How to Engineer Bulletproof Kevlar Solutions for Civilian Use?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar Evolution and Objectives

Kevlar, a synthetic fiber developed by DuPont in the 1960s, has revolutionized personal protection and industrial applications. Initially conceived as a replacement for steel in tires, Kevlar's exceptional strength-to-weight ratio quickly led to its adoption in bulletproof vests and other protective gear. The evolution of Kevlar technology has been driven by the constant need for improved safety and performance in both military and civilian sectors.

The development of Kevlar has progressed through several key stages. Early iterations focused on enhancing the fiber's tensile strength and heat resistance. Subsequent advancements aimed at improving its flexibility and comfort, crucial factors for wearable protective equipment. Recent innovations have explored the integration of Kevlar with other materials to create hybrid solutions that offer enhanced protection against a wider range of threats.

In the civilian context, the objectives for Kevlar engineering have expanded beyond traditional ballistic protection. There is a growing demand for lightweight, flexible, and discreet protective solutions that can be seamlessly incorporated into everyday clothing and accessories. This shift reflects the changing nature of security concerns in urban environments and the desire for protection without compromising mobility or style.

Current research in Kevlar technology is focused on several key areas. Scientists are exploring nanotechnology to enhance Kevlar's properties at the molecular level, potentially creating even stronger and lighter materials. Another area of interest is the development of "smart" Kevlar fabrics that can adapt to different threats or environmental conditions. Additionally, there are efforts to improve Kevlar's resistance to stabbing and slashing attacks, addressing a broader spectrum of potential dangers.

The ultimate goal in engineering bulletproof Kevlar solutions for civilian use is to strike an optimal balance between protection, comfort, and practicality. This involves not only improving the material itself but also innovating in design and manufacturing processes. Researchers are working on creating Kevlar-based materials that can be easily molded or 3D printed, opening up new possibilities for customized protective gear.

As Kevlar technology continues to evolve, the focus is increasingly on sustainability and environmental considerations. This includes developing more eco-friendly production methods and exploring ways to recycle or repurpose used Kevlar products. The future of Kevlar in civilian applications may also see its integration with emerging technologies such as wearable electronics, further expanding its functionality beyond mere physical protection.

The development of Kevlar has progressed through several key stages. Early iterations focused on enhancing the fiber's tensile strength and heat resistance. Subsequent advancements aimed at improving its flexibility and comfort, crucial factors for wearable protective equipment. Recent innovations have explored the integration of Kevlar with other materials to create hybrid solutions that offer enhanced protection against a wider range of threats.

In the civilian context, the objectives for Kevlar engineering have expanded beyond traditional ballistic protection. There is a growing demand for lightweight, flexible, and discreet protective solutions that can be seamlessly incorporated into everyday clothing and accessories. This shift reflects the changing nature of security concerns in urban environments and the desire for protection without compromising mobility or style.

Current research in Kevlar technology is focused on several key areas. Scientists are exploring nanotechnology to enhance Kevlar's properties at the molecular level, potentially creating even stronger and lighter materials. Another area of interest is the development of "smart" Kevlar fabrics that can adapt to different threats or environmental conditions. Additionally, there are efforts to improve Kevlar's resistance to stabbing and slashing attacks, addressing a broader spectrum of potential dangers.

The ultimate goal in engineering bulletproof Kevlar solutions for civilian use is to strike an optimal balance between protection, comfort, and practicality. This involves not only improving the material itself but also innovating in design and manufacturing processes. Researchers are working on creating Kevlar-based materials that can be easily molded or 3D printed, opening up new possibilities for customized protective gear.

As Kevlar technology continues to evolve, the focus is increasingly on sustainability and environmental considerations. This includes developing more eco-friendly production methods and exploring ways to recycle or repurpose used Kevlar products. The future of Kevlar in civilian applications may also see its integration with emerging technologies such as wearable electronics, further expanding its functionality beyond mere physical protection.

Civilian Market Demand Analysis

The civilian market for bulletproof Kevlar solutions has been experiencing significant growth in recent years, driven by increasing security concerns and a growing awareness of personal safety. This demand extends beyond traditional military and law enforcement applications, encompassing various civilian sectors.

One of the primary drivers of market demand is the rising interest in personal protection among civilians. High-profile incidents of violence and terrorism have led to a heightened sense of vulnerability, prompting individuals to seek protective gear for everyday use. This has resulted in a surge of demand for lightweight, concealable Kevlar products such as bulletproof vests, jackets, and backpacks.

The automotive industry represents another substantial market for civilian Kevlar applications. As vehicle safety becomes increasingly paramount, manufacturers are exploring the integration of Kevlar into car bodies and components to enhance crash protection and reduce vehicle weight. This trend is particularly evident in the luxury and high-performance vehicle segments, where consumers are willing to pay a premium for advanced safety features.

In the construction sector, there is growing interest in Kevlar-reinforced building materials. These materials offer enhanced structural integrity and blast resistance, making them attractive for use in high-risk facilities such as banks, government buildings, and critical infrastructure. The increasing focus on disaster-resistant construction in earthquake-prone regions has also contributed to the demand for Kevlar-based solutions.

The sports and recreation industry presents another promising market for civilian Kevlar applications. Manufacturers are incorporating Kevlar into protective gear for high-impact sports such as motorcycling, skiing, and extreme sports. The material's lightweight and flexible properties make it ideal for creating protective equipment that doesn't hinder performance.

Furthermore, the aerospace industry is exploring civilian applications of Kevlar in aircraft components and cabin interiors. The material's high strength-to-weight ratio makes it attractive for reducing aircraft weight while maintaining structural integrity, potentially leading to fuel savings and improved performance.

The global market for civilian Kevlar solutions is expected to continue its upward trajectory, with North America and Europe currently leading in terms of adoption and market share. However, emerging economies in Asia-Pacific and Latin America are showing rapid growth potential as awareness of personal safety increases and disposable incomes rise.

As the civilian market for Kevlar solutions expands, manufacturers are focusing on developing more versatile, comfortable, and aesthetically pleasing products to appeal to a broader consumer base. This includes innovations in Kevlar weaving techniques, composite materials, and design aesthetics to create products that seamlessly integrate into everyday civilian life while providing robust protection.

One of the primary drivers of market demand is the rising interest in personal protection among civilians. High-profile incidents of violence and terrorism have led to a heightened sense of vulnerability, prompting individuals to seek protective gear for everyday use. This has resulted in a surge of demand for lightweight, concealable Kevlar products such as bulletproof vests, jackets, and backpacks.

The automotive industry represents another substantial market for civilian Kevlar applications. As vehicle safety becomes increasingly paramount, manufacturers are exploring the integration of Kevlar into car bodies and components to enhance crash protection and reduce vehicle weight. This trend is particularly evident in the luxury and high-performance vehicle segments, where consumers are willing to pay a premium for advanced safety features.

In the construction sector, there is growing interest in Kevlar-reinforced building materials. These materials offer enhanced structural integrity and blast resistance, making them attractive for use in high-risk facilities such as banks, government buildings, and critical infrastructure. The increasing focus on disaster-resistant construction in earthquake-prone regions has also contributed to the demand for Kevlar-based solutions.

The sports and recreation industry presents another promising market for civilian Kevlar applications. Manufacturers are incorporating Kevlar into protective gear for high-impact sports such as motorcycling, skiing, and extreme sports. The material's lightweight and flexible properties make it ideal for creating protective equipment that doesn't hinder performance.

Furthermore, the aerospace industry is exploring civilian applications of Kevlar in aircraft components and cabin interiors. The material's high strength-to-weight ratio makes it attractive for reducing aircraft weight while maintaining structural integrity, potentially leading to fuel savings and improved performance.

The global market for civilian Kevlar solutions is expected to continue its upward trajectory, with North America and Europe currently leading in terms of adoption and market share. However, emerging economies in Asia-Pacific and Latin America are showing rapid growth potential as awareness of personal safety increases and disposable incomes rise.

As the civilian market for Kevlar solutions expands, manufacturers are focusing on developing more versatile, comfortable, and aesthetically pleasing products to appeal to a broader consumer base. This includes innovations in Kevlar weaving techniques, composite materials, and design aesthetics to create products that seamlessly integrate into everyday civilian life while providing robust protection.

Current Kevlar Tech Challenges

Kevlar, a high-strength synthetic fiber, has been widely used in military and law enforcement applications for decades. However, its potential for civilian use faces several significant challenges. One of the primary obstacles is the high cost of production and manufacturing, which limits its accessibility to the general public. The complex production process and specialized equipment required contribute to the elevated prices of Kevlar-based products.

Another challenge lies in the adaptability of Kevlar for everyday civilian use. While its strength-to-weight ratio is exceptional, the material's rigidity and lack of flexibility can make it uncomfortable for prolonged wear in non-combat situations. This limitation has hindered the development of more versatile civilian applications, such as protective clothing for industrial workers or outdoor enthusiasts.

The durability of Kevlar in diverse environmental conditions also presents a challenge. Although highly resistant to heat and chemicals, prolonged exposure to UV radiation can degrade its performance over time. This vulnerability necessitates additional protective measures or frequent replacement, further increasing the overall cost of Kevlar solutions for civilian use.

Regulatory hurdles and legal restrictions pose another significant challenge. In many jurisdictions, the use and distribution of high-grade protective materials are tightly controlled, limiting the availability of Kevlar-based products to civilians. Navigating these legal frameworks while ensuring compliance with safety standards adds complexity to the development and marketing of civilian Kevlar solutions.

The integration of Kevlar with other materials to enhance its properties and overcome its limitations is an ongoing technical challenge. Researchers are exploring composite materials that combine Kevlar with other fibers or substances to improve flexibility, breathability, and overall comfort without compromising its protective capabilities. However, achieving the right balance of properties while maintaining cost-effectiveness remains a significant hurdle.

Scalability in production is another critical challenge. While Kevlar manufacturing processes are well-established for military and law enforcement applications, scaling up production to meet potential civilian demand while maintaining quality and cost-effectiveness requires substantial investment and innovation in manufacturing technologies.

Lastly, public perception and education about Kevlar's capabilities and limitations in civilian applications present a unique challenge. Overcoming misconceptions and effectively communicating the benefits and appropriate uses of Kevlar-based products to the general public is crucial for widespread adoption and proper utilization in civilian contexts.

Another challenge lies in the adaptability of Kevlar for everyday civilian use. While its strength-to-weight ratio is exceptional, the material's rigidity and lack of flexibility can make it uncomfortable for prolonged wear in non-combat situations. This limitation has hindered the development of more versatile civilian applications, such as protective clothing for industrial workers or outdoor enthusiasts.

The durability of Kevlar in diverse environmental conditions also presents a challenge. Although highly resistant to heat and chemicals, prolonged exposure to UV radiation can degrade its performance over time. This vulnerability necessitates additional protective measures or frequent replacement, further increasing the overall cost of Kevlar solutions for civilian use.

Regulatory hurdles and legal restrictions pose another significant challenge. In many jurisdictions, the use and distribution of high-grade protective materials are tightly controlled, limiting the availability of Kevlar-based products to civilians. Navigating these legal frameworks while ensuring compliance with safety standards adds complexity to the development and marketing of civilian Kevlar solutions.

The integration of Kevlar with other materials to enhance its properties and overcome its limitations is an ongoing technical challenge. Researchers are exploring composite materials that combine Kevlar with other fibers or substances to improve flexibility, breathability, and overall comfort without compromising its protective capabilities. However, achieving the right balance of properties while maintaining cost-effectiveness remains a significant hurdle.

Scalability in production is another critical challenge. While Kevlar manufacturing processes are well-established for military and law enforcement applications, scaling up production to meet potential civilian demand while maintaining quality and cost-effectiveness requires substantial investment and innovation in manufacturing technologies.

Lastly, public perception and education about Kevlar's capabilities and limitations in civilian applications present a unique challenge. Overcoming misconceptions and effectively communicating the benefits and appropriate uses of Kevlar-based products to the general public is crucial for widespread adoption and proper utilization in civilian contexts.

Existing Civilian Kevlar Solutions

01 Kevlar-based bulletproof materials

Kevlar is a high-strength synthetic fiber widely used in bulletproof applications. Its unique molecular structure provides excellent tensile strength and impact resistance, making it ideal for personal protective equipment and vehicle armor. Kevlar-based bulletproof materials are often combined with other materials to enhance their protective capabilities.- Kevlar-based bulletproof materials: Kevlar is widely used in bulletproof applications due to its high strength-to-weight ratio and excellent energy absorption properties. It is often incorporated into various protective gear and structures to enhance ballistic resistance.

- Composite armor systems: Bulletproof solutions often involve composite armor systems that combine Kevlar with other materials such as ceramics, metals, or other synthetic fibers. These multi-layered structures provide enhanced protection against different types of ballistic threats.

- Kevlar-reinforced vehicle armor: Kevlar is utilized in vehicle armor applications to provide lightweight yet effective protection for military and civilian vehicles. This includes reinforcing doors, panels, and other vulnerable areas to enhance occupant safety against ballistic threats.

- Improved Kevlar manufacturing processes: Advancements in Kevlar manufacturing processes aim to enhance its bulletproof properties. These improvements may include new fiber spinning techniques, surface treatments, or molecular modifications to increase strength and energy absorption capabilities.

- Integration of Kevlar in personal protective equipment: Kevlar is incorporated into various personal protective equipment designs, such as bulletproof vests, helmets, and shields. These applications focus on optimizing the balance between protection, comfort, and mobility for law enforcement and military personnel.

02 Multilayer bulletproof structures

Bulletproof systems often employ multilayer structures to improve their protective performance. These structures may combine Kevlar with other materials such as ceramics, metals, or high-density polyethylene. The multiple layers work together to absorb and disperse the energy of incoming projectiles, enhancing overall protection.Expand Specific Solutions03 Lightweight bulletproof solutions

Developing lightweight bulletproof materials is crucial for improving mobility and comfort for users. Innovations in this area focus on reducing the weight of protective gear while maintaining or enhancing its protective capabilities. This may involve using advanced composites or novel material combinations to achieve optimal strength-to-weight ratios.Expand Specific Solutions04 Flexible bulletproof materials

Flexible bulletproof materials offer improved comfort and mobility compared to rigid alternatives. These materials often incorporate Kevlar fibers in a flexible matrix, allowing for better conformity to body contours. Innovations in this area aim to enhance flexibility without compromising protective performance.Expand Specific Solutions05 Enhanced ballistic protection techniques

Ongoing research focuses on improving the ballistic protection of Kevlar-based materials. This includes developing new fiber arrangements, incorporating nano-materials, or applying special coatings to enhance impact resistance and energy absorption. These techniques aim to provide better protection against a wider range of threats.Expand Specific Solutions

Key Kevlar Industry Players

The development of bulletproof Kevlar solutions for civilian use is in a mature stage, with a growing market driven by increasing safety concerns. The global bulletproof vest market size was valued at $1.65 billion in 2020 and is projected to reach $2.97 billion by 2028. Technologically, companies like DuPont, Honeywell, and Teijin have established a strong foothold in Kevlar production. Research institutions such as Beihang University and Beijing Institute of Technology are contributing to advancements in lightweight, flexible, and multi-functional protective materials. The industry is seeing a shift towards integrating smart technologies and exploring eco-friendly alternatives, indicating a dynamic and evolving competitive landscape.

Kennametal, Inc.

Technical Solution: Kennametal has developed advanced ceramic-metallic (cermet) composites for bulletproof applications. Their proprietary process combines ceramic particles with a metal matrix, resulting in a material that offers superior ballistic protection compared to traditional Kevlar[1]. The company's cermet solutions provide enhanced hardness and fracture toughness, crucial for stopping high-velocity projectiles. Kennametal's technology allows for the creation of lighter weight armor panels that maintain or exceed the protective capabilities of conventional Kevlar vests[2]. This innovation addresses the growing demand for more effective and comfortable personal protection equipment in civilian markets.

Strengths: Superior ballistic protection, lighter weight, and improved comfort for users. Weaknesses: Potentially higher production costs and limited flexibility compared to traditional Kevlar fabrics.

Ulbrichts Witwe GmbH

Technical Solution: Ulbrichts Witwe has pioneered a hybrid solution that combines titanium with aramid fibers (the base material for Kevlar) to create highly effective bulletproof helmets for civilian use[3]. Their VPAM 3 certified helmets can stop handgun ammunition while providing protection against rifle threats. The company's innovative layering technique involves a hard titanium alloy outer shell bonded with multiple layers of aramid fibers, creating a synergistic effect that enhances overall protection[4]. This approach allows for a significant reduction in backface deformation, crucial for preventing traumatic brain injuries. Ulbrichts' helmets are designed to be lightweight and comfortable for extended wear, making them suitable for law enforcement and private security personnel in civilian settings.

Strengths: Exceptional protection against both handgun and rifle threats, reduced risk of brain trauma. Weaknesses: Higher cost compared to traditional Kevlar-only solutions, potentially limited to head protection applications.

Core Kevlar Innovations

Amorphous alloy composite bullet resistant material and preparation method thereof

PatentActiveCN109808266A

Innovation

- Using amorphous alloy material particles, ultra-high molecular weight polyethylene fiber, water-based polyurethane, polyolefin resin, titanium boride powder and carbon nanotube film as raw materials, an amorphous alloy is prepared through specific ratios and processes. Composite bulletproof materials utilize the interface effect between polyolefin resin and ultra-high molecular weight polyethylene fiber and the high energy-absorbing properties of carbon nanotubes to enhance bulletproof performance and flexibility.

Reinforced composite material with high impact strength

PatentUndeterminedIN201931044509A

Innovation

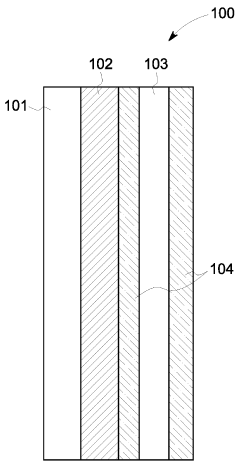

- A multi-layered reinforced laminated structure comprising an outer Kevlar layer for heat and penetration resistance, a middle graphene layer for resilience, and an inner carbyne layer stabilized by double-walled carbon nanotubes for rigidity, providing lightweight, high impact strength, and enhanced tensile strength and elasticity.

Kevlar Safety Regulations

The development and use of Kevlar for civilian applications necessitate adherence to stringent safety regulations to ensure public safety and product reliability. These regulations encompass various aspects of Kevlar production, testing, and implementation in civilian products. The manufacturing process of Kevlar is subject to strict quality control measures, including the monitoring of raw materials, production conditions, and final product specifications. Manufacturers must comply with industry standards and government regulations regarding the production and handling of synthetic fibers.

In the United States, the Occupational Safety and Health Administration (OSHA) sets guidelines for the safe handling and processing of Kevlar in industrial settings. These guidelines cover personal protective equipment, ventilation requirements, and proper disposal methods for Kevlar waste. Additionally, the Consumer Product Safety Commission (CPSC) oversees the safety of Kevlar-containing products intended for civilian use, ensuring they meet established safety standards.

For Kevlar-based bulletproof solutions, rigorous testing protocols are mandated to verify their effectiveness and durability. The National Institute of Justice (NIJ) in the United States provides standards for ballistic resistance of body armor, which includes Kevlar-based products. These standards specify the types of ammunition and impact velocities that the armor must withstand, as well as the maximum allowable deformation upon impact.

International standards, such as those set by the International Organization for Standardization (ISO), also play a crucial role in regulating Kevlar products. ISO 14876 specifically addresses the requirements for bullet-resistant vests and provides guidelines for testing and certification. Compliance with these standards is often a prerequisite for market entry in many countries.

Environmental regulations also impact the production and disposal of Kevlar products. Manufacturers must adhere to guidelines set by environmental protection agencies regarding emissions, waste management, and the use of potentially hazardous chemicals in the production process. The lifecycle assessment of Kevlar products, from raw material extraction to end-of-life disposal, is increasingly scrutinized to ensure environmental sustainability.

In the automotive industry, where Kevlar is used in various components, safety regulations extend to crash testing and durability standards. The National Highway Traffic Safety Administration (NHTSA) in the United States sets performance requirements for vehicle safety systems, some of which may incorporate Kevlar materials.

As Kevlar technology advances and finds new applications in civilian products, regulatory bodies continue to evolve their guidelines to address emerging safety concerns. This ongoing process involves collaboration between industry experts, government agencies, and research institutions to develop comprehensive and up-to-date safety regulations that protect consumers while fostering innovation in Kevlar-based solutions.

In the United States, the Occupational Safety and Health Administration (OSHA) sets guidelines for the safe handling and processing of Kevlar in industrial settings. These guidelines cover personal protective equipment, ventilation requirements, and proper disposal methods for Kevlar waste. Additionally, the Consumer Product Safety Commission (CPSC) oversees the safety of Kevlar-containing products intended for civilian use, ensuring they meet established safety standards.

For Kevlar-based bulletproof solutions, rigorous testing protocols are mandated to verify their effectiveness and durability. The National Institute of Justice (NIJ) in the United States provides standards for ballistic resistance of body armor, which includes Kevlar-based products. These standards specify the types of ammunition and impact velocities that the armor must withstand, as well as the maximum allowable deformation upon impact.

International standards, such as those set by the International Organization for Standardization (ISO), also play a crucial role in regulating Kevlar products. ISO 14876 specifically addresses the requirements for bullet-resistant vests and provides guidelines for testing and certification. Compliance with these standards is often a prerequisite for market entry in many countries.

Environmental regulations also impact the production and disposal of Kevlar products. Manufacturers must adhere to guidelines set by environmental protection agencies regarding emissions, waste management, and the use of potentially hazardous chemicals in the production process. The lifecycle assessment of Kevlar products, from raw material extraction to end-of-life disposal, is increasingly scrutinized to ensure environmental sustainability.

In the automotive industry, where Kevlar is used in various components, safety regulations extend to crash testing and durability standards. The National Highway Traffic Safety Administration (NHTSA) in the United States sets performance requirements for vehicle safety systems, some of which may incorporate Kevlar materials.

As Kevlar technology advances and finds new applications in civilian products, regulatory bodies continue to evolve their guidelines to address emerging safety concerns. This ongoing process involves collaboration between industry experts, government agencies, and research institutions to develop comprehensive and up-to-date safety regulations that protect consumers while fostering innovation in Kevlar-based solutions.

Ethical Use of Civilian Kevlar

The ethical use of civilian Kevlar requires careful consideration of various factors to ensure responsible application and prevent misuse. Primarily, it is essential to establish clear guidelines and regulations governing the production, distribution, and use of Kevlar-based products for civilian purposes. These guidelines should address safety standards, quality control measures, and proper handling procedures to minimize potential risks associated with the material.

One crucial aspect of ethical Kevlar use is ensuring that products are designed and marketed specifically for their intended civilian applications, such as protective gear for sports, industrial safety equipment, or automotive components. Manufacturers should clearly differentiate these products from military-grade armor to prevent confusion or misuse. Additionally, implementing strict sales and distribution controls can help prevent Kevlar products from falling into the hands of individuals or groups with malicious intent.

Education and awareness programs play a vital role in promoting the ethical use of civilian Kevlar. These initiatives should focus on informing consumers about the proper use, limitations, and maintenance of Kevlar-based products. By fostering a better understanding of the material's capabilities and restrictions, users can make informed decisions and avoid potential misuse or overreliance on Kevlar protection.

Transparency in the supply chain is another critical factor in ensuring ethical use. Manufacturers should be required to disclose the source of their Kevlar materials and provide detailed information about the production processes. This transparency helps prevent the use of substandard materials or unethical manufacturing practices that could compromise the integrity and effectiveness of Kevlar products.

Collaboration between industry stakeholders, regulatory bodies, and law enforcement agencies is essential to develop and enforce ethical guidelines for civilian Kevlar use. Regular audits and compliance checks can help maintain high standards and identify potential areas of concern. Furthermore, establishing a system for reporting and investigating misuse or illegal applications of Kevlar can contribute to overall safety and ethical practices within the industry.

Research and development efforts should focus on enhancing the performance and versatility of Kevlar for civilian applications while maintaining a strong emphasis on ethical considerations. This includes exploring new manufacturing techniques that reduce environmental impact, improving the recyclability of Kevlar products, and developing innovative applications that address pressing societal needs without compromising safety or ethical standards.

One crucial aspect of ethical Kevlar use is ensuring that products are designed and marketed specifically for their intended civilian applications, such as protective gear for sports, industrial safety equipment, or automotive components. Manufacturers should clearly differentiate these products from military-grade armor to prevent confusion or misuse. Additionally, implementing strict sales and distribution controls can help prevent Kevlar products from falling into the hands of individuals or groups with malicious intent.

Education and awareness programs play a vital role in promoting the ethical use of civilian Kevlar. These initiatives should focus on informing consumers about the proper use, limitations, and maintenance of Kevlar-based products. By fostering a better understanding of the material's capabilities and restrictions, users can make informed decisions and avoid potential misuse or overreliance on Kevlar protection.

Transparency in the supply chain is another critical factor in ensuring ethical use. Manufacturers should be required to disclose the source of their Kevlar materials and provide detailed information about the production processes. This transparency helps prevent the use of substandard materials or unethical manufacturing practices that could compromise the integrity and effectiveness of Kevlar products.

Collaboration between industry stakeholders, regulatory bodies, and law enforcement agencies is essential to develop and enforce ethical guidelines for civilian Kevlar use. Regular audits and compliance checks can help maintain high standards and identify potential areas of concern. Furthermore, establishing a system for reporting and investigating misuse or illegal applications of Kevlar can contribute to overall safety and ethical practices within the industry.

Research and development efforts should focus on enhancing the performance and versatility of Kevlar for civilian applications while maintaining a strong emphasis on ethical considerations. This includes exploring new manufacturing techniques that reduce environmental impact, improving the recyclability of Kevlar products, and developing innovative applications that address pressing societal needs without compromising safety or ethical standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!