Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89 results about "Superheating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In physics, superheating (sometimes referred to as boiling retardation, or boiling delay) is the phenomenon in which a liquid is heated to a temperature higher than its boiling point, without boiling. This is a so-called metastable state or metastate, where boiling might occur at any time, induced by external or internal effects. Superheating is achieved by heating a homogeneous substance in a clean container, free of nucleation sites, while taking care not to disturb the liquid.

Controller and a method for controlling an expansion valve of a refrigeration system

ActiveUS6854285B2Rapid responseImprove efficiencyTemperature control without auxillary powerFluid circulation arrangementControl signalRefrigeration

A controller for an expansion valve of a refrigeration system for cooling a medium is configured to include, in the generation of a control signal, a measure of the evaporation temperature (T0) of the refrigerant in an evaporator and a measure of a property of the cooled medium, preferably without influence from a measure of the superheat temperature (SH) of the refrigerant. The controller comprises a PI-element for integrating and for producing a control signal for the expansion valve for controlling the flow of refrigerant into the evaporator, the PI-element being arranged in an inner control loop, a reference for which is produced by an outer control loop. The controller allows for fast response to disturbances and / or fast response of the medium temperature when the operating conditions of the refrigeration system are changed and / or fast response during start-up of the refrigeration system and maintains stable operation conditions with low, but positive superheating and a stable evaporation pressure.

Owner:DANFOSS AS

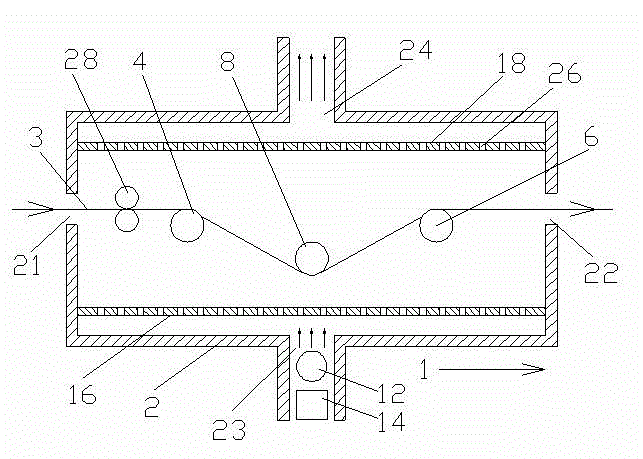

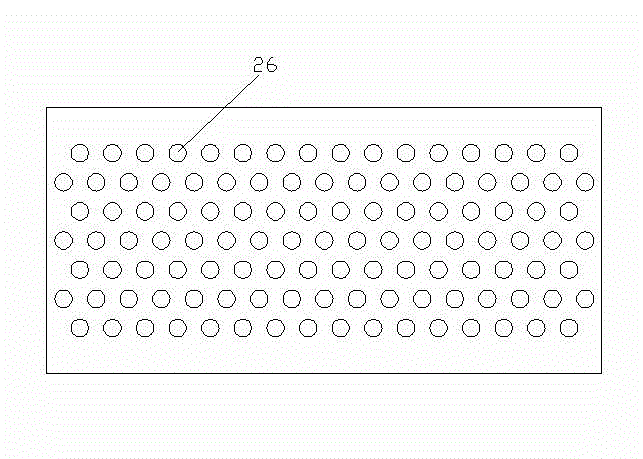

Efficient distribution dryer

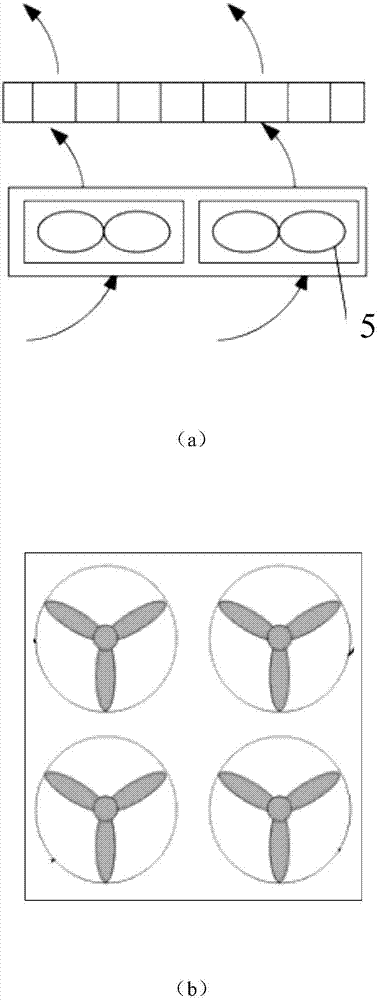

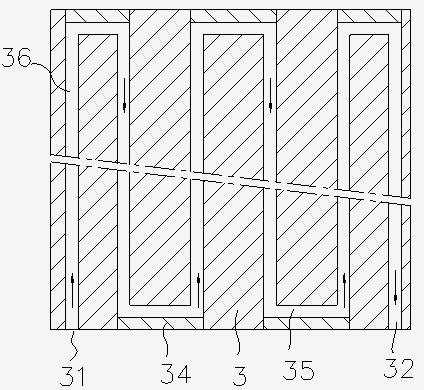

InactiveCN102914127AReduce the burden onPrevent local overheatingDrying chambers/containersDrying machines with progressive movementsSuperheatingCompressive deformation

The invention relates to an efficient distribution dryer which comprises a box housing. Two ends of the housing are provided with a cloth inlet and a cloth outlet. The housing is provided with an air inlet at the top and an air outlet at the bottom, or provided with an air inlet at the bottom and an air outlet at the top. A distribution conveying mechanism is disposed in an inner cavity of the housing. A heating pipe and a bower outside the heating pipe are disposed at the air inlet. The efficient distribution dryer is characterized in that transversely extending partitions are disposed in the inner cavity of the housing, and a plurality of intake through holes are arranged on the partitions in directions, along the distribution conveying direction and transversely perpendicular to the distribution conveying direction. The partitions with intake through holes are disposed in the efficient distribution dryer and disperse hot air from the single air inlet, so that local superheating and compressive deformation are prevented, drying quality is guaranteed and overall drying efficiency is also improved.

Owner:WUJIANG KESHIDA TEXTILE

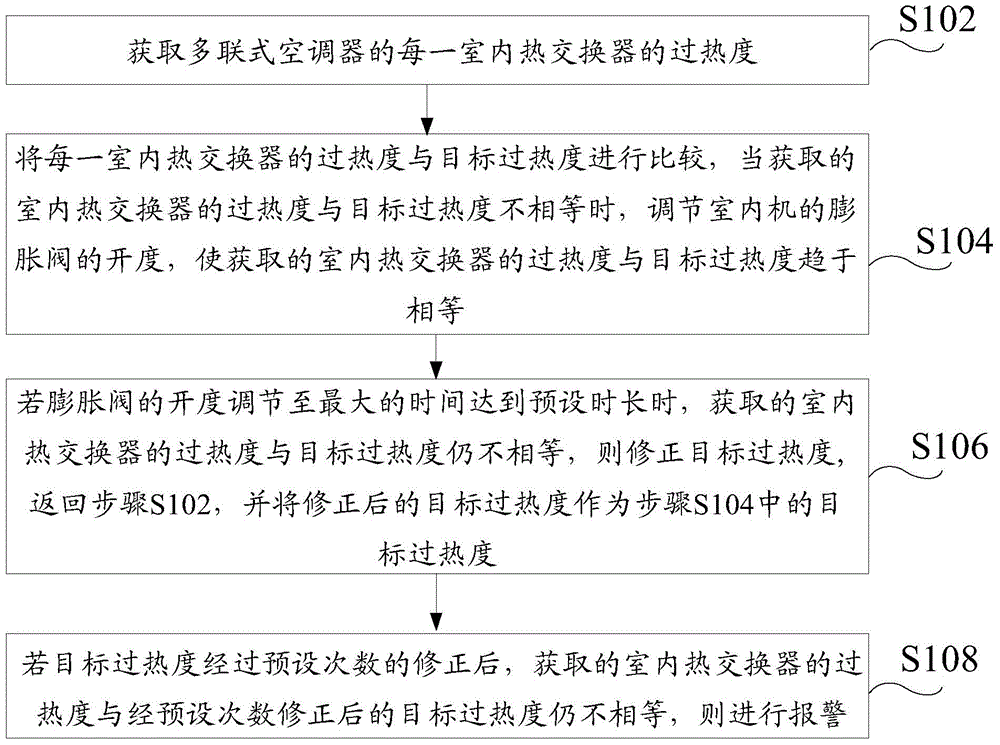

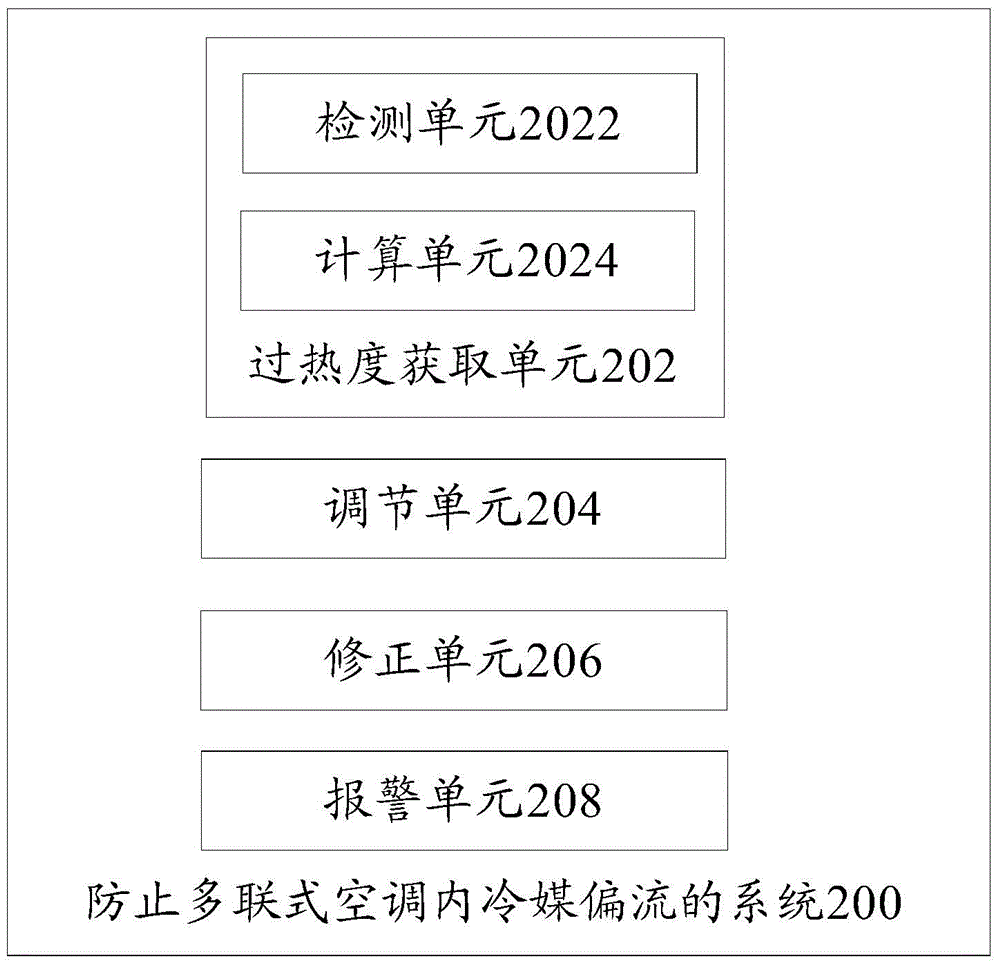

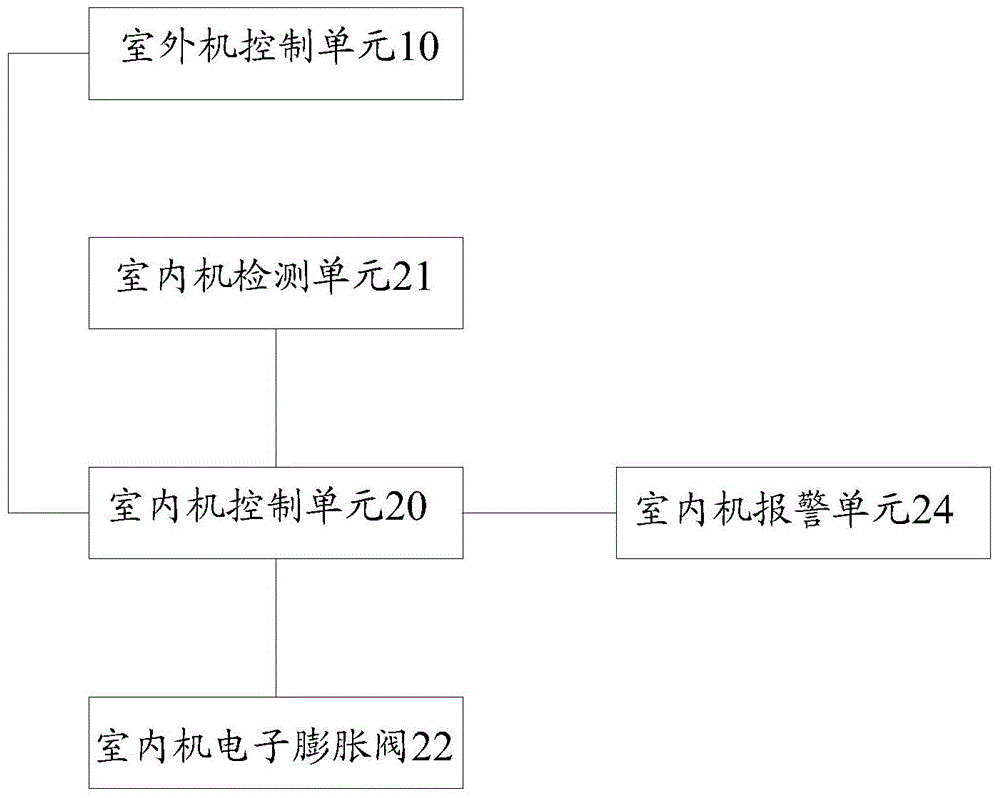

Method and system for preventing bias flowing of refrigerant in multi-split air conditioner and multi-split air conditioner

ActiveCN103982987AAvoid driftingReduce trafficSpace heating and ventilation safety systemsLighting and heating apparatusSuperheatingElectronic expansion valve

The invention provides a method and a system for preventing bias flowing of a refrigerant in a multi-split air conditioner and the multi-split air conditioner. The method for preventing the bias flowing of the refrigerant in the multi-split air conditioner comprises the steps of obtaining the superheating degree of each indoor heat exchanger; comparing the obtained superheating degree with the target superheating degree, adjusting the open degree of an expansion valve when the obtained superheating degree is not equal to the target superheating degree, and enabling the superheating degree of each indoor heat exchanger to tend to be equal to the target superheating degree; correcting the target superheating degree if the superheating degree of each indoor heat exchanger is still not equal to the target superheating degree when the maximum time for adjusting the open degree of the expansion valve is up to a preset time, and then adjusting the open degree of the expansion valve according to a comparison result of the superheating degree of each indoor heat exchanger and the corrected target superheating degree. According to the method for preventing the bias flowing of the refrigerant in the multi-split air conditioner, provided by the invention, the engineering installation situation and the actual load of indoor units are comprehensively considered, the open degree of an electronic expansion valve can be intelligently controlled, the bias flowing of the refrigerant is reduced, and the refrigerating effect of the indoor units is balanced.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

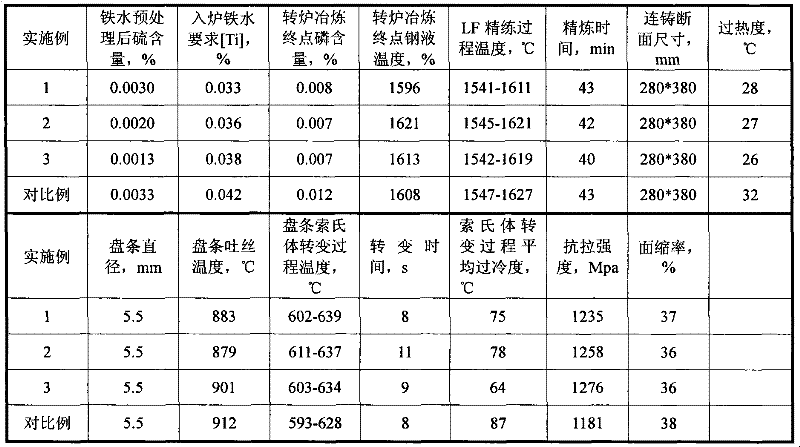

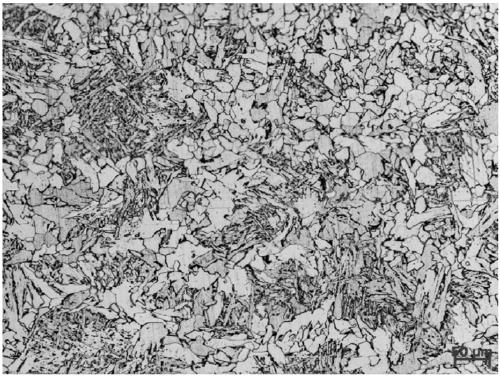

High-strength high-carbon steel wire rod and production method thereof

The invention provides a high-strength high-carbon steel wire rod and a production method thereof. The high-strength high-carbon steel wire rod comprises the following components by weight percentage: 0.85%-0.90% of C, 0.1%-1.0% of Si, 0.3%-1.0% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, less than or equal to 0.0010% of Ti and the rest Fe. The production method comprises the following steps of: 1), smelting: preprocessing molten iron, controlling sulfur to be less than 0.005%, and feeding less than or equal to 0.040% of Ti into a convertor, wherein the smelting final-point phosphorus content of the convertor is less than or equal to 0.010%, the final-point molten steel temperature of the convertor is at 1,570-1,680 DEG C, the refining process temperature is at 1,530-1,625 DEG C, and the refining time is for 20-50minutes; 2), continuous casting: adopting a large square ingot for the continuous casting, wherein the tundish molten steel superheating temperature is not more than 30 DEG C; and 3), continuous rolling and wire rod rolling, wherein the diameter of the wire rod is 5.5-8.0mm, the laying temperature is 870-910 DEG C, the sorbite transformation process temperature of the wire rod is controlled at 640-600 DEG C, the transformation time is controlled at 7-12seconds, and the sorbite transformation process average supercooling temperature of the wire rod is controlled at 60-80 DEG C. Due to the adoption of the high-strength high-carbon steel wire rod disclosed by the invention, the tensile strength can reach 1,200 MPa-1,300MPa, and the area reduction index is not less than 30%.

Owner:ANGANG STEEL CO LTD

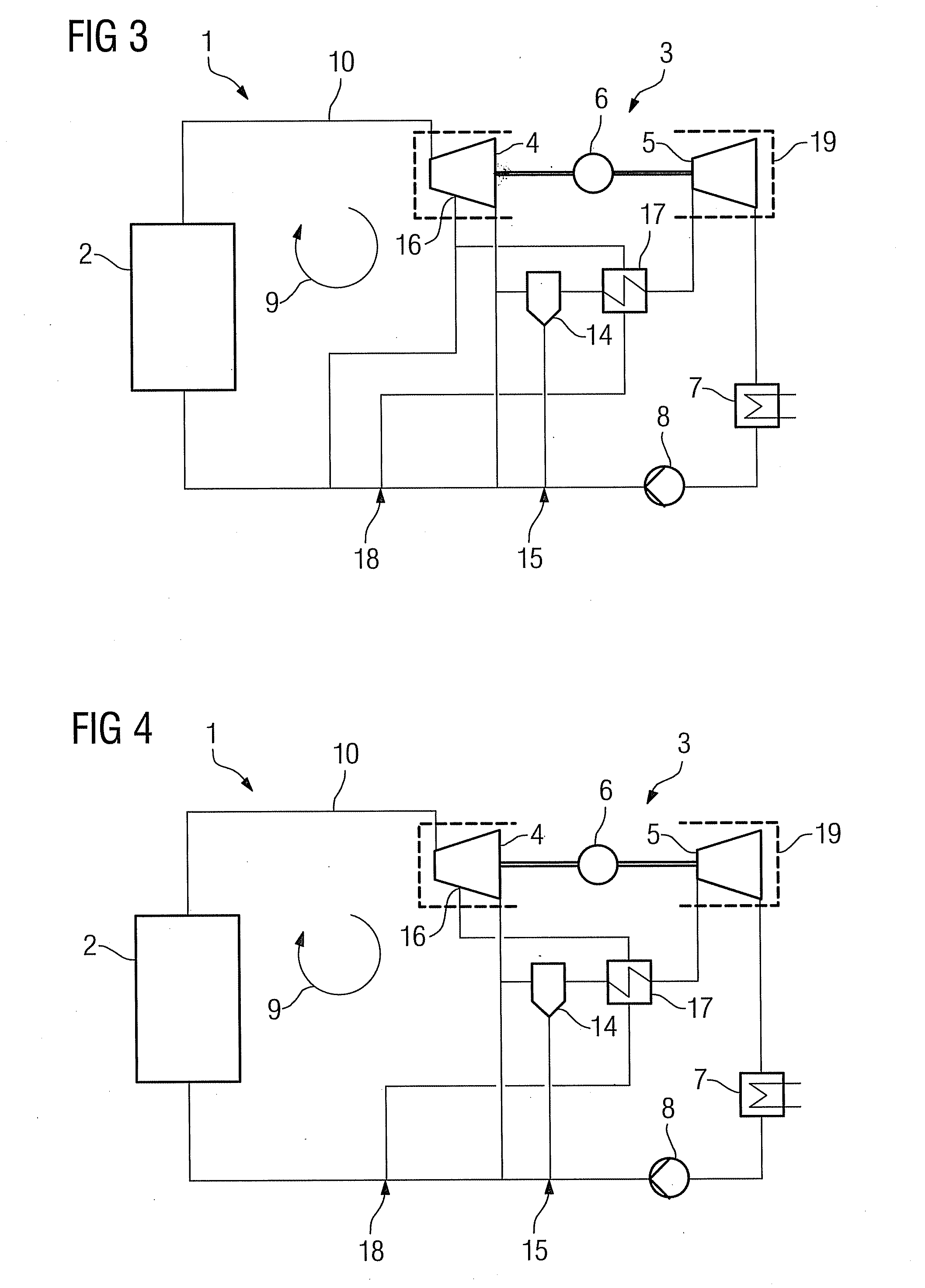

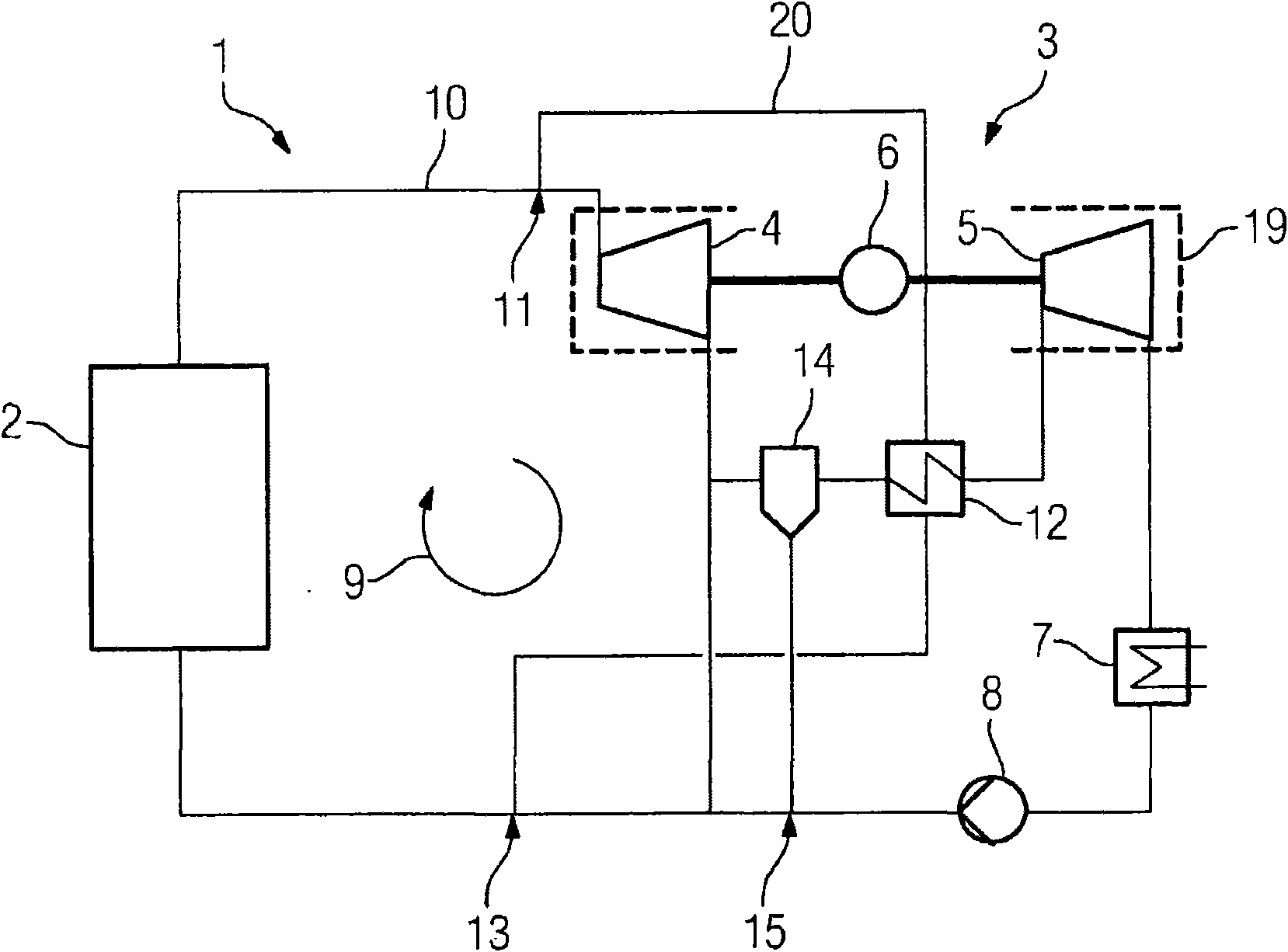

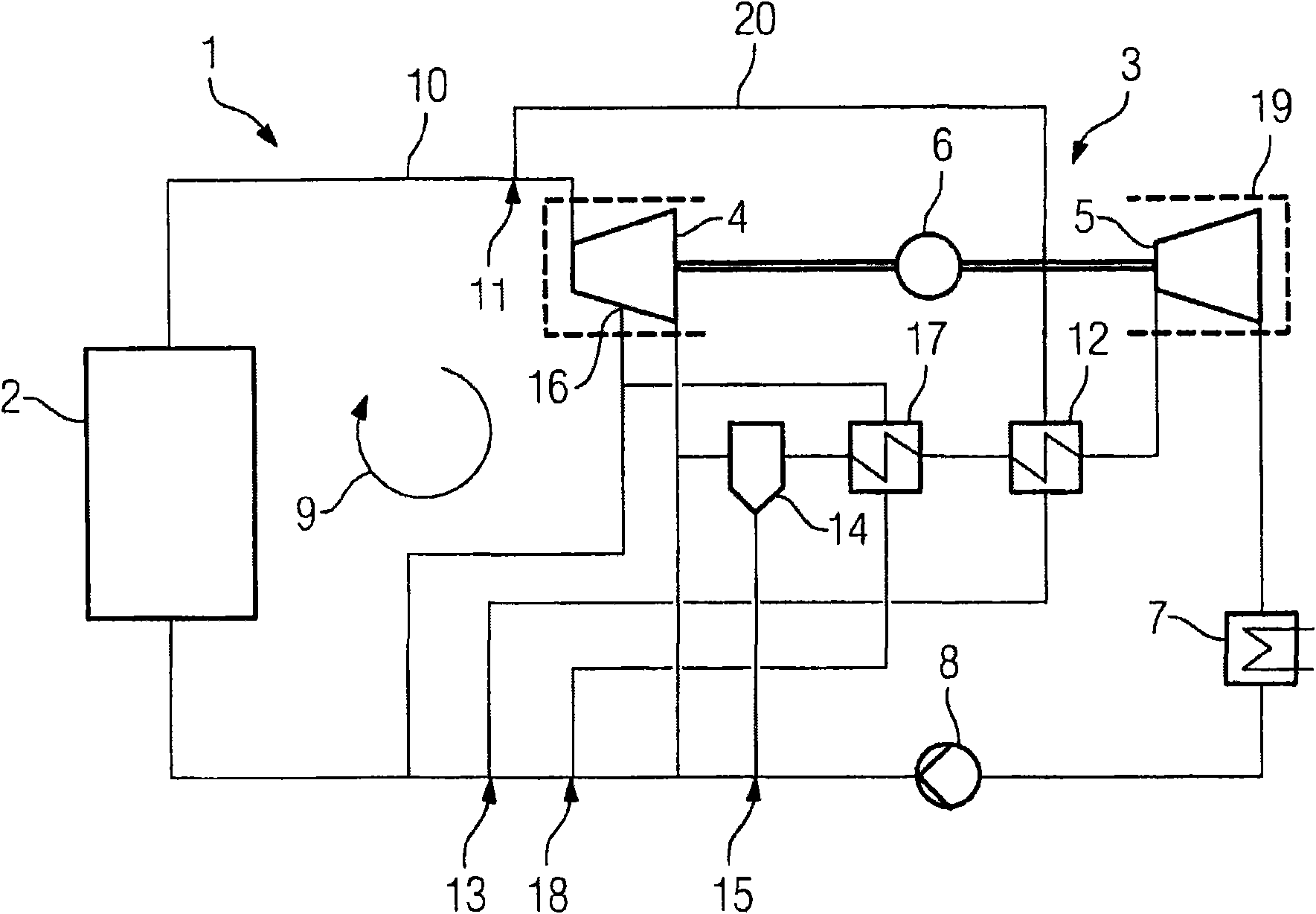

Method and device for intermediate superheating in solar direct evaporation in a solar-thermal power plant

InactiveUS20100162700A1High concentration factorHigh processing temperatureAuxillary drivesFrom solar energyWorking fluidEvaporation

A solar-thermal power plant is provided. The solar-thermal power plant includes a working fluid circuit, a solar steam generator based on direct evaporation and a steam turbine for relieving the working fluid on a relief path while the working fluid supplies technical work. The solar-thermal power plant also includes at least one intermediate superheater, which can be heated using the working fluid. The working fluid may be removed from the circuit upstream of the intermediate superheater and superheated using the working fluid thereof, which can be fed downstream of the heating removal using the relief path. A method for operating a solar-thermal power plant is also provided.

Owner:SIEMENS AG

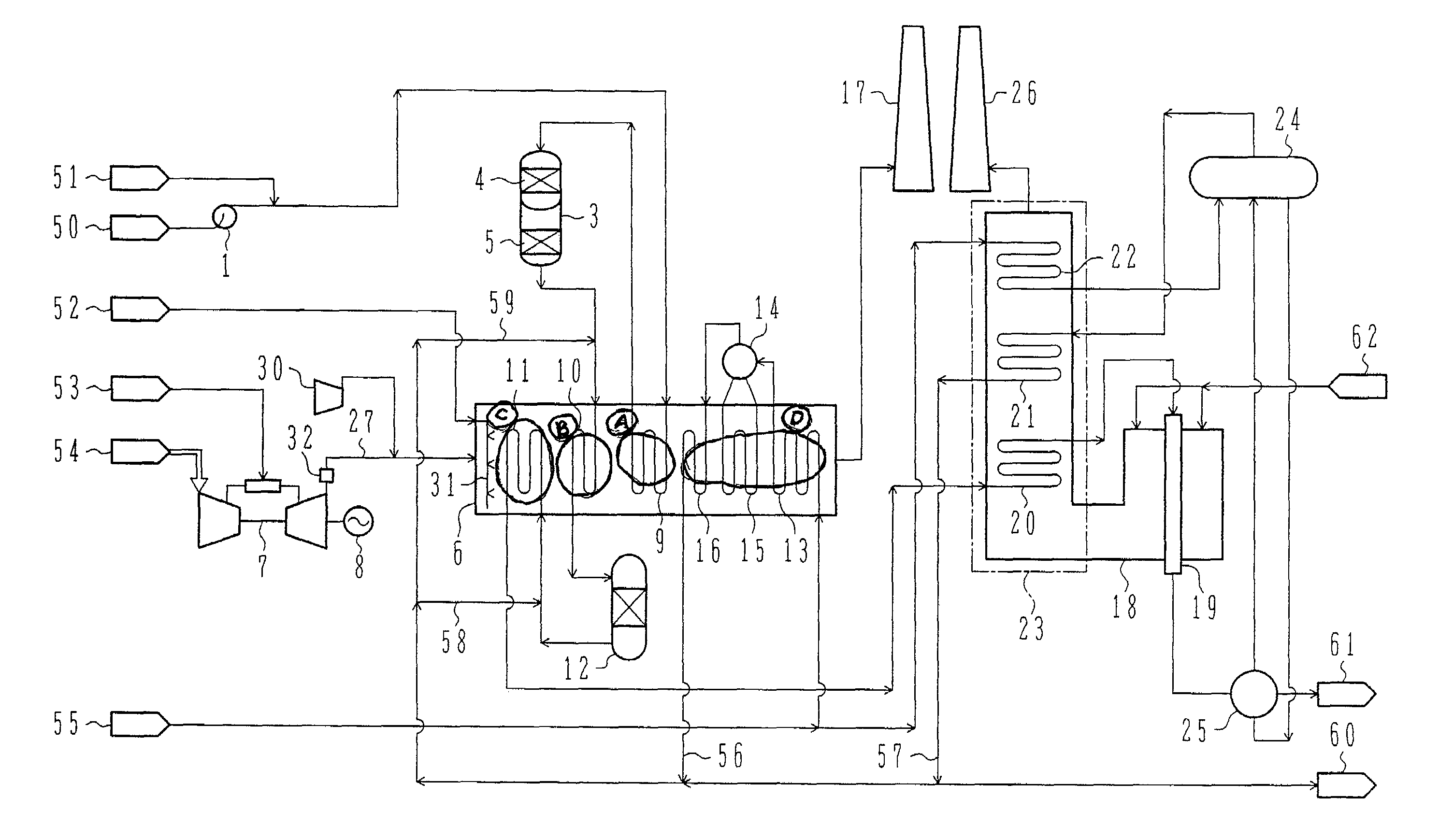

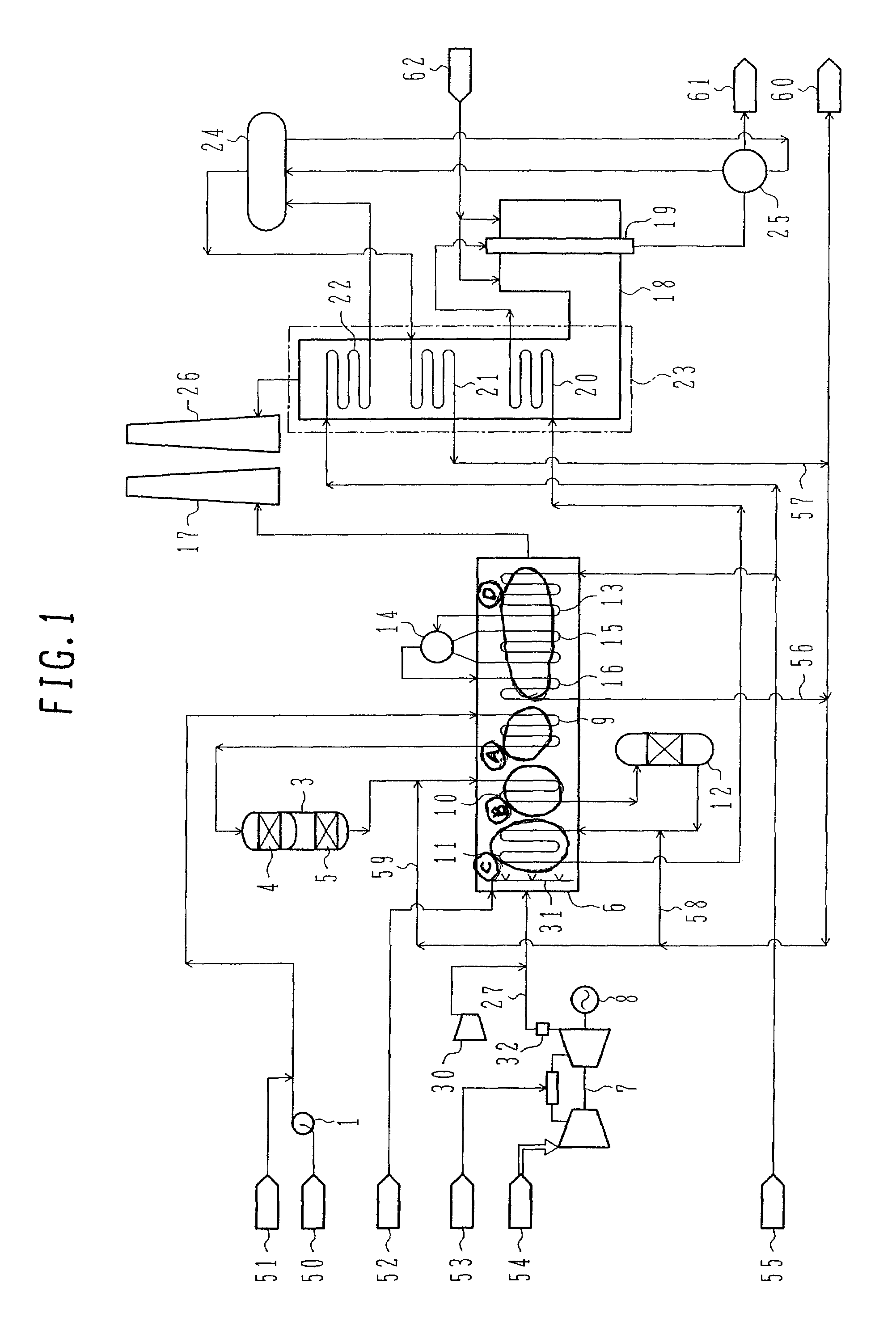

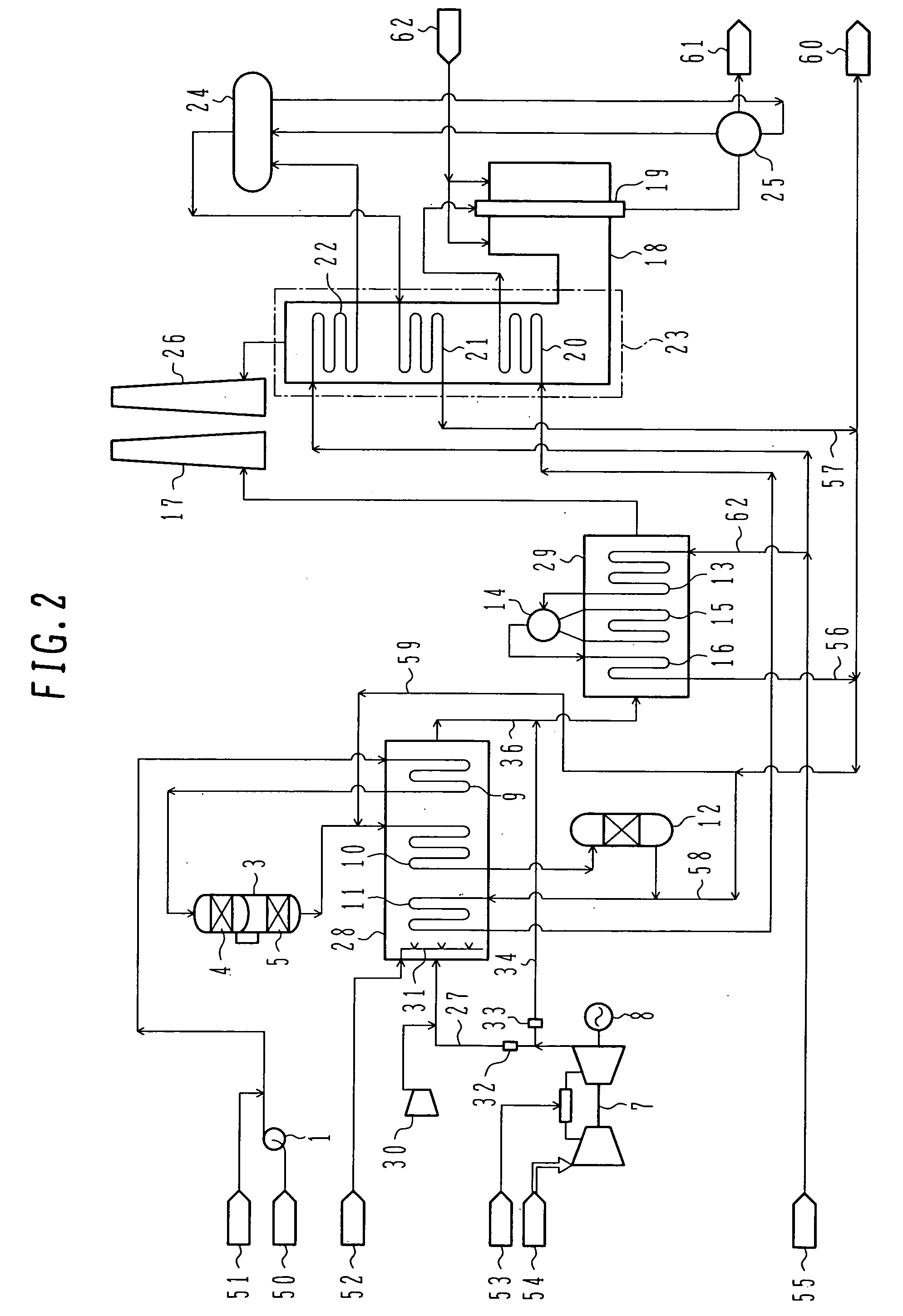

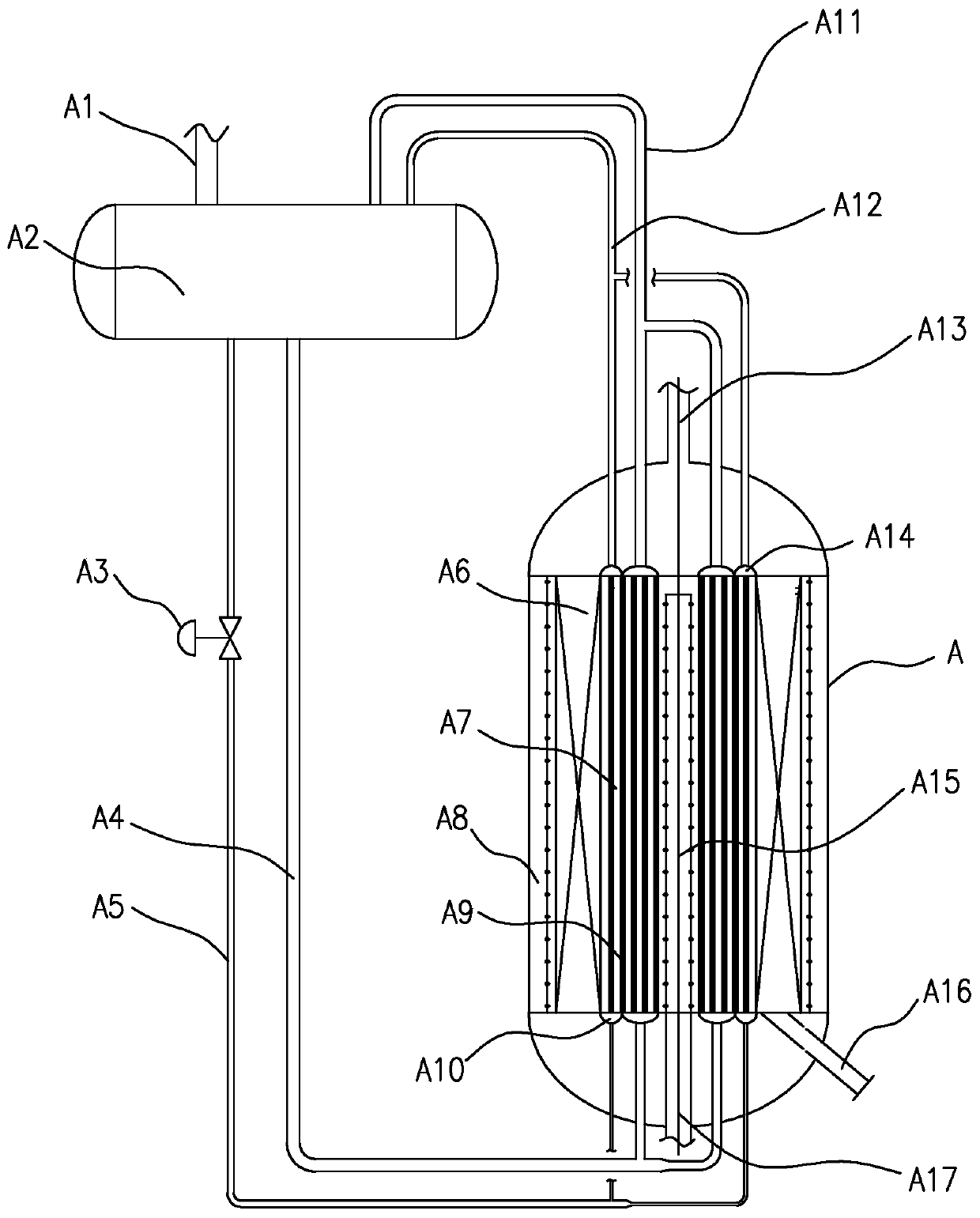

Steam reforming system

InactiveUS7707837B2Save consumptionLow calorific valueHydrogenOrganic compound preparationSteam reformingFlue gas

A steam reforming system with high thermal efficiency, which can compensate for a reduction in the amount of steam generated in a reformer without increasing the reformer size and without limiting the degree of freedom in layout of the reformer and a gas turbine. A gas turbine and a heat recovery exchanger are additionally installed such that the gas turbine generates electric power, and flue gases of the gas turbine are employed to preheat feedstocks supplied to the reformer and to generate steam used for the pre-reforming stage. The heat recovery exchanger is disposed in a downstream channel for the flue gases (at 500-600° C.) of the gas turbine to perform heat exchange between the high-temperature flue gases of the gas turbine and the feedstocks supplied to the reformer, thereby increasing the temperature of the feedstocks to a level suitable for vaporization and desulfurization, and to a level suitable for the pre-reforming stage in a pre-reformer. Generation and superheating of steam required for the pre-reforming stage are performed by the remaining heat of the flue gases of the gas turbine.

Owner:MITSUBISHI POWER LTD

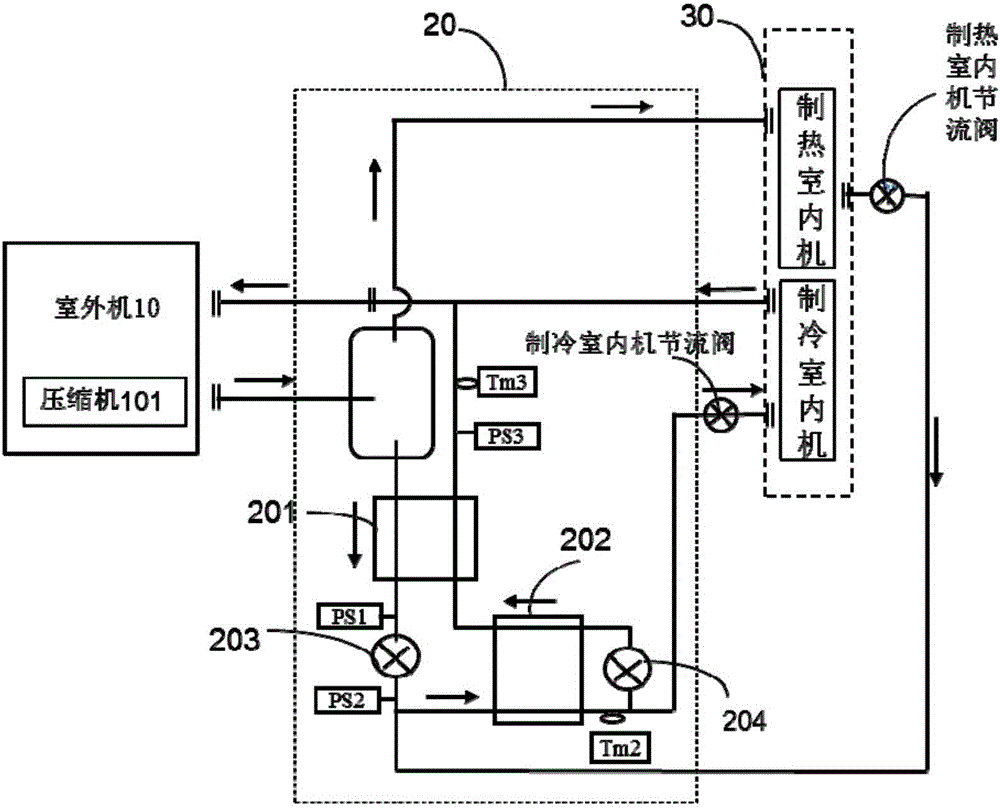

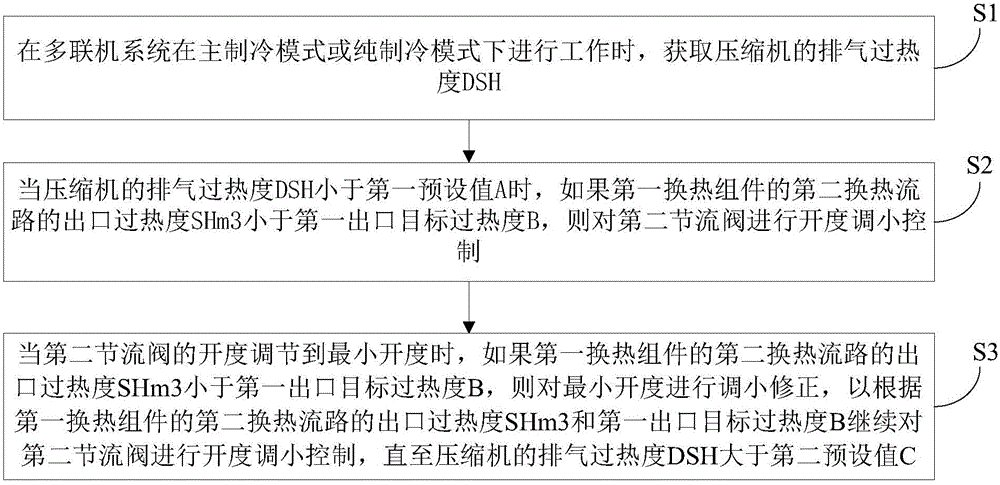

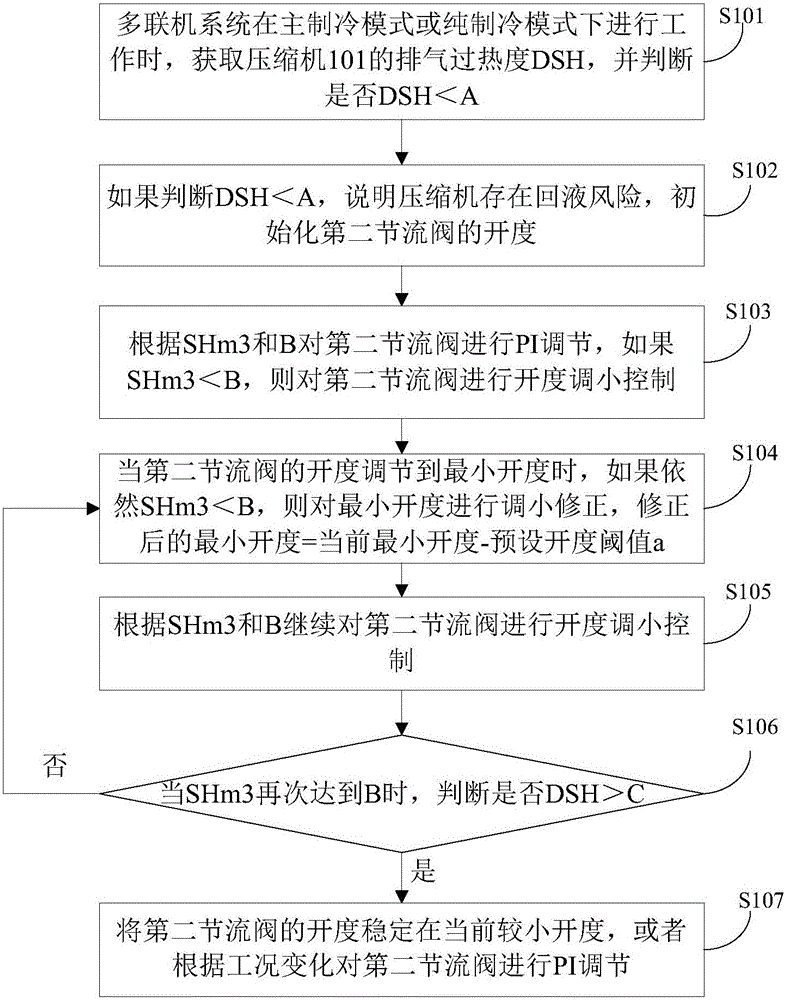

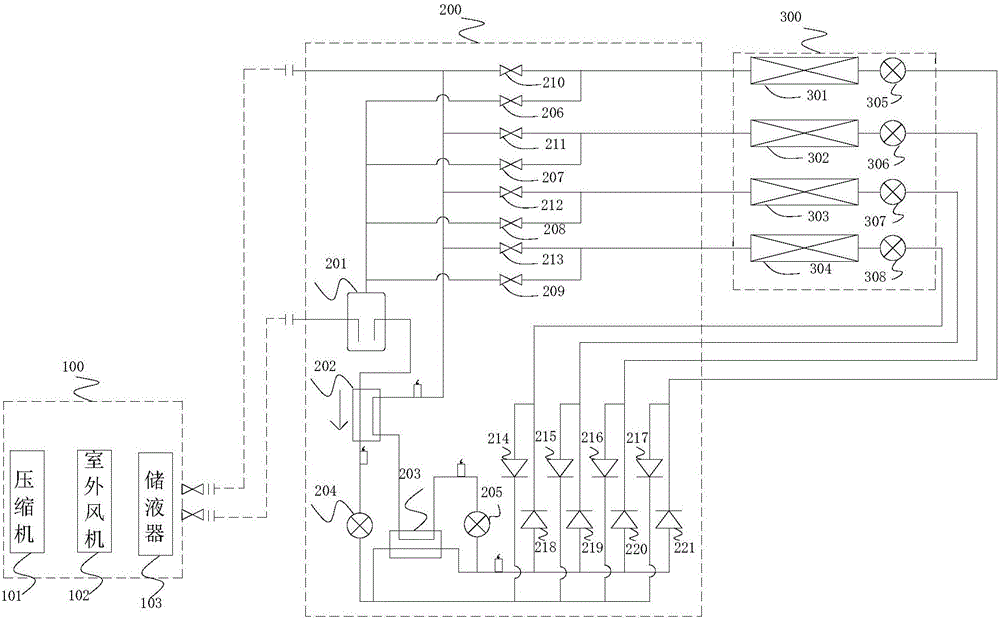

Multi-split system and valve control method of supercooling return circuit of multi-split system

ActiveCN105972860AReduce the risk of floodbackImprove cooling effectMechanical apparatusFluid circulation arrangementControl theorySuperheating

The invention discloses a multi-split system and a valve control method of a supercooling return circuit of the multi-split system. The valve control method comprises the following steps that an exhaust superheating degree of a compressor is acquired; when the exhaust superheating degree is less than a first preset value, if an outlet superheating degree of a second heat exchange flow path of a first heat exchange component is less than a first outlet target superheating degree, opening turning-down control is conducted on a second throttling valve; and when the opening of the second throttling valve is adjusted to the smallest, if the outlet superheating degree of the second heat exchange flow path of the first heat exchange component is less than the first outlet target superheating degree, the smallest opening is subjected to turning-down modification, and the opening turning-down control is conducted on the second throttling valve continuously till the exhaust superheating degree of the compressor is greater than a second preset value. According to the valve control method, when the compressor has a liquid return risk, through the adjustment on the opening of the second throttling valve, a situation that excessive refrigerant returns to the compressor is limited, the air return superheating degree can be increased and the liquid return risk of the compressor is reduced, thereby improving the refrigerating effect and the running safety of the multi-split system.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

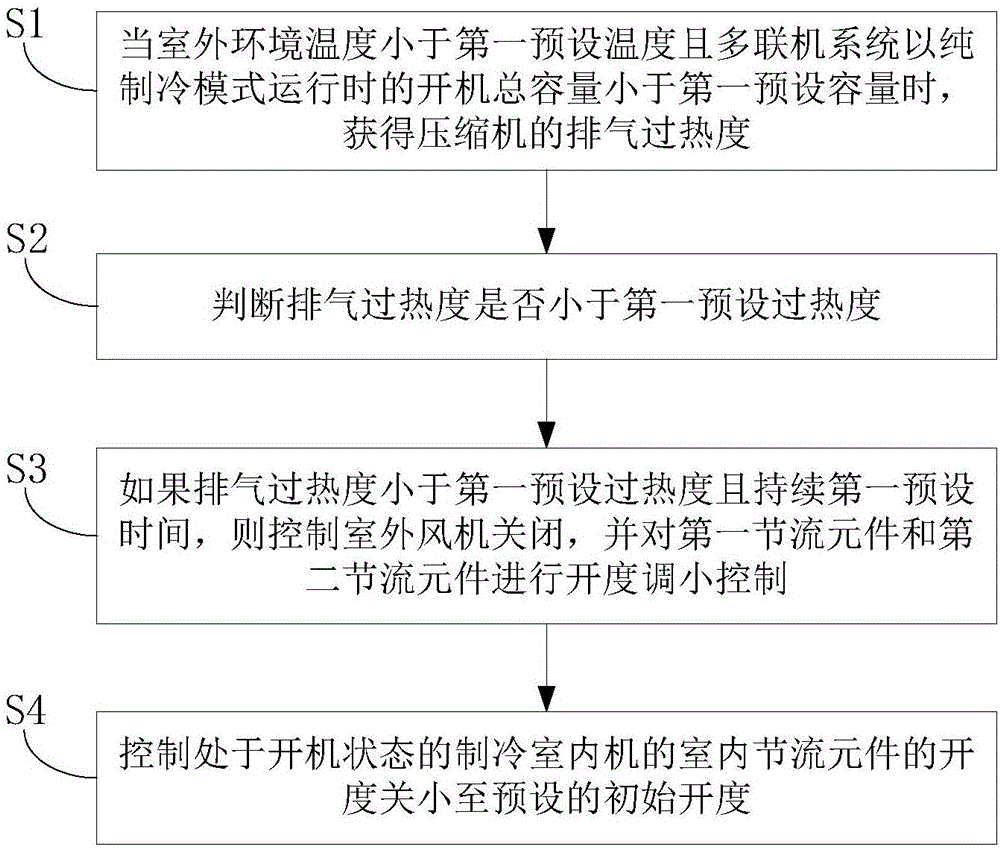

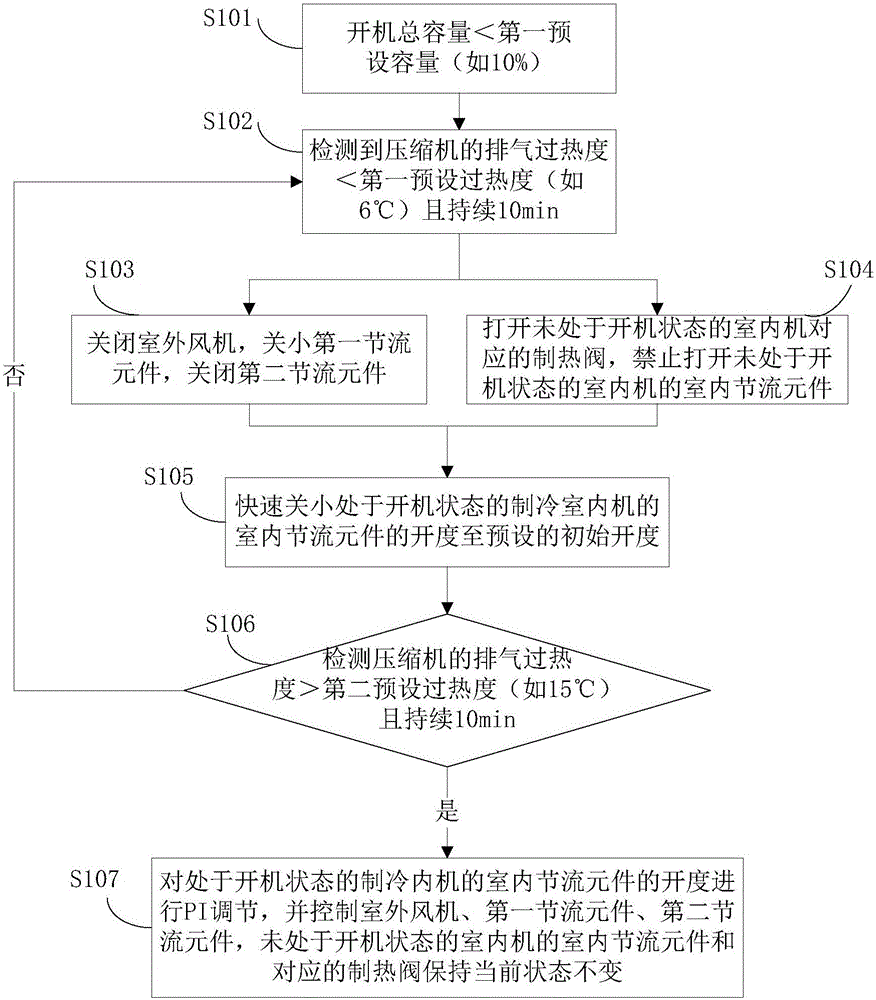

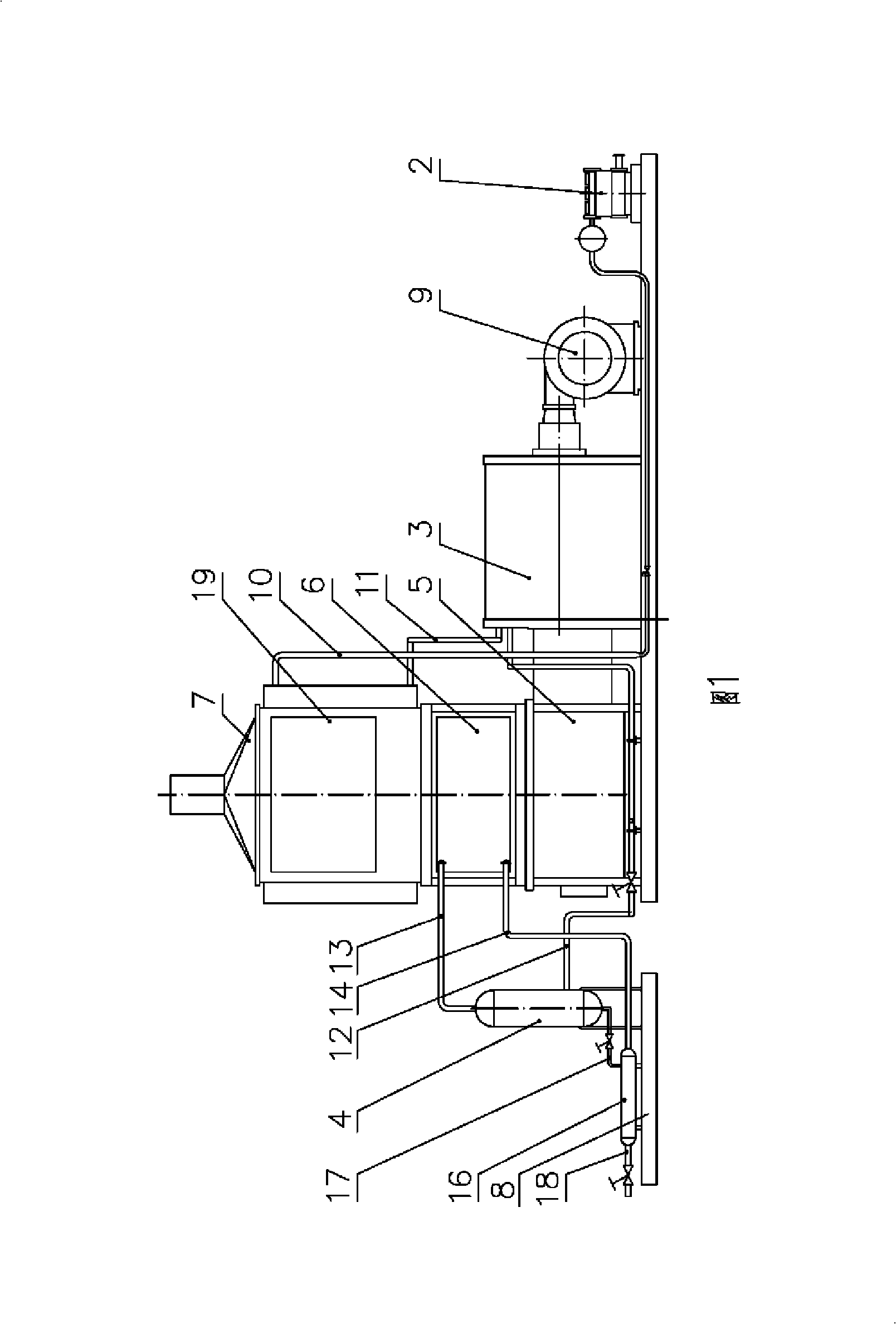

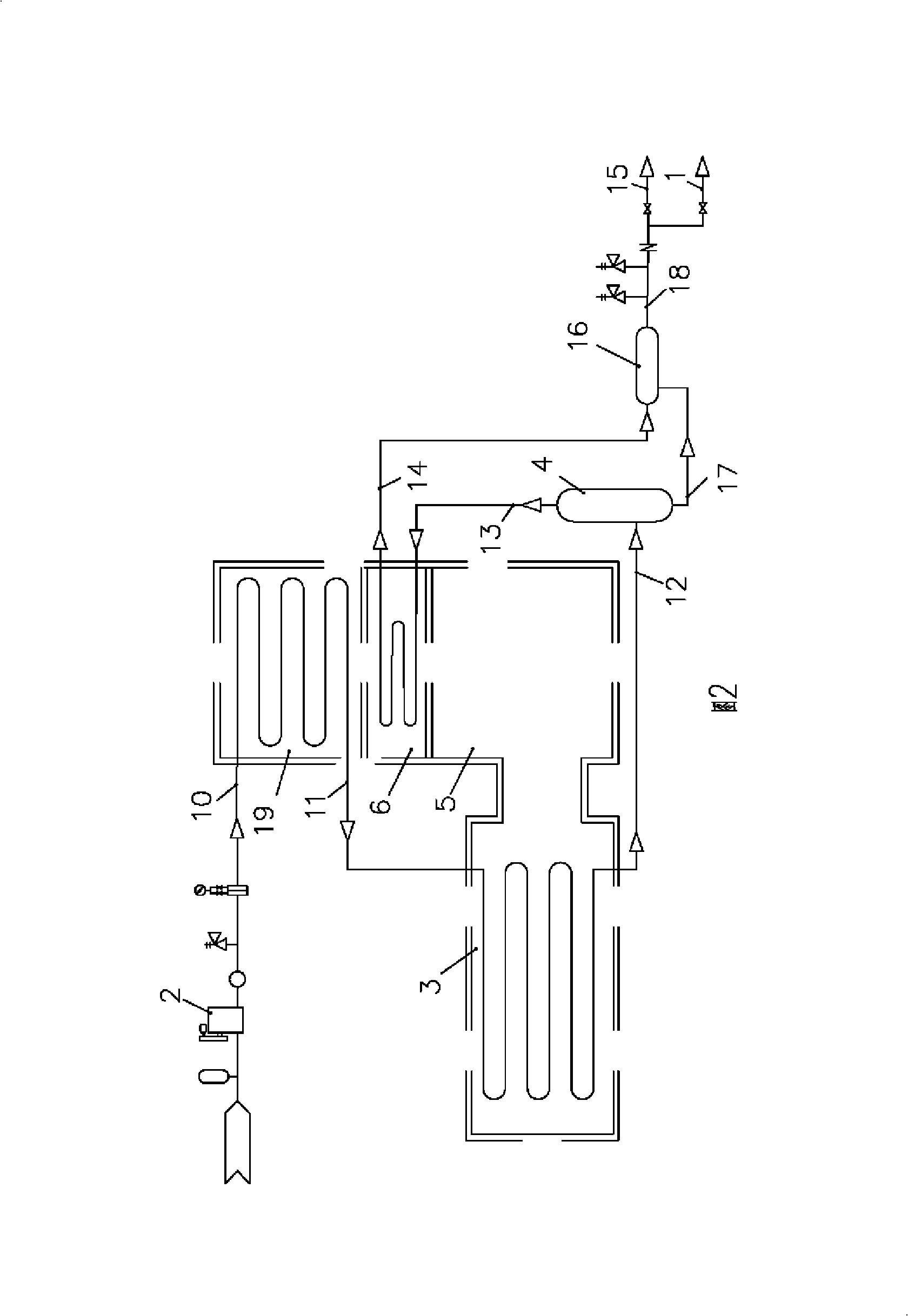

Multi-online system and control method thereof

ActiveCN106352445ADo not enter frequentlySafety exhaust superheat statusSpace heating and ventilation safety systemsLighting and heating apparatusLiquid stateEngineering

The invention discloses a multi-online system and a control method thereof. The control method comprises the following steps that when the outdoor environment temperature is smaller than first preset temperature and the starting total capacity of the multi-online system operating in a pure refrigeration mode is smaller than first preset capacity, the exhaust superheating degree of a compressor is obtained; whether the exhaust superheating degree is smaller than first preset superheating degree or not is judged; if the exhaust superheating degree is smaller than the first preset superheating degree and continues for first preset time, an outdoor fan is controlled to be turned off, and the opening degrees of a first throttling element and a second throttling element are controlled and adjusted to be small; the opening degree of the indoor throttling element of an inner refrigeration unit in a startup mode is controlled to preset initial opening degree through. By the adoption of the method, the inner refrigeration unit is not frequently switched to a freezing-prevention mode by decreasing the refrigerant amount flowing through the started inner refrigeration unit and decreasing the liquid state refrigerant flowing back to the outdoor unit as much as possible, a very good refrigeration effect is achieved, and it is ensured that the compressor has a safer exhaust superheating degree state.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

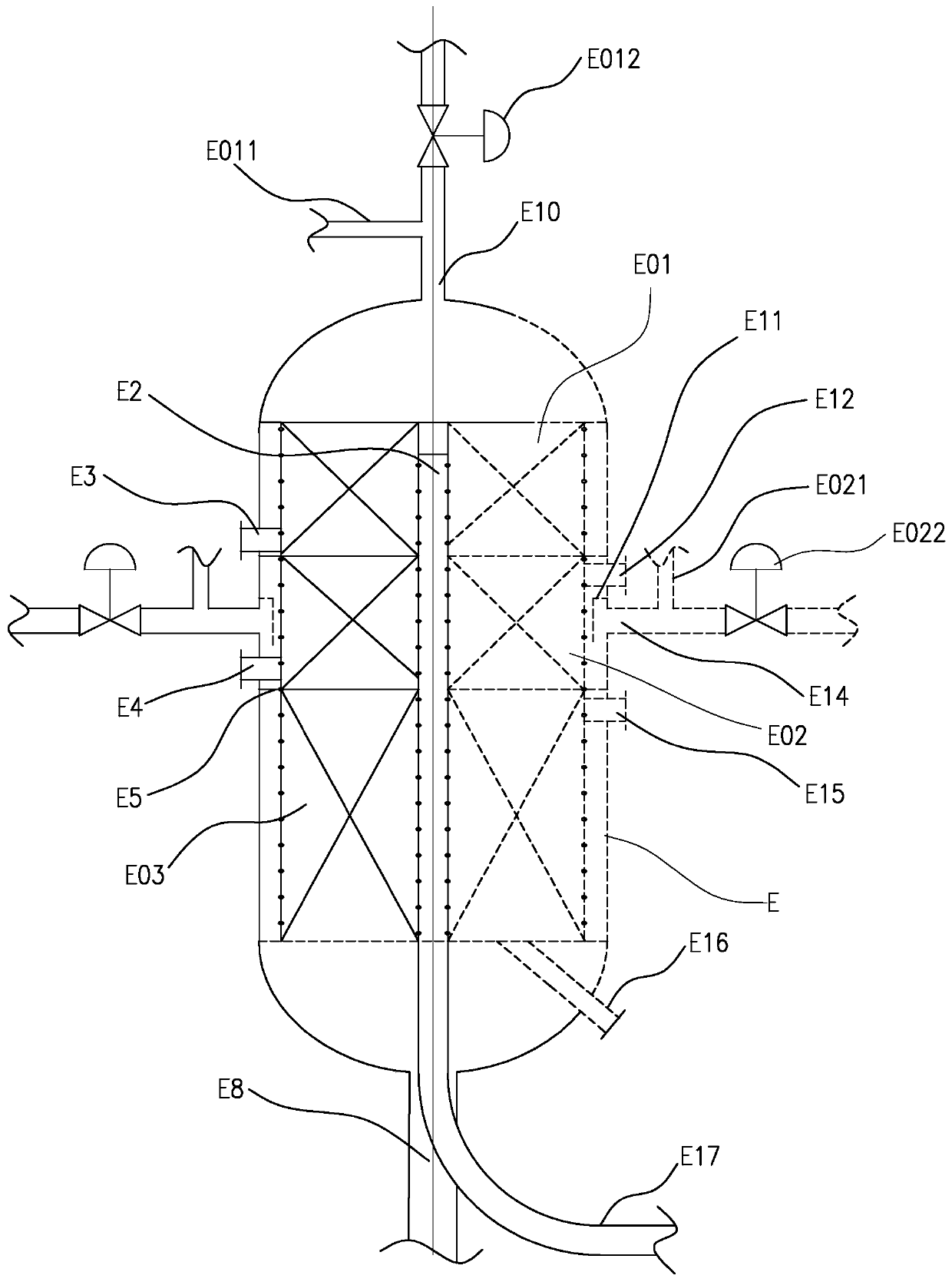

High-dryness oil field steam-injection boiler and high-dryness steam production method

ActiveCN101343989AMeet the requirements of the developed steam injection processImprove work efficiencyInsulationFluid removalOil fieldSuperheater

The invention provides a high dryness oil field steam injection boiler and a high dryness steam production method, belonging to the technical field of the oil field steam injection boiler. The high dryness oil field steam injection boiler comprises a radiation section, a convection section, a transition section, a boiler body, a water supplying pump and a steam-water separator; wherein, a steam superheater is fixedly installed in the boiler body between the convection section and the transition section; the water inlet of an inlet pipe of the convection section is communicated with the water outlet of the water supplying pump; and the water outlet of the inlet pipe of the convection section is communicated with the water inlet at the upper end of the convection section; the steam inlet of an outlet pipe of the convection section is communicated with the steam outlet at the lower end of the convection section, and the steam outlet of the outlet pipe of the convection section is communicated with a steam inlet of the radiation section. The invention has the advantages that the structure is reasonable and compact, the operation is convenient, the dryness of the steam can be ensured to reach 100 percent, and a certain superheating degree is provided, the invention can meet the requirements of the steam injection technology for developing ultra thick oil, so the working efficiency of the steam injection during the development of ultra thick oil is greatly improved, the thermal efficiency is improved, the energy consumption is reduced, and the manufacture cost is reduced.

Owner:XINJIANG PETROLEUM ADMINISTATION ENG TECH CO

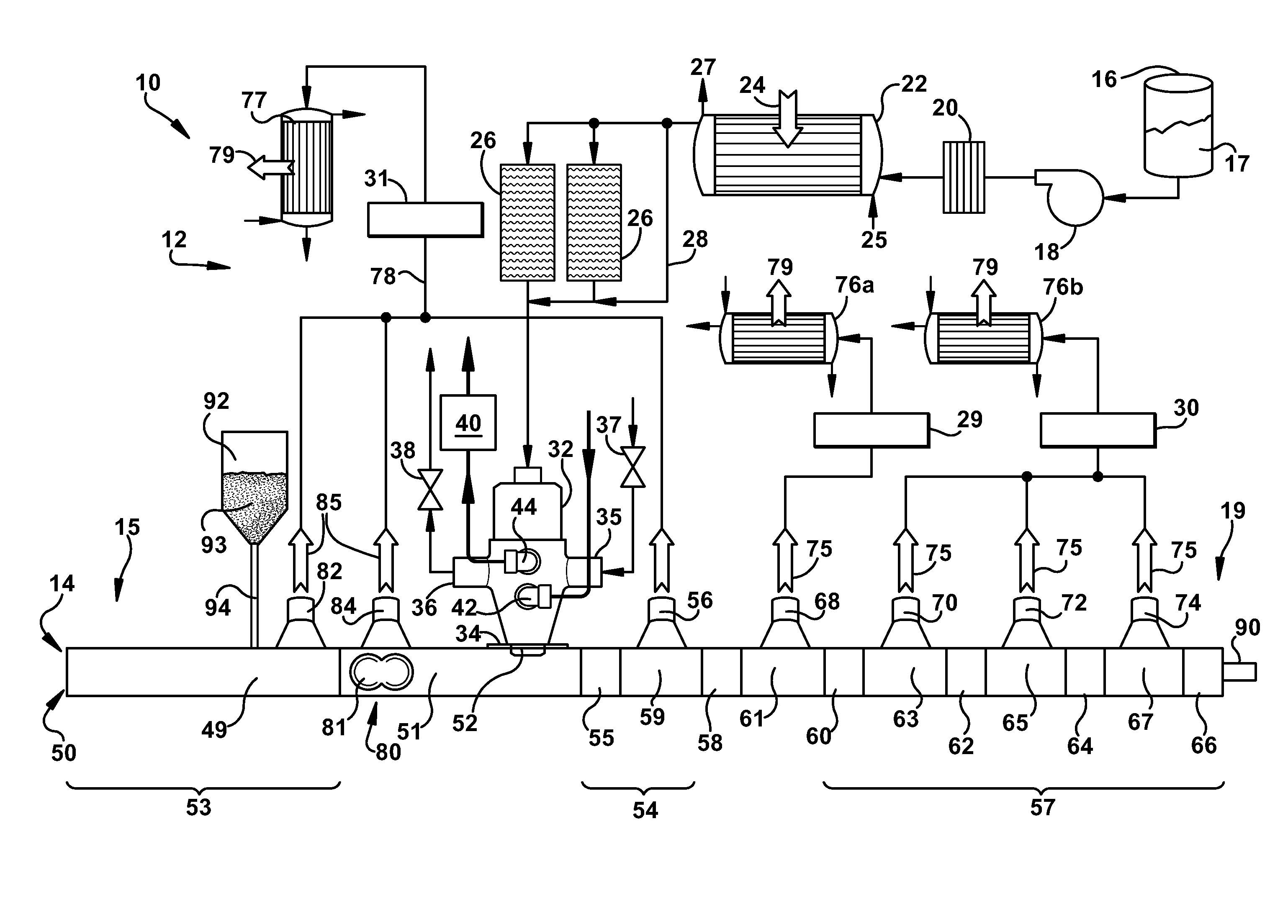

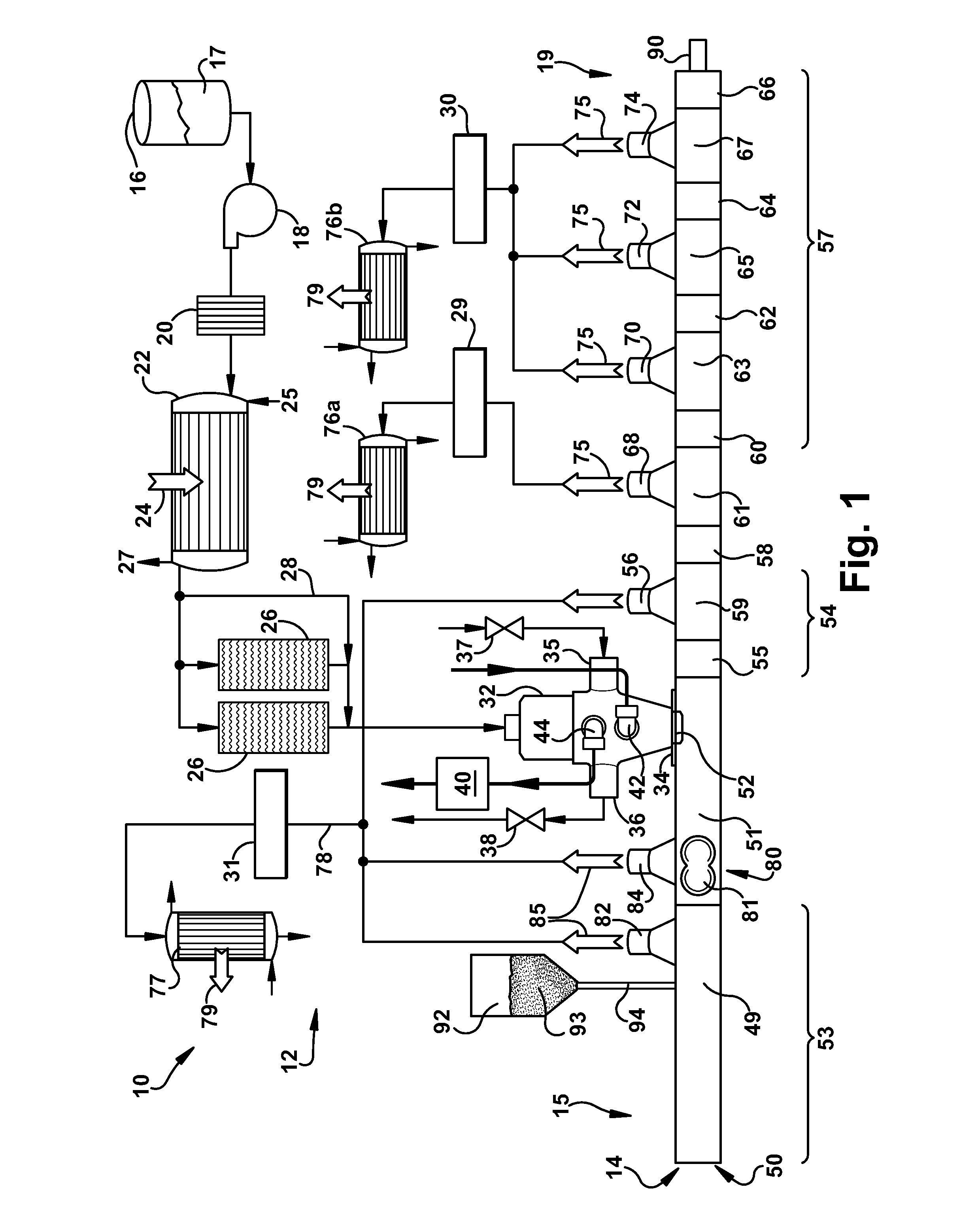

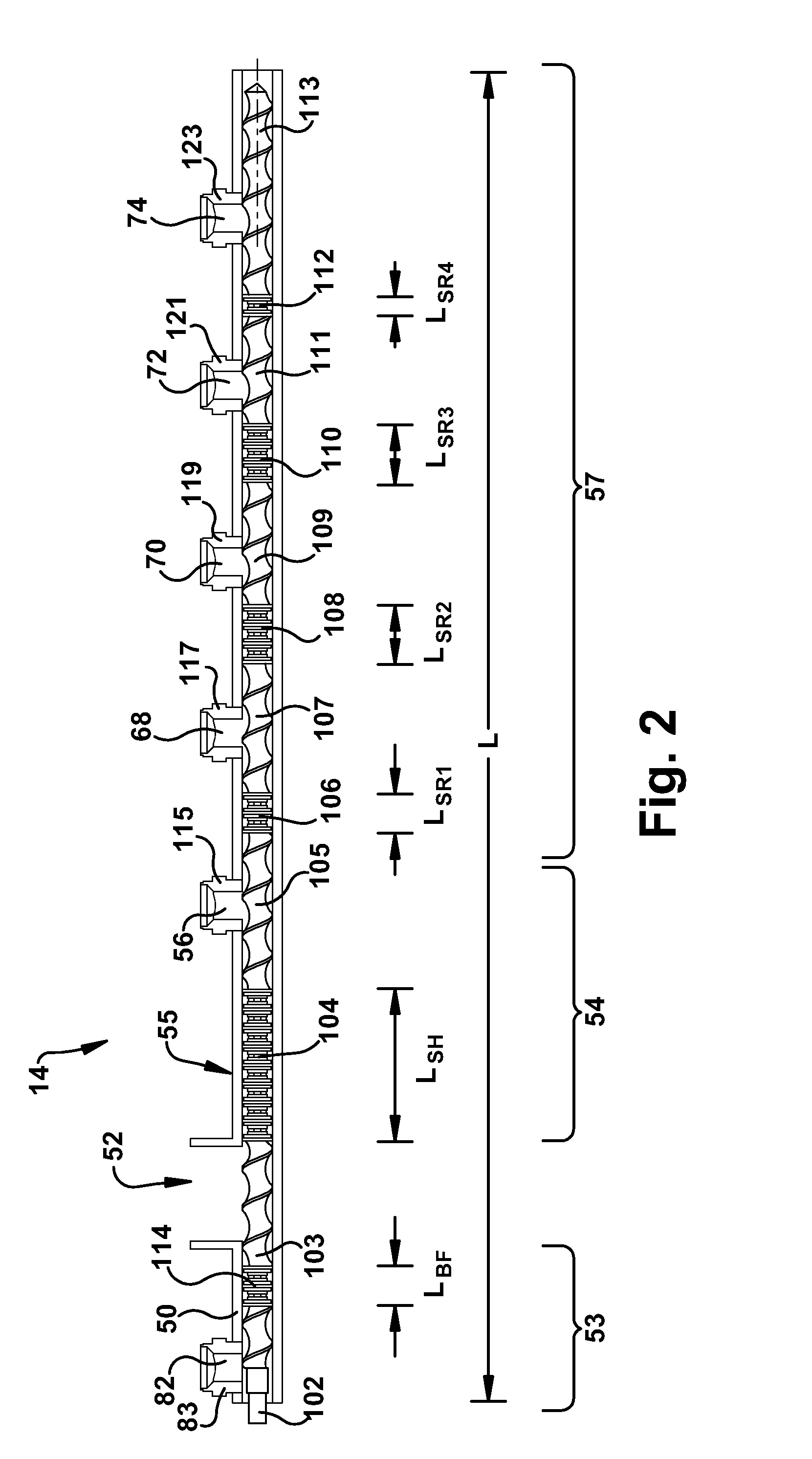

Apparatus and method of separating a polymer from a solvent

The present invention relates to various embodiments of a system and method for separating polymer from a solvent. In one embodiment a system for separating polymer from a solvent comprises an extrusion apparatus includes a hollow member having a first end portion, a second end portion, and a feed port between the first end portion and the second end portion. The extrusion apparatus includes a back flash vent port disposed upstream of the feed port and a forward flash vent port disposed downstream of the feed port. The extrusion apparatus further includes a vent insert located at the forward flash vent port, a screw disposed inside the hollow member, and an internal superheating section disposed between the feed port and the downstream vent opening of the hollow member such that the length of the internal superheating section is greater than about four times the diameter, 4D, of the hollow member.

Owner:SABIC INNOVATIVE PLASTICS IP BV

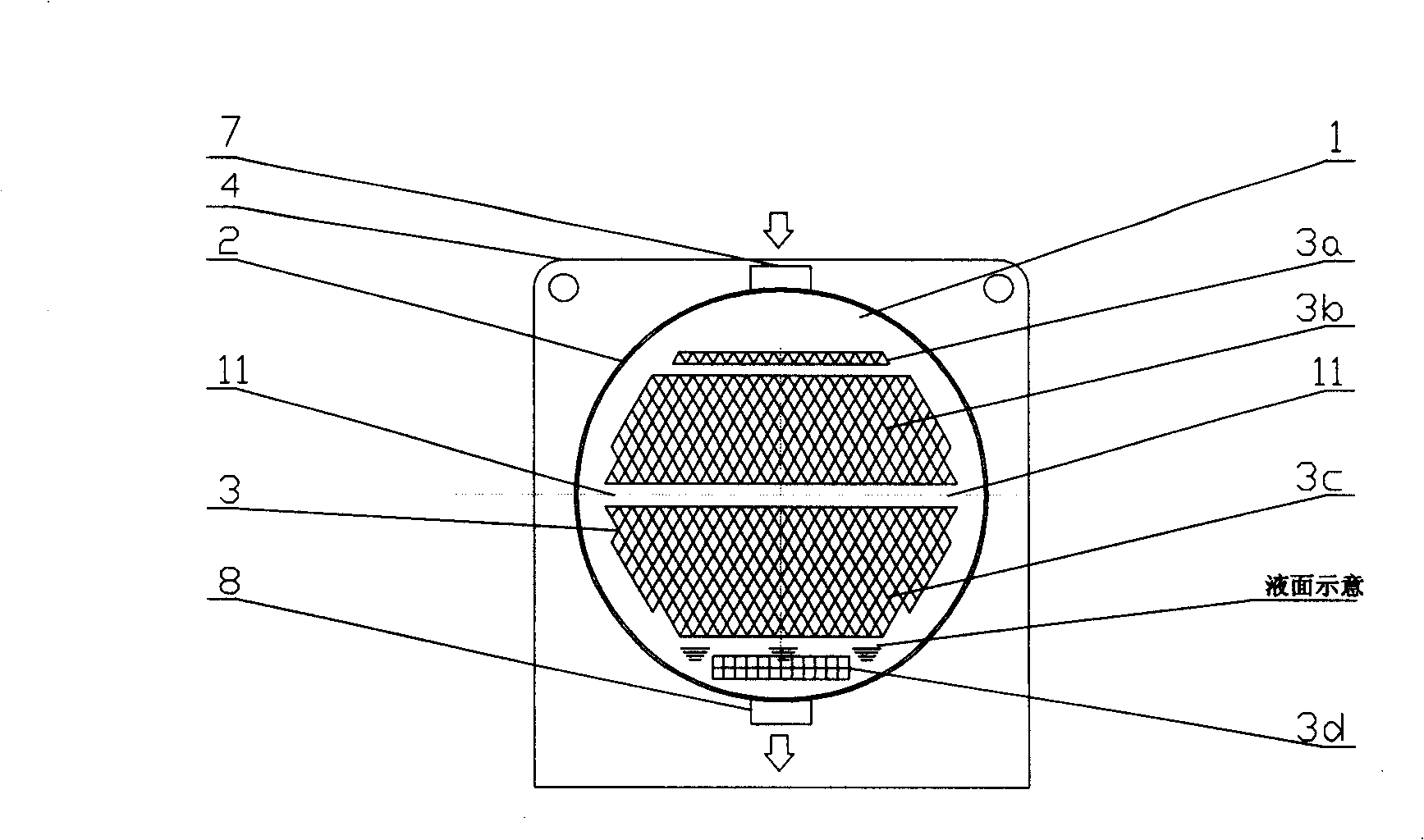

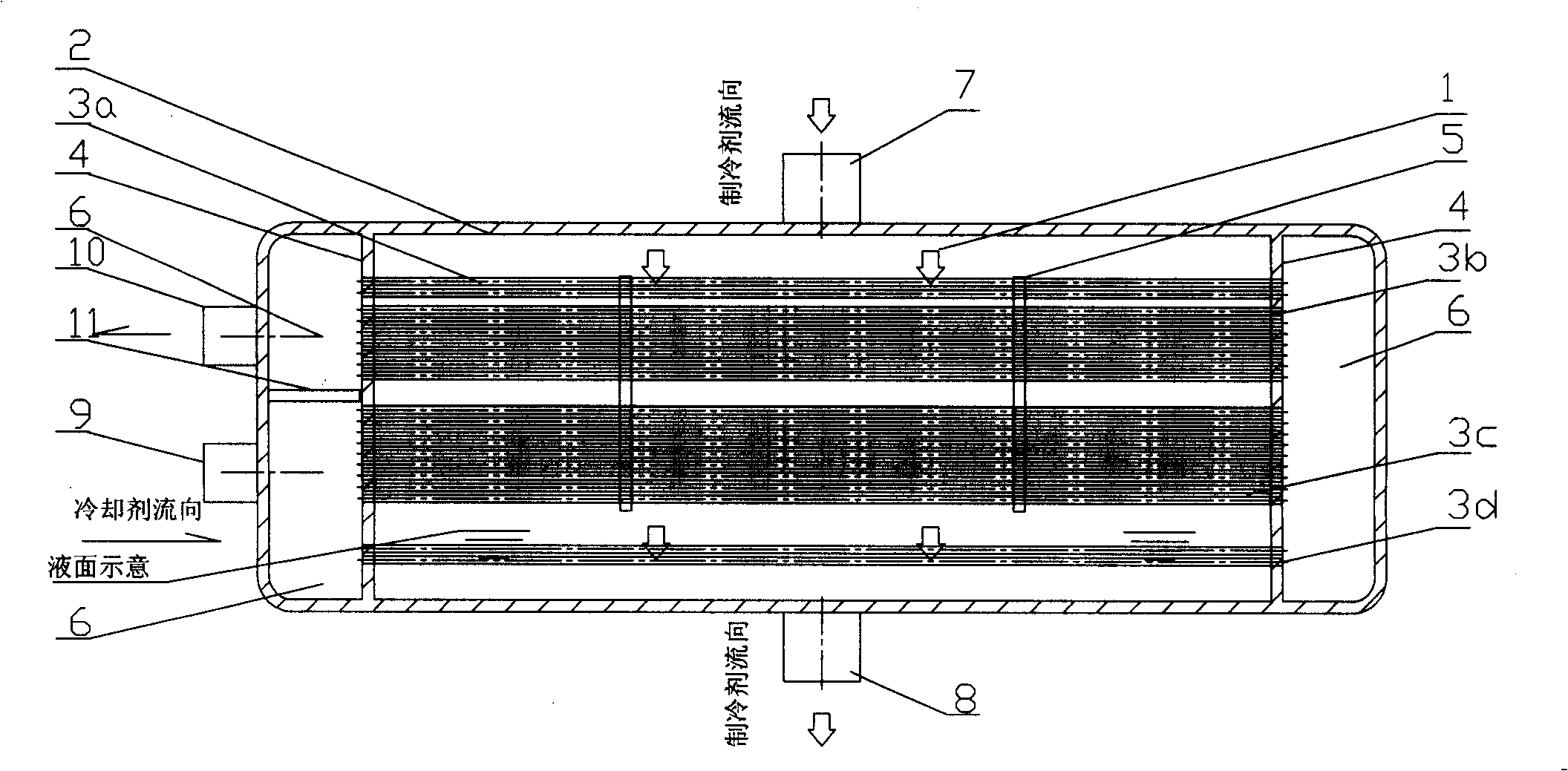

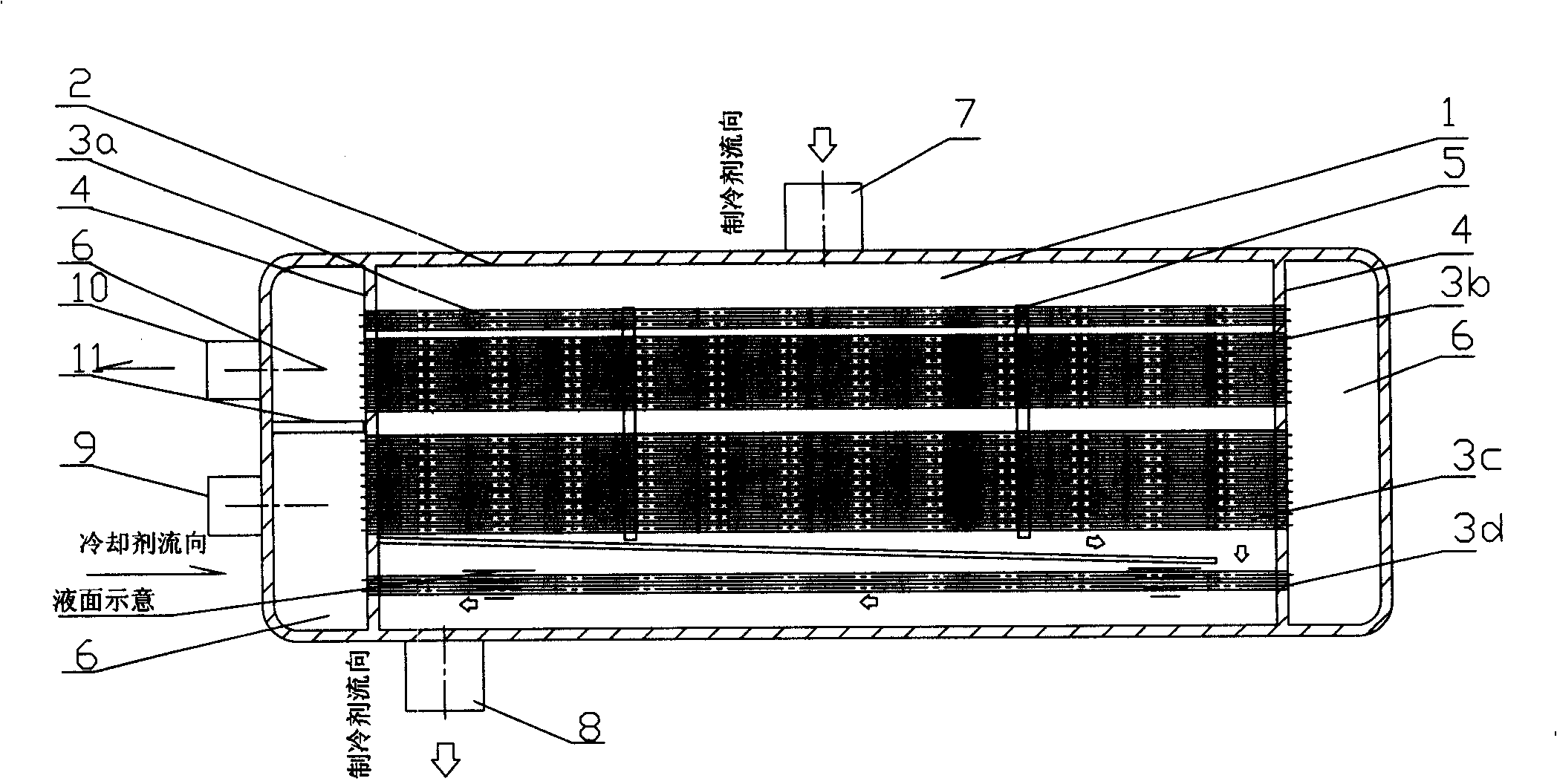

Efficient shell and tube type condenser

ActiveCN101338959AImprove heat transfer effectRaise the saturation temperatureEvaporators/condensersSteam/vapor condensersEngineeringTubes types

The invention discloses an efficient shell and tube typed condenser, including a heat transfer tube bundle and a shell. The condenser is characterized in that the heat transfer tube bundle is composed of two or even more heat transfer tubes; the heat transfer tube bundle is matched with corresponding heat transfer tubes according to three different heat exchange course, namely, gas superheating, gas condensing, and liquid overcooling. The condenser of the invention has the beneficial effects as follows: the optimal heat transfer tubes are correspondingly adopted for the condenser according to the different heat transfer course and the characteristics of the gas superheating tube bundle, a gas condensing upper layer tube bundle, a condensing lower layer tube bundle and an overcooling tube bundle. Compared with the traditional condenser which adopts the same heat transfer tube to optimize the heat exchange of the condensing upper bundle, the shell and tube typed condenser of the invention effectively improves the heat exchange effect of the condenser.

Owner:维联传热技术(上海)有限公司

Gas-liquid separator with heat-returning function and application method thereof to air conditioning unit

InactiveCN102645061AAvoid aspiration of fluidImprove performanceRefrigeration componentsVapor–liquid separatorReturn function

The invention discloses a gas-liquid separator with a heat-returning function and an application method thereof to an air conditioning unit. The gas-liquid separator with the heat-returning function comprises a superheating passageway and a supercooling passageway, and the superheating passageway is provided with an air inlet pipe used for bringing refrigerant vapour in the gas-liquid separator and an air outlet pipe used for exhausting the refrigerant vapour out of the gas-liquid separator; and the supercooling passageway is provided with one or more than one supercooling pipe arranged in the gas-liquid separator, refrigerant liquid flows through the supercooling pipe(s) so as to carry out heat exchange with the refrigerant vapour which is brought in the gas-liquid separator, thus realizing the superheating of the refrigerant vapour and supercooling of the refrigerant liquid. The gas-liquid separator and the application method provided by the invention can effectively promote the performance and efficiency of refrigerating / heating circulation and can be widely applied to the air conditioning unit.

Owner:四川同达博尔置业有限公司

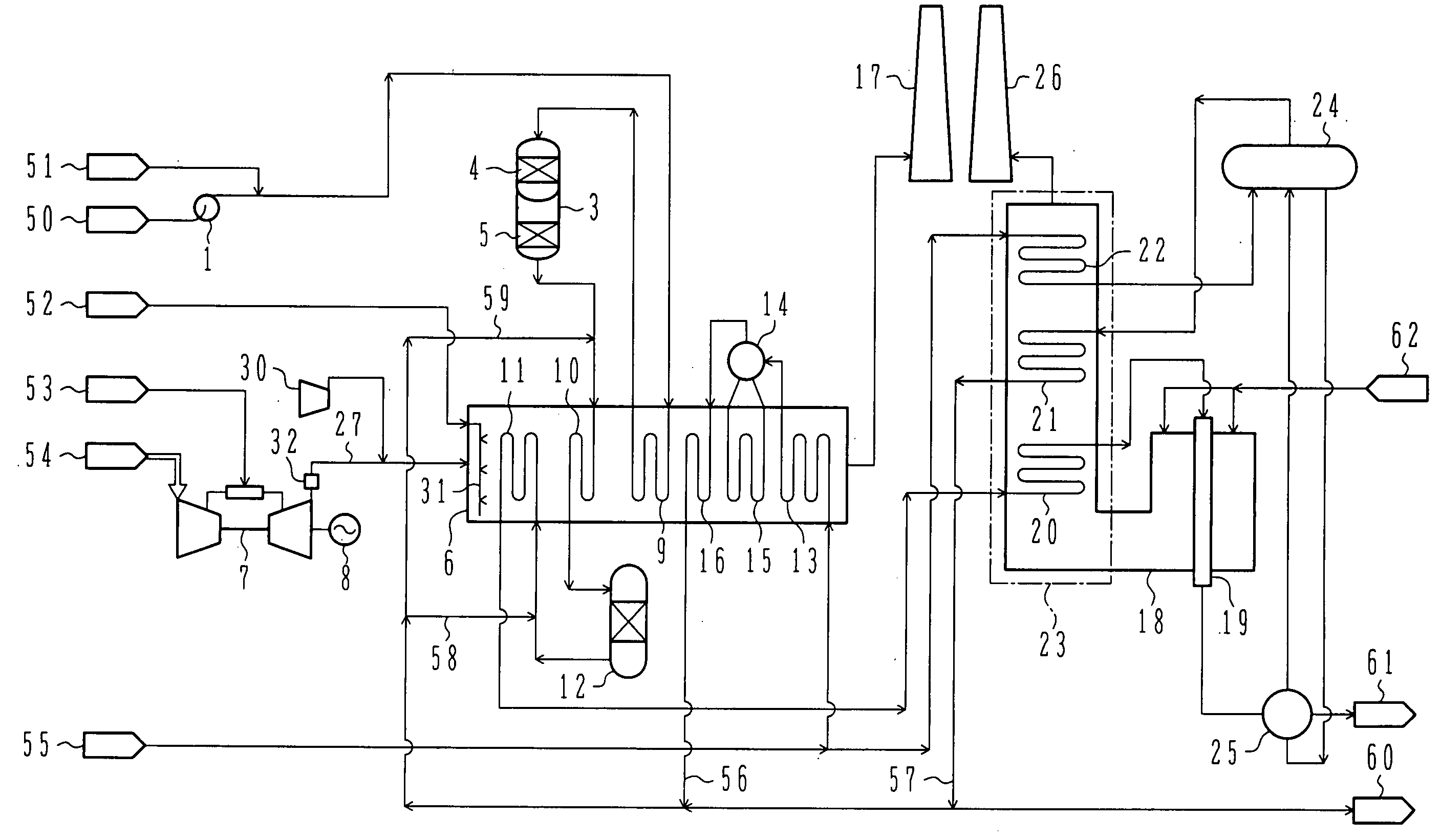

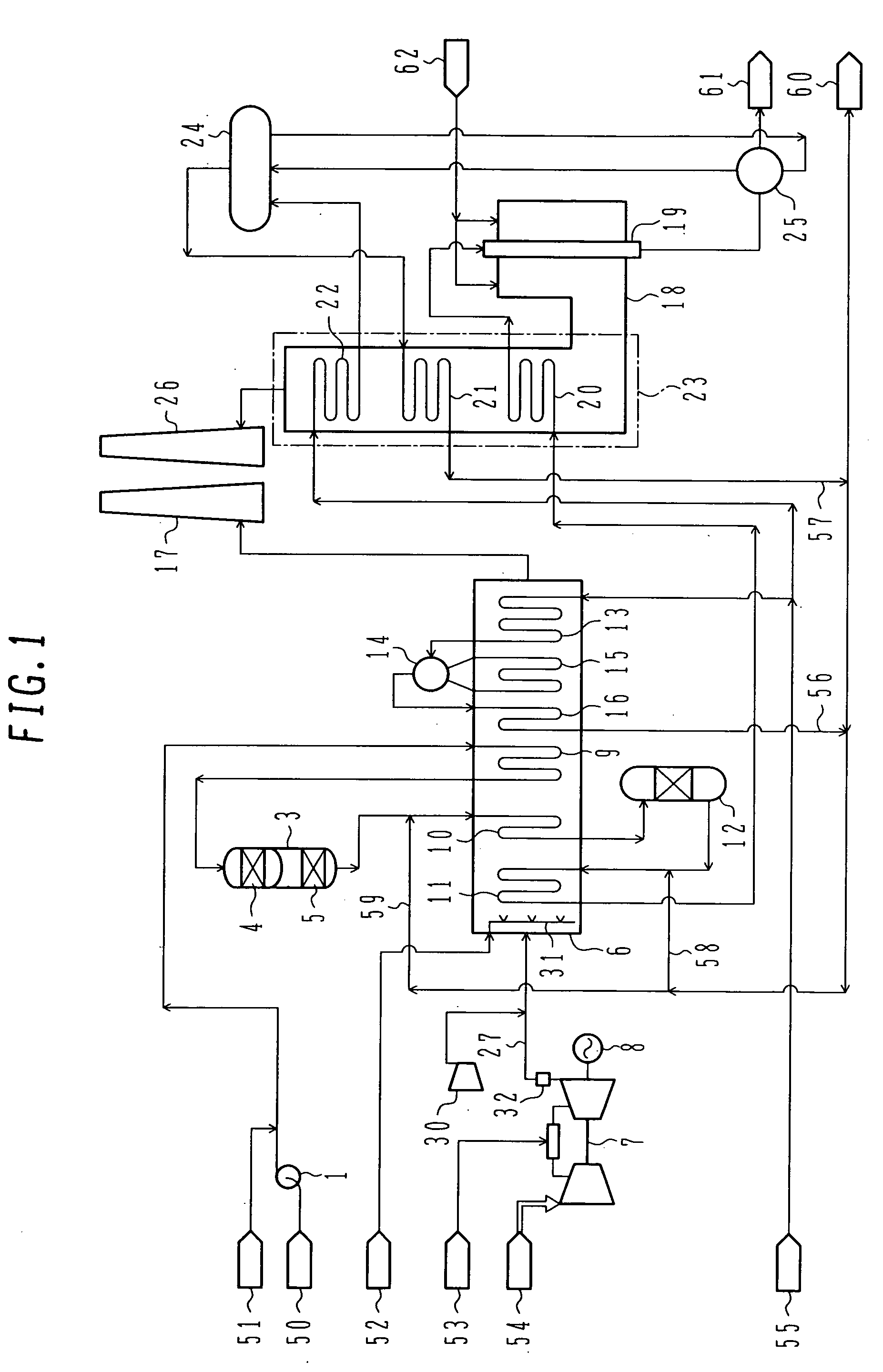

Steam reforming system

InactiveUS20050176831A1Increasing reformer sizeReduce facility costsHydrogenOrganic compound preparationSteam reformingFlue gas

A steam reforming system with high thermal efficiency, which can compensate for a reduction in the amount of steam generated in a reformer without increasing the reformer size and without limiting the degree of freedom in layout of the reformer and a gas turbine. A gas turbine and a heat recovery exchanger are additionally installed such that the gas turbine generates electric power, and flue gases of the gas turbine are employed to preheat feedstocks supplied to the reformer and to generate steam used for the pre-reforming stage. The heat recovery exchanger is disposed in a downstream channel for the flue gases (at 500-600° C.) of the gas turbine to perform heat exchange between the high-temperature flue gases of the gas turbine and the feedstocks supplied to the reformer, thereby increasing the temperature of the feedstocks to a level suitable for vaporization and desulfurization, and to a level suitable for the pre-reforming stage in a pre-reformer. Generation and superheating of steam required for the pre-reforming stage are performed by the remaining heat of the flue gases of the gas turbine.

Owner:MITSUBISHI POWER LTD

Strip-casting 550-MPa-level weathering resistant steel and production method thereof

PendingCN109881084AReduce C contentGuaranteed bending performanceMetal rolling arrangementsSuperheatingImpurity

The invention discloses strip-casting 550-MPa-level weathering resistant steel and a production method thereof. The method comprises the steps of 1), smelting: the chemical components of molten steelcomprises C lower than 0.03%, 0.20-0.80% of Si, Mn lower than 1.0%, 0.03-1.50% of P, S lower than or equal to 0.008%, N lower than or equal to 0.008%, 0.40-1.50% of Cu, 0.05-1.50% of Cr, Ni lower than0.10%, 0.05-0.20% of Nb and the balanced Fe and unavoidable impurities; 2), strip casting: continuous casting is conducted on molten steel on which qualified smelting is conducted by a pair of coppercasting rolls which are rotated in the same directions to produce a casting strip with the thickness of 1.4-2.5 mm, and the superheating of the molten steel is controlled to be lower than 80 DEG C; 3), casting strip online hot rolling: the hot rolling pressing amount is 15-65%, the temperature of pressed strip steel is 950-1050 DEG C; 4), cooling and winding: the temperature of strip steel on which hot rolling is conducted is cooled down to 450-600 DEG C through atomizing cooling to obtain fine and uniform ferrite and less amount of pearlite tissues. The 550-MPa-level weathering resistant steel has the advantages of short production procedure, low production cost, good strip steel shape and easy welding.

Owner:SHAGANG GROUP +2

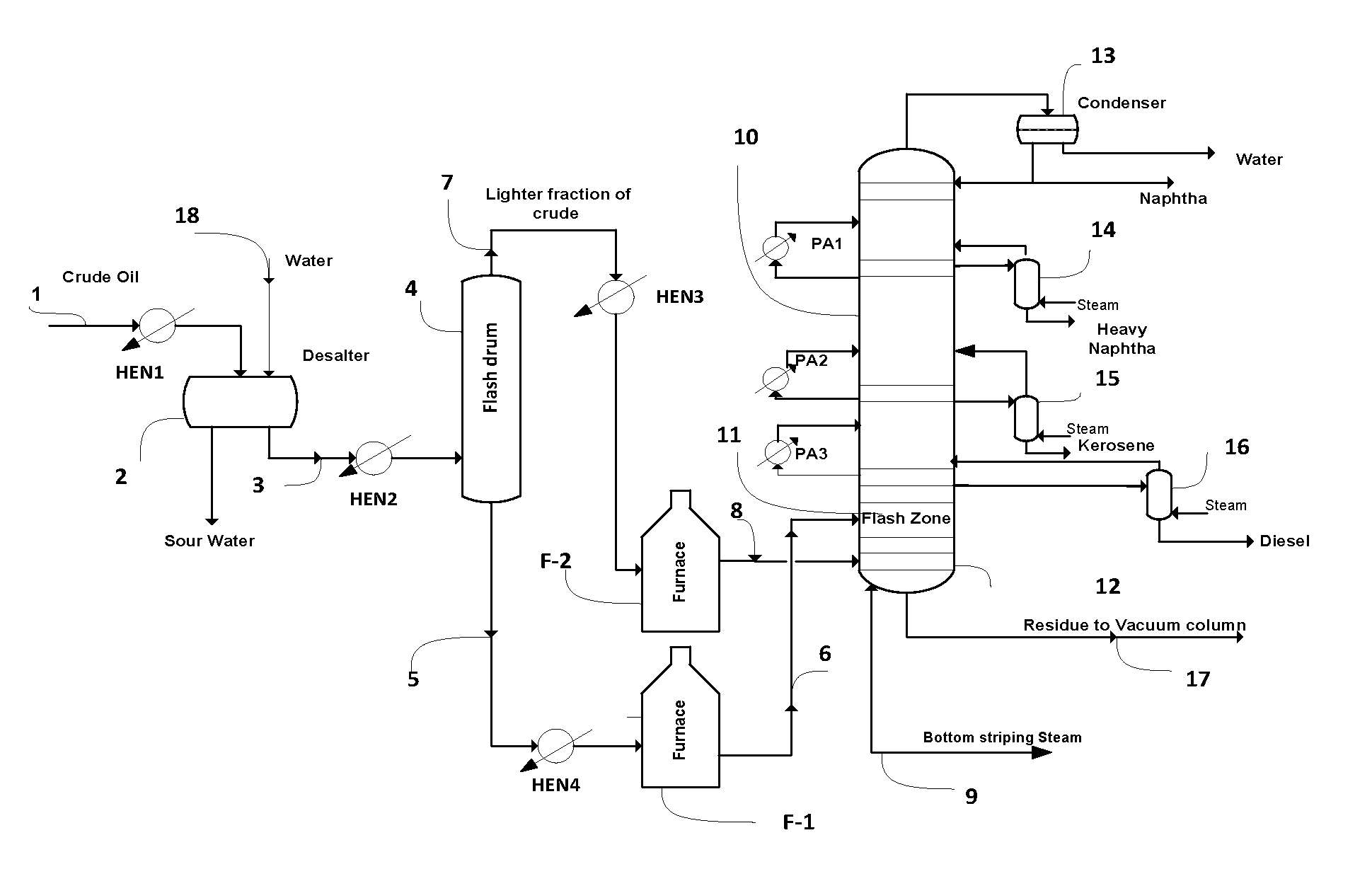

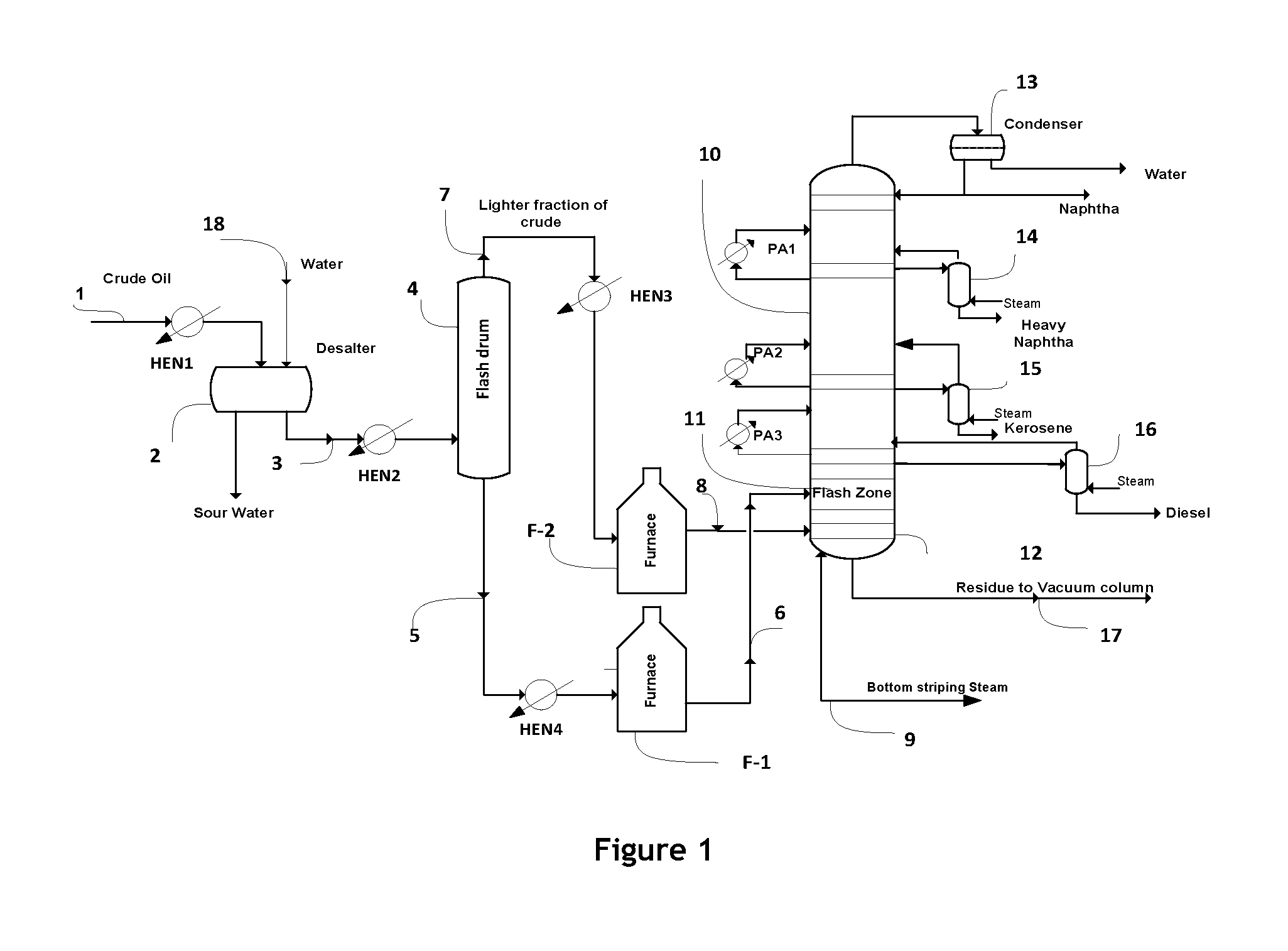

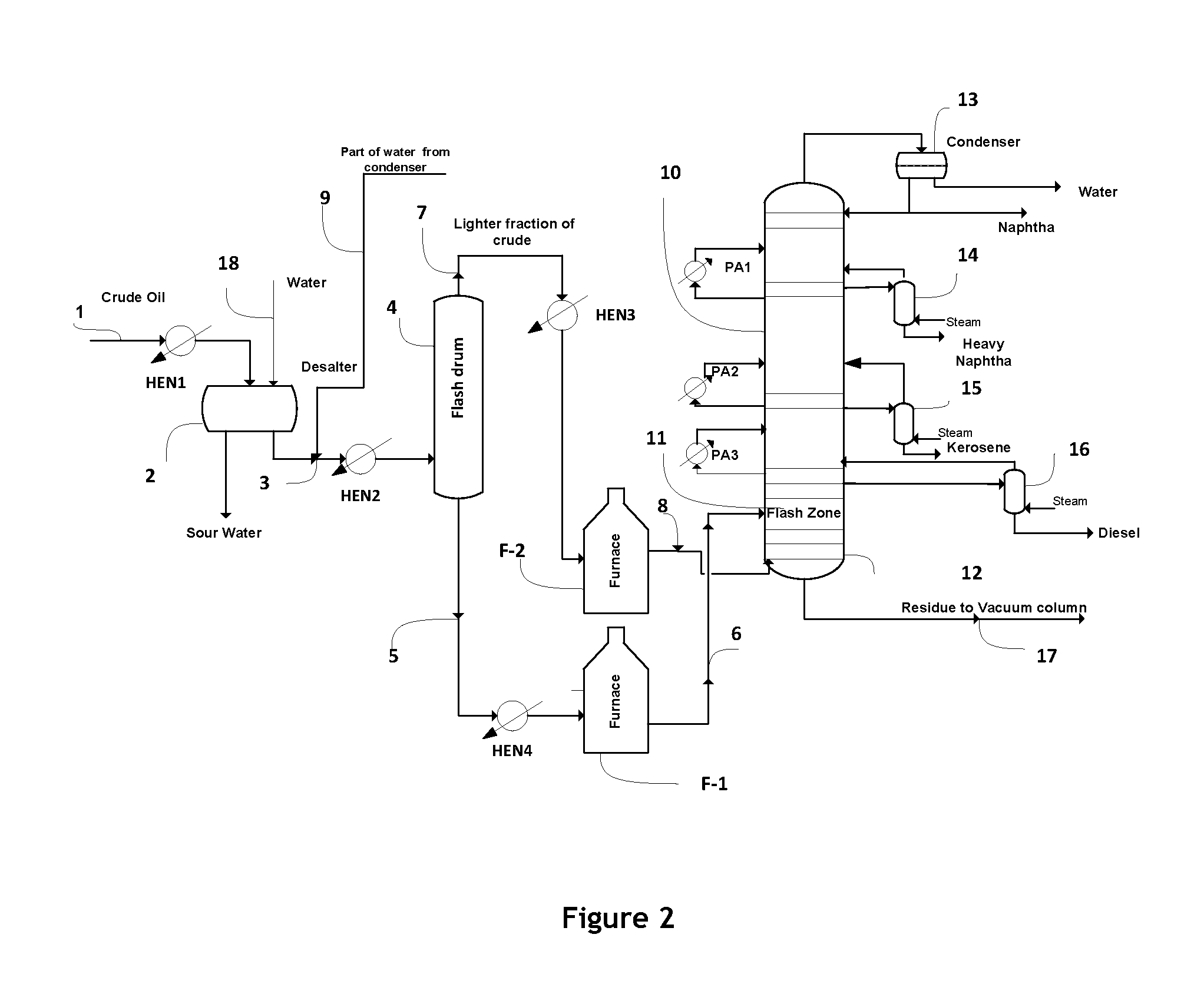

Method for increasing gas oil yield and energy efficiency in crude oil distillation

A method for significant increase in gas oil yield and energy efficiency in crude oil distillation is provided. The present invention relates to a method of separating the components of crude oil. This method utilizes the innovative and novel application of lighter fraction of crude through its superheating and its injection in the stripping section consisting of bottom to flash zone of main distillation column. Method also illustrates the innovative utilization of water in crude distillation unit to eliminate the bottom striping steam and for significant energy saving.

Owner:COUNCIL OF SCI & IND RES

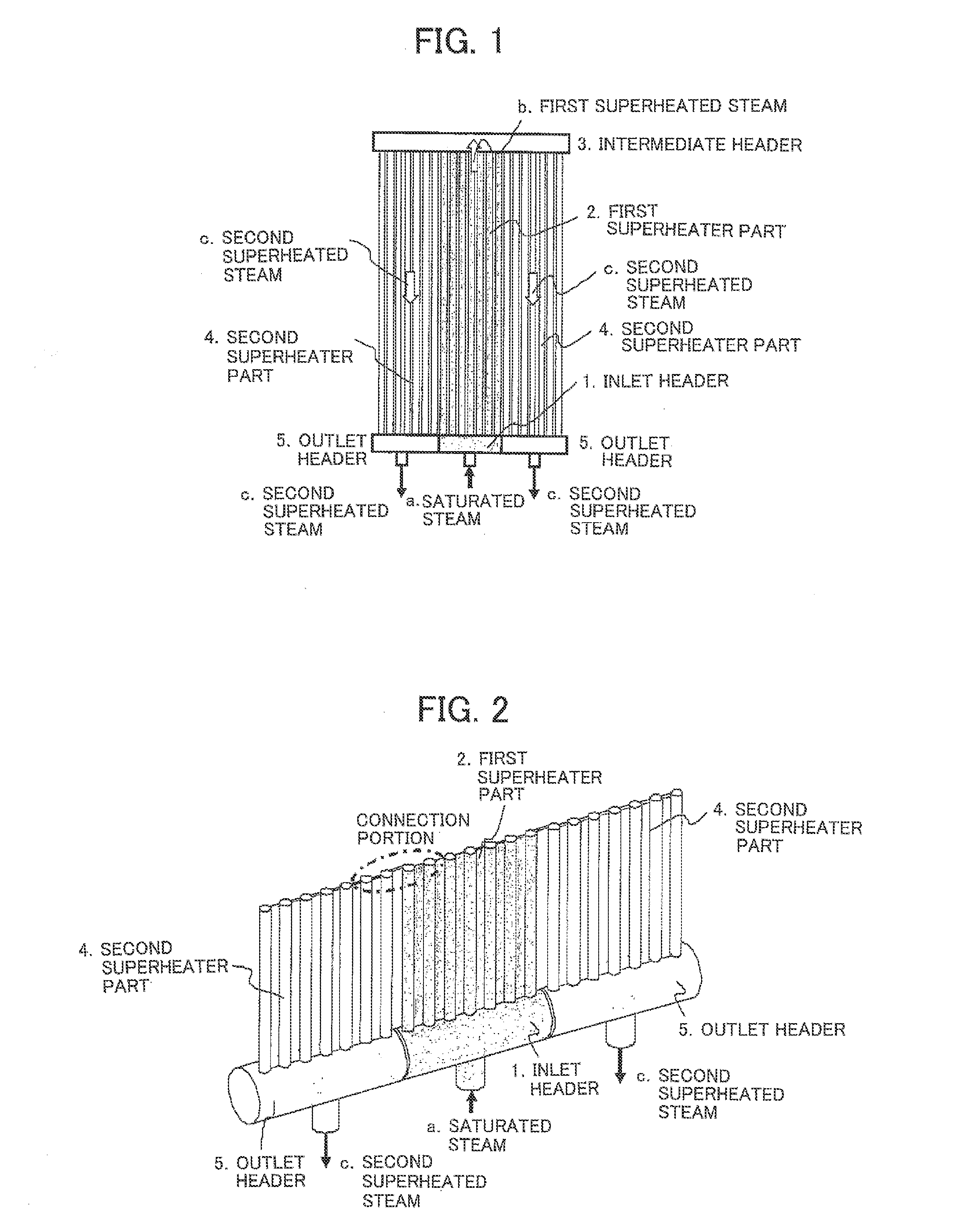

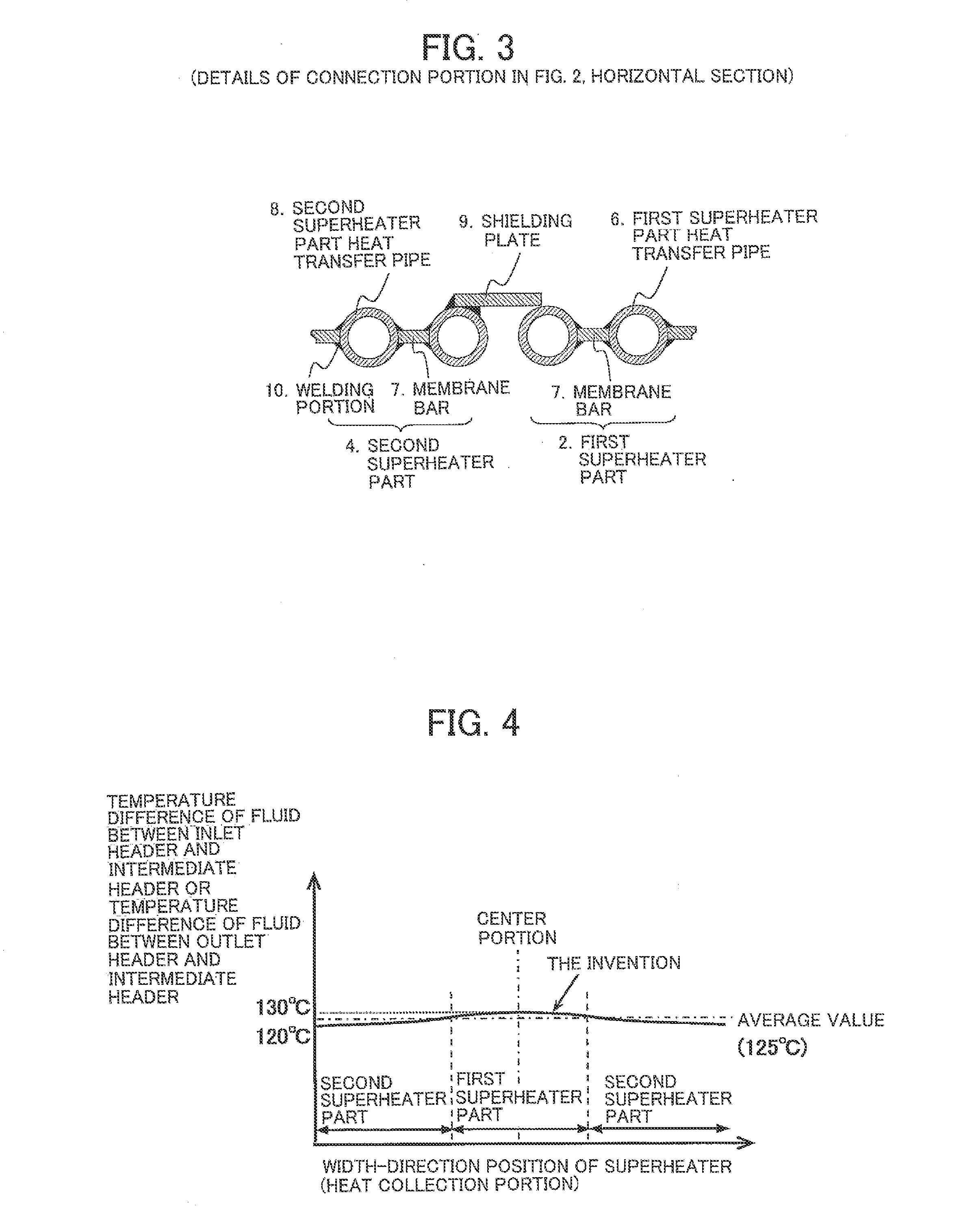

Solar Collector for Solar Heat Boiler, and Tower-Type Solar Heat Boiler Equipped with Same

InactiveUS20150192327A1Avoid damageReduce equipment costsSolar heating energySolar heat collector controllersHeat flowThermal expansion

A deviation between an inlet-outlet temperature difference of a first superheater part and an inlet-outlet temperature difference of each of second superheater parts can be reduced so that a difference in thermal expansion between the first superheater part and the second superheater part can be reduced. It is therefore possible to avoid damage on heat transfer pipes. A solar collector for a solar heat boiler is provided with: cylindrical headers (1,3,5) which are connected to opposite end portions of heat transfer pipes; and a solar heat collection portion including the heat transfer pipes and membrane bars fixing the heat transfer pipes to one another; wherein: the cylindrical headers include an inlet header (1) into which a fluid to be heated flows, an intermediate header (3) which is disposed in a position opposed to the inlet header (1) with interposition of the heat transfer pipes, and two outlet headers (5,5) which are provided to extend on opposite end sides of the inlet header and through which the fluid from the intermediate header can be discharged to the outside; and the solar heat collection portion includes a first superheating portion (2) which has a group of the heat transfer pipes connected between the inlet header (1) and the intermediate header (3) so as to form a center region of the solar heat collection portion, and second superheating portions (4,4) which have groups of the heat transfer pipes connected between the intermediate header (3) and the two outlet headers (5) so as to be formed on opposite sides of the first superheating portion (2) respectively.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

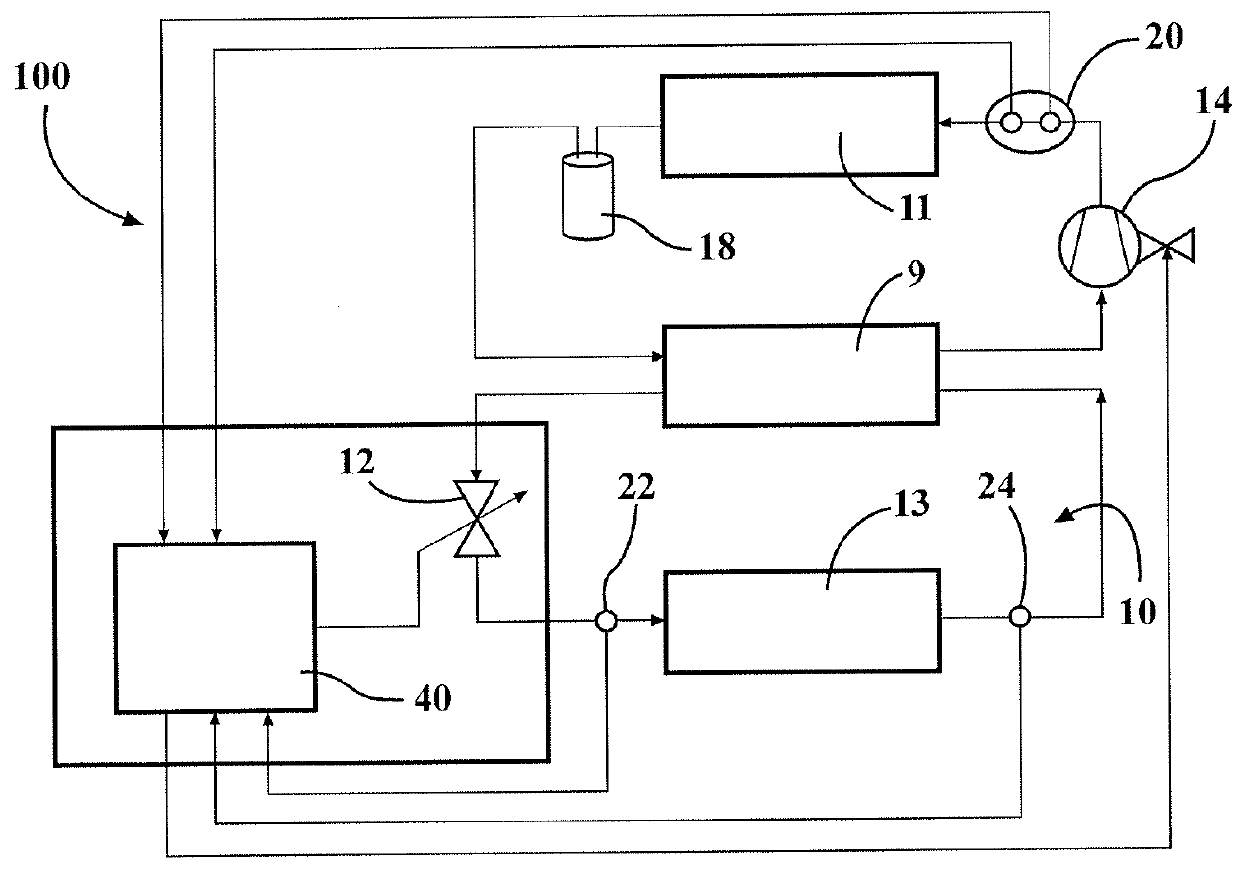

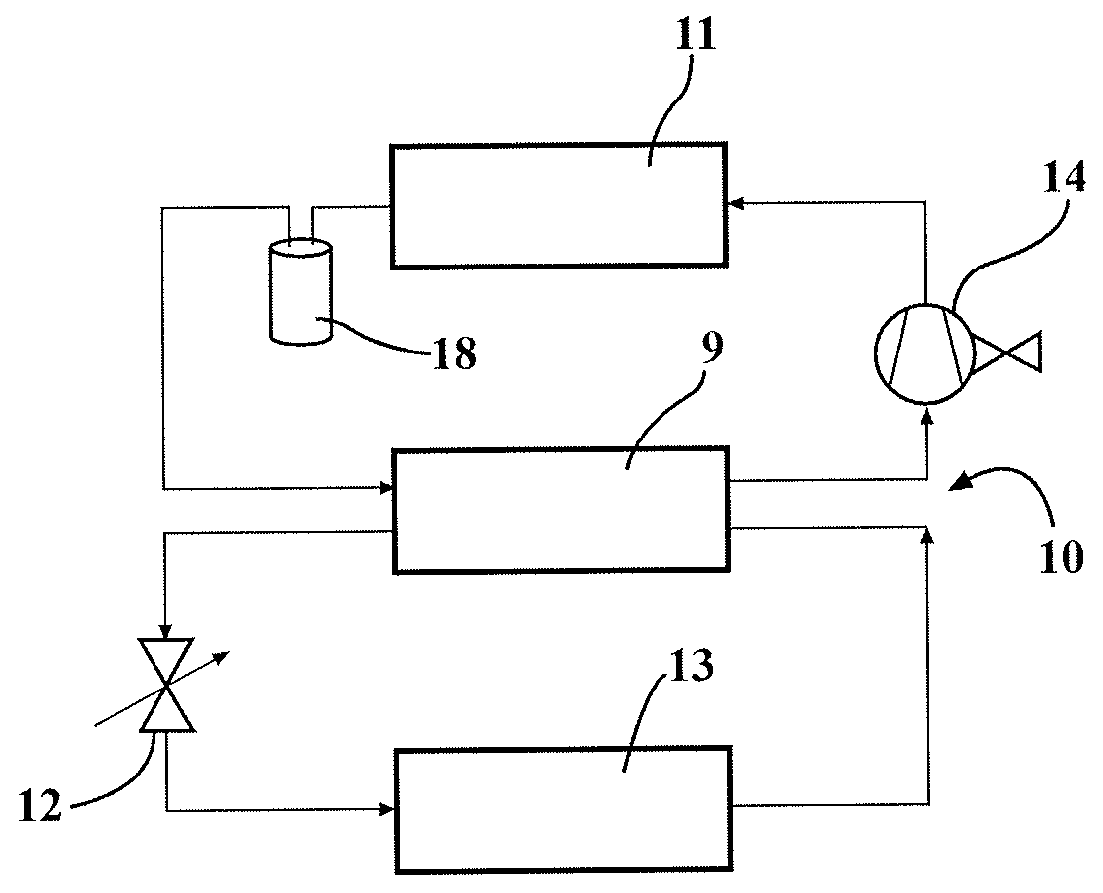

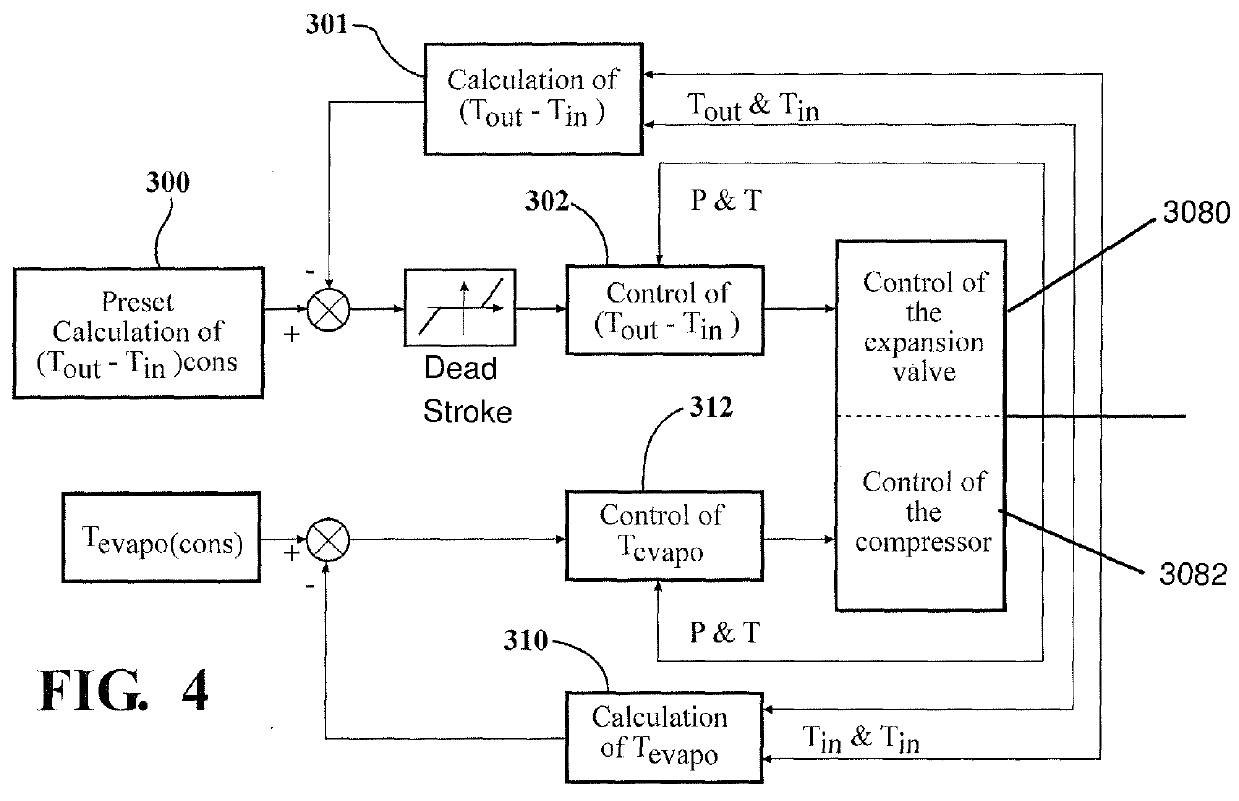

Air conditioning system provided with an electronic expansion valve

ActiveUS9341398B2Optimized coefficientReduce system costMechanical apparatusEfficient regulation technologiesControl signalAir conditioning

An air conditioning device is used in a motor vehicle. The air conditioning device includes air conditioning circuit, which includes a compressor (14), a condenser (11), and / or an internal exchanger, an electric expansion valve (12) which opening ratio is changed according to a control signal, and an evaporator (13), which are traversed in this order by a refrigerant fluid and a control unit (40) capable of controlling a control signal of the expansion valve so as to regulate a control variable relating to the superheating of the evaporator or to the sub-cooling of the condenser (11) according to a chosen regulation rule.

Owner:VALEO SYST THERMIQUES

Full conversion process for high-concentration carbon monoxide

ActiveCN110498391AExtensive processShort processEnergy inputHydrogen productionHigh concentrationTemperature control

The invention relates to a full conversion process for high-concentration carbon monoxide. The process provided by the invention has a short flow, a system is reliable and has small resistance, equipment has a less number and a small occupied area, and is simple to control, and the investment and operating costs are low; a segmented axial-radial shift reactor is used, so that the problems of easyover temperature and difficult temperature control caused by change of load of feed gas having a high content of carbon monoxide in a shift reaction are solved, and compared with an axial shift reactor with stratified air inflow, the segmented axial-radial shift reactor has reduced shift furnace pressure drop and a reduced diameter and height of equipment, so that the equipment investment is greatly reduced; high-pressure saturated steam produced by a controllable isothermal reactor can be superheated, so that an external superheating furnace or combination with other devices for heating is not needed, and the investment and operation difficulty are reduced; improvement of a water-gas ratio of the system can be satisfied by using a method of spraying chilled water and supplementing self-produced saturated steam, high-pressure superheated steam is not need to be introduced from outside of a boundary area, so that energy consumption is reduced; and a temperature-controllable saturated steam generating system with a control valve is arranged, so that the temperature of shift gas can be quickly and effectively adjusted.

Owner:SINOPEC NINGBO ENG +2

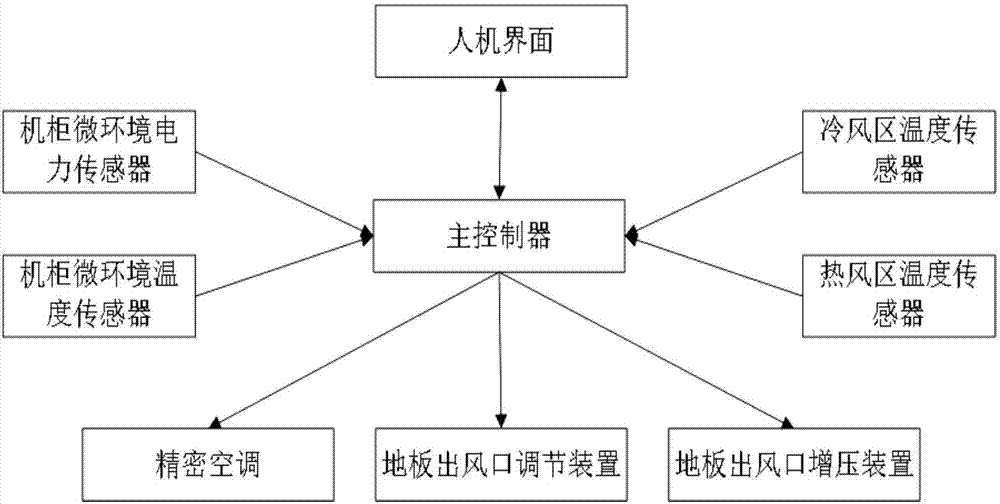

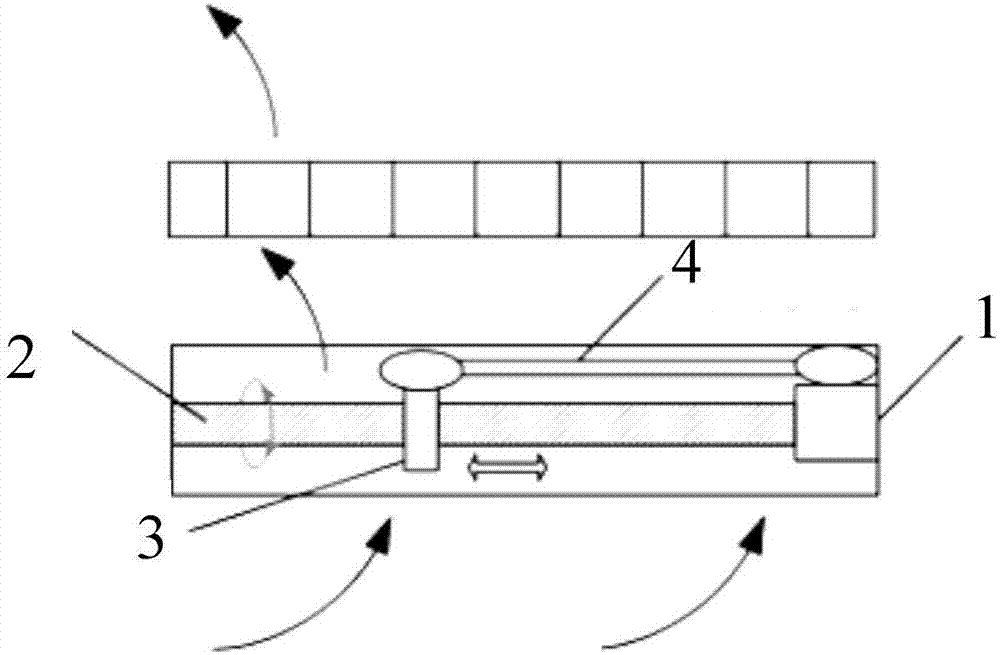

Data center computer room temperature control system and method

InactiveCN107388527AReduce cooling powerReduce energy consumptionSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringAir conditioning

The invention provides a data center computer room temperature control system and method, and belongs to the technical field of temperature control. The data center computer room temperature control method is based on precise air supplying principles, cold air sent out by an air conditioner is conveyed to each IT equipment cabinet through controllable air channels, so that the cold power and the wind power sent out by the air conditioner are utilized to the largest extent, and exchanged with the heating power generated by IT equipment, happening of the phenomenon that high temperature or partial superheating of the IT equipment is effectively avoided, the purpose that the equipment is cooled firstly and then the environment is cooled is achieved so as to reduce the refrigerating power of ineffective parts of the air conditioner, and the effects that the energy consumption is reduced and the energy is saved are achieved. The data center computer room temperature control system conducts real-time calculation on the heating power generated by each equipment cabinet based on the precise air supplying principles, the wind volumes of wind inlets and wind outlets of the equipment cabinets are adjusted intelligently so that each IT equipment can obtain sufficient heat exchange, an original partial superheating phenomenon is avoided, and the energy consumption of air conditioning equipment is reduced.

Owner:ANSTEEL GRP MINING CO LTD

Strip-casting 700-MPa-level weathering resistant steel and production method thereof

The invention discloses strip-casting 700-MPa-level weathering resistant steel and a production method thereof. The method comprises the steps of 1), smelting: the chemical components of molten steelcomprises C lower than 0.03%, 0.20-0.80% of Si, Mn lower than 1.0%, 0.03-1.50% of P, S lower than or equal to 0.008%, N lower than or equal to 0.008%, 0.40-1.50% of Cu, 0.80-1.50% of Cr, Ni lower than0.10%, 0.05-0.20% of Nb, 0.05-0.20% of V and the balanced Fe and unavoidable impurities; 2), strip casting: continuous casting is conducted on molten steel on which qualified smelting is conducted bya pair of copper casting rolls which are rotated in the same directions to produce a casting strip with the thickness of 1.4-2.5 mm, and the superheating of the molten steel is controlled to be lowerthan 80 DEG C; 3), casting strip online hot rolling: the hot rolling pressing amount is 15-65%, the temperature of pressed strip steel is 950-1050 DEG C; 4), cooling and winding: the temperature of strip steel on which hot rolling is conducted is cooled down to 300-450 DEG C through atomizing cooling to obtain fine and uniform ferrite and less amount of pearlite tissues. The 700-MPa-level weathering resistant steel has the advantages of short production procedure, low production cost, good strip steel shape and easy welding.

Owner:SHAGANG GROUP +2

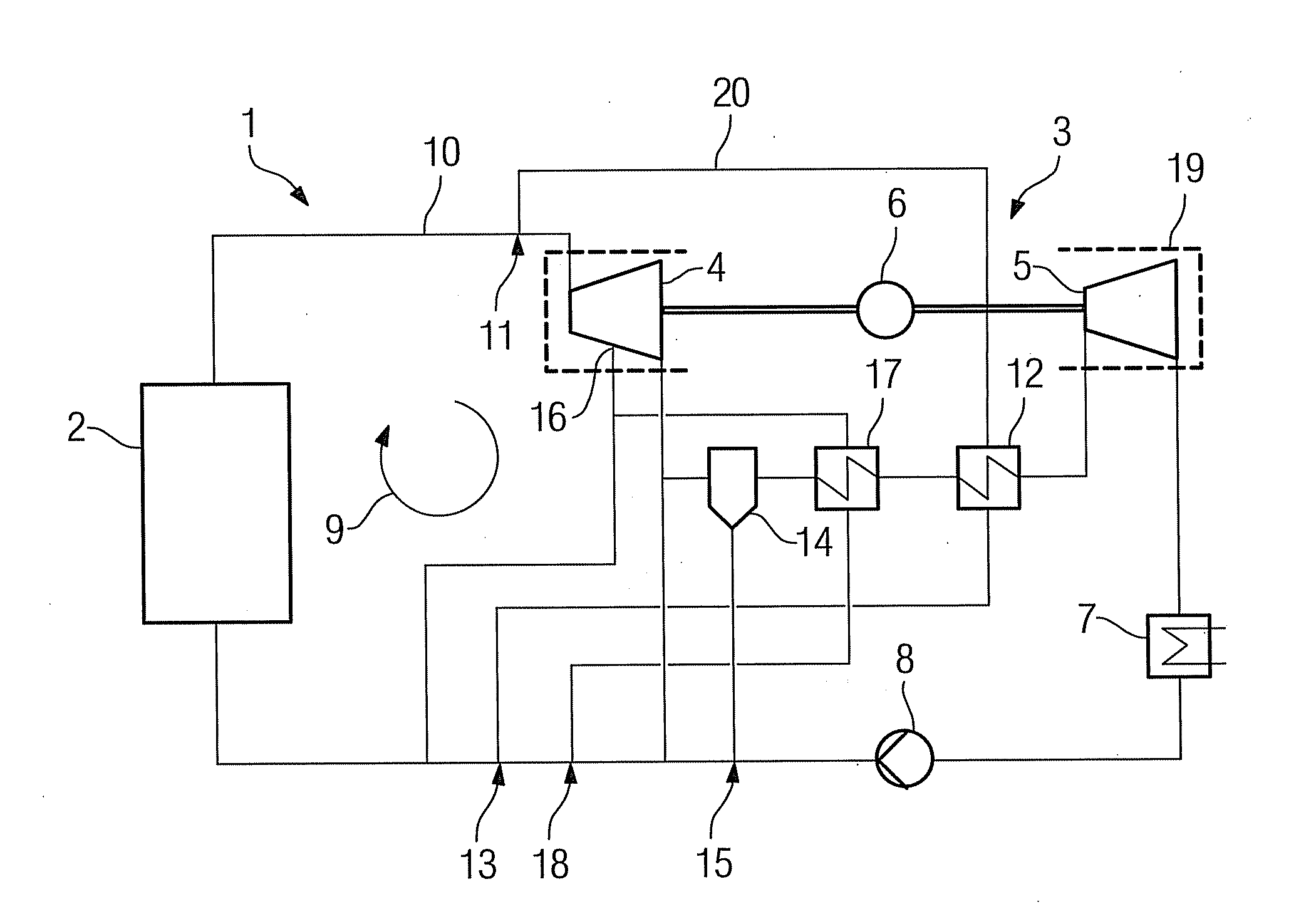

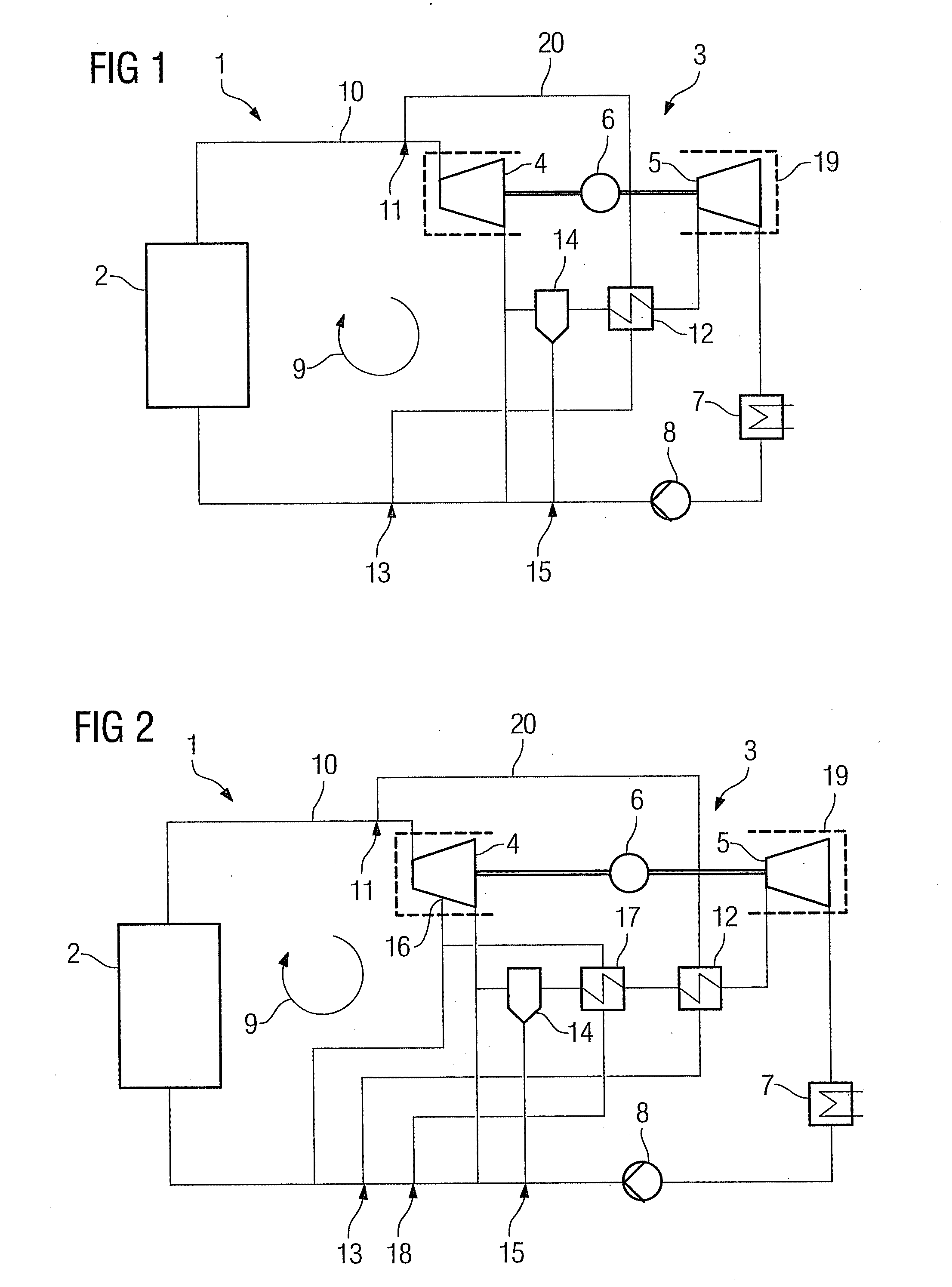

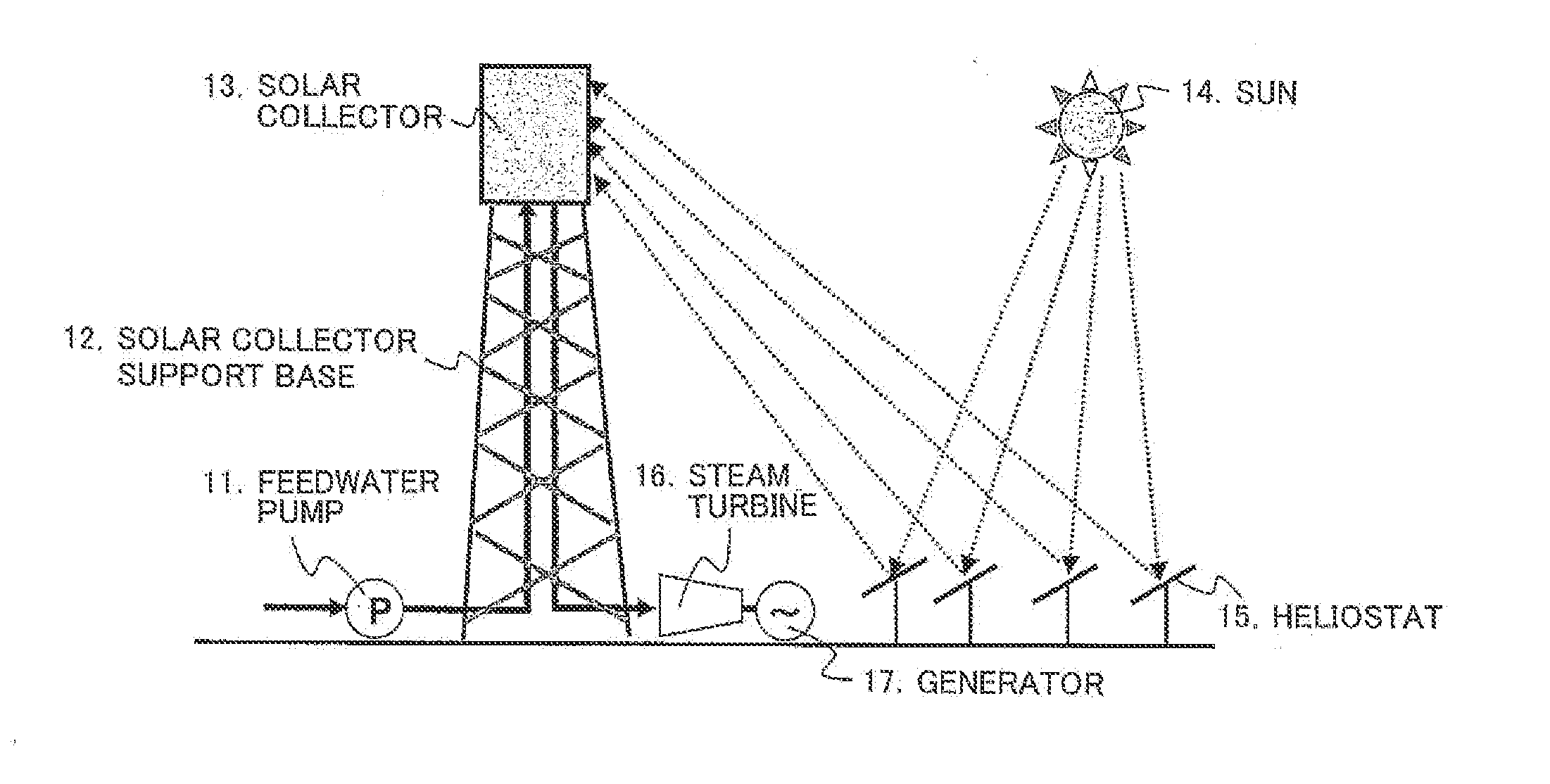

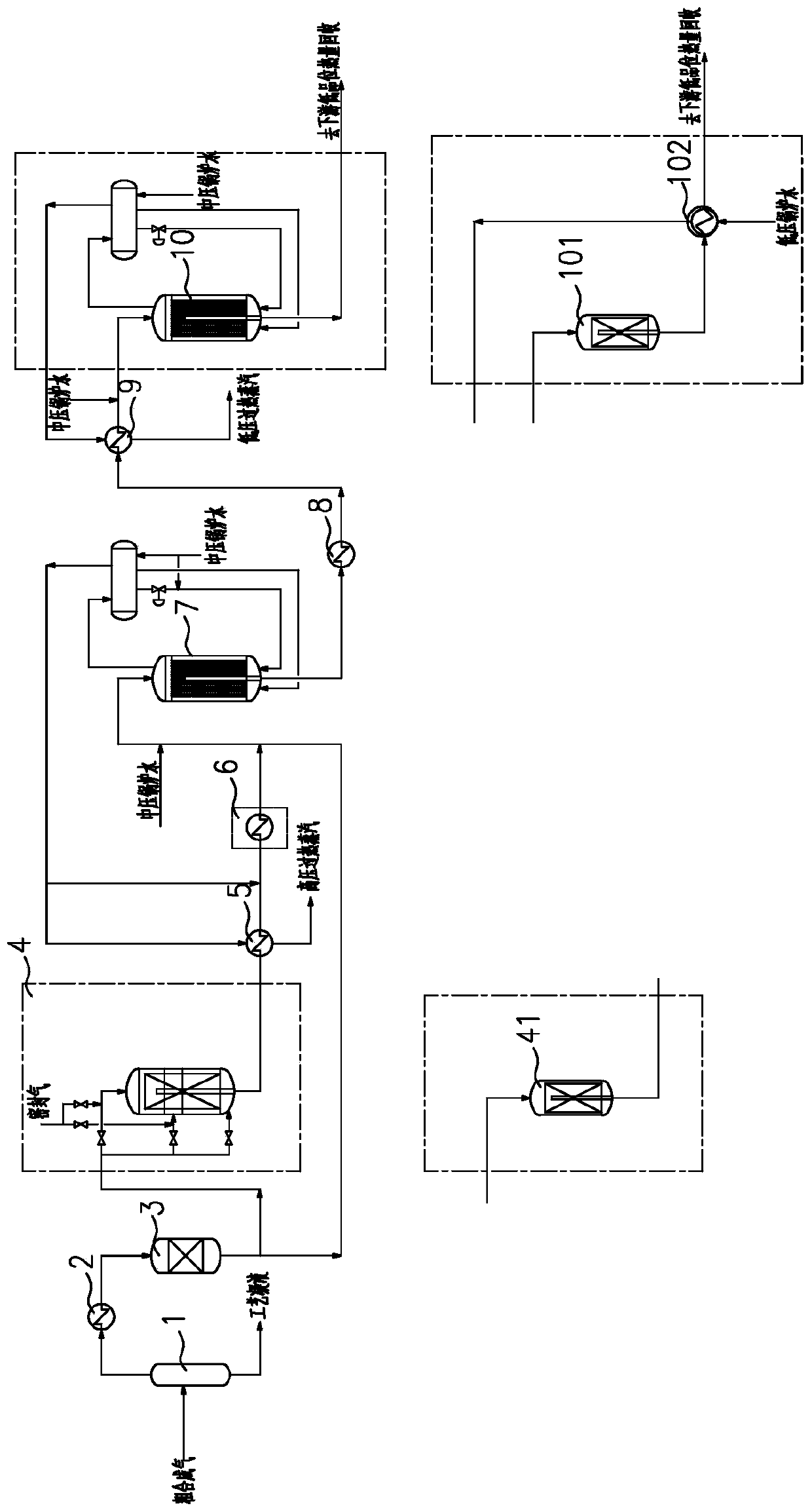

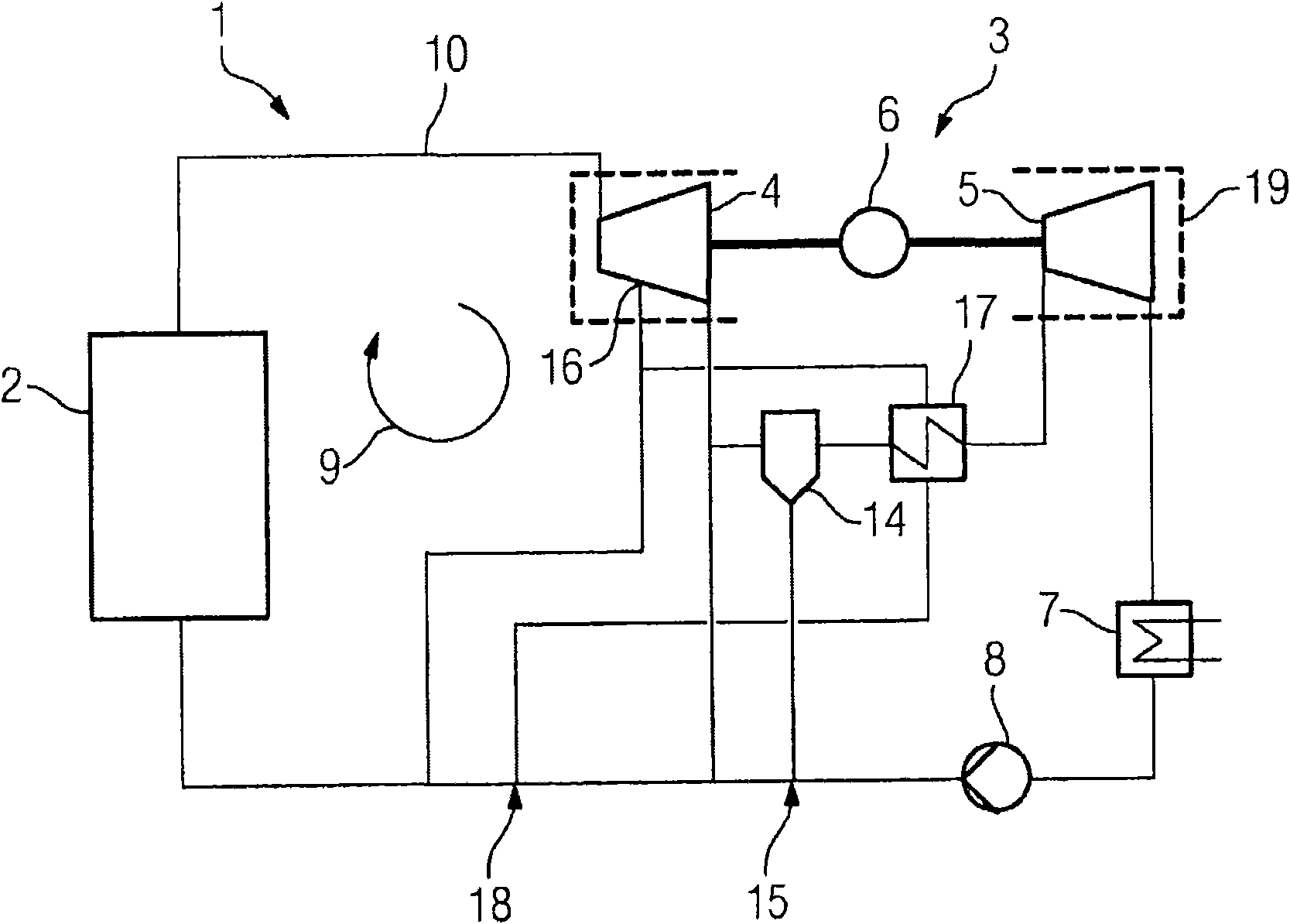

Method and device for intermediate superheating in solar direct evaporation in a solar-thermal power plant

The invention relates to a solar-thermal power plant (1), comprising a working fluid circuit (9), a solar steam generator based on direct evaporation, and a steam turbine (3) for relieving the workingfluid on a relief path (19) while supplying technical work, comprising at least one intermediate superheater, which can be heated by means of working fluid that can be removed from the circuit (9) upstream of the intermediate superheater and superheated by means of the working fluid thereof, which can be fed downstream of the heating removal by flowing into the relief path (19). The invention further relates to a method for operating such a plant.

Owner:SIEMENS AG

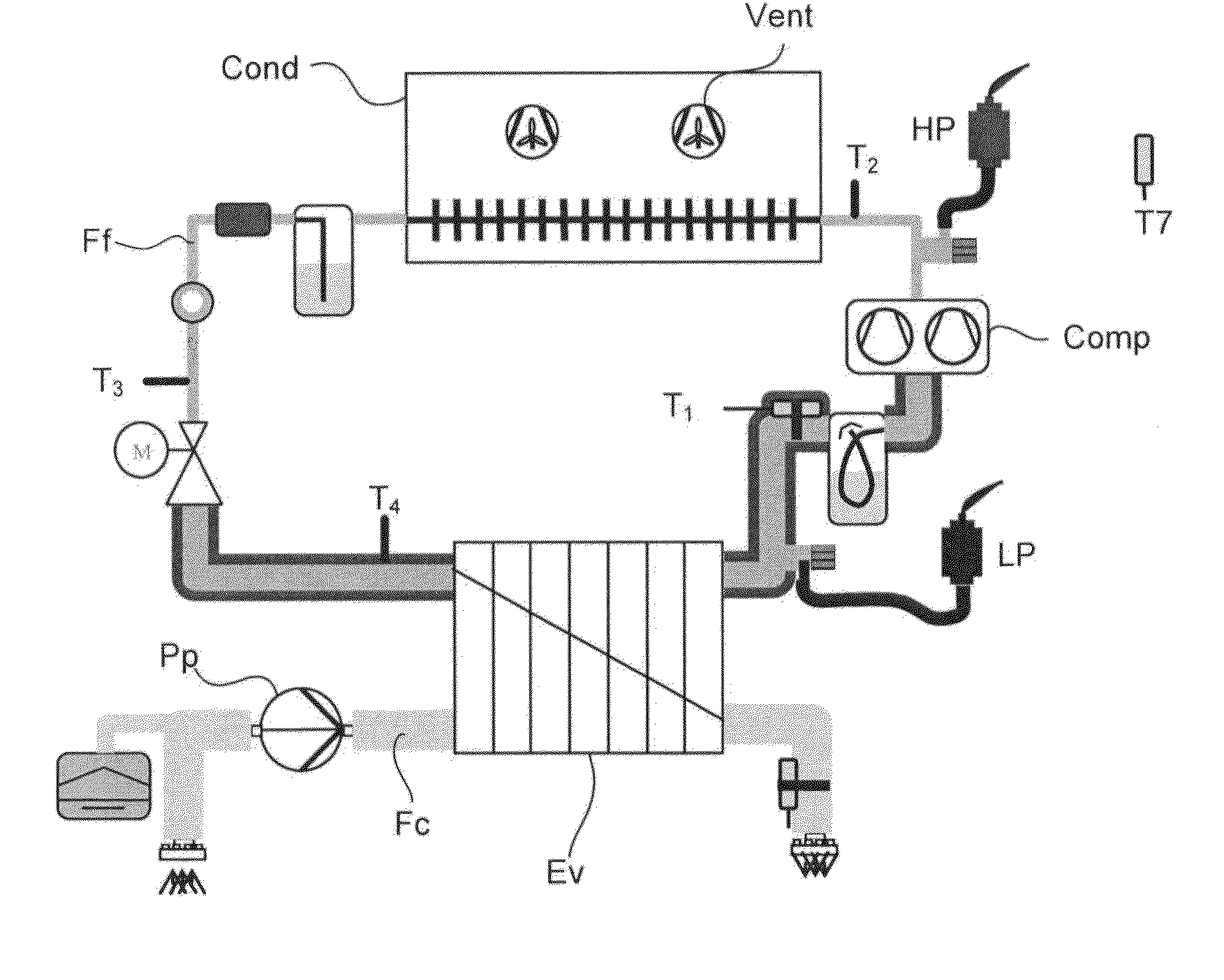

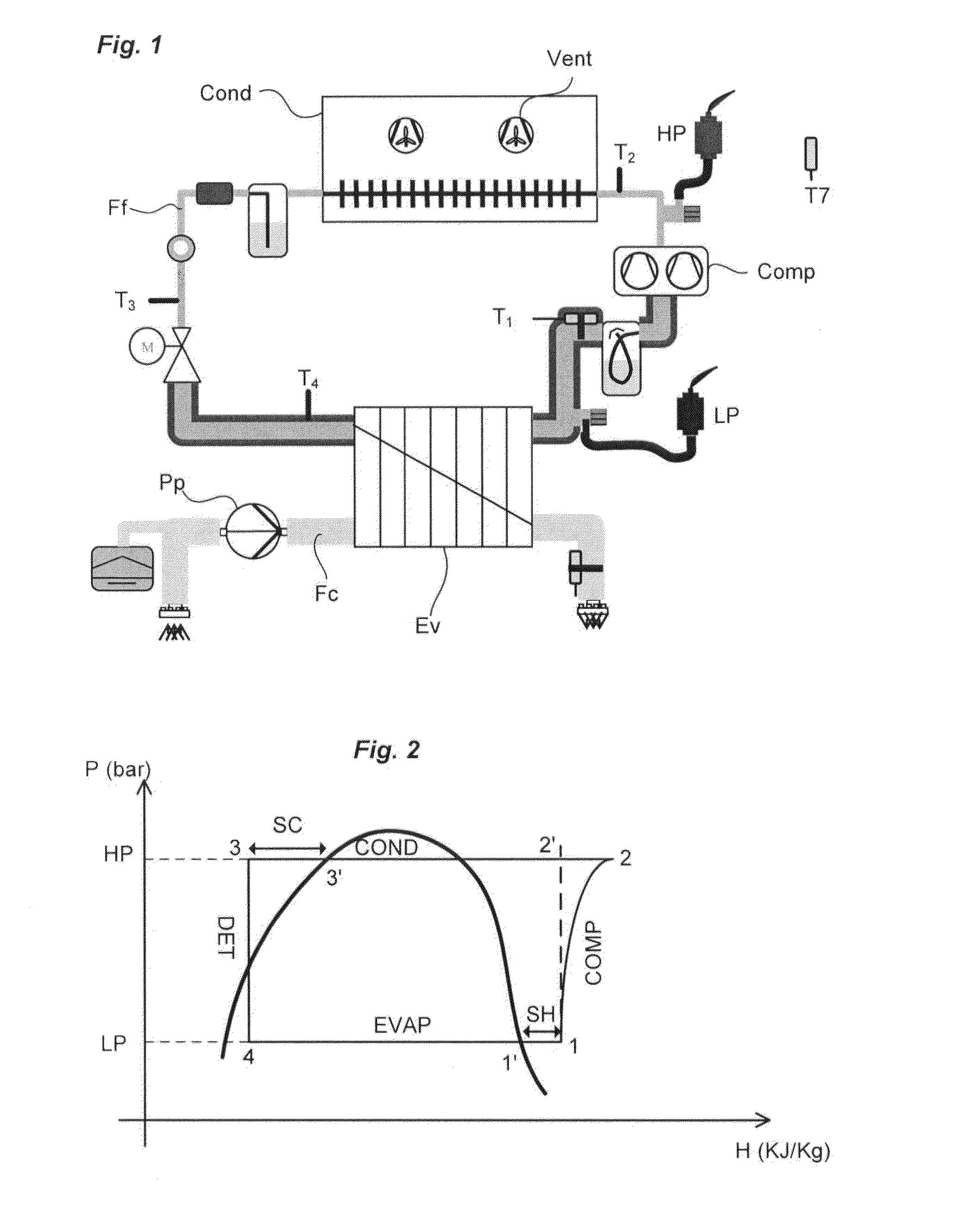

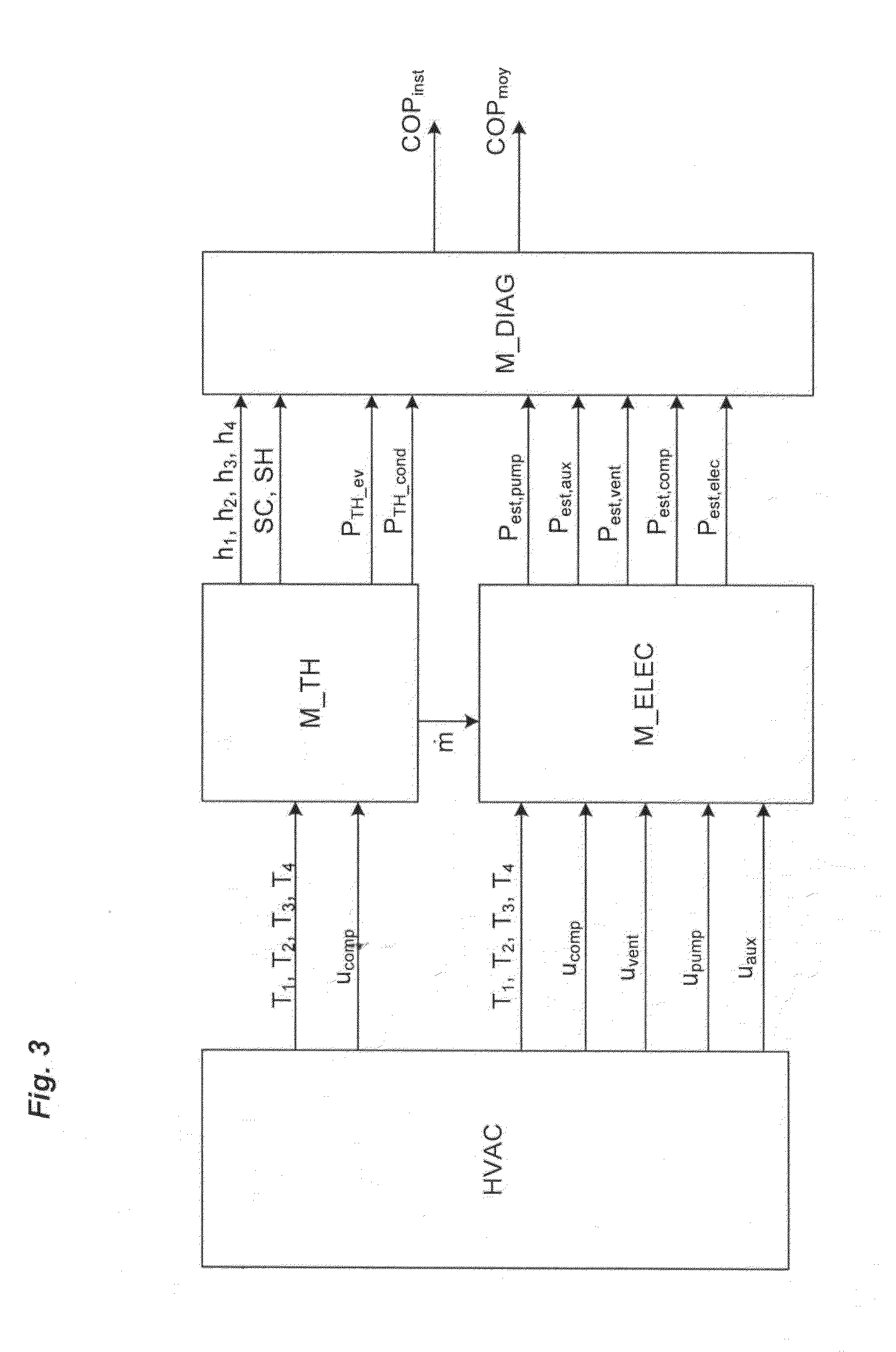

Method for the diagnostic analysis of a heating, ventilation and air-conditioning system (HVAC)

The invention relates to a method for the diagnostic analysis of a heating, ventilation and air-conditioning system (HVAC), comprising at least one compressor (Comp) connected to an air condenser (Cond) and designed for the circulation of a coolant fluid (Ff), an evaporator (Ev) connected to the air condenser (Cond) via a expansion device (Det) and permeated by a heat transfer fluid (Fc), wherein said air condenser comprises at least one ventilator (Vent). Said method permits the determination of enthalpies in the system at the compressor intake, the compressor discharge, the inlet to the expansion device and the outlet of the expansion device, together with the superheating of the system, using only three temperature measurements and the command function of the compressor.

Owner:SCHNEIDER ELECTRIC IND SAS

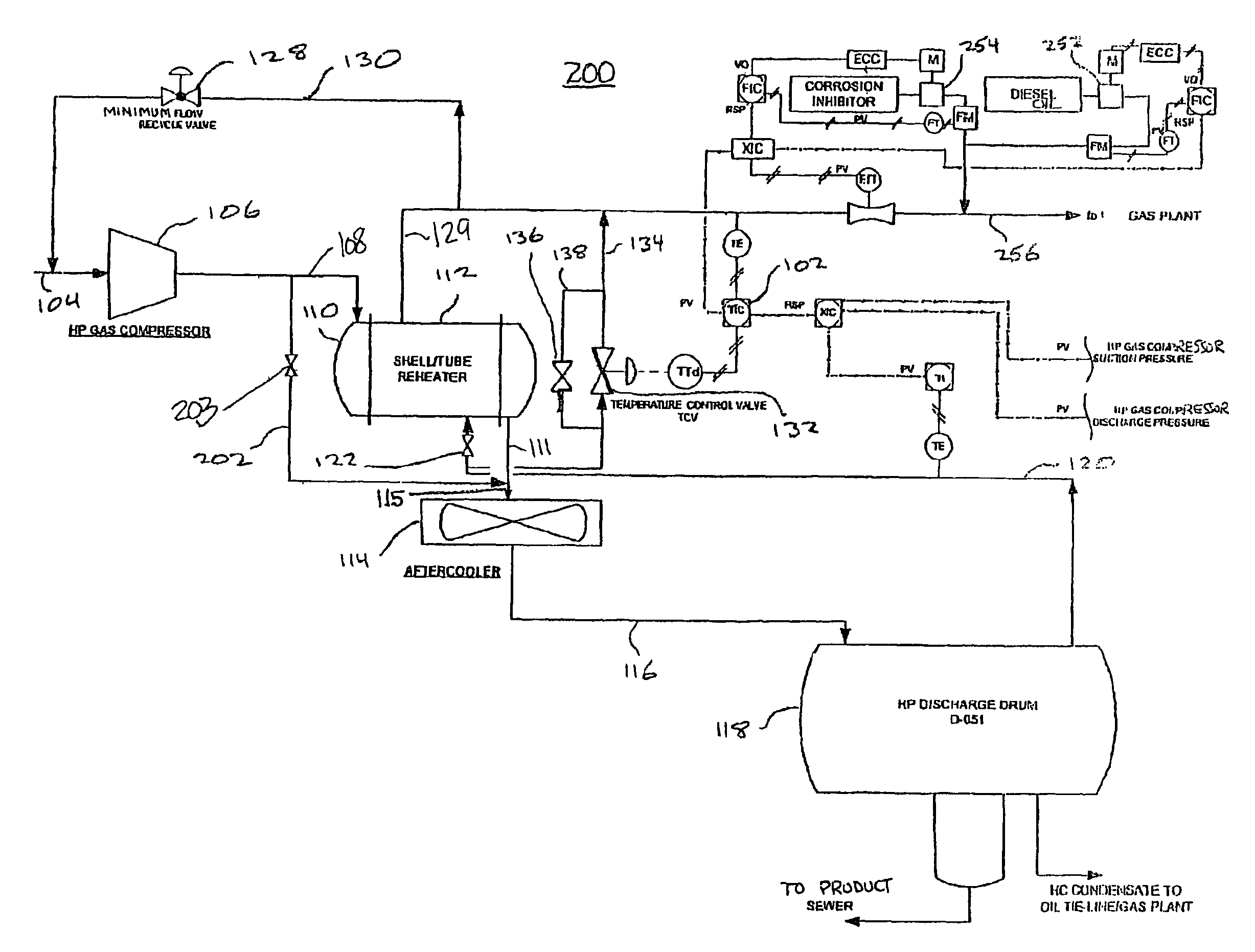

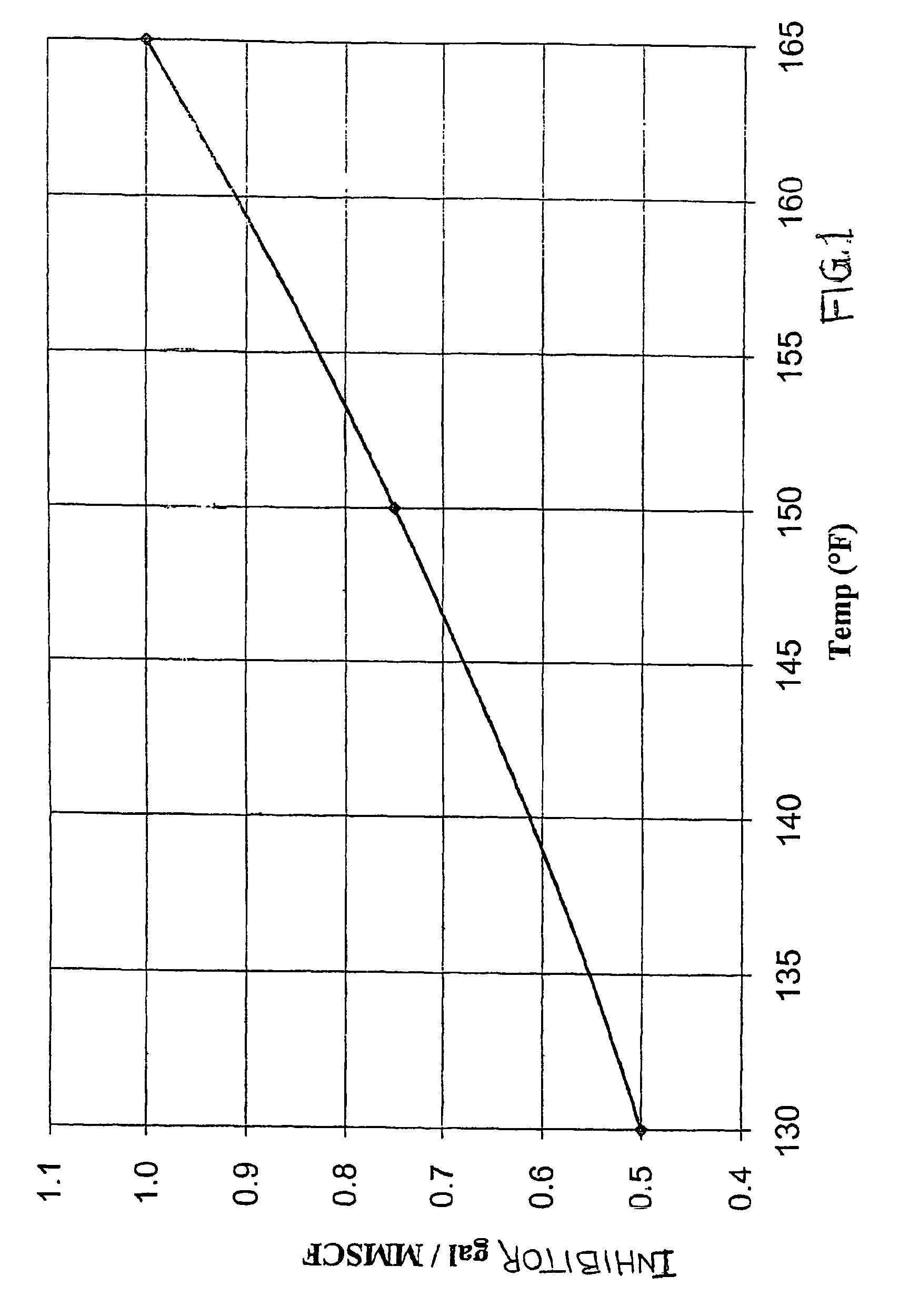

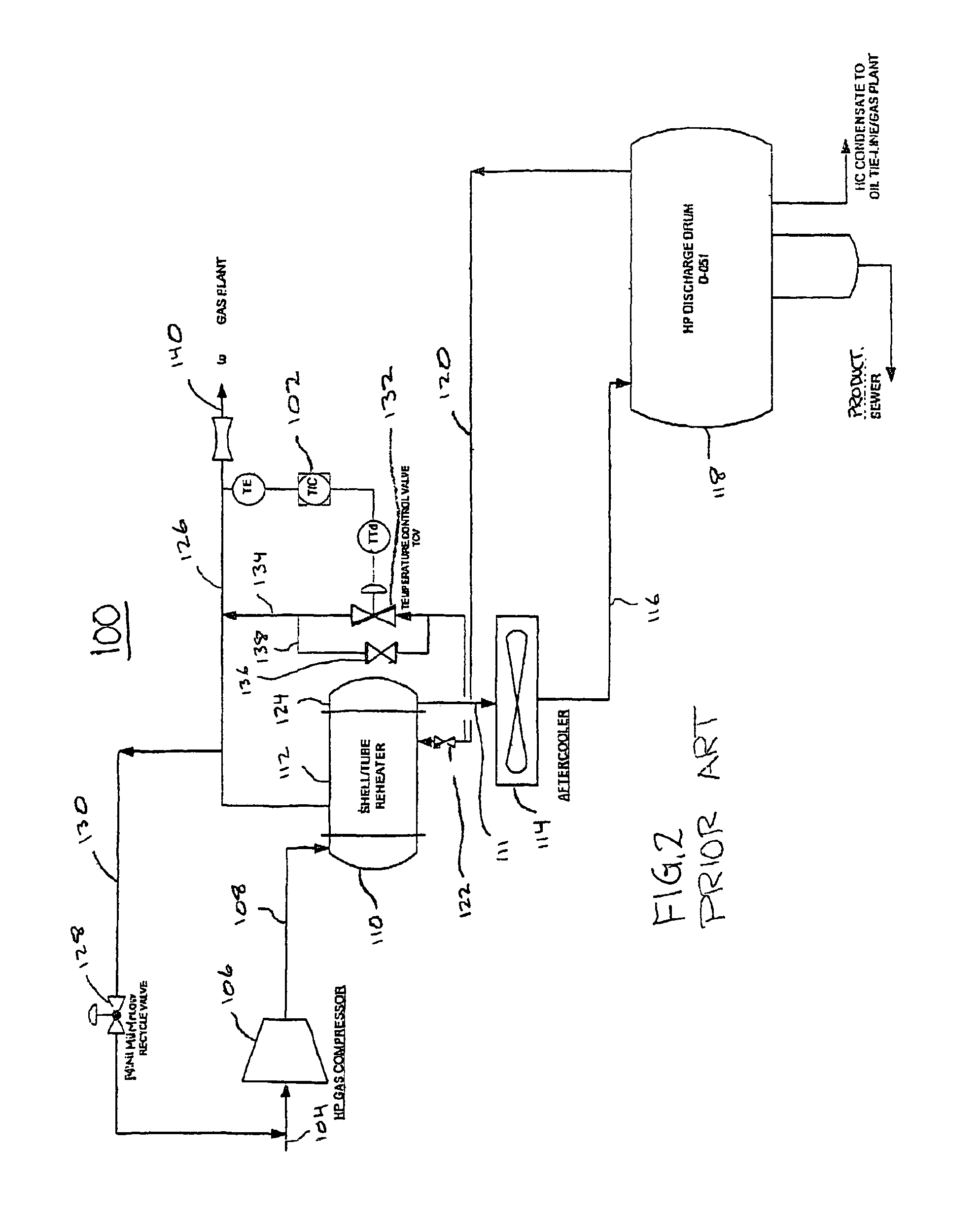

Controlled superheating of natural gas for transmission

ActiveUS7452390B1Low costImprove accuracyTemperatue controlHydrocarbon purification/separationAutomatic controlCompressed natural gas

A method is provided for controlling superheating and temperature of a compressed natural gas stream and the addition of a corrision inhibitor composition for transmission through a pipeline that includes: a. dividing a stream of natural gas discharged from a high pressure gas compressor (106) into a first portion (108) and a second portion (202); b. passing the first portion (108) of the gas from the gas compressor to a heat exchanger (112) to heat the gas to a predetermined temperature; c. passing the first portion of gas (111) exiting the heat exchanger to an aftercooler (114); d. passing the second portion (202) of natural gas discharged from the gas compressor (106) to the aftercooler (114) without passing it through the heat exchanger (112), the second portion of gas and the first portion of gas being mixed at the aftercooler inlet and cooled by the aftercooler and discharged from the aftercooler as a cooled gas stream (116) having a temperature no greater than a first temperature; e. passing the cooled gas stream (116) from the aftercooler to a liquid discharge drum (118) to remove condensate from the cooled gas and discharging from the drum a partially dried gas stream (120) at a second temperature; f. passing the partially dried gas stream (120) from the discharge drum to the heat exchanger (112) in heat exchanging relation with the first portion of gas (108) from the gas compressor, and superheating at least a portion of the gas stream (120) to a third temperature to provide a superheated gas stream (129), the third temperature being controlled by an automated control loop responsive to a differential pressure across the gas compressor (106); and g. passing the superheated gas stream (129) into a transmission tie-line (256) and injecting a predetermined amount of a corrosion inhibitor composition into the tie-line to mix with the superheated gas stream, where the amount of corrosion inhibitor injected is proportioned in response to the third temperature.

Owner:SAUDI ARABIAN OIL CO

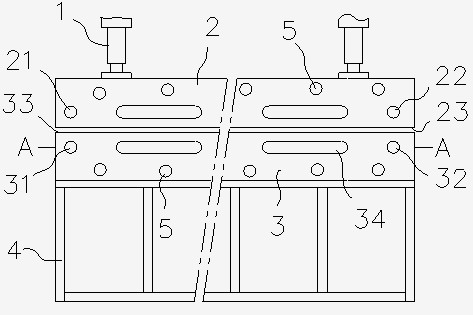

Hot press

InactiveCN102126328AImprove the effect of thermal processingSave electricityLaminationLamination apparatusFiberEngineering

The invention discloses a hot press used for processing a composite fiber plate, which comprises an upper press plate and a lower press plate, wherein the upper press plate and the lower press plate are provided with an electric heating device; the upper press plate and the lower press plate are internally provided with uniformly distributed heat conduction oil paths; and the side walls of the upper press plate and the lower press plate are respectively provided with an oil inlet and an oil return port which are communicated with the heat conduction oil paths. In the invention, heat conduction oil is adopted to absorb heat, relieve the heat transfer and balance the surface temperature of the press plates, so that the hot processing and molding effects of the composite fiber plate are improved, and the product defects of plate edge superheating and carbonization and insufficient low-temperature processing are overcome; and meanwhile, heat energy is slowly released through the heat conduction oil, thereby electric energy is saved.

Owner:铜陵华源汽车内饰材料有限公司

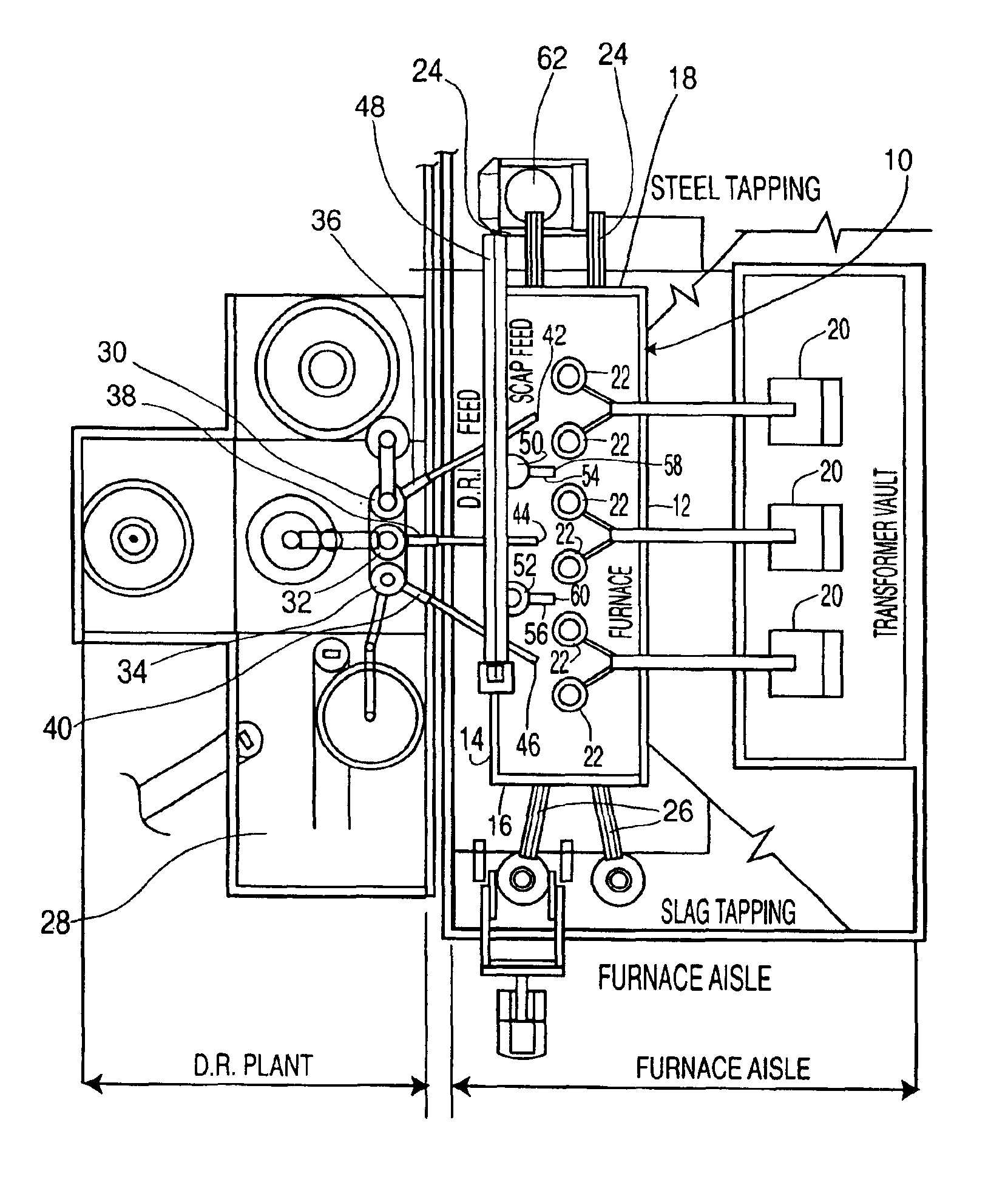

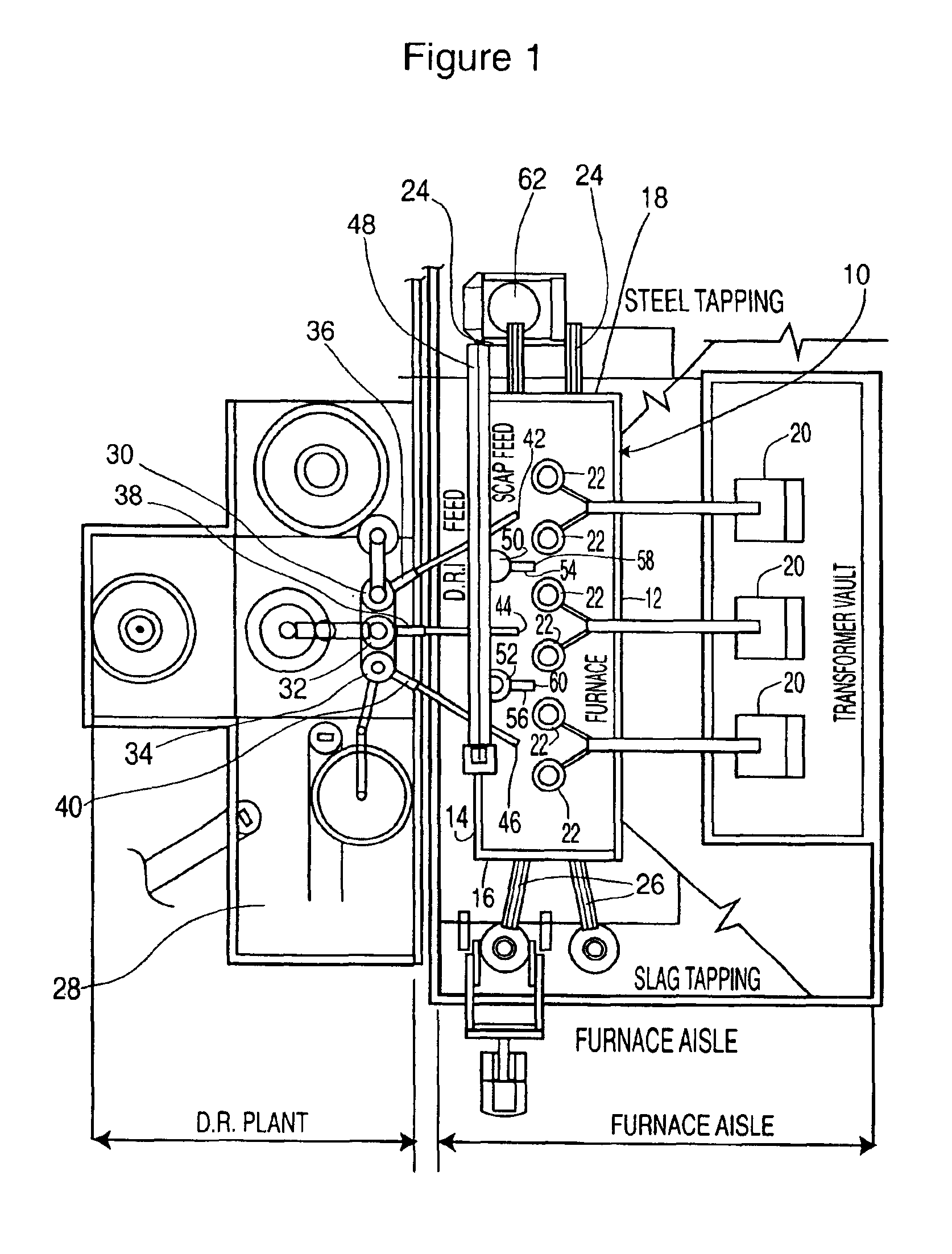

Continuous steelmaking process

InactiveUS6875251B2Refractory wear being minimizedHighly basicBlast furnace componentsBlast furnace detailsSteelmakingElectric arc furnace

A process for the manufacture of steel in which a charge material comprising direct reduced iron, and optionally containing steel scrap, is continuously charged into a stationary electric arc furnace. Inside the furnace, a bath of molten steel and a continuous slag layer are maintained, the steel bath preferably having a volume of approximately 7 to 13 tap volumes. Heat for melting the charge material is preferably provided by open arcs between the electrodes and the metal bath, with the slag layer preferably being superheated to about 40 to 150° C. above the bath temperature. In order to prevent excessive superheating, the slag preferably has a melting point substantially the same as, or greater than, the bath temperature, with the slag melting temperature being adjustable by varying the amount of MgO in the slag. The slag preferably has low basicity to reduce the rate of refractory erosion. The steelmaking process is preferably carried out in a steel manufacturing plant in which a direct reduction furnace is closely coupled to the electric arc furnace. Preferably, the direct reduction furnace is “stacked” above the electric arc furnace so that the direct reduced iron can be fed to the electric arc furnace by gravity through inclined conduits.

Owner:HATCH LTD

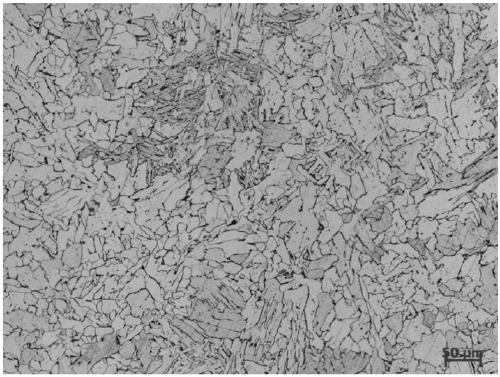

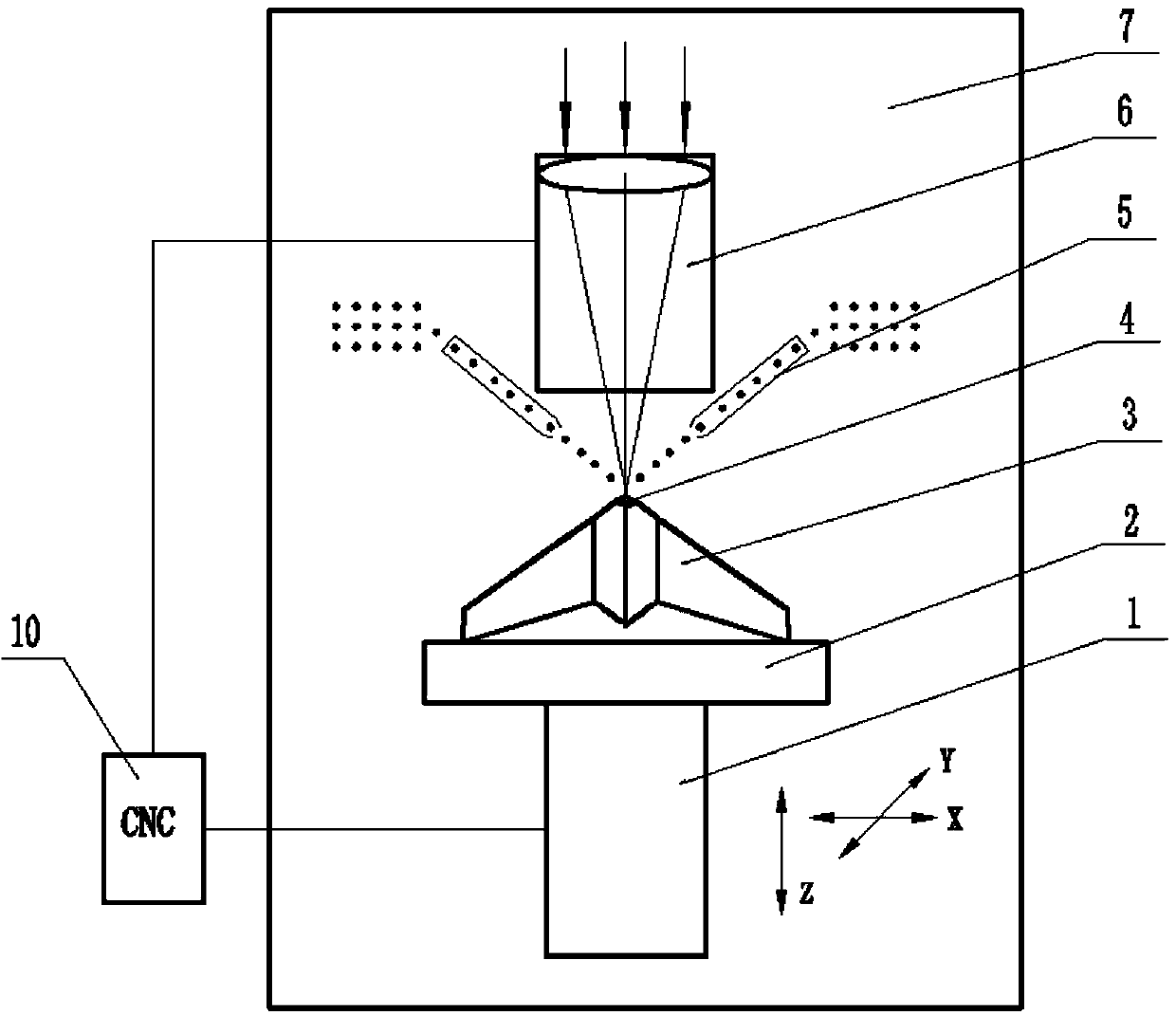

Titanium alloy thin-wall blade laser-cladding low-stress local orientation cooling restoration method

InactiveCN104046983ALow heat inputUniform microstructureMetallic material coating processesRestoration methodTitanium alloy

The invention discloses a titanium alloy thin-wall blade laser-cladding low-stress local orientation cooling restoration method. A certain amount of iron powder is previously bonded around the thin-wall blade defect restoration point, high temperature generated in the laser cladding process is utilized to melt the titanium alloy powder by utilizing the metal melting phase-change latent heat unsteady-state partial high-efficiency heat absorption principle, and heat is conducted to the periphery of the thin-wall blade so as to melt the iron powder; and the melting of the iron powder needs to absorb abundant heat, thereby lowering the superheating, deformation, overburning and burnout in the thin-wall blade cladding process. Meanwhile, since the iron powder is subjected to local orientation cooling, the influence area is small, the microstructure of the cladding layer is uniform, and the grains are refined, thereby obviously reducing the internal stress and cracks and effectively enhancing the restoration forming quality of the titanium alloy thin-wall blade; and the cladding layer has the advantages of higher hardness than the plasma cladding layer, small stress strain, fewer cracks and pores and high bonding strength.

Owner:XI AN JIAOTONG UNIV

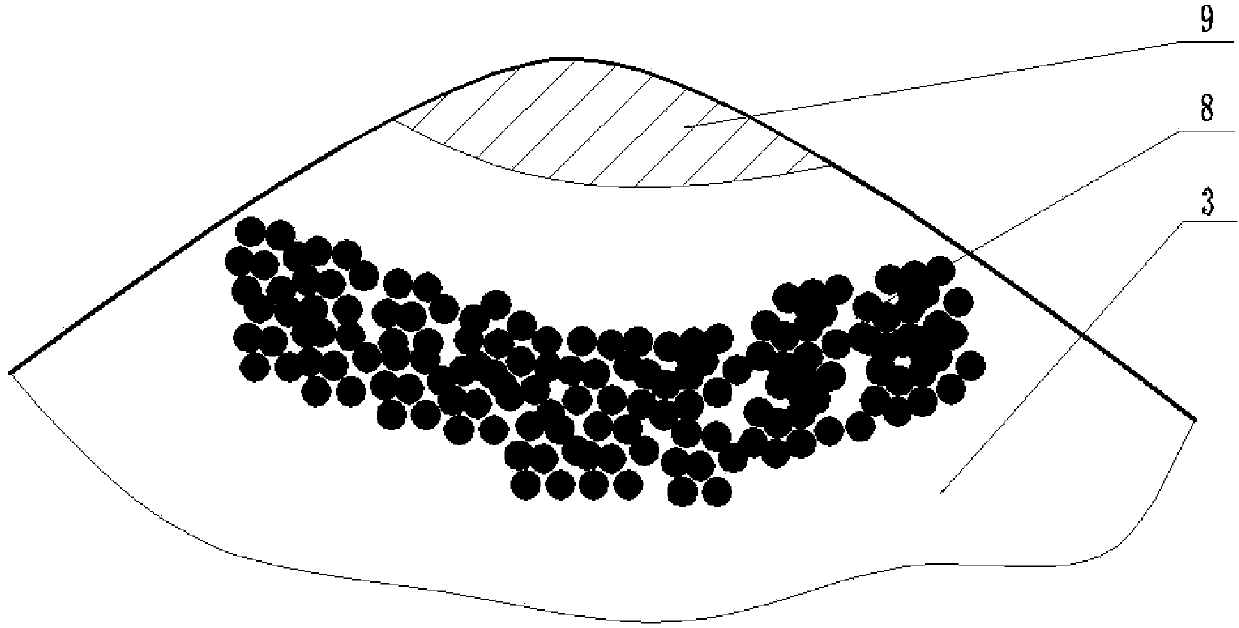

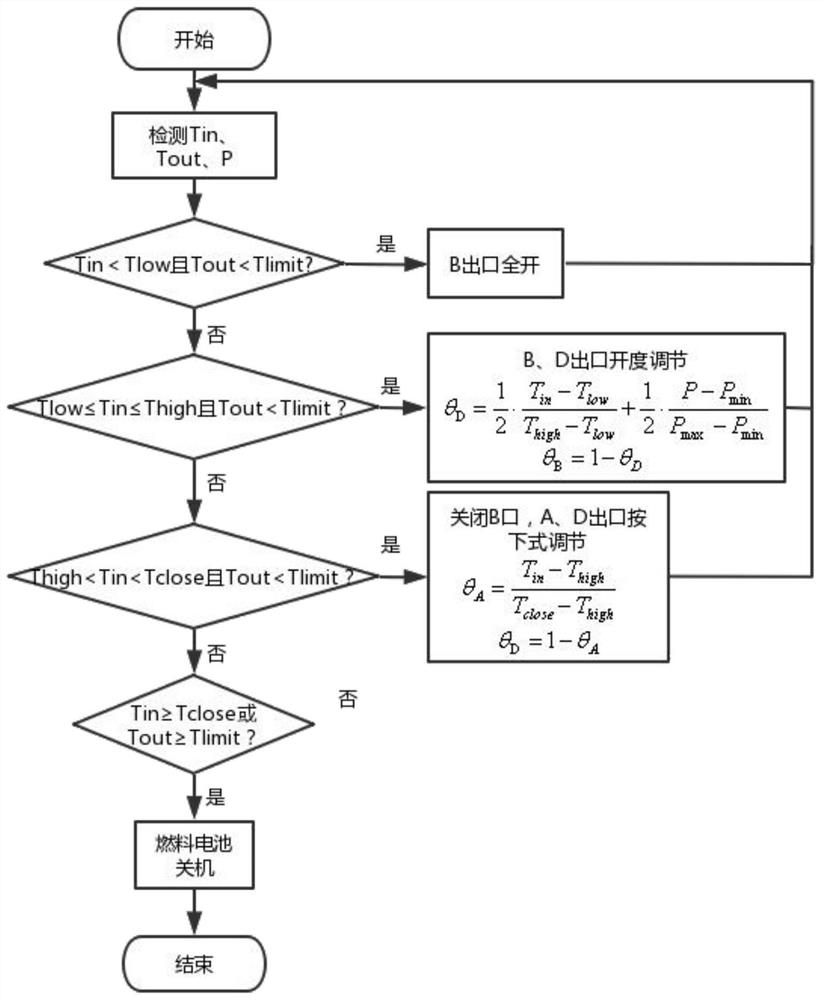

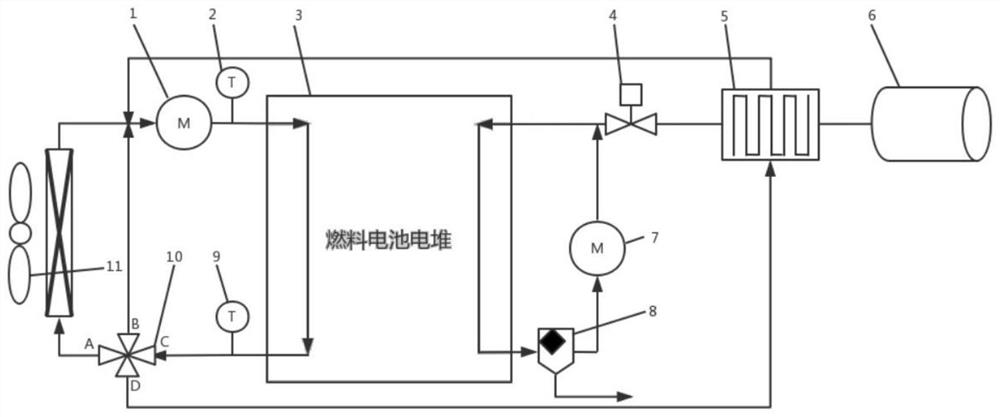

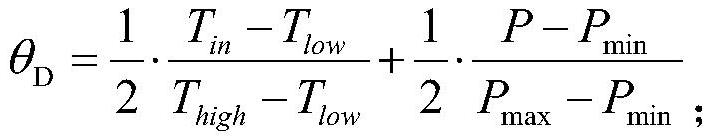

Control method of liquid hydrogen fuel cell waste heat recovery system

ActiveCN113258105AEfficient use ofReduce performance requirementsFuel cell heat exchangeHydrogen fuel cellLiquid hydrogen

The invention discloses a control method of a liquid hydrogen fuel cell waste heat recovery system, which comprises the following steps: when a fuel cell runs, the temperature Tin of a cooling liquid inlet of an electric pile and the temperature Tout of a cooling liquid outlet of the an electric pile are detected in real time, and the real-time power generation power P of the electric pile is calculated; and the detected temperature is compared with a temperature threshold, a four-way valve is adjusted through calculation based on the temperature and the generated power, and different waste heat recovery modes are started. The heat energy utilization rate is increased, the requirement for the heat dissipation capacity of a heat dissipation fan is lowered, the power consumption of a heat dissipation system is lowered, and meanwhile noise is reduced. The four-way valve is adjusted through calculation according to the temperature and the generated power, so that the internal temperature of the electric pile can be accurately regulated by utilizing waste heat, the condition of local supercooling or local superheating is avoided, and the performance of the fuel cell is favorably exerted.

Owner:四川荣创新能动力系统有限公司

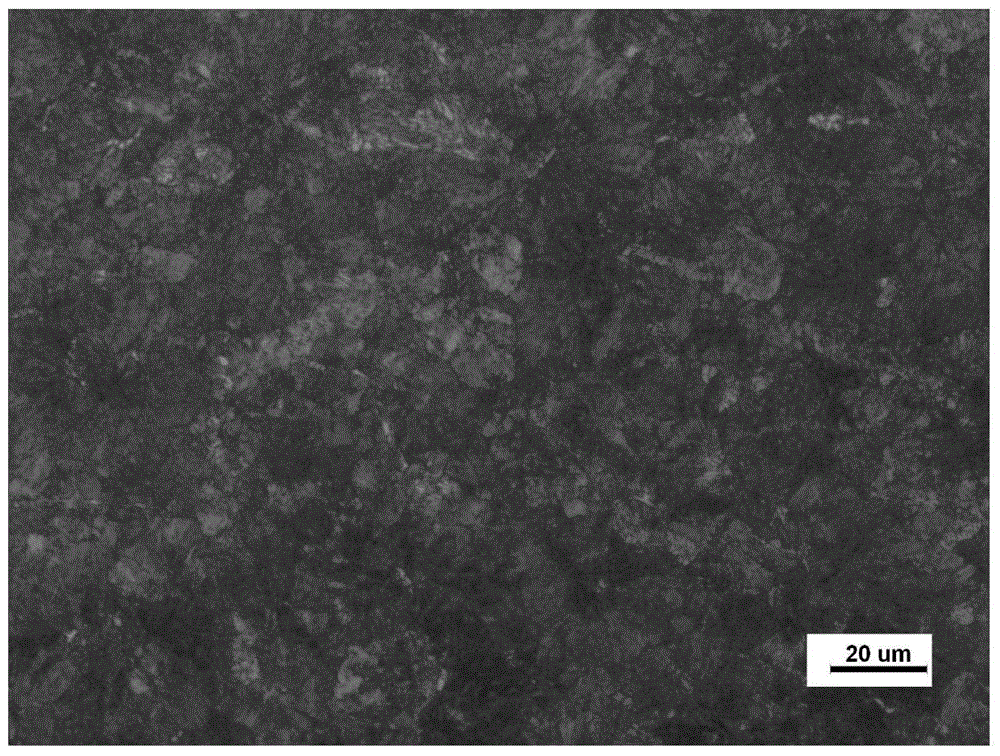

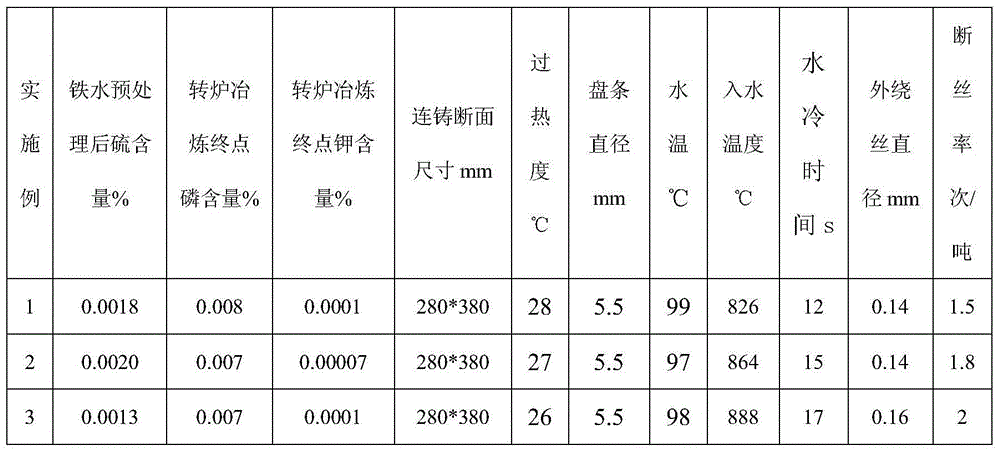

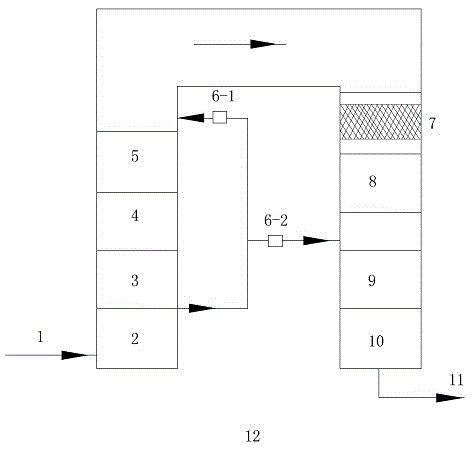

80 grade cord outer wire winding steel wire rod and production method thereof

The present invention provides a 80 grade cord outer wire winding steel wire rod, wherein the components comprise, by weight, 0.78-0.82% of C, 0.20-0.45% of Mn, 0.10-0.18% of Cr, 0.20-0.40% of Si, less than or equal to 0.010% of P, less than or equal to 0.010% of S, 0.0001-0.0004% of K, 0.0015-0.0025% of total oxygen, less than or equal to 0.05% of Cu, and the balance of iron and unavoidable impurities. According to the method, the temperature is controlled at 1530-1590 DEG C and the time is 50-120 min during the LF refining process, the middle ladle liquid steel superheating degree is not higher than 30 DEG C during the continuous casting process, the finishing rolling speed of the steel wire rod is 80-90 m / s, the steel wire rod phase change after the rolling is performed in water, the water temperature is controlled at 96-100 DEG C, the water inlet temperature is 810-890 DEG C, and the water cooling time is controlled at 10-20 s. According to the present invention, no mesh cementite precipitation is generated on the steel wire rod produced by using the method, the drawing diameter of the steel wire rod during the user outer wire winding production process is 0.15-0.18 mm, and the wire breaking rate is not more than 2 times / ton.

Owner:ANGANG STEEL CO LTD

Method and device for online removing refinery plant FCC device waste heat boiler scale

ActiveCN106765246AAvoid influenceWill not affect normal operationLighting and heating apparatusDispersed particle separationCombustion chamberFlue gas

The invention relates to a method for online removing refinery plant FCC device waste heat boiler ammonium bisulfate scale. In terms of the flue gas flowing direction, a combustion chamber, a high-temperature superheating section, a low-temperature superheating section, a high-temperature evaporation section, an SCR denitration section, a low-temperature evaporation section, a high-temperature economizer and a low-temperature economizer are arranged in a waste heat boiler in sequence. Two ways of high-temperature flue gas are led out from the rear portion of the combustion chamber of the waste heat boiler, wherein the first way of the high-temperature flue gas is mixed with flue gas after the high-temperature evaporation section to enable the mixed flue gas to reach the temperature of 350-400 DEG C, generating of ammonium bisulfate is reduced, and then the mixed flue gas enters the SCR denitration section to be subjected to denitration treatment; and the other way of the high-temperature flue gas is mixed with flue gas after the low-temperature evaporation section to enable the mixed flue gas to reach the temperature of 400-470 DEG C, and then the mixed flue gas enters the high-temperature economizer to enable the ammonium bisulfate condensed on a furnace pipe of the economizer to be gasified and decomposed, so that the purpose of removing the scale is achieved. The economizer of the FCC device waste heat boiler is effectively prevented from being blocked by the ammonium bisulfate, the increased pressure drop, caused by ammonium bisulfate blocking of the economizer, of the waste heat boiler is lowered, the purpose of efficient ash removing is achieved, and additionally normal operation of the boiler is not affected.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for effectively controlling generation of central cracks in medium-carbon steel plate

The invention discloses a method for effectively controlling generation of central cracks in a medium-carbon steel plate. Molten iron pretreatment, converter tapping pure aluminum block deoxidation, LF (ladle furnace) white slag refinement, RH vacuum treatment and other techniques are mainly utilized to control the molten steel purity and the continuous casting frequency, so that the tundish molten steel superheating temperature is controlled at 5-20 DEG C, the casting blank stacking slow cooling time is controlled to at least 45 hours, and the cooling speed of the rolled steel plate is controlled by an ultra-fast cooling system and a head / tail masking technique, thereby effectively controlling the generation of central cracks in the steel plate. The method improves the internal quality of the steel plate, enhances the performance qualification rate and the flaw detection qualification rate of flaw detection steel, and has favorable economical and social benefits.

Owner:NANJING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com