How to Exploit HDPE Properties for Industrial Solutions?

HDPE Properties and Industrial Applications

High-density polyethylene (HDPE) is a versatile thermoplastic polymer with a wide range of industrial applications due to its unique properties. HDPE exhibits excellent chemical resistance, high tensile strength, and low moisture absorption, making it an ideal material for various industrial solutions.

One of the key properties of HDPE is its high strength-to-density ratio, which allows for the production of lightweight yet durable components. This characteristic is particularly valuable in the automotive and aerospace industries, where weight reduction is crucial for improving fuel efficiency and overall performance. HDPE's resistance to impact and abrasion further enhances its suitability for these applications.

In the chemical processing industry, HDPE's exceptional chemical resistance proves invaluable. It can withstand exposure to a wide range of acids, bases, and organic solvents without degradation, making it an excellent choice for storage tanks, piping systems, and containment vessels. This property also extends to the food and beverage industry, where HDPE is used for packaging and storage solutions due to its inert nature and resistance to contamination.

HDPE's low moisture absorption and excellent electrical insulating properties make it suitable for various electrical and electronic applications. It is commonly used in cable insulation, wire coatings, and electrical conduits, providing reliable protection against moisture and electrical interference.

The material's high UV resistance and weatherability make it an ideal choice for outdoor applications. HDPE is extensively used in the construction industry for geomembranes, drainage pipes, and outdoor furniture. Its ability to withstand harsh environmental conditions without significant degradation ensures long-lasting performance in these applications.

In the medical and healthcare sectors, HDPE's biocompatibility and ease of sterilization make it a preferred material for medical devices, pharmaceutical packaging, and laboratory equipment. Its resistance to bacteria and fungi growth further enhances its suitability for these critical applications.

HDPE's recyclability and sustainability aspects have gained significant attention in recent years. Its ability to be recycled multiple times without significant loss of properties aligns with the growing emphasis on circular economy principles in industrial applications. This characteristic has led to increased use of HDPE in eco-friendly packaging solutions and sustainable product designs across various industries.

The material's excellent processability, including its suitability for injection molding, extrusion, and rotational molding, allows for the creation of complex shapes and structures. This versatility in manufacturing processes enables the production of a wide range of industrial components, from small precision parts to large-scale containers and tanks.

Market Demand Analysis for HDPE Solutions

The global market for High-Density Polyethylene (HDPE) solutions continues to expand, driven by the material's versatile properties and wide-ranging industrial applications. HDPE's excellent strength-to-density ratio, chemical resistance, and durability make it a preferred choice across various sectors, leading to a steady increase in demand.

In the packaging industry, HDPE remains a dominant material for containers, bottles, and films. The growing e-commerce sector and increasing consumer preference for sustainable packaging solutions have further boosted the demand for HDPE in this segment. Additionally, the food and beverage industry's need for safe, long-lasting packaging materials contributes significantly to market growth.

The construction sector represents another major market for HDPE solutions. The material's use in pipes, fittings, and geomembranes has seen substantial growth due to ongoing infrastructure development projects worldwide. HDPE's resistance to corrosion and its long service life make it an attractive option for water management systems and underground utilities.

In the automotive industry, the push for lightweight materials to improve fuel efficiency has led to increased adoption of HDPE components. From fuel tanks to interior parts, HDPE's properties align well with the industry's needs for durable, cost-effective, and recyclable materials.

The agriculture sector also contributes to the rising demand for HDPE solutions. The material's use in irrigation systems, greenhouse films, and storage containers has grown as farmers seek efficient and long-lasting equipment. HDPE's resistance to UV radiation and chemicals makes it particularly suitable for agricultural applications.

Environmental concerns and regulatory pressures have paradoxically both challenged and bolstered the HDPE market. While plastic waste issues have led to increased scrutiny, HDPE's recyclability has positioned it as a more sustainable option compared to other plastics. This has opened up new market opportunities in recycled HDPE products and circular economy initiatives.

Emerging applications in 3D printing and advanced manufacturing processes are creating new avenues for HDPE market growth. The material's properties make it suitable for producing complex, customized parts across various industries, from medical devices to consumer goods.

Geographically, Asia-Pacific remains the largest and fastest-growing market for HDPE solutions, driven by rapid industrialization, urbanization, and infrastructure development in countries like China and India. North America and Europe continue to be significant markets, with a focus on innovative applications and sustainable practices.

Current Challenges in HDPE Utilization

Despite the widespread use of High-Density Polyethylene (HDPE) in various industrial applications, several challenges persist in fully exploiting its properties. One of the primary issues is the material's susceptibility to stress cracking, particularly in environments with high temperatures or exposure to certain chemicals. This phenomenon can lead to premature failure of HDPE products, limiting their longevity and reliability in demanding industrial settings.

Another significant challenge lies in improving the barrier properties of HDPE. While the material offers good resistance to moisture and many chemicals, it still exhibits relatively high permeability to gases such as oxygen and carbon dioxide. This limitation restricts its use in certain packaging applications, especially for products requiring extended shelf life or protection from atmospheric gases.

The recyclability of HDPE, although generally considered good, presents its own set of challenges. The presence of additives and contaminants in recycled HDPE can affect the quality and performance of the recycled material, making it difficult to maintain consistent properties across multiple recycling cycles. This issue is particularly problematic for industries requiring high-performance materials with precise specifications.

HDPE's relatively low heat resistance compared to some other engineering plastics poses challenges in applications involving elevated temperatures. This limitation restricts its use in certain high-temperature industrial processes or in products that may be exposed to heat during their lifecycle. Improving the thermal stability of HDPE without compromising its other desirable properties remains an ongoing challenge for material scientists and engineers.

The material's inherent flexibility, while advantageous in many applications, can be a drawback in scenarios requiring high stiffness or dimensional stability. This characteristic limits HDPE's use in structural applications where rigidity is crucial, necessitating the development of composite materials or innovative reinforcement techniques to enhance its mechanical properties.

Furthermore, the surface properties of HDPE present challenges in certain industrial applications. Its low surface energy makes it difficult to print on or bond with other materials, requiring special surface treatments or adhesives. This limitation can complicate manufacturing processes and restrict design options in multi-material products.

Addressing these challenges requires a multifaceted approach, combining advances in polymer science, processing technologies, and application-specific engineering. Innovations in additives, composite formulations, and surface modification techniques are being explored to overcome these limitations and expand the industrial applications of HDPE. The ongoing research in these areas aims to unlock the full potential of HDPE, enabling its use in an even broader range of industrial solutions.

Existing HDPE Industrial Solutions

01 Mechanical properties of HDPE

High-density polyethylene (HDPE) exhibits excellent mechanical properties, including high tensile strength, impact resistance, and stiffness. These characteristics make it suitable for various applications requiring durability and structural integrity. The polymer's high crystallinity contributes to its superior mechanical performance compared to other polyethylene grades.- Mechanical properties of HDPE: High-density polyethylene (HDPE) exhibits excellent mechanical properties, including high tensile strength, impact resistance, and stiffness. These characteristics make it suitable for various applications requiring durability and structural integrity. The polymer's high crystallinity contributes to its superior mechanical performance compared to other polyethylene grades.

- Thermal properties of HDPE: HDPE demonstrates good thermal properties, including a relatively high melting point and thermal stability. It maintains its structural integrity over a wide temperature range, making it suitable for applications involving heat exposure. The material's low thermal conductivity also makes it useful for insulation purposes.

- Chemical resistance of HDPE: HDPE exhibits excellent chemical resistance to a wide range of substances, including acids, bases, and organic solvents. This property makes it ideal for use in chemical storage containers, pipes, and other applications where exposure to corrosive or reactive materials is expected. The material's non-polar nature contributes to its chemical inertness.

- Processing and fabrication of HDPE: HDPE can be processed using various methods, including injection molding, extrusion, and blow molding. Its high melt strength and good flow properties make it suitable for producing a wide range of products. The material can be easily colored, and its surface can be modified to improve adhesion or other properties.

- Environmental and recycling aspects of HDPE: HDPE is a recyclable material, making it environmentally friendly compared to some other plastics. It can be reprocessed multiple times without significant loss of properties. The material's durability also contributes to its long lifespan, reducing the need for frequent replacement. However, concerns about plastic waste and microplastics have led to increased focus on developing more sustainable HDPE formulations and recycling methods.

02 Thermal properties and processing of HDPE

HDPE demonstrates good thermal stability and a relatively high melting point, allowing for versatile processing methods. It can be molded, extruded, or blown into various shapes and forms. The material's thermal properties also contribute to its resistance to warping and shrinkage during processing, making it ideal for manufacturing consistent and dimensionally stable products.Expand Specific Solutions03 Chemical resistance and barrier properties

HDPE exhibits excellent chemical resistance to a wide range of solvents, acids, and bases. This property makes it suitable for packaging and containing various chemicals and substances. Additionally, HDPE possesses good barrier properties against moisture and gases, enhancing its suitability for packaging applications and extending the shelf life of products.Expand Specific Solutions04 Environmental and recycling aspects of HDPE

HDPE is a recyclable material, making it environmentally friendly compared to some other plastics. Its recyclability and durability contribute to its sustainability profile. However, efforts are ongoing to improve its biodegradability and reduce its environmental impact. Research focuses on developing more eco-friendly HDPE formulations and enhancing recycling processes.Expand Specific Solutions05 Modifications and blends to enhance HDPE properties

Various modifications and blending techniques are employed to enhance the properties of HDPE. These include the addition of fillers, reinforcing agents, or other polymers to improve specific characteristics such as impact strength, UV resistance, or flame retardancy. Such modifications expand the range of applications for HDPE and tailor its properties for specific use cases.Expand Specific Solutions

Key Players in HDPE Industry

The market for exploiting HDPE properties in industrial solutions is in a mature growth phase, with a global market size expected to reach $84 billion by 2026. The technology's maturity is evident from the involvement of major petrochemical companies like Chevron Phillips Chemical, ExxonMobil, and Dow Global Technologies. These industry leaders are continuously innovating to enhance HDPE's performance in various applications. Emerging players such as Borealis AG and LG Chem are also making significant contributions, particularly in developing specialized grades for specific industrial needs. The competitive landscape is characterized by a mix of established multinational corporations and regional players, with a growing focus on sustainable and high-performance HDPE solutions.

Dow Global Technologies LLC

Borealis AG

Innovative HDPE Property Enhancements

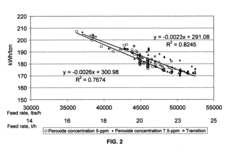

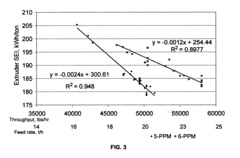

- The method involves selecting a catalyst and introducing specific free radical initiators, such as peroxides, and neutralizing species like alkali metal stearates, to control the rheology of polyethylene resins by measuring specific energy input (SEI) and adjusting process parameters, optimizing the ratio of variations in properties to achieve improved film performance.

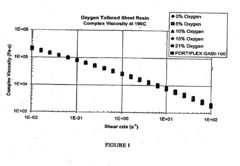

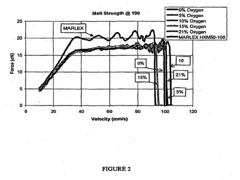

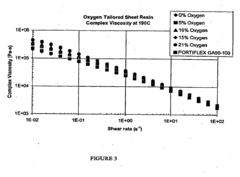

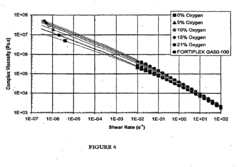

- The use of oxygen tailoring to introduce limited long chain branching in chromium-catalyzed HDPE resins during the extrusion process, enhancing melt strength without compromising extensibility, by exposing the resin to low levels of oxygen in the extruder's second melt zone and subsequent antioxidant treatment.

Environmental Impact of HDPE Usage

The environmental impact of HDPE usage in industrial solutions is a critical consideration for sustainable development. HDPE, while offering numerous advantages in terms of durability and versatility, presents significant environmental challenges throughout its lifecycle.

Production of HDPE involves the use of non-renewable fossil fuels, contributing to resource depletion and greenhouse gas emissions. The manufacturing process requires substantial energy inputs, further exacerbating its carbon footprint. Additionally, the production of HDPE generates various pollutants, including volatile organic compounds (VOCs) and particulate matter, which can negatively affect air quality and human health.

During its use phase, HDPE products generally have a lower environmental impact compared to many alternative materials. Their lightweight nature can lead to reduced transportation-related emissions, and their durability often results in longer product lifespans, potentially decreasing overall resource consumption.

However, the end-of-life stage of HDPE products poses significant environmental concerns. While HDPE is recyclable, the recycling rates remain relatively low globally. Improper disposal of HDPE products contributes to plastic pollution, particularly in marine environments. HDPE does not biodegrade readily, persisting in ecosystems for hundreds of years and potentially harming wildlife through ingestion or entanglement.

Microplastic pollution is another growing concern associated with HDPE usage. As HDPE products degrade over time, they break down into smaller particles, which can enter food chains and water systems, potentially impacting ecosystem health and human well-being.

Efforts to mitigate the environmental impact of HDPE usage in industrial solutions include improving recycling infrastructure and technologies, developing bio-based alternatives, and implementing circular economy principles. Some industries are exploring chemical recycling methods to break down HDPE into its constituent monomers, enabling the production of new, high-quality plastics.

Innovative approaches to HDPE waste management, such as incorporating it into construction materials or using it as a feedstock for energy production, are also being explored. These strategies aim to reduce the amount of HDPE entering landfills or the environment while potentially offsetting the use of other resources.

As industrial solutions continue to rely on HDPE, balancing its beneficial properties with environmental stewardship remains a crucial challenge. Addressing this issue requires a multifaceted approach, involving improvements in production efficiency, enhanced recycling capabilities, and the development of more sustainable alternatives.

HDPE Recycling and Circular Economy

The recycling of High-Density Polyethylene (HDPE) and its integration into the circular economy represent crucial aspects of sustainable industrial solutions. HDPE, known for its durability and versatility, has become a focal point in efforts to reduce plastic waste and promote resource efficiency. The circular economy model for HDPE involves several key stages, including collection, sorting, processing, and remanufacturing.

Collection systems for HDPE have evolved significantly, with many municipalities implementing curbside recycling programs that specifically target plastic containers. Advanced sorting technologies, such as near-infrared spectroscopy and artificial intelligence-driven robotic systems, have greatly improved the efficiency and accuracy of HDPE separation from mixed waste streams.

Once sorted, HDPE undergoes a series of processing steps to transform it into a reusable form. This typically involves shredding, washing, and pelletizing. Innovative decontamination techniques have been developed to address concerns about potential contaminants in recycled HDPE, ensuring its suitability for a wide range of applications, including food-grade packaging.

The remanufacturing stage has seen significant advancements, with recycled HDPE now being used in the production of various products, from outdoor furniture to automotive parts. Some companies have successfully closed the loop by incorporating recycled HDPE back into their original product lines, demonstrating the viability of a true circular economy model.

However, challenges remain in achieving a fully circular economy for HDPE. These include improving collection rates, addressing the variability in recycled HDPE quality, and developing more efficient recycling technologies. Efforts are underway to standardize HDPE recycling processes and create markets for recycled materials, with some regions implementing policies to mandate the use of recycled content in certain products.

The economic viability of HDPE recycling has improved with technological advancements and increased demand for sustainable materials. This has led to the emergence of specialized recycling facilities and the integration of recycling operations into existing manufacturing processes. The development of chemical recycling methods, which break down HDPE into its molecular components, offers promising opportunities for handling contaminated or mixed plastic waste streams.

As industries continue to explore ways to exploit HDPE properties for sustainable solutions, the focus on recycling and circular economy principles is driving innovation in product design, manufacturing processes, and waste management systems. This holistic approach not only addresses environmental concerns but also creates new economic opportunities and enhances resource security in the long term.