How Polysilane Drives Technological Evolutions in IoT Devices?

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane in IoT: Background and Objectives

Polysilane, a class of silicon-based polymers, has emerged as a promising material in the rapidly evolving field of Internet of Things (IoT) devices. The technological landscape of IoT has been continuously expanding, with an increasing demand for more efficient, compact, and versatile devices. In this context, polysilane has garnered significant attention due to its unique properties and potential applications.

The development of polysilane can be traced back to the 1920s, but it wasn't until recent decades that its potential in electronic and optoelectronic applications became apparent. As IoT technologies have advanced, the need for materials that can enhance device performance, reduce power consumption, and enable new functionalities has grown exponentially. Polysilane, with its silicon backbone and organic side groups, offers a unique combination of properties that align well with these requirements.

One of the primary objectives in exploring polysilane for IoT applications is to leverage its semiconducting properties. Unlike traditional silicon-based semiconductors, polysilane offers the potential for solution-processable electronics, which could lead to more cost-effective and flexible manufacturing processes for IoT devices. This aligns with the broader trend of seeking materials that can enable the production of lightweight, flexible, and even wearable IoT devices.

Another key goal is to exploit the photosensitive nature of polysilane. Its ability to undergo structural changes when exposed to light opens up possibilities for developing novel sensors and photoresponsive components in IoT devices. This could lead to advancements in areas such as smart lighting systems, environmental monitoring, and adaptive displays.

The exploration of polysilane in IoT also aims to address the growing concern of energy efficiency in connected devices. With billions of IoT devices expected to be deployed in the coming years, reducing power consumption is crucial. Polysilane's potential for low-power operation and its compatibility with organic electronics could contribute significantly to this objective.

Furthermore, researchers are investigating the integration of polysilane with other emerging technologies in the IoT space. This includes its potential role in quantum computing elements, which could revolutionize data processing capabilities in IoT networks. Additionally, the material's unique optical properties are being studied for potential applications in advanced communication systems, which are essential for the future of IoT infrastructure.

As we delve deeper into the technological evolution driven by polysilane in IoT devices, it's clear that the material holds promise for addressing many of the current challenges and future needs of the IoT ecosystem. The ongoing research and development in this field aim to unlock new possibilities and push the boundaries of what IoT devices can achieve, potentially leading to more intelligent, responsive, and efficient connected systems.

The development of polysilane can be traced back to the 1920s, but it wasn't until recent decades that its potential in electronic and optoelectronic applications became apparent. As IoT technologies have advanced, the need for materials that can enhance device performance, reduce power consumption, and enable new functionalities has grown exponentially. Polysilane, with its silicon backbone and organic side groups, offers a unique combination of properties that align well with these requirements.

One of the primary objectives in exploring polysilane for IoT applications is to leverage its semiconducting properties. Unlike traditional silicon-based semiconductors, polysilane offers the potential for solution-processable electronics, which could lead to more cost-effective and flexible manufacturing processes for IoT devices. This aligns with the broader trend of seeking materials that can enable the production of lightweight, flexible, and even wearable IoT devices.

Another key goal is to exploit the photosensitive nature of polysilane. Its ability to undergo structural changes when exposed to light opens up possibilities for developing novel sensors and photoresponsive components in IoT devices. This could lead to advancements in areas such as smart lighting systems, environmental monitoring, and adaptive displays.

The exploration of polysilane in IoT also aims to address the growing concern of energy efficiency in connected devices. With billions of IoT devices expected to be deployed in the coming years, reducing power consumption is crucial. Polysilane's potential for low-power operation and its compatibility with organic electronics could contribute significantly to this objective.

Furthermore, researchers are investigating the integration of polysilane with other emerging technologies in the IoT space. This includes its potential role in quantum computing elements, which could revolutionize data processing capabilities in IoT networks. Additionally, the material's unique optical properties are being studied for potential applications in advanced communication systems, which are essential for the future of IoT infrastructure.

As we delve deeper into the technological evolution driven by polysilane in IoT devices, it's clear that the material holds promise for addressing many of the current challenges and future needs of the IoT ecosystem. The ongoing research and development in this field aim to unlock new possibilities and push the boundaries of what IoT devices can achieve, potentially leading to more intelligent, responsive, and efficient connected systems.

IoT Market Demand Analysis

The Internet of Things (IoT) market has been experiencing rapid growth and transformation, driven by advancements in various technologies, including polysilane-based innovations. The demand for IoT devices and solutions continues to surge across multiple sectors, creating a vast and dynamic market landscape.

In the consumer segment, smart home devices have gained significant traction, with increasing adoption of connected appliances, security systems, and energy management solutions. The integration of polysilane-based sensors and components in these devices has enhanced their performance, energy efficiency, and durability, further fueling market growth.

Industrial IoT applications have also seen substantial expansion, particularly in manufacturing, logistics, and agriculture. Polysilane-enabled sensors and actuators have revolutionized predictive maintenance, asset tracking, and process optimization, leading to improved operational efficiency and cost savings for businesses.

The healthcare sector has emerged as a key growth area for IoT technologies, with remote patient monitoring, wearable devices, and smart medical equipment gaining prominence. Polysilane's unique properties have enabled the development of more sensitive and reliable biosensors, contributing to advancements in personalized medicine and early disease detection.

Smart cities and infrastructure projects represent another significant market opportunity for IoT solutions. Polysilane-based technologies have found applications in environmental monitoring, traffic management, and energy distribution systems, enhancing urban efficiency and sustainability.

The automotive industry has been a major driver of IoT adoption, with connected vehicles and autonomous driving technologies relying heavily on advanced sensors and communication systems. Polysilane's role in improving the performance and reliability of these components has been crucial in advancing vehicle safety and efficiency.

As the IoT ecosystem continues to evolve, there is a growing demand for more sophisticated, energy-efficient, and miniaturized devices. Polysilane's unique electronic and optical properties position it as a key enabler for next-generation IoT technologies, particularly in areas requiring high-performance, low-power sensors and flexible electronics.

The market for IoT security solutions has also expanded rapidly, driven by increasing concerns over data privacy and cyber threats. Polysilane-based technologies have shown promise in enhancing the security features of IoT devices, potentially addressing some of the critical challenges facing the industry.

Overall, the IoT market's trajectory indicates sustained growth and diversification, with polysilane playing an increasingly important role in driving technological advancements across various applications and industries.

In the consumer segment, smart home devices have gained significant traction, with increasing adoption of connected appliances, security systems, and energy management solutions. The integration of polysilane-based sensors and components in these devices has enhanced their performance, energy efficiency, and durability, further fueling market growth.

Industrial IoT applications have also seen substantial expansion, particularly in manufacturing, logistics, and agriculture. Polysilane-enabled sensors and actuators have revolutionized predictive maintenance, asset tracking, and process optimization, leading to improved operational efficiency and cost savings for businesses.

The healthcare sector has emerged as a key growth area for IoT technologies, with remote patient monitoring, wearable devices, and smart medical equipment gaining prominence. Polysilane's unique properties have enabled the development of more sensitive and reliable biosensors, contributing to advancements in personalized medicine and early disease detection.

Smart cities and infrastructure projects represent another significant market opportunity for IoT solutions. Polysilane-based technologies have found applications in environmental monitoring, traffic management, and energy distribution systems, enhancing urban efficiency and sustainability.

The automotive industry has been a major driver of IoT adoption, with connected vehicles and autonomous driving technologies relying heavily on advanced sensors and communication systems. Polysilane's role in improving the performance and reliability of these components has been crucial in advancing vehicle safety and efficiency.

As the IoT ecosystem continues to evolve, there is a growing demand for more sophisticated, energy-efficient, and miniaturized devices. Polysilane's unique electronic and optical properties position it as a key enabler for next-generation IoT technologies, particularly in areas requiring high-performance, low-power sensors and flexible electronics.

The market for IoT security solutions has also expanded rapidly, driven by increasing concerns over data privacy and cyber threats. Polysilane-based technologies have shown promise in enhancing the security features of IoT devices, potentially addressing some of the critical challenges facing the industry.

Overall, the IoT market's trajectory indicates sustained growth and diversification, with polysilane playing an increasingly important role in driving technological advancements across various applications and industries.

Polysilane Tech Status and Challenges

Polysilane technology has made significant strides in recent years, particularly in its application to IoT devices. The current status of polysilane in this field is characterized by promising advancements, yet it also faces several challenges that need to be addressed for widespread adoption.

One of the key developments in polysilane technology is its potential as a high-performance semiconductor material. Researchers have demonstrated that polysilane-based thin-film transistors can achieve electron mobilities comparable to or even surpassing those of amorphous silicon. This breakthrough has opened up new possibilities for flexible and wearable electronics in IoT applications.

However, the stability of polysilane materials remains a significant challenge. Exposure to UV light and oxygen can lead to degradation of the polymer backbone, affecting the long-term performance and reliability of devices. Scientists are actively working on developing more stable polysilane derivatives and protective coatings to mitigate this issue.

Another area of progress is the use of polysilanes in sensor technologies. The unique optical and electronic properties of polysilanes make them excellent candidates for chemical and biological sensors. Some polysilane-based sensors have shown high sensitivity and selectivity for detecting various gases and volatile organic compounds, which is crucial for environmental monitoring and smart home applications in the IoT ecosystem.

Despite these advancements, the large-scale production of high-quality polysilane materials remains challenging. Current synthesis methods often result in polydisperse products with varying chain lengths, which can affect the consistency of device performance. Developing more controlled polymerization techniques is an ongoing area of research.

In terms of geographical distribution, Japan and the United States lead in polysilane research and development, with significant contributions also coming from European countries and China. This global effort has led to a diverse range of polysilane materials tailored for specific applications.

The integration of polysilanes into existing manufacturing processes poses another challenge. While polysilanes offer unique properties, adapting current production lines to incorporate these materials can be costly and time-consuming. This has slowed down the adoption of polysilane-based technologies in commercial IoT devices.

Energy harvesting is an emerging application area where polysilanes show great promise. Their photovoltaic properties make them potential candidates for next-generation solar cells and energy-harvesting devices, which could revolutionize power management in IoT networks.

As the IoT landscape continues to evolve, addressing these challenges and leveraging the unique properties of polysilanes will be crucial. The ongoing research in improving material stability, developing more efficient synthesis methods, and exploring novel applications will likely drive further technological evolutions in IoT devices powered by polysilane technology.

One of the key developments in polysilane technology is its potential as a high-performance semiconductor material. Researchers have demonstrated that polysilane-based thin-film transistors can achieve electron mobilities comparable to or even surpassing those of amorphous silicon. This breakthrough has opened up new possibilities for flexible and wearable electronics in IoT applications.

However, the stability of polysilane materials remains a significant challenge. Exposure to UV light and oxygen can lead to degradation of the polymer backbone, affecting the long-term performance and reliability of devices. Scientists are actively working on developing more stable polysilane derivatives and protective coatings to mitigate this issue.

Another area of progress is the use of polysilanes in sensor technologies. The unique optical and electronic properties of polysilanes make them excellent candidates for chemical and biological sensors. Some polysilane-based sensors have shown high sensitivity and selectivity for detecting various gases and volatile organic compounds, which is crucial for environmental monitoring and smart home applications in the IoT ecosystem.

Despite these advancements, the large-scale production of high-quality polysilane materials remains challenging. Current synthesis methods often result in polydisperse products with varying chain lengths, which can affect the consistency of device performance. Developing more controlled polymerization techniques is an ongoing area of research.

In terms of geographical distribution, Japan and the United States lead in polysilane research and development, with significant contributions also coming from European countries and China. This global effort has led to a diverse range of polysilane materials tailored for specific applications.

The integration of polysilanes into existing manufacturing processes poses another challenge. While polysilanes offer unique properties, adapting current production lines to incorporate these materials can be costly and time-consuming. This has slowed down the adoption of polysilane-based technologies in commercial IoT devices.

Energy harvesting is an emerging application area where polysilanes show great promise. Their photovoltaic properties make them potential candidates for next-generation solar cells and energy-harvesting devices, which could revolutionize power management in IoT networks.

As the IoT landscape continues to evolve, addressing these challenges and leveraging the unique properties of polysilanes will be crucial. The ongoing research in improving material stability, developing more efficient synthesis methods, and exploring novel applications will likely drive further technological evolutions in IoT devices powered by polysilane technology.

Current Polysilane IoT Solutions

01 Synthesis and properties of polysilanes

Polysilanes are synthesized through various methods and exhibit unique properties. These silicon-based polymers have applications in electronics, optics, and materials science due to their electronic and optical characteristics. The synthesis methods and resulting properties can be tailored for specific applications.- Synthesis and properties of polysilanes: Polysilanes are synthesized through various methods and exhibit unique properties. These silicon-based polymers have applications in electronics, optics, and materials science due to their electrical conductivity, photosensitivity, and thermal stability. The synthesis and modification of polysilanes can be tailored to achieve specific properties for different applications.

- Polysilanes in photoresist compositions: Polysilanes are utilized in photoresist compositions for semiconductor manufacturing. These materials offer high sensitivity to UV light and excellent resistance to plasma etching. The incorporation of polysilanes in photoresist formulations enhances the resolution and pattern transfer in photolithography processes.

- Polysilane-based thin films and coatings: Polysilanes are used to create thin films and coatings with various functional properties. These films can be applied to substrates using techniques such as spin-coating or chemical vapor deposition. The resulting coatings exhibit characteristics like optical transparency, chemical resistance, and improved surface properties.

- Functionalization and modification of polysilanes: Polysilanes can be functionalized or modified to enhance their properties or introduce new functionalities. This includes the incorporation of various side groups, crosslinking agents, or other reactive moieties. Such modifications allow for the tailoring of polysilanes for specific applications in areas like optoelectronics, sensors, and advanced materials.

- Polysilanes in electronic and optical devices: Polysilanes find applications in electronic and optical devices due to their unique electronic structure and optical properties. They can be used as charge transport materials, light-emitting layers, or active components in various devices such as organic light-emitting diodes (OLEDs), photovoltaic cells, and optical waveguides.

02 Polysilane-based coatings and films

Polysilanes are used to create coatings and films with specific properties. These coatings can be applied to various substrates and may offer benefits such as improved durability, optical properties, or electronic characteristics. The formulation and application methods of polysilane-based coatings are crucial for their performance.Expand Specific Solutions03 Polysilanes in photoresist and lithography applications

Polysilanes play a role in photoresist formulations and lithography processes. Their unique properties make them suitable for use in semiconductor manufacturing and other micro-fabrication techniques. The photosensitivity and etch resistance of polysilanes are key factors in these applications.Expand Specific Solutions04 Functionalization and modification of polysilanes

Polysilanes can be functionalized or modified to enhance their properties or create new materials. This includes the addition of specific functional groups, copolymerization with other monomers, or post-polymerization modifications. These processes allow for the tailoring of polysilane properties for various applications.Expand Specific Solutions05 Polysilanes in composite materials

Polysilanes are incorporated into composite materials to impart specific properties or enhance performance. These composites may combine polysilanes with other polymers, inorganic materials, or nanoparticles. The resulting materials can exhibit improved mechanical, thermal, or electrical properties compared to their individual components.Expand Specific Solutions

Key Players in Polysilane IoT

The IoT device market driven by polysilane technology is in a growth phase, with increasing market size and evolving technological maturity. Major players like Samsung Electronics, Qualcomm, and Canon are investing heavily in R&D to leverage polysilane's potential in enhancing IoT device performance. The technology's application is expanding across various sectors, from consumer electronics to industrial IoT. While established companies lead in commercialization, research institutions like KIST and universities such as Northeastern and Harbin Institute of Technology are contributing to fundamental advancements. The competitive landscape is dynamic, with both tech giants and specialized firms like Wacker Chemie and JSR Corp competing to innovate and capture market share in this promising field.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has incorporated polysilane technology into its IoT device ecosystem, focusing on enhancing device performance and functionality. The company has developed polysilane-based thin-film transistors that offer improved electron mobility and stability, resulting in faster and more reliable IoT sensors[10]. Samsung's research also explores the use of polysilanes in flexible display technologies for wearable IoT devices, enabling the creation of more ergonomic and versatile products[11]. Additionally, the company has leveraged polysilane materials to improve the efficiency of energy storage components in IoT devices, extending battery life and reducing the need for frequent charging[12].

Strengths: Extensive resources for R&D, strong market presence in consumer electronics, and vertical integration capabilities. Weaknesses: Potential intellectual property constraints and dependence on external suppliers for specialized polysilane materials.

Nissan Chemical Corp.

Technical Solution: Nissan Chemical Corp. has pioneered the development of high-performance polysilane materials tailored for IoT applications. Their proprietary polysilane formulations exhibit exceptional thermal stability and electrical conductivity, making them ideal for use in IoT sensors and actuators[4]. The company has successfully implemented polysilane-based coatings that enhance the durability and functionality of IoT devices exposed to harsh environmental conditions[5]. Nissan Chemical's polysilane technology also enables the creation of ultra-thin, transparent conductive films, which are crucial for the development of next-generation IoT displays and touch interfaces[6].

Strengths: Advanced polysilane formulations, extensive experience in chemical engineering, and strong partnerships with IoT device manufacturers. Weaknesses: Limited global market presence compared to larger competitors and potential regulatory challenges in certain regions.

Core Polysilane IoT Innovations

Method of fabricating 3-dimensional transistor sensor, the sensor and sensor array thereof

PatentActiveUS20190072516A1

Innovation

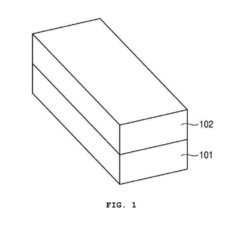

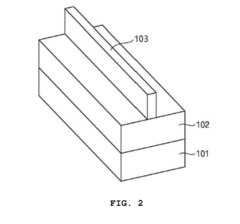

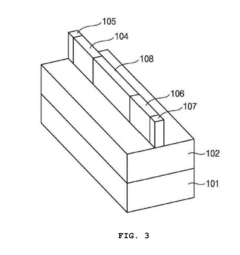

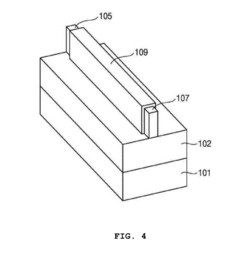

- A 3-dimensional transistor sensor is fabricated using a silicon on insulator (SOI) substrate with a 3-dimensional silicon fin structure, where a gate insulating layer surrounds three surfaces of the gate, and a sensing gate layer is formed to enhance sensitivity and power efficiency, allowing for high-speed operation with minimal power consumption.

Transistors with low contact resistance and method of fabricating the same

PatentInactiveUS20200152739A1

Innovation

- A transistor design with a larger contact area in the source and drain regions is implemented by configuring the source and drain contacts to contact at least three sides of the respective regions, using a substrate with buffer layers and a MoS2 channel region, and employing specific materials like Gold (Au) and Titanium (Ti) for contacts and Hafnium Oxide (HfO2) as a gate dielectric.

Environmental Impact of Polysilane

The environmental impact of polysilane in IoT devices is a critical consideration as the technology continues to evolve and proliferate. Polysilane, a silicon-based polymer, offers unique properties that drive advancements in IoT devices, but its production and use also raise environmental concerns.

Polysilane manufacturing processes often involve energy-intensive methods and the use of potentially hazardous chemicals. The production of high-purity silicon, a key component in polysilane synthesis, requires significant energy inputs and can result in greenhouse gas emissions. Additionally, the use of chlorosilanes and other precursors in polysilane production may lead to the generation of toxic by-products if not properly managed.

However, the environmental benefits of polysilane in IoT devices should not be overlooked. The material's excellent electrical and optical properties enable the development of more efficient and compact devices, potentially reducing overall energy consumption and material usage in IoT applications. This efficiency gain can contribute to a decrease in the carbon footprint of IoT networks and systems.

The durability and stability of polysilane-based components may also extend the lifespan of IoT devices, reducing electronic waste and the need for frequent replacements. This longevity aligns with sustainable design principles and circular economy concepts, potentially mitigating the environmental impact of electronic device production and disposal.

End-of-life considerations for polysilane-containing IoT devices present both challenges and opportunities. While the recycling of silicon-based materials is well-established, the complex nature of IoT devices may complicate the separation and recovery of polysilane components. Developing effective recycling and disposal methods for these devices will be crucial to minimize environmental impact and recover valuable materials.

The potential for polysilane to enable more energy-efficient IoT devices could have far-reaching environmental implications. As IoT technologies become increasingly integrated into smart cities, industrial processes, and environmental monitoring systems, the cumulative energy savings and improved resource management facilitated by polysilane-enhanced devices could contribute to broader sustainability goals.

However, the rapid growth of IoT deployments raises concerns about the scalability of polysilane production and its long-term environmental sustainability. As demand for polysilane increases, it will be essential to develop cleaner production methods, explore alternative precursors, and implement robust waste management strategies to mitigate potential environmental risks associated with large-scale polysilane use in IoT devices.

Polysilane manufacturing processes often involve energy-intensive methods and the use of potentially hazardous chemicals. The production of high-purity silicon, a key component in polysilane synthesis, requires significant energy inputs and can result in greenhouse gas emissions. Additionally, the use of chlorosilanes and other precursors in polysilane production may lead to the generation of toxic by-products if not properly managed.

However, the environmental benefits of polysilane in IoT devices should not be overlooked. The material's excellent electrical and optical properties enable the development of more efficient and compact devices, potentially reducing overall energy consumption and material usage in IoT applications. This efficiency gain can contribute to a decrease in the carbon footprint of IoT networks and systems.

The durability and stability of polysilane-based components may also extend the lifespan of IoT devices, reducing electronic waste and the need for frequent replacements. This longevity aligns with sustainable design principles and circular economy concepts, potentially mitigating the environmental impact of electronic device production and disposal.

End-of-life considerations for polysilane-containing IoT devices present both challenges and opportunities. While the recycling of silicon-based materials is well-established, the complex nature of IoT devices may complicate the separation and recovery of polysilane components. Developing effective recycling and disposal methods for these devices will be crucial to minimize environmental impact and recover valuable materials.

The potential for polysilane to enable more energy-efficient IoT devices could have far-reaching environmental implications. As IoT technologies become increasingly integrated into smart cities, industrial processes, and environmental monitoring systems, the cumulative energy savings and improved resource management facilitated by polysilane-enhanced devices could contribute to broader sustainability goals.

However, the rapid growth of IoT deployments raises concerns about the scalability of polysilane production and its long-term environmental sustainability. As demand for polysilane increases, it will be essential to develop cleaner production methods, explore alternative precursors, and implement robust waste management strategies to mitigate potential environmental risks associated with large-scale polysilane use in IoT devices.

Polysilane IoT Security Concerns

As the integration of polysilane into IoT devices continues to advance, it is crucial to address the security concerns that arise from this technological evolution. The unique properties of polysilane, while offering significant benefits in terms of device performance and functionality, also introduce new vulnerabilities that must be carefully considered and mitigated.

One of the primary security concerns related to polysilane in IoT devices is its potential susceptibility to environmental factors. Polysilane's sensitivity to light and temperature changes could potentially be exploited by malicious actors to manipulate device behavior or extract sensitive information. This vulnerability necessitates the development of robust protective measures and shielding techniques to ensure the integrity of polysilane-based components in IoT devices.

Another significant security issue stems from the increased connectivity and data processing capabilities that polysilane enables in IoT devices. As these devices become more sophisticated and handle larger volumes of data, they become more attractive targets for cyberattacks. The enhanced processing power facilitated by polysilane could potentially be hijacked for malicious purposes, such as distributed denial-of-service (DDoS) attacks or unauthorized data mining.

The integration of polysilane in IoT devices also raises concerns about data privacy and protection. The improved sensor capabilities and data processing efficiency enabled by polysilane mean that these devices can collect and analyze more personal and sensitive information than ever before. This increased data collection and processing capacity necessitates stringent data protection measures and compliance with evolving privacy regulations.

Furthermore, the novelty of polysilane technology in IoT applications means that there may be unforeseen security vulnerabilities that have yet to be discovered or addressed. As with any emerging technology, there is a risk of unknown exploits or weaknesses that could be leveraged by cybercriminals. This underscores the need for continuous security research and testing specific to polysilane-based IoT devices.

The supply chain security for polysilane components in IoT devices is another area of concern. As the production and integration of polysilane materials become more widespread, ensuring the authenticity and integrity of these components throughout the supply chain becomes crucial. Counterfeit or tampered polysilane components could potentially introduce backdoors or vulnerabilities into IoT devices, compromising their security.

To address these security concerns, a multi-faceted approach is required. This includes the development of specialized encryption methods for polysilane-based data processing, the implementation of robust authentication mechanisms, and the creation of secure update processes for polysilane-enabled IoT devices. Additionally, industry-wide standards and best practices for the secure implementation of polysilane in IoT devices need to be established and continuously updated.

One of the primary security concerns related to polysilane in IoT devices is its potential susceptibility to environmental factors. Polysilane's sensitivity to light and temperature changes could potentially be exploited by malicious actors to manipulate device behavior or extract sensitive information. This vulnerability necessitates the development of robust protective measures and shielding techniques to ensure the integrity of polysilane-based components in IoT devices.

Another significant security issue stems from the increased connectivity and data processing capabilities that polysilane enables in IoT devices. As these devices become more sophisticated and handle larger volumes of data, they become more attractive targets for cyberattacks. The enhanced processing power facilitated by polysilane could potentially be hijacked for malicious purposes, such as distributed denial-of-service (DDoS) attacks or unauthorized data mining.

The integration of polysilane in IoT devices also raises concerns about data privacy and protection. The improved sensor capabilities and data processing efficiency enabled by polysilane mean that these devices can collect and analyze more personal and sensitive information than ever before. This increased data collection and processing capacity necessitates stringent data protection measures and compliance with evolving privacy regulations.

Furthermore, the novelty of polysilane technology in IoT applications means that there may be unforeseen security vulnerabilities that have yet to be discovered or addressed. As with any emerging technology, there is a risk of unknown exploits or weaknesses that could be leveraged by cybercriminals. This underscores the need for continuous security research and testing specific to polysilane-based IoT devices.

The supply chain security for polysilane components in IoT devices is another area of concern. As the production and integration of polysilane materials become more widespread, ensuring the authenticity and integrity of these components throughout the supply chain becomes crucial. Counterfeit or tampered polysilane components could potentially introduce backdoors or vulnerabilities into IoT devices, compromising their security.

To address these security concerns, a multi-faceted approach is required. This includes the development of specialized encryption methods for polysilane-based data processing, the implementation of robust authentication mechanisms, and the creation of secure update processes for polysilane-enabled IoT devices. Additionally, industry-wide standards and best practices for the secure implementation of polysilane in IoT devices need to be established and continuously updated.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!