Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Low life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

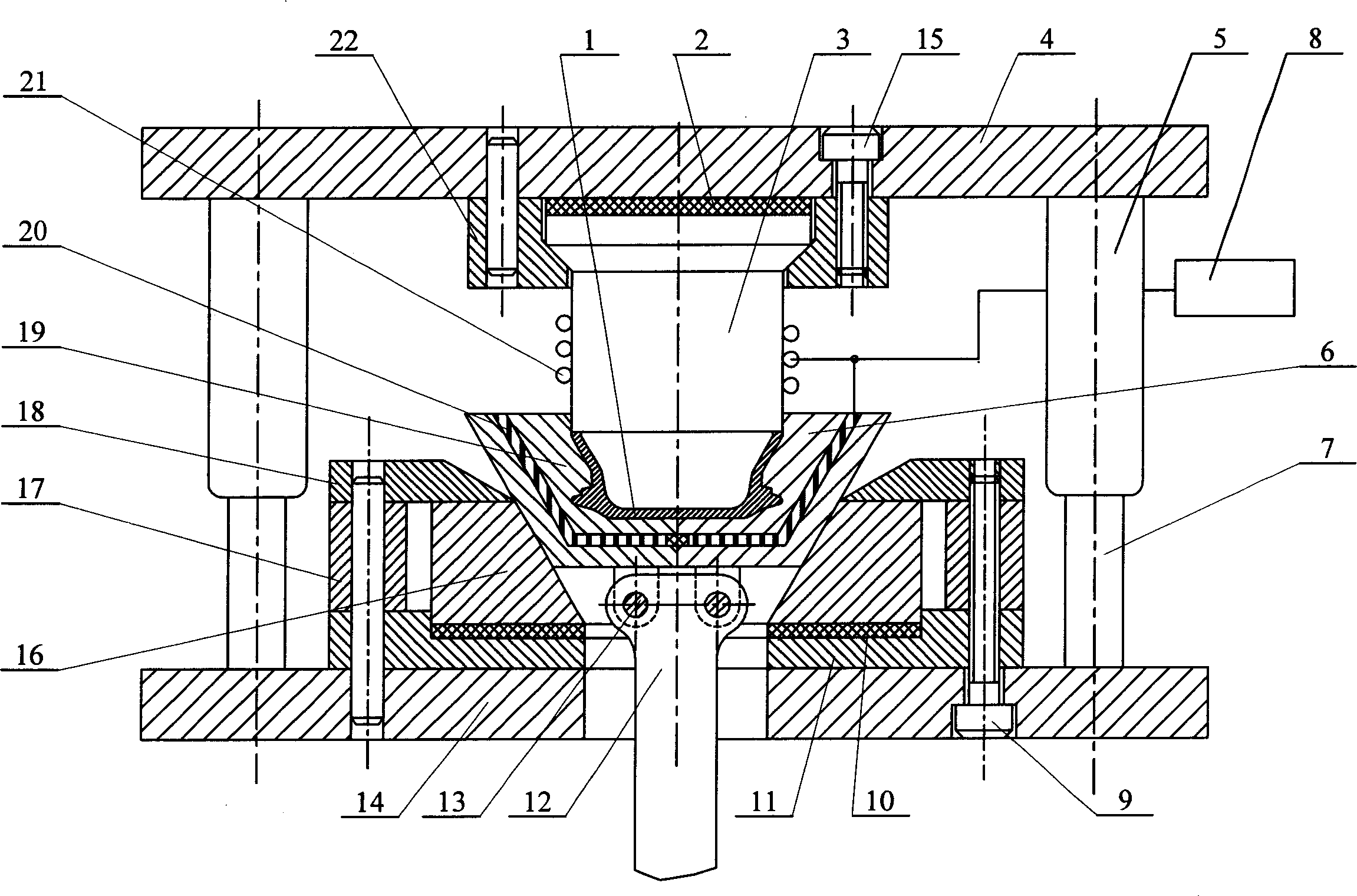

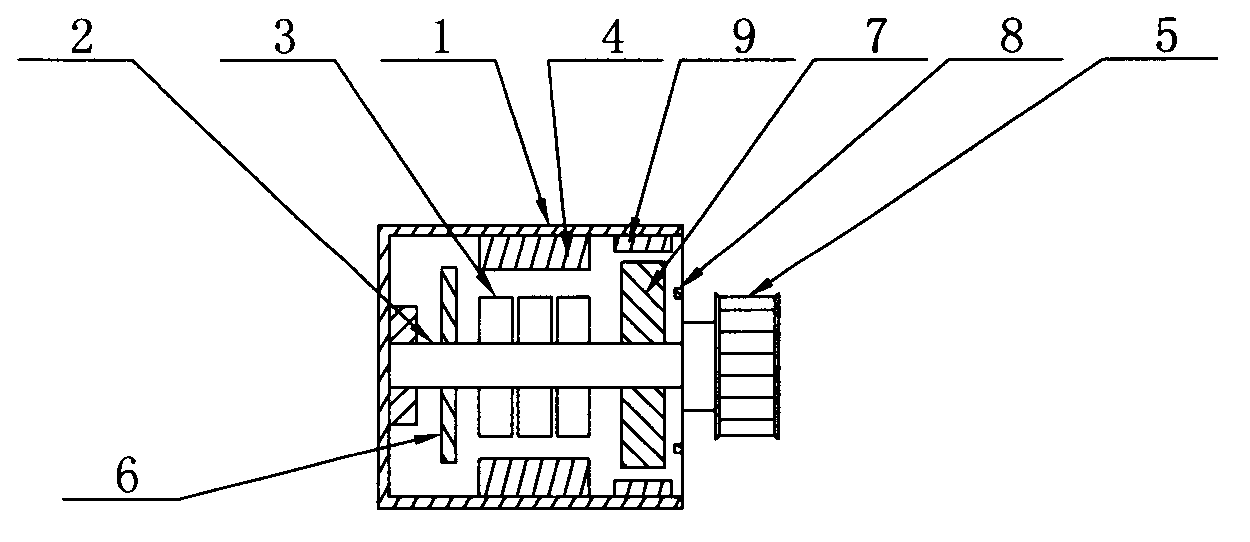

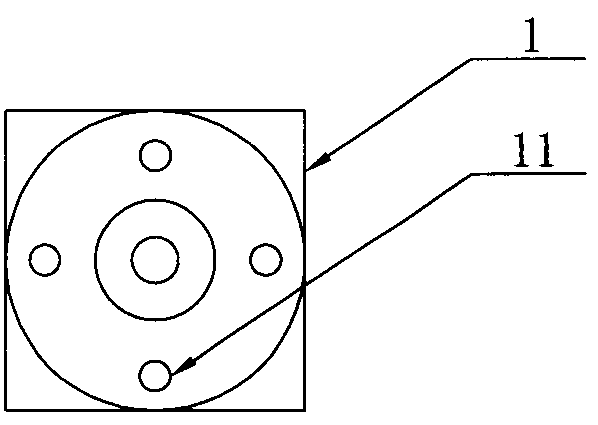

Shaping device of solid hot extrusion magnesium alloy wheel hub and shaping method thereof

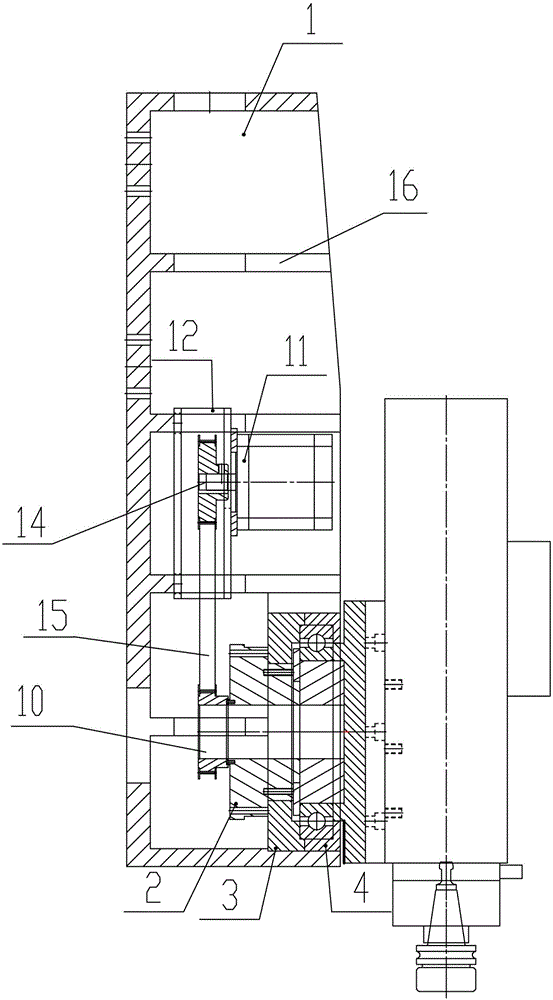

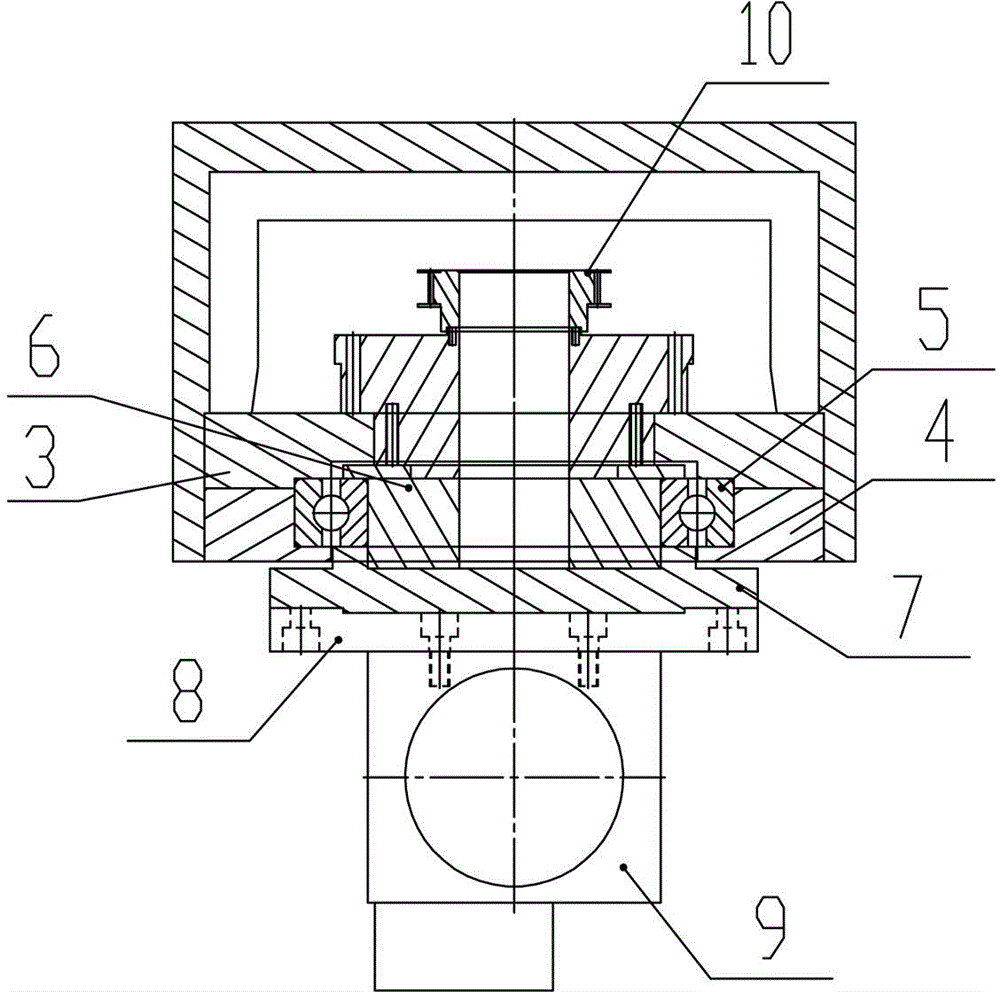

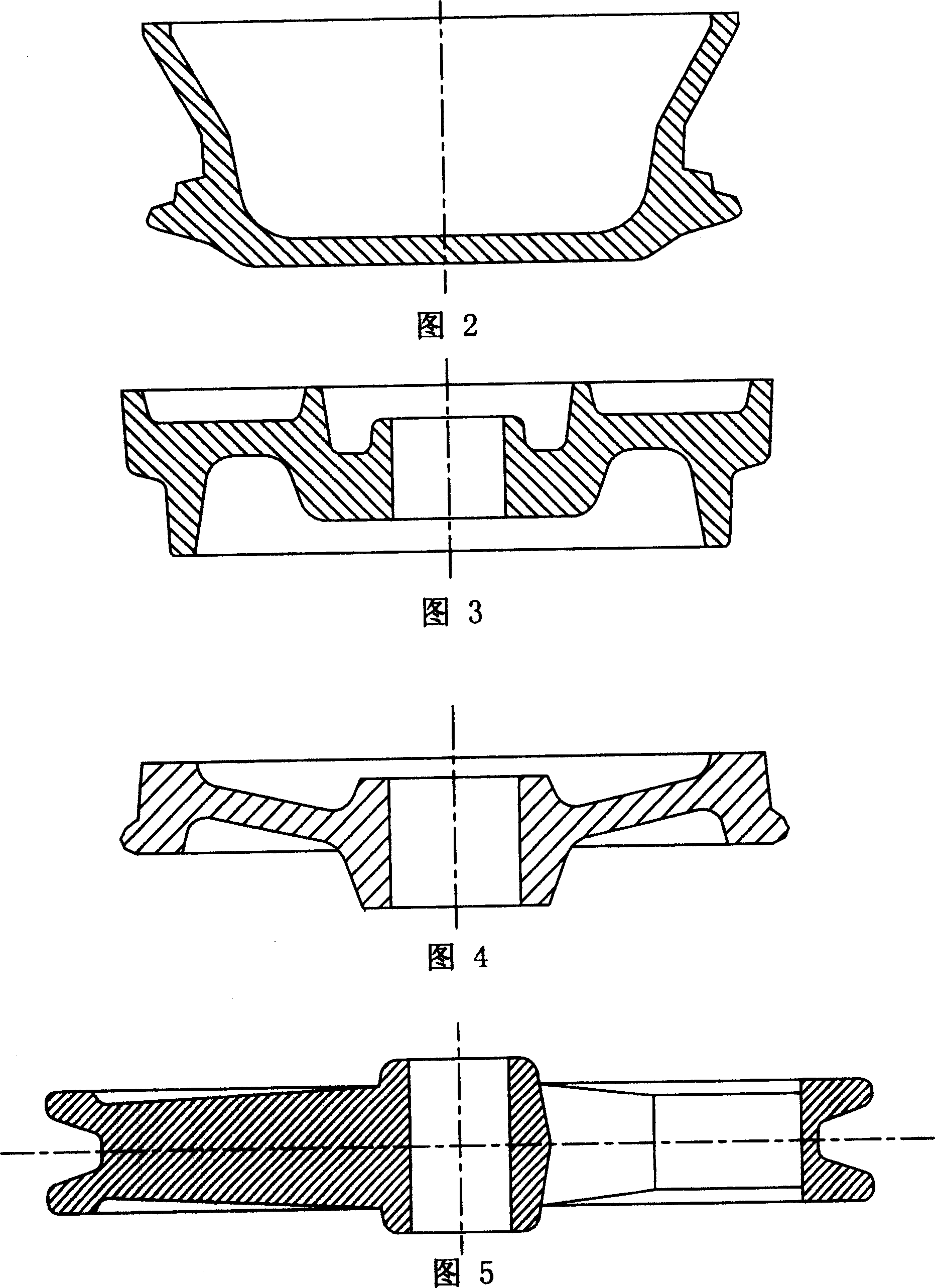

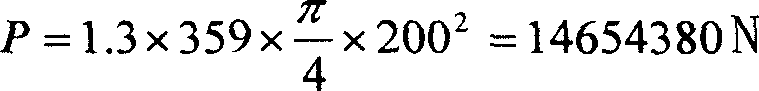

A solid-state hot squeezing apparatus for shaping the Mg-alloy wheel hub is composed of upper die plate, male die and its heater, heat isolating plate between said upper die plate and male die, moulding cavity heater for left and right moulding cavities, heat isolating plate between female die and its die plate, push-out rod, and temp controller. Its shaping method includes such steps as blanking, heating, holding temp, preheating die set squeezing cutting, surface treating and ageing treating.

Owner:HARBIN INST OF TECH

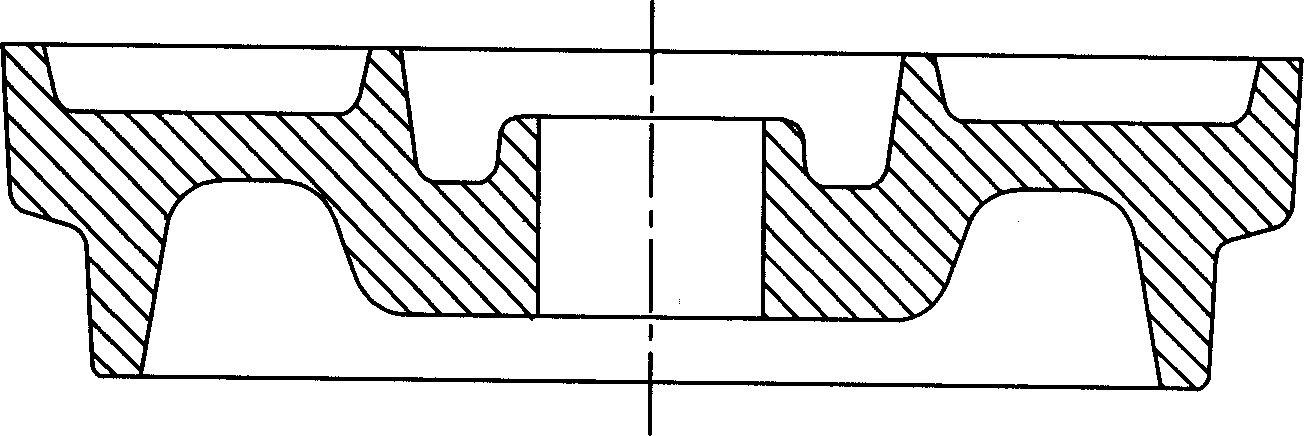

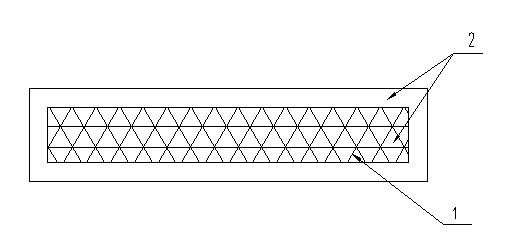

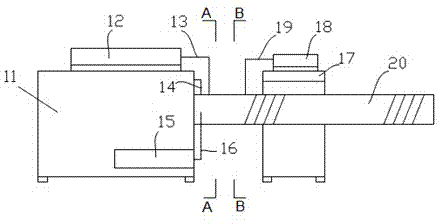

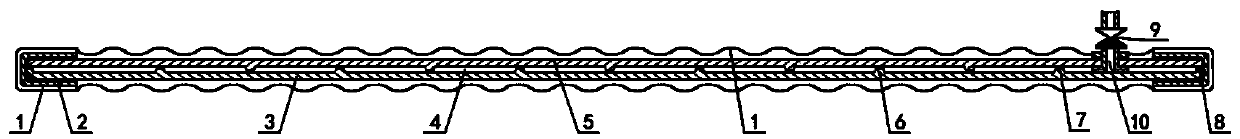

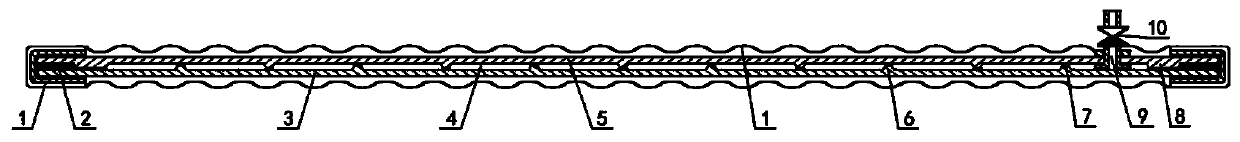

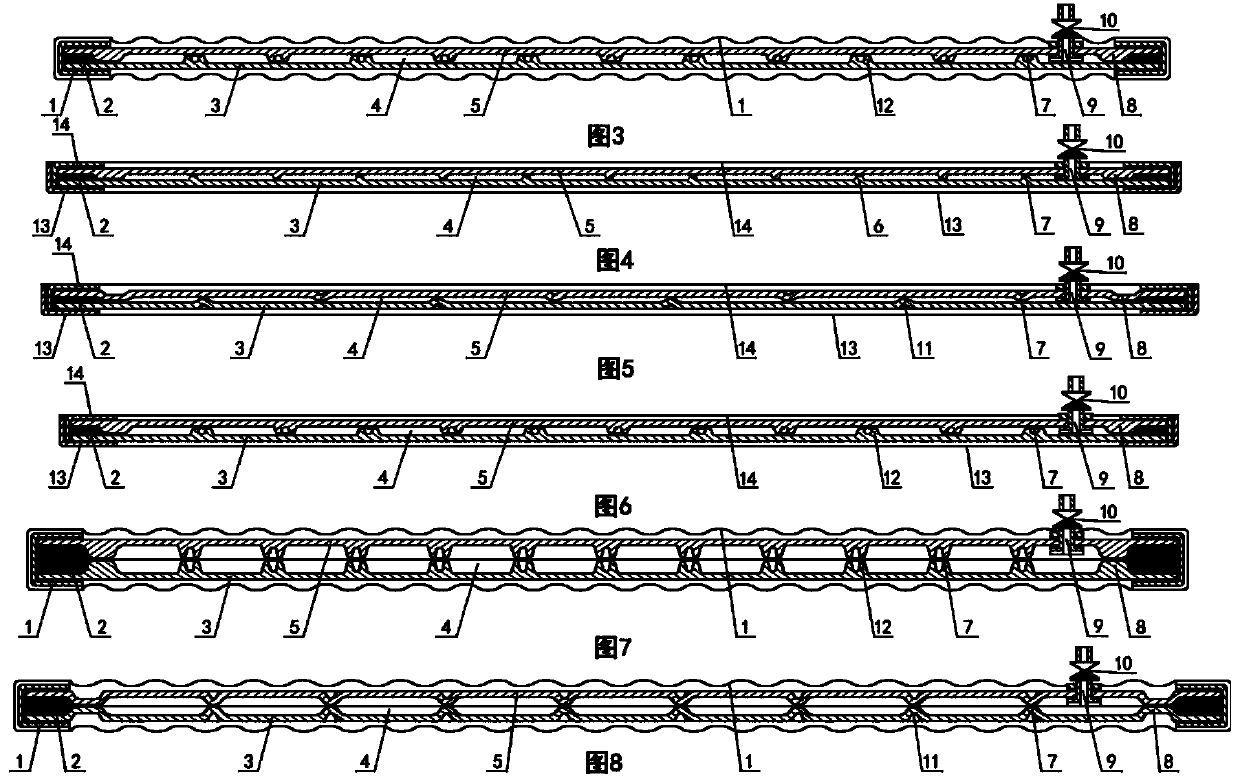

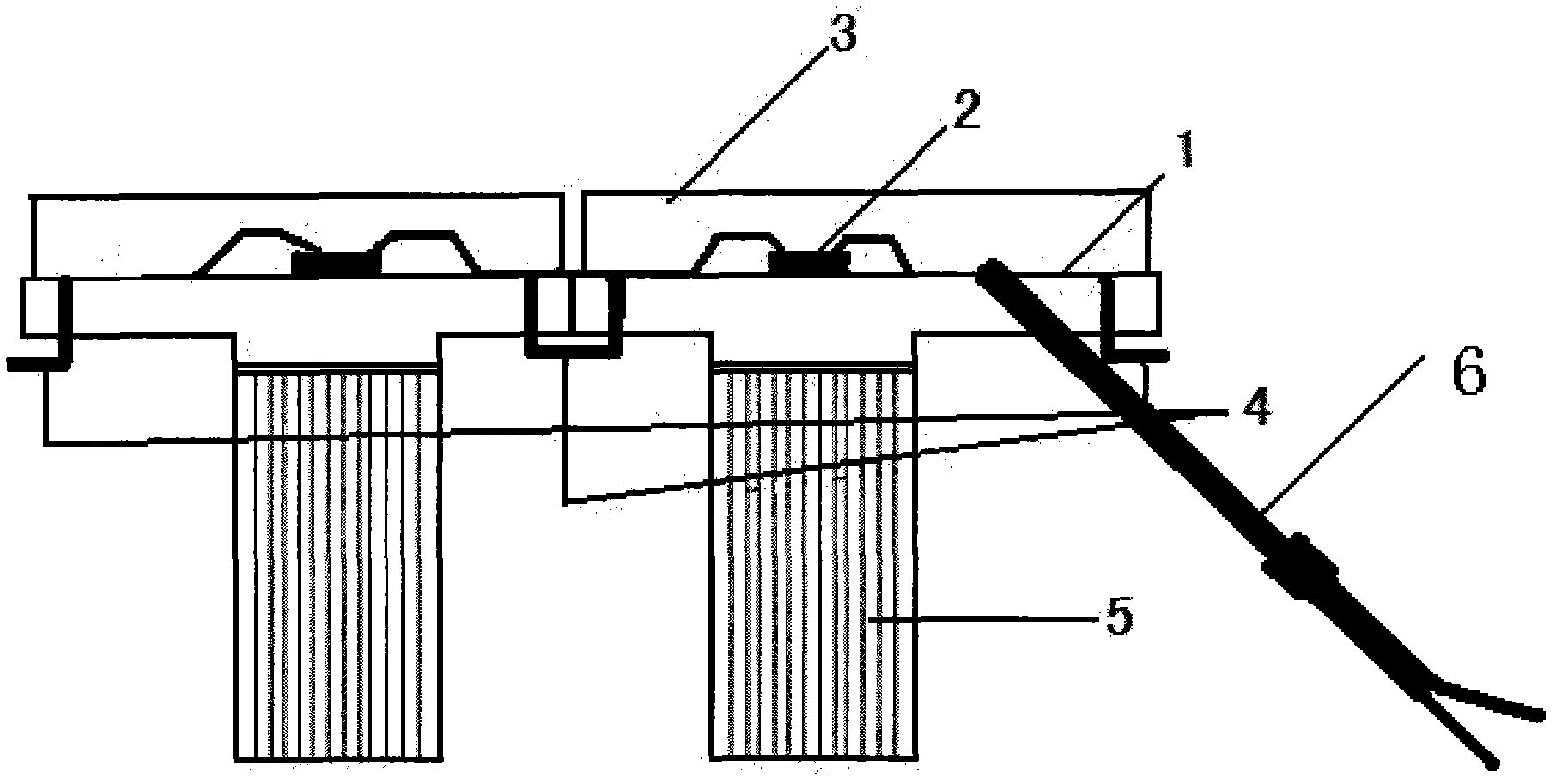

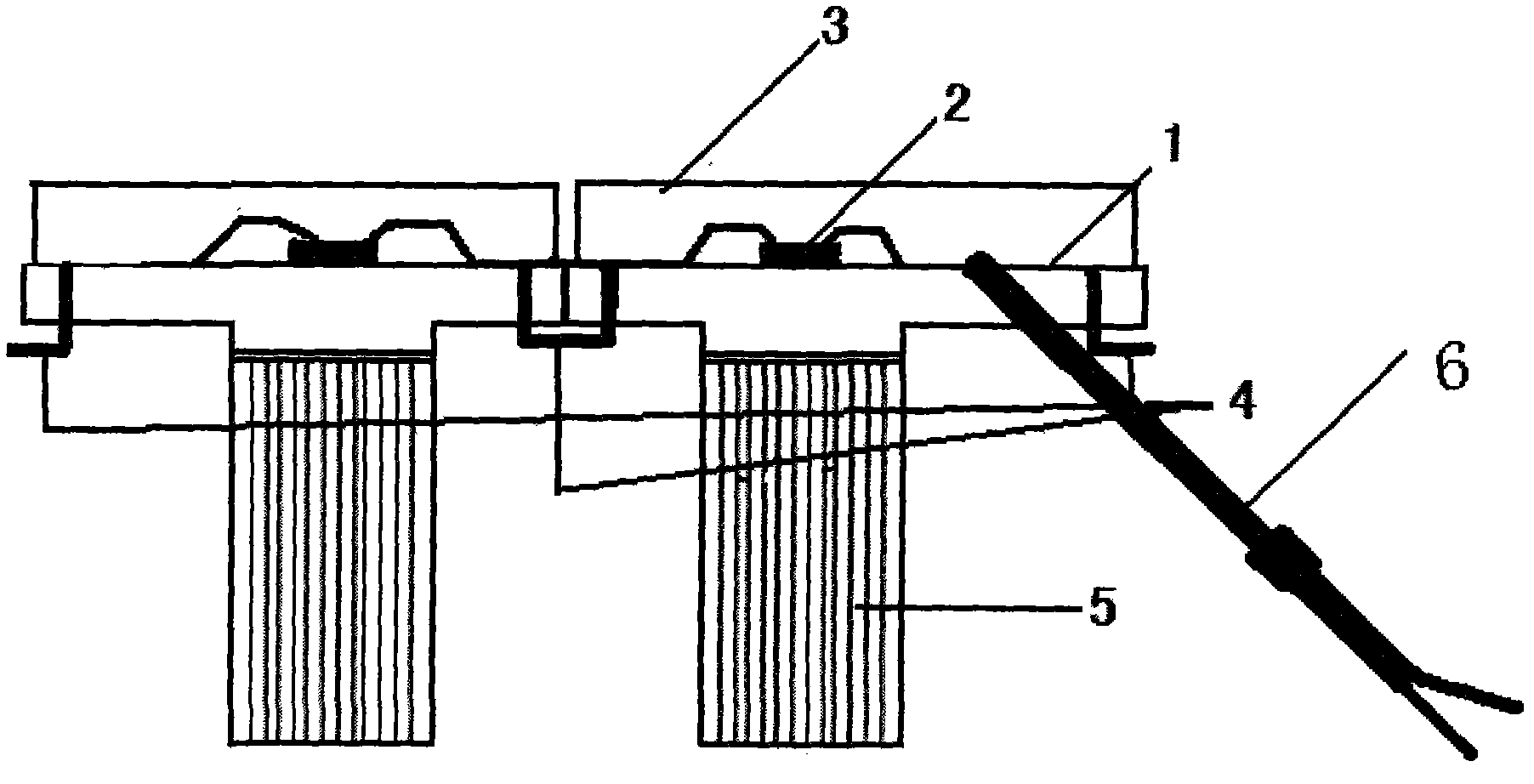

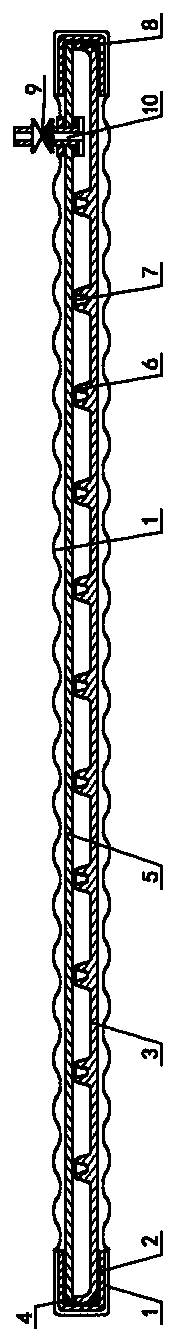

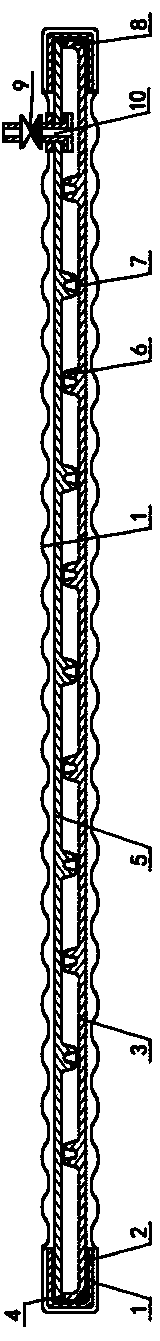

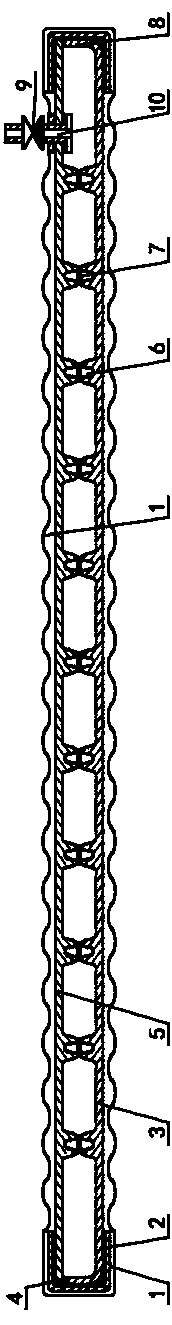

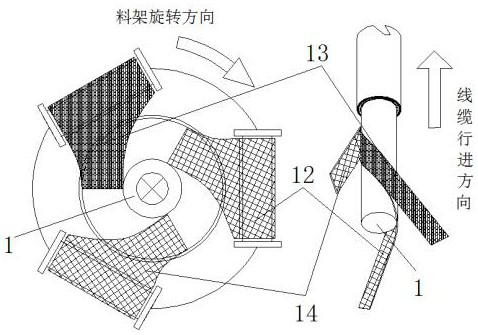

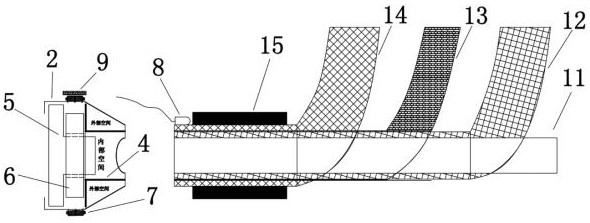

Special flat dragging tape for plastic-wrapping carbon fiber elevator

The invention relates to a special flat dragging tape for a plastic-wrapping carbon fiber elevator and belongs to the technical field of an elevator. The special flat dragging tape is prepared according to the following steps: firstly, weaving multi-strand carbon fiber thin ropes into a carbon fiber flat tape with meshes; performing injection molding on the synthetic plastics and carbon fiber flat tape; wrapping the carbon fiber flat tape in the synthetic plastics; and forming an integrated body by the synthetic plastics in the meshes of the carbon fiber flat tape and the synthetic plastics wrapped on the upper, lower and peripheral surfaces of the carbon fiber flat tape. The special flat dragging tape provided by the invention has the advantages that the tensile strength is 7-10 times of that of a steel tape with the same cross section; the weight is light; the density is only 1 / 4 of that of a common steel wire; the cross section of the dragging tape is reduced by 65%; the anti-breaking tensile force is increased by 70%; the durability is excellent; compared with the steel tape of the common elevator, the service life of the special flat dragging tape is increased by 4 times; the plastic-wrapping dragging tape is in tight contact with a wheel; a contact surface pressure ratio is low; no dragging abrasion exists; the bending capacity of rope is increased; a diameter of a dragging wheel is reduced; the driving power of a host machine is lowered; the cost is saved; and the special flat dragging tape is an ideal dragging transmission tape for elevator.

Owner:施凤鸣

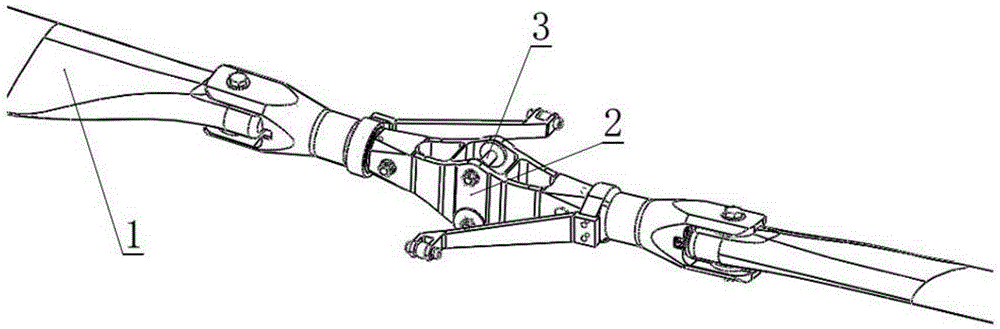

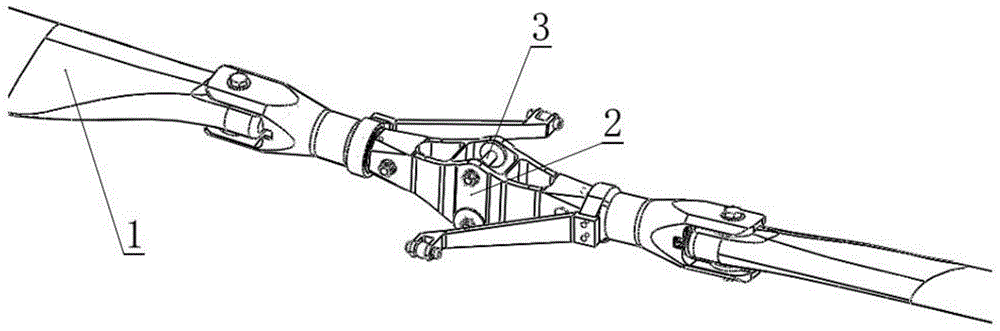

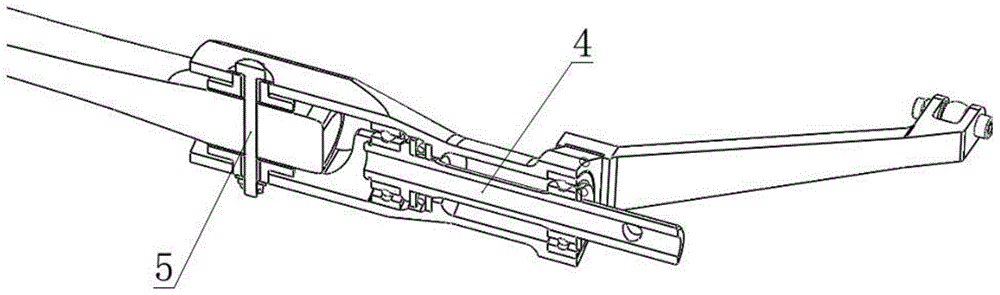

Rigid rotor system for helicopter

ActiveCN105292465AOvercoming structural complexityOvercoming structural weightRotocraftRigid rotorBall bearing

The invention discloses a rigid rotor system for a helicopter. The rigid rotor system comprises a rigid rotor propeller hub, a rigid rotor pitch control mechanism and rigid rotor paddles, wherein the rigid rotor pitch control mechanism and the rigid rotor paddles are glued integrally and are connected with the rigid rotor propeller hub by virtue of bolts. According to the system disclosed by the invention, deep groove ball bearings and thrust bearings in the conventional teeterboard type propeller hub structure are replaced by joint bearings, so that a series of complex structures such as pitch change shafts, flapping hinges and vertical hinges are removed, and the problems such as complexity of the conventional teeterboard type propeller hub structure, heavy weight and short service life can be solved. Meanwhile, the problems that retreating paddleseasily enter an aerodynamic stalling state so as to reduce the aerodynamic efficiency due to swinging during high-speed forward flight and the like are solved, and the rigid rotor system has the advantages of simple structure, light weight, long service life, high maintainability and the like.

Owner:维拓(南京)智能技术有限公司

Flexible and elastic electrode and application thereof

InactiveCN105935294APolarized electromotive force is smallReliable contactDiagnostic recording/measuringSensorsFiberIndium

The present invention discloses a flexible and elastic electrode and application thereof. The electrode comprises elastic fiber and silver alloy plated fiber, the proportion of the elastic fiber and the silver alloy plated fiber is 1:1-50, and the elastic fiber and the silver alloy plated fiber are integratedly connected in a knitting manner. The silver alloy is composed of silver and more than one metal elements selected from tin, zinc, nickel, copper, gold, cadmium, lead, bismuth, indium and gallium. In the silver alloy plated fiber, the silver makes up 10-70% of the fiber weight, and the one metal elements selected from tin, zinc, nickel, copper, gold, cadmium, lead, bismuth, indium and gallium make up 0.01-20% of the fiber weight. The electrode is especially suitable for a wearable device, reliable contact between the electrode and the human skin is ensured, the electrode has the characteristics of low power consumption, low impedance, long service lifetime, high elasticity, high strength, stretching resistance, light weight, small size and good flexibility, the electrode can be bent, folded and washed, is comfortable to wear, convenient use and not easy to be polarized, and is safe and reliable, and long-term monitoring of myoelectricity, brain electricity, electrocardio, heart rate, respiration and body temperature of a human body can be achieved.

Owner:BEIJING JLSUN HIGH TECH CO LTD

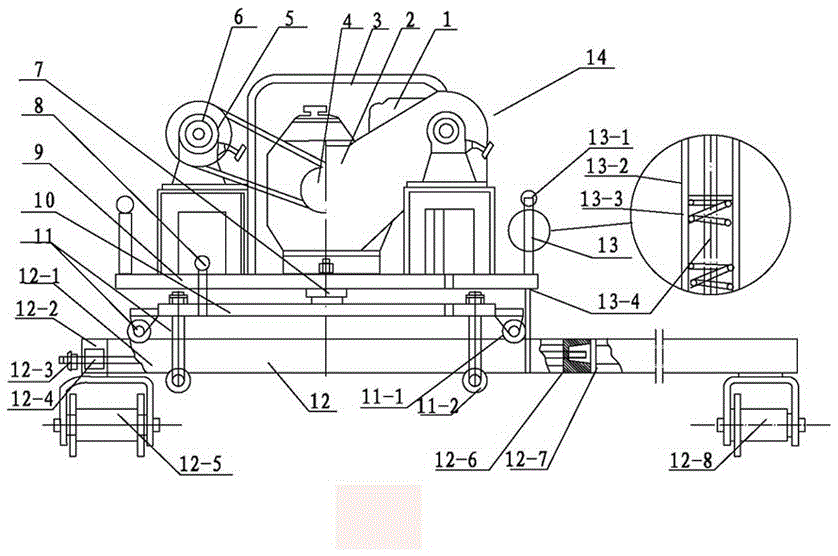

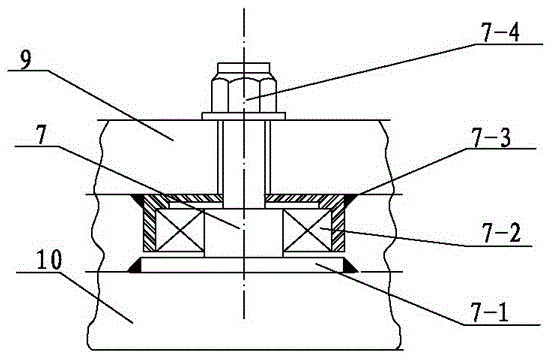

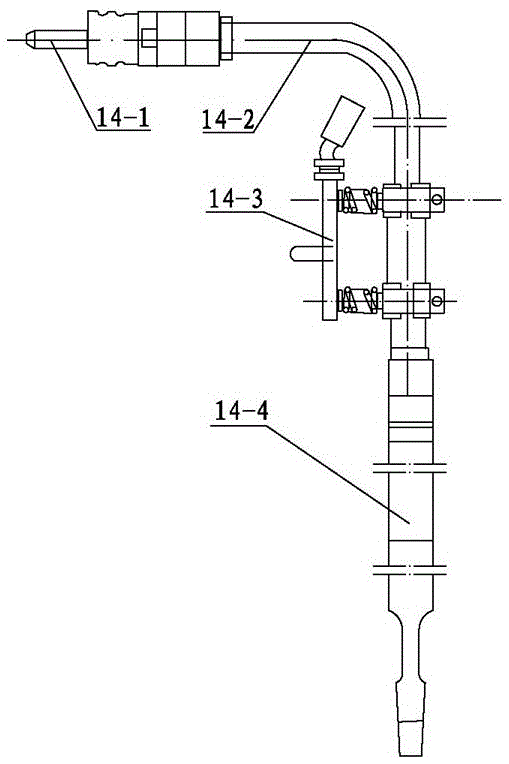

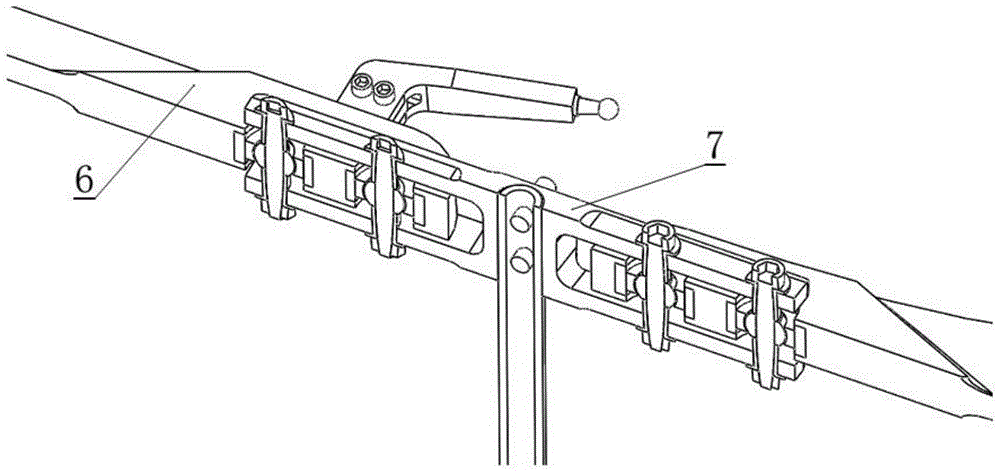

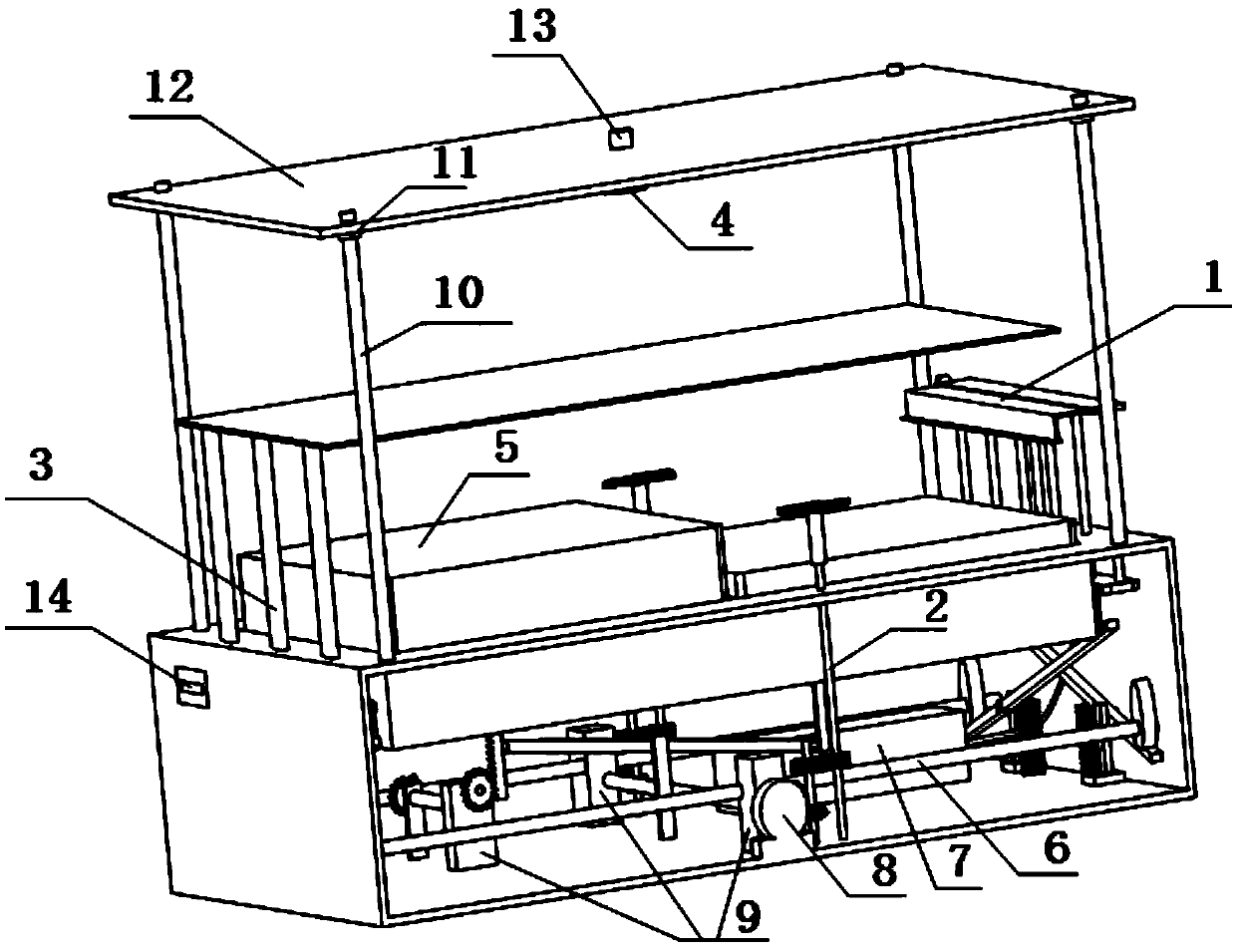

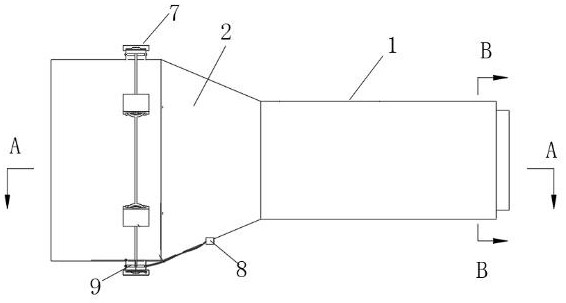

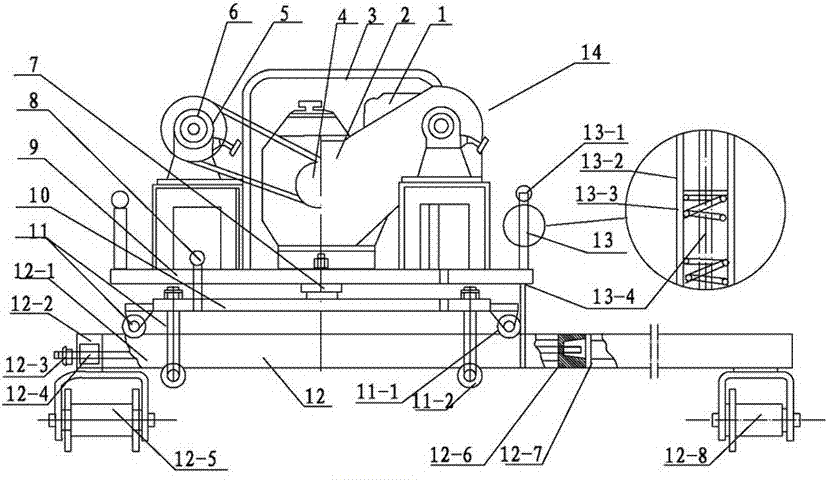

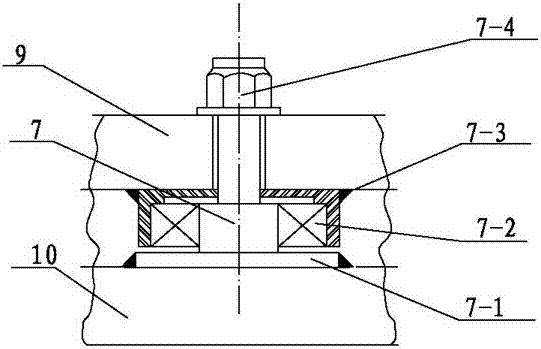

Gasoline engine type tamping machine with transverse moving, rotating and multi-point tamping functions

The invention discloses a gasoline engine type tamping machine with transverse moving, rotating and multi-point tamping functions, and belongs to the field of small railway maintenance machinery. The technical scheme includes that a gasoline engine with a clutch, a belt transmission gear and two output mechanisms are fixed onto an upper frame; the upper frame is connected with a middle frame by a rotating device and is positioned by a positioning pin; the middle frame is connected with a bottom frame by a transversely moving mechanism, the transversely moving mechanism comprises two pairs of double-edge insulating wheels, and the two pairs of double-edge insulating wheels are respectively fixedly connected to the middle frame and roll on the upper surface and the lower surface of a transverse beam of the bottom frame; the bottom frame can travel on tracks, two tamping devices are respectively connected with the output mechanisms to implement multi-point tamping, and lifting handles are arranged at two ends of the upper frame. The gasoline engine type tamping machine has the advantages that the gasoline engine type tamping machine can conveniently transversely move and rotate to carry out multi-point tamping, is high in applicability and production efficiency, comfortable to operate, excellent in insulating, long in service life, novel in design, reasonable in structure and easy and convenient to maintain, is light, safe and reliable and can quickly get on and off the tracks, accordingly, the driving safety, the construction safety and the personal safety can be guaranteed, and good tamping effects can be realized.

Owner:ANYANG YUBO RAILWAY DEVICE CO LTD

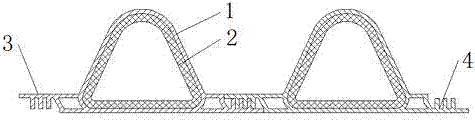

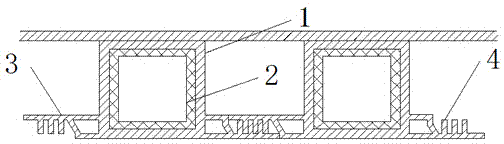

Double-plastic composite tube and production equipment thereof

InactiveCN104847972AImprove corrosion resistanceIncrease stiffnessRigid pipesTubular articlesPolyvinyl chlorideOperability

The invention discloses a double-plastic composite tube and production equipment thereof. The double-plastic composite tube comprises a polyethylene layer and a polyvinyl chloride layer, and the polyethylene layer is arranged outside the polyvinyl chloride layer. The double-plastic composite tube is excellent in corrosion resistance, long in service life, free of leakage, high in ring stiffness, good in toughness, lightweight, low in cost, capable of being made into large-diameter pipelines, convenient to transport, easy to mount and simple to connect, the polyethylene layer coats the polyvinyl chloride layer to form a composite plate strip which is made into the double-plastic composite tube through the double-plastic composite tube production equipment, and the production equipment is simple in structure, good in operability, high in production efficiency and low in cost.

Owner:SHANGHAI MEITONG PIPE TECH CO LTD

Stainless steel frame regulation and control vacuum glass prepared from glass and frames through complementary buckling and metal brazing

According to the invention, based on different metal conductivity, through combined action of a metal brazing process and a stainless steel frame, glass frame supporting point matrixes are organicallycombined; vacuumizing between tempered glass plates is achieved through heating and vacuumizing in a vacuum brazing furnace; the edges of the vacuum tempered glass plates are sealed through brazing to prepare a vacuum tempered glass plate; and a communicating sealing pipe member for communicating two sides is arranged on the vacuum tempered glass plate. According to the invention, the obtained glass overcomes the defect that existing vacuum glass is welded through brittle low-temperature glass, and achieves the vacuum brazing of a metal to stainless steel and glass through the metal with kovar characteristics; and the problems of the existing vacuum glass are solved, the vacuum glass is made into large-area vacuum glass on the premise that tempering is not lost, the process is simple, thebrazing sealing effect is good, the service life is long, the vacuum glass is tempered safety glass, and the vacuum glass is the development direction of the existing vacuum glass.

Owner:徐宝安

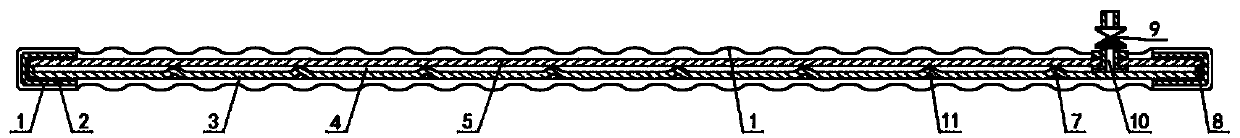

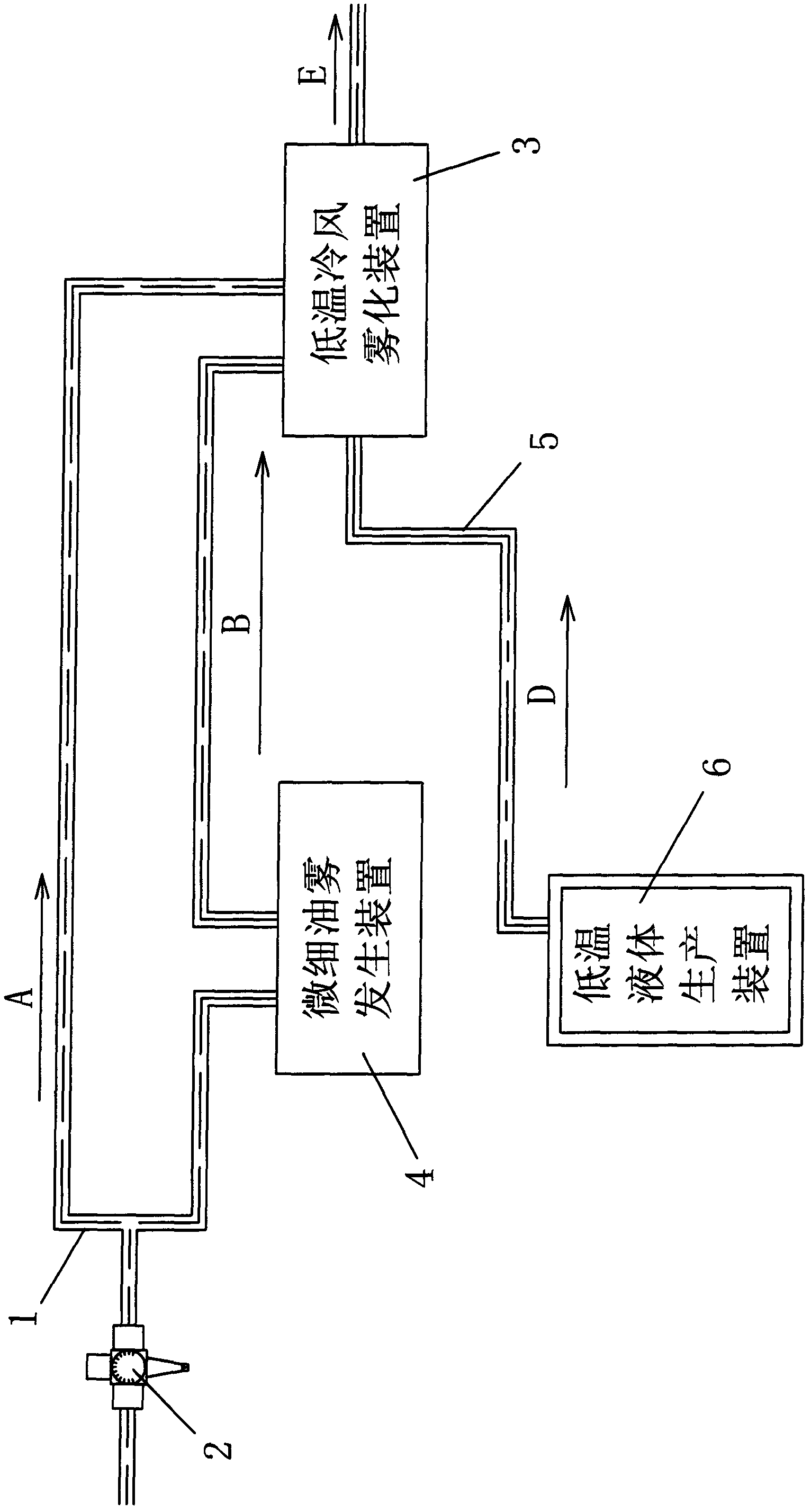

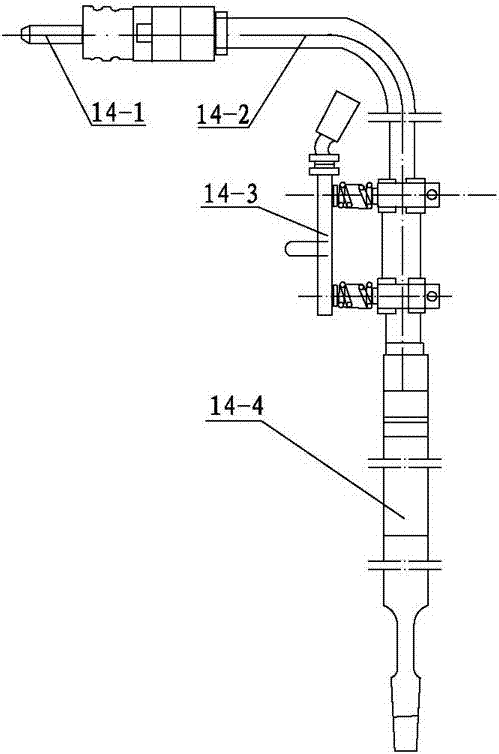

Low-energy-consumption low-temperature composite spray cutting system

ActiveCN102501132BEnsure adequate lubricationImprove the lubrication effectMaintainance and safety accessoriesLiquid storage tankCutting oil

The invention discloses a low-energy-consumption low-temperature composite spray cutting system and belongs to the technical field of machining and clean production. The low-energy-consumption low-temperature composite spray cutting system mainly comprises a filter pressure reducing valve, a fine oil spray generation device, a low-temperature liquid production device, a low-temperature cold air atomization device, a common conveying pipe and an insulation conveying pipe. The fine oil spray generation device comprises a partition plate, an atomization chamber, a precipitation chamber, a micro oil pump and an oil capacity control valve. The low-temperature liquid production device comprises a liquid storage tank, a semiconductor refrigerating or heating device, a liquid level control valve and an insulation conveying pipe; the low-temperature cold air atomization device comprises a vortex refrigeration device which produces cold air and a nozzle; and the nozzle comprises a fixed sheet, an oil spray thin pipe outlet, a water thin pipe outlet, a mixing cavity and a spray outlet channel. The system forms low-temperature composite oil spray in which a layer of thin oil film is covered on water drops by using purely oily plant oil based cutting oil with good performance, frozen low-temperature purified water and low-temperature cold air, accurately sprays the low-temperature composite oil spray onto a metal cutting area at high speed, and fulfills the aims of effective cooling and lubrication.

Owner:DG ARMORINE ENERGY EFFICIENT & ECO FRIENDLY TECH

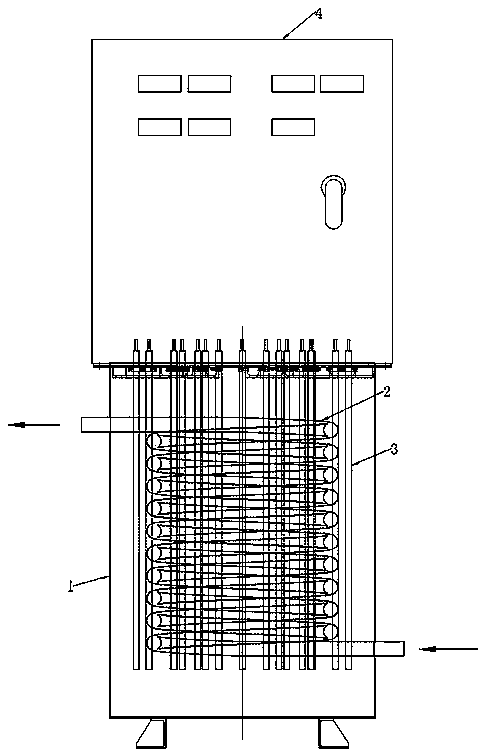

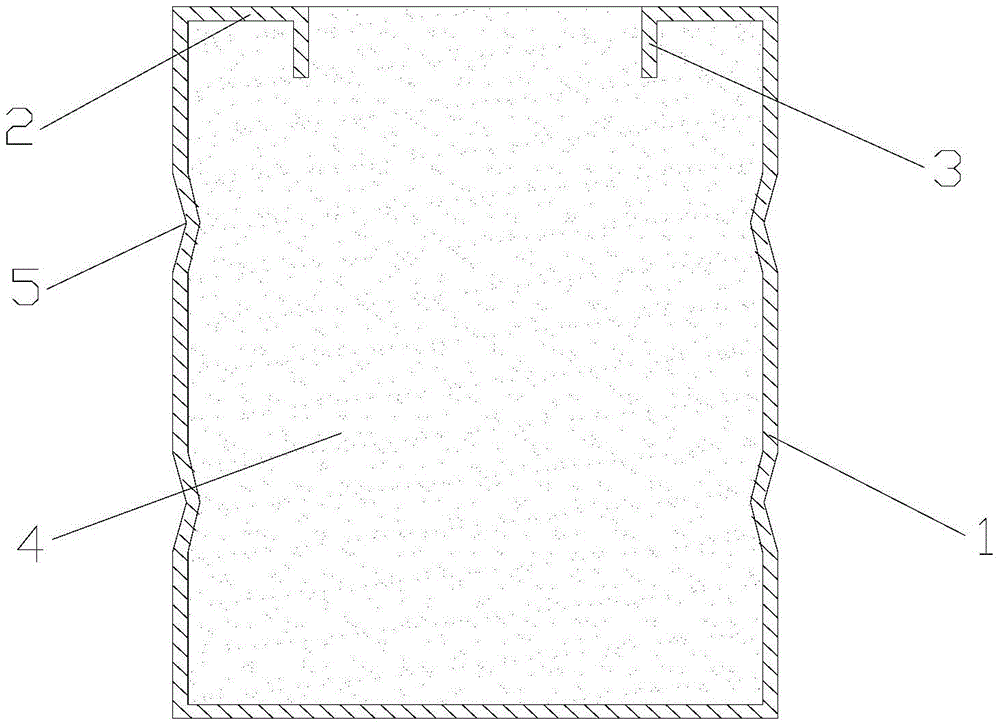

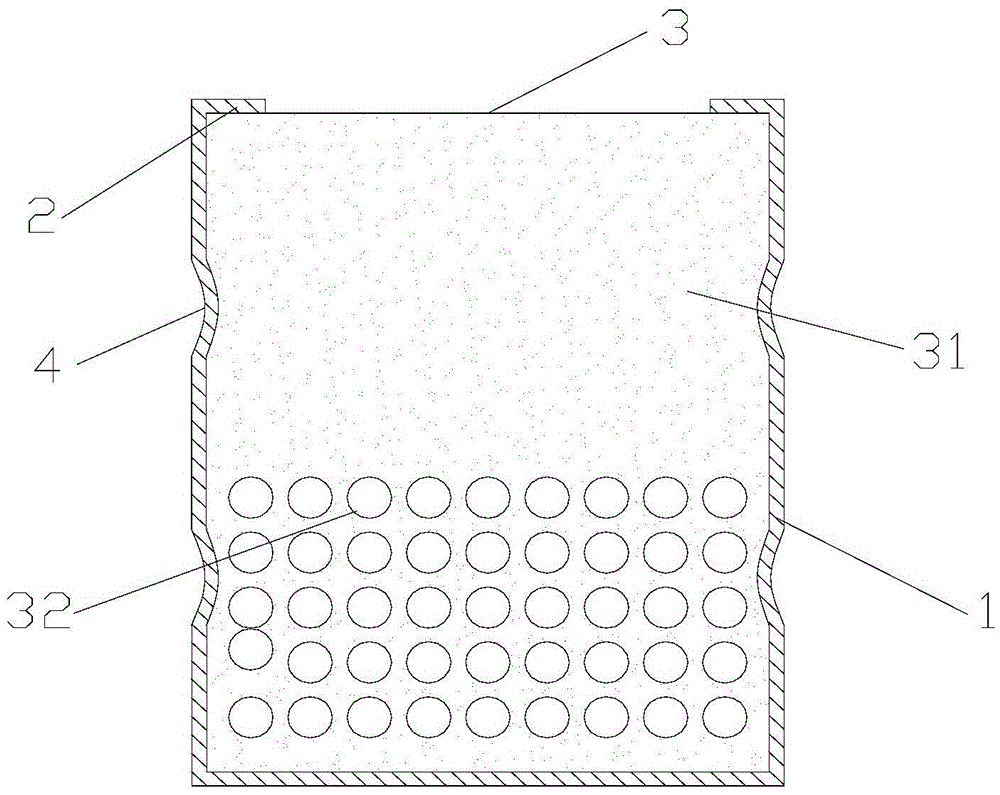

Electrical heating cast aluminum heat exchanger

The invention discloses an electrical heating cast aluminum heat exchanger which comprises a shell (1), a coil (2) and a plurality of heating rods (3) are arranged in the shell (1), and all the heating rods (3) are controlled through a control circuit which is located in an electronic control cabinet (4) on the upper portion of the shell (1). The electrical heating cast aluminum heat exchanger is characterized in that a cavity in the shell (1) except for the coil (2) and the heating rods (3) is filled with cast aluminum or cast aluminum alloy. The electrical heating cast aluminum heat exchanger is simple in structure, ingenuous in design, reasonable in layout, high in heat exchanging efficiency and capable of achieving high-temperature heating.

Owner:DALIAN MELAD TECH

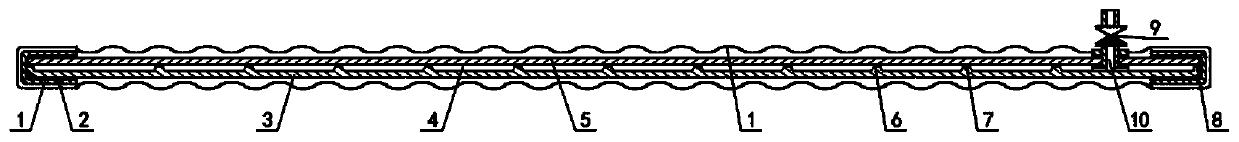

Laminated vacuum-adjusting thermal insulation glass provided with protective frame and rolling supporting frame through metal brazing

PendingCN111302663AEasy to operateImprove yieldGlass reforming apparatusThermal insulationToughened glass

According to the invention, based on different metal conductivity, through combined action of a metal brazing process and a stainless steel frame, glass frame supporting point matrixes are organicallycombined; vacuumizing between tempered glass plates is achieved through heating and vacuumizing in a vacuum brazing furnace; the edges of the vacuum tempered glass plates are sealed through brazing to prepare a vacuum tempered glass plate; and a communicating sealing pipe member for communicating two sides is arranged on the vacuum tempered glass plate. According to the invention, the obtained glass overcomes the defect that existing vacuum glass is welded through brittle low-temperature glass, and achieves the vacuum brazing of a metal to stainless steel and glass through the metal with kovar characteristics; and the problems of the existing vacuum glass are solved, the vacuum glass is made into large-area vacuum glass on the premise that tempering is not lost, the process is simple, thebrazing sealing effect is good, the service life is long, the vacuum glass is tempered safety glass, and the vacuum glass is the development direction of the existing vacuum glass.

Owner:徐宝安

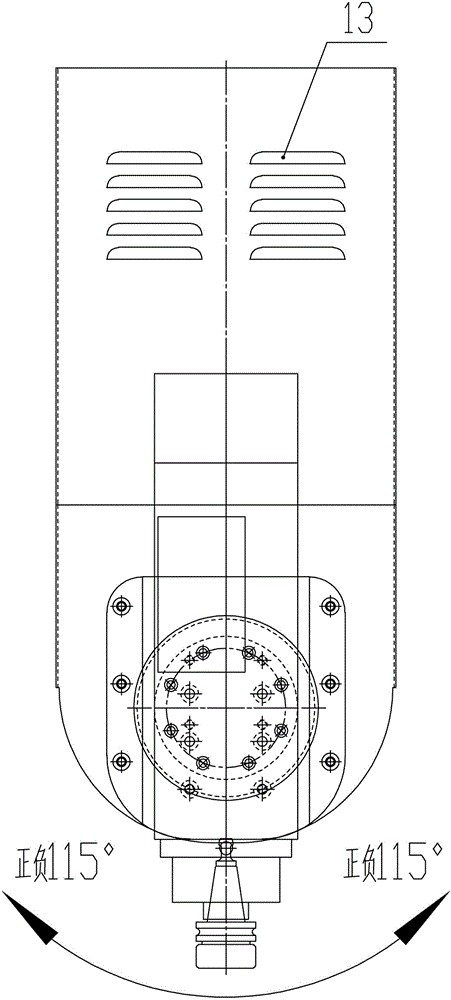

Carving swing head

The invention provides a carving swing head and belongs to the technical field of mechanical manufacture. A reducer installation plate is arranged at the bottom of a rotary box, a harmonic reducer is installed on the reducer installation plate, a bearing is installed between a bearing seat and the reducer installation plate, and a rotary shaft B is installed on the bearing and the output end of the harmonic reducer; a spindle head is installed on a spindle installation plate; the spindle head is installed on a rotary shaft installation plate with the spindle installation plate; reducer synchronous belt wheel and a motor synchronous belt wheel are installed on a harmonic reducer input shaft and a rotary motor shaft respectively and are connected through a synchronous belt; a rotary motor is installed on a rotary motor seat installed on the rotary box. The carving swing head has the advantages that the machining interference can be avoided during cambered surface machining, the box structural strength is enhanced greatly, a bearing is installed between a shaft C harmonic reducer output end and the spindle installation plate, and the axial load bearing capability is improved during the spindle machining.

Owner:SHANDONG CHENCAN MACHINERY INC CO

Shaping device of solid hot extrusion magnesium alloy wheel hub and shaping method thereof

A solid-state hot squeezing apparatus for shaping the Mg-alloy wheel hub is composed of upper die plate, male die and its heater, heat isolating plate between said upper die plate and male die, moulding cavity heater for left and right moulding cavities, heat isolating plate between female die and its die plate, push-out rod, and temp controller. Its shaping method includes such steps as blanking, heating, holding temp, preheating die set squeezing cutting, surface treating and ageing treating.

Owner:HARBIN INST OF TECH

Waterproof LED

InactiveCN102563433ALight attenuation is smallExtend your lifePoint-like light sourceLighting heating/cooling arrangementsLight sourceEngineering

The invention discloses a waterproof LED, which comprises a whole consisting of a circuit board and a plurality of radiators. At least one light emitting chip is arranged on the circuit board and the radiators, a package portion is arranged on each light emitting chip directly arranged on the corresponding radiator, and a water joint is connected onto the circuit board. Compared with a lamp consisting of common LEDs, the waterproof LED has the advantage that a plurality of thermal resistors are decreased, so that heat can be more rapidly dissipated, the LED is more effectively kept durable and stable, light attenuation is slowed down, and the service life of the LED is prolonged. Moreover, as a light source support, a primary lens and two layers of heat transfer paste or heat transfer pads are omitted, the weight of the whole lamp is lighter. As the LED is waterproof and the light emitting chips are directly fixed onto the radiators, compared with an original LED assembly lamp, the waterproof LED has the advantages that the process of welding the LED on an aluminum substrate is omitted, a waterproof device and reflow welding or manual welding are omitted, equipment investment, material cost and labor cost are reduced, and a pressure-balanced valve and the like are omitted.

Owner:刘慧

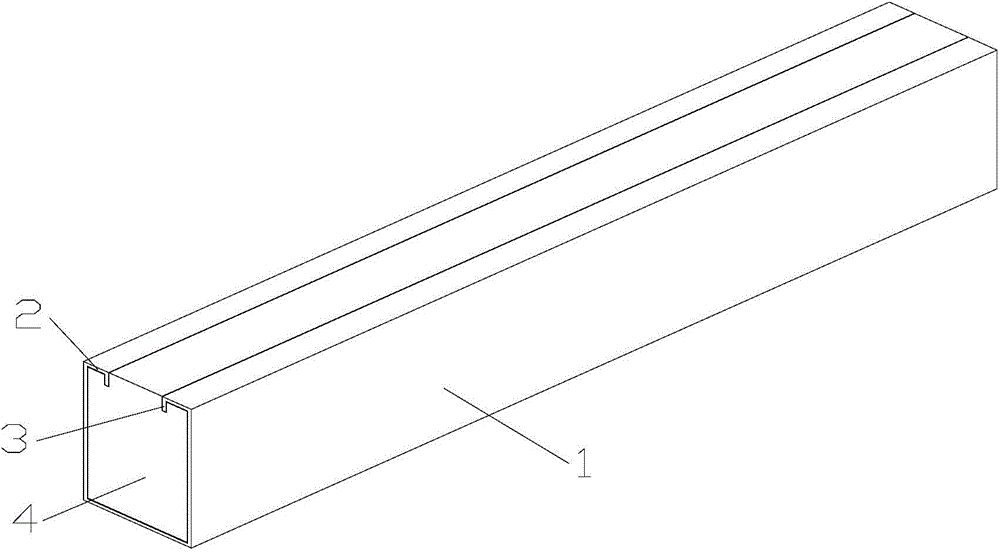

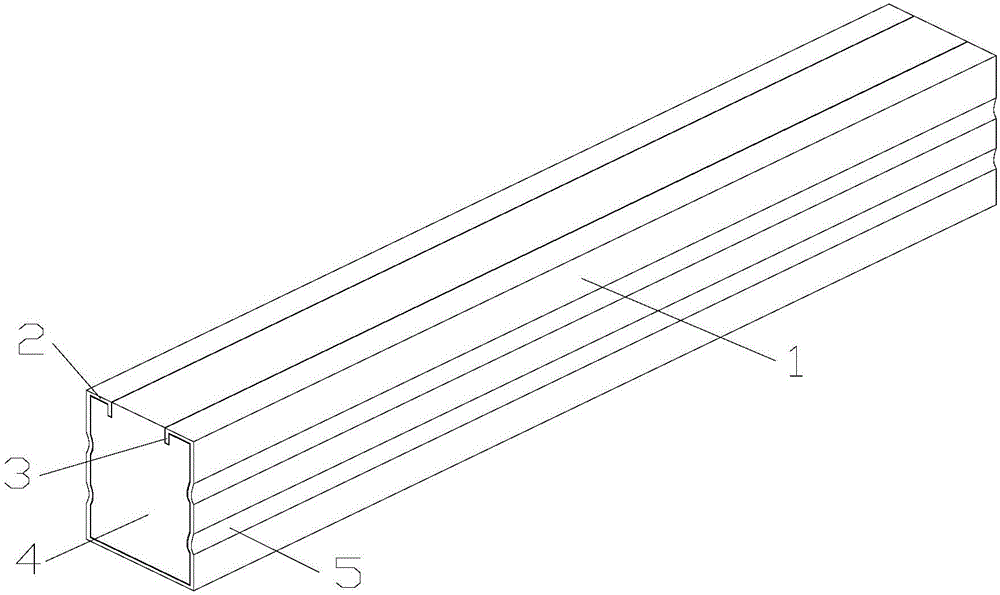

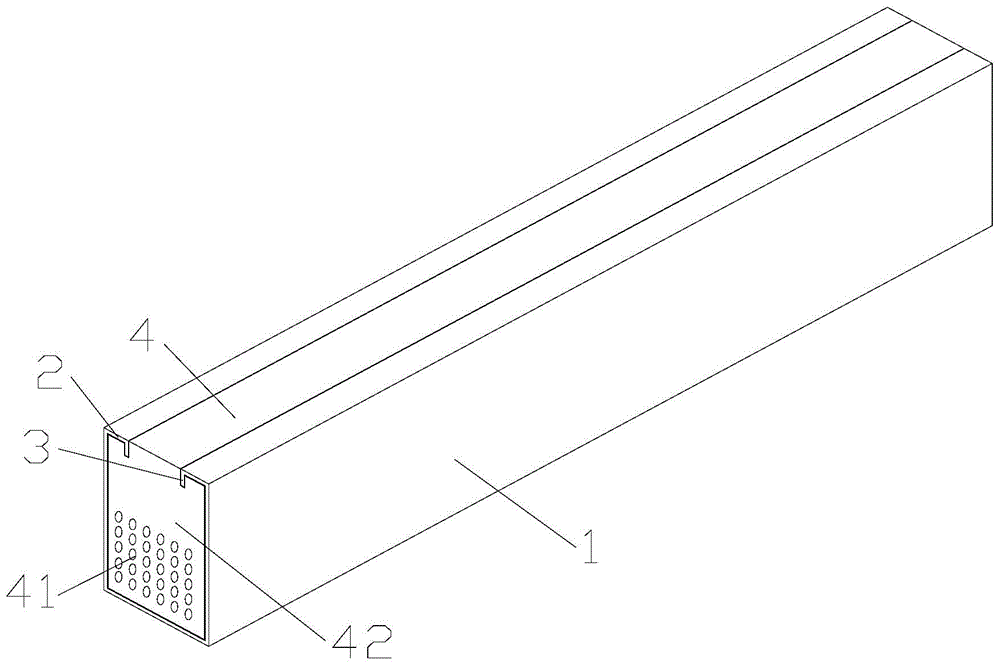

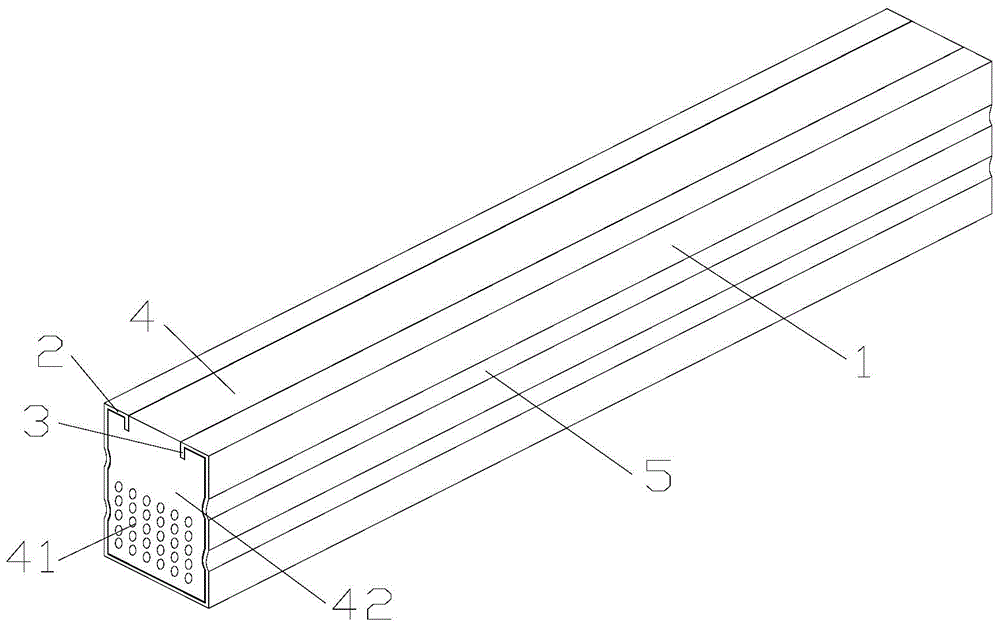

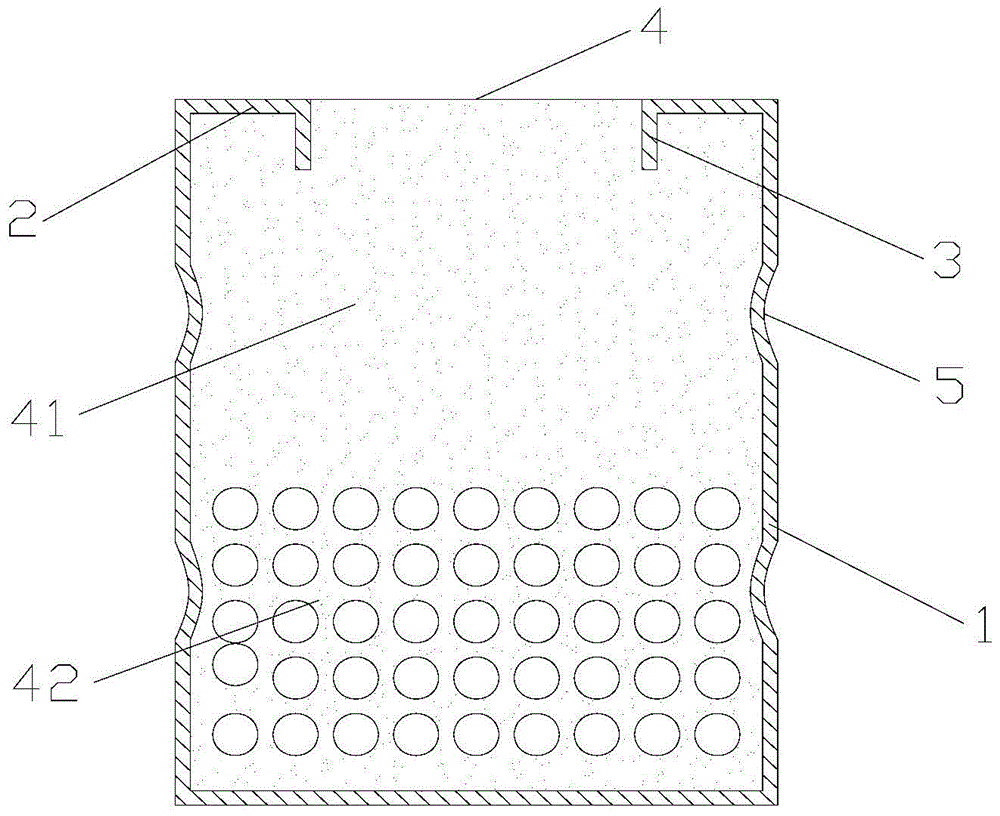

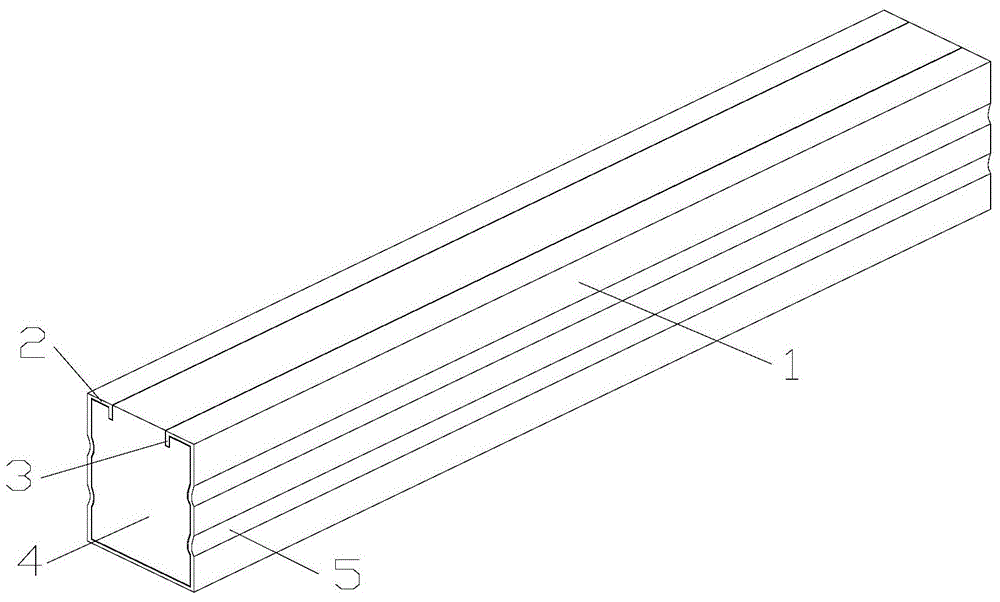

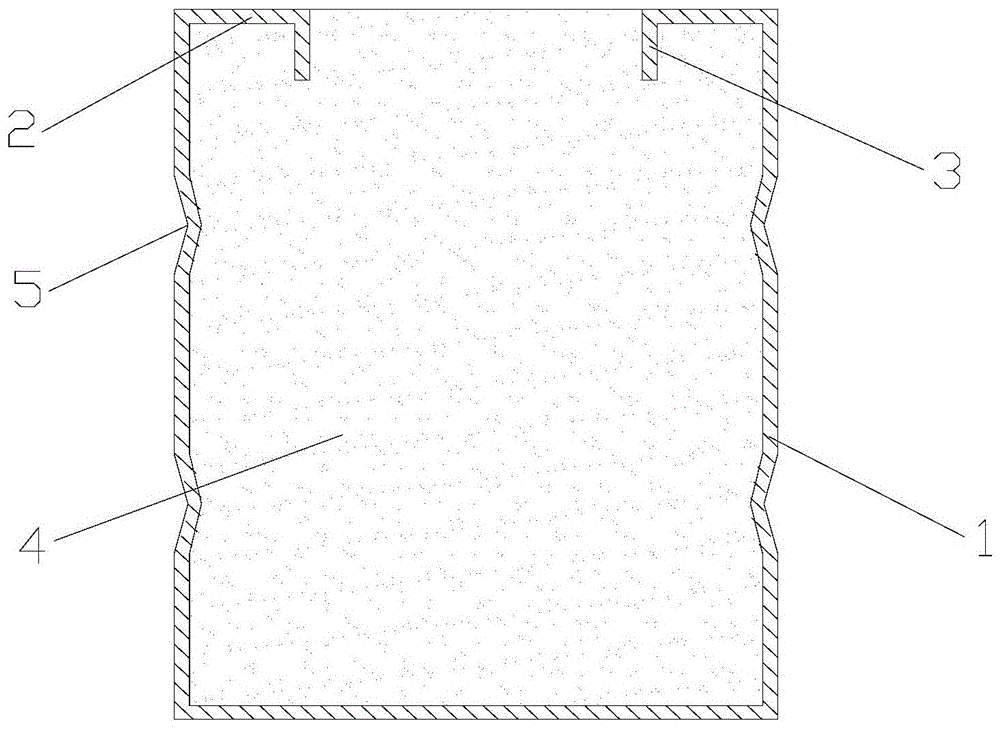

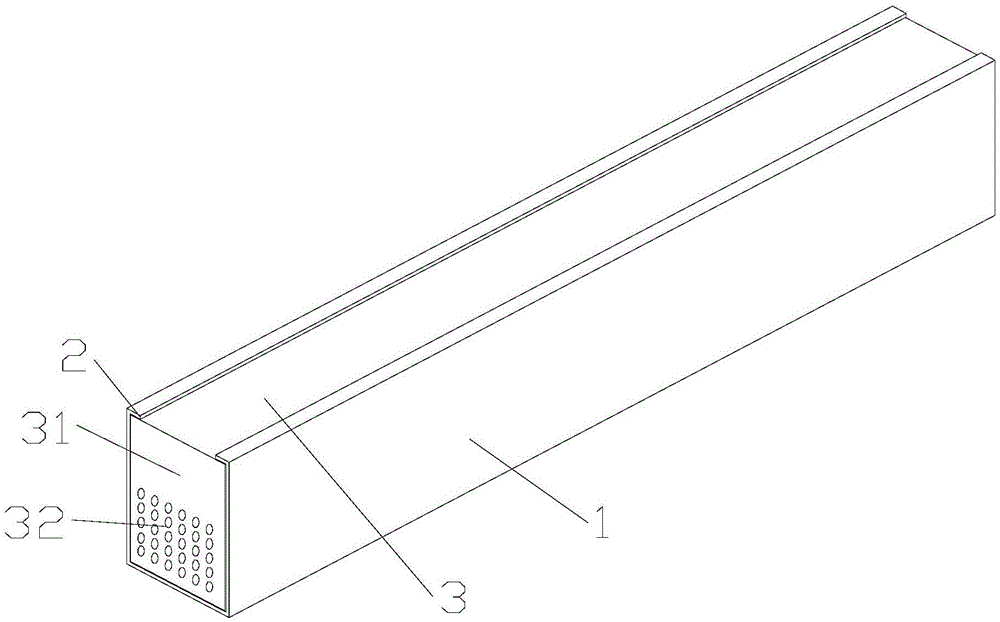

Composite building supporting piece and manufacturing method thereof

ActiveCN104018663AEasy to operateSimple processForming/stuttering elementsBuilding materialCorrosion resistant

The invention belongs to the technical field of building materials and discloses a composite building supporting piece and a manufacturing method thereof. The core body is combined with a metal shell, and the supporting piece has the rigidity of metals, also has the characteristics that the wood can be sawed, drilled, nailed and fixedly connected by using nails or bolts, can be corrosion-resistant and moisture-proof and is high in stability, difficult to deform, safe, reliable and light in weight. The overall quality of the building supporting piece is lightened, the construction safety is further guaranteed, and the supporting piece is simple in manufacturing process, high in operability, green and environmentally friendly.

Owner:江苏胜宏钢结构有限公司

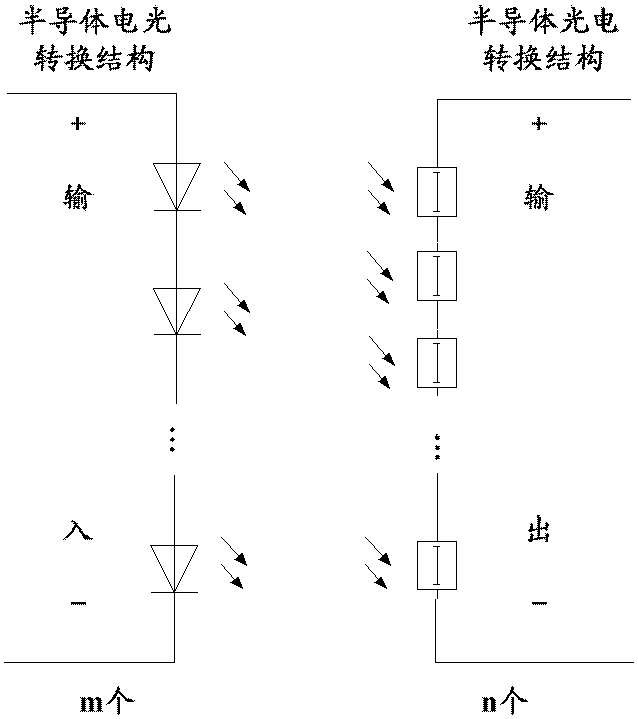

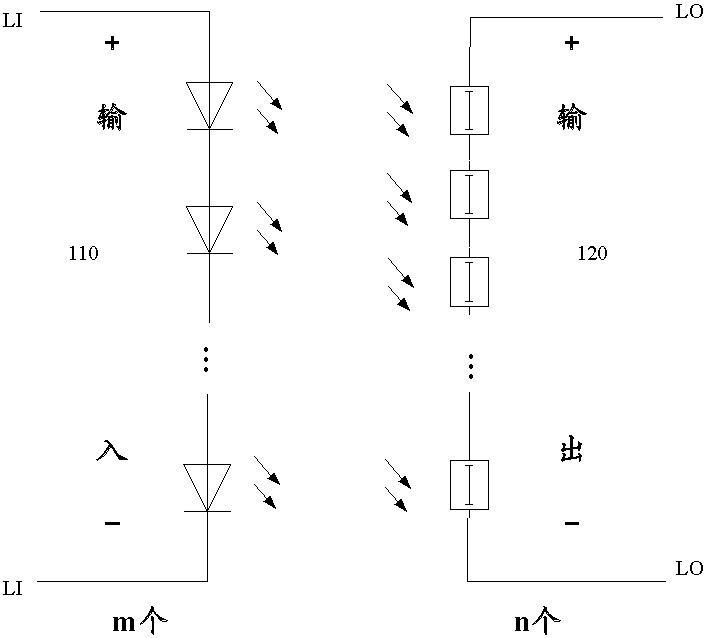

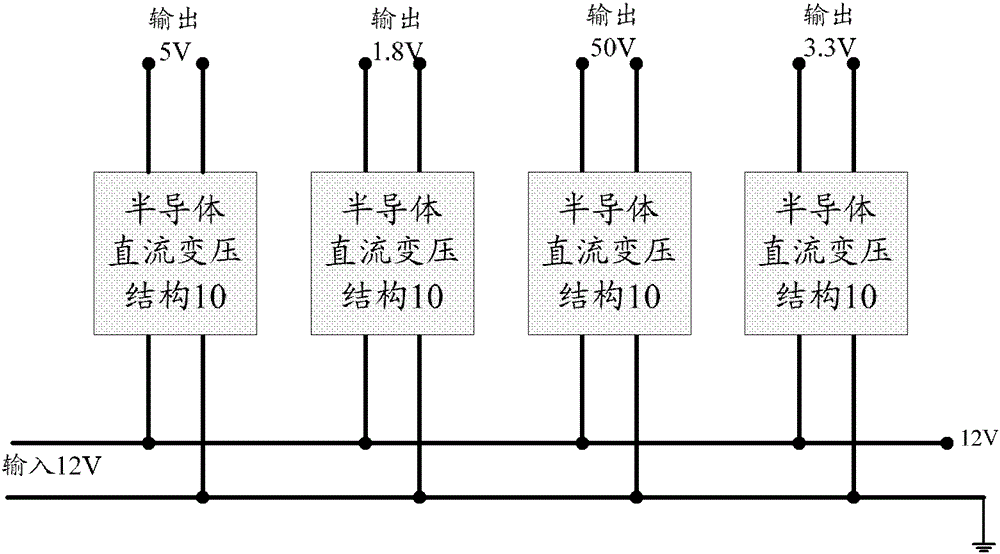

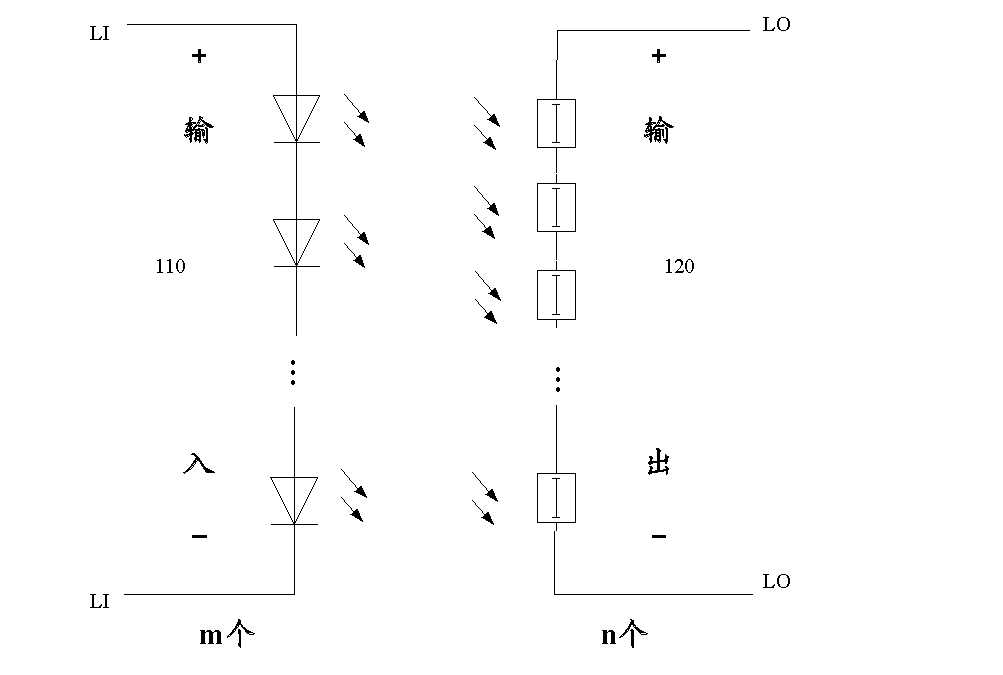

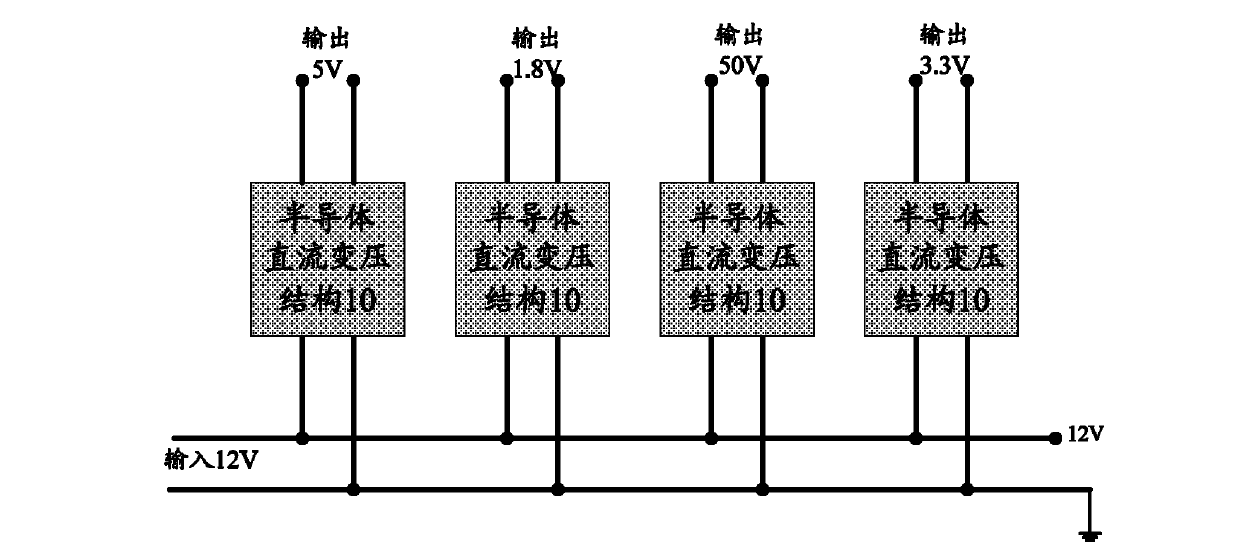

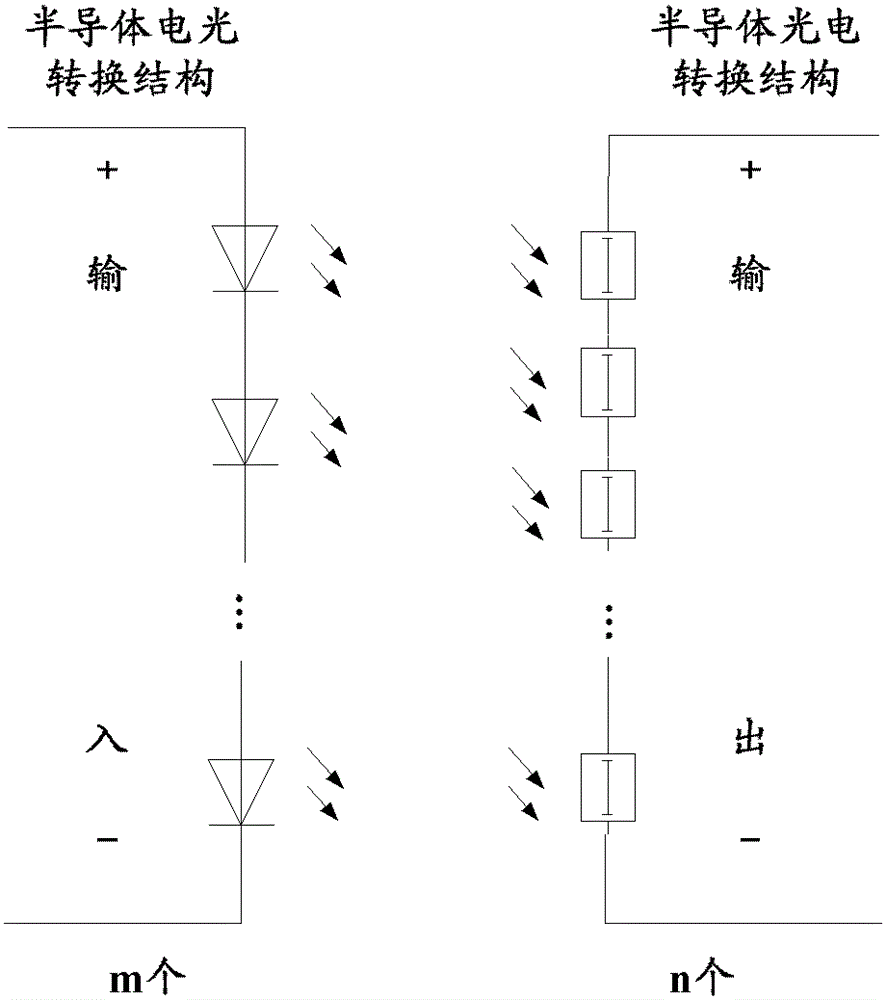

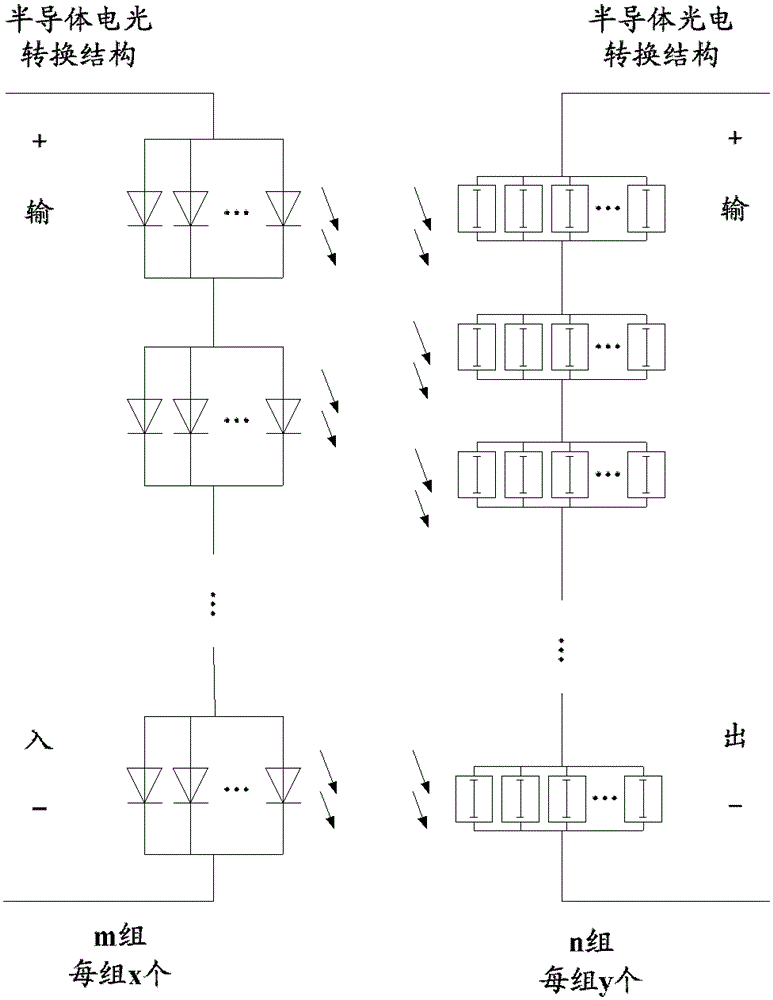

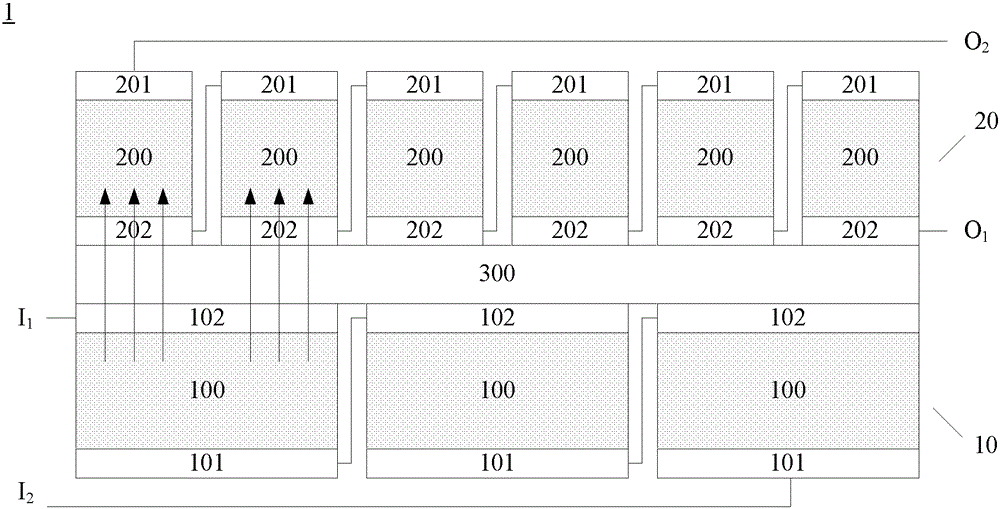

A semiconductor DC transformer

ActiveCN102569488BWith high pressureHigh pressure noSemiconductor devicesElectric lightDc transformers

The invention provides a semiconductor direct current transformer which comprises a substrate layer, a plurality of series connected semiconductor electric light conversion structures which are formed on the substrate layer and are used for converting input electric energy into luminous energy, and a plurality of series connected semiconductor photoelectric conversion structures which are formed on the substrate layer and are used for converting the luminous energy into output electric energy, wherein a number of the semiconductor electric light conversion structures is different from a number of the semiconductor photoelectric conversion structures so as to realize direct current transformation, and work light of the semiconductor electric light conversion structures is coupled with work light of the semiconductor photoelectric conversion structures. According to the embodiment, the semiconductor direct current transformer has the advantages of high voltage resistant, no electromagnetic radiation, no coil structure, being safe and reliable and the like.

Owner:郭磊

Laminated regulation and control vacuum tempered glass plate with double-rubber sealing groove edge supporting and buckling

According to the a regulation and control vacuum tempered glass plate, double glue sealing is performed or high-humidity air is introduced into a vacuum furnace; the hollow interlayer is subjected toair exhaust, so that the double-glue sealing glass can be rapidly cured, and the edge of the hollow glass is rapidly sealed and cured; and a communicating sealing pipe member for communicating two sides is arranged on the vacuum tempered glass plate. According to the invention, good glass airtight sealing bonding and structural bonding quality is achieved, the problem of tempering loss of vacuum glass is solved, and the safety problem of the vacuum glass is solved; the functional vacuum glass has the advantages that the manufacturing process is simple, the functional vacuum glass is widely made from common tempered glass, the manufacturing cost is greatly reduced, the safety and the yield are greatly improved, and the structural form can be diversified; and the tempered glass plate has thecharacteristics of thinness, light weight, high strength, safety, long service life, large size, high yield, strong functionality, low energy consumption, efficient light transmission, safety, low manufacturing cost, condensation prevention, convenience for large-scale production and the like.

Owner:徐宝安

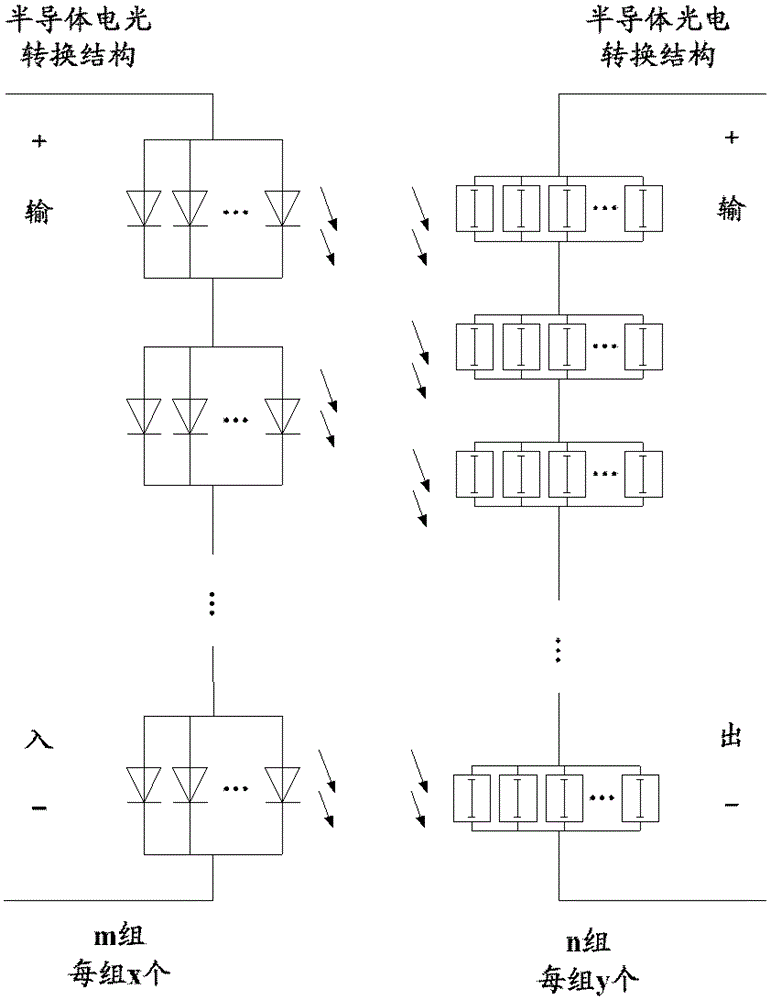

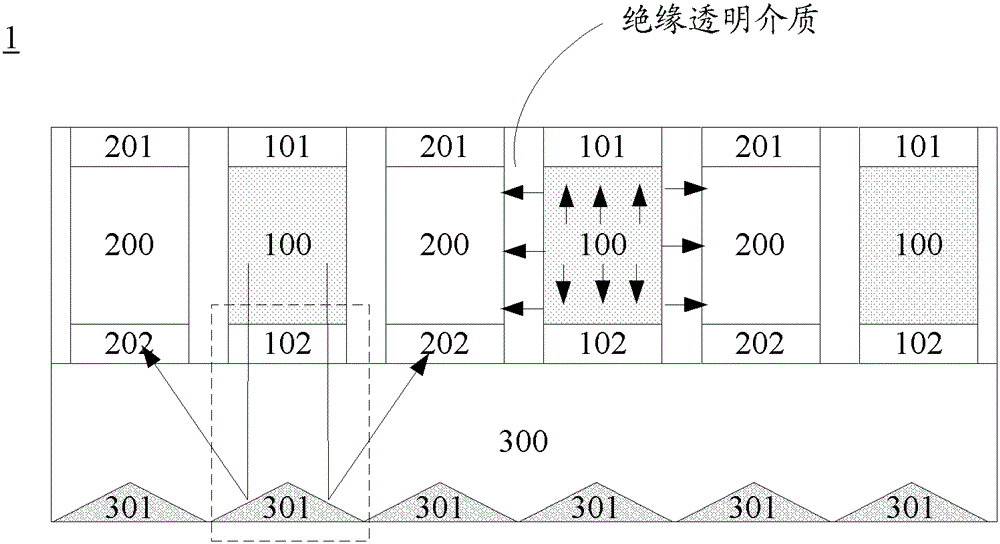

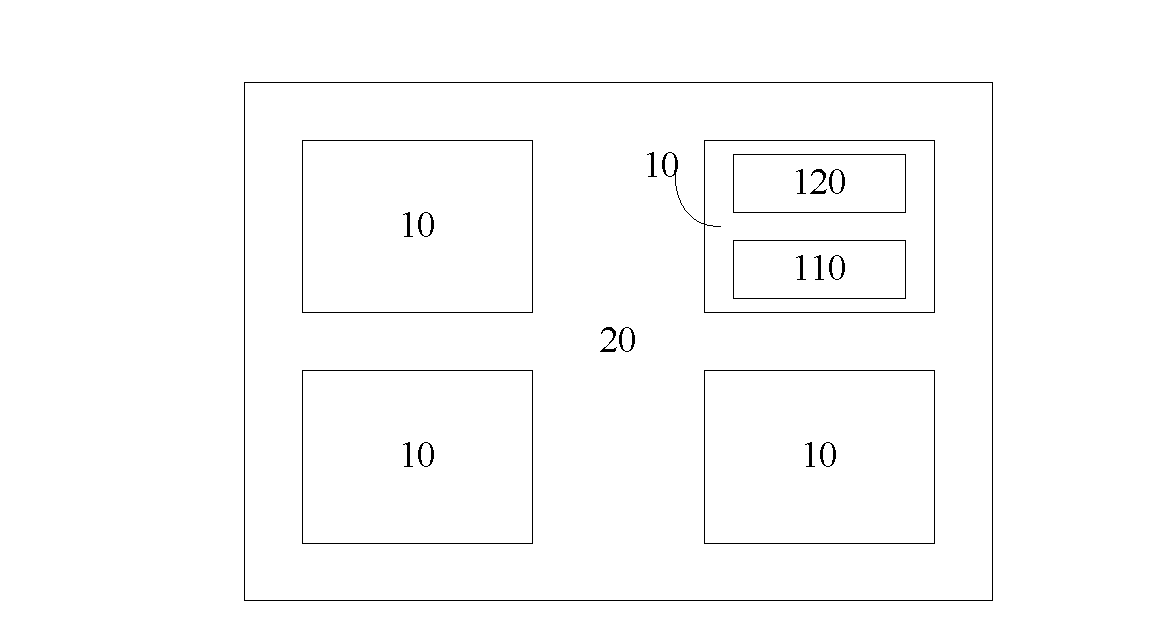

A chip with a semiconductor DC transformer structure

ActiveCN103378086BWith DC transformer functionIndependent isolation from each other is not affectedSolid-state devicesPhotovoltaic energy generationFrequency spectrumDc transformers

The invention provides a chip. The chip comprises a substrate and at least one semiconductor direct current voltage transformation structure. Each semiconductor direct current voltage transformation structure comprises at least one semiconductor electro-optic conversion unit and at least one semiconductor photoelectric conversion unit, wherein the semiconductor electro-optic conversion units are used for converting input electric energy into optical energy, the semiconductor photoelectric conversion units are used for converting the optical energy into the electric energy, the number of the semiconductor electro-optic conversion units and the number of the semiconductor photoelectric conversion units are in a certain proportion so as to achieve direct current voltage transformation, and the working light ray frequency spectrums of the semiconductor electro-optic conversion units and the working light ray frequency spectrums of the semiconductor photoelectric conversion units are matched. According to the chip, the direct current voltage transformation function can be achieved. The chip has the advantages of being simple in structure and capable of being integrated in a total sheet mode.

Owner:郭磊 +1

Embedded door machine motor

An embedded door machine motor relates to the technical field of elevator door machine motors. The embedded door machine motor comprises a motor shell, a rotating shaft, a rotor, a stator, a belt pulley and a radiating device, wherein the rotating shaft is installed inside the motor shell, the right end face of the motor shell is uniformly provided with four mounting holes, the rotor is sleeved on the rotating shaft, the stator is arranged on the outer side of the rotor, the belt pulley is installed at one end of the rotating shaft, and the radiating device is installed on one side of the rotating shaft and inside the motor shell. The embedded door machine motor further comprises a coded disc, Hall sensors and a microprocessor, wherein the coded disc is sleeved on the rotating shaft, four Hall sensors are uniformly arranged at the positions corresponding to the coded disc, and the microprocessor is arranged inside the motor shell and connected with the four Hall sensors. The embedded door machine motor disclosed by the invention can precisely control and measure rotating speed and displacement and is accurate in control, wider in application range, simplified in installation step and longer in service life.

Owner:南通赛福利机电科技有限公司

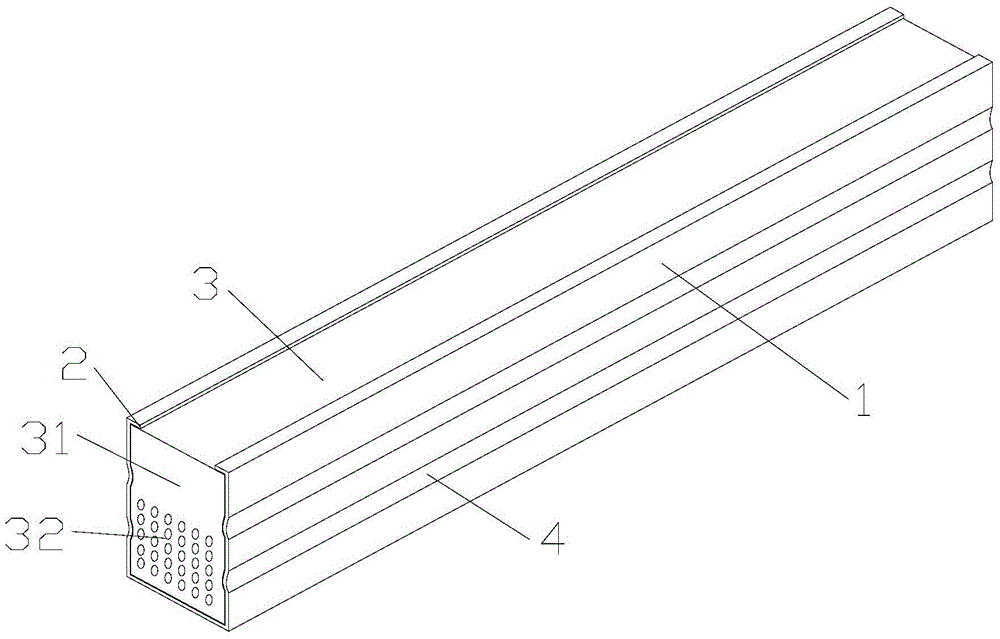

Composite building support structure and manufacturing method thereof

InactiveCN104018664BGuaranteed StrengthGuaranteed rigidityForming/stuttering elementsMaterials scienceCorrosion

The invention belongs to the technical field of building materials, and discloses a composite building support structure and a manufacturing method thereof. The combination of the core body and the metal shell has the rigidity of metal, and also has the properties of sawing, drilling, nailing and nailing of wood. Or bolt connection and fixing, it can also be anti-corrosion and moisture-proof, good stability, not easy to deform, safe and reliable, light in texture, which reduces the overall quality of the building support structure, and further ensures the safety of construction. At the same time, the manufacturing process is simple and the operability is strong. ,Green.

Owner:济南蓝标建筑安装工程有限公司

A rigid rotor system for a helicopter

The invention discloses a rigid rotor system for a helicopter. The rigid rotor system comprises a rigid rotor propeller hub, a rigid rotor pitch control mechanism and rigid rotor paddles, wherein the rigid rotor pitch control mechanism and the rigid rotor paddles are glued integrally and are connected with the rigid rotor propeller hub by virtue of bolts. According to the system disclosed by the invention, deep groove ball bearings and thrust bearings in the conventional teeterboard type propeller hub structure are replaced by joint bearings, so that a series of complex structures such as pitch change shafts, flapping hinges and vertical hinges are removed, and the problems such as complexity of the conventional teeterboard type propeller hub structure, heavy weight and short service life can be solved. Meanwhile, the problems that retreating paddleseasily enter an aerodynamic stalling state so as to reduce the aerodynamic efficiency due to swinging during high-speed forward flight and the like are solved, and the rigid rotor system has the advantages of simple structure, light weight, long service life, high maintainability and the like.

Owner:维拓(南京)智能技术有限公司

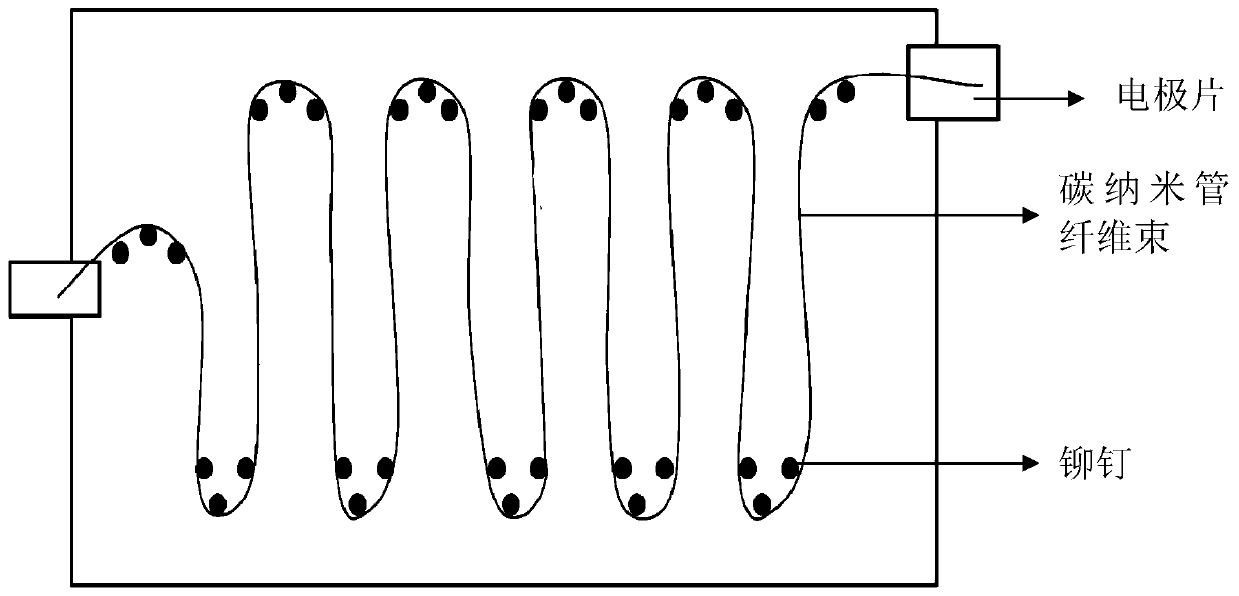

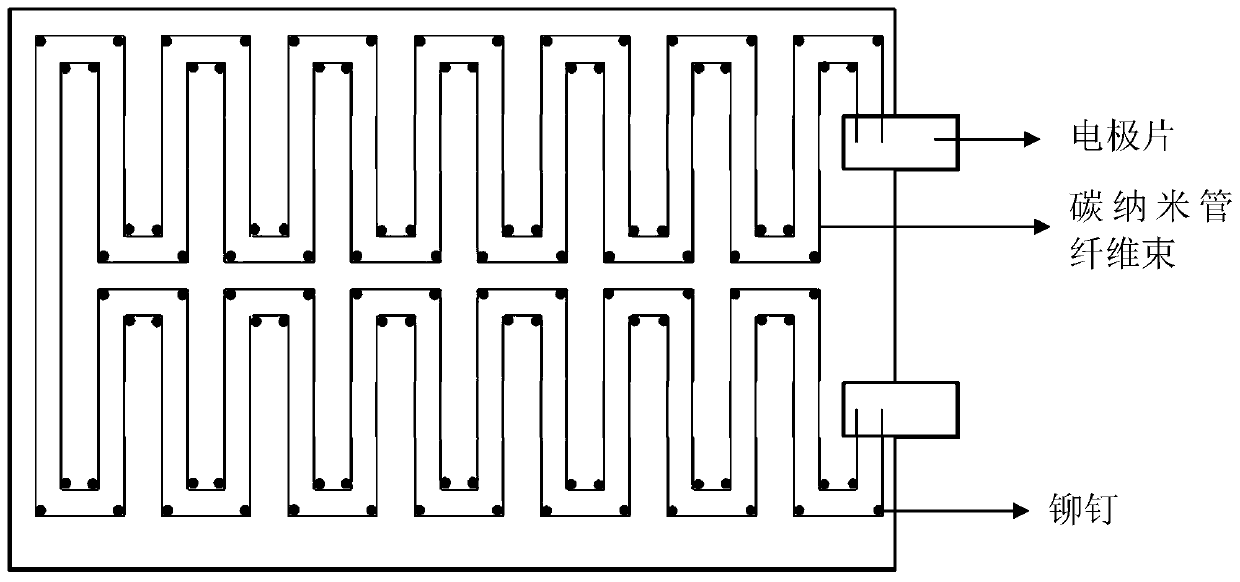

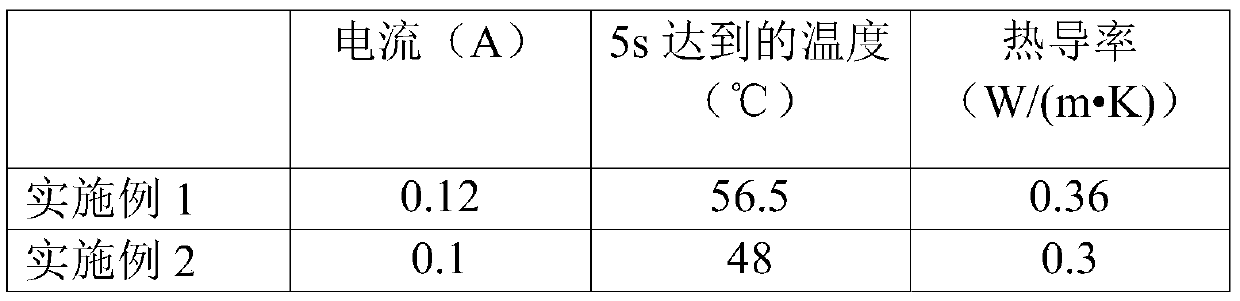

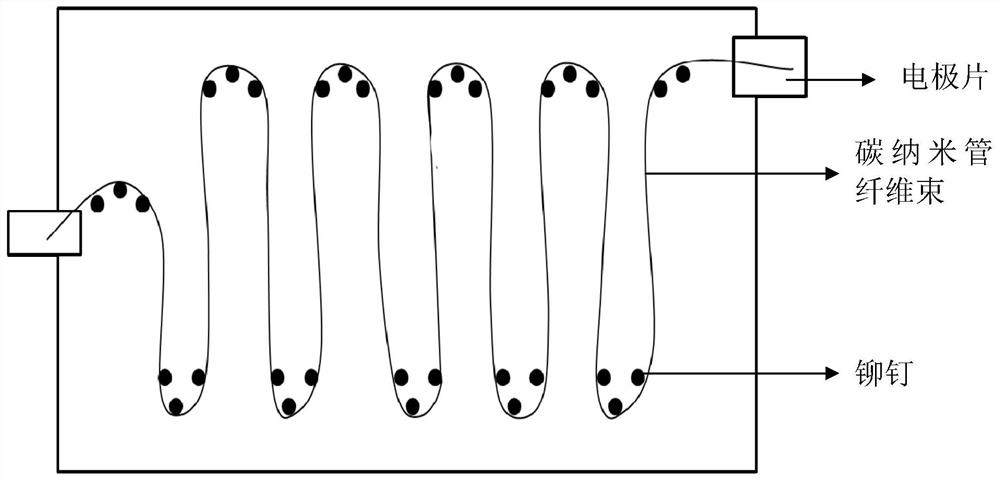

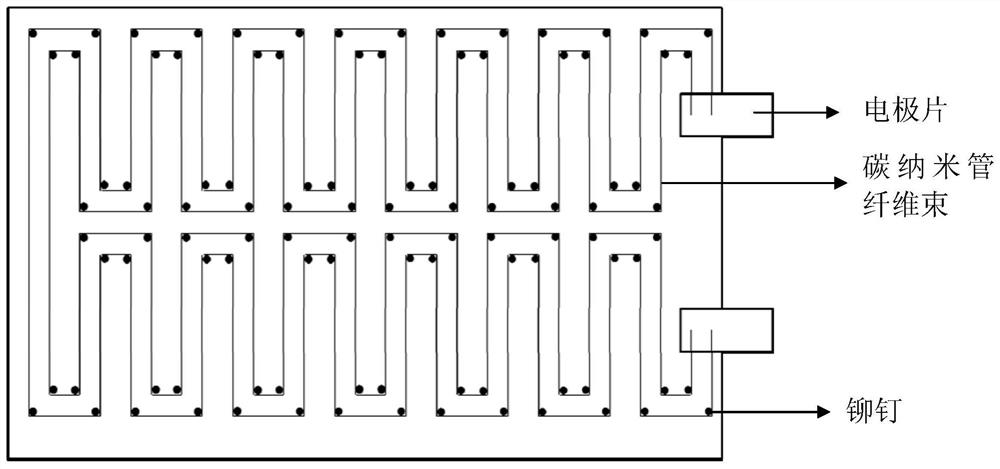

Flexible heating sheet and manufacturing method thereof

ActiveCN111050433AGood electrical conductivityExcellent electrothermal conversion performanceHeating element materialsCarbon nanotubeManufacturing engineering

The invention belongs to the technical field of heat conduction materials, and particularly relates to a manufacturing method of a flexible heating sheet. The method comprises the following steps: acquiring a carbon nanotube fiber bundle and a substrate, and arranging the carbon nanotube fiber bundle on the substrate according to a preset circuit diagram to obtain the substrate on which a fiber circuit diagram is arranged; and depositing a rubber mixed material on a surface of one side, provided with the fiber circuit diagram, of the substrate so that areas, except ends of the carbon nanotubefiber bundles, in the fiber circuit diagram arranged on the substrate are fixedly sealed in the rubber mixed material, and forming the heating sheet on the substrate, wherein the rubber mixed materialincludes a rubber and a curing agent. The manufacturing method of the flexible heating sheet provided by the invention is simple in process flow, flexible and convenient to operate, and suitable forindustrial large-scale production and application.

Owner:SHENZHEN XIWAN TECH CO LTD

A Portable Automatic Scanning Book Instrument

The invention aims at providing a portable and automatic book scanning instrument. The portable and automatic book scanning instrument comprises a static page turning mechanism, a vane page turning mechanism, a book surface flattening mechanism, a shooting part and a book surface compensation mechanism. The static page turning mechanism sucks up a page by utilizing static, and then the function of turning pages is realized under the action of the vane page turning mechanism. In order to guarantee the shooting quality, the book surface flattening mechanism presses the book surface downwards so as to flatten the book surface, then the shooting part shoots, and the shot high-definition photos are stored in a universal storage medium through a USB port so as to bring convenience for use and propagation. The portable and automatic book scanning instrument is simple in structure and relatively low in cost, can reduce the work intensity, saves a plenty of time, and is suitable for large-area popularization and application.

Owner:HARBIN ENG UNIV

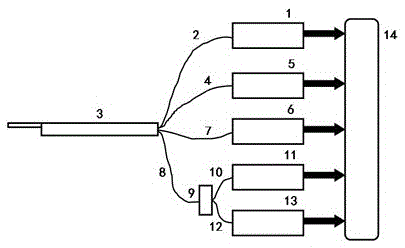

An arthroscopic system based on multimode spectroscopy

The invention relates to an arthroscope system based on the multi-mode spectrum technology. The arthroscope system is characterized by comprising an LED lamp cold light source, optical fibers, an arthroscope probe, an image sensor CCD, a femtosecond optical fiber laser, an optical fiber switch, a Raman spectrometer, a visible light spectrometer and a computer control processing unit, wherein the optical fiber switch can guide optical signals to different optical fibers. The arthroscope system based on the multi-mode spectrum technology is reasonable in design and ingenious in conception, and has wide development prospect and great significance in popularization.

Owner:FUJIAN NORMAL UNIV

Chip with semiconductor direct current voltage transformation structures

ActiveCN103378086AWith DC transformer functionIndependent isolation from each other is not affectedSolid-state devicesPhotovoltaic energy generationFrequency spectrumPhotoelectric conversion

The invention provides a chip. The chip comprises a substrate and at least one semiconductor direct current voltage transformation structure. Each semiconductor direct current voltage transformation structure comprises at least one semiconductor electro-optic conversion unit and at least one semiconductor photoelectric conversion unit, wherein the semiconductor electro-optic conversion units are used for converting input electric energy into optical energy, the semiconductor photoelectric conversion units are used for converting the optical energy into the electric energy, the number of the semiconductor electro-optic conversion units and the number of the semiconductor photoelectric conversion units are in a certain proportion so as to achieve direct current voltage transformation, and the working light ray frequency spectrums of the semiconductor electro-optic conversion units and the working light ray frequency spectrums of the semiconductor photoelectric conversion units are matched. According to the chip, the direct current voltage transformation function can be achieved. The chip has the advantages of being simple in structure and capable of being integrated in a total sheet mode.

Owner:郭磊 +1

A composite building support and its manufacturing method

ActiveCN104018663BGuaranteed StrengthGuaranteed rigidityForming/stuttering elementsComposite constructionMetal

Owner:江苏胜宏钢结构有限公司

A semiconductor DC transformer

ActiveCN102569489BWith high pressureHigh pressure noSemiconductor devicesElectric lightDc transformers

The invention provides a semiconductor direct current transformer which comprises a plurality of series connected semiconductor electric light conversion structures which are used for converting input electric energy into luminous energy and a plurality of series connected semiconductor photoelectric conversion structures which are used for converting the luminous energy into output electric energy, wherein a number of the semiconductor photoelectric conversion structures is different from a number of the semiconductor electric light conversion structures so as to realize direct current transformation, and work light of the semiconductor electric light conversion structures is coupled with work light of the semiconductor photoelectric conversion structures. According to the embodiment, the semiconductor direct current transformer has the advantages of high voltage resistant, no electromagnetic radiation, no coil structure, being safe and reliable and the like.

Owner:郭磊

Flexible heating sheet and preparation method thereof

ActiveCN111050433BExcellent electrothermal conversion performanceImprove stabilityHeating element materialsPolymer scienceFiber bundle

Owner:SHENZHEN XIWAN TECH CO LTD

High-power charging cable capable of absorbing heat and controlling temperature

PendingCN113948241ASo as not to damageSimple structureInsulated cablesInsulated conductorsTemperature controlWater wheel

The invention discloses a high-power charging cable capable of absorbing heat and controlling temperature, and relates to the technical field of charging cables. The surface of the protected heating wire core is wound with three layers of hydrophilic porous materials which are different in pore diameter and are communicated with one another, the inner layer and the outer layer are large-pore-diameter foam metal layers and serve as reciprocating channels of cooling liquid, and the middle layer is a heat absorption cooling liquid channel changing layer. A cold source is fixedly installed at one end in the refrigeration end shell, a mixed-flow water wheel is arranged on the cold source in a sleeved mode, and during use, high-temperature cooling liquid circularly flows under traction force of the water wheel and is cooled by absorbing heat at the position of the cold source. Therefore, the temperature controllability of the heating cable is achieved, the problem that the cable is damaged due to high temperature is solved, power is large, efficiency is high, temperature control performance is good, and operation is easy. Meanwhile, the structure is simple, machining and assembling are convenient, and therefore the input cost is reduced, and the use safety and convenience are improved. The cable can be widely popularized and applied in the field of heating cables, and deep development of green electric energy is promoted.

Owner:万智豹

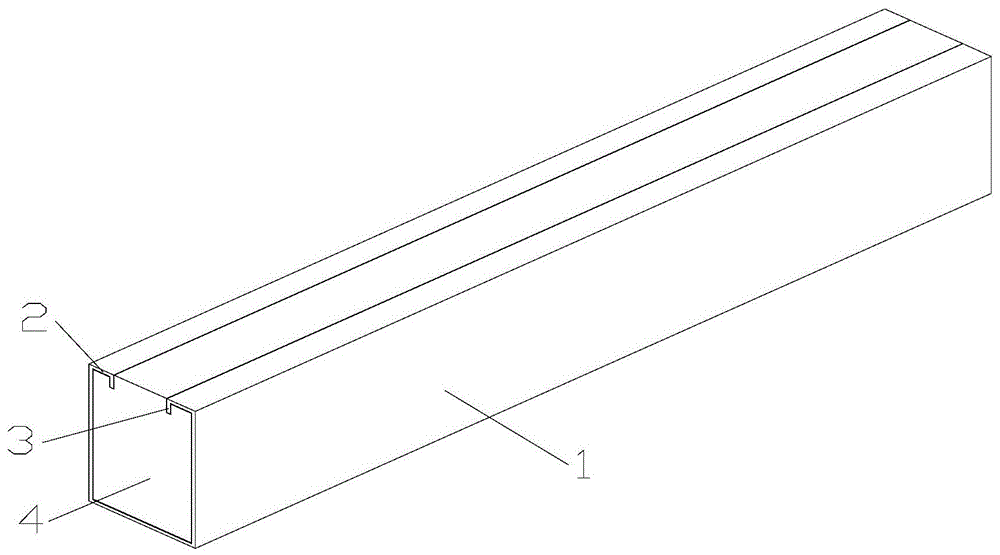

A hollow composite building support structure and its manufacturing method

ActiveCN104018662BGuaranteed StrengthGuaranteed rigidityForming/stuttering elementsOperabilityMoisture

The invention belongs to the technical field of building materials and discloses a hollow composite building supporting structure piece and a manufacturing method thereof. The core body is combined with a metal shell, and the structure piece has the rigidity of metals, also has the characteristics that the wood can be sawed, drilled, nailed and fixedly connected by using nails or bolts, can be corrosion-resistant and moisture-proof and is high in stability, difficult to deform, safe, reliable and light in weight. The overall quality of the building supporting structure piece is lightened, the construction safety is further guaranteed, and the structure piece is simple in manufacturing process, high in operability, green and environmentally friendly.

Owner:大连亿通建设集团有限公司

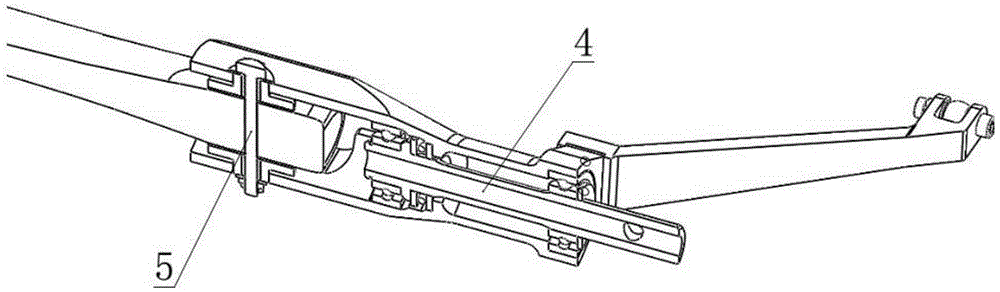

A gasoline engine type tamping machine capable of laterally moving and rotating multi-point tamping

The invention discloses a gasoline engine type tamping machine with transverse moving, rotating and multi-point tamping functions, and belongs to the field of small railway maintenance machinery. The technical scheme includes that a gasoline engine with a clutch, a belt transmission gear and two output mechanisms are fixed onto an upper frame; the upper frame is connected with a middle frame by a rotating device and is positioned by a positioning pin; the middle frame is connected with a bottom frame by a transversely moving mechanism, the transversely moving mechanism comprises two pairs of double-edge insulating wheels, and the two pairs of double-edge insulating wheels are respectively fixedly connected to the middle frame and roll on the upper surface and the lower surface of a transverse beam of the bottom frame; the bottom frame can travel on tracks, two tamping devices are respectively connected with the output mechanisms to implement multi-point tamping, and lifting handles are arranged at two ends of the upper frame. The gasoline engine type tamping machine has the advantages that the gasoline engine type tamping machine can conveniently transversely move and rotate to carry out multi-point tamping, is high in applicability and production efficiency, comfortable to operate, excellent in insulating, long in service life, novel in design, reasonable in structure and easy and convenient to maintain, is light, safe and reliable and can quickly get on and off the tracks, accordingly, the driving safety, the construction safety and the personal safety can be guaranteed, and good tamping effects can be realized.

Owner:ANYANG YUBO RAILWAY DEVICE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com