Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

100results about How to "Easy to grow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

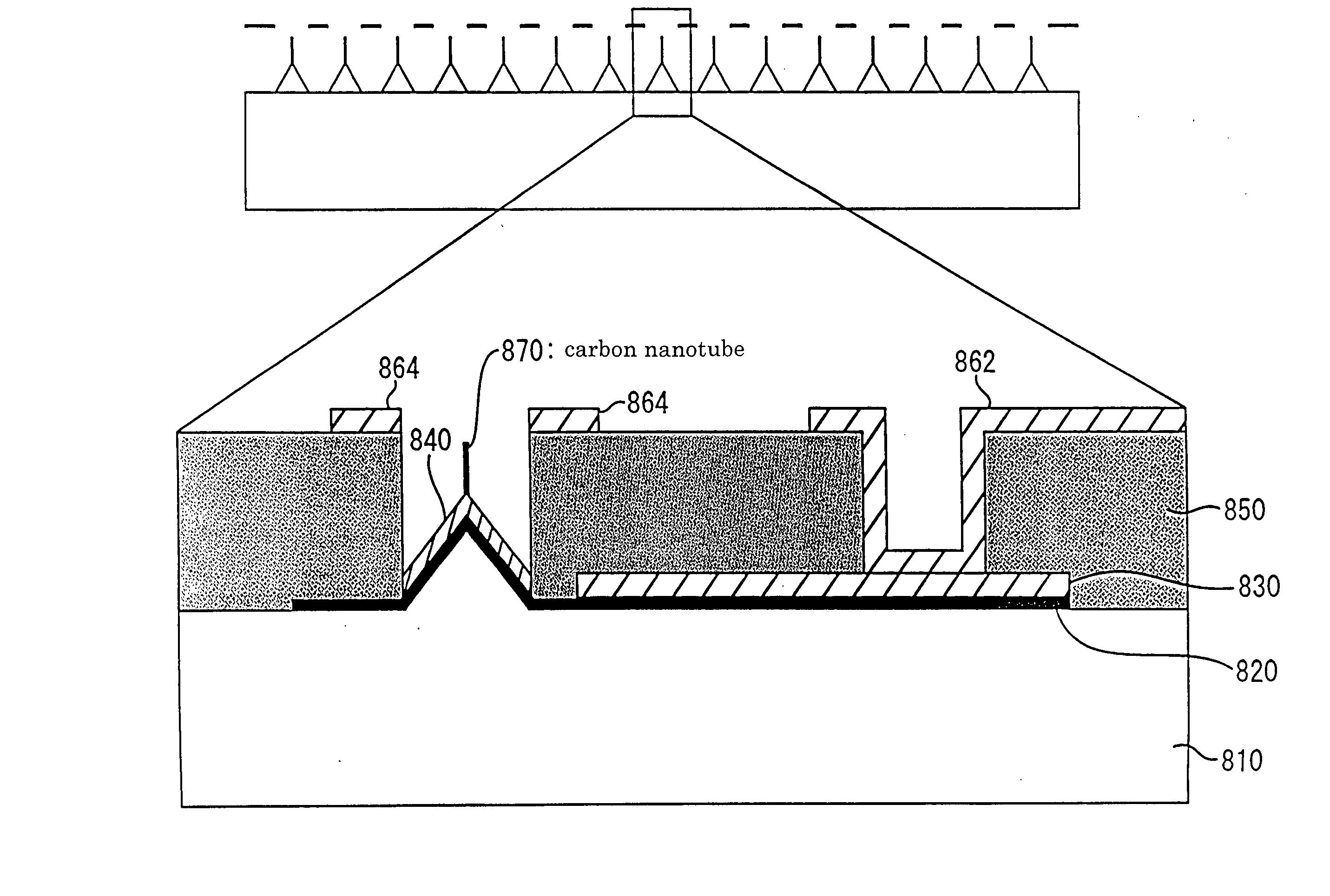

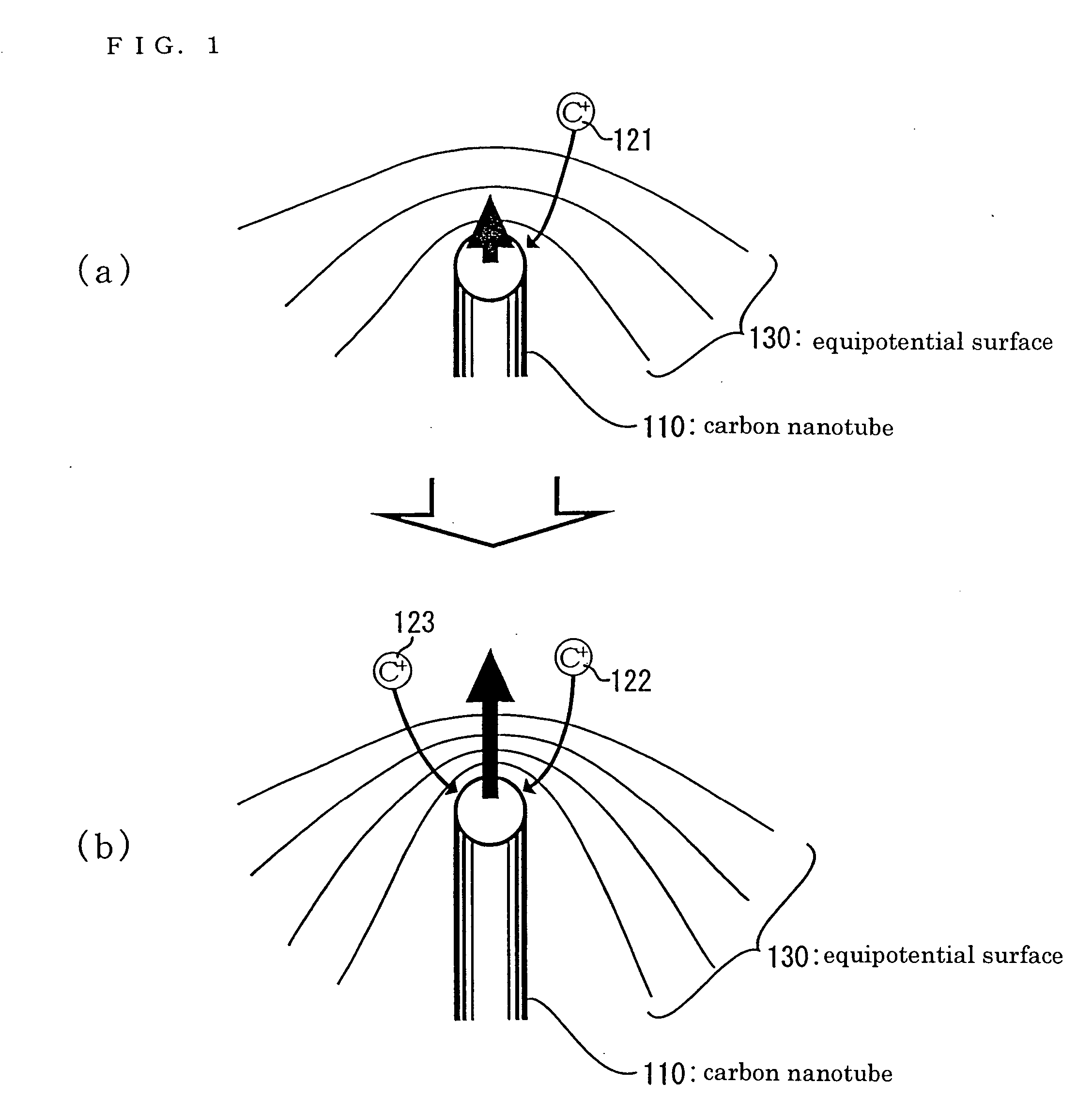

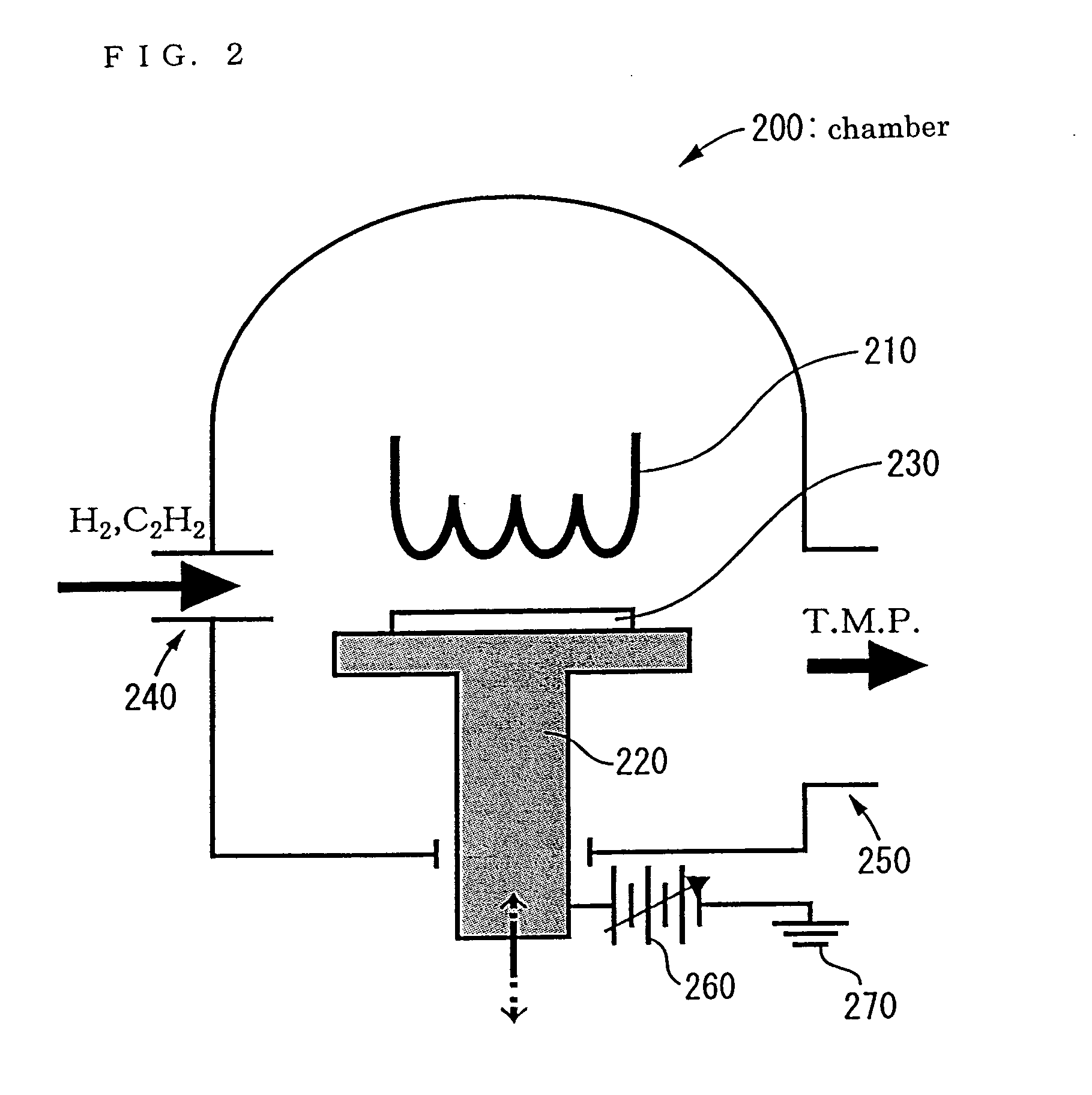

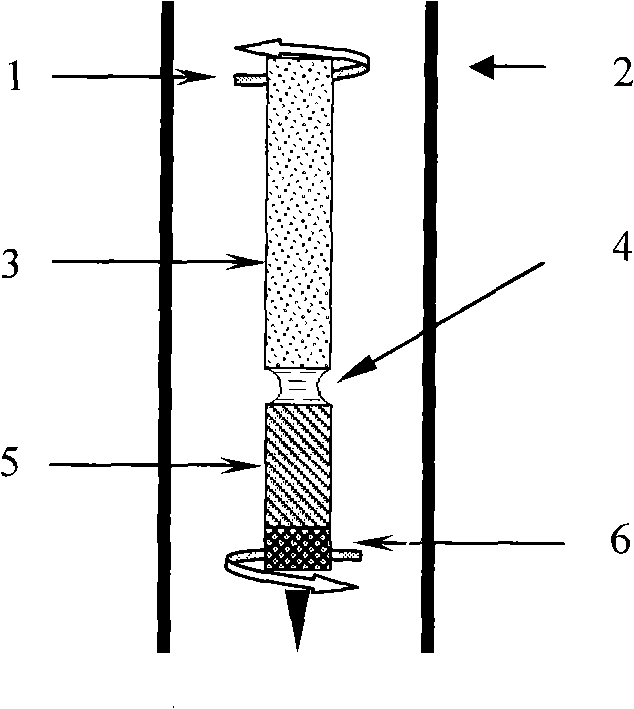

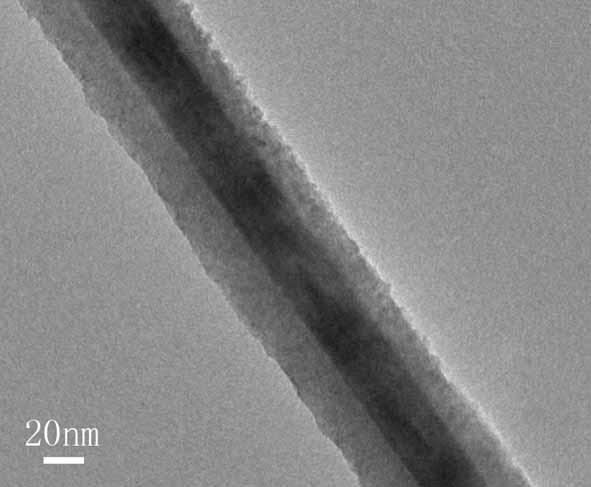

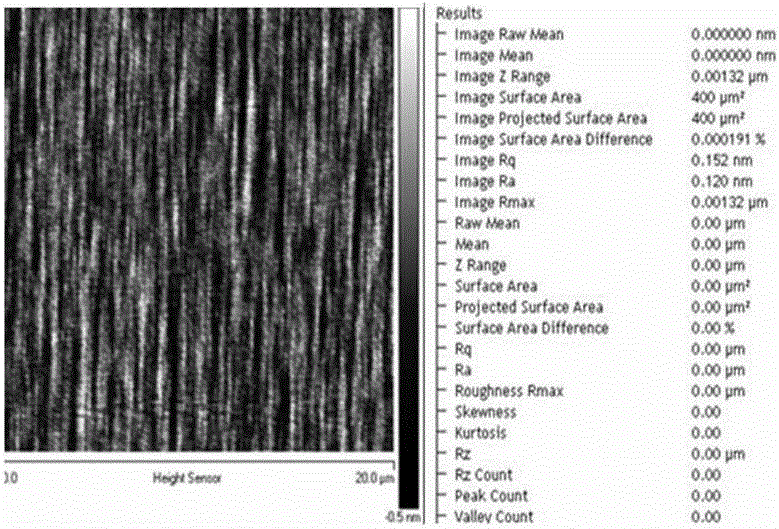

Fabrication method of carbon nanotubes

InactiveUS20040036403A1Easy to growPromote growthMaterial nanotechnologyNanostructure manufactureCarbon nanotubeHot filament

In this invention, protrusions are formed on a substrate such as silicon and quartz glass, and catalytic metal of transition element, such as nickel, iron and cobalt are coated on the substrate, and carbon nanotubes are grown by hot-filament chemical vapor deposition or microwave-plasma enhanced chemical vapor deposition under an application of negative voltage to the substrate. Where the substrate is heated. In these methods, carbon nanotubes can be selectively grown from the apex of protrusions. As a substrate, silicon probe for scanning probe microscopy (SPM) can be used. The carbon nanotube probe can be applied to high resolution SPM probe for imaging a precise topographic image.

Owner:TOHOKU TECHNO ARCH CO LTD

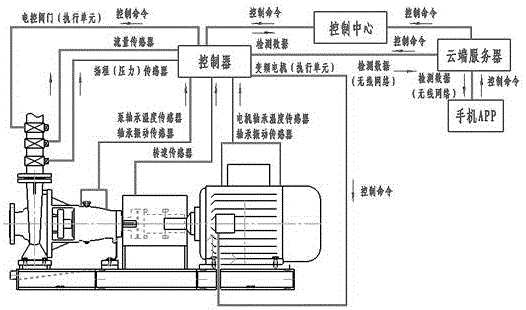

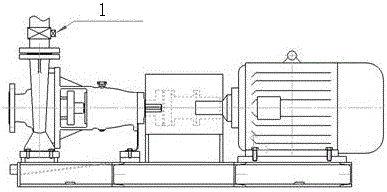

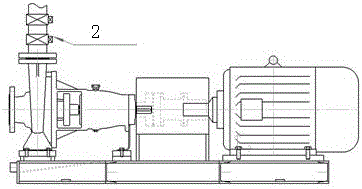

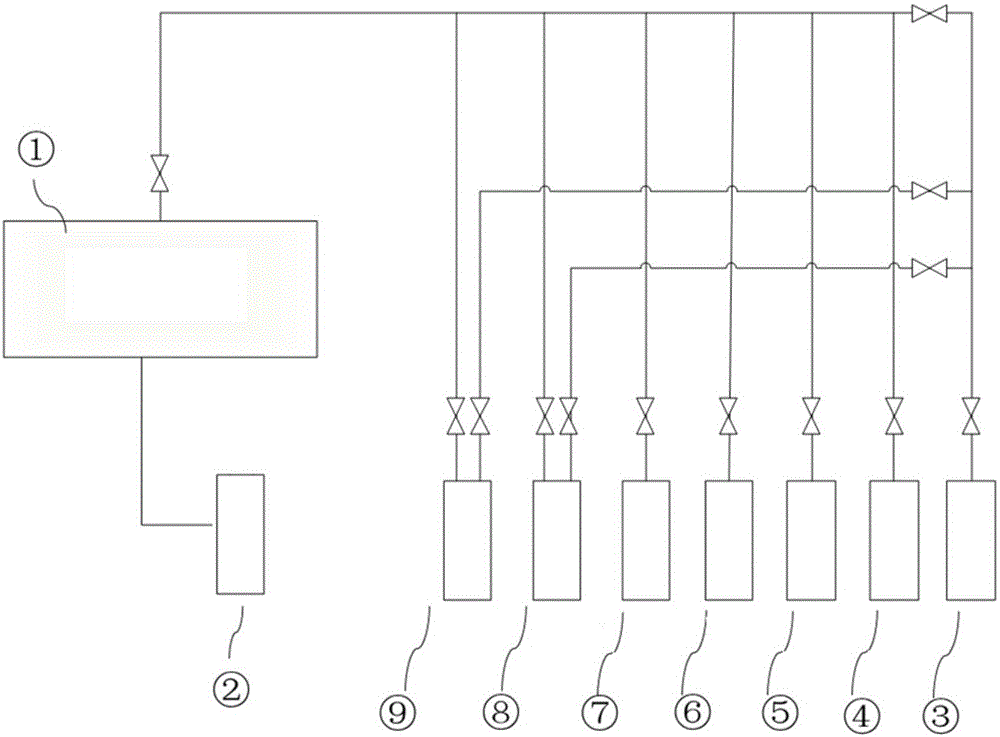

Pump remote intelligent control system based on mobile Internet

InactiveCN105673467AReal-time monitoring operationEasy to implement remote diagnosisPump controlPositive-displacement liquid enginesCloud processingEngineering

The invention provides a pump remote intelligent control system based on a mobile Internet. The pump remote intelligent control system based on the mobile Internet is a remote monitoring and control system. Signals of sensors are transmitted to a control center and a cloud processing system through a controller; workers in the control center can process the signals according to data; the cloud processing system can transmit the processed data to a mobile phone APP; a client can remotely monitor the running condition of a pump; and if the pump needs to be controlled, the rotating speed of a motor of the pump and the opening degree of an exit valve can be controlled directly through a mobile phone, and therefore the flow and the lift of the pump are controlled, and the pump can run on a high-efficiency point as far as possible. If the data exceed a preset value, an alarm can be given through the mobile phone, the client is informed of the situation, pre-warning is performed in advance, and large safety accidents are avoided.

Owner:YANTAI SUNSHINE PUMP

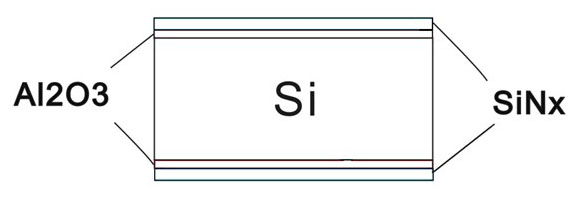

Double-layer passivating method for crystalline silicon solar battery

InactiveCN102064237AEasy to growEasy to industrializeFinal product manufactureVacuum evaporation coatingHydrogenThermal chemical vapor deposition

The invention discloses a double-layer passivating method for a crystalline silicon solar battery, comprising the following steps: (1) selecting a silicon chip, cleaning, and polishing or texturing; (2) growing Al2O3 on the silicon chip obtained in step (1) by an ALD (atomic layer deposition) or PECVD (plasma enhanced chemical vapor deposition) method, wherein the refractive index is 1.5-1.7, the thickness is 10-80nm; (3) growing SiNx on the silicon chip obtained in step (2) by the PECVD or PVD (physical vapor deposition) method, wherein the refractive index is 1.9-2.2, the thickness is 30-150nm; and (4) annealing the sample obtained in step (3) at the temperature of 200-600 DEG C in the atmosphere of N2 or a hydrogen argon gas mixture for 1-30 minutes to obtain a double-layer passivated dielectric film. The passivating method provided by the invention can reduce the surface recombination velocity of the silicon chip to below 10cm / s, can be well applied to surface passivation of a crystalline silicon solar battery, and obtains high conversion efficiency.

Owner:ALTUSVIA ENERGY TAICANG

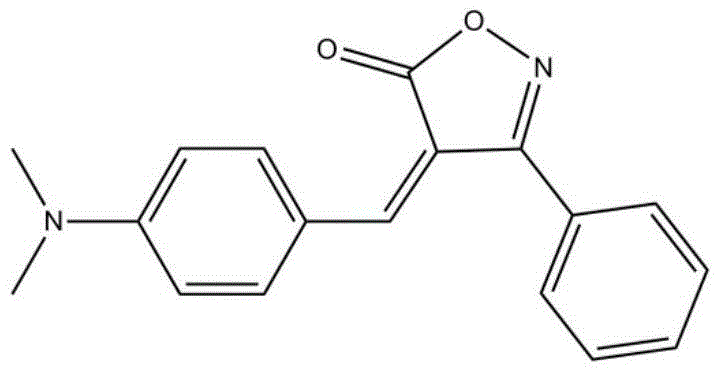

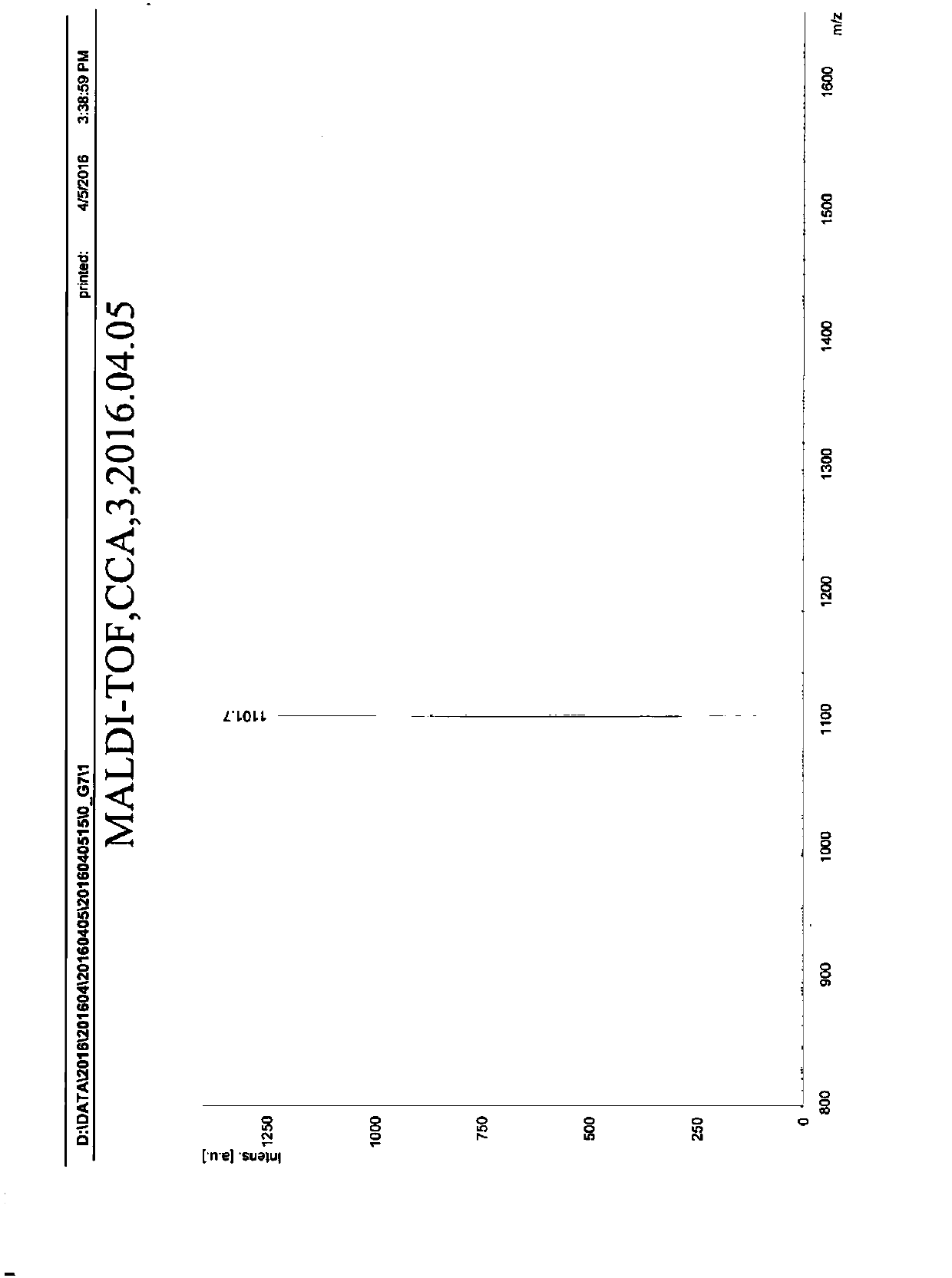

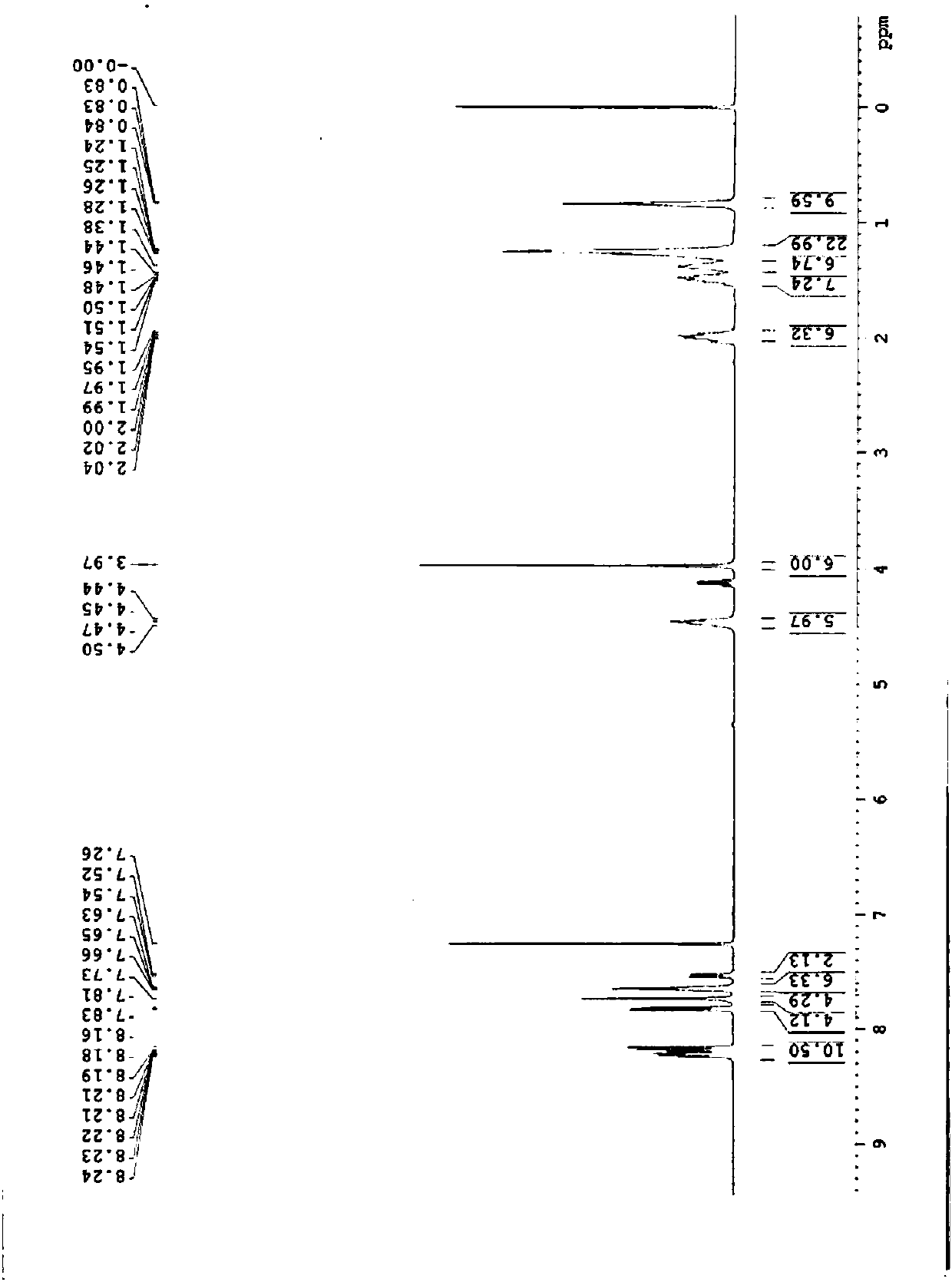

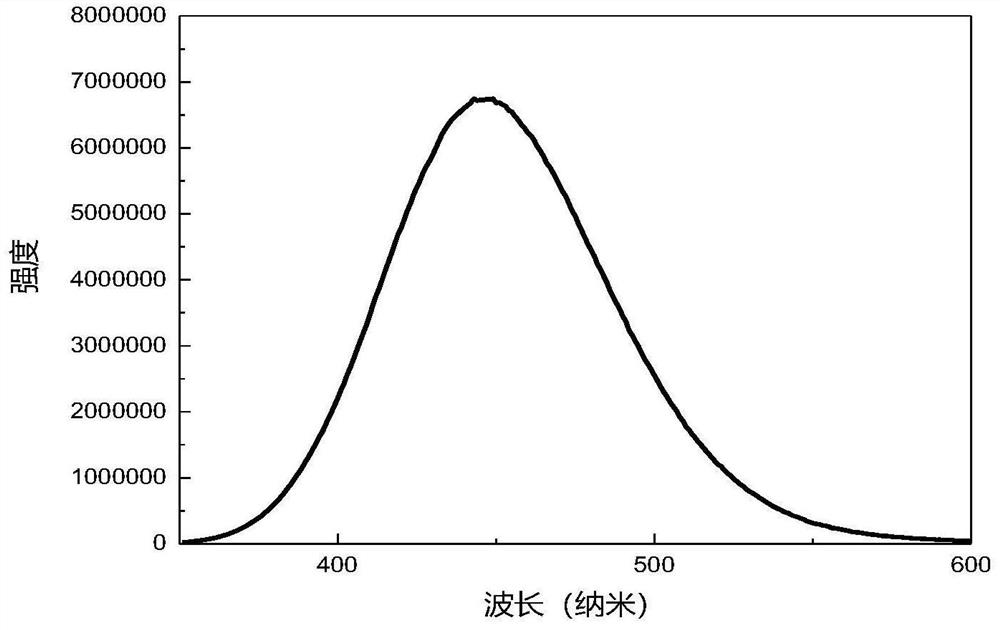

Organic fluorescent sensing material with high-sensitivity fluorescent response to several explosives, and preparation method application of organic fluorescent sensing material

ActiveCN106278996AQuick Security CheckPortable Security DetectionOrganic chemistryFluorescence/phosphorescenceCarbazoleFluorescence

The invention relates to an organic fluorescent sensing material with high-sensitivity fluorescent response to several explosives, and a preparation method application of the organic fluorescent sensing material. The material is obtained by self-assembling one or various carbazole derivatives through pi-pi interaction. The organic fluorescent sensing material disclosed by the invention has a typical P type material characteristic and high luminous stability, is suitable for being used for performing fluorescence detection on the explosives, and is particularly very effective for the detection of trace explosives (the concentration is at the ng level).

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for planting pod peppers

InactiveCN103766106ALow costEasy to operateSeed and root treatmentHorticultureSite managementPest control

The invention discloses a method for planting pod peppers, and belongs to the technical field of crop planting. The method for planting the pod peppers comprises the steps of seed treatment, sowing and seedling raising, seedbed management, timely transplanting, field management, pest control and the like. According to the method for planting the pod peppers, the pod peppers with high yield can be produced, the peppery characteristic of the pod peppers can be guaranteed, the pod peppers can be popularized and planted in large area, and cost is lowered. Operation is simple, the planting method is simple and easy to achieve, and method for planting the pod peppers is suitable for being popularized and applied in western mountainous areas.

Owner:吴燕

Non-crucible growing method for magneto-optic rear earth ferrite crystal

InactiveCN101255602AEliminate Crucible ContaminationEasy to growPolycrystalline material growthBy zone-melting liquidsAir atmosphereMagneto

The invention relates to a crucibleless growing method for a magneto-optical crystal of rare earth ferrite, which belongs to single crystal growth filed. The invention has the characteristics that oxide is used for resource material and preburned according to proportion, a material rod is obtained through static pressure molding and high temperature sintering, and then the material rod is set into a crucibleless crystal growth furnace and is grown in air condition. The invention has the characteristics that a crucibleless technology is used for growing RFeO<3>crystal, and none complete fusion is needed, and pollution for the complete fusion and a copple in the growing process are utmostly decreased, impurity defect in a magneto-optical crystal is sharply decreased, and crystal quality is progressed.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

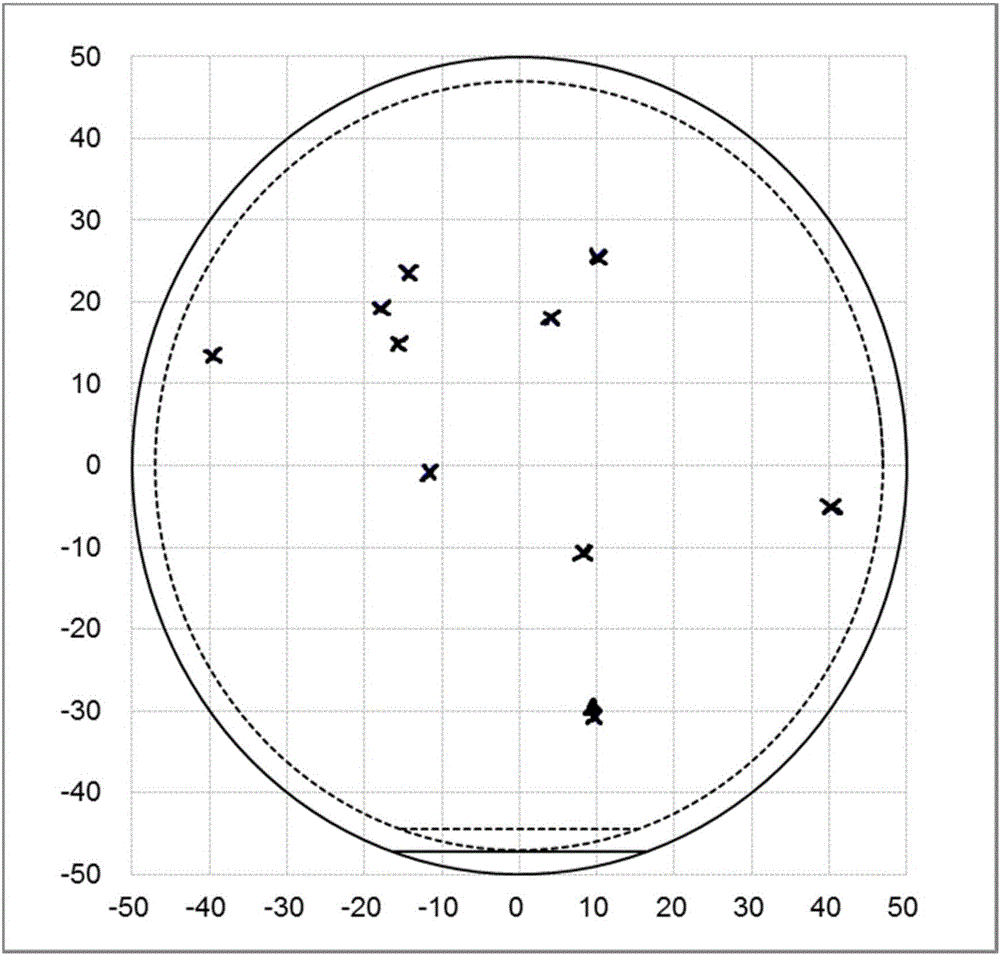

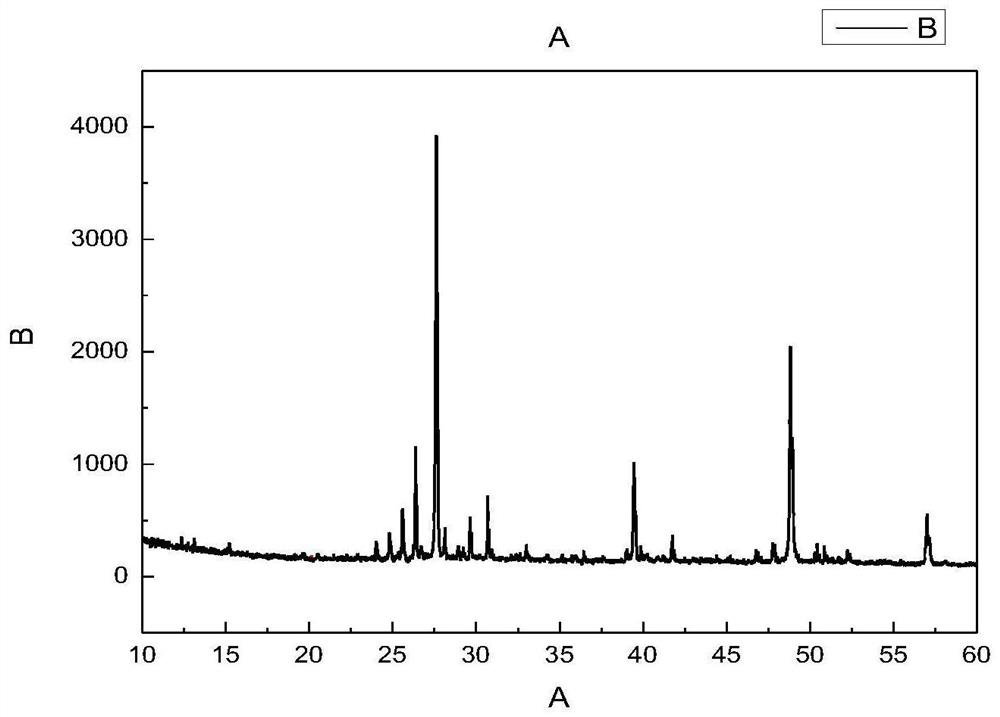

Non-linear optical device with C18H16N2O2 single crystal and preparation method of non-linear optical device

InactiveCN104630896AStable physical and chemical propertiesEasy to growPolycrystalline material growthFrom normal temperature solutionsElectromagnetic radiationSeed crystal

The invention relates to a C18H16N2O2 non-linear optical device and a preparation method thereof. The C18H16N2O2 crystal can be prepared by using a spontaneous crystallization cooling method and a seed crystal method, and the growing method of the C18H16N2O2 crystal is simple, easy to operate and low in cost; the prepared C18H16N2O2 non-linear optical crystal has a relatively wide penetration wave section of 0.55-2.2mu m, the powder frequency-doubled effect intensity of the C18H16N2O2 non-linear optical crystal is of 2-3 times of OH1, and the C18H16N2O2 non-linear optical crystal is stable in physical and chemical property and free from deliquescence; the C18H16N2O2 non-linear optical crystal can be used for preparing a non-linear optical device, and at the room temperature, an Ho:Tm:Cr:YAG Q-adjusting laser is used as a light source for inputting infrared light of which the wavelength is 2090nm and outputting infrared laser of which the wavelength is 1045nm; the C18H16N2O2 non-linear optical device comprises a device in which at least one beam of incident electromagnetic radiation passes through at least one piece of the C18H16N2O2 single crystal so as to generate at least one beam of output radiation of which the frequency is different from that of the incident electromagnetic radiation; the device can be a terahertz wave generator, a secondary harmonic generator, an upper frequency converter, a lower frequency converter or an optical parametric oscillator.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method for organically planting pecans

ActiveCN105481510AThe planting method is simple and easyAbundant raw material resourcesSuperphosphatesBacteriaChemistryMaltitol

The invention discloses a method for organically planting pecans. The method comprises the steps of field planting, fertilization and watering, and is characterized in that in the fertilization step, an organic bio-compound fertilizer is adopted; the organic bio-compound fertilizer is prepared from the following raw materials: 78-82 parts of organic fertilizer, 8-12 parts of inorganic fertilizer and 1-3 parts of liquid microbial agent; the organic fertilizer is prepared from the following raw materials in percentage by weight: 1-3 percent of enzyme vigor sustaining agent, 10-20 percent of paddy, 15-25 percent of sunflower stem, 10-20 percent of wood flour, 5-15 percent of cow dung, 5-15 percent of chicken manure and the balance of water; the enzyme vigor sustaining agent is formed by mixing trehalose, mannitol and maltitol. The method for organically planting the pecans is a green and ecological organic planting method, and obeys the natural laws, farming, physical, chemical and biological methods are adopted to improve soil fertility and prevent insect disease, the biodiversity and virtuous circle of a planting ecosystem are maintained and established, and the safe and high-yield pecans are obtained.

Owner:CHANGZHOU WANGZHE QINGCHENG ECOLOGY SIGHTSEE CO LTD

Method for improving photoelectric detector performance by cutting band gap wavelength in lattice matching system

InactiveCN102176489APromote growthNo significant increase in difficultyFinal product manufactureSemiconductor devicesVapour phase epitaxyElectron

The invention relates to a method for improving photoelectric detector performance by cutting band gap wavelength in lattice matching system. The method comprises the following steps of: growing a buffer layer, a light absorption layer and a wide band gap cap layer which hare matched with lattices on a substrate by using an MBE (molecular beam epitaxy) method or metallorganics vapour phase epitaxy method to obtain an epitaxial structure of a photoelectric detector, wherein the band gap of the light absorption layer can be cut and set during the growth process, and the wide band gap is selected on the premise of meeting cut-off wavelength requirement of the long wave end of the photoelectric detector. According to the invention, the material growing method is simple; by cutting and setting the band gap of the light absorption layer of the photoelectric detector, the device performance can be obviously improved under the condition of basically not changing the original design of the device, and the detectivity can be enhanced by more than three times. The method is not only suitable for manufacturing photoelectric detectors in different kinds of III-V compound material systems, but also suitable for manufacturing other types of photoelectric devices and electronic devices; and the application of the method can be widened to other material systems. The method has a good application prospect.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

New CuI Crystal and growing method thereof

InactiveCN1609285AHigh purityReduce stressFrom gel statePolycrystalline material growthX-rayGamma ray

The present invention discloses one kind of CuI crystal and its growth method, and the CuI crystal is in regular gamma phase tetrahedron structure of size greater than 2 mm. The crystal growth process adopts concentration controlling technology, combines complexing and de-complexing, and has the advantages of simple equipment, low cost, low growth temperature, easy-to-control growth process, etc. The grown CuI crystal has high gamma phase purity, less stress, less faults, good appearance and relatively large size. As one new generation of very fast scintillator, the present invention may find its important application in high speed X-ray counting, gamma ray, electronic beam measurement, etc. and may be also used as fast ion conductor.

Owner:TONGJI UNIV

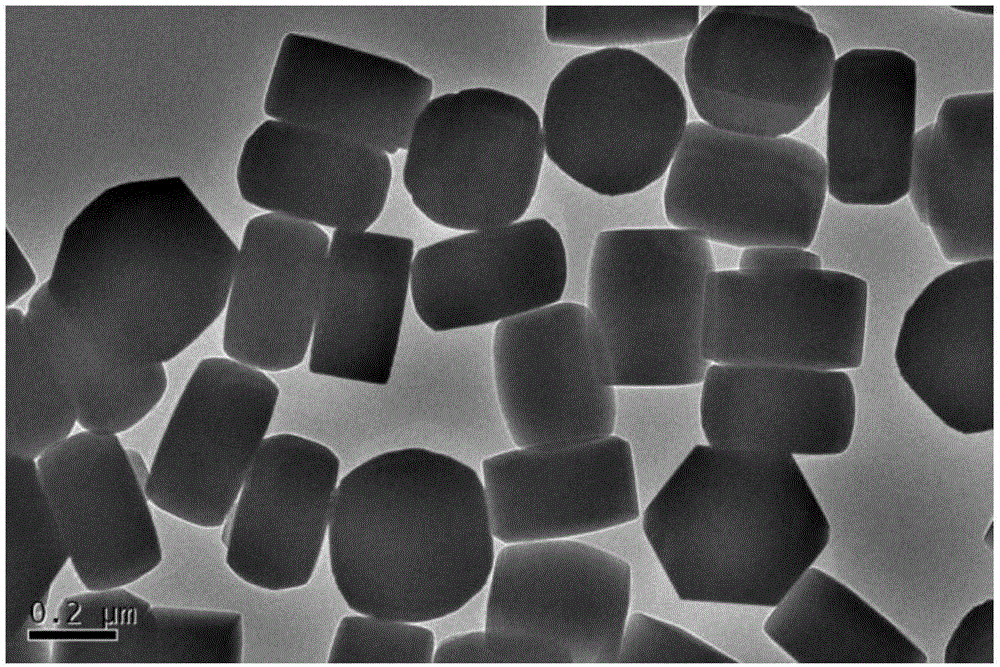

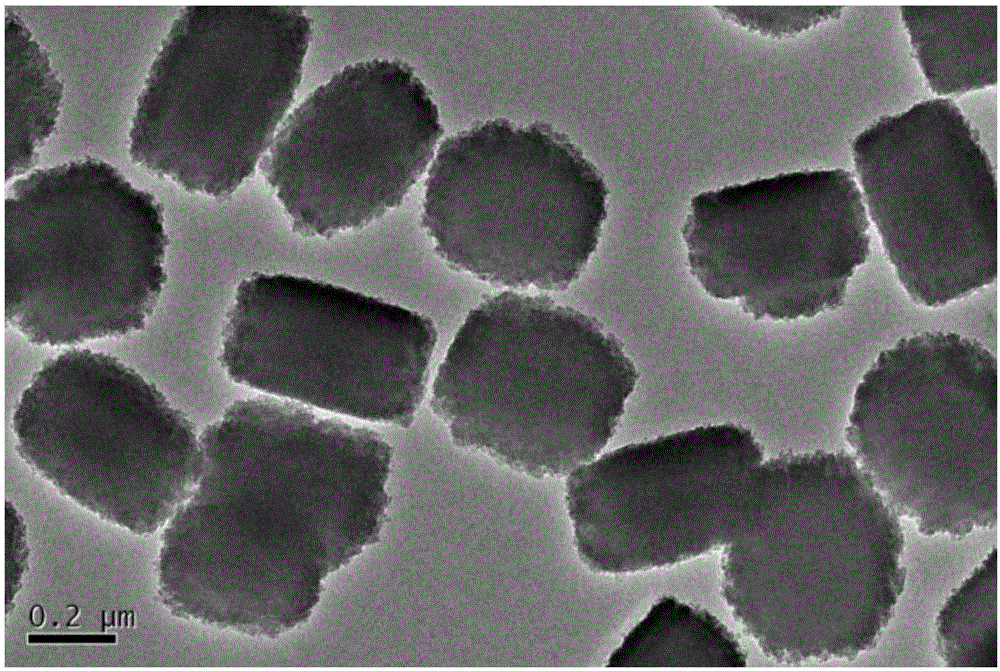

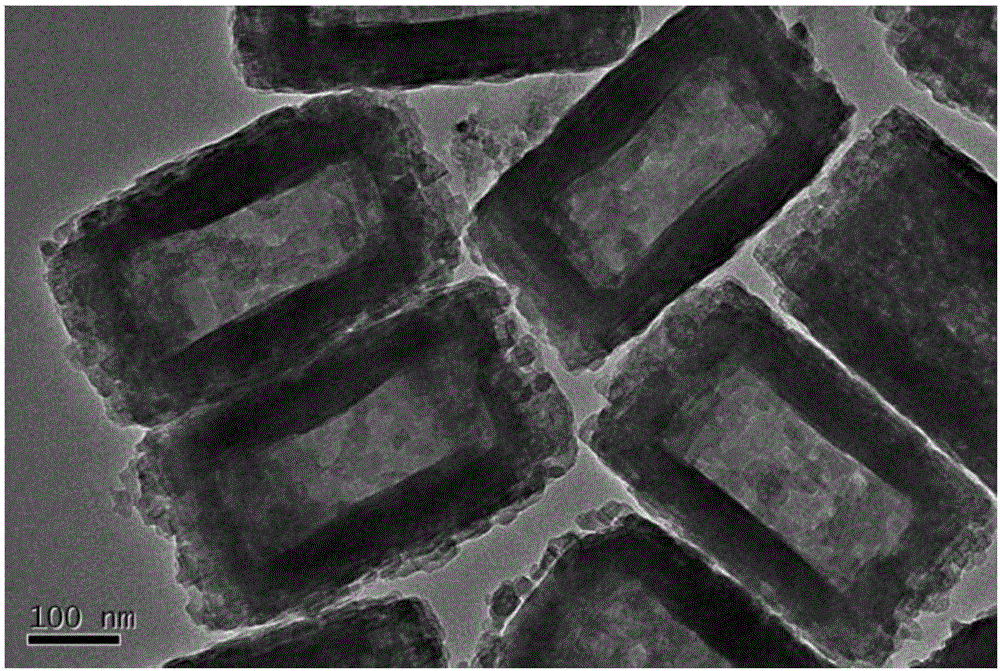

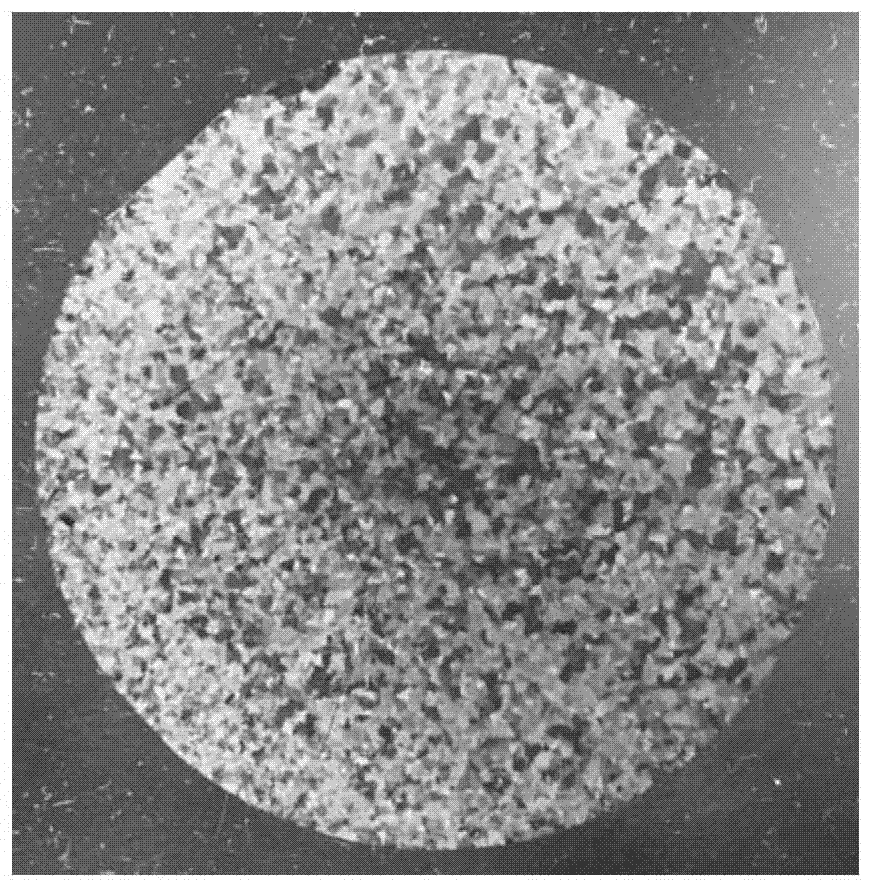

Hollow molecular sieve, and preparation method and application thereof

ActiveCN106082257AEasy to growResizeMolecular sieve catalystsMolecular sieve catalystBeta typePhotochemistry

The invention provides a hollow molecular sieve, and a preparation method and application thereof. The hollow molecular sieve has an external diameter of 50 nm to 10 [mu]m, an internal diameter of 20 nm to 9 [mu]m, and a specific surface area of 200 to 1000 m<2> / g; the shell of the hollow molecular sieve is composed of three layers of isomorphous molecular sieves with different Si / Al ratios; and the hollow molecular sieve may be one or more selected from a group consisting of a ZSM-5 type hollow molecular sieve, a beta type hollow molecular sieve and a Y type hollow molecular sieve. The hollow molecular sieve can effectively overcome the problem of diffusion in practical application; the size and shell thickness of the hollow molecular sieve can be regulated by changing a feed ratio and crystallization conditions; and a super-weak-solution-phase epitaxial growth method used in the invention is simple, has a wide application scope, can prepare three layers of isomorphous molecular sieve structures with different Si / Al ratios in a shell structure, is applicable to ZSM-5, beta and Y type molecular sieves and has low preparation cost.

Owner:TSINGHUA UNIV

Preparation and application for organic fluorescence sensing array capable of distinguishing plurality of explosives by fluorescence method

ActiveCN107936946AAchieve fluorescence discriminationSimple compositionOrganic chemistryFluorescence/phosphorescenceFluorescence sensingPi interaction

The invention relates to a fluorescence sensing array composed of a plurality of fluorescence sensing materials and capable of detecting and distinguishing five explosives, and a preparation method and an application of the fluorescence sensing array. The fluorescence sensing array is composed of a plurality of nanometer materials which are self-assembled by carbazole derivatives under the pi-pi interaction. The component materials in the fluorescence sensing array provided by the invention are organic fluorescence sensing materials, and have typical characteristics of P-type materials and good luminescence stability; and the fluorescence sensing array composed of the materials has good distinguishing effect to explosives.

Owner:INST OF CHEM CHINESE ACAD OF SCI

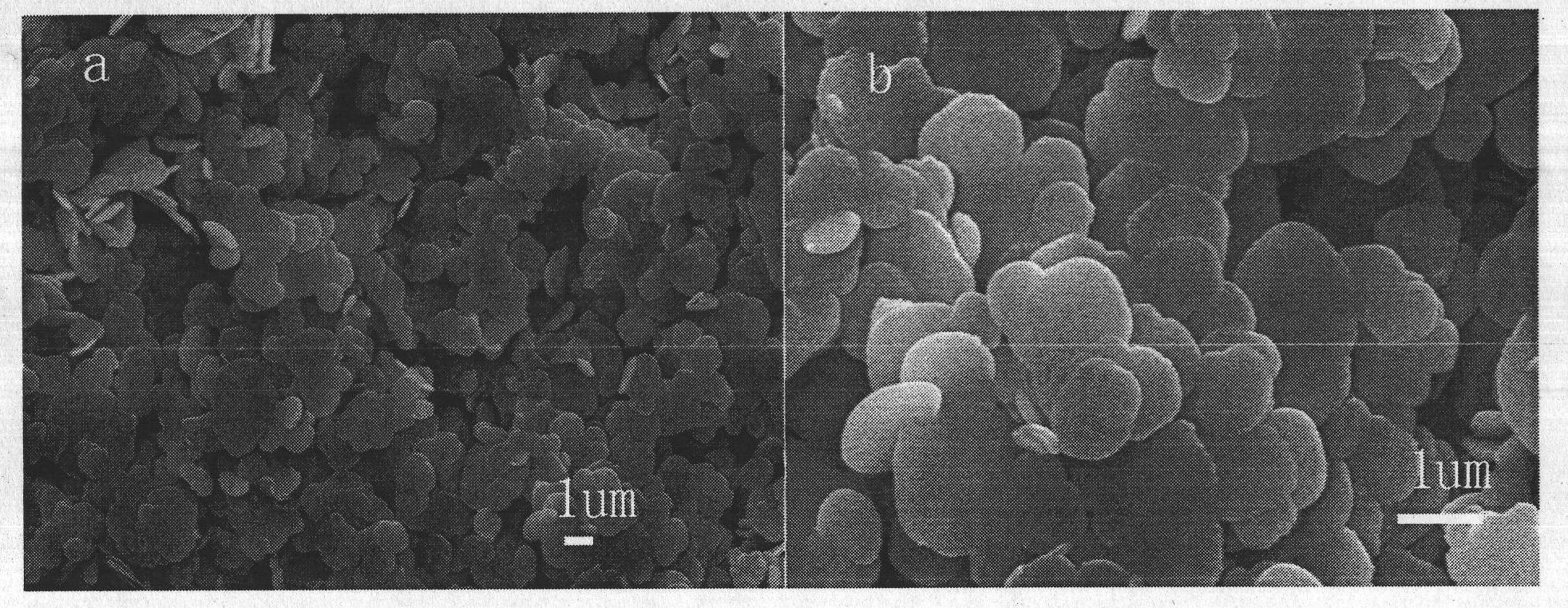

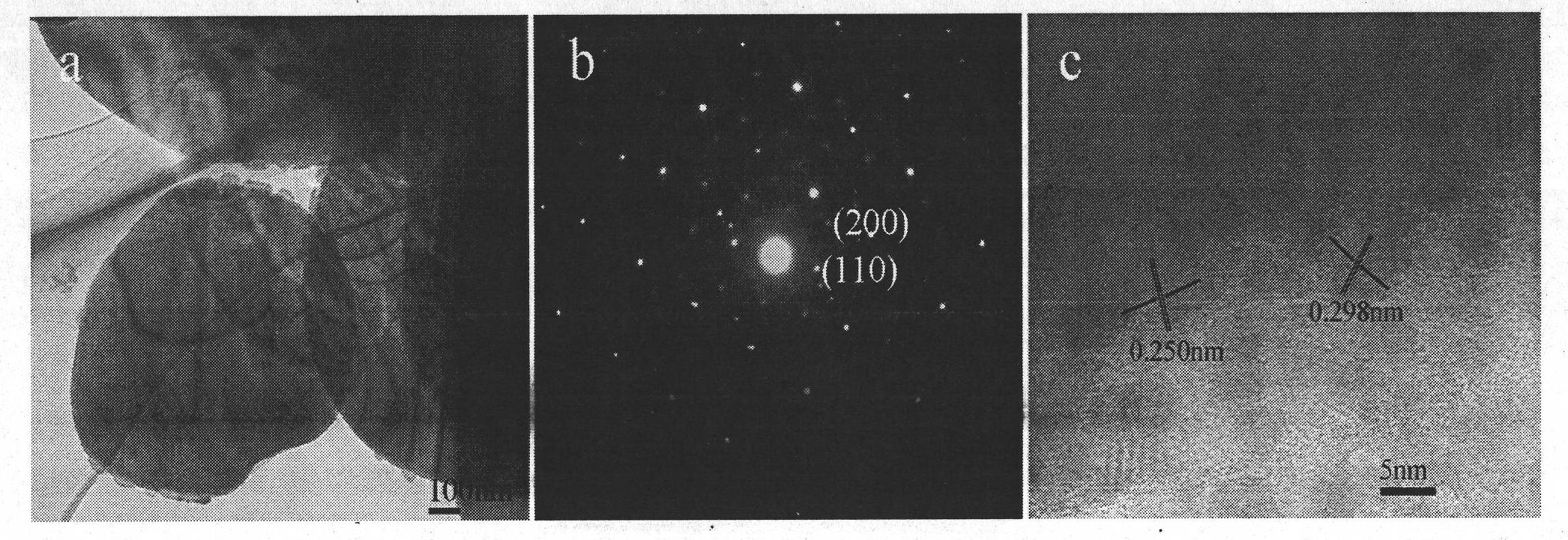

Method for preparing BiOCl monocrystalline nano-chip

InactiveCN102162126AStrong absorption capacityWith photocatalytic propertiesPolycrystalline material growthFrom normal temperature solutionsDispersitySteel jacket

The invention provides a method for preparing a BiOCl monocrystalline nano-chip with a solvent heat method. The preparation is carried out in a stainless steel high-pressure reactor consisting of a polytetrafluoroethylene liner (with the volume of 45ml) and a stainless steel jacket. The preparation is realized by the following technological processes: (1) placing raw materials including BiCl3 (with the purity not smaller than 99.1wt%) and KBH4 (with the purity not smaller than 98.0wt%) into 20-30ml of a mixed solution of deionized water and absolute alcohol, and stirring for reaction, wherein the molar ratio of BiCl3 to KBH4 is 3 / 5, and the mixed volume ratio of the deionized water to the absolute alcohol is 1 / 4-1 / 3; (2) then, pouring the mixed solution with the filling amount of 4 / 9-2 / 3 into the polytetrafluoroethylene liner, sleeving the stainless steel jacket, placing into an environment with the temperature of 160-200 DEG C, and preserving the temperature for 16-24 hours; and (3) finally, cooling the high-pressure reactor to room temperature, collecting a reaction product, cleaning, separating, and finally collecting and drying to obtain a BiOCl monocrystalline nano-chip. The BiOCl monocrystalline nano-chip synthesized with the method has the advantages of good dispersity, thin thickness, uniformity in size distribution and good color, and can be widely applied to the fields of coating, inorganic pigments, high-quality cosmetics, pearlescent accessories and the like. The method has the advantages of low raw material price and simple process, and is easy for large-scale industrial production.

Owner:XINJIANG UNIVERSITY

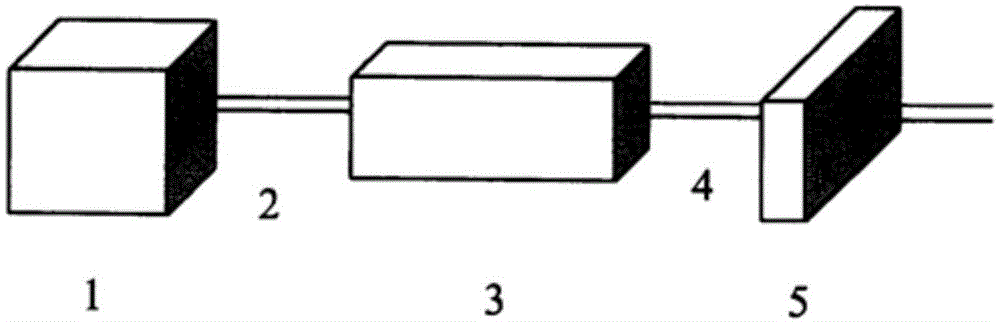

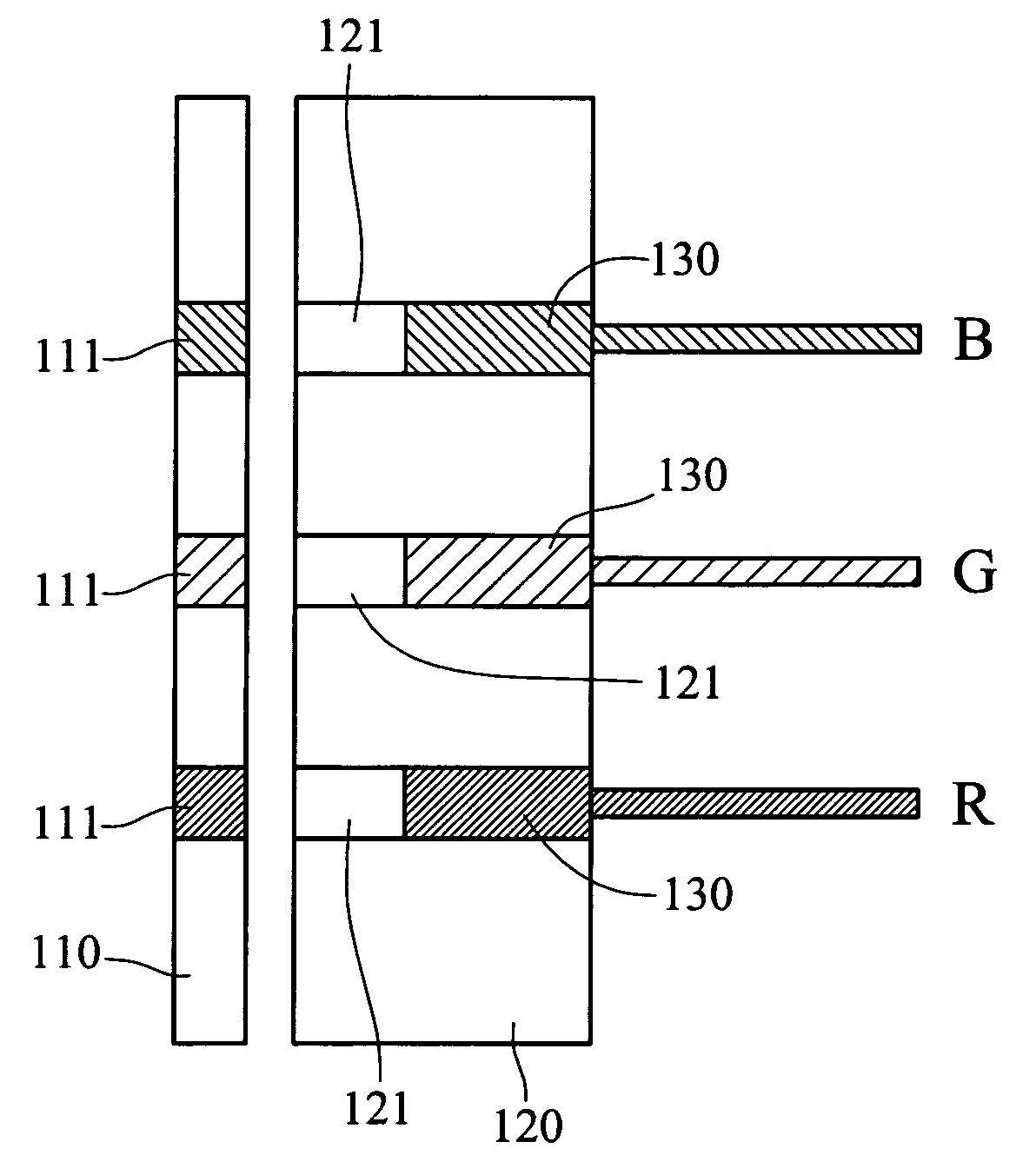

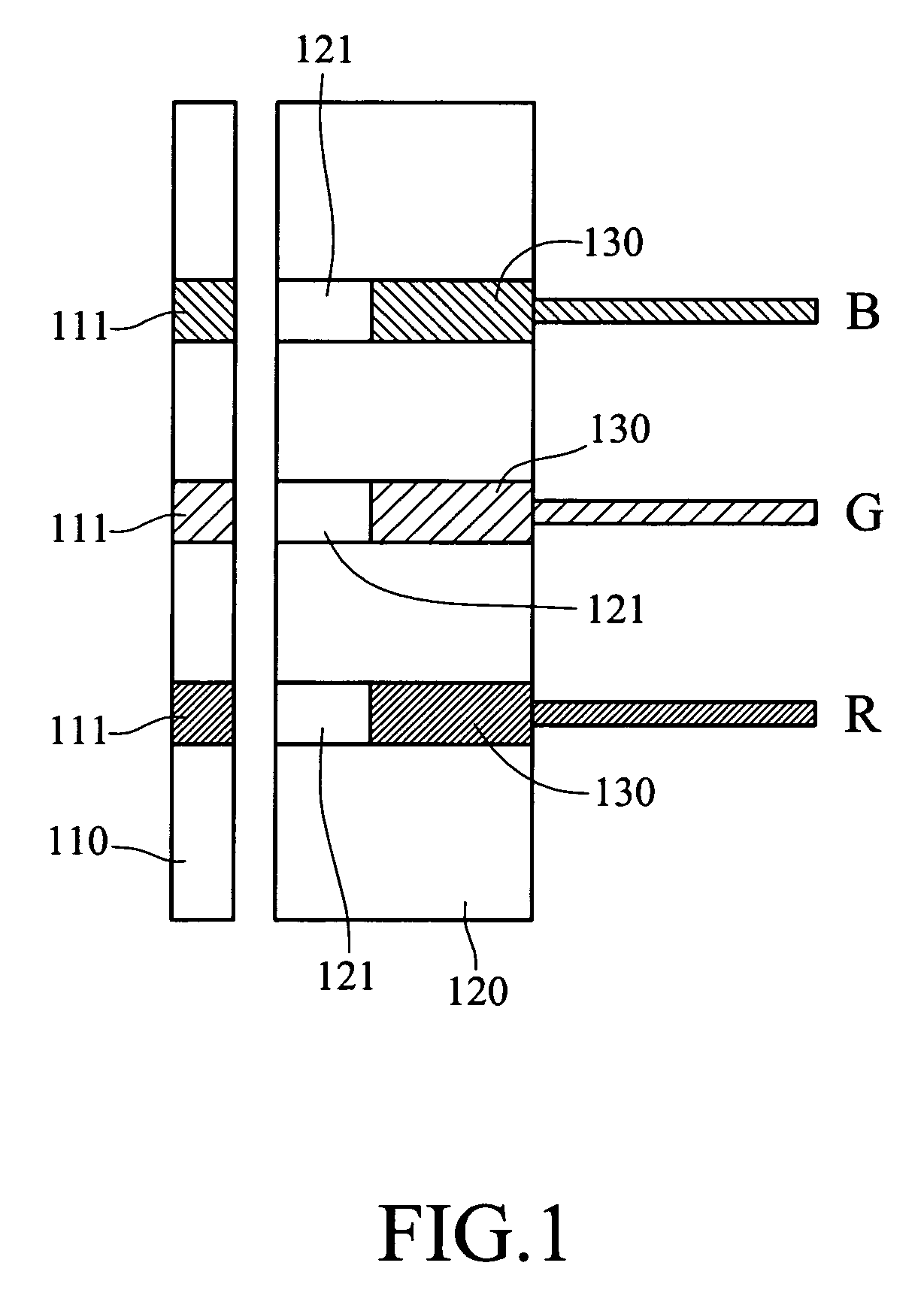

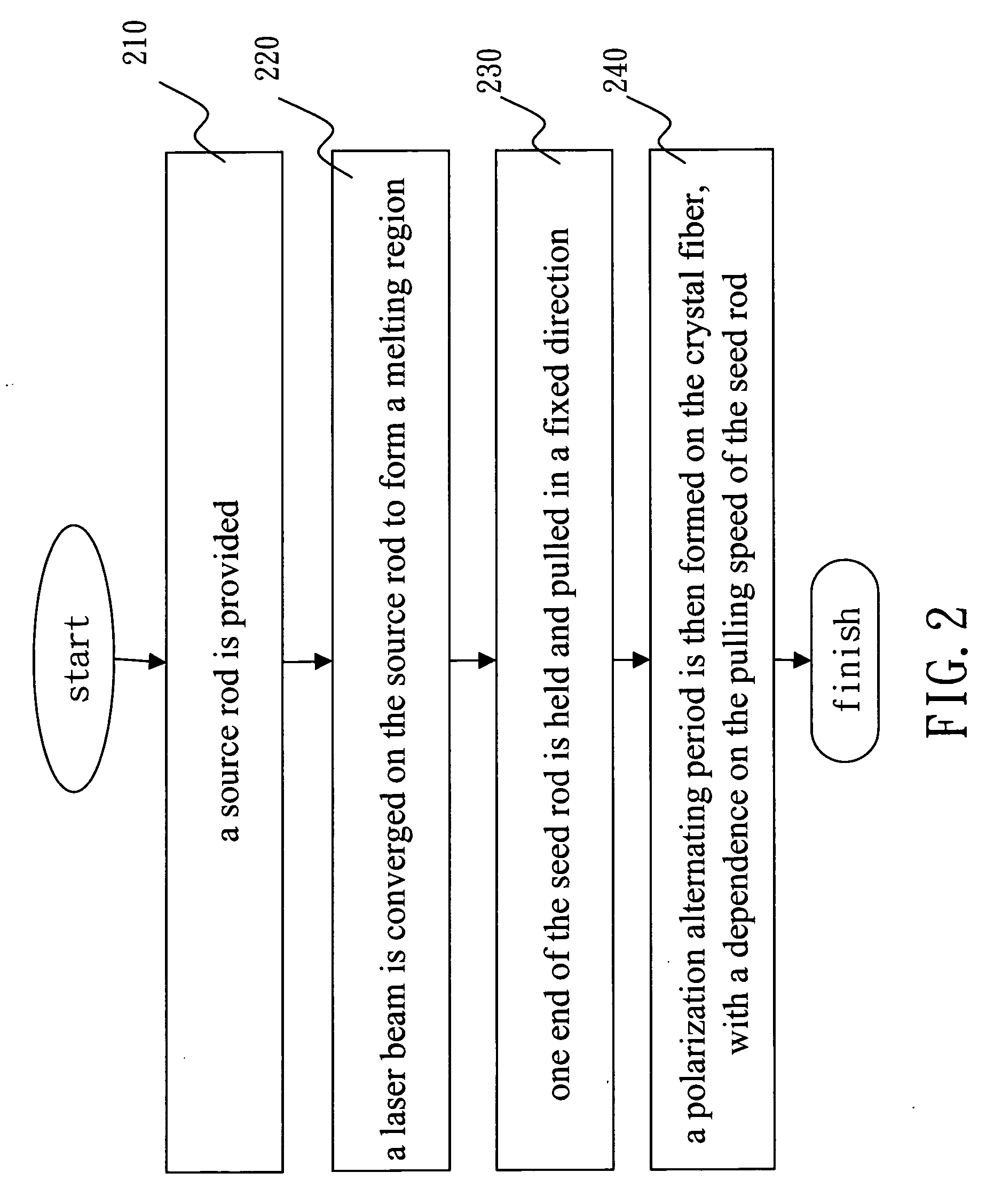

Micro crystal fiber lasers and method of making frequency-doubling crystal fibers

ActiveUS20060002433A1Easy to growFast growth speedLaser using scattering effectsSemiconductor laser structural detailsBase frequencyLaser fiber

A method of fabricating micro crystal fiber lasers and frequency-doubling crystal fibers is disclosed. The micro crystal fiber laser contains gain crystal fibers, frequency-doubling crystal fibers, and a semiconductor laser. The semiconductor laser provides a laser beam. The gain crystal fibers receive the laser beam and generate a base-frequency beam. The frequency-doubling crystal fibers have a polarization alternating period. The frequency-doubling crystal fibers are coupled to the gain crystal fibers to double the frequency of the base-frequency beam and provide a double-frequency beam with the required wavelength. In addition to providing a monochromic crystal fiber laser, the crystal fiber lasers in red, green, and blue light may be combined into an array, providing a color laser. The frequency-doubling crystal fiber can be formed using the LHPG method. During the production process, a polarization alternating external field is continuously imposed on the frequency-doubling crystal fiber, resulting in a polarization alternating period.

Owner:IND TECH RES INST

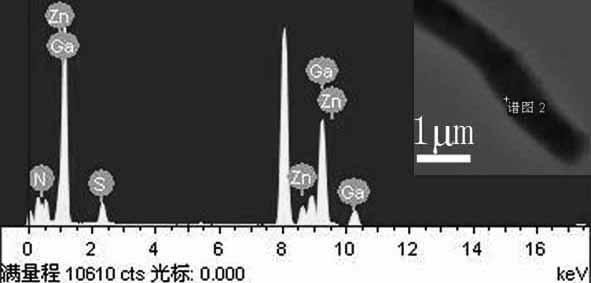

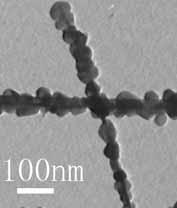

Method for preparing gallium nitride/zinc sulfide nano heterojunction by two-step method

InactiveCN102659174AEasy to growLow costMaterial nanotechnologyNitrogen-metal/silicon/boron binary compoundsHeterojunctionNanowire

The invention discloses a method for preparing a gallium nitride / zinc sulfide nano heterojunction by a two-step method, which is implemented by the following technical process of placing a ceramic boat with a certain quantity of gallium oxide powder (the purity is 99.999 percent by mass) at the center of a horizontal alundum tube furnace with the length of 100cm; placing a gold-plating substrate at the position with a distance of 20cm to 25cm far away from the ceramic boat; sealing the tube furnace; vacuumizing to the pressure of 2*10<-2>-10<-3>Pa; after heating the horizontal tube furnace to the temperature of 900 to 1,080DEG C under the protection of Ar gas, filling 200sccm of NH3 gas to perform the reaction for two hours; naturally cooling to the room temperature under the protection of the Ar gas to obtain a flaxen product on the substrate; and then placing the substrate on which the flaxen product is deposited on a vacuum thermal evaporating device and ensuring the surface on which the flaxen product is deposited over against a zinc sulfide source (the purity is 99.995 percent by mass), wherein the distance between the source and the substrate is 1 to 2cm and the heating current is 100 to 180A; and the gallium nitride / zinc sulfide nano heterojunction is finally obtained after the color of the product on the substrate is changed into deep yellow. The gallium nitride / zinc sulfide nano heterojunction prepared by the method disclosed by the invention has the characteristic that the gallium nitride / zinc sulfide nano heterojunction with two different heterostructures, i.e. a nano linear core-shell structure and a heterostructure which is of a shape of tomatoes on sticks, is prepared by the two-step method.

Owner:XINJIANG UNIVERSITY

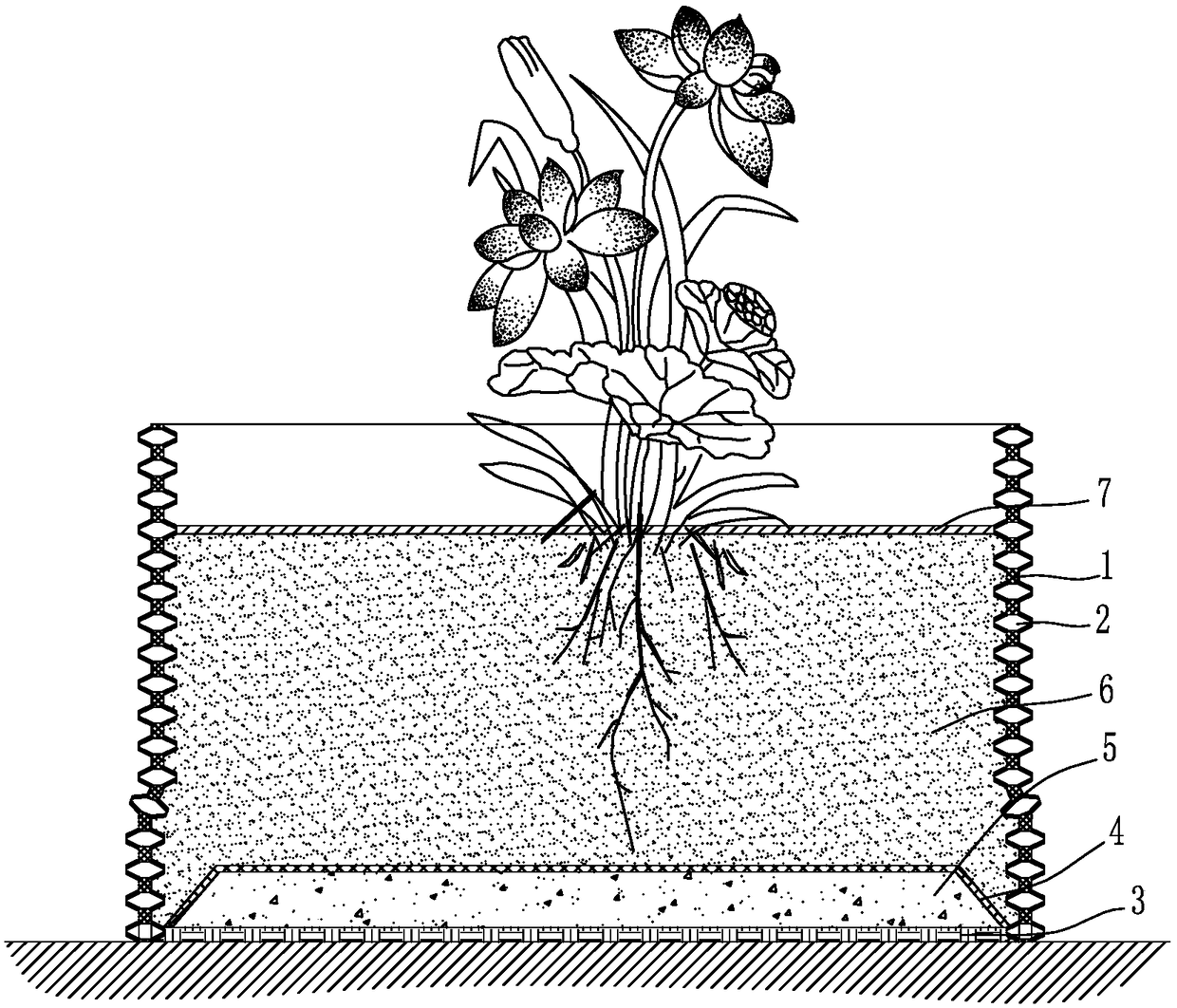

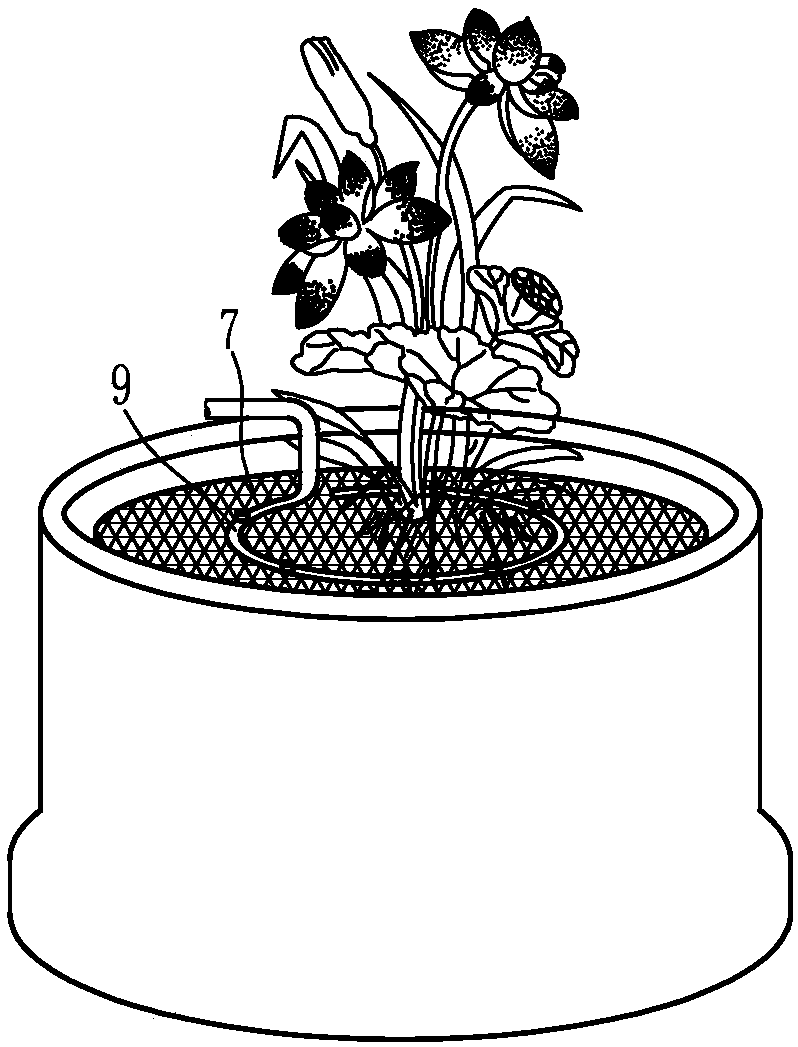

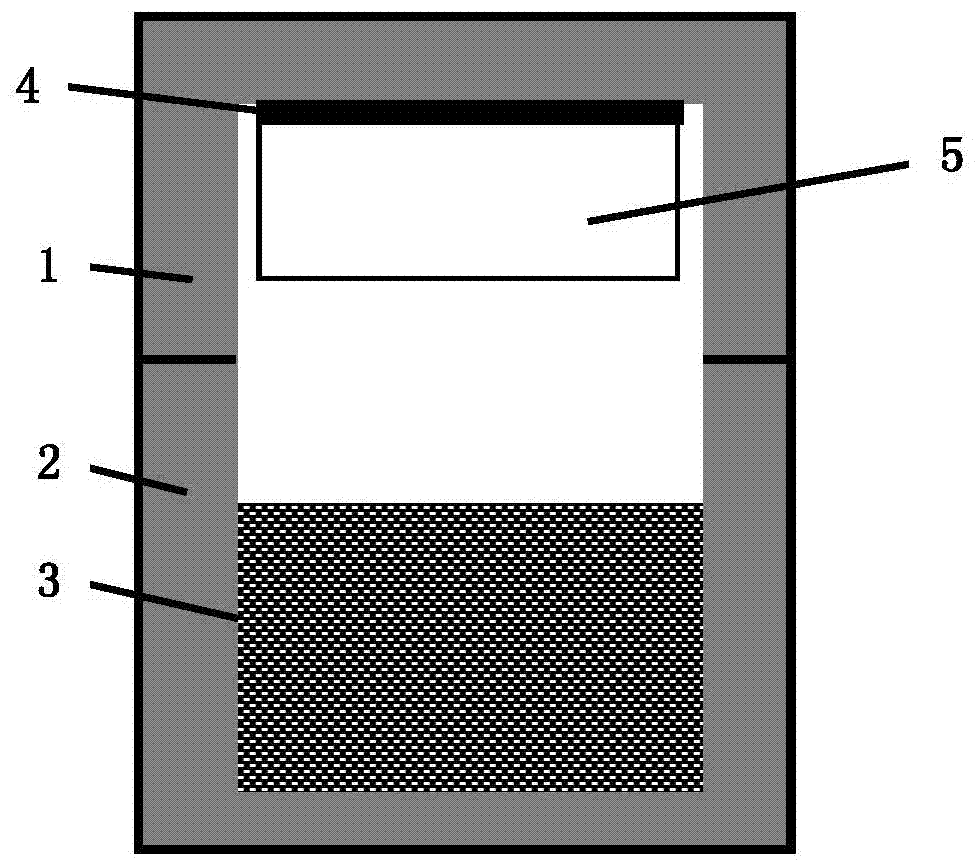

Saline and alkaline land greening cultivating device

InactiveCN108323349AEasy to growConducive to centralized nutrient supply and efficient use of fertilizer and waterReceptacle cultivationNutrientFertilizer

The invention discloses a saline and alkaline land greening cultivating device. The saline and alkaline land greening cultivating device comprises a cultivating cylinder which is provided with an opened top and an opened bottom and is surrounded into a cylinder by the peripheries, and several vent holes are formed in the peripheral wall of the cultivating cylinder; breathable and waterproof degradable film is laid at the bottom of the cultivating cylinder, a breathable supporting net covers the portion, located above the breathable and waterproof degradable film, in the cultivating cylinder, the portion between the breathable supporting net and the breathable and waterproof degradable film is filled with breathable filler, the portion, located above the breathable supporting net, in the cultivating cylinder is filled with greening soil, and a moisture preserving layer is laid above the greening soil. The saline and alkaline land greening cultivating device is simple and reasonable in structure, preserves moisture and is breathable, nutrient supplement and efficient utilization of fertilizer and water are integrated, and the saline and alkaline land cultivating device is convenientto manage and control and particularly applicable to multi-point greening in a saline and alkaline land area.

Owner:WEIFANG YOURONG IND

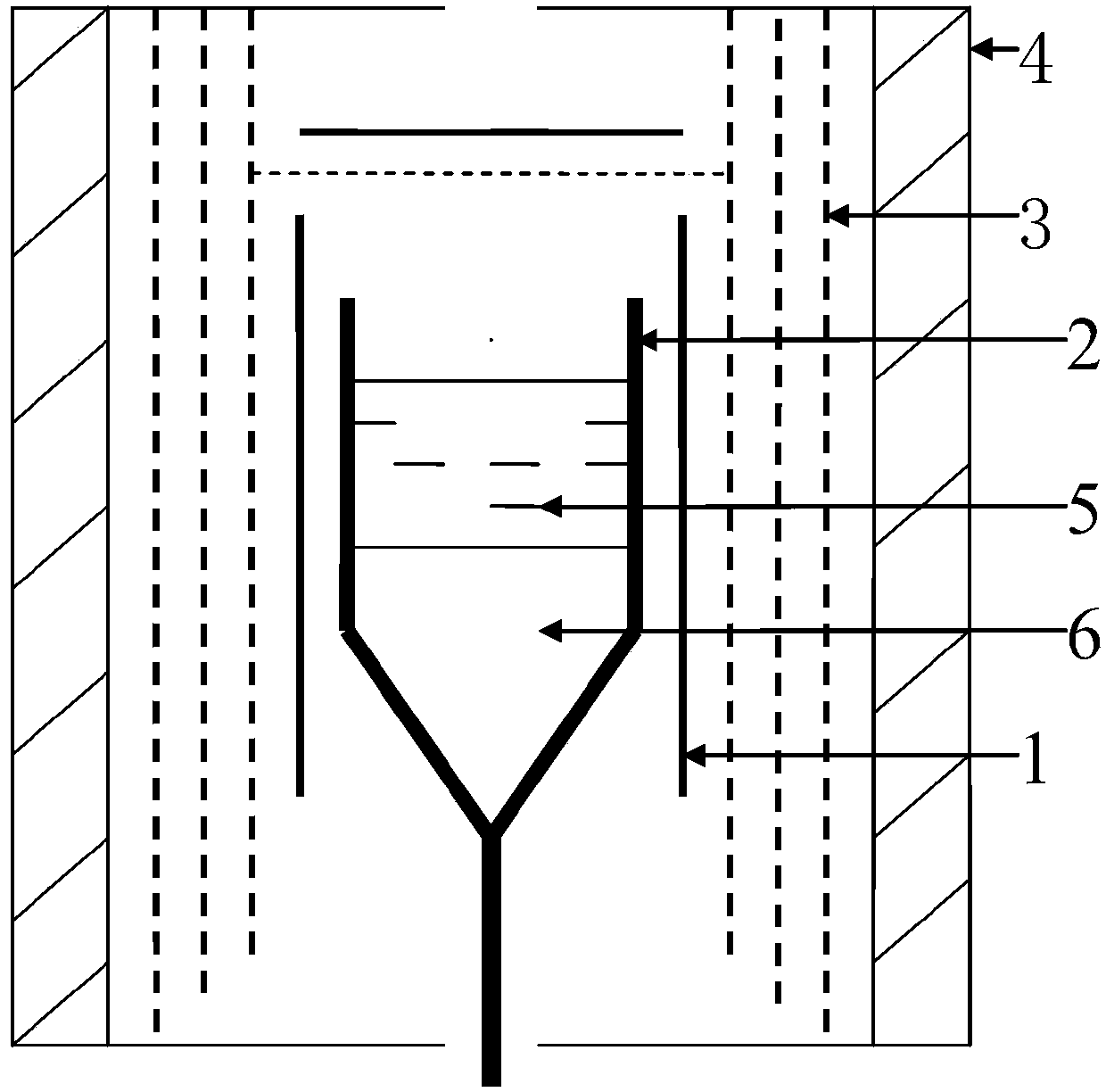

Silicon carbide epitaxial growth system and growth method thereof

PendingCN105869996AQuality improvementReduce defectsSemiconductor/solid-state device manufacturingFrom chemically reactive gasesCarbide siliconEtching

The invention provides a silicon carbide epitaxial growth system and a growth method thereof. By the epitaxial system provided by the invention, multifunctional silicon carbide epitaxial growth of slow growth, fast growth, N-type doping, P-type doping, single-layer epitaxial growth, multi-layer epitaxial growth, thin-film epitaxial layer growth, thick-film epitaxial layer growth, selective etching and the like can be carried out; and a growth mode can be selected by the system according to the epitaxial structure requirements to grow a proper epitaxial material. The epitaxial material grown according to the technical scheme is relatively excellent in quality, relatively few in defects, relatively suitable for being applied to a high-voltage power electronic device, wide in suitable range, simple in growth method, low in processing cost and suitable for industrial production.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

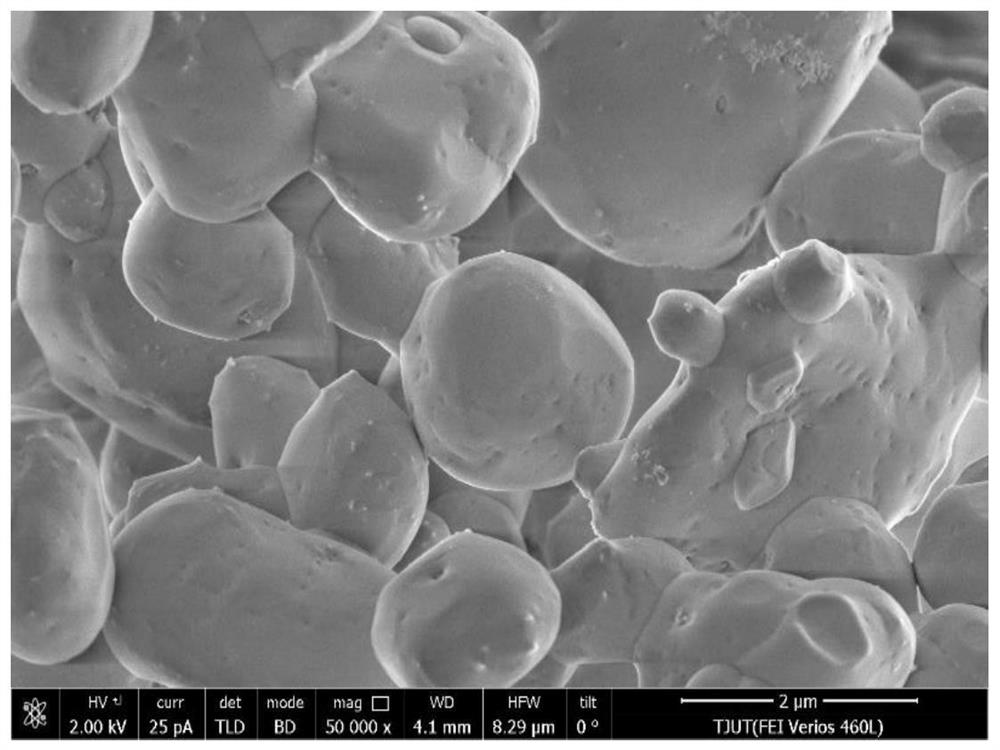

Method for synthesizing copper-based perovskite powder by low-temperature solvent method

InactiveCN112280555ALow costShort preparation cycleCopper compoundsLuminescent compositionsCupric bromideCopper chloride

The invention relates to a method for synthesizing copper-based perovskite powder by a low-temperature solvent method. The method comprises the following steps: adding CsX and CuX into a polar organicmixed solution, and stirring for 4-6 hours at 40-70 DEG C, wherein the polar organic mixed solution is a mixed solution of N, N-dimethylformamide (DMF)and dimethyl sulfoxide (DMSO), the CsX is cesiumchloride, cesium bromide or cesium iodide, and the CuX is copper chloride, copper bromide or copper iodide. According to the synthesis process, constant-temperature growth on a hot plate is not needed, synthesis is directly conducted on a magnetic stirrer, the synthesis process has the advantages of being short in manufacturing period, low in cost, simple in growth step, environmentally friendlyand the like, and Cs3Cu2X5 powder with high crystallization quality is separated out within 5 hours.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

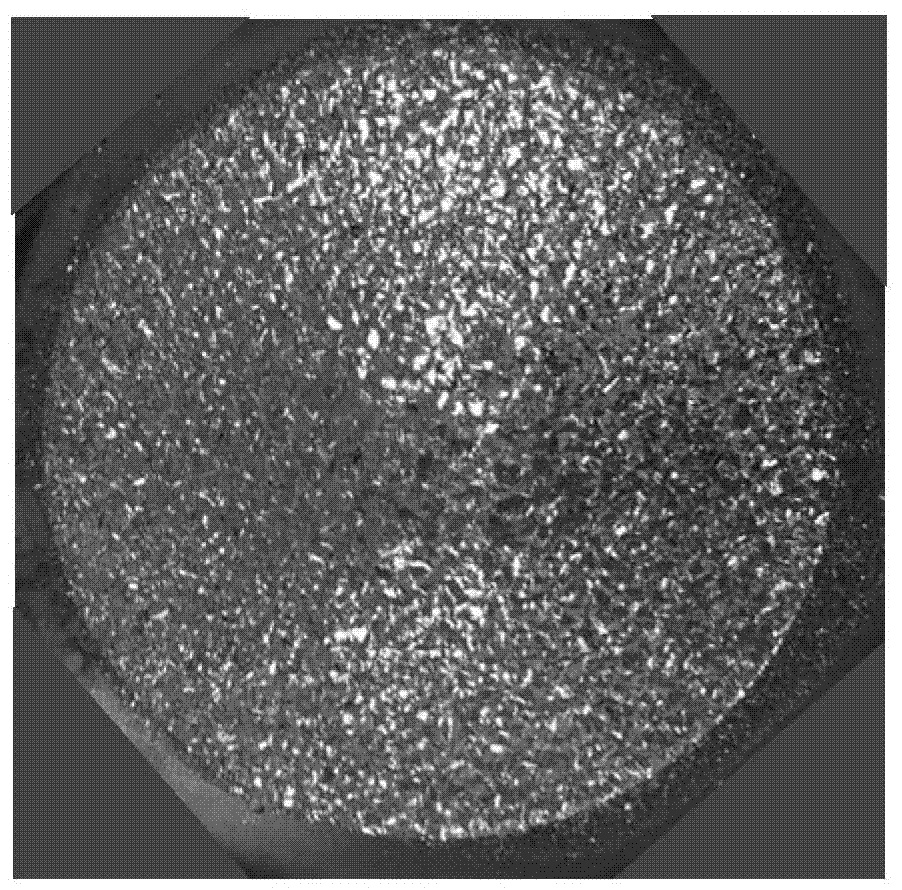

Growth method of large-sized silicon carbide polycrystalline ceramic adjustable in electrical resistivity

ActiveCN107190322AQuality improvementHigh yieldPolycrystalline material growthSingle crystal growth detailsCarbide siliconCarbon film

The invention relates to a growth method of a large-sized silicon carbide polycrystalline ceramic adjustable in electrical resistivity. A silicon carbide raw material is contained by adopting a graphite crucible, the graphite crucible is composed of a graphite crucible top cover and a graphite crucible body, the inner surface of the graphite crucible is provided with a carbon film layer, the silicon carbide raw material is put in the graphite crucible body, the graphite crucible top cover is put on, the graphite crucible body is put in a growth furnace, the bottom and / or the lower portion of the graphite crucible body is located in a heating zone to make the temperature at the bottom of the graphite crucible body higher than that of the graphite crucible top cover, and a silicon carbide polycrystalline ceramic material grows on the surface of the carbon film layer by adopting a physical gaseous phase transmission method or a high-temperature chemical vapor deposition method. The growth method is simple, and the silicon carbide polycrystalline ceramic is more excellent in performance, better in uniformity, better in compactness, higher in purity and better in thermal conductivity compared with a traditional silicon carbide ceramic.

Owner:安徽微芯长江半导体材料有限公司

Method for growing Ce: YAG monocrystal fluorescent material

InactiveCN103469306ASmall sizeReduce defectsPolycrystalline material growthFrom frozen solutionsFurnace temperatureCrucible

The invention discloses a method for growing a Ce: YAG monocrystal fluorescent material. The chemical formula of the Ce: YAG monocrystal fluorescent material is (Y<1-x-m>AxCem)3(Al<1-y>By)5O12, wherein x is not less than 0 and not greater than 1, y is not less than 0 and not greater than 1, m is not less than 0 and not greater than 0.05, A is one type from Lu, Tb, Pr, La and Gd, and B is one type from Ga, Ti, Mn, Cr and Zr. The furnace temperature range for crystal growth is 1900 to 2000 DEG C, the temperature gradient of a solid liquid interface in the descending direction of a crucible is 10-50 DEG C / cm, the descending speed of the crucible is 0.1-5mm / h, the directions of (111), (100) and (001) can be adopted for seed crystals, the diameter of the crucible is 30-120 mm, and the height of the crucible is 50-200mm. Through adoption of the Bridgman-Stockbarger method, the method for growing the Ce: YAG monocrystal fluorescent material has the advantages of simplicity in operation, low cost, large size of grown Ce: YAG crystals, less internal defects, high doping concentration and the like.

Owner:KUSN KAIWEI ELECTRONICS

Multifunctional air heating device

InactiveCN109169381AEasy to growImprove filtering effectGas treatmentDispersed particle filtrationWater storage tankEngineering

The invention discloses a multifunctional air heating device, which comprises a base. A support rod is arranged on the upper end of the base. A servo motor is arranged on the upper end of the supportmotor. A rotating shaft is arranged on the upper end of the servo motor. A support plate is arranged at the upper end of the rotating shaft. An electric telescopic rod is fixed on the upper end of thesupport plate. A fixed plate is arranged on the upper end of the electric telescopic rod. A mounting plate is arranged on the upper end of the fixed plate. An air duct is arranged on the upper end ofthe mounting plate. A filter cartridge is installed on the right side inside the air duct. A first filter net, a second filter net and a third filter net are arranged in turn from right to left inside the filter cartridge. A heating box is fixed inside the air duct. A number of heating plates are installed in the heating box. The heating box is provided with an air inlet and an air outlet on theleft and right sides thereof respectively. The air duct is internally provided with a fixed rod which is arranged at the left end of the heating box. A blower is installed on the fixed rod. A water storage tank is installed on the upper end of the air duct. A water pump is installed at the inner bottom of the water storage tank. The water pump is connected with a spray pipe through a connecting pipe. A number of atomizing nozzles are arranged at the lower end of the spray pipe.

Owner:温海青

Culture medium for nutrition-rich pleurotus eryngii

InactiveCN103408361AThe preparation process is simpleEasy to growFertilizer mixturesPleurotus eryngiiWater content

A culture medium for nutrition-rich pleurotus eryngii comprises cornstalk, rice bran, bean cake, cane sugar, quick lime, hydrated lime, calcium phosphate and magnesium sulphate, wherein the root of the cornstalk is kept; the bean cake is made by squeezing rapeseeds of the current year; the cornstalk with root is aired and soaked in a soaking pool; in the soaking process, the cornstalk is turned over and hammered every 10 days, until more than half of the cornstalk is crushed; the crushed and soaked cornstalk is aired till the water content of the cornstalk is not higher than 50%; the cornstalk, the rice bran and the bean cake are mixed uniformly and are layed as the base layer of the culture medium; the cane sugar, the quick lime, the calcium phosphate and the magnesium sulphate are mixed to prepare nutrition liquid; the nutrition liquid is sprayed onto the surface of the base layer. The culture medium provided by the invention is high in nutrition content, can cultivate the pleurotus eryngii quickly, and the pleurotus eryngii has a plurality of amino-acids and essential elements for a human body.

Owner:江苏惠发农业科技发展有限公司

Natural textile dye and sound wave dyeing application thereof

InactiveCN105754370ALower requirementEasy to growNatural dyesDyeing processProcess economicsAntibiosis

The invention relates to the technical field of textile printing and dyeing, and concretely relates to a natural textile dye and a sound wave dyeing application thereof. Whole plants of Polygonum orientale, Dicliptera chinensis, Kochia scop aria, Siberia Cocklebur, Artemisia argyi and garden sorrel undergo microwave extraction, and one or more of above obtained extracts is / are adopted as a dye to dye a processed economic fabric. The dye is prepared through extracting pigments from plants, so the dye contains no chemical components, and is green and environmentally friendly; and the dye is used in low-temperature sound wave dyeing of textiles, and the textiles dyed with the dye have the advantages of uniform coloring and antibiosis function.

Owner:张发民

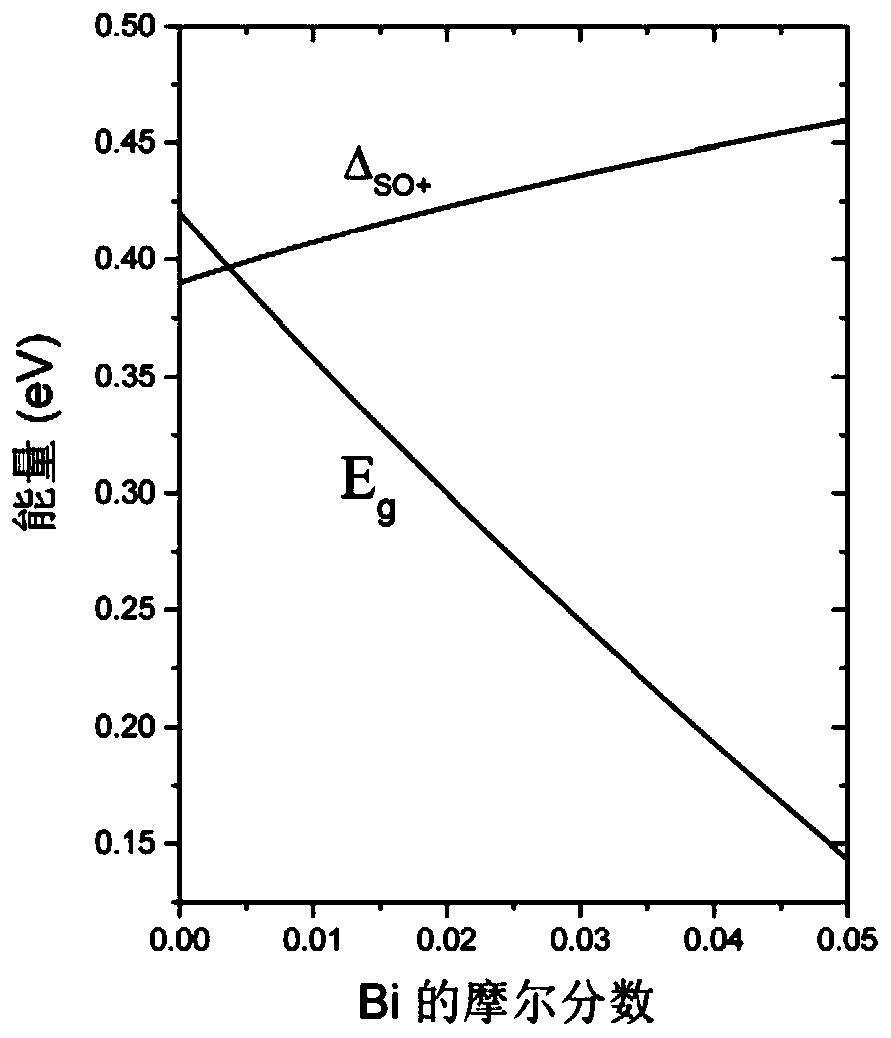

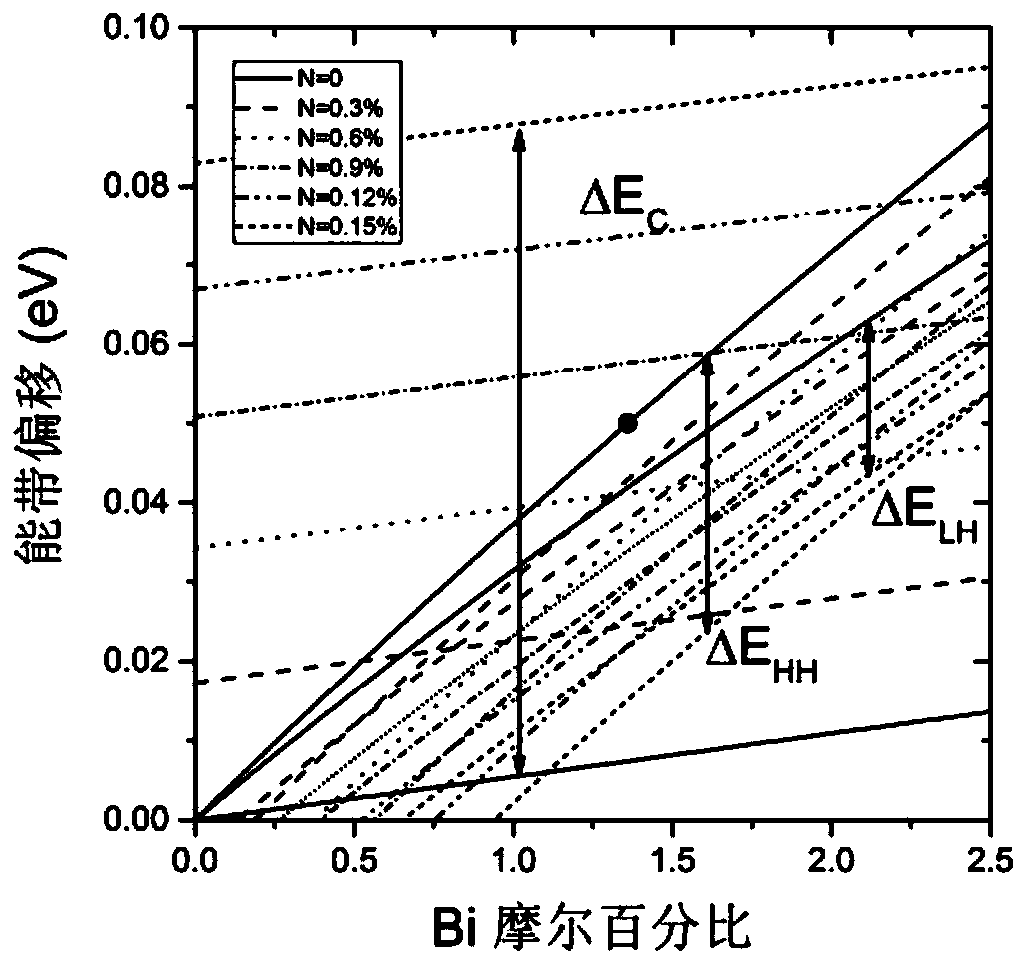

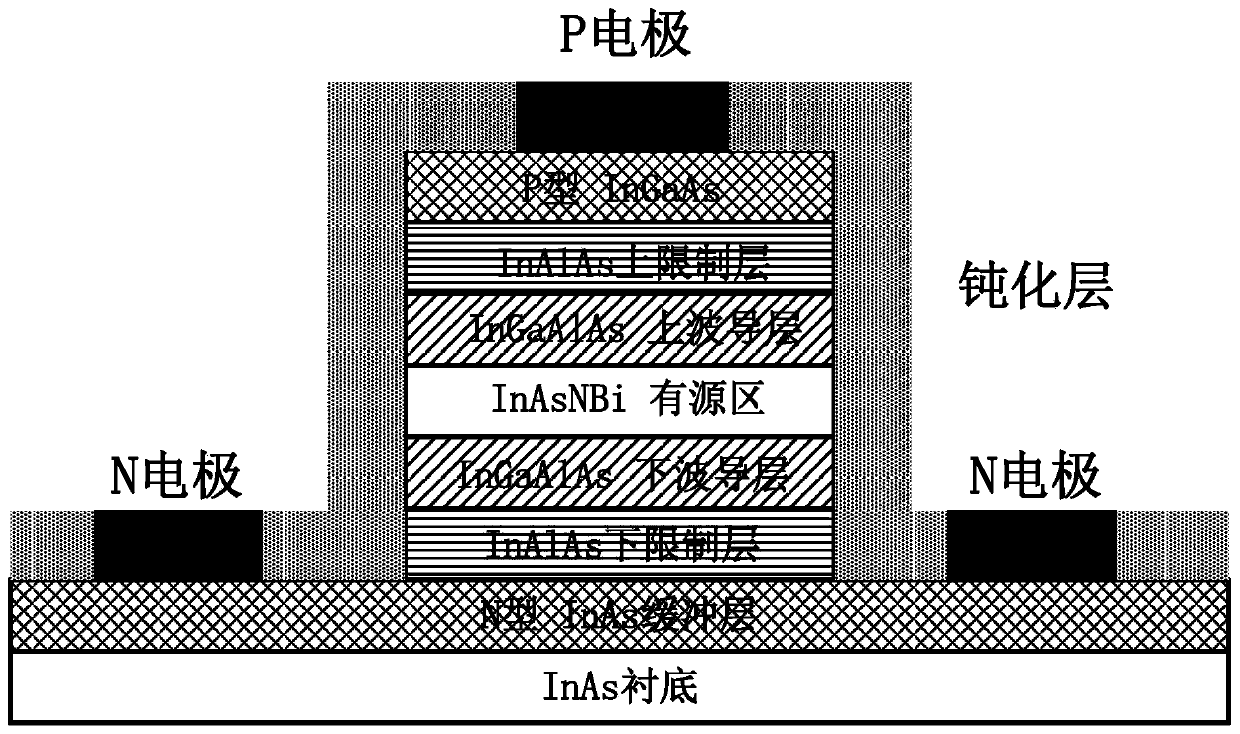

Indium-arsenic-nitrogen-bismuth semiconductor material, laser using material, detector and preparation method

ActiveCN109920861AEasy to growSimple structure and operation processLaser detailsFinal product manufactureSolubilityIndium

The invention discloses an indium-arsenic-nitrogen-bismuth semiconductor material, a laser using the material, a detector and a preparation method, and relates to the field of preparation of semiconductor photoelectric materials. The material comprises a substrate layer, a buffer layer and an indium-arsenic-nitrogen-bismuth semiconductor material. A certain concentration of Bi atoms and N atoms are doped in the InAs semiconductor in a co-doping manner, so that the forbidden bandwidth of the InAs material can be effectively adjusted, the coverage of the near-infrared-to-mid-infrared waveband can be realized, and the material is applied to an optoelectronic device. The doping of the Bi atoms enables the materials to grow more easily and more stably, and the introduction of N atoms can improve the solubility of Bi. In the InAs semiconductor, N atoms are doped at the same time, and the Bi atoms can effectively adjust the energy band structure of the compound. The material can grow by adopting various methods such as conventional molecular beam epitaxy, metal organic compound chemical vapor deposition and the like, and is simple in structure and operation process and easy to control.

Owner:诺迪克(余姚)光电产业研究院有限公司

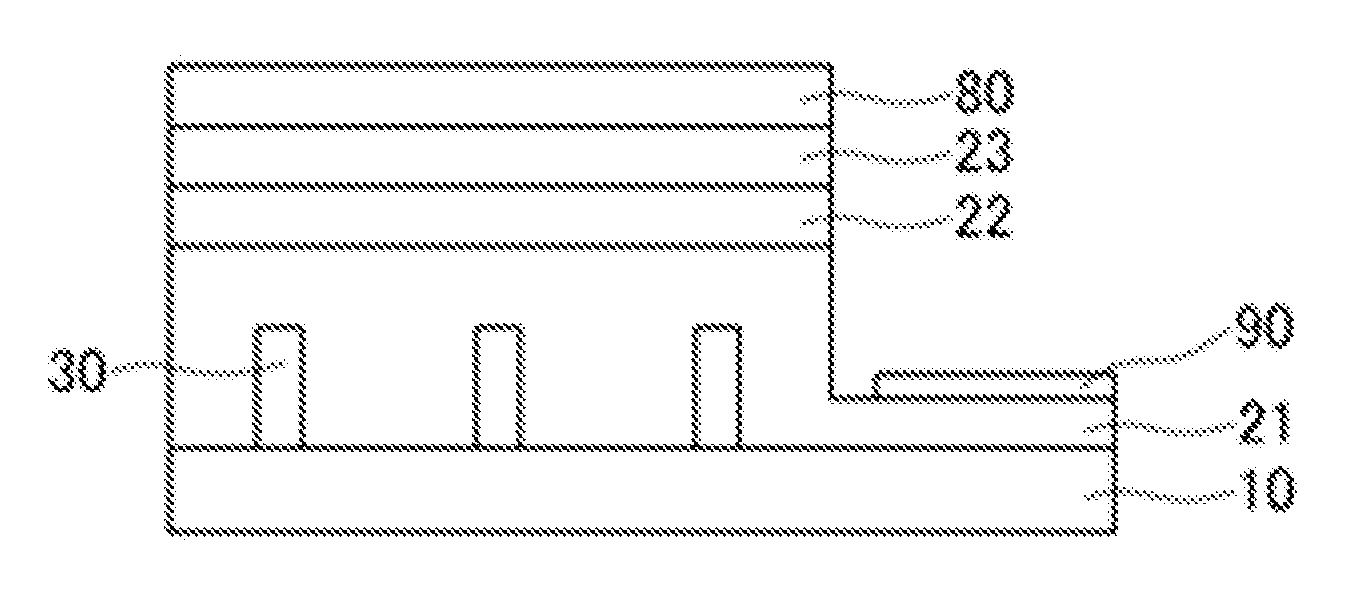

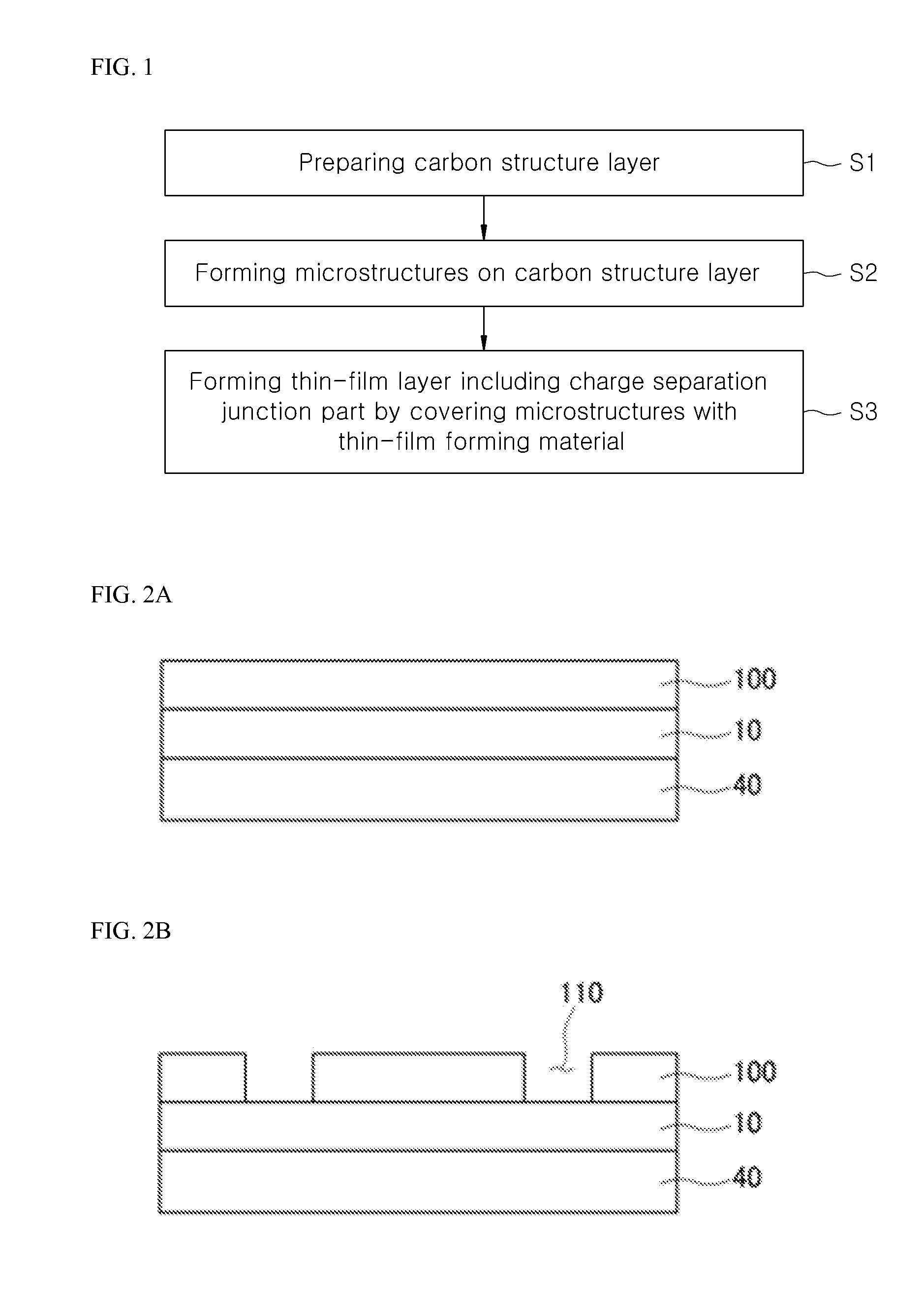

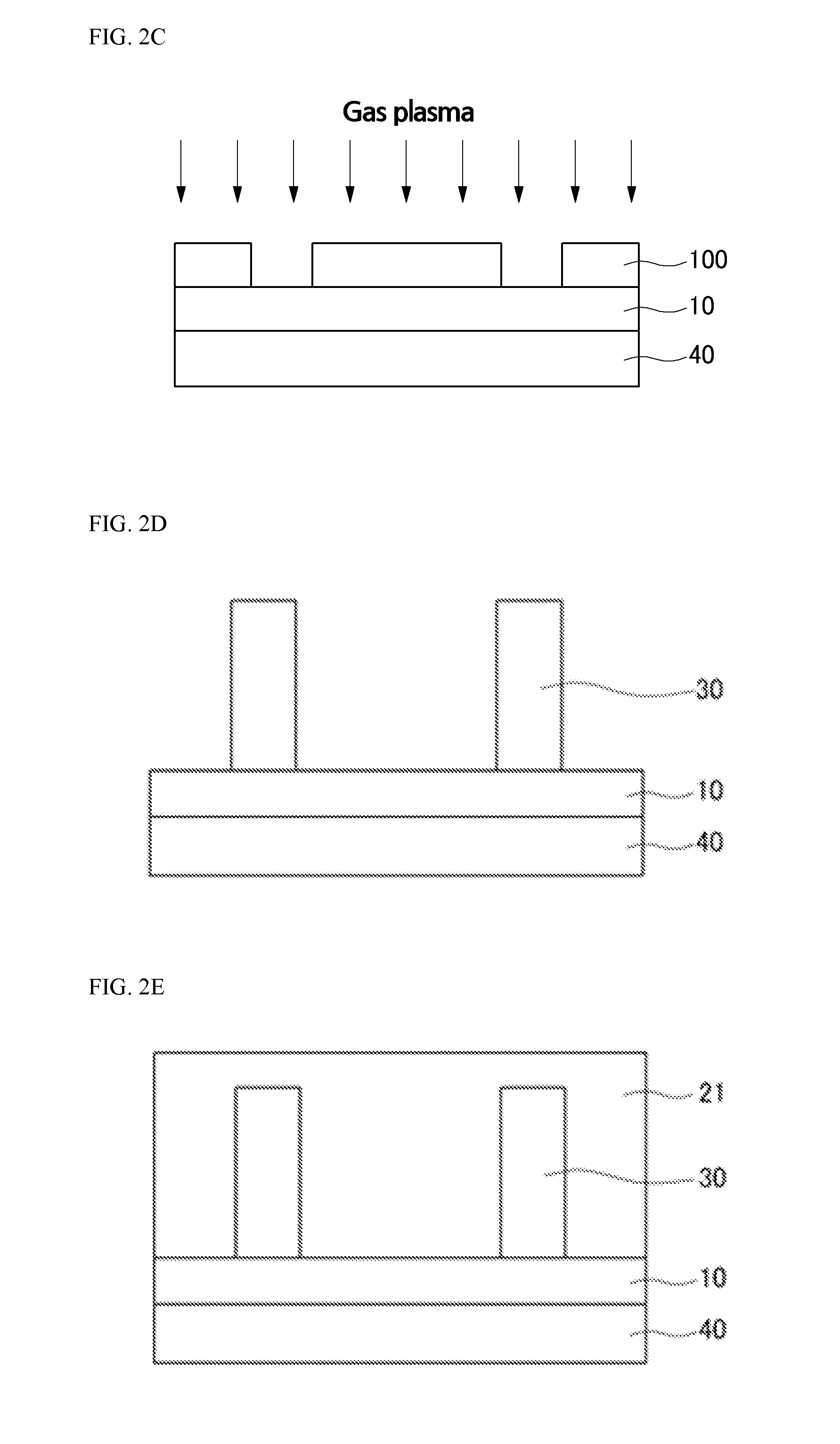

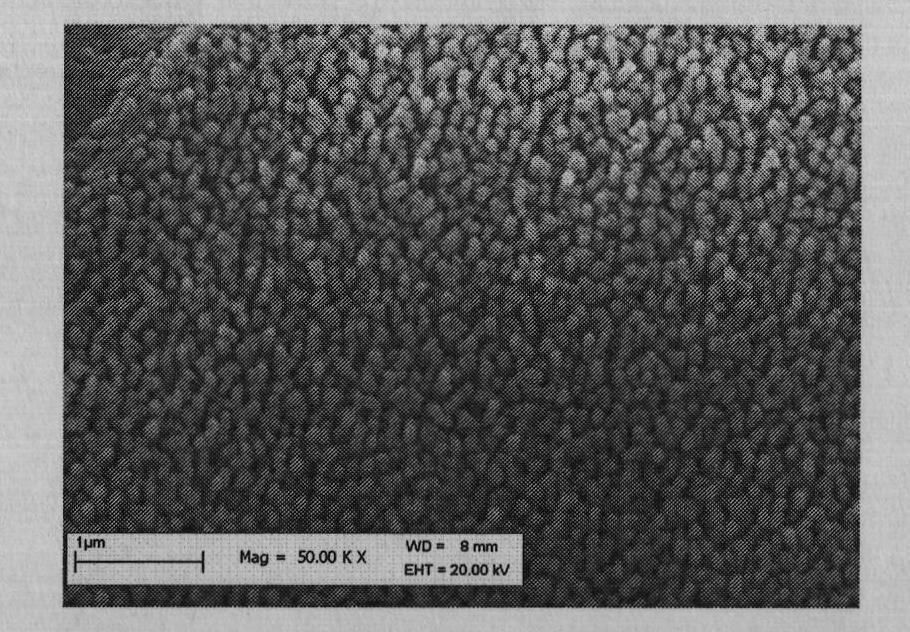

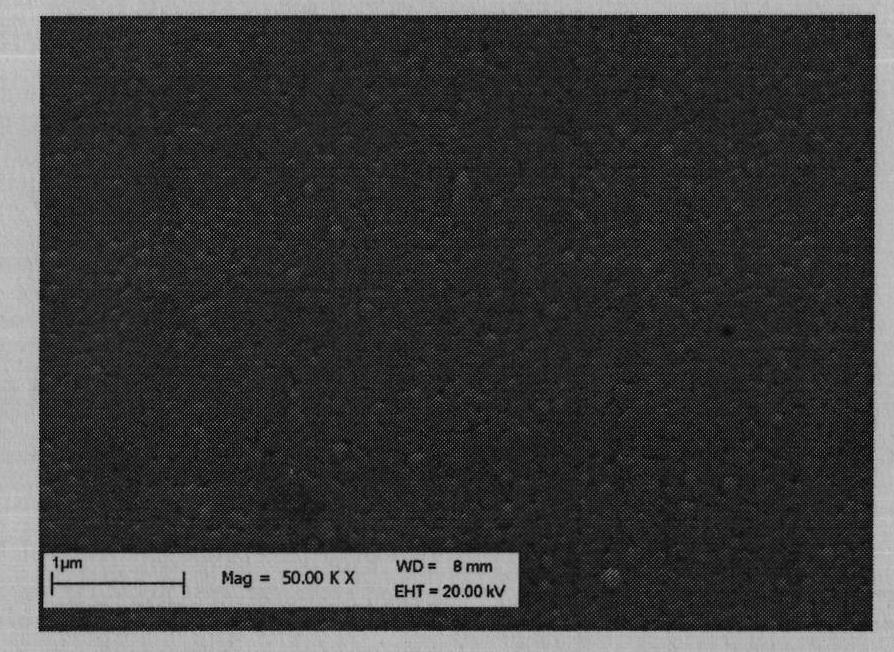

Solar cell and method for manufacturing same

ActiveUS20130213463A1Excellent electrical and optical propertyEasy to growSemiconductor/solid-state device manufacturingPhotovoltaic energy generationMicrostructureCharge separation

The invention relates to a solar cell and to a method for manufacturing same. The solar cell contains a carbon structure layer; a microstructure formed on the carbon structure layer; and a thin-film layer covering the microstructure and including a charge separation junction part.

Owner:SEOUL NAT UNIV R&DB FOUND

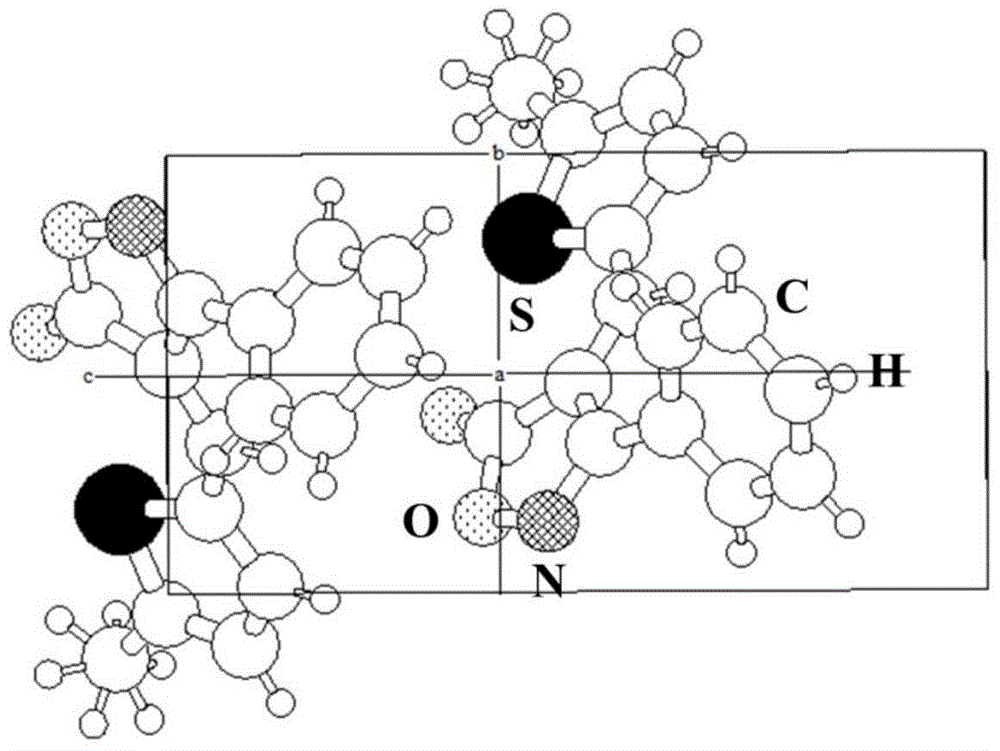

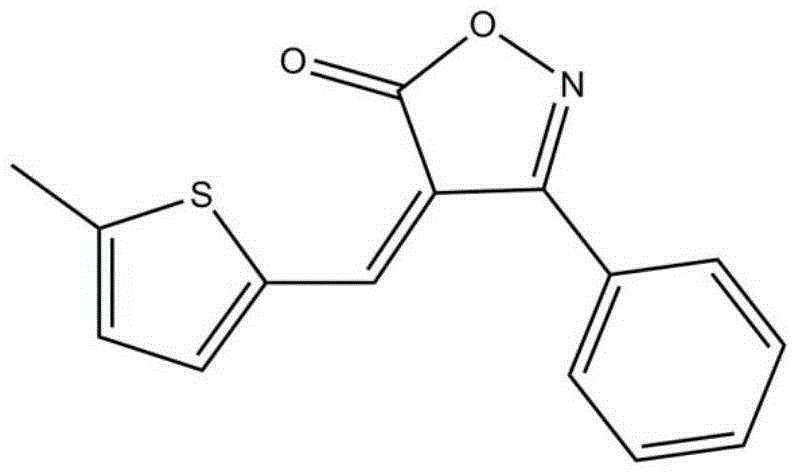

C15H11NO2S nonlinear optical crystal and preparation method and application thereof

InactiveCN104947195AEasy to growStable physical and chemical propertiesPolycrystalline material growthFrom normal temperature solutionsNonlinear optical crystalSpace group

The invention discloses a C15H11NO2S nonlinear optical crystal which does not have a symmetry center, and belongs to a monoclinic system. The space group is Pc, and the cell parameters are as follows: a=9.466 A', b=6.060 A', c=11.771 A', alpha=gamma=90 degrees, beta=106.248 degrees, Z=2, and V=648.3 A'<3>; a spontaneous crystallization volatilization method, a falling temperature method and a seed crystal method can be adopted for crystal growth, the characteristics of high growth rate and low cost are achieved, and the large-size and high-quality crystal can easily grow; the obtained C15H11NO2S crystal powder has the double-frequency effect strength being 1-2 times of OH1, is stable in chemical property, does not deliquesce, meets needs of infrared band laser frequency conversion, and can be used for manufacturing a nonlinear optical apparatus; the apparatus comprise a device which can enable at least one beam of incident electromagnetic radiation to pass through at least one piece of C15H11NO2S nonlinear optical crystal so as to generate at least one beam of output radiation of which the frequency is different from that of the incident electromagnetic radiation.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

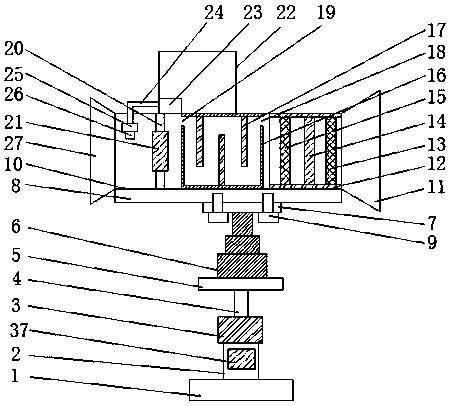

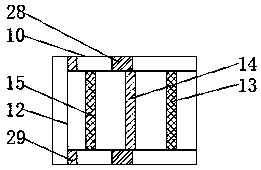

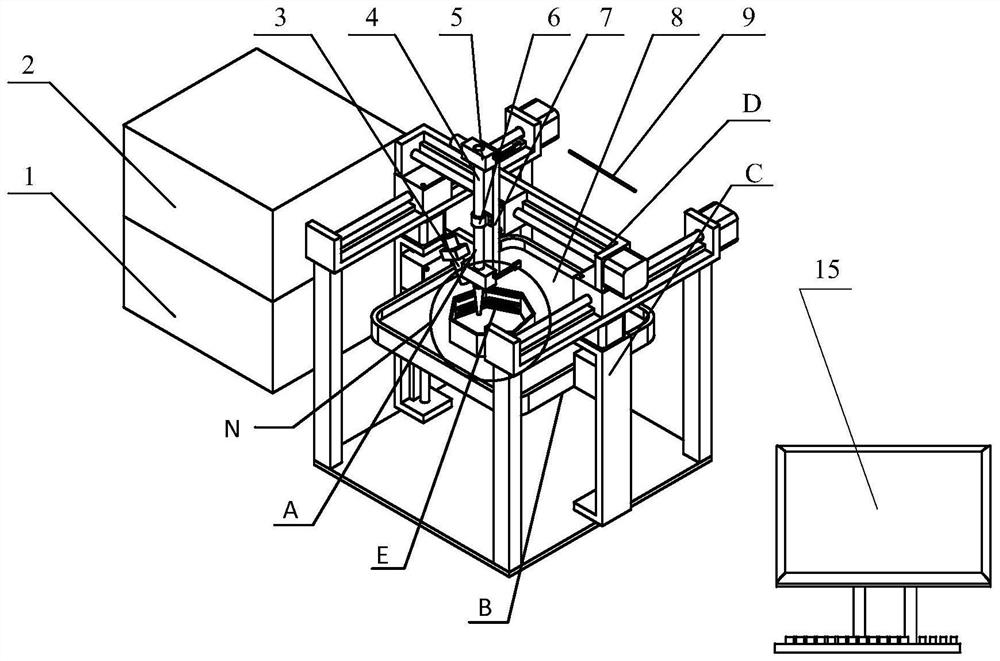

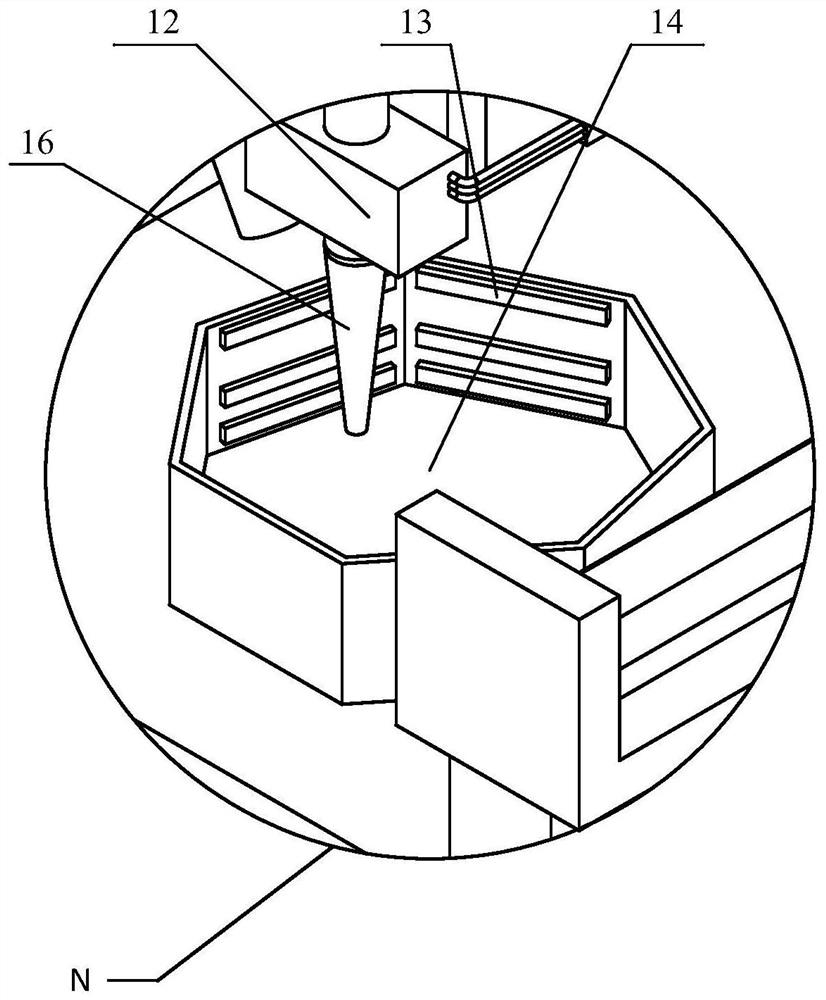

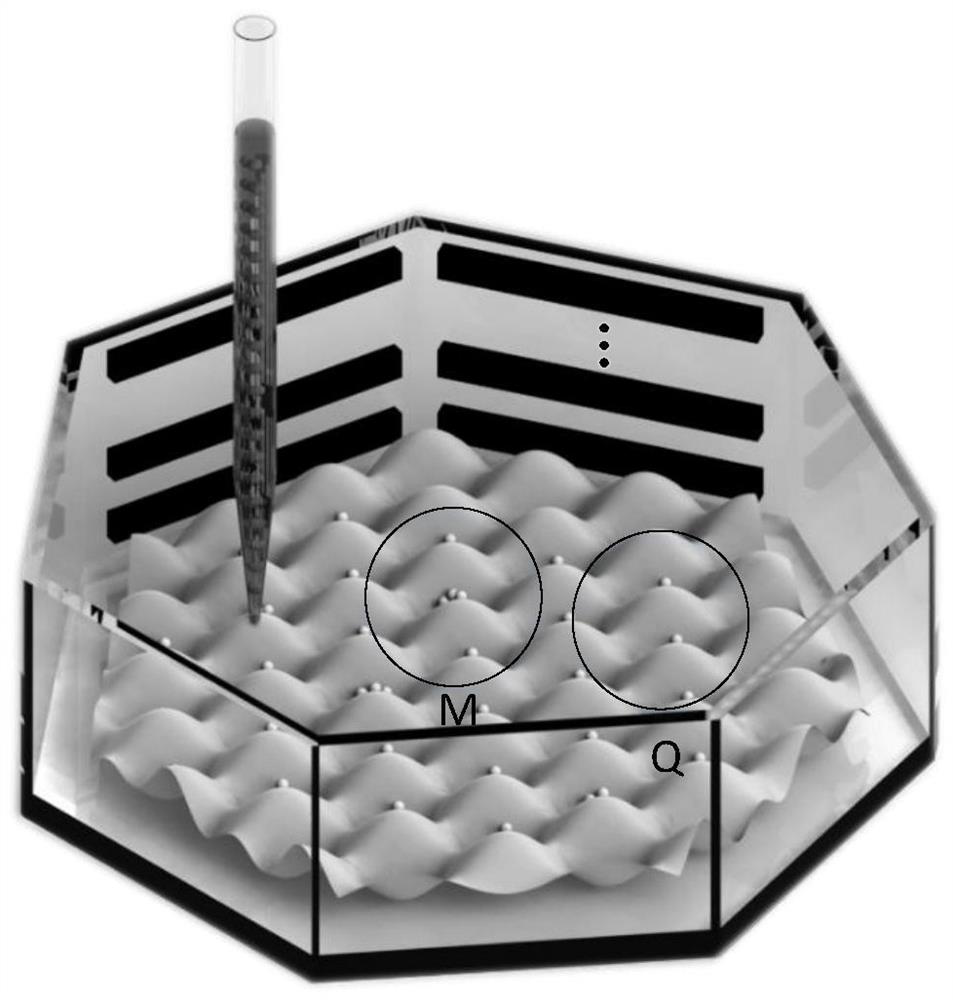

Three-dimensional ultrasonic array scaffold-free cell printing device and printing process thereof

ActiveCN112776325AImprove applicabilityImprove universalityAdditive manufacturing apparatusTissue/virus culture apparatusEngineeringMechanical engineering

The invention provides a three-dimensional ultrasonic array scaffold-free cell printing device and a printing process thereof. The three-dimensional ultrasonic array scaffold-free cell printing device comprises a cell conveying mechanism, a printing platform, a platform driving mechanism, a conveying driving mechanism and a three-dimensional ultrasonic array micro potential well generation system, wherein the printing platform is installed on the platform driving mechanism; the cell conveying mechanism is installed on the conveying driving mechanism; the three-dimensional ultrasonic array micro potential well generation system is connected with the printing platform; a planar sound pressure micro potential well is formed in the printing platform; a plurality of planar sound pressure micro potential wells with different heights are formed on the printing platform, so that cells needing to be printed at different heights are positioned; and a cell three-dimensional system is constructed in the mode of constructing a three-dimensional array sound pressure potential well, controllability is better, and the three-dimensional ultrasonic array scaffold-free cell printing device can be used for cell three-dimensional printing under various cells and various environments and has excellent universality.

Owner:HANGZHOU DIANZI UNIV

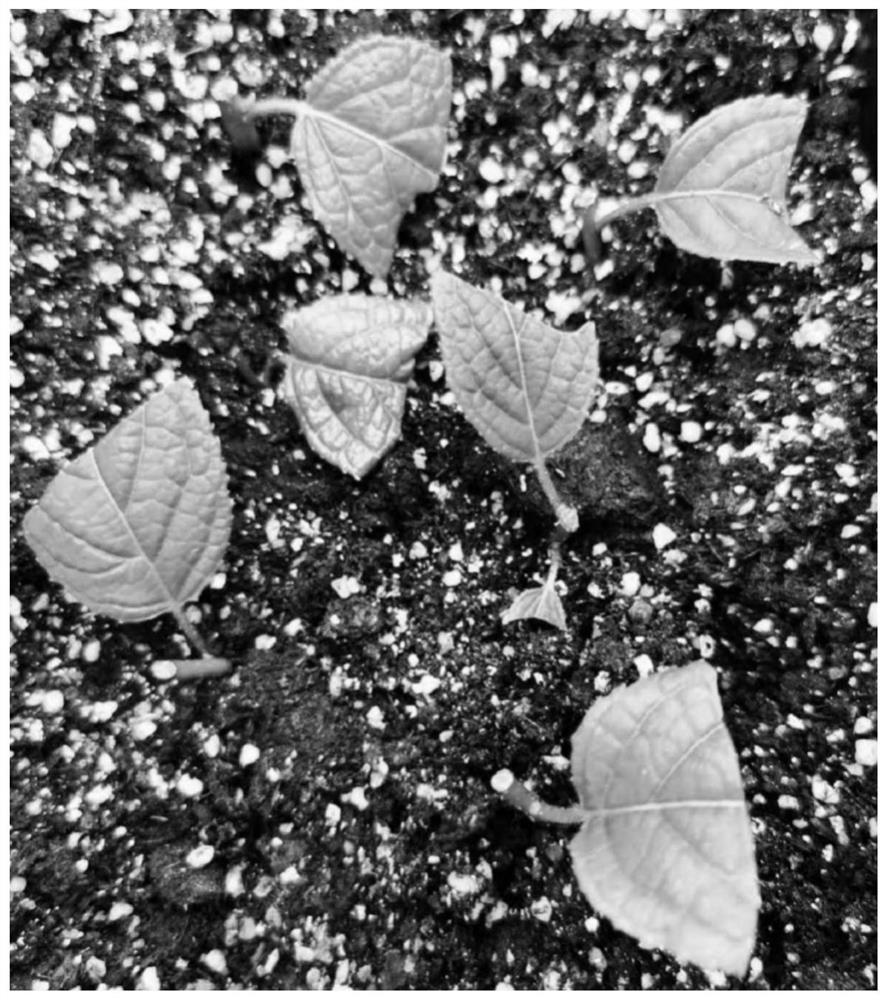

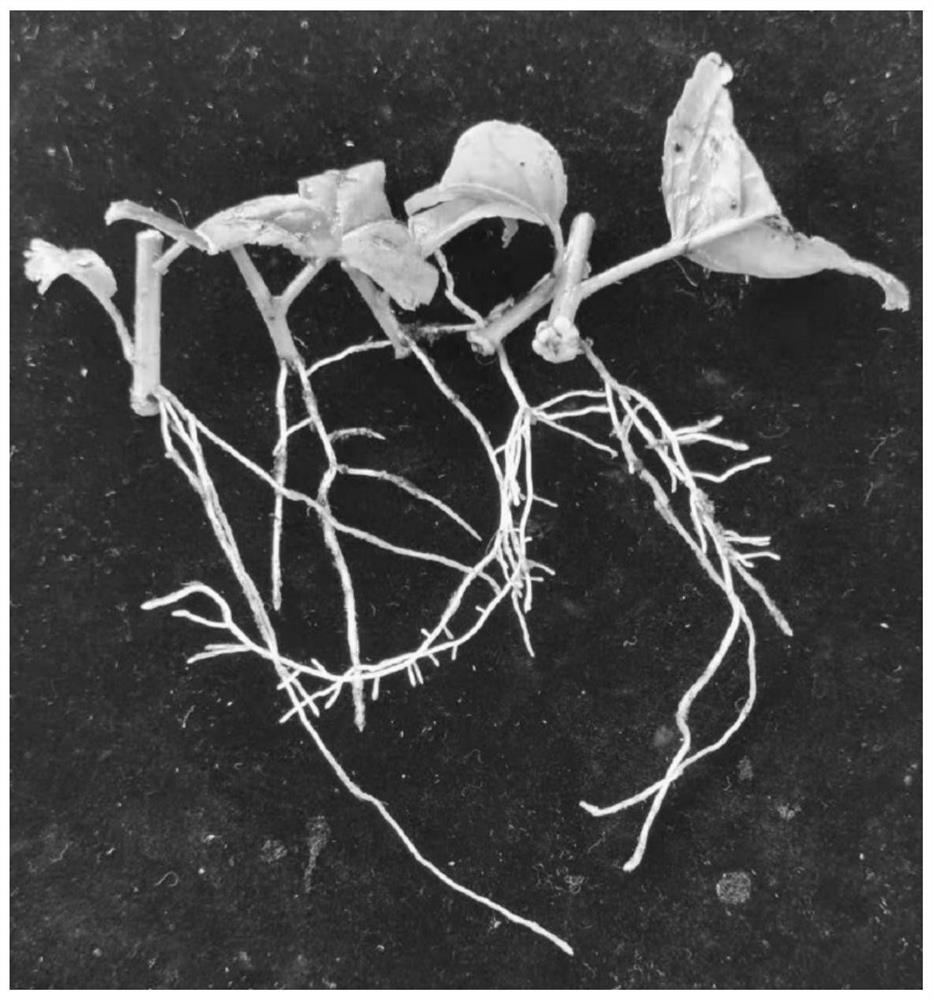

Low-cost rapid micropropagation method for excellent eucommia ulmoides seedlings

ActiveCN113080064AHigh speedAvoid the defects of low survival rate of domestication and transplantingHorticulture methodsPlant tissue cultureAxillary budPlantlet

The invention discloses a low-cost rapid micropropagation method for excellent eucommia ulmoides seedlings. The method comprises the following steps: by taking a micro-stem segment with one leaf and one bud of an eucommia ulmoides strain as an explant, performing pretreatment, performing adventitious root induction treatment, performing field planting of the explant, performing adventitious root induction culture, performing axillary bud germination induction of the explant, performing seedling culture and the like. A rooting inducer is adopted to treat the stem segments for 30 s, adventitious root primordia are formed in 7-10 d, complete eucommia ulmoides regenerated plants can be obtained in 22 d, the speed is higher than that of rapid propagation of eucommia ulmoides through a traditional propagation method and a tissue culture technology, and the propagation period is greatly shortened; and according to the method, the micro-stem segments are inserted into a seedling raising plate filled with a nutrient medium and directly take roots and seedlings in a greenhouse, on one hand, the influence and limitation of natural factors such as seasons and regions are avoided, and on the other hand, the defects that the tissue culture and breeding process of eucommia ulmoides is tedious and the domestication and transplanting survival rate of subsequent tissue culture regeneration seedlings is low are overcome.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

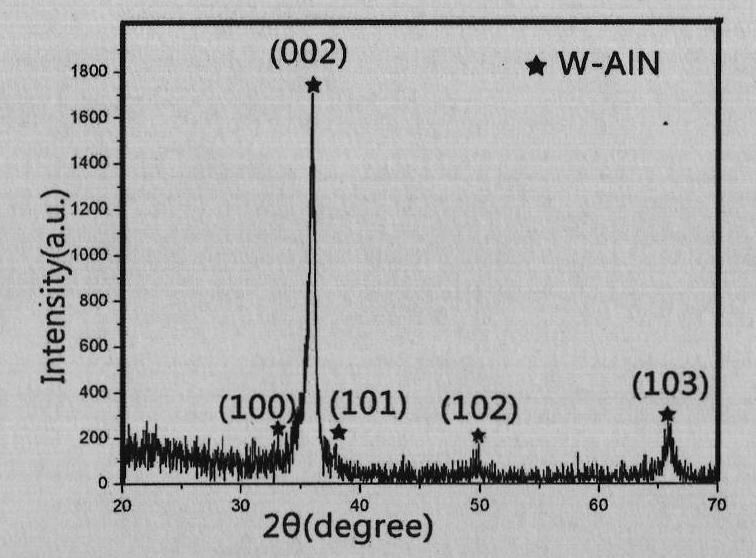

Method for preparing independent self-supporting transparent aluminium nitride nanocrystalline film

InactiveCN102154627AHigh light transmittanceLow costNanotechnologyChemical vapor deposition coatingTube furnaceThin membrane

The invention discloses a method for preparing an independent self-supporting transparent aluminium nitride nanocrystalline film, and the method is realized through the following processes: placing a ceramic boat loaded with a certain quantity of absolute AlCl3 (with the purity of 98-99wt%) powder on a position, 6-9cm away from a tube orifice, on the upstream of the airflow direction of a horizontal tube furnace with the length of 100cm; placing a quartz tube, a ceramic sheet and the like on a position 20-25cm away from the ceramic boat so as to be used as a product collector; vacuumizing the sealed tube furnace to 2*10<-2>-10<3>Pa; heating the horizontal tube furnace to 760-900 DEG C in the presence of Ar gas; introducing 200-300sccm of NH3 for reaction for four hours; and naturally cooling to room temperature in the presence of the Ar gas to obtain the independent self-supporting transparent aluminium nitride film on the collector. The film prepared in the invention is the aluminium nitride of a wurtzite structure and is characterized of being a nano crystal array microcosmically and an independent self-supporting and transparent aluminium nitride film macrocosmically.

Owner:XINJIANG UNIVERSITY

Processing method for producing walnut oil

InactiveCN105087145AFully retain the original nutrientsHigh freezing pointFatty-oils/fats refiningFatty-oils/fats productionNutritive valuesWater vapor

The invention discloses a processing method for producing walnut oil. The processing method comprises the steps of airing, grinding, heat preservation, cake preparation, stewing, squeezing and filtering and specially comprises the steps of taking shelled walnut kernels; airing the shelled walnut kernels to obtain dried walnut kernels; grinding in a grinder, sealing the ground walnut kernels in a container, and carrying out heat preservation at the temperature of 55+ / -5 DEG C for 2 hours; preparing cakes, putting the cakes in a food steamer for stewing by virtue of vapor; and after stewing, squeezing to obtain crude walnut oil; and precipitating the crude walnut oil for 36-48 hours and then filtering to obtain finished walnut oil. According to the invention, the walnut oil is intense and soft in taste, is beneficial to body health if used for a long time due to high monounsaturated fatty acid, and has high nutritive value and health effect.

Owner:饶世柱

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com