Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

104 results about "Iron agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Imaging inflammatory conditions using superparamagnetic iron oxide agents

InactiveUS20060093555A1Low toxicityImprove toleranceNanomedicineDiagnostic recording/measuringImaging conditionIron agent

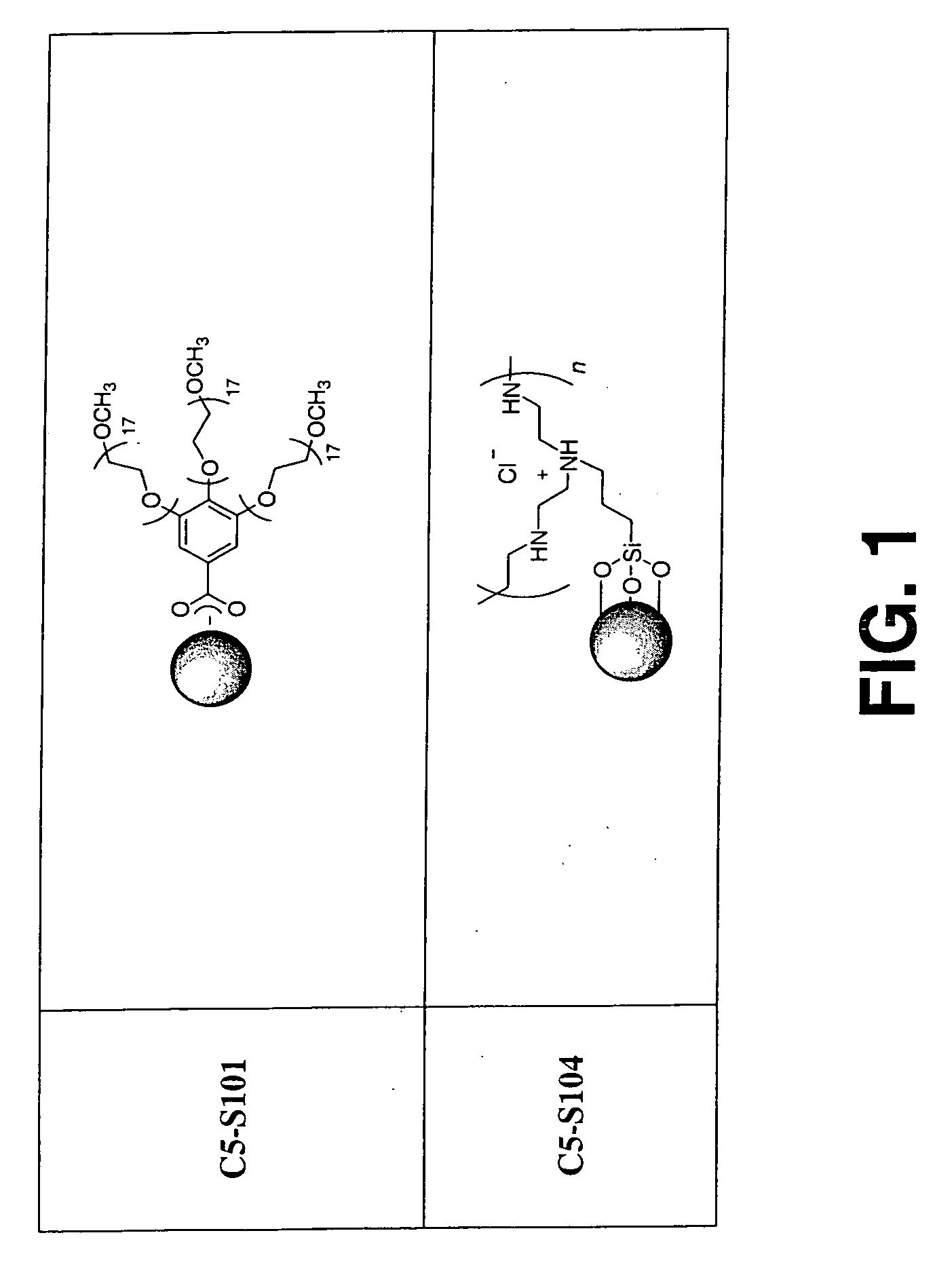

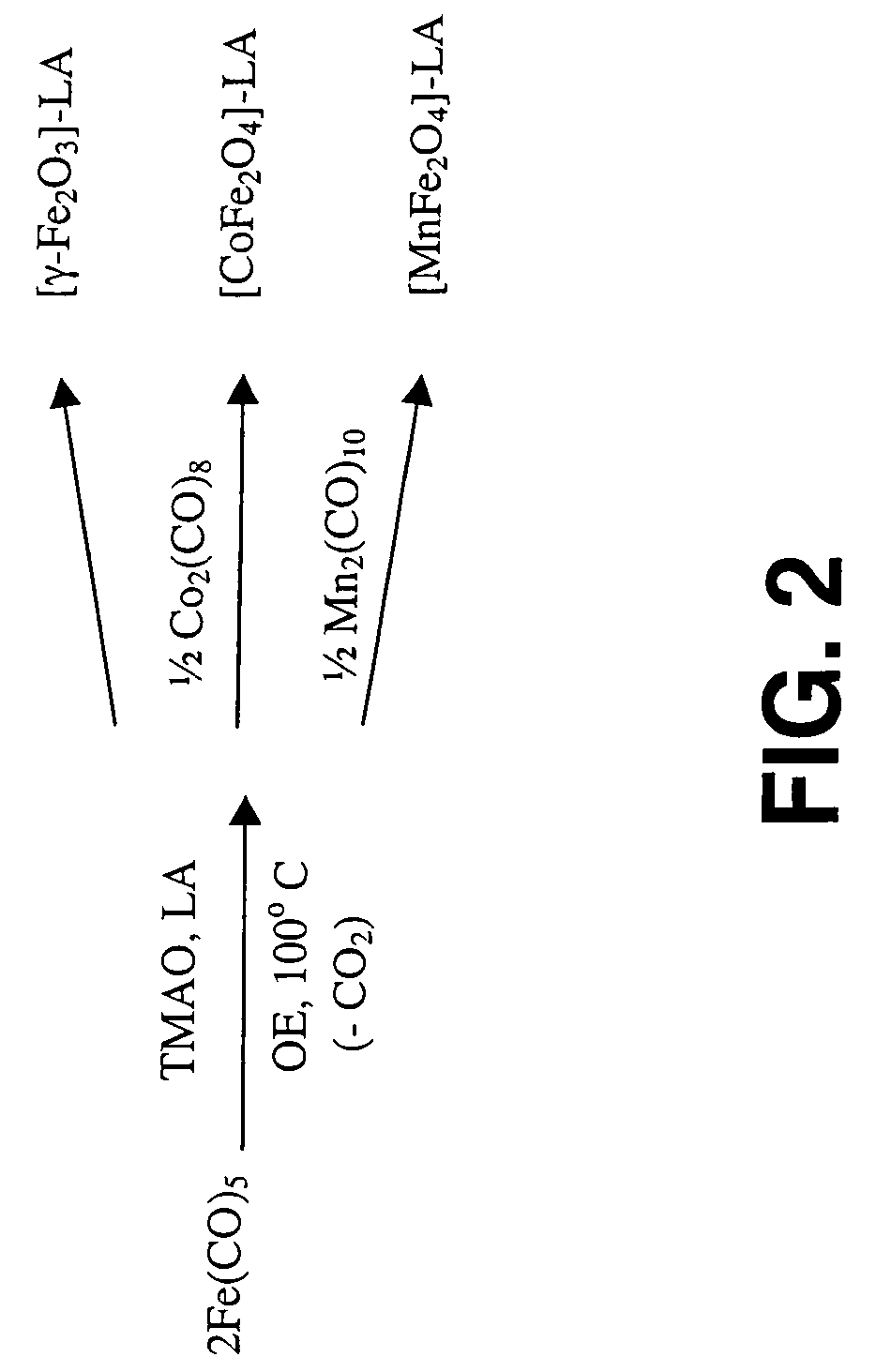

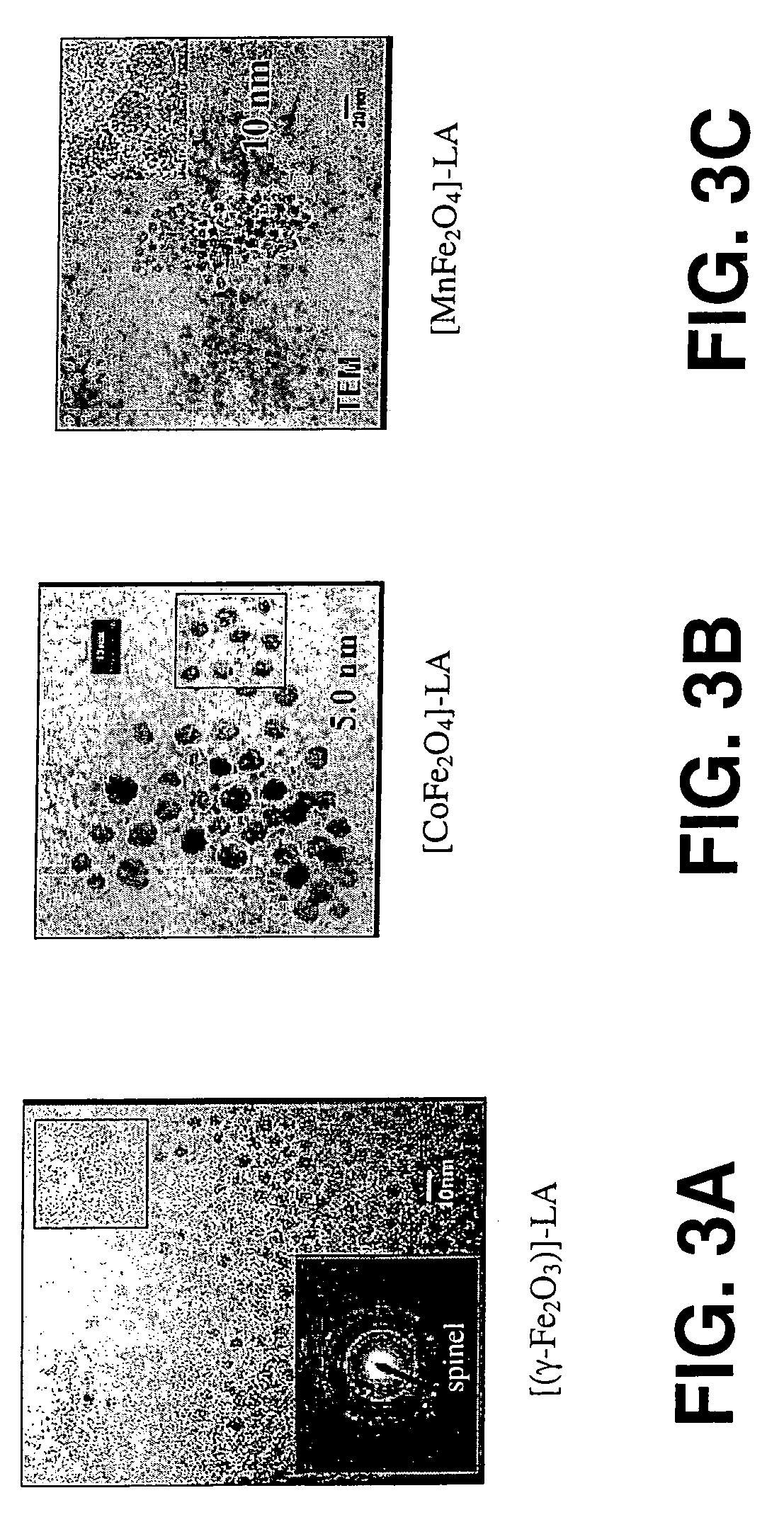

The present invention is directed to the field of magnetic resonance imaging (MRI) using superparamagnetic iron oxide (SPIO) agents. In particular, the present invention is directed to cationic, nonagglomerated, nontoxic SPIO agents, methods for imaging conditions associated with inflammatory responses using the disclosed SPIO agents, and methods for managing inflammatory conditions using the disclosed SPIO agents.

Owner:GENERAL ELECTRIC CO

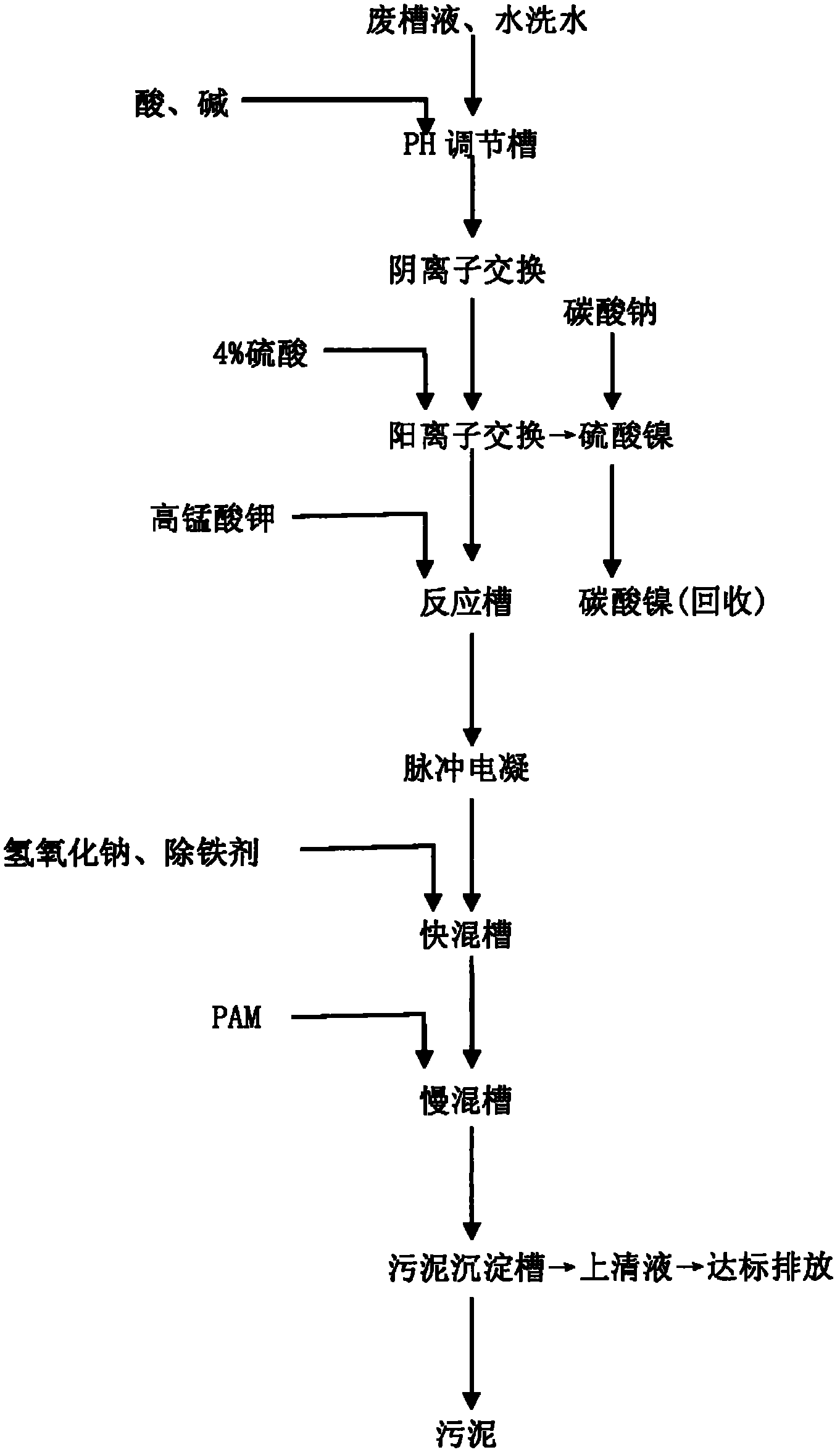

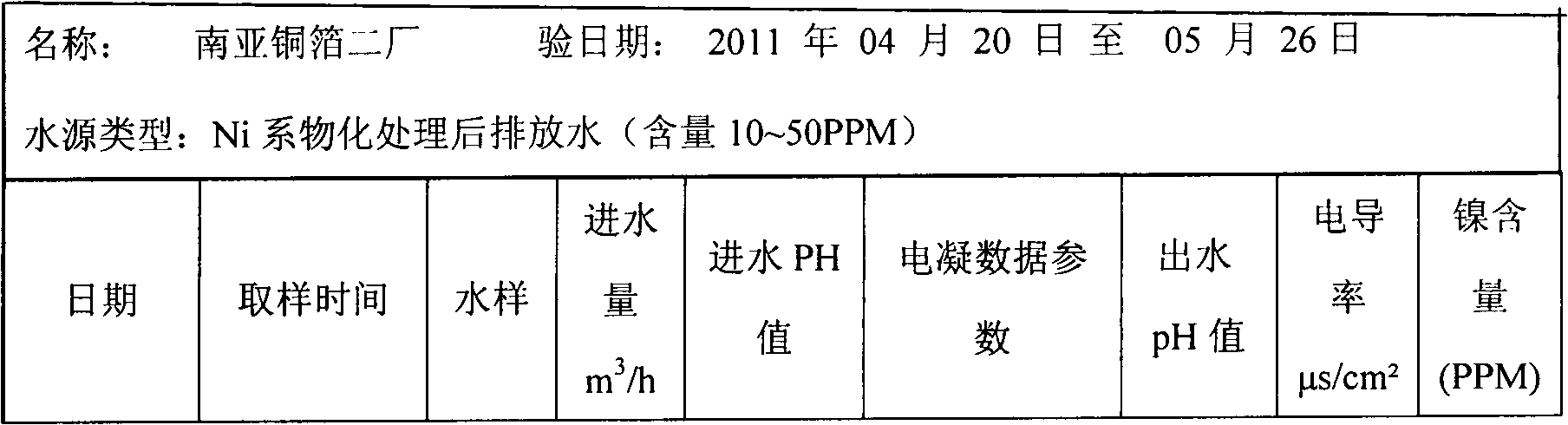

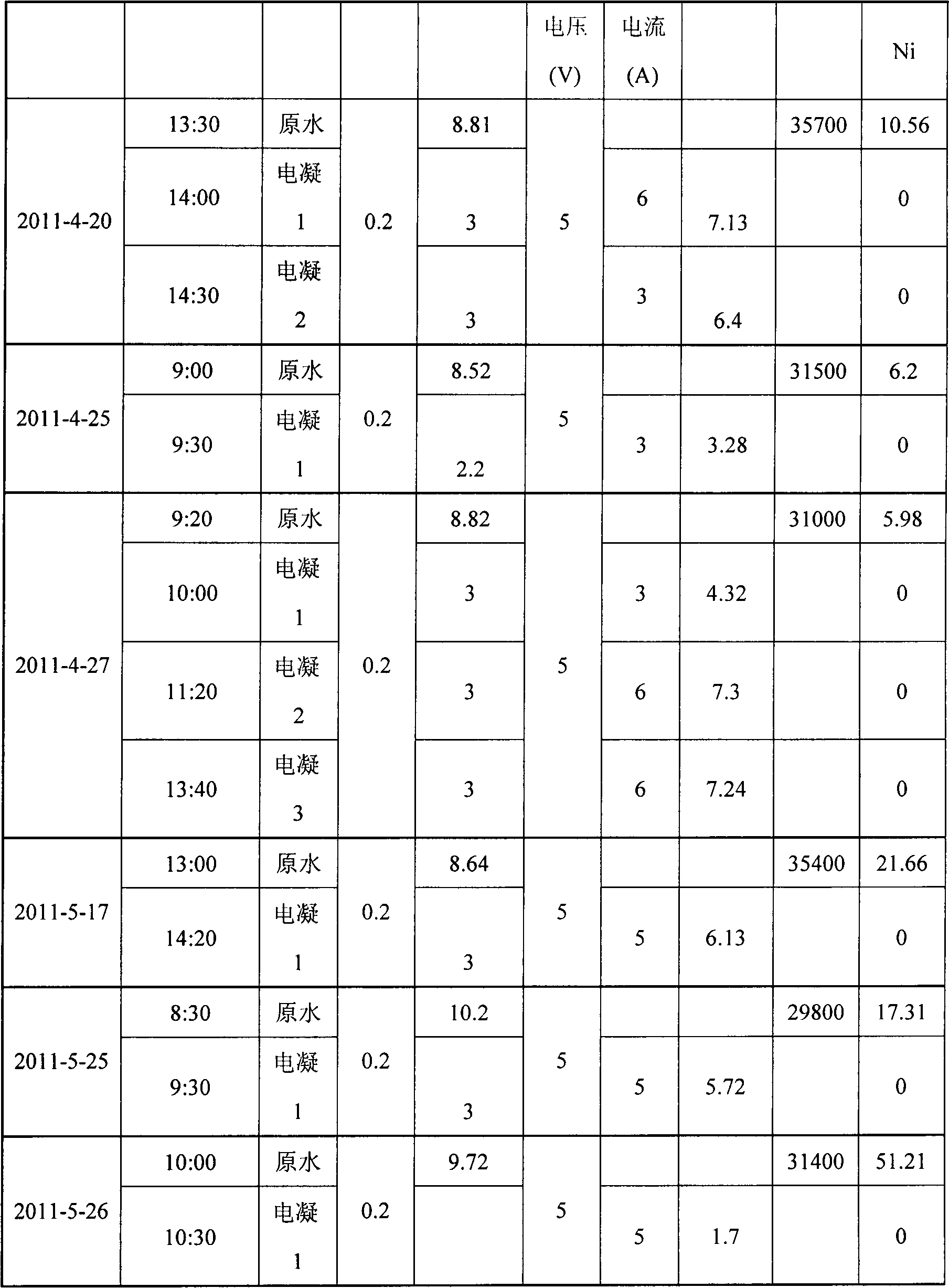

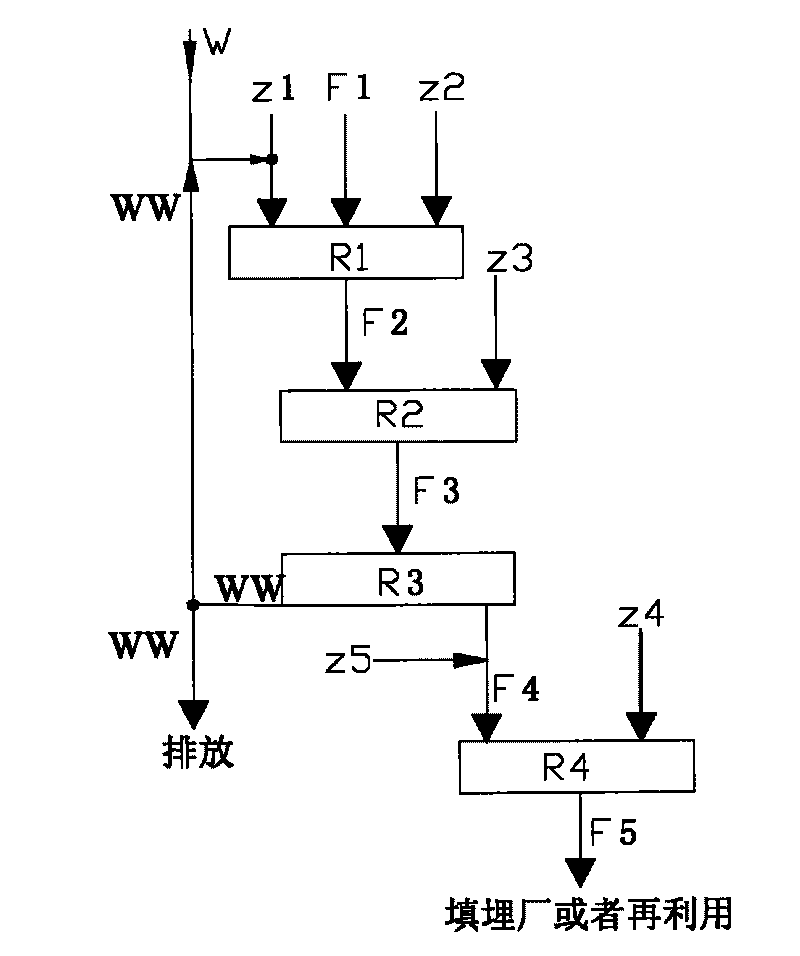

Treatment method of chemical nickel-plating wastewater

ActiveCN102329030AImprove processing economicsAchieve recyclingWaste water treatment from metallurgical processWater/sewage treatment by ion-exchangePhosphateIon-exchange resin

The invention discloses a treatment method of chemical nickel-plating wastewater. The method comprises the following steps: (1) treating nickel-plating wastewater with strongly basic anion-exchange resin so as to destabilize nickel complex; (2) adsorbing nickel ions contained in the nickel-plating wastewater with strongly acidic cation-exchange resin; (3) adding a strong oxidant in the nickel-plating wastewater so that hypophosphite, phosphite and macromolecular organic acid complexing agent which are contained in the wastewater are oxidized so as to form phosphate and organic micromolecules;(4) carrying out pulse electrocoagulation on the nickel-plating wastewater so that the phosphate forms iron phosphate to be precipitated and residual nickel ions are oxidized to form oxidized scale precipitate at the same time; and (5) regulating the wastewater to alkalinity so that iron ions in the wastewater are precipitated, successively adding a deironing agent and a flocculant to remove ferrous ions and suspended matters in the wastewater, and directly discharging supernate. According to the invention, the content of the nickel ions in the wastewater treated by the process is far less than 0.1ppm and meets a national primary standard, the recycle of nickel resources can be realized, and the economic benefits of wastewater treatment are improved.

Owner:中新联科环境科技(安徽)有限公司

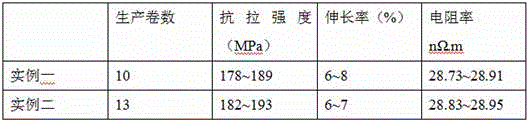

Manufacturing process of 7005 aluminum alloy

The invention discloses a manufacturing process of a 7005 aluminum alloy. The 7005 aluminum alloy comprises the following chemical components in percentage by weight: 0.1-0.2 percent of Si, 0.1-0.3 percent of Fe, 0.03-0.08 percent of Cu, 0.3-0.4 percent of Mn, 1.5-1.7 percent of Mg, 0.08-0.15 percent of Cr, 4.4-4.8 percent of Zn, 0.06-0.08 percent of Ti, 0.12-0.15 percent of Zr, and the balance of Al. The manufacturing process comprises the following steps of: electrolyzing a primary aluminum liquid; analyzing components; adding a copper iron agent; electromagnetically stirring; determining contents of copper and iron components in the aluminum liquid; regulating temperature; purifying in a furnace; standing in the furnace; purifying outside the furnace; degassing on line; continuously casting; shearing blanks; continuously rolling; winding up and packaging; and checking to obtain a round aluminum rod finished product. The alloy round aluminum rod is mainly used for machining an aluminum alloy cable with high conductivity; and compared with a copper core cable, the cable manufactured by the aluminum alloy round aluminum rod is relatively high in anticorrosion creep resistant performance, the elastic wall copper core cable is reduced by 40 percent, the flexibility performance is higher 24 percent than that of the copper core cable, the memory effect is eliminated, and the heat stability is good.

Owner:河南省圣昊新材料股份有限公司

Method for stabilizing fly ash from refuse incineration by combination of complementary type medicaments

InactiveCN101690934AReduce usageReduce processing costsSolid waste disposalFerric hydroxidePrecipitation types

The invention belongs to the technical field of the harmless treatment of dangerous solid waste and particularly relates to a method for stabilizing fly ash from refuse incineration by the combination of complementary type medicaments. The stabilizing method combines a reducing inorganic medicament (I type medicament) capable of precipitating and absorbing Pb, Zn, Cd, Hg, Cr, Cu and other heavy metals and an heavy metal ion precipitation type organic chelating agent (II type medicament). The method comprises the following steps: firstly mixing the I type medicament with the fly ash first in aqueous solution or in the presence of water for reaction to generate ferric hydroxide for absorbing and precipitating heavy metals or generating sulfides of the heavy metals to precipitate the heavy metals; and then adding the II type medicament in the system to allow the II type medicament to further generate precipitate type chelates with the residual heavy metals, particularly Pb, Cd, Hg and the like. The first step of the method is characterized in that reducing atmosphere still remains after the reaction. As a major part of heavy metals are stabilized by chalybeate or the chalybeate, so the dosage of the II type medicament is reduced considerably.

Owner:TONGJI UNIV +1

Method of iron extraction and removal with solvent extraction agent

InactiveCN103160689ADecrease in positive chargeReduce acidityProcess efficiency improvementSolventPrecipitation

The invention relates to a method of iron extraction and removal with solvent extraction agent and belongs to the technical field of wet metallurgy. The method includes processes of extraction, reverse extraction and iron precipitation conversion. The detailed operation is that an organic phase is used for extracting iron in an aqueous phase, then an iron-rich organic phase is obtained, iron reverse extraction agent is directly used for reversely extracting iron, or firstly, non-ferrous metals are reversely extracted with mineral acid, and then the iron reverse extraction agent is again used for reversely extracting the iron. The iron reverse extraction agent is hydrochloric acid-chloride solution, wherein the concentration of C1- is 4-18 mol / L, and the concentration of H+ is 0.2-3 mol / L. At the time of reverse extraction, contact reverse extraction is carried out on the iron-rich organic phase and the reverse extraction iron agent according to the volume rate of 0.3-3:1. After phase splitting, an iron content water phase and a blank organic phase are obtained. The blank organic phase is washed with acid water and then returned to the extraction process for recycling. Alkaline substance is added into the iron content water phase and the value of potential of hydrogen (pH) is adjusted to 2.5-8.5, iron precipitation is filtered, and iron containing filter residues and chloride solution are obtained. The hydrochloric acid is added into the chloride solution, the concentration of H+ is adjusted to 0.2-3mol / L, then the chloride solution is returned to the iron reverse extraction process for recycling, and iron is comprehensively recovered from the iron content filter residues. The method of the iron extraction and removal with the solvent extraction agent has the advantages of being simple in the technology, good in iron reverse extraction, low in production cost, environment-friendly and the like and is suitable for industrial production.

Owner:CENT SOUTH UNIV

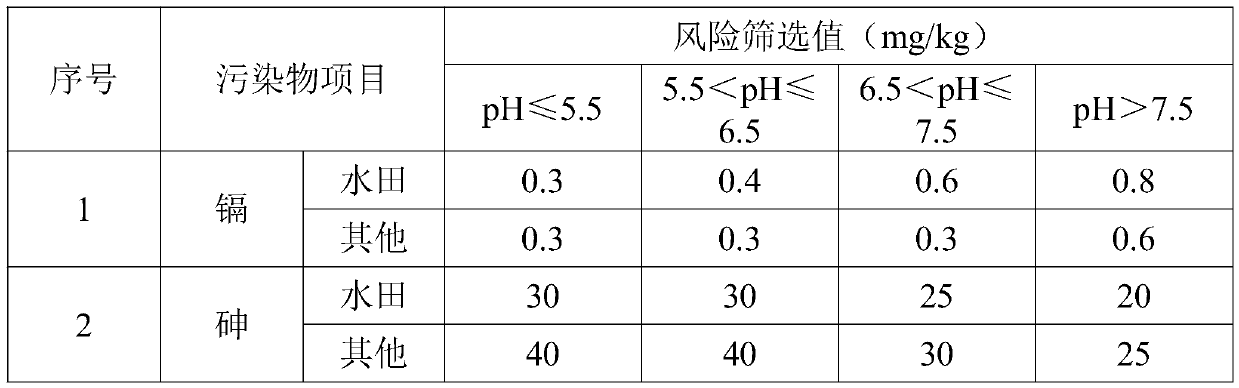

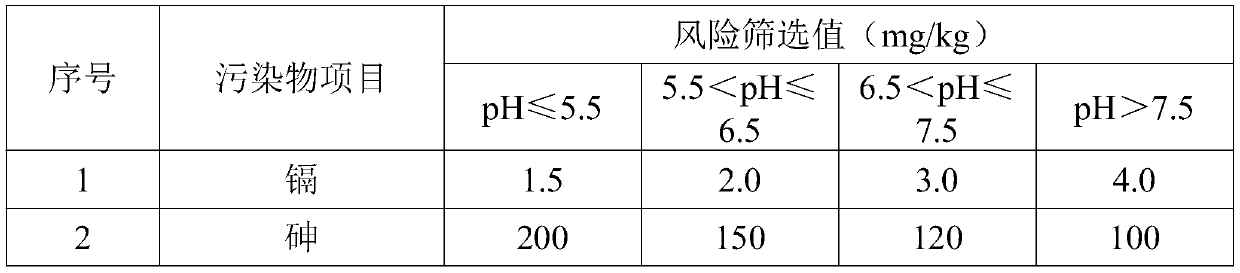

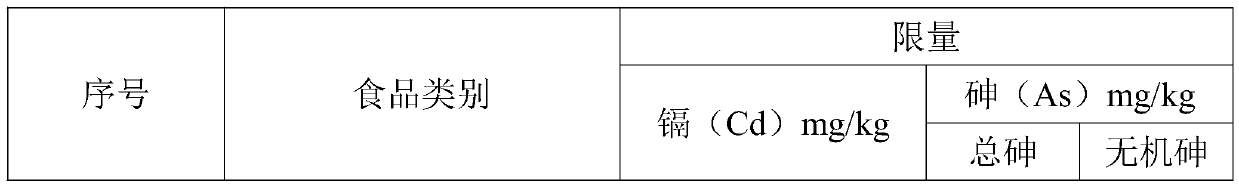

Soil remediation agent formula for cadmium-arsenic polluted rice planting, and preparation method thereof

InactiveCN111154493AImprove fertilityReduce secondary pollutionAgriculture tools and machinesOther chemical processesRice grainNatural mineral

The invention discloses a soil remediation agent formula for cadmium-arsenic polluted rice planting. The soil remediation agent formula is prepared from, by weight, 25-30 parts of quicklime, 10-15 parts of an iron agent, 8-10 parts of a silicon raw material, 5-8 parts of phosphate, 10-15 parts of a natural mineral material, 6-10 parts of humic acid, 8-10 parts of acidified activated carbon, 5-8 parts of weathered lignite, 9-12 parts of sepiolite powder and 2-4 parts of chitosan. The invention further discloses a preparation method of the soil remediation agent formula for cadmium-arsenic polluted rice planting. The effective-state cadmium content and the effective-state arsenic content in rice planting cultivated land (paddy field) polluted soil are effectively reduced, so that the rice cadmium content and the rice arsenic content in rice grains are reduced; meanwhile, the effects of increasing the rice yield and improving the soil fertility are achieved; and the formula has the advantages of no secondary pollution, strong practicability and simple process, and has huge development potential in the soil combined pollution remediation application of the rice planting farmland (paddyfield).

Owner:湖南省和清环境科技有限公司

Ferrum replenishing jelly and its preparation technology

InactiveCN101142974AChange formEasy to takeHeavy metal active ingredientsFood preparationFlavorTrace element

The invention relates to iron supplementing jelly and preparation process and provides iron supplementing jelly which can supplement trace element iron necessary for human body and has no need of mastication due to appropriate flavor, with easy preparation, low cost, easy carrying and taking. The invention comprises the following components: jelly sandwich particle and outer jelly; the composition and weight shares of jelly sandwich particle are as follows: iron of 0.1 to 2 shares, folate of 0 to 1 shares, jelly powder or food glue of 20 to 60 shares, filler of 1 to 5 shares, sweetener and / or edible taste correcting substance of 0.5 to 5 shares, edible flavor of 0.1 to 5 shares and water of 20 to 70 shares, and the composition and weight shares of outer jelly ingredient are as follows: jelly powder or food glue of 15 to 50 shares, filler of 1 to 5 shares, sweetener and / or edible taste correcting substance of 0.5 to 5 shares, food flavor of 0.1-5 shares and water of 20 to 70 shares. The product provided by the invention is suitable for various crowds.

Owner:HEILONGJIANG UNIV

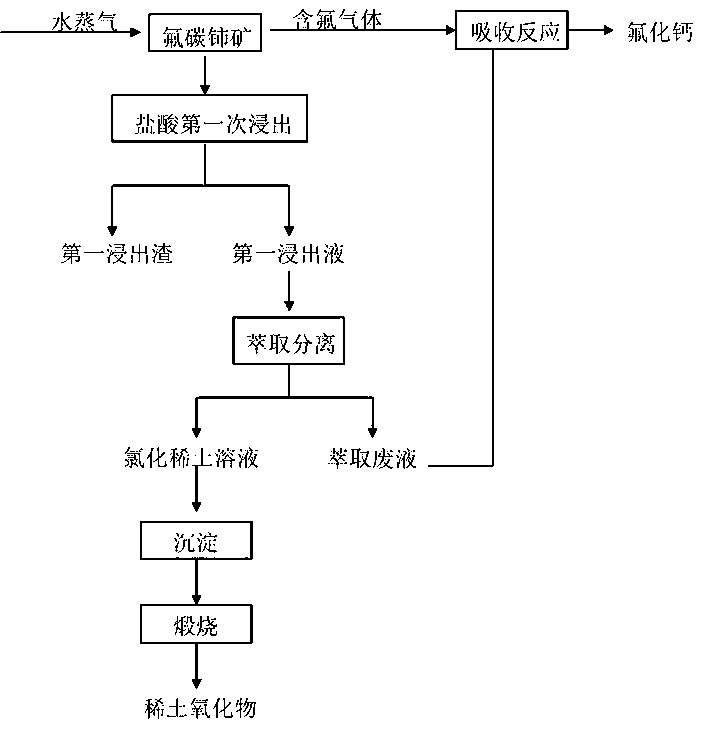

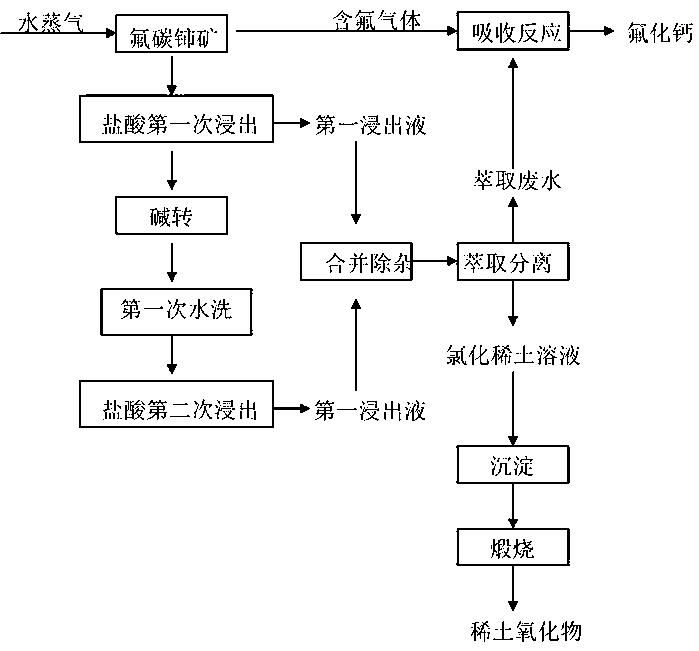

Smelting method for comprehensively recovering rare earth and fluorine from bastnaesite

ActiveCN109517974AImprove leaching rateIncrease profitCalcium/strontium/barium fluoridesProcess efficiency improvementWater vaporRare earth

The invention discloses a method for comprehensively recovering rare earth and fluorine from bastnaesite, and relates to the technical field of smelting separation of bastnaesite. The method for comprehensively recovering rare earth and fluorine from bastnaesite comprises the steps that vapor is guided into bastnaesite for roasting, so that roasted ore and fluorine-containing gas are obtained; theroasted ore is dissolved for the first time with hydrochloric acid, so that first leaching residues and a first leaching solution containing rare-earth chloride are obtained, wherein the first leaching solution is a rare earth solution; an extraction agent is saponified with a calcium-containing iron agent, the rare earth solution is saponified with the saponified extraction agent, and calcium-containing extraction waste water is discharged; afterwards, the rare earth solution is reversely extracted in hydrochloric acid, so that a rare earth chloride solution is obtained; the calcium-containing extraction waste water reacts with the fluorine-containing gas to prepare a calcium fluoride product; and the rare earth chloride solution is deposited with sodium carbonate to obtain rare earth carbonate, and the rare earth carbonate is calcined at a high temperature to obtain rare earth oxide. According to the method for comprehensively recovering rare earth and fluorine from bastnaesite, thesteps are simple, the hydrochloric acid leaching rate of the bastnaesite is increased; and meanwhile, the resources are efficiently recovered and utilized.

Owner:中稀(凉山)稀土有限公司 +1

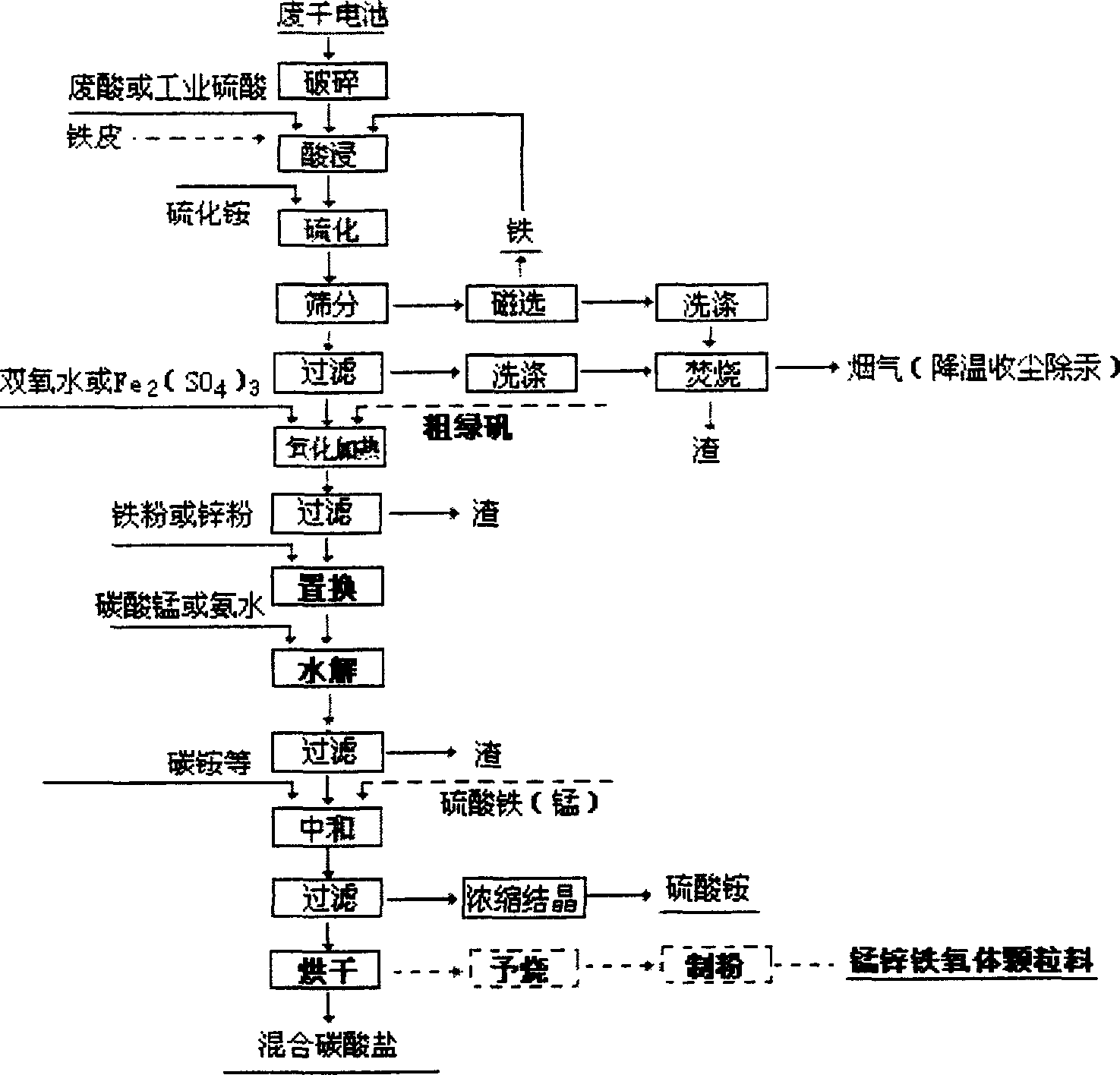

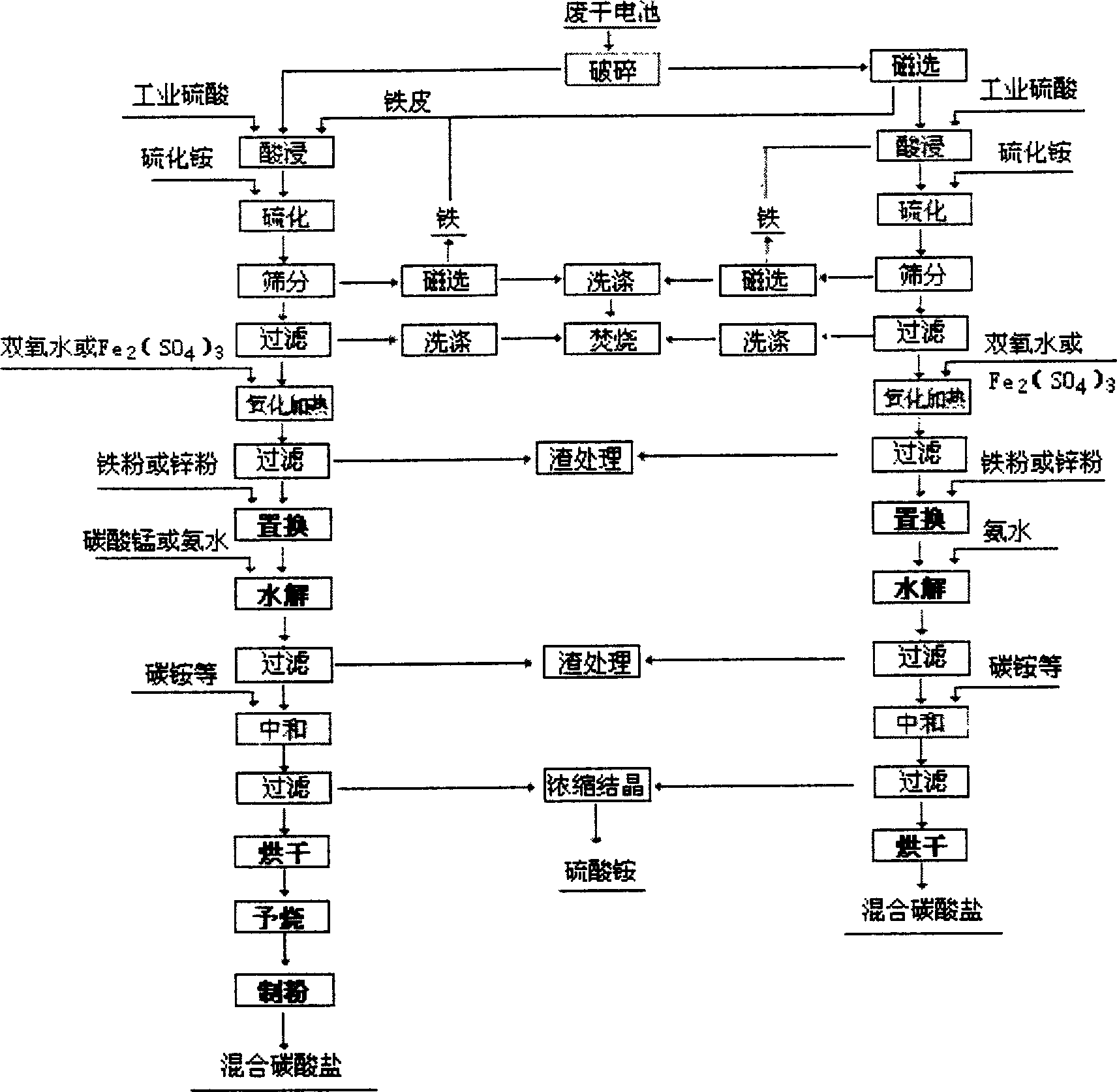

Method for producing manganese-zinc ferrite particle material and mixed carbonate utilizing waste dry battery

InactiveCN1674331AThe wet mercury removal method is simple and effectiveNo pollutionReclaiming serviceable partsBattery recyclingSulfateIron agent

The present invention is characterized by that utilizing waste sulfuric acid or industrial sulfuric acid to soak the broken waste dry battery, utilizing sulfurization process to make the mercury in the form of mercuric sulfide be centralized in the filter residue, then making treatment, making the filtrate oxidation, heating, replacement, hydrolysis and purification, then utilizing sulfate solution to make neutralization, precipitating, washing and drying so as to obtain mixed carbonate for preparing manganese-zinc ferrite granule material, concentrating and crystallizing the neutralized mother liquid to produce ammonium sulfate, in the process, adding a certain quantity of iron and manganese elements and making the obtained mixed carbonate pre-combustion and granulation so as to obtain manganese-zinc ferrite granule material product.

Owner:张晓东

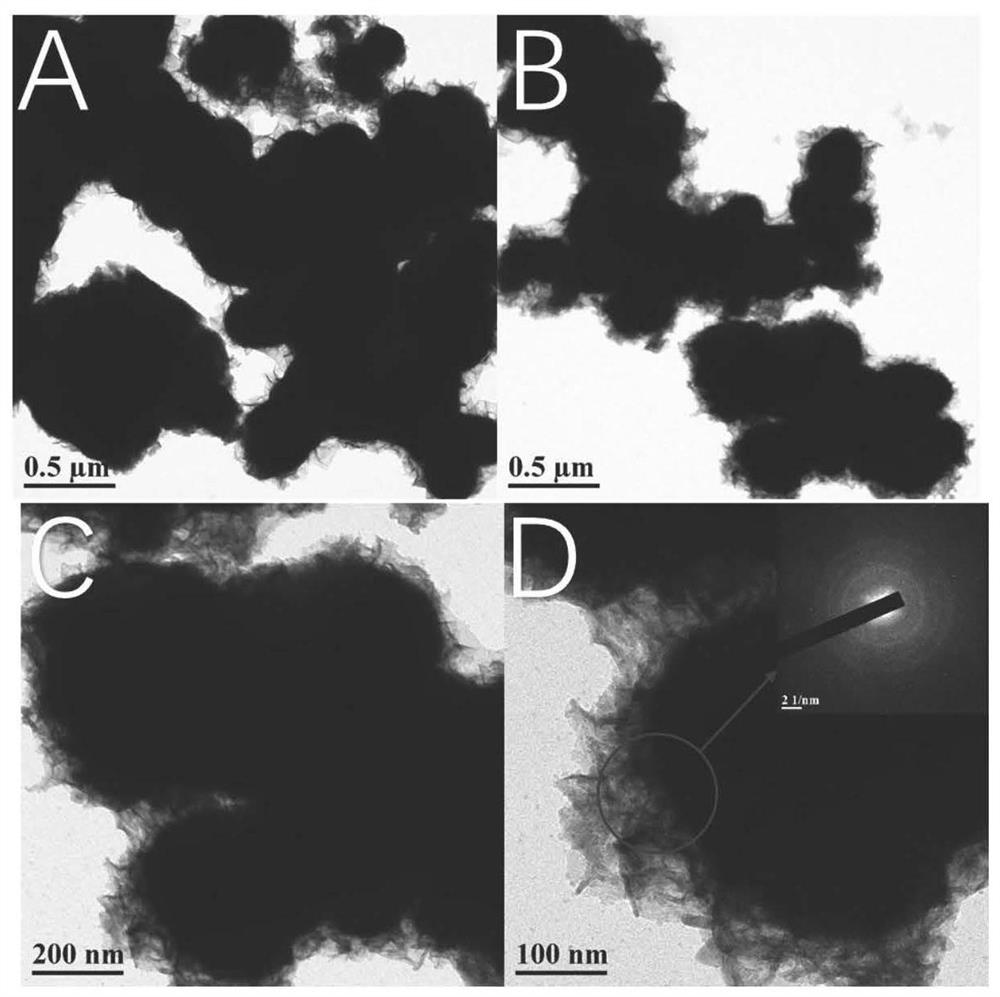

Zero-valent iron agent modified by aromatic carboxylic acid, and preparation method and application thereof

ActiveCN113371809AIncrease profitShort preparation timeMaterial nanotechnologyWater treatment compoundsFerrous saltsCarboxylic acid

The invention discloses a preparation method of an aromatic carboxylic acid modified zero-valent iron agent. The method comprises the following steps: adding a zero-valent iron agent into a solvent under the condition of normal temperature by taking an aromatic carboxylic acid aqueous solution as the solvent, carrying out complexation reaction, and separating to obtain the aromatic carboxylic acid modified zero-valent iron agent, or sequentially or simultaneously adding sodium borohydride and a vulcanizing agent into a ferric salt and / or ferrous salt, carrying out reduction reaction and vulcanization reaction, and separating to obtain the aromatic carboxylic acid modified vulcanized nano zero-valent iron. Iron oxide, iron sulfide or iron nitride on the surface of the aromatic carboxylic acid modified zero-valent iron agent is complexed with carboxyl functional groups in aromatic carboxylic acid, so that passivation of zero-valent iron is inhibited, more electrons can be released to degrade pollutants, and the degradation efficiency is improved.

Owner:ZHEJIANG UNIV OF TECH

Strengthening and iron compensating black rice medicinal granules, and method for preparing the same

InactiveCN101152466ARegulate immunityReasonable compositionHeavy metal active ingredientsMetabolism disorderCelsius DegreeIron agent

The present invention relates to a black rice granule which is used for reinforced iron supplementation and the preparation method; the raw materials proportions are 50 portion to 55 portion of brown black rice powder, 15 portion to 20 portion of red jujube extract, 10 portion to 25 portion of hepatin and 0.008 portion to 0.25 portion of iron agents. The implementation steps are that the brown black rice powder, red jujube extract, hepatin and iron agent pass 50 to 60 mesh screens; the raw materials with the proportions are weighed through the process mesh screen; the iron agent and red jujube extract are accurately weighed according to the preparation rate and mixed through the method of equal gradual increase; and then the mixture is mixed evenly with the brown black rice and the hepatin; an internal packer is used for bulking of the internal bag; the operational environment is that the temperature is 18 to 26 Celsius degrees and the relative humidity is less than or equal to 65 percent. The product is refined into nutritious health food for iron supplementation with scientific preparation; the absorption rate is high and the granule does not stimulate intestines and stomach. The present invention can be used for comprehensively regulating the body of people and overcomes the defect of iron supplementation with single medicament.

Owner:TIANJIN TIANSHI BIOLOGICAL DEV

Nutritive composition with iron replenishing function and preparation method thereof

InactiveCN101380110AImprove absorption rateRigorous selection of materialsMetabolism disorderBlood disorderWheat germBamboo shoot

The invention relates to a nutrition composition with the function of supplementing iron and a preparation method thereof. The nutrition composition comprises the following powder components by weight percentages: 40-50% of wheat germ powder, 10-20% of bamboo shoot, 2-8% of walnut kernel, 2-8% of kelp, 2-8% of carrot, 2-8% of dried edible fungus and 2-8% of jujube, which are mixed with 5-15% of poultry eggs that are sterilized, dried and made into powder to obtain a mixture, the mixture is added with 1-3% of a flavoring agent for cooking, and then added with 0.01-0.125% of chalybeate heme iron, evenly mixed, packaged and sterilized to obtain the finished product. The heme iron contained in the nutrition composition is directly absorbed by intestinal mucosal cells, and has high absorptivity. The nutrition composition is made from natural raw materials, contains various nutritive materials essential to human body, and can consciously supplement iron while eating. The preparation method of the nutrition composition has the advantages of precise selection of raw materials, scientific formula, reasonable process and high operability.

Owner:TAIXIANG GRP TECH DEV

Medicine for treating anemia and preparing method

ActiveCN1554386APromote absorptionImprove actual functionsBird material medical ingredientsBlood disorderCodonopsis pilosulaOphiopogon japonicus

The medicine for treating anemia is prepared with Dangshen, tuckahoe, white atractylodes rhizome, astragalus root, date and other four kinds of Chinese medicinal materials, and through preparing extractum, adding medicinal iron agent, vitamins and proper amount of supplementary material. The present invention has unique recipe and no upset caused, and is used in treating iron deficiency caused anaemia of children and adult.

Owner:JIANMIN PHARMA GRP CO LTD

Preparation method of gynostemma pentaphyllum polysaccharide-iron complex

ActiveCN103330718AGood dissolution effectImprove stabilityHeavy metal active ingredientsOrganic active ingredientsWater bathsDigestion

The invention discloses a gynostemma pentaphyllum polysaccharide-iron complex. The complex comprises the following components in percentage by weight: 2%-4% of iron and 40%-60% of gynostemma pentaphyllum polysaccharide, and the dissolvability of the complex in per 100mL of water at 25 DEG C is 10g-11g. A preparation method of the gynostemma pentaphyllum polysaccharide-iron complex comprises the steps of: dissolving the gynostemma pentaphyllum polysaccharide and a complexing agent into distilled water, heating in water bath, and dropwise adding a ferric iron compound water solution while stirring, wherein the mass ratio of the gynostemma pentaphyllum polysaccharide to the complexing agent to the ferric iron compound is 3:1:2; and after the reaction, washing with ethanol to obtain the gynostemma pentaphyllum polysaccharide-iron complex. According to the preparation method, the gynostemma pentaphyllum, which is abundant and low in cost, is adopted as a main raw material, the digestion property and stability of the product are better, the water solution is neutral, and the gynostemma pentaphyllum polysaccharide-iron complex can substitute for an existing iron-supplementary agent for supplementing iron for a human body; the preparation technique is simple and easy to popularize; and a new raw material is provided for producing a novel iron-deficiency iron supplementation agent.

Owner:GUANGXI UNIV

Method for recycling copper and iron in acid mine wastewater by high-polymer chelating-precipitating agent two-step process

InactiveCN103214121AIncrease consumptionNo secondary pollutionWaste water treatment from quariesMultistage water/sewage treatmentSlagEmission standard

The invention discloses a method for recycling copper and iron in acid mine wastewater by a high-polymer chelating-precipitating agent two-step process, relates to a wastewater treatment method and provides a method for recycling copper and iron in acid mine wastewater by a high-polymer chelating-precipitating agent two-step process, and the method adopts the two-step process, is simple in process and free of secondary pollution, capable of changing the outlet slag into finished products and easily pressing and filtering the slag, so that the zero storage capacity is achieved, the outlet water can completely satisfy the standards and the outlet water can be recycled for mineral processing. The method comprises the following steps of: adding liquid caustic soda to the acid mine wastewater for entering a next stirring reaction slot after regulating the pH of the wastewater to 2.7; adding the high-polymer cheating copper-extracting agent for regulating the pH to 4.2-4.4; adding flocculating agent for carrying out sedimentation and solid-liquid separation, wherein the sediment is copper concentrate with 20%-30% of copper, and the liquid supernatant enters an ion-extracting reaction slot; the high-polymer cheating iron-extracting agent is added to regulate the pH to 8.2-8.5; and the flocculating agent is added for carrying out sedimentation and solid-liquid separation, wherein the sediment is iron concrete, and the liquid supernatant can reach the first-level emission standards and can be directly exhausted or recycled.

Owner:FUJIAN GELIN NUOBEIER ENVIRONMENTAL PROTECTION TECH

Hexavalent chromium contaminated soil remediation agent and preparation method thereof

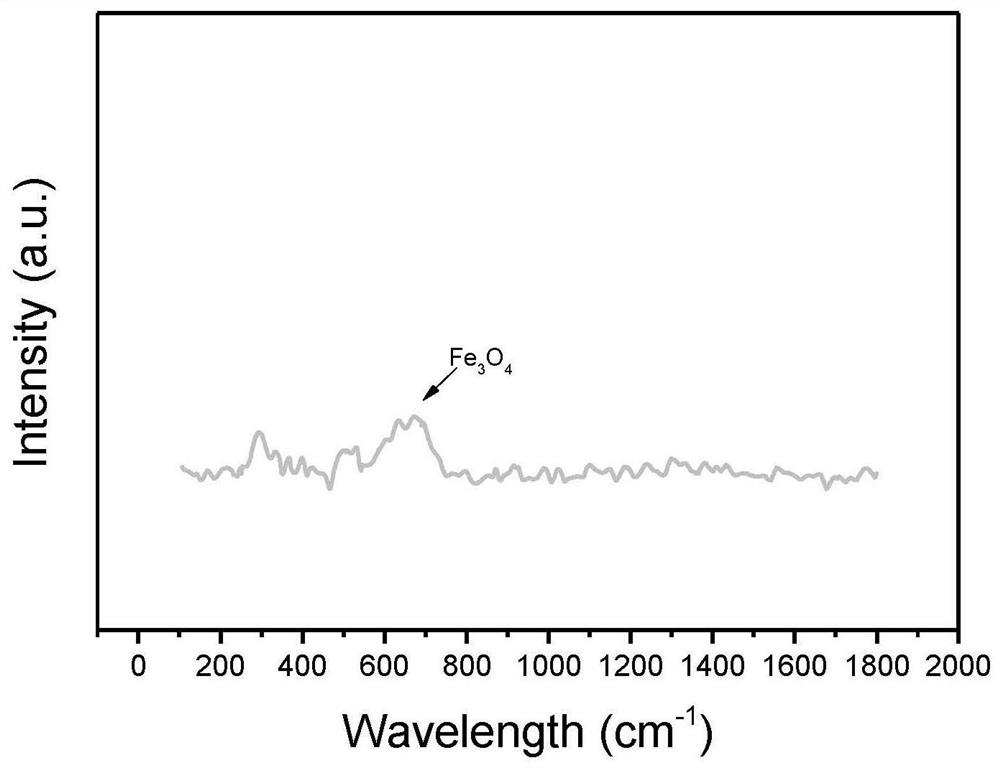

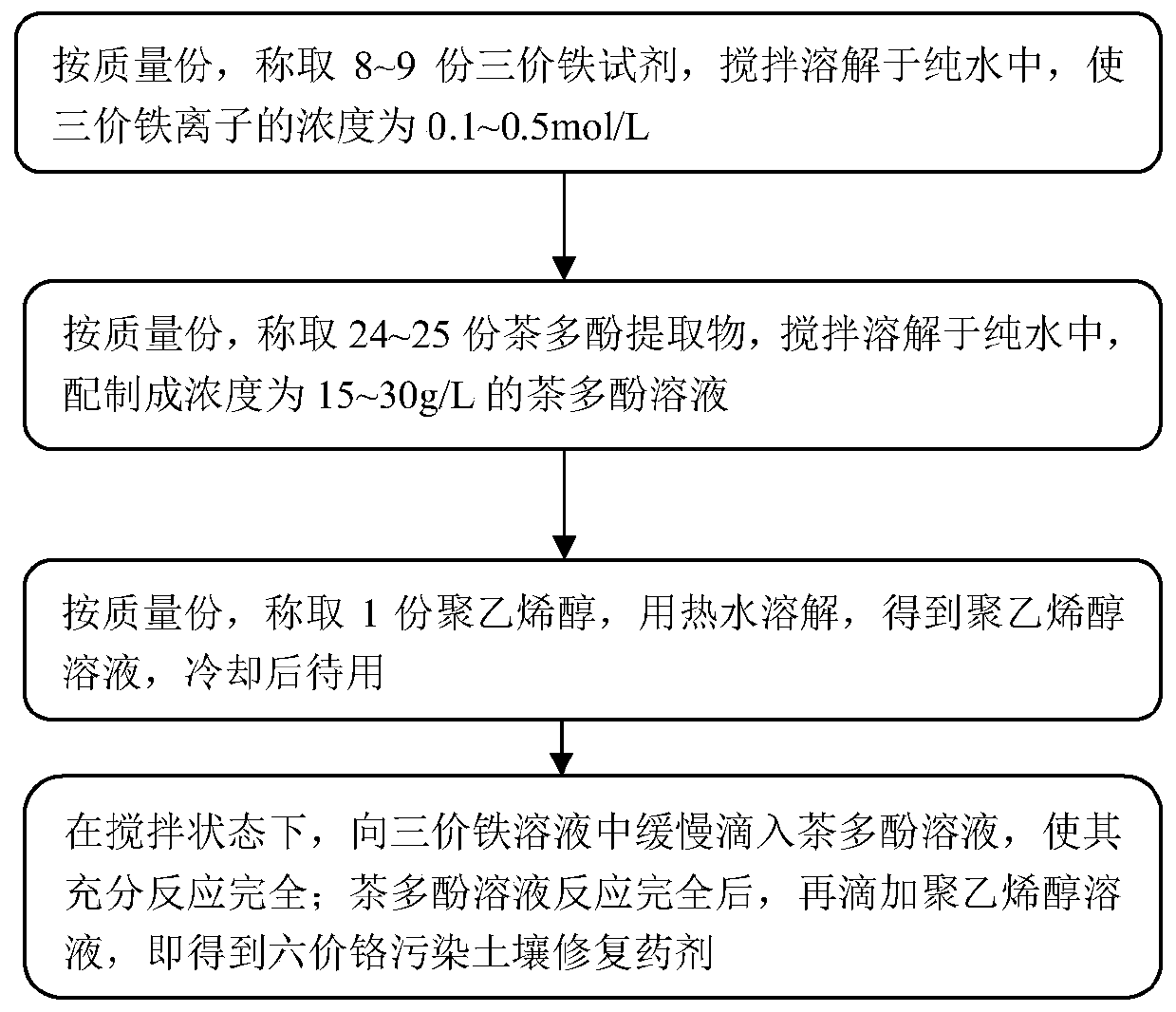

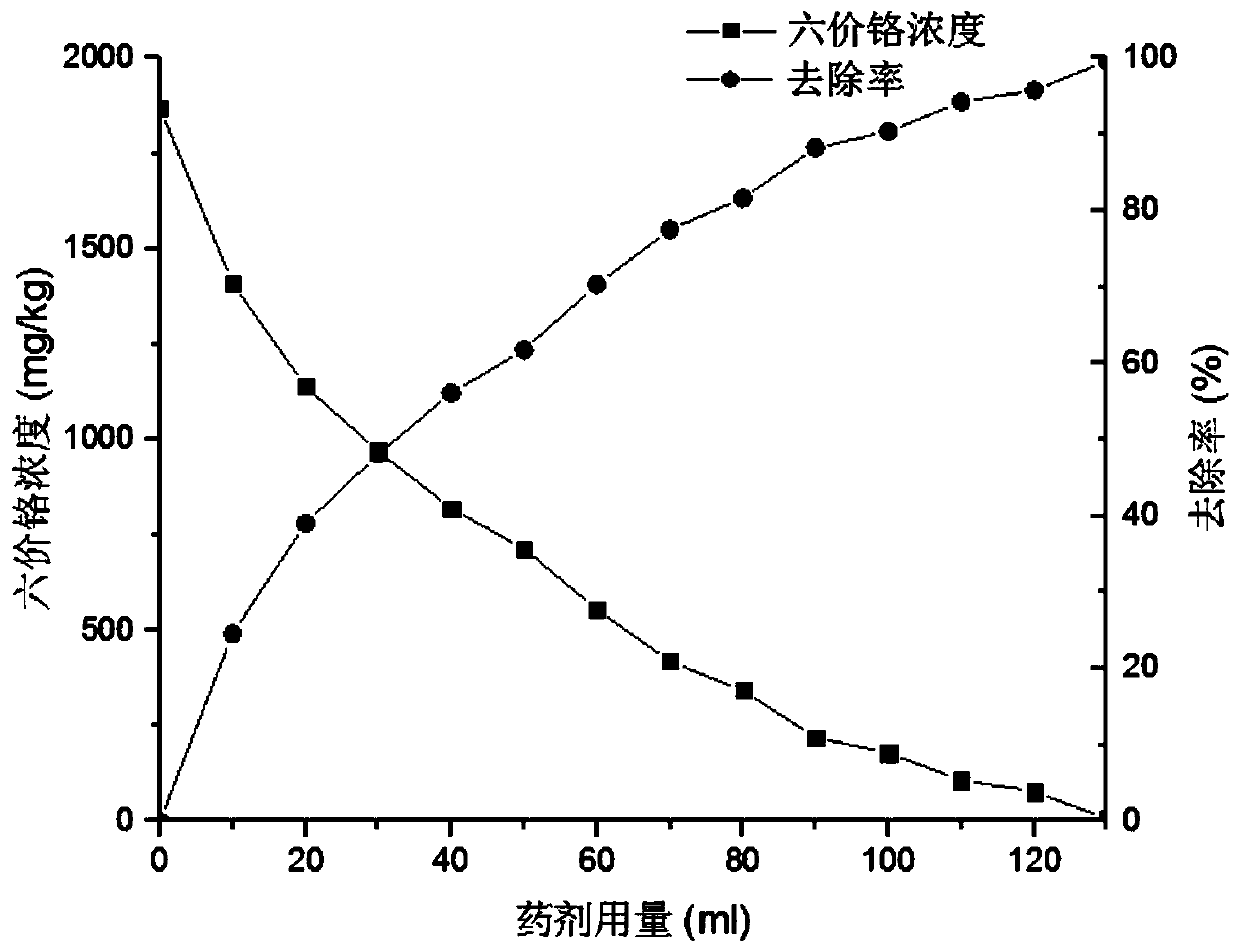

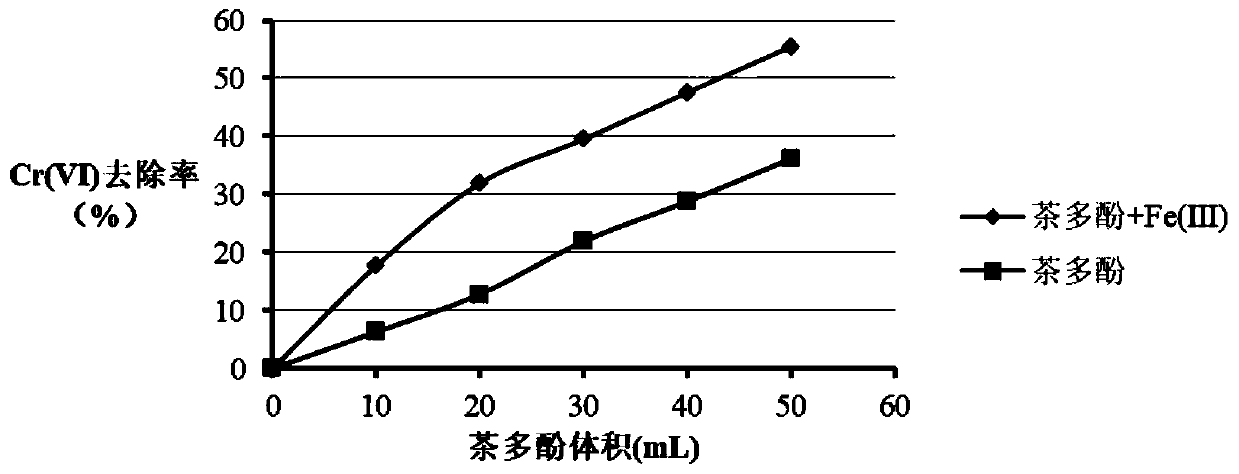

InactiveCN109913225AThe stabilizer polyvinyl alcohol improves the stability of the drug on the one handWill not cause secondary pollutionAgriculture tools and machinesOther chemical processesPolyvinyl alcoholPolyphenol

The invention provides a hexavalent chromium contaminated soil remediation agent. The remediation agent comprises the following raw materials in parts by mass: 24-25 parts of a tea polyphenol extract,8-9 parts of a trivalent iron reagent and 1 part of polyvinyl alcohol. The invention also provides a preparation method of the hexavalent chromium contaminated soil remediation agent. The method comprises the following steps: weighing the trivalent iron agent, and stirring and dissolving the agent in pure water to obtain a ferric iron solution; weighing the tea polyphenol extract, and stirring and dissolving the extract in pure water to obtain a tea polyphenol solution; weighing and dissolving polyvinyl alcohol in pure water to obtain a polyvinyl alcohol solution; dropwise adding the tea polyphenol solution to the prepared ferric iron solution during stirring to enable the tea polyphenol solution and the ferric iron solution to be subjected to sufficient reaction, and dropwise adding thepolyvinyl alcohol solution to obtain the hexavalent chromium contaminated soil remediation agent after sufficient reaction of the tea polyphenol solution and the ferric iron solution. After the prepared soil remediation agent is used for remediating soil, the pH value of soil is restored from strong alkalinity to neutrality, the proportion of organic carbon content of soil is increased, and the soil structure and fertility are improved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Compound micro iron agent facilitating in-situ injection and preparation method of compound micro iron agent

InactiveCN107473315AImprove stabilityGuaranteed stabilityOther chemical processesAlkali metal oxides/hydroxidesMaterials scienceIon

The invention discloses a compound micro iron agent facilitating in-situ injection and relates to the technical field of in-situ remediation of soil and underground water. The compound micro zero-valent iron agent is prepared from zero-valent ion powder, a dispersant, a thickener and water through uniform mixing in a high-speed stirring manner. The zero-valent iron powder, the dispersant and the thickener account for 5%-40%, 0.3%-1% and 2%-6% of the total water quantity respectively in percentage by weight. Compared with existing commercially available micro iron compound agents, the compound micro zero-valent iron agent has very high stability and excellent migration liquidity, facilitates in-situ injection of the agent during remediation, can be injected into a target remediation layer under lower pressure, has larger diffusion radius and has good removal effects on heavy metals and organic pollutants. The compound micro zero-valent iron agent comprises green and environmentally friendly components, is wide in application range, is beneficial to sustainable development of the enjoinment and cannot exert adverse effects on the underground water environment.

Owner:北京市科学技术研究院资源环境研究所

Wrinkling-resistant ironing agent and preparation method thereof

ActiveCN104818618AQuality improvementFor long-term storageFibre treatmentPolymer sciencePreservative

The invention provides a wrinkling-resistant ironing agent and belongs to the technical field of daily chemical products. The wrinkling-resistant ironing agent is composed of, by mass, 1-10% of modified starch, 0.1-5% of organic silicone, 0.1-5% of fibroin finishing agent, 0.05-2% of odor neutralizer, 0.02-0.5% of essence, 0.02-0.5% of preservative, 0.02-0.5% of pH adjuster and 83-95% of water. The wrinkling-resistant ironing agent is stable in quality, supportive of long-time storage and mild and nonirritant to skin, and fabric after being ironed by using the wrinkling-resistant ironing agent has wrinkling-resistant and antistatic effect.

Owner:WALCH GUANGZHOU COMMODITY

Production process for round aluminium alloy rod

ActiveCN106676300AReduce lossRealize long-span and long-distance high-voltage power transmissionConductive materialMetal/alloy conductorsRare earthHigh pressure

The invention relates to a production process for a round aluminium alloy rod for electrical engineering. The production process is characterized by adopting a continuous tandem rolling production manner, and comprising the following steps: (1) filling molten aluminium with an aluminium content of more than 99.60% in a smelting furnace, and controlling the temperature of the molten aluminium at 710-770 DEG C; (2) adding 1kg of industrial silicon, 5kg of iron agent with an iron content of 75% and 3kg of copper agent with a copper content of 75% per ton of aluminium; (3) standing for 10-20 minutes, and adding 3kg of rare-earth alloy and 4.5kg of aluminium-boron alloy per ton of aluminium; (4) controlling a temperature in the furnace at 720-760 DEG C, starting up electromagnetic stirring and stirring an aluminium alloy melt for 15-40 minutes; (5) spraying a refining agent by virtue of argon with a pressure of 0.1-0.2MPa and refining for 10-30 minutes after a sampling analysis meets alloy standard requirements; and (6) standing for 20-40 minutes and rotating the furnace after the refining is completed. The elongation of the round aluminium alloy rod obtained by the production process disclosed by the invention meets the drawing requirement of an aluminium rod, greatly reduces loss during a power transmission process, and can realize large-span long-distance high-voltage power transmission.

Owner:YUNNAN ALUMINUM

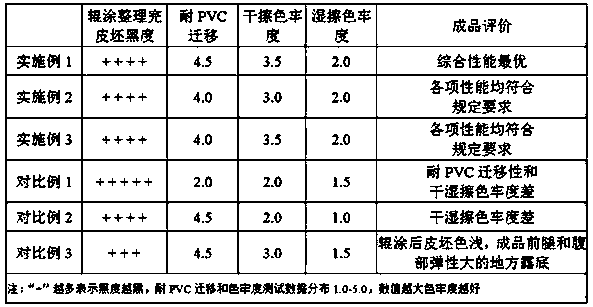

Black plate light-colored fur leather product coating process

ActiveCN110295258AGood fleece effectAvoid the risk of hair upLeather/skins/hides/pelt chemical treatment apparatusLeather surface finishingThermal sprayingIron agent

The invention belongs to the technical field of processing of leather products and discloses a black plate light-colored fur leather product coating process. The process comprises pre-coating, finishing of semi-finished products, post-coating and finishing of finished products. Pre-coating includes horizontal toggling, roller coating, drying, water spraying and cage rotating; finishing of the semi-finished products includes staking and polishing; post-coating includes vertical toggling, bottom covering, spraying of a bottoming coat, one-time ironing, spraying of a surface coat and ironing of the finished products; finishing of the finished products includes fur ironing, fur shearing, brushing of a fur ironing agent, ironing of the finished products and warehousing of the finished products.A roll coating material includes, by weight, 200-500 parts of a penetrating agent Metoxi, 500-800 parts of a penetration leveling agent 0240, 100-200 parts of dye water 5915, 80-120 parts of ultrafine pigment paste 5450 and 100-200 parts of BASF black dye water, wherein the total use amount of the dye water 5915 and the BASF black dye water is 280-300 parts. The process reduces the discharge of dyeing wastewater and saves water and chemicals, and the production is safer and more environmentally friendly.

Owner:HENAN PROSPER SKINS & LEATHER ENTERPRISE

Production method of ferric pyrophosphate to be added into foods containing vitamins

InactiveCN109170911AImprove fluidityEasy to processFood ingredientsCalcium borogluconateFerric Pyrophosphate

The invention discloses a production method of ferric pyrophosphate to be added into foods containing vitamins. The production method of the ferric pyrophosphate to be added into the foods containingthe vitamins comprises the following steps: performing ultrafine crushing on a commercially available ferric pyrophosphate raw-material; adding water, polyacrylic resin III, starch sodium octenyl succinate and calcium gluconate in proportion so as to obtain a suspension by performing blending, and adjusting the pH value of the suspension to 6.0-8.0; and then, performing high-speed shearing and homogenizing on the blended suspension, and carrying out spray-drying so as to obtain a finished ferric pyrophosphate powder product. The production method of the ferric pyrophosphate to be added into the foods containing the vitamins has the following advantages: carbohydrates are used as a wall material so as to perform embedding treatment on a common ferric pyrophosphate raw-material by adopting amicroencapsulation technology, so that, the treated ferric pyrophosphate has good fluidity; and thus, processing performance of the ferric pyrophosphate is improved. Therefore, being used in the foods containing the vitamins as an iron fortifier, reaction between the treated ferric pyrophosphate and the vitamins can be avoided; and thus, no black precipitate is produced during brewing process. The foods added with the ferric pyrophosphate are good in taste and healthier for drinking.

Owner:郑州瑞普生物工程有限公司

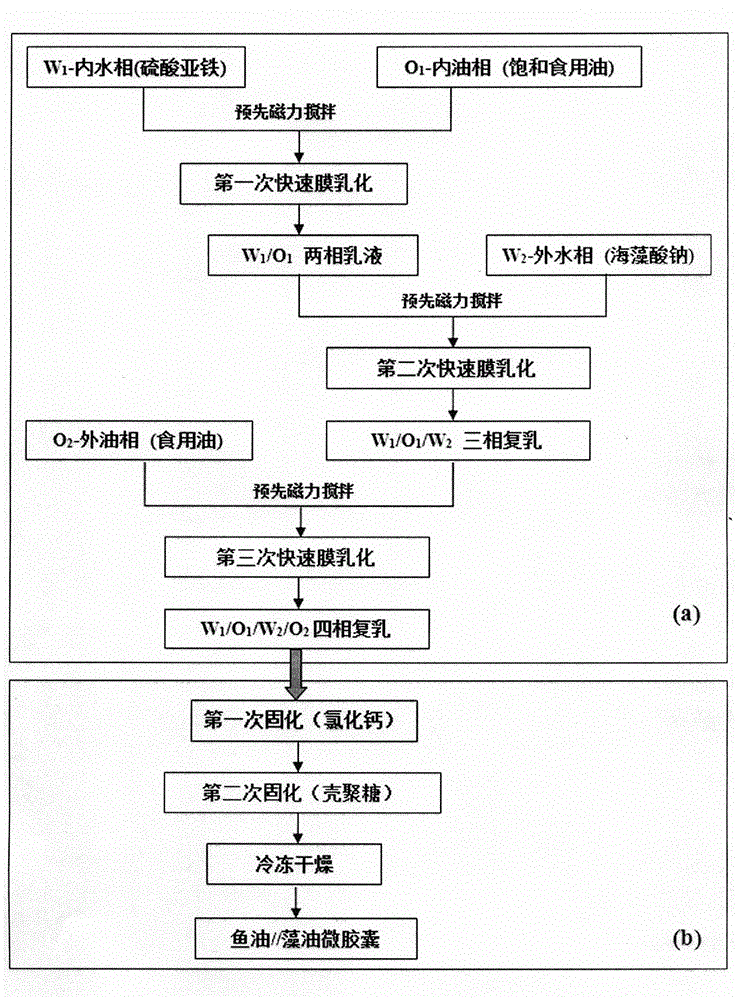

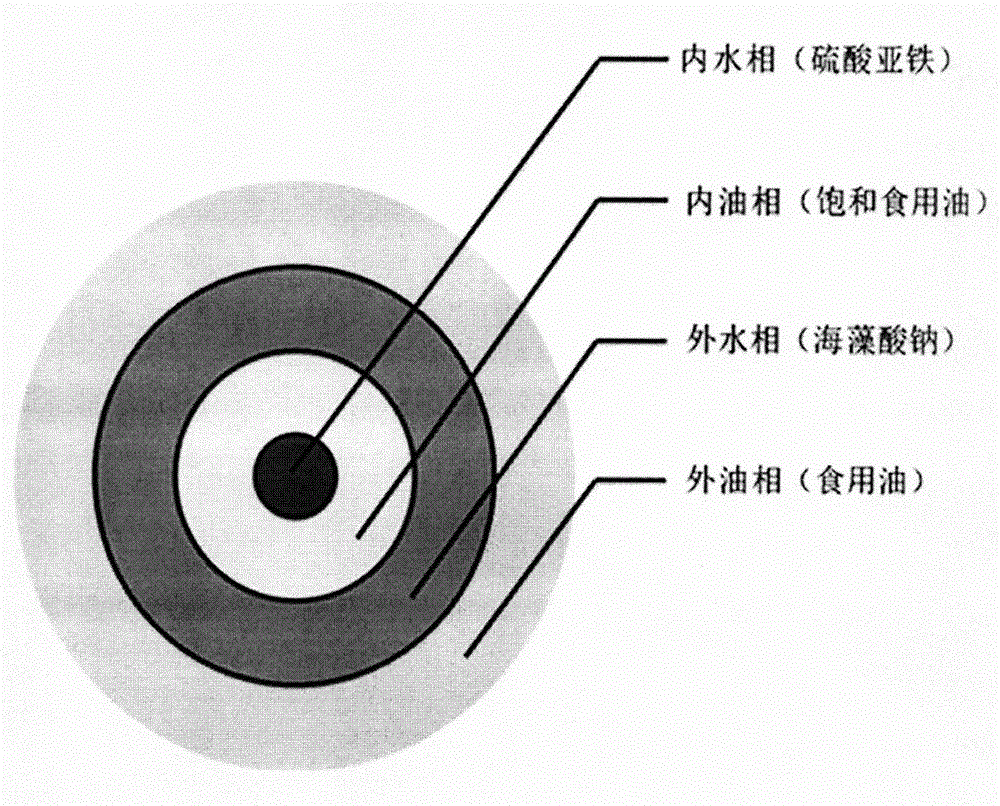

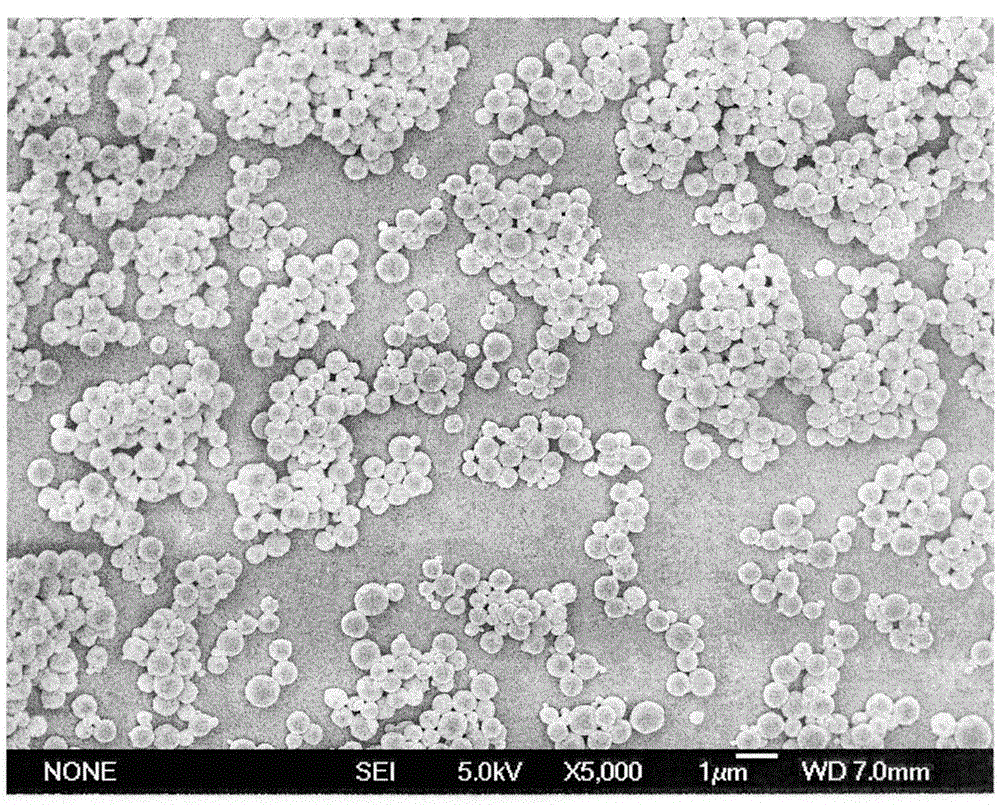

Nano-level ferrous sulfate nutritional supplement micro-capsule product and preparation process thereof

ActiveCN105477014AAvoid contactImprove stabilityHeavy metal active ingredientsMetabolism disorderMembrane emulsificationMicro-encapsulation

The invention relates to a nano-level ferrous sulfate nutritional supplement micro-capsule product and a preparation process thereof. The preparation process includes firstly, preparing stable four-phase multiple emulsion by means of three times of premix membrane emulsification; secondly, preparing wall material based on sodium alginate through twice curing process by respectively adding calcium chloride and chitosan into the four-phase multiple emulsion. With particle size controlled within the nano level, the ferrous sulfate nutritional supplement micro-capsule products prepared by the process are uniform in size, have the advantages such as slow release, enteric coating, effective absorption and low production cost, and are particularly applicable to large range of food nutrition enrichment and prevention of iron deficiency anemia.

Owner:NAT INST FOR NUTRITION & HEALTH CHINESE CENT FOR DISEASE CONTROL & PREVENTION +1

Preparing method of anodic oxidation die-casting aluminum alloy

The invention discloses a preparing method of an anodic oxidation die-casting aluminum alloy. The preparing method comprises following steps: an aluminum ingot is put into a smelting furnace to be smelted, and when the temperature rises to 880 DEG C to 900 DEG C, an iron agent and a manganese agent are put into the smelting furnace; molten metal is repeatedly stirred, and after stirring each time, standing is carried out; manganese and zinc are put into the molten metal to be smelted, and the molten metal is stirred; when the temperature of molten alloy ranges from 780 DEG C to 800 DEG C, a refining agent is added for refining and slag removal; after sufficient stirring, a sample is taken out to be subject to the test; nitrogen is led into the molten metal to achieve gas removal; if the tested component is within the set range, an alterant is added into the molten metal, and stirring and standing are carried out; pouring is carried out, and during pouring, the temperature of the molten metal is kept at 780 DEG C to 800 DEG C. The preparing method of the anodic oxidation die-casting aluminum alloy is provided and solves the technical problem that an existing die-casting aluminum alloy cannot be subject to anodic oxidation.

Owner:GUANGZHOU ZHIYUAN ALLOY PROD CO LTD

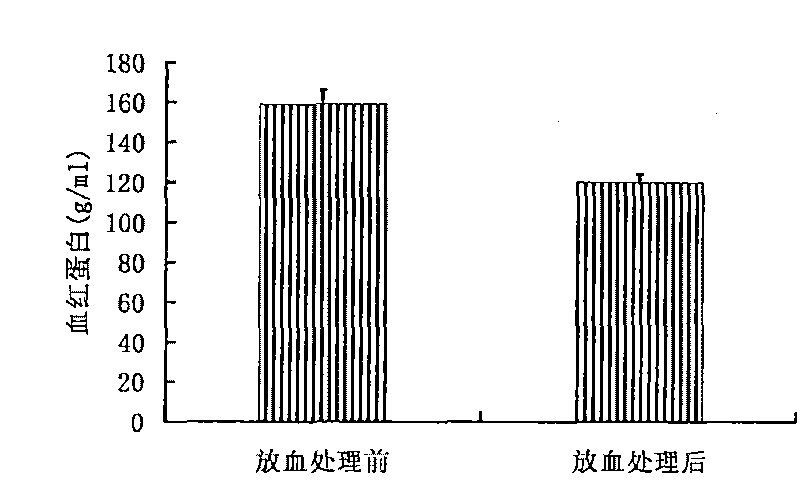

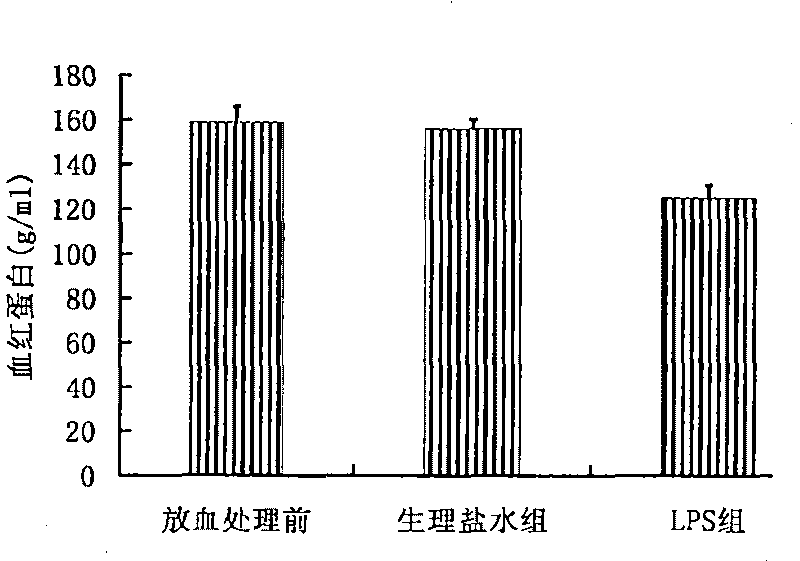

Medicine application of iron liposome

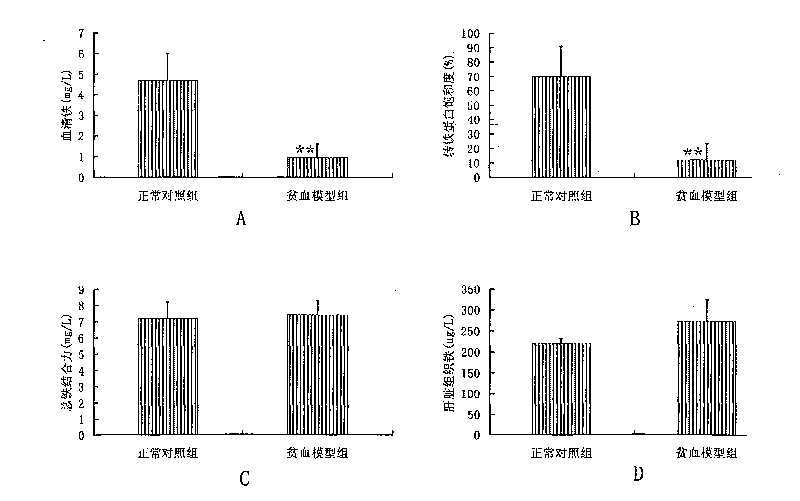

InactiveCN101708184AIncreases available ironIncrease serum iron levelsHeavy metal active ingredientsBlood disorderFood additiveTreatment effect

The invention discloses a medicine application of iron liposome. By taking animals with chronic inflammation as a model, a brand-new medicine which treats anaemia caused by the dysfunction of the iron absorption of the small intestine to relevant protein molecules and takes the iron liposome as an effective component is provided. The invention takes white rats with inflammatory anaemia as a model, adopts an oral stomach infusion method and compares the curative effect of the iron liposome for the anaemia with that of a chalybeate which is not enveloped by the liposome, and the iron liposome can obviously enhance the levels of the hemoglobin, the blood cell volume, the serum iron and the saturation rate of the transferrin of an organism in a short time, can act as a very good curative effect to the inflammatory anaemia and can not cause injuries to the health of the organism. The iron liposome is obviously superior to the traditional iron-replenished preparation. The invention can be used for treating the anaemia caused by the dysfunction of the iron absorption of the small intestine to the protein molecules because of various known or unknown reasons. Various tablets, capsules, dripping pills, oral liquid and food additives which are taken orally and contain the iron liposome are prepared.

Owner:HEBEI NORMAL UNIV

Preparation method for AL-Cu alloy circular aluminum rods

InactiveCN108467980AComply with drawing requirementsReduce lossMetal rolling arrangementsAluminiumIron agent

The invention discloses a preparation method forAL-Cu alloy circular aluminum rods. The preparation method comprises the following steps that an aluminum furnace is filled with aluminum liquid with the aluminum content being 99.5% or above; 1 kg of elemental silicon, 5 kg of iron agents with the iron content being 75% and 3 kg of copper agents with the copper content being 75% are added in per tonof the aluminum liquid; still standing is conducted for 10-20 min, and then 3 kg of rare earth alloys and 4.5 kg of aluminum-boron alloys are added; raw materials are led into the furnace to be smelted into alloy solution; the alloy solutionis delivered to a continuous casting machine and is casted into alloy ingots; the alloy ingots are rolled into the Al-Cu alloy circular aluminum rods througha continuous rolling machine; the rolled Al-Cu alloy circular aluminum rods are treated through a cleaning cooling pipeline; then the Al-Cu alloy circular aluminum rods are transferred to a rod winderto be wound; and packaging and checking are conducted, the AL-Cu alloy circular aluminum rods are sent out through a travelling vehicle, weighed and stored in a warehouse. The tensile strength of thealloy aluminum rods obtained by the preparation method reaches 160-200 MPa, and meanwhile the resistance rate can be controlled to be 29.0 n omega.m or below; and the elongation meets the requirementof aluminum rod tensioning, the loss in the power transmission process is greatly reduced, and large-span and long-distance high-voltage power transmission can be achieved.

Owner:安徽润藤电缆材料科技有限公司

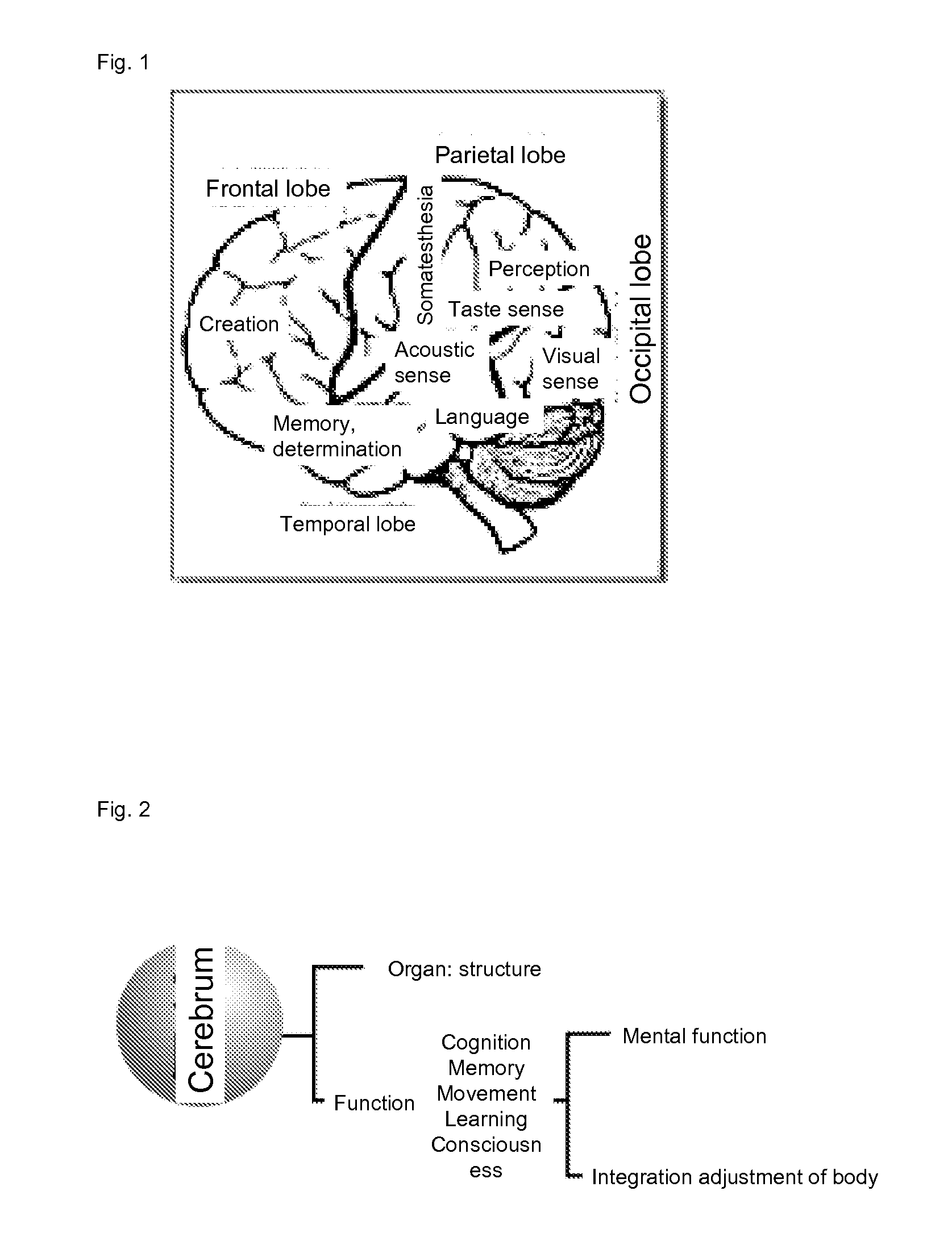

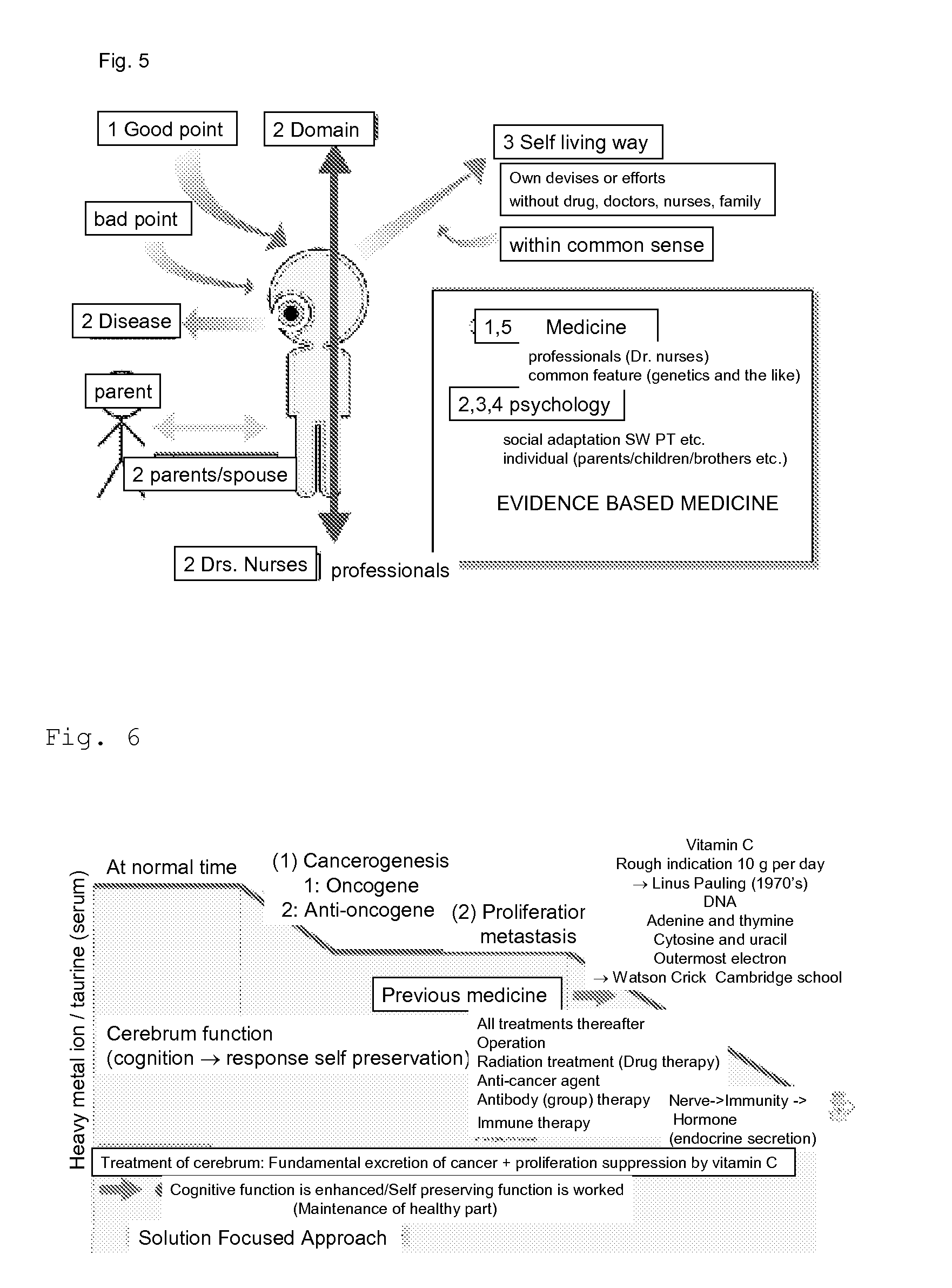

Method for treating/preventing disease using cognitive ability of cerebrum and pharmaceutical

InactiveUS20110092548A1Undesired side effect can be avoidedGood effectHeavy metal active ingredientsBiocideDiseaseVitamin C

An object of the present invention is to develop a method of enhancing the cognitive ability of a brain to fundamentally cure a disease. It has been found out that, by using a medicament for treating or preventing a disease including a combination of a major tranquilizer, and vitamin C or a salt thereof and, if necessary, drip infusion, an antidepressant and an iron agent, the cognitive ability of a brain is enhanced, thus, an arbitrary disease including various cancers can be treated. The present invention also provides a method for treating or preventing a disease including a step of administering a major tranquilizer, and vitamin C or a salt thereof to a subject suffering from the disease.

Owner:MINOWADA TAKURO

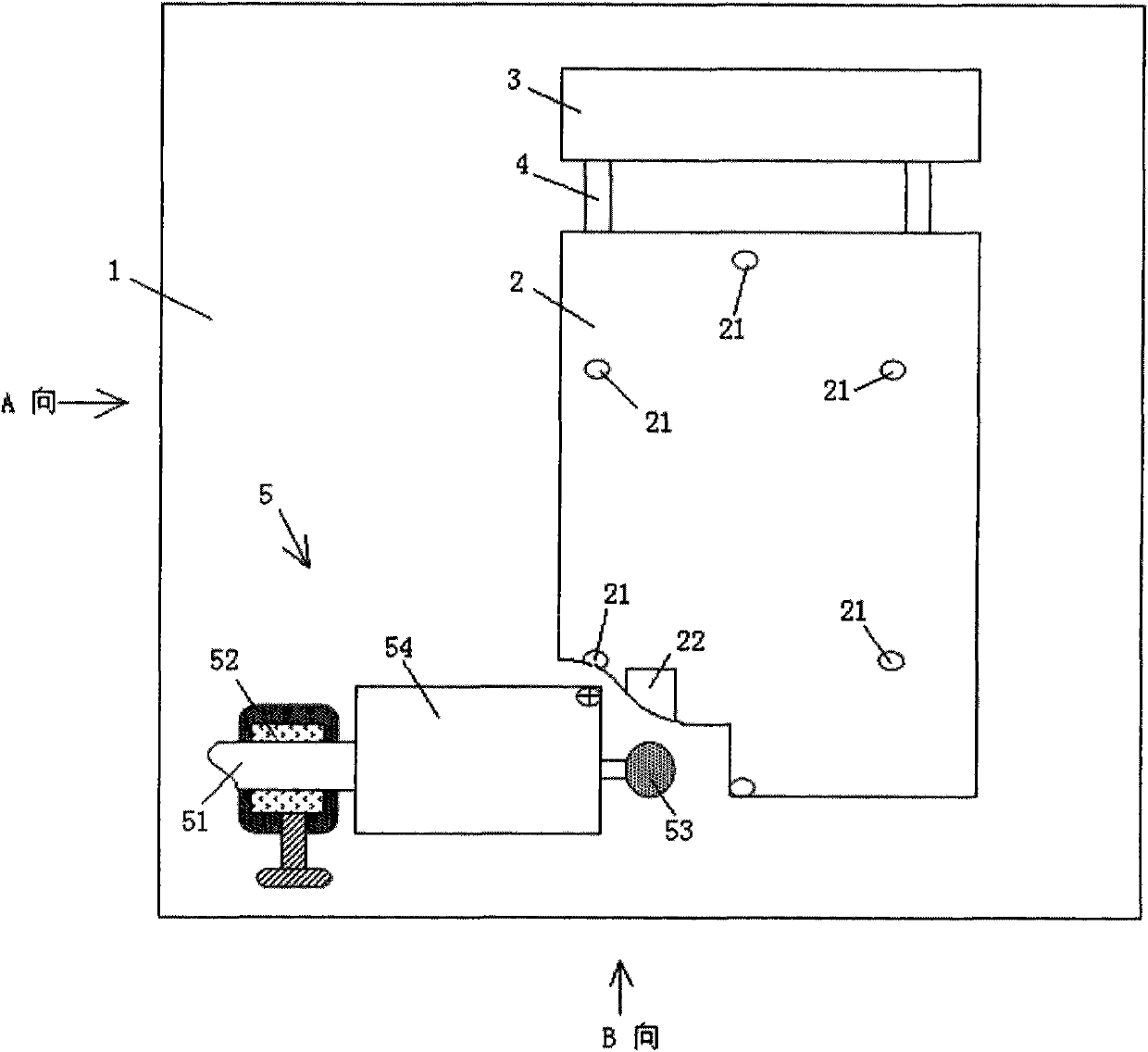

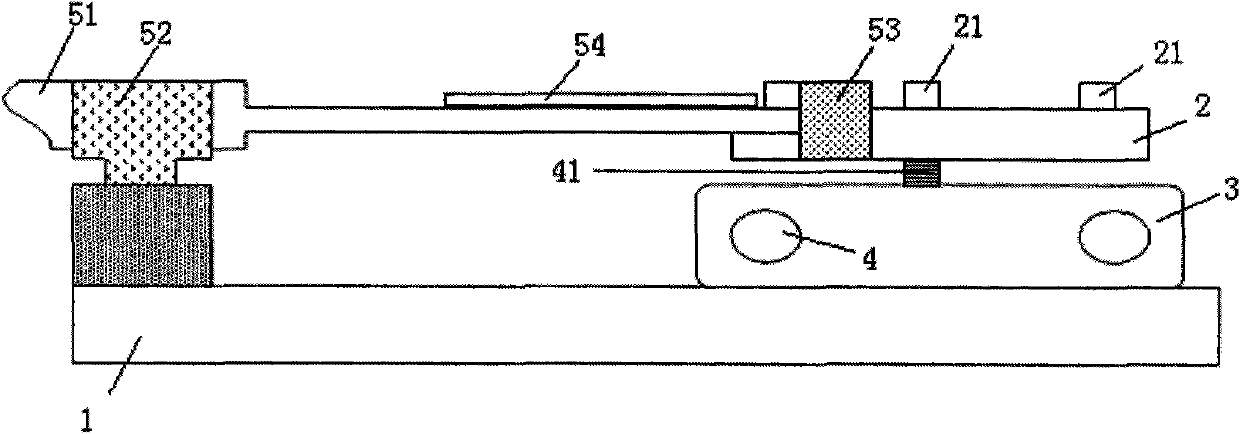

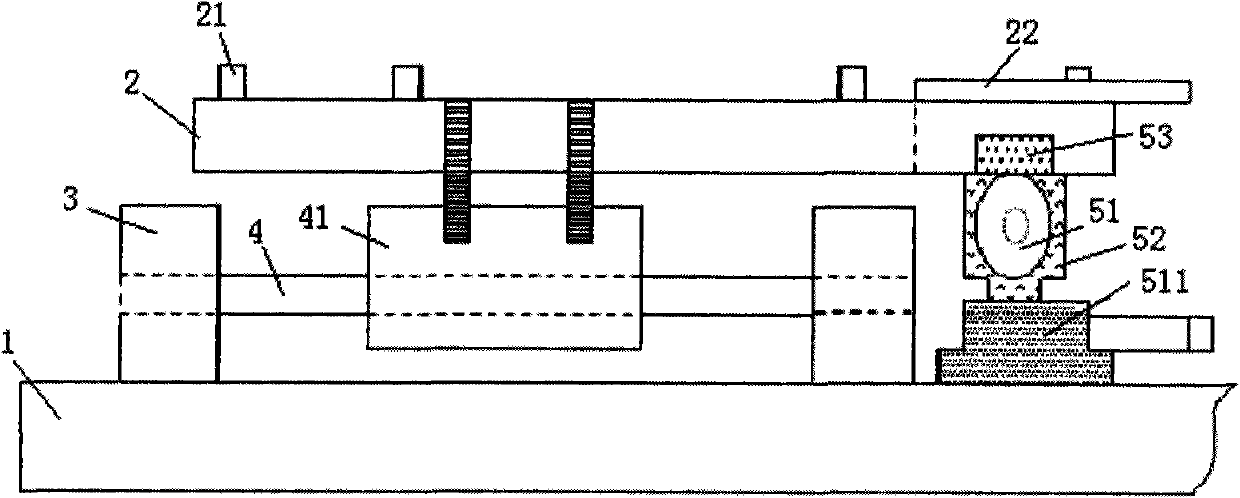

Non-destructive welding device of micro-PCB (printed circuit board) device

InactiveCN102573322ASolution feasibilityOvercome feasibilityPrinted circuit assemblingNon destructiveIron agent

The invention discloses a non-destructive welding device of a micro-PCB (printed circuit board) device. The non-destructive welding device comprises a bottom board, a moving platform which is movably arranged on the bottom board and further used for moving a micro-PCB and a heating device which is fixedly arranged on the bottom board, wherein the heating device is close to one side of the moving platform. The non-destructive welding device disclosed by the invention can solve the follow-up industry process that a device without the resistance to high temperature can not be repair-welded in a device dense region by an electric iron agent, a hot air gun and the like of the PCB, effectively solve the feasibility of a PCB local welding process, reduce the requirements on operation skills of operators and improve operation efficiency and process implementation precision in a breakthrough manner.

Owner:SHENYANG CHENXUN SIMCOM TECH

Method for reducing particle size of foaming agent

InactiveCN104478764ASolve problems that create foamSolve the problem of generating foamOrganic chemistryFoaming agentBiurea

The invention discloses a method for reducing the particle size of a foaming agent. The method comprises the following steps: (1) adding water into a biurea solid to prepare a biurea suspension liquid of which the water content is 30% to 50%; (2) adding a defoaming agent of which the mass is 0.1% to 5% of the mass of the biurea into the biurea suspension liquid and adding a catalyst sodium bromide of which the mass is 1% to 5% of the mass of the biurea and a catalyst aid, namely an iron agent of which the mass is 0.5% to 2% of the mass of the biurea, and uniformly stirring; (3) continuously adding an excessive amount of an oxidant into the solution, continuously stirring at the temperature of 30 to 80 DEG C, and further stirring for 15-30 minutes after the oxidant is completely added dropwise; (4) after the reaction is ended, filtering and washing the solid, drying in an oven at the temperature of 105 DEG C until the solid is constant in weight, filtering and recycling the mother liquid. The method disclosed by the invention has the beneficial effects that the defoaming agent is taken as an additive, so that a remarkable particle size reduction effect is realized, and particles can be reduced from 40 micrometers to about 25 micrometers in particle size.

Owner:HANGZHOU HI TECH FINE CHEM

Preparation method of iron sucrose composite solution with low heavy metal content, and product

InactiveCN109893540AUnique preparation processHigh process removal rateOrganic active ingredientsHeavy metal active ingredientsFerric hydroxideSucrose

The invention discloses a preparation method of an iron sucrose composite solution with the low heavy metal content, and a product. According to a preparation process of an iron sucrose composite, through unique ferric hydroxide intermediate preparation and purification processes and process control and by comprehensively considering heavy metal introduction of a complex reaction vessel, the removal rate of heavy metal can be remarkably increased, the problems that the risk of heavy metal element impurities in an existing iron sucrose crude drug process technology is high, and particularly thecontent of the heavy metal element impurities of manganese, nickel and cobalt is high are solved, the heavy metal toxicity of an iron sucrose intravenous iron supplement in a human body is effectively lowered, drug use safety is improved, and the advantages that process operation is easy, and industrialization is easy to realize are achieved.

Owner:南京恒生制药有限公司

Method for preparing nutritional health-care soy sauce

InactiveCN101884407ANourish blood and soothe the nervesPhysical and intellectualFood preparationPhysical healthIron agent

The invention relates to a method for preparing a seasoning, in particular to a method for preparing a nutritional health-care soy sauce with nutritional health-care effects. The nutritional health soy sauce is prepared by adding chalybeate, calcium, vitamins and seasonings into the soy sauce, dissolving and mixing. The soy sauce has effects of seasonings, contains substances such as ferrum, zinc, vitamins and the like, and can strengthen absorption of nutrient components required by human body. The soy sauce has the effects of nourishing the blood, tranquilizing, improving physical health and promoting intelligence.

Owner:周良碧

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com