Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "No burning loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light metal surface laser impact micronano particle injection reinforcing method

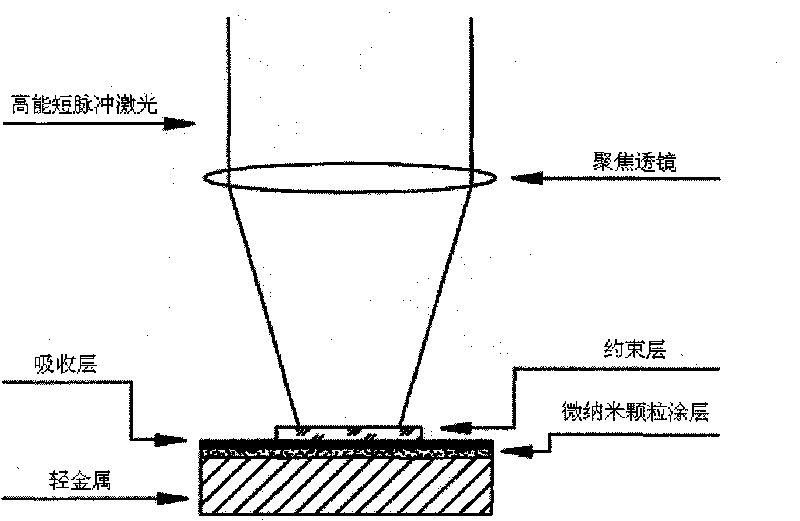

The invention relates to a light metal surface laser impact micronano particles injection reinforcing method, comprising the following steps: 1) removing the oxide layer probably existing on the surface of the light metal by a mechanical polishing or chemical corrosion method, then grinding and polishing with sand paper, and finally cleaning the surface of the light metal alloy with acetone or alcohol; 2) precoating the micronano particles on the surface of the light metal with inorganic bonding agent, recoating a layer of black paint on the surface of the micronano particle coating layer to serve as the absorption layer of laser impact after drying, and drying naturally; 3) impacting the absorption layer and the micronano particle layer with high-energy short pulse laser, and utilizing K9 glass or running water as a restriction layer during laser impact; and 4) soaking the micronano particle coating layer processed by acetone, and then removing the absorption layer through washing with running water or ultrasonic washing to obtain the micronano particle injection reinforcing layer. The invention integrates the actions of laser impact reinforcement, nano particle reinforcement and nano particle reinforcement, can dramatically improve hardness, abrasion resistance and fatigue resistance property of light metal surface layer, and has wide application prospect.

Owner:TSINGHUA UNIV

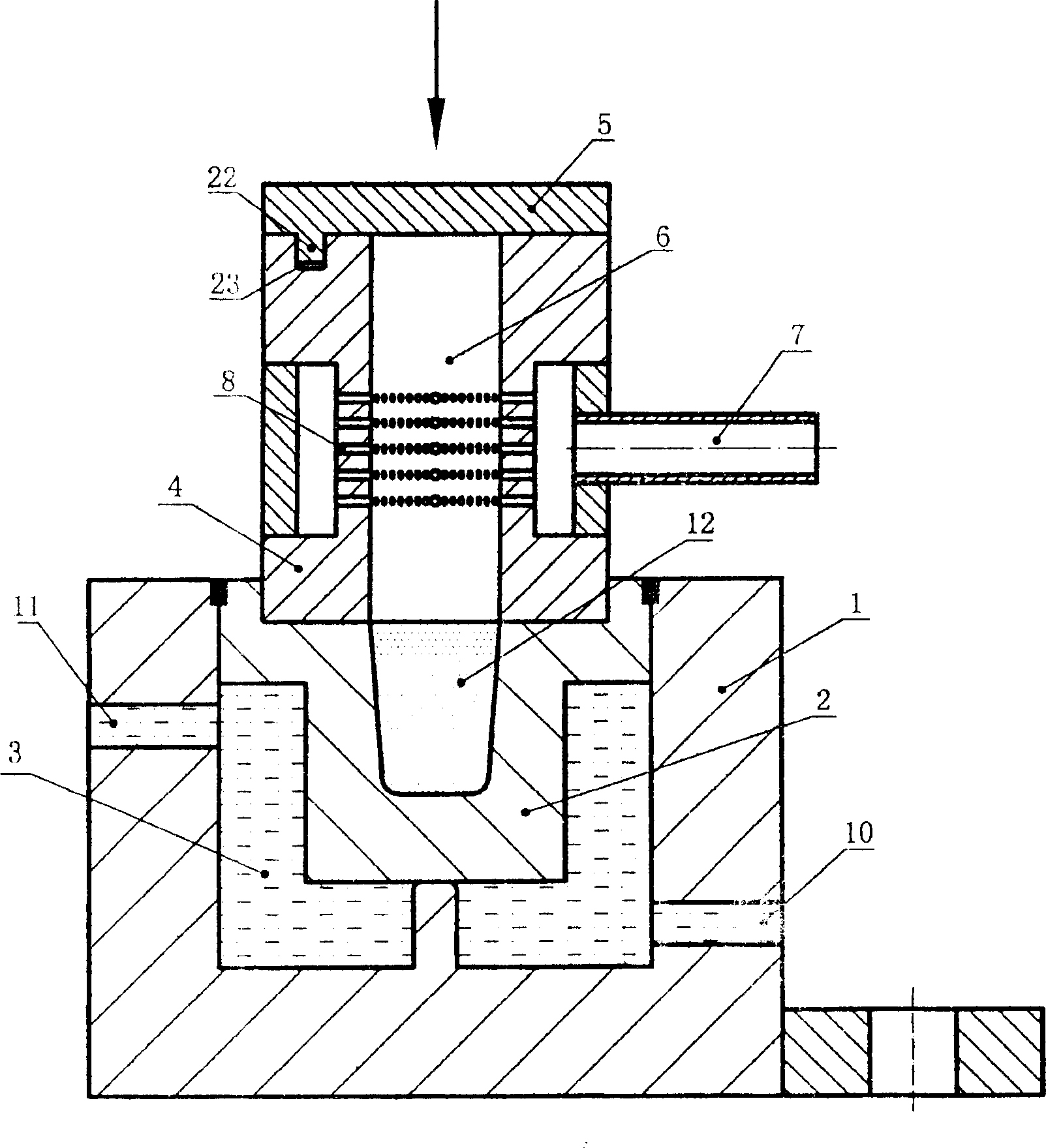

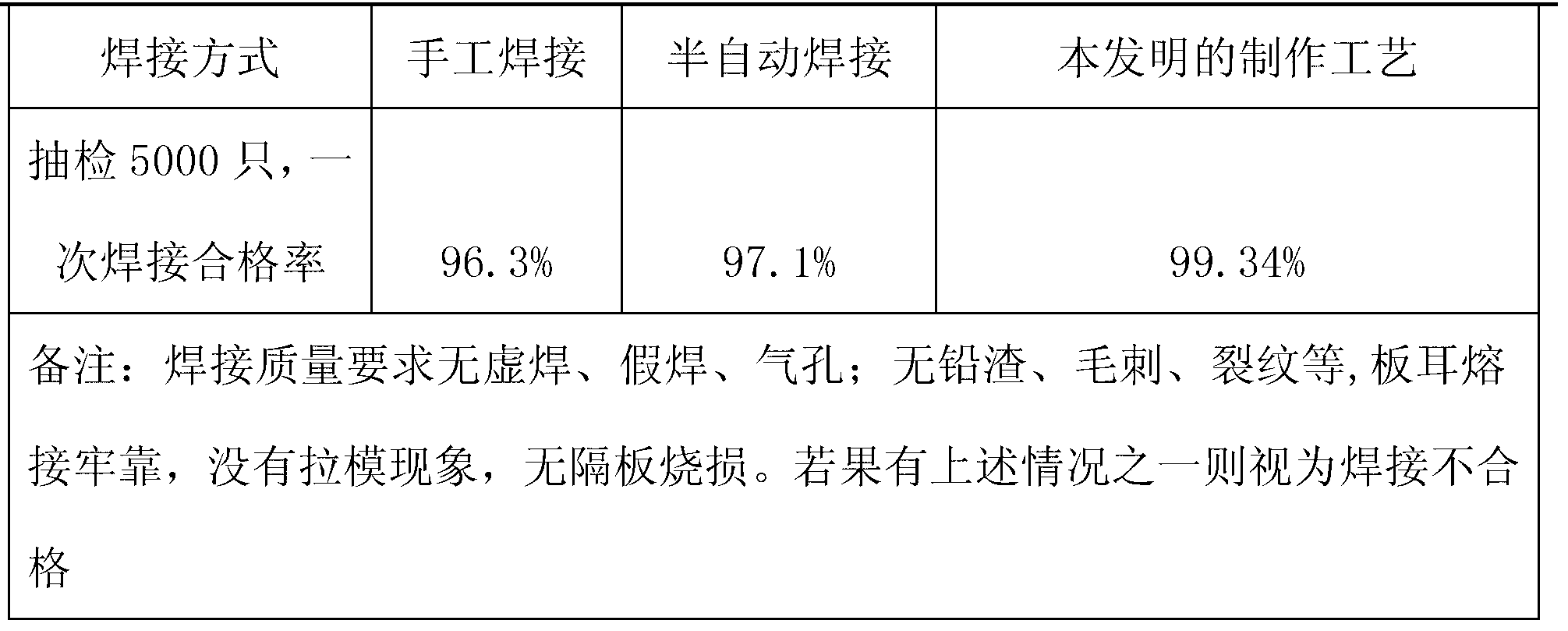

Production process of inner formation storage battery

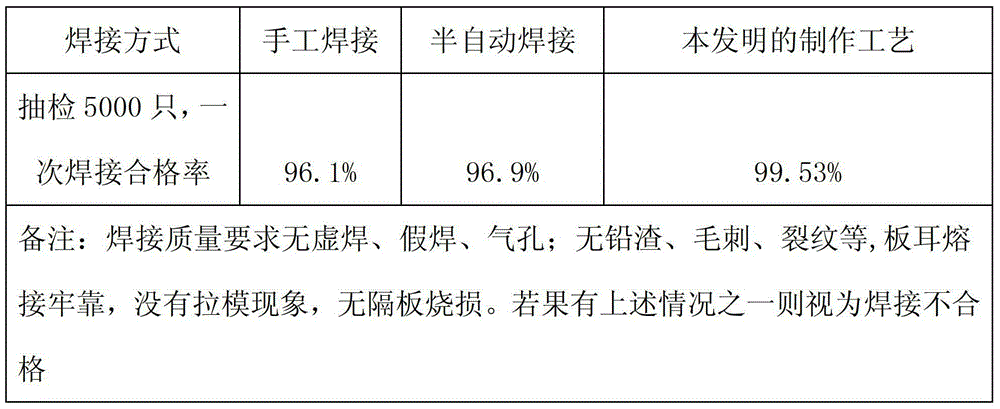

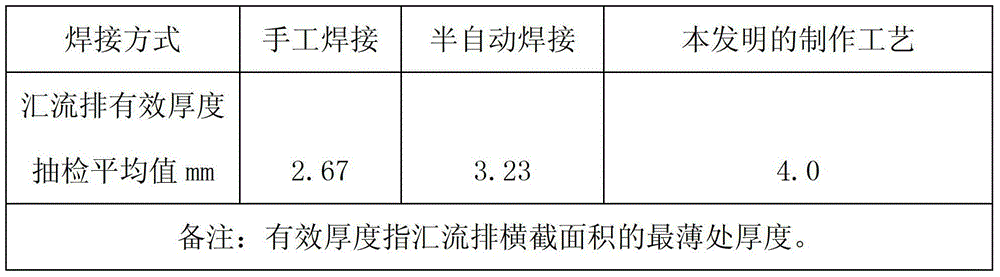

ActiveCN103268963AGood corrosion resistanceNo burning lossFinal product manufactureCell component detailsGrid alloyL&D process

The invention discloses a production process of an inner formation storage battery, and belongs to the field of a lead-acid storage battery, and solves the easily occurring welding quality problem of a bus-bar and a lug. The process comprises the following steps of loading a plate group into an assembling box, arranging a lug, cutting and brushing the lug, dipping soldering flux, cast welding, inspecting and qualification and down-conversion, wherein the cast welding flow is carried out by adopting a cast welding machine. The cast welding flow comprises the following steps of (1) heating a lead pot; (2) loading a mold and preheating the mold; (3) scraping the lead liquid; (4) cast welding the plate group; (5) cooling the plate group through water; (6) cooling the plate group collectively through water and air; (7) cooling the plate group through the air; (8) loading the mold and preheating the mold again; and (9) loading the plate group into a tank. The production process is suitable for the cast welding of the inner formation storage battery with positive grid alloy being lead calcium tin aluminum or lead calcium alloy series grid.

Owner:CHAOWEI POWER CO LTD

High-strength, high-ductility rare earth aluminum alloy material and method of producing the same

The invention relates to a rare earth aluminium alloy material with high strength and high toughness and the preparation method thereof, belonging to the technical field of metal alloy and the preparation thereof. The invention is characterized in that the invention comprises Mg, Si, Fe, a rare earth compound additive and Al, with the weight percentages as follows: Mg: 0.50-0.60%; Si: 0.35-0.45%; Fe less than or equal to 0.35%; rare earth additive less than or equal to 0.065-0.2%; the margin being Al. The preparation method comprises charging and melting down the 6063 aluminum alloy furnace materials in accordance with the conventional methods, adjusting the furnace temperature, deairing, refining and purifying the melt and then adding Al-RE, Al-Sr and Al-Zr master alloys at the temperature between 720 DEG C and 760 DEG C and preserving heat for 30min-7h, then carrying out homogenization treatment on electromagnetic stirring components and detection, pouring and casting, finally carrying out homogenization treatment and subsequent quick cooling treatment, rapid heating before extrusion, extrusion and on-line quenching treatment as well as artificial aging treatment. The product section obtained from the invention has rapid extrusion and high mechanical property of the section and can improve the apparent mass of the section and increase the modification of oxide film density.

Owner:BAOTOU JI TAI RARE EARTH ALUMINUM CO LTD +1

Laser smelting furnace with water cooled copper mould and method for smelting ingot

Owner:BEIHANG UNIV

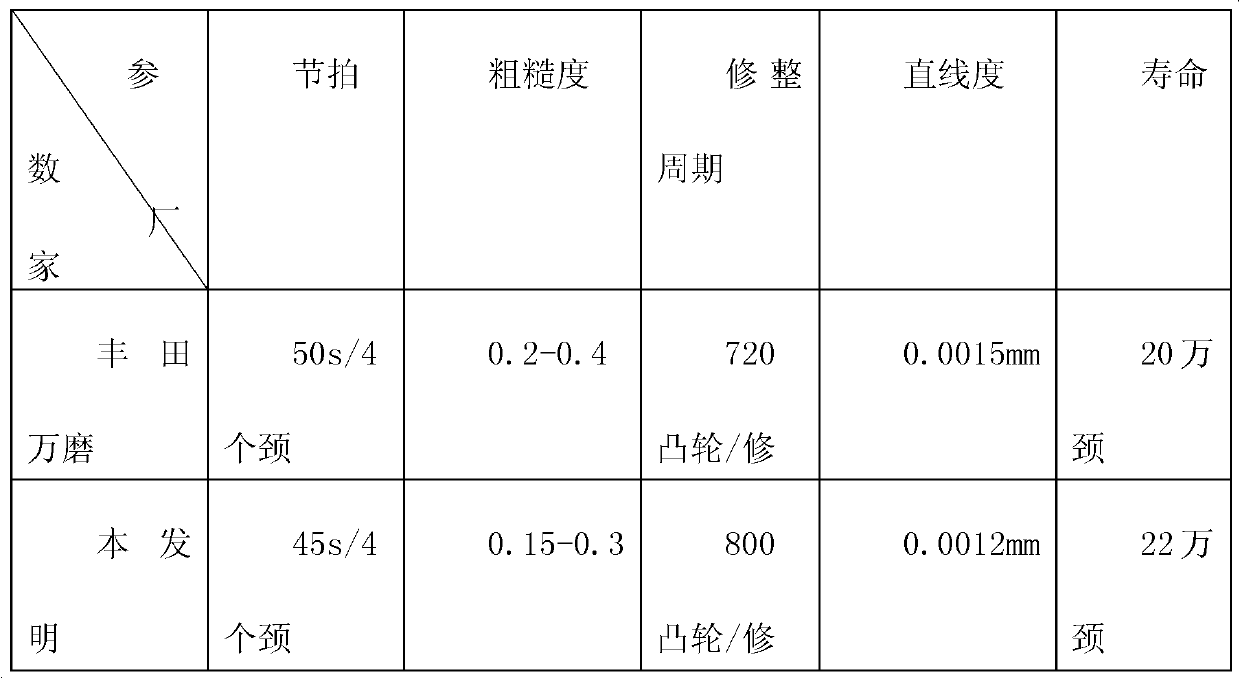

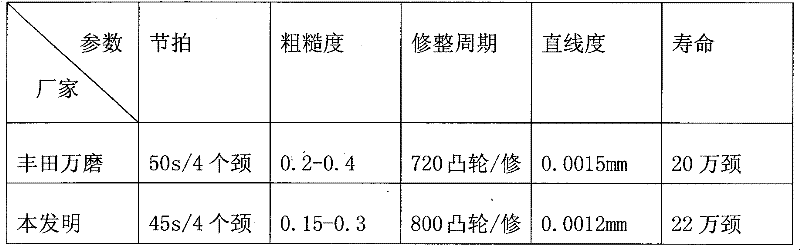

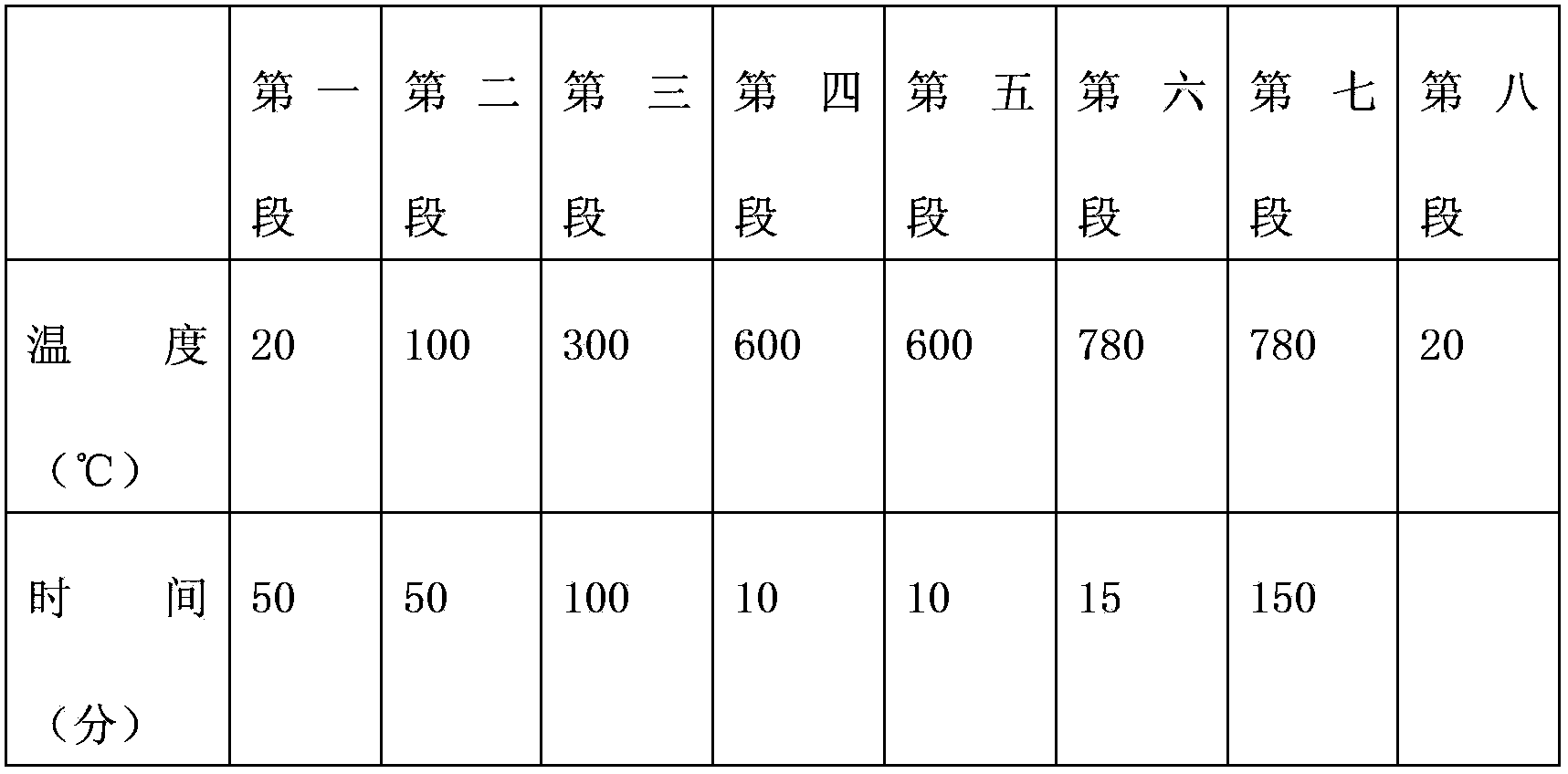

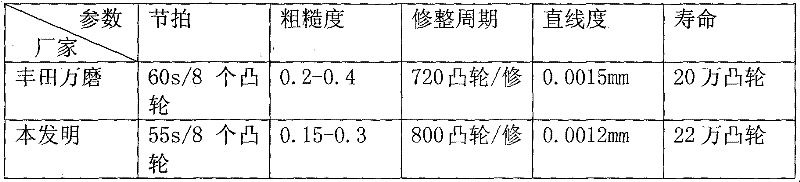

Cubic boron nitride (CBN) grinding wheel preparing method

InactiveCN103465185AImprove flexural strengthImprove cutting performanceGrinding devicesBreaking strengthTemperature curve

The invention discloses a cubic boron nitride (CBN) grinding wheel preparing method. A CBN grinding wheel comprises a steel substrate and a working grinding material layer. The working grinding material layer comprises a grinding material layer and a middle transition layer. The CBN grinding wheel preparing method includes the following steps that (1) premelting ceramic powder is prepared; (2) ceramic bond is prepared; (3) the grinding material layer is prepared by using, by mass, 4-7 parts of ceramic floating bead, 30-32 parts of ceramic bond, 4-6 parts of white corundum and 25-35 parts of CBN; the middle transition layer is prepared by using, by mass, 40-47 parts of 150-mesh ceramic balls and 20-25 parts of ceramic bond; the materials are arranged on the steel substrate according to a general method, sintering is conducted according to a set temperature curve, and a CBN grinding wheel finished product is obtained; in a sintering process, inert gas is adopted for protection. By means of the CBN grinding wheel preparing method, ceramic bond is low in sintering temperature, the CBN grinding wheel is high in breaking strength, and the CBN strength is basically not lost.

Owner:CHANGSHU JULI GRINDING WHEEL

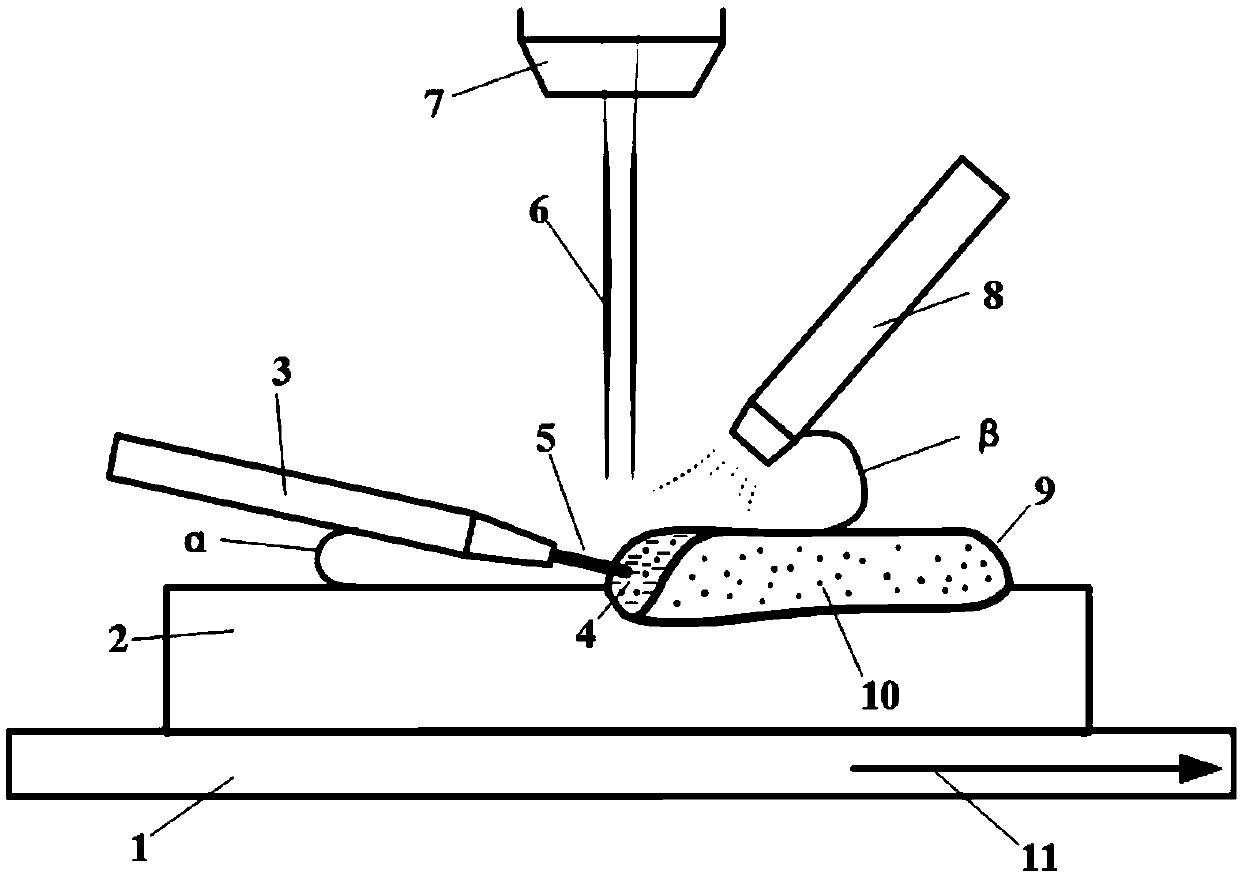

Laser melting deposition ceramic particle enhanced metal-base composite coating based on tubular powder core wire and machining method

InactiveCN110965060AEvenly distributedLow dilution rateMetallic material coating processesMachiningLaser

The invention discloses a laser melting deposition ceramic particle enhanced metal-base composite coating based on a tubular powder core wire and a machining method. A tubular metal layer serves as ametal base body, a filler serves as a ceramic particle enhancing phase, the advantages of the powder sending type and the advantages of the wire sending type are combined, and under the action of lasers, not only can the stable and smooth globular transfer process in the ceramic particle even distribution process be formed, but also the cladding efficiency, material utilization rate and automationdegree are high; and the continuous stable injection transition process can be realized through the wire. In addition, since the lasers are used as a heat source, heat input is precise and controllable, and the compact no-defect composite coating with low dilution rate and evenly distributed enhancing particles can be prepared.

Owner:TIANJIN UNIV

Technology for producing lead-acid storage batteries through temperature control method

The invention discloses a technology for producing lead-acid storage batteries through temperature control method, belongs to the field of lead-acid storage battery production and solves the problem of the poor battery welding quality of a cast-welding technology through a time control method. The method comprises the processes of feeding of plate packs in an assembly box, electrode tab arranging, cutting and brushing of electrode tabs, dipping of flux, cast-welding, inspection and discharging after qualification. The cast-welding process is completed through a cast-welding machine and comprises the following steps: 1) heating of a lead pan; 2) preheating of a lower die; 3) scrapping of molten lead; 4) electrode tab cast-welding; 5) die removal; and 6) secondary preheating of the lower die. The technology is used for manufacturing lead-acid storage batteries.

Owner:CHAOWEI POWER CO LTD

Method of recovering carbon fibers by low-temperature microwave efficient treatment of carbon fiber composite material

InactiveCN107216480AImprove the efficiency and effectiveness of recyclingHeating fastSolid productEnergy source

The invention relates to a method of recovering carbon fibers by low-temperature microwave efficient treatment of a carbon fiber composite material and belongs to the technical field of fiber composite materials. The method comprises the following steps: firstly, putting a waste carbon fiber composite material in a microwave heating device; introducing oxygen or oxygen-containing mixed gas; feeding microwaves, the frequencies of which are 2450+ / -50MHz or 915+ / -50MHz till the temperature is raised to 350-500 DEG C; performing low-temperature treatment for 0.1-1.0h; then naturally reducing the temperature to below 200 DEG C; and taking out the solid product to obtain the carbon fibers. The method is a method of uniformly and efficiently recovering high value carbon fibers from the waste carbon fiber composite material at a low temperature at a normal pressure. According to the method, organic matters of resin are oxidized to combust at the low temperature, and the integrity of the carbon fibers is ensured. The carbon fibers are regenerated and recycled while the mechanical property and recovery rate of the carbon fibers are increased, the reaction time is shortened, the reaction flow is simplified, the energy source is saved and the environment is protected.

Owner:KUNMING UNIV OF SCI & TECH

Large-size high-niobium high-temperature 706 alloy ingot and smelting process thereof

ActiveCN111876651AIncrease temperatureFully uniform temperatureIncreasing energy efficiencyVacuum induction meltingSmelting process

The invention discloses a large-size high-niobium high-temperature 706 alloy ingot and a smelting process thereof. The problems that the serious melting loss of Al and Ti elements is prone to occurring to an existing smelting process and metallurgical defects of black spots and white spots are prone to occurring to the prepared high-niobium high-temperature 706 alloy ingot are solved. The smeltingprocess comprises the steps that vacuum induction melting is carried out, a plurality of vacuum induction ingots with the same component are prepared, then electroslag electrodes with the same numberare prepared, (CaF2-CaO-Al2O3-TiO2) quaternary slag is used for exchanging electroslag remelting, then prepared electroslag ingots are used for preparing consumable electrodes, and then the consumable electrodes are used as initial raw materials to perform twice vacuum consumable remelting. By adopting the smelting process, the high-niobium high-temperature 706 alloy large-size ingot with the ingot weight of more than 15 tons and the diameter of more than 800mm can be prepared, the formation of the metallurgical defects of the black spots and the white spots is restrained to the utmost extent, and the melting loss rate of the Al and Ti elements is reduced.

Owner:BEIJING CISRI GAONA TECH +1

Cubic boron nitride (CBN) ceramic high speed grinding wheel and preparation method and application

ActiveCN102815946AAchieve the expected purposeLower firing temperatureHigh-speed grindingBoron nitride

The invention discloses a cubic boron nitride (CBN) ceramic high speed grinding wheel which comprises a steel substrate and a working abrasive layer. The working abrasive layer comprises an abrasive layer and a middle transition layer. The abrasive layer comprises the following materials: low temperature binding agent, white corundum, ceramic floating bead and CBN. The middle transition layer comprises the following materials: low temperature binding agent and 150-mesh ceramic balls. The low temperature binding agent includes the following materials by volume: 8-12 parts of nanoscale aluminumoxide, 8-12 parts of nanoscale silica and 75-85 parts of premelting ceramic powder. The premelting ceramic powder includes the following materials by volume: 25-35 parts of aluminum oxide, 27-37 parts of silica, 4.5-5.5 parts of sodium oxide, 1.5-2.5 parts of potassium oxide, 1.5-2.5 parts of magnesium oxide, 0.8 part to 1.2 parts of calcium oxide and 5-11 parts of diboron trioxide. The CBN ceramic high speed grinding wheel has the advantages that firing temperature of the ceramic binding agent is 750 DEG C, rupture strength can reach 115MPa, and the CBN strength is basically not lost under the temperature, so that cutting performance of the CBN grinding wheel is greatly improved. A preparation method and the application of the CBN ceramic high speed grinding wheel are further provided.

Owner:沈阳中科超硬磨具磨削研究所

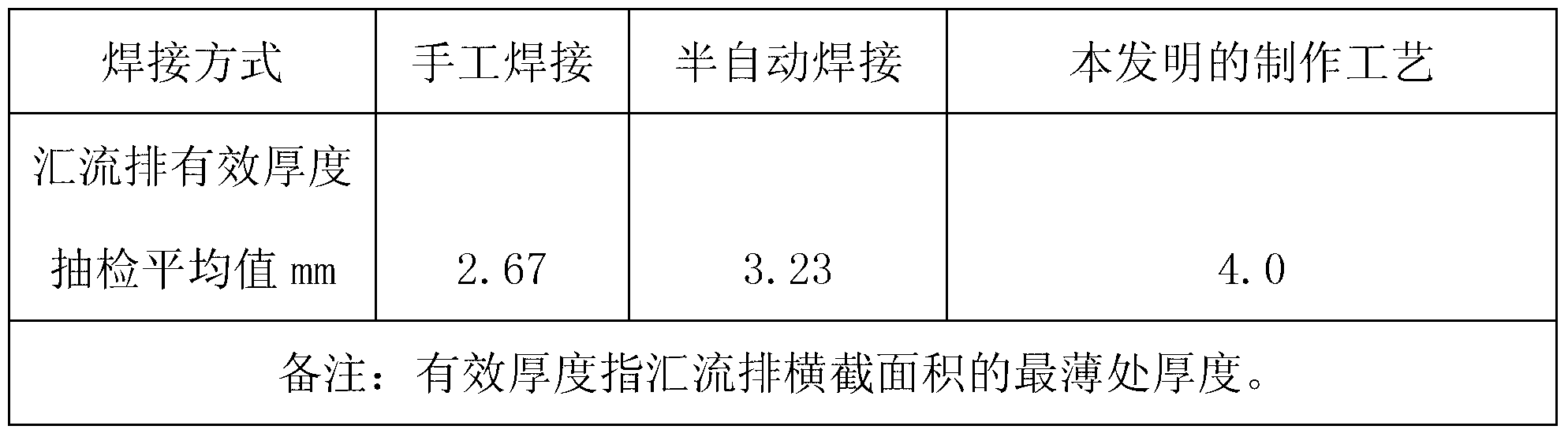

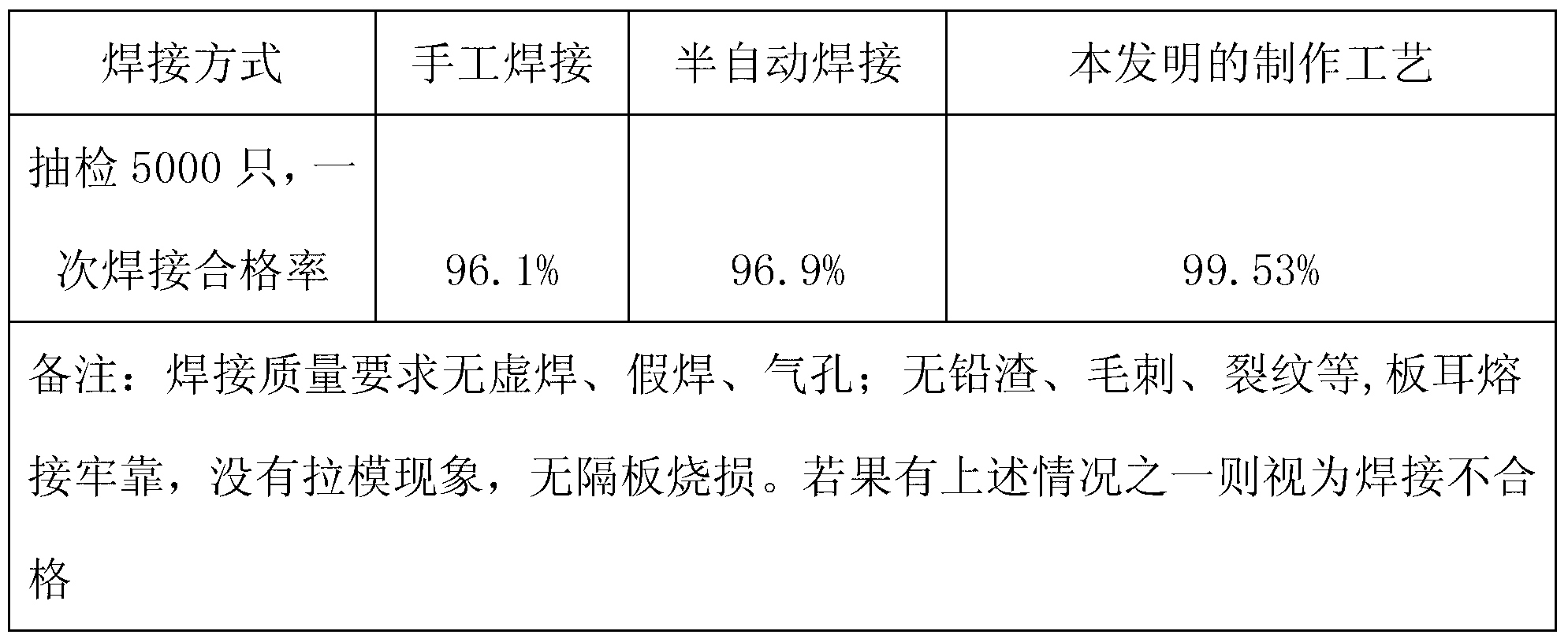

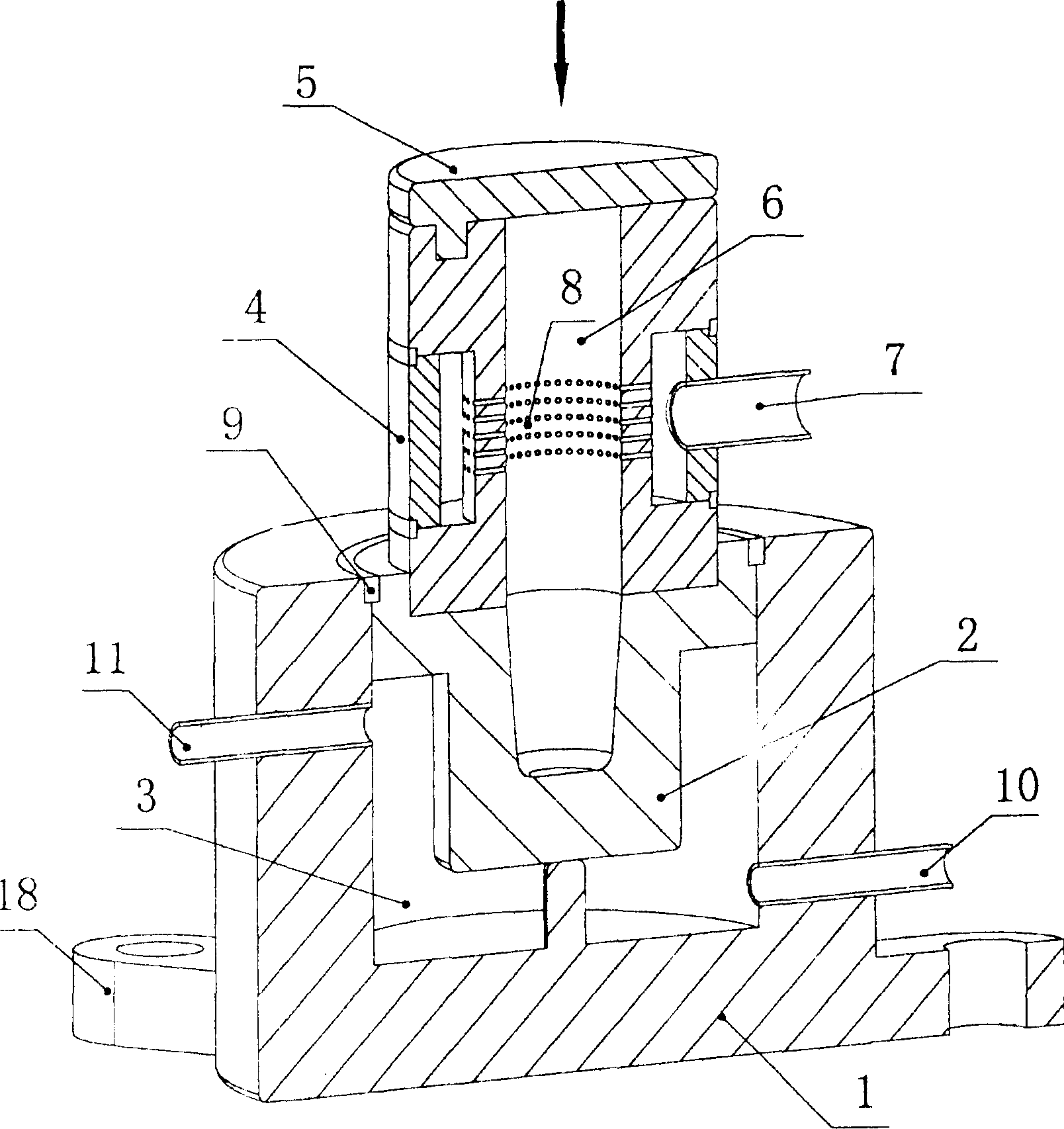

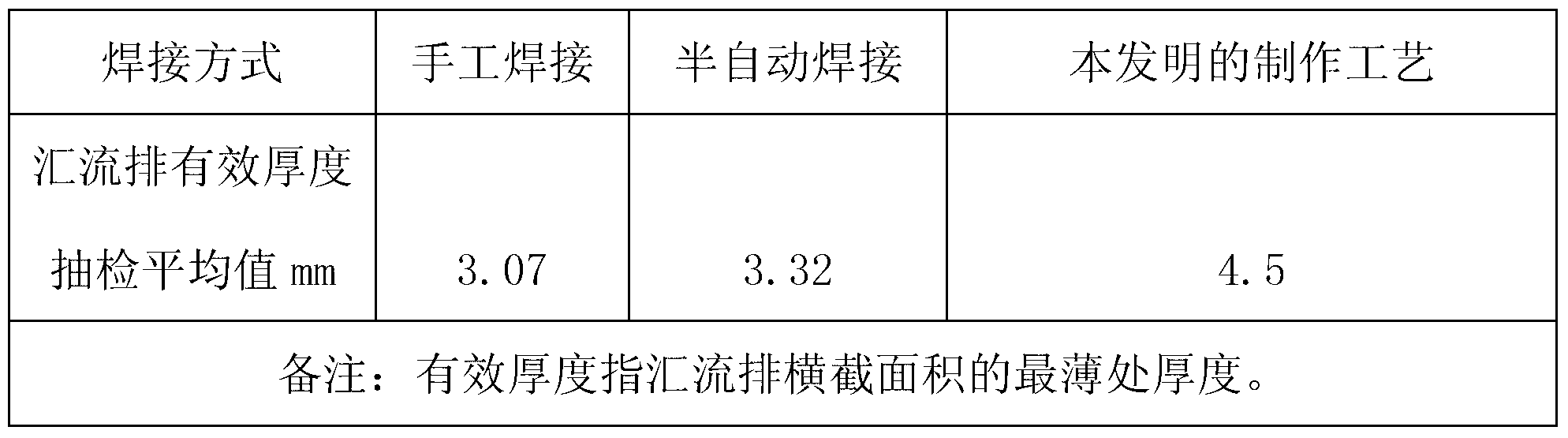

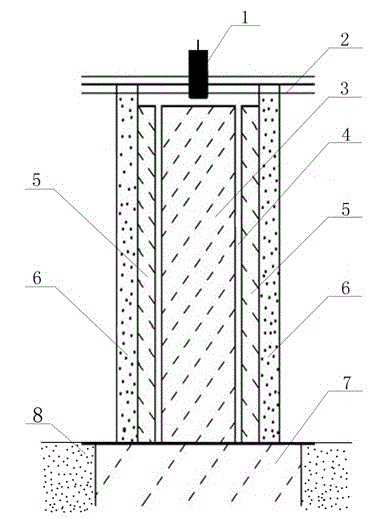

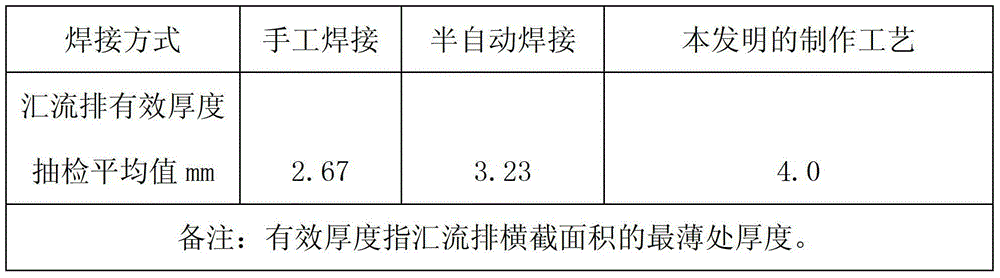

Tank formation manufacturing technology for storage batteries

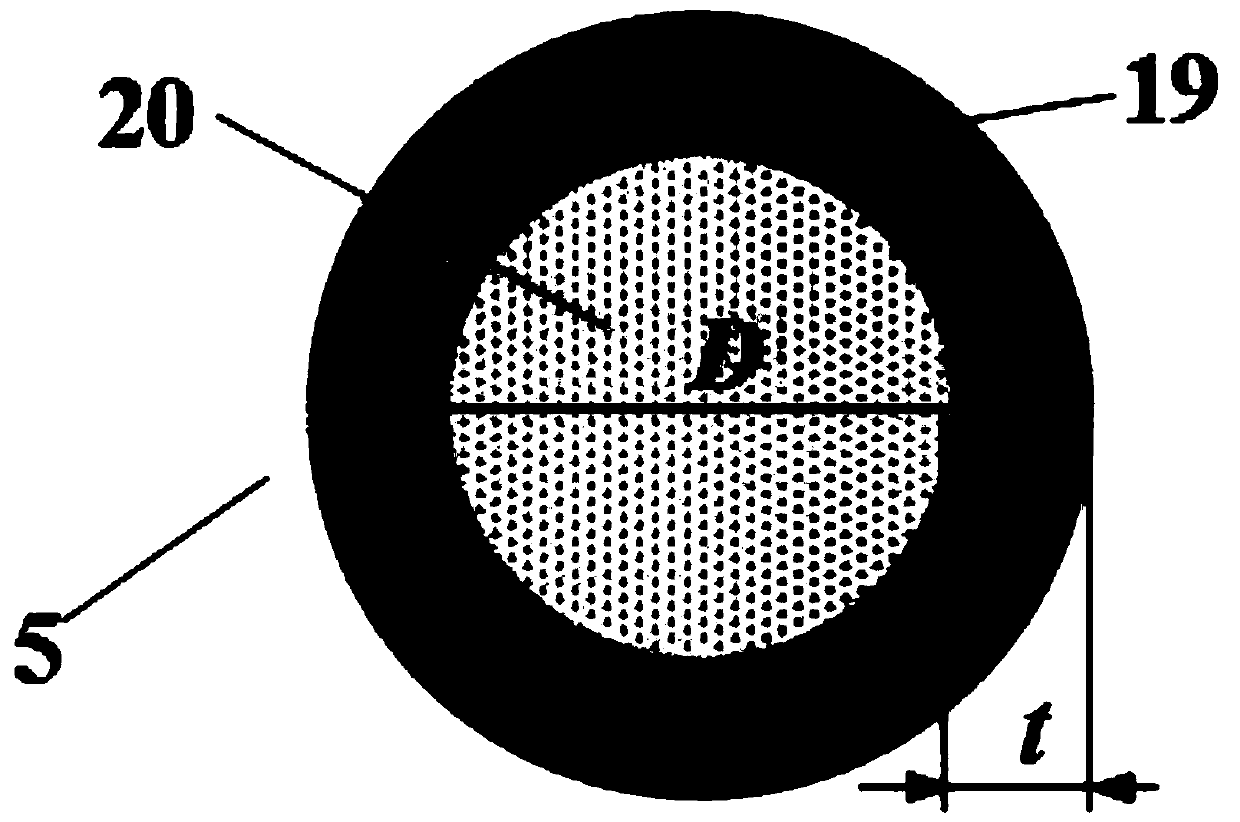

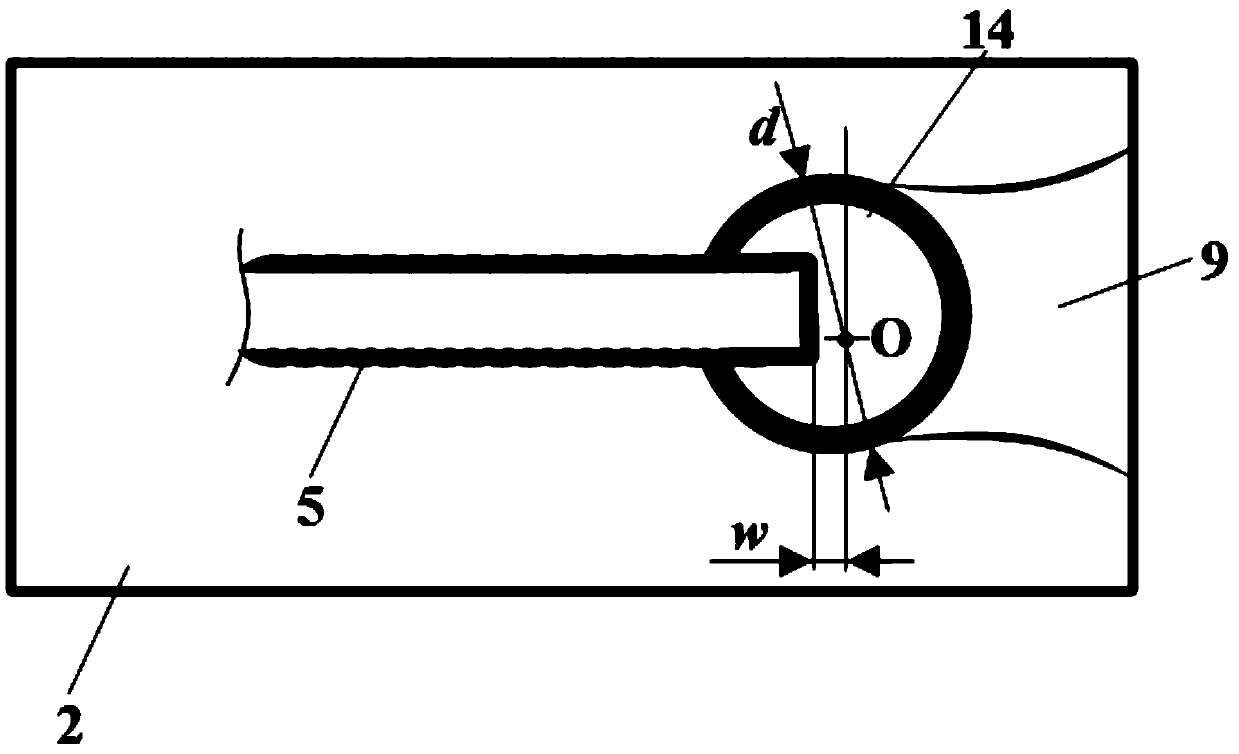

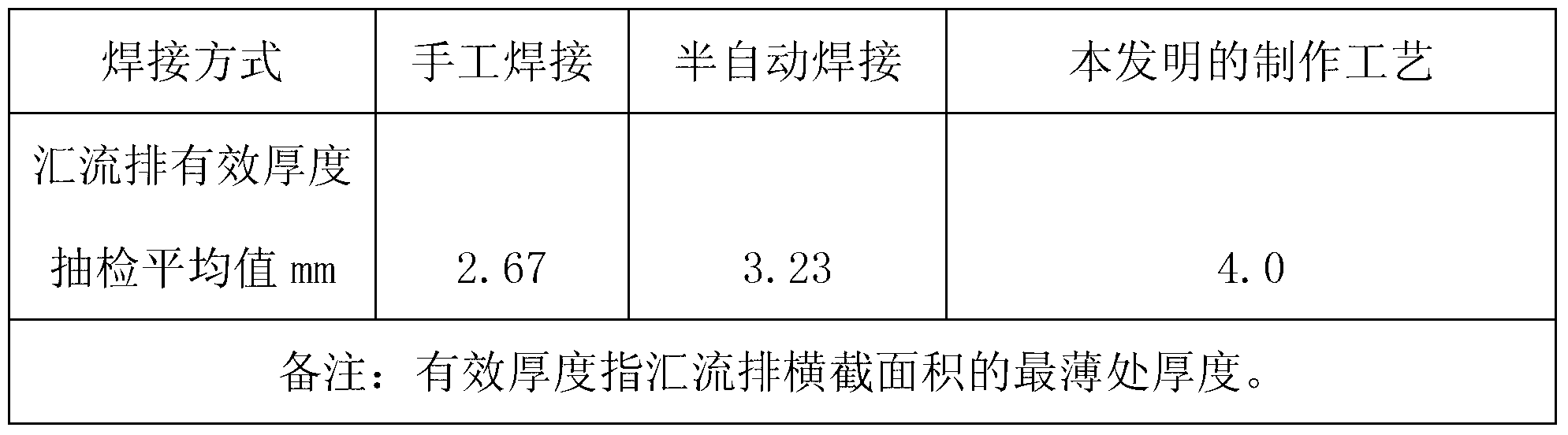

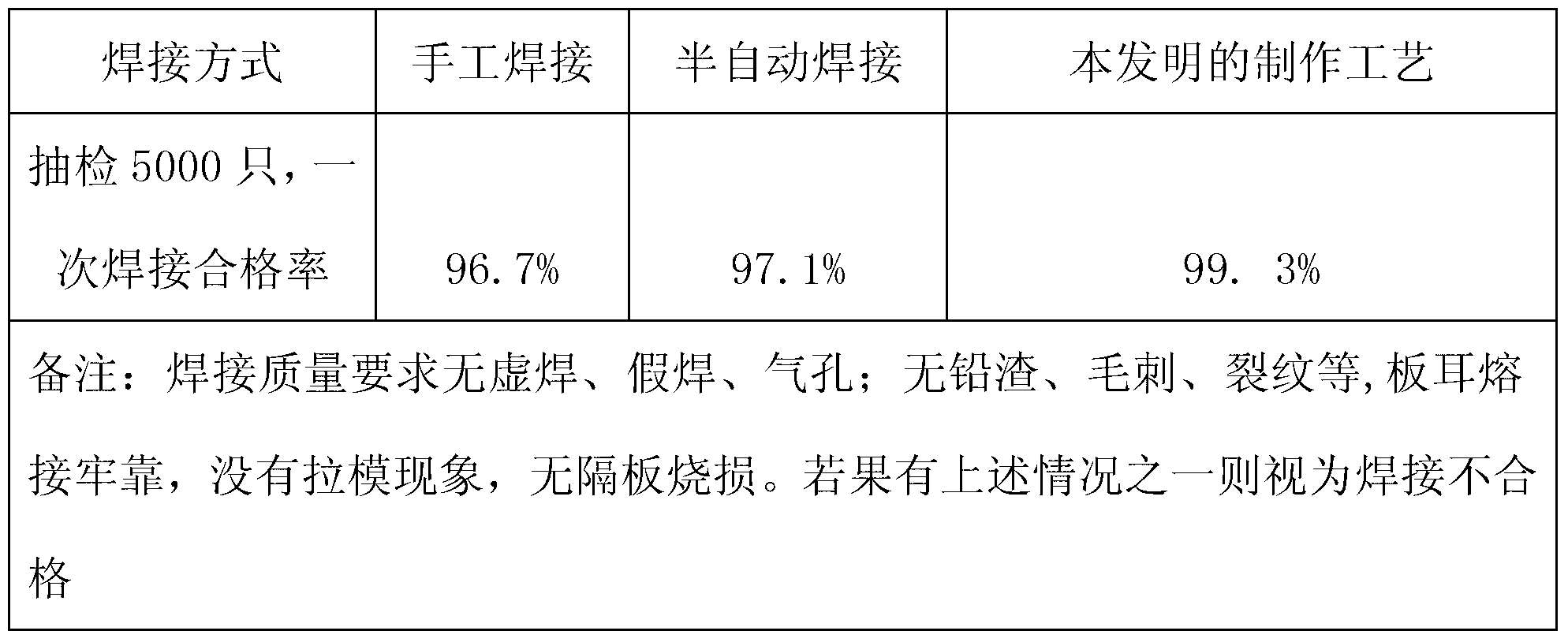

ActiveCN103264154AIncrease the effective thicknessImprove welding qualityManufacturing technologyWater vapor

The invention discloses a tank formation manufacturing technology for storage batteries,relates to the field of lead-acid storage battery production and solves the problem of the poor welding quality between bus-bars and electrode tabs. The manufacturing technology comprises the technological processes of feeding of plate packs in an assembly box, electrode tab arrangement, cutting and brushing of electrode tabs, dipping of flux, cast-welding, inspection and discharging after qualification. The cast-welding process is performed through a cast-welding machine and comprises the following steps: 1) heating of a lead pan; 2) preheating of a lower die; 3) scrapping of molten lead; 4) electrode tab cast-welding; 5) water cooling; 6) water vapor mixing cooling; 7) gas cooling; 8) secondary preheating of the lower die; and 9) feeding of the electrode tabs in battery containers. The manufacturing technology is used for cast-welding of lead-acid storage battery grids.

Owner:CHAOWEI POWER CO LTD

Preparation technology of high-speed grinding CBN (Cubic Boron Nitride) ceramic grinding wheel

ActiveCN102009393BLower firing temperatureImprove flexural strengthAbrasion apparatusGrinding devicesBreaking strengthMullite

The invention discloses a preparation technology of a high-speed grinding CBN (Cubic Boron Nitride) ceramic grinding wheel, which comprises the steps of: mixing raw materials according to the following volume ratio: 30 to 50 parts of feldspar, 40 to 60 parts of boron glass, 3 to 7 parts of K2CO3 and 3 to 7 parts of Na2CO3; firing at high temperature; ball-milling and uniformly mixing nano SiO2powder, nano mullite powder and pre-melting ceramic powder according to the mass rate of 2:3:5 to obtain a bonding agent; preparing an abrasive layer from 35% of the bonding agent, 8% of white corundum, 7% of alumina hollow ball and 50% of CBN; preparing a transition layer from 35% of the bonding agent and 65% of ceramic balls of 150 meshes; uniformly mixing the weighed materials; adding the materials to a polythene water solution; pressing to form a fixed shape; drying; and sintering in a high-temperature furnace. The preparation technology has the advantages of low firing temperature of the bonding agent, high breaking strength and good bonding performance to abrasives, enhances the wettability of the bonding agent to the abrasives, enhances the cutting efficiency of abrasive particles, reduces the cost, and enhances the enwrapping capability, strength and sintering temperature of the bonding agent to the abrasive, and in addition, CBN strength is not changed and no burning loss is generated on a surface.

Owner:沈阳中科超硬磨具磨削研究所

Anti-nuclear radiation composite material

ActiveCN107227454AHigh strengthReduce porosityPolyurea/polyurethane coatingsHeat inorganic powder coatingZirconium hydrideHigh energy

The invention discloses an anti-nuclear radiation composite material capable of protecting high-energy neutrons and gamma rays properly. The composite material comprises a pair of stainless steel substrates. One side surface of each stainless steel substrate is provided with at least two high-energy neutron protective coatings, and the other side surface of the stainless steel substrate is provided with at least one gamma ray protective coating so that anti-nuclear radiation panels are formed. The innermost coating in the high-energy neutron protective coatings comprises, by weight, 40-70 parts of aluminum-based metal, 20-40 parts of boron carbide and 10-20 parts of samarium oxide, and the outermost coating comprises, by weight, 30-70 parts of the aluminum-based metal, 20-50 parts of aluminum fluoride and 10-20 parts of zirconium hydride. The sides, provided with the gamma ray protective coatings, of the anti-nuclear radiation panels are combined together back to back. The composite material can be widely used for making nuclear radiation protection devices.

Owner:ZHANGJIAGANG CITY GUANGCHUAN ELECTRONICS

Silver-based braze welding material and preparing method of silver-based braze welding material

InactiveCN104227267AQuality improvementFlat surfaceWelding/cutting media/materialsSoldering mediaCrucibleSmelting process

The invention discloses a silver-based braze welding material and a preparing method of the silver-based braze welding material, and solves the problems that the surface and the inside of a braze material ingot still have defects such as air pores and slag inclusions, so the braze material quality is unstable. The silver-based braze welding material comprises the following ingredients in percentage by weight: 29.0 to 57 percent of Ag, 10.0 to 46.0 percent of Cu, 10.0 to 36.0 percent of Zn, 0 to 2.5 percent of Ni and 0 to 25.0 percent of Cd. The preparing method comprises the following steps that (1) the silver-based braze welding material is prepared into a braze material according to a certain ingredient proportion to be added into a crucible; (2) the braze material is heated to 825 to 925 DEG C under the protection of Ar protection gas and is in a fused state; (3) the braze material in the fused state is uniformly stirred; (4) the braze material stops heating and is slowly cooled, and through consolidation forming, the braze material ingot is obtained; (5) the braze material ingot is poured out from the crucible. The silver-based braze welding material and the preparing method of the silver-based braze welding material have the advantages that in the smelting process, no burning loss exists, the ingredients are stable, the surface and the inside of the obtained braze material ingot cannot generate defects such as air pores and slag inclusions, and the quality of the braze material is stable.

Owner:宁波银马焊材科技有限公司

Plasma cladding process for crust breaking hammer

InactiveCN108048834AFast heatingImprove efficiencyMetallic material coating processesPlasma torchHigh energy

The invention discloses a plasma cladding process for a crust breaking hammer. The plasma cladding process comprises the steps that one end of a metal base body which is machined and formed is fixed on a rotary disc of a surfacing welding machine; prepared alloy powder is baked at the temperature of 150 DEG C for 1-2 hours; and the baked alloy powder is placed in a container, the program of the surfacing welding machine is set according to requirements, a plasma torch protective argon source and a power supply of the surfacing welding machine are started, the alloy powder is clad on the metalbase body through a continuous jetting method, through high-energy density automatic welding, the alloy powder and the surface of the base body are molten and then rapidly solidified, so that a surface coating which is in metallurgical bonding with the surface of the base material is formed on the surface of the base material, and the thickness of the coating is 2-5 mm. The plasma cladding processfor the crust breaking hammer has the advantages that the surfacing welding layer is good in performance, high in bonding strength, and good in compactness, the melting depth of a workpiece is controllable, the dilution rate of the surfacing welding layer is low, the formed shape of the surfacing welding layer is regular, the pollution is small, and the cost is low.

Owner:宁国市开源电力耐磨材料有限公司

Method for preparing composite material for radiator

ActiveCN103551825AHigh bonding strengthComposite ratio is well controlledUltimate tensile strengthMaterials science

The invention provides a method for preparing a composite material for a radiator, which has the advantages of simple and convenient process, convenience in operation, low cost, high material yield, no phenomena of welding layer and expansion on an interface, no burn-down of the outer surface, high bonding strength and good control of the compounding rate.

Owner:YINBANG CLAD MATERIAL

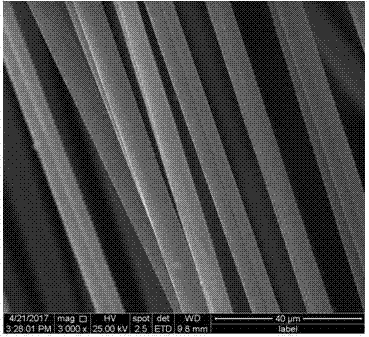

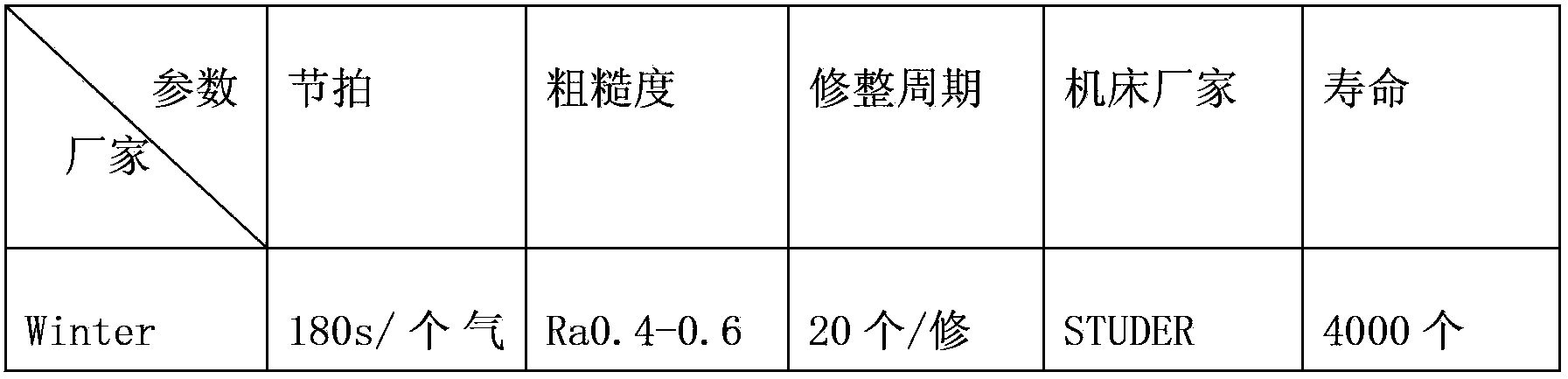

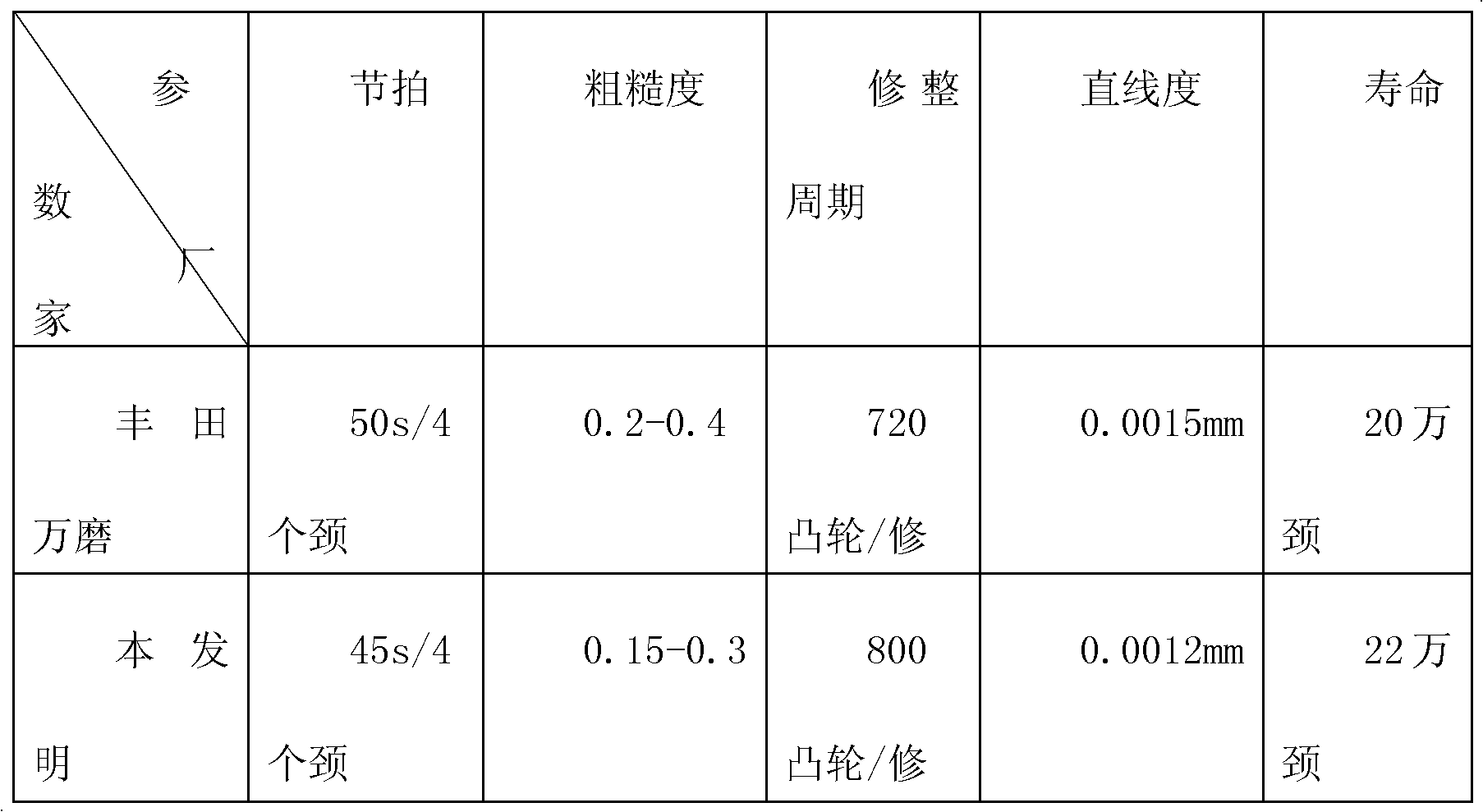

Preparation method of CBN ceramic high-speed grinding wheel used for high-speed grinding of air valve of internal combustion locomotive

The invention discloses a preparation method of a CBN ceramic high-speed grinding wheel used for high-speed grinding of an air valve of an internal combustion locomotive. Pre-melting ceramic powder is prepared from following components by weight: 25-33 of Al2O3, 40-48 of SiO2, 3-4 of Na2O, 1-1.5 of MgO, 4-5 of K2O and 8-9 of B2O3. A binding agent is prepared by sintering 1 part of nanoscale titanium dioxide and 9 parts of the pre-melting ceramic powder according to a preset temperature curve. The firing temperature of the ceramic binding agent is 730 DEG C, but the breaking strength of the ceramic binding agent can reach 110 MPa. At the temperature, the CBN strength has nearly no loss and cutting edge angles are clear, thus largely improving machinability of the CBN grinding wheel.

Owner:沈阳中科超硬磨具磨削研究所

Laser-cladding MoB/CoCr metal ceramic coating and preparation method thereof

InactiveCN102383125ANo burning lossImprove coating qualityMetallic material coating processesHardnessWear resistance

The invention provides a preparation method for a laser-cladding MoB / CoCr metal ceramic coating. MoB / CoCr metal ceramic is used as a coating material, wherein the MoB / CoCr metal ceramic comprises the following components in percentage by weight: 22.5 percent of Co, 19.7 percent of Cr, 9.5 percent of B, 1.6 percent of W and the balance of Mo. The preparation method has the advantages that: the inner part of the prepared laser-cladding MoB / CoCr metal ceramic coating is compact and free of air voids, cracks and the like; and the coating is hundreds of microns thick. During laser cladding, argon is adopted, so the coating material cannot be damaged by burning; therefore, the original high hardness, high abrasion resistance and high corrosion resistance of the coating material can be retained.

Owner:JIUJIANG UNIVERSITY

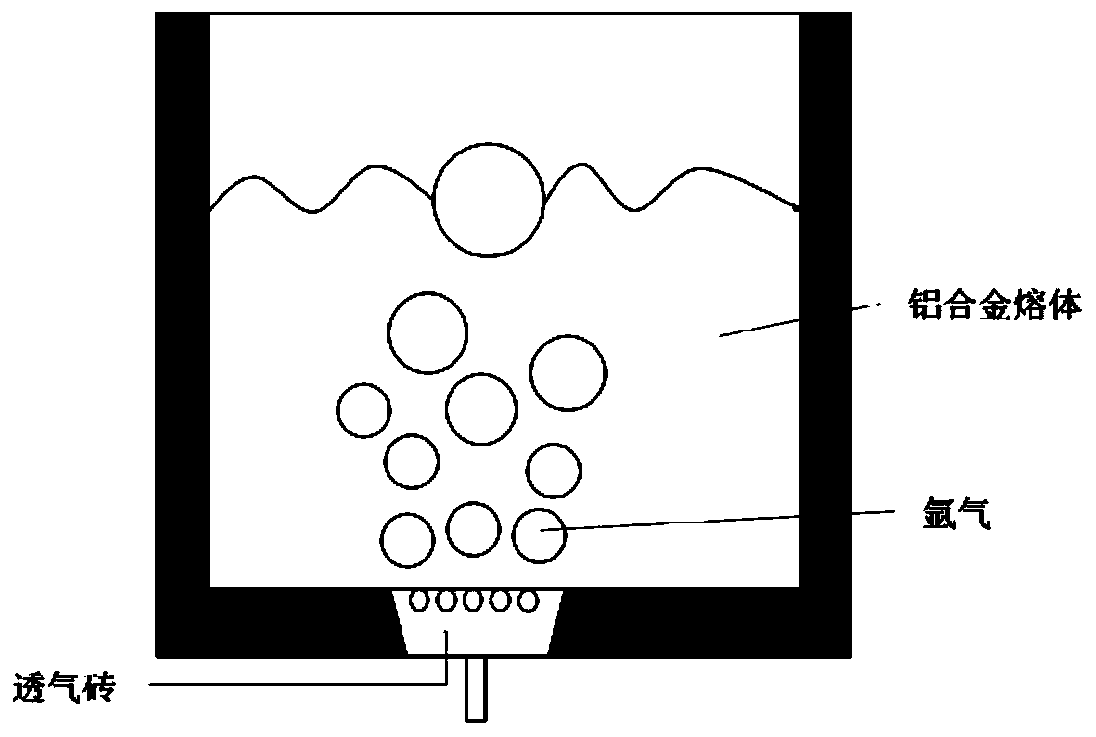

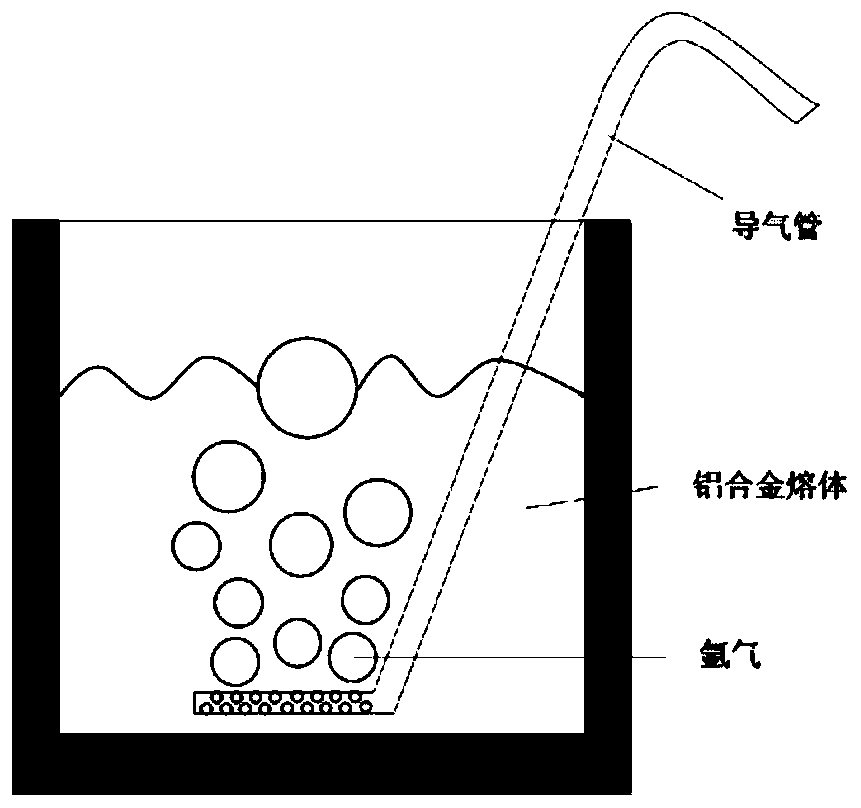

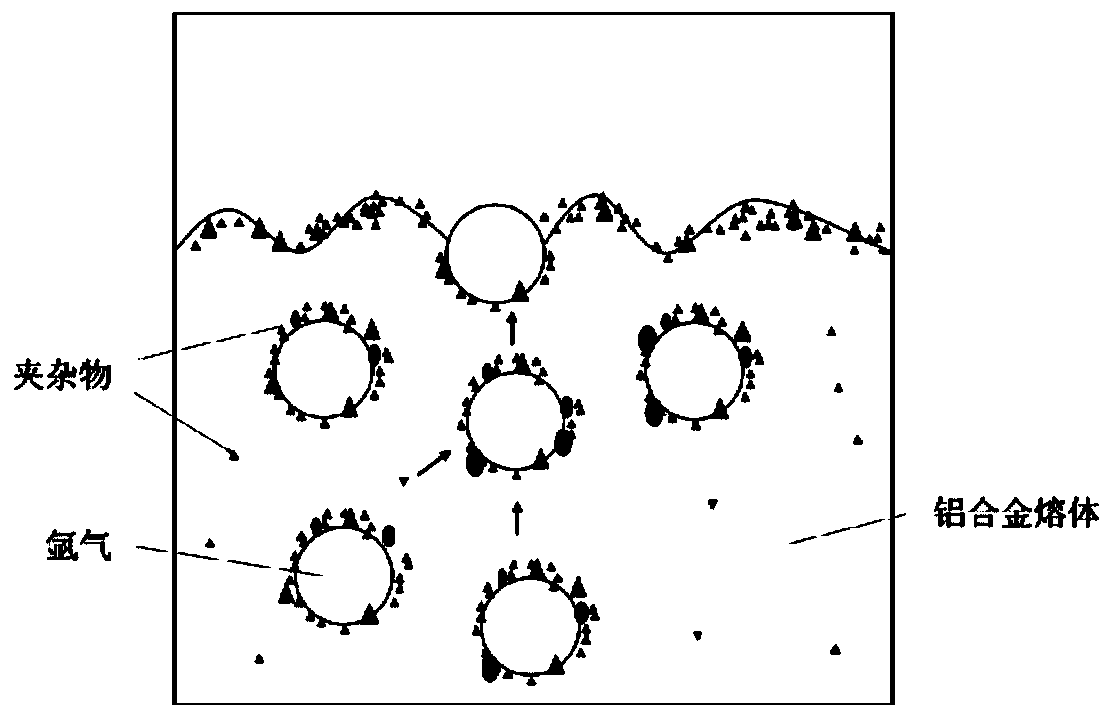

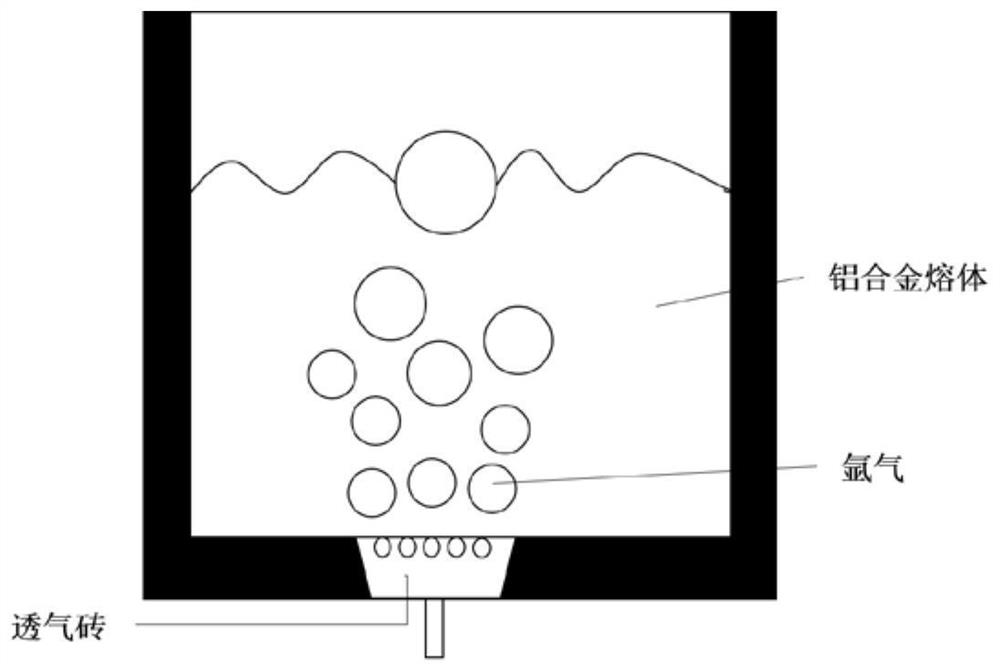

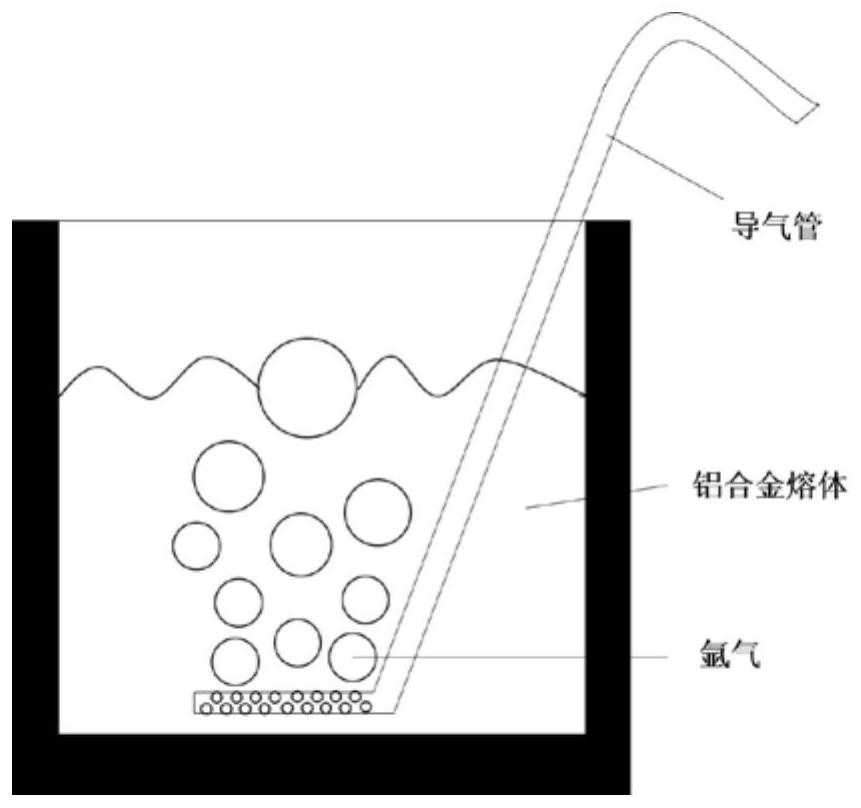

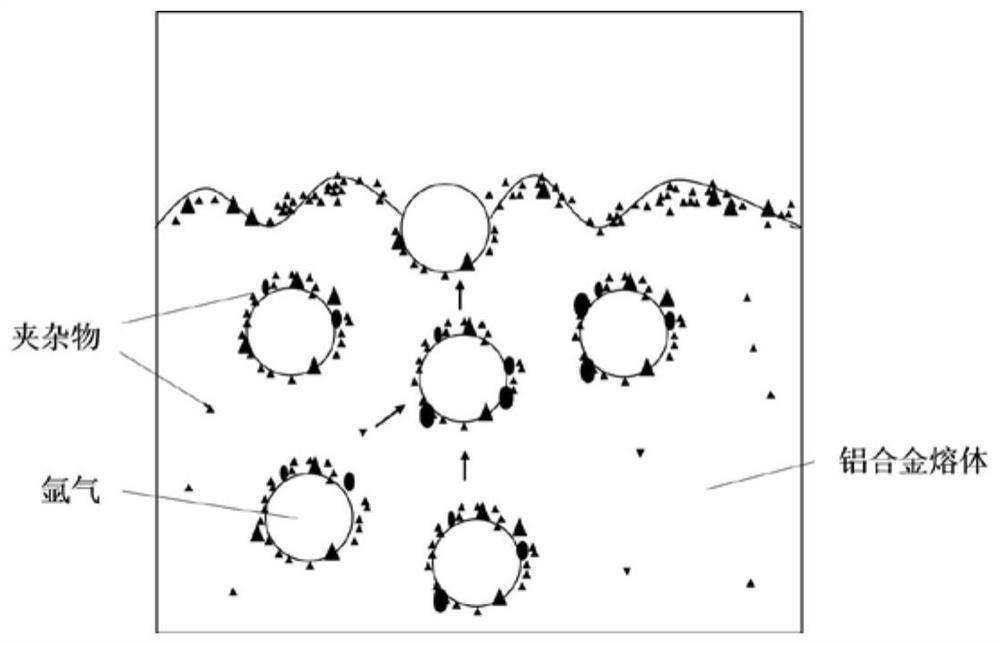

Green smelting method for recycled aluminum alloy

The invention relates to the technical field of recycled aluminum, and provides a green smelting method for recycled aluminum alloy. After aluminum secondary resources obtained after paint removal aresmelted and subjected to component adjustment, argon refining and argon degassing are adopted at a certain temperature, argon is introduced into a recycled aluminum alloy melt, inclusions and hydrogen are brought out of the melt, and a recycled aluminum alloy melt with high purity and low hydrogen content is obtained; the argon is fine and dispersed argon bubbles when introduced; the argon introduction mode is one or two of introduction from air-permeable bricks at the bottom of a smelting furnace and introduction from an air guide pipe; and the average size of the bubbles during argon introduction is 0.5-20.0 mm. According to the method, salt refining agents and nitrogen degassing agents are not used, the nitrogen burning loss is avoided, generated aluminum slag does not contain pollutants such as salt and aluminum nitride, and the obtained recycled aluminum melt is low in hydrogen and inclusions content. The quality of a recycled aluminum product is good, the method is simple and effective, and the application prospect is wide.

Owner:DELTA ALUMINUM IND

Preparation technology of CBN (cubic boron nitride) ceramic grinding wheel for wholly grinding end surface and outer circle of crank shaft flange

ActiveCN102059658BLower firing temperatureImprove flexural strengthAbrasion apparatusPolyvinyl alcoholNano al2o3

The invention relates to a preparation technology of a CBN (cubic boron nitride) ceramic grinding wheel for wholly grinding the end surface and the outer circle of a crank shaft flange, which comprises the following steps: mixing the following raw materials in parts: 15-20 parts of boric anhydride, 35-45 parts of lepidolite, 30-40 parts of soda feldspar and 5-10 parts of Na2CO3; firing at high temperature; carrying out ball milling on nano Al2O3 powder, nano mullite powder and the pre-molten ceramic powder according to a mass ratio of 2:2:6, and uniformly mixing to obtain a bonding agent; based on the volume percent, uniformly mixing 35% of low-temperature bonding agent, 5% of white alundum, 10% of Al2O3 hollow sphere and 50% of CBN, and prepressing into a sheet to obtain an end surface abrasive layer; based on the volume percent, uniformly mixing 35% of bonding agent, 8% of white alundum, 7% of Al2O3 hollow sphere and 50% of CBN, and prepressing into a sheet to obtain an outer circle abrasive layer; laminating the end surface abrasive layer sheet and the outer circle abrasive layer sheet, and adding the two sheets to an aqueous polyvinyl alcohol solution; and pressing into a fixed shape, and sintering in a high-temperature furnace. The bonding agent has low firing temperature, high folding strength and favorable abrasive binding property; the invention improves the abrasive wetting property of the bonding agent, improves the cutting efficiency of the abrasive, lowers the cost, enhances the abrasive coating capability and strength of the bonding agent and raises the sintering temperature of the bonding agent; and the strength of the CBN is not changed, and the surface is not subjected to burning loss.

Owner:沈阳中科超硬磨具磨削研究所

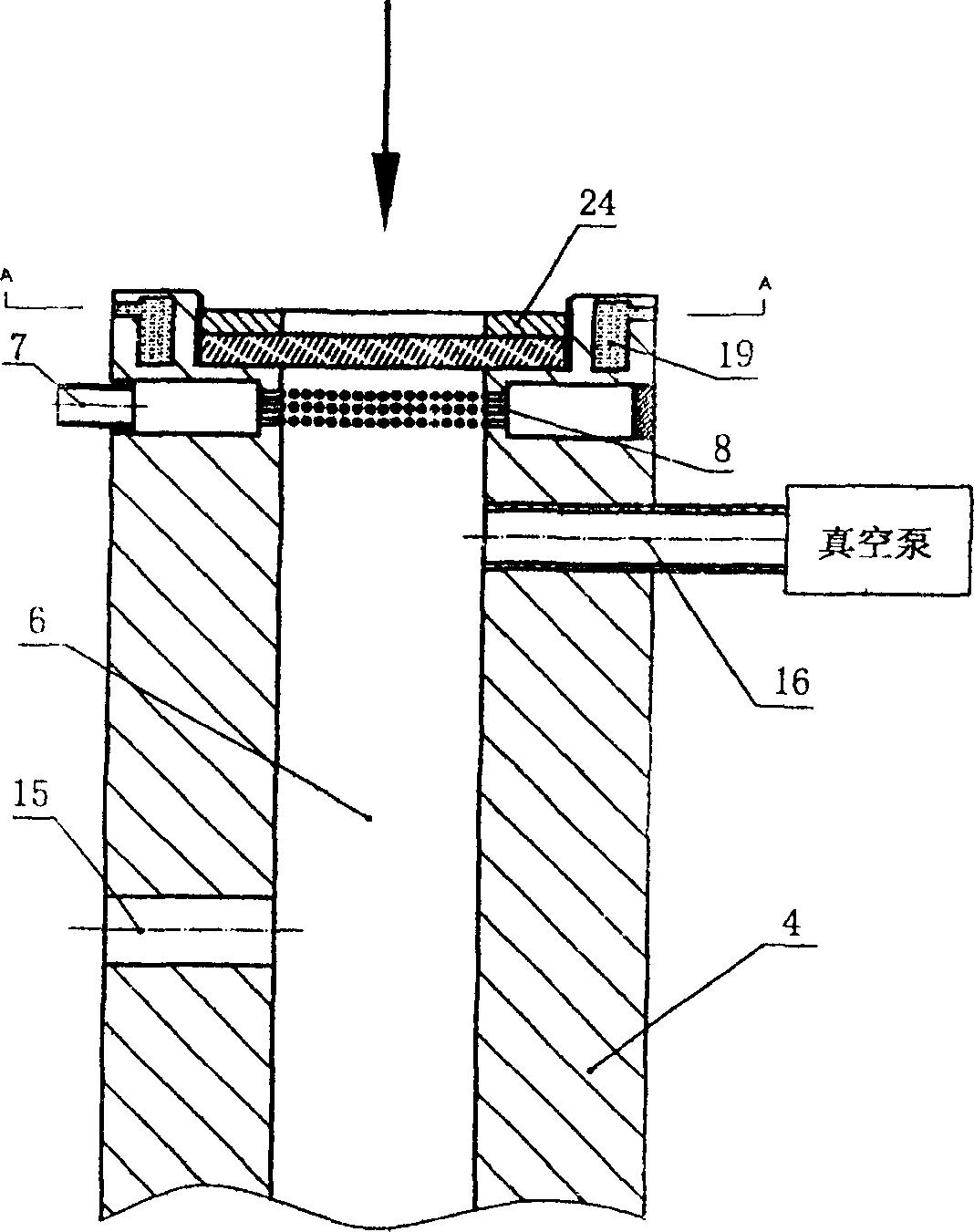

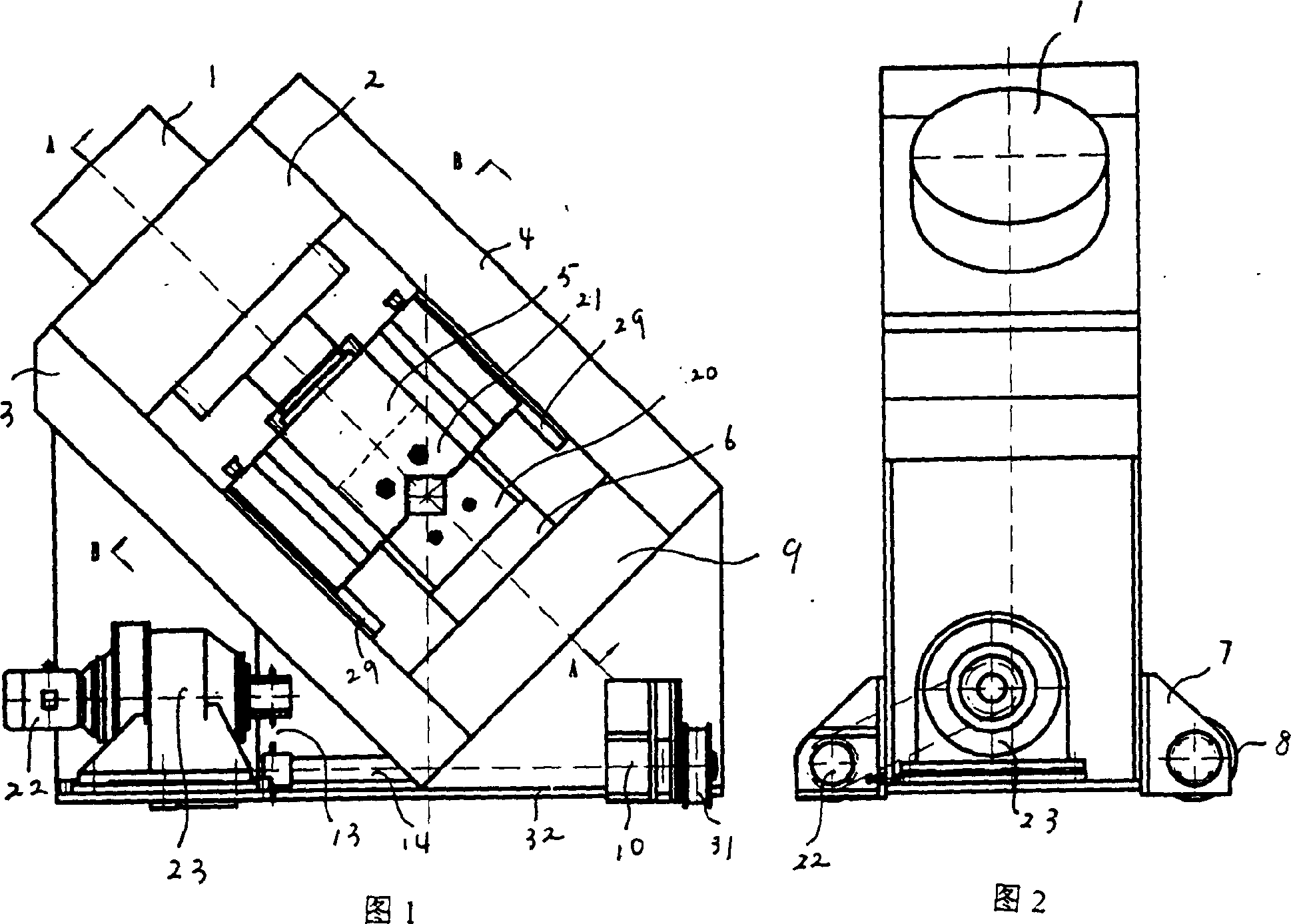

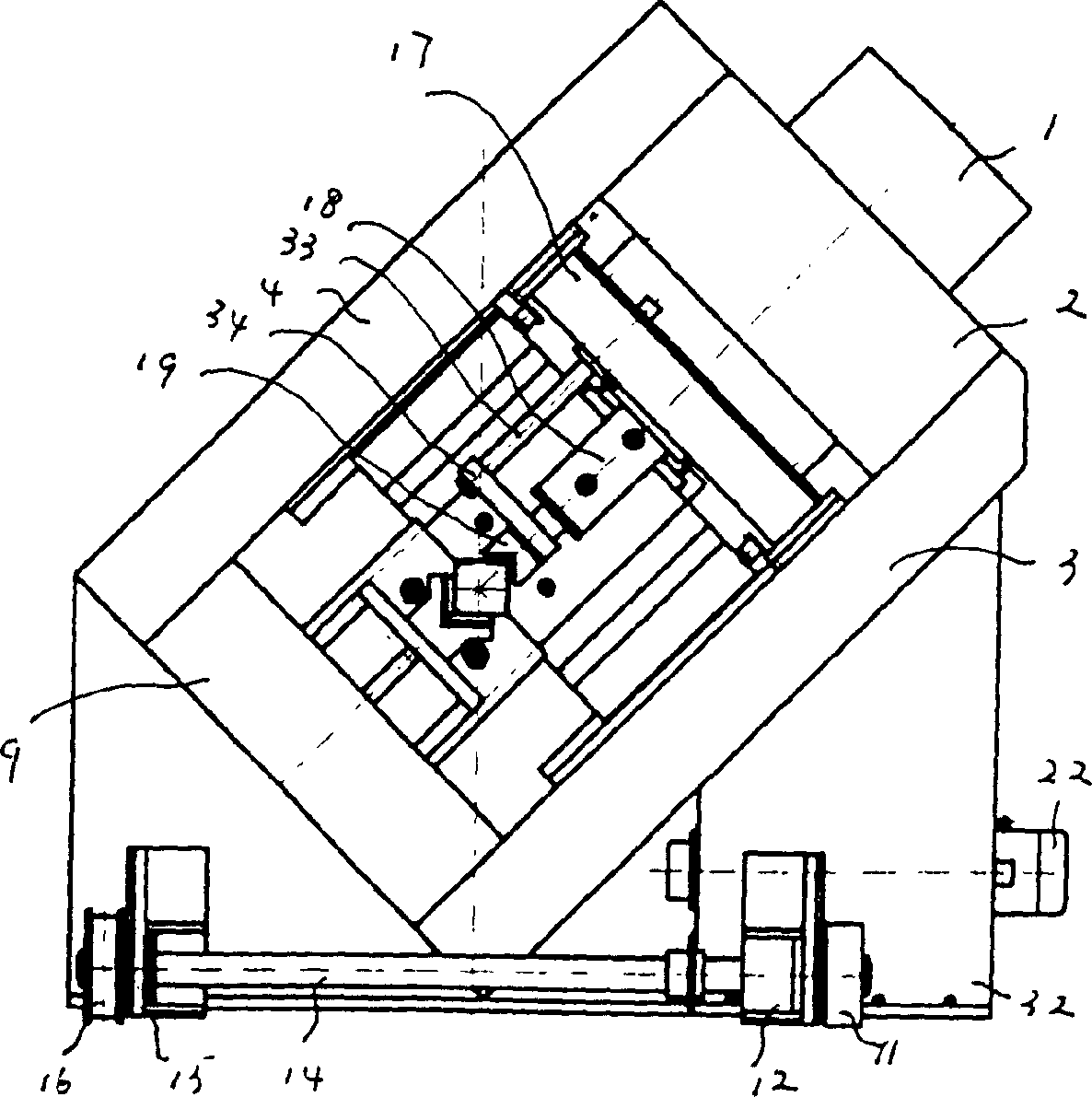

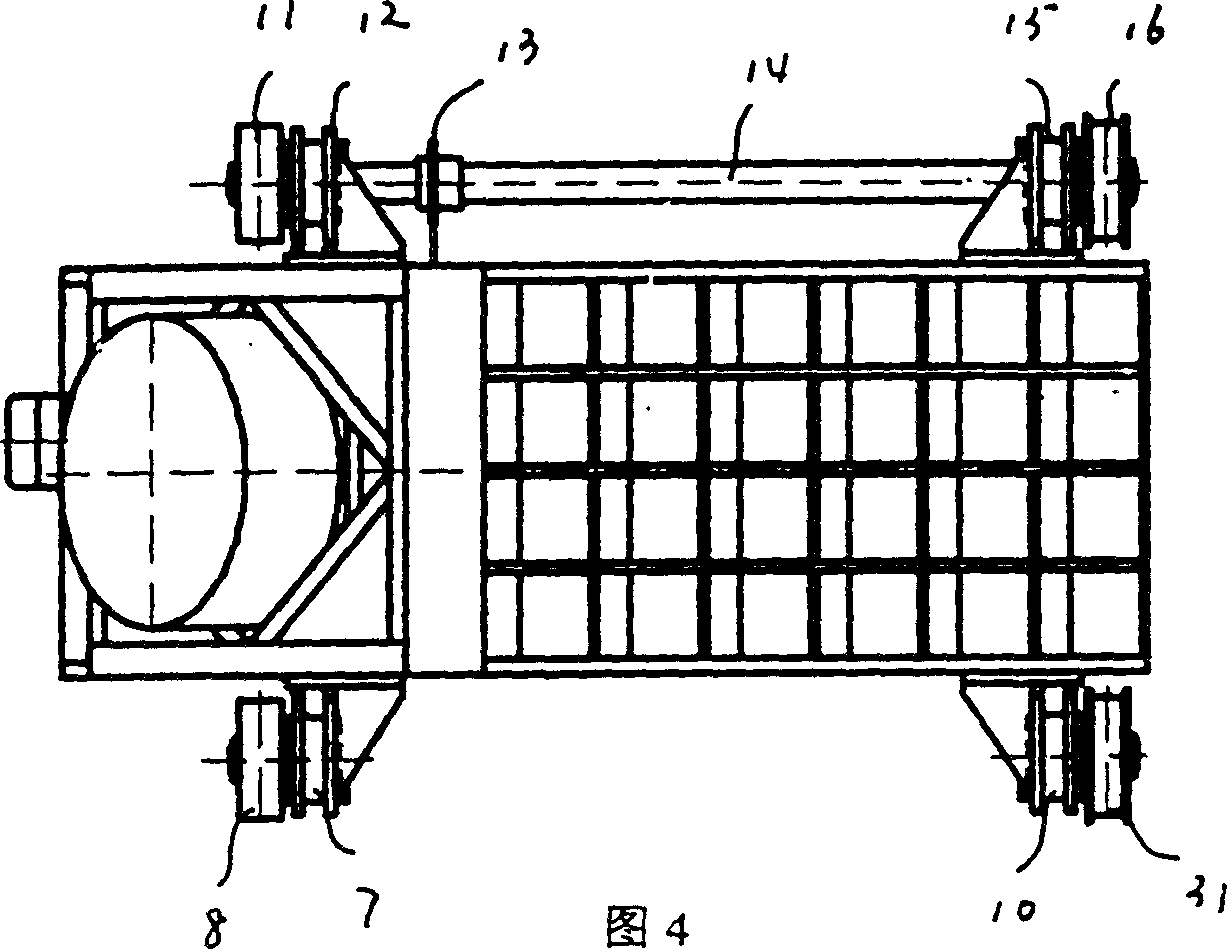

Full automatic on-line hydraulic bevel shearing machine for steel billet

InactiveCN1273252CNo burning lossReduce consumptionStock shearing machinesManufacturing lineHydraulic pressure

A full-automatic in-line hydraulic bevel shearing machine for bevel shearing of hot steel billet on conticasting production line is composed of base, machine frame arranged obliquely on the base and consisting of left and right frames and upper and lower beams, guide tracks on left and right frames, shearing unit consisting of upper and lower V-shaped shearing knives and their holders, press unit consisting of cylinder and its supporter, pressing head and guide rod, and walking unit on said base.

Owner:JIANGSU HUAHONG TECH STOCK

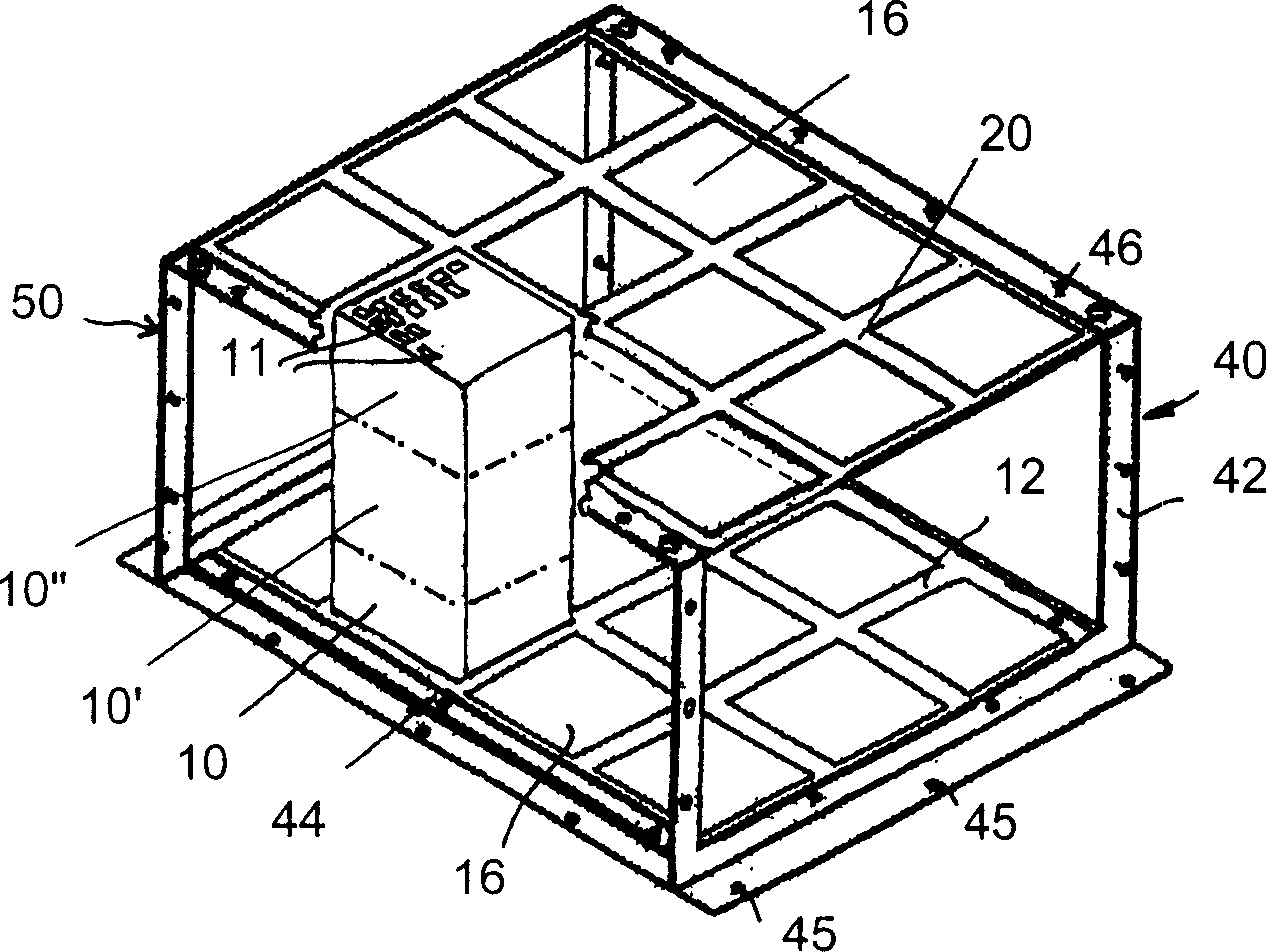

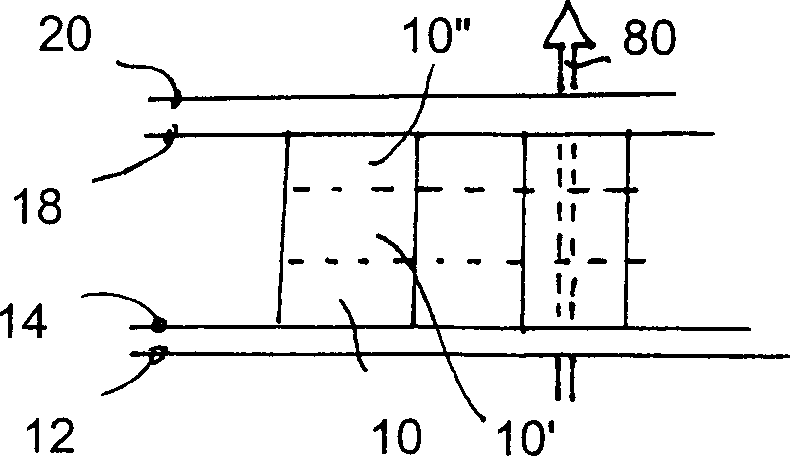

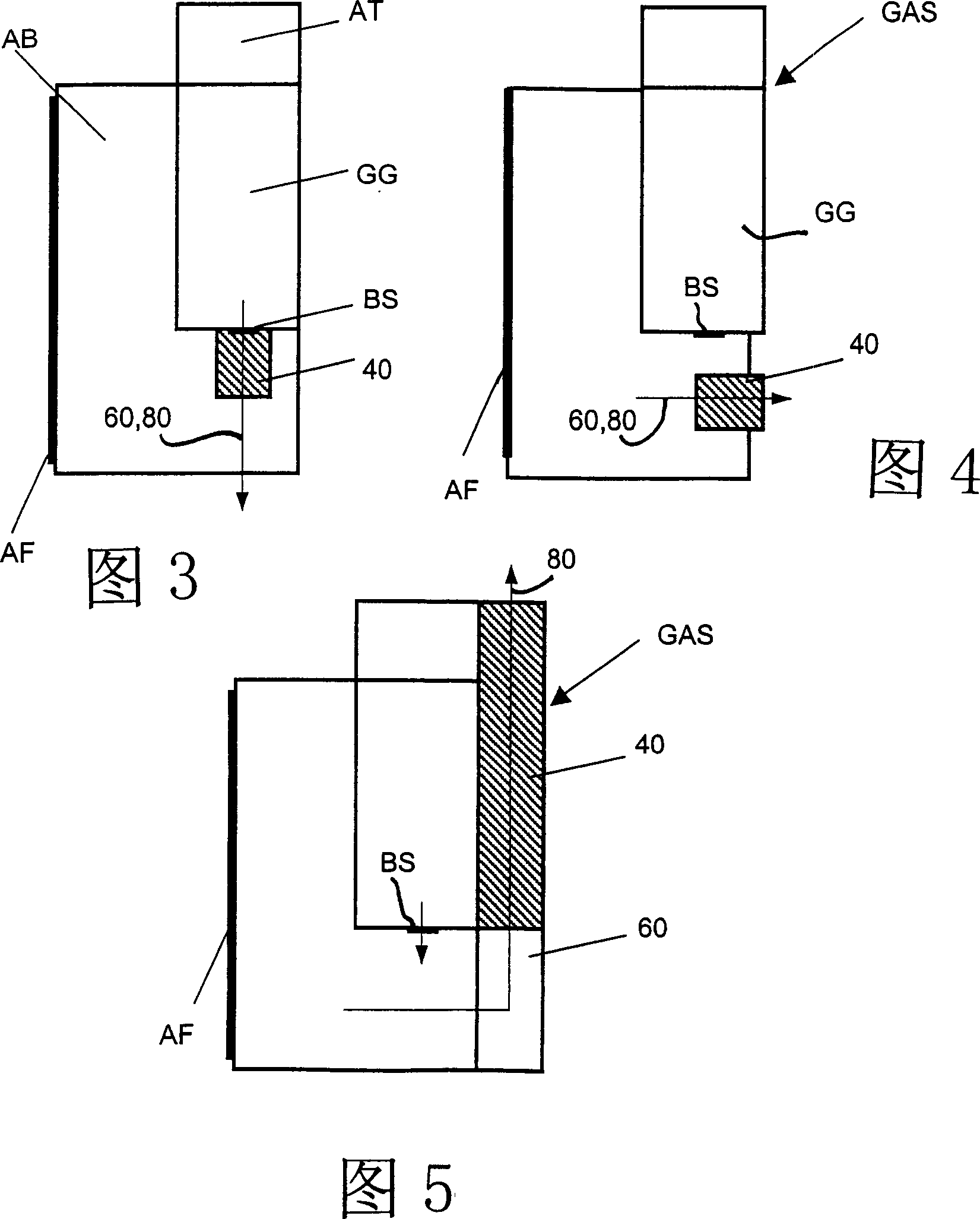

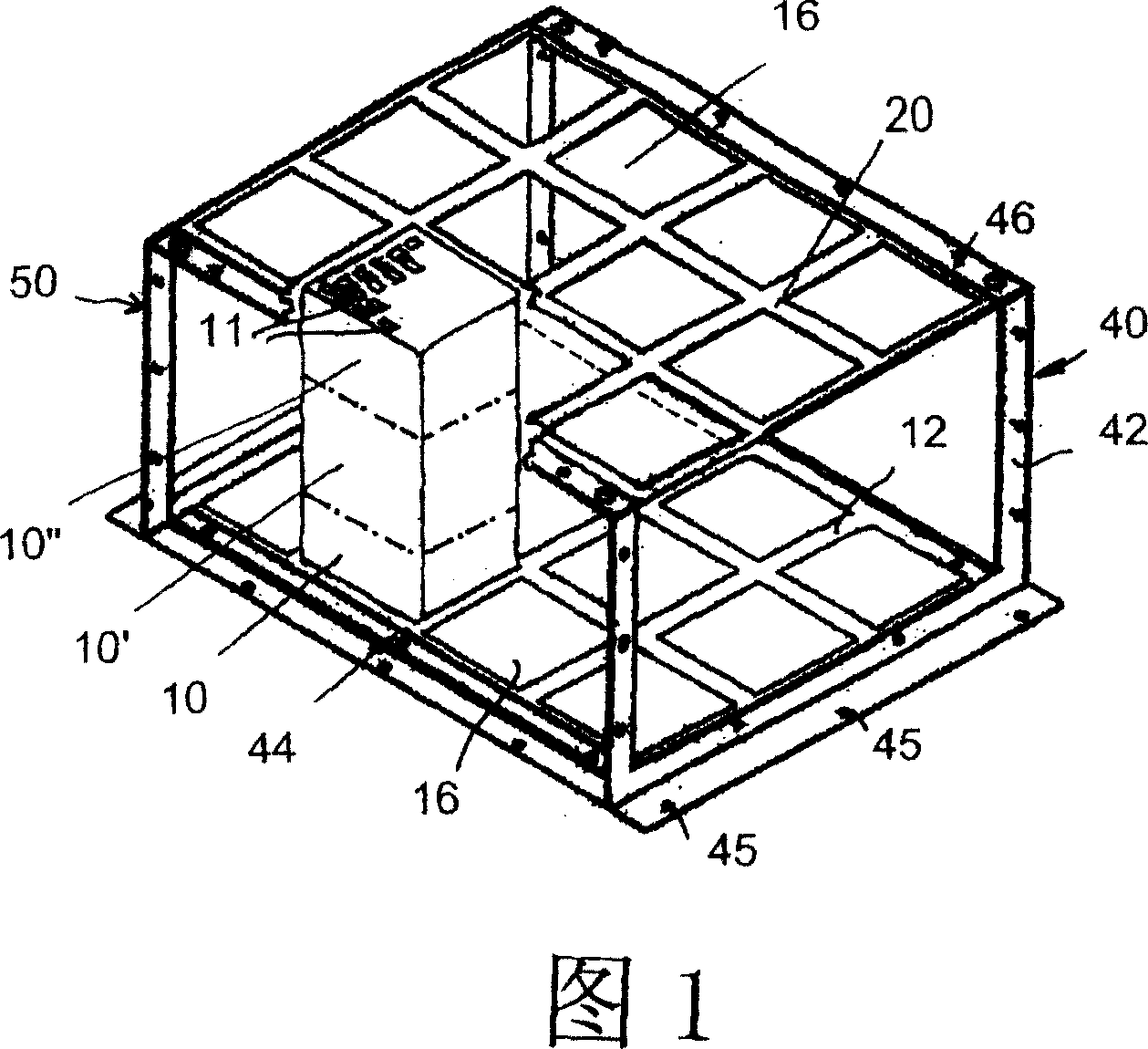

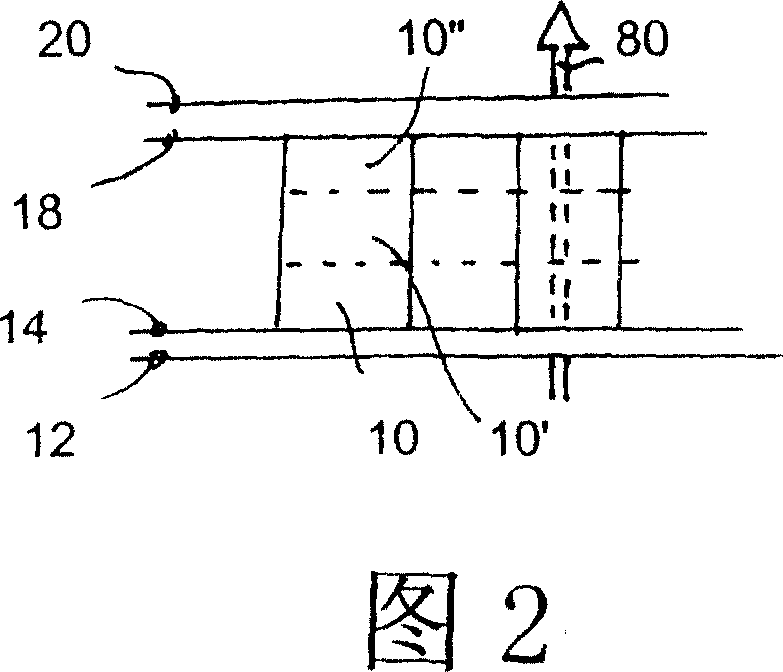

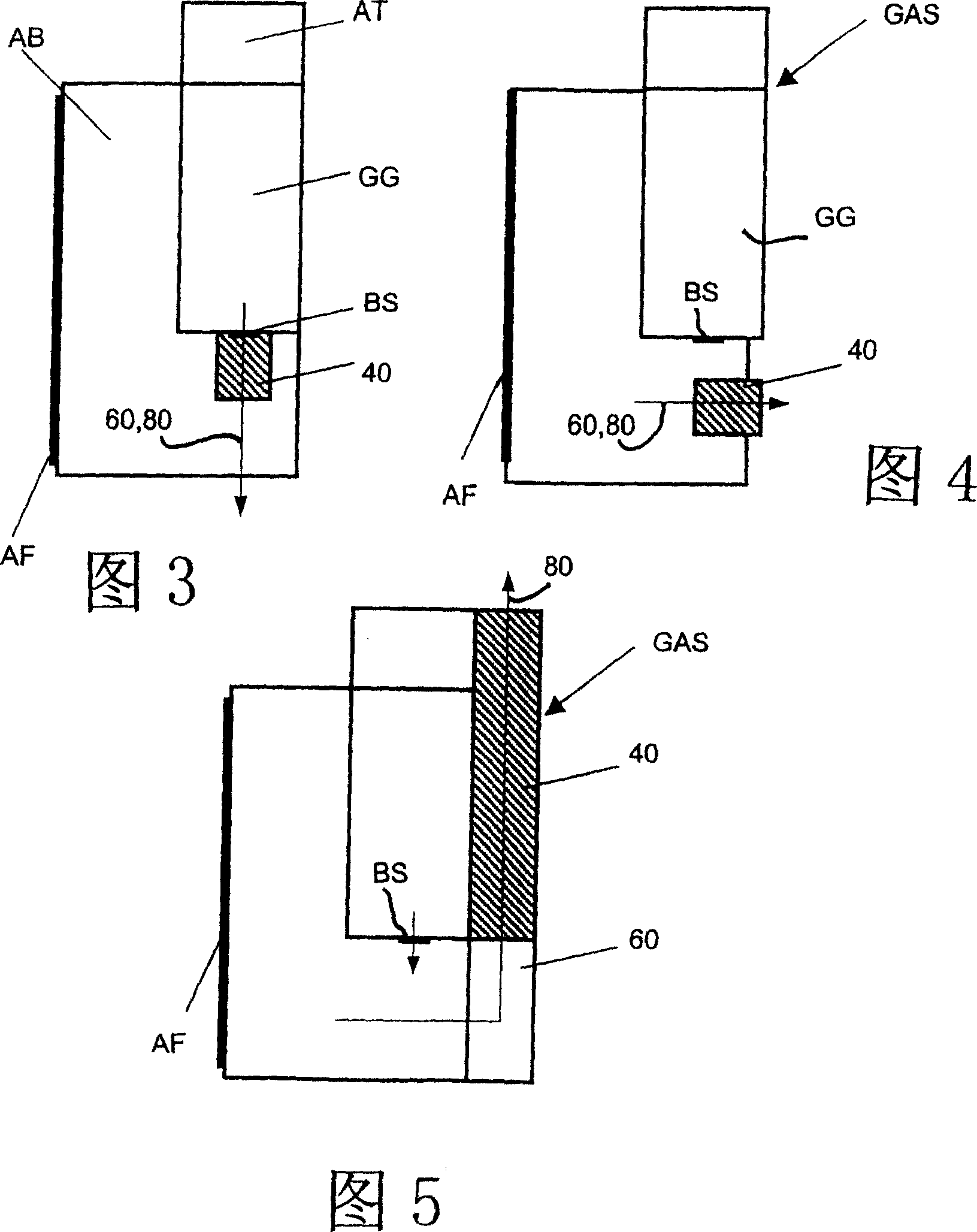

Construction unit for accepting absorbers

InactiveCN1525511AHigh heat exchange stabilityLarge shape latchSwitchgear arrangementsHigh-tension/heavy-dress switchesEngineeringHigh pressure

The module has the hot gas directed to at least one flow path containing at least one monolithic ceramic absorber element (10,10',10'') packed into a flow chamber (40) for the hot gas and provided with channels (11) for passage of the hot gas having a cross-section of between 2 and 10 mm and extending in the main flow direction.

Owner:ORMAZABAL ANLAGENTECHN

Cubic boron nitride (CBN) ceramic high speed grinding wheel and preparation method and application

The invention discloses a cubic boron nitride (CBN) ceramic high speed grinding wheel which comprises a steel substrate and a working abrasive layer. The working abrasive layer comprises an abrasive layer and a middle transition layer. The abrasive layer comprises the following materials: low temperature binding agent, white corundum, ceramic floating bead and CBN. The middle transition layer comprises the following materials: low temperature binding agent and 150-mesh ceramic balls. The low temperature binding agent includes the following materials by volume: 8-12 parts of nanoscale aluminum oxide, 8-12 parts of nanoscale silica and 75-85 parts of premelting ceramic powder. The premelting ceramic powder includes the following materials by volume: 25-35 parts of aluminum oxide, 27-37 parts of silica, 4.5-5.5 parts of sodium oxide, 1.5-2.5 parts of potassium oxide, 1.5-2.5 parts of magnesium oxide, 0.8 part to 1.2 parts of calcium oxide and 5-11 parts of diboron trioxide. The CBN ceramic high speed grinding wheel has the advantages that firing temperature of the ceramic binding agent is 750 DEG C, rupture strength can reach 115MPa, and the CBN strength is basically not lost under the temperature, so that cutting performance of the CBN grinding wheel is greatly improved. A preparation method and the application of the CBN ceramic high speed grinding wheel are further provided.

Owner:沈阳中科超硬磨具磨削研究所

A large-size high-niobium high-temperature 706 alloy ingot and its smelting process

ActiveCN111876651BNo burning lossImproved melt stabilityIncreasing energy efficiencySmelting processNiobium

The invention discloses a large-size high-niobium high-temperature 706 alloy ingot and its smelting process, which are used to solve the problem of serious burning loss of Al and Ti elements in the existing smelting process and the high-niobium high-temperature 706 alloy ingot easily produced Metallurgical defects of black and white spots. The smelting process includes: vacuum induction smelting, making multiple vacuum induction ingots with the same composition, and then making the same number of electroslag electrodes, using (CaF 2 ‑CaO‑Al 2 o 3 ‑TiO 2 ) quaternary slag, exchange electroslag remelting, and then use the obtained electroslag ingot to make a consumable electrode, and then use the consumable electrode as the starting material to carry out two vacuum consumable remelting. This process can realize the preparation of large-size ingots of high-niobium high-temperature 706 alloys with an ingot weight of more than 15 tons and a diameter of more than 800mm, which can minimize the formation of black spots and white spots and reduce the burning rate of Al and Ti elements.

Owner:BEIJING CISRI GAONA TECH +1

A green smelting method for recycled aluminum alloy

The invention relates to the technical field of recycled aluminum, and provides a green smelting method for recycled aluminum alloy. After aluminum secondary resources obtained after paint removal aresmelted and subjected to component adjustment, argon refining and argon degassing are adopted at a certain temperature, argon is introduced into a recycled aluminum alloy melt, inclusions and hydrogen are brought out of the melt, and a recycled aluminum alloy melt with high purity and low hydrogen content is obtained; the argon is fine and dispersed argon bubbles when introduced; the argon introduction mode is one or two of introduction from air-permeable bricks at the bottom of a smelting furnace and introduction from an air guide pipe; and the average size of the bubbles during argon introduction is 0.5-20.0 mm. According to the method, salt refining agents and nitrogen degassing agents are not used, the nitrogen burning loss is avoided, generated aluminum slag does not contain pollutants such as salt and aluminum nitride, and the obtained recycled aluminum melt is low in hydrogen and inclusions content. The quality of a recycled aluminum product is good, the method is simple and effective, and the application prospect is wide.

Owner:DELTA ALUMINUM IND

Technology for producing CBN (Cubic Boron Nitride) high-speed ceramics grinding wheel

ActiveCN102009392BLower firing temperatureImprove flexural strengthAbrasion apparatusGrinding devicesMulliteBoron nitride

The invention discloses a technology for producing a CBN (Cubic Boron Nitride) high-speed ceramics grinding wheel, comprising the following steps of: mixing following raw materials in part by weight: 15 to 20 parts of boron anhydrous, 35 to 45 parts of lepidolite, 30 to 40 parts of albite and 5 to 10 parts of Na2CO3; firing at a high temperature; carrying out the ball milling and uniform mixing on nanometer AL2O3 powder, nanometer mullite powder, pre-melted ceramics powder according to the mass ratio of 2:3:5 to obtain the product of binding agent, wherein a grinding material layer comprises 35% of binding agent, 8% of white corundum, 7% of alumina hollow ball and 50% of CNB, an intermediate layer comprises 35% of binding agent and 65% of ceramics balls of 150 meshes; after equably mixing the materials, adding a polyethylene water solution; pressing into a fixed shape; and firing in a high temperature furnace after drying. The technology for preparing the CBN high speed ceramics grinding wheel has the advantages that the binding agent has low firing temperature and strong rupture strength and can bind the grinding material well and wet the grinding material better, the cutting efficiency of abrasive particles is improved, the cutting cost of abrasive particles is reduced, the packaging capacity of the binding agent to the grinding material, the intensity and the sintering temperature are increased, the CNB intensity is not changed and the surface of the CNB is not burnt.

Owner:沈阳中科超硬磨具磨削研究所

A manufacturing process of internalized storage battery

ActiveCN103268963BNo burning lossReliable weldingFinal product manufactureCell component detailsDip solderingAlloy

The invention discloses a production process of an inner formation storage battery, and belongs to the field of a lead-acid storage battery, and solves the easily occurring welding quality problem of a bus-bar and a lug. The process comprises the following steps of loading a plate group into an assembling box, arranging a lug, cutting and brushing the lug, dipping soldering flux, cast welding, inspecting and qualification and down-conversion, wherein the cast welding flow is carried out by adopting a cast welding machine. The cast welding flow comprises the following steps of (1) heating a lead pot; (2) loading a mold and preheating the mold; (3) scraping the lead liquid; (4) cast welding the plate group; (5) cooling the plate group through water; (6) cooling the plate group collectively through water and air; (7) cooling the plate group through the air; (8) loading the mold and preheating the mold again; and (9) loading the plate group into a tank. The production process is suitable for the cast welding of the inner formation storage battery with positive grid alloy being lead calcium tin aluminum or lead calcium alloy series grid.

Owner:CHAOWEI POWER CO LTD

High-strength, high-ductility rare earth aluminum alloy material and method of producing the same

The invention relates to a rare earth aluminium alloy material with high strength and high toughness and the preparation method thereof, belonging to the technical field of metal alloy and the preparation thereof. The invention is characterized in that the invention comprises Mg, Si, Fe, a rare earth compound additive and Al, with the weight percentages as follows: Mg: 0.50-0.60%; Si: 0.35-0.45%;Fe less than or equal to 0.35%; rare earth additive less than or equal to 0.065-0.2%; the margin being Al. The preparation method comprises charging and melting down the 6063 aluminum alloy furnace materials in accordance with the conventional methods, adjusting the furnace temperature, deairing, refining and purifying the melt and then adding Al-RE, Al-Sr and Al-Zr master alloys at the temperature between 720 DEG C and 760 DEG C and preserving heat for 30min-7h, then carrying out homogenization treatment on electromagnetic stirring components and detection, pouring and casting, finally carrying out homogenization treatment and subsequent quick cooling treatment, rapid heating before extrusion, extrusion and on-line quenching treatment as well as artificial aging treatment. The product section obtained from the invention has rapid extrusion and high mechanical property of the section and can improve the apparent mass of the section and increase the modification of oxide film density.

Owner:BAOTOU JI TAI RARE EARTH ALUMINUM CO LTD +1

A kind of temperature control method lead-acid storage battery manufacturing process

The invention discloses a technology for producing lead-acid storage batteries through temperature control method, belongs to the field of lead-acid storage battery production and solves the problem of the poor battery welding quality of a cast-welding technology through a time control method. The method comprises the processes of feeding of plate packs in an assembly box, electrode tab arranging, cutting and brushing of electrode tabs, dipping of flux, cast-welding, inspection and discharging after qualification. The cast-welding process is completed through a cast-welding machine and comprises the following steps: 1) heating of a lead pan; 2) preheating of a lower die; 3) scrapping of molten lead; 4) electrode tab cast-welding; 5) die removal; and 6) secondary preheating of the lower die. The technology is used for manufacturing lead-acid storage batteries.

Owner:CHAOWEI POWER CO LTD

Construction unit for accepting absorbers

InactiveCN1317726CHigh heat exchange stabilityLarge shape latchSwitchgear arrangementsHigh-tension/heavy-dress switchesHigh pressureMechanical engineering

The module has the hot gas directed to at least one flow path containing at least one monolithic ceramic absorber element (10,10',10'') packed into a flow chamber (40) for the hot gas and provided with channels (11) for passage of the hot gas having a cross-section of between 2 and 10 mm and extending in the main flow direction.

Owner:ORMAZABAL ANLAGENTECHN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com