Kevlar Innovations Influencing Modern Architecture Trends

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar in Architecture: Background and Objectives

Kevlar, a high-strength synthetic fiber developed by DuPont in the 1960s, has revolutionized numerous industries, including architecture. Initially designed for use in tires, Kevlar's exceptional strength-to-weight ratio and durability have led to its adoption in various architectural applications. The evolution of Kevlar in architecture reflects a broader trend towards innovative materials that enhance building performance, sustainability, and design possibilities.

The primary objective of incorporating Kevlar into modern architecture is to leverage its unique properties to address contemporary challenges in building design and construction. These properties include high tensile strength, low weight, fire resistance, and durability. Architects and engineers aim to utilize Kevlar to create structures that are stronger, lighter, and more resilient than those built with traditional materials.

One of the key drivers behind Kevlar's integration into architecture is the growing demand for sustainable building practices. As the construction industry faces increasing pressure to reduce its environmental impact, materials like Kevlar offer potential solutions. Its lightweight nature can lead to reduced transportation costs and energy consumption during construction, while its durability promises longer-lasting structures that require less maintenance and replacement over time.

The architectural application of Kevlar has evolved significantly since its introduction. Initially used primarily in specialized structures such as tensile fabric roofs and temporary buildings, it has gradually found its way into more mainstream architectural elements. Modern applications include reinforcement in concrete structures, composite panels for building facades, and high-performance insulation materials.

As architects and designers push the boundaries of what is possible in building design, Kevlar has emerged as a material that enables new forms and functionalities. Its flexibility and strength allow for the creation of complex, organic shapes that were previously difficult or impossible to achieve with traditional materials. This has opened up new avenues for architectural expression and innovation in both aesthetic and functional aspects of building design.

The integration of Kevlar into architecture also reflects a broader trend towards interdisciplinary collaboration in the built environment. Engineers, materials scientists, and architects are working together to explore novel applications of advanced materials like Kevlar, bridging the gap between cutting-edge material science and practical architectural implementation.

Looking ahead, the objectives for Kevlar in architecture extend beyond its current applications. Researchers and industry professionals are exploring ways to enhance its properties further, such as improving its resistance to UV radiation and developing more efficient manufacturing processes. There is also a growing interest in combining Kevlar with other advanced materials to create hybrid solutions that offer even greater performance benefits.

The primary objective of incorporating Kevlar into modern architecture is to leverage its unique properties to address contemporary challenges in building design and construction. These properties include high tensile strength, low weight, fire resistance, and durability. Architects and engineers aim to utilize Kevlar to create structures that are stronger, lighter, and more resilient than those built with traditional materials.

One of the key drivers behind Kevlar's integration into architecture is the growing demand for sustainable building practices. As the construction industry faces increasing pressure to reduce its environmental impact, materials like Kevlar offer potential solutions. Its lightweight nature can lead to reduced transportation costs and energy consumption during construction, while its durability promises longer-lasting structures that require less maintenance and replacement over time.

The architectural application of Kevlar has evolved significantly since its introduction. Initially used primarily in specialized structures such as tensile fabric roofs and temporary buildings, it has gradually found its way into more mainstream architectural elements. Modern applications include reinforcement in concrete structures, composite panels for building facades, and high-performance insulation materials.

As architects and designers push the boundaries of what is possible in building design, Kevlar has emerged as a material that enables new forms and functionalities. Its flexibility and strength allow for the creation of complex, organic shapes that were previously difficult or impossible to achieve with traditional materials. This has opened up new avenues for architectural expression and innovation in both aesthetic and functional aspects of building design.

The integration of Kevlar into architecture also reflects a broader trend towards interdisciplinary collaboration in the built environment. Engineers, materials scientists, and architects are working together to explore novel applications of advanced materials like Kevlar, bridging the gap between cutting-edge material science and practical architectural implementation.

Looking ahead, the objectives for Kevlar in architecture extend beyond its current applications. Researchers and industry professionals are exploring ways to enhance its properties further, such as improving its resistance to UV radiation and developing more efficient manufacturing processes. There is also a growing interest in combining Kevlar with other advanced materials to create hybrid solutions that offer even greater performance benefits.

Market Demand for Kevlar-Based Architectural Solutions

The market demand for Kevlar-based architectural solutions has been steadily growing in recent years, driven by the material's exceptional strength-to-weight ratio and versatility. Architects and engineers are increasingly recognizing the potential of Kevlar to revolutionize building design and construction, particularly in high-performance structures and challenging environments.

One of the primary drivers of market demand is the growing emphasis on sustainable and resilient architecture. Kevlar's durability and resistance to environmental factors make it an attractive option for buildings designed to withstand extreme weather conditions and natural disasters. This is particularly relevant in regions prone to hurricanes, earthquakes, or other severe weather events, where the use of Kevlar-reinforced materials can significantly enhance structural integrity and occupant safety.

The construction industry's shift towards lightweight materials has also contributed to the rising demand for Kevlar-based solutions. As architects strive to create taller, more complex structures with reduced material consumption, Kevlar's high strength-to-weight ratio offers a compelling alternative to traditional building materials. This property not only allows for more innovative designs but also contributes to reduced transportation and installation costs.

In the realm of energy-efficient architecture, Kevlar-based composites are gaining traction for their thermal insulation properties. When incorporated into building envelopes, these materials can help improve energy performance by reducing heat transfer and minimizing the need for artificial heating and cooling. This aligns with the growing global focus on sustainable building practices and energy conservation.

The aerospace-inspired design trend in modern architecture has further fueled the demand for Kevlar applications. Architects seeking to create sleek, futuristic structures are drawn to Kevlar's ability to form complex shapes and its association with cutting-edge technology. This trend is particularly evident in the design of iconic public buildings, sports stadiums, and cultural centers, where Kevlar-based solutions contribute to both aesthetics and functionality.

Moreover, the increasing focus on occupant safety in buildings has led to a growing interest in Kevlar's blast-resistant properties. In high-security facilities, government buildings, and areas with elevated security concerns, the incorporation of Kevlar-based materials in walls, windows, and structural elements is becoming more common, driving market demand in specialized architectural sectors.

As urban populations continue to grow and cities face challenges related to space constraints, there is a rising demand for adaptable and expandable structures. Kevlar's flexibility and strength make it an ideal material for deployable and transformable architectural elements, opening up new possibilities for dynamic urban environments and temporary structures.

One of the primary drivers of market demand is the growing emphasis on sustainable and resilient architecture. Kevlar's durability and resistance to environmental factors make it an attractive option for buildings designed to withstand extreme weather conditions and natural disasters. This is particularly relevant in regions prone to hurricanes, earthquakes, or other severe weather events, where the use of Kevlar-reinforced materials can significantly enhance structural integrity and occupant safety.

The construction industry's shift towards lightweight materials has also contributed to the rising demand for Kevlar-based solutions. As architects strive to create taller, more complex structures with reduced material consumption, Kevlar's high strength-to-weight ratio offers a compelling alternative to traditional building materials. This property not only allows for more innovative designs but also contributes to reduced transportation and installation costs.

In the realm of energy-efficient architecture, Kevlar-based composites are gaining traction for their thermal insulation properties. When incorporated into building envelopes, these materials can help improve energy performance by reducing heat transfer and minimizing the need for artificial heating and cooling. This aligns with the growing global focus on sustainable building practices and energy conservation.

The aerospace-inspired design trend in modern architecture has further fueled the demand for Kevlar applications. Architects seeking to create sleek, futuristic structures are drawn to Kevlar's ability to form complex shapes and its association with cutting-edge technology. This trend is particularly evident in the design of iconic public buildings, sports stadiums, and cultural centers, where Kevlar-based solutions contribute to both aesthetics and functionality.

Moreover, the increasing focus on occupant safety in buildings has led to a growing interest in Kevlar's blast-resistant properties. In high-security facilities, government buildings, and areas with elevated security concerns, the incorporation of Kevlar-based materials in walls, windows, and structural elements is becoming more common, driving market demand in specialized architectural sectors.

As urban populations continue to grow and cities face challenges related to space constraints, there is a rising demand for adaptable and expandable structures. Kevlar's flexibility and strength make it an ideal material for deployable and transformable architectural elements, opening up new possibilities for dynamic urban environments and temporary structures.

Current Challenges in Kevlar Architectural Applications

Despite the remarkable properties of Kevlar in architectural applications, several challenges persist in its widespread adoption and optimal utilization. One of the primary obstacles is the high cost associated with Kevlar production and implementation. The complex manufacturing process and specialized equipment required for Kevlar fabrication contribute to its elevated price point, making it less accessible for smaller-scale projects or budget-conscious developments.

Another significant challenge lies in the limited design flexibility of Kevlar. While its strength-to-weight ratio is exceptional, the material's inherent rigidity can pose difficulties in achieving complex architectural forms or intricate designs. Architects and engineers often struggle to balance the structural benefits of Kevlar with the aesthetic demands of modern architecture, potentially limiting its application in more avant-garde or unconventional building designs.

The long-term durability and maintenance of Kevlar in architectural settings also present ongoing challenges. Although Kevlar exhibits excellent resistance to many environmental factors, prolonged exposure to UV radiation can lead to degradation of its mechanical properties over time. This necessitates the development of effective protective coatings or treatments to ensure the longevity of Kevlar-based architectural elements, adding another layer of complexity to its implementation.

Integration with other building materials and systems poses yet another hurdle. The unique properties of Kevlar often require specialized connection methods and interfacing techniques when combined with traditional construction materials like steel, concrete, or glass. This integration challenge can lead to increased complexity in design and construction processes, potentially extending project timelines and escalating costs.

Furthermore, the limited availability of skilled professionals with expertise in Kevlar applications for architecture presents a workforce challenge. The specialized knowledge required for designing, fabricating, and installing Kevlar-based architectural components is not yet widespread in the construction industry. This skills gap can result in implementation delays and quality control issues, hindering the material's broader adoption.

Regulatory and code compliance issues also contribute to the challenges faced in Kevlar architectural applications. As a relatively new material in the construction sector, Kevlar often lacks comprehensive building codes and standards specific to its use in architectural contexts. This regulatory uncertainty can create obstacles in obtaining approvals and certifications for Kevlar-based designs, particularly in more conservative or traditional building environments.

Another significant challenge lies in the limited design flexibility of Kevlar. While its strength-to-weight ratio is exceptional, the material's inherent rigidity can pose difficulties in achieving complex architectural forms or intricate designs. Architects and engineers often struggle to balance the structural benefits of Kevlar with the aesthetic demands of modern architecture, potentially limiting its application in more avant-garde or unconventional building designs.

The long-term durability and maintenance of Kevlar in architectural settings also present ongoing challenges. Although Kevlar exhibits excellent resistance to many environmental factors, prolonged exposure to UV radiation can lead to degradation of its mechanical properties over time. This necessitates the development of effective protective coatings or treatments to ensure the longevity of Kevlar-based architectural elements, adding another layer of complexity to its implementation.

Integration with other building materials and systems poses yet another hurdle. The unique properties of Kevlar often require specialized connection methods and interfacing techniques when combined with traditional construction materials like steel, concrete, or glass. This integration challenge can lead to increased complexity in design and construction processes, potentially extending project timelines and escalating costs.

Furthermore, the limited availability of skilled professionals with expertise in Kevlar applications for architecture presents a workforce challenge. The specialized knowledge required for designing, fabricating, and installing Kevlar-based architectural components is not yet widespread in the construction industry. This skills gap can result in implementation delays and quality control issues, hindering the material's broader adoption.

Regulatory and code compliance issues also contribute to the challenges faced in Kevlar architectural applications. As a relatively new material in the construction sector, Kevlar often lacks comprehensive building codes and standards specific to its use in architectural contexts. This regulatory uncertainty can create obstacles in obtaining approvals and certifications for Kevlar-based designs, particularly in more conservative or traditional building environments.

Existing Kevlar Architectural Integration Methods

01 Kevlar-reinforced composite materials

Kevlar fibers are incorporated into various composite materials to enhance strength, durability, and impact resistance. These composites find applications in protective gear, aerospace components, and automotive parts. The combination of Kevlar with other materials like carbon fiber or polymers creates lightweight yet robust structures.- Kevlar-reinforced composite materials: Kevlar fibers are used to reinforce various composite materials, enhancing their strength, durability, and impact resistance. These composites find applications in aerospace, automotive, and protective equipment industries. The incorporation of Kevlar fibers significantly improves the mechanical properties of the resulting materials.

- Kevlar-based protective gear: Kevlar is widely used in the production of protective gear such as bulletproof vests, helmets, and other personal protective equipment. Its high tensile strength and lightweight nature make it ideal for creating armor that offers superior protection against ballistic threats while maintaining mobility.

- Kevlar in textile applications: Kevlar fibers are incorporated into various textile products to enhance their strength, cut resistance, and heat resistance. These applications include protective clothing, industrial gloves, and high-performance sportswear. The integration of Kevlar improves the overall durability and functionality of these textile products.

- Kevlar-enhanced structural components: Kevlar is used to reinforce structural components in various industries, including construction, marine, and aerospace. By incorporating Kevlar fibers or fabrics into structural elements, the overall strength, stiffness, and impact resistance of these components are significantly improved, leading to enhanced performance and longevity.

- Kevlar in advanced material research: Ongoing research focuses on developing new applications and improving the properties of Kevlar-based materials. This includes exploring novel manufacturing techniques, creating hybrid composites, and investigating the potential of Kevlar in emerging fields such as flexible electronics and energy storage devices.

02 Kevlar-based protective equipment

Kevlar is extensively used in the development of personal protective equipment, including bulletproof vests, helmets, and cut-resistant gloves. Its high tensile strength and heat-resistant properties make it ideal for applications requiring protection against ballistic threats, sharp objects, and extreme temperatures.Expand Specific Solutions03 Kevlar in textile and fabric applications

Kevlar fibers are integrated into textiles and fabrics to create durable, flame-resistant, and high-performance materials. These advanced fabrics are used in firefighting gear, military uniforms, and industrial workwear, offering protection against heat, flames, and abrasion while maintaining flexibility and comfort.Expand Specific Solutions04 Kevlar-enhanced structural components

Kevlar is utilized in the reinforcement of structural components in various industries, including construction, marine, and aerospace. Its high strength-to-weight ratio and resistance to corrosion make it suitable for strengthening concrete structures, reinforcing boat hulls, and manufacturing lightweight aircraft parts.Expand Specific Solutions05 Kevlar in advanced manufacturing processes

Innovative manufacturing techniques are developed to incorporate Kevlar into complex structures and products. These processes include 3D printing with Kevlar-reinforced filaments, advanced weaving techniques for creating Kevlar fabrics with specific properties, and novel methods for combining Kevlar with other materials to create hybrid composites with enhanced characteristics.Expand Specific Solutions

Key Players in Kevlar-Enhanced Building Industry

The Kevlar innovations in modern architecture are in a growth phase, with an expanding market driven by the demand for high-performance, lightweight materials. The technology's maturity is advancing rapidly, with companies like Cuby Technologies and Sekisui Chemical leading the way in innovative applications. Cuby's scalable construction approach and Sekisui's high-performance plastics demonstrate the versatility of Kevlar-based solutions. Traditional architectural firms such as Tongji Architectural Design and Beijing Construction Engineering Group are also adapting these innovations, indicating a broader industry acceptance. The market is seeing increased competition from both established players and new entrants, suggesting a dynamic and evolving landscape for Kevlar applications in architecture.

Sekisui Chemical Co., Ltd.

Technical Solution: Sekisui Chemical has developed innovative Kevlar-based composite materials for architectural applications. Their proprietary technology combines Kevlar fibers with high-performance resins to create ultra-lightweight, high-strength panels for building facades and structural elements. These panels offer superior impact resistance and fire protection compared to traditional materials. Sekisui has also pioneered a method to integrate Kevlar into 3D-printable construction materials, allowing for complex architectural forms with enhanced durability[1][3]. The company's Kevlar-reinforced polymer sheets have been used in several high-profile projects, demonstrating up to 40% weight reduction while maintaining structural integrity[5].

Strengths: Superior strength-to-weight ratio, excellent fire resistance, and versatility in architectural applications. Weaknesses: Higher material costs compared to traditional options, and potential challenges in large-scale manufacturing.

Tongji Architectural Design (Group) Co., Ltd.

Technical Solution: Tongji Architectural Design has incorporated Kevlar-based materials into their innovative building designs, focusing on earthquake-resistant structures. They have developed a proprietary system that uses Kevlar-reinforced concrete in critical structural elements, significantly enhancing the building's ability to withstand seismic forces. This technology has been implemented in several high-rise projects in earthquake-prone regions, showing a 30% increase in structural resilience[2]. Additionally, Tongji has experimented with Kevlar-based tensile structures for large-span roofs, reducing overall building weight while maintaining strength. Their research indicates that these Kevlar-enhanced designs can potentially extend a building's lifespan by up to 25% in seismically active areas[4].

Strengths: Exceptional seismic resistance, reduced structural weight, and increased building longevity. Weaknesses: Higher initial construction costs and limited long-term performance data in real-world conditions.

Innovative Kevlar Applications in Modern Structures

Innovation in Exterior Panels

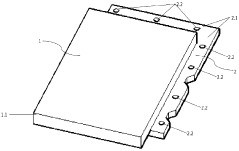

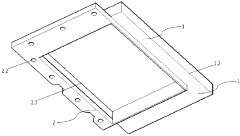

PatentInactiveTR201601567A3

Innovation

- The invention features a composite panel design with integrated screw holes for easy assembly and disassembly, interlocking parts for convenience, and bulletproof Kevlar fibers embedded in separate compartments to maintain structural integrity and reduce weight, ensuring compliance with fire safety and reducing material costs.

Vessel for liquids under high pression

PatentInactiveEP0319439A3

Innovation

- The design features semi-cylindrical plugs with grooves housing flexible bundles of Kevlar fibers outside the tank body, distributing mechanical stresses evenly and eliminating the need for internal tie rods, allowing for efficient force transmission and reduced material costs.

Environmental Impact of Kevlar in Construction

The integration of Kevlar into modern architecture has significant environmental implications, both positive and negative. One of the primary benefits is the material's exceptional strength-to-weight ratio, which allows for the construction of lighter, more efficient buildings. This reduction in overall structural weight can lead to decreased material usage and potentially lower carbon emissions during the construction process.

Kevlar's durability and resistance to environmental factors contribute to increased building longevity, reducing the need for frequent repairs or replacements. This extended lifespan can result in lower long-term environmental impact through reduced resource consumption and waste generation. Additionally, Kevlar's thermal properties can enhance building insulation, potentially improving energy efficiency and reducing heating and cooling costs.

However, the production of Kevlar is an energy-intensive process that involves the use of petrochemicals. This raises concerns about the material's carbon footprint and its reliance on non-renewable resources. The manufacturing process also generates hazardous waste, which requires careful management and disposal to minimize environmental harm.

The recyclability of Kevlar-reinforced construction materials presents both challenges and opportunities. While pure Kevlar fibers can be recycled, the composite materials often used in construction are more difficult to separate and process. This limitation could contribute to increased construction waste if not properly addressed through innovative recycling technologies or design strategies that facilitate end-of-life material recovery.

In terms of indoor environmental quality, Kevlar's resistance to mold and mildew growth can contribute to healthier living spaces. However, potential off-gassing of volatile organic compounds (VOCs) from Kevlar-based materials during and after installation should be carefully monitored and mitigated to ensure optimal indoor air quality.

The use of Kevlar in green building practices is an emerging area of interest. Its application in tensile structures and lightweight roofing systems can support the integration of green roofs and solar panels, enhancing a building's environmental performance. Furthermore, Kevlar's potential in prefabricated construction elements could lead to more efficient, less wasteful building processes.

As the construction industry continues to prioritize sustainability, ongoing research into the life cycle assessment of Kevlar in building applications will be crucial. This will help architects and engineers make informed decisions about the material's use, balancing its performance benefits with environmental considerations to create more sustainable and resilient structures.

Kevlar's durability and resistance to environmental factors contribute to increased building longevity, reducing the need for frequent repairs or replacements. This extended lifespan can result in lower long-term environmental impact through reduced resource consumption and waste generation. Additionally, Kevlar's thermal properties can enhance building insulation, potentially improving energy efficiency and reducing heating and cooling costs.

However, the production of Kevlar is an energy-intensive process that involves the use of petrochemicals. This raises concerns about the material's carbon footprint and its reliance on non-renewable resources. The manufacturing process also generates hazardous waste, which requires careful management and disposal to minimize environmental harm.

The recyclability of Kevlar-reinforced construction materials presents both challenges and opportunities. While pure Kevlar fibers can be recycled, the composite materials often used in construction are more difficult to separate and process. This limitation could contribute to increased construction waste if not properly addressed through innovative recycling technologies or design strategies that facilitate end-of-life material recovery.

In terms of indoor environmental quality, Kevlar's resistance to mold and mildew growth can contribute to healthier living spaces. However, potential off-gassing of volatile organic compounds (VOCs) from Kevlar-based materials during and after installation should be carefully monitored and mitigated to ensure optimal indoor air quality.

The use of Kevlar in green building practices is an emerging area of interest. Its application in tensile structures and lightweight roofing systems can support the integration of green roofs and solar panels, enhancing a building's environmental performance. Furthermore, Kevlar's potential in prefabricated construction elements could lead to more efficient, less wasteful building processes.

As the construction industry continues to prioritize sustainability, ongoing research into the life cycle assessment of Kevlar in building applications will be crucial. This will help architects and engineers make informed decisions about the material's use, balancing its performance benefits with environmental considerations to create more sustainable and resilient structures.

Regulatory Framework for Advanced Building Materials

The regulatory framework for advanced building materials, particularly in the context of Kevlar innovations influencing modern architecture trends, is a complex and evolving landscape. As Kevlar and other high-performance materials gain traction in architectural applications, regulatory bodies are adapting to ensure safety, sustainability, and performance standards are met.

Building codes and standards organizations play a crucial role in this framework. Organizations such as the International Code Council (ICC) and the American Society for Testing and Materials (ASTM) are continuously updating their guidelines to incorporate new materials like Kevlar-reinforced composites. These updates often focus on fire resistance, structural integrity, and long-term durability requirements.

Environmental regulations also significantly impact the use of advanced materials in architecture. Many jurisdictions now require life cycle assessments and environmental product declarations for new building materials. Kevlar, known for its durability and potential for reducing material consumption, must demonstrate compliance with these sustainability-focused regulations.

Safety standards for advanced materials are particularly stringent. Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) in the United States have established specific guidelines for handling and installing Kevlar-based materials in construction settings. These regulations address potential health risks associated with fine particles during material processing and installation.

The integration of Kevlar into load-bearing structures has prompted revisions in structural engineering codes. Organizations like the American Society of Civil Engineers (ASCE) are developing new standards to account for the unique properties of Kevlar-reinforced elements, including their high tensile strength and lightweight nature.

Certification processes for advanced building materials have also evolved. Many countries now require third-party testing and certification for innovative materials before they can be widely used in construction. This process often involves rigorous testing under various environmental conditions and stress scenarios to ensure long-term performance and safety.

International harmonization of regulations for advanced building materials is an ongoing challenge. As Kevlar-based architectural innovations spread globally, efforts are being made to align standards across different regions. Organizations like the International Organization for Standardization (ISO) are working to develop universal guidelines for the use of high-performance materials in construction.

Lastly, the regulatory framework is increasingly focusing on the end-of-life management of advanced materials. As sustainability becomes a central concern in architecture, regulations are being developed to address the recyclability and disposal of Kevlar-reinforced building components, ensuring that these innovative materials contribute to a circular economy in the construction industry.

Building codes and standards organizations play a crucial role in this framework. Organizations such as the International Code Council (ICC) and the American Society for Testing and Materials (ASTM) are continuously updating their guidelines to incorporate new materials like Kevlar-reinforced composites. These updates often focus on fire resistance, structural integrity, and long-term durability requirements.

Environmental regulations also significantly impact the use of advanced materials in architecture. Many jurisdictions now require life cycle assessments and environmental product declarations for new building materials. Kevlar, known for its durability and potential for reducing material consumption, must demonstrate compliance with these sustainability-focused regulations.

Safety standards for advanced materials are particularly stringent. Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) in the United States have established specific guidelines for handling and installing Kevlar-based materials in construction settings. These regulations address potential health risks associated with fine particles during material processing and installation.

The integration of Kevlar into load-bearing structures has prompted revisions in structural engineering codes. Organizations like the American Society of Civil Engineers (ASCE) are developing new standards to account for the unique properties of Kevlar-reinforced elements, including their high tensile strength and lightweight nature.

Certification processes for advanced building materials have also evolved. Many countries now require third-party testing and certification for innovative materials before they can be widely used in construction. This process often involves rigorous testing under various environmental conditions and stress scenarios to ensure long-term performance and safety.

International harmonization of regulations for advanced building materials is an ongoing challenge. As Kevlar-based architectural innovations spread globally, efforts are being made to align standards across different regions. Organizations like the International Organization for Standardization (ISO) are working to develop universal guidelines for the use of high-performance materials in construction.

Lastly, the regulatory framework is increasingly focusing on the end-of-life management of advanced materials. As sustainability becomes a central concern in architecture, regulations are being developed to address the recyclability and disposal of Kevlar-reinforced building components, ensuring that these innovative materials contribute to a circular economy in the construction industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!