Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

705 results about "Cinnabar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cinnabar (/ˈsɪnəbɑːr/) or cinnabarite (/sɪnəˈbɑːraɪt/), likely deriving from the Ancient Greek: κιννάβαρι (kinnabari), refers to the common bright scarlet to brick-red form of mercury(II) sulfide (HgS) that is the most common source ore for refining elemental mercury, and is the historic source for the brilliant red or scarlet pigment termed vermilion and associated red mercury pigments.

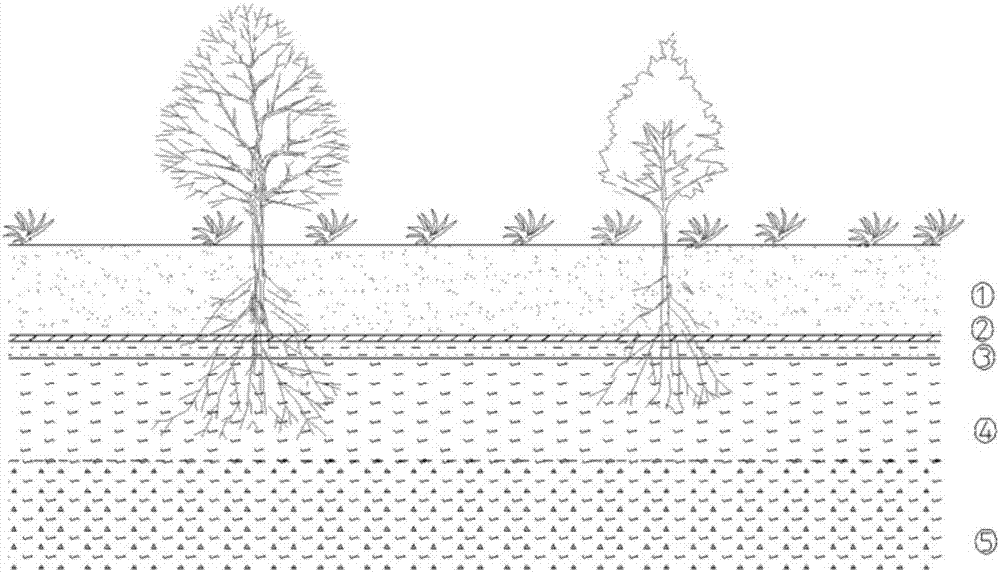

Five-layer coverage forced reduction in-situ mineralization restorative method

ActiveCN107363083AAvoid pollutionReduce penetrationSolid waste disposalContaminated soil reclamationSolubilityReaction layer

The invention provides a five-layer coverage forced reduction in-situ mineralization restorative method, and belongs to the technical field of mine environment ecological restoration. A five-layer structure involved in the method particularly comprises a non-pollution new soil layer, a clay sealing layer, a biomass reduction sealing layer, a main reaction layer and an original tailing layer. The method comprises the steps that organic matter in biomass on the main reaction layer is taken as the reducing agent, arsenic in a high oxidation state is reduced into arsenic in a low oxidation state or in a reduced state under the effect of anaerobic bacteria, and sulphur in a high oxidation state is reduced into sulphur in a reduced state, so that the minerals of realgar, orpiment and the like are formed again; and meanwhile, a large amount of iron is reduced to form iron pyrite, arsenopyrite, pyrrhotite and other minerals with the low solubility, and the heavy metals of Pb<2+>, Zn<2+>, Cu<2+>, Hg<2+>, Cd<2+>, Sb<3+> and the like form galena, blende, copper pyrites, cinnabar, greenockite, stibnite and other sulfide minerals with the extremely low solubility, so that mine heavy metal pollution in-situ mineralization restoration is achieved.

Owner:北科蕴宏环保科技(北京)有限公司

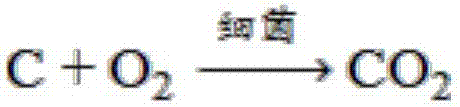

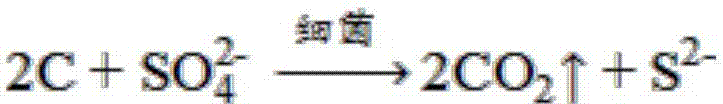

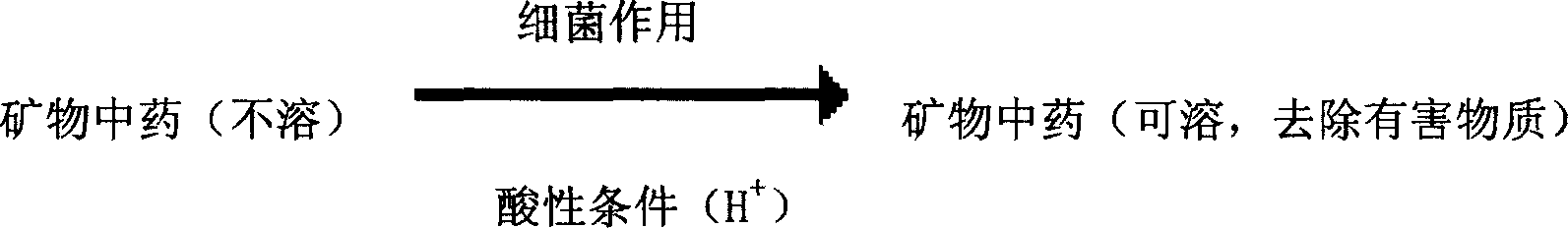

Heavy metal removal method from mineral drug

InactiveCN1839880APerformance is not affectedPlay effectivelyInorganic active ingredientsFermentationOrpimentCinnabar

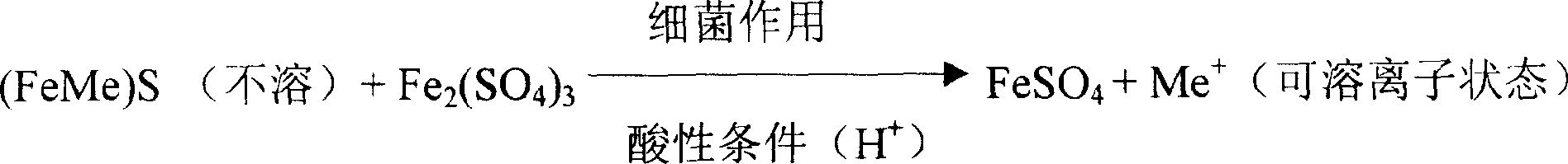

The invention discloses a process for processing mineral medicaments such as cinnabar, orpiment, native copper, magnetite, and reddle, especially the method for dissolving and removing hazardous materials in the medicaments, which comprises processing the minerals with bacteria, dissolving the minerals insoluble to water into aqueous solutions under the action of bacteria, then removing unwanted ions in the solution through chemical or physical methods.

Owner:LANZHOU UNIVERSITY

External traditional Chinese medicine for treating burn and scald

InactiveCN101874872ASignificant effectHeavy metal active ingredientsInorganic boron active ingredientsCentipedeCinnabar

The invention discloses an external traditional Chinese medicine for treating burn and scald, which is characterized in that the external traditional Chinese medicine is prepared from the following medicinal materials by weight: 10 to 20 kilograms of garden burnet root, 10 to 20 kilograms of Sinkiang arnebia root, 10 to 20 kilograms of borneol, 10 to 20 kilograms of beeswax, 10 to 20 kilograms of myrrh, 10 to 30 kilograms of notoginseng root, 10 to 20 kilograms of Chinese angelica, 10 to 20 kilograms of cinnabar, 10 to 20 kilograms of honeysuckle, 10 to 15 kilograms of swordlike atractylodes rhizome, 10 to 15 kilograms of Chinese gall, 10 to 15 kilograms of cortex phellodendri, 10 to 20 kilograms of rhubarb, 10 to 15 kilograms of bletilla hyacinthina reichb, 5 to 10 kilograms of centipede, 5 to 10 kilograms of golden thread, 10 to 20 kilograms of divaricate saposhnikovia root, 10 to 20 kilograms of natural indigo, 10 to 20 kilograms of gardenia jasminoides, 5 to 10 kilograms of margarita and 10 to 20 kilograms of sodium borate. The external traditional Chinese medicine is used for treating the burn and scald, and has the advantages of short treatment time, obvious curative effect and no scars after curing.

Owner:苏德才

Traditional Chinese medicine pillow for soothing nerves and preparation method thereof

The invention provides a traditional Chinese medicine pillow for soothing nerves and a preparation method thereof. The traditional Chinese medicine pillow comprises a pillow interior and a pillowcase; materials filled in the pillow interior comprises the components of aizoon stonecrop herb, concha ostreae, magnet, acanthopanax, concha margaritiferallsta, erosaria caputserpentis, amethyst, poria with hostwood, spina date seed, caulis polygoni multiflori, longan aril, lotus seed, lily, lucid ganoderma, cortex albiziae, folium apocyni veneti, rhizoma anemones altaicae, ginseng, polygala tenuifolia, platycladi seed, stigma croci, valerian, fructus choerospondiatis, cinnabar, physochlaina macrophylla and henbane. The preparation method comprises the following steps: cleaning and drying the raw materials; grinding; filtering through a filter net to obtain raw material powder; uniformly mixing the raw material powder according to the ratio; sterilizing through an ultraviolet lamp; packaging into a silk pillow interior; then sleeving the pillowcase to obtain the traditional Chinese medicine pillow. According to the traditional Chinese medicine pillow for soothing nerves and the preparation method thereof, all components in the formula are reasonably matched, which is beneficial for helping sleeping and can treat neurological disease well; all the components coordinately act and complement each other; the preparation process is simple, and mass production applies.

Owner:SUZHOU TIANLING CHINESE TRADITIONAL MEDICINE SLICE

Chinese traditional medicine composite for depressive neurosis, preparation method and application thereof

InactiveCN101204575AGood curative effectLong lastingHeavy metal active ingredientsPowder deliveryCinnabarSide effect

The invention belongs to the field of a Chinese traditional medicine preparation and in particular relates to a Chinese traditional medicine combination for curing depressive neurosis as well as a preparation method and application thereof.The ingredients composition of the combination are: Chinese thorowax root of 10-20 proportion, atractylodes ovata of 10-30 proportion, white peony root of 10-30 proportion, Chinese angelica root of 8-20 proportion, indian bread of 20-40 proportion, coptis root of 4-20 proportion, jujube kernel of 20-40 proportion, Chinese arborvitae kernel of 10-20 proportion, fresh rehmannia root of 10-20 proportion, dried tangerine peel of 5-18 proportion, magnolia officinalis of 5-20 proportion, pinellia of 5-15 proportion, thinleaf milkwort root of 8-20 proportion, dragon bone of 20-40 proportion, oyster of 20-40 proportion, szechwan lovage rhizome of 10-30 proportion, mint of 3-10 proportion, liquorice of 5-15 proportion, vermilion cinnabar of 3-10 proportion, fresh ginger of 1-2 proportion.According to clinical verification, the Chinese traditional medicine combination has the advantages of safety and no side effects, good treating effects, effectiveness rate of over 99 per cent and lasting medicine potency as well as low cost of the adopted components, low curing expense and the invention is convenient for promoting to be used among the patients with the depressive neurosis.

Owner:董建国

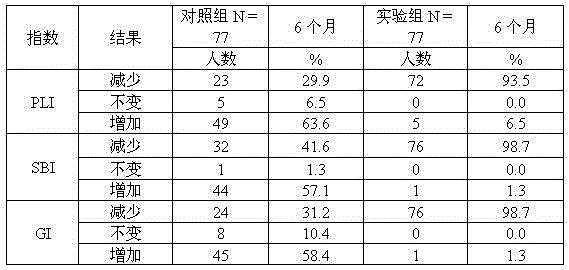

Biological lysozyme compound preparation and preparation method thereof

InactiveCN104800095AEfficient killingCompletely killAntibacterial agentsCosmetic preparationsCinnabarCarrageenan

The invention relates to a biological lysozyme compound preparation and a preparation method thereof. The preparation method comprises the following steps: dissolving lysozyme, amino acid, proteolytic enzyme, lysostaphin and peroxidase in water according to a certain proportion, transferring the mixed solution into a mixing tank, adding sorbitol, hydrated silica, aluminium hydroxide, glycerol, sodium lauroyl sarcosine, edible essence, cellulose gum, carrageenan, hydroxyethyl cellulose, sodium phytate, saccharin sodium, strontium chloride, trisodium phosphate, borneols, sodium borate, cinnabar, natrii sulfas exsiccatus and allantoin according to corresponding proportion, reacting for 47-49 h under a constant temperature condition of 38-42 DEG C to prepare the activated biological lysozyme compound preparation finished product. The biological lysozyme compound preparation belongs to a novel non-hormonic and non-antibiotic protein function preparation, has extremely great capacities of bacteriolyzing, reducing inflammation and enhancing immunity, and various effects of resisting various infections and promoting rehabilitation.

Owner:JIANGSU XUE BAO DAILY CHEM CO

Epilepsy therapy capsule and preparation method thereof

InactiveCN101559195APromote circulationEliminate pathological excitatory fociHeavy metal active ingredientsNervous disorderCinnabarMyrrh

The invention relates to an epilepsy therapy capsule and a preparation method thereof. The epilepsy therapy capsule comprises 36 herbs, namely uncaria, rhizoma gastrodiae, alum calcinata, realgar, frankincense, myrrh, polygala, grass-leaved sweetflag, jujube kernels, tuber pinellia, bamboo shavings, citrus aurantium, arisaema cum bile, ligustrum lucidum, schisandra chinensis, cyperus tuber, cinnabar, amber, centipedes, scorpions, muscardine silkworms, white peony roots, keels, oyster, nacre mothers, tuber fleeceflower stems,mulberries, leeches, earthworms, panax notoginseng, cassia twigs, kudzu roots, rhizomes of chuanxiong, safflowers, radix curcumae and liquorice, wherein the tuber fleeceflower stems,the kudzu roots and the liquorice are decocted for 3 times, supernatant fluid is condensed into cream, dried below 60 DEG C and crashed, the other 33 herbs are dried below 45 DEG C and processed into fine powder to be mixed with the herbs and screened to prepare the capsule. The epilepsy therapy capsule is suitable for curing various types of epilepsy and has obvious effect.

Owner:苗卫萍

External medicine formulation for treating anhypnia-depression and technology for making plaster using same

InactiveCN1742941AIncreased sensitivityStrong drug penetrationNervous disorderMammal material medical ingredientsCinnabarCodonopsis

The present invention discloses a prescription of medicine for external application for curing insomnic depression with obvious therapeutic effect. Said prescription is formed from 30 Chinese medicinal materials of cinnabar, epimedium, musk, silk tree bark, bamboo sugar, acanthopanax root bark, bovine bezoar and others.

Owner:徐涛

Light-converting luminous high-light-energy weather-resistant agricultural film and its manufacturing method

InactiveCN1709033AExtend the light timeShorten the growth cyclePlant protective coveringsLow-density polyethyleneCinnabar

The present invention discloses a light-converting night-light high-photoenergy weatherable agricultural film and its preparation method. It is made up by using basic resin and adjuvant. The basic resin can be polychlorovinyl, lower-density polyethylene, linear lower-density polyethylene, ethylene and polyvinylacetate copolymer or their mixture, and the adjuvant includes visible light excited long persistence light-converting agent A and B, in which A is rare earth doped aluminum hydrochloride and B is rare earth doped yttrium cinnabar, said invention provides their molecular formulae. Besides, said invention also provides its preparation method and application.

Owner:彭子飞

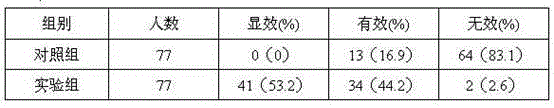

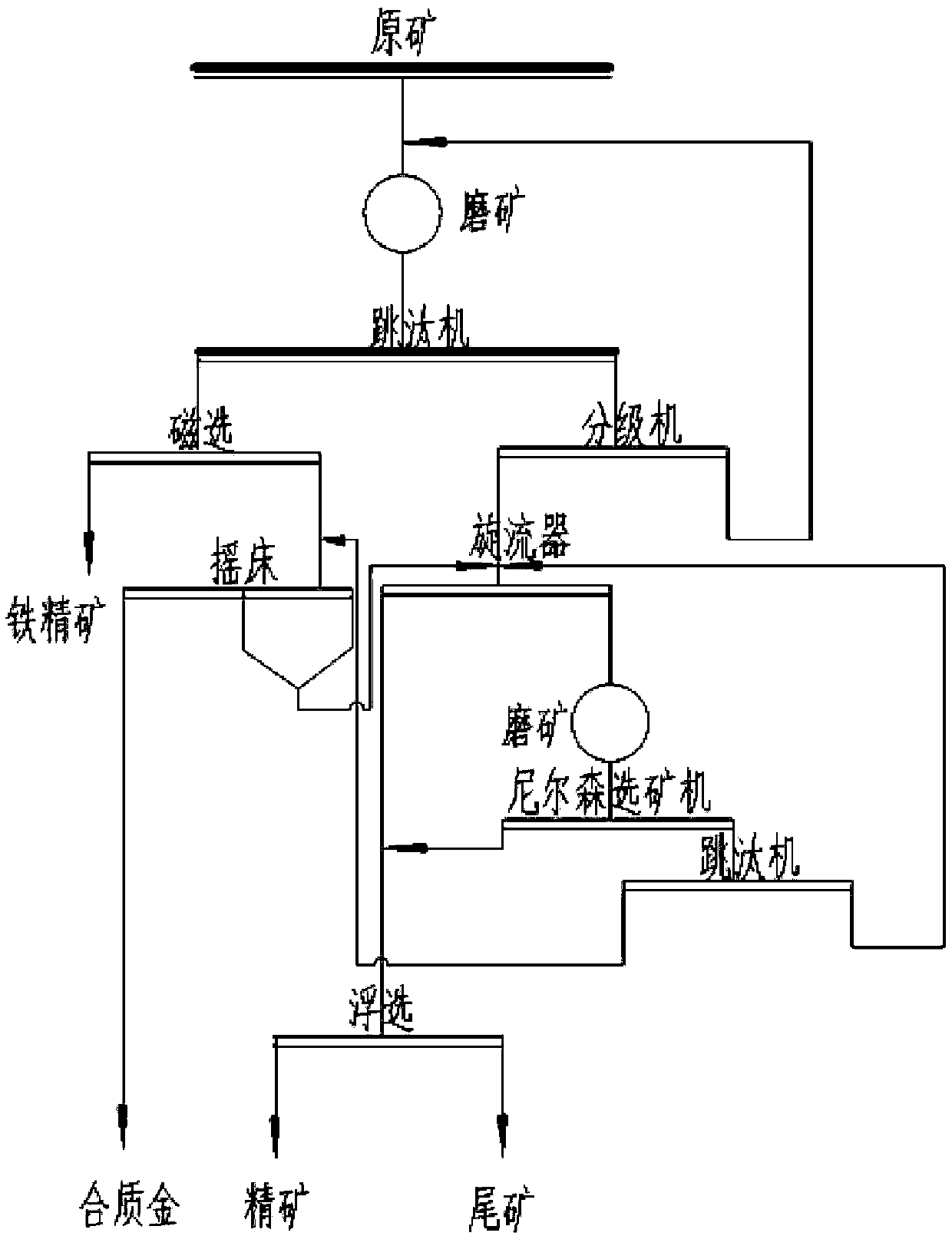

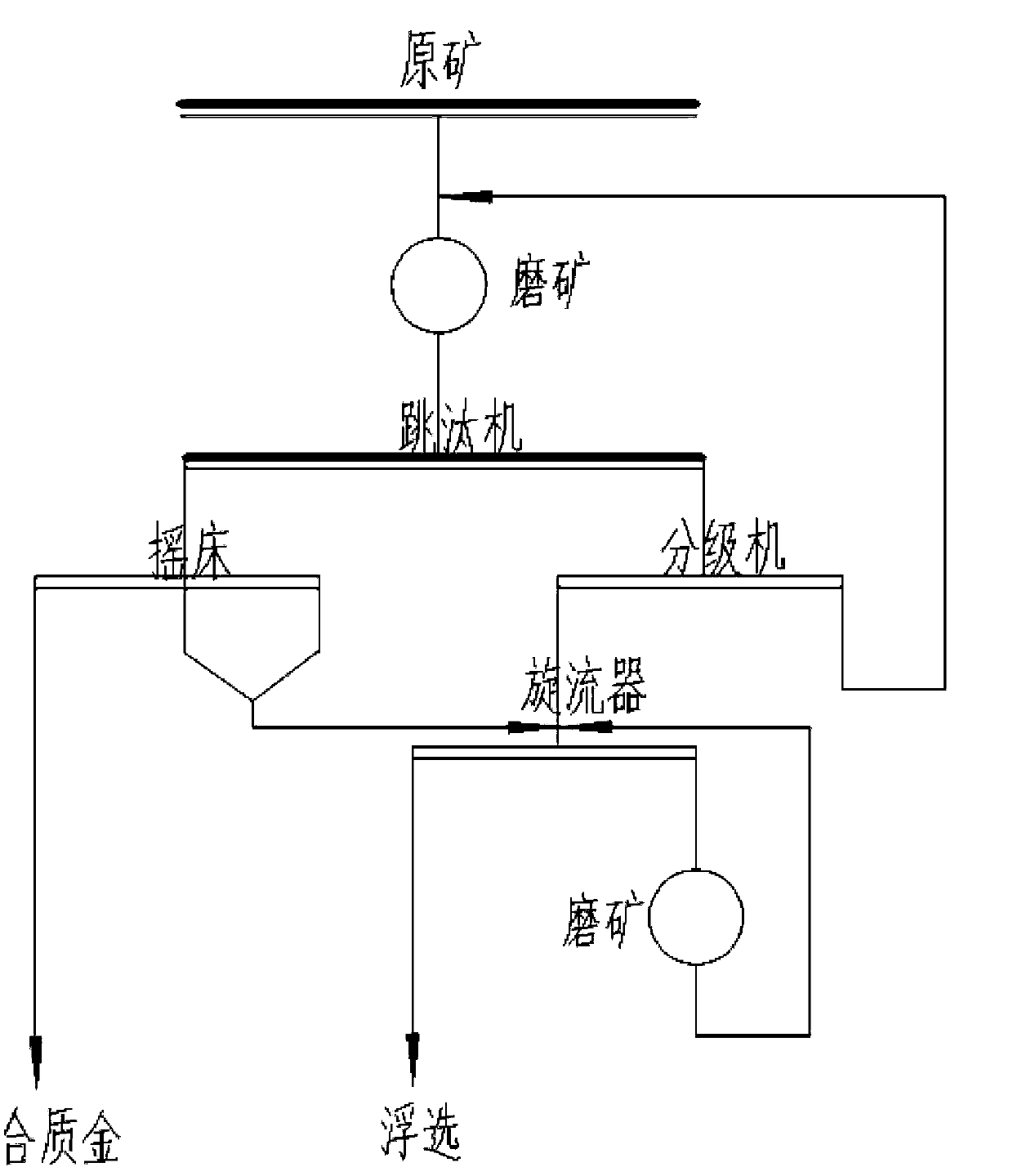

Reselection recovery method and device for gold

The invention discloses a reselection recovery method for gold. The method comprises the following steps that primary ore grinding is carried out on raw ore, ore pulp generated after ore grinding is sorted by a jigging machine, magnetic separation is carried out on jigged concentrates, and jigged tailings enter a classifier; the magnetic concentrates are selected finely to obtain iron ore concentrates, the magnetic tailings enter a table concentrator, and concentrates of the table concentrator are adopted as alloy gold; classification and machine overflowing are carried out on middlings and tailings of the table concentrator, the middlings and the tailings enter the cyclone, and coarse particles return to a first-stage ball grinder to be ground again; the cyclone carries out overflowing, the floatation operation is executed, secondary ore grinding is carried out on cinnabar, and materials obtained after ore grinding enter a Nelson concentrating machine; floatation is carried out on tailings of the Nelson concentrating machine, and concentrates begin to be jigged; the jigged concentrates enter the table concentrator, and jigged tailings return to the cyclone to be classified; the concentrates and the tailings are obtained through flotation. According to the reselection recovery method for the gold, the reselection recovery rate is improved by 22.11 percent, and the total recovery rate of ore dressing is improved by 2.69 percent.

Owner:HABAHE JINBA MINING

Guangdong Jun Blue glaze prepared from commonly used raw materials in ceramics factory and preparation method of Guangdong Jun Blue glaze

The invention belongs to the preparation field of traditional Guangdong Jun glaze in Foshan Shiwan art ceramics, and discloses a Guangdong Jun Blue glaze prepared from commonly used raw materials in a ceramics factory and a preparation method of the Guangdong Jun Blue glaze. The method comprises the following steps: using common glaze raw materials widely applied in the existing ceramics factory such as feldspar, quartz, limestone, calcined talc, black clay, cattle and sheep ashes and chemical toners CuO, CoO, Fe2O3 and the like to replace the lead-containing traditional raw materials such as ramulus mori ashes, miscellaneous wood ashes, straw ashes, canal mud, jade powder, carnelian cobble, copper ore, yellow stone, star cinnabar, graphite and Lion mountain ashes which are complex or expensive in treatment, or nearly exhausted, or large in toxicity to the environment. The Guangdong Jun glaze disclosed by the invention is wide in raw material resource, low in cost, simple in preparation process, and unnecessary to renovate the equipment, the obtained Guangdong Jun glaze formula is simple in composition, smooth in glaze, high in stability, and has the color characteristics of the Guangdong Jun glaze.

Owner:FOSHAN UNIVERSITY

Medicament for treating nocturnal fretfulness infants and preparation method thereof

InactiveCN101912548AReasonable compositionCompatibility is simpleNervous disorderDigestive systemJuncus bufoniusDisease

The invention discloses a medicament for treating nocturnal fretfulness infants, which is characterized by being mainly prepared from the following raw materials in part by weight: 1 to 20 parts of rose, 1 to 20 parts of seville orange flower, 1 to 20 parts of golden thread, 1 to 20 parts of abalone shell, 1 to 20 parts of uncaria, 1 to 20 parts of bamboo leaves, 1 to 20 parts of Juncus bufonius, 1 to 20 parts of cinnabar root poria, 1 to 20 parts of vine of multiflower knotweed, 1 to 20 parts of mix-fried licorice, 1 to 20 parts of calcined dragon bone, 1 to 20 parts of calcined oyster, 1 to 20 parts of rehmannia root, 1 to 20 parts of spiny jujube kernel, and 1 to 20 parts of over 95 percent edible alcohol. The medicament can be absorbed by spleen and stomach through oral administration, can be absorbed by skin through external use, and can be compositely absorbed through oral administration and external use. The medicament has reasonable formula, simple compatibility and accurate curative effect, and can treat both principal and secondary aspects of disease. The invention also provides a method for preparing the medicament.

Owner:葛德钜 +1

Black-body celadon body material, black-body celadon ware and production method of black-body celadon ware

The invention discloses black-body celadon body material, black-body celadon ware and a production method of the black-body celadon ware. The black-body celadon body material comprises, by weight, 26-31 parts of Huangshixuan porcelain clay, 3-8 parts of Mudaikou Zijin clay, 1-6 parts of Gaojitou Zijin clay, 25-30 parts of Jindan porcelain clay and 22-27 parts of Baogeng porcelain clay. The black-body celadon ware using the body material is high in yield during firing and stable in quality and has the cinnabar color of pure Longquan porcelain. The black-body celadon ware is stable in quality, attractive and pure in color and high in yield.

Owner:龙泉市建春青瓷厂

Alumina-silica drainage agent and preparation method thereof

ActiveCN104493150AImprove performanceNo pollution in the processMelt-holding vesselsCinnabarSteelmaking

The invention provides an alumina-silica drainage agent and a preparation method thereof and belongs to the field of amorphous surface fireproofing materials for steelmaking industries. According to the technical scheme, the alumina-silica drainage agent is prepared from pottery cinnabar with the granularity of 0.5-1.2mm, desert silica sand with the granularity of 0.3-0.9mm, flake graphite with the granularity smaller than or equal to 75 mu m, and an adhesive. The preparation method includes first drying the pottery cinnabar and the desert silica sand, adding the flake graphite and the adhesive, and performing stirring in a barrel type stirrer to prepare the alumina-silica drainage agent. The alumina-silica drainage agent is clean, environmentally friendly, and capable of effectively increasing a pouring rate of a product to above 98%, meanwhile substantially reducing product costs, effectively reducing discharge of exhaust gases and dust, and meeting requirements for product qualities, prices and steel liquid purity degrees in present steel industries.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Disease preventing and curing medicinal mouth-muffle and medicinal composite

InactiveCN101524190AEasy to wearShort course of treatmentAntibacterial agentsHeavy metal active ingredientsCinnabarMyrrh

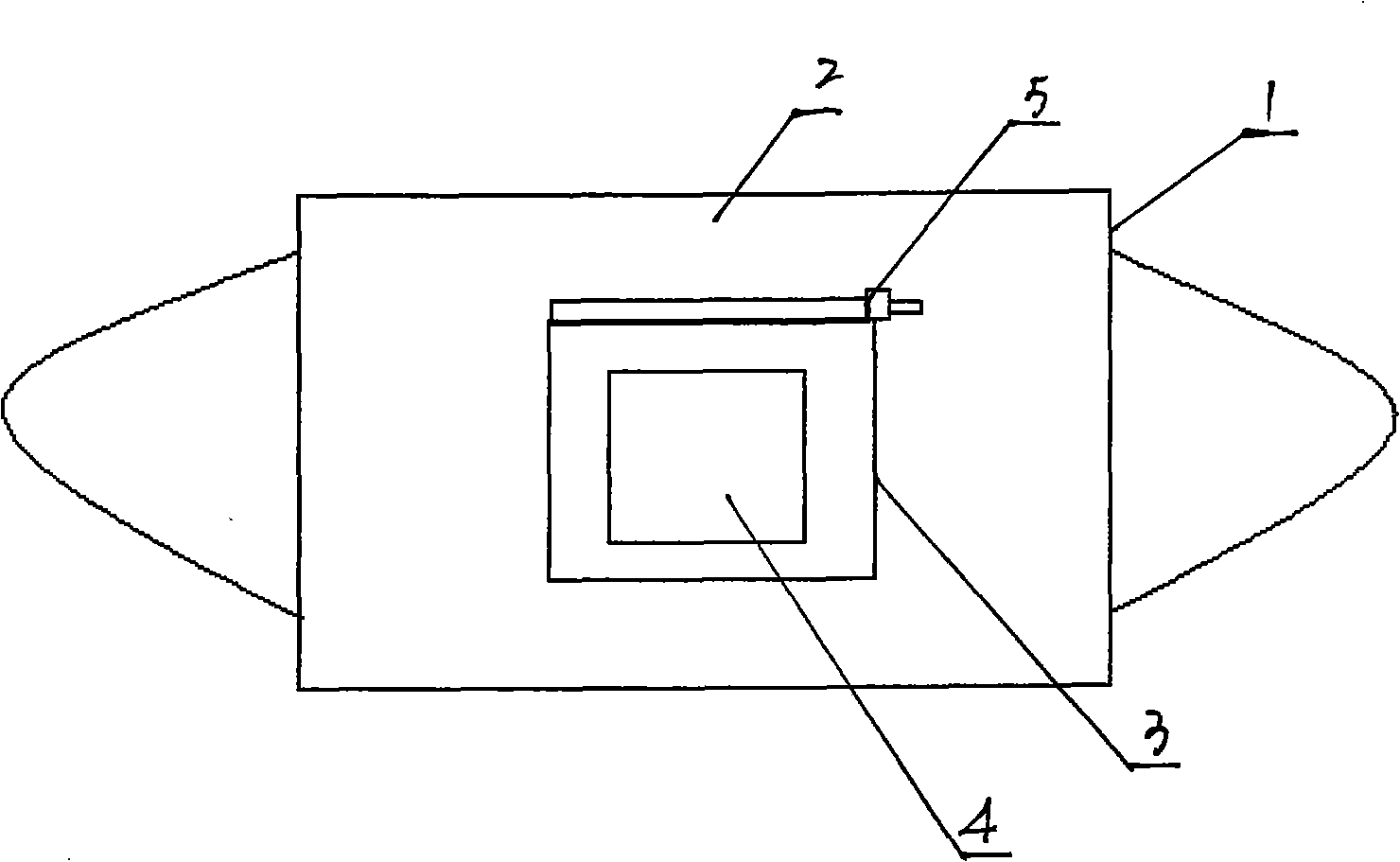

The invention relates to a disease preventing and curing medicinal mouth-muffle and a medicinal composite. The disease preventing and curing medicinal mouth-muffle (1) comprises a mouth-muffle body (2), one surface of the mouth-muffle body (2) is provided with an insert pocket (3), and a powder bag (4) which packages the medicinal composite is placed in the insert pocket (3). The medicinal composite comprises the following Chinese herbs by weight: 2.2 percent of chrysanthemum and muskiness, 4.2 percent of cinnamon, good ginger, long pepper, radix aconite, frankincense, myrrh and clove, 5.0 percent of vermilion, 6.4 percent of asarum, eaglewood, croton, resina draconis, early plum flowers and rhizoma ligustici wallichii and 7.6 percent of tooth soap, arsenic sulphide and brain sand. The disease preventing and curing medicinal mouth-muffle internally carries the medicinal composite which plays a role during the mouth-muffle wearing process, thereby having disease prevention and cure and being simple and direct and also effective in treatment.

Owner:孙永春

Externally used traditional Chinese medicine and its preparing process

ActiveCN101011444AWith detoxificationWith detumescencePowder deliveryHeavy metal active ingredientsCinnabarMyrrh

The invention relates to an external traditional drug, formed by 1-15 deals of traditional drug powder, 5-30 deals of mentha-camphor, 5-30 deals of baras camphor, and 920-990 deals of base material, wherein, the traditional drug powder comprises toad venoms, snail, moschus, frank incense, myrrh, aerugo, bluestone, cinnabar, orpiment or the like. And the preparation comprises that 1, breaking themoschus, toad venoms, orpiment, and cinnabar into powder; adding left materials, drying, and returning to 20-30Deg. C, breaking into powder; mixing powders uniformly, screening into fine powder; 2, adding fine powder into base material, adding mentha-camphor and baras camphor, to be mixed uniformly to obtain the final product. The invention can be used to treat malignant boil or the like, with fewer side effects.

Owner:GUANGDONG TAIANTANG PHARMA

Medicine for removing toxic substances and promoting tissue regeneration and preparation method thereof

InactiveCN101658609ALow priceEliminate infectionPowder deliveryHeavy metal active ingredientsHalloysiteCinnabar

A medicine for removing toxic substances and promoting tissue regeneration combines powder for removing toxic substances and promoting tissue regeneration and ointment for removing toxic substances and promoting tissue regeneration. The powder for removing toxic substances and promoting tissue regeneration is made from the following raw materials by weight proportions: elephant skin, pearl, borneol, cinnabar, dragon's blood, calcined dragon's bone, gypsum and licorice; and the ointment for removing toxic substances and promoting tissue regeneration is made from the following raw materials by weight proportions: dragon's blood, carbonized human hair, pangolin, dahurian angelica root, rehmannia root, Japanese ampelopsis, elephant skin, red peony root, raw gardenia, rheum officinale baill, frankincense, realgar, angelica, red halloysite, musk, figwirt root, peach branches, apricot branches, willow branch and starch. The powder and the ointment are used in combination, and the raw materials have unique compatibility. The medicine solves the problems of long resistance to treatment of surgical infections and wounds with Chinese traditional medicine, has advantages of obvious curative effect, low price and no side effect, can quickly eliminate wound infection, and accelerate wound healing.

Owner:白瑞

Nano Chinese medicinal preparation of 'An Gong Niu Huang Wan' and preparation method thereof

InactiveCN1883685APrevent redoxAvoid lostHeavy metal active ingredientsHydroxy compound active ingredientsOrpimentCurcuma aromatica

The invention discloses a nano resurrection Chinese medicinal preparatoin and its preparing process, wherein the preparation is prepared from goldthread root, baikal skullcap root, cape jasmine, curcuma aromatica, cow-bezoar, buffalo horn concentrated powder, musk, pearl powder, cinnabar, orpiment and boneol. The preparation can be made into dose forms including tablets, capsules, granules, and drop pills.

Owner:张晴龙

Spot-bronze coloring liquid and application thereof

InactiveCN104404499AGood color controllabilityShorten the timeMetallic material coating processesCinnabarBronze coloring

The invention discloses a spot-bronze coloring liquid and an application thereof, and belongs to the field of metal material surface treatment and handicraft making. The coloring liquid is prepared by using the following raw materials, by weight, 10-20 parts of copper sulfate, 6-15 parts of potassium chloride, 1-4 parts of potassium borate, 4-12 parts of cinnabar and 150-300 parts of distilled water. The coloring liquid is used in spot-bronze production to obtain dark red spot-bronze, and spot-bronze obtained in the invention has unsophisticated and beautiful appearance; the color of the spot-bronze can be controlled according to the time length and personal preference, and can be dark or brilliant, and the preparation process is flexible and controllable; the obtained spot-bronze has the characteristics of stability, and no color change or fading; and a making method of the spot-bronze has the advantages of simple operation, low production cost, non-restriction by the shape of a product, and beautiful color of the product.

Owner:KUNMING UNIV OF SCI & TECH

Technique for filling cinnabar to hollow pattern of transparent object

InactiveCN102529552AVividColorfulDecorative surface effectsSpecial ornamental structuresCinnabarMaterials science

The invention relates to a technique for filling cinnabar to a hollow pattern of a transparent object, comprising the following steps: (A) cutting the transparent object into a shape of a required block; engraving the required pattern on a transparent block according to a drawing; (B) cleaning the engraved hollow pattern, and drying in the air; (C) uniformly blending cinnabar powder with gum water at a ratio of 1:1; (D) filling the uniformly blended mixture into the hollow pattern and then drying; and (E) cleaning the dried transparent handiwork and then packaging. The technique of invention is simple in operation, and can process various vivid, colorful and animated handiworks with great attractiveness to people.

Owner:GUIZHOU WANSHAN DC DANYUAN CINNABAR CRAFTS CO LTD

Externally applied medicament for treating oral diseases and preparation method thereof

InactiveCN101703525AGood treatment effectHeavy metal active ingredientsAnthropod material medical ingredientsMedicinal herbsCinnabar

The invention discloses an externally applied medicament for treating oral diseases, which is mainly prepared from the following Chinese medicinal raw materials in part by weight: 100 to 120 parts of Chinese gall, 12 to 15 parts of borneol, 2 to 3 parts of pearl, and 15 to 20 parts of cinnabar. The medicament uses the Chinese gall as a basic remedy to astringe dampness and aphtha, and to detoxify toxins, and uses the borneol, the pearl and the cinnabar as adjuvant to clear heat, relieve pain and detoxify toxins so as to together play a role in clearing heat and detoxifying toxins. The externally applied medicament mainly treats canker sore and thrush, and also has remarkable curative effect of treating sore throat and gum swelling and pain. If 1 to 2 parts of bezoar and 1 to 2 parts of musk by weight are added into the medicament, the medicament has better effec; because the bezoar has the effect of stopping endogenous wind and detoxifying toxins, and the musk has the effects of reducing swelling and relieving pain, the curative effect of the medicament can be more prominent after the addition of the bezoar and the musk. The externally applied medicament adopts Chinese medicinal herbs as raw materials, has no toxic or side effect, sufficient medicament sources and low cost, has the advantages of good curative effect, short treatment course and high healing rate, and is convenient for use without adverse reactions.

Owner:陈冰昆

Traditional Chinese medicine composition for treating weak constitution and enhancing immunity, as well as preparation method and application thereof

ActiveCN103202986AWell mixedMix well mix wellHeavy metal active ingredientsHydroxy compound active ingredientsCinnabarCurative effect

The invention discloses a traditional Chinese medicine composition for treating weak constitution and enhancing immunity, as well as a preparation method and application thereof, and belongs to the field of traditional Chinese medicine. The traditional Chinese medicine composition is prepared from the fried rhizoma cyperi, asarum, root of three-nerved spicebush, fructus piperis longi, pogostemon cablin, radix bupleuri, schizonepeta, fructus amomi, mint, clove, fried dried tangerine, amomum kravanh, radix angelicae pubescentis, liquorice, fried ligusticum wallichii, radix trichosanthis, folia perillae acutae, gastrodia elata, radix angelicae, sandalwood, rhizoma pinellinae paeparata and radices sileris which are used as raw materials, as well as cinnabar, borneol and realgar which are used as auxiliary materials. The traditional Chinese medicine composition disclosed by the invention has an excellent curative effect on treatment of weak constitution and enhancement of the immunity.

Owner:GUANGDONG LIANKANG PHARMA

Method for removing heavy metal from mineral Chinese medicine

InactiveCN1682757AControl effective contentDoes not affect performanceInorganic active ingredientsInanimate material medical ingredientsCinnabarMedicine

The present invention relates to medicine material treating method, and method of removing harmful heavy metals and arsenic from mineral Chinese medicinal materials, such as cinnabar, realgar, native copper, magnet, hematite, etc. The method includes bacteria treatment of mineral Chinese medicinal materials to convert the water insoluble components in the mineral Chinese medicinal materials into water soluble components, and subsequent specific chemical deposition reaction, membrane dialysis and / or other steps to eliminate harmful ions in the solution.

Owner:LANZHOU UNIVERSITY

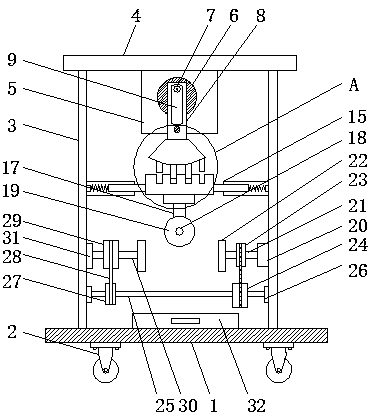

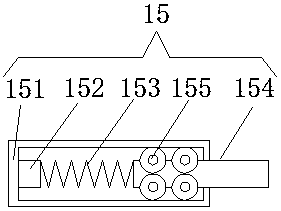

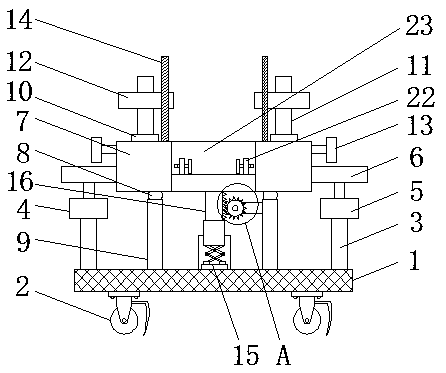

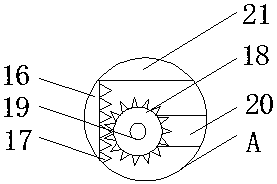

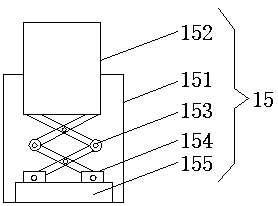

Cinnabar artware processing device and method with grinding wheel vertical row

InactiveCN108115523AImprove aestheticsSimple structureGrinding carriagesGrinding drivesCinnabarPulp and paper industry

The invention discloses a cinnabar artware processing device with a grinding wheel vertical row in the technical field of cinnabar artware processing. The device comprises a base, side plates are installed on the left side and the right side of the top of the base respectively, and a transverse plate is installed on the tops of the two side plates; a fixed plate is arranged in the center of the bottom of the transverse plate, and a boss is arranged on the side, away from the circle center, of a rotary plate; a connecting rod is arranged on the boss in a sliding mode, and a clamping groove matched with the boss is formed in the connecting rod, the bottom of the connecting rod is fixed to the fixed plate through a pin shaft, and a connecting block is arranged at the bottom of the connectingrod; teeth are arranged at the bottom of the connecting block, a movable plate is arranged at the bottoms of the teeth, and a tooth groove matched with the teeth is formed in the movable plate. The device is simple in structure and convenient to use, the grinding efficiency is improved, the situation that the shape is irregular due to manual grinding is effectively avoided, the attractiveness of cinnabar artware is improved, dust generated by grinding is collected through a collecting box, and environment pollution is prevented.

Owner:苏州智吉兴敏电子科技有限公司

Medicine for treatment of skin ulcer

InactiveCN103830478ASafe and effective treatmentGood treatment effectHeavy metal active ingredientsHydroxy compound active ingredientsDiseaseCinnabar

The present invention relates to a medicine for treatment of skin ulcer. The medicine comprises, by weight, 5-15 parts of selaginella tamariscina, 3-8 parts of borneol, 10-20 of rheum officinale; 5-15 parts of litharge; 5-15 parts of catechu; 10-20 parts of crude fossil fragments; 10-20 parts of Chinese angelica; 3-8 parts of cinnabar; 5-15 parts of frankincense; 3-8 parts of dragon's blood; 4-12 parts of lithospermum; 6-14 parts of Chinese magnoliavine; and 10-16 parts of calamine. Traditional Chinese medicines of the invention are formulated by clinical combination for several times, The medicine has effects of invigorating blood circulation and dispelling slough, relieving pain and promoting regeneration, engendering flesh, astringing sore and solidifying skin, nourishing blood, moistening skin and dispelling turgescence. The medicine is based on systemic treatment, treats both principal and secondary aspect of disease after being used. Proved by hundreds of clinical experiments, the medicine has obvious effects for severe and lingering ulcer, complex wound (such as cutting, stamping contusion, open fracture, and the like), bedsore, lower limb ulcer, and the like. The effective rate achieves 92%. The medicine has high cure rate.

Owner:马翠霞

Medicament for treating senile dementia and preparation method thereof

InactiveCN101912597AReasonable compositionCompatibility is simpleHeavy metal active ingredientsNervous disorderCinnabarConvulsion

The invention discloses a medicament for treating senile dementia, which is characterized by mainly preparing from the following raw materials in part by weight: 1 to 20 parts of rose, 1 to 20 parts of seville orange flower, 1 to 20 parts of honey-fried astragalus, 1 to 20 parts of szechwon tangshen root, 1 to 20 parts of stir-fried spiny jujube kernel, 1 to 20 parts of loadstone and cinnabar pill, 1 to 20 parts of root of red-rooted salvia, 1 to 20 parts of black sliced aconite, 1 to 20 parts of stir-fired large-headed atractylodes rhizome, 1 to 20 parts of irkutsk anemone rhizome, 1 to 20 parts of cinnabar thinleaf milkwort root-bark, 1 to 20 parts of Chinese magnoliavine fruit, 1 to 20 parts of fresh ginger and 1 to 20 parts of over 95 percent edible ethanol. The medicament can be absorbed by the spleen and stomach through oral administration or absorbed by skin through external use and can be absorbed through the combination of oral administration and external use. The medicament has the advantages of addressing both the symptoms and root causes, along with reasonable formula, simple compatibility and definite curative effect, and is suitable for patients with convulsions, epilepsy and dementia and diagnosed as patients deficient in origin and excessive in superficiality. The invention also provides the preparation method of the medicament.

Owner:葛德钜 +1

Preparation method of notoginseng-containing tablet for treating traumatic injury

ActiveCN1840052APromote absorptionAppropriate fine powder meshHeavy metal active ingredientsHydroxy compound active ingredientsCinnabarBLACK CATECHU

The invention relates to a preparation method of notoginseng-containing tablet for treating traumatic injury, which comprises comminuting cinnabar, musk, dragon's blood resin, baras camphor, notoginseng, myrrh, safflower, frankincense, Chinese angelica root and black catechu, mixing and sieving to obtain granules, drying and charging musk, baras camphor fines, mixing homogenously and tabletting.

Owner:重庆希尔安药业有限公司

Stomach medicine and preparation method thereof

ActiveCN102908525AWide range of treatmentSignificant effectHeavy metal active ingredientsDigestive systemCinnabarSide effect

The invention relates to a stomach medicine and a preparation method thereof. The stomach medicine provided by the invention comprises the following components according to certain weight proportion: elephant hide, pearl, tendril-leaved fritillary bulb, radix notoginseng, bletilla striata, yugu, shiluoke, radix codonopsitis, honey-fried licorice root, white paeony root, tortoise plastron, turtle shell, cornus, Asiatic striga, membranous milkvetch root, dried alum, gedanite, fossilizid, oyster and cinnabar. The stomach medicine provided by the invention has the advantages of low cost, little side effects and obvious curative effect and reduces recurrence rate of the patient. The preparation method of the stomach medicine is simple and feasible and the stomach medicine can be self-prepared.

Owner:余福海 +1

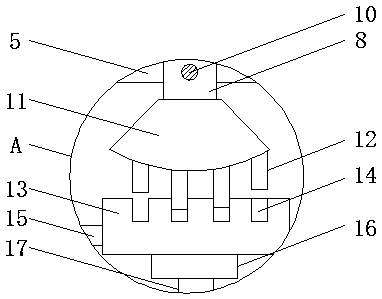

Cinnabar handicraft processing device with multiple grinding wheels in transverse row and method

InactiveCN108311968AEfficient grindingPolished evenlyGrinding carriagesRevolution surface grinding machinesCinnabarEngineering

The invention discloses a cinnabar handicraft processing device with multiple grinding wheels in a transverse row in the technical field of cinnabar handicraft processing. The device comprises a base;a rotating disk is engaged between two gears; the left side and the right side of the bottom of the rotating disk are each connected with a fixing rod through a rolling ball; the grinding wheels arearranged on a movable rod in the horizontal direction; a lifting device is installed on the top center of the base; a fixing plate is installed on the top of the lifting device; gear teeth are arranged on the outer wall of the right side of the fixing plate; a rotating gear is engaged with the right side of the gear teeth; an object containing table is installed on the top of the fixing plate; anda clamp is installed on the top of the object containing table. By means of the device, the grinding efficiency is improved, meanwhile, the clamp can be used for clamping cylindrical cinnabar stone,semicircular anti-slip protrusions effectively prevent the cylindrical cinnabar stone from rotating during grinding, the grinding efficiency is improved, grinding is uniform, the condition of an irregular shape is effectively avoided, manpower and material resources are saved, and cinnabar handicrafts are more attractive.

Owner:苏州盛迪通电子科技有限公司

Medicine for treating rhinitis and method for preparing the same

InactiveCN101112483ASignificant effectNo side effectsHeavy metal active ingredientsPowder deliveryCinnabarNasal cavity

The present invention relates to a drug for treating rhinitis and the preparation method, the method includes that the Chinese eaglewood, frankincense, costustoot, croton cream, Szechuan pepper, cinnabar, realgar, Sanguis Draconis, sal ammoniac etc. are mixed and smashed, then the musk is added, the red date paste (removing the core) is used for even mixing, and then the pill is prepared. When in use, the present invention is inserted into the nasal cavity for local absorption, no pain, no trauma, and thus is applicable to people of all ages; furthermore, the present invention is safe and has no adverse reactions. The present invention has significant effects particularly for the treatment of dizziness, headache, runny nose, stuffy nose etc. caused by acute and chronic rhinitis, sinusitis and frontal sinusitis, which is a pure traditional Chinese medicine to treat the rhinitis fundamentally.

Owner:郭金梁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com