Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

106results about How to "Overcome the cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

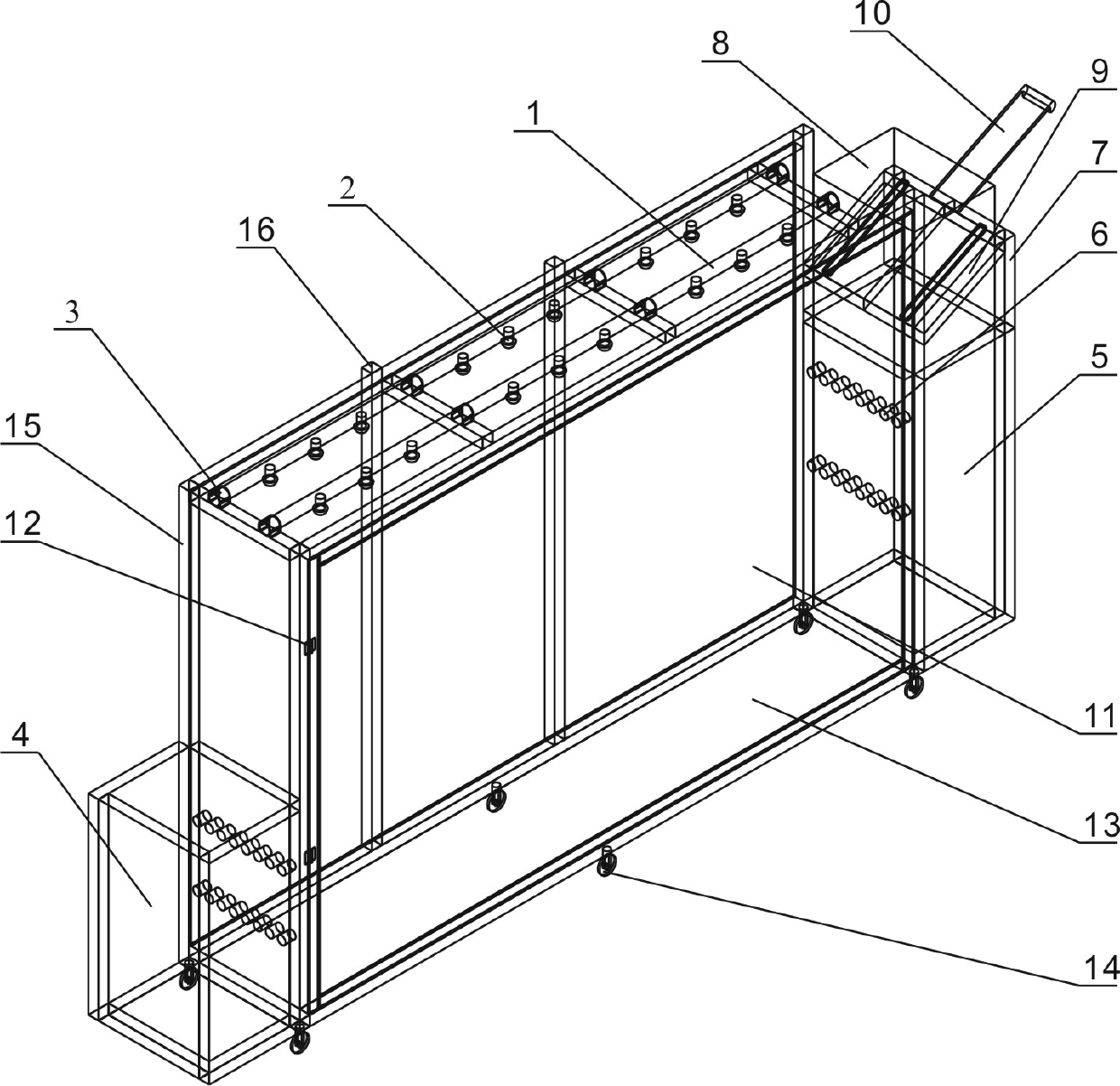

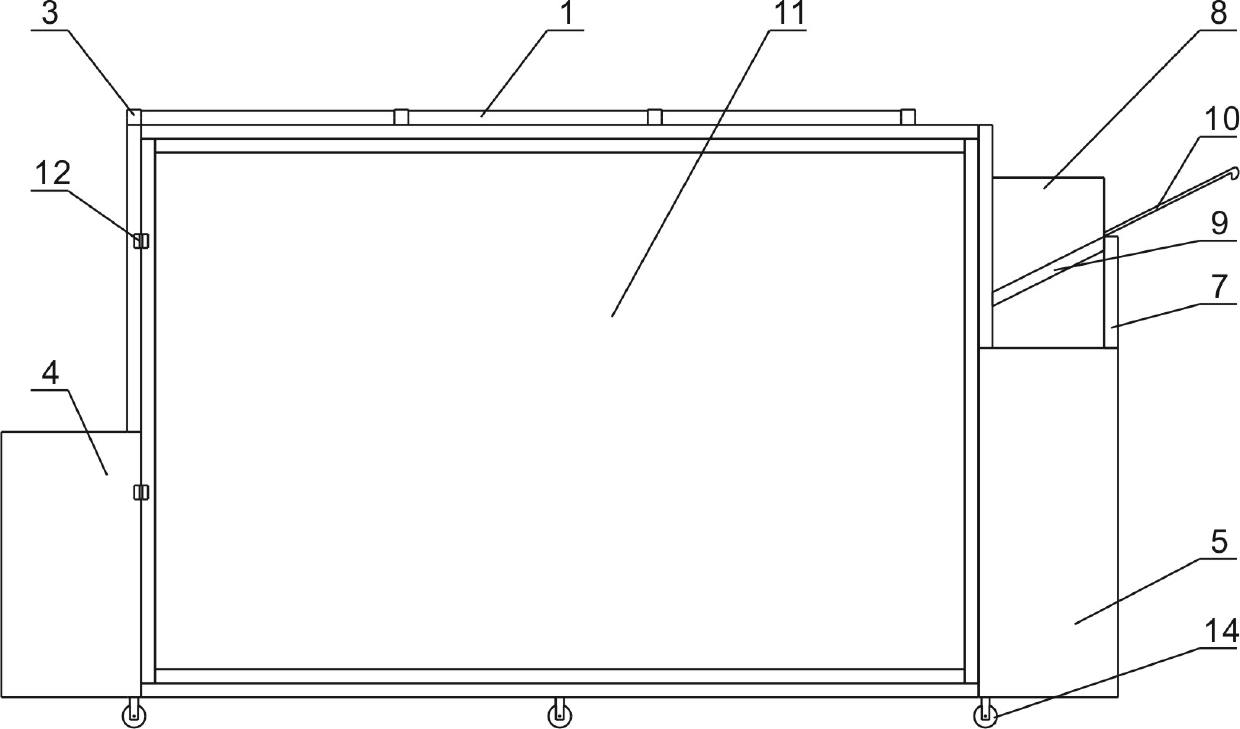

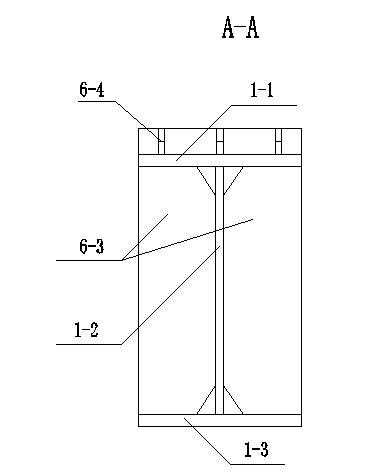

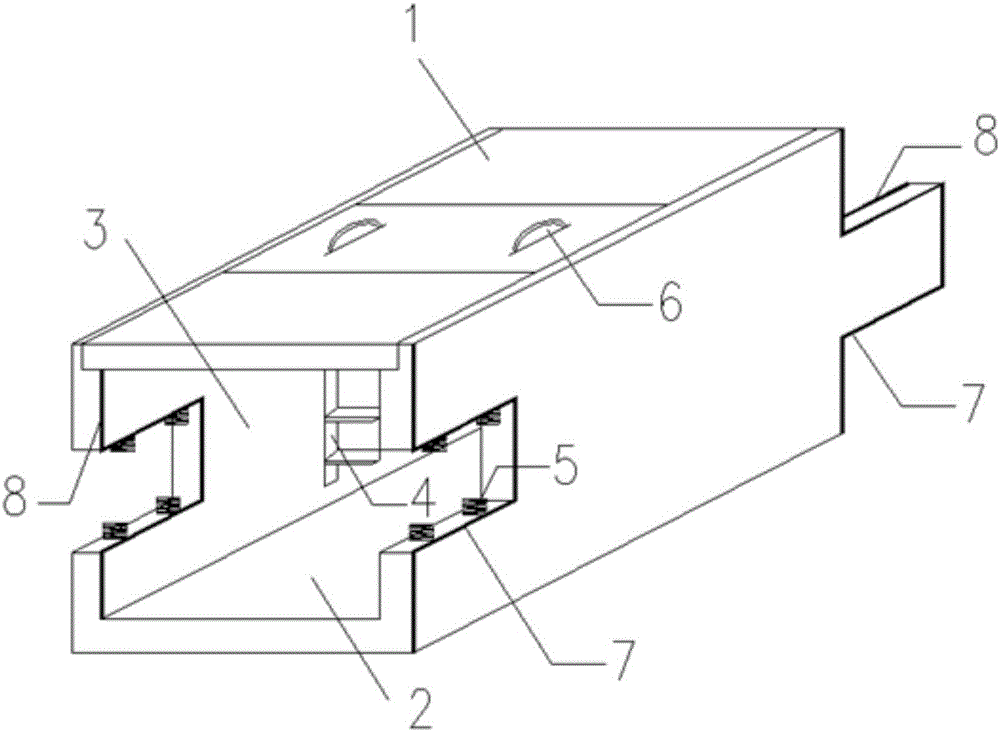

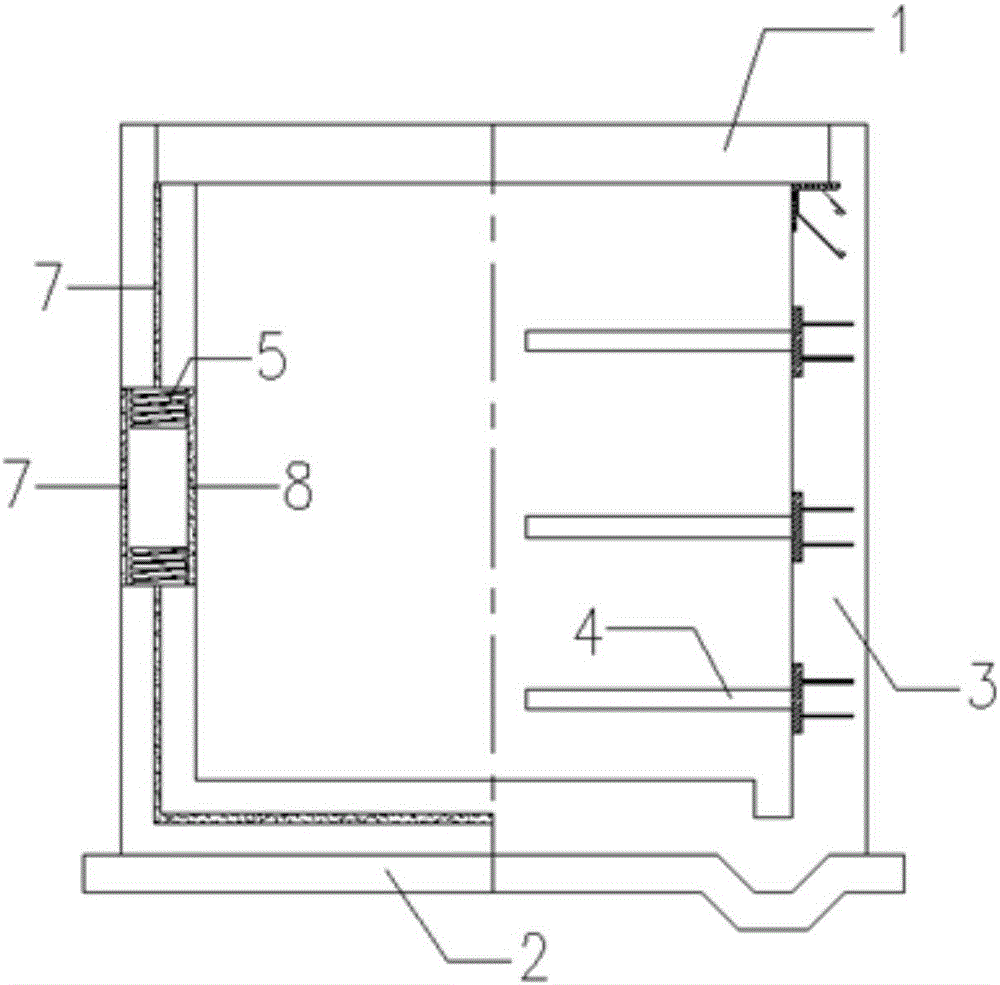

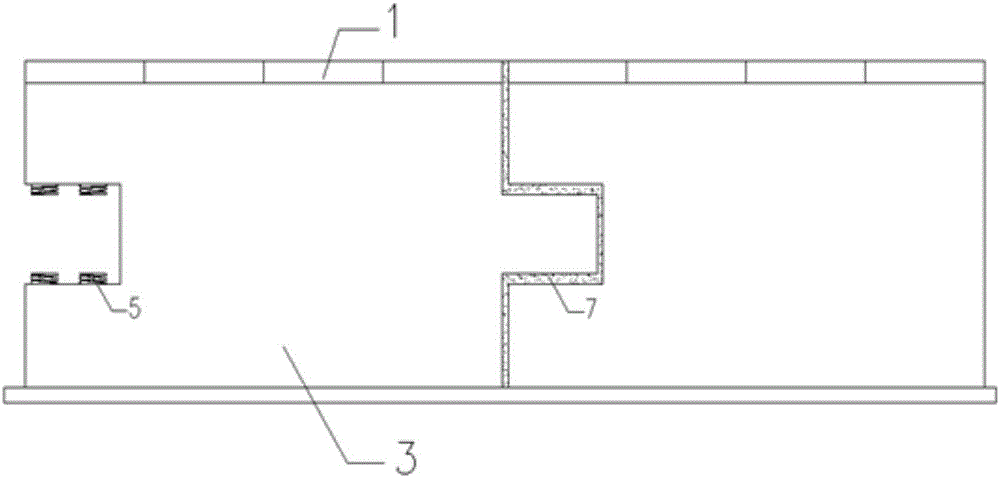

Multi-operating mode frame type portable landslide testing device for geomechanical model

ActiveCN102681028AReduce sizeOvercome the cycleEarth material testingGeological measurementsLandslideEngineering

A multi-operating mode frame type portable landslide testing device for a geomechanical model belongs to the field of geological hazard model test. The testing device comprises a frame-beam-type testing bed, a rainfall simulator, a water level regulator and a self-weight horizontal loading mechanism, wherein the frame-beam-type testing bed mainly comprises a cuboid framework, a front panel, a rear panel and a base plate; the rainfall simulator is arranged at the top of the frame-beam-type testing bed and comprises a plurality of spraying pipes and nozzles on the spraying pipes and is used for simulating rainfall in the frame-beam-type testing bed; the water level regulator comprises a left-side trough and a right-side trough respectively formed on the left and the right sides of the frame-beam-type testing bed, and a plurality of drainage holes are respectively formed on the right panel of the left-side trough and the left panel of the right-side trough and used for changing the water levels of water level simulation libraries in the left-side trough and the right-side trough; and the self-weight horizontal loading mechanism is arranged above the right-side trough and used for bearing weights, so as to exert horizontal load to the landslide model in the frame-beam-type testing bed.

Owner:中部知光技术转移有限公司

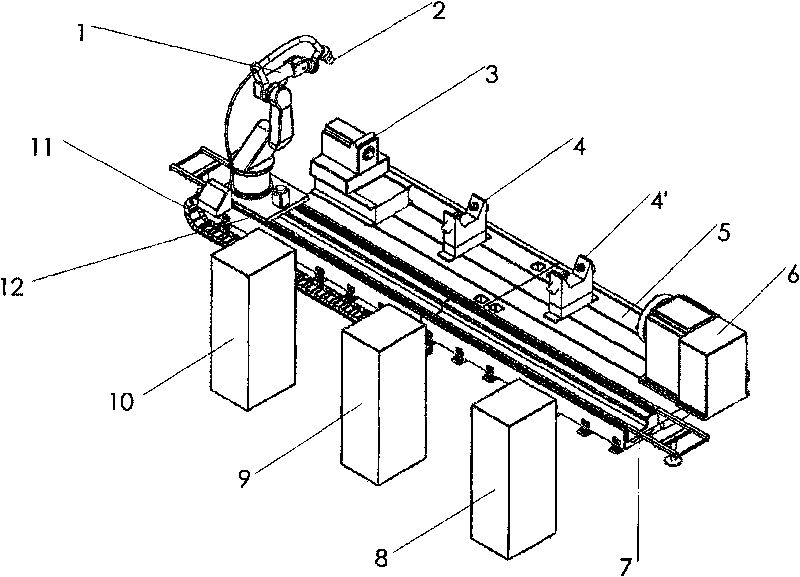

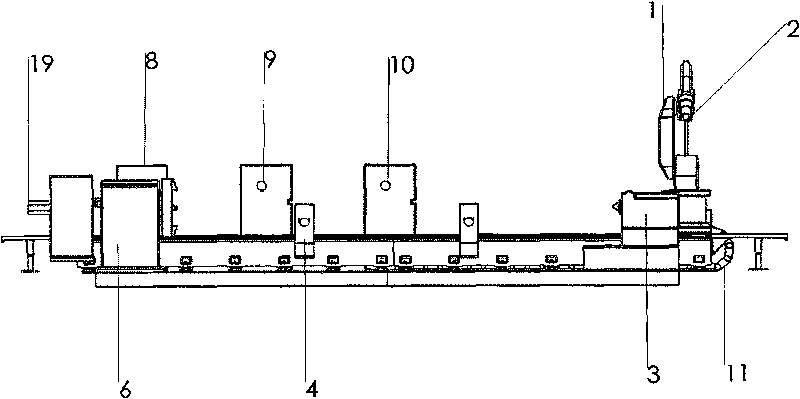

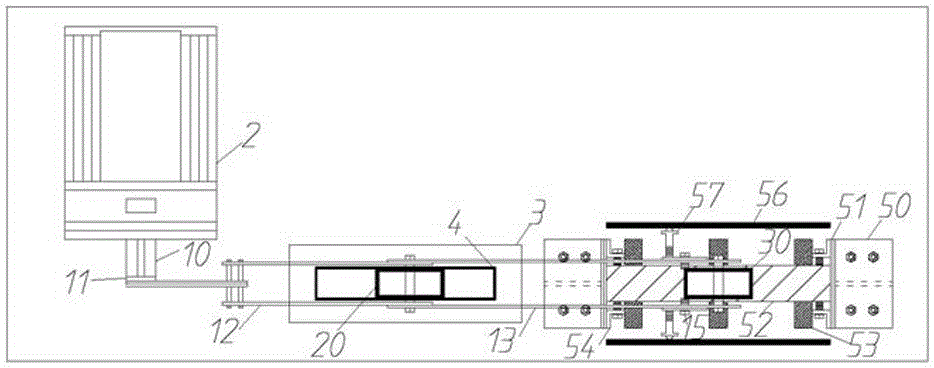

Multi-axis linkage numerical control laser processing system

InactiveCN101690993AOvercoming complexityDifficult to overcome controlLaser beam welding apparatusNumerical controlLaser processing

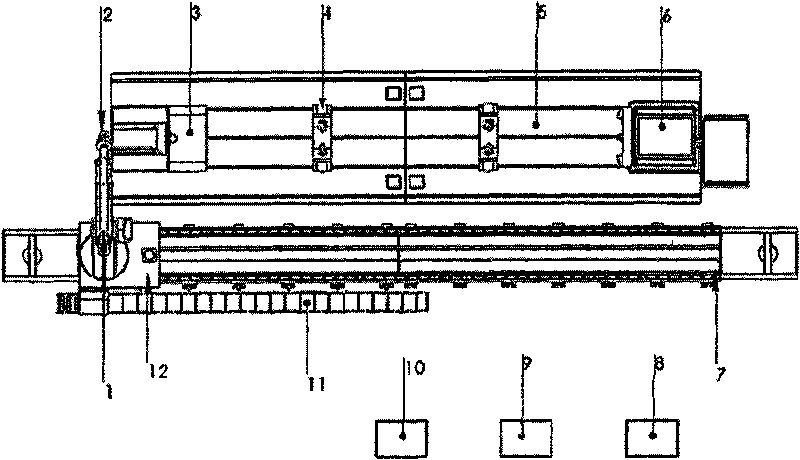

The invention provides a multi-axis linkage numerical control laser processing system, which is structurally characterized in that a workbench is provided with a linear guide rail, two ends of the guide rail are provided with a workbench tail seat and a headstock respectively, and two open center brackets are movably arranged on the guide rail and are positioned between the workbench tail seat and the headstock; a guide rail stand is arranged beside the workbench, the guide rail stand is provided with another parallel guide rail, and a movable sliding stand is movably arranged on the guide rail; a robot is fixed on the movable sliding stand, and a laser processing head is arranged at the tail end of a last joint of the robot; and a controller is connected with the robot and the movable sliding stand through control wires respectively so as to control the robot and control the movable sliding stand to drive the robot to move on the guide rail stand. The system solves the problem that a joint robot laser processing system has a small processing range, and can meet the numerical control laser processing requirements of parts of large size and super-large size.

Owner:HUAZHONG UNIV OF SCI & TECH

Integrated flue gas treatment device and method

ActiveCN104857835ARealize resource utilizationReduce wateringCombination devicesMagnesium nitratesLiquid wasteReaction layer

The invention discloses an integrated flue gas treatment device and method. The device comprises flue gas treatment equipment, ozone supply equipment, hydrogen peroxide supply equipment, evaporation and concentration equipment, cyclic sedimentation equipment and the like, wherein the flue gas treatment equipment comprises an ozone spray oxidation reaction layer, a hydrogen peroxide spray oxidation reaction layer, an absorber spray area, a slurry circulation area and a dust and mist removal area; both the ozone spray oxidation reaction layer and the hydrogen peroxide spray oxidation reaction layer are arranged in the absorber spray area; the dust and mist removal area is positioned above the absorber spray area; both the evaporation and concentration equipment and the cyclic sedimentation equipment are arranged in the flue gas treatment equipment. The device and the method disclosed by the invention are suitable for comprehensive treatment of flue gas containing SO2, NOX, Hg and dust and resource utilization of liquid waste in coal fired boilers, iron and steel sintering machines, pellets, industry kiln stoves and the like.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

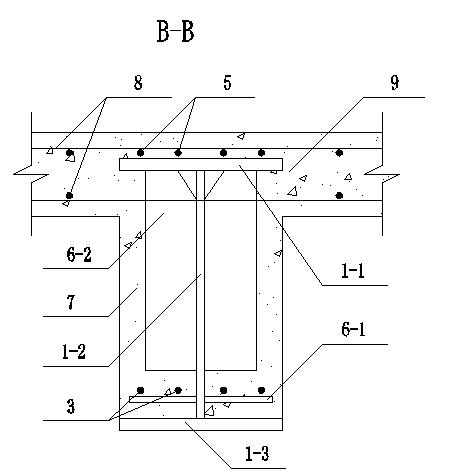

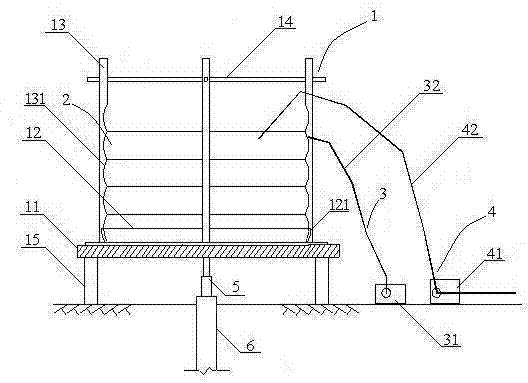

Bailey beam suspension formwork supporting system and construction method thereof

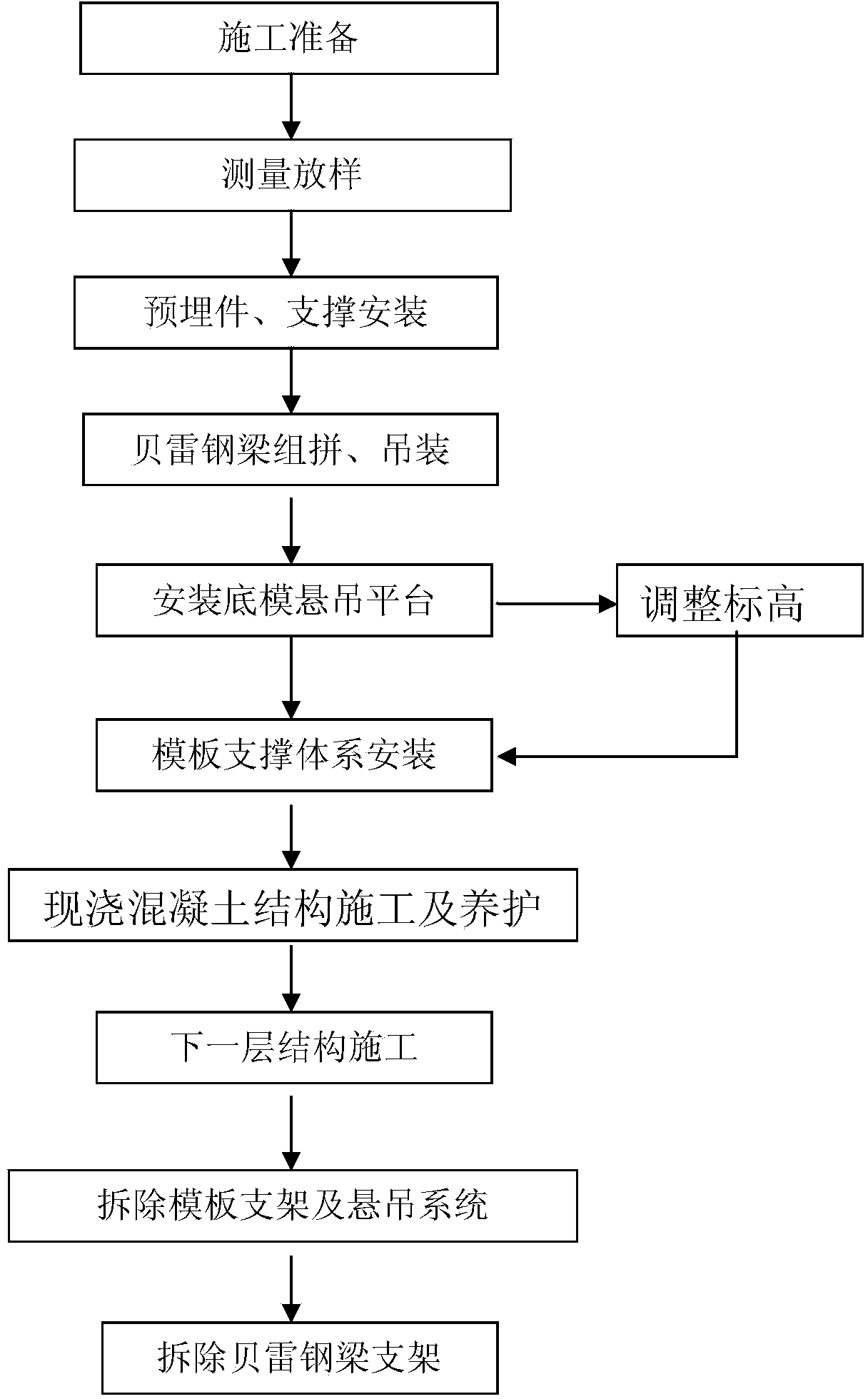

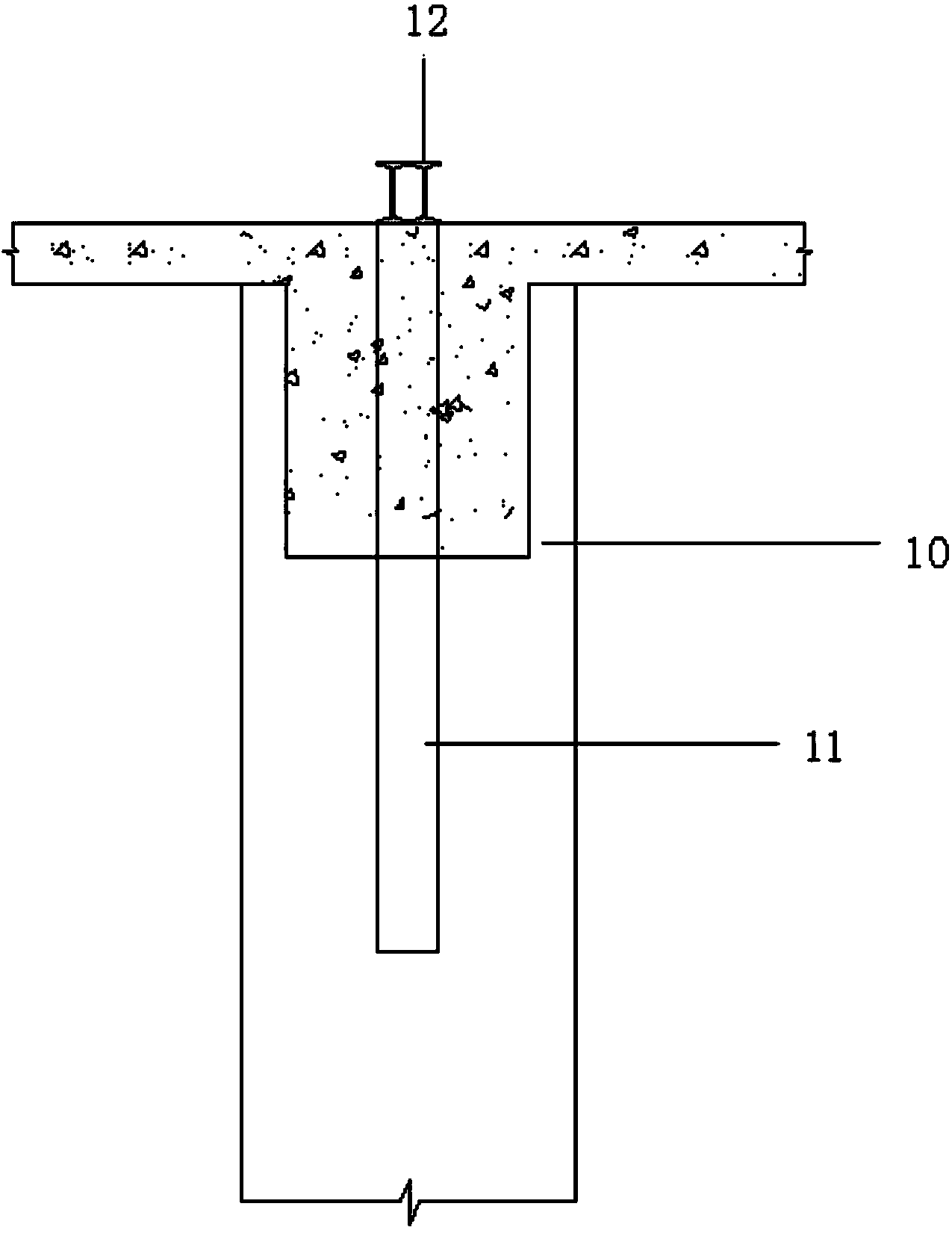

ActiveCN104141383ASimple structureEasy to transportForms/shuttering/falseworksBuilding material handlingFalseworkSupporting system

The invention discloses a bailey beam suspension formwork supporting system and a construction method thereof. The bailey beam suspension formwork supporting system comprises longitudinal and transverse stress trusses (2) consisting of bailey beams (1); suspenders (5) are arranged on transverse bailey beams (3) and the suspenders penetrate through a concrete layer structure bottom formwork (6) for suspending a bidirectional I-shaped steel load-bearing platform (7); a steel pipe scaffolding formwork supporting system (8) is arranged above the platform, the transverse bailey beams are perpendicularly arranged above the longitudinal bailey beams (9) according to spacing, and the longitudinal bailey beams (9) are supported on a framework structure or temporary supports (10). The construction method of the bailey beam suspension formwork supporting system comprises the following steps: erecting a bailey beam formwork supporting system suspension system at the upper part of an additionally constructed layer in advance, and laying a formwork support operating platform below. The bailey beam suspension formwork supporting system and the construction method thereof have the advantages that the construction site is not occupied, the system and the method are suitable for cast-in-situ concrete construction of aerial connecting corridors, high and large muntin and transfer layer engineering of reinforced concrete or section steel combined structures, are particularly suitable for additionally constructed engineering which does not have a stress relationship with original structures, and have unique advantages.

Owner:北京万兴建筑集团有限公司

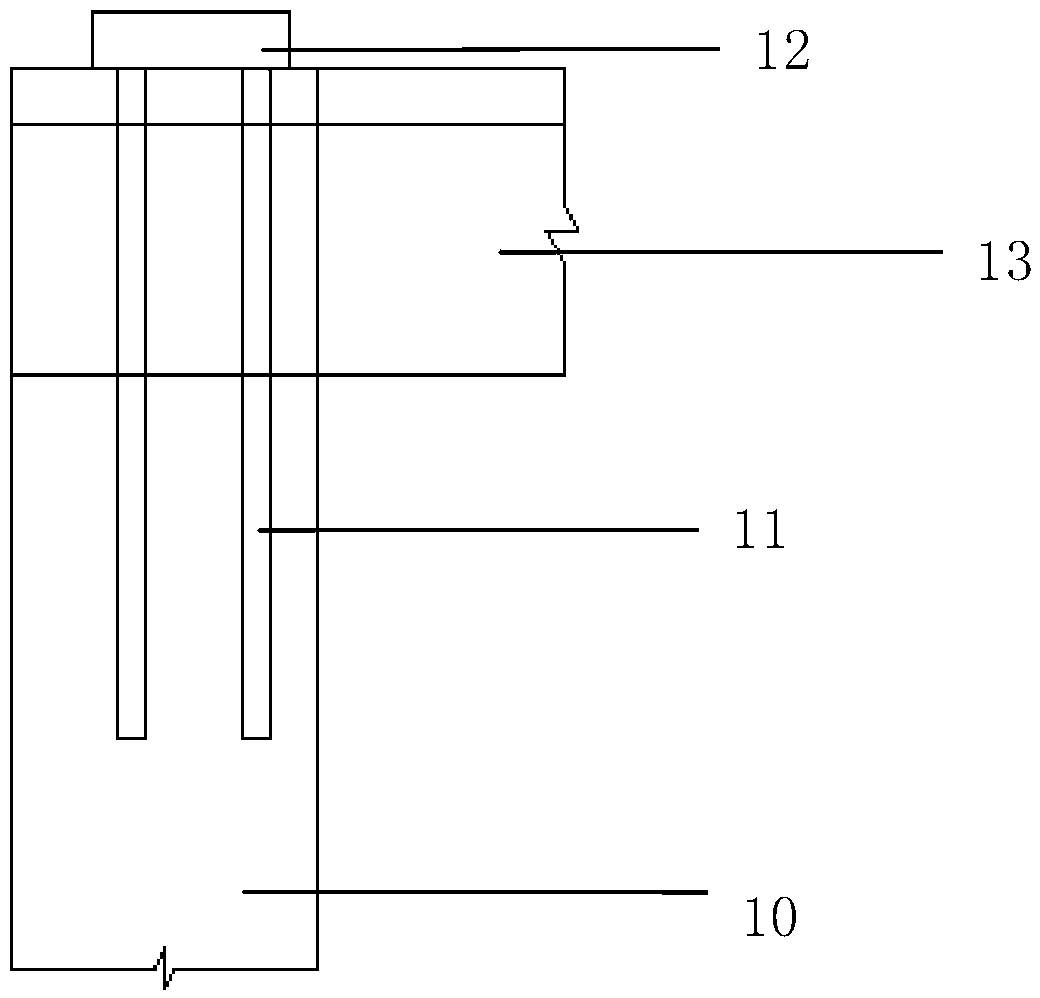

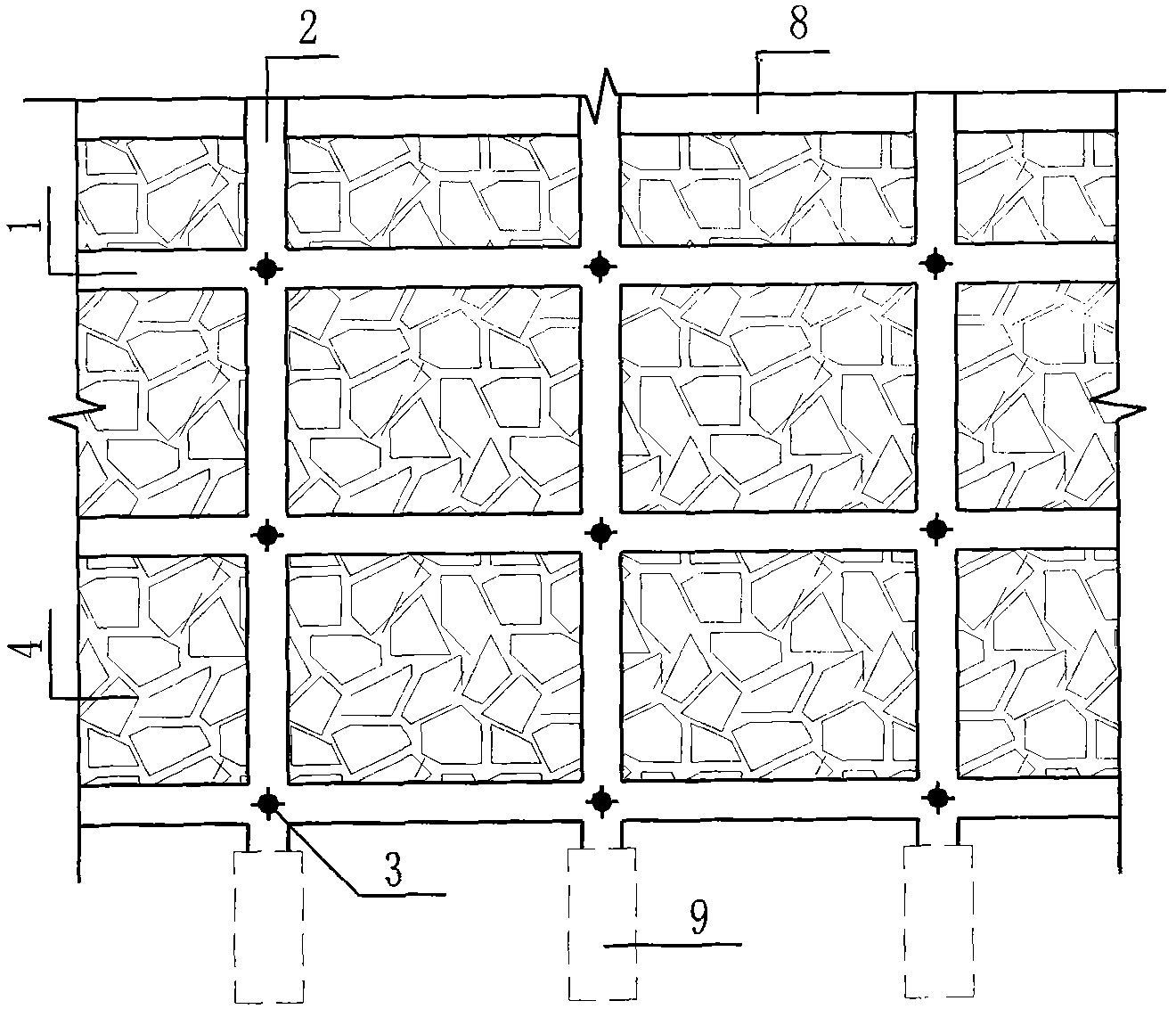

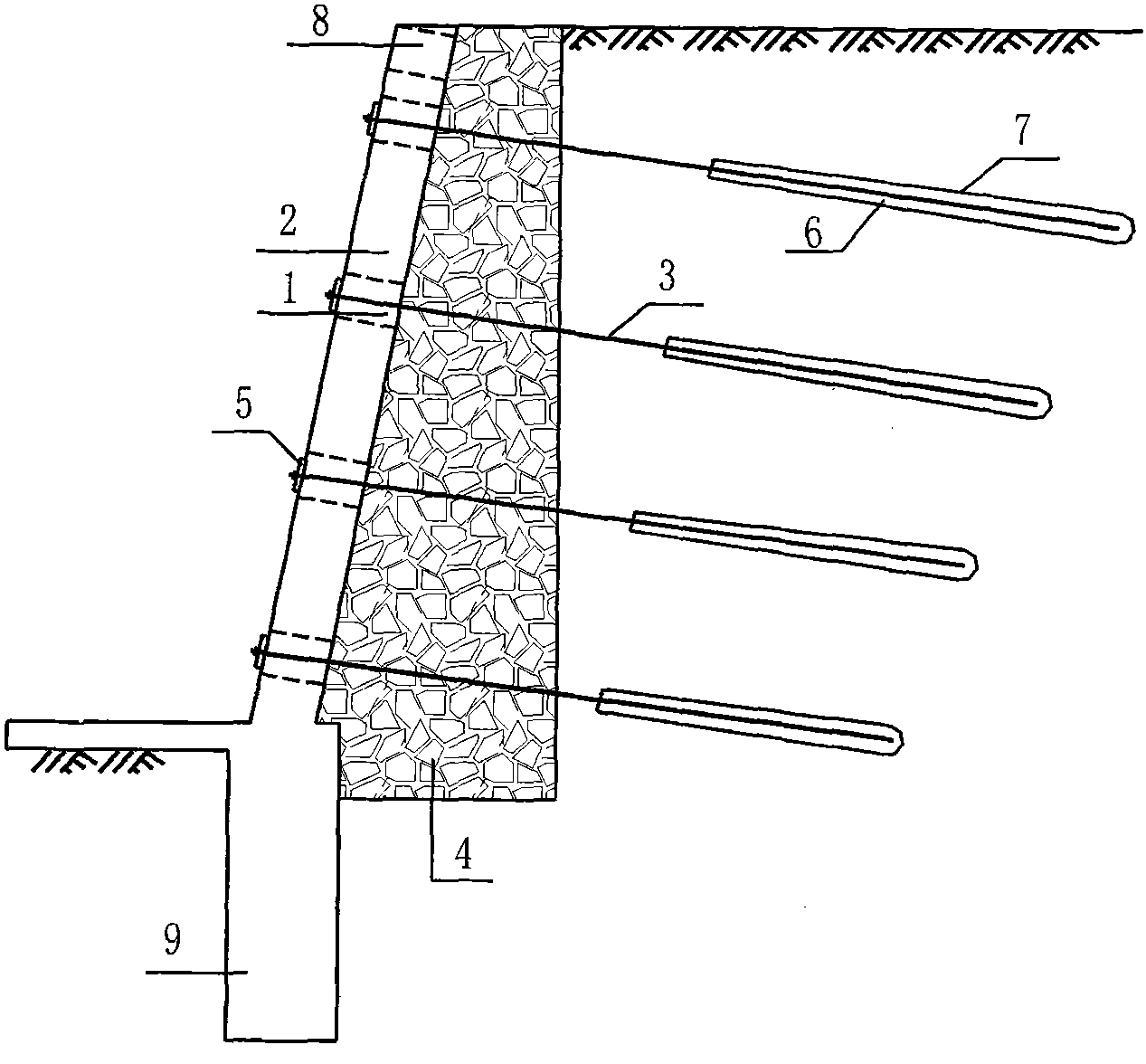

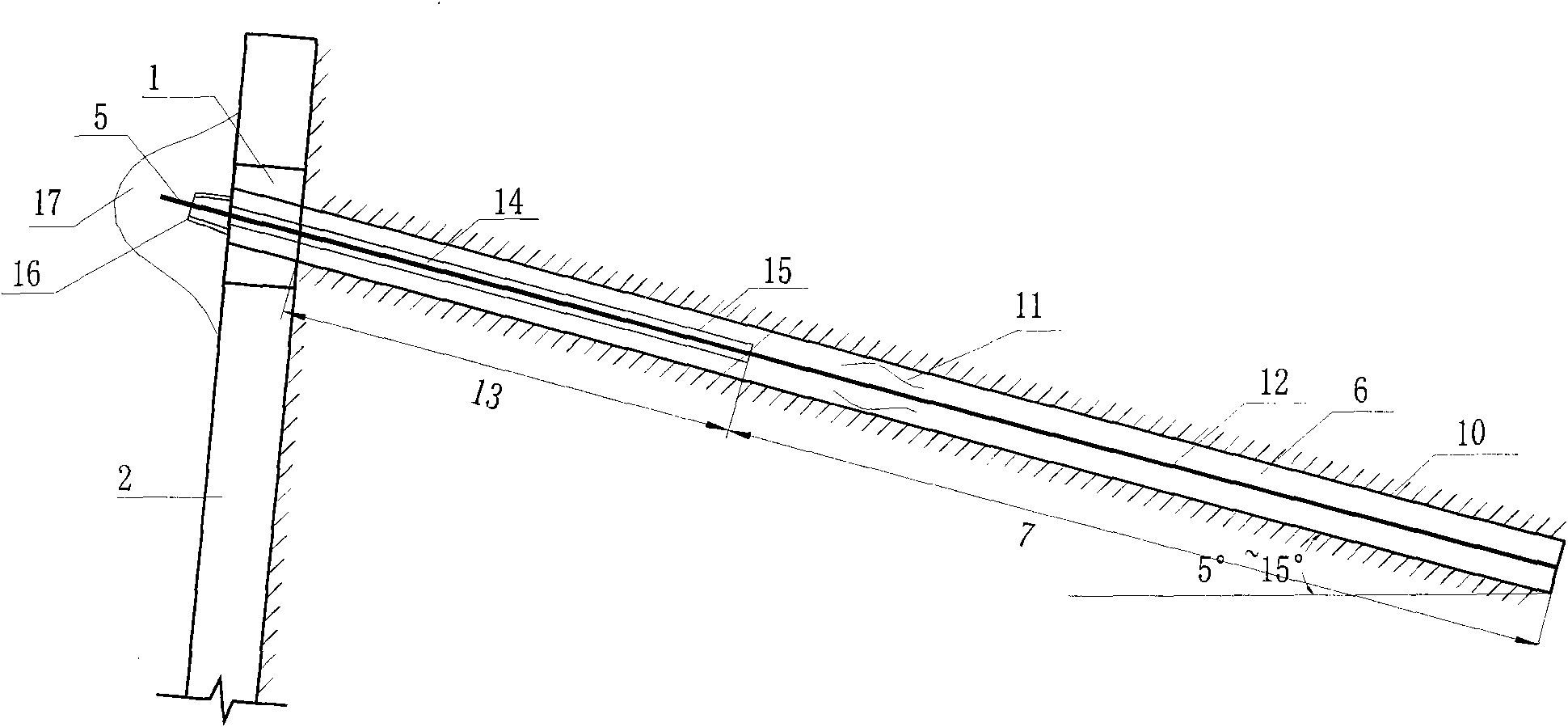

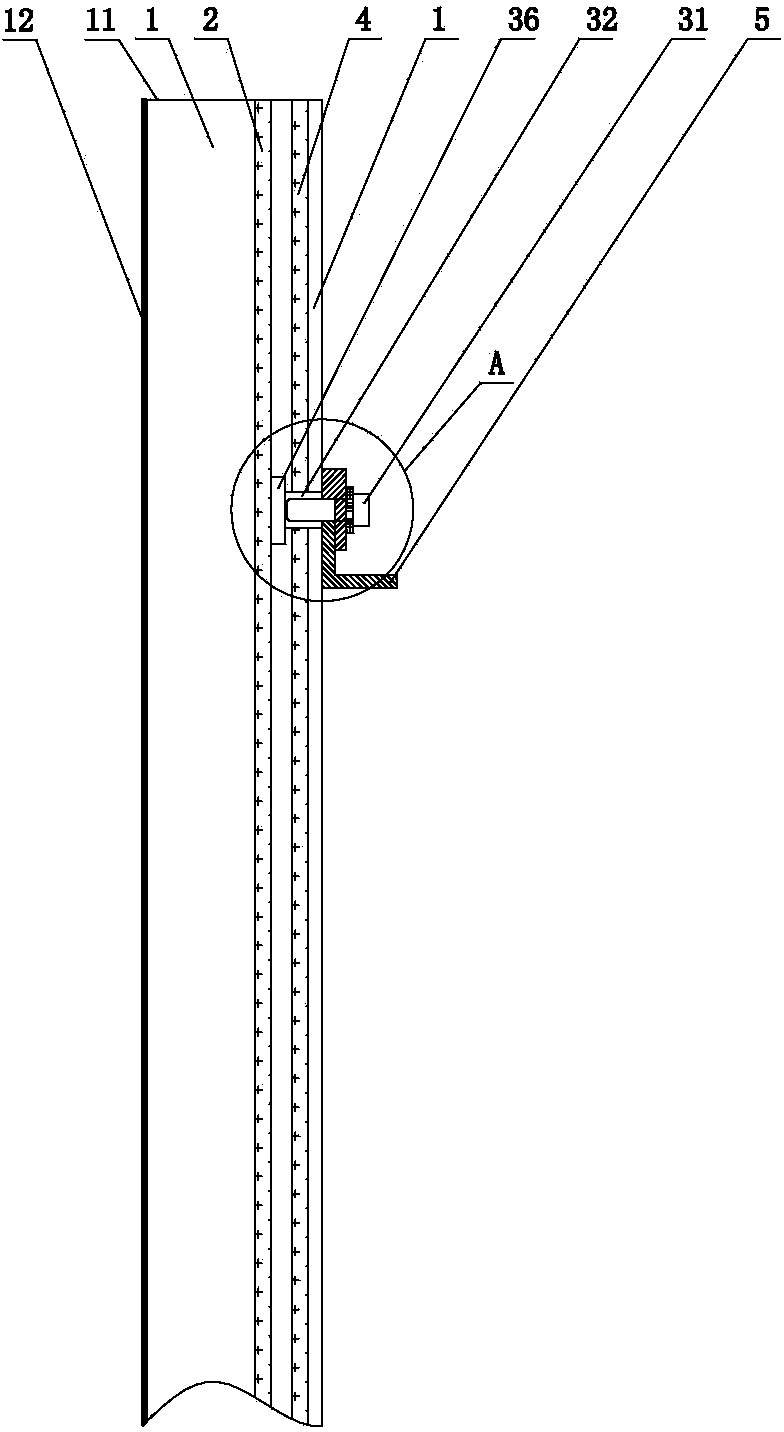

Framework prestress anchor rod-reinforced supporting structure for gravity type retaining wall and construction method thereof

InactiveCN102251525AImprove stabilityOvercome the costExcavationsBulkheads/pilesPre stressCement mortar

The invention discloses a framework prestress anchor rod-reinforced supporting structure for a gravity type retaining wall and a construction method thereof. In the structure, a prestress anchor rod (3) penetrates through a crossed part of a cross beam (1) and an upright post (2) as well as a gravity type retaining wall (4) and is fixedly embedded inside a reinforced soil body; cement mortar is wrapped on the periphery of an anchor section (7) of the prestress anchor rod (3); a free section (13) of the prestress anchor rod (3) is coated with a layer of corrosion resistant material (14); a plastic casing (15) is sleeved outside the corrosion resistant material (14); and the end part of the prestress anchor rod (3) is anchored at the crossed part of the cross beam (1) and the upright post (2) by using an anchor head (5). The construction method comprises the following specific steps of: carrying out manufacturing and constructing on the prestress anchor rod (3); casting a capping crown beam (8), the upright post (2) and the cross beam (1); locking the anchor head (5) which is connected with the prestress anchor rod (3) in a fastening manner by using an anchor appliance (16); carrying out construction on the prestress anchor rod (3), the cross beam (1) and the the upright post (2) on next work surface according to the previous steps; finishing tensioning and anchoring of the prestress anchor rod (3) on each layer; and casting a foundation pile (9).

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

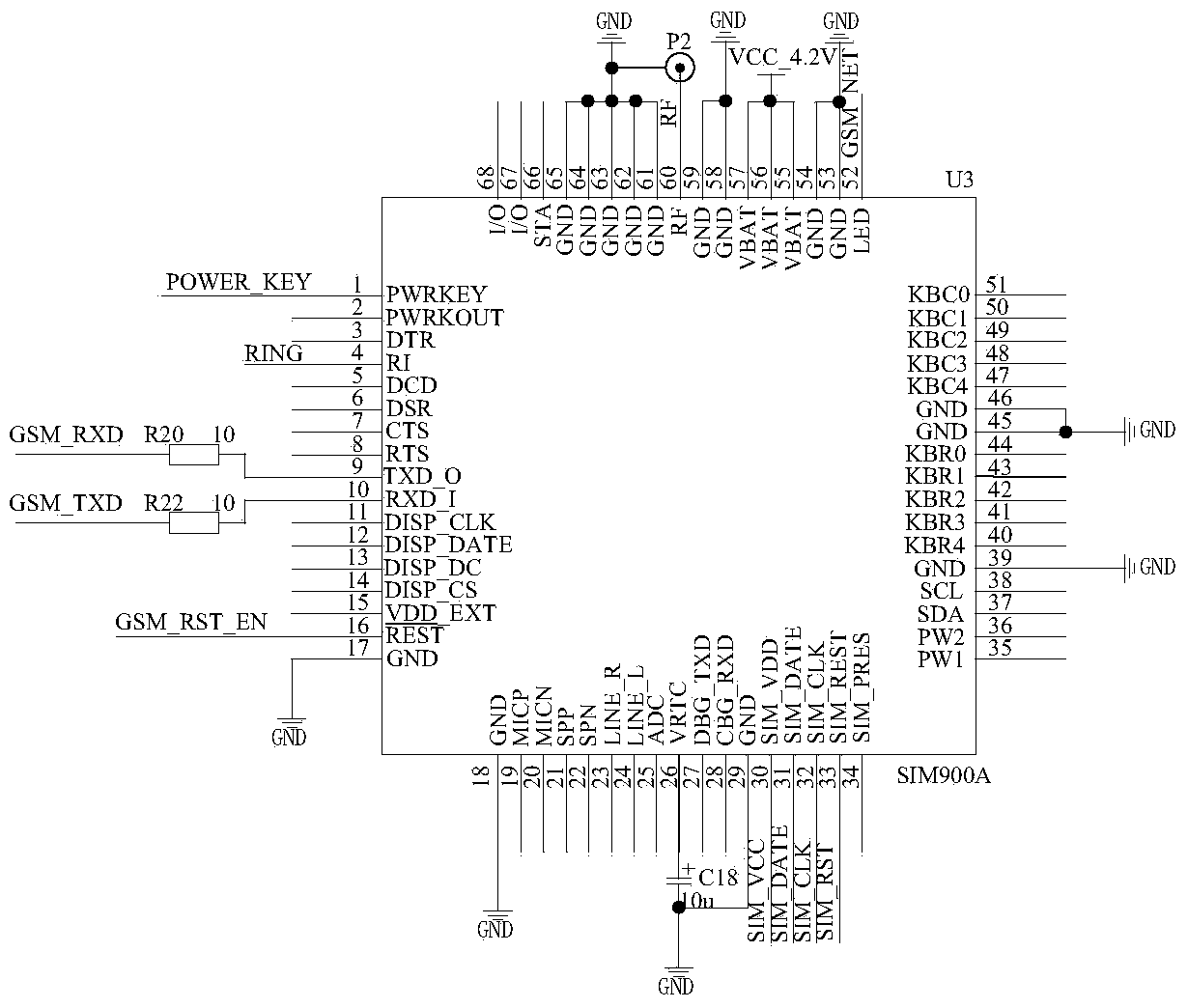

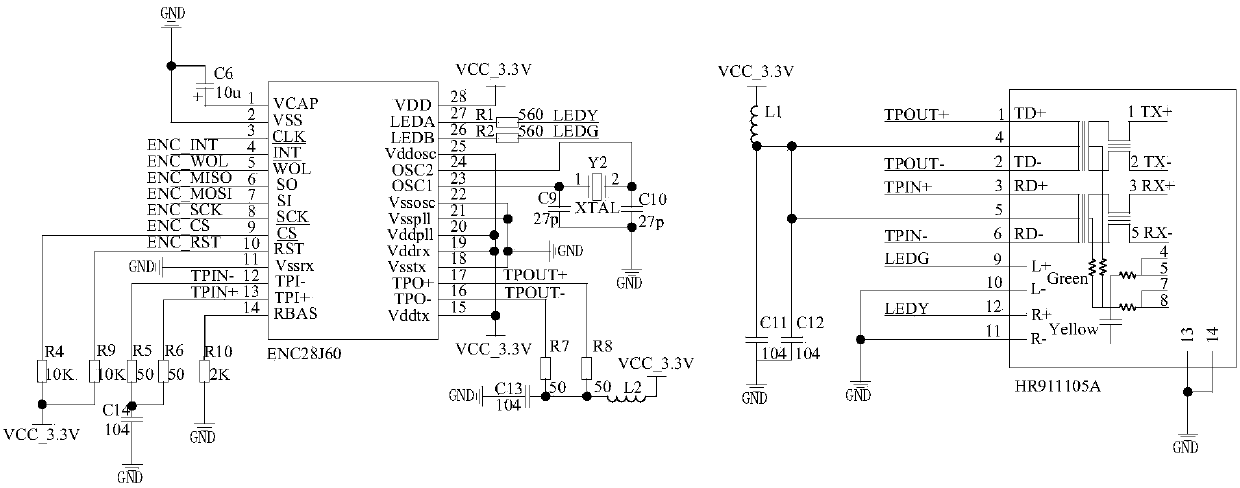

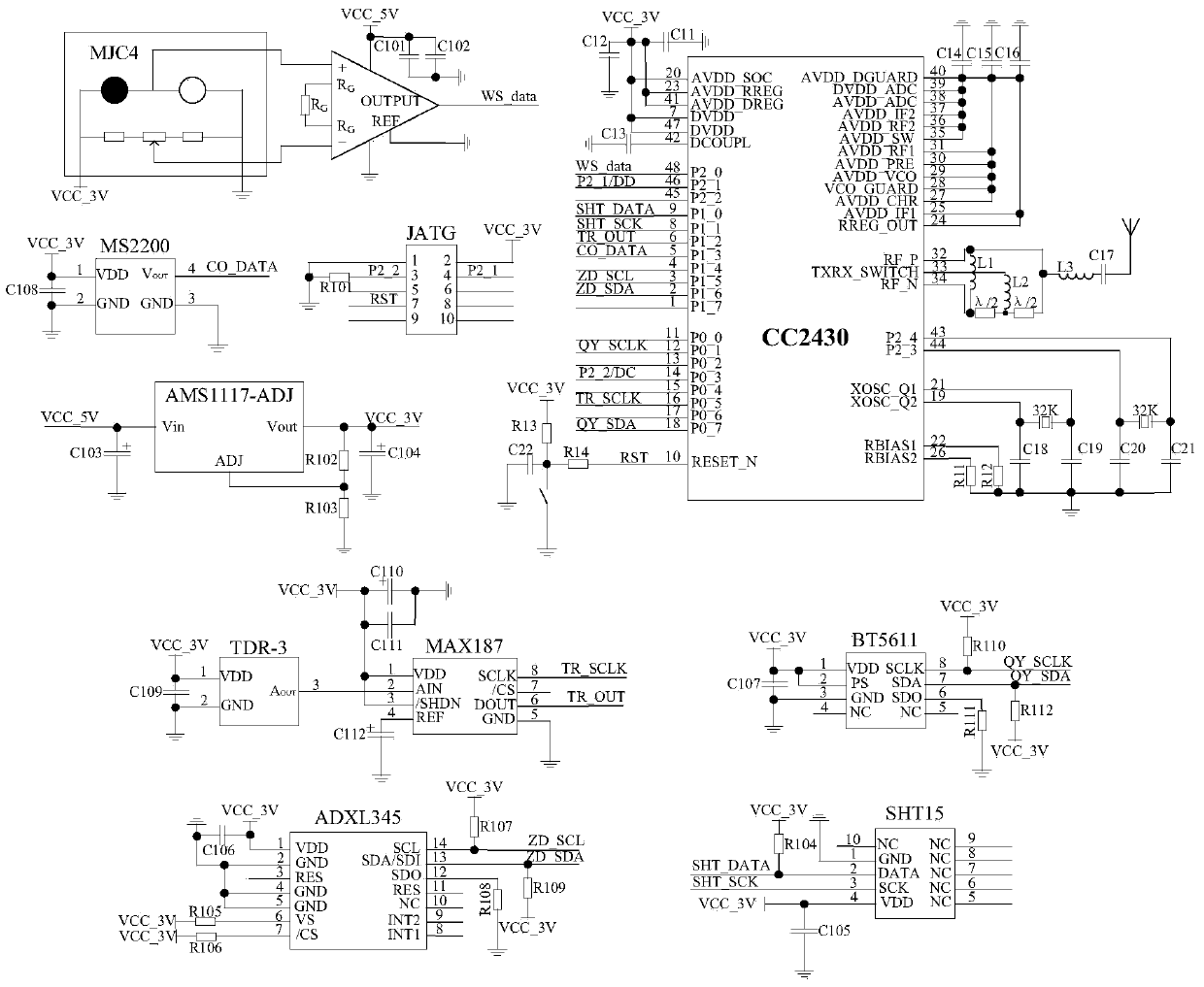

System and method for monitoring subway tunnel construction management based on Internet of Things

InactiveCN103744358AReal time monitoringOvercome difficultyTotal factory controlProgramme total factory controlData acquisitionTerminal equipment

The invention discloses a system and a method for monitoring subway tunnel construction management based on Internet of Things. The system comprises a mobile terminal device, a remote central control center, a main control unit, a plurality of data acquisition units and a plurality of Zigbee terminal nodes. The main control unit comprises a wireless communication module, a man-machine interaction module, a power supply module, a Zigbee network module and a micro-control unit core module (MCU 1 core module). Each data acquisition unit comprises a power supply module, a MCU 2 core module and a data acquisition module. After the initialization of the system is succeeded, the remote central control center is used to select either a hand-operated mode or an automatic mode to be communicated with the main control unit and the data acquisition units, and control and query instructions are sent to obtain information of various sensors in the system for monitoring the subway tunnel construction management. The system can timely monitor subway tunnel environments and construction personnel to effectively reduce probability of accidents.

Owner:RX MICROSYST WUHAN CHINA

Cast-in-place steel-concrete composite beam

ActiveCN101845871AFast constructionFast integrityLoad-supporting elementsFloor slabReinforced concrete

The invention discloses a cast-in-place steel-concrete composite beam, which relates to a composite beam. The cast-in-place steel-concrete composite beam solves the problems that a reinforced concrete beam and a column connection node in the existing steel structure and the existing steel-concrete composite structure have complex structures and are difficult to construct, the problems that a common composite beam has a large steel consumption and a high structure manufacturing cost, and the problems that a composite beam of which the publication number is CN101215855 is complex in operation and is inconvenient to construct when connected with a reinforced concrete wall column, and has low bearing capacity, small rigidity, weak spanning capacity, large fracture width for tensile region concrete and small application range. Bottom flanges of two I-shaped steel beam sections of the cast-in-place steel-concrete composite beam and a tensile region steel plate are made into an integral body; a longitudinal steel plate ribbed stiffener is connected through a fire-resisting longitudinal bar; top flanges of the two I-shaped steel beam sections are connected through a tensile region longitudinal bar; stirrups are uniformly arranged along the longitudinal direction of the fire-resisting longitudinal bar; floor steel bars are paved on a stiffening framework of the composite beam; and concrete is poured on the floor steel bars and the stiffening framework of the composite beam. The cast-in-place steel-concrete composite beam is applied to civil engineering constructions.

Owner:HARBIN INST OF TECH

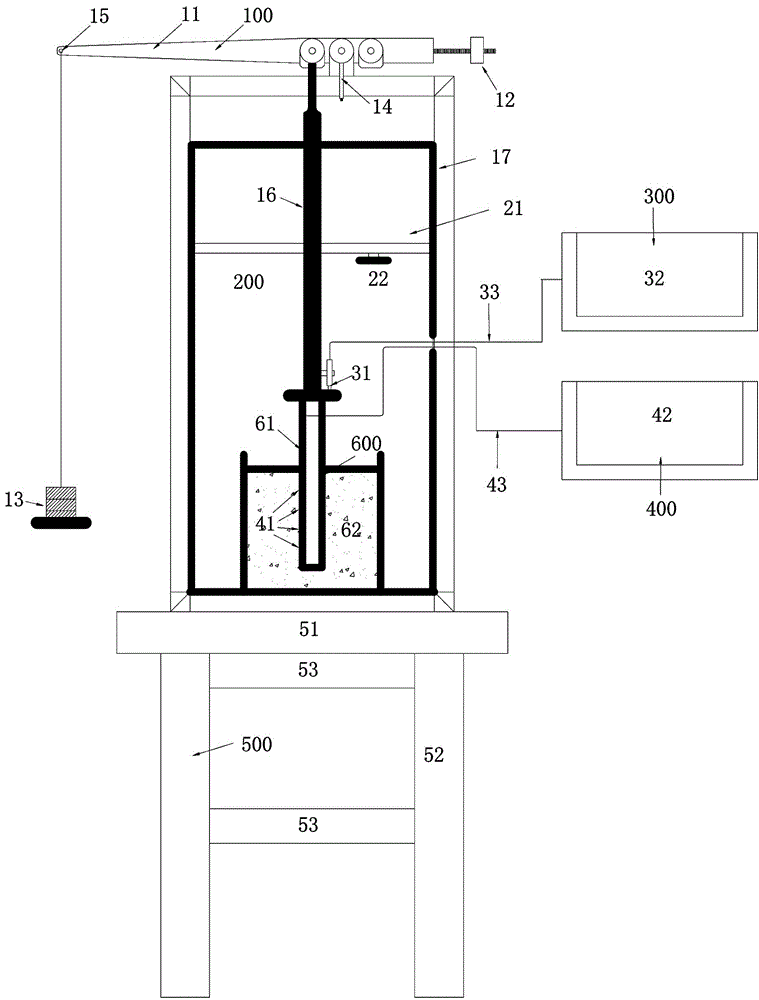

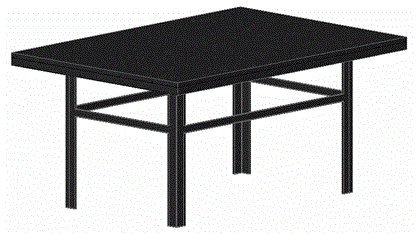

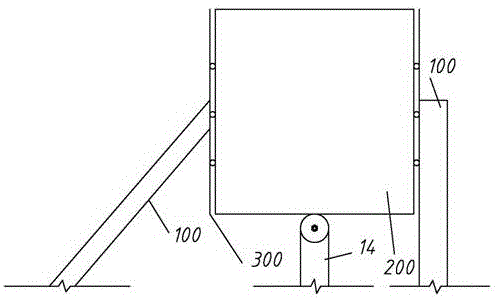

Indoor frozen soil model pile static force loading experimental device and method

InactiveCN104913977AOvercome costsOvercome the costMaterial strength using tensile/compressive forcesSoil modelStatic force

The invention discloses an indoor frozen soil model pile static force loading experimental device and method. The device comprises a workbench, a loading framework, a self-balance lever static force loading device, a refrigerating system, a pile soil model, a displacement measurement system and a strain testing system, wherein the workbench is arranged on a horizontal plane; the loading framework is vertically welded on the workbench; the self-balance lever static force loading device, the refrigerating system and the pile soil model are installed from the top of the outer side to the bottom of the inner side of the overloading framework in a matched mode from top to bottom sequentially; the displacement measurement system and the strain testing system are arranged on the external side wall of the loading framework; the displacement measurement system extends into the loading framework and is connected to the part between the refrigerating system and the pile soil model; the strain testing system extends into the pile soil model. The indoor frozen soil model pile static force loading experimental device and method can overcome defects of high cost, high maintenance expense, long time and the like in the prior art so as to achieve the advantages of low cost, low maintenance expense and short time.

Owner:LANZHOU JIAOTONG UNIV

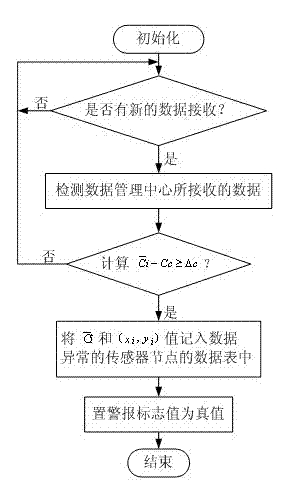

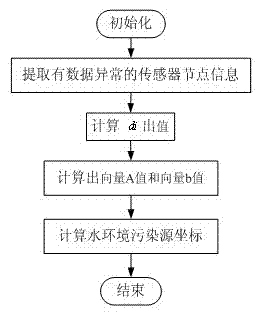

Detecting method of water environment pollution source based on wireless sensor networks

InactiveCN102495187ATimely positioningPrecise positioningNetwork topologiesTesting waterEnvironmental engineeringSensor node

The invention relates to a detecting method of water environment pollution source based on wireless sensor networks. The technical scheme is that, firstly, n sensor nodes are uniformly arrayed in a to-be-detected water environment area, the sensor nodes are all connected with a sink node in a wireless multi-hop method, the sink node is wirelessly connected with a gateway, and the gateway is connected with a data management center through a data wire; a management software is mounted in the data management center and includes a detecting module and a positioning module of the water environment pollution source; and finally, as long as the collected data of the sensor nodes is substituted into the detecting module and the positioning module of the water environment pollution source by the management software of the data management center, the pollution source can be detected and the position coordinates of the pollution source can be calculated. Therefore, the invention has the advantages of simplicity and convenience for carrying out, high precision, strong operability, low cost and short-time efficiency, and provides a more advanced method for the actual detecting and positioning of the water environment pollution source.

Owner:WUHAN UNIV OF SCI & TECH

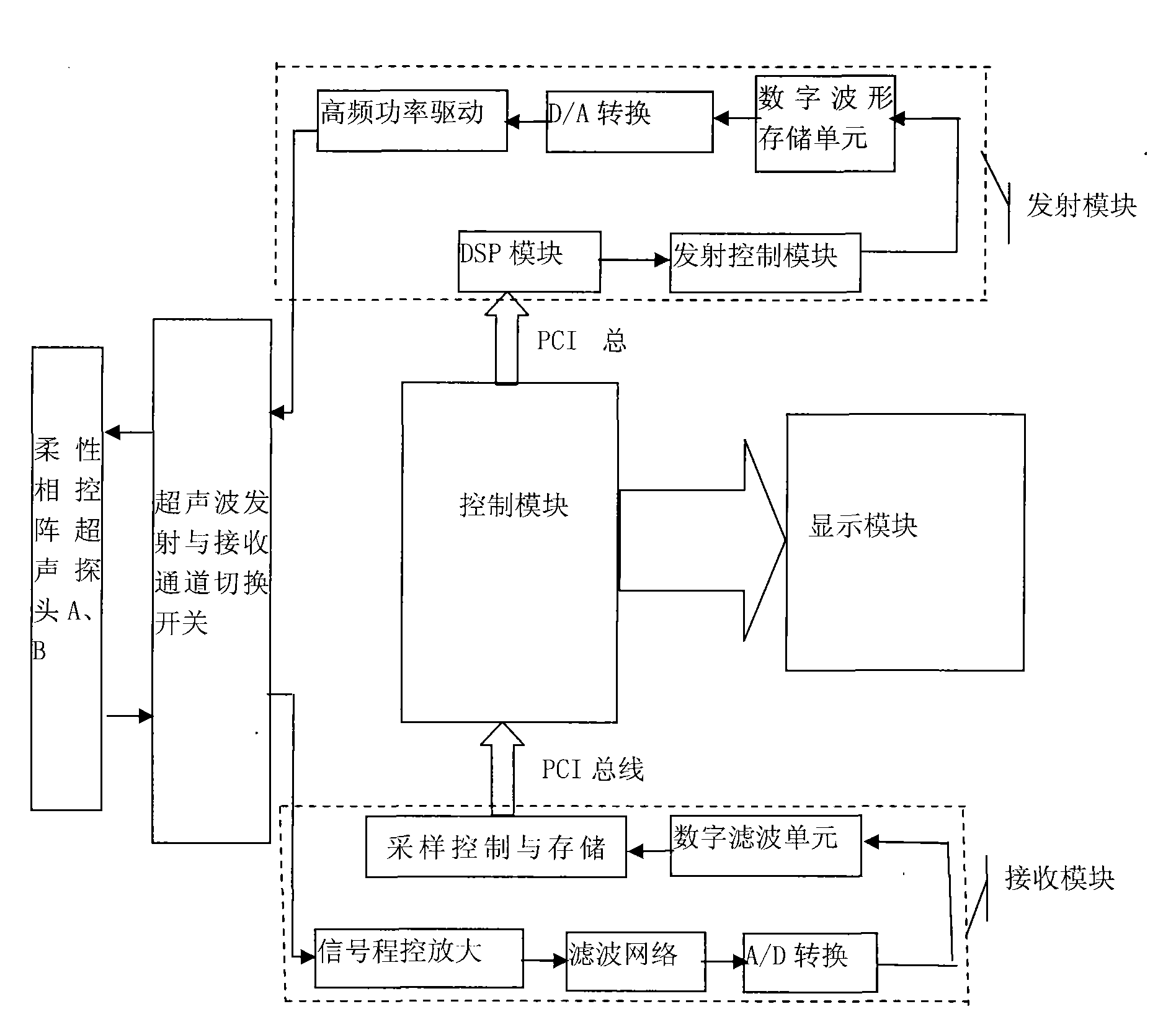

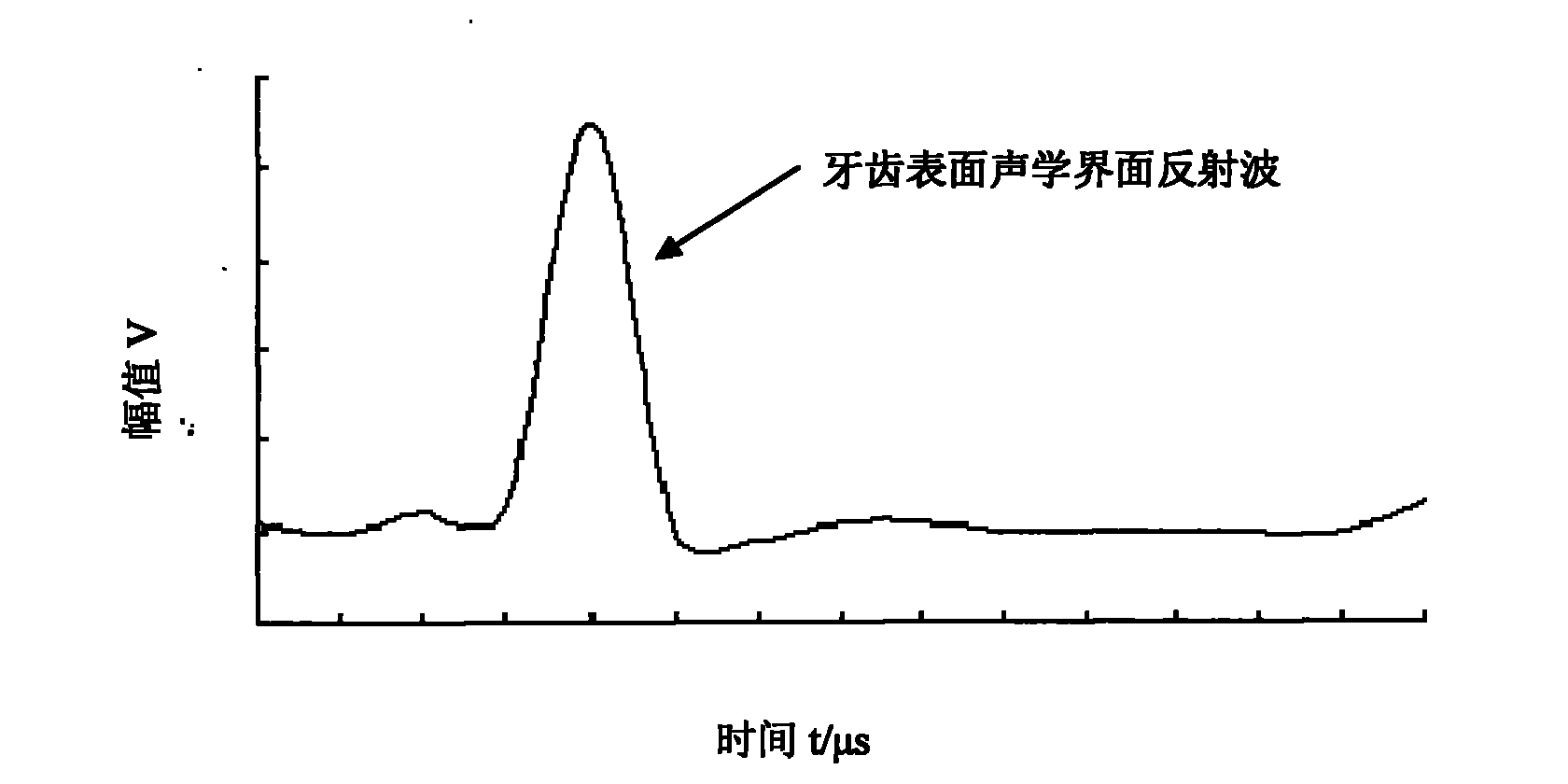

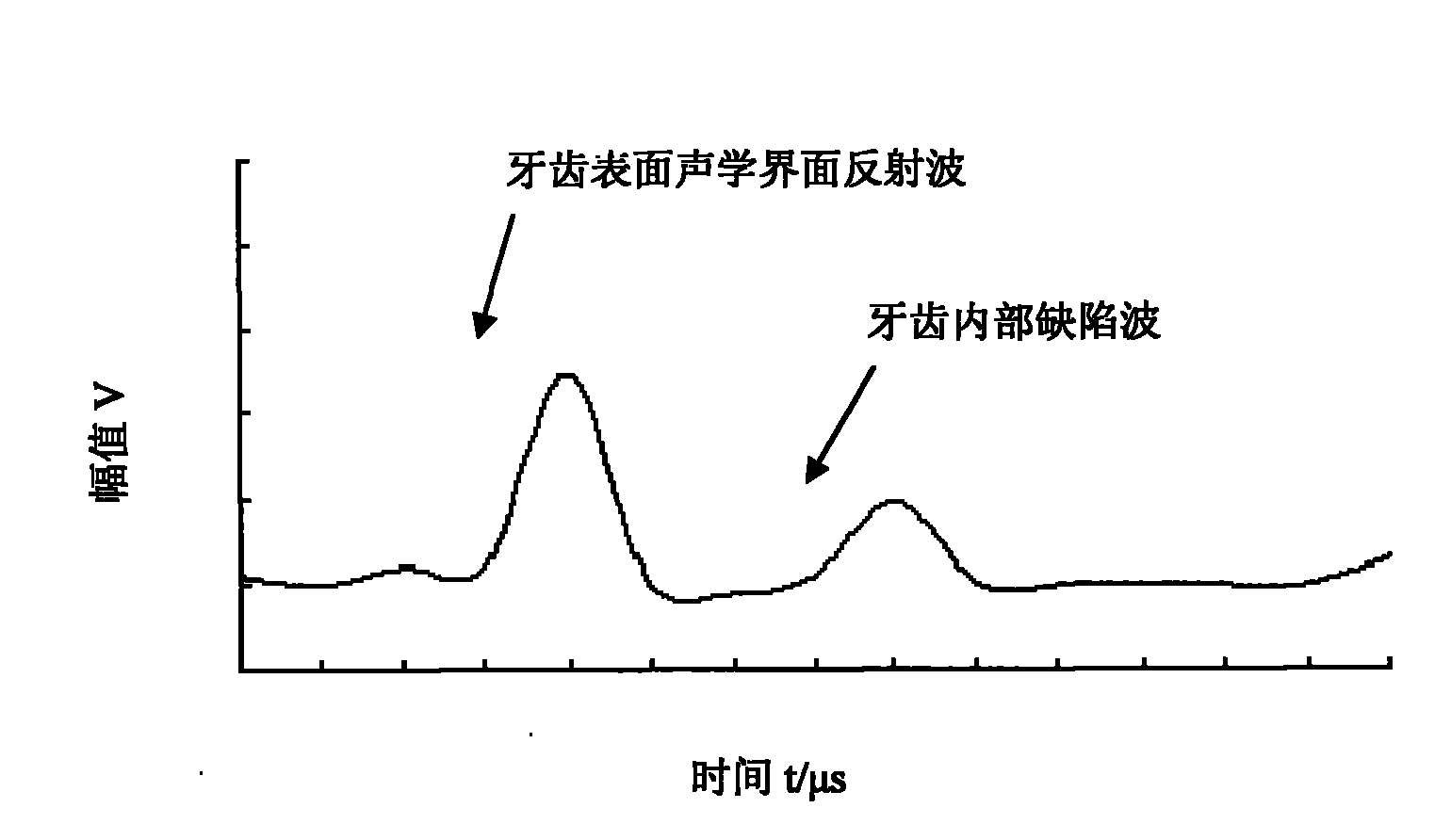

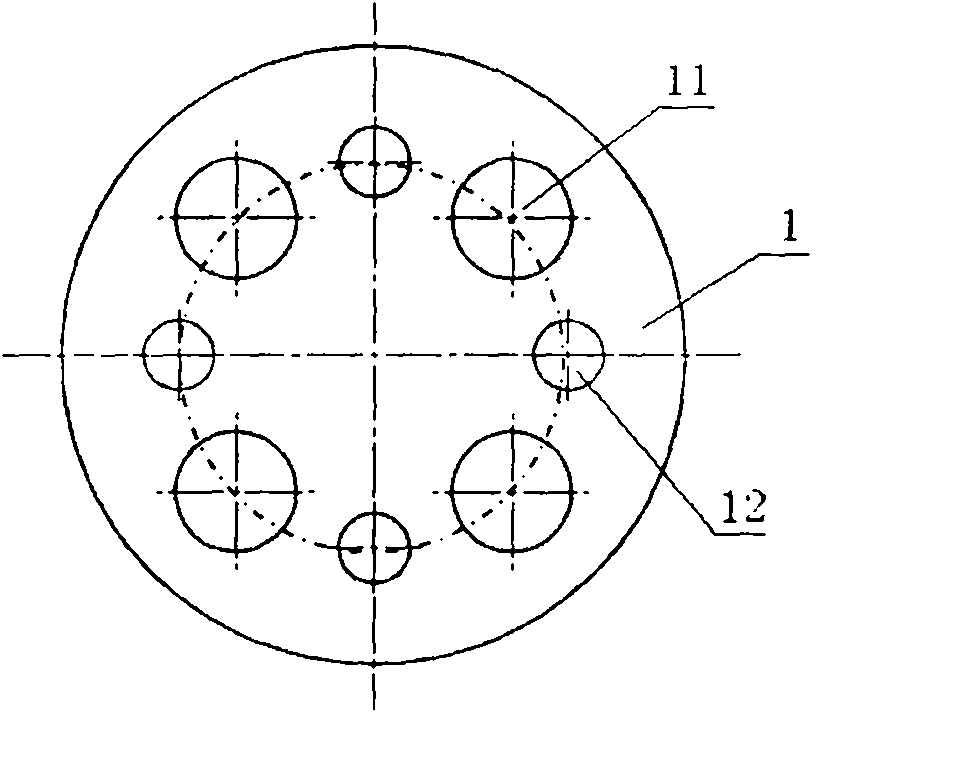

Oral cavity comprehensive detecting method and apparatus based on flexible phase controlled ultrasonic array

InactiveCN101966088AOvercoming detectionOvercome the costUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsUltrasound attenuationMedicine

The invention discloses oral cavity comprehensive detecting method and apparatus based on a flexible phase controlled ultrasonic array. The apparatus comprises a display module, a phase controlled ultrasonic transmitting module and a phase controlled ultrasonic receiving module connected with a control module, respectively. The phase controlled ultrasonic transmitting module and the receiving module are further connected with a flexible phased array ultrasonic transducer array. The method comprises the following steps of: performing ultrasonic scanning to detect teeth facing outwards skin in periphery of the oral cavity on the face or in all directions of other soft tissues of the oral cavity through the flexible phased array ultrasonic transducer array; transmitting ultrasonic waves with set frequency to detection points through the phased array focused ultrasound when detecting the teeth so as to detect the amplitude of the reflected wave and detect whether defect waves exist in the reflected wave; and transmitting ultrasounds with different frequencies to the detection points through the phased array focused ultrasound and detecting the attenuation of the transmitted wave with different frequencies at the other end when detecting the soft tissues of the oral cavity so as to obtain broadband ultrasonic attenuation parameters. Therefore, health states of the soft tissues of oral cavity can be obtained rapidly.

Owner:SOUTH CHINA UNIV OF TECH

Flue gas absorbent which simultaneously has functions of desulphurization and denitration and preparation method and application thereof

InactiveCN102350208ALow investment costLow running costDispersed particle separationFlue gasWastewater

The invention discloses a flue gas absorbent which simultaneously has functions of desulphurization and denitration and a preparation method and an application thereof. Calculated according to 1L of deionized water, the flue gas absorbent provided by the invention is composed of 1.66-594g of an oxidizing agent, 3.8-1144g of a buffering agent, 2.7-222g of a stabilizing agent and 1L of deionized water. The preparation method provided by the invention comprises the following steps of: adding the buffering agent into 1L of deionized water, dissolving and uniformly mixing, adding the stabilizing agent, dissolving and uniformly mixing, adding the oxidizing agent, fully dissolving and uniformly mixing to obtain the absorbent. The absorbent provided by the invention and a calcium-based absorbent are simultaneously used so as to realize desulphurization and denitration in a same device, have high removal efficiency, and have less corrosion to the device with no discharge of desulphurization wastewater. In addition, desulphurization byproducts are dry, which is in favor of comprehensive utilization, disposal and stacking.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

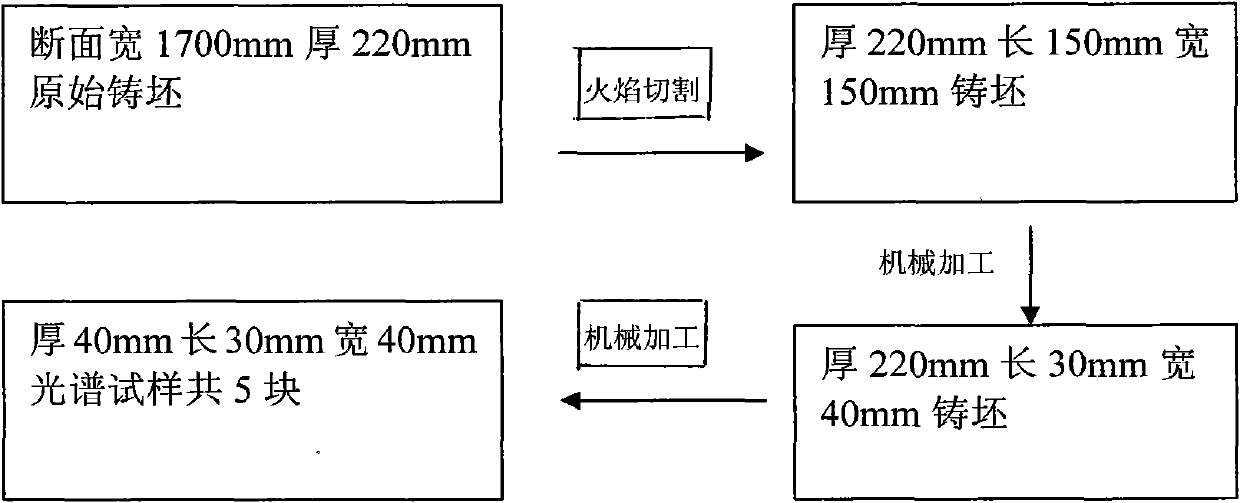

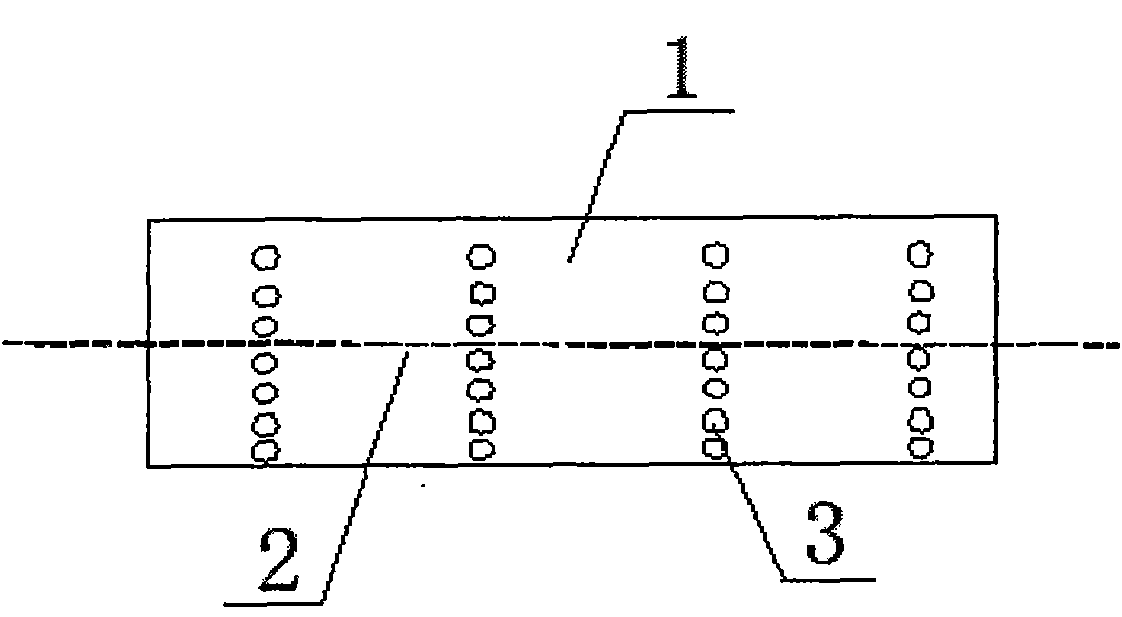

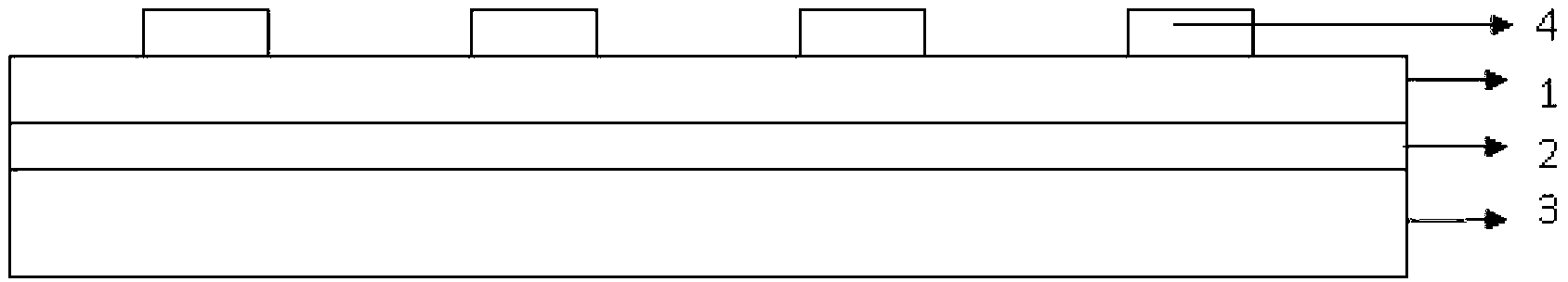

Method for rapidly testing casting blank segregation by utilizing direct-reading spectrometer

InactiveCN101949851AMeet the general quantitative detectionOvercoming complexityPreparing sample for investigationAnalysis by electrical excitationMetallurgical assayTest sample

The invention discloses a method for rapidly testing casting blank segregation by utilizing a direct-reading spectrometer, which is suitable for the quantitative and trending detection in the casting blank segregation, belonging to the technical field of metallurgy analyzing and detecting. In the method, the direct-reading spectrometer is adopted to simulate an in-situ analyzer to detect the casting blank segregation; and the direct-reading spectrometer segments and dots a test sample, and simulates the in-situ analyzer to analyze the test sample, so as to quantitatively detect the continuously cast blank macrosegregation. The method can overcome the defects that the in-situ analysis sample preparation is complex, the testing period is long, the detection cost is high and the like, satisfies the generalized quantitative detection to the casting blank in the continuous casting production, and provides a good popularization and reference method for the iron and steel enterprises owning rapid spectrum analyzers in the trending and quantitative detection of the continuously cast blank segregation. Compared with the traditional pickling method for detecting the casting blank segregation, the method has the same trend on the description of the casting blank segregation as that of the pickling method; the casting blank segregation result detected by the direct-reading spectrometer not only can describe the casting blank segregation condition, simultaneously can clearly describe the component segregation curve of each element, and has the visual digitized function.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

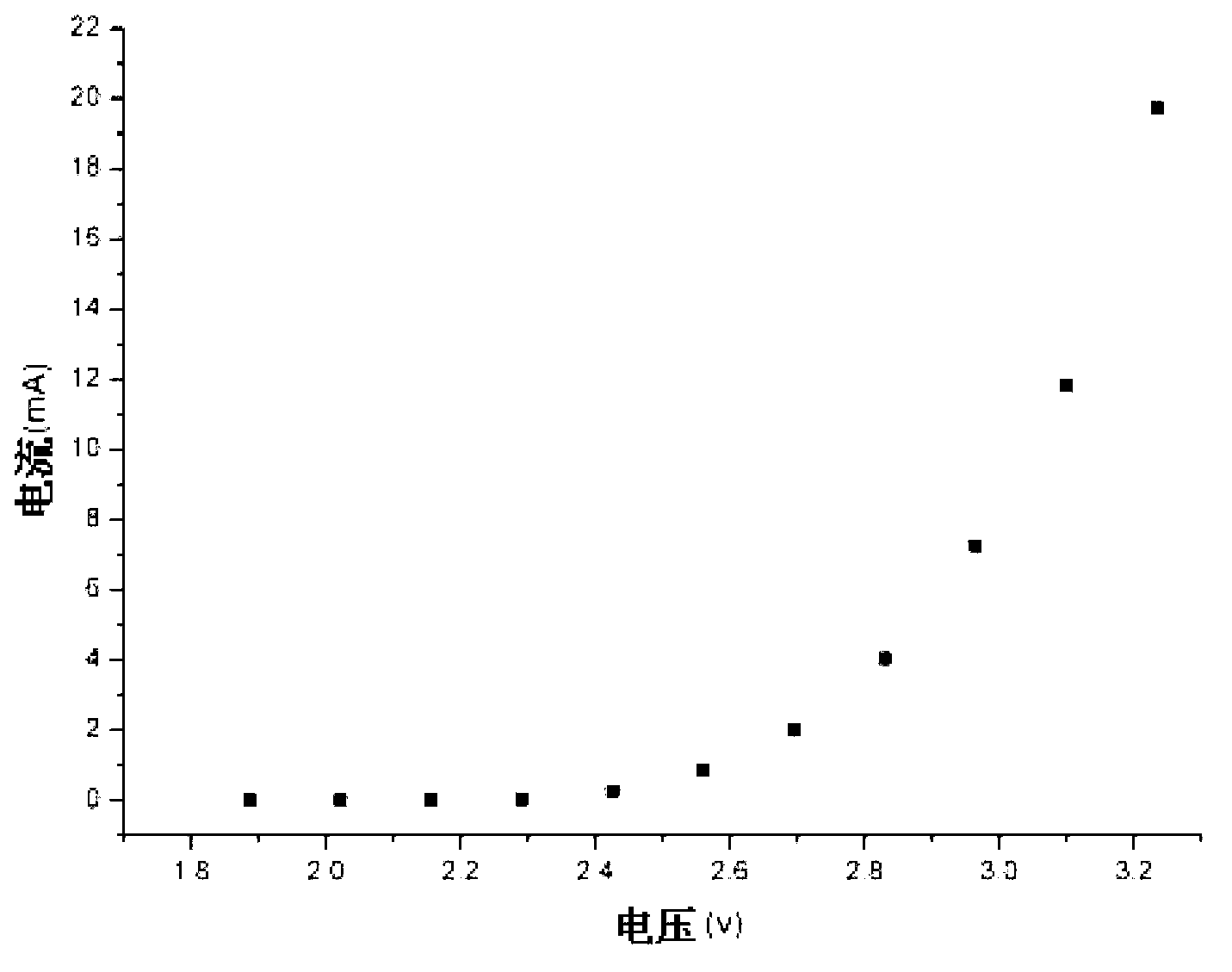

Transparent display screen and manufacture method thereof

ActiveCN102855827AOvercome the thicknessOvercome uniformity issuesIdentification meansSurface mountingConductive materials

The invention discloses a transparent display screen, which comprises a transparent conductive material, a transparent base and a display unit, wherein the transparent conductive material is used for conducting a component in the transparent display screen; the transparent base is connected with the transparent conductive material to serve as a base material of the transparent display screen, and the display unit is connected with the transparent conductive material for displaying the content of the transparent display screen. The transparent display screen utilizes a low-cost transparent conductive film, and the conductive film is divided into a plurality of areas by an etching technology; a surface-mounting light emitting diode is fixed on the transparent conductive base through transparent crystalline solid rubber to form a light emitting diode matrix, and the transparent display is achieved by external circuit drive. The invention also discloses a manufacture method of the transparent display screen.

Owner:EAST CHINA NORMAL UNIV

Blood cell analysis method based on machine vision

InactiveCN1837819AOvercome the priceOvercome the costBiochemistry apparatusBiological testingPattern recognitionColor image

This invention relates to a blood cell analysis method based on machine vision. Inputting the blood sample into a computer by a camera to convert the color image into the black-and-white and then the binary one and scale the binary image; calculating the area and taking count of the scaled image to obtain the number of RBC, WBC and platelet. This invention has high efficiency and accuracy with low cost.

Owner:李奕

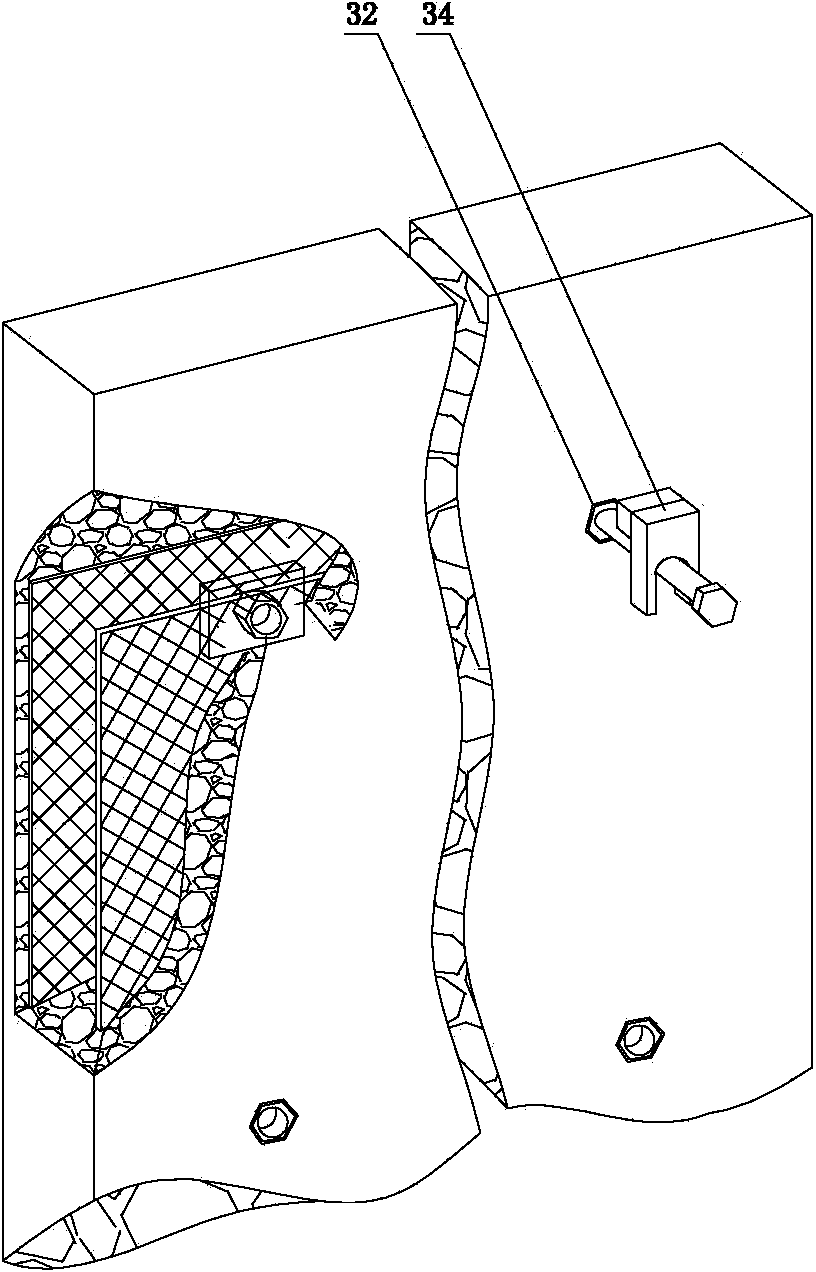

Full circle once lining segregation type nose girder module bench and its construction method

ActiveCN1908374AReduce consumptionOvercoming weightUnderground chambersTunnel liningNoseBeam walking

The invention relates to a linear separated guide beam template table, wherein its annular linear beam is connected to the inner side of template; the annular linear beam and the table support top template support screw disc, side template support lead screw and bottom template support lead screw between them; the table via walking device is supported on the table walking steel track above the bottom template; one table and two bottom templates are alternatively matched; the bottom template is fixed with guide beam walking steel track which supports the detachable support guide beam; the bottom of detachable support guide beam has walking wheel, while its top is detachably connected via adjustable base and table; the end of detachable support guide beam via the end base of guide beam is supported on the support concrete structure, while its one end is connected to the drawing system; another bottom template is at the concrete pouring position. And it can be used on the template table machine whose section diameter is 6-3m, with large operation space and lower cost.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Wheel-rail relation simulation fatigue test device and method

The invention discloses a wheel-rail relation simulation fatigue test device and method.The device comprises a basis platform arranged on the horizontal plane.A load box is connected to the upper portion of a loading frame fixedly installed on the basis platform in a sliding mode.A motor is installed on the basis platform and serves as a drive wheel to drive a crank to rotate.The crank is connected with a transmission mechanism.The transmission mechanism drives a simulation wheel to horizontally reciprocate on a steel rail test piece, the simulation wheel is connected with the load box through a load connecting rod, and horizontal reciprocation of the simulation wheel can drive the load box to vertically reciprocate through the load connecting rod, and therefore dynamic loads are applied to the steel rail test piece placed under the simulation wheel.The defects that in the prior art, cost is high, the maintenance cost is high, and consumed time is long are overcome, and the advantages of being low in cost, low in maintenance cost, short in consumed time and the like are achieved.

Owner:LANZHOU JIAOTONG UNIV

Remote control-type water surface waste cleaning and collecting device

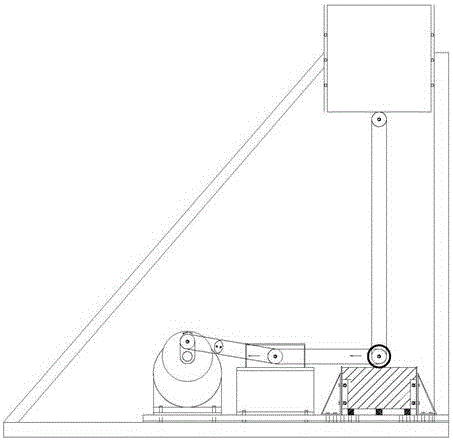

PendingCN108001634AOvercome labor intensityOvercome efficiencyWater cleaningWaterborne vesselsMotor driveRemote control

The invention discloses a remote control-type water surface waste cleaning and collecting device, belongs to environmental sanitation equipment and aims at providing a fishing device capable of substituting for manual water surface waste removal. The remote control-type water surface waste cleaning and collecting device is composed of a floater, a fishing device, a collecting device and a power device, wherein the floater is composed of two floating floors (1); the fishing device is composed of a driving roller (10), a driven roller (11) fixed under the floater, a conveying belt (5) arranged between the two floating floors (1) and connected in an inclined mode to the two rollers, scrapers (6) arranged on the conveying belt, and a first motor driving the driving roller (10); the collectingdevice is composed of a dustbin (9) under the driving roller (10); the power device is composed of paddle wheels (7) and second motors driving the paddle wheels (7) to rotate; the floater is providedwith a wireless receiving device and a control circuit. The remote control-type water surface waste cleaning and collecting device is applicable to various complex weather and water surface environments.

Owner:GUIZHOU INST OF TECH +1

Artificial stone plate and curtain wall thereof

InactiveCN104110092AHas a large damagePollutedConstruction materialWallsEnvironmental resistanceSocial benefits

The invention relates to an artificial stone plate and a curtain wall thereof. The artificial stone plate comprises a stone plate made of a concrete material. Two layers of steel wire meshes are embedded in the stone plate; two rows of fastening nuts are embedded in a back surface of the stone plate; inner ends of the fastening nuts are connected to a strip plate between the two layers of the steel wire meshes; the fastening nuts penetrate through one layer of the steel wire meshes; and the outer ends of the fastening nuts reach the back surface of the stone plate. The artificial stone plate has the advantages of light weight, low cost, and convenient and fast installation, overcomes the disadvantages of high cost of stone installation framework, and complex program and high labor cost for stone slotting, punching and fixed installation; the surface of the stone is treated by a plurality of surface treatment methods, thereby achieving a decoration effect of natural stone completely; and a hydrophobic layer can effectively prevent phenomena of water seepage, discoloration and efflorescence. The artificial stone plate is synthesized by using regenerated resources, overcomes the disadvantages of large disruption to the environment and radiation pollution in stone exploration, has the advantages of low cost and environment protection, and has very good economic benefits and social benefits.

Owner:钟兵

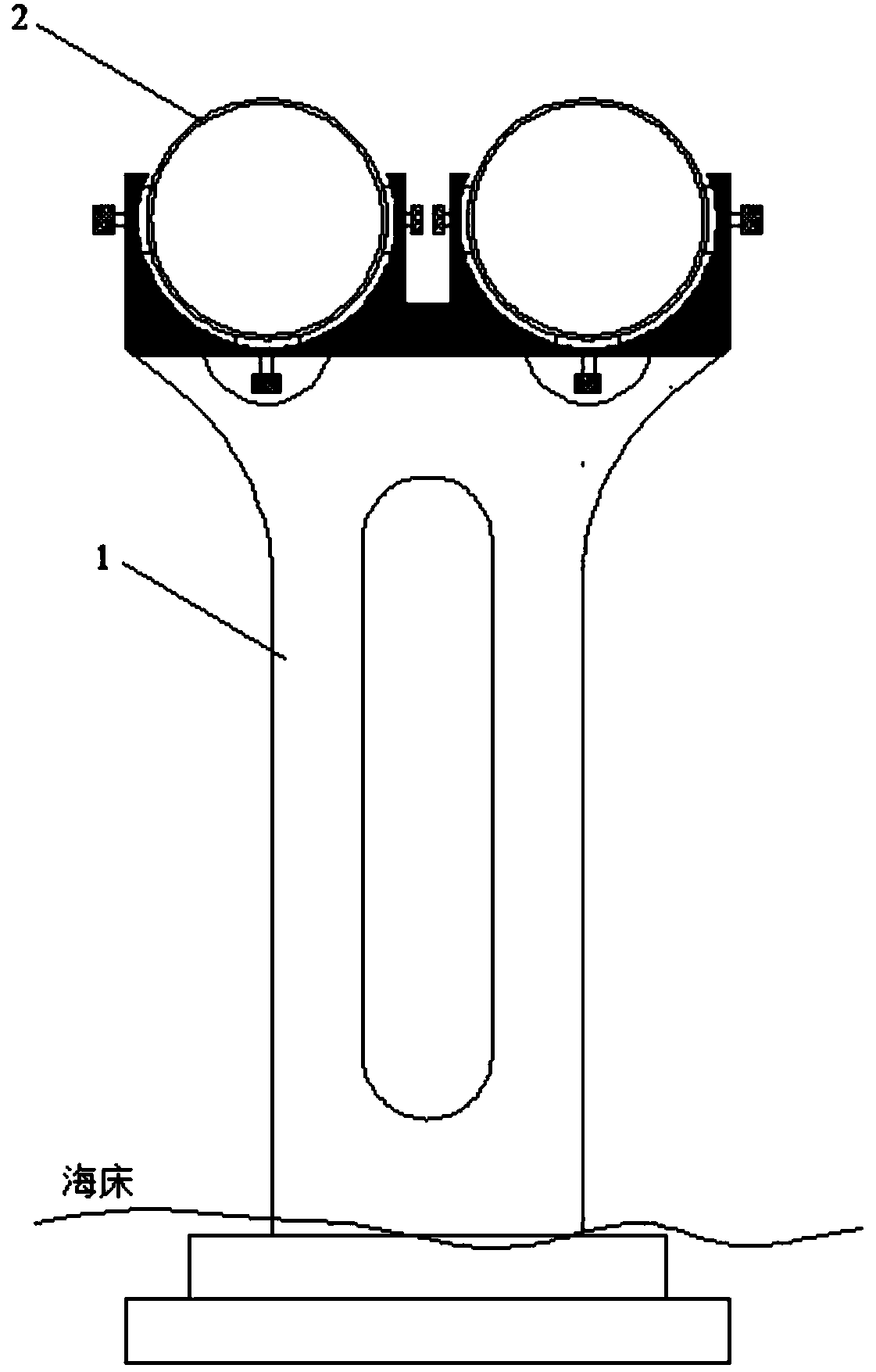

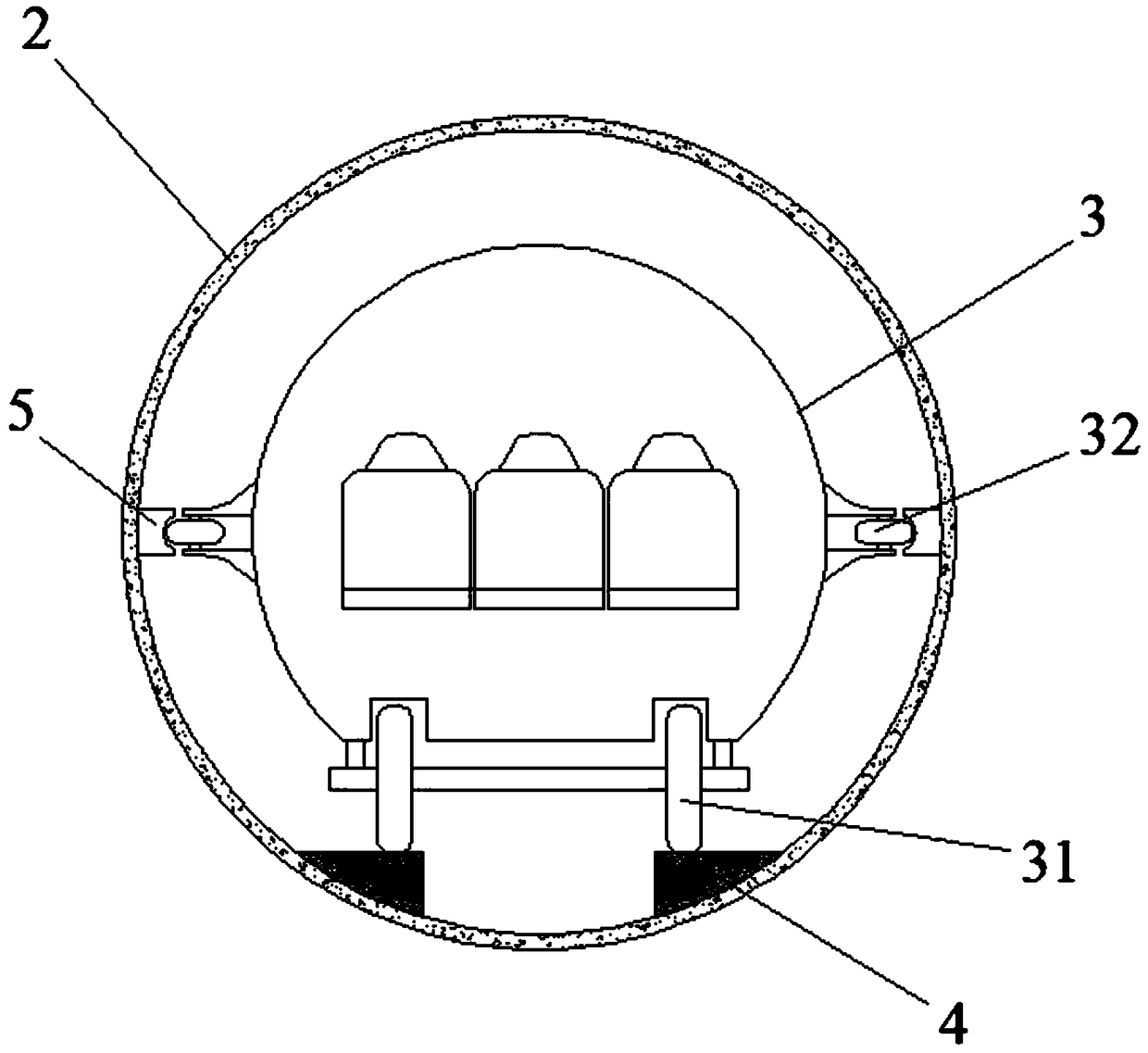

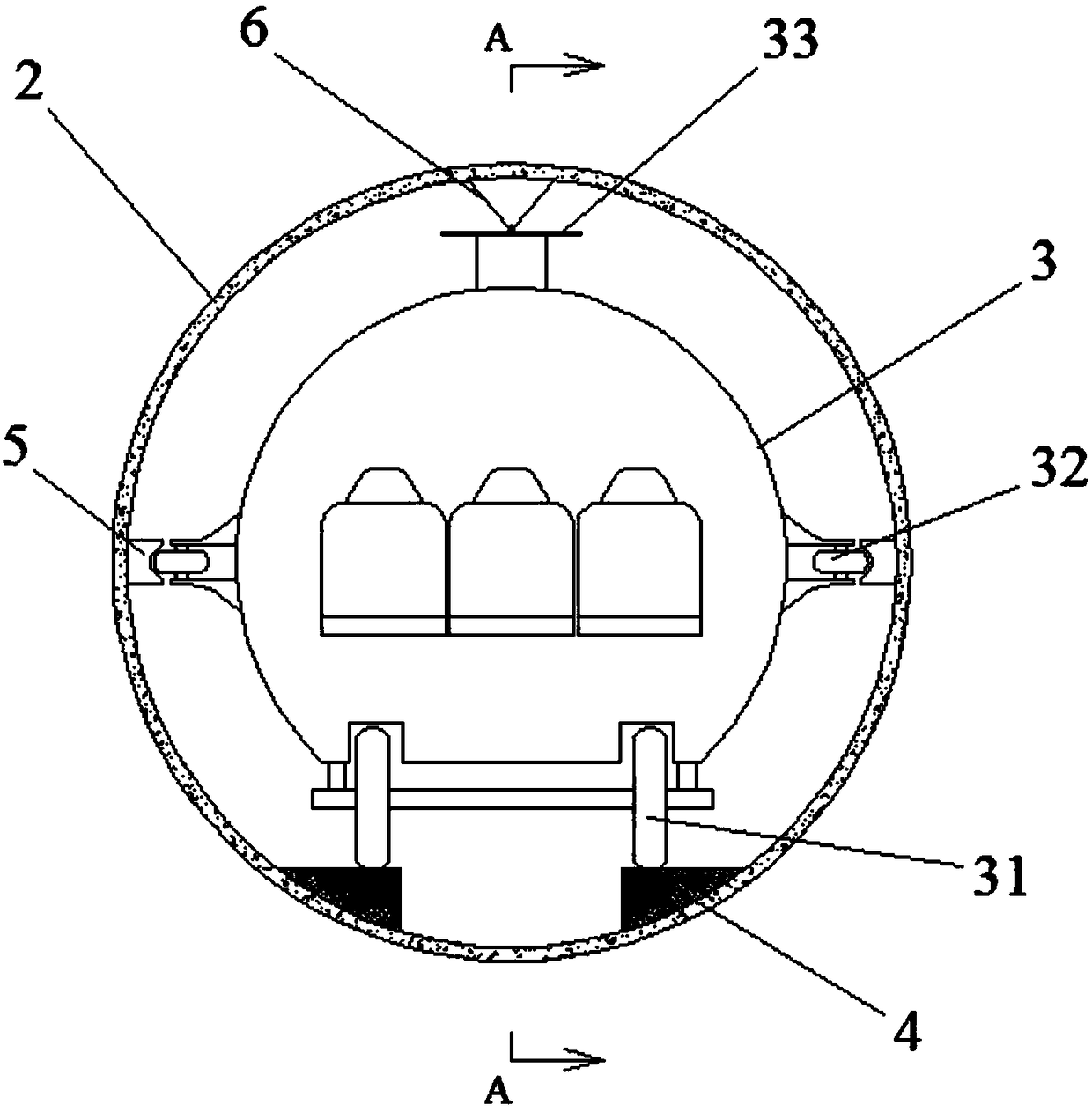

Undersea vacuum pipeline transportation system for wheeled vehicle equipped with side guide wheels

The invention discloses an undersea vacuum pipeline transportation system for a wheeled vehicle equipped with side guide wheels. The system comprises pipe piers arranged on a seabed. Pipelines are erected on the pipe piers. Smooth rail plates are laid at the inner bottoms of the pipelines. The side surfaces of the pipelines are equipped with side guide rails. The bottom of the vehicle is equippedwith wheels which roll on the rail plates. Two sides of the vehicle are both equipped with side guide wheels matching the side guide rails. The side guide wheels offer guide acting force to vehicle driving. The vehicle comprises an air-tight passenger cabin, in which a life guarantee system is arranged. A complicated and expensive guide system for rail traffic and road traffic is avoided. The structure features of pipelines are fully leveraged. Guide mechanisms are arranged for the vehicle. A wheeled vehicle scheme with mature technology and low cost is utilized in order to provide a cost-effective and easily-implemented technical scheme for the undersea vacuum pipeline transportation system across straits and bays.

Owner:XIJING UNIV

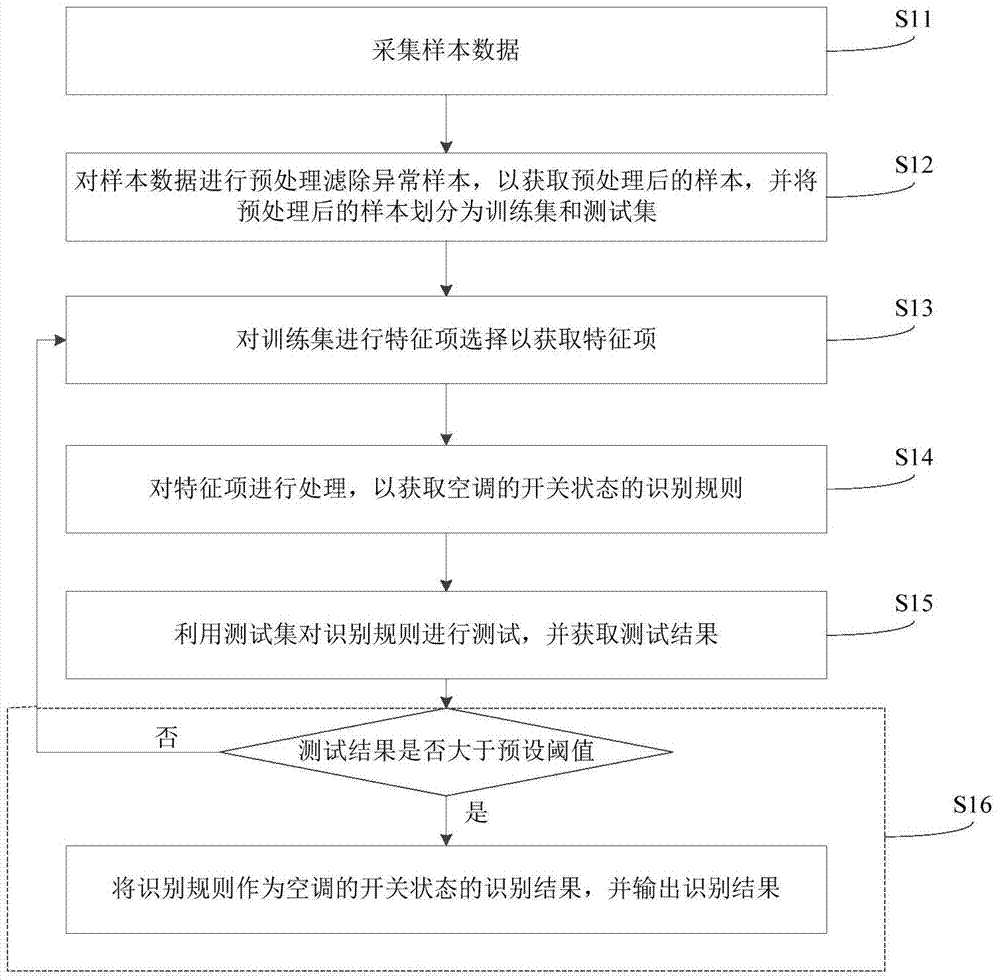

Identification method and system of on-off state of air conditioner and estimation method and system of on-off state of air conditioner

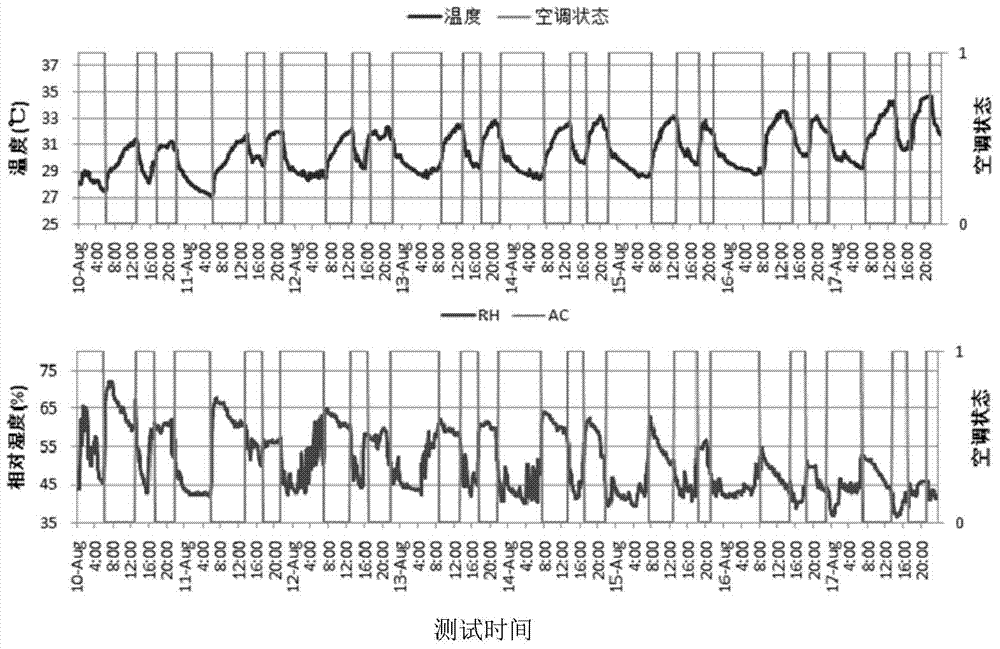

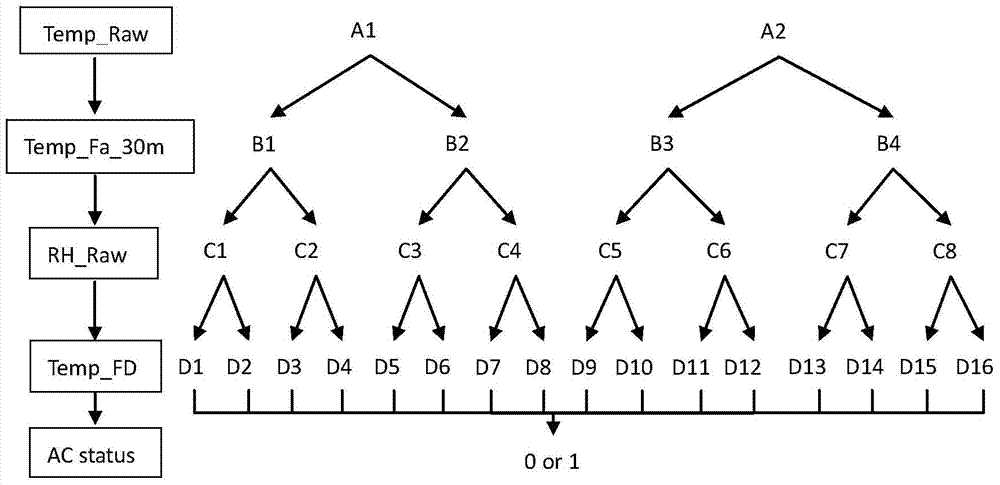

ActiveCN104748305AOvercome the inconvenience of long-term behavior recordsOvercome the costMechanical apparatusSpace heating and ventilation safety systemsItem selectionEstimation methods

The invention provides an identification method of the on-off state of an air conditioner. The identification method comprises the following steps that S11, sample data are collected; S12, the sample data are preprocessed, and abnormal samples are filtered out, so that preprocessed samples are obtained and divided to a training set and a testing set; S13, characteristic item selection is conducted on the training set to obtain characteristic items; S14, the characteristic items are processed to obtain identification rules of the on-off state of the air conditioner, wherein the rules comprise temperature and humidity sections and the corresponding on-off state of the air conditioner; S15, the testing set is used for testing the identification rules to obtain a test result; S16, whether the test result is larger than a preset threshold is judged, if yes, the identification rules are used as an identification result, and if not, the S13-S16 steps are executed repeatedly until sample data testing is completed. The method is high in accuracy, good in real-time performance, efficient and convenient to implement. The invention further provides an identification system of the on-off state of the air conditioner and an estimation method and system of the on-off state of the air conditioner.

Owner:智联华科技(北京)有限公司

Prefabricated cable trench applied to subsidence areas

ActiveCN106786321AOvercome costsOvercome long construction periodCable installations on groundBrickReinforced concrete

The invention discloses a prefabricated cable trench applied to subsidence areas. The cable trench comprises a plurality of pipe joint units. Each of the pipe joint units comprises a top plate, two side walls and a base plate, wherein two side edges of the top plate are connected with upper edges of the two side walls, two side edges of the base plate are connected with lower edges of the two side walls, and then a pipe-shaped structure with two ends open is formed; a bulgy portion is arranged in the middle of one end of each of the side walls while concave portions are arranged in the middles of other ends thereof, and the concave portions and the bulgy portions are corresponding in position and shape respectively; every two adjacent pipe joint units are connected detachably through the concave portions and the opposite bulgy portions. The prefabricated cable trench applied to the subsidence areas has the advantages that disadvantages including high construction and maintenance costs, long construction time and severe environmental impacts of a traditional cast-in-place reinforced concrete or bricked cable trench can be overcome, and the economic and environment-friendly prefabricated cable trench high in production precision can be produced mechanically.

Owner:SHANGHAI ELECTRIC POWER DESIGN INST

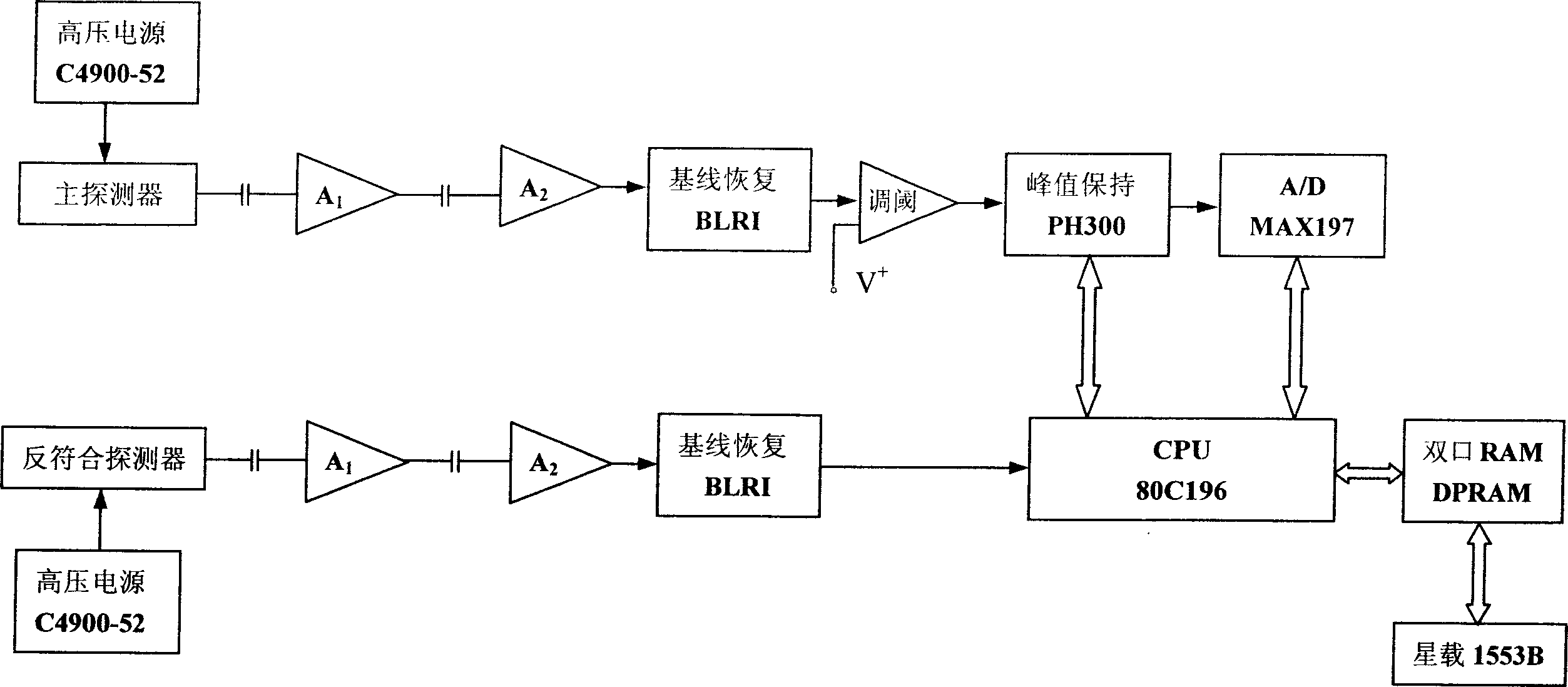

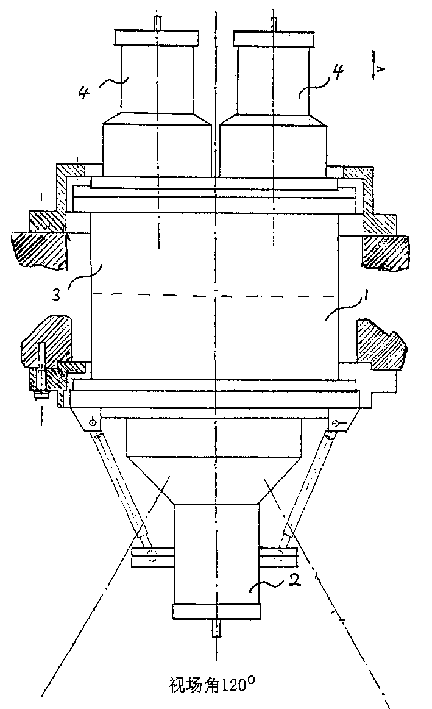

Special gamma spectrograph for moon exploration

InactiveCN1421708AIncrease the receiving areaHigh sensitivityX/gamma/cosmic radiation measurmentSpectrographData acquisition

The special gamma spectrograph for moon exploration is provided with crystal scintillator connected to photomultiplier tube and data acquisition circuit successively and features that there are main detector and anticoincidence detector with scintillator connected to one other photomultiplier tube and that the photomultiplier tube of both the main detector and the anticoincidence detector are connected to the data acquisition circuit simultaneously. The data acquisition circuit has microprocessor. The novel gamma ray detection instrument has high sensitivity, low cost, optimal background radiation inhibiting effect and increased detector effective area. The optimal scheme has CsI (Ti) crystal in anticoincidence detector and crystal scintillator of several crystals adhered together.

Owner:ZIJINSHAN ASTRONOMICAL OBSERVATORY CHINESE ACAD OF SCI

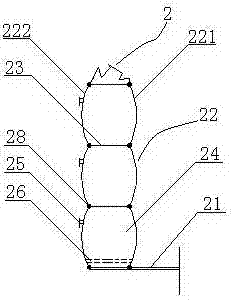

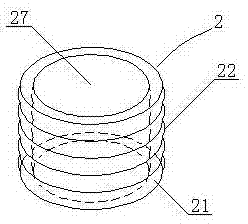

An inflatable multi-stage water bag loading test pile method and its device

The invention discloses a test pile loading method and device of an inflatable multistage water bag, belonging to the technical field of pile loading tests. The test pile loading device comprises a support device, a multistage water bag, a water bag inflation system and a water bag water injection system. The inflatable multistage water bag is divided into a plurality of layers and can be folded for storage and carrying usually. The bottom layer of the water bag is shaped as a circle, and the side wall of the water bag is provided with a plurality of independent annular gas storage bins. During the use, the gas storage bins are inflated from bottom to top by layers, the inflated water bag can automatically stand by stages to form a cylindrical water storage space for loading, and the peripheral arc line of the cylindrical water storage space is matched and fixed with the support device. The height of the multistage water bag can be regulated according to the quantity of the inflated gas storage bins, thus loading requirements on different water storage capacities are met. After the loading is finished, water in the water bag is discharged, and then gas in the gas storage bins is emitted from top to bottom, thus the water bag can be collected. The invention has the advantages of simple calculation, safety and reliability, simple equipment and convenience for construction.

Owner:SHAOXING UNIVERSITY

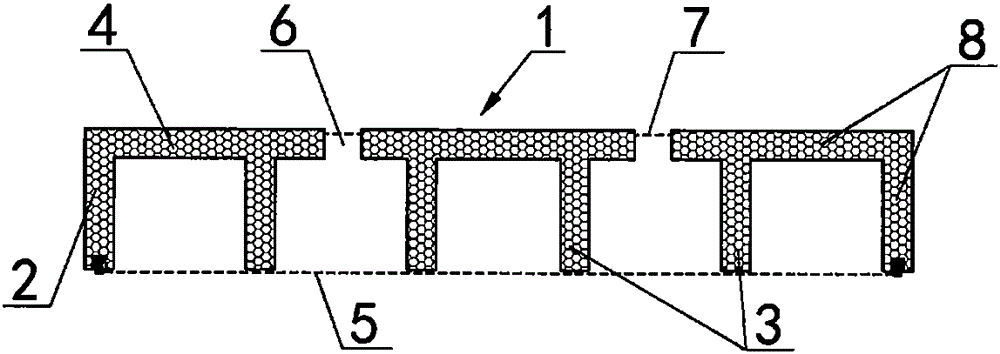

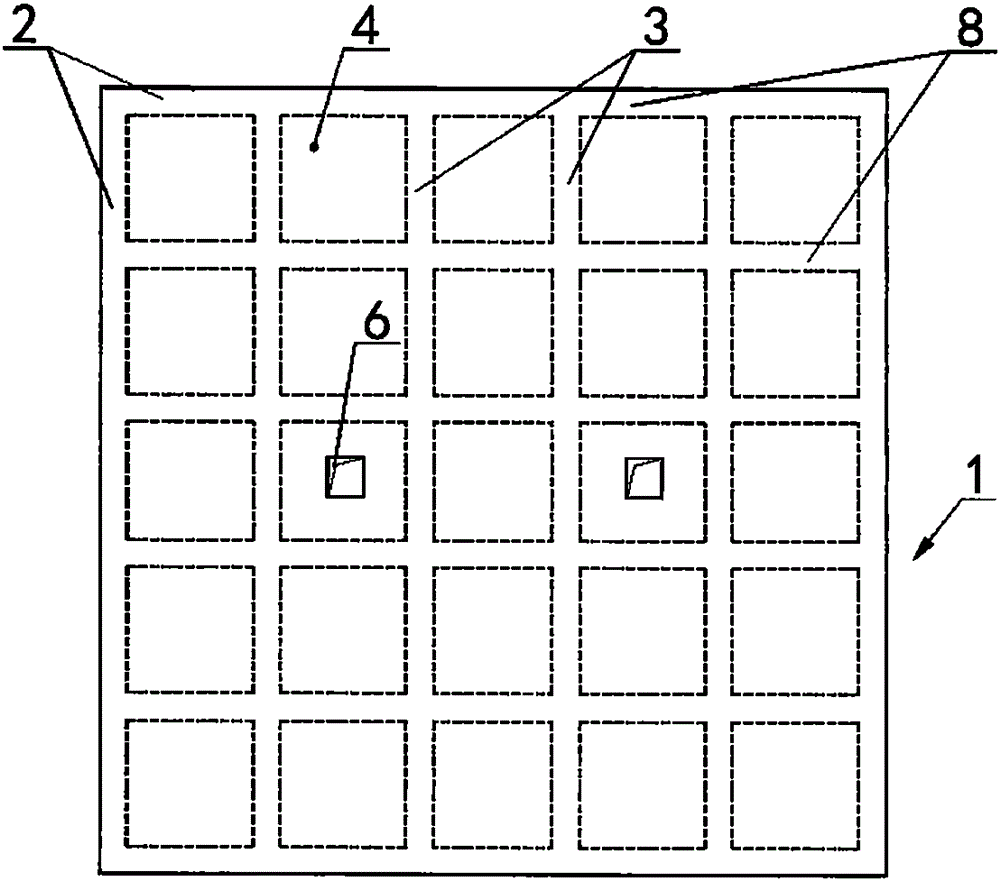

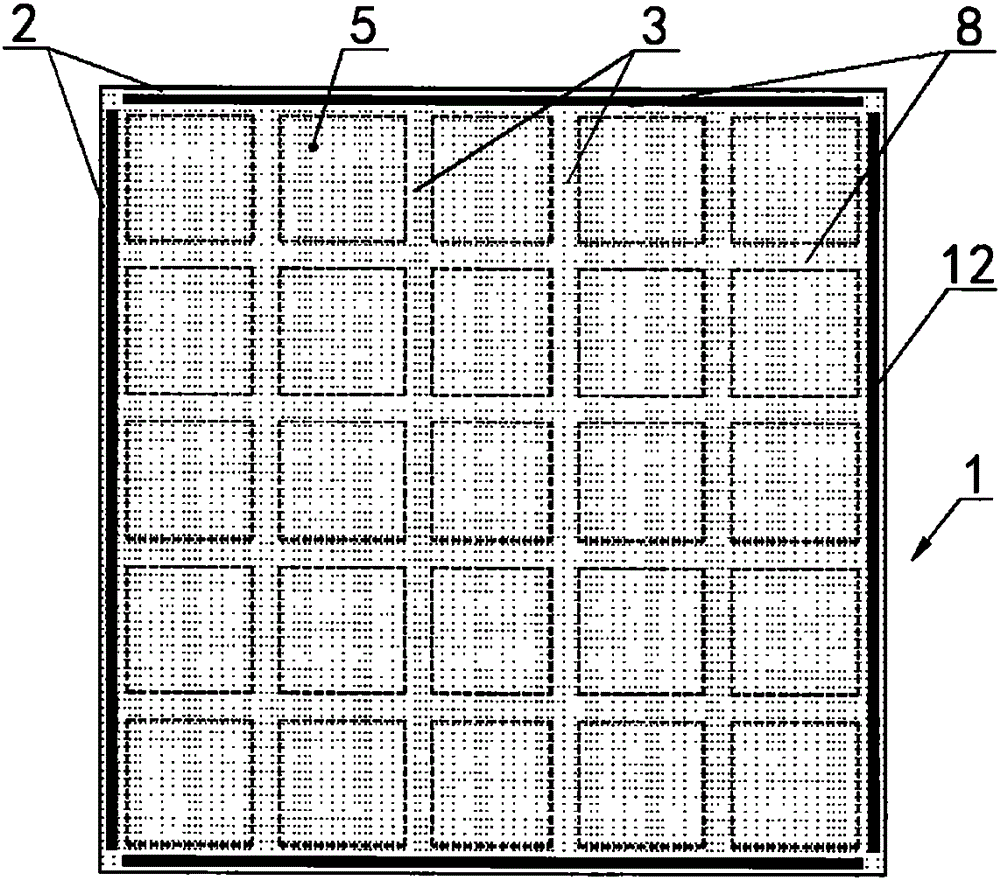

Filling box with bottom ventilation net and upper part exhaust holes

The invention relates to a filling box with a bottom ventilation net and upper part exhaust holes and a manufacturing method of the filling box, and belongs to the field of building construction. The filling box (1) comprises side frame plates (2), stiffening inner plates (3), a top cover plate (4) and the ventilation net (5), wherein the four side frame plates (2) in end-to-end connection define a rectangular plane; more than one stiffening inner plate is at least arranged in each direction; the stiffening inner plates in different directions are in mutual orthogonality; at least one exhaust hole (6) is formed in the top cover plate; an exhaust net (7) is arranged in each exhaust hole; the top cover plate, the stiffening inner plates and the side plate plates made of nonmetallic materials form a box-shaped structure (8) with an open bottom surface together; the ventilation net is fixed on the bottom of the box-shaped structure in various connecting modes; and the ventilation net and the exhaust nets are made of metal or plastic materials. The filling box provided by the invention has the advantages that the production, the transportation and the installation are very convenient; the mechanical property is good; and a hollow floor slab formed by the product has high reliability, good earthquake-resistant performance and good anti-crack performance.

Owner:北京东方京宁建材科技有限公司

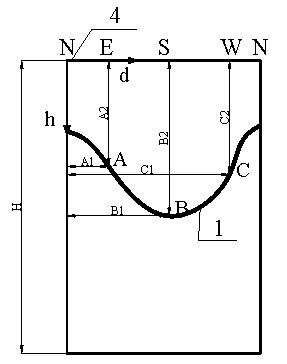

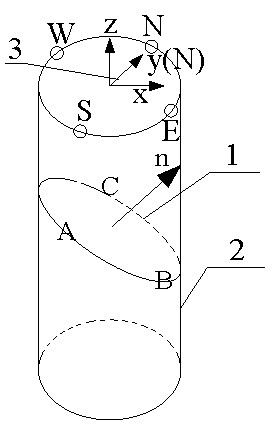

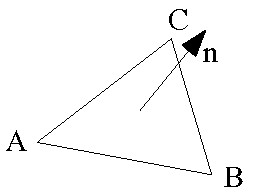

Method for determining deep rock structural surface attitude by utilizing television image of single vertical drilling hole

InactiveCN102419457AObjective Local Occurrence FeaturesObjectively reflect the characteristics of local occurrenceOptical prospectingImage extractionGeomorphology

The invention relates to a method for determining a deep rock structural surface attitude by utilizing a television image of a single vertical drilling hole. The method comprises the following sequential steps of: 1. marking a geographic orientation point on a drilling hole and carrying out drilling television and image extraction; 2. marking a corresponding geographic orientation point on a television spreading image and establishing a two-dimensional coordinate system; 3. marking the rock structural surface to be determined on attitude, on the image, selecting three non-collinear points from the structural surface and measuring plane coordinate values of the three non-collinear points; 4. coiling the image into a cylinder according to the drilling hole shape, vertically arranging the cylindrical image and establishing a three-dimensional rectangular coordinate system; and 5. calculating a vector of a structural surface normal by applying a space vector geometric theory and calculating the attitude of the structural surface. The method is favorable for overcoming the defects of high cost for determining the deep structural surface by three drilling holes, large same structural surface identification errors and poor precision of other geophysical prospecting methods relative to a small-scale structural surface, and the like, can be used for fully utilizing the structural surface information of the single drilling hole and is adapted to the statistic analysis of various structural surface attitudes.

Owner:CHONGQING UNIV

Electric driving membrane treatment process for acid bath wastewater in viscose fiber production

InactiveCN106868635ARealize deep recoveryEnvironmentally friendlySemi-permeable membranesArtificial filament recoveryZinc hydroxideSulfate

The invention provides an electric driving membrane treatment process for acid bath wastewater in viscose fiber production. The electric driving membrane treatment process comprises the following steps: A, pre-treating an acid solution after spinning; B, conveying the pre-treated acid solution after spinning to an electrodialysis membrane module for electrodialysis treatment, and when the contents of sulfuric acid, sodium sulfate and zinc sulfate in a receiving liquid achieves the technical requirements of an acid bath before spinning, performing recovery for spinning; C, performing acid-base neutralization of the raw material liquid subjected to electrodialysis, adjusting the pH value to 8-10 to generate sodium sulfate and zinc hydroxide precipitation, and performing solid-liquid separation to obtain a sodium sulfate solution and a zinc hydroxide solid; and D, conveying the sodium sulfate solution and the acid bath solution after spinning to a bipolar membrane apparatus, performing electrodialysis to recover acid and base, and directly using the acid bath solution and the base solution obtained from electrodialysis to the production system. Deep recovery of sulfuric acid from the acid bath after spinning is achieved, and the acid bath before spinning is directly formed and reused to the production system. According to the process, steam consumption is prevented, and inventory problem of sodium sulfate is solved.

Owner:YIBIN GRACE GROUP CO LTD

Method for shortening mango breeding period

ActiveCN109197206AShorten the flowering and fruiting cycleLow lignificationGraftingCultivating equipmentsFruit treeHybrid seed

The invention discloses a method for shortening the mango breeding period and belongs to the technical field of fruit tree breeding. According to the method, a four-season honey mango is selected as arootstock tree, a hybrid parent is grafted to obtain hybrid seeds, hybrid seed seedlings are sown and cultivated at the right time, old-mature strong buds of first shoots taken out from the seedlingsare used as scions, the scions are grafted at the top of mother branches of the four-season honey mango adult tree which are about to bloom, the flowering hormone accumulated and formed by the adultfruit branches are utilized to induce the scion shoots which are still in childhood, and the grafted shoots can blossom and bear fruit 3 to 5 months after grafting. Flowering and pollination are carried out through utilizing blow flies, and the flowering result rate is over 90%. The method is simple and easy to perform, 10 months are required from sowing and seedling to flowering, hybrid offspringcan be initially evaluated and selected, new varieties can be selected within 2 to 3 years, and the mango hybrid breeding period is greatly shortened.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI +1

Method for measuring forward tensile strength of welding spots and fixtures

ActiveCN101900651AOvercome formability disadvantagesOvercoming processabilityMaterial strength using tensile/compressive forcesWelding apparatusEngineeringSpot welding

The invention provides a method for accurately measuring forward tensile strength of welding spots and fixtures which are not limited by mouldability of a material. The method comprises the following steps: firstly drilling through holes of the same position and size on two test boards, wherein the through holes are uniformly distributed on one circumference and comprise first through holes with larger bore diameter and second through holes with smaller bore diameter, and the first through holes and the second through holes have equal number and alternately arranged; selecting two fixtures, and drilling through holes with the same position and size as those of the test boards on mounting surfaces of the two fixtures; stacking the two test boards together for spot welding to form the welding spots at the center of the circumference of the first through holes and the second first through holes, and respectively fixing the fixtures with the test boards at the same side by bolts and nuts; and finally stretching the two fixtures at a certain stretching speed until the welding spots of the test boards are ruptured, recording experimental data and carrying out tensile load-displacement curve analysis.

Owner:CHERY AUTOMOBILE CO LTD

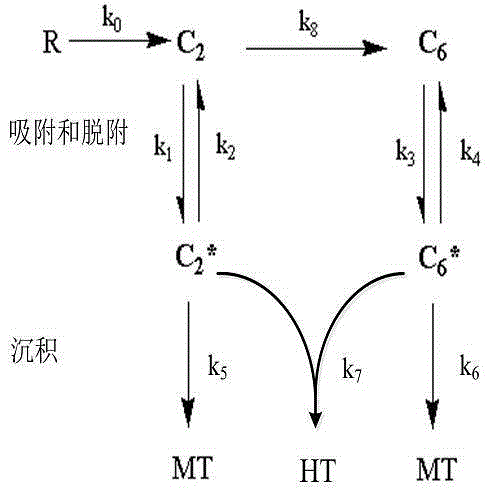

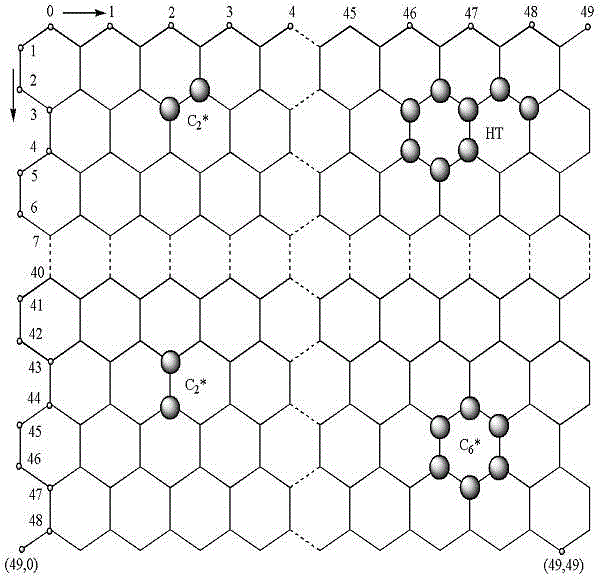

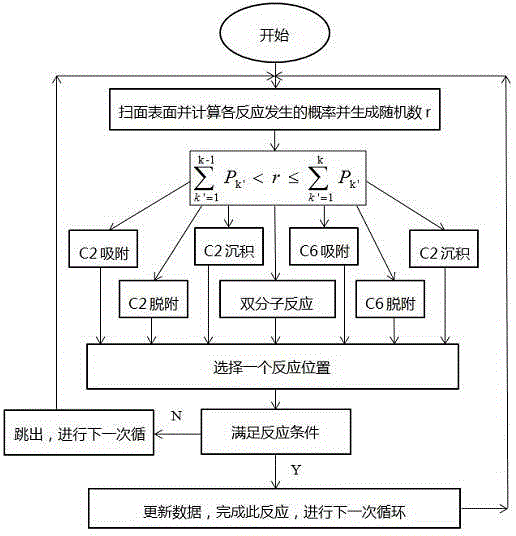

Monte carlo based method for simulating carbon/ carbon composite material texture

InactiveCN104573370ATime consuming to overcomeOvercome the costSpecial data processing applicationsCarbon compositesPyrolytic carbon

The invention discloses a monte carlo based method for simulating a carbon / carbon composite material texture. The method comprises the steps of performing chemical kinetics modeling for pyrolytic carbon matrix deposition; performing monte carlo modeling for pyrolytic carbon deposition process; compiling C++ program of simulated pyrolytic carbon deposition process; setting the program into 20000 MCS, wherein 1MCS=50*50 cycles; the simulation results are drawn into a map. According to the method, the characteristic of monte carlo simulation randomness is utilized successfully; the deposition of pyrolytic carbon on the matrix surface during CVI process is simulated, so as to really reflect the influence of the CVI process parameters to the whole reaction process; the method is of good technical guide significance for industrial production.

Owner:SHANGHAI UNIV

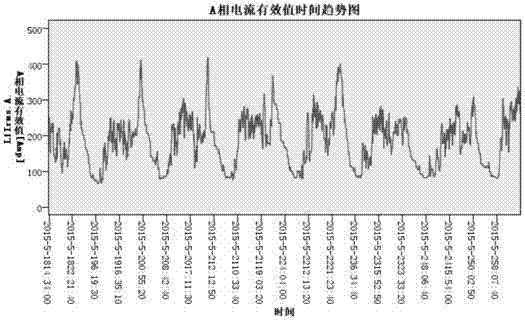

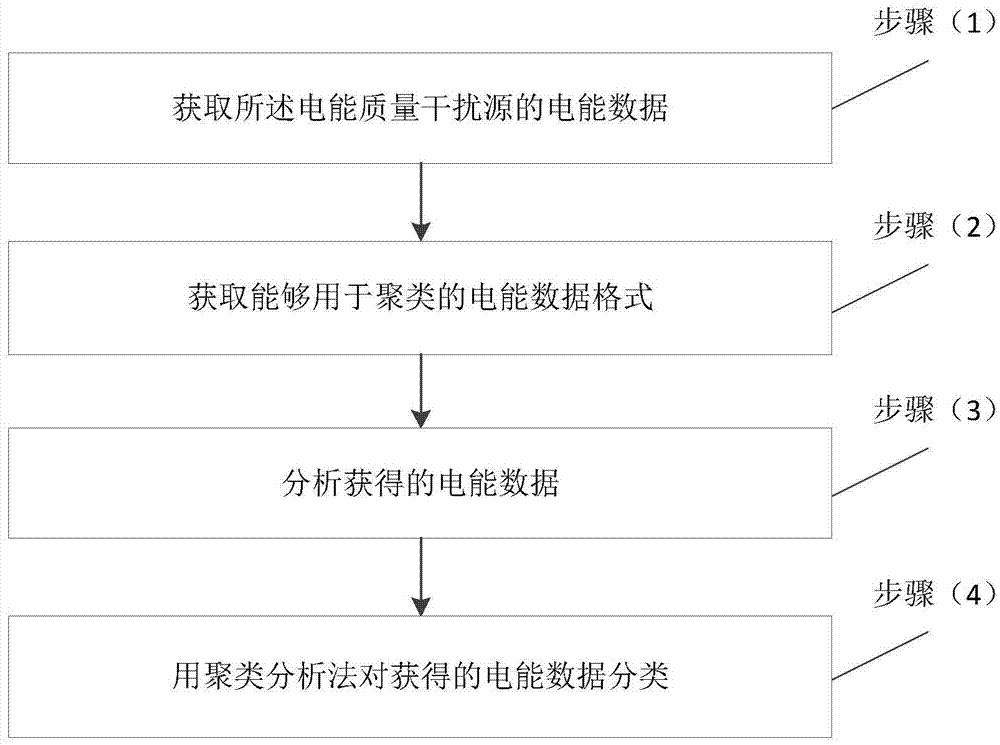

Power quality disturbance source working condition identifying method

ActiveCN105445577AOvercome efficiencyOvercome the costElectrical testingPower qualityLarge scale data

The invention relates to a power quality disturbance source working condition identifying method comprising the following steps: (1) acquiring power data of a power quality disturbance source; (2) acquiring a power data format which can be used for clustering; (3) analyzing the acquired power data; and (4) classifying the acquired power data using a clustering analysis method. The method provided by the invention overcomes the defects of the traditional power quality analysis method such as low efficiency, high cost and unsuitability for large-scale data set processing, is practical and efficient in the aspect of power quality disturbance source working condition identification, and is of low cost and good performance.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com