Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

199results about How to "Realize the craft" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Super-early-strength PCE (polycarboxylate ether) superplasticizer and preparation method thereof

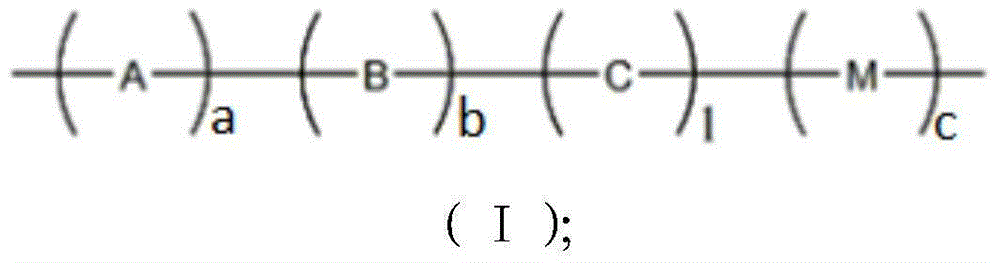

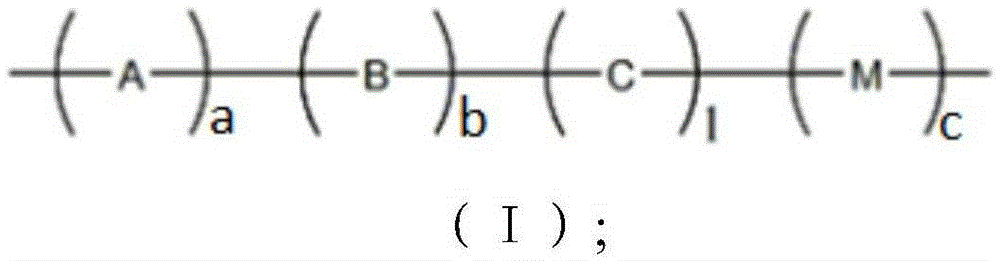

The invention provides a super-early-strength PCE (polycarboxylate ether) superplasticizer. The super-early-strength PCE superplasticizer is a compound shown in formula (I) and is synthesized with active macro-monomers used as raw materials, the space hindrance effect of the superplasticizer is further improved, and meanwhile, positive ions with good cement resistance are introduced in molecules, so that the superplasticizing rate, the cement resistance and the cement adaptability of the superplasticizer are increased. The superplasticizer has better tolerance and cannot have a continuous intercalation reaction with the cement. The positive ions of the super-early-strength PCE superplasticizer can inhibit expansion of the cement so as to reduce adsorption of the cement to an additive. The super-early-strength PCE superplasticizer can accelerate the hydration function of the cement and has the super-early-strength function. The super-early-strength PCE superplasticizer has super-early-strength and cement-resistant functions in common concrete.

Owner:GUANGDONG REDWALL NEW MATERIALS

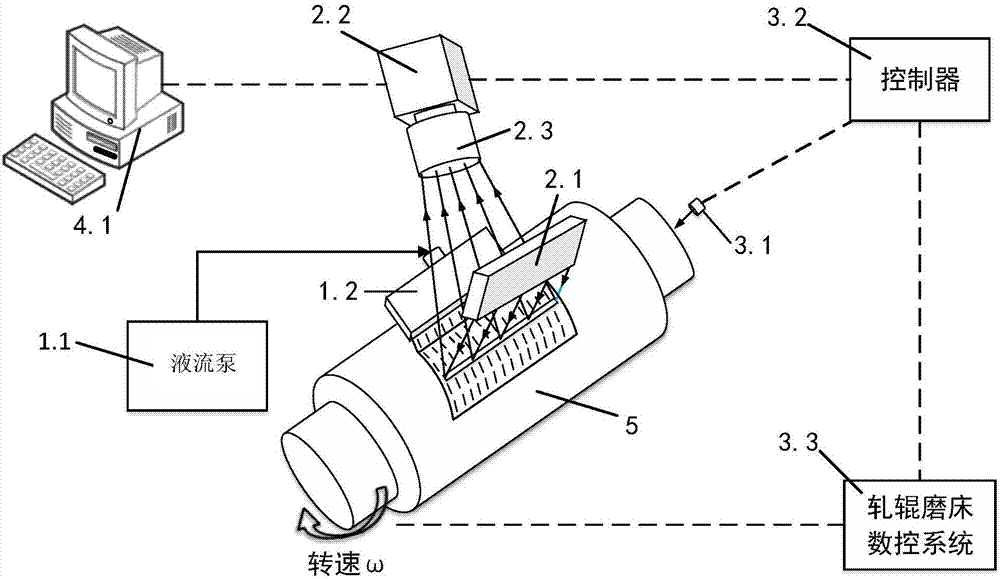

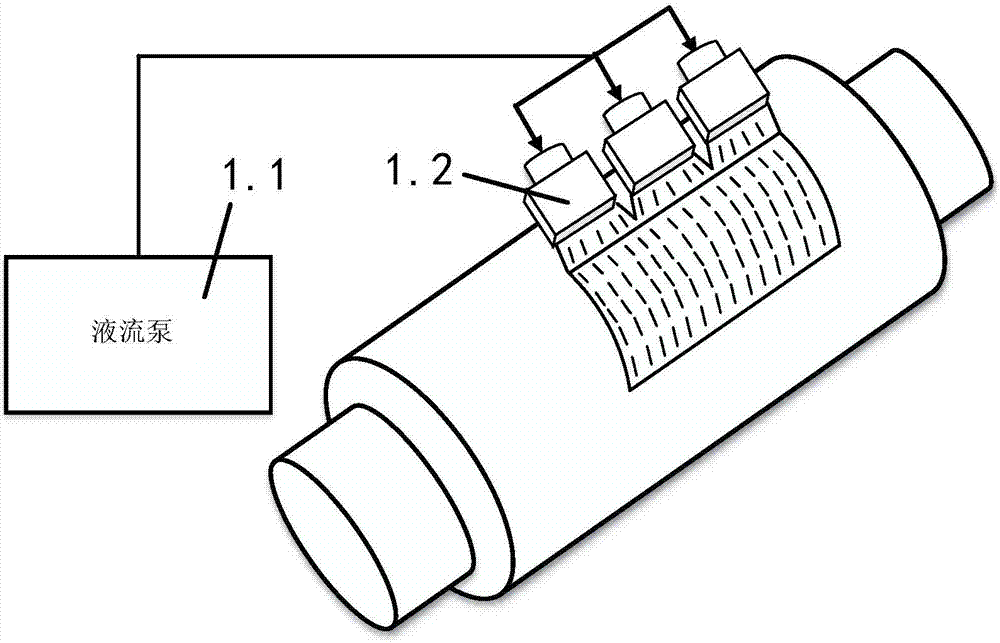

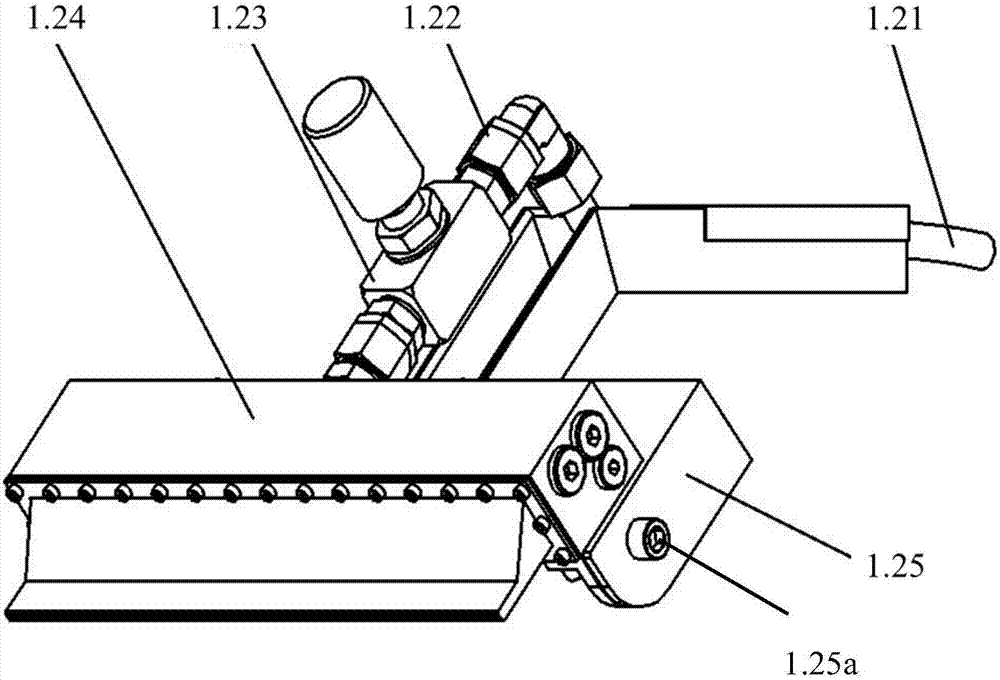

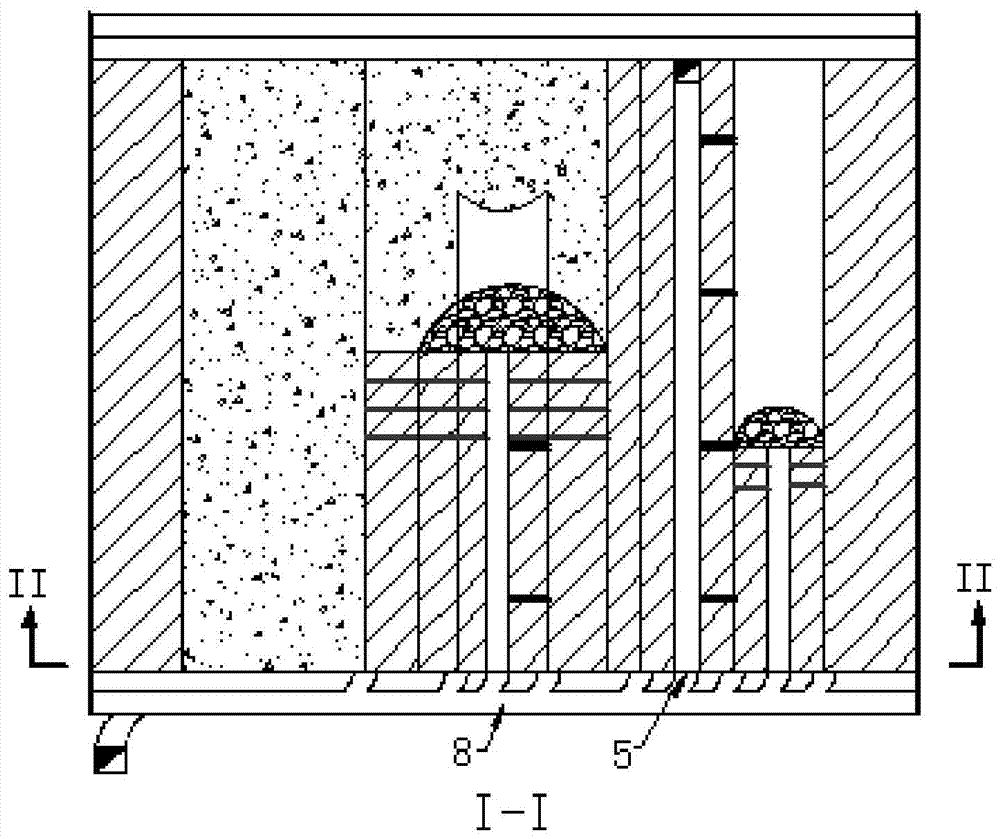

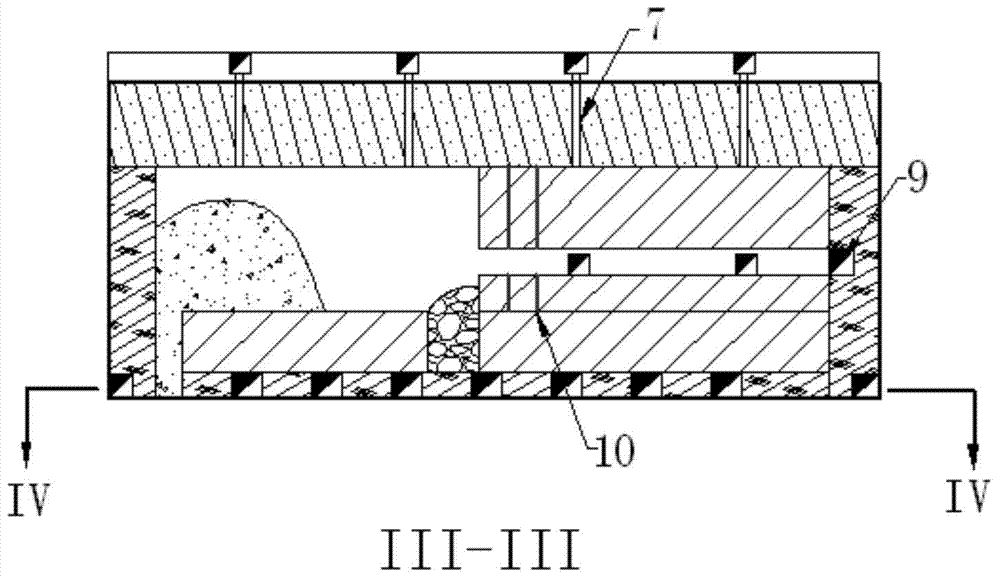

Machine vision detecting system for detecting defects of rolling roll grinding surface

InactiveCN107576664AClear imagingUniform brightness distributionOptically investigating flaws/contaminationLiquid layerMachine vision

The invention discloses a machine vision detecting system for detecting defects of a rolling roll grinding surface, belonging to the field of grinding processing surface defect detection. The system comprises a cleaning device, an image acquisition device, an image acquisition control unit and an image processing and analysis unit, wherein the cleaning device can be used for forming a uniform laminar flow liquid layer on the surface of a rolling roll to be detected; the image acquisition device is arranged around the rolling roll to be detected; the image acquisition control unit is respectively connected with the rolling roll to be detected and the image acquisition device; the image processing and analysis unit is electrically connected with the image acquisition device and is used for realizing defect classification identification, defect evaluation and over-limit alarm as well as fault diagnosis. The machine vision detecting system can be used for carrying out qualitative and quantitative detection on the defects such as short scratches, micro-vibration, spots, spiral patterns and reticulate patterns on the rolling roll grinding surface, overcomes the defects that the existingartificial naked eye detection method is high in subjectivity and lower in accuracy, easily causes inspection missing, can not realize quantitative detection, and the like, and improves detection efficiency, accuracy and reliability.

Owner:TSINGHUA UNIV +1

Subsection-studding all-open-stoping backfilling collaborative mining method

ActiveCN103615250AControl limit exposure areaGuarantee mining safetyUnderground miningSurface miningLarge sizeProtection layer

The invention discloses a subsection-studding all-open-stoping backfilling collaborative mining method. A panel ore block is divided into primary studdings and secondary studdings; a retrusive mining working mode that the mining is carried out out at intervals, the secondary studdings are mined and then the primary studdings are stoped is adopted; when each secondary studding is stoped, a certain thickness of an ore body is reserved on the top of the ore body and is used as a temporary protection layer; a drilling drift is arranged in each primary studding and is used for drilling the top ore body and the ore body of the primary studding; meanwhile, the drilling drift has a function of filling the drift, the function of filling the drift is achieved by a goaf of a low-level secondary studding; a filling hole is formed in the wall of the drift and is used for immediately filling the goaf of each secondary studding; a large-size stope structure parameter is designed in the ore body; a production mode of mechanical mining work is adopted; a drill jumbo is used for drilling, and a scraper discharges ores, so that the safety and high-efficiency mining is realized. The subsection-studding all-open-stoping backfilling collaborative mining method disclosed by the invention is high in ore recycling rate and high in safety under the condition that a roof surrounding rock is unsteady.

Owner:CENT SOUTH UNIV +1

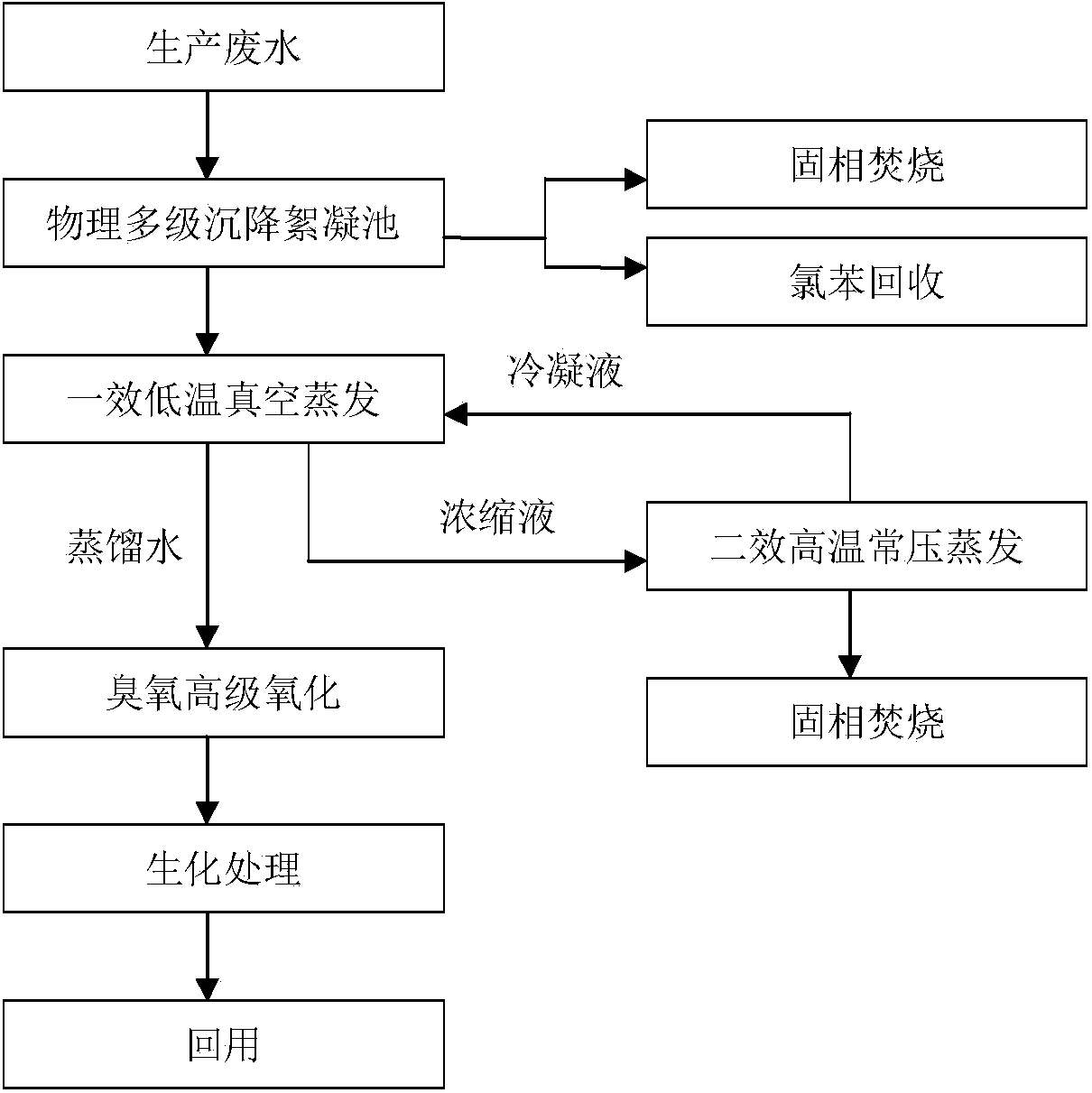

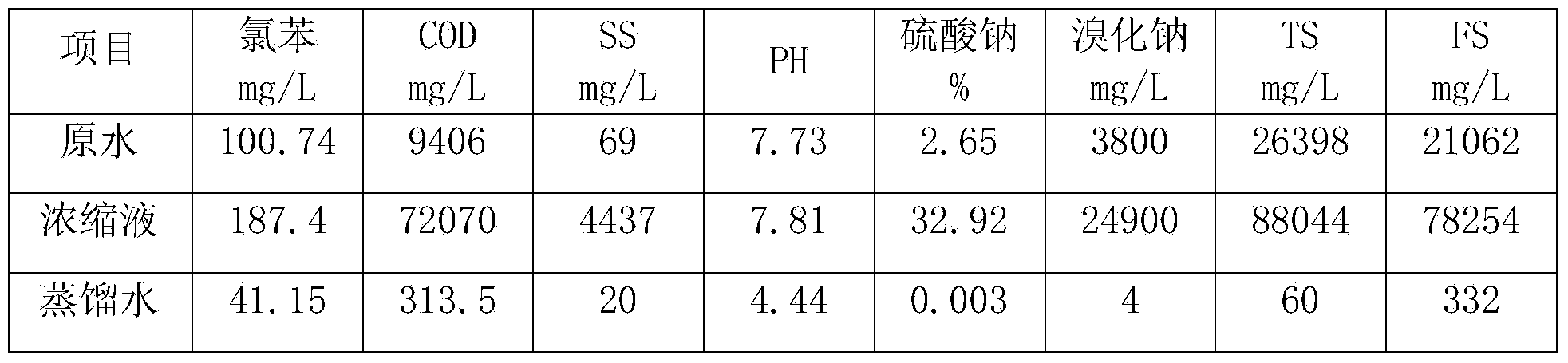

Method for treating and recycling TBBP (tetrabromobisphenol)-A production wastewater

InactiveCN103466894AAchieve removalRealize harmless and up-to-standard dischargeMultistage water/sewage treatmentNature of treatment waterFlocculationChlorobenzene

The invention discloses a method for treating and recycling TBBP (tetrabromobisphenol)-A production wastewater, which comprises the main steps of physical multistage settling, flocculation and recovery, two-effect high / low-temperature evaporative desalination, advanced ozone oxidation and biochemical treatment. According to the invention, the removal of harmful hardly-degradable substances in TBBP-A wastewater is realized, the pH value of wastewater subjected to treatment is neutral, the COD (chemical oxygen demand) can be degraded to below 100 mg / L, and chlorobenzene can be completely decomposed by cutting, thereby reaching reuse and discharge standards, and achieving the purposes of the harmless and up-to-standard discharge of wastewater and the recycling of process water.

Owner:天津长芦汉沽盐场有限责任公司

Smelting process for efficient slagging and desulfurization of LF aluminum killed steel

ActiveCN112322837AShort processing cycleRealize reducing pre-desulfurizationManufacturing convertersProcess efficiency improvementSteelmakingSmelting process

The invention discloses a smelting process for efficient slagging and desulfurization of LF aluminum killed steel. The smelting process for efficient slagging and desulfurization of the LF aluminum killed steel comprises the following steps that S1, converter steelmaking is carried out, and the end point temperature of a converter is controlled within 1610-1660 DEG C; the adding amount of scrap steel is less than or equal to 70 tons; and a strong bottom blowing mode is adopted in the later converter blowing stage to enhance molten pool stirring. According to the smelting process for efficientslagging and desulfurization of LF aluminum killed steel, converter tapping, argon blowing station and LF refining tasks are adjusted through process design to form a three-in-one refining process ofconverter tapping, argon blowing station and LF refining, LF slagging work is advanced, a rapid slagging process system is formulated, 80% or above of slagging slag materials are added in the tappingprocess through design optimization, and slag melting is promoted by fully utilizing tapping steel flow impact kinetic energy, molten steel sensible heat and ladle bottom argon blowing stirring kinetic conditions; an argon station adopts a top-bottom strong stirring proper deoxidation process, slag is rapidly formed to promote steel slag reaction, top slag reduction pre-desulfurization is realized, and LF slagging desulfurization burden is reduced; and an LF target is heated once to basically complete slagging and desulfurization tasks.

Owner:MAANSHAN IRON & STEEL CO LTD

Method and device for continuously producing dyes

ActiveCN103146221ARealize automatic continuous productionThree wastes are produced lessMonoazo dyesWash waterReaction temperature

The invention discloses a method and a device for continuously producing dyes. The method comprises the following steps: adding diazotization reaction raw materials into an ingredient kettle, controlling temperature in the kettle, allowing the materials to flow in a tubular reactor through an overflow orifice, detecting the reaction state through an online detection device, continuously discharging the diazotization compound solution obtained through the reaction, continuously feeding the diazotization compound solution and a coupling component solution according to a specified ratio, allowing the materials to flow into the tubular reactor through the overflow orifice, detecting the reaction state through the online detection device, transferring the coupling reaction materials into a crystal transformation kettle, performing crystal transformation, and performing filter pressing to obtain a dye filter cake, wherein the filter cake mother solution and the wash water are circulated for preparing the coupling component solution. The reaction temperature, material flow and reaction state detection device are automatically subjected to interconnected control. According to the method, automatic and continuous dye production is realized, the production capacity, the product quality and yield are improved, the labor intensity and working conditions of workers are improved, the waste water, water gas and waste residue amounts in the dye production process are greatly reduced, and circular economy and cleaner production process are realized.

Owner:ZHEJIANG DIBANG CHEM

Online monitoring method for covert faults and joint process defects of power cable

The invention discloses an online monitoring method for covert faults and joint process defects of a power cable. The online monitoring method comprises seven steps, namely current acquisition, fault recording, data caching, data transmission, map drawing, comprehensive analysis and fault positioning. The online monitoring method comprises the specific steps of: acquiring transition and mutation of transfinite current of all earthing points in a cable sheath layer by using a current transformer arranged on the cable; uploading the acquired data to a monitoring host by a fault recording device connected with the current transformer; transmitting the received data to a monitoring platform in a TCP / IP (Transmission Control Protocol / Internet Protocol) Ethernet interface manner by the monitoring host; and carrying out comparative judgment, fault reason analysis and fault segment positioning on the acquired transition and mutation data of the transfinite current according to a specific analytic method by a server arranged in the monitoring platform. According to the system, the early finding of the covert faults and the joint process defects of the power cable can be realized and the basis for ensuring long-term normal operation of the power cable is provided; and comprehensive monitoring, accurate fault positioning and early warning can be realized.

Owner:康威通信技术股份有限公司

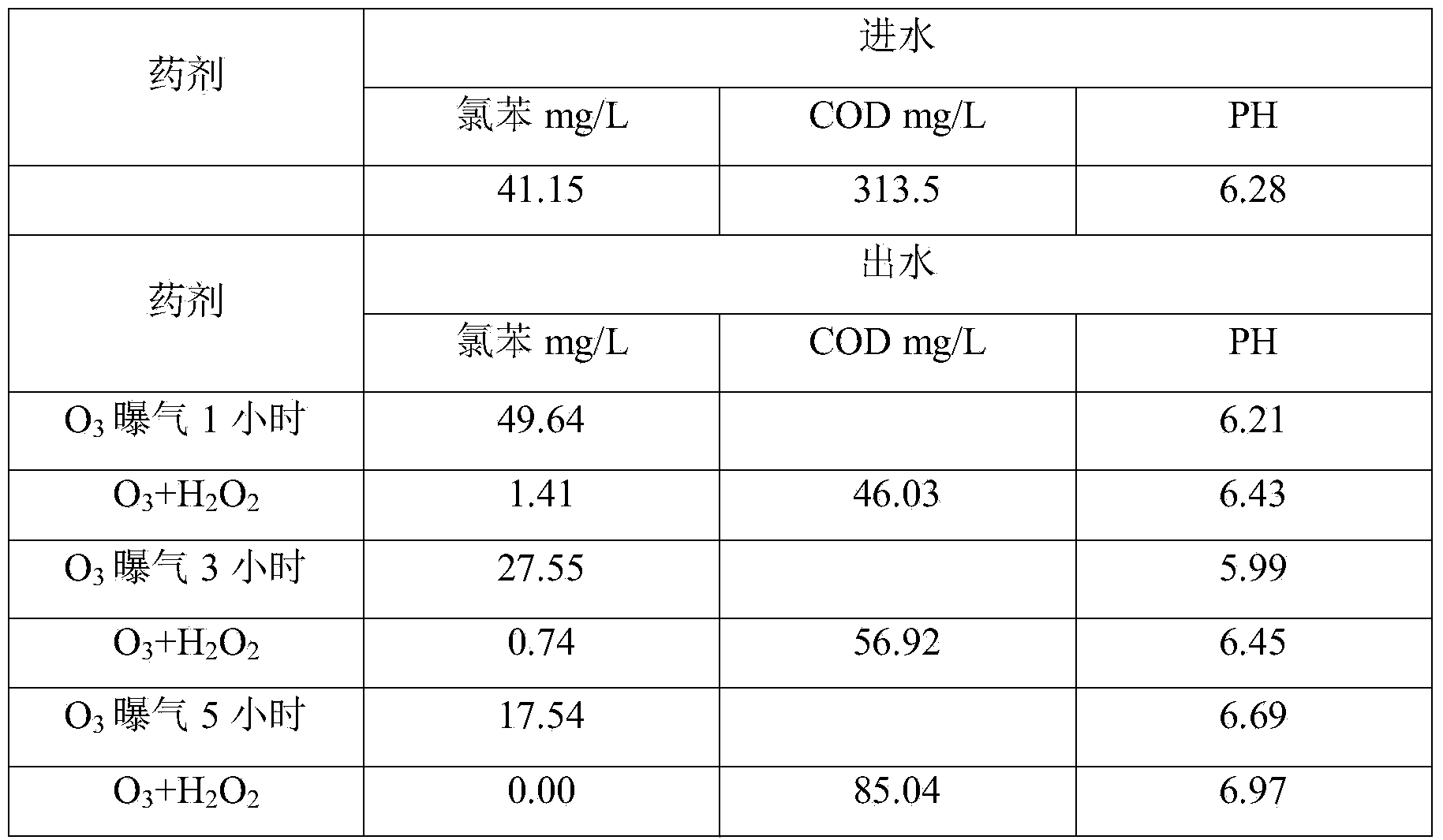

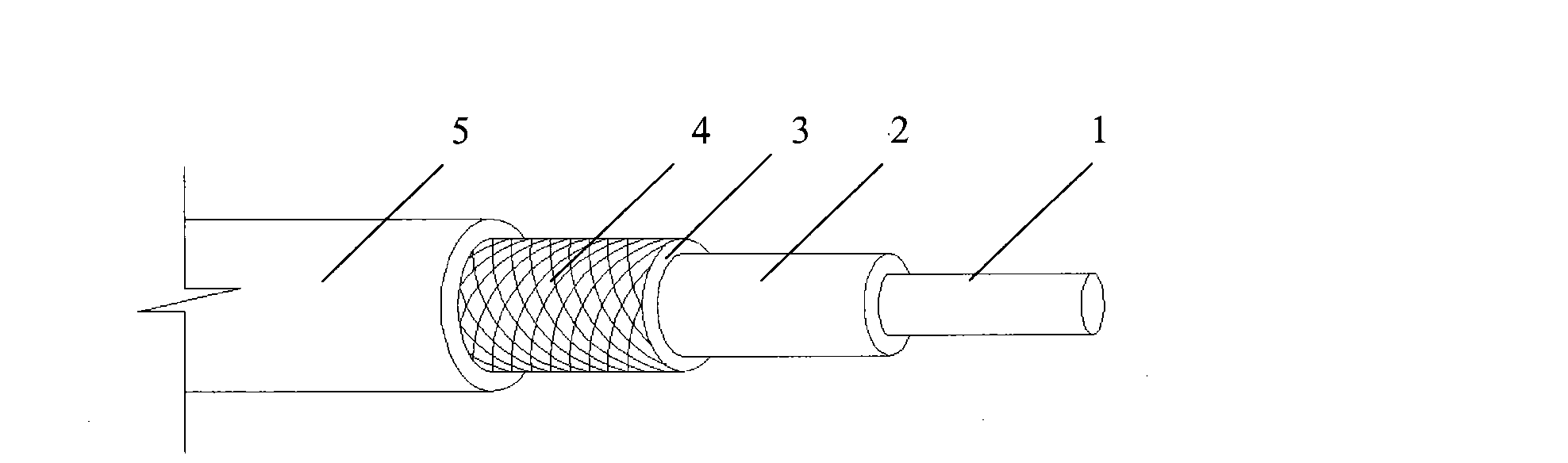

Ultraviolet light resistant ring protective cover material and white concentric cable produced thereof

InactiveCN101492557AExcellent resistance to UV radiationEnvironmental protection is goodPlastic/resin/waxes insulatorsUltraviolet lightsSocial effects

An ultra violet radiation resistant environmental protection sheathing material is mainly prepared by the following materials according to the parts by weight: 40-50 pars of polyvinyl chloride resin, 6-8 parts of trioctyl trimellitate, 4-6 parts of dioctyl sebacate, 7-9 parts of dioctylphthalate, 4-6 parts of ca-zn composite stabilizer, 1-1.5 parts of epoxidized soybean oil, 1-1.5 parts of diantimony trioxide, 1-1.5 parts of diantimony trioxide, 10-13 parts of magnesium hydrate, 8-10 parts of refined calcium carbonate, 8-10 parts of titanium dioxide, and 0.3-0.5 parts of ultraviolet absorbent. The invention technically solves the difficult point of compound formulation of the ultra violet radiation resistant white sheathing material, greatly increases the resistance to ultra violet radiation performance of the product, has strong practicability and lays the material foundation for the design and development of resistance to ultra violet radiation coaxial-cables. Based on the resistance to ultra violet radiation white polyvinyl chloride sheathing material, the resistance to ultra violet radiation environmental protection sheathing material technically solves the technical difficulties of resistance to ultra violet radiation performance, softness, UL mechanical physical property, ROHS environment requirements and the like which are difficult to be achieved completely, meets the strict requirements of the application of products on tropical and subtropical regions and has remarkable social effect.

Owner:ZHEJIANG WANMA GRP SPECIAL ELECTRONCABLE

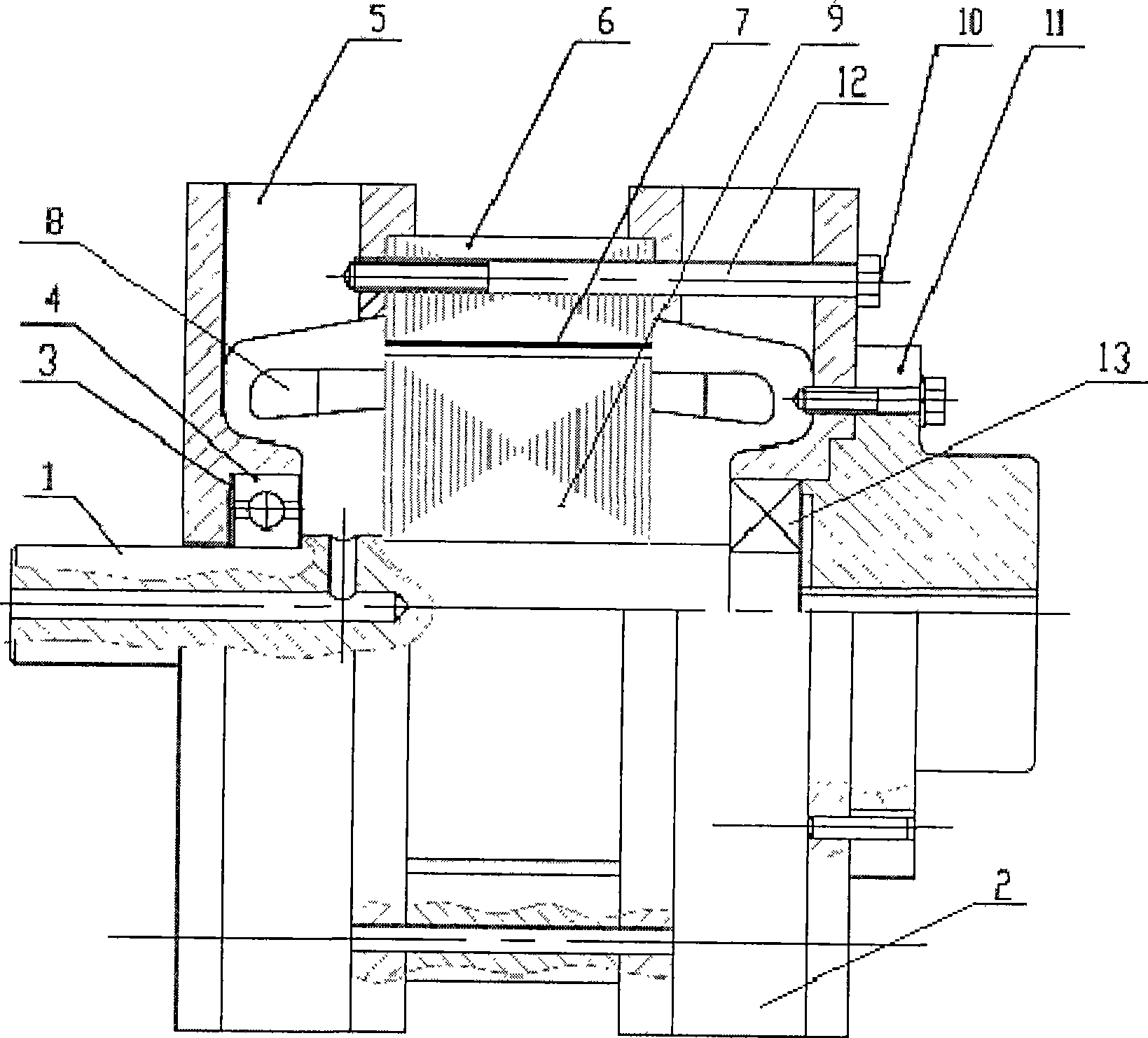

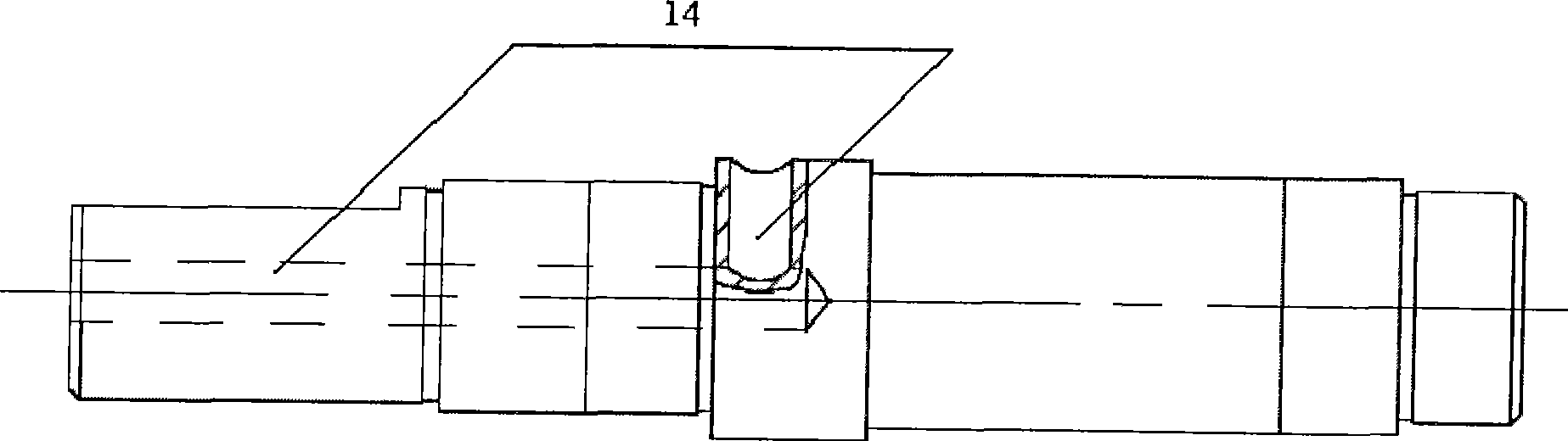

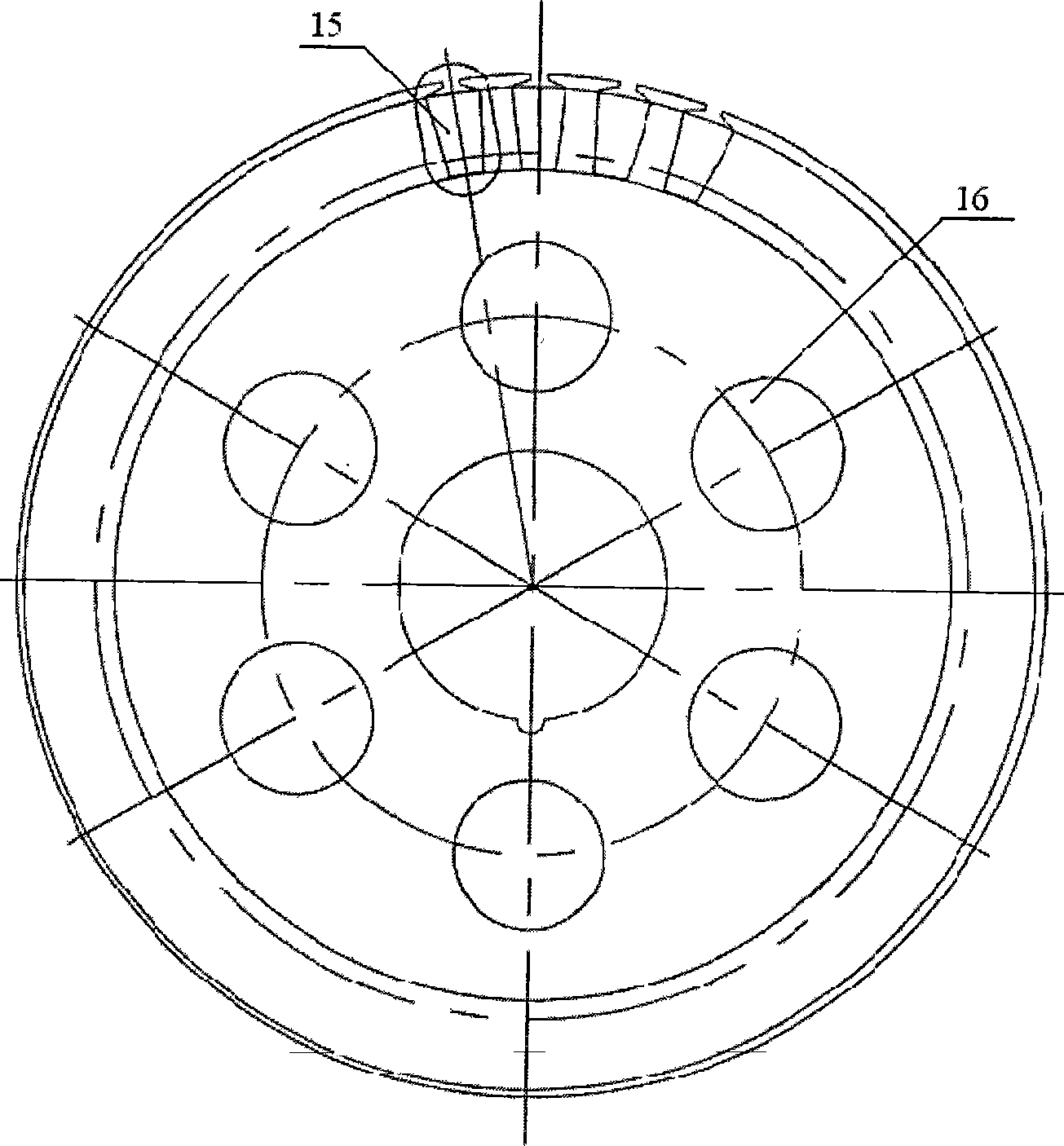

Outer rotor direct driving type permanent magnet synchronous torque servo motor

InactiveCN101459367AReduce temperature riseSimple processMagnetic circuit rotating partsSynchronous machine detailsPhysicsMotor shaft

The invention relates to an outer rotor direct drive type permanent magnet synchronous moment servo motor, which comprises a stator and a rotor, wherein the stator comprises a motor shaft, a stator iron core and a stator winding, the rotor comprises a rotor iron core, a permanent magnet body, a front end cover and a rear end cover, the inner surface of the rotor iron core is evenly distributed with projecting rotor tooth, the permanent magnet body is fixed between adjacent rotor tooth, the inner portion of the stator iron core is equipped with an axial via hole, and a hollow copper pipe is put in the axial via hole. The front end cover and the rear end cover are evenly equipped with radial strip vents or strip vents with an inclination angle. The outer rotor direct drive type permanent magnet synchronous moment servo motor can achieve the closed loop control of a position sensor or the vector open-loop control of a without position sensor, has heat dissipation function, compact structure, simple process, big output torque, low rotating speed, reliable operation, high efficiency and saves energy, and is particularly suitable for the direct driving of electric vehicles and mechanical equipment.

Owner:HUAZHONG UNIV OF SCI & TECH

Polycarboxylate superplasticizer with super high early strength and preparation method of polycarboxylate superplasticizer

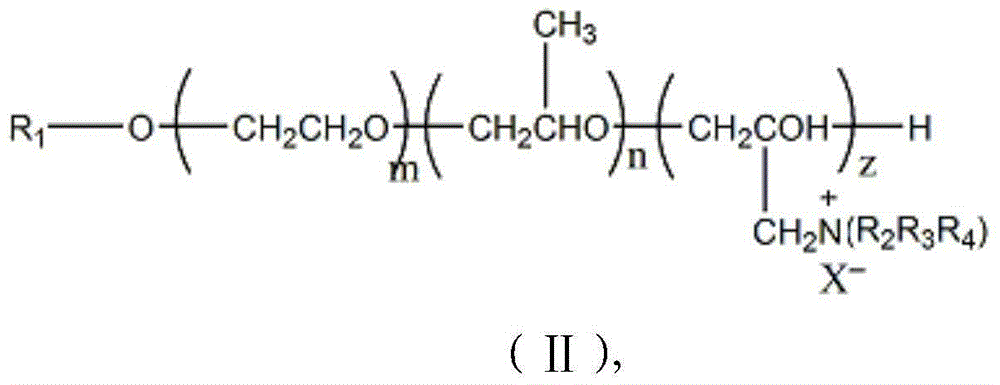

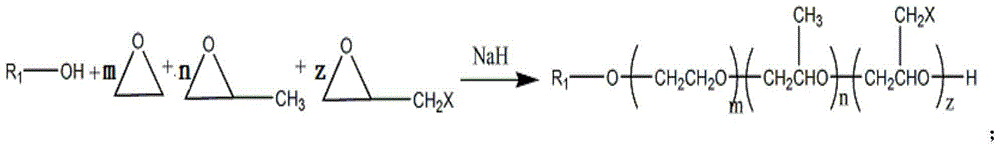

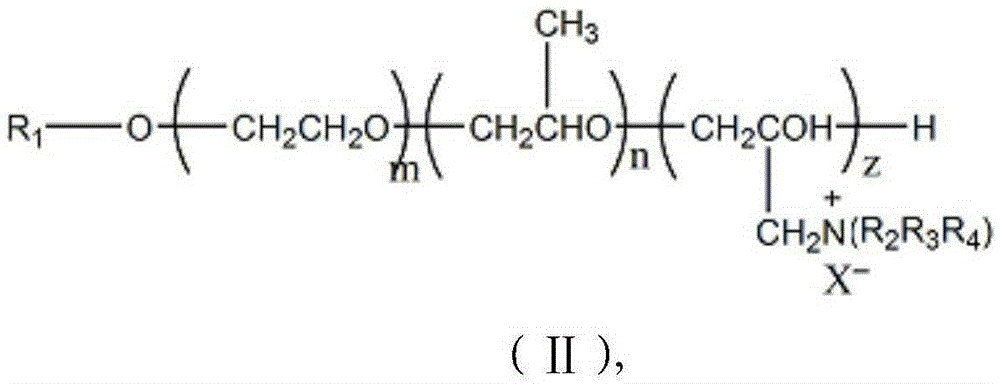

ActiveCN105271900AIncreased steric hindranceHigh water reduction rateIntercalation reactionSuperplasticizer

The invention provides a polycarboxylate superplasticizer with super high early strength. The polycarboxylate superplasticizer with super high early strength is a compound shown in the formula (I) and is synthesized with an active macromonomer as the raw material, cations are introduced into molecules while the steric hindrance effect of the superplasticizer is further improved, the cations have good soil resistance, so that the water-reducing rate of the superplasticizer is increased, and the soil resistance and the cement adaptability of the superplasticizer are improved. The polycarboxylate superplasticizer has better tolerance for soil and does not have an intercalation reaction with the soil. The cations of the polycarboxylate superplasticizer with super high early strength can inhibit soil expansion, so that admixture adsorption by the soil is reduced. The polycarboxylate superplasticizer with super high early strength can accelerate hydration of cement and has the super high early strength function. The polycarboxylate superplasticizer with super high early strength has super high early strength and soil resistance functions when applied to common concrete.

Owner:GUANGDONG REDWALL NEW MATERIALS

Polycarboxylate superplasticizer with super high early strength and preparation method of polycarboxylate superplasticizer

ActiveCN105271902AIncreased steric hindranceHigh water reduction rateHydration reactionSuperplasticizer

The invention discloses a polycarboxylate superplasticizer with super high early strength and a preparation method of the polycarboxylate superplasticizer. A molecular structure of the polycarboxylate superplasticizer with super high early strength contains cationic charges, a hydration reaction of cement is promoted, strength development of hardened concrete is accelerated, and the super high early strength function is realized; the polycarboxylate superplasticizer has specific cement particle dispersion capability by the aid of specific amphiphilic structure and steric hindrance effect, the water-reducing rate is high, and the soil resistance is good.

Owner:GUANGDONG REDWALL NEW MATERIALS

Industrialized production method of solar level polysilicon

InactiveCN101575733AImprove productivityImprove product qualityPolycrystalline material growthSingle crystal growth detailsElectrolysisSilicon alloy

The invention discloses an industrialized production method for extracting solar level polysilicon from industrial silicon. The industrialized production method adopts a combined method which comprises the steps of: preparation of aluminium silicon alloy by fusion electrolysis, smelting purification by electromagnetic induction, fractional crystallization purification and vacuum distillation purification. The production method reduces production cost which is high in the chemical method, simplifies production equipment of the physical method, leads the mass percentage purity of the prepared solar level polysilicon to be 99.9999 percent to 99.99999 percent and is more suitable for processing solar cells.

Owner:BEIHANG UNIV

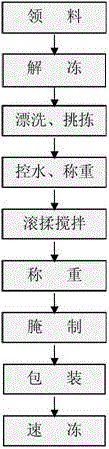

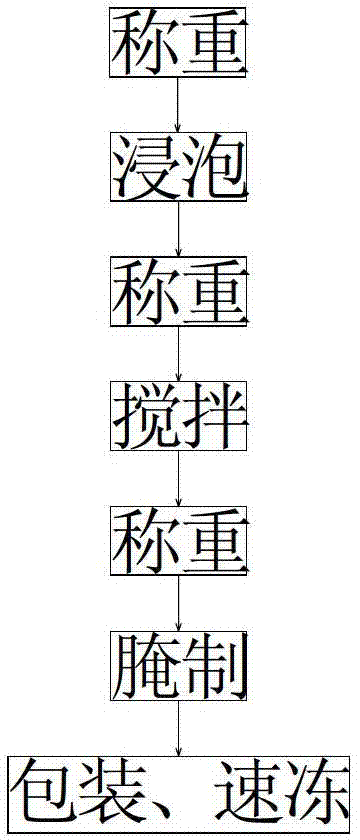

Pickled cabbage cuttlefish and preparation method thereof

InactiveCN102715563ARealize the standardization of raw materialsRealize the craftFood preparationSodium bicarbonateMonosodium glutamate

The invention relates to pickled cabbage cuttlefish and a preparation method thereof. The pickled cabbage cuttlefish mainly comprises the following components in part by weight: 950 to 1,050 parts of main material cuttlefish, 140 to 160 parts of green pickled cabbage, 8 to 10 parts of monosodium glutamate, 4 to 5 parts of salt, 5 to 6 parts of white granulated sugar and 4 to 6 parts of sodium bicarbonate. According to the invention, raw material standardization, product standardization and process standardization of the pickled cabbage cuttlefish can be realized.

Owner:SUZHOU HAODELAI FOOD

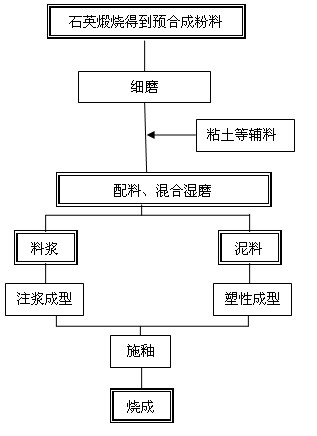

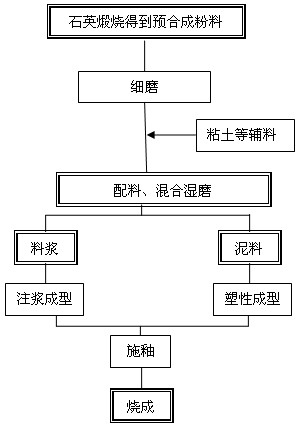

Ceramic manufacturing method using quartz as matrix material and product

The invention discloses a ceramic manufacturing method using quartz as a matrix material and a product. Silicon dioxide is used as the matrix material; aluminum oxide, basic oxide and magnesium oxide are used as auxiliary materials; and the ceramic comprises the following materials in part by weight: 90 to 94 percent of silicon dioxide, 3 to 6 percent of aluminum oxide, 0.5 to 1.5 percent of basic oxide, 0.2 to 1 percent of magnesium oxide and the balance of impurities. The method comprises the following steps of: calcining the silicon dioxide serving as the matrix material to obtain pre-synthesized powder, wherein the beta-quartz is converted into alpha-quartz by crystal transfer in the calcining process; grinding the obtained pre-synthesized powder, wherein the granularity distribution of the ground pre-synthesized powder meets certain requirements; weighing and proportioning the ground pre-synthesized powder and auxiliary materials in a ratio, performing wet milling in a ball mill to obtain slurry, and molding the slurry to obtain a daily ceramic blank; and preparing a ceramic product by the processes of drying, glazing, temperature controlled sintering and the like.

Owner:HUNAN HUALIAN CHINA IND

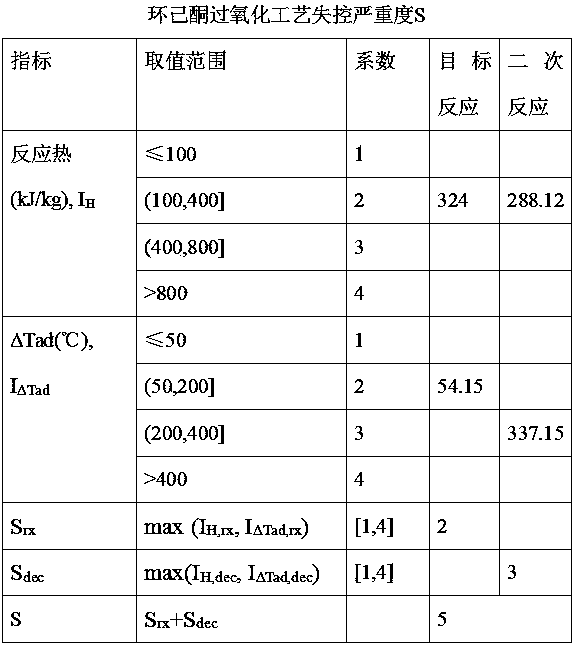

Method for evaluating thermal runaway risk degree of chemical process

ActiveCN110414868AIncrease diversityImprove accuracyResourcesManufacturing computing systemsDecompositionRisk index

The invention belongs to the field of chemical process risk assessment, and relates to a method for evaluating the thermal runaway risk degree of the chemical process. The method comprises the following steps: 1) collecting thermal risk data of raw materials, products and reaction processes; 2) determining a substance coefficient MF, wherein the substance coefficient MF is determined by the initial decomposition temperature Tonset and the maximum exothermic power MPD of the substance; 3) determining a reaction thermal runaway risk index RI, wherein RI is the product of the consequence severityS and the possibility P of the runaway reaction; and 4) calculating a thermal runaway risk index ITHI of the technological process, and determining a thermal runaway risk grade of the technological process according to an ITHI thermal runaway risk grading standard. Substance thermal risks and reaction runaway risks are combined. A quantitative evaluation method for the thermal runaway risk of thechemical technological process is provided.

Owner:NANJING UNIV OF TECH

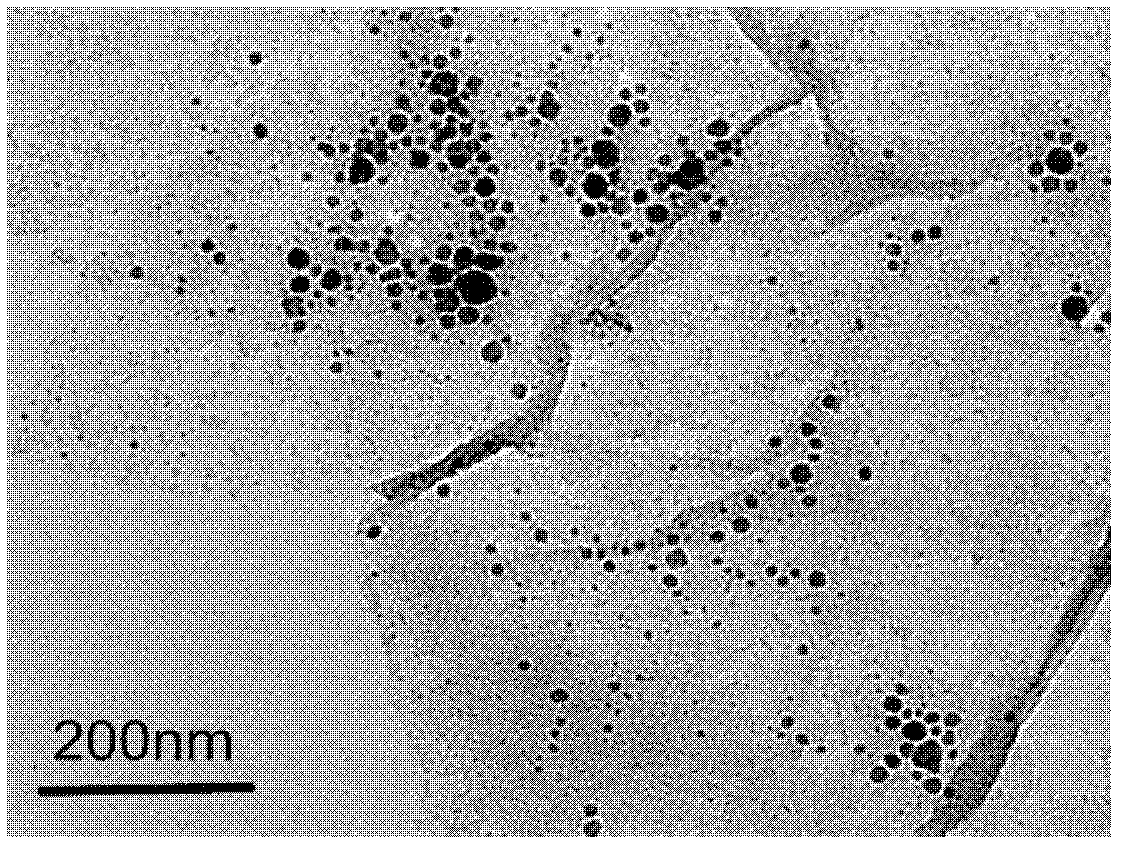

Preparation method of iron-coated graphene nanocomposite material

InactiveCN102602920AAdjustable coverageAdjustable sizeCarbon compoundsChemical vapor deposition coatingGraphene nanocompositesThermal expansion

A preparation method of an iron-coated graphene nanocomposite material comprises the following steps: (1) conducting thermal-expansion stripping on graphite oxide under a high temperature to obtain multi-layer graphene; (2) putting the multi-layer graphene and an organic solvent into a four-mouth flask, and mechanically stirring and mixing uniformly; (3) introducing pentacarbonyl iron steam into the mixed solution for thermal decomposition under a continuously stirring protection atmosphere; (4) conducting the thermal decomposition in a reflux condensation process; and (5) after the reaction,cooling to room temperature under the nitrogen protection, separating a product by a magnet, then cleaning the product by adopting an organic solvent, and drying the product under the nitrogen protection to obtain the iron-coated graphene nanocomposite material. According to the preparation method, Fe nanoparticles with a size of 20-50nm can be coated on the graphene sheet layers uniformly, the process is simple and controllable, the cost is low, and the industrial production is facilitated.

Owner:NANJING UNIV

Orleans bullfrog and preparation method thereof

InactiveCN102771799ARealize the standardization of raw materialsRealize the craftFood preparationGinkgo GenusSodium bicarbonate

The invention relates to an Orleans bullfrog and a preparation method thereof. The Orleans bullfrog is mainly prepared from 950-1050 parts of bullfrog, 55-65 parts of green bean, 20-25 parts of spice, 55-65 parts of ginkgo, 8-10 parts of starch, 8-10 parts of chicken essence, 4-5 parts of ginger and 4-6 parts of sodium bicarbonate. By adopting the invention, the raw-material standardization, the product standardization and the process standardization of the Orleans bullfrog can be realized.

Owner:SUZHOU HAODELAI FOOD

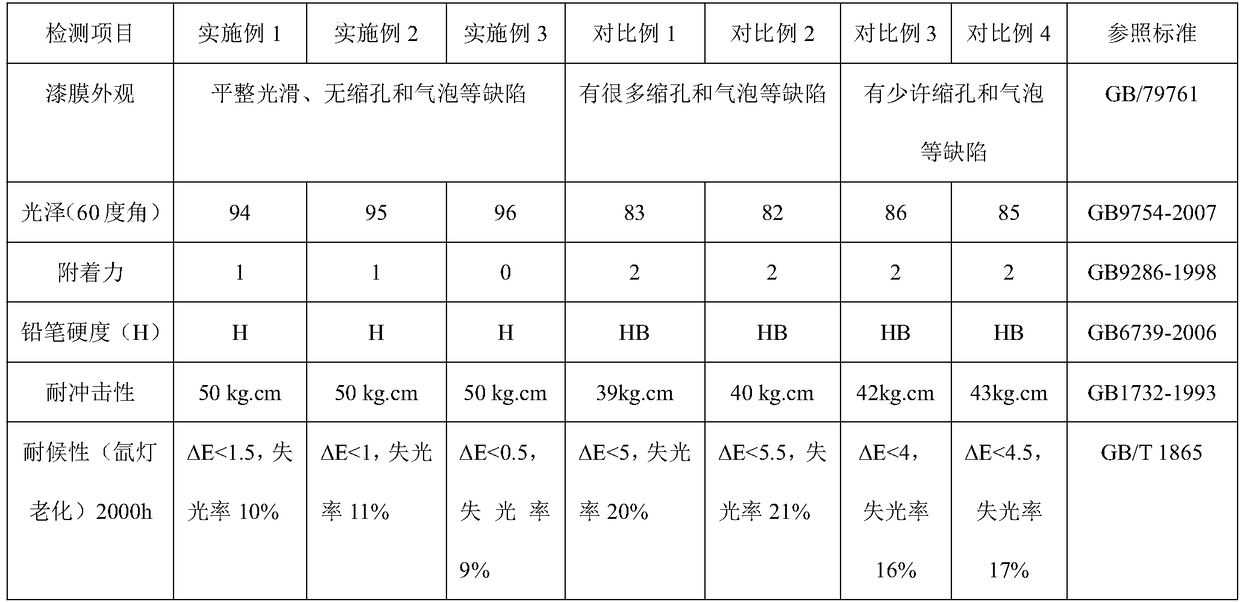

Single-component middle coating can be used for wet-on-wet and dry jet wet, and preparation method thereof

InactiveCN109181433AExtension of timeImprove efficiencyPolyurea/polyurethane coatingsPriming paintsWater basedPolyol

The invention belongs to the technical field of paint, and more specifically relates to a single-component middle coating can be used for wet-on-wet and dry jet wet. The single-component middle coating can be used for wet-on-wet and dry jet wet comprises, by mass, 35 to 45% of a grinding component slurry, 15 to 25% of a water-based acrylic polyol dispersion, 5 to 15% of a water-based polyurethanedispersion, 3 to 7% of an aqueous auxiliary agent, 0.5 to 1.5% of an amine neutralizer, 0.5 to 2% of ethylene glycol monobutyl ether, 0.3 to 0.7% of a wetting leveling agent, 2 to 8% of a methylated amino resin, 0.3 to 0.7% of a thickening agent, and 8 to 14% of water. The single-component middle coating can be used for wet-on-wet and dry jet wet is capable of increasing production efficiency greatly, is universal in et-on-wet and dry jet wet, is capable of saving production time and baking energy consumption greatly, and reducing research and development cost.

Owner:GUANGDONG YATU CHEM

Cold-resistant, soft and down-proof coating adhesive for textile and preparation method

The invention relates to a preparation method of cold-resistant, soft and down-proof coating adhesive for textile. The preparation method is characterized by comprising the steps of stirring 80-90 parts by weight of polyurethane binder and 0.3-0.5 parts by weight of defoaming agent for 10-30min at room temperature, adding 1.5-2.0 parts by weight of associated polyurethane rheological assistant, stirring for 30-45min, adding 5-10 parts by weight of hand feeling agent, stirring for 20-30min, and filtering and discharging to obtain the product. The adhesive is applicable to pure cotton, dacron and chinlon shell fabrics.

Owner:LIAONING FIXED STAR FINE CHEM

Crane flipping process

ActiveCN108726359AReduce investmentRealize the craftCargo handling apparatusPortable liftingEngineeringShackle

The invention discloses a crane flipping process which comprises a longitudinal flipping process and a transverse flipping process. A main hook group and a secondary hook are arranged on a crane, themain hook group comprises a first main hook and a second main hook, one end of the first main hook is fixedly connected with a shackle at one end of a hanging beam, and one end of the second main hookis fixed on a shackle at the other end of the hanging beam; and the two ends of the hanging beam are connected with hanging lugs on both sides of a single pile, the secondary hook is connected with ahook of the single pile, and the longitudinal flipping process of the single pile is achieved; and the first main hook is fixedly connected to the shackles at the two ends of the hanging beam, the shackles at the two ends of the hanging beam are respectively connected to the hanging lugs on both sides of the single pipe, the second main hook is connected with the hook of the single pile, and thetransverse flipping process of the single pile is achieved. According to the crane flipping process, through the flipping way, the construction process is optimized, the invested mechanical device isless, and the cost and manpower is reduced.

Owner:中天科技集团海洋工程有限公司

Three-way shock isolation device for satellite

ActiveCN104358814AAvoid transmissionGuaranteed installation rigidityCosmonautic vehiclesCosmonautic partsRelative displacementEnergy absorption

The invention discloses a three-way shock isolation device for a satellite. The three-way shock isolation device mainly comprises a frame body, a cover plate, a bottom plate and four energy absorption material blocks, wherein the cover plate is mounted on the frame body, and is in surface contact with the frame body; the cover plate and the frame body relatively displace on the surface of the cover plate, so that a shock energy absorption action space is formed in the direction; the bottom plate is mounted on the frame body, and is not in contact with the cover plate; the four energy absorption material blocks are respectively mounted in four independent spaces formed by the frame body, the cover plate and the bottom plate, and are in tight fit with the frame body, the bottom plate and the cover plate. The three-way shock isolation device can bear objects subjected to shock isolation reliably and safely, ensures the mounting rigidity, the strength, the position precision and the like of the objects subjected to shock isolation, meanwhile, effectively isolates the shock transmission in three directions, ensures that the objects subjected to shock isolation are in a small enough shock environment reliably, and achieves the purpose that the objects subjected to shock isolation or shock sensitive parts are in on-track operation safely.

Owner:SHANGHAI SATELLITE ENG INST

Process of preparaing methyl acrylate by waste organic glass and apparatus thereof

InactiveCN1560021AAdvanced equipment and process parametersHigh yield and purityOrganic compound preparationCarboxylic acid esters preparationMethyl methacrylateEngineering

The invention relates to a technique of preparing methyl methacrylate (MMA) by waste organic glass and its device, disclosing a semicontinuous cracking method and an integrated cracking and distilling device. It implements a technique of combining cracking and distilling and the technical courses: crushing the waste organic glass, adding the made glass particles in cracking kettles continuously, orderly and properly, temperature range 140-380 deg.C, as the glass particles reaches a certain quantity, stopping feeding and making final-period cracking and processing, where the average time of cracking and distilling in each a kettle in a cycle (by 1000 kg raw material) is 5-7 hours. On at 140 deg.C can it generate cracked MMA; the MMA product at 140-280 deg.C is dehydrated and becomes a transparent and clear liquid; the MMA purity is 97-99% and the MMA yield is 85-92%.

Owner:廖活强

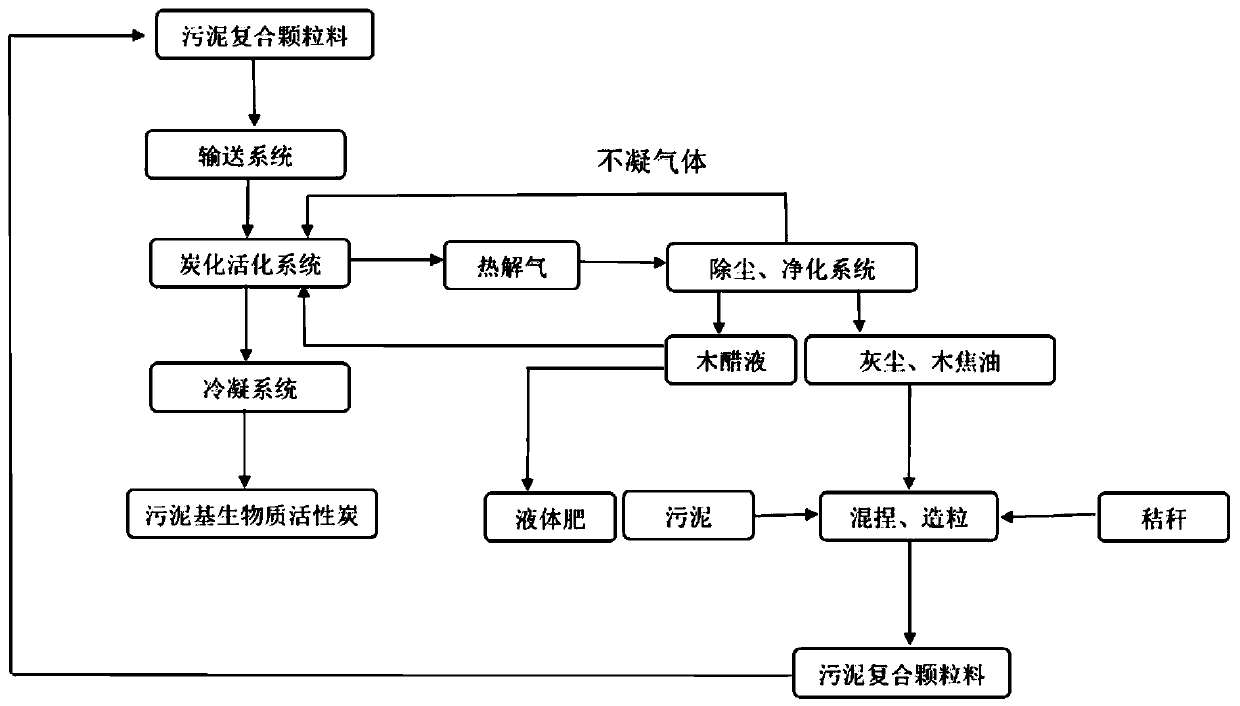

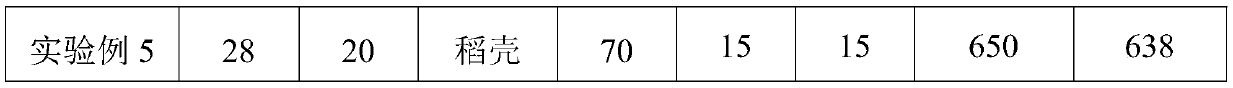

Preparation method of sludge-straw composite biomass activated carbon

The invention relates to a preparation method of sludge-straw composite biomass activated carbon, which comprises the following steps (1) sufficiently mixing and kneading municipal sludge as a main raw material, agricultural waste as an auxiliary material and wood tar as a binder, granulating, and drying to obtain sludge-straw composite particles, (2) feeding the sludge-straw composite particles into a carbonization furnace, carbonizing and activating at the same time under an oxygen-free or oxygen-limited condition to obtain a product sludge-based biomass activated carbon and pyrolysis gas, cooling the sludge-based biomass activated carbon, and packaging the cooled sludge-based biomass activated carbon, and (3) performing dust removal and purification on the pyrolysis gas to obtain wood tar, wood vinegar and non-condensable gas, returning the non-condensable gas as fuel to the carbonization furnace, returning a part of the wood vinegar as an activating agent to be sprayed into the carbonization furnace, and recycling the wood tar as a granulation raw material. The activated carbon is prepared from the sludge and the agricultural straw, the preparation method is simple, the price is relatively low, good economic benefits and ecological benefits are achieved, and high market competitiveness and popularization value are achieved.

Owner:SHANGHAI RES INST OF CHEM IND

Machining process model sequential modeling method based on characteristic identification removal

InactiveCN102609592ARealize browsingImplement querySpecial data processing applicationsQuality by DesignMachining process

The invention relates to a machining process model sequential modeling method based on characteristic identification removal, which includes the steps: 1) blank preparation; 2) technological decision making; 3) process design; 4) judgment of whether one next process is proceeded or not, repeating of the step 2 and the step 3 if the next process is proceeded, and continuing if the next process is not proceeded; 5) technological release; and 6) visual manufacture. The method makes full use of geometric features of an original part model, solves the problem of design quality requirements of three-dimensional technological design on the original part model, and is capable of creating the process model according to the practical machining technological operation sequence, so that integral efficiency of a three-dimensional technological design system is improved.

Owner:SHENYANG AIRCRAFT CORP +1

Black pepper beefsteak and preparation method thereof

InactiveCN102715519AImprove knot strengthImprove taste and section effectFood preparationSodium bicarbonateMonosodium glutamate

The invention relates to black pepper beefsteak and a preparation method thereof. The black pepper beefsteak is mainly prepared from the following components in part by weight: 950 to 1,050 parts of main material beef, 40 to 50 parts of starch, 15 to 20 parts of chicken essence, 15 to 20 parts of dark soy sauce, 14 to 16 parts of black pepper powder, 12 to 14 parts of white granulated sugar, 6 to 8 parts of salt, 6 to 8 parts of monosodium glutamate, 1.5 to 2 parts of white pepper powder and 5 to 8 parts of auxiliary material sodium bicarbonate. According to the invention, raw material standardization, product standardization and process standardization of the black pepper beefsteak can be realized.

Owner:SUZHOU HAODELAI FOOD

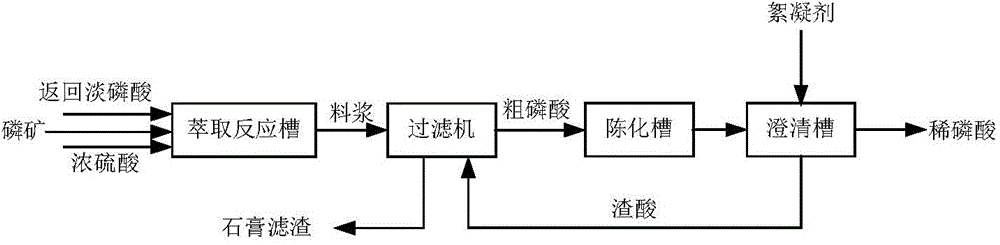

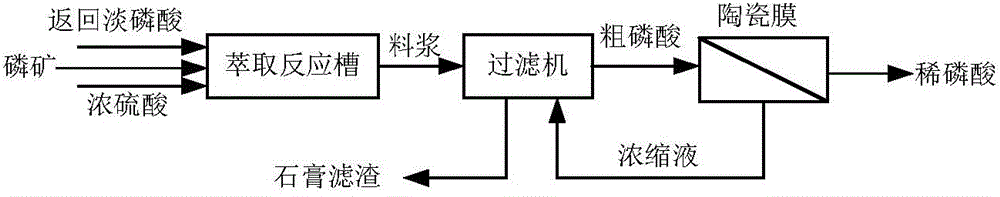

Wet phosphoric acid production process through ceramic membrane method

ActiveCN104828795AExcellent resistance to phosphoric acid corrosionLow resistance to phosphoric acid corrosionPhosphorus compoundsPhosphoric acidSmall footprint

The invention relates to a wet phosphoric acid production process through a ceramic membrane method. The wet phosphoric acid production process is characterized in that crude phosphoric acid filtered by a filter is pumped into a ceramic membrane separation system to be filtered, so that suspended matter in the crude phosphoric acid is removed, and clarified and transparent diluted phosphoric acid is obtained; and a ceramic membrane concentrated solution returns into the filter to circulate and is discharged along with gypsum filter residues. Compared with a conventional wet phosphoric acid production process, the wet phosphoric acid production process provided by the invention has the characteristics that the crude phosphoric acid filtered by the filter is not aged and clarified and directly enters the ceramic membrane separation system to be filtered, and therefore, the technological process and the crude phosphoric acid processing time are shortened; furthermore, a flocculating agent is not needed in the treating process; and, after the crude phosphoric acid is filtered, the solid content in the crude phosphoric acid is reduced to 0.01 wt% and below. The wet phosphoric acid production process disclosed by the invention can effectively solve the technical problems of long technological process and crude phosphoric acid processing time and low suspended matter removing efficiency in the traditional wet phosphoric acid production process; simultaneously, the ceramic membrane separation system in the invention is simple in equipment and small in occupation area; and continuous operation can be realized.

Owner:NANJING UNIV OF TECH

One-way impact isolating device for satellite

ActiveCN104290927AAvoid transmissionGuaranteed installation rigidityCosmonautic safety/emergency devicesRelative displacementEngineering

The invention discloses a one-way impact isolating device for a satellite. The one-way impact isolating device is mainly composed of a frame body, a cover plate, a bottom plate and two energy absorption material blocks. The cover plate is mounted on the frame body and is in surface contact with the frame body, a relative displacement section is formed inside the plate surface of the cover plate between the cover plate and the frame body, and thus an impact energy absorption action space exists in the direction. The bottom plate is mounted on the frame body, and the bottom plate and the cover plate are in surface contact. The energy absorption material blocks are contained into two enclosed spaces which are defined by the frame body, the cover plate and the bottom plate and are in close fit with the frame body and the cover plate. According to the one-way impact isolating device for the satellite, an impact-isolated object can be borne reliably and safely, the mounting rigidity, strength, position accuracy and the like of the impact-isolated object are guaranteed, meanwhile, impact transmission can be effectively isolated in one certain direction, it can be reliably guaranteed that the impact-isolated object has a sufficiently small impact environment, and the purpose that the impact-isolated object or an impact sensitive component can operate safely in an on-orbit mode for working is achieved.

Owner:SHANGHAI SATELLITE ENG INST

Reverse sanding process

The invention provides a reverse sanding process comprising the following steps that: (1) a ceramic anilox roller with 80-120 wires is utilized, and the requirements are as follows: in the area with one square meter, more than 40000 ink cells exist, the angle of each ink cell is 60 degrees, and the depth of each ink cell is 13-33micrometers; (2) the temperature of a production environment is kept between 22 DEG C-29 DEG C, and the humidity is controlled between 45 degrees-65 degrees; (3) single-set colorless transparent ultraviolet (UV) light curing oil ink and single-set colorless transparent UV light curing UV are selected, and the viscosity is 45-60PaS; (4) five 15KW UV lamps are selected, the wavelengths of ultraviolet rays of the UV lamps are 200-400, the first group of control power and the second group of control power are 50%, and the control power of the three UV lamps of a paper absorbing drying channel is 100%; and (5) the printing is conducted according to an existing offset print operation procedure. According to the reverse sanding process provided by the invention, the printing and sanding process of printing materials with six colors or less then six colors can be completed at one time, the large-area sanding and surface mirror effects can be realized, and the printing precision problem can be solved effectively.

Owner:富康集团有限公司

Diced chicken gristle and preparation method thereof

InactiveCN102715535AImprove knot strengthImprove taste and section effectFood preparationChemistrySodium bicarbonate

The invention provides a diced chicken gristle and a preparation method thereof. The diced chicken gristle mainly comprises the following ingredients: 950 to 1050 parts of chicken, 340 to 360 parts of chicken gristle, 65 to 75 parts of green beans, 20 to 25 parts of spice, 15 to 20 parts of starch, 14 to 16 parts of essence of chicken, 2 to 4 parts of table salt, 8 to 10 parts of spicy pulp covering powder and 5 to 8 parts of sodium bicarbonate. According to the diced chicken gristle, the raw material standardization, the product standardization and the technology standardization of the diced chicken gristle can be achieved.

Owner:SUZHOU HAODELAI FOOD

Gelatinization sintering treatment method of waste incineration fly ash and waste treatment method

The invention discloses a gelatinization sintering treatment method of waste incineration fly ash. The gelatinization sintering treatment method of waste incineration fly ash comprises the following steps: S1, performing sintering pretreatment on the waste incineration fly ash so as to form solidified fly ash; S2, conveying the solidified fly ash into an incinerator used for incinerating household wastes, and performing sintering treatment on the solidified fly ash so as to generate accumulated waste incineration fly ash. According to the gelatinization sintering treatment method of waste incineration fly ash, the incinerator used in waste incineration is utilized for sintering, the waste incineration fly ash and the household wastes are conveyed into the incinerator together for combustion, sintering conditions and equipment are not needed to be additionally set, technical problems are not needed to be additionally overcome, the cost is low, the flow path is short, the operation is convenient, and the method is convenient in construction and large-range engineering application; in addition, when the waste incineration fly ash is subjected to a gelatinization sintering process, after heavy metals and dioxin in the waste incineration fly ash are subjected to high-temperature sintering, slags in the incinerator have stable physical properties, cannot pollute environment and can be recycled.

Owner:李先旺

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com