Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

323 results about "Chromic salt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of preparing chromium oxide powder using water heat reducing chromate

InactiveCN100999335AControl particle size distributionGood dispersionChromium trioxideSlurrySurface-active agents

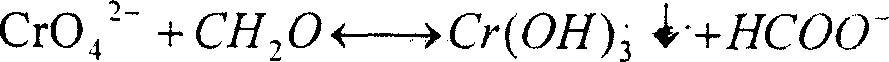

This invention relates to a preparation method that prepares chromic oxide powder by using water heat to deoxidize chromate. Use chromate water solution as raw material, CO2 as acidifying agent, process by surface active agent, directly deoxidize at condition of heat water, get hydrated Cr2O3 slurry, centrifugalize, separate, dry, calcinate hydrated Cr2O3 at different temperature, prepare globular Cr2O3 micropowder. Its grade size is between submicron and nanometer. This invention utilizes surface active agent to control sexavalent chromic salt which can be directly deoxidized to get trivalence chrome crystal. It can control hydrated chromic oxide calcinating temperature to prepare globular Cr2O3 micropowder of which grade size can be controlled.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

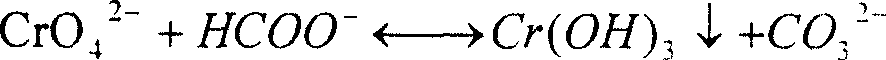

Method for preparing pigment grade chromium hemitrioxide green by using gaseous reducing agent low temperature reduction chromate salt

The invention discloses a method for preparing pigment-grade chromium oxide green. The method comprises the steps of taking reducing gas as a reducing agent, allowing chromic salt to react with the reducing gas for 0.5 to 3 hours at a temperature between 300 and 800 DEG C, cooling, using water to wash and hydrolyzing a reaction mixture, mixing the reaction mixture with additives at a temperature between 700 and 1,300 DEG C, activating and sintering the reaction mixture and the additives for 0.5 to 3 hours, washing, drying and grading the sintered material to obtain the pigment-grade chromium oxide green, wherein the chromic salt is chromate or bichromate; the reducing gas is hydrogen, natural gas, ammonia gas, coal gas or a mixture thereof; and the additives are silicon compounds, titanium compounds, boron compounds, phosphorus compounds, aluminum compounds, barium compounds, zinc compounds and other compounds, such as SiO2, K2SiO3, Na2SiO3, TiO2, K2TiO3, B2O3, H2BO3, H3PO4, P2O3, Al2O3, Al(OH)3, Al2(SO4)3, AlCl3, Al(NO3)3, BaO, Ba(OH)2, BaSO4, BaCl2, Ba(NO3)2, ZnO, ZnCl2, ZnSO4, Zn(NO)3, Sb2O3 and other substances.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

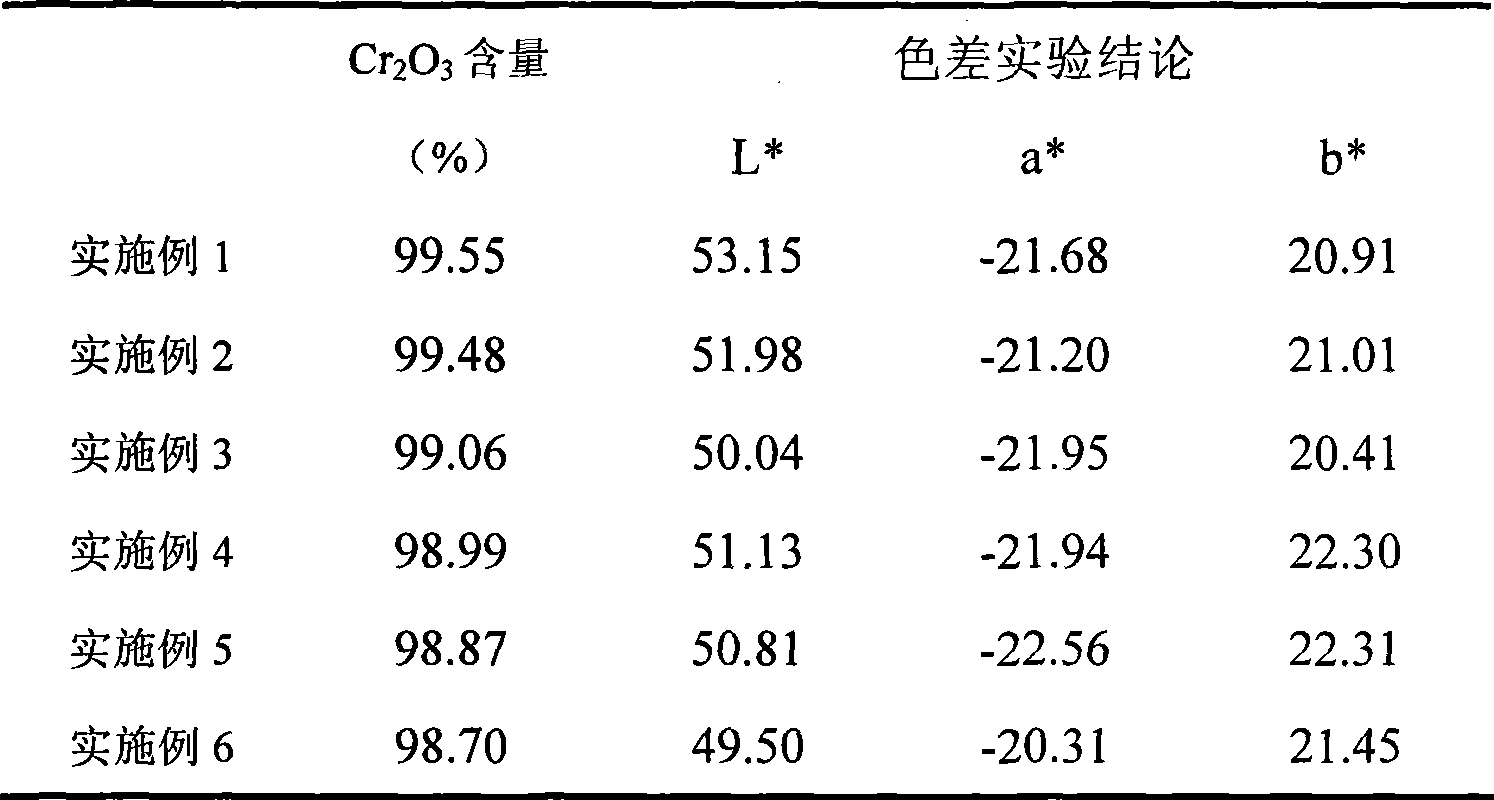

Ferrous phosphate doping lithium anode material and preparation process

InactiveCN1921187AImprove discharge capacityLow costElectrode manufacturing processesPhosphorus compoundsPhosphateFerrous salts

The invention relates to a lithium anode material doped with phosphate ferrous iron, and relative preparation. Wherein, the product has common advantages of lithium battery, while its discharge capacity can reach 150mAh / g, the 500-circled capacity is over 90%, with low cost. The invention is characterized in that: its formula is LiFe0.99M0.01PO4 / C; M is Cr, Zn, and Ca; the preparation comprises that (1) mixing and grinding lithium carbonate, ferrous salt, chromate salt, zinc salt, calcium salt, phosphorus source and glucose; (2), preheating the powder material in step (1) in inertia gas and low temperature; (3), grinding the material in step (2), under inertia gas, to be burnt, cooled and screened at 300-deal screen. The invention can be used in the anode of lithium battery.

Owner:XINXIANG ZHONGKE SCI&TECH

Trivalent chromic rainbow color passivating agent for galvanizing and its production

ActiveCN1584117ANo pollutionLarge operating rangeMetallic material coating processesRainbowNitrogen dioxide

A trivalent chromic ion iridescent passivating agent for galvanizing and its preparing method are disclosed. It consists of trivalent chromic salt, chelating agent, oxidant, the mol ration is 1:1:2.5-1:2:5.5, the trivalent chromic ion concentration in passivating groove liquid is 2.5-25g / L. It is prepared by adding the components into reactor, heating, mixing and chelating reacting, boiling and back-flowing to remove nitrogen dioxide after reacting, adding water and adjusting to obtain passivating agent concentrate with Cr3+ ionic concentration 30-80g / l after discharging. It achieves no pollution and wide range.

Owner:江西伟邦化工有限公司

Trivalent chromium pearl opal passivator for galvanizing and manufacturing method thereof

The invention discloses a trivalent chromium pearl opal passivator for galvanizing, whose composition and mol ratio is : trivalent chromium salt: nitrate or nitric acid : fluoride being 1:1:0.25-1:10:1.25, trivalent chromium ion concentration in passivation liquid being 1-10g / L. The invention also discloses the passivator production method, i.e. adding each ingredient in stirrer and stirring, resolving material, then adding water, acid, adjusting passivator concentration liquid Cr#+[3+]ion concentration to 25-30g / l,pH 0.8-1. The inventive passivator not only has no production of hexavalent chrome pollution in production process, but does not contain hexavalent chrome itself, which comprehensively promote the product quality, appearing color uniformity, and more resistance to corrosion than Cr#+[6+].

Owner:江西伟邦化工有限公司

Clean production method for preparing potassium chromate from chromic iron

InactiveCN101481144AImprove liquidityReduced corrosion resistance requirementsChromates/bichromatesForeign matterPotassium nitrate

The invention belongs to the field of a method for producing chromic salt, in particular relates to a method for producing and cleaning potassium chromate. The method comprises the steps that chromite is reacted with oxidant with a chemical dose inside KOH-KNO3-H2O medium to obtain a mixed resultant of reaction containing alkali liquor, potassium chromate and slag after reaction, wherein the mass ratio of KOH and chromite is 1:1 to 2:1, and the mass ratio of KNO3 and chromite is 0.5:1 to 2:1. Through the leaching of the mixed resultant of reaction, the phases of potassium chromate macrocrystal-alkali liquor containing potassium nitrate-slag are separated, foreign matters in the solution are removed, the mixture is evaporated and crystallized, the obtained potassium chromate crystal is eluted and the pure product of potassium chromate is obtained. The percent conversion of chromium is higher than 99 percent and the rate of containing chromium in slag is less than 0.2 percent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation for aluminum or aluminum alloy trivalent chromium chemical conversion film

InactiveCN101275225ASolve the disadvantages of high toxicityMeet environmental protection requirementsMetallic material coating processesCleaning using liquidsPhosphoric acidReaction temperature

The invention discloses a method of preparing aluminum or aluminum alloy trivalent chromium chemical conversion film, comprising: aluminum or aluminum alloy work pieces are activated for 1 to 2 minutes in sodium hydroxide solution with a concentration of 50g / L to 100g / L and activation reaction temperature is 5 deg C to 30 deg C; using deionized water to wash the work pieces; putting the washed work pieces into mixed aqueous solution of soluble chromic salt and phosphoric acid to make a chromaking for 6 to 10 minutes, wherein, chromium ion has a concentration of 1g / L to 20g / L, and the phosphoric acid has a concentration of 1g / L to 25g / L; using dilute sodium hydroxide or dilute sulfuric acid to adjust reaction system PH value to 1.6 to 4.0 and the chromaking temperature to 10 deg C to 60 deg C. The invention solves a shortcoming that in existing technology hexavalent chromium has great toxicity. Technological process and products of the invention reach environmental requirements. The produced trivalent chromium chemical conversion film has the same quality with hexavalent chromium chemical conversion.

Owner:CENT SOUTH UNIV

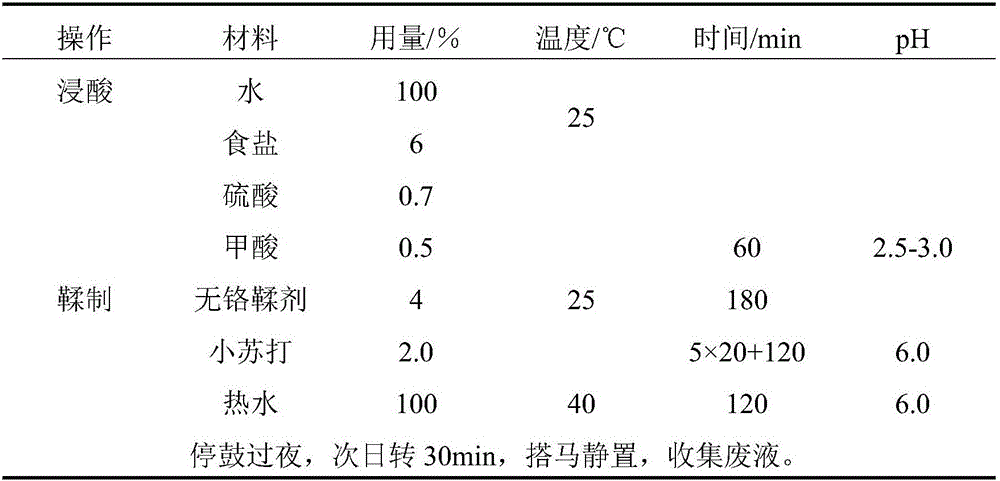

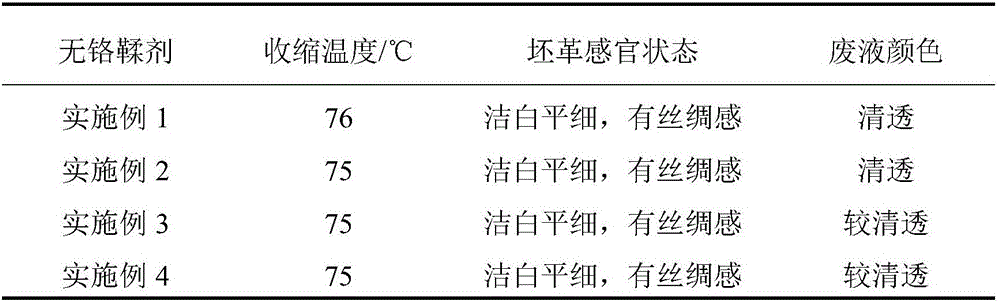

Clean production method of chromium-free automobile cushion leather

The clear production method for Cr-free vehicle seat cushion comprises: hair-saving, combing acid and base for expansion; ammonia-free deliming, dipping weak acid and low slat, Cr-free bating, composite batting, and adding strong-absorption fat for dyeing to treat skin from pig, cattle or sheep. The product has shrinkage temperature up to 110Deg, shows well hand feeling and resistance to thermal and age. This invention reduces material quantity and 30-50% sewage discharge, improves absorption rate, and brings a new way for Cr-free leather.

Owner:SICHUAN UNIV

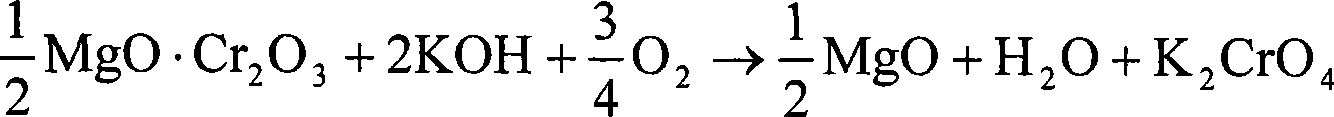

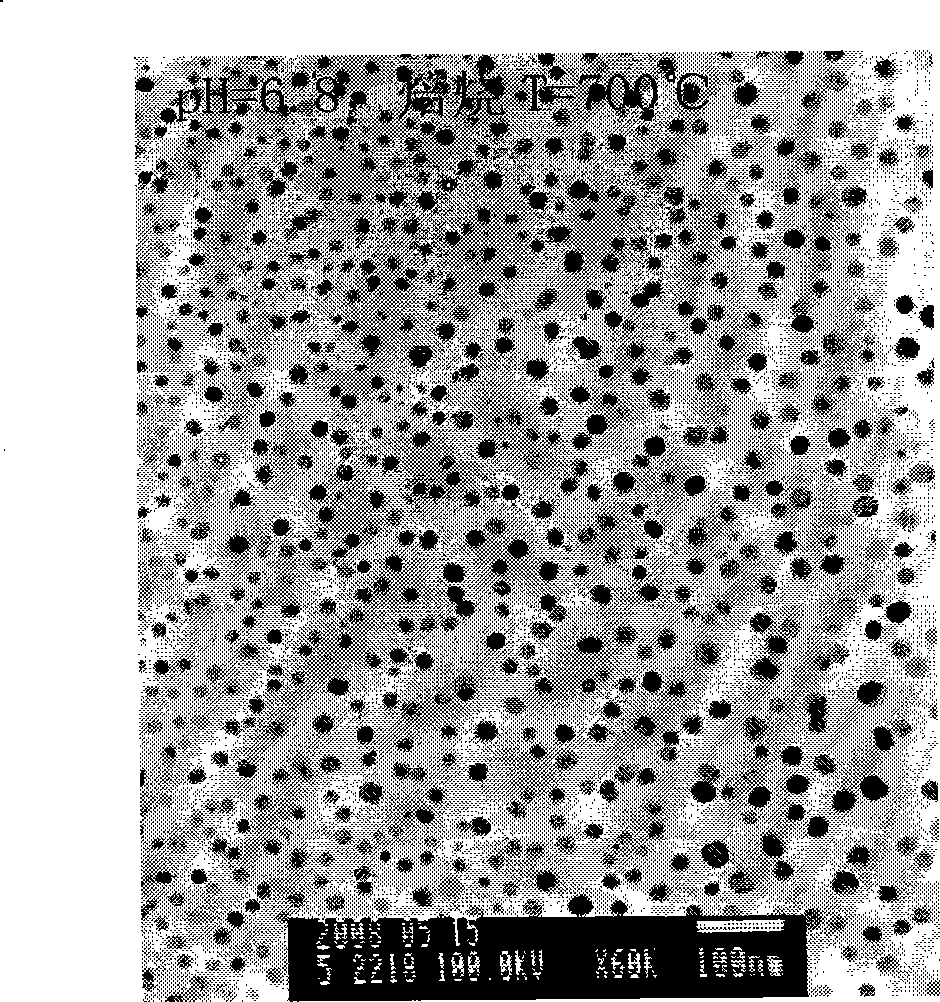

Method for preparing nano-catalyst copper chromite and copper ferrite

InactiveCN101367044AHigh puritySmall particle sizeMetal/metal-oxides/metal-hydroxide catalystsWater bathsNano catalyst

The invention discloses a method for preparing a nano-size catalyst of copper chromite and copper ferrite, and belongs to the technical field of nano-size catalyst preparation. The method of the invention comprises a sol-gel process and a vacuum freezing drying (VFD) process. Firstly, a mixed solution is prepared from a soluble copper salt and a soluble chromium salt or iron salt, added with a surface active agent, and mixed uniformly, and then the system is added with a precipitating agent to carry out precipitation reaction under the condition that the pH value is between 6.8 and 9.5, then is kept stand, aged, washed and melted in a water bath for 2 to 8 hours at a temperature of between 70 and 95 DEG C, thus sol is obtained; then the sol is subjected to freezing drying in a vacuum freezing dryer to obtain dried gel which is a precursor of the catalyst; finally, the dried gel is roasted to obtain the nano-size catalyst of copper chromite (CuCr2O4) or copper ferrite (CuFe2O4). The catalyst prepared by the method has the advantages of high purity, small grain diameter, good dispersivity, high catalytic activity, and the like.

Owner:TSINGHUA UNIV

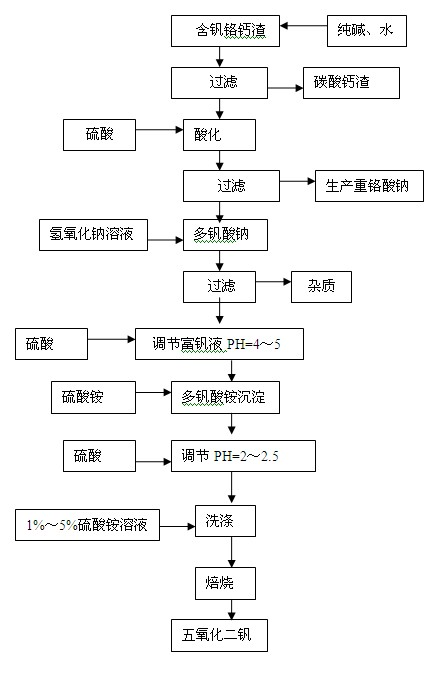

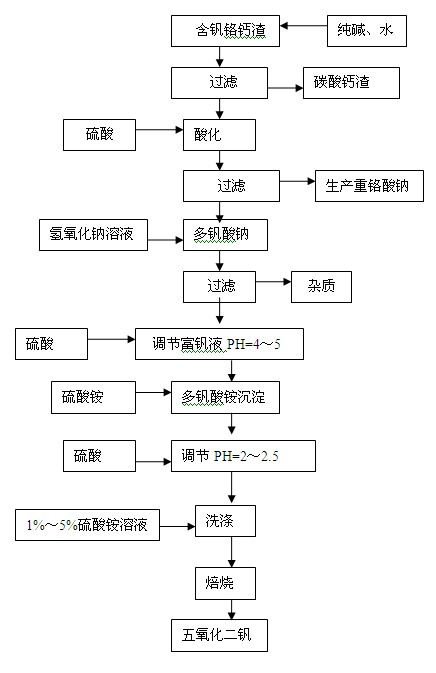

Method for recycling vanadium pentoxide and sodium dichromate

ActiveCN102021345AEfficient separationRealize comprehensive utilizationSolid waste disposalProcess efficiency improvementProcess engineeringSodium dichromate

Owner:GANSU JINSHI CHEM

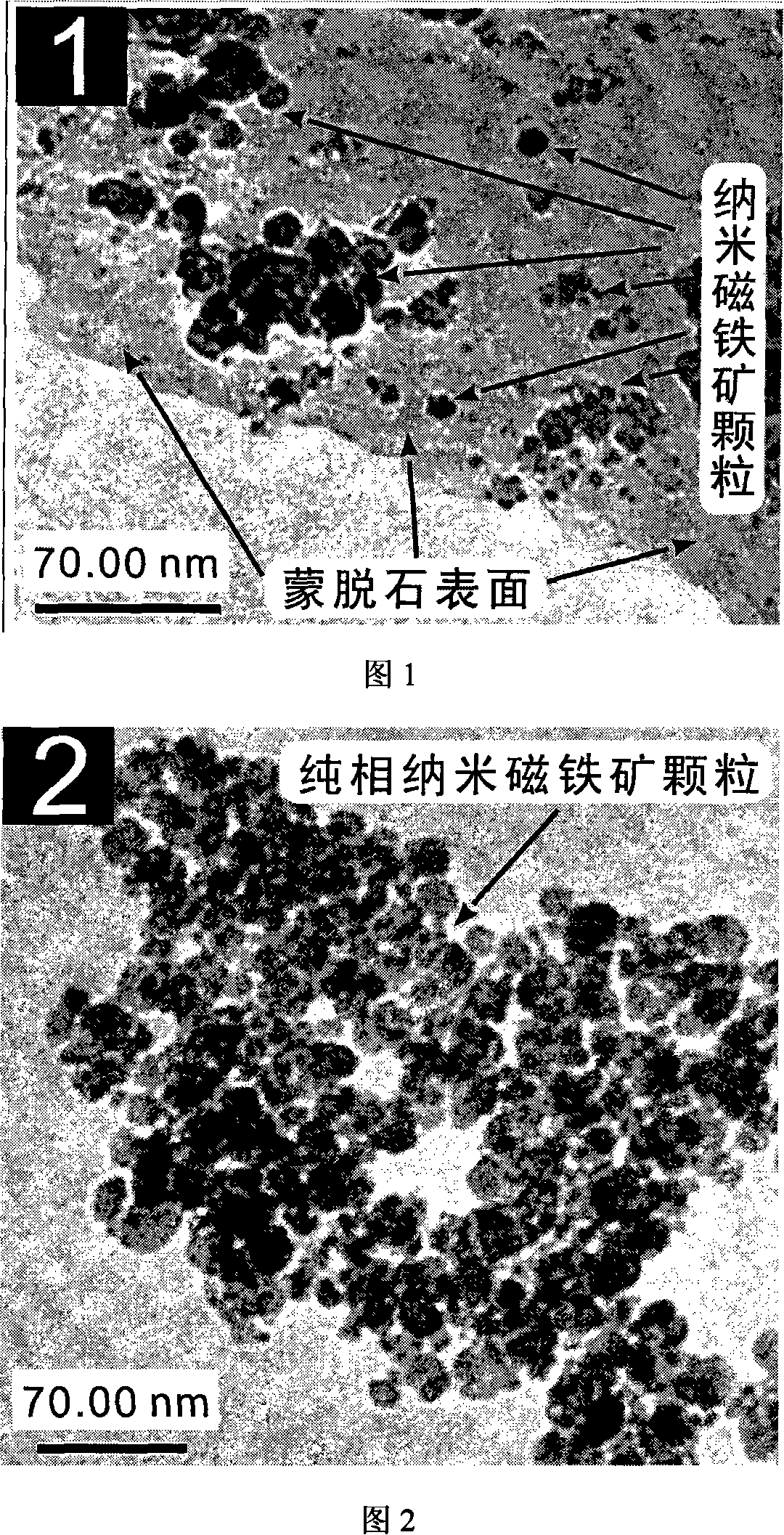

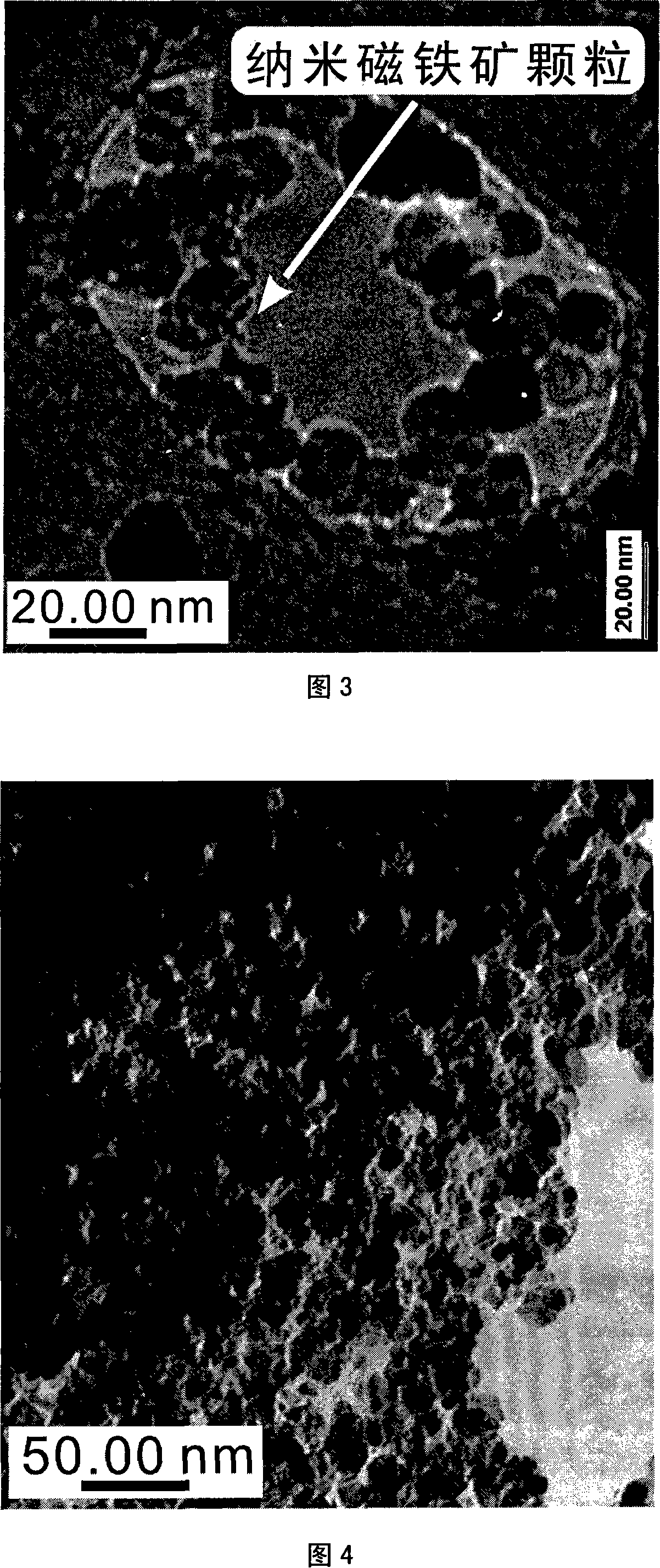

Method for treating Cr6+ in waste water and method for preparing montmorillonite-base nano magnetite used thereof

InactiveCN101215041AEasy to recycleGuaranteed MagneticOther chemical processesWater/sewage treatment by sorptionChemical industryIron salts

Provided is a process for treating Cr6+ in waste water, which comprises: adding nano magnetite of montmorillonite substrate in waste water containing hexavalent chromium, stirring for 5 minutes to 2 hours at normal temperature and then placing for 15 minutes to 2 hours, employing magnet or additional magnetic field to recycle adsorption materials. The process for preparation by employing the nano magnetite of montmorillonite substrate comprises that mixing ferric salt and ferrous iron salt solution, adding by ammonia spirit, adding by hydrochloric acid after filtering, rinsing and solid-liquid separation treatment, adding by montmorillonite then solid-liquid separating, drying and dewatering and the like. The invention of treating waste water containing Cr6+ has the advantages of high efficiency, low cost, simple operation and the like, and can be widely used for waste water treatment in a plurality of fields, such as tanning, plating, metallurgy, pharmacy, ferrochrome smelting, pigment, chromic salt chemical industry and the like.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Conductive anodic oxidation process for aluminum and alloy part

The invention provides a conductive anode oxidation technology of aluminum and alloy parts thereof, which comprises the following steps: (a) alkaline corrosion: the aluminum and the alloy parts are put into an alkaline solution for removing an oxide skin generated in natural state; (b) bright dipping: the aluminum and the alloy parts are put into 40 to 70 percent nitric acid solution for removing the dust so as to lead the aluminum and the alloy parts to expose metal luster; (c) anode oxidation: the aluminum and the alloy parts are put into a mixed electrolytic solution prepared by chromic salts and villaumite, 10 to 35V of voltage and 0.5 to 5A / dm<2> anodic current density are exerted to the solution at normal temperature, and the time for anode oxidation is 5 to 30min; and (e) drying. A film layer presents slightly transparent rainbow color and is bright, and has smooth and compact appearance. The technology has excellent welding performance, good electric conductivity and better antirust property, and solves the contradiction between the aluminum and the alloy parts, and the electric conductivity and the welding performance.

Owner:四川泛华航空仪表电器有限公司

Pre-treating agent for surfaces of aluminum profile and aluminum alloy profile

ActiveCN103132067AAvoid pollutionImprove corrosion resistanceMetallic material coating processesSolubilityZirconate

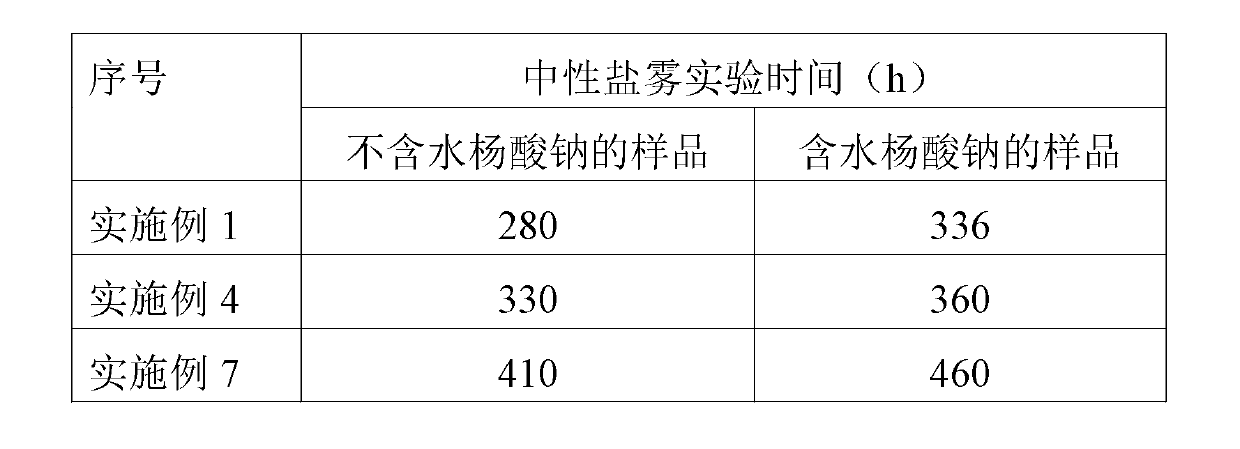

The invention discloses a pre-treating agent for surfaces of an aluminum profile and an aluminum alloy profile. The pre-treating agent comprises the following constituents by mass: 35-45 percent of water-solubility chromic salt, 0.1-3 percent of alkali metal zirconate, 0.1-2 percent of sodium salicylate, 5-10 percent of water-solubility coalescing agents, and 5-10 percent of wetting agents with the balance being water. The pre-treating agent for the surfaces of the aluminum profile and the aluminum alloy profile does not contain hexavalent chromium, and therefore environmental pollution is avoided, the pre-treating agent is stable in property and long in using period, a layer of transparent or light colored corrosion-resisting conversion coating can be formed on the surface of an aluminum profile workpiece, and a treated aluminum profile still maintains original metal characteristics. The conversion coating has extremely good corrosion-resistant performance and is firm in bonding, and the bonding force between the workpiece and the conversion coating and between the workpiece and paint can be notably increased. Besides, the using temperature range of the pre-treating agent is from the room temperature to 100 DEG C, the pre-treating agent can turn into a membrane quickly at the room temperature, and the effect is optimal when the pre-treating agent is heated to 20-50 DEG C.

Owner:武汉风帆电化科技股份有限公司

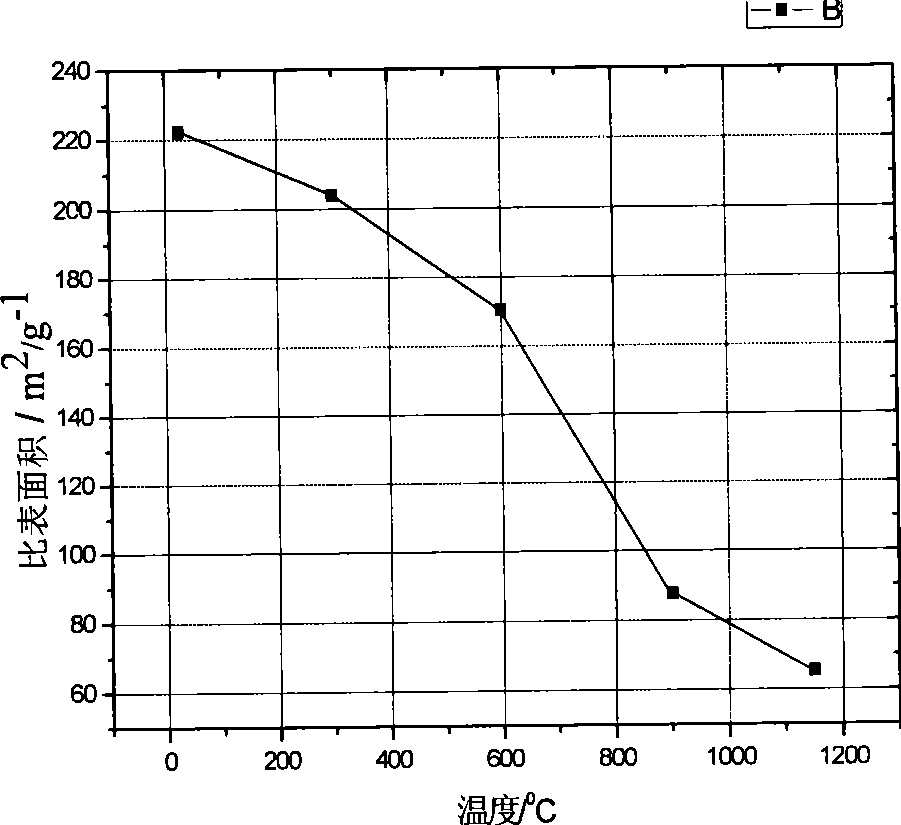

Method for preparing high specific surface area chromium series fluorating catalyst former body chromic oxide

InactiveCN101417816ALarge specific surface areaEasy to makeChromium oxides/hydratesMetal/metal-oxides/metal-hydroxide catalystsGas phasePolyethylene glycol

The invention relates to a preparation method for precursor chromic oxide of a chromic fluorination catalyst with high specific surface area, which is characterized by comprises the following steps of: completely dissolving an organic addition agent which can be a polyglycol-series PEG1000-6000, or nonionic surface active agents Tween40, Tween80, or a cation surface active agent dodecyl cetyl trimethyl ammonium bromide in soluble chromic salt solution, controlling the weight ratio of the organic addition agent and the soluble chromic salt to be 0.1: 1 to 0.8: 1, and precipitating by a precipitator under stirring condition, filtering, washing and drying. By adding the organic additive, the method effectively improves the specific surface area of Cr2O3 question mark nH2O (n is less than 3 and more than 0) and has simple and easily operated preparation process and good experimental reproducibility. The prepared compound can be used for producing the fluorination catalyst of HFCs which is the substitute of Freon in a gas phase method after high temperature roasting and activation.

Owner:江苏梅兰化工有限公司

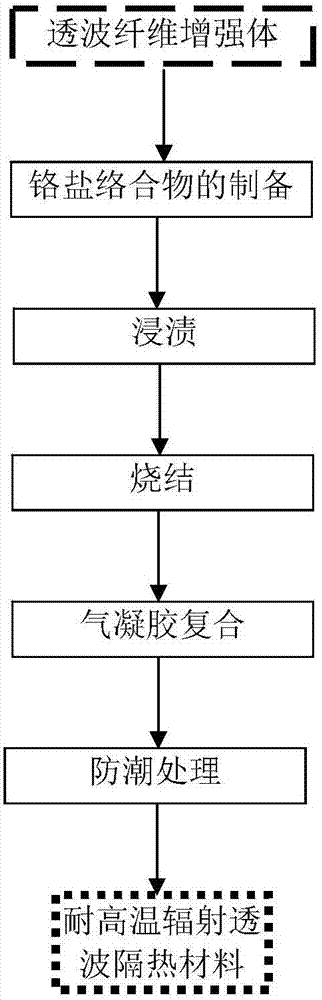

Wave-transmission and thermal-insulation material with high-temperature radiation resistance and preparation method of material

ActiveCN107032736AMeet working hoursSatisfies the requirement of stable high temperature wave transmission performanceThermal insulationOxide composite

The invention provides a wave-transmission and thermal-insulation material with high-temperature radiation resistance and a preparation method of the material. Specifically, the method comprises steps as follows: chromic salt is diluted and dissolved, an alkaline reagent is added, and a chromium salt complex solution is obtained; wave-transmission fiber reinforcement is soaked with the chromium salt complex solution, treated with sol-gel and dried, and a fiber preform is obtained; the fiber preform is sintered, and a chromium (III) oxide composited fiber reinforcement matrix is obtained; the fiber reinforcement matrix is soaked with silicon dioxide sol, treated with sol-gel, subjected to aging and solvent replacement and dried, and a fiber reinforced aerogel composite material is obtained; the fiber reinforced aerogel composite material is subjected to dampproof treatment, and the wave-transmission and thermal-insulation material with high-temperature radiation resistance is obtained. The invention further provides the wave-transmission and thermal-insulation material with high-temperature radiation resistance and an application of the material. According to the method, grain size and crystal form of chromium (III) oxide can be controlled, and excellent high-temperature radiation resistance and dielectric property of the material are guaranteed.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

High-corrosion-resistance trivalent chromium blue white passivation concentrated solution and preparation method thereof

ActiveCN106756955AEven and bright blueSolution to short lifeMetallic material coating processesCobalt saltSolvent

The invention discloses high-corrosion-resistance trivalent chromium blue white passivation concentrated solution. The passivation solution comprises the following raw materials and contents: 100-350 g / L of chromic salt, 50-250 g / L of cobalt salt, 50-200 g / L of complexing agent, 50-200 g / L of oxidizing agent, and 10-120 g / L of pH conditioning agent; and solvent is water. The passivation concentrated solution adopts the most advanced international trivalent chromium, contains no hexavalent chromium, belongs to the new generation of environment-friendly product, and is simple in process operation, easy to operate and control, excellent in stability, uniform and bright in blue of a passivation membrane, compact and firm in film formation, higher in corrosion and collision resistance and meanwhile, longer in service life.

Owner:济南德锡科技有限公司

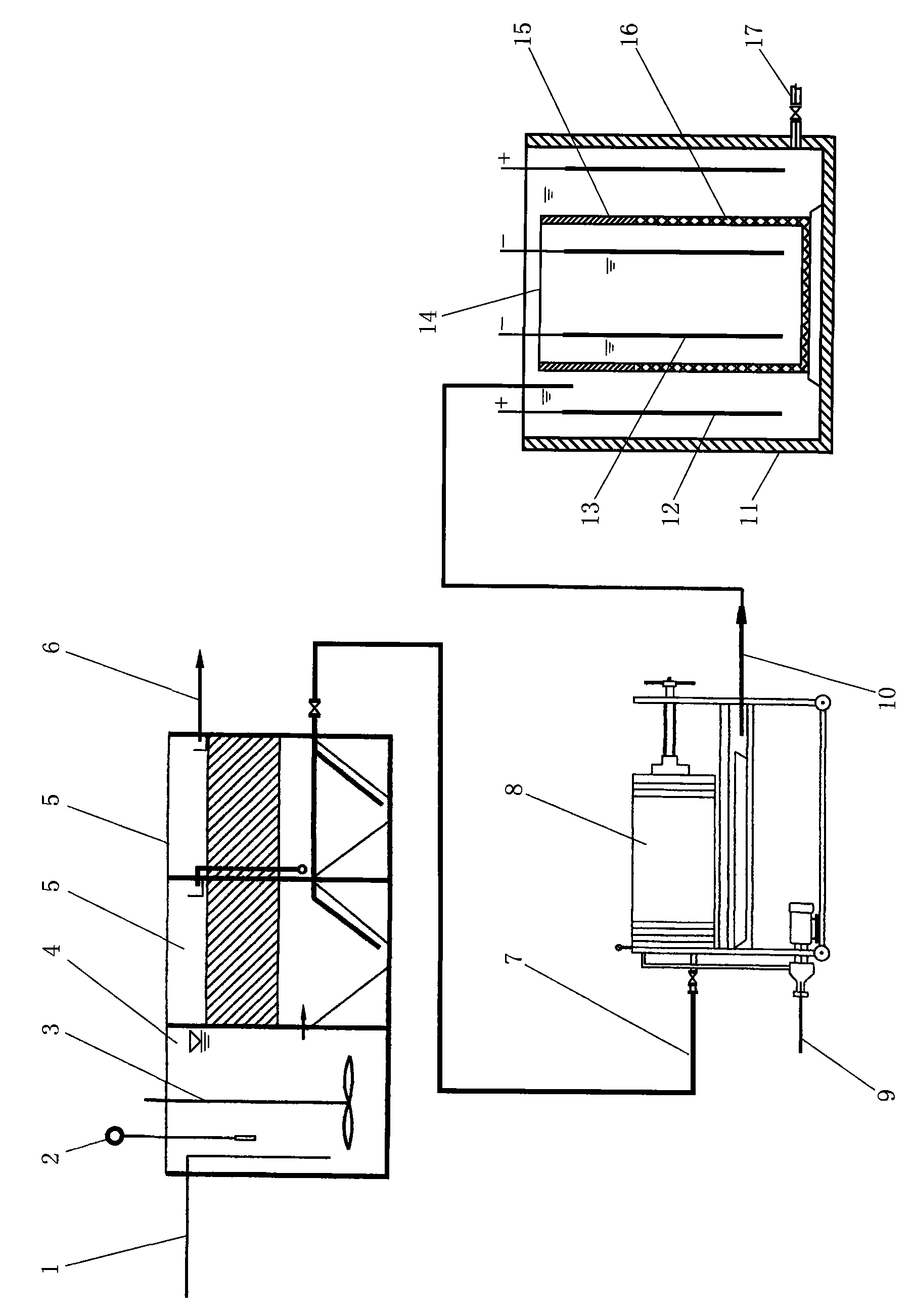

Method for electrolyzing and recovering hexavalent chrome in chromium-electroplating waste water

InactiveCN101549925ASmall footprintLess investmentWaste water treatment from metallurgical processMultistage water/sewage treatmentSodium carbonateChromic salt

The invention relates to a method for electrolyzing and recovering hexavalent chromium in chromium-electroplating waste water. Aiming at overcoming defects that chromium recovered from chromium waste water by the prior chromium-electroplating waste water treatment method cannot be reused for an electroplating tank, the invention provides the method for electrolyzing and recovering the hexavalent chromium in the chromium-electroplating waste water, which has simple operation and low recovering cost. The method comprises the following steps: sulfuric acid solution, sodium metabisulfite and sodium carbonate solution are sequentially added to the chromium-electroplating waste water; the reacted chromium-electroplating waste water flows into a precipitator for precipitation; through the precipitation, supernatant fluid flows into a neutralization pond for neutralization, the chromium-electroplating waste water is input a press filter for press filtering, and obtained chromic salts are washed with clear water; the chromium-electroplating waste water, the chromic salts and sulphuric acid are added in an electrolytic tank of a concentration purifier, and the sulphuric acid is added in a porous pot of the concentration purifier; when the concentration of the hexavalent chromium is larger than 20g / l and the concentration of trivalent chromium is smaller than 1g / l by electrolysis in the chromium-electroplating waste water in the electrolytic tank of the concentration purifier, the chromium-electroplating waste water can be used as a replenishing liquor for the electroplating chromium.

Owner:吴秋波

Trivalent chromium electroplate liquid capable of forming black clad layer

The invention discloses trivalent chromium electroplate liquid capable of forming a black clad layer. Each liter of the trivalent chromium electroplate liquid comprises the following raw materials: a cylinder opening agent, 20 to 150g of stabilizing agent, 10 to 20g of cobalt chloride or manganese chloride, 0.6 to 1.5g of ferric chloride, and 1 to 10g of wetting agent, wherein each liter of cylinder opening agent consists of 5 to 30g of blackening agent, 90 to 140g of chromic salt, 180 to 300g of L conducting salt, 25 to 90g of pH buffering agent. The trivalent chromium electroplate liquid capable of forming the black clad layer has simple components and is easy to maintain; and the formed black clad layer has deep black color and high adhesion.

Owner:GOOD CHEM SCI & TECH

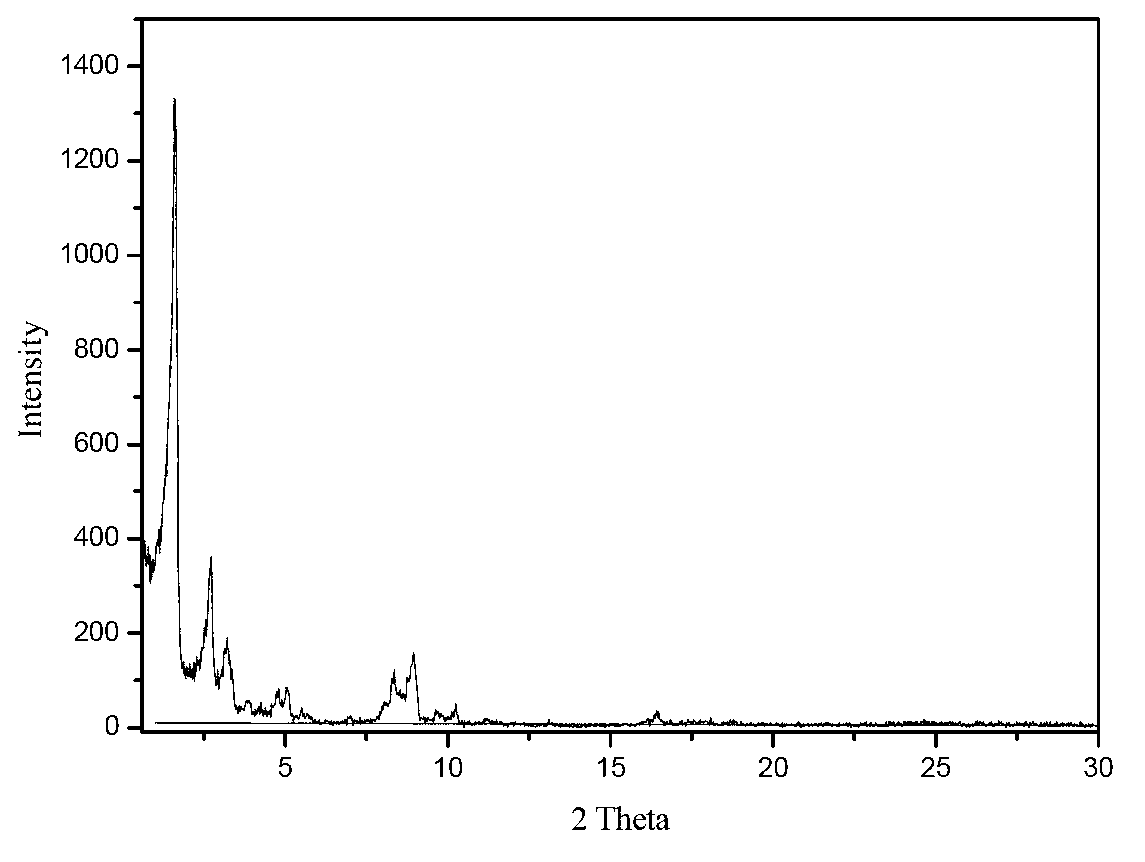

Method for synthesizing MIL-101 chrome metal organic framework by nitrogen heterocyclic

InactiveCN102838636ASynthesis temperature is lowHigh yieldGroup 6/16 element organic compoundsMetal-organic frameworkNitrogen

The invention discloses a method for synthesizing an MIL-101 chrome metal organic framework by nitrogen heterocyclic. The method comprises the following steps of: using the nitrogen heterocyclic as an additive; adding the additive to water; stirring the additive and the water; and then adding an organic ligand terephthalic acid to the water; stirring the organic ligand terephthalic acid and the water; and finally adding a water soluble metal chromic salt to the water; and stirring the water until the metal chromic salt is dissolved; transferring an obtained mixture into a stainless steel high pressure reaction kettle with a polytetrafluoroethylene lining or a high pressure stirring reaction kettle with a polytetrafluoroethylene lining; crystallizing the mixture at a constant temperature 150 DEG C for 34 hours so as to obtain a product, wherein the yield of the MIL-101 chrome metal organic framework material is 60-90%. The method for synthesizing the MIL-101 chrome metal organic framework by the nitrogen heterocyclic, disclosed by the invention, has the advantages of low synthesis temperature, high purity and high yield.

Owner:DALIAN UNIV OF TECH

Grain size adjustable spherical chromium oxide superfine powder preparing method

InactiveCN1454850ALess craftLess investment in equipmentOxide/hydroxide preparationChromium trioxideSURFACTANT BLENDLiquid phase

The preparation method of spherical Cr2O3 high-purity ultrafine powder body by using liquid phase method which can control grain size. It uses Na2Cr2O7 as raw material and adopts the processes of acidity reduction, surfactant treatment, pH value regulation, using composite precipitant to control precipitation, solid-liquor separation and roacting to obtain the fresh green spherical Cr2O3 ultrafine powder body with different grain size ranges, and its grain size can be controlled in the range of submicrometer and nanometer range according to the requirements. Said invention also provides a simple method for controlling its granule form and granule size, and said product has extensive application in functional coating material, special product special-purpose additive or special field special-purpose material field.

Owner:DALIAN UNIV OF TECH

Trivalent chromium natural colour passivation solution for processing aluminium alloy

InactiveCN102002704ABright white surfaceNo effect on healthMetallic material coating processesCadmium CationChromic salt

The invention relates to a trivalent chromium natural colour passivation solution for processing an aluminium alloy, comprising the following components by contents: 1-2 g / L of chromic salt, 0.05-0.1 g / L of zirconium salt, 0.01-0.03 g / L of nickel sulfate NiSO4.6H2O, 0.4-0.8 g / L of film-forming agents, 0.4-0.6 g / L of trisodium citrate Na3C6H5O7.2H2O, and the balance of water. The trivalent chromium natural colour passivation solution does not contain harmful substances, i.e. hexavalent chromium, lead, mercury, cadmium, polybrominated diphenyl ethers, polybrominated biphenyl, and the like, can be recycled, realize the clean production, passivate at normal temperature and save the energy; in addition, the aluminium alloy processed by the trivalent chromium natural-colour passivation solution has white and bright surface colour and lustre, colour approximate to the natural colour of the aluminium alloy and film neutral salt spray corrosion property meeting the national standard and can realize the substitution of the trivalent chromium passivation solution for a hexavalent chromium passivation solution.

Owner:SOUTHWEST UNIVERSITY +1

Method for synthesizing 2-methyl-1, 4-naphthoquinone

InactiveCN102516054AAvoid pollutionMild conditionsQuinone preparation by oxidationIce waterPtru catalyst

The invention relates to a method for synthesizing 2-methyl-1, 4-naphthoquinone through taking 2-methylnaphthalene as a raw material, which comprises the following steps of: taking the 2-methylnaphthalene as the raw material, taking glacial acetic acid as a solvent, taking hydrogen peroxide as an oxidizing agent and catalyzing with a catalyst to synthesize the 2-methyl-1, 4-naphthoquinone. The reaction temperature is 20-80 DEG C, and the dripping rate is 0.02-1 mL / min. After the end of dripping, the temperature is preserved for 0.5-4 hours. After the reaction is ended, and feed liquid is concentrated to 1 / 2-1 / 6 of the original volume, the feed liquid is poured into ice water with the volume being 3-6 times that of the feed liquid and is then stewed, filtered and dried to obtain the 2-methyl-1, 4-naphthoquinone. The method has the beneficial effects that a mixed acid catalytic system is used; compared with a traditional chromate oxidation method, the method has the advantages of good selectivity and high yield; and the pollution to a large quantity of chromium metal ions generated in the traditional industrial production can be avoided, and therefore, the industrial application value is higher.

Owner:SOUTHEAST UNIV

Zirconium salt chemical conversion treatment method for surface of die-casting aluminum alloy

InactiveCN102534592AStrong anti-salt spray performanceImprove corrosion resistanceMetallic material coating processesChromium CompoundsActive agent

The invention belongs to the field of metallic materials and relates to a chemical conversion solution and a treatment method for the surface of a die-casting aluminum alloy. The conversion solution is formed by compounding an A ingredient and a B ingredient, the A ingredient consists of a zirconium salt, a surfactant and a trivalent chromium salt; the B ingredient consists of a complexing agent and a film-forming accelerant; in the A ingredient, the content of the zirconium salt is 5-60 g / L, the content of the surfactant is 2-10 g / L, and the content of the trivalent chromium salt is 5-50 g / L; in the B ingredient, the content of the complexing agent is 4-20 g / L, and the content of the film-forming accelerant is 2-15 g / L; and the method comprises the pretreatment on the surface of the die-casting aluminum alloy and the zirconium salt chemical conversion treatment. A chemical conversion coating contains zirconium phosphate compounds and a small amount of trivalent chromium compounds, wherein the coating has uniform light blue and the thickness of about 0.5-1 micron. The zirconium salt chemical conversion coating prepared by the method has excellent corrosion resistance, the bonding strength between the coating and a substrate is high, the product, the waste water and the waste liquor obtained after the chemical conversion treatment do not contain hexavalent chrome which is harmful to the environment and the health of human bodies.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of nano magnetite/diatomite composition for removing Cr6+ in water

InactiveCN101215042AGood dispersionEasy to recycleWater/sewage treatment by sorptionWater/sewage treatment by reductionChemical industryFerrous salts

The invention relates to a process for preparing compound of nano magnetite and diatomite capable of removing hexavalent chromium (Cr6+) from water, which comprise: proportionally mixing ferric salt and ferrous salt aqueous solutions with the same concentration of 0.02-0.5mol / L at room temperature, adding by diatomite powder and uniformly stirring, heating and stirring to slowly add ammonium hydroxide solution, then, stopping adding till the pH value of suspension reaching 8-9, solid-liquid separating and rinsing; vacuum grinding and disintegrating. The invention employed to treat hexavalent chromium in the waste water has the advantages of low cost, high efficiency, simple operation, easy recovery and the like, and can be widely used for waste water treatment in fields of plating, tanning, metallurgy, pigment, chromic salt chemical industry and the like.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Production and using method of chromium zinc selenium fertilizer

ActiveCN102515947ANo pollution in the processImprove disease resistanceFood preparationFertilizer mixturesSelenateContinuous use

The invention relates to a chromium zinc selenium fertilizer, which comprises the following components by weight: 10-20 of selenate or selenite, 35-50 of a chromic salt, 25-35 parts of zinc sulfate, 10-15 of boric acid or borax, 2-5 of sodium nitrophenolate, and 2-5 of citric acid. The production process of the fertilizer consists of: material preparation, burdening, stirring, crushing, inspection, and packaging. And the using method includes: use for plants: dissolving the chromium zinc selenium fertilizer in water, and spraying the solution on the front and reverse side of a leaf as well ason a fruit with a spraying amount that generates no droplet but sprays plants wet; use for livestock and laying hens: blending the chromium zinc selenium fertilizer uniformly in feed for continuous use. The chromium zinc selenium fertilizer of the invention fills the domestic gap of chromium zinc selenium fertilizers, substantially increases the content of selenium, zinc, and chromium of agricultural products, and improves quality. It can also significantly improve the disease-resistant ability of crops. The using technology of the invention is fully mature, and has very strong paleogenesis, stability, and operability.

Owner:颜送贵

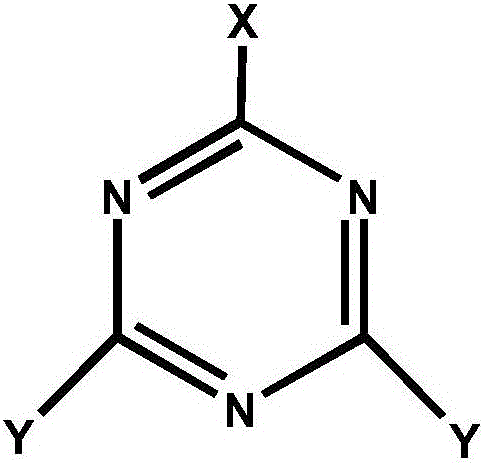

Preparation method of chromium-free tanning agent

ActiveCN106674141AImprove tanning effectImprove performanceOrganic chemistryTanning treatmentChromium freeBenzaldehyde

The invention relates to a preparation method of a chromium-free tanning agent, comprising the following steps: adding a hydrophilic group containing active compound and deionized water into a four-necked flask, neutralizing with sodium hydroxide, continuously stirring till dissolution, putting into an ice bath, adding cyanuric chloride, and regulating the pH value of the system with a solution of an acid binding agent to obtain a mixture A; heating the mixture A, dropwise adding p-hydroxy benzaldehyde dissolved in acetone while stirring, regulating the pH value of the system with the solution of the acid binding agent, and continuing the reaction after the materials are added; heating the system, dropwise adding p-hydroxy benzaldehyde dissolved in acetone, regulating the pH value of the system with the solution of the acid binding agent, continuing the reaction after the materials are added, cooling and discharging to obtain a mixture B; and filtering the mixture B, carrying out vacuum drying on the filter cake to obtain solid C, grinding and pulverizing the solid C to obtain the white powdered form chromium-free tanning agent. The chromium-free tanning agent can eliminate pollution from chromic salt, aluminum salt and formaldehyde and can be well absorbed, and the tanned crust leather has a white fine grain surface and is easy to be dyed into light-colored leather.

Owner:SHAANXI UNIV OF SCI & TECH

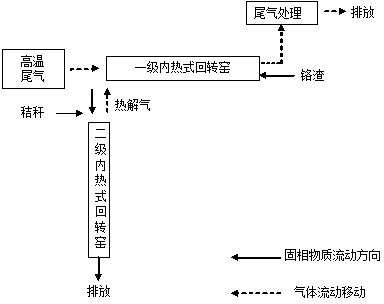

Chromium slag pyrolysis treatment method with high efficiency, low consumption, and low pollution

The invention discloses a chromium slag pyrolysis treatment method capable of realizing high efficiency chromium slag treatment, and reducing emission amount of harmful substances such as tar at the same time. According to the chromium slag pyrolysis treatment method, chromium slag and straw are mixed and reacted at a high-temperature area; obtained high-temperature tar gas flows to a low-temperature area, a part of the high-temperature tar gas is cooled onto the surface of the chromium slag which is delivered to the high-temperature area, and is reacted with Cr (VI) on chromium slag surface, and the other part of the high-temperature tar gas is removed via reaction with oxygen at the low-temperature area; at the same time, because of full utilization of the tar gas, effective reduction of Cr (VI) in the chromium slag is realized, and oxidation of chromium is controlled effectively; and in addition, another by-product of the chromium slag pyrolysis treatment method, high temperature tail gas is taken as a heat source to heat the chromium slag, so that energy consumption is reduced greatly.

Owner:光大理工环境技术研究院(青岛)有限公司

Electric steel insulating paint with high comprehensive performance

The invention provides an electric steel insulating paint with a high comprehensive performance. The electric steel insulating paint is characterized by comprising the following components in percentage by weight: 1 to 40 percent of hexavalent chromic salt, 0.01 to 10 percent of calcium salt, 0.5 to 35 percent of magnesium salt, 0.2 to 20 percent of borate, 0.05 to 15 percent of phosphate, 0.05 to 10 percent of silicon dioxide, 0.5 to 40 percent of organic resin emulsion, 0.5 to 15 percent of polyhydric alcohol, 0.05 to 1 percent of polyether modified polydimethyl siloxane and 0.03 to 3 percent of paint additive. A coating layer employing the electric steel insulating paint has the high comprehensive performance.

Owner:MAANSHAN IRON & STEEL CO LTD

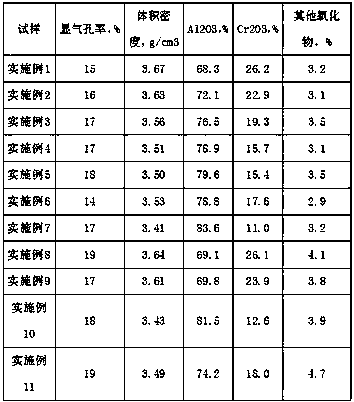

Aluminum oxide-chromic oxide refractory product and preparation method thereof

The invention belongs to the field of refractory materials, and mainly relates to an aluminum oxide-chromic oxide refractory product and a preparation method thereof. The raw materials of aluminum oxide-chromic oxide refractory product comprise aggregate and a matrix; the aggregate comprises white fused alumina particles, brown fused alumina particles and chromic oxide particles; the matrix comprises one or a mixture of more in chromic oxide fine powder, chromic oxide micro powder, aluminum oxide fine powder or aluminum oxide micro powder; metallic Al and metallic Cr alumina-chrome slag particles are further contained in the aggregate; chromic salt slag fine powder and micro powder are further added in the matrix. The refractory product reasonably and effectively utilizes hazardous wastes,and improves the problem that the traditional pink fused alumina brick is low in cost performance in industrial production with low service temperature requirement.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

High corrosion resistance passivation solution for zinc alloy die castings and passivation method

InactiveCN104141123AImprove conductivityEasy to useMetallic material coating processesNitrateSalt spray test

The invention provides a high corrosion resistance passivation solution for zinc alloy die castings and a passivation method. The high corrosion resistance passivation solution comprises 1% to 10% of chromic salts, 1% to 8% of rare earth compounds, 0.1% to 5% of mixed accelerant, 0.01% to 0.05% of surface active agents and the balance water. The mixed accelerant is a mixture of cerous nitrate, ammonium bifluoride and sodium nitrate, wherein the mass ratio of the cerous nitrate to the ammonium bifluoride to the sodium nitrate is (0.5-2):(0.5-2):(3-8). The cleaned zinc alloy die castings are immersed into a working solution prepared by the high corrosion resistance passivation solution to be passivated, cleaned and dried. According to the high corrosion resistance passivation solution, the components are synergized by optimizing the component formula ratio, the passivation time is short, a passivation film layer is dark blue and is uniform, compact and high in corrosion resistance, no corrosion exists in a salt spray test 168H, the electrical conductivity of the film layer is good, the zinc alloy die castings with the oxidized surfaces can be treated, the passivation quality of non-fresh zinc alloy workblanks is greatly improved, and the requirement for industrial production is met.

Owner:SHENZHEN XINMINGDA ENVIRONMENTAL PROTECTION SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com