Insights on Polysilane's Role in Circuit Miniaturization

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane Background

Polysilanes, a class of silicon-based polymers, have emerged as a promising material in the field of circuit miniaturization. These unique compounds consist of a backbone of silicon atoms, typically with organic side groups attached. The history of polysilanes dates back to the early 20th century, but their potential in electronics was not fully recognized until the 1980s.

The development of polysilanes can be traced to the work of Frederic Stanley Kipping in the early 1900s. Kipping's pioneering research on organosilicon compounds laid the foundation for the synthesis and study of polysilanes. However, it wasn't until the late 1970s and early 1980s that researchers began to explore the electronic properties of these materials in earnest.

Polysilanes possess unique electronic and optical properties due to their silicon-silicon backbone. The delocalization of electrons along this backbone results in interesting conductivity and photoconductivity characteristics. These properties make polysilanes particularly attractive for applications in electronic and optoelectronic devices, including their potential role in circuit miniaturization.

The structure of polysilanes allows for a high degree of customization through the variation of side groups attached to the silicon backbone. This versatility enables researchers to tailor the properties of polysilanes for specific applications, making them adaptable to various requirements in circuit design and fabrication.

One of the key advantages of polysilanes in the context of circuit miniaturization is their ability to form thin films with excellent uniformity and stability. These films can be deposited using various techniques, including spin-coating and chemical vapor deposition, allowing for precise control over thickness and composition. This characteristic is crucial for the development of ultra-thin and high-performance electronic components.

Furthermore, polysilanes exhibit interesting photochemical properties, including photodegradation and photocrosslinking. These properties have been exploited in the development of photoresists for lithography processes, which are essential in the fabrication of miniaturized circuits. The high sensitivity and resolution achievable with polysilane-based photoresists make them valuable tools in pushing the boundaries of circuit miniaturization.

As research in the field of polysilanes has progressed, their potential applications have expanded beyond traditional electronic circuits. They have shown promise in areas such as organic light-emitting diodes (OLEDs), photovoltaic cells, and sensors. This versatility underscores the importance of polysilanes in the broader context of advanced materials for next-generation electronic devices.

The development of polysilanes can be traced to the work of Frederic Stanley Kipping in the early 1900s. Kipping's pioneering research on organosilicon compounds laid the foundation for the synthesis and study of polysilanes. However, it wasn't until the late 1970s and early 1980s that researchers began to explore the electronic properties of these materials in earnest.

Polysilanes possess unique electronic and optical properties due to their silicon-silicon backbone. The delocalization of electrons along this backbone results in interesting conductivity and photoconductivity characteristics. These properties make polysilanes particularly attractive for applications in electronic and optoelectronic devices, including their potential role in circuit miniaturization.

The structure of polysilanes allows for a high degree of customization through the variation of side groups attached to the silicon backbone. This versatility enables researchers to tailor the properties of polysilanes for specific applications, making them adaptable to various requirements in circuit design and fabrication.

One of the key advantages of polysilanes in the context of circuit miniaturization is their ability to form thin films with excellent uniformity and stability. These films can be deposited using various techniques, including spin-coating and chemical vapor deposition, allowing for precise control over thickness and composition. This characteristic is crucial for the development of ultra-thin and high-performance electronic components.

Furthermore, polysilanes exhibit interesting photochemical properties, including photodegradation and photocrosslinking. These properties have been exploited in the development of photoresists for lithography processes, which are essential in the fabrication of miniaturized circuits. The high sensitivity and resolution achievable with polysilane-based photoresists make them valuable tools in pushing the boundaries of circuit miniaturization.

As research in the field of polysilanes has progressed, their potential applications have expanded beyond traditional electronic circuits. They have shown promise in areas such as organic light-emitting diodes (OLEDs), photovoltaic cells, and sensors. This versatility underscores the importance of polysilanes in the broader context of advanced materials for next-generation electronic devices.

Market Demand Analysis

The market demand for polysilane in circuit miniaturization has been steadily growing, driven by the relentless pursuit of smaller, faster, and more efficient electronic devices. As the semiconductor industry continues to push the boundaries of Moore's Law, polysilane has emerged as a promising material for enabling further miniaturization of integrated circuits.

The global semiconductor market, valued at over $500 billion in 2021, is expected to reach $1 trillion by 2030, with a significant portion of this growth attributed to advancements in circuit miniaturization technologies. Polysilane, with its unique electronic properties and potential for high-resolution patterning, is poised to capture a growing share of this market.

In the realm of photolithography, polysilane-based photoresists have shown exceptional performance in achieving sub-10 nm feature sizes. This capability aligns perfectly with the industry's roadmap for next-generation chip manufacturing processes, where traditional materials are reaching their physical limits. The demand for polysilane in this application is expected to grow at a compound annual growth rate (CAGR) of over 15% in the next five years.

Furthermore, polysilane's potential as a precursor for silicon-based thin films has garnered significant attention in the development of advanced transistor architectures. As the industry moves towards 3D and gate-all-around (GAA) transistor designs, the precise control over film thickness and composition offered by polysilane-derived materials becomes increasingly valuable. This application segment is projected to see a CAGR of 20% over the next decade.

The automotive and consumer electronics sectors are driving substantial demand for miniaturized circuits, with applications ranging from advanced driver-assistance systems (ADAS) to wearable devices. These markets are expected to consume a growing volume of polysilane-enabled components, contributing to an estimated market size of several billion dollars by 2025.

However, challenges remain in scaling up polysilane production to meet the anticipated demand. Current manufacturing processes are complex and costly, which could potentially limit widespread adoption. Industry analysts predict that overcoming these production hurdles could unlock a market potential of over $10 billion for polysilane in circuit miniaturization applications by 2030.

In conclusion, the market demand for polysilane in circuit miniaturization is robust and growing, underpinned by the semiconductor industry's relentless drive towards smaller and more powerful electronic devices. As technological advancements continue to address production challenges, polysilane is well-positioned to play a crucial role in shaping the future of nanoelectronics.

The global semiconductor market, valued at over $500 billion in 2021, is expected to reach $1 trillion by 2030, with a significant portion of this growth attributed to advancements in circuit miniaturization technologies. Polysilane, with its unique electronic properties and potential for high-resolution patterning, is poised to capture a growing share of this market.

In the realm of photolithography, polysilane-based photoresists have shown exceptional performance in achieving sub-10 nm feature sizes. This capability aligns perfectly with the industry's roadmap for next-generation chip manufacturing processes, where traditional materials are reaching their physical limits. The demand for polysilane in this application is expected to grow at a compound annual growth rate (CAGR) of over 15% in the next five years.

Furthermore, polysilane's potential as a precursor for silicon-based thin films has garnered significant attention in the development of advanced transistor architectures. As the industry moves towards 3D and gate-all-around (GAA) transistor designs, the precise control over film thickness and composition offered by polysilane-derived materials becomes increasingly valuable. This application segment is projected to see a CAGR of 20% over the next decade.

The automotive and consumer electronics sectors are driving substantial demand for miniaturized circuits, with applications ranging from advanced driver-assistance systems (ADAS) to wearable devices. These markets are expected to consume a growing volume of polysilane-enabled components, contributing to an estimated market size of several billion dollars by 2025.

However, challenges remain in scaling up polysilane production to meet the anticipated demand. Current manufacturing processes are complex and costly, which could potentially limit widespread adoption. Industry analysts predict that overcoming these production hurdles could unlock a market potential of over $10 billion for polysilane in circuit miniaturization applications by 2030.

In conclusion, the market demand for polysilane in circuit miniaturization is robust and growing, underpinned by the semiconductor industry's relentless drive towards smaller and more powerful electronic devices. As technological advancements continue to address production challenges, polysilane is well-positioned to play a crucial role in shaping the future of nanoelectronics.

Current Challenges

The miniaturization of integrated circuits has been a driving force in the semiconductor industry for decades, but as we approach the physical limits of traditional silicon-based technologies, new challenges emerge. Polysilane, a silicon-based polymer, has shown promise in addressing some of these challenges, yet its implementation in circuit miniaturization faces several significant hurdles.

One of the primary challenges in utilizing polysilane for circuit miniaturization is achieving consistent and controllable molecular weight distribution. The electrical and optical properties of polysilane are heavily dependent on its chain length and structure. Variations in these parameters can lead to inconsistent performance across devices, making large-scale production and integration difficult.

Another critical issue is the stability of polysilane under various environmental conditions. Exposure to heat, light, and certain chemicals can cause degradation of the polymer structure, potentially altering its electrical properties and compromising the reliability of the circuits. This sensitivity poses significant challenges for both manufacturing processes and long-term device performance.

The integration of polysilane with existing silicon-based technologies presents another set of challenges. While polysilane offers unique properties that could enhance circuit performance, developing fabrication processes that seamlessly incorporate this material into current semiconductor manufacturing workflows requires substantial research and development efforts.

Furthermore, the electrical conductivity of polysilane, while promising, still falls short of the levels required for many high-performance computing applications. Enhancing the conductivity without compromising other desirable properties of the material remains a significant technical hurdle.

The potential for defect formation during the deposition and patterning of polysilane layers is another concern. These defects can act as charge traps or recombination centers, negatively impacting the electrical characteristics of the circuits. Developing precise deposition techniques and effective defect mitigation strategies is crucial for the successful implementation of polysilane in miniaturized circuits.

Lastly, the scalability of polysilane-based technologies presents a significant challenge. While promising results have been demonstrated in laboratory settings, translating these successes to large-scale, cost-effective production remains a formidable task. This includes not only the scaling of material synthesis but also the development of compatible manufacturing equipment and processes.

One of the primary challenges in utilizing polysilane for circuit miniaturization is achieving consistent and controllable molecular weight distribution. The electrical and optical properties of polysilane are heavily dependent on its chain length and structure. Variations in these parameters can lead to inconsistent performance across devices, making large-scale production and integration difficult.

Another critical issue is the stability of polysilane under various environmental conditions. Exposure to heat, light, and certain chemicals can cause degradation of the polymer structure, potentially altering its electrical properties and compromising the reliability of the circuits. This sensitivity poses significant challenges for both manufacturing processes and long-term device performance.

The integration of polysilane with existing silicon-based technologies presents another set of challenges. While polysilane offers unique properties that could enhance circuit performance, developing fabrication processes that seamlessly incorporate this material into current semiconductor manufacturing workflows requires substantial research and development efforts.

Furthermore, the electrical conductivity of polysilane, while promising, still falls short of the levels required for many high-performance computing applications. Enhancing the conductivity without compromising other desirable properties of the material remains a significant technical hurdle.

The potential for defect formation during the deposition and patterning of polysilane layers is another concern. These defects can act as charge traps or recombination centers, negatively impacting the electrical characteristics of the circuits. Developing precise deposition techniques and effective defect mitigation strategies is crucial for the successful implementation of polysilane in miniaturized circuits.

Lastly, the scalability of polysilane-based technologies presents a significant challenge. While promising results have been demonstrated in laboratory settings, translating these successes to large-scale, cost-effective production remains a formidable task. This includes not only the scaling of material synthesis but also the development of compatible manufacturing equipment and processes.

Existing Solutions

01 Polysilane synthesis and properties

Polysilanes are synthesized and characterized for their unique electronic and optical properties. These materials exhibit high electron mobility and can be used in various electronic applications, including circuit miniaturization. The synthesis methods and resulting properties are crucial for developing advanced polysilane-based electronic components.- Polysilane synthesis and properties: Polysilanes are synthesized and characterized for their unique electrical and optical properties. These materials exhibit high electron mobility and can be used in various electronic applications, including circuit miniaturization. The synthesis methods and resulting properties are crucial for developing advanced electronic components.

- Thin film formation for miniaturized circuits: Polysilane thin films are developed for use in miniaturized circuits. These films can be deposited using various techniques, such as spin-coating or vapor deposition, to create ultra-thin layers suitable for compact electronic devices. The thin film formation process is optimized to ensure uniform coverage and desired electrical characteristics.

- Photolithography and patterning techniques: Advanced photolithography and patterning techniques are employed to create miniaturized circuit patterns using polysilane materials. These methods allow for the precise fabrication of nanoscale features, enabling the development of highly compact and efficient electronic circuits. The patterning process is crucial for achieving high-resolution structures in polysilane-based devices.

- Doping and modification of polysilanes: Polysilanes are doped or modified with various elements or functional groups to enhance their electrical properties and improve their suitability for miniaturized circuits. These modifications can alter the band gap, conductivity, and other characteristics of the material, allowing for tailored performance in specific electronic applications.

- Integration with other materials for hybrid circuits: Polysilanes are integrated with other materials, such as traditional semiconductors or organic compounds, to create hybrid circuits with enhanced functionality and miniaturization potential. This approach combines the unique properties of polysilanes with complementary materials to achieve advanced electronic performance in compact form factors.

02 Polysilane-based thin films for electronic devices

Thin films of polysilanes are developed and applied in electronic devices. These films can be used as active layers in transistors, photoresistors, and other miniaturized circuit components. The deposition techniques and film characteristics are optimized to achieve better performance in small-scale electronic applications.Expand Specific Solutions03 Polysilane-based photoresists for circuit fabrication

Polysilanes are utilized as photoresist materials in the fabrication of miniaturized circuits. These materials offer high resolution and sensitivity, allowing for the creation of smaller circuit features. The development of polysilane-based photoresists contributes to the advancement of circuit miniaturization techniques.Expand Specific Solutions04 Functionalized polysilanes for enhanced electronic properties

Polysilanes are functionalized with various chemical groups to enhance their electronic properties. These modifications can improve conductivity, charge transport, and other characteristics relevant to circuit miniaturization. The development of functionalized polysilanes expands their potential applications in advanced electronic devices.Expand Specific Solutions05 Polysilane-based nanostructures for miniaturized circuits

Nanostructures based on polysilanes are developed for use in miniaturized circuits. These include nanowires, nanoparticles, and other nanoscale architectures that can be incorporated into small-scale electronic components. The creation and integration of polysilane nanostructures contribute to the advancement of circuit miniaturization technologies.Expand Specific Solutions

Key Industry Players

The competitive landscape for polysilane's role in circuit miniaturization is evolving rapidly, with the industry in a growth phase. The market size is expanding as demand for smaller, more efficient electronic devices increases. Technologically, polysilane is still in the early stages of maturity, with ongoing research and development efforts. Key players like JSR Corp., Wacker Chemie AG, and Intel Corp. are investing in polysilane technology, leveraging their expertise in semiconductor materials. Companies such as Taiwan Semiconductor Manufacturing Co. and Micron Technology are also exploring polysilane applications to enhance their chip manufacturing processes. As the technology advances, collaboration between research institutions and industry leaders is likely to accelerate innovation and commercialization in this field.

JSR Corp.

Technical Solution: JSR Corporation has made significant strides in polysilane-based materials for circuit miniaturization. Their research focuses on developing polysilane-based photoresists with high resolution and sensitivity for advanced lithography processes[5]. JSR's polysilane materials demonstrate excellent etching resistance and pattern fidelity at sub-10 nm nodes[6]. The company has also explored the use of polysilanes as low-k dielectric materials, achieving dielectric constants as low as 2.2 while maintaining good mechanical strength[7]. Additionally, JSR has developed polysilane-based conductive materials that can be used for interconnects in highly miniaturized circuits[8].

Strengths: High-resolution photoresists, low-k dielectric materials, and potential for conductive applications. Weaknesses: May require significant changes to existing manufacturing processes for widespread adoption.

Wacker Chemie AG

Technical Solution: Wacker Chemie AG has developed advanced polysilane materials for circuit miniaturization. Their approach involves synthesizing high-purity polysilanes with controlled molecular weight and narrow polydispersity[1]. These materials exhibit excellent thermal stability and can be processed into ultra-thin films with thicknesses below 10 nm[2]. Wacker's polysilanes demonstrate high electron mobility and low dielectric constants, making them ideal for use in next-generation semiconductor devices[3]. The company has also developed novel cross-linking techniques to enhance the mechanical properties of polysilane films, improving their durability in integrated circuits[4].

Strengths: High-purity materials, excellent thermal stability, and ability to form ultra-thin films. Weaknesses: Potential challenges in large-scale production and integration with existing semiconductor manufacturing processes.

Core Innovations

Method for processing semiconductor substrate

PatentWO2020066669A1

Innovation

- A method involving the application of a silicon-containing film-forming composition containing polycarbosilane and a solvent, followed by treatments such as radiation exposure, reactive gas exposure, plasma exposure, ion exposure, contact with reactive liquids, or heating at 400°C or higher, and subsequent removal using an acid or base solution to minimize substrate damage.

Silicon carbonaceous film forming composition comprising polycarbosilane and method for manufacturing silicon carbonaceous film using the same

PatentWO2019030206A1

Innovation

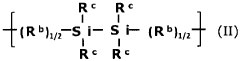

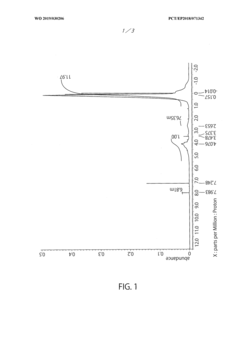

- A silicon carbonaceous film forming composition comprising polycarbosilane with a specific molecular structure and solvent, applied and cured at lower temperatures, where the polycarbosilane is produced by heat-treating polydimethylsilane under controlled conditions, enhancing the film's filling and electrical properties.

Material Properties

Polysilane, a unique class of silicon-based polymers, exhibits remarkable material properties that make it a promising candidate for circuit miniaturization. The backbone of polysilane consists of silicon atoms bonded together, which gives rise to its distinctive electronic and optical characteristics. One of the most notable properties of polysilane is its high electron mobility, which surpasses that of many traditional semiconductor materials. This enhanced electron mobility allows for faster charge transport, potentially enabling the creation of high-speed electronic devices with reduced dimensions.

The optical properties of polysilane are equally impressive. It demonstrates strong UV absorption and efficient photoluminescence, making it suitable for optoelectronic applications. The ability to tune these optical properties through structural modifications offers versatility in device design. Furthermore, polysilane exhibits excellent thermal stability, maintaining its structural integrity at elevated temperatures. This thermal resilience is crucial for ensuring the reliability of miniaturized circuits operating under demanding conditions.

Another significant attribute of polysilane is its solution processability. Unlike conventional semiconductor materials that often require complex deposition techniques, polysilane can be easily processed from solution. This property facilitates the fabrication of thin films and coatings with precise thickness control, which is essential for creating ultra-thin layers in miniaturized circuits. The solution processability also opens up possibilities for large-area fabrication and roll-to-roll manufacturing, potentially reducing production costs and enabling flexible electronics.

Polysilane's unique chemical structure contributes to its exceptional mechanical properties. The polymer chains can be engineered to achieve varying degrees of flexibility or rigidity, allowing for customization based on specific application requirements. This adaptability is particularly valuable in the context of circuit miniaturization, where materials must withstand mechanical stress while maintaining electrical performance.

The surface properties of polysilane films can be tailored through chemical modifications, enabling better adhesion to substrates and improved compatibility with other materials used in circuit fabrication. This versatility in surface chemistry facilitates the integration of polysilane into complex multilayer structures, which is often necessary for advanced miniaturized circuits.

In terms of electrical insulation, polysilane exhibits low dielectric constants, which is advantageous for reducing signal interference and minimizing power consumption in densely packed circuits. This property becomes increasingly important as circuit components are brought closer together in miniaturized designs. Additionally, the ability to dope polysilane with various elements allows for fine-tuning of its electrical properties, potentially enabling the creation of both n-type and p-type semiconducting regions within the same material system.

The optical properties of polysilane are equally impressive. It demonstrates strong UV absorption and efficient photoluminescence, making it suitable for optoelectronic applications. The ability to tune these optical properties through structural modifications offers versatility in device design. Furthermore, polysilane exhibits excellent thermal stability, maintaining its structural integrity at elevated temperatures. This thermal resilience is crucial for ensuring the reliability of miniaturized circuits operating under demanding conditions.

Another significant attribute of polysilane is its solution processability. Unlike conventional semiconductor materials that often require complex deposition techniques, polysilane can be easily processed from solution. This property facilitates the fabrication of thin films and coatings with precise thickness control, which is essential for creating ultra-thin layers in miniaturized circuits. The solution processability also opens up possibilities for large-area fabrication and roll-to-roll manufacturing, potentially reducing production costs and enabling flexible electronics.

Polysilane's unique chemical structure contributes to its exceptional mechanical properties. The polymer chains can be engineered to achieve varying degrees of flexibility or rigidity, allowing for customization based on specific application requirements. This adaptability is particularly valuable in the context of circuit miniaturization, where materials must withstand mechanical stress while maintaining electrical performance.

The surface properties of polysilane films can be tailored through chemical modifications, enabling better adhesion to substrates and improved compatibility with other materials used in circuit fabrication. This versatility in surface chemistry facilitates the integration of polysilane into complex multilayer structures, which is often necessary for advanced miniaturized circuits.

In terms of electrical insulation, polysilane exhibits low dielectric constants, which is advantageous for reducing signal interference and minimizing power consumption in densely packed circuits. This property becomes increasingly important as circuit components are brought closer together in miniaturized designs. Additionally, the ability to dope polysilane with various elements allows for fine-tuning of its electrical properties, potentially enabling the creation of both n-type and p-type semiconducting regions within the same material system.

Environmental Impact

The environmental impact of polysilane in circuit miniaturization is a critical aspect that requires careful consideration. As the semiconductor industry continues to push the boundaries of miniaturization, the use of polysilane materials presents both opportunities and challenges from an environmental perspective.

Polysilane-based processes for circuit miniaturization generally require less energy consumption compared to traditional silicon-based manufacturing methods. This reduced energy demand translates to lower greenhouse gas emissions associated with the production of integrated circuits. Additionally, the potential for room-temperature processing of polysilane materials further contributes to energy savings in the manufacturing process.

However, the production and disposal of polysilane compounds raise concerns about their environmental footprint. The synthesis of polysilanes often involves the use of chlorosilanes, which can be harmful if released into the environment. Proper handling and disposal protocols are essential to mitigate potential risks to ecosystems and human health.

The recyclability of polysilane materials is an area of ongoing research. While some polysilanes can be recycled or repurposed, the process is not yet as efficient or widely implemented as silicon recycling in the semiconductor industry. Developing effective recycling methods for polysilane-based circuits could significantly reduce the environmental impact of electronic waste.

Water usage in polysilane-based circuit manufacturing is generally lower than in traditional silicon processes. This reduction in water consumption is particularly beneficial in regions facing water scarcity issues. However, the potential for water contamination during production and disposal stages must be carefully managed through advanced wastewater treatment systems.

The long-term environmental effects of polysilane degradation in landfills or natural environments are not yet fully understood. Research is ongoing to assess the potential for these materials to break down into harmful byproducts or persist as microplastics in ecosystems. This uncertainty underscores the need for comprehensive life cycle assessments of polysilane-based electronic components.

As the industry moves towards more sustainable practices, the adoption of polysilane technologies in circuit miniaturization must be balanced with environmental considerations. Innovations in green chemistry approaches to polysilane synthesis, coupled with advancements in recycling and waste management, will be crucial in minimizing the environmental footprint of this promising technology.

Polysilane-based processes for circuit miniaturization generally require less energy consumption compared to traditional silicon-based manufacturing methods. This reduced energy demand translates to lower greenhouse gas emissions associated with the production of integrated circuits. Additionally, the potential for room-temperature processing of polysilane materials further contributes to energy savings in the manufacturing process.

However, the production and disposal of polysilane compounds raise concerns about their environmental footprint. The synthesis of polysilanes often involves the use of chlorosilanes, which can be harmful if released into the environment. Proper handling and disposal protocols are essential to mitigate potential risks to ecosystems and human health.

The recyclability of polysilane materials is an area of ongoing research. While some polysilanes can be recycled or repurposed, the process is not yet as efficient or widely implemented as silicon recycling in the semiconductor industry. Developing effective recycling methods for polysilane-based circuits could significantly reduce the environmental impact of electronic waste.

Water usage in polysilane-based circuit manufacturing is generally lower than in traditional silicon processes. This reduction in water consumption is particularly beneficial in regions facing water scarcity issues. However, the potential for water contamination during production and disposal stages must be carefully managed through advanced wastewater treatment systems.

The long-term environmental effects of polysilane degradation in landfills or natural environments are not yet fully understood. Research is ongoing to assess the potential for these materials to break down into harmful byproducts or persist as microplastics in ecosystems. This uncertainty underscores the need for comprehensive life cycle assessments of polysilane-based electronic components.

As the industry moves towards more sustainable practices, the adoption of polysilane technologies in circuit miniaturization must be balanced with environmental considerations. Innovations in green chemistry approaches to polysilane synthesis, coupled with advancements in recycling and waste management, will be crucial in minimizing the environmental footprint of this promising technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!