Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

333results about How to "Carbon reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

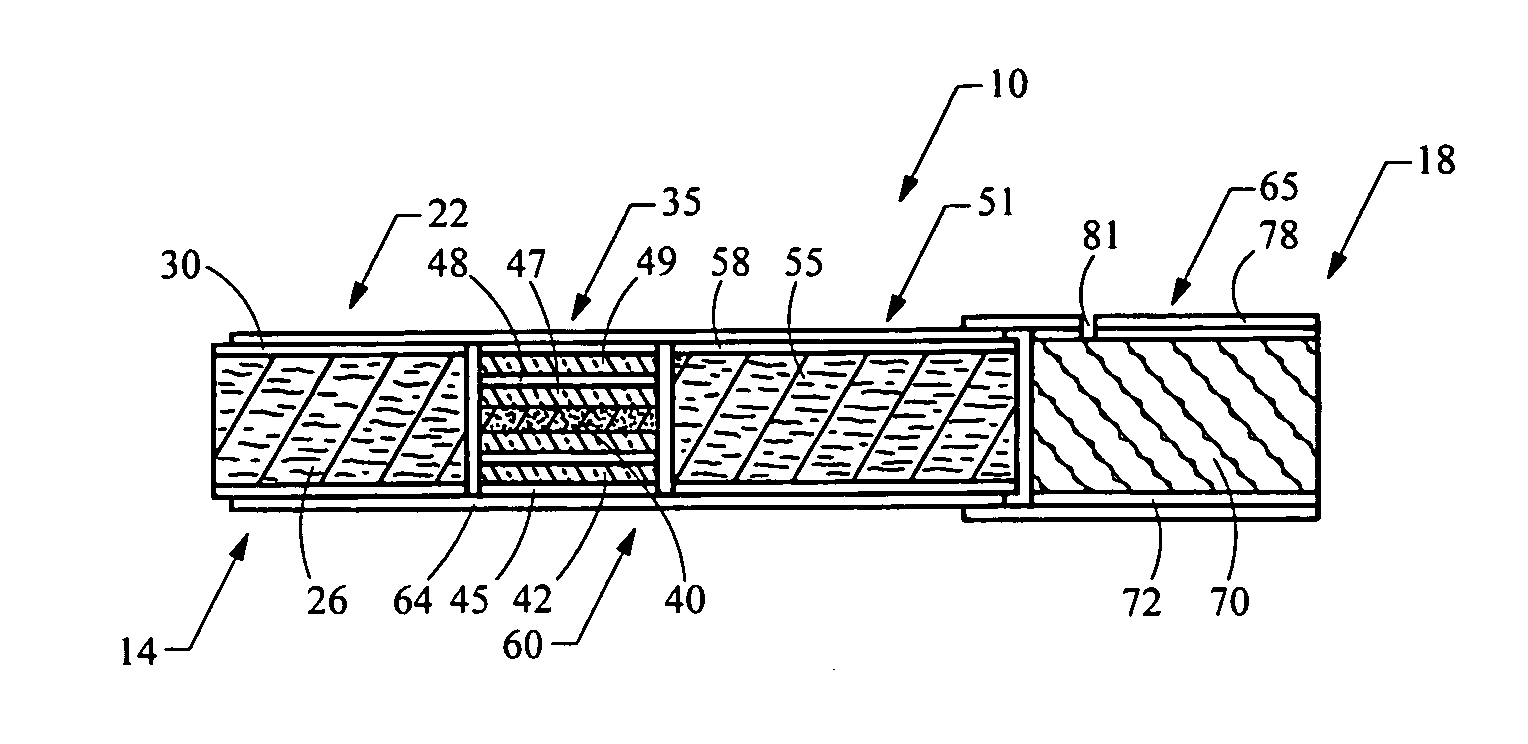

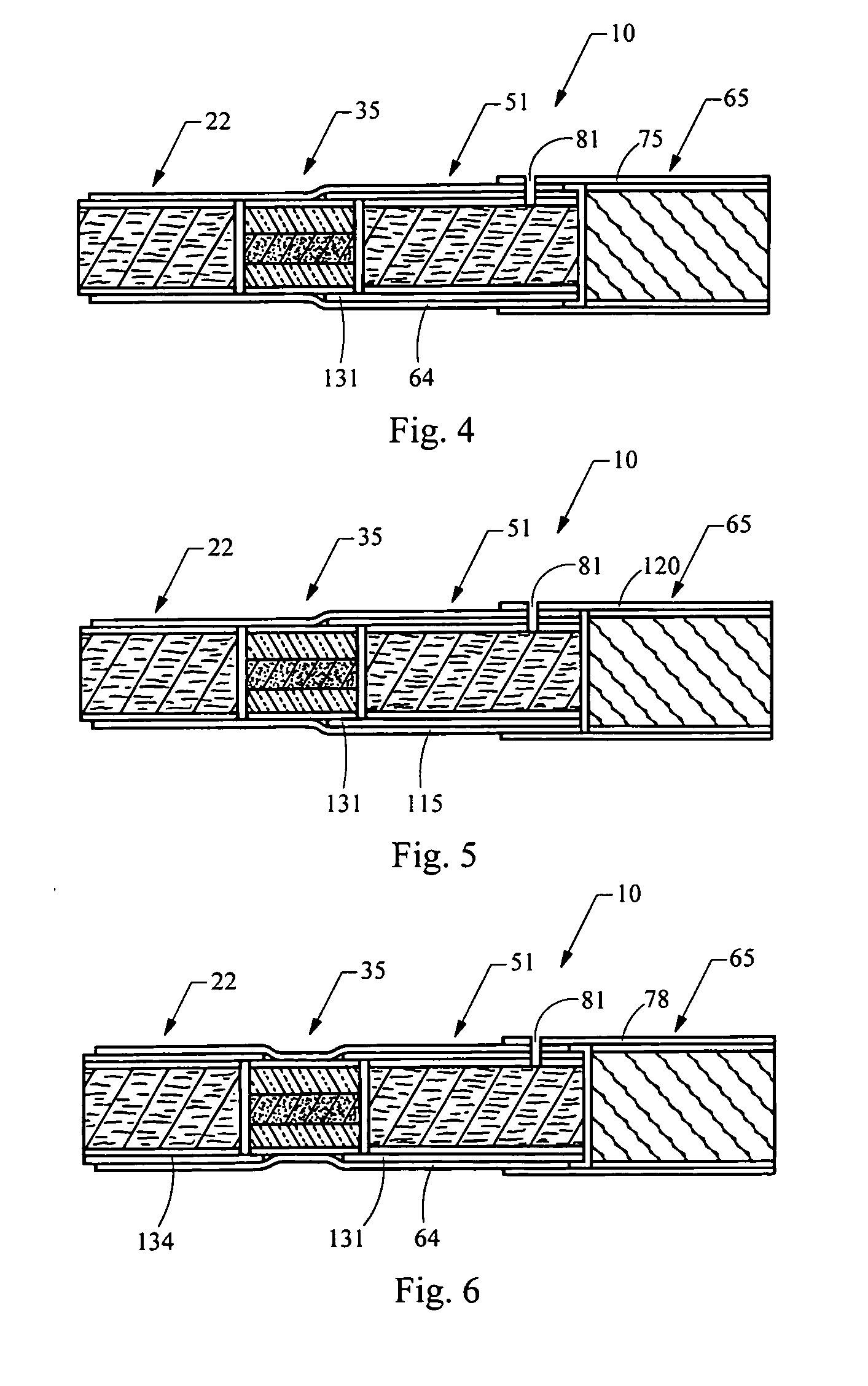

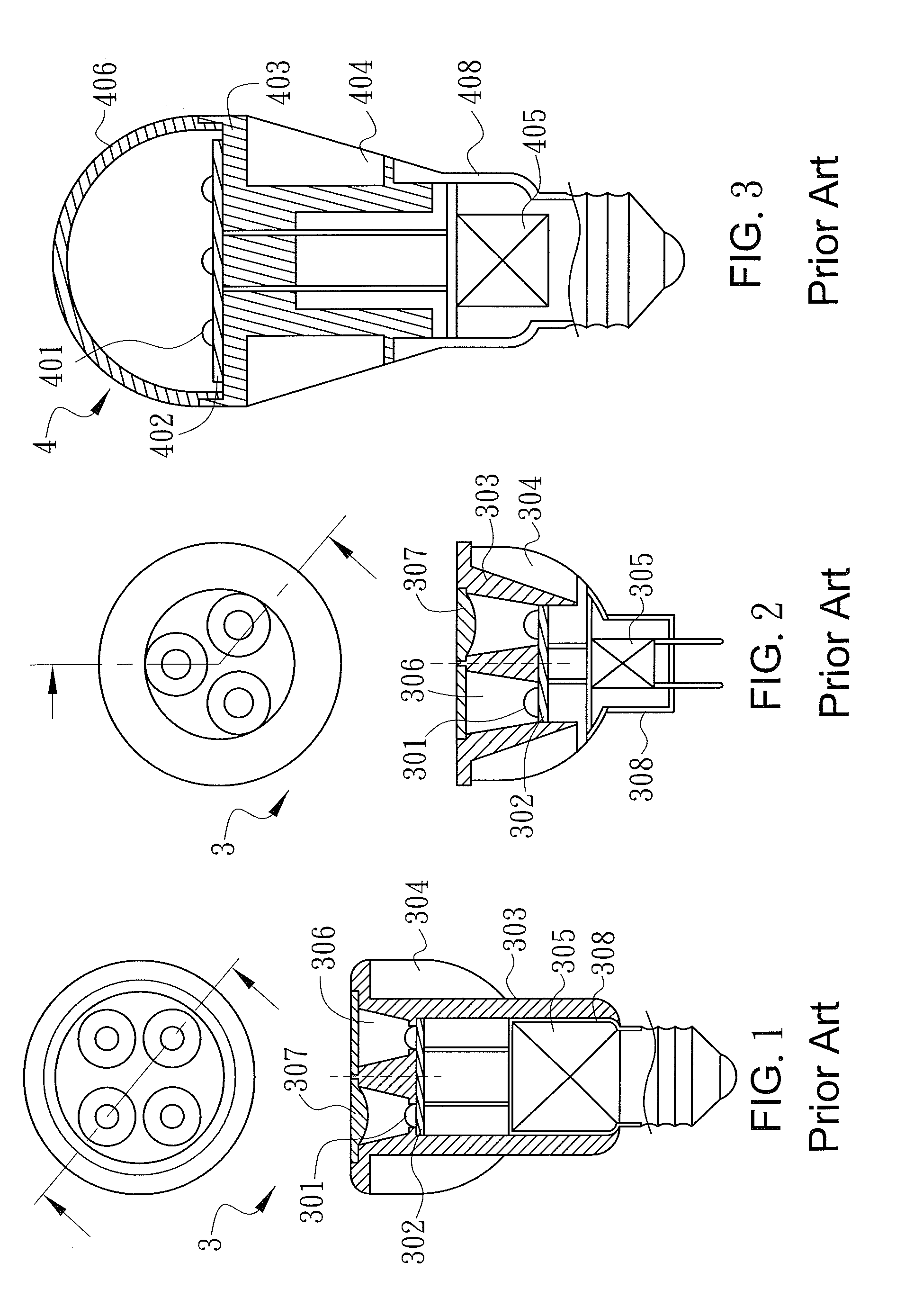

Smoking article

ActiveUS20070215168A1Reduce amountCarbon reductionTobacco preparationTobacco treatmentEngineeringFood flavor

A smoking article, such as a cigarette, includes a carbonaceous heat source. A mouth end piece segment is located at the mouth end of the smoking article, and the mouth end piece segment allows the smoking article to be placed in the mouth of the smoker to be drawn upon. The smoking article further incorporates an aerosol-generating segment located between the heat generation segment and the mouth end piece segment. The aerosol-generating segment incorporates an aerosol-forming material (e.g., glycerin and flavors). The heat generation segment is in a heat exchange relationship with the aerosol-generating region such that heat generated by the burning fuel element acts to volatilize aerosol-forming material for aerosol formation. The carbonaceous heat source is in intimate contact with coarse, fine or ultrafine particles of materials such as cerium oxide, or mixtures of cerium oxide and palladium chloride.

Owner:R J REYNOLDS TOBACCO COMPANY

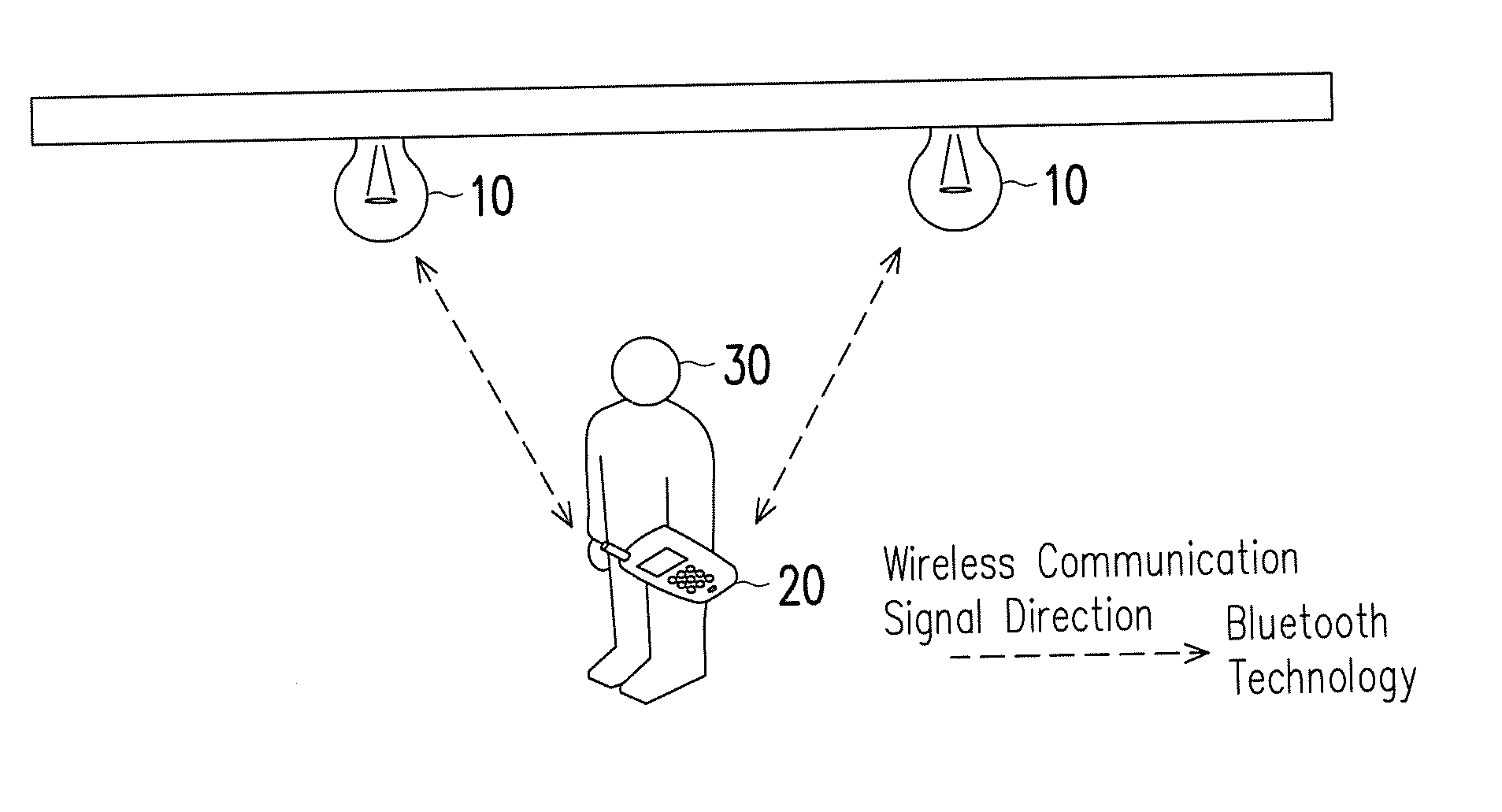

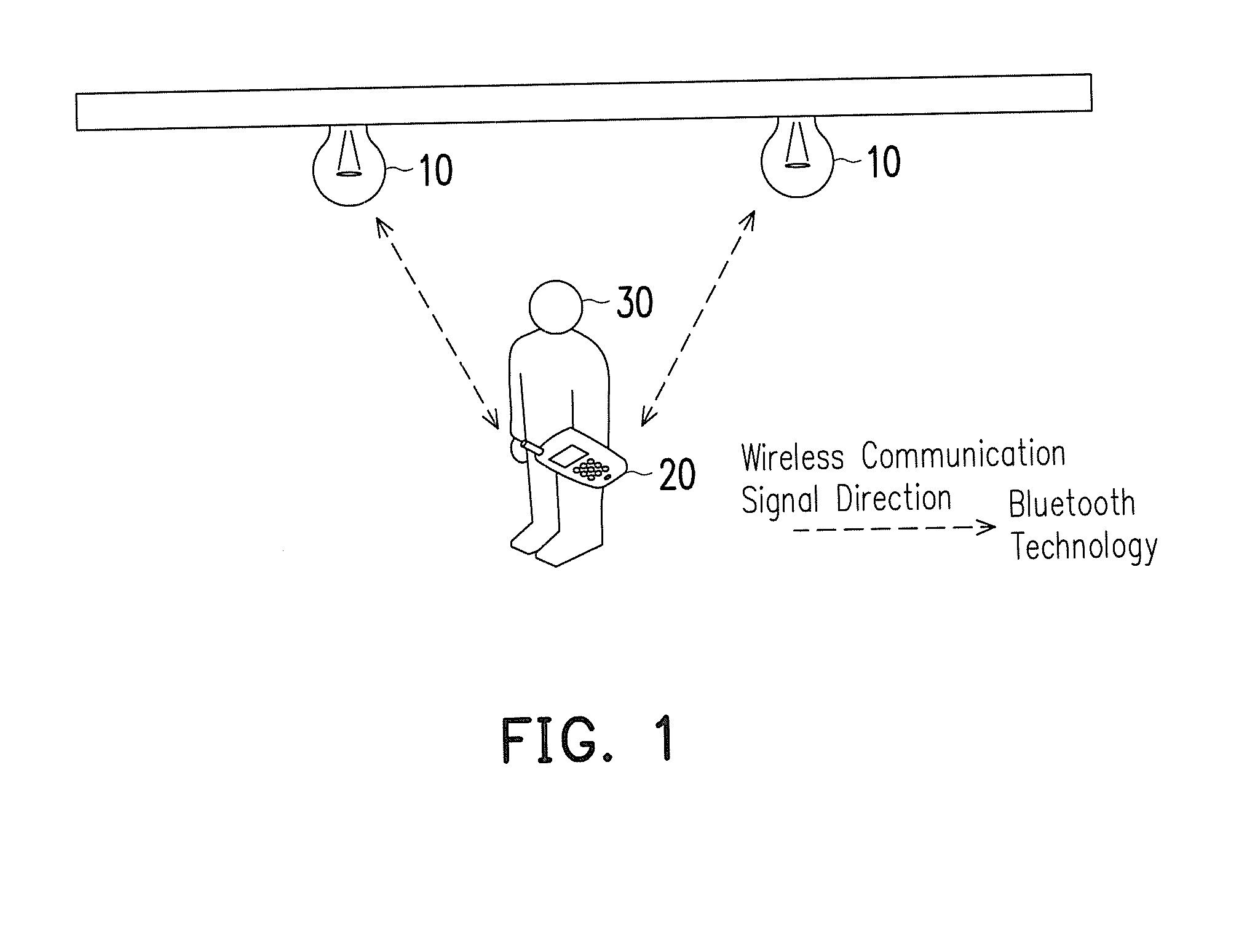

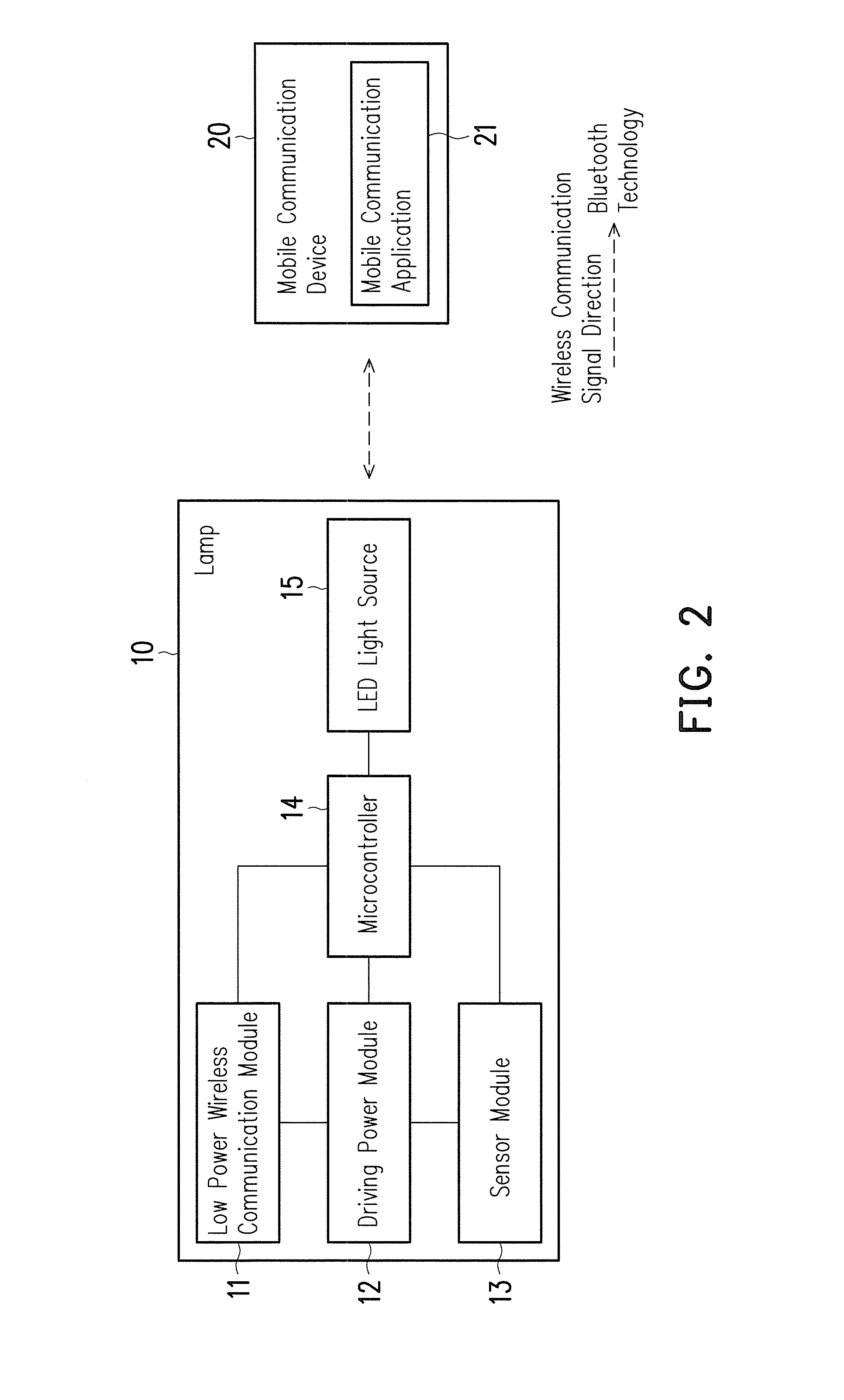

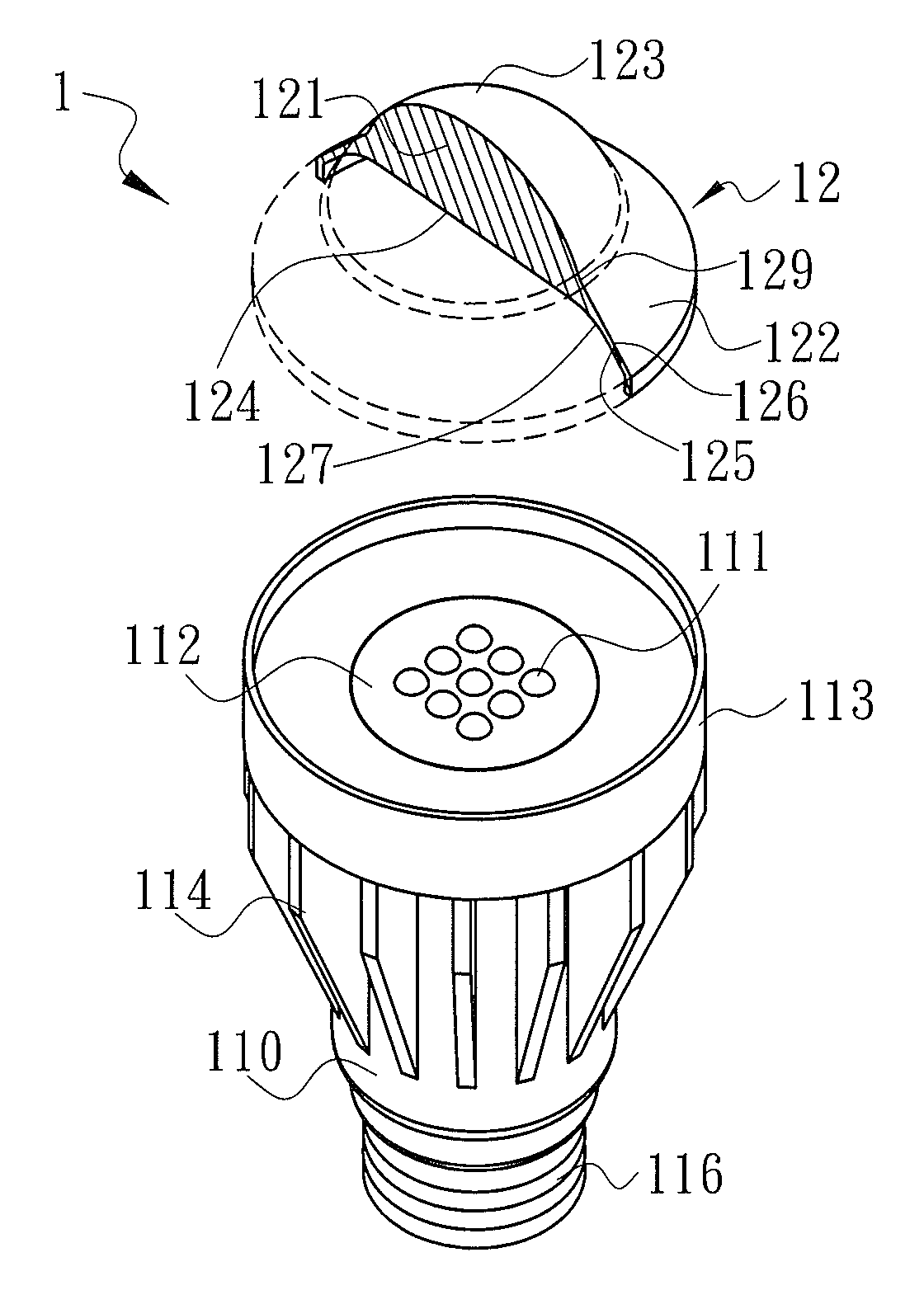

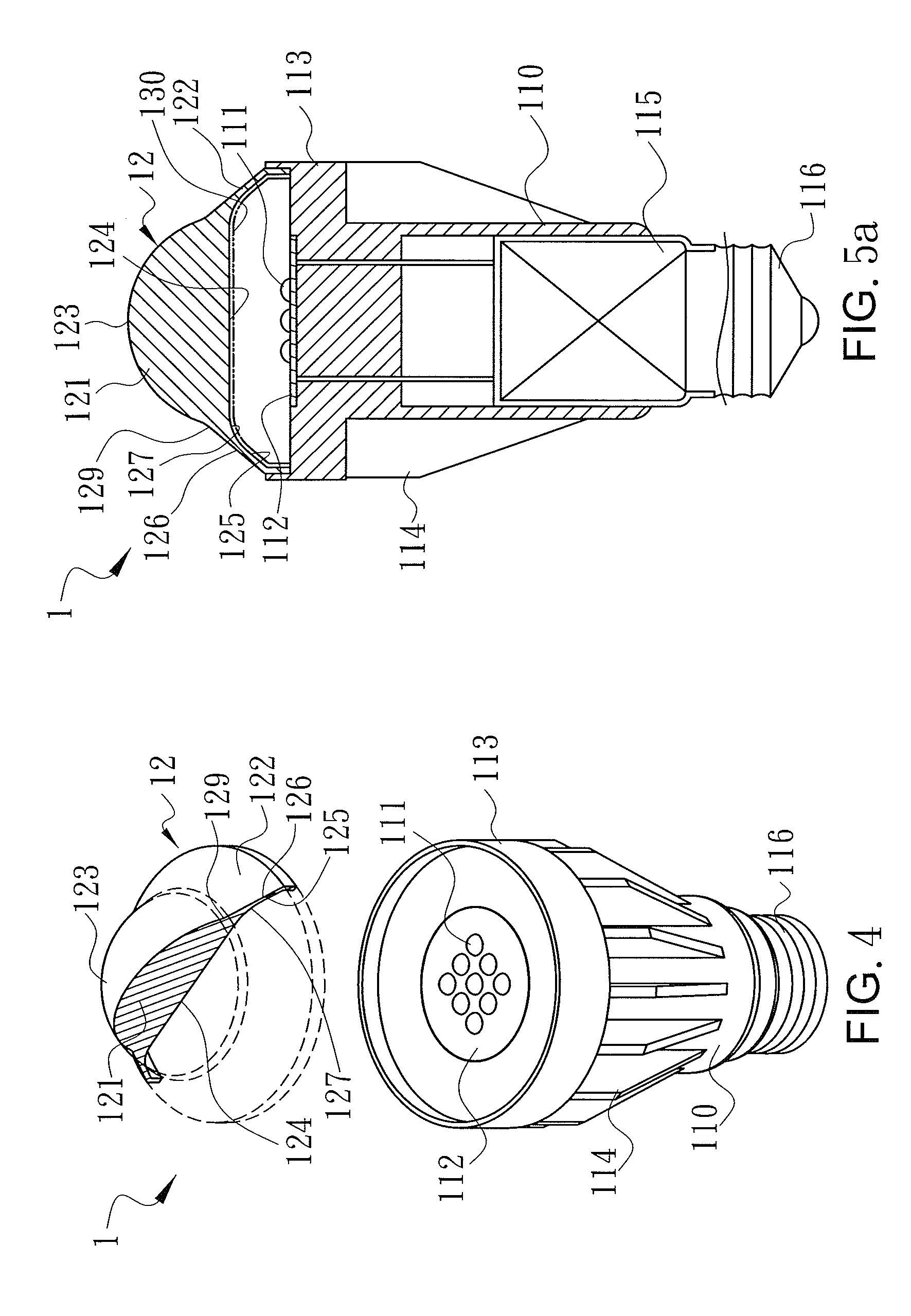

Illumination control system

ActiveUS20140285113A1Prevent alarms from going off and interruptingSave energyElectrical apparatusElectroluminescent light sourcesLatitudeWireless data transmission

An illumination control system provides wireless data transmission with a lamp through a mobile communication device. The lamp has a built-in wireless communication module and a microcontroller. The microcontroller stores a location of the lamp with latitude-longitude values and height values. Accordingly, a user may use the mobile communication device to read the latitude-longitude values and height values of the lamps to achieve an indoor positioning function by calculating a positioning information of the user through indoor positioning algorithms, and thereby enable illumination control through the mobile communication device according to the positioning information.

Owner:INT MOBILE IOT

Integrated photoelectrochemical cell and system having a liquid electrolyte

InactiveUS20050211290A1Improve hydrogen efficiencyImprove oxygen production efficiencyCellsLight-sensitive devicesHydrogenPhotoelectrochemical cell

An integrated photoelectrochemical (PEC) cell generates hydrogen and oxygen from water while being illuminated with radiation. The PEC cell employs a liquid electrolyte, a multi-junction photovoltaic electrode, and a thin ion-exchange membrane. A PEC system and a method of making such PEC cell and PEC system are also disclosed.

Owner:UNIVERSITY OF TOLEDO

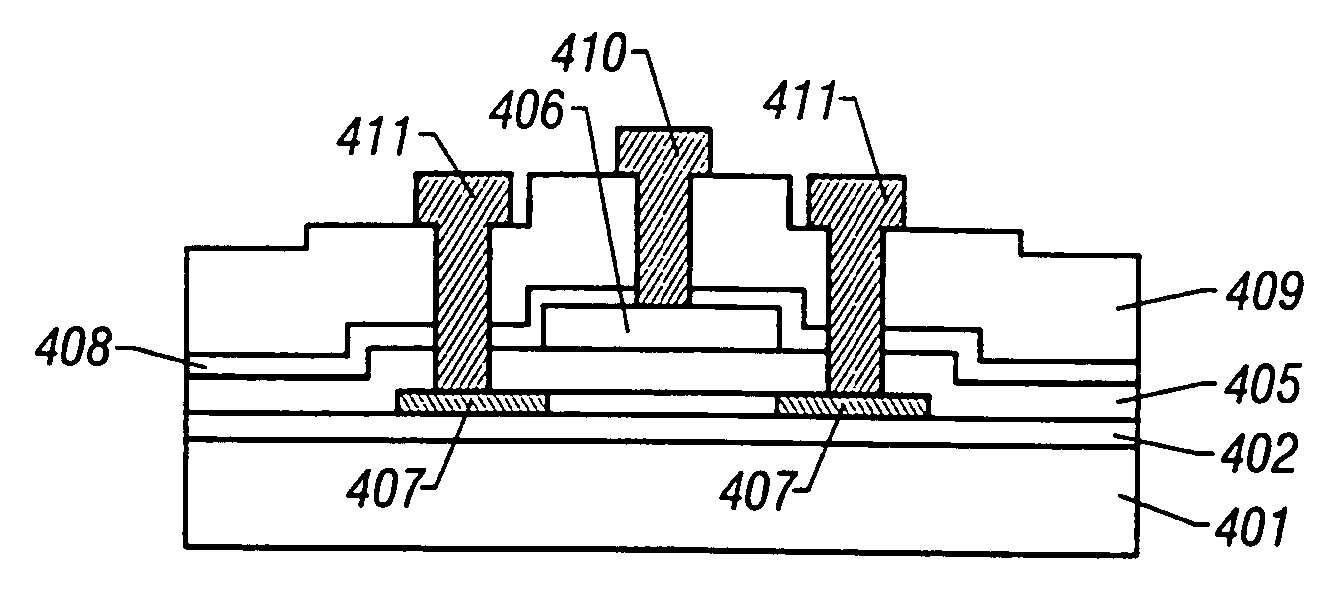

Post ECP multi-step anneal/H2 treatment to reduce film impurity

InactiveUS20050227479A1Improve reliabilityReduce defect densitySemiconductor/solid-state device manufacturingCopper interconnectCarbon impurities

A method of forming a copper interconnect in a dual damascene scheme is described. After a diffusion barrier layer and seed layer are sequentially formed on the sidewalls and bottoms of a trench and via in a dielectric layer, a first copper layer is deposited by a first ECP process at a 10 mA / cm2 current density to fill the via and part of the trench. A first anneal step is performed to remove carbon impurities and optionally includes a H2 plasma treatment. A second ECP process with a first deposition step at a 40 mA / cm2 current density and second deposition step at a 60 mA / cm2 current density is used to deposit a second copper layer-that overfills the trench. After a second anneal step, a CMP process planarizes the copper layers. Fewer copper defects, reduced S, Cl, and C impurities, and improved Rc performance are achieved by this method.

Owner:TAIWAN SEMICON MFG CO LTD

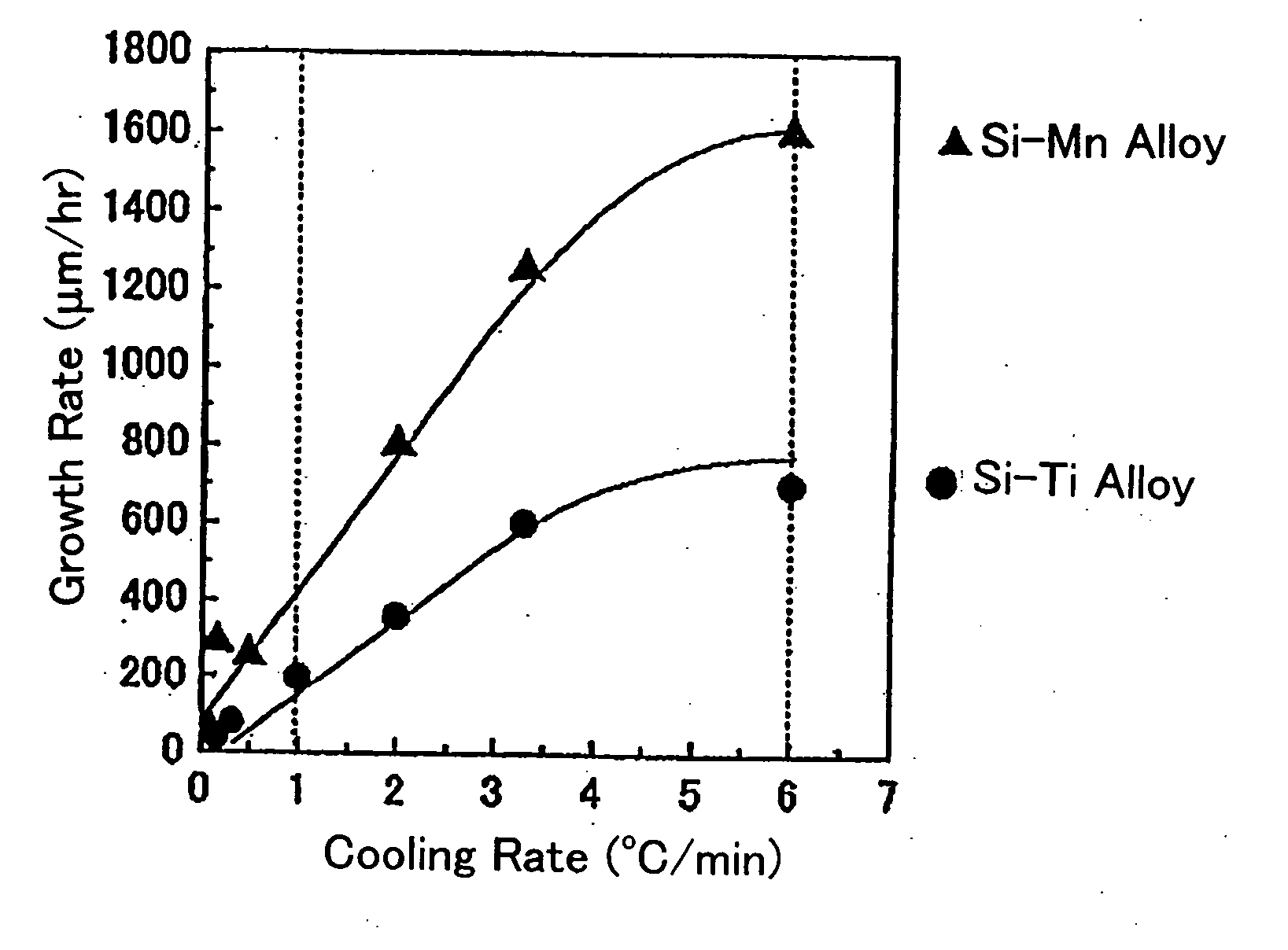

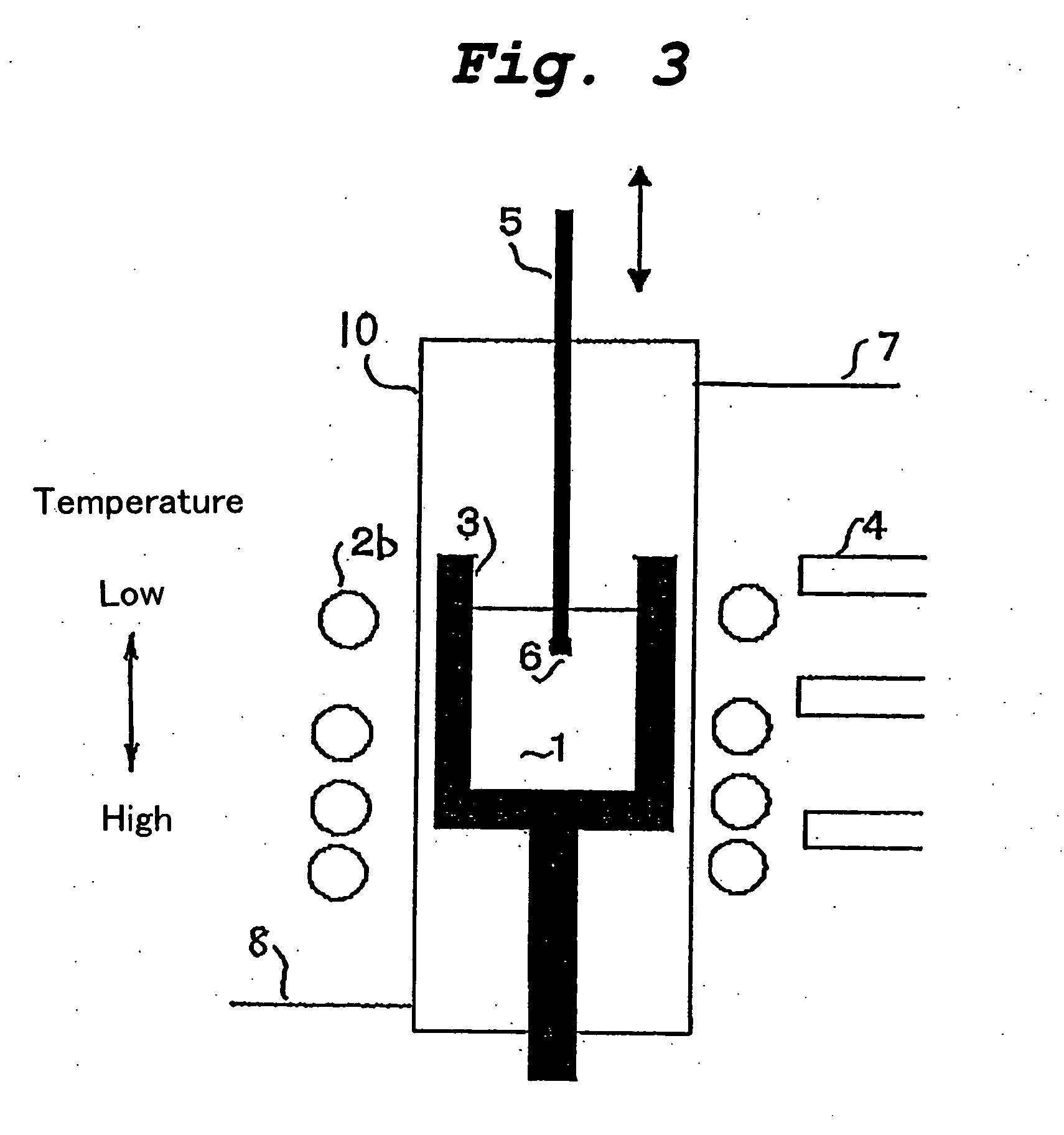

Silicon carbide single crystal and a method for its production

InactiveUS20050183657A1Easy to handleStable productionFrom gel statePolycrystalline material growthAlloyDissolution

A bulk silicon carbide single crystal of good crystalline quality which includes a minimized number of structural defects and is free from micropipe defects can be produced by crystal growth in a melt of an alloy comprising Si, C, and M (wherein M is either Mn or Ti) and having an atomic ratio between Si and M in which the value of x, when express as Si1-xMx, is 0.1≦×≦0.7 in the case where M is Mn or 0.1≦×≦0.25 in the case where M is Ti at a temperature of the melt which is below 2000° C. The C component is preferably supplied into the melt by dissolution of a graphite crucible which contains the melt such that the melt is free from undissolved C. One method of crystal growth is performed by cooling the melt after a seed substrate is immersed in the melt.

Owner:NIPPON STEEL CORP

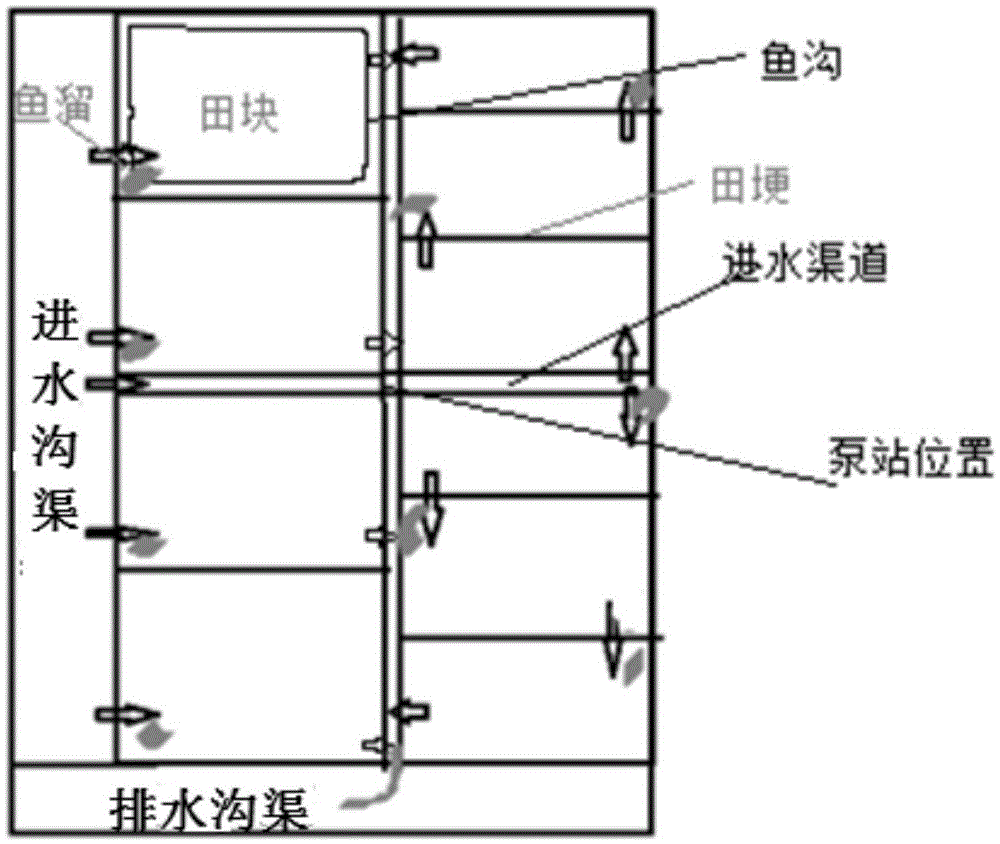

Organic ecological farming system for rice field

InactiveCN105532342ALabor savingRealization costClimate change adaptationFertilising methodsFertilizerDitch

The invention relates to an organic ecological farming system for a rice field. The system is characterized in that a water inlet canal, a drainage canal, a water inlet channel and a drainage channel are crossed to form the cross-shaped drainage rice field, a pump station is arranged at the crossed position of the crossed canals and channels, the rice field is divided into multiple field pieces in the type of plain terraced fields, fish ditches are arranged on the peripheries of the field pieces, and a fish pit is arranged at one corner of each field piece. According to the organic ecological farming system, high harvesting benefits of both rice and fish are achieved, and meanwhile the water conservation fertilizer conservation, low carbon and high ecosystem service functions are achieved; organic ecological farming can be carried out by transforming a common rice field near a good water source appropriately, and the optimized technology for transforming low yield fields and bottom land is achieved.

Owner:HUAIAN SUZE ECOLOGICAL AGRI CO

Fuel reforming apparatus and method of controlling same

InactiveUS20020046889A1Avoid heatingIncrease temperatureElement comparisonGas modification by gas mixingHydrogenFuel cells

In a fuel reforming apparatus having a reformer for reforming a raw fuel containing a hydrocarbon-containing compound so as to produce a hydrogen-rich fuel gas for use in a fuel cell, a carbon removal process for removing carbon deposited on a reforming catalyst contained in the reformer is executed by controlling the amount of the raw fuel supplied to the reformer and the amount of the oxygen supplied to the reformer so that a ratio of the number of oxygen atoms O supplied to the reformer to the number of carbon atoms supplied to the reformer becomes larger than an appropriate range of the O / C ratio that is to be established during a normal operation of the reformer.

Owner:TOYOTA JIDOSHA KK

Water-based paint for Christmas glass ornaments, and preparation method and application thereof

The invention discloses a water-based paint for Christmas glass ornaments, and a preparation method and application thereof, belonging to the field of paints. The water-based paint comprises the following components in parts by weight (totaling 100 parts): 10-45 parts of water-based acrylic resin, 0-10 parts of water-soluble curing agent, 0-20 parts of filler, 0.1-1 part of water-based defoaming agent, 0-1 part of water-based dispersant, 0.1-1 part of water-based wetting agent, 0.1-2 parts of coupling agent, 4-30 parts of cosolvent and the balance of deionized water. The preparation method comprises the following steps: adding water-based resin and part of cosolvent into a stirring kettle, adding defoaming agent, dispersant and wetting agent, respectively and sequentially adding filler, water-soluble curing agent and silane coupling agent, finally adding residual cosolvent and water, and stirring to form a uniform water-based paint. The paint has the advantages of simple technique, low cost, low carbon, environmental protection, favorable water resistance and favorable weather resistance, and can be used for large-area mechanical construction.

Owner:NANJING CHANGJIANG PAINT

Semiconductor device

InactiveUS20140015019A1Improve reliabilityImprove energy efficiencySolid-state devicesSemiconductor devicesPower semiconductor devicePower flow

The reliability of a field effect transistor made of a nitride semiconductor material is improved. An ohmic electrode includes a plurality of unit electrodes isolated to be separated from each other. With this configuration, an on-state current can be prevented from flowing in the unit electrodes in a y-axial direction (negative direction). Further, in the respective unit electrodes, a current density of the on-state current flowing in the y-axial direction (negative direction) can be prevented from increasing. As a result, an electromigration resistance of the ohmic electrode can be improved.

Owner:RENESAS ELECTRONICS CORP

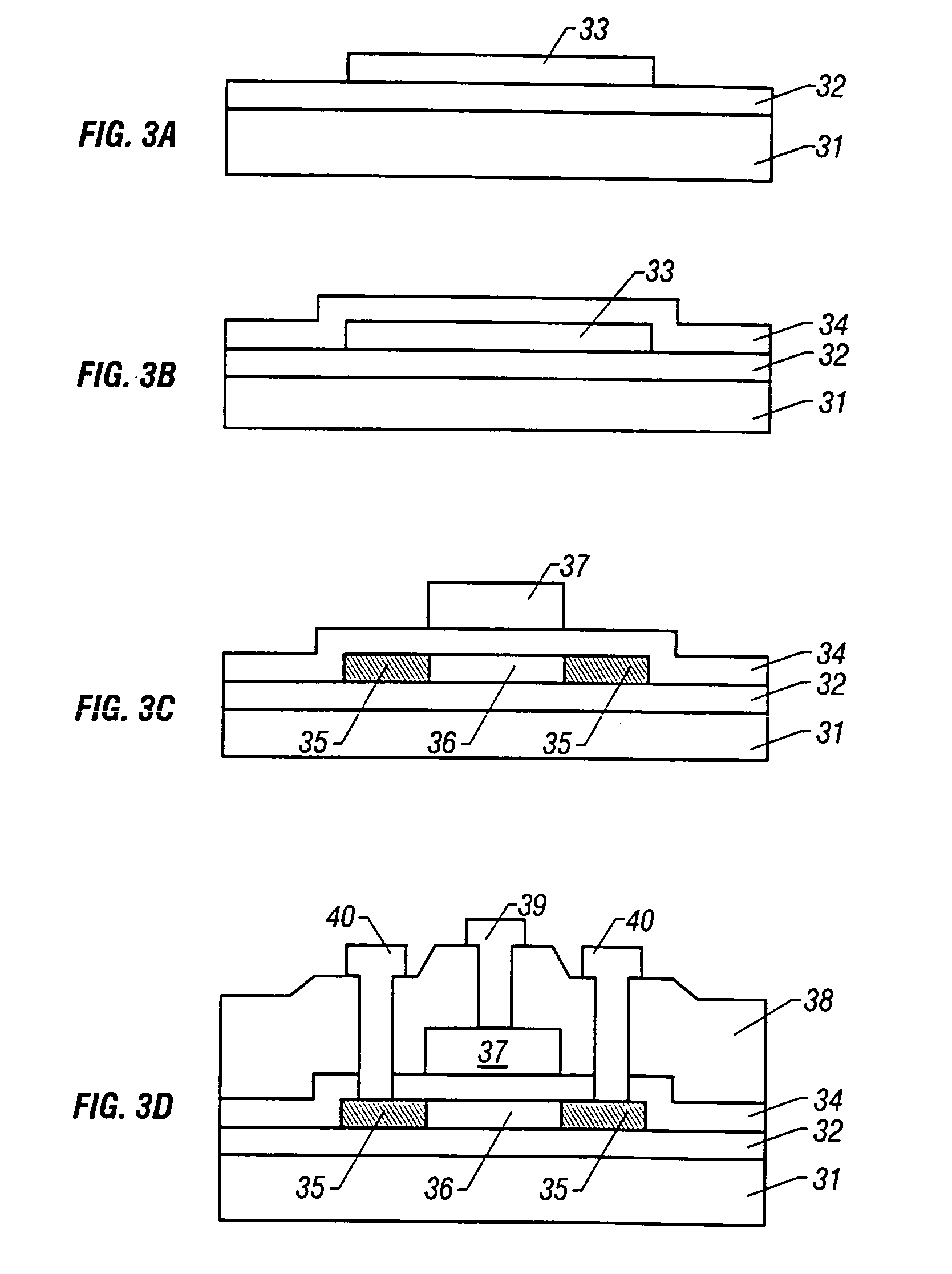

Method of fabricating SiC semiconductor device

InactiveUS20050064639A1Carbon reductionLow densitySemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialSemiconductor

Owner:HISADA YOSHIYUKI +2

Paperless transaction receipt equipment and system

InactiveCN102609838AStrengthen awareness of rights and interestsReduce processing costsNear-field systems using receiversPoint-of-sale network systemsReceiptDecision-making

Owner:北京互帮国际技术有限公司

Modified rare-earth-containing molecular sieve catalyst as well as preparation method and use thereof

ActiveCN101468318ACarbon reductionLow reaction temperatureMolecular sieve catalystsHydrocarbon from oxygen organic compoundsRare earthPetrochemical

The invention relates to a rare-earth-containing ZSM-5 molecular sieve catalyst modified with metallic oxide, which ensures high propylene selectivity, high methanol conversion rate and long life span of the catalyst in reaction which takes methanol and / or dimethyl ether as raw material to prepare low-carbon olefin. The catalyst consists of metallic oxide, binder and modified molecular sieves, wherein the metallic oxide accounts for 1 to 10 percent; the binder accounts for 5 to 30 percent; the modified molecular sieves account for 60 to 90 percent; and the modified molecular sieves contain rare earth oxide Ce2O3 and La2O3. The catalyst is used in the field of petrochemical industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

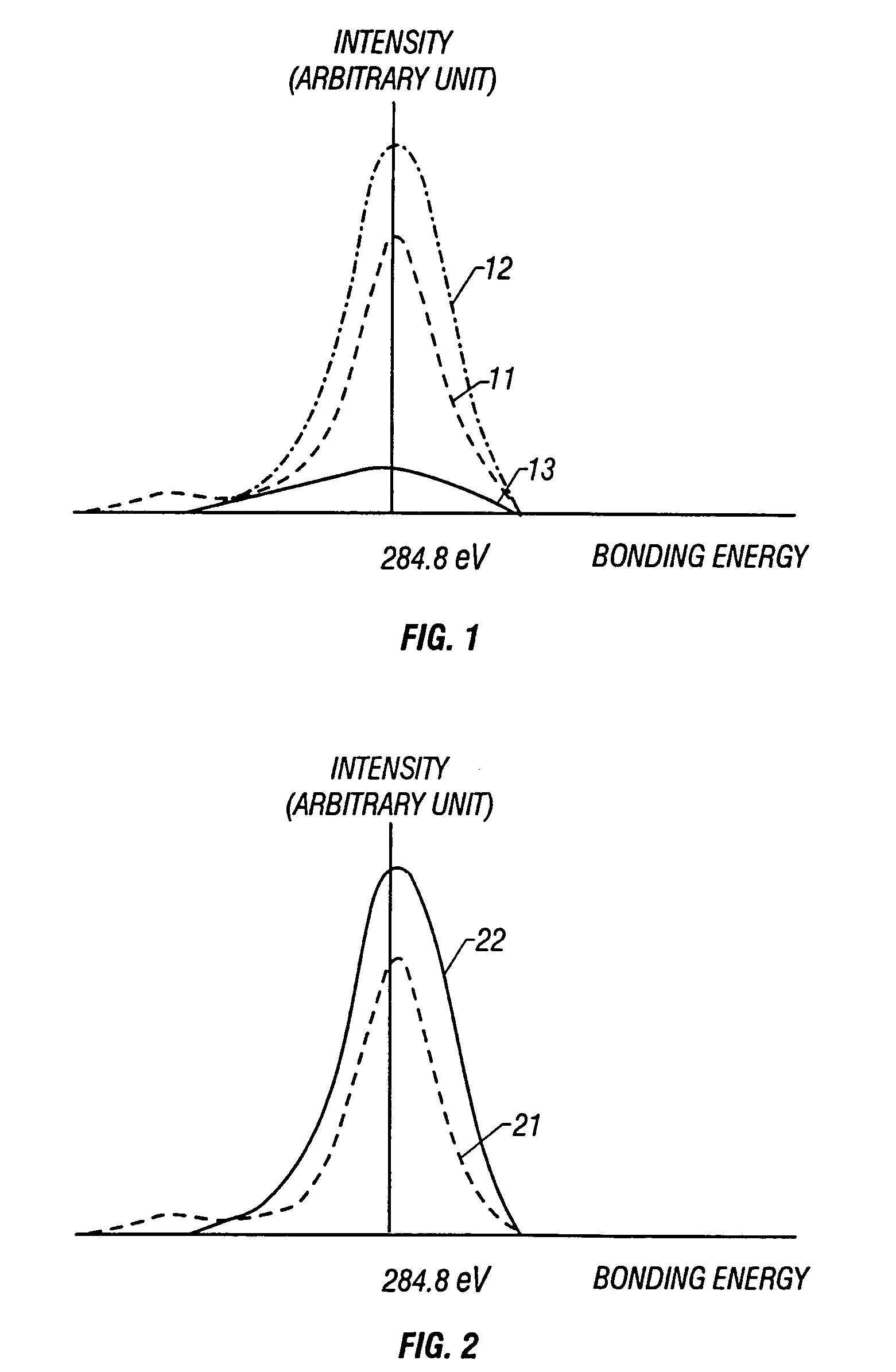

Carbon materials for carbon implantation

InactiveUS20110021011A1Improve efficiencyCarbon reductionElectric discharge tubesVacuum evaporation coatingCarbon dioxideCarbon source

A method of implanting carbon ions into a target substrate, including: ionizing a carbon containing dopant material to produce a plasma having ions; optionally co-flowing an additional gas or series of gases with the carbon-containing dopant material; and implanting the ions into the target substrate. The carbon-containing dopant material is of the formula CwFxOyHz wherein if w=1, then x>0 and y and z can take any value, and wherein if w>1 then x or y is >0, and z can take any value. Such method significantly improves the efficiency of an ion implanter tool, in relation to the use of carbon source gases such as carbon monoxide or carbon dioxide.

Owner:ENTEGRIS INC

Plasma dielectric etch process including ex-situ backside polymer removal for low-dielectric constant material

A plasma etch process for etching a porous carbon-doped silicon oxide dielectric layer using a photoresist mask is carried out first in an etch reactor by performing a fluoro-carbon based etch process on the workpiece to etch exposed portions of the dielectric layer while depositing protective fluoro-carbon polymer on the photoresist mask. Then, in an ashing reactor, polymer and photoresist are removed by heating the workpiece to over 100 degrees C., exposing a peripheral portion of the backside of said workpiece, and providing products from a plasma of a hydrogen process gas to reduce carbon contained in polymer and photoresist on said workpiece until the polymer has been removed from a backside of said workpiece. The process gas preferably contains both hydrogen gas and water vapor, although the primary constituent is hydrogen gas. The wafer (workpiece) backside may be exposed by extending the wafer lift pins.

Owner:APPLIED MATERIALS INC

Illumination control system

ActiveUS9807857B2Save energyCarbon reductionPhotometry using reference valueElectrical apparatusMicrocontrollerLongitude

An illumination control system provides wireless data transmission with a lamp through a mobile communication device. The lamp has a built-in wireless communication module and a microcontroller. The microcontroller stores a location of the lamp with latitude-longitude values and height values. Accordingly, a user may use the mobile communication device to read the latitude-longitude values and height values of the lamps to achieve an indoor positioning function by calculating a positioning information of the user through indoor positioning algorithms, and thereby enable illumination control through the mobile communication device according to the positioning information.

Owner:INT MOBILE IOT

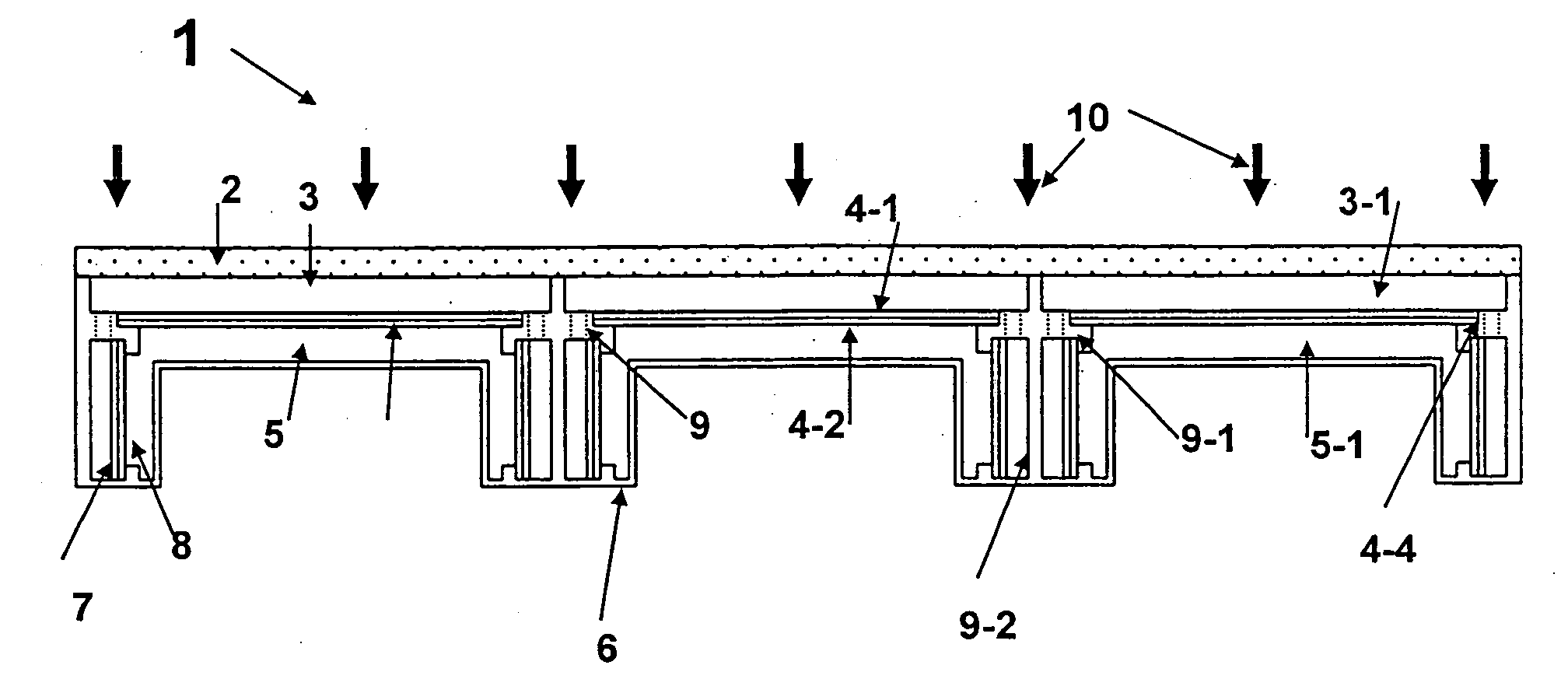

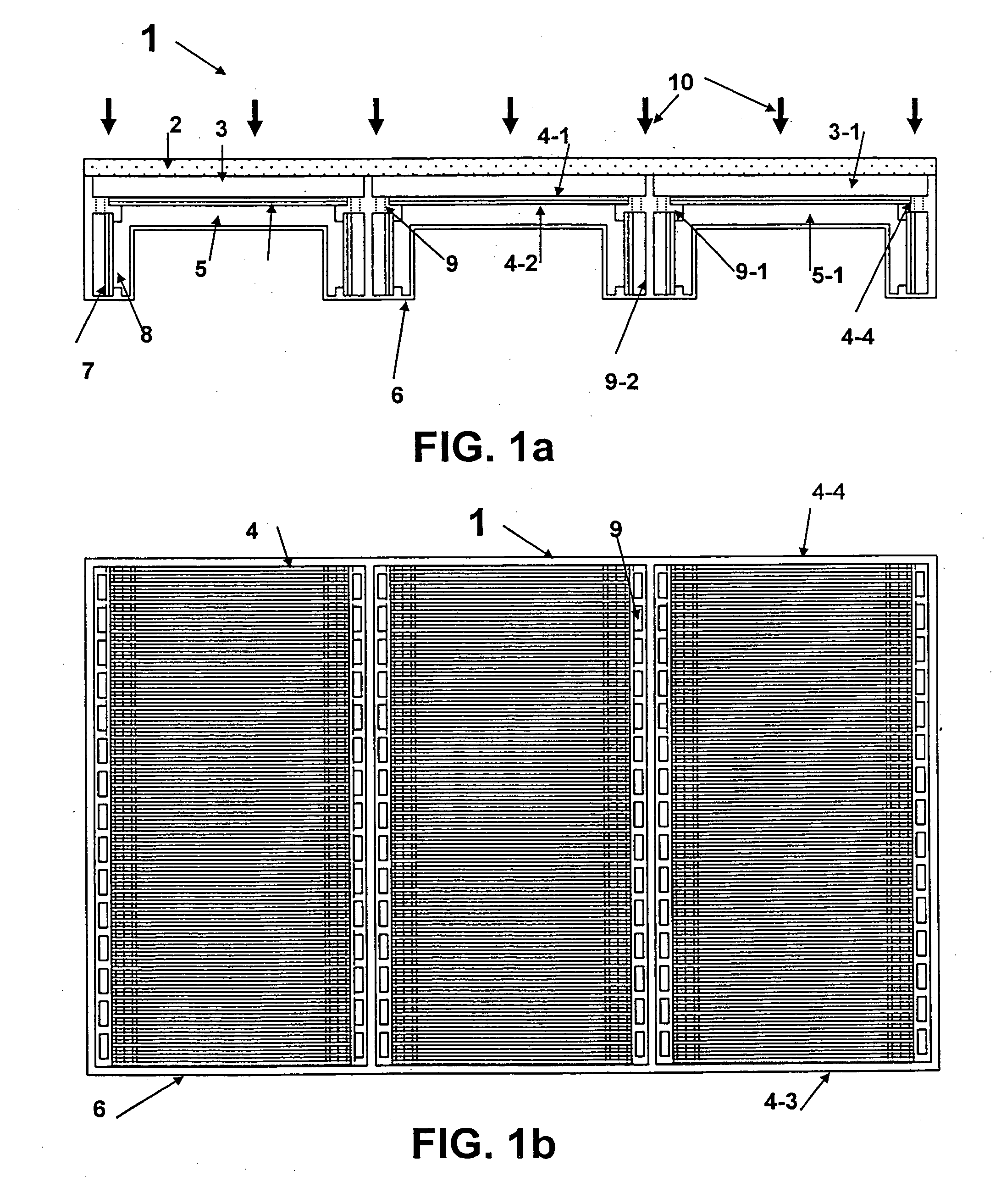

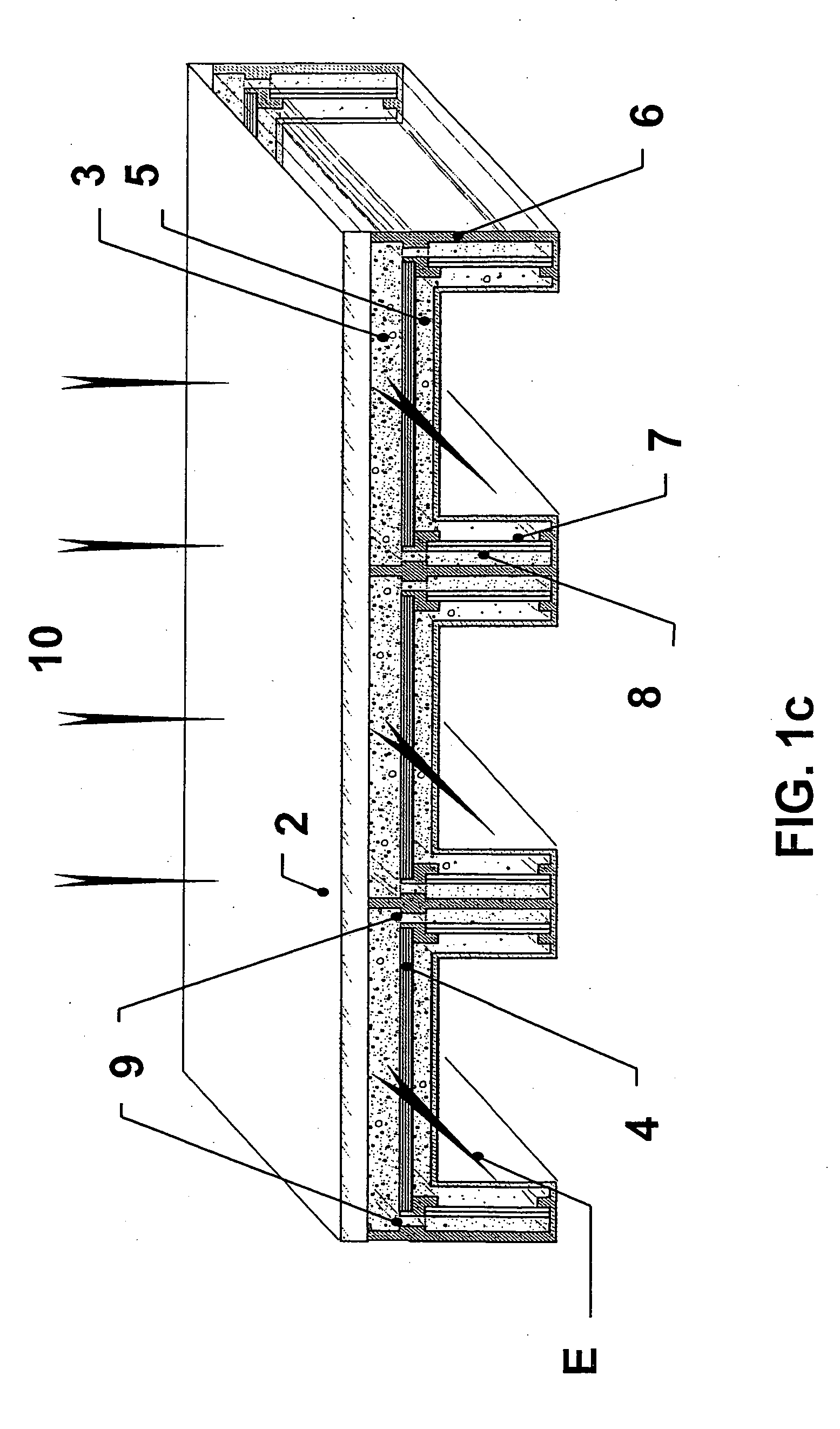

Integrated photoelectrochemical cell and system having a liquid electrolyte

InactiveUS7750234B2Improve efficiencyLow costCellsLight-sensitive devicesPhotoelectrochemical cellIon-exchange membranes

An integrated photoelectrochemical (PEC) cell generates hydrogen and oxygen from water while being illuminated with radiation. The PEC cell employs a liquid electrolyte, a multi-junction photovoltaic electrode, and a thin ion-exchange membrane. A PEC system and a method of making such PEC cell and PEC system are also disclosed.

Owner:UNIVERSITY OF TOLEDO

Method for Production of Metal Nitride and Oxide Powders Using an Auto-Ignition Combustion Synthesis Reaction

InactiveUS20080131350A1Readily useReadily shapeMaterial nanotechnologyOxide/hydroxide preparationOxideAuto ignition

A method of preparing a high purity metal nitride and / or oxide powder is provided, comprising: heating a metal salt and an organic fuel to an ignition temperature in a nitrogen-rich atmosphere, forming a first composition; and optionally heating the first composition to a heat treatment temperature, which heat treatment temperature is above the ignition temperature and below 1000° C., in a nitrogen-rich atmosphere until the metal nitride and / or oxide powder is formed.

Owner:COLORADO SCHOOL OF MINES

Cyanate resin for hot-melt prepregs and preparation method thereof

The invention relates to a cyanate resin for hot-melt prepregs and a preparation method thereof, belonging to the technical field of hot-melt prepregs. The cyanate resin is composed of 60-95 parts of modified cyanate resin and 5-40 parts of toughener. The cyanate resin for hot-melt prepregs has the advantages of simple technique and no solvent volatilization, and is suitable for industrial production. A hot-melt process can be adopted to prepare the prepreg. The prepreg has favorable manufacturability and long storage period. The prepared cyanate resin fiber composite material has the advantages of higher comprehensive mechanical properties, favorable heat resistance and favorable radiation resistance, can widely satisfy the requirements for high-performance aerospace structure materials, and has favorable application prospects.

Owner:长春长光宇航复合材料有限公司

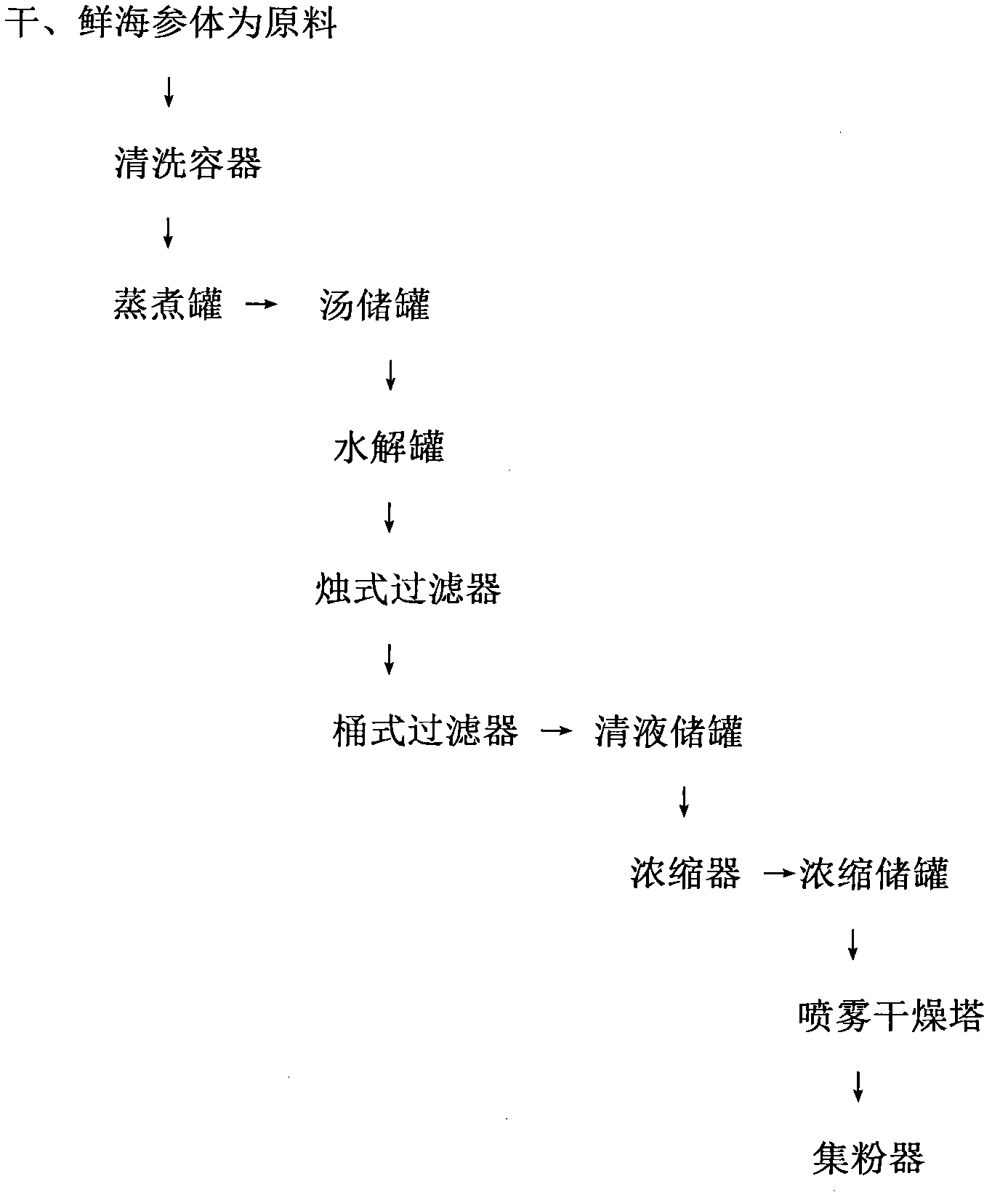

Extraction method of sea cucumber polypeptide

ActiveCN102488073AIndividual smallIncrease elasticityProtein composition from fishHigh pressureStorage tank

An extraction method of sea cucumber polypeptide contains steps of: embathing, high-pressure stewing, enzymatic hydrolysis, deodorizing, filtering, condensation, drying and finished product packaging. The extraction method is characterized in that high-pressure stewing: the temperature is 120-130 DEG C, the pressure is 0.13-0.15 MPa and stewing lasts for 2 hours at constant temperature and constant pressure; enzymatic hydrolysis: the temperature is cooled to 54-56 DEG C after heating and sterilizing, NaOH is added to adjust PH to 7.0 and 0.5% of sea cucumber special-purpose enzyme to perform enzymatic hydrolysis for 6 hours; deodorizing: 17% of active carbon is added for deodorizing; filtering: a standing liquid firstly passes through a candle filter, then passes through a barrel filter and is finally filtered to a clear liquid storage tank; and condensation: condensation pressure is minus 0.04-minus 0.06 MPa, condensation temperature is 75-80 DEG C, and Baume degree determined during the condensation process is controlled at 10. The invention has the following advantages of: sea cucumber is changed into a fully water soluble active component after biological enzyme hydrolysis; the content of small peptides in the product is high, which is more beneficial to the absorption and utilization of the sea cucumber active component; and sea cucumber polypeptide is more acceptable in taste after deodorizing by active carbon. The invention is suitable for the extraction method of sea cucumber polypeptide.

Owner:吴庆林

Battery testing system with energy circulation

InactiveUS20140055143A1Extended service lifeProlong lifeMaterial analysis by electric/magnetic meansElectrical testingPower batteryElectricity

A battery testing system with energy circulation includes a battery module to be tested, an electric power storage module, a bi-directional conversion module and a control module, and the control module controls the bi-directional conversion module to discharge the electric power storage module and charge the battery module to be tested, or discharge the battery module to be tested and charge the electric power storage module, so that the electricity can be fully and repeatedly used, and the electric power storage module can use a second-used power battery to save the cost of the electric power storage module while the battery testing system can be isolated from the grid of utility power to avoid creating a burden to the grid of the utility power.

Owner:NAT CHUNG SHAN INST SCI & TECH

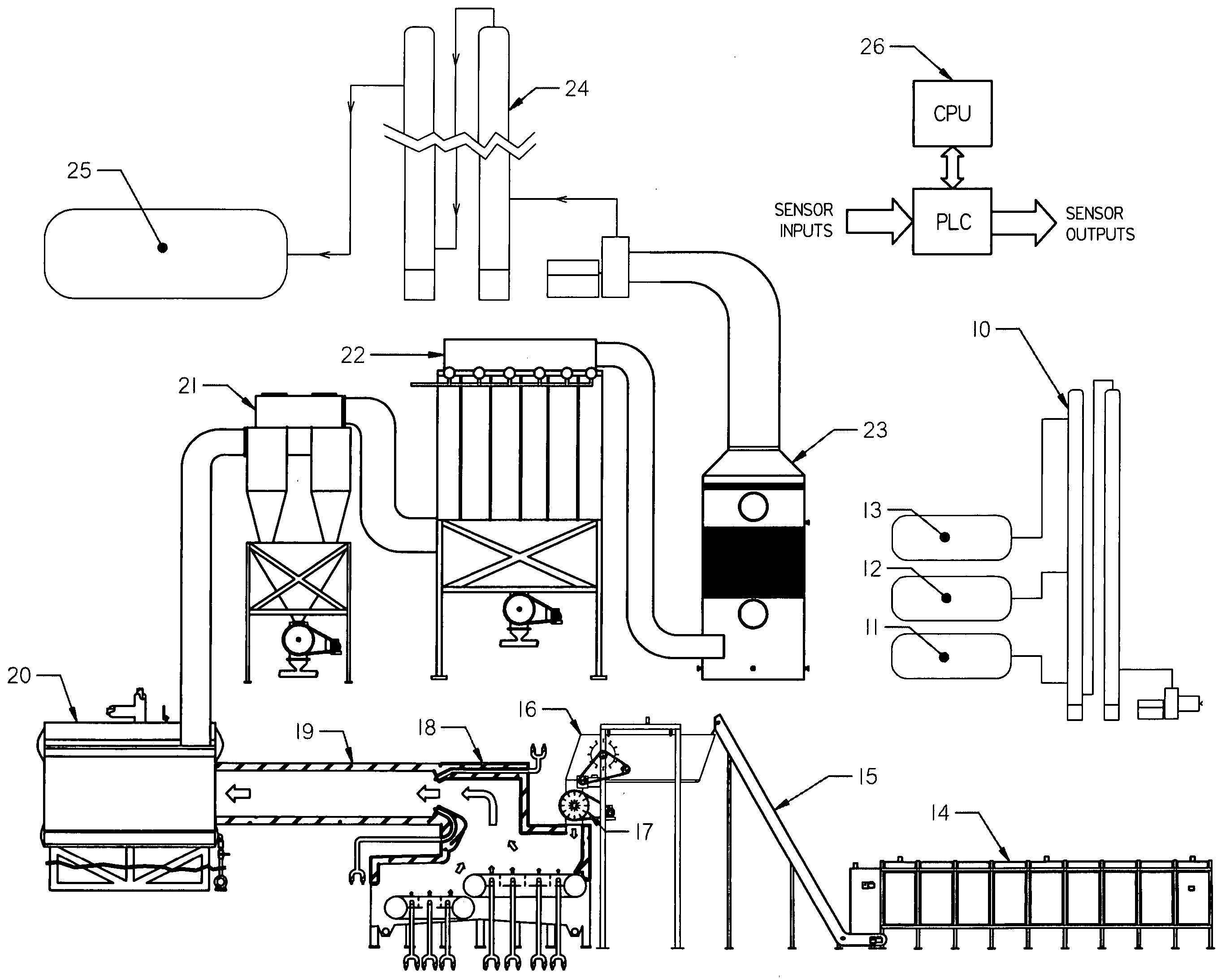

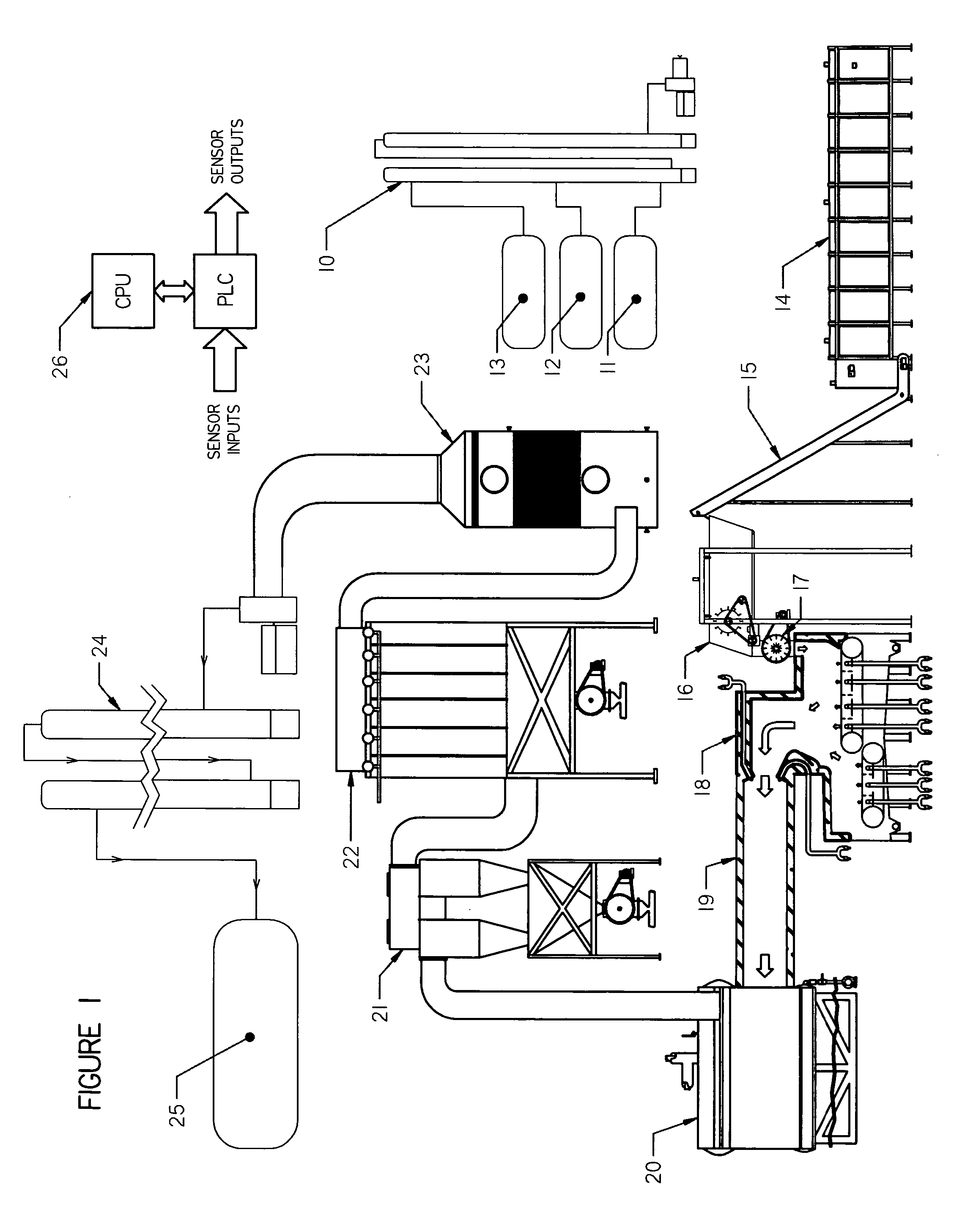

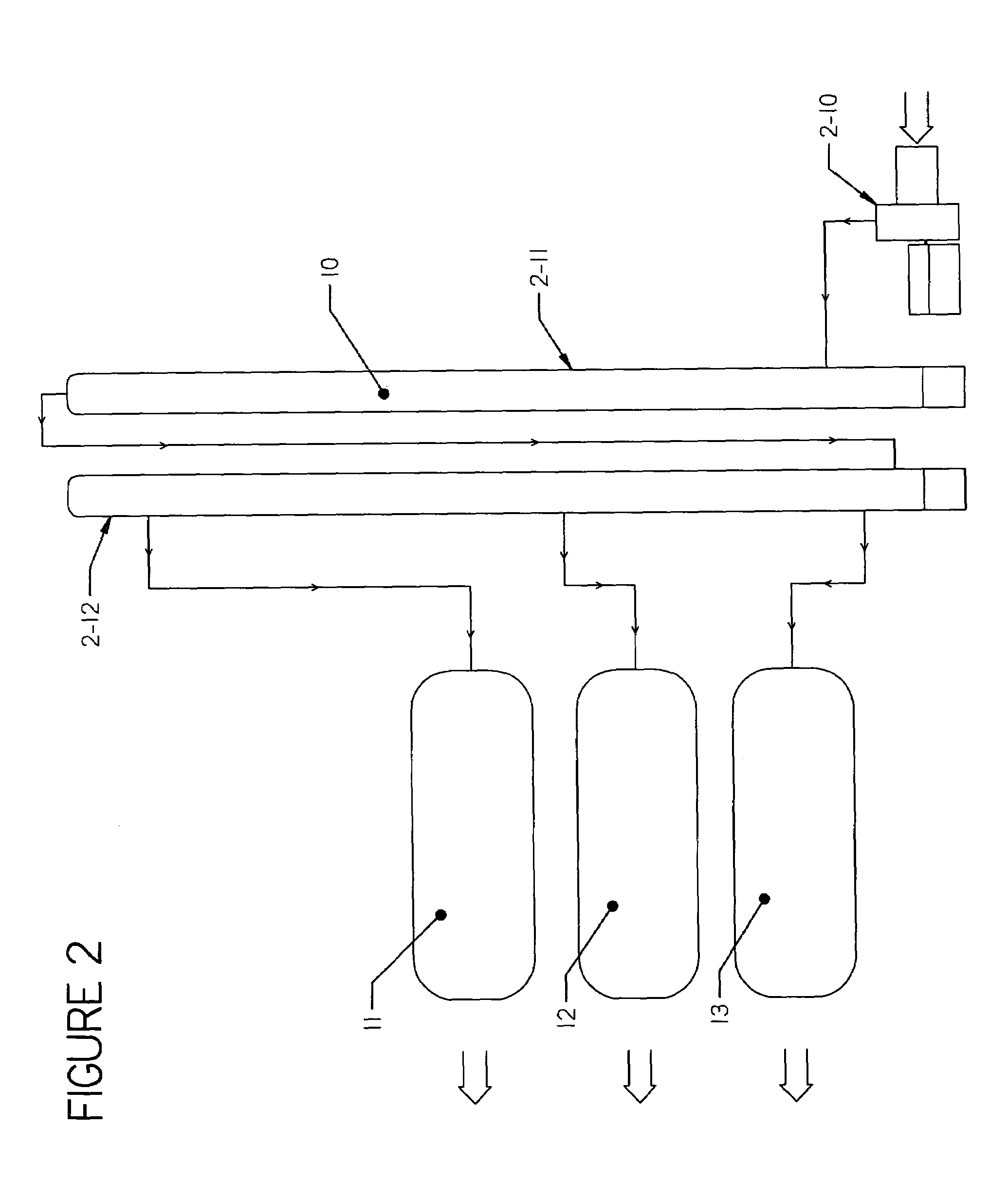

Oxygen-based biomass combustion system and method

InactiveUS7007616B2Heat loss from heating unnecessary oxidant is minimizedReduce heat lossSolidificationLiquefactionCombustion chamberOxygen

An oxygen-based biomass solid fuel combustion system and method has an air separator for separating oxygen from air providing a supply of oxygen for feeding oxygen to a solid fuel combustion chamber. An airlock feeds a metered amount of solid fuel to the solid fuel combustion chamber. A burner stage having a firetube for collecting fuel gases from the solid fuel combustion chamber combusts the collected fuel gases with further oxygen from the separator and heats a boiler to generate steam. A heat utilization device (e.g. an electrical generator) may be connected to the steam boiler. Nitrogen-free diluent gases (e.g. argon and carbon dioxide) are used to control combustion process temperatures. The usable heat energy and useful byproducts are extracted from the different stages of the process.

Owner:MUNIZ CESAR A

Method for improving north acidified soil by utilizing biochar

InactiveCN102671931AQuality improvementImprove Nutrient Utilization EfficiencyContaminated soil reclamationMass ratioRoom temperature

The invention relates to a method for improving north acidified soil by utilizing biochar. The method comprises the steps of: grinding peanut shells into slices with diameter of 2cm, drying at 60 DEG C, putting in a vacuum tubular furnace, leading in N for 230 minutes at flow velocity of 500ml / min, emptying gas in the furnace body, heating to 400 DEG C under condition of rising rate of 5 DEG C / min, maintaining 400 DEG C for two hours, then cooling to room temperature, thus obtaining black biochar; and grinding the biochar into powder with diameter smaller than 2mm, and applying the biochar and soil with 1 to 5 percent mass ratio into orchard soil or farmland to be restored. The method has the advantages of being simple to use, obviously improving the quality of soil, improving utilization rate of soil nutrient, being simple to use and obvious and endurable in effects, and providing a new way for improving north acidified soil.

Owner:青岛贝尔卡环境生物工程有限公司

Post ECP multi-step anneal/H2 treatment to reduce film impurity

InactiveUS7030016B2Improve reliabilityReduce defect densitySemiconductor/solid-state device manufacturingCopper interconnectCarbon impurities

A method of forming a copper interconnect in a dual damascene scheme is described. After a diffusion barrier layer and seed layer are sequentially formed on the sidewalls and bottoms of a trench and via in a dielectric layer, a first copper layer is deposited by a first ECP process at a 10 mA / cm2 current density to fill the via and part of the trench. A first anneal step is performed to remove carbon impurities and optionally includes a H2 plasma treatment. A second ECP process with a first deposition step at a 40 mA / cm2 current density and second deposition step at a 60 mA / cm2 current density is used to deposit a second copper layer-that overfills the trench. After a second anneal step, a CMP process planarizes the copper layers. Fewer copper defects, reduced S, Cl, and C impurities, and improved Rc performance are achieved by this method.

Owner:TAIWAN SEMICON MFG CO LTD

Light-Transmissive Shell Capable Of Intensifying Illuminant And Wide-Angle Light Transmission

InactiveUS20120014116A1Improve lighting efficiencyImprove efficiencyPlanar light sourcesMechanical apparatusAcute angleSurface structure

A light-transmissive shell capable of intensifying an illuminant and wide-angle light transmission includes a lens body and an extension portion integrally extended from the lens body in a vertical direction or at an acute angle to the vertical direction. The lens body includes an outer top surface structured as a convexity and an inner bottom surface structured as a flat surface or an inner concavity. The extension portion includes an inner surface extending around from the inner bottom surface of the lens body. An arcuate surface is formed as a joint between the inner bottom surface of the lens body and the inner surface of the extension portion. The light emitted by an illuminant is intensified through the lens body and guided into a wide-angle light through the extension portion.

Owner:HU WEN SUNG

Method of manufacturing a semiconductor device

InactiveUS7393723B2Improving decarbonizationImproving step coverage propertyTransistorSolid-state devicesHydrogenEngineering

A method of manufacturing a semiconductor device that forms laminate layers includes the steps of reducing contamination containing the single bond of carbon on at least one part of a surface on which the laminate films are formed by activated hydrogen before the laminate films are formed, and forming the laminate films on the surface on which the laminate films are formed.

Owner:SEMICON ENERGY LAB CO LTD

Method for preparing hot rolling strip steel capable of preventing edge crack of extremely thin rolled strip steel

InactiveCN102179407AUniform temperatureReduce temperature differenceTemperature control deviceMetal rolling arrangementsTemperature differenceAlloy

The invention relates to a method for preparing hot rolling strip steel capable of preventing edge crack of extremely thin rolled strip steel. The method comprises the following steps of: (1) smelting, namely desulfurizing molten iron, smelting by using a converter, blowing argon at an argon station, and performing continuous casting to form slabs; (2) performing hot rolling, namely heating the slabs to 1,210 to 1260 DEG C, wherein the temperature difference of the same slab is less than or equal to 30 DEG C; performing rough rolling, and finish rolling, wherein the side pressure delta B when the slab with the width B is subjected to rough rolling is controlled according to the following formula: delta B ranges from 35*B / 1,250*(B-1,050) / (1,250-1,050)+35*B / 1,050*(1,250-B) / (1,250-1,050) to 50; and finally reeling to obtain the hot rolling strip steel. The method is simple and practical, is stable in use and high in uniformity, reduces the alloy cost and shortens the production cycle; and the steel plate heat commercial (SPHC) hot rolling strip steel prepared by the method has the obvious effect of preventing the edge crack of extremely thin cold-rolled sheet.

Owner:NINGBO IRON & STEEL

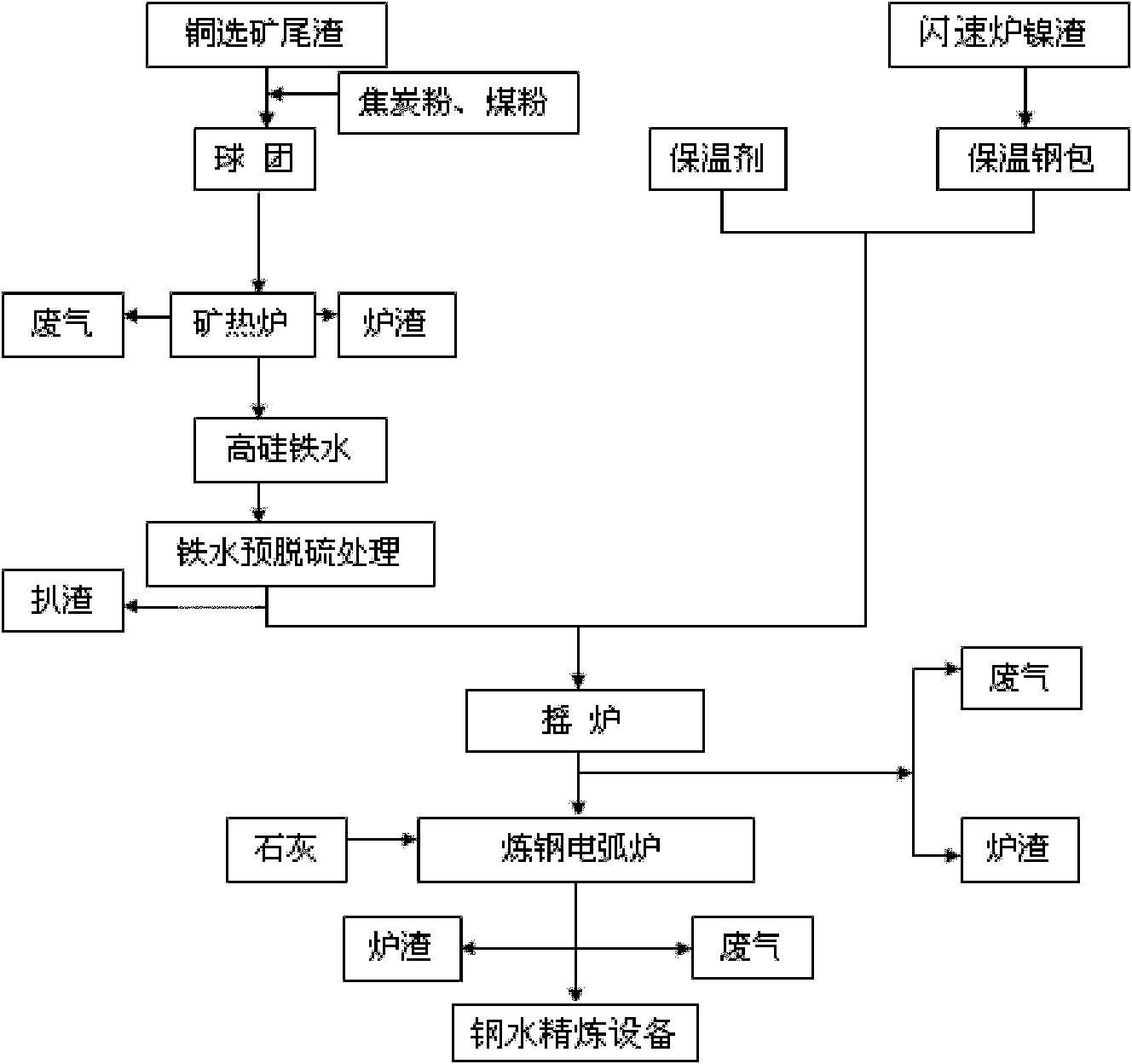

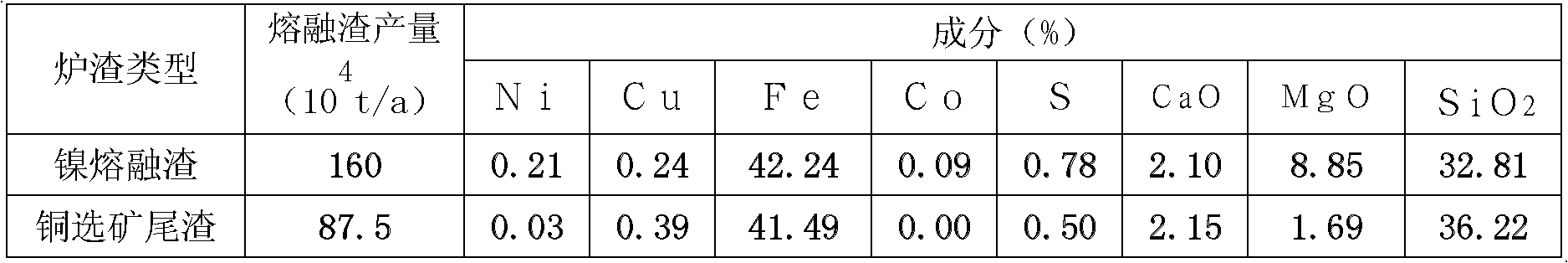

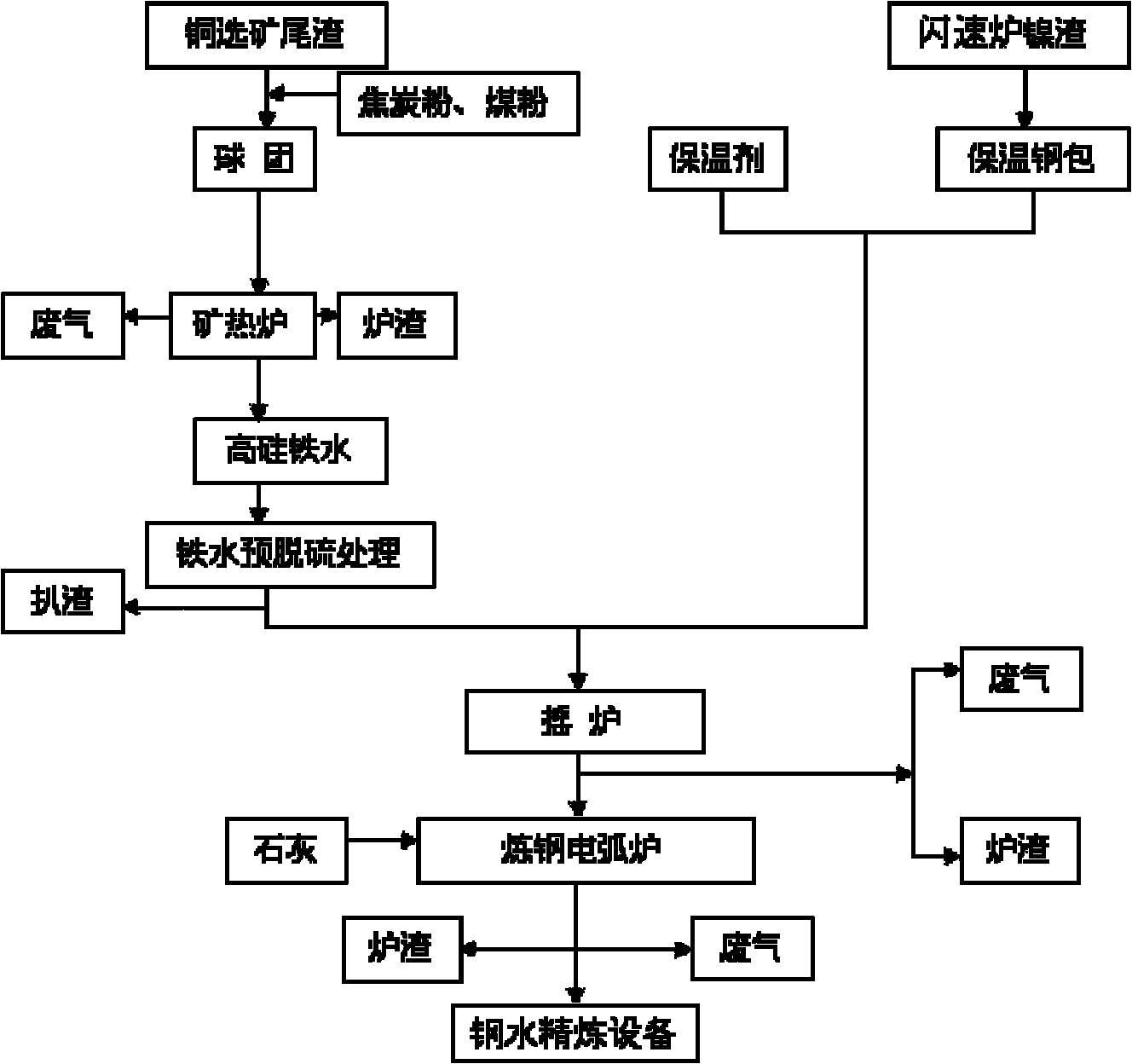

Iron extracting and steelmaking process for comprehensively treating copper ore tailing and nickel molten slag

InactiveCN102051428AGood reduction kinetics conditionsImprove smelting efficiencySteelmakingProcess equipment

The invention discloses an iron extracting and steelmaking process for treating copper ore tailing and nickel molten slag by an ore heating furnace, a shaking furnace, a steelmaking electric arc furnace and a refining furnace. The iron extracting and steelmaking process comprises the following steps of: (1) uniformly mixing copper ore tailing and a carbonaceous reducing agent and granulating into pellet lump ore; (2) charging the pellet lump ore into the ore heating furnace and smelting to obtain silicon-contained molten iron; (3) desulfurating and deslagging the silicon-contained molten iron to obtain low-sulphur-silicon molten iron or confirming whether sulphur is removed according to the sulphur content of the silicon-contained molten iron; (4) transporting the nickel molten slag to an iron extracting station in a heat preserving way; (5) charging the nickel molten slag into the shaking furnace, adding lime and low-sulphur-silicon molten iron, mixing and stirring to obtain reduced molten iron; and (6) conveying the reduced molten iron into the electric arc furnace and adding lime for desulfurating, decarbonizing and dephosphorizing to obtain molten steel. The process reasonably utilizes the components of the copper ore tailing, fully recovers valuable metals in the copper ore tailing and the nickel molten slag, achieves the aim of comprehensive utilization, has reasonable design, is convenient for mastering and construction and is suitable for industrialized application.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

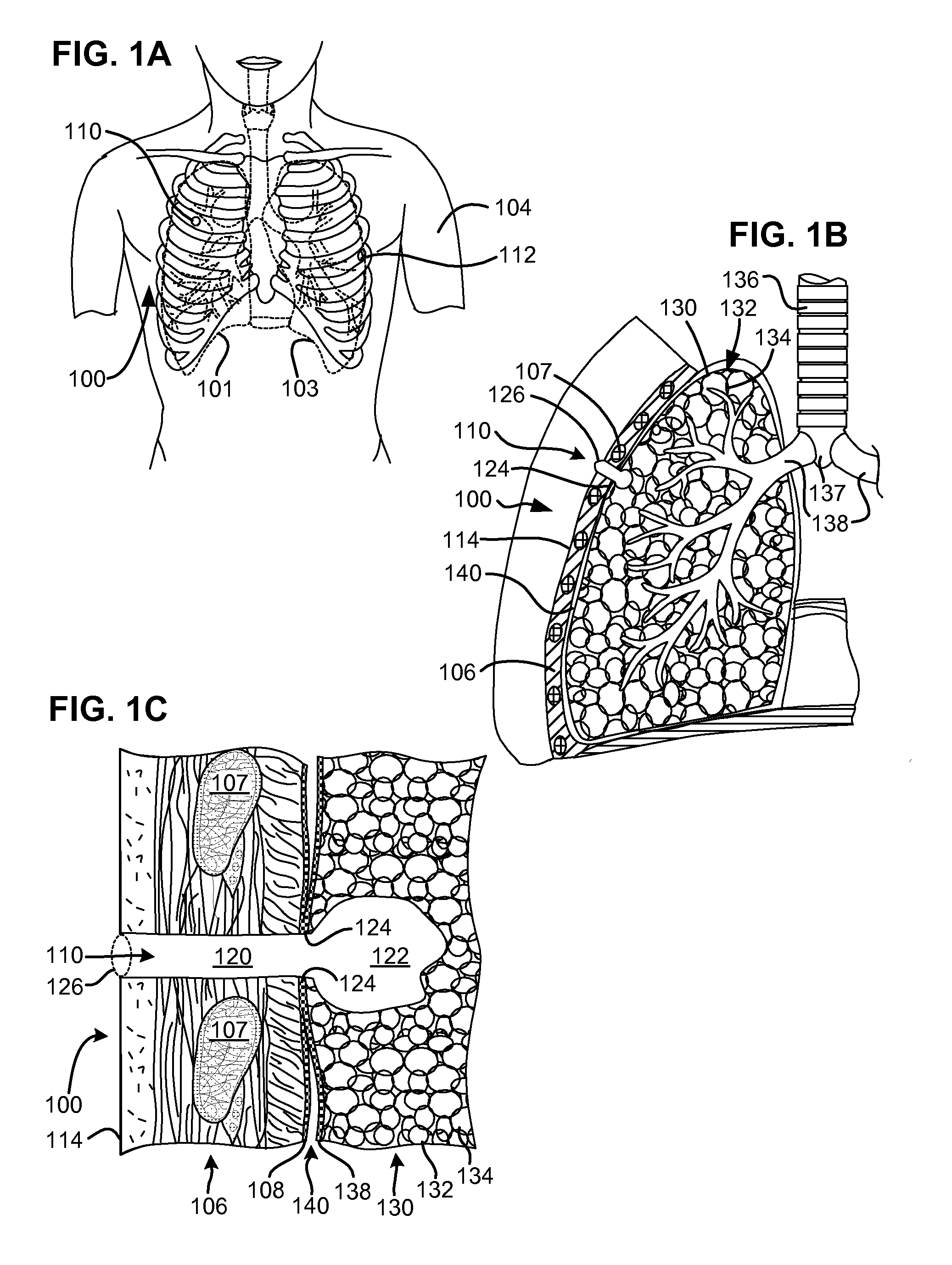

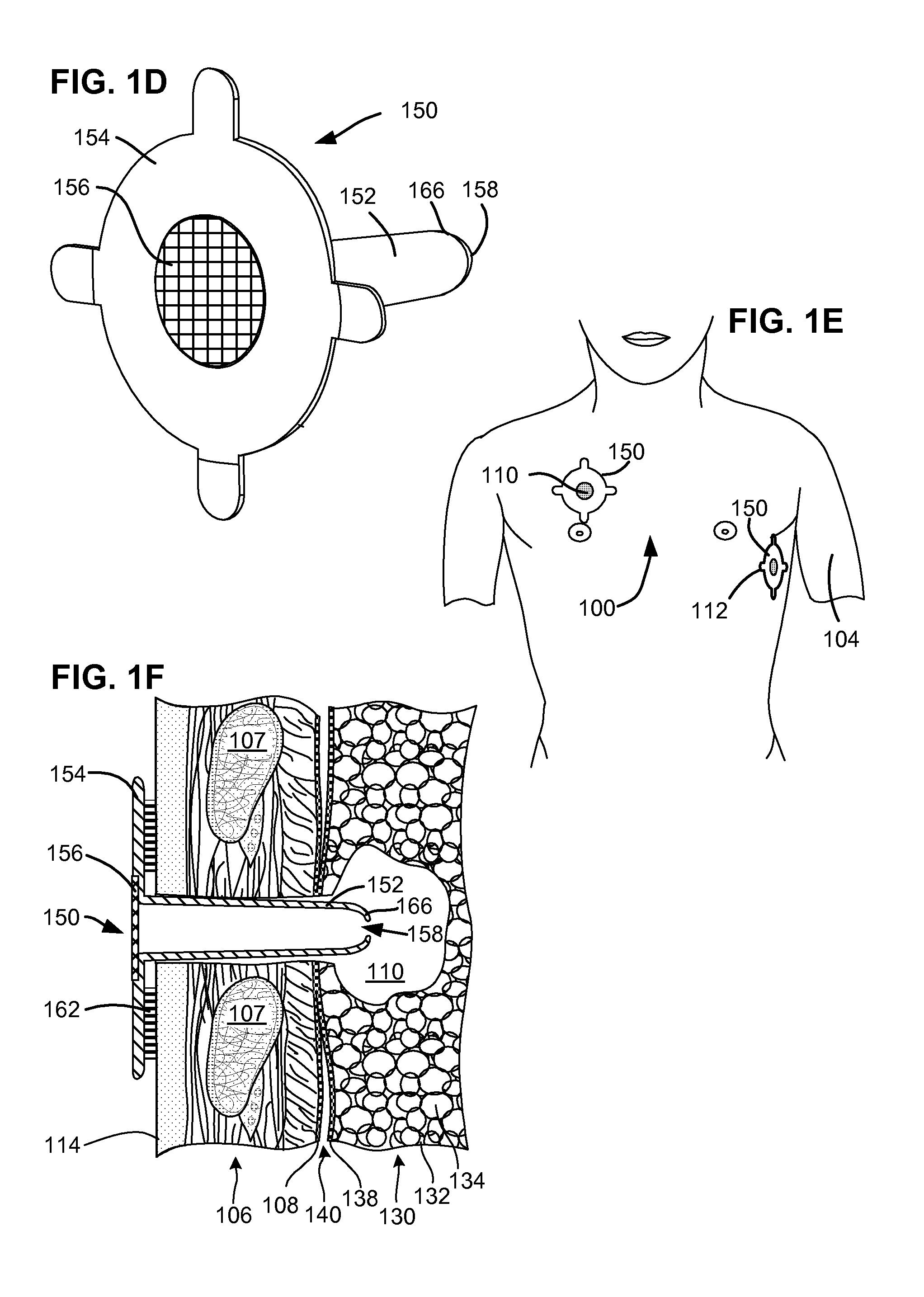

Methods and devices for follow-up care and treatment of a pneumstoma

InactiveUS20110180064A1Stable artificial apertureAvoid cavitiesUltrasonic/sonic/infrasonic diagnosticsBronchoscopesFollow up careTreatment modality

A pneumostoma assessment and treatment system includes methods and devices for aftercare of a pneumostoma and for additional patient care utilizing a pneumostoma. The system utilizes a number of modalities to assess the health and functionality of the pneumostoma, the lungs and / or the patient as a whole. In response to an assessment of the health and functionality of the pneumostoma, lungs and patient, the tissues of pneumostoma may be treated with a treatment device and utilizing one or more different modalities to preserve or enhance the health and function of the pneumostoma and / or treat other conditions of the patient. Particular treatment modalities may be utilized to reduce tissue growth in and around the pneumostoma in order to prevent stenosis and maintain patency of the pneumostoma.

Owner:PORTAERO

Resin composition, molded body and composite molded body

In accordance with the present invention, by using a resin composition including lignin and a curing agent in which the lignin is soluble in an organic solvent and contained in the resin composition in an amount of from 10 to 90% by mass, there are provided a molded product and a composite molded product which are obtained from plant resources as a main raw material and to which a good flame retardance and a good antibacterial property are imparted.

Owner:HITACHI CHEM CO LTD

Removing Carbon Dioxide From Gaseous Emissions

InactiveUS20110064634A1Reduce the amount requiredIncrease productionGas treatmentDispersed particle separationProduct gasCarbonate

The present invention provides methods and apparatuses for removing carbon dioxide from gaseous emissions. In particular, the present invention provides methods and apparatuses for removing carbon dioxide from gaseous emissions as a metallic carbonate precipitate.

Owner:AUXSOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com