Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

120 results about "Reduced product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In model theory, a branch of mathematical logic, and in algebra, the reduced product is a construction that generalizes both direct product and ultraproduct. Let {Sᵢ | i ∈ I} be a family of structures of the same signature σ indexed by a set I, and let U be a filter on I. The domain of the reduced product is the quotient of the Cartesian product ∏ᵢ∈ISᵢ by a certain equivalence relation ~: two elements (aᵢ) and (bᵢ) of the Cartesian product are equivalent if {i∈I:aᵢ=bᵢ}∈U If U only contains I as an element, the equivalence relation is trivial, and the reduced product is just the original Cartesian product.

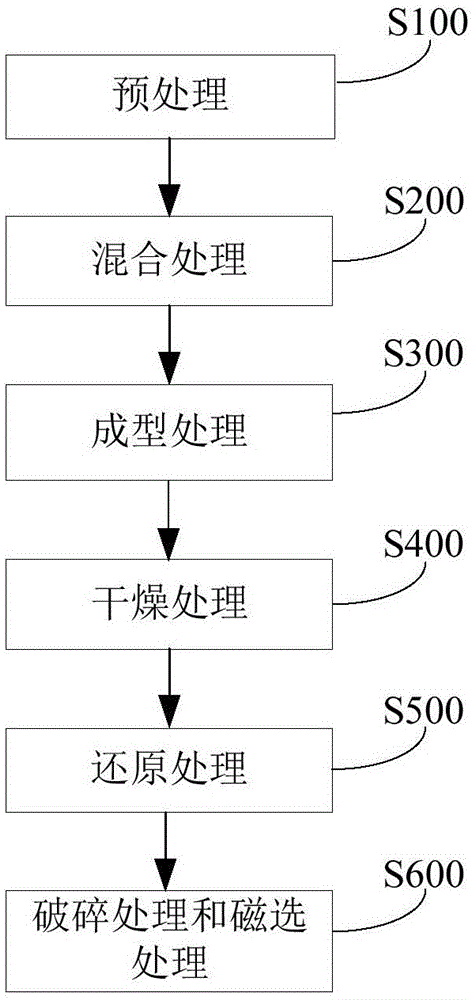

Method for treating copper slag

InactiveCN105039728AAchieve recyclingReduce consumptionProcess efficiency improvementProduct containing ironMixed materials

The invention discloses a method for treating copper slag. The method includes the steps that (1) the copper slag, a reducing agent and additives are pre-treated respectively; (2) the pre-treated copper slag, the pre-treated reducing agent and the pre-treated additives are mixed so that a mixed material can be obtained; (3) the mixed material is formed so that copper slag pellets can be obtained; (4) the copper slag pellets are dried so that the dried copper slag pellets can be obtained; (5) at the temperature of 1,350-1,550 DEG C, the dried copper slag pellets are reduced so that a solid reduced product containing iron-copper alloy particles and smoke containing lead and zinc can be obtained; and (6) the solid reduced product containing the iron-copper alloy particles is broken and magnetically separated so that the iron-copper alloy particles and tailings can be obtained respectively. According to the method, multiple metal elements in the copper slag can be comprehensively recycled, and the higher recovery rate is achieved.

Owner:SHENWU TECH GRP CO LTD

Process for manufacturing iron pellets from low-grade complex refractory ore through molten slag method

ActiveCN102329911AImprove efficiencyIncrease production capacityFluidised-bed furnacesReducing atmosphereMolten slag

The invention relates to a process for manufacturing iron pellets from low-grade complex refractory ore through the molten slag method, belonging to the field of direct reduction of metal metallurgy. The invention has the technical scheme that the process comprises the following steps of: fully mixing the low-grade complex refractory ore with a reducing agent and additives, pelletizing, drying the carbonic pellets, adding lime stone, coal dust and clay to mix, pressing the mixture into hollow or solid bricks, spraying clay slurry to the surfaces of the bricks, and loading the bricks into reduction equipment; discharging the reduced product, immediately cooling the product in a cooling protection chamber with reducing atmosphere, and pulverizing and sorting the cooled material product to obtain the raw material for steel making. The invention has the advantages that a slag forming agent promotes non-iron oxide gangue components to be quickly aggregated and remove metal element to form ore slag, and metal aggregation agent promotes oxidized metal metals to be quickly reduced and separate ore slag to form iron pellets. The material forming iron pellets can greatly improve the efficiency of subsequent ore grinding and magnetic separation procedures. By applying the process, the capacity of a single kiln can be increased to the maximum extent.

Owner:TANGSHAN OUTSTANDING SCI & TECH

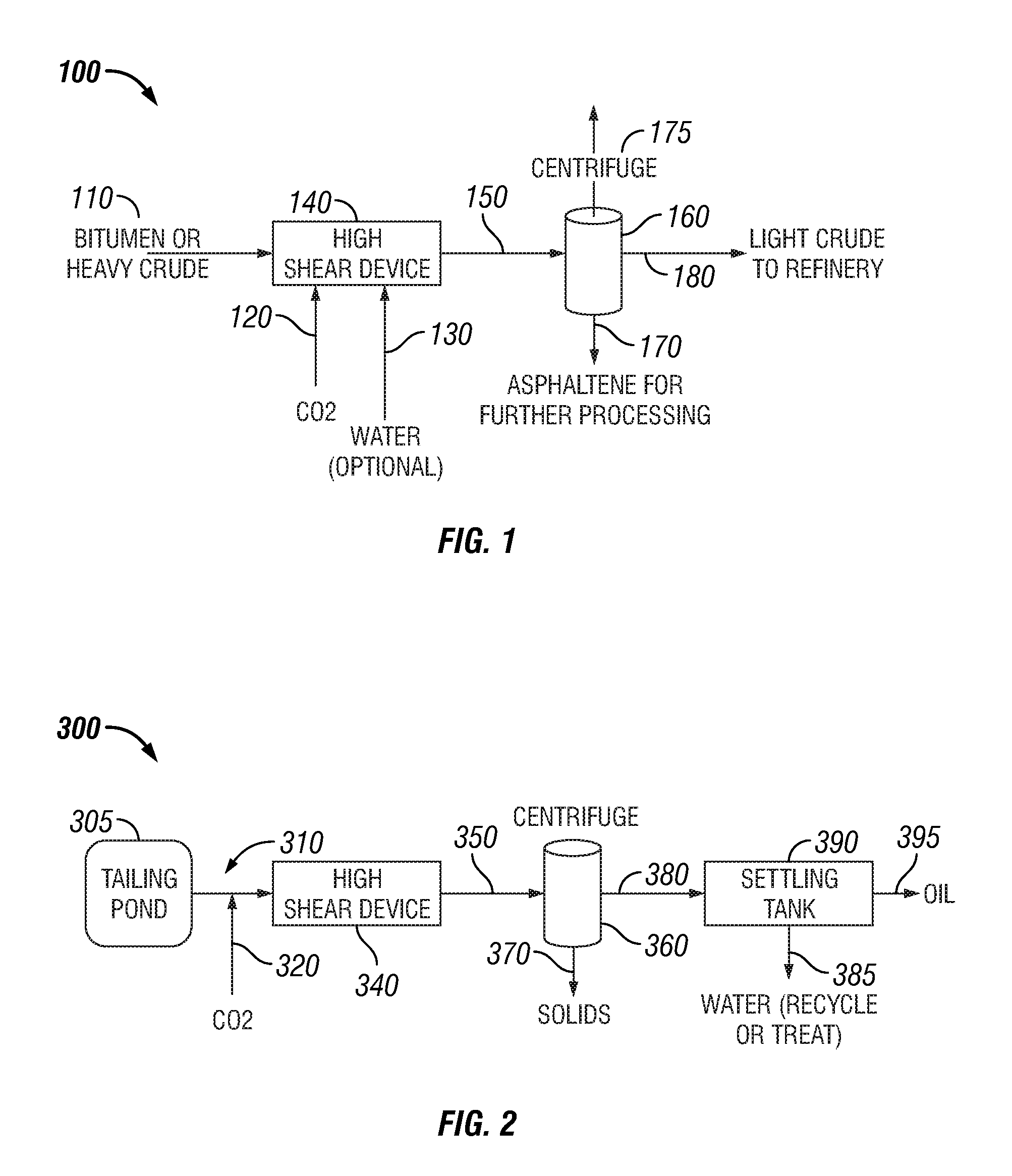

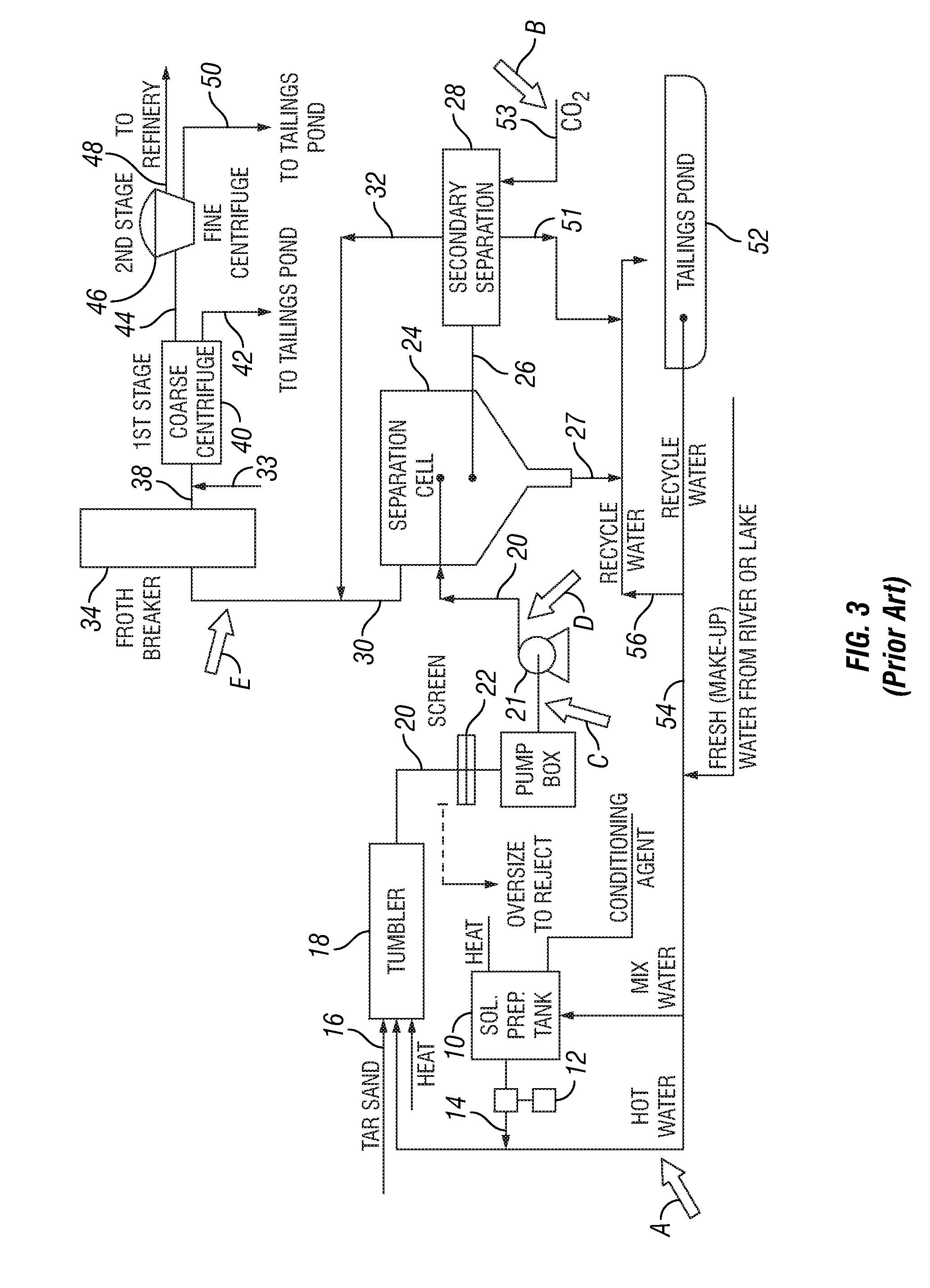

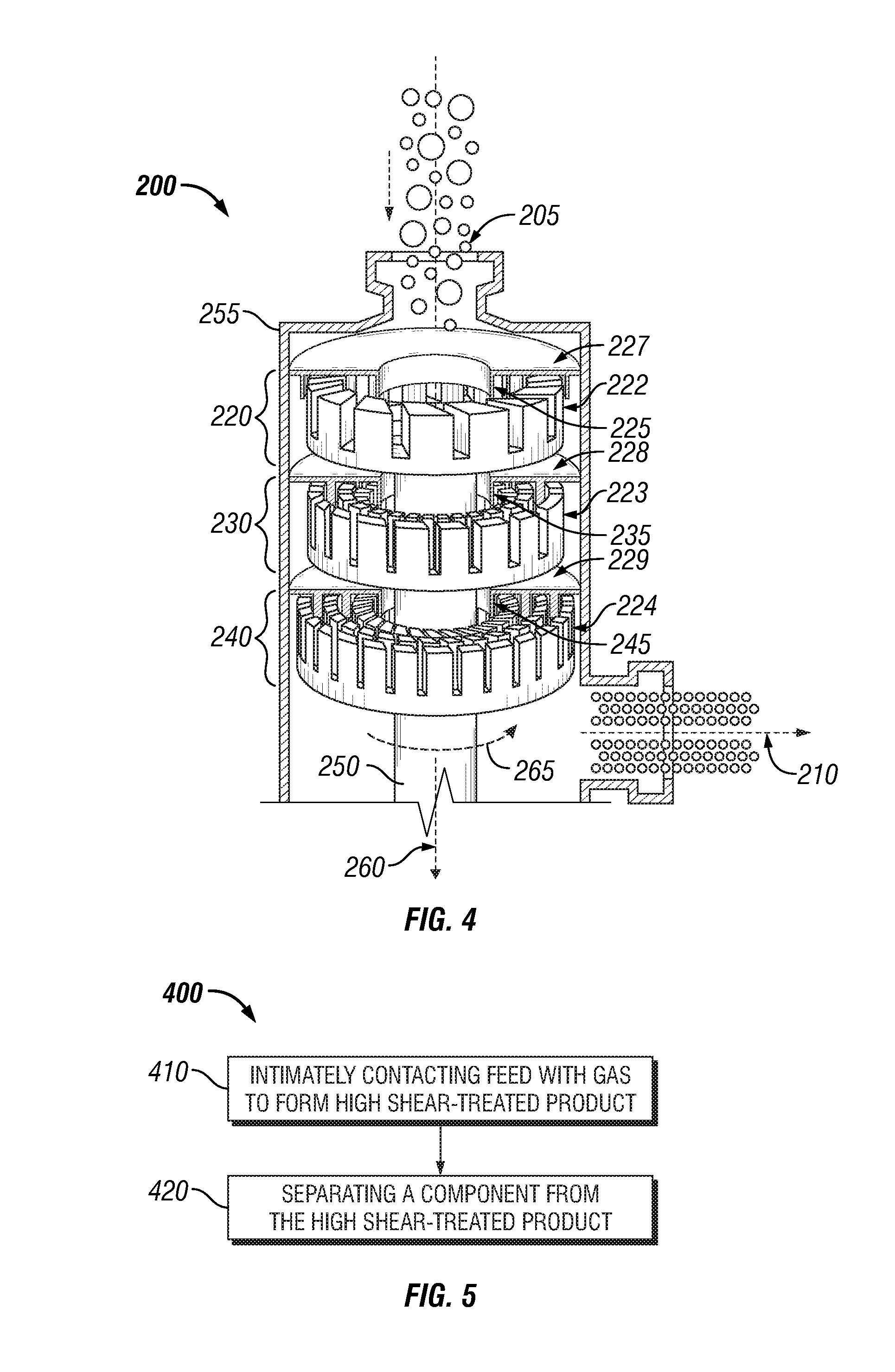

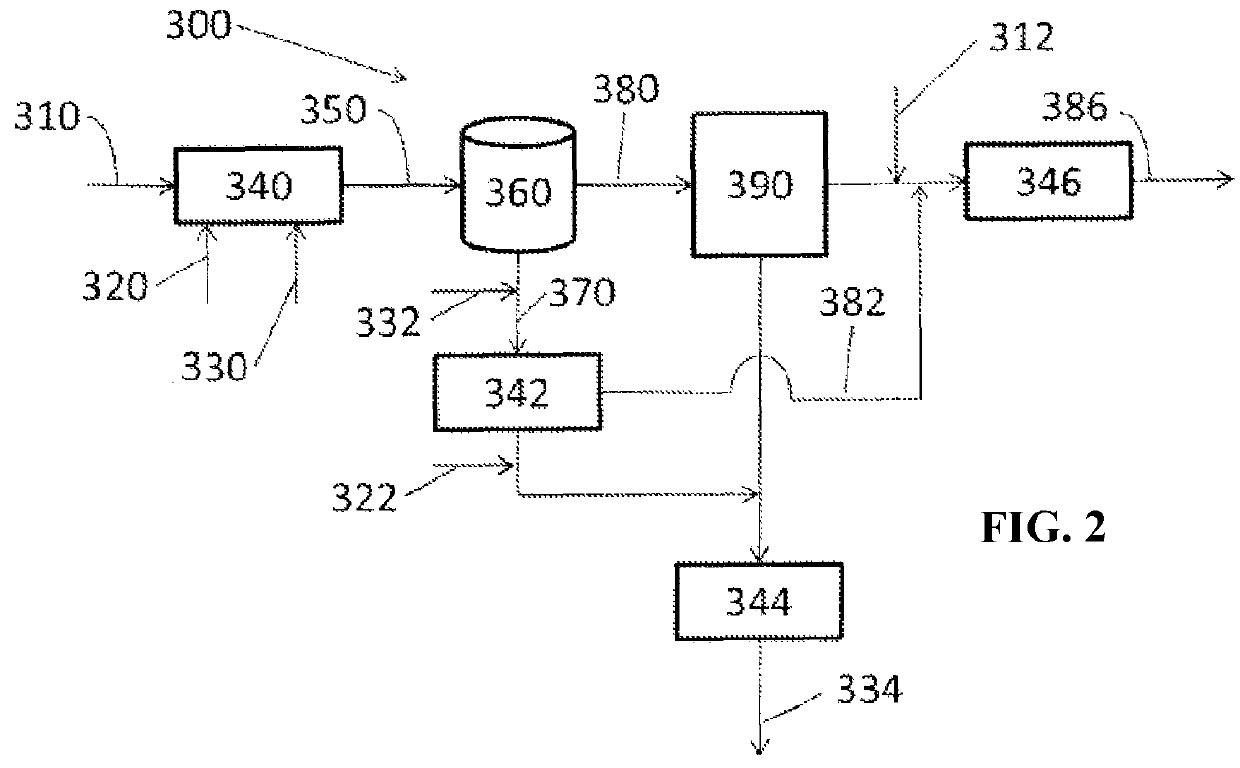

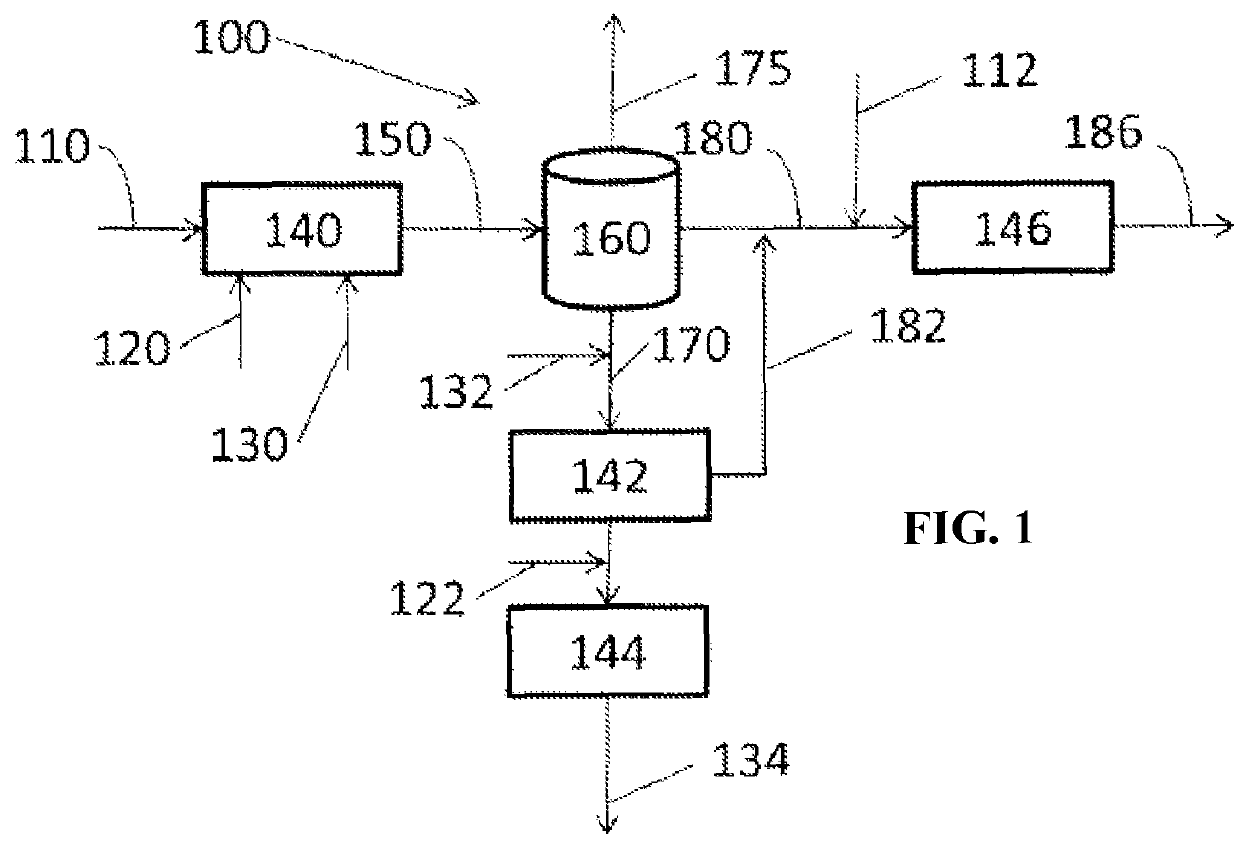

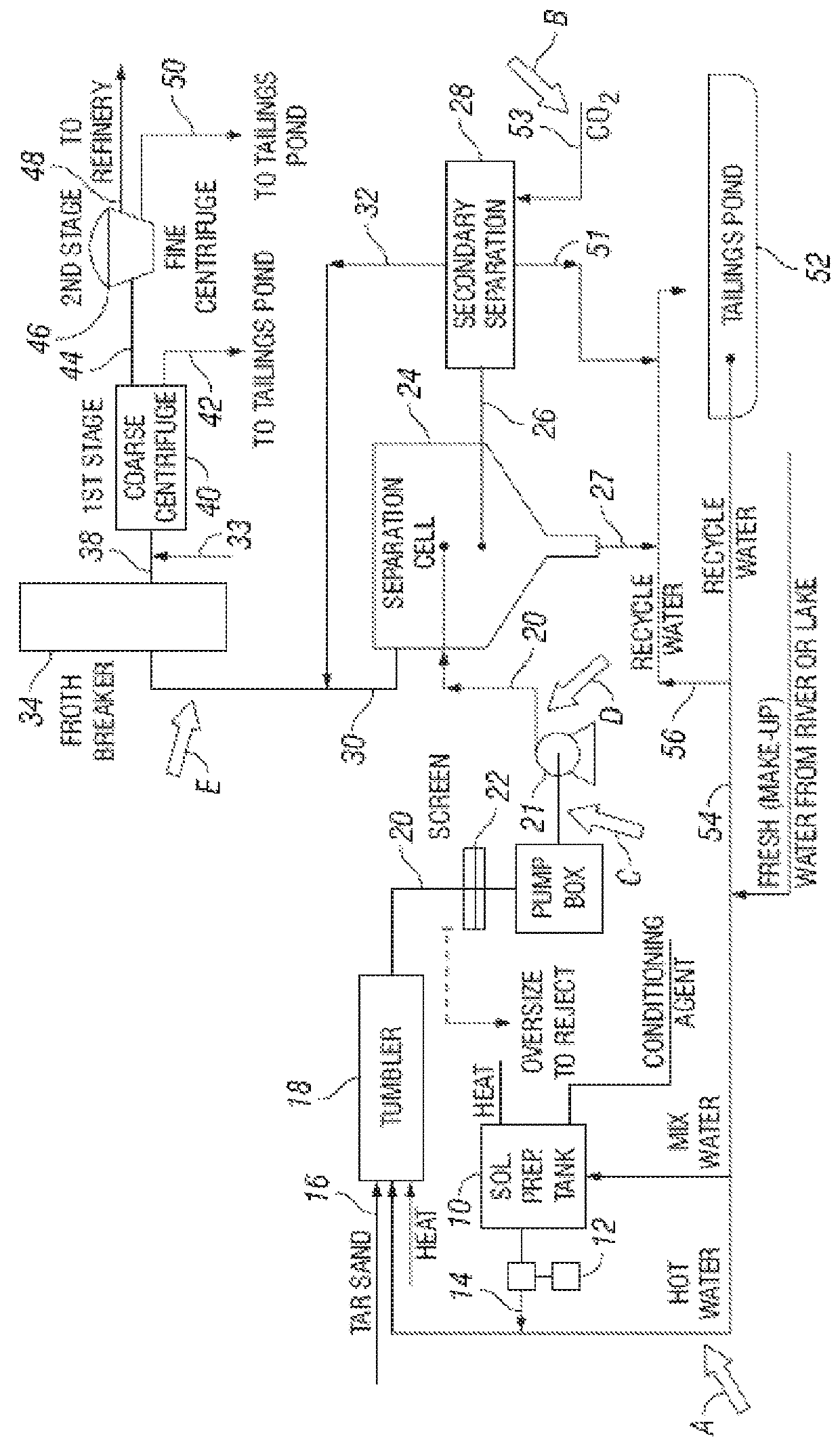

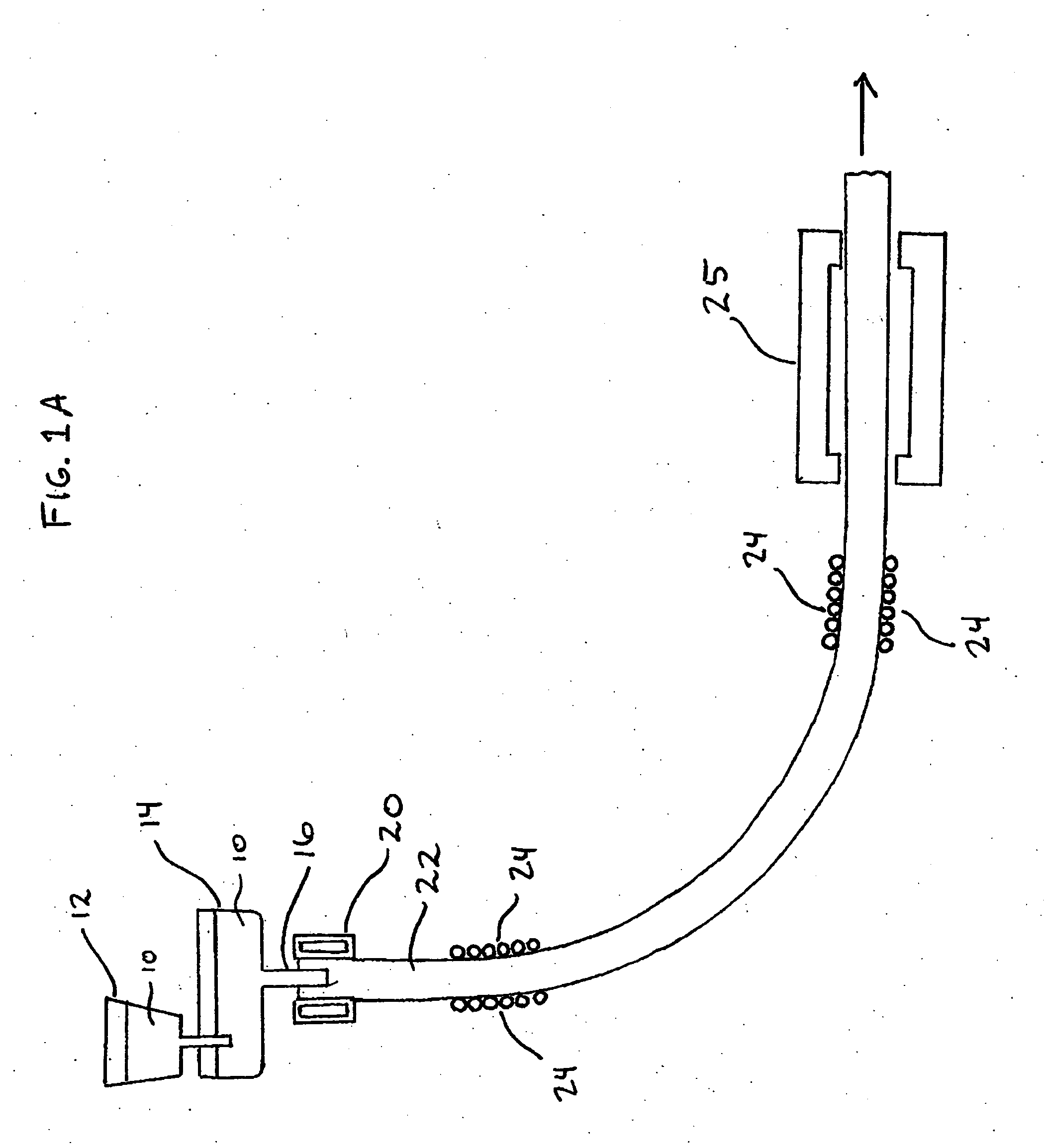

Bitumen extraction and asphaltene removal from heavy crude using high shear

InactiveUS20110266198A1Promote recoverySimple processLiquid hydrocarbon mixture productionFlotationShear rateComponents of crude oil

Herein disclosed is a method of removing at least one component from a feed by subjecting the feed to high shear in the presence of carbon dioxide to produce a high shear-treated product and separating the at least one component from the high shear-treated product to produce a component-reduced product. Also disclosed is a method of removing asphaltenes from asphaltenic oil by subjecting the asphaltenic oil to a shear rate of at least 10,000 s−1 in the presence of carbon dioxide to produce a high shear-treated product and separating asphaltenes from the high shear-treated product to produce an asphaltene-reduced product oil. Systems are also provided for carrying out the methods.

Owner:HRD CORP

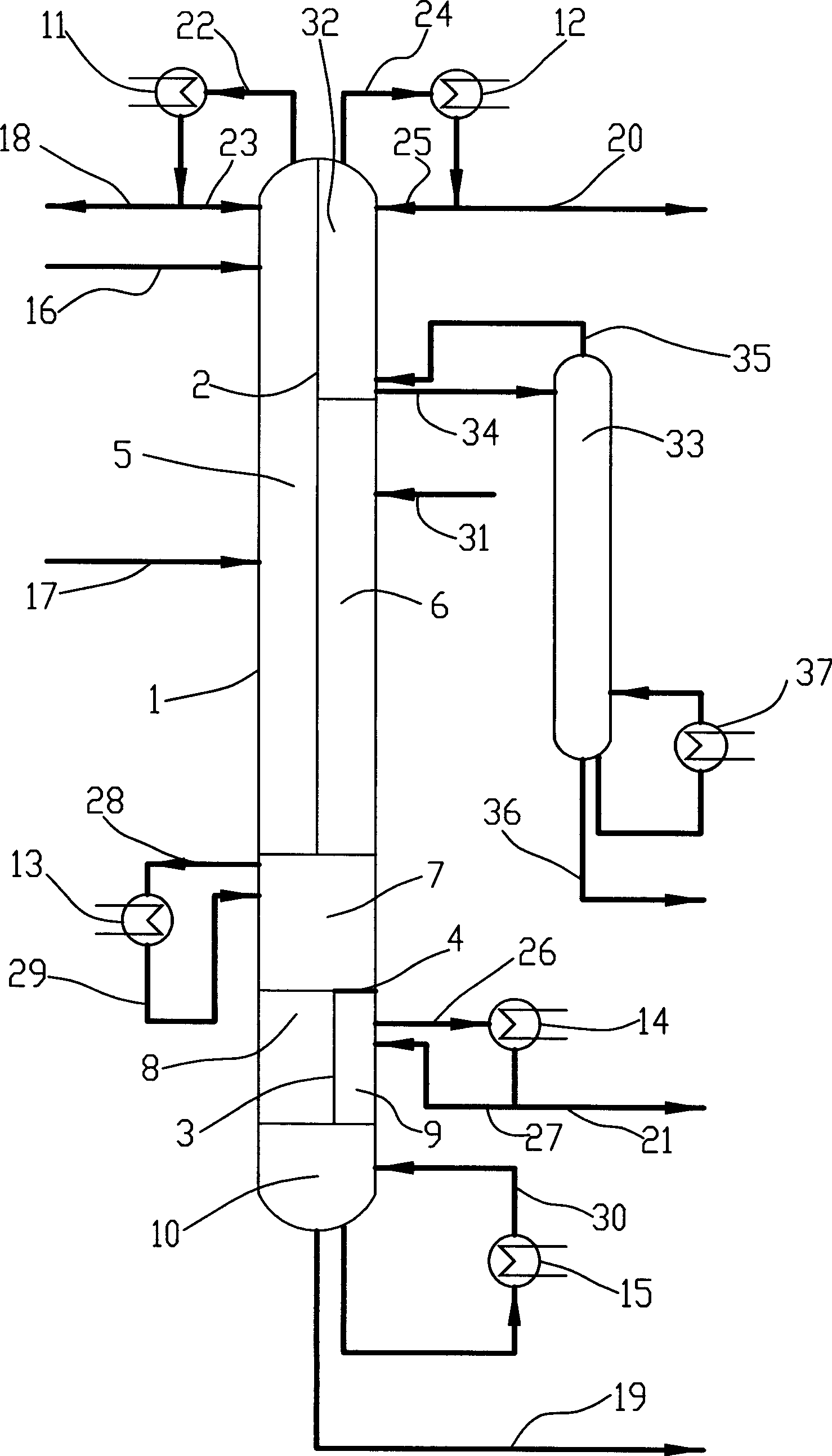

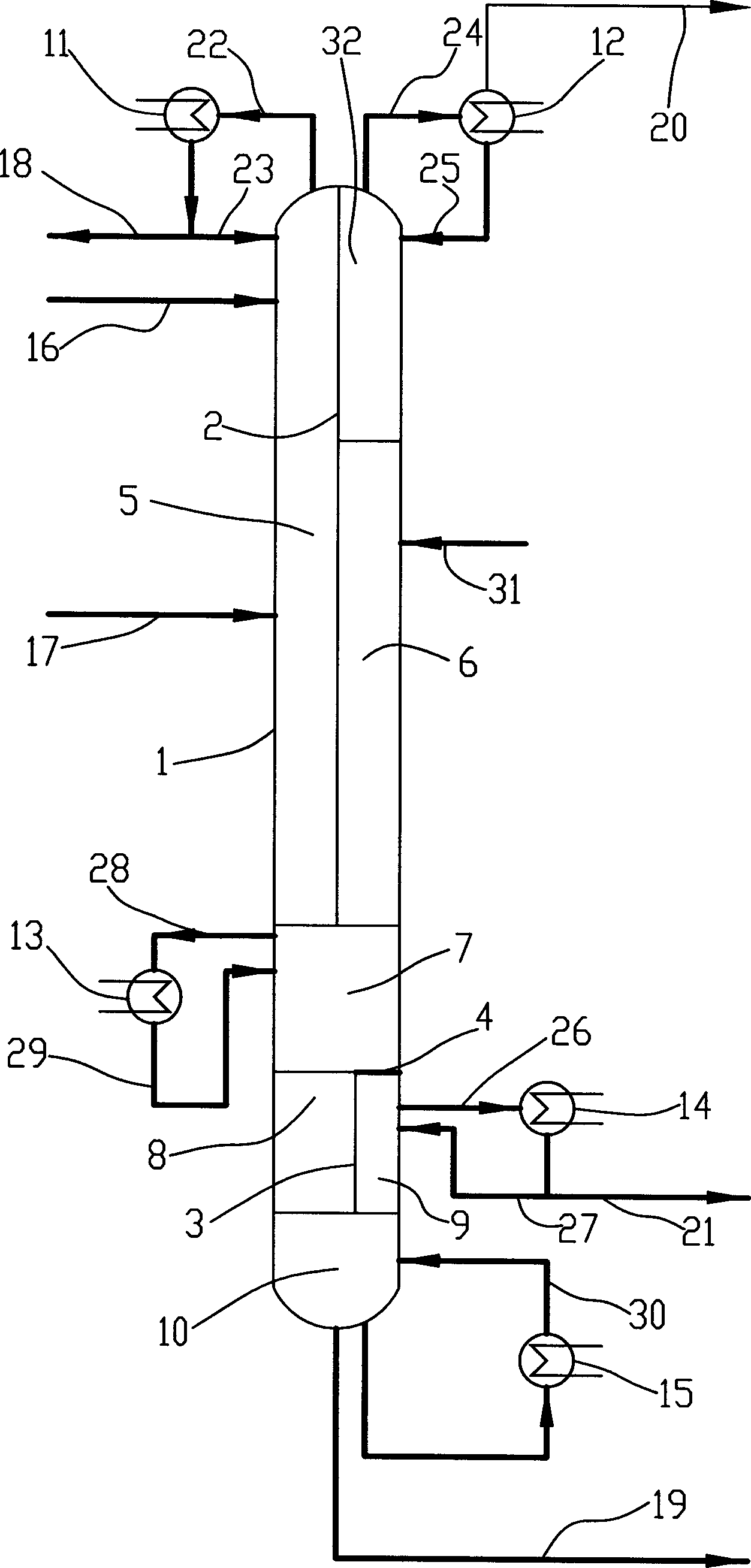

Apparatus for extracting coarse 1,3-butadiene by double baffle plated tower and method thereof

ActiveCN1789223AReduce consumptionLess investmentDistillation purification/separationExtractive distillationAcetonitrile

The invention relates to a device and method for separating butylenes and removing butynol and heavy component to get coarse 1,3-butynol from carbon four mixture through extractive distillation by using water-bearing acetonitrile as dissolvent in double baffle tower. The extractive distillation operation is carried out in the baffle tower with up and low two section longitudinal baffle, the inner structure of the baffle tower comprises butadiene extraction and distillation section, heavy component stripping section, alkyne extraction and distillation section, shared middle tower zone, dissolvent analysizing section, alkyne steaming section and shared lower tower zone. Introducing the liquid in the middle of heavy component stripping section and alkyne extraction and distillation section to side tower to strip the heavy component, dislodging the side tower and relative equipment if the heavy component is not needed stripping. The inventive device and method complish the traditional two-time extraction and distillation and part of heavy component stripping in one tower, and is characterized by small investment, simple operation, low energy consumption and reduced product cost.

Owner:QINGDAO ECSS SOFT TECH

Method for preparing CLT acid (6-chloro-3-aminotoluene-4-sulfoacid) by utilizing o-chlorotoluene direct nitrification method

InactiveCN101906057AReduce pollutionLow equipment requirementsSulfonic acid preparationO-chlorotolueneRaw material

The invention relates to a method for preparing 6-chloro-3-aminotoluene-4-sulfoacid (hereinafter referred to as CLT acid) in a direct nitrification way by taking o-chlorotoluene as a raw material. The method comprises the following steps of: obtaining o-chlorotoluene nitrate by taking acidic Beta zeolite as a catalyst and acetyl nitrate as a nitrifying agent; reducing the o-chlorotoluene nitrate by utilizing iron powder; recrystallizing the reduced product and separating out 6-chloro-3-aminotoluene crystal and 6-chloro-4-aminotoluene containing little 6-chloro-3-aminotoluene by adopting an acid extraction method; adding dichlorobenzene and sulfuric acid in the 6-chloro-3-aminotoluene crystal, and carrying out sulfonation at 170-190 DEG C to obtain the CHLOROT acid; and carrying out sulfonation on the 6-chloro-4-aminotoluene containing little 6-chloro-3-aminotoluene to obtain 2B acid containing little CLT acid. The invention has the characteristics of low pollution, high yield, simple process, low device requirements, and the like.

Owner:YANBIAN UNIV

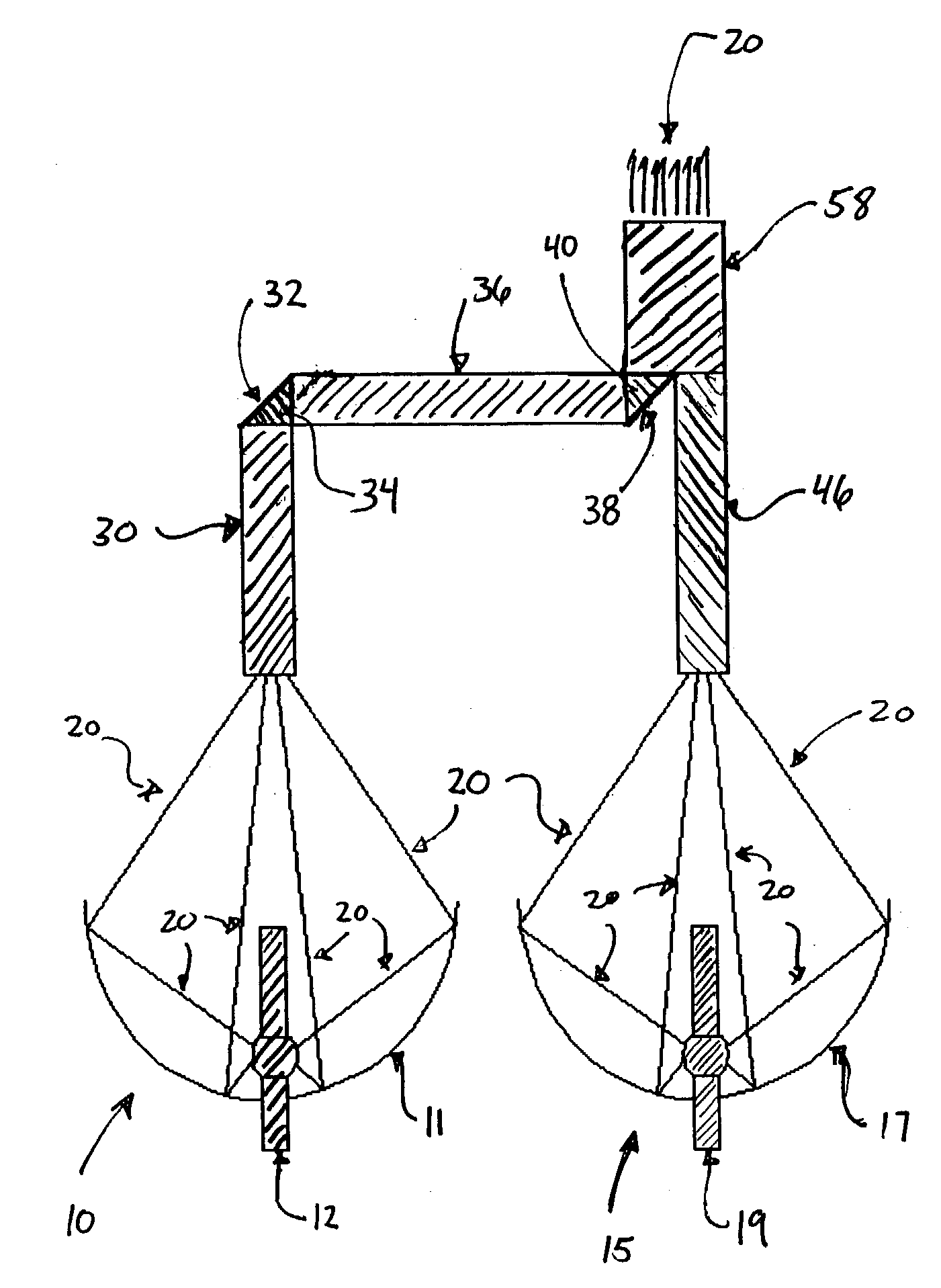

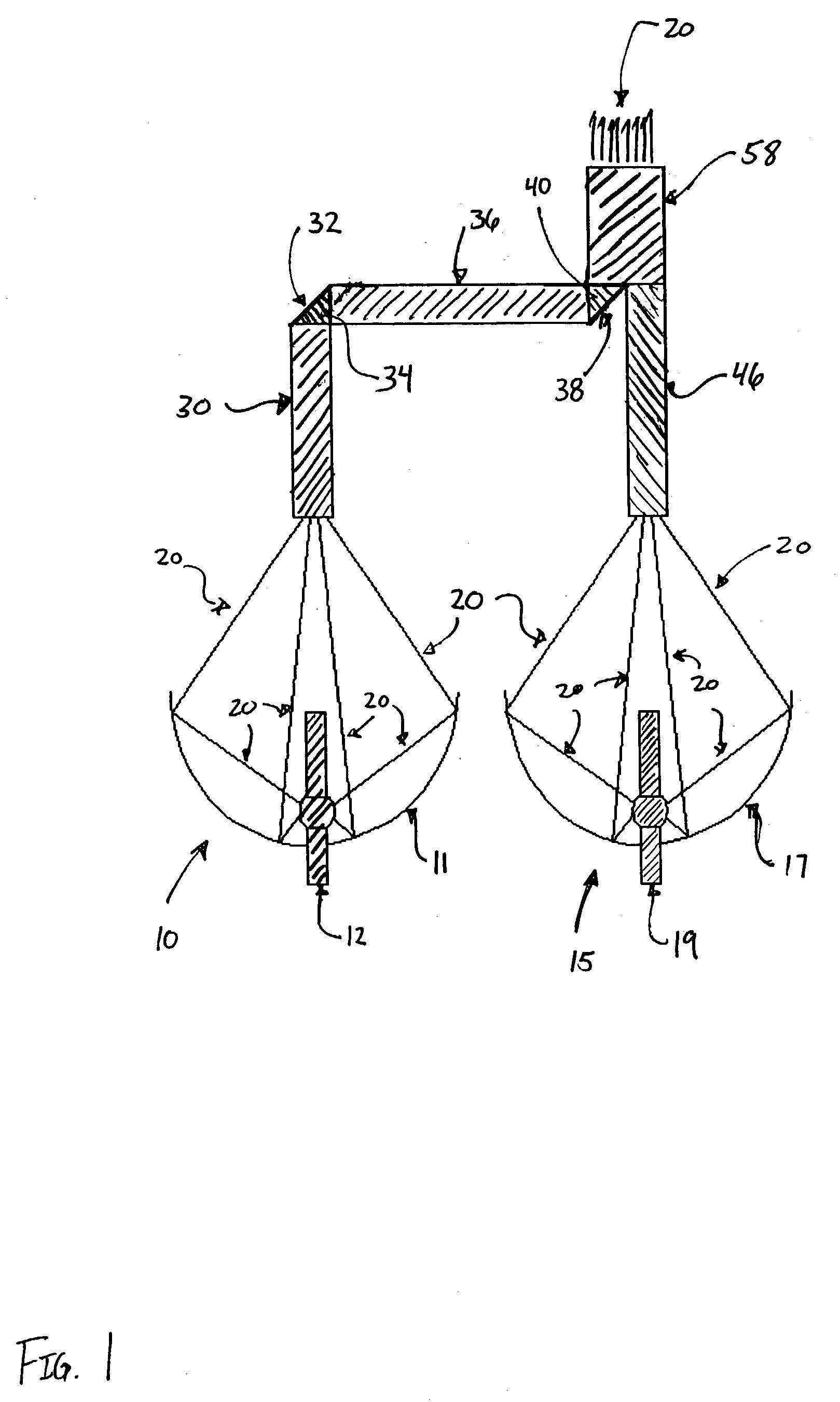

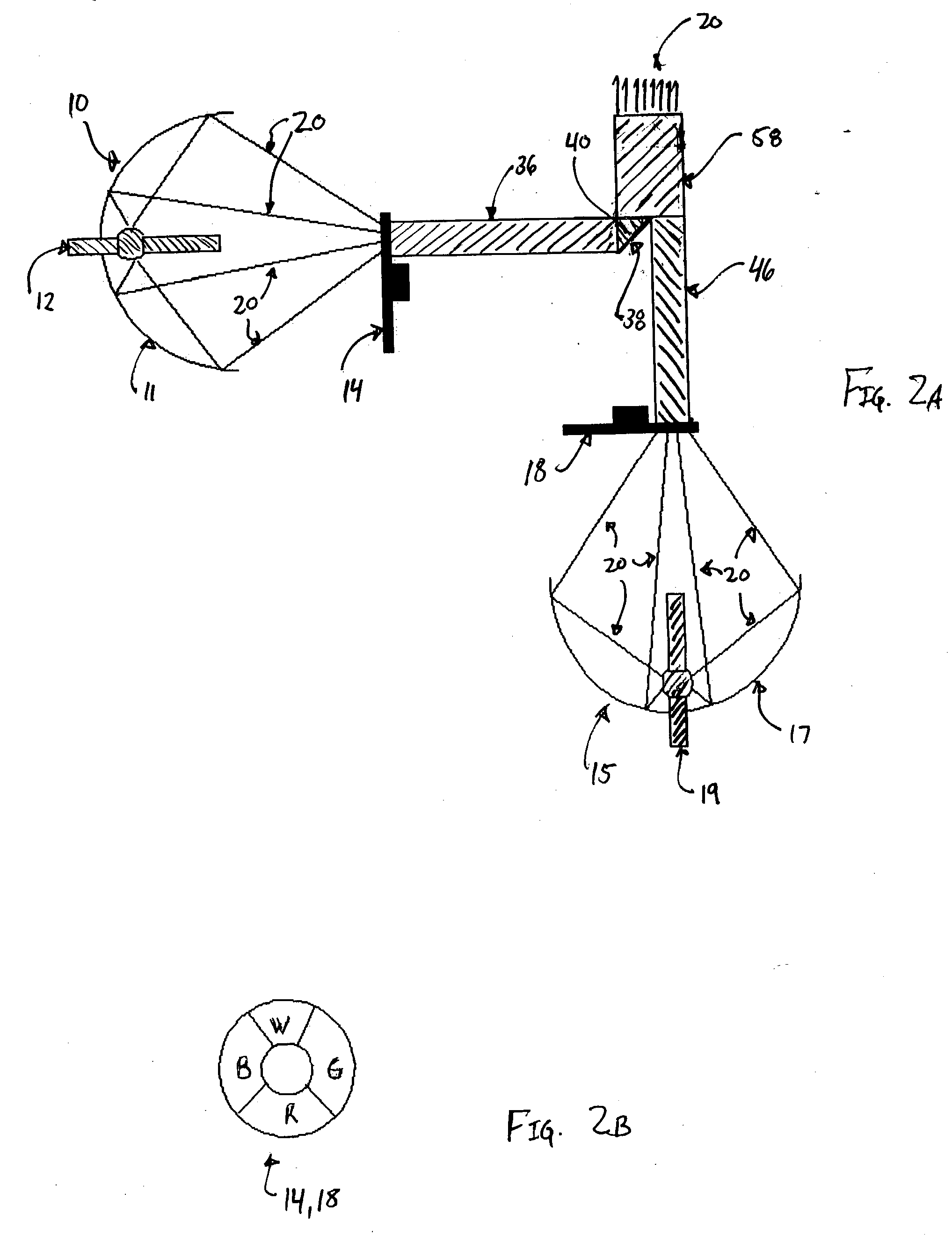

Multi-lamp arrangement for optical systems

Owner:PROJECTIONDESIGN

Method of high shear comminution of solids

InactiveUS9227196B2Refining by water treatmentLiquid hydrocarbon mixture productionSolid componentParticle density

Herein disclosed in a method comprising: shearing a feed comprising a solid component in a high shear device to produce a product, at least a portion of which comprises sheared solids; and separating at least some of the sheared solids from the product to produce a component-reduced product, wherein the solid component in the feed stream comprises a first particle density, and wherein the sheared solids in the product comprise a second particle density greater than the first particle density. In some embodiments, the solid component of the feed comprises gas trapped therein, and wherein at least a portion of said gas is released from the solid component upon shearing. Herein also is disclosed a method of comminuting solids in a feed stream comprising a solid component by processing the feed stream in a high shear device to produce a product stream comprising comminuted solids.

Owner:HRD CORP

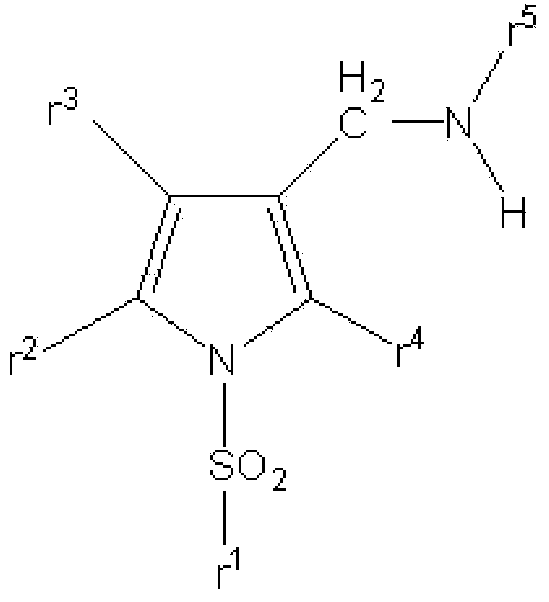

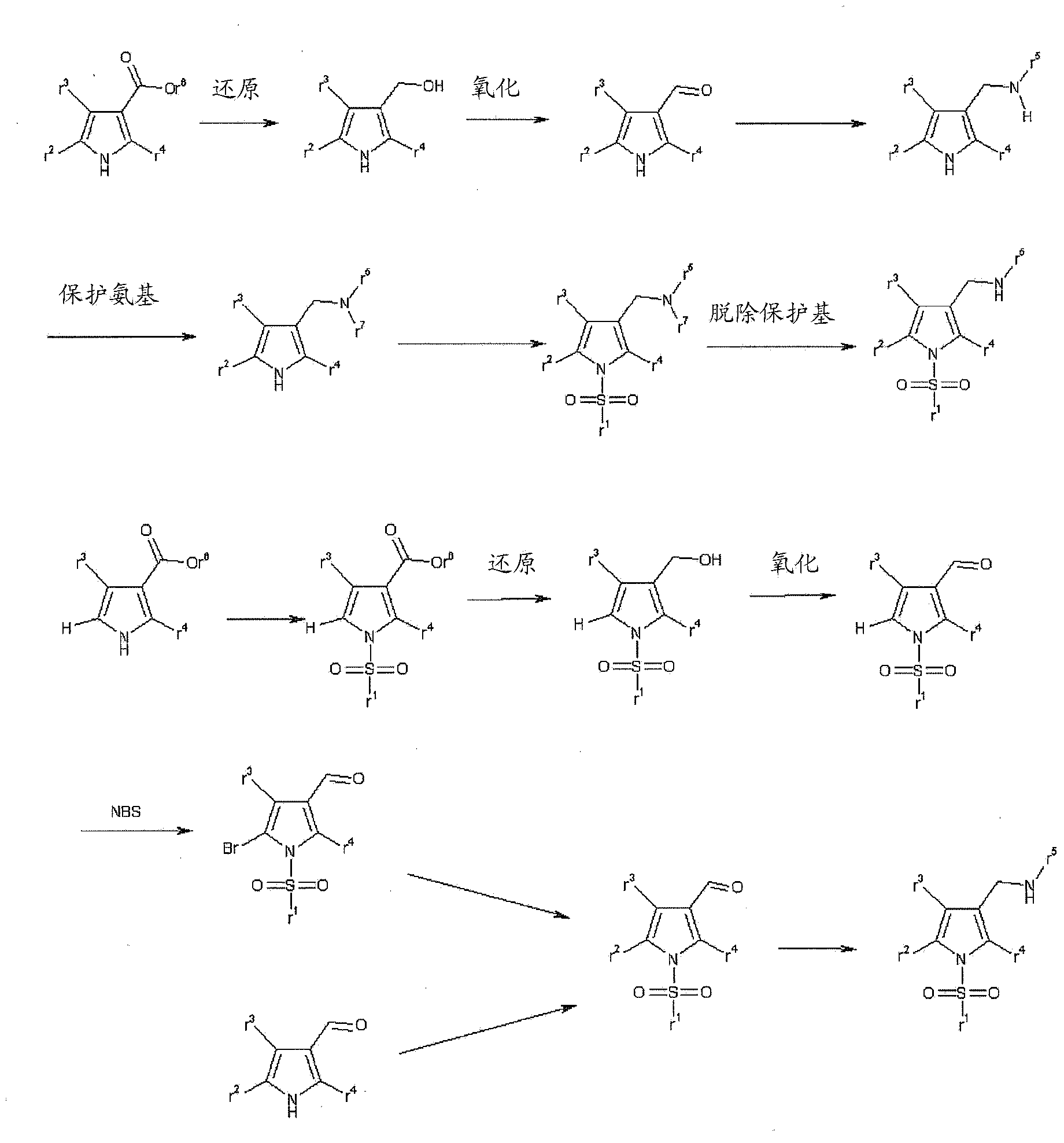

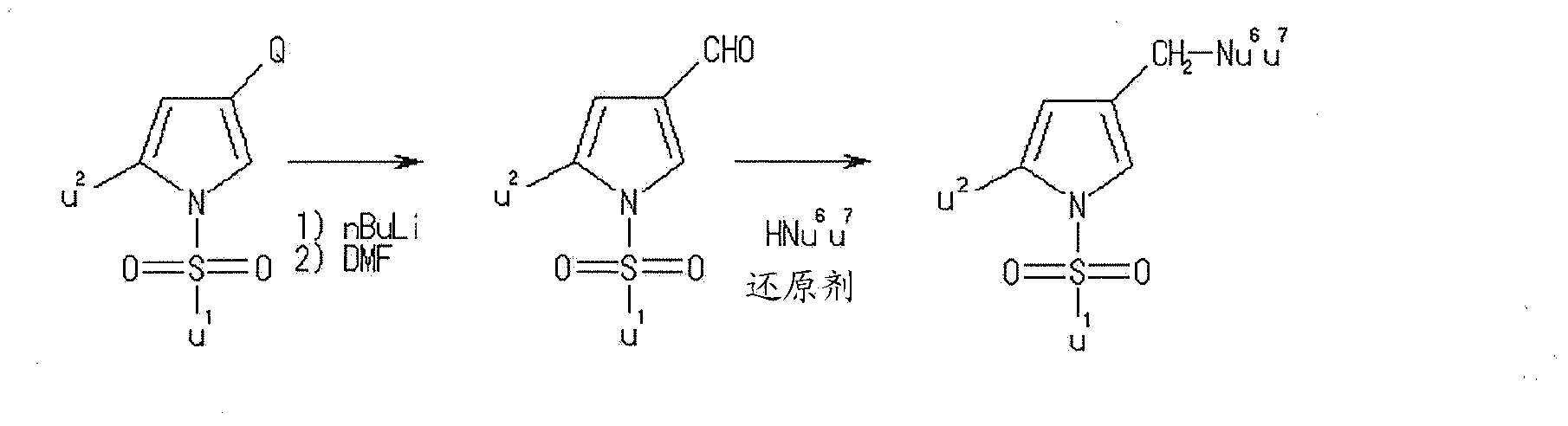

Process for producing pyrrole compound

ActiveCN104211618ALow costCarboxylic acid nitrile preparationOrganic compound preparationPyrroleAmination

Owner:TAKEDA PHARMA CO LTD

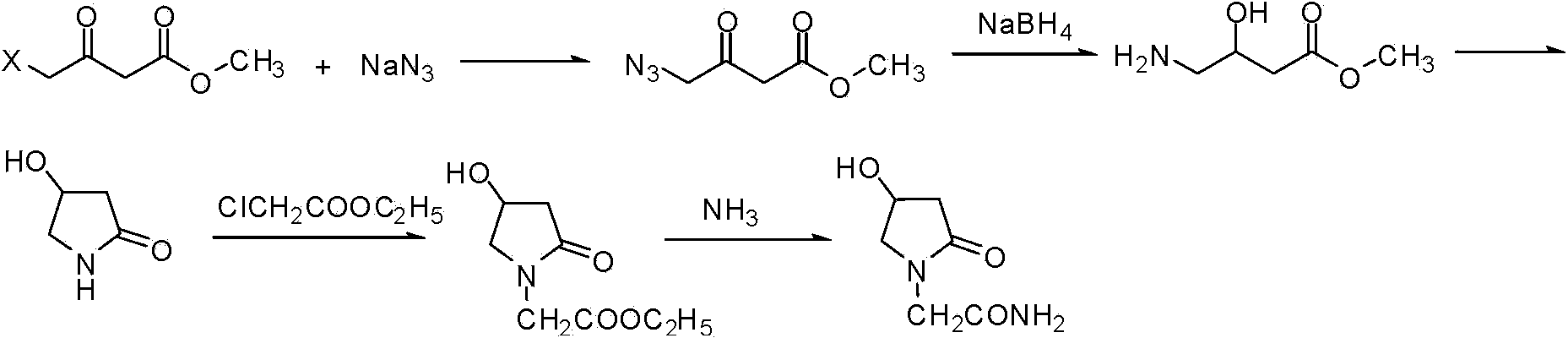

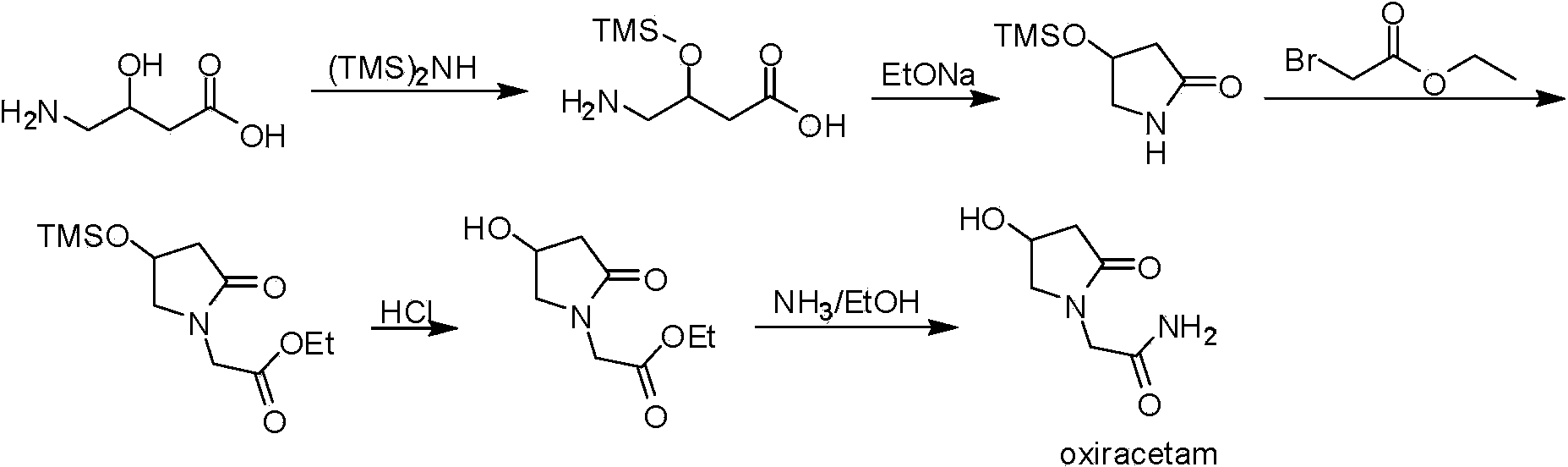

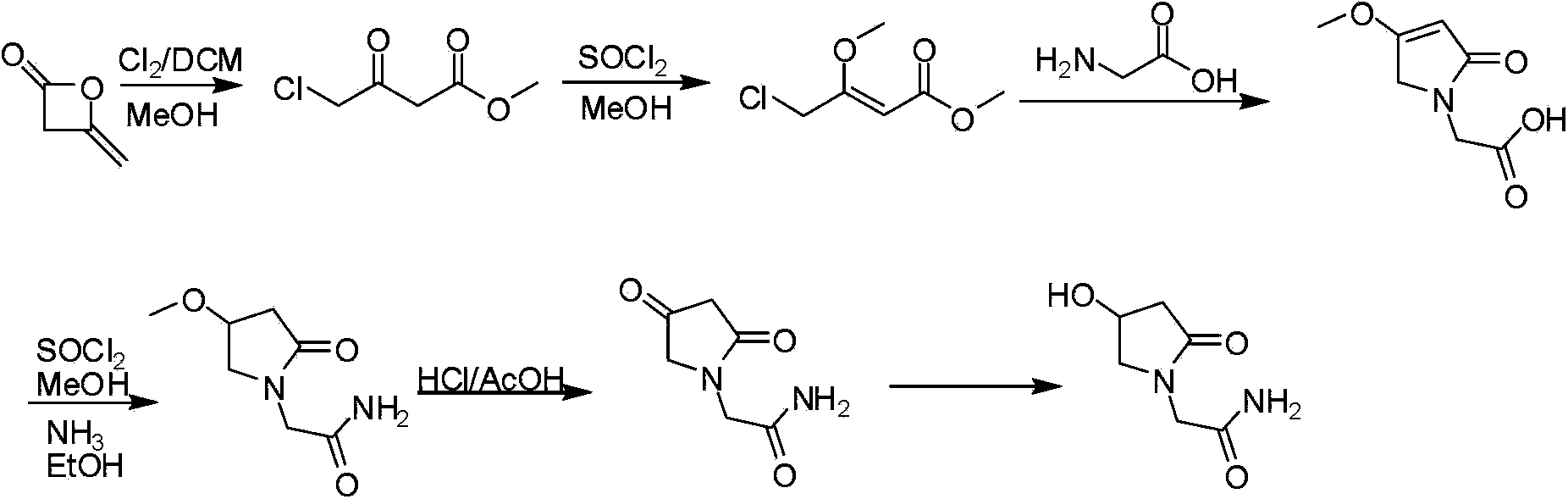

Synthetic method of oxiracetam

The invention discloses a synthetic method of oxiracetam. The synthetic method is characterized in that acety ketene is used as a raw material, and four steps of bromination, esterification, reduction and ring closure are carried out to obtain the oxiracetam. The synthetic method provided by the invention has the advantages of easy operation, high safety, environmental protection, cheap and easily available raw materials, mild reaction conditions, high yield and substantially reduced product cost, thereby being more suitable for industrial production.

Owner:广安凯特制药有限公司 +2

Method for utilizing pyrite to simultaneously reduce phosphogypsum and titanium white waste residue green vitriol for producing sulfuric acid

InactiveCN108383089AHigh recovery rateSimple ingredientsSulfur compoundsIron compoundsSteelmakingDecomposition

The invention discloses a method for utilizing pyrite to simultaneously reduce phosphogypsum and titanium white waste residue green vitriol for producing sulfuric acid. The technological process comprises the following steps: evenly mixing the pyrite, the phosphogypsum and the titanium white waste residue green vitriol, which are finely ground into a certain particle size, according to a certain proportion; (2) after the mixture is tabletted, directly enabling the mixture to react for a certain period of time at certain temperature to obtain a solid reduced product and SO2-containing tail gas,wherein the obtained solid reduced product is used as a pre-melt type steelmaking slagging agent; (3) carrying out dust removal and purification on the SO2-containing tail gas obtained in the step (2), and then sending the purified product to a sulfuric acid system to prepare the finished product sulfuric acid. The process utilizes the pyrite to simultaneously reduce the phosphogypsum and the titanium white waste residue green vitriol producing sulfuric acid, thus realizing the treatment and recycling of the phosphogypsum and the titanium white waste residue green vitriol, and obtaining sulfuric acid and the steelmaking slagging agent-calcium ferrite product. The phosphogypsum decomposition rate of the method can reach 98wt% or above, the SO2 concentration of the kiln gas can reach 15 vol% or above, and the purity of the solid phase product calcium ferrite can reach 90wt% or above. The method is simple in process, free from discharge of three wastes, and remarkable in environmental and economic benefit advantages.

Owner:SICHUAN UNIV

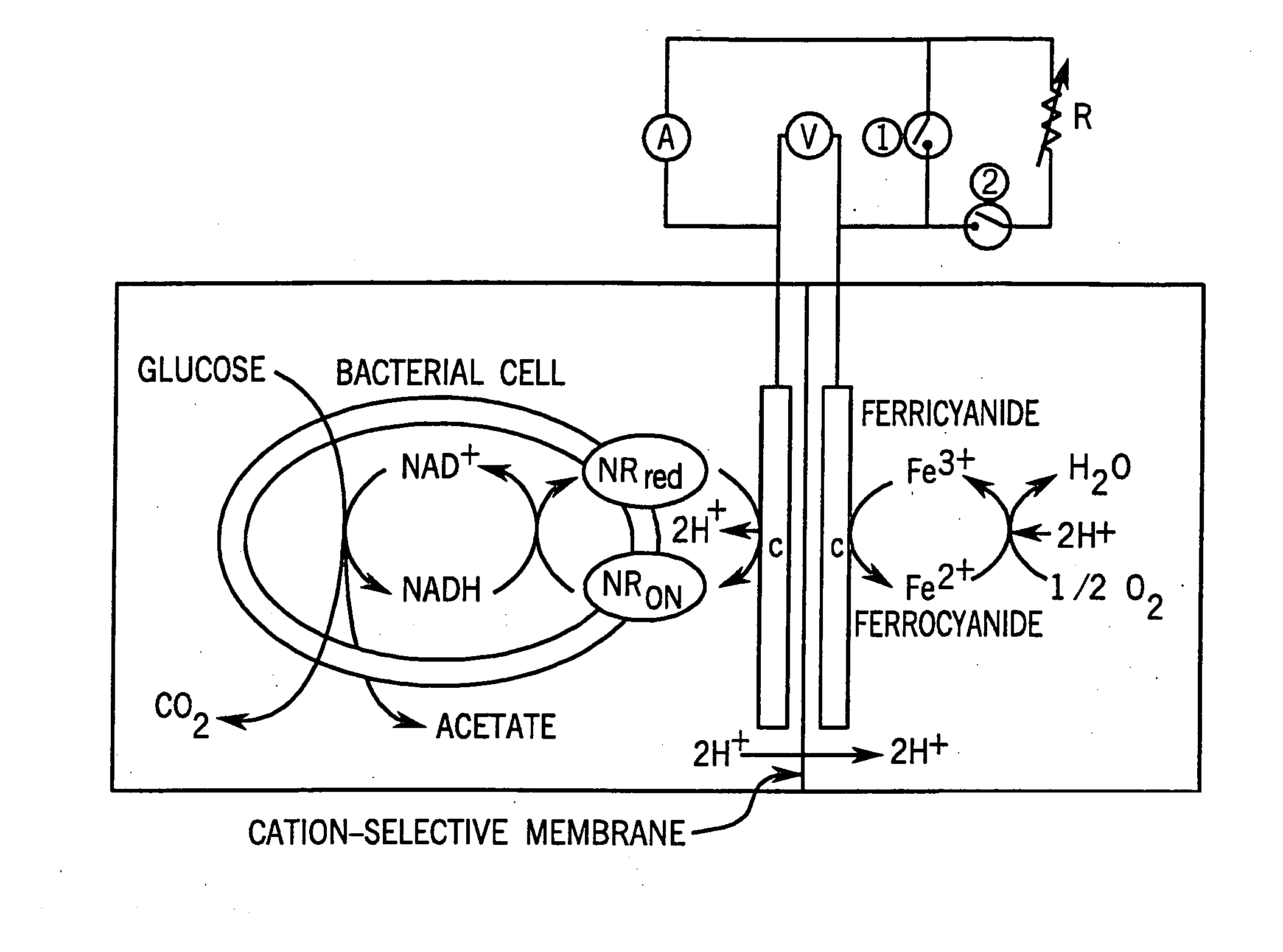

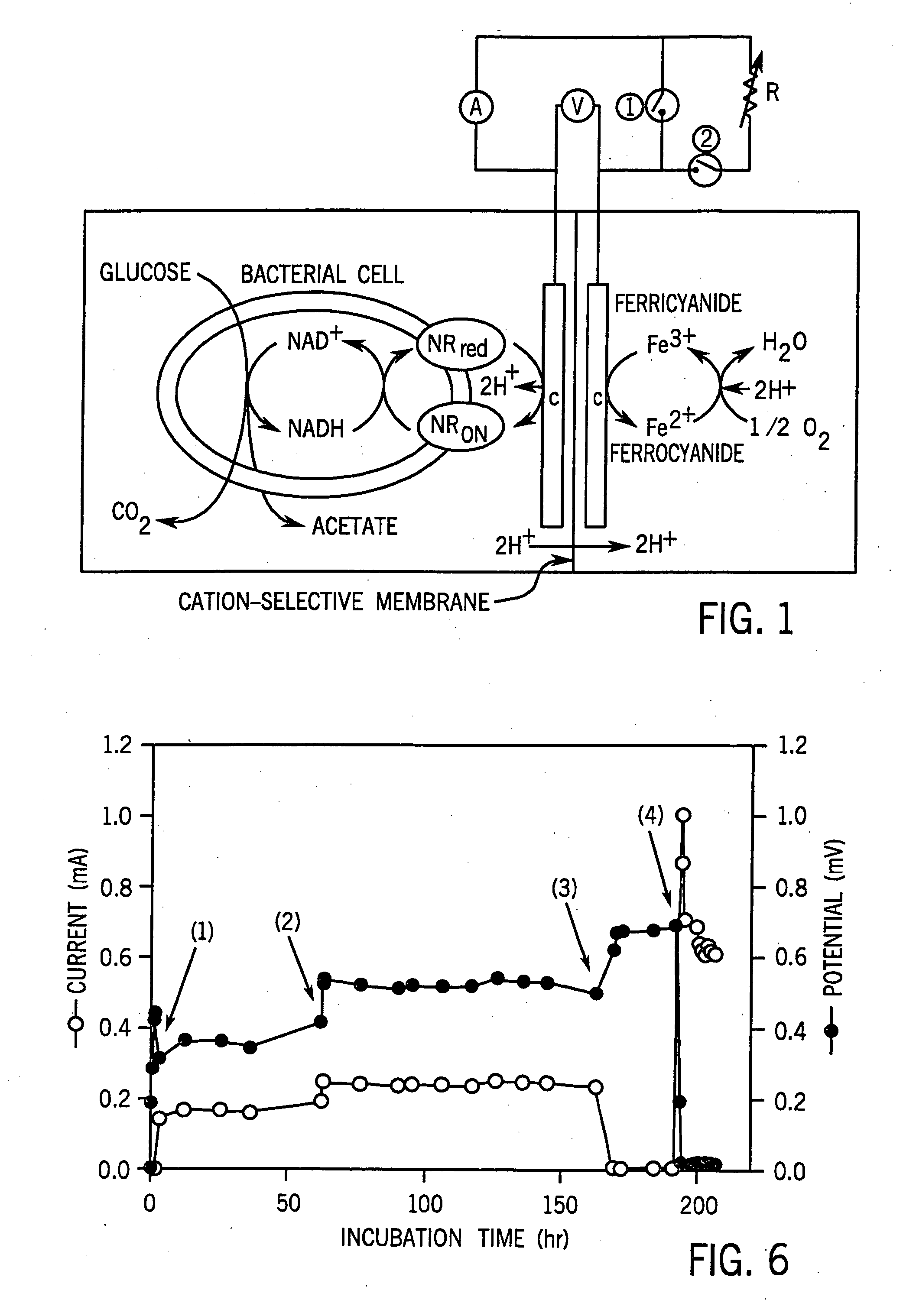

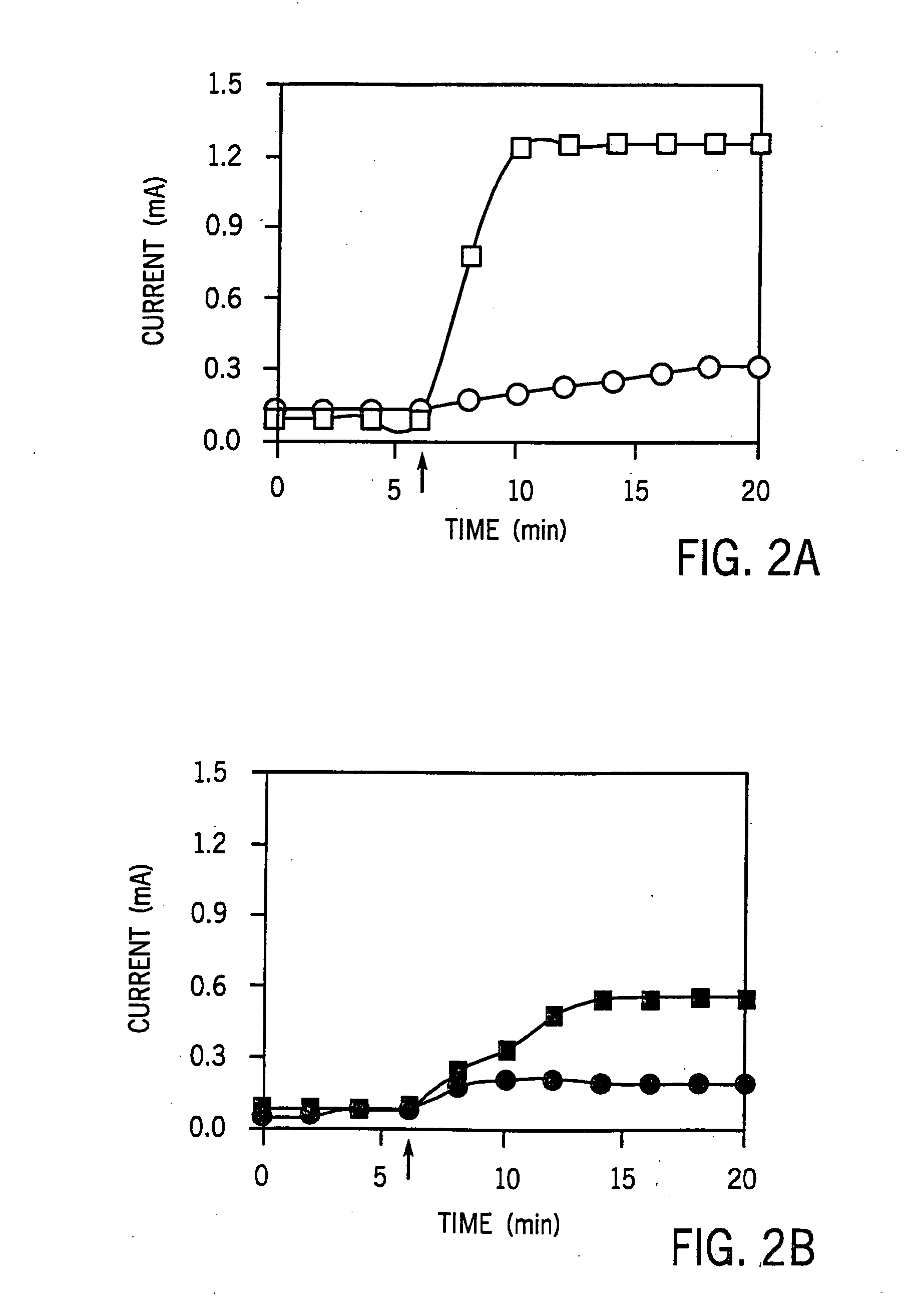

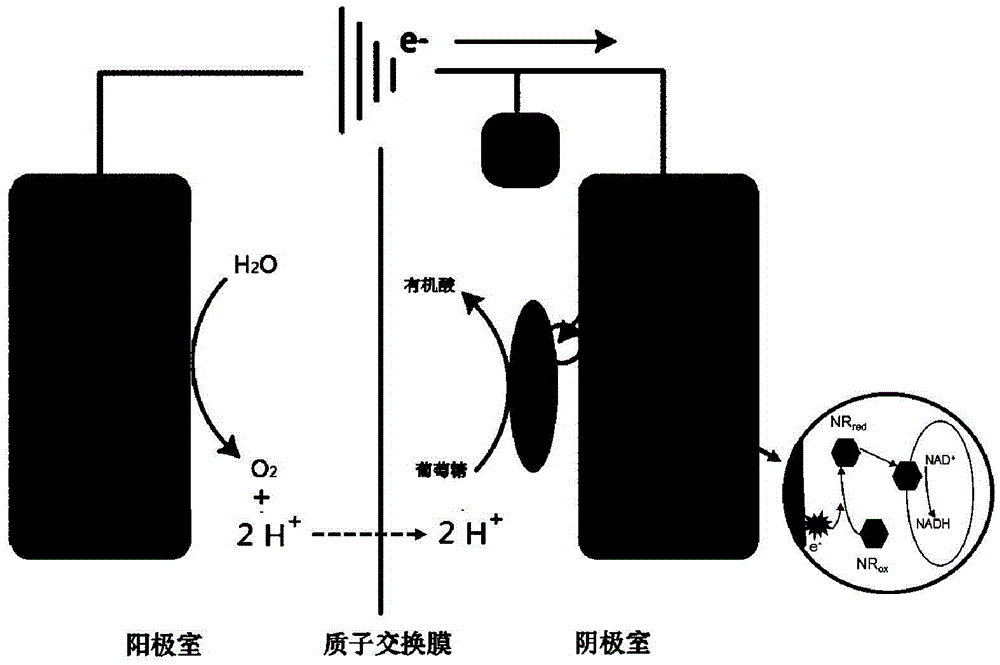

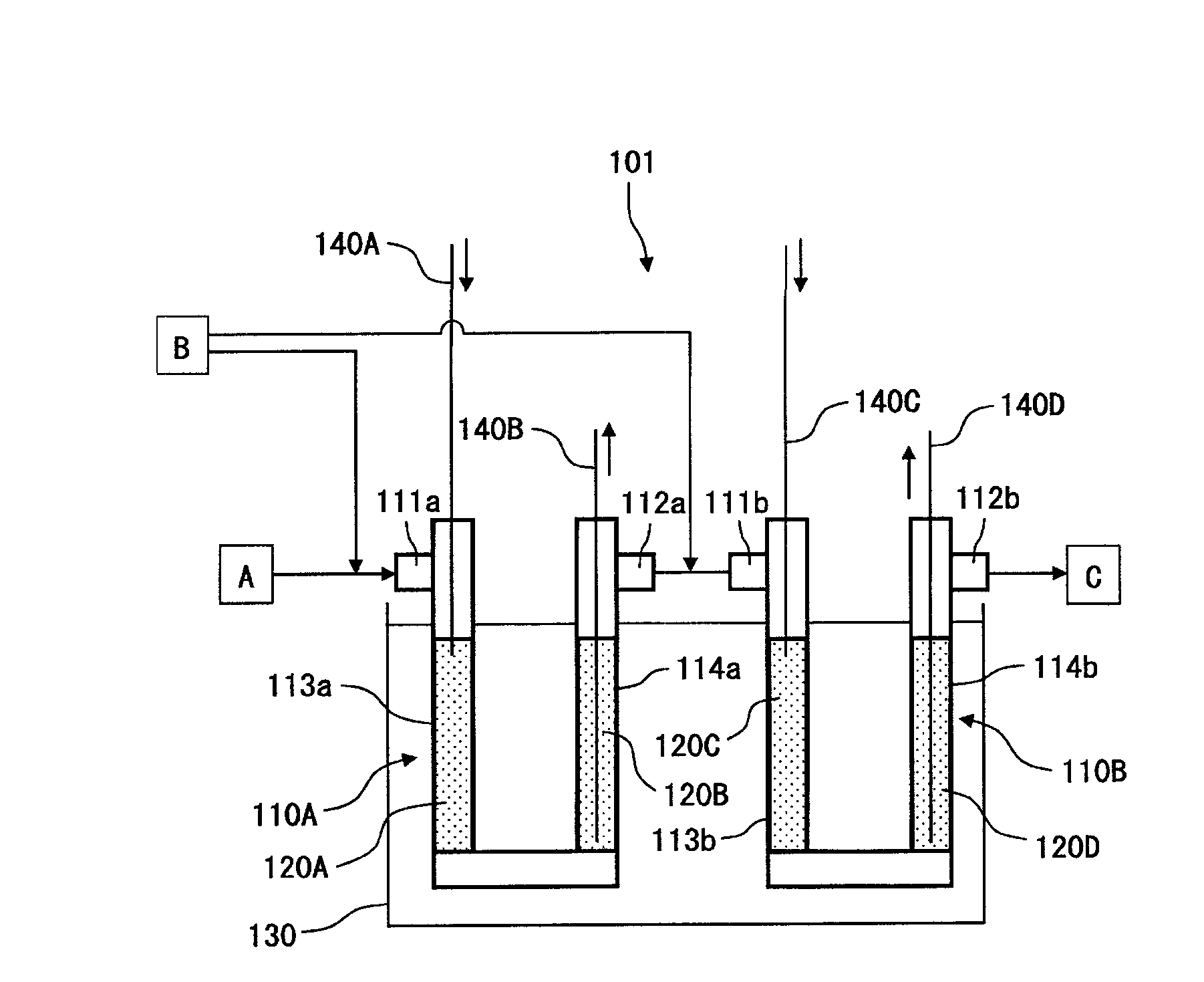

Electrochemical methods for generation of a biological proton motive force and pyridine nucleotide cofactor regeneration

InactiveUS20060063043A1Promote cell growthPromote fermentationElectrolysis componentsMicrobiological testing/measurementNucleotideElectrochemistry

Disclosed are methods using neutral red to mediate the interconversion of chemical and electrical energy. Electrically reduced neutral red has been found to promote cell growth and formation of reduced products by reversibly increasing the ratio of the reduced:oxidized forms of NAD(H) or NADP(H). Electrically reduced neutral red is able to serve as the sole source of reducing power for microbial cell growth. Neutral red is also able to promote conversion of chemical energy to electrical energy by facilitating the transfer of electrons from microbial reducing power to a fuel cell cathode.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

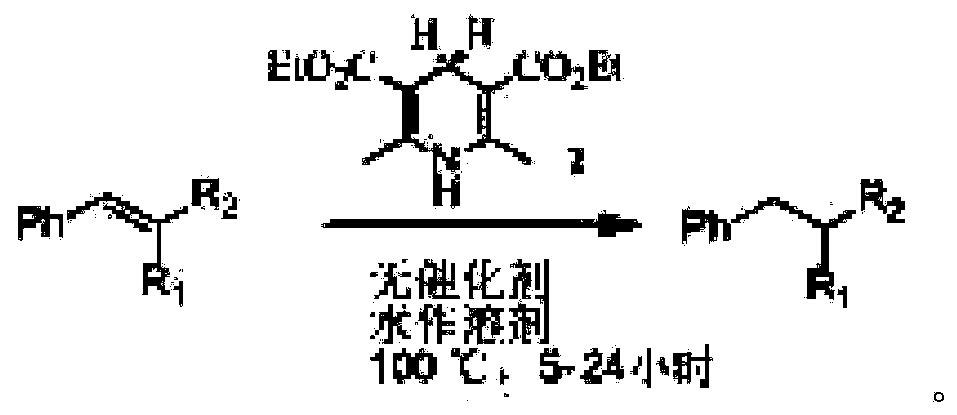

Green conjugated double bond reduction method

ActiveCN103467223AAchieve restorationReaction conditions greenOrganic reductionCarboxylic acid nitrile preparationDistillationOrganic layer

The invention relates to a green conjugated double bond reduction method capable of taking water as a solvent and dihydropyridine ester as a hydrogen source, and selectively reducing the conjugated double bond with strong electron-withdrawing groups. By adopting the method, conjugated carbon-carbon double bonds with strong electron-withdrawing groups are selectively reduced by taking water as the solvent and the dihydropyridine ester as the hydrogen source under the condition that no catalyst is needed. The method comprises the following steps: (1) adding a compound of conjugated carbon-carbon double bonds with strong electron-withdrawing groups and the dihydropyridine ester to water according to the molar ratio of (1:1) to (1:3), heating and warming to 60-100 DEG C; stirring and reacting for 5-24 hours at the temperature; (2) adding an organic solvent to the solution obtained in the step (1) to extract for at least three times according to the volume ratio of 2:5; (3) merging, drying and carrying out reduced pressure distillation on an organic layer of the product obtained in the step (2), and then carrying out column chromatography, so as to obtain the reduced product. The green conjugated double bond reduction method has the advantages of being non-toxic, mild in reaction condition, free of adding of a catalyst, high in chemical selectivity and the like.

Owner:无锡富泽药业有限公司

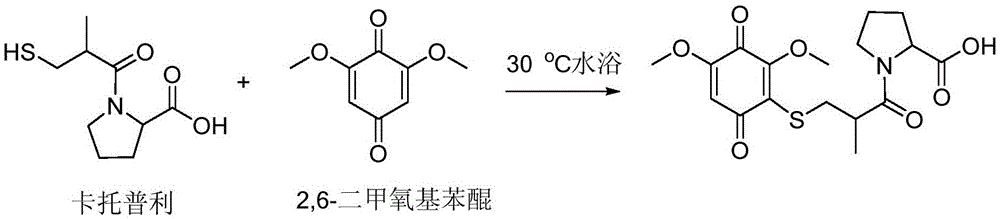

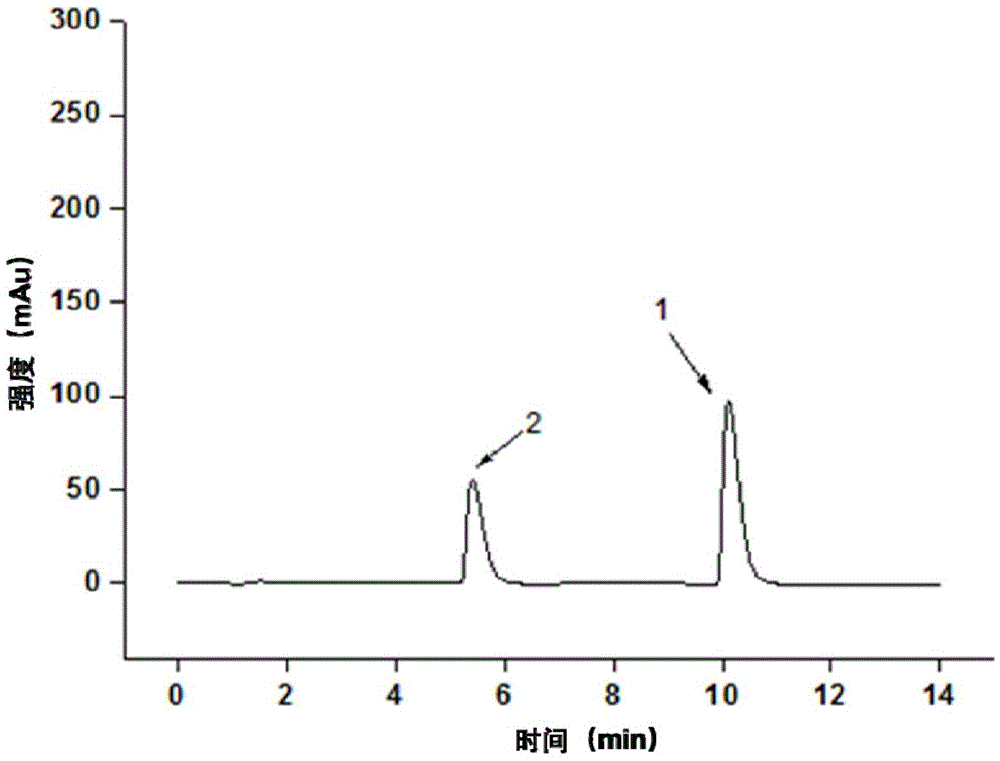

Thiol medicine content detection method

InactiveCN105628813AOxidative side reaction inhibitionAccurate dataComponent separationDrug contentThiol

The invention provides a thiol medicine content detection method. The thiol medicine content detection method includes the following steps that 1, a reducing reagent is added in a thiol medicine solution, and a dithio polymer in the solution is reduced to obtain a reduced product solution; 2, the reduced product solution and a quinones derivatization reagent perform derivatization reaction to obtain a derivatization product solution; 3, the content of a derivatization product is detected to obtain the content of a thiol medicine. According to the method, the thiol medicine is subjected to derivatization pretreatment by using a quinone compound after being reduced, the stable derivatization product is quickly generated, then the content of the derivatization product is separated and determined by adopting a detection means, and the thiol medicine content in a sample can be accurately calculated. The thiol medicine content detection method is high in recovery rate, simple and easy to operate, high in accuracy rate, quick to detect and high in sensitivity and can be used in the fields of detection of the thiol medicine content, study of human body fluid pharmacokinetics and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

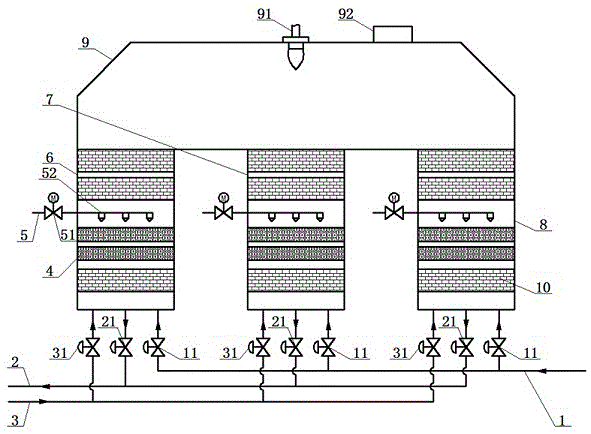

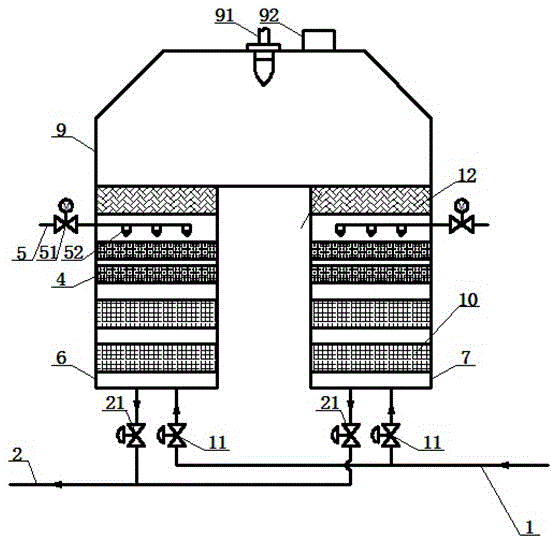

Heat accumulating type oxidation device for catalysis denitration

InactiveCN105536521AEfficient denitrificationEasy to handleGas treatmentDispersed particle separationExhaust valveCombustor

Owner:HARBIN INST OF TECH AT WEIHAI

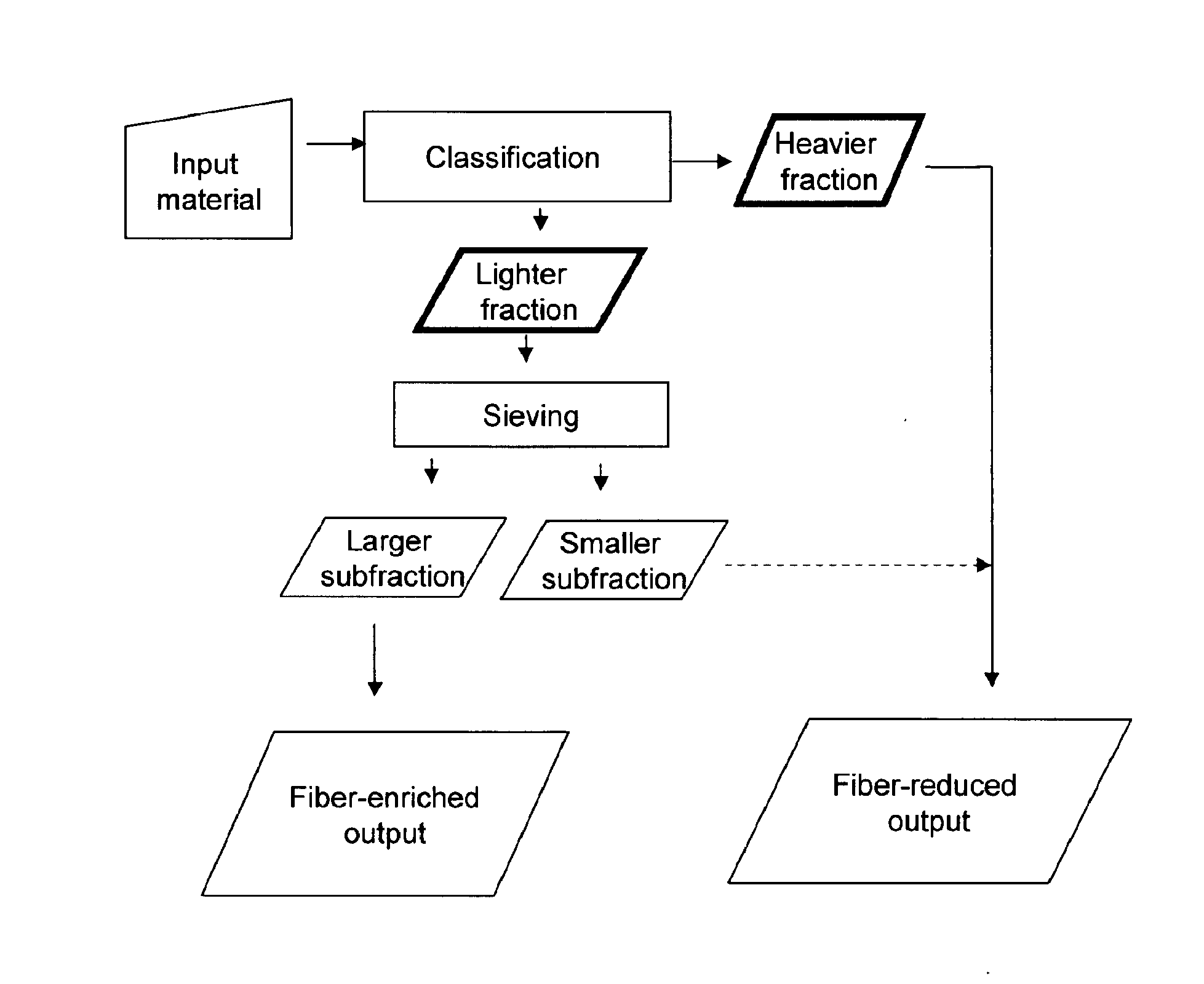

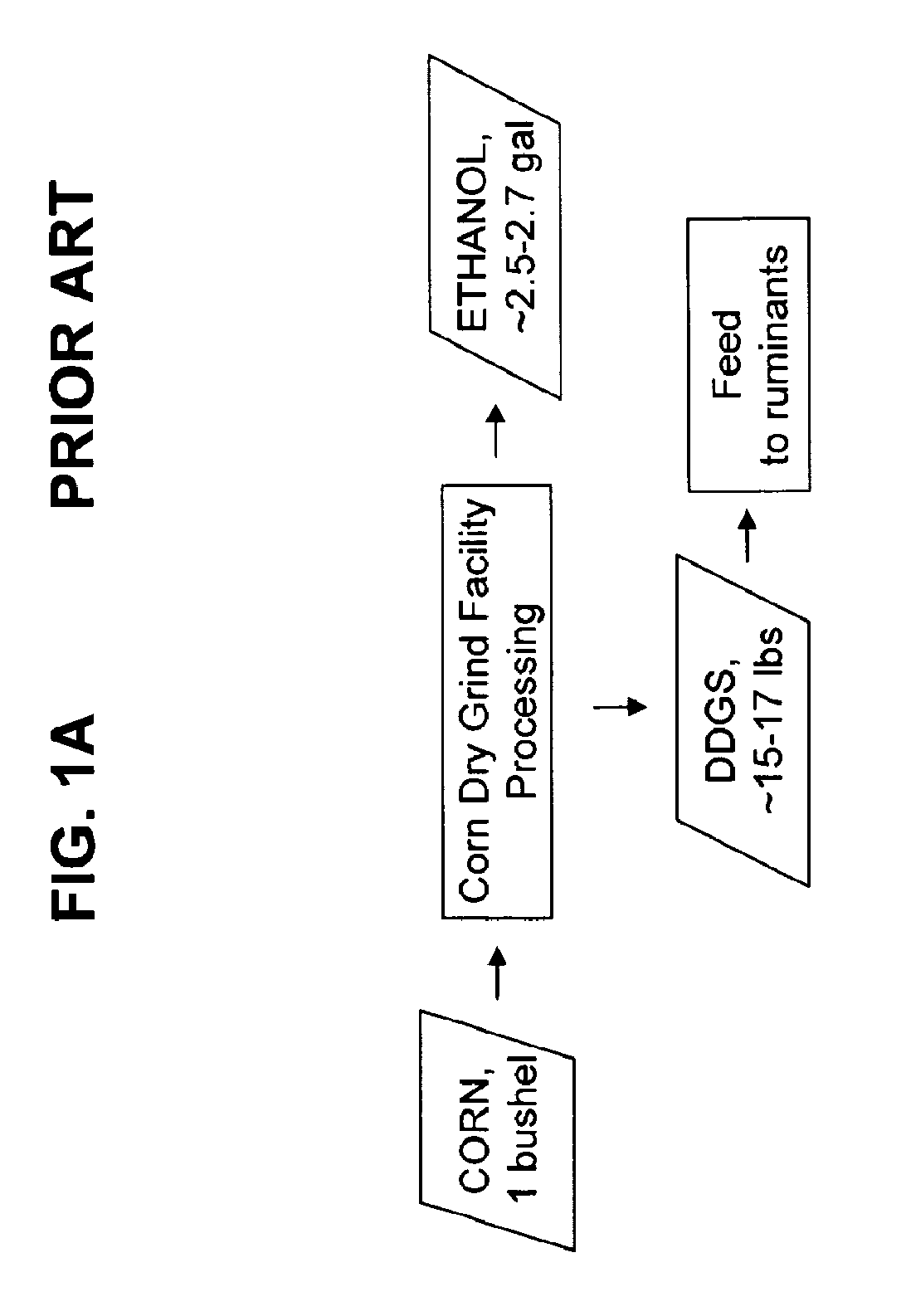

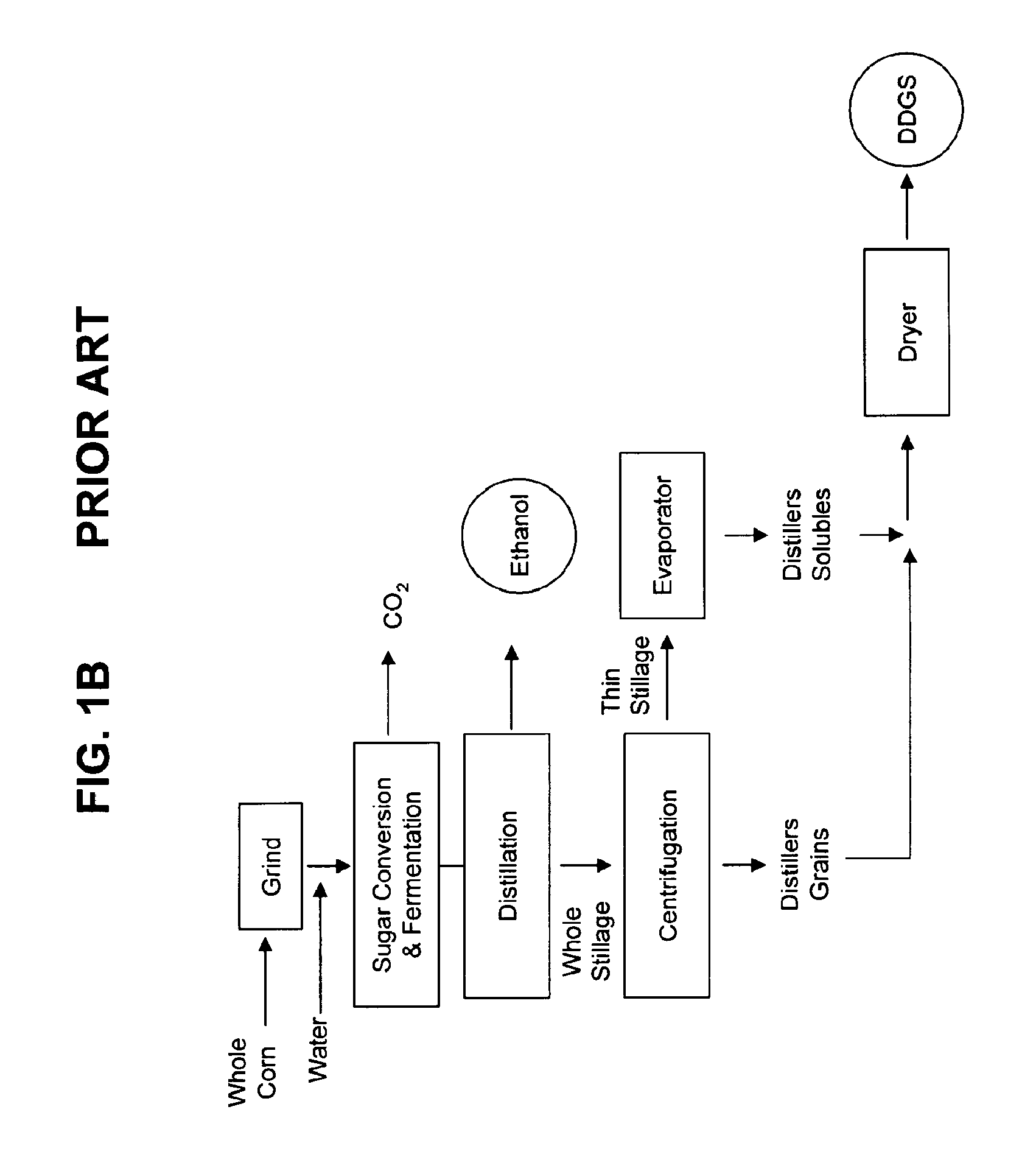

Fiber separation using elusieve process

ActiveUS20100206780A1Easy to adaptLower blood cholesterol levelsFood processingBiofuelsFiberWheat middlings

Methods, devices, and compositions relating to processed grain products are disclosed for ground corn flour, soybean meal, cottonseed meal, and wheat middlings. An exemplary method disclosed is a fiber separation process for the ethanol industry corn products of Distillers Dried Grains (DDG) and Distillers Dried Grains with Solubles (DDGS) resulting from the widely used dry grind technology. A disclosed process and apparatus allows the removal and separate recovery of fiber-reduced products with expanded potential for use as a non-ruminant feed product in addition to the removal and separate recovery of a fiber-enriched product. The fiber enriched and fiber reduced products each have uses in the feed industry. The specific processes, devices, and compositions disclosed are readily adaptable to feed mills.

Owner:MISSISSIPPI STATE UNIV RES TECH

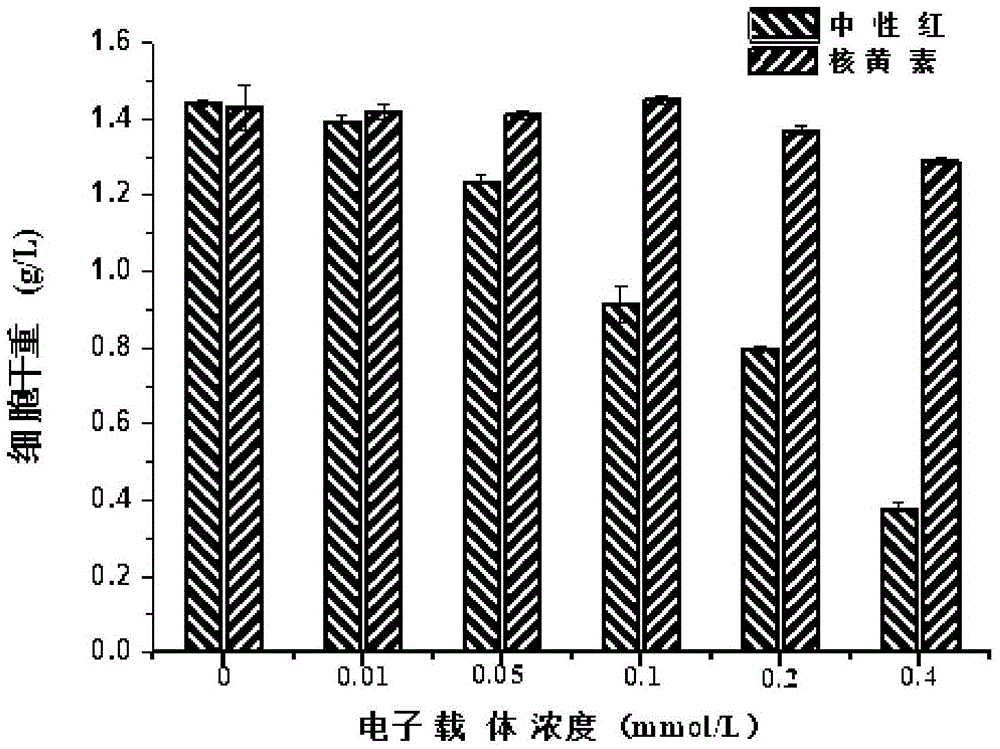

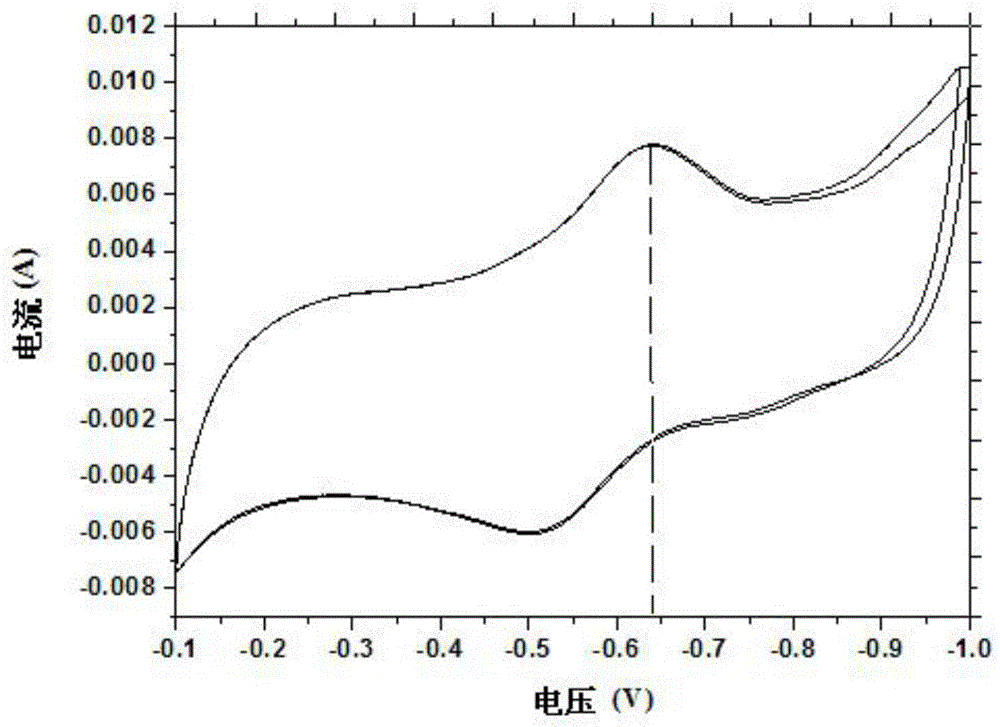

Method for fermented production of succinic acid on the basis of electrochemical system for regulating intracellular reducing power regeneration

ActiveCN105483167AReduce outputIncrease productionMicroorganism based processesFermentationSuccinic acidRiboflavin

The invention discloses a method for fermented production of succinic acid on the basis of an electrochemical system for regulating intracellular reducing power regeneration. The method comprises three steps including strain activation, seed culture and anaerobic fermentation production of succinic acid, anaerobic fermentation adopts electrochemical fermentation, an electron carrier is added to a fermentation medium, the corresponding voltage is applied to a cathode, and the concentration of the electron carrier is in a range of 0.01-0.5 mmol / L. the electron carrier is neutral red or riboflavin. The cathode voltage applied to the cathode is scanned and determined in the range from 0.1 V to 1 V with the cyclic voltammetry at the scanning speed of 5-10 mV / s. When fermentation is performed in an electrochemical device under the anaerobic condition, the total amount of intracellular NADH is increased under the assistance of the electron carrier, the intracellular reducing power (NADH / NAD+) level is tripled, the succinic acid accumulation reaches 15.06 g / L, and efficient synthesis of the reduced product, namely, the succinic acid, is facilitated.

Owner:NANJING UNIV OF TECH

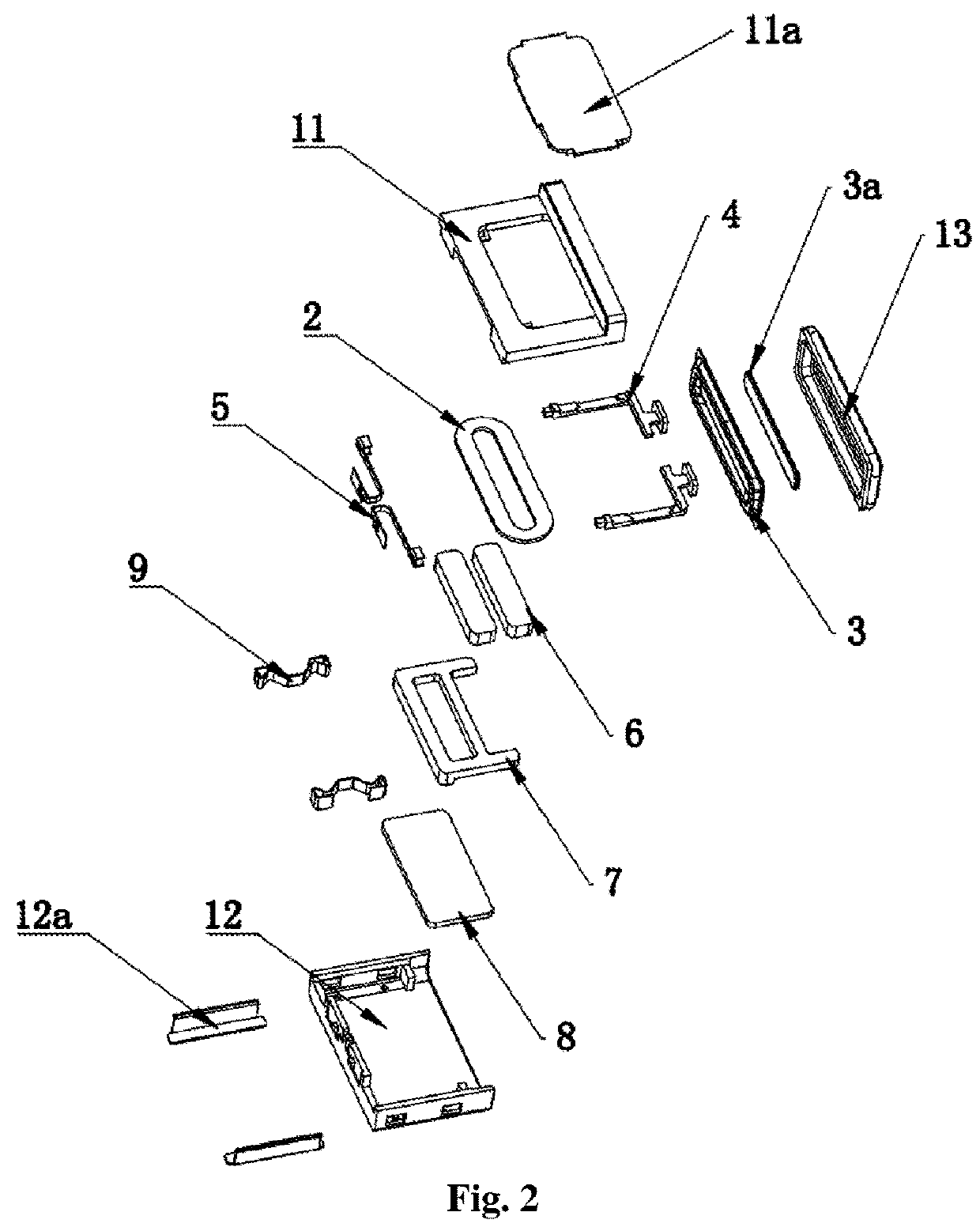

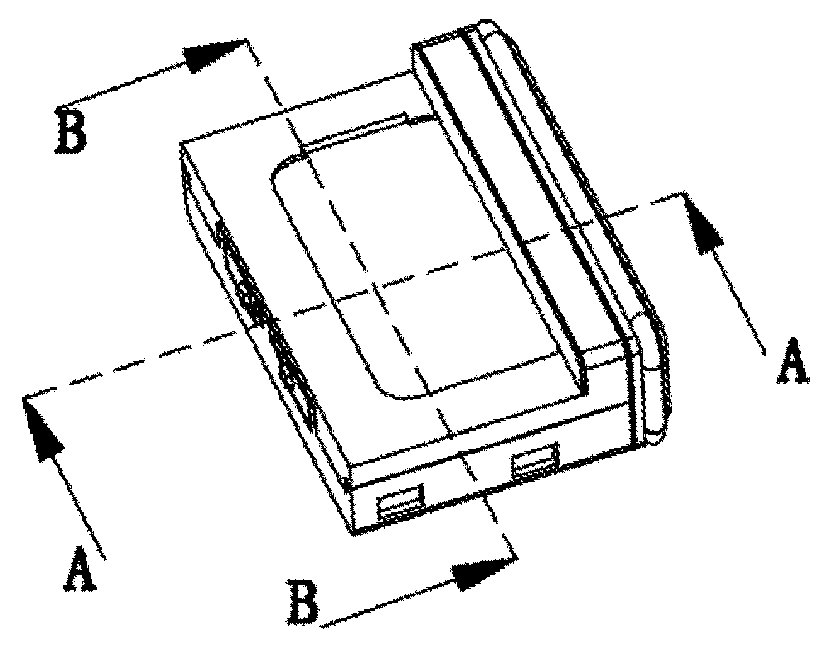

Vibration sound-producing apparatus

ActiveUS20180184209A1Reduce occupancyConducive to thin designLoudspeaker transducer fixingLoudspeakersAcousticsMagnet

Disclosed is a vibration sound-producing apparatus. A sound output aperture of the vibration sound-producing apparatus is provided at a lateral surface. A diaphragm corresponds to the position of the sound output aperture. A flat sound coil is perpendicular to the diaphragm. A magnet is parallel to the sound coil. The vibrating direction of the sound coil avoids a thickness direction. The vibrating direction of the magnet and a mass block also avoids the thickness direction. The mass block is fixedly joined to a housing via a flexible piece. This facilitates reduced product thickness, increased product performance, and a simplified product production process. Therefore, the vibration sound-producing apparatus of the present invention has the advantages of a great thickness-reduced design, great performance, and simple assembly.

Owner:GOERTEK INC

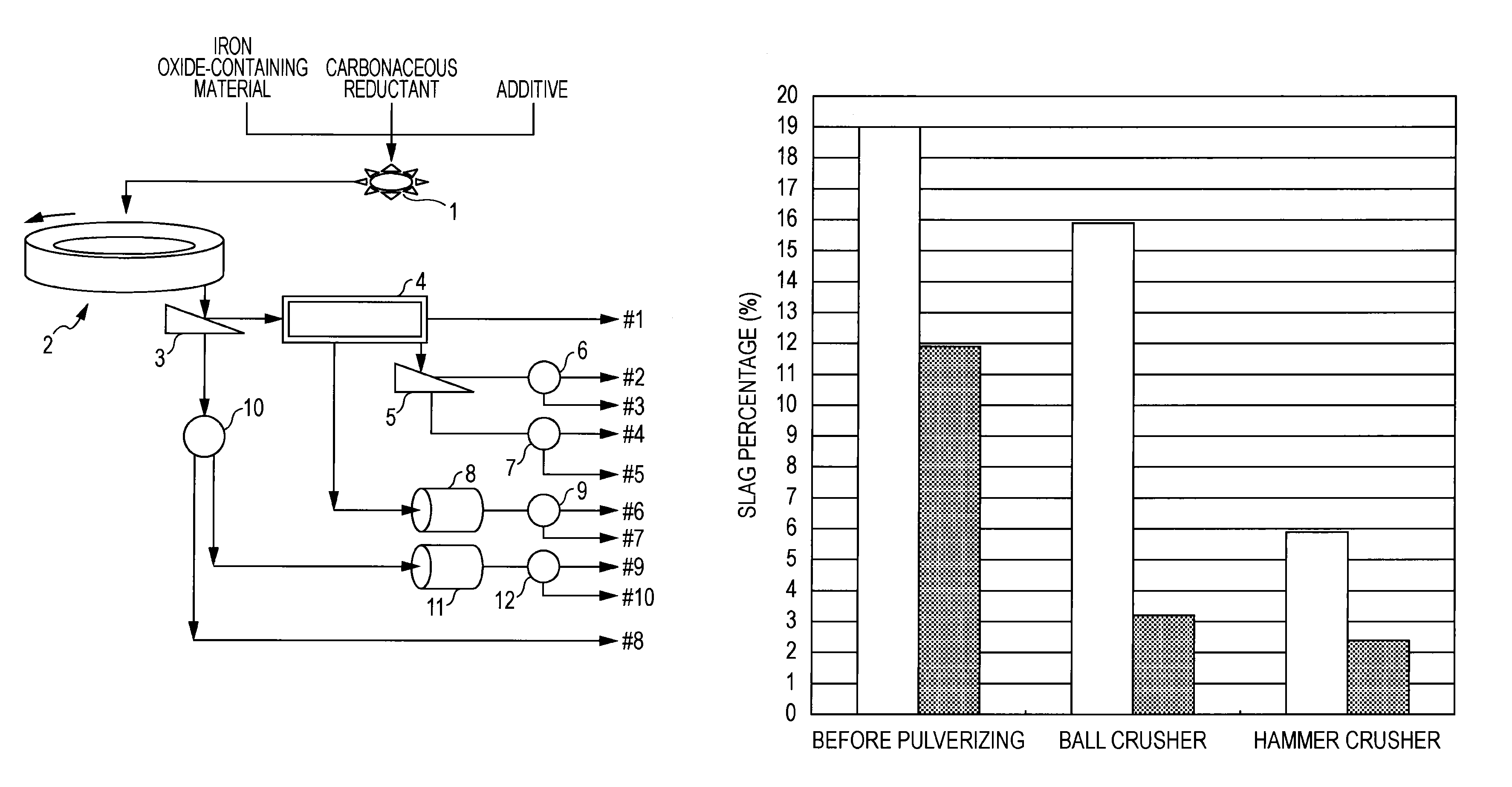

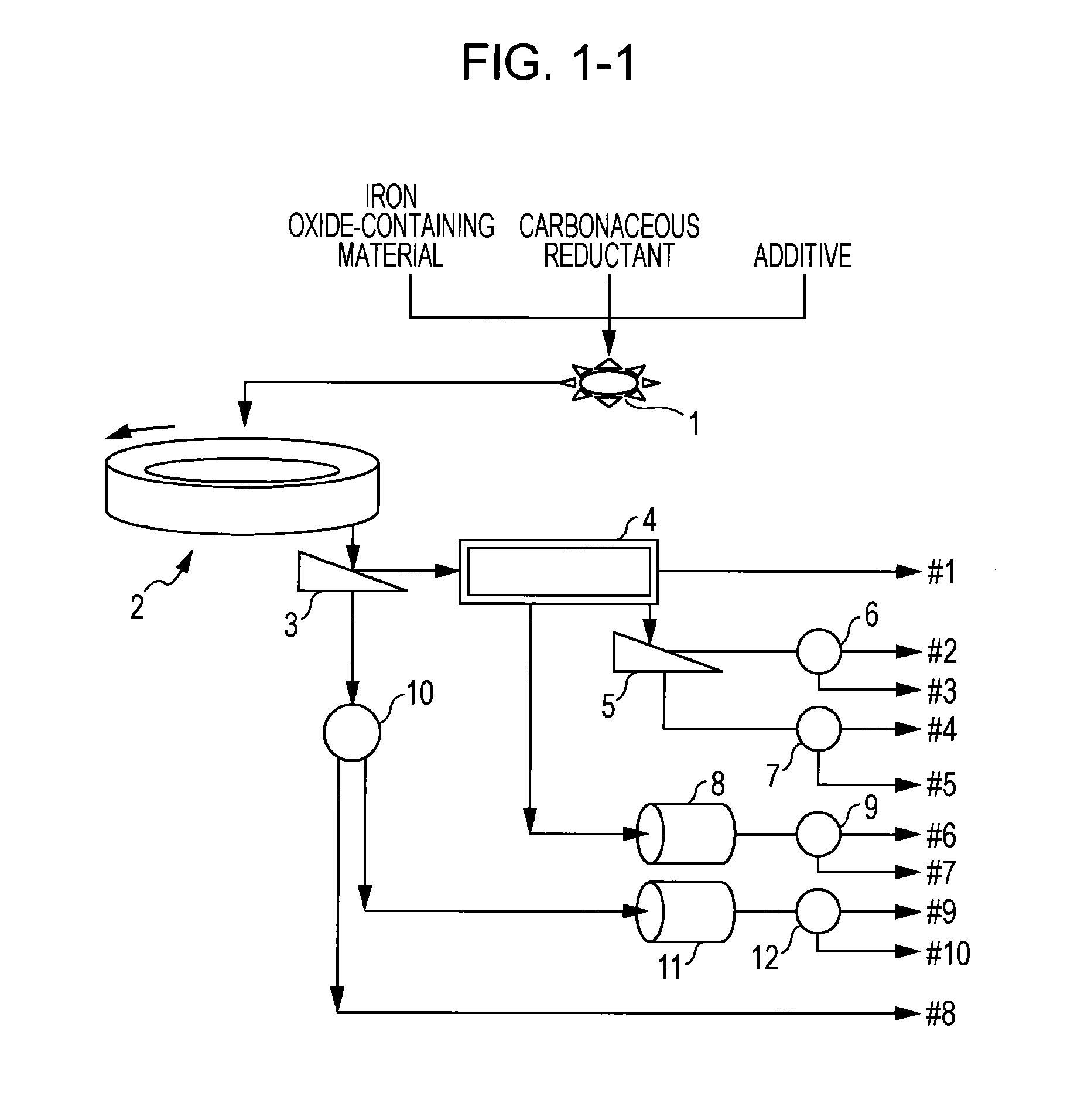

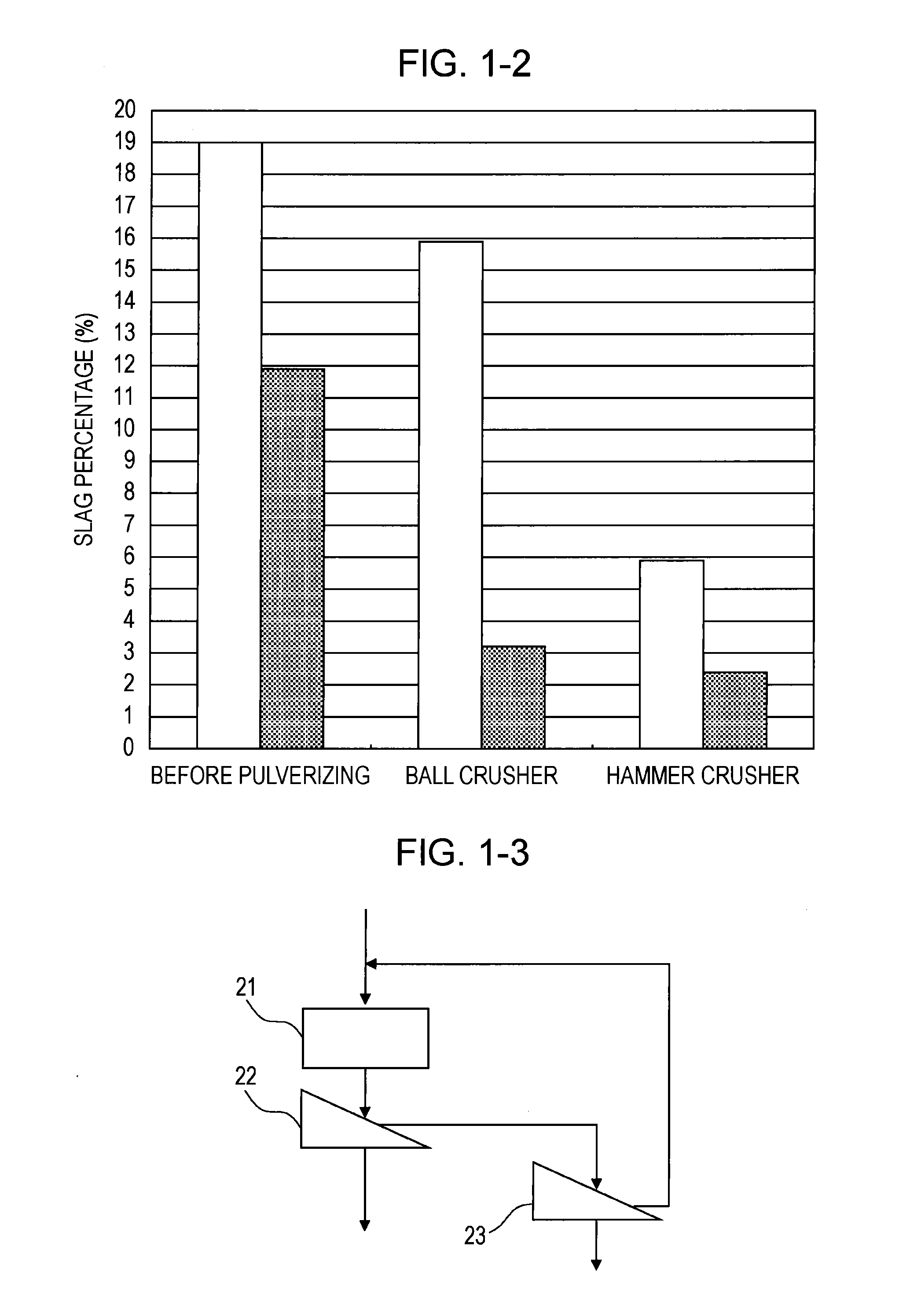

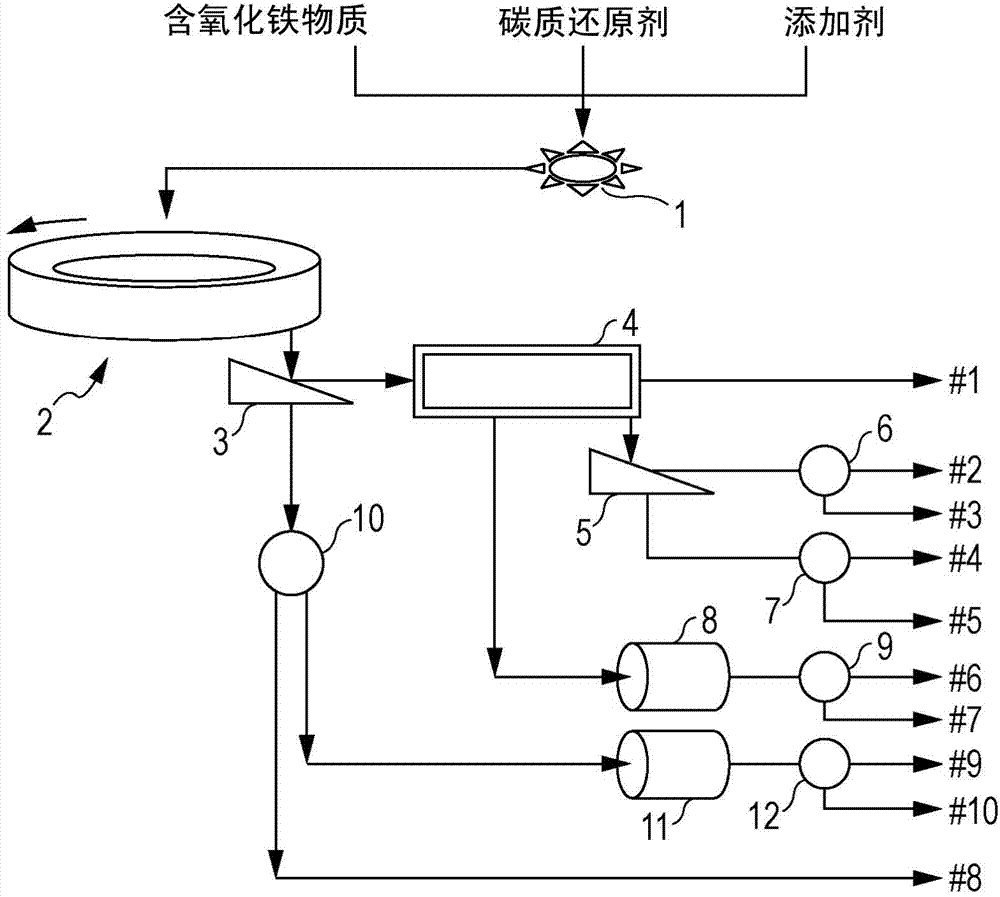

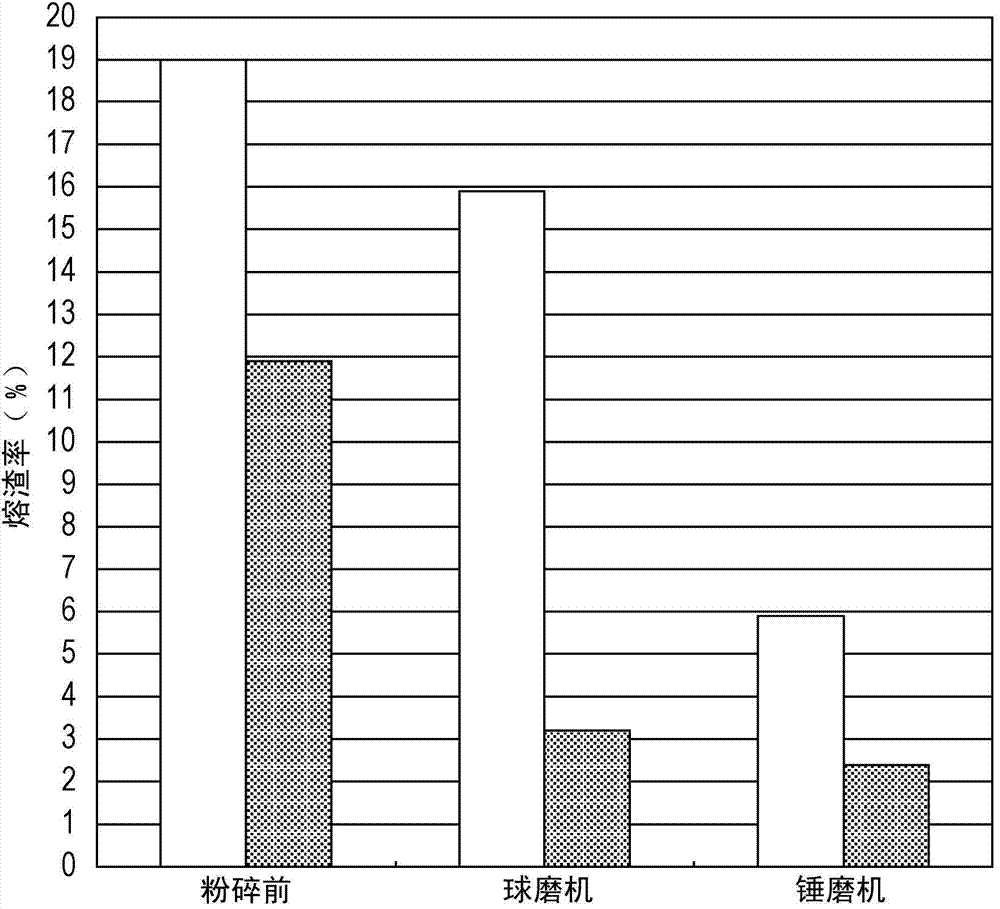

Method for producing metallic iron

InactiveUS20150203931A1Efficient collectionEfficient separationGas current separationProcess efficiency improvementSlagIron oxide

The first purpose of the present invention is to provide a method for producing metallic iron, whereby, in the production of metallic iron by heating an agglomerate, which comprises an iron oxide-containing material and a carbonaceous reductant, in a movable hearth type heating furnace, metallic iron can be efficiently collected from a reduced product containing metallic iron and a slag, said reduced product being obtained by heating the agglomerate. The method for producing metallic iron according to the first embodiment of the present invention comprises: a step for forming an agglomerate of a mixture which comprises an iron oxide-containing material and a carbonaceous reductant; a step for introducing the obtained agglomerate into a movable hearth type heating furnace and reducing the same by heating; a step for crushing a reduced product containing metallic iron and a slag, said reduced product being discharged from the movable hearth type heating furnace, using an impact crusher; and a step for selecting and collecting the metallic iron using a separator.

Owner:KOBE STEEL LTD

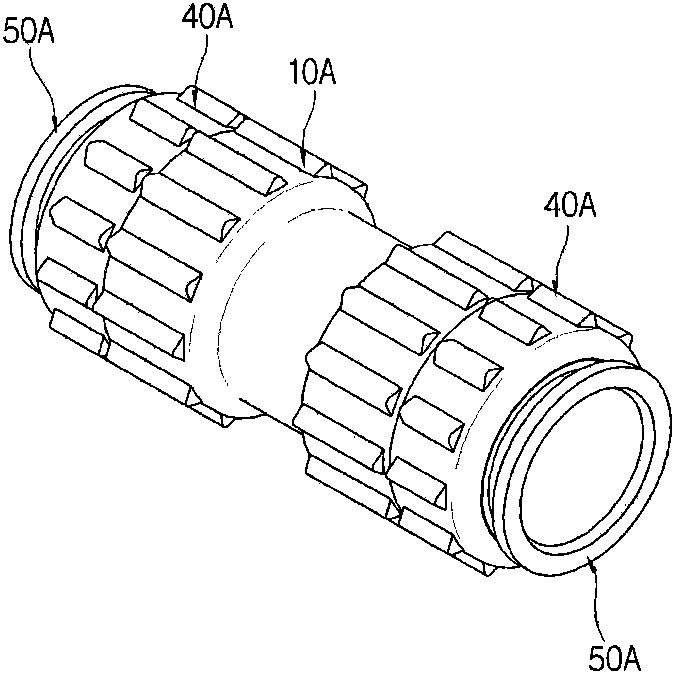

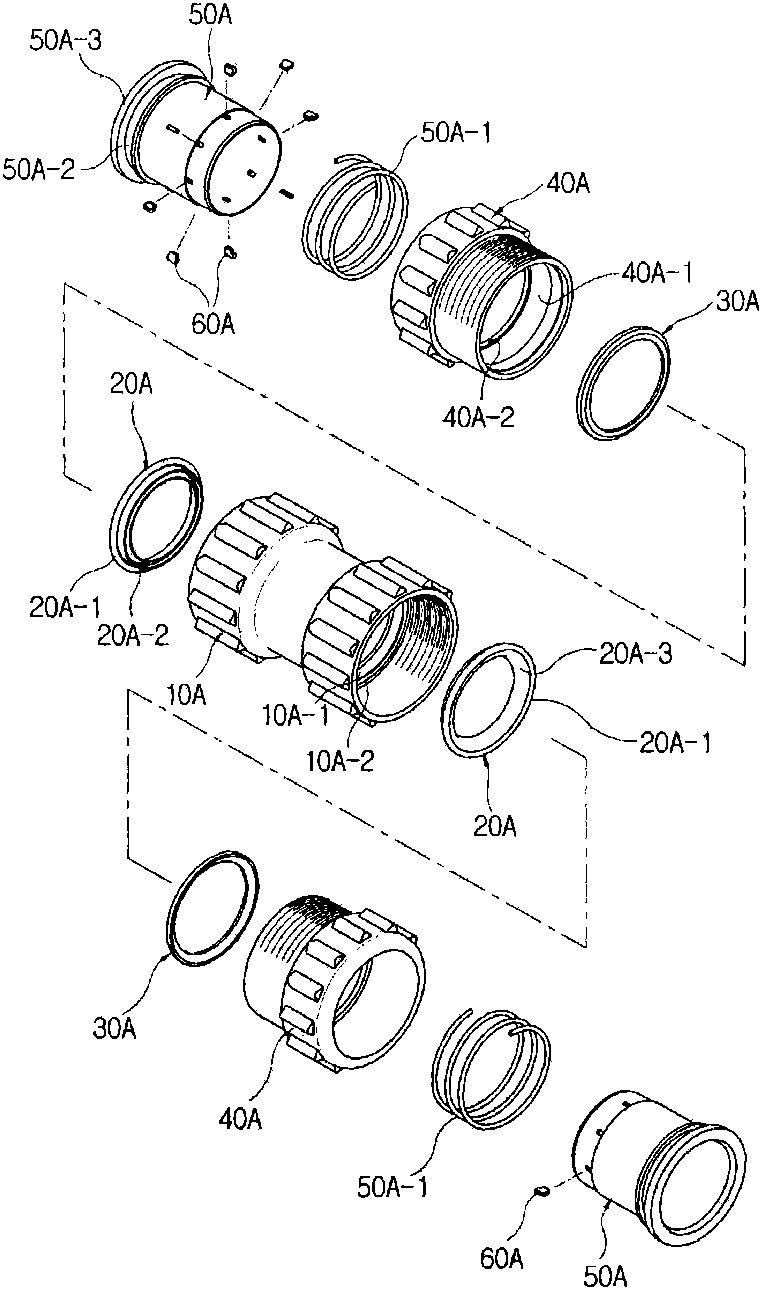

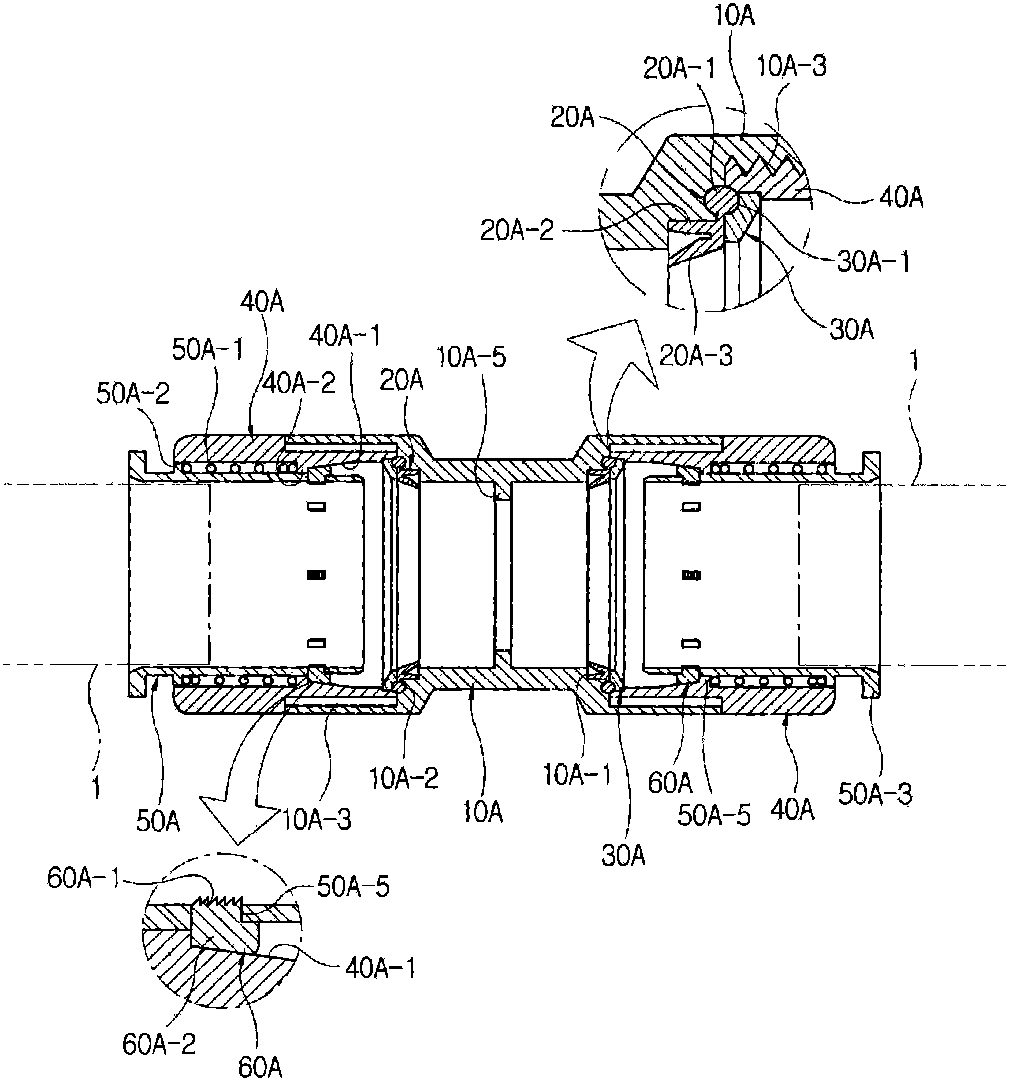

One touch-type pipe connection apparatus

The present invention relates to a one touch-type pipe connection apparatus which can solve certain problems, e.g. a weakened fixing force caused by loosened bolts, or construction inconveniences, of existing pipe connection apparatuses fixed to pipelines by bolts, while further providing superior watertightness and fixing force during the connection of pipes and which can ensure a convenient assembly process and reduced product size. To this end, the one touch-type pipe connection apparatus of the present invention is characterized by consisting of: a first main body member (10A) into which a pipe (1) is inserted; first watertight members (20A) opposing each other about the center of the first main body member (10A) so as to ensure watertightness; support members (30A) for pressing the first watertight members (20A) in the direction of a straight line; coupling members (40A) spirally coupled to the first main body member (10A); push members (50B) which are inserted into the coupling members (40A) and which move outwardly by means of compression springs (50A-1); and tight contact members (60A) installed at the push members (50B) such that the tight contact members (60A) tightly contact an outer surface of the pipe (1) during the movement of the push members (50B).

Owner:WATER TAKE

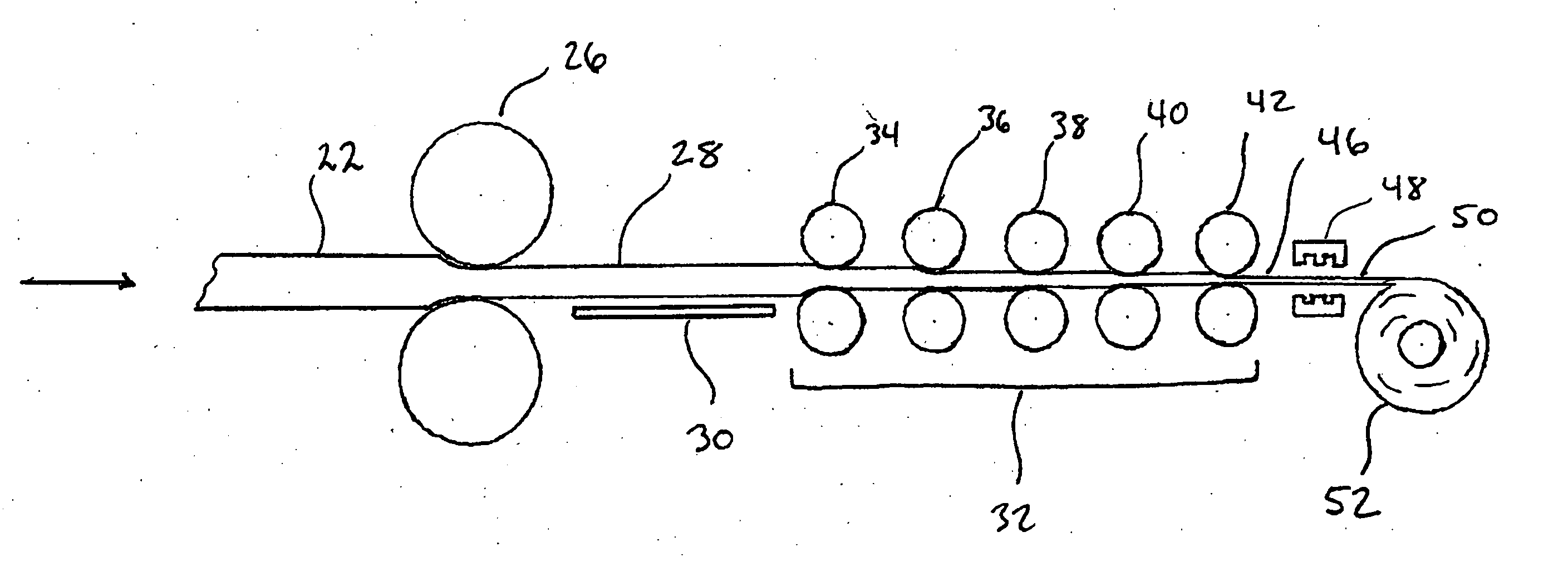

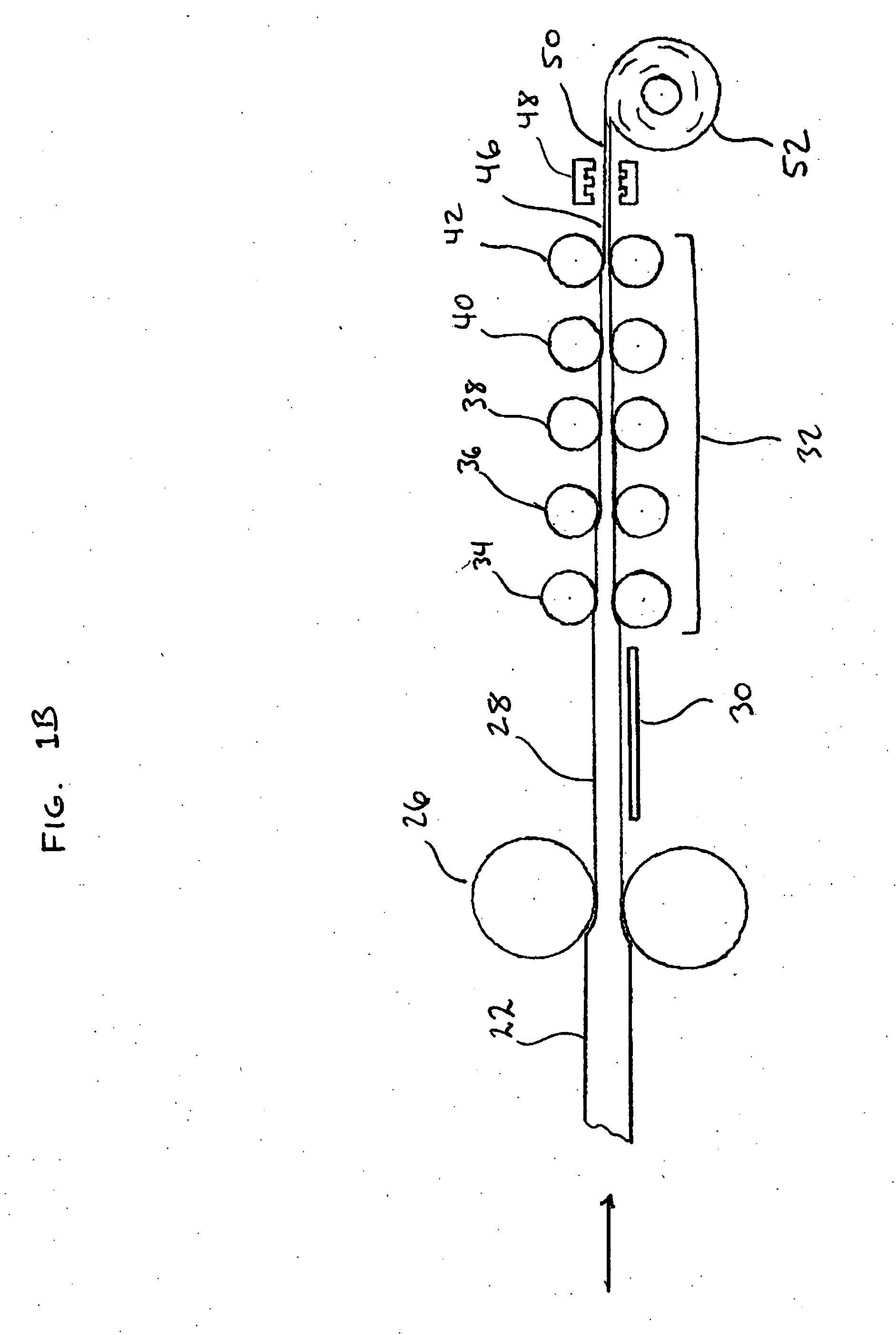

High strength steel product with improved formability and steel manufacturing process

A process and apparatus are disclosed for manufacturing high strength low alloy (HSLA) flat rolled steel products having high yield strength and formability. A preferred process comprises the formation of an as-cast product; reducing the thickness of the as cast product in a roughing mill; holding the temperature of the rough-reduced product at a temperature sufficient to permit substantially complete recrystallization of austenite grains in the rough-reduced product; followed by a final reduction step in a hot rolling strip mill. In this process, there is little or no precipitation of microalloy until after the material passes through the strip mill and therefore the material being rolled is relatively soft compared to known processes. Therefore, less power is required to roll the material to its final dimensions, with a corresponding improvement in dimensional control. The material produced according to this process has a strength of at least about 70 ksi, more preferably at least about 80 ksi, and a formability as measured by n-value within the range of from about 0.1 to about 0.15.

Owner:ALGOMA STEEL

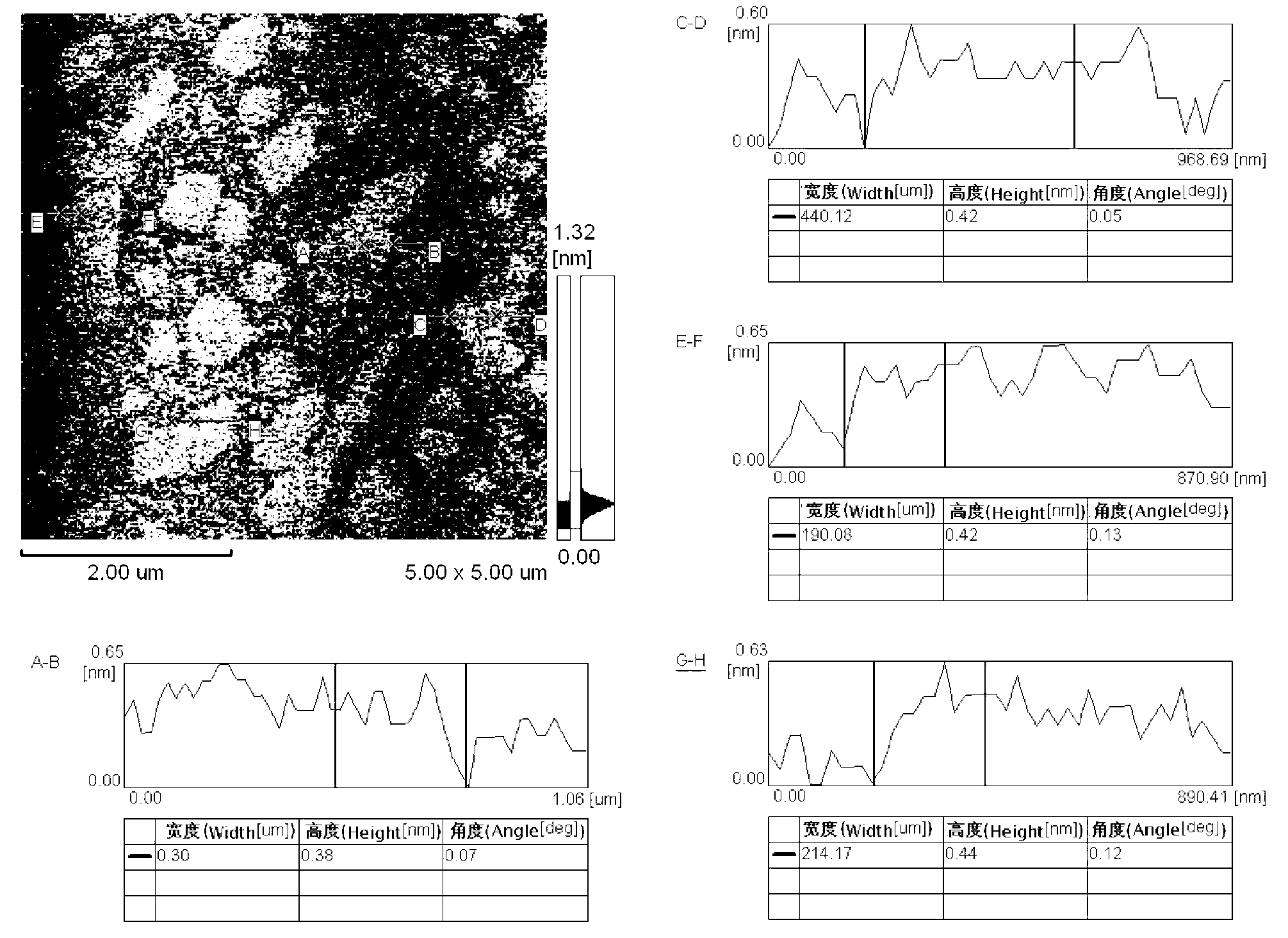

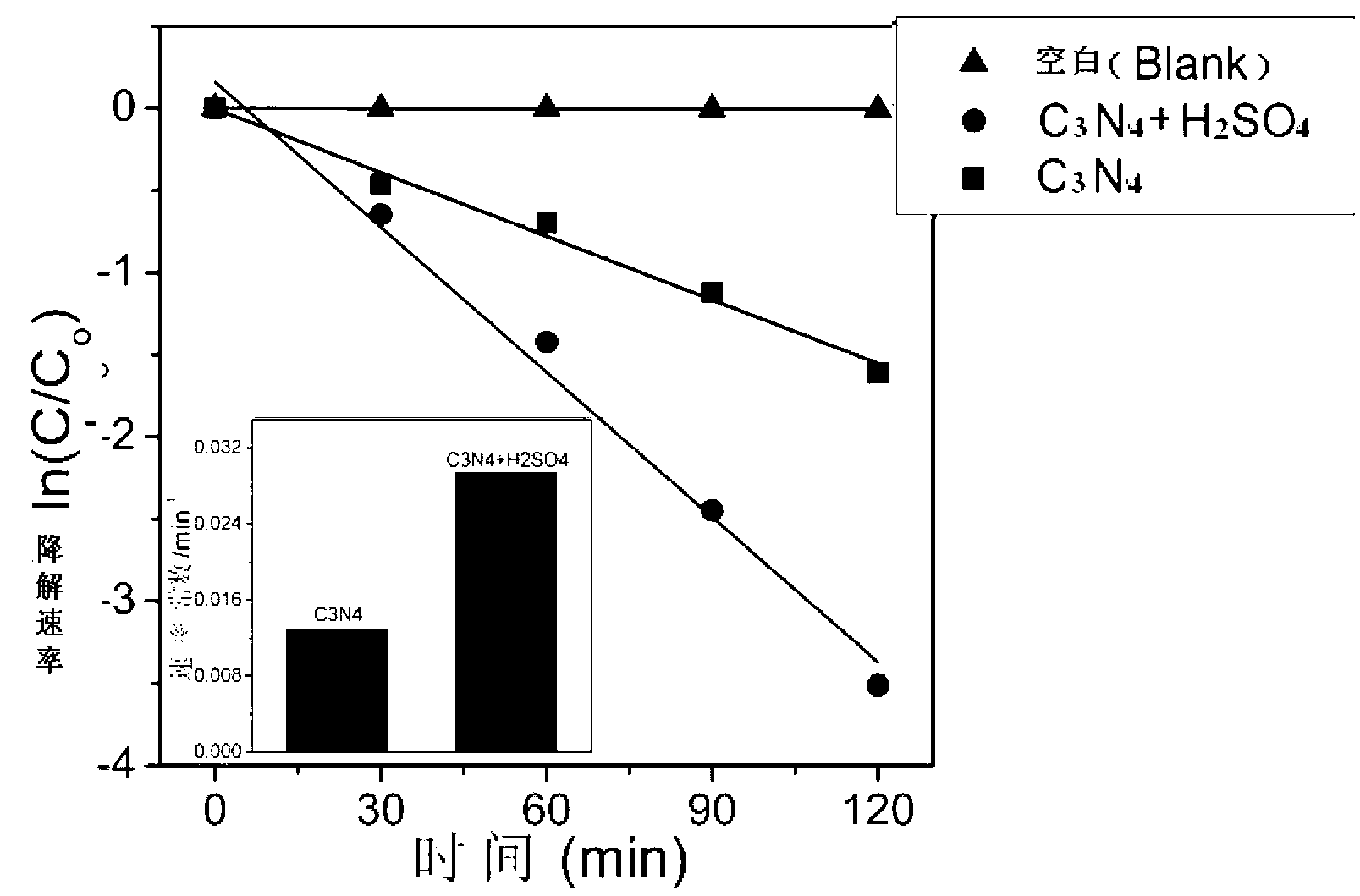

Carbon-nitrogen alkene photocatalyst and preparation method thereof

InactiveCN102974377ASave raw materialsSimple processPhysical/chemical process catalystsPhotocatalytic degradationPhotocurrent

The present invention discloses a carbon-nitrogen alkene photocatalyst and a preparation method thereof. The method comprises the following steps: (1) dispersing carbon nitride in concentrated sulfuric acid and stirring to obtain a mixed liquid; (2) adding deionized water to the obtained mixed liquid to obtain a diluted solution; and (3) carrying out centrifugation on the diluted solution, and adopting deionized water to wash the obtained precipitate after centrifugation to achieve a neutral state to obtain the carbon-nitrogen alkene photocatalyst. The single-layer sheet-like structure carbon-nitrogen alkene photocatalyst prepared by the preparation method has good performances of photocatalysis degradation of pollutants and photocurrent response. The preparation method has characteristics of inexpensive raw materials, simple process and effectively reduced product cost, is suitable for industrial mass production, and has high application prospects and practical values.

Owner:TSINGHUA UNIV

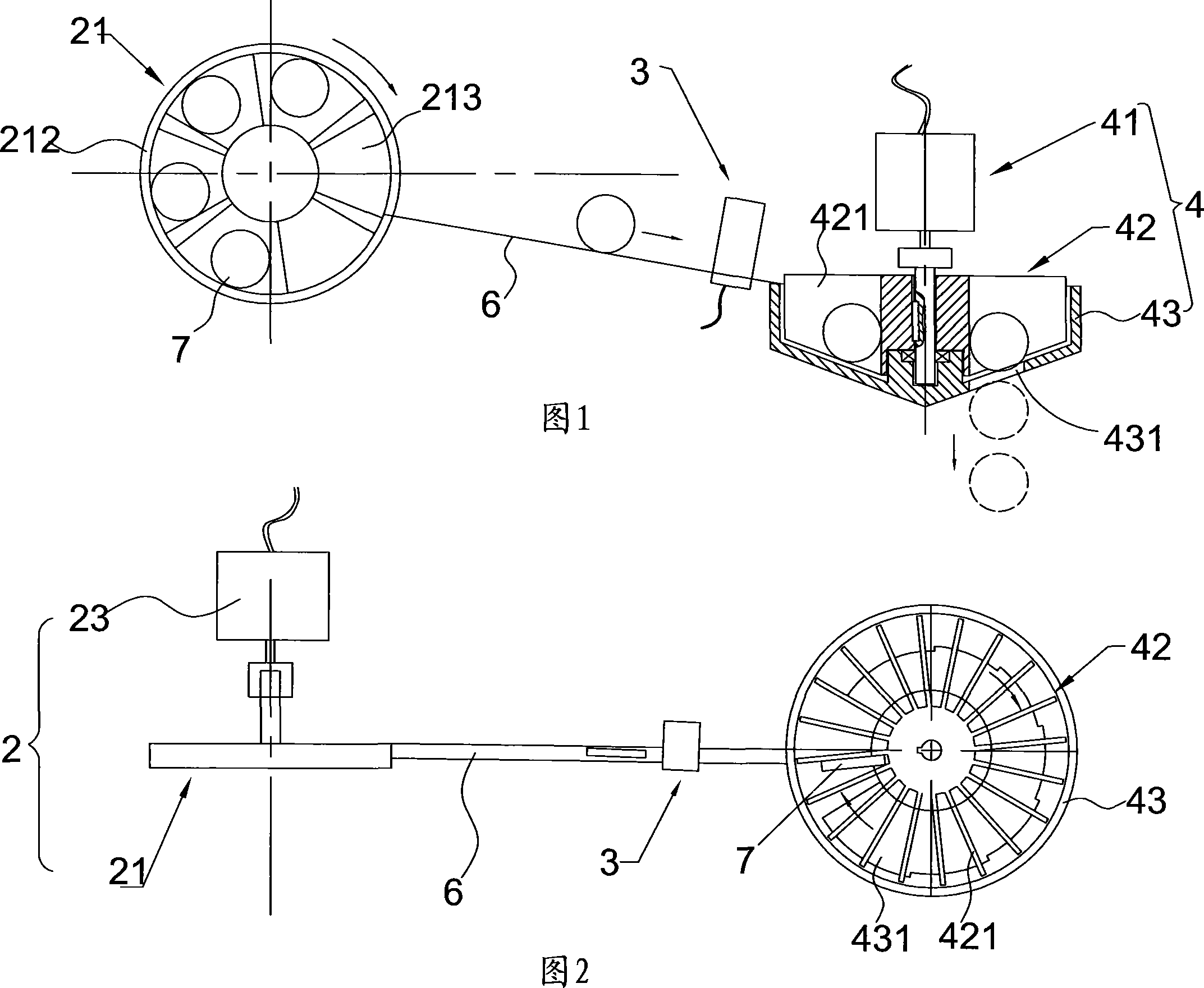

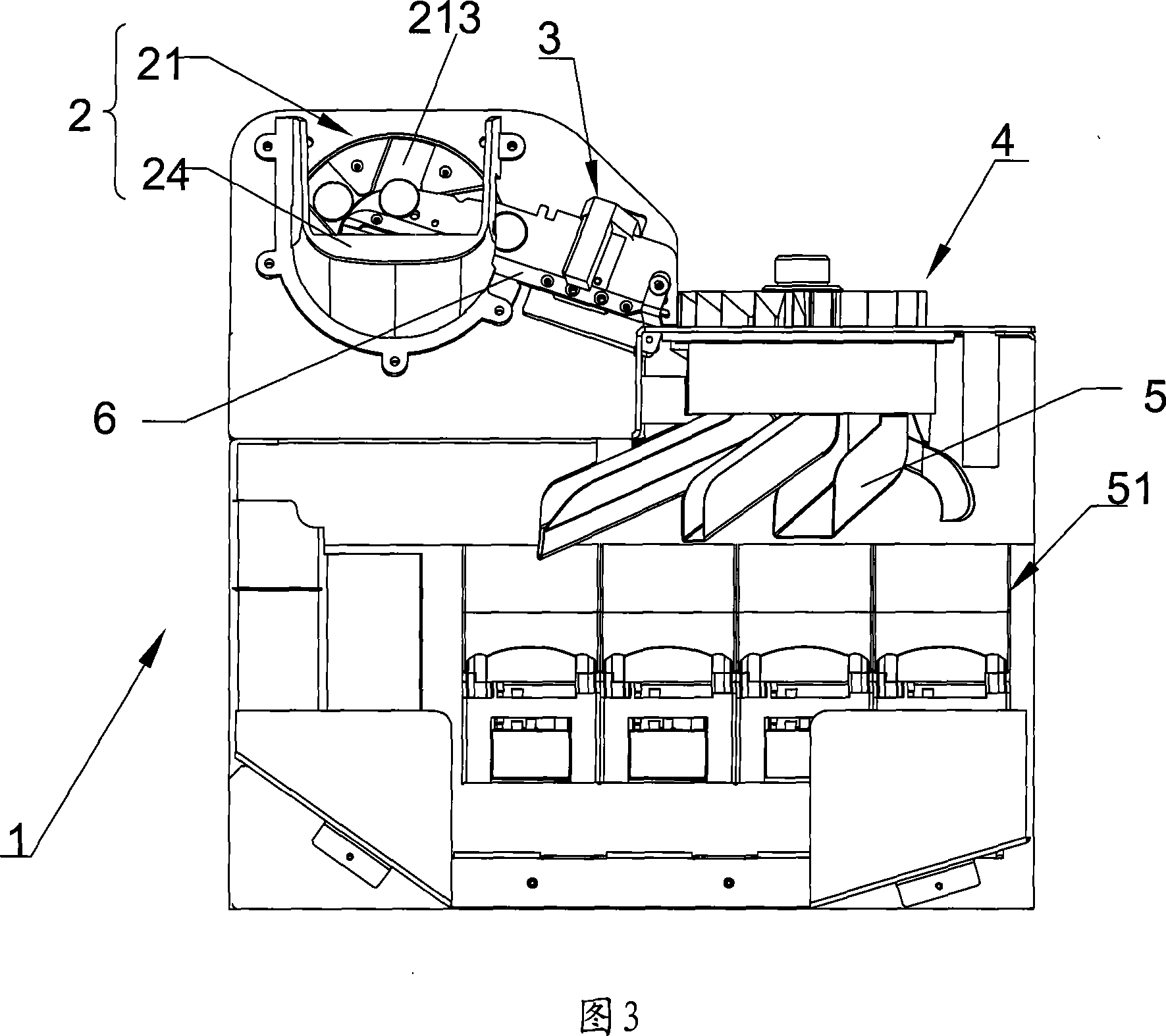

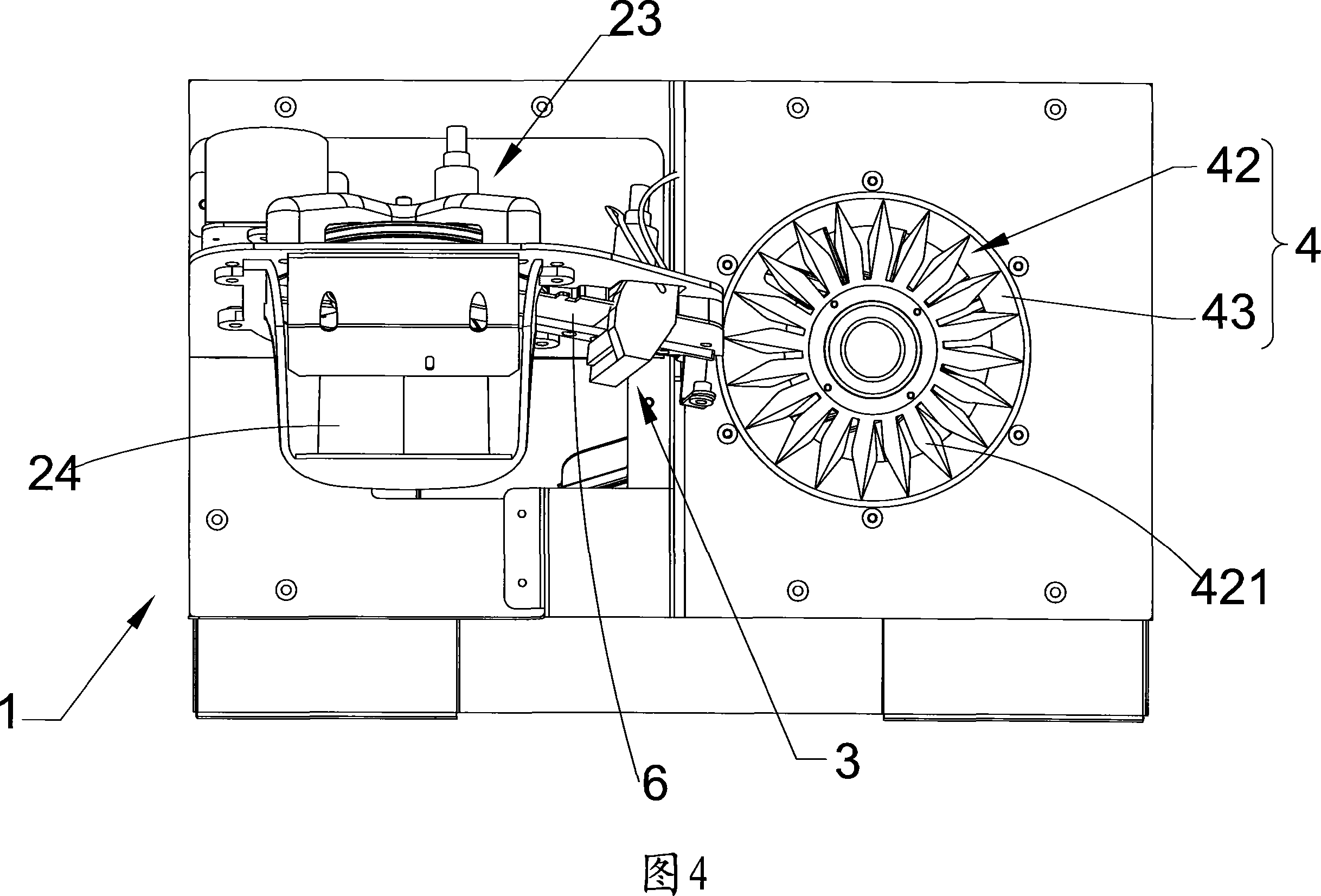

Coin sorting device

InactiveCN101059884AAvoid the influence of location uncertaintiesWon't pile upCoin/paper handlersImpellerElectrical and Electronics engineering

A coil calculating device comprises a base, a feeding device, a selector, a guide groove, and a collecting box at the descending of the selector, wherein the width of the guide groove is some larger than the thickness of the coin, the selector comprises a calculating disc, a blade wheel, and a calculating motor, while the calculating disc is arranged with a plurality of coil outlets which diameters are arranged from small to large along the rotation direction of the blade wheel, the blade wheel is provided with a plurality of blades radial arranged, and the coil is vertically inserted between two nearby blades. The invention can calculate many coins in one time to improve efficiency, with reduced product volume, compact structure, and confirmed accuracy via avoided coil accumulation in the calculating disc.

Owner:吴时欣

Process for producing high-carbon-chromium iron

The present invention relates to the method of producing high carbon ferrochromium with solid carbon reductant. The materials including ferrochromium ore powder, iron ore powder, coal powder or coke, slaked lime, silica, etc. are first mixed, pressed into blocks or pellets and dried and then reduced at high temperature of 1350-1500 deg.c. The reduced product is pulverized naturally in the cooling course and sieved to obtain granulized ferrochromium separated from slag. The present invention has simple technological process, relaxed requirement of material, low power consumption, low production cost, environment friendship, capacity of eliminating partial sulfur and phosphorus and other advantages.

Owner:WUHAN UNIV OF SCI & TECH

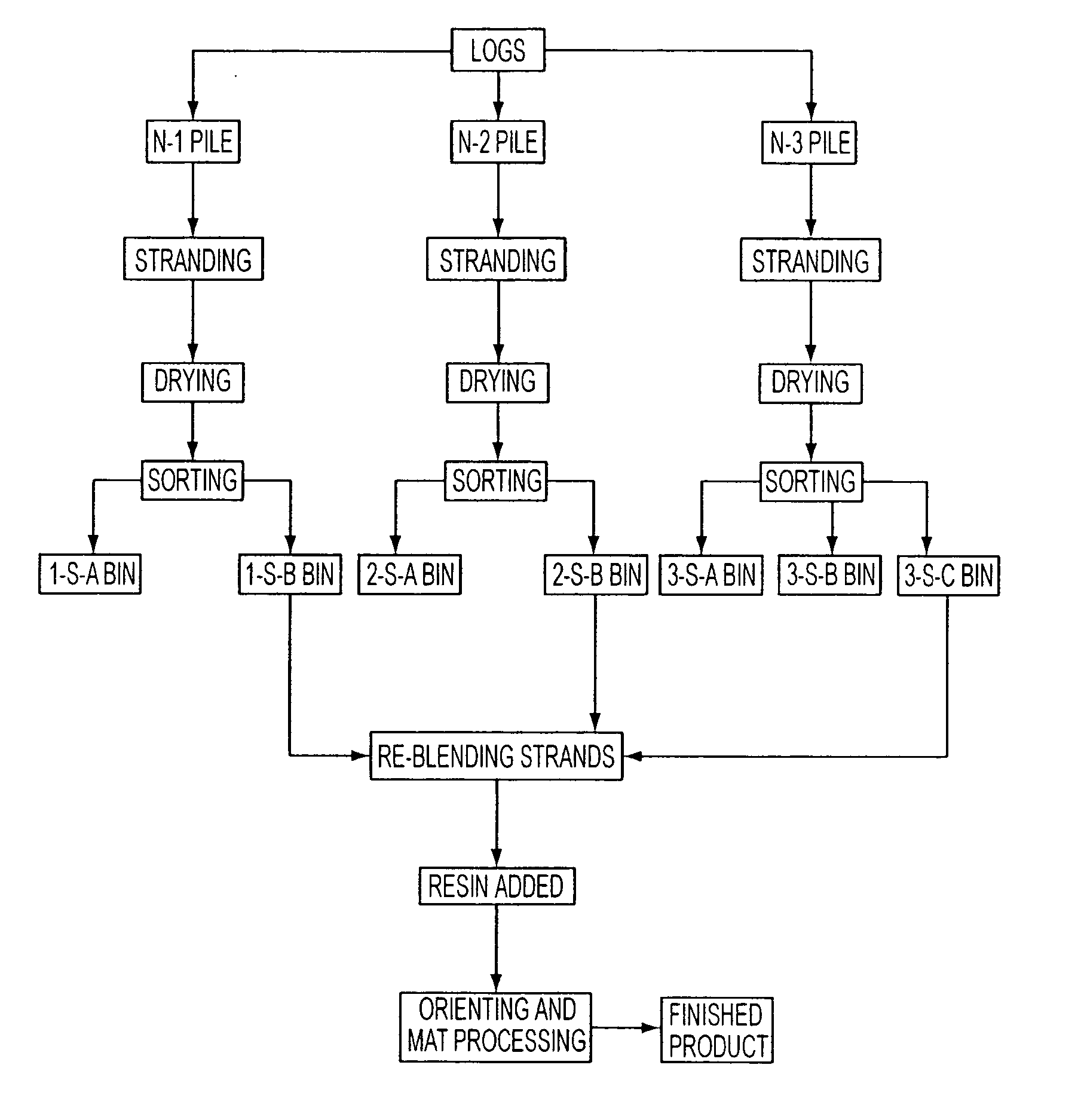

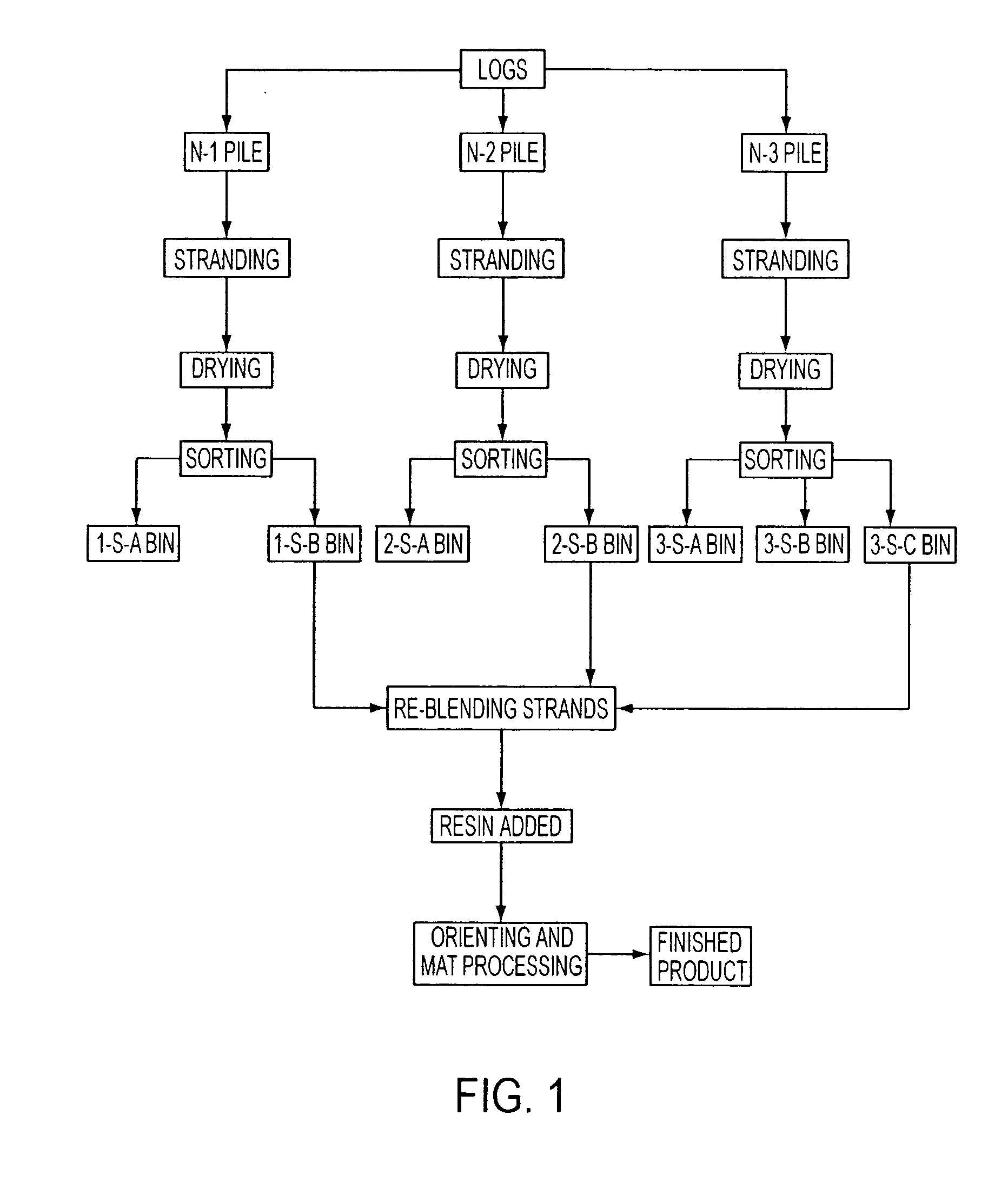

Process for manufacture of oriented strand lumber products

The present teachings are directed toward a process for the production of engineered wood products, or oriented strand wood products, having certain desired or predetermined properties by selection of the strands used in the products. The present teachings provide a process which has enhanced utilization of wood resources, reduced product variability, and can produce engineered wood product of various grades and properties on the same production line.

Owner:HUBER ENGINEERED WOODS

Process for producing 2,3,3,3-tetrafluoropropene

InactiveUS8766021B2Suppress formation of HFC-254ebPreparation by dehalogenationPreparation by hydrogen halide split-offHydrogenHFO-1234yf

In the production of 2,3,3,3-tetrafluoropropene (HFO-1234yf), formation of HFC-254eb as an excessively reduced product is suppressed.A process for producing 2,3,3,3-tetrafluoropropene, which comprises reacting a raw material compound gas composed of at least one of 1,1-dichloro-2,3,3,3-tetrafluoropropene and 1-chloro-2,3,3,3-tetrafluoropropene, and hydrogen gas, in the presence of a catalyst, wherein the catalyst is a catalyst having palladium supported on active carbon, and the ratio of the number of moles of the hydrogen gas to the number of moles of chlorine atoms in the raw material compound gas (H2 / Cl) is at most 0.7.

Owner:ASAHI GLASS CO LTD

Method for producing metallic iron

InactiveCN104508151AEfficient recyclingEfficient separationProcess efficiency improvementMagnetic separationSlagHeating furnace

The first purpose of the present invention is to provide a method for producing metallic iron, whereby, in the production of metallic iron by heating an agglomerate, which comprises an iron oxide-containing material and a carbonaceous reducing agent, in a movable hearth type heating furnace, metallic iron can be efficiently collected from a reduced product containing metallic iron and a slag, said reduced product being obtained by heating the agglomerate. The method for producing metallic iron according to the first embodiment of the present invention comprises: a step for forming an agglomerate of a mixture which comprises an iron oxide-containing material and a carbonaceous reducing agent; a step for introducing the obtained agglomerate into a movable hearth type heating furnace and reducing the same by heating; a step for milling a reduced product containing metallic iron and a slag, said reduced product being discharged from the movable hearth type heating furnace, using an impact mill; and a step for selecting and collecting the metallic iron using a separator.

Owner:KOBE STEEL LTD

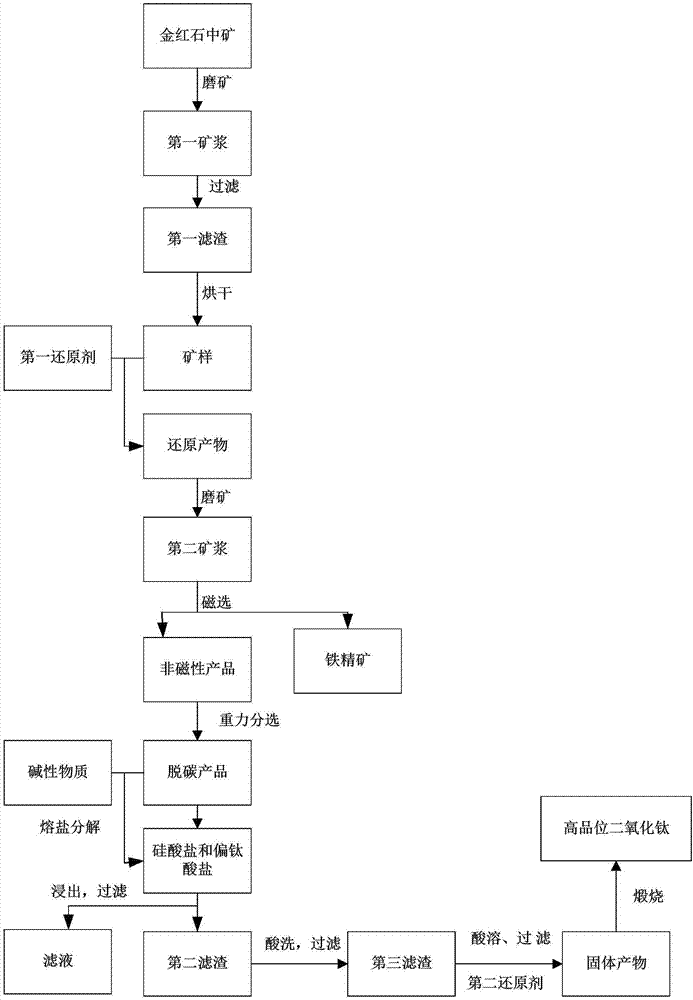

Comprehensive utilization process of rutile middlings

ActiveCN107127046AIncrease profitIncrease contentTitanium dioxideMagnetic separationDecompositionNon magnetic

A comprehensive utilization process of rutile middlings comprises the following steps that the rutile middlings are ground, and first ore pulp is obtained; the first ore pulp is filtered to obtain first filter residues, and then the first filter residues are dried to obtain sample ore; a first reducing agent is added into the sample ore to obtain reduced products; the reduced products are subjected to ore grinding and then manufactured into second ore pulp; the second ore pulp is subjected to magnetic separation, and iron ore concentrates and non-magnetic products are obtained; the non-magnetic products are subjected to gravity sorting to obtain decarbonizing products; the decarbonizing products are dried, then the decarbonizing products and alkaline matter are subjected to fused salt decomposition, and silicate and metatitanic acid salt are obtained; the products obtained after fused salt decomposition are leached, and filter liquor and second filter residues are obtained through filtering; the second filter residues are subjected to acid pickling and then filtered, and third filter residues are obtained; the third filter residues are subjected to acid solution, a second reducing agent is added, and solid products are obtained through filtering; and the solid products are roasted, and high-grade titanium dioxide is obtained. According to the comprehensive utilization process, the comprehensive utilization rate of the rutile middlings can be effectively increased.

Owner:SHANGLUO UNIV

Preparation method of porous g-C3N4 with high specific surface area

The invention relates to a preparation method of porous g-C3N4 with high specific surface area. The preparation method comprises: re-crystallizing urea by using a certain proportion of a methanol-glycerol system, washing the crystal by using anhydrous ethanol, drying, placing the crystal in a covered crucible, calcining for 2 h at a temperature of 400 DEG C in a muffle furnace, and calcining for 2h at a temperature of 550 DEG C to obtain the pale yellow pure g-C3N4. According to the present invention, g-C3N4 with different specific surface areas and different pore volumes can be obtained by adjusting the ratio of the methanol-glycerol to the urea, and the prepared g-C3N4 has the specific surface area of 133.05-210.80 m<2> / g and the pore volume of 0.497-1.537 cm<3> / g; and the method has advantages of simple operation steps, low cost of the raw materials, effectively reduced product cost, high application prospect and high practical value.

Owner:GUANGXI UNIV FOR NATITIES

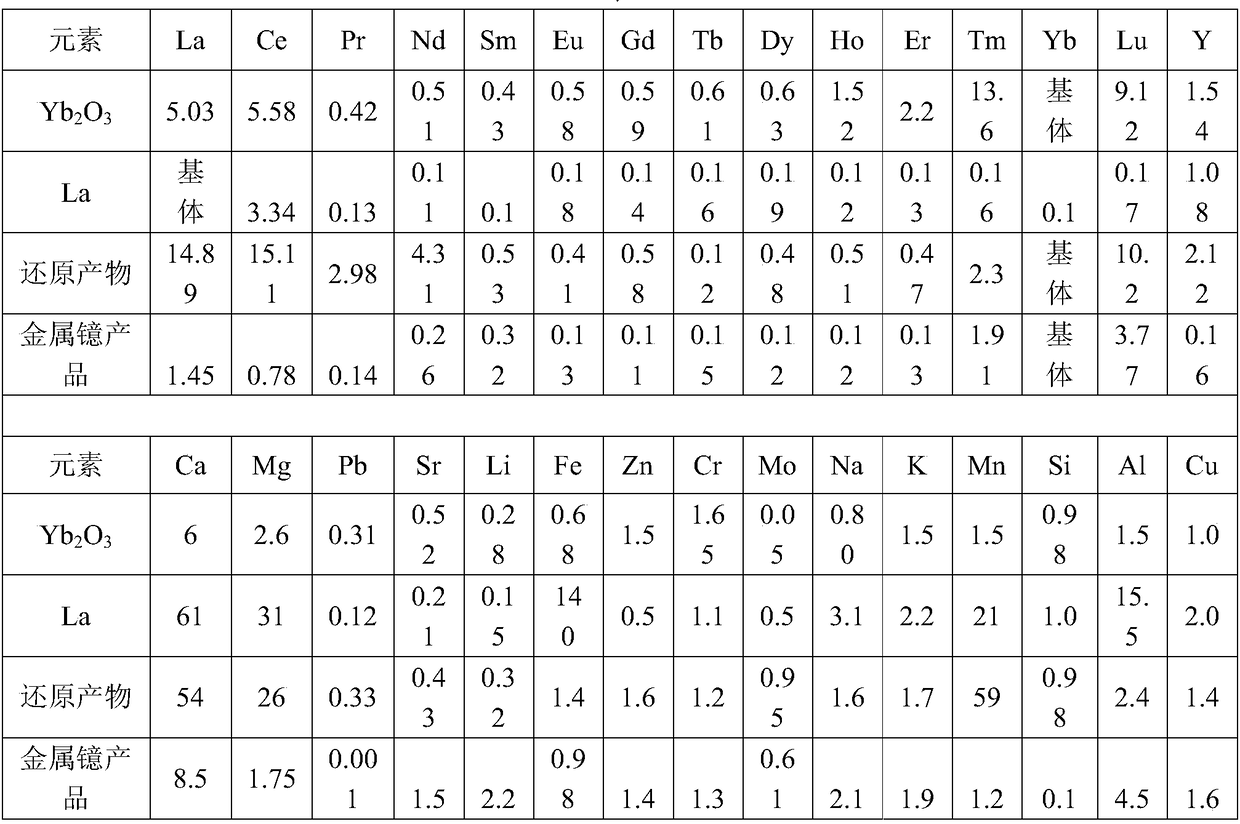

Preparation method of ytterbium metal

The invention relates to a preparation of ytterbium metal. The preparation method comprises the following steps that ytterbium oxide and a reducing agent are mixed, the temperature is increased to thefirst temperature at the speed of 10-15 DEG C / min under the condition that the vacuum degree is higher than 5*10<-2> Pa, heat preservation is conducted till the vacuum degree is stable, then the temperature is increased to the second temperature at the speed of 2.5-10 DEG C / min, heat preservation is conducted for 30 min or above, a reduction reaction is conducted, evaporated components are collected, and thus a reduced product is obtained; and the reduced product is heated up to the third temperature under the condition that the vacuum degree is higher than 5*10<-4> Pa, heat preservation is conducted for 5-20 h, then the temperature is increased to the fourth temperature, components evaporated in the time period that the third temperature is increased to the fourth temperature are collected, and thus the ytterbium metal is obtained. The preparation method is divided into the two steps of low-temperature reduction and distillation impurity-removing to be conducted respectively so as toachieve the purpose of simultaneously removing rare earth impurities and part of non-rare earth impurities, and the ytterbium metal with high purity is prepared accordingly.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

Preparation technology of superfine spherical nickel, cobalt and iron ternary alloy powder

The invention relates to a preparation technology of superfine spherical nickel, cobalt and iron ternary alloy powder and belongs to the field of powder metallurgy. The preparation technology includes the four steps of burdening, liquid phase reduction, high energy ball milling and post-processing. Nickel, cobalt and iron salt materials are added in a liquid phase reduction agent to be reduced. Ethyl alcohol is added in obtained reduced products, and mixtures are ball-milled in a high-energy ball mill. Then products are obtained through vacuum drying and packaging. The preparation technology of the superfine spherical nickel, cobalt and iron ternary alloy powder is provided. The technological process is short; production efficiency is high; waste water containing ammonia and nitrogen is not generated; cost is low; particle size distribution of obtained nickel, cobalt and iron is uniform; the Fsss particle size is small; and the nickel, cobalt and iron ternary alloy powder is spherical.

Owner:兰云科

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com