Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

301results about How to "Quick investment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

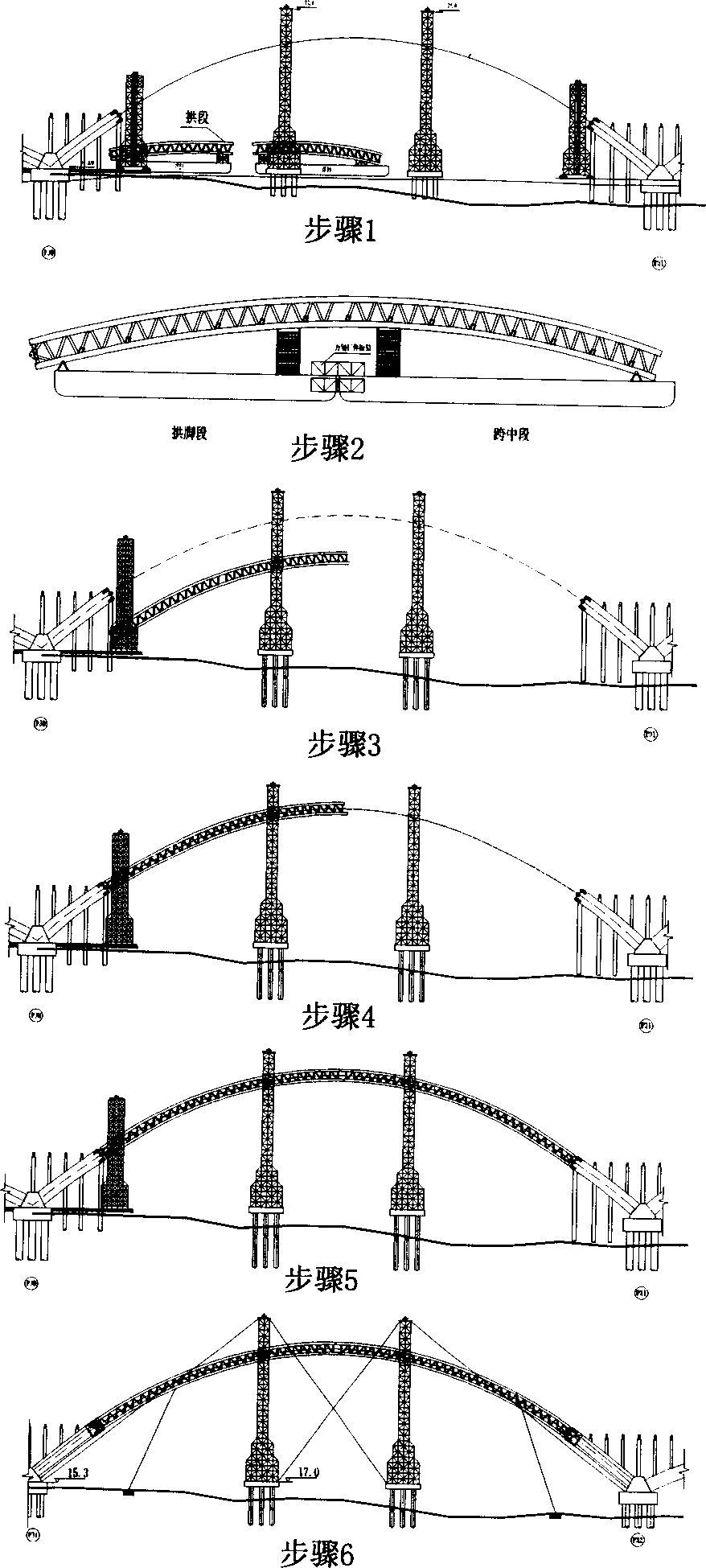

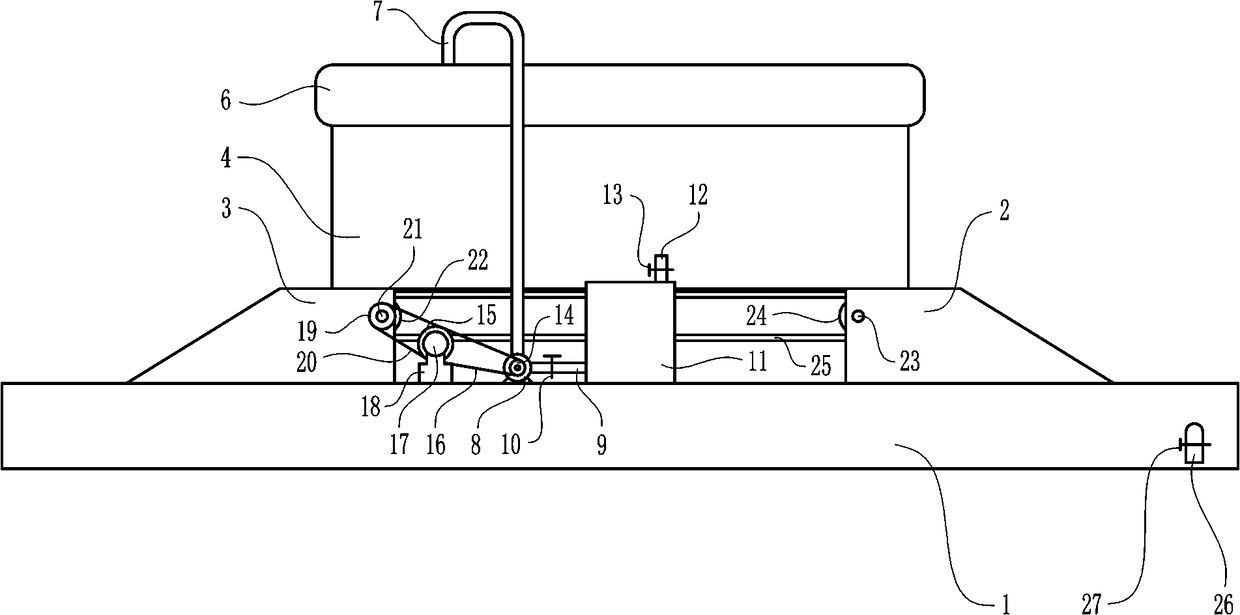

Gate-type crane semiarch integral-hoisting steel-pipe arch process

InactiveCN1851137AQuick investmentImprove securityBridge erection/assemblyArch-type bridgeSpandrelSteel tube

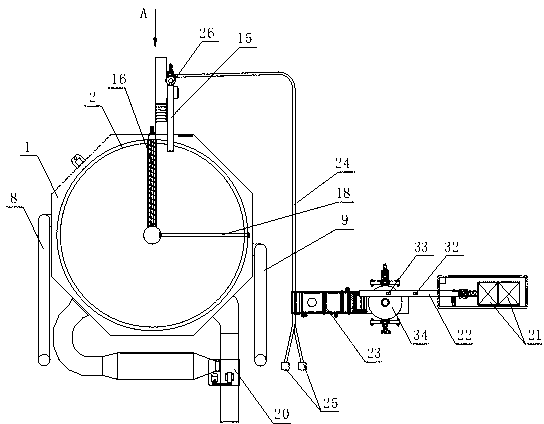

The invention relates to erecting construction of a steel pipe concrete arch bridge, especially a door crane-used half-arch integral steel pipe arch hoisting process, dividing each arch rib into two hoisted units, where each 1 / 2 arch is hoisted by two door cranes, where a fixed door crane serves as an arch span hoister and an active door crane serves as an arch foot hoister. And the invention is applied to bottom, middle and top bearing arch bridges constructed by bracket-free process. And the span of the steel pipe arch installed by the invention can reach above 300 meters, and the weight of the installed steel pipe can reach above 2000 tons. And it does not influence navigation, able to applied to single- or multiple- span construction; the hoisting safety is higher; and the shape of the arch axis is good; it needs no huge anchoring system and applied to various arch bridges.

Owner:CHINA RAILWAY FIRST GRP CO LTD

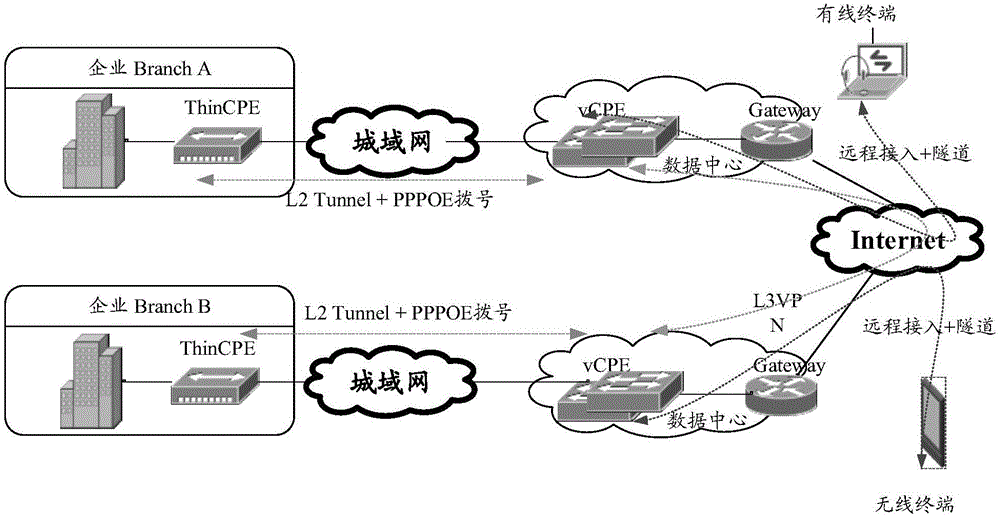

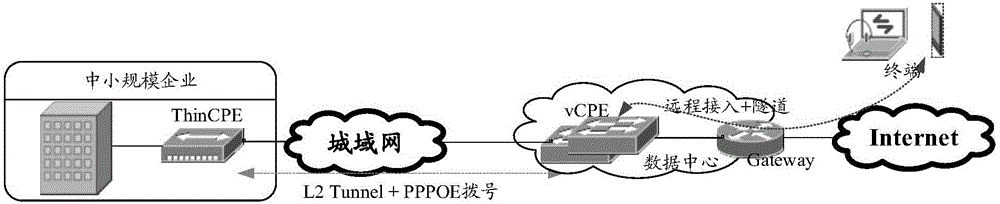

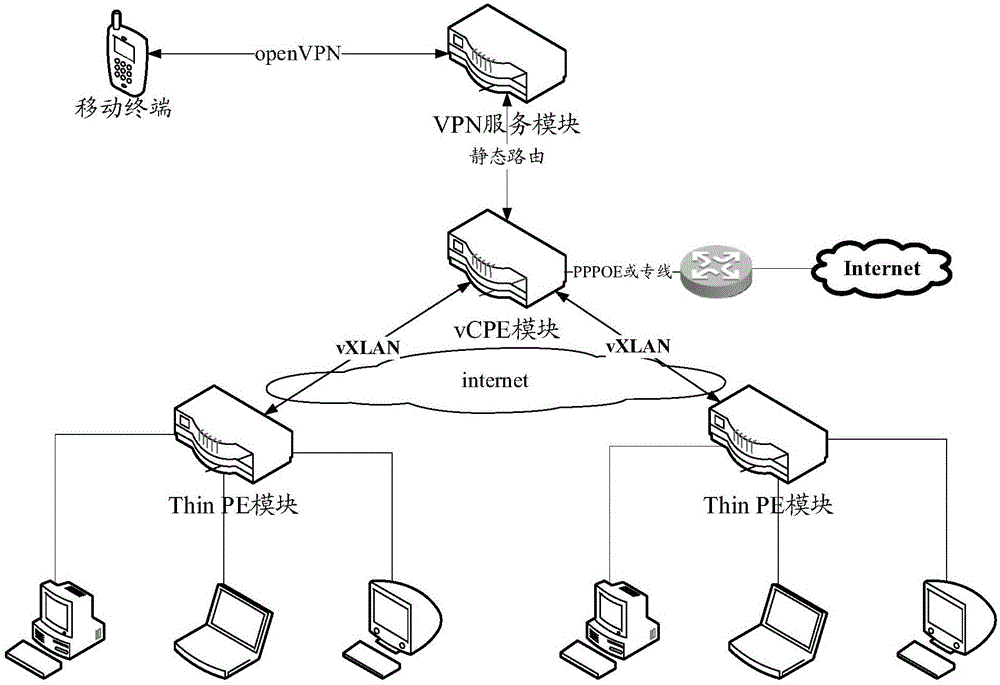

System of realizing vCPE virtualization enterprise network based on NFV and method thereof

ActiveCN105978708ASave and protect your investmentEasy to operateNetworks interconnectionVirtualizationStructure of Management Information

The invention relates to a system of realizing a vCPE virtualization enterprise network based on NFV and a method thereof. The system comprises a vCPE module and a ThinPE module. The vCPE module is communicated with a network through a gateway. An enterprise internal network terminal is communicated with the vCPE module through the ThinPE module. By using the system of realizing the vCPE virtualization enterprise network based on the NFV and the method thereof, an NFV technology is used to separate software and hardware, and a hardware environment where the software is operated is converted into general physical server hardware from special hardware so that investments are saved and protected; a server of a ground floor introduces a cloud calculating technology, a scale up / down operation is easy to perform, capacity expanding can be performed according to a service need and balance of the investments and a capacity expanding frequency does not need to be considered; an enterprise does not need to buy expensive non-universal hardware equipment and only has to rent vCPE equipment from an operator; when vCPE introduces a new service, smooth performance can be achieved, an enterprise internal network user does not feel, an experience and efficiency are increased and a wide application scope is possessed.

Owner:CERTUS NETWORK TECHNANJING

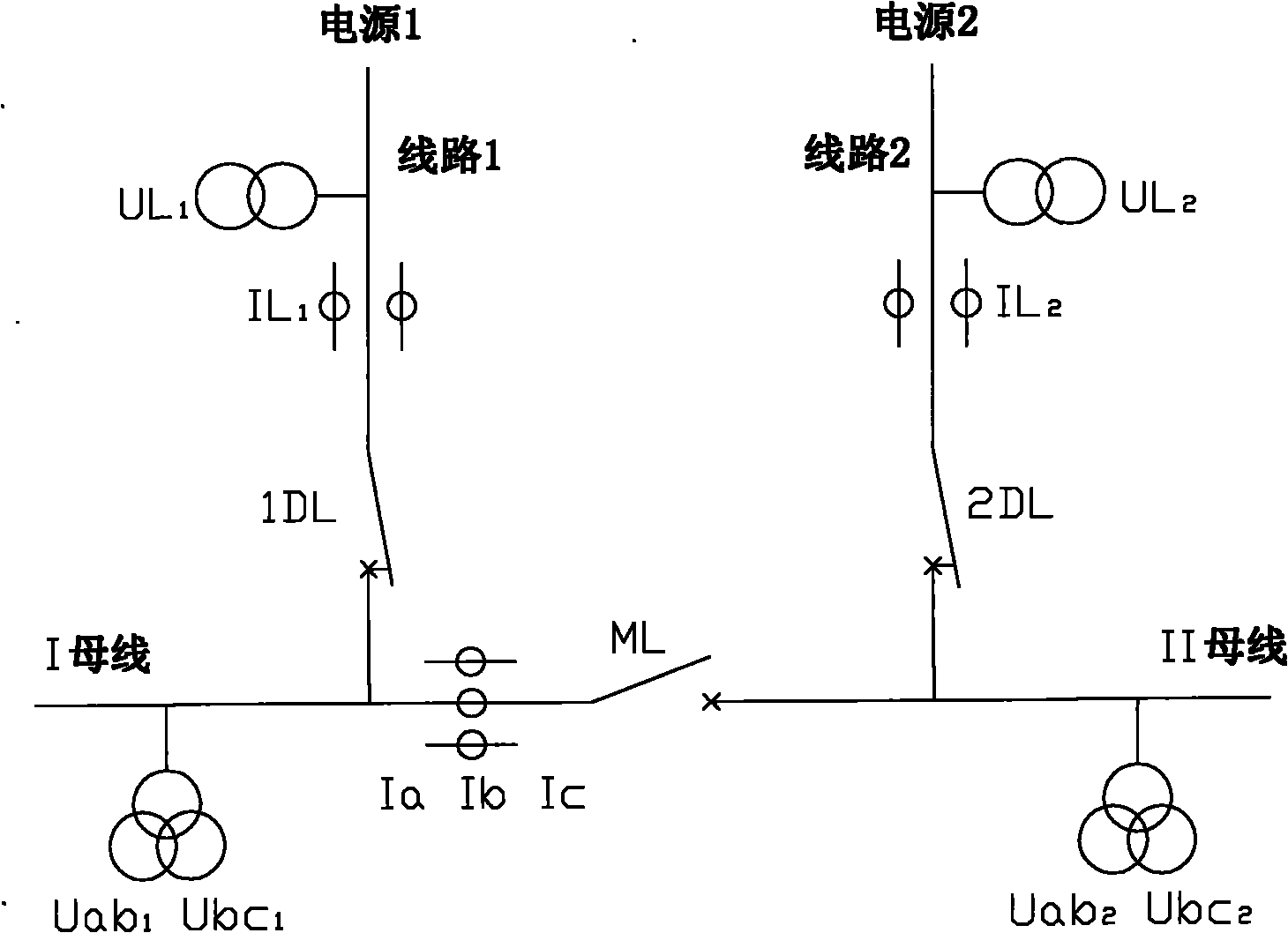

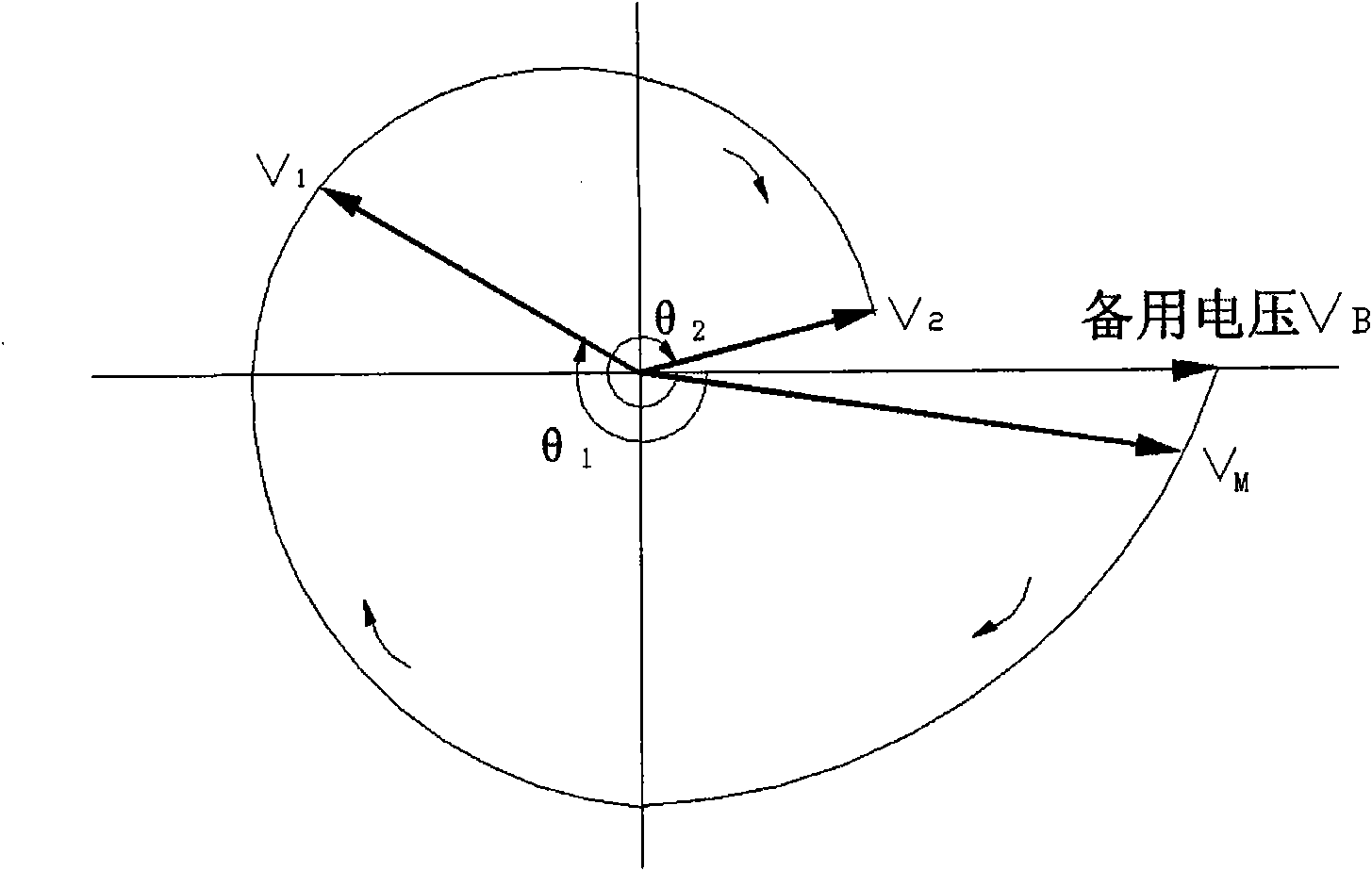

Method and system for switching backup power supply

ActiveCN101917058AQuick switchQuick investmentPower network operation systems integrationInformation technology support systemPower switchingStandby power

The invention relates to a method and a system for switching a backup power supply. The method comprises the following steps of: starting switching and tripping off a working power switch; acquiring the operation condition of the backup power supply; and if a condition is accordant with the tripping off criterion of the working power switch and the operation condition of the backup power supply, performing a power supply switching action and putting the backup power supply into operation, wherein the execution of the starting switching and the stripping off of the working power switch comprises one or more of the following criteria: frequency voltage quality starting, frequency difference starting, frequency difference non-current starting, reverse power starting and frequency difference reverse power starting. At least one of five criteria is adopted, so that the power supply can be switched rapidly and correctly. Moreover, a multi-judgment backup power supply operation condition is adopted, so that the backup power supply can be put into operation correctly and the backup power supply is switched rapidly and correctly and put into operation.

Owner:深圳市国立智能电力科技有限公司

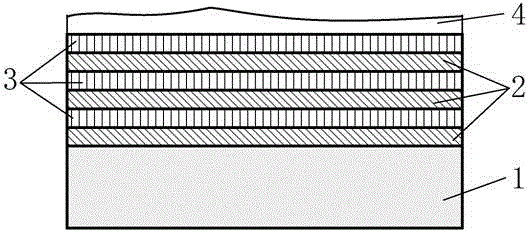

Method used for manufacturing multi-layer circuit board by employing 3D printing technology

InactiveCN104486910ALess prone to defectsReduced responseConductive pattern formationInsulation layerCam

The invention provides a method used for manufacturing a multi-layer circuit board by employing the 3D printing technology. The method is additionally provided with a heatproof insulation layer on the basis of an original printed circuit board. Raw material powder of the circuit comprises copper alloy powder and tin powder which are in a certain proportion, the heatproof insulation layer is ceramic powder, the 3D molding method is a laser irradiation molding method. During processing, the computer auxiliary manufacturing (CAM) technology is firstly utilized, circuit board design is accomplished on computer software and is transmitted to a 3D printer. The ceramic powder is fixed on the circuit board to form the heatproof insulation layer by utilizing the laser 3D printer, circuit molding of the powder is directly carried out on the heatproof insulation layer base body by utilizing the 3D printing technology, the steps above are repeated, and thereby the multi-layer circuit board is formed. Compared with a traditional printed circuit board, the multi-layer circuit board can be rapidly produced in a lab or under the small-batch production condition, moreover, the circuit does not easily generate defects, cost is low, response is rapid, equipment investment is small, and the method employing the 3D printing technology provides feasible small-batch customized production.

Owner:ANHUI NEOFOUND TECH +2

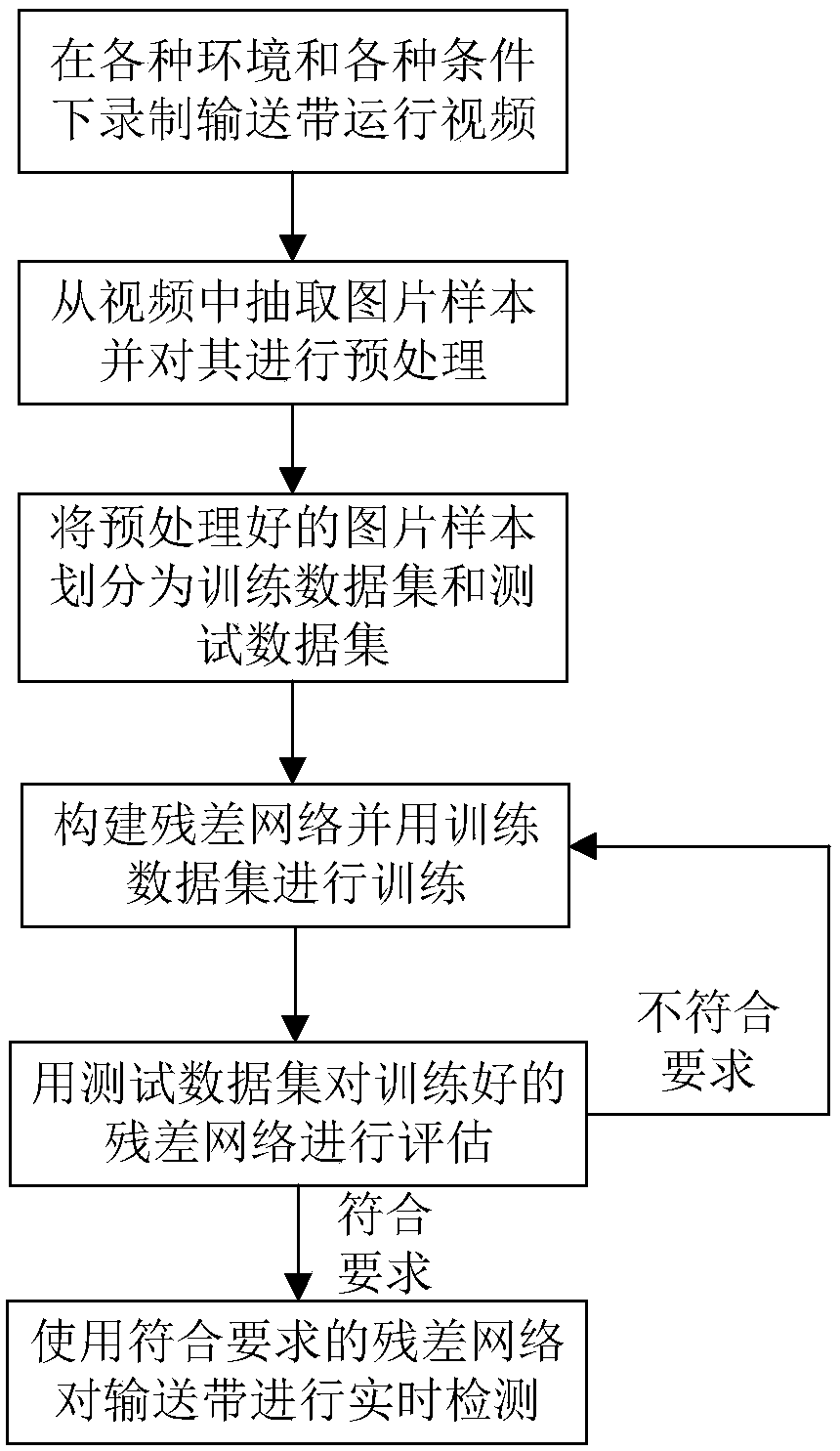

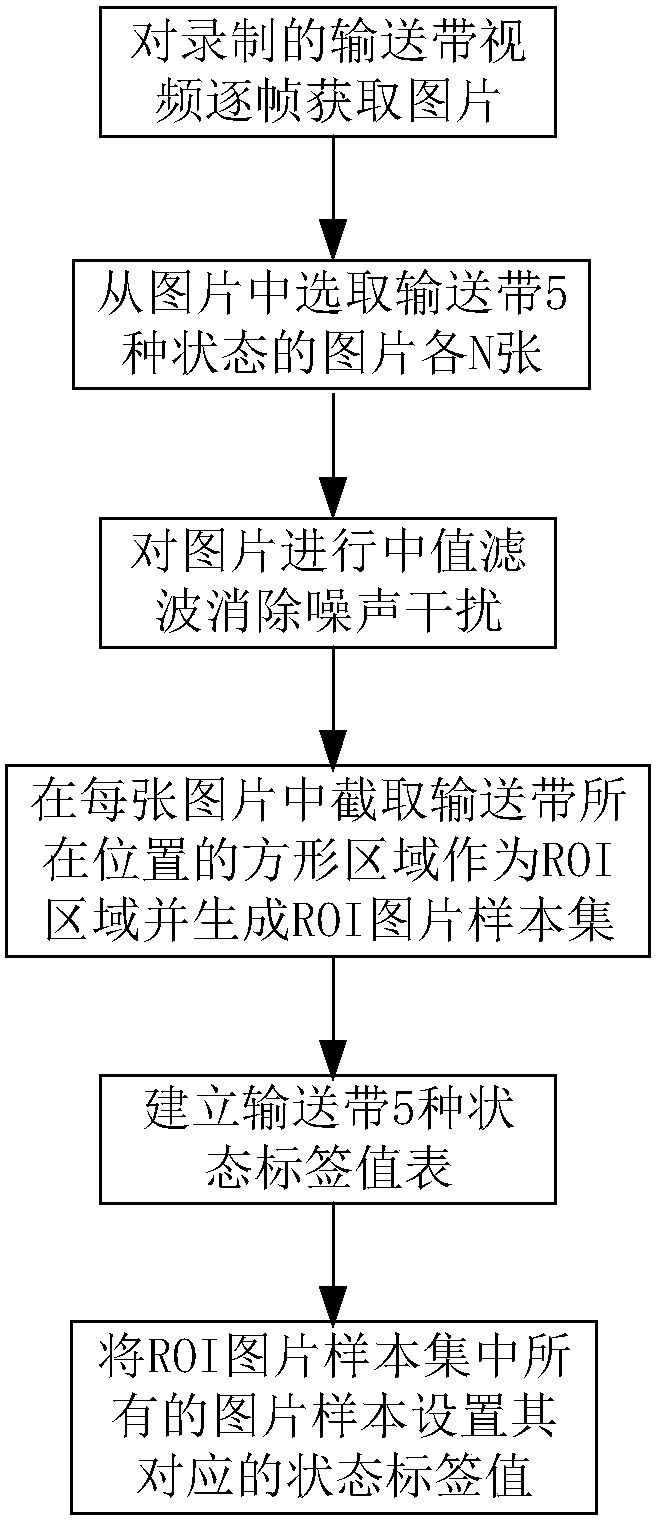

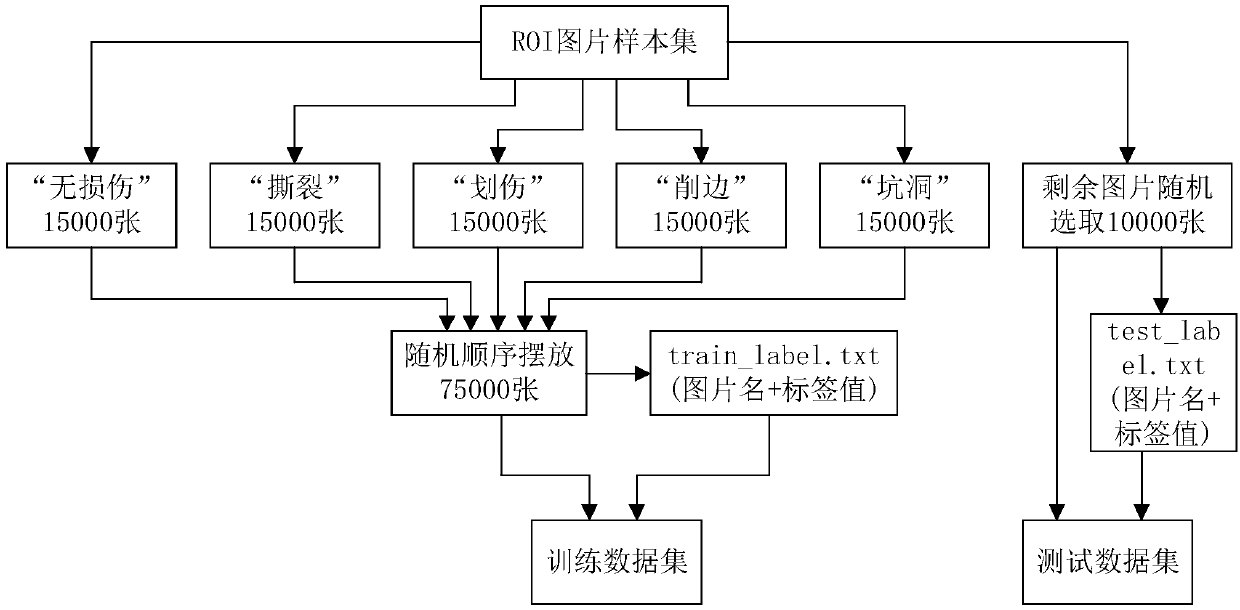

Residual error network-based detection method for four types of damage of conveyer belt

ActiveCN108510488AAvoid workloadSimple hardware supportImage analysisControl devices for conveyorsData setAlgorithm

The invention discloses a residual error network-based detection method for four types of damage of a conveyer belt. The method comprises the steps of recording a conveyer belt running video; extracting picture samples from the video and performing preprocessing; dividing a training data set and a test data set; constructing a residual error network and performing training by using the training data set; performing assessment by using the test data set; and performing a series of processes of real-time detection on the conveyer belt by using the residual error network meeting the requirements,thereby real-time detection of the four types of the damage, including "tear", "scratch", "chamfered edges" and "holes", of the conveyer belt. According to the method, the detection of the four typesof the damage of the conveyer belt is realized through the video, so that complicated work due to use of a large amount of sensor detection apparatuses is avoided and the cost is reduced; and an identification network is constructed by using the residual error network, so that the network training precision is improved and the identification error rate is reduced.

Owner:ANHUI UNIV OF SCI & TECH

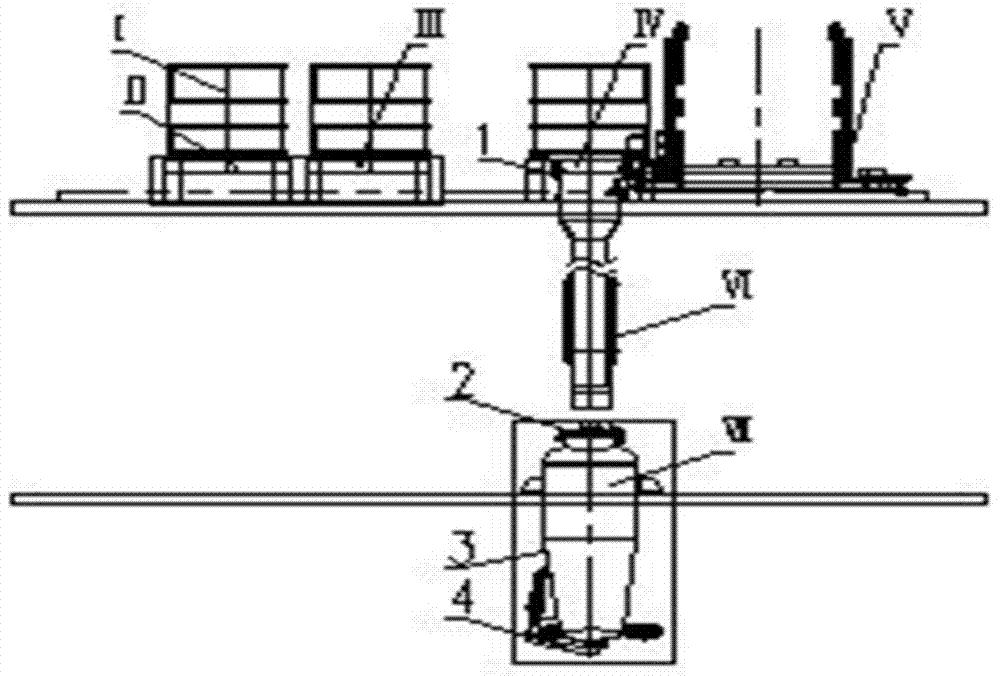

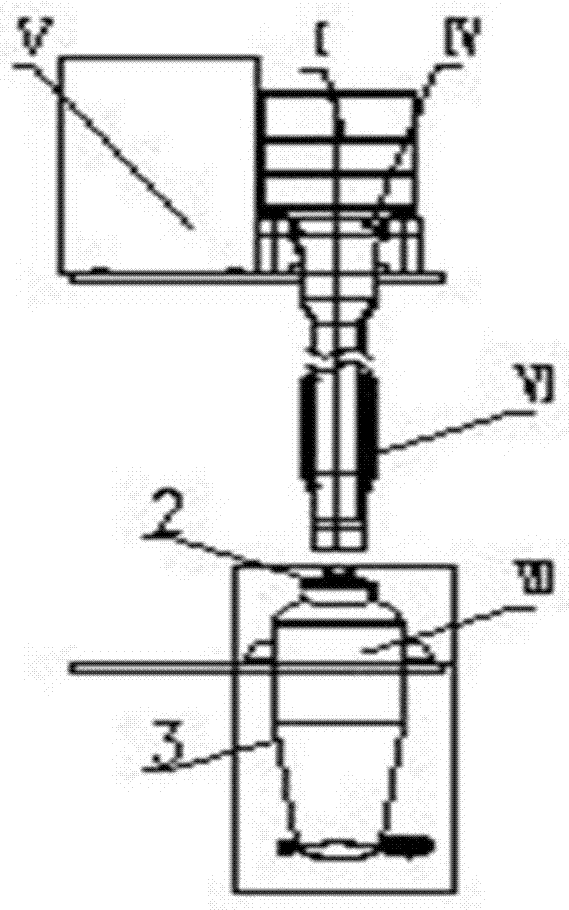

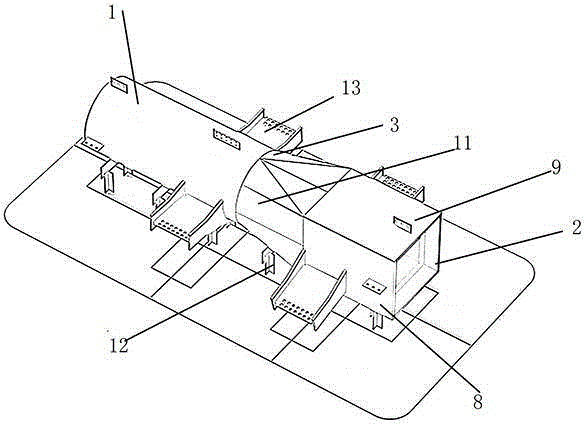

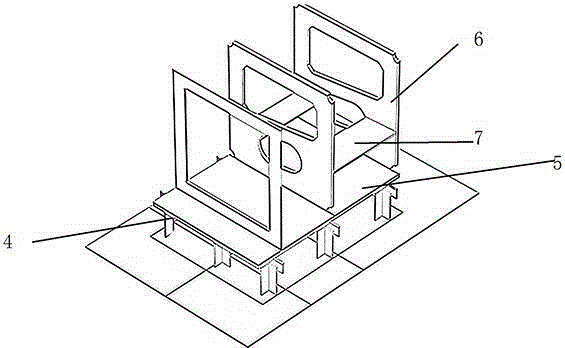

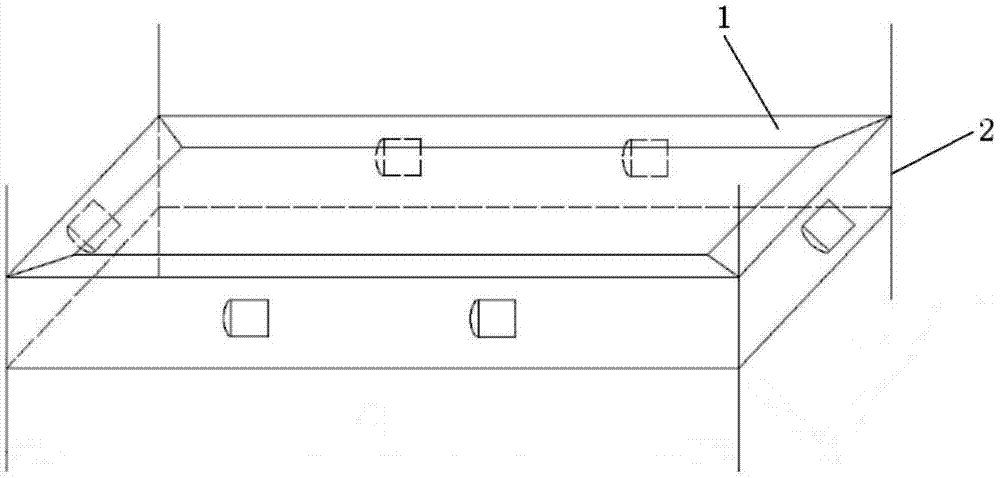

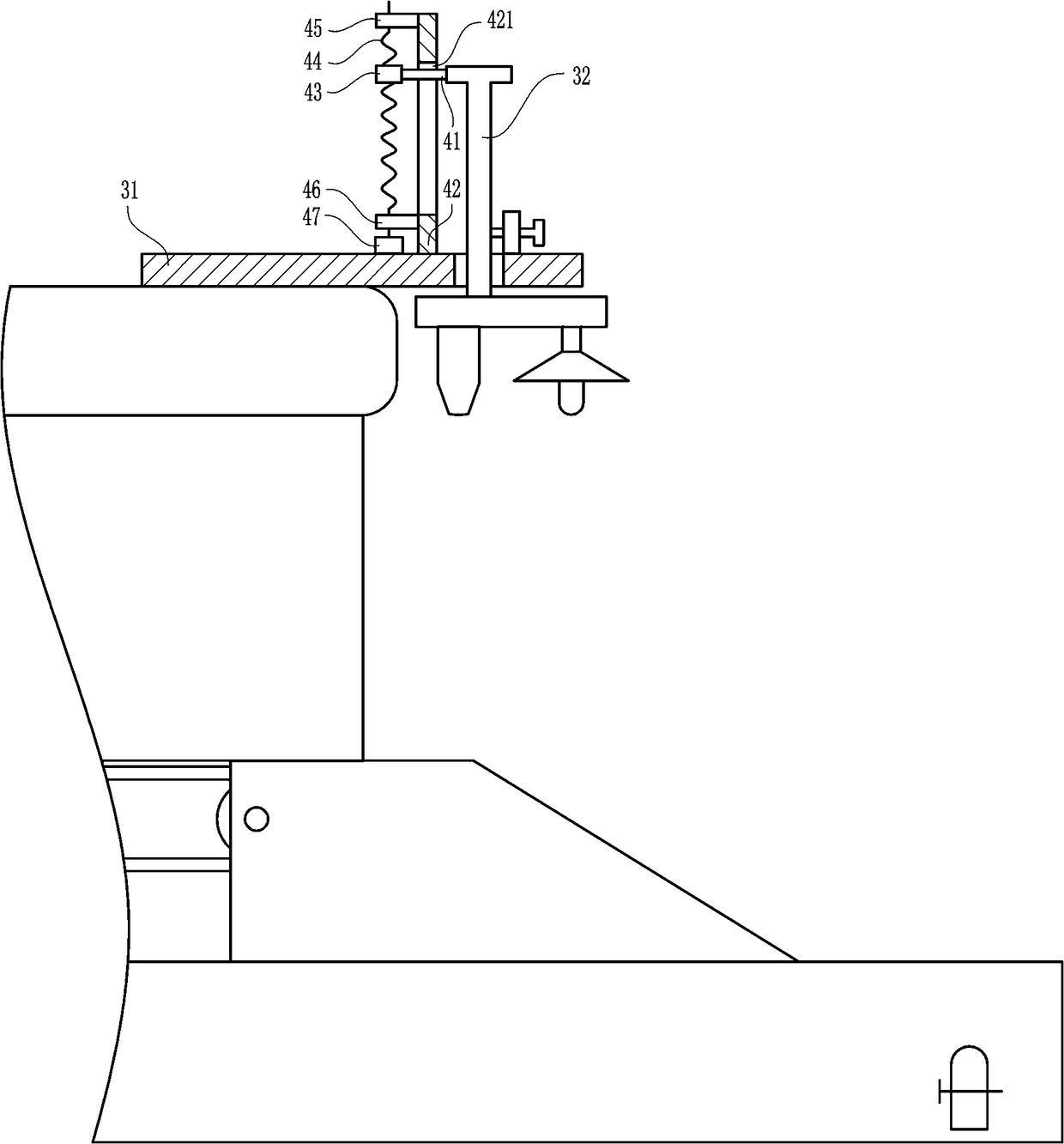

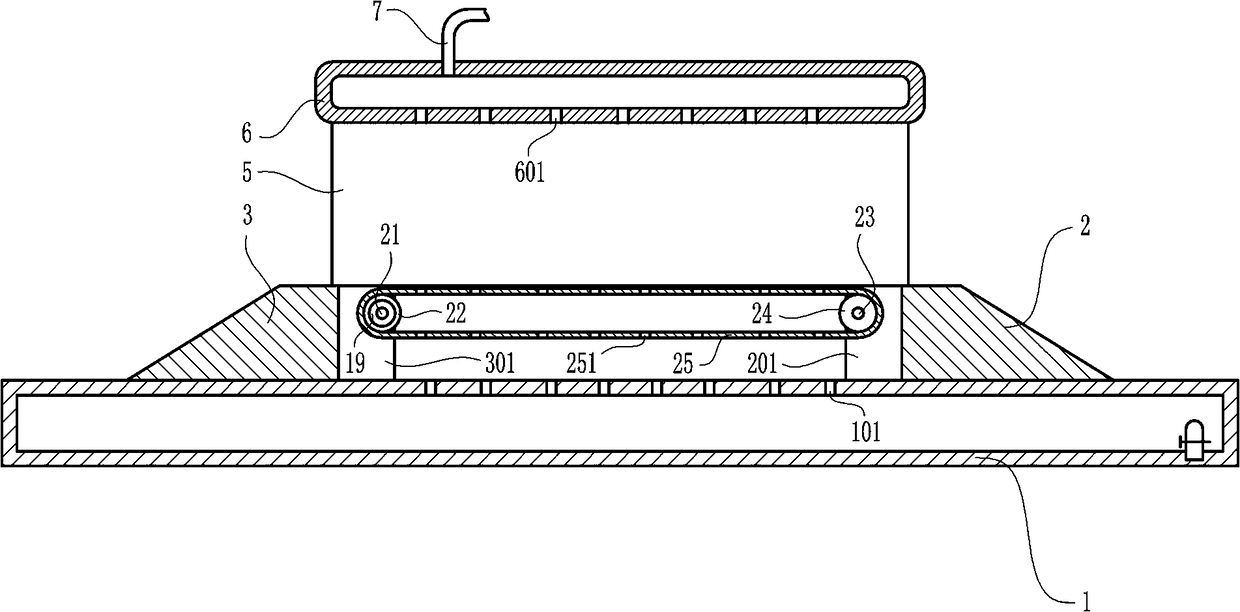

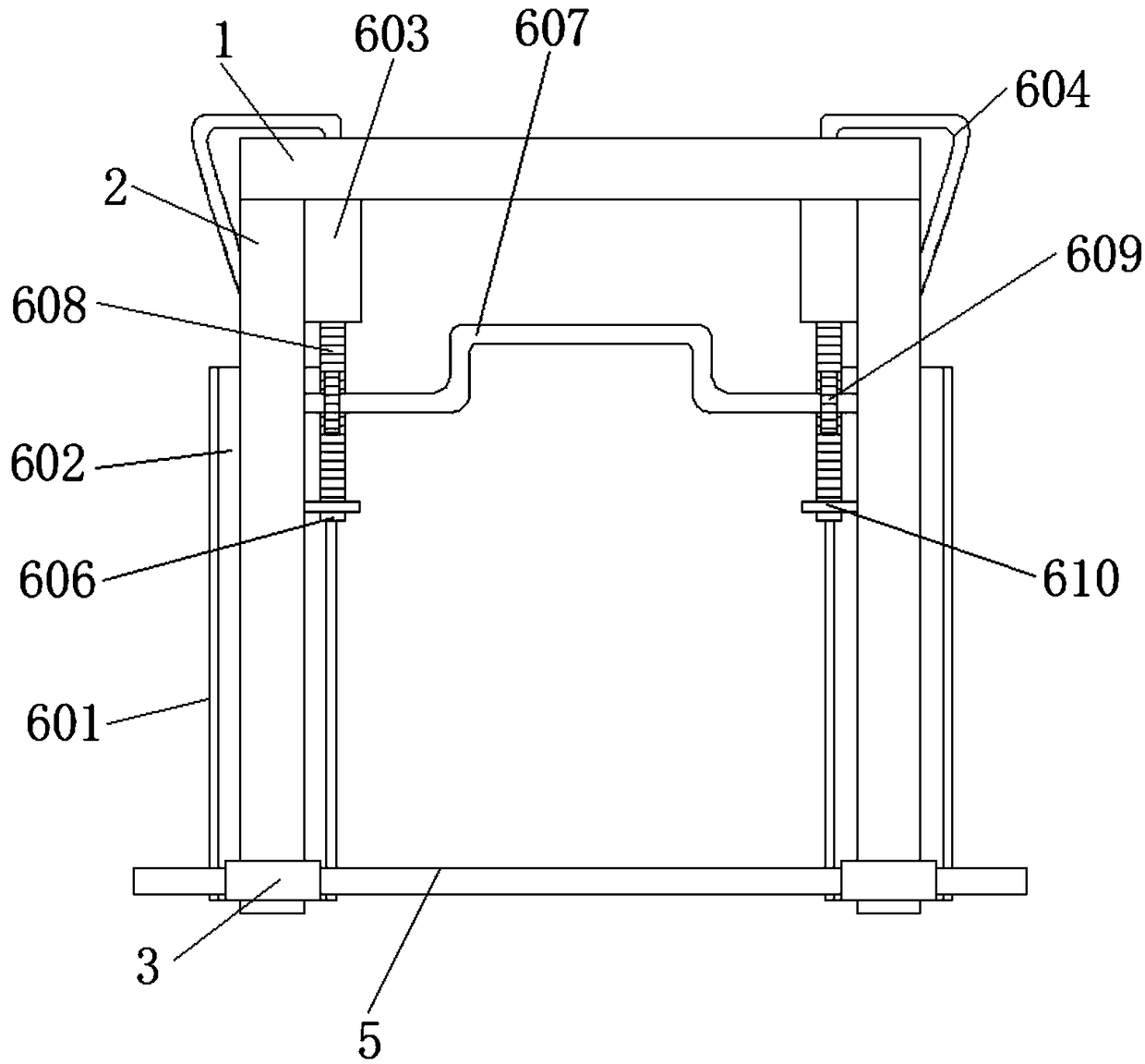

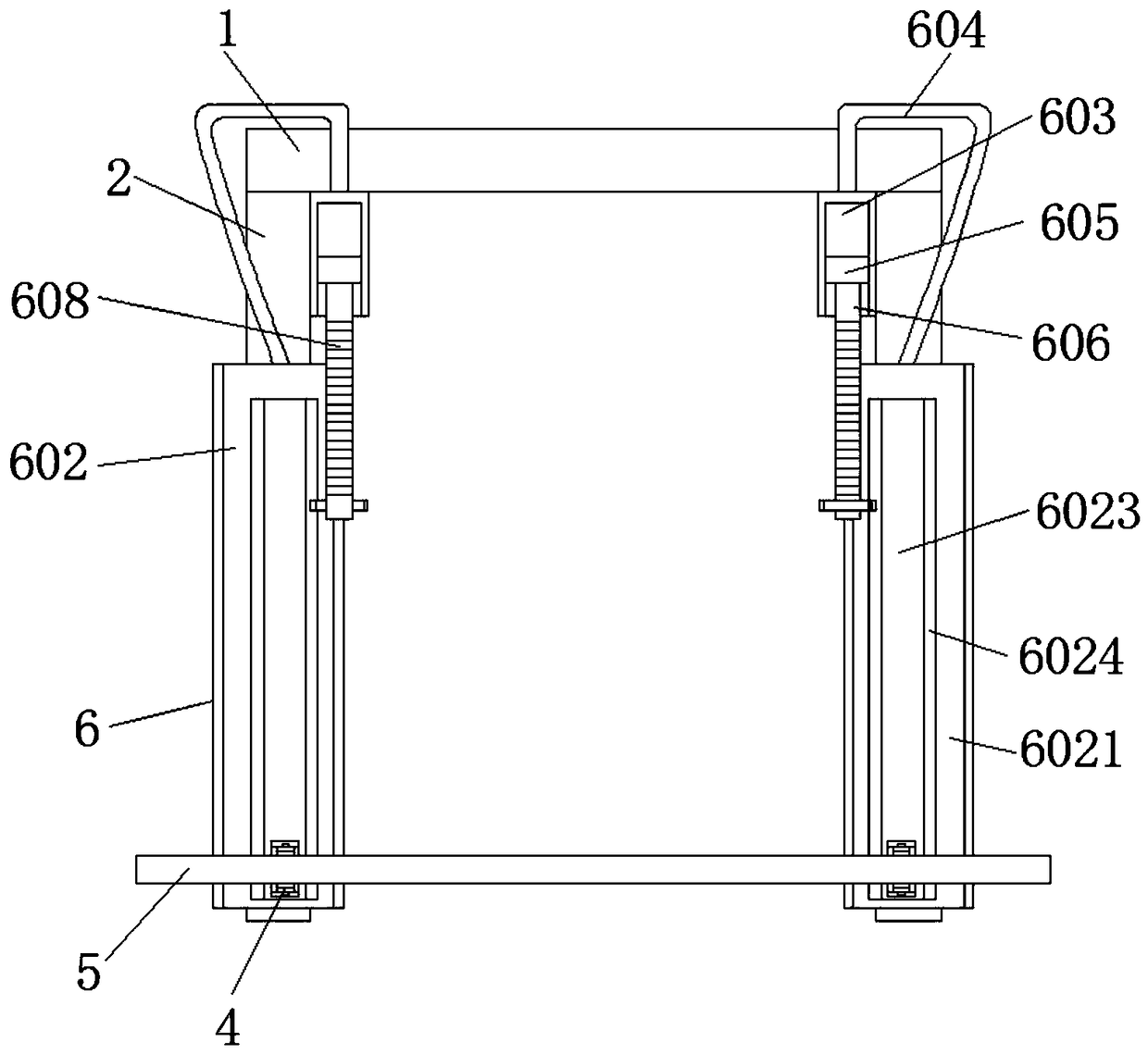

Automatic feeding system with inlet at top and outlet at bottom and feeding method for extracting Chinese traditional medicine

InactiveCN103693455AEasy to moveEasy to cleanSolid solvent extractionLoading/unloadingBreakage rateEngineering

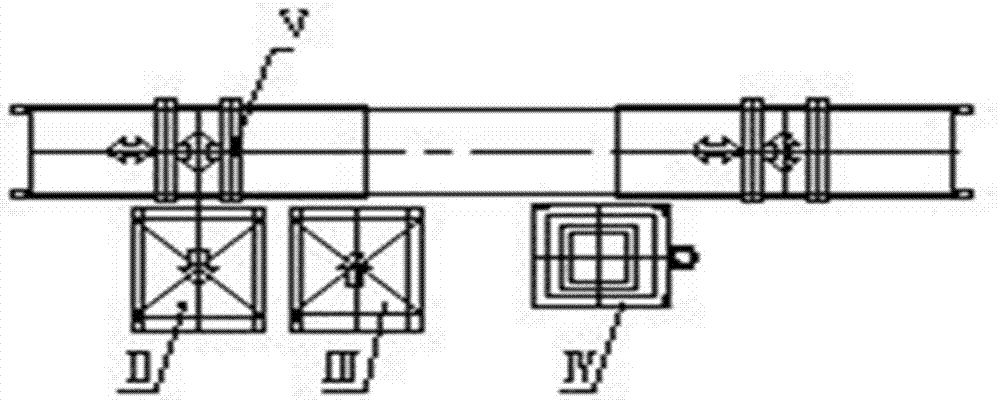

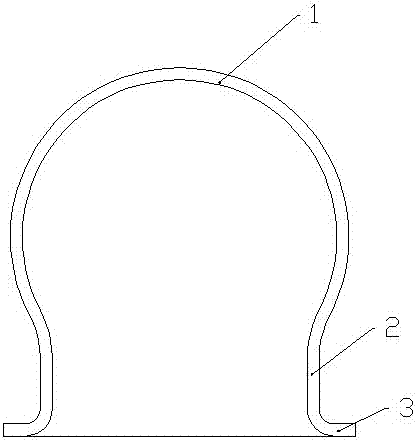

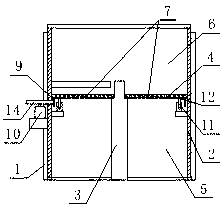

The invention provides an automatic feeding system with an inlet at the top and an outlet at the bottom and a feeding method for extracting Chinese traditional medicine. The system comprises an entrance platform (III) and an exit platform (II) which can carry a feeding box (I); a feeding platform (IV), for feeding an extraction pot; the extraction pot (VII), located below the feeding platform (IV); a flexible feeding pipe (VI), wherein the top of the flexible feeding pipe is connected with the outlet (1) at the lower end of the feeding platform, and the lower end of the flexible feeding pipe stretches into the feeding port (2) at the top of the extraction port body (3); a transferring device (V) for connecting the entrance platform with the feeding platform and connecting the feeding platform with the exit platform, the bottom of the extraction pot is provided with downward open cover device (4), and the feeding platform is provided with a transition hopper. According to the automatic feeding system with the inlet at the top and the outlet at the bottom and the feeding method for extracting Chinese traditional medicine, the material feeding accuracy is improved, the operating time is saved, the manual intervention is reduced, the man-made pollution is avoided, the product quality is improved. And the system has the advantages of simple structure, safe and reliable operation, high automation degree, high transferring efficiency, low material breakage rate and easiness to clean material containing devices.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

Cupping jar disinfection device

ActiveCN107350242AFast cleaningAvoid corrosionHollow article cleaningHeating arrangementDisinfectantEngineering

The invention relates to the field of medical disinfection, and particularly discloses cupping jar disinfection equipment. When the disinfection equipment disinfects a glass jar, a brush can be constantly attached to the inner wall of the glass jar under the action of centrifugal force and via a cleaning box, meanwhile, the brush can rotate, then, impurities on the inner wall of the glass jar can be removed, disinfectant can be sprayed out of a water outlet hole during cleaning, the glass jar is comprehensively disinfected, the workload of medical workers can be greatly reduced, and the glass jar disinfection efficiency is improved. According to the scheme, the glass jar disinfection efficiency can be improved, and the labor intensity of the medical workers is relieved.

Owner:宁波隆锐机械制造有限公司

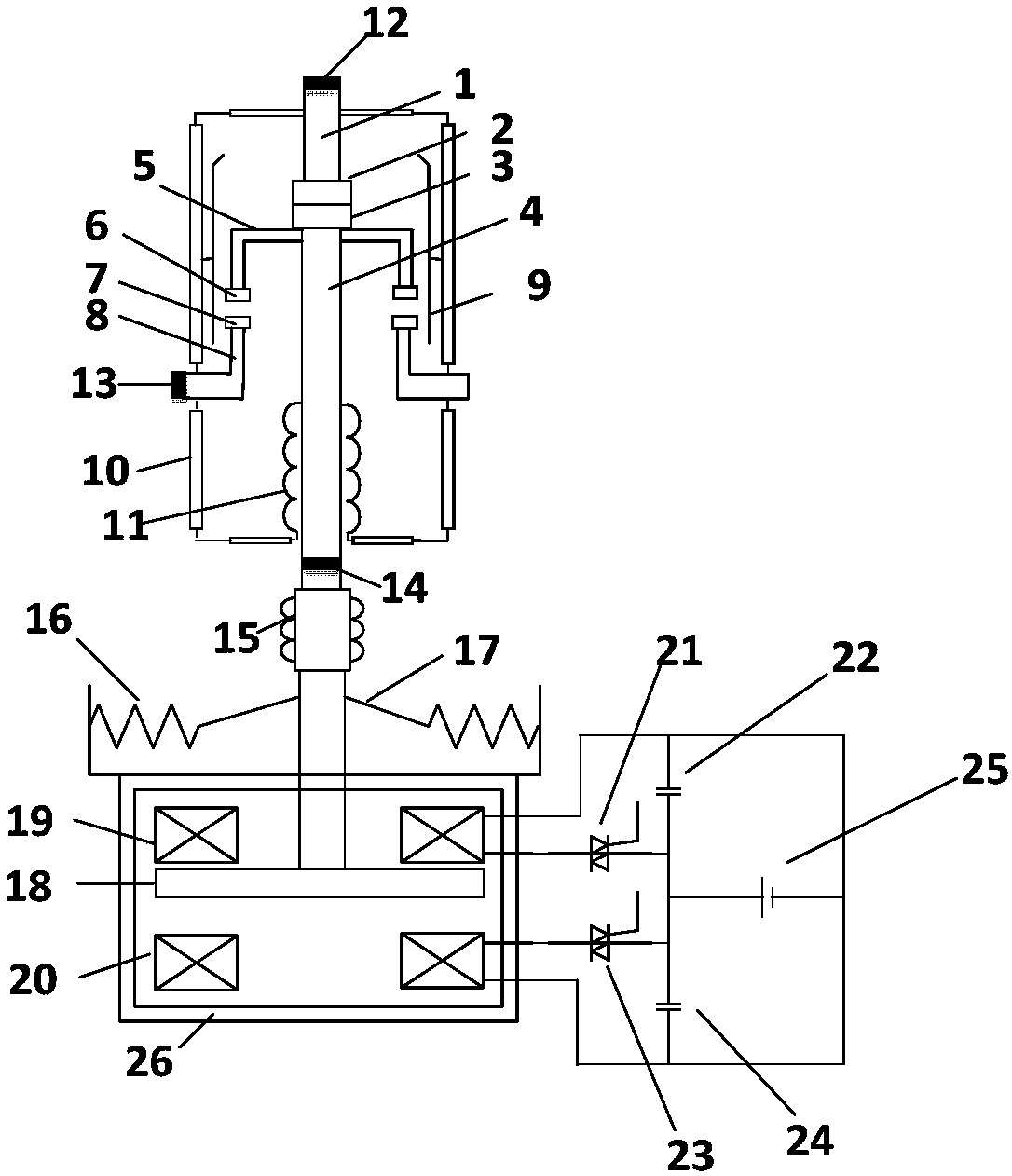

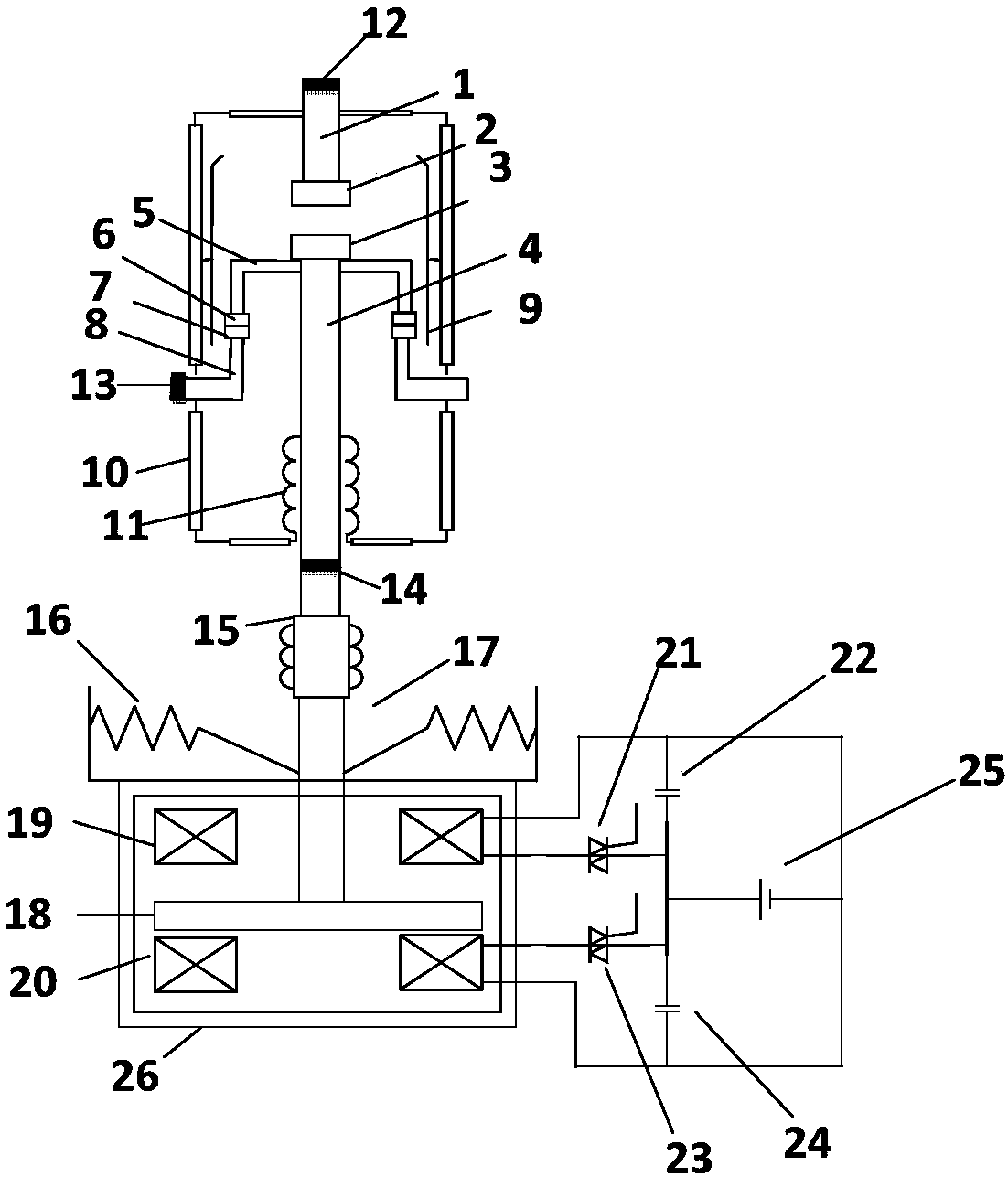

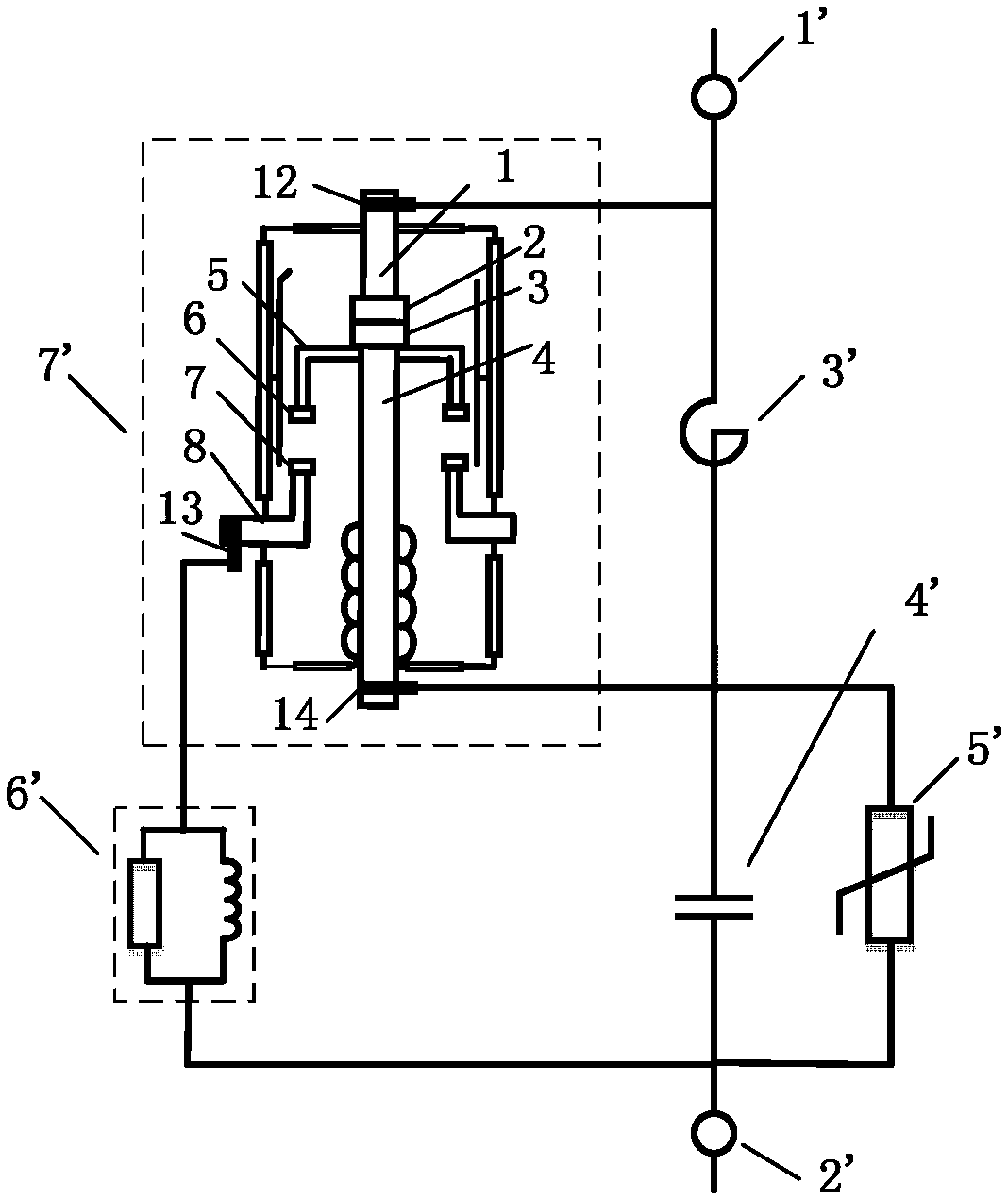

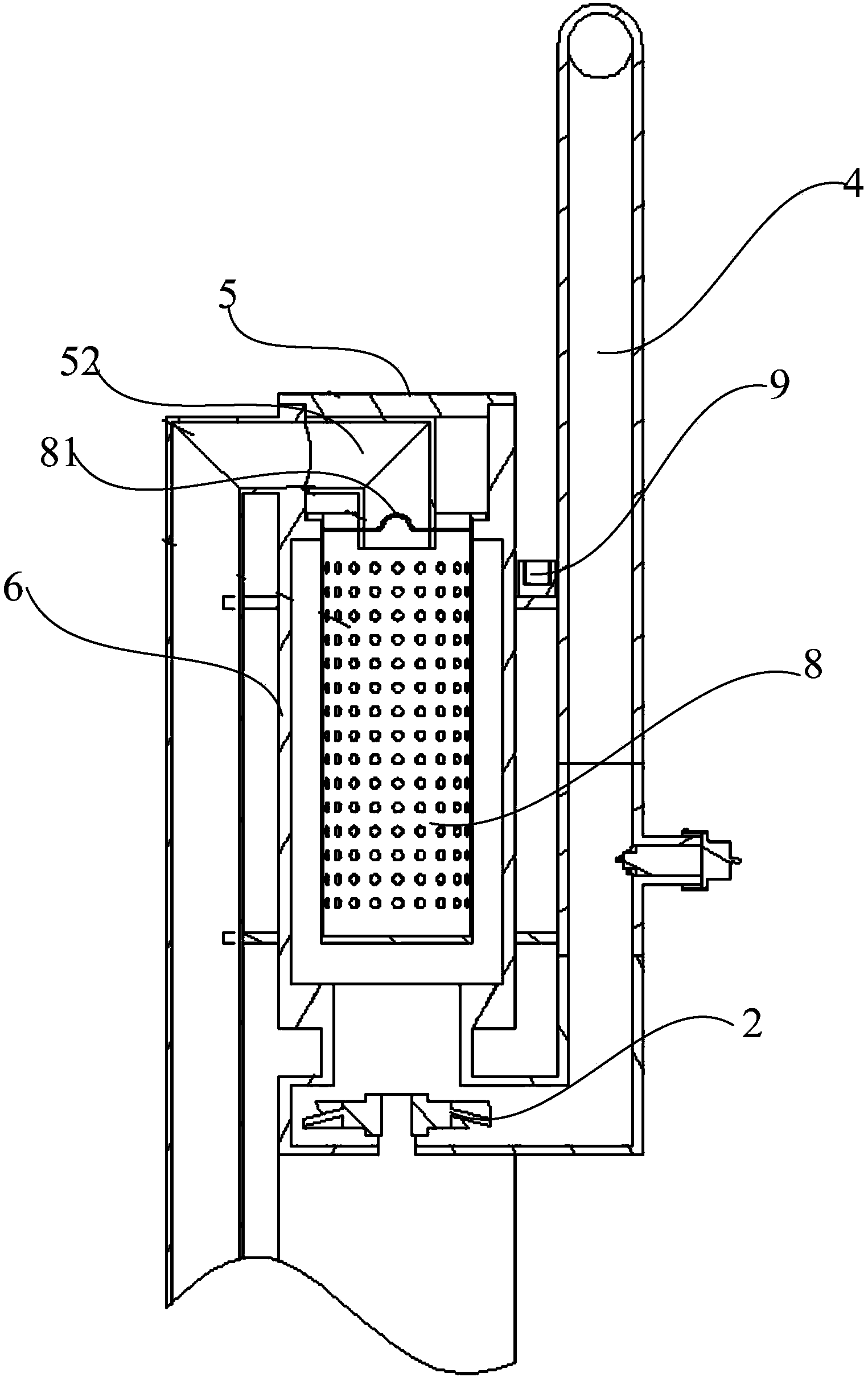

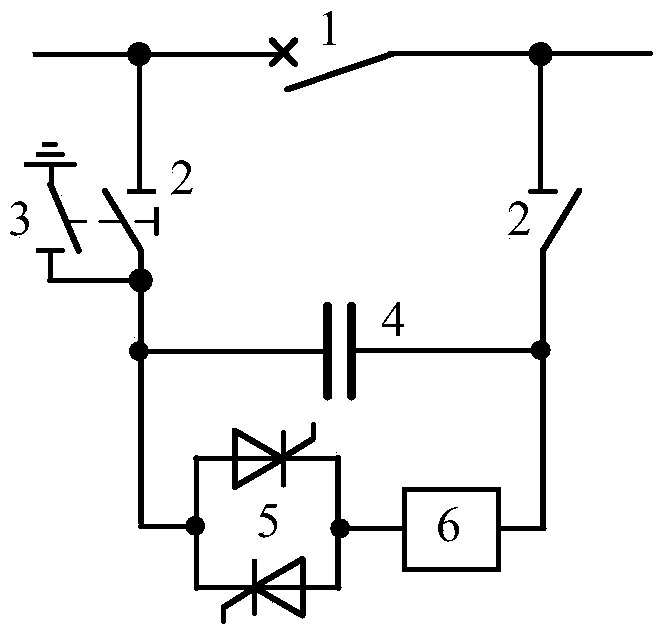

Interlocking vacuum switch and series compensation type current limiting device and method based on same

PendingCN108133862ARealize "single pole double throw" functionIncrease contact areaHigh-tension/heavy-dress switchesAir-break switchesSeries compensationControl engineering

An interlocking vacuum switch and a series compensation type current limiting device and method based on the same are provided. The switch uses an interlocking vacuum interrupter. A fast repulsion mechanism is selected to cooperate with the interlocking vacuum interrupter to realize fast switching of the series compensation type current limiting device between the two functions of series compensation and current limiting. When the line of a traction network runs normally, a series compensation capacitor is accessed, and the device works in a series compensation state. When the line is short-circuited, an interlocking vacuum switch acts to short-circuit the capacitor, and a current limiting reactor is put into use in the system to limit the short circuit current of the line. Inside the sameinterrupter, a main static contact and a main moving contact constitute a first contact group to switch on / off the current limiting reactor, and an auxiliary static contact and an auxiliary moving contact constitute a second contact group to switch on / off the compensation capacitor. A single vacuum interrupter and a set of operating mechanism are adopted to realize the switching of a traction system between the functions of series compensation and current limiting. The volume cost and economic cost of the device can be reduced, and the reliability of the system can be improved.

Owner:XI AN JIAOTONG UNIV +1

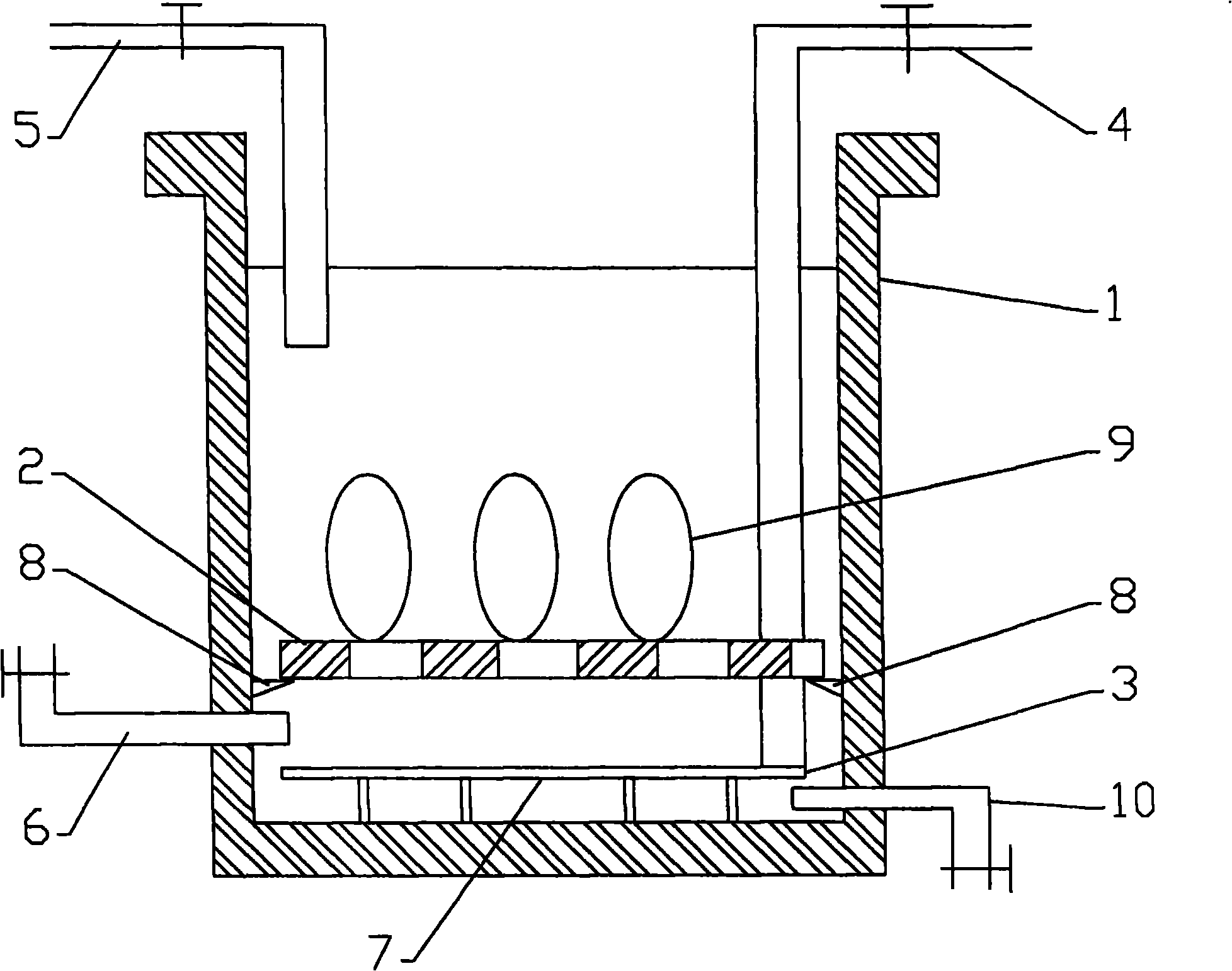

Nuclear power station underwater foreign matter suction apparatus

InactiveCN104051036ASimple structureReduce volumeNuclear energy generationReactor fuel elementsForeign matterNuclear power

The invention provides a nuclear power station underwater foreign matter suction apparatus. The apparatus comprises a water pump with a motor, a water inlet pipe, a water outlet pipe and a filter barrel connected with the inlet of the water pump and placed over the water pump, the filter barrel comprises a shell, a barrel-shaped filter screen placed in the shell and a top cover hinged to the shell and used for sealing the top of the shell, one end of the water inlet pipe stretches into the filter barrel, the other end of the water inlet pipe is connected with a foreign matter suction pipe, and the water outlet pipe is connected with the outlet of the water pump. The water pump is adopted to form a negative pressure in the filter barrel, so water in a reactor pool goes through the water inlet pipe, enters the filter barrel and is filtered, foreign matters enter the filter barrel with water flow, and above processes are repeated in order to suck the foreign matters in water. The suction apparatus has the advantages of simple structure, small size, easy placement in water by an operator, easy operation, realization of the rapid catching of the foreign matters in water without accurate positioning, and time saving.

Owner:STATE NUCLEAR POWER PLANT SERVICE

Magnesia-alumina spinel material prepared by waste activated alumina and preparation method thereof

InactiveCN101580383AGood economic and social benefitsStrong market competitivenessSolid waste disposalActivated aluminaMagnesium

The invention provides a magnesia-alumina spinel material prepared by waste activated alumina and a preparation method thereof. The raw material formula mainly comprises the waste activated alumina and basic magnesium carbonate; and the preparation method comprises the following steps of: taking the waste activated alumina and the basic magnesium carbonate as raw materials, mixing, pressing and forming the raw materials, leading the raw materials to react at high temperature, cooling the reaction products, thus obtaining the prepared magnesia-alumina spinel material. The material and the method are beneficial for waste utilization and solve the severe pollution of the waste activated alumina on the environment; the produced products have high-quality refractories which have high added value and no pollution, save the production cost, and have obvious economic benefits and popularization and application values.

Owner:FUZHOU UNIVERSITY

Series capacitor compensation device for power distribution network

ActiveCN104218593AEasy to layoutSmall footprintReactive power adjustment/elimination/compensationReactive power compensationThyratronEngineering

The invention provides a series capacitor compensation device for a power distribution network. The series capacitor compensation device for the power distribution network comprises a series capacitor group which is connected with two ends of a by-pass circuit breaker through series disconnecting switches, positions between the series disconnecting switches and the series capacitor group are connected with grounded switches, and the series capacitor group is in parallel connection with a thyristor and a damping device which are in series connection. The series capacitor compensation device is suitable for the power distribution network, a main circuit structure is simplified, the reliability is high, and power failure of a line where the series capacitor compensation device is located can not occur during maintaining and replacing due to own faults of the series capacitor compensation device by means of the main circuit structure.

Owner:STATE GRID CORP OF CHINA +1

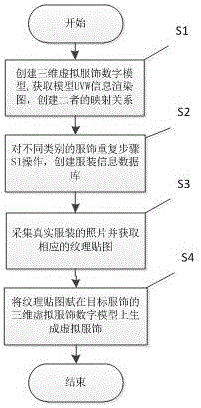

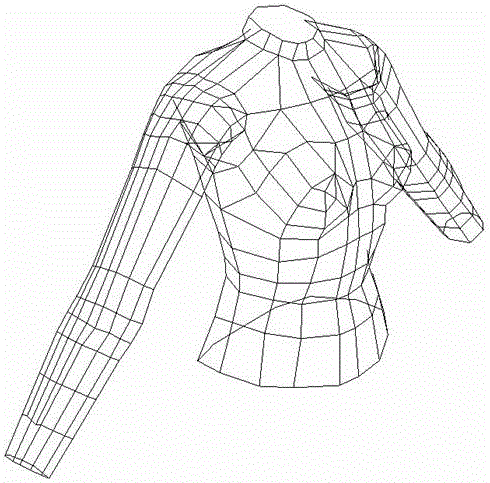

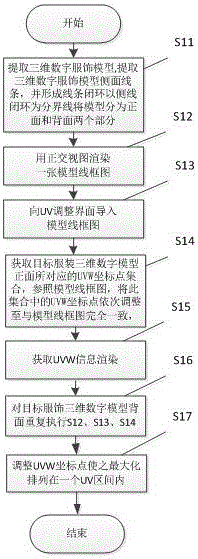

Method and system for fast conversion of real clothes to three-dimensional virtual clothes

InactiveCN105913496APreserve the 3D effectFitted seams are smooth and compactDetails involving processing stepsComputer graphics (images)Digital mockup

The invention discloses a method and system for fast conversion of real clothes to three-dimensional virtual clothes. The method of the invention comprises steps of creating a three-dimensional virtual clothes digital model, performing UVW information rendering on a three-dimensional virtual clothes digital model, establishing a one-to-one mapping relation between an UVW information rendering image and a corresponding three-dimensional virtual clothes digital model, establishing a clothes information database corresponding to the UVW information rendering images and the three-dimensional virtual clothes digital models, retrieving a three-dimensional virtual clothes digital model having an identical type with a real clothes type in the clothes information database when three-dimensional conversion on the real clothes is needed, transmitting a contour line of the UVW information rendering image to a real clothes picture collection device, collecting a real clothes picture having the same contour line as the UVW information rendering image and obtaining a texture map, and applying the texture map to the real clothes three-dimensional virtual digital model according to the UVW information to generate three-dimensional virtual clothes. The method and system for fast conversion of real clothes to three-dimensional virtual clothes are fast and simple in an operation process, can produce the three-dimensional virtual clothes with strong sense of reality and can be quickly and massively put in operation.

Owner:CHENGDU JINGHE QIANCHENG TECH CO LTD

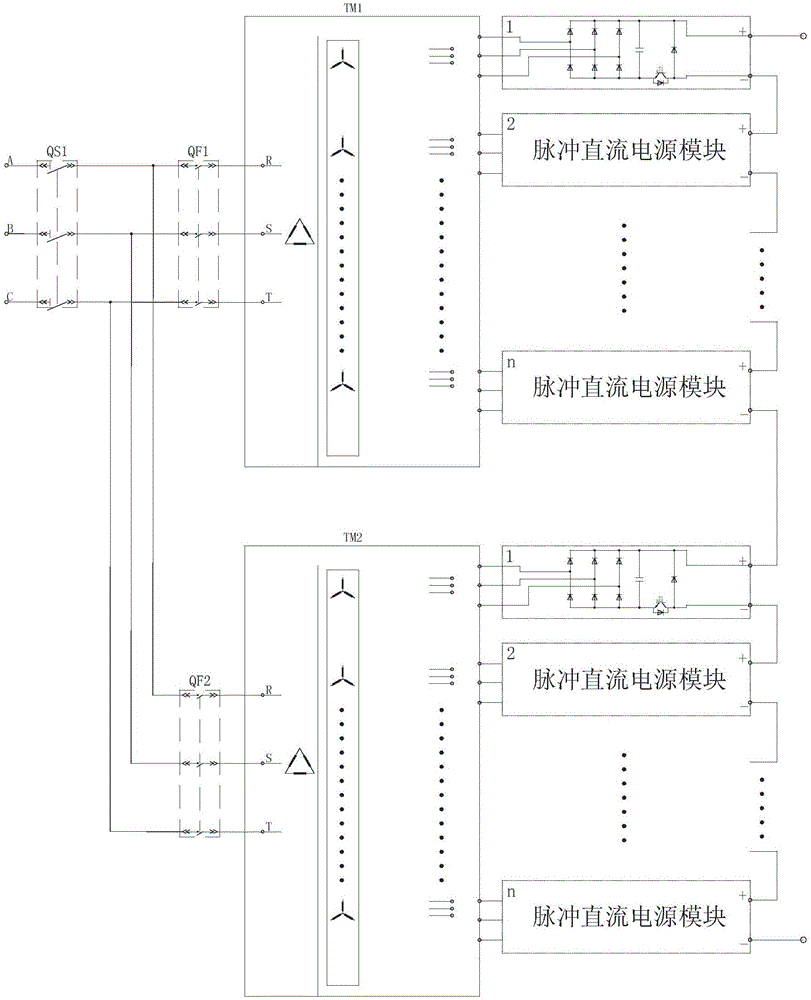

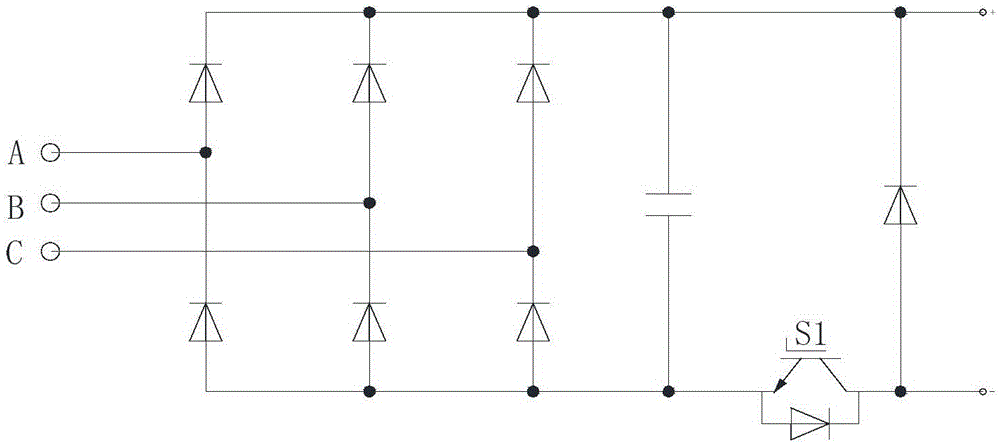

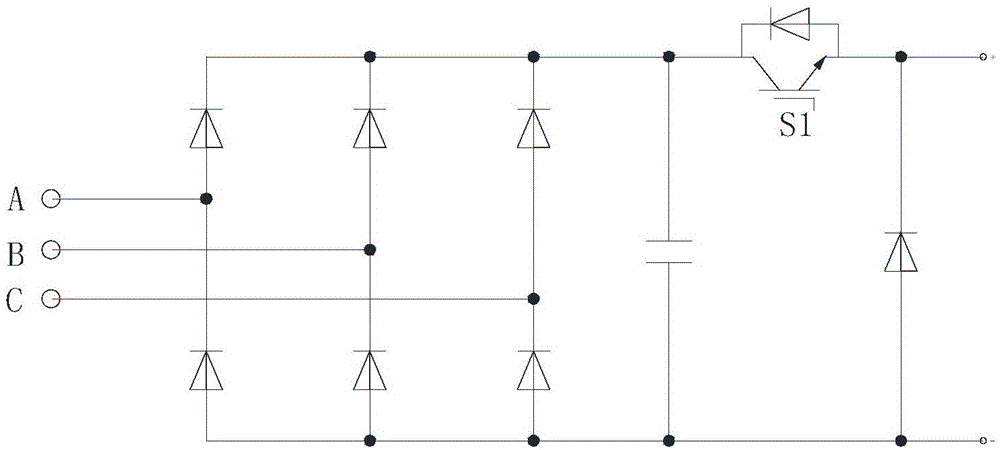

Long pulse large power high voltage power supply

InactiveCN105141170ASimple structureEasy to replaceElectric variable regulationSingle phaseThree phase windings

The present invention discloses a long pulse large power high voltage power supply. The long pulse large power high voltage power supply is characterized by mainly being composed of a multi-winding isolation transformer and a plurality of AC / DC unit modules each of which has two voltage output gears, wherein the multi-winding isolation transformer adopts a mode that the secondary three phase windings are all unfastened, each secondary single phase winding supplies power to one AC / DC unit module, and the three AC / DC unit modules corresponding to the three secondary single phase windings obtained by unfastening the secondary three phase windings are in synchronous control; there are existed two types of AC / DC unit modules, one type of AC / DC unit module is a switch power supply module of which the output voltage is a fixed value, and the other type of AC / DC unit module is a continuous voltage adjustment module of which the output voltage is continuously adjustable; the output ends of the AC / DC unit modules are connected in series mutually. The long pulse large power high voltage power supply of the present invention enables the number of the unit modules and the input transformer secondary windings to be reduced substantially, can realize the smooth and continuous adjustment of the voltage, is stronger in practicality, higher in efficiency and smaller in size, and is more convenient to maintain.

Owner:江苏同芯电气科技有限公司 +1

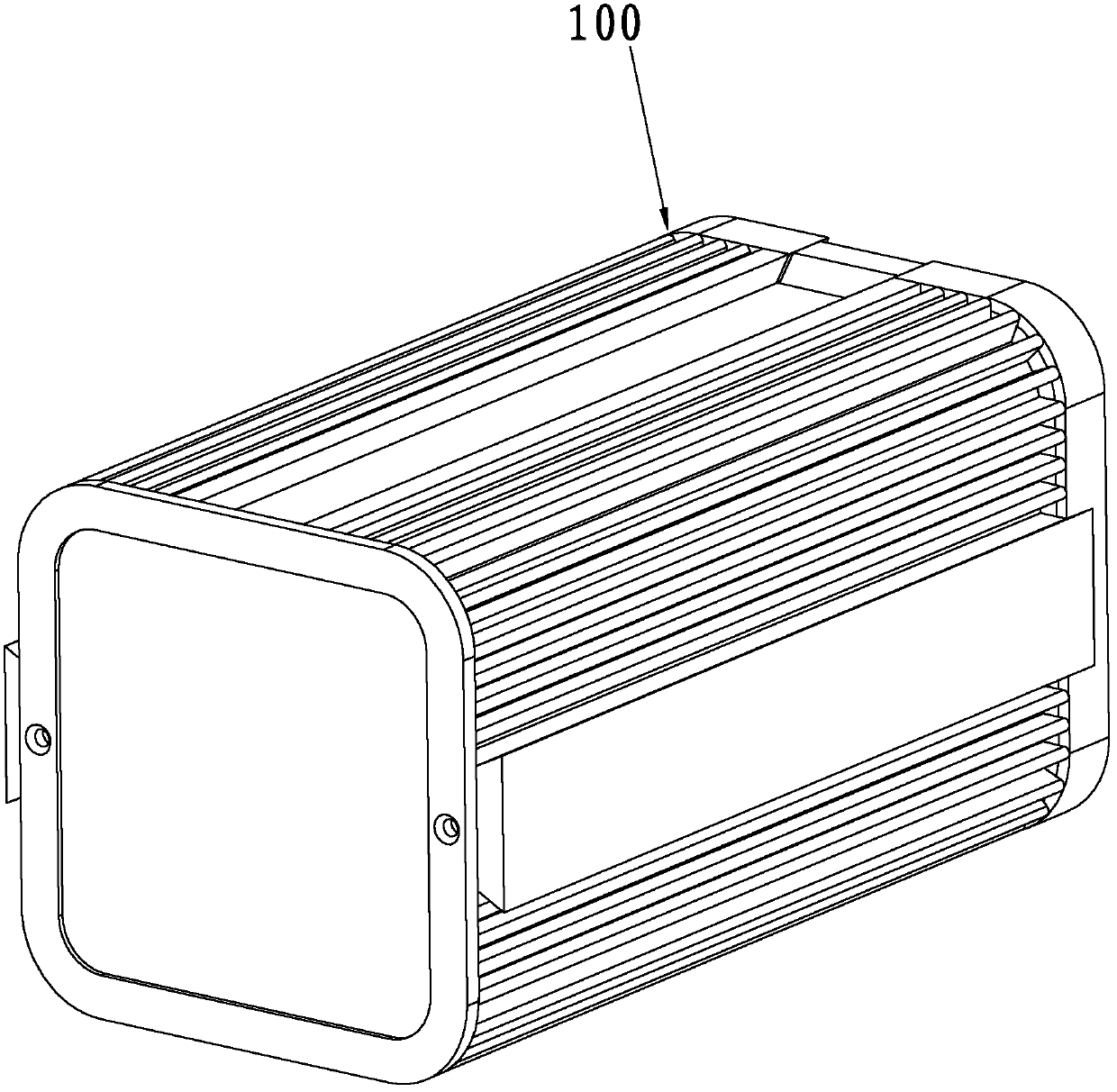

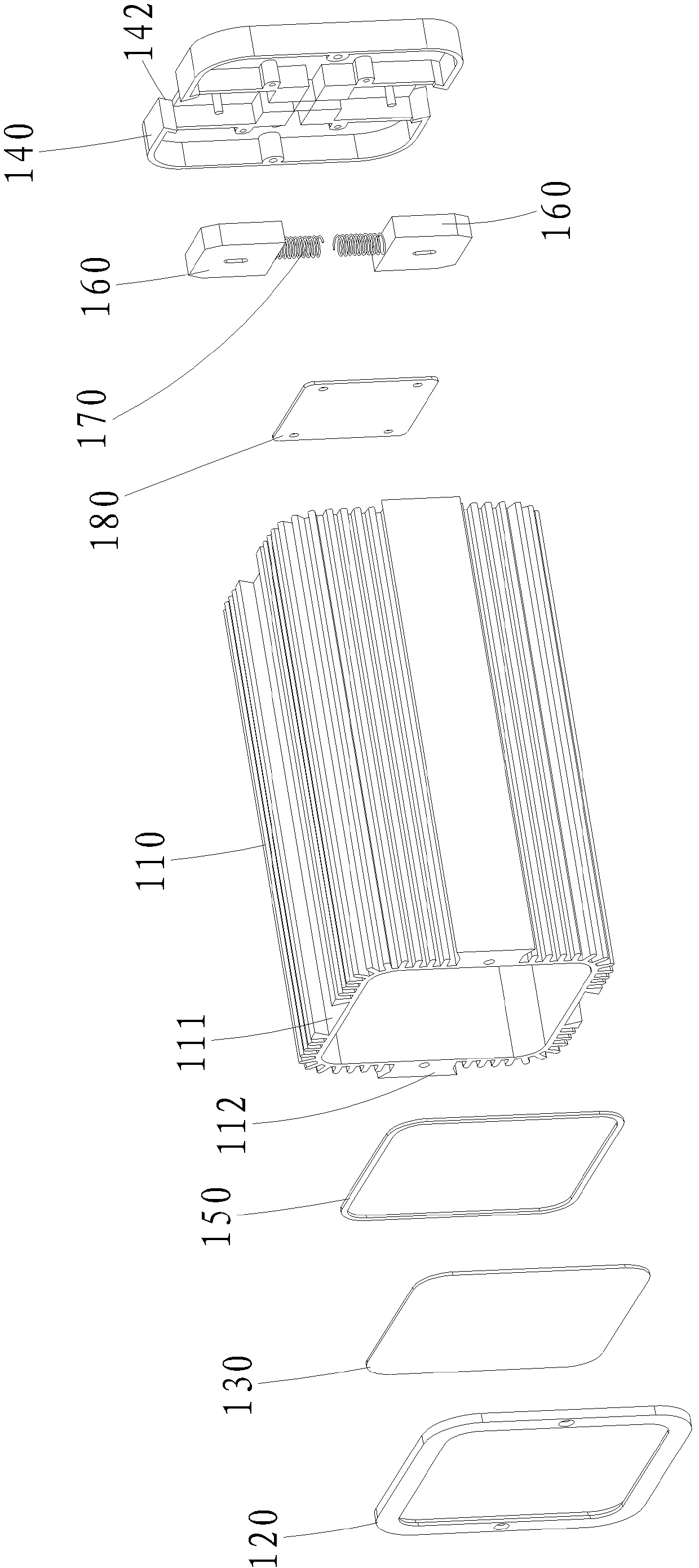

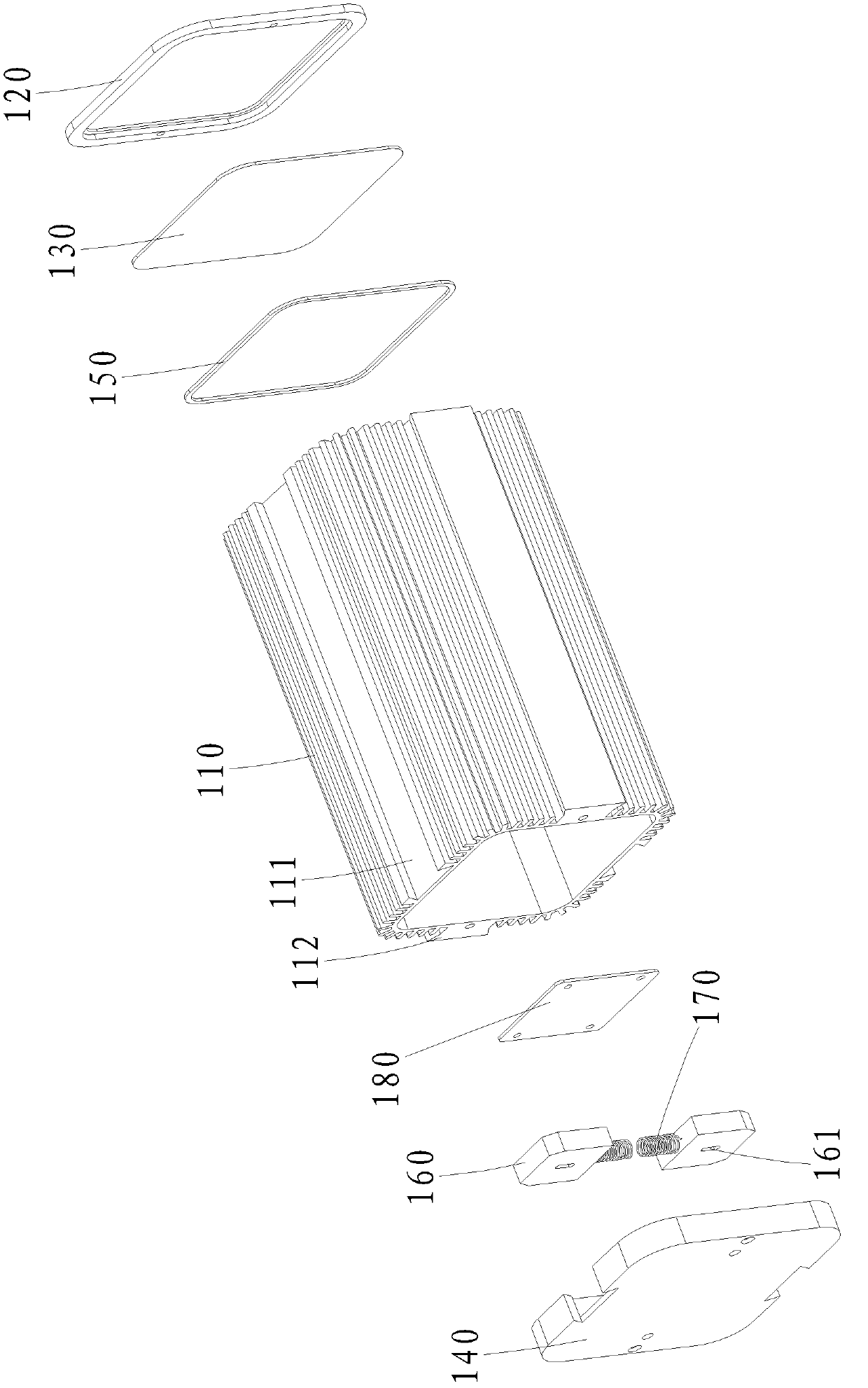

Lamp

InactiveCN103307461ARealize combined installationQuick investmentElectric lightingLight fasteningsEngineeringLight fixture

The invention is suitable for the technical field of lamps, and discloses a lamp. The lamp comprises a housing assembly, wherein the housing assembly is internally provided with a light-emitting part; the housing assembly comprises a lamp housing, a front shell, a transparent part and a back shell; the front shell is locked at one end of the lamp housing, and the back shell is locked at the other end of the lamp housing; the transparent part is fixedly clamped between the front shell and the lamp housing; and the outer side surface of the lamp housing is provided with a back-off clamping slot and a clamping strip capable of being buckled with a back-off clamping slot of a lamp housing on another adjacent lamp. According to the lamp provided by the invention, the back-off clamping slot and the clamping strip are arranged on the lamp housing, so that a plurality of lamp housings can be assembled into an integral combined lamp; a proper amount of lamps can be arranged by a user according to practical lighting requirements and are combined and assembled into an integral body without setting a plurality of installation fixed points; the installation process is simple and easy to implement; the proper amount of lamps can be quickly put into field use without using tools; and the lamp brings convenience for the user.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Micro-electrolytic reactor

ActiveCN102079558AEasy to transformReduce investmentWater/sewage treatmentExpanded clay aggregateElectrolytic capacitor

The invention relates to a micro-electrolytic reactor comprising a waste water reservoir with a water inlet and a water outlet, wherein an acid and corrosion resistant coating layer is coated on the inner wall of the reservoir; a grille is arranged at the lower part of the reservoir and used for supporting a microelectrode; an aeration pipe network is arranged at the bottom of the reservoir; the microelectrode is contained in a corrosion resistant mesh bag which is made of filter cloth; 50-200 meshes of holes are uniformly distributed on the corrosion resistant mesh bag to guarantee air and water permeability; and the microelectrode is composed of haydite, silica, titanium dioxide, carbon powder and iron powder and has the total specific gravity of about 1. In the micro-electrolytic reactor, the structure of a conventional waste water reservoir is adopted for solving a microelectrode deposition problem which troubles the waste water treatment industry for a long time, greatly enhancing the efficiency of a micro-electrolytic reaction and prolonging the service life of a microelectrode material in the waste water treatment, and benefiting the replacement of the microelectrode material; in the mean time, the reforming of a traditional waste water reservoir is easy with little input and quick response; and moreover, the stirring intensity during the treatment process can be greatly reduced, and the operation and maintenance costs of equipment are reduced.

Owner:魏焕曹

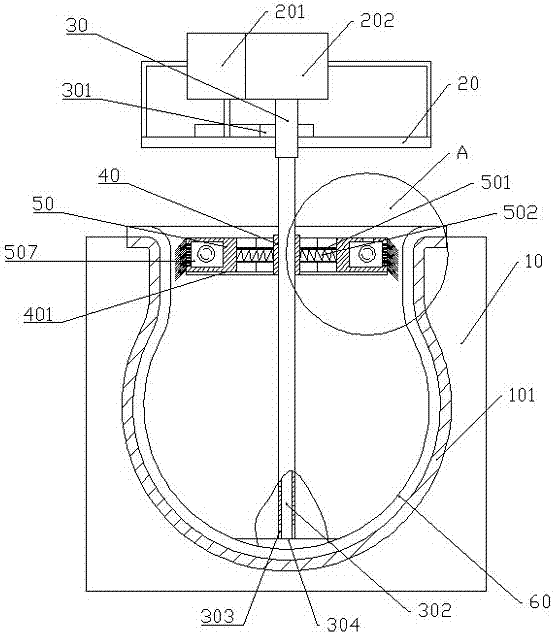

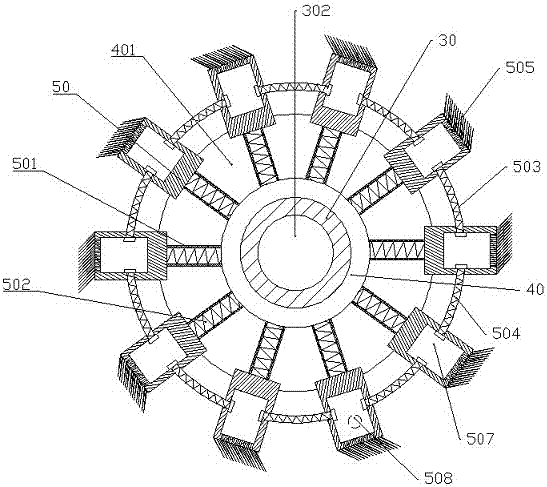

Disc type moldy bran preparing machine

InactiveCN103013760AIncrease outputSmall footprintAlcoholic beverage preparationAgricultural engineeringSmall footprint

The invention discloses a disc type moldy bran preparing machine. The disc type moldy bran preparing machine comprises a frame, wherein a yeast preparing chamber of which the bottom and the top are airtight is connected to the frame; a main shaft is arranged in the middle of the yeast preparing chamber; a yeast preparing tray of which the periphery is in seal fit with the inner wall of the yeast preparing chamber is rotatablely connected to the main shaft and is driven to rotate by a power device; the inner space of the yeast preparing chamber is dived into a steam inlet cavity and a yeast preparing cavity from bottom to top by the yeast preparing tray; a plurality of air holes are densely distributed on the yeast preparing tray; a screw feeder and a pneumatic discharger which extend into the upper part of the yeast preparing tray are connected to the upper side wall of the yeast preparing chamber; a steam inlet pipe which is communicated with the steam inlet cavity is connected to the lower side wall of the yeast preparing chamber; and a steam discharge pipe which is communicated with the yeast preparing cavity is connected to the upper side wall of the yeast preparing chamber. By adopting the disc type moldy bran preparing machine, moldy bran can be prepared continuously. The disc type moldy bran preparing machine has the beneficial effects of small floor area, high production efficiency and high yeast preparing quality.

Owner:SHANDONG JINGZHI WINE

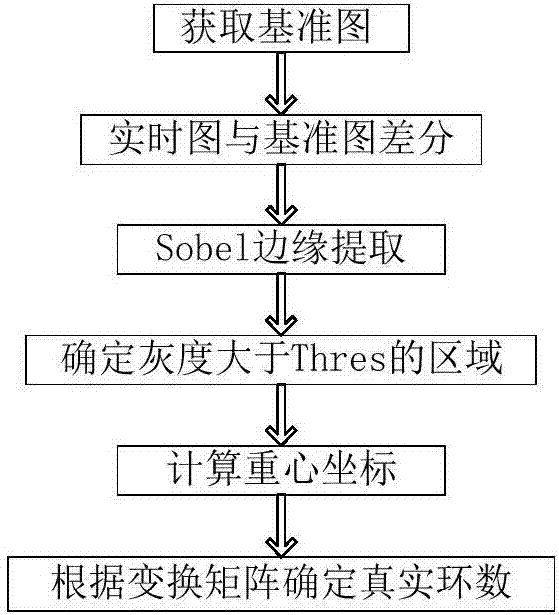

Chinese chess game intelligent virtual live-streaming method based on machine vision

ActiveCN107392157AImprove viewing experienceWith audio commentaryCharacter and pattern recognitionTime changesLive streaming

The invention proposes a Chinese chess game intelligent virtual live-streaming method based on machine vision. The method comprises the steps: firstly collecting a stationary chessboard image, carrying out the coordinate calibration of the chessboard, and building a coordinate conversion relation between a real chessboard and a virtual chessboard; secondly building a state information table for describing the comprehensive features of the chessboard according to the position, name and color information of chess pieces in the chessboard image; thirdly setting a chessboard state change detection bidirectional reference line which is used for the dynamic detection of the changes of the chessboard; fourthly obtaining a real-time change image of the chessboard, determining the attribute of the chess pieces and the initial and target positions, and updating the state information table in real time; finally achieving the virtual live streaming of the game process through combining with a chess game rule, wherein the virtual live streaming contents comprise the voice explanation, virtual linkage and game replay. According to the invention, the method can achieve the onsite virtual live streaming of a Chinese chess game, is high in reliability, is high in adaptability, is convenient to use, can be used for the live streaming of various types of chess games, such as Go and Gobang.

Owner:中国人民解放军火箭军工程大学

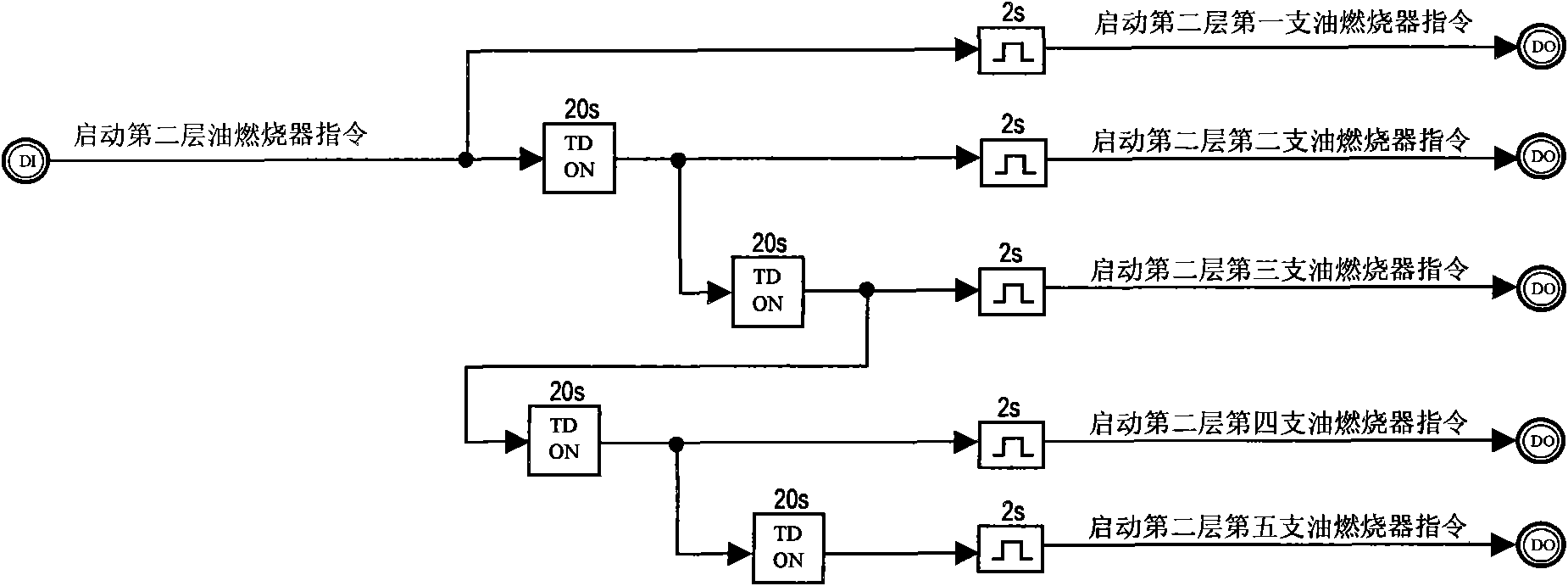

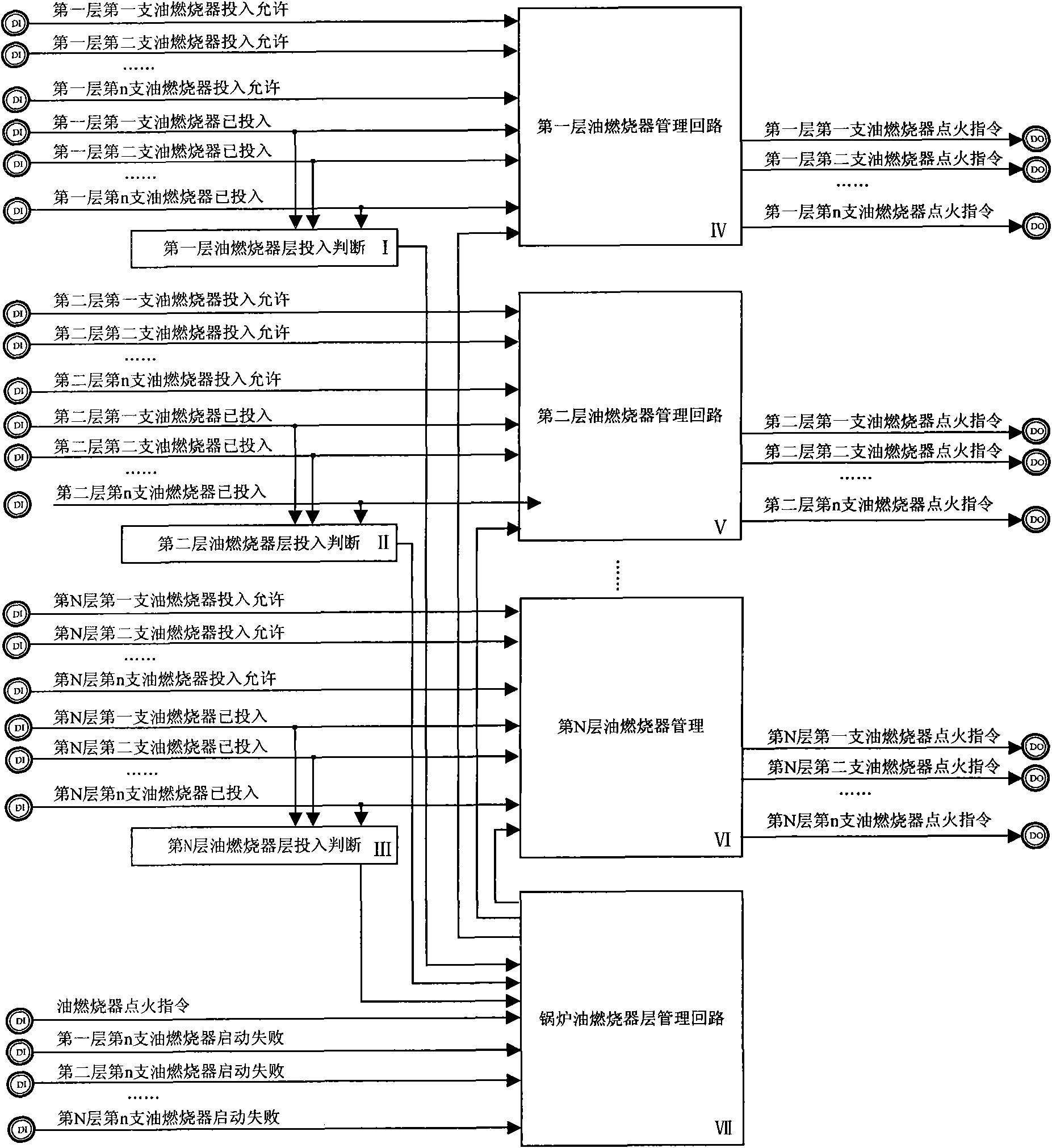

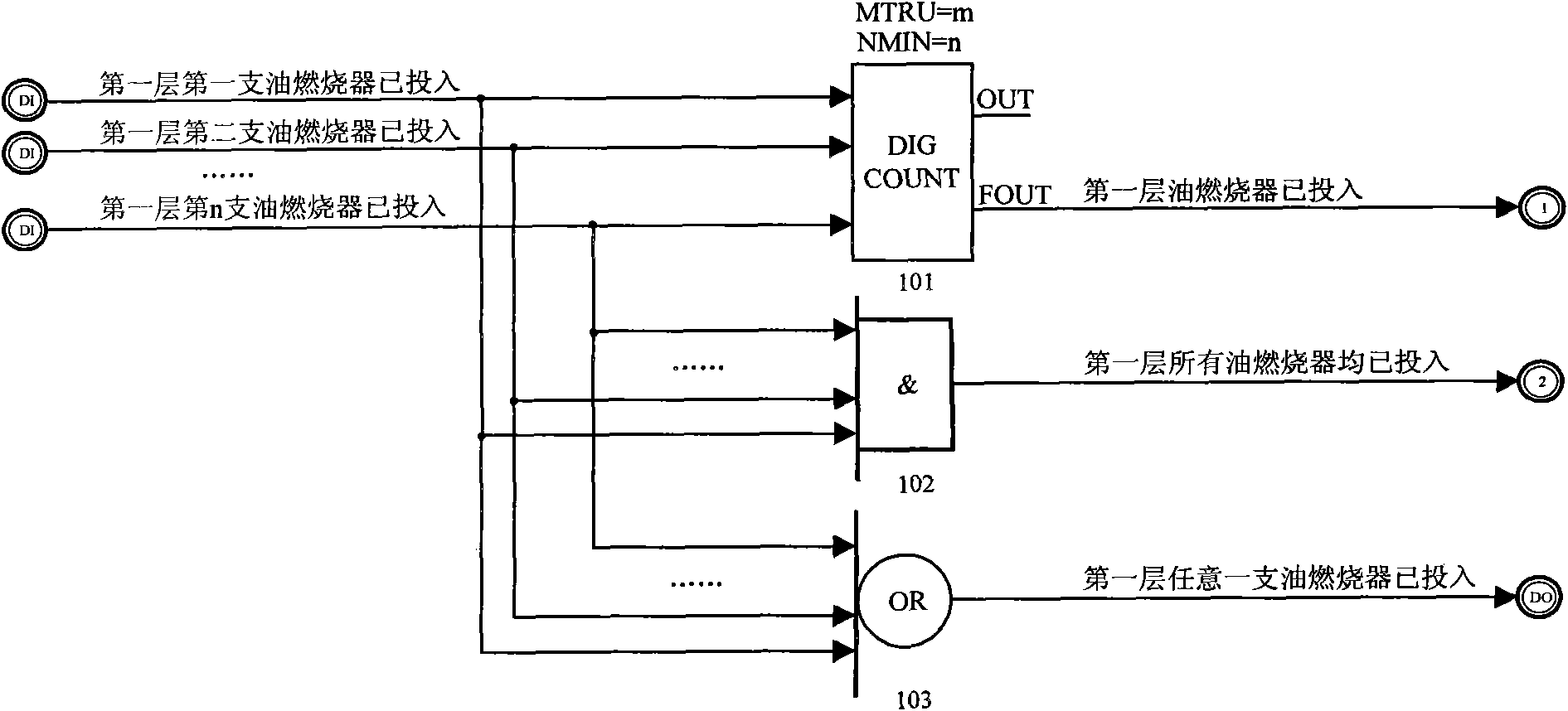

Automatic control method for boiler oil burner and device thereof

The invention relates to an automatic control method for boiler oil burners, which comprises the following steps: a, the oil burner is partitioned into a plurality of layers; b, the oil boiler is operated taking a layer as a unit when an instruction of inputting or quitting is received; c, the next layer of the oil burner is operated until all of layers of the oil burner are operated when the operating amount of the oil burner in one layer is larger than 80 percent; and d, when an instruction of operating or stopping operating is received in one layer, a corresponding oil burner is sequentially operated, if the oil burner is operated, or the operation is not allowed, the next oil burner is operated. The device for realizing the automatic control method comprises an oil burner layer operating judgment loop, a boiler oil burner layer management loop and a layer oil burner management loop, wherein the oil burner layer operating judgment loop inputs the operating signals of the oil burners in the layer and outputs the signals to the boiler oil burner layer management loop; the boiler oil burner layer management loop also inputs an oil burner ignition instruction and the last signal of the failed starting of the oil burner in each layer, and outputs starting instructions of the oil burners in each layer to each oil burner management loop; and the layer oil burner management loop inputs operating allowing and operating signals of the oil burners of each layer and starting instructions of the oil burner of each layer and outputs ignition instructions of the oil burner of each layer.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

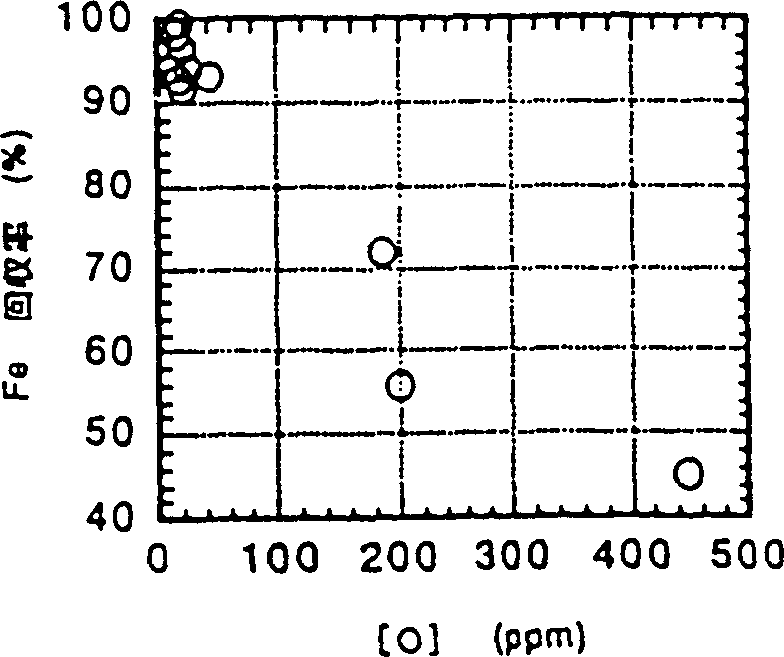

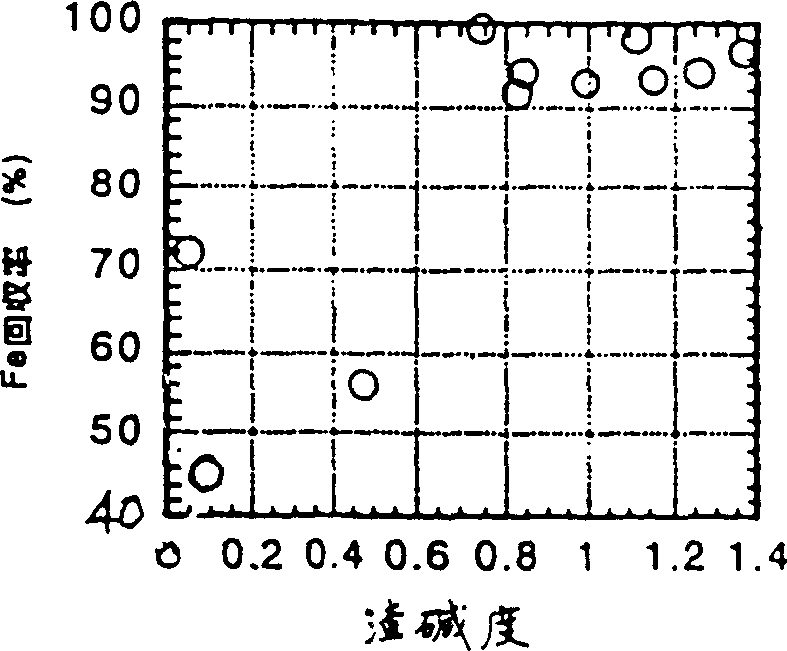

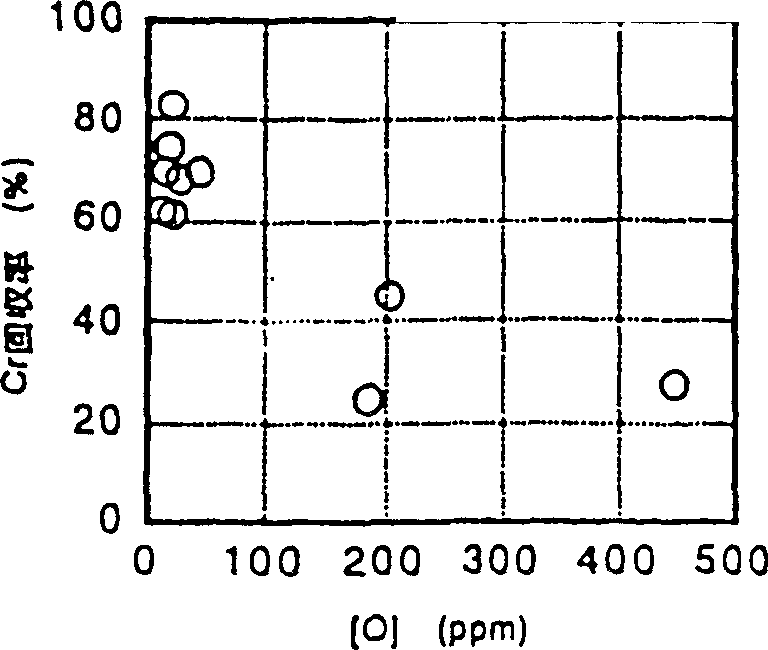

Method for recycling valuable metal from stainless steel dust

A process for recovering the valuable metals from stainless steed dust features that the reducer is used to reduce the oxides of the valuable metals in said stainless steel dust to become the valuable metals. Said reducer is composed of aluminium powder (53-100 wt.%), adhesive (0-20) and ion oxide scale powder (0-27). Said reducer is mixed with the stainless steel dust and then sphericized. After smelting, the valuable metals can be recovered. Its advantages are high recovery rate and low cost.

Owner:青岛森田金属有限公司

A big data talent bank analysis system for human resource management

InactiveCN108090743AShorter time to hireEasy accessDatabase management systemsOffice automationHuman resource managementResource management

The invention provides a big data talent bank analysis system for human resource management. Through data analysis and push, the system enables enterprises to find talented people meeting the requirements thereof quickly, shortens the recruitment time of enterprises, enables enterprises to get on track quickly, enables people to find enterprises suitable for them, and enables people to throw themselves into work quickly. Through personnel screening and training and establishment of respective talent banks of enterprises, the system enables enterprises to have reserves of talent and thus improves the development of enterprises. The system enables unique human resource management modes of enterprises to be formed, enables enterprises to devote themselves to development, improves the capability of enterprise personnel and achieves reasonable personnel assignment.

Owner:广州市海捷计算机科技有限公司

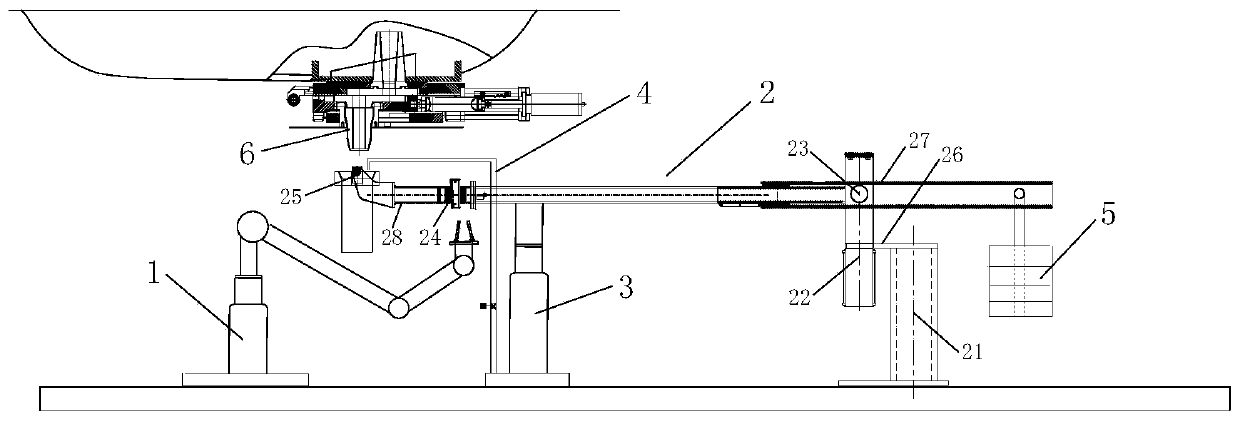

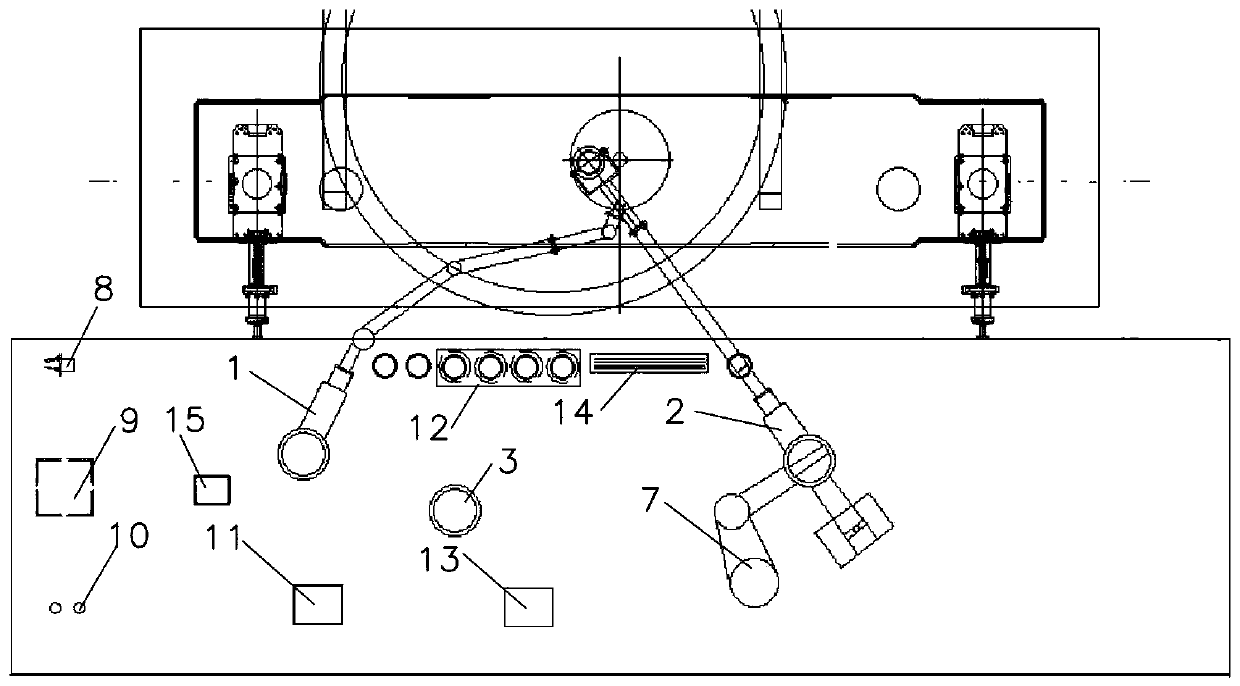

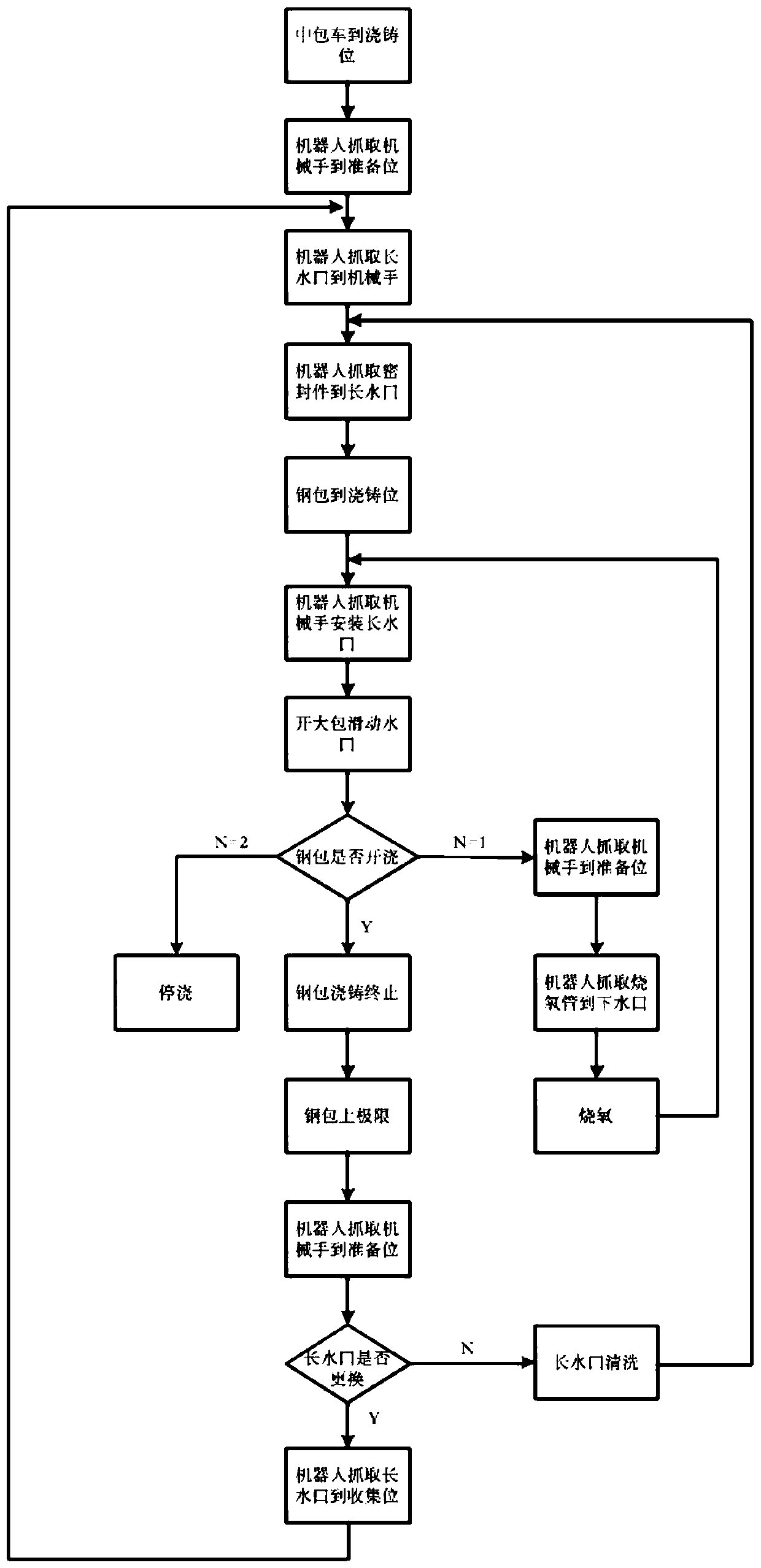

Unmanned system and operation method of steel ladle casting area

ActiveCN111168051AEnsure health and safetyReduce investmentMelt-holding vesselsCasting parameters measurement/indication devicesRobot handEngineering

The invention relates to an unmanned system and operation method of a steel ladle casting area. The method comprises the steps that a mechanical arm is prepared, wherein a robot grabs the mechanical arm from a mechanical arm standby station, the mechanical arm is placed into a fixed bayonet of a locating pile, and the mechanical arm is released; a long nozzle is prepared, wherein the robot takes out the long nozzle from a long nozzle storage device, the long nozzle approaches a mechanical arm long nozzle backing ring according to the set position, the position of the long nozzle is finely adjusted through a robot vision recognition system and a mechanical arm recognition mark, and then the long nozzle is placed into the long nozzle backing ring; a sealing part is mounted, wherein the sealing part is grabbed by the robot from a sealing part storage device and is placed into the long nozzle; and the long nozzle is mounted, wherein after a steel ladle rotates in place, the mechanical armis grabbed by the robot to drive the long nozzle and a lower nozzle to be aligned, the long nozzle is mounted in, the robot retreats, and the mechanical arm supports the long nozzle and presses the lower nozzle all the time. The unmanned system and operation method have the advantages that the mechanical arm and the robot cooperate to replace manual operation, and operations of long nozzle replacement, tundish molten steel temperature measuring and sampling, tundish covering agent adding and steel ladle oxygen pipe burning are completed.

Owner:ANGANG STEEL CO LTD

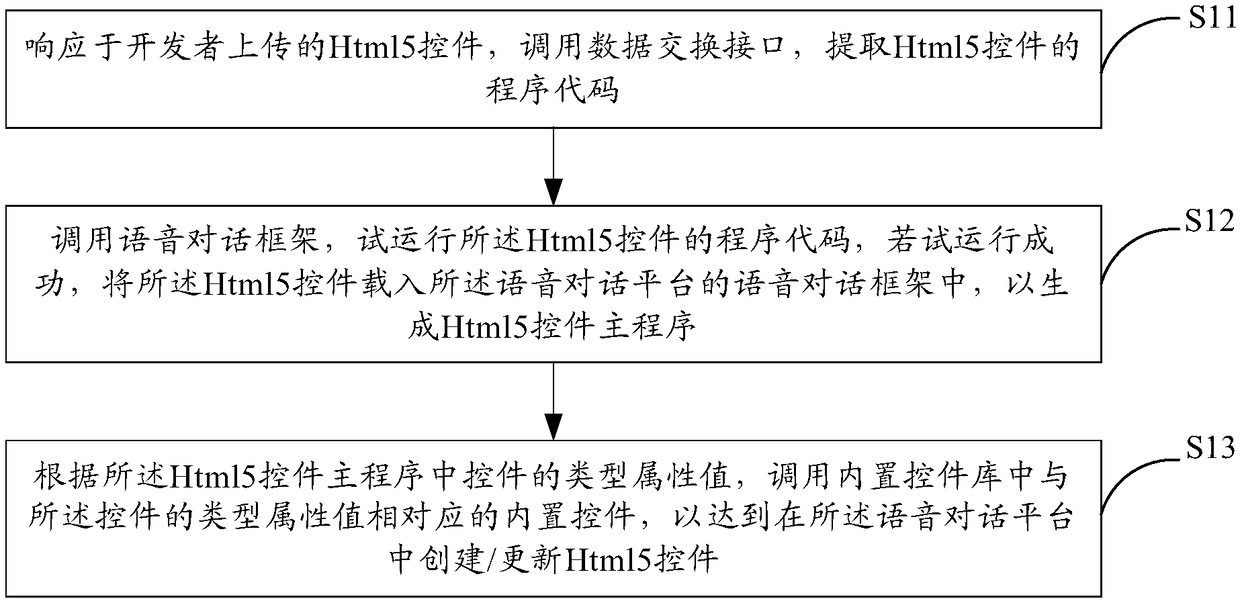

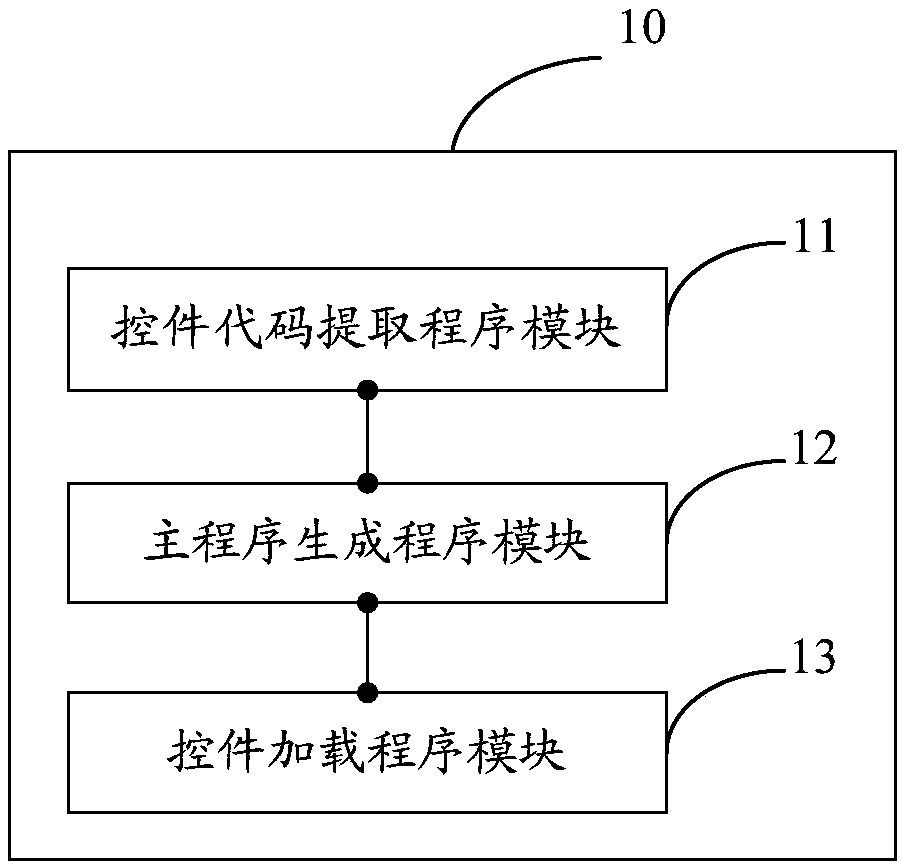

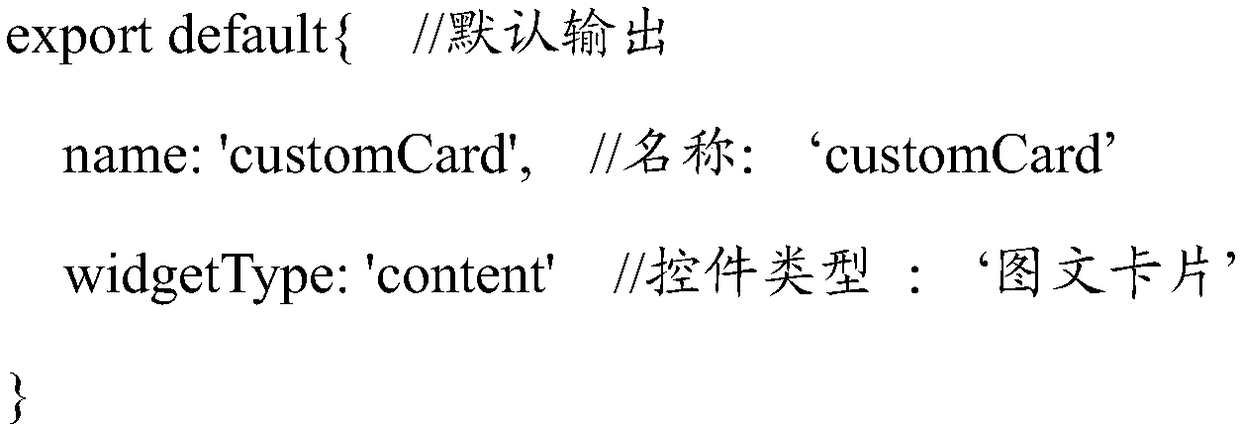

Method and system for loading control in voice conversation platform

ActiveCN108491232AReduce learning costsEfficient use ofProgram loading/initiatingData exchangeProgram code

An embodiment of the invention provides a method for loading a control in a voice conversation platform. The method comprises the steps of calling a data exchange interface in response to an Html5 control uploaded by a developer, and extracting program codes of the Html5 control; calling a voice conversation framework, performing trial running on the program codes of the Html5 control, and if thetrial running succeeds, loading the Html5 control into the voice conversation framework of the voice conversation platform to generate an Html5 control main program; and according to a type attributevalue of the control in the Html5 control main program, calling an internal control corresponding to the type attribute value of the control in an internal control library, thereby creating / updating the Html5 control in the voice conversation platform. An embodiment of the invention furthermore provides a system for loading the control in the voice conversation platform. According to the method and the system, the control is loaded in the voice conversation platform; by enabling the voice conversation platform to be compatible with an Html5 technology, the developer can master the Html5 technology more easily, so that the learning cost of the developer is reduced; and cross-platform use is realized by utilizing characteristics of Html5.

Owner:AISPEECH CO LTD

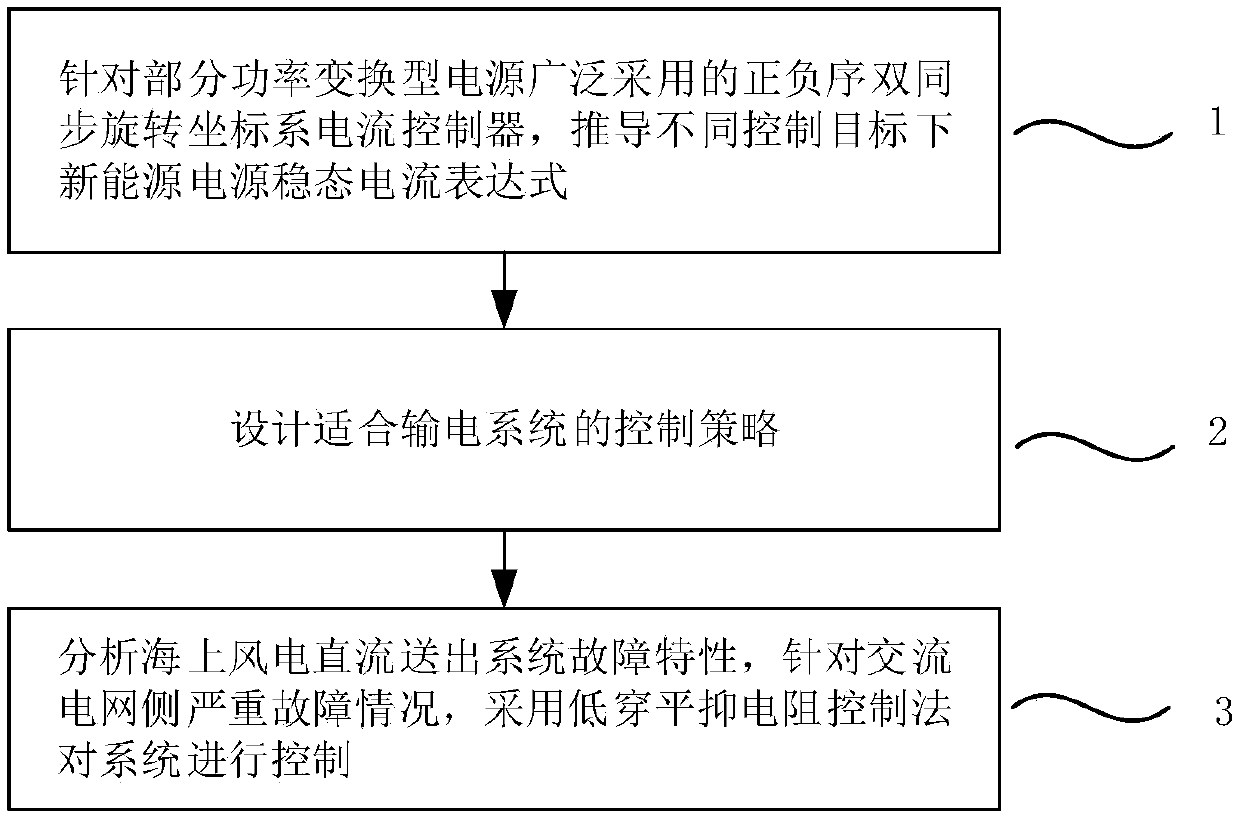

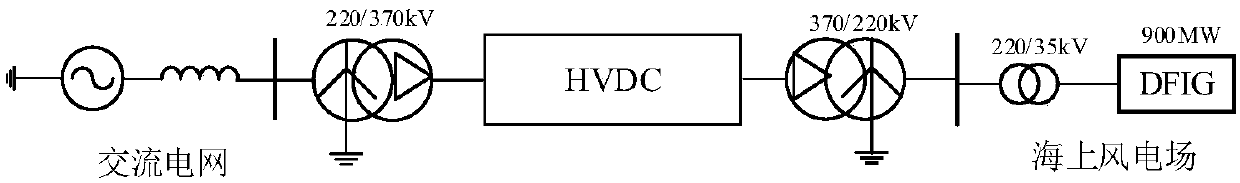

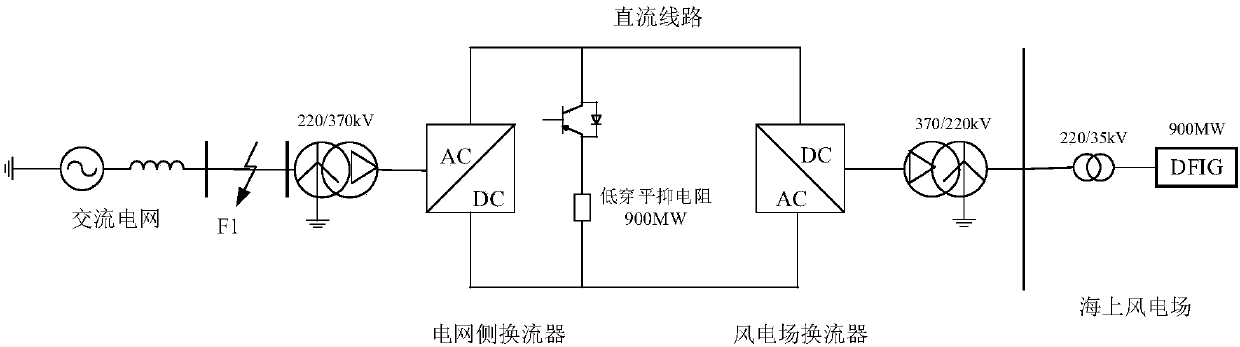

Fault control method and device of offshore wind power DC sending-out system

ActiveCN107863780AAvoid situations where the voltage continues to riseQuick investmentElectric power transfer ac networkSingle network parallel feeding arrangementsOvervoltageNew energy

The invention discloses a fault control method and device of an offshore wind power DC sending-out system. A system control strategy under an existing fault only can be used for performing fault control under a certain wind power plant voltage and frequency range, and a DC voltage cannot be enabled to be limited at a value near to the highest limit value. According to the fault control method, a steady-state current expression of a new energy power supply under different control targets is derived with regard to a part of power conversion power supply employing a positive- and negative-sequence dual-synchronous rotation reference frame current controller; on the basis, a power transmission system control strategy is designed due to particularity of offshore new energy equipment; and surplus power on a DC circuit is consumed by low-tunneling suppression resistor, DC voltage rising is prevented, damage of overvoltage to a flexible DC power transmission line is prevented, stable running of the system is maintained, and the running safety and reliability of the offshore wind power DC sending-out system are improved.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER COMPANY ECONOMIC TECHN INST +2

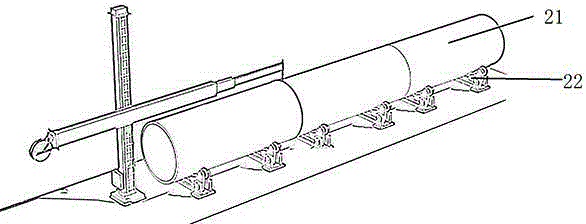

Circular pipe transfer box type column and manufacturing method thereof

ActiveCN105171354AImprove support abilityGuaranteed stabilityStrutsPillarsWall plateWelding residual stress

The invention discloses a circular pipe transfer box type column which comprises a cylinder body, a box body, a body with the circular top and the square bottom, supporting jig frames, a box body bottom plate, a transverse partition plate, a stiffening plate, side sealing plates, a top sealing plate, a second supporting jig frame, a wall plate, a whole jig frame and brackets. The cylinder body and the box body are arranged on the circular opening end and the square opening end of the body with the circular top and the square bottom. The brackets are arranged on the cylinder body and the box body. The circular pipe transfer box type column is formed by combing the cylinder body, the body with the circular top and the square bottom and the box body. The body with the circular top and the square bottom is in a drooping body shape. The top and the bottom of the body with the circular top and the square bottom are matched with the cylinder body and the box body respectively, the whole cylinder body reaches maximum supporting capacity, the stability of a steel structure is guaranteed, and the use safety of the steel structure is improved; meanwhile, the box body is provided with a sensor and a vibrator, and the welding condition can be detected efficiently and quickly; and meanwhile, the bottom of the box body is further provided with a rubber pad, the welding residual stress of the whole box is eliminated effectively, and the construction requirement can be well met.

Owner:JIANGSU HUNING STEEL MECHANISM

Method for utilizing running water net cages to breed whitmania pigra

The invention discloses a method for utilizing running water net cages to breed whitmania pigra. The method includes the following steps that (1) the net cages are manufactured; (2) the net cages are placed at the sheltered and sunny positions in a water area, and the interval between every two adjacent net cages ranges from 2m to 3m; (3) the net cages are placed into water 10 days before the whitmania pigra is placed into the net cages, meanwhile, water hyacinth, lemna minor and other aquatic plants are placed into the cages, and the placed aquatic plants account for 35-40% of the net cage water surface area; (4) food of the whitmania pigra is placed in the water area, wherein the weight of food is 2-3 times the weight of the whitmania pigra; (5) in an appropriate cloudy day early in July, the young whitmania pigra is placed into the different net cages of a river channel according to the body sizes, and the 3000 whitmania pigra is placed in each net cage; (6) in general, nets are hauled and the whitmania pigra is caught from late October. Due to the adoption of the method, the defects that artificial running water breeding cost is high, the yield of the whitmania pigra bred in natural running water surfaces is low, and the whitmania pigra is not easy to catch can be well overcome. The practice shows that due to the adoption of the method, the yield can be effectively improved and social benefits and economic benefits are remarkable.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

Disinfection device for gynaecology and obstetrics stretching bed

InactiveCN108543092AConvenient for centralized processingShorten the timeLavatory sanitoryChemicalsEngineeringVALVE PORT

The invention relates to a disinfection device for gynaecology and obstetrics, in particular to a disinfection device for a gynaecology and obstetrics stretching bed. The technical problem of the invention is characterized in that the disinfection device for the gynaecology and obstetrics stretching bed can rapidly conduct clean and thorough disinfection and can prevent cross infection of puerpera. The technical scheme of the invention is characterized in that the disinfection device for the gynaecology and obstetrics stretching bed comprises a box body, a first trapezoid block, a second trapezoid block, a first supporting board, a second supporting board, a shell, a first connection pipe, a pump body, a second connection pipe, a first valve and the like. A plurality of first liquid leaking holes are formed in the top of the box body, the first trapezoid block and the second trapezoid block are both arranged on the box body, and the bottom of the first trapezoid block is connected withthe right side of the top of the box body. The disinfection device for the gynaecology and obstetrics stretching bed can rapidly conduct clean and thorough disinfection, has the good disinfection effect, is clean and sanitary, can prevent cross infection of puerpera, is beneficial for health and safety of the puerpera, and is simple in structure, convenient to use and low in labor intensity.

Owner:马鹤

Large-arm-span multi-rotor suspension type pesticide spray device

InactiveCN108910048ASimplify complex requirementsExpand fastAircraft componentsInsect catchers and killersRotary wingAgricultural engineering

The invention provides a large-arm-span multi-rotor suspension type pesticide spray device which comprises a movable material rack and further comprises one suspension support or one set of suspensionsupports. Multiple rotors are distributed on the suspension support. Each rotor is fixed to the suspension support through a rotary shaft. The lower end of each rotor is provided with one nozzle or one set of nozzles. Each nozzle is sequentially connected to a high-pressure pesticide pipe, or each nozzle is connected with a pesticide tank through the high-pressure pesticide pipe. The pesticide tank is fixedly arranged on the movable material rack. A high-pressure pump is arranged between the high-pressure pesticide pipe and the pesticide tank, and pesticide liquid in the pesticide tank is pumped to the pesticide pipe through the high-pressure pump and sprayed through each nozzle.

Owner:杨艳鹏

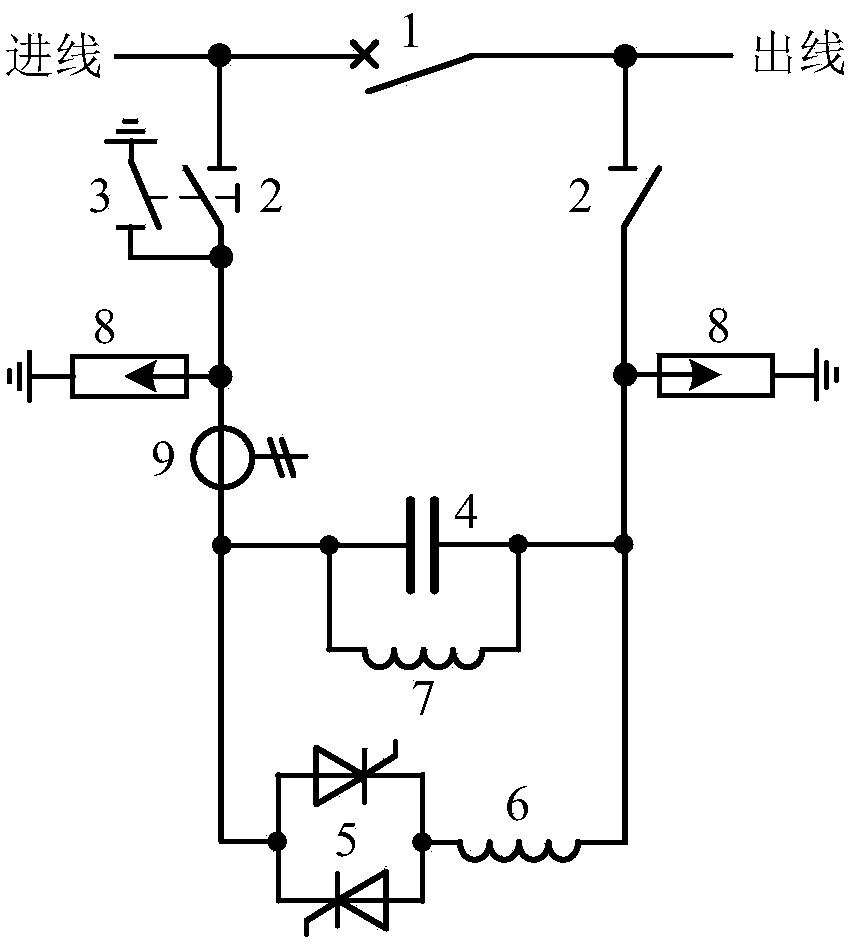

Multi-terminal flexible DC power grid fault current limiting method and device

ActiveCN110350496ALimit fault currentQuick investmentEmergency protective circuit arrangementsCapacitanceElectrical resistance and conductance

The invention discloses a multi-terminal flexible DC power grid fault current limiting method and device. Blocking of a converter station can be avoided so as to ensure high power supply reliability.The method comprises the following steps: constructing a topology structure of a current limiting device; determining the current of the current limiting device in the discharge stage of the energy storage capacitor and the input stage of the current limiting resistor; setting the input criterion of the current limiting device; selecting the key parameters of the current limiting device; and controlling on / off of the thyristor in the current limiting device when the DC side of the flexible DC system fails and serially connecting the current limiting resistor in the fault loop to realize faultcurrent limiting.

Owner:SHANDONG UNIV

Safety friction-type hard-pulling training auxiliary device

InactiveCN109260663AEasy to adjustQuick investmentDumb-bellsFrictional force resistorsEngineeringWeight-bearing

The invention belongs to the technical field of fitness equipment and discloses a safety friction-type hard-pulling training auxiliary device. The safety friction-type hard pull training auxiliary device Includes a top frame, the four corners of the lower surface of the top frame are fixedly connected with the top ends of four upright columns, the four upright columns are equal in length and parallel to each other, the two upright columns located on the front side of the top frame are fixedly sleeved with connecting rings, the back surfaces of the two connecting rings are movably connected with the two ends of the grabbing rod through a connecting mechanism, and a resistance adjusting mechanism is installed on the top frame and the two upright columns on the rear side of the top frame. According to the safety friction-type hard pull training auxiliary device, through the setting of the resistance adjusting mechanism, the sliding friction between the bracket and the resistance capsule is formed by squeezing the bracket by the resistance capsule so as to provide the load, and the load can be adjusted conveniently and quickly in the process of individual practice, and the trainer doesnot need to move the training position, so that the trainer is convenient to put into the training quickly.

Owner:丁海丰

Formula for preparing dimension stone of magnesia alumina spinel by using sludge from factory of aluminum section, and preparation method

InactiveCN1958458ARaw material innovationWith eco-friendly technologyAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSludgeRefractory

This invention provides formula and method for preparing magnesium aluminate spinel material by using sludge from aluminum profile plants as the raw material. The formula comprises sludge from aluminum profile plants and basic magnesium carbonate as the major raw materials. The method comprises: mixing the raw materials, pressing for shaping, reacting at high temperatures, and cooling the product to obtain magnesium aluminate spinel material. The method utilizes sludge from aluminum profile plants as the raw material to prepare magnesium aluminate spinel material, thus can solve the problem of serious environmental pollution caused by the sludge, save the production cost and have a high profit. The prepared magnesium aluminate spinel material has excellent high-temperature thermal properties, mechanical properties and chemical stability, especially obvious chemical stability in alkaline conditions, and is widely used in the fields of refractory materials and ceramics.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com