Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Simple energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

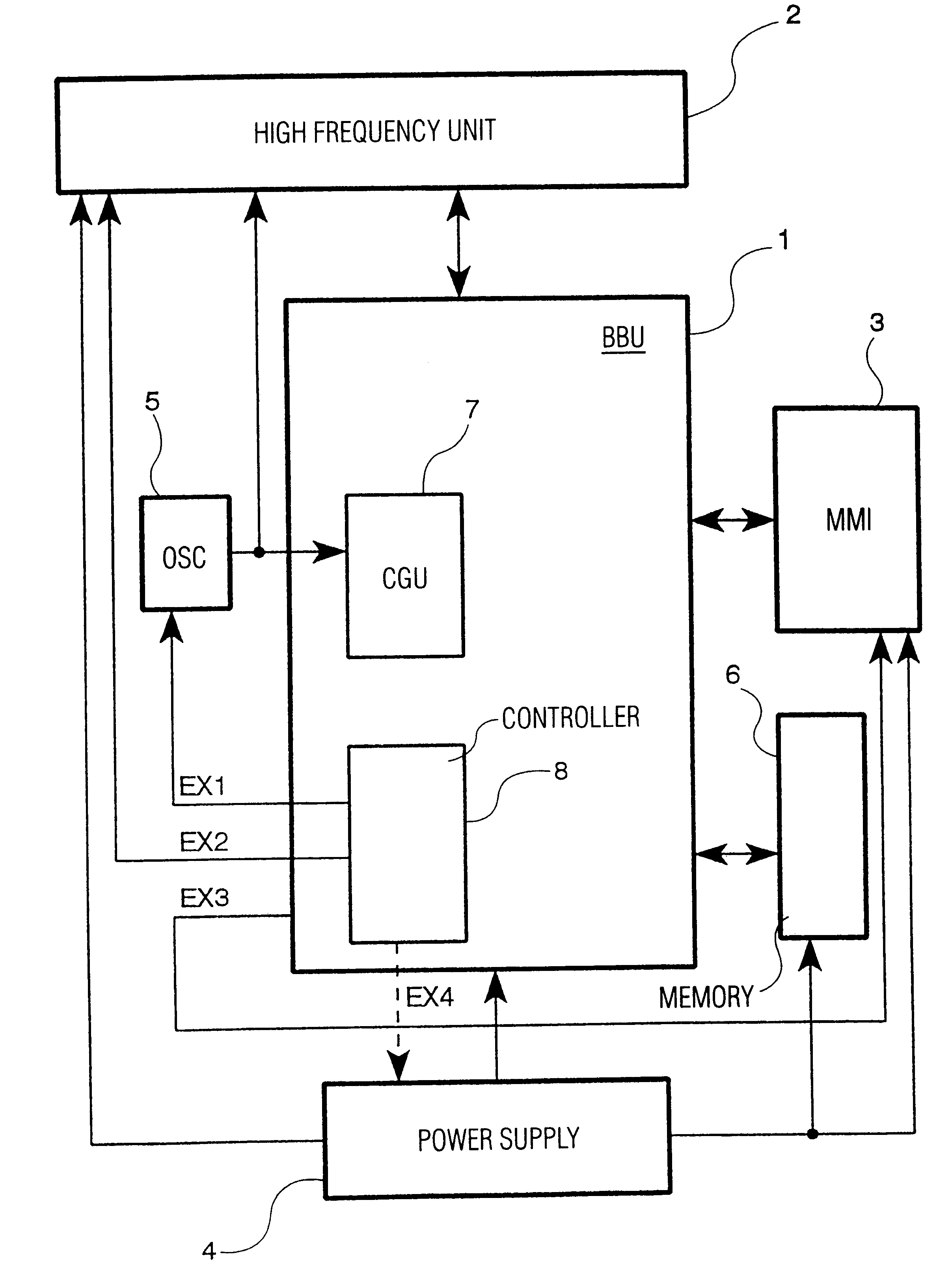

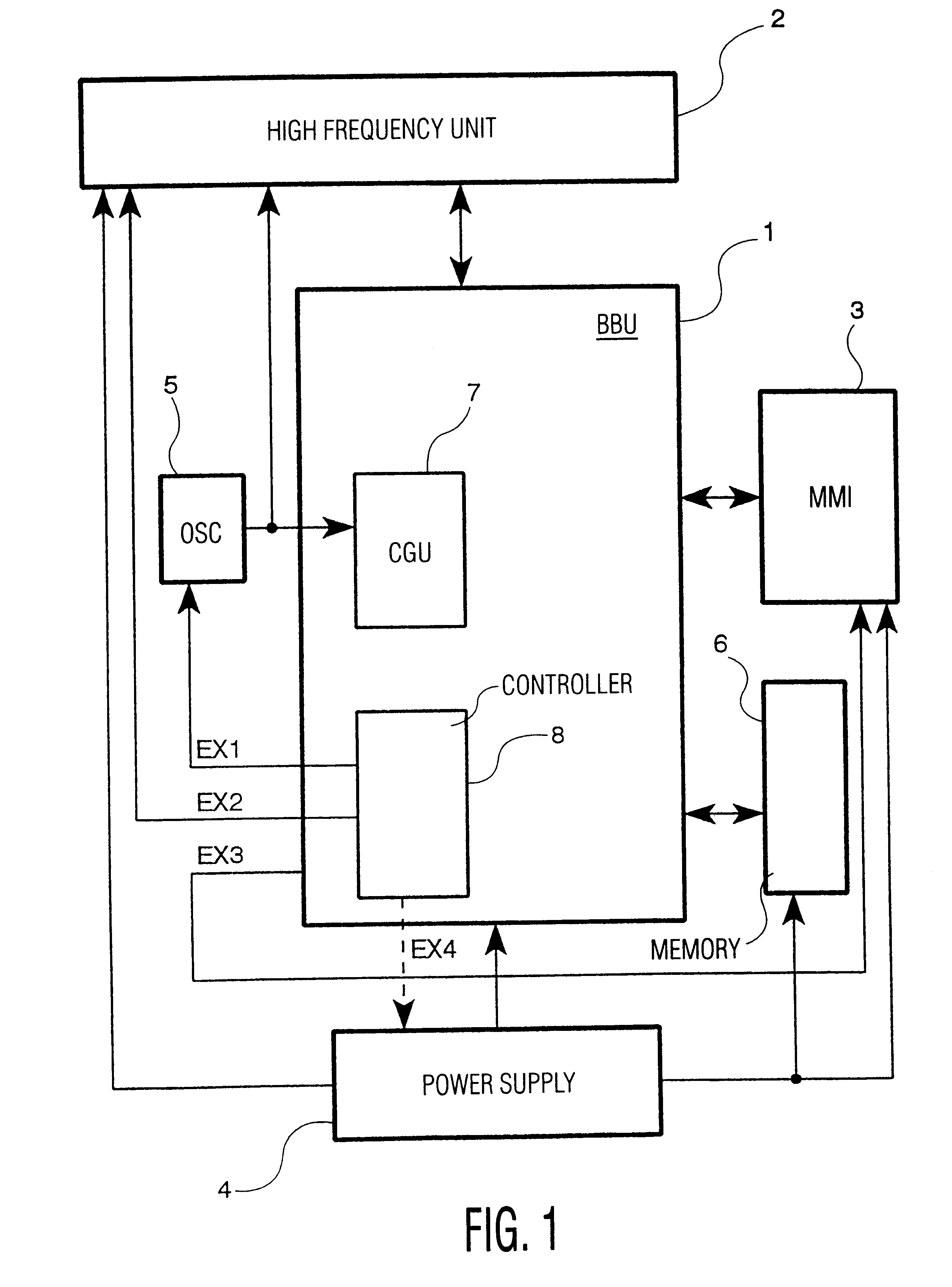

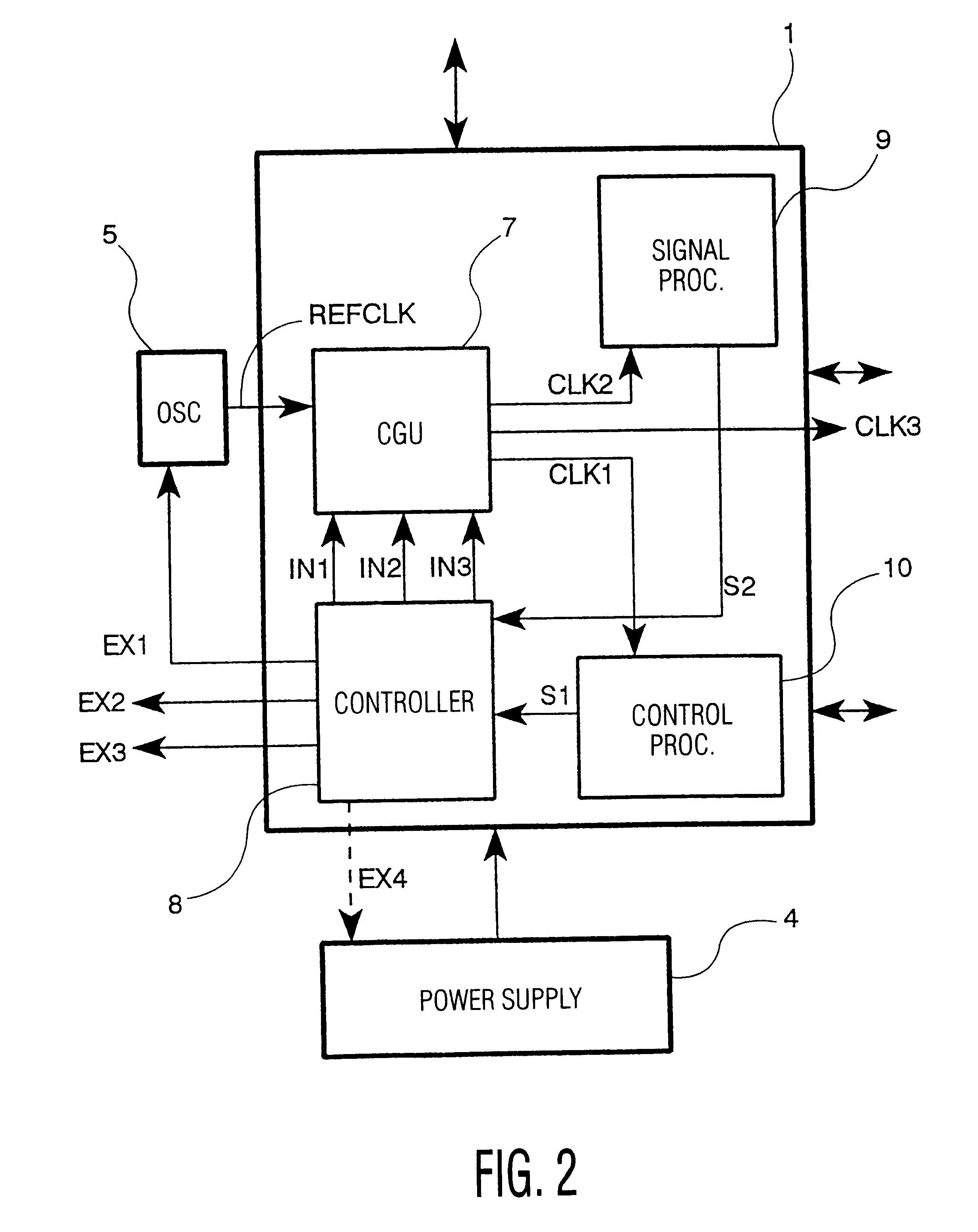

Mobile radio telephone set

InactiveUS6442407B1Reduce energy consumptionIncrease the supply rateCordless telephonesEnergy efficient ICTOperation modeSignal processing

The invention discloses a mobile radio telephone set including at least one control processor and at least one signal processor which are at least occasionally not in an active mode. To reduce the energy consumption of the mobile radio telephone set in the simplest manner possible, a control unit selects operating modes at least for the control processor and / or the signal processor. By utilizing a separate control unit, more particularly two or more coupled processors or other switching units of the whole mobile radio telephone set may be controlled independently. Each coupled unit may at once individually be set to its own operating mode to operate only the currently necessary units in this manner and reduce the energy consumption in this manner.

Owner:TELEFON AB LM ERICSSON (PUBL)

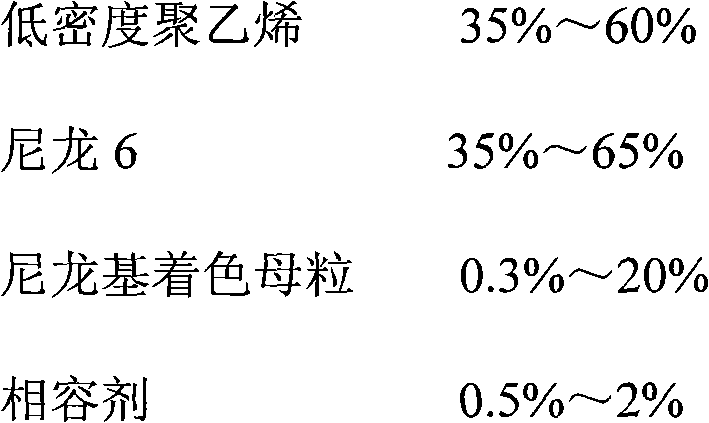

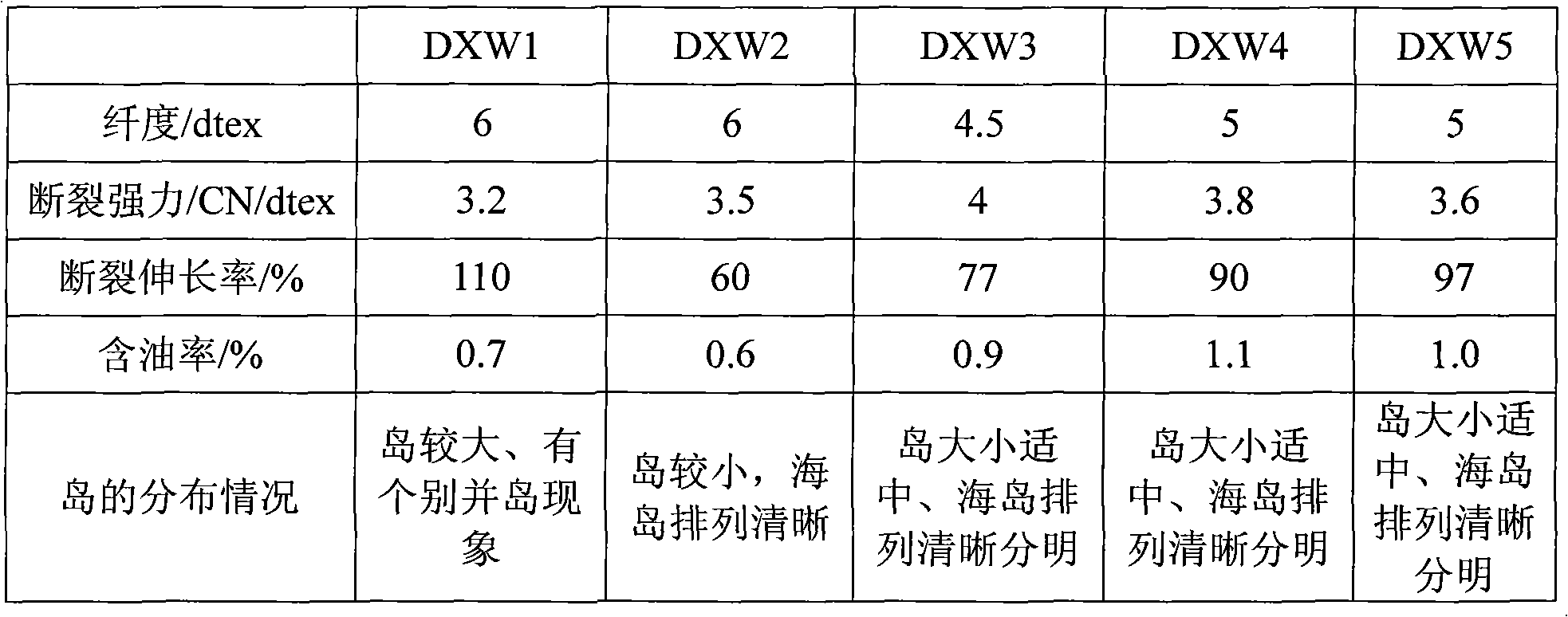

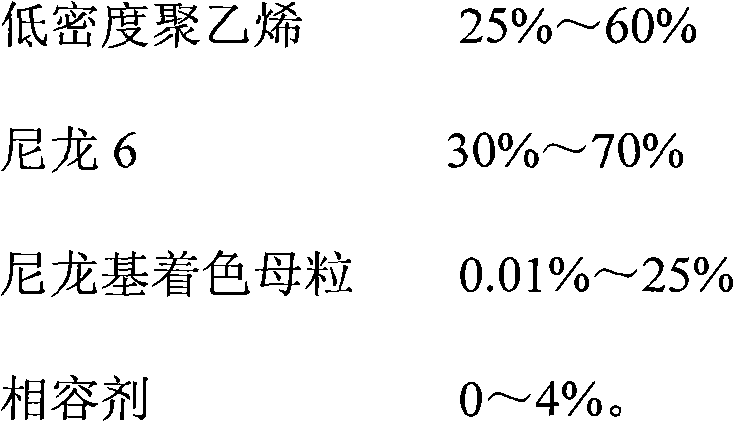

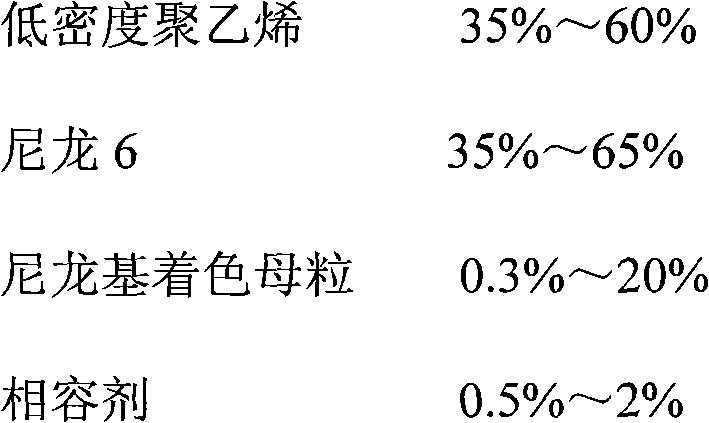

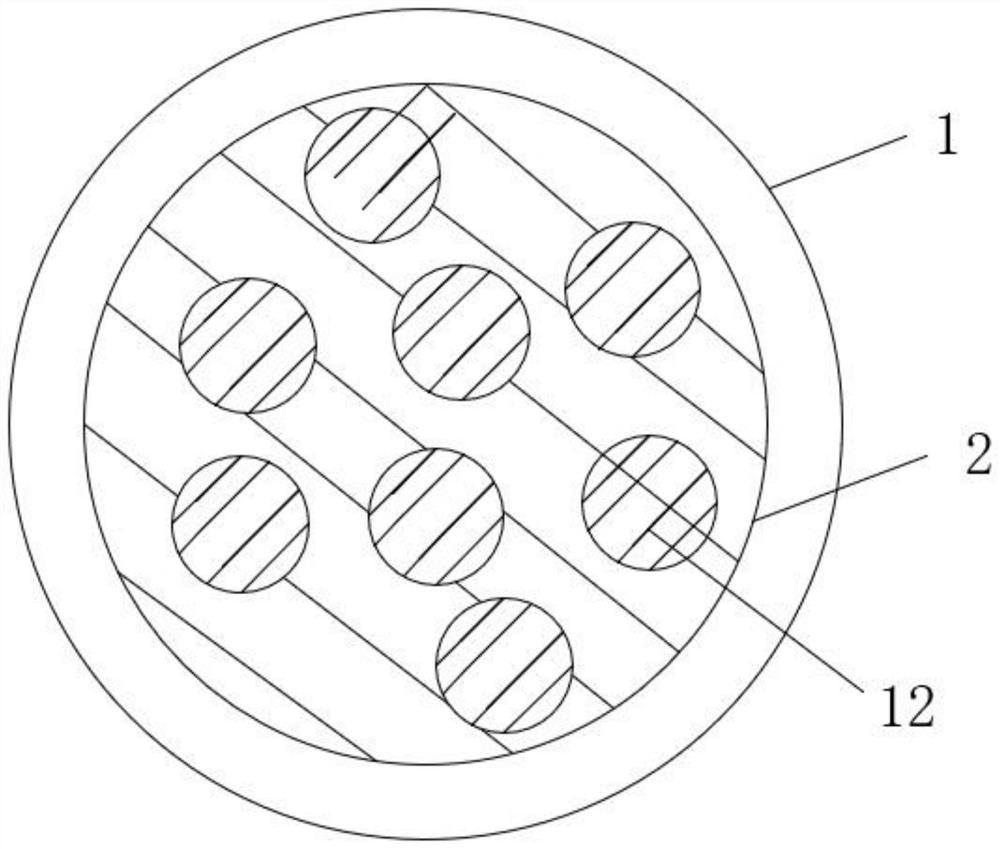

Color fixed island composite short fiber and preparation method thereof

ActiveCN102650081AColorfulUniform colorFilament/thread formingConjugated synthetic polymer artificial filamentsLow-density polyethyleneCarding

The invention provides a color fixed island composite short fiber and a preparation method thereof. The color fixed island composite short fiber comprises the following components by weight: 25-60 percent of low density polyethylene, 30-70 percent of nylon (6), 0.01-25 percent of nylon base coloring master batch and 0-4 percent of compatilizer. Compared with the prior art, the number of the islands of the color fixed island composite short fiber is fixed, as well as the size and the distribution of the short fiber are regular; color super-fine fiber synthetic leather prepared by adopting the preparation method has the advantages of bright and uniform color, high color fastness, no color difference between different batches, uniform carding, strong woolen sensation, high abrasion resistance, easiness in removing of dust after leather abrading, low probability of dust dropping during friction and the like; and besides, high energy consumption and high pollution dyeing process is simplified, and the preparation cost is reduced to a great extent.

Owner:HUAFON MICROFIBER SHANGHAI

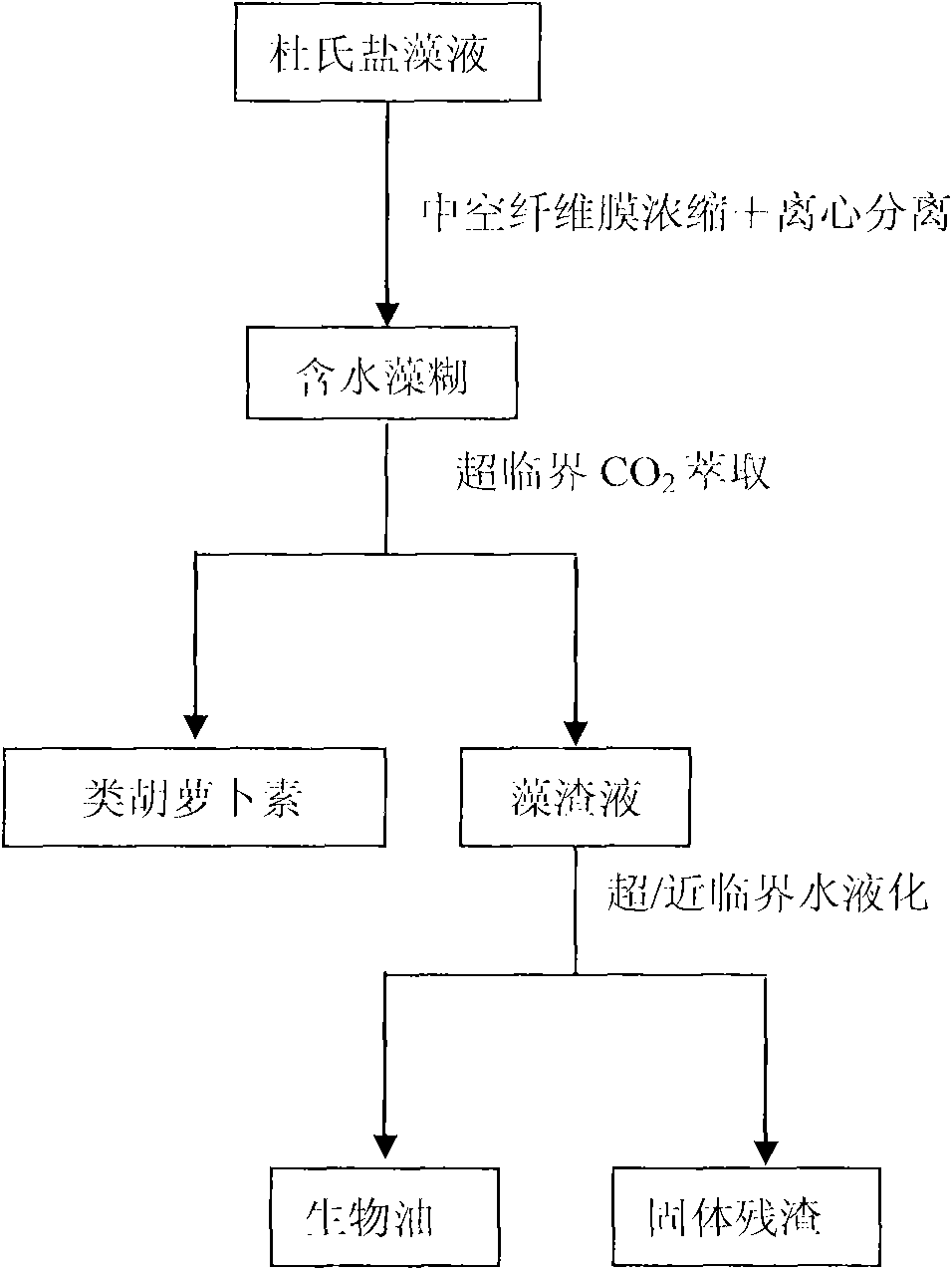

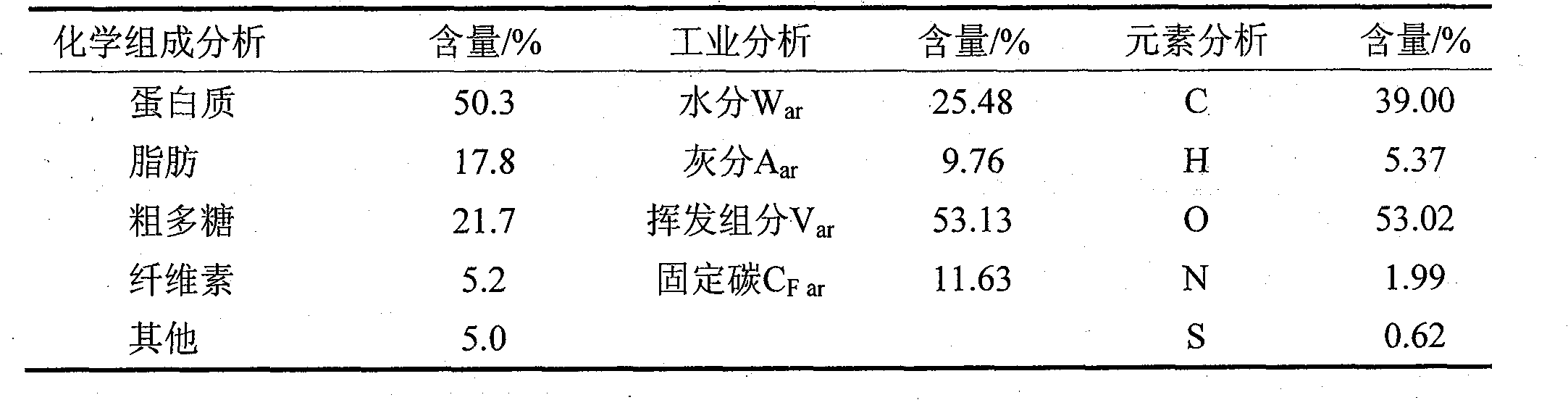

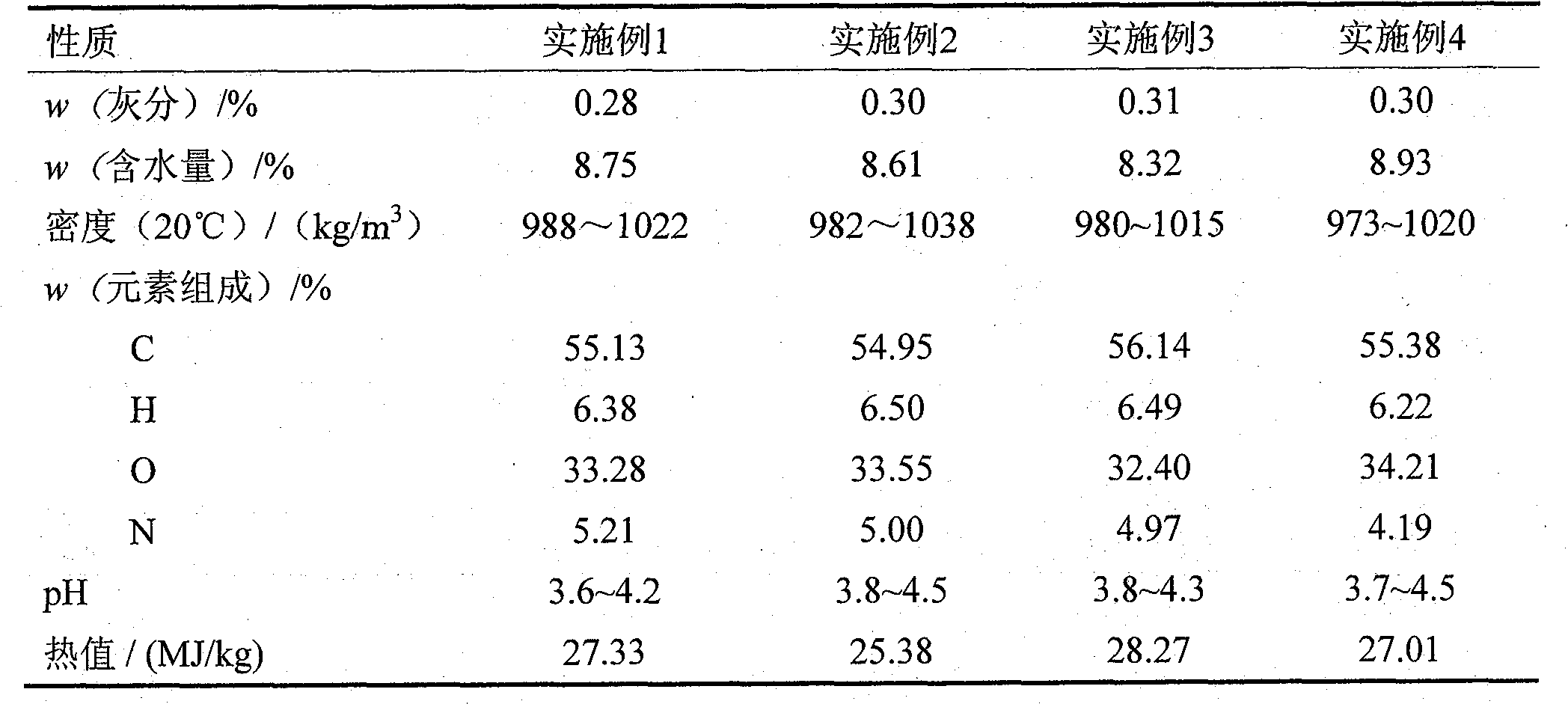

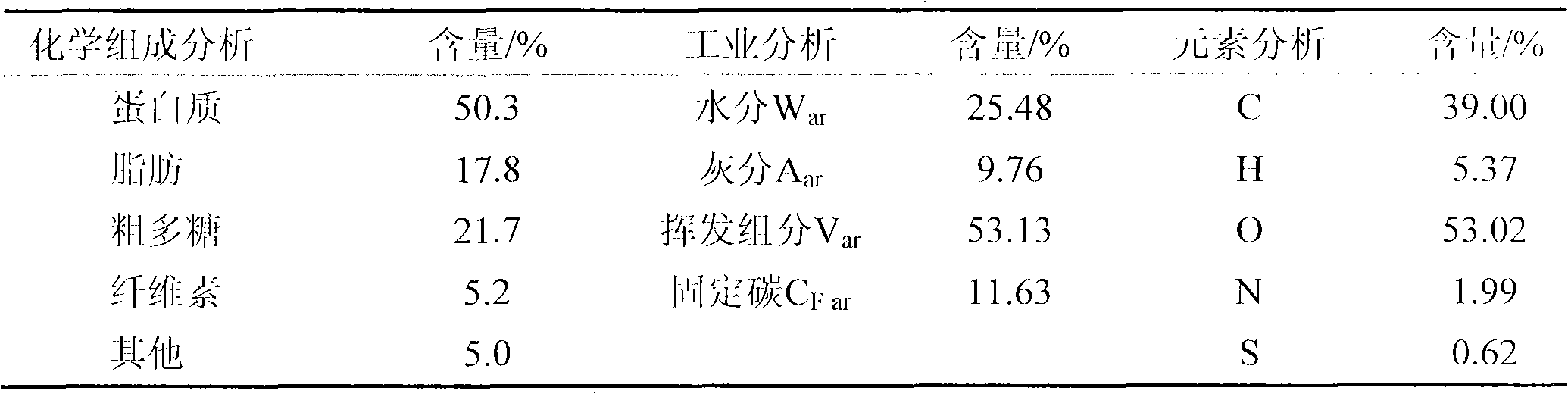

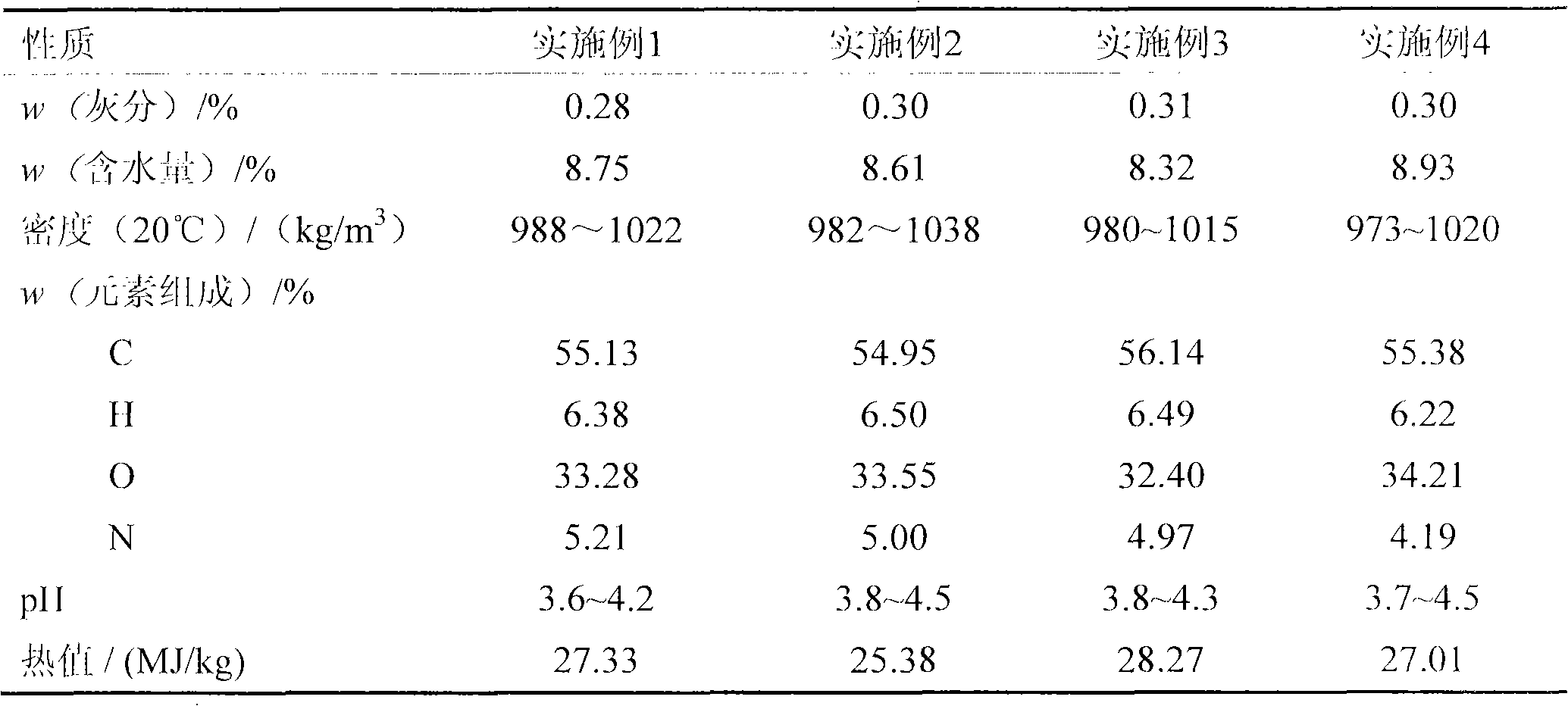

Method for extracting carotenoid and liquid biological fuel from Dunaliella sallina

ActiveCN101774956AHigh yieldHigh calorific valueOrganic chemistryLiquid hydrocarbon mixture productionFiberCarotenoid

The invention discloses a method for extracting carotenoid and liquid biological fuel from Dunaliella sallina, which belongs to the technical fields of bioactive substance extraction and biological energy. The method comprises the following steps of: concentrating a Dunalielle sallina liquid by using a hollow fiber membrane and a centrifugal separation method to obtain an aqueous sallina paste, extracting the aqueous sallina paste by using supercritical carbon dioxide to obtain a carotenoid product and a sallina residue liquid, and liquefying the sallina residue liquid by using supercritical / near-critical water to obtain the biological fuel. The invention has the advantages of no need of drying raw materials, low energy consumption, environment protection for entire process, simple technology, high utilization ratio of equipment, conduction of extraction using supercritical carbon dioxide and liquefaction using supercritical / near-critical water in the same reaction kettle, high yield of carotenoid and the biological fuel, low production cost and suitability for large-scale production.

Owner:TSINGHUA UNIV

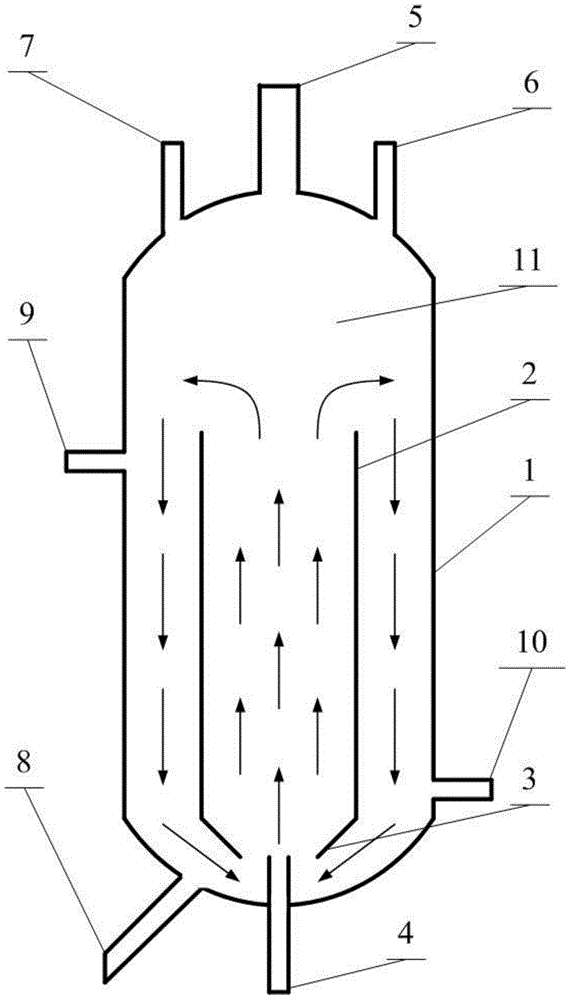

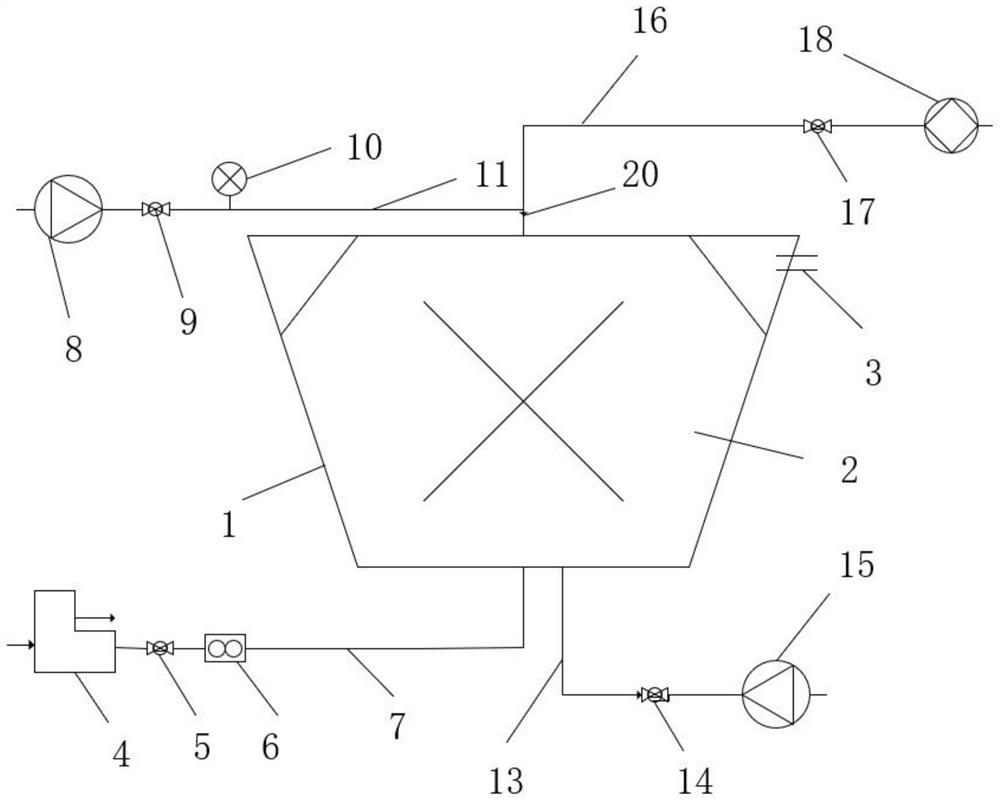

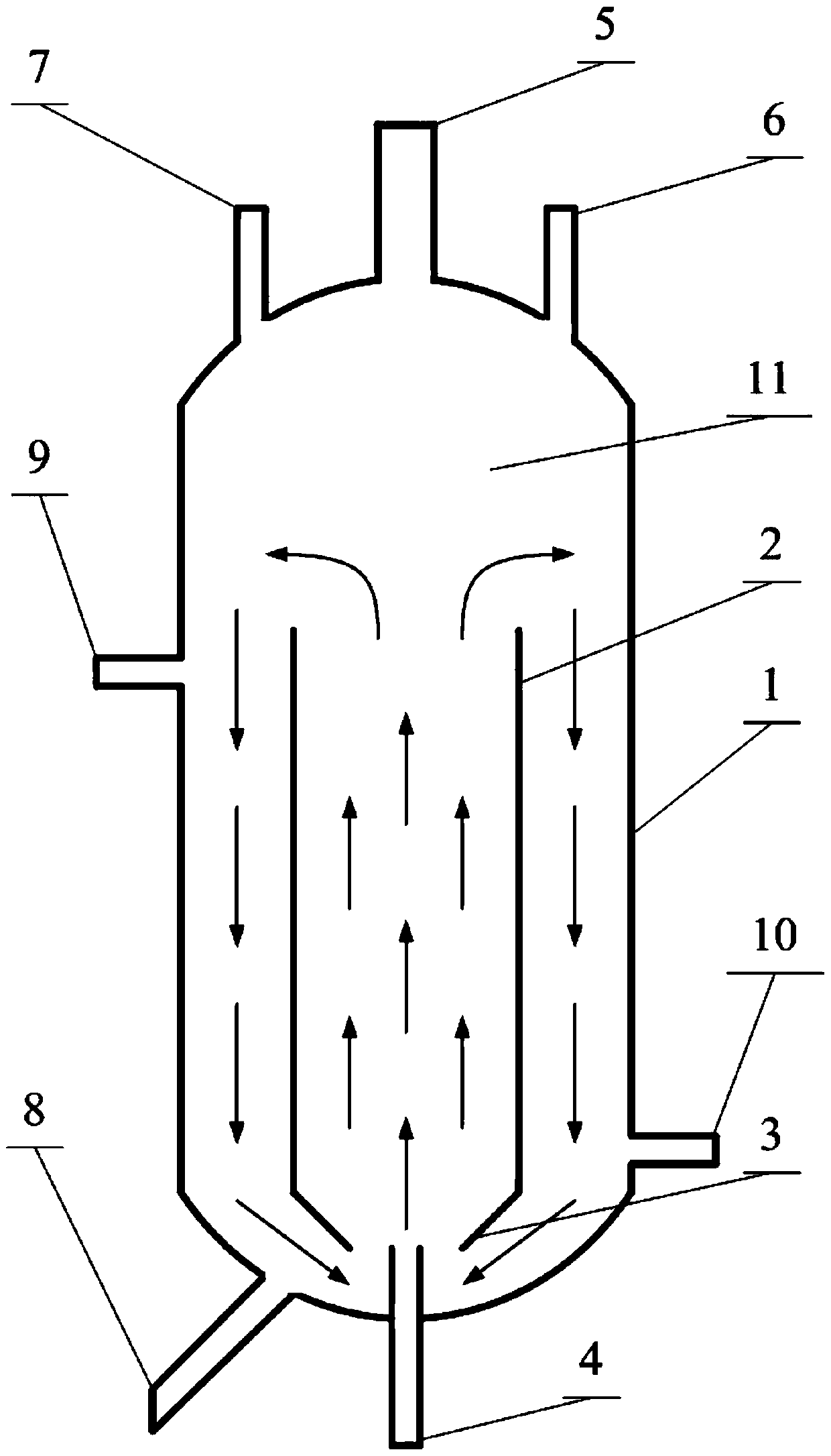

Reactor for mineralization fixation of carbon dioxide by fortified calcium-base solid wastes in ammonia medium system and application method thereof

InactiveCN104907010AReduce consumptionIncrease profitCalcium/strontium/barium carbonatesTransportation and packagingReaction temperatureHigh pressure

The invention relates to a reactor for mineralization fixation of carbon dioxide by fortified calcium-base solid wastes in an ammonia medium system and an application method thereof. The invention is characterized in that a pressurized loop reactor is used in the ammonia medium system's fortified calcium-base solid wastes mineralization fixation process of carbon dioxide. During the process, the reaction temperature is 60-200 DEG C, duration time of the reaction is 5-60 min, CO2 gas partial pressure is 1-40bar, and CO2 gas concentration is 20-99.99%. By the adoption of the pressurized loop reactor, defects such as high kinetic energy consumption of a stirred-tank reactor, large sealing difficulty of an overpressure system, easy deposition of solid materials in a mechanical agitation-free bubble column reactor and the like are overcome. The reactor provided by the invention has advantages as follows: pneumatic stirring replaces mechanical agitation; energy consumption is low; and the reactor is easy to process and is simple to clean, maintain and operate. The reactor is especially suitable for the ammonia medium system's fortified calcium-base solid wastes mineralization fixation process of carbon dioxide, has characteristics of high pressure gas and high solid content, and is easy for industrial scale-up.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

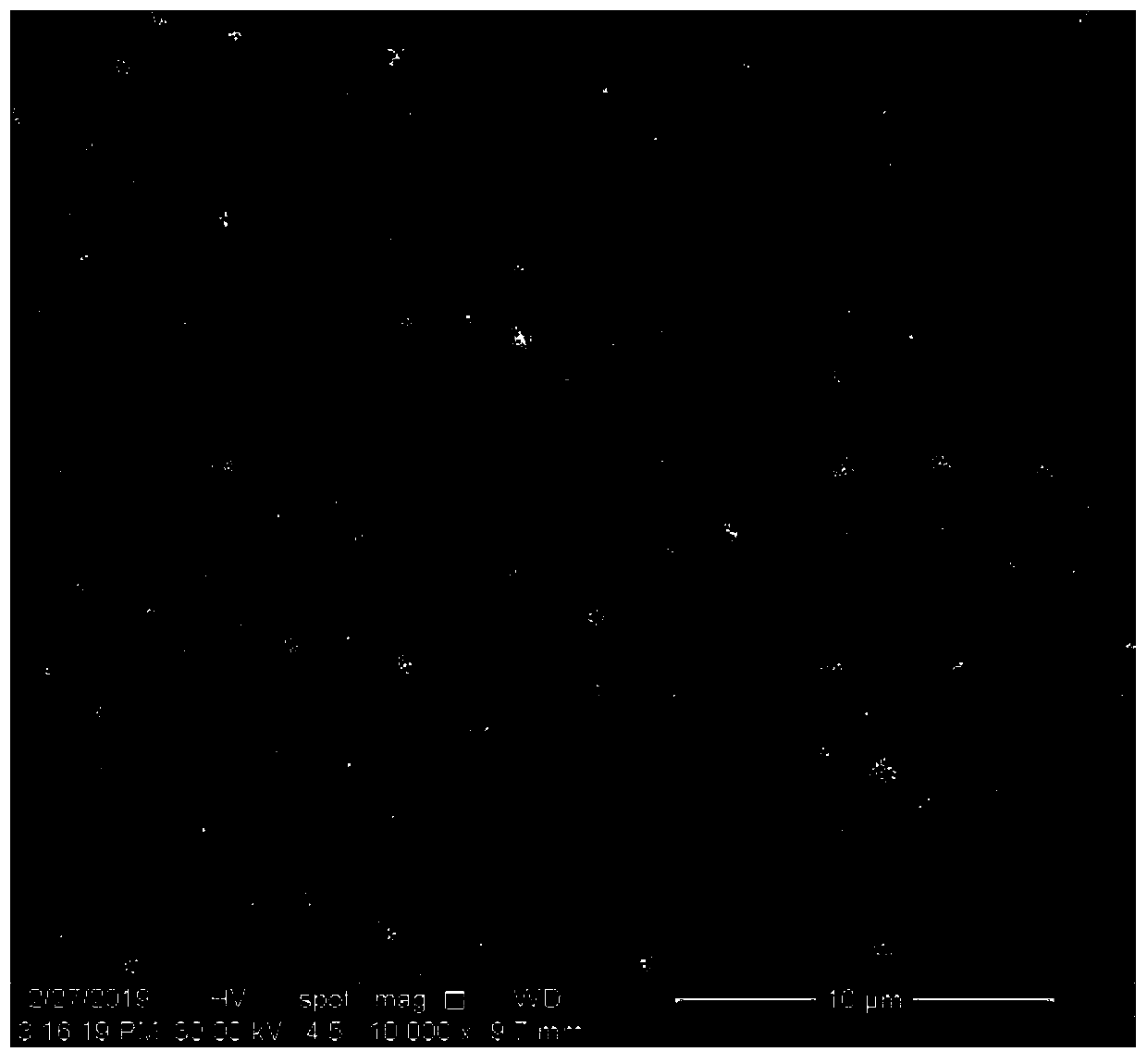

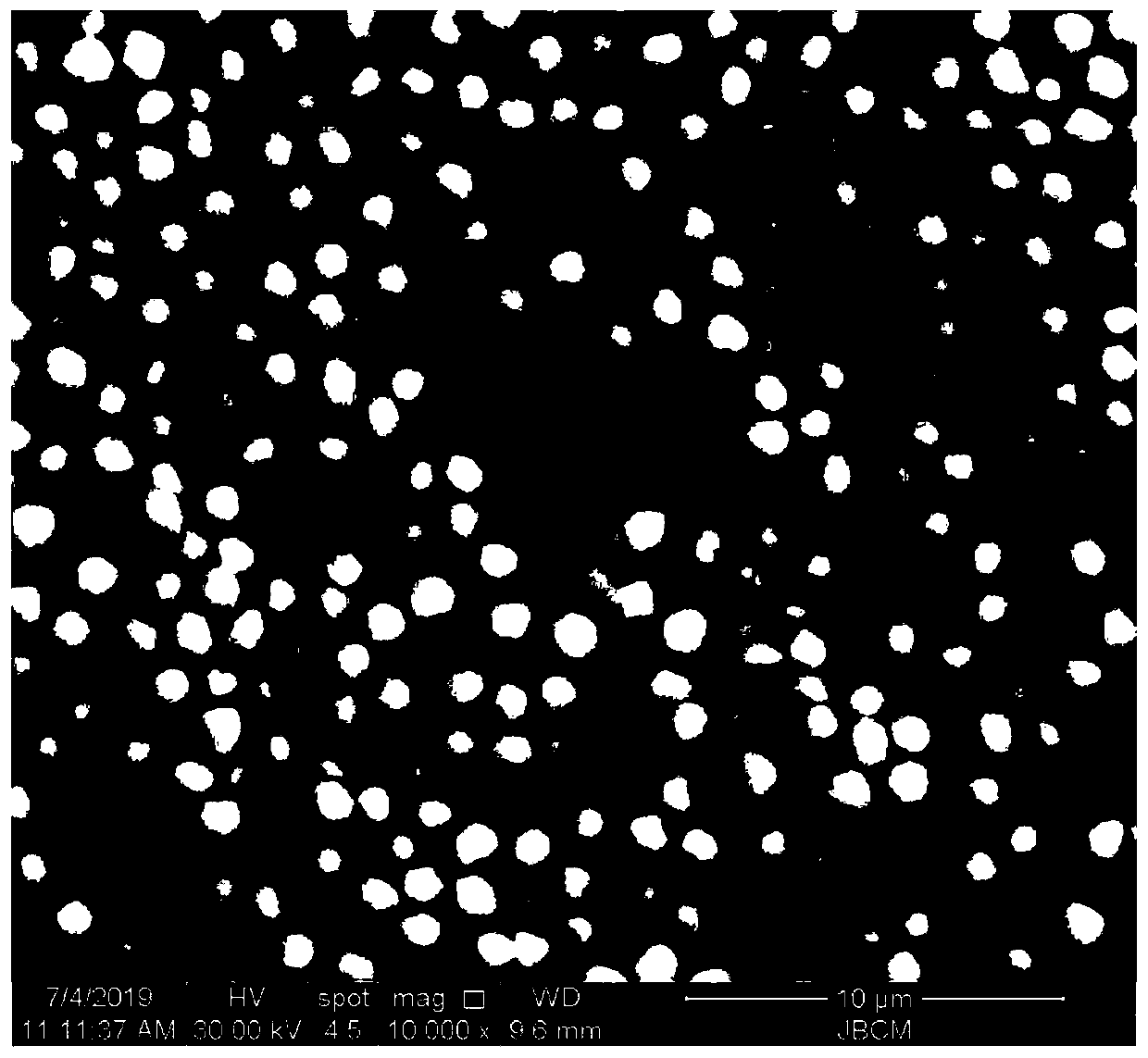

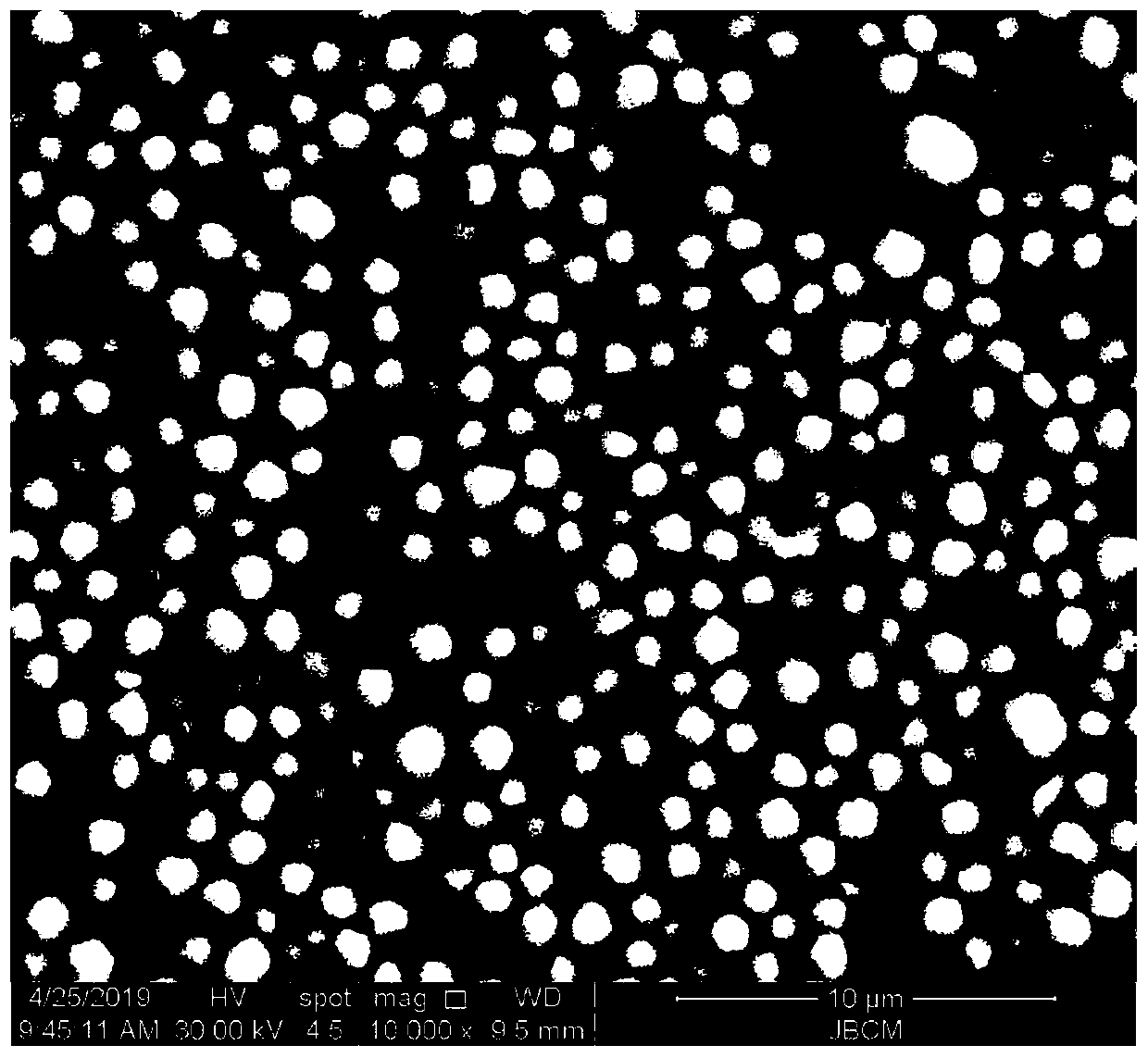

Preparation method of microcrystalline silver powder with hollow structure

ActiveCN110355382AGood dispersionShape is easy to controlTransportation and packagingMetal-working apparatusDispersityHydrazine compound

The invention relates to the technical field of new metal powder materials, in particular to a preparation method of a microcrystalline silver powder with a hollow structure. The preparation method ofthe microcrystalline silver powder with the hollow structure comprises the steps of synthesizing high crystallinity microcrystalline silver powder, oxidizing a hydrazine hydrate with an emulsifier toform gas, and taking gas as the core to generate the microcrystalline silver powder with the hollow structure. By means of the preparation method, the microcrystalline silver powder with the excellent dispersity, controllable morphology and hollow structure is obtained, and the whole process is non-toxic, pollution-free, low energy consumption and easy to operate.

Owner:山东建邦胶体材料有限公司

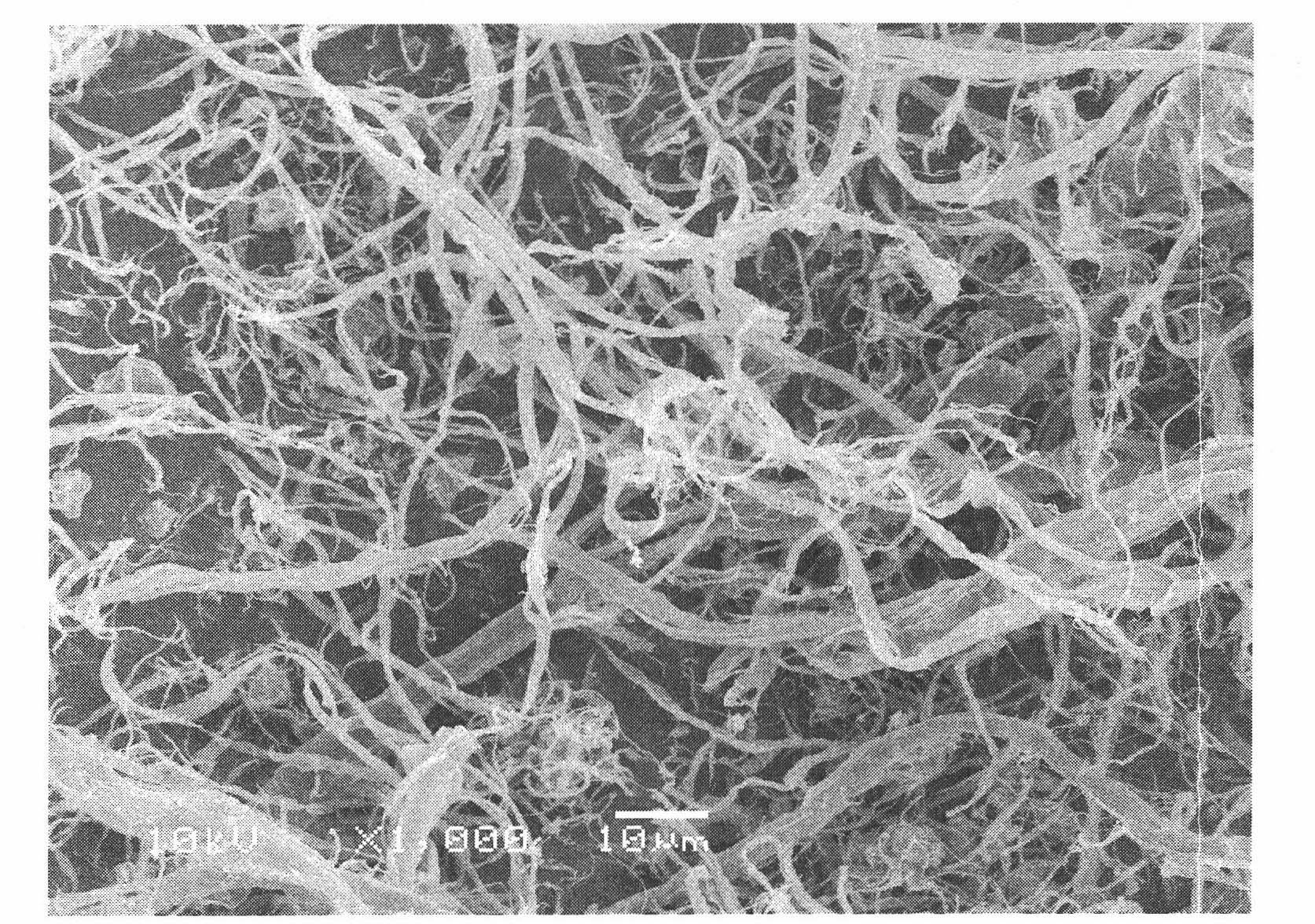

Para-aramid-acrylic compound pulp

InactiveCN102094353AEfficient production processSimple energy consumptionPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperTemperature resistanceMicrofiber

The invention discloses a continuous manufacturing method of para-aramid-polyacrylonitrile compound pulp-shaped fiber (hereinafter referred to as para-aramid-acrylic compound pulp), comprising the steps of: inputting and pumping para-aramid chopped fiber, polyacrylonitrile chopped fiber internally rich in microfiber and water into grinding equipment; and continuously mixing, dispersing and grinding under a high chopping rate to form the highly fibrillated para-aramid-polyacrylonitrile compound pulp-shaped fiber which has even structure and abundant surface hair feather, wherein the whole process is completed in one step, the process is continuous and simple and the energy consumption is lower. The compound pulp replaces asbestos and is applied to friction sealing materials, not only has the properties such as high intensity, high mould and high temperature resistance of the para-aramid, but also has the excellent compound property of the polyacrylonitrile, greatly reduces the cost of replacing the asbestos, and has higher cost performance.

Owner:YANCHENG LANBANG TECHN FIBER +1

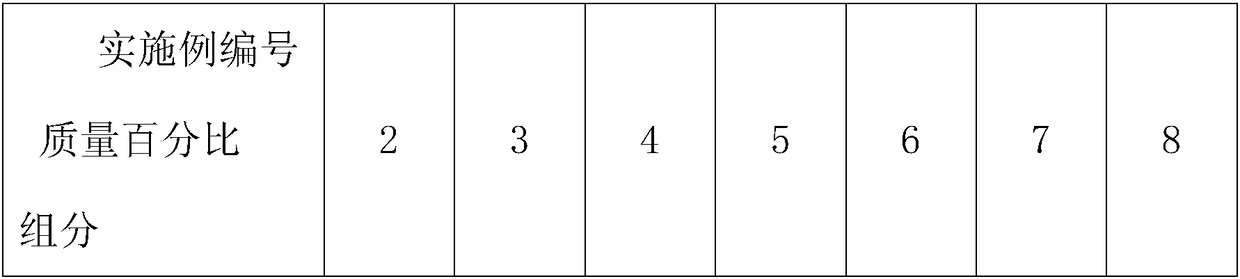

Inorganic phase-change energy storing particles, floor heating mortar and preparation method thereof

The invention provides inorganic phase-change energy storing particles, floor heating mortar and a preparation method thereof. The inorganic phase-change energy storing particles comprise the following components in percentage by mass: 20-50% of inorganic phase-change material, 10-25% of water, 0.1-1.5% of phosphorylated starch gum, 0.1-1.5% of water-absorbent resin, 10-35% of gypsum, and 15-35% of cement. The inorganic phase-change energy storing particles are prepared by the steps of preparing phosphorylated starch gum, preparing materials, mixing, pelletizing, coating, and covering with films. The floor heating mortar comprises 15-35% of cement, 10-25% of sand, 20-50% of inorganic phase-change energy storing particles, and 20-30% of water. The floor heating mortar is prepared by preparing materials, and mixing. According to the inorganic phase-change energy storing particles, the floor heating mortar and the preparation method thereof, the raw materials are wide in source; the chemical stability is high; the phase change temperature is low; leakage is avoided; the energy storing particles are good in energy storing effect, and high in stability; the floor heating mortar is highin strength, and the indoor temperature can be effectively conditioned, and the energy saving effect is good; and various buildings such as a house, a school and a hospital widely apply.

Owner:SOUTHWEAT UNIV OF SCI & TECH

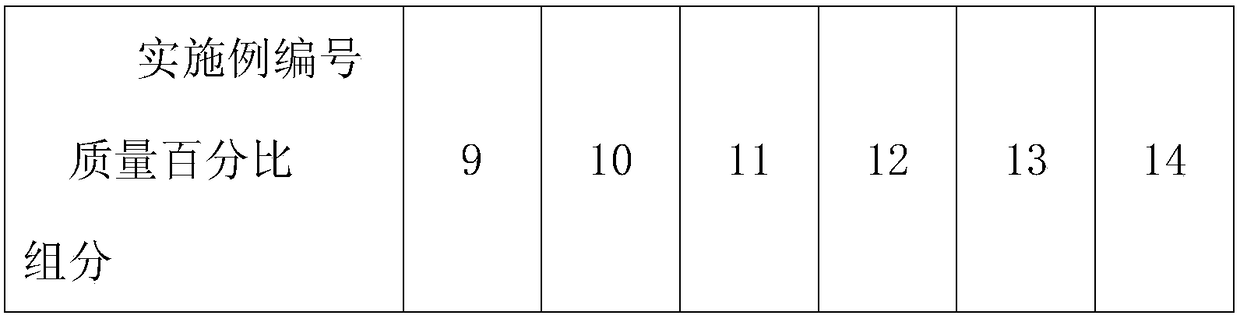

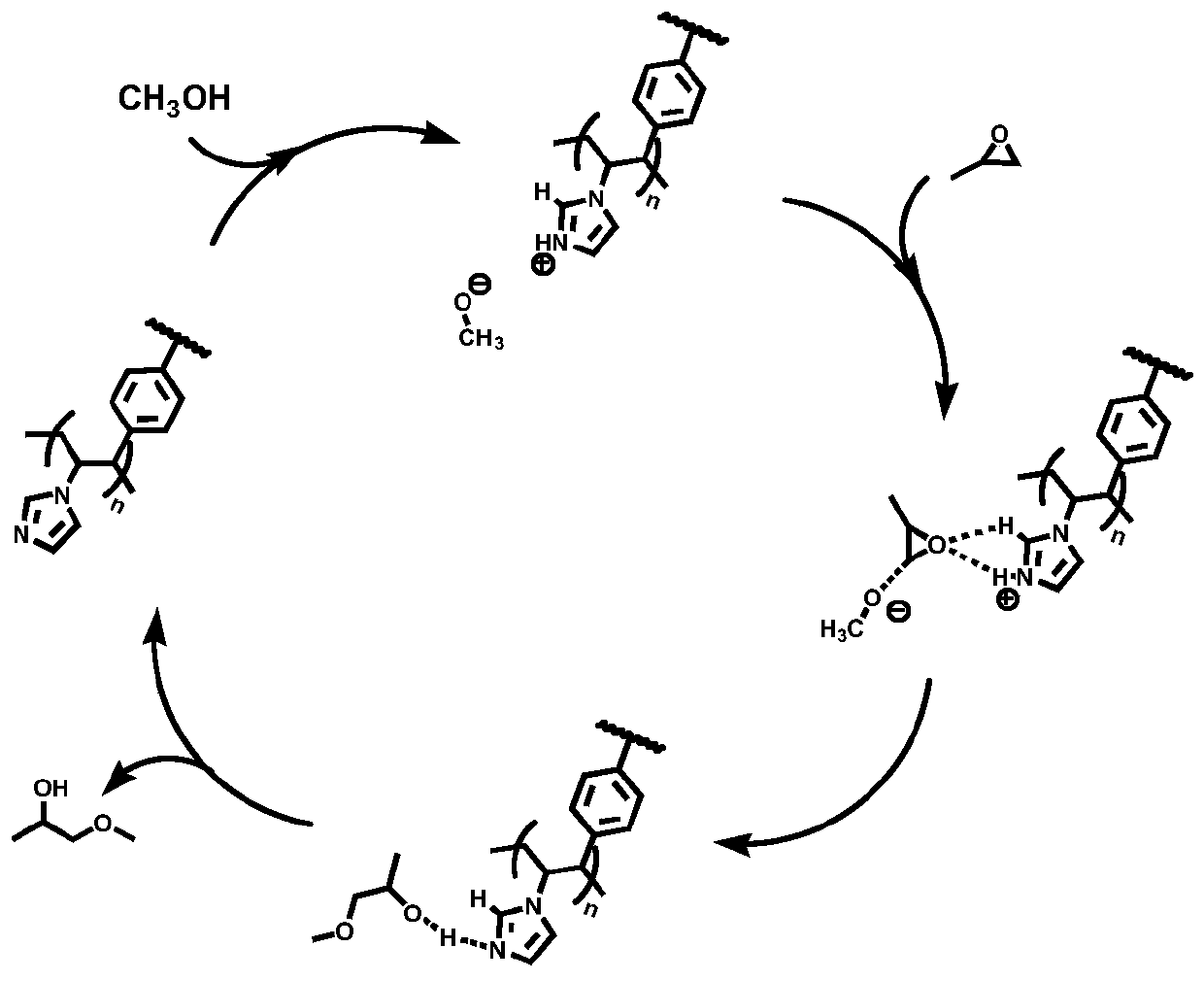

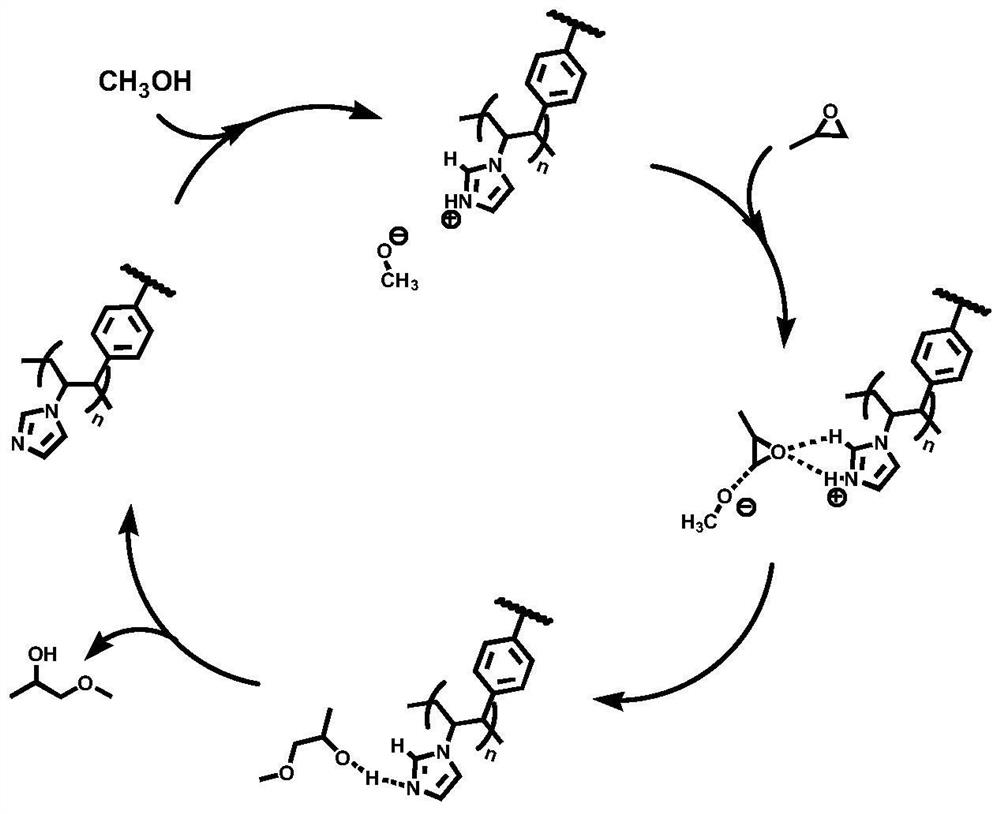

Catalyst for synthesizing propylene glycol ether and preparation method thereof

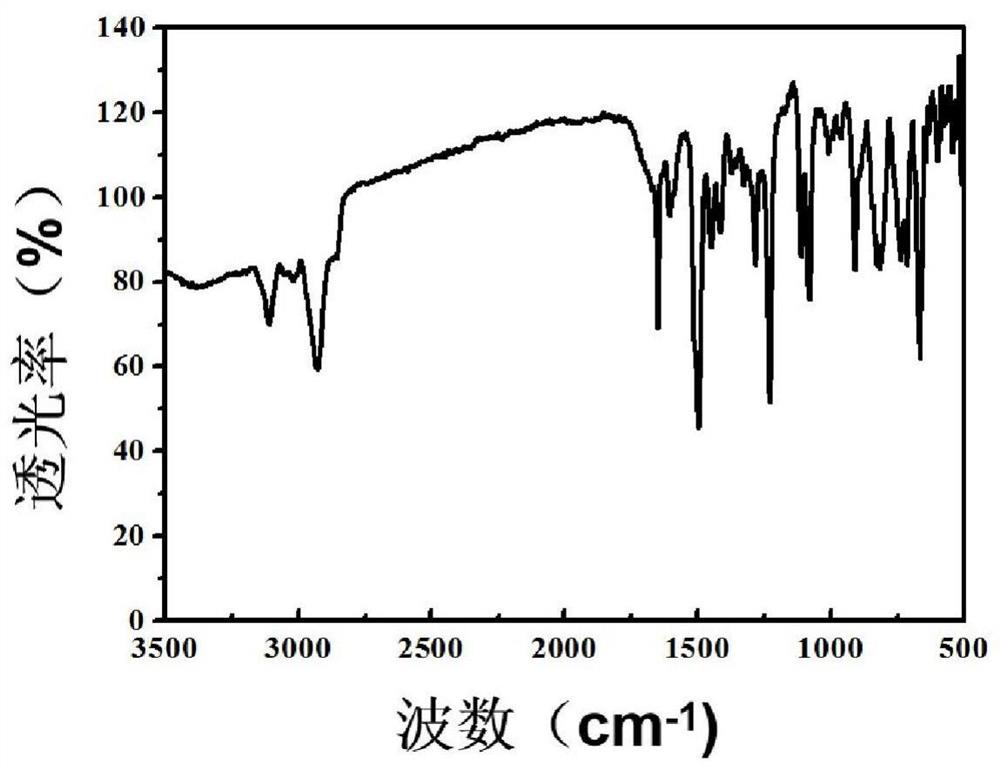

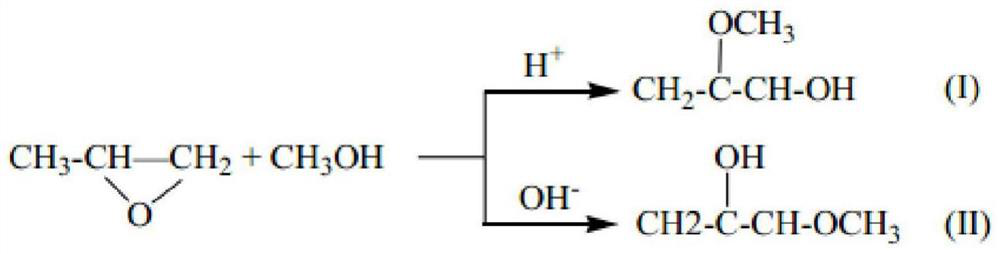

ActiveCN110947423ASimple preparation processReduce manufacturing costOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation from oxiranesPolymer sciencePtru catalyst

The invention relates to the technical field of chemical catalysis. The invention discloses a catalyst for synthesizing propylene glycol ether. The catalyst is polyvinyl imidazole-divinyl benzene. A preparation method of the catalyst comprises the following steps: adding azodiisobutyronitrile into an ethyl acetate solution of 1-vinylimidazole with the concentration of 0.5-1.2 mol / L, heating the solution to 65-90 DEG C in the presence of N2 or inert gas, maintaining the temperature for 0.5-2 hours, adding an ethyl acetate solution of divinyl benzene into the solution, keeping the temperature at65-90 DEG C for 12-24 hours, and cooling and drying the product to obtain the catalyst for synthesizing propylene glycol ether, wherein the addition amount of azodiisobutyronitrile is 0.01-5wt% of that of 1-vinylimidazole, and the molar ratio of 1-vinylimidazole to divinylbenzene is 1: (0.01-20). The obtained catalyst for synthesizing propylene glycol ether has the advantages of high activity, high selectivity, low energy consumption, easiness in separation and the like, is low in production cost and is suitable for industrial production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

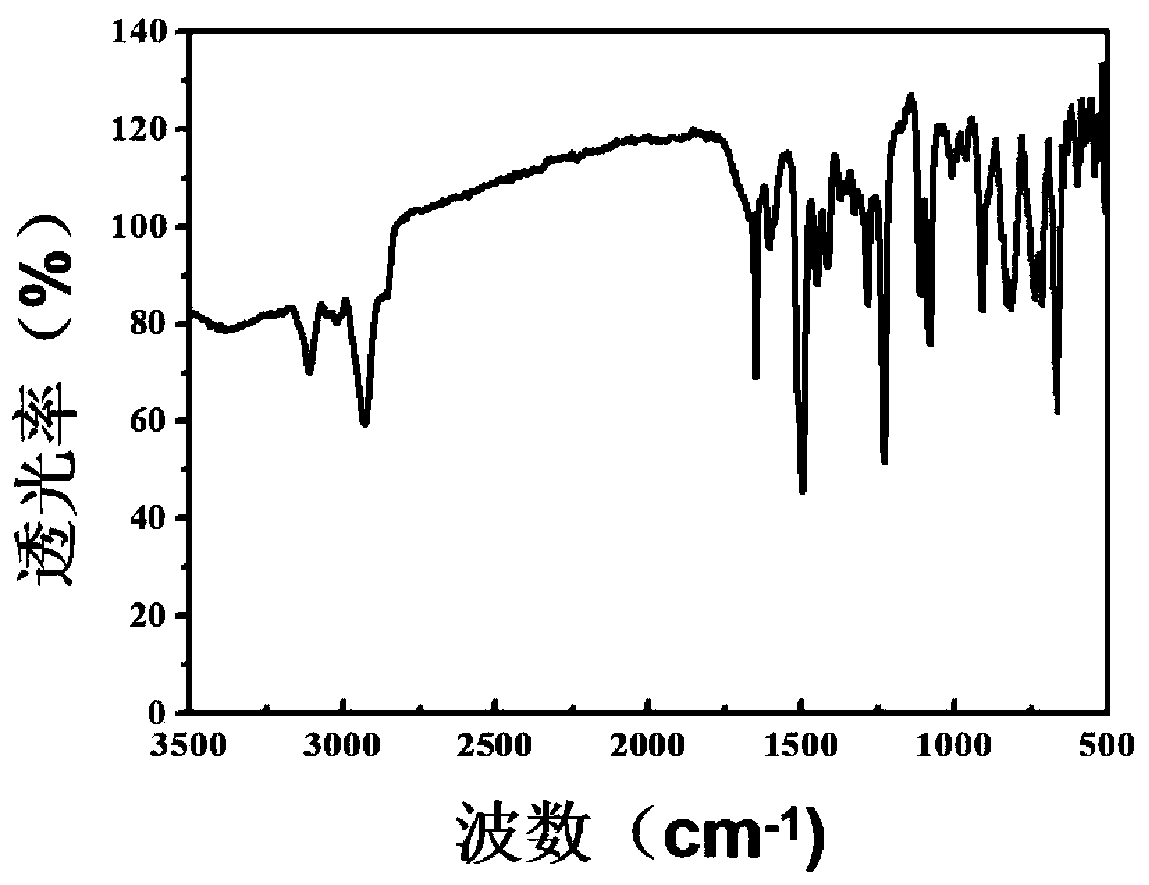

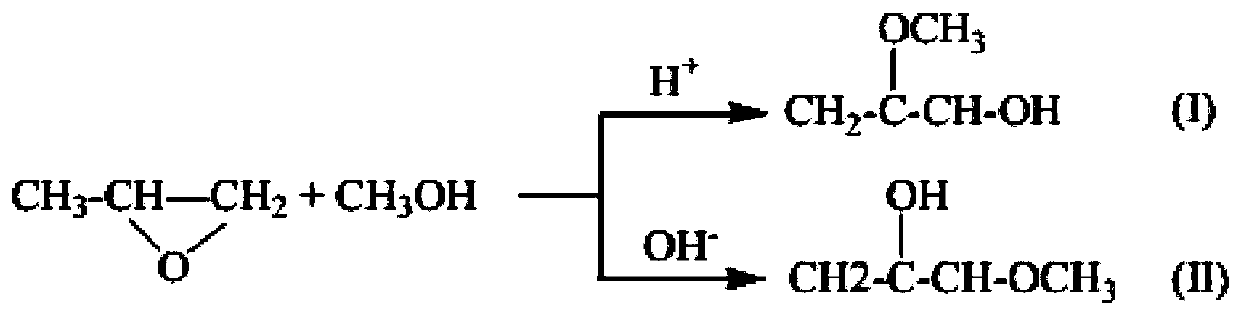

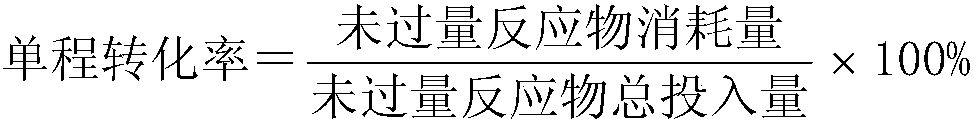

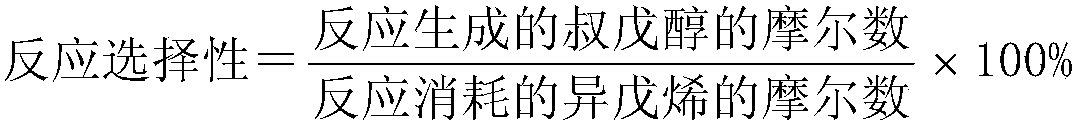

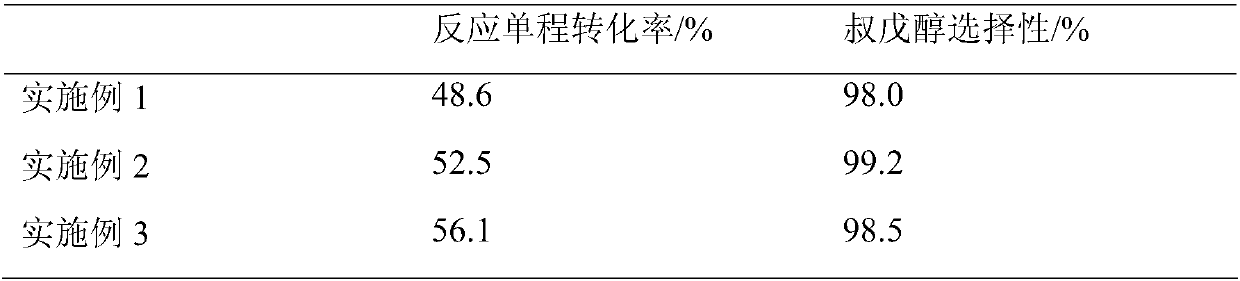

Method for preparation of tert-amyl alcohol by isoamylene hydration

InactiveCN108017508ARaise the ratioReduce the ratioPreparation by hydroxy group additionHydration reactionFixed bed

The invention discloses a method for preparation of tert-amyl alcohol by isoamylene hydration. The method specifically includes the steps of: mixing an isoamylene component rich in 2-methyl-1-butene and 2-methyl-2-butene, water and acetone, then loading the mixture into a fixed bed reactor holding a strong acidic cation exchange resin catalyst, and carrying out hydration reaction to obtain tert-amyl alcohol. The method provided by the invention uses acetone as the solvent, which is free of azeotropy with water and is easy to recover; the solvent ratio is low, the energy consumption of reactionproduct post-treatment is saved, and the production operation cost is also saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

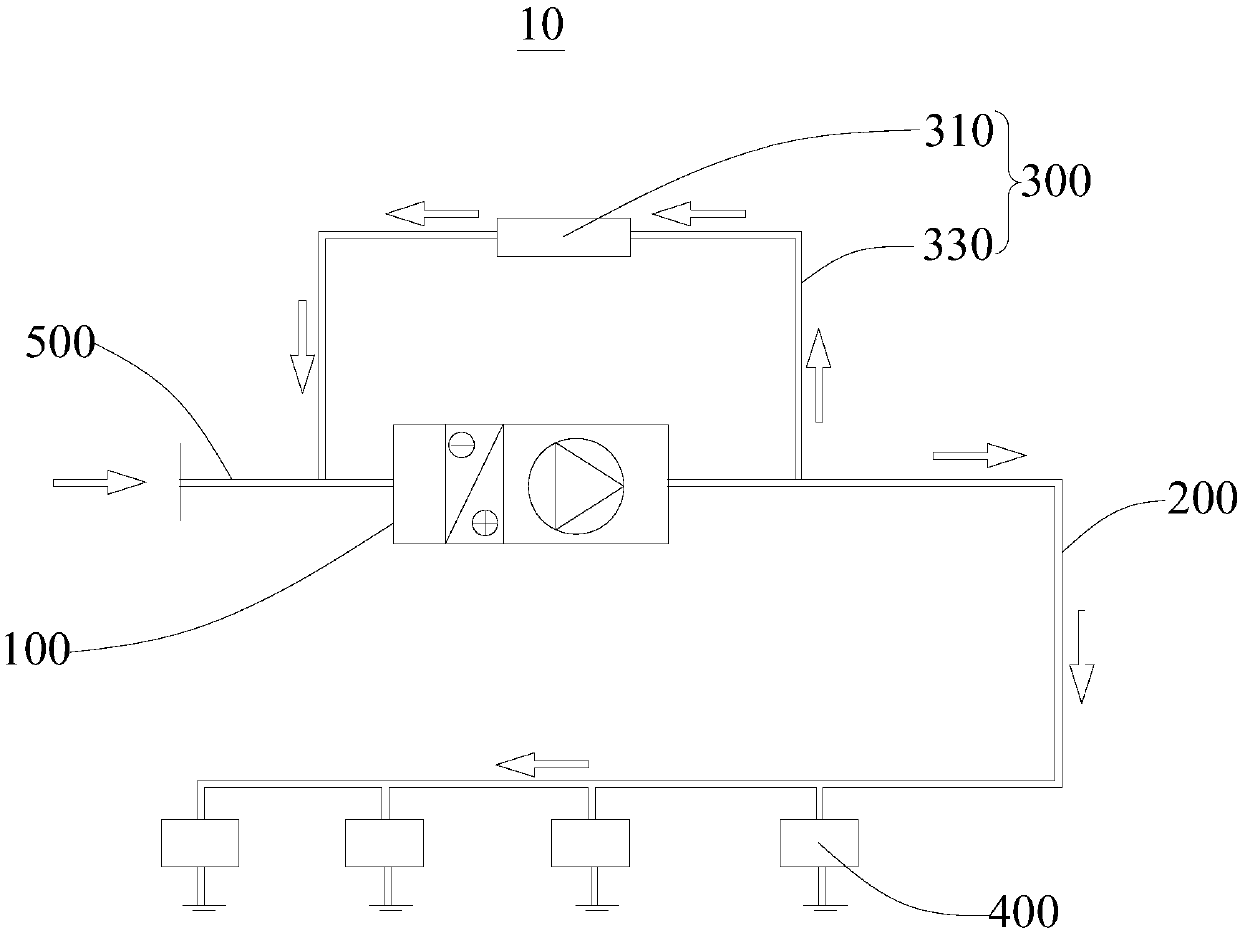

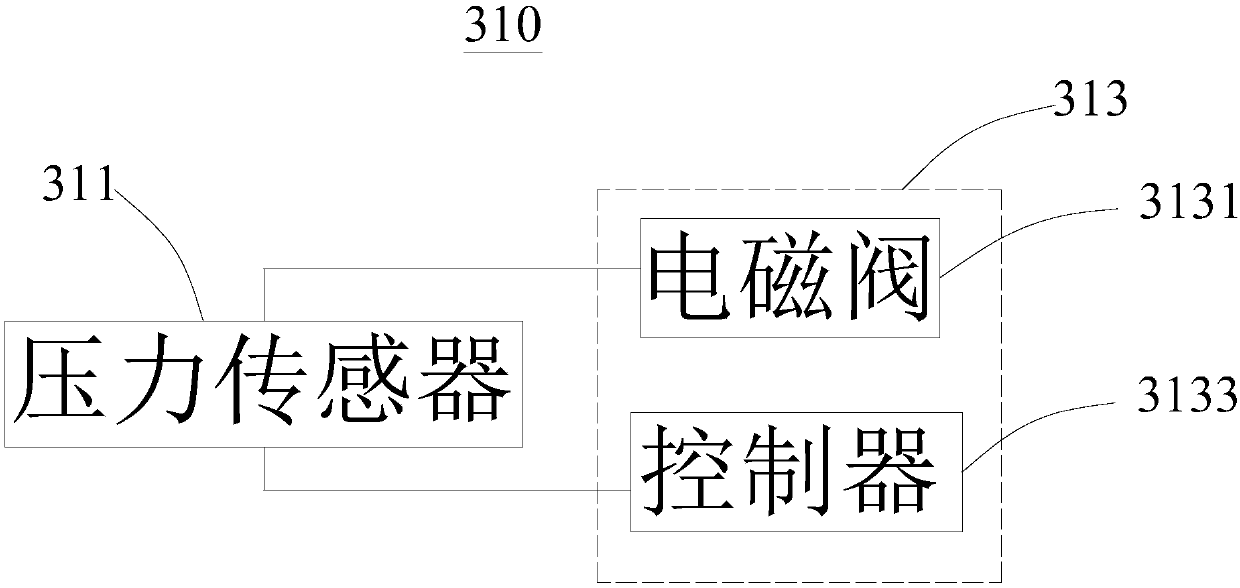

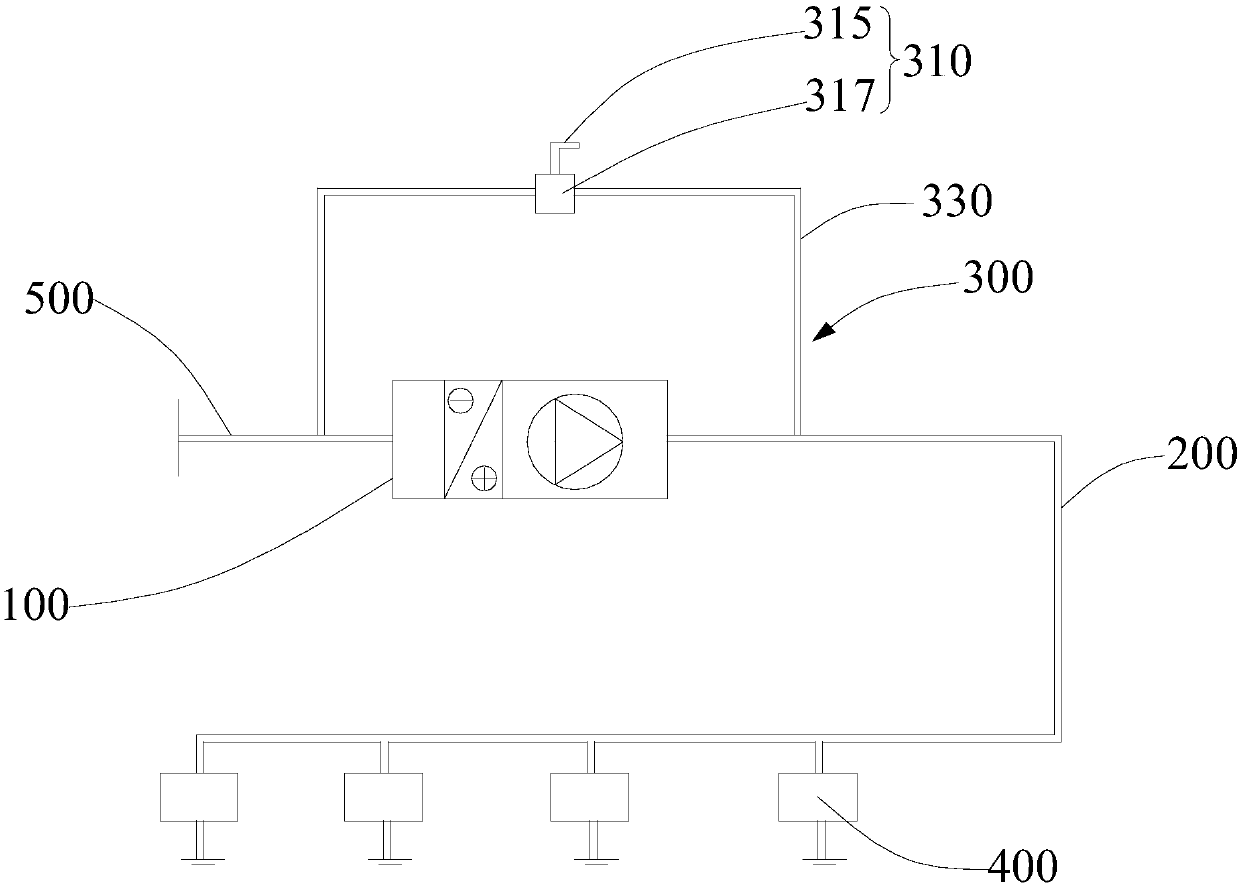

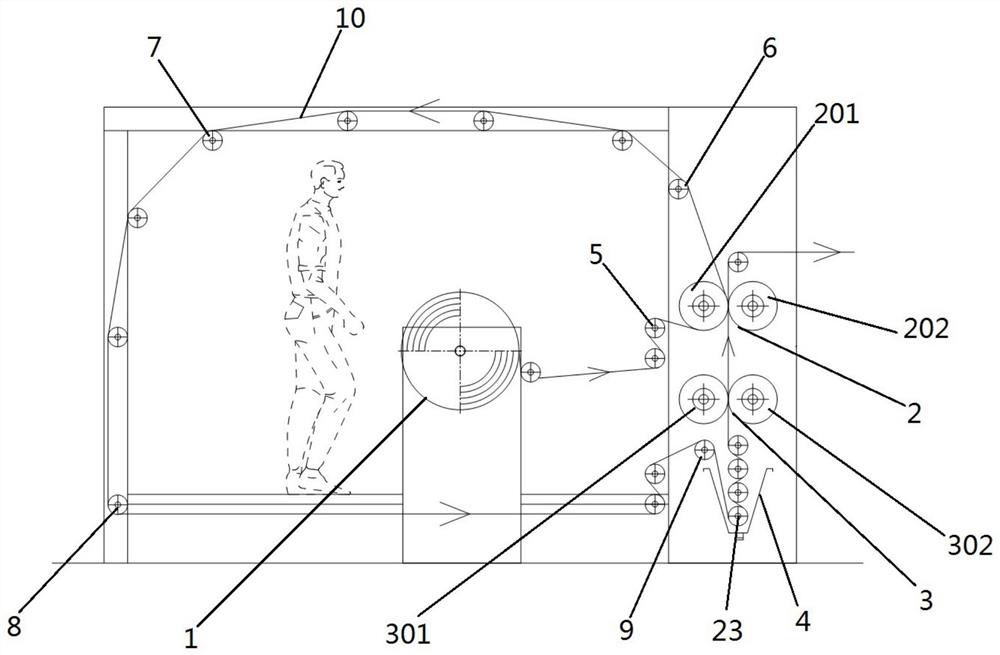

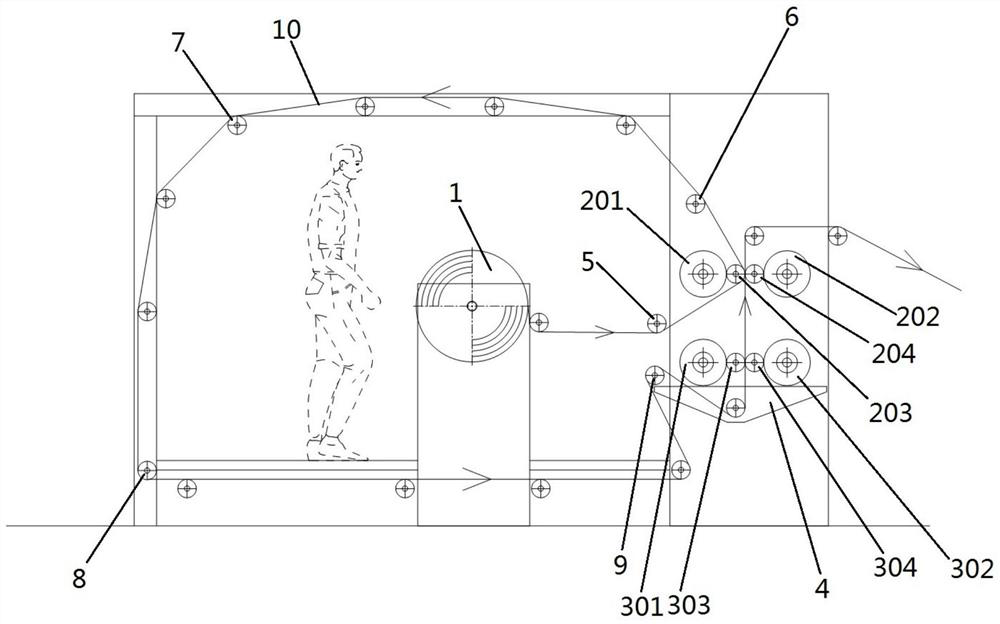

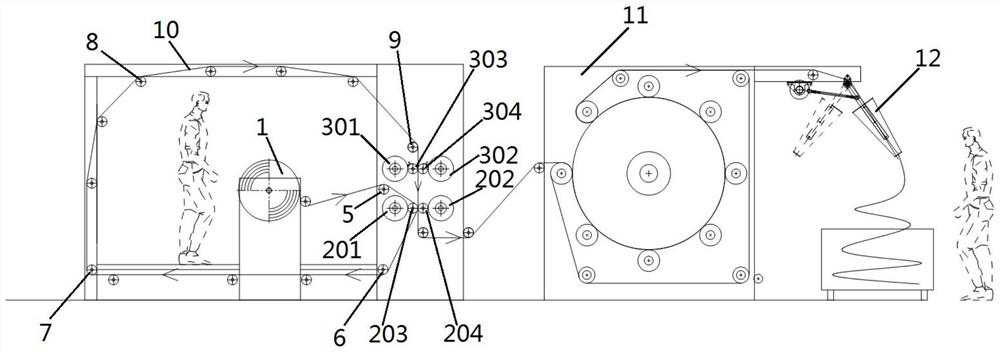

Energy-saving fresh air system

PendingCN108036438AStable structureSimple structureMechanical apparatusSpace heating and ventilation safety systemsStart stopFresh air

The invention provides an energy-saving fresh air system, and relates to a building internal air conditioning system which comprises a fresh air unit, a fresh air pipeline, a bypass mechanism and a tail end start-stop mechanism. The fresh air unit is provided with an air inlet end and an air outlet end. One end of the fresh air pipeline is connected to the air outlet end, the other end of the fresh air pipeline is connected to the tail end start-stop mechanism, one end of the bypass mechanism is connected to the end, close to the fresh air unit, of the fresh air pipeline, the other end of thebypass mechanism is connected to the air inlet end, and the fresh air pipeline and the air inlet end are selectively connected according to the static pressure value of the fresh air pipeline. Compared with the prior art, the energy-saving fresh air system is simple in structure, low in manufacturing cost, easy to popularize, stable, easy to maintain, and capable of greatly reducing fresh air energy consumption and saving energy.

Owner:核工业西南勘察设计研究院有限公司

Preparation method of grass carp feed additive containing auricularia auricula polysaccharide

InactiveCN108157678AGood dispersionPromote absorptionClimate change adaptationAccessory food factorsFood additiveRadix Ophiopogonis

The invention discloses a preparation method of a grass carp feed additive containing auricularia auricula polysaccharide. The preparation method comprises the following steps of performing low-temperature continuous drying on red-knees herbs, Chinese galls, rhizoma kaempferiae, radix ophiopogonis and garlic according to the quantity of a formula, performing primary crushing, performing uniform mixing, then performing superfine crushing, then adding the auricularia auricula polysaccharide, vitamin E and mineral powder, and performing uniform mixing so as to obtain the grass carp feed additivecontaining auricularia auricula polysaccharide. The preparation method has the beneficial effects that the preparation method of the feed additive is high in working efficiency, the energy consumptionis reduced, the production energy consumption and the production cost are reduced, the bioavailability of medicines can be improved, the dosage of the medicines is reduced, the uniformity of granulesis improved to a certain extent, the feed additive is easily and uniformly dispersed in the feed, and the obtained additive can strengthen the capacity of grass carps for resisting stress response, enhance immunity and improve the meat quality of the grass carps.

Owner:磐安县派普特生物科技有限公司

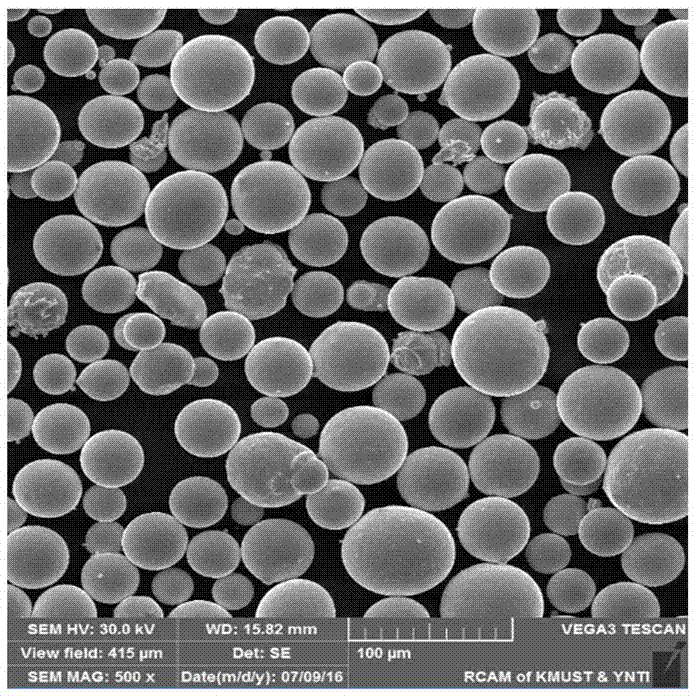

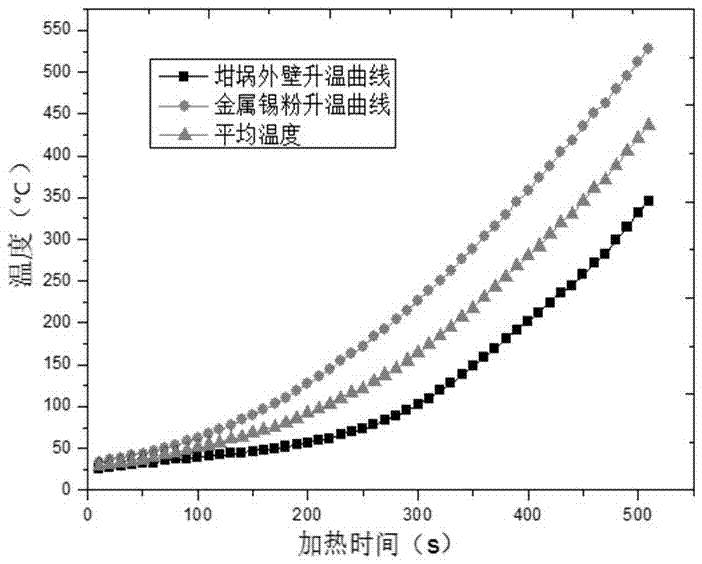

High-efficiency and high-recovery-rate method for recovering industrial tin powder

InactiveCN107012338AHigh recovery rateReduce smelting energy consumptionProcess efficiency improvementShielding gasPollution

The invention discloses a high-efficiency and high-recovery-rate method for recovering industrial tin powder. The high-efficiency and high-recovery-rate method for recovering the industrial tin powder comprises the steps of pretreatment, smelting and aftertreatment and specifically comprises the steps that the tin powder to be recovered is screened till the grain diameters are smaller than 200 micrometers; the tin powder to be recovered is loaded to a crucible, the crucible is put into an airtight microwave heating cavity, and then, under the protective gas, microwave smelting is carried out to obtain a material a; and the material a is cast into a final product, namely metallic tin or a tin alloy ingot. According to the high-efficiency and high-recovery-rate method for recovering the industrial tin powder, rapid smelting of the metallic tin powder and tin alloy powder can be achieved through microwave heating, and the method has the characteristics of high heating speed and high heat efficiency; by adjusting the microwave power, the metallic tin powder can be melted within 8-15 minutes; compared with a traditional method, the method has the beneficial effects that the smelting time is shortened by 10 times or above, the heating efficiency can be improved by 5 times, and the energy consumption can be reduced by about 80 %; smelting is carried out under the condition of nitrogen, argon or mixed gas protection, the technological process is simple, operation is easy, the production cost is low, safety is achieved, no pollution is caused, and the performance of the cast ingot is relatively excellent.

Owner:KUNMING UNIV OF SCI & TECH

Inorganic phase change energy storage particles, floor heating mortar and preparation method thereof

An inorganic phase change energy storage particle, floor heating mortar and a preparation method thereof, wherein the mass percentage composition of the inorganic phase change energy storage particle includes: 20%-50% inorganic phase change material, 10%-25% water, 0.1%-1.5% Phosphated starch glue, 0.1%-1.5% water-absorbing resin, 10%-35% gypsum and 15%-35% cement; prepared phosphated starch glue, ingredients, mixing, granulation and coating, and coating The ground heating mortar is composed of 15% to 35% cement, 10% to 25% sand, 20% to 50% inorganic phase change energy storage particles, and 20% to 30% water; it is prepared by batching and mixing. The invention has wide sources of raw materials, good chemical stability, low phase transition temperature, no leakage, good energy storage effect of energy storage particles, high stability, high strength of floor heating mortar, can effectively adjust indoor temperature, good energy saving effect, and can be widely used It is widely used in residential buildings, schools, hospitals and other buildings.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Power taking system of single-live-wire switch, control method thereof and single-live-wire switch

PendingCN112311260ASimple energy consumptionPower managementCircuit arrangementsElectric energyElectric equipment

The invention relates to a power taking system for a single-live-wire switch, a control method thereof and a single-live-wire switch. The power taking system is connected with electrical equipment anda wireless controller, the wireless controller controls a switch module used for changing the operation state of the electrical equipment. The power taking system comprises a power taking module anda control module; the power taking module is connected between a power supply and the wireless controller; the power supply supplies power to the wireless controller and the electrical equipment; thepower taking module is configured to obtain electric energy from the power supply and provide the obtained electric energy to the wireless controller during the power-on period of the electrical equipment; and the control module is connected to the power taking module and is configured to detect the energy consumption of the wireless controller and provide a control signal to the power taking module according to the energy consumption change of the wireless controller so as to adjust the electric energy obtained from the power supply by the power taking module.

Owner:赛万特科技有限责任公司

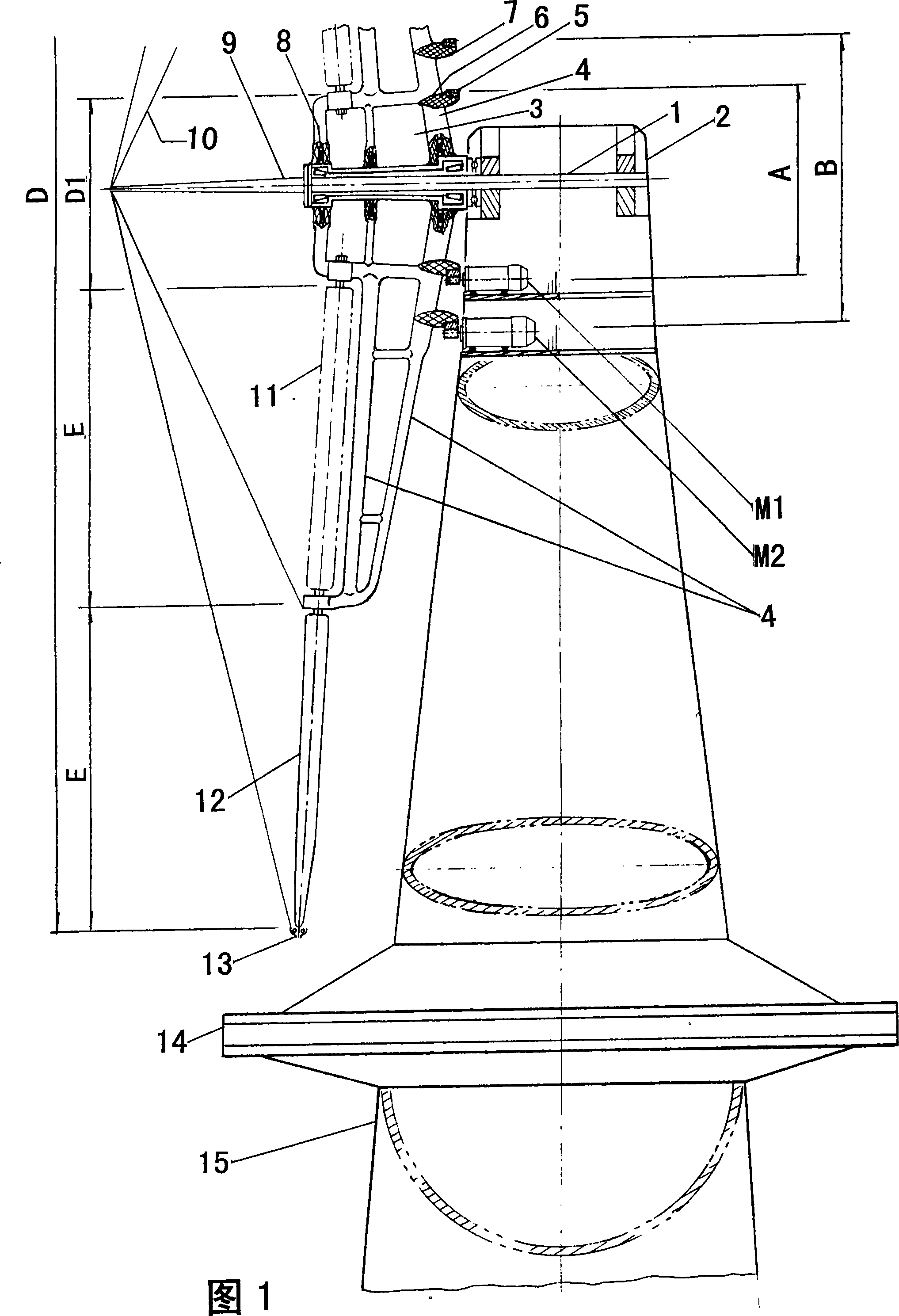

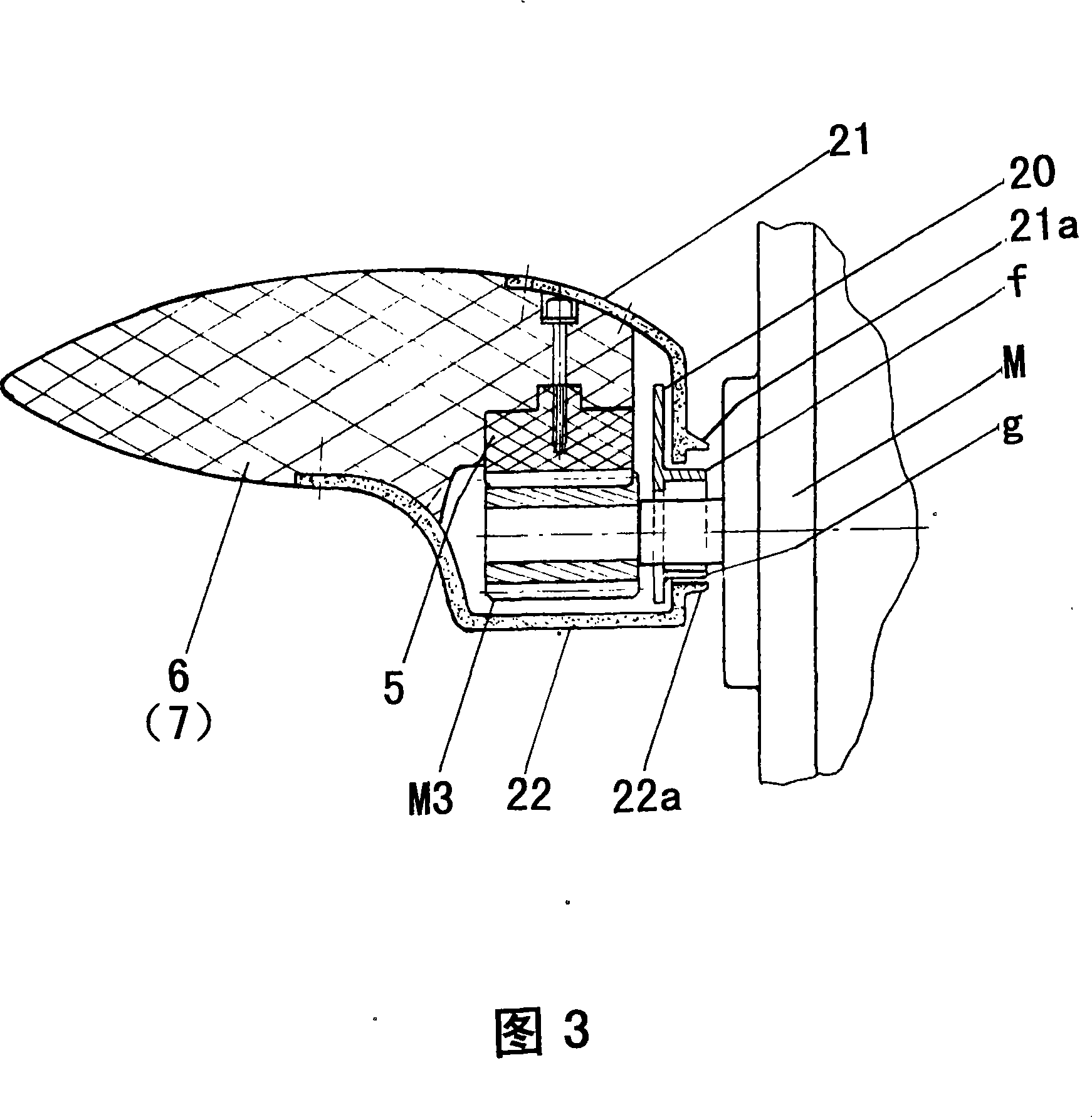

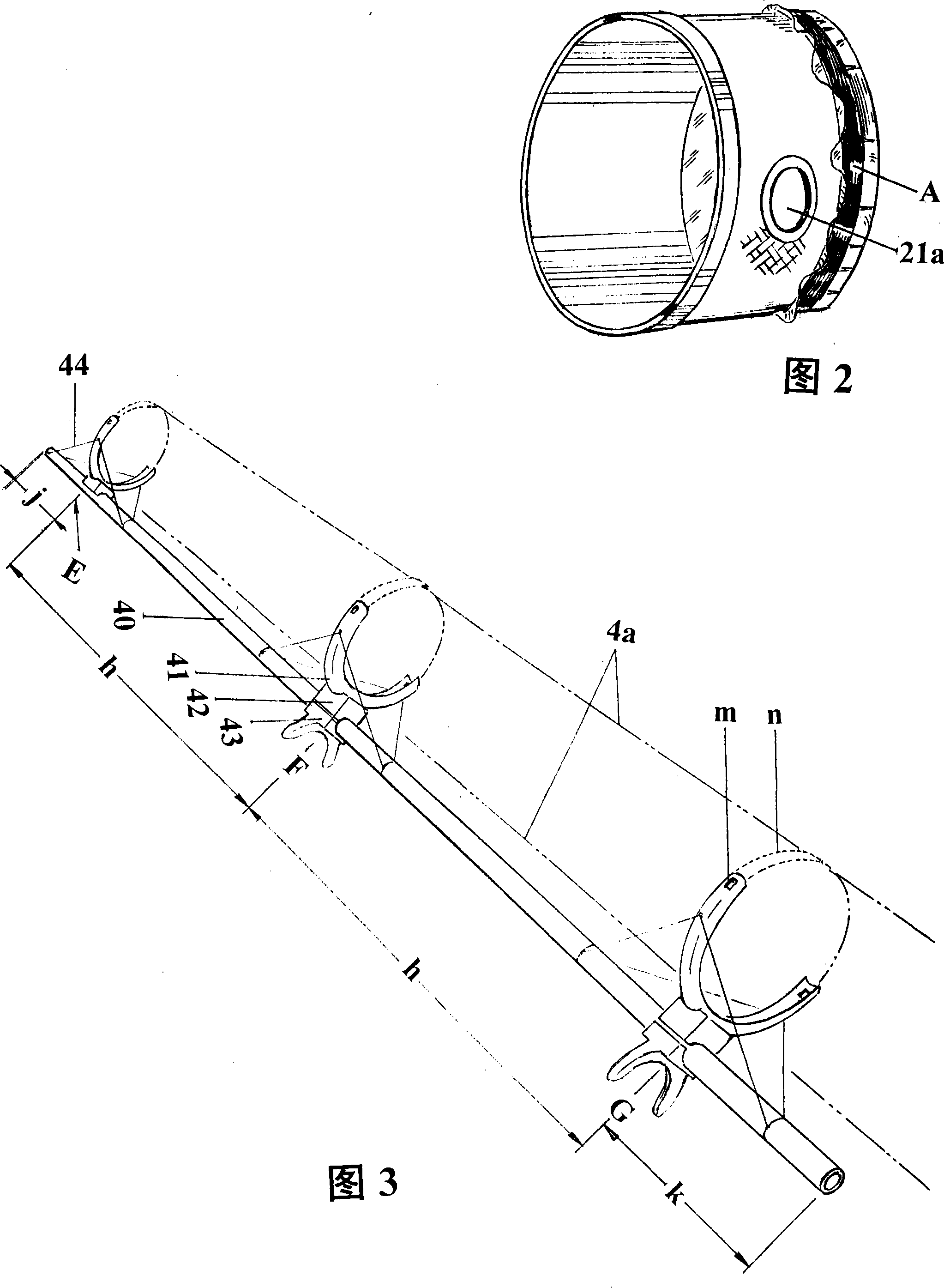

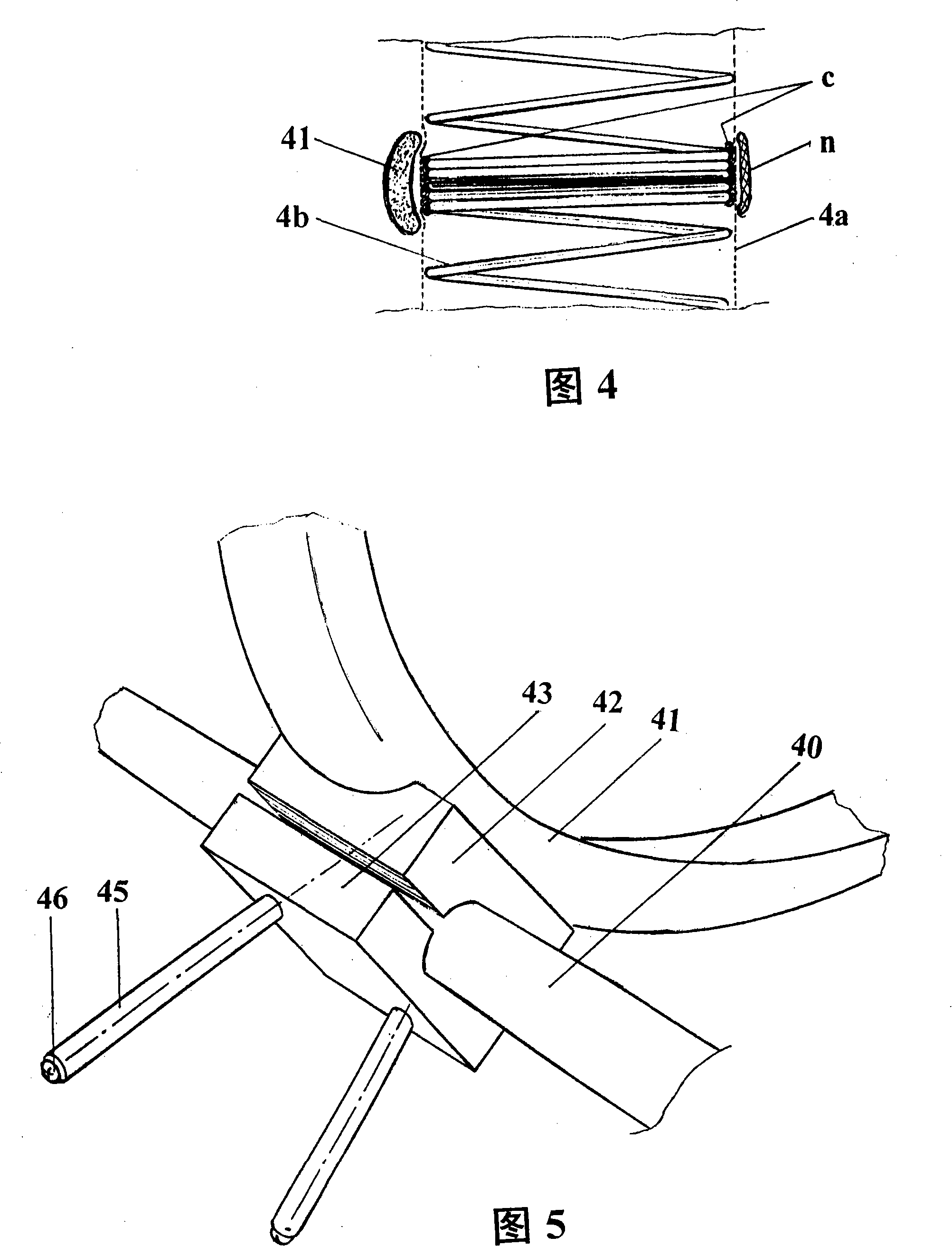

Large wind wheel single-stage wheel gear power generation

InactiveCN101235803BSimple energy consumptionMachines/enginesWind motor combinationsSingle stageGear wheel

A big wind wheel single-grade gear generator is disclosed, which is characterized in that a main shaft 1 is tightened on a tower head 2 for centering action of a wind wheel only, the wind wheel adopts a hub 3 and a wheel support 4 to connect as an integral for supporting an inner vane 11 and an outer vane 12 to approach external diameter of big circumference as near as possible in order to improve the speed and efficiency of the vane tip. Simultaneously, the segment is an axial inner vane 11 and outer vane 12, which not only reaches the goal of hyper-big wind wheel, but also shortens the vanelength and reduces bending torque and vane weight. The wheel support 4 can be an inner ring which is provided with a gear coil 5 and big gear kinetic energy output device of the external ring 7, which separately gear small gear of a motor M1 and a motor M2 to generate. The big wind wheel single-grade gear generator has the advantages of that firstly saving a verbose drive chain and energy consumption of the prior technique, secondly being beneficial to break through bottleneck of the hyper big wind wheel.

Owner:黄金伦

A kind of catalyst and preparation method for synthesizing propylene glycol ether

ActiveCN110947423BSimple preparation processReduce manufacturing costOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation from oxiranesPolymer sciencePtru catalyst

The invention relates to the technical field of chemical industry catalysis, and discloses a catalyst for synthesizing propylene glycol ether. The catalyst is polyvinylimidazole-divinylbenzene, and its preparation method comprises the following steps: ‑Azobisisobutyronitrile is added to the ethyl acetate solution of vinylimidazole, N 2 Or heated to 65-90°C under inert gas, kept for 0.5-2h, then added divinylbenzene ethyl acetate solution, kept at 65-90°C for 12-24h, cooled, and the product was dried to obtain the synthetic propylene glycol ether The catalyst, wherein the added amount of azobisisobutyronitrile is 0.01-5wt% of 1-vinylimidazole, and the molar ratio of 1-vinylimidazole to divinylbenzene is 1:0.01-20. The obtained catalyst for synthesizing propylene glycol ether has the advantages of high activity, high selectivity, low energy consumption, easy separation, and low production cost, and is suitable for industrial production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A kind of aluminum core flexible cable and its manufacturing process

ActiveCN109166673BEasy to break wireAvoid breakingManufacturing extensible conductors/cablesInsulating conductors/cablesElectrical conductorElectric cables

The invention discloses an aluminum core flexible cable and a manufacturing process thereof. 2, rough pulling; The aluminum rod is drawn into a thick aluminum wire with the diameter of 1.0 to 2.5 mm;3, pulling that small wire; The thick aluminum wire is drawn into fine aluminum wire with the diameter <= 0. 51mm; 4, thread; 5, bunch filament; 6, twist; Adopt layered twisting according to conductorstructure requirements; 7, time effect; 8, wrap that bag; 9, extrude that insulating lay and vulcanizing to obtain the aluminum core flexible cable. The process aluminium wire strand of the inventioncan be ageing after completion, can reduce the energy consumption of the edge ageing, is not easy to break the wire, has high wire drawing speed, and can reach 400-600m / min, and greatly improves theefficiency.

Owner:FAR EAST CABLE +2

Color fixed island composite short fiber and preparation method thereof

ActiveCN102650081BColorfulUniform colorFilament/thread formingConjugated synthetic polymer artificial filamentsLow-density polyethyleneCarding

The invention provides a color fixed island composite short fiber and a preparation method thereof. The color fixed island composite short fiber comprises the following components by weight: 25-60 percent of low density polyethylene, 30-70 percent of nylon (6), 0.01-25 percent of nylon base coloring master batch and 0-4 percent of compatilizer. Compared with the prior art, the number of the islands of the color fixed island composite short fiber is fixed, as well as the size and the distribution of the short fiber are regular; color super-fine fiber synthetic leather prepared by adopting the preparation method has the advantages of bright and uniform color, high color fastness, no color difference between different batches, uniform carding, strong woolen sensation, high abrasion resistance, easiness in removing of dust after leather abrading, low probability of dust dropping during friction and the like; and besides, high energy consumption and high pollution dyeing process is simplified, and the preparation cost is reduced to a great extent.

Owner:HUAFON MICROFIBER SHANGHAI

Frost prevention fan easy to store

InactiveCN101292613BIncrease employment opportunitiesReduce energy consumptionPlant protectionTemperature controlElectricity

The invention provides a frost-resistant fan which can be stored and delivered easily. A hoist rope goes around pulleys at a masthead to lift a supporting bamboo which is used for keeping an inhalation tube straight and lift an inhalation opening to the height of 7.7m (far higher than a mast). The lower end of the inhalation tube is connected with a fan shell and a fan base which are arranged on the ground; the fan in the fan base utilizes an electric blower in seasonal idle and removes a cast iron bottom plate and a vertical column which are not adopted by the invention. When a temperature controlled probe detects the temperature in a tea bush is lower than 3.5 DEG C, the fan then starts to run and the inhalation tube sucks the air not less than 5 DEG C from the upper space and transmitsthe air through a transverse tube and an exhaust ring to the tea bush to increase the temperature and blow away frost and coldness. The fan has the advantage that the price of each fan is less than one twentieth of that of an imported fan.

Owner:黄金伦

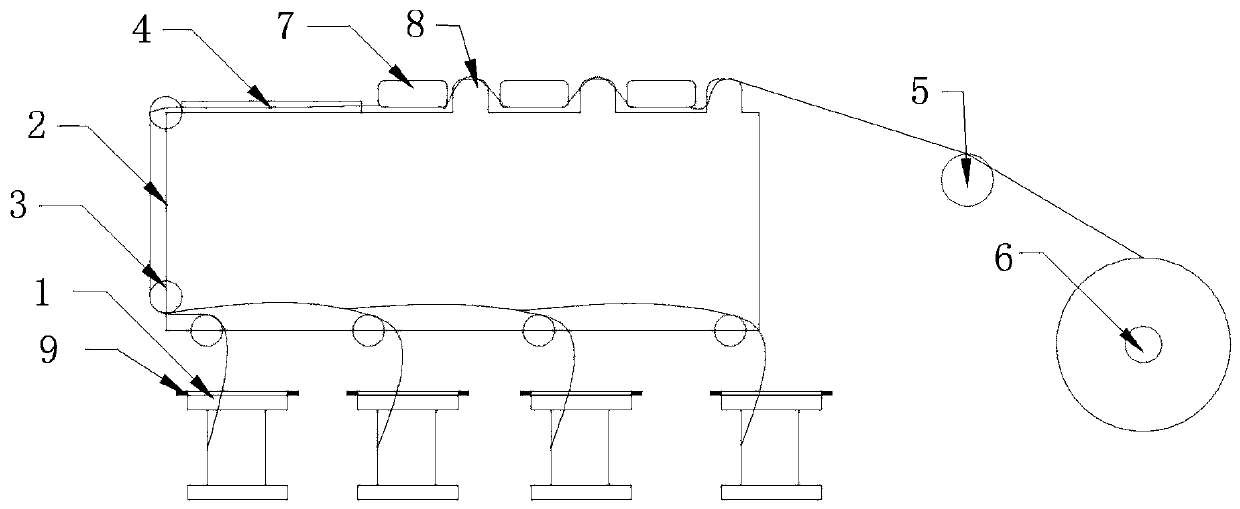

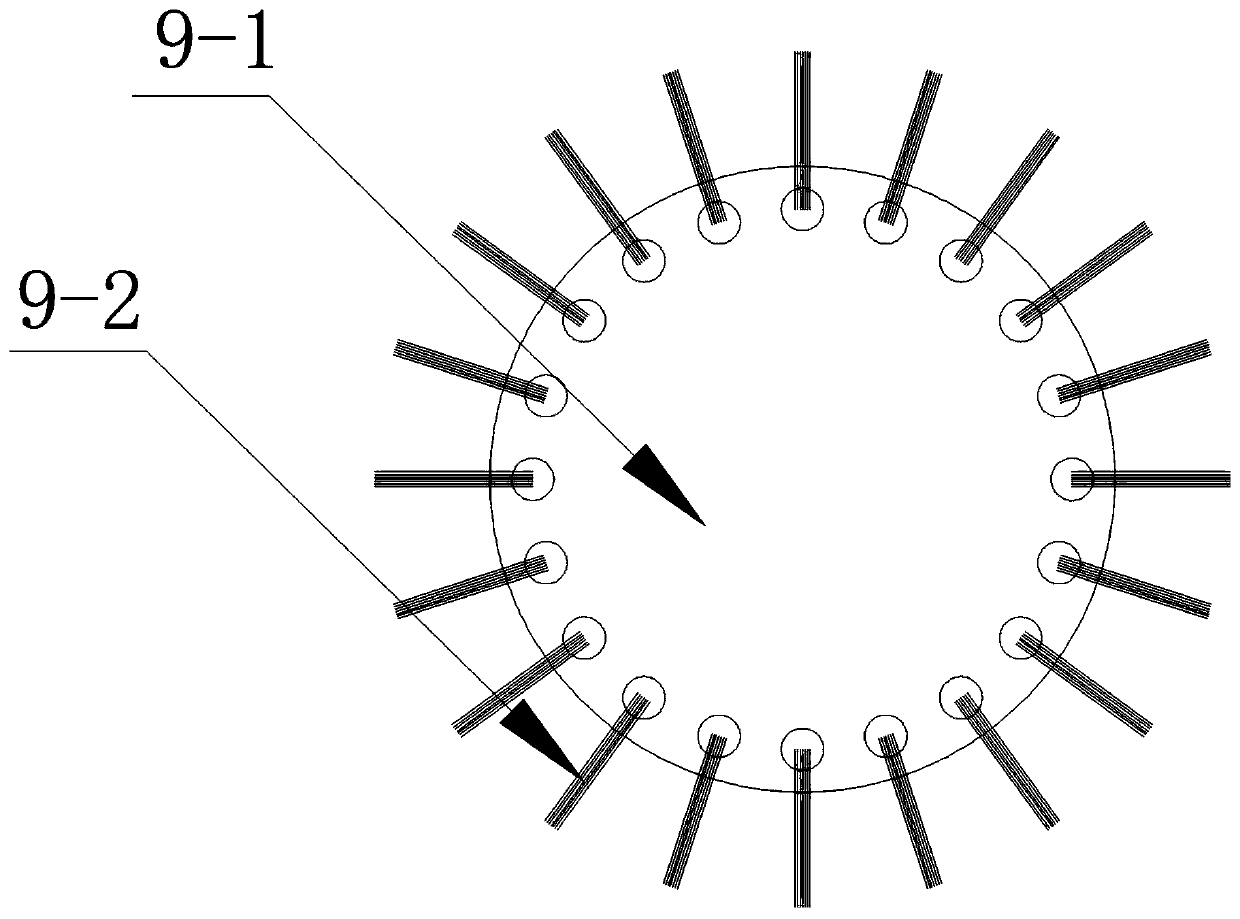

One-dipping multi-rolling type padder with low liquid carrying amount

PendingCN111778658AReduce liquid volumeWith liquid evenlyTextile treatment carriersLiquid/gas/vapor textile treatmentEngineeringMechanical engineering

The invention discloses a one-dipping and multi-rolling type padder with low liquid carrying capacity, which is used for solving the technical problems of high liquid carrying capacity and non-uniformliquid carrying capacity of rolled cloth in the existing rolling mode for dyeing the cloth. In the invention, a rolling device is arranged on a rack, the rolling device at least comprises a first rolling device and a second rolling device, and the first rolling device at least comprises a first roller and a second roller; the second rolling device at least comprises a third roller and a fourth roller; a guide wheel device at least comprises a first guide wheel, a second guide wheel, a third guide wheel, a fourth guide wheel and a fifth guide wheel; the first guide wheel is arranged between acloth sending device and the rolling device; the second guide wheel is arranged at the discharge end of the first rolling device; the fifth guide wheel is arranged at the feeding end of a material groove; the fifth guide wheel is used for guiding cloth into the material groove; a closed-loop structure is formed among the second guide wheel, the third guide wheel, the fourth guide wheel, the fifthguide wheel, the third roller and the first roller; and the first guide wheel and the cloth sending device are arranged in the closed-loop structure.

Owner:李雅

Preparation of tri(dimethylin) borane

ActiveCN101440101BWell mixedGood miscibilityGroup 3/13 element organic compoundsAeration rateBoron trichloride

The invention relates to a method for preparing a compound, in particular to a method for preparing tris(dimethylamino)borane. The method directly uses a target product, namely tris(dimethylamino)boron, with the content over 90 percent as a solvent, introduces raw materials, namely boron trichloride and a dimethylamine solution into the solvent to react under a stirring condition so as to preparethe tris(dimethylamino)borane. The method is safe and environment friendly, saves the solvent, and reduces cost. When a reacting condition is selected properly, the tris(dimethylamino)borane can be prepared with quite high yield, and side products can be smoothly removed in a filtering process, so that purer tris(dimethylamino)borane can be obtained. The side products can be used as raw materialsfor recycling, or be used as products for sale after proper treatment, and are friendly to environment. The method has the advantages of mild and smooth reaction performance, controllable reaction velocity and reaction temperature through controlling aeration rate, and safety. After the reaction is finished, excess dimethylamine can be recycled.

Owner:DALIAN NETCHEM CHIRAL TECH

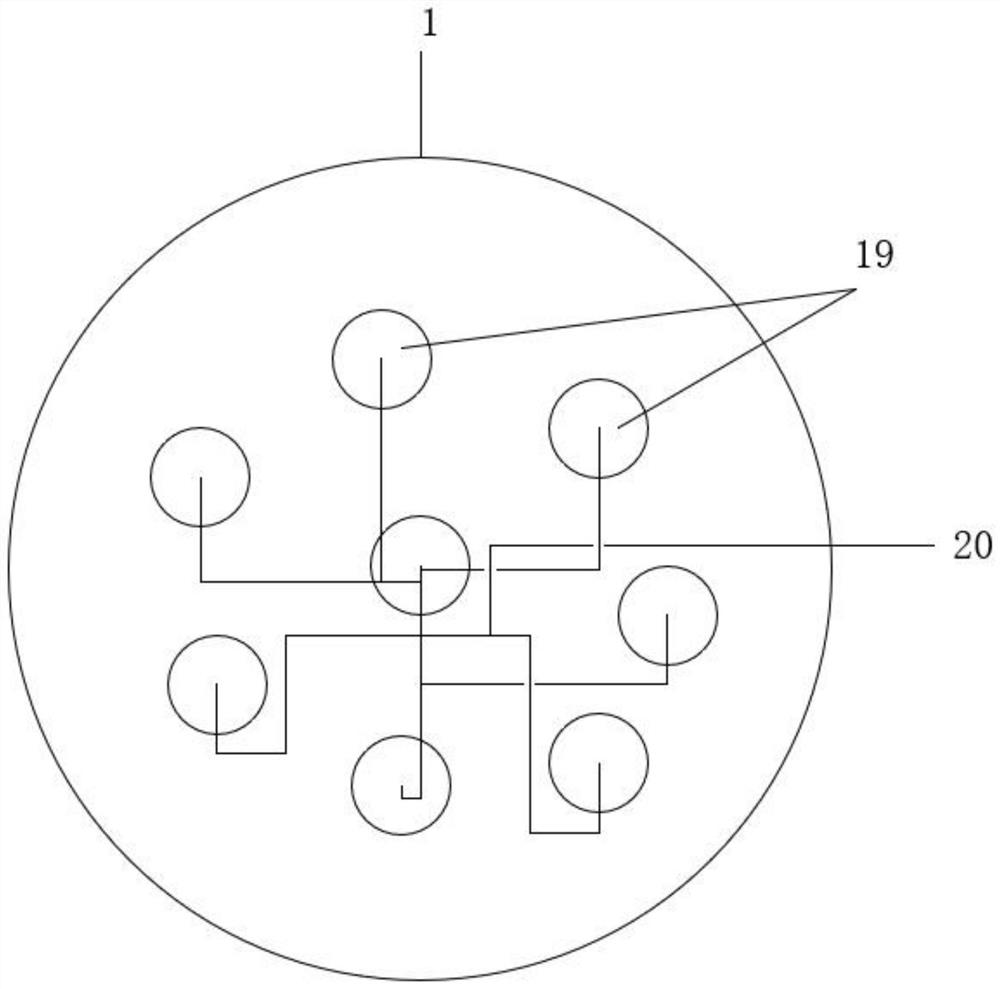

Energy-saving low-consumption membrane-free aeration bioreactor

InactiveCN113666497ASimple structureEasy to manufacture and assembleWater contaminantsTreatment with aerobic and anaerobic processesAmmoniacal nitrogenSewage

The invention discloses an energy-saving low-consumption membrane-free aeration bioreactor, which comprises a box body, a porous filler, a feeding pump, an air compressor and a micro-nano aeration disc. The equipment is simple in structure, easy to assemble and manufacture and low in investment; compared with a traditional aeration tank, the energy consumption is low and the treatment efficiency is high; compared with MBR, the investment is low, and the energy consumption is low; the micro-nano bubbles can increase the content of dissolved organic matters in the sewage and improve the biodegradability of the sewage, so that the advantage of the sewage treatment agent in the aspect of degrading refractory organic matters is improved; a hydrophilic porous filler can quickly and uniformly diffuse micro-nano bubbles, so that the effective utilization rate of the micro-nano bubbles is improved; meanwhile, particulate matters can be filtered by the hydrophilic porous filler, and the SS content of an effluent is extremely low; the use effect of the bioreactor can be changed by adjusting the oxygen supply amount operation parameters, so that the bioreactor is suitable for different water treatment processes; the occupied area is greatly saved, the bioreactor can be conveniently added into an old water treatment process, and COD and ammonia nitrogen are effectively reduced.

Owner:波塞冬(江苏)新材料科技有限公司

Smilax saponin, flavonoid extract and preparation method thereof

The invention discloses a smilax saponin, a flavonoid extract and a preparation method thereof. The method comprises (1) processing the raw material of the smilax, including vacuum drying, crushing and enzymatic hydrolysis of the raw material. (2) The extraction of smilax saponins and flavonoids is refluxed with ethanol under the assistance of ultrasonic waves and then combined and concentrated, degreased with petroleum ether and extracted with chloroform and ethyl acetate respectively, and vacuum-dried to obtain the finished product after recovering the solvent. The flavonoid extract of Poria cocos contains 30-80% of flavonoid compounds; the obtained saponin extract of Smilax cocos contains 20-70% of saponin compounds. The present invention is characterized in that compound plant extract enzyme is used for pretreatment, and it is equipped with ultrasonic assisted extraction technology, so that the utilization of raw materials and medicinal materials is high, the product yield is high, the energy consumption is low, and the operation is simple and convenient. Extracts of flavonoids and saponins are widely used in the fields of raw materials, intermediates and health food, and have broad market prospects.

Owner:湖南湘泉药业股份有限公司

Preparation of tri(dimethylin) borane

ActiveCN101440101ALow costSmooth responseGroup 3/13 element organic compoundsAeration rateProper treatment

The invention relates to a method for preparing a compound, in particular to a method for preparing tris(dimethylamino)borane. The method directly uses a target product, namely tris(dimethylamino)boron, with the content over 90 percent as a solvent, introduces raw materials, namely boron trichloride and a dimethylamine solution into the solvent to react under a stirring condition so as to prepare the tris(dimethylamino)borane. The method is safe and environment friendly, saves the solvent, and reduces cost. When a reacting condition is selected properly, the tris(dimethylamino)borane can be prepared with quite high yield, and side products can be smoothly removed in a filtering process, so that purer tris(dimethylamino)borane can be obtained. The side products can be used as raw materials for recycling, or be used as products for sale after proper treatment, and are friendly to environment. The method has the advantages of mild and smooth reaction performance, controllable reaction velocity and reaction temperature through controlling aeration rate, and safety. After the reaction is finished, excess dimethylamine can be recycled.

Owner:DALIAN NETCHEM CHIRAL TECH

Method for extracting carotenoid and liquid biological fuel from Dunaliella sallina

ActiveCN101774956BHigh yieldHigh calorific valueOrganic chemistryLiquid hydrocarbon mixture productionCarotenoidHollow fiber membrane

Owner:TSINGHUA UNIV

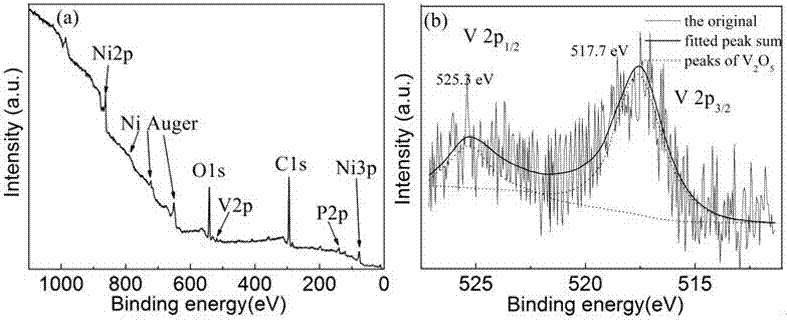

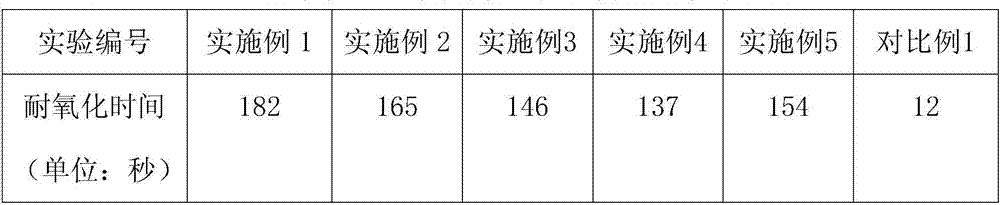

Method for preparing chromate-free passivation film capable of improving oxidative resistance of chemical plating Ni-P layer

ActiveCN107881493AImprove oxidation resistanceSimple Oxidation ResistanceLiquid/solution decomposition chemical coatingChemical platingChromate free

The invention discloses a method for preparing a chromate-free passivation film capable of improving oxidative resistance of a chemical plating Ni-P layer. The method comprises the following steps: S1, under normal temperature, dissolving salt containing VO3<-> in deionized water, and adjusting the molar concentration and pH of the VO3<-> solution to 0.01-0.1 mol / L and 1.0-1.5 to prepare passivation solution; S2, adopting deionized water to wash the chemical plating Ni-P layer prepared on the surface of a part; S3, under normal temperature, dipping the part in the S2 in the passivation solution prepared in the S1, and standing for 10-120 minutes; and S4, taking the part out of the passivation solution, washing the part with deionized water, and preparing the chromate-free passivation filmwith high oxidative resistance on the chemical plating Ni-P layer on the surface of the part. The method is suitable for popularization and application in improvement operation of the oxidative resistance of the chemical plating Ni-P layer in a large-scale and commercialized manner and is broad in market prospect.

Owner:SICHUAN ENG TECHN COLLEGE

A reactor for strengthening calcium-based solid waste mineralization and fixing carbon dioxide in an ammonia medium system and its use method

InactiveCN104907010BReduce consumptionIncrease profitCalcium/strontium/barium carbonatesTransportation and packagingReaction temperatureHigh pressure

The invention relates to a reactor for strengthening calcium-based solid waste mineralization and fixing carbon dioxide in an ammonia medium system and a use method thereof, which is characterized in that the pressurized circulation reactor is used in the process of ammonia medium system strengthening calcium-based solid waste mineralization and fixing carbon dioxide, Wherein the adopted reaction temperature is 60-200° C., the reaction residence time is 5-60 minutes, the CO2 gas partial pressure is 1-40 bar, and the CO2 gas concentration is 20-99.99%. The pressurized loop reactor overcomes the disadvantages of large kinetic energy consumption of a stirred tank reactor, difficulty in sealing a high-pressure system, and easy deposition of solid materials in a bubble column reactor without mechanical stirring. The advantage of this reactor is that it adopts pneumatic stirring instead of mechanical stirring, has low energy consumption, and is easy to process, clean, maintain and operate, and is especially suitable for the process of strengthening calcium-based solid waste mineralization and fixing carbon dioxide in ammonia medium system with high-pressure gas and High solid content feature, easy for industrial scale-up.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

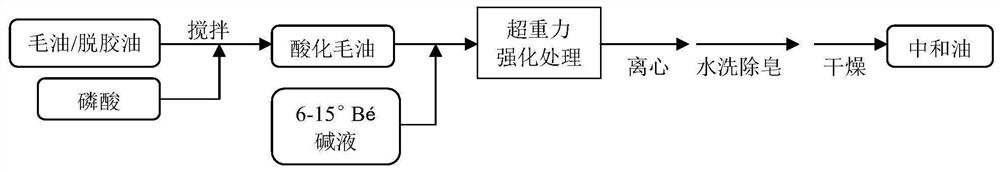

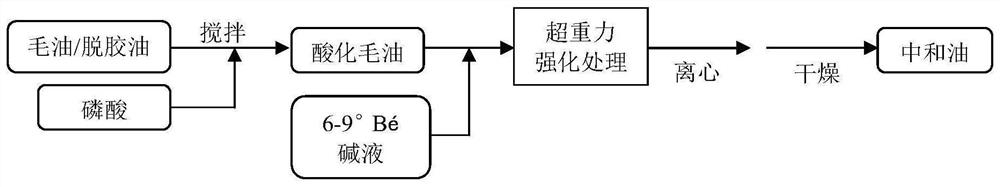

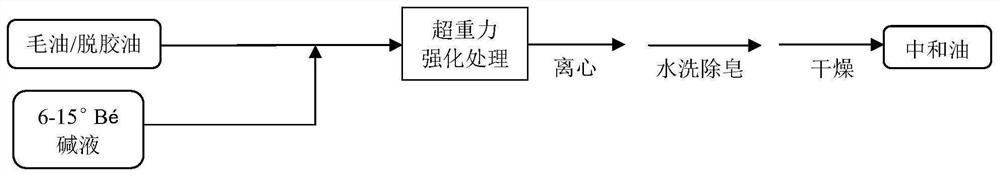

Method for carrying out alkali adding treatment, alkali refining and refining on crude oil through supergravity technology

PendingCN113416604AWide applicabilityGood sizeFatty-oils/fats refiningFree acidContinuous production

The invention provides a method for carrying out alkali adding treatment, alkali refining and refining on edible plant crude oil through a supergravity technology. The method can realize rapid and full contact between the crude oil and alkali liquor, enables free acid in the crude oil to be rapidly neutralized, avoids oil product loss and nutrient substance loss caused by contact between the oil product and the alkali liquor in the prior art, can realize continuous production, and has the advantages of high production efficiency, small occupied area and low energy consumption. The method is suitable for various alkali liquor concentrations, various crude oils and various working conditions, part of process steps can be simplified according to actual conditions, and the method has bright industrial application prospects.

Owner:BEIJING UNIV OF CHEM TECH +1

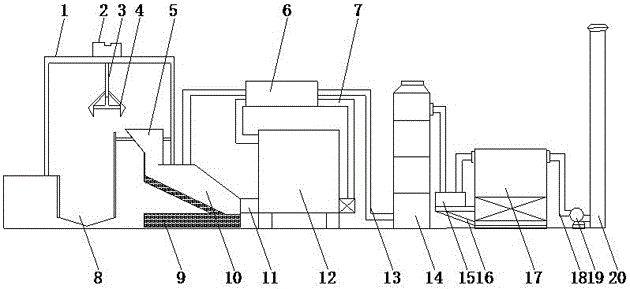

Residue processing device

The invention discloses a residue processing device which comprises a traveling crane frame and a filtering device. A traveling crane installed on the traveling crane frame is connected with a traveling crane grab bucket through a rope. A garbage storage bin and a feeding hopper are installed below the traveling crane frame. A heating device is arranged below a combustion furnace installed below the feeding hopper. An air inlet pipe installed on one side of the feeding hopper is arranged on the combustion furnace. Water pipes installed on the two sides of a metal recycling furnace are installed on the two sides of a desulphurizing device correspondingly. The desulphurizing device is connected with a neutralization reaction tower through the air inlet pipe. The filtering device is installed on a mounting rack on one side of a dust collector. The dust collector is connected with a sucking pump which is installed on one side of a chimney through a sucking pipe. The stage treatment technology is adopted, waste residues of hazardous substance can be processed, and waste residues containing hazardous substance or hazardous gas can be processed, so that the investment of waste residue innocent treatment equipment is reduced, and the construction cost is reduced.

Owner:王保锋

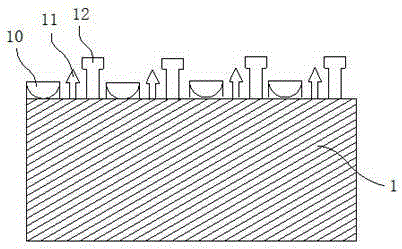

Production method of boron cast iron cylinder sleeve

The invention discloses a production method of a boron cast iron cylinder sleeve. The boron cast iron cylinder sleeve comprises, by weight, 3.5-3.7% of C, 2.5-2.8% of Si, 0.7-1.0% of Mn, 0.04-0.045% of B, 0.008-0.15% of Cr, and the balance of Fe. The production method of the boron cast iron cylinder sleeve has the advantages of high automation degree, low energy consumption and low pollution; the produced boron cast iron cylinder sleeve has good mechanical strength and hardness, is suitable for being promoted and applied in production running, has a simple structure, and has ingenious design; different external diameter surface designs are adopted, so the boron cast iron cylinder sleeve produced through the method is easy to combine, mount and dismount; and three layers of projections with different heights are arranged on the surface, so the combination force between parts is effectively increased, a gap between the parts is reduced, the service life of the boron cast iron cylinder sleeve is prolonged, and oil consumption is reduced.

Owner:张凌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com