HDPE Manufacturing: Enhancing Process Efficiency

HDPE Evolution & Objectives

High-density polyethylene (HDPE) has undergone significant evolution since its discovery in the 1950s. Initially developed as a more durable and versatile alternative to low-density polyethylene, HDPE has become a cornerstone material in various industries due to its excellent strength-to-density ratio, chemical resistance, and processability.

The manufacturing process for HDPE has seen continuous improvements over the decades. Early production methods relied on Ziegler-Natta catalysts, which revolutionized polyethylene synthesis. As technology progressed, the introduction of metallocene catalysts in the 1990s allowed for greater control over polymer structure and properties, leading to enhanced product quality and process efficiency.

In recent years, the focus of HDPE manufacturing has shifted towards sustainability and efficiency. The industry has been exploring bio-based feedstocks and developing more energy-efficient production methods to reduce the environmental impact of HDPE manufacturing. Concurrently, advancements in process control and automation have led to significant improvements in production consistency and output.

The current objectives in HDPE manufacturing center around enhancing process efficiency while maintaining or improving product quality. Key goals include reducing energy consumption, minimizing waste generation, and optimizing catalyst performance. There is also a growing emphasis on developing HDPE grades with improved mechanical properties and processability to meet evolving market demands.

Another critical objective is the integration of Industry 4.0 technologies into HDPE production. This includes the implementation of advanced sensors, real-time data analytics, and machine learning algorithms to optimize process parameters and predict maintenance needs. Such innovations aim to increase overall equipment effectiveness (OEE) and reduce downtime in HDPE manufacturing facilities.

Furthermore, the industry is striving to address the challenges posed by the circular economy concept. This involves developing more easily recyclable HDPE formulations and improving recycling technologies to increase the use of post-consumer HDPE in new products. The ultimate goal is to create a closed-loop system for HDPE production and consumption, aligning with global sustainability initiatives.

As we look to the future, the evolution of HDPE manufacturing is likely to continue along these trajectories, with a strong focus on efficiency, sustainability, and adaptability to changing market needs. The industry's objectives will increasingly align with broader societal goals of resource conservation and environmental protection, driving innovation in both materials and manufacturing processes.

HDPE Market Dynamics

The global High-Density Polyethylene (HDPE) market has been experiencing steady growth, driven by increasing demand across various industries. HDPE's versatility, durability, and cost-effectiveness have made it a preferred material in packaging, construction, automotive, and consumer goods sectors. The market has shown resilience even in the face of economic uncertainties, with a compound annual growth rate (CAGR) consistently outpacing GDP growth in many regions.

In recent years, the packaging industry has emerged as the largest consumer of HDPE, accounting for a significant portion of the total market share. This trend is primarily attributed to the rising demand for flexible and rigid packaging solutions in the food and beverage, personal care, and pharmaceutical industries. The construction sector follows closely, with HDPE pipes and fittings gaining popularity due to their corrosion resistance and long service life.

Geographically, Asia-Pacific has been the dominant market for HDPE, led by China and India. The rapid industrialization, urbanization, and growing middle-class population in these countries have fueled the demand for HDPE products. North America and Europe, while mature markets, continue to show steady growth, particularly in specialized applications and high-performance HDPE grades.

The automotive industry has also been a key driver in the HDPE market, with manufacturers increasingly adopting lightweight materials to improve fuel efficiency and reduce emissions. HDPE's high strength-to-weight ratio makes it an ideal choice for fuel tanks, interior components, and under-the-hood applications.

Environmental concerns and sustainability initiatives have begun to shape the HDPE market dynamics. There is a growing emphasis on recycling and the development of bio-based HDPE alternatives. This shift has led to increased investments in recycling infrastructure and research into sustainable production methods, potentially altering the competitive landscape in the coming years.

Price volatility in the petrochemical industry, particularly fluctuations in ethylene prices, has been a significant factor influencing HDPE market dynamics. As HDPE is derived from ethylene, changes in oil and natural gas prices directly impact production costs and, consequently, market prices. This volatility has prompted some manufacturers to explore alternative feedstocks and more efficient production processes to maintain competitive pricing.

The HDPE market is characterized by intense competition among major players, leading to continuous innovation in product development and manufacturing processes. Companies are focusing on enhancing process efficiency to reduce costs and improve product quality, aligning with the broader industry trend of optimizing HDPE manufacturing.

HDPE Production Hurdles

High-density polyethylene (HDPE) manufacturing faces several significant hurdles that impact process efficiency and overall production quality. One of the primary challenges is maintaining consistent temperature control throughout the polymerization process. Fluctuations in temperature can lead to variations in molecular weight distribution and crystallinity, affecting the final product's properties. This issue is particularly pronounced in large-scale reactors where heat transfer becomes more complex.

Another major hurdle is catalyst efficiency and management. The choice and handling of catalysts significantly influence the polymerization rate and product characteristics. Ensuring uniform catalyst distribution and activity across the reactor volume remains a persistent challenge. Additionally, catalyst deactivation and fouling can lead to reduced productivity and increased downtime for reactor cleaning.

Pressure control presents another critical challenge in HDPE production. Maintaining optimal pressure conditions is essential for controlling reaction kinetics and preventing unwanted side reactions. Pressure fluctuations can result in inconsistent product quality and potentially compromise safety in extreme cases.

The management of hydrogen, used as a chain transfer agent to control molecular weight, poses its own set of challenges. Precise control of hydrogen concentration is crucial for achieving desired product specifications. However, the low solubility of hydrogen in the reaction medium and its tendency to form gradients within the reactor complicate this process.

Monomer purity and comonomer incorporation represent additional hurdles. Impurities in the ethylene feedstock can interfere with catalyst performance and product quality. For copolymers, achieving uniform comonomer distribution throughout the polymer chain is essential for consistent product properties but remains challenging to control precisely.

Scale-up issues present significant obstacles when transitioning from laboratory or pilot-scale production to industrial-scale manufacturing. Heat and mass transfer limitations become more pronounced at larger scales, necessitating careful reactor design and process optimization.

Post-polymerization processing, including pelletization and degassing, also presents challenges. Efficient removal of residual hydrocarbons and catalyst residues is crucial for product quality and safety but can be time-consuming and energy-intensive.

Lastly, addressing environmental concerns and meeting increasingly stringent regulations pose ongoing challenges for HDPE manufacturers. Reducing energy consumption, minimizing emissions, and improving overall process sustainability are becoming increasingly important considerations in process design and optimization.

Current HDPE Processes

01 Optimization of polymerization conditions

Improving the efficiency of HDPE manufacturing by optimizing polymerization conditions such as temperature, pressure, and catalyst concentration. This approach aims to enhance reaction kinetics, increase yield, and reduce energy consumption during the production process.- Optimization of polymerization process: Improving the efficiency of HDPE manufacturing by optimizing the polymerization process. This includes adjusting reaction conditions, catalyst systems, and process parameters to enhance productivity and product quality. Advanced control systems and modeling techniques are employed to achieve optimal operating conditions.

- Enhanced reactor design and configuration: Developing innovative reactor designs and configurations to improve HDPE production efficiency. This involves modifications to reactor geometry, mixing systems, and heat transfer mechanisms. Advanced reactor technologies, such as multi-zone reactors or cascaded reactor systems, are implemented to increase throughput and product consistency.

- Advanced catalyst and co-catalyst systems: Utilizing advanced catalyst and co-catalyst systems to enhance HDPE manufacturing efficiency. This includes developing novel catalyst formulations, optimizing catalyst activation methods, and improving catalyst delivery systems. High-performance catalysts contribute to increased productivity, improved product properties, and reduced energy consumption.

- Process monitoring and control optimization: Implementing advanced process monitoring and control systems to optimize HDPE manufacturing efficiency. This involves the use of real-time data analytics, machine learning algorithms, and predictive modeling to enhance process stability and product quality. Automated control systems are employed to maintain optimal operating conditions and reduce variability.

- Energy efficiency and waste reduction: Improving energy efficiency and reducing waste in HDPE manufacturing processes. This includes implementing heat recovery systems, optimizing equipment performance, and developing recycling strategies for process waste. Advanced separation and purification techniques are employed to maximize raw material utilization and minimize environmental impact.

02 Advanced catalyst systems

Developing and implementing advanced catalyst systems to enhance HDPE production efficiency. These catalysts can improve polymerization rates, control molecular weight distribution, and reduce the formation of unwanted byproducts, leading to higher quality HDPE and increased process efficiency.Expand Specific Solutions03 Process control and automation

Implementing advanced process control and automation systems to optimize HDPE manufacturing. This includes real-time monitoring, data analytics, and machine learning algorithms to adjust process parameters, minimize variability, and maximize overall production efficiency.Expand Specific Solutions04 Reactor design improvements

Enhancing HDPE manufacturing efficiency through innovative reactor designs. This includes optimizing reactor geometry, improving heat transfer, and implementing novel mixing technologies to ensure uniform polymerization conditions and increase production capacity.Expand Specific Solutions05 Recycling and waste reduction

Incorporating recycling and waste reduction strategies in HDPE manufacturing to improve overall process efficiency. This involves developing methods for reprocessing off-spec material, recovering unreacted monomers, and minimizing energy waste throughout the production cycle.Expand Specific Solutions

HDPE Industry Leaders

The HDPE manufacturing industry is in a mature stage, with a global market size expected to reach $84 billion by 2026. The technology for enhancing process efficiency is continuously evolving, driven by the need for cost reduction and sustainability. Major players like SABIC, Dow Global Technologies, and ExxonMobil are at the forefront of innovation, focusing on catalyst improvements and process optimization. Companies such as Borealis AG and Chevron Phillips Chemical are investing in advanced control systems and digitalization to boost efficiency. The technology maturity varies, with established firms leading in commercial applications, while research institutions like Indian Institute of Technology Bombay and Beijing University of Chemical Technology contribute to fundamental advancements in HDPE manufacturing processes.

Dow Global Technologies LLC

Chevron Phillips Chemical Co. LP

HDPE Catalyst Innovations

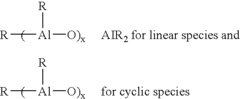

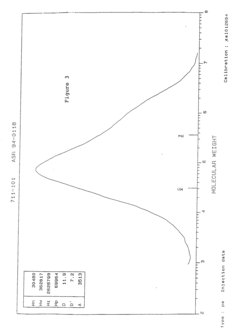

- The use of a metallocene catalyst to adjust the hydrogen response of a Zeigler-Natta catalyst in a polymerization process, allowing for the production of bimodal HDPE with reduced hydrogen venting, achieved by adding the metallocene catalyst in a downstream reactor or simultaneously with the Zeigler-Natta catalyst, thereby controlling the molecular weight distribution without wasting hydrogen.

- A process involving two interconnected gas-phase reactors with different polymerization zones, where ethylene is polymerized under fast fluidization conditions in one zone and densified flow in another, allowing for the separation and reintroduction of polymer particles, enabling the incorporation of comonomers only into the high molecular weight fraction to achieve a broad and homogeneous molecular weight distribution.

Environmental Impact

The environmental impact of HDPE manufacturing is a critical consideration in enhancing process efficiency. The production of High-Density Polyethylene (HDPE) involves energy-intensive processes and the use of fossil fuel-derived raw materials, which contribute to greenhouse gas emissions and climate change. However, advancements in manufacturing techniques and a focus on sustainability have led to significant improvements in reducing the environmental footprint of HDPE production.

One of the primary environmental concerns in HDPE manufacturing is energy consumption. Traditional production methods require high temperatures and pressures, resulting in substantial energy use and associated carbon emissions. Recent innovations in catalyst technology and process optimization have enabled lower operating temperatures and pressures, reducing energy requirements and improving overall efficiency. Additionally, the integration of renewable energy sources, such as solar and wind power, into manufacturing facilities has further decreased the carbon intensity of HDPE production.

Water usage and wastewater management are also important environmental aspects of HDPE manufacturing. The production process typically involves cooling systems and product washing stages, which can consume significant amounts of water. Implementing closed-loop water recycling systems and advanced wastewater treatment technologies has helped minimize water consumption and reduce the discharge of pollutants into local water bodies.

The raw materials used in HDPE production, primarily ethylene derived from fossil fuels, contribute to resource depletion and environmental degradation. However, the industry has been exploring alternative feedstocks, including bio-based materials and recycled plastics, to reduce reliance on virgin fossil resources. These efforts not only decrease the environmental impact but also promote a circular economy approach to plastic production.

Waste reduction and recycling initiatives have become increasingly important in HDPE manufacturing. Improved process control and quality management systems have minimized production waste, while advancements in recycling technologies have made it possible to reintegrate a higher percentage of post-consumer HDPE into new products. This not only reduces the demand for virgin materials but also addresses the growing concern of plastic waste in the environment.

Air emissions from HDPE manufacturing, including volatile organic compounds (VOCs) and particulate matter, have been a focus of environmental regulations and industry efforts. The implementation of advanced air pollution control technologies, such as thermal oxidizers and scrubbers, has significantly reduced these emissions. Furthermore, the development of low-emission resins and additives has contributed to cleaner production processes and improved air quality around manufacturing facilities.

As the demand for HDPE continues to grow, balancing production efficiency with environmental stewardship remains a key challenge for the industry. Ongoing research and development efforts are focused on developing more sustainable production methods, including the use of renewable hydrogen in the manufacturing process and the exploration of carbon capture and utilization technologies. These innovations promise to further reduce the environmental impact of HDPE production while maintaining its vital role in various applications across industries.

HDPE Quality Control

Quality control is a critical aspect of HDPE manufacturing, ensuring the production of high-quality materials that meet industry standards and customer specifications. In the context of enhancing process efficiency, implementing robust quality control measures is essential for minimizing waste, reducing production costs, and maintaining consistent product quality.

The quality control process for HDPE typically involves several key steps and techniques. Firstly, raw material testing is conducted to verify the properties and composition of incoming polyethylene resins and additives. This includes checks for contamination, moisture content, and melt flow index. By ensuring the quality of input materials, manufacturers can prevent downstream issues and maintain process stability.

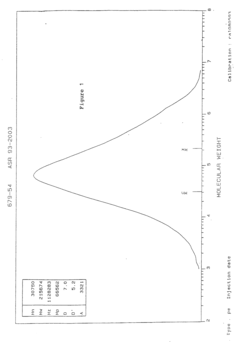

During the production process, in-line monitoring systems are employed to continuously assess critical parameters such as temperature, pressure, and flow rates. Advanced sensors and real-time data analysis tools enable operators to detect and respond to deviations promptly, minimizing the risk of off-spec production. Additionally, regular sampling and testing of the molten polymer are performed to evaluate properties such as density, molecular weight distribution, and additive dispersion.

Post-production quality control measures involve comprehensive testing of the finished HDPE products. This includes mechanical property testing, such as tensile strength, impact resistance, and elongation at break. Thermal analysis techniques like differential scanning calorimetry (DSC) are used to assess the material's melting behavior and crystallinity. Spectroscopic methods, including Fourier-transform infrared spectroscopy (FTIR), help identify any chemical irregularities or contamination.

To enhance process efficiency, many HDPE manufacturers are adopting advanced statistical process control (SPC) techniques. These methods involve the collection and analysis of large datasets to identify trends, predict potential quality issues, and optimize process parameters. Machine learning algorithms are increasingly being applied to quality control data, enabling predictive maintenance and adaptive process control.

Furthermore, the implementation of automated inspection systems, such as optical scanners and X-ray detectors, allows for rapid and accurate detection of defects in HDPE products. These technologies can identify issues such as gels, contamination, and dimensional inconsistencies at high production speeds, reducing the reliance on manual inspection and improving overall efficiency.

As part of a comprehensive quality control strategy, HDPE manufacturers are also focusing on traceability and documentation. Advanced manufacturing execution systems (MES) enable the tracking of raw materials, process parameters, and quality data throughout the production cycle. This not only facilitates compliance with regulatory requirements but also supports continuous improvement initiatives by providing valuable insights into the relationship between process conditions and product quality.