Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

868 results about "Solid metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Description of Metals. A solid is considered to be a metal if it has high electrical and thermal conductivity. The chemical definition of a metal also includes having a characteristic surface luster or shine. It is characteristic of metals that they are malleable (can be hammered into sheets) and ductile (can be drawn into wires).

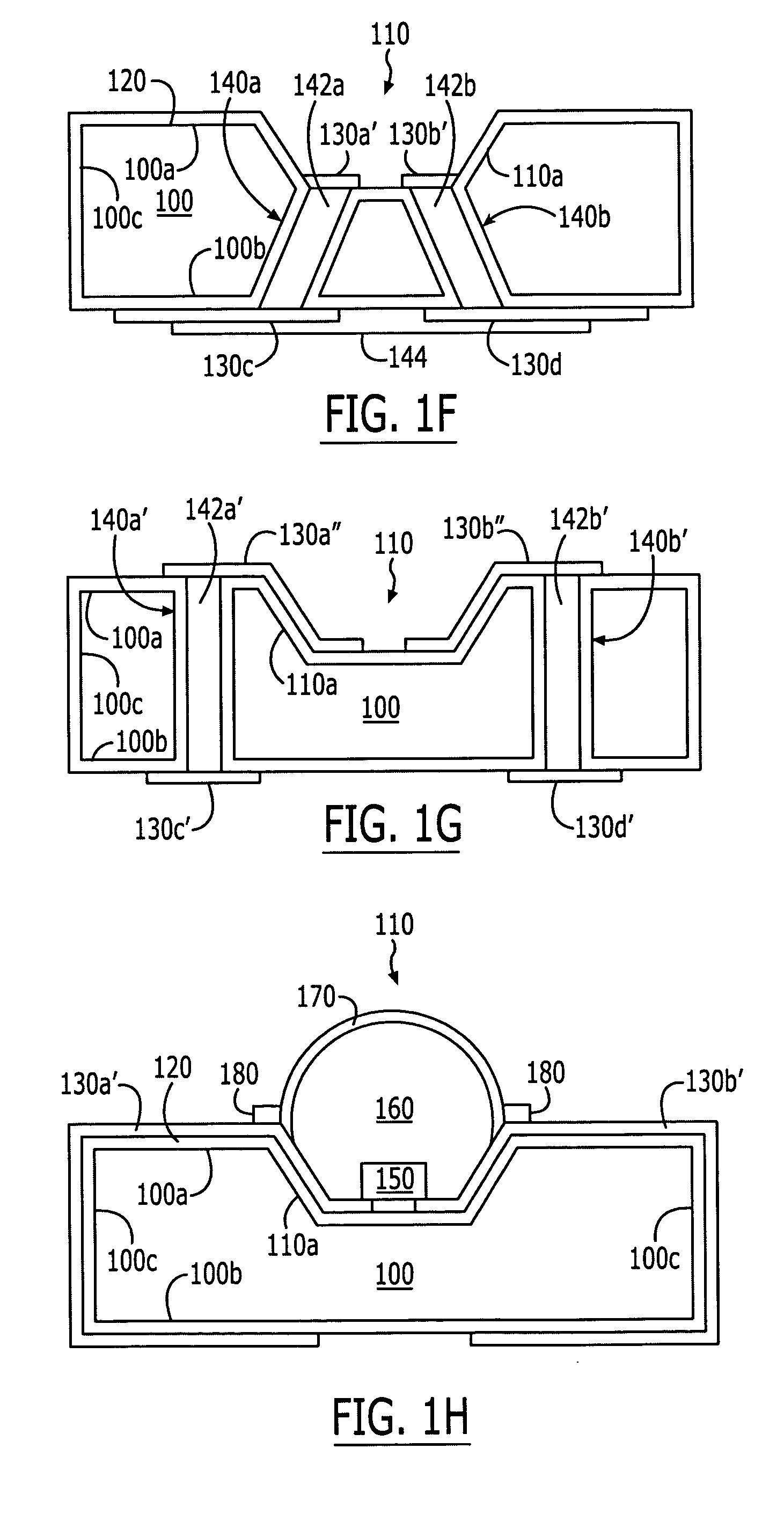

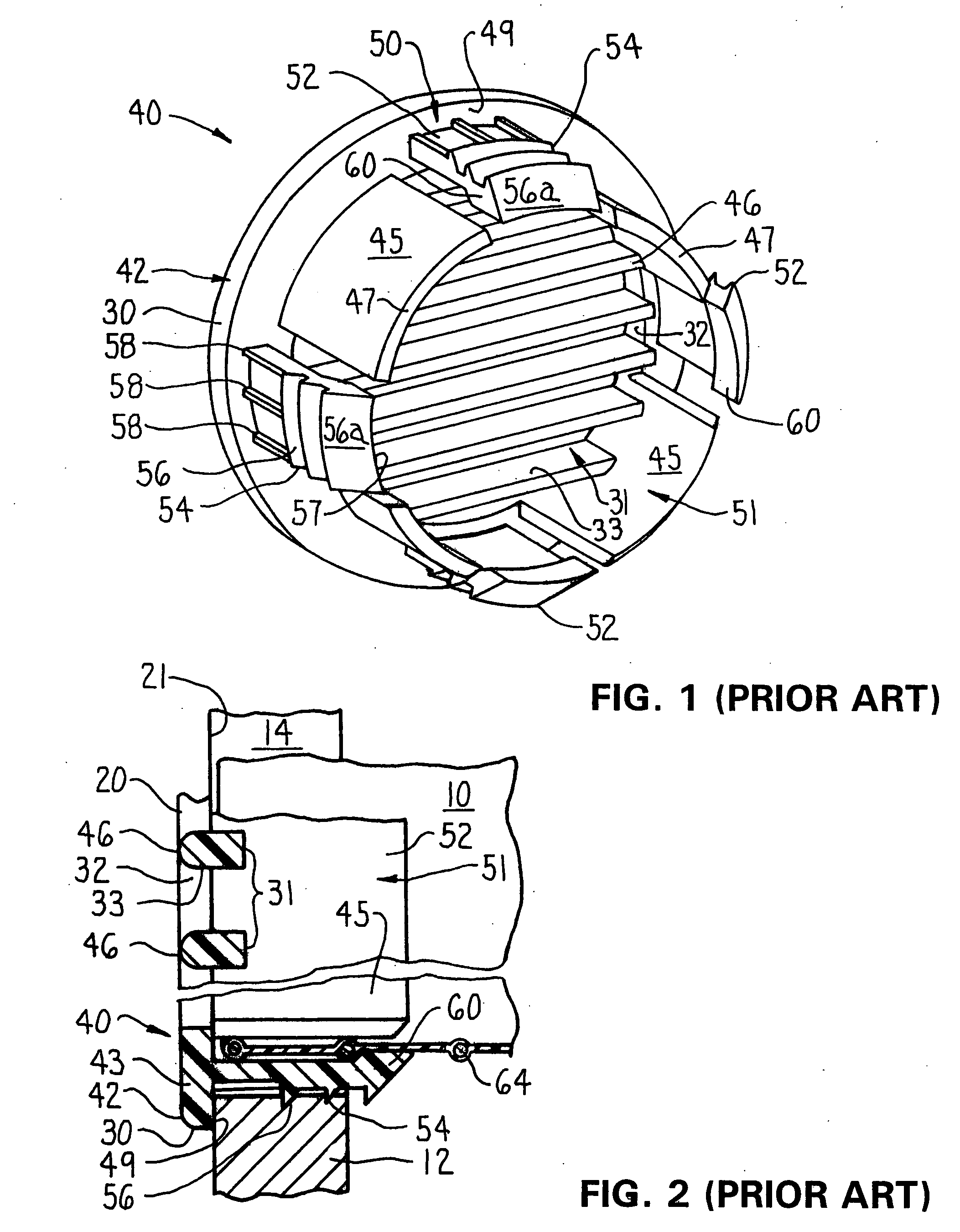

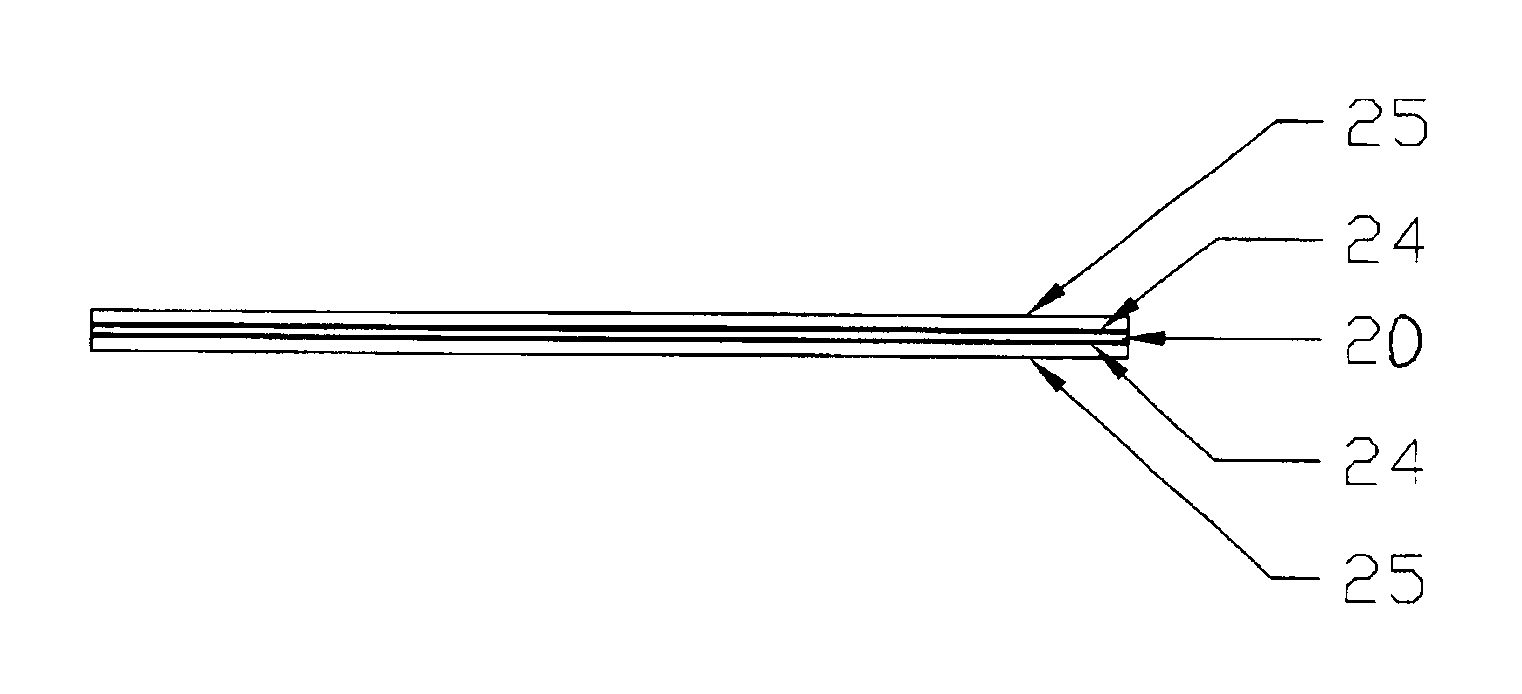

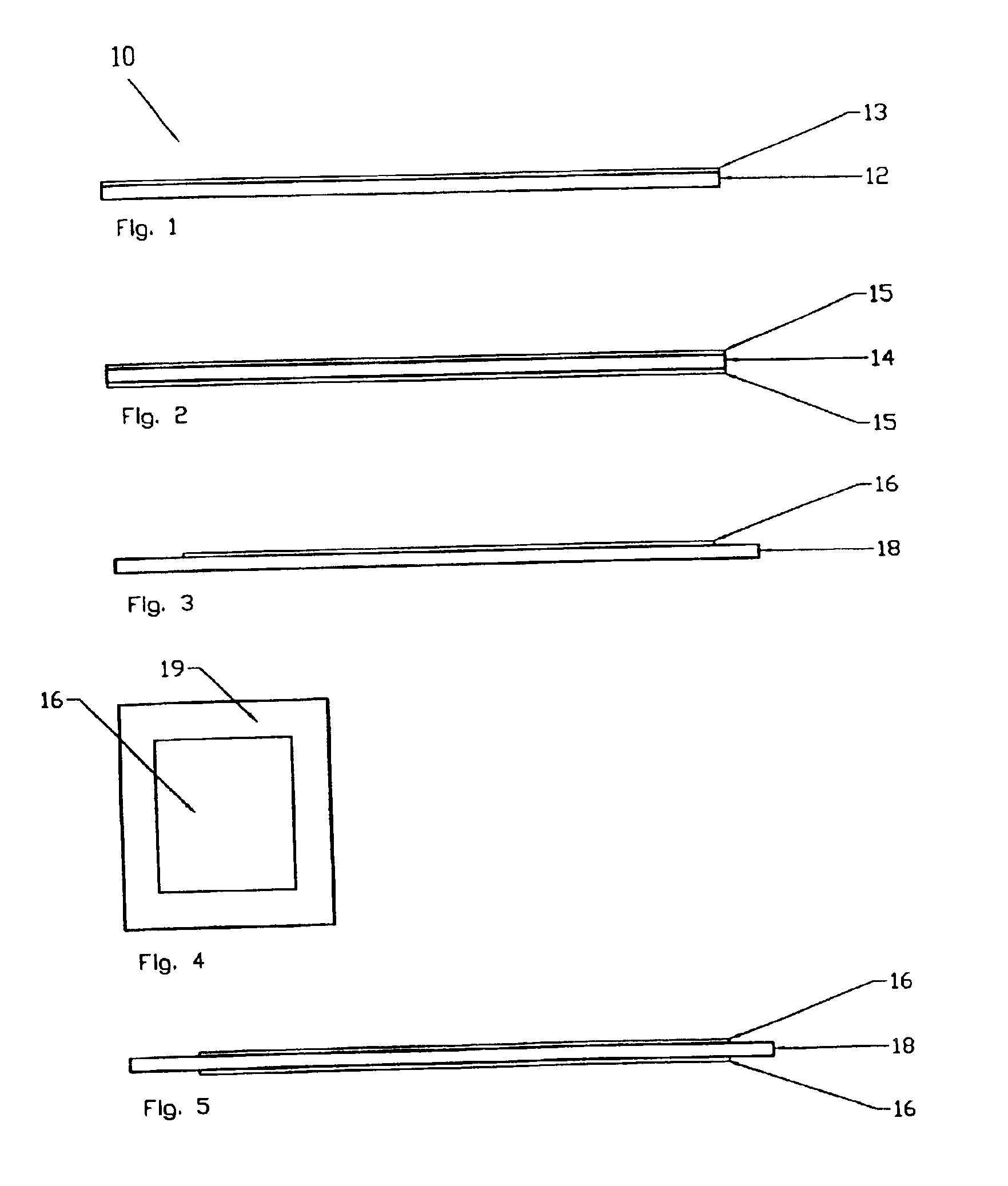

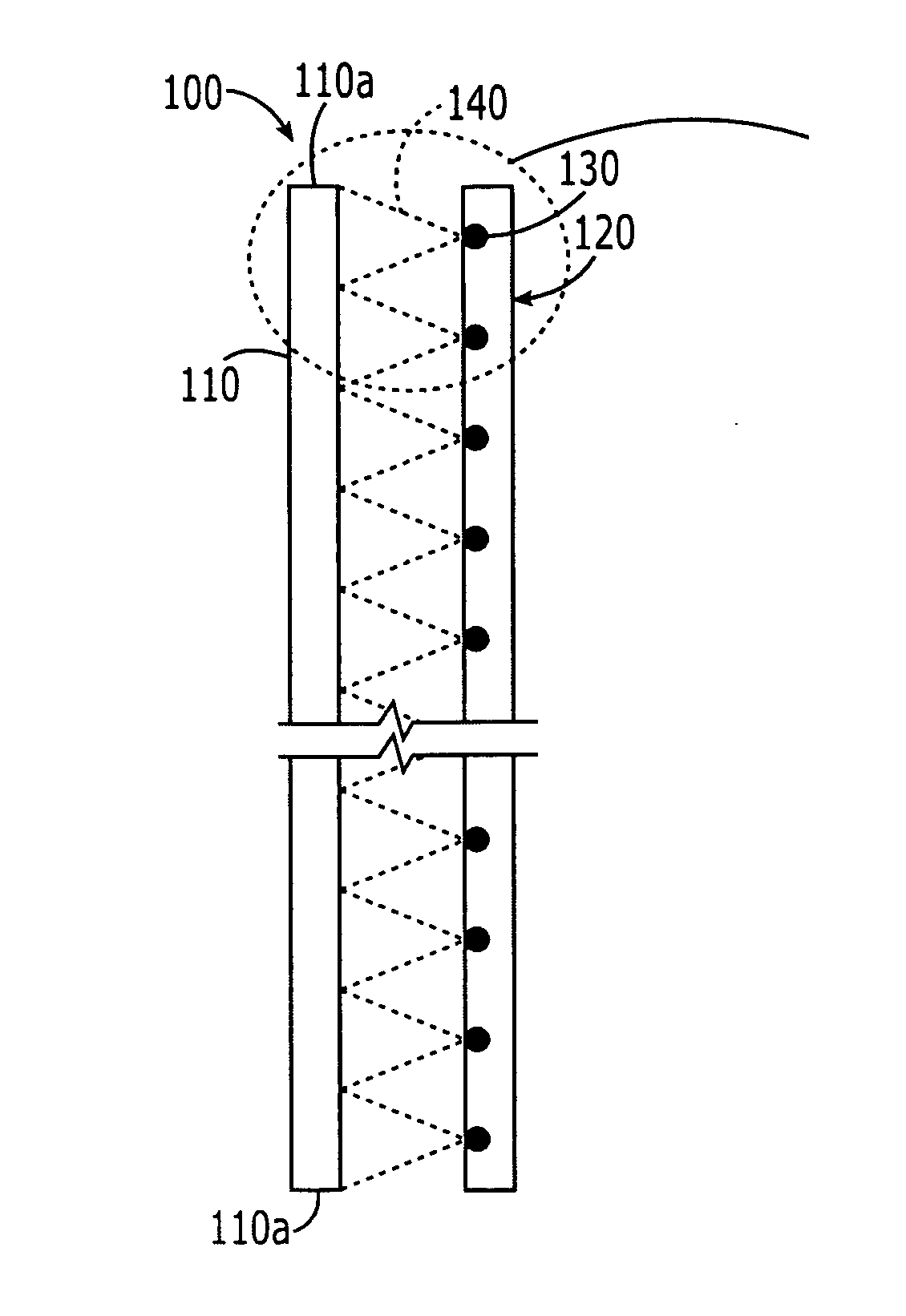

Microstrip patch antenna for high temperature environments

ActiveUS7283096B2Improve performanceImprove reliabilitySimultaneous aerial operationsAntenna adaptation in movable bodiesMicrostrip patch antennaSpray coating

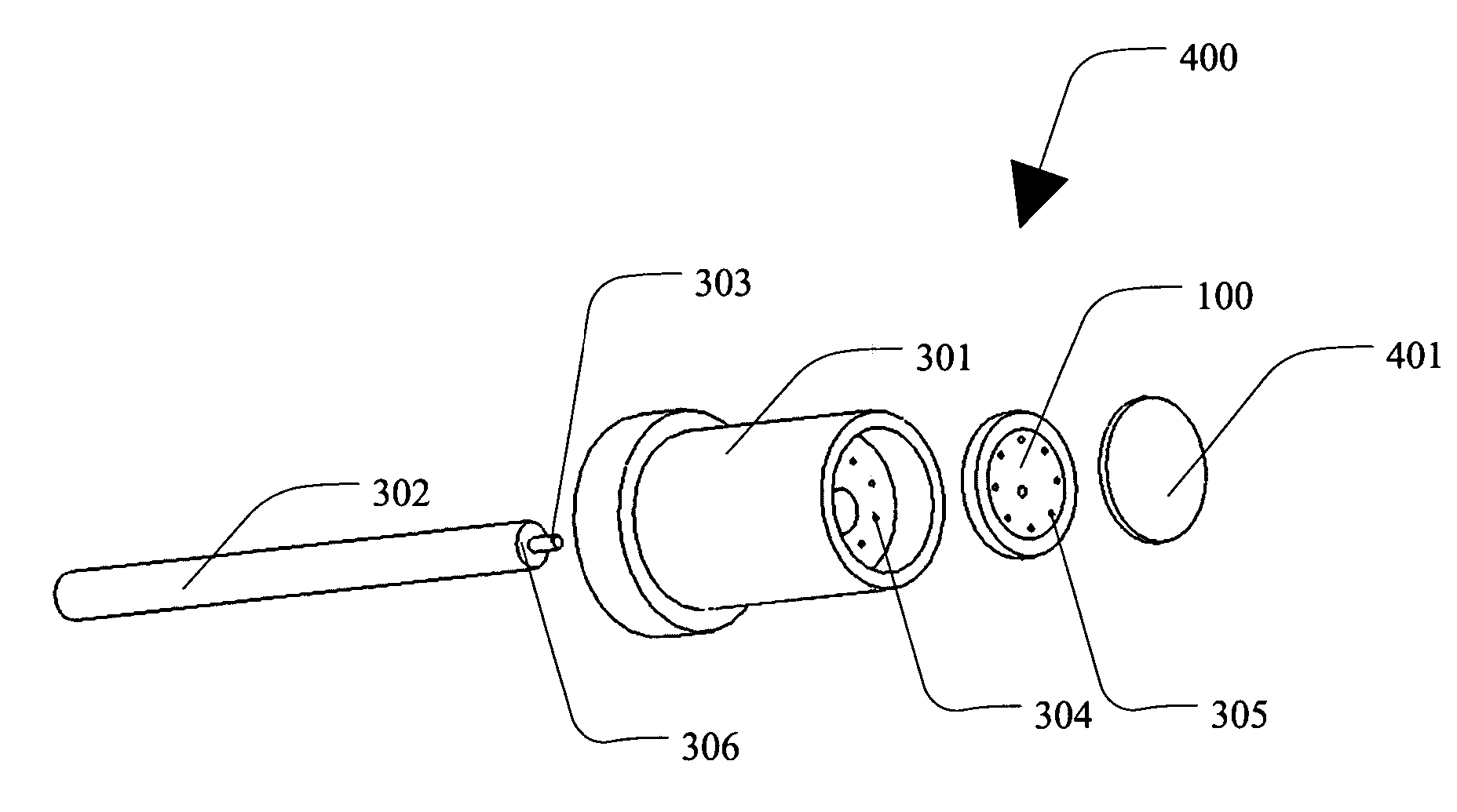

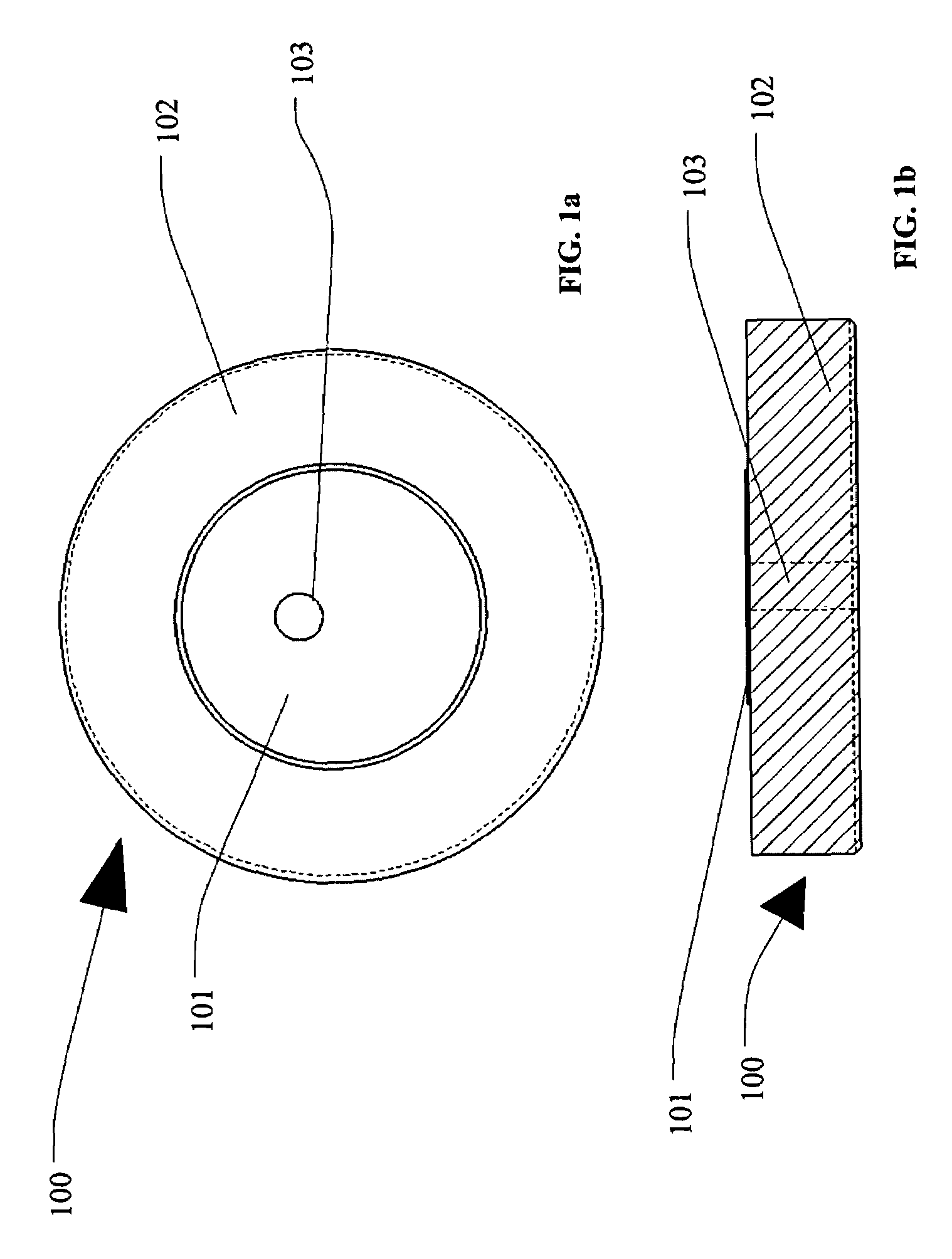

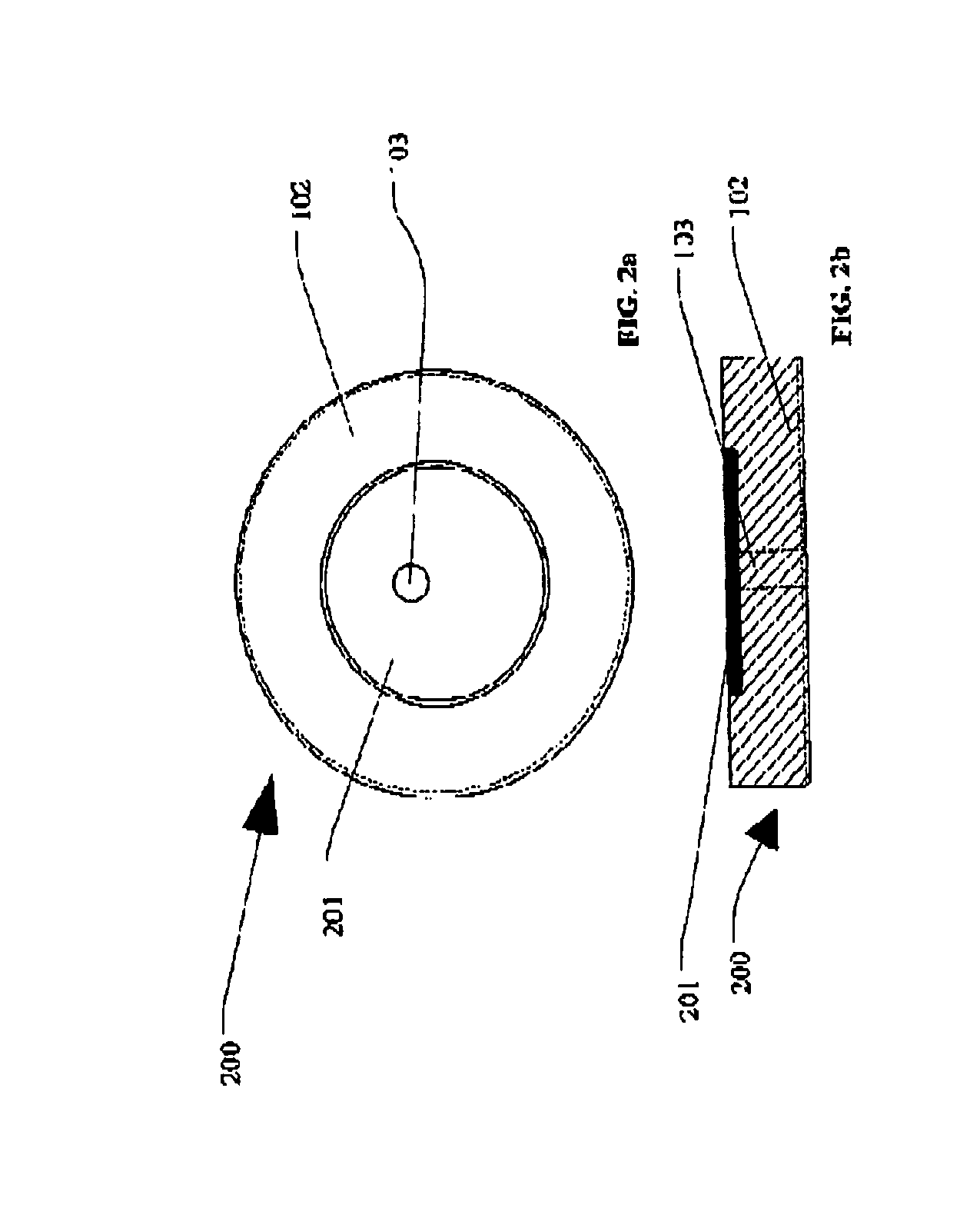

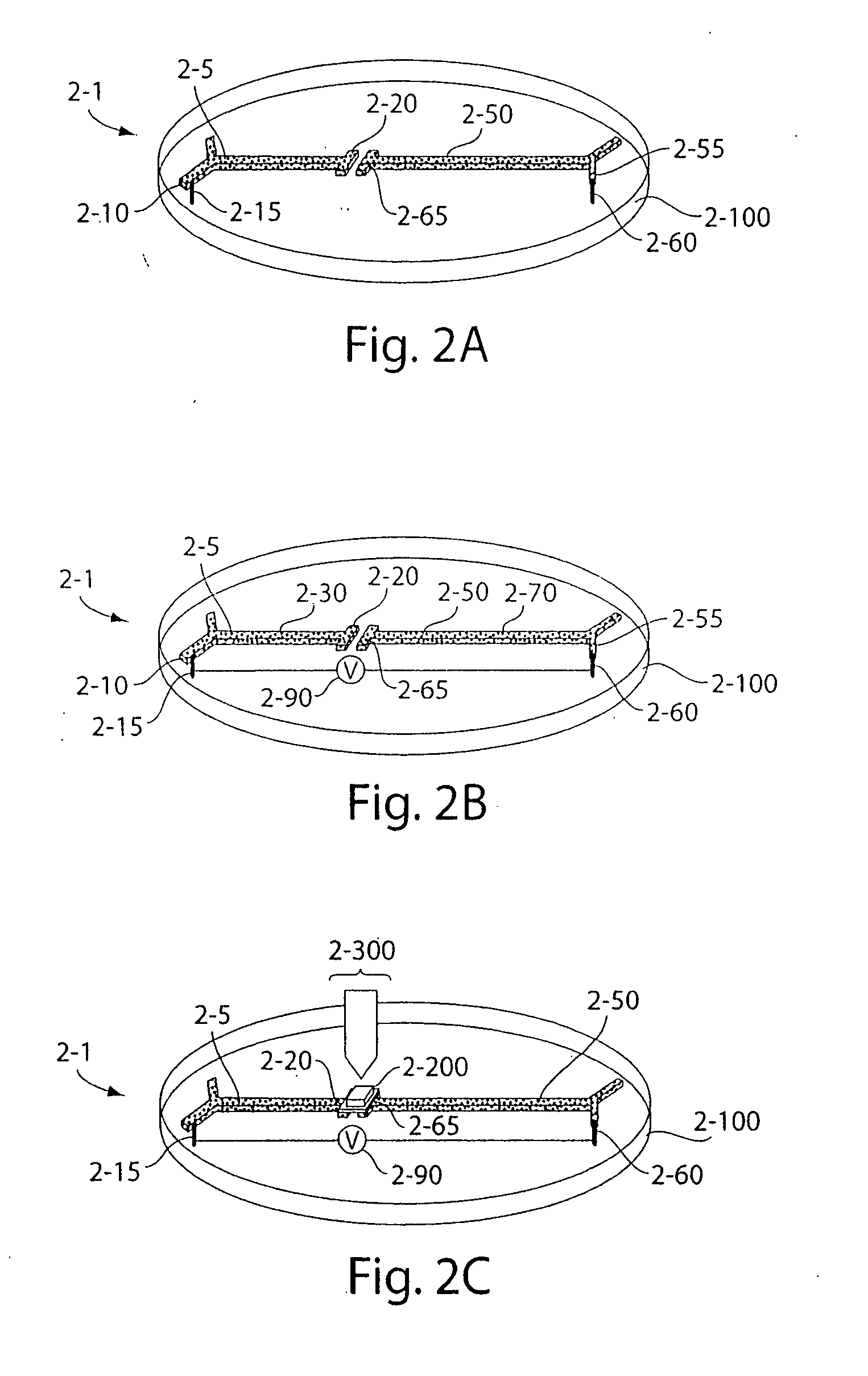

A patch antenna for operation within a high temperature environment. The patent antenna typically includes an antenna radiating element, a housing and a microwave transmission medium, such as a high temperature microwave cable. The antenna radiating element typically comprises a metallization (or solid metal) element in contact with a dielectric element. The antenna radiating element can include a dielectric window comprising a flame spray coating or a solid dielectric material placed in front of the radiating element. The antenna element is typically inserted into a housing that mechanically captures the antenna and provides a ground plane for the antenna. Orifices or passages can be added to the housing to improve high temperature performance and may direct cooling air for cooling the antenna. The high temperature microwave cable is typically inserted into the housing and attached to the antenna radiator to support the communication of electromagnetic signals between the radiator element and a receiver or transmitter device.

Owner:MEGGITT SA

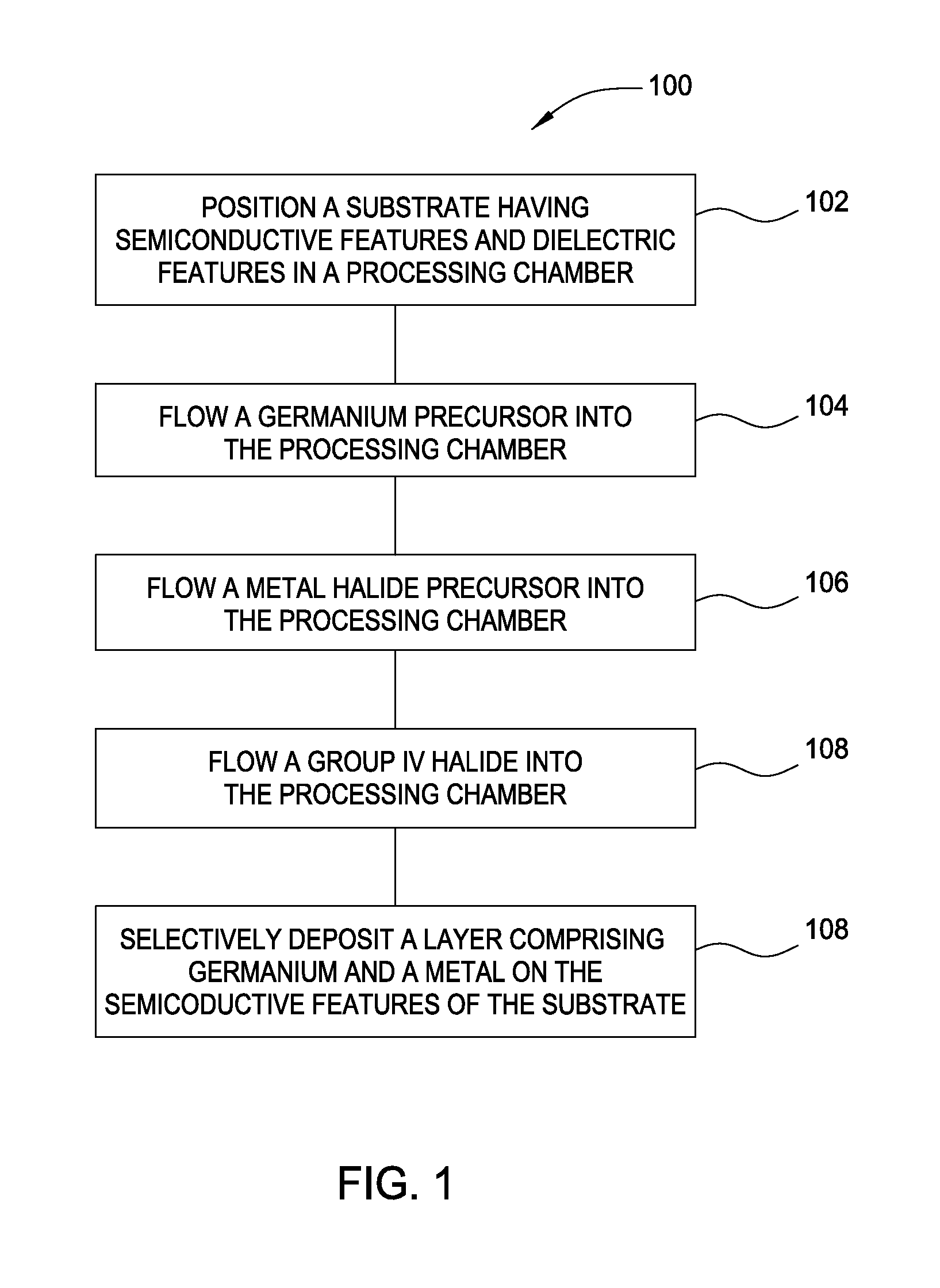

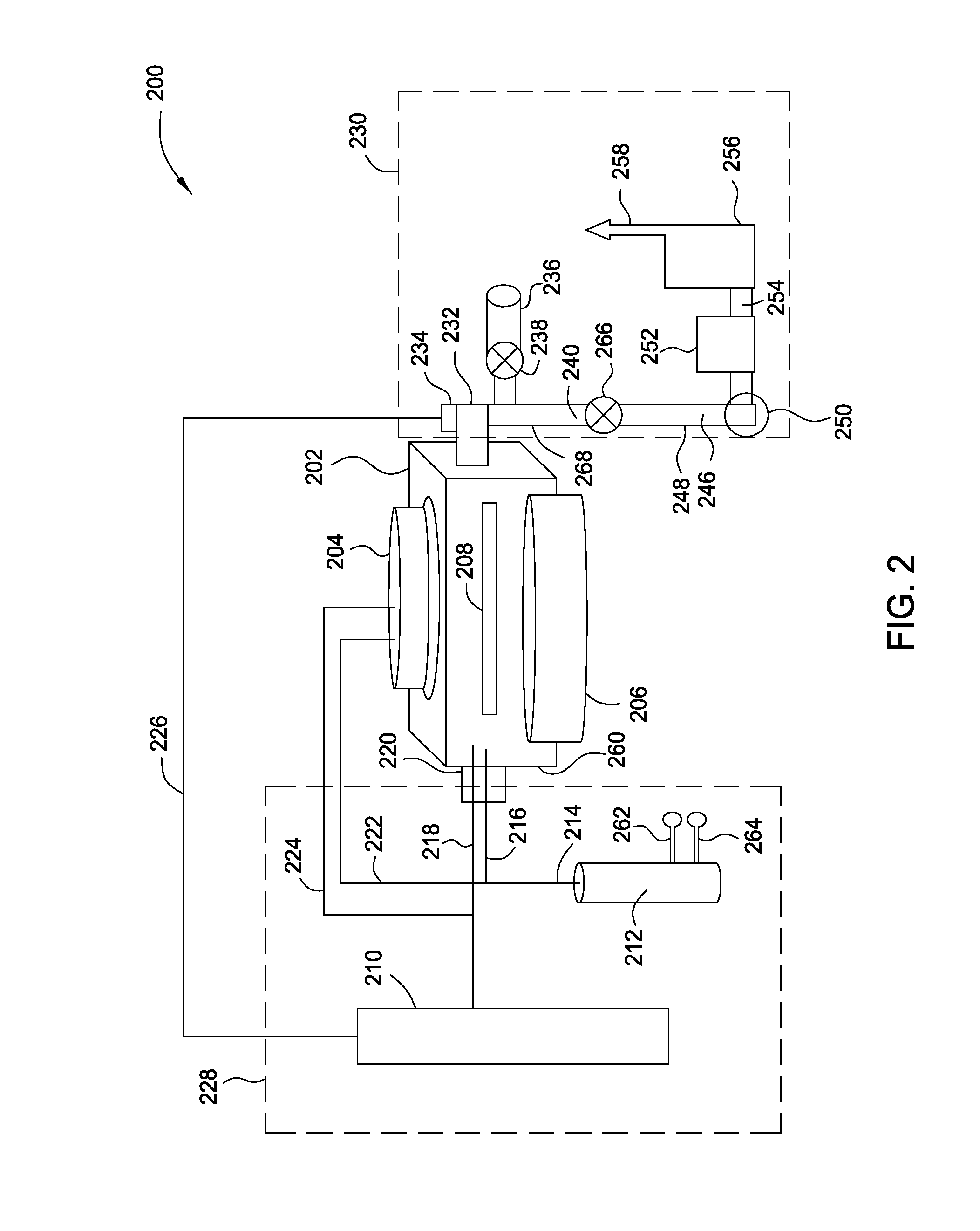

Method and apparatus for germanium tin alloy formation by thermal CVD

InactiveUS20130280891A1Polycrystalline material growthSemiconductor/solid-state device manufacturingSelective depositionLiquid metal

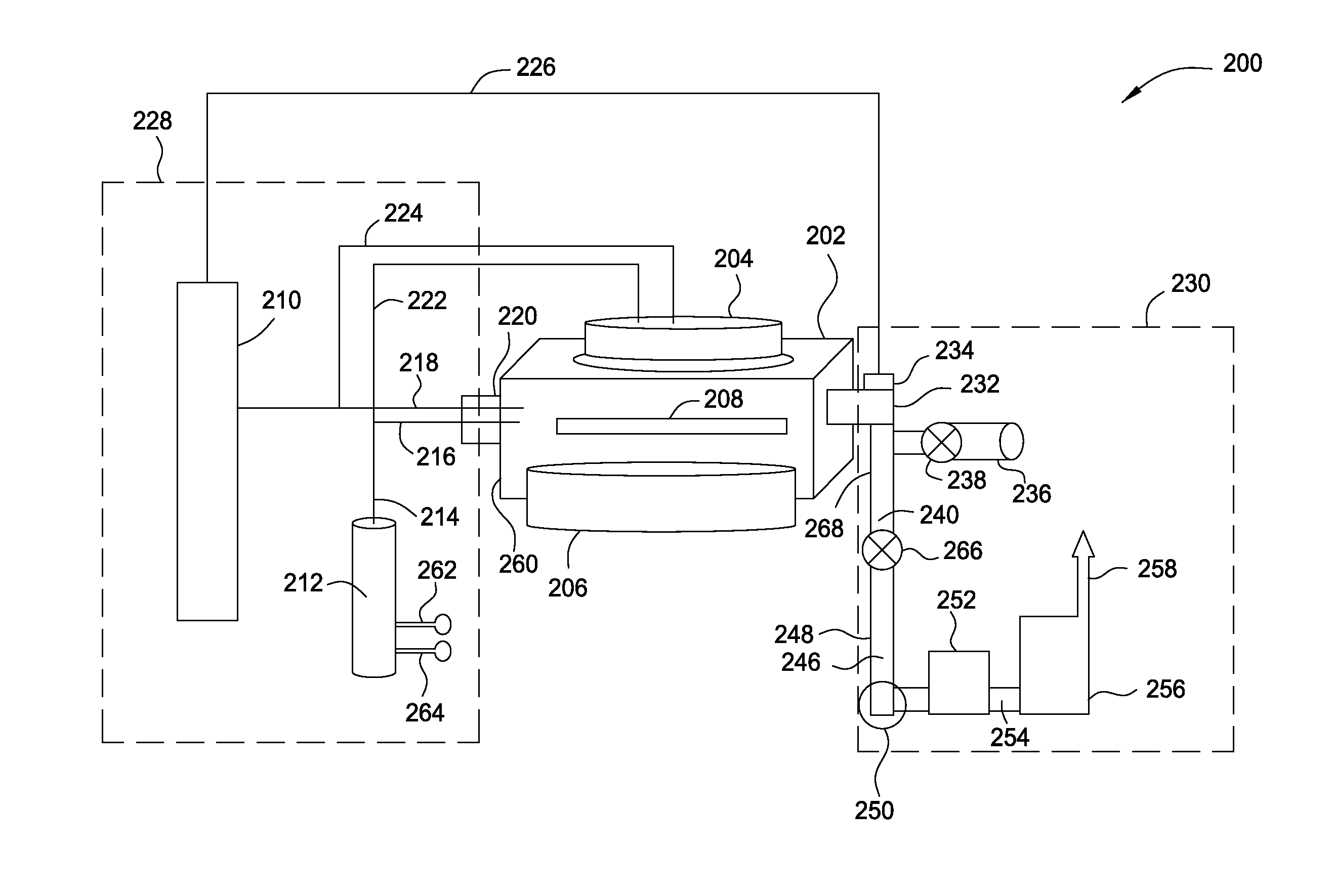

A method and apparatus for forming semiconductive semiconductor-metal alloy layers is described. A germanium precursor and a metal precursor are provided to a chamber, and an epitaxial layer of germanium-metal alloy, optionally including silicon, is formed on the substrate. The metal precursor is typically a metal halide, which may be provided by evaporating a liquid metal halide, subliming a solid metal halide, or by contacting a pure metal with a halogen gas. A group IV halide deposition control agent is used to provide selective deposition on semiconductive regions of the substrate relative to dielectric regions. The semiconductive semiconductor-metal alloy layers may be doped, for example with boron, phosphorus, and / or arsenic. The precursors may be provided through a showerhead or through a side entry point, and an exhaust system coupled to the chamber may be separately heated to manage condensation of exhaust components.

Owner:APPLIED MATERIALS INC

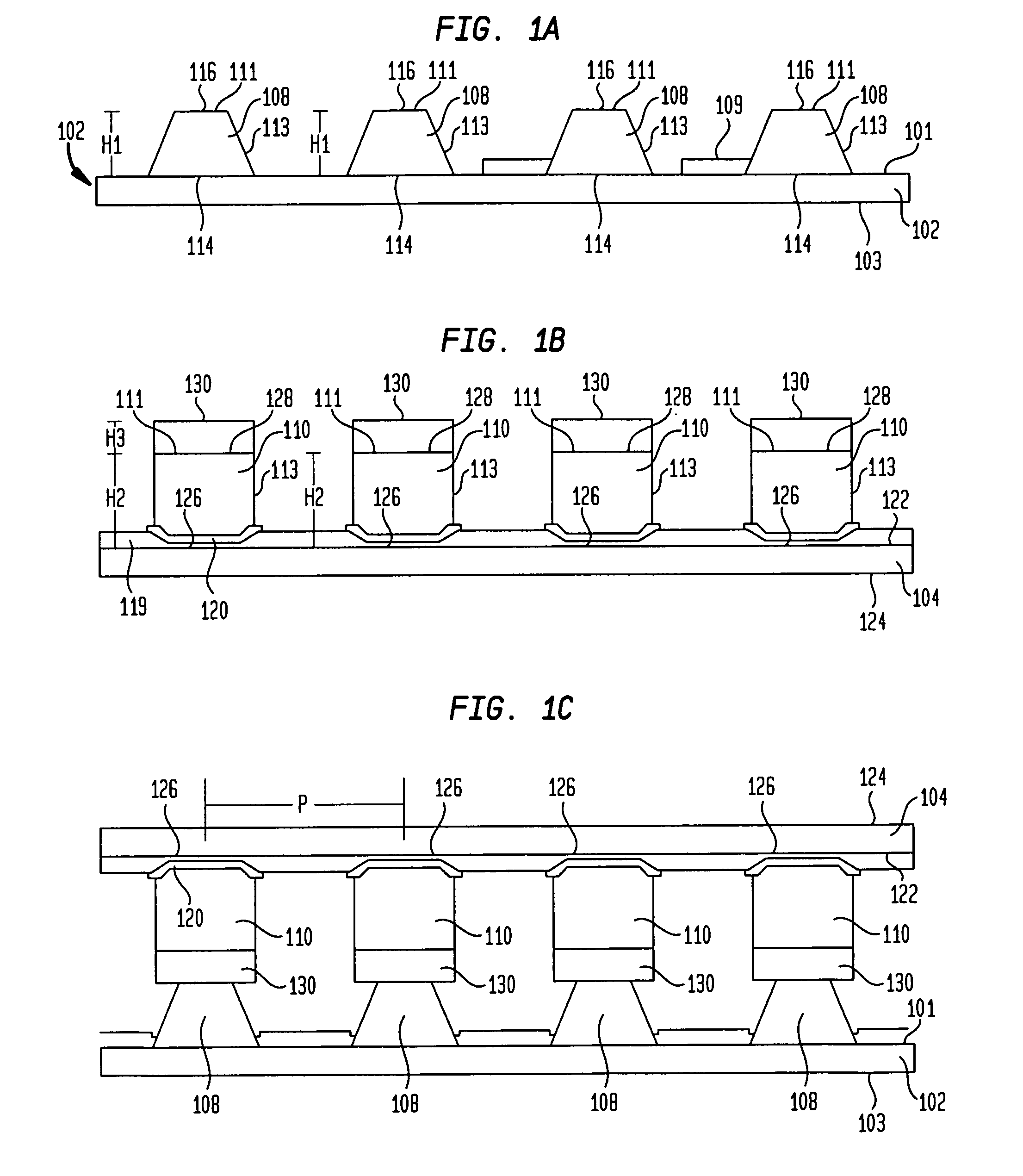

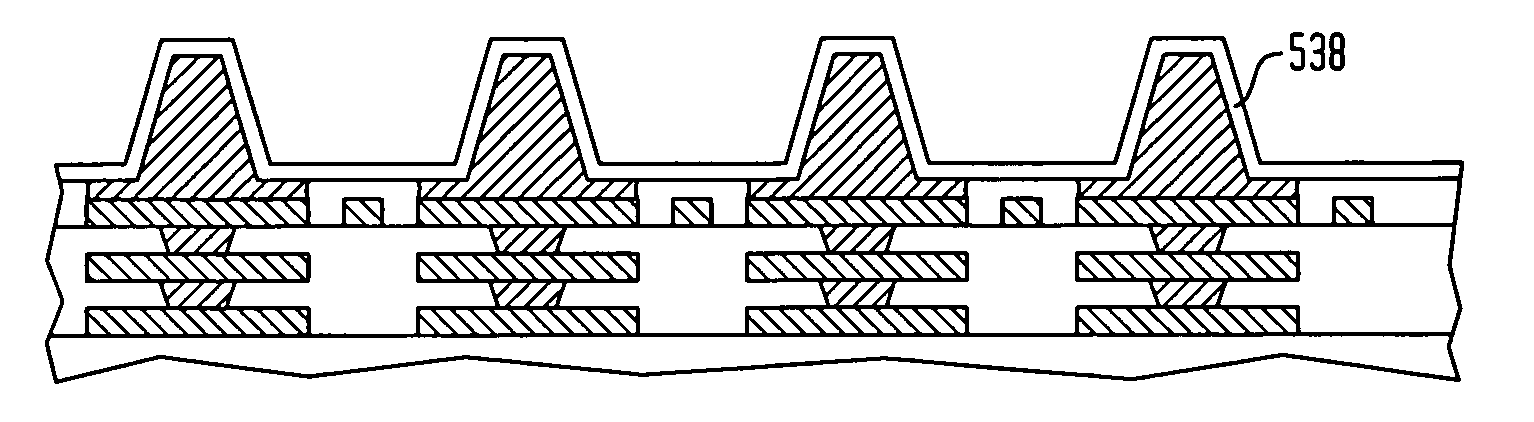

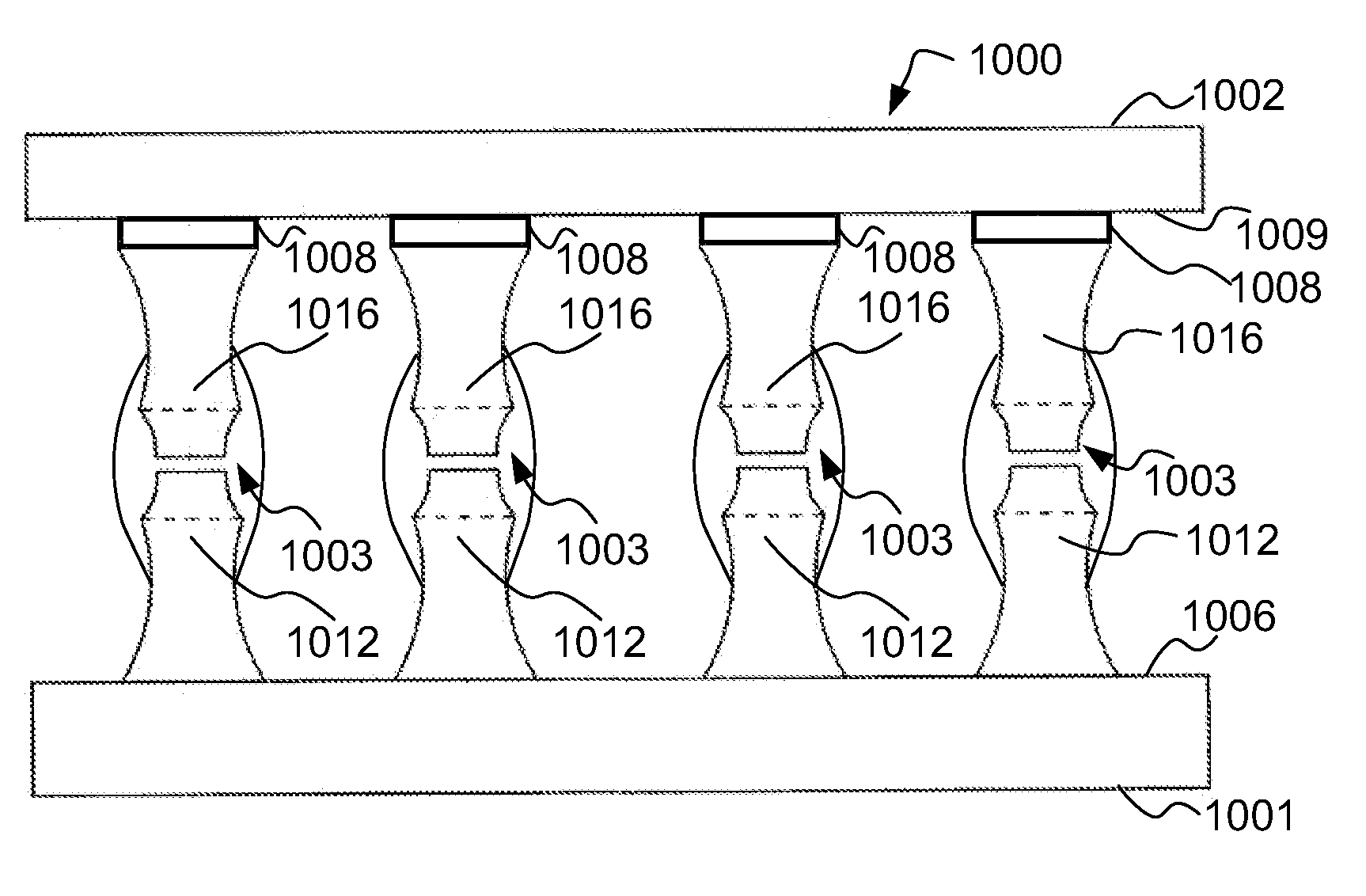

Flip Chip Interconnection with double post

ActiveUS20090146303A1Semiconductor/solid-state device detailsSolid-state devicesInterconnectionEngineering

A packaged microelectronic assembly includes a microelectronic element having a front surface and a plurality of first solid metal posts extending away from the front surface. Each of the first posts has a width in a direction of the front surface and a height extending from the front surface, wherein the height is at least half of the width. There is also a substrate having a top surface and a plurality of second solid metal posts extending from the top surface and joined to the first solid metal posts.

Owner:TESSERA INC

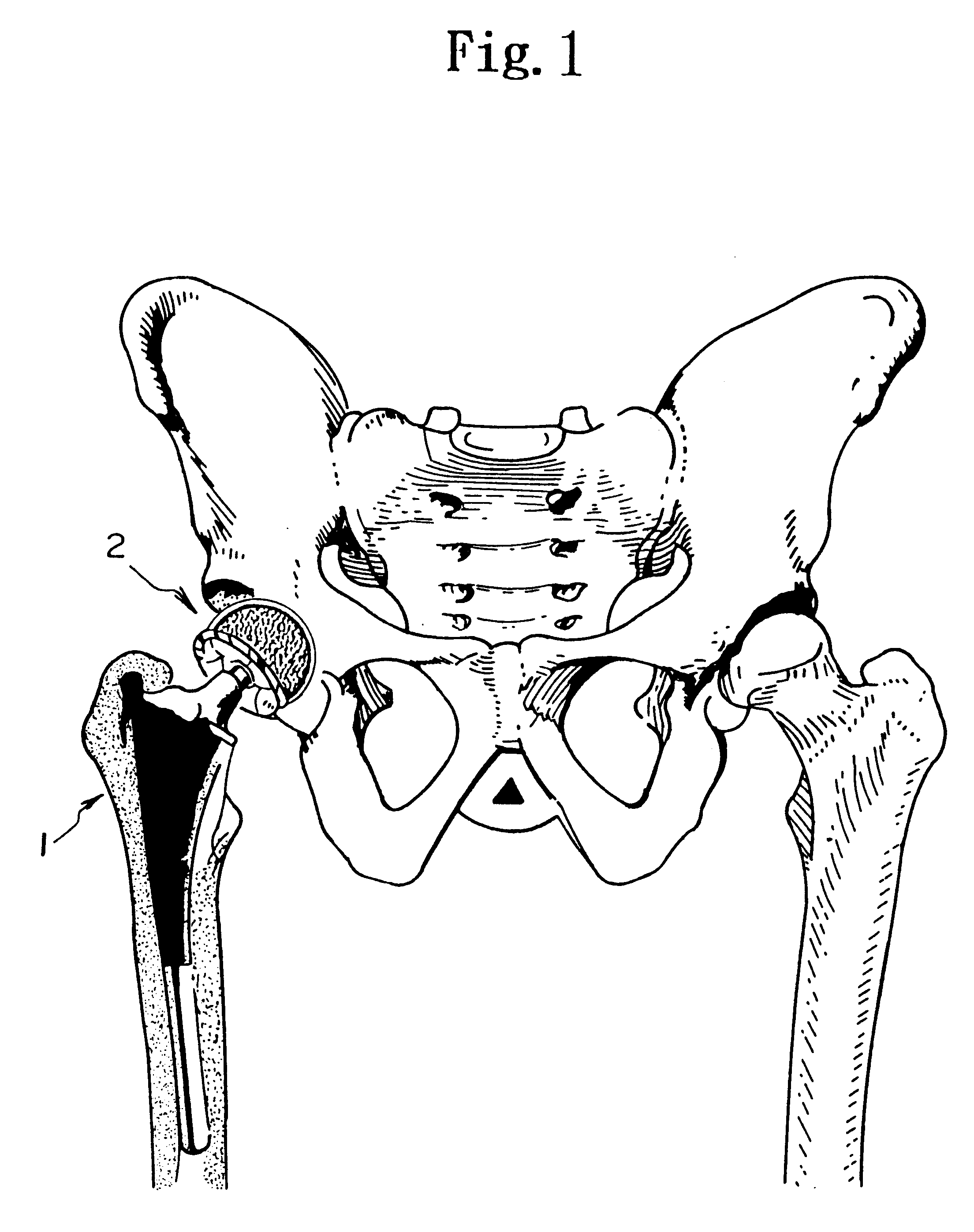

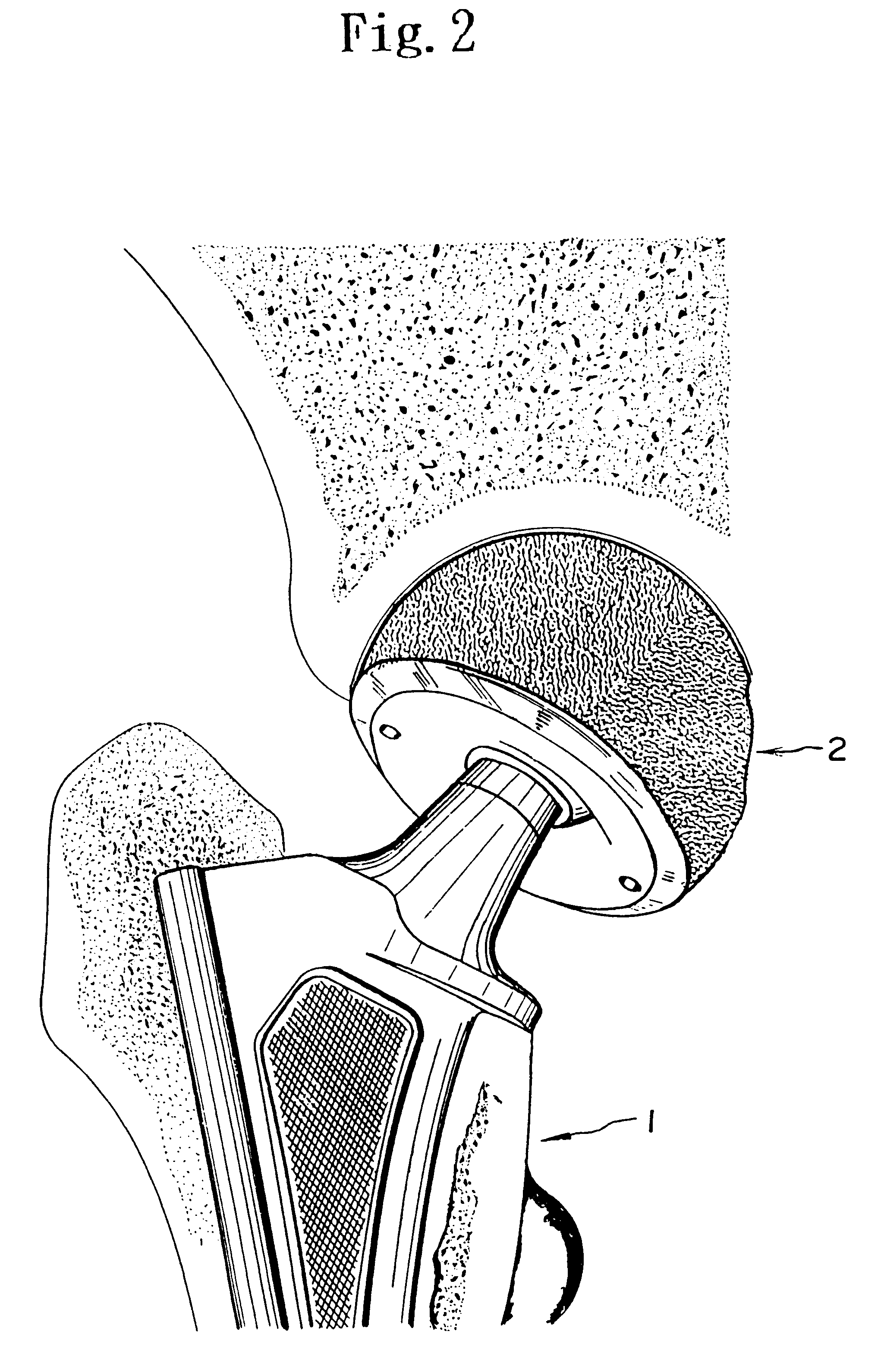

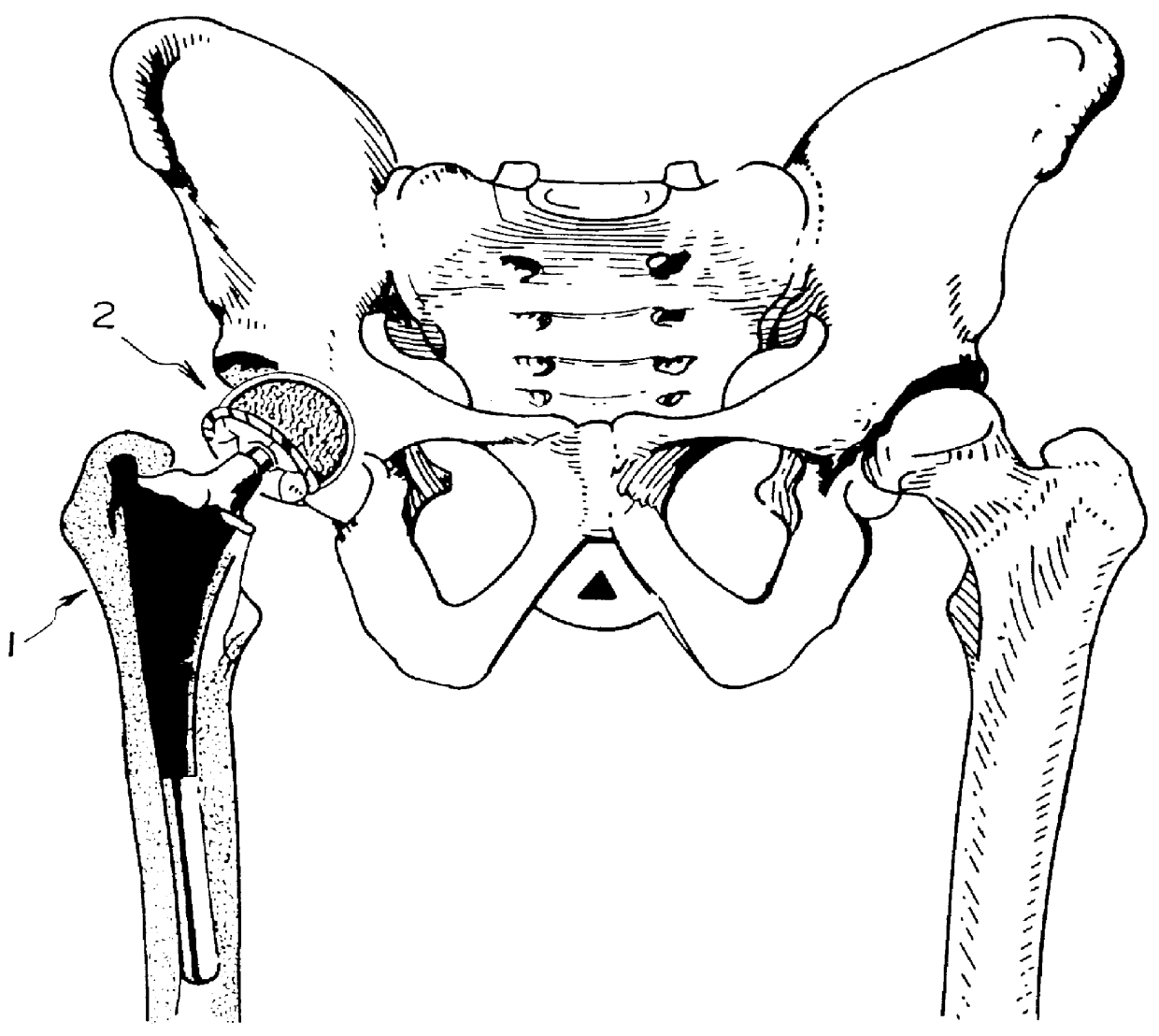

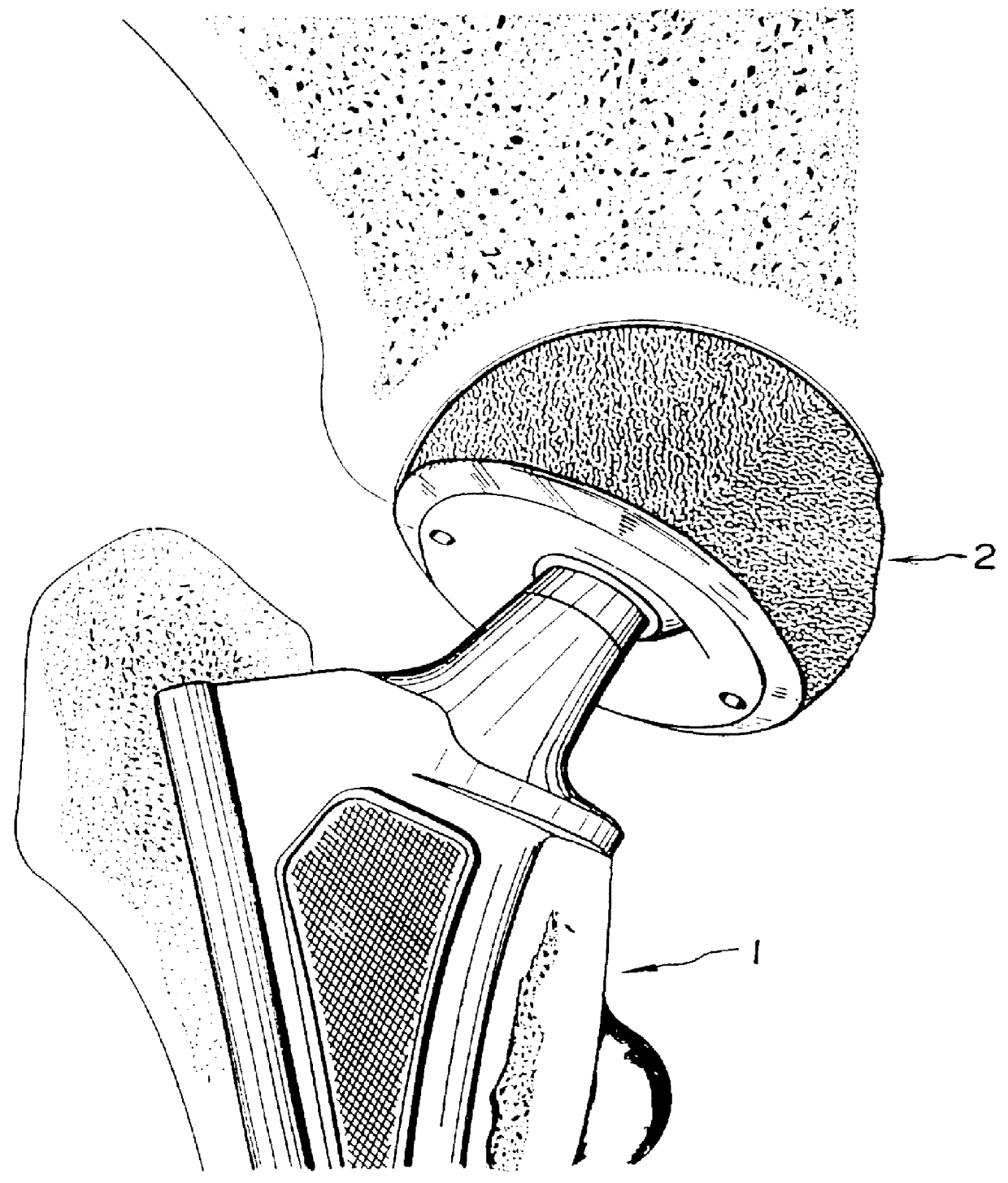

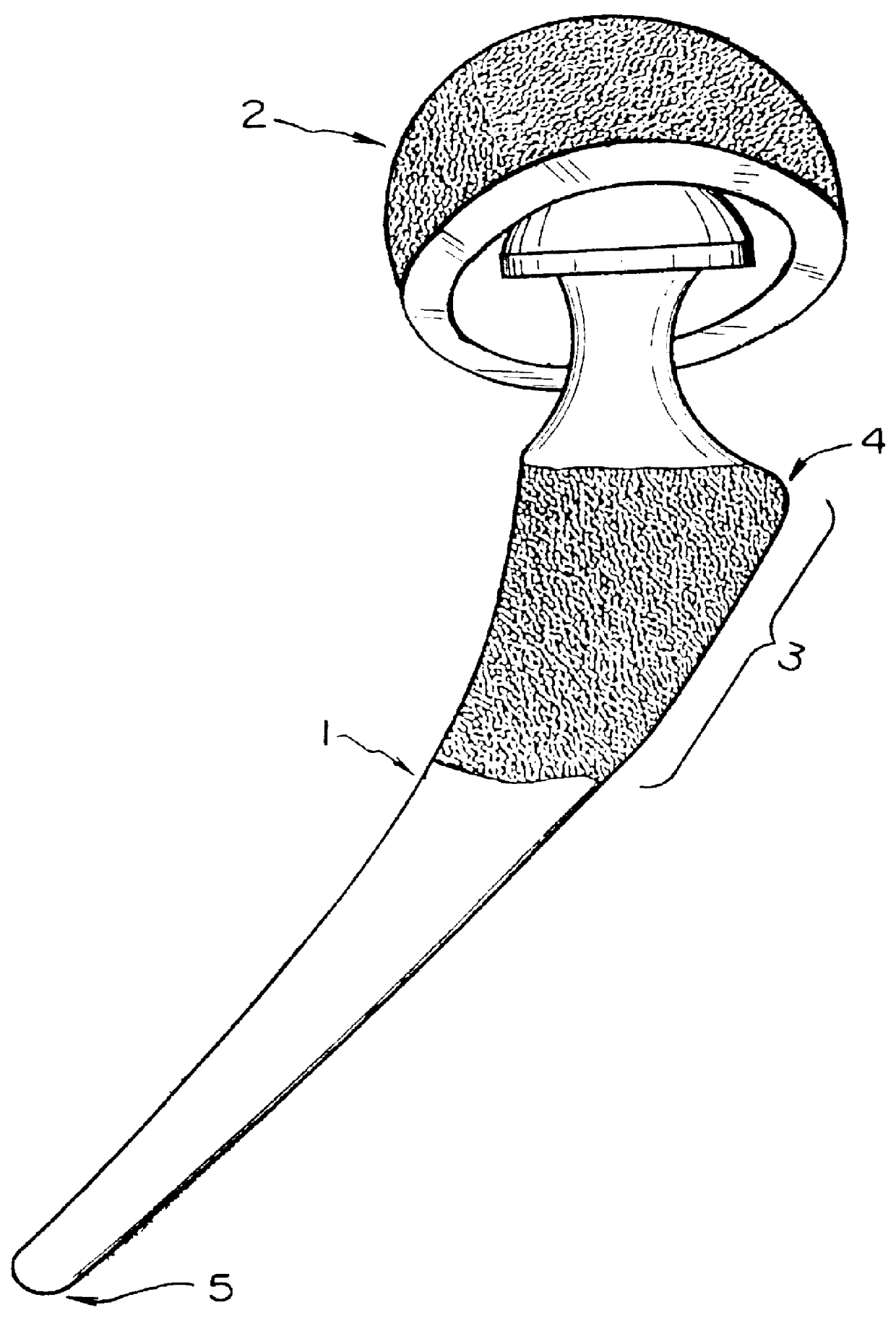

Orthopedic implant system

InactiveUS6312473B1Easy to fixAvoid excessive temperatureSurgical adhesivesBone implantFemoral stemPolymethyl methacrylate

It is an object of the present invention to provide an improved orthopedic implant system with satisfied biological, mechanical and morphological compatibilities.Solid metal femoral stem and solid metal acetabular head are covered with diffusion-bonded foamed-shaped sheet made of commercially pure titanium or titanium alloy(s). The open-cells in said foamed metal sheet are impregnated with biocompatible polymethyl methacrylate resin cement, which is reinforced with selected oxides including alumina, magnesia, zirconia, or a combination of these oxides along with an application of a small amount of a metal primer agent.

Owner:OSHIDA YOSHIKI

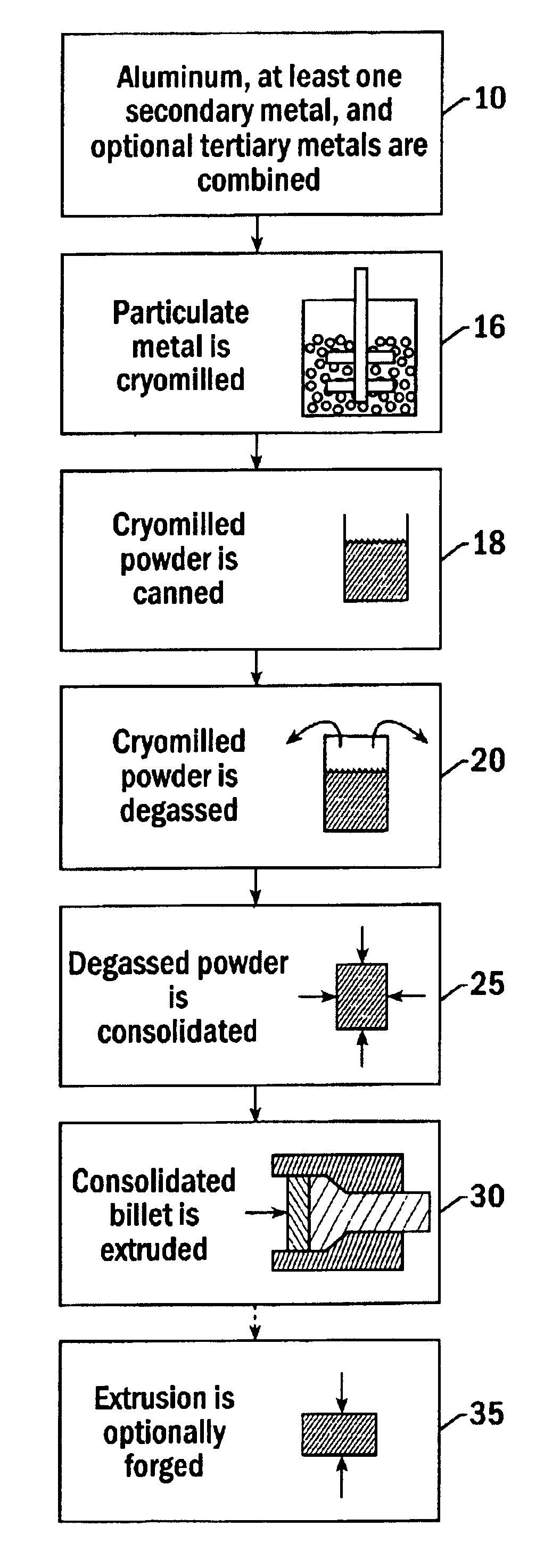

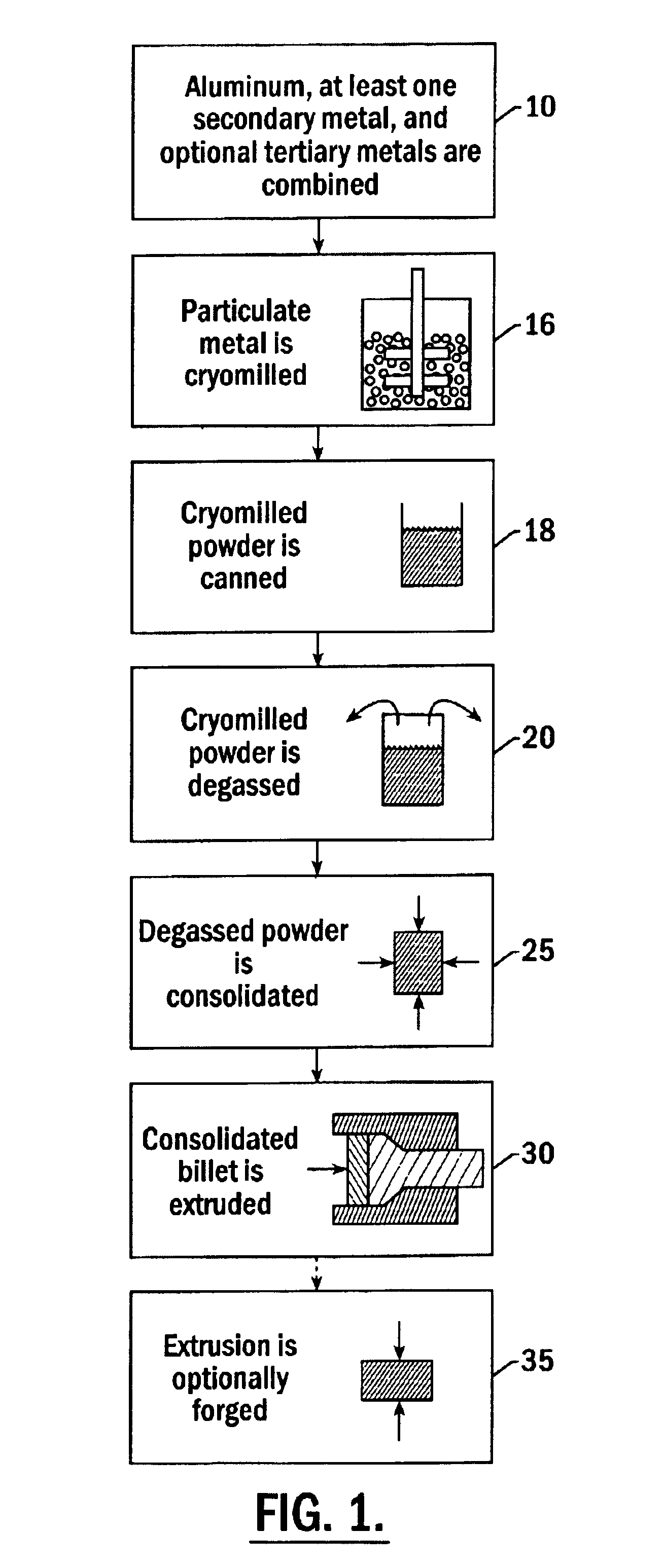

Method for preparing cryomilled aluminum alloys and components extruded and forged therefrom

InactiveUS6902699B2Stable structureHigh strengthTransportation and packagingMetal-working apparatusNanostructureAluminium alloy

High strength aluminum alloy powders, extrusions, and forgings are provided in which the aluminum alloys exhibit high strength at atmospheric temperatures and maintain high strength and ductility at extremely low temperatures. The alloy is produced by blending about 89 atomic % to 99 atomic % aluminum, 1 atomic % to 11 atomic % of a secondary metal selected from the group consisting of magnesium, lithium, silicon, titanium, zirconium, and combinations thereof, and up to about 10 atomic % of a tertiary metal selected from the group consisting of Be, Ca, Sr, Ba, Ra, Sc, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Y, Nb, Mo, Tc, Ru, Rh, Pd, Ag, Cd, W, and combinations thereof. The alloy is produced by nanostructure material synthesis, such as cryomilling, in the absence of refractory dispersoids. The synthesized alloy is then canned, degassed, consolidated, extruded, and optionally forged into a solid metallic component. Grain size within the alloy is less than 0.5 μm, and alloys with grain size less than 0.1 μm may be produced.

Owner:THE BOEING CO

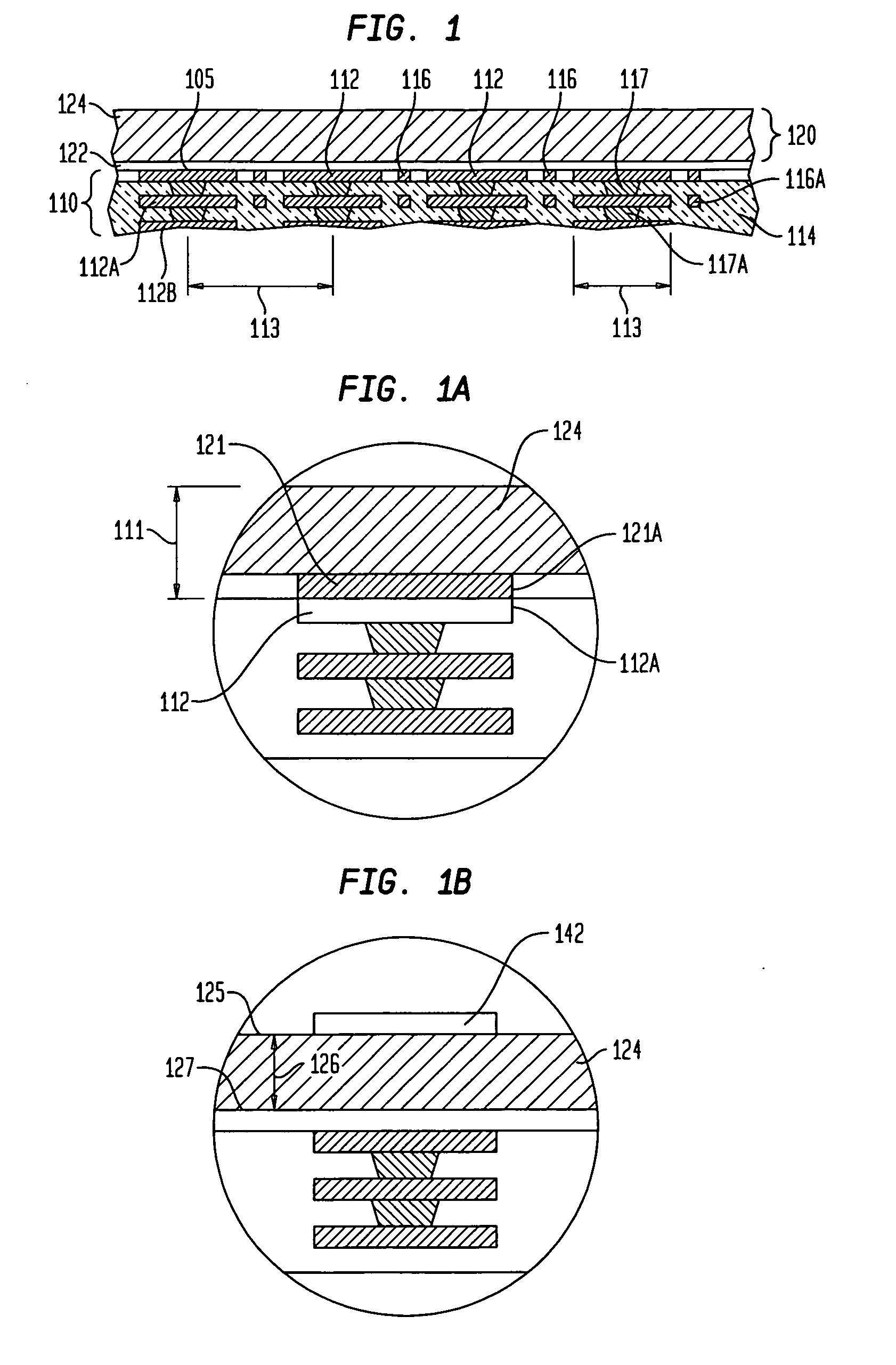

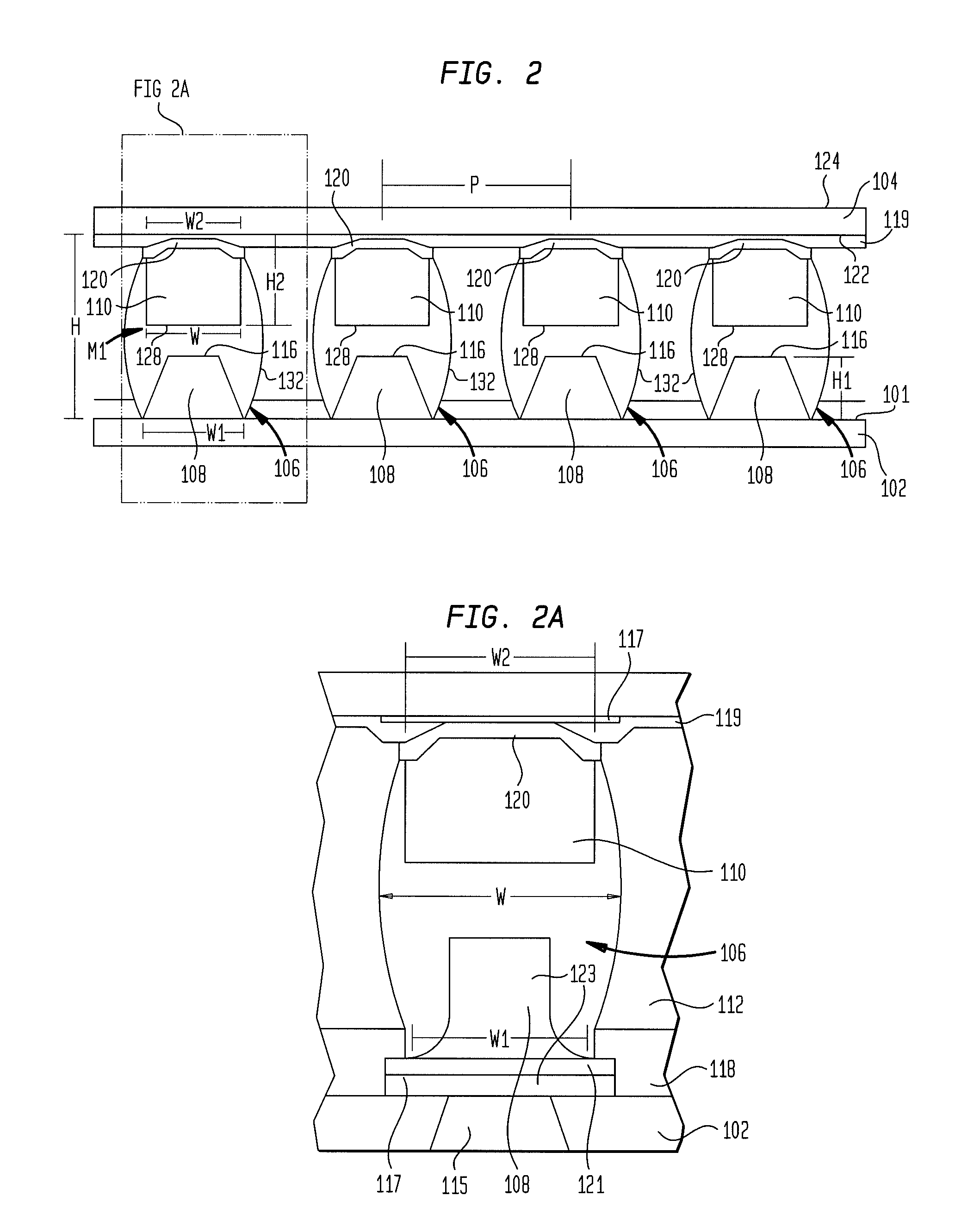

Microelectronic substrate or element having conductive pads and metal posts joined thereto using bond layer

InactiveUS20100044860A1High melting temperatureSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

Owner:INVENSAS CORP

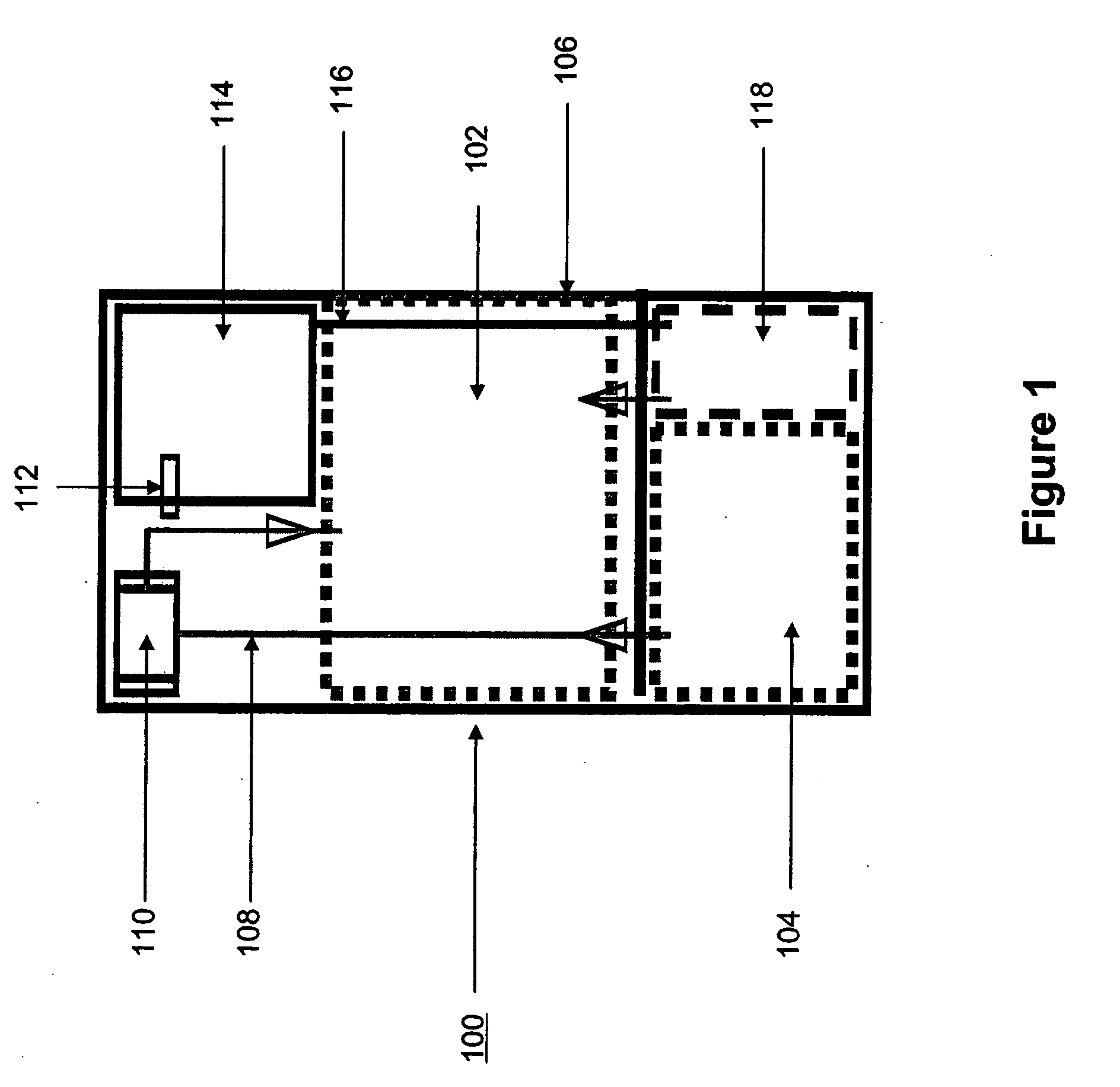

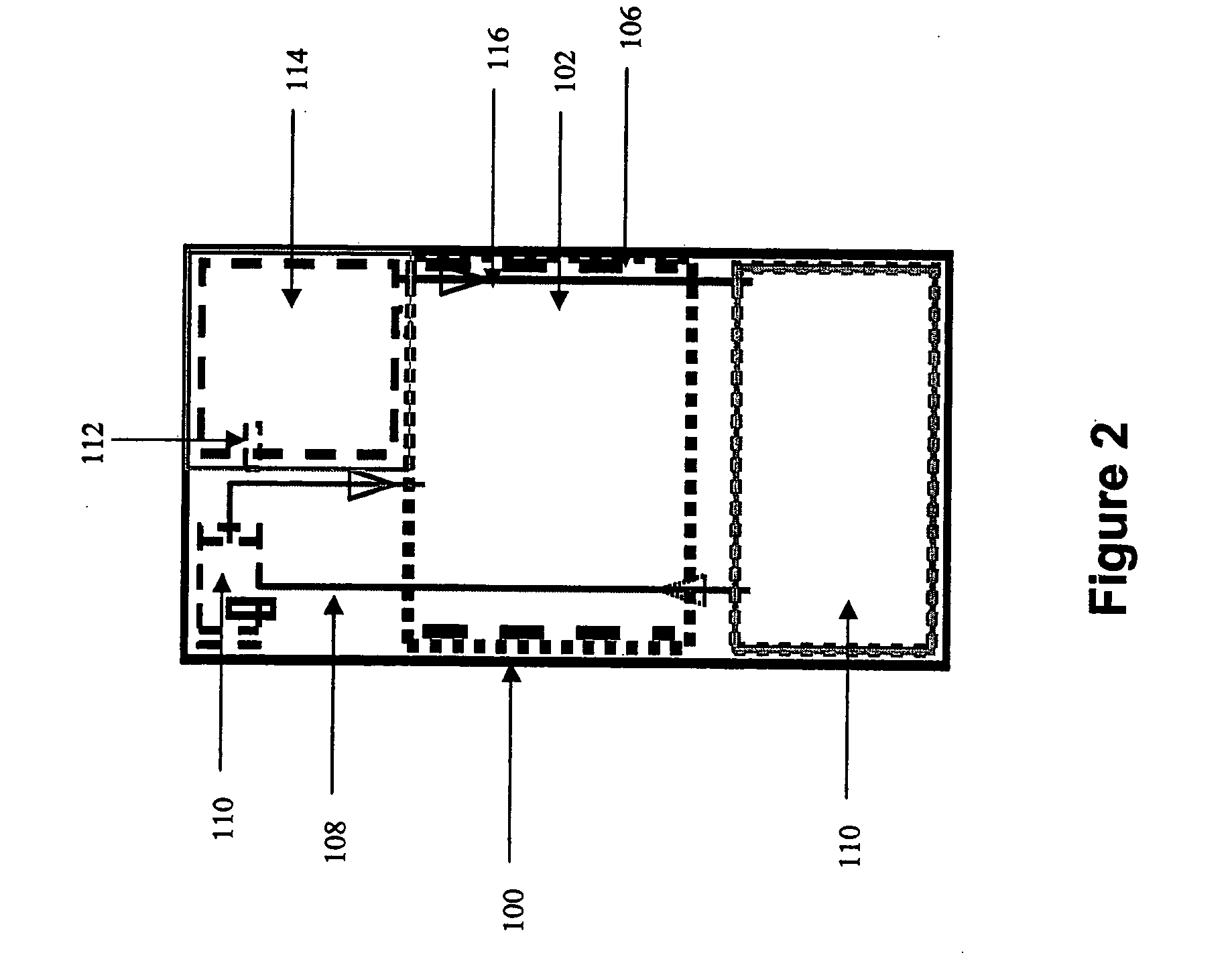

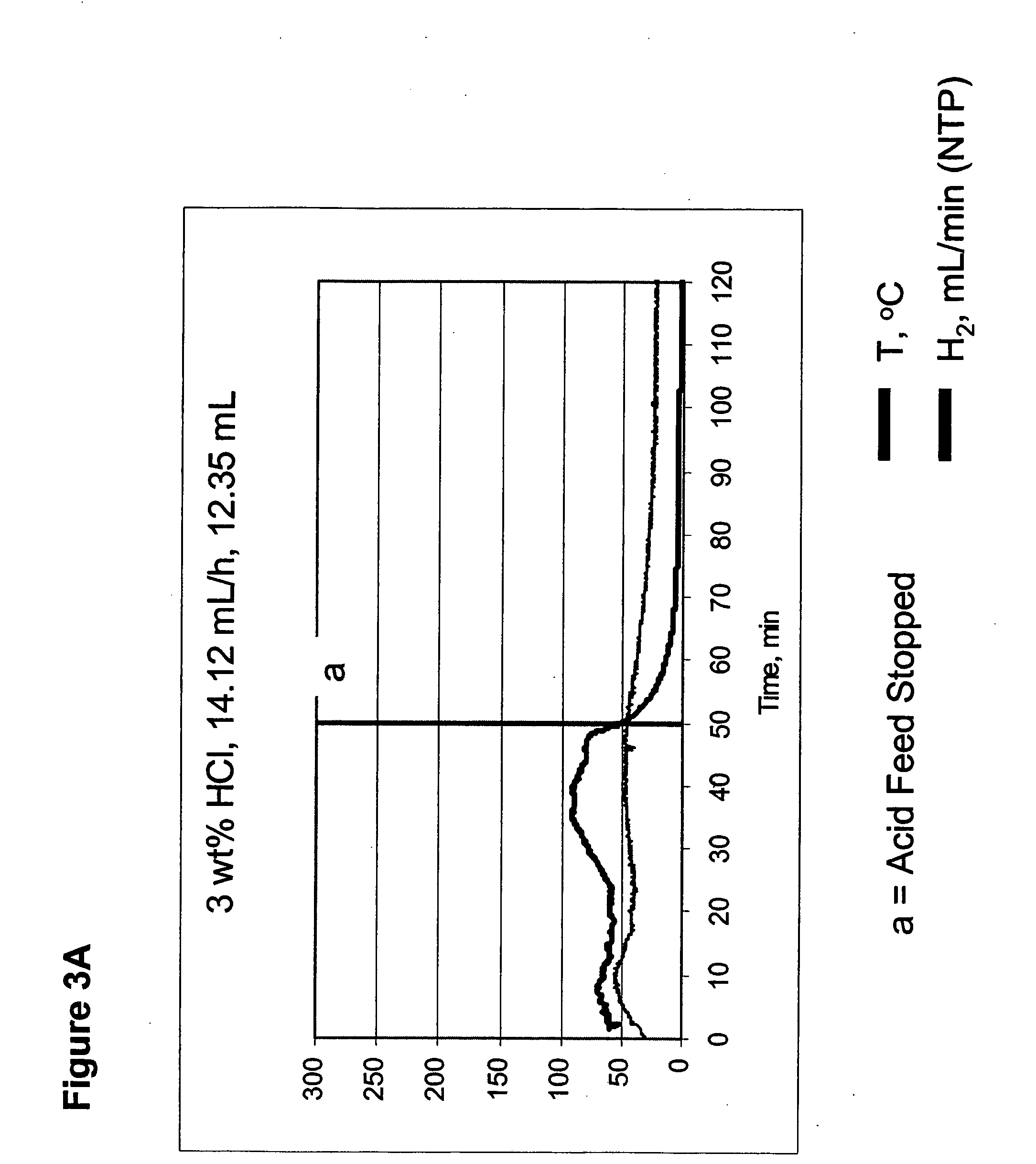

Systems and methods for hydrogen generation from solid hydrides

InactiveUS20050238573A1Regulate rateReactant parameters controlHydrogen productionO-Phosphoric AcidAlkaline earth metal

A system is disclosed for hydrogen generation based on hydrolysis of solid chemical hydrides with the capability of controlled startup and stop characteristics wherein regulation of acid concentration, acid feed rate, or a combination of both control the rate of hydrogen generation. The system comprises a first chamber for storing a solid chemical hydride and a second chamber for storing an acidic reagent. The solid chemical hydride is a solid metal borohydride having the general formula MBH4, where M is selected from the group consisting of alkali metal cations, alkaline earth metal cations, aluminum cation, zinc cation, and ammonium cation. The acidic reagent may comprise inorganic acids such as the mineral acids hydrochloric acid, sulfuric acid, and phosphoric acid, and organic acids such as acetic acid, formic acid, maleic acid, citric acid, and tartaric acid, or mixtures thereof.

Owner:MILLENNIUM CELL

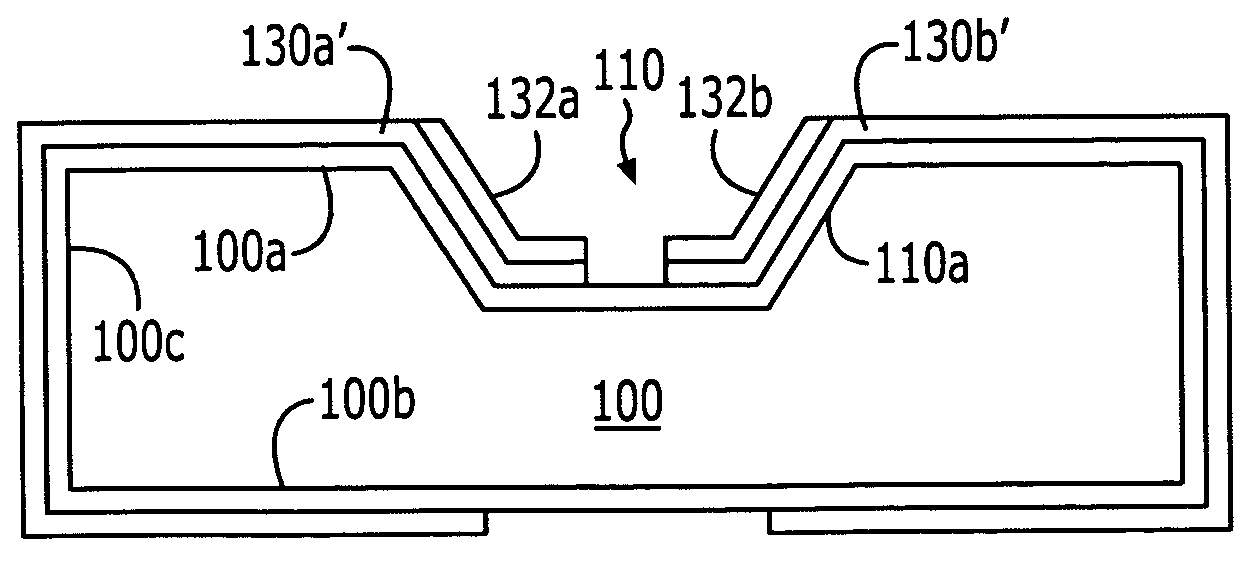

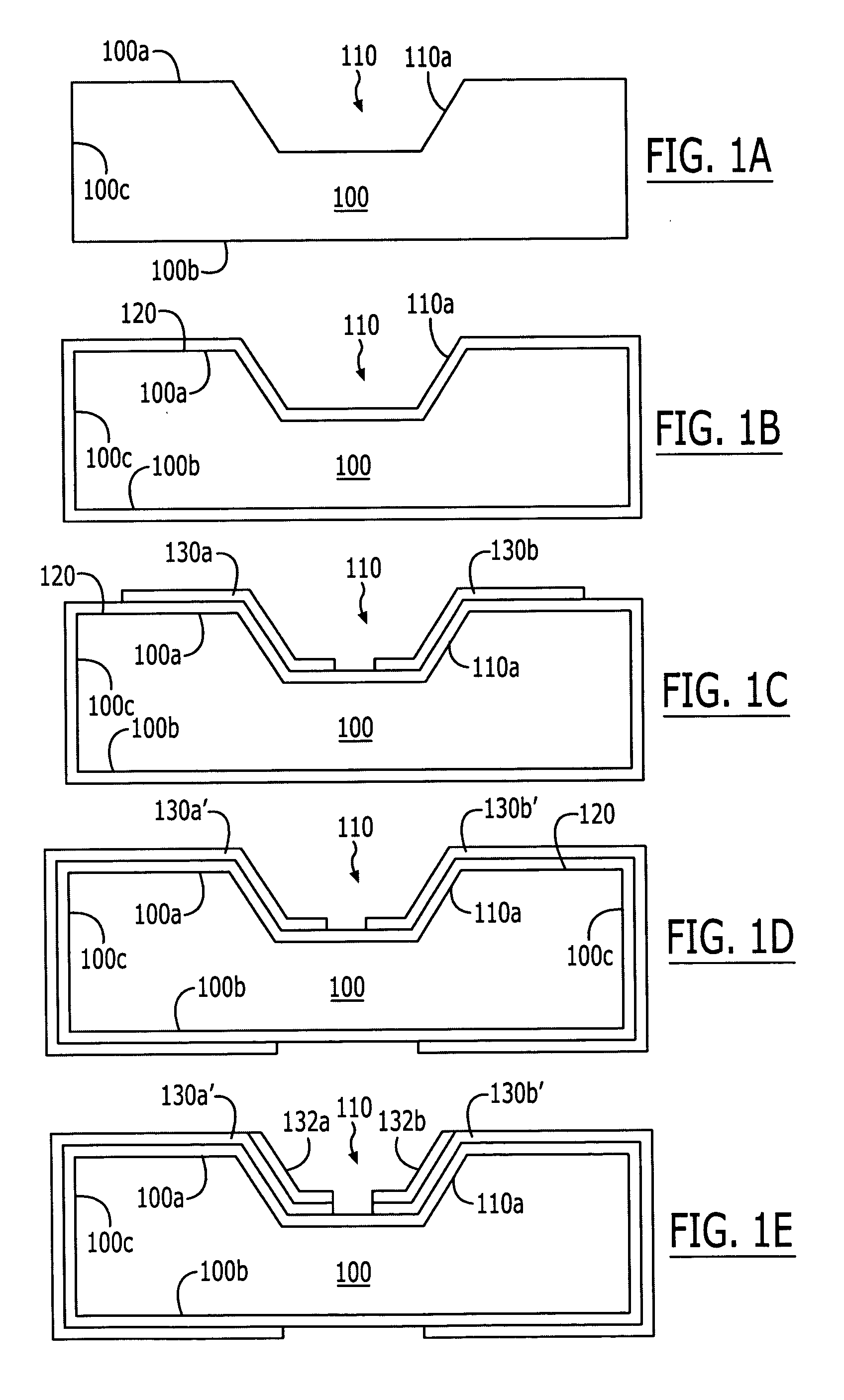

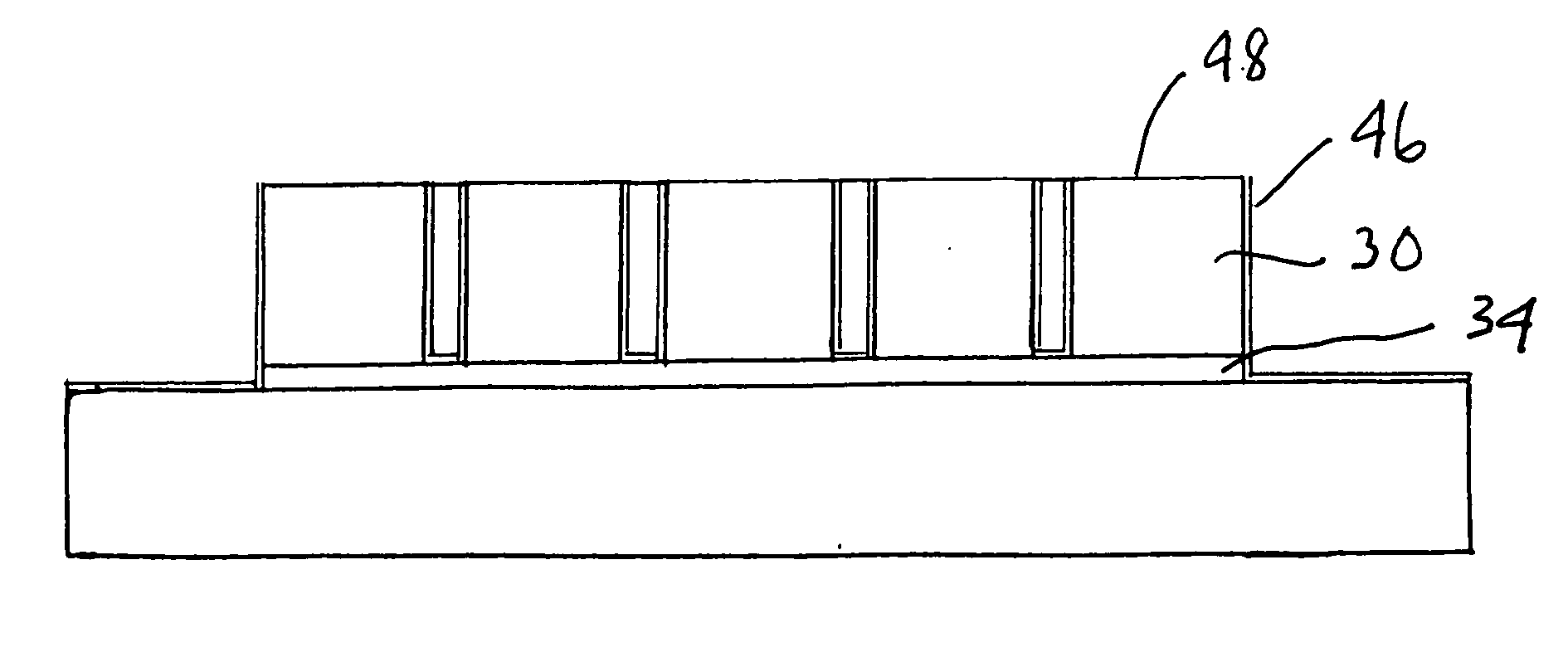

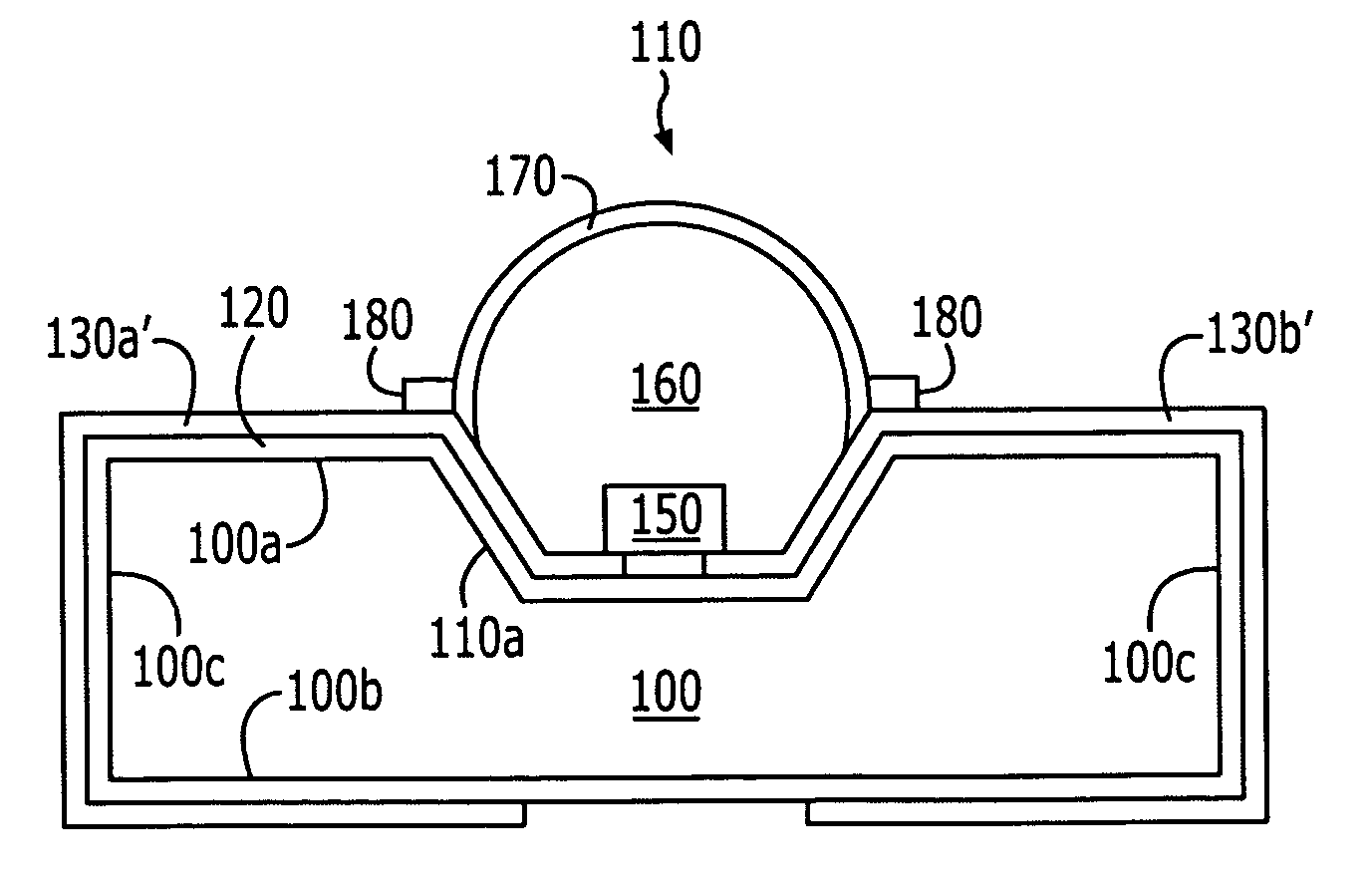

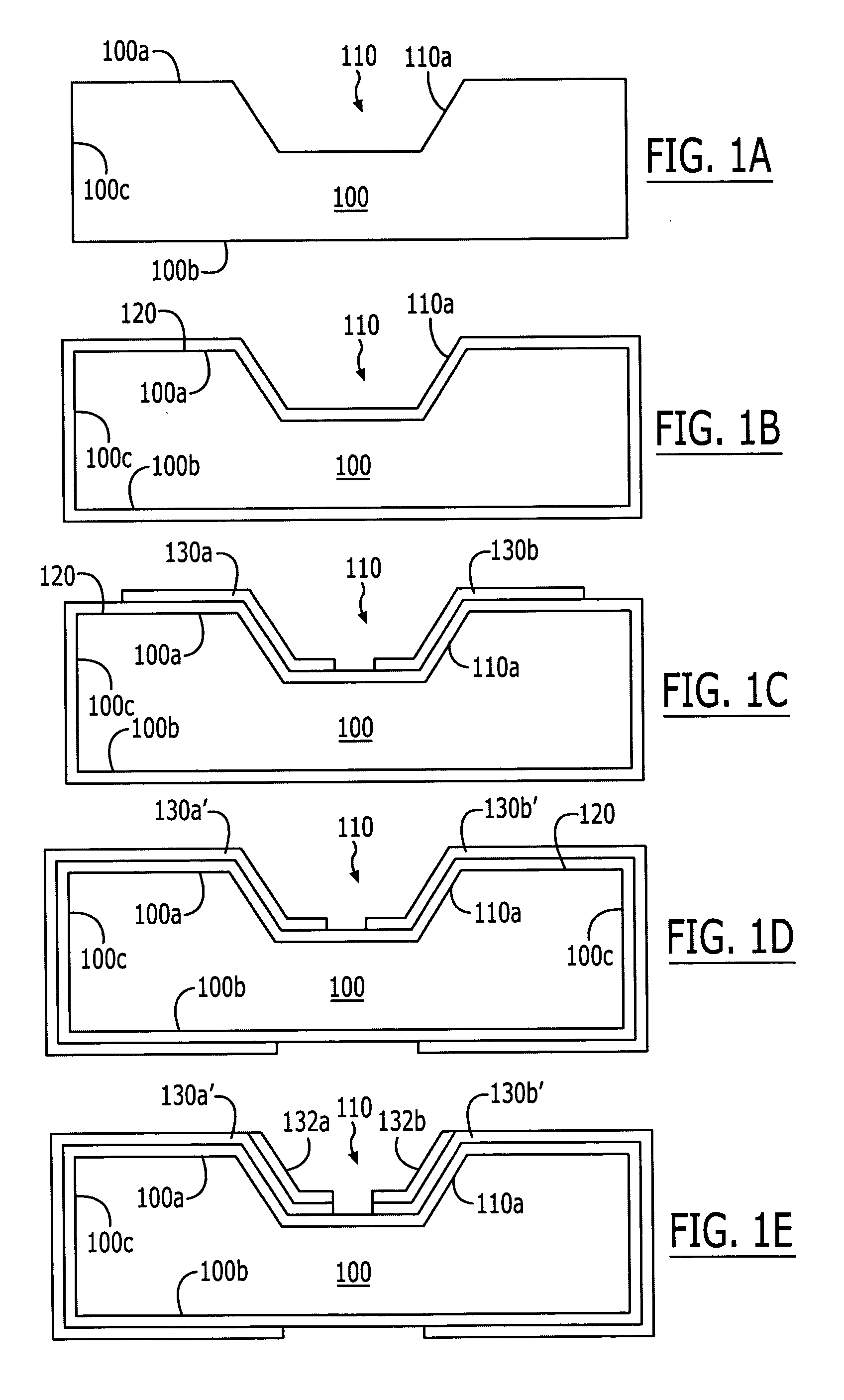

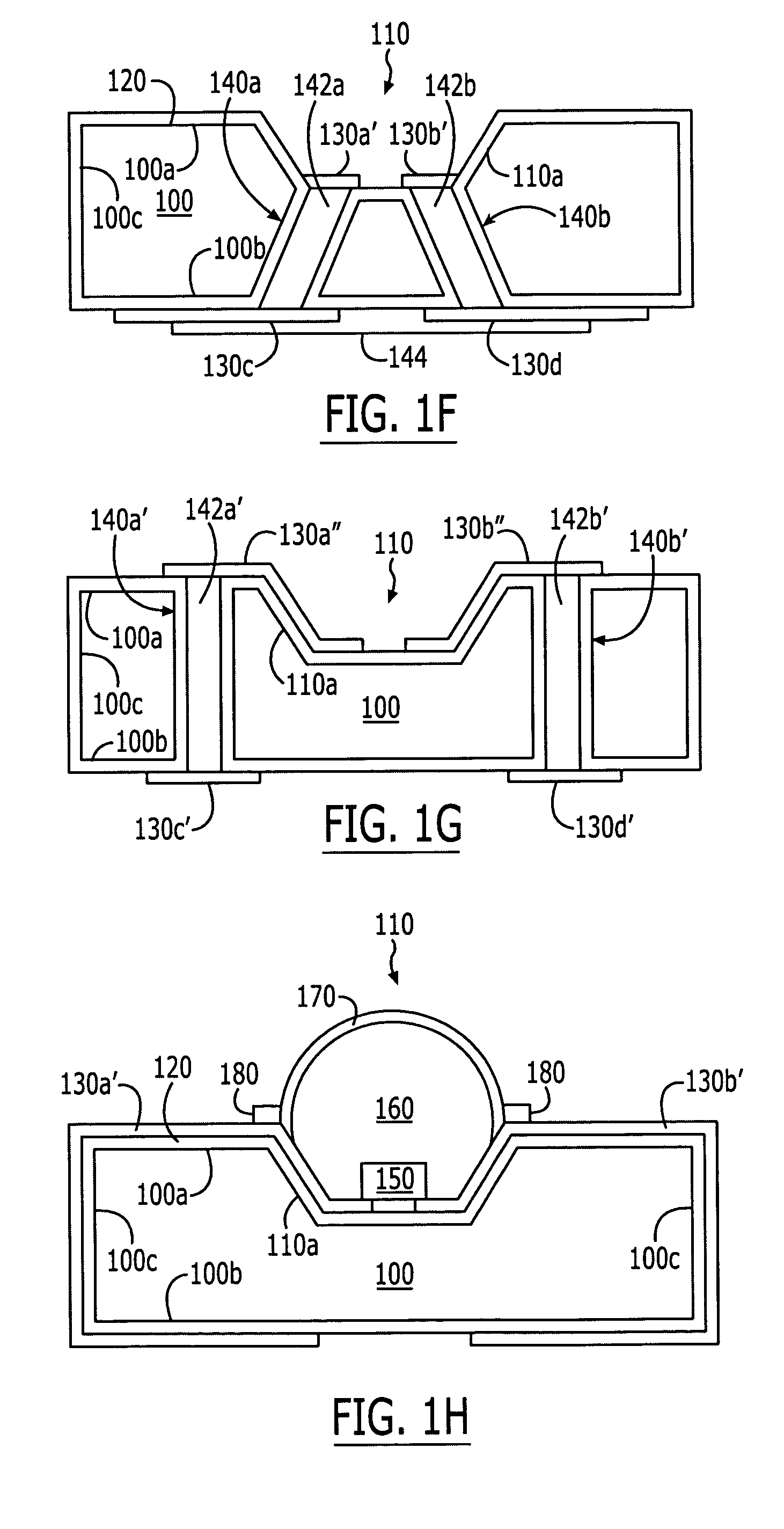

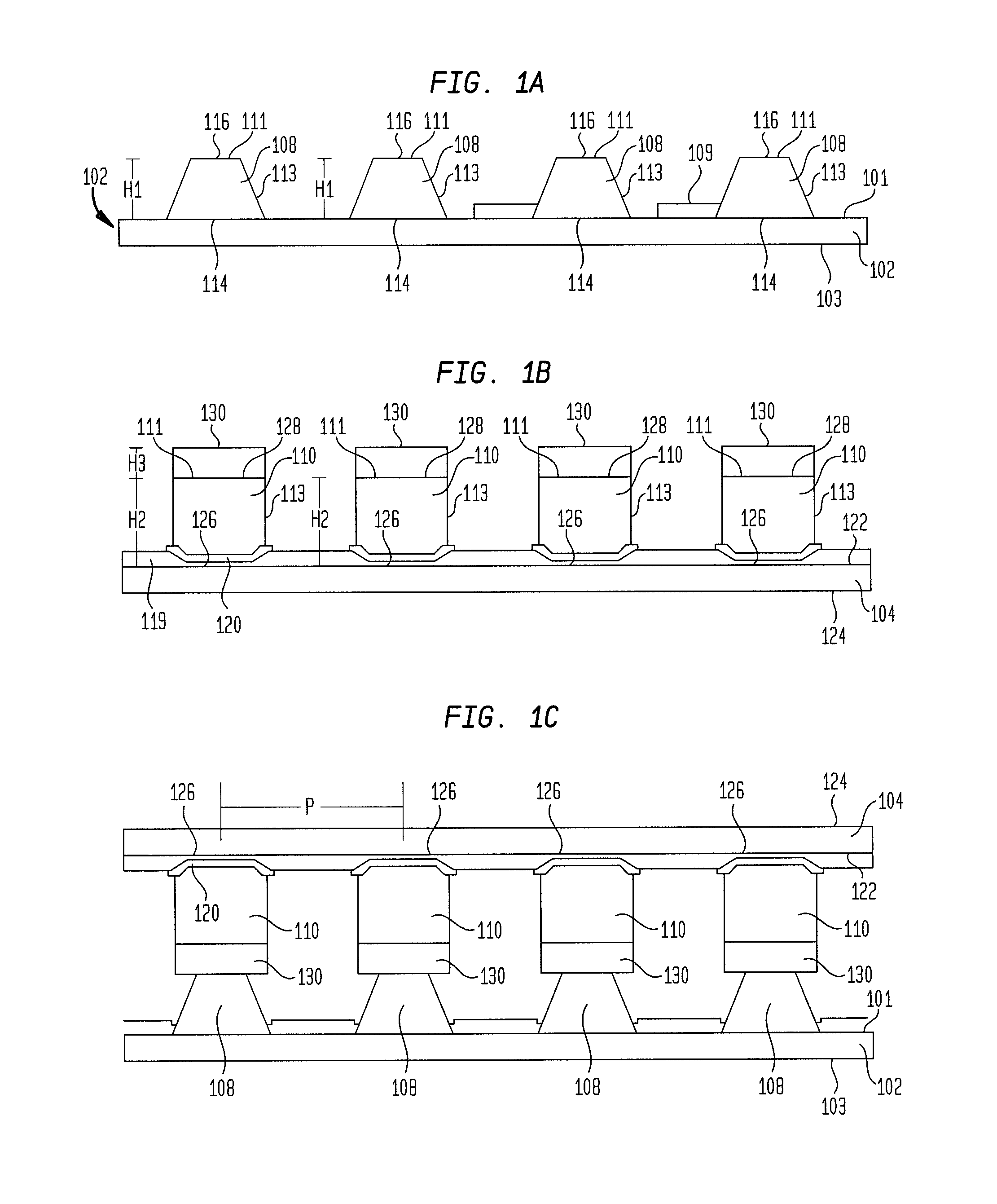

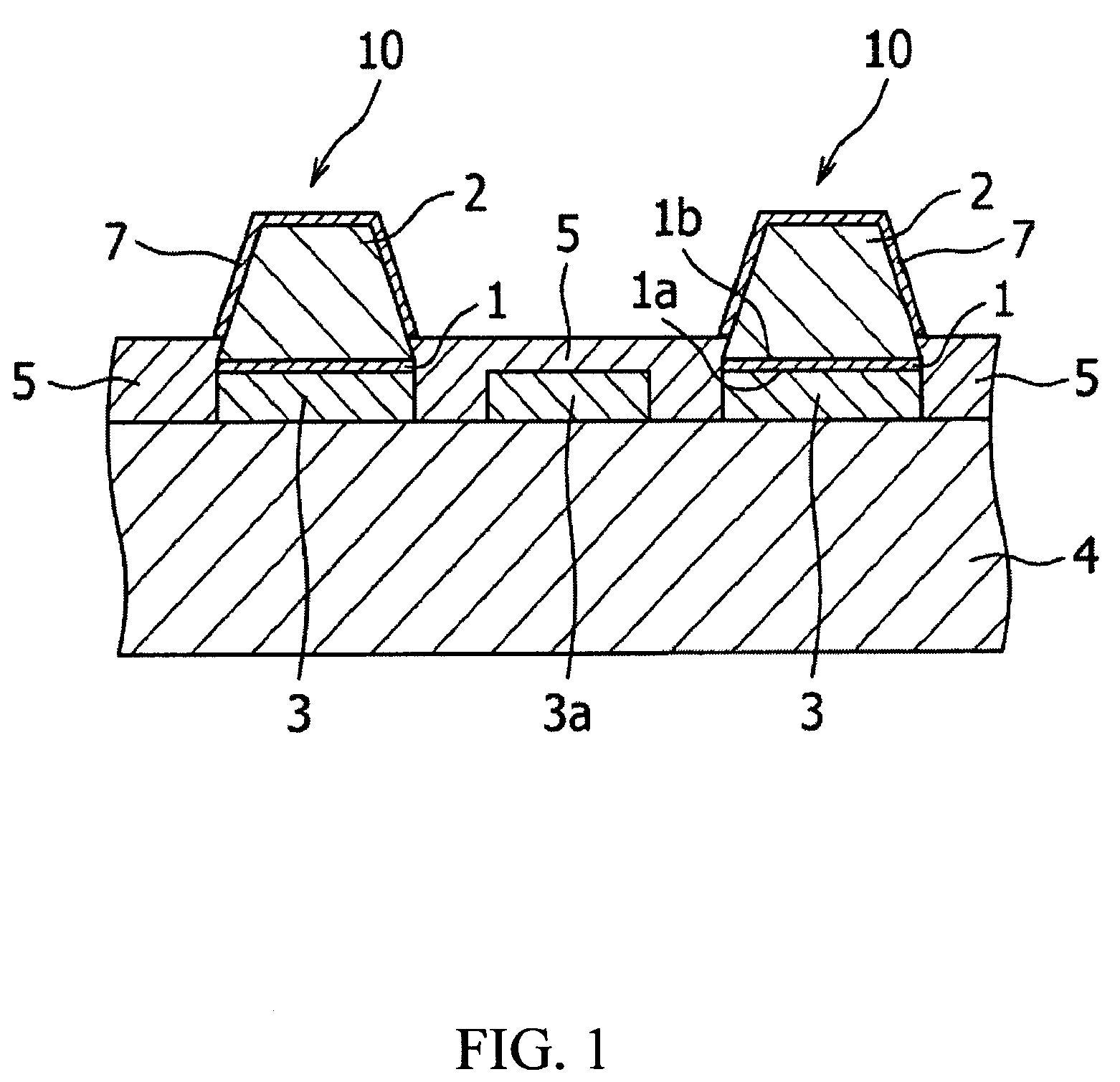

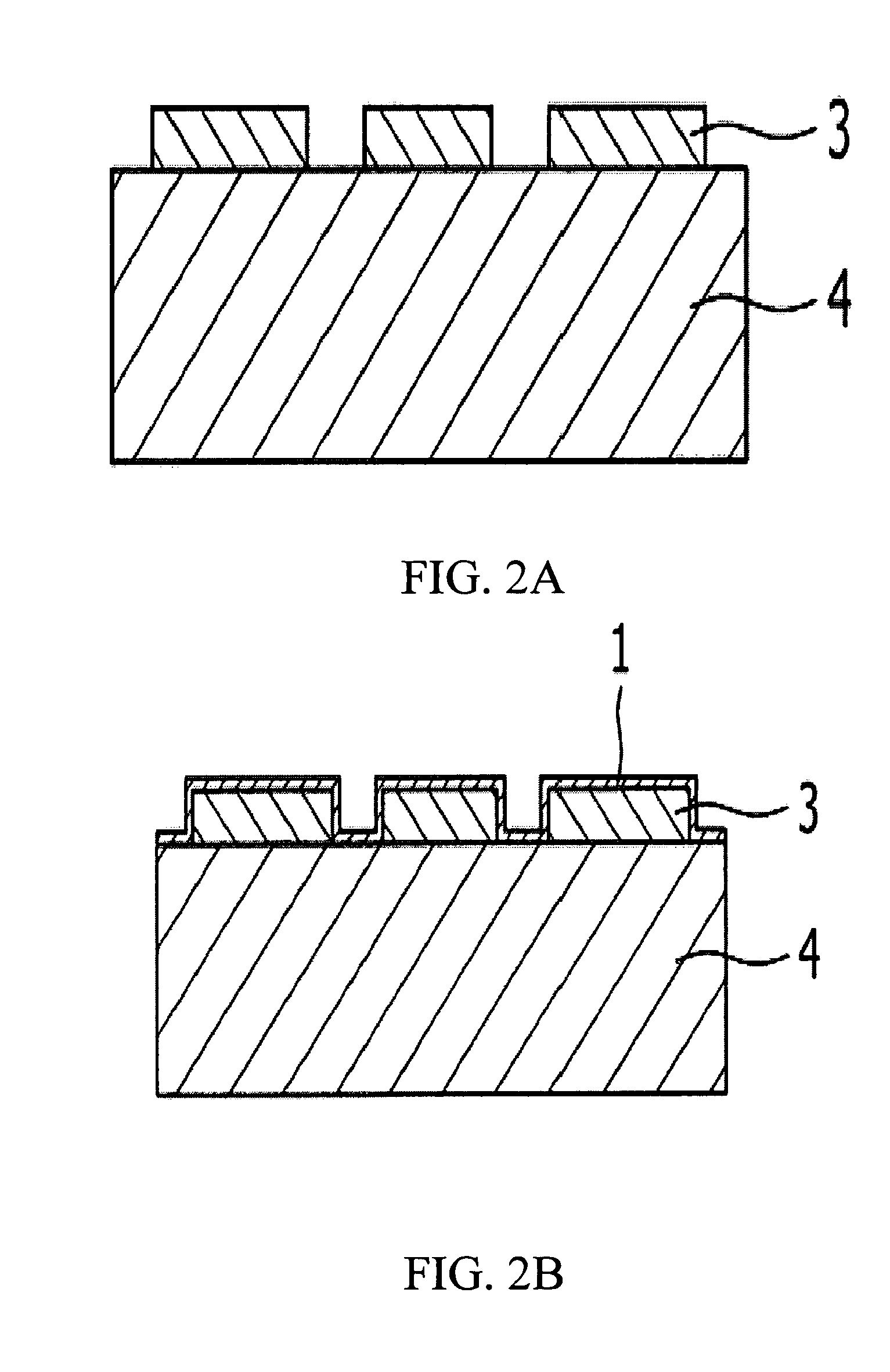

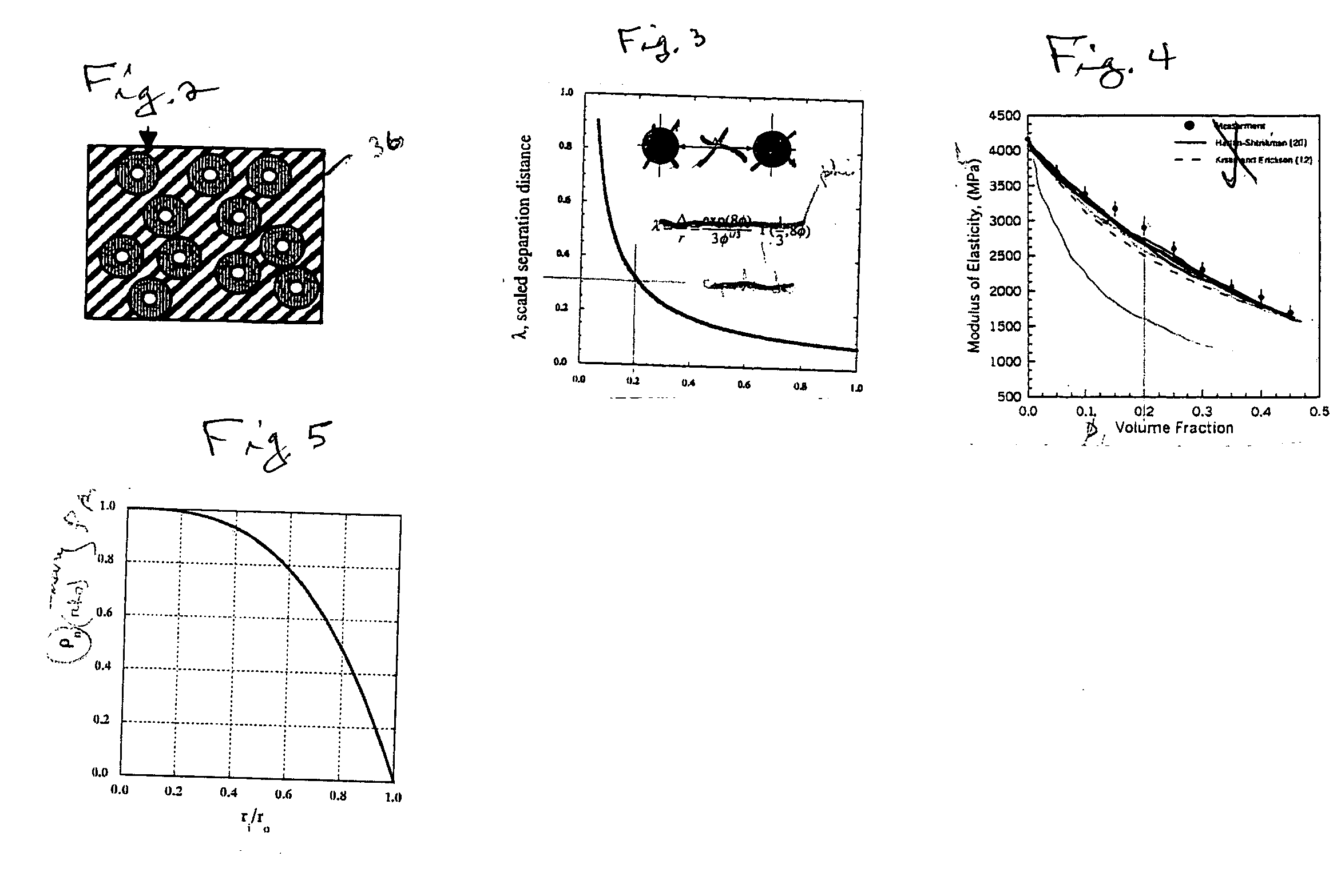

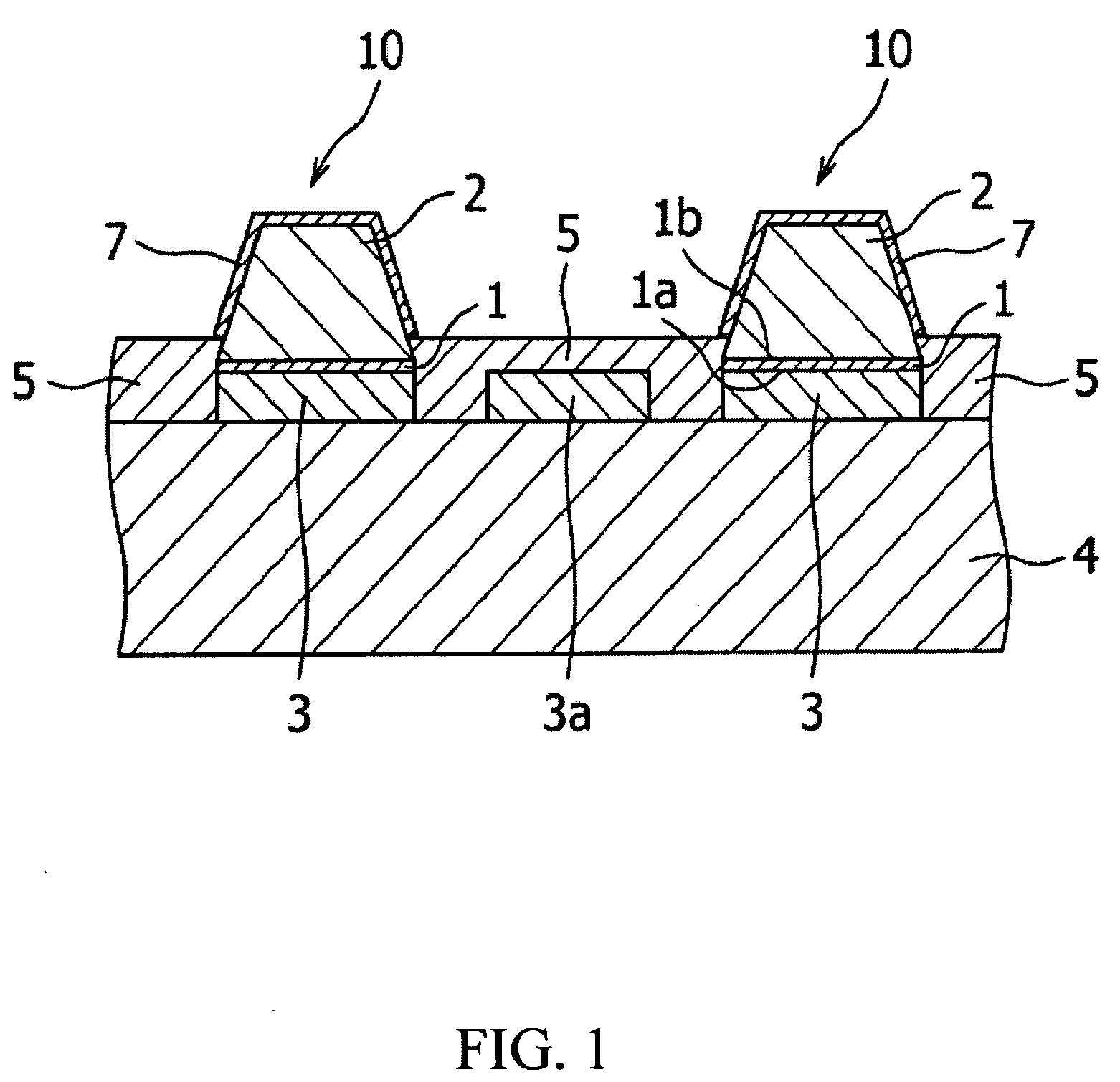

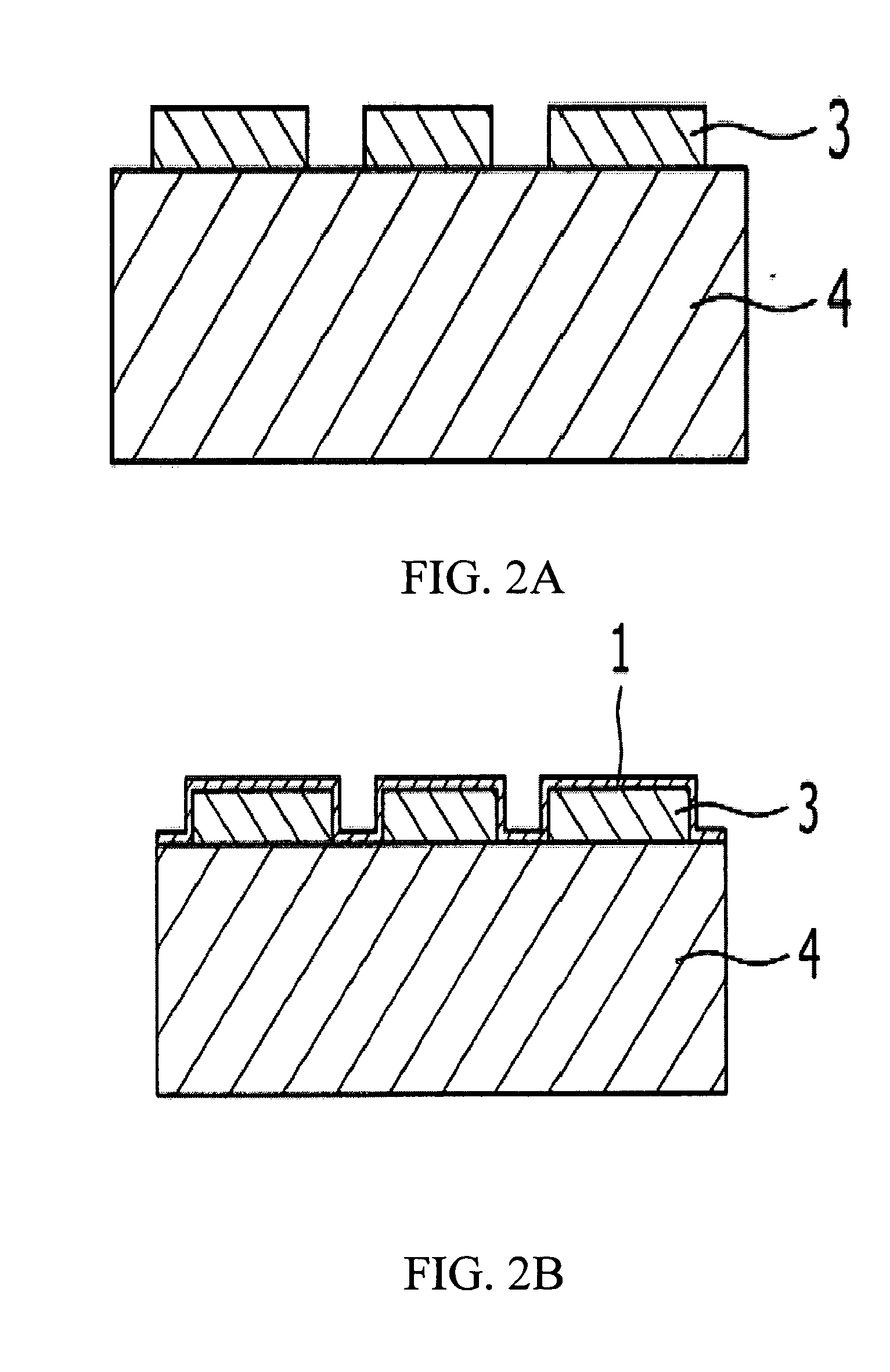

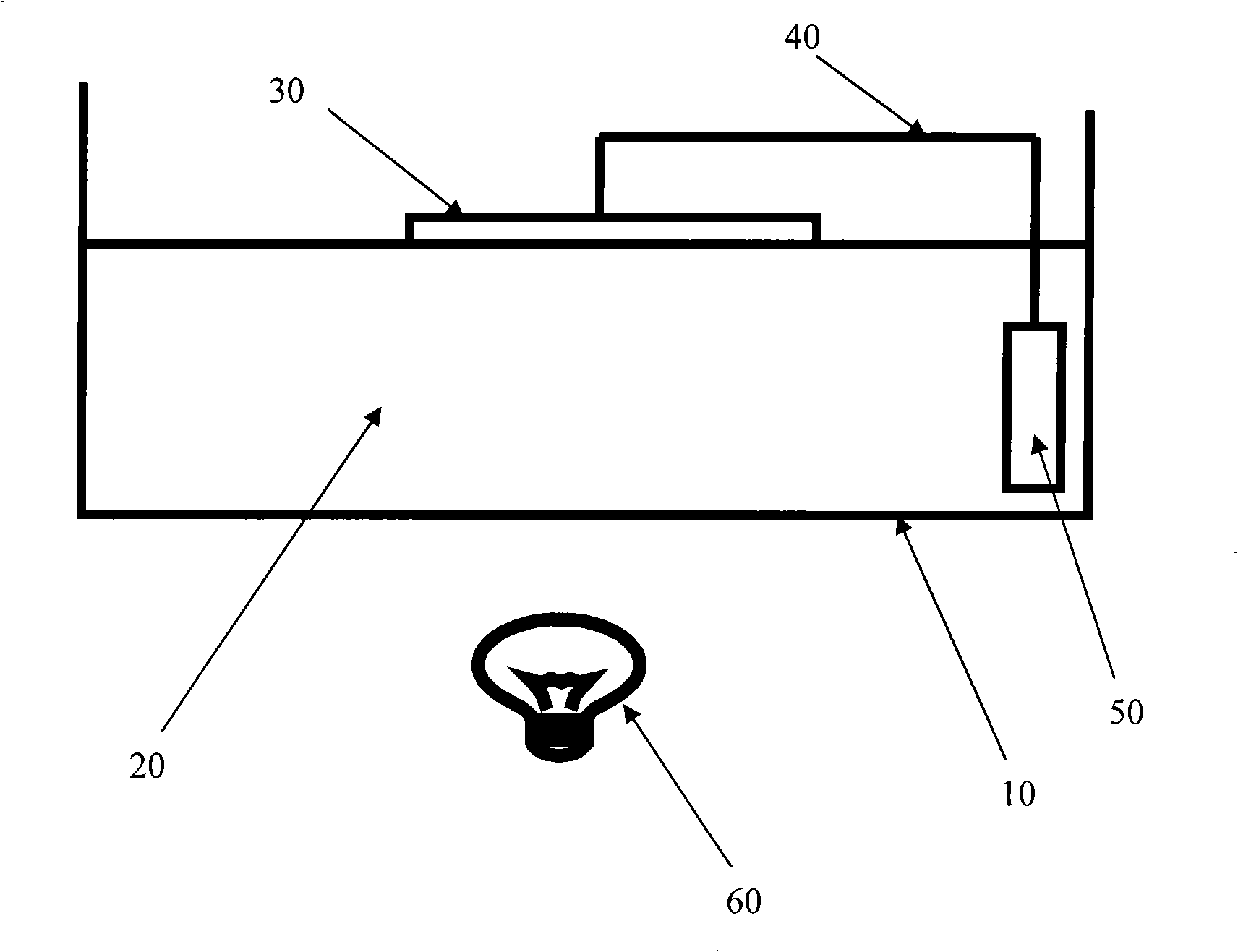

Solid metal block mounting substrates for semiconductor light emitting devices, and oxidizing methods for fabricating same

ActiveUS20050051789A1Solid-state devicesSemiconductor/solid-state device manufacturingEngineeringLight emitting device

A mounting substrate for a semiconductor light emitting device includes a solid metal block having a cavity in a face thereof that is configured for mounting a semiconductor light emitting device therein. An insulating coating is provided in the cavity, and first and second spaced apart conductive traces are provided on the insulating coating in the cavity that are configured for connection to a semiconductor light emitting device. The mounting substrate may be fabricated by providing a solid aluminum block including a cavity in a face thereof that is configured for mounting a semiconductor light emitting device therein. The solid aluminum block is oxidized to form an aluminum oxide coating thereon. The first and second spaced apart electrical traces are fabricated on the aluminum oxide coating in the cavity.

Owner:CREELED INC

Metal-containing composite materials

InactiveUS20060167147A1Robust processingStable materialPowder deliveryInorganic active ingredientsMetallic materialsMaterials science

The present invention relates to a process for the manufacture of metal-containing materials or composite materials, the process comprising the steps of encapsulating at least one metal-based compound in a polymeric shell, thereby producing a polymer-encapsulated metal-based compound and / or coating a polymeric particle with at least one metal-based compound; forming a sol from suitable hydrolytic or non-hydrolytic sol / gel forming components; combining the polymer-encapsulated metal-based compound and / or the coated polymeric particle with the sol, thereby producing a combination thereof; and converting the combination into a solid metal-containing material. The present invention further relates to metal-containing materials produced in accordance with the above process.

Owner:CINVENTION AG

Microelectronic packages with dual or multiple-etched flip-chip connectors

ActiveUS20120007232A1Semiconductor/solid-state device detailsSolid-state devicesEdge surfaceEngineering

A packaged microelectronic element includes a microelectronic element having a front surface and a plurality of first solid metal posts extending away from the front surface. A substrate has a major surface and a plurality of conductive elements exposed at the major surface and joined to the first solid metal posts. In particular examples, the conductive elements can be bond pads or can be second posts having top surfaces and edge surfaces extending at substantial angles away therefrom. Each first solid metal post includes a base region adjacent the microelectronic element and a tip region remote from the microelectronic element, the base region and tip region having respective concave circumferential surfaces. Each first solid metal post has a horizontal dimension which is a first function of vertical location in the base region and which is a second function of vertical location in the tip region.

Owner:TESSERA INC

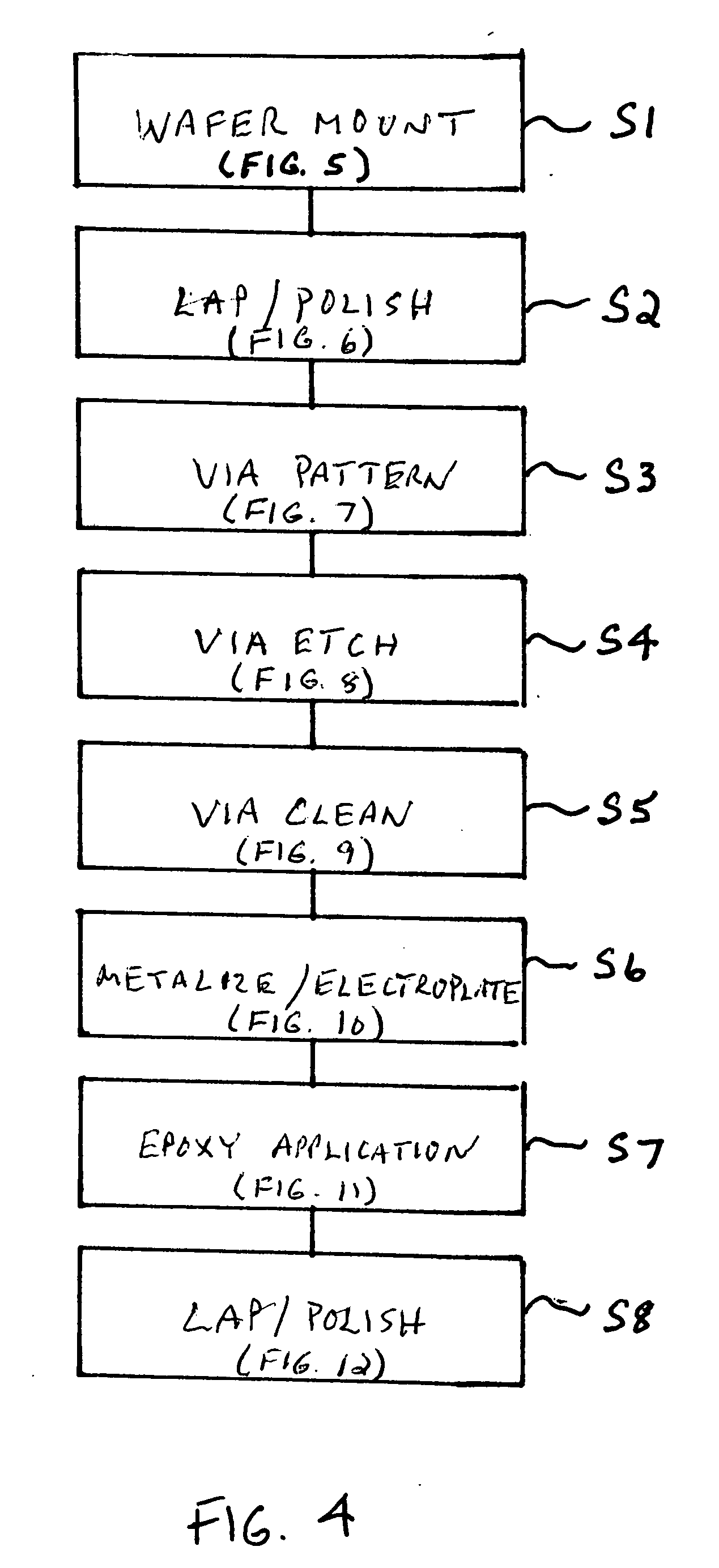

Semiconductor structures having via structures between planar frontside and backside surfaces and methods of fabricating the same

Methods of backside planarization processes have been developed to gain a high resolution backside process lithography and to make possible the development of dual faced MMICs and circuits. Two different processes have been employed to planarize via structures of various depths, one including epoxy-fill via structures with depths of 10 mils and the other solid-metal via structures with depths of 3.5 mils. Application of a wafer fabricated using methods of the present invention has been demonstrated in a monolithic circuit, where bias control to the frontside of the wafer was established by solder bumps on the planarized backside surface of a wafer including epoxy-filled via structures.

Owner:TELEDYNE LICENSING

Orthopedic implant system

InactiveUS6066176AStrong interlocking fixationEasy to fixSurgical adhesivesBone implantPolymethyl methacrylateFemoral stem

It is an object of the present invention to provide an improved orthopedic implant system with satisfied biological, mechanical and morphological compatibilities. Solid metal femoral stem (entirely or partially) and solid metal acetabular head (entirely or partially) are covered with diffusion-bonded foamed-shaped sheet made of commercially pure titanium or titanium alloy(s). The open-cells in said foamed metal sheet are impregnated with biocompatible polymethyl methacrylate resin cement, which is reinforced with selected oxides (e.g., alumina, magnesia, zirconia, or a combination of these oxides) along with an application of a small amount of a metal primer agent.

Owner:OSHIDA YOSHIKI

Solid metal block mounting substrates for semiconductor light emitting devices

ActiveUS7183587B2Solid-state devicesSemiconductor/solid-state device manufacturingEngineeringLight emitting device

Owner:CREELED INC

Topical application of solid antimicrobials to carpet pile fibers during carpet manufacture

InactiveUS6641829B1Good light fastnessShampoo durabilityBiocideBiochemical fibre treatmentFiberLiquid medium

Carpeted floor covering articles comprising carpet pile fibers to which a topical antimicrobial application of solid particles has been applied either during or after product manufacture (such as part of a cleaning or treatment process) are provided. Such a topical treatment includes specific inorganic antimicrobial metal ion-based solid compounds, such as silver ion-exchange compounds, silver zeolites, and / or silver glasses, which may or may not be dispersed within a liquid medium for ease in handling and application. Such treatments also optionally include compositions of stain resistant agents, anti soil-redeposition compounds and liquids, surfactants, antistatic agents, and the like, to impart other characteristics to the target carpeted products. Such carpeted products thus exhibit excellent antimicrobial characteristics at both the surface of the carpet pile, as well as within the pile itself. Furthermore, it has been found that application of such solid metal-ion based antimicrobials permits the ability to increase antimicrobial activity for the target carpet product after vacuuming.

Owner:SAGE AUTOMOTIVE INTERIORS INC

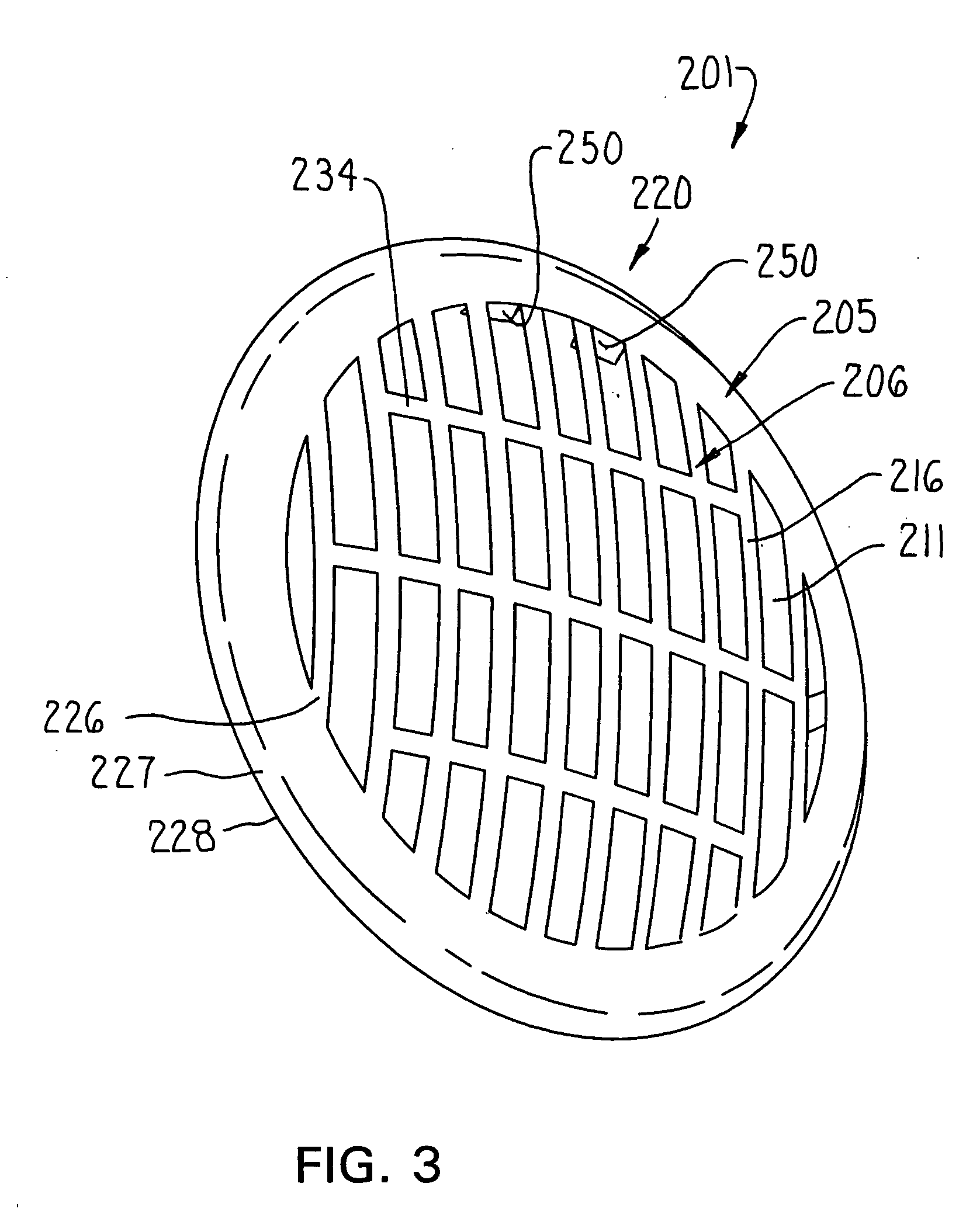

Vent assembly

A vent assembly, suitable for marine use including, for example, venting an enclosure, such as an engine compartment, on a boat. The vent assembly has substantially the external appearance of a cast or machined, one piece, stainless steel vent, at a cost very little more than a molded plastics vent. A molded plastics vent has a head perforated by a pattern of ventilating slots separated by flanking strips. A decorative, corrosion-resistant, sheet metal cover shell lies tight against the front side of the molded plastics vent and has a pattern of slots and strips mapping substantially on the pattern of slots and strips of the molded plastics vent. Snap-fit fasteners fix the cover shell on the vent so that the cover shell slots are a substantially flush continuation of the vent slots, so as to provide the decorative appearance of a solid metal vent at substantially lower cost and without compromising or through flow capability.

Owner:ITC LIMITED

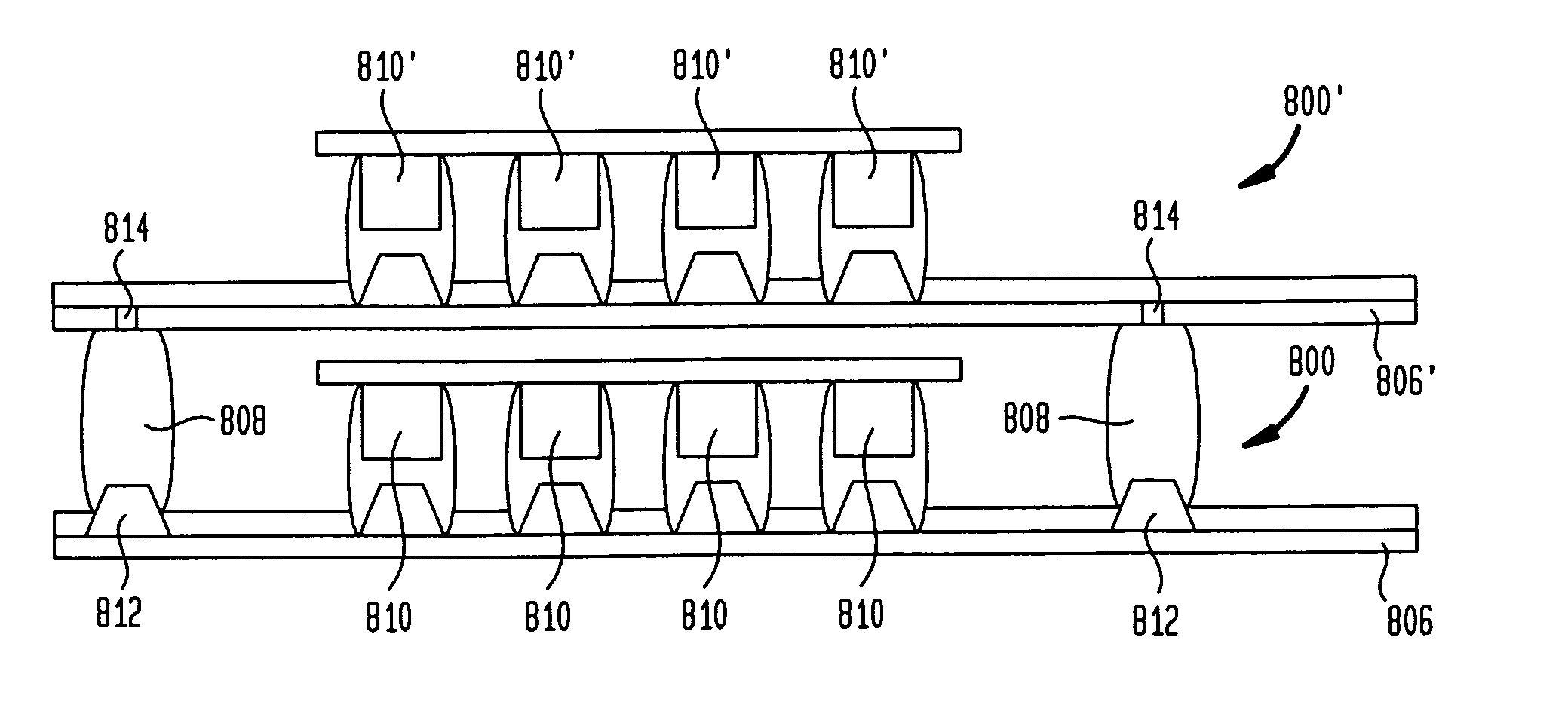

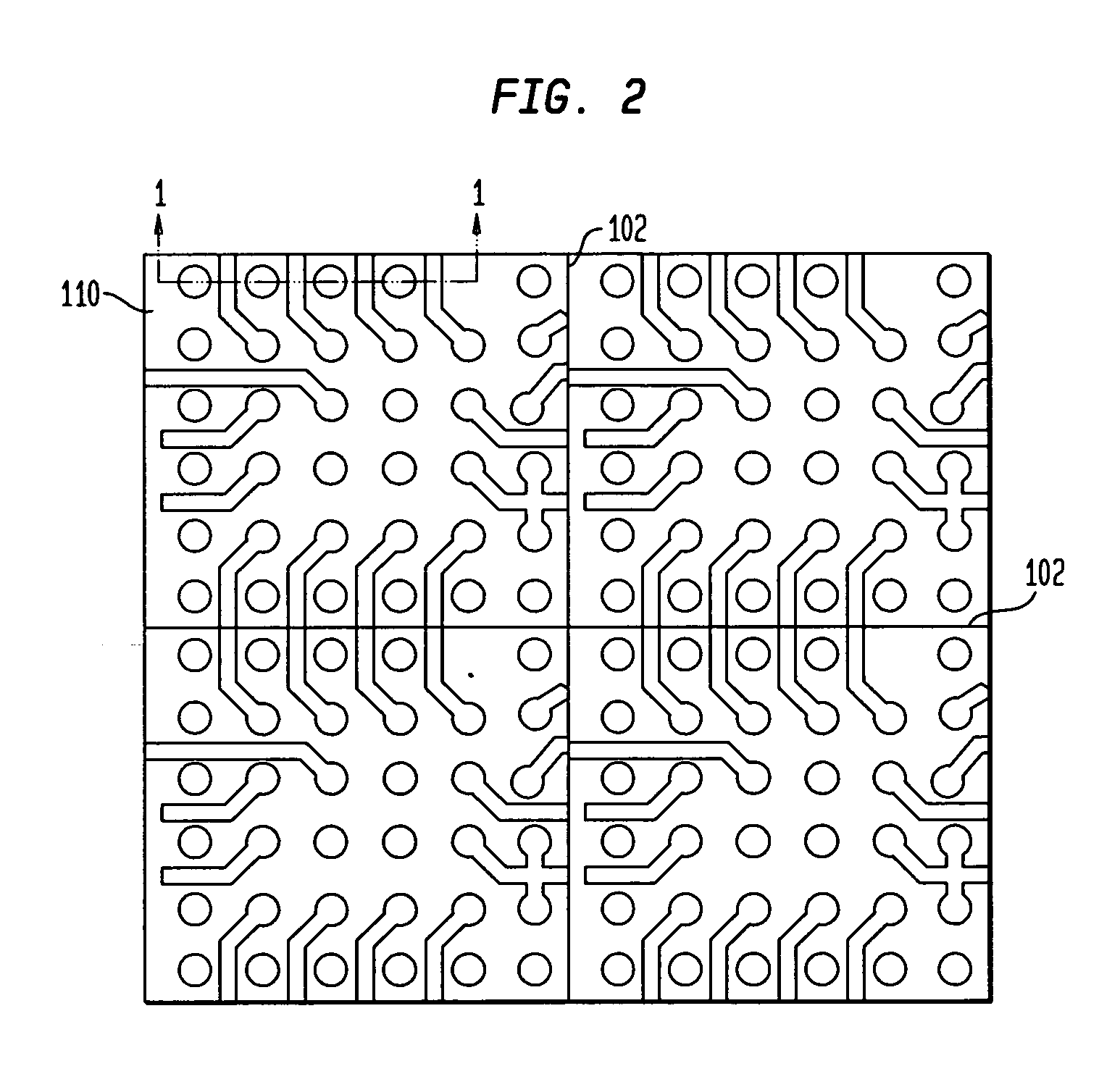

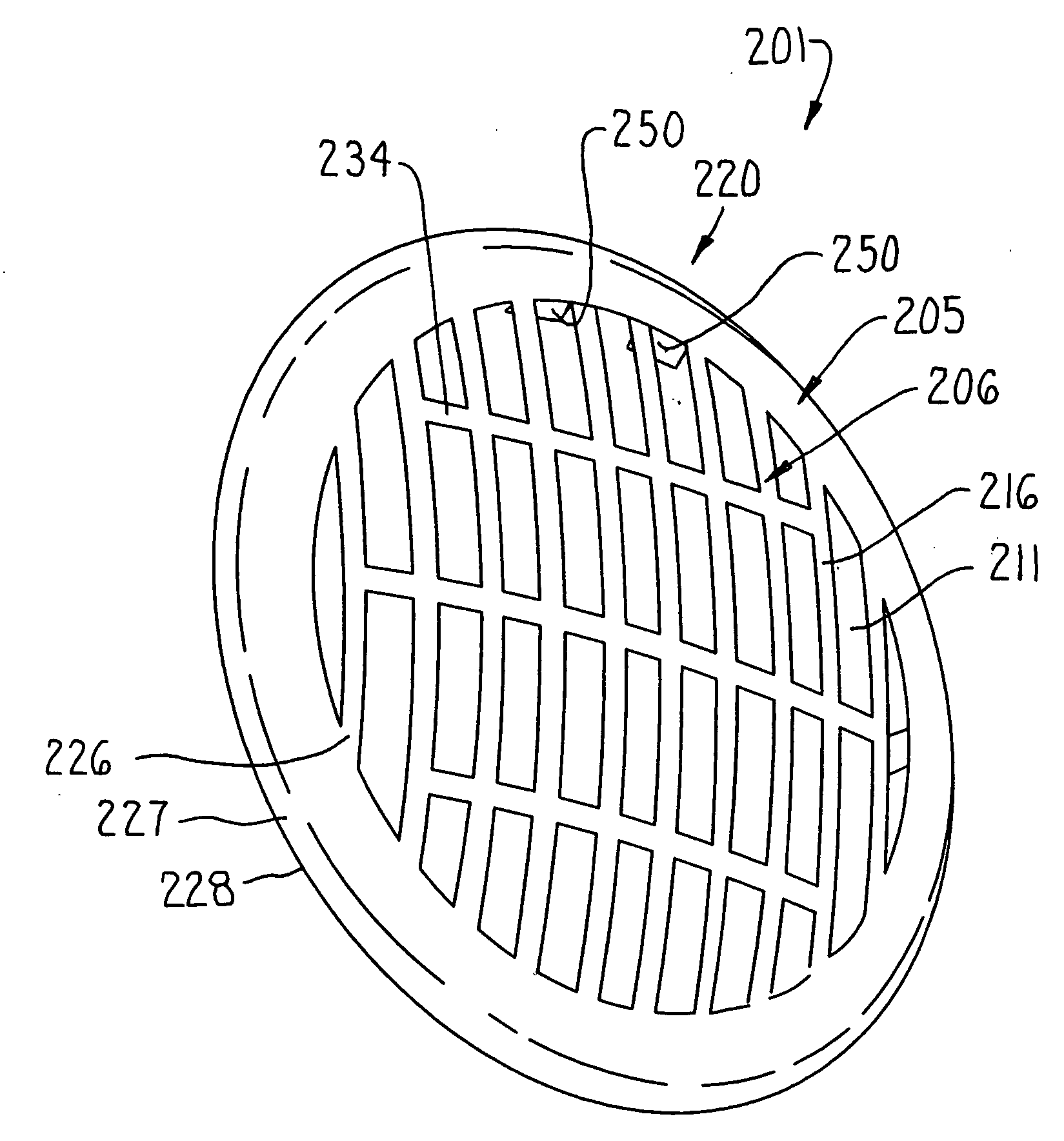

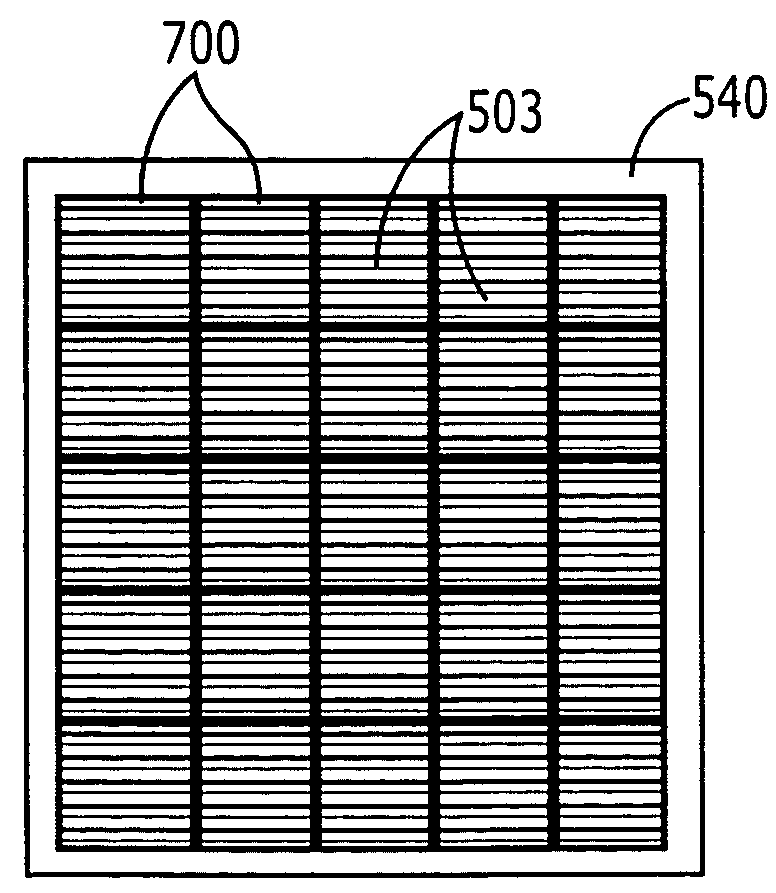

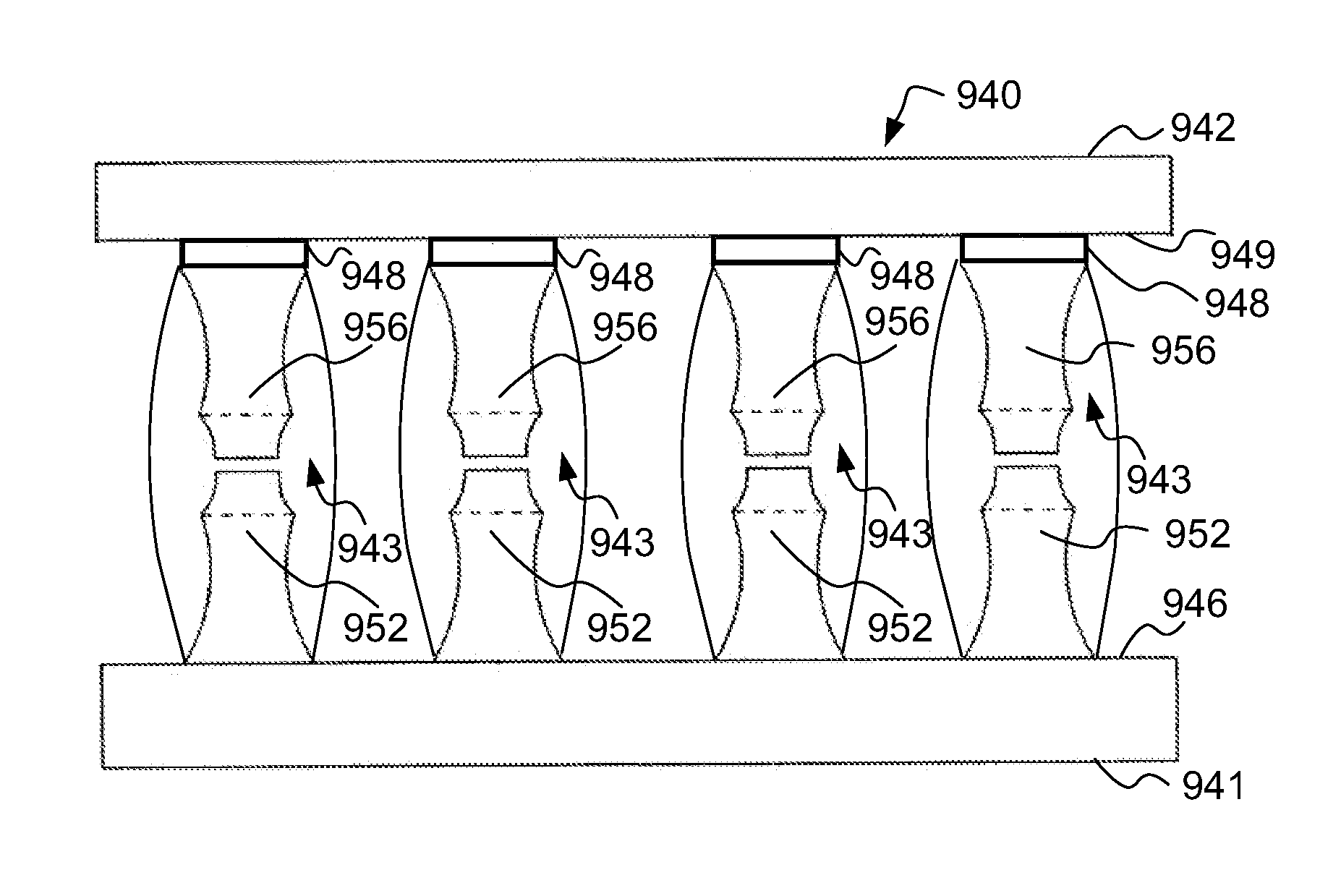

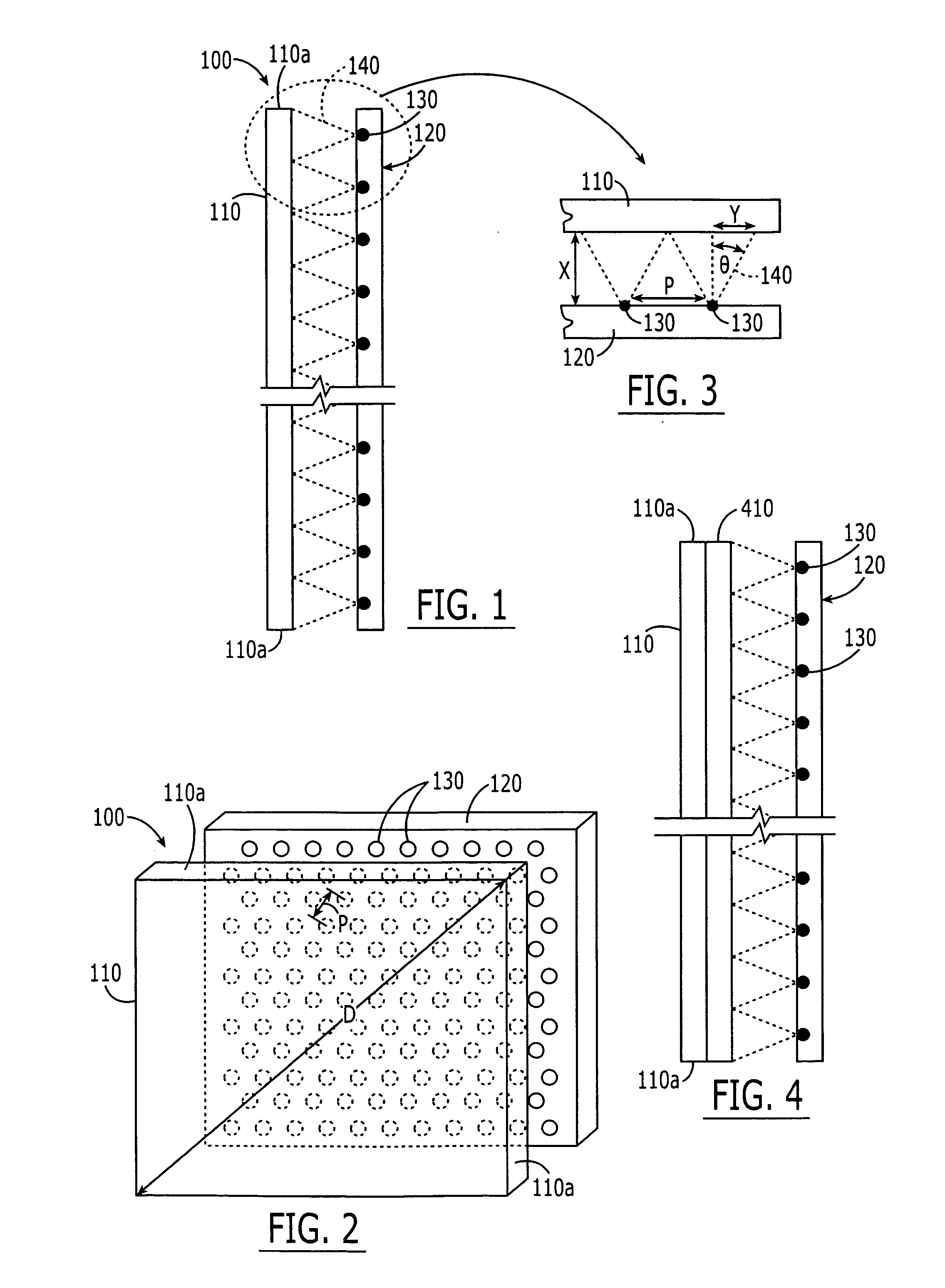

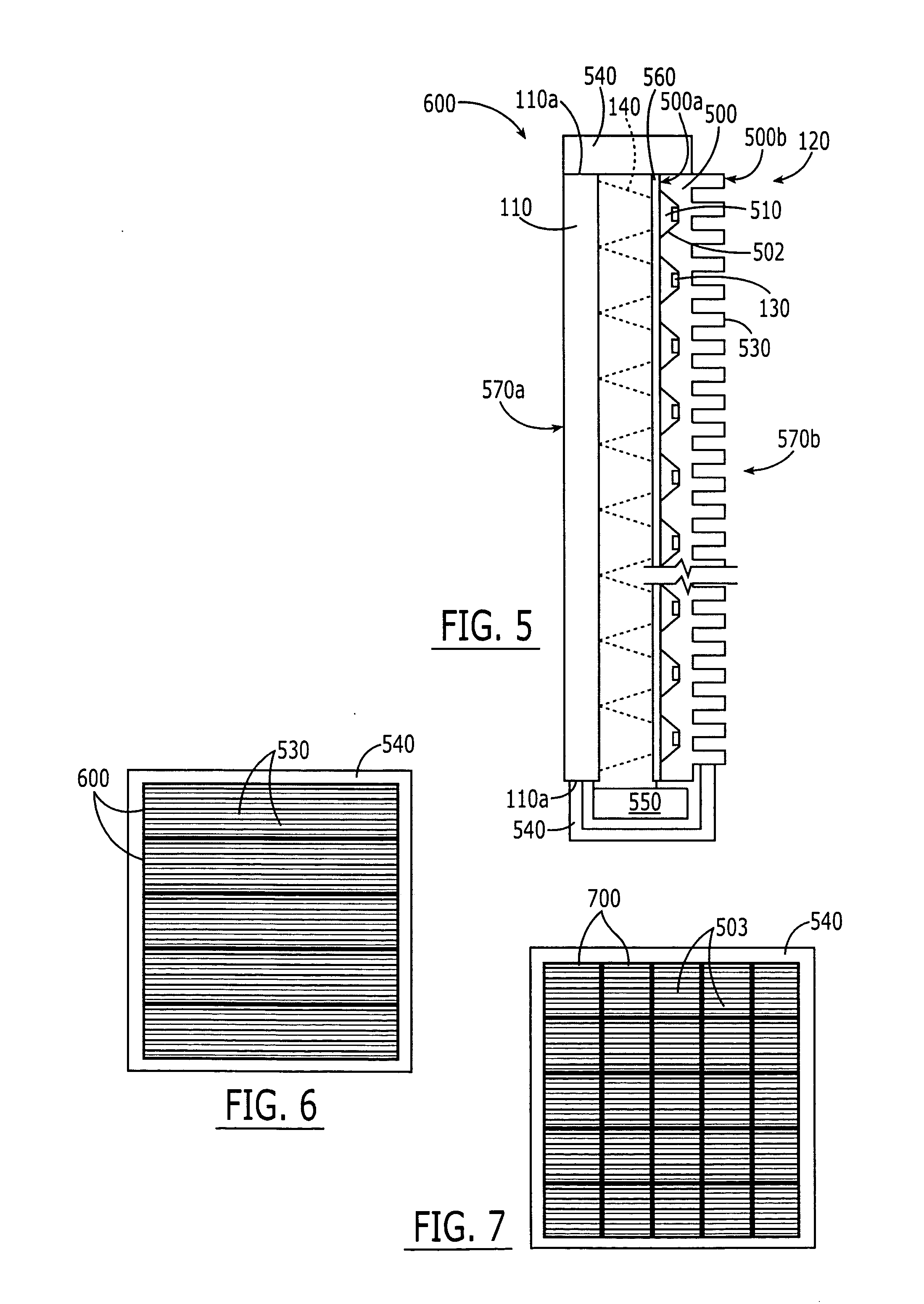

Light emitting diode arrays for direct backlighting of liquid crystal displays

ActiveUS7322732B2Uniform backlightLighting heating/cooling arrangementsNon-linear opticsLiquid-crystal displayDisplay device

A display panel for a flat panel display includes a planar array of LCD devices and a planar array of LED devices that is closely spaced apart from the planar array of LCD devices, at least some of the LED devices being disposed within a periphery of the array of LCD devices such that, in operation, the planar array of LED devices provides backlighting for the planar array of LCD devices. The planar array of LED devices can include at least one solid metal block having first and second opposing metal faces. The first metal face includes therein an array of reflector cavities, and the second metal face includes therein heat sink fins that are exposed at the back face of the flat panel display.

Owner:BRIGHTPLUS VENTURES LLC

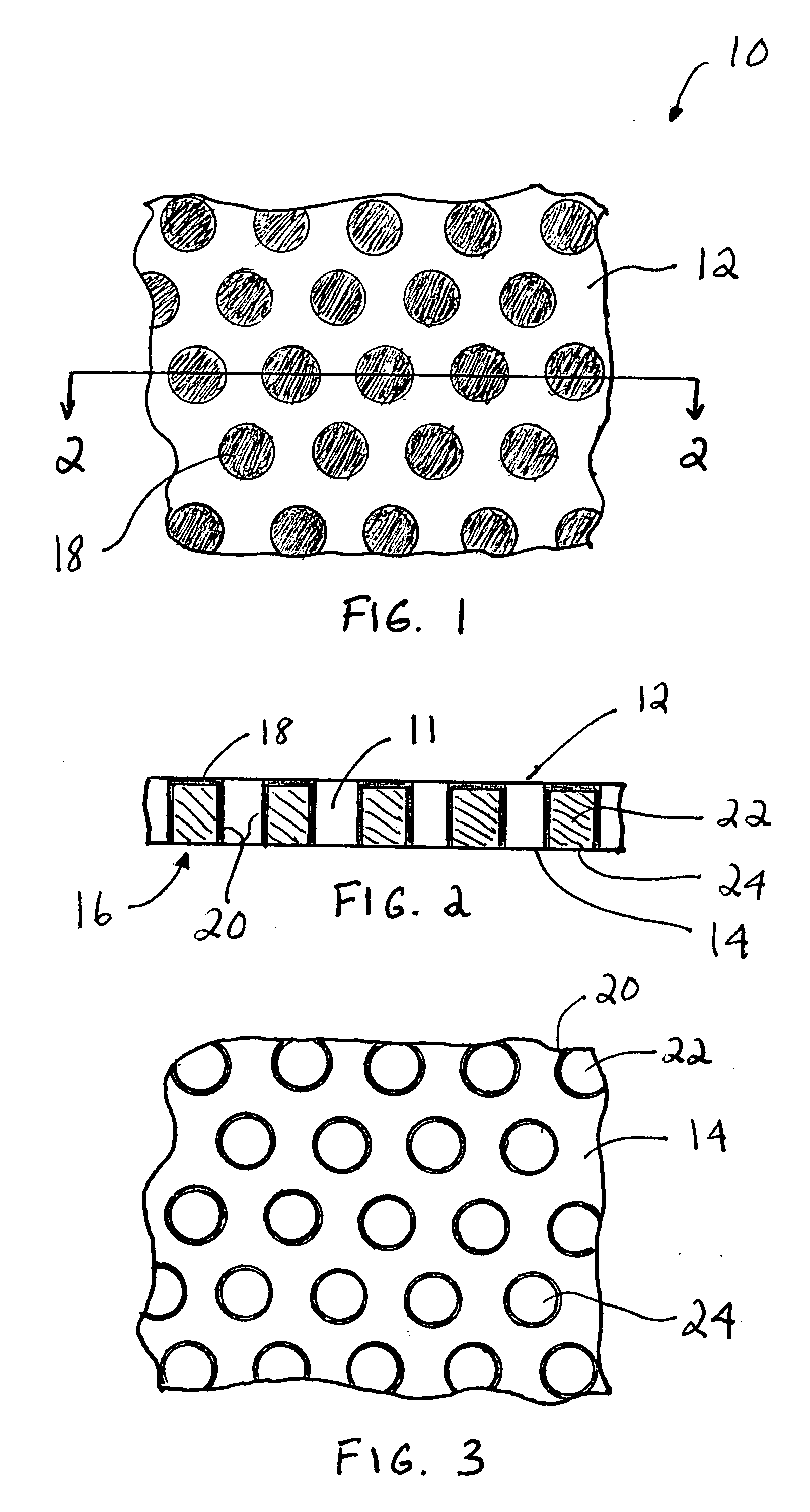

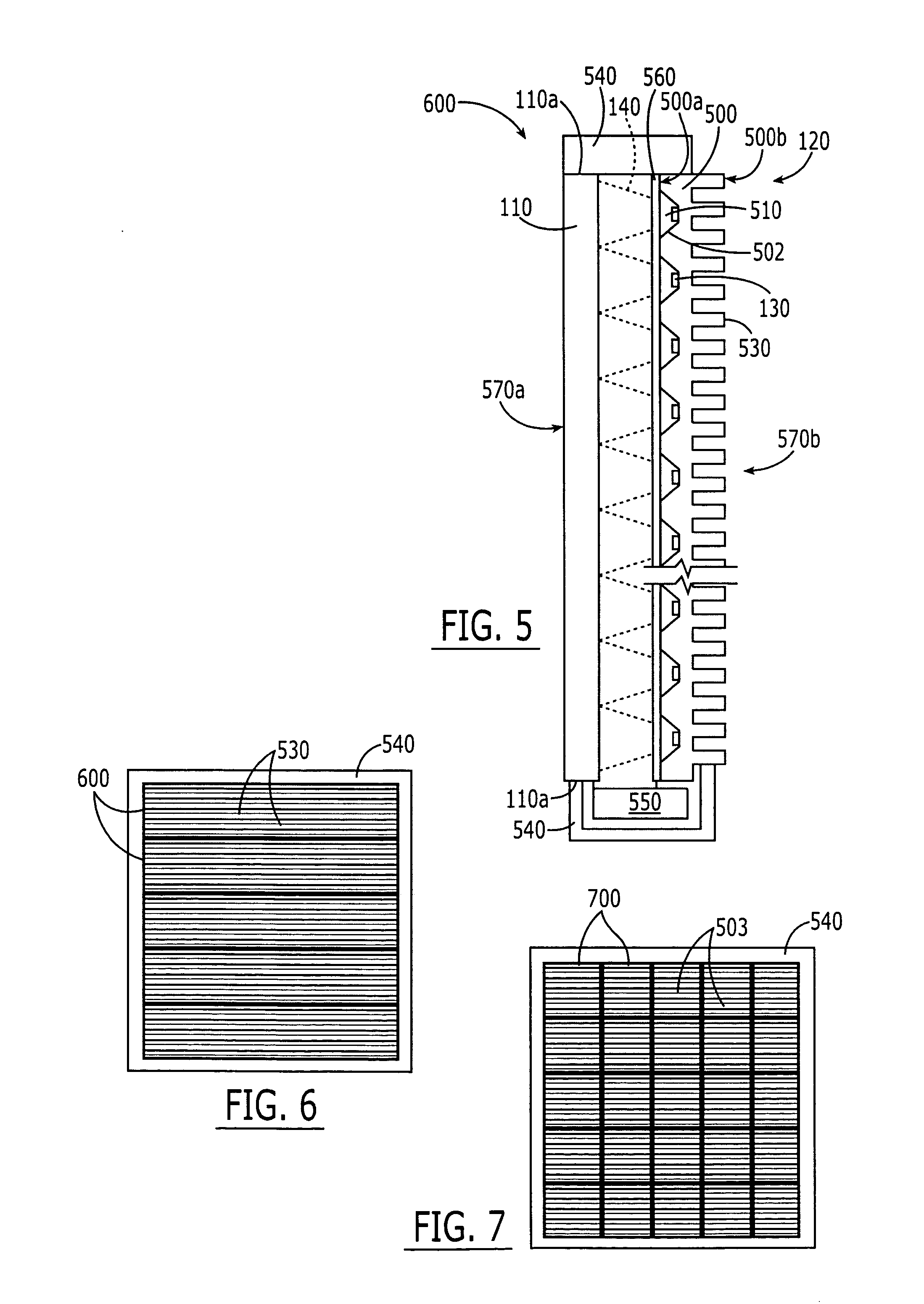

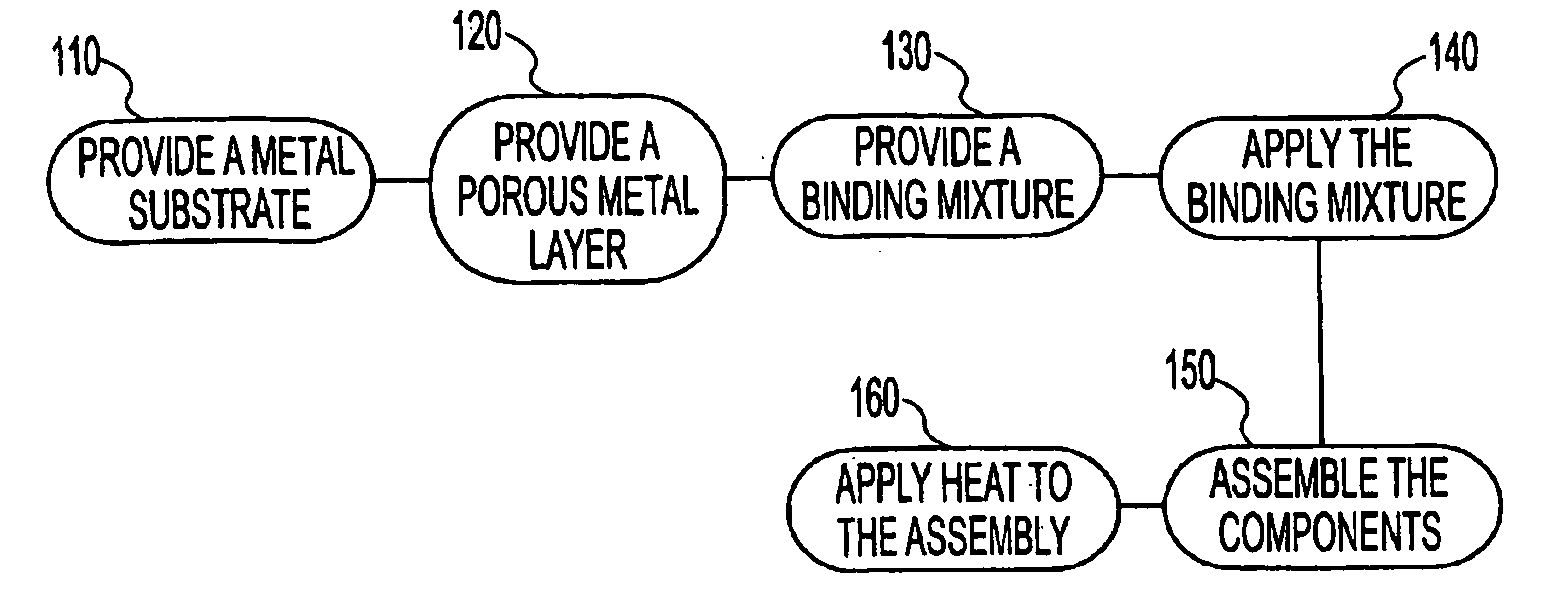

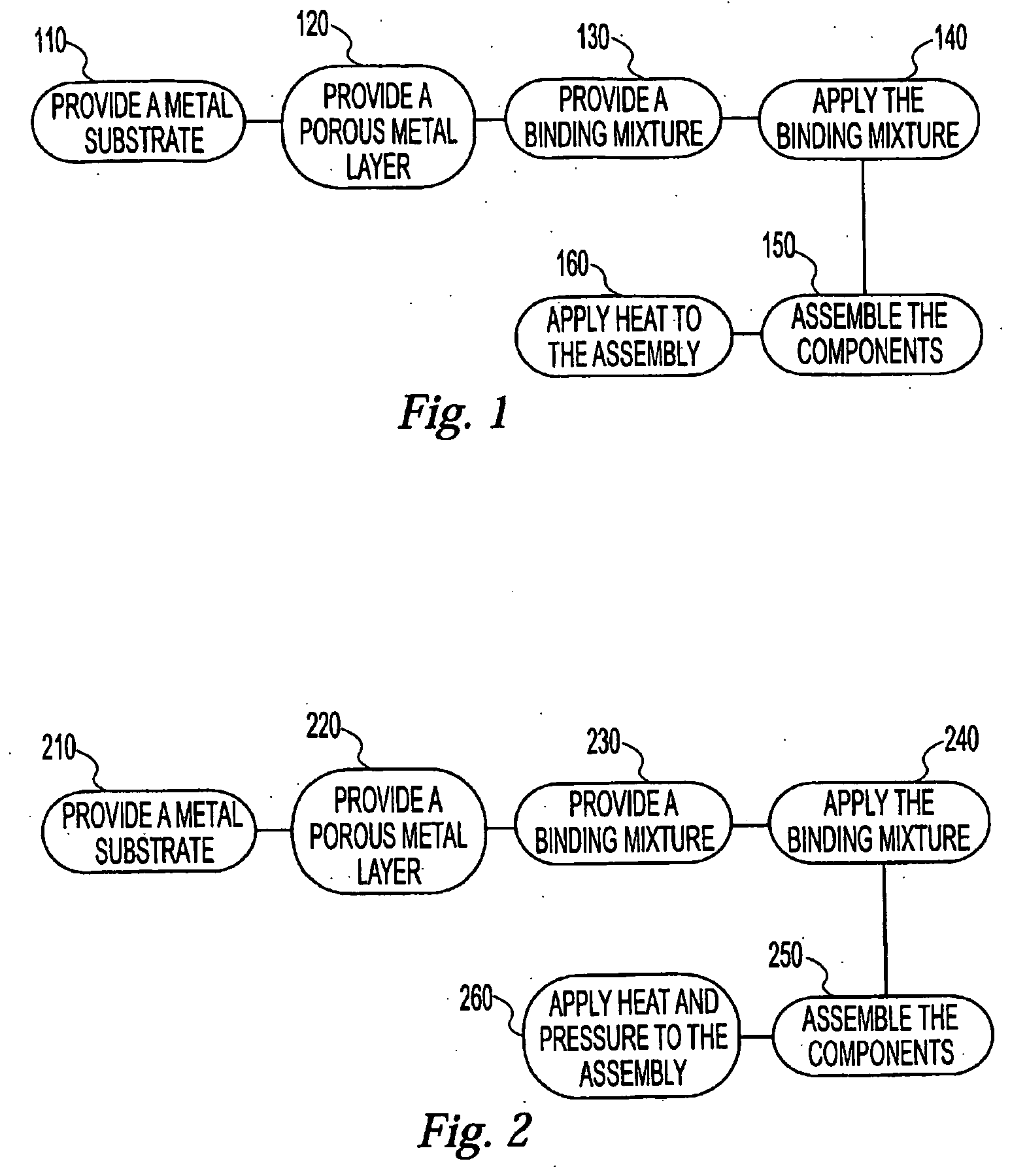

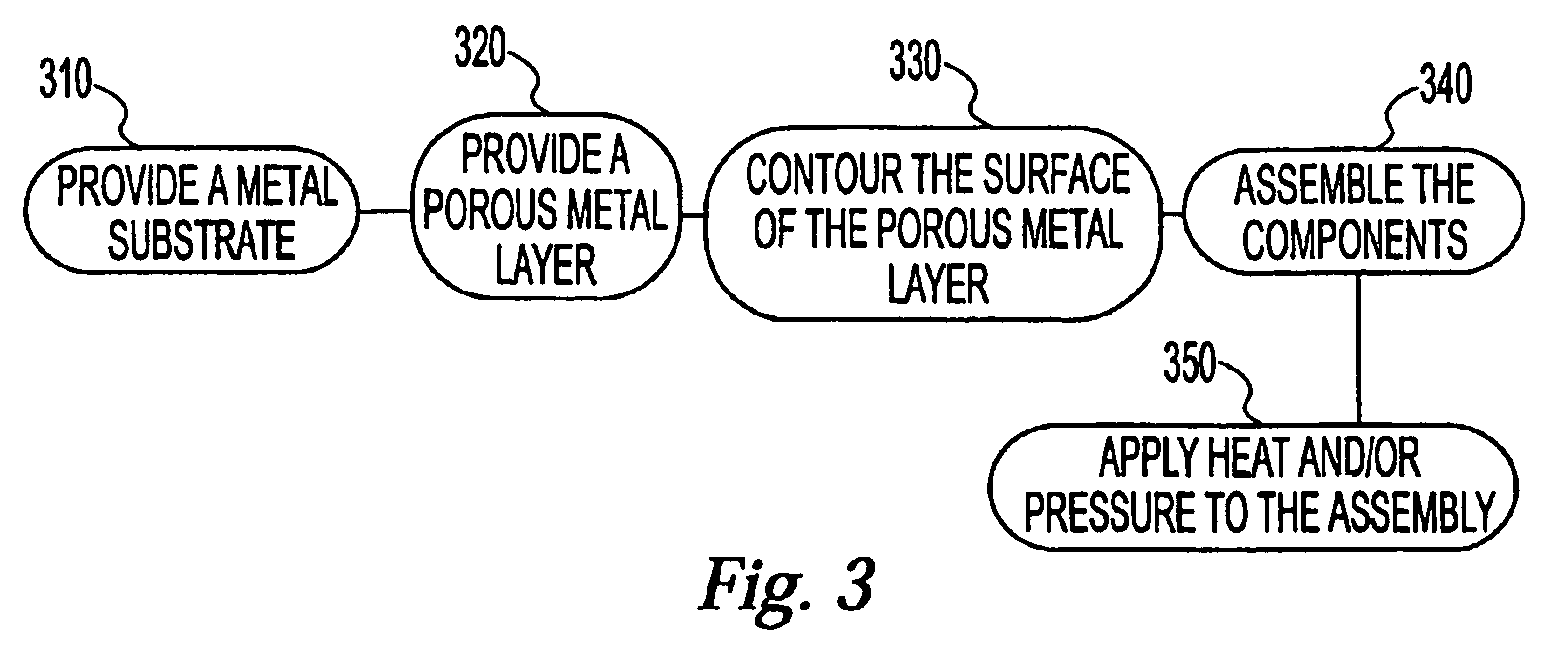

Method for attaching a porous metal layer to a metal substrate

ActiveUS20050184134A1Increase resistanceHigh strengthBone implantSemiconductor/solid-state device manufacturingThermal expansionSurgical implant

A method for attaching a porous metal layer to a dense metal substrate, wherein the method is particularly useful in forming orthopedic implants such as femoral knee components, femoral hip components, and / or acetabular cups. The method, in one embodiment thereof, comprises providing a solid metal substrate; providing a porous metal structure; contouring a surface of the porous metal structure; placing the porous structure against the substrate such that the contoured surface of the porous metal structure is disposed against the substrate, thereby forming an assembly; applying heat and pressure to the assembly in conjunction with thermal expansion of the substrate in order to metallurgically bond the porous structure and the substrate; and removing mass from the substrate after the porous structure is bonded to the substrate, thereby finish processing the assembly.

Owner:ZIMMER INC

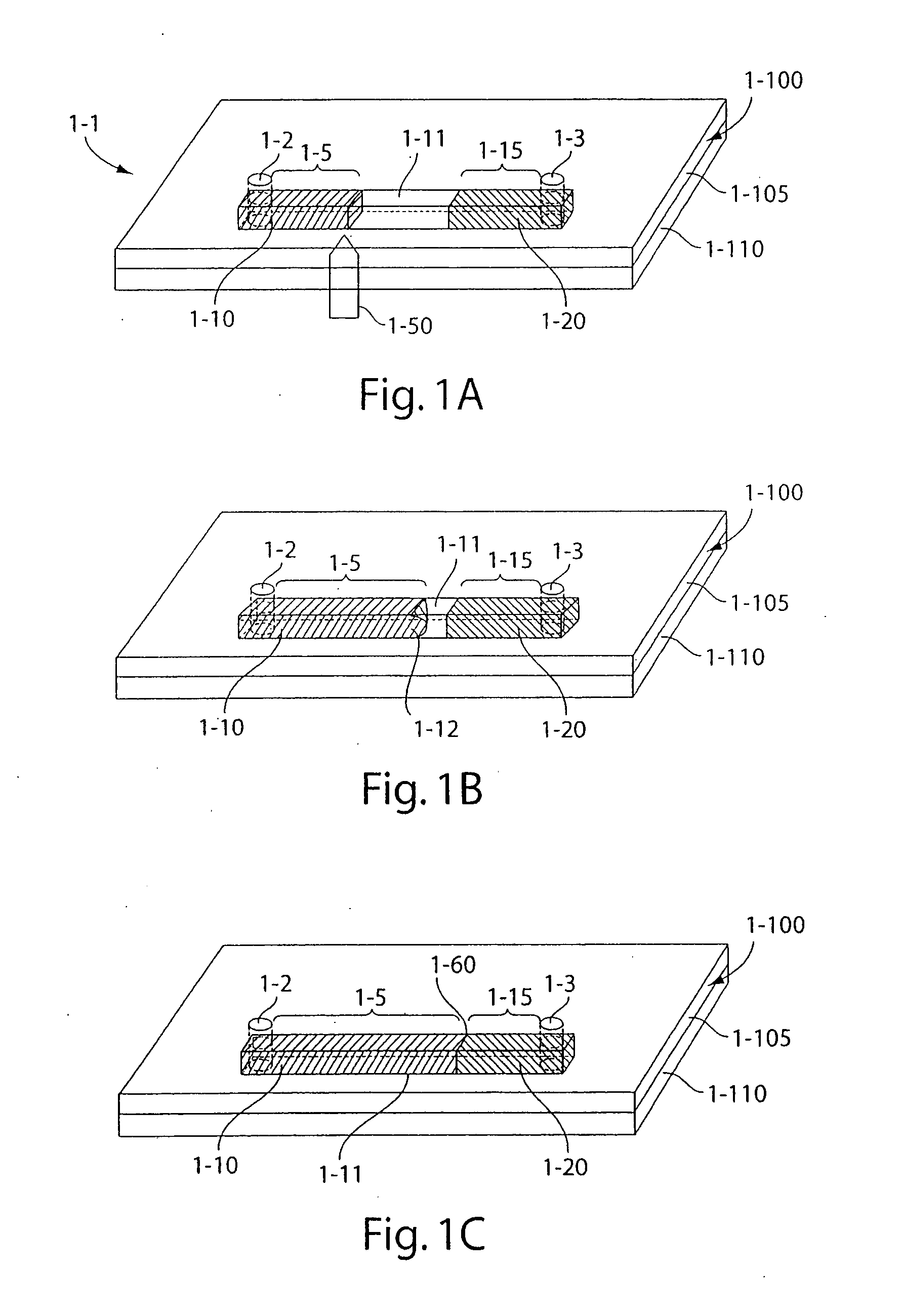

Interconnection element for electric circuits

ActiveUS8299368B2Efficient heat transferImprove installation strengthLine/current collector detailsSemiconductor/solid-state device detailsElectrical conductorInterconnection

Owner:INVENSAS CORP

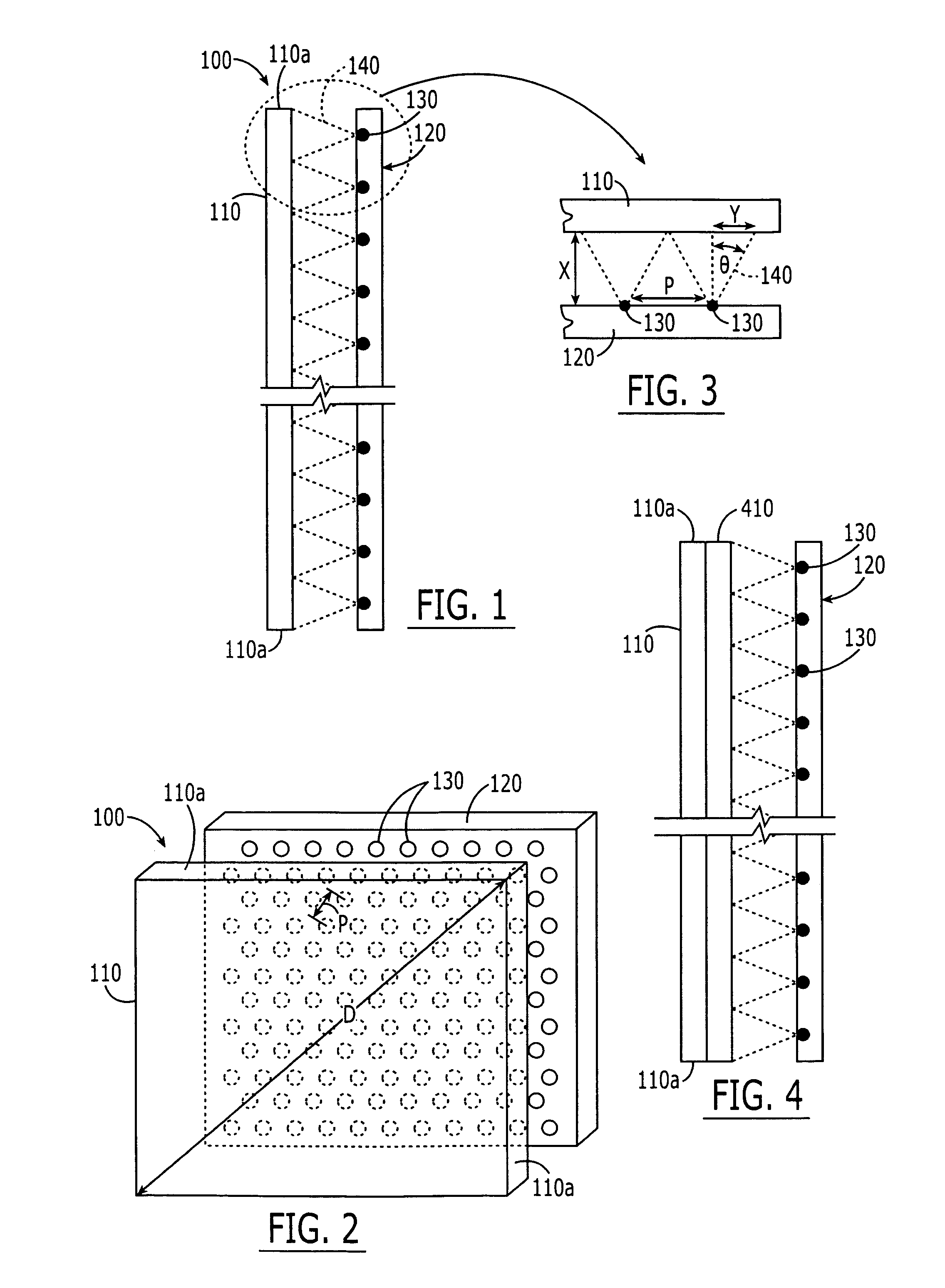

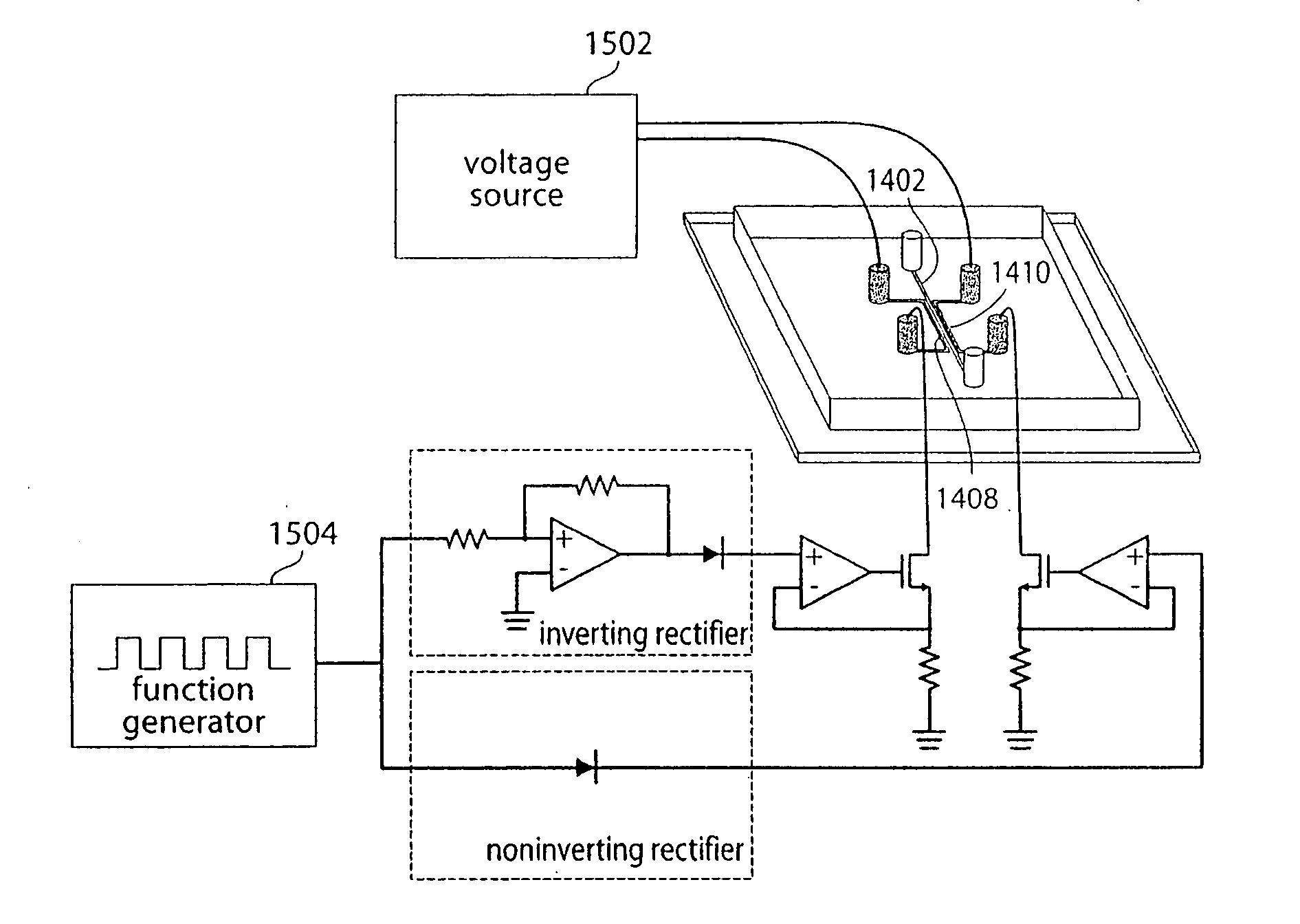

Fabrication of conductive pathways, microcircuits and microstructures in microfluidic networks

ActiveUS20110045577A1Bioreactor/fermenter combinationsBiological substance pretreatmentsThermal energyElectricity

Disclosed herein are a variety of microfluidic devices and solid, typically electrically conductive devices that can be formed using such devices as molds. In certain embodiments, the devices that are formed comprise conductive pathways formed by solidifying a liquid metal present in one or more microfluidic channels (such devices hereinafter referred to as “microsolidic” devices). In certain such devices, in which electrical connections can be formed and / or reformed between regions in a microfluidic structure; in some cases, the devices / circuits formed may be flexible and / or involve flexible electrical components. In certain embodiments, the solid metal wires / conductive pathways formed in microfluidic channel(s) may remain contained within the microfluidic structure. In certain such embodiments, the conductive pathways formed may be located in proximity to other microfluidic channel(s) of the structure that carry flowing fluid, such that the conductive pathway can create energy (e.g. electromagnetic and / or thermal energy) that interacts withy and / or affects the flowing fluid and / or a component contained therein or carried thereby. In other embodiments, a microsolidic structure may be removed from a microfluidic mold to form a stand-alone structure. In certain embodiments, the solid metal structures formed may interact with light energy incident upon a structure or may be used to fabricate a light-weight electrode. Another aspect of the invention relates to the formation of self-assembled structures that may comprise these electrically conductive pathways / connections.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

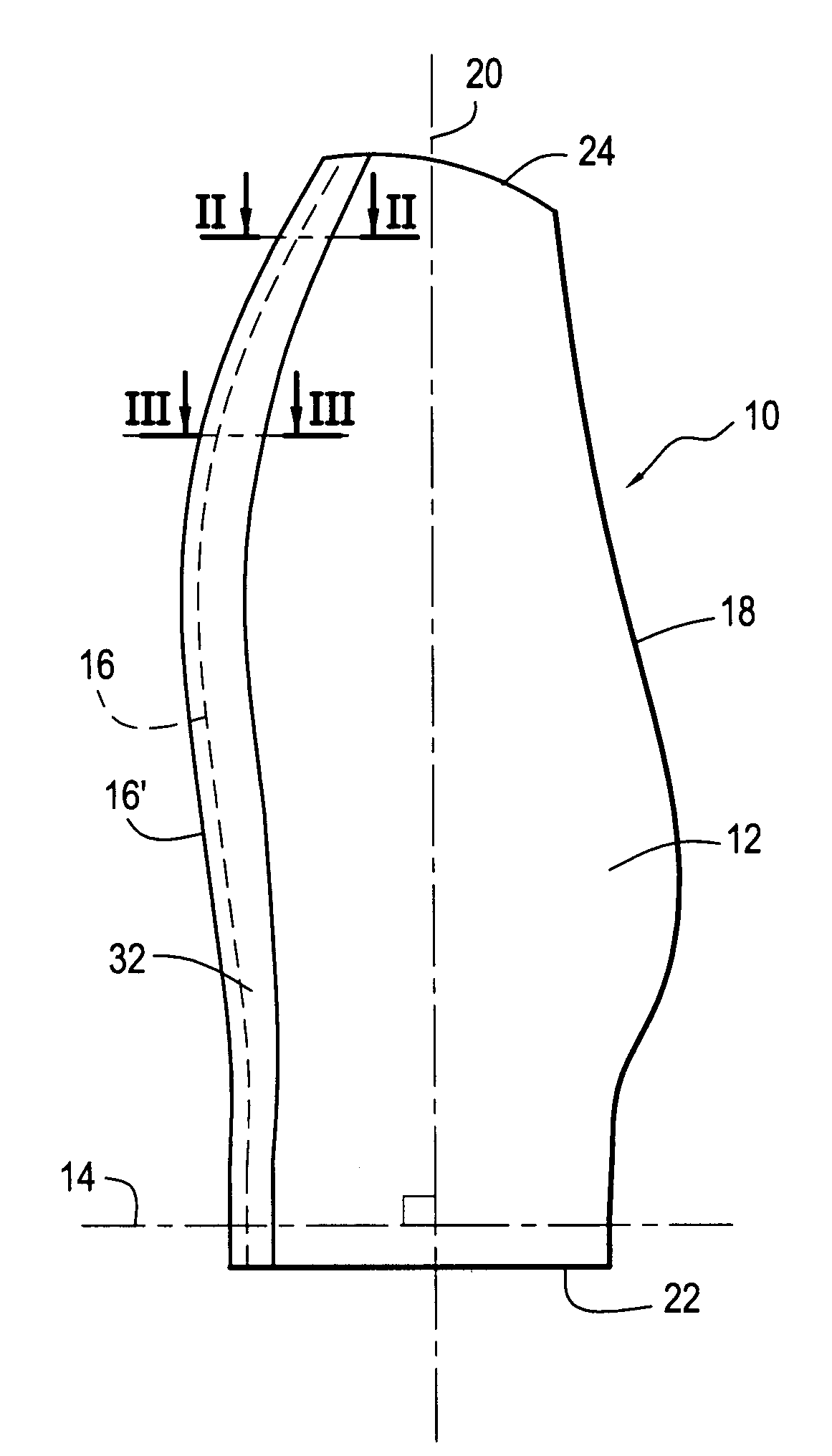

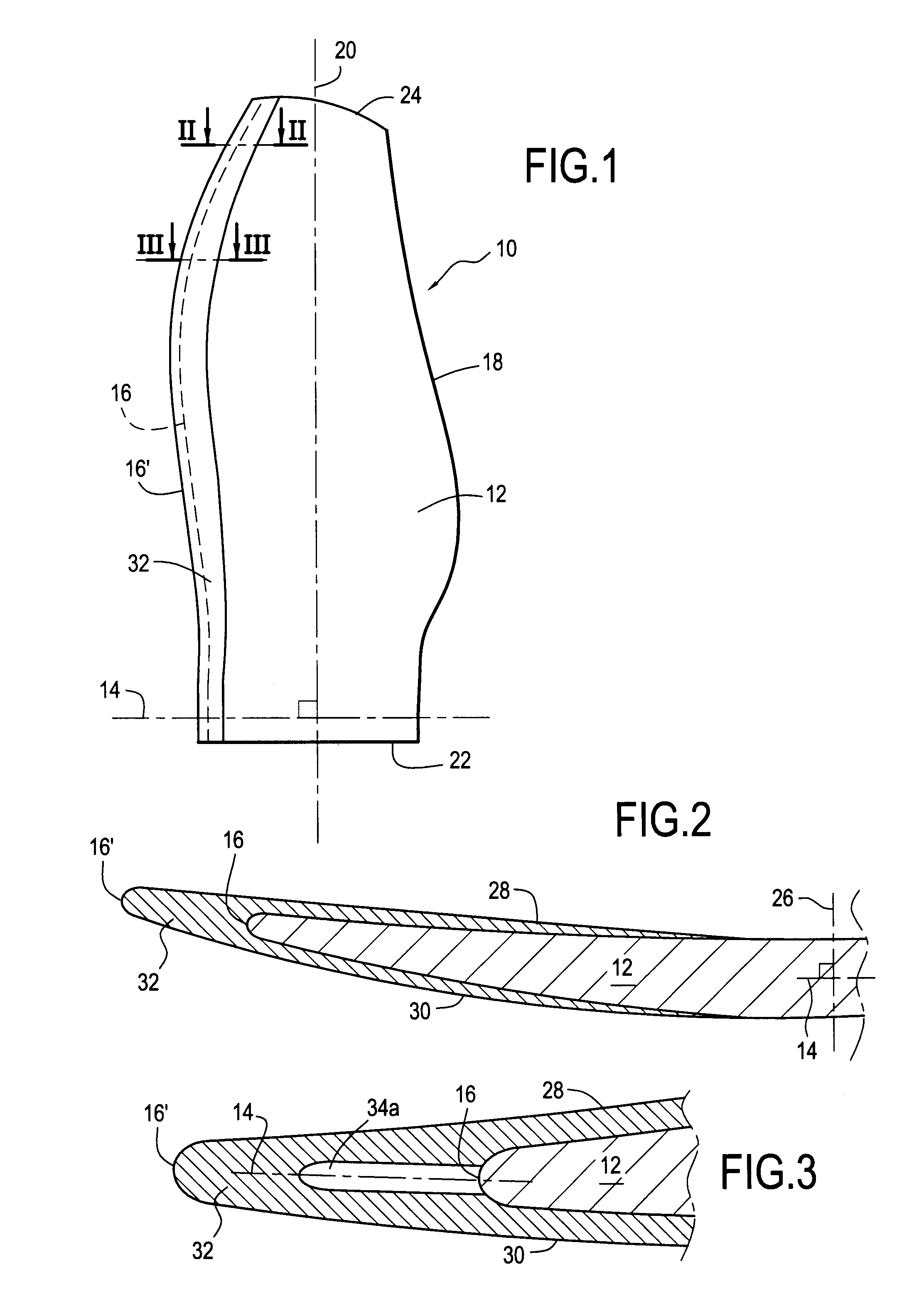

Composite turbomachine blade with metal reinforcement

The invention relates to a turbomachine blade comprising an aerodynamic surface made of a composite material and extending in a first direction between a leading edge and a trailing edge, and in a second direction between a root and a tip of the blade. The blade includes solid metal reinforcement that is adhesively bonded to the leading edge of its aerodynamic surface, which reinforcement extends along the first direction beyond the leading edge of the aerodynamic surface and along the second direction between the root and the tip, and includes at least one recess for absorbing at least a portion of the energy that results from an impact of a foreign body against the leading edge of the blade.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Porous metallic product and method for making same

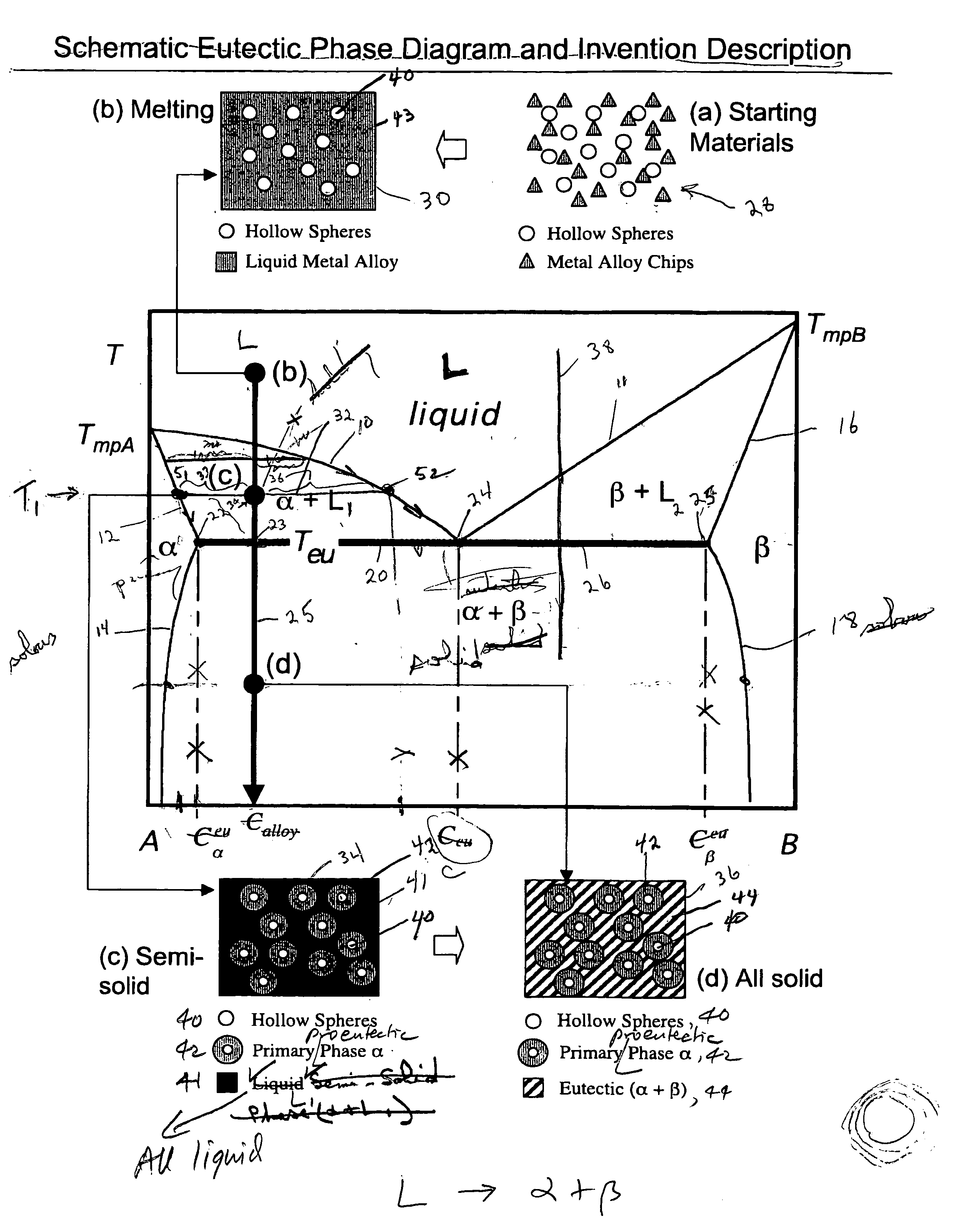

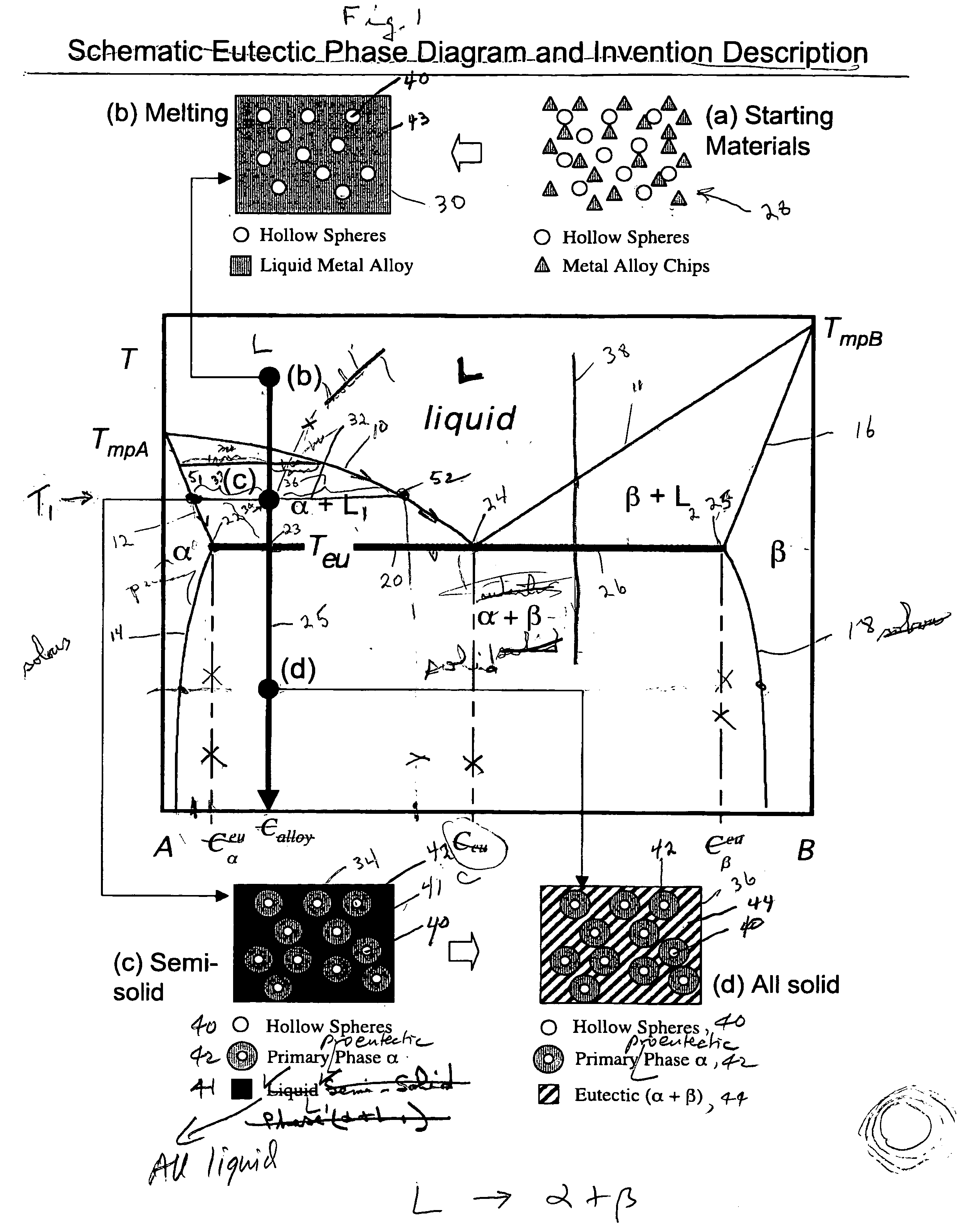

This invention pertains to a product and a method for making the product. The product is a lightweight solid porous metallic product containing small solid spheres having a coating of a primary alpha phase thereon disposed in a solid metal alloy eutectic matrix. The method includes the steps of mixing the hollow rigid spheres and a metal alloy, which metal alloy can be preheated to render it molten, in order to form a dispersion of the spheres distributed in the molten alloy; initially cooling the dispersion to render it semi-solid whereby the spheres are coated by a solid and the coated spheres are disposed in the semi-solid mixture of the solid and liquid; and finally cooling the sphere-containing semi-solid mixture to a temperature at which the sphere-containing semi-solid mixture becomes solid and the product is formed.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Flexible lithium metal cell negative pole and preparation method thereof

The invention discloses a flexible lithium metal cell negative pole and a preparation method thereof, and belongs to the technical field of lithium metal cells. The flexible lithium metal cell negative pole is prepared from two-phase structures of lithium metal and a framework material, wherein the content of the lithium metal is 10-99.9wt.%, and the framework material is a conductive material or an insulating material; the flexible lithium metal cell negative pole can be bent within 0-180 degrees, and the losses of electrochemical performance in the bending process is 0.001-50%. Solid metal lithium is melt into liquid or gasified into gas, and then the liquid or the gas is mixed with the framework material, so that the flexible lithium metal cell negative pole is prepared. Compared with a lithium sheet negative pole, the lithium metal cell negative pole effectively improves the mechanical property of lithium metal negative poles, restrains dendritic growth and alleviates the volume swelling of an electrode in the lithium removing and inlaying process; if a flexible positive pole is matched with the negative pole to obtain flexible cells, realization of the business application to flexible wearable electronic equipment with high energy density can be facilitated.

Owner:TSINGHUA UNIV

Interconnection element for electric circuits

ActiveUS20090188706A1Increased mechanical mounting strengthImprove radiation efficiencyDecorative surface effectsSemiconductor/solid-state device detailsElectrical conductorInterconnection

An interconnection element and method for making same is disclosed. The interconnection element may include a plurality of metal conductors, a plurality of solid metal bumps and a low melting point (LMP) metal layer. The solid metal bumps overly and project in a first direction away from respective ones of the conductors. Each bump has at least one edge bounding the bump in at least a second direction transverse to the first direction. The low melting point (LMP) metal layer has a first face joined to the respective ones of the conductors and bounded in the second direction by at least one edge and a second face joined to the bumps. The edges of the bumps and the LMP layer are aligned in the first direction, and the LMP metal layer has a melting temperature substantially lower than the conductors.

Owner:INVENSAS CORP

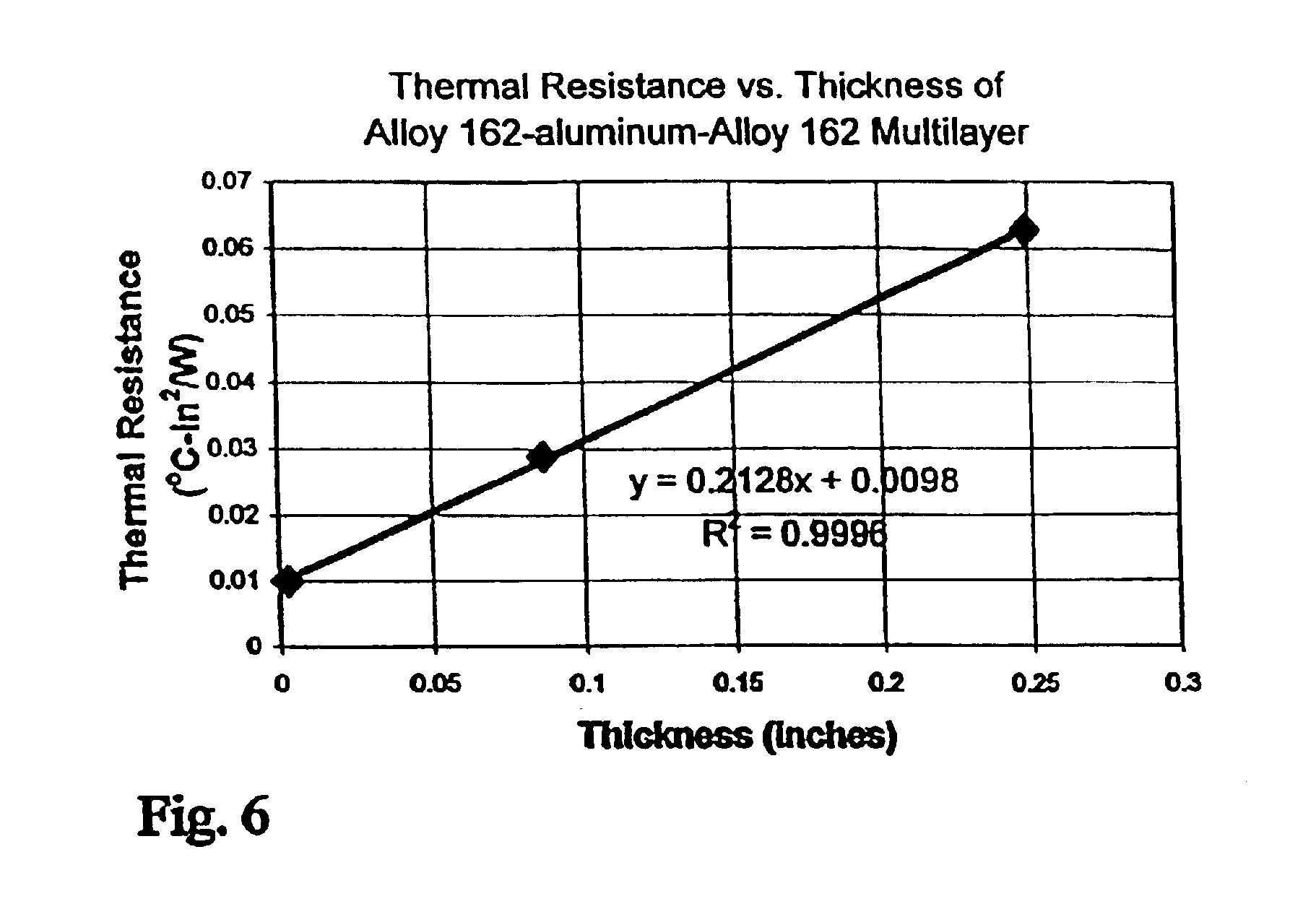

Thermal interface structure for placement between a microelectronic component package and heat sink

InactiveUS6940721B2Improve thermal conductivityReduce thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesMetal alloyCopper

A multi-layer thermal interface structure for placement between a microelectronic component package and a heat sink so that the structure has a total thermal resistance of no greater than about 0.03° C.-in2 / W. The structure comprises a plurality of superimposed metallic layers including a core layer of a solid metal or metal alloy of high thermal conductivity preferably composed of aluminum or copper, a second layer having phase change properties and a third layer of nickel separating the solid metal layer from the layer having phase change properties.

Owner:LAIRD TECH INC

Light emitting diode arrays for direct backlighting of liquid crystal displays

ActiveUS20060139945A1Uniform backlightLighting heating/cooling arrangementsNon-linear opticsLiquid-crystal displayDisplay device

A display panel for a flat panel display includes a planar array of LCD devices and a planar array of LED devices that is closely spaced apart from the planar array of LCD devices, at least some of the LED devices being disposed within a periphery of the array of LCD devices such that, in operation, the planar array of LED devices provides backlighting for the planar array of LCD devices. The planar array of LED devices can include at least one solid metal block having first and second opposing metal faces. The first metal face includes therein an array of reflector cavities, and the second metal face includes therein heat sink fins that are exposed at the back face of the flat panel display.

Owner:BRIGHTPLUS VENTURES LLC

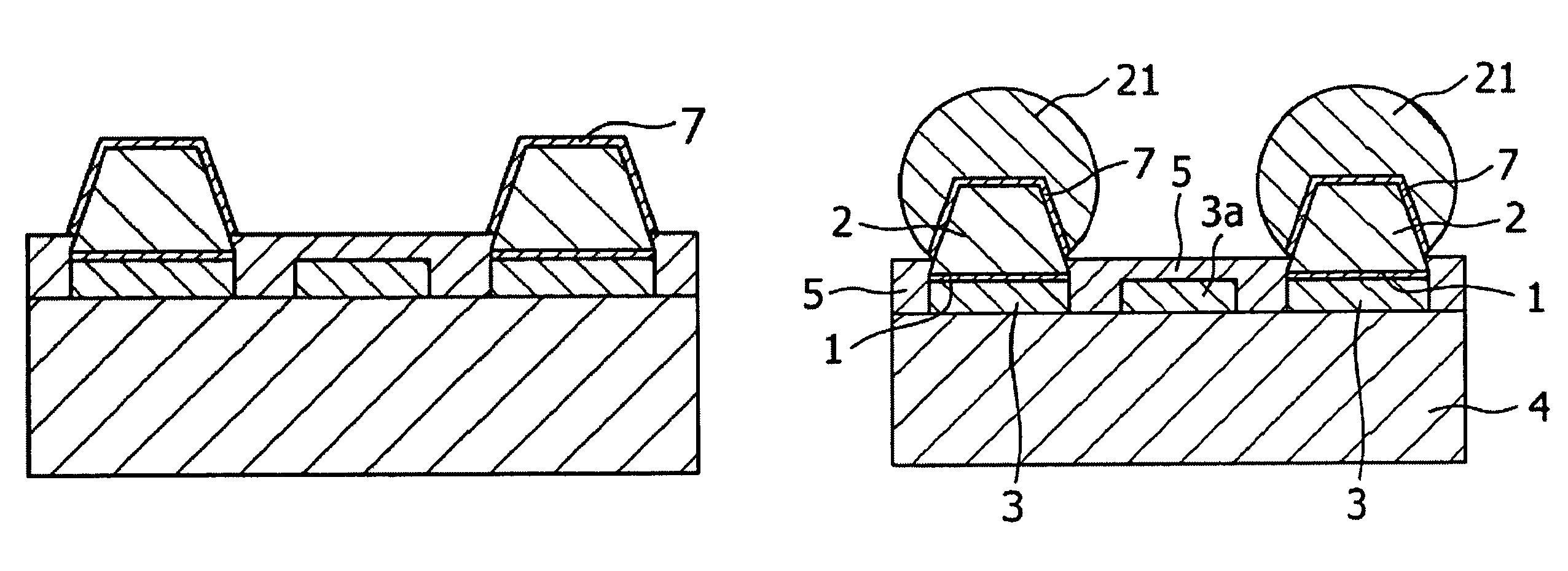

Electrode and method of making same

InactiveUS6426483B1Improve the immunityEasy to controlElectrode supporting devicesWelding/cutting media/materialsMaterials scienceSolid metal

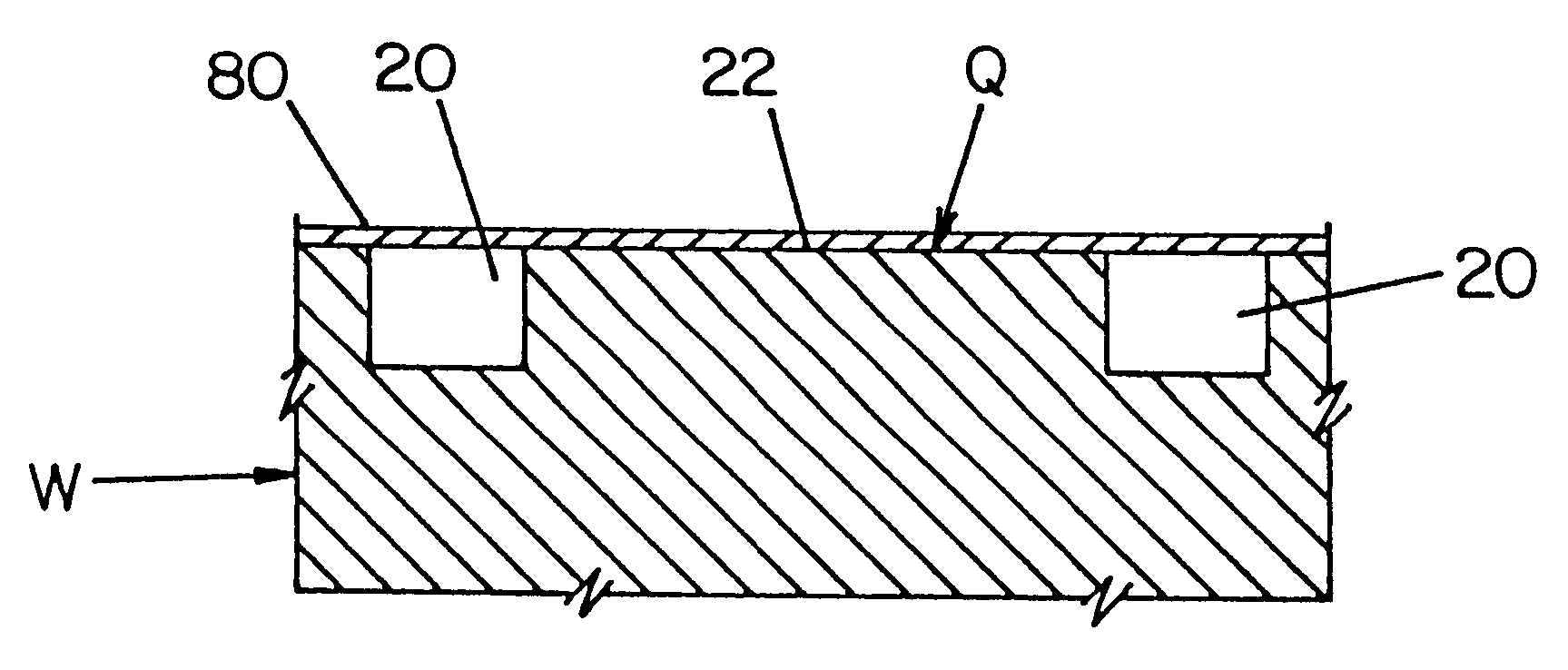

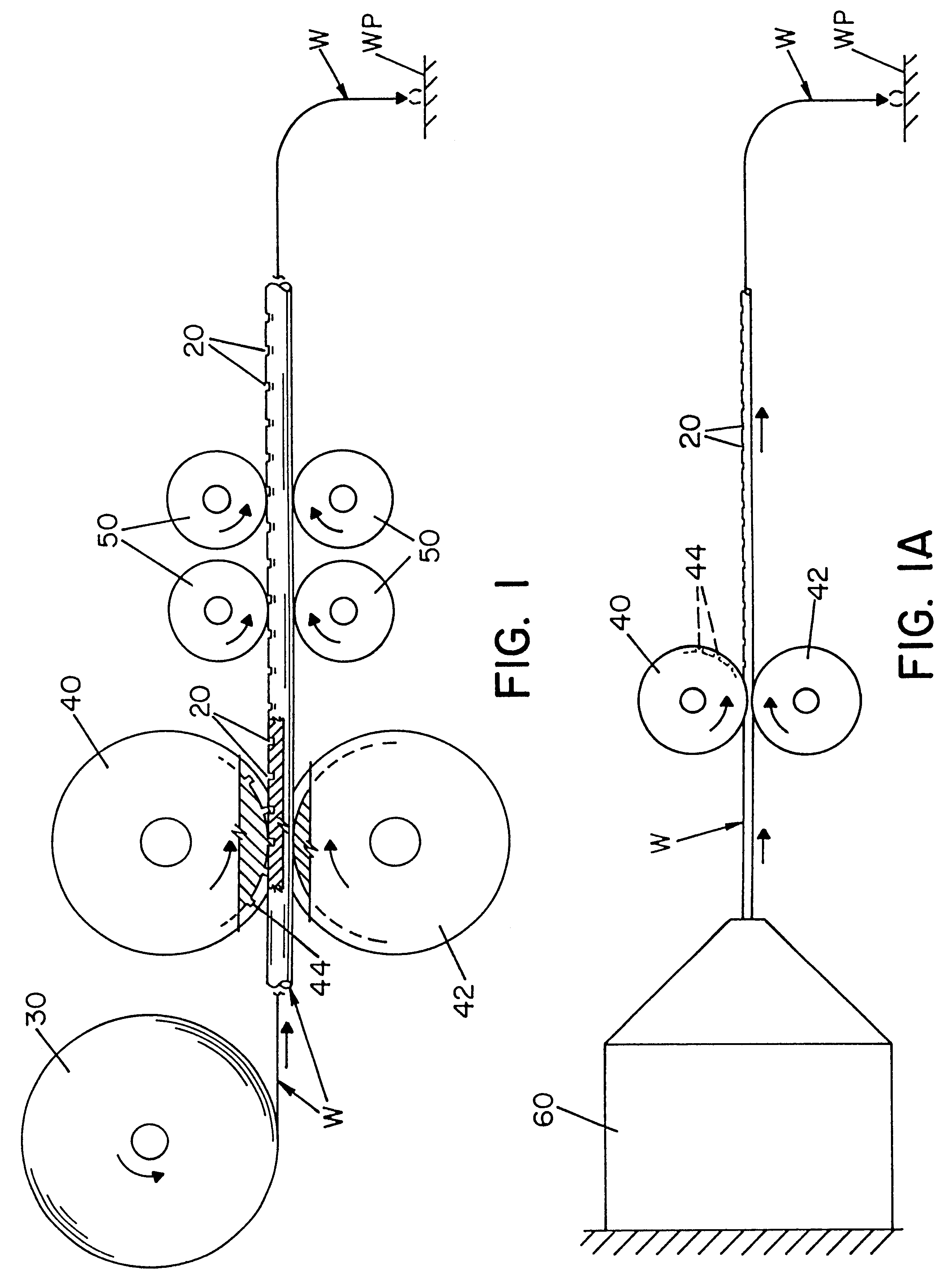

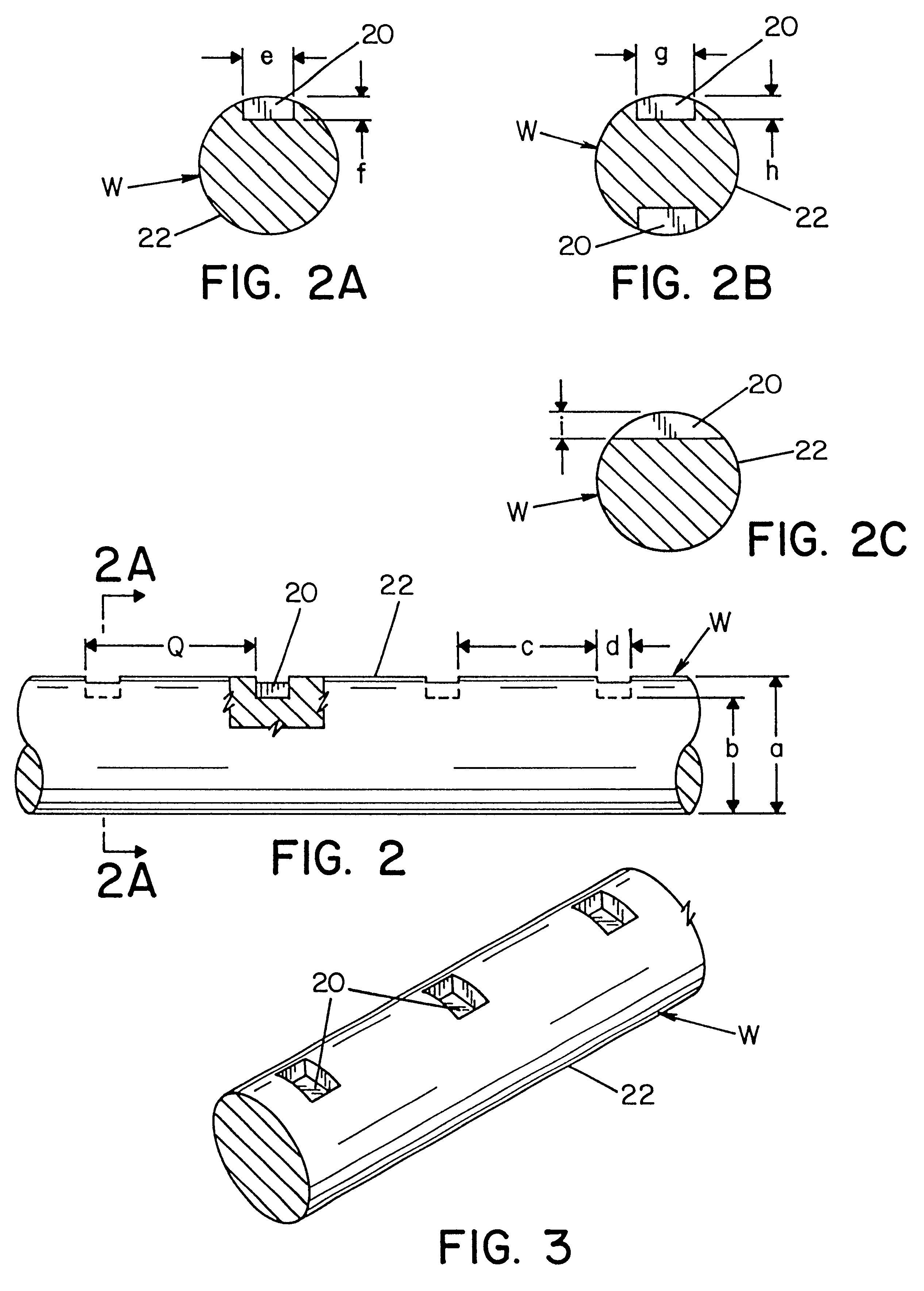

A welding wire for use in electric arc welding and method of making same, wherein the wire has an effective outer diameter and comprises a length of solid metal formed into a series of distinct segments each having a selected volume and having an indented and non-indented region with the cross sectional area of the solid metal at said non-indented region being greater than the cross sectional area of the solid metal at the indented region.

Owner:LINCOLN GLOBAL INC

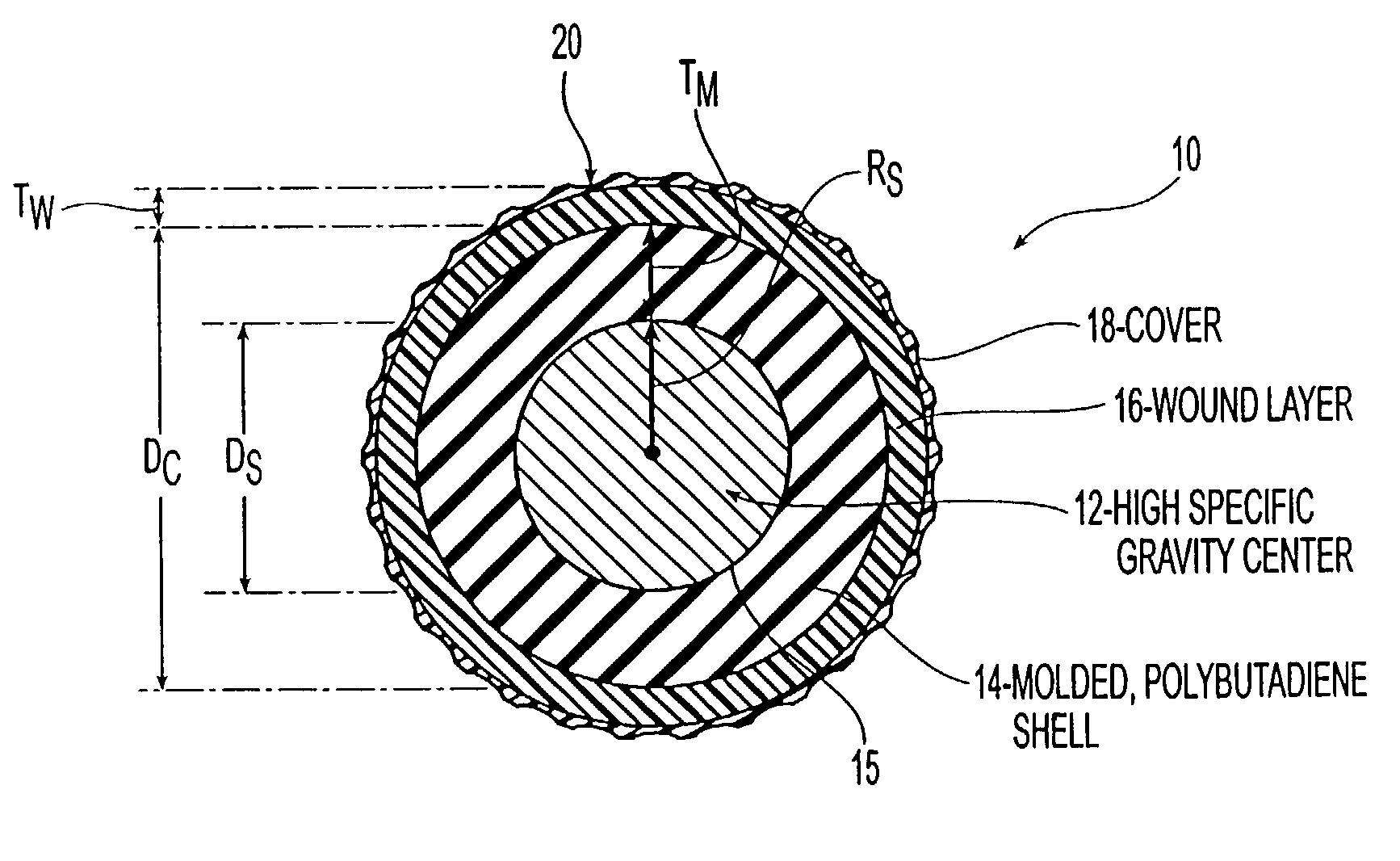

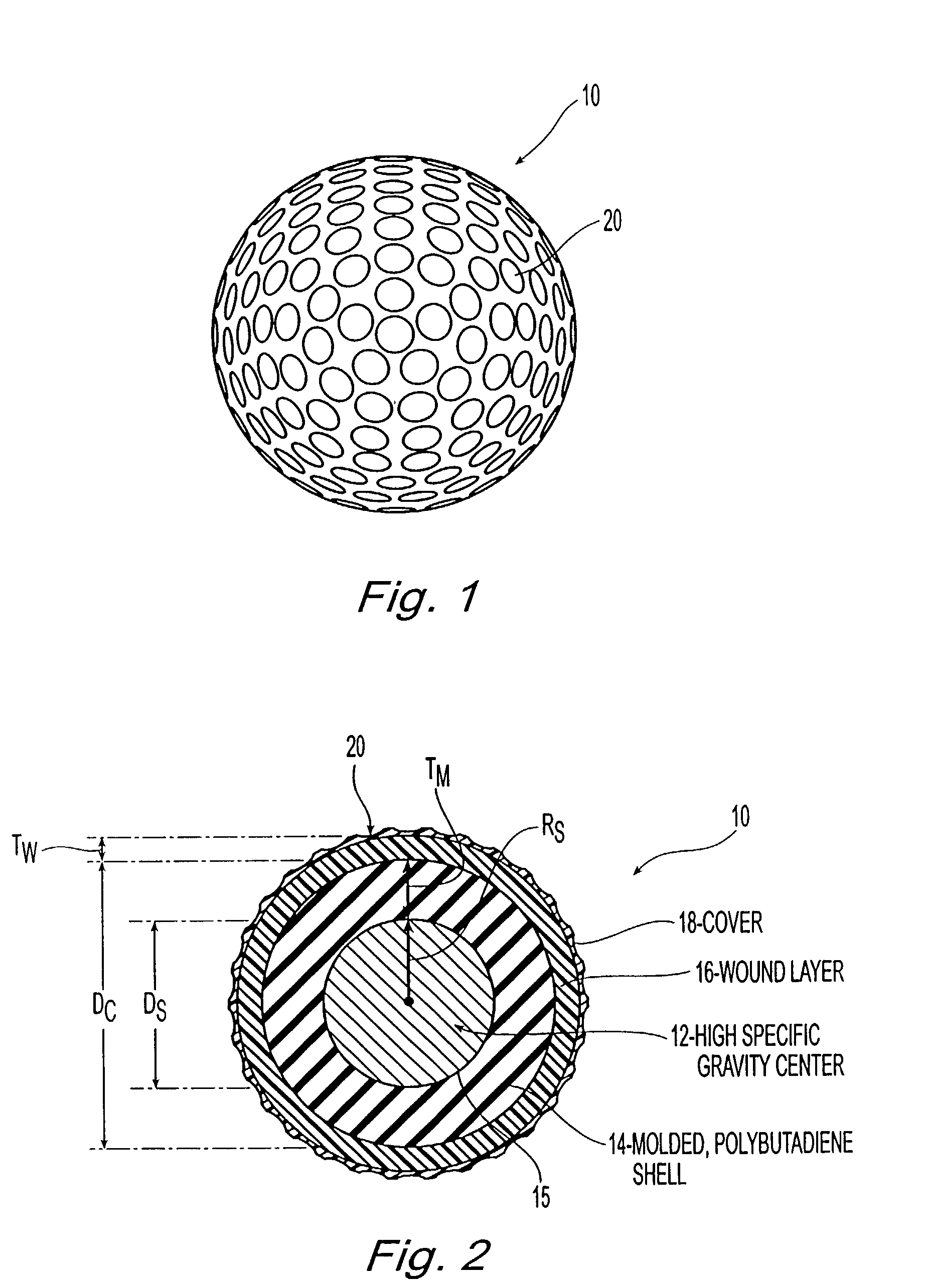

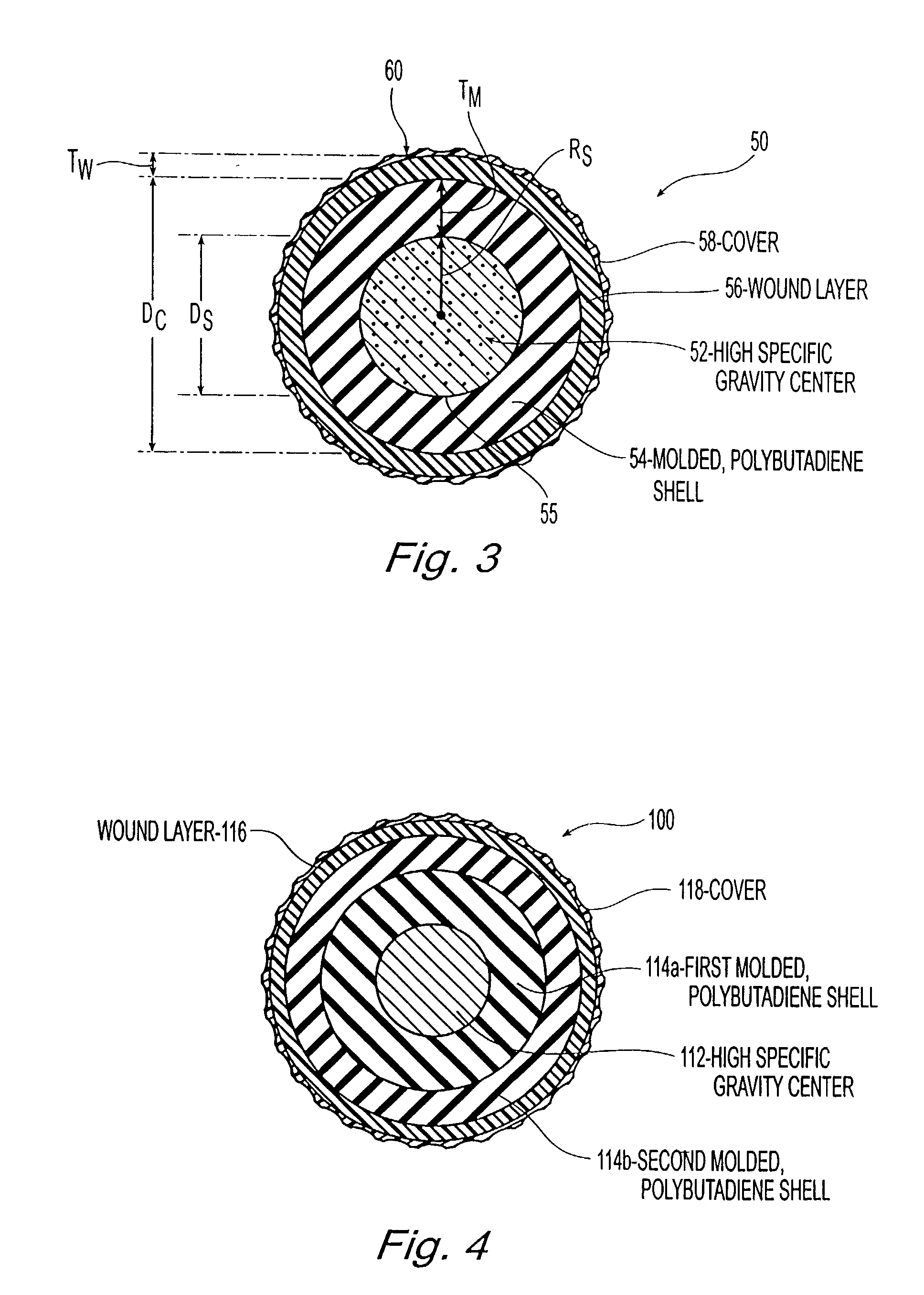

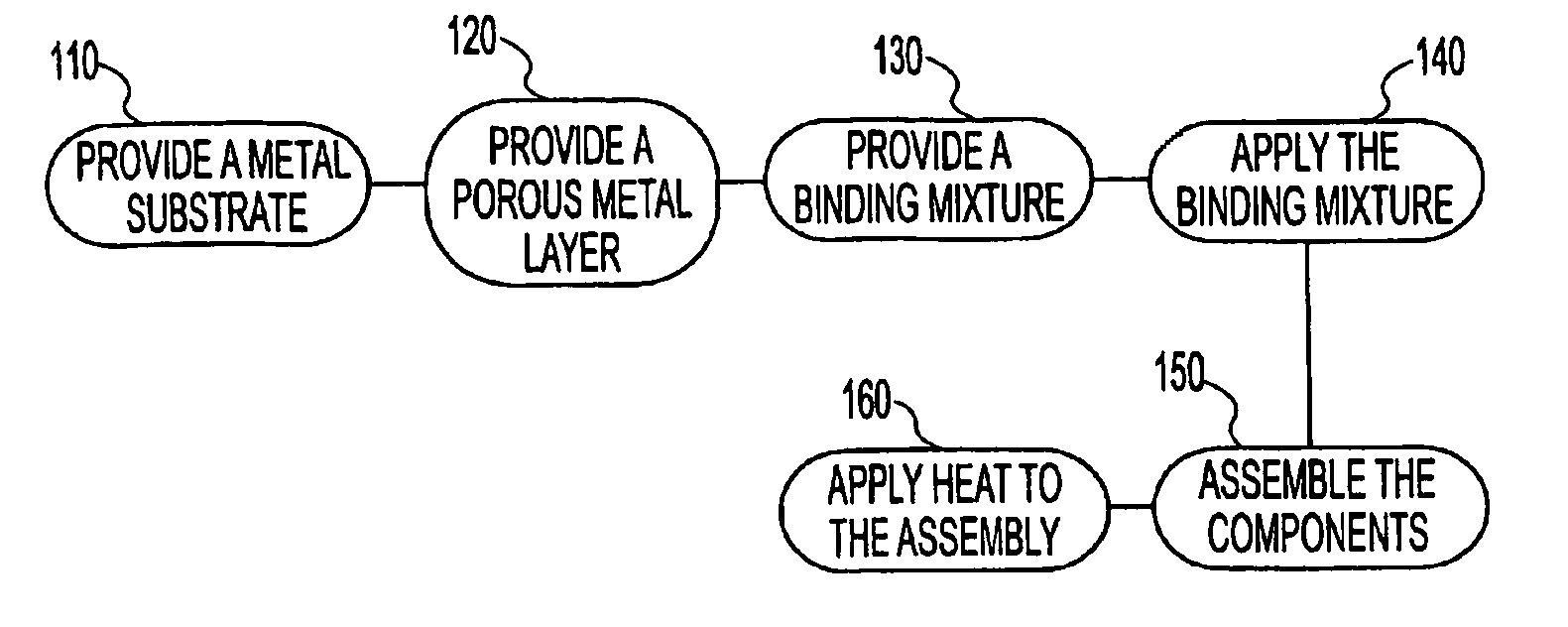

Wound golf balls with high specific gravity centers

The present invention is directed towards an improved golf ball that includes a high-specific gravity central sphere encapsulated in a soft and resilient shell layer. The soft-resilient shell may be formed of polybutadiene rubber. This shell is subsequently wound with thread a wound core, which is then covered. The sphere can be formed of a solid metal or molded of high-specific gravity powder retained in a binding material.

Owner:ACUSHNET CO

Method for attaching a porous metal layer to a metal substrate

ActiveUS7918382B2Increase resistanceHigh strengthBone implantJoint implantsThermal expansionSurgical implant

A method for attaching a porous metal layer to a dense metal substrate, wherein the method is particularly useful in forming orthopedic implants such as femoral knee components, femoral hip components, and / or acetabular cups. The method, in one embodiment thereof, comprises providing a solid metal substrate; providing a porous metal structure; contouring a surface of the porous metal structure; placing the porous structure against the substrate such that the contoured surface of the porous metal structure is disposed against the substrate, thereby forming an assembly; applying heat and pressure to the assembly in conjunction with thermal expansion of the substrate in order to metallurgically bond the porous structure and the substrate; and removing mass from the substrate after the porous structure is bonded to the substrate, thereby finish processing the assembly.

Owner:ZIMMER INC

Method for electrochemical depositing solar cell metallic electrode

ActiveCN101257059AAvoid unevennessAvoid damagePhotovoltaic energy generationSemiconductor devicesElectrochemical responseMetallic electrode

Owner:WUXI SUNTECH POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com