Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

209 results about "Cyclic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carboxylic acids that have a homocyclic ring structure in which all the ring atoms are carbon.

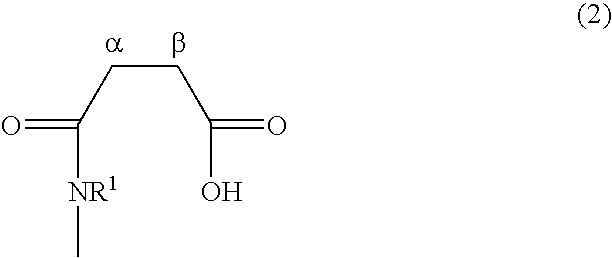

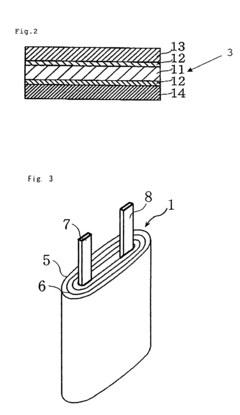

Light-sensitive lithographic printing plate

InactiveUS20050214677A1High developing latitudeExcellent printing durabilityPhotosensitive materialsLithographyOrganic acidPlanographic printing

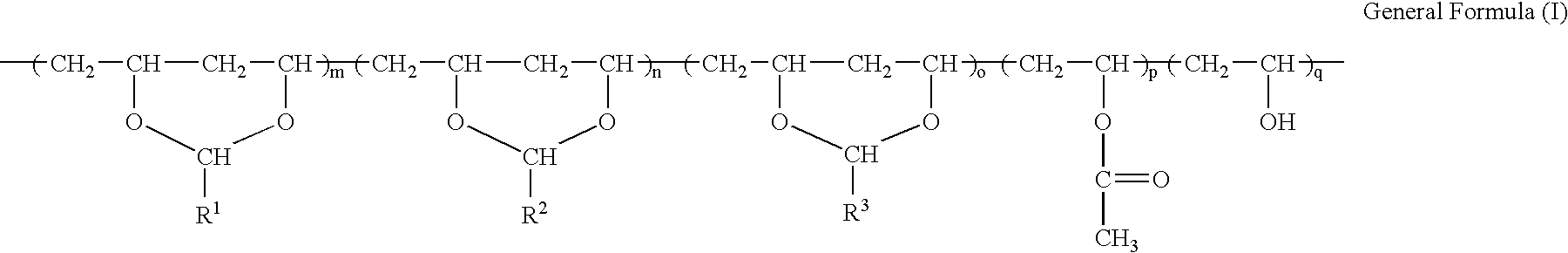

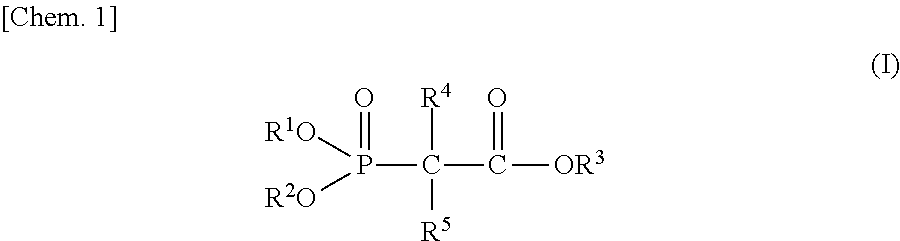

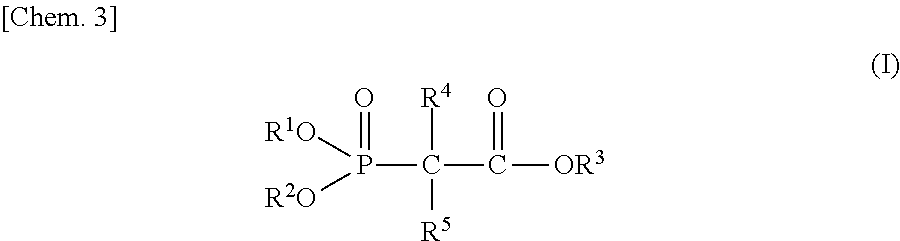

A light-sensitive lithographic printing plate comprising a hydrophilic substrate provided thereon with a layer sensitive to infrared light rays comprising (A) a polymer represented by the following general formula (I); (B) an organic acid and / or a cyclic acid anhydride; and (C) a light-heat conversion substance. The light-sensitive lithographic printing plate is excellent in the both printing durability and the developing latitude.

Owner:FUJIFILM HLDG CORP

Skin lightening composition

InactiveUS20060142382A1Good effectGood whitening effectBiocideCosmetic preparationsEngineeringTranexamic acid

A composition which comprises (i) tranexamic acid or a salt thereof, (ii) L-cysteine, a derivative thereof or a salt thereof and, as occasion demands, (iii) L-ascorbic acid, a derivative thereof or a salt thereof.

Owner:DAIICHI PHARMA CO LTD

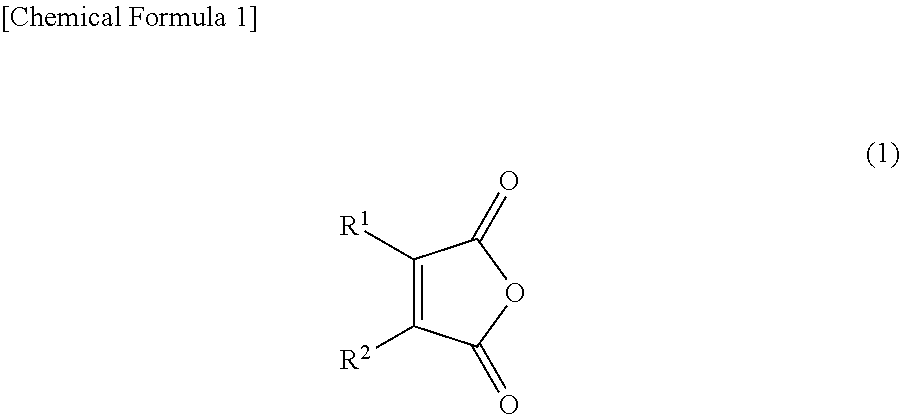

Battery

InactiveUS20060228625A1Improve featuresAvoid reactionOrganic electrolyte cellsActive material electrodesHalogenSuccinic anhydride

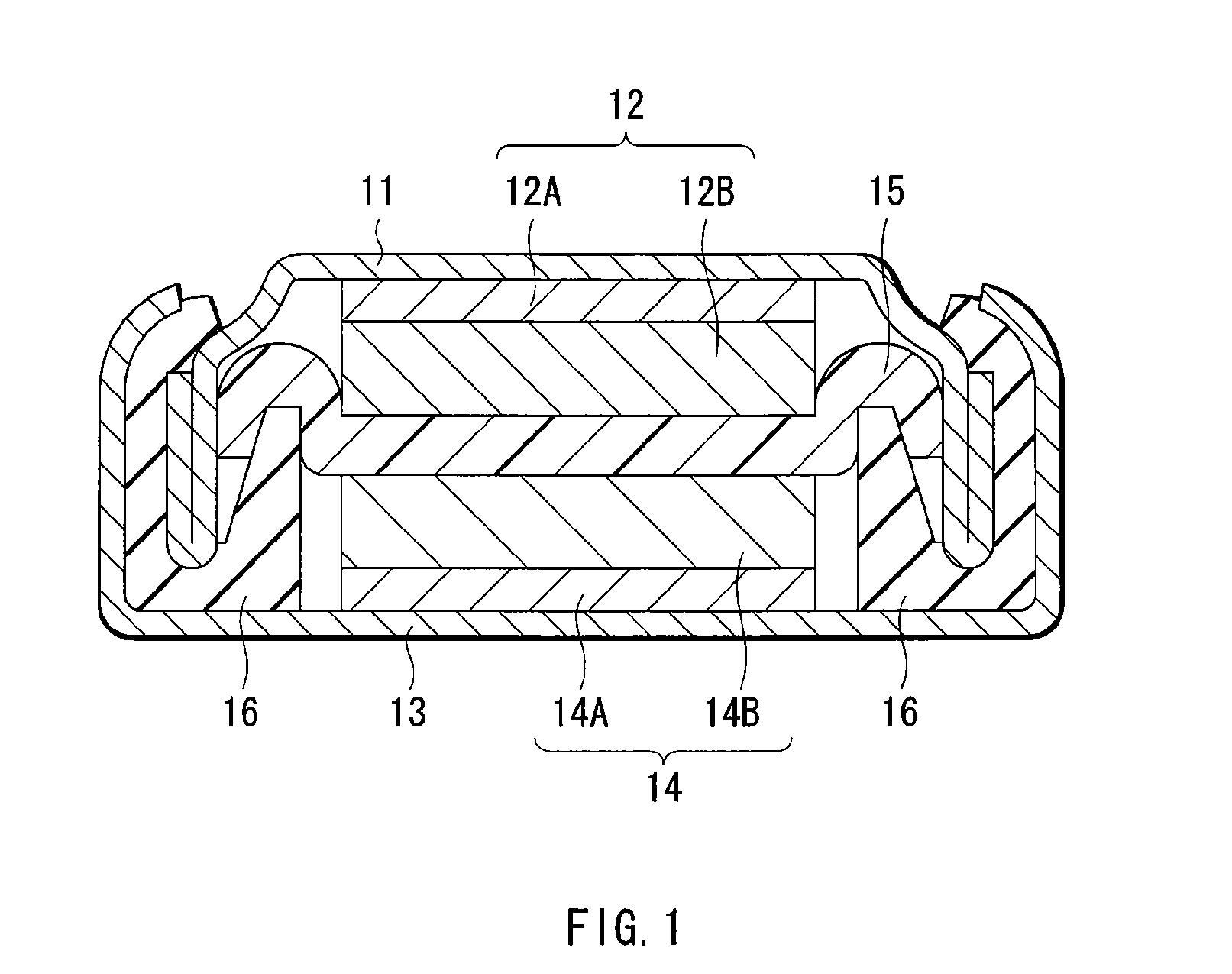

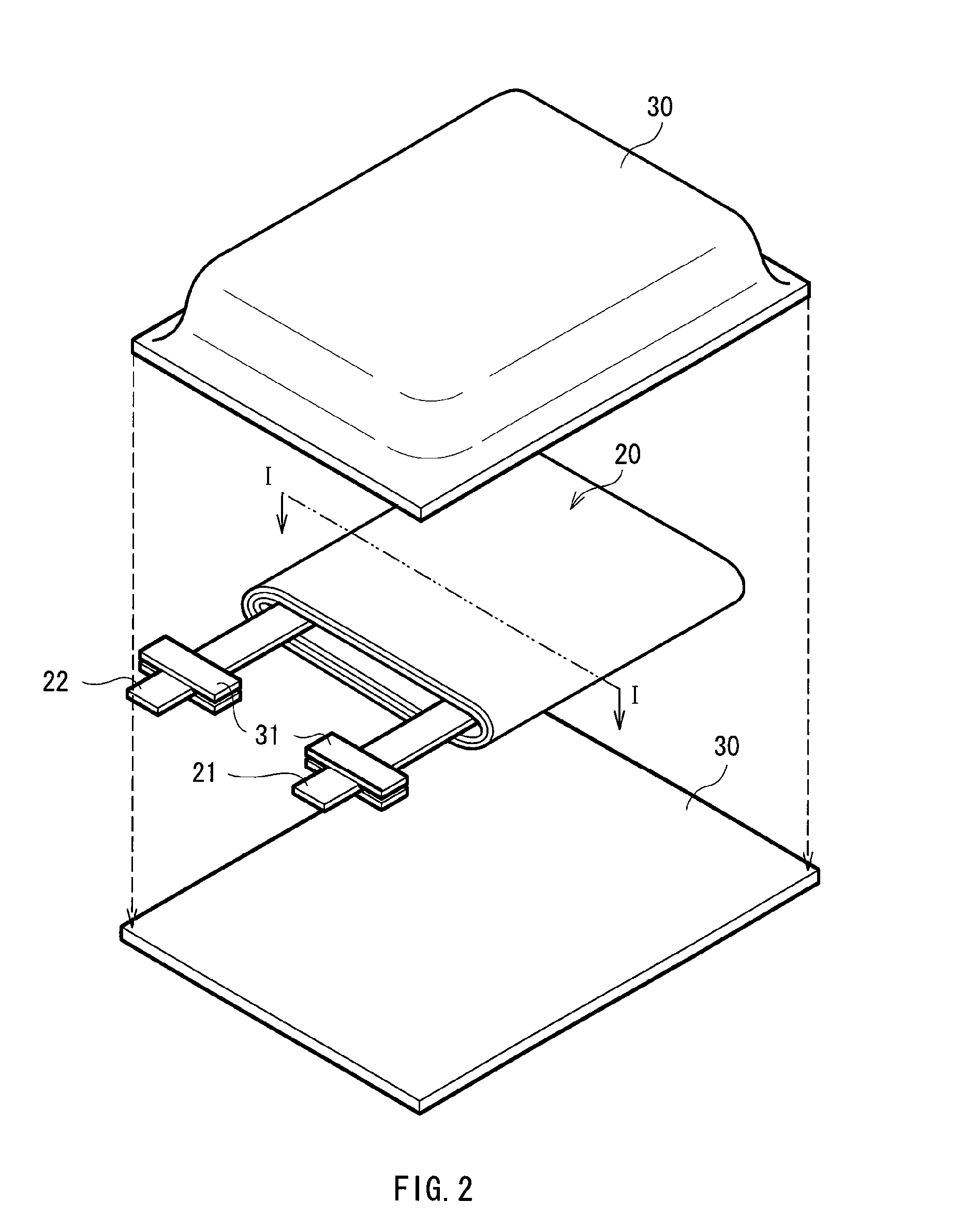

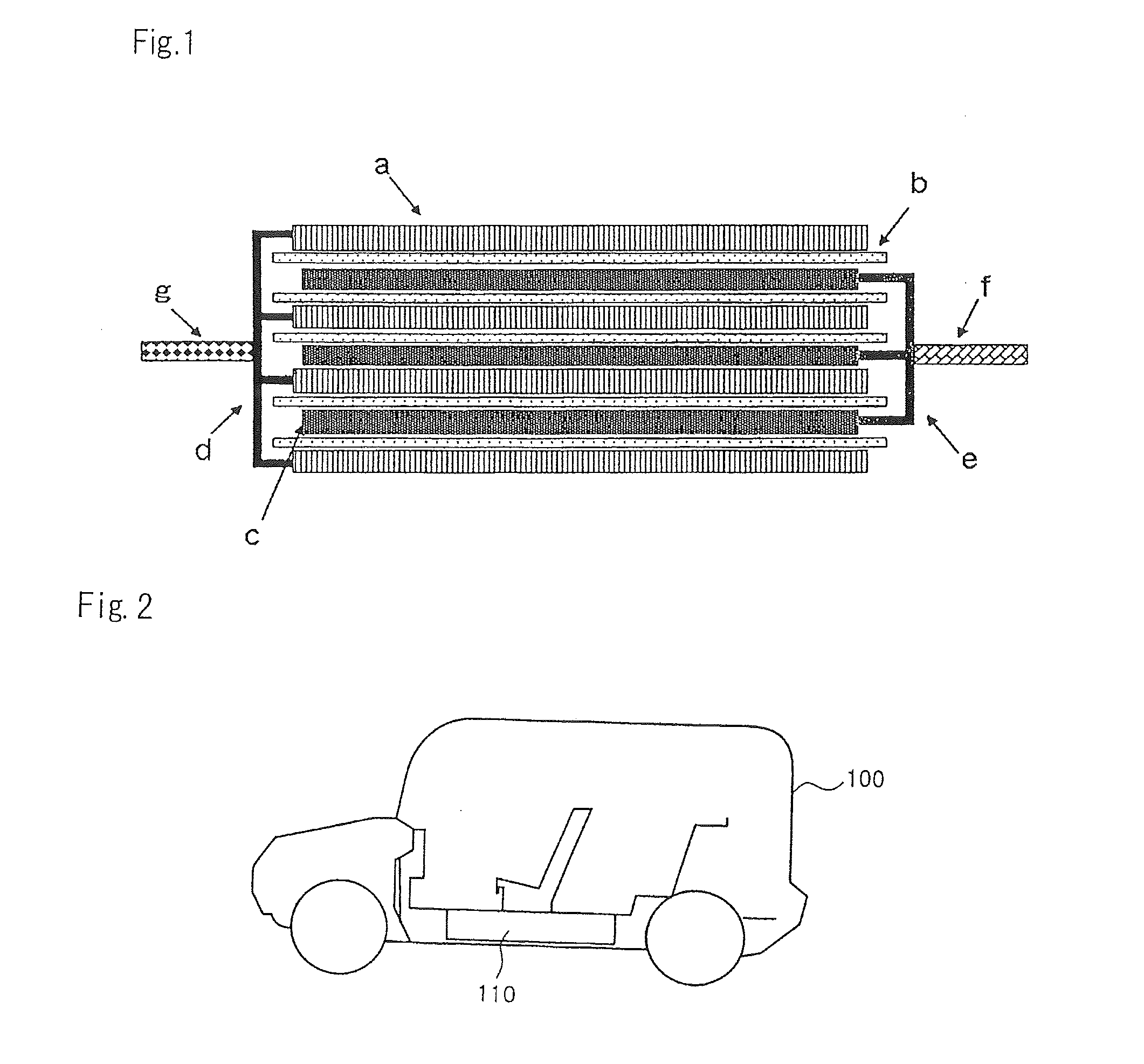

A battery capable of improving cycle characteristics is provided. A cathode and an anode are oppositely arranged with a separator in between. An electrolytic solution is impregnated in the separator. The electrolytic solution contains a derivative of cyclic carbonate having halogen atoms such as 4-fluoro-1,3-dioxolane-2-one and 4-chloro-1,3-dioxolane-2-one; and a cyclic acid anhydride such as succinic anhydride. The anode has an anode current collector and an anode active material layer which is provided on the anode current collect and is alloyed with the anode current collector at least at part of the interface with the anode current collector

Owner:MURATA MFG CO LTD

Non-aqueous electrolyte lithium secondary battery

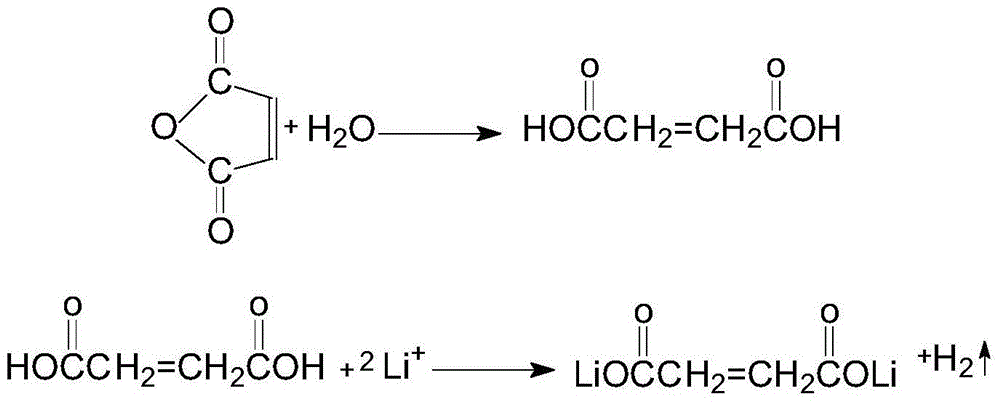

ActiveUS20110111305A1Excellent charge and discharge characteristicsInhibitory responseNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsOrganic solventCarbonate ester

A non-aqueous electrolyte includes (i) an inhibitor against a reaction between an anode and a linear ester; (ii) a mixed organic solvent containing cyclic carbonate and the linear ester; and (iii) an electrolyte salt, wherein the inhibitor is any one compound or a mixture of at least two compounds selected from the group consisting of cyclic carbonate with a vinyl group, fluorinated ethylene carbonate, vinylene carbonate, cyclic acid anhydride, a compound having a cyclic S═O group and an acrylate-based compound. Also, an electrochemical device includes a cathode, an anode and the above non-aqueous electrolyte.

Owner:LG ENERGY SOLUTION LTD

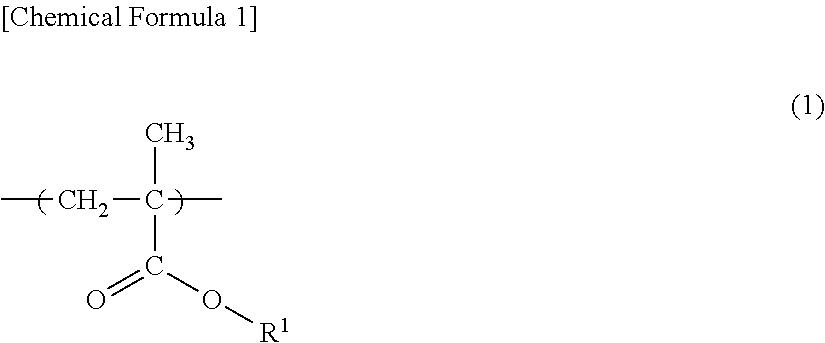

Positive resist composition and patterning process

ActiveUS20120220112A1Improve adhesionExpand coveragePhotosensitive materialsSemiconductor/solid-state device manufacturingResistImage resolution

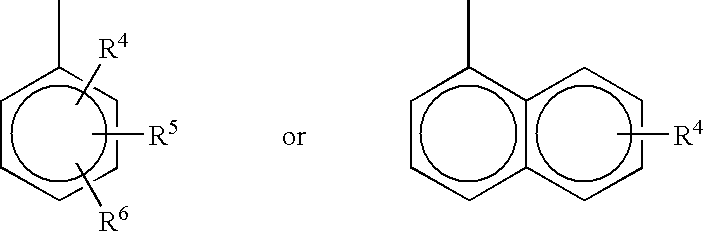

A positive resist composition based on a polymer comprising recurring units of (meth)acrylate having a cyclic acid labile group and a dihydroxynaphthalene novolak resin, and containing a photoacid generator is improved in resolution, step coverage and adhesion on a highly reflective stepped substrate, has high resolution, and forms a pattern of good profile and minimal edge roughness through exposure and development.

Owner:SHIN ETSU CHEM IND CO LTD

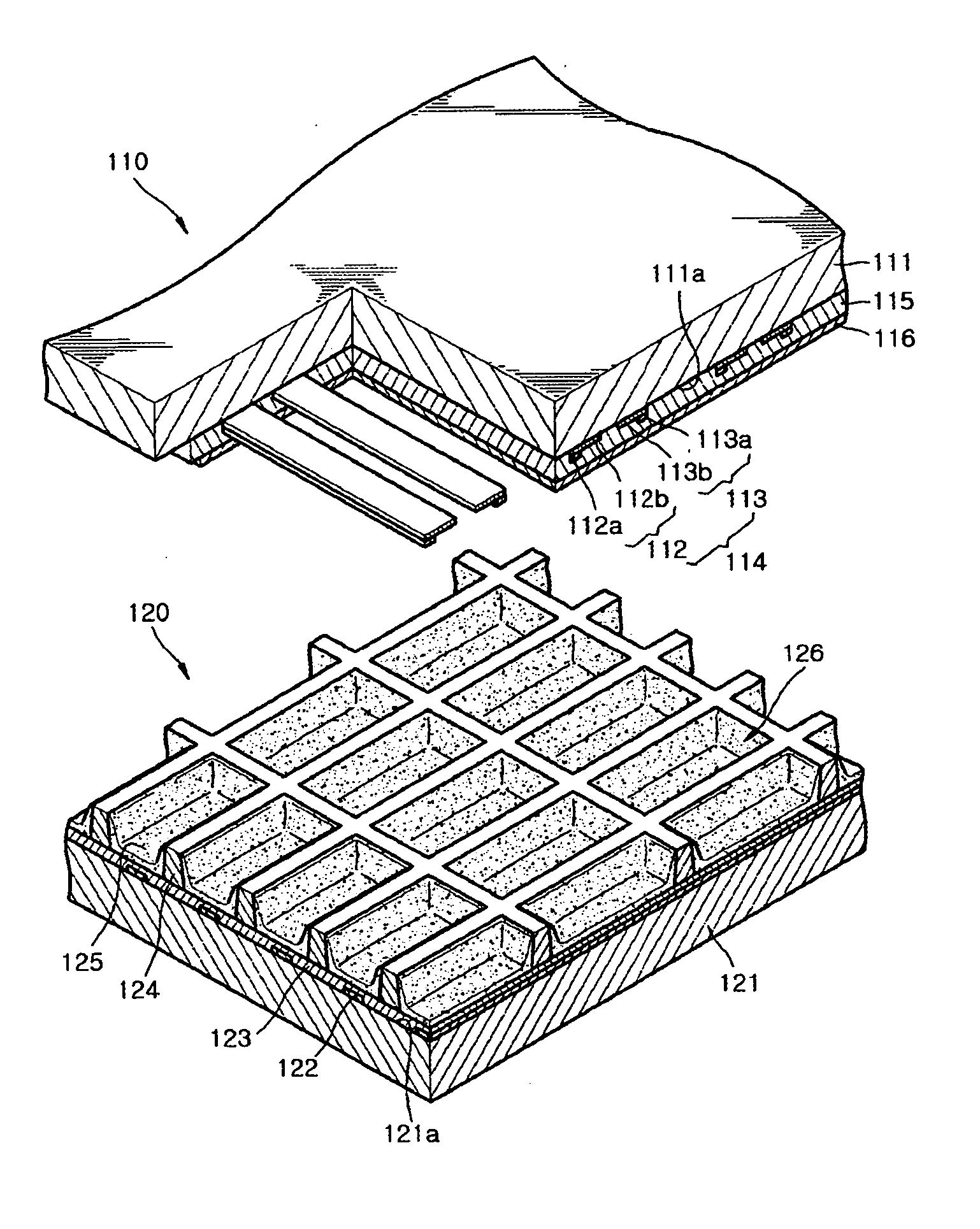

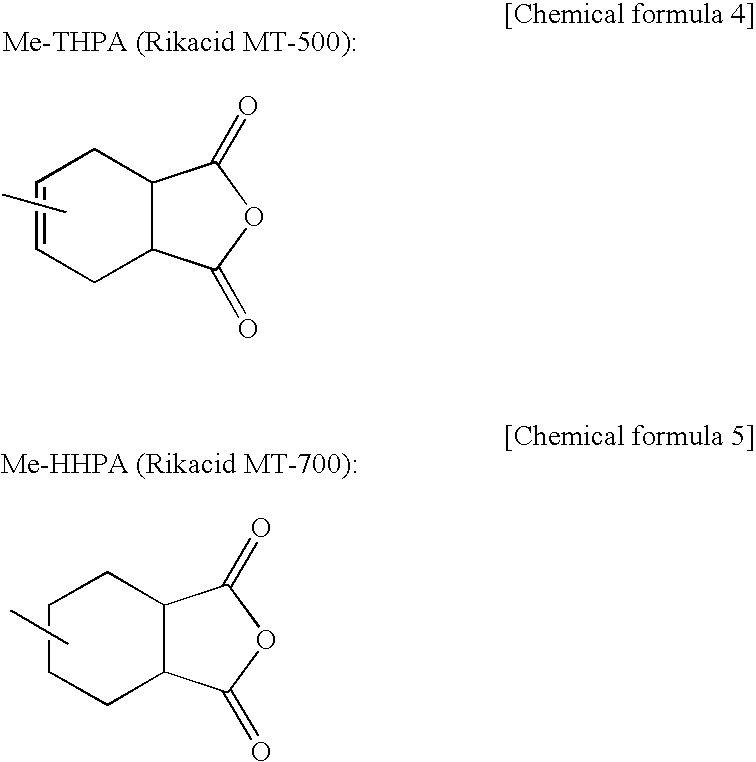

Conductive adhesive

ActiveUS20070185243A1Reduced adhesion strengthImprove long-term reliabilityPrinted circuit assemblingNon-macromolecular adhesive additivesAdhesiveSurface mounting

The present invention provides a conductive adhesive that is applicable as means for forming conductive junction to process for surface mounting of electronic parts for vehicle loading and process for the manufacture of the electronic parts per se for the purpose of substituting soldering therewith. The conductive adhesive according to the present invention is a conductive adhesive produced by dispersing a conductive medium, such as silver powder, in a binder resin component of a one-component epoxy thermosetting resin which has such a composition that the resin comprises, as essential components, an epoxy resin component composed mainly of an epoxy compound with a polycyclic aromatic ring skeleton, and a cyclic acid anhydride as a curing agent component thereof, and is further added with a coupling agent as an adherence imparting agent therefor.

Owner:DENSO CORP +1

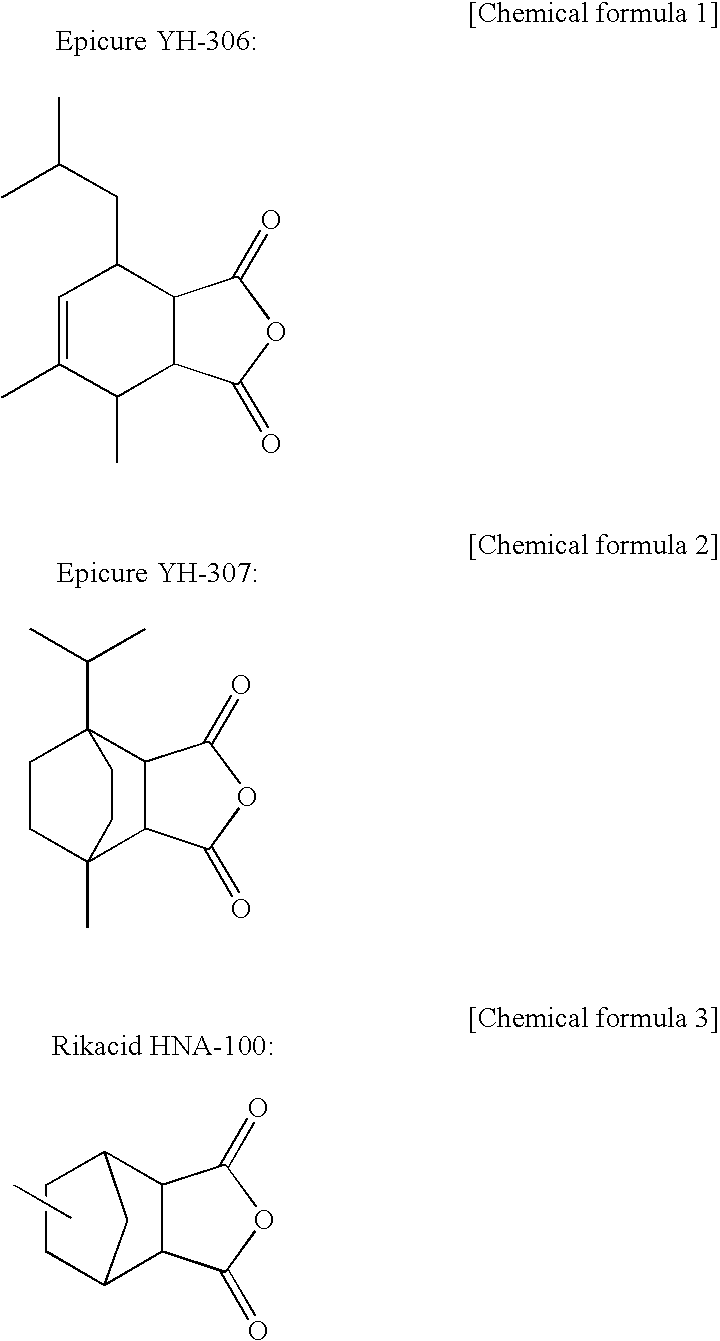

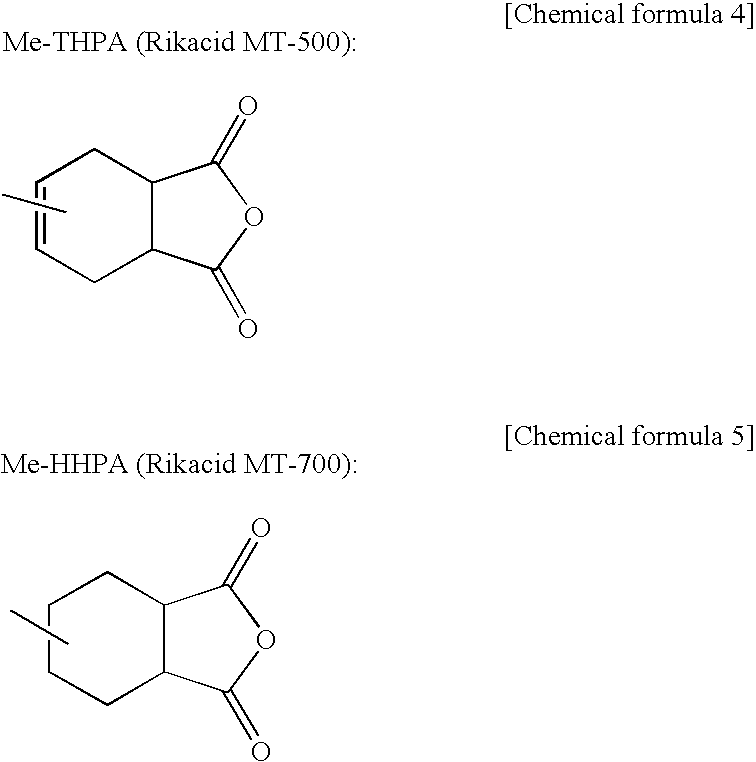

Photosensitive paste composition and plasma display panel manufactured using the same

InactiveUS20060166113A1Sharp contrastGood storage stabilityMaterial nanotechnologyGas-filled discharge tubesNanoparticleContrast enhancement

A photosensitive paste composition for forming a black layer on top of plasma display panel (PDP) barrier ribs includes black pigment nanoparticles for contrast enhancement and a cyclic acid anhydride for fundamentally preventing the gelation of the paste composition. The photosensitive paste composition prevents electrical or optical crosstalk between adjacent discharge cells to achieve better contrast. The fundamental prevention of the gelation of the paste composition permits the paste composition to have good storage stability.

Owner:SAMSUNG SDI CO LTD

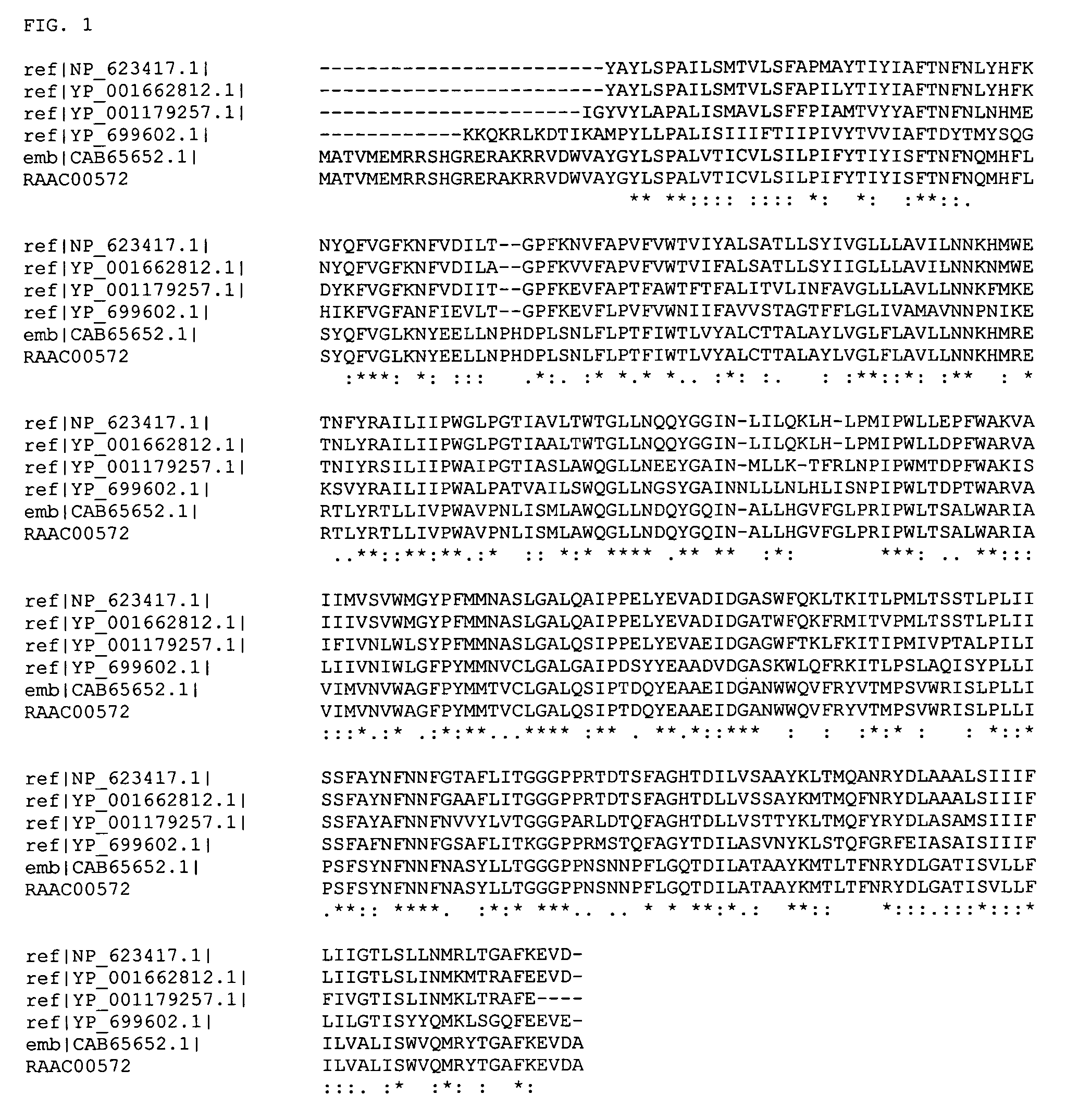

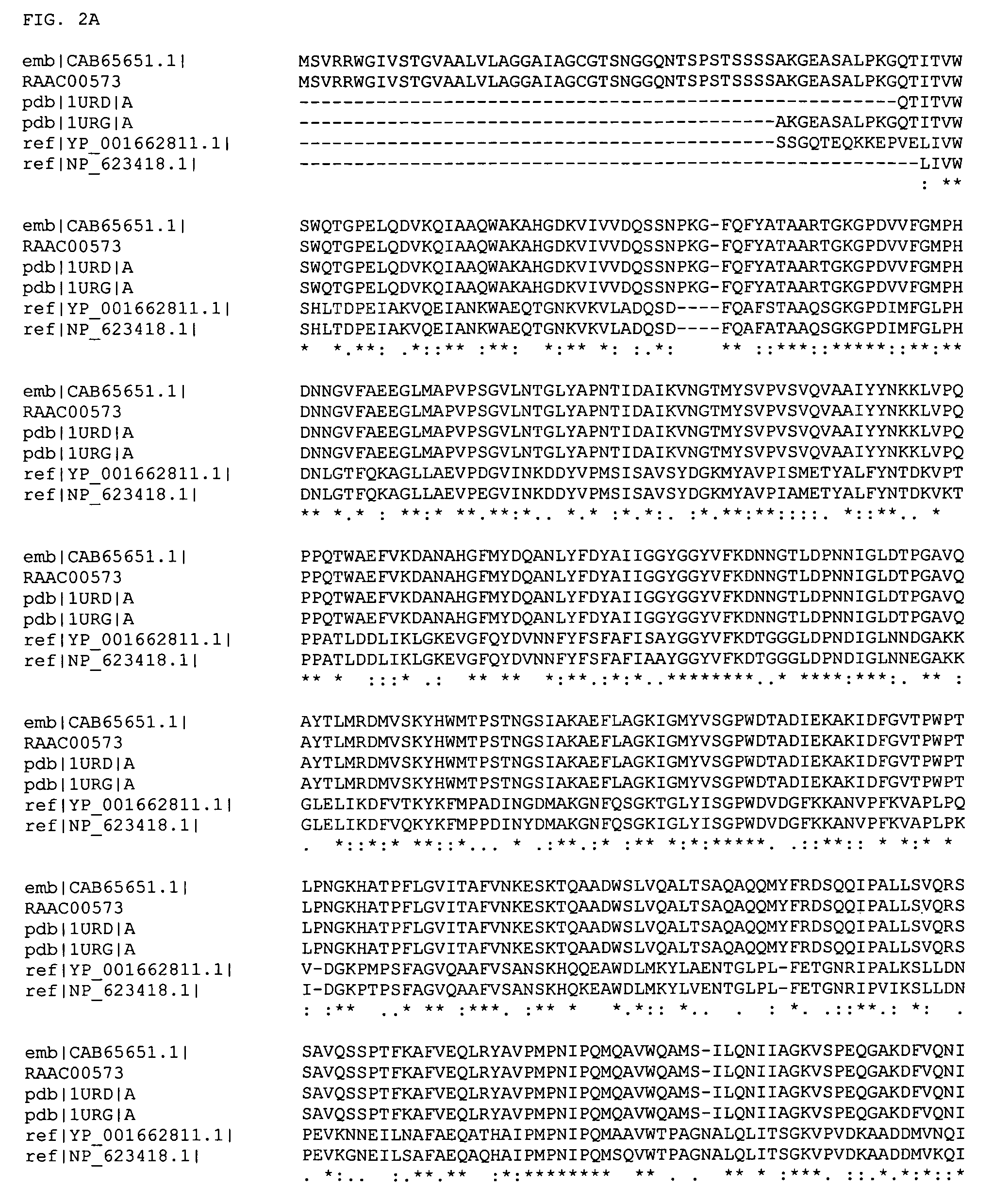

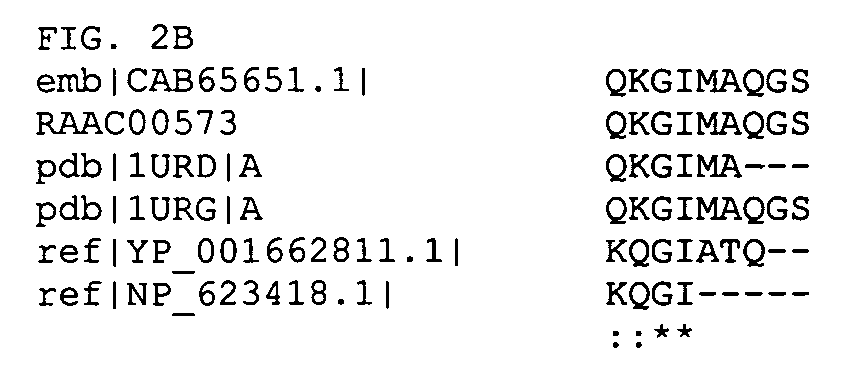

Thermophilic and thermoacidophilic sugar transporter genes and enzymes from alicyclobacillus acidocaldarius and related organisms, methods

InactiveUS7960534B2Decreasing proteolysisAllow stabilizationSugar derivativesDepsipeptidesNucleic acid sequencingAlicyclobacillus pohliae

Isolated and / or purified polypeptides and nucleic acid sequences encoding polypeptides from Alicyclobacillus acidocaldarius are provided. Further provided are methods for transporting sugars across cell membranes using isolated and / or purified polypeptides and nucleic acid sequences from Alicyclobacillus acidocaldarius.

Owner:BATTELLE ENERGY ALLIANCE LLC

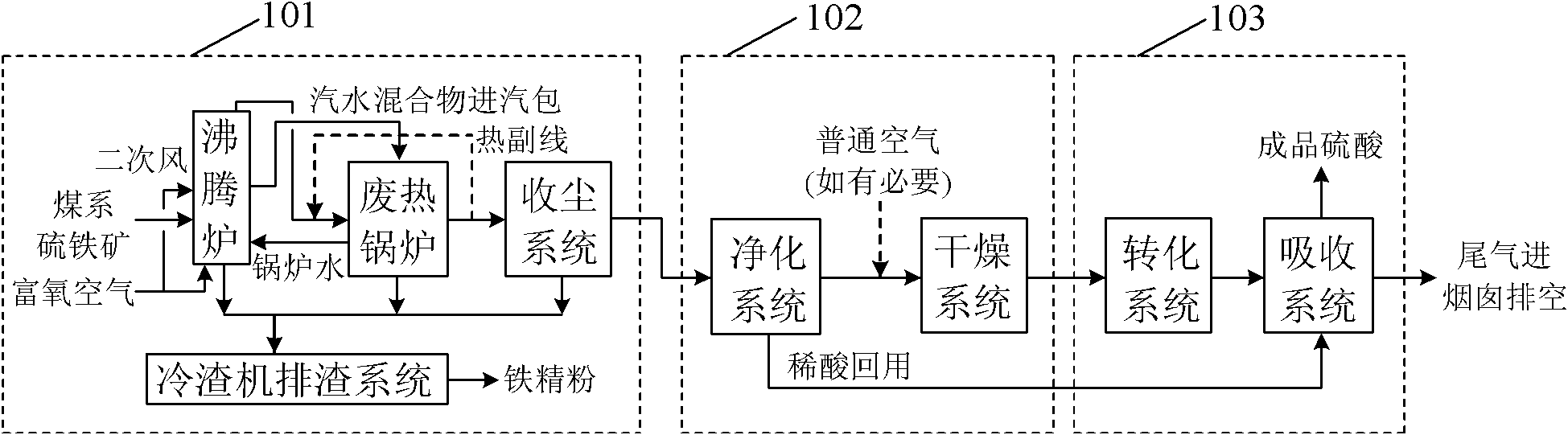

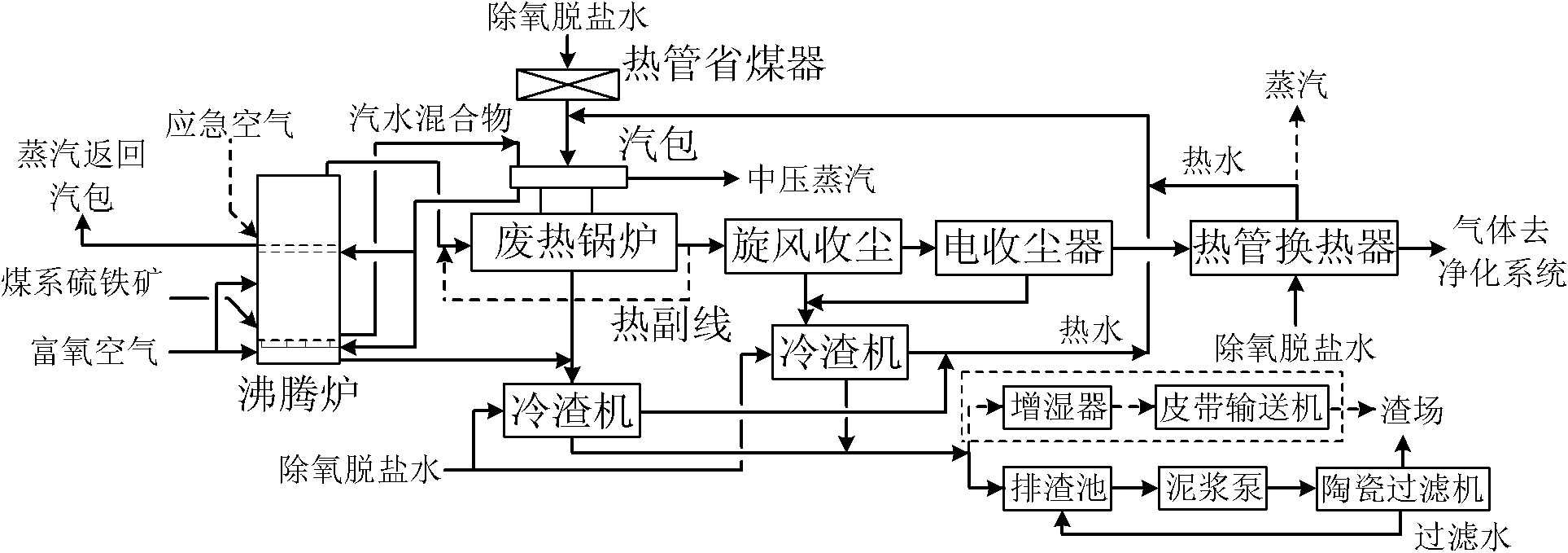

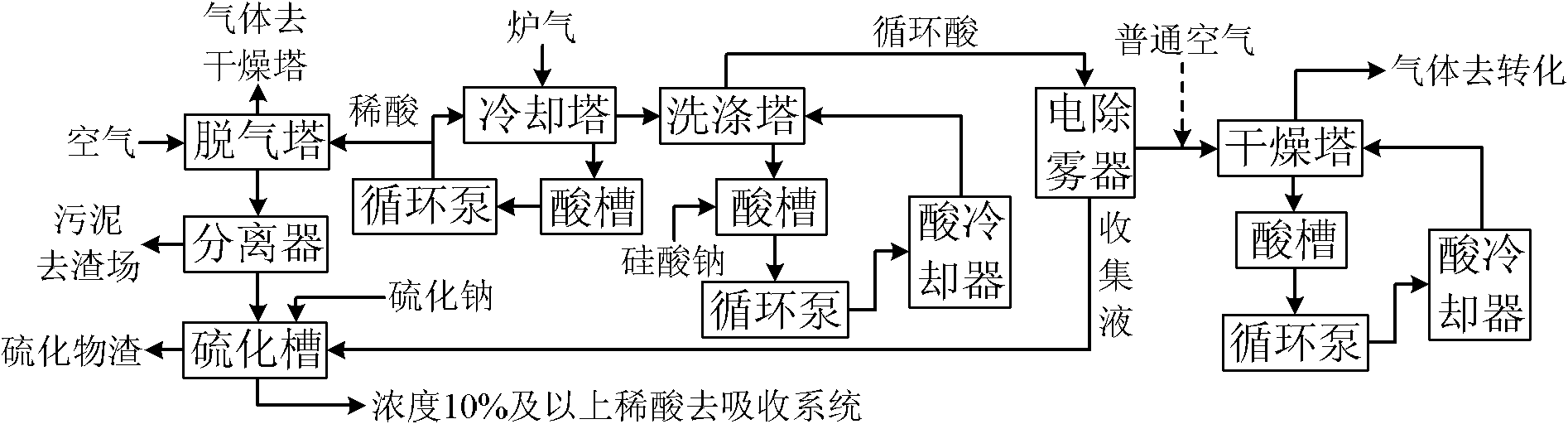

Method for preparation of sulfuric acid and combined production of fine flour iron through calcination of coal-derived pyrite in presence of oxygen-rich air

ActiveCN102367169AImprove recycling efficiencyBreak down completelySulfur compoundsEnergy inputSlagResource utilization

The invention provides a method for preparation of sulfuric acid and combined production of fine flour iron through calcination of coal-derived pyrite in presence of oxygen-rich air, which belongs to the technical field of resource utilization of coal-containing pyrite. The method comprises the following steps: delivering pretreated coal-derived pyrite and oxygen-rich air into a fluidized bed roaster for calcination, carrying out cooling and dust collecting on high temperature furnace gas through a water pipe, a waste heat boiler and the like, carrying out cooling and demisting on furnace gasby using a one-stage dynawave scrubber--a packed scrubbing column--a two-stage electric mist collector, supplementing a proper amount of common air before furnace gas enters into a drying column, controlling the volume ratio of oxygen to sulfur dioxide in gas in a converter to be greater than 0.8, carrying out reforming and absorption two times after gas enters into a reforming and absorption system, discharging tail gas when the tail gas reaches the standard, and recovering heat energy of furnace gas, slag and dust, furnace gas treated by an electric dust collector, reforming gas of a reforming system and cyclic acid of an absorption system for by-production of middle and low pressure steam. According to the invention, high-level and middle-level heat energy produced in the process of production of sulfuric acid is fully utilized, and the resource of dilute sulfuric acid is recycled; therefore, the advantages of small production investment, low production cost, a high recovery rate of waste heat, clean production and no pollution in production of sulfuric acid are realized.

Owner:CHINA PETROCHEMICAL CORP +1

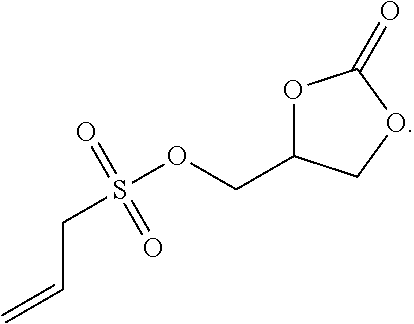

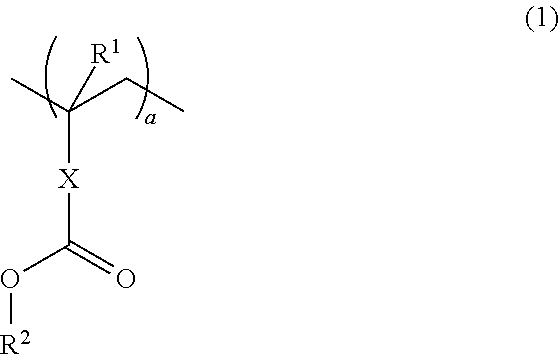

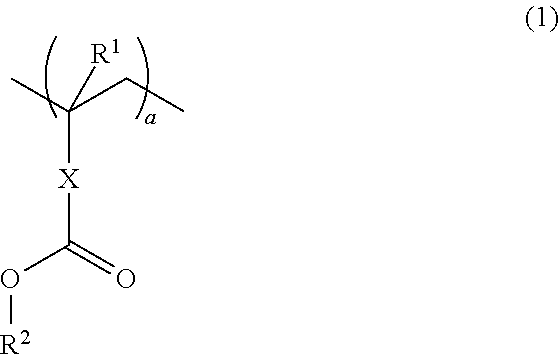

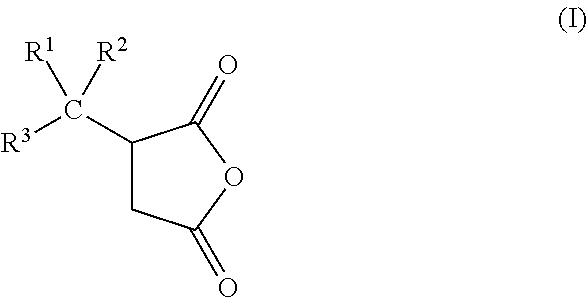

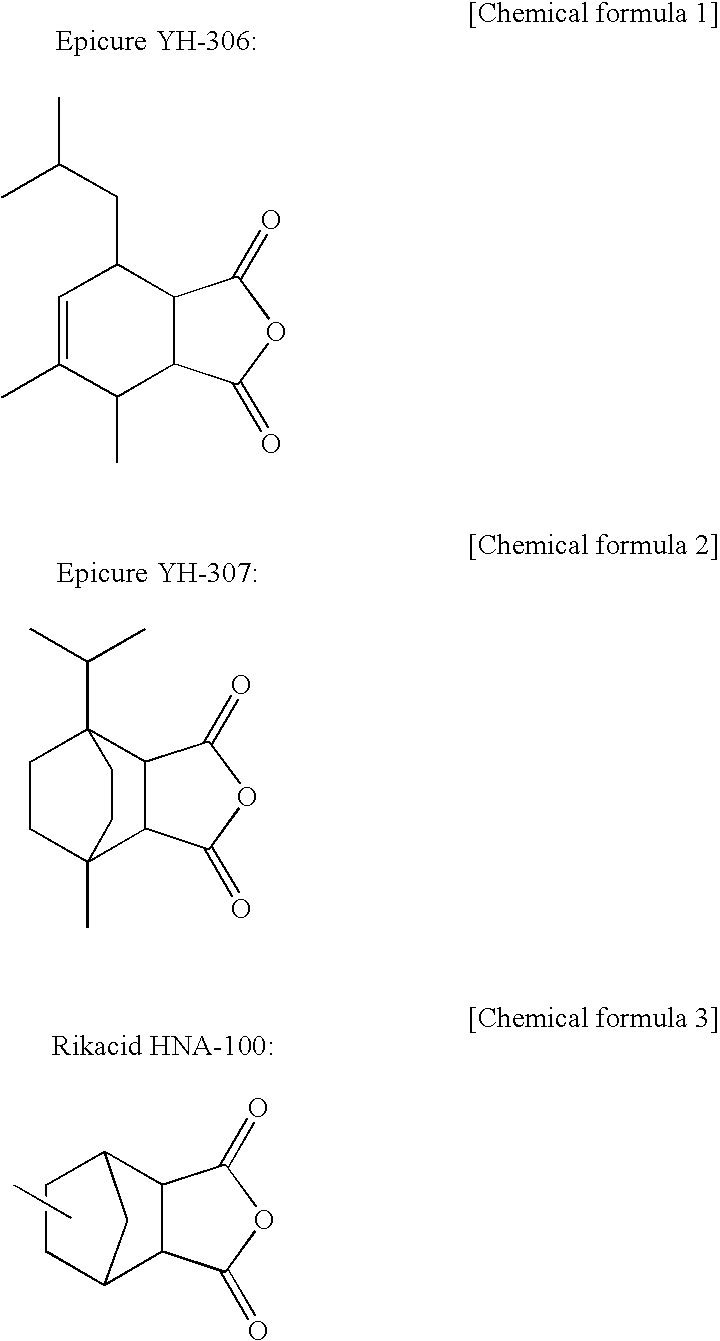

Non-aqueous electrolyte solution and electricity-storage device using same

ActiveUS20140234727A1Improve featuresHybrid capacitor electrolytesHybrid capacitor electrodesElectrolytic agentSide chain

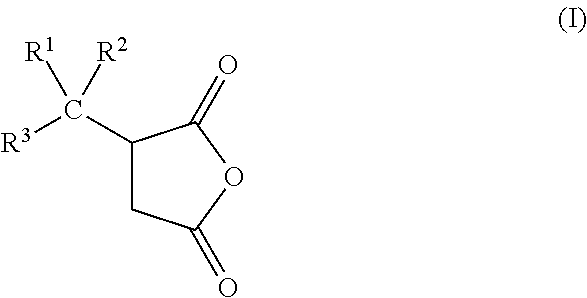

A nonaqueous electrolytic solution that is capable of improving the electrochemical characteristics in a broad temperature range, and an energy storage device using the same are provided, and the nonaqueous electrolytic solution contains a nonaqueous solvent having dissolved therein an electrolyte salt, in which the nonaqueous solvent contains two or more kinds of cyclic carbonates selected from ethylene carbonate, propylene carbonate, 1,2-butylene carbonate, 2,3-butylene carbonate, 4-fluoro-1,3-dioxolan-2-one, trans- or cis-4,5-difluoro-1,3-dioxolan-2-one, vinylene carbonate, vinyl ethylene carbonate and 4-ethynyl-1,3-dioxolan-2-one, and the nonaqueous electrolytic solution further contains a cyclic acid anhydride represented by the following general formula (I) having bonded thereto a side chain that has 3 or more carbon atoms and has a double bond or a triple bond at an end thereof in an amount of from 0.01 to 10% by mass:wherein R1 and R2 each independently represent a hydrogen atom, a halogen atom or an alkyl group having from 1 to 6 carbon atoms, at least one hydrogen atom of which may be substituted by a halogen atom; and R3 represents a linear or branched alkenyl group having from 2 to 4 carbon atoms and having a double bond at an end thereof or a linear or branched alkynyl group having from 2 to 4 carbon atoms and having a triple bond at an end thereof.

Owner:MU IONIC SOLUTIONS CORP

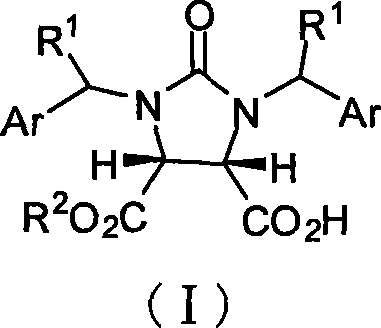

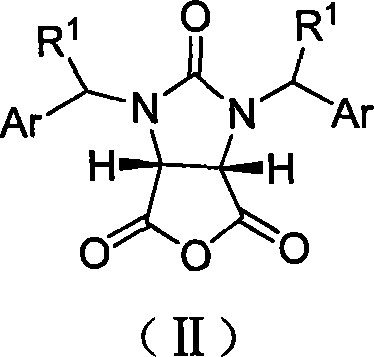

Method for synthesizing (4S,5R)- half-ester

InactiveCN101157655AHigh enantioselective catalytic effectHigh yieldOrganic-compounds/hydrides/coordination-complexes catalystsAsymmetric synthesesAlcoholOrganic solvent

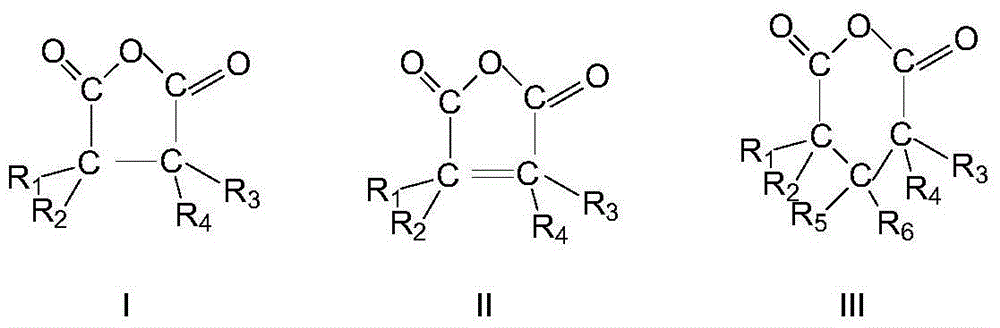

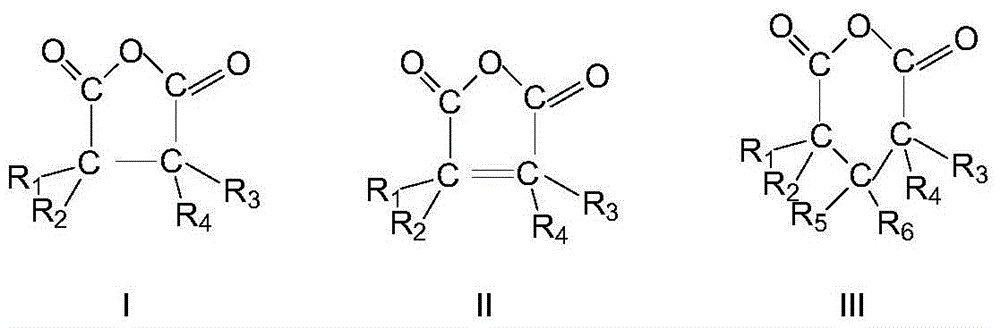

The invention pertains to the technical field of organic chemistry, in particular to a synthesis method of (4S, 5R)-semi-ester. The method carries out the enantioselective open-loop of cyclic acid anhydride and alcohol under the catalysis of cinchona alkaloid so as to prepare the (4S, 5R)-semi-ester. The reaction is carried out in the organic solvent in the states of normal pressure, compression or decompression, the reaction temperature is -80 DEG C to 25 DEG C, the reaction time is 10 to 80 hours, the total yield is more than 90 percent, and the ee is more than 98.5 percent. The raw materials of the method of the invention are easy to obtain, the catalyst can be reclaimed quantitatively, the reaction conditions are mild, and the yield and the stereoselectivity are high, so the invention is applicable to industrialization production.

Owner:FUDAN UNIV

Medicinal toothpaste composition and preparation method and application thereof

InactiveCN104644460AReduce inflammationShorten the course of the diseaseCosmetic preparationsAntipyreticOral ulcersToothpaste

The invention discloses a medicinal toothpaste composition which comprises the following raw materials in percentage by weight: 0.01%-0.05% of sodium guaiazulene sulfonate, 0.1%-0.5% of paeonol, 0.1-0.5w / w% of allantoin, 0.1-0.5w / w% of tranexamic acid, and toothpaste matrix on the basis of the total weight. In addition, the invention further discloses a preparation method of the medicinal toothpaste composition and applications in resisting bacteria, diminishing inflammation, easing pain, shortening the treatment course of dental ulcer, and promoting oral wound healing.

Owner:北京华素制药股份有限公司

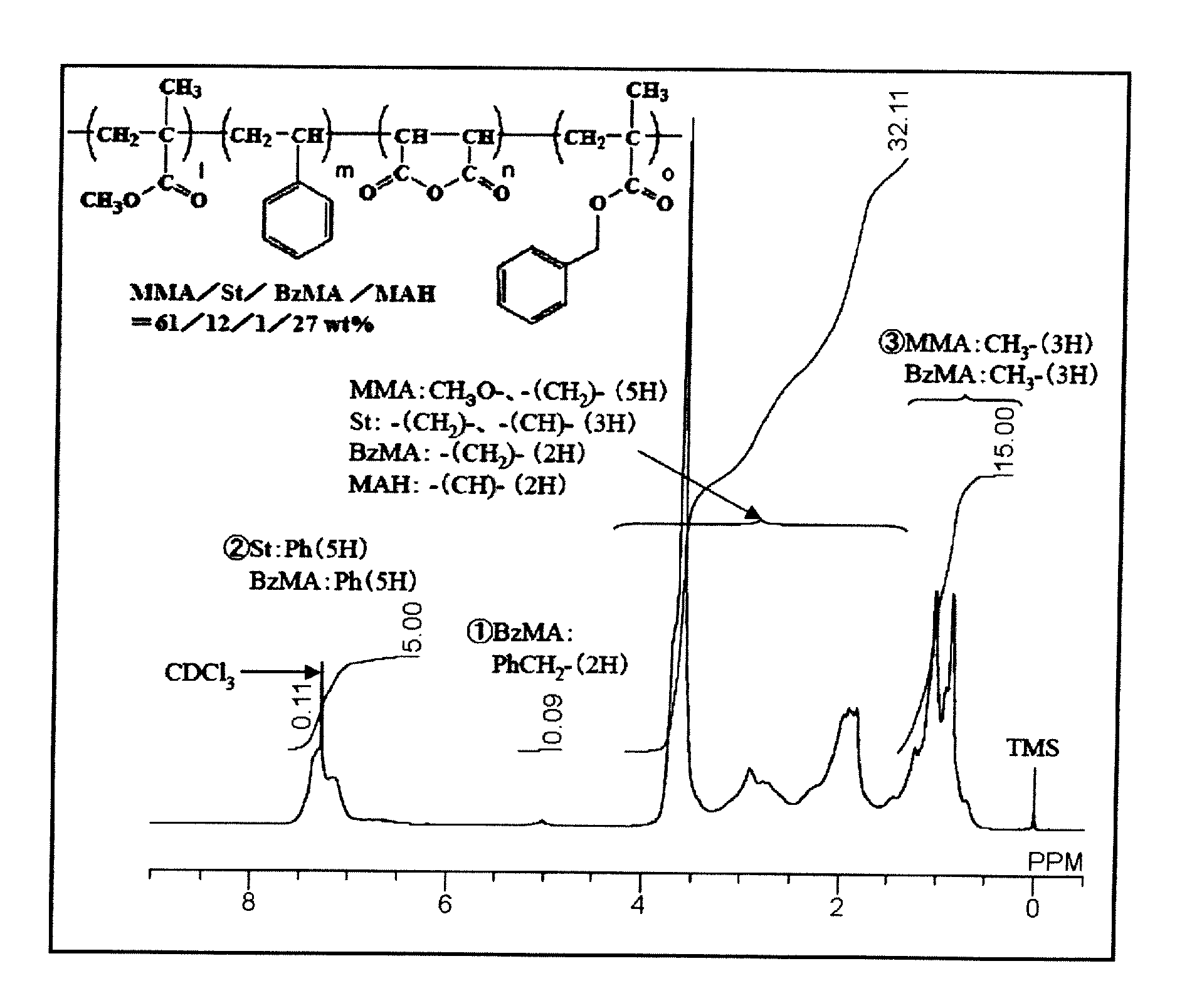

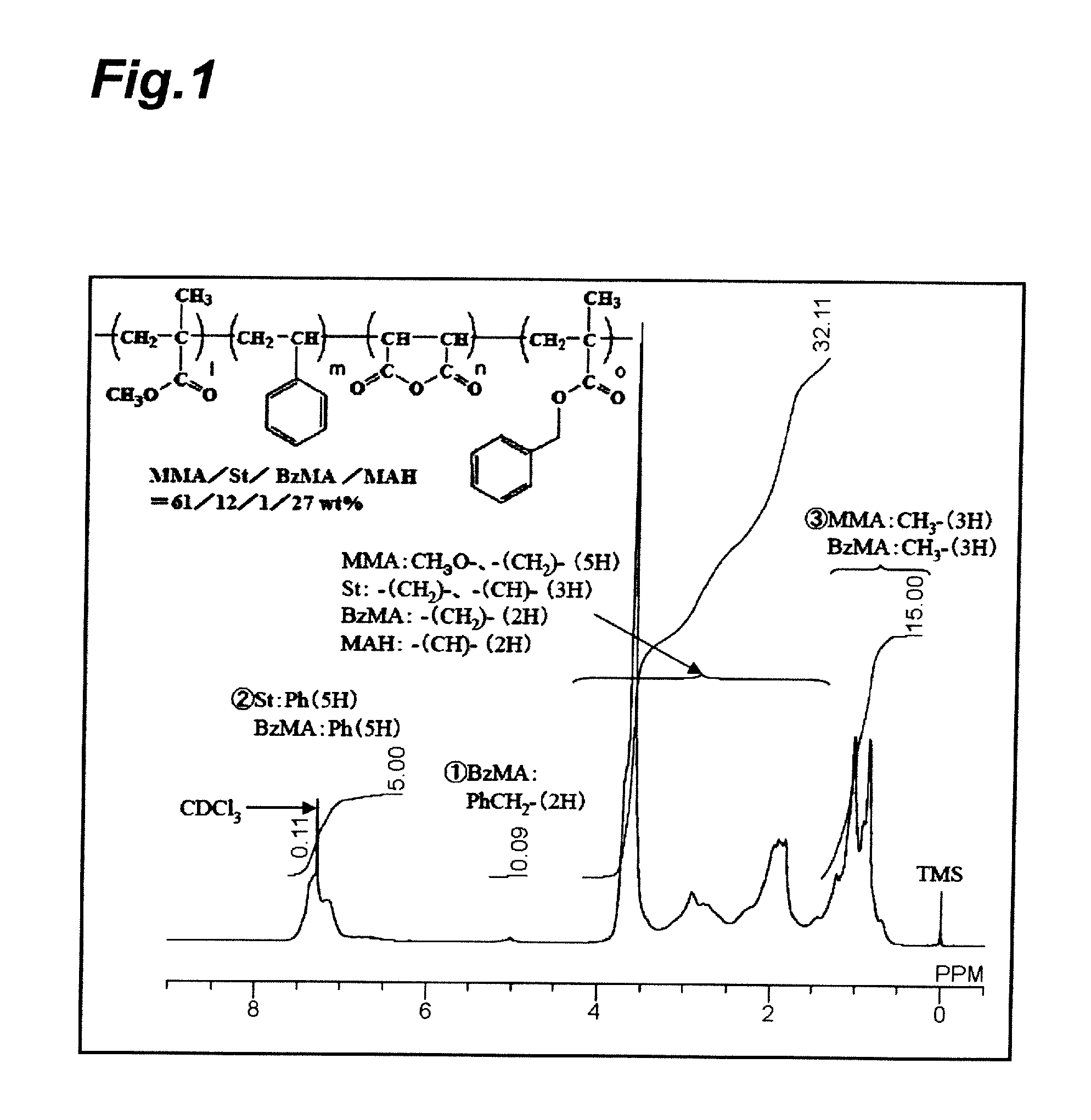

Thermoplastic Acrylic Resin, and Molded Product Thereof

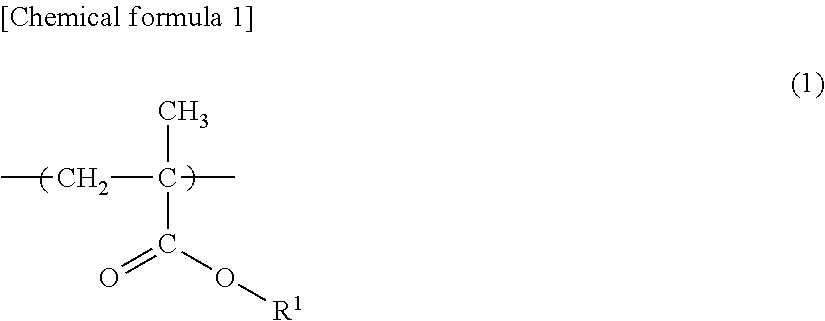

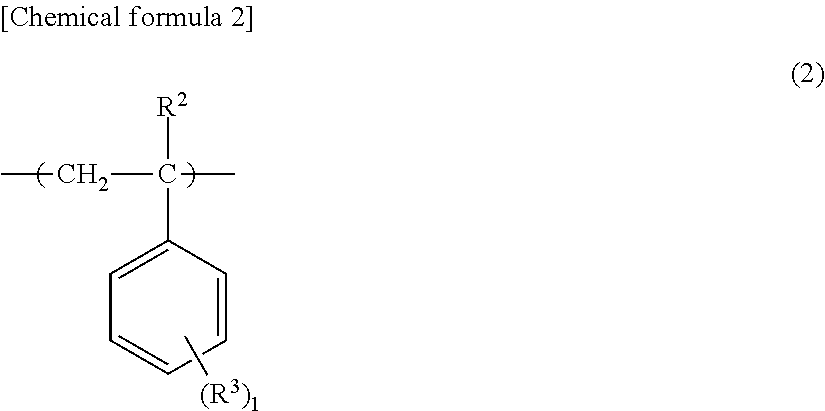

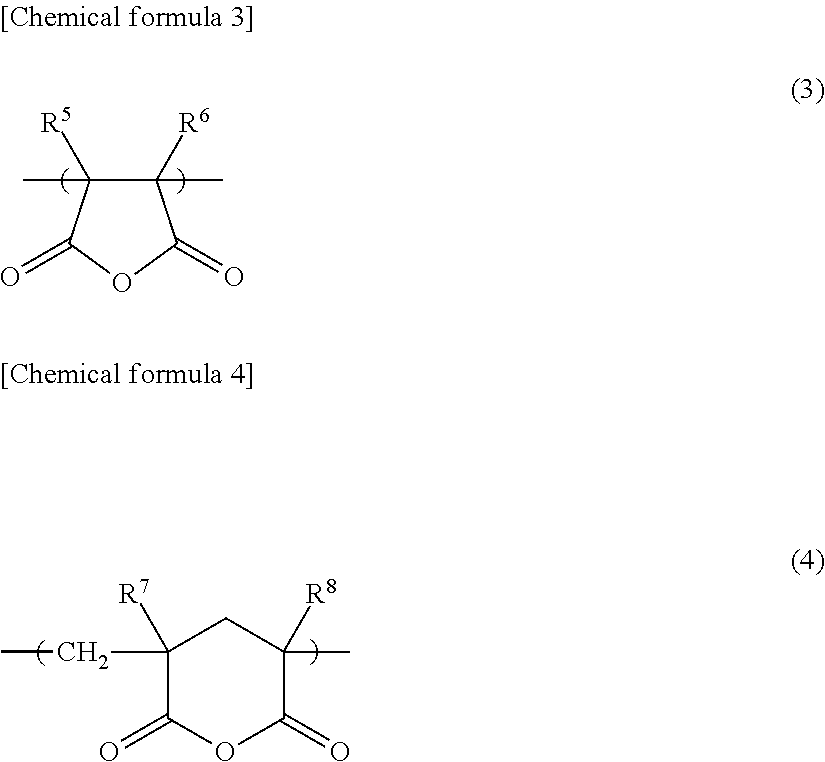

ActiveUS20110130535A1Improve thermal stabilityImprove heat resistancePolarising elementsMethacrylateAcrylic resin

The present invention provides a thermoplastic acrylic resin of a copolymer comprising 10 to 70% by weight of a repeating unit derived from the particular methacrylate monomer, 5 to 40% by weight of a repeating unit derived from the particular vinyl aromatic monomer, and 20 to 50% by weight of a repeating unit of the particular cyclic acid anhydride, characterized in that a molar ratio (B / A) is within the range of more than 1 to not more than 10, wherein (A) is a content of the repeating unit of the vinyl aromatic monomer and (B) is a content of the repeating unit of the cyclic acid anhydride, and the total amount of remaining monomers to 100 parts by weight of the copolymer is not more than 0.5 part by weight.

Owner:ASAHI KASEI CHEM CORP

Non-aqueous electrolyte and power storage device using same

ActiveUS20150221985A1Improve degradation rateHigh capacity retentionHybrid capacitor electrolytesCell electrodesPhosphoric Acid EstersHydrogen

Provided are a nonaqueous electrolytic solution having an electrolyte salt dissolved in a nonaqueous solvent, the nonaqueous electrolytic solution containing from 0.001 to 5% by mass of 1,3-dioxane and further containing from 0.001 to 5% by mass of at least one selected from a specified phosphoric acid ester compound, a specified cyclic sulfonic acid ester compound, and a cyclic acid anhydride containing a side chain having allyl hydrogen; and an energy storage device using the same. This nonaqueous electrolytic solution is capable of improving electrochemical characteristics at high temperatures and further capable of not only improving a capacity retention rate after a high-temperature cycle test but also decreasing a rate of increase of an electrode thickness.

Owner:MU IONIC SOLUTIONS CORP

Electrolyte of lithium ion battery taking lithium titanate as cathode

InactiveCN104466249AImprove high temperature storageImprove high temperature cycle performanceSecondary cellsElectrolytesCooking & bakingHigh temperature storage

The invention discloses electrolyte of a lithium ion battery taking lithium titanate as cathode. The electrolyte comprises the organic solvent, lithium salt and additive dissolved in the organic solvent; the additive comprises one or the combination of the adiponitrile, butanedinitrile, 1,3-propane sultone, wherein the additive further comprises one or the combination of the cyclic acid anhydride and / or the derivate thereof, the total weight of the additive is 1-10% of the weight of the electrolyte, the weight of the cyclic acid anhydride and / or the derivate thereof, is 0.01-1% of the weight of the electrolyte. The additive comprises the cyclic acid anhydride and / or the derivate which have chemical reaction with the water in the battery, the combination water in the lithium titanate material, the water, the hydroxy and other groups for generating one component of the electrolyte, the defect that the water cannot be removed totally in the conventional vacuum baking process is compensated. The catalytic reaction for the hydroxy can be effectively avoided while having reaction with the Ti-OH bond on the surface of the lithium titanate particle, and the high temperature storage performance and the high temperature circulation performance of the lithium titanate battery are improved.

Owner:东莞市天丰电源材料有限公司

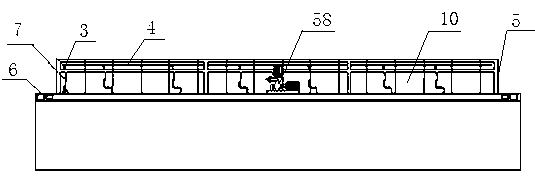

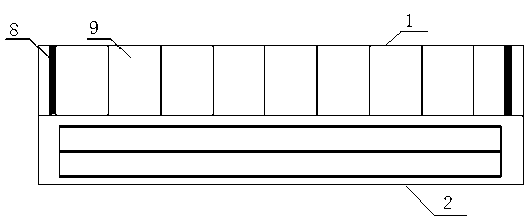

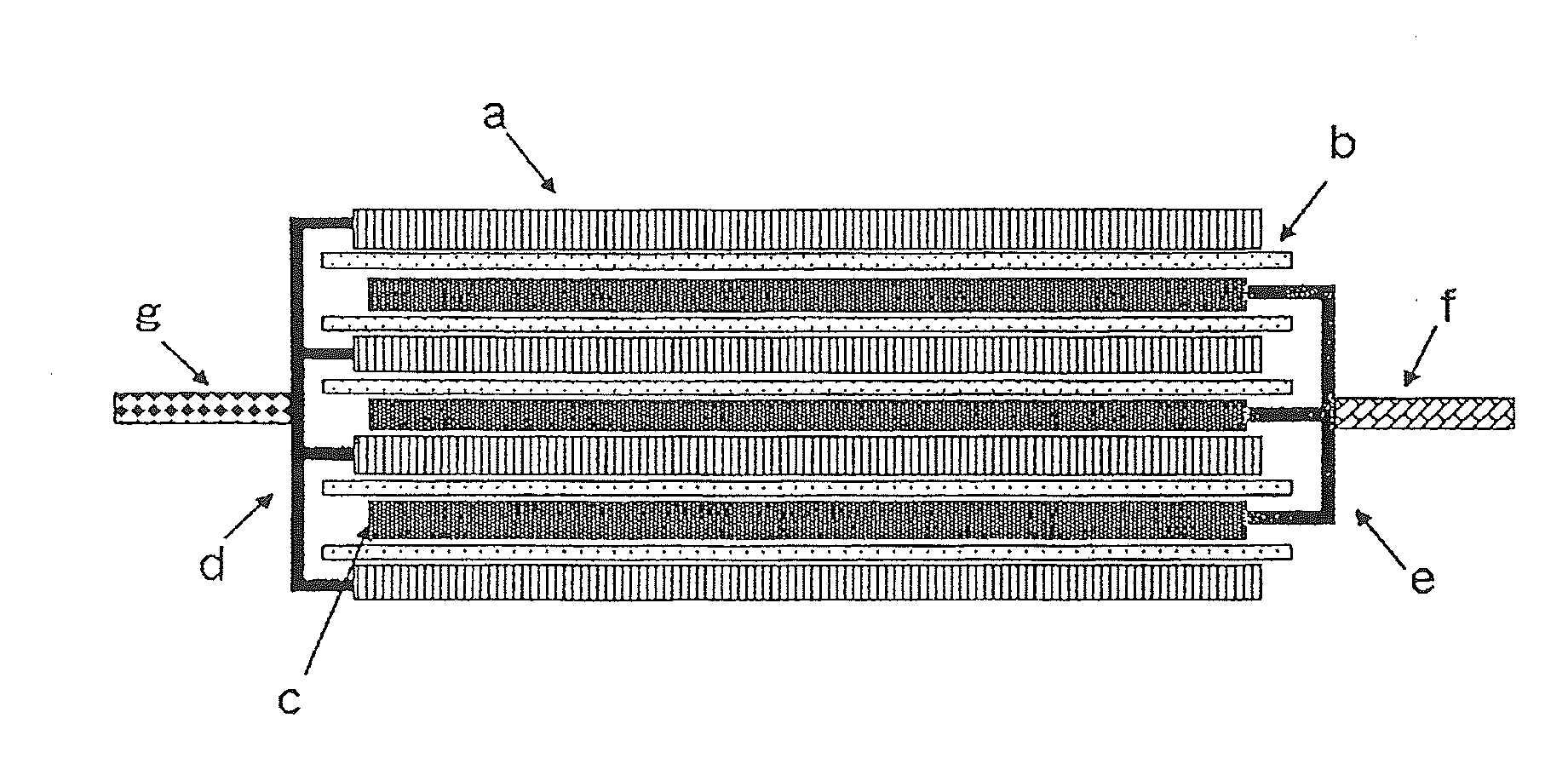

Cyclic acid pickling device and method of trough type pickling tank

The purpose of the invention is to provide a cyclic acid pickling device of a trough type pickling tank and a cyclic acid pickling method of a trough type pickling tank. Rusts and other impurities adhering to the inner and outer surfaces of a pipeline can be efficiently removed through the device and the method provided by the invention; the production cost is reduced and the discharge of waste acids is reduced because the acid pickling solution is cyclically filtered and used repeatedly; and therefore, actual use effects of energy conservation and emission reduction are achieved. According to the invention, the processes of soaking acid pickling, side spray forced cyclic acid pickling, cyclic acid pickling by injecting an acid into a pipeline and acid pickling by spraying outside the pipeline are adopted to performing multi-directional acid pickling on the pipeline, and the acid pickling effect on the pipelines which are deep in rusting degree, large in pollutant adsorption quantity, and multiply bent are especially obvious; simultaneously, a method of cyclically filtering and recycling the acid pickling solution and complete covering with soft plastics is adopted, so that the purposes of energy conservation and emission reduction are achieved.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Non-aqueous electrolyte lithium secondary battery

ActiveCN101779325ANon-aqueous electrolyte accumulatorsActive material electrodesOrganic solventCarbonate

Owner:LG ENERGY SOLUTION LTD

Multilayer coating film- forming method

InactiveUS20080268256A1Improve the immunitySynthetic resin layered productsPretreated surfacesPolymer scienceOrganic solvent

This invention provides a multilayer coating film-forming method by 2-coat-1-bake coating using a clear coat paint comprising a carboxyl group- and / or cyclic acid anhydride group-containing compound and polyepoxide, in which the coating workability and electrostatic coatability are improved by blending a specific organic solvent in the clear coat paint.

Owner:KANSAI PAINT CO LTD

Lithium secondary cell

ActiveUS20140120415A1Large capacitySolution to short lifeFinal product manufactureLi-accumulatorsLithiumLarge capacity

An object of the present invention is to provide a high-capacity, long-life lithium secondary cell suppressing a reduction in capacity particularly with respect to use under a high-temperature environment, and having improved cycle properties. The lithium secondary cell comprises a positive electrode active material layer containing a positive electrode active material, a negative electrode active material layer containing a silicon-based material as a negative electrode active material, and an electrolytic solution in which the positive electrode active material layer and the negative electrode active material layer are immersed, the electrolytic solution contains one or more of specific cyclic acid anhydrides.

Owner:NEC CORP

Conductive adhesive

ActiveUS7524893B2Printed circuit assemblingNon-macromolecular adhesive additivesEpoxySurface mounting

The present invention provides a conductive adhesive that is applicable as means for forming conductive junction to process for surface mounting of electronic parts for vehicle loading and process for the manufacture of the electronic parts per se for the purpose of substituting soldering therewith. The conductive adhesive according to the present invention is a conductive adhesive produced by dispersing a conductive medium, such as silver powder, in a binder resin component of a one-component epoxy thermosetting resin which has such a composition that the resin comprises, as essential components, an epoxy resin component composed mainly of an epoxy compound with a polycyclic aromatic ring skeleton, and a cyclic acid anhydride as a curing agent component thereof, and is further added with a coupling agent as an adherence imparting agent therefor.

Owner:DENSO CORP +1

Ratification of highly purified tranexamic acid injection and quality standard thereof

InactiveCN101199477ARaise quality standardsReduce potential adverse reactionsPeptide/protein ingredientsComponent separationTranexamic Acid InjectionMedicine

The invention in the end effectively reduces the impurities in tranexamic acid injection preparation through controlling the conductivity of the injection water to control the quality of the tranexamic acid injection preparation, and limits and controls the sort and the quantity of the impurities according to quality standard, thus obviously improving the stability of the preparation and the quality of the tranexamic acid injection preparation.

Owner:BEIJING JIACHENG MEDICINE

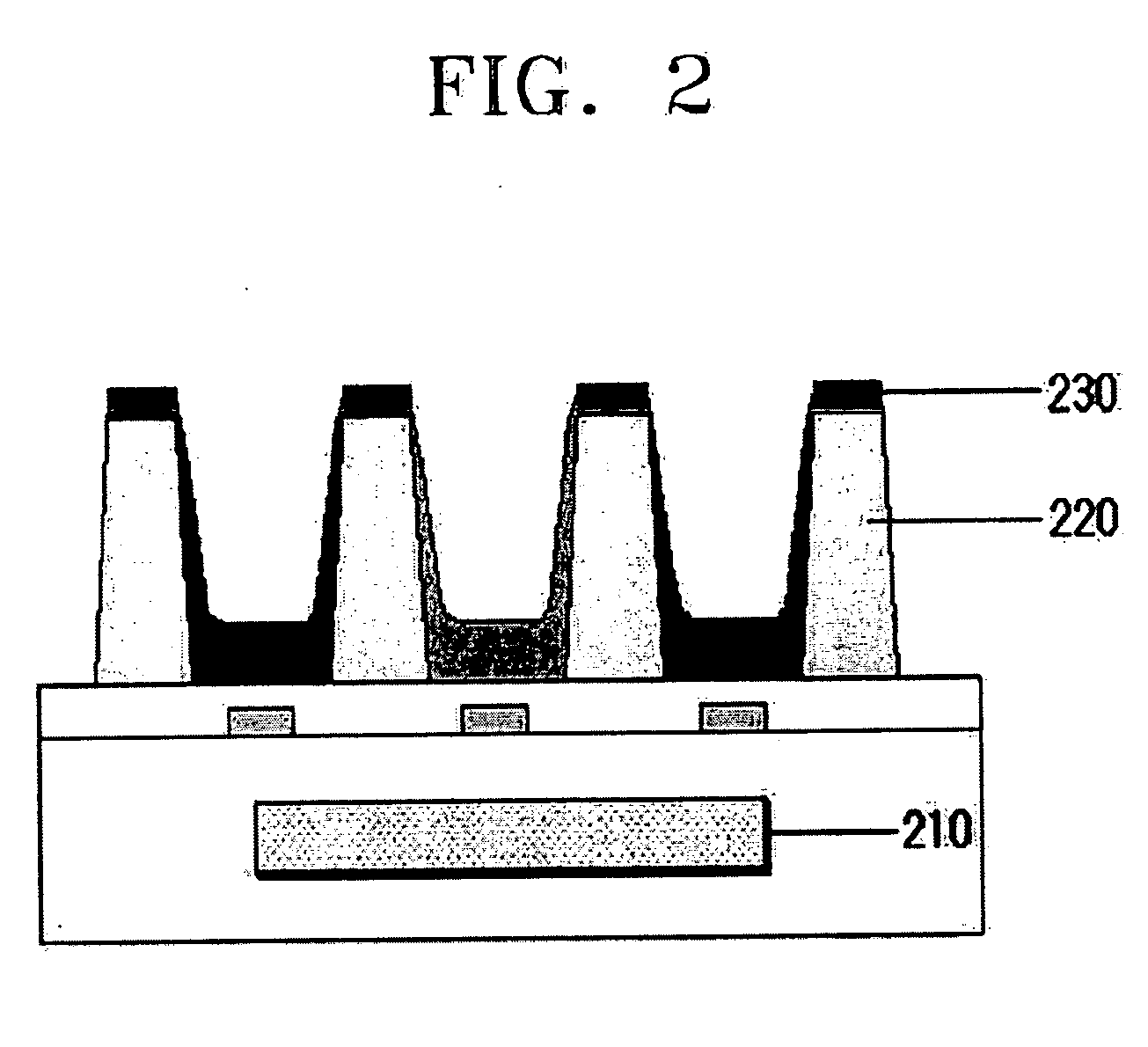

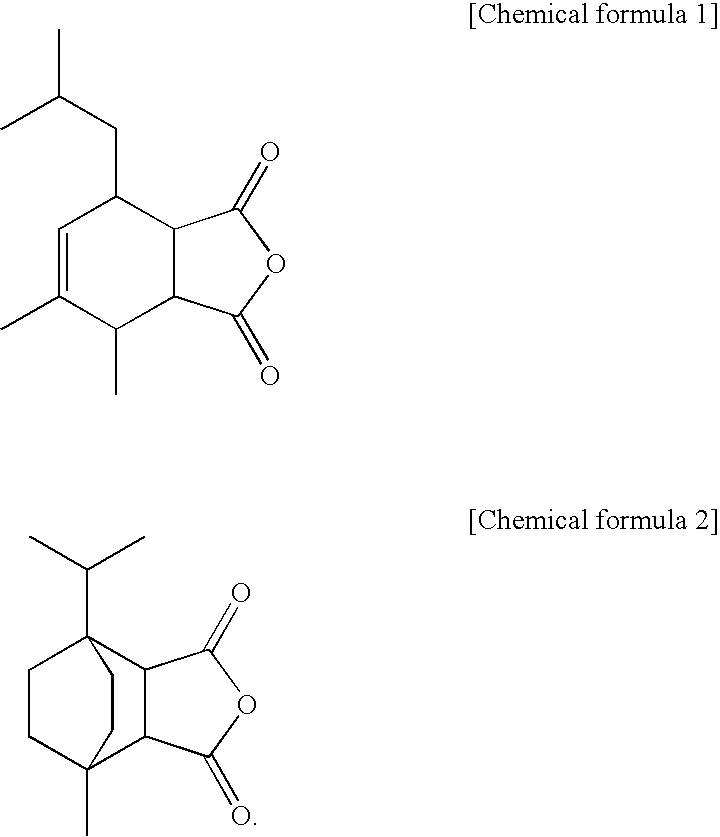

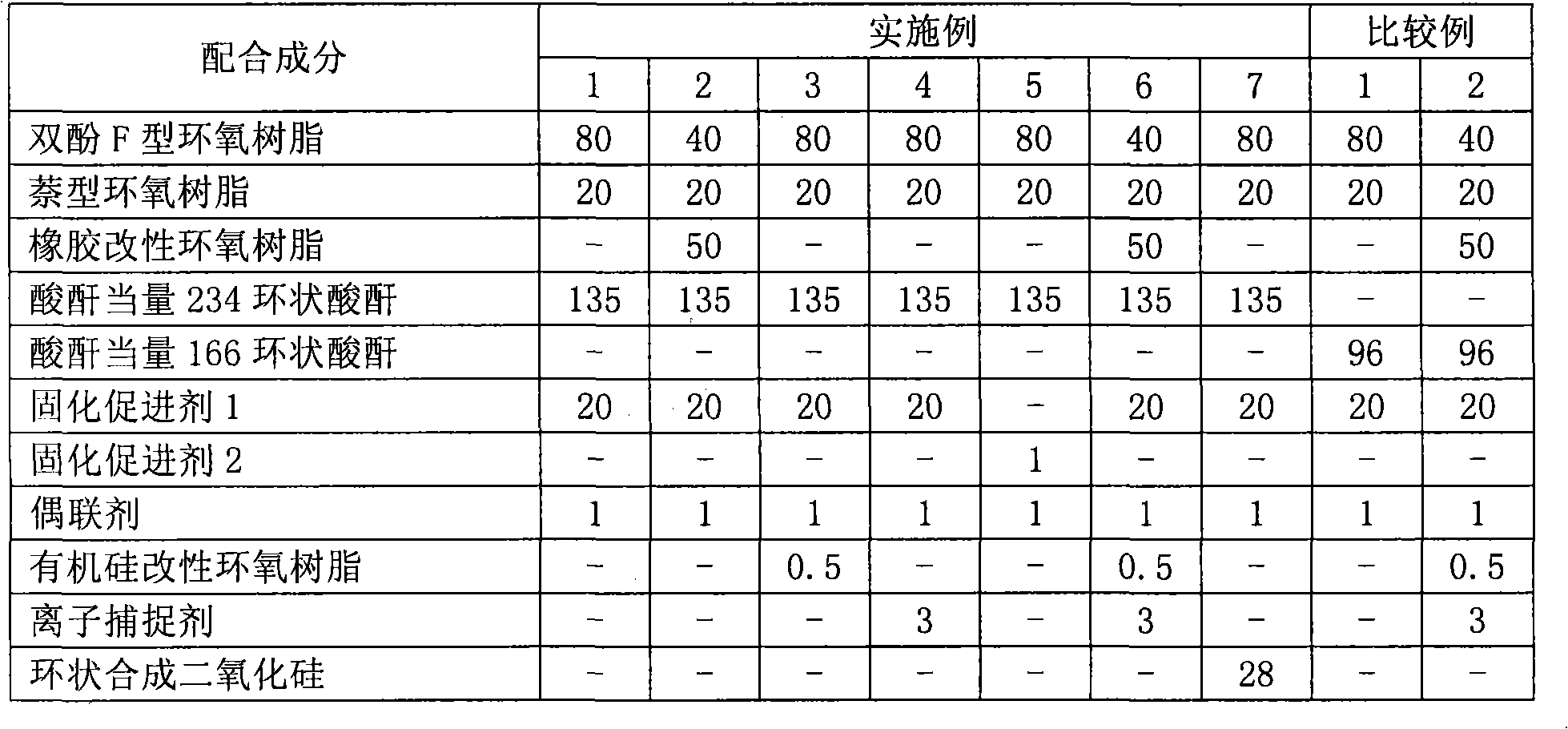

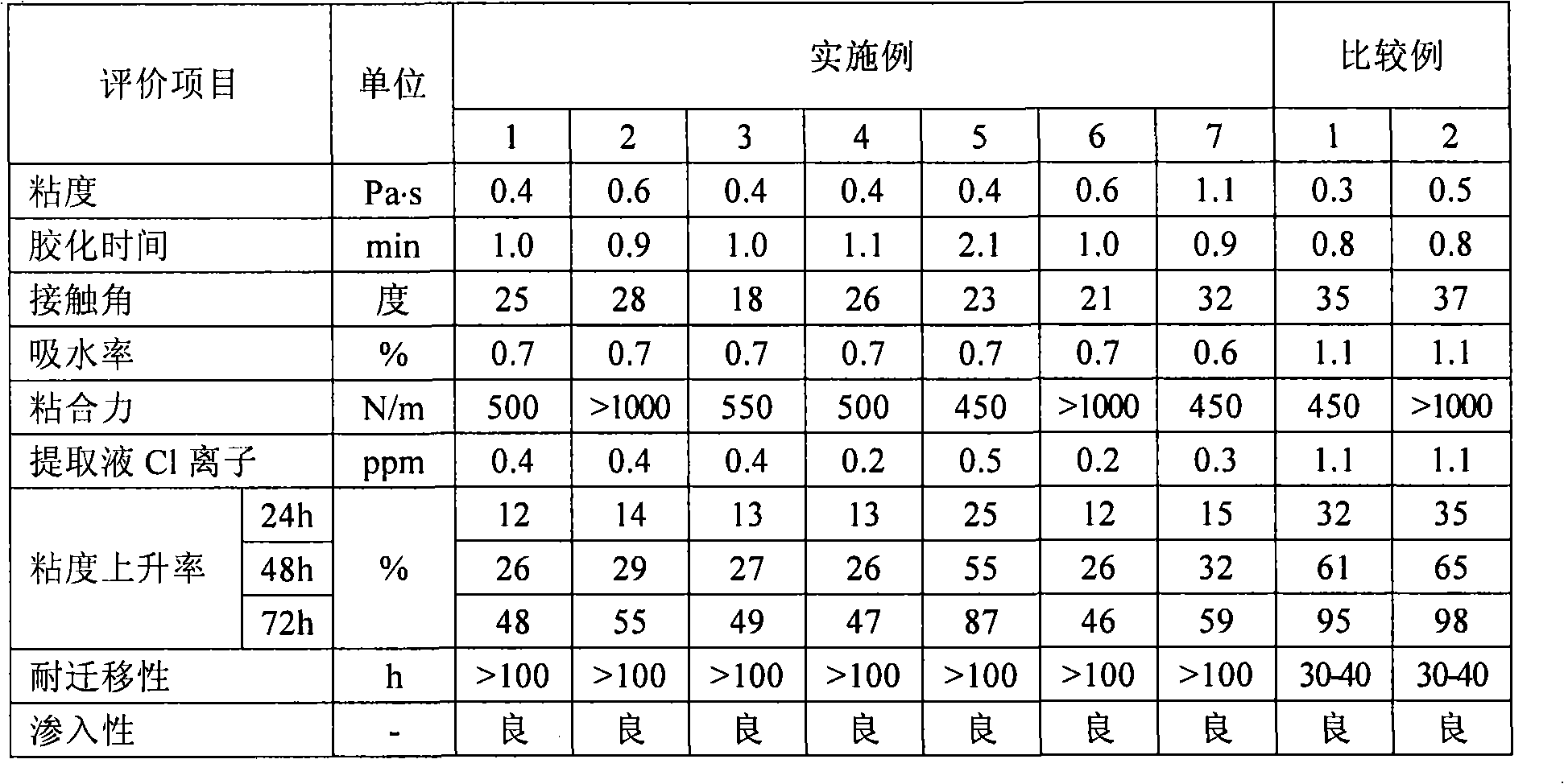

Liquid resin composition for electronic parts and electronic parts device

InactiveCN101313006AImprove migration resistanceGood formabilitySemiconductor/solid-state device detailsSolid-state devicesLiquid stateRoom temperature

Disclosed is a liquid resin composition for electronic components which has good migration resistance, while being excellent in moldability and reliability. Also disclosed is an electronic component device which is sealed with such a liquid resin composition. Specifically disclosed is a liquid resin composition for electronic components, which contains an epoxy resin (A), a cyclic acid anhydride (B) which is in a liquid state at room temperature and has an acid anhydride equivalent weight of not less than 200, and a coupling agent (C).

Owner:RESONAC CORP

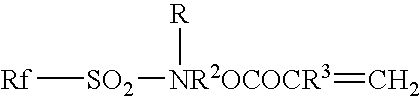

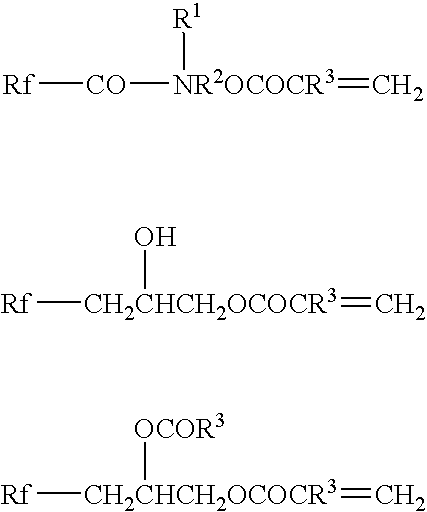

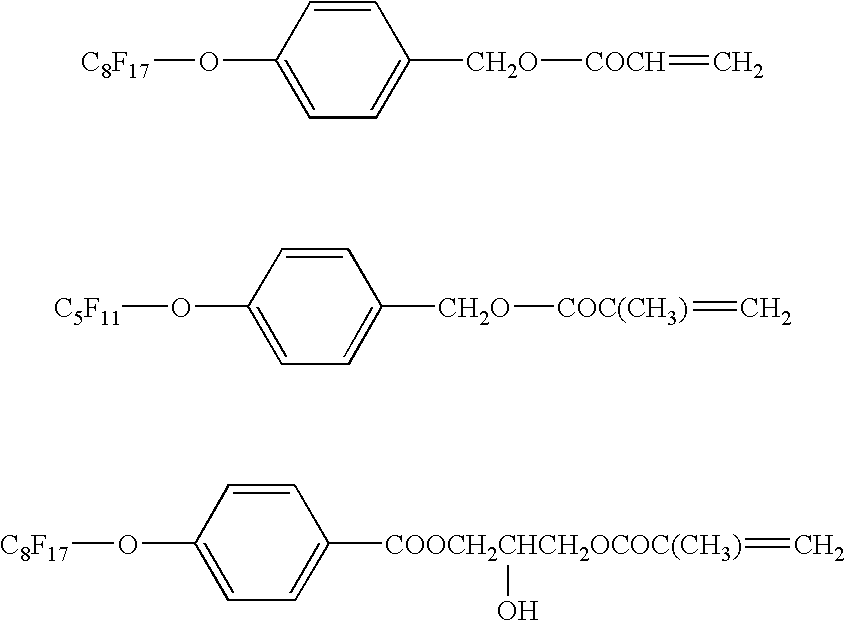

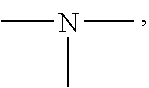

Graft copolymer and solvent-based water-and oil-repellant composition comprising the same

A solvent-based water- and oil-repellent agent composition, which contains a graft copolymer having a repeating unit derived from a vinyl monomer having a perfluoroalkyl group and a repeating unit derived from a polymerizable cyclic acid anhydride and an organic solvent, has high product stalibity and high dilution stability and can give high water- and oil-repellency.

Owner:DAIKIN IND LTD

Thermoplastic elastomer and thermoplastic elastomer composition

A thermoplastic elastomer obtained by reacting an elastomeric polymer containing a cyclic acid anhydride group in its side chain and a polyamine compound having two or more primary amino groups, and a thermoplastic elastomer composition containing the thermoplastic elastomer are provided. The thermoplastic elastomer exhibits excellent physical properties such as mechanical strength and in particular tensile strength while retaining its excellent recyclability.

Owner:THE YOKOHAMA RUBBER CO LTD

Polyamic acid solution composition and polyimide film

ActiveCN107949597AGood light transmissionSmall phase differenceCoatingsCircuit susbtrate materialsImidePolymer science

The invention discloses a polyamic solution composition and a polyimide film. The present invention pertains to a polyimide film comprising mainly a polyimide obtained by polymerizing a tetracarboxylic acid component and a diamine component, wherein the tetracarboxylic acid component consists of one or more phthalic anhydride structure-free tetracarboxylic dianhydrides (a1) in which at least one of the bonds connecting the two cyclic acid anhydride structures in the molecule is a freely rotatable bond, and one or more tetracarboxylic dianhydrides (a2) with no freely rotatable bonds in the molecule having an alicyclic structure and the two cyclic acid anhydride structures sharing at least one carbon-carbon bond with an alicyclic structure, and the diamine component includes 5-50 mol% of oneor more diamines having a 9,9-diphenylfluorene structure.

Owner:UBE IND LTD

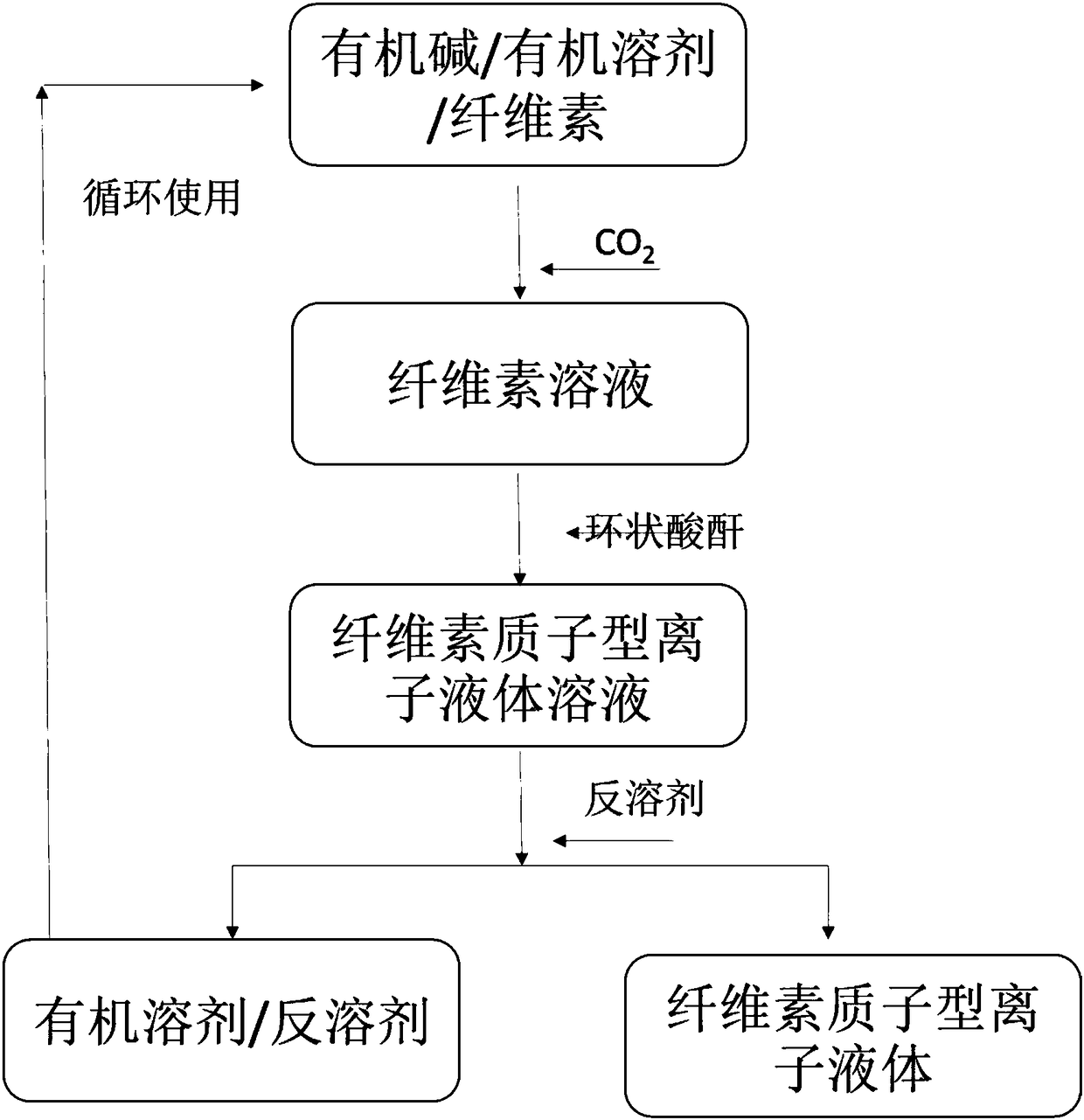

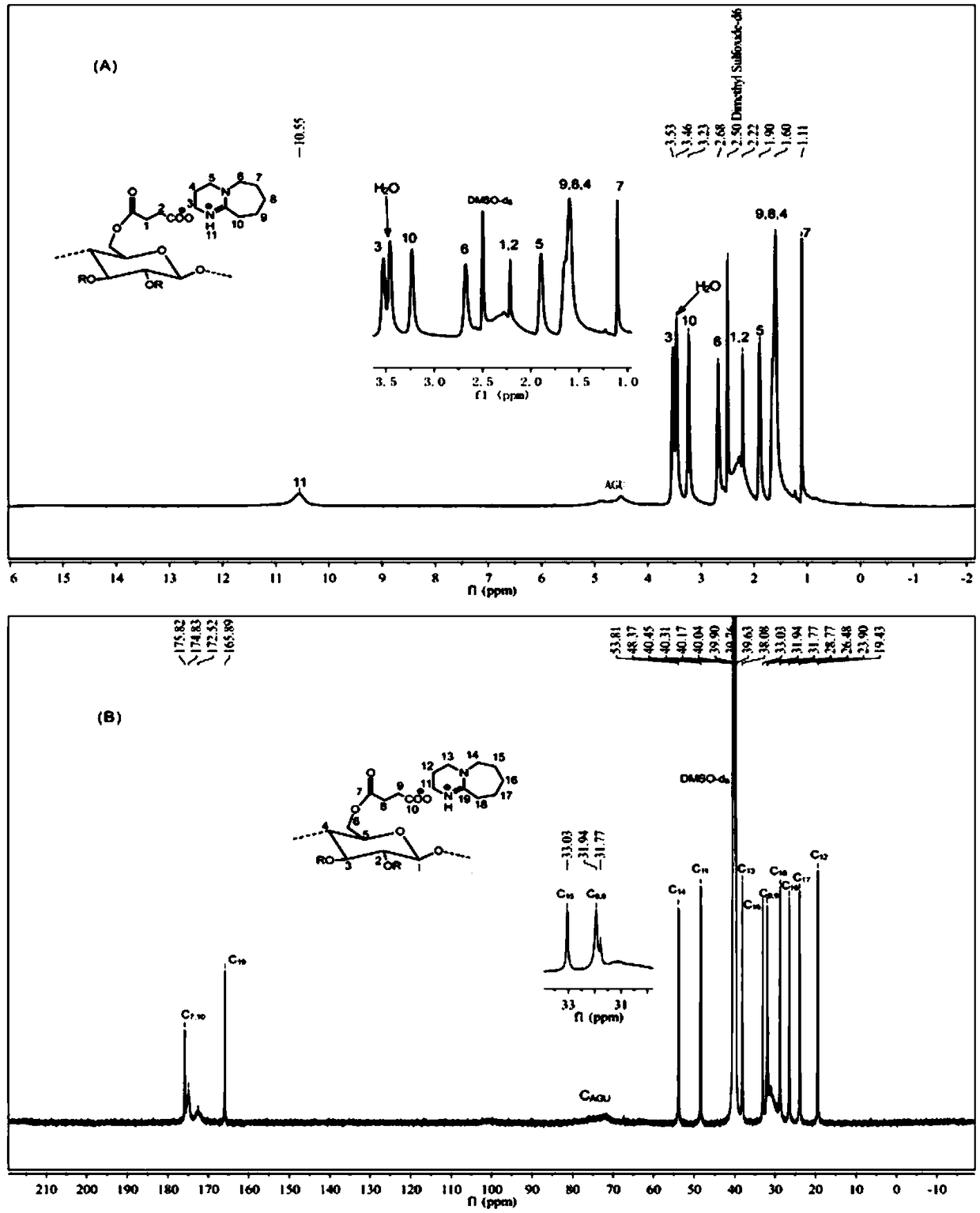

Method for producing cellulose protic ionic liquid by using cellulose

The invention discloses a method for producing cellulose protic ionic liquid by using cellulose. Based on existence of organic base, cellulose and CO2 are reacted in order to realize reversible derivatization dissolving, and organic base is used as an effective component for dissolving cellulose and is used as an organic functional catalyst subsequently, in order to catalyze a reaction between cellulose and cyclic acid anhydrides; one step method by using cellulose is used for preparing the cellulose protic ionic liquid; the dissolving processing system has the advantages of cheap price, easypreparation, and easy recycling, and the system has catalysis performance and other characteristics; the method provides good applications to dissolving processing and graft modification of cellulose.

Owner:GUIZHOU UNIV

Nonaqueous electrolyte cell with improved high temperature characteristics

InactiveUS7410729B2Improve featuresLower performance requirementsNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsPolyesterPhysical chemistry

A non-aqueous electrolyte cell that excels in the high-temperature cycle characteristics and that is without the possibility of solution leakage. The non-aqueous electrolyte cell includes a polymer electrolyte. This polymer electrolyte is a polymerization of a prepolymer included in a prepolymer electrolyte that includes a non-aqueous solvent, an electrolyte salt, and the prepolymer. The prepolymer includes a polyester-based monomer. The polymer electrolyte further includes a vinylene carbonate derivative and cyclic acid anhydride.

Owner:SANYO ELECTRIC CO LTD

Photosensitive resin composition and curing product thereof

InactiveUS20060102051A1Increase photosensitivitySatisfactory flexibilityPhotosensitive materialsPolyureas/polyurethane adhesivesSolder maskDiol

A photosensitive resin composition that excels in sensitivity to actinic energy rays (photosensitivity), is hardenable within a short period of time and can form pattern through development with a diluted aqueous alkali solution and that gives a cured film through thermal curing in the postcuring step, the cured film having satisfactory flexibility and being suitable to a solder mask ink of high insulation excelling in adherence and resistances of gold plating, electroless gold plating and tin plating; and a curing product thereof. In particular, a photosensitive resin composition characterized by comprising (1) a urethane resin (A) soluble in aqueous alkali solutions, the urethane resin obtained by urethanizing in the absence of catalyst a diisocyanate compound (a), a diol compound having an ethylenically unsaturated group in its molecule (b) and a diol compound having a carboxyl group in its molecule (c) optionally together with a diol compound not having any ethylenically unsaturated group or carboxyl group in its molecule (d) and reacting the reaction product with a cyclic acid anhydride (e); (2) photopolymerization initiator (B); and (3) a reactive crosslinking agent (C).

Owner:NIPPON KAYAKU CO LTD

Thermoplastic acrylic resin and molded body for optical member

The present invention provides a thermoplastic acrylic resin comprising (i) a repeating unit derived from a methacrylate monomer, (ii) a repeating unit derived from a vinyl aromatic monomer, (iii) a repeating unit derived from an aromatic group-containing methacrylate monomer, and (iv) a cyclic acid anhydride repeating unit, and a molding for optical material comprising the same.

Owner:ASAHI KASEI CHEM CORP

Carnuba silicone wax

A carnuba silicone wax which does not contain free silicone oil. This wax is obtained by reacting a silicone compound having a substituent with reactivity to the hydroxyl group in natural carnuba wax, with this hydroxyl group. A carboxyl group may be introduced into the molecule by reacting this hydroxyl group with a cyclic acid anhydride, and a silicone compound having a group which can react directly with this carboxyl group is made to react. Alternatively, a hydrogen silicone may be hydrosilylated by a double bond introduced by reacting an epoxy compound having a double bond with this carboxyl group.

Owner:SHIN ETSU CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com