Kevlar’s Enhancement of Electric Vehicle Fire Safety Measures

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar in EV Safety: Background and Objectives

Kevlar, a high-strength synthetic fiber developed by DuPont in the 1960s, has found a new and critical application in enhancing the fire safety measures of electric vehicles (EVs). As the automotive industry rapidly shifts towards electrification, the unique challenges posed by EV battery fires have necessitated innovative safety solutions. Kevlar's exceptional heat-resistant properties and structural integrity make it an ideal candidate for addressing these concerns.

The evolution of EV technology has been marked by significant advancements in battery capacity, charging speeds, and overall performance. However, this progress has also brought to light the potential fire risks associated with lithium-ion batteries, which are the primary power source for most EVs. The thermal runaway phenomenon, where a battery cell overheats and triggers a chain reaction, has been a particular focus of safety research and development efforts.

In response to these challenges, the integration of Kevlar into EV safety systems represents a convergence of materials science and automotive engineering. The primary objective of this technological application is to enhance the fire resistance of EV battery enclosures and other critical components, thereby mitigating the risk of catastrophic failures and improving overall vehicle safety.

The use of Kevlar in EV safety measures aims to address several key goals. Firstly, it seeks to contain potential battery fires, preventing their spread to other parts of the vehicle and reducing the risk to passengers and first responders. Secondly, it aims to provide additional time for safe evacuation in the event of a thermal incident. Lastly, it strives to improve the overall structural integrity of the battery compartment, offering protection against external impacts that could compromise battery safety.

As the EV market continues to expand globally, regulatory bodies and consumers alike are placing increased emphasis on vehicle safety standards. This has created a strong impetus for automotive manufacturers to explore and implement advanced materials like Kevlar in their safety designs. The adoption of such technologies is not only crucial for meeting stringent safety regulations but also for building consumer confidence in EV technology.

The integration of Kevlar into EV safety systems represents a significant technological trend that is likely to shape the future of electric vehicle design and manufacturing. As research and development in this area progress, we can expect to see further innovations in the application of high-performance materials to address the unique safety challenges posed by electric vehicles.

The evolution of EV technology has been marked by significant advancements in battery capacity, charging speeds, and overall performance. However, this progress has also brought to light the potential fire risks associated with lithium-ion batteries, which are the primary power source for most EVs. The thermal runaway phenomenon, where a battery cell overheats and triggers a chain reaction, has been a particular focus of safety research and development efforts.

In response to these challenges, the integration of Kevlar into EV safety systems represents a convergence of materials science and automotive engineering. The primary objective of this technological application is to enhance the fire resistance of EV battery enclosures and other critical components, thereby mitigating the risk of catastrophic failures and improving overall vehicle safety.

The use of Kevlar in EV safety measures aims to address several key goals. Firstly, it seeks to contain potential battery fires, preventing their spread to other parts of the vehicle and reducing the risk to passengers and first responders. Secondly, it aims to provide additional time for safe evacuation in the event of a thermal incident. Lastly, it strives to improve the overall structural integrity of the battery compartment, offering protection against external impacts that could compromise battery safety.

As the EV market continues to expand globally, regulatory bodies and consumers alike are placing increased emphasis on vehicle safety standards. This has created a strong impetus for automotive manufacturers to explore and implement advanced materials like Kevlar in their safety designs. The adoption of such technologies is not only crucial for meeting stringent safety regulations but also for building consumer confidence in EV technology.

The integration of Kevlar into EV safety systems represents a significant technological trend that is likely to shape the future of electric vehicle design and manufacturing. As research and development in this area progress, we can expect to see further innovations in the application of high-performance materials to address the unique safety challenges posed by electric vehicles.

EV Fire Safety Market Analysis

The electric vehicle (EV) fire safety market has experienced significant growth in recent years, driven by the rapid expansion of the EV industry and increasing concerns about battery-related fire incidents. As the global EV market continues to expand, with projections indicating a compound annual growth rate of over 20% in the coming years, the demand for advanced fire safety solutions is expected to grow proportionally.

The market for EV fire safety measures encompasses a wide range of products and services, including fire-resistant materials, advanced battery management systems, thermal runaway prevention technologies, and specialized firefighting equipment. Among these, fire-resistant materials like Kevlar have gained particular attention due to their potential to enhance the overall safety of electric vehicles.

Current market trends indicate a growing emphasis on proactive fire prevention rather than reactive measures. This shift has led to increased investment in research and development of innovative materials and technologies that can mitigate the risk of battery fires at their source. Kevlar, known for its high strength-to-weight ratio and heat-resistant properties, has emerged as a promising material in this context.

The adoption of Kevlar in EV fire safety applications is driven by several factors. Firstly, the material's ability to withstand high temperatures and provide excellent thermal insulation makes it ideal for protecting battery packs and other critical components. Secondly, Kevlar's lightweight nature aligns with the automotive industry's ongoing efforts to reduce vehicle weight and improve energy efficiency.

Market analysis reveals that major automotive manufacturers and tier-one suppliers are increasingly incorporating Kevlar-based solutions into their EV designs. This trend is particularly evident in premium and high-performance electric vehicles, where safety and performance are paramount concerns. However, as production scales up and costs decrease, it is anticipated that Kevlar-enhanced fire safety measures will become more prevalent across a broader range of EV models.

The regulatory landscape also plays a crucial role in shaping the EV fire safety market. Stringent safety standards and regulations imposed by governments and automotive safety organizations worldwide are driving the adoption of advanced fire safety technologies. This regulatory push is expected to further accelerate the integration of materials like Kevlar into EV fire safety systems.

Looking ahead, the EV fire safety market is poised for continued growth and innovation. As battery technologies evolve and energy densities increase, the need for more robust fire safety measures will become even more critical. Kevlar, with its unique properties and proven track record in various high-performance applications, is well-positioned to play a significant role in addressing these challenges and shaping the future of EV fire safety.

The market for EV fire safety measures encompasses a wide range of products and services, including fire-resistant materials, advanced battery management systems, thermal runaway prevention technologies, and specialized firefighting equipment. Among these, fire-resistant materials like Kevlar have gained particular attention due to their potential to enhance the overall safety of electric vehicles.

Current market trends indicate a growing emphasis on proactive fire prevention rather than reactive measures. This shift has led to increased investment in research and development of innovative materials and technologies that can mitigate the risk of battery fires at their source. Kevlar, known for its high strength-to-weight ratio and heat-resistant properties, has emerged as a promising material in this context.

The adoption of Kevlar in EV fire safety applications is driven by several factors. Firstly, the material's ability to withstand high temperatures and provide excellent thermal insulation makes it ideal for protecting battery packs and other critical components. Secondly, Kevlar's lightweight nature aligns with the automotive industry's ongoing efforts to reduce vehicle weight and improve energy efficiency.

Market analysis reveals that major automotive manufacturers and tier-one suppliers are increasingly incorporating Kevlar-based solutions into their EV designs. This trend is particularly evident in premium and high-performance electric vehicles, where safety and performance are paramount concerns. However, as production scales up and costs decrease, it is anticipated that Kevlar-enhanced fire safety measures will become more prevalent across a broader range of EV models.

The regulatory landscape also plays a crucial role in shaping the EV fire safety market. Stringent safety standards and regulations imposed by governments and automotive safety organizations worldwide are driving the adoption of advanced fire safety technologies. This regulatory push is expected to further accelerate the integration of materials like Kevlar into EV fire safety systems.

Looking ahead, the EV fire safety market is poised for continued growth and innovation. As battery technologies evolve and energy densities increase, the need for more robust fire safety measures will become even more critical. Kevlar, with its unique properties and proven track record in various high-performance applications, is well-positioned to play a significant role in addressing these challenges and shaping the future of EV fire safety.

Current Challenges in EV Fire Protection

Electric vehicle (EV) fire safety remains a critical concern in the automotive industry, with current challenges primarily centered around battery thermal runaway and the unique characteristics of lithium-ion battery fires. The high energy density of EV batteries, while beneficial for performance, poses significant risks during thermal events. When a battery cell is damaged or experiences a short circuit, it can lead to a rapid increase in temperature, triggering a chain reaction across adjacent cells, resulting in a phenomenon known as thermal runaway.

One of the main challenges in EV fire protection is the difficulty in extinguishing lithium-ion battery fires. These fires can reach extremely high temperatures, often exceeding 1000°C, and can reignite even after appearing to be extinguished. Traditional firefighting methods using water or foam are often ineffective, as they do not address the root cause of the thermal runaway process.

Another significant challenge is the delayed onset of fires in EVs following a collision or battery damage. Unlike conventional vehicle fires, which typically manifest immediately after an incident, EV fires can occur hours or even days after the initial impact. This delayed reaction complicates emergency response procedures and poses risks long after an accident has occurred.

The location and design of battery packs within EVs also present challenges for fire protection. Many EVs have battery packs integrated into the vehicle's floor, making access difficult for firefighters and increasing the risk of fire spread to the passenger compartment. Additionally, the high voltage systems in EVs create additional safety concerns for first responders during rescue operations.

Current fire suppression systems in EVs often struggle to effectively contain and extinguish battery fires once they have started. The sealed nature of battery packs, while necessary for normal operation, can hinder the penetration of fire-suppressing agents to the source of the fire. This limitation necessitates the development of more advanced and targeted fire suppression technologies.

The environmental impact of EV fires is another challenge that needs addressing. The toxic gases and materials released during a lithium-ion battery fire pose significant health and environmental risks, requiring specialized containment and disposal procedures. This aspect of EV fire safety extends beyond immediate fire suppression to long-term environmental management strategies.

Lastly, the rapid evolution of battery technologies and EV designs presents an ongoing challenge for fire safety measures. As manufacturers strive to increase energy density and reduce costs, new battery chemistries and configurations are constantly being introduced. This rapid pace of innovation requires equally dynamic development of fire safety technologies and protocols to keep pace with the changing landscape of EV design.

One of the main challenges in EV fire protection is the difficulty in extinguishing lithium-ion battery fires. These fires can reach extremely high temperatures, often exceeding 1000°C, and can reignite even after appearing to be extinguished. Traditional firefighting methods using water or foam are often ineffective, as they do not address the root cause of the thermal runaway process.

Another significant challenge is the delayed onset of fires in EVs following a collision or battery damage. Unlike conventional vehicle fires, which typically manifest immediately after an incident, EV fires can occur hours or even days after the initial impact. This delayed reaction complicates emergency response procedures and poses risks long after an accident has occurred.

The location and design of battery packs within EVs also present challenges for fire protection. Many EVs have battery packs integrated into the vehicle's floor, making access difficult for firefighters and increasing the risk of fire spread to the passenger compartment. Additionally, the high voltage systems in EVs create additional safety concerns for first responders during rescue operations.

Current fire suppression systems in EVs often struggle to effectively contain and extinguish battery fires once they have started. The sealed nature of battery packs, while necessary for normal operation, can hinder the penetration of fire-suppressing agents to the source of the fire. This limitation necessitates the development of more advanced and targeted fire suppression technologies.

The environmental impact of EV fires is another challenge that needs addressing. The toxic gases and materials released during a lithium-ion battery fire pose significant health and environmental risks, requiring specialized containment and disposal procedures. This aspect of EV fire safety extends beyond immediate fire suppression to long-term environmental management strategies.

Lastly, the rapid evolution of battery technologies and EV designs presents an ongoing challenge for fire safety measures. As manufacturers strive to increase energy density and reduce costs, new battery chemistries and configurations are constantly being introduced. This rapid pace of innovation requires equally dynamic development of fire safety technologies and protocols to keep pace with the changing landscape of EV design.

Existing Kevlar-based EV Fire Safety Solutions

01 Kevlar-based fire-resistant protective clothing

Protective clothing made with Kevlar fibers offers enhanced fire safety. These garments are designed to resist ignition, provide thermal insulation, and maintain structural integrity under high temperatures. The incorporation of Kevlar in firefighting gear, industrial workwear, and military uniforms significantly improves user safety in fire-prone environments.- Kevlar-based fire-resistant protective clothing: Protective clothing made with Kevlar fibers offers enhanced fire safety. These garments are designed to resist flames and high temperatures, providing crucial protection for firefighters and industrial workers in hazardous environments. The incorporation of Kevlar improves the overall durability and heat resistance of the protective gear.

- Fire-resistant composite materials using Kevlar: Composite materials incorporating Kevlar fibers exhibit improved fire resistance properties. These composites are used in various applications, including building materials, vehicle components, and aerospace structures. The addition of Kevlar enhances the material's ability to withstand high temperatures and maintain structural integrity during fire events.

- Kevlar-reinforced fire safety equipment: Fire safety equipment, such as hoses, ropes, and harnesses, are reinforced with Kevlar fibers to improve their strength and heat resistance. This reinforcement enhances the equipment's performance and reliability in firefighting operations and emergency situations, providing greater safety for first responders.

- Fire-resistant coatings and treatments for Kevlar: Specialized coatings and treatments are applied to Kevlar fibers and fabrics to further enhance their fire-resistant properties. These treatments can improve flame retardancy, reduce smoke generation, and increase the overall fire safety performance of Kevlar-based materials in various applications.

- Kevlar-based fire detection and suppression systems: Innovative fire detection and suppression systems incorporate Kevlar components for improved durability and performance. These systems utilize Kevlar's unique properties to enhance the reliability of sensors, actuators, and delivery mechanisms in fire safety installations, contributing to more effective fire prevention and control measures.

02 Kevlar-reinforced fire-resistant building materials

Kevlar fibers are used to reinforce various building materials to enhance their fire resistance properties. These materials include insulation panels, structural components, and fire barriers. The addition of Kevlar improves the overall fire safety of buildings by increasing the time it takes for materials to ignite and slowing the spread of flames.Expand Specific Solutions03 Kevlar-based fire-resistant composites

Composite materials incorporating Kevlar fibers exhibit improved fire resistance and mechanical properties. These composites are used in aerospace, automotive, and marine applications where fire safety is critical. The Kevlar reinforcement enhances the material's ability to withstand high temperatures and maintain structural integrity during fire events.Expand Specific Solutions04 Kevlar-enhanced fire safety equipment

Fire safety equipment, such as fire hoses, fire blankets, and protective covers, are improved by incorporating Kevlar fibers. These enhanced products offer better durability, heat resistance, and overall performance in firefighting and fire prevention applications. The use of Kevlar in such equipment contributes to more effective fire control and increased safety for firefighters and civilians.Expand Specific Solutions05 Kevlar-based fire-resistant coatings and treatments

Coatings and treatments incorporating Kevlar fibers or particles are developed to enhance the fire resistance of various surfaces and materials. These applications can be used on textiles, wood, plastics, and metals to improve their fire safety characteristics. The Kevlar-based treatments provide an additional layer of protection against ignition and flame spread.Expand Specific Solutions

Key Players in EV Safety and Kevlar Industry

The competitive landscape for Kevlar's enhancement of electric vehicle fire safety measures is evolving rapidly. The industry is in a growth phase, with increasing market size driven by the global shift towards electric vehicles. The technology's maturity is advancing, with major players like Hyundai Motor Co., Ltd. and Kia Corp. investing heavily in research and development. Companies such as EVE Energy Co., Ltd. and Starkoff are focusing on innovative battery and charging solutions, while others like Aeonus Co., Ltd. are developing charging infrastructure. The involvement of established automotive suppliers like Robert Bosch GmbH and Danfoss A/S indicates a growing recognition of the importance of fire safety in EVs. This competitive environment is fostering rapid technological advancements and diverse approaches to enhancing EV fire safety measures.

Hyundai Motor Co., Ltd.

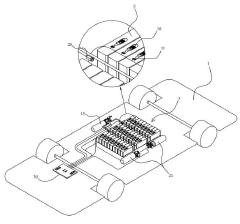

Technical Solution: Hyundai has developed an innovative fire safety system for electric vehicles incorporating Kevlar-reinforced battery enclosures. The company's approach involves a multi-layered protection strategy, combining Kevlar-enhanced battery casings with advanced thermal management systems. The Kevlar-reinforced enclosure provides superior impact resistance and heat dissipation properties, significantly reducing the risk of battery puncture and thermal runaway[1]. Additionally, Hyundai has implemented a state-of-the-art Battery Management System (BMS) that continuously monitors cell temperatures and voltage levels, triggering preventive measures at the first sign of anomalies[3]. The company has also integrated a rapid depowering mechanism that can quickly isolate the battery pack in case of a detected fault, further enhancing safety[5].

Strengths: Enhanced impact resistance, improved heat dissipation, and advanced fault detection. Weaknesses: Potential increase in vehicle weight and production costs due to Kevlar integration.

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive Kevlar-enhanced fire safety solution for electric vehicles, focusing on both prevention and mitigation. Their system incorporates Kevlar-reinforced battery modules with intelligent cell monitoring technology. The Kevlar-enhanced modules provide exceptional structural integrity and fire resistance, while the smart monitoring system uses AI algorithms to predict and prevent thermal events[2]. Bosch's solution also includes a novel fire suppression system that utilizes environmentally friendly, non-conductive agents specifically designed for lithium-ion battery fires[4]. This system can rapidly deploy in milliseconds upon detecting a thermal event, effectively containing and extinguishing fires before they can spread[6].

Strengths: Comprehensive approach combining prevention and mitigation, rapid response fire suppression. Weaknesses: Complex integration process, potentially higher initial costs for vehicle manufacturers.

Kevlar Innovations for EV Fire Protection

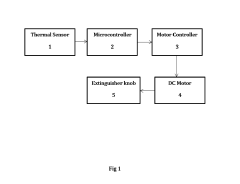

A device for fire safety in e-vehicle

PatentPendingIN202441033076A

Innovation

- A device for fire safety in electric vehicles, comprising a thermal sensor to detect abnormal temperatures, a microcontroller system to interpret data and trigger responses, and a DC motor-controlled fire extinguisher to deploy suppression agents, ensuring swift and precise fire mitigation.

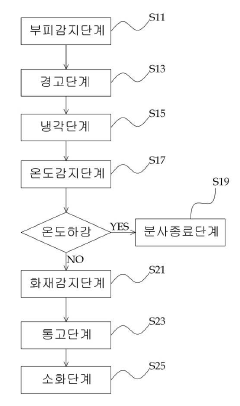

Fire extinguishing method for the energy storage system of an electric vehicle and the apparatus of it

PatentInactiveKR1020210057278A

Innovation

- A fire extinguishing method and device that includes volume and temperature sensing, followed by the injection of a fire extinguishing agent to cool and suppress fires, with a control system to manage agent injection and notification of potential hazards.

Regulatory Framework for EV Fire Safety

The regulatory framework for electric vehicle (EV) fire safety is a critical aspect of ensuring the safe adoption and operation of EVs worldwide. As the automotive industry transitions towards electrification, governments and regulatory bodies have been developing and refining safety standards to address the unique challenges posed by EV batteries and their potential fire risks.

In the United States, the National Highway Traffic Safety Administration (NHTSA) has been at the forefront of establishing EV safety regulations. The agency has implemented Federal Motor Vehicle Safety Standards (FMVSS) that specifically address EV battery safety, including requirements for crash protection, thermal management, and electrical isolation. These standards are continuously evolving to keep pace with technological advancements and emerging safety concerns.

The European Union has also taken significant steps in regulating EV fire safety. The United Nations Economic Commission for Europe (UNECE) has developed regulations such as UN Regulation No. 100, which outlines specific requirements for the construction, functional safety, and hydrogen emission characteristics of battery electric vehicles. Additionally, the EU has implemented the General Safety Regulation (GSR) that mandates advanced safety features for all new vehicles, including EVs.

In Asia, countries like China and Japan have established their own regulatory frameworks for EV fire safety. China's Ministry of Industry and Information Technology (MIIT) has issued guidelines on EV battery safety, including requirements for thermal runaway prevention and fire suppression systems. Japan's regulatory approach focuses on comprehensive testing and certification processes for EV batteries and related components.

International organizations play a crucial role in harmonizing global EV safety standards. The International Organization for Standardization (ISO) has developed several standards related to EV safety, such as ISO 6469, which covers safety specifications for electrically propelled road vehicles. These standards provide a common framework for manufacturers and regulators worldwide.

As the technology evolves, regulatory bodies are increasingly focusing on specific aspects of EV fire safety, such as battery management systems, thermal runaway prevention, and fire suppression technologies. The integration of advanced materials like Kevlar into EV safety measures is likely to influence future regulatory developments, potentially leading to new standards that specifically address the use of such materials in fire protection systems.

The regulatory landscape for EV fire safety continues to evolve, with ongoing research and collaboration between industry stakeholders, government agencies, and research institutions. This collaborative approach aims to ensure that safety regulations keep pace with technological advancements and effectively mitigate the risks associated with EV fires.

In the United States, the National Highway Traffic Safety Administration (NHTSA) has been at the forefront of establishing EV safety regulations. The agency has implemented Federal Motor Vehicle Safety Standards (FMVSS) that specifically address EV battery safety, including requirements for crash protection, thermal management, and electrical isolation. These standards are continuously evolving to keep pace with technological advancements and emerging safety concerns.

The European Union has also taken significant steps in regulating EV fire safety. The United Nations Economic Commission for Europe (UNECE) has developed regulations such as UN Regulation No. 100, which outlines specific requirements for the construction, functional safety, and hydrogen emission characteristics of battery electric vehicles. Additionally, the EU has implemented the General Safety Regulation (GSR) that mandates advanced safety features for all new vehicles, including EVs.

In Asia, countries like China and Japan have established their own regulatory frameworks for EV fire safety. China's Ministry of Industry and Information Technology (MIIT) has issued guidelines on EV battery safety, including requirements for thermal runaway prevention and fire suppression systems. Japan's regulatory approach focuses on comprehensive testing and certification processes for EV batteries and related components.

International organizations play a crucial role in harmonizing global EV safety standards. The International Organization for Standardization (ISO) has developed several standards related to EV safety, such as ISO 6469, which covers safety specifications for electrically propelled road vehicles. These standards provide a common framework for manufacturers and regulators worldwide.

As the technology evolves, regulatory bodies are increasingly focusing on specific aspects of EV fire safety, such as battery management systems, thermal runaway prevention, and fire suppression technologies. The integration of advanced materials like Kevlar into EV safety measures is likely to influence future regulatory developments, potentially leading to new standards that specifically address the use of such materials in fire protection systems.

The regulatory landscape for EV fire safety continues to evolve, with ongoing research and collaboration between industry stakeholders, government agencies, and research institutions. This collaborative approach aims to ensure that safety regulations keep pace with technological advancements and effectively mitigate the risks associated with EV fires.

Environmental Impact of Kevlar in EV Safety

The integration of Kevlar in electric vehicle (EV) fire safety measures has significant environmental implications that warrant careful consideration. While Kevlar enhances the safety and durability of EVs, its production and disposal processes present environmental challenges.

Kevlar manufacturing requires energy-intensive processes and the use of harmful chemicals, contributing to greenhouse gas emissions and potential pollution. The production of para-aramid fibers, the main component of Kevlar, involves the use of sulfuric acid and other toxic substances. These chemicals, if not properly managed, can lead to environmental contamination and pose risks to ecosystems and human health.

However, the longevity and strength of Kevlar can potentially offset some of these environmental concerns. The material's durability means that Kevlar-enhanced safety components in EVs may require less frequent replacement, reducing the overall environmental impact associated with manufacturing and disposing of these parts over the vehicle's lifetime.

In terms of end-of-life management, Kevlar presents both challenges and opportunities. The material is not biodegradable, which raises concerns about its long-term environmental impact when EVs are decommissioned. However, research into recycling methods for Kevlar is ongoing, with some promising developments in mechanical and chemical recycling techniques that could help mitigate its environmental footprint.

The use of Kevlar in EV safety measures may also indirectly contribute to positive environmental outcomes. By enhancing fire safety in EVs, Kevlar could potentially increase consumer confidence in electric vehicles, thereby accelerating the transition from fossil fuel-powered vehicles to more environmentally friendly electric alternatives. This shift could lead to significant reductions in transportation-related carbon emissions over time.

It is crucial to consider the life cycle assessment of Kevlar in EV applications to fully understand its environmental impact. This includes evaluating the material's production, use phase, and end-of-life management. Balancing the environmental costs of Kevlar production against its benefits in EV safety and potential contributions to the broader adoption of electric vehicles is essential for making informed decisions about its use in the automotive industry.

As the automotive sector continues to prioritize sustainability, there is a growing focus on developing eco-friendly alternatives to traditional materials like Kevlar. Research into bio-based and recyclable materials that can match Kevlar's performance in fire safety applications is ongoing. These efforts aim to address the environmental concerns associated with Kevlar while maintaining or improving upon its protective properties in EV safety systems.

Kevlar manufacturing requires energy-intensive processes and the use of harmful chemicals, contributing to greenhouse gas emissions and potential pollution. The production of para-aramid fibers, the main component of Kevlar, involves the use of sulfuric acid and other toxic substances. These chemicals, if not properly managed, can lead to environmental contamination and pose risks to ecosystems and human health.

However, the longevity and strength of Kevlar can potentially offset some of these environmental concerns. The material's durability means that Kevlar-enhanced safety components in EVs may require less frequent replacement, reducing the overall environmental impact associated with manufacturing and disposing of these parts over the vehicle's lifetime.

In terms of end-of-life management, Kevlar presents both challenges and opportunities. The material is not biodegradable, which raises concerns about its long-term environmental impact when EVs are decommissioned. However, research into recycling methods for Kevlar is ongoing, with some promising developments in mechanical and chemical recycling techniques that could help mitigate its environmental footprint.

The use of Kevlar in EV safety measures may also indirectly contribute to positive environmental outcomes. By enhancing fire safety in EVs, Kevlar could potentially increase consumer confidence in electric vehicles, thereby accelerating the transition from fossil fuel-powered vehicles to more environmentally friendly electric alternatives. This shift could lead to significant reductions in transportation-related carbon emissions over time.

It is crucial to consider the life cycle assessment of Kevlar in EV applications to fully understand its environmental impact. This includes evaluating the material's production, use phase, and end-of-life management. Balancing the environmental costs of Kevlar production against its benefits in EV safety and potential contributions to the broader adoption of electric vehicles is essential for making informed decisions about its use in the automotive industry.

As the automotive sector continues to prioritize sustainability, there is a growing focus on developing eco-friendly alternatives to traditional materials like Kevlar. Research into bio-based and recyclable materials that can match Kevlar's performance in fire safety applications is ongoing. These efforts aim to address the environmental concerns associated with Kevlar while maintaining or improving upon its protective properties in EV safety systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!