Kevlar’s Role in Strengthening Power Transmission Lines

JUL 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar in Power Lines: Background and Objectives

Kevlar, a synthetic fiber developed by DuPont in the 1960s, has revolutionized various industries due to its exceptional strength-to-weight ratio and heat-resistant properties. In the context of power transmission lines, Kevlar has emerged as a game-changing material, offering significant improvements in strength, durability, and overall performance.

The evolution of power transmission technology has been driven by the increasing demand for electricity and the need for more efficient and reliable power distribution systems. Traditional materials used in power lines, such as steel and aluminum, have limitations in terms of weight, tensile strength, and thermal expansion. These limitations have led to challenges in long-distance power transmission, particularly in areas prone to extreme weather conditions or where terrain poses installation difficulties.

Kevlar's introduction to the power transmission industry marks a significant milestone in addressing these challenges. Its unique molecular structure, consisting of strong intermolecular hydrogen bonds, provides exceptional tensile strength while maintaining a low weight profile. This combination of properties makes Kevlar an ideal candidate for reinforcing power transmission lines, potentially revolutionizing the way electricity is distributed across long distances.

The primary objective of incorporating Kevlar into power transmission lines is to enhance the overall reliability and efficiency of electrical grids. By strengthening the core of power lines, Kevlar can help reduce sagging, increase span lengths between towers, and improve the lines' ability to withstand extreme weather conditions such as high winds, ice loading, and temperature fluctuations.

Furthermore, the integration of Kevlar in power transmission lines aims to address several key industry challenges. These include reducing transmission losses, increasing the capacity of existing infrastructure, and extending the lifespan of power lines. The material's resistance to corrosion and fatigue also promises to lower maintenance costs and improve the overall sustainability of power transmission systems.

As the global energy landscape continues to evolve, with a growing emphasis on renewable energy sources and smart grid technologies, the role of advanced materials like Kevlar becomes increasingly crucial. The technology's potential to enable more efficient long-distance transmission of electricity from remote renewable energy installations to urban centers aligns with the broader goals of creating a more sustainable and resilient energy infrastructure.

In conclusion, the application of Kevlar in power transmission lines represents a convergence of materials science and energy technology, with the potential to address long-standing challenges in the power distribution sector. As research and development in this area progress, it is expected that Kevlar will play an increasingly important role in shaping the future of global energy infrastructure, contributing to more reliable, efficient, and sustainable power transmission systems.

The evolution of power transmission technology has been driven by the increasing demand for electricity and the need for more efficient and reliable power distribution systems. Traditional materials used in power lines, such as steel and aluminum, have limitations in terms of weight, tensile strength, and thermal expansion. These limitations have led to challenges in long-distance power transmission, particularly in areas prone to extreme weather conditions or where terrain poses installation difficulties.

Kevlar's introduction to the power transmission industry marks a significant milestone in addressing these challenges. Its unique molecular structure, consisting of strong intermolecular hydrogen bonds, provides exceptional tensile strength while maintaining a low weight profile. This combination of properties makes Kevlar an ideal candidate for reinforcing power transmission lines, potentially revolutionizing the way electricity is distributed across long distances.

The primary objective of incorporating Kevlar into power transmission lines is to enhance the overall reliability and efficiency of electrical grids. By strengthening the core of power lines, Kevlar can help reduce sagging, increase span lengths between towers, and improve the lines' ability to withstand extreme weather conditions such as high winds, ice loading, and temperature fluctuations.

Furthermore, the integration of Kevlar in power transmission lines aims to address several key industry challenges. These include reducing transmission losses, increasing the capacity of existing infrastructure, and extending the lifespan of power lines. The material's resistance to corrosion and fatigue also promises to lower maintenance costs and improve the overall sustainability of power transmission systems.

As the global energy landscape continues to evolve, with a growing emphasis on renewable energy sources and smart grid technologies, the role of advanced materials like Kevlar becomes increasingly crucial. The technology's potential to enable more efficient long-distance transmission of electricity from remote renewable energy installations to urban centers aligns with the broader goals of creating a more sustainable and resilient energy infrastructure.

In conclusion, the application of Kevlar in power transmission lines represents a convergence of materials science and energy technology, with the potential to address long-standing challenges in the power distribution sector. As research and development in this area progress, it is expected that Kevlar will play an increasingly important role in shaping the future of global energy infrastructure, contributing to more reliable, efficient, and sustainable power transmission systems.

Market Analysis for Kevlar-Enhanced Transmission Lines

The market for Kevlar-enhanced transmission lines is experiencing significant growth, driven by the increasing demand for reliable and efficient power distribution infrastructure. As electricity consumption continues to rise globally, power utilities are seeking innovative solutions to enhance the performance and durability of their transmission networks. Kevlar, a high-strength synthetic fiber, has emerged as a promising material for reinforcing power transmission lines, offering superior strength-to-weight ratio and resistance to environmental factors.

The adoption of Kevlar in transmission line applications is primarily fueled by the need to address several critical challenges faced by the power industry. These include the growing frequency of extreme weather events, the expansion of power grids to remote areas, and the increasing load demands on existing infrastructure. Kevlar-enhanced transmission lines provide a compelling solution to these issues by offering improved mechanical strength, reduced sag, and enhanced resistance to wind and ice loading.

Market analysis indicates that the global demand for Kevlar-enhanced transmission lines is projected to grow at a compound annual growth rate (CAGR) of over 6% in the next five years. This growth is particularly pronounced in regions prone to severe weather conditions, such as North America, parts of Europe, and Asia-Pacific. The market is also seeing increased traction in developing economies, where rapid urbanization and industrialization are driving the expansion of power transmission networks.

The competitive landscape of the Kevlar-enhanced transmission line market is characterized by a mix of established players and new entrants. Major cable manufacturers are investing in research and development to incorporate Kevlar into their product lines, while specialty materials companies are forming strategic partnerships to leverage their expertise in advanced fiber technologies. This has led to a diverse range of product offerings, from fully Kevlar-reinforced conductors to hybrid designs that combine Kevlar with traditional materials.

Pricing trends in the market reflect the premium nature of Kevlar-enhanced solutions. While the initial cost of these transmission lines is higher compared to conventional alternatives, the long-term benefits in terms of reduced maintenance, increased lifespan, and improved reliability are driving adoption among forward-thinking utilities. The market is also seeing innovations in manufacturing processes aimed at optimizing the use of Kevlar and reducing production costs, which is expected to improve the cost-competitiveness of these products over time.

Regulatory factors play a significant role in shaping the market for Kevlar-enhanced transmission lines. Governments and industry bodies are increasingly recognizing the importance of resilient power infrastructure, leading to updated standards and guidelines that favor the adoption of advanced materials like Kevlar. This regulatory support, coupled with growing awareness of the benefits of Kevlar-enhanced transmission lines among utility operators, is expected to further accelerate market growth in the coming years.

The adoption of Kevlar in transmission line applications is primarily fueled by the need to address several critical challenges faced by the power industry. These include the growing frequency of extreme weather events, the expansion of power grids to remote areas, and the increasing load demands on existing infrastructure. Kevlar-enhanced transmission lines provide a compelling solution to these issues by offering improved mechanical strength, reduced sag, and enhanced resistance to wind and ice loading.

Market analysis indicates that the global demand for Kevlar-enhanced transmission lines is projected to grow at a compound annual growth rate (CAGR) of over 6% in the next five years. This growth is particularly pronounced in regions prone to severe weather conditions, such as North America, parts of Europe, and Asia-Pacific. The market is also seeing increased traction in developing economies, where rapid urbanization and industrialization are driving the expansion of power transmission networks.

The competitive landscape of the Kevlar-enhanced transmission line market is characterized by a mix of established players and new entrants. Major cable manufacturers are investing in research and development to incorporate Kevlar into their product lines, while specialty materials companies are forming strategic partnerships to leverage their expertise in advanced fiber technologies. This has led to a diverse range of product offerings, from fully Kevlar-reinforced conductors to hybrid designs that combine Kevlar with traditional materials.

Pricing trends in the market reflect the premium nature of Kevlar-enhanced solutions. While the initial cost of these transmission lines is higher compared to conventional alternatives, the long-term benefits in terms of reduced maintenance, increased lifespan, and improved reliability are driving adoption among forward-thinking utilities. The market is also seeing innovations in manufacturing processes aimed at optimizing the use of Kevlar and reducing production costs, which is expected to improve the cost-competitiveness of these products over time.

Regulatory factors play a significant role in shaping the market for Kevlar-enhanced transmission lines. Governments and industry bodies are increasingly recognizing the importance of resilient power infrastructure, leading to updated standards and guidelines that favor the adoption of advanced materials like Kevlar. This regulatory support, coupled with growing awareness of the benefits of Kevlar-enhanced transmission lines among utility operators, is expected to further accelerate market growth in the coming years.

Current Challenges in Power Line Reinforcement

Power transmission line reinforcement faces several critical challenges in the current landscape. One of the primary issues is the aging infrastructure across many countries. Numerous power lines were installed decades ago and are now approaching or exceeding their intended lifespan. This aging process leads to decreased structural integrity, increased susceptibility to environmental stressors, and a higher risk of failures or outages.

Environmental factors pose another significant challenge. Extreme weather events, such as hurricanes, ice storms, and high winds, are becoming more frequent and severe due to climate change. These events can cause substantial damage to power lines, leading to widespread outages and costly repairs. Additionally, the increased occurrence of wildfires in certain regions presents a unique threat, as power lines can both be damaged by fires and potentially spark new ones.

The growing demand for electricity in both developed and developing nations is straining existing power transmission infrastructure. As energy consumption continues to rise, power lines are required to carry heavier loads, which can lead to overheating, sagging, and reduced efficiency. This increased stress on the system further accelerates the degradation of power line components.

Urbanization and land scarcity present challenges in upgrading and expanding power line networks. In densely populated areas, there is often limited space for new installations or reinforcements, and existing lines may need to be relocated or upgraded to meet growing demand while minimizing visual impact and electromagnetic field concerns.

The cost of reinforcing and upgrading power transmission lines is a significant barrier for many utility companies and governments. The extensive nature of power grids means that even small improvements can require substantial investments. Balancing these costs with the need for reliable electricity supply is an ongoing challenge for decision-makers.

Technical limitations also play a role in current reinforcement challenges. Traditional materials used in power line construction, such as aluminum and steel, have inherent limitations in terms of strength-to-weight ratio and conductivity. Finding materials that can provide enhanced performance without significantly increasing costs or requiring complete infrastructure overhauls is a key focus area for researchers and engineers.

Lastly, the integration of renewable energy sources into existing power grids presents unique challenges for line reinforcement. The intermittent nature of renewable energy generation can lead to fluctuations in power flow, requiring more robust and flexible transmission systems. Additionally, many renewable energy sources are located far from population centers, necessitating the construction of new long-distance transmission lines or the significant upgrading of existing ones.

Environmental factors pose another significant challenge. Extreme weather events, such as hurricanes, ice storms, and high winds, are becoming more frequent and severe due to climate change. These events can cause substantial damage to power lines, leading to widespread outages and costly repairs. Additionally, the increased occurrence of wildfires in certain regions presents a unique threat, as power lines can both be damaged by fires and potentially spark new ones.

The growing demand for electricity in both developed and developing nations is straining existing power transmission infrastructure. As energy consumption continues to rise, power lines are required to carry heavier loads, which can lead to overheating, sagging, and reduced efficiency. This increased stress on the system further accelerates the degradation of power line components.

Urbanization and land scarcity present challenges in upgrading and expanding power line networks. In densely populated areas, there is often limited space for new installations or reinforcements, and existing lines may need to be relocated or upgraded to meet growing demand while minimizing visual impact and electromagnetic field concerns.

The cost of reinforcing and upgrading power transmission lines is a significant barrier for many utility companies and governments. The extensive nature of power grids means that even small improvements can require substantial investments. Balancing these costs with the need for reliable electricity supply is an ongoing challenge for decision-makers.

Technical limitations also play a role in current reinforcement challenges. Traditional materials used in power line construction, such as aluminum and steel, have inherent limitations in terms of strength-to-weight ratio and conductivity. Finding materials that can provide enhanced performance without significantly increasing costs or requiring complete infrastructure overhauls is a key focus area for researchers and engineers.

Lastly, the integration of renewable energy sources into existing power grids presents unique challenges for line reinforcement. The intermittent nature of renewable energy generation can lead to fluctuations in power flow, requiring more robust and flexible transmission systems. Additionally, many renewable energy sources are located far from population centers, necessitating the construction of new long-distance transmission lines or the significant upgrading of existing ones.

Existing Kevlar Applications in Power Line Technology

01 Kevlar fiber reinforcement in composites

Kevlar fibers are used to reinforce various composite materials, enhancing their strength and durability. These composites find applications in aerospace, automotive, and protective equipment industries due to their high strength-to-weight ratio.- Kevlar fiber reinforcement in composites: Kevlar fibers are used to reinforce various composite materials, enhancing their strength and durability. These composites find applications in aerospace, automotive, and protective equipment industries due to their high strength-to-weight ratio and impact resistance.

- Kevlar-based protective gear: Kevlar is utilized in the manufacturing of protective gear such as bulletproof vests, helmets, and other personal protective equipment. Its high tensile strength and ability to absorb impact energy make it ideal for these applications, providing enhanced safety for users.

- Kevlar-reinforced structural elements: Kevlar fibers are incorporated into structural elements to improve their strength and reduce weight. This includes applications in construction, civil engineering, and transportation infrastructure, where Kevlar-reinforced materials offer superior performance compared to traditional materials.

- Kevlar in high-performance textiles: Kevlar is used in the production of high-performance textiles for various applications, including fire-resistant clothing, cut-resistant gloves, and industrial fabrics. These textiles benefit from Kevlar's strength, heat resistance, and durability.

- Kevlar-enhanced sporting goods: Sporting goods and equipment incorporate Kevlar to improve performance and durability. This includes applications in racquet sports, cycling, and outdoor gear, where Kevlar's strength and lightweight properties contribute to enhanced product performance and longevity.

02 Kevlar-based protective gear

Kevlar is utilized in the manufacture of protective gear such as bulletproof vests, helmets, and other personal protective equipment. Its high tensile strength and impact resistance make it ideal for these applications.Expand Specific Solutions03 Kevlar-reinforced ropes and cables

Kevlar fibers are incorporated into ropes and cables to increase their tensile strength while maintaining flexibility. This makes them suitable for use in marine, construction, and industrial applications where high strength and low weight are crucial.Expand Specific Solutions04 Kevlar in automotive applications

The automotive industry utilizes Kevlar in various components to enhance strength and reduce weight. Applications include tire reinforcement, brake pads, and body panels, contributing to improved fuel efficiency and safety.Expand Specific Solutions05 Kevlar-enhanced sporting goods

Sporting goods manufacturers incorporate Kevlar into products such as tennis rackets, bicycle frames, and kayaks to improve strength and performance while reducing weight. This enhances the durability and efficiency of these items for athletes and enthusiasts.Expand Specific Solutions

Key Players in Kevlar and Power Transmission Industries

The market for Kevlar's application in strengthening power transmission lines is in a growth phase, driven by increasing demand for reliable electricity infrastructure. The global market size for advanced materials in power transmission is expanding, with projections indicating significant growth in the coming years. Technologically, the use of Kevlar in this application is maturing, with companies like DuPont (inventor of Kevlar), Bando Chemical Industries, and Mitsubishi Materials leading innovation. Other players such as Sumitomo Electric Industries, Furukawa Electric, and LS Cable & System are also contributing to advancements in this field, indicating a competitive landscape with diverse expertise in materials science and power transmission technologies.

3M Innovative Properties Co.

Technical Solution: 3M has developed a composite conductor reinforced with Kevlar fibers for power transmission lines. This innovative solution combines the strength of Kevlar with traditional conductor materials to create a lightweight, high-strength alternative to conventional steel-core conductors. The Kevlar-reinforced composite core provides excellent tensile strength and thermal stability, allowing for increased current-carrying capacity and reduced sag[1]. 3M's technology also incorporates a proprietary resin system that enhances the composite's resistance to environmental factors such as UV radiation and moisture[2]. The company has reported that their Kevlar-reinforced conductors can increase transmission line capacity by up to 30% compared to traditional ACSR (Aluminum Conductor Steel Reinforced) lines[3].

Strengths: Lightweight, high strength-to-weight ratio, increased current-carrying capacity, and reduced sag. Weaknesses: Potentially higher initial costs compared to traditional steel-core conductors, and limited long-term performance data in extreme environments.

Sumitomo Electric Industries Ltd.

Technical Solution: Sumitomo Electric has developed a novel approach to incorporating Kevlar in power transmission lines by using it as a protective sheath for their aluminum-alloy conductors. This technology, known as "Kevlar-wrapped ACCC" (Aluminum Conductor Composite Core), combines the benefits of high-strength aluminum alloys with the superior tensile strength and lightweight properties of Kevlar[10]. The Kevlar wrapping provides additional protection against environmental factors such as bird strikes and ice loading. Sumitomo's research has shown that their Kevlar-wrapped conductors can increase the current-carrying capacity by up to 40% compared to conventional ACSR lines while maintaining similar overall diameters[11]. The company has also developed specialized installation techniques to ensure the integrity of the Kevlar sheath during the stringing process[12].

Strengths: Increased current-carrying capacity, improved environmental protection, and compatibility with existing infrastructure. Weaknesses: Potential challenges in splicing and repairing damaged sections of the conductor.

Core Innovations in Kevlar-Based Line Reinforcement

Sensor cable for long downhole

PatentWO2012142207A1

Innovation

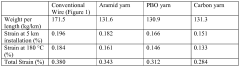

- The cable design incorporates a metallic tube with a strengthening member, such as aramid yarn or Polyacrylonitrile carbon fiber, to reduce weight and thermal expansion, thereby minimizing strain caused by tension and temperature, while maintaining protection for the optical fibers.

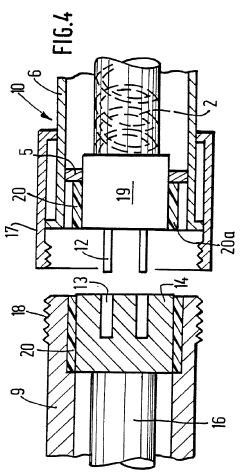

Device for the mechanical transmission of a rotation motion

PatentWO1986003266A1

Innovation

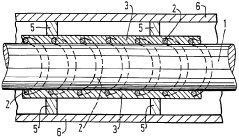

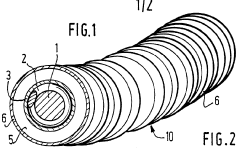

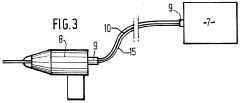

- A device utilizing a Kevlar spiral with an incompressible outer sheath and optionally multiple parallel spirals, along with a compression-hardening synthetic rubber sheath, to transmit rotational movement efficiently, reducing the risk of breakage and increasing flexibility and torque resistance without significant weight or diameter increase.

Environmental Impact of Kevlar-Enhanced Power Lines

The integration of Kevlar into power transmission lines represents a significant advancement in infrastructure technology, but it also raises important environmental considerations. The use of Kevlar-enhanced power lines has both positive and negative impacts on the environment, which must be carefully evaluated.

One of the primary environmental benefits of Kevlar-enhanced power lines is their increased durability and longevity. These reinforced lines are more resistant to weather-related damage, reducing the frequency of repairs and replacements. This translates to fewer disruptions in natural habitats during maintenance operations and a decrease in the overall carbon footprint associated with manufacturing and installing new lines.

The improved strength of Kevlar-enhanced lines also allows for longer spans between support structures. This can lead to a reduction in the number of towers or poles required, minimizing land use and habitat fragmentation. In sensitive ecosystems, this can be particularly beneficial, preserving more contiguous natural areas and reducing the impact on wildlife corridors.

However, the production of Kevlar itself has environmental implications. The manufacturing process involves the use of strong acids and organic solvents, which can contribute to air and water pollution if not properly managed. Additionally, Kevlar is not biodegradable, raising concerns about its long-term environmental persistence and potential accumulation in ecosystems.

The enhanced conductivity of Kevlar-reinforced lines may also lead to increased energy efficiency in power transmission. This could result in reduced energy losses and, consequently, lower greenhouse gas emissions from power generation. However, this benefit must be weighed against the environmental costs of producing and disposing of Kevlar materials.

Another consideration is the potential impact on avian populations. While the reduced number of support structures may decrease bird collisions, the potentially thinner profile of Kevlar-enhanced lines could make them less visible to birds in flight. This necessitates careful design considerations and possibly the implementation of additional visual markers to mitigate this risk.

The recycling and disposal of Kevlar-enhanced power lines at the end of their life cycle present both challenges and opportunities. While Kevlar is difficult to recycle, advancements in materials science may lead to more efficient recycling processes in the future. Proper disposal methods must be developed to prevent these materials from contributing to landfill waste or environmental contamination.

In conclusion, the environmental impact of Kevlar-enhanced power lines is multifaceted. While they offer potential benefits in terms of reduced maintenance, land use, and energy efficiency, concerns regarding production processes, biodegradability, and end-of-life management must be addressed. A comprehensive life cycle assessment is crucial to fully understand and mitigate the environmental implications of this technology.

One of the primary environmental benefits of Kevlar-enhanced power lines is their increased durability and longevity. These reinforced lines are more resistant to weather-related damage, reducing the frequency of repairs and replacements. This translates to fewer disruptions in natural habitats during maintenance operations and a decrease in the overall carbon footprint associated with manufacturing and installing new lines.

The improved strength of Kevlar-enhanced lines also allows for longer spans between support structures. This can lead to a reduction in the number of towers or poles required, minimizing land use and habitat fragmentation. In sensitive ecosystems, this can be particularly beneficial, preserving more contiguous natural areas and reducing the impact on wildlife corridors.

However, the production of Kevlar itself has environmental implications. The manufacturing process involves the use of strong acids and organic solvents, which can contribute to air and water pollution if not properly managed. Additionally, Kevlar is not biodegradable, raising concerns about its long-term environmental persistence and potential accumulation in ecosystems.

The enhanced conductivity of Kevlar-reinforced lines may also lead to increased energy efficiency in power transmission. This could result in reduced energy losses and, consequently, lower greenhouse gas emissions from power generation. However, this benefit must be weighed against the environmental costs of producing and disposing of Kevlar materials.

Another consideration is the potential impact on avian populations. While the reduced number of support structures may decrease bird collisions, the potentially thinner profile of Kevlar-enhanced lines could make them less visible to birds in flight. This necessitates careful design considerations and possibly the implementation of additional visual markers to mitigate this risk.

The recycling and disposal of Kevlar-enhanced power lines at the end of their life cycle present both challenges and opportunities. While Kevlar is difficult to recycle, advancements in materials science may lead to more efficient recycling processes in the future. Proper disposal methods must be developed to prevent these materials from contributing to landfill waste or environmental contamination.

In conclusion, the environmental impact of Kevlar-enhanced power lines is multifaceted. While they offer potential benefits in terms of reduced maintenance, land use, and energy efficiency, concerns regarding production processes, biodegradability, and end-of-life management must be addressed. A comprehensive life cycle assessment is crucial to fully understand and mitigate the environmental implications of this technology.

Cost-Benefit Analysis of Kevlar Integration

The integration of Kevlar into power transmission lines represents a significant technological advancement with potential for substantial long-term benefits. However, a comprehensive cost-benefit analysis is crucial to determine the economic viability of this innovation.

Initial implementation costs for Kevlar-reinforced transmission lines are considerably higher than traditional alternatives. The raw material expense of Kevlar, coupled with the need for specialized manufacturing processes and equipment, contributes to elevated upfront costs. Additionally, the installation of these advanced lines may require specialized training for workers and potentially new installation techniques, further increasing initial expenditures.

Despite higher initial costs, the long-term benefits of Kevlar integration are noteworthy. The superior strength-to-weight ratio of Kevlar allows for longer spans between towers, potentially reducing the overall number of support structures required. This can lead to significant savings in construction and land acquisition costs, particularly in challenging terrains or densely populated areas.

The durability and resistance to environmental factors offered by Kevlar-reinforced lines translate into reduced maintenance requirements and extended operational lifespans. This results in lower lifecycle costs, as the frequency of repairs and replacements decreases. The improved reliability of the transmission network can also lead to reduced downtime and associated economic losses from power outages.

Enhanced capacity for power transmission is another key benefit. Kevlar-reinforced lines can potentially carry higher electrical loads without sagging, allowing for increased power transfer capabilities without the need for additional infrastructure. This improved efficiency can defer the need for new transmission line construction, providing substantial cost savings over time.

Environmental benefits, while challenging to quantify economically, should also be considered. The reduced need for support structures and the potential for longer-lasting infrastructure contribute to lower environmental impact, which may translate to cost savings in terms of regulatory compliance and public relations.

To accurately assess the cost-benefit ratio, utilities must consider their specific operational contexts, including geographical factors, regulatory environments, and long-term energy demand projections. A comprehensive analysis should include not only direct costs and savings but also factor in risk mitigation benefits, such as improved resilience against extreme weather events.

In conclusion, while the initial investment in Kevlar-reinforced transmission lines is substantial, the long-term economic benefits, including reduced maintenance costs, improved reliability, and enhanced capacity, present a compelling case for adoption. However, a detailed, context-specific analysis is essential to determine the optimal implementation strategy and to justify the investment in this advanced technology.

Initial implementation costs for Kevlar-reinforced transmission lines are considerably higher than traditional alternatives. The raw material expense of Kevlar, coupled with the need for specialized manufacturing processes and equipment, contributes to elevated upfront costs. Additionally, the installation of these advanced lines may require specialized training for workers and potentially new installation techniques, further increasing initial expenditures.

Despite higher initial costs, the long-term benefits of Kevlar integration are noteworthy. The superior strength-to-weight ratio of Kevlar allows for longer spans between towers, potentially reducing the overall number of support structures required. This can lead to significant savings in construction and land acquisition costs, particularly in challenging terrains or densely populated areas.

The durability and resistance to environmental factors offered by Kevlar-reinforced lines translate into reduced maintenance requirements and extended operational lifespans. This results in lower lifecycle costs, as the frequency of repairs and replacements decreases. The improved reliability of the transmission network can also lead to reduced downtime and associated economic losses from power outages.

Enhanced capacity for power transmission is another key benefit. Kevlar-reinforced lines can potentially carry higher electrical loads without sagging, allowing for increased power transfer capabilities without the need for additional infrastructure. This improved efficiency can defer the need for new transmission line construction, providing substantial cost savings over time.

Environmental benefits, while challenging to quantify economically, should also be considered. The reduced need for support structures and the potential for longer-lasting infrastructure contribute to lower environmental impact, which may translate to cost savings in terms of regulatory compliance and public relations.

To accurately assess the cost-benefit ratio, utilities must consider their specific operational contexts, including geographical factors, regulatory environments, and long-term energy demand projections. A comprehensive analysis should include not only direct costs and savings but also factor in risk mitigation benefits, such as improved resilience against extreme weather events.

In conclusion, while the initial investment in Kevlar-reinforced transmission lines is substantial, the long-term economic benefits, including reduced maintenance costs, improved reliability, and enhanced capacity, present a compelling case for adoption. However, a detailed, context-specific analysis is essential to determine the optimal implementation strategy and to justify the investment in this advanced technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!