Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

261 results about "Fernico" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fernico describe a family of metal alloys made primarily of iron, nickel and cobalt. The family includes Kovar, FerNiCo I, FerNiCo II, and Dumet. The name is made up of the chemical symbols of its constituent three elements. "Dumet" is a portmanteau of "dual" and "metal," because it is a heterogeneous alloy, usually fabricated in the form of a wire with an alloy core and a copper cladding. These alloys possess the properties of electrical conductivity, minimal oxidation and formation of porous surfaces at working temperatures of glass and thermal coefficients of expansion which match glass closely. These requirements allow the alloys to be used in glass seals, such that the seal does not crack, fracture or leak with changes in temperature.

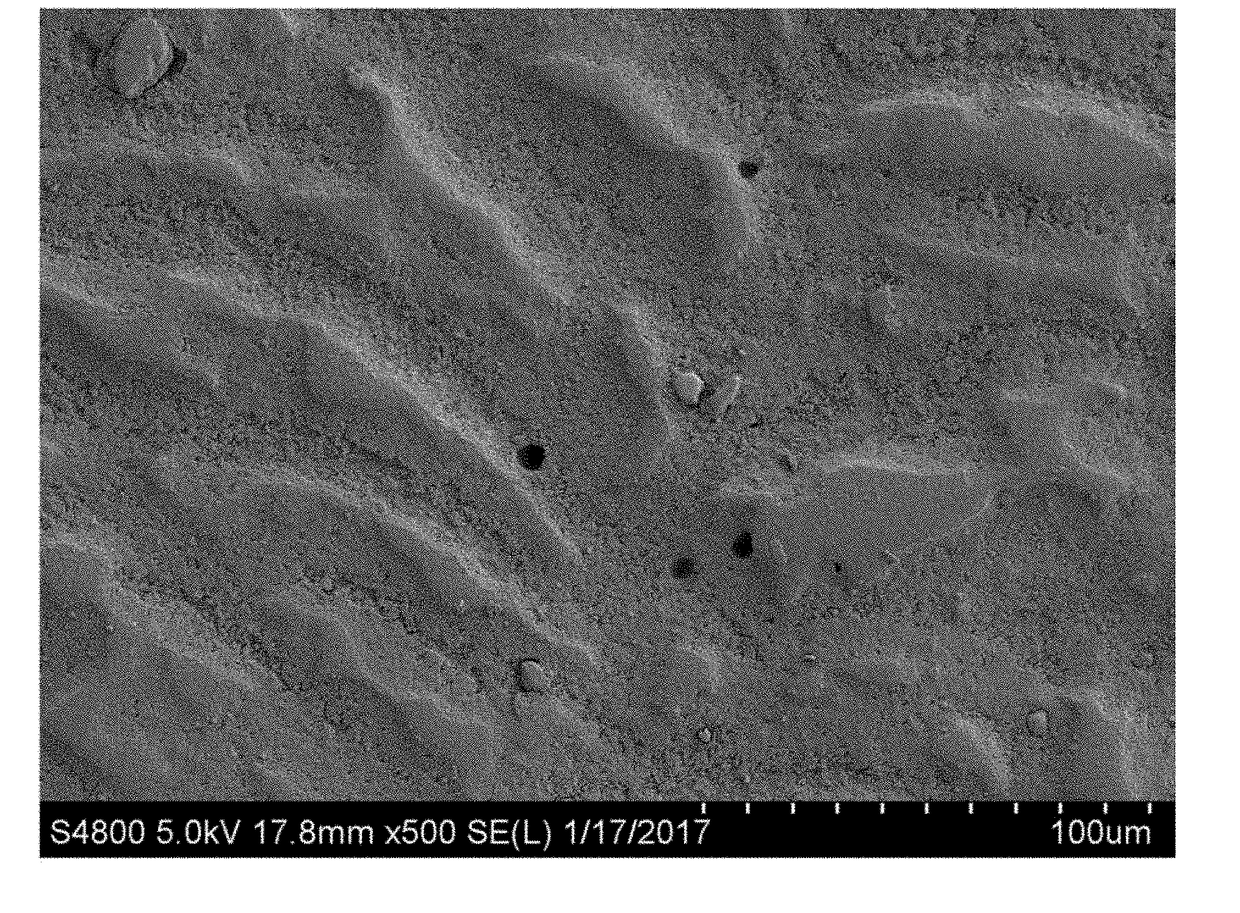

Additive manufacturing with nanofunctionalized precursors

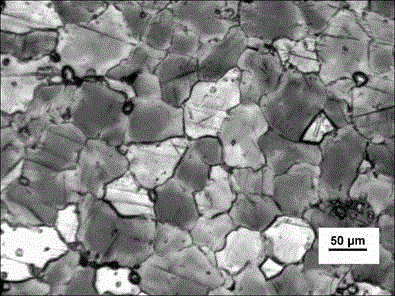

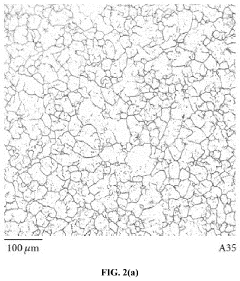

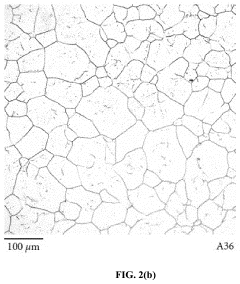

Some variations provide a process for additive manufacturing of a nanofunctionalized metal alloy, comprising: providing a nanofunctionalized metal precursor containing metals and grain-refining nanoparticles; exposing a first amount of the nanofunctionalized metal precursor to an energy source for melting the precursor, thereby generating a first melt layer; solidifying the first melt layer, thereby generating a first solid layer; and repeating many times to generate a plurality of solid layers in an additive-manufacturing build direction. The additively manufactured, nanofunctionalized metal alloy has a microstructure with equiaxed grains. Other variations provide an additively manufactured, nanofunctionalized metal alloy comprising metals selected from aluminum, iron, nickel, copper, titanium, magnesium, zinc, silicon, lithium, silver, chromium, manganese, vanadium, bismuth, gallium, or lead; and grain-refining nanoparticles selected from zirconium, tantalum, niobium, titanium, or oxides, nitrides, hydrides, carbides, or borides thereof, wherein the additively manufactured, nanofunctionalized metal alloy has a microstructure with equiaxed grains.

Owner:HRL LAB

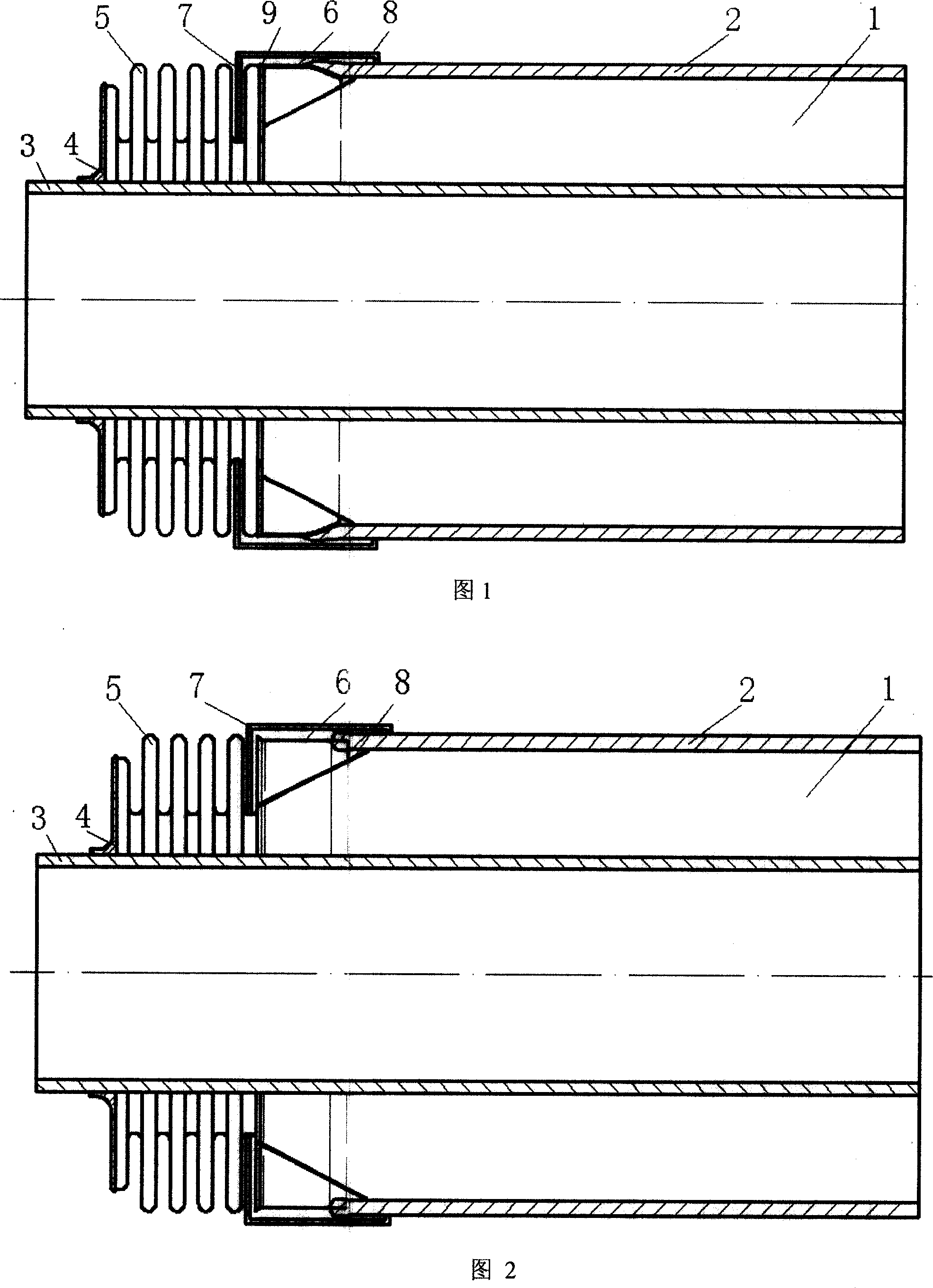

High-temperature solar thermal-collecting tube and manufacturing process thereof

InactiveCN101135501ARadiation immuneExtended service lifeSolar heating energySolar heat devicesEngineeringCobalt

A high temperature solar heat collecting tube and its producing technology mainly applies to tank type solar high temperature heat electric power generation field. The heat collecting tube includes external glass tube and coaxial metal internal tube, corrugated pipe with expansion compensation function is joined with the metal tube by connecting parts, the other end of the corrugated pipe is welded with metal-glass transition parts kovar ring, then the kovar ring is sealed-in with the glass tube, in order to protect glass and glass sealing-in part against radiation, a sunshade hood is mounted at the outer side of sealing-in part, a thin-wall lightproof ring is welded on the corrugated tube. The said glass tube is made of DM308; DM305 or DM320 molybdenum group glass, the kovar ring is made of 4j29 or 4j30 iron-nickel-cobalt low expansion alloy.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

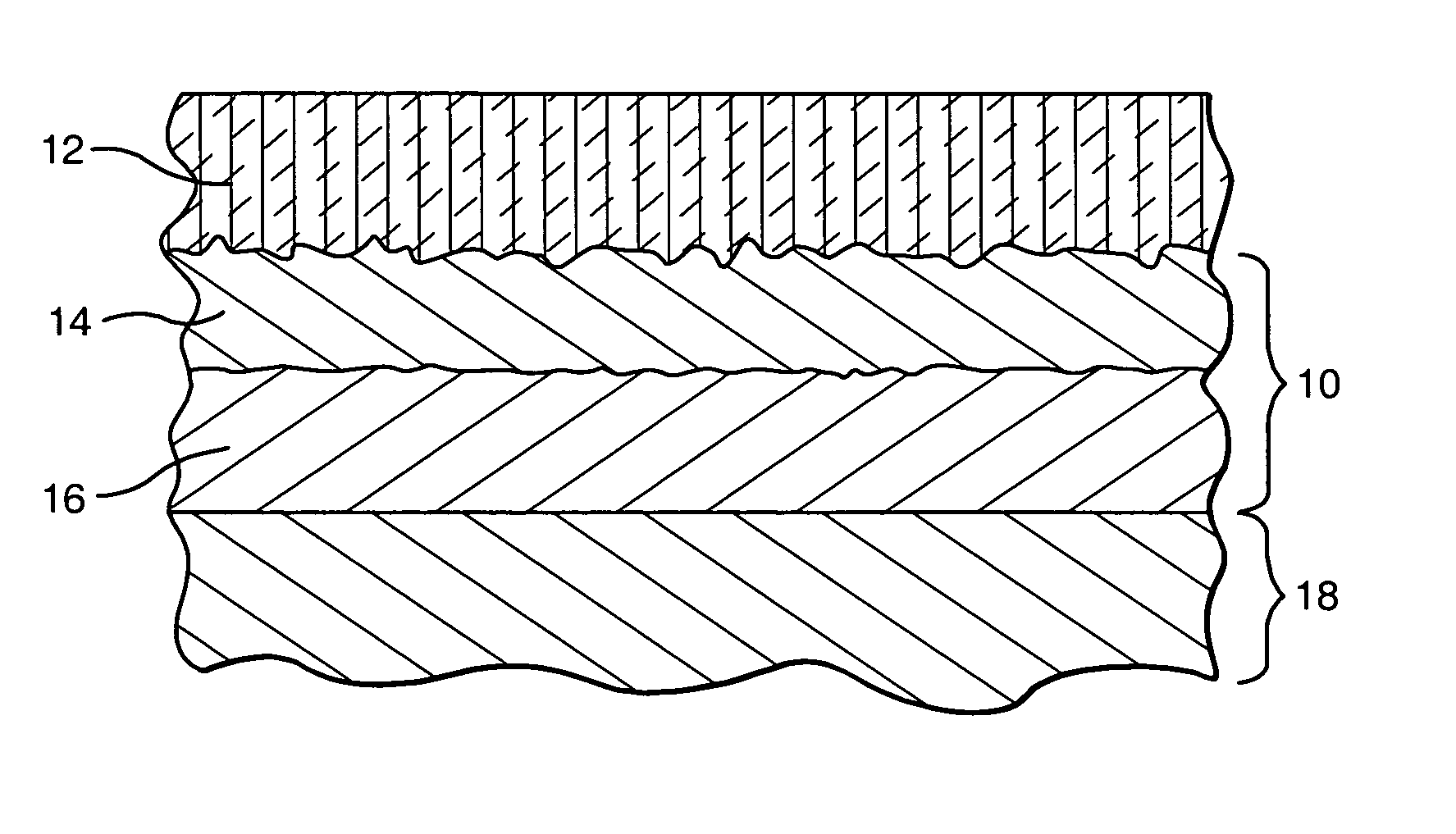

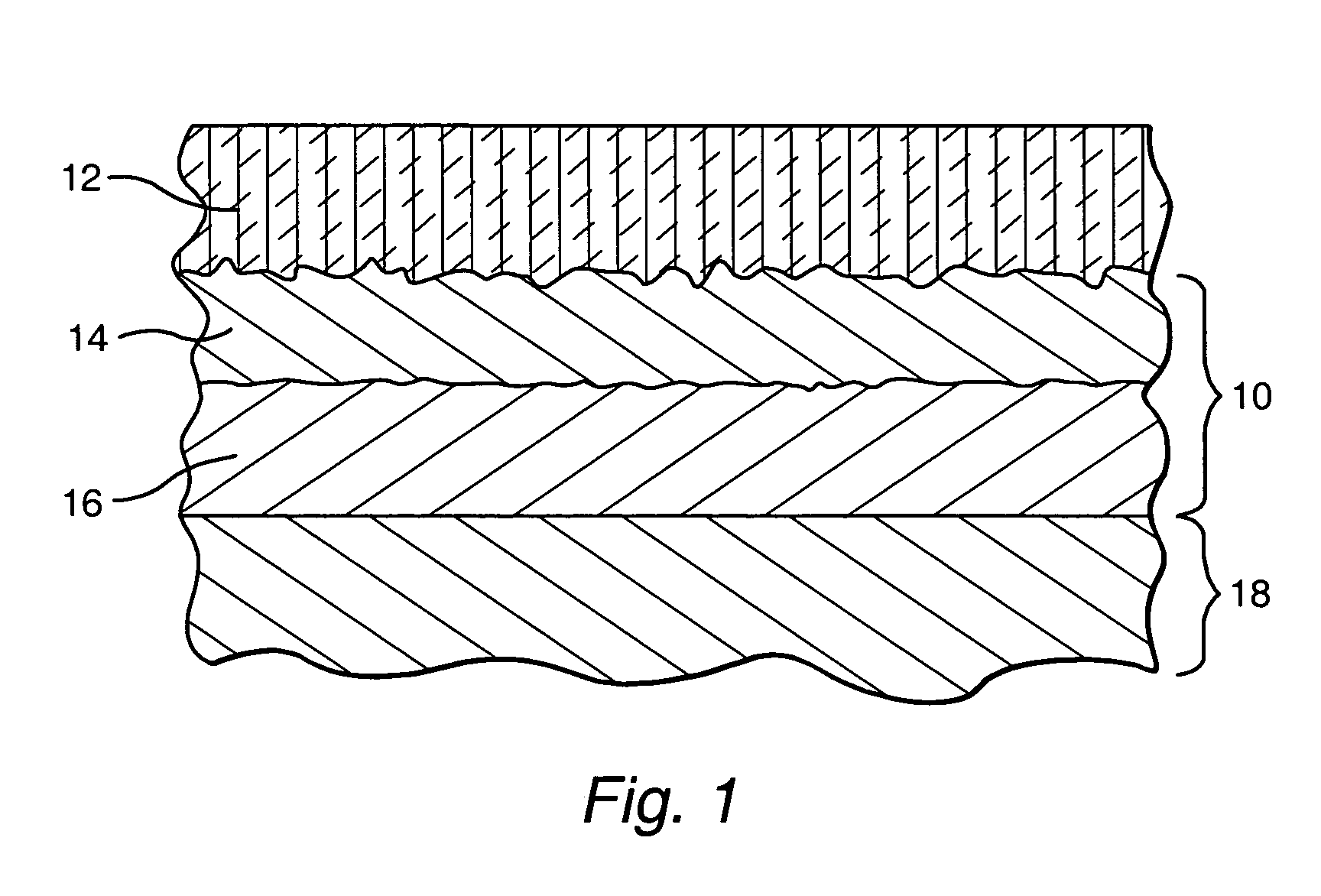

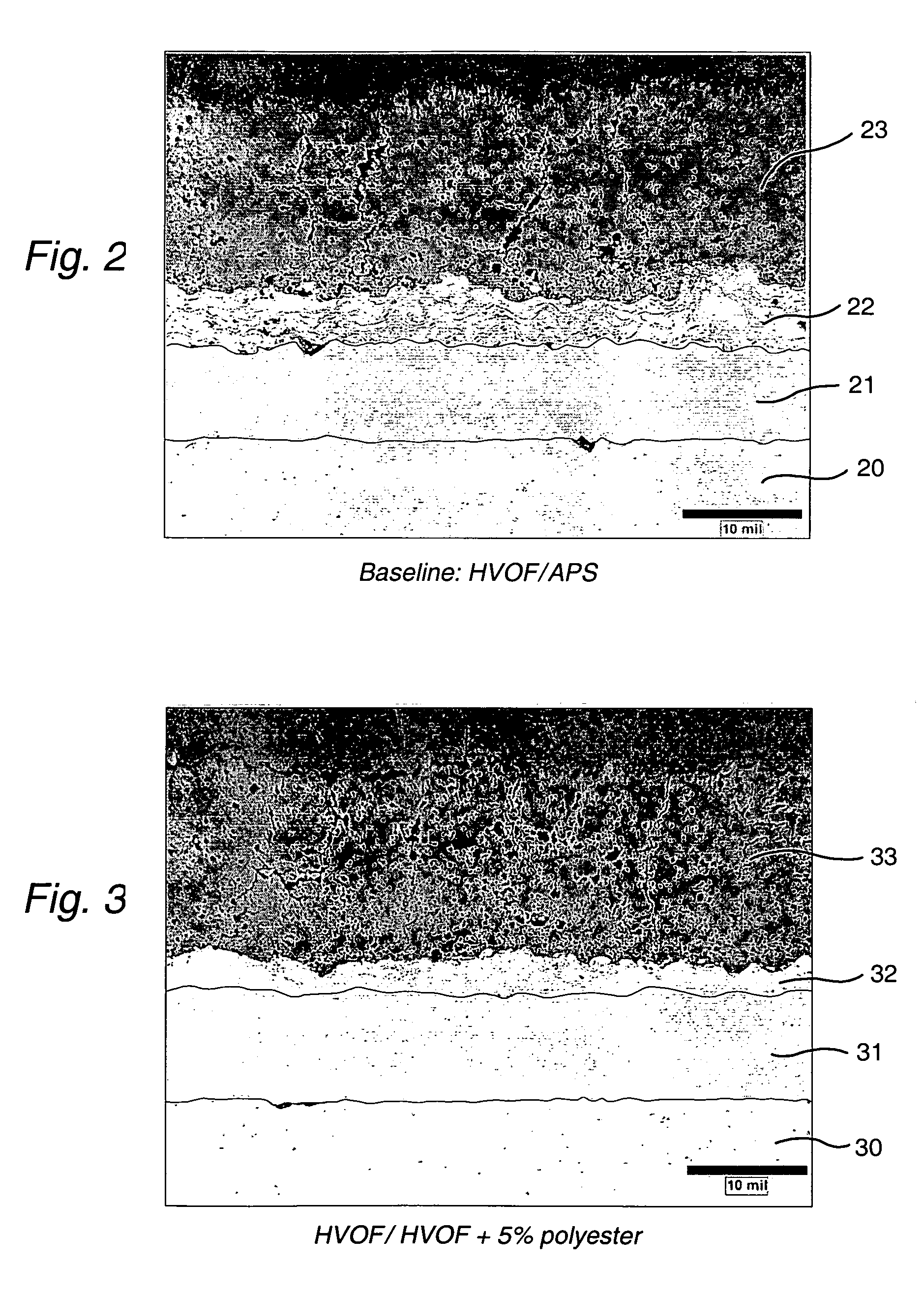

Bi-layer HVOF coating with controlled porosity for use in thermal barrier coatings

InactiveUS7150921B2Increase roughnessImprove ductilityMolten spray coatingPretreated surfacesPorosityPolyester

A bi-layer bond coating for use on metal alloy components exposed to hostile thermal and chemical environment, such as a gas turbine engine, and the method for applying such coatings. The preferred coatings include a bi-layer bond coat applied to the metal substrate using high velocity oxy-fuel (HVOF) thermal spraying. Bi-layer bond coatings in accordance with the invention consist of a dense first inner layer (such as iron, nickel or cobalt-based alloys) that provides oxidation protection to the metal substrate, and a second outer layer having controlled porosity that tends to promote roughness, mechanical compliance, and promotes adherence of the thermal barrier coating (TBC). Preferably, the outer, less dense layer of the bi-layer bond coat is formed from a mixture of metallic powder and polyester to adjust and control the porosity, but without sacrificing mechanical compliance.

Owner:GENERAL ELECTRIC CO

Atomized alloyed powder substituting cobalt and nickel in diamond tools

The invention discloses an alloy powder manufactured by high pressure water atomization, and the compositions (weight percentage) of the alloy powder are: 0 to 60 percent of copper, 20 to 50 percent of iron, 5 to 20 percent of nickel, 0 to 15 percent of cobalt, 0 to 15 percent of tin, 0 to 5 percent of molybdenum, 0 to 5 percent of titanium, 0 to 5 percent of rare earth elements, 0 to 5 percent of aluminum, and 0 to 5 percent of silicon. Materials are high temperature molten and alloyed according to a certain proportion and are atomized by high-pressure water; the obtained alloy powder is dried, reduced by hydrogen, finally the atomized alloy powder is prepared. The alloy powder can be taken as a bonding agent for producing diamond tools and replace the originally used cobalt powder and nickel powder; the alloy powder can achieve performances no less than the original cobalt or nickel composition bonding agents, and greatly reduce the manufacturing cost of diamond tools.

Owner:上海芬迪超硬材料科技有限公司

High temperature refractory joining paste

InactiveUS6199747B1Affect qualityLow melting pointWelding/cutting media/materialsSoldering mediaRefractoryCobalt

A method of and novel composition for transient liquid phase bonding of refractory metal structures is described herein. Preferably, the composition comprises a first component substantially similar to the composition of the refractory metal structure, and a second component having a lower melting temperature than the first component comprising a metallic constituent selected from the group consisting of iron, nickel and cobalt. The second component acts as a melting point depressant to temporarily lower the melting point of the first component so that the join can be accomplished without melting the structure itself. Upon applying the composition to the surfaces of refractory metal structures in need of joining, the assembly is heated to a eutectic point defined as the lowest melting point of the composition. A localized liquid region is formed at the interface of the two structures which solidifies when the second component diffuses into the structures such that the region becomes increasingly refractory thereby solidifying into a substantially refractory joint.

Owner:IBM CORP

Compositions of nanometal particles containing a metal or alloy and platinum particles for use in fuel cells

InactiveUS20070227300A1Maximize surface interactionMaterial nanotechnologyCell electrodesIon-exchange membranesIonomer

A composition of nanoparticles of metal or an alloy or having a metal and alloy core with an oxide shell in admixture with platinum particles is useful as a component for electrodes. More particularly, such composition is useful as an electrode ink for the reduction of oxygen as well as the oxidation of hydrocarbon or hydrogen fuel in a direct oxidation fuel cell, such as, but not limited to, the direct methanol fuel cell. These electrodes encompass a catalyst ink containing platinum, the nanoparticles, and a conducting ionomer which may be directly applied to a conductive support, such as woven carbon paper or cloth. This electrode may be directly adhered onto an ion exchange membrane. The nanoparticles comprise nanometer-sized transition metals such as cobalt, iron, nickel, ruthenium, chromium, palladium, silver, gold, and copper. In this invention, these catalytic powders substantially replace platinum as a catalyst in fuel cell electrooxidation and electroreduction reactions.

Owner:BRICOLEUR PARTNERS LP

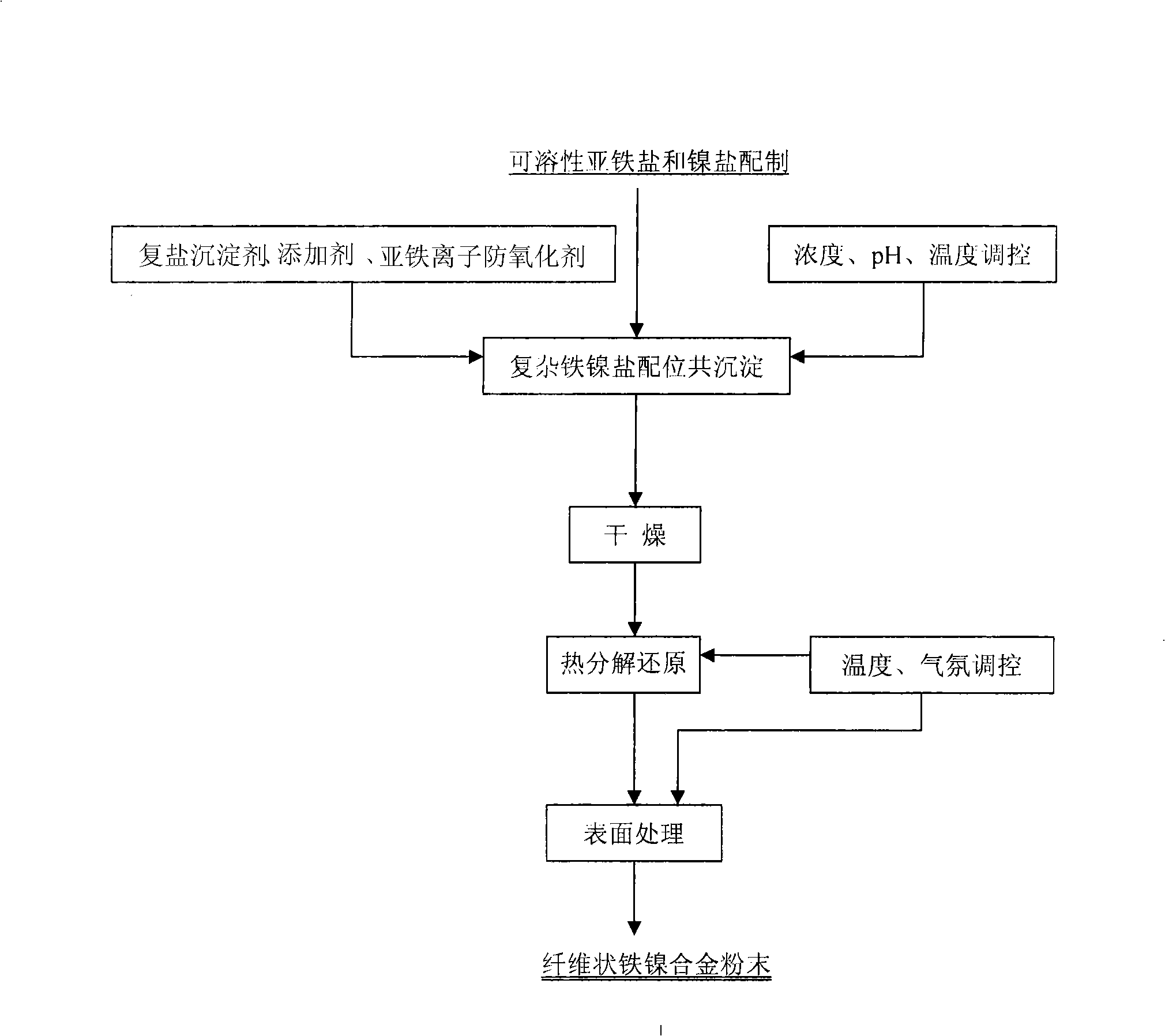

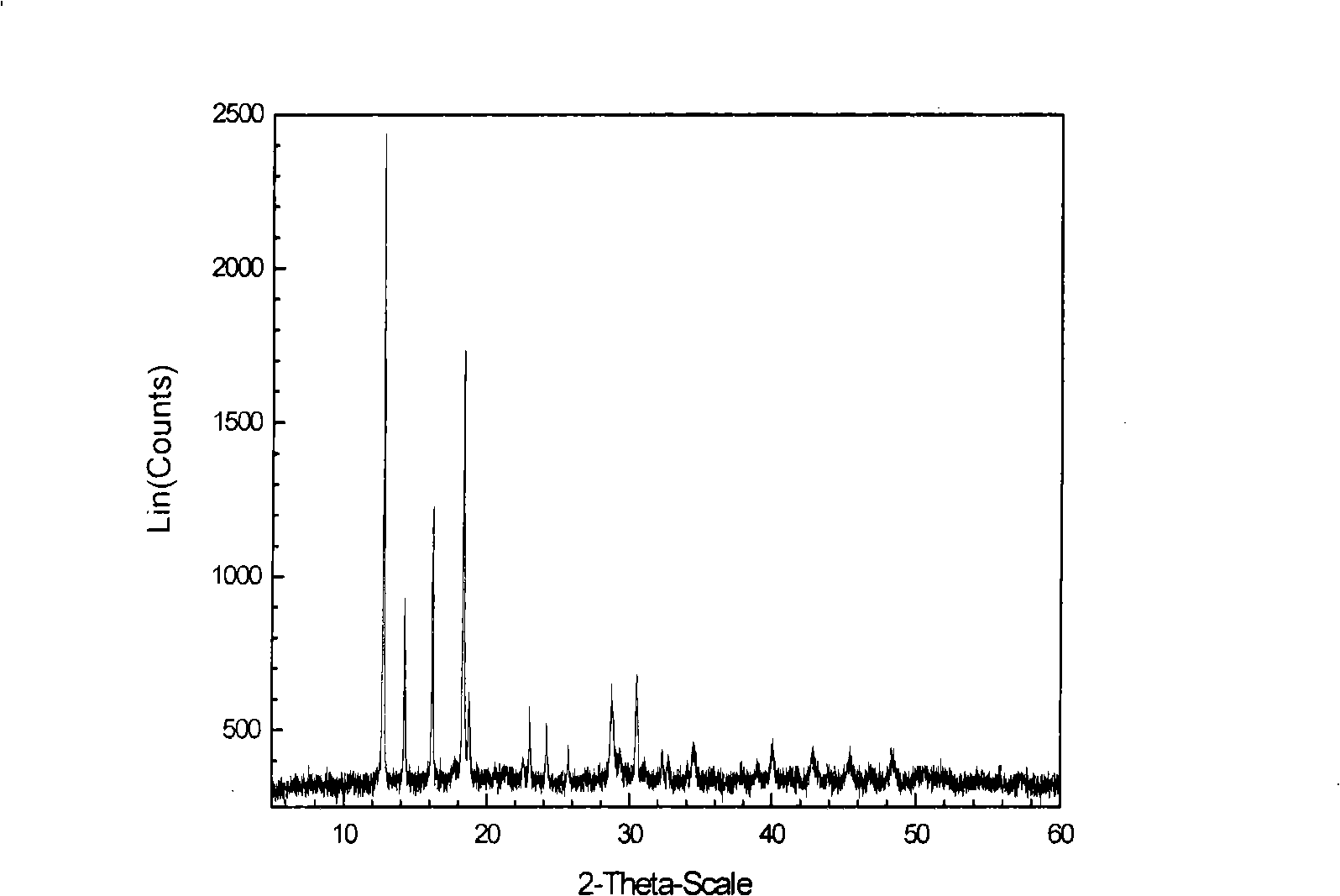

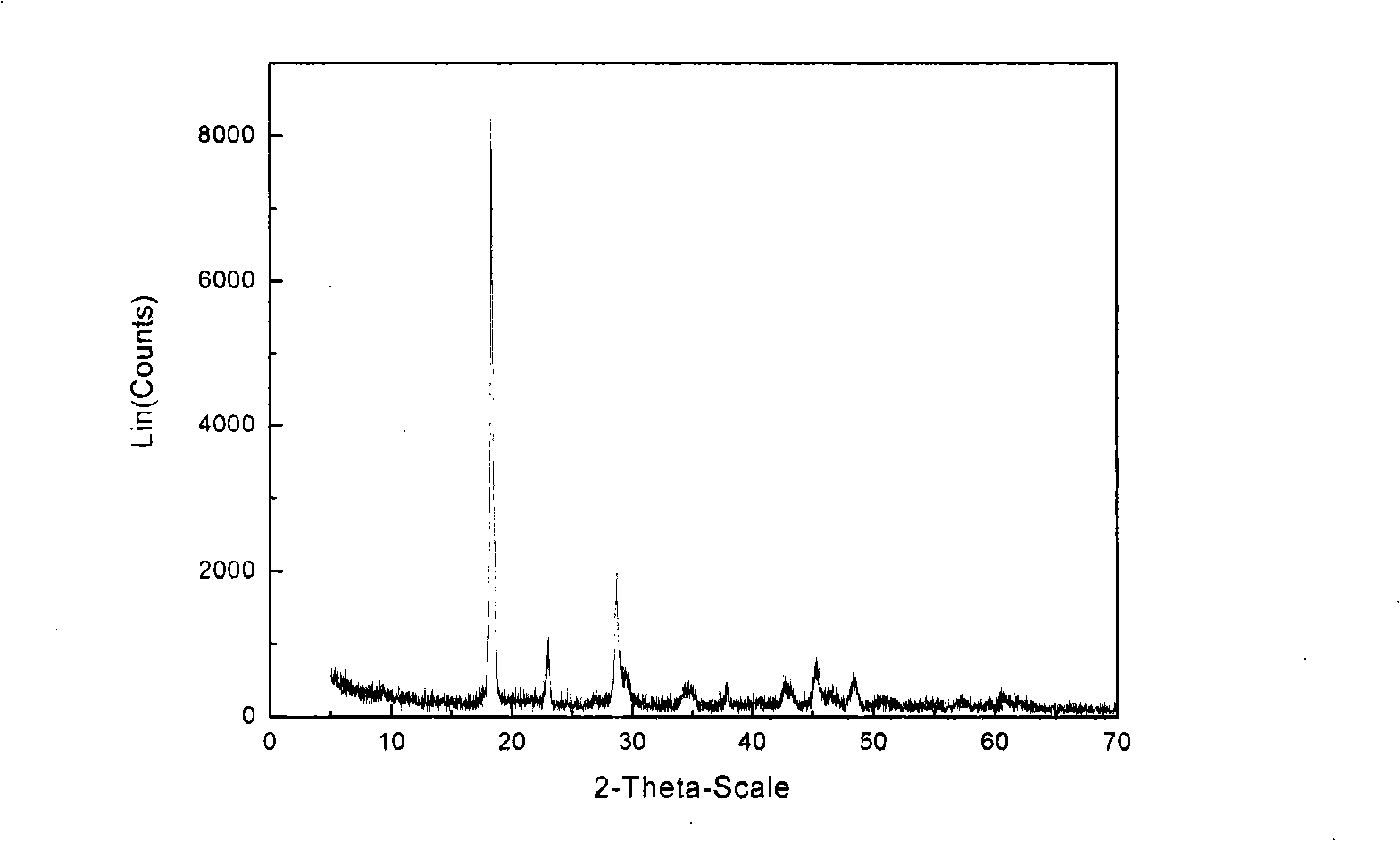

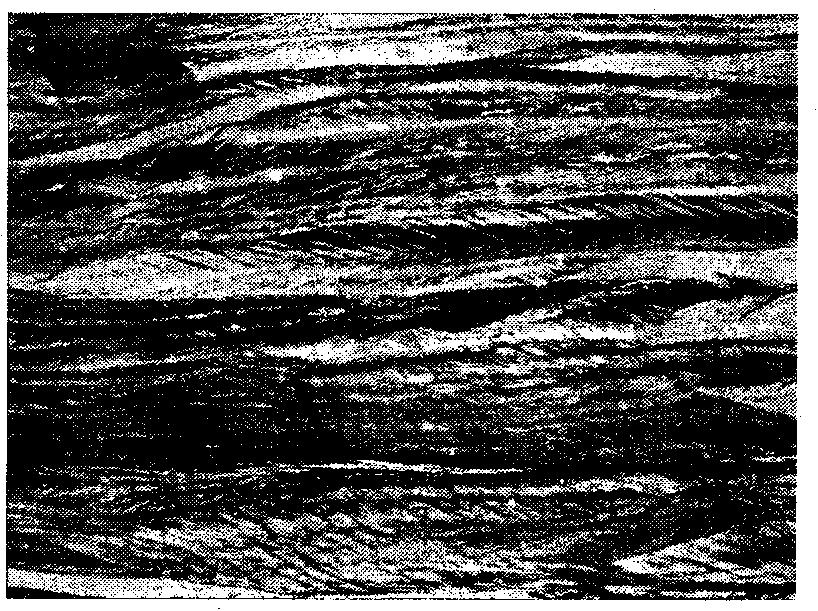

Preparation method of fibrous iron-nickel alloy powder

The invention relates to a preparation technology of a powder functional material, in particular to a preparation method of fibrous iron-nickel alloy powder. A coordinated coprecipitation-thermal decomposition-reduction process is adopted to synthesize a precursor coprecipitate product of the fibrous iron-nickel alloy powder in a Ni<2+>-Fe<2+>-H2NCH2CH2NH2-(H3NCH2CH2NH3)<2+>-SG<n->-C2O4<2->-H2O system at the normal temperature and pressure (SG<n-> stands for Cl<->, SO4<2->, NO3<-> and CH3COO<->), and the precursor is thermally decomposed and reduced under an weak reducing atmosphere to obtain the fibrous iron-nickel alloy powder; anti-oxidation treatment of surface of the fibrous iron-nickel alloy powder is carried out in the same device under the regulation and control of the temperature and atmosphere. The whole preparation process is safe, reliable, nontoxic and pollution-free. The iron-nickel alloy powder produced by the preparation method is fibrous and porous, and has small particle size, large specific surface area; and the iron-nickel alloy powder has strong oxidation resistance, and can meet requirements of a plurality of purposes.

Owner:CENT SOUTH UNIV

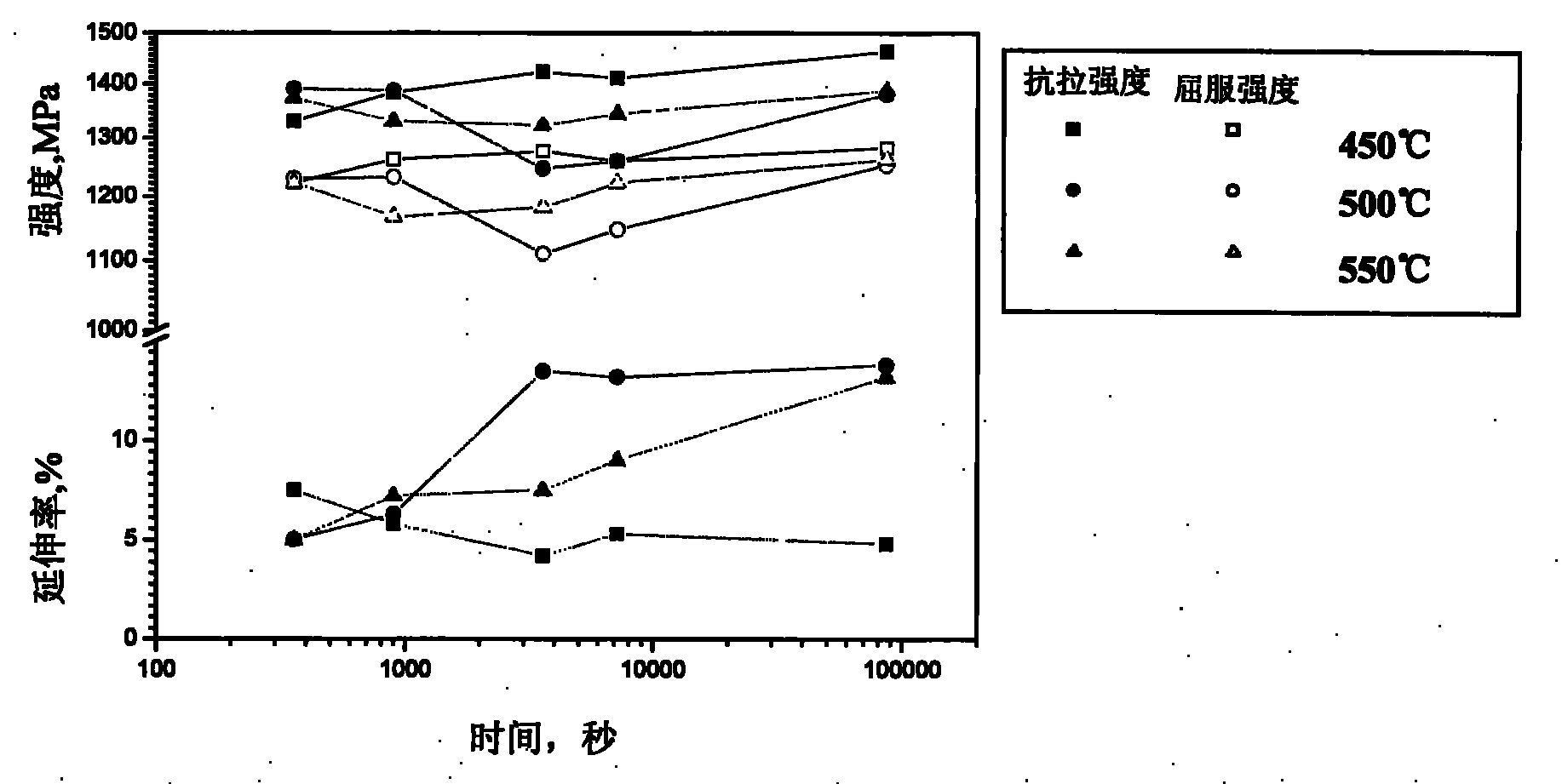

Deformation induced maraging stainless steel and machining process thereof

The invention belongs to the field of iron nickel-based martensite precipitation hardening-type alloys, and in particular relates to deformation induced maraging stainless steel with high strength, high toughness and high corrosion resistance and a machining process thereof. The stainless steel is a novel material mainly applied to the important fields of aviation, spaceflight, machinofacture, atomic energy and the like. The steel comprises the following components in percentage by weight: 11.0-13.0 percent of Cr, 11.0-14.0 percent of Ni, 1.5-2.1 percent of Ti, 0.1-1.0 percent of Mo, 0.5-2.0 percent of Cu, 1.5-2.2 percent of Co, 0.5-1.5 percent of Mn, 0.1-1.0 percent of Si, 1.0-2.0 percent of Al, less than 0.01 percent of Nb, less than 0.01 percent of C, less than 0.01 percent of N, less than 0.01 percent of V and the balance of Fe. The machining process comprises the following steps of: (1) heating and forging in an austenite single phase zone, and air-cooling to the room temperature after the forging is ended, wherein the forge and press ratio is 6-9; (2) hot-rolling after the forging is ended and air-cooling to the room temperature after the rolling is ended, wherein the blooming temperature is 1100-1200 DEG C, and the finished rolling temperature is 800-900 DEG C. The invention obtains a martensite matrix with high-order dislocation density through deformation induced martensite phase change and simultaneously obtains high strength, high toughness and high corrosion resistance through adding the proper matching of precipitation strength elements, such as Ni, Ti, Mo, Cu and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

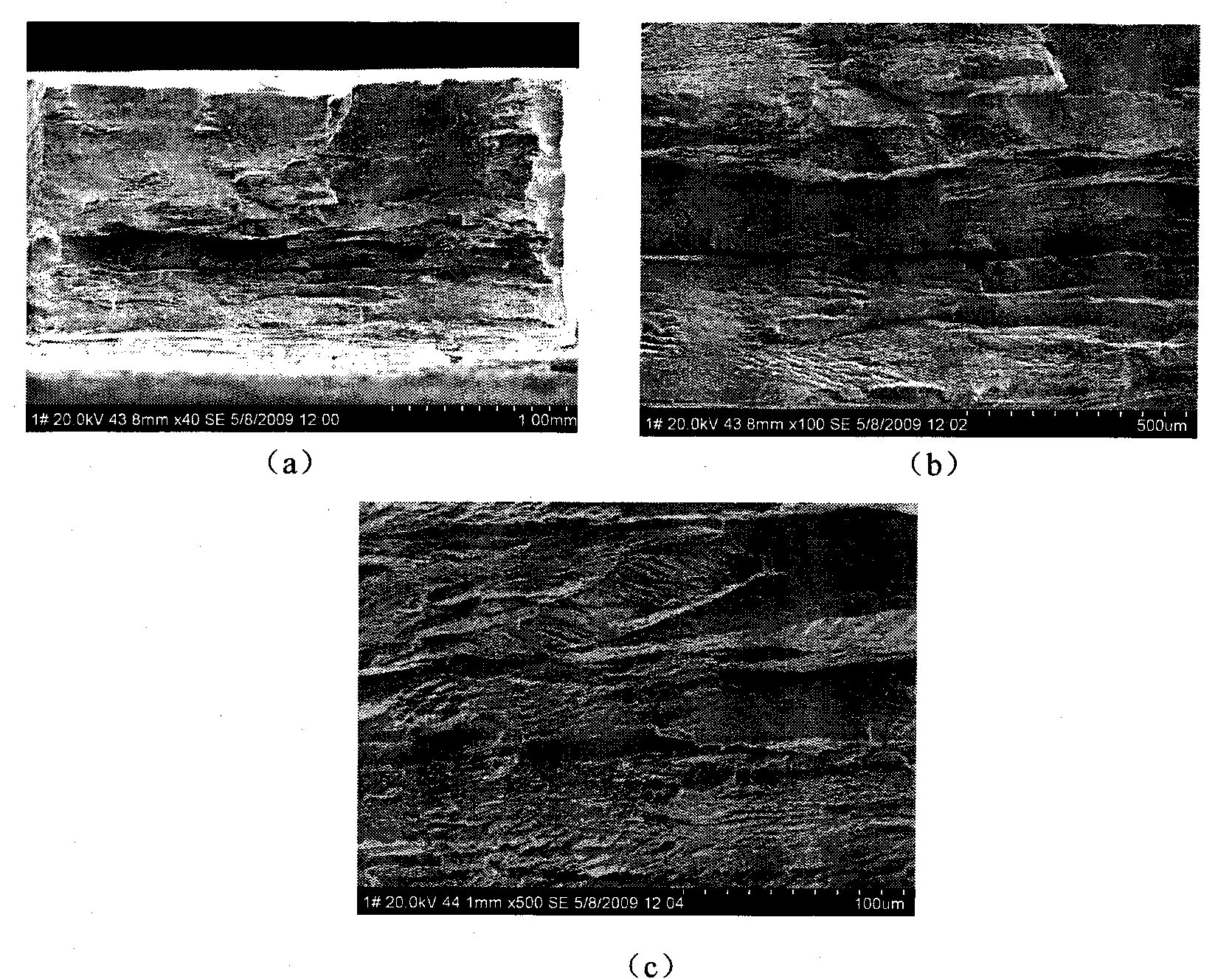

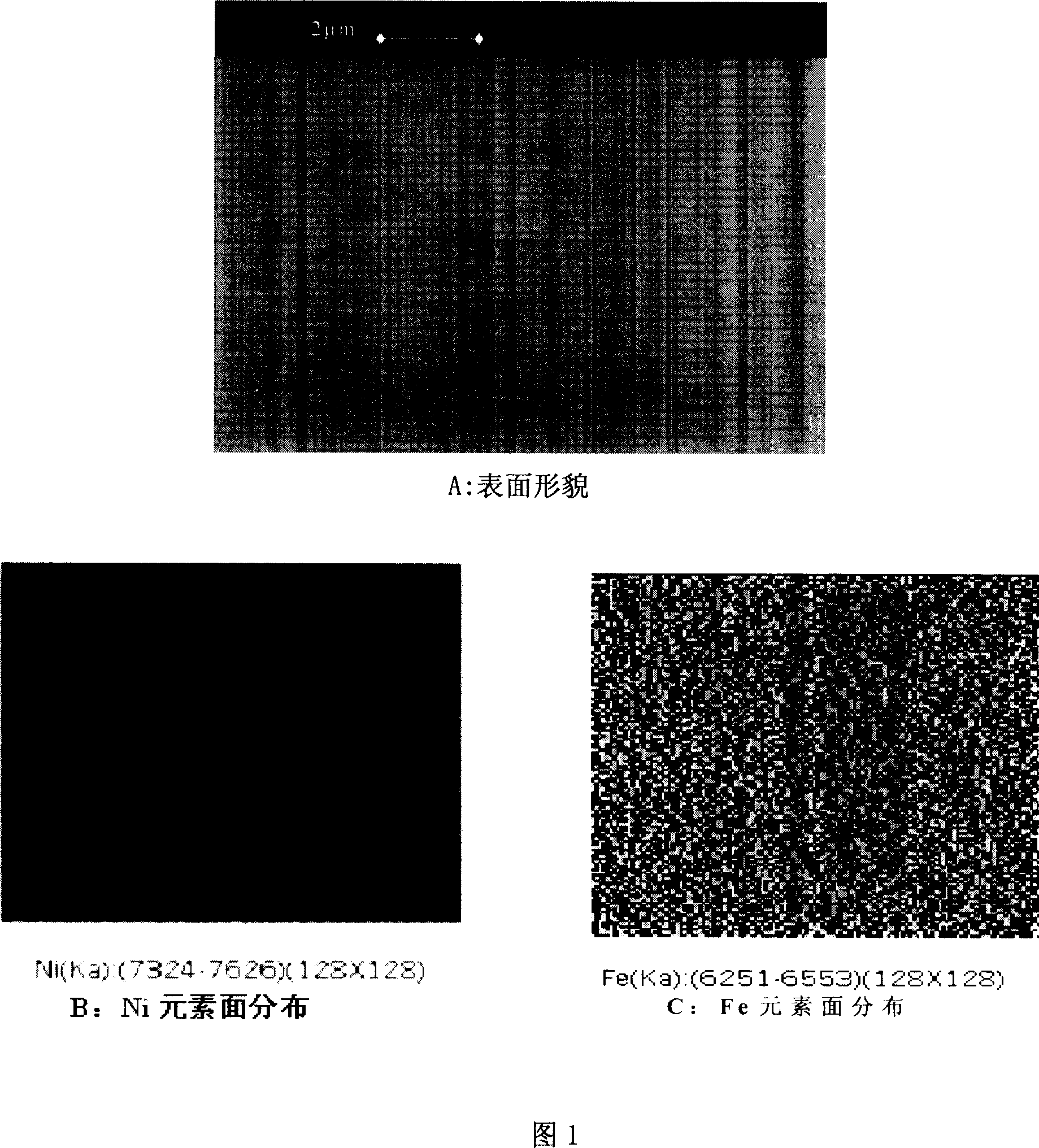

Pumping rod or oil sucking pipe electroplating iron-nickel/tungsten alloy double-layer coating and surface processing technology

ActiveCN101042044ANot easy to miss platingImprove protectionDrilling rodsDrilling casingsCorrosion resistantCarbon dioxide

It relates to a surface treatment process. It uses oxide inert electrodes as the anode to apply ferro plating. It uses ferric persulfate, nickel sulfate dip, nickel carbonate, boracic acid and citrate as the main material, the electrodeposition coating mainly composed of FexNiy, with x=20-45, y=55-80, being amorphous nanocrystalline structure. The coating is the bottom layer, then tungsten alloy to get the final dual layer plating surface treatment. The plating layer is corrosion resistant, with hardness of 480-950Hv, with extensive application.

Owner:湖南纳菲尔新材料科技股份有限公司

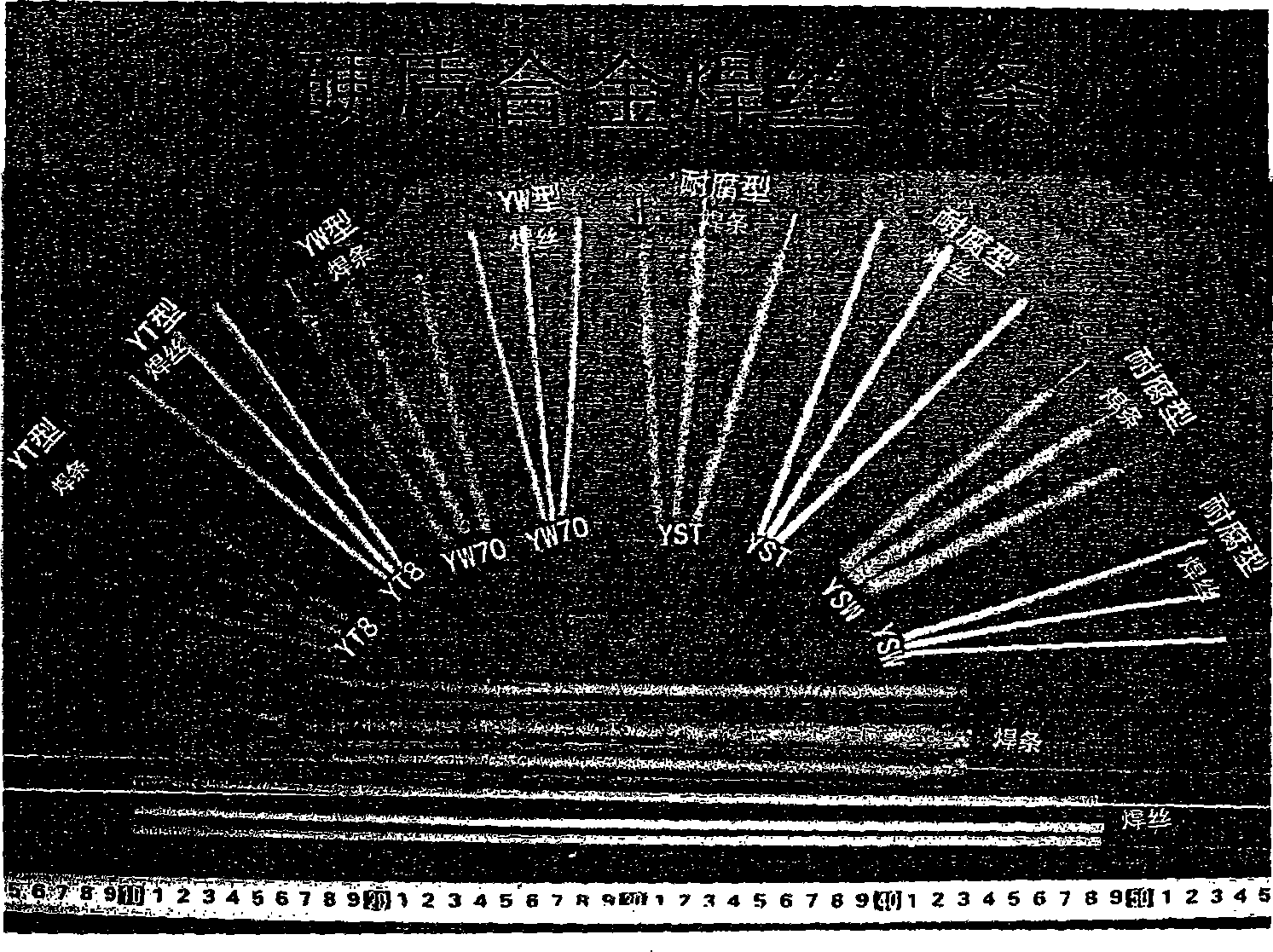

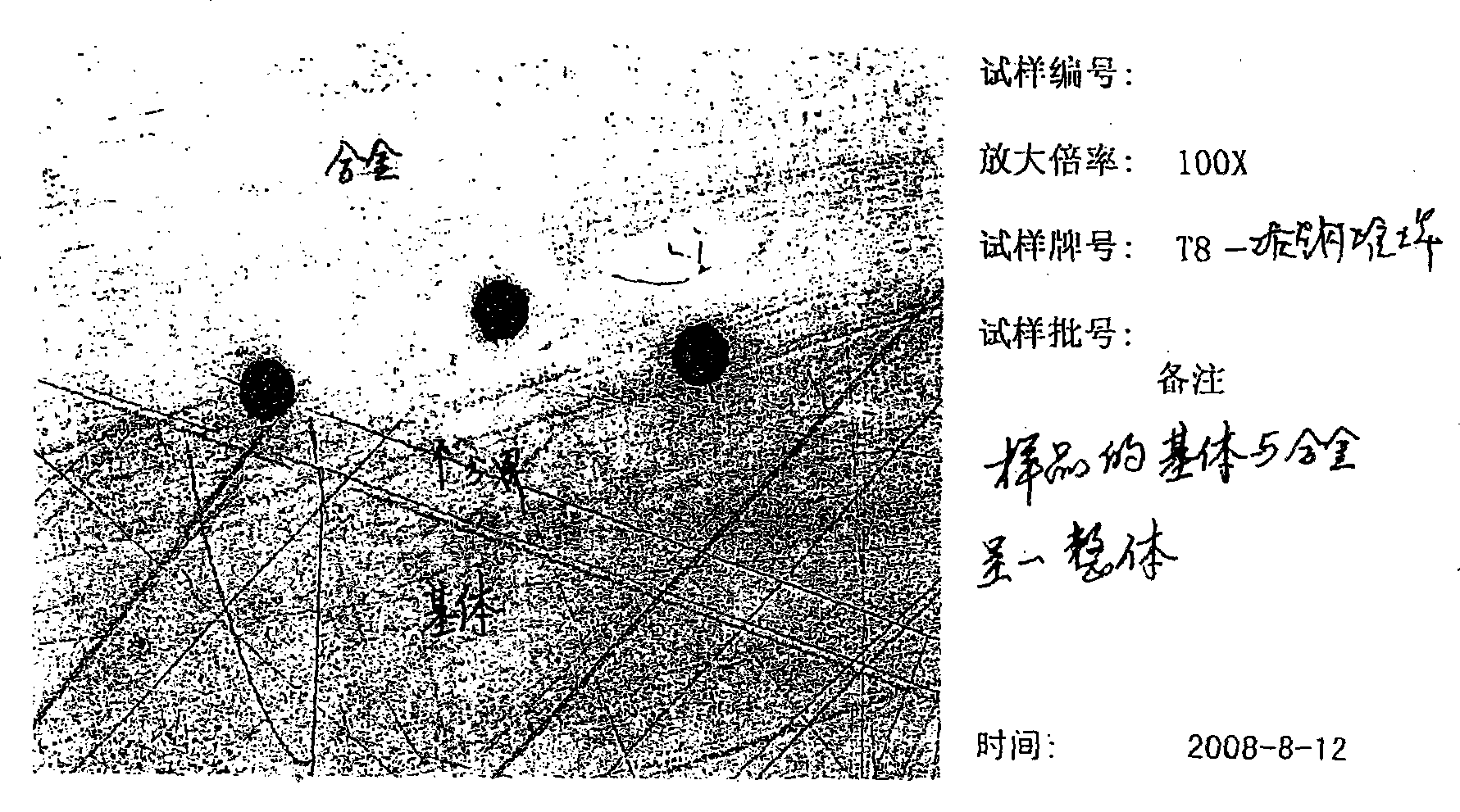

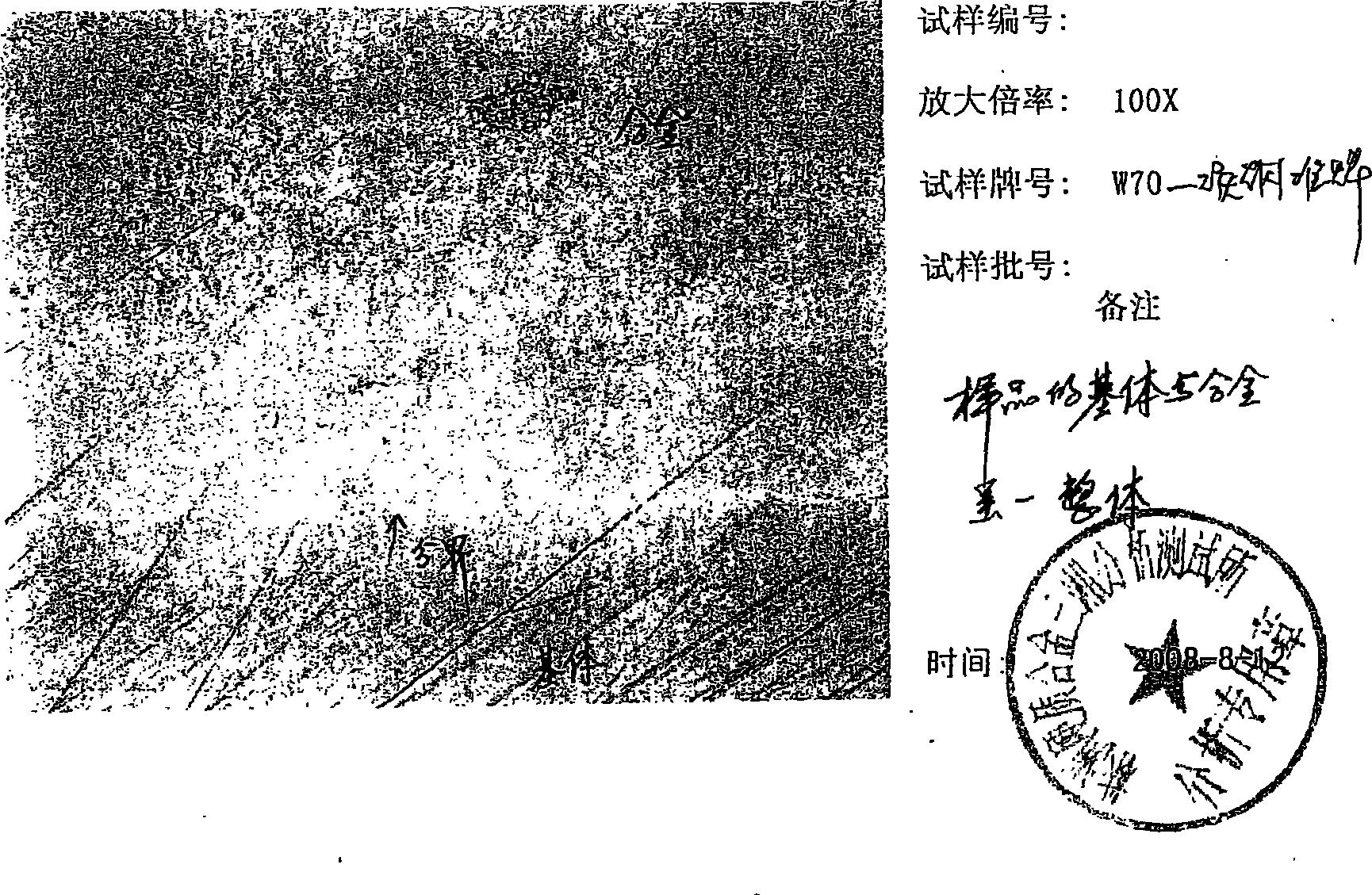

Carbide alloy welding wire or welding rod as well as manufacturing method and application thereof

InactiveCN101462206AImprove bindingHigh strengthWelding/cutting media/materialsSoldering mediaNiobiumManganese

The invention relates to a hard alloy welding wire or welding rod. The welding wire or welding rod is prepared from the following compositions: tungsten carbide, titanium carbide or tungsten carbide and titanium carbide is used as a hard phase; one, two or three of iron, nickel and cobalt are used as a bonding phase; specific compositions have the following weight percentage accounting for the gross weight: 30 to 85 percent of the hard phase and 15 to 70 percent of the bonding phase; and in the mixture ratio of the hard phase or the bonding phase, the hard phase or the bonding phase comprises one or more of chrome, manganese, copper, molybdenum, vanadium, tantalum, niobium and carbide accounting for less than 15 percent of the gross weight and C with proper amount is added. The hard alloy welding wire or welding rod has the advantages of high rigidity, high wearing resistance, impact resistance, corrosion resistance, easy welding, low cost, simple operation and wide application range.

Owner:郭庆虎 +2

Mixed ultra-hard abrasive honing stone

InactiveCN104400614AReduce processing costsEasy to manufactureOther chemical processesAbrasion apparatusNickelHot press

The invention discloses a mixed ultra-hard abrasive honing stone. The mixed ultra-hard abrasive honing stone is characterized by comprising the following components in percentage by weight: 20-40 percent of copper, 2-6 percent of silver, 1-10 percent of aluminum, 2-6 percent of zinc, 2-20 percent of tin, 10-20 percent of iron, 5-10 percent of nickel, 5-30 percent of cobalt, 1-9 percent of lead, 5-10 percent of a bonding agent and the balance of an ultra-hard material, wherein the volume ratio is 60-100 percent; the metal purity of the copper, the silver, the aluminum, the zinc, the tin, the iron, the nickel, the cobalt and the lead is over 99 percent; the granularity of the ultra-hard material is 200-1,000 meshes; the honing stone is prepared by performing mixing, cold press molding and vacuum hot press process on the raw materials according to the mixture ratio. The mixed ultra-hard abrasive honing stone disclosed by the invention has the advantages of sharp grinding, high grinding efficiency, large grinding weight, short grinding time, long service life, superior self-sharpening property, low process cost, easiness and convenience in preparation, and the like.

Owner:YINCHUAN HENGYIDA MACHINERY

Low carbon martensite aged stainless steel with high strength high toughness and high decay resistance performances

InactiveCN101886228AHigh strengthImprove corrosion resistanceUltimate tensile strengthPrecipitation hardening

The invention belongs to the ferronickel base martensite precipitation-hardening alloy technical field, in particular relates to a low carbon martensite aged stainless steel with high strength high toughness and high decay resistance performances, novel material mainly applied to the important fields of aviation, space flight, machinery manufacturing and atomic energy. The steel comprises the following components by weight percent: 0.08-0.15% of C, 11.0-12.0% of Cr, 4.0-5.0% of Ni, 0.2-1.0% of Ti, 0.5-1.0% of Mo, 2.0-3.0% of Cu, 2.0-3.0% of Co, 0.1-0.5% of Nb, 0.5-1.5% of Mn, 0.5-1.5% of Si, less than 0.01% of N, less than 0.01% of V, less than 0.01% of Al and balance of Fe. The invention can obtain high strength high toughness and decay resistance performances by appropriate collocation of five precipitation strength elements of Ni, Ti, Mo, Cu and Nb.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Degradable magnesium alloy plate and bar for fracture internal fixation and preparation methods thereof

InactiveCN104630587AReduce the chance of infectionGood biocompatibilitySurgeryFernicoPhysical chemistry

The invention relates to a degradable magnesium alloy plate and a bar for fracture internal fixation. The degradable magnesium alloy plate and bar are prepared by adding one or two of Sr, Ca and Ag based on a Mg-Zn-Zr alloy, wherein the degradable magnesium alloy plate comprises the following components in percentage by mass: 3.0wt% of Zn, 0.5wt% of Zr, 0.0-1.0 wt% of Ca, 0.0-1.0wt% of Ag, 0.0-1.5wt% of Sr, and the balance of Mg, wherein the content of each of iron, nickel, copper, aluminum single impurity element is less than 0.05% and the total amount of the impurities is not more than0.4%. The degradable magnesium alloy plate and the bar have the advantages of high purity, good uniformity composition and microstructure and higher strength and corrosion resistance; the contained elements such as calcium and strontium can promote bone growth so that the alloy has better biocompatibility; the silver element is added so as to improve antibacterial property of an implant; and the degradable magnesium alloy plate and the bar is suitable for being applied in fracture fixation materials.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

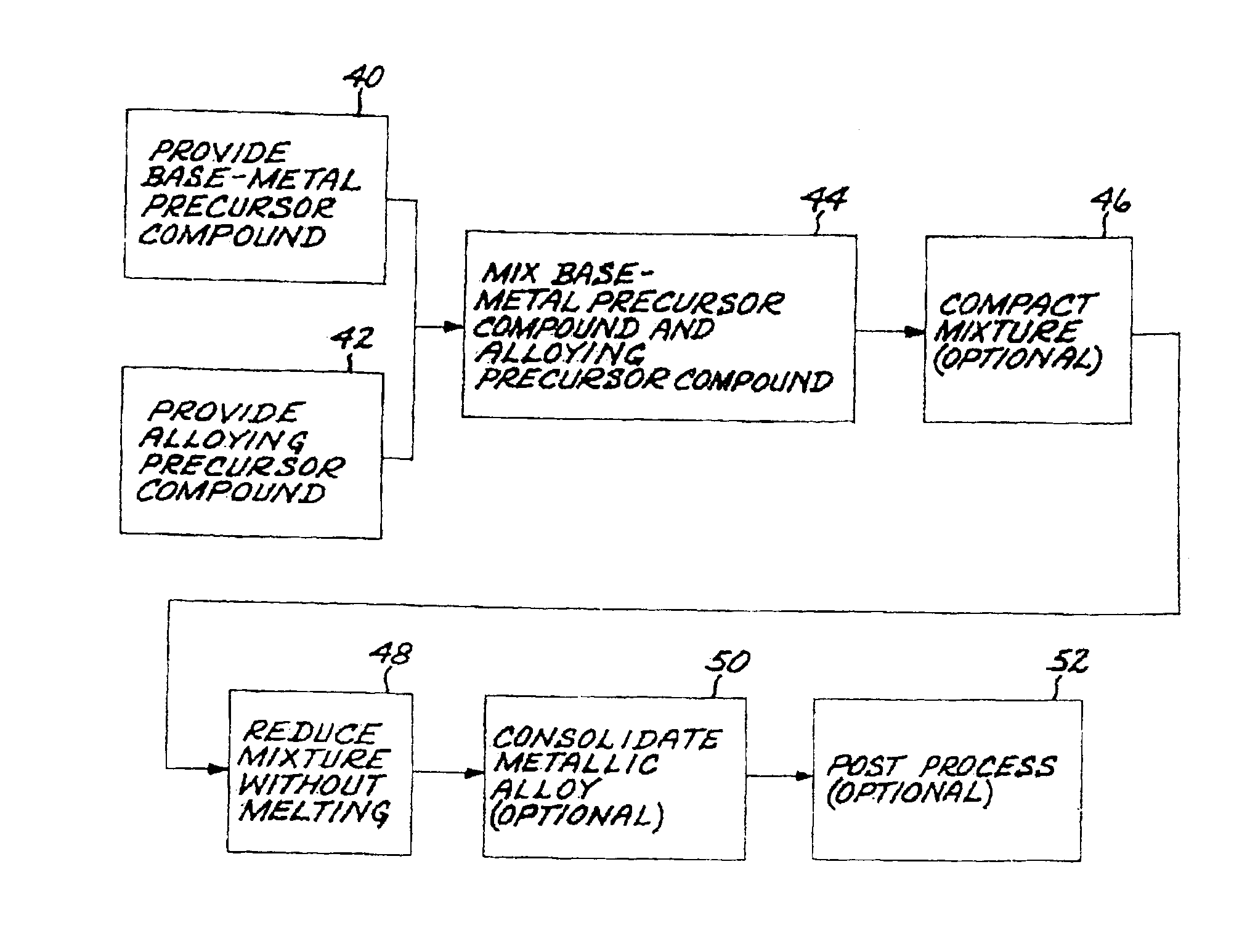

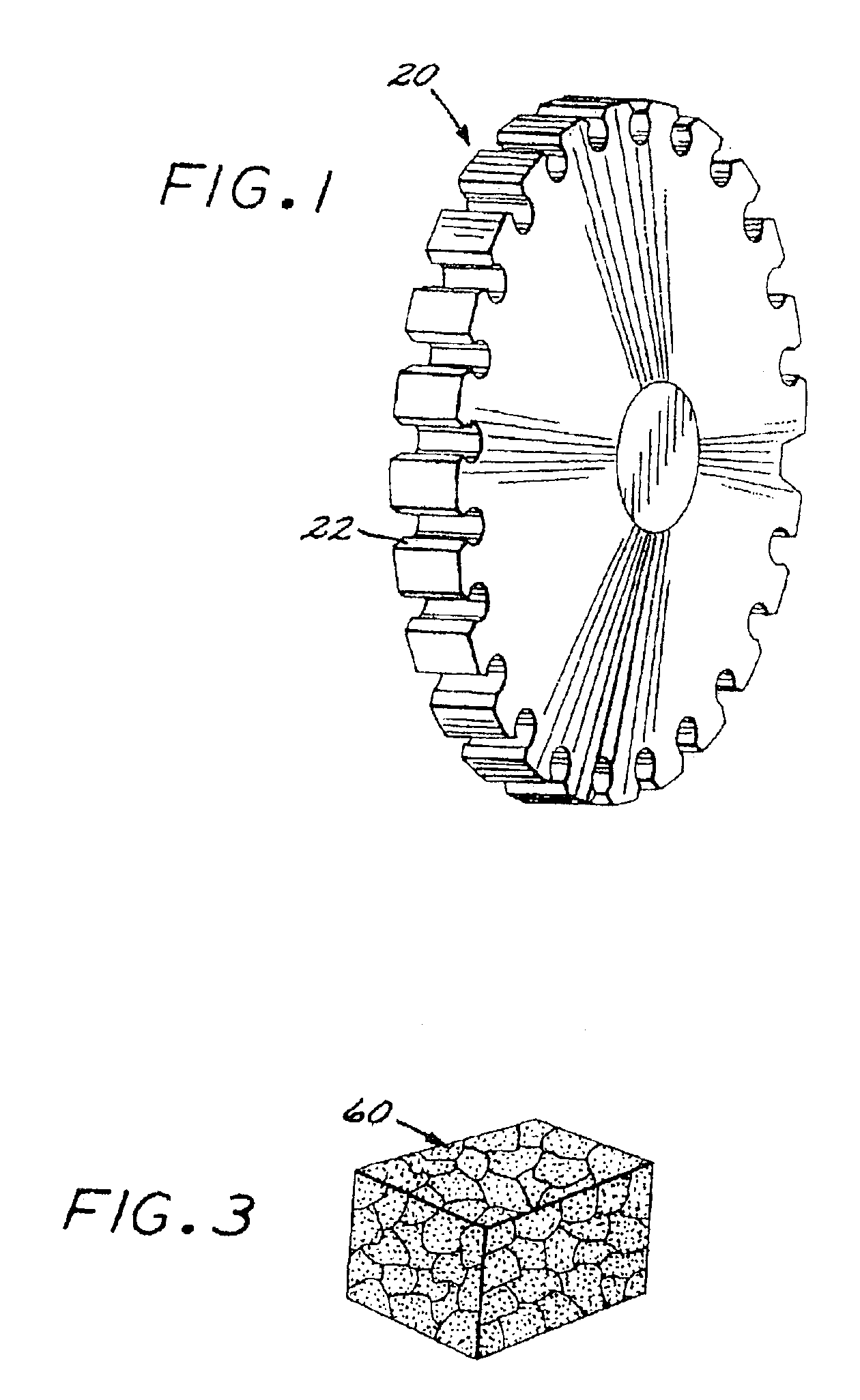

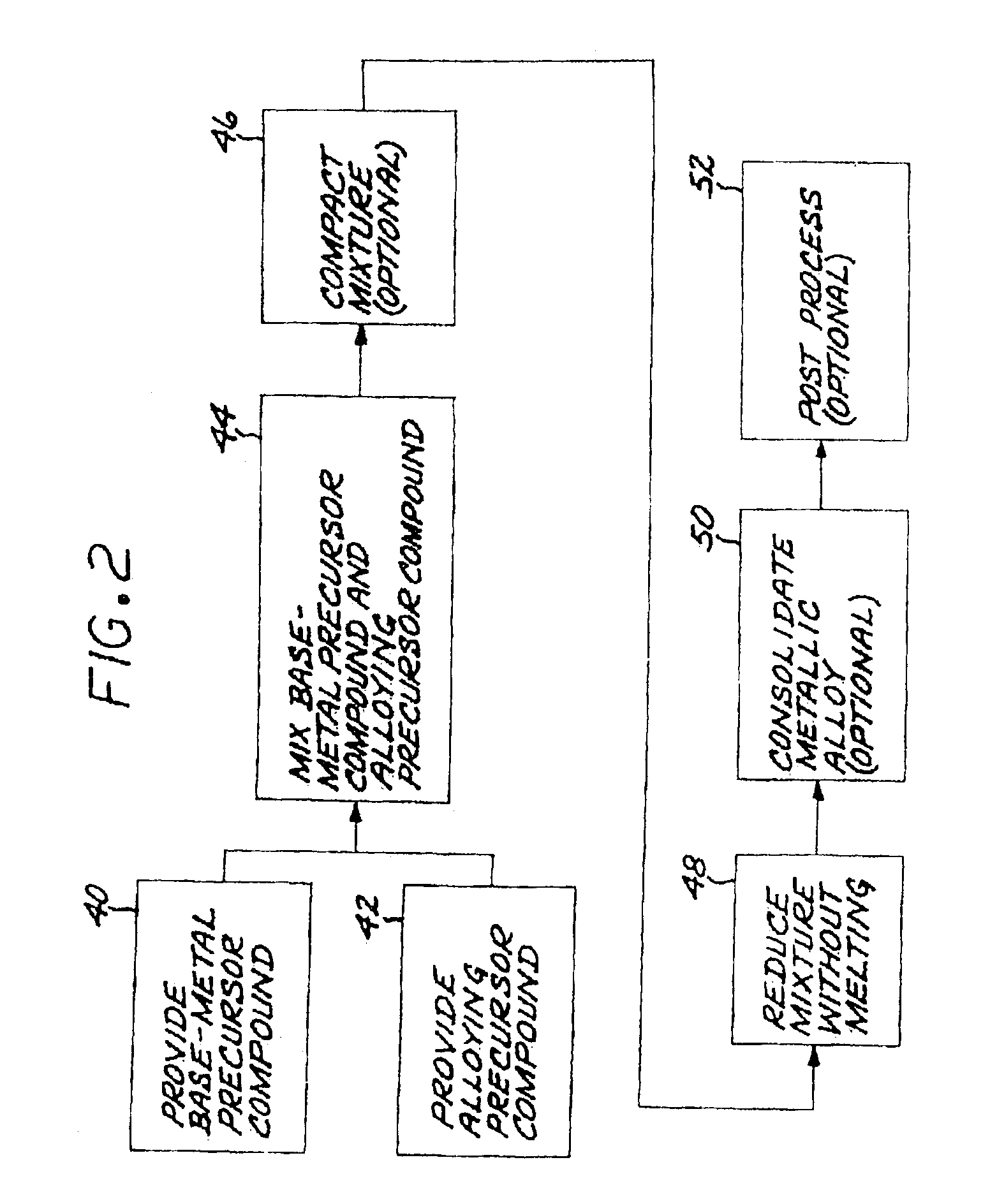

Method for preparing metallic superalloy articles having thermophysically melt incompatible alloying elements, without melting

An article of a base metal alloyed with an alloying element is prepared by mixing a chemically reducible nonmetallic base-metal precursor compound of a base metal and a chemically reducible nonmetallic alloying-element precursor compound of an alloying element to form a compound mixture. The base metal is nickel, cobalt, iron, iron-nickel, or iron-nickel-cobalt. One or more of the alloying elements are thermophysically melt incompatible with the base metal. The method further includes chemically reducing the compound mixture to a metallic superalloy, without melting the metallic superalloy, and thereafter consolidating the metallic superalloy to produce a consolidated metallic article, without melting the metallic superalloy and without melting the consolidated metallic article.

Owner:GENERAL ELECTRIC CO

High-strength high-toughness antioxidant iron-nickel-based high-temperature alloy and preparation method thereof

The invention discloses a high-strength high-toughness antioxidant iron-nickel-based high-temperature alloy and a preparation method thereof. The iron-nickel-based high-temperature alloy comprises thefollowing components in percentage by weight: 35-45% of Fe, 15-21% of Cr, 0.5-1.4% of Mo, 0.1-0.8% of W, 1.8-2.5% of Ti, 0.8-2.5% of Al, not greater than 1.0% of Mn, not greater than 0.1% of Nb, nottreater than 2% of Co, not greater than 0.05% of Si, 0.03-0.10% of C, 0.001-0.005% of B, not greater than 0.01% of P, and the balance Ni. The weight percentage of Cr + Ni is greater than 50%; and theweight percentage of W + Mo is 0.6-1.5%. The iron-nickel-based high-temperature alloy is high in endurance strength, high in impact toughness and excellent in steam oxidation resistance; a gamma' phase and M23C6 are main strengthening phases; and compared with the prior art, the iron-nickel-based high-temperature alloy is equivalent in machining performance and low in material cost, is more excellent in structure stability, high-temperature strength and impact toughness, and can be used for manufacturing such high-temperature parts as main steam pipes, headers and high-temperature section rotors of ultra-supercritical thermal power generating units of 650 DEG C or above.

Owner:HUANENG POWER INTERNATIONAL +1

Fe-Ni alloy pipe stock and method for manufacturing the same

ActiveUS20070175547A1Improve mechanical propertiesEasy to manufactureMetal rolling arrangementsChemical compositionAlloy

An Fe—Ni alloy pipe stock having a chemical composition comprising, by mass %, C≦0.04%, Si≦0.50%, Mn: 0.01 to 6.0%, P≦0.03%, S≦0.01%, Cr: 20 to 30%, Ni: 30 to 45%, Mo: 0 to 10%, W: 0 to 20%, with Mo(%)+0.5W(%): more than 1.5% to not more than 10%, Cu: 0.01 to 1.5%, Al≦0.01% and N: 0.0005 to 0.20%, and the balance substantially being Fe, with 1440−6000P−100S−2000C≧1300, Ni+10(Mo+0.5W)+100N≦120, (Ni−35)+10(N−0.1)−2(Cr−25)−5(Mo+0.5W−3)+8≧0, can be manufactured into a seamless pipe by use of a Mannesmann piercing and rolling mill because of its excellent inner surface properties. The resulting seamless pipe has excellent mechanical properties and moreover has excellent corrosion resistance in a sour gas environment, and thus, the Fe—Ni alloy pipe stock can be used as a pipe stock for oil country tubular goods and line pipes and further as a pipe stock for various structural members of nuclear power plants and chemical industrial plants.

Owner:NIPPON STEEL CORP

Soft magnetic composite material for integrated injection molded inductor and preparation method thereof

InactiveCN107778847ALow costSimple processInorganic material magnetismCeriumInjection molding machine

The invention relates to a soft magnetic composite material for an integrated injection molded inductor and a preparation method thereof. The preparation method comprises the following steps: (1) utilizing one of manganese zinc ferrite magnetic powder, carbonyl iron powder, ferrum silicon chromium, ferrum silicon aluminum, cerium ferrum nitrogen and ferrum nickel soft magnetic powder to be meltedand mixed with thermoplastic macromolecule resin to obtain the soft magnetic composite material for the inductor; (2) putting a wound enameled wire coil into a mold cavity of an injection mold, then melting the soft magnetic composite material prepared in the first step, injecting into the mold by an injection molding machine to completely wrap the coil which is arranged in the mold in advance toobtain an inductor device and opening the mold after cooling to obtain the integrated injection molded inductor. Compared with a traditional inductor preparation method and raw materials thereof, theinductor prepared from the soft magnetic composite material disclosed by the invention has the characteristics of simple work procedures, high production efficiency, good sealing performance of inductor products, long service life and low cost.

Owner:HANGZHOU QIANSHI TECH

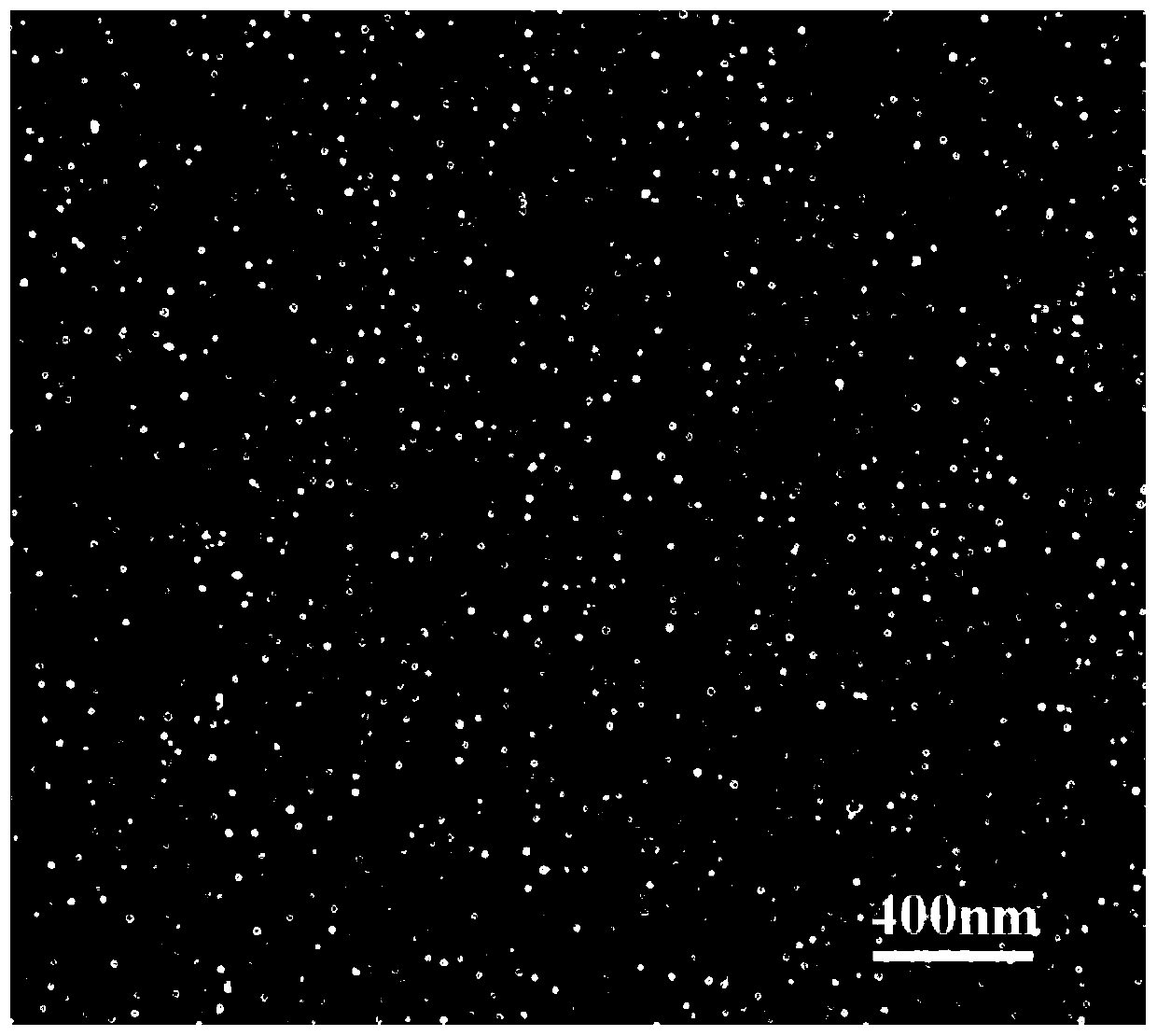

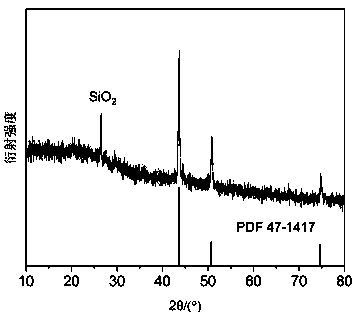

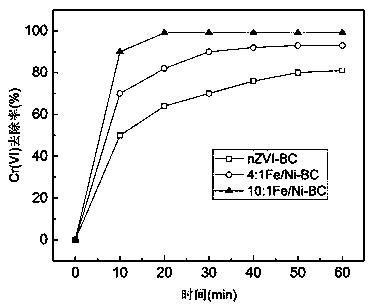

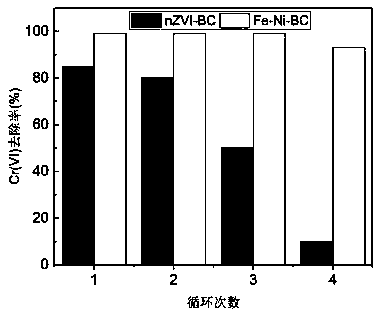

Method for removing hexavalent chromium in water by using biochar-loaded nanometer iron-nickel composite material

InactiveCN110745935AHigh activityImprove stabilityWater contaminantsWater/sewage treatment by reductionMetallic materialsZerovalent iron

The invention discloses a method for removing hexavalent chromium in water by using a biochar-loaded nanometer iron-nickel composite material, and relates to a remediation method for heavy metal pollution in a water body. According to the invention, the biochar-loaded nanometer zero-valent iron-nickel bimetallic composite material is prepared in one step by using a simplified biochar-supported bimetallic material preparation process without the use of a high-cost strong reducing agent, and is applied to removal of Cr (VI) in water, so that the problems of easy surface passivation, low reactionactivity and low utilization rate in the treatment of heavy metals in a water body with nanometer zero-valent iron; and the method has advantages of low cost, simple operation and no secondary pollution, and the Cr (VI) removal activity and the stability of the biochar-loaded iron-nickel bimetallic material are higher than the Cr (VI) removal activity and the stability of the biochar-loaded nanometer zero-valent iron material.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

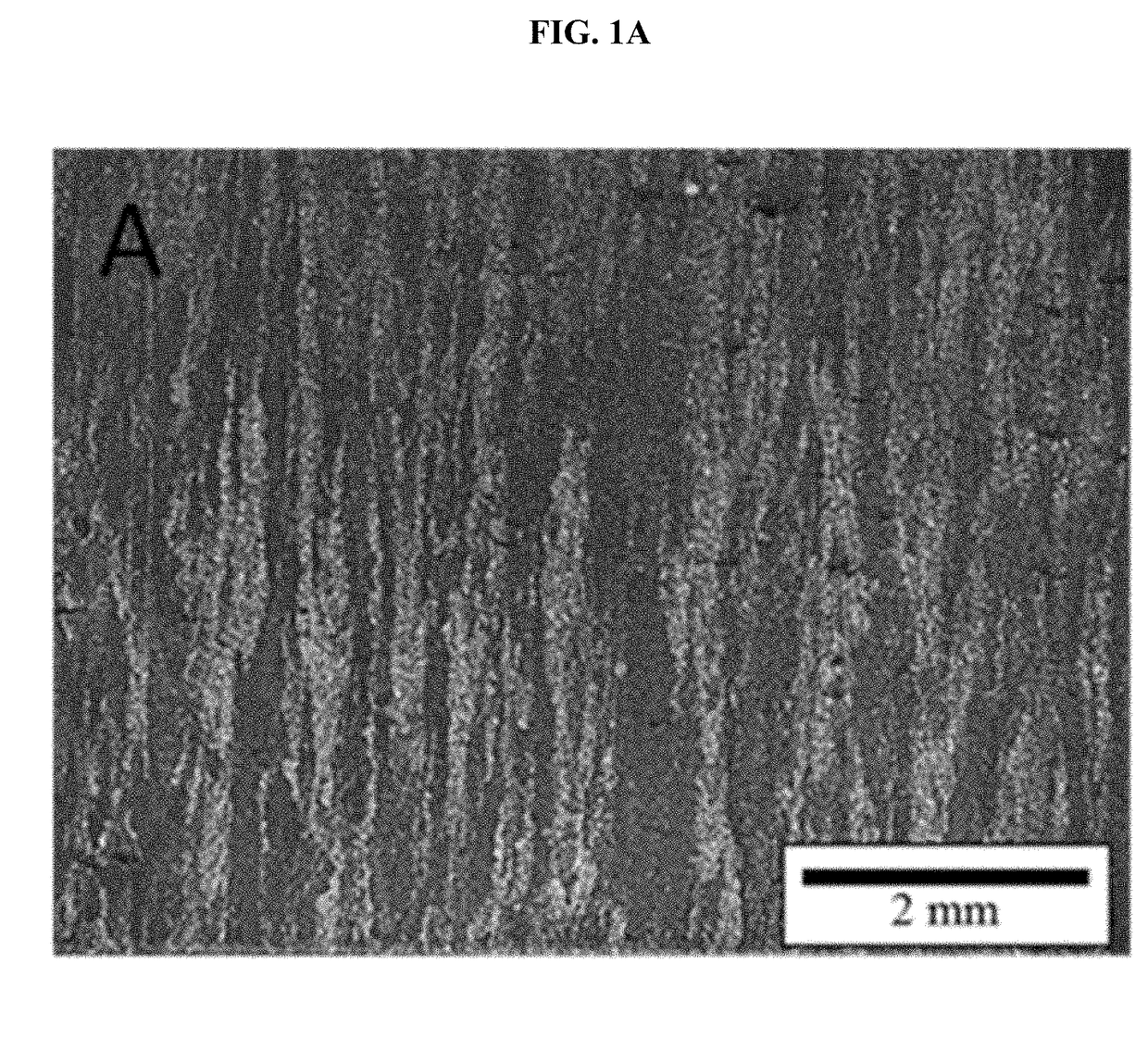

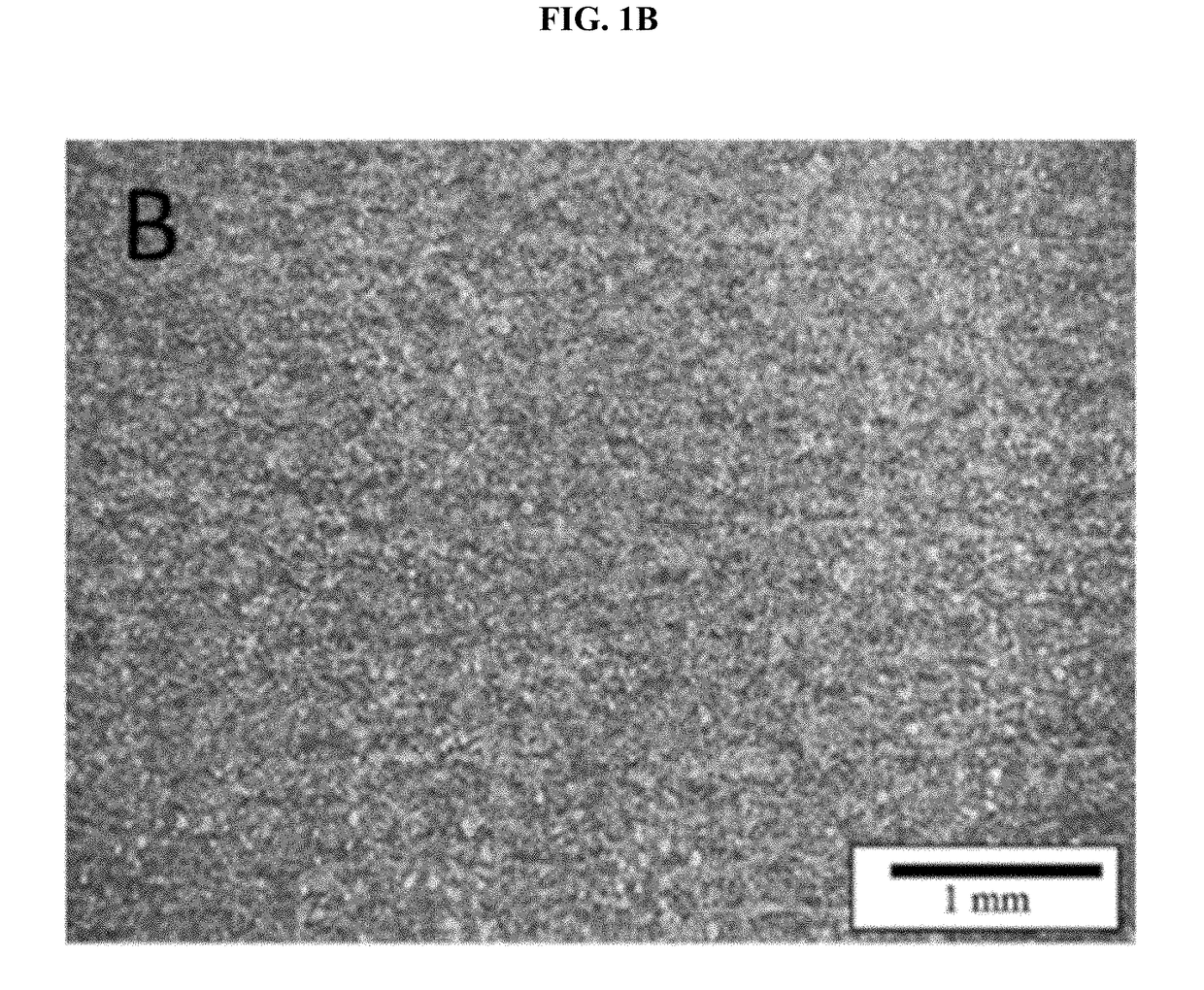

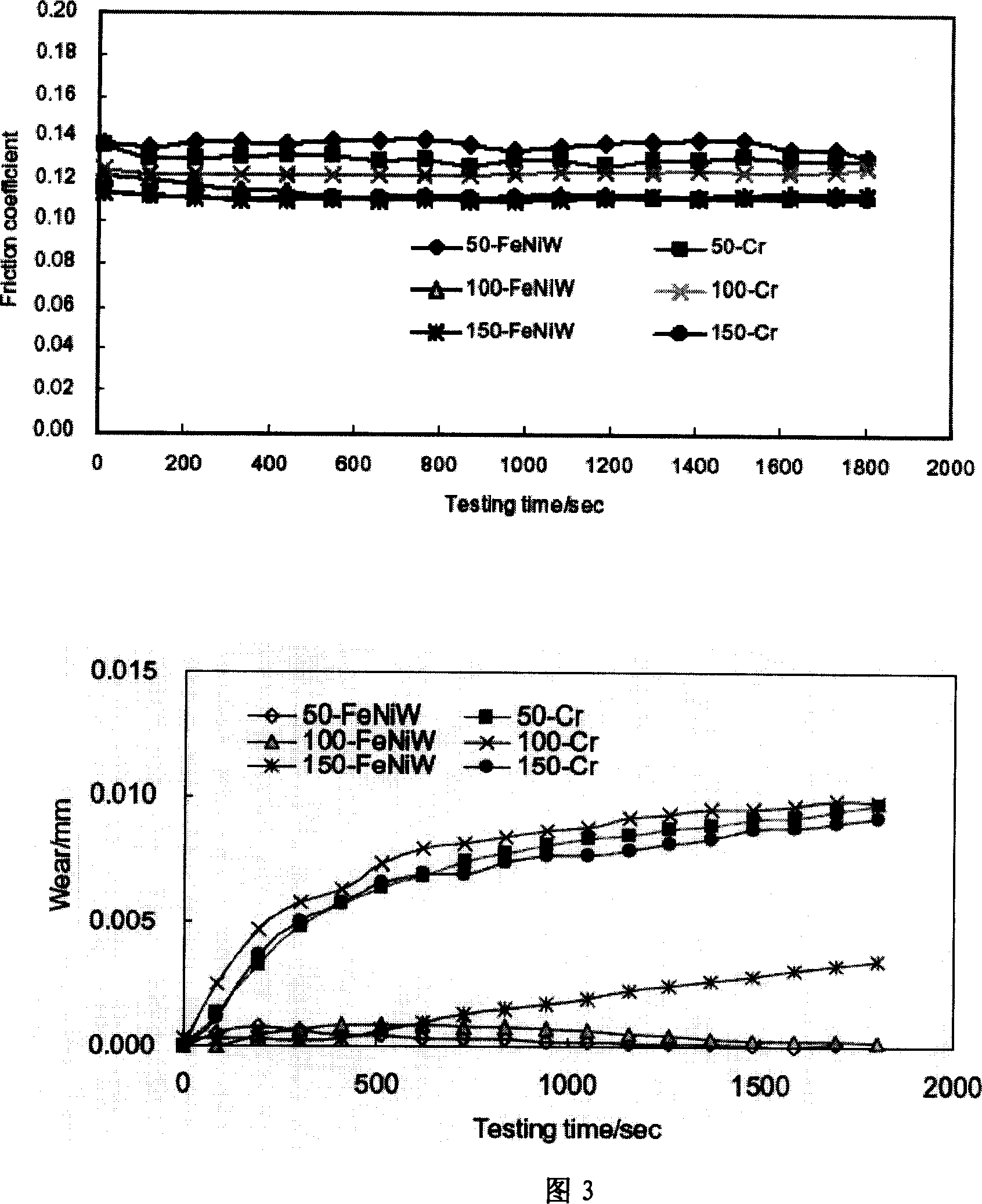

Ti-Fe-Ni-C series reaction thermal spraying composite powder and preparation technique thereof

InactiveCN101148749AHigh bonding strengthEasy to separateMolten spray coatingPorosityThermal spraying

The present invention is one kind of composite hot sprayed Ti-Fe-Ni-C powder capable of forming composite TiC / Fe-Ni alloy coating and its preparation process. The composite Ti-Fe-Ni-C powder containing Ni in the amount of 32-45 wt% of Fe+Ni content and Ti+C in over 70 wt% is prepared with sucrose as the precursor of C. The TiC / Fe-Ni alloy coating formed through hot spraying with Fe-Ni alloy as the adhering phase has the advantages of small stress, low porosity, high bonding strength between the Fe-Ni alloy and TiC, excellent high temperature antiwear and anticorrosion performance and small TiC grain size.

Owner:UNIV OF SCI & TECH BEIJING

Self-grinding diamond tool matrix material

The invention discloses a self-grinding diamond tool matrix material. The self-grinding diamond tool matrix material comprises the following components in percentage by weight: 91 to 99.5 percent of FAM cobalt-substitute pre-alloy powder and 0.5 to 9 percent of a grinding material; the FAM cobalt-substitute pre-alloy powder comprises the following components in percentage by weight: 25 to 50 percent of electrolytic fernico powder with a nano cellular structure, 40 to 60 percent of copper-iron alloy powder, and 10 to 30 percent of copper-tin alloy powder. The self-grinding diamond tool matrix material has the following characteristics: firstly, through the adoption of the ultrafine FAM cobalt-substitute pre-alloy powder in the matrix, the holding force of the matrix on a diamond can be increased, and the function of each diamond can be performed fully; meanwhile, the sintering temperature can be lowered, so as to reduce damage of high temperature to the diamond and reduce the production cost; secondly, through the addition of ordinary grinding materials such as alumina, silicon carbide, quartz sand or cooked mica into the matrix, the matrix has a self-grinding or self-weakening effect, but the holding force of the matrix on the diamond is not influenced, so as to achieve relatively-great diamond protrusion height.

Owner:HUNAN FORLONG ADVANCED MATERIALS CO LTD

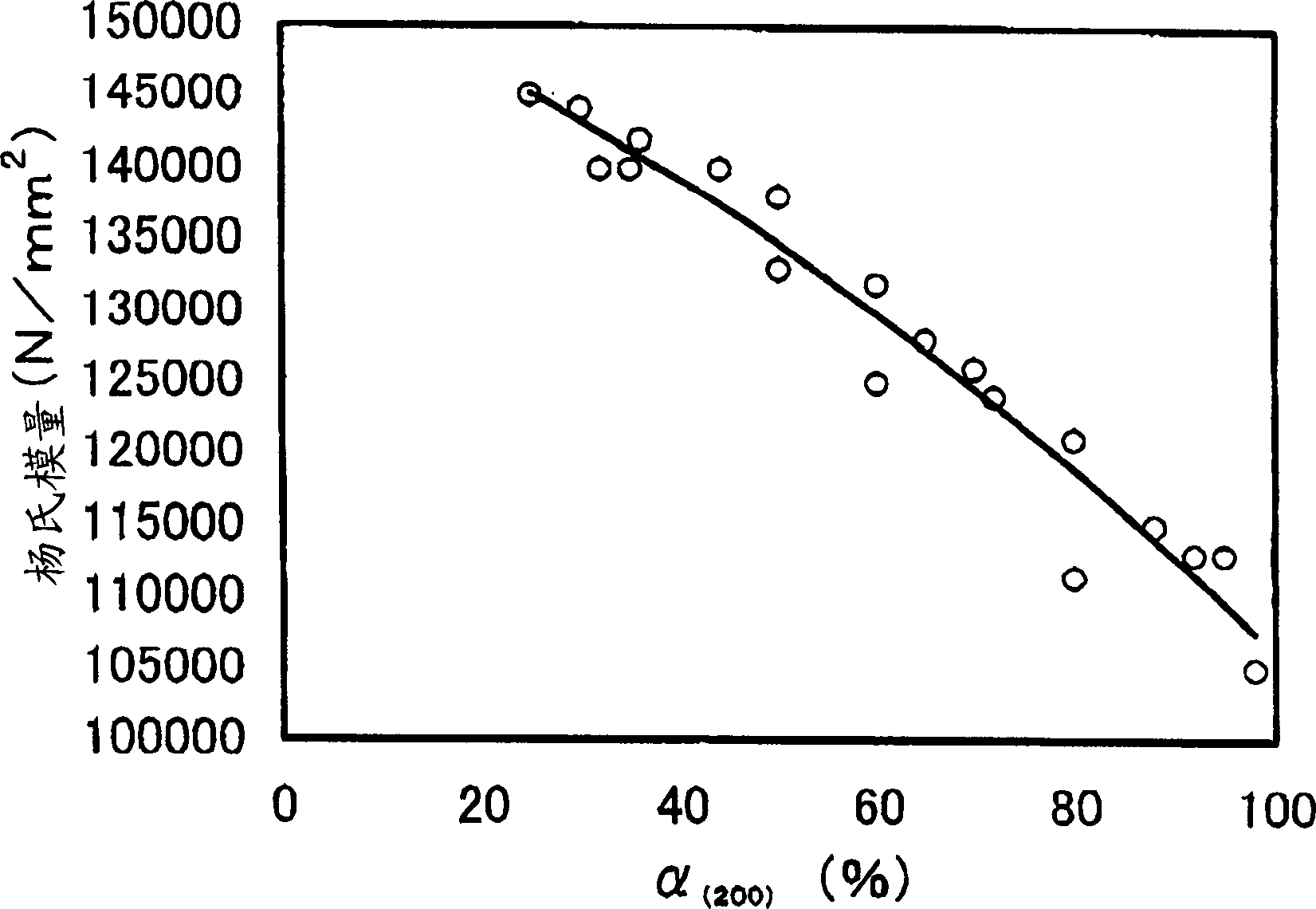

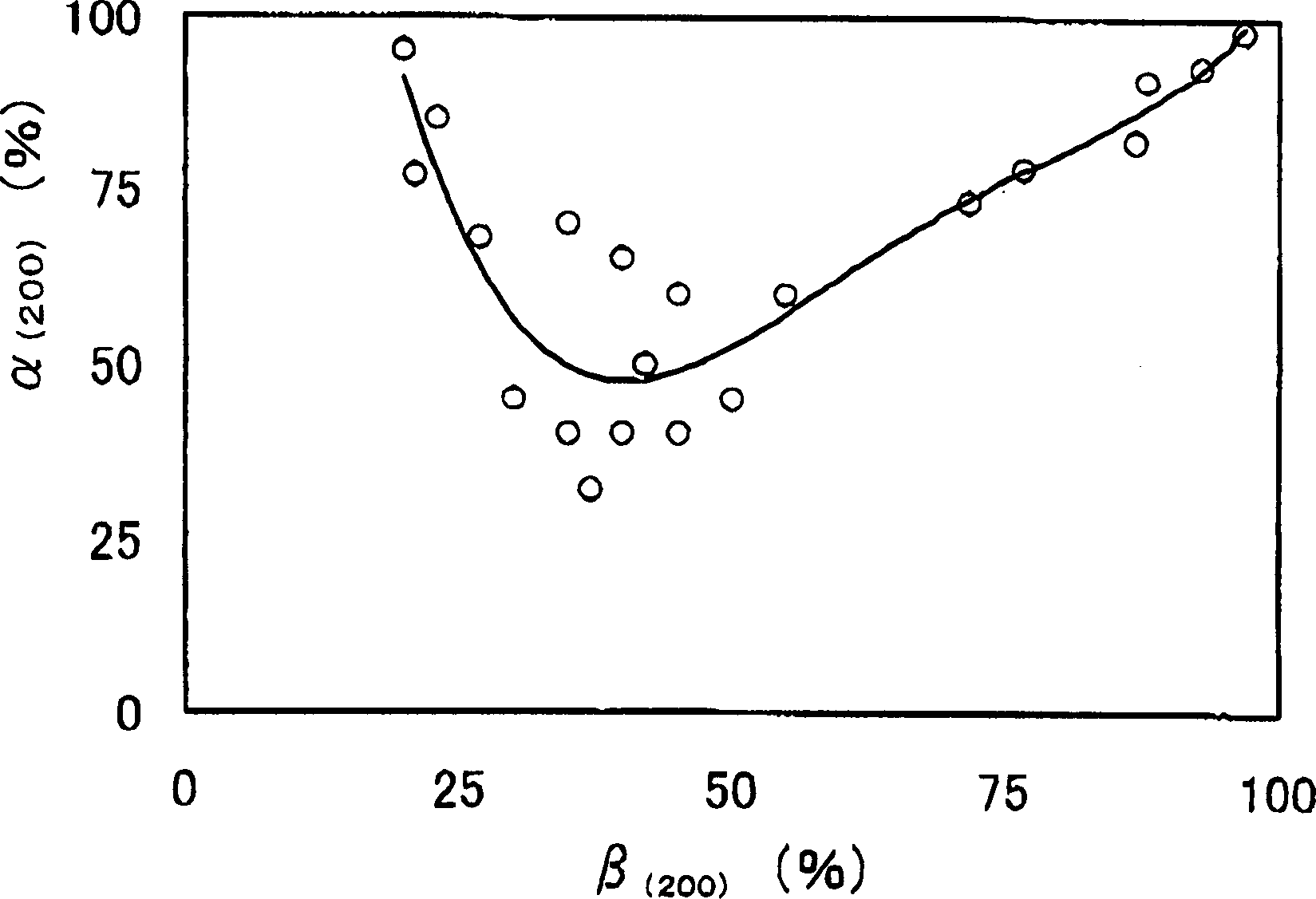

Pressed Fe-Ni alloy and Fe-Ni-Co alloy thin belt for planar aperture mask

The invention provides a mask for the flat press-forming. A Fe-Ni-Co alloy ribbon for the press-formed flat mask includes, by mass% (hereafter, expressed as %), 30-35% Ni, 2-8% Co, and 0.01-0.5% Mn, further 0.01-0.8% in total of one or two selected from 0.01-0.8% Nb and 0.01-0.8% Ti, and the balance Fe with unavoidable impurities, which include 0.0020-0.0070% C, 0.001-0.030% Si, 0.0005-0.0050% N, and 0.0015% or less S; has a sheet thickness of 0.05-0.3 mm; has a composing ratio of X-ray diffraction intensity for the face (200), of 80% or less, on the surface after the layer of 5% or thicker is removed in the sheet thickness direction from the surface, after the ribbon is annealed at 700 DEG C or higher; and has improved Young's modulus after softening annealed.

Owner:JX NIPPON MINING & METALS CO LTD

Method for strengthening surface of runner blade of metal hydraulic turbine through combination of electro-sparking deposition and laser cladding

InactiveCN103805992AReduce processingExtended service lifeMetallic material coating processesFernicoWater turbine

The invention relates to a method for strengthening the surface of a runner blade of a metal hydraulic turbine through combination of electro-sparking deposition and laser cladding. By performing combined treatment of electro-sparking deposition and laser cladding on the runner blade of the metal hydraulic turbine, the problems that the performances including hardness, wear resistance, corrosion resistance and impact resistance of the surface of the runner blade of the hydraulic turbine are low and the service life of a runner of the metal hydraulic turbine is short can be effectively solved. The method comprises the steps of cladding iron-nickel base alloy powder on the surface of the runner blade of the hydraulic turbine by using laser beams to form a hard alloy coating layer; then, performing electro-sparking deposition on a WC (wolfram carbine) ceramic hard alloy on the basis of the laser cladding coating layer to form a composite coating layer with combination of electro-sparking deposition and laser cladding. The method disclosed by the invention is simple, high in production efficiency and good in product quality, and the problem of treating the surface of the blade of the hydraulic turbine is effectively solved, so that the performances including hardness, wear resistance, corrosion resistance and impact resistance of the surface of the runner blade of the hydraulic turbine are improved, the service life of the runner of the metal hydraulic turbine is prolonged, and great economic and social benefits are achieved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Alloy inert anode for aluminium electrolysis and preparation method thereof

The invention relates to an alloy inert anode for aluminium electrolysis and a preparation method thereof, and in particular relates to an alloy inert anode for aluminium electrolysis with a high-temperature anti-oxidative and anti-corrosion coat and a preparation method thereof. The alloy inert anode disclosed by the invention structurally comprises an alloy inert anode substrate for the aluminium electrolysis and is characterized in that an inner iron-nickel based alloy coat prepared by utilizing a plasma spray coating method is on the surface of the alloy inert anode substrate for the aluminium electrolysis; and an outer oxide ceramic coat prepared by utilizing the plasma spray coating method is on the surface of the inner iron-nickel based alloy coat. According to the invention, the outer oxide ceramic coat prepared by utilizing the plasma spray coating method is compact in structure and low in porosity and is capable of effectively reducing the corrosion of the alloy inert anode; simultaneously, the inner iron-nickel based alloy coat can be reacted with oxygen entering through diffusion of the outer oxide ceramic coat to form oxide ceramic; oxygen entering the alloy substrate through diffusion is reduced; the corrosion consumption of the outer oxide coat is supplied by reaction generated oxide; and long-term steady corrosion protection is provided for the anode.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method for detecting and manufacturing temperature measurement heating element and device

InactiveCN101419097ASolve the problem of temperature controlSolve the problem of the cause of temperature difference changeThermometers using electric/magnetic elementsUsing electrical meansTemperature controlElectrical resistance and conductance

The invention provides 'a detection method, an inspection method and a manufacturing method for a temperature measuring electrothermal tube' and simultaneously provides 'a PTC electrothermal alloy characteristic apparatus', a detection device, an inspection device and a manufacturing device. The method comprises the relation between the resistance temperature coefficient and the resistivity of PTC electrothermal alloy, four stages of the development and evolution process of the temperature measuring electrothermal tube, the operating principle of the PTC electrothermal alloy characteristic apparatus, the process of manufacturing the temperature measuring electrothermal tube by utilization of the PTC electrothermal alloy characteristic apparatus, preparation of a PTC electrothermal alloy wire through auxiliary materials such as iron element and nickel element, the method for manufacturing the temperature measuring electrothermal tube by utilization of the PTC electrothermal alloy wire, the detection, the inspection and the method for forming the device. The invention analyzes various important temperature spots of the temperature measuring electrothermal tube, solves the problem of errors caused by various factors of the manufacturing technique of the temperature measuring electrothermal tube, meets the precision requirement, and simplifys temperature sensing, strain and heating of intelligent materials of the PTC alloy wire into an element to replace the lagged temperature control method of sensing, temperature signal processing and execution, simplifies the structure, and reduces the cost.

Owner:赵放

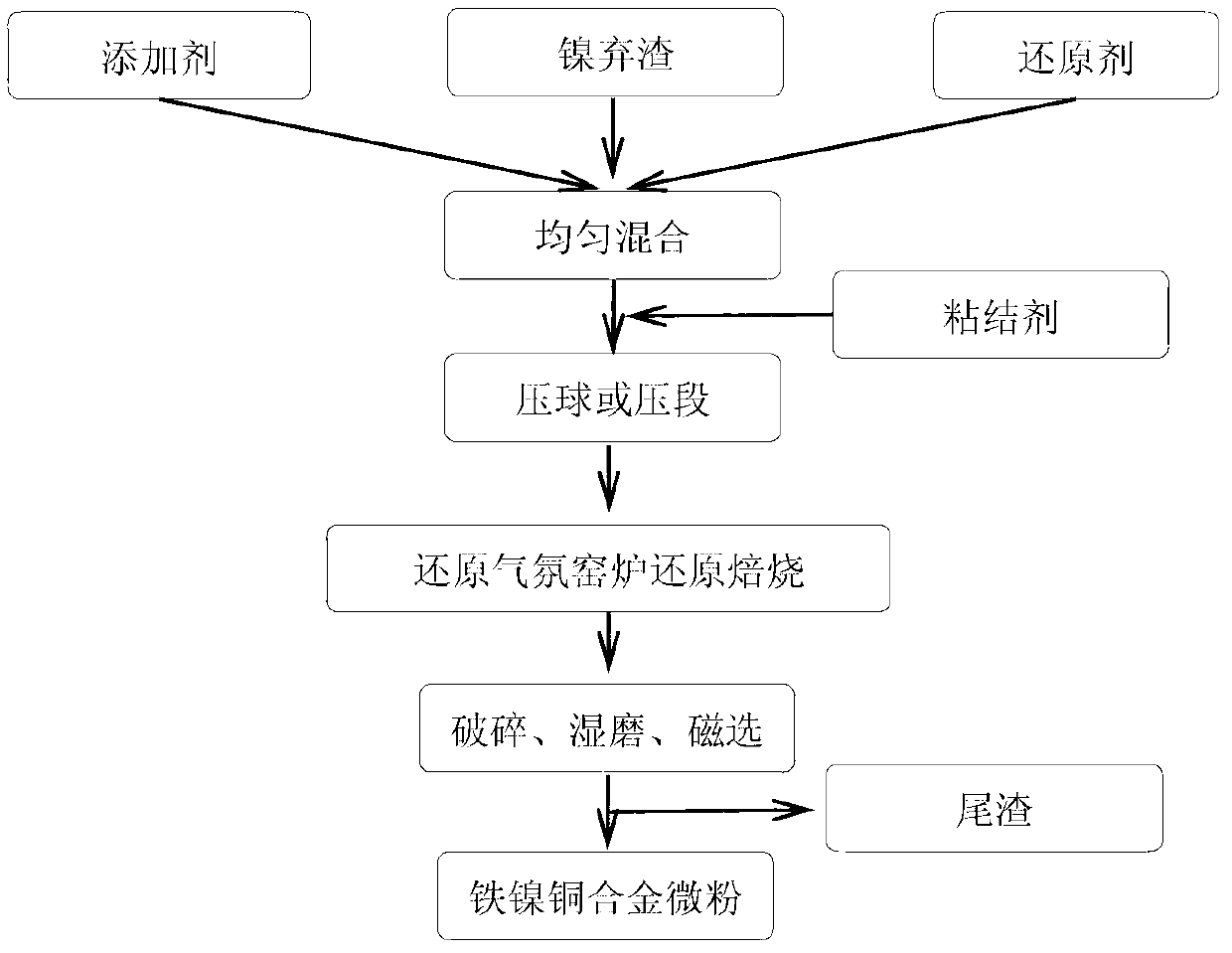

Method for rapidly reducing nickel slag to produce iron-nickel-copper alloy powder in kiln under reducing atmosphere

ActiveCN103276294AIncrease added valueEnable recyclingProcess efficiency improvementSlagNickel copper alloy

The invention relates to a method for rapidly reducing nickel waste slag to produce iron-nickel-copper alloy powder in a kiln under the reducing atmosphere. The method is characterized by comprising the following steps of: proportionally mixing the nickel waste slag, reducing agents and additives, crushing or levigating the mixture to 200 meshes to obtain 20-40% of residues on sieve; doping agglomerants and water occupying 5-20% of all materials on a dry mass basis, and uniformly mixing; preparing small balls with the diameter of 15-33 mm or small cylinders with the diameter and the height of 15-30 mm by using a ball press machine or a section making machine; drying; flatly paving the materials at the bottom of the kiln, wherein the thickness of the material layer is 20-45 mm, the reducing temperature of the material layer is 1,250-1,450 DEG C, and the reducing time is 10-40 minutes; and performing cooling, crushing, wet grinding and wet magnetic separation on the reduced balls or sections to obtain iron-nickel-copper alloy micropowder with the iron recovery rate of 85-99 %, wherein in the obtained product, the iron content is 88-98 %, the nickel content is 0.13-1.98 %, the copper content is 0.14-1.29 % and the particle size is 3-100 microns, and the product can serve as a raw material for smelting weather-resistant steel. The tailings after wet grinding and wet magnetic separation can serve as raw materials for extracting aedelforsite or producing hollow sintered bricks.

Owner:UNIV OF SCI & TECH BEIJING

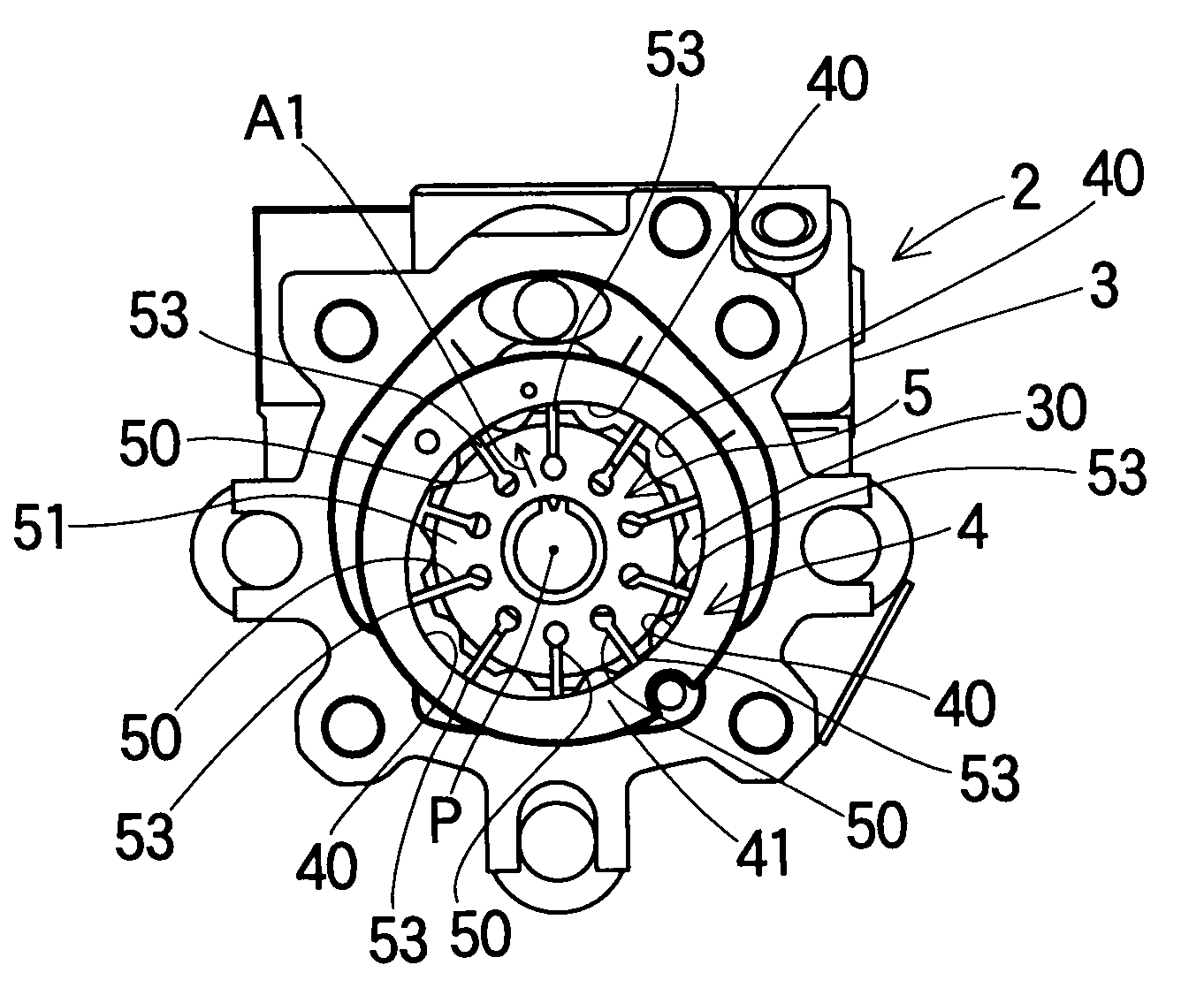

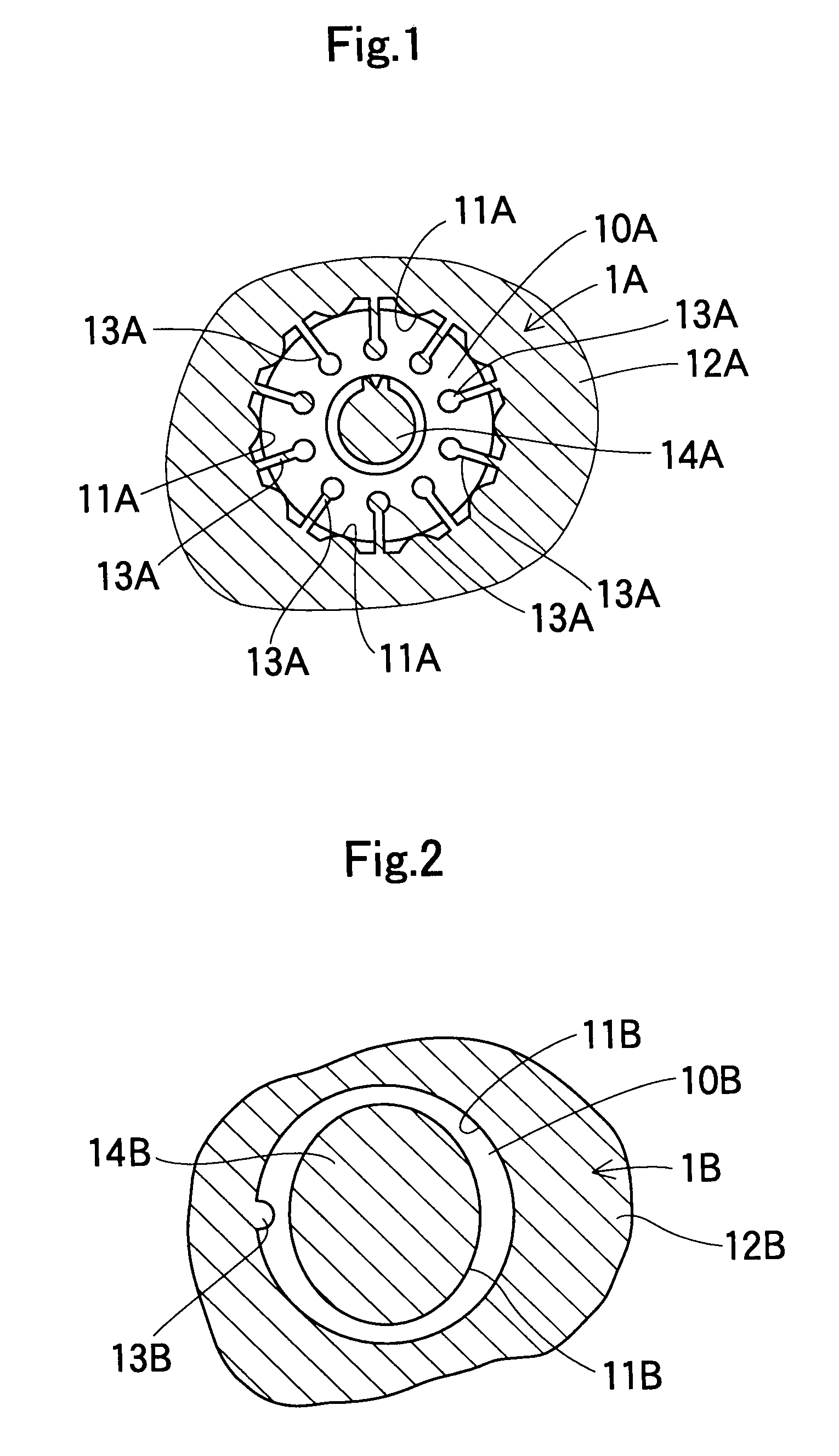

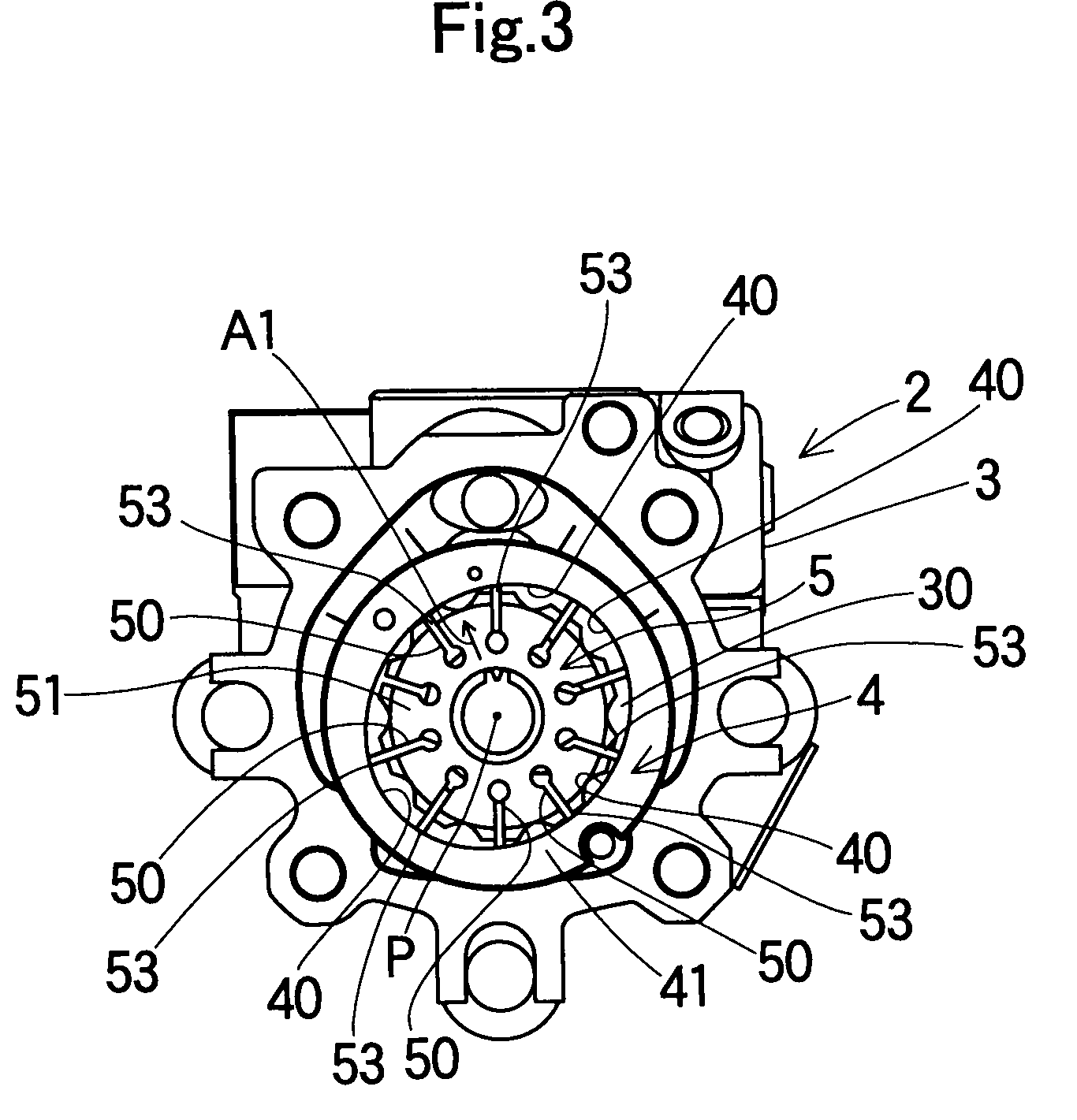

Iron-base sintered part, manufacturing method of iron-base sintered part and actuator

InactiveUS20090114046A1Abrasion be increasedHigh strengthOscillating piston enginesGearingVolumetric Mass DensityActuator

An iron-base sintered part having high density and totally enhanced strength, toughness and abrasion resistance, a manufacturing method of the iron-base sintered part, and an actuator are disclosed. The iron-base sintered part is formed by an iron-nickel-molybdenum-carbon-based sintered alloy, has density of 7.25 g / cm3 or more, and has a carburization quenched structure. A method for manufacturing the iron-base sintered part includes a molding process of charging a raw mixture powder of an iron-nickel-molybdenum-based metal powder and a carbon-based powder into a cavity of a molding die and compressing the raw powder in the cavity to form a consolidation body, a sintering process of sintering the consolidation body at a sintering temperature to form a sintered alloy, and a carburization quenching process of heating the sintered alloy in a carburization atmosphere and quenching the heated alloy.

Owner:JTEKT CORP

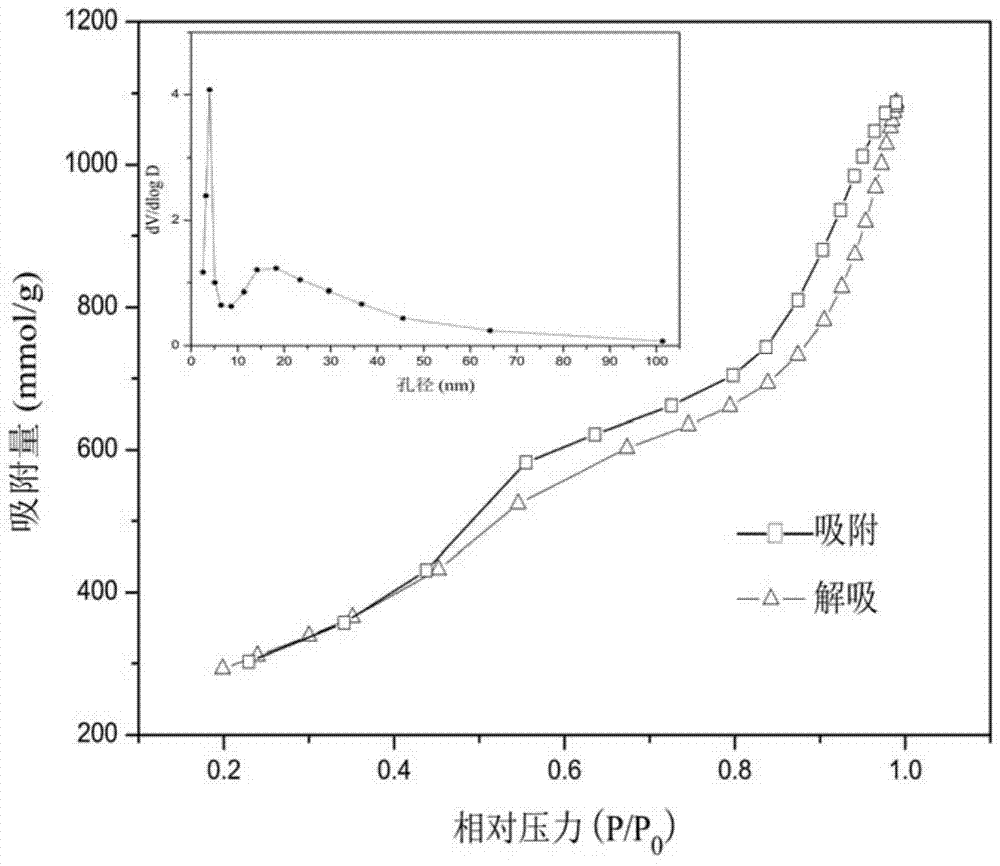

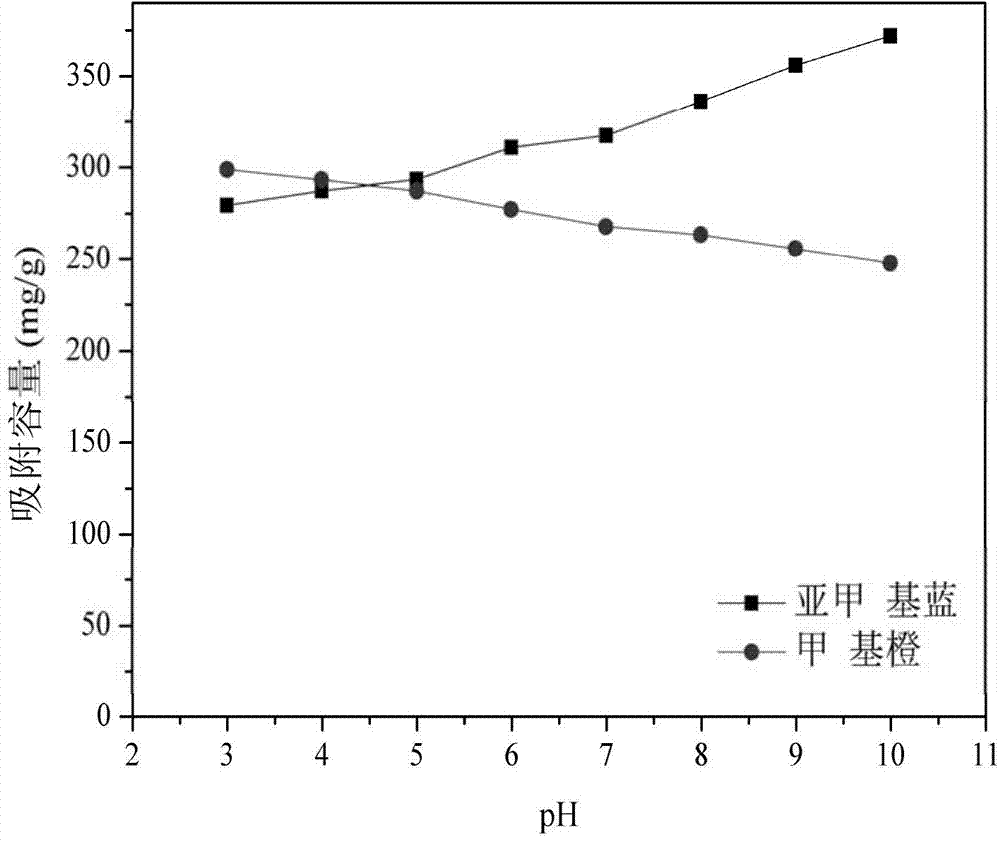

Magnetic two-peak mesoporous carbon containing iron-nickel double metals, preparation method and application thereof

InactiveCN104324690AImprove magnetic propertiesEvenly distributedOther chemical processesAlkali metal oxides/hydroxidesIncipient wetness impregnationMesoporous carbon

The invention discloses magnetic two-peak mesoporous carbon containing iron-nickel double metals, a preparation method and an application thereof. The magnetic two-peak mesoporous carbon adopts magnetic two-peak mesoporous carbon as a carrier, iron-nickle alloy nano particles are dispersed in the magnetic two-peak mesoporous carbon to form an ordered two-peak mesoporous structure with the hole diameters being 4nm-5nm and 15nm-20nm. The preparation method comprises the steps of preparing a mesoporous silicon template, preparing a compound, preparing the magnetic two-peak mesoporous carbon containing the iron-nickel double metals and the like. The invention adopts an initial-wetting impregnation method to prepare the magnetic two-peak mesoporous carbon containing the iron-nickel double metals; the prepared magnetic two-peak mesoporous carbon containing the iron-nickel double metals is large in specific surface area, uniform in distribution of iron-nickle alloy nano particles, difficult in aggregation, excellent in magnetic performance and stable in physicochemical property, can be applied to removal of dyestuff pollutants in water bodies, and has the advantages of large adsorption capacity, high removing efficiency, wide application range, simplicity and convenience in operation, strong practicability and the like.

Owner:HUNAN UNIV

High-Performance Corrosion-Resistant High-Entropy Alloys

This disclosure provides alloy compositions comprising the main constituent elements iron, nickel, cobalt, molybdenum, and chromium. In one embodiment, the alloy comprises 10.0 to 30.0 wt % iron; 30.0 to 60.0 wt % nickel; 10.0 to 25.0 wt % cobalt; 1.0 to 15.0 wt % molybdenum; 15.0 to 25.0 wt % chromium by weight; where the sum of iron and nickel is at least 50 wt %; and, where the balance comprises minor elements, the total amount of minor elements being about 5% or less by weight. The alloy compositions have use as coatings to protect metals and alloys from corrosion in extreme environments where corrosion is a major concern such as with exposure to sea water or sea water with CO2.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Two-step method for vacuum annealing of iron-nickel soft magnetic alloy

ActiveCN102719628AIncreased nickel content1J79 with higher nickel contentHeat treatment process controlTwo stepVacuum annealing

The invention provides a vacuum annealing method for iron-nickel soft magnetic alloy. The method comprises two annealing processes; the primary annealing process is a conventional vacuum annealing process, wherein the cooling speed of an ordering area is controlled when in alloy cooling, and the ordering area is a temperature range of transforming alloy from order into disorder; and the secondary annealing process is a two-section continuous vacuum annealing process which is used for stabilizing the magnetic performance of the alloy. The method can remarkably improve the magnetic performance of the iron-nickel soft magnetic alloy and can reduce the deformation of the alloy, thereby being suitable for batch production.

Owner:SHAANXI CHANGLING ELECTRONICS TECH

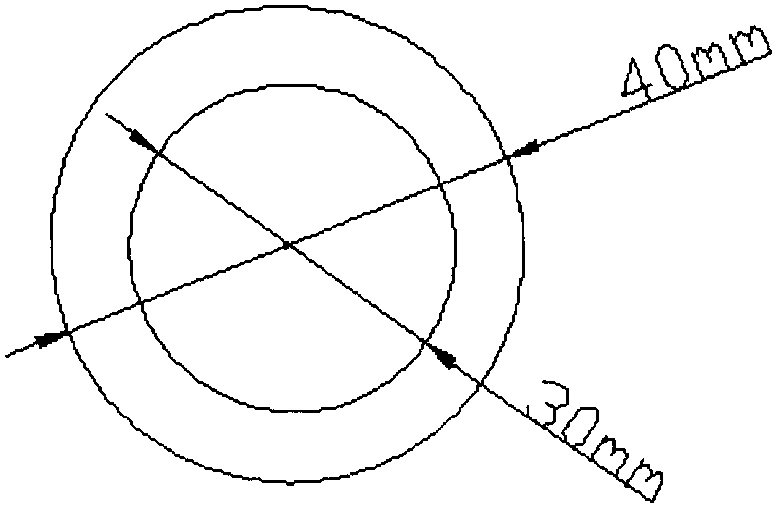

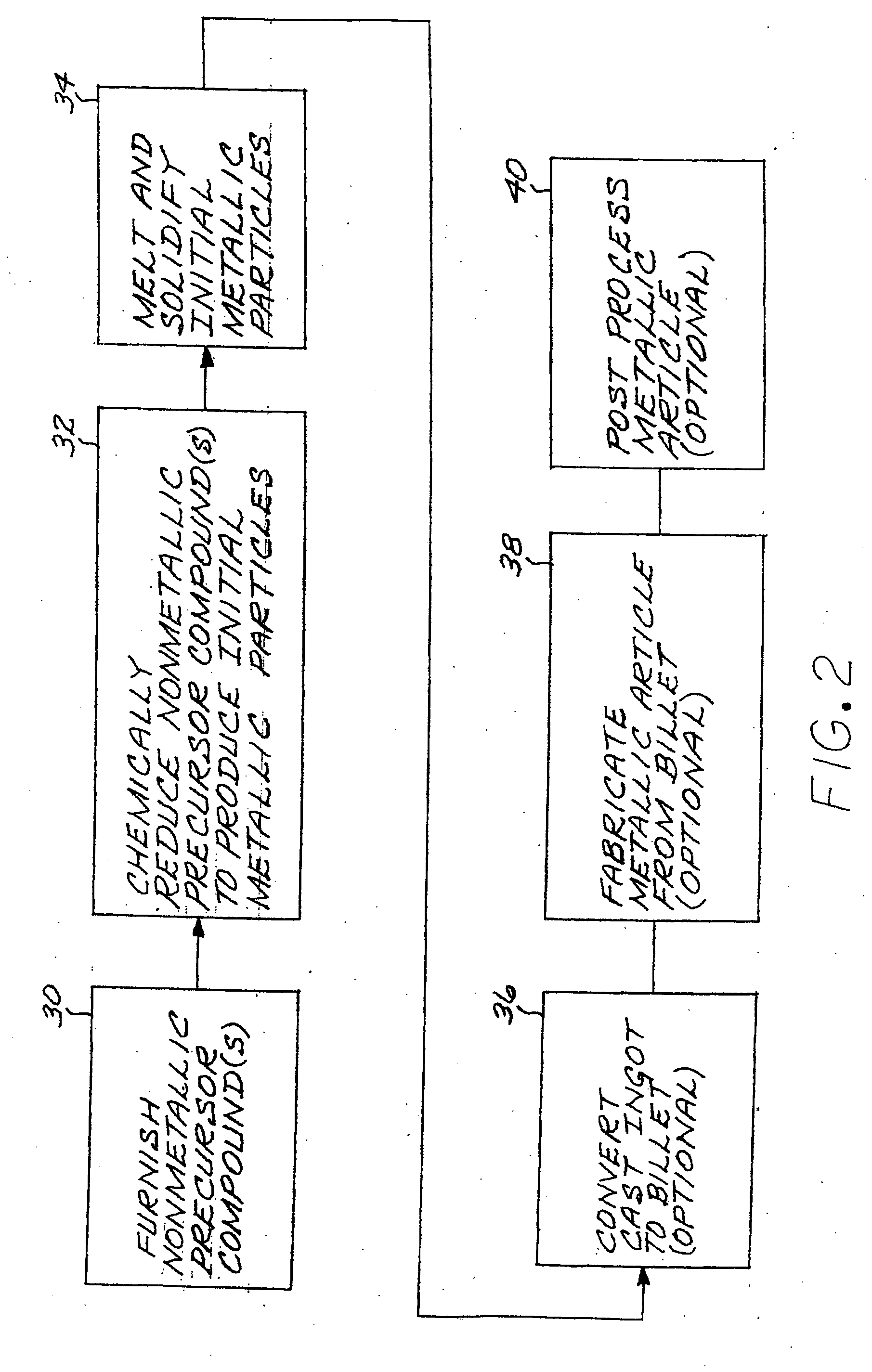

Producing nickel-base, cobalt-base, iron-base, iron-nickel-base, or iron-nickel-cobalt-base alloy articles by reduction of nonmetallic precursor compounds and melting

A metallic article is produced by furnishing one or more nonmetallic precursor compound comprising the metallic base nickel, cobalt, iron, iron-nickel, or iron-nickel-cobalt, and at least one alloying element. The nonmetallic precursor compound(s) are chemically reduced to produce an initial metallic particle without melting the initial metallic particle. The initial metallic particle is thereafter melted and solidified to produce the metallic article. The melted-and-solidified metal may be used in the as-cast form, or it may be converted to billet and further worked to the final form.

Owner:GENERAL ELECTRIC CO

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com