Advances in HDPE Coating for Corrosion Protection

HDPE Coating Evolution

High-density polyethylene (HDPE) coating has undergone significant evolution since its introduction as a corrosion protection solution. Initially developed in the 1960s, HDPE coatings were primarily used for water pipelines due to their excellent resistance to chemical attack and moisture penetration.

The 1970s saw the expansion of HDPE coating applications to oil and gas pipelines, driven by the need for more durable and cost-effective protection in harsh environments. During this period, advancements in extrusion technology and polymer science led to improved coating adhesion and mechanical properties.

In the 1980s and 1990s, the focus shifted towards enhancing the long-term performance of HDPE coatings. Researchers developed multi-layer coating systems, combining HDPE with other materials like fusion-bonded epoxy (FBE) to create more robust protection against corrosion and mechanical damage. This era also saw the introduction of crosslinked polyethylene (XLPE) coatings, offering superior temperature resistance and mechanical strength.

The turn of the millennium brought about a renewed interest in HDPE coatings due to their environmental benefits and recyclability. Manufacturers began incorporating nanomaterials and advanced additives to further improve the coating's barrier properties and UV resistance. This period also witnessed the development of specialized HDPE formulations for extreme temperature applications, both in cryogenic and high-temperature environments.

Recent years have seen a focus on smart HDPE coatings, incorporating sensors and monitoring capabilities to detect and report potential corrosion or damage in real-time. Additionally, researchers have been exploring bio-based HDPE coatings derived from renewable resources, aiming to reduce the environmental impact of corrosion protection solutions.

The evolution of HDPE coating technology has been driven by continuous improvements in polymer science, processing techniques, and application methods. From simple single-layer coatings to advanced multi-functional systems, HDPE has proven its versatility and effectiveness in corrosion protection across various industries. As environmental concerns and performance requirements continue to evolve, HDPE coatings are expected to adapt and innovate, maintaining their position as a crucial component in the fight against corrosion.

Market Demand Analysis

The market demand for HDPE coating in corrosion protection has been steadily increasing due to its superior performance and cost-effectiveness. This growth is primarily driven by the expanding oil and gas industry, where HDPE coatings are extensively used to protect pipelines, storage tanks, and offshore structures from corrosive environments. The global oil and gas pipeline coating market, of which HDPE is a significant component, is projected to grow substantially in the coming years.

Another key factor contributing to the rising demand for HDPE coatings is the growing infrastructure development across various sectors. The construction industry, in particular, has shown a significant uptake in HDPE coating applications for reinforcing steel in concrete structures, enhancing their durability and lifespan. This trend is especially prominent in regions with harsh environmental conditions or coastal areas prone to salt-induced corrosion.

The automotive industry has also emerged as a potential growth market for HDPE coatings. As vehicle manufacturers strive to improve corrosion resistance and extend the lifespan of their products, HDPE coatings are being increasingly considered for underbody protection and other vulnerable areas of vehicles.

In the marine sector, HDPE coatings have gained traction for protecting ships, offshore platforms, and port facilities from the corrosive effects of seawater. The increasing focus on extending the service life of marine assets and reducing maintenance costs has further boosted the demand for advanced HDPE coating solutions.

The water treatment industry represents another significant market for HDPE coatings. As municipalities and industrial facilities upgrade their water infrastructure, there is a growing need for corrosion-resistant coatings to protect pipes, tanks, and treatment equipment. HDPE coatings offer an effective solution to extend the lifespan of these critical assets and ensure water quality.

Market trends indicate a shift towards environmentally friendly coating solutions, which has positively impacted the demand for HDPE coatings. As a thermoplastic material, HDPE is recyclable and does not release harmful volatile organic compounds (VOCs) during application, aligning with increasingly stringent environmental regulations and sustainability goals across industries.

The Asia-Pacific region is expected to witness the highest growth in HDPE coating demand, driven by rapid industrialization, infrastructure development, and increasing investments in oil and gas exploration activities. North America and Europe continue to be significant markets, with a focus on rehabilitation and maintenance of aging infrastructure.

Technical Challenges

Despite the widespread use of High-Density Polyethylene (HDPE) coatings for corrosion protection, several technical challenges persist in advancing this technology. One of the primary issues is the adhesion of HDPE to metal substrates. The non-polar nature of HDPE makes it inherently difficult to achieve strong and durable bonding with metal surfaces, which are typically polar. This adhesion problem can lead to coating delamination and subsequent corrosion of the underlying metal.

Another significant challenge is the permeability of HDPE to corrosive agents. While HDPE is known for its excellent chemical resistance, it is not completely impermeable to all substances. Over time, small molecules of water, oxygen, and other corrosive agents can diffuse through the coating, eventually reaching the metal surface and initiating corrosion processes. This permeation issue is particularly problematic in harsh environments or for long-term protection requirements.

The thermal stability of HDPE coatings presents another technical hurdle. HDPE has a relatively low melting point compared to other protective coatings, which limits its use in high-temperature applications. As temperatures approach or exceed the melting point of HDPE, the coating can soften, deform, or even melt, compromising its protective properties. This thermal limitation restricts the use of HDPE coatings in certain industrial settings where elevated temperatures are common.

Surface preparation and application techniques also pose challenges in HDPE coating technology. Achieving a uniform and defect-free coating layer is crucial for effective corrosion protection. However, the high viscosity of molten HDPE and its rapid solidification can make it difficult to apply evenly, especially on complex geometries or large surfaces. Inadequate surface preparation or improper application can lead to coating defects, such as pinholes, bubbles, or uneven thickness, which can significantly reduce the coating's protective performance.

The long-term durability and aging characteristics of HDPE coatings under various environmental conditions remain areas of concern. Exposure to UV radiation, temperature fluctuations, and mechanical stresses can cause degradation of the HDPE coating over time. This degradation can manifest as embrittlement, cracking, or chalking of the coating surface, potentially compromising its protective function. Understanding and mitigating these aging processes is crucial for ensuring the long-term effectiveness of HDPE coatings in corrosion protection applications.

Lastly, the environmental impact and recyclability of HDPE coatings present both technical and sustainability challenges. While HDPE is recyclable, the presence of additives and the difficulty in separating the coating from the metal substrate complicate the recycling process. Developing eco-friendly formulations and efficient recycling methods for HDPE coatings is an ongoing challenge that aligns with growing environmental concerns and regulations in the industry.

Current HDPE Solutions

01 HDPE coating composition for corrosion protection

High-density polyethylene (HDPE) coatings are formulated with specific additives to enhance corrosion protection properties. These compositions may include stabilizers, antioxidants, and other functional additives to improve the coating's durability and resistance to environmental factors.- HDPE coating composition for corrosion protection: High-density polyethylene (HDPE) coatings are formulated with specific additives and applied to metal surfaces to provide effective corrosion protection. These coatings create a barrier against moisture, chemicals, and other corrosive elements, extending the lifespan of the protected materials.

- Application methods for HDPE coatings: Various techniques are employed to apply HDPE coatings for corrosion protection, including extrusion coating, powder coating, and spray application. These methods ensure uniform coverage and strong adhesion to the substrate, enhancing the coating's protective properties.

- Surface preparation for HDPE coating adhesion: Proper surface preparation is crucial for optimal adhesion of HDPE coatings. Techniques such as sandblasting, chemical cleaning, and plasma treatment are used to remove contaminants and increase surface roughness, promoting better bonding between the coating and the substrate.

- Multi-layer HDPE coating systems: Multi-layer HDPE coating systems are developed to enhance corrosion protection. These systems typically include a primer layer for improved adhesion, an HDPE layer for barrier protection, and sometimes a top coat for additional chemical resistance or UV protection.

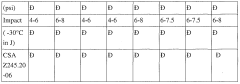

- Performance testing of HDPE coatings: Rigorous testing methods are employed to evaluate the performance of HDPE coatings in corrosion protection. These tests include salt spray exposure, electrochemical impedance spectroscopy, and accelerated weathering to assess the coating's durability and protective capabilities under various environmental conditions.

02 Application methods for HDPE coatings

Various techniques are employed to apply HDPE coatings for corrosion protection, including extrusion coating, powder coating, and spray coating. These methods ensure uniform coverage and optimal adhesion to the substrate, enhancing the overall corrosion resistance of the coated surface.Expand Specific Solutions03 Surface preparation for HDPE coating application

Proper surface preparation is crucial for effective HDPE coating adhesion and corrosion protection. Techniques such as sandblasting, chemical cleaning, and priming are used to ensure optimal bonding between the substrate and the HDPE coating, thereby improving the coating's protective properties.Expand Specific Solutions04 Multilayer HDPE coating systems

Multilayer coating systems incorporating HDPE are developed to provide enhanced corrosion protection. These systems may include primer layers, adhesive layers, and top coats, each contributing to the overall performance and durability of the protective coating.Expand Specific Solutions05 Performance testing of HDPE coatings for corrosion protection

Various testing methods are employed to evaluate the corrosion protection performance of HDPE coatings. These may include accelerated weathering tests, salt spray tests, and electrochemical impedance spectroscopy, which help assess the coating's long-term effectiveness in preventing corrosion under different environmental conditions.Expand Specific Solutions

Industry Leaders

The competitive landscape for advances in HDPE coating for corrosion protection is characterized by a mature market with steady growth. The industry is in a consolidation phase, with major players like BASF, DuPont, and 3M leading innovation. Market size is substantial, driven by increasing demand in oil and gas, infrastructure, and automotive sectors. Technological maturity is high, with companies like Guangzhou Lushan New Materials and Jiangsu Lushan New Materials focusing on specialized applications. Research institutions such as Southwest Research Institute and University of Akron contribute to ongoing advancements, while collaborations between industry leaders and academic institutions drive further innovation in this field.

BASF Coatings GmbH

DuPont de Nemours, Inc.

Key HDPE Innovations

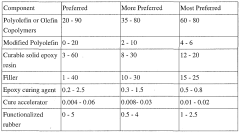

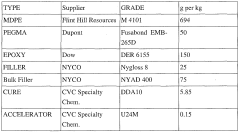

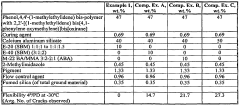

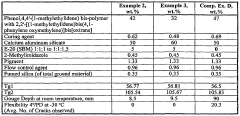

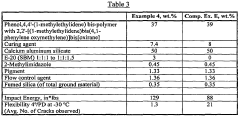

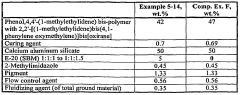

- A dual layer coating composition comprising a curable epoxy resin, a curing agent, a polyolefin component with a compatibilizer or functionalized rubber, and a filler, where the viscosities of the polyolefin and epoxy components are closely matched to prevent phase separation, allowing for a cost-effective and simplified application process.

- A composition comprising a cross-linkable epoxy resin, a polystyrene-polybutadiene-polymethylmethacrylate tri-block copolymer, and a filler material, with a concentration ratio of about 1:1:1 to 1:1.5, which enhances flexibility and maintains toughness, allowing for increased elongation without negatively affecting other coating properties.

Environmental Impact

The environmental impact of HDPE coating for corrosion protection is a critical consideration in its application and development. HDPE coatings offer several environmental benefits compared to traditional corrosion protection methods. Firstly, HDPE is a non-toxic material, which reduces the risk of harmful substances leaching into the environment during its lifecycle. This is particularly important for applications in sensitive ecosystems or water-related infrastructure.

HDPE coatings also contribute to resource conservation. By effectively protecting metal surfaces from corrosion, these coatings extend the lifespan of infrastructure and equipment, reducing the need for frequent replacements. This, in turn, leads to a decrease in raw material consumption and energy use associated with manufacturing and installing new components.

However, the production of HDPE coatings does have some environmental drawbacks. The manufacturing process of HDPE involves the use of fossil fuels, contributing to greenhouse gas emissions. Additionally, the disposal of HDPE coatings at the end of their lifecycle can be challenging, as they are not biodegradable and can persist in the environment for extended periods if not properly managed.

Recent advances in HDPE coating technology have focused on mitigating these environmental concerns. Researchers are exploring bio-based alternatives to traditional HDPE, using renewable resources to create more sustainable coating materials. These bio-based coatings aim to reduce the carbon footprint associated with production while maintaining the excellent corrosion protection properties of HDPE.

Another area of development is the improvement of recycling processes for HDPE coatings. Enhanced recycling technologies are being developed to more efficiently separate and process HDPE coatings from metal substrates, allowing for better material recovery and reducing waste sent to landfills.

The application method of HDPE coatings is also being optimized to minimize environmental impact. Advanced application techniques, such as powder coating and electrostatic spraying, are being refined to reduce material waste and volatile organic compound (VOC) emissions during the coating process.

Furthermore, research is ongoing to enhance the durability and performance of HDPE coatings, which indirectly benefits the environment by further extending the service life of protected assets and reducing the frequency of maintenance and replacement activities.

In conclusion, while HDPE coatings offer significant environmental advantages in terms of non-toxicity and resource conservation, ongoing research and development efforts are crucial to address the environmental challenges associated with their production and end-of-life management. The future of HDPE coatings for corrosion protection lies in balancing their protective properties with enhanced environmental sustainability throughout their lifecycle.

Cost-Benefit Analysis

The cost-benefit analysis of HDPE coating for corrosion protection reveals significant advantages in terms of long-term economic efficiency and performance. Initial installation costs for HDPE coating systems are generally higher compared to traditional protective methods such as paint or galvanization. However, the extended lifespan and reduced maintenance requirements of HDPE coatings offer substantial cost savings over time.

HDPE coatings typically last 20-30 years, significantly outlasting conventional protective measures. This longevity translates to fewer replacement cycles and reduced labor costs associated with reapplication. The superior corrosion resistance of HDPE coatings also minimizes the risk of structural damage, potentially averting costly repairs or premature asset replacement.

Maintenance expenses for HDPE-coated structures are notably lower. The coating's resistance to chemical degradation, UV radiation, and physical abrasion reduces the need for frequent inspections and touch-ups. This decreased maintenance burden not only cuts direct costs but also minimizes operational disruptions and associated indirect expenses.

In marine and offshore applications, HDPE coatings demonstrate particular cost-effectiveness. The harsh saltwater environment rapidly degrades many traditional coatings, necessitating frequent reapplication. HDPE's excellent resistance to saltwater corrosion extends protection intervals, reducing the need for costly offshore maintenance operations.

Energy savings represent another economic benefit of HDPE coatings. The smooth surface of HDPE reduces friction in fluid-handling applications, potentially improving energy efficiency in pipelines and other flow systems. This can lead to lower operational costs over the lifetime of the coated equipment.

While the upfront costs of HDPE coating may be higher, the total cost of ownership (TCO) analysis often favors this solution. When factoring in reduced maintenance, extended asset life, and improved operational efficiency, HDPE coatings frequently emerge as the more economical choice for long-term corrosion protection strategies.

It's important to note that the cost-benefit ratio can vary depending on the specific application, environmental conditions, and expected service life of the coated asset. A thorough analysis considering these factors is crucial for determining the most cost-effective corrosion protection strategy for a given project or infrastructure.