Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1177 results about "Oxygen plasma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxygen plasma refers to any plasma treatment performed while introducing oxygen to the plasma chamber. Oxygen is often used to clean surfaces prior to bonding. Oxygen(O 2) is the most common gas used in plasma cleaning technology due to its low cost and wide availability. Oxygen plasma is created by utilizing an oxygen source on a plasma system.

Method of depositing silicon oxide films

InactiveUS20090041952A1Semiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingOxygen plasmaGas phase

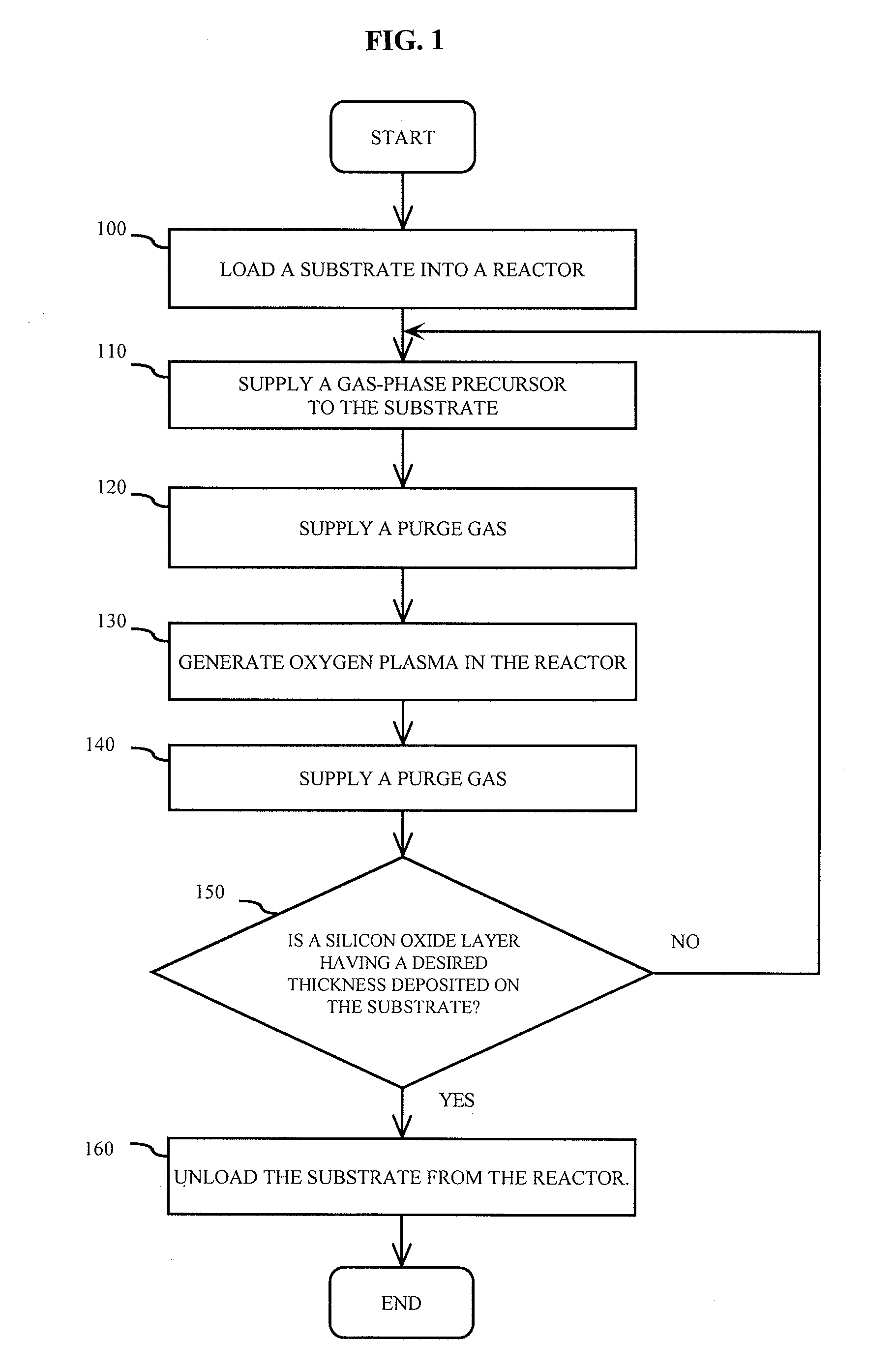

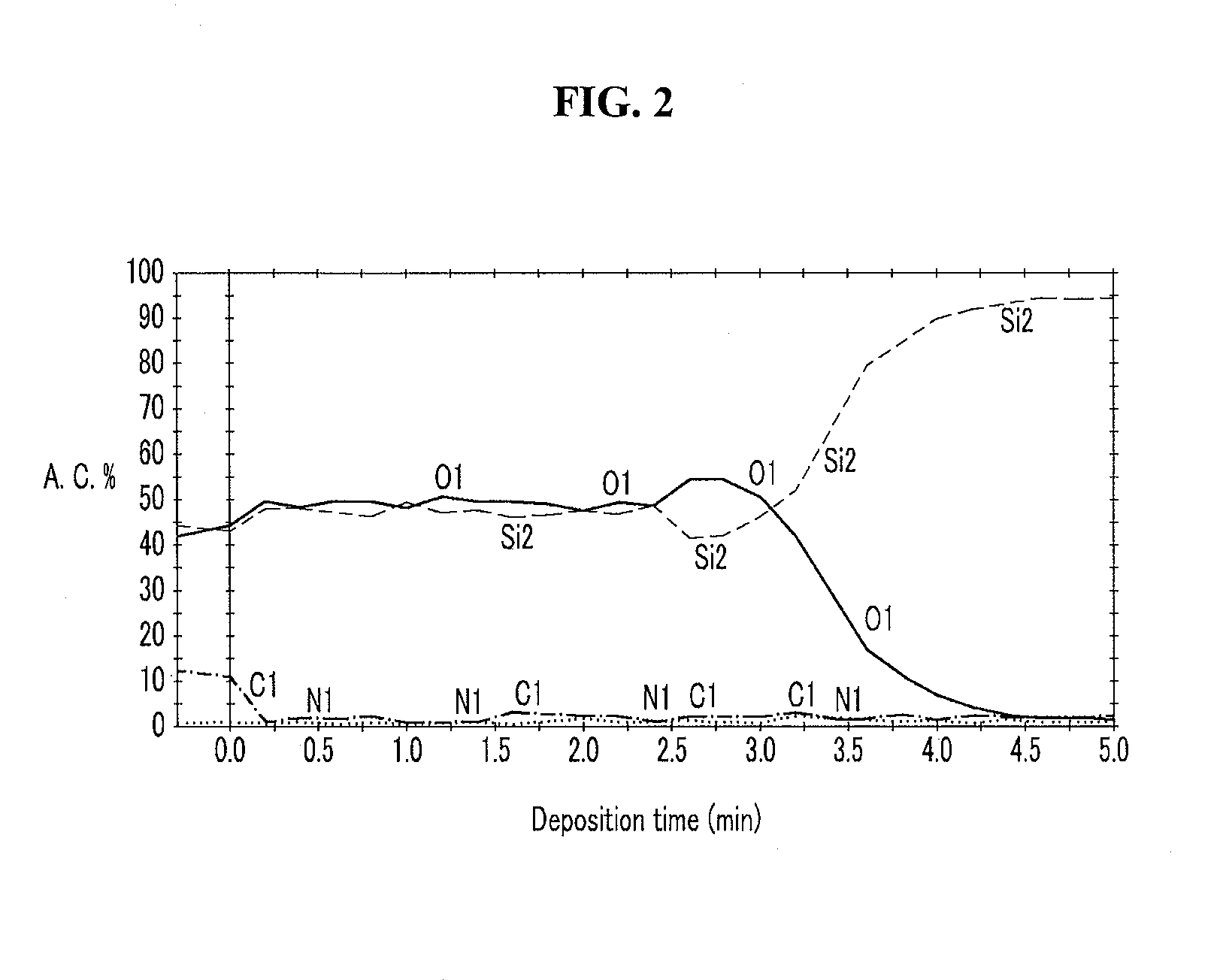

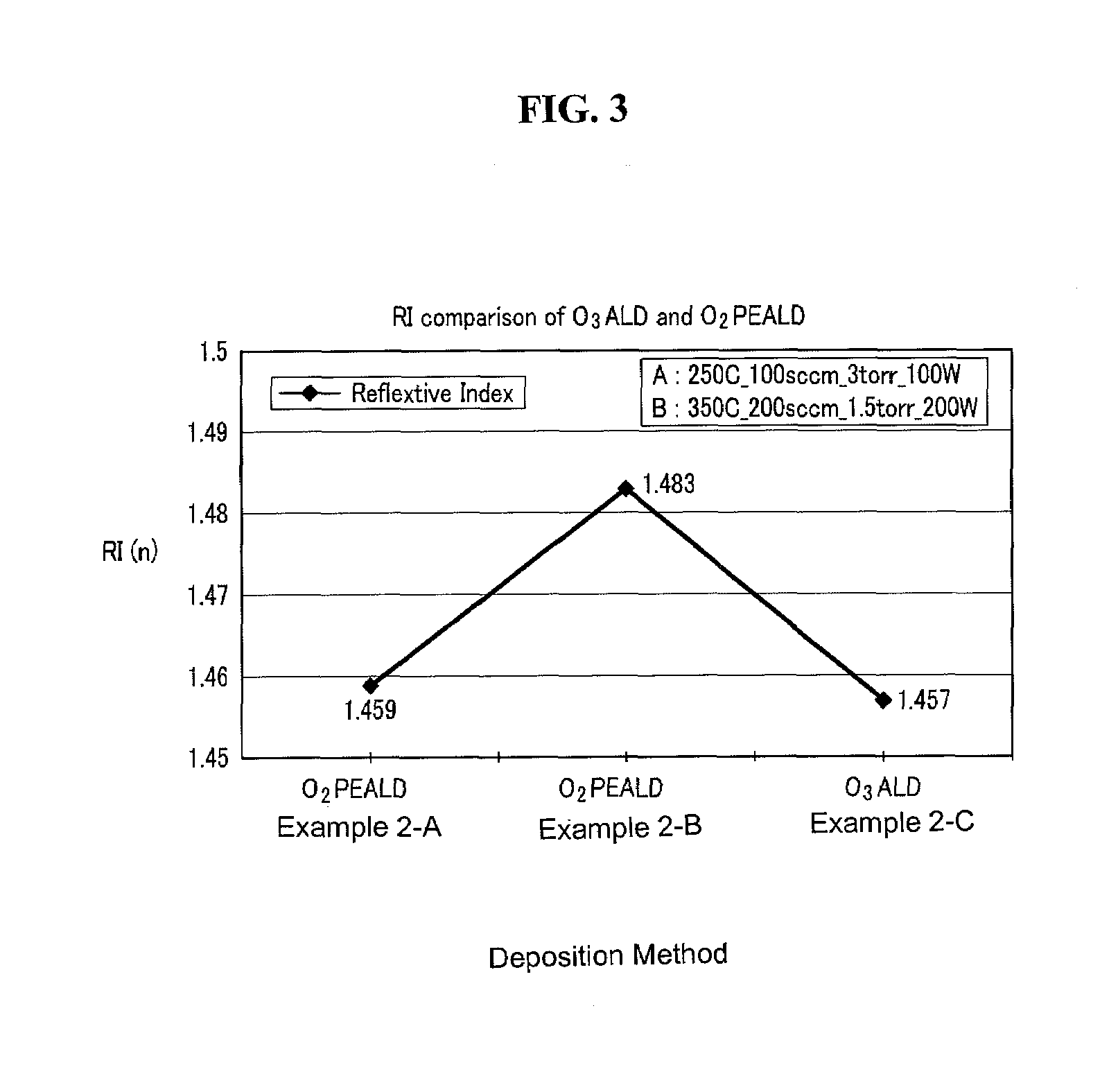

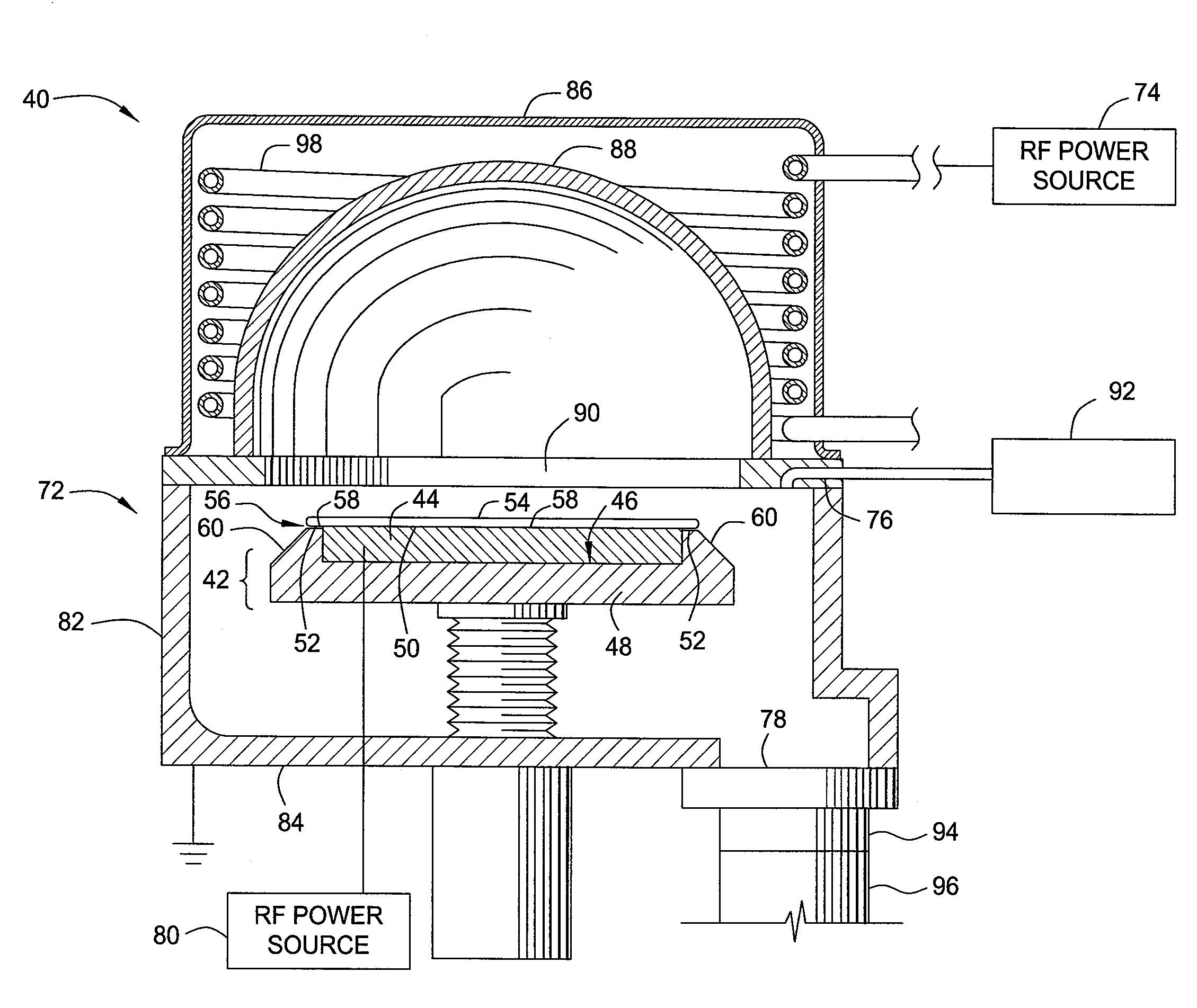

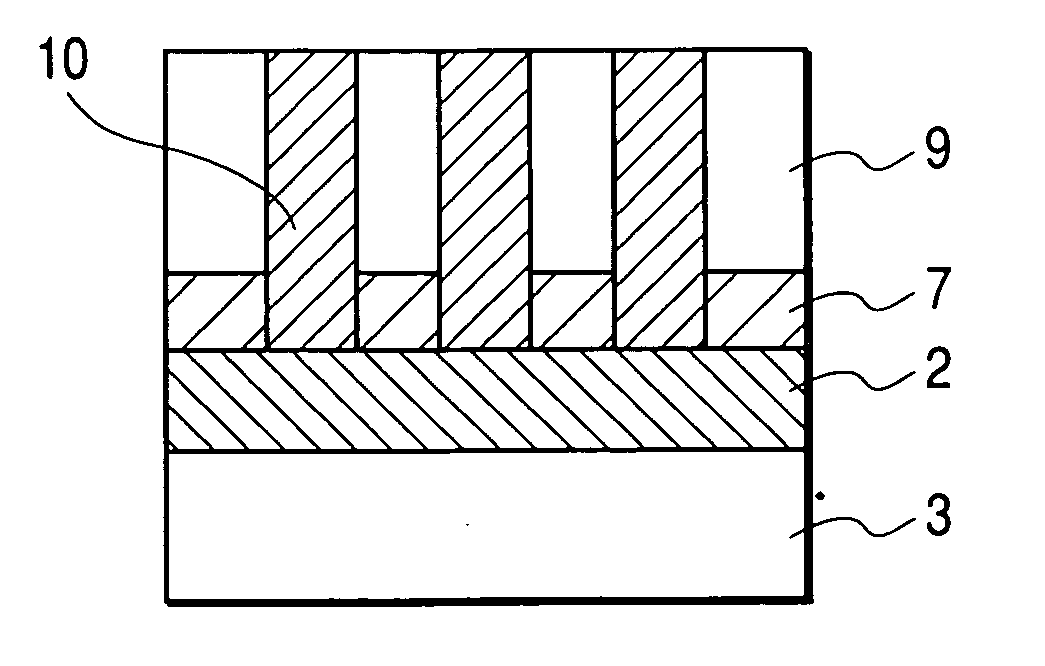

Methods of depositing a silicon oxide film are disclosed. One embodiment is a plasma enhanced atomic layer deposition (PEALD) process that includes supplying a vapor phase silicon precursor, such as a diaminosilane compound, to a substrate, and supplying oxygen plasma to the substrate. Another embodiment is a pulsed hybrid method between atomic layer deposition (ALD) and chemical vapor deposition (CVD). In the other embodiment, a vapor phase silicon precursor, such as a diaminosilane compound, is supplied to a substrate while ozone gas is continuously or discontinuously supplied to the substrate.

Owner:ASM KOREA LTD

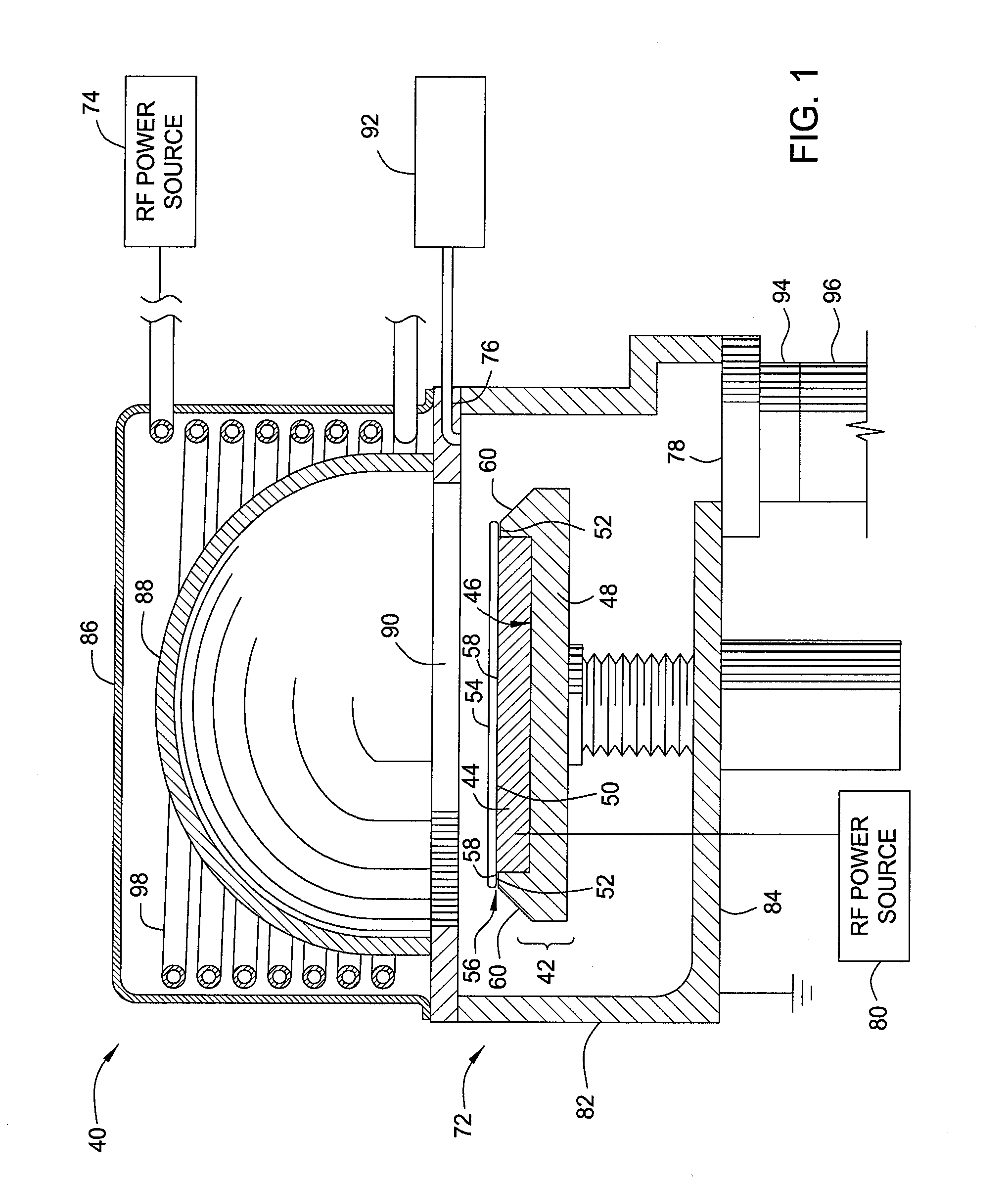

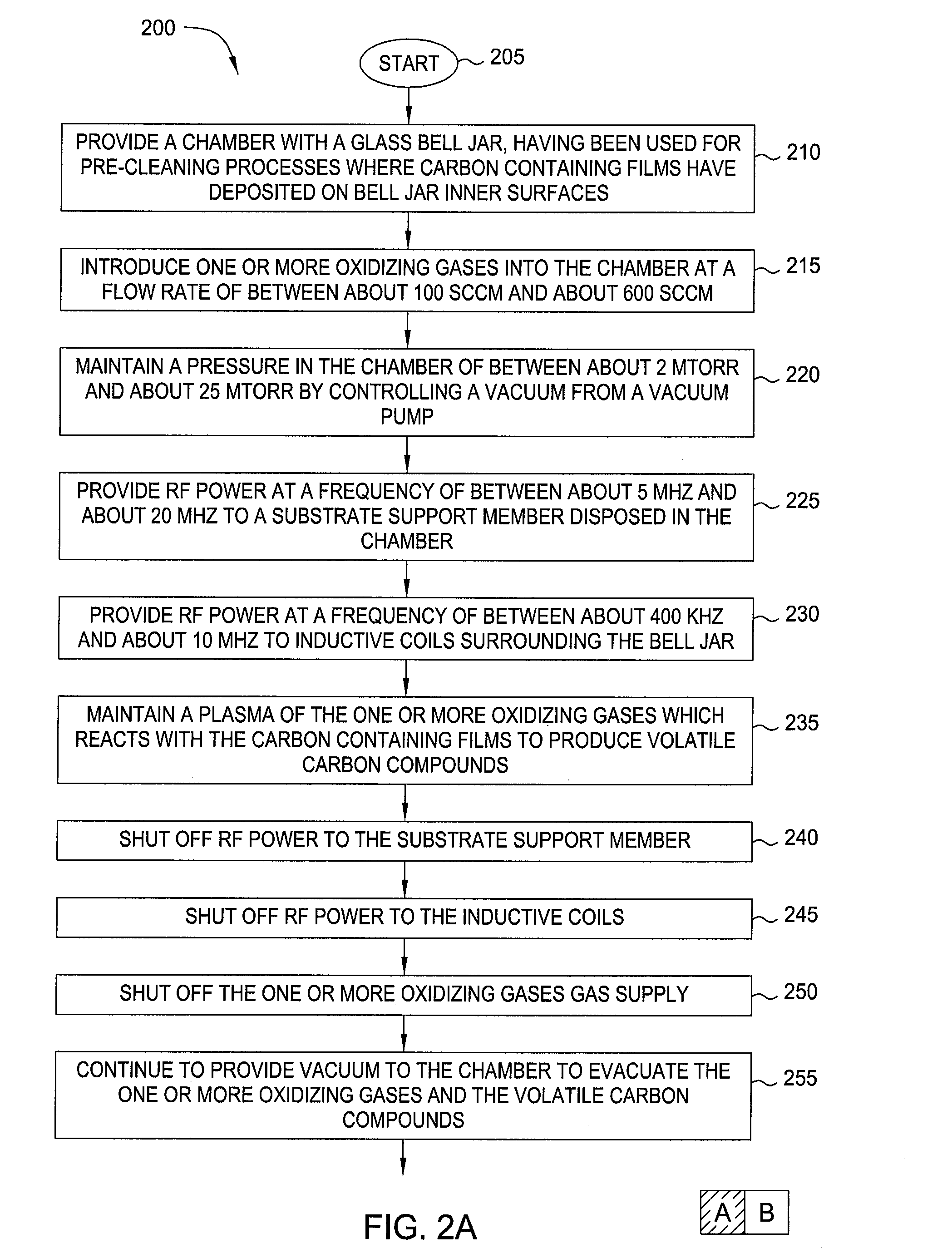

Oxygen plasma clean to remove carbon species deposited on a glass dome surface

InactiveUS20080173326A1Decorative surface effectsHollow article cleaningChemical compoundOxygen plasma

A method for in-situ cleaning of a dielectric dome surface having been used in pre-clean processes is provided. Carbon containing deposits are removed by providing a plasma of one or more oxidizing gases which react with the carbon containing films to form volatile carbon containing compounds.

Owner:APPLIED MATERIALS INC

Atomic layer deposition of noble metal oxides

Electrically conductive noble metal oxide films can be deposited by atomic layer deposition (ALD)-type processes. In preferred embodiments, Re, Ru, Os and Ir oxides are deposited by alternately and sequentially contacting a substrate with vapor phase pulses of a noble metal precursor and an oxygen source. The noble metal precursor is preferably a betadiketonate compound and the oxygen source is preferably ozone or oxygen plasma. The deposition temperature may be less than about 200° C.

Owner:ASM INTERNATIONAL

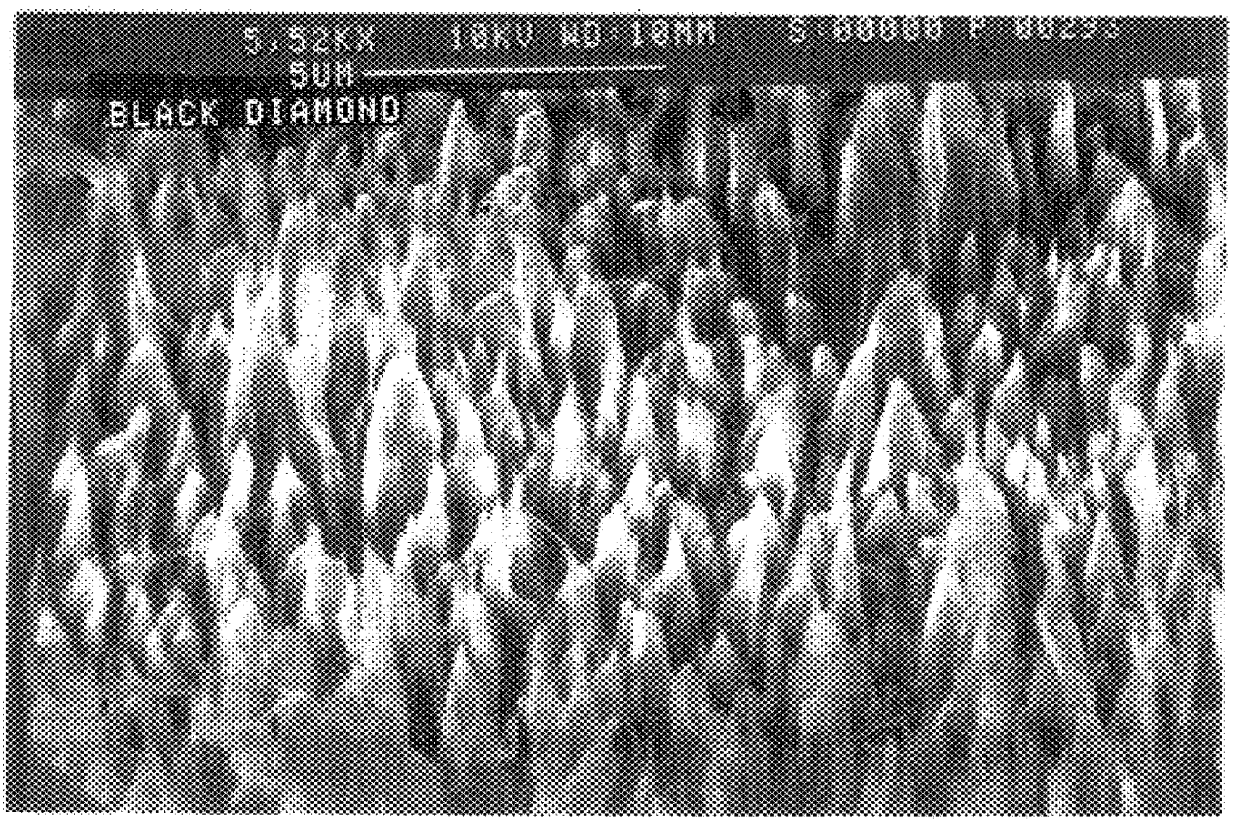

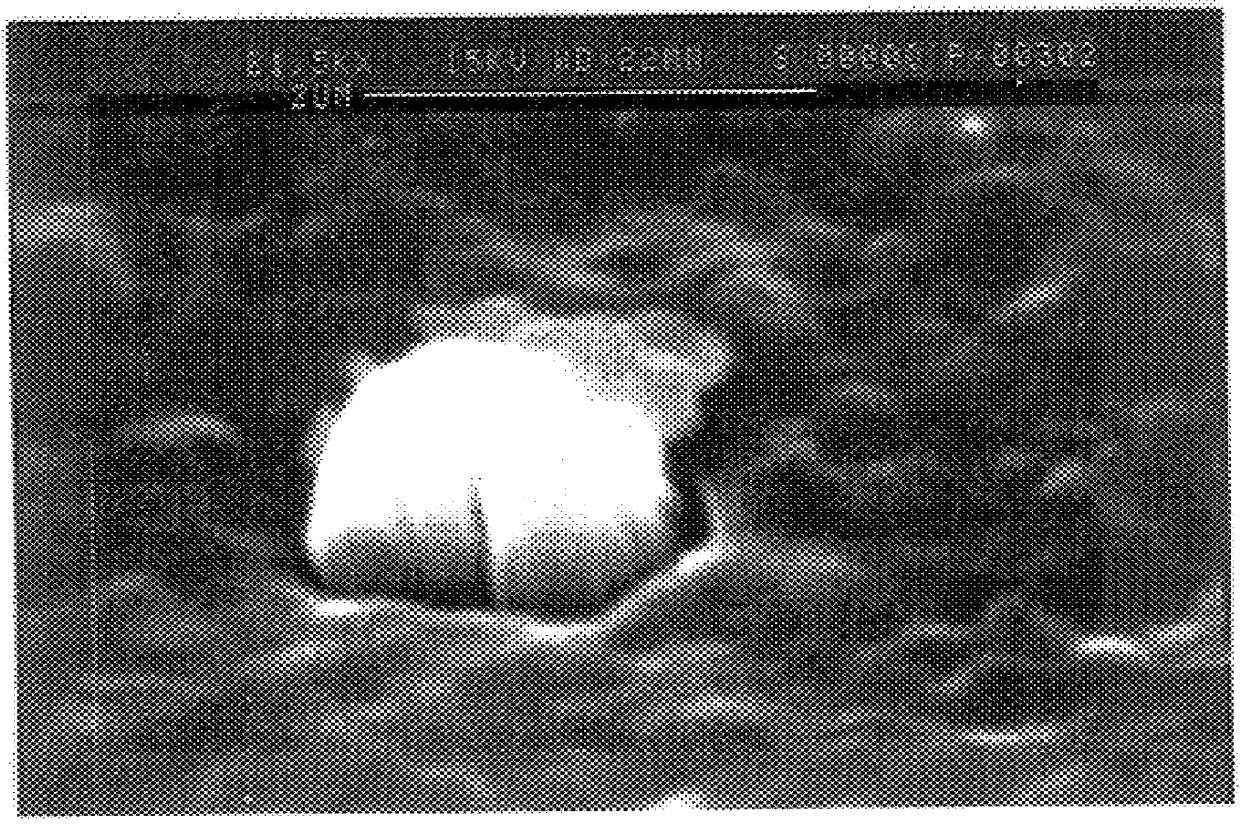

Method of polishing CVD diamond films by oxygen plasma

InactiveUS6013191APolycrystalline material growthAfter-treatment detailsFluorinated gasesOxygen plasma

A method for polishing the surface of a diamond film with a low power density plasma in a reactor which comprises disposing O2 gas and a fluorinated gas such as SF6, NF3, and C2F6 in the reactor, providing power to the reactor so that the power density in the reactor is between about 1.0 watts / cm2 and about 1.1 watts / cm2 for a first duration, and maintaining temperature in the reactor at between about 200 DEG to about 400 DEG . The method may alternatively comprise disposing a sputter gas such as Ar,O2 or N2 in the reactor, providing power to the reactor so that the power density in the reactor is between about 3.0 watts / cm2 and about 7.5 watts / cm2 for a first duration, and performing a sputter etch, disposing O2 gas and a fluorinated gas such as SF6, NF3, and C2F6 in the reactor, and providing power to the reactor so that the power density in the reactor is between about 1.5 watts / cm2 and about 3.0 watts / cm2 for a second duration.

Owner:ADVANCED REFRACTORY TECH INC

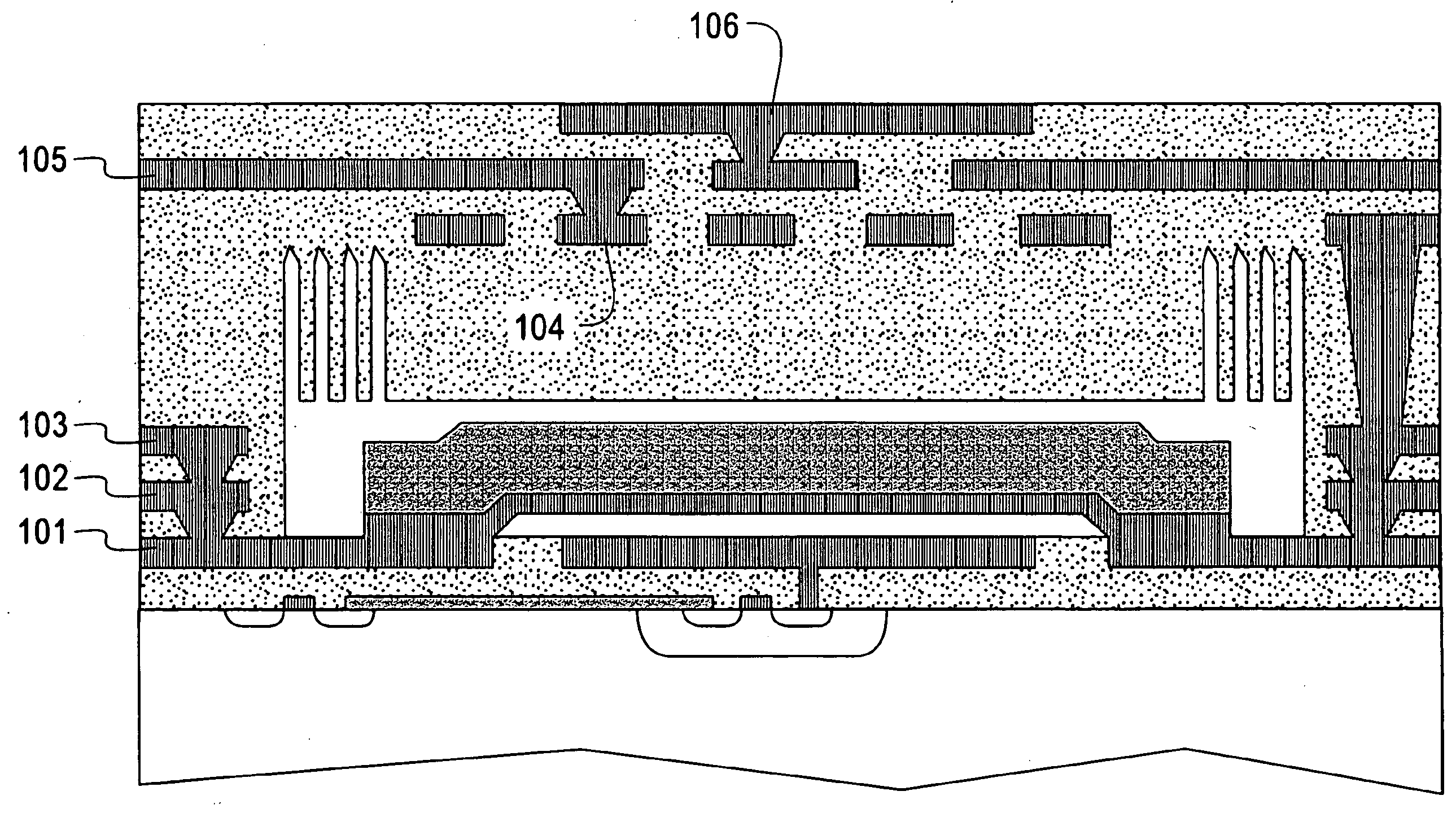

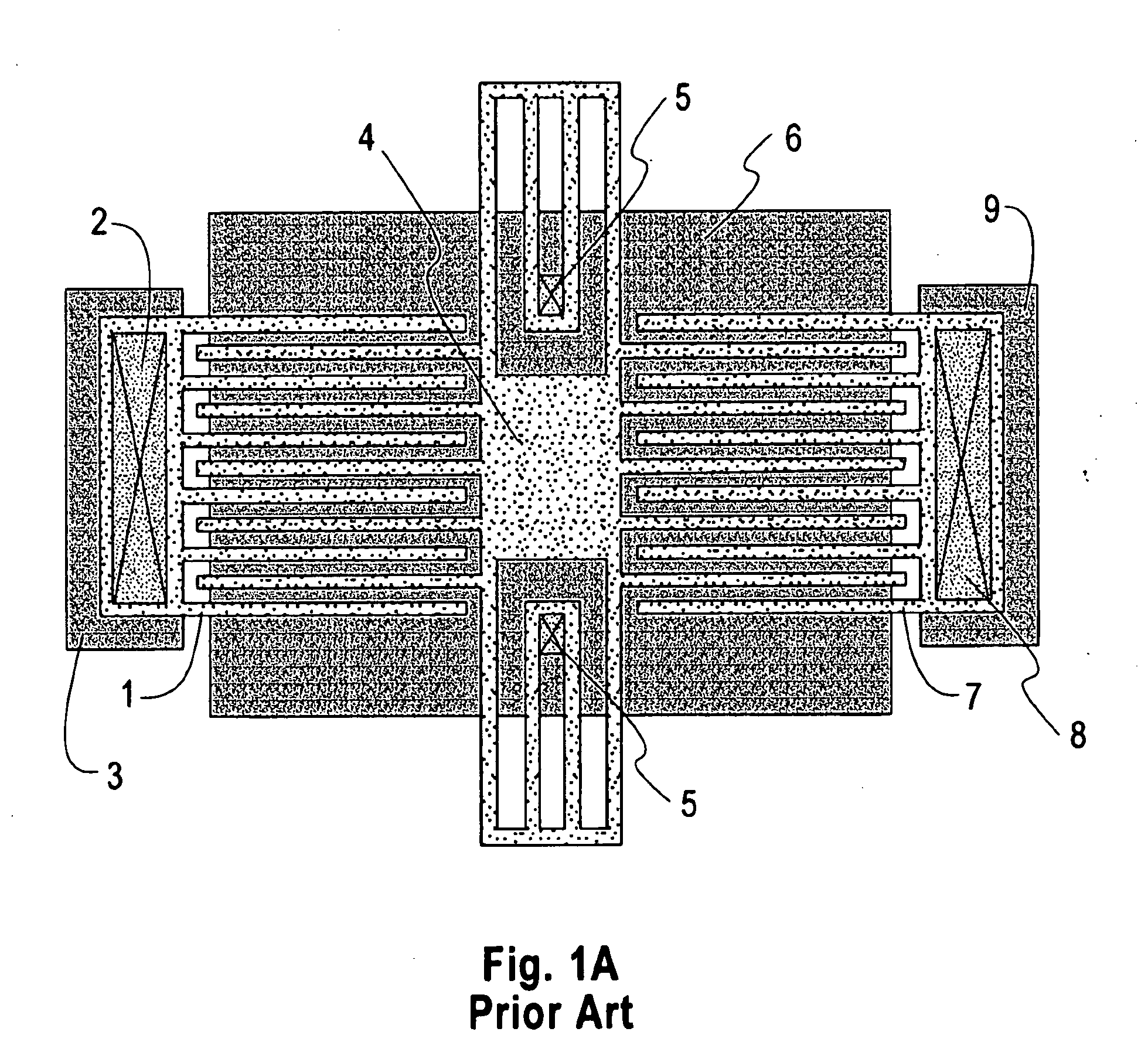

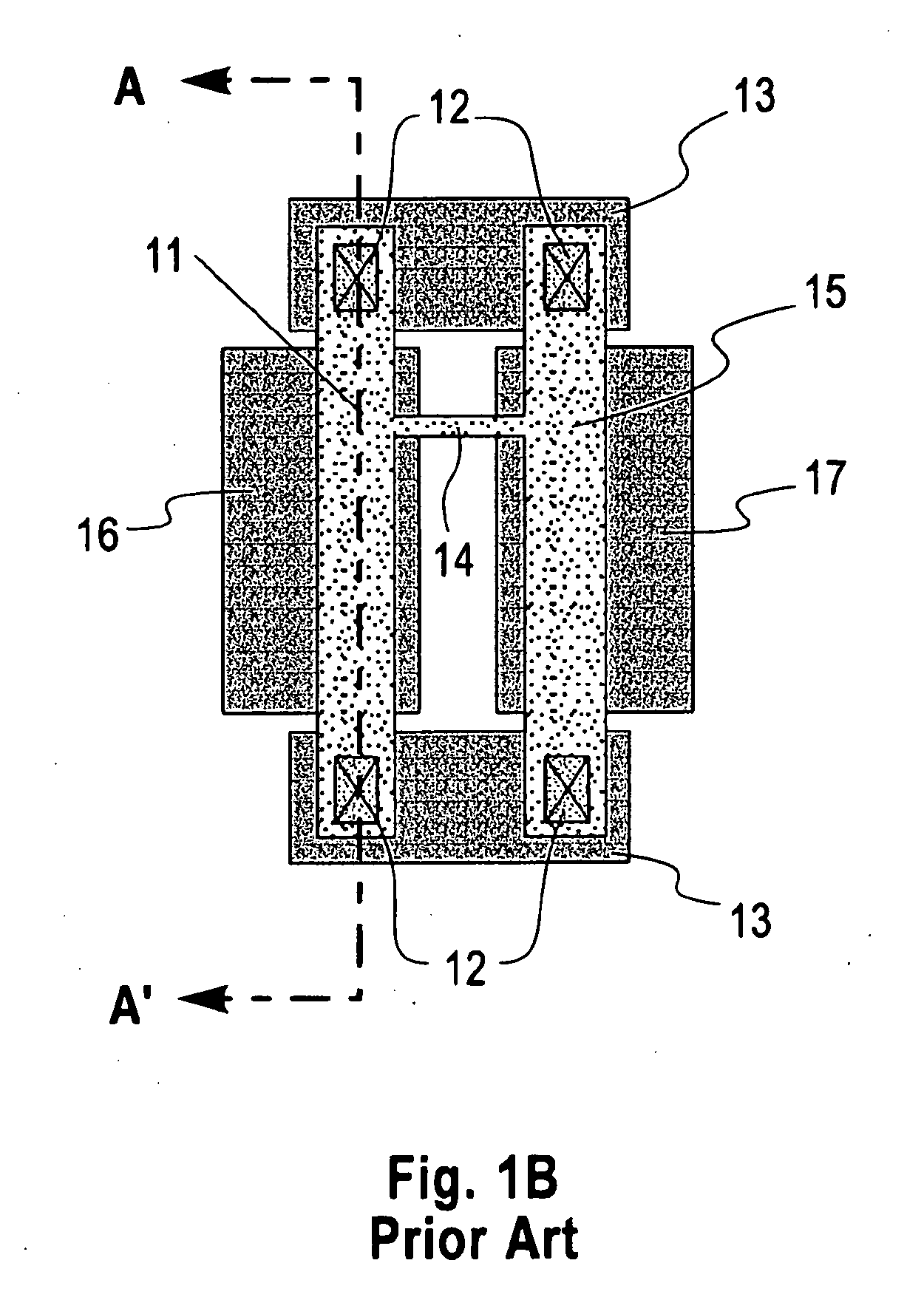

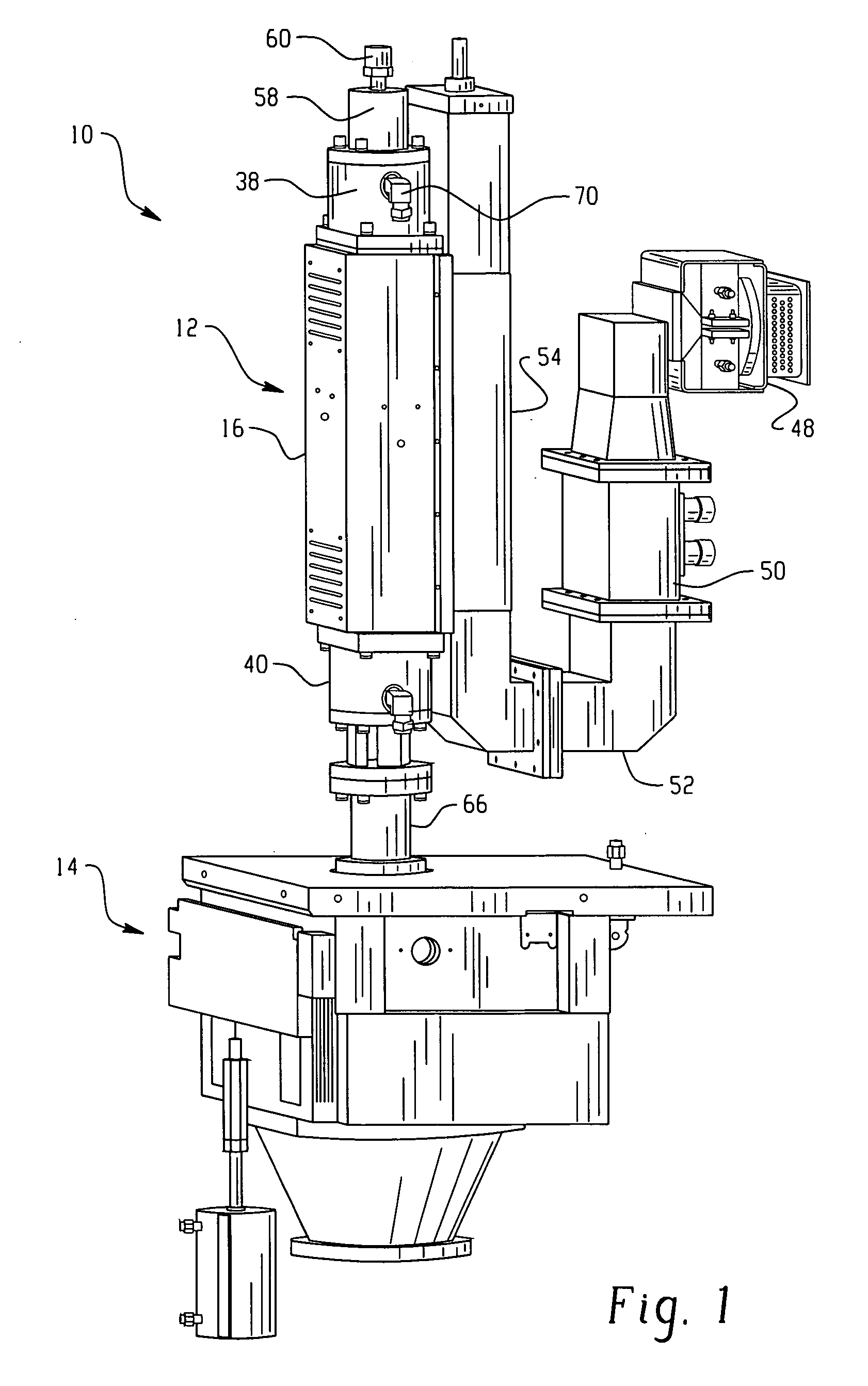

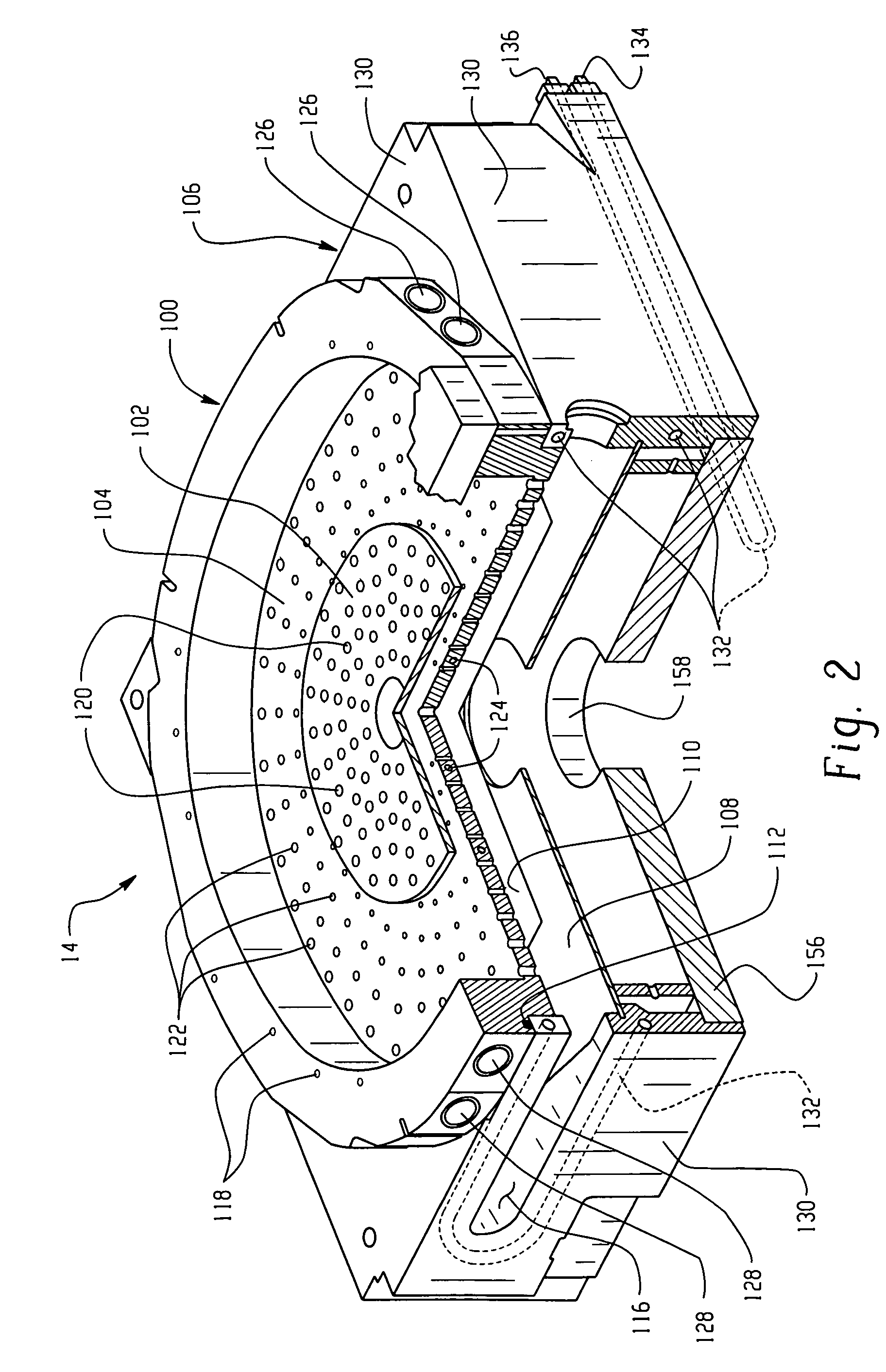

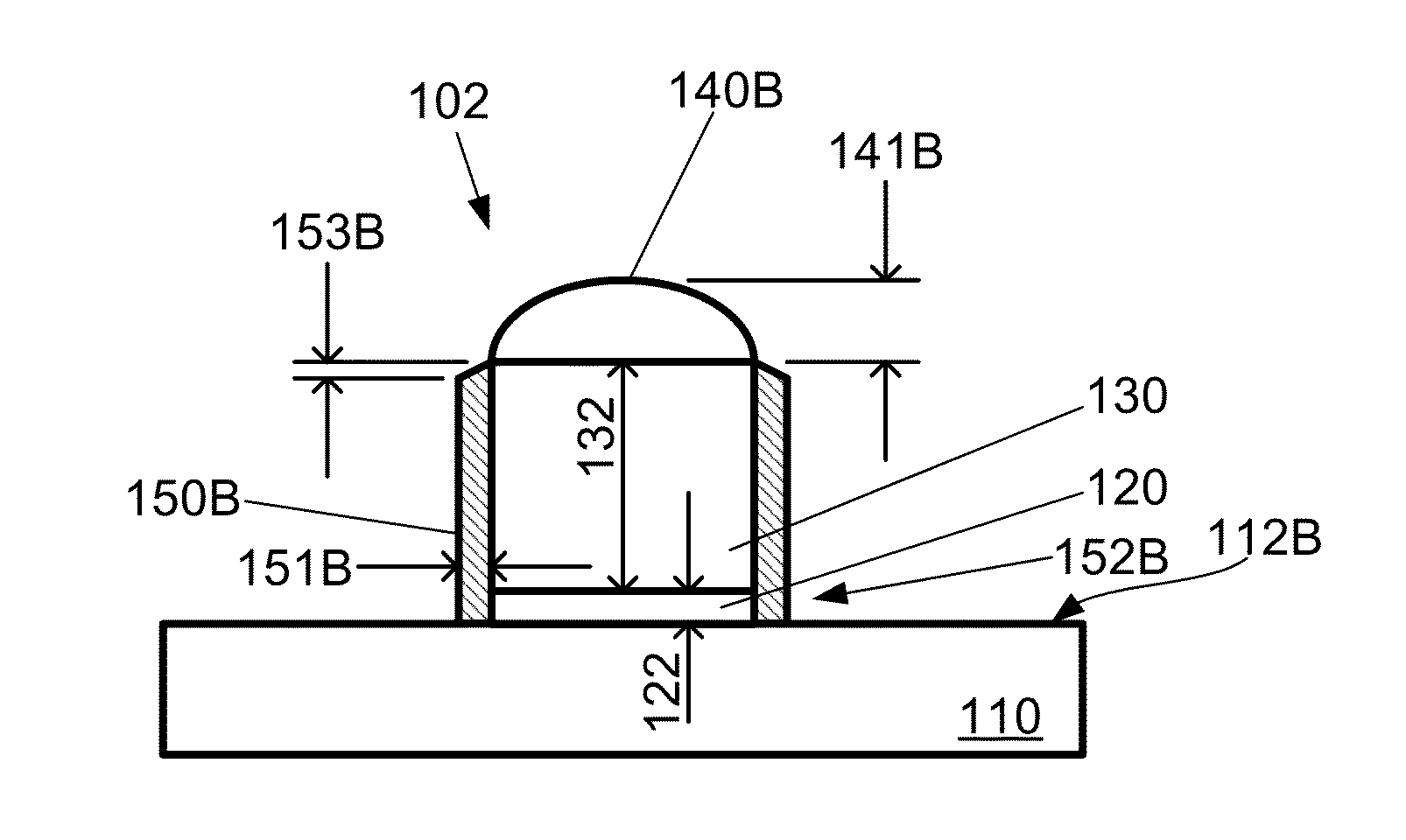

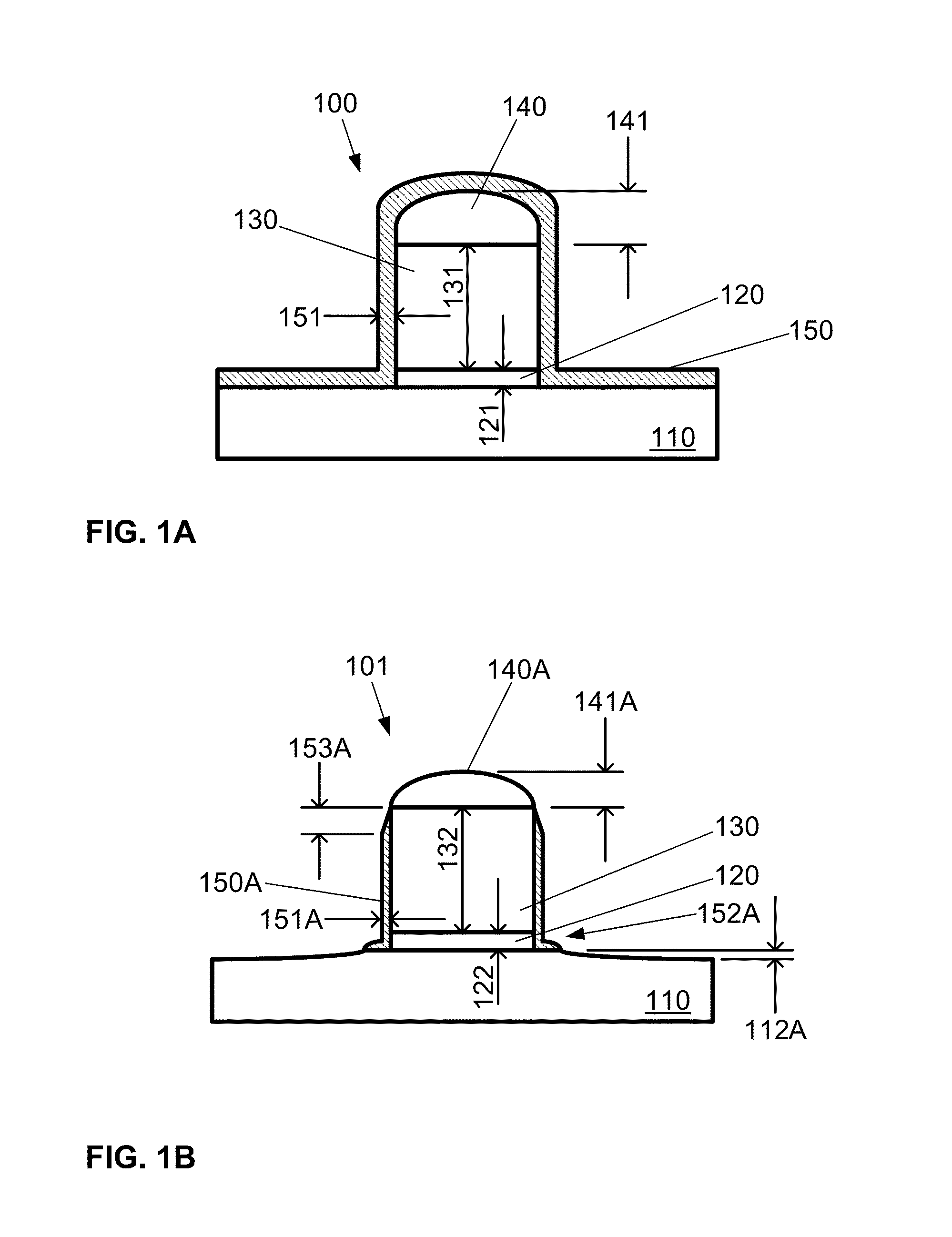

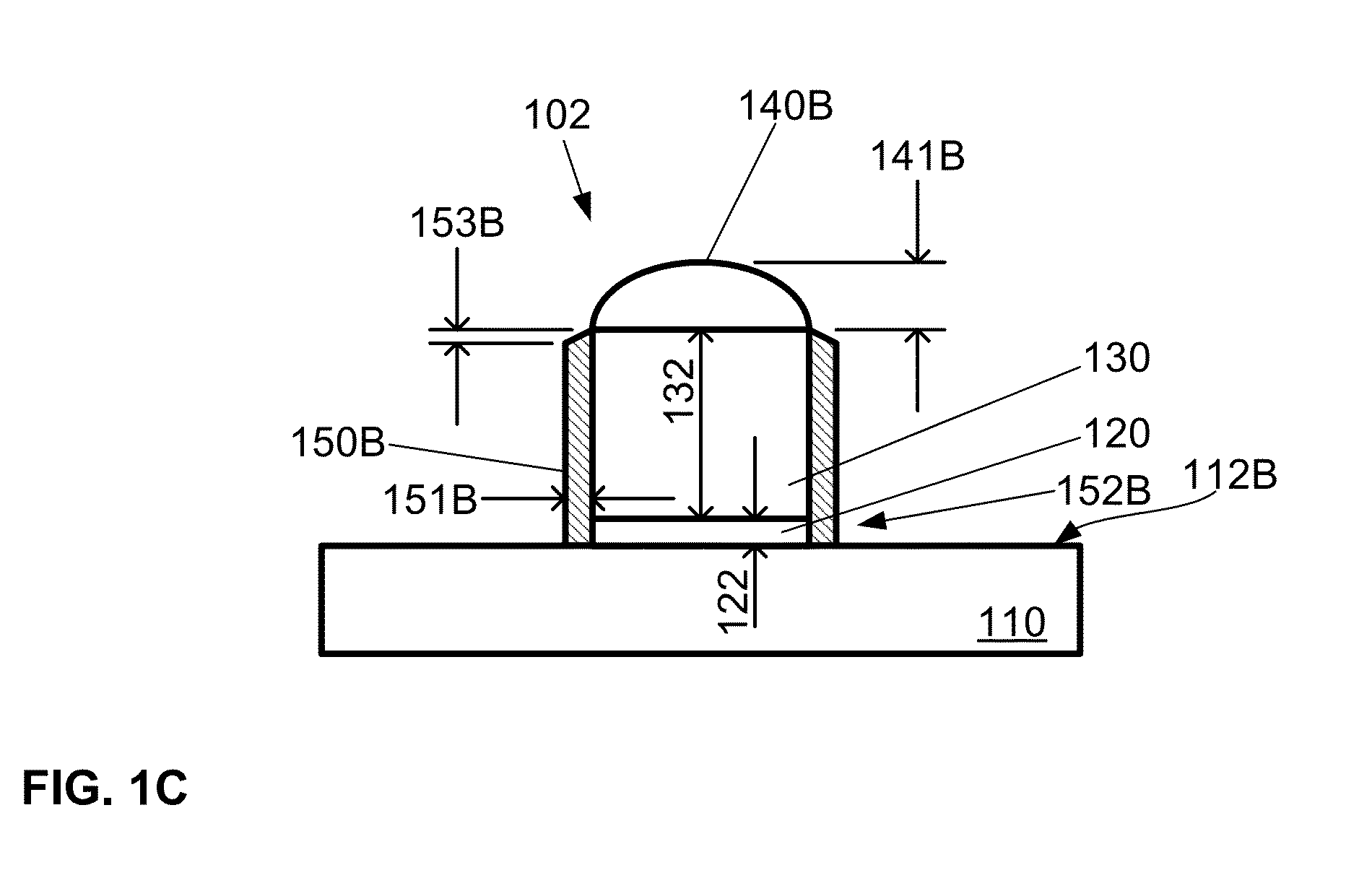

Low temperature bi-CMOS compatible process for MEMS RF resonators and filters

InactiveUS20090108381A1Impedence networksSemiconductor/solid-state device detailsMetal interconnectOxygen plasma

A method of formation of a microelectromechanical system (MEMS) resonator or filter which is compatible with integration with any analog, digital, or mixed-signal integrated circuit (IC) process, after or concurrently with the formation of the metal interconnect layers in those processes, by virtue of its materials of composition, processing steps, and temperature of fabrication is presented. The MEMS resonator or filter incorporates a lower metal level, which forms the electrodes of the MEMS resonator or filter, that may be shared with any or none of the existing metal interconnect levels on the IC. It further incorporates a resonating member that is comprised of at least one metal layer for electrical connection and electrostatic actuation, and at least one dielectric layer for structural purposes. The gap between the electrodes and the resonating member is created by the deposition and subsequent removal of a sacrificial layer comprised of a carbon-based material. The method of removal of the sacrificial material is by an oxygen plasma or an anneal in an oxygen containing ambient. A method of vacuum encapsulation of the MEMS resonator or filter is provided through means of a cavity containing the MEMS device, filled with additional sacrificial material, and sealed. Access vias are created through the membrane sealing the cavity; the sacrificial material is removed as stated previously, and the vias are re-sealed in a vacuum coating process.

Owner:IBM CORP

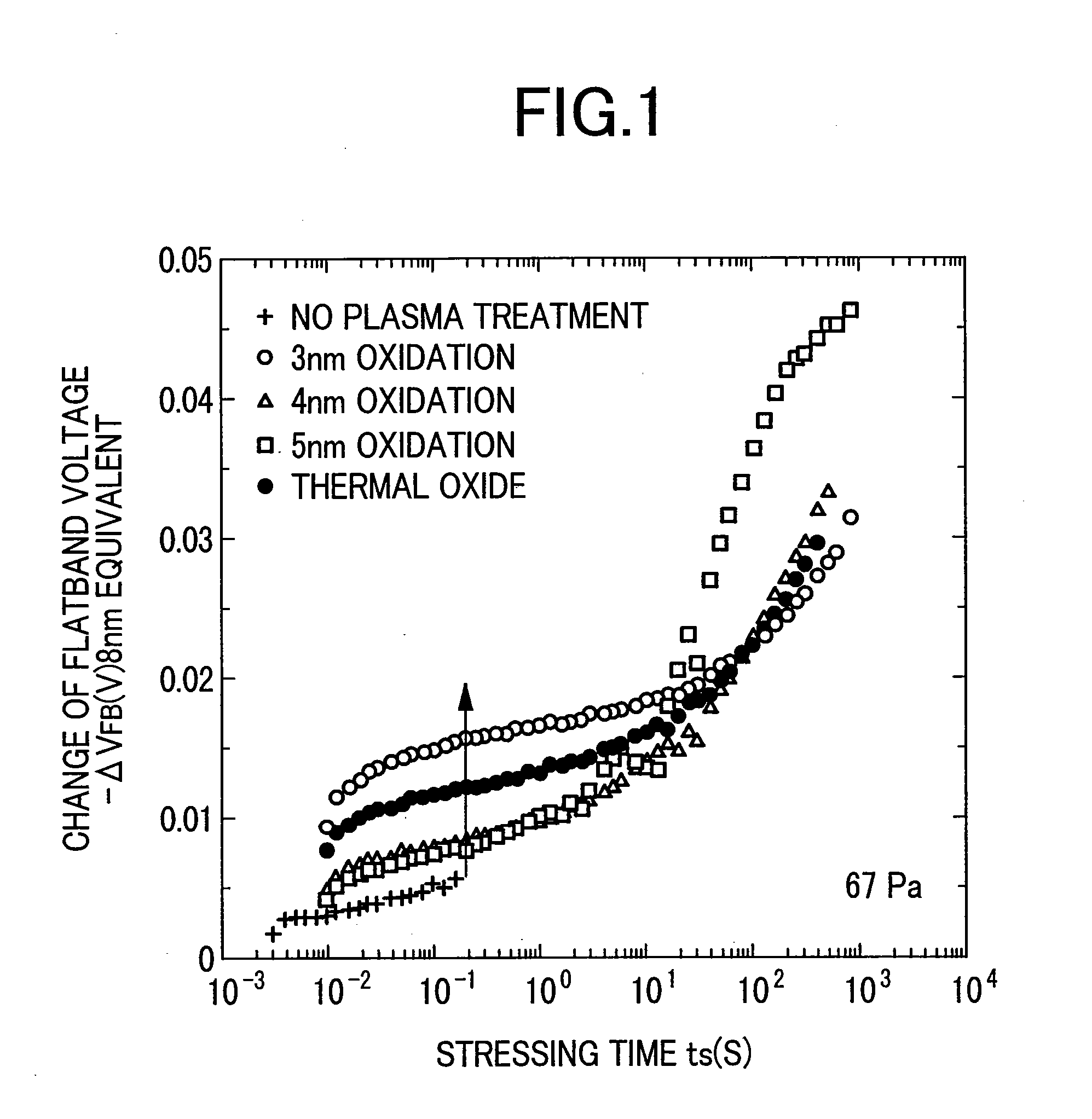

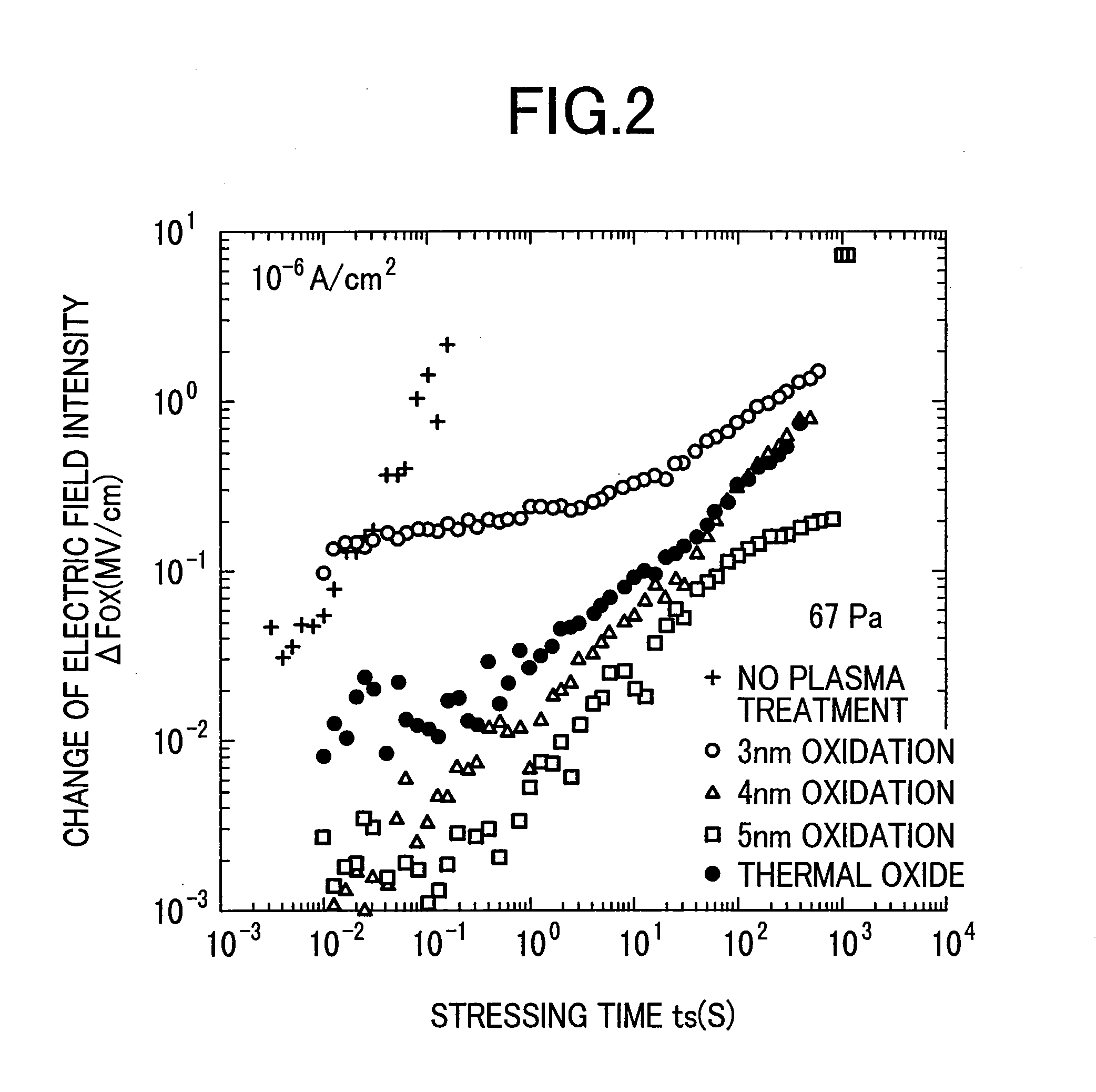

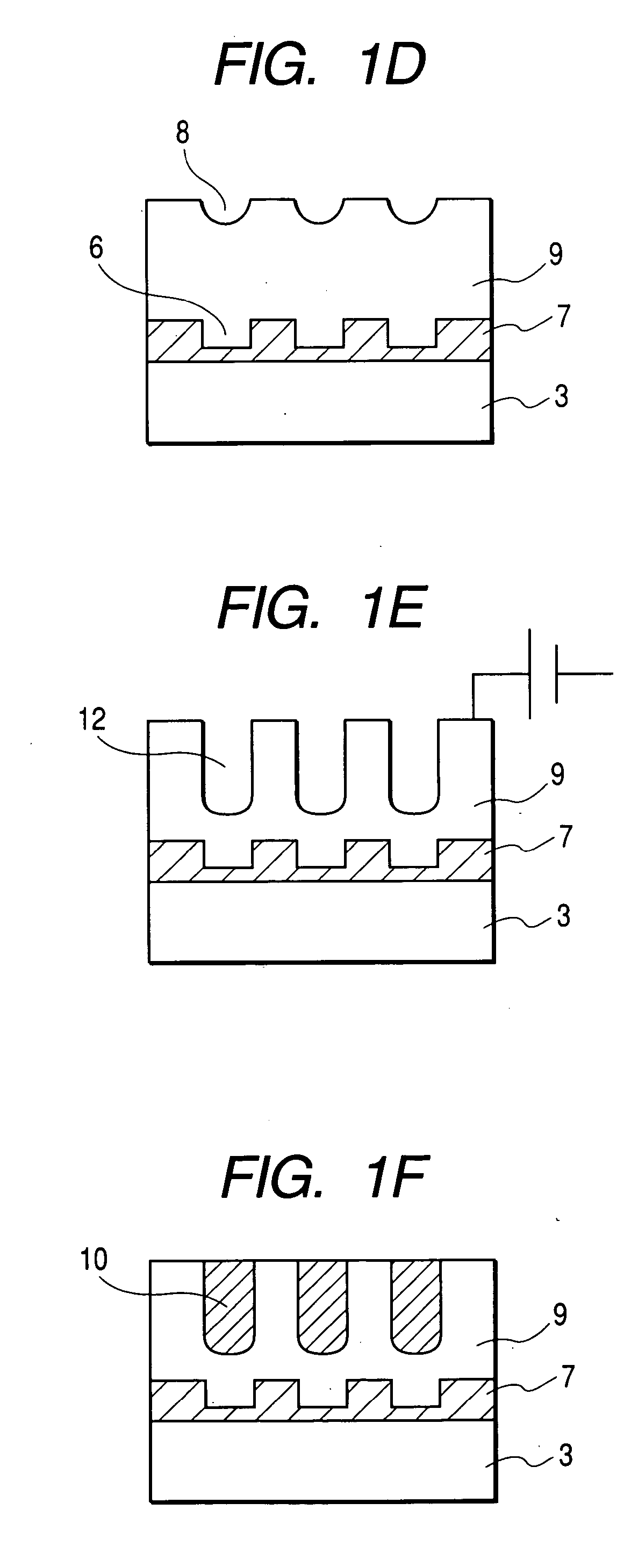

Method for fabricating semiconductor devices

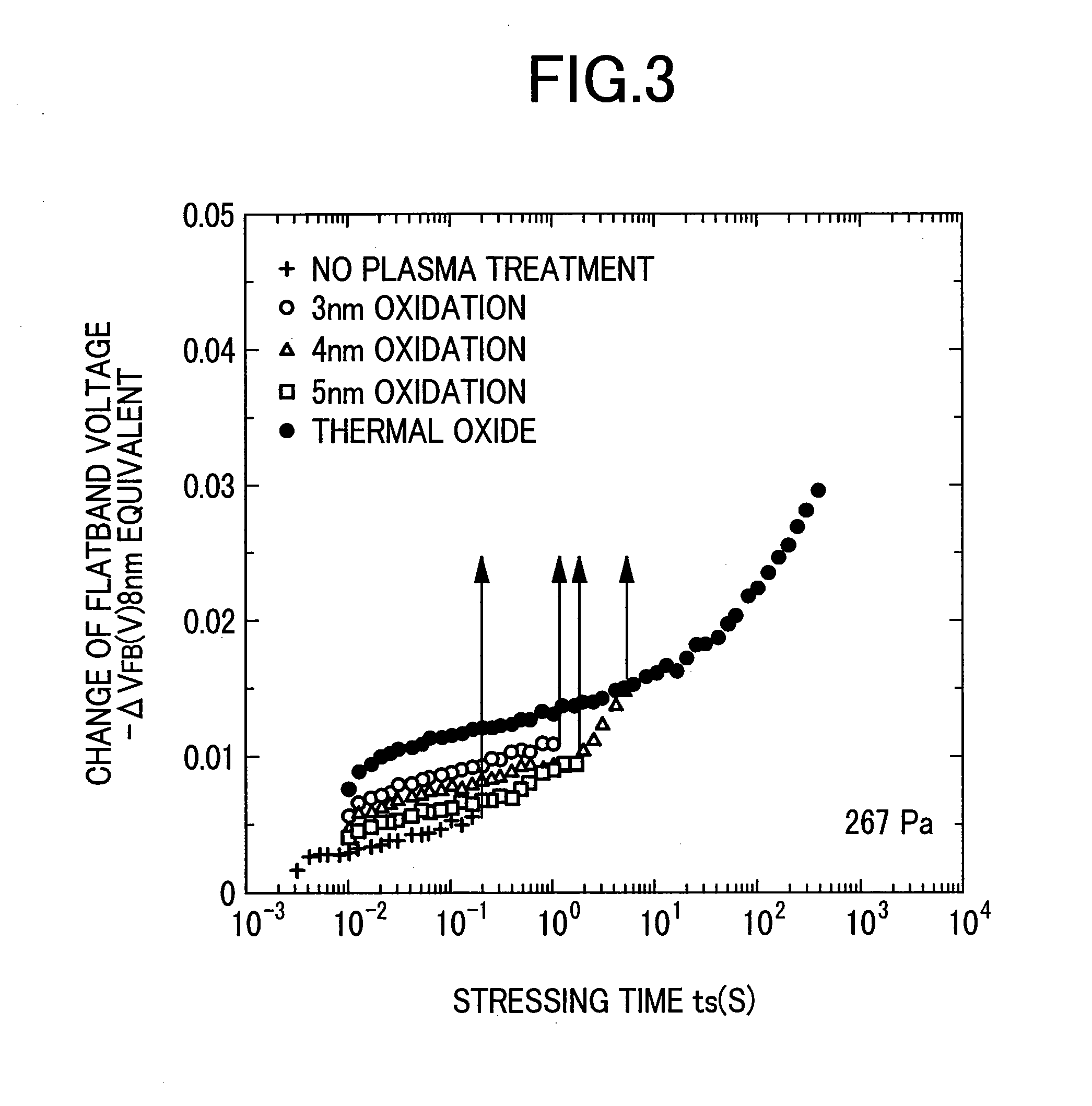

InactiveUS20070190744A1TransistorSemiconductor/solid-state device detailsOxygen plasmaGate insulator

Owner:RENESAS ELECTRONICS CORP

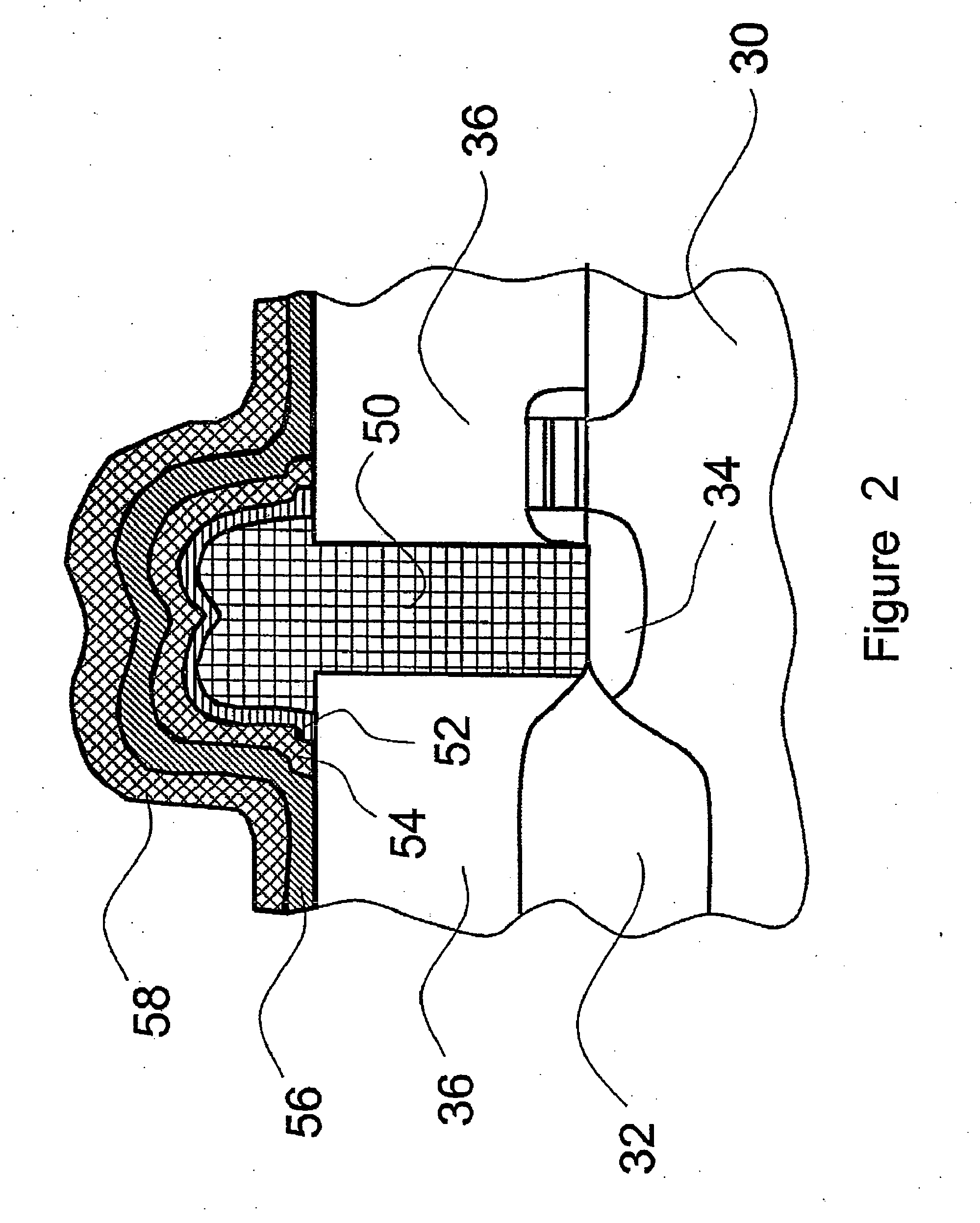

Apparatus and plasma ashing process for increasing photoresist removal rate

InactiveUS20060046470A1Reduce the temperatureAshing rateElectric discharge tubesPhotomechanical apparatusHydrogenOxygen plasma

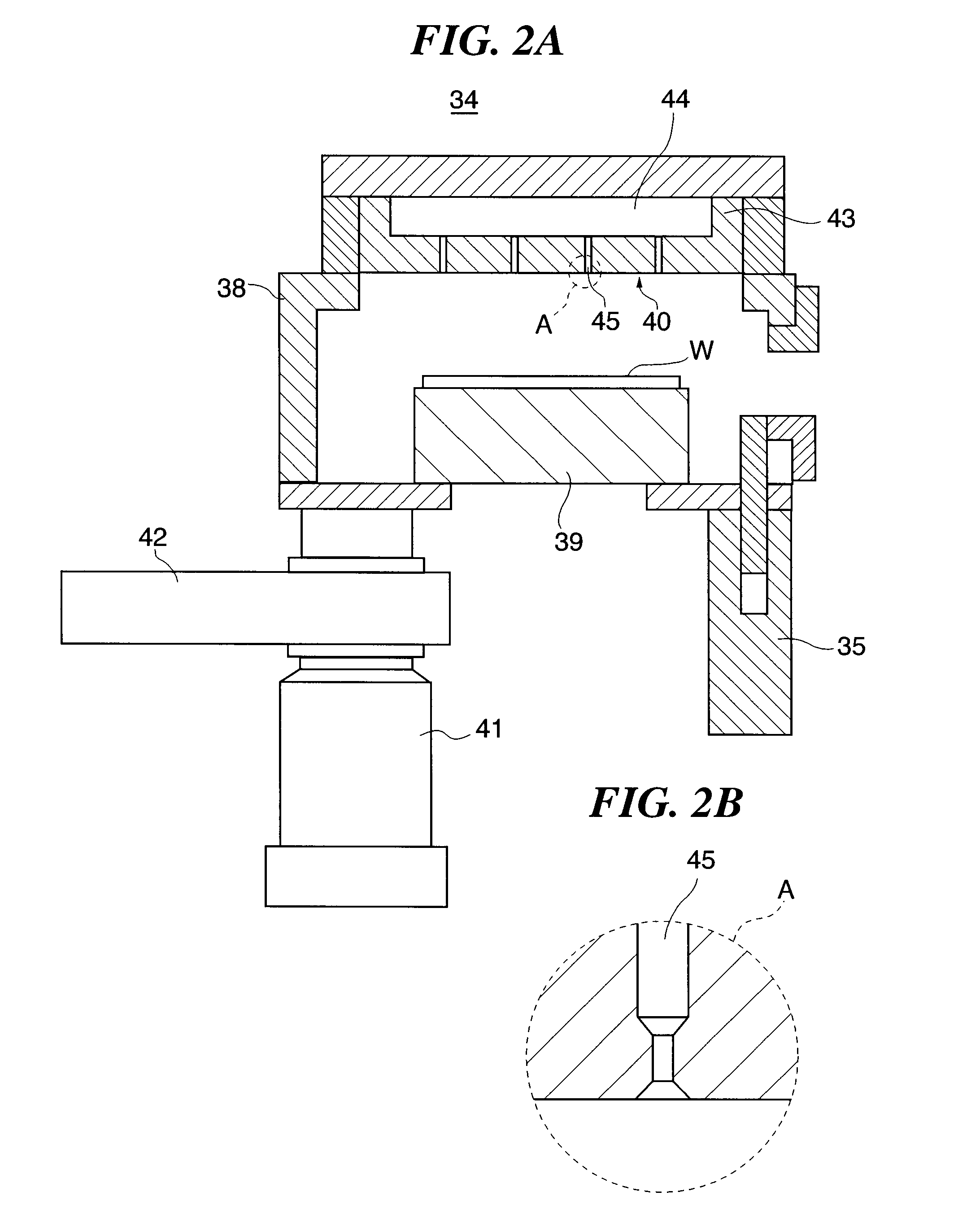

A plasma ashing process for removing photoresist material and post etch residues from a substrate comprising carbon, hydrogen, or a combination of carbon and hydrogen, wherein the substrate comprises a low k dielectric layer, the process comprising forming a plasma from an essentially oxygen free and nitrogen free gas mixture; introducing the plasma into a process chamber, wherein the process chamber comprises a baffle plate assembly in fluid communication with the plasma; flowing the plasma through the baffle plate assembly and removing photoresist material, post etch residues, and volatile byproducts from the substrate; periodically cleaning the process chamber by introducing an oxygen plasma into the process chamber; and cooling the baffle plate assembly by flowing a cooling gas over the baffle plate assembly. A process chamber adapted for receiving downstream plasma, the process chamber comprising an upper baffle plate comprising at least one thermally conductive standoff in thermal communication with a wall of the process chamber; and a lower baffle plate spaced apart from the upper baffle plate.

Owner:LAM RES CORP

Method for depositing silicon oxide film having improved quality by peald using bis(diethylamino)silane

ActiveUS20210057214A1Avoid thermal decompositionImprove film qualitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorOxygen plasma

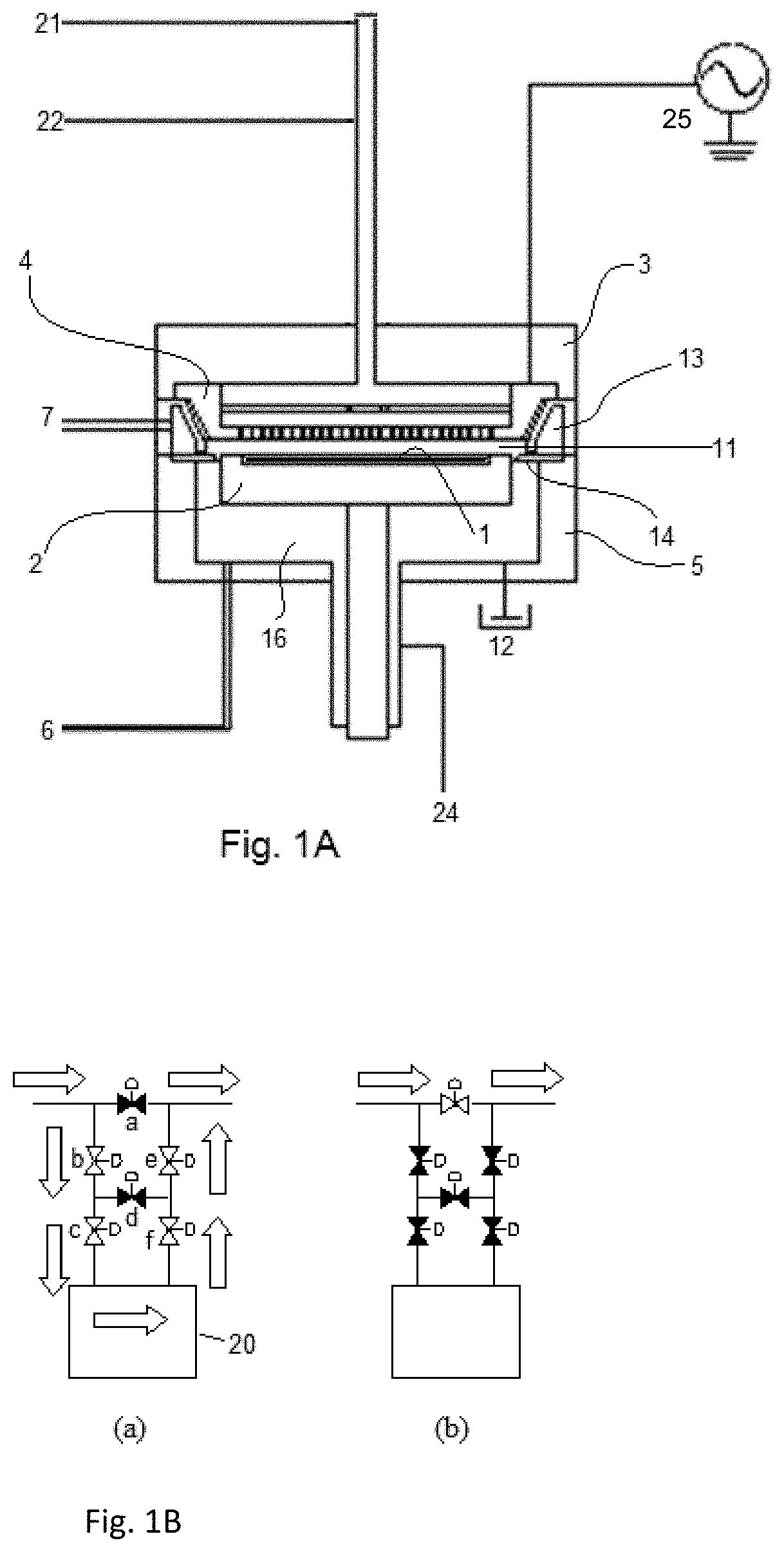

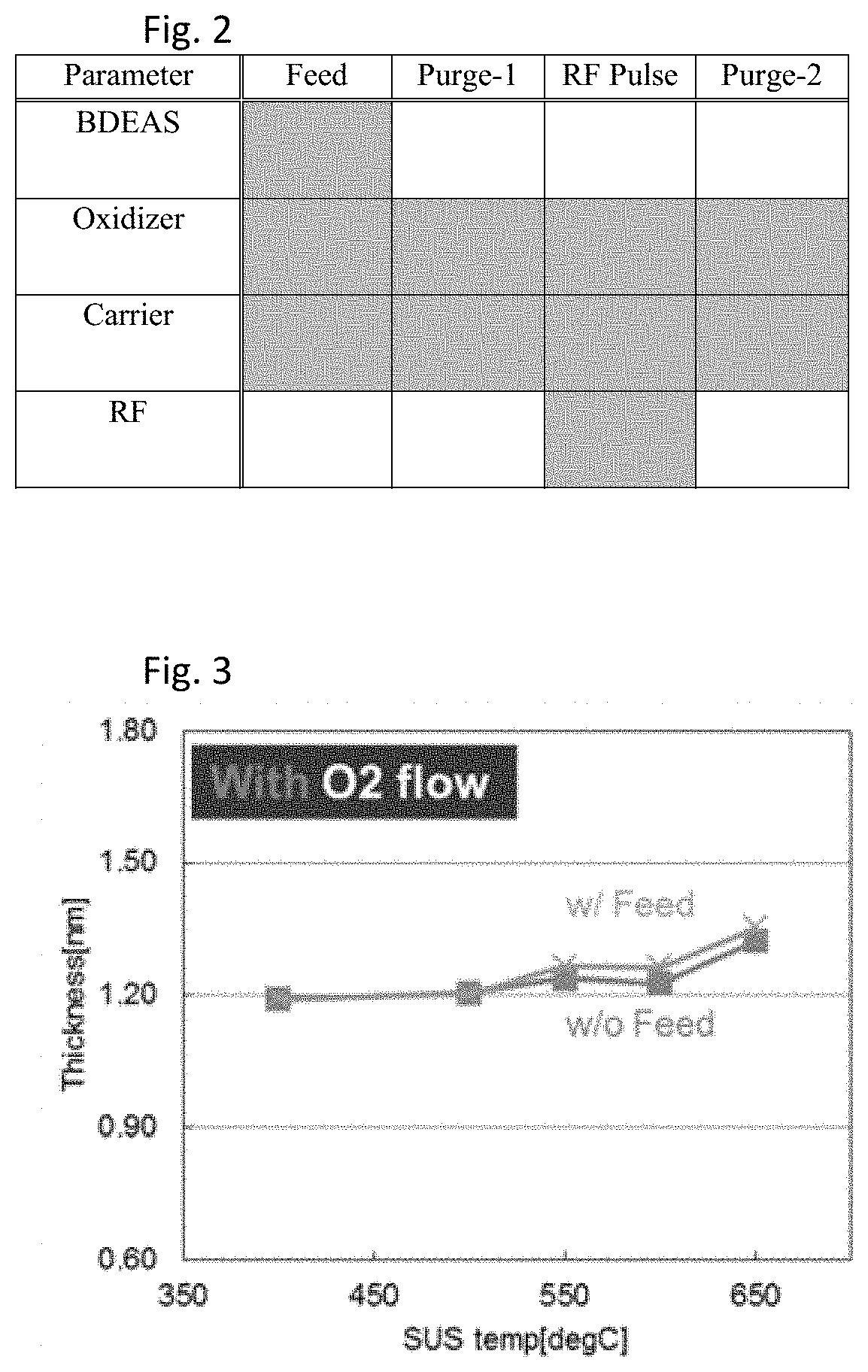

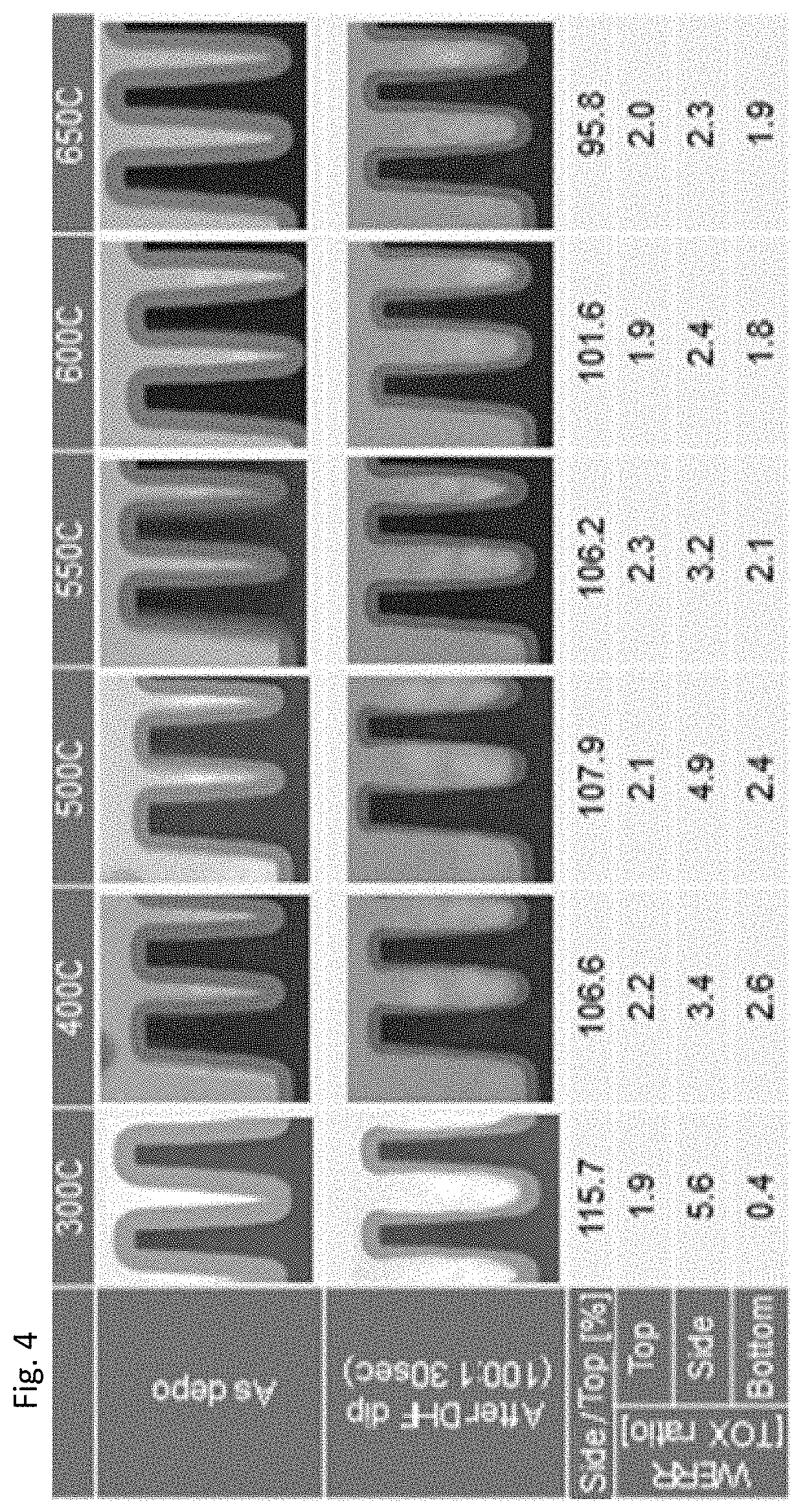

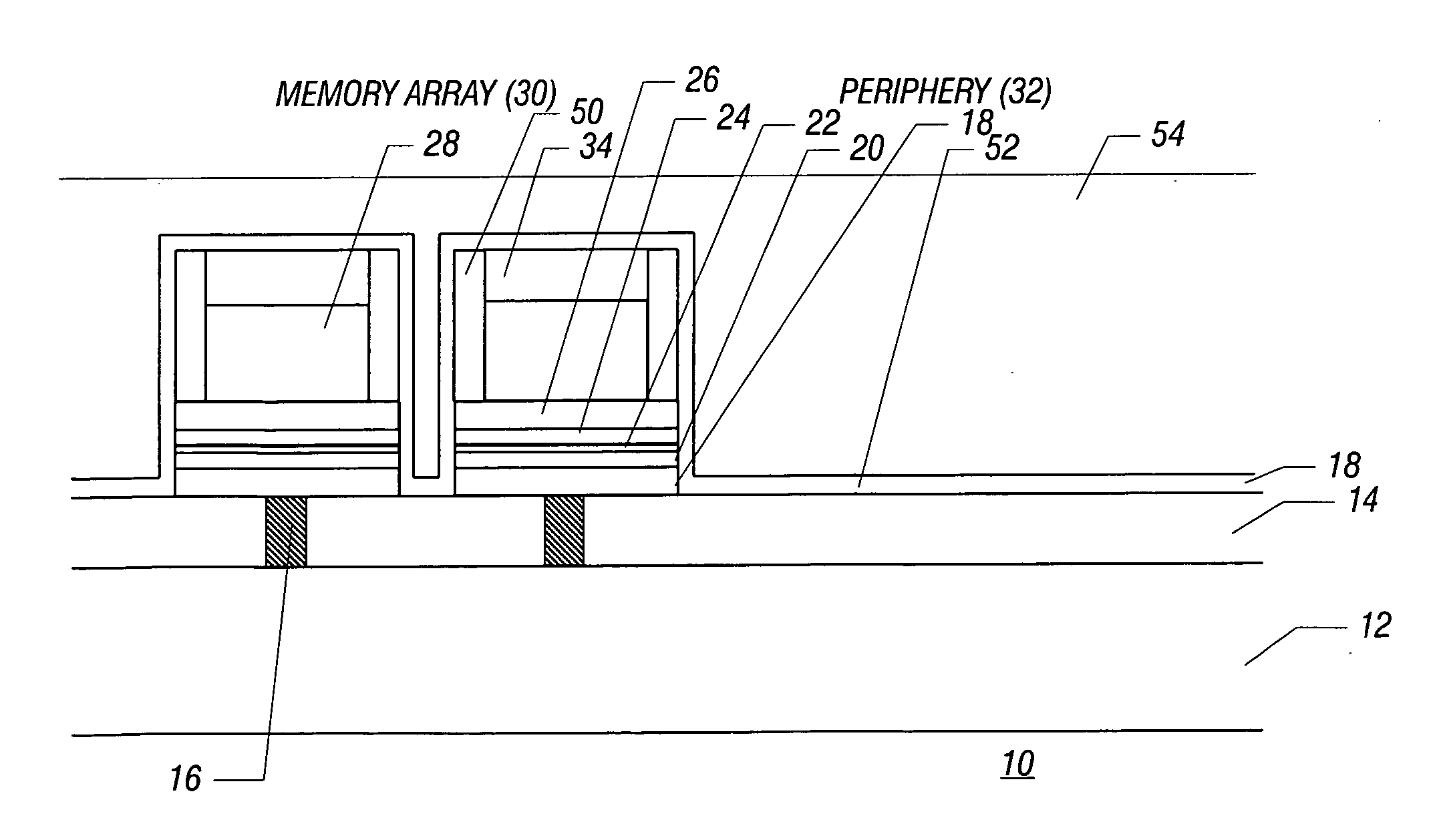

In a method of depositing a silicon oxide film using bis(diethylamino)silane (BDEAS) on a substrate in a reaction space by plasma-enhanced atomic layer deposition (PEALD), each repeating deposition cycle of PEALD includes steps of: (i) adsorbing BDEAS on the substrate placed on a susceptor having a temperature of higher than 400° C. in an atmosphere substantially suppressing thermal decomposition of BDEAS in the reaction space; and (ii) exposing the substrate on which BDEAS is adsorbed to an oxygen plasma in the atmosphere in the reaction space, thereby depositing a monolayer or sublayer of silicon oxide.

Owner:ASM IP HLDG BV

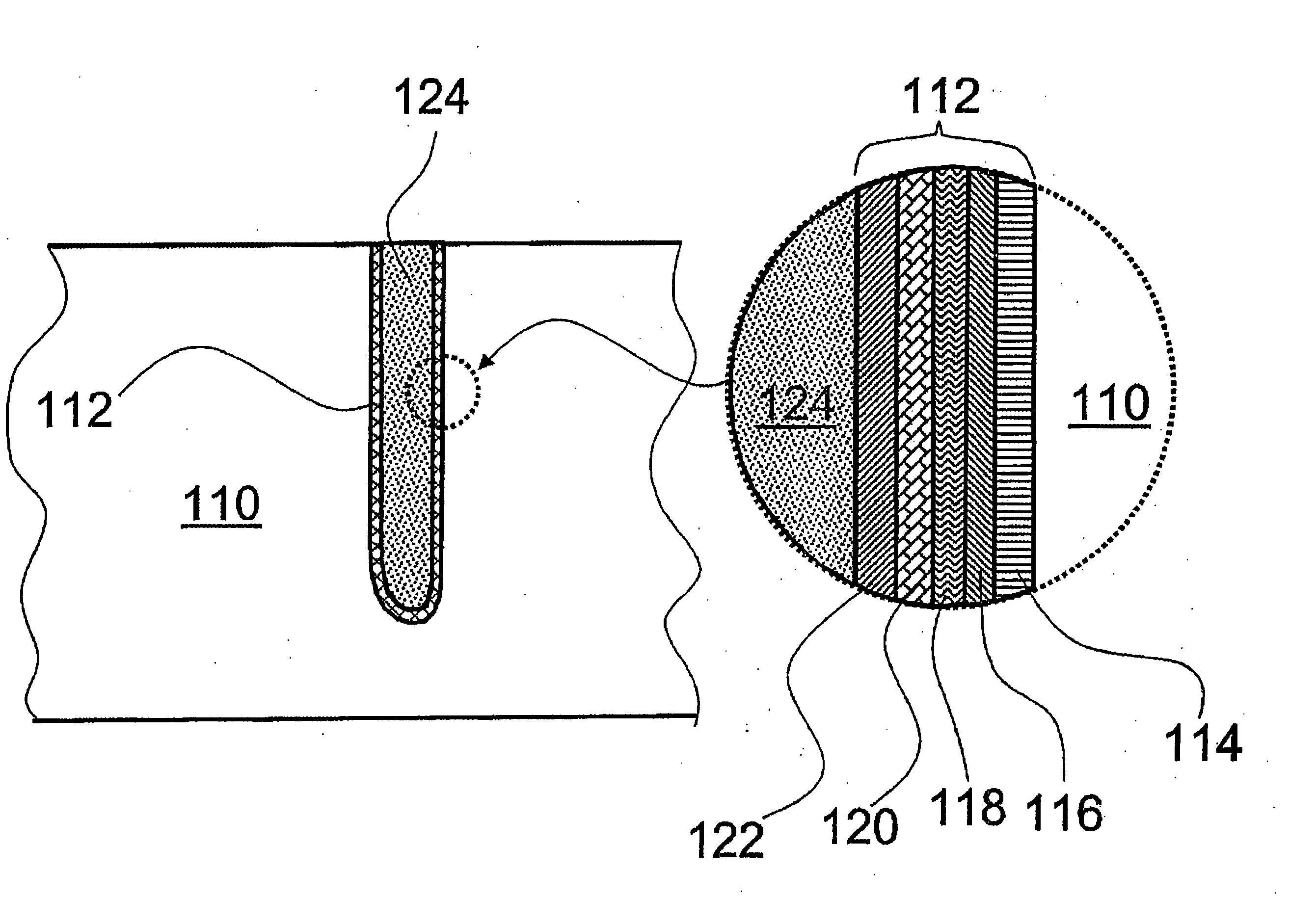

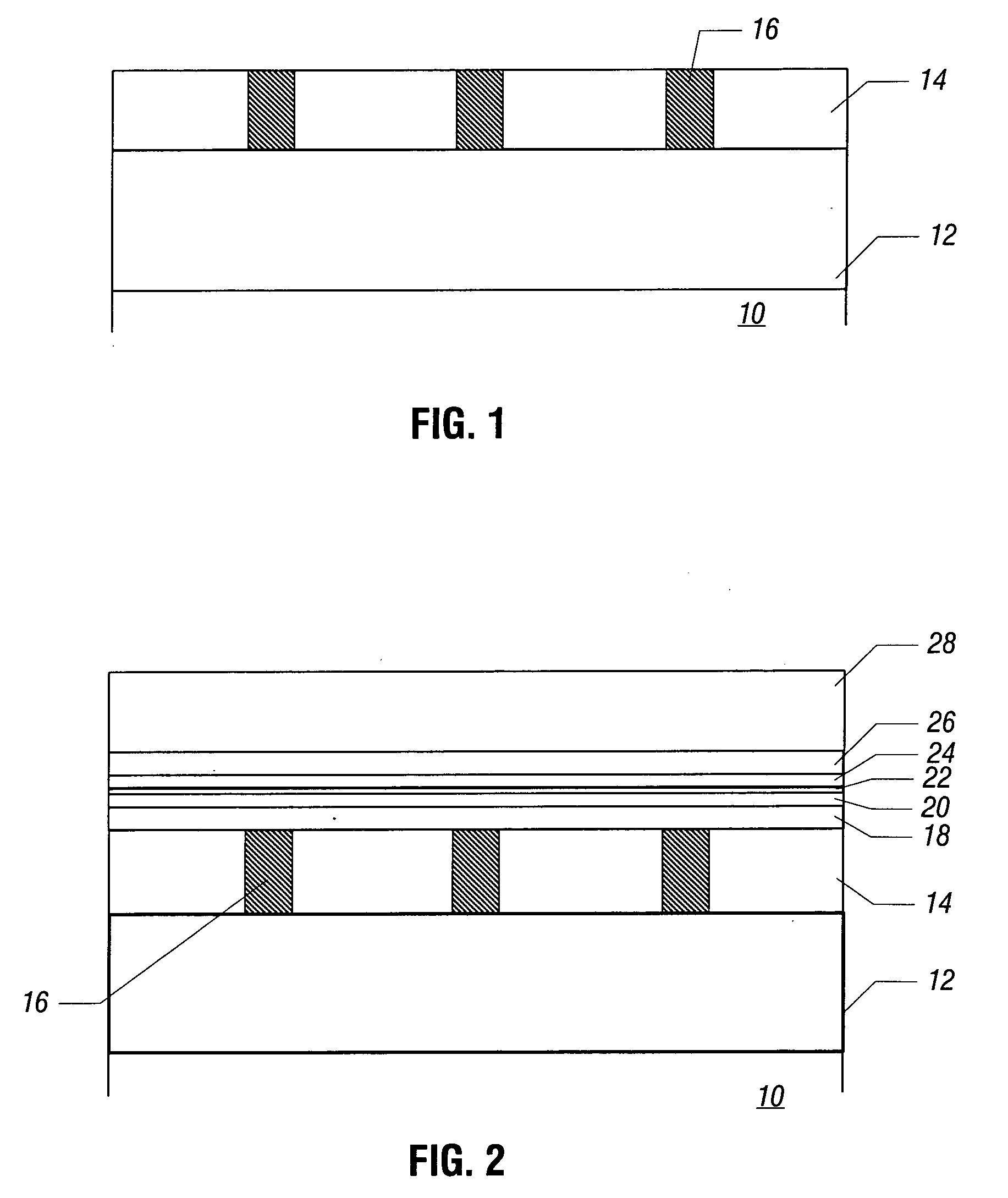

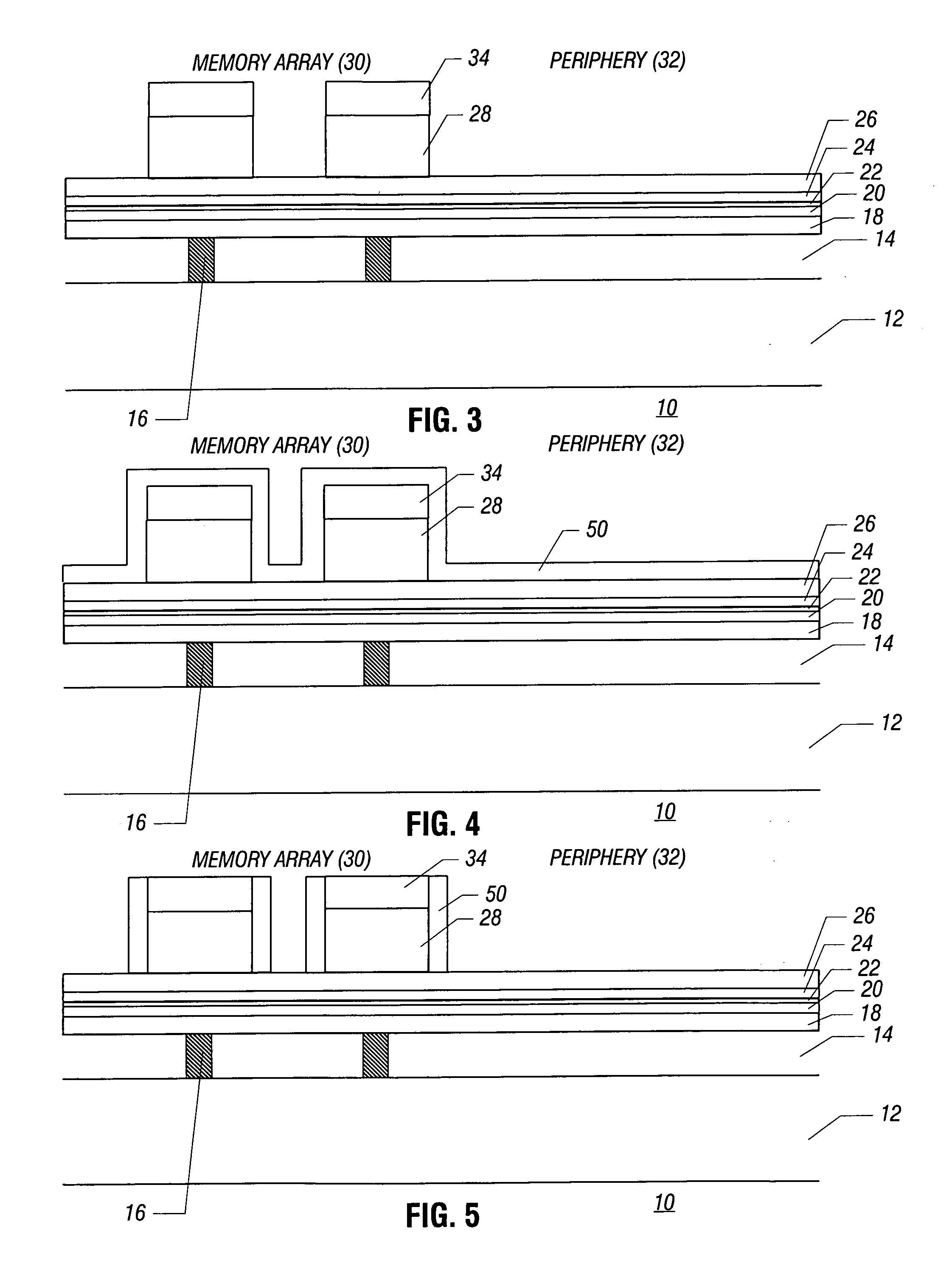

Reducing oxidation of phase change memory electrodes

A phase change memory may be formed in a way which reduces oxygen infiltration through a chalcogenide layer overlying a lower electrode. Such infiltration may cause oxidation of the lower electrode which adversely affects performance. In one such embodiment, an etch through an overlying upper electrode layer may be stopped before reaching a layer which overlies said chalcogenide layer. Then, photoresist used for such etching may be utilized in a high temperature oxygen plasma. Only after such plasma treatment has been completed is that overlying layer removed, which ultimately exposes the chalcogenide.

Owner:INTEL CORP

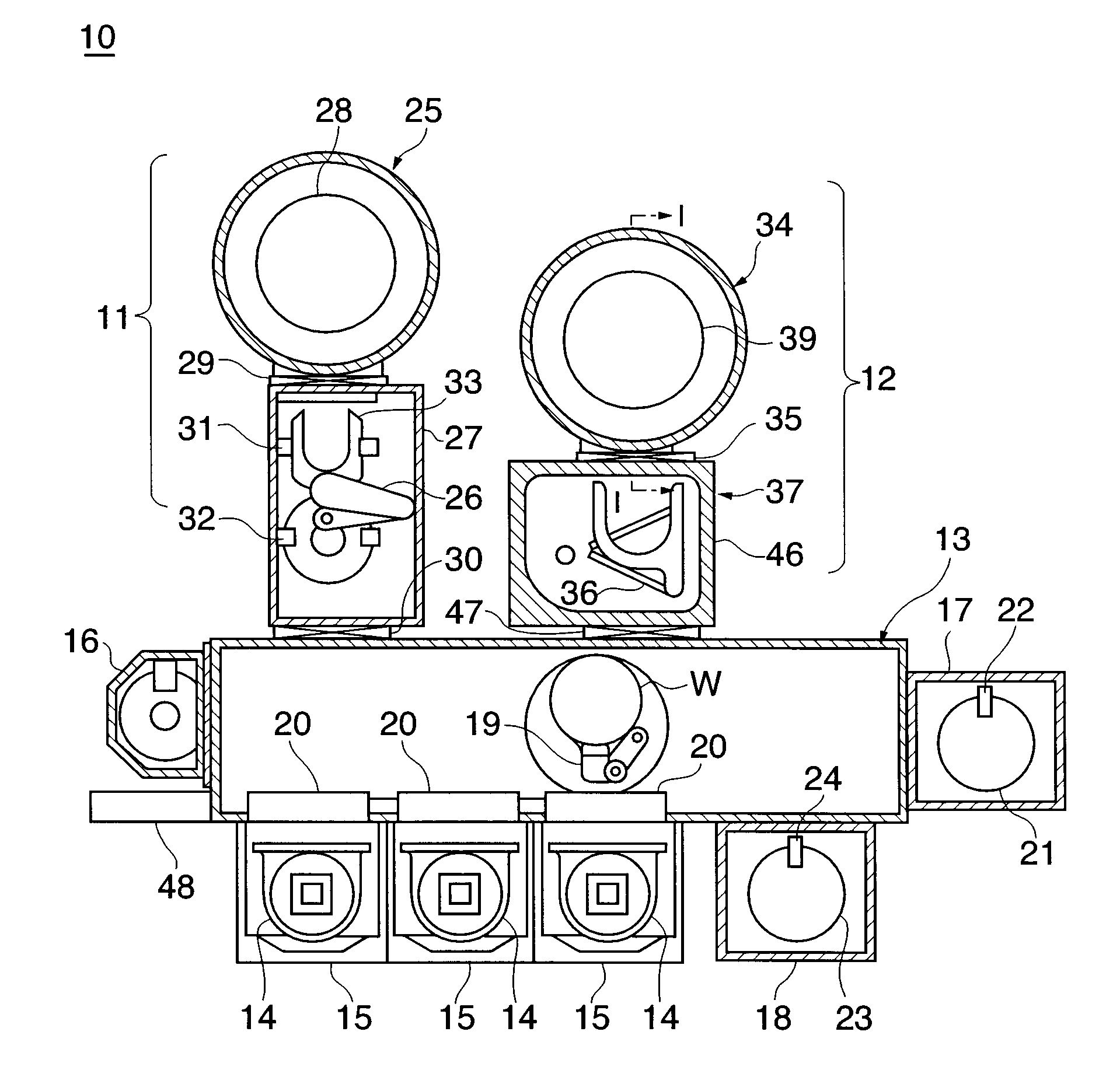

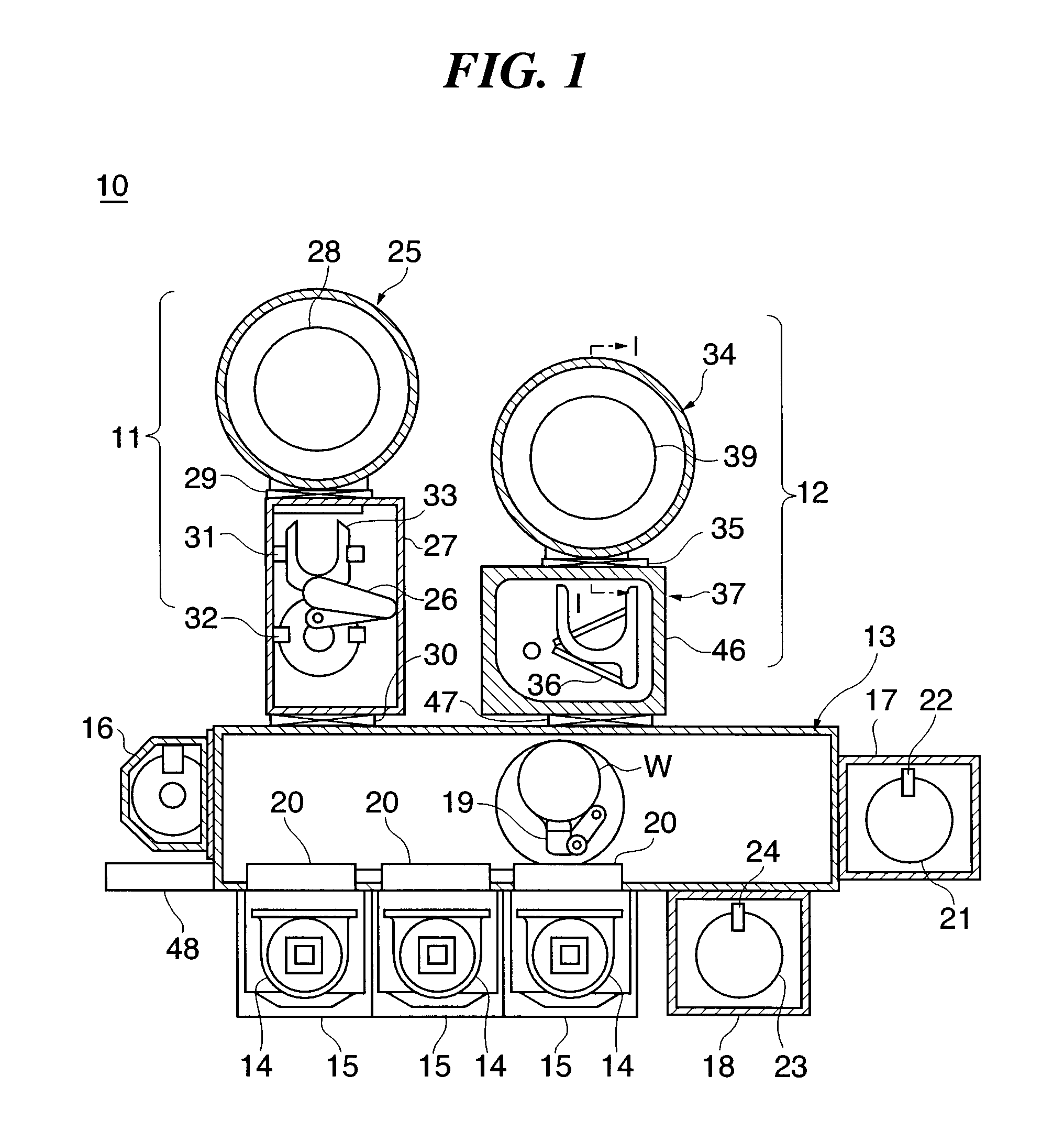

Substrate processing method and substrate processing apparatus

ActiveUS20080003836A1Achieve effectSelectively remove the flat portion of the nitride filmSemiconductor/solid-state device manufacturingHydrofluoric acidSilicon monoxide

A substrate processing method capable of selectively removing a nitride film. Oxygen plasma containing plasmarized oxygen gas is made to be in contact with a silicon nitride film, which is made of SiN, of a wafer to thereby cause the silicon nitride film to be changed to a silicon monoxide film. The silicon monoxide film is selectively etched by hydrofluoric acid generated from HF gas supplied toward the silicon monoxide film.

Owner:TOKYO ELECTRON LTD

Wafer-less auto clean of processing chamber

InactiveUS20150050812A1Easy to cleanElectric discharge tubesElectrostatic cleaningWaferingOxygen plasma

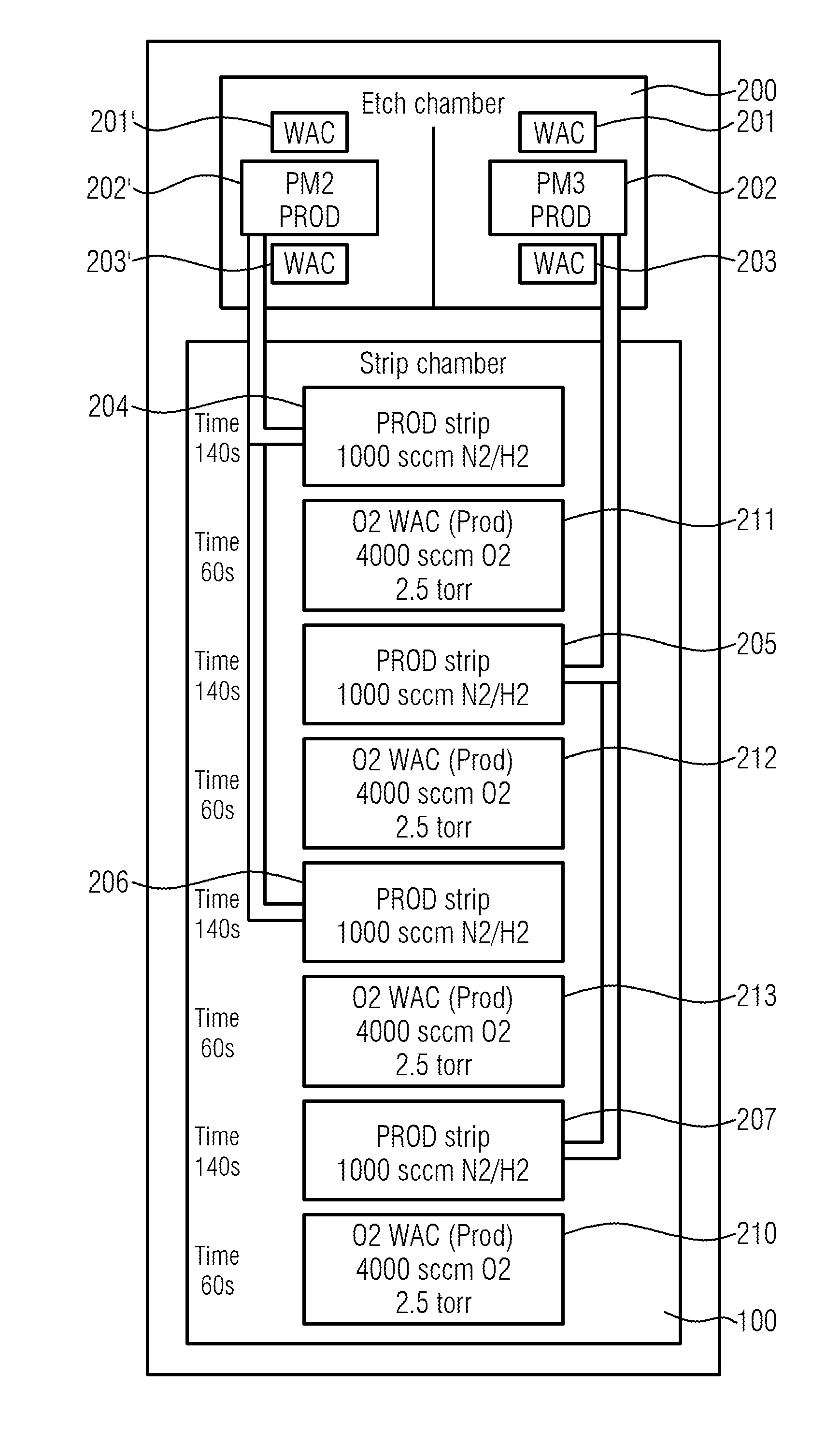

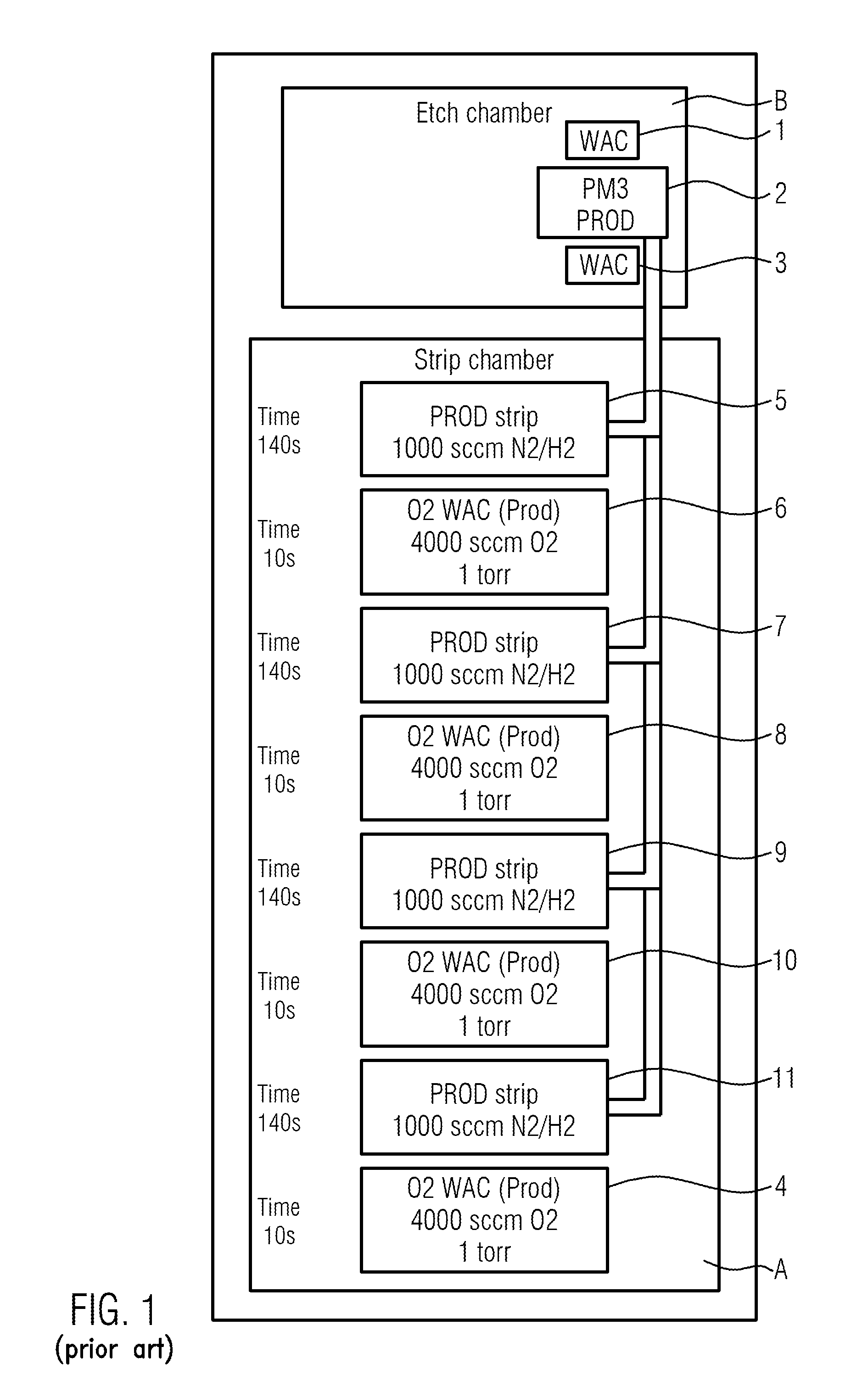

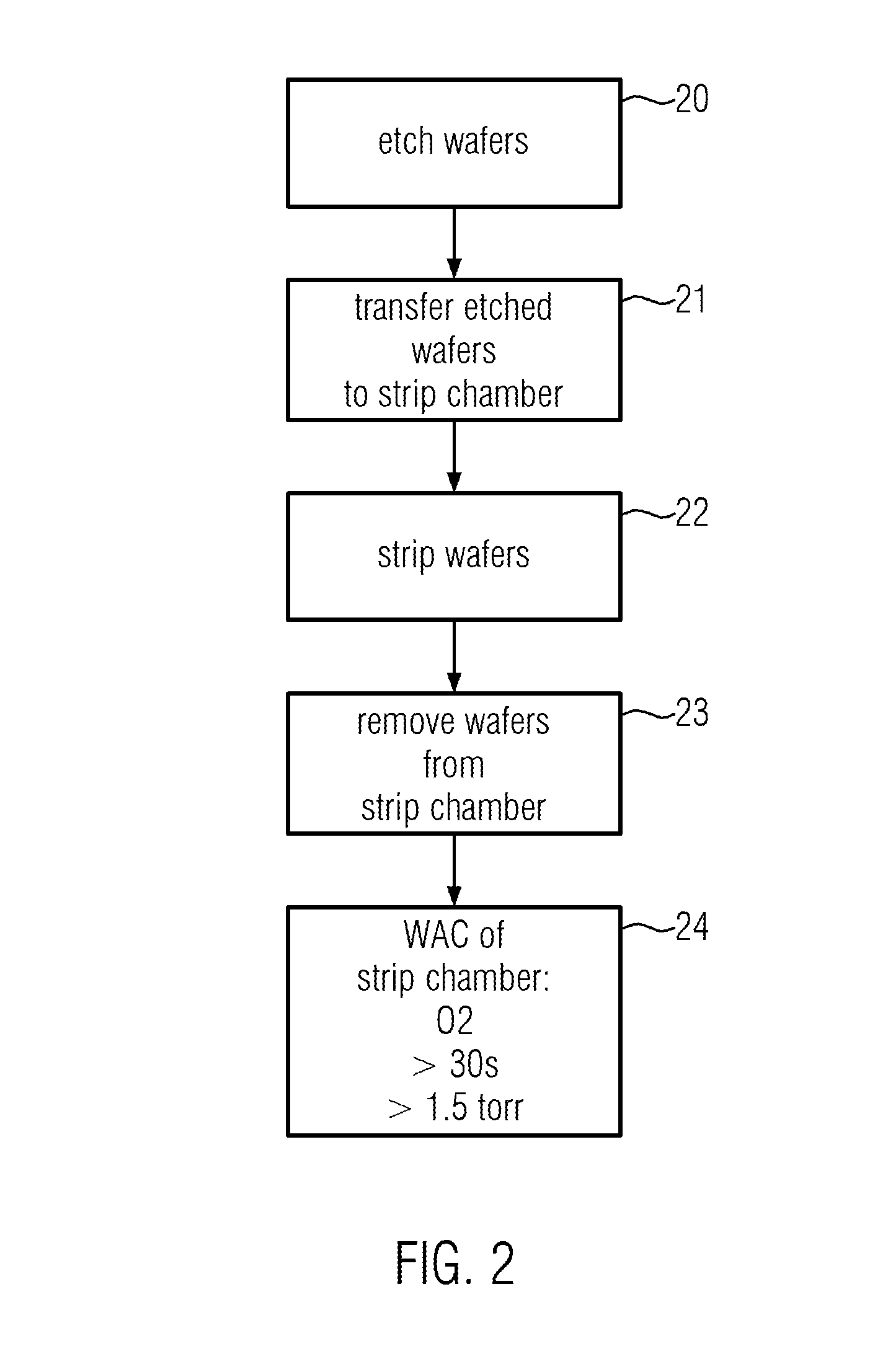

A method for cleaning a processing chamber, for example, a strip chamber, configured for processing a wafer is provided which includes the steps of introducing an oxygen-containing gas into the processing chamber, generating an oxygen plasma from the oxygen-containing gas in the processing chamber, establishing a pressure of the oxygen plasma in the processing chamber of at least 1 Torr and maintaining the pressure of at least 1 Torr for at least 40 seconds. A system is also provided including a strip chamber for receiving and stripping the wafer and including a gas inlet and plasma generator means, as well as a controller configured for performing, when no wafer is present in the strip chamber, controlling inflow of an oxygen-containing gas into the processing chamber through the gas inlet and controlling the plasma generator means to generate an oxygen plasma.

Owner:GLOBALFOUNDRIES INC

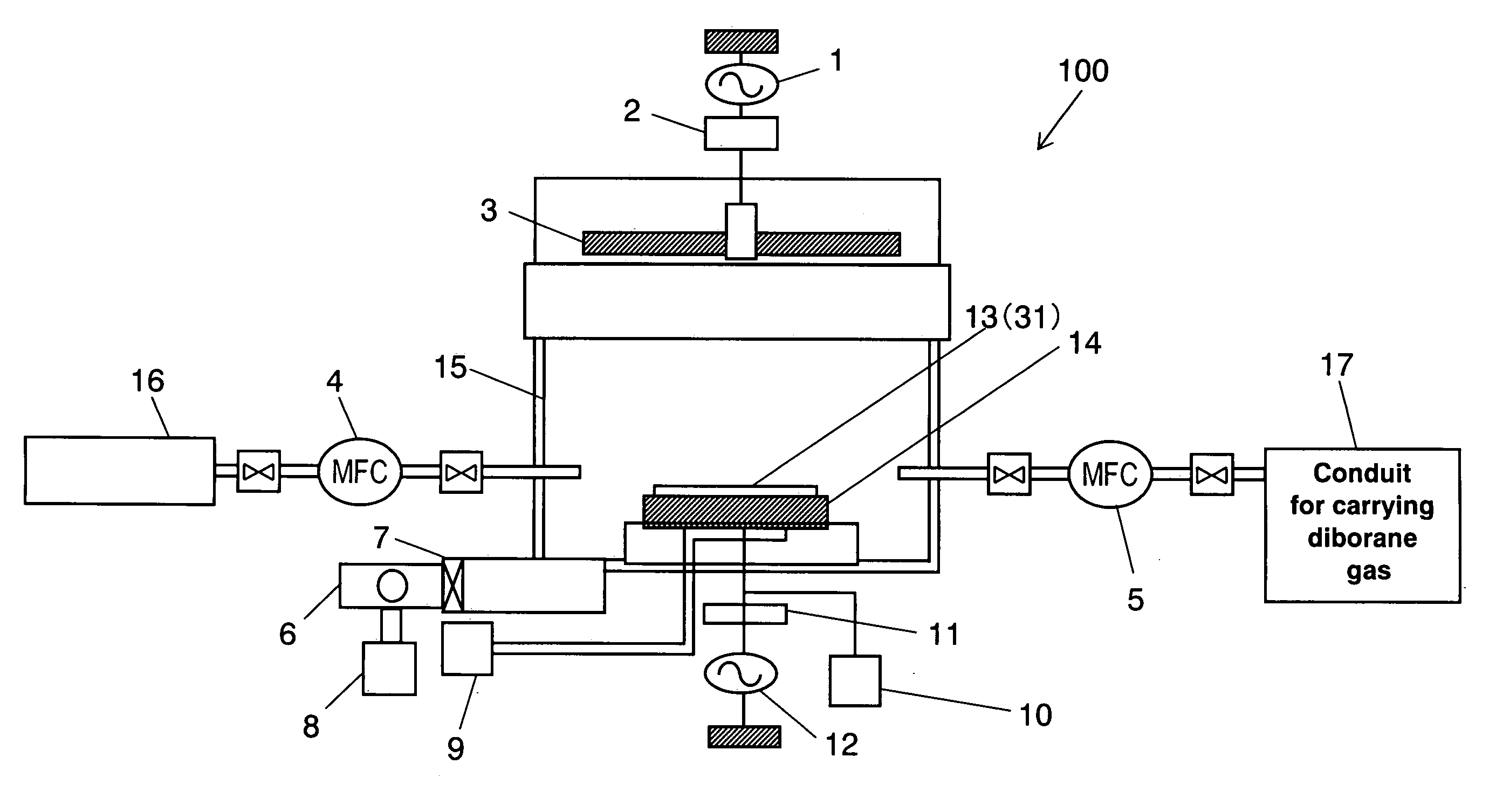

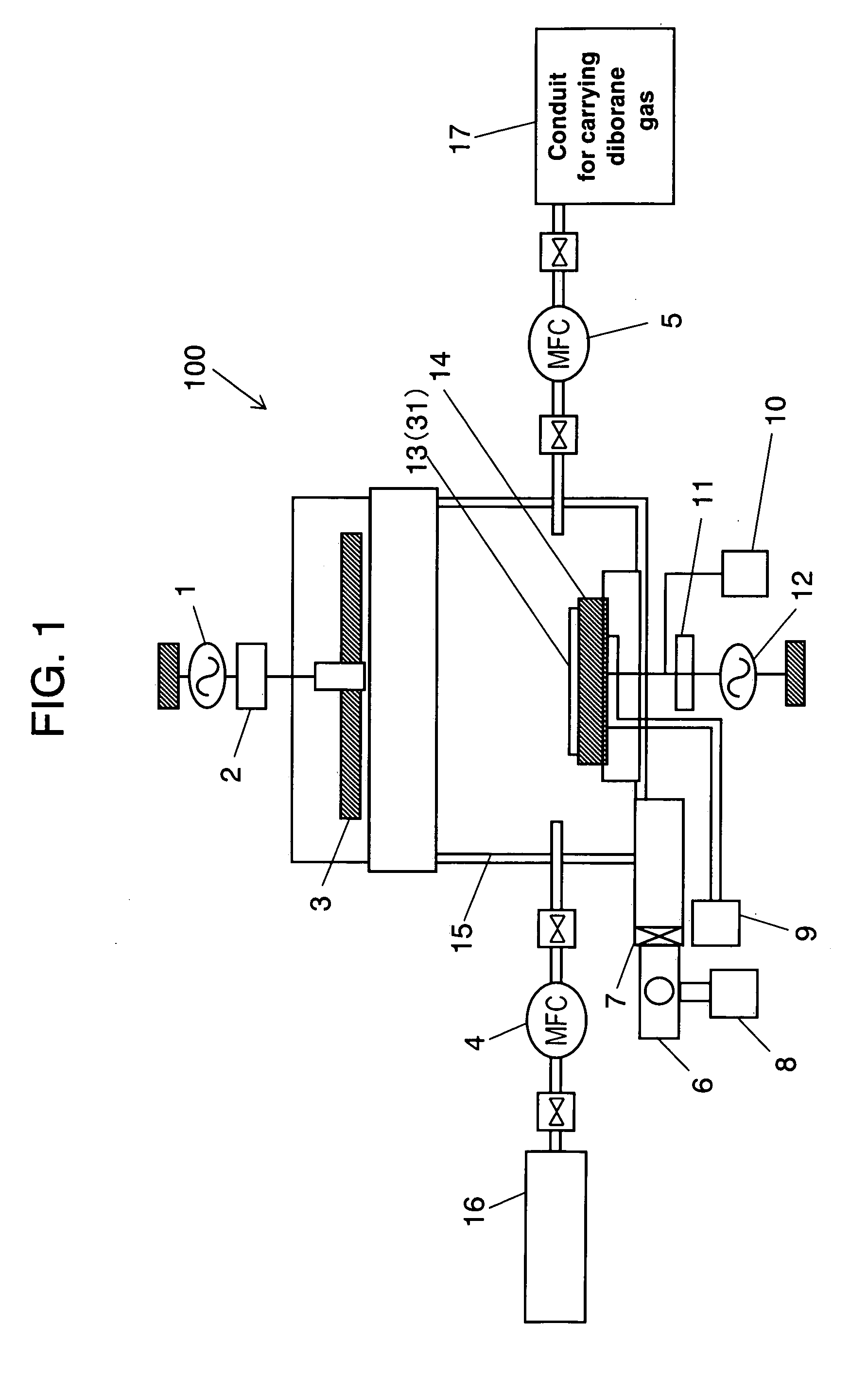

Method for formng impurity-introduced layer, method for cleaning object to be processed apparatus for introducing impurity and method for producing device

A method of forming an impurity-introduced layer is disclosed. The method includes at least a step of forming a resist pattern on a principal face of a solid substrate such as a silicon substrate (S27); a step of introducing impurity into the solid substrate through plasma-doping in ion mode (S23), a step of removing a resist (S28), a step of cleaning metal contamination and particles attached to a surface of the solid substrate (S25a); a step of anneal (S26). The step of removing a resist (S28) irradiates the resist with oxygen-plasma or brings mixed solution of sulfuric acid and hydrogen peroxide water, or mixed solution of NH4OH, H2O2 and H2O into contact with the resist. The step of cleaning (S25a) brings mixed solution of sulfuric acid and hydrogen peroxide water, or mixed solution of NH4OH, H2O2 and H2O into contact with the principal face of the solid substrate. The step of removing a resist (S28) and the step of cleaning (S25a) can be conducted simultaneously by bringing mixed solution of sulfuric acid and hydrogen peroxide water, or mixed solution of NH4OH, H2O2 and H2O into contact with the principal face of the solid substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

Fabricating a tapered hole incorporating a resinous silicon containing film

Owner:SEMICON ENERGY LAB CO LTD

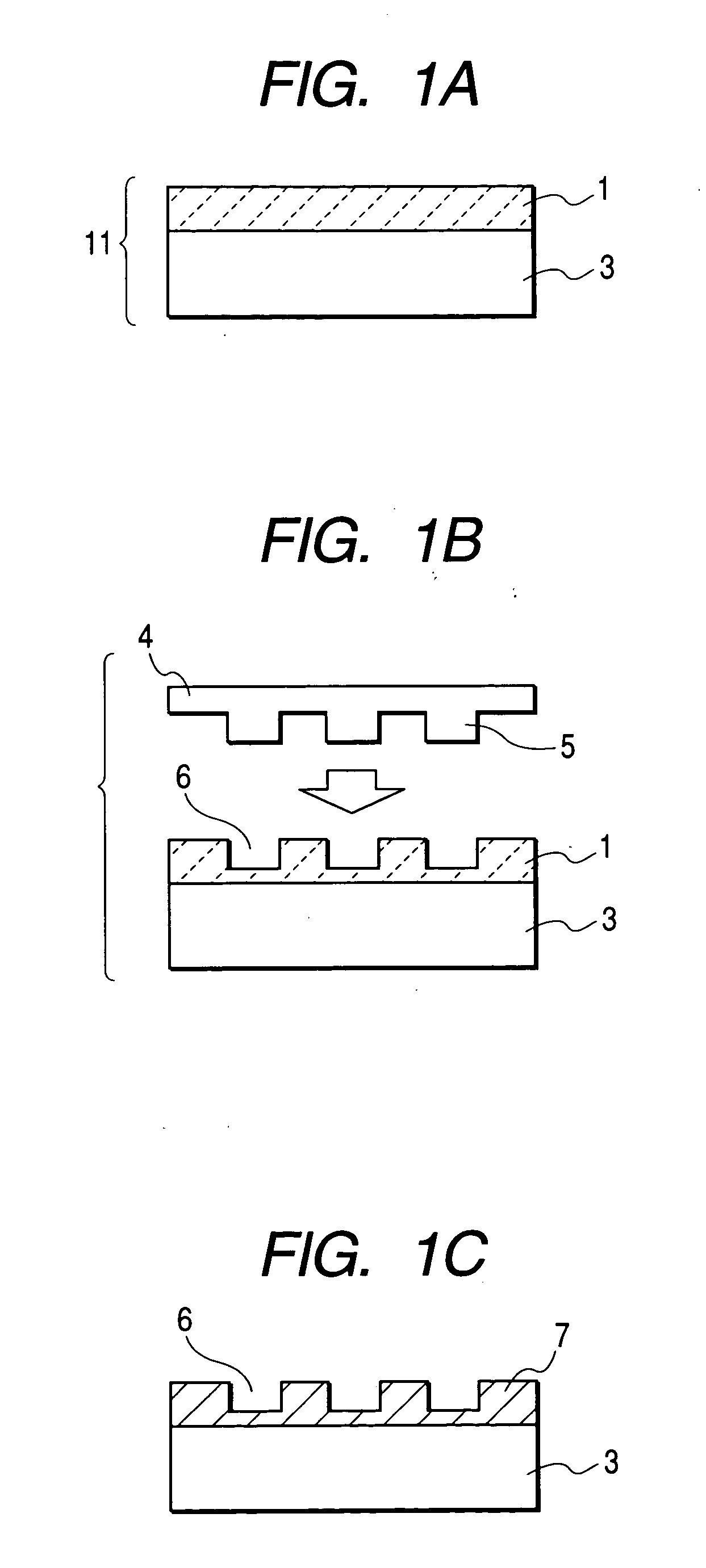

Method for pattern formation

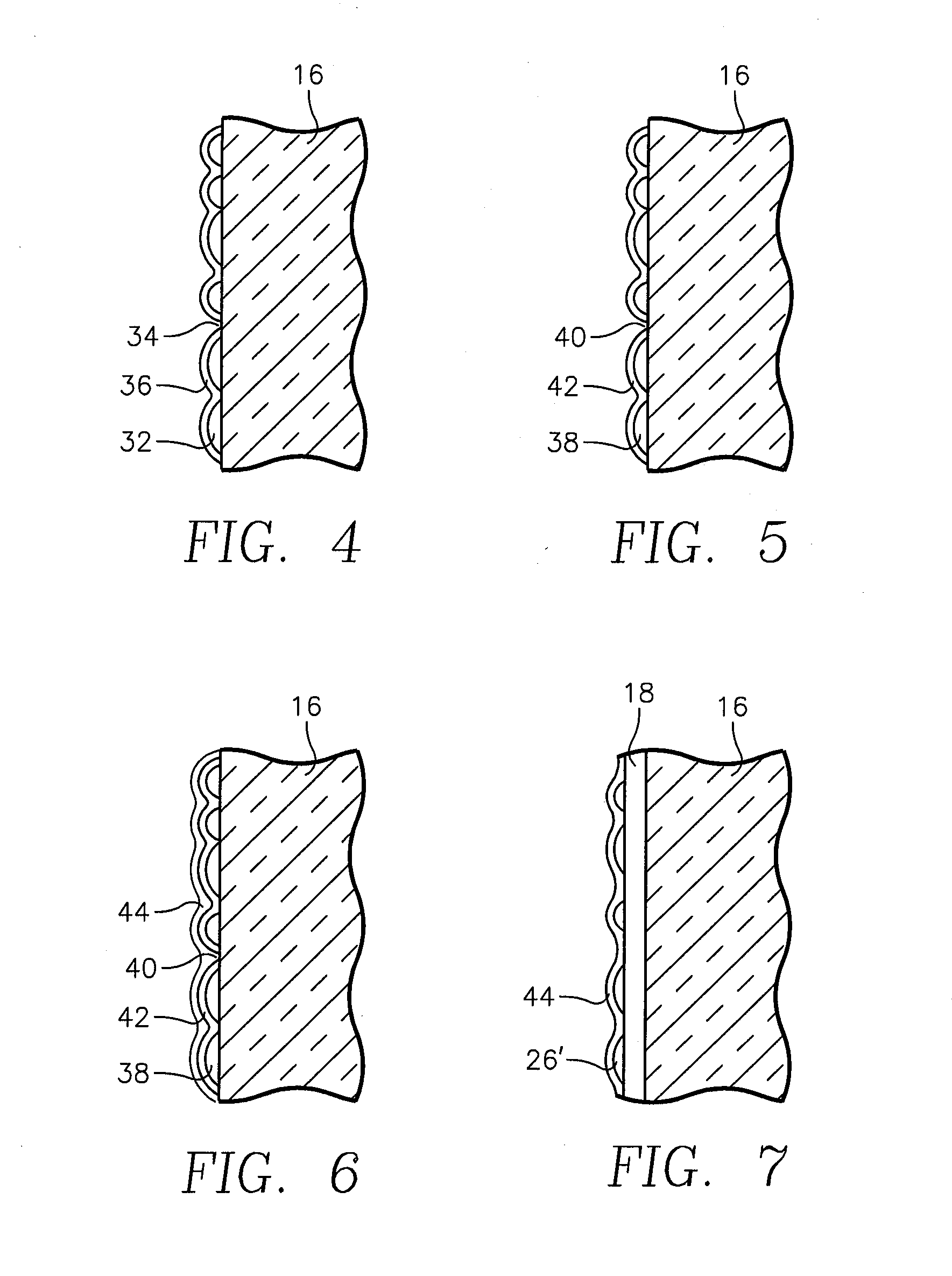

InactiveUS20080041818A1Satisfactory etching resistanceHigh aspect ratioDecorative surface effectsNanoinformaticsOxygen plasmaSolvent

There is provided a method for pattern formation, including a step of coating a composition comprising a block copolymer, a silicon compound, and a solvent for dissolving these components onto an object to form a layer of the composition on the object, a step of subjecting the layer of the composition to self-organization of the block copolymer to cause phase separation into a first phase, in which the silicon compound is localized, having higher etching resistance by heat treatment or / and oxygen plasma treatment, and a second phase comprising a polymer phase and having lower etching resistance by heat treatment or / and oxygen plasma treatment, and thereby forming a pattern layer with a fine pattern, and a step of etching the object using as a mask the thus formed pattern layer.

Owner:KK TOSHIBA

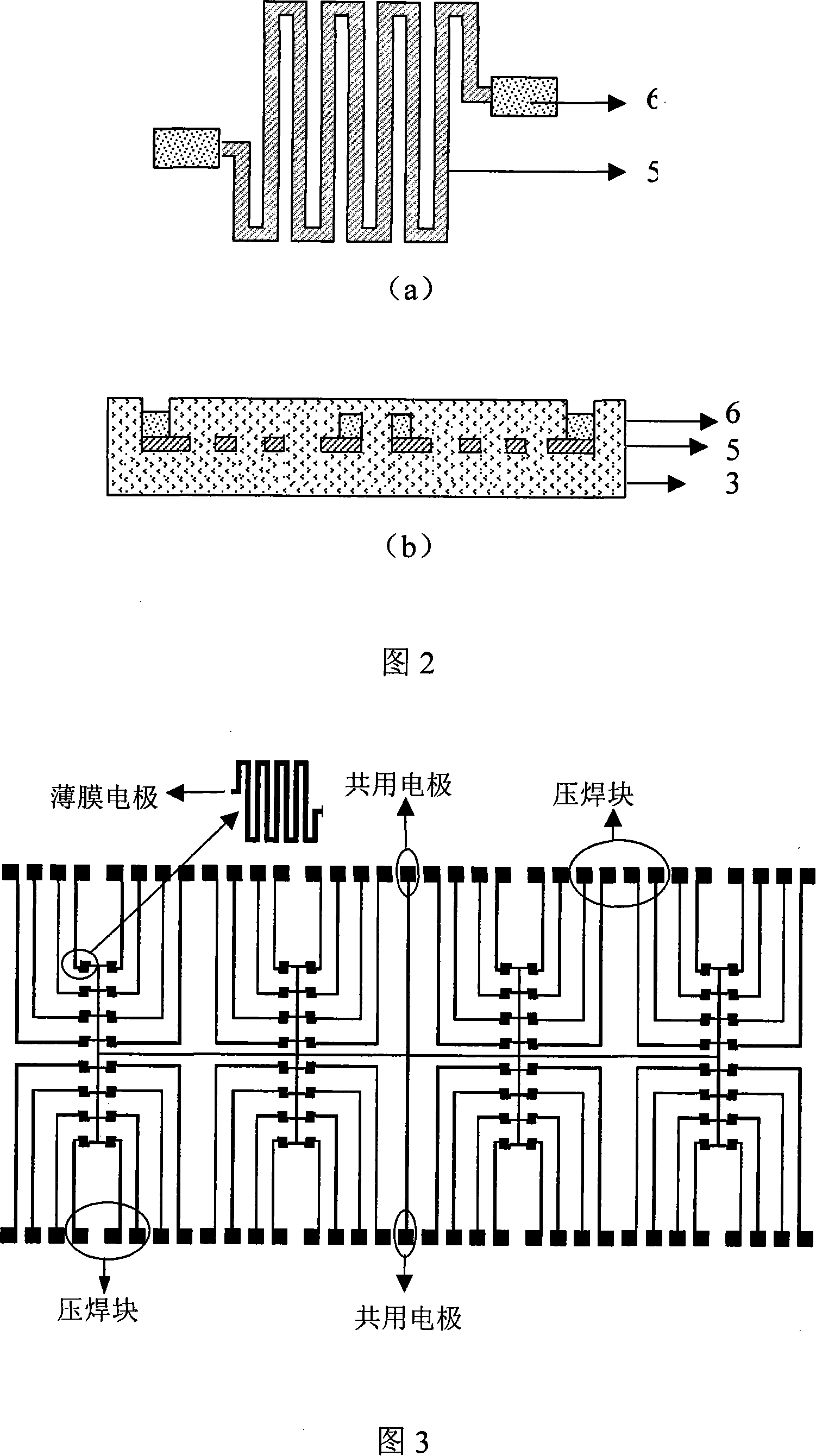

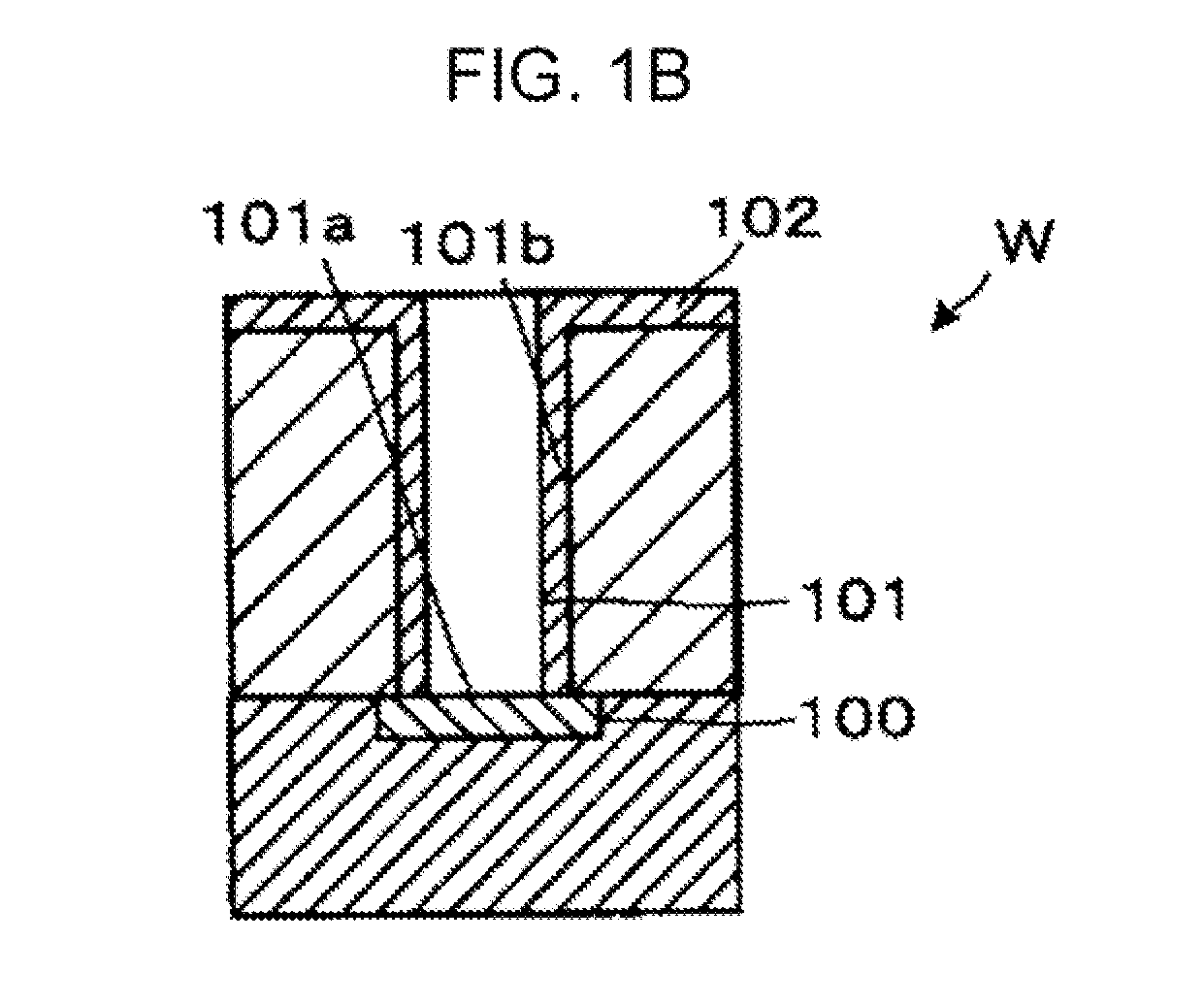

Method for making flexibility temperature sensor

InactiveCN101082523AAchieve integrationSimple preparation processThermometers using electric/magnetic elementsUsing electrical meansEngineeringDimethyl siloxane

This invention discloses a production method of flexibility humidity sensor. Its character is washing a dimethyl siloxane interlayer on silicon dice carrier firstly, after solidification in room-temperature, activing the surface with oxygen plasma, then washing high viscosity polyimide again and procuring with staged technology, then, overlapping and depositing all the metal coating and using stripping technology and wet-method corroding figure technology to firm mental humidity-dependent resistor and electric connector, after this, overlapping a light low viscosity PI protective layer, using wet method to corrode the outside metal press welding part; then putting the device on the heating plate and peeling the interlayer from the flexible carrier, after all, putting the flexible carrier peeled into the bake oven to solidify it to two PI membranous layers completely, so realizing the compatible craft. The method to make it is simple, the cost is low and the rate of finished products is high, and it is more near the achievement of mass production and the integration of the high density sensor.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Method of manufacturing semiconductor device

InactiveUS20130089983A1Avoid it happening againQuality improvementSemiconductor/solid-state device manufacturingOxygen plasmaEngineering

The method includes forming a hole penetrating from one surface of a substrate to an electrode formed on the other surface of the substrate; forming an organic insulating film in the hole; removing at least a part of the organic insulating film formed in a bottom portion of the hole and not the organic insulating film formed on a side wall portion of the hole, to expose the electrode; cleaning an exposed surface of the electrode by using plasma of an inert gas; filling a conductive metal in the hole; removing at least a part of a surface of the organic insulating film by the reaction of oxygen plasma; and annealing the substrate in a dysoxidative atmosphere.

Owner:TOKYO ELECTRON LTD

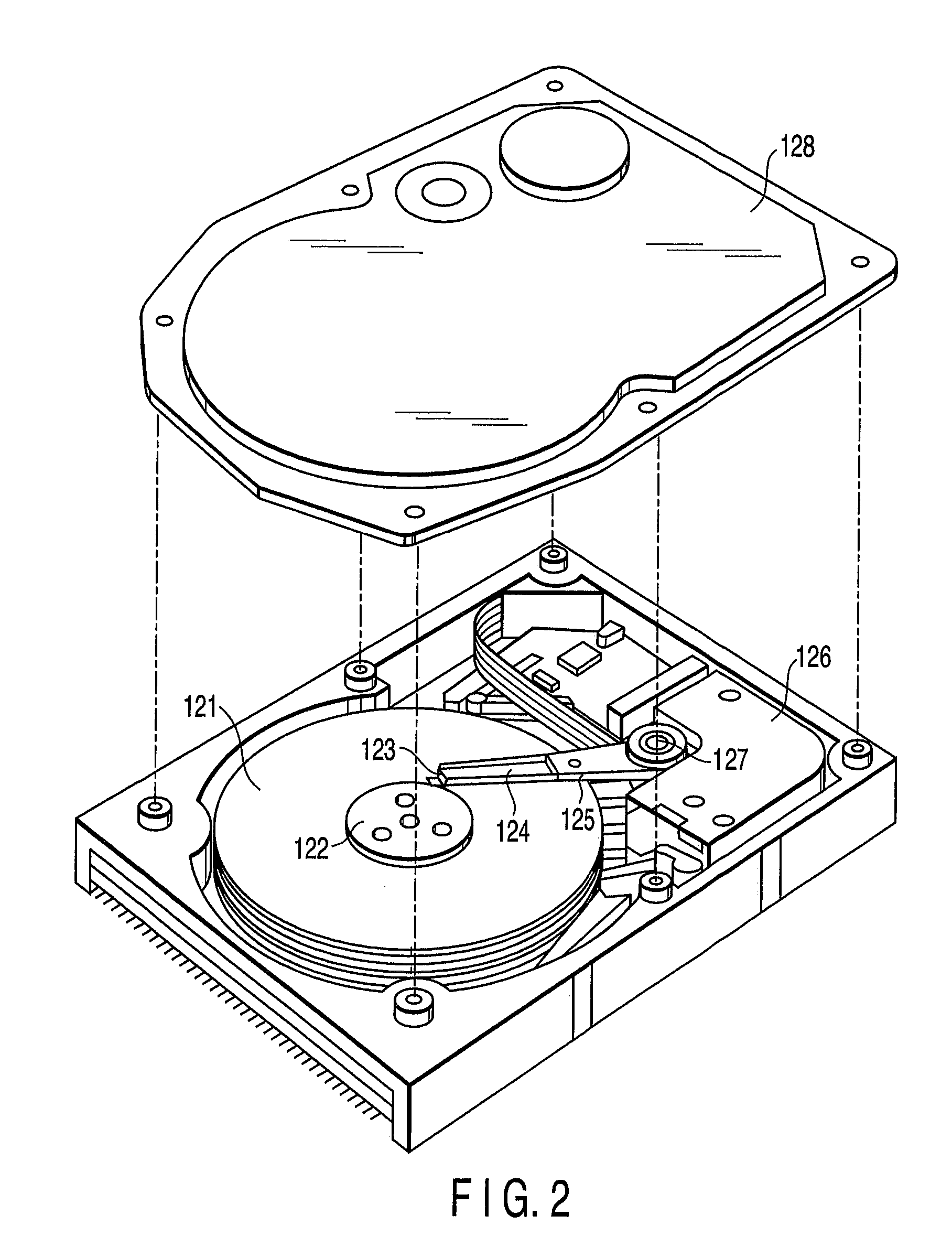

Magnetic recording medium, method of manufacturing the same, and magnetic recording/reproducing apparatus

A magnetic recording medium is obtained by easily patterning a magnetic recording layer without deteriorating its electromagnetic conversion characteristics, by forming a silicon-based protective film between the magnetic recording layer and a photoresist, and performing dry etching and oxygen plasma processing.

Owner:KK TOSHIBA

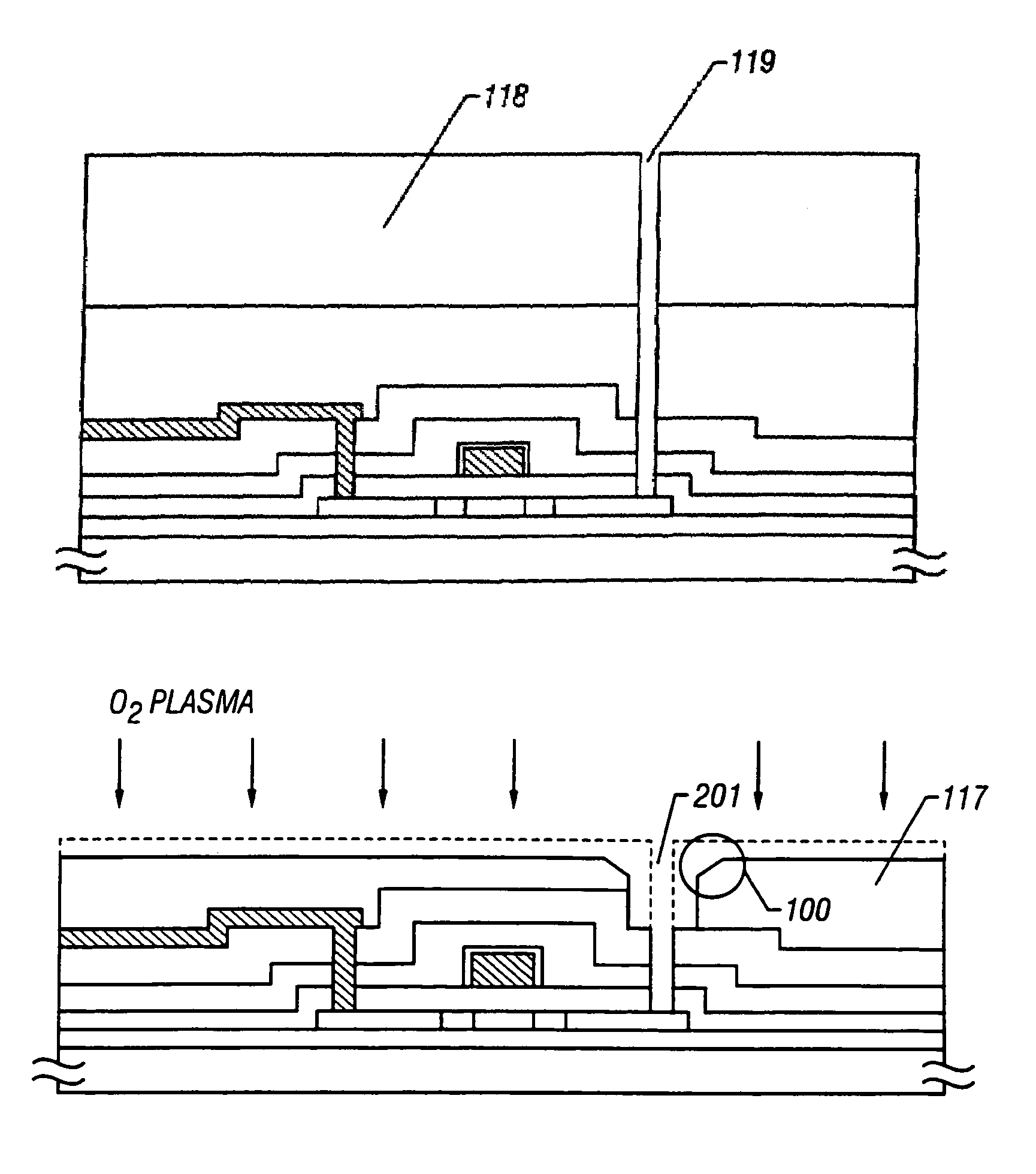

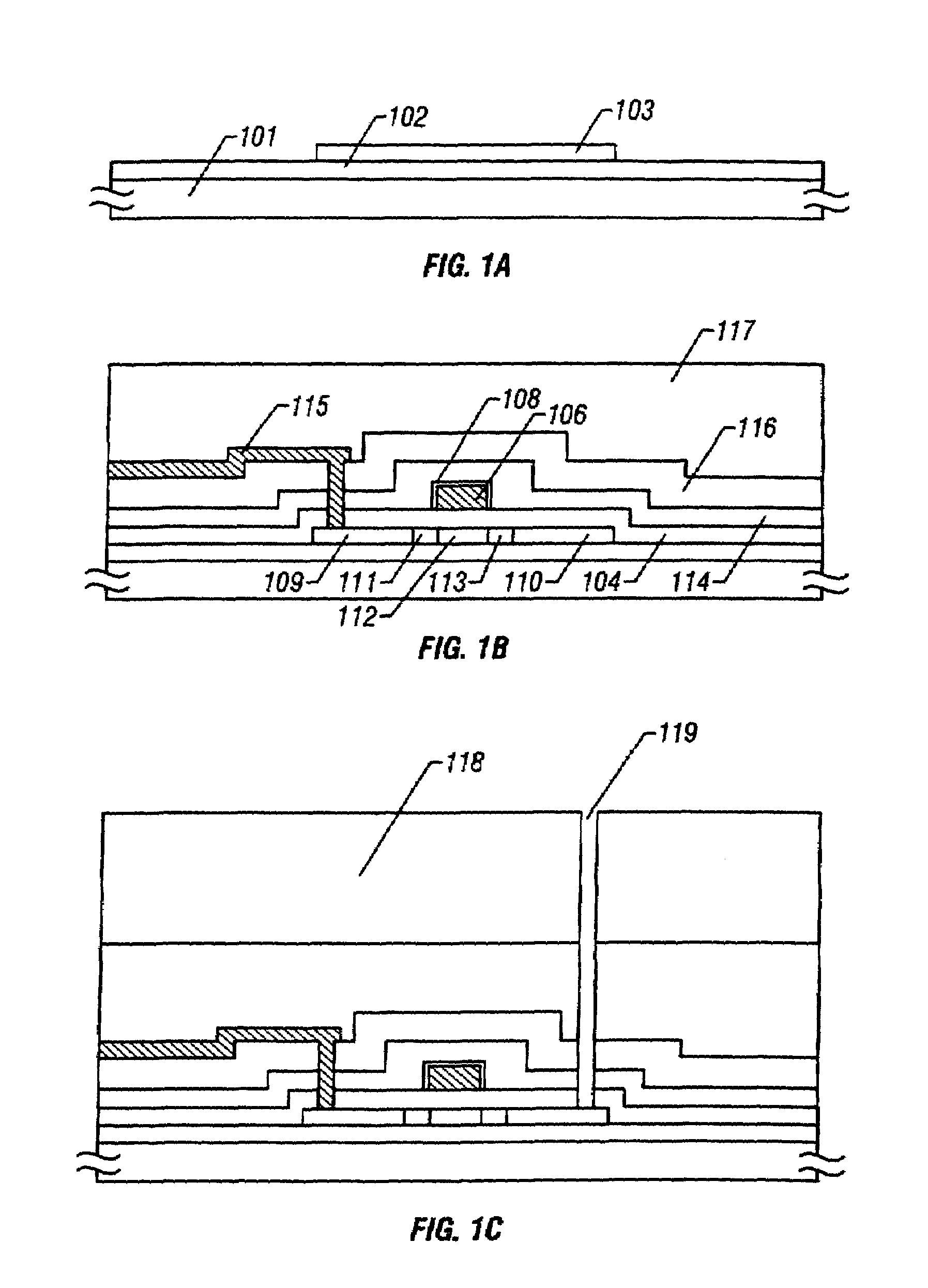

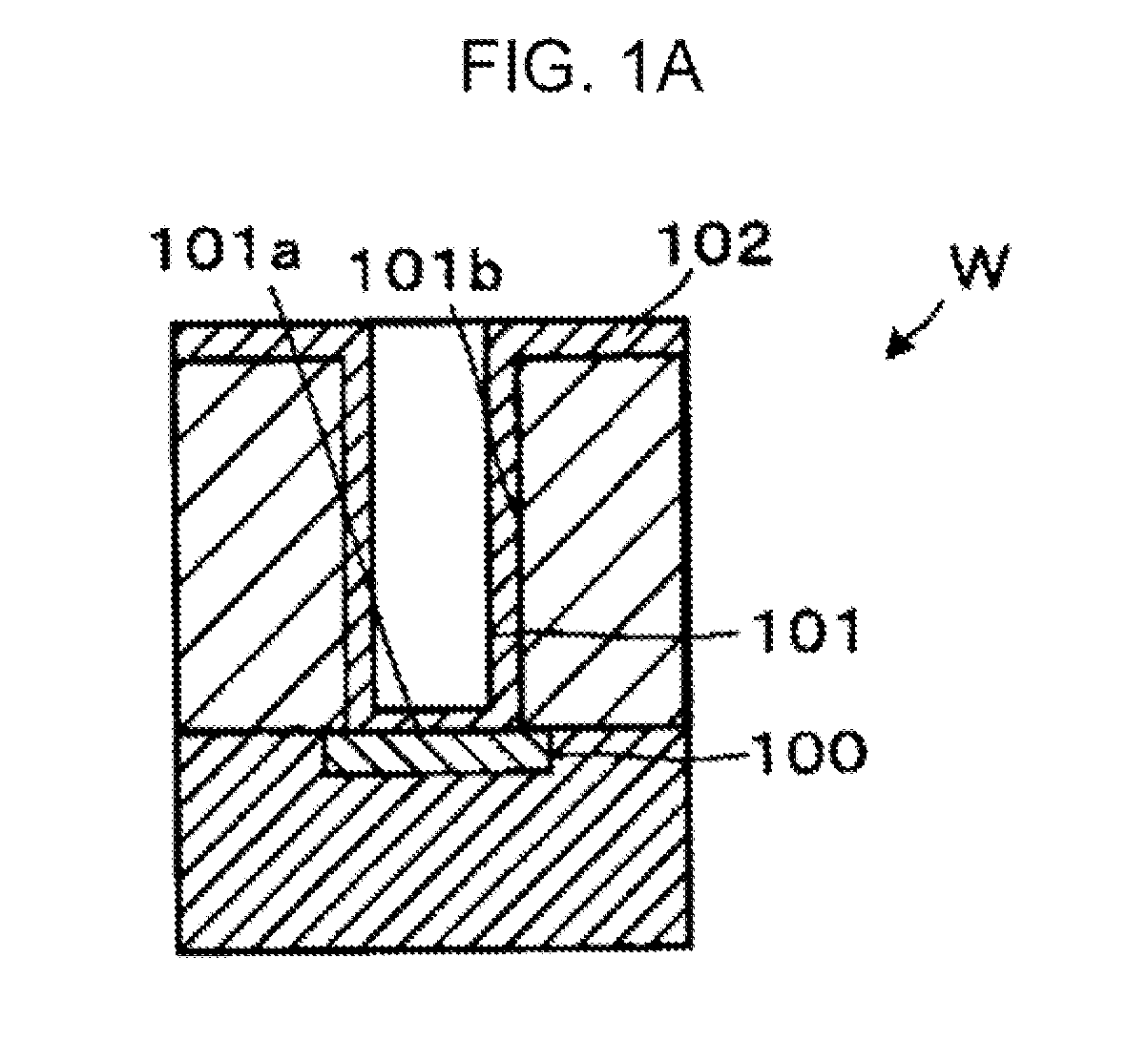

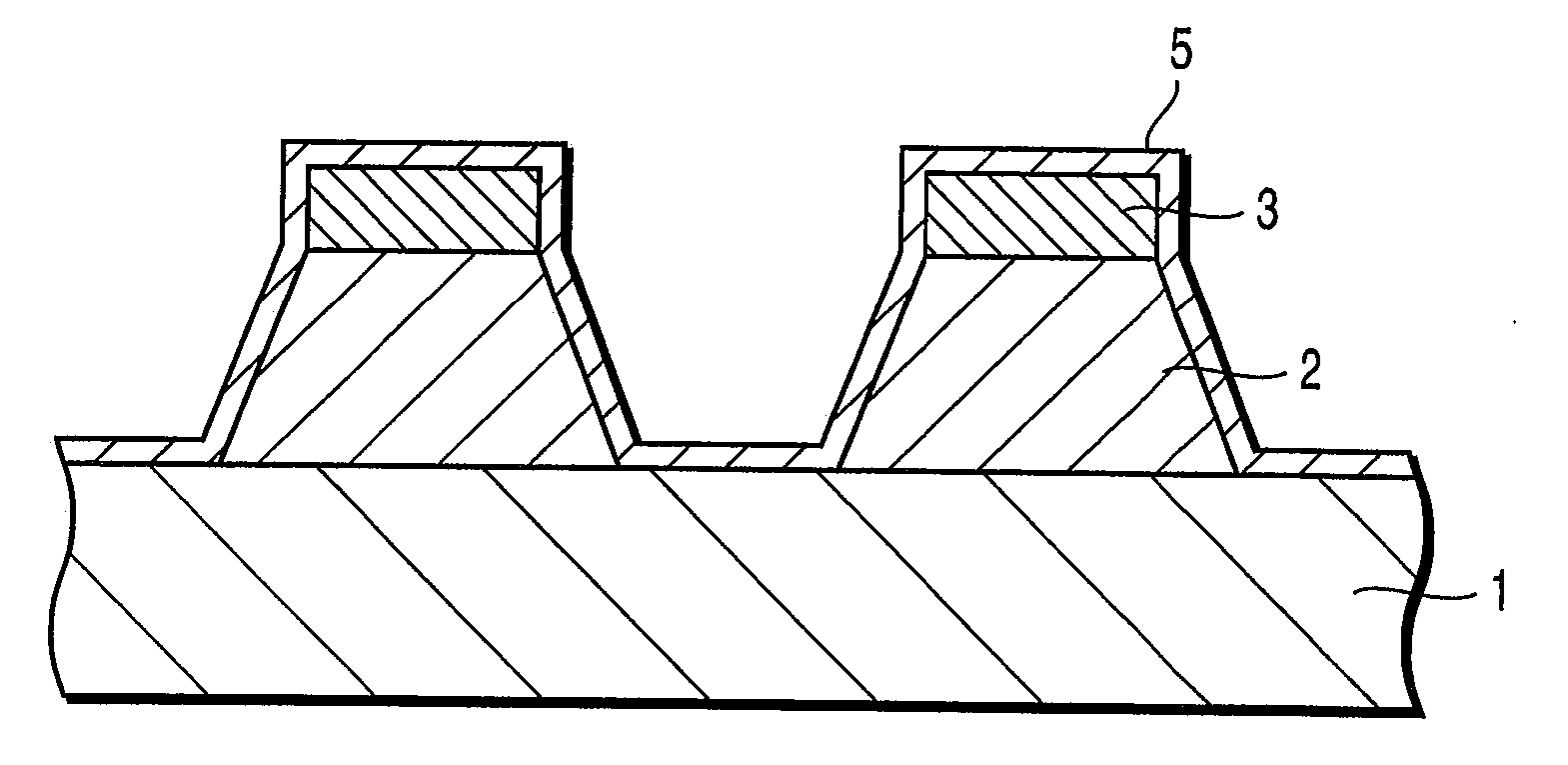

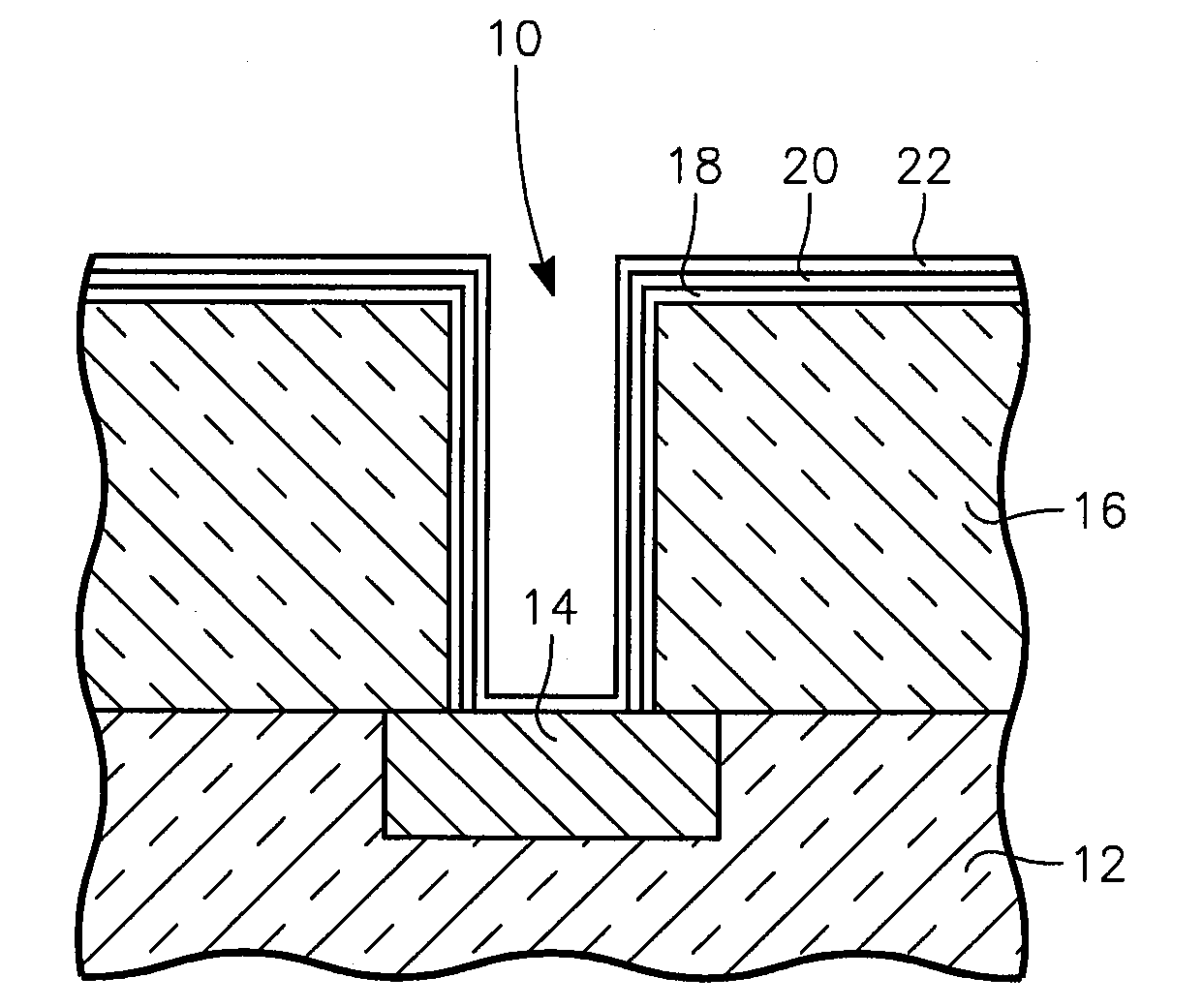

Semiconductor device and method of fabricating same

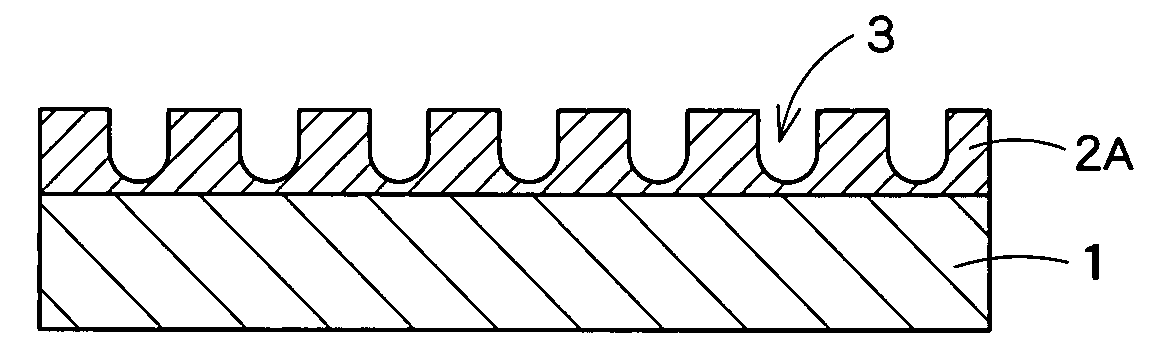

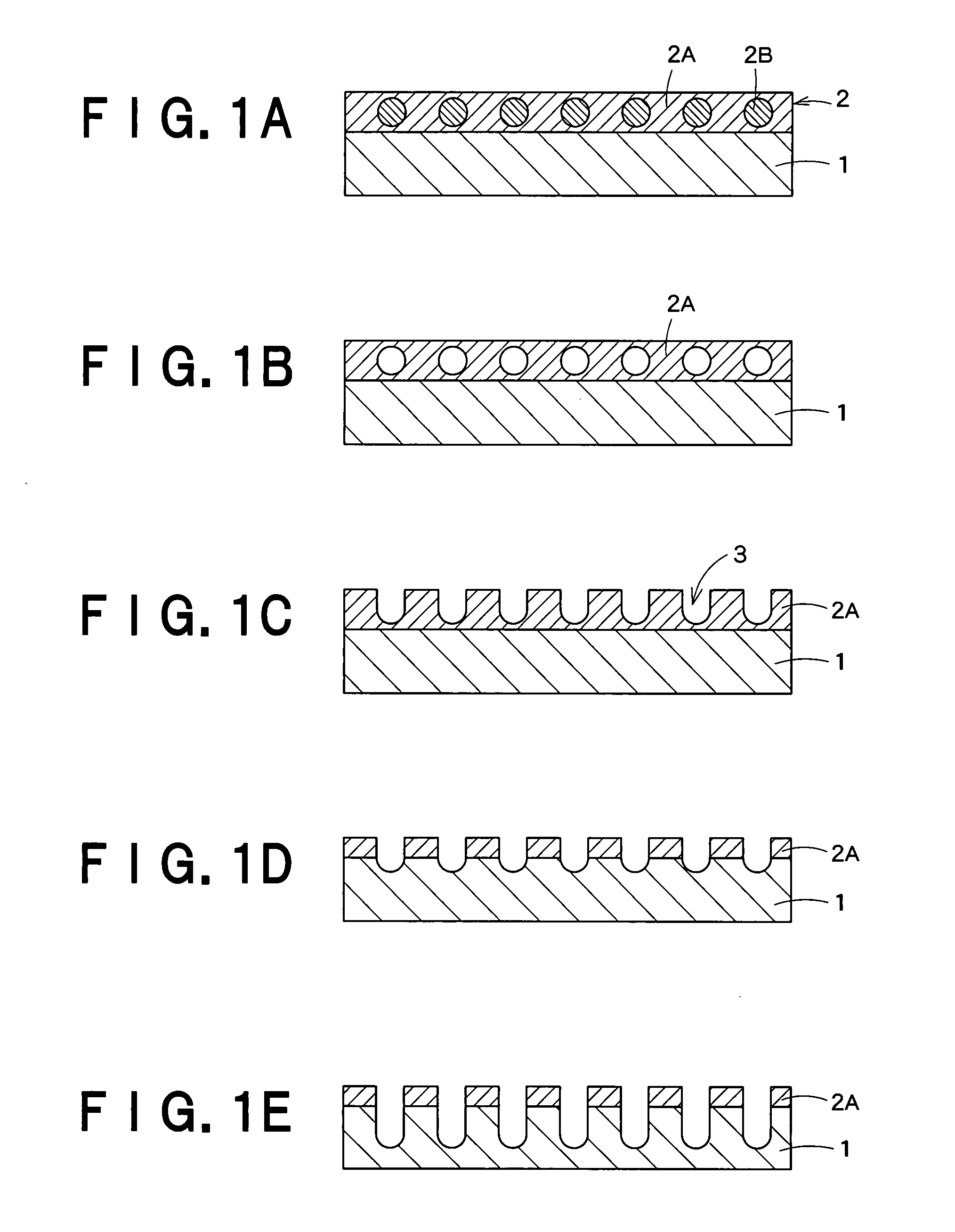

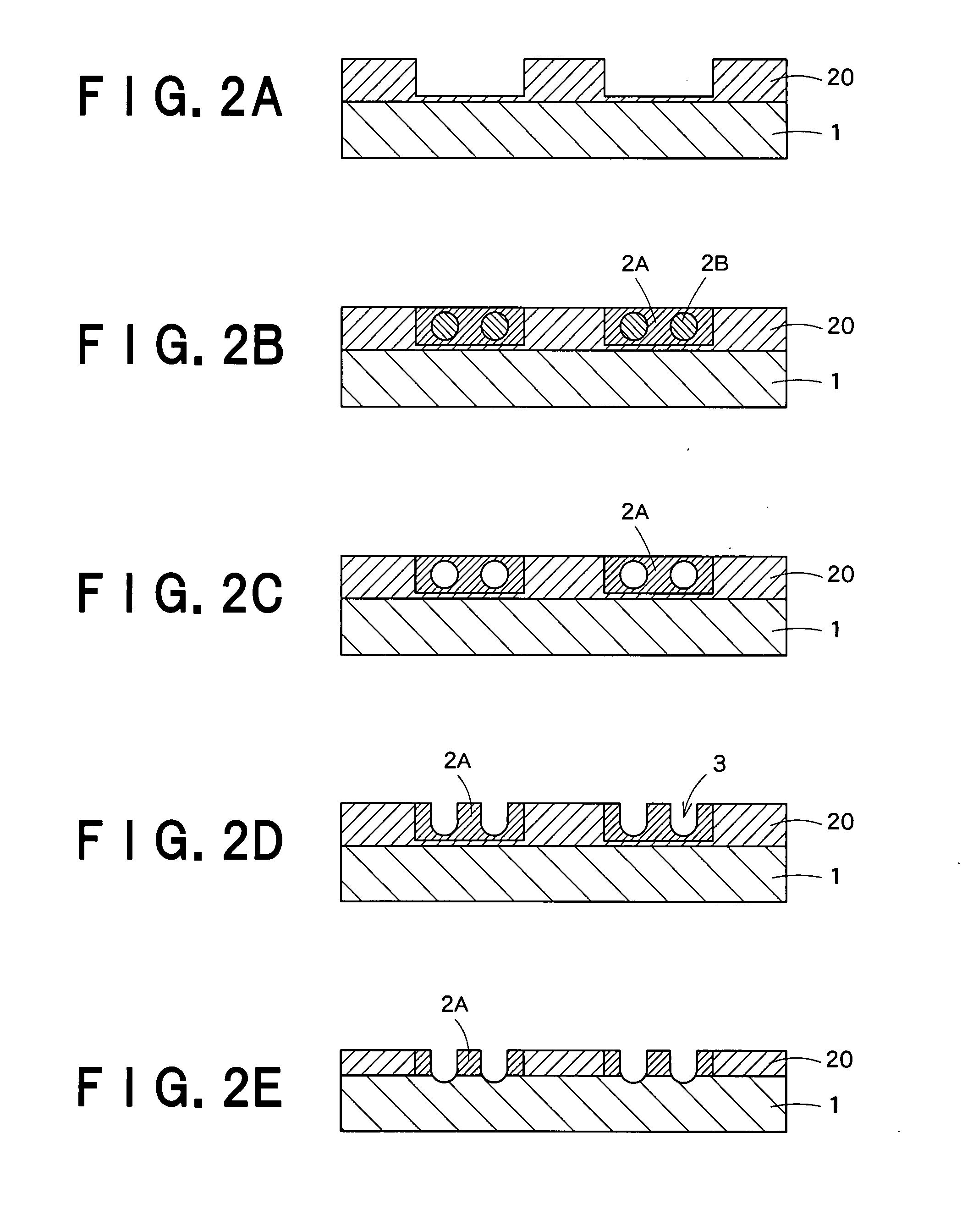

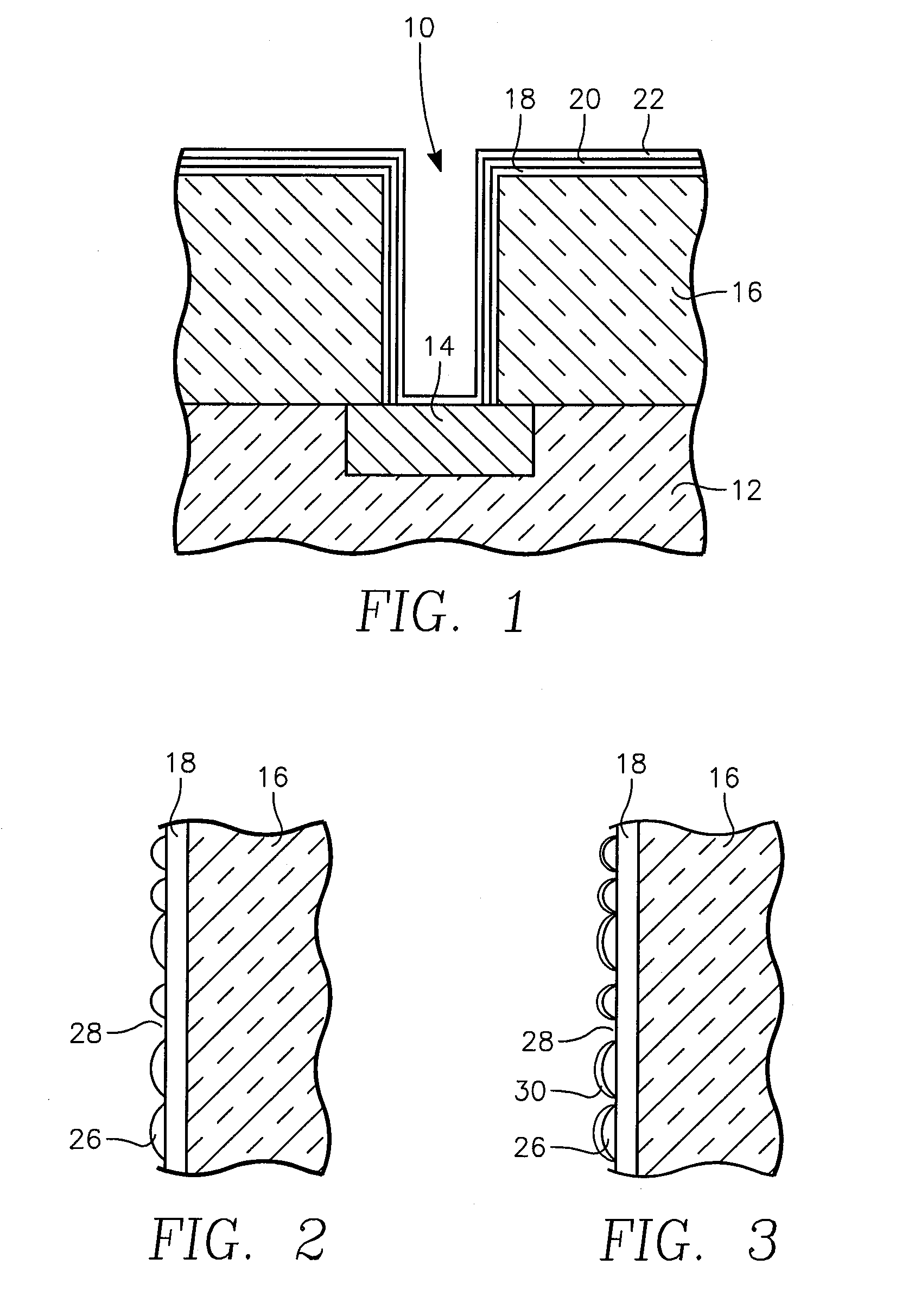

A semiconductor device having reliable electrode contacts. First, an interlayer dielectric film is formed from a resinous material. Then, window holes are formed. The interlayer dielectric film is recessed by oxygen plasma. This gives rise to tapering window holes. This makes it easy to make contacts even if the circuit pattern is complex.

Owner:SEMICON ENERGY LAB CO LTD

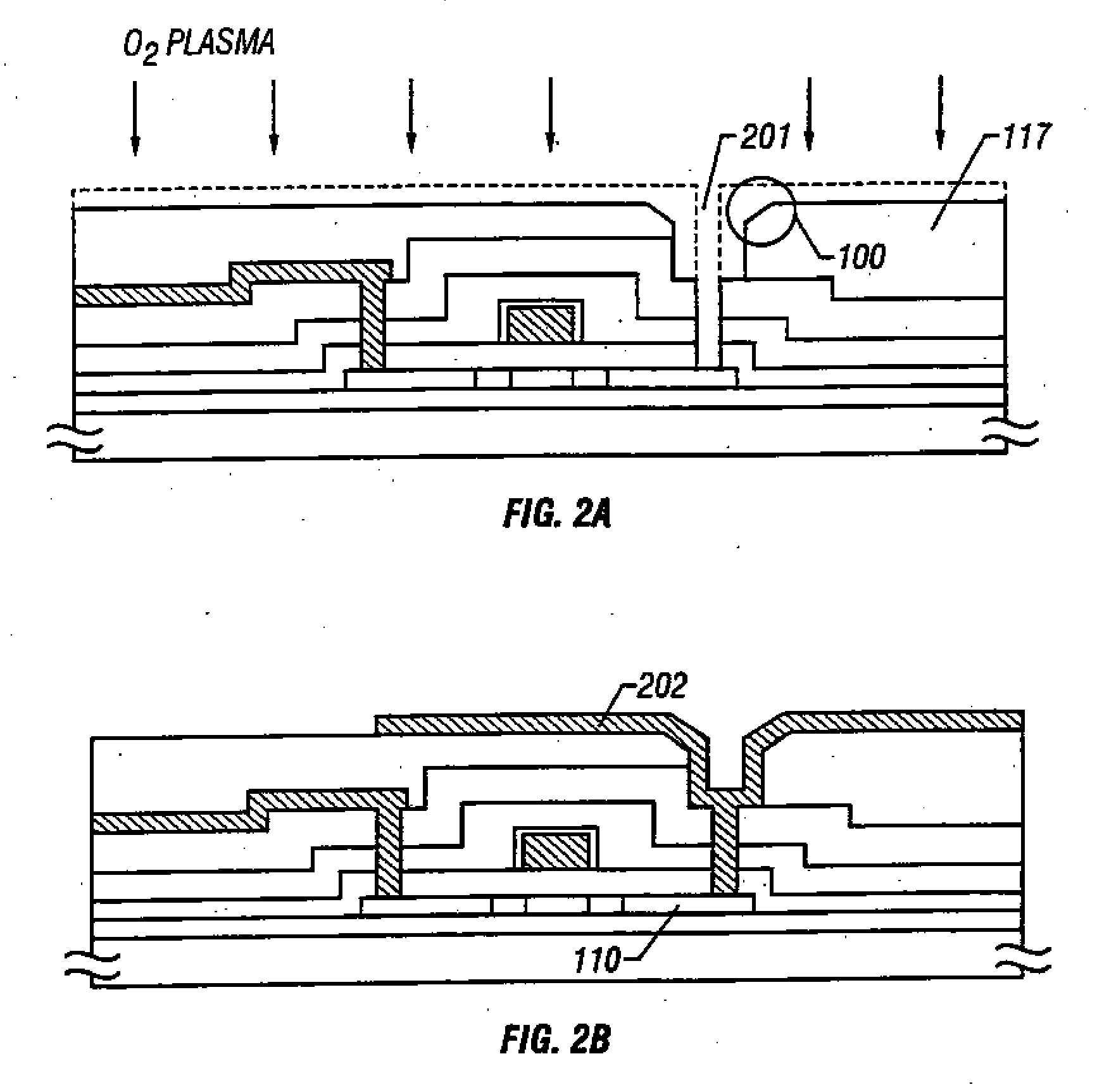

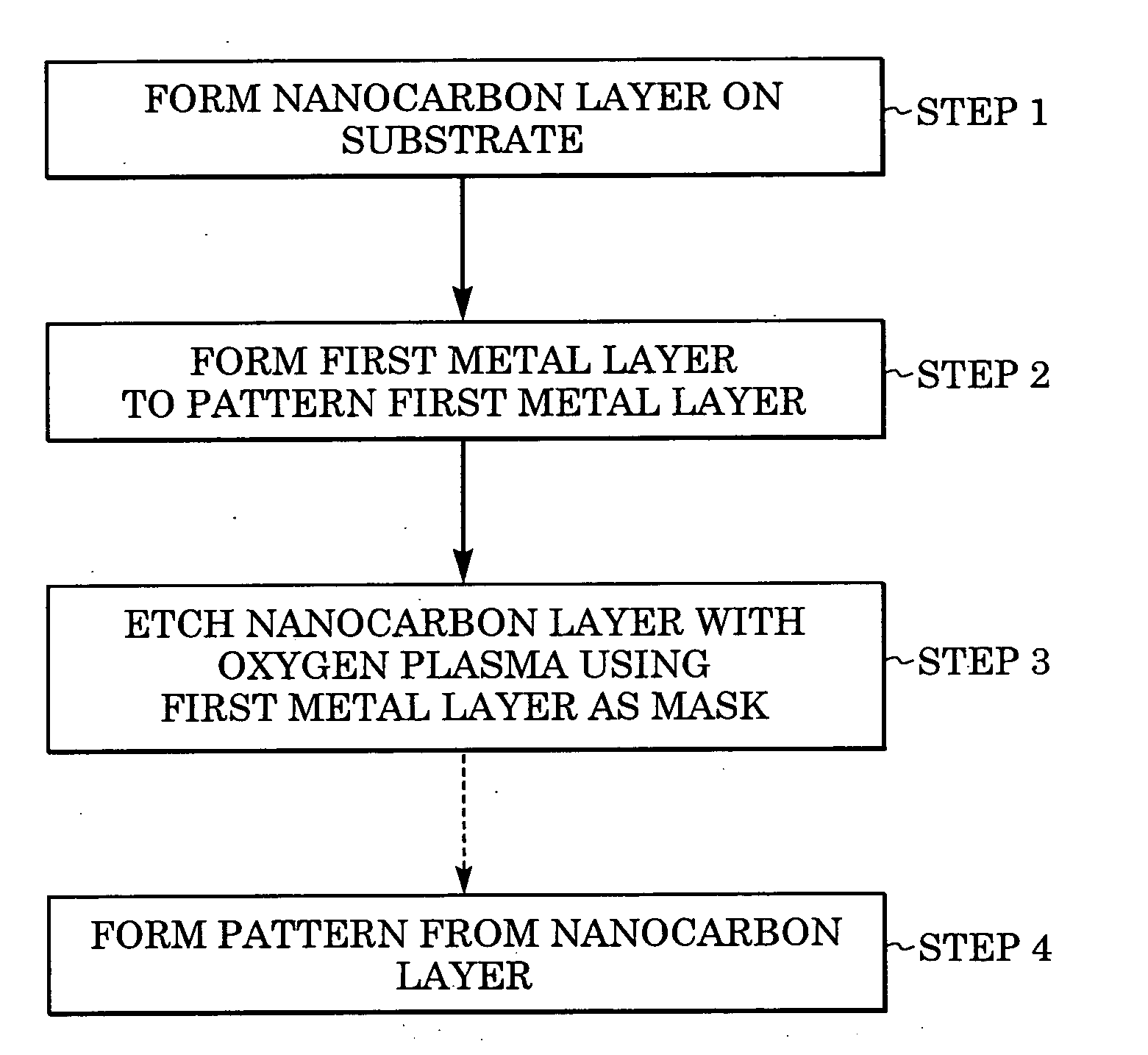

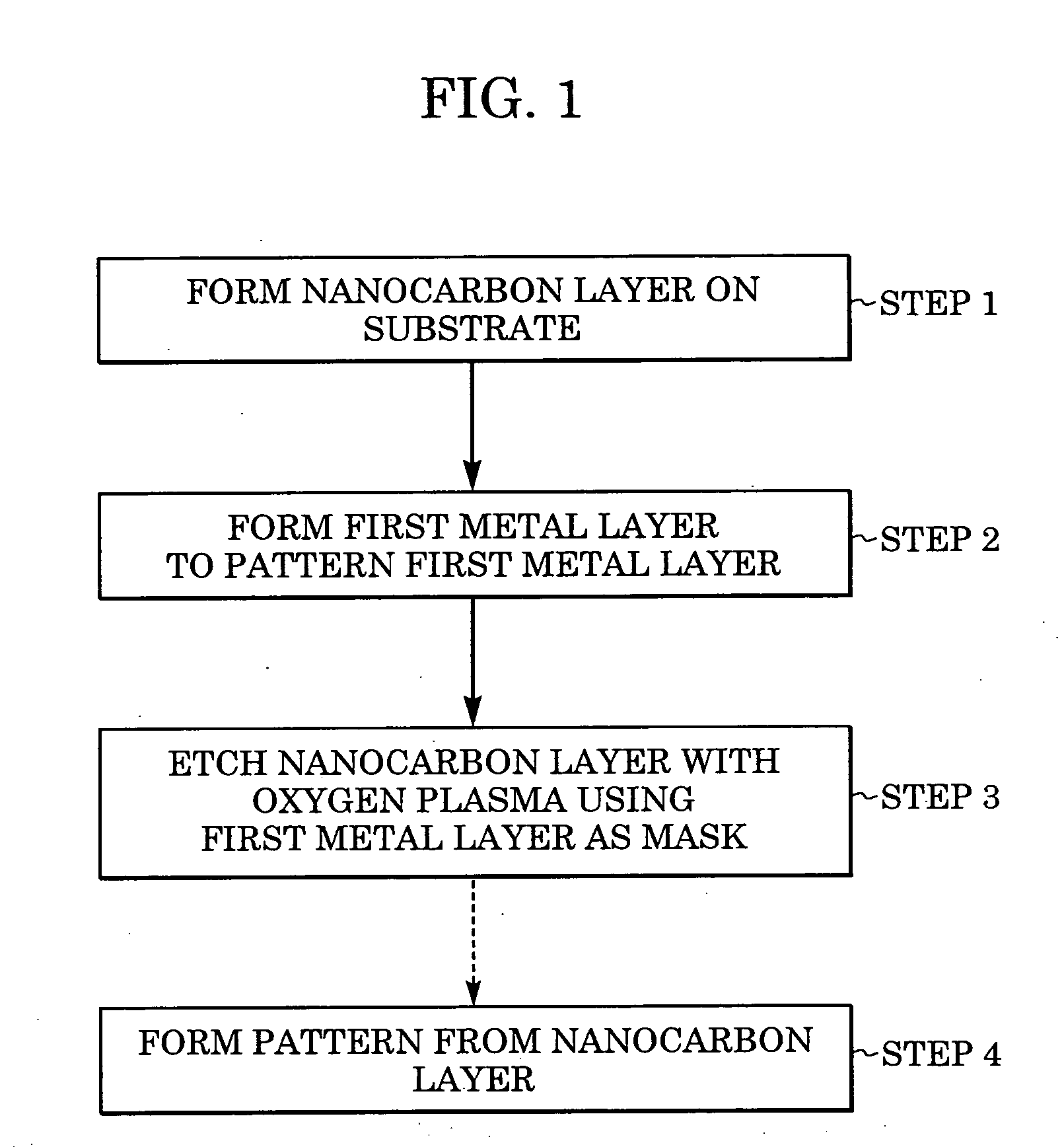

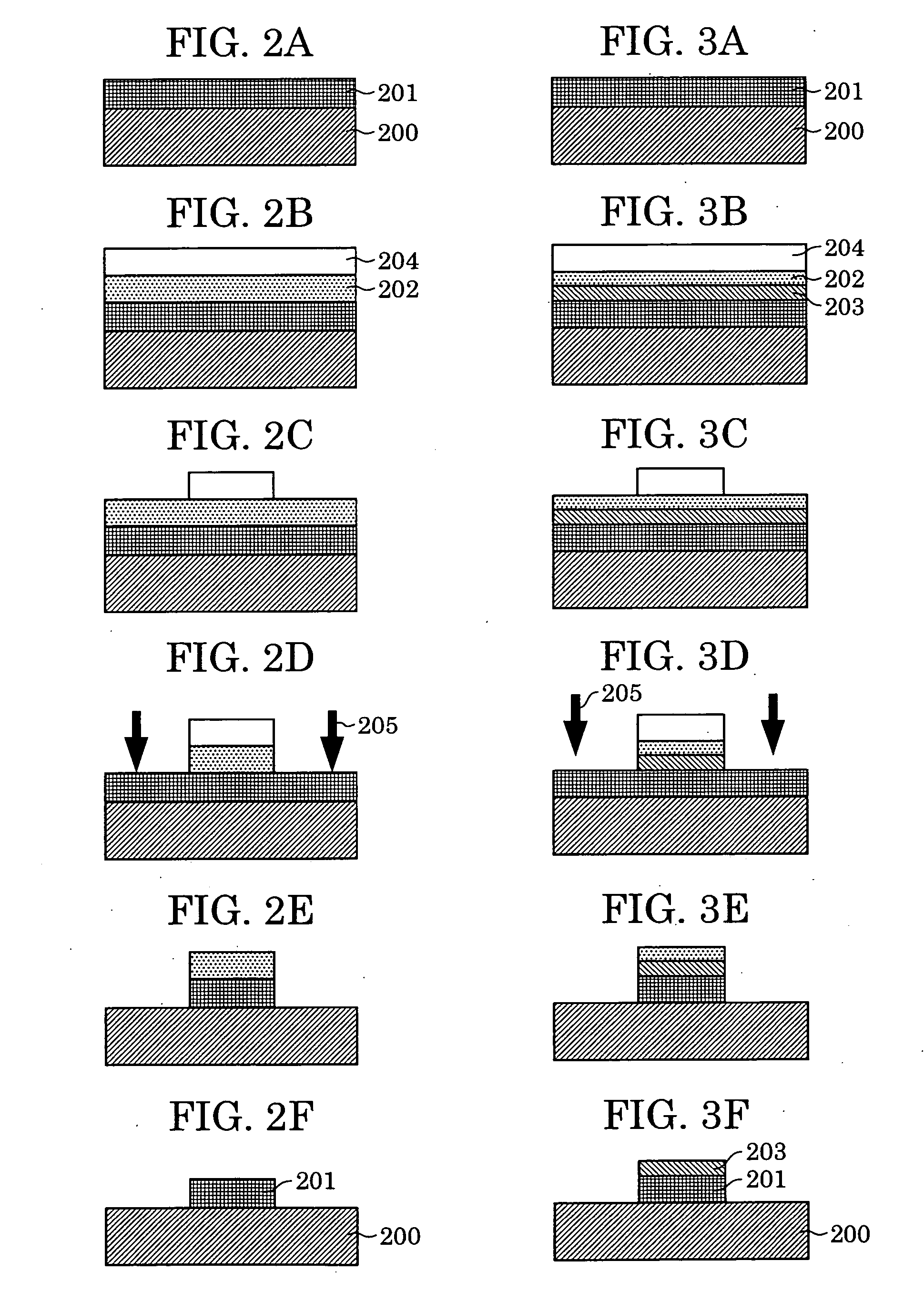

Process for patterning nanocarbon material, semiconductor device, and method for manufacturing semiconductor device

InactiveUS20050266605A1Easy to makeMaterial nanotechnologyElectric discharge tubesIndiumDevice material

A process for patterning a nanocarbon material includes a step of forming a nanocarbon layer on a substrate; a step of forming a first metal layer on the nanocarbon layer to pattern the first metal layer, the first metal layer containing at least one selected from the group consisting of zinc, tin, indium, aluminum, and titanium; and a step of etching the nanocarbon layer with oxygen plasma using the first metal layer as a positive pattern. Also, a method for manufacturing a semiconductor device including a semiconductor layer containing a nanocarbon material includes a step of patterning a nanocarbon material by the above process; and, a semiconductor device containing a nanocarbon material includes a semiconductor layer including a nanocarbon sub-layer patterned by the process.

Owner:CANON KK

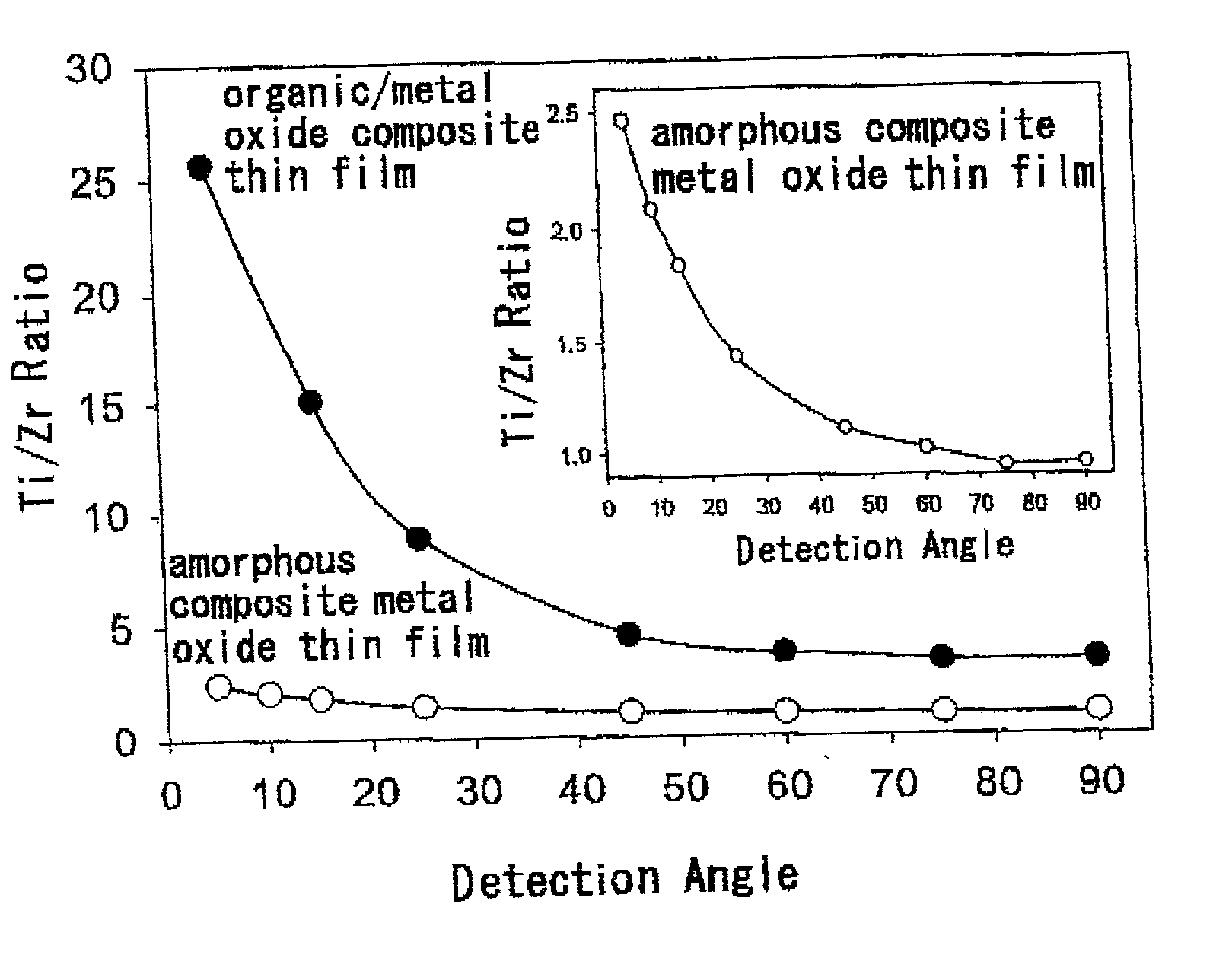

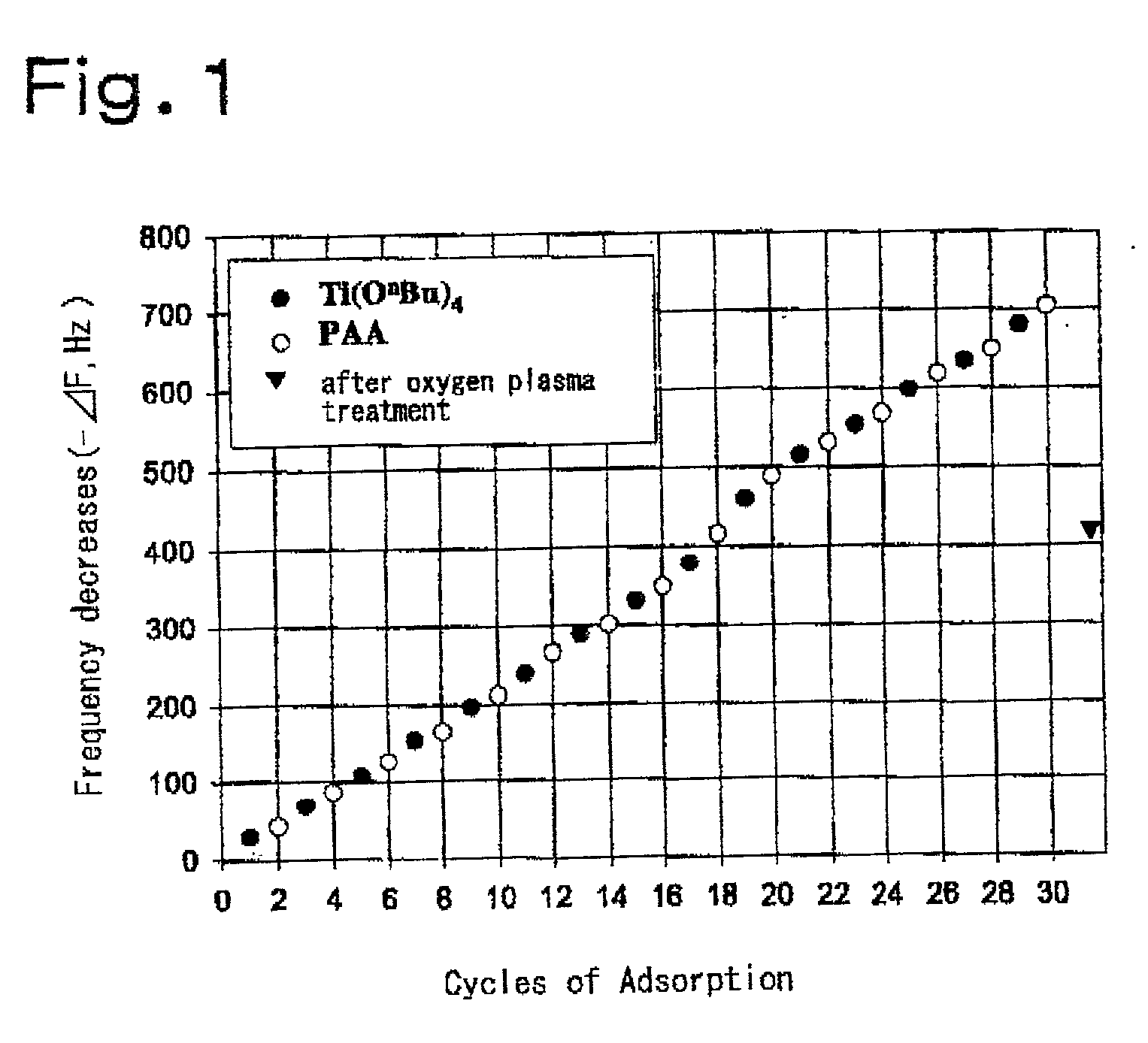

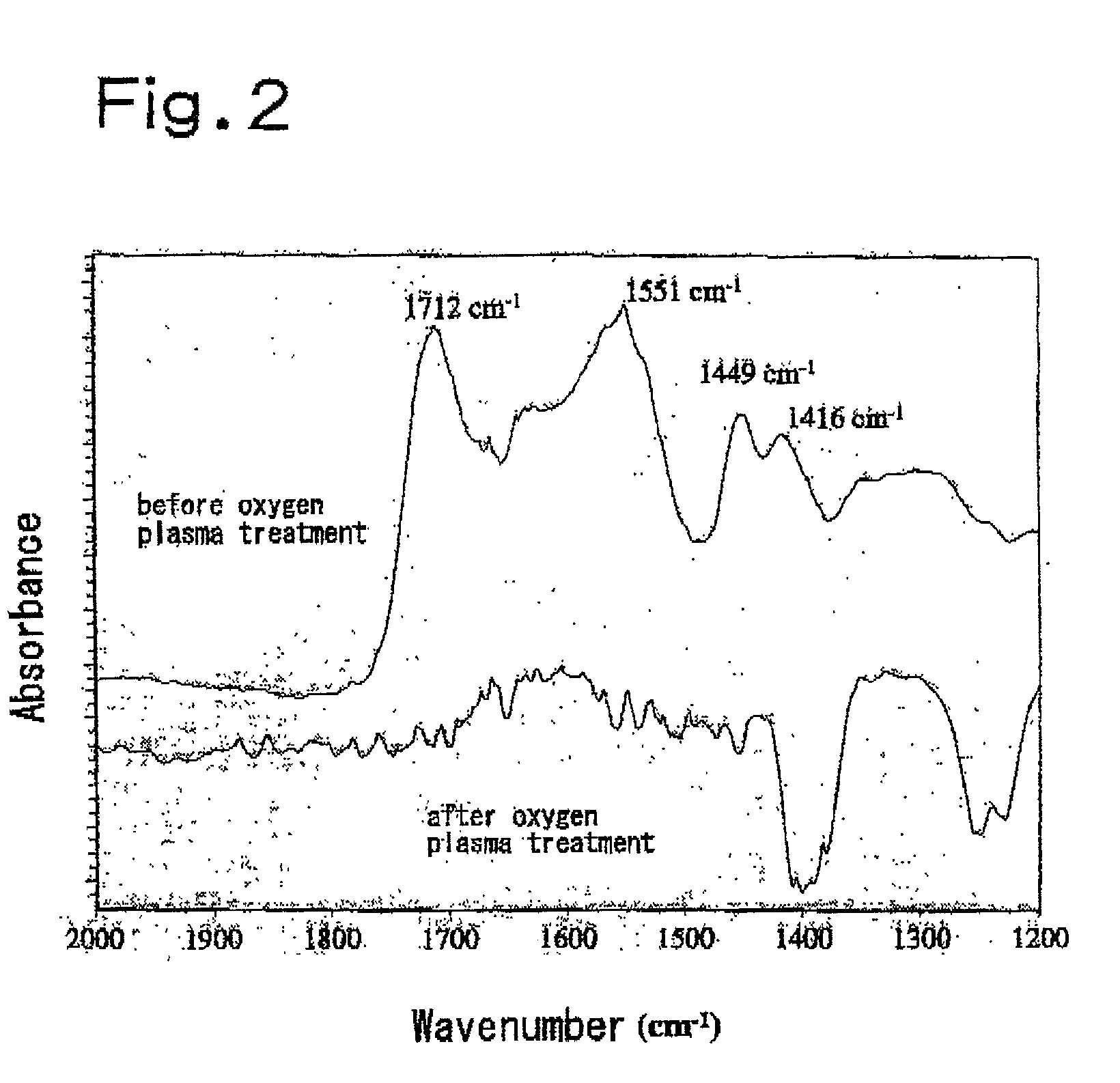

Thin film materials of amorphous metal oxides

InactiveUS20020190251A1Oxide/hydroxide preparationSemiconductor/solid-state device manufacturingOxygen plasmaOxide composite

Amorphous metal oxide thin film is produced by removing through oxygen plasma treatment the organic component from an organics / metal oxide composite thin film having thoroughly dispersed therein such organic component at molecular scale. This ensures production of amorphous metal oxide thin film with low density and excellent thickness precision.

Owner:RIKEN

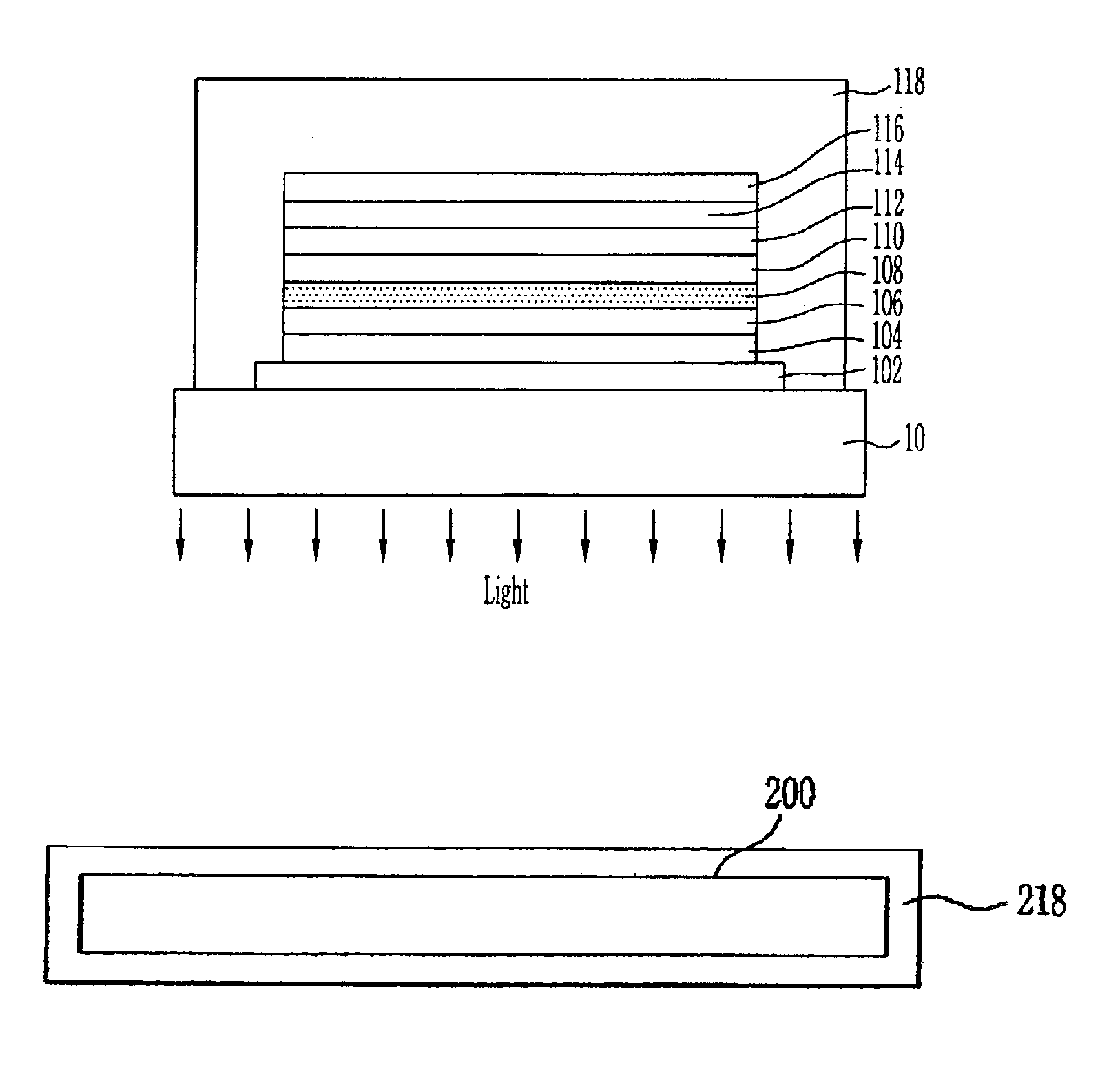

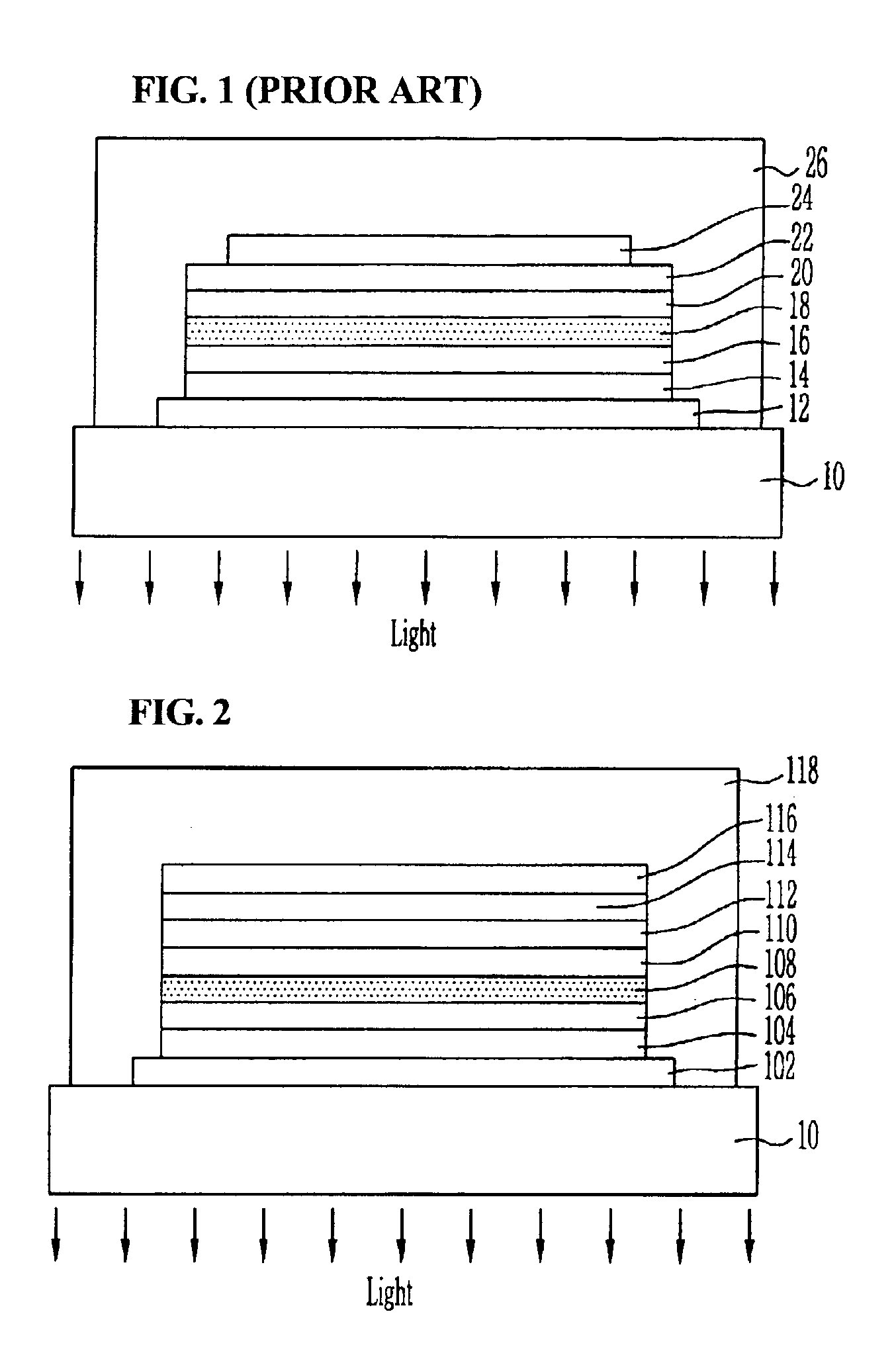

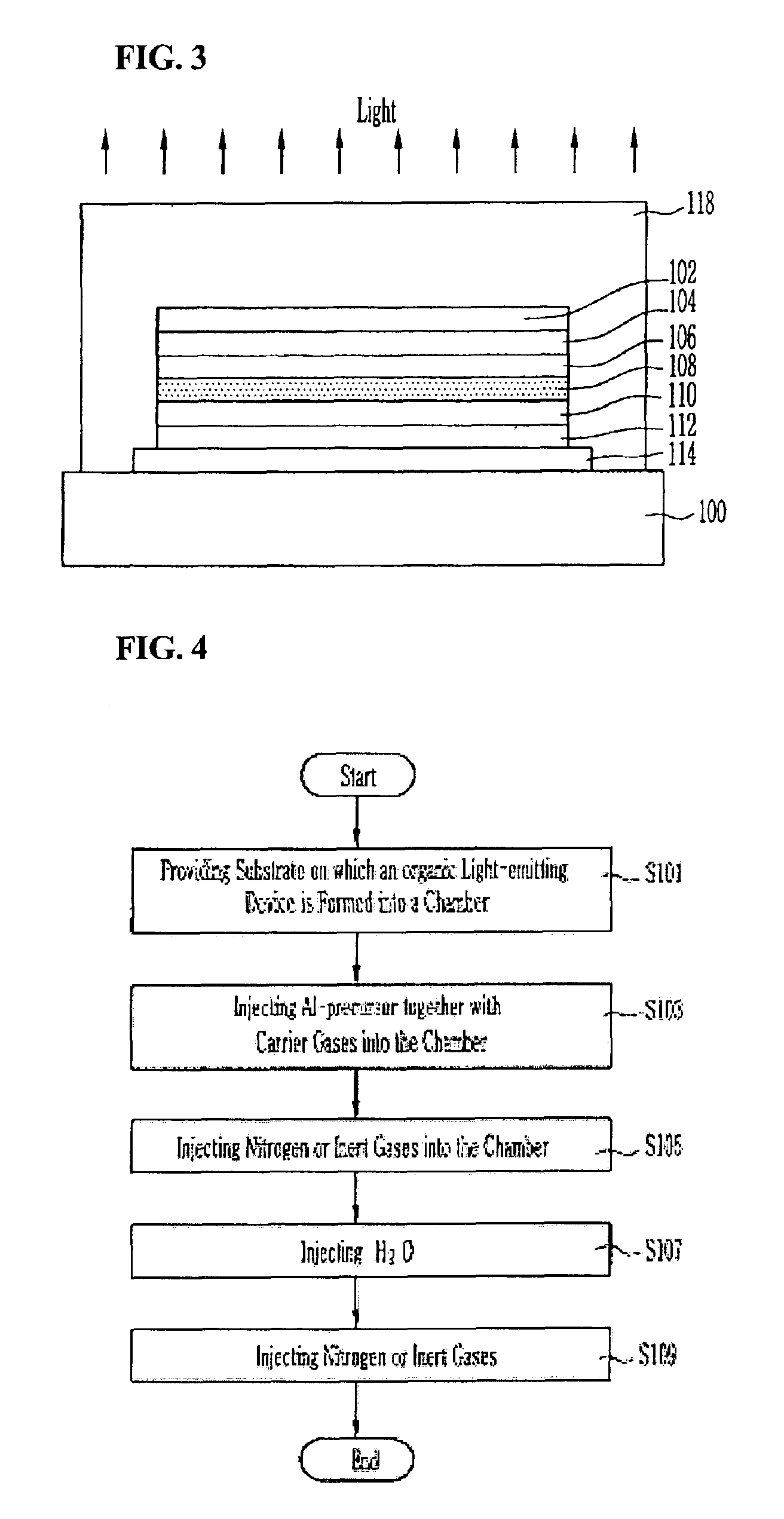

Flat panel display device and method of forming passivation film in the flat panel display device

InactiveUS6926572B2Improve featuresSimple processSolid-state devicesPretreated surfacesNitrogen plasmaOxygen plasma

A method of forming a passivation film in a flat panel display device includes forming the flat panel display device on a substrate, bringing the flat panel display device into a chamber in order to form the passivation film, injecting precursors containing constituent elements of the passivation film into the chamber where the precursors include at least oxygen plasma, ammonia plasma, or nitrogen plasma, and forming the passivation film of an inorganic insulating material at a temperature of 20-220° C. through a surface chemical reaction between the precursors by a plasma enhanced atomic layer deposition method.

Owner:UNILOC 2017 LLC

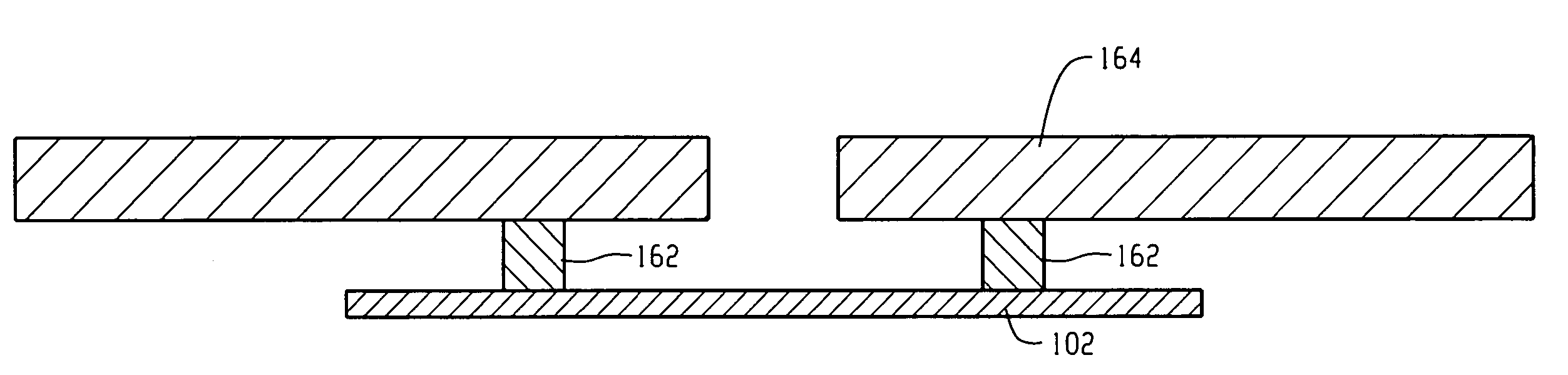

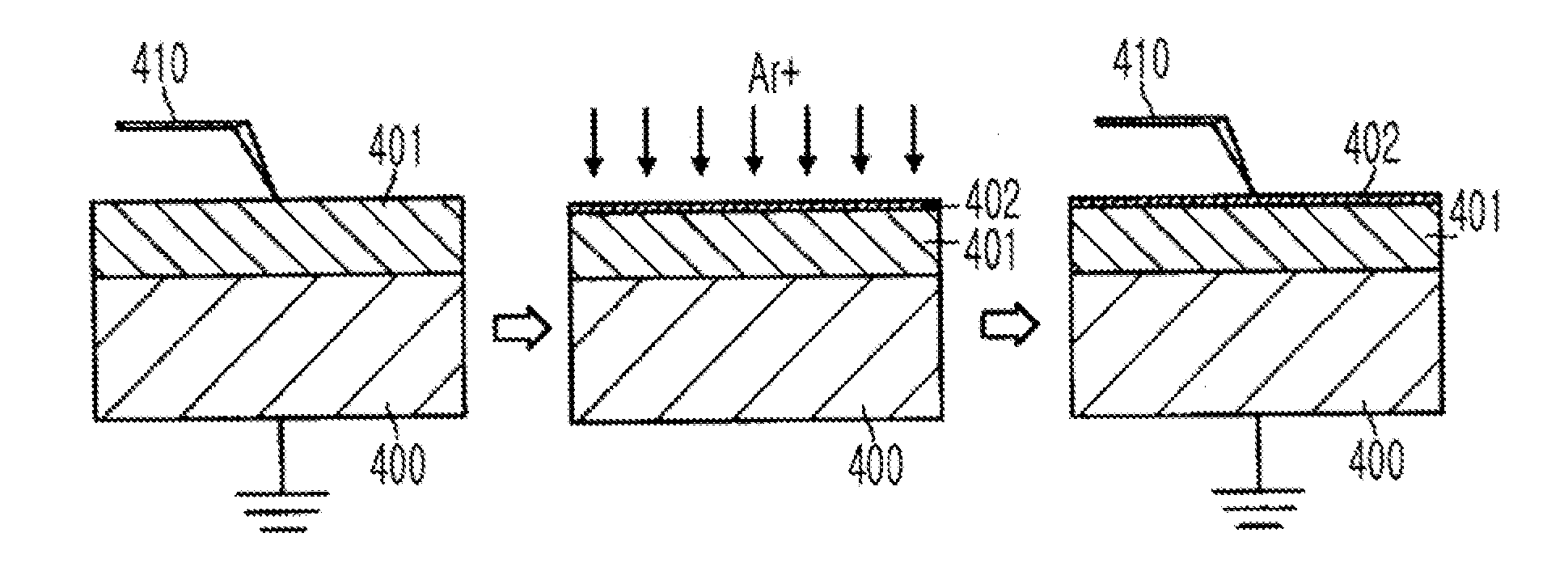

Germanium-on-insulator fabrication utilizing wafer bonding

InactiveUS20050067377A1Decorative surface effectsSemiconductor/solid-state device manufacturingOxygen plasmaWafer bonding

Methods of forming a germanium on insulator structure and its associated structures are described. Those methods comprise forming an epitaxial germanium layer on a sacrificial silicon layer, removing a portion of the epitaxial germanium layer, activating the epitaxial germanium layer and an oxide layer disposed on a silicon substrate in an oxygen plasma, and bonding the epitaxial germanium layer to the oxide layer to form a germanium on insulator structure.

Owner:INTEL COROIRATION

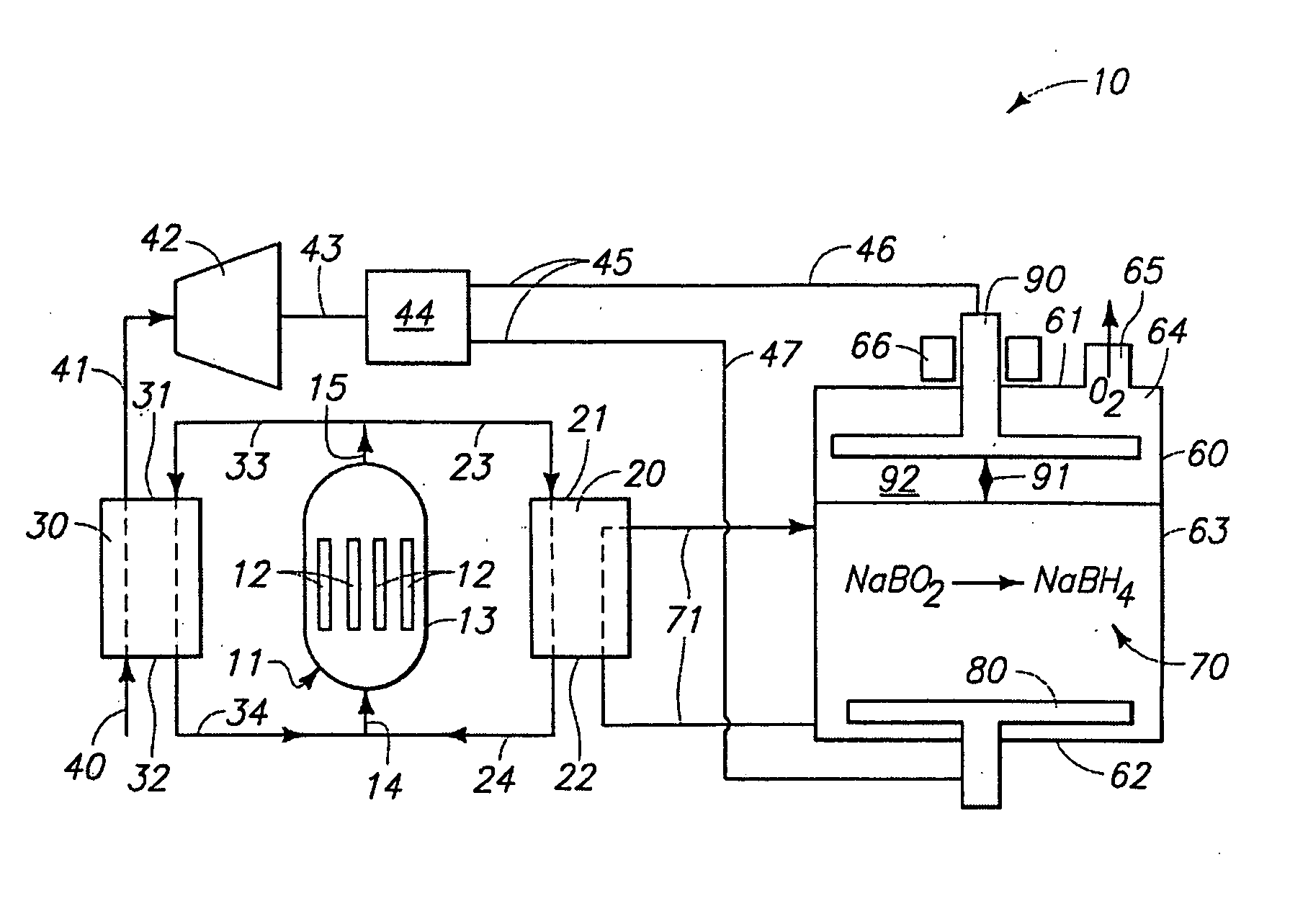

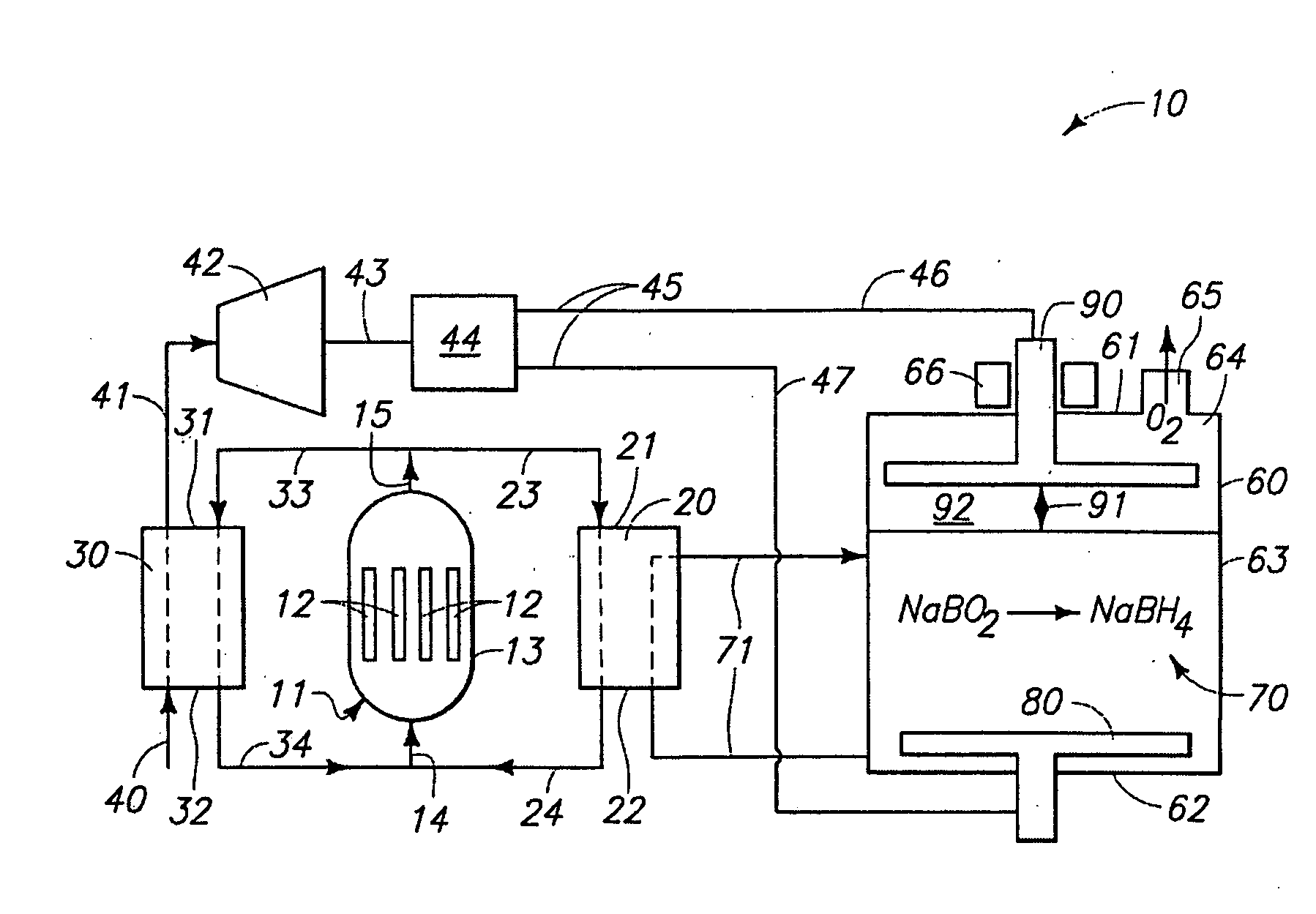

Method and apparatus for chemical synthesis

InactiveUS20050087435A1Encourage formationFacilitates chemical generationEnergy based chemical/physical/physico-chemical processesBoron compoundsChemical synthesisElectrolysis

A method and apparatus for forming a chemical hydride is described and which includes a pseudo-plasma-electrolysis reactor which is operable to receive a solution capable of forming a chemical hydride and which further includes a cathode and a movable anode, and wherein the anode is moved into and out of fluidic, ohmic electrical contact with the solution capable of forming a chemical hydride and which further, when energized produces an oxygen plasma which facilitates the formation of a chemical hydride in the solution.

Owner:BATTELLE ENERGY ALLIANCE LLC

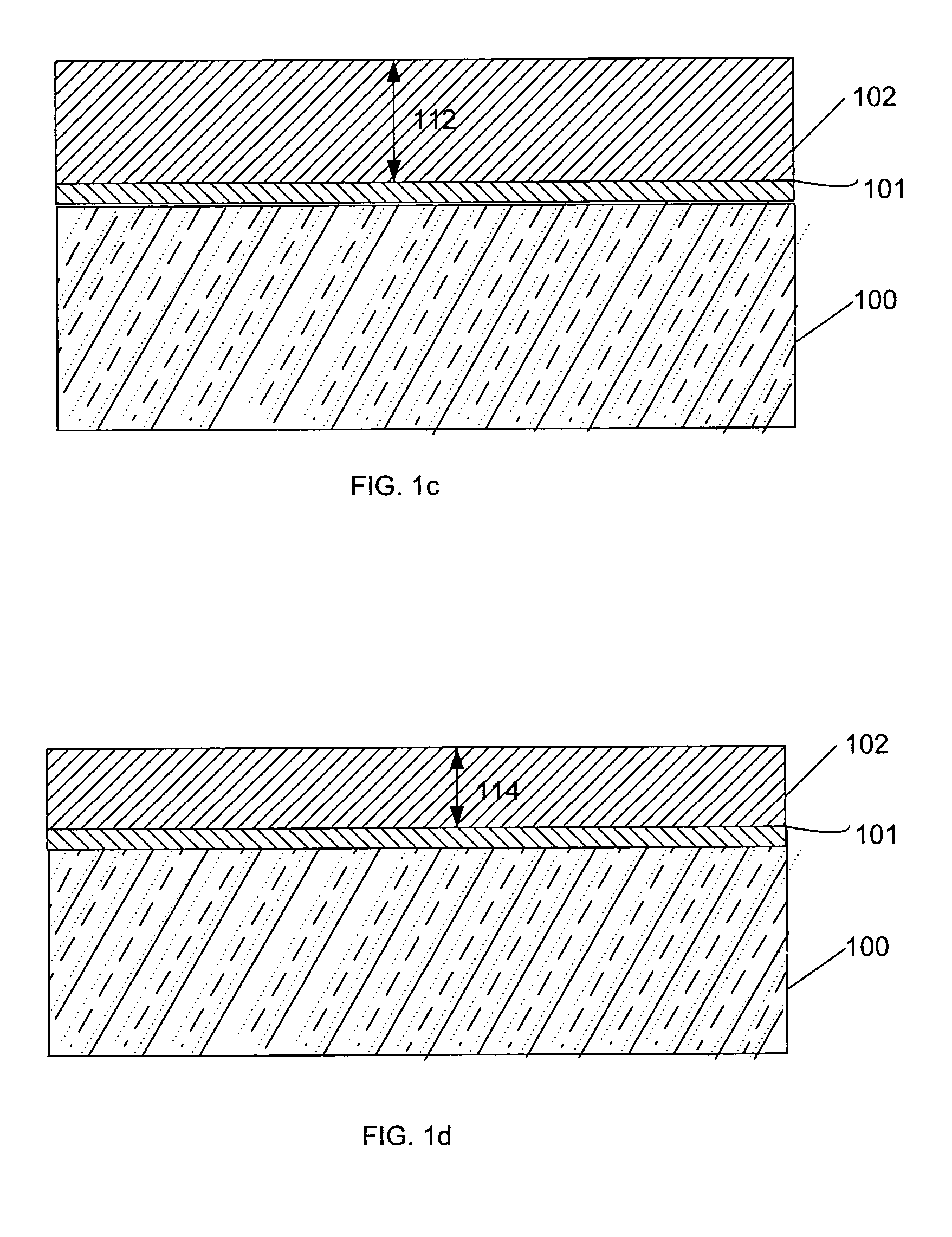

Oxidized Barrier Layer

InactiveUS20080237029A1Semiconductor/solid-state device detailsSolid-state devicesChemical physicsOxygen plasma

A method and resultant produce of forming barrier layer based on ruthenium tantalum in a via or other vertical interconnect structure through a dielectric layer in a multi-level metallization. The RuTa layer in a RuTa / RuTaN bilayer, which may form discontinuous islands, is actively oxidized, preferably in an oxygen plasma, to thereby bridge the gaps between the islands. Alternatively, ruthenium tantalum oxide is reactive sputtered onto the RuTaN or directly onto the underlying dielectric by plasma sputtering a RuTa target in the presence of oxygen.

Owner:APPLIED MATERIALS INC

Structure manufacturing method

A liquid application material that is capable of forming an oxidized insulator as a result of baking is applied onto a support substrate to produce an object of processing. Then, a mold having projection structures with intervals of nanometers is pressed against the applied liquid material to produce corresponding recess structures. Thereafter, the applied liquid material is baked in oxygen-containing gas or oxidized in ozone or oxygen plasma to make it electrically highly resistive. Subsequently, a layer to be anodized is formed on said oxidized insulator. Then, the layer to be anodized is actually anodized in an acidic solution to form fine holes that are aligned with the respective recess structures in the anodized layer. Accordingly, fine recess structures can be manufactured with ease.

Owner:CANON KK

Method for producing hydrophilic foam dressing and hydrophilic foam dressing produced thereby

Disclosed herein is a method for producing a polyurethane foam dressing that protects injuries such as wounds or burns and is useful for wound healing. More particularly, the present invention provides a method for manufacturing a polyurethane foam dressing with remarkably improved productivity and processing efficiency, which can improve physical properties of the polyurethane foam dressing. Themethod comprises: preparing a moisture permeable waterproof polyurethane film layer; preparing a polyurethane prepolymer; preparing a polyurethane foaming mixture; obtaining a tacky gel type polyurethane foam layer; laminating the tacky gel type polyurethane foam layer on the polyurethane film layer; and winding the produced polyurethane foam dressing in a roll form and then ageing the foam dressing. The method further includes, impregnating the polyurethane foam with a moisturizer and drying the foam and, then, treating the foam with oxygen plasma to modify a surface of the foam dressing, thereby improving absorption rate of the foam dressing. The method of the present invention has advantages such as remarkably improved productivity and processing efficiency allowing mass production of foam dressings, thereby considerably reducing production costs and enabling supply of low cost foam dressings with improved physical properties.

Owner:株式会社元比金

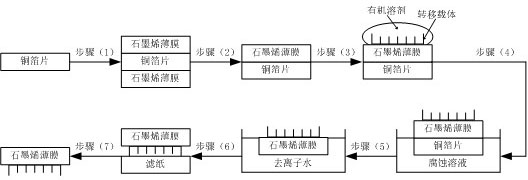

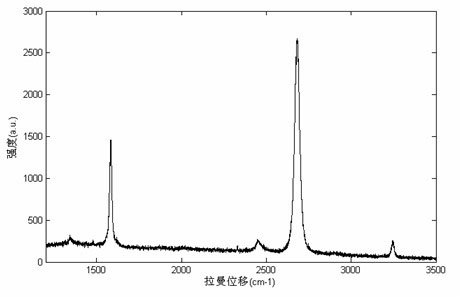

Direct graphene film transfer method

The invention relates to a direct graphene film transfer method. Currently, transferring graphene films from metal surfaces is quite inconvenient. The method includes: using the chemical vapor deposition method to grow a graphene film on a copper foil; using oxygen plasma cleaner to clear graphene on one side of the copper foil to obtain a combination of the single-layer graphene film with the copper foil; flatly attaching a transfer carrier onto the surface of the graphene film and drip adding an organic solvent of a proper quality to increase the interaction between the transfer carrier andthe graphene film; using etchant solution to clear the copper foil to obtain a combination of the single-layer graphene film with the transfer carrier; using deionized water to clean the graphene film for multiple times; and using a filter paper to clear the deionized water on the surface of the graphene film. Using the direct graphene film transfer method avoids the graphene films from being damaged by transfer media such as organic colloid and the like, single-layer graphene films of 100 micrometers or more can be obtained, simple equipment is required, product dimension is controllable, production safety is high, and industrial application is easy to implement.

Owner:ZHEJIANG UNIV

Spacer material modification to improve k-value and etch properties

ActiveUS20150249017A1Electric discharge tubesSemiconductor/solid-state device manufacturingNitrogen plasmaOxygen plasma

A method for performing a spacer etch process is described. The method includes conformally applying a spacer material over a gate structure on a substrate, and performing a spacer etch process sequence to partially remove the spacer material from a capping region of the gate structure and a substrate region on the substrate adjacent a base of the gate structure, while retaining a spacer sidewall positioned along a sidewall of the gate structure. The K-value of high-K spacer materials are reduced to an acceptable range with oxidation using an oxygen plasma treatment. The etch rate of low-K spacer materials are reduced to a target range using a nitrogen plasma treatment. Integration of the spacer etch processing is selected based on impact to the other structures in the substrate.

Owner:TOKYO ELECTRON LTD

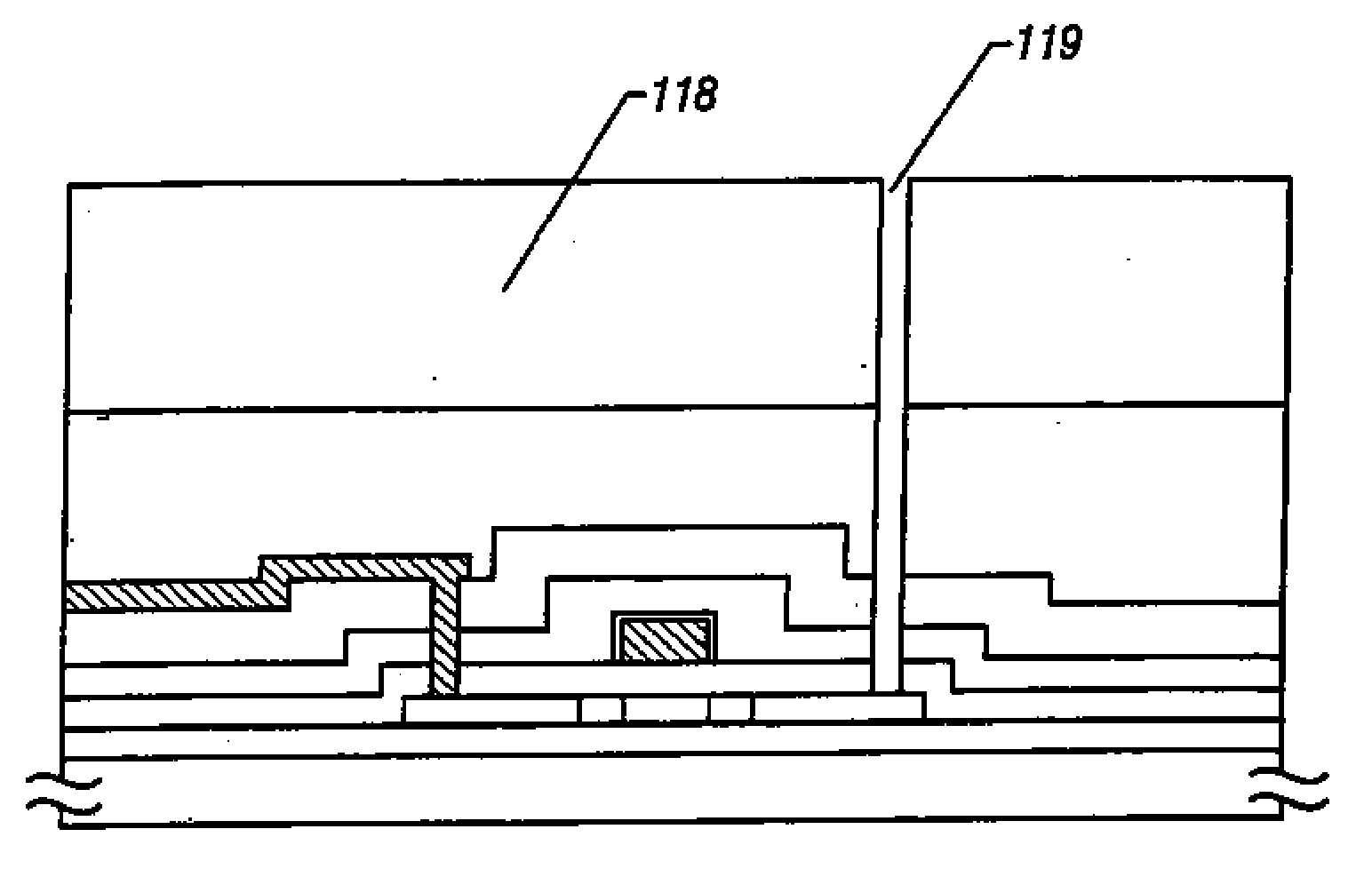

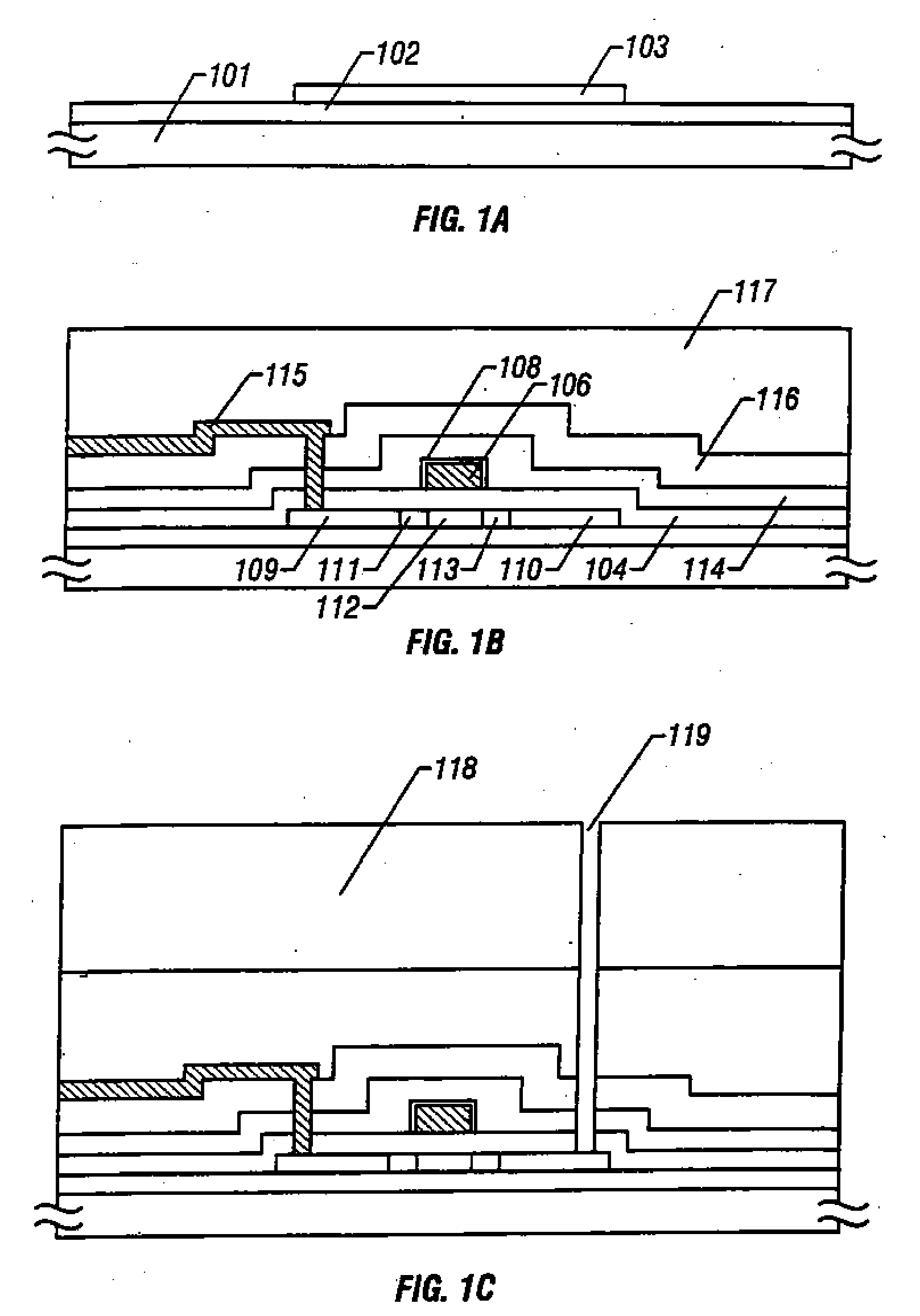

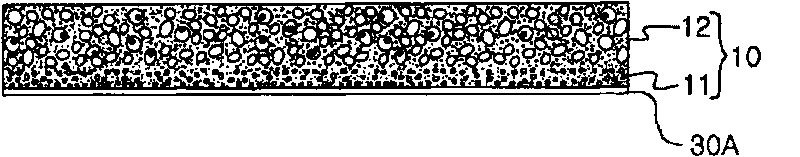

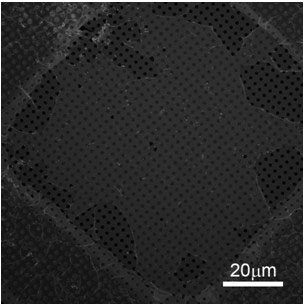

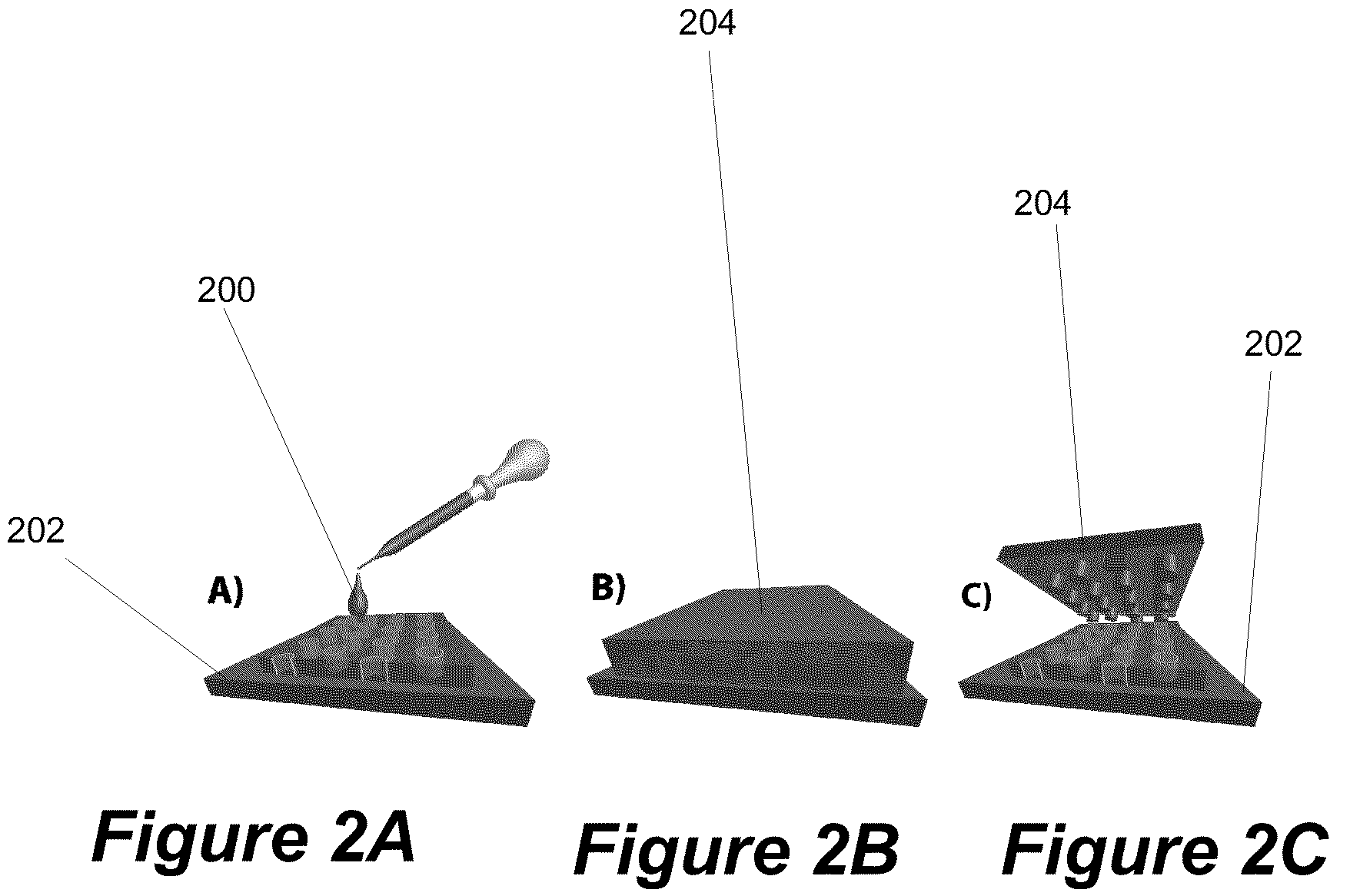

Surface and composition enhancements to high aspect ratio C-MEMS

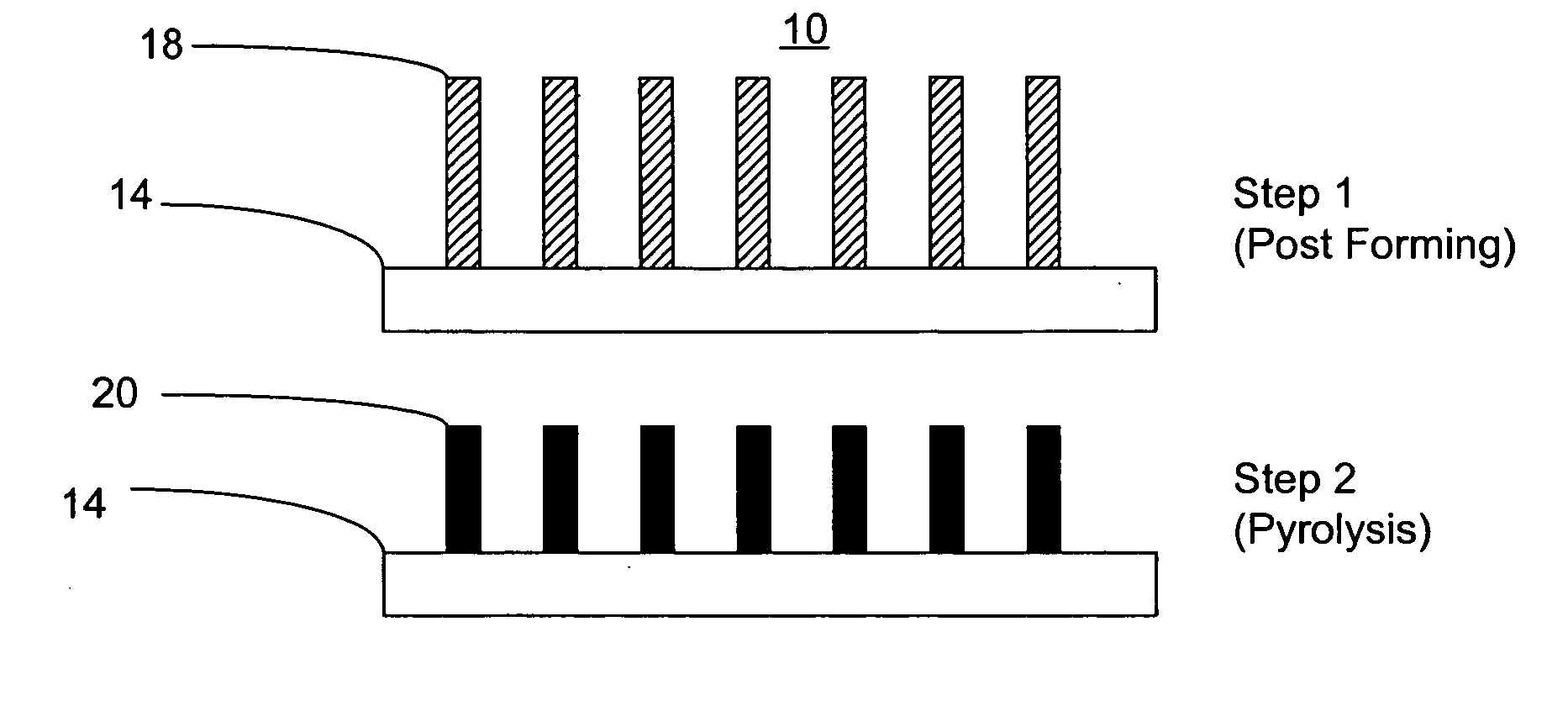

ActiveUS20060068107A1Increase surface areaHigh aspect ratioMaterial nanotechnologyChemical vapor deposition coatingForming gasOxygen plasma

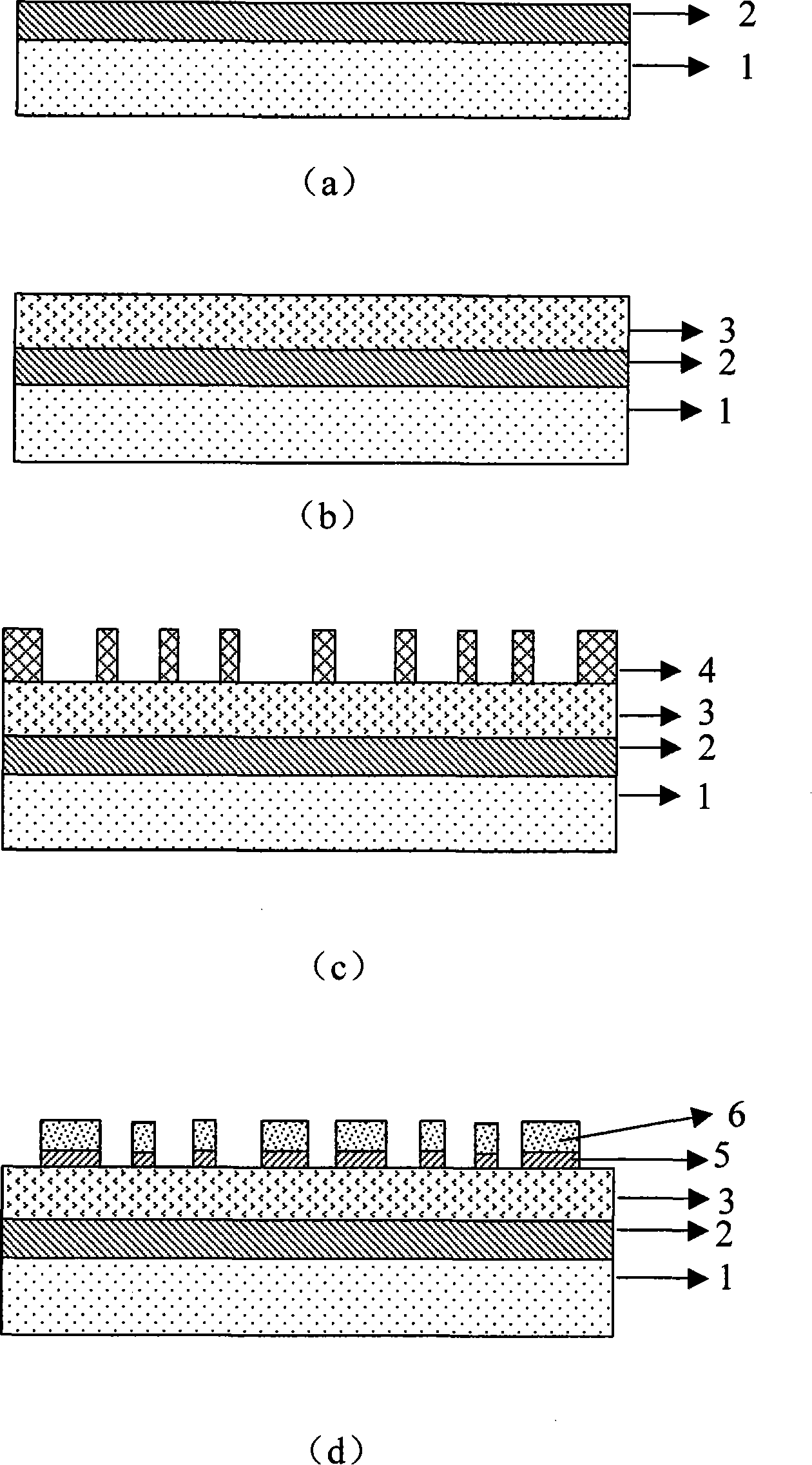

C-MEMS architecture having carbon structures with high surface areas due to high aspect ratios and nanoscale surface enhancements, and improved systems and methods for producing such structures are provided. Specifically, high aspect ratio carbon structures are microfabricated by pyrolyzing a patterned carbon precursor polymer. Pyrolysing the polymer preferably comprises a multi-step process in an atmosphere of inert and forming gas at high temperatures that trail the glass transition temperature (Tg) for the polymer. The surface area of the carbon microstructures is increases by nanotexturing the surface through oxygen plasma exposure, and by integrating nanoscale structures with the carbon microstructures by exposing the carbon microstructures and a catalyst to hydrocarbon gas. In a preferred embodiment, the carbon microstructures are the source of carbon gas.

Owner:RGT UNIV OF CALIFORNIA

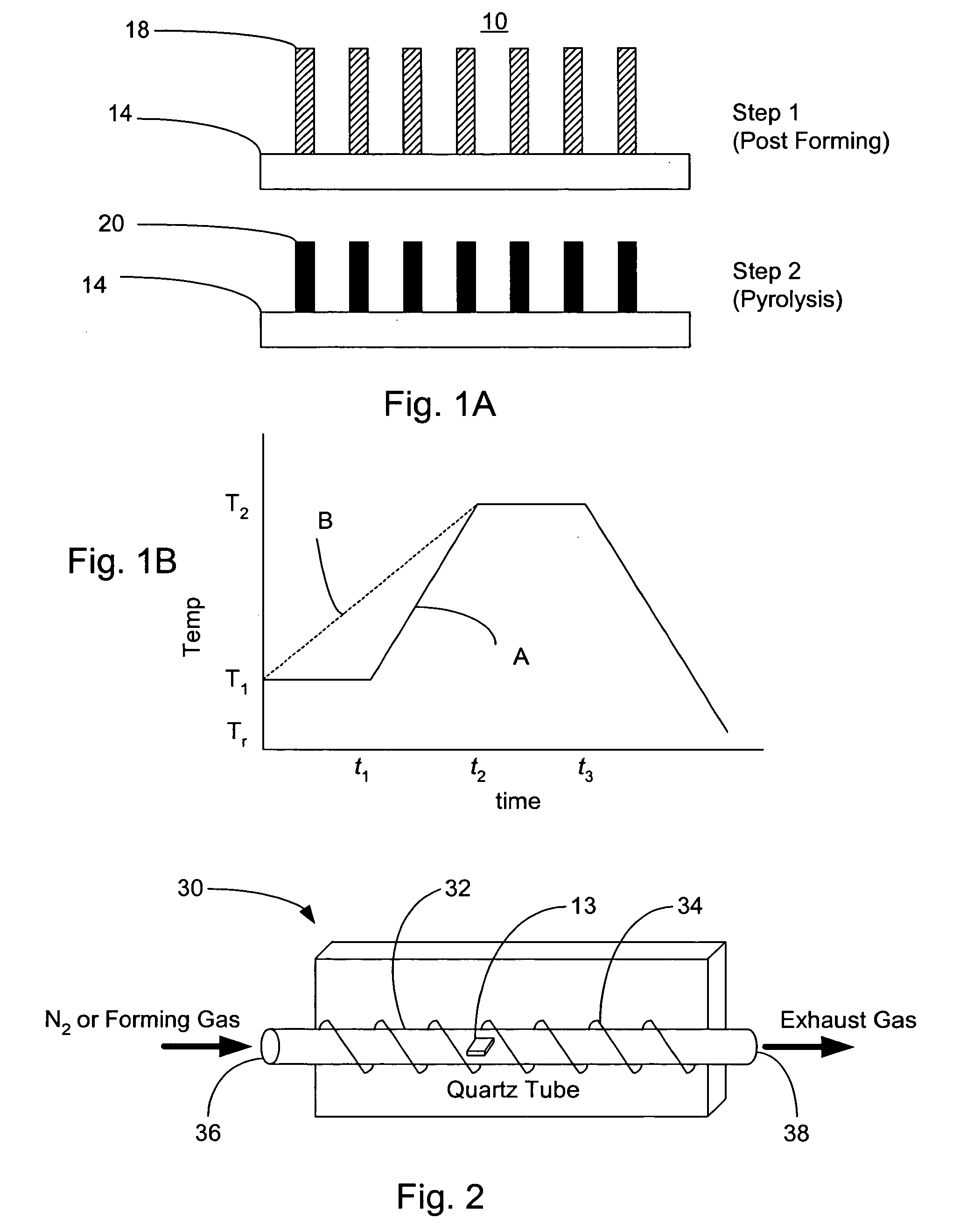

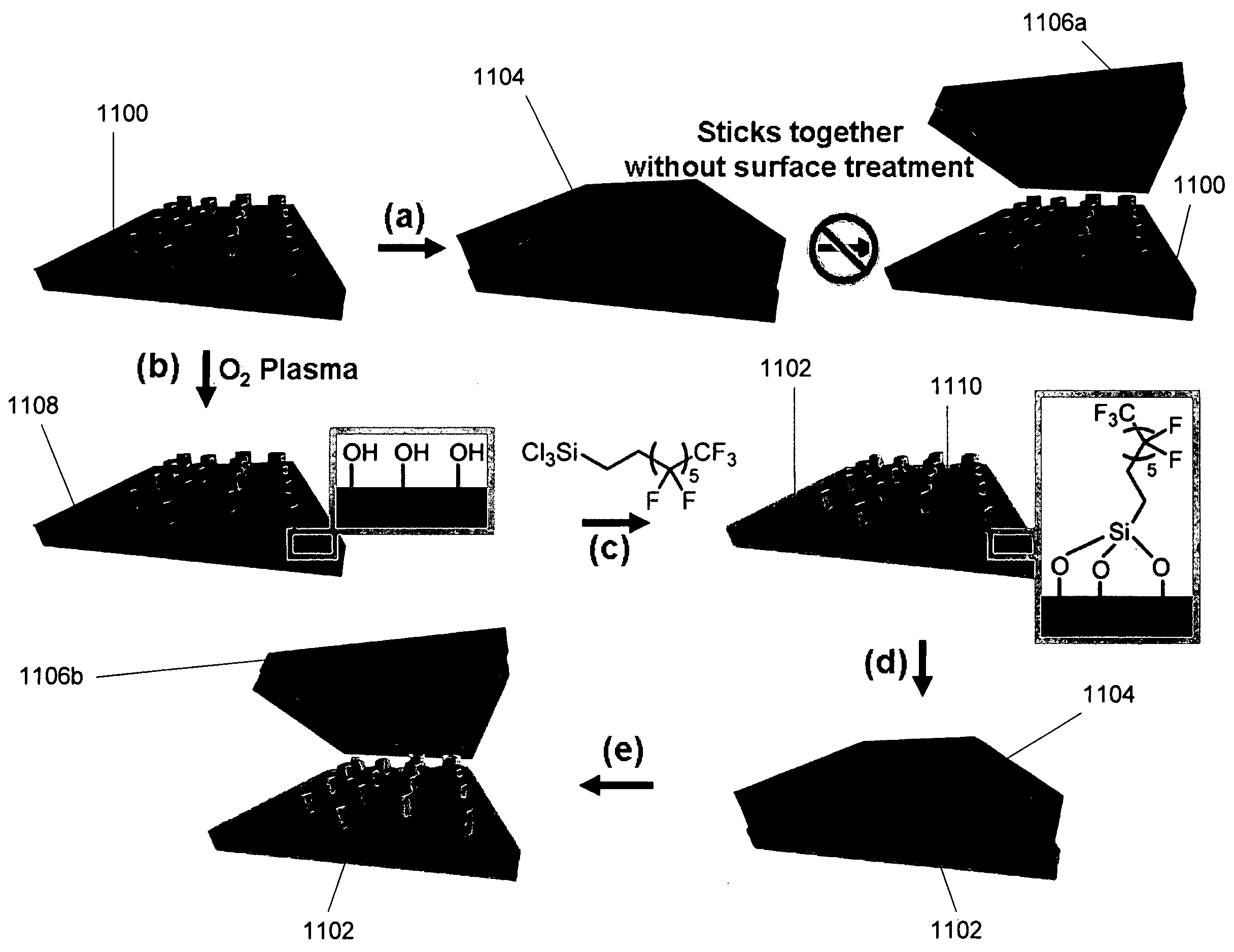

Thiol-ene based poly(alkylsiloxane) materials

A stamp is comprised of a thiol-ene polymer, wherein the thiol-ene polymer allows for creation of micro-scale or nano-scale patterns useful in soft or imprint lithography. A patterned thiol-ene polymer is fabricated by casting a thiol-ene mixture onto a patterned mold, curing the thiol-ene mixture to form the patterned thiol-ene polymer, and peeling off the patterned thiol-ene polymer from the silicon mold. A stamp comprised of a thiol-ene polymer may be replicated by exposing the to oxygen plasma to form a hydrophilic mold, exposing the hydrophilic mold to a fluorinating agent under vacuum conditions to form a functionalized surface of the hydrophilic mold, casting a thiol-ene mixture on top of the functionalized surface, photocuring the thiolene mixture to form a replica thiol-ene polymer, and peeling off the replica thiol-ene polymer.

Owner:RGT UNIV OF CALIFORNIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com