How Polysilane Enhances Radar System Performance?

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane Radar Enhancement Background

Polysilane, a class of silicon-based polymers, has emerged as a promising material for enhancing radar system performance. The development of polysilane for radar applications stems from the increasing demand for more efficient and reliable radar systems across various sectors, including defense, automotive, and aerospace industries.

The history of polysilane research dates back to the 1920s, but it wasn't until the 1980s that significant advancements were made in synthesizing and characterizing these materials. The unique electronic and optical properties of polysilanes, particularly their high electron mobility and tunable bandgap, caught the attention of researchers in the field of radar technology.

Radar systems have been a crucial component of detection and ranging technologies since World War II. However, traditional radar systems face limitations in terms of resolution, signal-to-noise ratio, and performance in challenging environments. The integration of polysilane into radar systems addresses these challenges by leveraging the material's exceptional properties.

One of the key drivers for polysilane adoption in radar systems is the growing need for improved target detection and identification capabilities. As threats become more sophisticated and diverse, radar systems must evolve to provide higher accuracy and reliability. Polysilane offers a potential solution by enhancing the overall sensitivity and resolution of radar systems.

The automotive industry has also played a significant role in driving polysilane research for radar applications. With the rise of advanced driver assistance systems (ADAS) and autonomous vehicles, there is an increasing demand for high-performance, compact radar systems that can operate reliably in various weather conditions and complex urban environments.

In the aerospace sector, the need for lightweight, durable, and high-performance radar systems has further fueled interest in polysilane-enhanced technologies. These materials offer the potential to reduce the size and weight of radar components while improving their overall performance, which is crucial for both military and civilian aircraft applications.

The development of polysilane for radar enhancement aligns with broader trends in materials science and nanotechnology. As researchers continue to explore novel materials and their applications, polysilane represents a promising avenue for advancing radar technology and addressing the evolving needs of various industries relying on accurate and efficient detection and ranging capabilities.

The history of polysilane research dates back to the 1920s, but it wasn't until the 1980s that significant advancements were made in synthesizing and characterizing these materials. The unique electronic and optical properties of polysilanes, particularly their high electron mobility and tunable bandgap, caught the attention of researchers in the field of radar technology.

Radar systems have been a crucial component of detection and ranging technologies since World War II. However, traditional radar systems face limitations in terms of resolution, signal-to-noise ratio, and performance in challenging environments. The integration of polysilane into radar systems addresses these challenges by leveraging the material's exceptional properties.

One of the key drivers for polysilane adoption in radar systems is the growing need for improved target detection and identification capabilities. As threats become more sophisticated and diverse, radar systems must evolve to provide higher accuracy and reliability. Polysilane offers a potential solution by enhancing the overall sensitivity and resolution of radar systems.

The automotive industry has also played a significant role in driving polysilane research for radar applications. With the rise of advanced driver assistance systems (ADAS) and autonomous vehicles, there is an increasing demand for high-performance, compact radar systems that can operate reliably in various weather conditions and complex urban environments.

In the aerospace sector, the need for lightweight, durable, and high-performance radar systems has further fueled interest in polysilane-enhanced technologies. These materials offer the potential to reduce the size and weight of radar components while improving their overall performance, which is crucial for both military and civilian aircraft applications.

The development of polysilane for radar enhancement aligns with broader trends in materials science and nanotechnology. As researchers continue to explore novel materials and their applications, polysilane represents a promising avenue for advancing radar technology and addressing the evolving needs of various industries relying on accurate and efficient detection and ranging capabilities.

Market Demand Analysis

The market demand for enhanced radar system performance through polysilane technology is driven by several key factors in both military and civilian sectors. In the defense industry, there is a growing need for more advanced radar systems capable of detecting and tracking increasingly sophisticated threats. Polysilane-enhanced radar systems offer improved sensitivity, range, and resolution, making them highly attractive for military applications such as air defense, missile guidance, and surveillance.

In the commercial aviation sector, the demand for more efficient and reliable radar systems is rising due to increasing air traffic and the need for enhanced safety measures. Polysilane-based radar technology can provide better weather detection capabilities and improved situational awareness for pilots and air traffic controllers, contributing to safer and more efficient air travel.

The automotive industry is another significant market driver for polysilane-enhanced radar systems. With the rapid development of advanced driver assistance systems (ADAS) and autonomous vehicles, there is a growing demand for high-performance radar sensors that can operate reliably in various environmental conditions. Polysilane technology offers the potential for more compact, energy-efficient, and cost-effective radar solutions for vehicles, supporting the industry's push towards safer and more autonomous transportation.

Maritime applications represent another area of increasing market demand for improved radar systems. Shipping companies and naval forces require more accurate and reliable radar technology for navigation, collision avoidance, and maritime security. Polysilane-enhanced radar systems can provide better performance in challenging sea conditions, enhancing safety and operational efficiency in the maritime sector.

The telecommunications industry is also showing interest in polysilane-enhanced radar technology for its potential applications in 5G and future 6G networks. As these networks require precise beam-forming and high-frequency operation, the improved performance offered by polysilane-based radar systems could play a crucial role in optimizing network coverage and capacity.

In the field of meteorology and climate research, there is a growing need for more accurate and sensitive radar systems to improve weather forecasting and climate monitoring. Polysilane-enhanced radar technology can potentially provide more detailed atmospheric data, contributing to better prediction models and enhanced understanding of climate patterns.

As the global focus on security and surveillance intensifies, the demand for advanced radar systems in border control, critical infrastructure protection, and urban security applications is also increasing. Polysilane-based radar technology offers the potential for more effective detection and tracking of potential threats in these contexts.

In the commercial aviation sector, the demand for more efficient and reliable radar systems is rising due to increasing air traffic and the need for enhanced safety measures. Polysilane-based radar technology can provide better weather detection capabilities and improved situational awareness for pilots and air traffic controllers, contributing to safer and more efficient air travel.

The automotive industry is another significant market driver for polysilane-enhanced radar systems. With the rapid development of advanced driver assistance systems (ADAS) and autonomous vehicles, there is a growing demand for high-performance radar sensors that can operate reliably in various environmental conditions. Polysilane technology offers the potential for more compact, energy-efficient, and cost-effective radar solutions for vehicles, supporting the industry's push towards safer and more autonomous transportation.

Maritime applications represent another area of increasing market demand for improved radar systems. Shipping companies and naval forces require more accurate and reliable radar technology for navigation, collision avoidance, and maritime security. Polysilane-enhanced radar systems can provide better performance in challenging sea conditions, enhancing safety and operational efficiency in the maritime sector.

The telecommunications industry is also showing interest in polysilane-enhanced radar technology for its potential applications in 5G and future 6G networks. As these networks require precise beam-forming and high-frequency operation, the improved performance offered by polysilane-based radar systems could play a crucial role in optimizing network coverage and capacity.

In the field of meteorology and climate research, there is a growing need for more accurate and sensitive radar systems to improve weather forecasting and climate monitoring. Polysilane-enhanced radar technology can potentially provide more detailed atmospheric data, contributing to better prediction models and enhanced understanding of climate patterns.

As the global focus on security and surveillance intensifies, the demand for advanced radar systems in border control, critical infrastructure protection, and urban security applications is also increasing. Polysilane-based radar technology offers the potential for more effective detection and tracking of potential threats in these contexts.

Current Challenges in Radar Systems

Modern radar systems face several significant challenges that limit their performance and effectiveness in various applications. One of the primary issues is the increasing complexity of the electromagnetic environment, which leads to signal interference and reduced detection capabilities. As more wireless devices and communication systems populate the spectrum, radar systems struggle to distinguish between genuine targets and false positives caused by electromagnetic clutter.

Another critical challenge is the need for improved resolution and accuracy in target detection and tracking. Current radar systems often struggle to provide precise information about small or fast-moving objects, particularly in cluttered environments or against sophisticated countermeasures. This limitation becomes especially problematic in military applications and autonomous vehicle navigation.

The demand for longer detection ranges while maintaining high accuracy presents a significant technical hurdle. Achieving this balance requires advancements in signal processing algorithms and hardware capabilities, which are often constrained by power consumption and size limitations, particularly in mobile or airborne radar systems.

Adaptability to diverse environmental conditions remains a persistent challenge. Radar performance can be significantly affected by atmospheric conditions, terrain, and weather phenomena. Developing systems that can maintain optimal performance across a wide range of scenarios without manual reconfiguration is an ongoing area of research and development.

The increasing sophistication of stealth technologies and electronic countermeasures poses a substantial threat to radar effectiveness. Modern radar systems must evolve to detect and track targets with reduced radar cross-sections and those employing active jamming or deception techniques. This arms race between radar capabilities and countermeasures drives continuous innovation in the field.

Cost-effectiveness and energy efficiency are also major concerns, especially for widespread deployment in commercial applications. The need for high-performance components and advanced signal processing capabilities often results in expensive systems with high power requirements, limiting their practical implementation in many potential use cases.

Lastly, the integration of radar systems with other sensing technologies and data fusion algorithms presents both opportunities and challenges. While multi-sensor approaches can enhance overall system performance, they also introduce complexity in data processing, synchronization, and interpretation, requiring advanced software solutions and increased computational power.

Another critical challenge is the need for improved resolution and accuracy in target detection and tracking. Current radar systems often struggle to provide precise information about small or fast-moving objects, particularly in cluttered environments or against sophisticated countermeasures. This limitation becomes especially problematic in military applications and autonomous vehicle navigation.

The demand for longer detection ranges while maintaining high accuracy presents a significant technical hurdle. Achieving this balance requires advancements in signal processing algorithms and hardware capabilities, which are often constrained by power consumption and size limitations, particularly in mobile or airborne radar systems.

Adaptability to diverse environmental conditions remains a persistent challenge. Radar performance can be significantly affected by atmospheric conditions, terrain, and weather phenomena. Developing systems that can maintain optimal performance across a wide range of scenarios without manual reconfiguration is an ongoing area of research and development.

The increasing sophistication of stealth technologies and electronic countermeasures poses a substantial threat to radar effectiveness. Modern radar systems must evolve to detect and track targets with reduced radar cross-sections and those employing active jamming or deception techniques. This arms race between radar capabilities and countermeasures drives continuous innovation in the field.

Cost-effectiveness and energy efficiency are also major concerns, especially for widespread deployment in commercial applications. The need for high-performance components and advanced signal processing capabilities often results in expensive systems with high power requirements, limiting their practical implementation in many potential use cases.

Lastly, the integration of radar systems with other sensing technologies and data fusion algorithms presents both opportunities and challenges. While multi-sensor approaches can enhance overall system performance, they also introduce complexity in data processing, synchronization, and interpretation, requiring advanced software solutions and increased computational power.

Existing Polysilane-based Solutions

01 Optical and electronic properties of polysilanes

Polysilanes exhibit unique optical and electronic properties, making them suitable for various applications. They possess high photosensitivity, good charge transport capabilities, and can be used as photoresists or in optoelectronic devices. The performance of polysilanes can be tuned by modifying their molecular structure and composition.- Optical and electronic properties of polysilanes: Polysilanes exhibit unique optical and electronic properties, making them suitable for various applications. They possess high photosensitivity, good charge transport capabilities, and can be used as photoresists or in optoelectronic devices. The performance of polysilanes can be tuned by modifying their molecular structure and composition.

- Thermal stability and processing of polysilanes: Polysilanes demonstrate good thermal stability and can be processed into various forms such as films, coatings, and fibers. Their thermal properties allow for high-temperature applications and improved durability. The processing methods can influence the final performance characteristics of polysilane-based materials.

- Polysilane synthesis and modification techniques: Various synthesis methods and modification techniques have been developed to enhance polysilane performance. These include the use of different catalysts, controlling molecular weight distribution, and incorporating functional groups. Such techniques allow for tailoring polysilanes to specific applications and improving their overall performance.

- Polysilane composites and blends: Polysilanes can be combined with other materials to form composites or blends with enhanced properties. These combinations can improve mechanical strength, thermal stability, or introduce new functionalities. The performance of such composites often surpasses that of individual components, expanding the range of potential applications.

- Applications of polysilanes in advanced technologies: Polysilanes find applications in various advanced technologies due to their unique properties. They are used in photoresists for semiconductor manufacturing, as precursors for silicon carbide production, in solar cells, and as components in organic light-emitting diodes (OLEDs). The performance of polysilanes in these applications is continually being improved through research and development efforts.

02 Synthesis and processing of polysilanes

Various methods for synthesizing and processing polysilanes have been developed to enhance their performance. These include novel polymerization techniques, purification processes, and the use of catalysts to control molecular weight and structure. Improved synthesis methods can lead to polysilanes with better thermal stability and mechanical properties.Expand Specific Solutions03 Polysilane-based composite materials

Polysilanes can be combined with other materials to create high-performance composites. These composites may exhibit enhanced mechanical strength, thermal stability, or specific functional properties. The incorporation of polysilanes into composite materials can lead to improved performance in applications such as coatings, adhesives, and structural materials.Expand Specific Solutions04 Polysilanes in photoresist applications

Polysilanes have shown promising performance as photoresist materials in lithography processes. Their high photosensitivity and ability to form stable patterns make them suitable for use in semiconductor manufacturing and other microfabrication applications. The performance of polysilane photoresists can be optimized through careful control of their chemical structure and processing conditions.Expand Specific Solutions05 Functionalization and modification of polysilanes

The performance of polysilanes can be enhanced through functionalization and modification of their chemical structure. This includes the incorporation of various side groups, cross-linking agents, or reactive moieties. Such modifications can improve the solubility, processability, and specific functional properties of polysilanes, expanding their potential applications in areas such as sensors, membranes, and electronic devices.Expand Specific Solutions

Key Players in Polysilane Radar Industry

The radar system performance enhancement through polysilane technology is currently in an early development stage, with a growing market potential as the demand for advanced radar systems increases across various sectors. The global market for radar systems is expanding, driven by applications in defense, automotive, and aerospace industries. While the technology is still emerging, several key players are actively involved in research and development. Companies like Robert Bosch GmbH, Airbus Defence & Space GmbH, and The Boeing Co. are likely to be at the forefront of this innovation, leveraging their expertise in radar systems and materials science. As the technology matures, we can expect increased competition and potential collaborations between electronics manufacturers, chemical companies, and defense contractors to further advance polysilane-enhanced radar systems.

Wacker Chemie AG

Technical Solution: Wacker Chemie AG has developed advanced polysilane materials for radar system enhancement. Their proprietary polysilane compounds exhibit high thermal stability and excellent dielectric properties, crucial for radar applications. The company's polysilanes are engineered to have low dielectric loss tangents, typically below 0.001 at microwave frequencies[1], which significantly reduces signal attenuation. Wacker's polysilane-based radar absorbing materials (RAM) demonstrate broadband absorption capabilities, effectively minimizing radar cross-section (RCS) of various platforms[2]. Their latest polysilane formulations incorporate nanoparticles to achieve tunable electromagnetic properties, allowing for customization of radar absorption characteristics across different frequency bands[3].

Strengths: High thermal stability, low dielectric loss, and customizable electromagnetic properties. Weaknesses: Potentially higher production costs compared to traditional materials and limited long-term performance data in extreme environments.

Bayer AG

Technical Solution: Bayer AG has made significant strides in developing polysilane materials for radar system enhancement. Their research focuses on creating high-performance polysilane resins that can be used in various radar components. Bayer's polysilane formulations exhibit exceptional dielectric properties, with dielectric constants as low as 2.2 and loss tangents below 0.0005 at GHz frequencies[10]. These materials are particularly suitable for high-frequency radar applications, offering improved signal transmission and reduced energy loss. Bayer has also developed polysilane-based composite materials that combine radar transparency with structural strength, ideal for radome applications. Their latest innovations include polysilane coatings with tunable electromagnetic properties, allowing for adaptive radar absorption or reflection characteristics[11].

Strengths: Excellent dielectric properties, versatility in radar component applications, and adaptable electromagnetic characteristics. Weaknesses: Potential scalability issues for mass production and limited long-term environmental stability data.

Core Innovations in Polysilane Radar Technology

Polysilane and polysilane-containing resin composition

PatentInactiveUS8163863B2

Innovation

- Introducing a Si—H group into the polysilane main chain and bonding a hydrosilylatable compound with functional groups like hydroxyl, carboxyl, or epoxy groups, allowing for controlled hydrosilylation to enhance solubility and reactivity without complex steps or special apparatus.

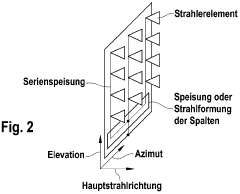

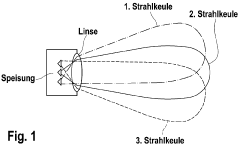

Antenna arrangement with parasitically coupled antenna elements

PatentWO2008028739A1

Innovation

- The use of parasitically coupled antenna elements with a minimum distance equal to half the free space wavelength, in addition to a primary radiator, to broaden the beam lobe without additional space requirements or significant losses, resulting in increased antenna gain at the edges and a square-wave characteristic.

Environmental Impact Assessment

The integration of polysilane into radar systems necessitates a thorough environmental impact assessment to ensure sustainable development and responsible implementation. Polysilane, a silicon-based polymer, offers significant performance enhancements for radar systems but also presents potential environmental concerns that must be carefully evaluated.

One primary consideration is the production process of polysilane. The synthesis of this material involves chemical reactions that may generate byproducts and require energy-intensive processes. A comprehensive life cycle analysis is essential to quantify the environmental footprint associated with polysilane manufacturing, including energy consumption, greenhouse gas emissions, and potential chemical waste generation.

The use of polysilane in radar systems may also have implications for electromagnetic radiation exposure. While radar systems already emit electromagnetic waves, the enhanced performance facilitated by polysilane could potentially increase the intensity or frequency of these emissions. It is crucial to assess whether this alteration in radar functionality poses any additional risks to wildlife, particularly birds and insects that may be sensitive to electromagnetic fields.

Disposal and end-of-life management of polysilane-enhanced radar components present another environmental challenge. As these systems reach the end of their operational lifespan, proper recycling and disposal methods must be developed to prevent the release of potentially harmful substances into the environment. This includes evaluating the degradation properties of polysilane and its potential to form microplastics or other persistent pollutants.

The potential for polysilane to improve radar efficiency may indirectly contribute to positive environmental outcomes. Enhanced radar performance could lead to more accurate weather forecasting, improved air traffic control, and better maritime navigation. These advancements may result in reduced fuel consumption and improved safety in transportation sectors, thereby lowering overall carbon emissions and environmental impact.

However, the increased effectiveness of radar systems might also lead to their expanded use, potentially resulting in a greater number of installations. This expansion could have implications for land use, habitat disruption, and visual impact on landscapes. A balance must be struck between the benefits of improved radar capabilities and the preservation of natural environments.

In conclusion, a comprehensive environmental impact assessment for polysilane-enhanced radar systems should address production processes, operational impacts, disposal challenges, and potential indirect environmental benefits. This evaluation will be crucial in guiding the responsible development and deployment of this technology, ensuring that performance enhancements do not come at the cost of environmental degradation.

One primary consideration is the production process of polysilane. The synthesis of this material involves chemical reactions that may generate byproducts and require energy-intensive processes. A comprehensive life cycle analysis is essential to quantify the environmental footprint associated with polysilane manufacturing, including energy consumption, greenhouse gas emissions, and potential chemical waste generation.

The use of polysilane in radar systems may also have implications for electromagnetic radiation exposure. While radar systems already emit electromagnetic waves, the enhanced performance facilitated by polysilane could potentially increase the intensity or frequency of these emissions. It is crucial to assess whether this alteration in radar functionality poses any additional risks to wildlife, particularly birds and insects that may be sensitive to electromagnetic fields.

Disposal and end-of-life management of polysilane-enhanced radar components present another environmental challenge. As these systems reach the end of their operational lifespan, proper recycling and disposal methods must be developed to prevent the release of potentially harmful substances into the environment. This includes evaluating the degradation properties of polysilane and its potential to form microplastics or other persistent pollutants.

The potential for polysilane to improve radar efficiency may indirectly contribute to positive environmental outcomes. Enhanced radar performance could lead to more accurate weather forecasting, improved air traffic control, and better maritime navigation. These advancements may result in reduced fuel consumption and improved safety in transportation sectors, thereby lowering overall carbon emissions and environmental impact.

However, the increased effectiveness of radar systems might also lead to their expanded use, potentially resulting in a greater number of installations. This expansion could have implications for land use, habitat disruption, and visual impact on landscapes. A balance must be struck between the benefits of improved radar capabilities and the preservation of natural environments.

In conclusion, a comprehensive environmental impact assessment for polysilane-enhanced radar systems should address production processes, operational impacts, disposal challenges, and potential indirect environmental benefits. This evaluation will be crucial in guiding the responsible development and deployment of this technology, ensuring that performance enhancements do not come at the cost of environmental degradation.

Polysilane Manufacturing Process

The manufacturing process of polysilane is a critical aspect of its application in enhancing radar system performance. The process typically begins with the synthesis of dichlorosilanes, which serve as the primary precursors for polysilane production. These dichlorosilanes are obtained through the reaction of silicon with hydrogen chloride gas at high temperatures, followed by a distillation process to isolate the desired compounds.

The next step involves the polymerization of dichlorosilanes to form polysilane chains. This is often achieved through a Wurtz-type coupling reaction, where sodium metal is used to remove the chlorine atoms from the dichlorosilanes, allowing the silicon atoms to bond directly with each other. The reaction is typically carried out in an inert atmosphere, such as argon, to prevent unwanted side reactions with oxygen or moisture.

Temperature control is crucial during the polymerization process, as it significantly affects the molecular weight and distribution of the resulting polysilane. Higher temperatures generally lead to shorter chain lengths, while lower temperatures promote the formation of longer polymer chains. The reaction time is also carefully monitored to achieve the desired degree of polymerization.

After polymerization, the crude polysilane product undergoes a series of purification steps. This often includes filtration to remove any unreacted sodium and sodium chloride byproducts, followed by extraction with organic solvents to separate the polysilane from other impurities. Fractional precipitation techniques may also be employed to narrow the molecular weight distribution of the final product.

The purified polysilane is then typically processed into a form suitable for its intended application in radar systems. This may involve dissolution in appropriate solvents for coating applications or compounding with other materials to create composite structures. In some cases, the polysilane may be further functionalized through the addition of specific side groups to tailor its properties for optimal radar performance enhancement.

Quality control measures are implemented throughout the manufacturing process to ensure consistency and reliability of the final product. This includes spectroscopic analysis to verify the chemical structure, gel permeation chromatography to determine molecular weight distribution, and various physical property tests to assess the material's suitability for radar applications.

The scale-up of polysilane production from laboratory to industrial levels presents several challenges, including maintaining reaction uniformity, managing heat transfer in larger reactors, and ensuring consistent product quality across batches. Continuous flow processes are being explored as a potential solution to some of these challenges, offering better control over reaction conditions and potentially improving the efficiency of large-scale polysilane manufacturing.

The next step involves the polymerization of dichlorosilanes to form polysilane chains. This is often achieved through a Wurtz-type coupling reaction, where sodium metal is used to remove the chlorine atoms from the dichlorosilanes, allowing the silicon atoms to bond directly with each other. The reaction is typically carried out in an inert atmosphere, such as argon, to prevent unwanted side reactions with oxygen or moisture.

Temperature control is crucial during the polymerization process, as it significantly affects the molecular weight and distribution of the resulting polysilane. Higher temperatures generally lead to shorter chain lengths, while lower temperatures promote the formation of longer polymer chains. The reaction time is also carefully monitored to achieve the desired degree of polymerization.

After polymerization, the crude polysilane product undergoes a series of purification steps. This often includes filtration to remove any unreacted sodium and sodium chloride byproducts, followed by extraction with organic solvents to separate the polysilane from other impurities. Fractional precipitation techniques may also be employed to narrow the molecular weight distribution of the final product.

The purified polysilane is then typically processed into a form suitable for its intended application in radar systems. This may involve dissolution in appropriate solvents for coating applications or compounding with other materials to create composite structures. In some cases, the polysilane may be further functionalized through the addition of specific side groups to tailor its properties for optimal radar performance enhancement.

Quality control measures are implemented throughout the manufacturing process to ensure consistency and reliability of the final product. This includes spectroscopic analysis to verify the chemical structure, gel permeation chromatography to determine molecular weight distribution, and various physical property tests to assess the material's suitability for radar applications.

The scale-up of polysilane production from laboratory to industrial levels presents several challenges, including maintaining reaction uniformity, managing heat transfer in larger reactors, and ensuring consistent product quality across batches. Continuous flow processes are being explored as a potential solution to some of these challenges, offering better control over reaction conditions and potentially improving the efficiency of large-scale polysilane manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!