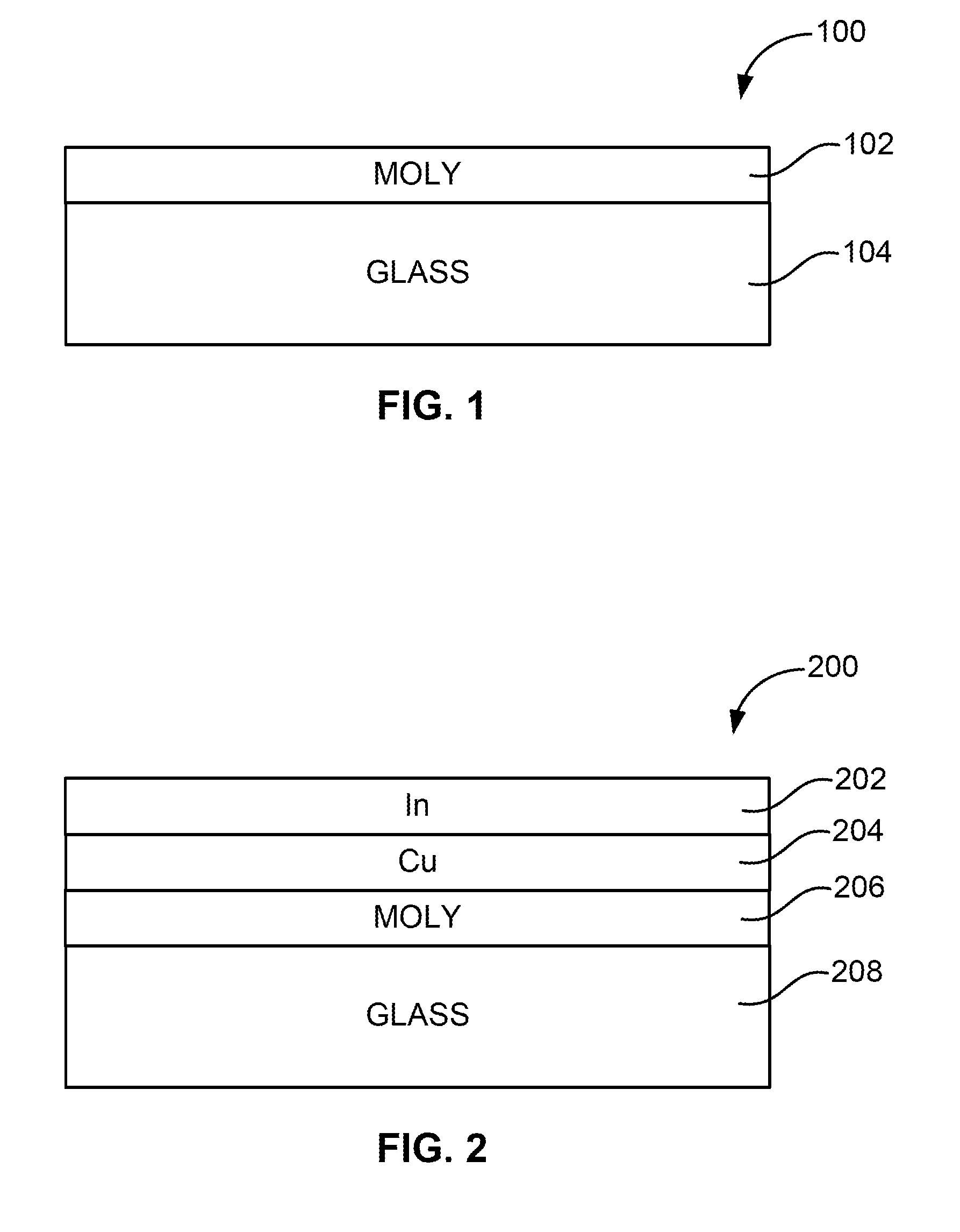

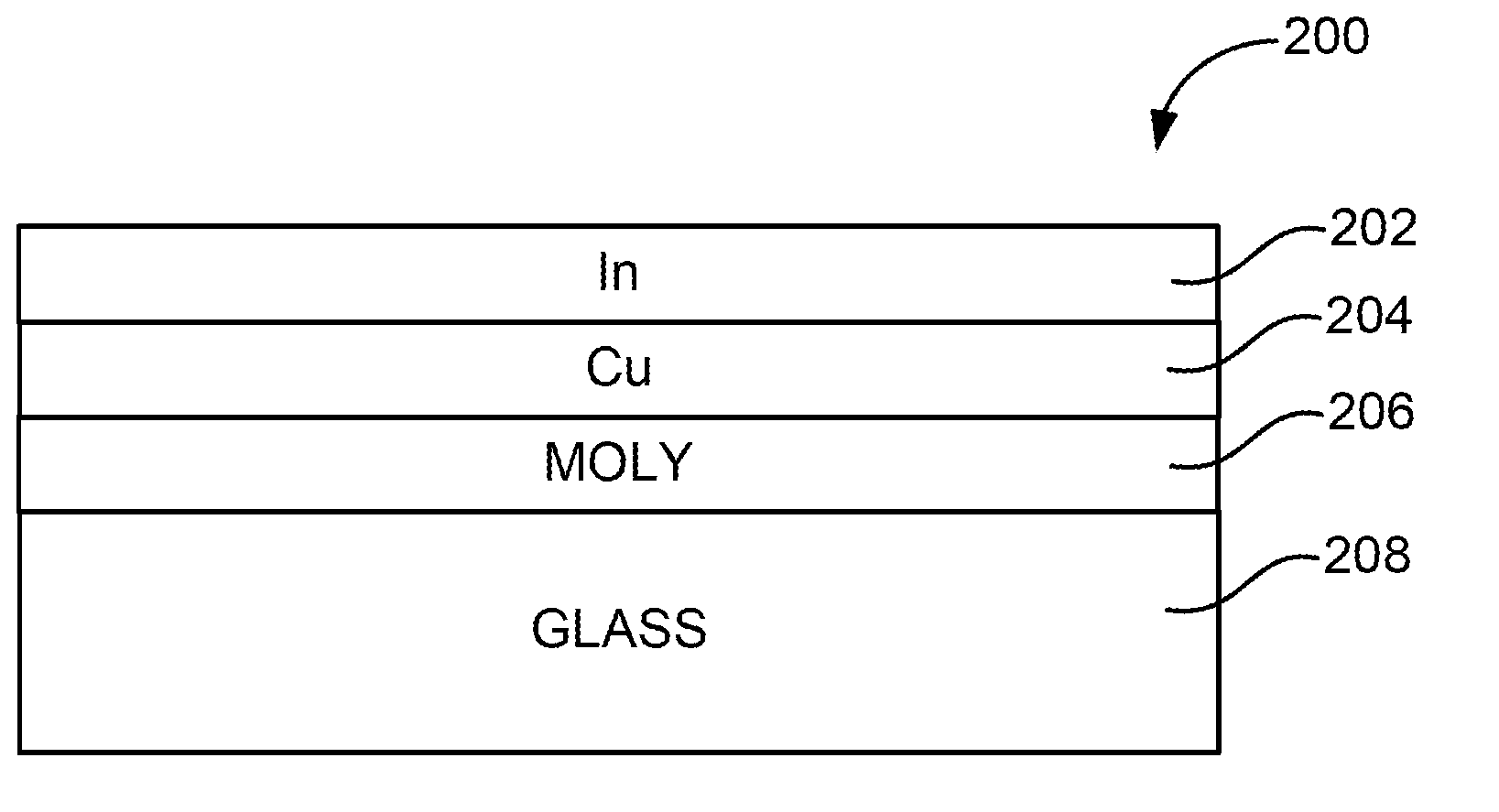

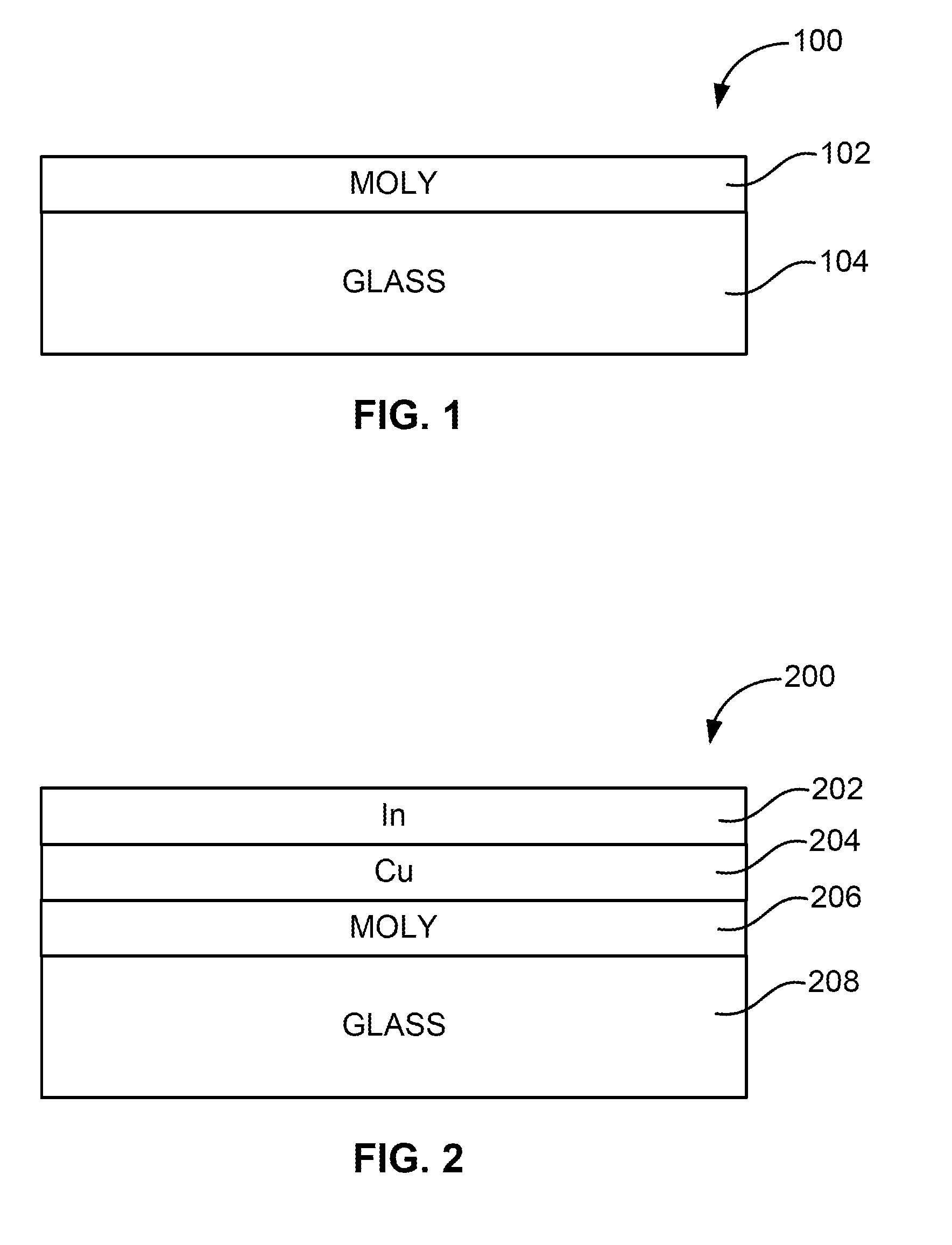

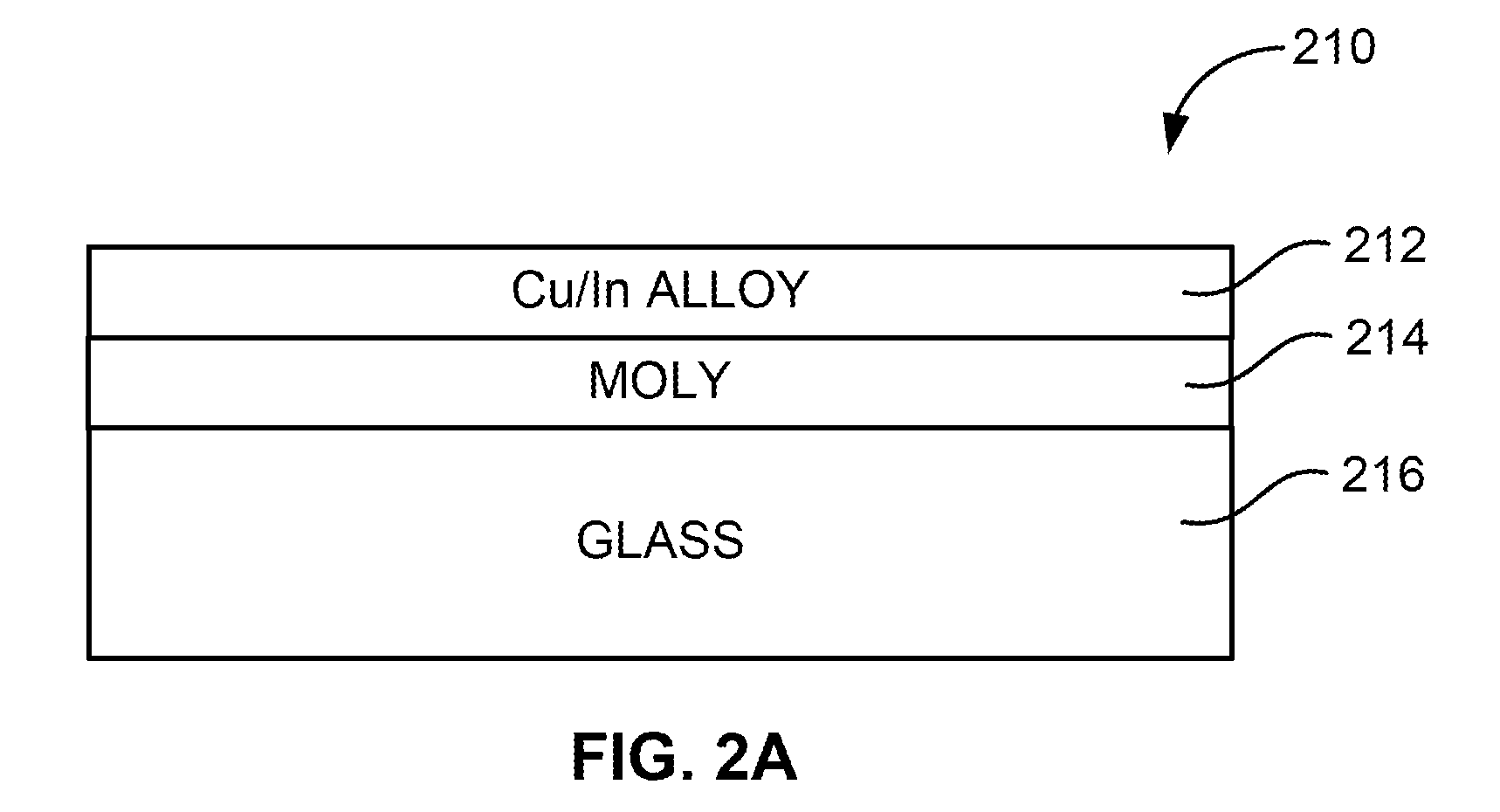

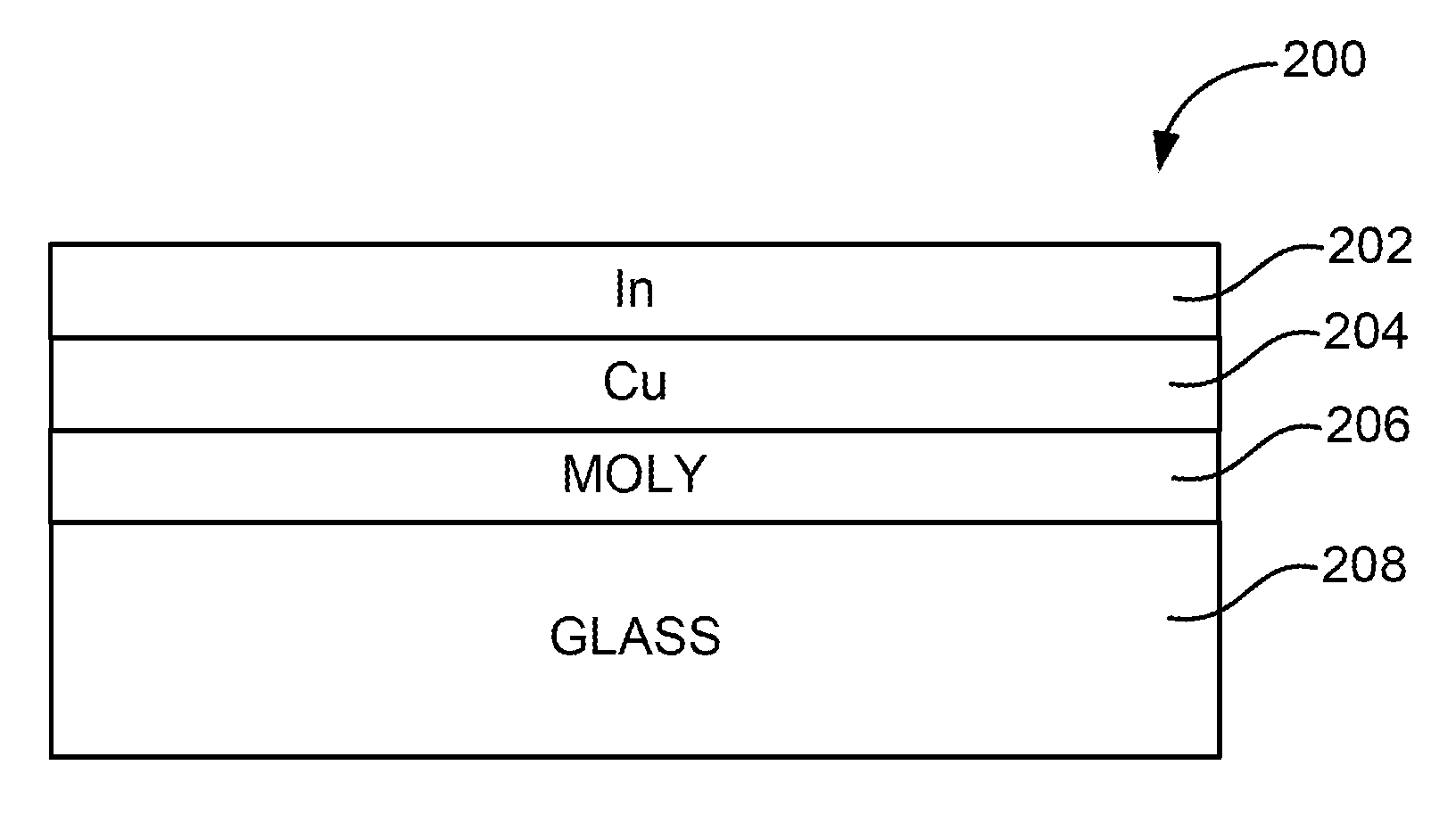

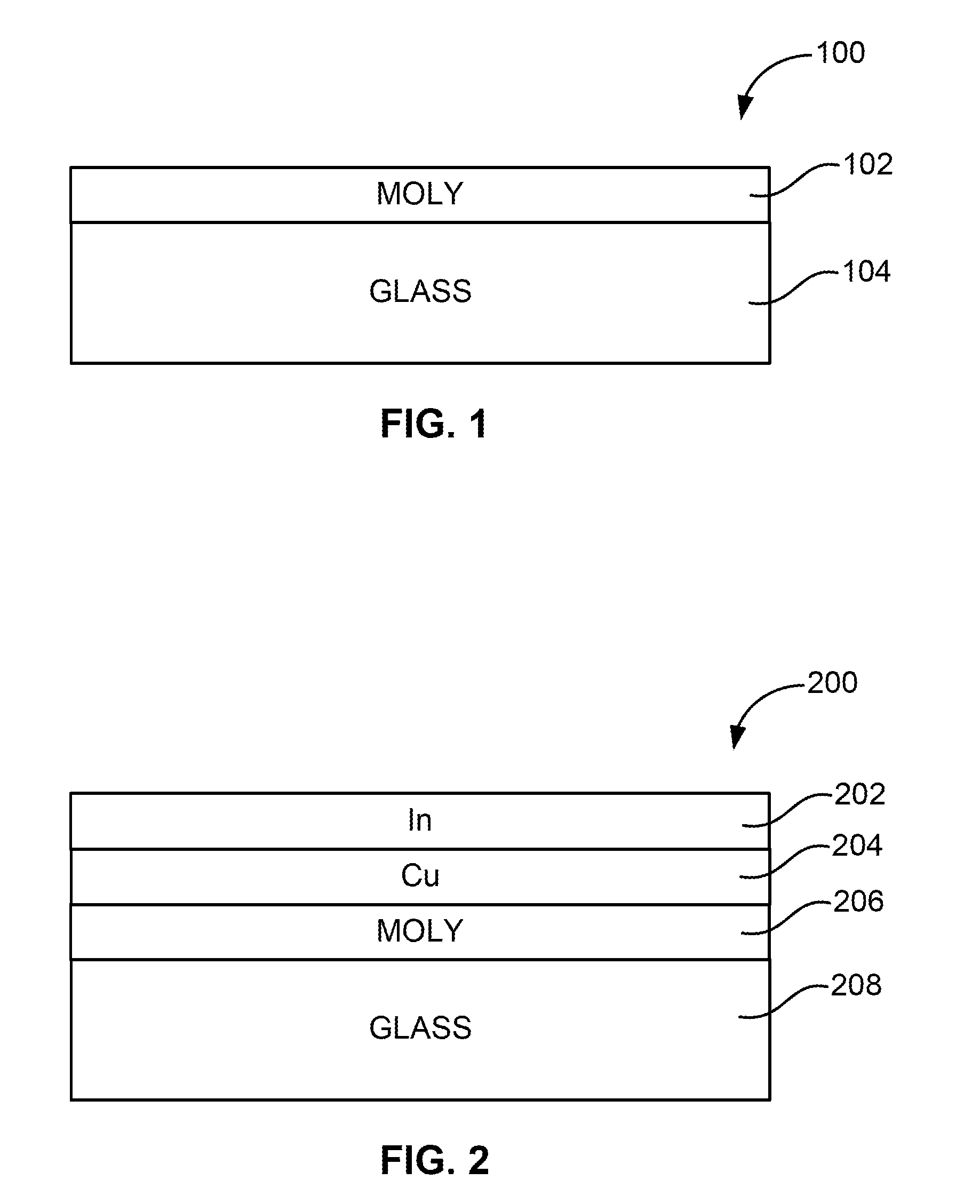

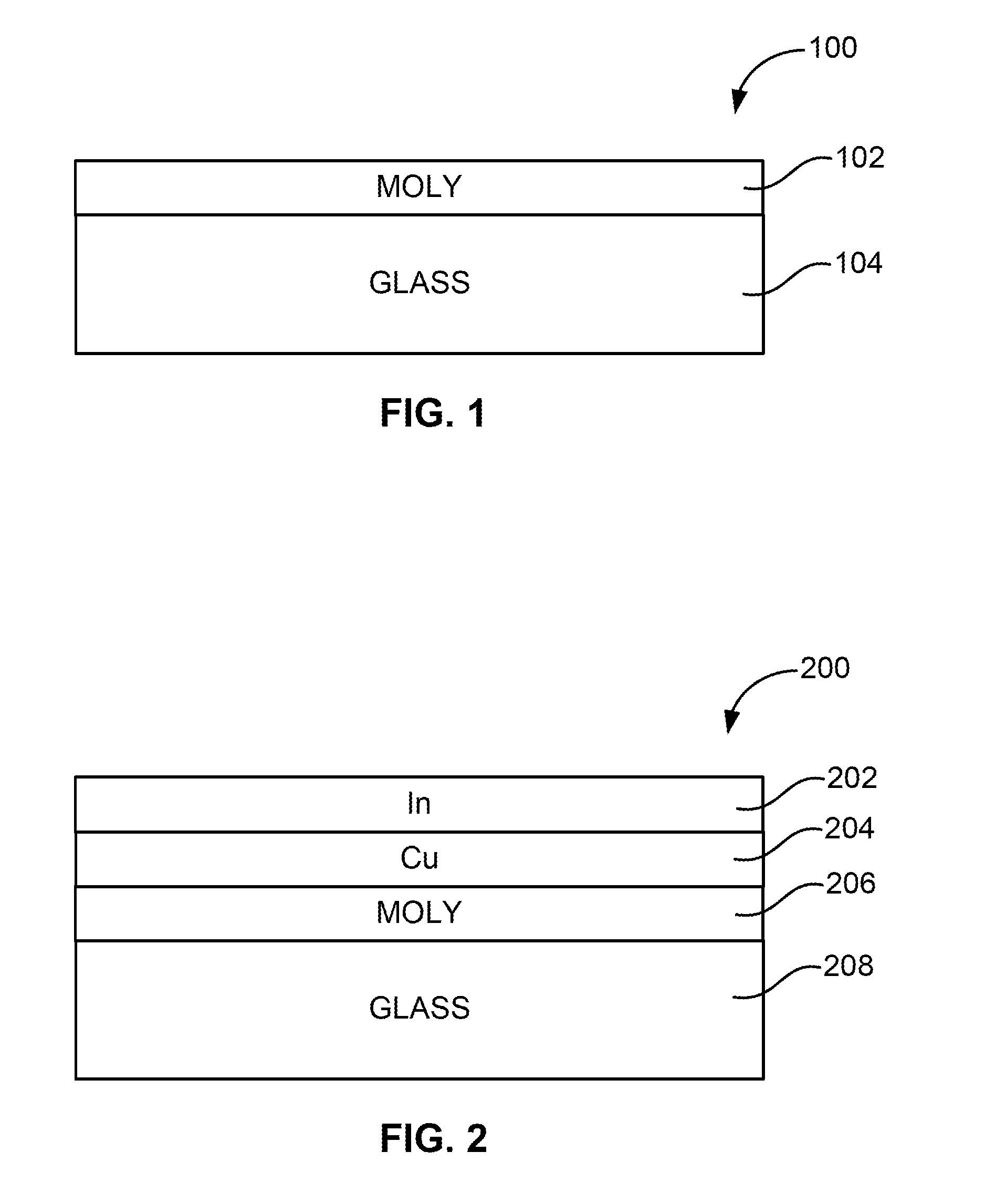

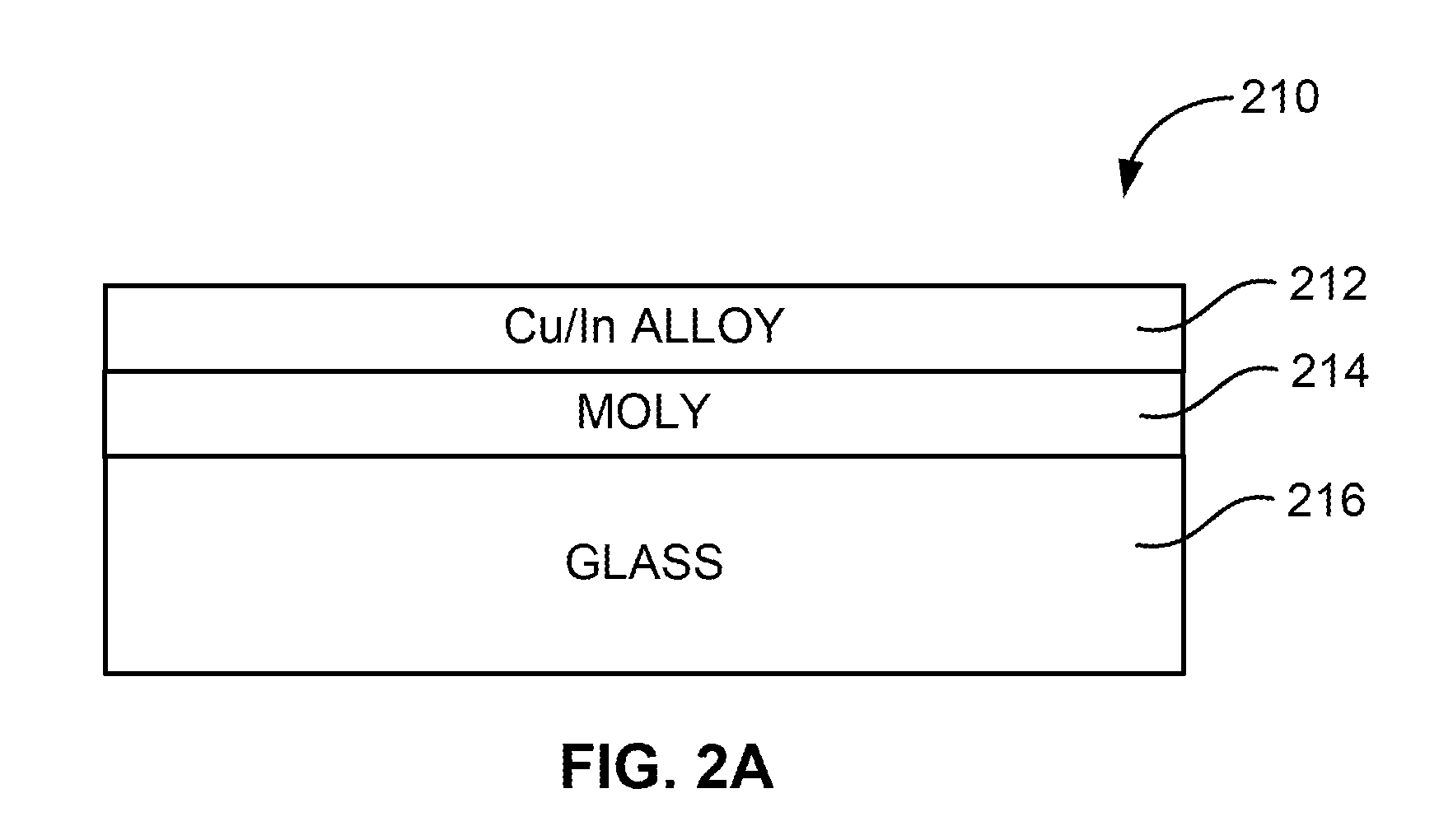

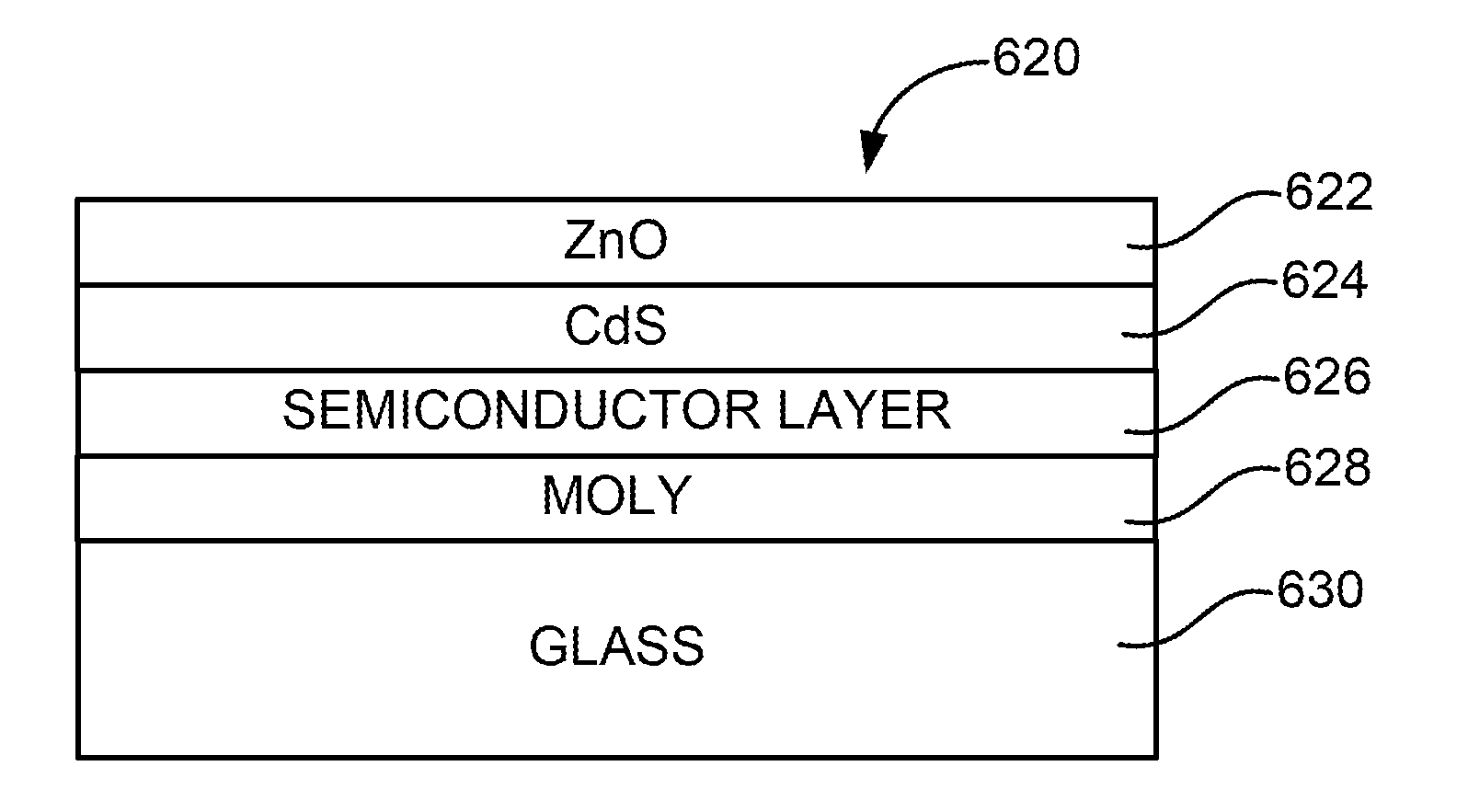

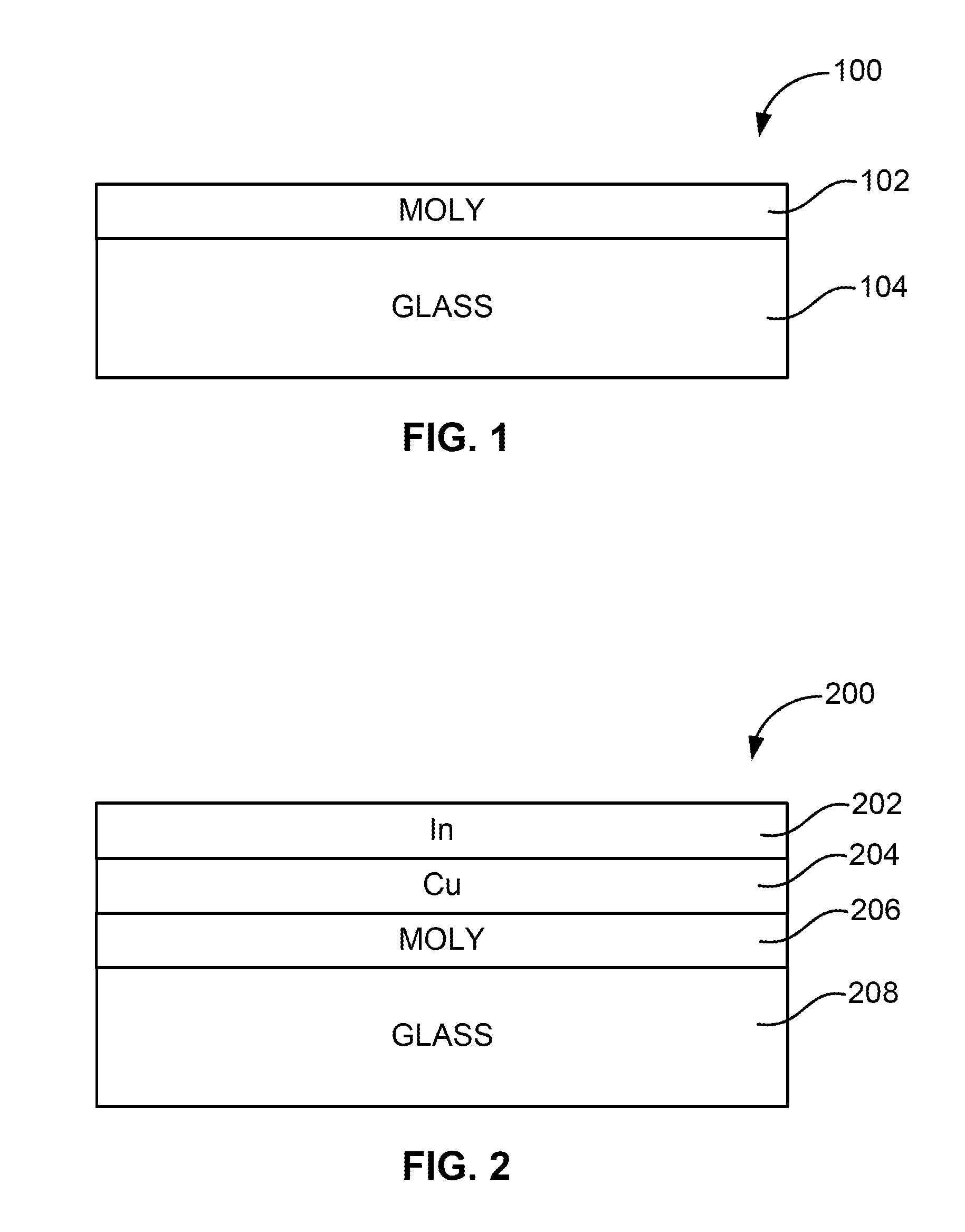

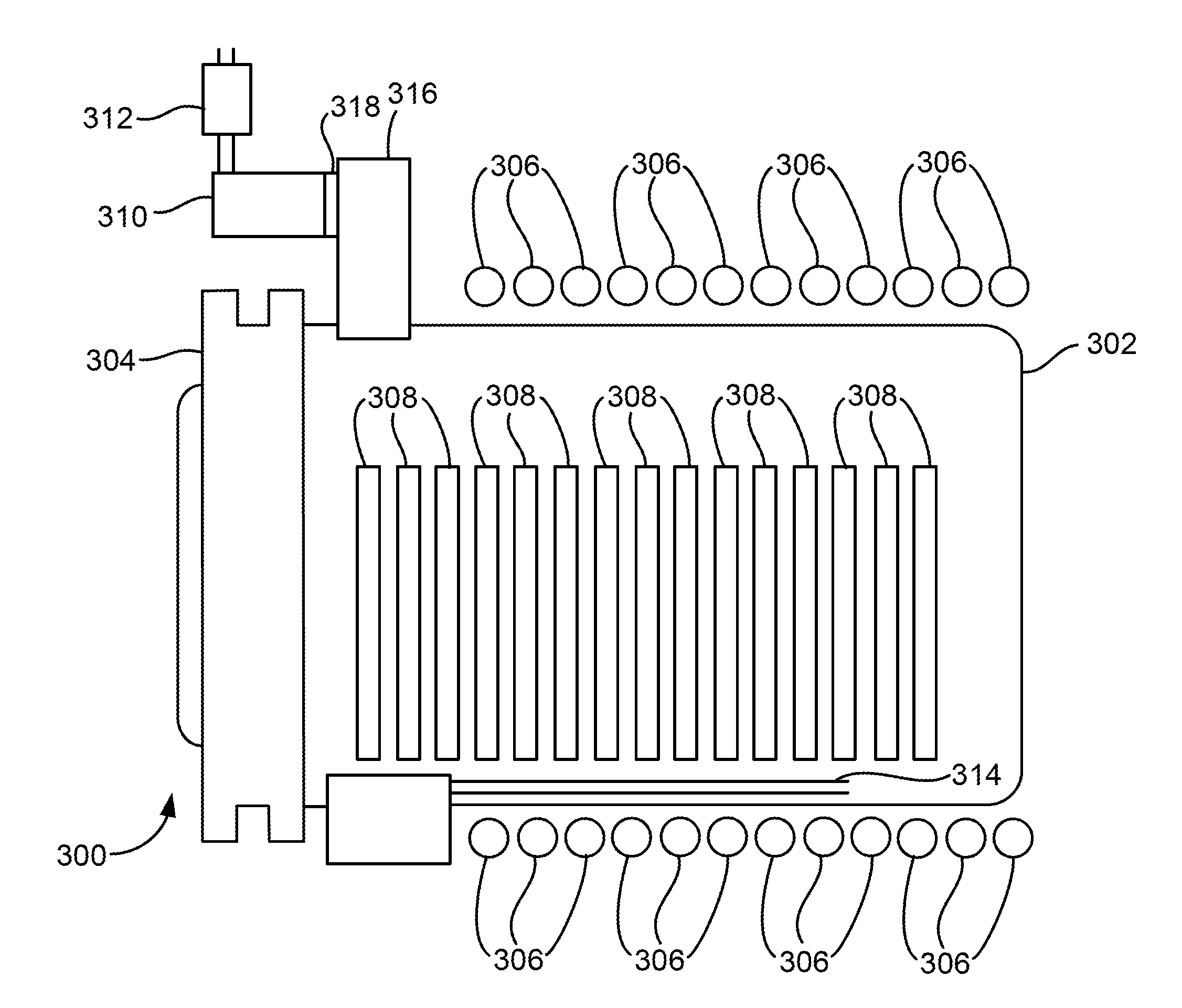

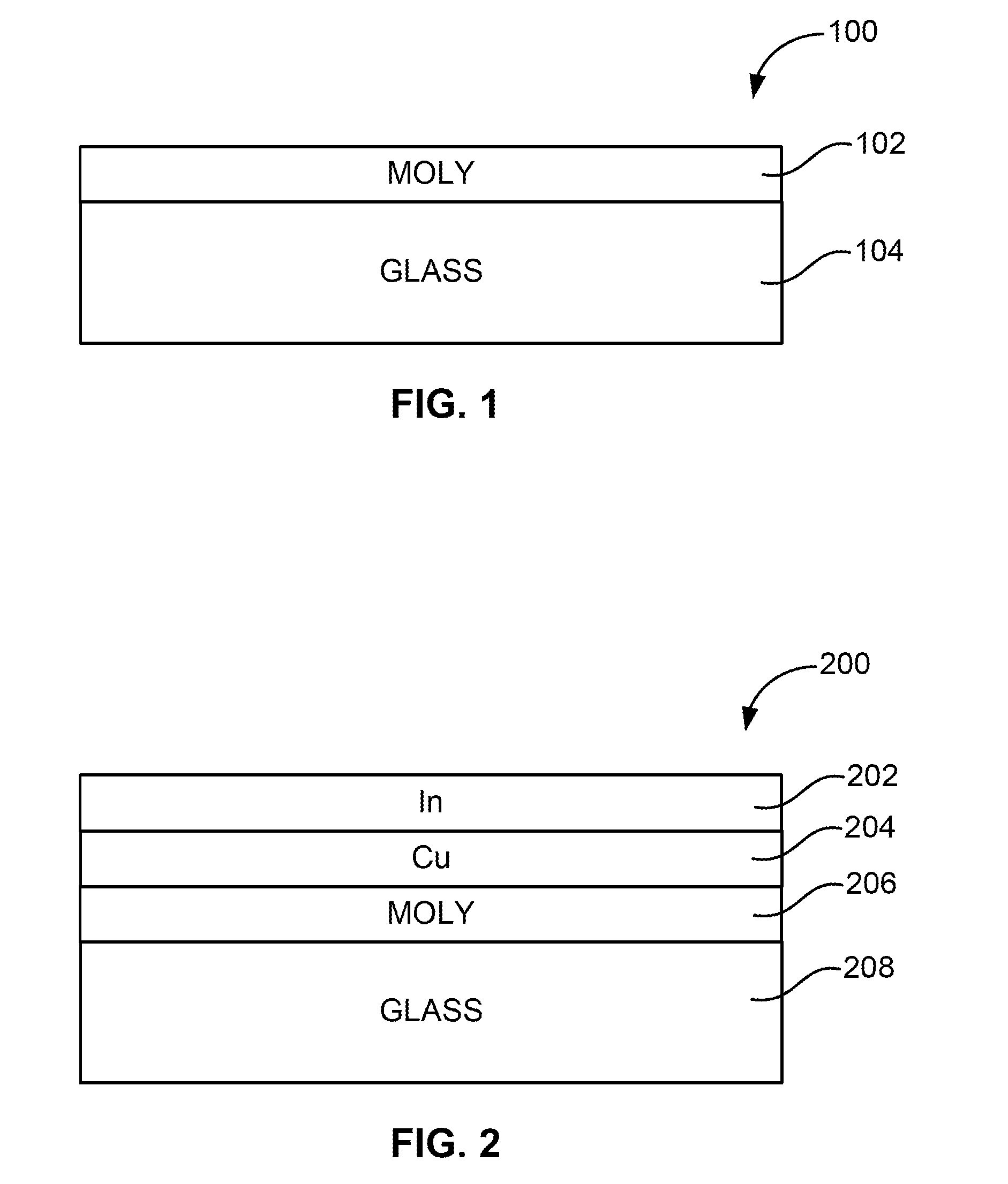

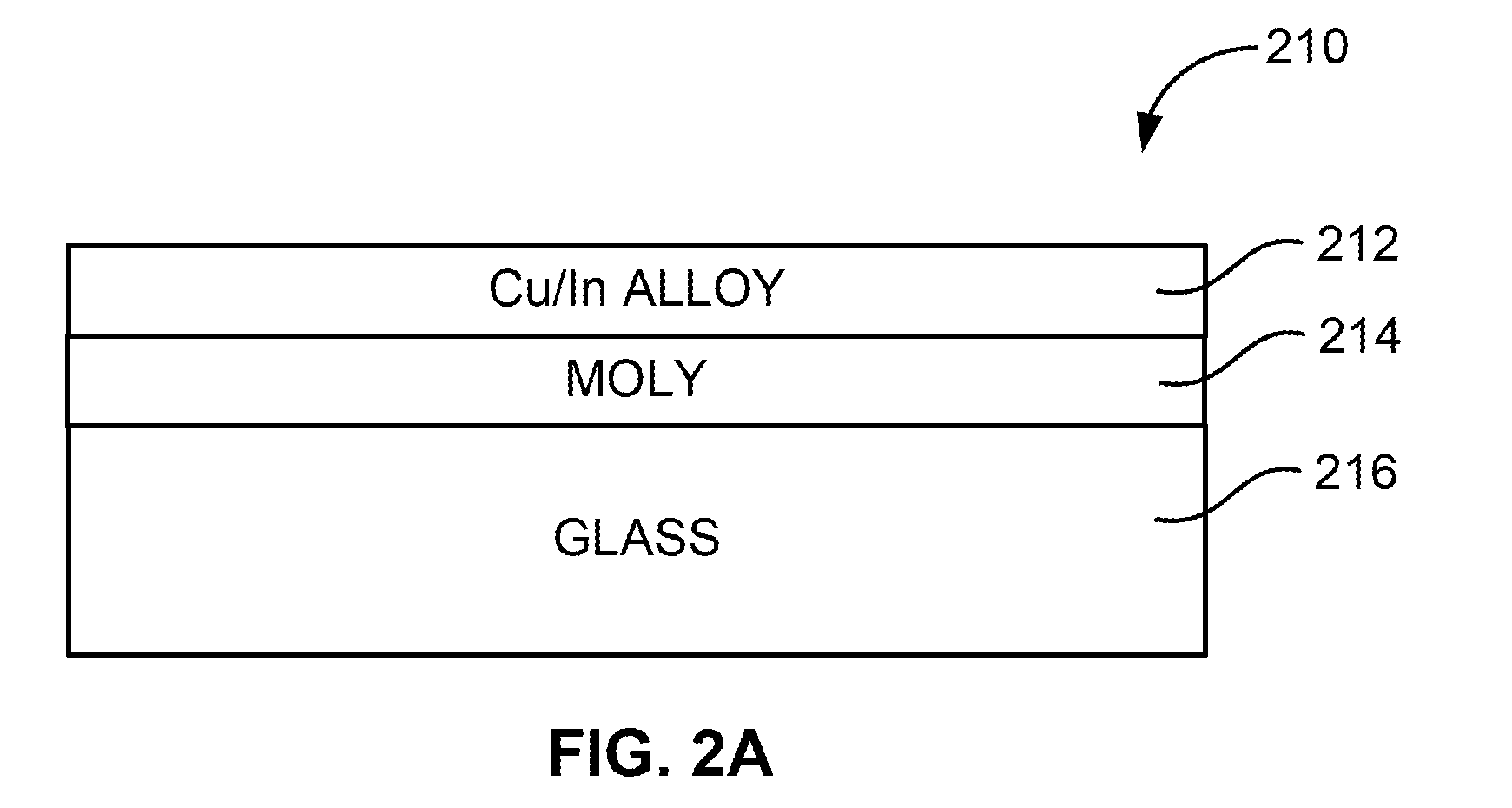

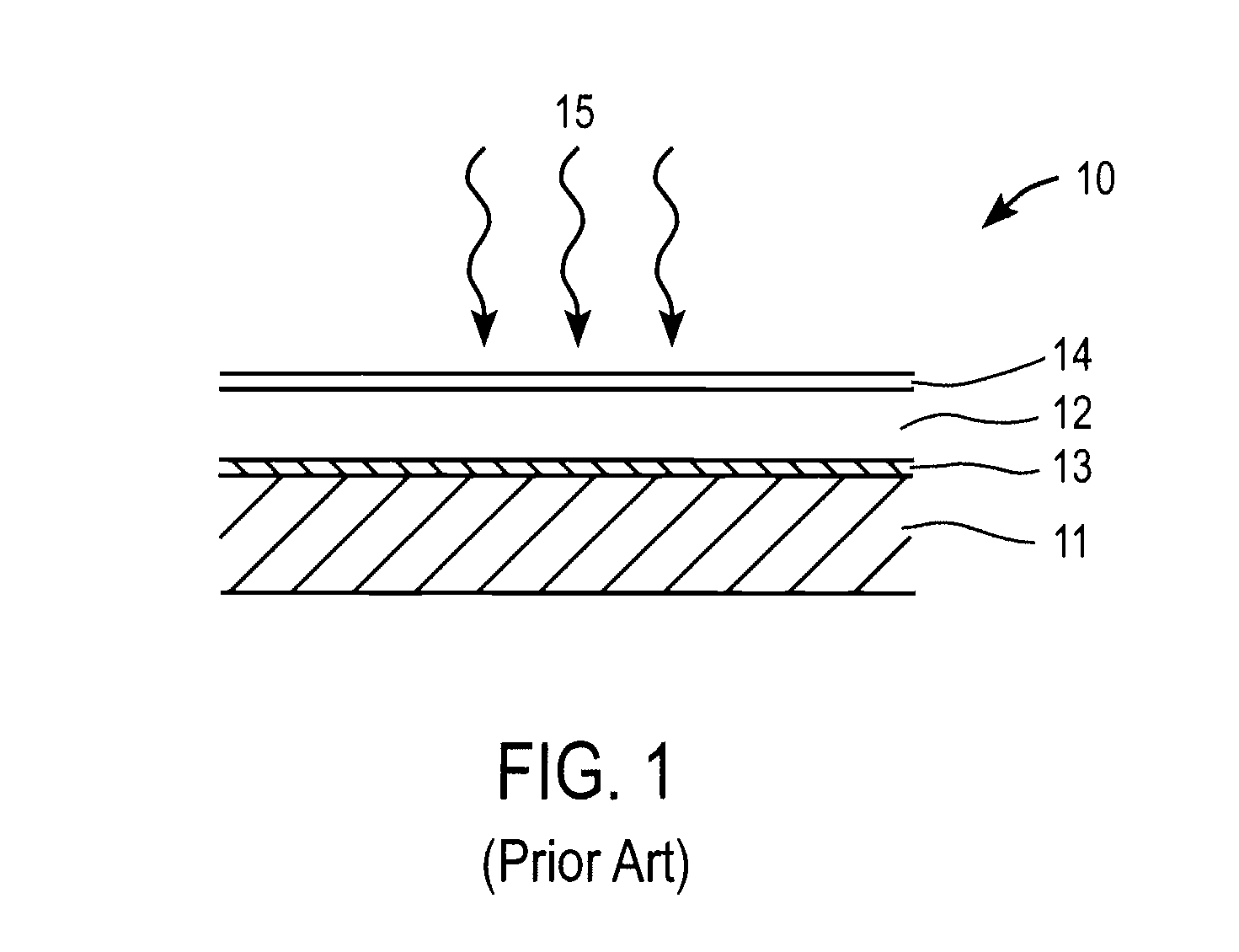

Thermal management and method for large scale processing of CIS and/or CIGS based thin films overlying glass substrates

InactiveUS7910399B1Implemented cost-effectivelyMaintain structural integrityFinal product manufactureSemiconductor/solid-state device manufacturingThermal energyIndium

The thermal management and method for large scale processing of CIS and / or CIGS based thin film overlaying glass substrates. According to an embodiment, the present invention provides a method for fabricating a copper indium diselenide semiconductor film. The method includes providing a plurality of substrates, each of the substrates having a copper and indium composite structure. The method also includes transferring the plurality of substrates into a furnace, each of the plurality of substrates provided in a vertical orientation with respect to a direction of gravity, the plurality of substrates being defined by a number N, where N is greater than 5. The method further includes introducing a gaseous species including a selenide species and a carrier gas into the furnace and transferring thermal energy into the furnace to increase a temperature from a first temperature to a second temperature, the second temperature ranging from about 350° C. to about 450° C. to at least initiate formation of a copper indium diselenide film from the copper and indium composite structure on each of the substrates.

Owner:CM MFG

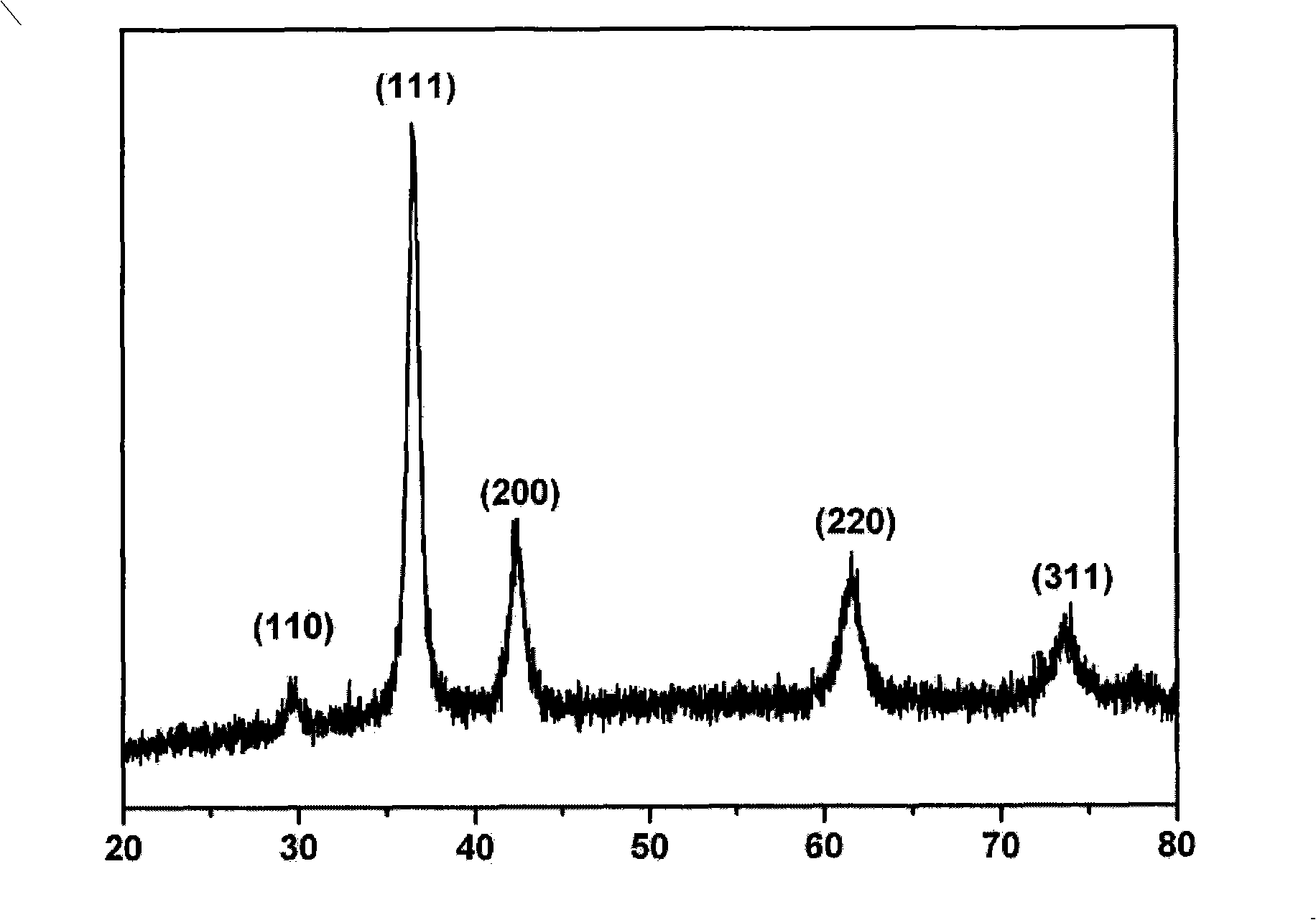

Synthesis of several metal selenides and tellurides as semiconductor material

InactiveCN1384047AOvercome the problems of high temperature, highly toxic raw materials, complicated process, etc.Low reaction temperatureSemiconductor/solid-state device manufacturingBinary selenium/tellurium compoundsSemiconductor materialsHydroxylamine

By using the soluble salt of transition metalz Zn, Cd, Pb, Mn, Co, Ni, Cu, Ag, Sb and Bi, selenious acid or its solutl salt, or antimonous acid or its soluble salt as raw material, and hydrazine hydrate, sodium borohydride, potassium borohydride, hydroxylamine or hydrazine sulfate as reductant, and through hydrothermal reduction reaction at 100-200 deg.c in a sealed container for 2 hr to 5 days, selenides or tellurides of the said metals as semiconductor material may be synthesized. Unlike available synthesis process, which needs high temperature, toxic feedstock and complex technological course, the present invention has the advantages of low-cost material, simple apparatus, easy control, good technological reproducibility, stable product quality, etc.

Owner:TSINGHUA UNIV

Thermal management and method for large scale processing of cis and/or cigs based thin films overlying glass substrates

ActiveUS20110070690A1Cost effectiveMaintain structural integrityFinal product manufactureSemiconductor/solid-state device manufacturingThermal energyIndium

The thermal management and method for large scale processing of CIS and / or CIGS based thin film overlaying glass substrates. According to an embodiment, the present invention provides a method for fabricating a copper indium diselenide semiconductor film. The method includes providing a plurality of substrates, each of the substrates having a copper and indium composite structure. The method also includes transferring the plurality of substrates into a furnace, each of the plurality of substrates provided in a vertical orientation with respect to a direction of gravity, the plurality of substrates being defined by a number N, where N is greater than 5. The method further includes introducing a gaseous species including a selenide species and a carrier gas into the furnace and transferring thermal energy into the furnace to increase a temperature from a first temperature to a second temperature, the second temperature ranging from about 350° C. to about 450° C. to at least initiate formation of a copper indium diselenide film from the copper and indium composite structure on each of the substrates.

Owner:CM MFG

Thermal management and method for large scale processing of cis and/or cigs based thin films overlying glass substrates

InactiveUS20110070683A1Cost effectiveMaintain structural integrityFinal product manufactureSemiconductor/solid-state device manufacturingThermal energyIndium

The thermal management and method for large scale processing of CIS and / or CIGS based thin film overlaying glass substrates. According to an embodiment, the present invention provides a method for fabricating a copper indium diselenide semiconductor film. The method includes providing a plurality of substrates, each of the substrates having a copper and indium composite structure. The method also includes transferring the plurality of substrates into a furnace, each of the plurality of substrates provided in a vertical orientation with respect to a direction of gravity, the plurality of substrates being defined by a number N, where N is greater than 5. The method further includes introducing a gaseous species including a selenide species and a carrier gas into the furnace and transferring thermal energy into the furnace to increase a temperature from a first temperature to a second temperature, the second temperature ranging from about 350° C. to about 450° C. to at least initiate formation of a copper indium diselenide film from the copper and indium composite structure on each of the substrates.

Owner:CM MFG

Thermal management and method for large scale processing of cis and/or cigs based thin films overlying glass substrates

InactiveUS20110070684A1Cost effectiveMaintain structural integrityFinal product manufactureSemiconductor/solid-state device manufacturingThermal energyIndium

The thermal management and method for large scale processing of CIS and / or CIGS based thin film overlaying glass substrates. According to an embodiment, the present invention provides a method for fabricating a copper indium diselenide semiconductor film. The method includes providing a plurality of substrates, each of the substrates having a copper and indium composite structure. The method also includes transferring the plurality of substrates into a furnace, each of the plurality of substrates provided in a vertical orientation with respect to a direction of gravity, the plurality of substrates being defined by a number N, where N is greater than 5. The method further includes introducing a gaseous species including a selenide species and a carrier gas into the furnace and transferring thermal energy into the furnace to increase a temperature from a first temperature to a second temperature, the second temperature ranging from about 350° C. to about 450° C. to at least initiate formation of a copper indium diselenide film from the copper and indium composite structure on each of the substrates.

Owner:CM MFG

Thermal management and method for large scale processing of cis and/or cigs based thin films overlying glass substrates

InactiveUS20110070685A1Cost effectiveMaintain structural integrityFinal product manufactureSemiconductor/solid-state device manufacturingThermal energyIndium

The thermal management and method for large scale processing of CIS and / or CIGS based thin film overlaying glass substrates. According to an embodiment, the present invention provides a method for fabricating a copper indium diselenide semiconductor film. The method includes providing a plurality of substrates, each of the substrates having a copper and indium composite structure. The method also includes transferring the plurality of substrates into a furnace, each of the plurality of substrates provided in a vertical orientation with respect to a direction of gravity, the plurality of substrates being defined by a number N, where N is greater than 5. The method further includes introducing a gaseous species including a selenide species and a carrier gas into the furnace and transferring thermal energy into the furnace to increase a temperature from a first temperature to a second temperature, the second temperature ranging from about 350° C. to about 450° C. to at least initiate formation of a copper indium diselenide film from the copper and indium composite structure on each of the substrates.

Owner:CM MFG

Thermal management and method for large scale processing of cis and/or cigs based thin films overlying glass substrates

InactiveUS20110070682A1Cost effectiveMaintain structural integrityFinal product manufactureSemiconductor/solid-state device manufacturingThermal energyIndium

Owner:CM MFG

Thermal management and method for large scale processing of cis and/or cigs based thin films overlying glass substrates

ActiveUS20110070688A1Cost effectiveMaintain structural integrityFinal product manufactureSemiconductor/solid-state device manufacturingThermal energyIndium

Owner:CM MFG

Thermal management and method for large scale processing of cis and/or cigs based thin films overlying glass substrates

InactiveUS20110070687A1Cost effectiveMaintain structural integrityFinal product manufactureSemiconductor/solid-state device manufacturingThermal energyIndium

The thermal management and method for large scale processing of CIS and / or CIGS based thin film overlaying glass substrates. According to an embodiment, the present invention provides a method for fabricating a copper indium diselenide semiconductor film. The method includes providing a plurality of substrates, each of the substrates having a copper and indium composite structure. The method also includes transferring the plurality of substrates into a furnace, each of the plurality of substrates provided in a vertical orientation with respect to a direction of gravity, the plurality of substrates being defined by a number N, where N is greater than 5. The method further includes introducing a gaseous species including a selenide species and a carrier gas into the furnace and transferring thermal energy into the furnace to increase a temperature from a first temperature to a second temperature, the second temperature ranging from about 350° C. to about 450° C. to at least initiate formation of a copper indium diselenide film from the copper and indium composite structure on each of the substrates.

Owner:CM MFG

Thermal management and method for large scale processing of cis and/or cigs based thin films overlying glass substrates

ActiveUS20110070689A1Cost effectiveMaintain structural integrityFinal product manufactureSemiconductor/solid-state device manufacturingThermal energyIndium

Owner:CM MFG

Thermal management and method for large scale processing of cis and/or cigs based thin films overlying glass substrates

InactiveUS20110070686A1Cost effectiveMaintain structural integrityFinal product manufactureSemiconductor/solid-state device manufacturingThermal energyIndium

The thermal management and method for large scale processing of CIS and / or CIGS based thin film overlaying glass substrates. According to an embodiment, the present invention provides a method for fabricating a copper indium diselenide semiconductor film. The method includes providing a plurality of substrates, each of the substrates having a copper and indium composite structure. The method also includes transferring the plurality of substrates into a furnace, each of the plurality of substrates provided in a vertical orientation with respect to a direction of gravity, the plurality of substrates being defined by a number N, where N is greater than 5. The method further includes introducing a gaseous species including a selenide species and a carrier gas into the furnace and transferring thermal energy into the furnace to increase a temperature from a first temperature to a second temperature, the second temperature ranging from about 350° C. to about 450° C. to at least initiate formation of a copper indium diselenide film from the copper and indium composite structure on each of the substrates.

Owner:CM MFG

Thermal management and method for large scale processing of CIS and /or CIGS based thin films overlying glass substrates

InactiveUS7955891B2Cost effectiveMaintain structural integrityFinal product manufactureSemiconductor/solid-state device manufacturingThermal energyIndium

The thermal management and method for large scale processing of CIS and / or CIGS based thin film overlaying glass substrates. According to an embodiment, the present invention provides a method for fabricating a copper indium diselenide semiconductor film. The method includes providing a plurality of substrates, each of the substrates having a copper and indium composite structure. The method also includes transferring the plurality of substrates into a furnace, each of the plurality of substrates provided in a vertical orientation with respect to a direction of gravity, the plurality of substrates being defined by a number N, where N is greater than 5. The method further includes introducing a gaseous species including a selenide species and a carrier gas into the furnace and transferring thermal energy into the furnace to increase a temperature from a first temperature to a second temperature, the second temperature ranging from about 350° C. to about 450° C. to at least initiate formation of a copper indium diselenide film from the copper and indium composite structure on each of the substrates.

Owner:CM MFG

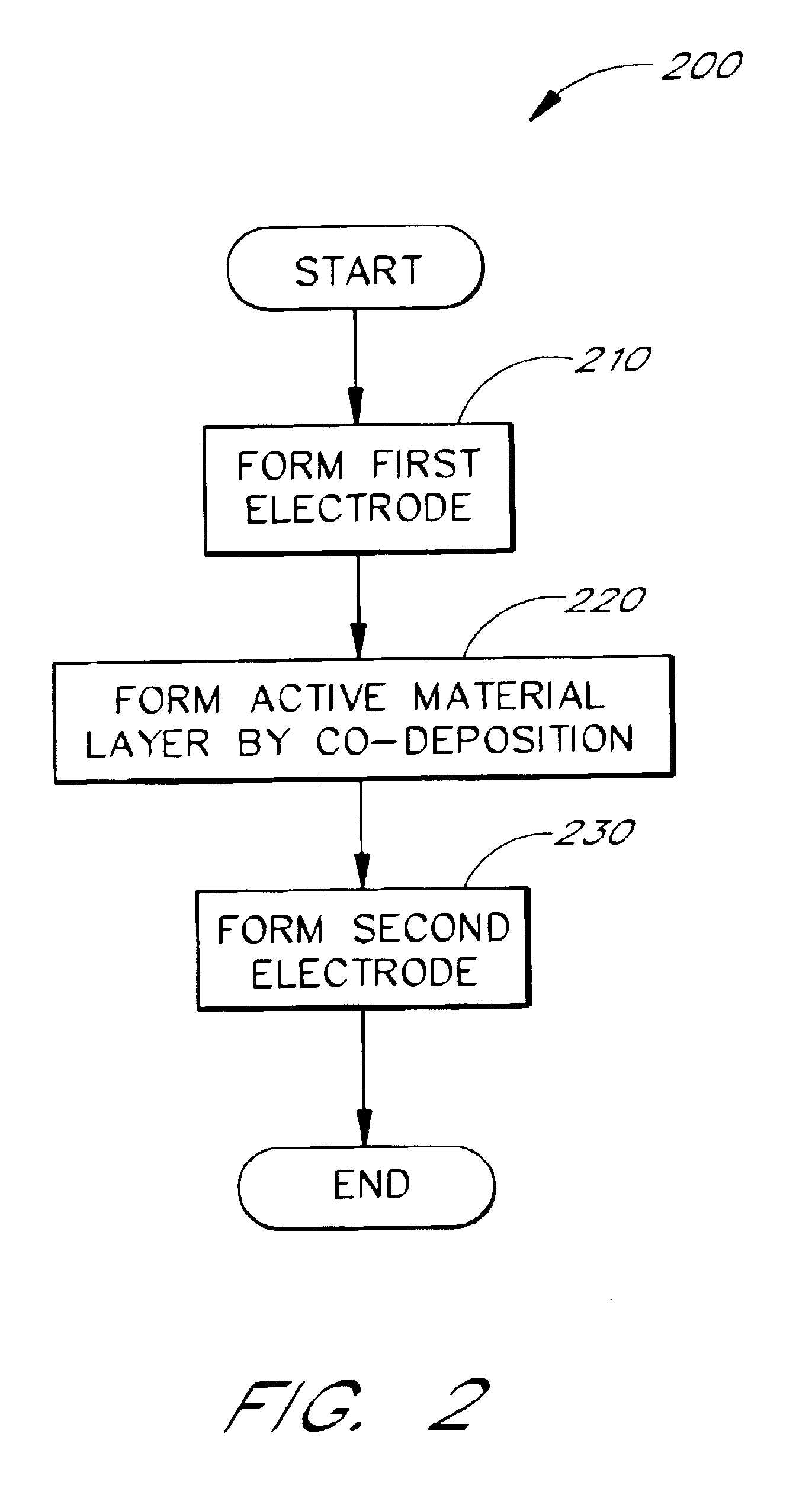

Methods and apparatus for resistance variable material cells

InactiveUS6849868B2Increase chanceFast switching speedSolid-state devicesPhotomechanical apparatusElectrical resistance and conductanceSulfur

The present invention is related to methods and apparatus to produce a memory cell or resistance variable material with improved data retention characteristics and higher switching speeds. In a memory cell according to an embodiment of the present invention, silver selenide and a chalcogenide glass, such as germanium selenide (GexSe(1−x)) are combined in an active layer, which supports the formation of conductive pathways in the presence of an electric potential applied between electrodes. Advantageously, embodiments of the present invention can be fabricated with relatively wide ranges for the thicknesses of the silver selenide and glass layers.

Owner:OVONYX MEMORY TECH LLC

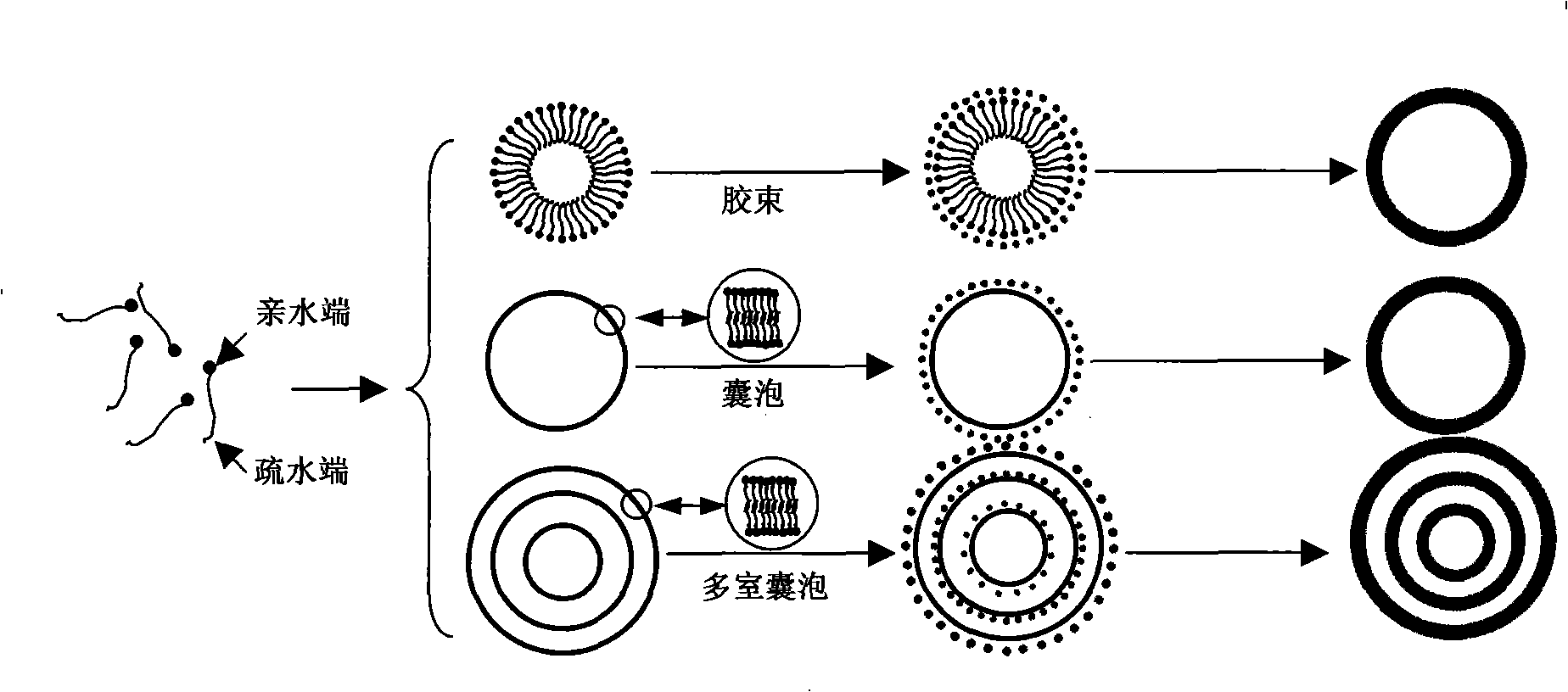

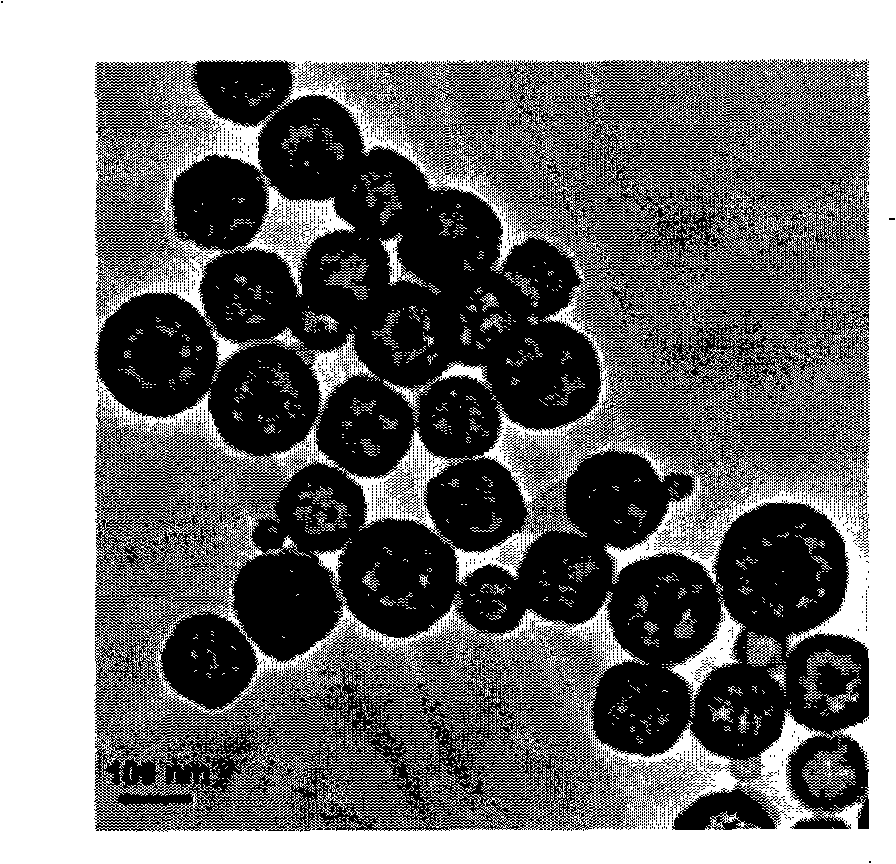

Method for producing multi-layer hollow pellet or stephanoporate pellet with multi-chamber vesicle mould plate method

InactiveCN101293192AEasy to makeControllable structureMicroballoon preparationMicrocapsule preparationActive agentSingle crystal

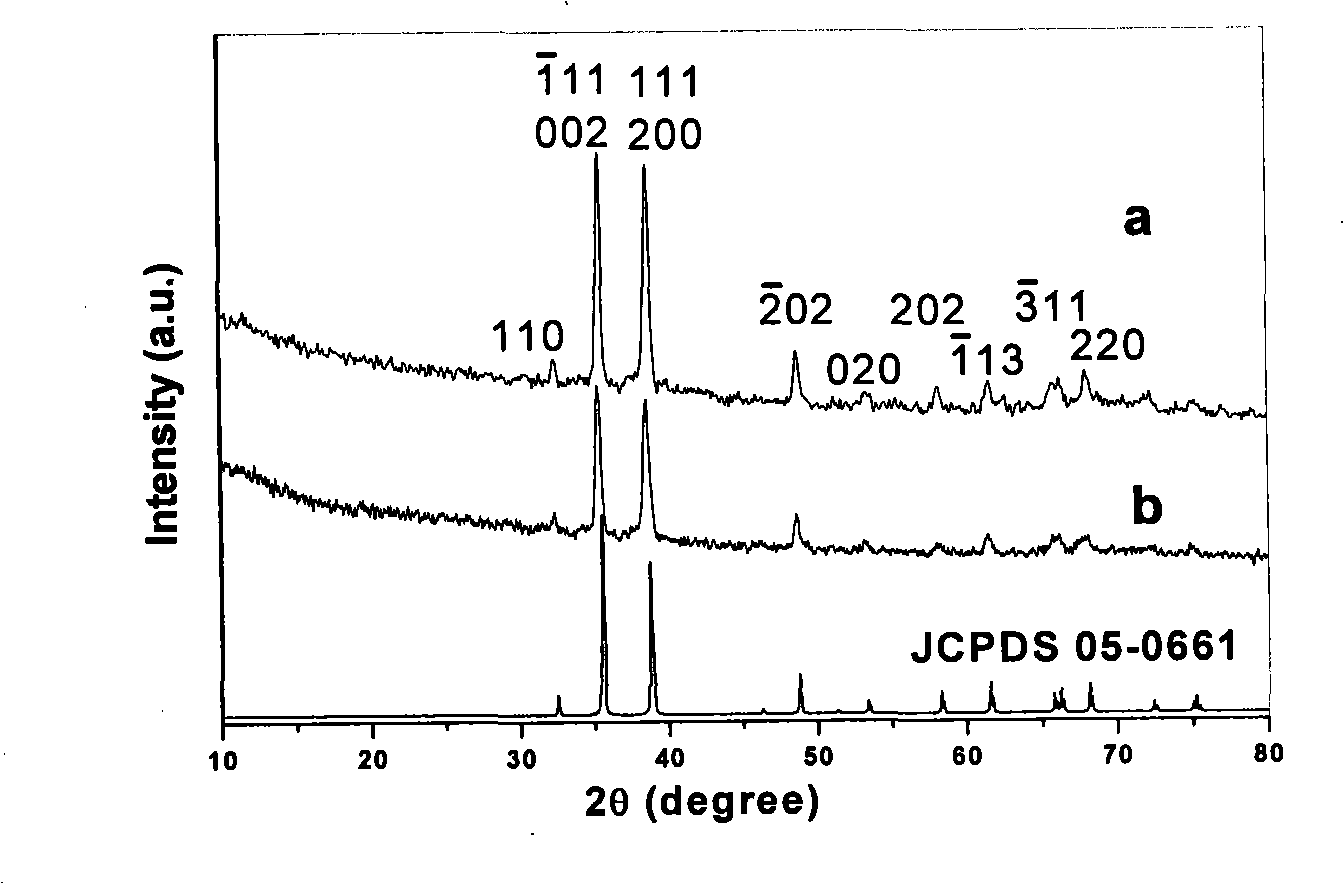

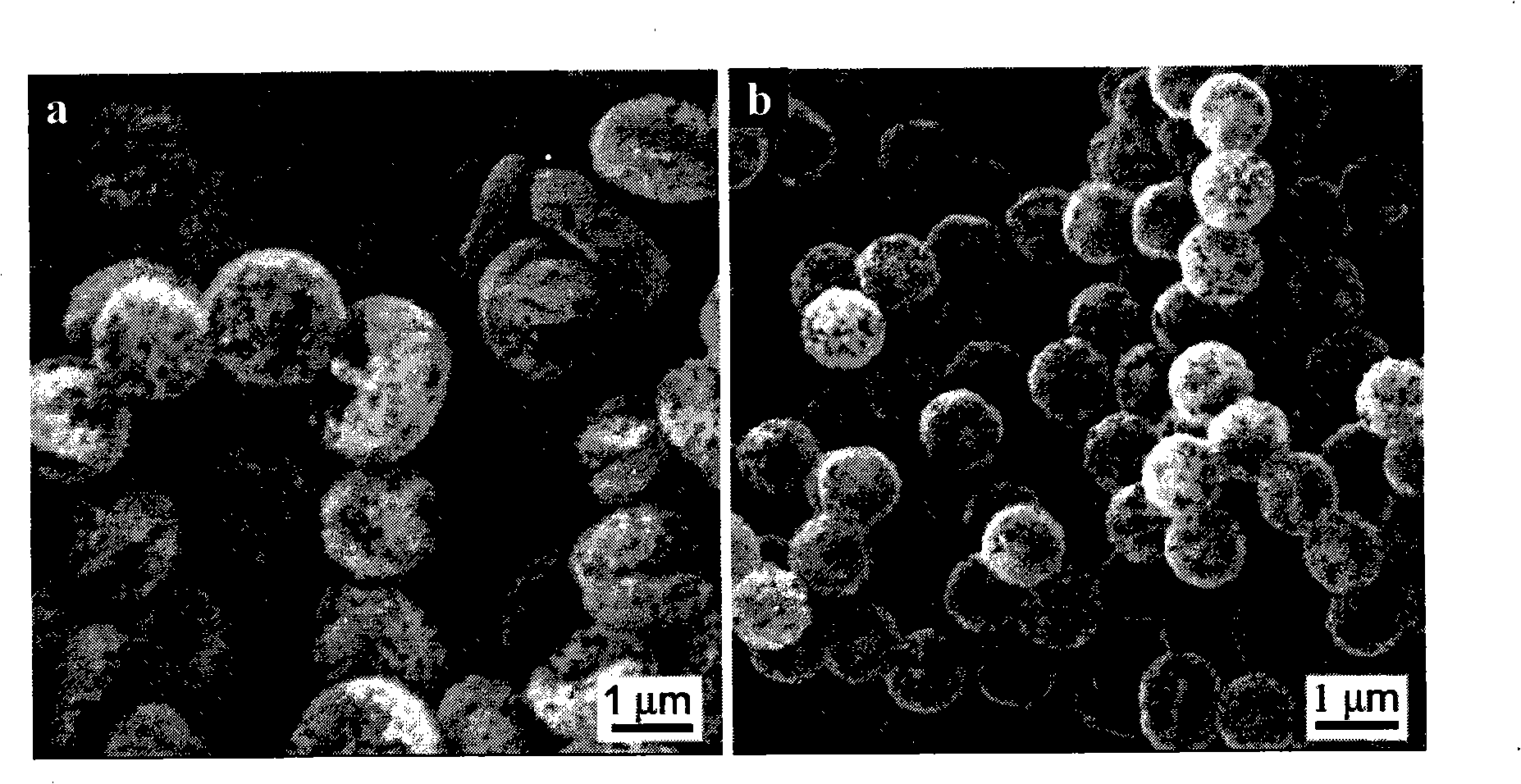

The present invention relates to a hollow sphere or porous sphere preparation method through vesicle and multi-chamber vesicle template method. The preparation method is characterized in that a surface active agent forms vesicle and multi-chamber as the soft template under certain conditions; inorganic material carries out nucleus growth on the surface of the soft template so as to copy the shape of the vesicle and multi-chamber vesicle and obtain a single-layer hollow sphere and multi-layer hollow sphere structure; due to different growing ways of crystal, the formed hollow sphere can be single crystal, polycrystal or multiaperture. The surface active agent is anion surface active agent, cation active agent or a mixer of the two surface active agents. The deposited inorganic material includes oxide, sulfide, simple metal substance, selenide, hydroxid or inorganic salts, which form core and grow on the surface of the vesicle and multi-chamber vesicle and finally obtain the single-layer and multi-layer hollow sphere structure and the porous sphere structure. Cu2O and ZnS hollow sphere or porous sphere is taken as the embodiment for detailed description.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

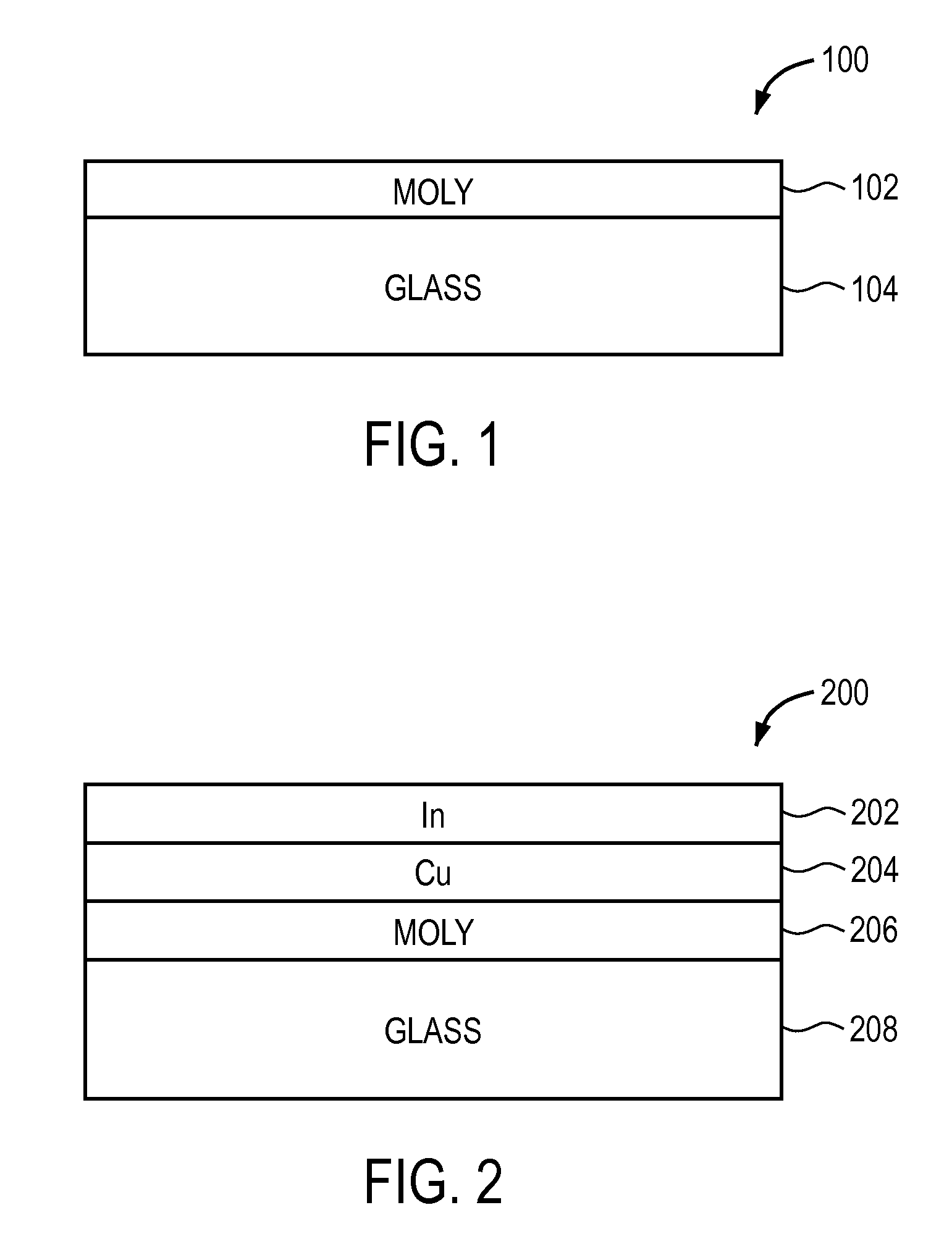

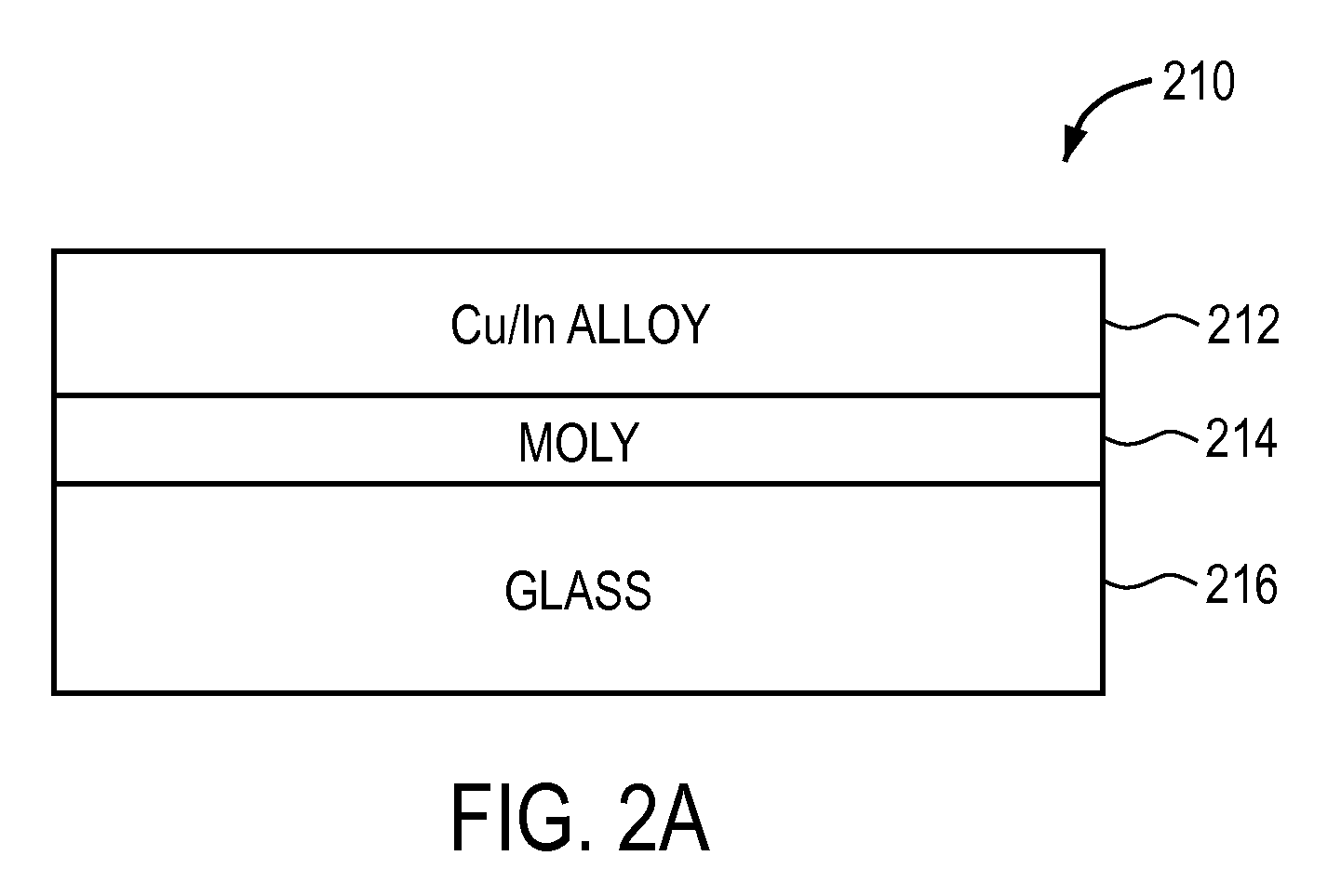

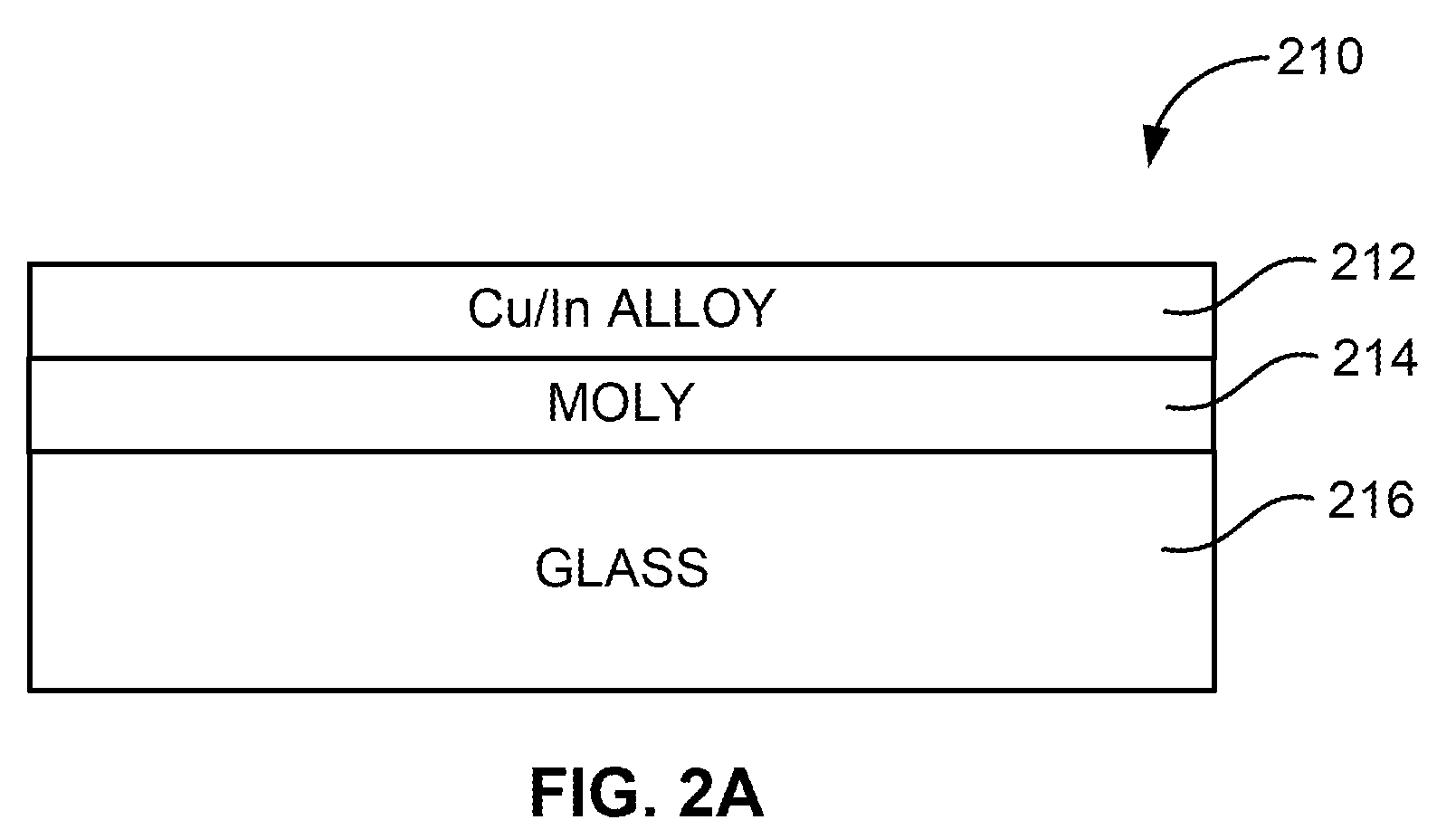

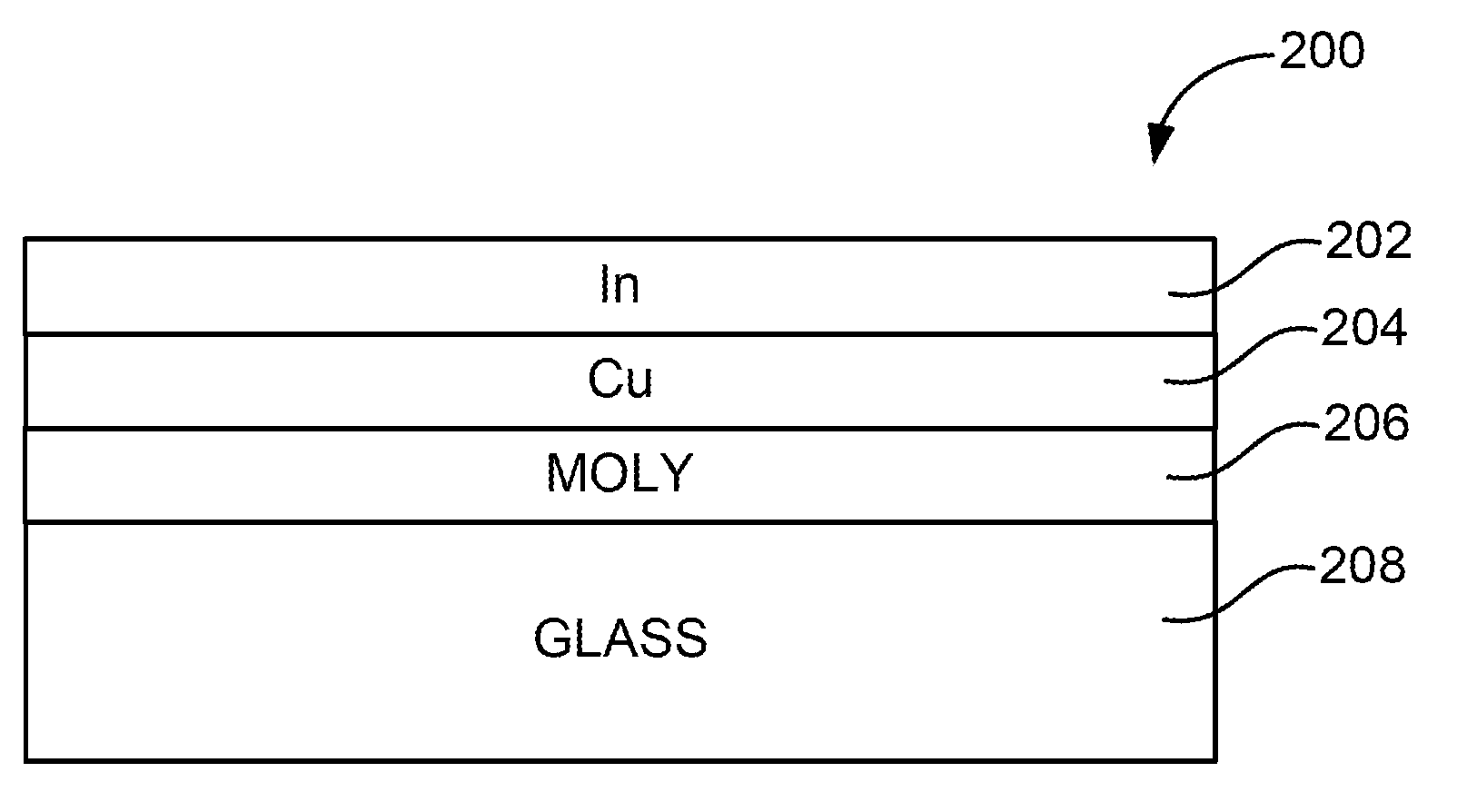

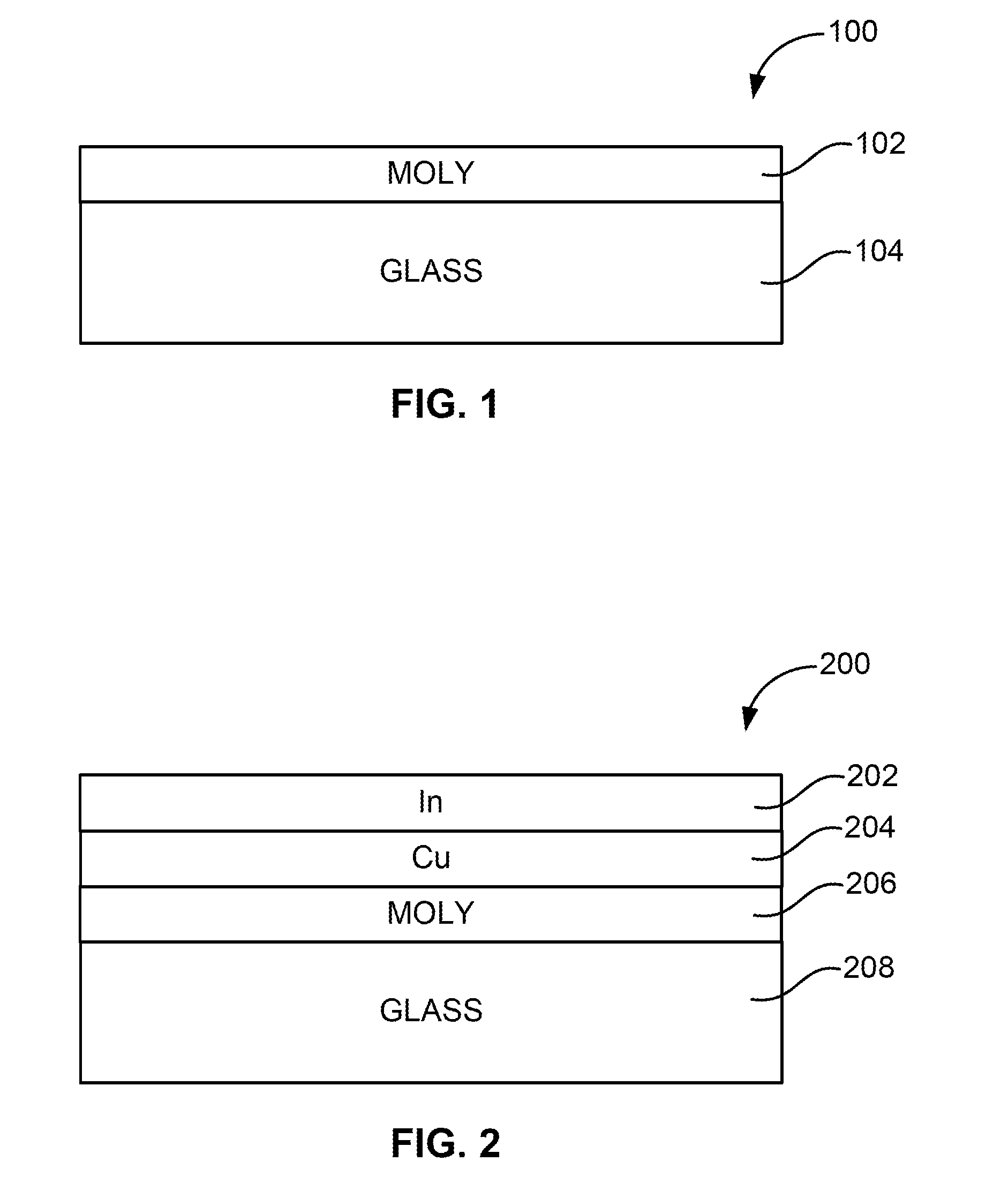

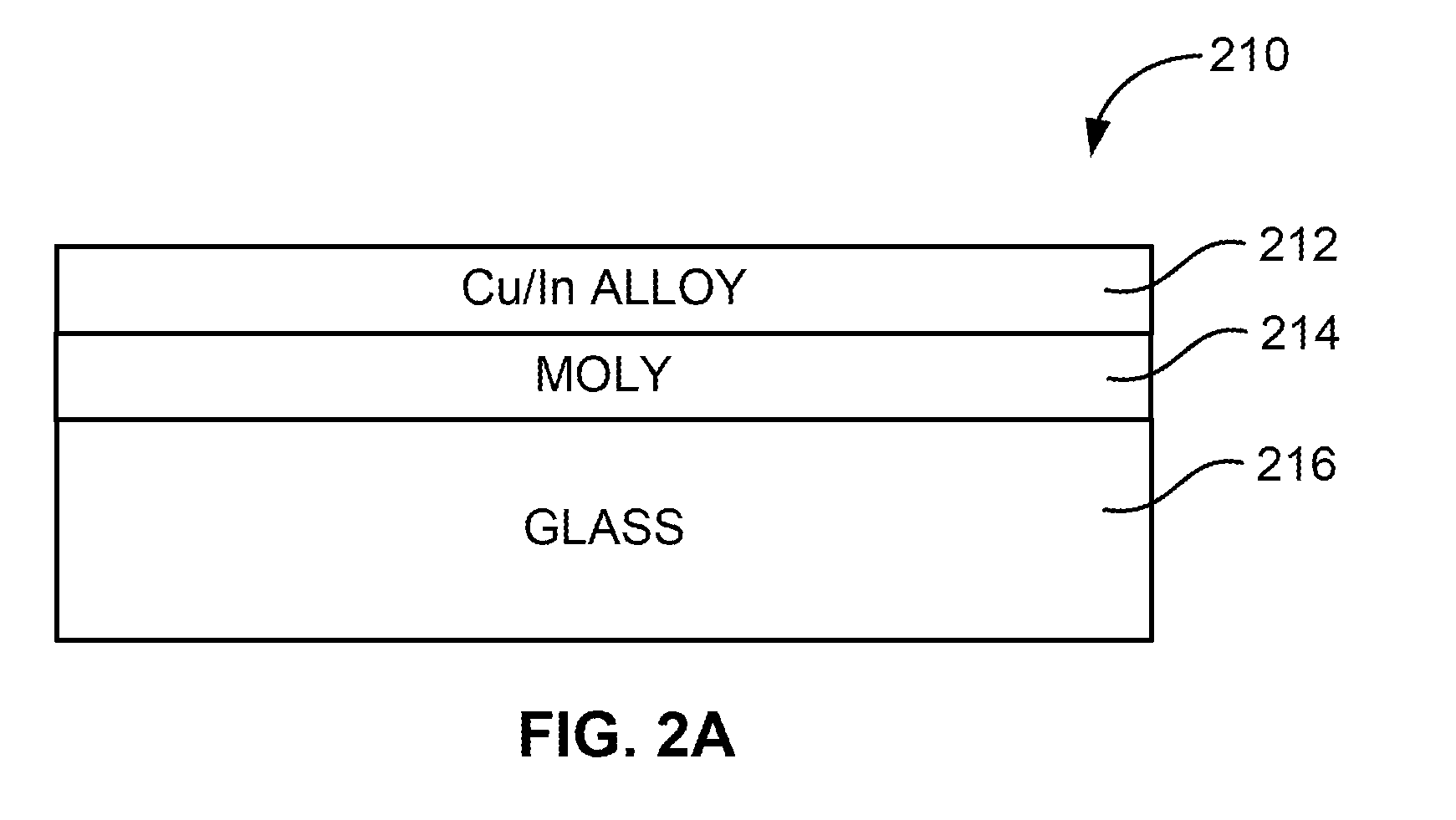

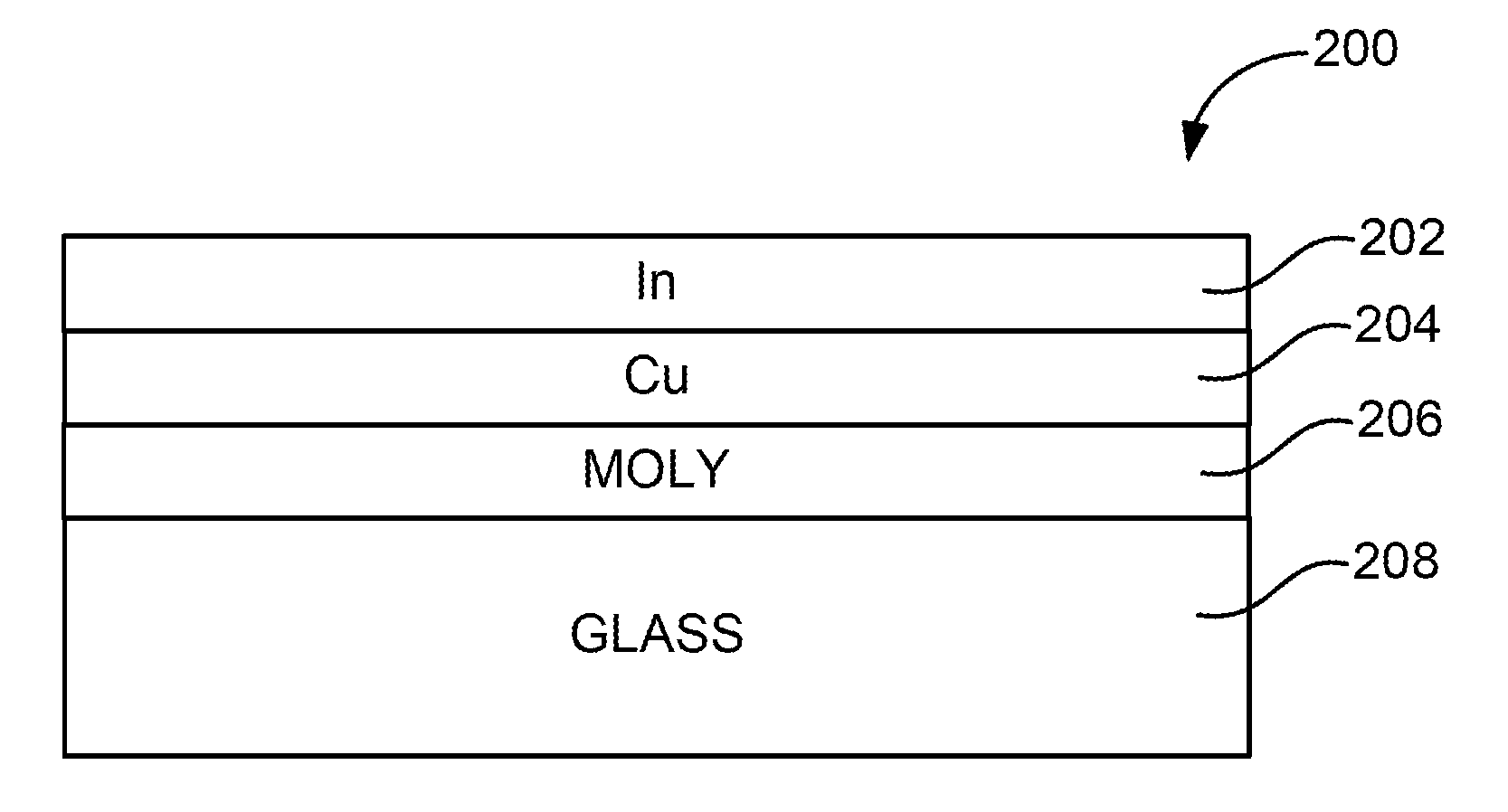

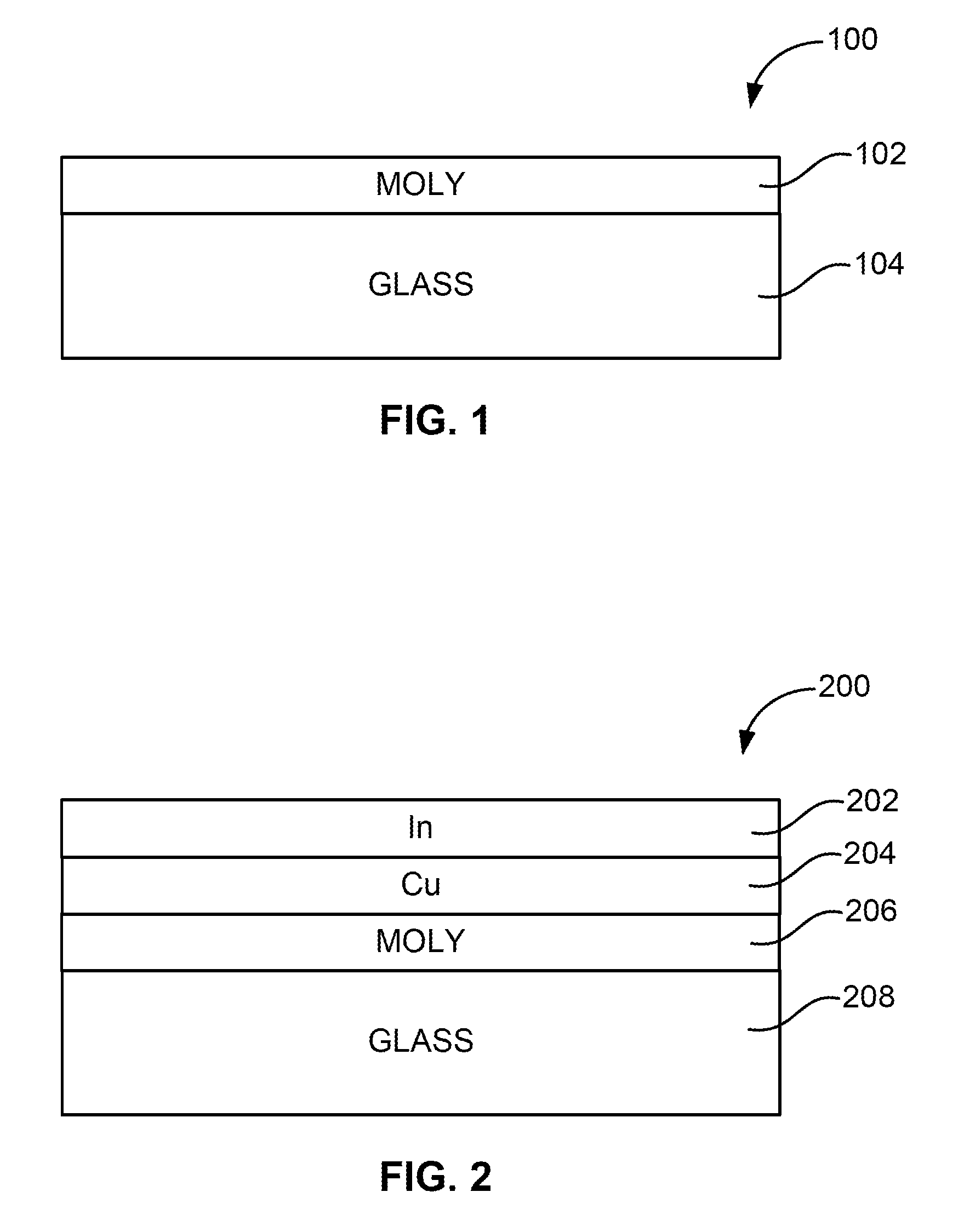

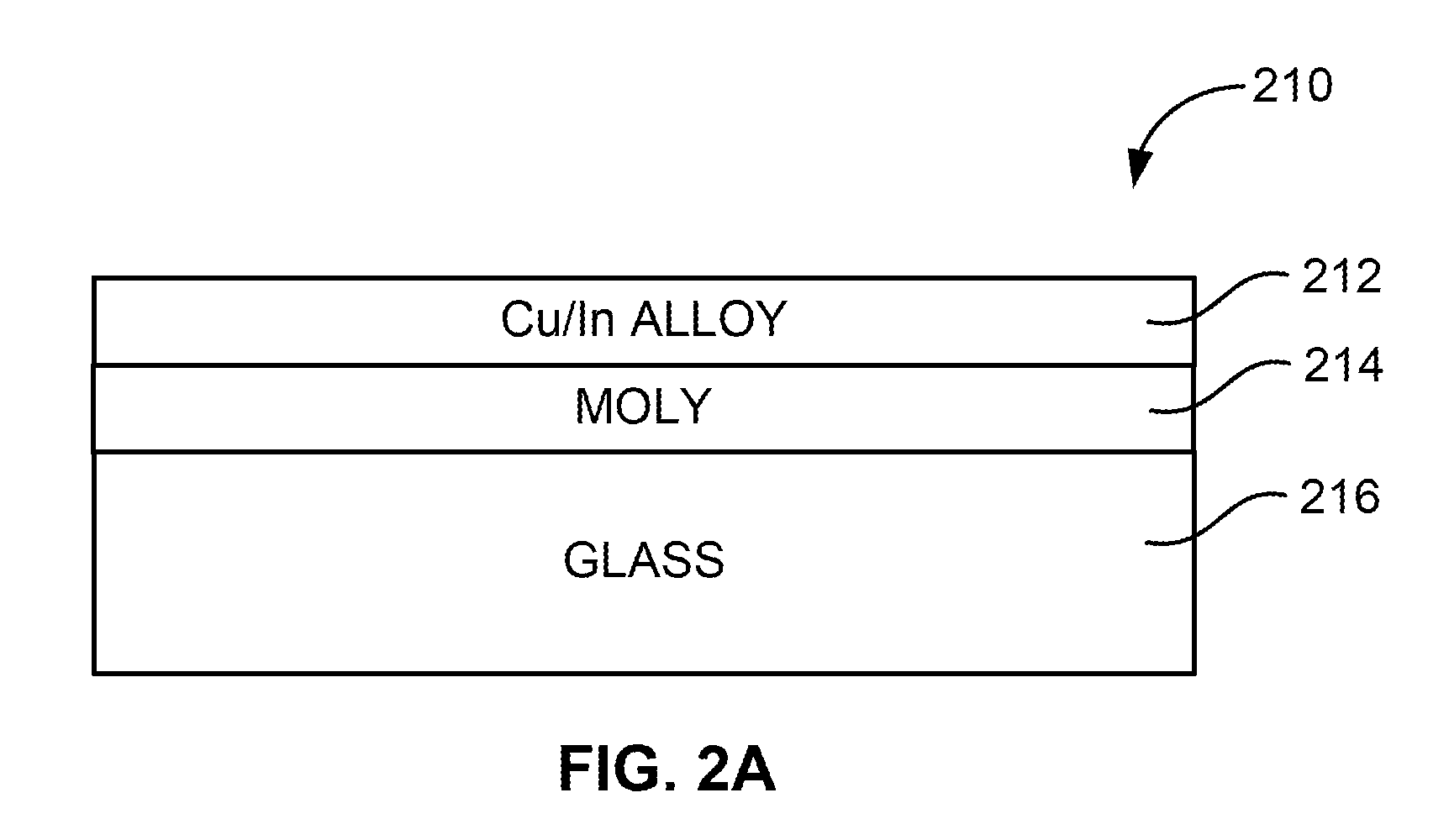

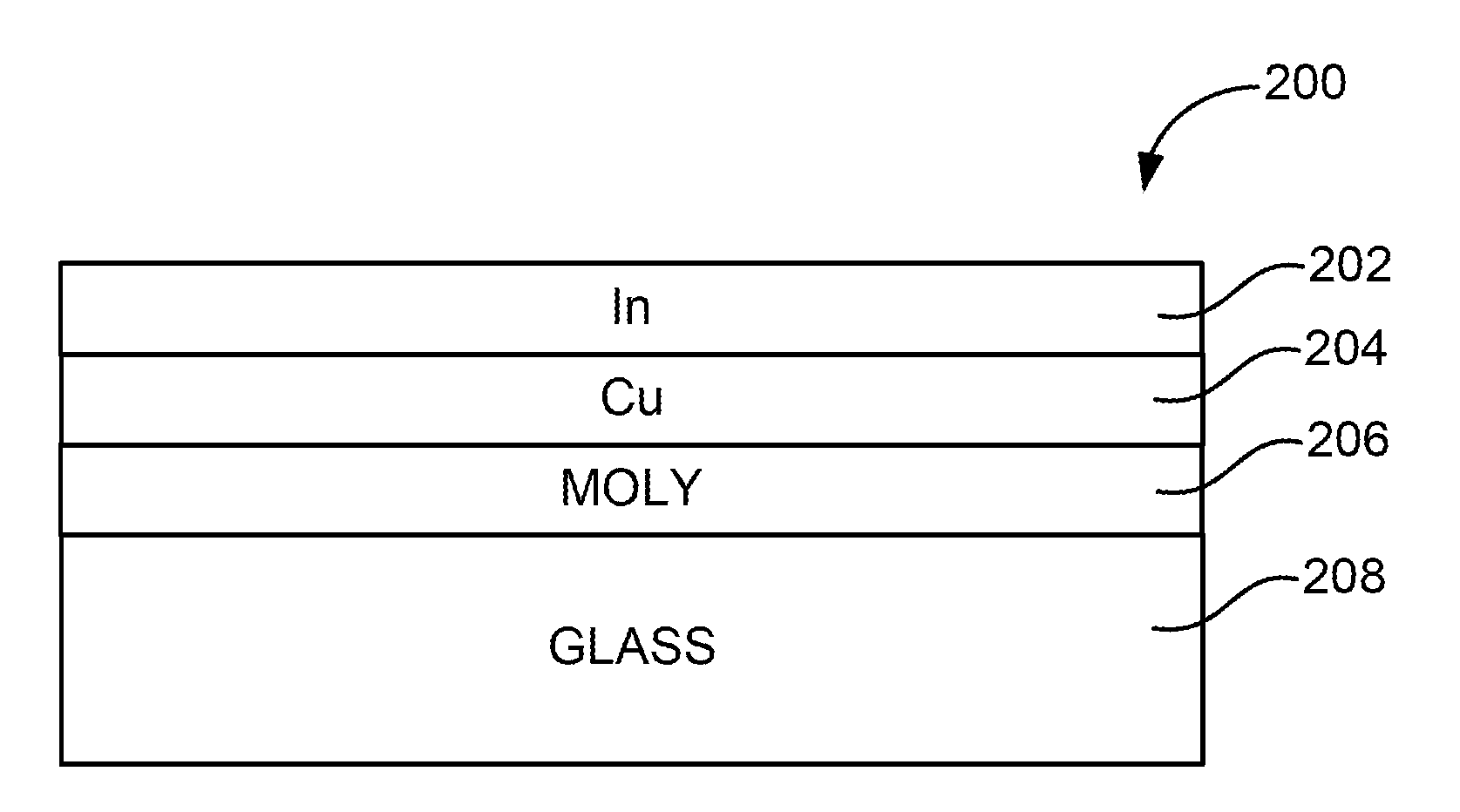

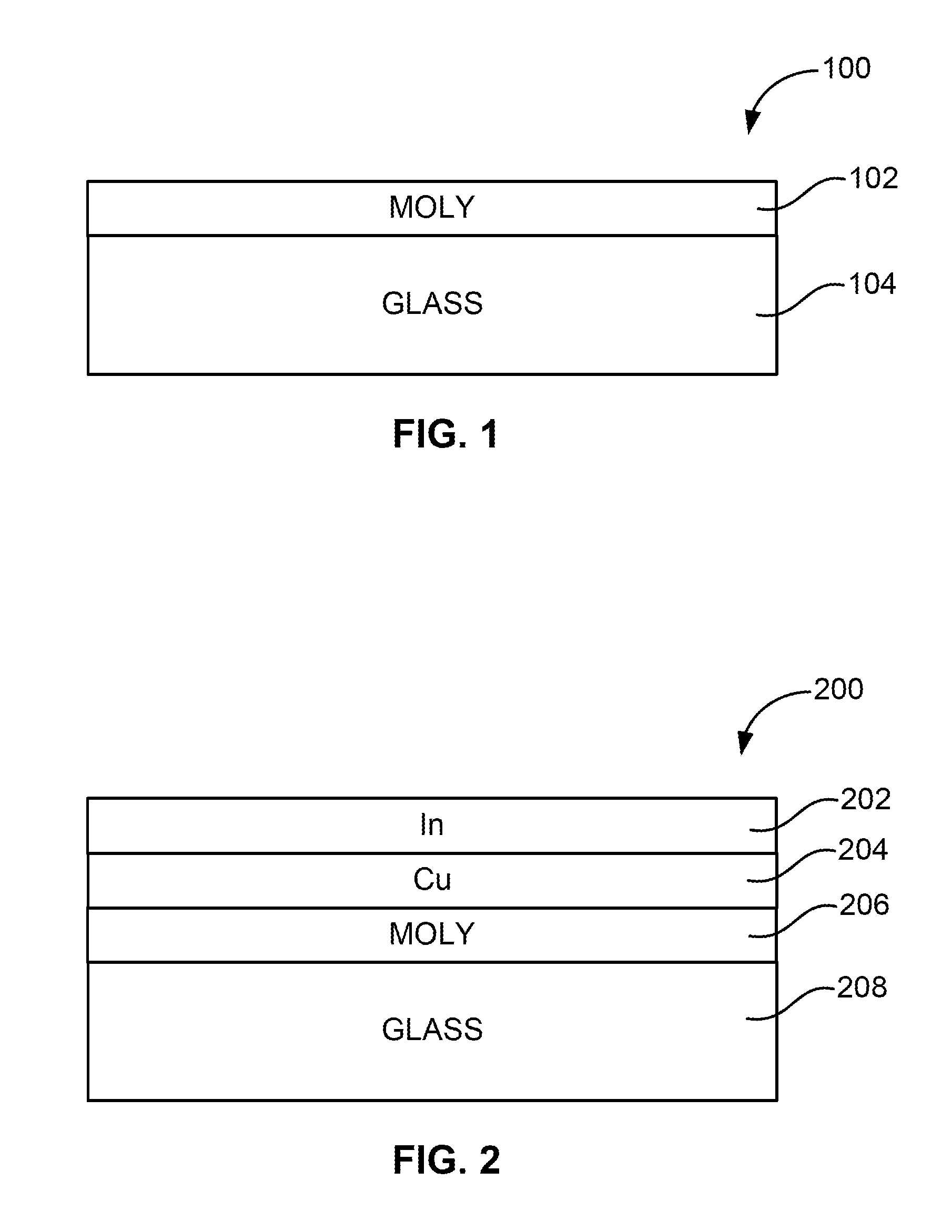

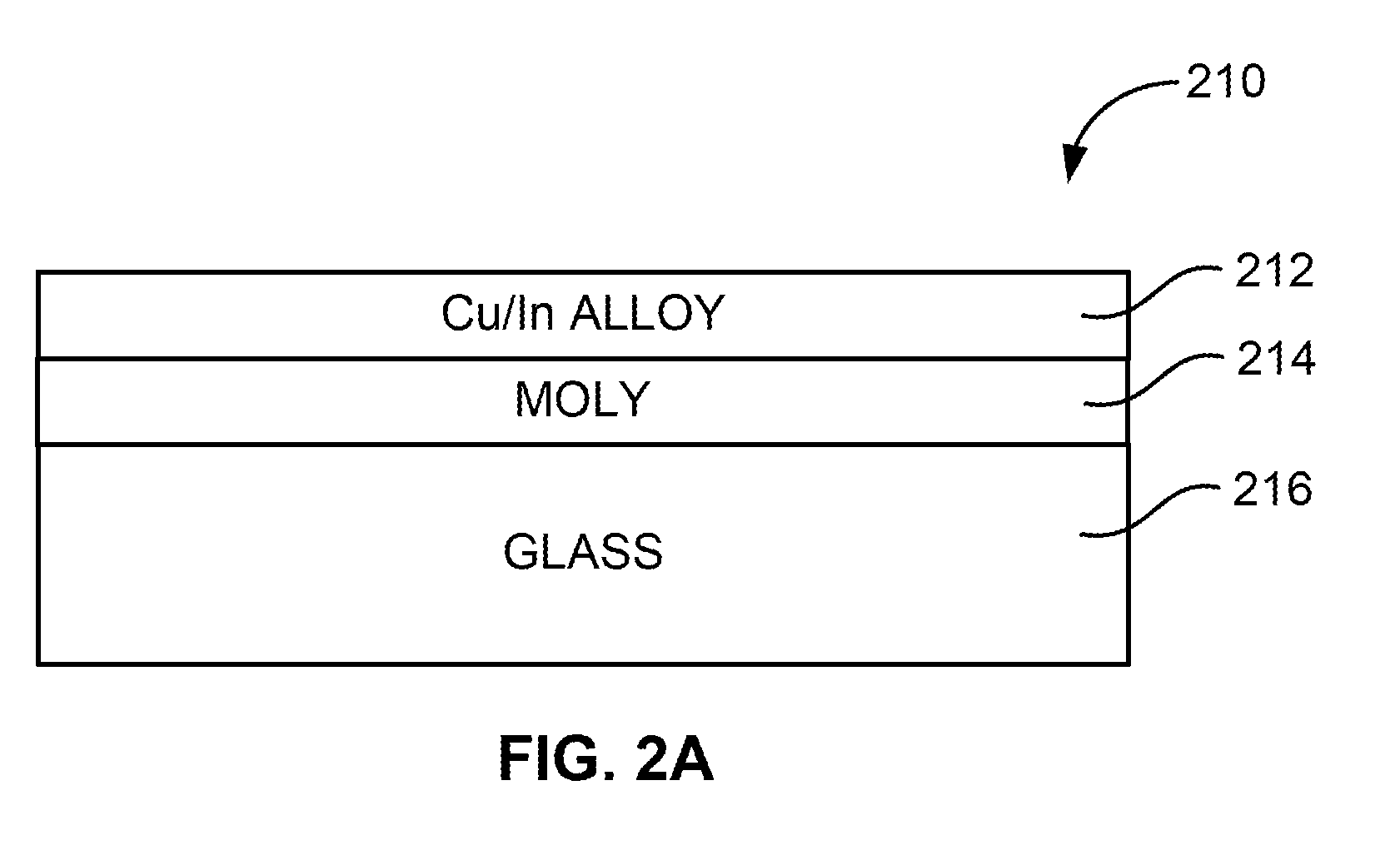

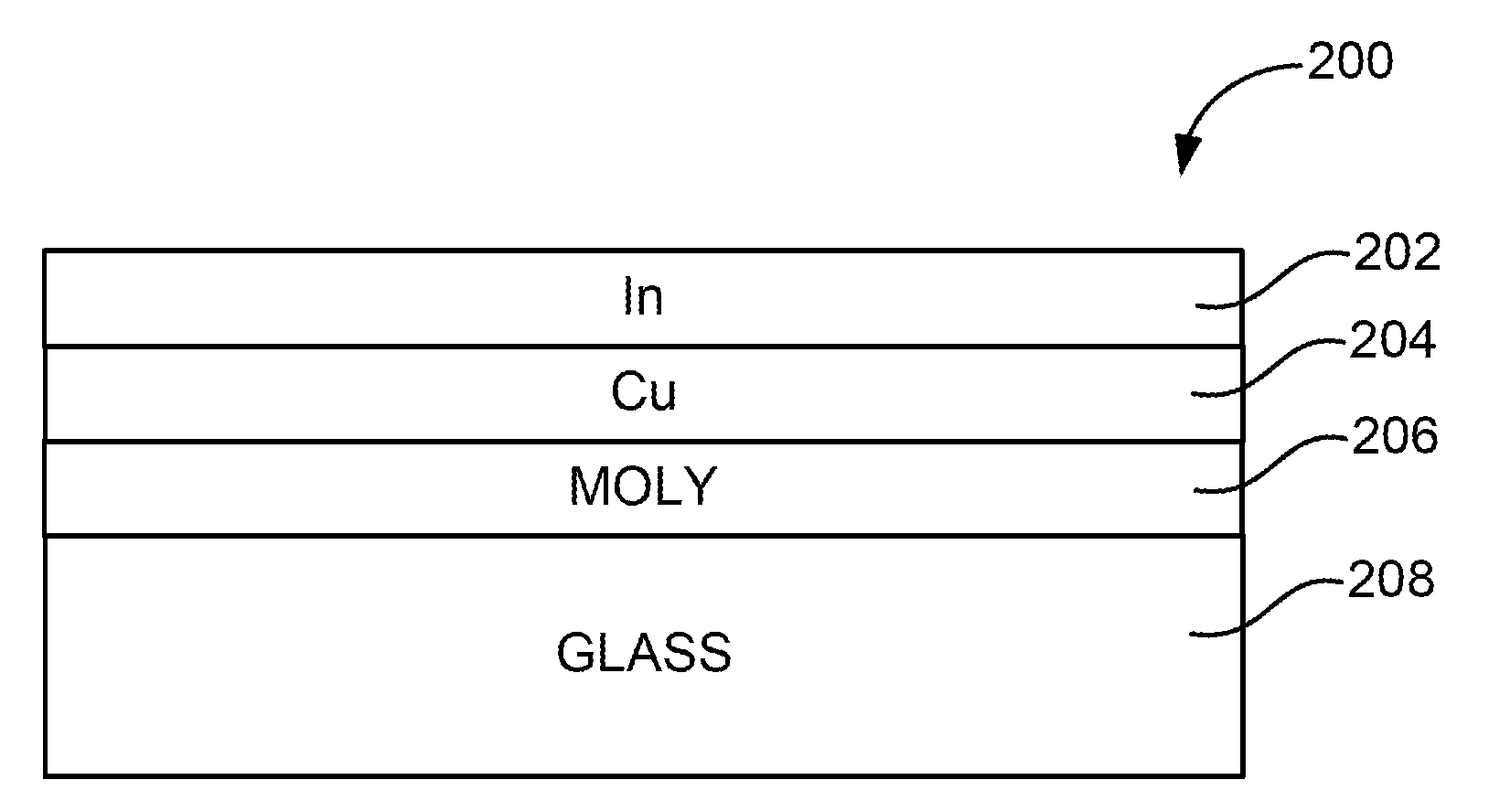

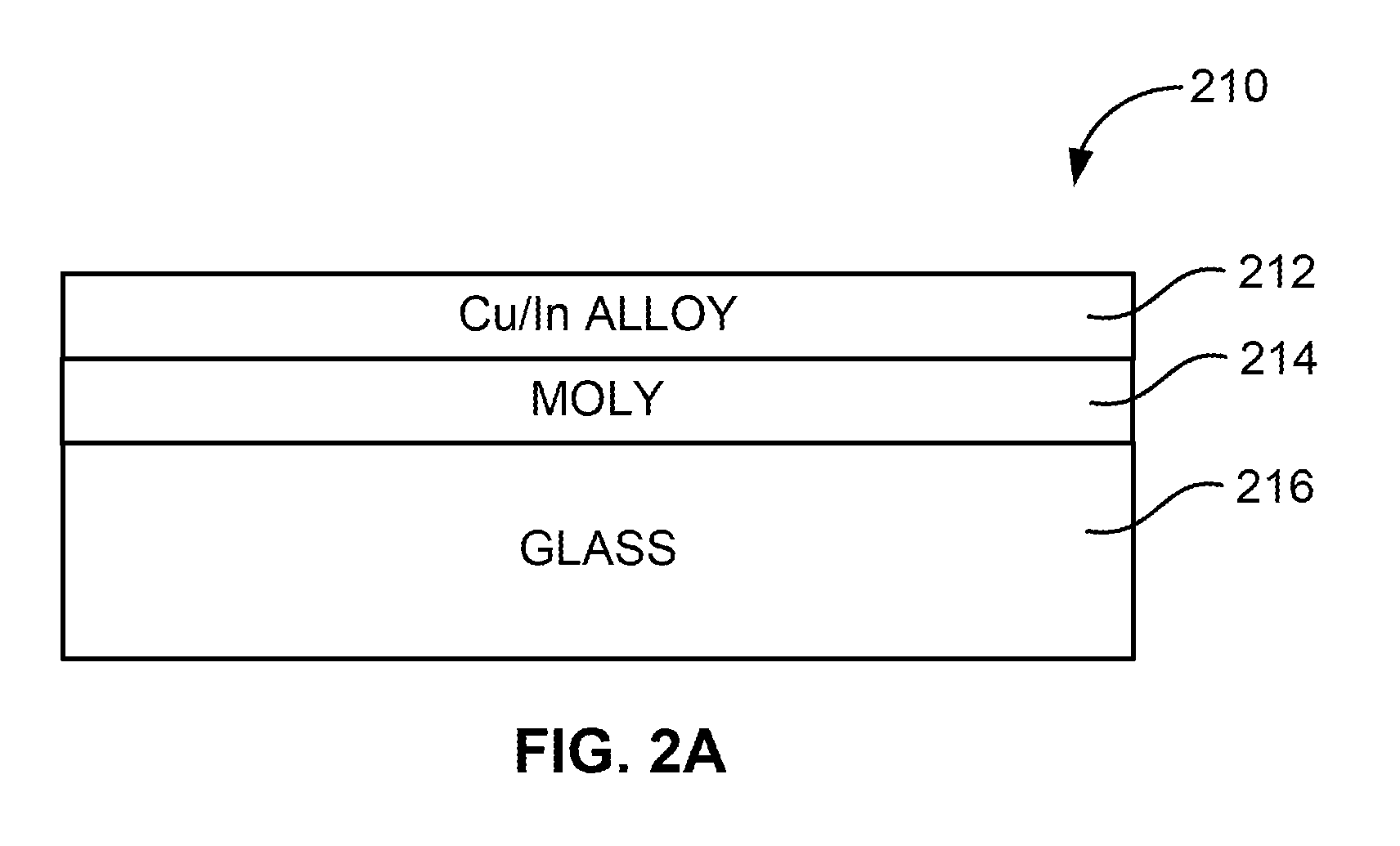

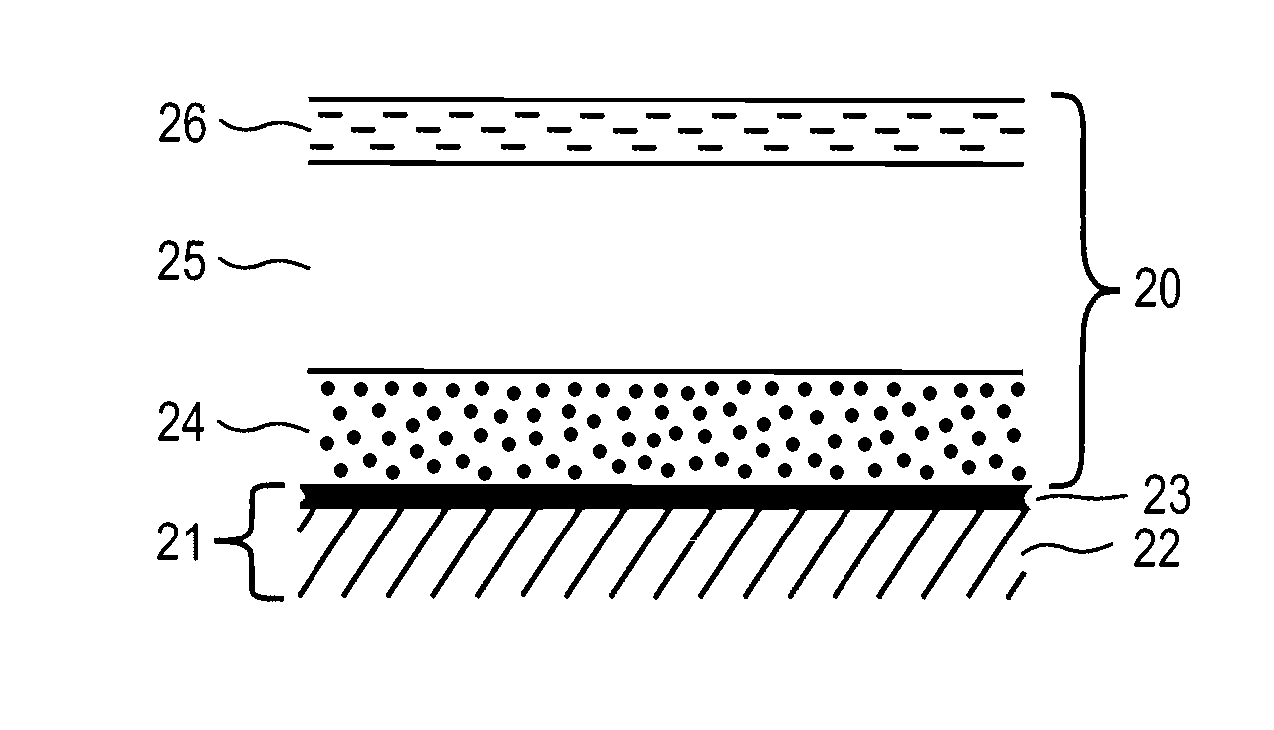

Precursor Containing Copper Indium And Gallium For Selenide (Sulfide) Compound Formation

InactiveUS20070166964A1Easy to useSemiconductor/solid-state device manufacturingPhotovoltaic energy generationIndiumSolar cell

The present invention relates to systems and methods for preparing metallic precursor thin films for the growth of semiconductor compounds to be used for radiation detector and solar cell fabrication. In one aspect, there is provided a method of efficiently using expensive materials necessary for the making of solar cells.

Owner:SOLOPOWER

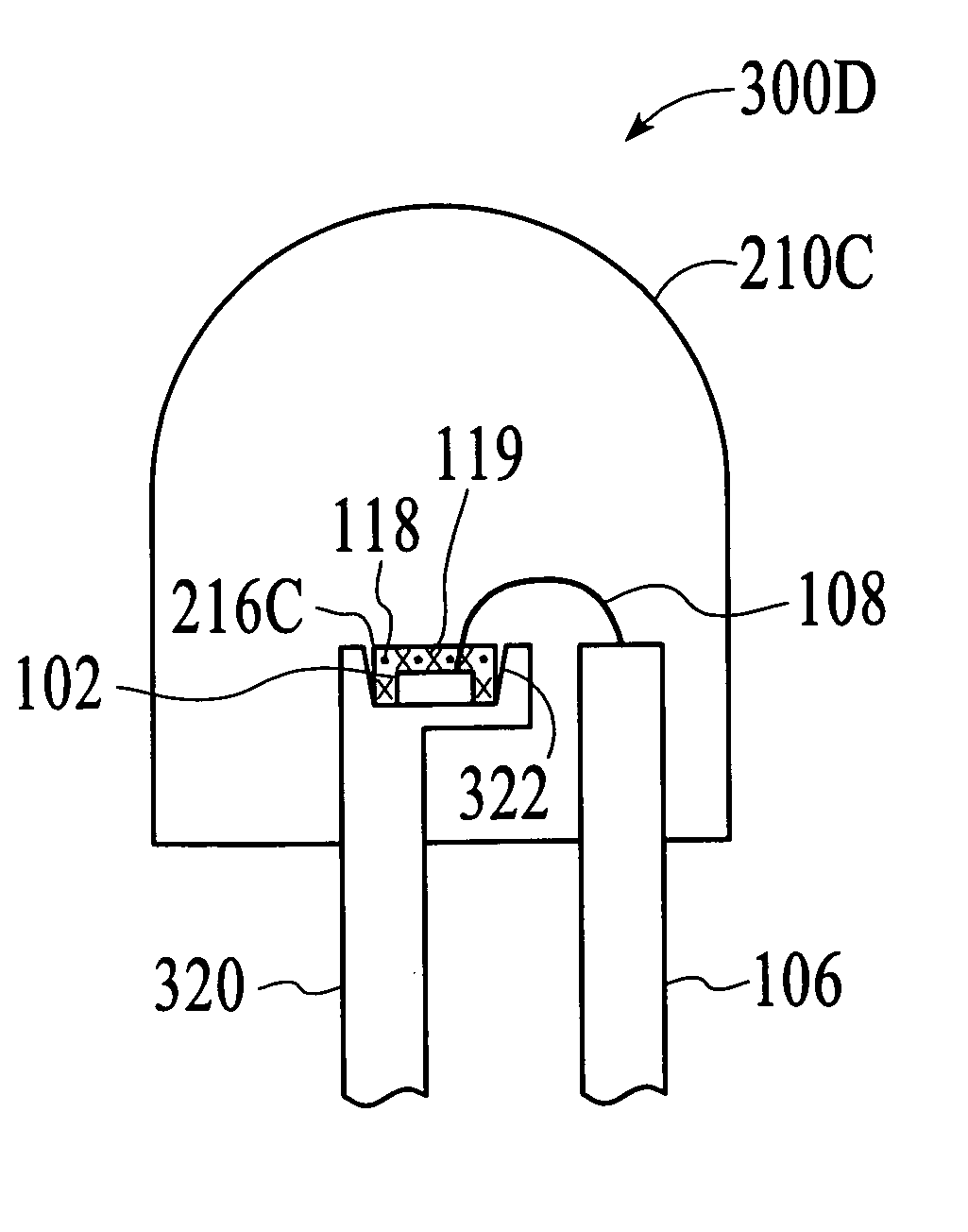

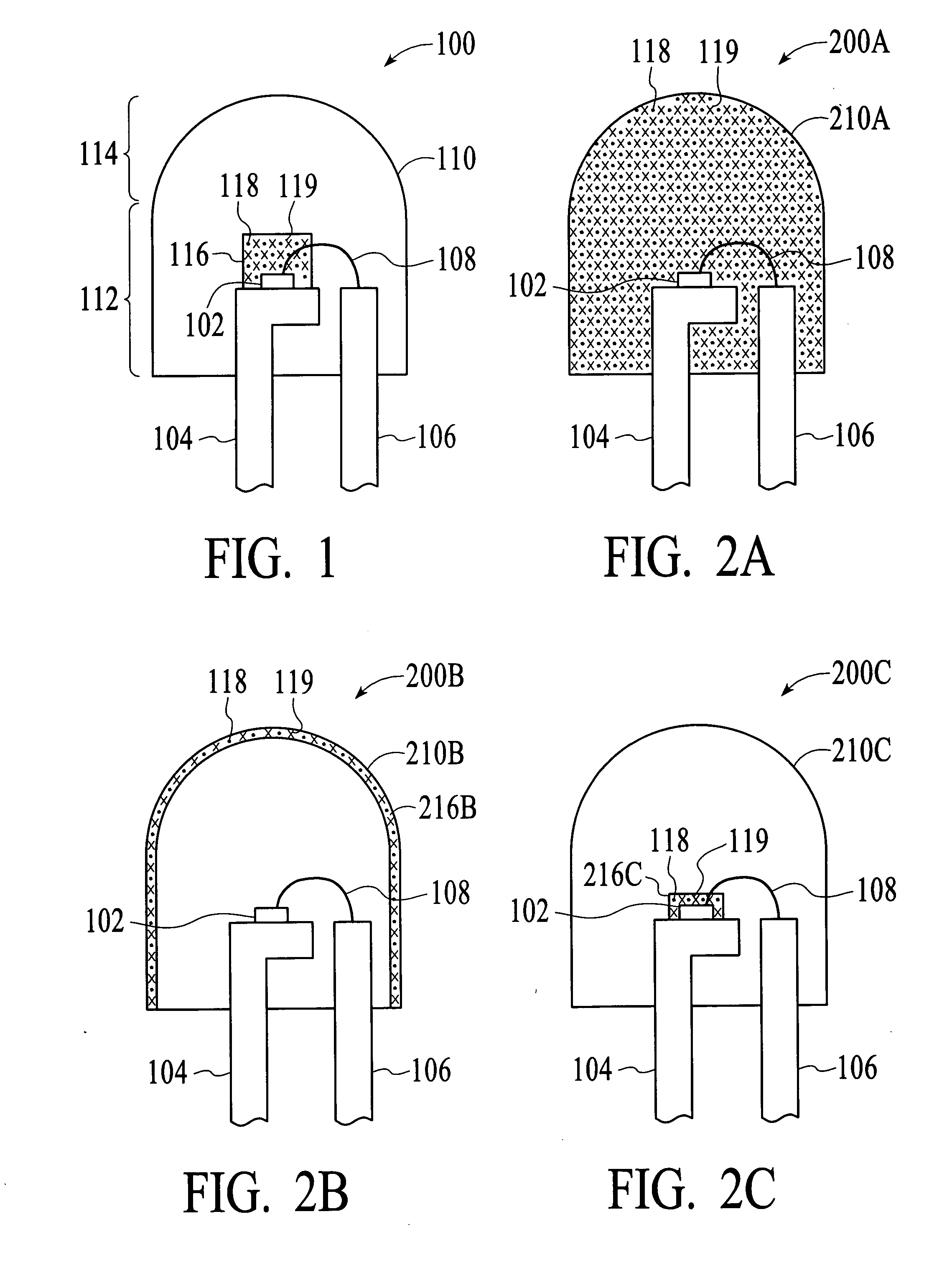

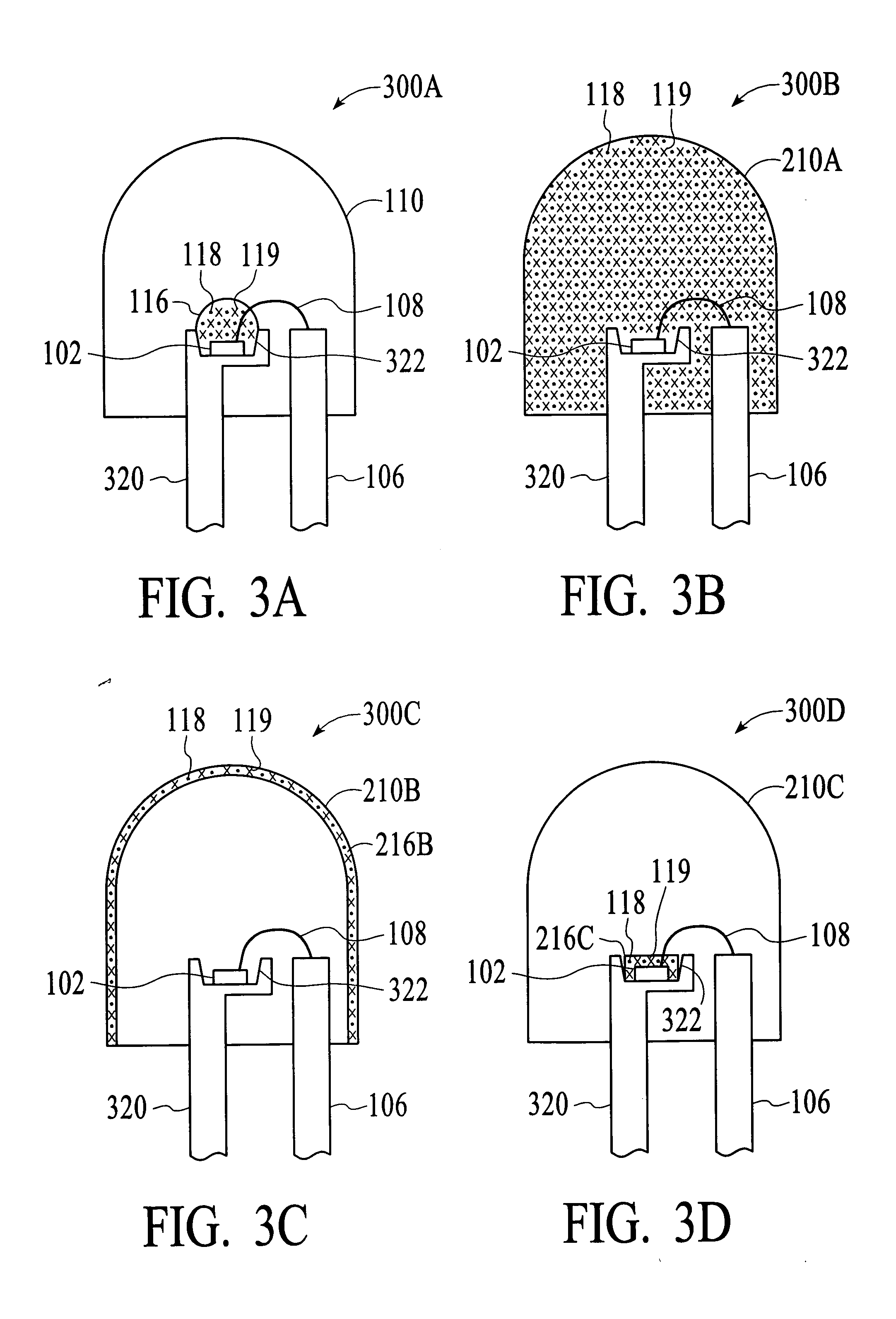

Device and method for emitting output light using group IIB element selenide-based and group IIA element gallium sulfide-based phosphor materials

InactiveUS20050156510A1Discharge tube luminescnet screensElectroluminescent light sourcesGallium sulfidePhosphor

A device and method for emitting output light utilizes a mixture of Group IIB element Selenide-based phosphor material and Group IIA element Gallium Sulfide-based phosphor material in which the Group IIA element includes Calcium, Strontium and / or Barium to convert some of the original light emitted from a light source of the device to longer wavelength light to change the optical spectrum the output light. Thus, the device and method can be used to produce white color light. The mixture of Group IIB element Selenide-based and Group IIA element Gallium Sulfide-based phosphor materials is included in a wavelength-shifting region optically coupled to the light source, which may be a blue light emitting diode (LED) die.

Owner:AVAGO TECH ECBU IP (SINGAPORE) PTE LTD +1

Cu-In-Ga-Se or Cu-In-Al-Se solar cell absorption layer target material and preparation method thereof

InactiveCN101397647AAvoid lostReduce adverse effectsVacuum evaporation coatingSputtering coatingIndiumElectrical battery

The invention discloses a Cu-In-Ga-Se or Cu-In-Al-Se solar battery absorbing layer target pertaining to the field of photoelectric functional materials, and a preparation method thereof. High-purity cuprous selenide powder, indium selenide powder, gallium selenide powder or aluminum selenide powder are fully mixed evenly according to the stoichiometric ratio of a CuIn1-xGaxSe2 or CuIn1-xAlxSe2 solar battery absorbing layer, and then sintered and molded by hot-pressing under protective atmosphere or made into a biscuit after cold press molding or cold isostatic pressing, and the biscuit is sintered under protective atmosphere and certain pressure or does not go through pressure sintering. The technique of the invention is simple and convenient, has high efficiency and low cost, and the produced sputtering target is provided with uniform composition and homogeneous CuIn1-xGaxSe2 or CuIn1-xAlxSe2 phase, with the relative density more than 90 percent and stable performance. The invention is mainly applied to the preparation of a Cu-In-Ga-Se and Cu-In-Al-Se solar thin film battery absorbing layer.

Owner:TSINGHUA UNIV +1

Fabrication of single polarity programmable resistance structure

InactiveUS7087454B2Read-only memoriesSemiconductor/solid-state device manufacturingChalcogenide glassData retention

Owner:OVONYX MEMORY TECH LLC

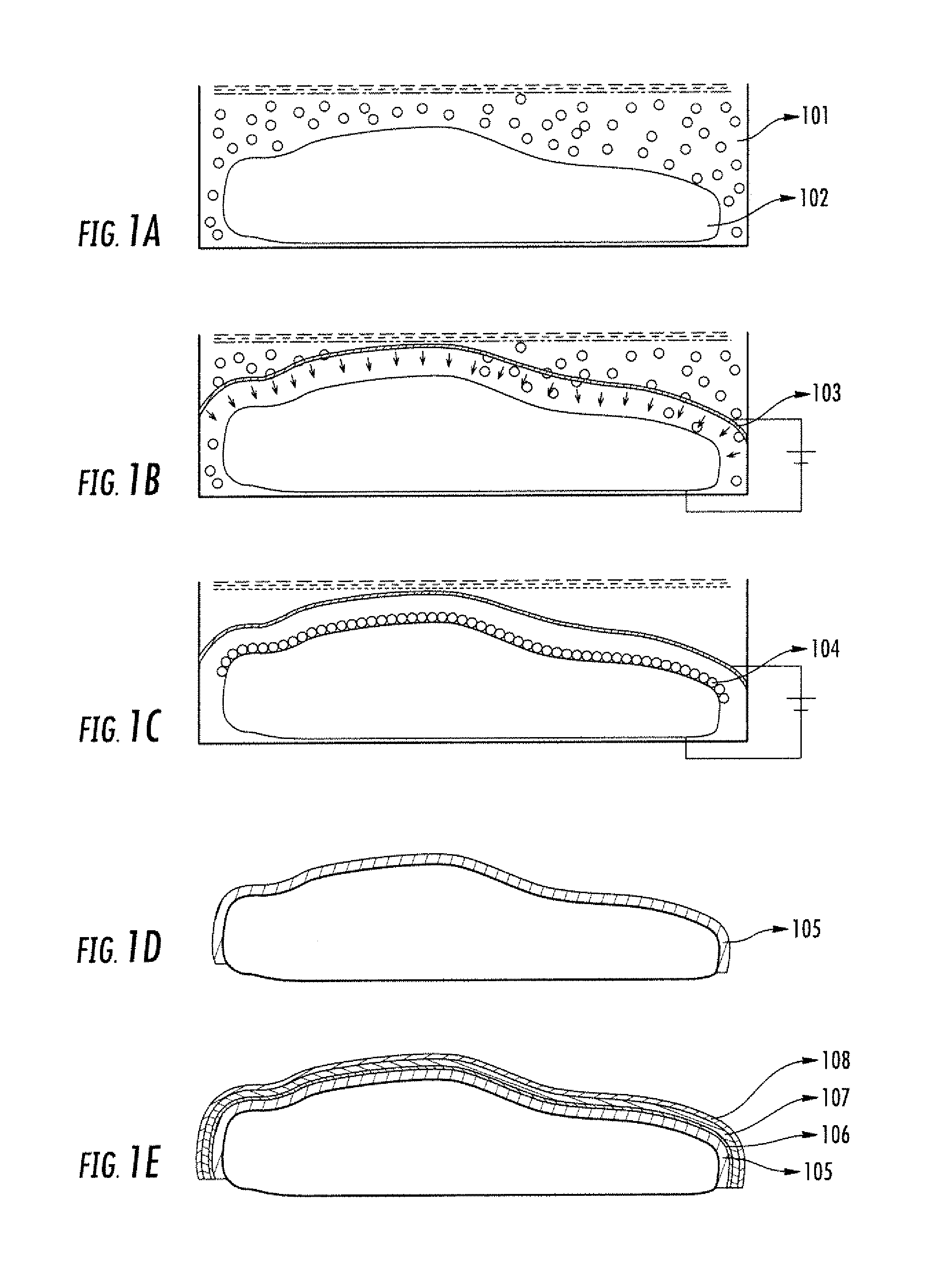

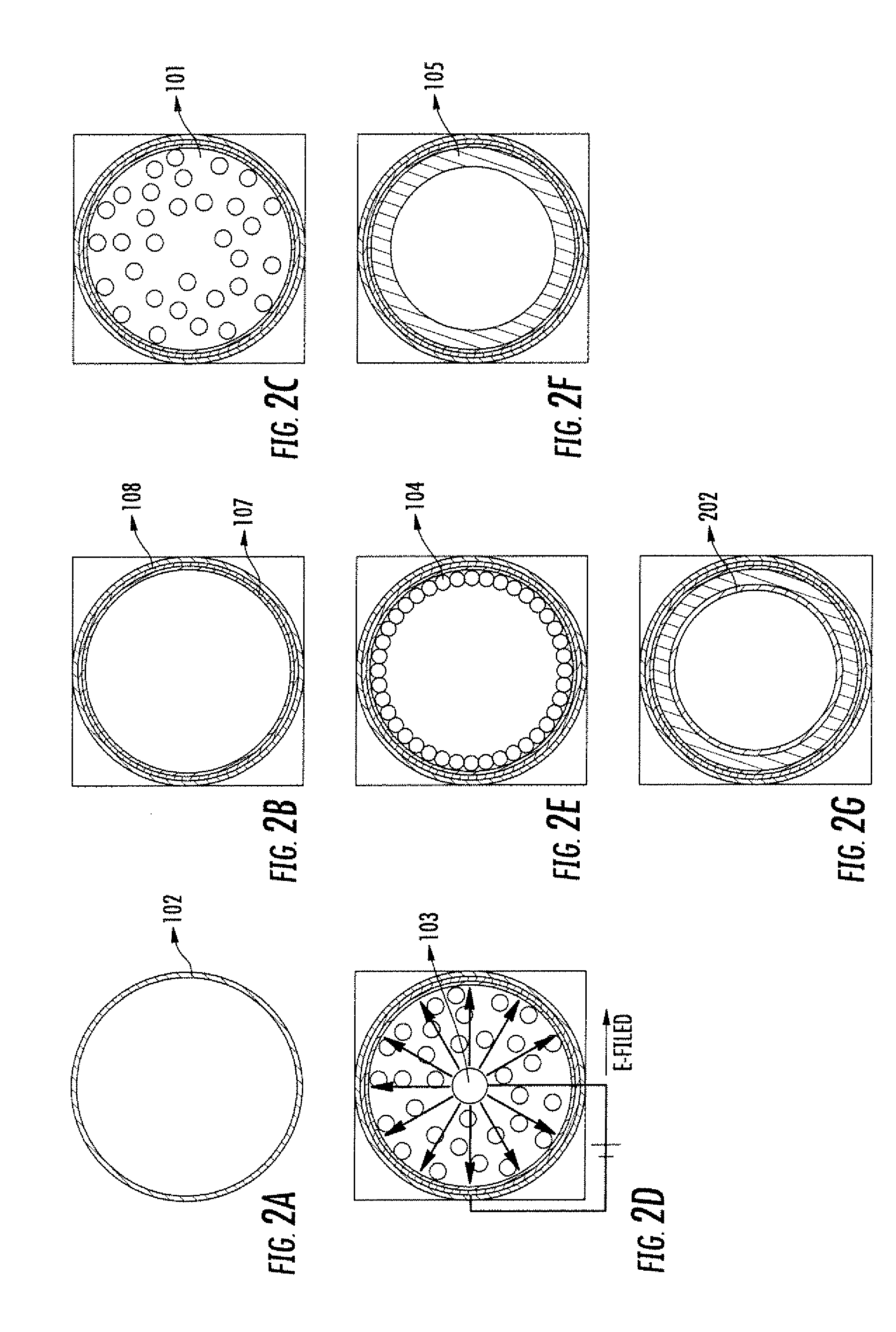

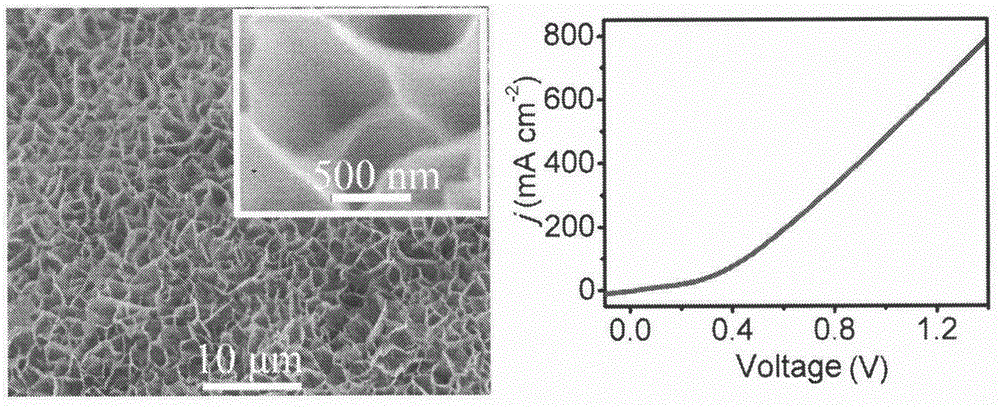

Method for preparation of metal chalcogenide solar cells on complexly shaped surfaces

InactiveUS20120100660A1Electrolytic coatingsSemiconductor/solid-state device manufacturingIndiumMetal chalcogenides

Methods for fabricating a photovoltaic device on complexly shaped fabricated objects, such as car bodies are disclosed. Preferably the photovoltaic device includes absorber layers comprising Copper, Indium, Gallium, Selenide (CIGS) or Copper, Zinc, Tin, Sulfide (CZTS). The method includes the following steps: a colloidal suspension of metal surface-charged nanoparticles is formed; electrophoretic deposition is used to deposit the nanopartieles in a metal thin film onto a complexly shaped surface of the substrate; the metal thin film is heated in the presence of a chalcogen source to convert the metal thin film into a metal chalcogenide thin film layer; a buffer layer is formed on the metal chalcogenide thin film layer using a chemical bath deposition; an intrinsic zinc oxide insulating layer is formed adjacent to a side of the buffer layer, opposite the metal chalcogenide thin film layer, by chemical vapor deposition; and finally, a transparent conducting oxide is formed adjacent to a side of the intrinsic zinc oxide, opposite the buffer layer, by chemical vapor deposition.

Owner:IMRA AMERICA

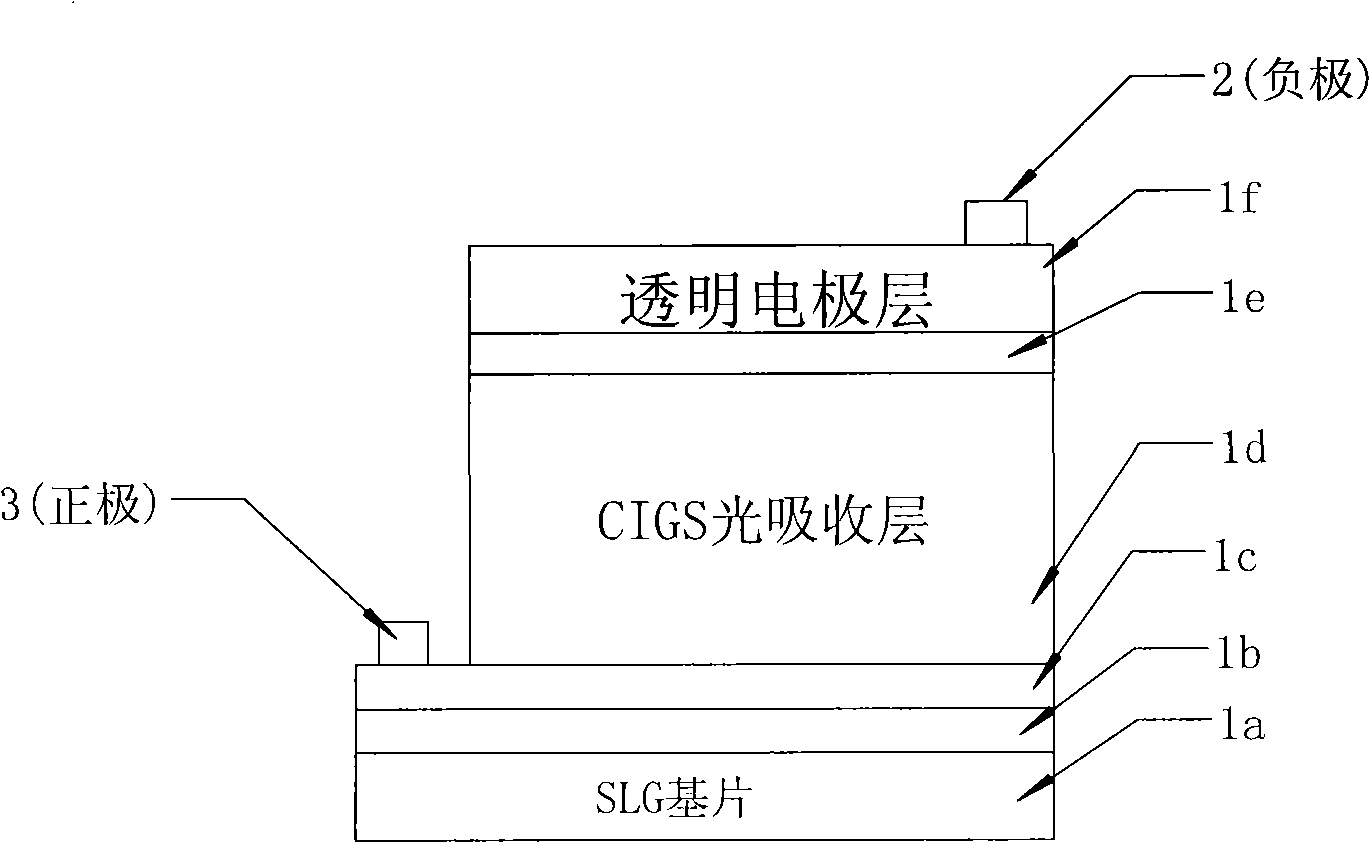

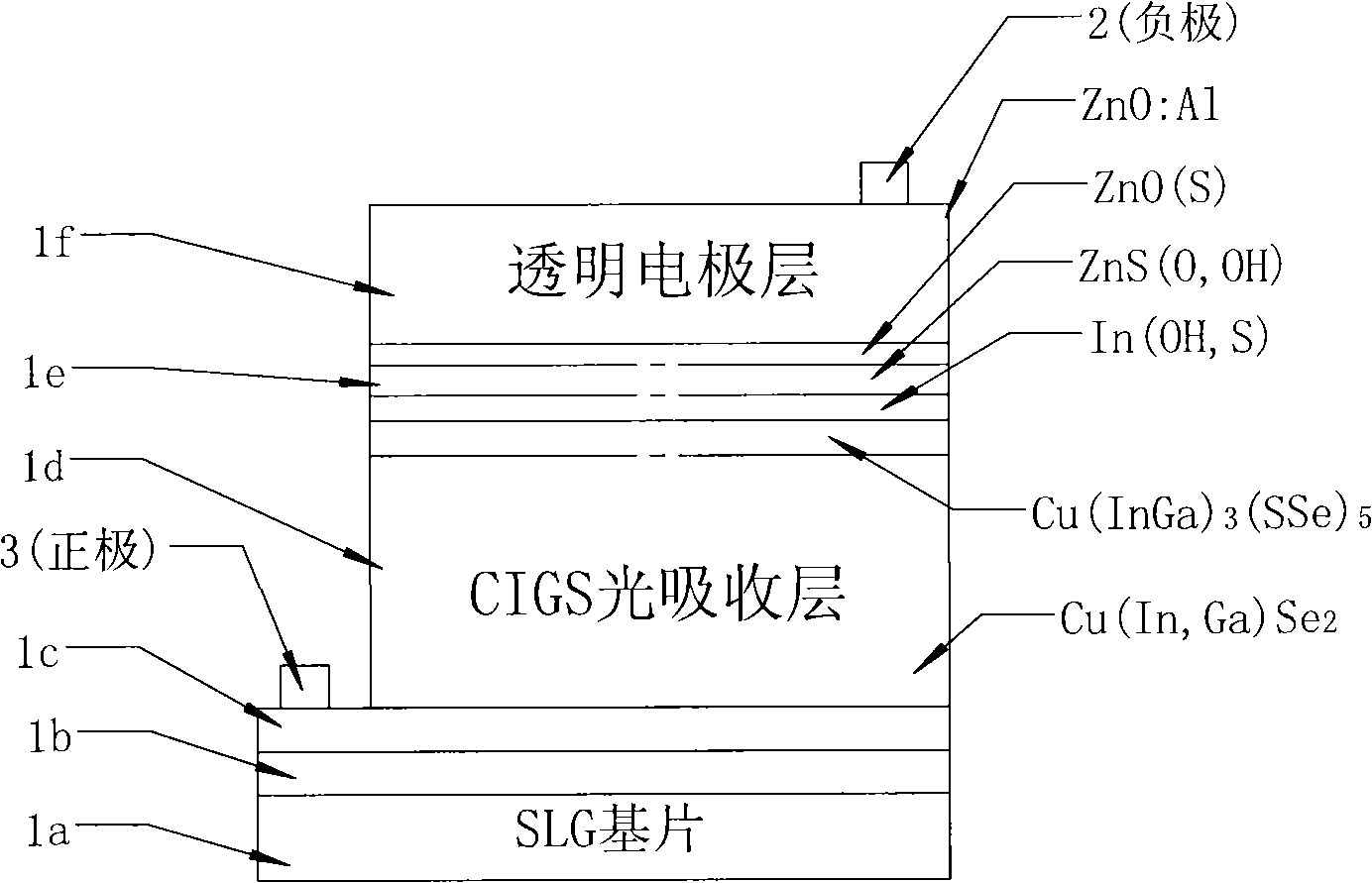

Selenide forerunner thin film and method for producing film cell through rapid selenium vulcanizing thermal treatment

InactiveCN101299446AObtain photoelectric conversion efficiencyFinal product manufactureSemiconductor devicesSolar cellCadmium Cation

The invention relates to a method of a low cost selenide van thin film and the fast selenium sulfuration heat treatment to prepare the solar cell, which can be used in the nm selenide paint roll coating or the electrodeposit method to prepare the selenide van film, through the vacuum flash selenium sulfuration heat treatment, the high efficiency cadmium-free thin film solar cell or the photovoltaic integrated module. The thin film cell adsorption layer band gap is in the v-shaped distribution, and the flash selenium sulfuration heat treatment causes the CuSe in the porous loose thin film fusing, soaking, liquid phase serving the reaction growth of the CIGS film crystal and the self densification of the film with the In4Se3, reactive sputtering In2Se3 or In2S3 to neutralize the excessive CuxSe adsorbed by the film surface layer, going on splashing the micro excessive In2S3 to generate n-high-ohmic resistor Cu(In<1-y>Gay)<3>(SxSe<1-x>)<5> thin film cell shallow burying, then reacting the splashing deposit n-type In(OH,S) / ZnS(O,OH) / Zno(S) buffer layer with the i-layer, linking the slashing transparent conductive film / and laserprocessing collecting ellectrode to complete the preparation of the thin film cell.

Owner:NANKAI UNIV +2

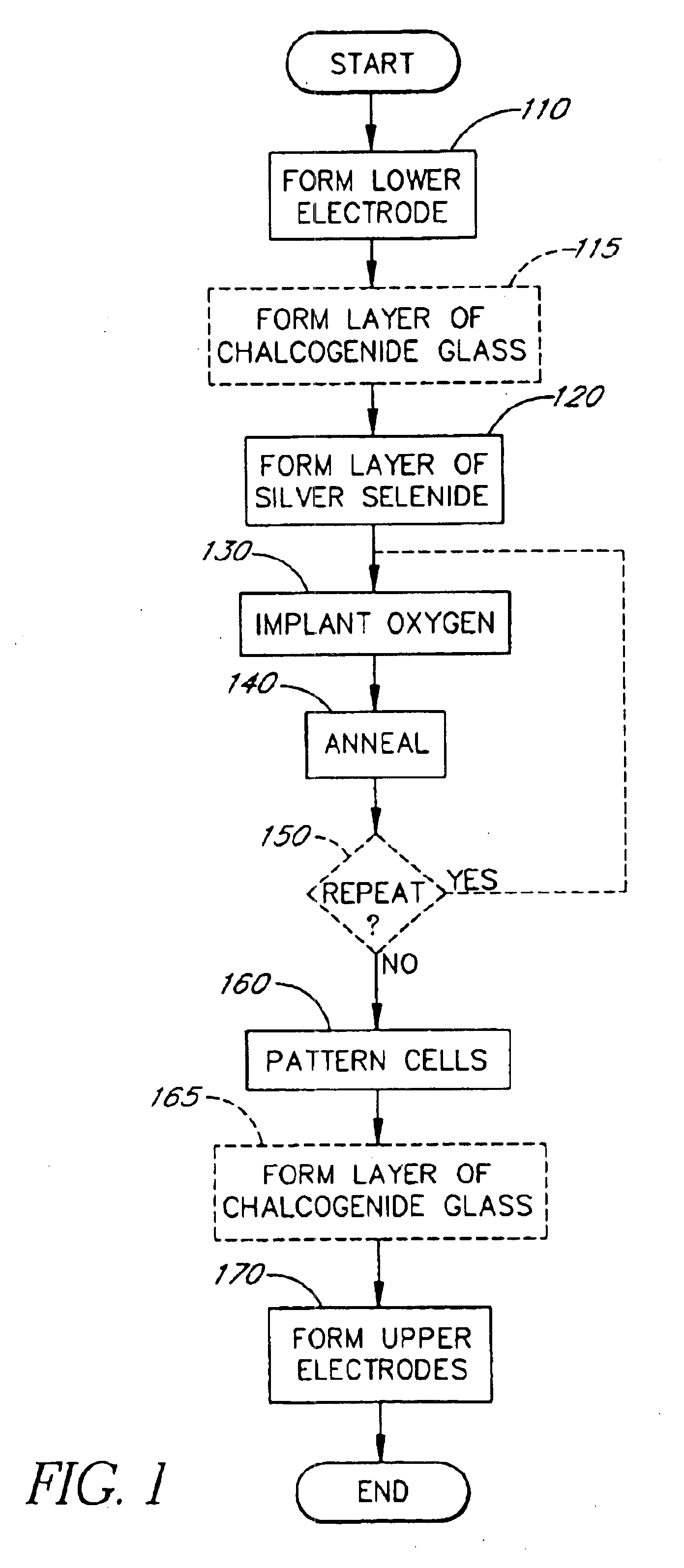

Methods to form a memory cell with metal-rich metal chalcogenide

InactiveUS6867114B2Improve uniformityEasy to controlSolid-state devicesSemiconductor/solid-state device manufacturingSulfurMetal chalcogenides

The invention relates to the fabrication of a resistance variable material cell or programmable metallization cell. The processes described herein can form a metal-rich metal chalcogenide, such as, for example, silver-rich silver selenide. Advantageously, the processes can form the metal-rich metal chalcogenide without the use of photodoping techniques and without direct deposition of the metal. For example, the process can remove selenium from silver selenide. One embodiment of the process implants oxygen to silver selenide to form selenium oxide. The selenium oxide is then removed by annealing, which results in silver-rich silver selenide. Advantageously, the processes can dope silver into a variety of materials, including non-transparent materials, with relatively high uniformity and with relatively precise control.

Owner:MICRON TECH INC

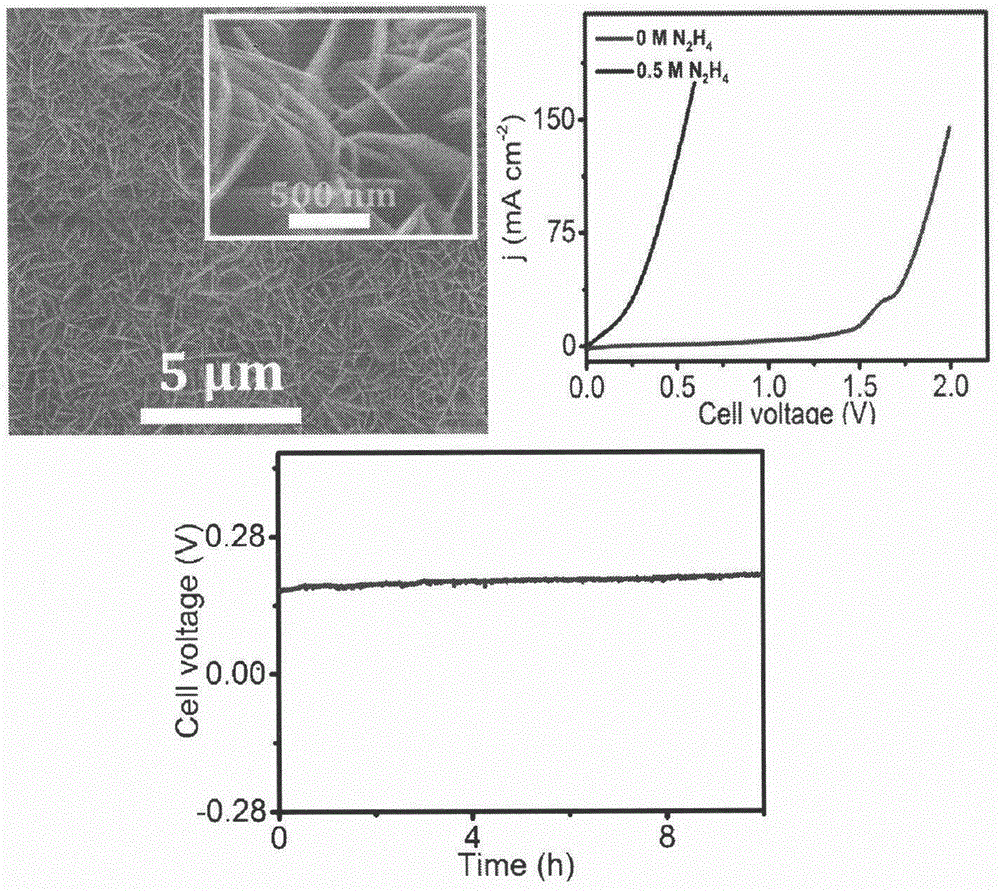

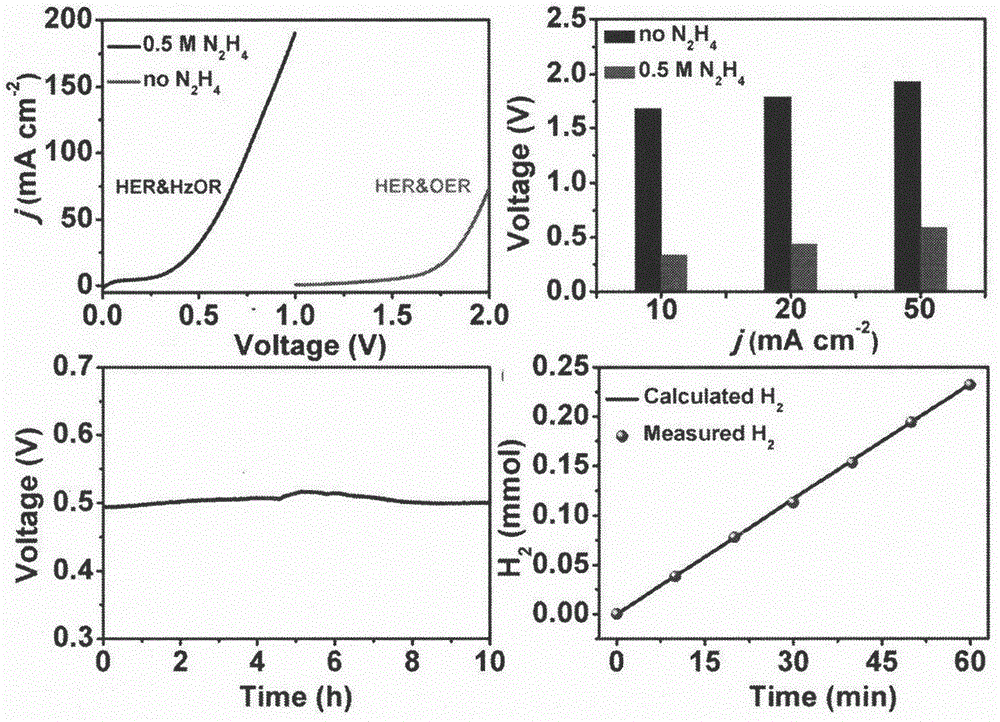

Low-energy-consumption electrochemical hydrogen production system based on difunctional nano array electrode

InactiveCN106498430AEfficient electrochemical hydrogen productionGood activity and stabilityPhysical/chemical process catalystsEnergy inputElectrolysisOxygen evolution

The invention discloses a transition metal compound (including phosphide, sulfide, selenide and nitride) nano array which is applied to low-energy-consumption electrochemical hydrogen production as a small-molecule electrooxidation and water-electricity reduction difunctional catalytic electrode and belongs to the fields of hydrogen energy and fuel cells. According to the transition metal compound nano array, the difunctional non-noble-metal array catalytic electrode is applied to small-molecule electrooxidation and water-electricity reduction simultaneously for the first time; an electrochemical oxygen evolution reaction is replaced with a small-molecule electrooxidation reaction low in oxidation potential, and a double-electrode electrolysis system based on the difunctional catalytic electrode is constructed; low-energy-consumption and stable electrochemical hydrogen production is achieved; and the transition metal compound nano array is applicable to large-scale industrial hydrogen production.

Owner:成都玖奇新材料科技有限公司

Waste solution mercury removal adsorbent, preparation method and application method thereof

ActiveCN103623771ARealize recyclingTo achieve the purpose of mercury removalOther chemical processesWater/sewage treatment by sorptionLiquid wasteSorbent

Owner:SHANGHAI JIAO TONG UNIV

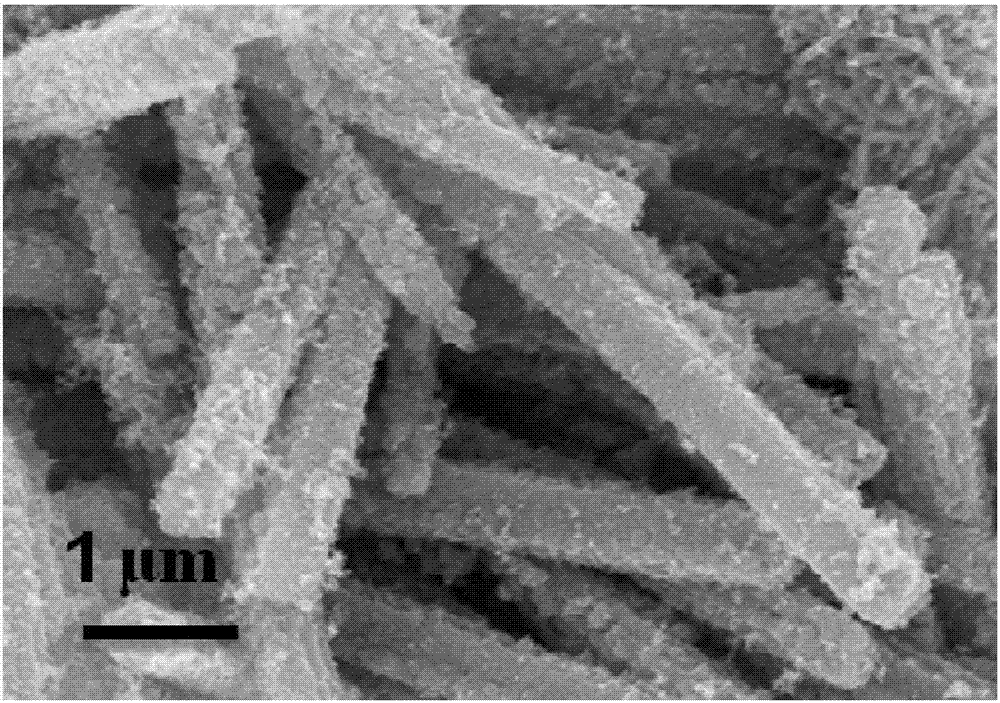

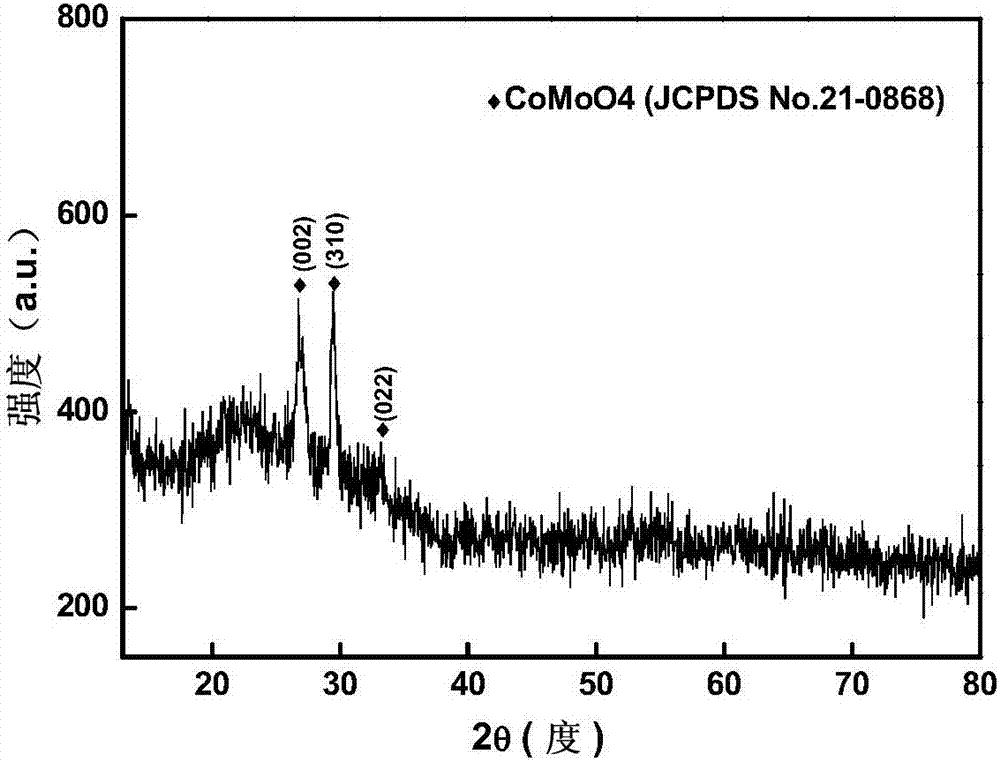

MoSe2/Co0.85Se composite material for electrocatalytic water decomposition as well as preparation method and application thereof

InactiveCN107051550AFor subsequent applicationFacilitate catalytic performance testingPhysical/chemical process catalystsElectrodesDecompositionCobalt

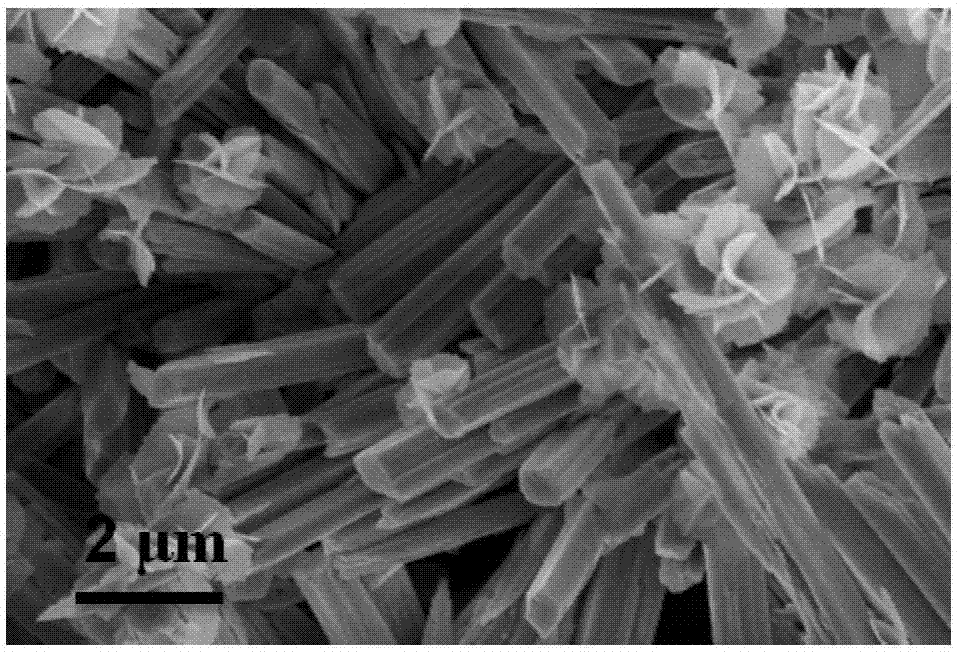

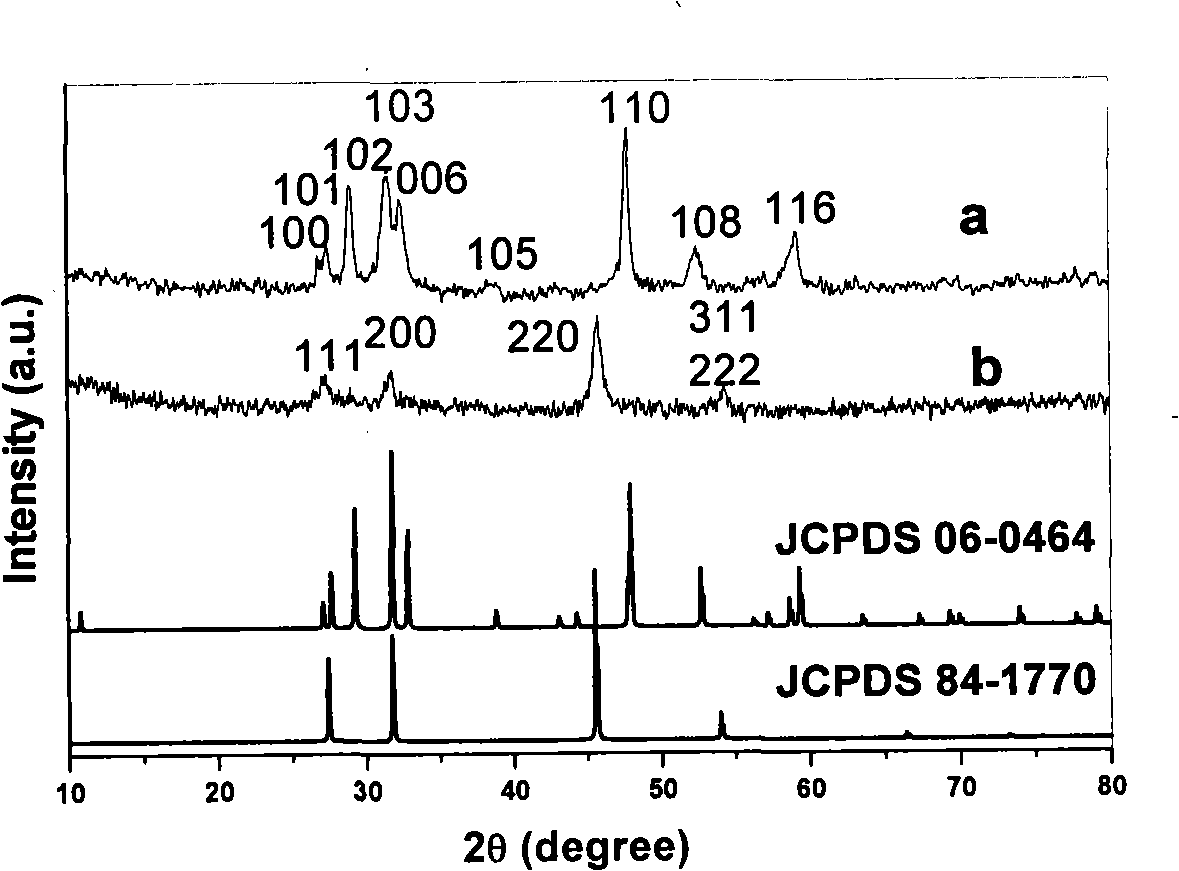

The invention relates to a MoSe2 / Co0.85Se composite material for electrocatalytic water decomposition. The microtopography of the composite material is that a micron / nano rod of a MoSe2 / Co0.85Se compound is loaded with a nano sheet of a molybdenum selenide / cobaltous selenide compound; the micron / nano rod has the length of is 1.5 to 3.5 microns and a diameter of 0.2 to 0.5 micron. A composite-material precursor CoMoO4 is firstly prepared and obtained through a hydrothermal reaction by using cobalt nitrate and sodium molybdate as reactive raw materials; afterwards, the composite material is made through the hydrothermal reaction by using sodium borohydride, selenium powder and the prepared composite-material precursor as raw materials. A preparation method of the MoSe2 / Co0.85Se composite material is simple; the raw materials are easily obtained; the cost is low; the industrialized production is easily realized; the prepared and obtained composite material is good in electrocatalytic effect, and further, has favorable stability.

Owner:SHANDONG UNIV

Universal synthesis method for porous hollow metallic oxide

InactiveCN101274749AReduce manufacturing costGood dispersionOxide/hydroxide preparationCopper oxides/halidesDispersityThiourea

The invention belongs to to the field of the preparation of inorganic non-metallic material, more particularly relates to a common method for synthesizing hollow metal oxide with high porosity. The method of the invention adopts soluble transition metal nitrate (MNO3, M is equal to Cu, Ni, Co), soluble sulfur source (thiourea) and selenium source (sodium selenite, Na2SeO3) as raw materials; metal sulfides (CuS, Cu2S, NiS, CoS) and the precursor of a selenide (CuSe) are first prepared and then treated with temperature programming and high temperature oxidation to obtain a corresponding porous metal oxide hollow framework (CuO, NiO and Co3O4). The method of the invention overcomes the defects such as high cost of material and production and complex process, etc., in the prior preparation method and the prepared metal oxides has large specific surface area, high thermal stability and good dispersity without need of being added with costly macromolecular organic templates and is easy to achieve industrialized production.

Owner:DALIAN UNIV OF TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com