Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

944results about How to "UV resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Powder coating with super-weathering resistance, preparation method and application thereof

InactiveCN101671518AWith super weather resistanceThe ratio is scientific and reasonablePowdery paintsPolyester coatingsPliabilityUltraviolet

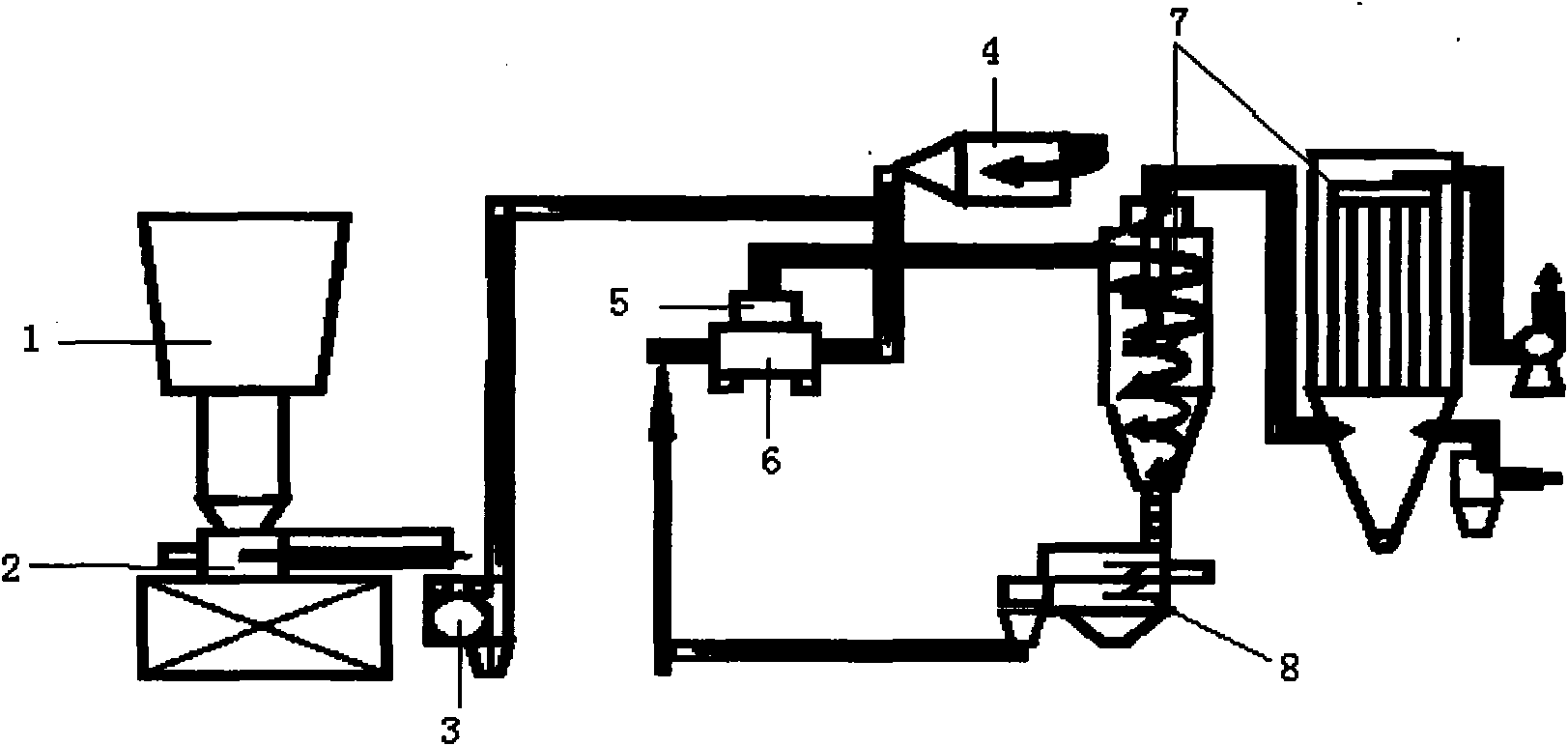

The invention discloses powder coating with super-weathering resistance, a preparation method and an application thereof. The powder coating comprises the following raw materials in parts by weight: 40-90 parts of weather-resistant polyester resin, 3-30 parts of thermosetting fluorocarbon resin, 4-50 parts of curing agent, 0.1-1.5 parts of flatting agent, 0.2-0.8 part of degasifying agent, 0-4.5 parts of defoaming agent and 4-45 parts of pigment and filler. The powder coating with super-weathering resistance provided by the invention has scientific and reasonable proportioning in the aspects of raw material composition and raw materials, fine comprehensive properties such as flexibility, hardness, adhesive force and the like, stable chemical property, easy storage, performances of acid rain, ozone, ultraviolet ray and chemical medicine resistance and the like in long-term outdoor use, environment protection and wide application range. The preparation method provided by the invention has reasonable processes, strong operability, high qualified rate of finished products and capability of realizing industrialized production.

Owner:TIGER DRYLAC TAICANG

Uvioresistant polyurethane acrylic ester water coating adhesive and preparation thereof

InactiveCN101280156AWith PU performanceWith PA performanceCoatingsTextiles and paperPolymer scienceEmulsion

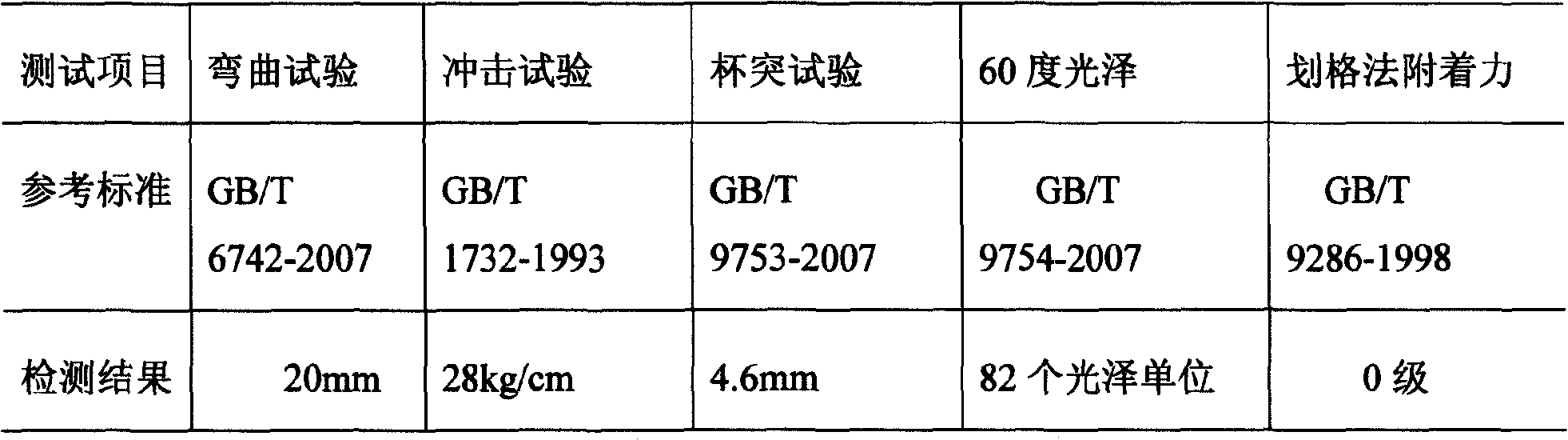

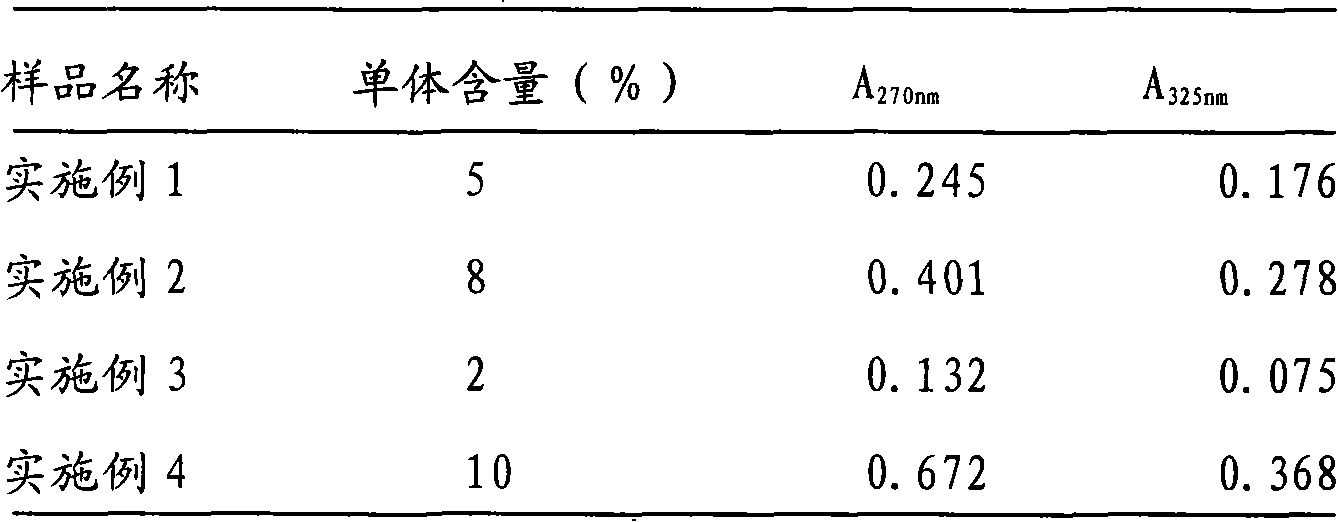

The invention discloses anti-ultraviolet urethane acrylate waterborne coating adhesive and the preparation method; the urethane acrylate emulsion in the prior art cannot have the anti-ultraviolet function and can only be applicable to the weaving coating field. The invention adopts the means of molecular structure design that firstly, the group with the anti-ultraviolet function is introduced to acrylic ester emulsion to prepare the acrylic ester emulsion with the anti-ultraviolet function, and then the means of molecular structure design is adopted to prepare polyurethane emulsion with double bond; the interpenetrating polymer networks method is adopted to process copolymerization of the two emulsions to obtain the anti-ultraviolet urethane acrylate waterborne coating adhesive with the interpenetrating polymer networks structure. The waterborne coating adhesive in the invention has the properties of PU property, PA property and anti-ultraviolet property and extends the application range of the coating adhesive, enabling the coating adhesive not only to be applicable to the weaving coating field, but also to be applicable to the fields of paper-making, coating, packaging and leather.

Owner:传化智联股份有限公司

Fabric product with antibiosis, deodorization, heat emission and cooling function

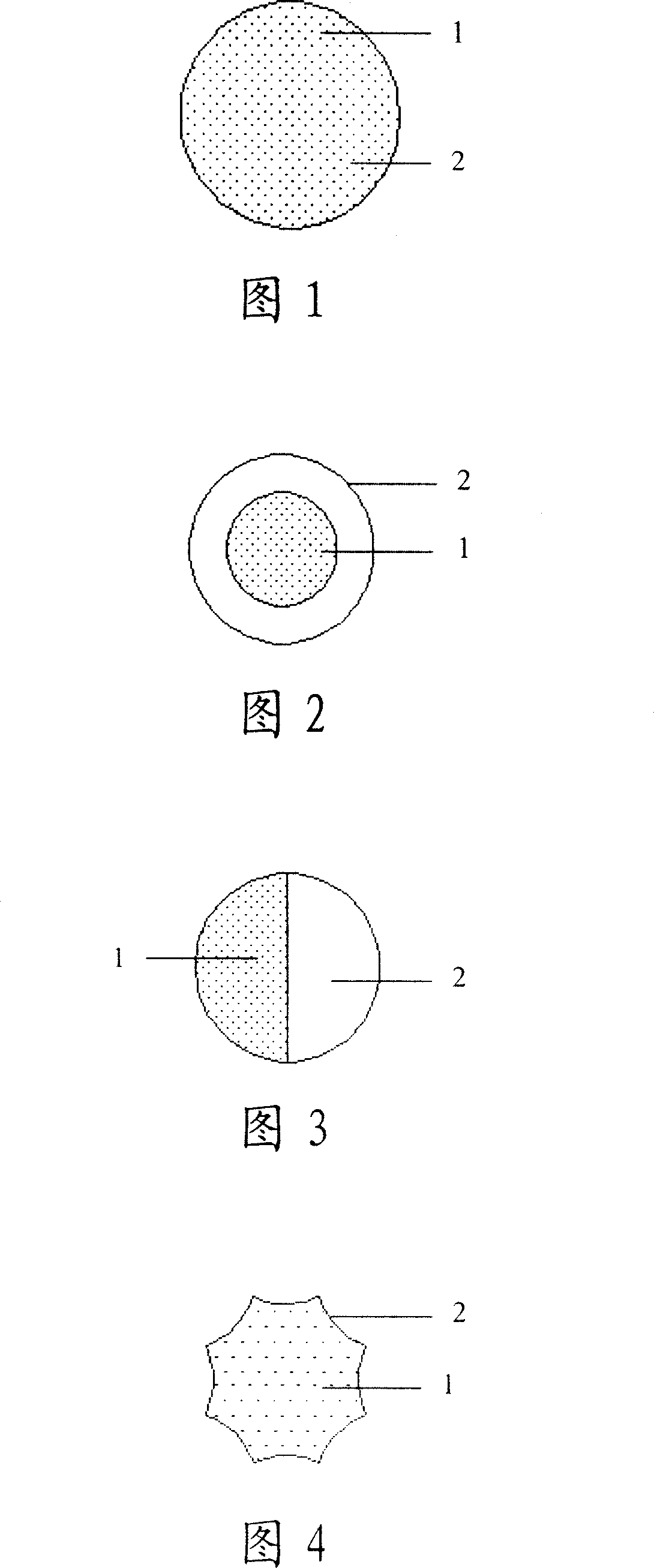

ActiveCN101144217AGood dispersionPhenomena that do not seriously degrade the functionWeft knittingWarp knittingAntibiosisMasterbatch

The present invention relates to a fiber product having the performances of antibiosis, odor elimination, heat dissipation and cooling. The present invention comprises woven fabric, knitted fabric, non woven fabric film or a combination body of the fabric and the film, and is made by weaving continuous filament fiber or short fiber having various different cross section shapes, sizes, colors, structures, etc. The fiber adopts sub-micron or nanometer powder with high heat diffusion coefficient and low heat conduction coefficient, and is added into thermoplastic plastic grains in a quantitative way after being decentralized with an interfacial agent. The thermoplastic plastic grains are fully mixed with the sub-micron or nanometer powder with the high heat diffusion coefficient and the low heat conduction coefficient by a mixing machine or a kneading machine or by utilizing the chemical synthesis method, and then are made into masterbatch with a granulating machine, finally the fiber product having the functions of antibiosis, odor elimination, heat dissipation and cooling can be made by using the melting, and the dry and the wet spinning technologies and through the pre-designed spinneret.

Owner:郑国彬

Nano graphene fragment modified corrosion-resistant coating and preparation method thereof

The invention relates to a nano graphene fragment modified corrosion-resistant coating and a preparation method thereof. The invention adopts the technical scheme as follows: the corrosion-resistant coating comprises the following chemical components in percentage by weight: 20-80% of a film-forming agent, 10-30% of a solvent, 0.1-20% of nano graphene fragments, 1-10% of pigments, 1-10% of filler and 1-20% of auxiliaries. The preparation method comprises the following steps: proportioning the chemical components of the corrosion-resistant coating in percentage by weight; then carrying out ultrasonic dispersion for 5-20 minutes so as to obtain the nano graphene fragment modified corrosion-resistant coating. The nano graphene fragment modified corrosion-resistant coating and the preparation method provided by the invention have the characteristics of being simple in process and low in cost and the prepared nano graphene fragment modified corrosion-resistant coating is good in corrosion-resistant effect and wide in application range.

Owner:WUHAN UNIV OF SCI & TECH

Preparation of multifunctional textile lining

InactiveCN101280485AMoisture absorption and quick dryingUV resistantFilament/thread formingWoven fabricsPolyesterAnti bacterial

The invention discloses a textile technology, in particular to a textile technology of textile fabrics. In the invention, the quick-drying polyester yarns with moisture absorption, anti-ultraviolet polyester yarns, anti-bacterial polyester and nylon yarns, bamboo charcoal polyester, the coated yarns of spandex or Dow elastomer yarns, the coated yarns of conductive yarn and polyamide yarns, metal wires or the coated yarns of cotton and so on with specific properties are taken as the raw materials. Then the ingenious design and weaving are proceeded for the fabric structure. At last the fabric is dyed or in post preparation, and the modeling is also included. The invention has the advantages that the prepared fabric has moisture adsorption, quick-drying, anti-UV, anti-bacterial, anti-static, anti-radiation, flexibility and other functions. Therefore, the invention can be widely applied in many occasions, including the use as medicine or for decoration purpose.

Owner:ZHEJIANG SCI-TECH UNIV

Nano modified water-base multifunctional sound-absorbing paint and preparation method thereof

InactiveCN103980771ABasic mechanicsBasic sound-absorbing functionCoatingsWater basedThermal insulation

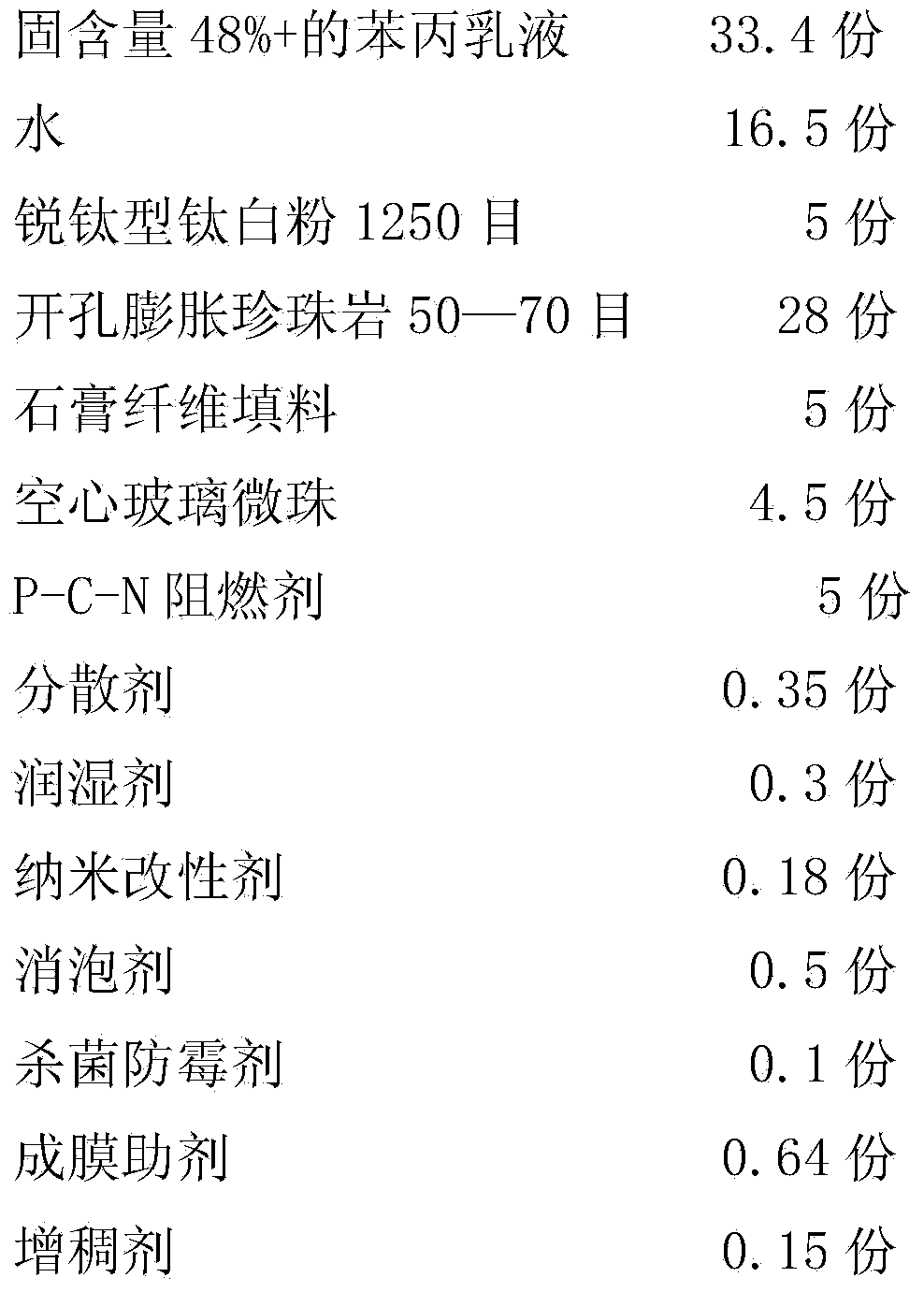

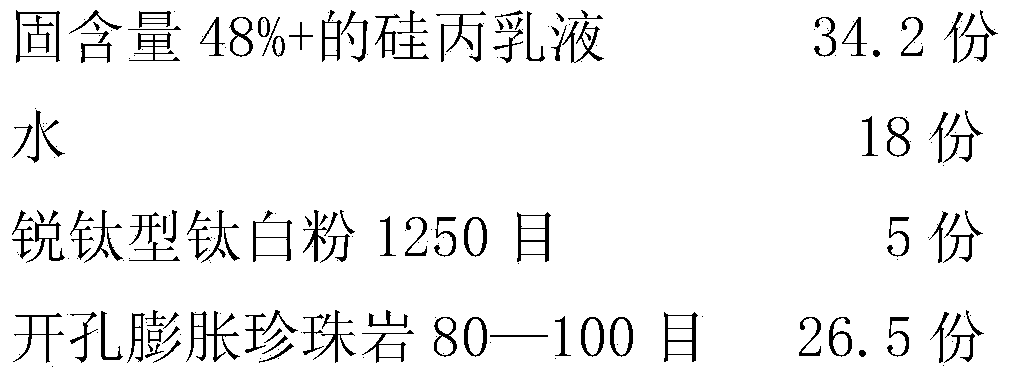

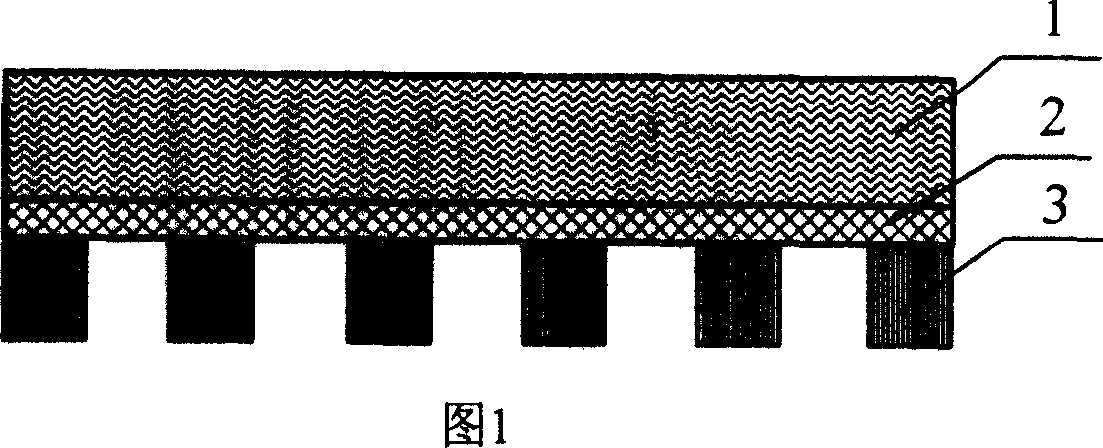

The invention discloses a nano modified water-base multifunctional sound-absorbing paint and a preparation method thereof. The paint is composed of the following components in parts by weight: 28-38 parts of emulsion, 2-10 parts of pigment, 30-45 parts of filler, 15-25 parts of water, 4-8 parts of flame retardant and 2.25-5.43 parts of assistant. By optimizing the paint system structure, the polymer and filler are selected, modified and proportioned to ensure the basic mechanical properties and sound-absorbing function, and the paint has high-value service properties, such as thermal insulation, moisture resistance, fire resistance, aging resistance, fouling resistance, sterilization, air purification and the like, and is especially suitable for rooms and other occasions with higher environmental requirements.

Owner:南京创宁空间新材料科技有限公司

Multifunctional knitting sportswear face fabric and manufacture method thereof

InactiveCN1920144ASatisfy moisture absorption and quick dryingMeet antistaticWeft knittingLiquid/gas/vapor textile treatmentEngineeringPolypropylene

The invention relates to a multifunctional knitting exercise clothes and relative production, wherein it uses four machines to prepare the face fabric with inner layer, middle connecting layer and outer layer; the outer layer is the polyester filament yarn of 75D / 100F and C-O shaped section and porous structure; the middle connecting layer is polypropylene or polyester filament yarn; the inner layer is the polyester filament yarn with ultraviolet resistance, at 75D / 72F + type or Y-shaped, H-shaped, and five-pointed star shape, which is treated with semi delustring. Said material is treated with alkali reduction before doping, and to be softened after doping. The invention and quickly adsorb the sweaty and release the sweaty outside the fabric, to avoid skin cancer, etc.

Owner:河南纺织高等专科学校

Water-based environment-friendly finishing paint and preparation method thereof

InactiveCN101712833AGood anti-corrosion decoration effectHigh hardnessEpoxy resin coatingsWater basedEpoxy

The invention discloses a water-based environment-friendly finishing paint, which is prepared from the following compositions in part by weight: 20 to 70 parts of water borne acrylic resin solution of which the solid content is 30 to 80 percent and / or 20 to 70 parts of water borne epoxy resin solution of which the solid content is 30 to 80 percent, 4 to 10 parts of water borne amino resin solution of which the solid content is 60 to 98 percent; 1 to 5 parts of organic amine, 0.2 to 2 parts of wetting and leveling agent, 0.2 to 2 parts of thickener, 0.1 to 0.8 part of defoaming agent, 1 to 5 parts of adhesion promoter, 0.2 to 5 parts of catalyst, 10 to 30 parts of alcohol diluting solvent and / or 1 to 5 parts of nontoxic ether diluting solvent, and 20 to 50 parts of deionized water, wherein the catalyst is one or more of ammonias, alcohols and benzenesulfonic acids. The water-based environment-friendly finishing paint has the advantages of wide applicable range, high hardness, good flexibility, strong adhesion, good scratchproof performance, and environmental protection. Simultaneously, the invention also discloses a method for preparing the water-based environment-friendly finishing paint.

Owner:重庆亢石新材料科技有限公司

Aqueous environment-friendly packaging steel drum paint and preparation method thereof

InactiveCN101735703AGood anti-corrosion decoration effectHigh hardnessAnti-corrosive paintsEpoxy resin coatingsEpoxyAcrylic resin

The invention relates to an aqueous environment-friendly packaging steel drum paint, which is prepared by mixing the following compositions in part by weight: 20 to 70 parts of aqueous solution of acrylic resin with a solid content of 30 to 80 percent and / or aqueous solution of epoxy resin with the solid content of 30 to 80 percent, 4 to 10 parts of aqueous solution of amino resin with the solid content of 60 to 98 percent, 1 to 5 parts of organic amine, 1 to 50 parts of filling materials with the granularity of more than 2,000 meshes, 0.5 to 10 parts of color paste, 0.2 to 2 parts of wetting levelling agent, 0.2 to 2 parts of thickening agent, 0.1 to 0.8 part of antifoaming agent, 1 to 5 parts of adhesive force accelerant, 0.2 to 5 parts of catalyst, 0 to 30 parts of alcohol diluting solvent and / or 0 to 5 parts of non-toxic ether diluting solvent, and 20 to 50 parts of deionized water. The aqueous environment-friendly packaging steel drum paint has the advantages of wide application range, high rigidity, good flexibility, strong adhesive force and good anti-scraping and anti-collision properties and environmental protection; and meanwhile, the invention discloses a preparation method for the aqueous environment-friendly packaging steel drum paint.

Owner:重庆亢石新材料科技有限公司

Aqueous fluorine-containing acrylate modified polyurethane coating, preparation method and application thereof

The present invention belongs to the field of polymer material synthesis, relates to aqueous polyurethane acrylate emulsion modification, and especially to an aqueous fluorine-containing acrylate modified polyurethane coating, a preparation method and an application thereof. The preparation method comprises: dissolving polyether polyol in an N-methyl pyrrolidone solution of dimethylol propionic acid; adding diisocyanate in a dropwise manner; adopting dibutyltin dilaurate as a catalyst, and adding hydroxyethyl methacrylate to carry out end capping; adding triethylamine to form a salt, then adding deionized water to prepare an aqueous polyurethane acrylate prepolymer emulsion; and finally adding hexafluorobutyl acrylate and azodiisobutyronitrile to prepare the aqueous fluorine-containing acrylate modified polyurethane coating. The synthesized emulsion of the present invention has the following advantages that: dispersion is uniform; stability is good; water resistance and mechanical property of the cured film are substantially improved; elasticity and mechanical property of polyurethane are provided; ultraviolet resistance, nuclear radiation resistance, flexibility, excellent surface properties, water resistance and corrosion resistance of the fluorine-containing material are provided; and the coating can be adopted as coatings for building and furniture.

Owner:BOMEX CHEM SHANGHAI

Coating of non-velvet lightproof coated cloth

The invention belongs to the technical field of coating supplies, particularly relates to a coating of non-velvet lightproof coated cloth, and discloses the coating of the non-velvet lightproof coated cloth. The coating of the non-velvet lightproof coated cloth is characterized in that the coating of the non-velvet lightproof coated cloth comprises a waterproof agent layer, a whitewash layer, a blackwash layer, a color scraping material layer and a protection film. The whitewash layer is composed of, by weight, 40-60% of textile emulsion, 10-30% of water, 0.1-0.5% of dispersing agent, 10-20% of titanium dioxide, 1-5% of foam stabilizer, 0.1-0.5% of thickener, 0.1-0.5% of catalyst and 1-5% of acrylic emulsion. The coating of the non-velvet lightproof coated cloth has the advantages of being lightproof, waterproof, capable of insulating heat, absorbing sound and resisting ultraviolet rays and the like.

Owner:CHEN HONG TEXTILES TECH

Waterproof ultraviolet-resistant high-strength light and thin fabric and preparation method thereof

ActiveCN106480581AIncreased mechanical strength and electromagnetic shielding performanceExcellent UV resistanceUltrasonic/sonic fibre treatmentWoven fabricsSolventPlain weave

The invention provides a method for preparing a waterproof ultraviolet-resistant high-strength light and thin fabric. The method comprises the following steps: blending ceramic fibers and triangular special-shaped polyester fibers to form warp yarns, blending spandex fibers and titanium-nickel alloy fibers to form weft yarns, weaving plain weaves or basket weaves serving as a fabric structure to form base cloth; adding colloidal silica sol and nanometer titania sol into a solvent, fully stirring, adding graphene oxide solution, dripping a polystyrene high polymer, homogenizing and stirring so as to obtain a coating finishing agent; washing and airing the base cloth, performing low-temperature plasma treatment so as to obtain modified base cloth in a nitrogen atmosphere; spraying deionized water on the surface of the modified base cloth, wetting, repeatedly coating the coating finishing agent, drying, roasting, washing, well-pressing, and performing tenter setting, thereby obtaining the product.

Owner:SHAOXING DAFABRIC CLOTH TRADE

Light heat preservation silicon and calcium compound plate

InactiveCN102888900APromote environmental protectionNo side effectsCeramic shaping apparatusHeat proofingEnvironmental resistanceSide effect

The invention discloses a light heat preservation silicon and calcium compound plate, which consists of an outer layer structure and an inner layer structure. The plate is manufactured by waste coal ash generated by local rich coal mine resources and crop stalks, so that waste is recovered, and the plate is beneficial to environment friendliness. The plate takes inorganic substances such as powder quartz, quartz sand, sanding powder and the like as main raw materials, has the advantages of high strength, aging resistance, ultraviolet resistance, water resistance, fire prevention, heat preservation and the like, is widely applied, does not have toxic or side effect and is pollution-free.

Owner:SUZHOU WANAN NEW ENVIRONMENTAL PROTECTION BUILDING MATERIAL

Whitening mask and preparation method thereof

InactiveCN104971029APromote cell regenerationUV resistantCosmetic preparationsToilet preparationsGlycerolAloe Extract

The invention discloses a whitening mask which is prepared by dipping a liquid prepared from the following raw materials in parts by weight: 0.1-3 parts of micromolecular hyaluronic acid, 0.1-2.5 parts of macromolecular hyaluronic acid, 0.7-30 parts of synthetic egg white powder, 1-7 parts of an aloe extract, 0.7-9 parts of propylene glycol, 5-50 parts of 1,2-butanediol, 5-30 parts of glycerinum, 40-80 parts of a ginseng extract liquid, 0.1-1 part of glabridin, 0.3-2 parts of alpha-arbutin, 0.1-1 part of phloretin, 0.1-1 part of apple stem cells, 1-5 parts of raspberry ketone glucoside, 0.1-1 part of tetrahydropiperine, 1-10 parts of vitamin c ethyl ether, 1-5 parts of tranexamic acid, 1-10 parts of hydrolyzed pearl and added to 1000 parts of water on mask paper. The whitening mask has the efficacies of promoting skin absorption of various effective components, repairing damaged cells, activating resting cells, promoting cell regeneration, moisturizing the skin, rapidly and efficiently whitening the skin and removing freckles, and is free of irritation, allergy or damage to the skin.

Owner:GUILIN HONGXU BIOTECH CO LTD

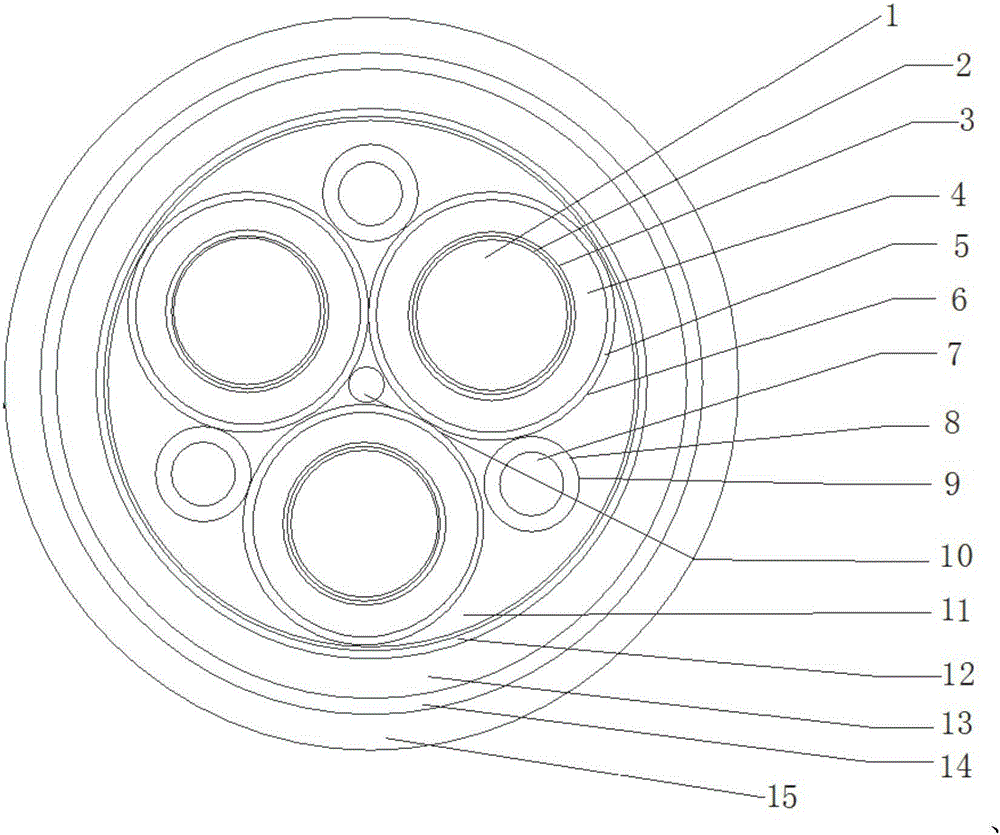

Irradiation crosslinking low-smoke halogen-free flame-retardant polyolefin cable material for photovoltaic cables

The invention provides an irradiation crosslinking low-smoke halogen-free flame-retardant polyolefin cable material for photovoltaic cables. The cable material is prepared from the following raw materials in parts by weight: 40-50 parts of polyethylene (PE), 30-40 parts of polyvinyl chloride resin, 20-30 parts of CSM2305, 10-12 parts of ethylene-acrylate copolymer, 10-15 parts of epichlorohydrin rubber T3100, 5-10 parts of epoxidized soybean oil, 2-3 parts of carbonyl iron powder, 10-12 parts of high abrasion carbon black N330, 5-10 parts of light calcium carbonate, 1-2 parts of zinc oxide, 5-10 parts of wollastonite powder, 4-5 parts of vermiculite, 1-2 parts of polytetrafluoroethylene micro powder, 1-2 parts of graphite, 1-2 parts of nano boron carbide, 2-3 parts of ferric oxide, 0.1-0.2 part of UV-O, 0.1-0.2 part of UV-53, 0.1-0.2 part of flame retardant TBC, 10-12 parts of aluminium hypophosphite, 5-8 parts of decabromodiphenyl ether, 8-10 parts of dioctyl terephthalate, 6-8 parts of trioctyl trimellitate, 8-10 parts of triethyl citrate, 1-2 parts of calcium stearate, 0.2-0.4 part of stearic acid, 0.1-0.2 part of oxidized polyethlene wax, 0.2-0.3 part of ethylene bis stearamide, 0.1-0.2 part of DCP, and 12-15 parts of modified filler. The cable material has the characteristics of high flame retardance, high ultraviolet resistance and high ageing resistance, and meanwhile, has a good mechanical property, and is environment-friendly.

Owner:温州市粤来电子加速器应用有限公司

Electric-insulation epoxy resin castable for outdoor mutual inductor

ActiveCN103709608AExcellent physical and chemical propertiesHeat resistantPlastic/resin/waxes insulatorsPolymer scienceFirming agent

The invention relates to an electric-insulation epoxy resin castable for an outdoor mutual inductor. The epoxy resin castable comprises the following materials by weight percent: 21-26% of resin, 45-55% of filling, 15-25% of a curing agent and 2-6% of other auxiliary agents, wherein the resin is formed by mixing organic silicon modified epoxy resin, phenolic aldehyde epoxy resin, brominated epoxy resin and bisphenol F-type epoxy resin; the filling is silane-processed silica powder; the curing agent is modified methylhexahydrophthalic anhydride; the other auxiliary agents include a curing catalyst, a plasticizer, a reactive diluent, a silane coupling agent, a coloring agent and an antioxidant. The electric-insulation epoxy resin castable has excellent physical and chemical properties and has the performance of heat resistance, low temperature resistance, ultraviolet irradiation resistance, ageing resistance and the like. The electric-insulation epoxy resin castable is applicable to the electric insulation of the outdoor mutual inductor and other electrical equipment.

Owner:JIANGXI TENGDE IND

Giant salamander oligosaccharide peptide, preparation method and application thereof in cosmetics

InactiveCN101812116AImprove the ability of monocytes to phagocytize bacteriaEnhance monocyte vitalityCosmetic preparationsToilet preparationsMolecular sieveChemistry

The invention discloses giant salamander oligosaccharide peptide, a preparation method and application thereof in cosmetics, wherein the molecular weight of the prepared giant salamander oligosaccharide peptide is smaller than 4000Da, a sugar chain is connected with serine or threonine through GalNAc, and the giant salamander oligosaccharide peptide has a -Galbeta1-3GalNAcalpha-O-Ser / Thr structure. The preparation method comprises the following steps of: homogenizing giant salamander grume at the temperature of 0-10 DEG C; adding 1-3 time volume of 0.01-0.1M phosphate buffer and complex enzyme into a homogenate and carrying out enzymolysis for 12-48 hours, wherein the pH value of the phosphate buffer is 7-8, the mass ratio of the complex enzyme to the homogenate is 0.1-1 percent, and the complex enzyme is formed by proportionally mixing ocean alkali protease, papain, pepsin and trypsinase in the activity unit ratio of 3:3:2:2; centrifugalizing to obtain a supernatant, separating by adopting an ultrafiltration membrane separator with the interception molecular weight of below 4000Da and obtaining a liquid permeating an ultrafiltration membrane; collecting an OD280nm absorption peak through a Sephadex LH-20 molecular sieve chromatography column; and freezing and drying the collected liquid after passing through macroporous absorbent resin and activated carbon to prepare the giant salamander oligosaccharide peptide.

Owner:ZHANGJIAJIE JINCHI ANDRIAS DAVIDIANUS BIOLOGICAL SCI

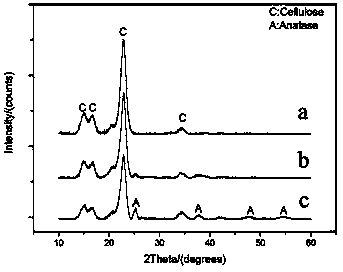

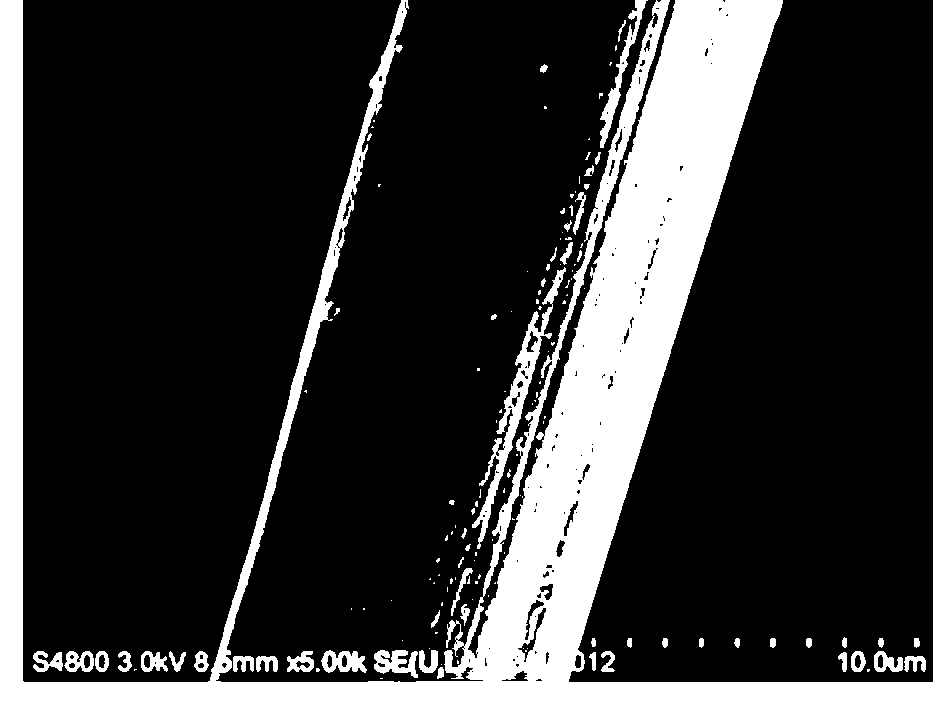

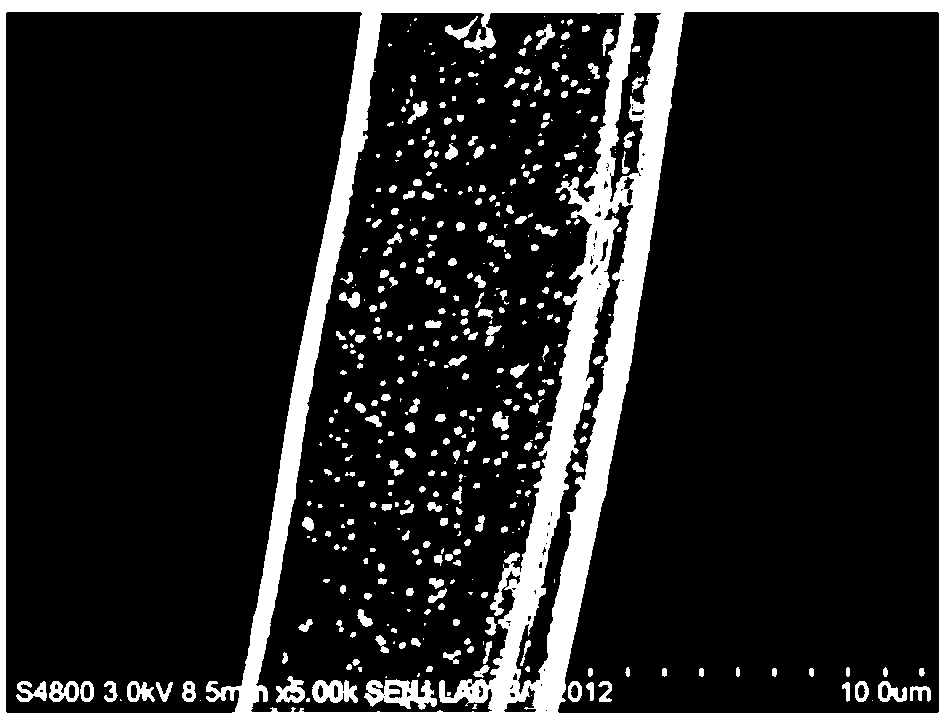

Nano-titanium dioxide sol finishing agent prepared at low temperature and application thereof

ActiveCN103397513AImprove responseFacilitate rearrangementTitanium dioxideVegetal fibresFiberEvaporation

The invention relates to a nano-titanium dioxide sol finishing agent prepared at low temperature and an application thereof. The nano-titanium dioxide sol finishing agent is prepared from the following components in parts by weight: 10-40 parts of nano-titanium dioxide sol, 2-10 parts of hand feeling regulating agent and 900-950 parts of deionized water, and the prepared nano-titanium dioxide sol finishing agent can be used for finishing fabric. Compared with the prior art, the temperature of the nano-titanium dioxide sol finishing agent is low when used for treating the fabric, and the sol can be uniformly dispersed onto the fabric and forms the firm combination with the fabric without adding a dispersing agent; and when the fabric is treated by water boiling evaporation, the titanium dioxide sol can be hydrolyzed and condensed on a fiber surface, the TiO2 sol can be converted to gel to be fixed on cotton, and the combination with the cotton is firmer.

Owner:SHANGHAI UNIV OF ENG SCI

Colourful environmental-friendly synthesized polymer waterproof paint

InactiveCN102108234AWith comprehensive performanceImprove physical performance indicatorsPolyurea/polyurethane coatingsMulticolor effect coatingsUltravioletSynthetic Polymeric Macromolecules

The invention relates to a colourful environmental-friendly synthesized polymer waterproof paint which comprises the following components in parts by weight: 3-7 parts of petroleum resin, 5-15 parts of styrene-ethylene-butylene-styrene (SEBS), 5-15 parts of styrene-butylene-styrene (SBS), 5-10 parts of thermoplastic polyurethane elastomer, 4-8 parts of terpene resin, 4-8 parts of poly-alpha-methyl styrene, 2-5 parts of tung oil, 10-15 parts of mica powder, 0.2-0.5 part of antiager D, 0.2-0.5 part of antioxidant 264, 0.2-0.5 part of defoaming agent, 0.3-0.5 part of ultraviolet absorber, 35-45 parts of 120 # solvent, 5-15 parts of butyl acetate and 1-3 parts of color paste. The paint has the characteristics of unique waterproof property, acid-base resistance, ultraviolet irradiation resistance, heat insulation, anti-aging property, high adhesion strength, water repellent, good leakage-resisting effect, heat resistance, frost resistance and good elongation; and the paint also has the advantages of wide application range, moderate price, environmental friendliness, durability and the like, and is convenient to use, thereby meeting the demand of people in a real life.

Owner:白铁林

Adhesive tape used for solar cell assembly and preparation method thereof

InactiveCN102816536AGood adhesionGood initial tackFilm/foil adhesivesEster polymer adhesivesAmmonium sulfateEmulsion

The invention relates to a double-sided adhesive tape, and specifically relates to the double-sided adhesive tape used for a solar cell assembly and a preparation method thereof. The double-sided adhesive tape comprises a substrate, an adhesive, a backlining and backlining glue, wherein the adhesive mainly comprises the following components of, by weight, 0.5-1 part of ammonium sulfate, 5-10 parts of methyl methacrylate, 55-65 parts of butyl acrylate, 20-30 parts of hydroxymethyl acrylamide, 1-2 parts of a composite emulsifier, 60-70 parts of a tackifying resin, 0.2-0.8 part of acrylic acid, 1-2 parts of hydroethyl methacrylate, 1-1.5 parts of 2-acrylamide-2-methylpro panesulfonic acid and 1-3 parts of 3-(methacryloxy)propyltrimethoxysilane. The preparation method comprises the steps of firstly pre-preparing a high-strength organosilicone and acrylate co-polymeric emulsion pressure-sensitive adhesive; and then performing operations of double roll reverse coating, drying, compositing, transferring and the like with a B-50 multifunctional coating machine, wherein both the font side and the back side of the backlining of the substrate are already coated by a layer of low-adhesivity backlining glue.

Owner:SUZHOU DATONG ADVANCED MATERIAL

Water wall paint for external wall

The present invention features that by selecting different sort and amount of emulsion and assistants, four kinds of wall finish paint, including styrene-acrylate wall finish paint, acrylate wall finish paint, organosilicon modified acrylate wall finish paint and high elasticicty wall finish paint, of different performance / cost ratio are proposed. They features the introduction of hydroxyethyl cellulose and non-transparent hollow polymer. Therefore, the outer wall finish paint has excellent alkali resistance, color maintaining property, antifouling property, ultraviolet ray resistance, freeze thawing resistance, waterproof property, etc.

Owner:GUANGDONG BADESE CHEM

Flax scribbled yarn and its production

One flax blended yarn and its preparation technology. The blending ratio of the chemical fiber is 20-80:80-20, the Separatist degrees of flax fiber used is more than 2000. the preparation technology is that flax fiber and chemical fiber blend by the equipment of Cotton-cleaning, carding strip, drawing, roving, spinning, finally winding into yarn. The flax fiber and chemical fiber blend in the cleaning cotton disk. Add the equipment of spinning core spun slub Yarn. The beneficial effect of the present invention is: owing to the improvement in the procedure, the blended yarn with multi-fiber and more varieties is available, which satisfy the demand of customers; the Ma in yarn and other fiber are mixed uniformly, which leads to easy dye; the fabrics produced by the mix of Ma yarn and chemical fiber has the following advantages: wrinkle resistant, wear-resistant, can not afford ball, overhanging flexible, antibacterial antibiotics, anti-UV, thin smoothness, cool, breathable, moisture absorption, scattered wet fast, and so on.

Owner:曲阜市锦绣纺织有限公司

Preparation method of nano-silver antibacterial real silk

InactiveCN102936835ALong-lasting antibacterial functionGood washabilityAnimal fibresLong actingFibroin

The invention discloses a preparation method of nano-silver antibacterial real silk. The method comprises the following steps of: placing the un-degummed real silk thread or product in neutral silk proteinate mixed liquid to remove sericin, soaking the product in a silver nitrate aqueous solution, performing padding treatment in plant leaf extract dispersion liquid, taking out the product, and washing, drying or airing to obtain the antibacterial real silk or product with in-situ formation of nano-silver. According to the technical scheme of the invention, the fibril structure of fibroin fiber is partially separated or puffed and then subjected to two-step impregnation to sequentially realize adsorptive fixation, in-situ growth and reduction of silver ions on the real silk surface and in the fiber; the generated nano-silver is permeated and diffused inside and on the surface of the real silk fiber / textile; and the obtained nano-silver antibacterial real silk product has a long-acting antibacterial function and good washing resistance.

Owner:SUZHOU UNIV

Transparent and toughening polylactic acid resin and method for preparing the same

The invention provides a transparent and toughening polylactic acid resin and method for preparing the same. The polylactic acid resin consists of polylactic acid, methyl methacrylate-butyl acrylate copolymer as the flexibilizer, citrate plasticizer, pentaerythritol toltetranitrate (Benzenepropanoic acid, 3,5-bis(1,1-dimethylethyl)-4-hydroxy-) as the antioxidant and tris (2,4-ditert-butylphenyl) phosphate. First, premix is prepared by mixing polylactic acid, flexibilizer, plasticizer and antioxidant mechanically. Then the premix is subject to melt extrusion and granulation by utilizing double-screw extruder. The above method has the advantages of increasing the anti-impact strength, tensile strength and elongation at break of polylactic acid and maintaining the transparency thereof. In addition, the viscosity of the blends is decreased, thereby remedying the defects of brittleness of polylactic acid and improving the rheological behavior of materials obviously. The impact strength is up to 60.1KJ / M2.The light transmittance and the haze of the products are 89% and 8.5% respectively when the thickness thereof is 0.04mm.The above polylactic acid resin, instead of PE and PVC, is applicable to the preparation of films, plates, sheet materials, foamings and injection moulding plastics.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

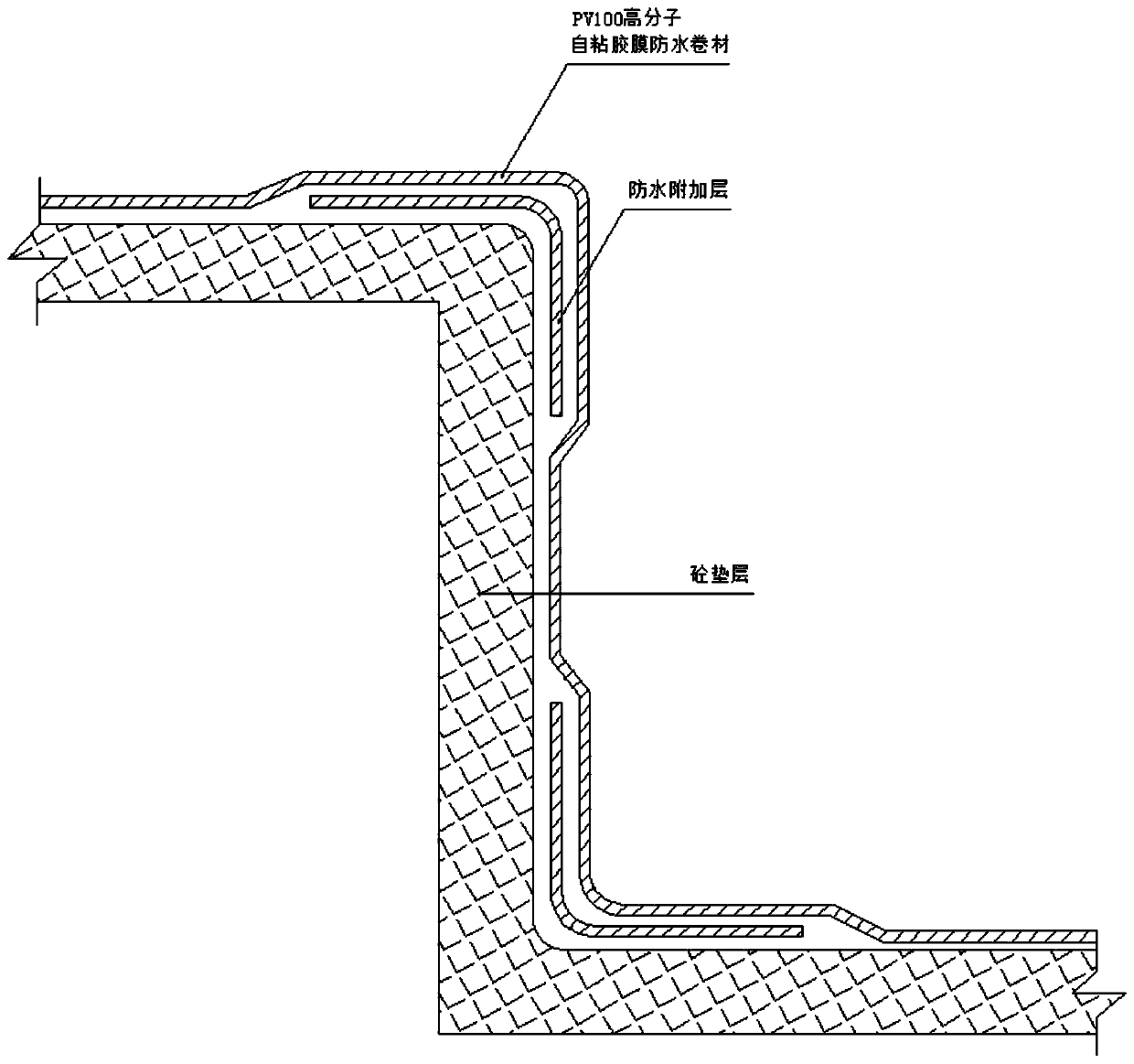

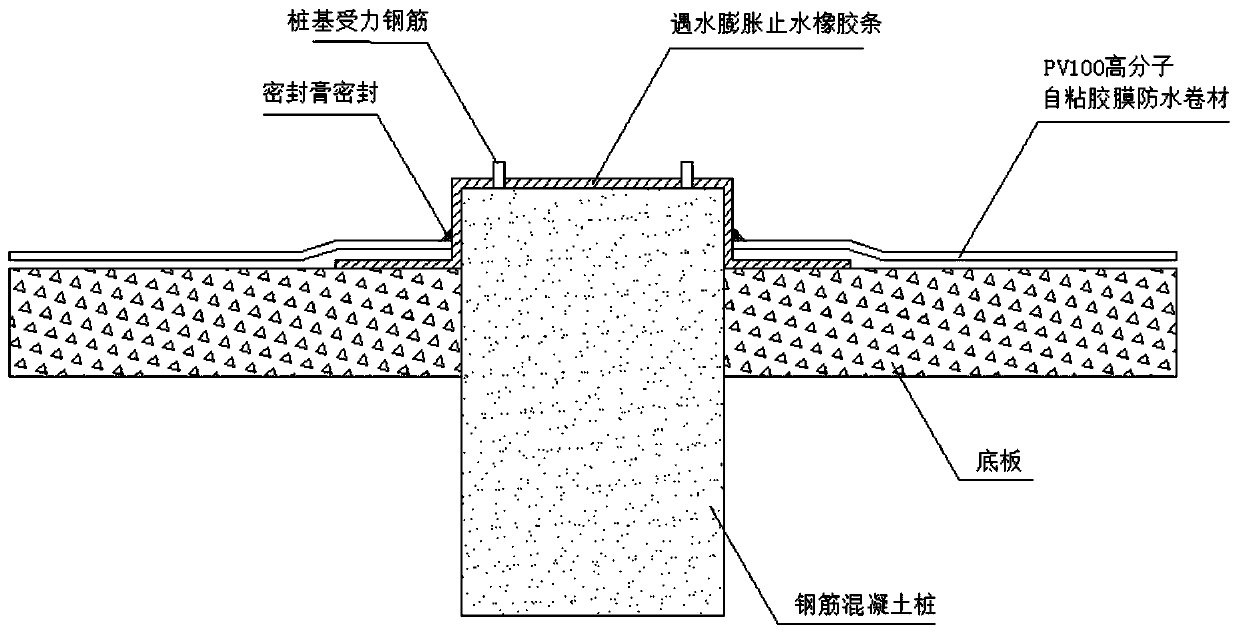

Waterproofing construction method for basement of building engineering

ActiveCN110607809AImprove waterproof performanceStrong toughnessProtective foundationGasketsBasementReinforced concrete

The invention discloses a waterproofing construction method for a basement of building engineering. The method comprises the following steps: S1, dust, sundries, oil stains and visible water on the surface of a base are cleared to make the surface flat and clean; S2, a control line for coil laying is released on the base, so as to accurately control the laying position and lap width of a coil andprevent dislocation, deflection and the like during coil laying; S3, on the basis of foundation treatment and elastic line positioning, construction of 1:2.5 waterproofing mortar is conducted on internal and external corners, the internal and external corners shall be round corners, and R of the arc of the internal and external corners is larger than or equal to 50. Waterproofing performance of inner reinforced concrete is strengthened by the PV100 waterproofing coil, and the PV100 waterproofing coil can form continuous and permanent full adhesion combination with poured concrete, so that water channeling is effectively prevented; the waterproofing coil is tightly adhered to the structure, cannot be affected by uneven settlement of the base, and construction of the next process can be directly performed without construction of a protective layer.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

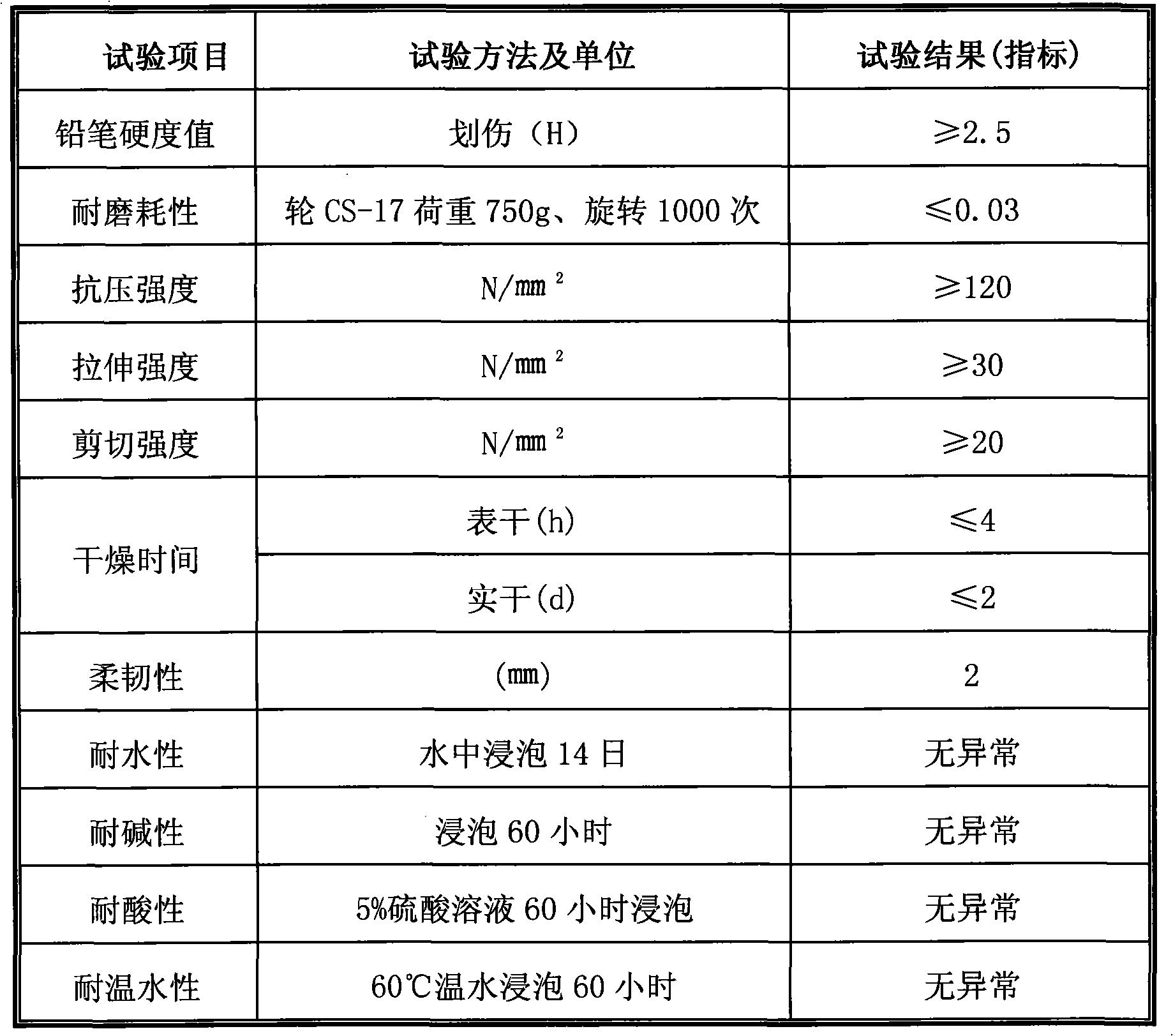

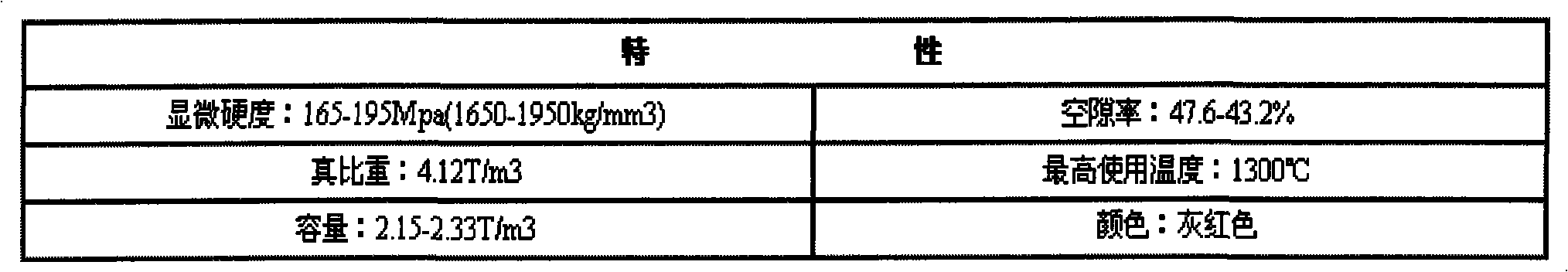

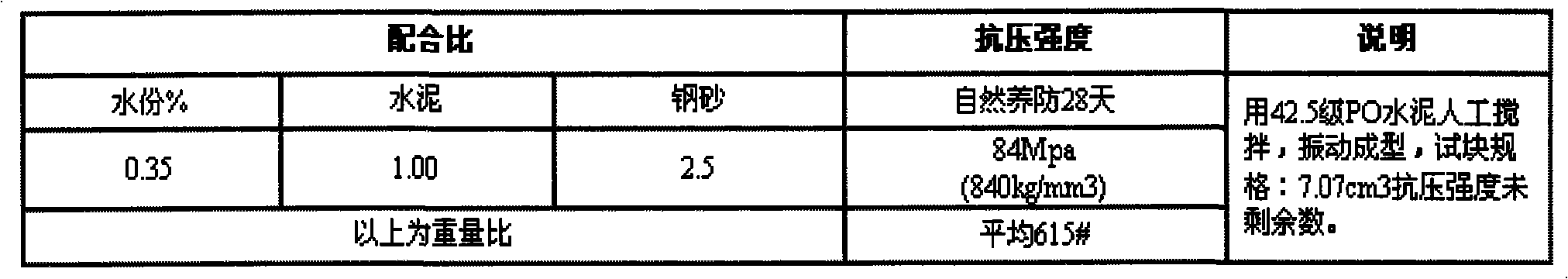

Construction method of wear-resistant non-slip ramp

InactiveCN101914886AStrong orientationReduce driving noiseIn situ pavingsClimate change adaptationWeather resistanceWear resistant

The invention discloses a construction method of a wear-resistant non-slip ramp, which comprises the following steps: clearing a concrete base, coating a base finishing agent, constructing a base coat, painting a high-strength putty layer, constructing wear-resistant non-slip size, processing a closing cover layer, constructing polished surface coating and maintaining. The ramp prepared by the invention has simple structure, convenient construction, low cost, slip prevention, wear resistance, pressure resistance, impact resistance, oil stain resistance and weather resistance.

Owner:LONGXIN CONSTR GRP

Wear-resistant, drag-resistant and low-temperature resistant flexible cable and fabrication method thereof

ActiveCN106373646AStable structureStructural symmetryPower cables with screens/conductive layersFlexible cablesCopper conductorCross-link

The structure of a wear-resistant, drag-resistant and low-temperature resistant flexible cable comprises a cable core, wherein the cable core is formed by twisting three main wire cores, three ground wire cores and a cable core gap semiconductive filler, each main wire core comprises a cross-linking wire core formed by co-extruding a conductor, a semiconductive nylon strap, a conductor shielding layer, an insulation layer and an insulation shielding steam continuous vulcanization layer, each ground wire core comprises a conductor and a semiconductive material steam continuous vulcanization extruded on a surface of the conductor, an isolation strip, an inner sheath, a fiber weaving reinforcement piece and an outer sheath are sequentially applied outside the cable core to form a finished cable, the conductors adopt tin-plated annealed copper conductors, filaments of the tin-plated annealed copper conductors are more slim, and the diameter ranges of the filaments are 0.1-0.41 millimeter. A cable fabrication method comprises the steps of fabricating the main wire cores and the ground wire cores; fabricating the cable core; winding an isolation strip; extruding the inner sheath; weaving the reinforcement layer; and performing steam continuous vulcanization extruding or radiating the cross-linking outer sheath. The cable fabricated according to the method can conform to the design and application requirements, and meanwhile, the qualified rate reaches over 99%.

Owner:JIANGSUSNGSHANG CABLE GROUP

Low-smoke halogen-free flame-retardant cable material

InactiveCN105037899ASoft textureHigh tensile strengthPlastic/resin/waxes insulatorsInsulated cablesEpoxyAntioxidant

The invention discloses a low-smoke halogen-free flame-retardant cable material, and belongs to the field of materials. The low-smoke halogen-free flame-retardant cable material solves the problem that an existing cable material is poor in mechanical property and electrical property. The low-smoke halogen-free flame-retardant cable material is composed of 50-60 parts of high density polyethylene, 20-30 parts of ethylene-ethyl acrylate copolymers, 20-30 parts of methyl vinyl silicone rubber resin, 1-3 parts of magnesium stearate, 2-5 parts of novolac epoxy resin, 15-25 parts of isopropyl phenyl diphenyl phosphate, 1-2 parts of dilauryl thiodipropionate, 10-20 parts of dimellitate, 1-2 parts of antioxidants 1010, 1-1.5 parts of antioxidants CA, 10-20 parts of maleic anhydride grafting ethylene-octylene copolymers, 5-10 parts of polysiloxane, 20-30 parts of nano magnesium hydroxide, 13-18 parts of nano clay, 3-7 parts of zinc oxide, 5-10 parts of polyethylene wax and 3-8 parts of calcium stearate. The low-smoke halogen-free flame-retardant cable material can be widely used as insulation and sheathing materials of various electric wires and cables.

Owner:国网山东莒南县供电公司 +2

Formula of aviation tire tread glue adaptive to ocean environment

ActiveCN101200560AUV resistantAnti-moisture agingSpecial tyresRolling resistance optimizationAviationUltraviolet

The present invention provides a recipe of aviation tyre tread rubber applicable to the marine environment. The rubber is made of natural rubber which is used as the main material, butadiene styrene rubber, cracking prevention agent, heat stabilizer, high abrasion-resistant carbon black with novel process and high structure, high dispersion white carbon black, silicon alkyl coupling agent, para-phenylene diamine type anti-aging agent and ketoamine type anti-aging agent which are used as the main auxiliary materials according to a certain proportion. The tyre tread rubber provided by the present invention has the advantages of UV-light resistance, ozone resistance, atmosphere aging resistance, salt atmosphere resistance and fungus corrosion resistance, as well as good comprehensive performance required by aviation tyre; therefore, the present invention is particularly applicable to aviation tyres used in the marine environment.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

Method for preparing functional vinyl polysiloxane nanofiber membrane through electrostatic spinning

ActiveCN104805599ANo pollution in the processGuaranteed uniformitySucessive textile treatmentsLiquid/gas/vapor removalAir filtrationChemical industry

The invention relates to a method or preparing a functional vinyl polysiloxane nanofiber membrane, belonging to the technical field of processing of textile materials. The method comprises the following steps: mixing vinyl polysiloxane, functional nanoparticles and an organic solvent according to proportions to prepare a spinning solution; carrying out electrostatic spinning by using an electrostatic spinning machine; collecting; and finally drying to obtain the functional vinyl polysiloxane nanofiber membrane. The functional vinyl polysiloxane nanofiber membrane prepared by the preparation method disclosed by the invention can realize a synergistic effect of multiple functions, can be widely used for biomedicine, energy and chemical industry, water purification, air filtration, lithium ion battery separators and carrier materials and also can be used for preparing self-cleaning, waterproof and windproof, windproof and heat preservation, moisture-permeable and air-permeable textile materials. The preparation method disclosed by the invention is simple, high in production efficiency, low in energy consumption, free of pollution to the ecological environment and suitable for industrial production.

Owner:WUHAN TEXTILE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com