Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2646 results about "Solid matter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cosmetic and pharmaceutical foam with solid matter

InactiveUS20050186147A1Good lookingLower yield strengthCosmetic preparationsAerosol deliveryMedicineSolvent

A foamable composition includes about 2 to about 30% by weight solid particles; about 2 to about 75% by weight hydrophobic solvent; about 10 to about 85% by weight water; about 0.1% to about 5% by weight surface-active agent; about 0.1% to about 5 wt % by weight stabilizer / gelling agent; and a liquefied or compressed gas propellant in a container, which upon release provides a breakable foam suitable for topical administration.

Owner:FOAMIX PHARMACEUTICALS LIMITED

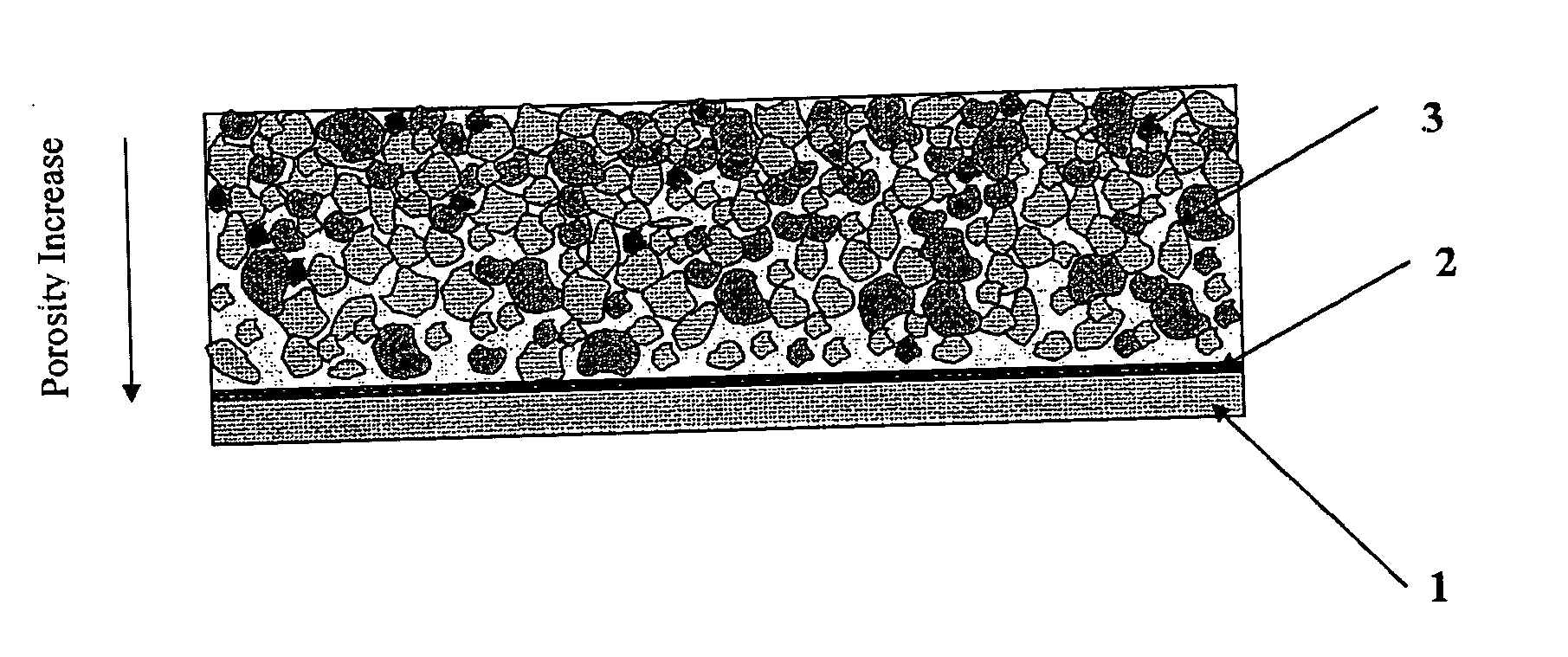

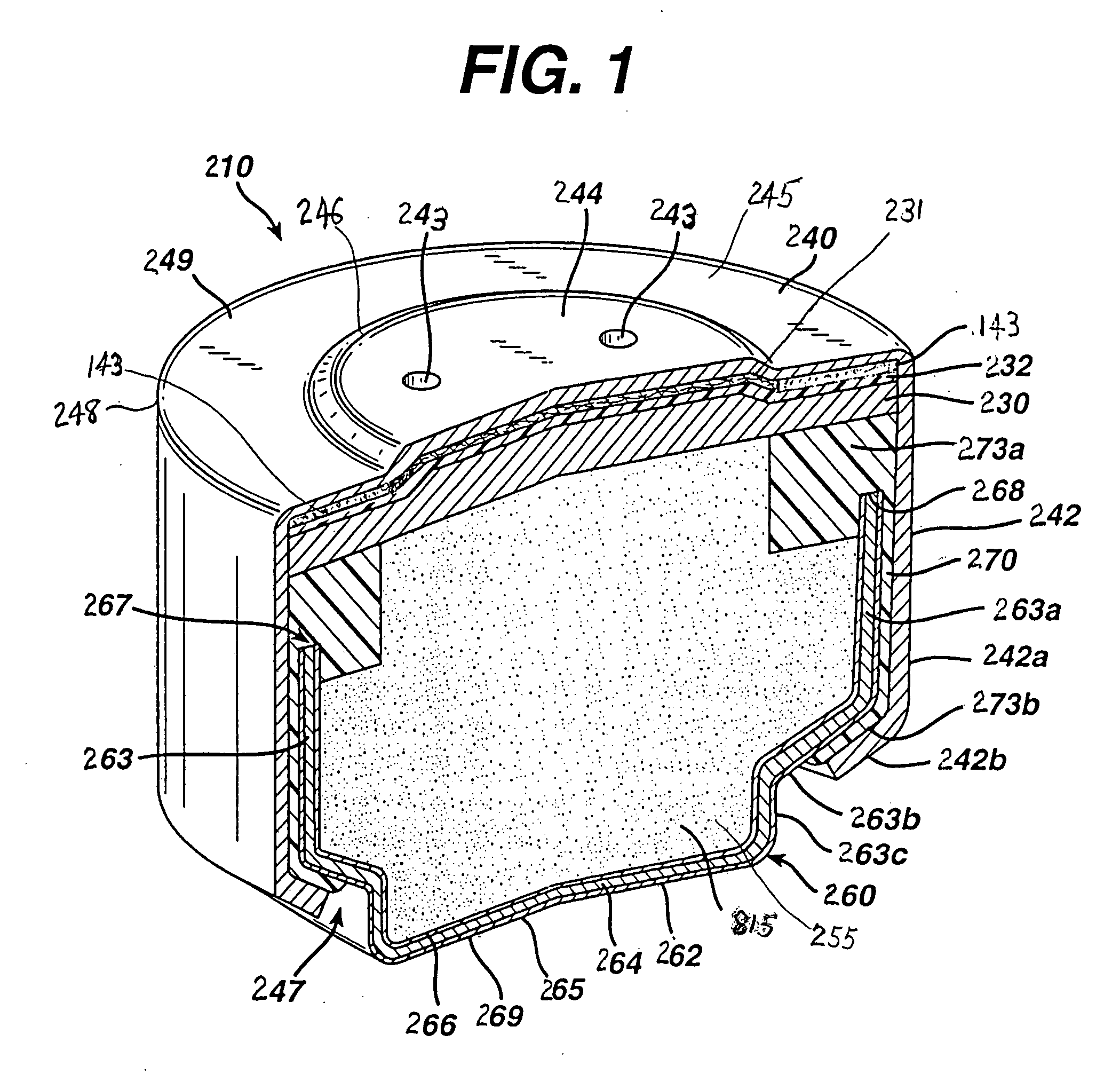

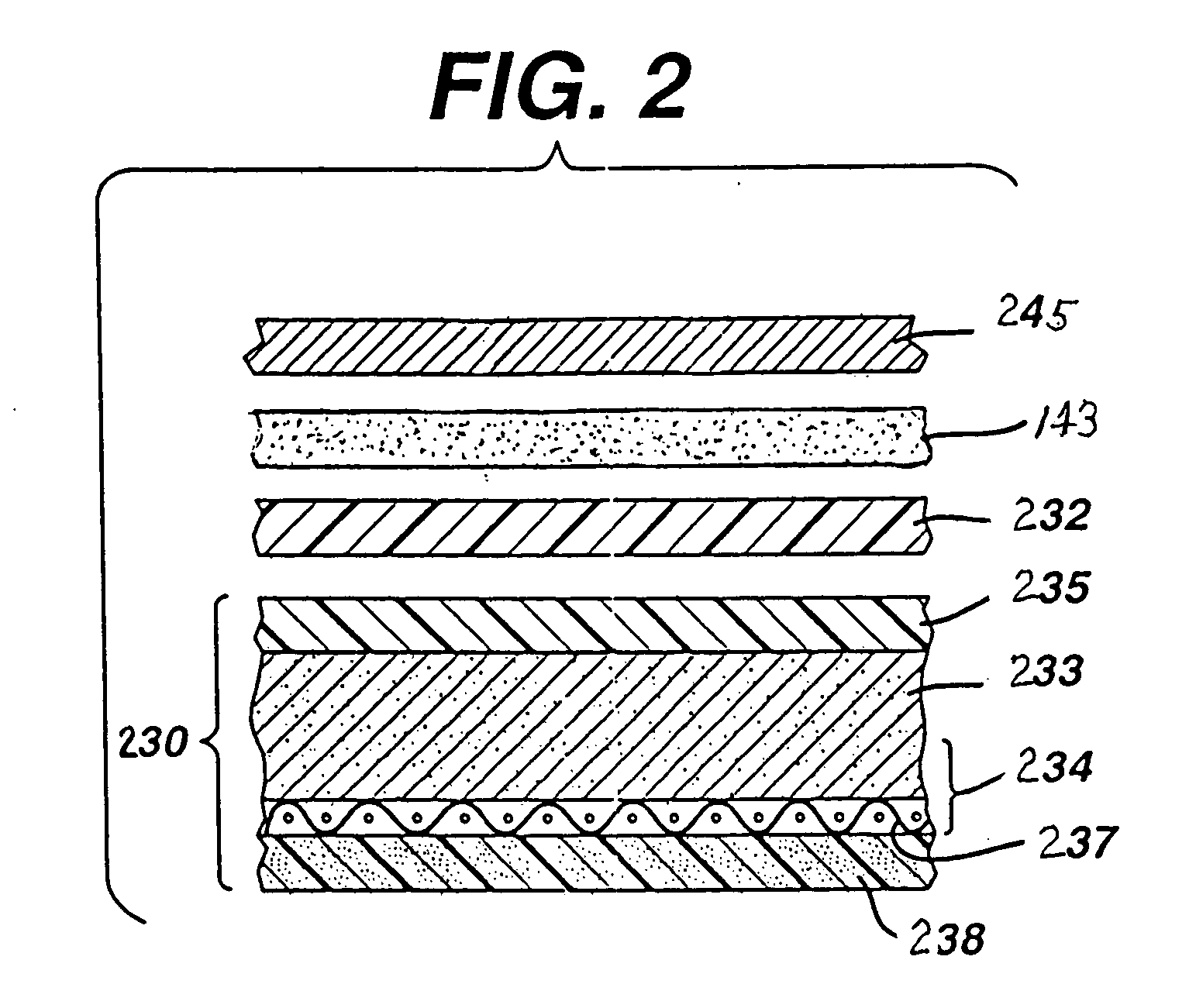

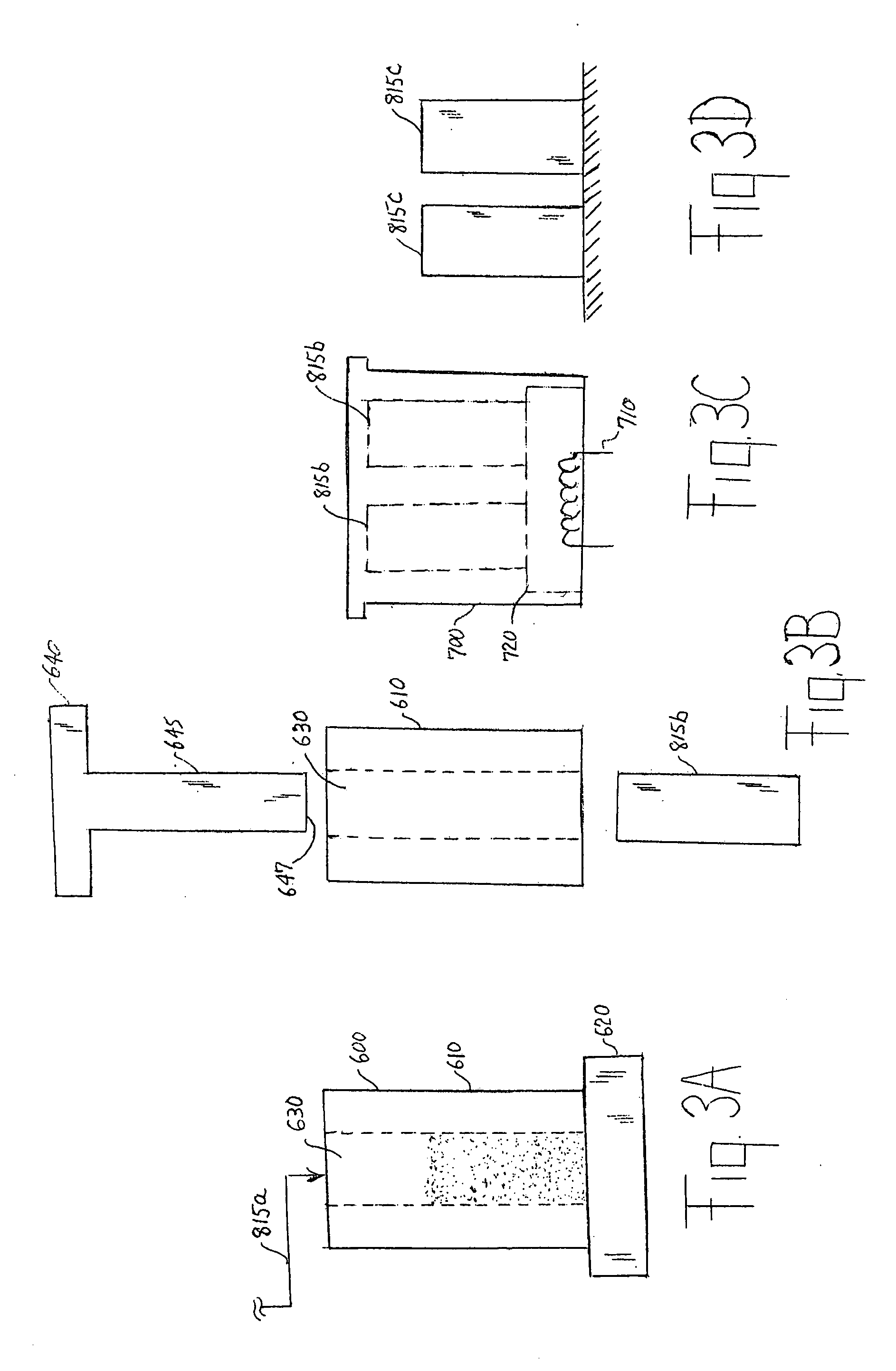

Battery electrode structure and method for manufacture thereof

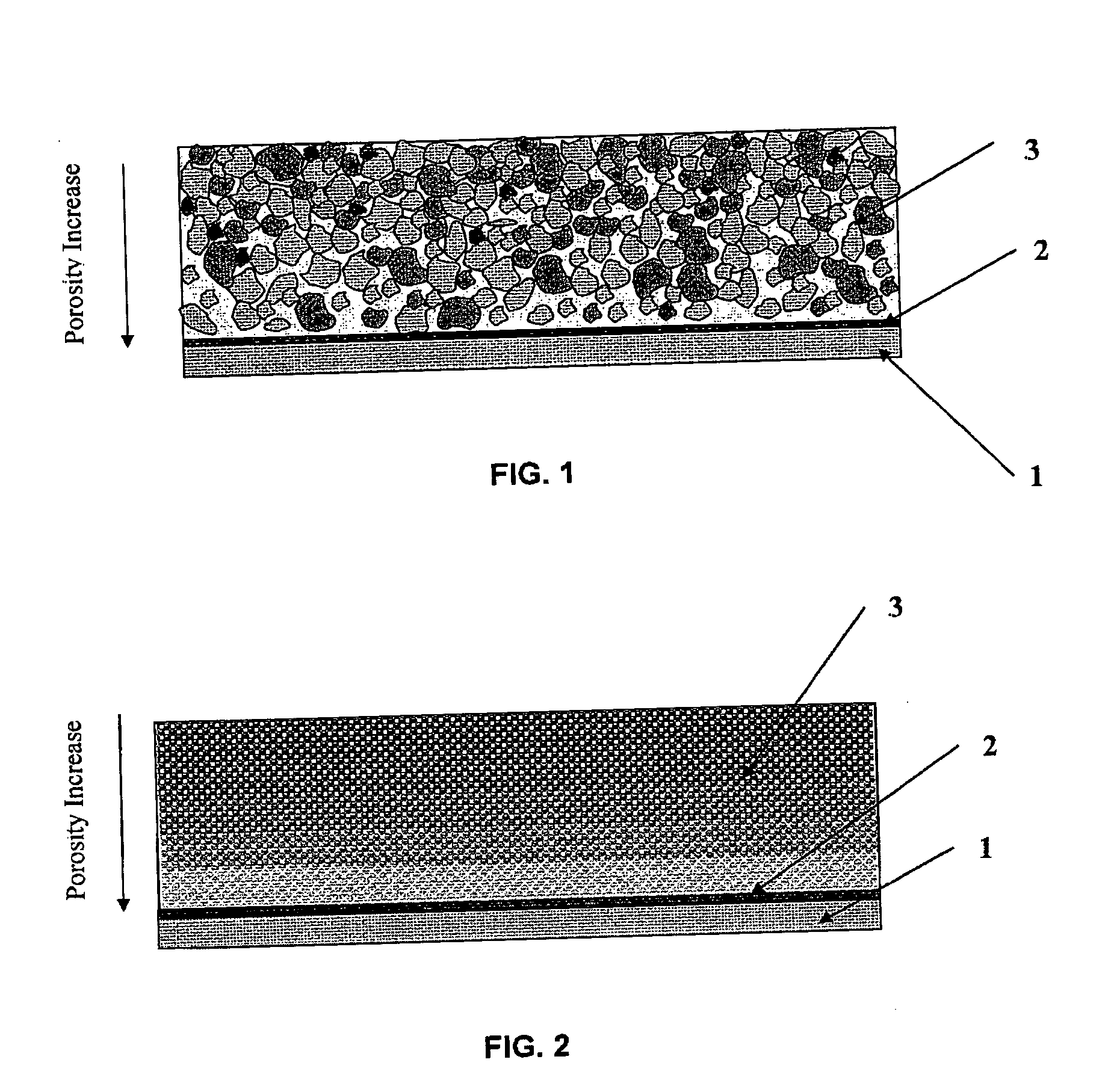

InactiveUS20060024579A1Increase energy densityReduce porositySecondary cellsActive material electrodesPorosityComposite electrode

There are disclosed solid composite electrodes with electrode active layers that include an electrode active material, an optional election conductive material, an optional binder and other optional additives. The solid composite electrodes are formed by the deposition of an electrode composition (slurry) onto a current collector in one or many layers. The electrode structure may be characterised by a porosity of the electrode composition layer that decreases in a direction from the back side of the layer (close to the current collector) towards the outer side of the layer. The gradient of the decrease in the porosity is controlled by the content of solid substance in the slurry, by the composition of the solvent in the slurry, by the temperature of the layer drying after deposition, as well as by the pressing or calendering conditions for each layer. The electrode structures can be used in for example chemical sources of electric energy such as primary (non-rechargeable) as well as secondary (rechargeable) batteries.

Owner:OXIS ENERGY

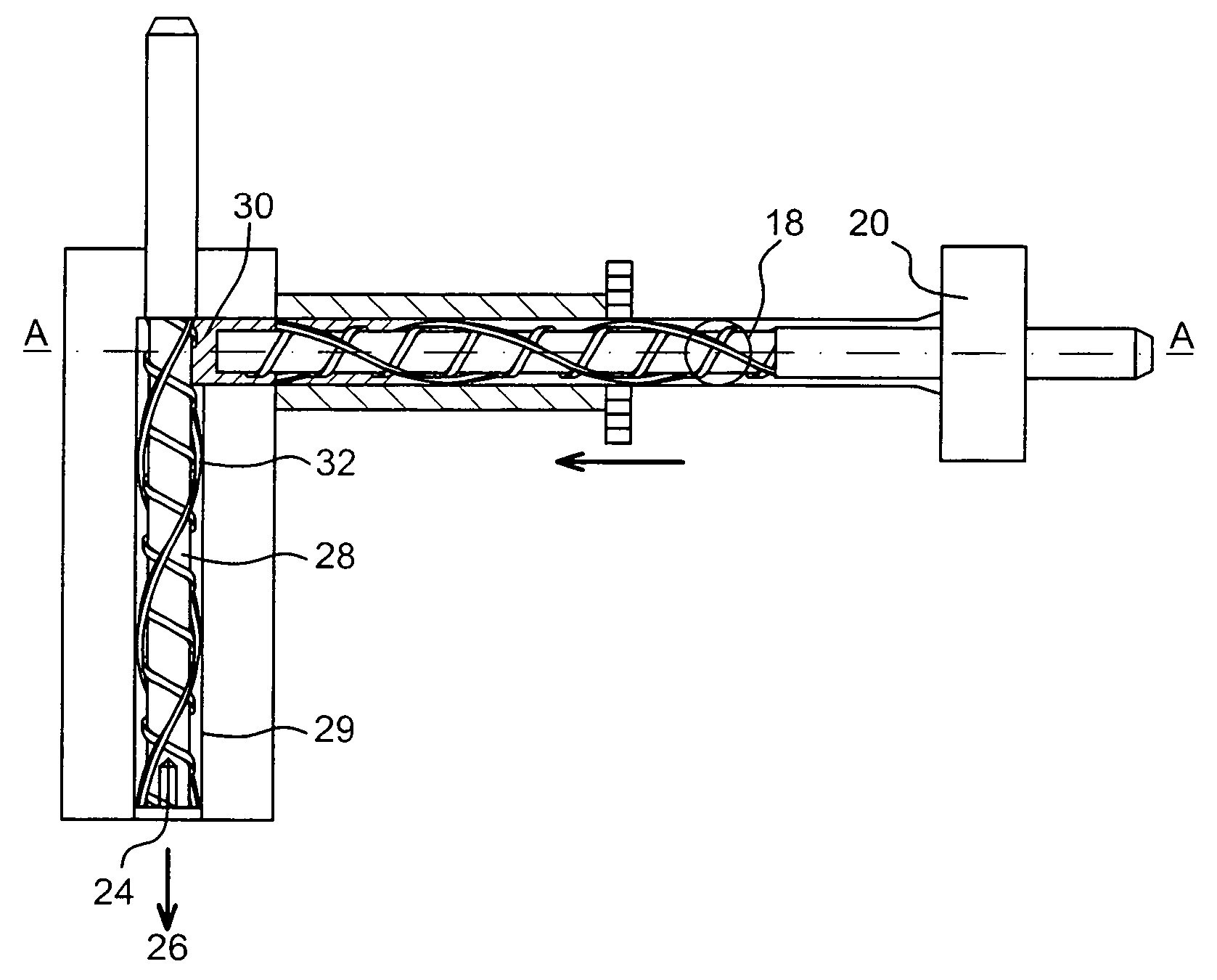

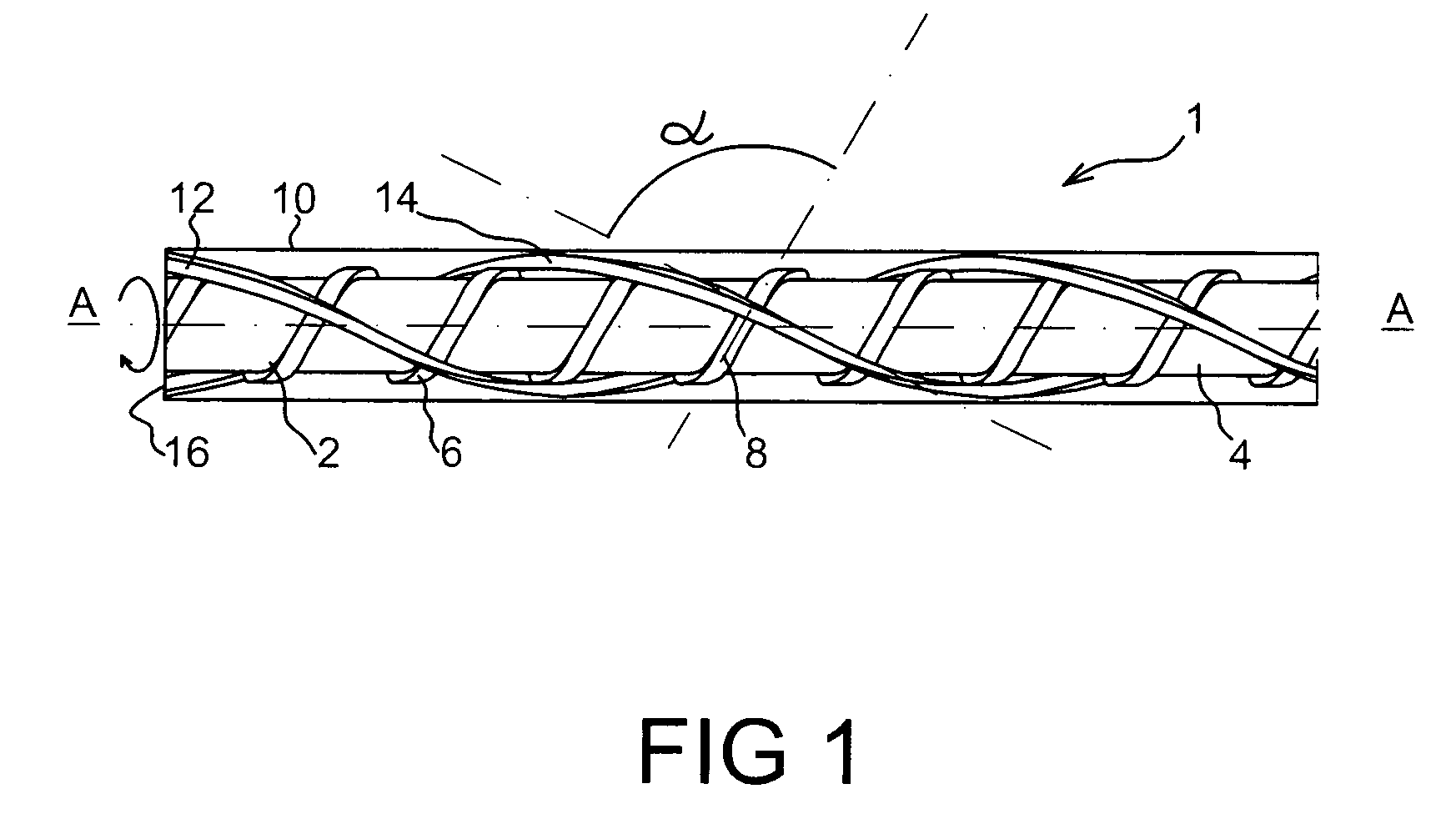

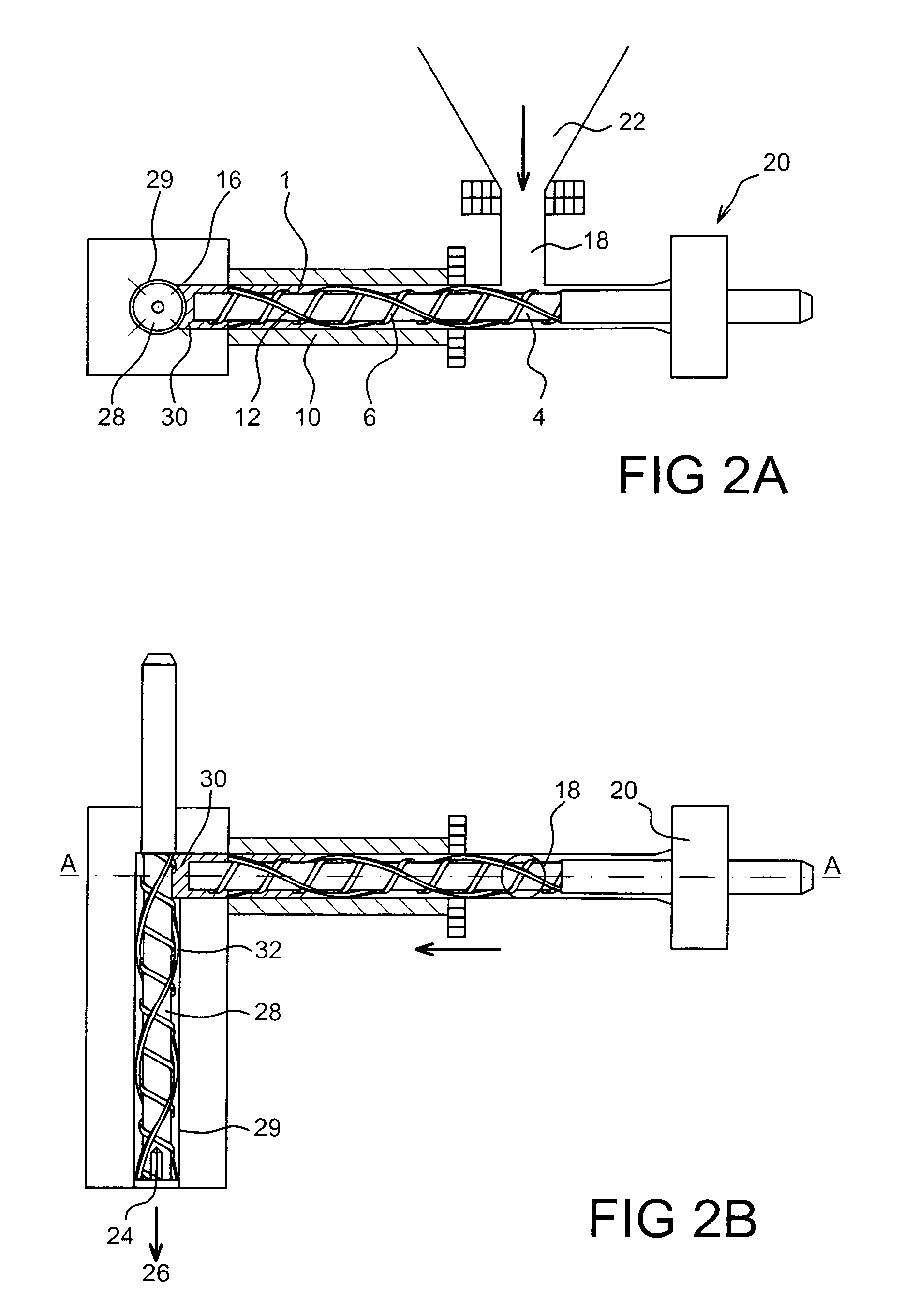

Water-absorbing resin and method for manufacturing the same

The present invention provides a highly productive method for manufacturing a water-absorbing resin, the amounts of fine powder and dust of which are small, the amount of residual monomer of which is small, and whose absorption rate is high. That is, the method for manufacturing the water-absorbing resin of the present invention is a method for crosslinking and polymerizing an aqueous solution of an acid-group containing unsaturated monomer, and is characterized in that stationary polymerization is carried out in such a manner that a solid matter is added to the monomer aqueous solution, and an initiation temperature of the polymerization is adjusted to 40° C. or more or a maximum temperature of the polymerization is adjusted to 100° C. or more.

Owner:NIPPON SHOKUBAI CO LTD

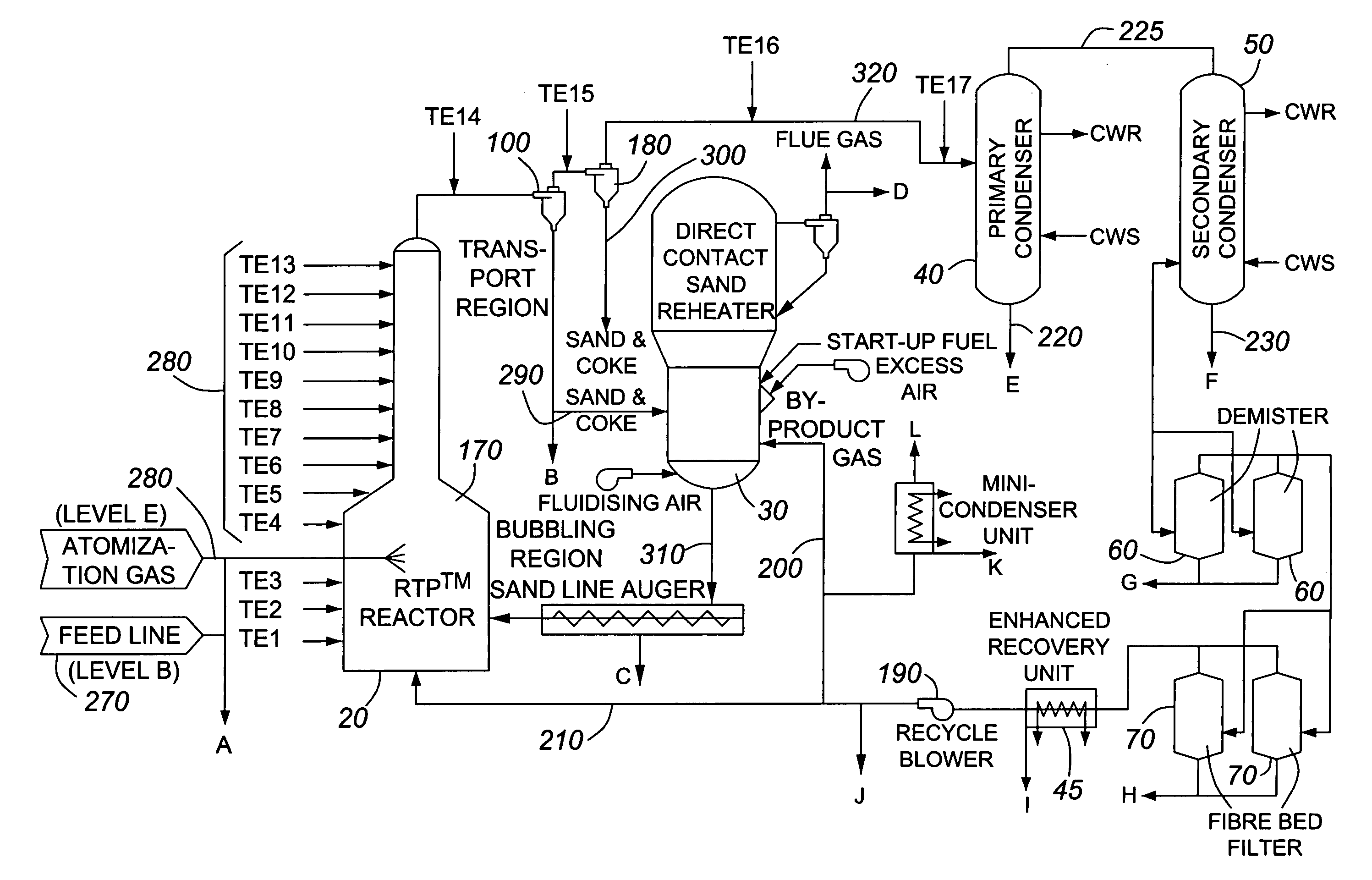

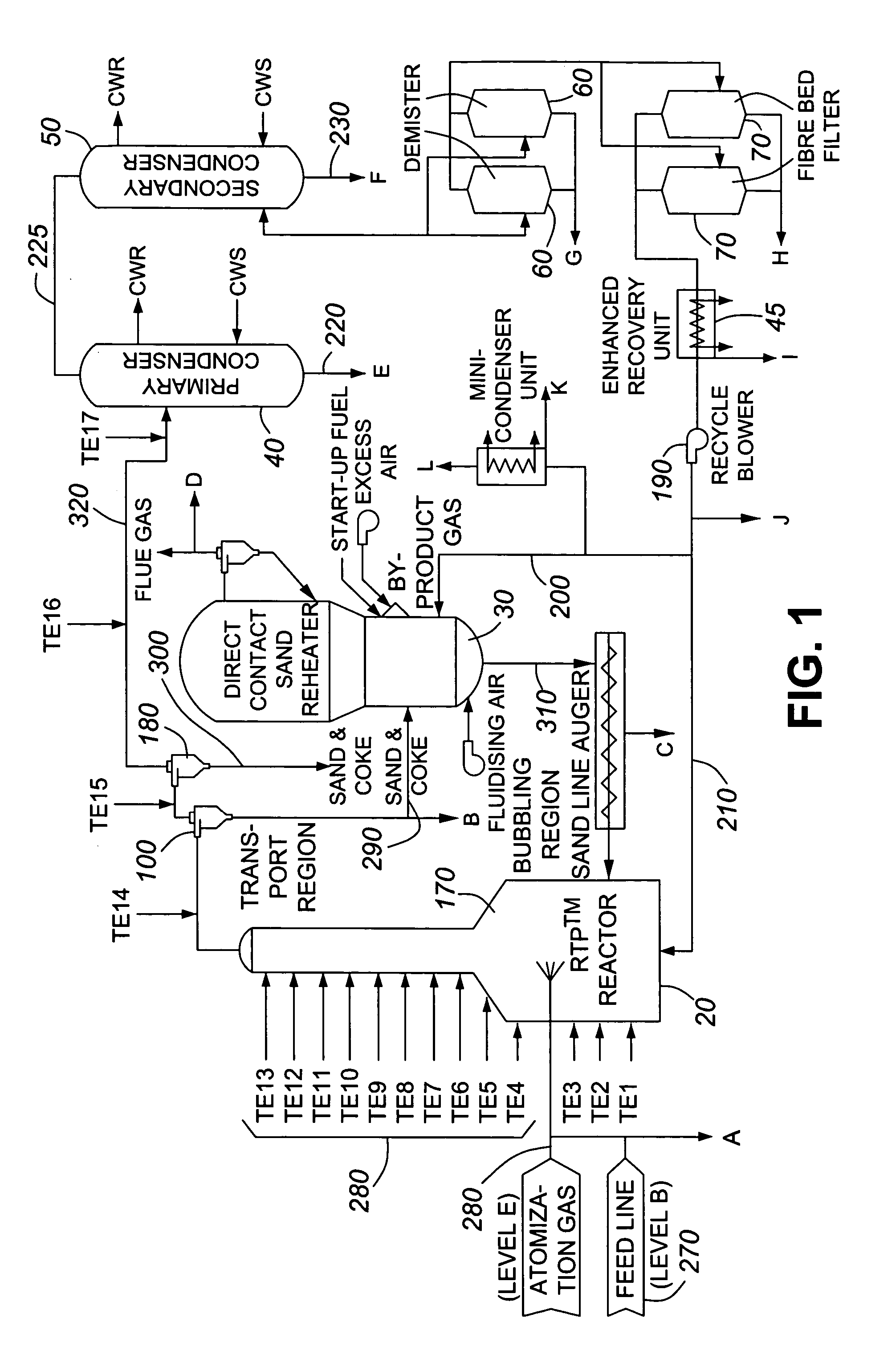

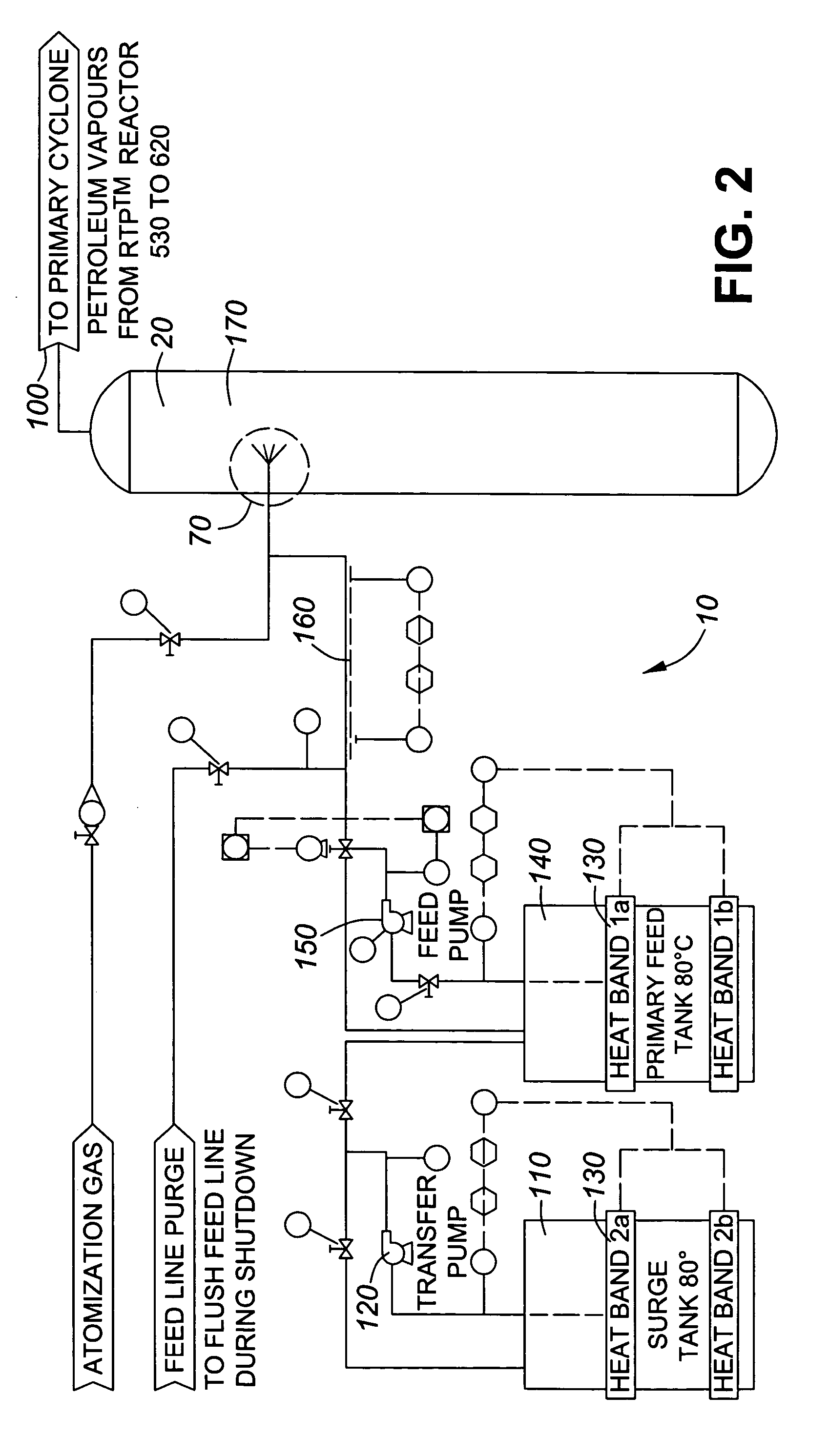

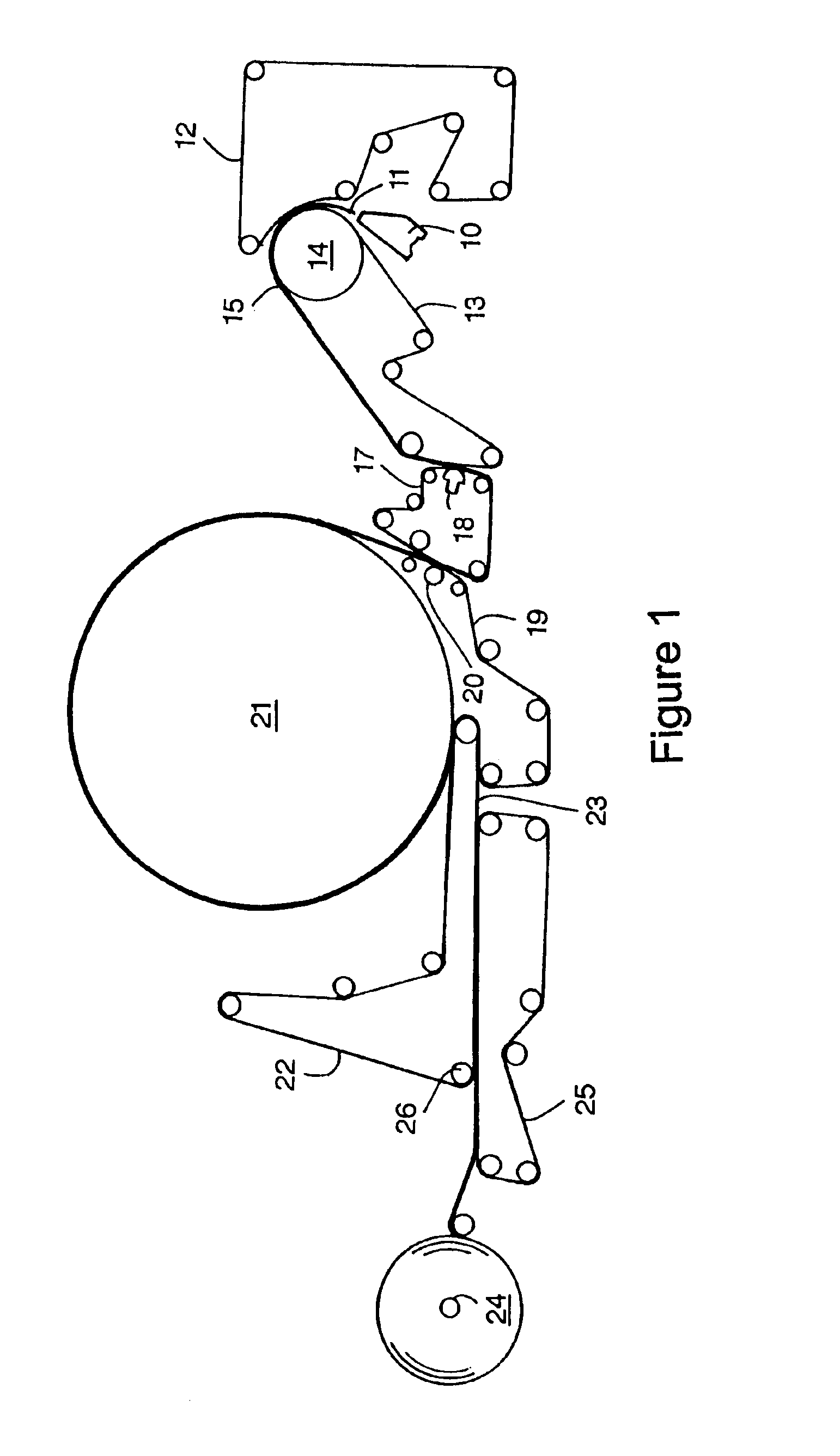

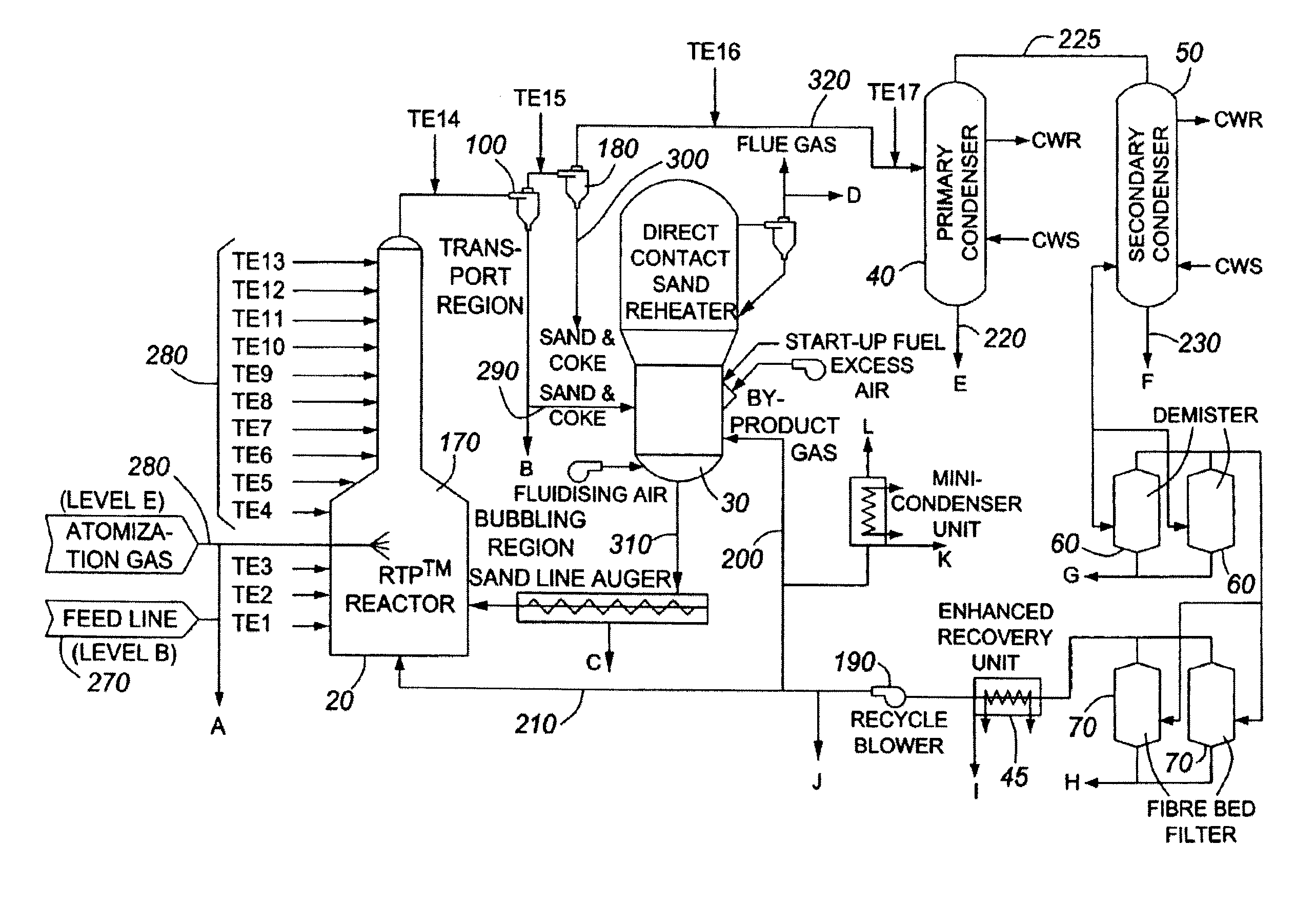

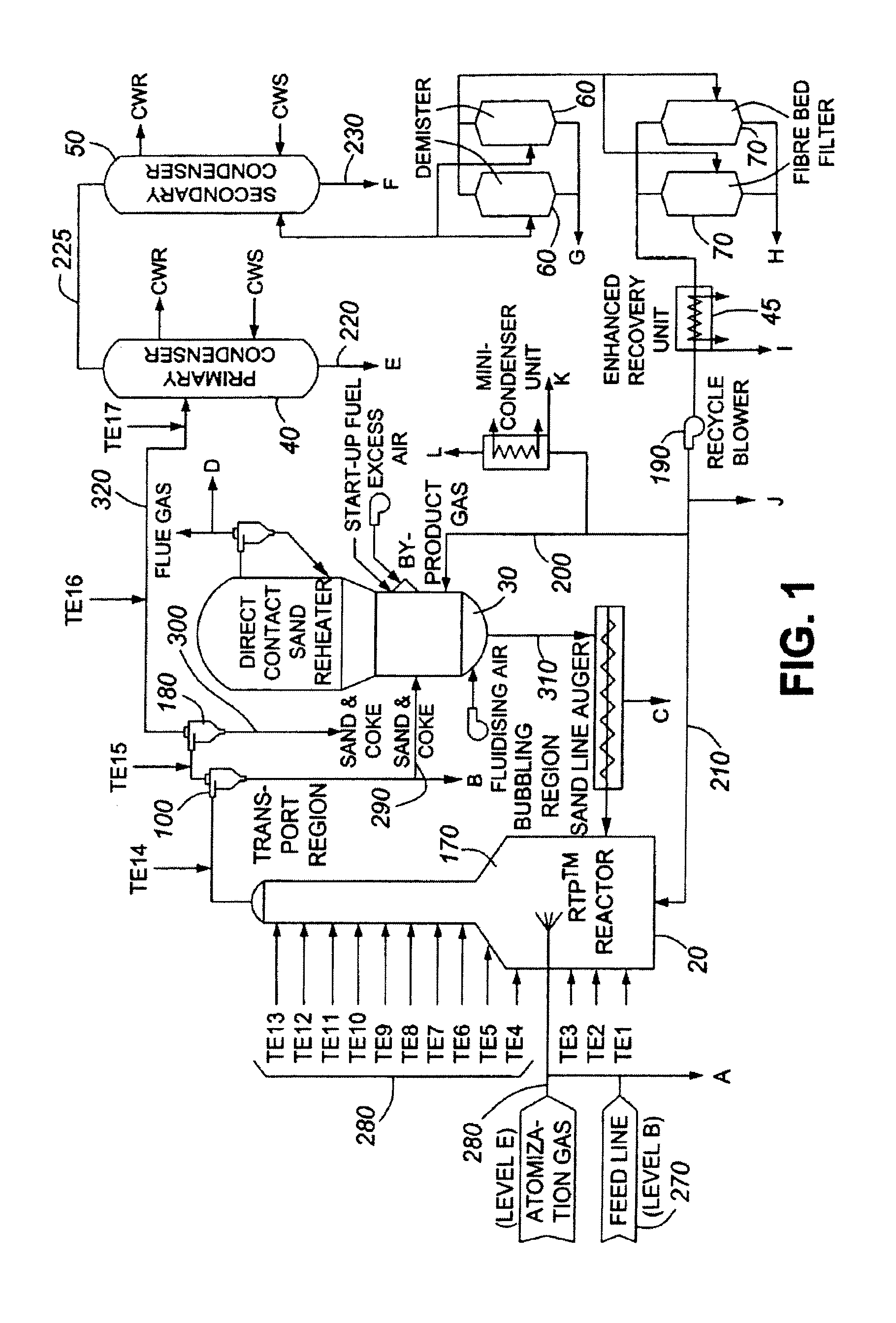

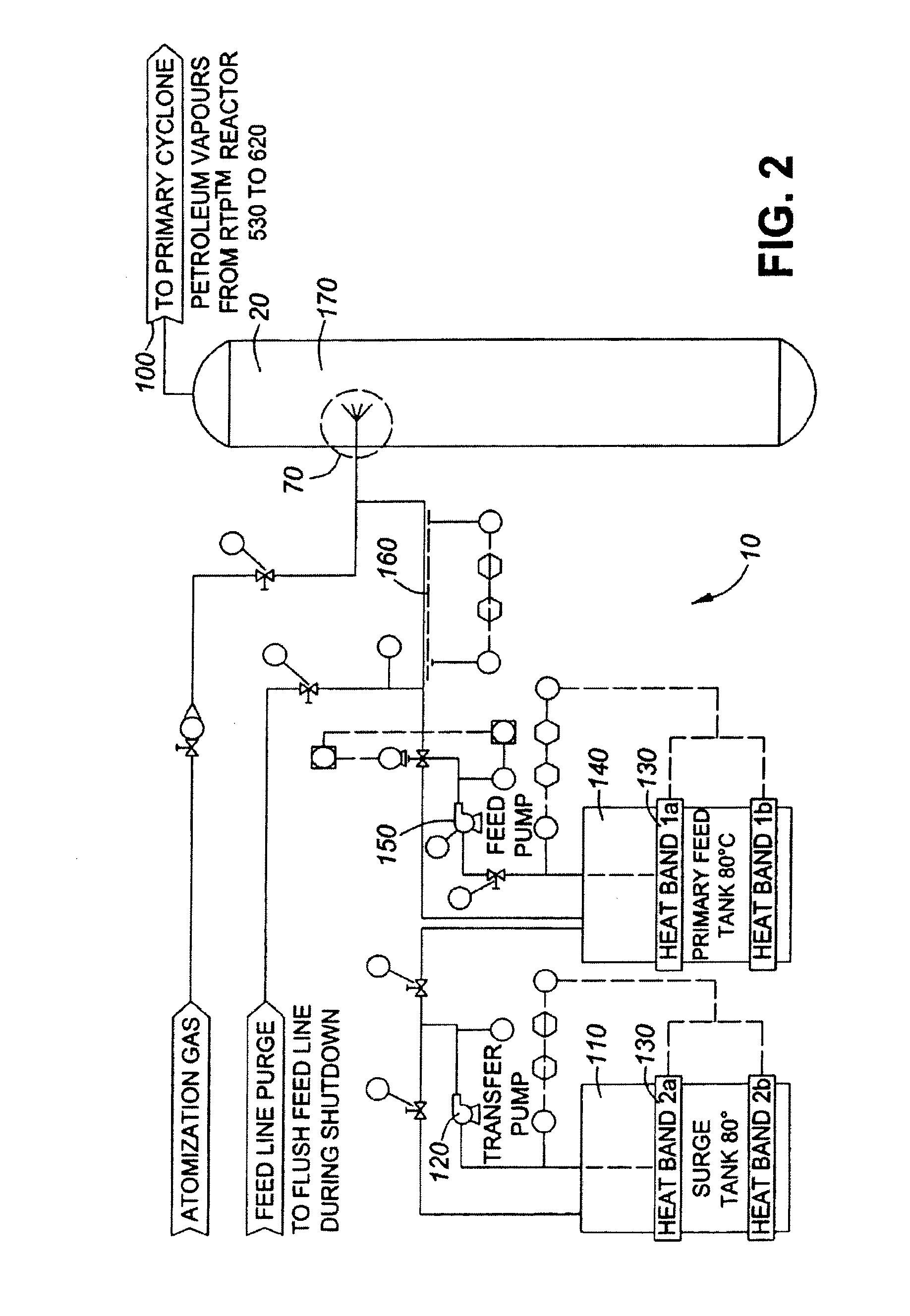

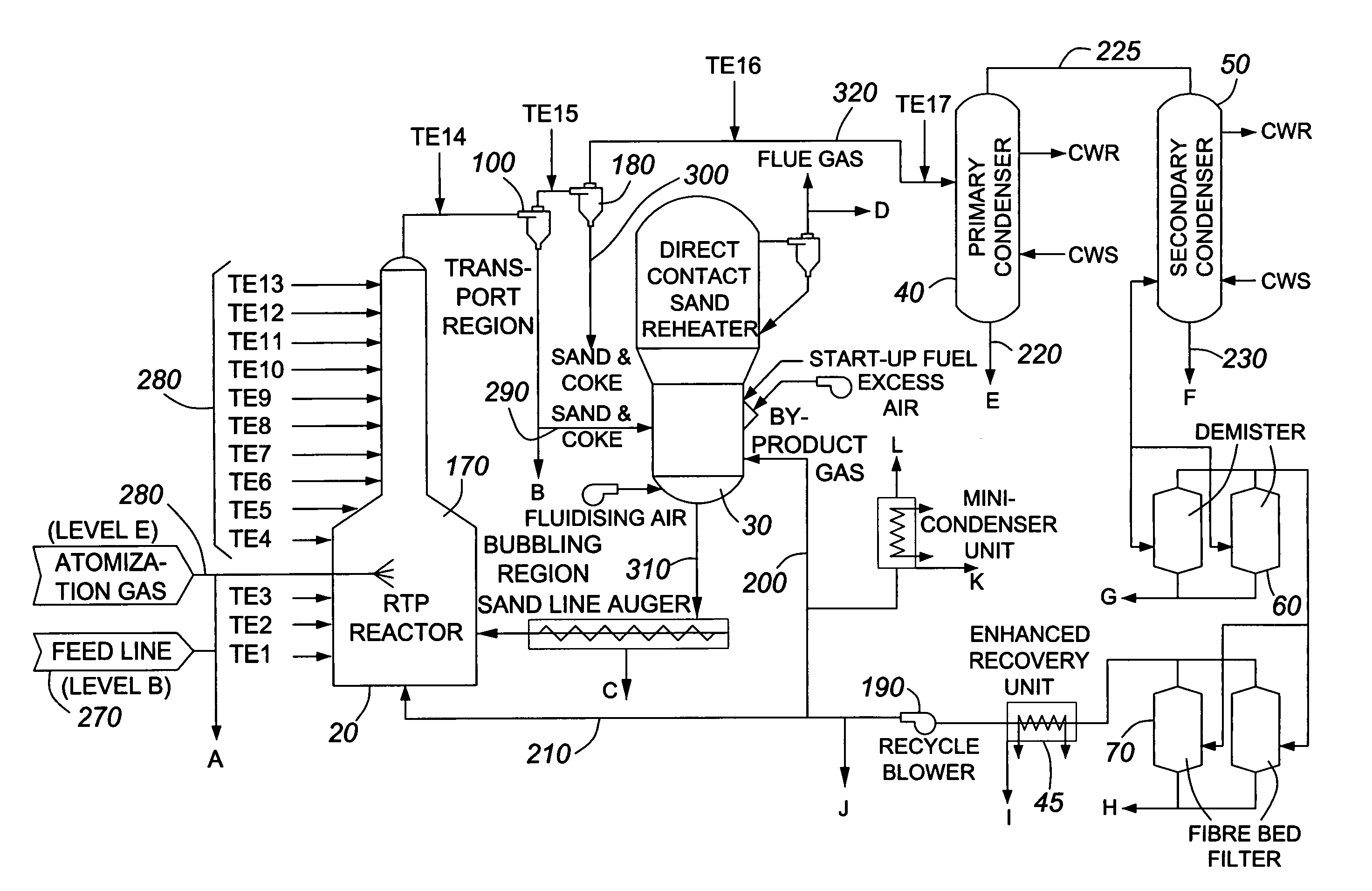

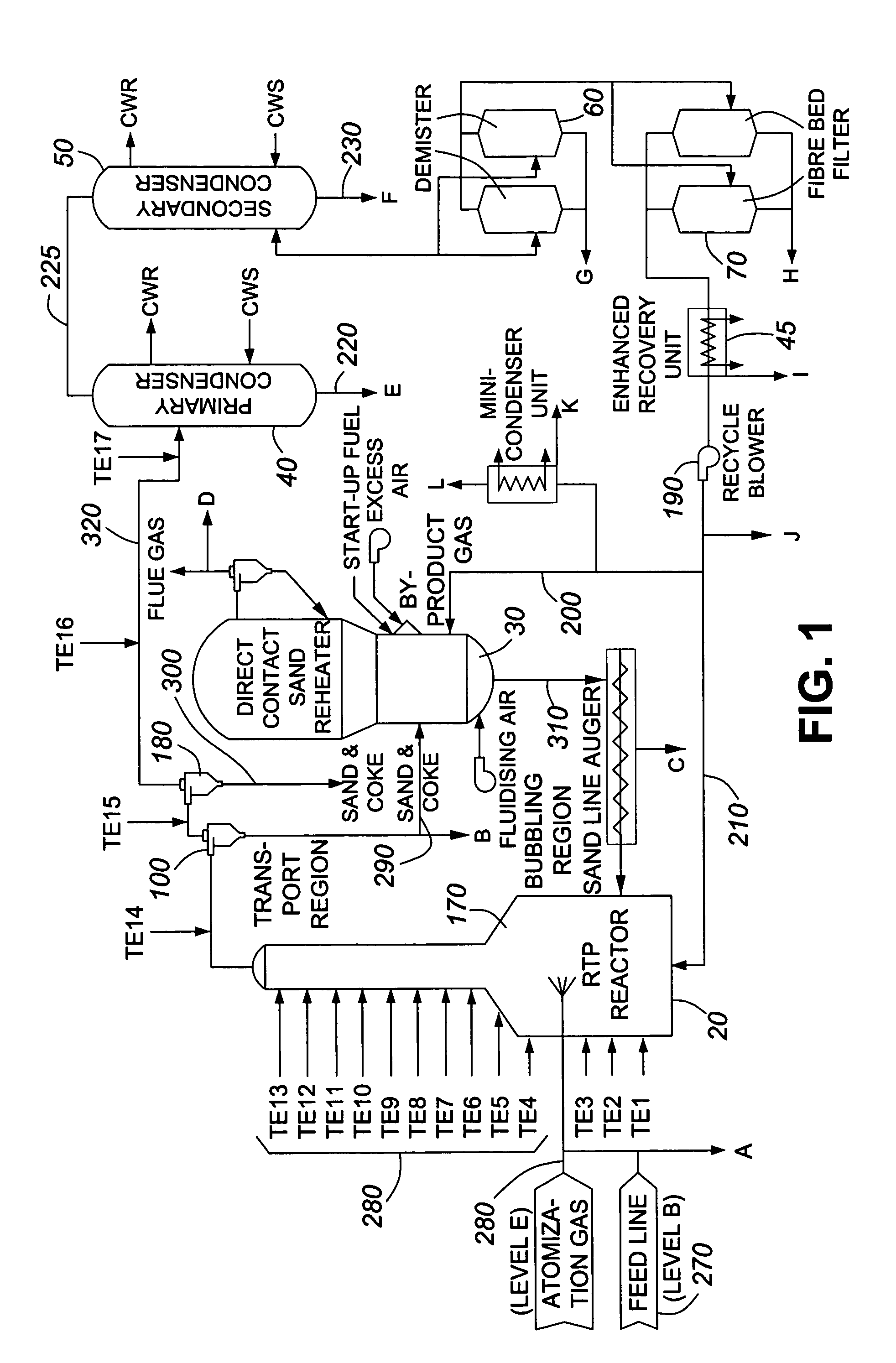

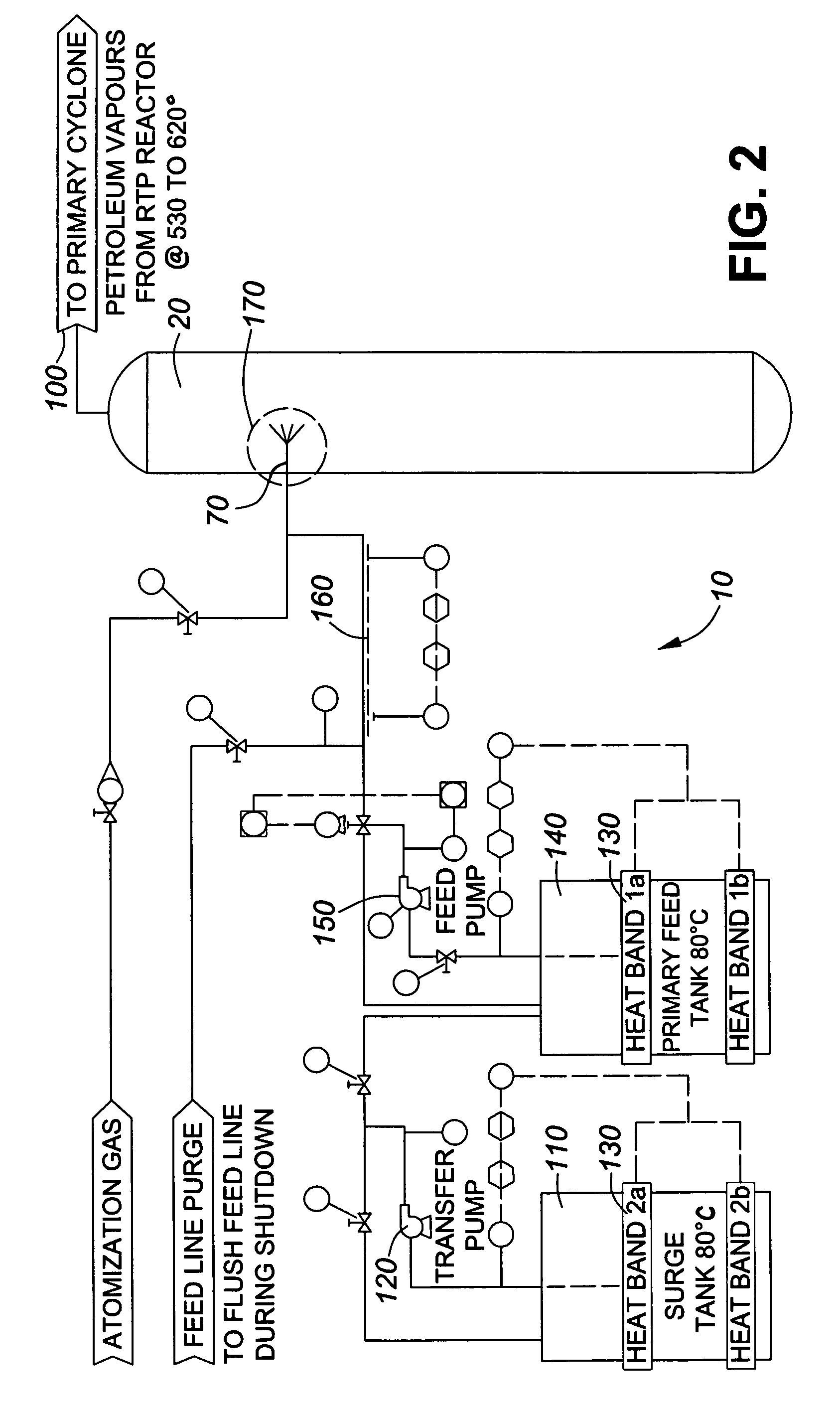

Modified thermal processing of heavy hydrocarbon feedstocks

InactiveUS7572362B2Quick upgradeReducing H2S contentThermal non-catalytic crackingTreatment with plural serial cracking stages onlyLiquid productParticulates

The present invention is directed to the upgrading of heavy petroleum oils of high viscosity and low API gravity that are typically not suitable for pipelining without the use of diluents. It utilizes a short residence-time pyrolytic reactor operating under conditions that result in a rapid pyrolytic distillation with coke formation. Both physical and chemical changes taking place lead to an overall molecular weight reduction in the liquid product and rejection of certain components with the byproduct coke. The liquid product is upgraded primarily because of its substantially reduced viscosity, increased API gravity, and the content of middle and light distillate fractions. While maximizing the overall liquid yield, the improvements in viscosity and API gravity can render the liquid product suitable for pipelining without the use of diluents. This invention particularly relates to reducing sulfur emissions during the combustion of byproduct coke (or coke and gas), to reducing the total acid number (TAN) of the liquid product, and to reducing the hydrogen sulfide content of one, or more than one component of the product stream. The method comprises introducing a particulate heat carrier into an up-flow reactor, introducing the feedstock at a location above the entry of the particulate heat carrier, allowing the heavy hydrocarbon feedstock to interact with the heat carrier for a short time, separating the vapors of the product stream from the particulate heat carrier and liquid and byproduct solid matter, regenerating the particulate heat carrier in the presence of the calcium compound, and collecting a gaseous and liquid product from the product stream.

Owner:IVANHOE HTL GASOLINEEUM

Solid catalyst component for ethylene polymerization and catalyst therefor

InactiveCN1463991AOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePtru catalyst

The catalyst components for polymerization or copolymerization of ethylene includes at least one titanium compound, at least one electron donor and at least one activator carried onto one kind of Mg / Ti containing solid matter. The catalyst components has relatively narrow grain size distribution and relatively small average grain size, and the catalyst with the catalyst components has relativelyhigher activity and is especially suitable for slurry polymerization and gaseous polymerization to obtain polymer with lower fine powder content. The catalyst is especially suitable for ethylene polymerization with slurry feeding and gaseous fluidized bed polymerization.

Owner:CHINA PETROLEUM & CHEM CORP +1

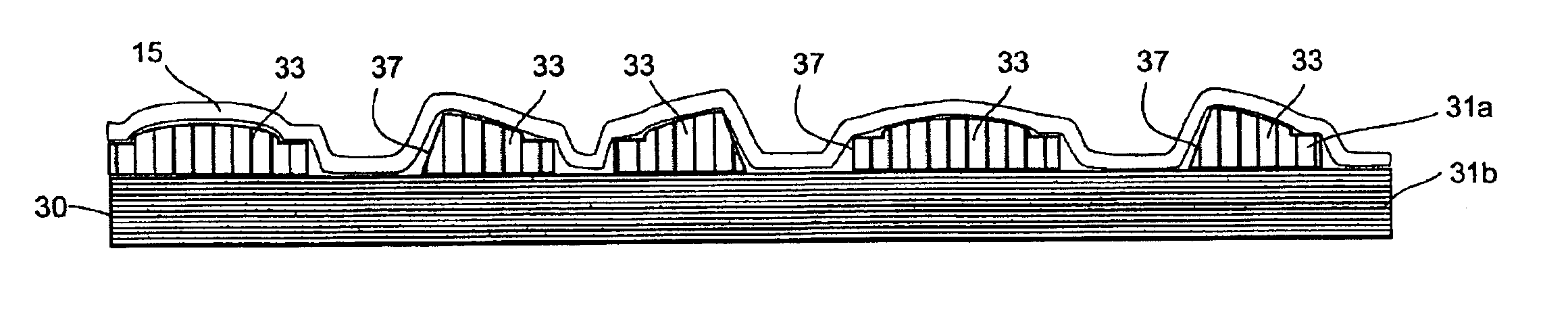

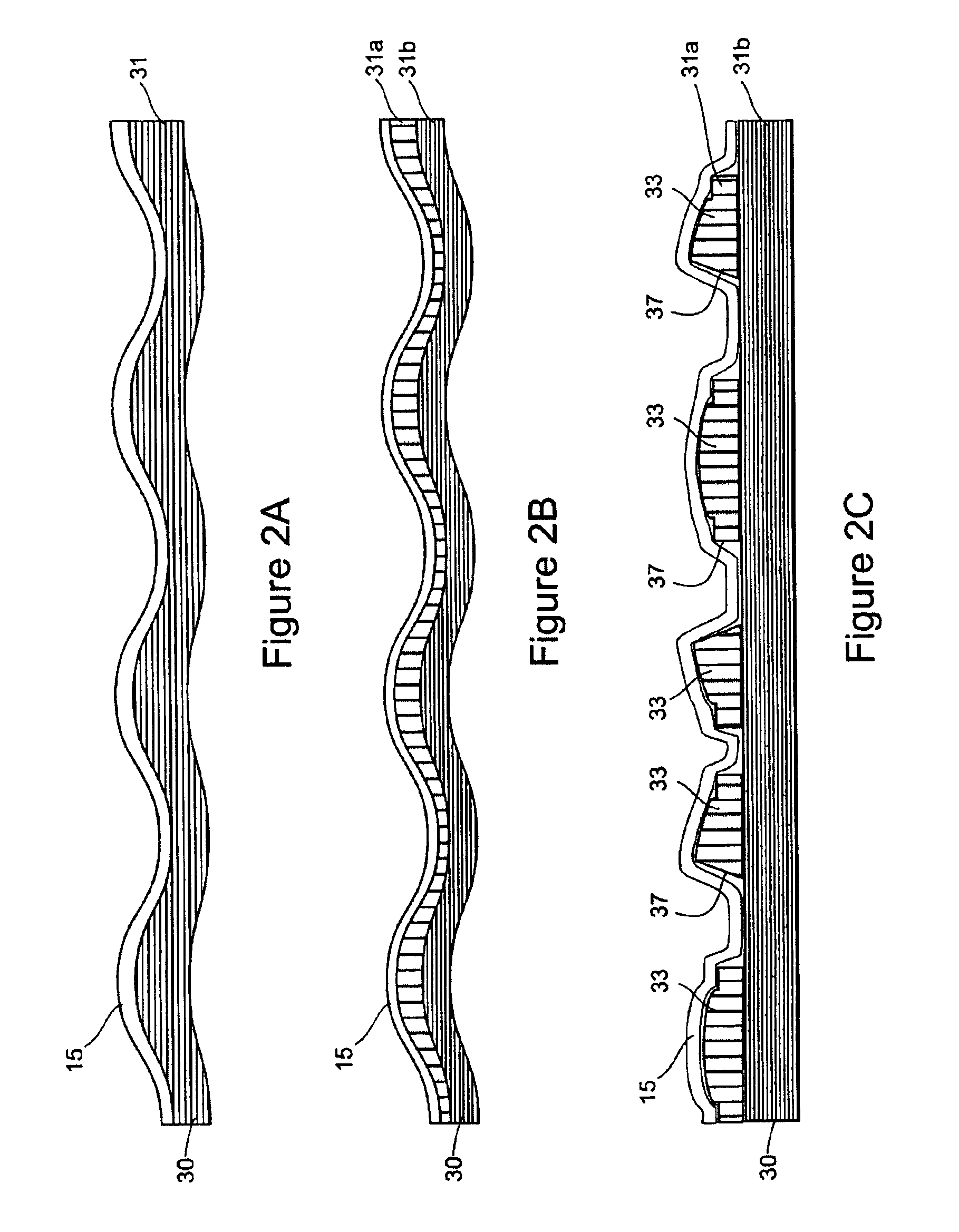

Non-woven through air dryer and transfer fabrics for tissue making

InactiveUS6878238B2High fabric strengthHigh thicknessNon-fibrous pulp additionNatural cellulose pulp/paperNonwoven fabricAir dryer

One embodiment of the present invention is an endless non-woven tissue making fabric having a three-dimensional texture suitable for use as a fabric for producing three-dimensional fibrous webs. The endless non-woven tissue making fabric comprises a plurality of substantially parallel adjoining sections of non-woven material. Each section of non-woven material has a width substantially less than the width of the non-woven tissue making fabric. Each section of non-woven material may be joined to at least one other adjoining section of non-woven material. The non-woven tissue making fabric has a machine direction, a cross-machine direction, a tissue contacting surface and a tissue machine contacting surface. The tissue contacting surface comprises solid matter at a plurality of heights such that the tissue contacting surface of the non-woven tissue making fabric has an Overall Surface Depth of at least 0.2 mm in regions of solid matter on the tissue contacting surface.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Methods and Systems for Producing Reduced Resid and Bottomless Products from Heavy Hydrocarbon Feedstocks

InactiveUS20080230440A1Cost controlReduce operating costsThermal non-catalytic crackingTreatment with plural serial cracking stages onlyParticulatesLiquid product

The present invention is directed to the upgrading of heavy petroleum oils of high viscosity and low API gravity that are typically not suitable for pipelining without the use of diluents. The method comprises introducing a particulate heat carrier into an up-flow reactor, introducing the feedstock at a location above the entry of the particulate heat carrier, allowing the heavy hydrocarbon feedstock to interact with the heat carrier for a short time, separating the vapors of the product stream from the particulate heat carrier and liquid and byproduct solid matter, collecting a gaseous and liquid product mixture comprising a mixture of a light fraction and a heavy fraction from the product stream, and using a vacuum tower to separate the light fraction as a substantially bottomless product and the heavy fraction from the product mixture.

Owner:IVANHOE HTL GASOLINEEUM

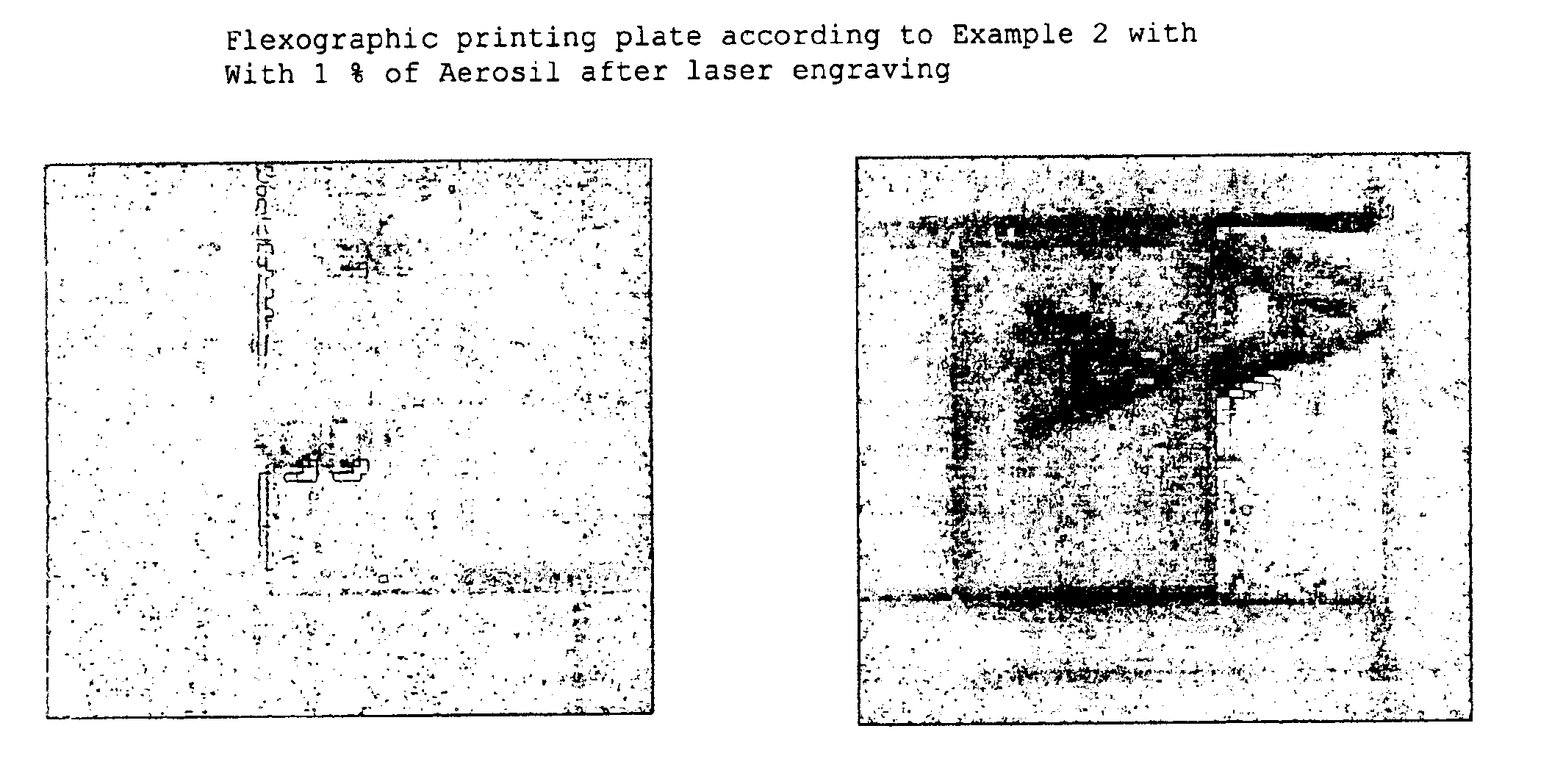

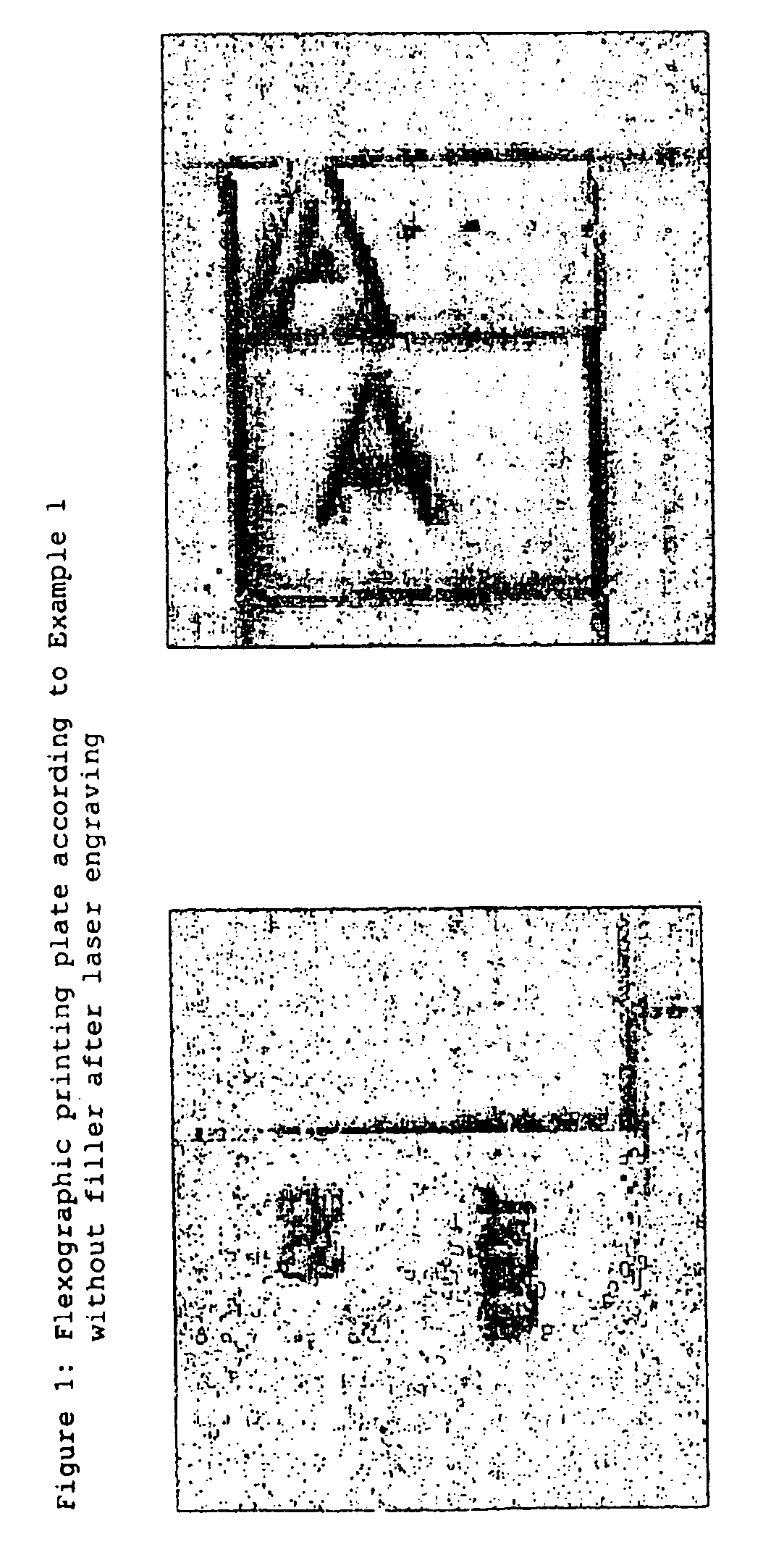

Method for producing flexographic printing plates by means of laser engraving

InactiveUS6935236B2High resolutionAvoid it happening againDuplicating/marking methodsSemiconductor/solid-state device manufacturingCross-linkLaser engraving

The invention relates to a method for producing flexographic printing forms by engraving a printing relief on a flexographic printing element that can be laser engraved, said element having a photochemically cross-linked relief layer. The relief layer is transparent and comprises oxidic, siliceous or zeolitic solid matter with a particle size between 1 and 400 nm in a quantity of between 0.1 and 8 wt. % in relation to the quantity of all components in the relief layer.

Owner:XSYS PRINT SOLUTIONS DEUT GMBH

Heat insulation coating capable of reflecting solar heat rays

InactiveCN101121858AImprove reflection efficiencyIncrease thermal resistanceFireproof paintsPolyurea/polyurethane coatingsPolymer resinThermal radiation

A heat-insulating coating for reflecting solar heat rays, which is composed of two parts: a primer and a top-coat. 10-50%, adhesive polymer resin 10-70%; the percentage of solid matter in the top coating is: surface coating reflective heat ray composite material 5-40%, heat reflective material 10-50%, adhesive Polymer resin 10-70%. The coating of the present invention is mainly used as the exterior surface coating of buildings, automobiles, trains, pipelines, storage tanks, etc. When the thickness of the dry coating film is 0.3-0.5mm, the total reflectance to heat rays can reach 85-90%, which can effectively prevent Thermal radiation from the sun.

Owner:马承银

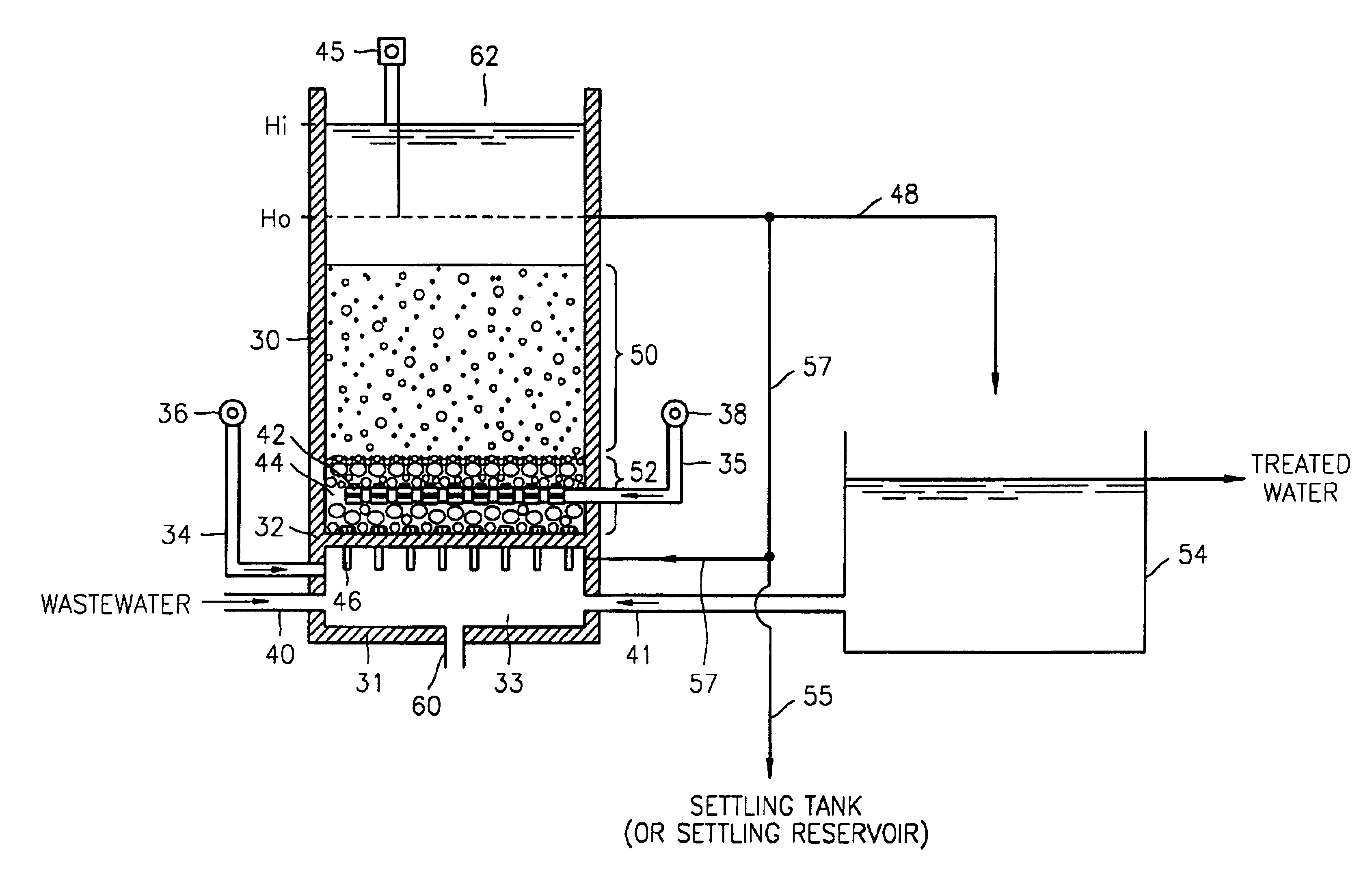

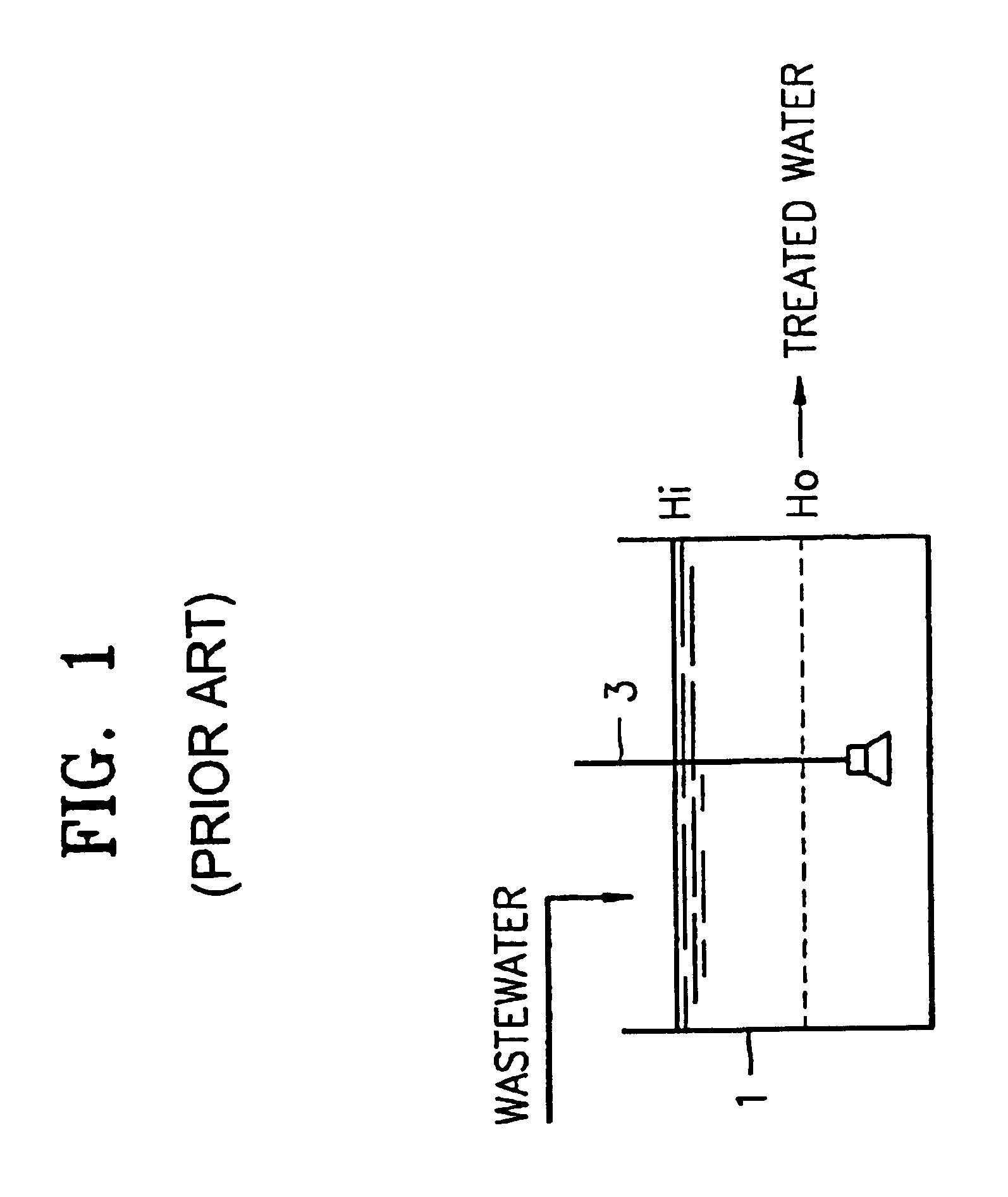

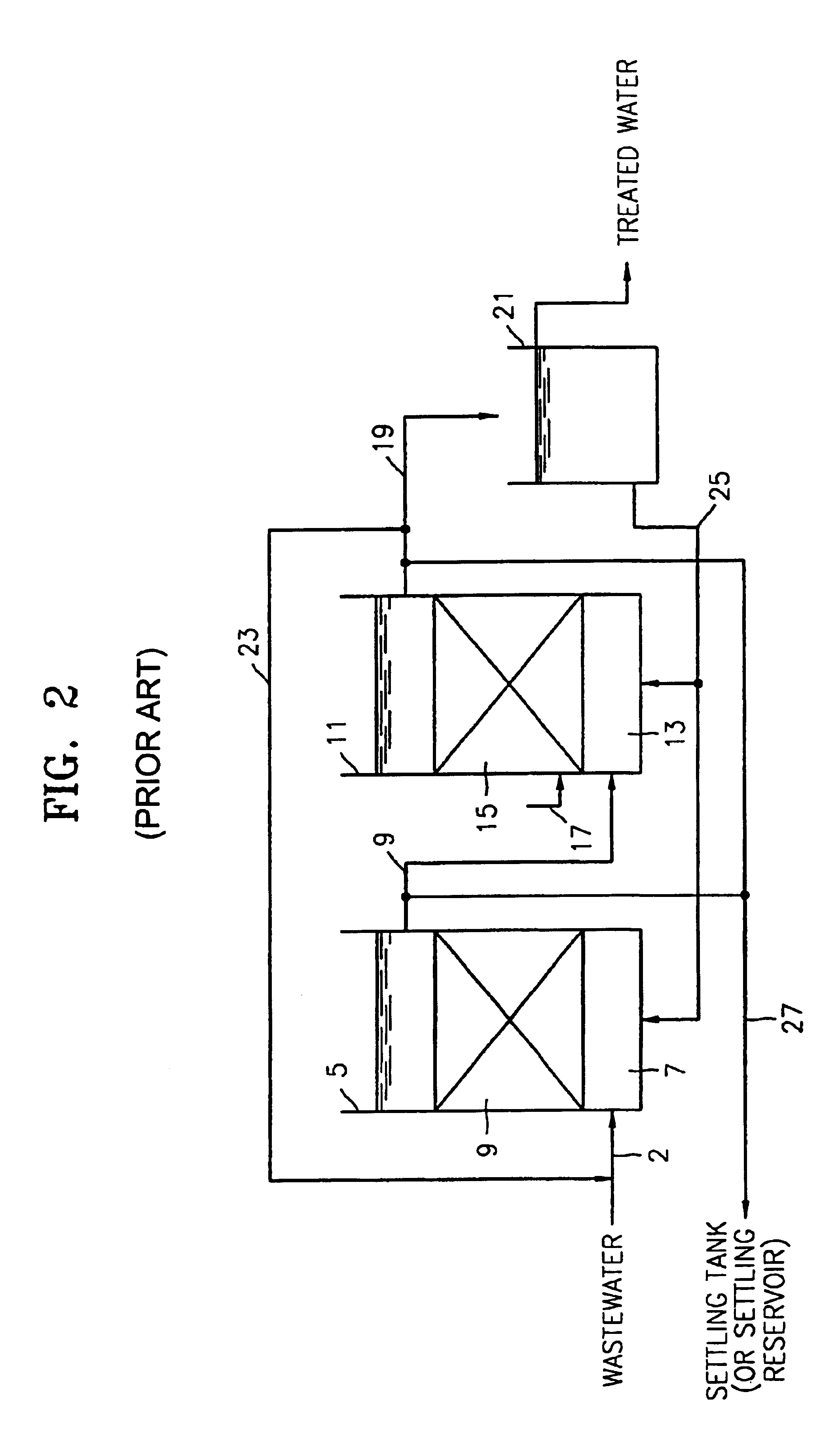

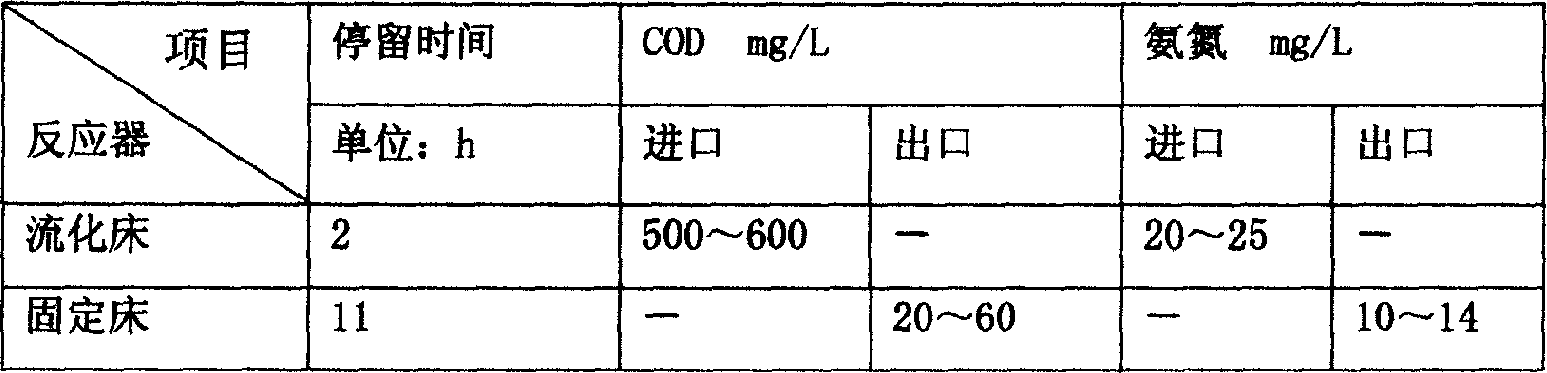

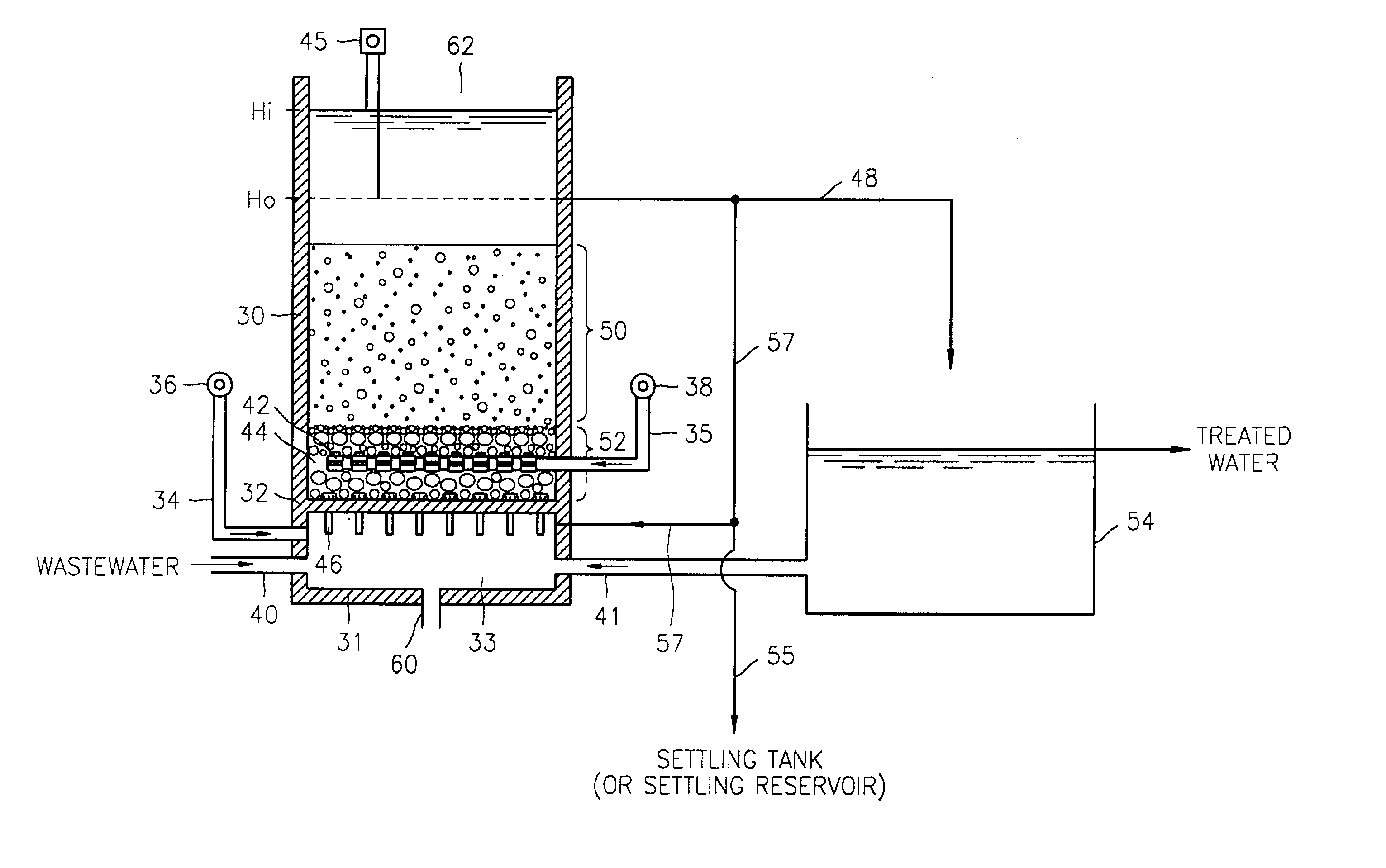

Batch style wastewater treatment apparatus using biological filtering process and wastewater treatment method using the same

InactiveUS6790347B2Simple configurationEasy to operateTreatment using aerobic processesSpecific water treatment objectivesBio filtrationSludge

Provided is a wastewater treatment apparatus including a bottom portion and a plate formed above and spaced apart from the bottom portion to form a lower chamber with the bottom portion, an outlet installed on the bottom portion for drawing off water and sludge in the lower chamber before backwashing, a filter medium layer supported to the upper portion of the plate by the plate, the upper layer of which forms a bottom portion of an upper chamber, a wastewater introducing means connected to the lower chamber, for introducing wastewater to be treated into the lower chamber, a process air introducing means for supplying process air to the filter medium layer formed over the plate, a plurality of aerators formed over and spaced apart a predetermined distance from the plate, and mounted in a plurality of air flow pipes led to the process air introducing means, a backwash air introducing means for supplying backwash air to the lower chamber during backwashing, a backwash water introducing means for supplying backwash water to the lower chamber during backwashing, a plurality of nozzles extending from the lower chamber to the filter medium layer through the plate, a treated water discharging means for discharging the treated water having passed through the filter medium layer, and a returned water introducing means for returning the treated water having passed through the filter medium layer to the lower chamber. A batch style wastewater treatment apparatus utilizing biological filtering process efficiently removes the organic matter, suspended solid matter, nitrogen and phosphorus.

Owner:SAMSUNG ENGINEERING CO LTD

Modified thermal processing of heavy hydrocarbon feedstocks

InactiveUS7572365B2Quick upgradeReduce sulfur emissionsThermal non-catalytic crackingTreatment with plural serial cracking stages onlyLiquid productParticulates

The present invention is directed to the upgrading of heavy petroleum oils of high viscosity and low API gravity that are typically not suitable for pipelining without the use of diluents. It utilizes a short residence-time pyrolytic reactor operating under conditions that result in a rapid pyrolytic distillation with coke formation. Both physical and chemical changes taking place lead to an overall molecular weight reduction in the liquid product and rejection of certain components with the byproduct coke. The liquid product is upgraded primarily because of its substantially reduced viscosity, increased API gravity, and the content of middle and light distillate fractions. While maximizing the overall liquid yield, the improvements in viscosity and API gravity can render the liquid product suitable for pipelining without the use of diluents. This invention particularly relates to reducing sulfur emissions during the combustion of byproduct coke (or coke and gas) and to reducing the total acid number (TAN) of the liquid product. The method comprises introducing a particulate heat carrier into an up-flow reactor, introducing the feedstock at a location above the entry of the particulate heat carrier, allowing the heavy hydrocarbon feedstock to interact with the heat carrier for a short time, separating the vapors of the product stream from the particulate heat carrier and liquid and byproduct solid matter, regenerating the particulate heat carrier in the presence of the calcium compound, and collecting a gaseous and liquid product from the product stream.

Owner:IVANHOE HTL GASOLINEEUM

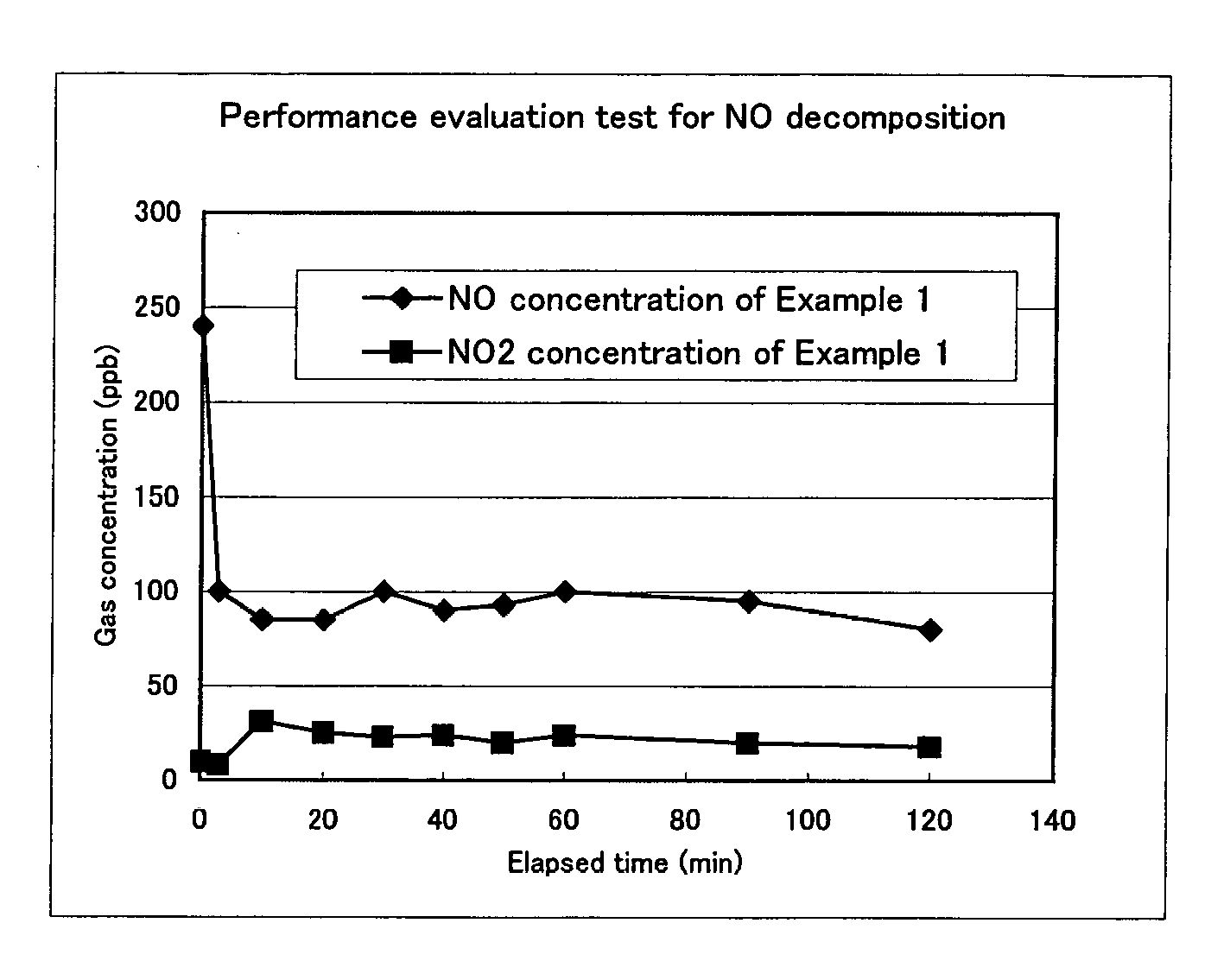

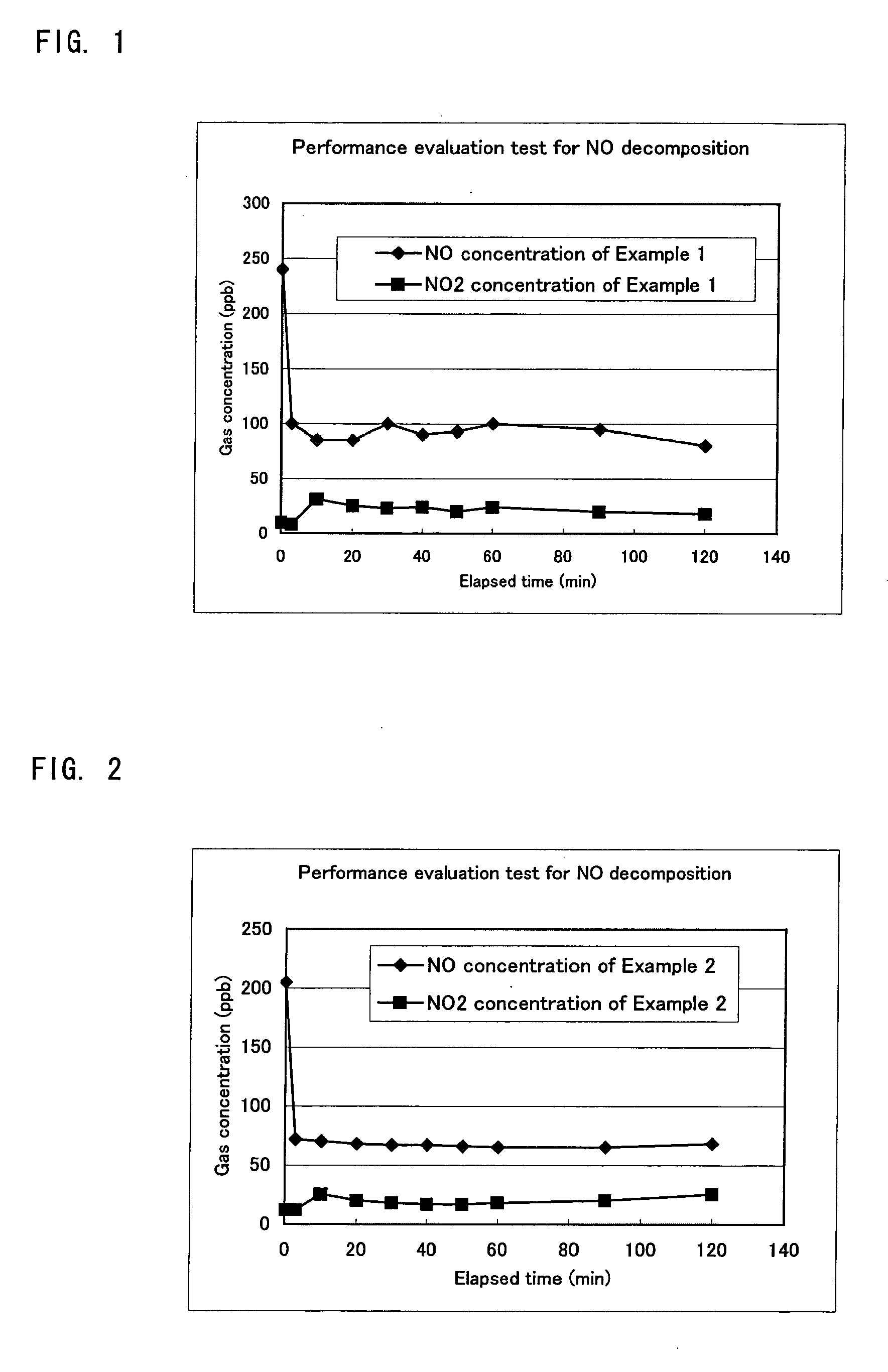

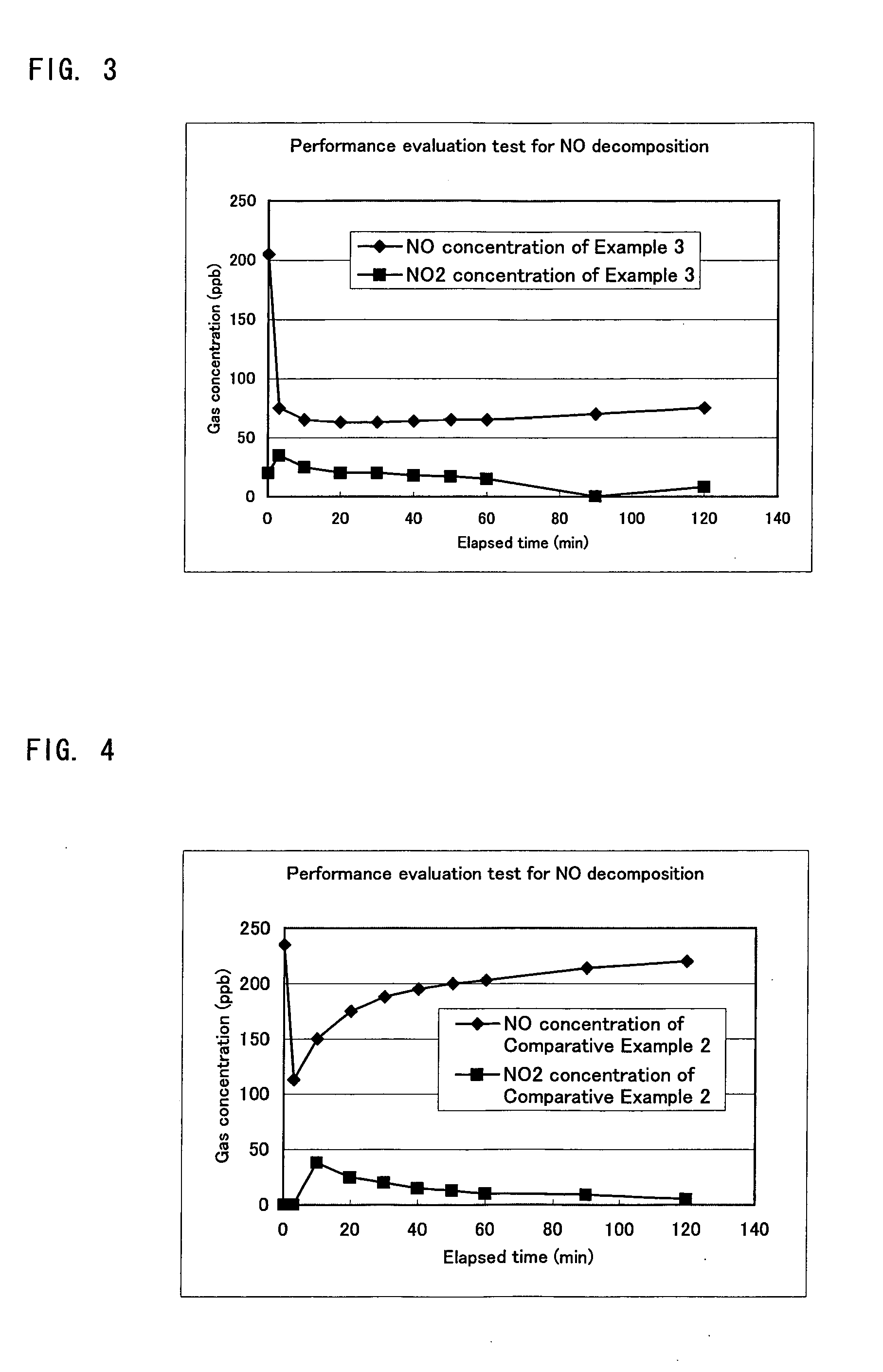

Photocatalytic coating material, photocatalytic composite material and method for producing the same, and self-cleaning water-based coating composition and self-cleaning member

InactiveUS20050277543A1Small contact angleInhibition effectMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsWater basedAdditive ingredient

This invention is intended to provide a photocatalytic coating material which includes: at least (a) photocatalytic oxide particles; (b) a hydrophobic-resin emulsion; and (c) water, wherein the average particle size of the photocatalytic oxide particles is smaller than that of the particles dispersed in the hydrophobic-resin emulsion. This invention is also intended to provide a self-cleaning water-base coating composition which includes: (a) water-based silicone emulsion or the like; (b) photocatalytic particles or a photocatalytic sol; and (c) water, wherein the solid matter of the ingredient (b) constitutes less than 5% by weight of the total solid matter of the coating composition. This invention is also intended to provide a self-cleaning water-base coating composition which includes: (a) water-based silicone emulsion or the like; (b) whisker or the like; (c) photocatalytic particles; (d) an inorganic coloring pigment; and (e) water.

Owner:TOTO LTD +1

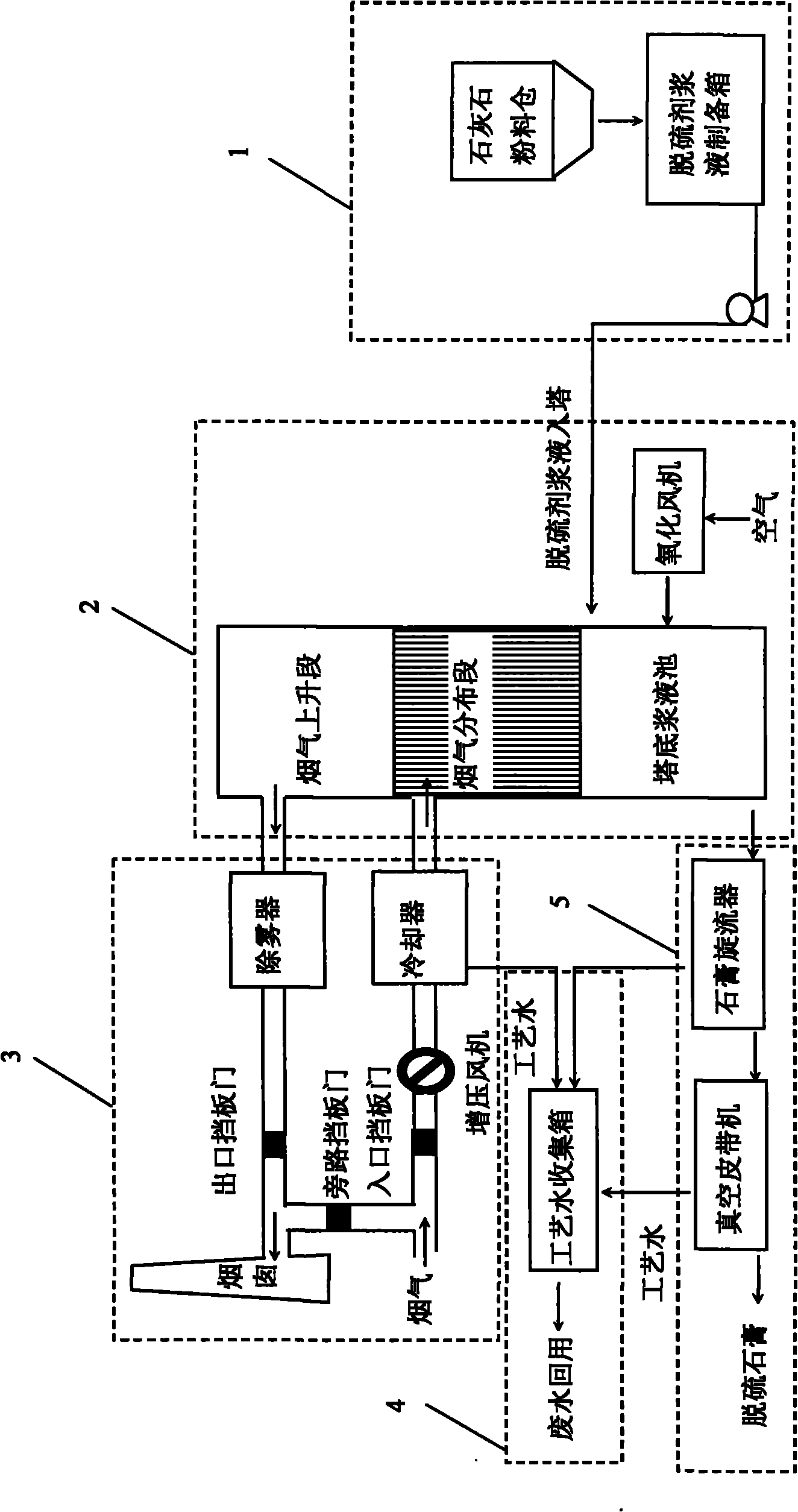

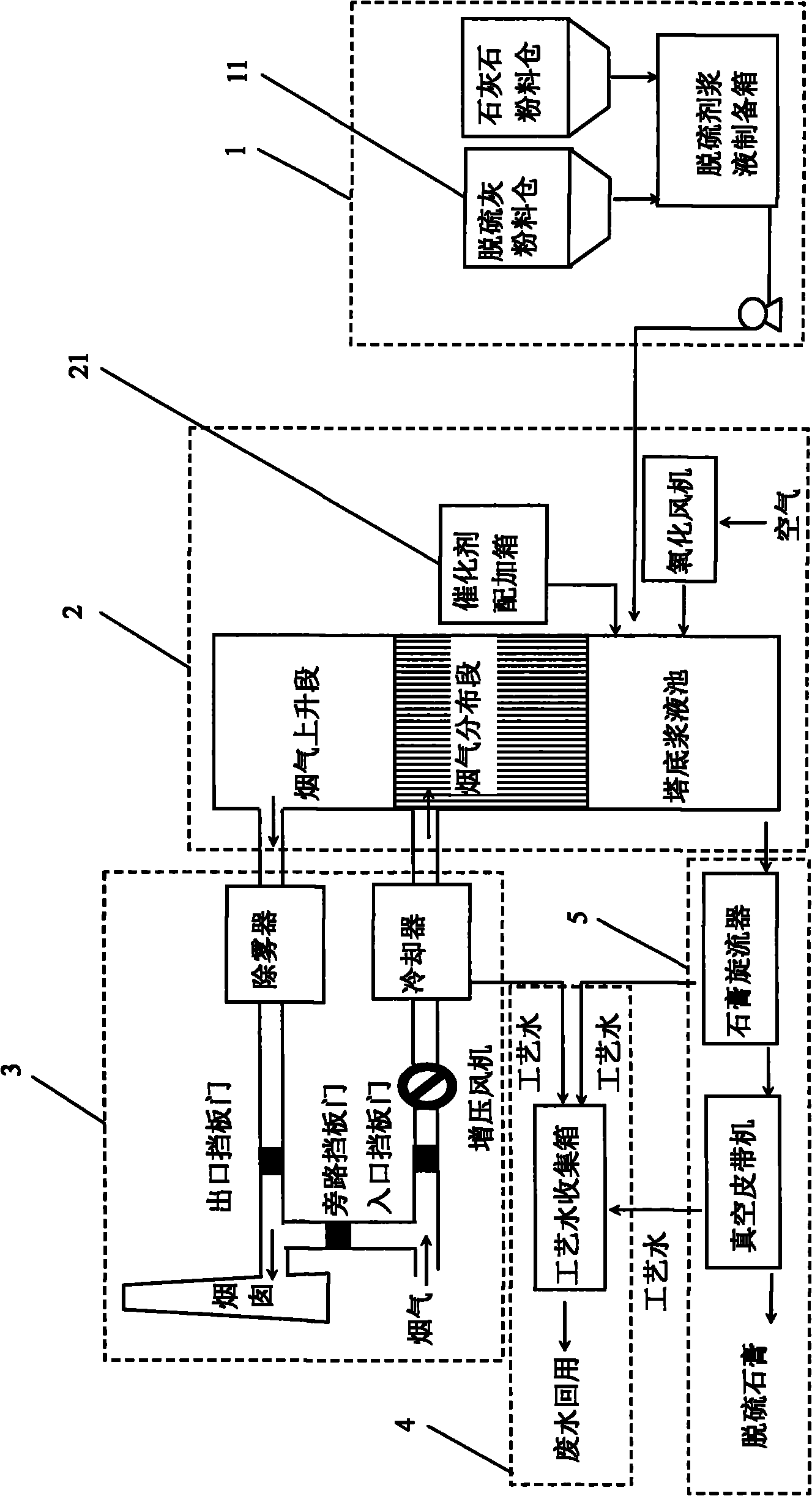

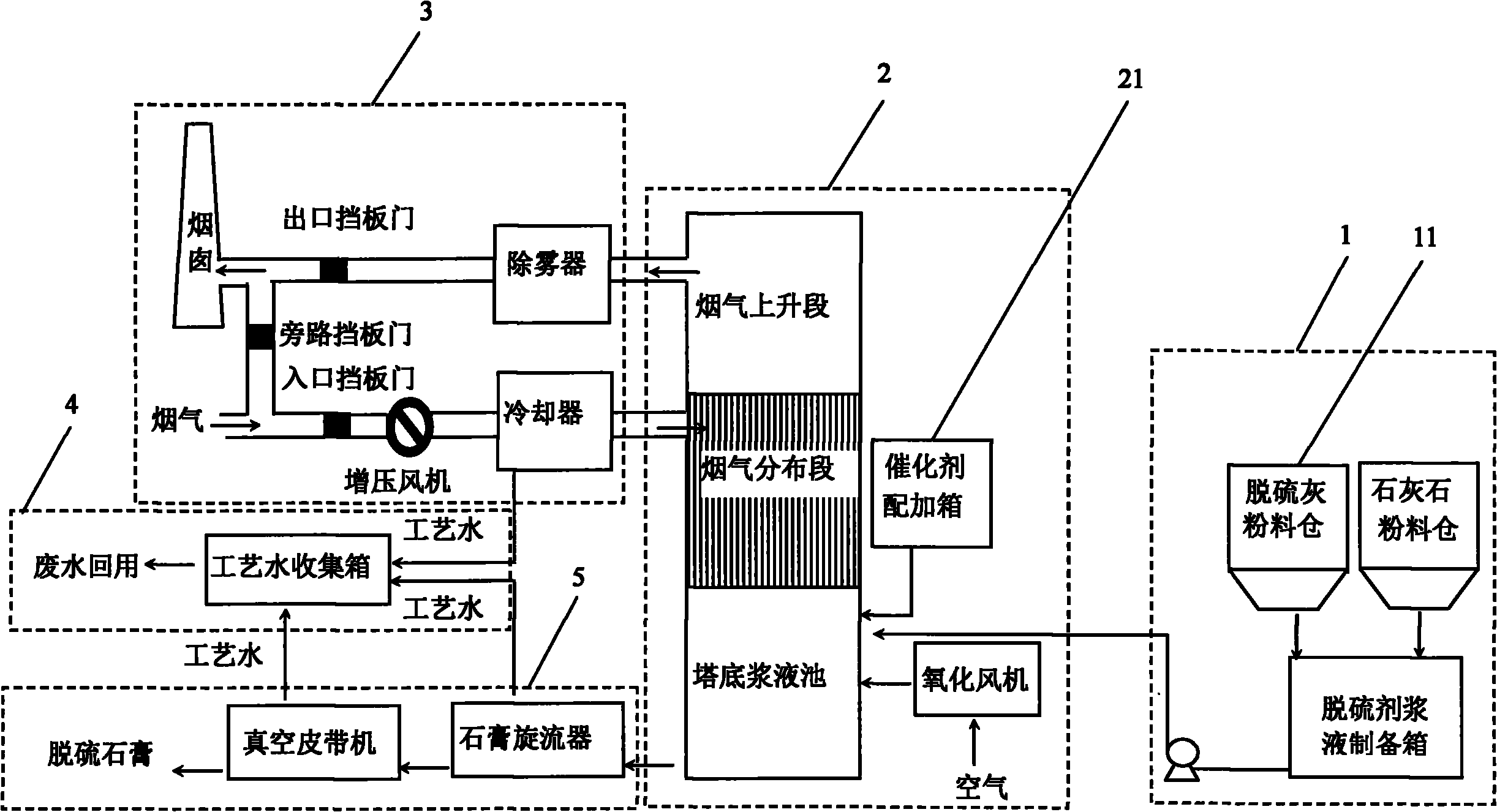

Method for treating desulfurization ash

ActiveCN102000481AEliminate hidden dangersEfficient use ofDispersed particle separationRetention timeProper treatment

The invention discloses a method for treating desulfurization ash. The method comprises the following steps of: mixing the desulfurization ash generated by a dry / semidry desulphurization process and limestone powder, which serve as raw materials of a desulfurizer in a wet flue gas desulfurization process, according to a proportion; uniformly stirring the desulfurizer and pumping the desulfurizer into a slurry pond of an absorption tower; adding a catalyst into the slurry pond; introducing oxidation air into the slurry pond; introducing flue gas into the slurry pond through a flue; reacting the desulfurizer with SO2 in the flue gas under the action of the oxidation air and the catalyst; controlling the pH value of the slurry in the absorption tower, the slurry temperature, the content of solid matters contained in the slurry and the retention time of the desulfurizer in the slurry pond; after the reaction is completed, performing vortex concentration and vacuum filtration to obtain a gypsum by-product; and adding wastewater produced in the process into a process water collection box for recycling. The method is simple, is easy to realize, has remarkable effect, provides a safe and proper treatment way for the dry / semidry desulfurization ash and has good economic and social benefits.

Owner:BAOSHAN IRON & STEEL CO LTD

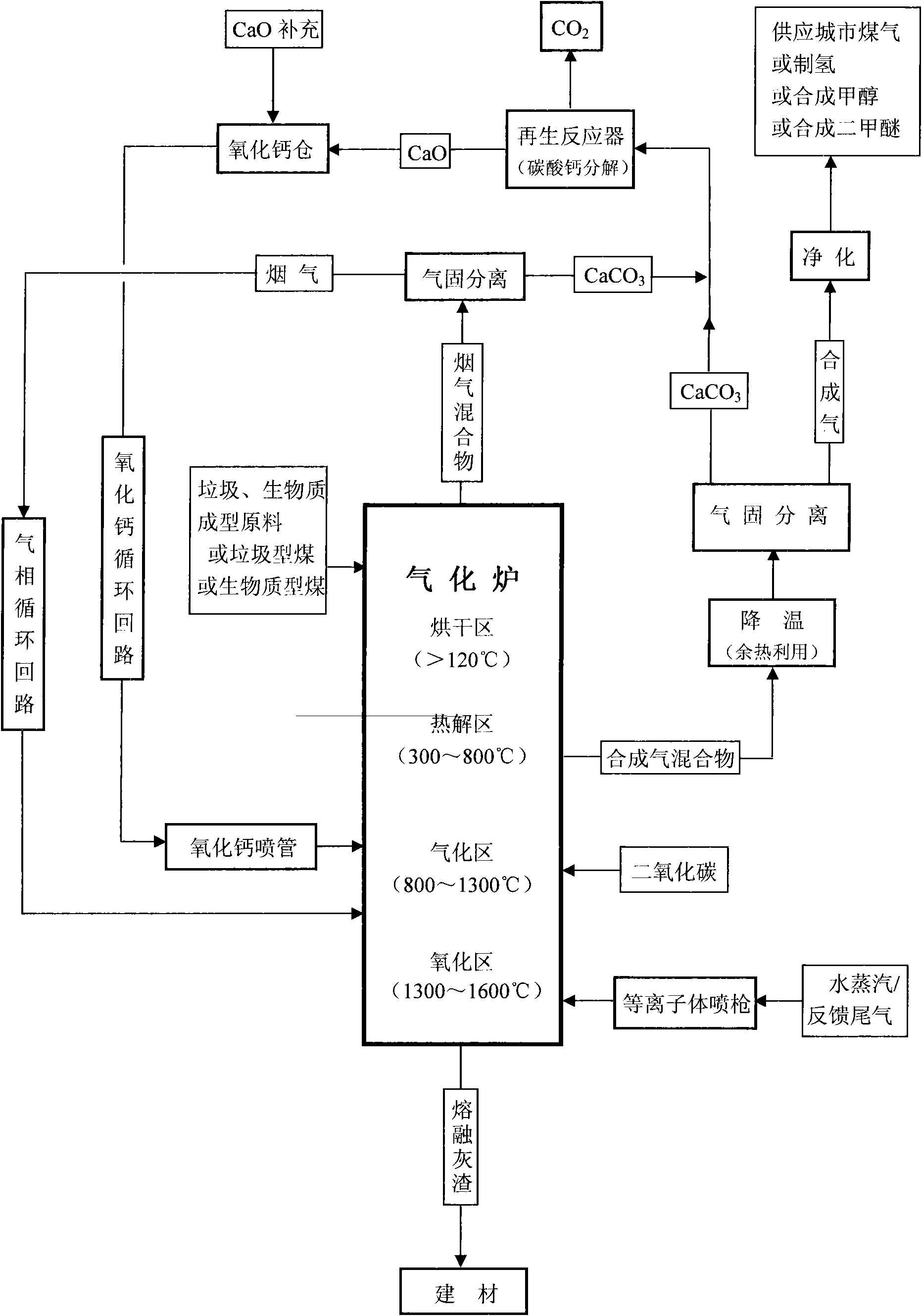

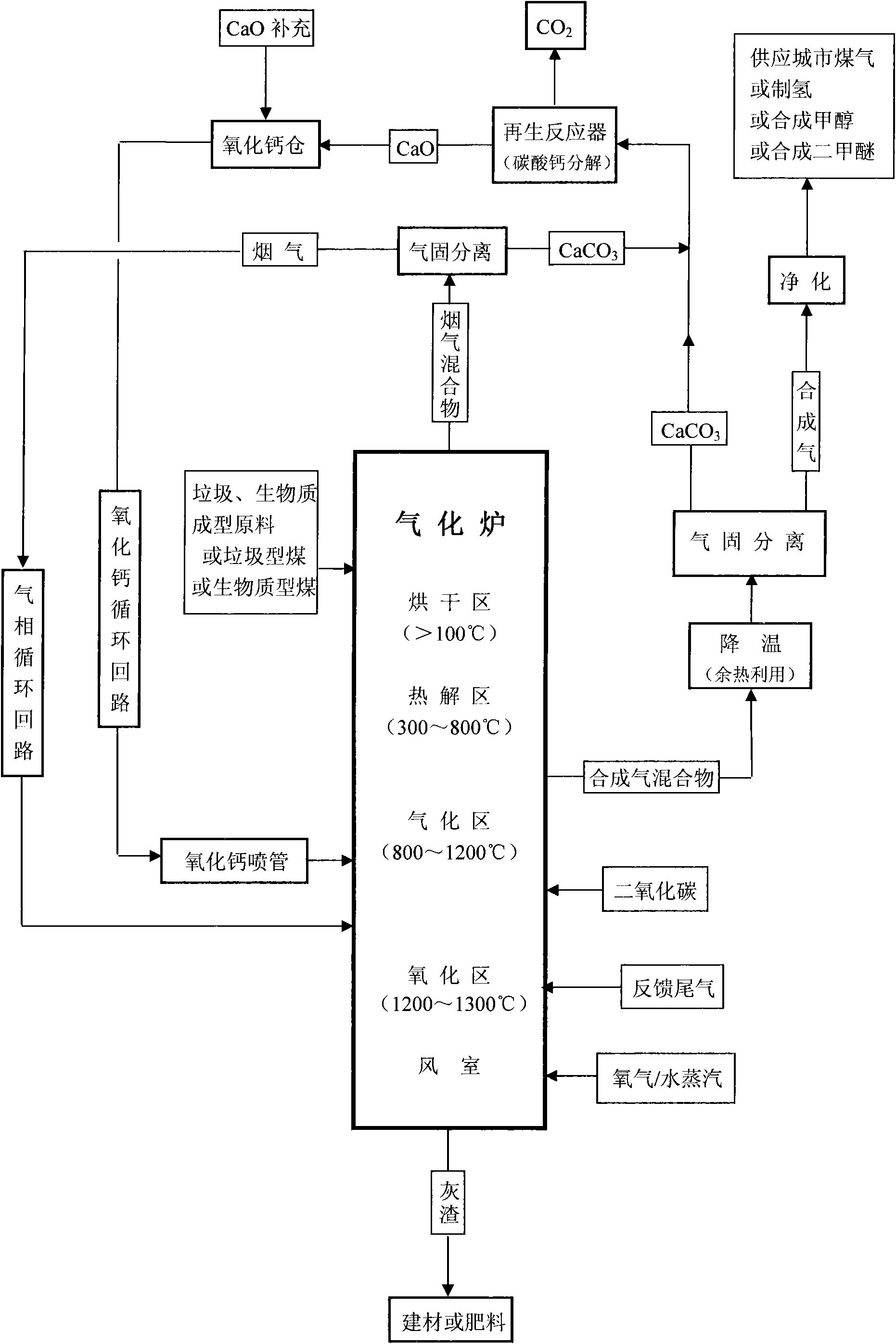

Gasification process for producing synthesis gas from garbage and biomass raw materials

InactiveCN101525118AEliminate pollutionHarmlessHydrogen productionSpecial form destructive distillationGas phaseWater vapor

The invention provides a gasification process for producing synthesis gas from garbage and biomass raw materials, which relates to a gasification processing technique of garbage and biomasses. The gasification process is characterized in that the technological process mainly comprises a raw material solid matter process, a gas phase circulation loop, a calcium oxide circulation loop and a synthesis gas drawing process; one or a mixture of more garbage, the biomasses and coal is sent into a gasification furnace to perform gasification so as to generate the synthesis gas; and simultaneously, calcium oxide is sent into the gasification furnace, an exothermic reaction of absorbing carbon dioxide by the calcium oxide provides the heat required by the gasification reaction in the furnace, and water vapor is sent into a plasma spraying gun and is heated to more than 3,100 DEG C to generate H2, O, O2 and H2O<*> which are sprayed into the gasification furnace to perform reactions with the garbage and the biomasses and supply heat into the furnace. The gasification process adopts a measure to spray the calcium oxide into the furnace to not only greatly reduce the electric energy consumption of the plasma spraying gun, but also improve the quality and the yield of the synthesis gas, thus the aim of transforming the garbage and the biomasses into clean energy can be achieved easily.

Owner:周开根

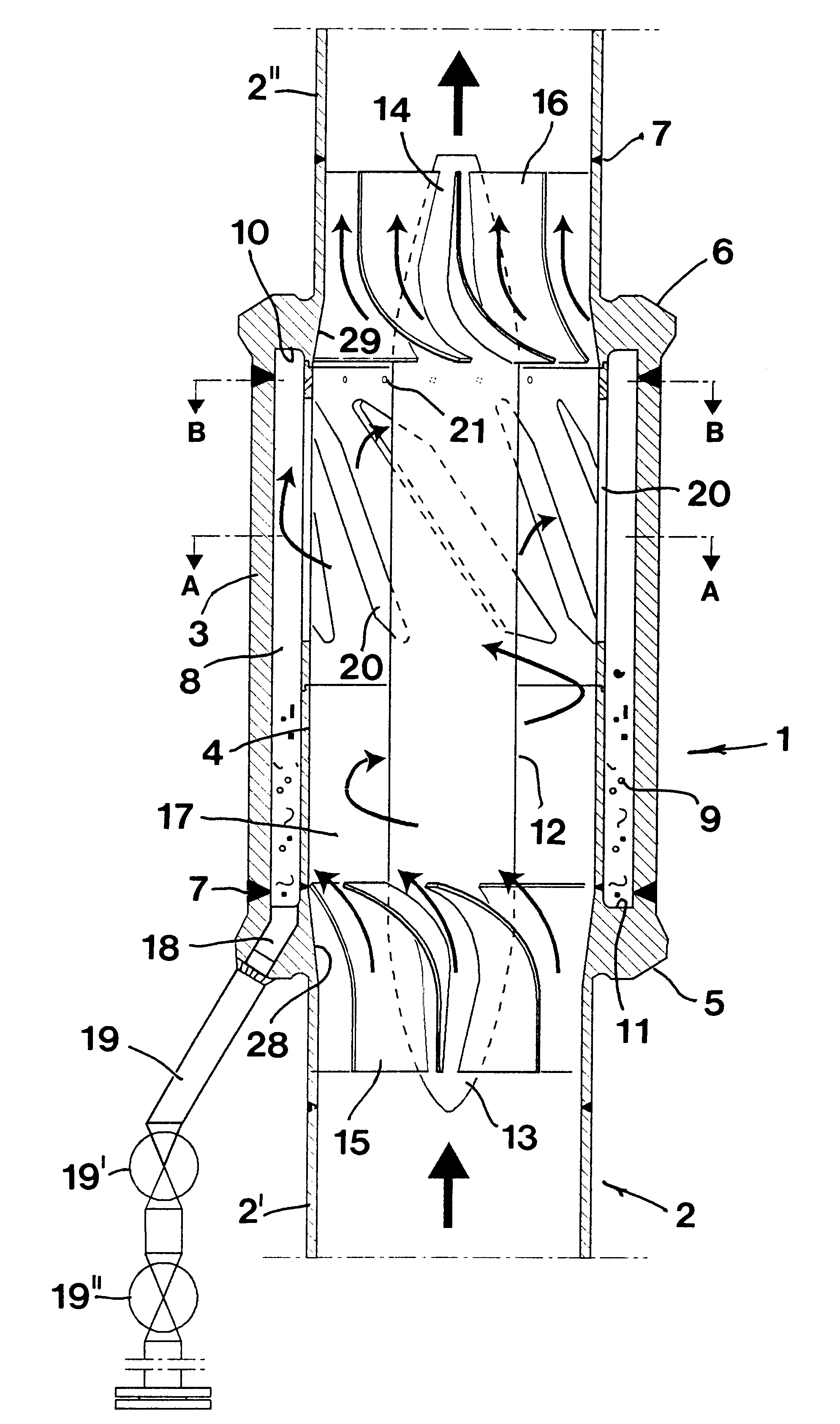

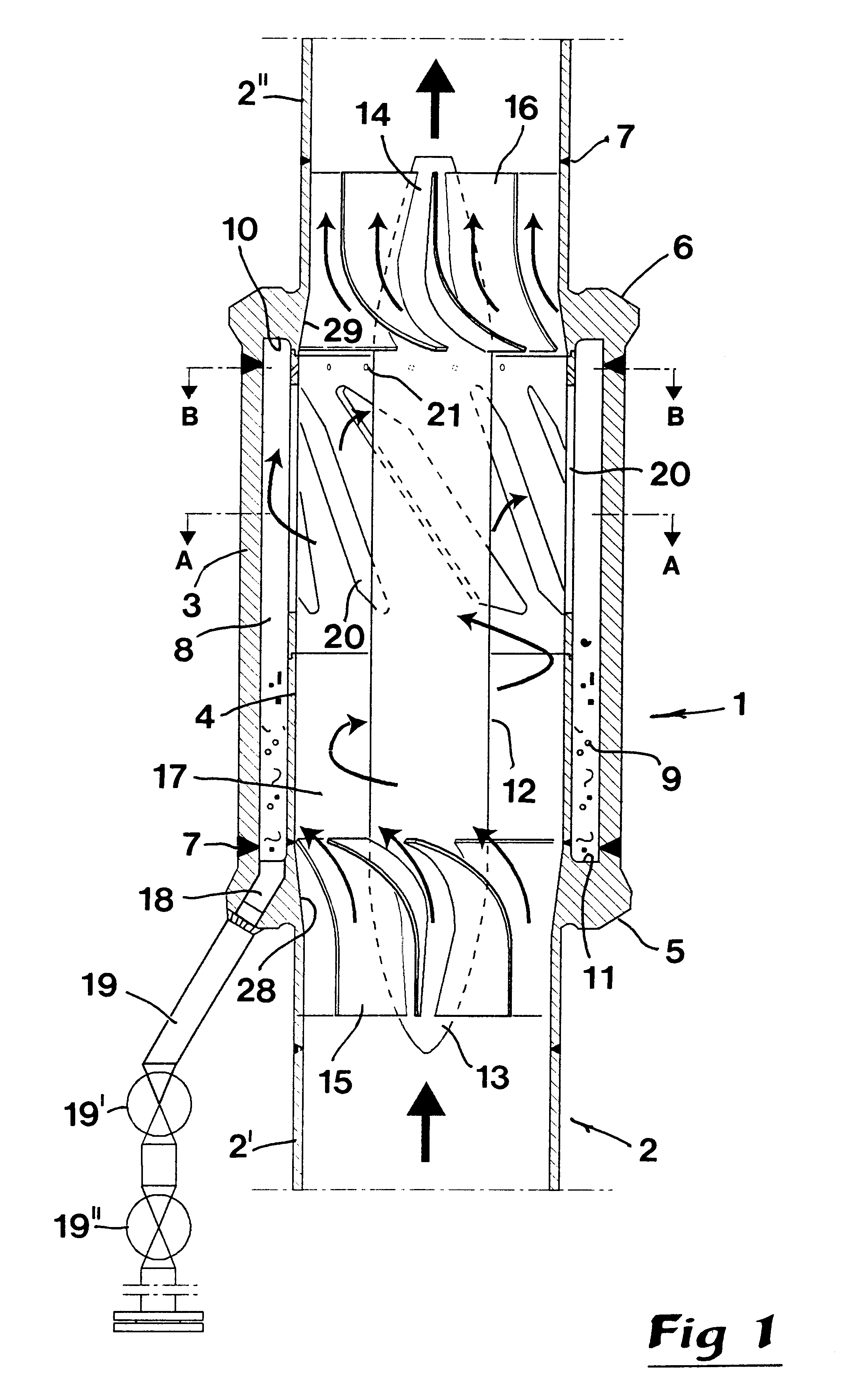

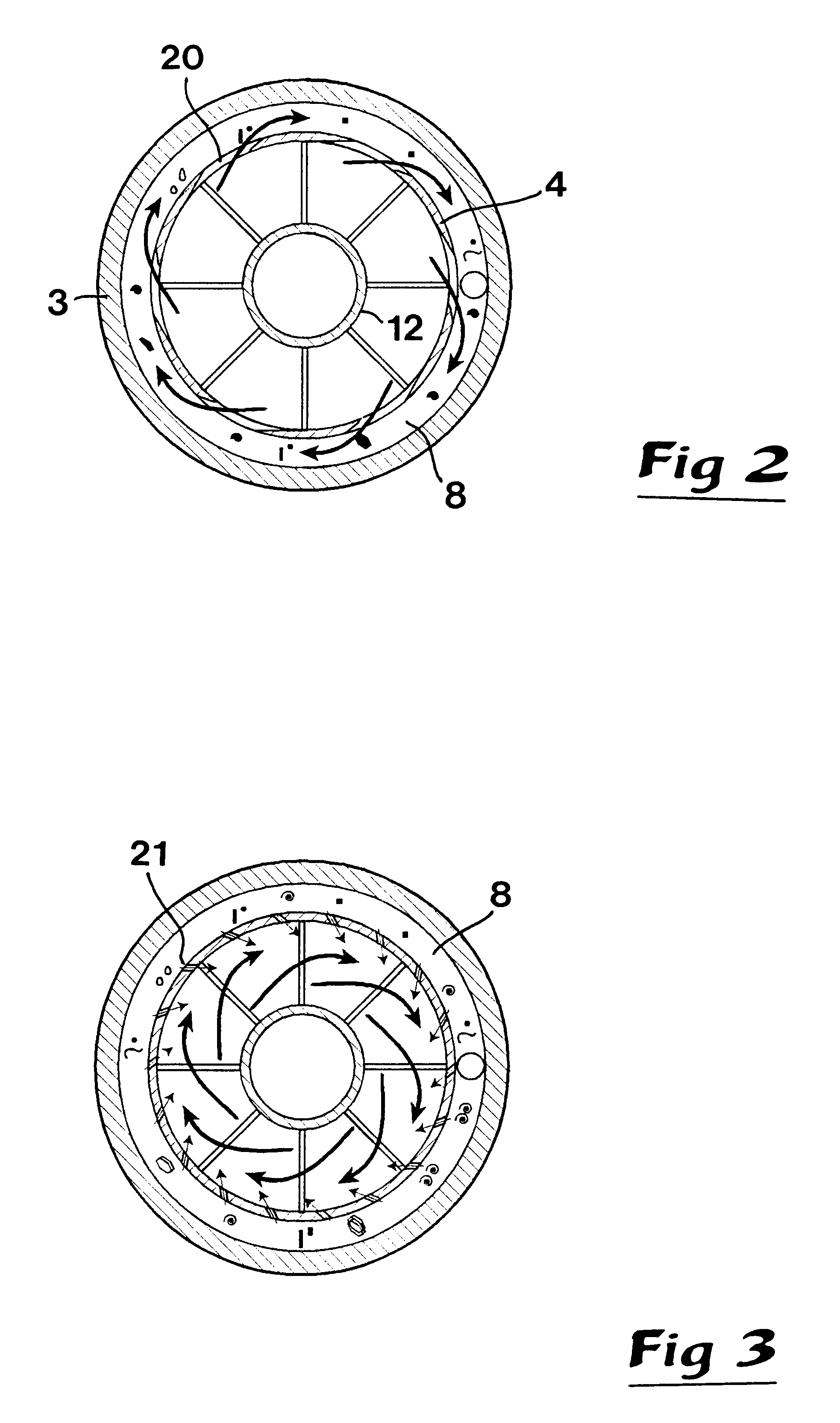

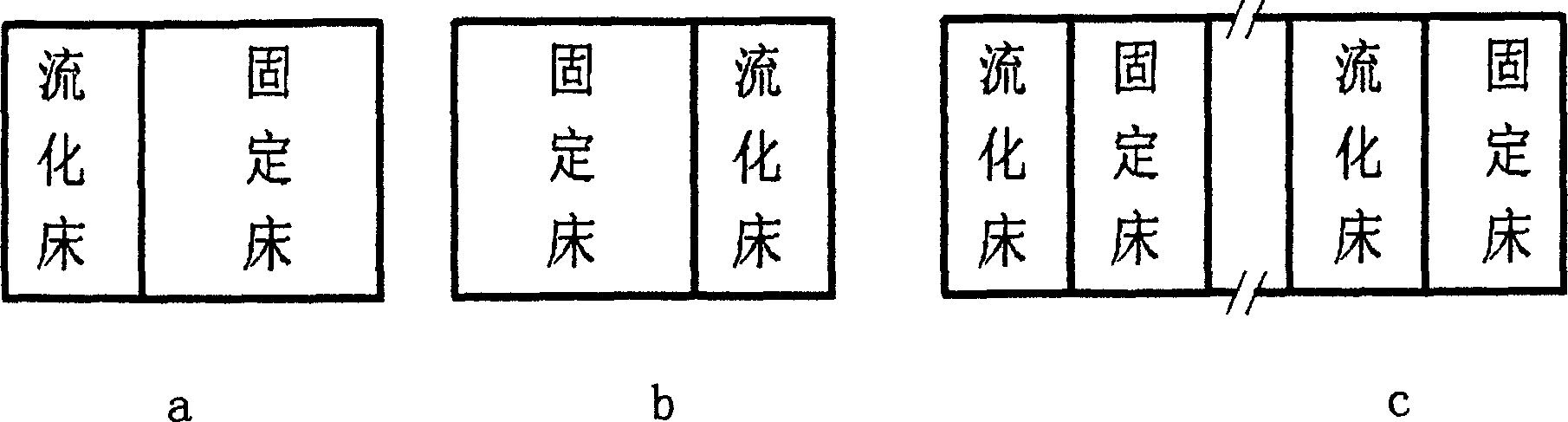

Device for the separation of solid objects from a flowing fluid

InactiveUS6666338B1Water/sewage treatment by centrifugal separationDispersed particle separationScrapEngineering

A device for the separation of solid objects (9) from fluid flowing in a conduit tube (2) includes a housing that includes a tubular outer wall (3) and a tubular inner wall (4). Between these is delimited a collecting space (8). Concentrically relative to the inner wall (4) is provided a rotation-symmetrical central body (12) which at opposing ends cooperates with flow converting devices (15, 16), which transform incoming flow to a rotative motion and outgoing flow to an axial motion. In the inner wall (4) are recessed tangentially separated holes (20) of elongated shape, through which the scrap objects may pass and be collected in a collecting space (8). In the collecting space (8) a calm flow operation is obtained which guarantees that collected scrap objects are not carried away and returned to the main fluid flow through the separation device.

Owner:VATTENFALL

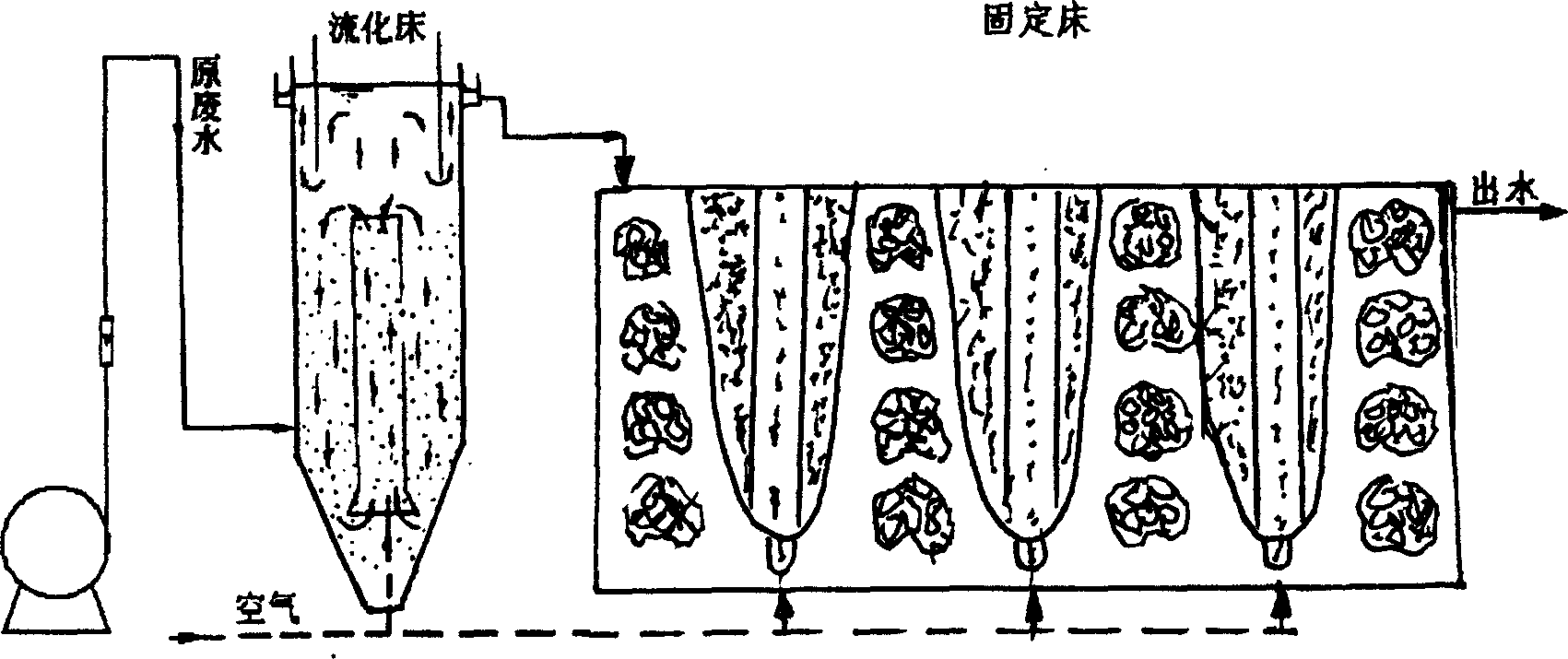

Process for treating waste water by aerobic-anaerobic microbic repeated coupling

ActiveCN1554599AEfficient removalAchieve decompositionSludge processingTreatment with aerobic and anaerobic processesSludgeDecomposition

The present invention belongs to the field of waste water treating technology, and is especially repeated aerobic-anaerobic microbe coupling process of treating waste water in environment protection. Biological fluidizing beds and biological fixed beds are connected serially with overflow partition boards and added with two different kinds of porous biological carriers. Via repeated aerobic-anaerobic microbe coupling in different layers, the present invention disposes organic matter and nitrogen compound in waste water while in-situ decomposing sludge. The present invention realizes the effective elimination of organic matter and nitrogen in waste water, the forced separation of the solid particles from water in the fixed beds and the digestion, degradation and final complete decomposition of solid matter. The present invention has high efficiency, low power consumption and low running cost.

Owner:TSINGHUA UNIV

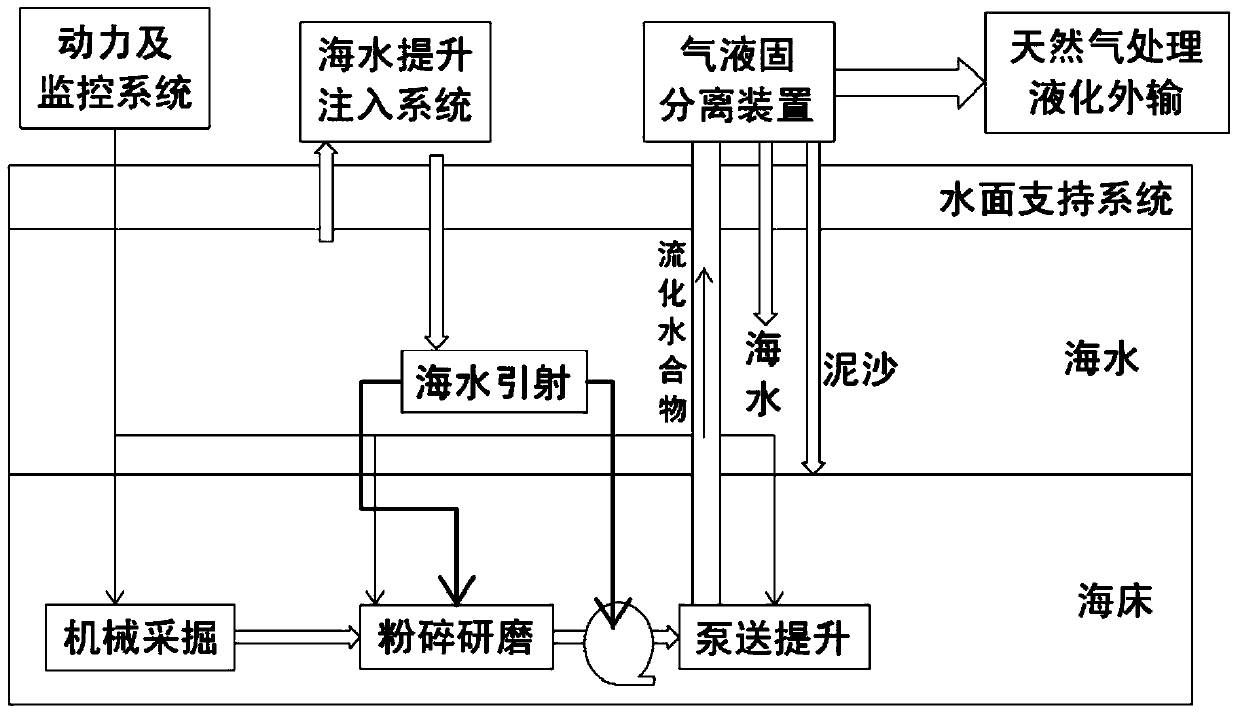

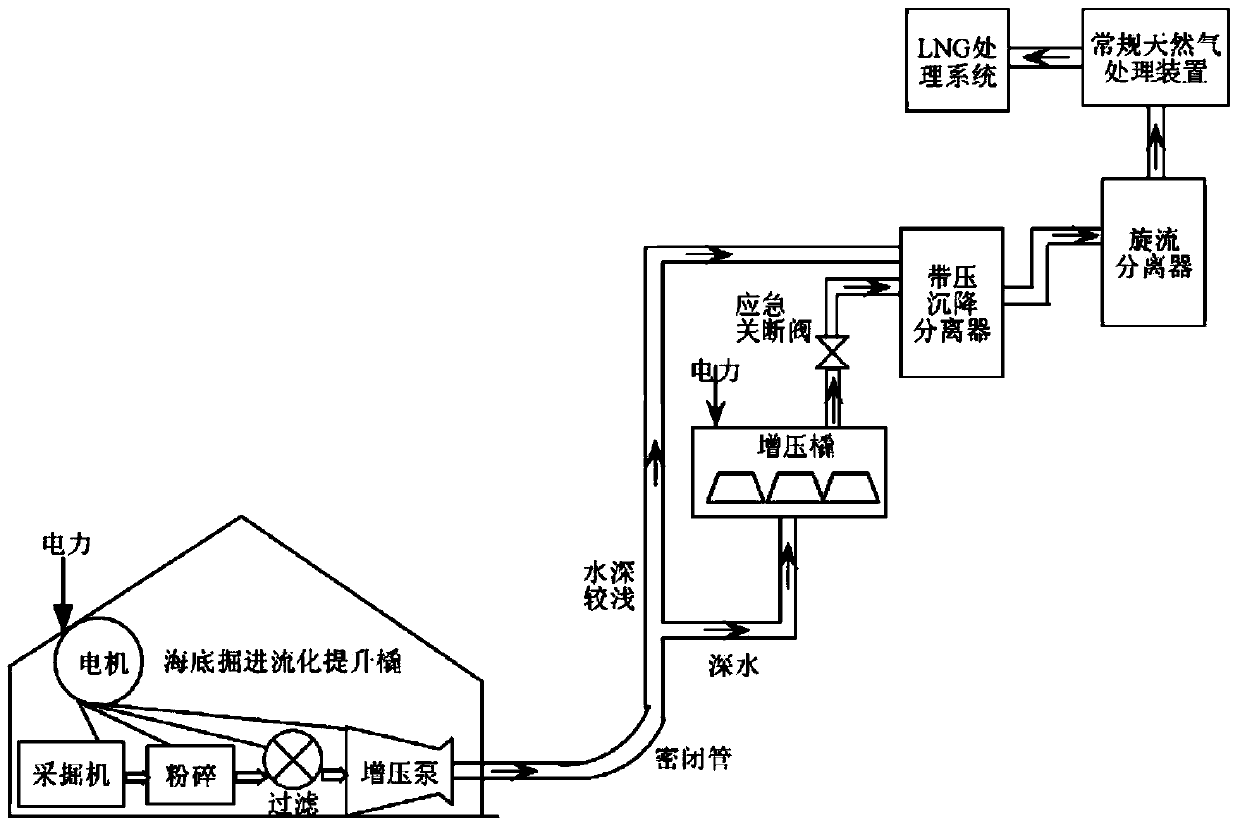

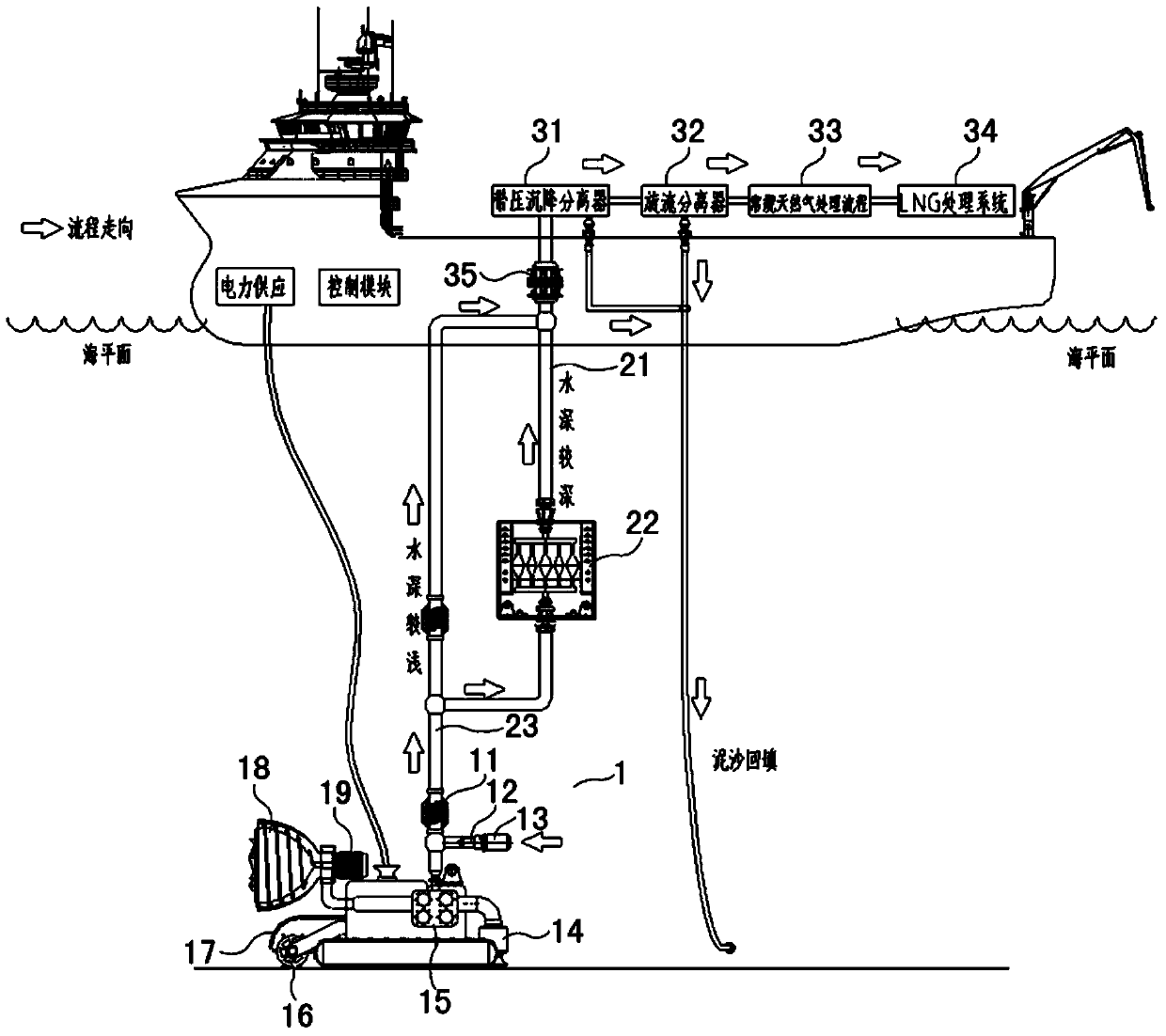

Green mining system of natural gas hydrate from non-lithified stratums of deep-sea seabed superficial layers

ActiveCN103628880ANo change in temperature and pressure conditionsEnabling in-situ solid-state developmentMineral miningParticulatesForming gas

The invention discloses a green mining system of natural gas hydrate. The green mining system is used for mining natural gas hydrate from non-lithified stratums of deep-sea seabed superficial layers. The green mining system comprises a seabed tunneling-fluidifying-lifting pry, a closed fluidifying gathering pipeline and a sea surface separating and processing system, wherein the seabed tunneling-fluidifying-lifting pry is used for excavating a natural gas hydrate reservoir in a solid state in a storage region of the natural gas hydrate by virtue of the temperature and pressure in a natural environment, collecting solid matter of the natural gas hydrate, and crushing the solid matters of the natural gas hydrate into particulate matters, and seawater and the particulate matters are mixed through injection to form gas-liquid-solid multiphase mixture flow; the closed fluidifying gathering pipeline comprises a closed pipeline which is connected with the seabed tunneling-fluidifying-lifting pry so as to lift the gas-liquid-solid multiphase mixture flow to the sea surface; the sea surface separating and processing system is arranged at a sea surface support system and comprises a separating device and a processing device, the separating device is used for separating a gas-liquid-solid multiphase mixture lifted to the sea surface through the closed pipeline, and the processing device is used for processing separated matters. According to the green mining system, the safe and green mining of the deep-sea natural gas hydrate is realized, and potential hazards in multiple aspects are avoided.

Owner:CHINA NAT OFFSHORE OIL CORP

Feeding of a pressurised device with variable grain sizing solid

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

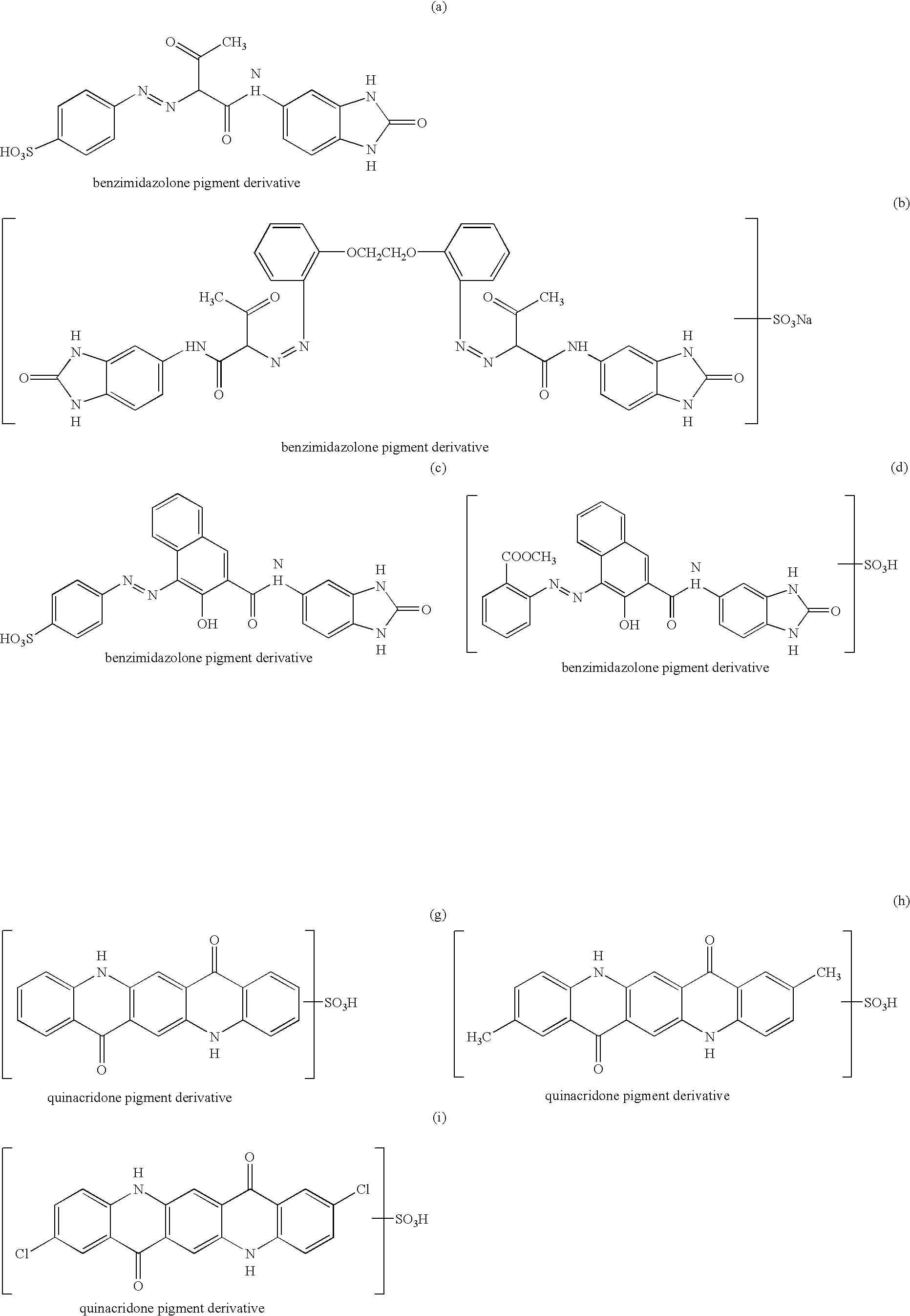

Aqueous pigment dispersion, process for producing the same, and water-based ink comprising the same

A water-based pigment dispersion in which a pigment is dispersed with a water soluble or self-emulsifying thermoplastic resin containing carboxylic group, characterized in that the ratio of the pigment to the thermoplastic resin containing the carboxylic group (pigment / thermoplastic resin containing carboxylic group (weight ratio of effective solid matter)) is 10 / 10 to 10 / 1, the thermoplastic resin containing the carboxylic group is cross-linked with a cross-linking agent after the pigment is dispersed with the thermoplastic resin, and the ratio of the cross-linking agent to the thermoplastic resin containing the carboxylic group (cross-linking agent / thermoplastic resin containing carboxylic group (weight ratio of effective solid matter)) is 1 / 100 to 50 / 100; a process for preparing the same; and a water-based ink containing the same. The water-based pigment dispersion shows excellent light resistance, water resistance, alkali resistance, solvent resistance and stability during the passage of time at the same time.

Owner:MIKUNI SHIKISO

Zinc/air cell with improved anode

InactiveUS20050003271A1Eliminate disadvantagesSufficient structural integrityFuel and primary cellsAlkaline accumulatorsSolid massPolyvinyl alcohol

A method of forming an anode comprising zinc for a zinc / air cell. The method involves mixing zinc particles with binders including preferably polyvinylalcohol, surfactant and water to form a wet paste. The wet paste is compacted and molded into the near shape of the cell's anode cavity and then heated to evaporate water. A solid porous zinc mass is formed wherein the zinc particles are held bound within a network with microscopic void spaces between the zinc particles. The solid mass can be inserted into the cell's anode cavity and aqueous alkaline electrolyte, preferably comprising potassium hydroxide, then added. The solid mass absorbs the aqueous electrolyte and expands to fill the anode cavity to form the final fresh anode.

Owner:DURACELL U S OPERATIONS

Batch style wastewater treatment apparatus using biological filtering process and wastewater treatment method using the same

InactiveUS20030111412A1Simple configurationEasy to operateTreatment using aerobic processesSpecific water treatment objectivesBio filtrationSludge

Provided is a wastewater treatment apparatus including a bottom portion and a plate formed above and spaced apart from the bottom portion to form a lower chamber with the bottom portion, an outlet installed on the bottom portion for drawing off water and sludge in the lower chamber before backwashing, a filter medium layer supported to the upper portion of the plate by the plate, the upper layer of which forms a bottom portion of an upper chamber, a wastewater introducing means connected to the lower chamber, for introducing wastewater to be treated into the lower chamber, a process air introducing means for supplying process air to the filter medium layer formed over the plate, a plurality of aerators formed over and spaced apart a predetermined distance from the plate, and mounted in a plurality of air flow pipes led to the process air introducing means, a backwash air introducing means for supplying backwash air to the lower chamber during backwashing, a backwash water introducing means for supplying backwash water to the lower chamber during backwashing, a plurality of nozzles extending from the lower chamber to the filter medium layer through the plate, a treated water discharging means for discharging the treated water having passed through the filter medium layer, and a returned water introducing means for returning the treated water having passed through the filter medium layer to the lower chamber. By means of batch style wastewater treatment apparatus utilizing biological filtering process, the organic matter, suspended solid matter, nitrogen and phosphorus can be efficiently removed.

Owner:SAMSUNG ENGINEERING CO LTD

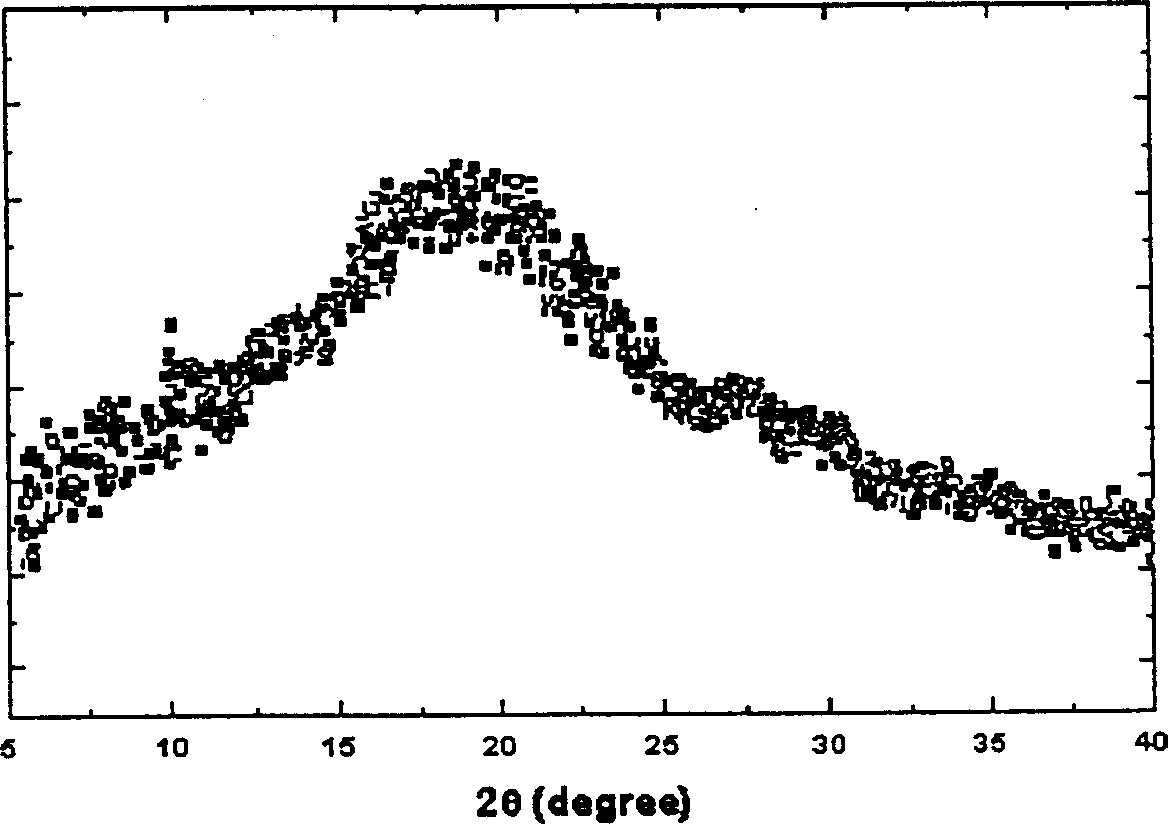

Amorphous Adefuweizhi ester amorphous solid matter and its prepn

InactiveCN1374314AEasy to filterKeep dryOrganic active ingredientsGroup 5/15 element organic compoundsSolid matterChemistry

The present invention is amorphous Adefuweichi ester solid matter and its preparation process. The amorphous Adefuweichi ester solid matter is solid powder obtained through solidifying oil amorphous Adefuweichi ester and has, X-ray test shows, at least 80% amorphous component. The amorphous Adefuweichi ester solid matter of the present invention is easy to filter and dry, has excellent flowability and bulk density performance, and the present invention makes it easy to produce medicine composite containing Adefuweichi ester and its suitable for industrial production.

Owner:上海仲夏化学有限公司

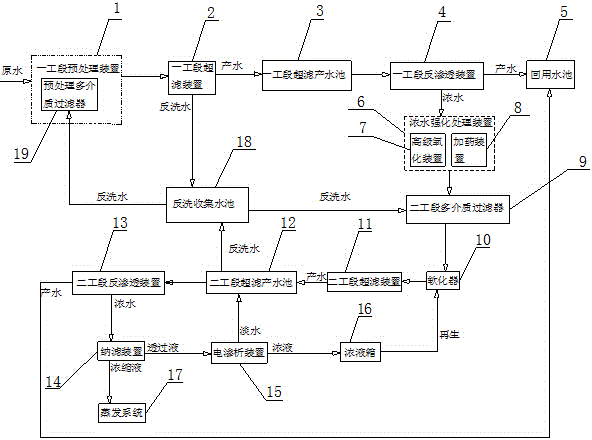

Treatment method for zero discharge of high-hardness high-salinity wastewater

ActiveCN104370405AImprove recycling ratesSolve pollutionWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentFiltrationUltrafiltration

The invention relates to the technical field of water treatment, and particularly relates to and discloses a treatment method for zero discharge of high-hardness high-salinity wastewater. The method comprises the steps of pretreating; ultrafiltering in a first section; carrying out reverse osmosis treatment in the first section; carrying out enhancing treatment on reverse osmosis concentrate in the first section; filtering by multiple mediums, softening, and ultrafiltering and carrying out reverse osmosis treatment in a second section; passing the reverse osmosis concentrate in the second section through a nano-filtration device; passing nano-filtration permeate through an electrodialysis device; introducing fresh water generated by the electrodialysis device into ultrafiltration water of the second section, and taking concentrate in the electroldialysis device for regenerating a softener; feeding nano-filtration concentrate into an evaporation system to obtain a solid matter, and taking water in reverse osmosis treatment of the first and second sections as reuse water. According to the treatment method for zero discharge of high-hardness high-salinity wastewater, physicochemical treatment, membrane integration technology and evaporation technology are combined, so that the problem that the environment is polluted by high-hardness high-salinity concentrate discharge can be effectively solved, the requirement for zero discharge can be met, the effluent water quality is stable, and the water utilization rate is improved.

Owner:ZHEJIANG CREATION ENVIRONMENT TECH

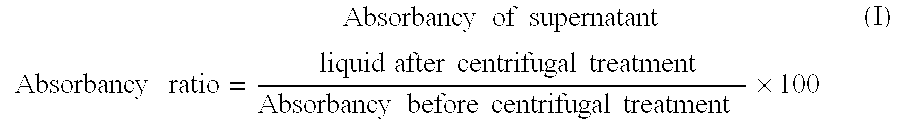

Rapid preparation method of carbon quantum dots

The invention provides a rapid preparation method of carbon quantum dots. The rapid preparation method comprises the following steps: dispersing a carbon source into a solvent; stirring until the carbon source is dissolved; then adding an alkaline source, and carrying out ultrasonic treatment to uniformly mix the alkali source; after heating to boil a solution, continuously heating until the solution is transformed into a sticky matter or a solid matter; then stopping heating and cooling to room temperature to obtain a solid product; dispersing the solid product into a solvent according to a mass ratio of 1 : (100 to 1000) and carrying out the ultrasonic treatment to uniformly disperse the solid product; then putting a solution in a high-speed centrifugal machine and centrifuging to obtainsupernatant, namely a solution containing the carbon quantum dots. Compared with a traditional method for preparing the carbon quantum dots, the rapid preparation method provided by the invention hasthe characteristics of simple operation method, short reaction time, moderate needed conditions and the like, and the aim of rapidly producing the high-quality carbon quantum dots in a large scale can be realized under a low energy consumption condition. The carbon quantum dots prepared by the rapid preparation method have a uniform size and the yield of fluorescent quanta is high. The method provided by the invention is suitable for large-scale industrial production of the high-quality carbon quantum dots.

Owner:烟台好前程文具有限公司

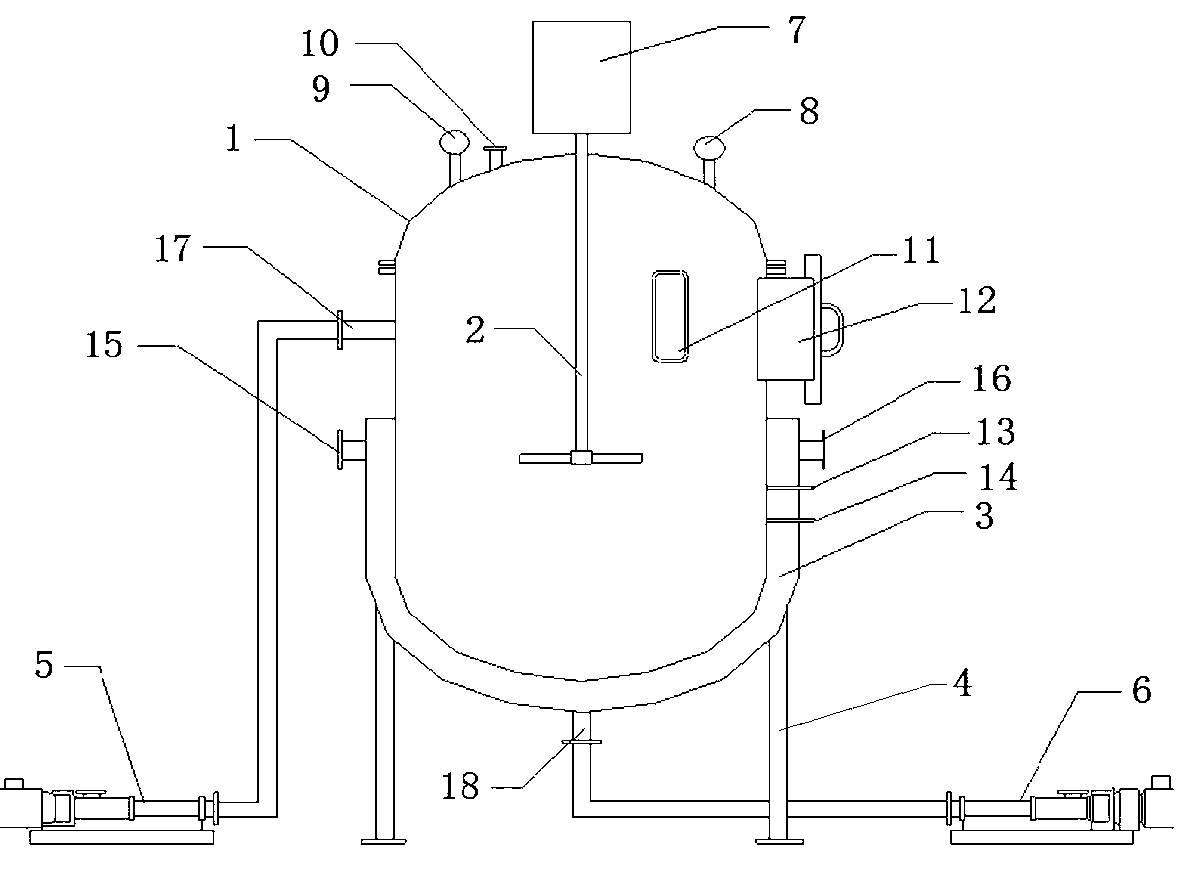

Kitchen waste disposal method and anaerobic fermentation reaction device

InactiveCN102703514ASpeed up the fermentation processHigh yieldBiological substance pretreatmentsGas production bioreactorsMicrobial transformationBiogas production

The invention discloses a kitchen waste disposal method, which comprises the following steps of: (1) screening and crushing kitchen waste; (2) carrying out damp and hot hydrolytic treatment; (3) carrying out solid-liquid separation; (4) carrying out fat separation; (5) pulping; (6) carrying out fermentation pretreatment, and (7) converting solid matter microorganism. According to the kitchen waste disposal method disclosed by the invention, from the view point of improving the biodegradation efficiency and the biogas production efficiency of the kitchen waste, the methane is prepared from compound microorganism bacterium agent and the processed kitchen waste by mixing and fermenting, and the microorganism bacterium agent fundamentally solves the problems of high saline matter and high fat of the kitchen waste and odour in a biological treatment process, and greatly improves the efficiency of producing the methane by anaerobic digestion.

Owner:无锡丰陆环保科技有限公司

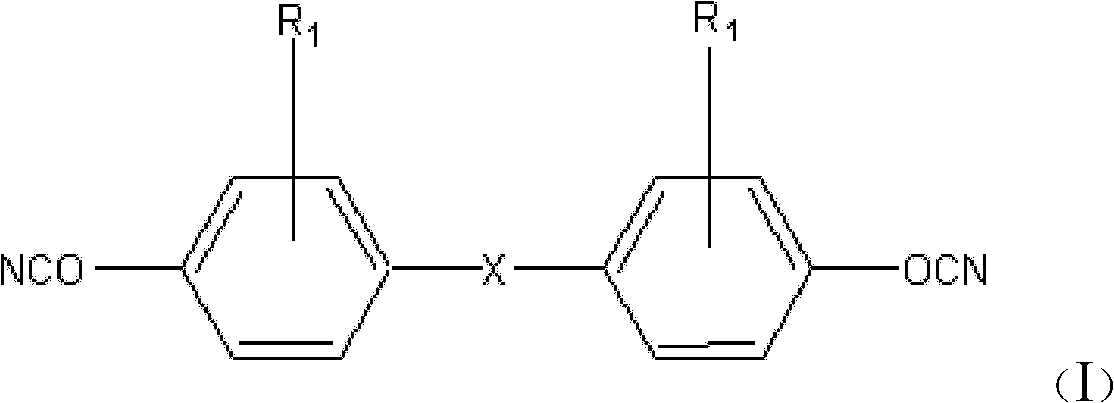

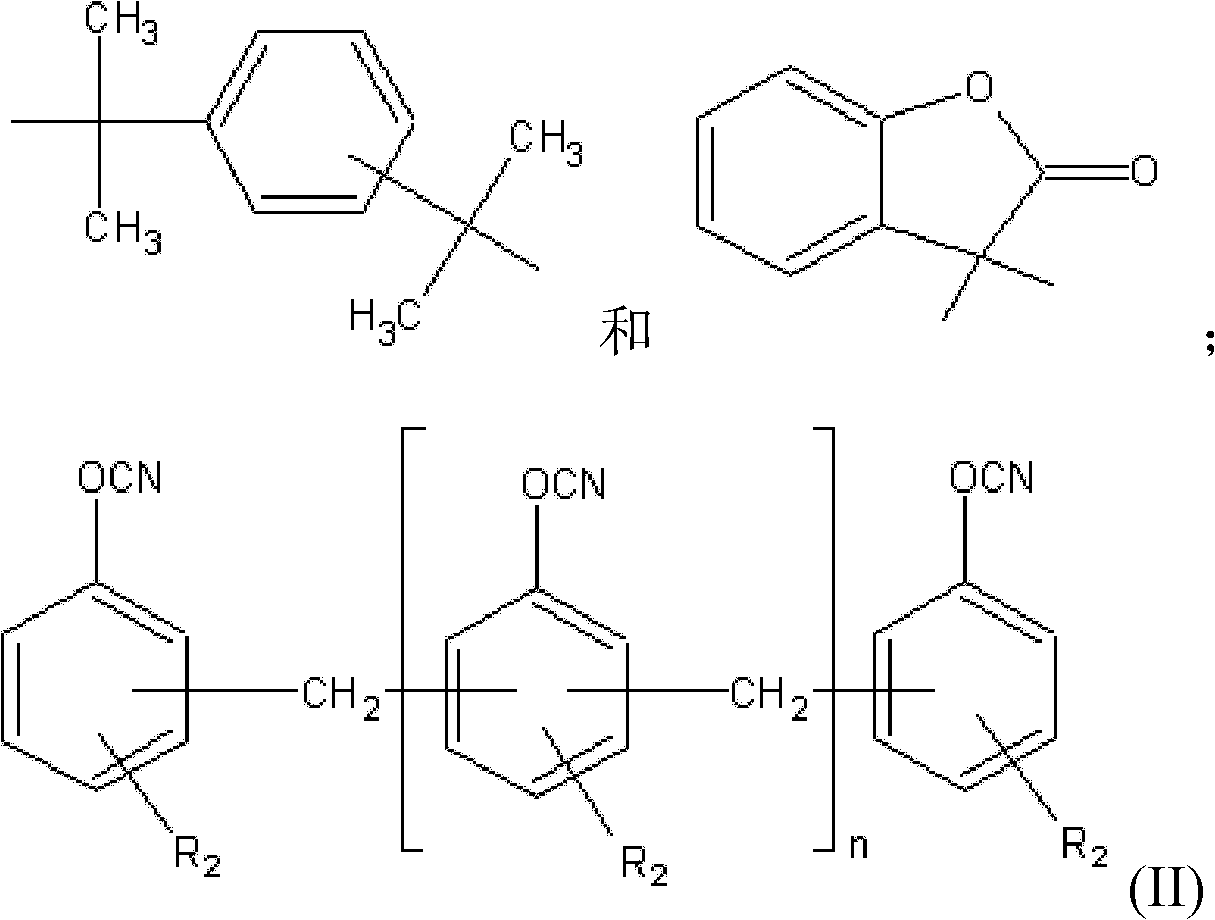

Halogen-free Tg resin composite and presoaked material and laminated board made by adopting same

ActiveCN102134375AExcellent dielectric propertiesLow dielectric propertiesPrinted circuit aspectsSynthetic resin layered productsVitrificationPhosphonium

The invention relates to a halogen-free Tg resin composite and a presoaked material and a laminated board made by adopting the composite. Counted by part by weight of organic solid matters, the halogen-free high-Tg resin composite contains the following components according to part by weight: (A) 10 to 50 parts by weight of cyanate resin; (B) 10 to 50 parts by weight of at least one compound withdihydro-benzoxazine ring; (C) 10 to 50 parts by weight of at least one kind of bismaleimides resin; (D) 10 to 50 parts by weight of at least one kind of poly-epoxy compound; and (E) 5 to 30 parts by weight of at least one kind phosphonium flame retardant. The halogen-free high-Tg resin composite has the performances of low water absorption, low CTE (coefficient of thermal expansion), high Tg, good dielectric property and the like, and the presoaked material and laminated board made by adopting the composite has the characteristics of high vitrification transition temperature, low CTE, low dielectric constant, low water absorption, high thermal resistance and the like, thus being application to multi-layer circuit boards.

Owner:GUANGDONG SHENGYI SCI TECH

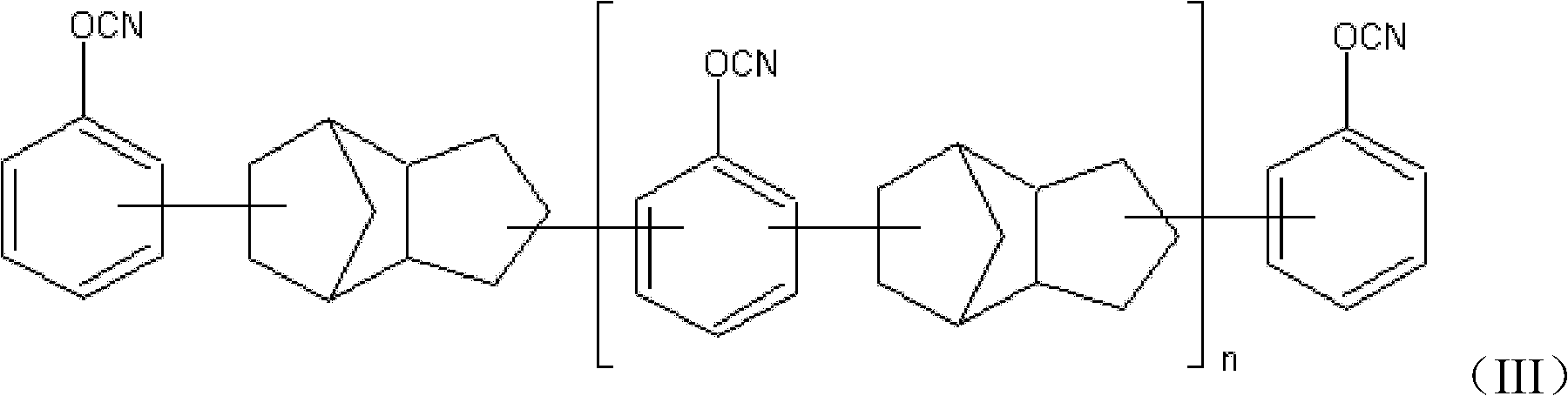

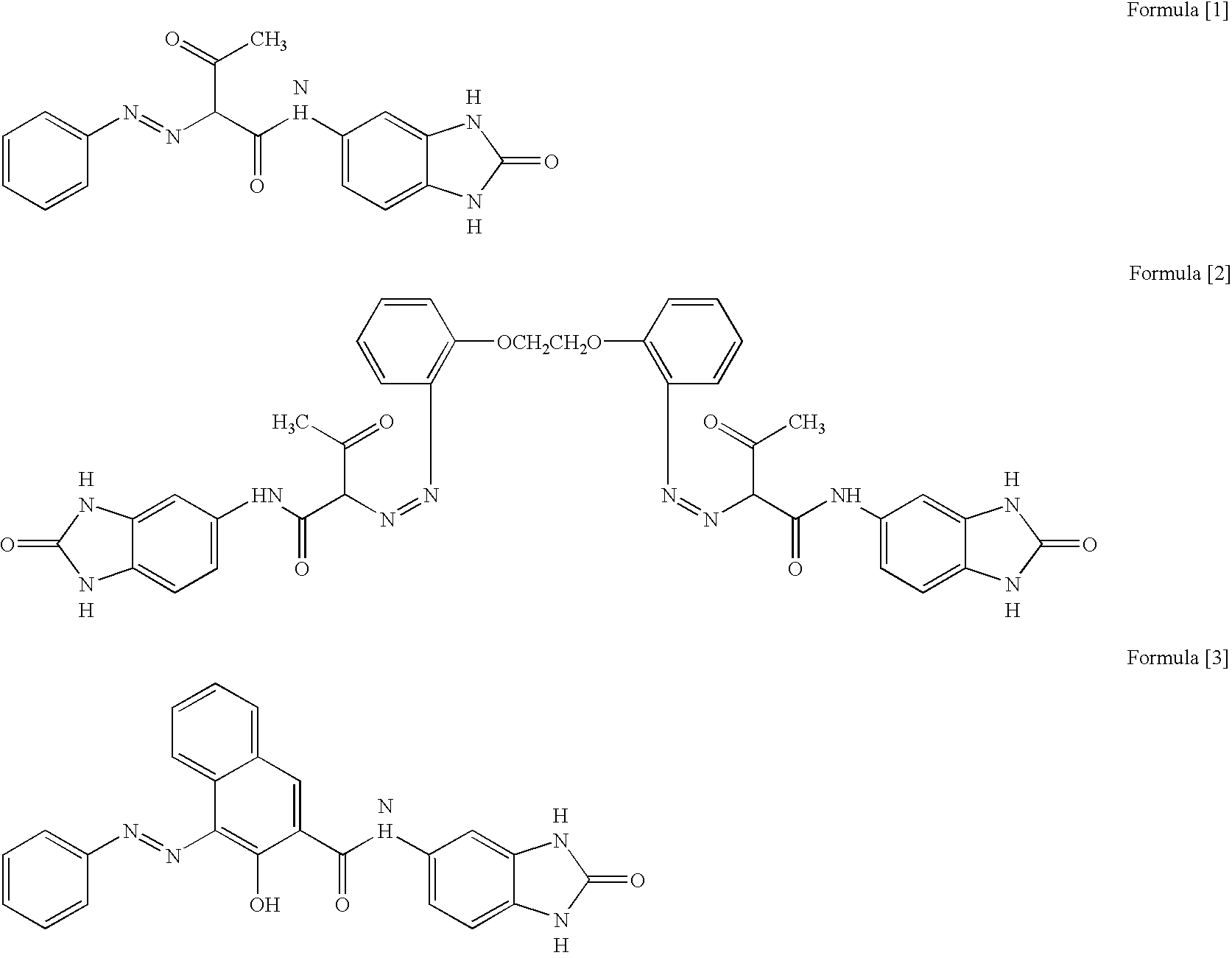

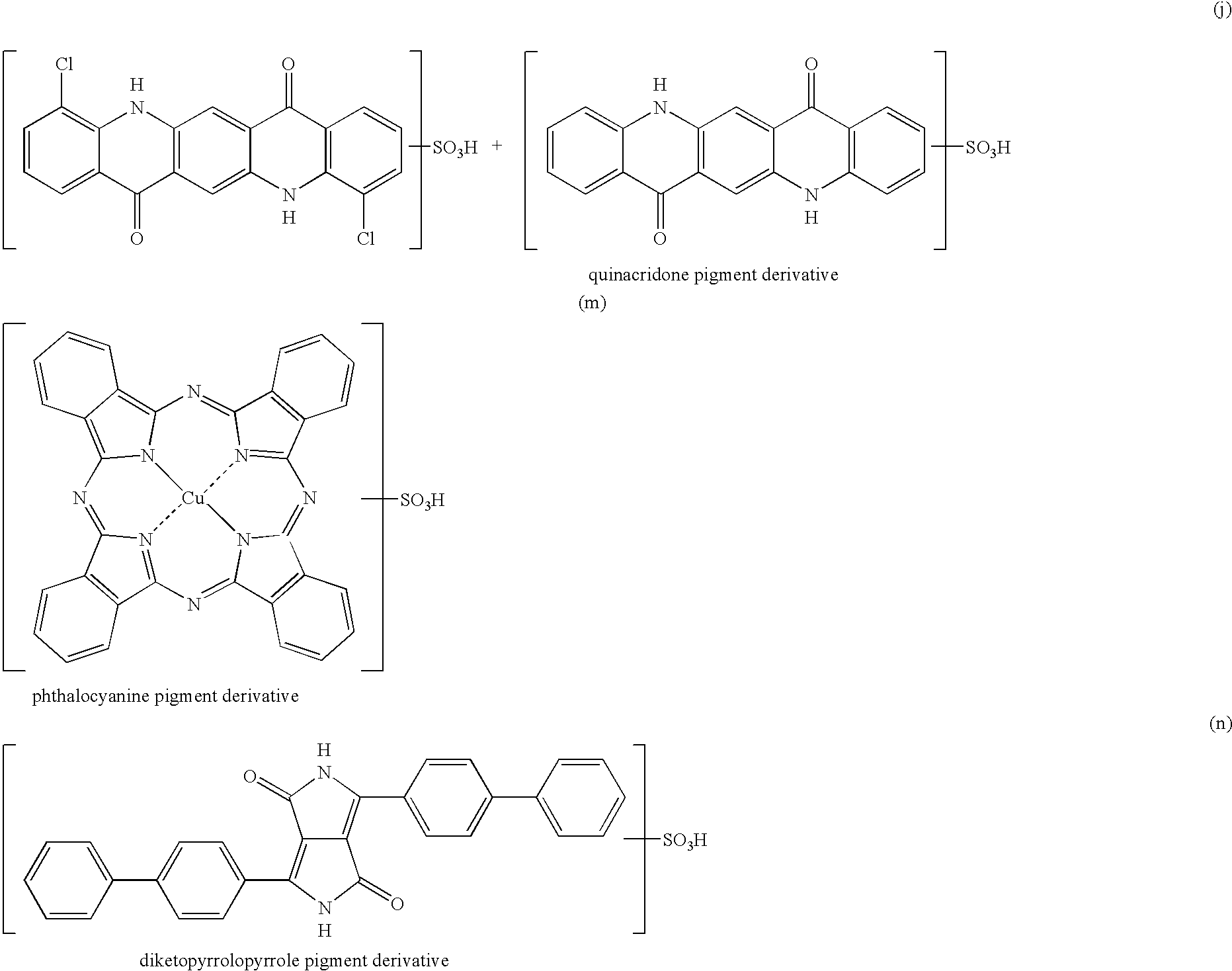

Water-based pigment dispersion, use thereof and process for the production thereof

A water-based pigment dispersion comprising 100 parts by weight of a pigment, 3 to 30 parts by weight of a sulfonic acid group-containing pigment derivative and water, wherein the sulfonic acid group-containing pigment derivative has only one sulfonic acid group in a molecule of a pigment of which the type is the same as the type of the pigment to be dispersed, the sulfonic acid group forms at least one salt selected from the group consisting of ammonia salt, an organic amine salt and a salt in which at least 15% of the sulfonic acid group is liberated and the rest is a salt with monovalent metal, the content of metal ion having a valence of at least 2 in a solid matter of the above water-based pigment dispersion is 500 ppm or less, and the above pigment is dispersed in water according to electrostatic repulsion due to the sulfonic acid group-containing pigment derivative adsorbed on the particle surface of the pigment, an inkjet recording liquid containing the same and process for the production thereof.

Owner:TOYO INK SC HOLD CO LTD

High-efficiency purifier of biological enzyme

InactiveCN101306867AImprove biological activityRealize the combinationBiological water/sewage treatmentTreatment effectWater quality

The invention provides a biological enzyme high-efficiency water purifier. The raw materials of the water purifier by weight portion comprise the following compositions: 24 to 52 potions of biological enzyme, 10 to 20 potions of microorganism, 0 to 4 potions of plant extract additive, and 40 to 63 potions of water or 28 to 53 potions of filler. The water purifier is a biological preparation for treating pollution sources that the prior pollution treatment technologies fail to treat through a biocatalysis technology with a biodegradation function, can greatly get rid of odor, quickly degrade liquid pollutants, reduce the volume of solid matters, and quickly purify polluted substances, has good treatment effect, greatly reduces running cost of wastewater treatment, ensures that purified water quality is more stable, is energy saving and high efficient in treating pollution, is suitable for the treatment of various sewage, has no side effect, and has remarkable economic benefit and environmental benefit.

Owner:江苏晨翔环境科技股份有限公司

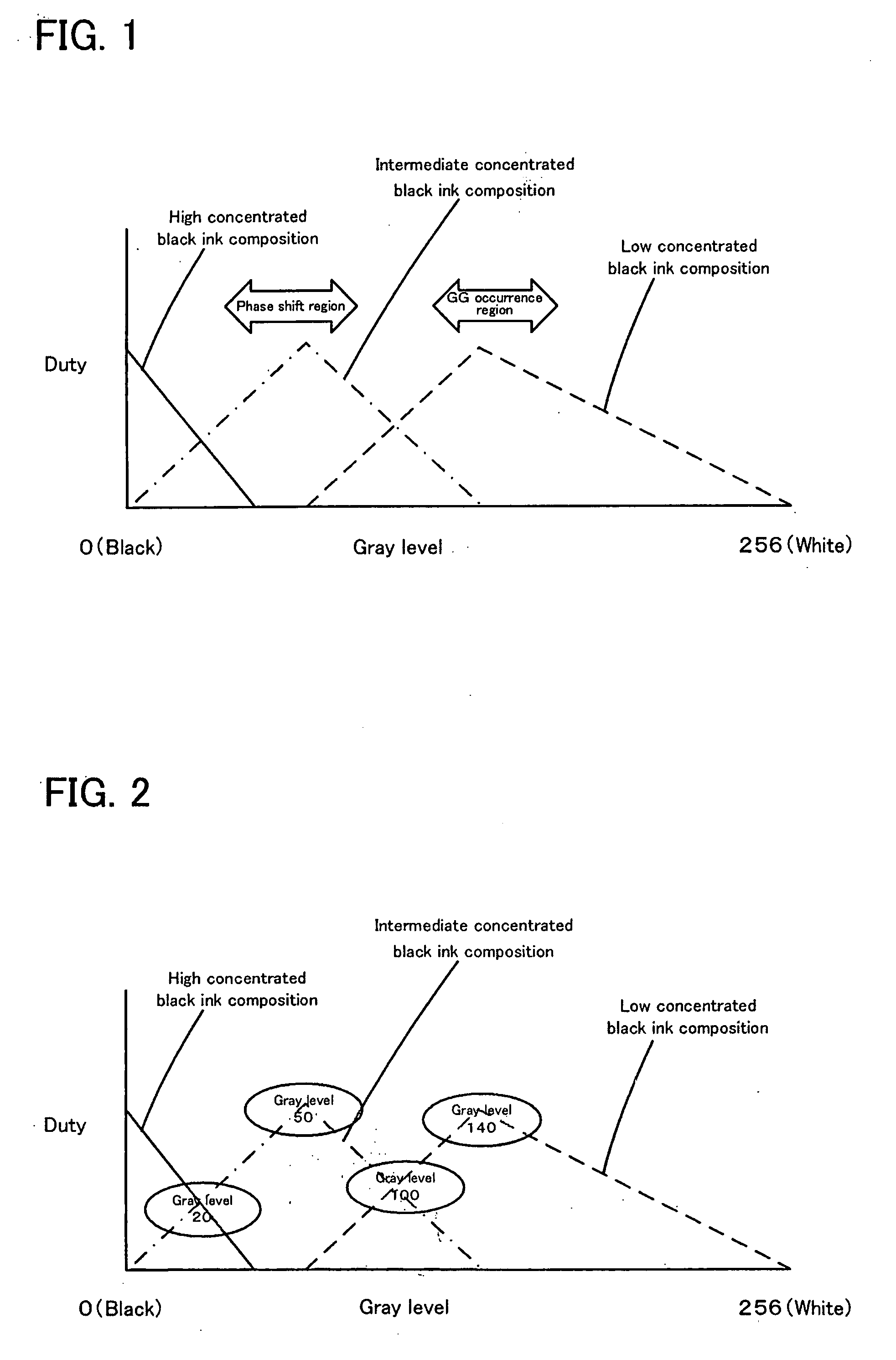

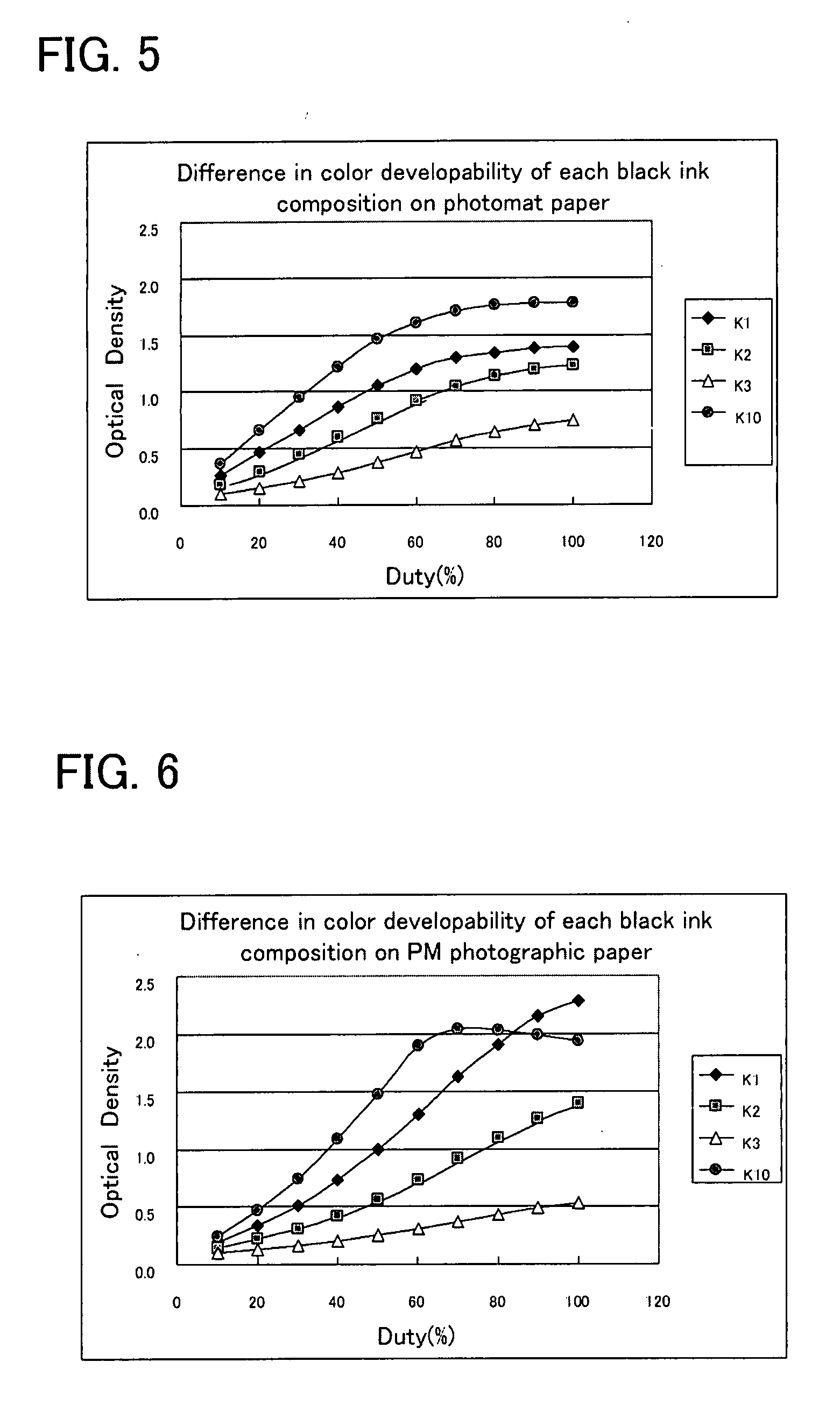

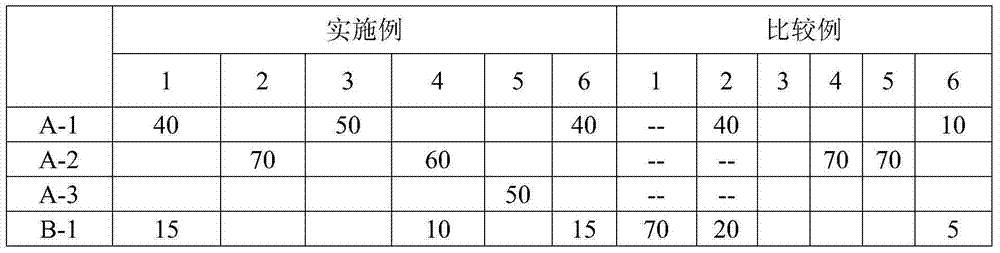

Aqueous Ink Composition and Urethane Resin Composition for Aqueous Ink Composition

ActiveUS20080022887A1Fine surface defect is suppressedSuppression of surface defectsInksWater solubleSolid matter

An object of the present invention is to provide a black ink composition by which a recorded matter in which a fine surface defect on a recorded matter is effectively suppressed, can be obtained. For this object, the present invention is a black ink composition containing water, carbon black, and a water-soluble polyurethane resin, wherein when a content of carbon black is not less than 0.4% by weight and less than 1.5% by weight, a content of a solid matter of the water-soluble polyurethane resin is not less than 0.67-fold and not more than 2.5-fold a content of the carbon black and, when a content of the carbon black is less than 0.4% by weight, a content of a solid matter of the water-soluble polyurethane resin is not less than 7.5-fold a content of the carbon black.

Owner:SEIKO EPSON CORP

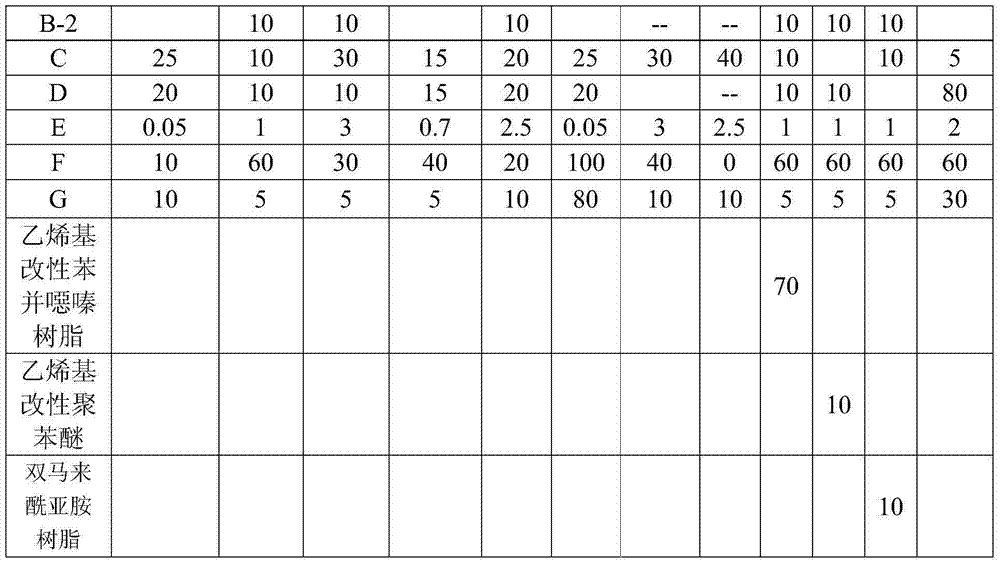

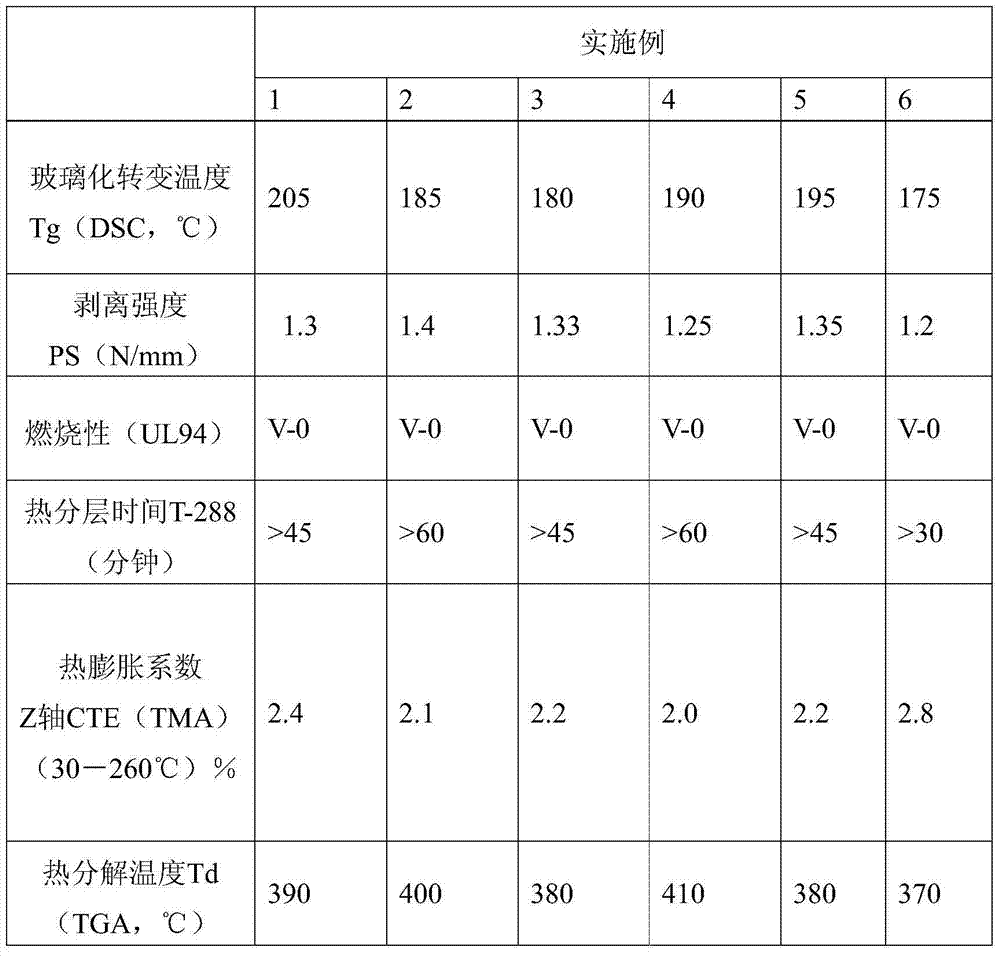

Halogen-free resin composite and use thereof

ActiveCN104845363AImprove heat resistanceImprove electrical performancePrinted circuit aspectsSynthetic resin layered productsHeat resistanceDielectric loss

Disclosed in the present invention is a halogen-free composition and prepreg material and laminate made thereof; based on organic solid matter parts by weight, said halogen-free resin composition comprises: (A) 40-80 parts by weight of allyl modified benzoxazine resin; (B) 10-20 parts by weight of hydrocarbon resin; (C) 10-40 parts by weight of allyl modified polyphenylene ether resin; (D) 10-20 parts by weight of allyl modified bismaleimide resin; (E) 0.01-3 parts by weight of initiator agent; (F) 10-100 parts by weight of filler; and (G) 0-80 parts by weight of phosphorus-containing flame retardants. Prepreg material and laminate made using the present halogen-free resin composition have a low dielectric constant and dielectric loss tangent value, high peel strength, a high glass transition temperature, good thermal resistance, and good flame retardancy.

Owner:GUANGDONG SHENGYI SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com