How to Enhance HDPE's Acoustic Properties?

HDPE Acoustic Enhancement Background and Objectives

High-density polyethylene (HDPE) has been widely used in various industries due to its excellent mechanical properties, chemical resistance, and low cost. However, its acoustic performance has been a limiting factor in certain applications, particularly in noise-sensitive environments. The enhancement of HDPE's acoustic properties has become a critical area of research and development in recent years, driven by the increasing demand for noise reduction solutions in automotive, construction, and industrial sectors.

The evolution of HDPE acoustic enhancement technologies can be traced back to the early 2000s when researchers began exploring ways to improve the material's sound absorption and transmission loss characteristics. Initial efforts focused on modifying the polymer structure and incorporating additives to alter its acoustic behavior. As the field progressed, more sophisticated approaches emerged, including the development of composite materials and the application of advanced manufacturing techniques.

The primary objective of enhancing HDPE's acoustic properties is to create a material that can effectively attenuate sound across a wide frequency range while maintaining its desirable mechanical and chemical properties. This goal encompasses several key aspects, including improving sound absorption, increasing transmission loss, and reducing resonance effects. Additionally, researchers aim to develop cost-effective and scalable solutions that can be readily integrated into existing manufacturing processes.

Current technological trends in HDPE acoustic enhancement include the exploration of nanocomposites, the development of multi-layer structures, and the optimization of material porosity. These approaches seek to leverage the unique properties of HDPE while addressing its inherent limitations in acoustic performance. The integration of smart materials and adaptive systems is also emerging as a promising direction for future research, potentially enabling dynamic acoustic properties that can respond to changing environmental conditions.

The market demand for acoustically enhanced HDPE is driven by stringent noise regulations in various industries, as well as the growing awareness of the impact of noise pollution on human health and well-being. Key application areas include automotive interiors, building materials, industrial machinery enclosures, and consumer products. The global market for acoustic materials is projected to grow significantly in the coming years, with HDPE-based solutions poised to capture a substantial share due to their potential for combining acoustic performance with other desirable properties.

As research in this field continues to advance, the development of HDPE acoustic enhancement technologies is expected to lead to new product innovations and expanded applications. The successful realization of these objectives will not only address current market needs but also open up new opportunities for HDPE in acoustically demanding environments, further solidifying its position as a versatile and indispensable material in modern engineering and manufacturing.

Market Analysis for Acoustic HDPE Applications

The market for acoustic HDPE applications is experiencing significant growth, driven by increasing demand for noise reduction solutions across various industries. High-density polyethylene (HDPE) has emerged as a promising material for acoustic applications due to its unique properties, including durability, chemical resistance, and potential for sound absorption when properly engineered.

In the construction sector, there is a growing need for acoustic HDPE products in both residential and commercial buildings. Soundproofing walls, floors, and ceilings are becoming essential features in modern architecture, particularly in urban areas where noise pollution is a concern. The automotive industry also presents a substantial market opportunity for acoustic HDPE applications, as manufacturers seek lightweight materials to improve fuel efficiency while maintaining or enhancing sound insulation in vehicles.

The packaging industry is another key market for acoustic HDPE, with a focus on reducing noise in manufacturing and logistics processes. Conveyor belts, material handling equipment, and packaging machinery are areas where acoustic HDPE can provide significant benefits. Additionally, the marine industry is showing interest in acoustic HDPE for applications such as boat hulls and underwater noise reduction systems.

The global market for acoustic materials is projected to grow steadily, with HDPE-based solutions poised to capture a significant share. Factors contributing to this growth include stringent noise regulations, increasing awareness of the health impacts of noise pollution, and the ongoing urbanization trend worldwide.

Geographically, North America and Europe are currently the largest markets for acoustic HDPE applications, owing to their advanced construction and automotive industries. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, infrastructure development, and increasing adoption of noise control measures in countries like China and India.

Key market players are investing in research and development to enhance the acoustic properties of HDPE, focusing on innovations such as foam structures, composite materials, and surface treatments. This ongoing innovation is expected to expand the potential applications and market reach of acoustic HDPE products.

Challenges in the market include competition from traditional acoustic materials like fiberglass and mineral wool, as well as the need for education and awareness about the benefits of HDPE in acoustic applications. However, as sustainability becomes increasingly important, HDPE's recyclability and long lifespan are likely to become significant selling points.

In conclusion, the market for acoustic HDPE applications shows strong potential for growth across multiple industries. As research continues to improve HDPE's acoustic properties, its market share is expected to expand, offering new opportunities for manufacturers and solution providers in the noise control sector.

Current Limitations in HDPE Acoustic Performance

High-density polyethylene (HDPE) is widely used in various applications due to its excellent mechanical properties, chemical resistance, and low cost. However, when it comes to acoustic performance, HDPE faces several limitations that hinder its effectiveness in noise reduction and sound insulation applications.

One of the primary limitations of HDPE in acoustic performance is its relatively high sound transmission. HDPE has a low density compared to other materials used for sound insulation, which allows sound waves to pass through more easily. This characteristic makes it challenging to achieve high levels of sound attenuation, especially in low-frequency ranges.

Another significant limitation is HDPE's low sound absorption coefficient. The material's smooth surface and non-porous structure result in poor sound absorption capabilities. When sound waves hit an HDPE surface, they tend to reflect rather than be absorbed, leading to increased reverberation and reduced acoustic comfort in enclosed spaces.

HDPE also exhibits limited damping properties, which affects its ability to dissipate sound energy effectively. This limitation results in prolonged vibrations and resonance, particularly at certain frequencies, further compromising its acoustic performance in applications where vibration control is crucial.

The material's thermal properties pose additional challenges in acoustic applications. HDPE has a relatively high coefficient of thermal expansion, which can lead to dimensional changes in response to temperature fluctuations. These changes may affect the integrity of acoustic systems, potentially creating gaps or altering the designed acoustic properties over time.

Furthermore, HDPE's homogeneous structure limits its natural acoustic variability. Unlike materials with inherent acoustic variations, such as wood or certain composites, HDPE's uniform composition makes it difficult to achieve diverse acoustic responses without additional modifications or treatments.

The material's low stiffness-to-weight ratio also impacts its acoustic performance, particularly in structural applications. This characteristic can result in increased flexural vibrations, which may contribute to unwanted noise transmission in certain scenarios.

Lastly, HDPE's chemical inertness, while beneficial in many applications, poses challenges in acoustic enhancement. The material's resistance to chemical bonding makes it difficult to apply traditional acoustic treatments or coatings effectively, limiting options for improving its sound absorption and insulation properties through surface modifications.

These limitations collectively contribute to HDPE's suboptimal performance in acoustic applications, necessitating innovative approaches and material modifications to enhance its acoustic properties and expand its potential use in noise control and sound management systems.

Existing HDPE Acoustic Enhancement Techniques

01 Acoustic properties of HDPE composites

High-density polyethylene (HDPE) can be combined with various materials to create composites with enhanced acoustic properties. These composites can be used in applications requiring sound insulation or absorption. The addition of fillers or reinforcing agents to HDPE can significantly alter its acoustic behavior, making it suitable for noise reduction in various environments.- Acoustic properties of HDPE composites: High-density polyethylene (HDPE) can be combined with various materials to create composites with enhanced acoustic properties. These composites can be used in applications requiring sound insulation or absorption. The addition of fillers or reinforcing materials to HDPE can significantly alter its acoustic behavior, making it suitable for noise reduction in various environments.

- HDPE foam for acoustic applications: HDPE foam exhibits excellent acoustic properties, making it suitable for sound insulation and absorption. The cellular structure of HDPE foam contributes to its ability to attenuate sound waves. These foams can be engineered with specific densities and cell structures to optimize their acoustic performance for different applications, such as automotive interiors or building materials.

- Acoustic properties of HDPE blends: Blending HDPE with other polymers or materials can result in improved acoustic properties. These blends can be tailored to achieve specific sound transmission loss or absorption characteristics. The combination of HDPE with elastomers or other thermoplastics can create materials with unique acoustic profiles suitable for various noise control applications.

- HDPE-based acoustic panels and barriers: HDPE can be used to manufacture acoustic panels and barriers with excellent sound insulation properties. These panels can be designed with specific surface textures or perforations to enhance their acoustic performance. HDPE-based acoustic barriers are particularly useful in outdoor applications due to their durability and weather resistance.

- Modification of HDPE for improved acoustic properties: Various methods can be employed to modify HDPE and enhance its acoustic properties. These include chemical modifications, the addition of nanoparticles, or the creation of multilayer structures. Such modifications can alter the material's sound absorption coefficient, transmission loss, or resonance characteristics, making it more effective in specific acoustic applications.

02 HDPE foam for acoustic applications

HDPE foam exhibits promising acoustic properties, making it suitable for sound insulation and absorption. The cellular structure of HDPE foam contributes to its ability to attenuate sound waves. Various manufacturing techniques can be employed to produce HDPE foam with specific acoustic characteristics, tailored for different applications in construction, automotive, and industrial sectors.Expand Specific Solutions03 Acoustic properties of HDPE blends

Blending HDPE with other polymers or materials can result in improved acoustic properties. These blends can offer a balance between mechanical strength and sound insulation capabilities. The acoustic behavior of HDPE blends can be fine-tuned by adjusting the composition and processing parameters, allowing for customized solutions in various noise control applications.Expand Specific Solutions04 Surface modifications for acoustic enhancement

The acoustic properties of HDPE can be enhanced through various surface modification techniques. These modifications can include texturing, coating, or chemical treatments that alter the surface characteristics of HDPE. Such modifications can improve sound absorption, reflection, or diffusion properties, making HDPE more effective in acoustic applications.Expand Specific Solutions05 HDPE-based acoustic panels and structures

HDPE can be used to create acoustic panels and structures with specific sound-controlling properties. These panels can be designed with various geometries, thicknesses, and compositions to achieve desired acoustic performance. HDPE-based acoustic panels find applications in building interiors, outdoor noise barriers, and industrial settings where noise reduction is crucial.Expand Specific Solutions

Key Players in Acoustic HDPE Development

The acoustic properties enhancement of HDPE is in a developing stage, with a growing market driven by increasing demand for noise reduction solutions. The technology's maturity varies among key players, with companies like SABIC Global Technologies BV, Dow Global Technologies LLC, and Borealis AG leading in innovation. These firms are investing in research to improve HDPE's sound absorption and insulation capabilities. Other notable contributors include Kingfa Sci. & Tech. Co., Ltd. and China Petroleum & Chemical Corp., who are exploring novel composite materials and manufacturing processes. The market is characterized by a mix of established petrochemical giants and specialized materials companies, indicating a competitive landscape with potential for significant advancements in HDPE acoustic performance.

SABIC Global Technologies BV

Dow Global Technologies LLC

Innovative Approaches to HDPE Acoustic Modification

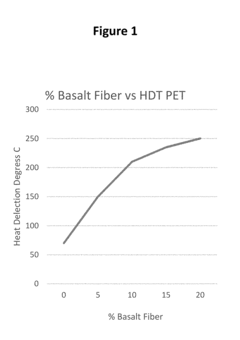

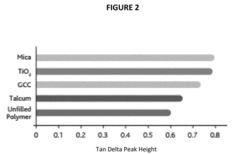

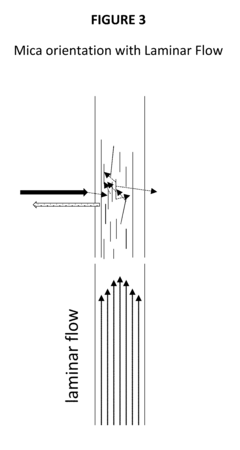

- A composition comprising polyethylene terephthalate (PET) as the base polymer blended with mica and basalt fibers, which can be molded into a single piece to provide heat deflection and noise suppression without the need for additional heat shields and pads, utilizing recycled PET and fillers like mica and basalt to enhance thermal and acoustic performance.

- A foamable polymer composition comprising a polyolefin polymer, specifically linear low density polyethylene, combined with a blowing agent like citric acid or expandable polymeric microspheres, which allows for controlled foaming to enhance flexibility and tensile properties, thereby improving the cable's installation and durability.

Environmental Impact of Acoustic HDPE Materials

The environmental impact of acoustic HDPE materials is a crucial consideration in the development and application of enhanced HDPE for acoustic purposes. As the demand for noise reduction solutions grows, it is essential to evaluate the ecological footprint of these materials throughout their lifecycle.

HDPE, being a thermoplastic polymer, offers the advantage of recyclability. When used in acoustic applications, the material can be recycled at the end of its life, reducing waste and conserving resources. This recyclability aligns with circular economy principles and contributes to sustainable material management practices.

However, the production of HDPE and its acoustic modifications can have environmental implications. The manufacturing process typically involves the use of fossil fuels as raw materials and energy sources, contributing to greenhouse gas emissions. Additionally, the incorporation of additives or fillers to enhance acoustic properties may introduce complexities in the recycling process or potentially harmful substances into the environment if not properly managed.

The durability of acoustic HDPE materials can be viewed as a double-edged sword from an environmental perspective. On one hand, their long lifespan reduces the need for frequent replacements, minimizing waste generation and resource consumption. On the other hand, this durability means that any environmental impact associated with their production is spread over a longer period.

When considering the use of acoustic HDPE materials in outdoor applications, such as noise barriers or sound-absorbing panels, it is important to assess their resistance to weathering and potential for leaching. While HDPE is generally resistant to environmental degradation, the additives used to enhance its acoustic properties may have different environmental fates and impacts.

The energy efficiency of buildings or structures incorporating acoustic HDPE materials should also be taken into account. If these materials contribute to better insulation and reduced energy consumption for heating or cooling, they may indirectly lead to lower greenhouse gas emissions over their lifetime.

In terms of end-of-life management, the recyclability of acoustic HDPE materials presents opportunities for closed-loop systems. However, the presence of acoustic-enhancing additives may require specialized recycling processes to maintain material quality and prevent the accumulation of potentially harmful substances in recycled products.

As research and development in acoustic HDPE materials progress, there is a growing focus on incorporating bio-based or recycled content to reduce the reliance on virgin petroleum-based resources. This shift towards more sustainable raw materials could significantly improve the overall environmental profile of acoustic HDPE products.

Standardization of Acoustic HDPE Testing Methods

The standardization of acoustic HDPE testing methods is crucial for ensuring consistent and reliable evaluation of High-Density Polyethylene's acoustic properties. Currently, there is a lack of universally accepted protocols, which hinders accurate comparisons and impedes progress in enhancing HDPE's acoustic performance.

To address this issue, a comprehensive framework for standardized testing methods must be developed. This framework should encompass various aspects of acoustic testing, including sample preparation, measurement techniques, and data analysis. Standardized sample sizes and shapes are essential to eliminate variations caused by geometry. Additionally, consistent environmental conditions, such as temperature and humidity, must be maintained across all tests to ensure reproducibility.

One key area for standardization is the measurement of sound absorption coefficients. A unified approach using impedance tube testing, following ISO 10534-2 guidelines, could be adopted as the primary method. This technique allows for precise measurements across a wide frequency range and is particularly suitable for HDPE materials.

Transmission loss testing is another critical aspect that requires standardization. The implementation of ASTM E90 or ISO 10140 standards for airborne sound insulation measurements could provide a solid foundation for evaluating HDPE's sound transmission properties. These methods should be adapted specifically for HDPE materials, taking into account their unique characteristics.

Standardization efforts should also focus on impact sound insulation testing, which is particularly relevant for HDPE applications in flooring and construction. Adapting ISO 10140-3 standards for laboratory measurements of impact sound insulation could offer a consistent approach to assessing HDPE's performance in this area.

To ensure widespread adoption, these standardized methods must be validated through inter-laboratory studies. This process would involve multiple testing facilities conducting identical experiments on the same HDPE samples, allowing for the identification and resolution of any discrepancies in results.

Furthermore, the development of reference materials with known acoustic properties is essential for calibrating equipment and verifying test results across different laboratories. These reference materials should be carefully selected to represent a range of HDPE formulations commonly used in acoustic applications.

Lastly, the standardization process should include guidelines for reporting results, specifying the minimum required information and preferred formats. This would facilitate easier comparison of data across studies and accelerate the development of improved HDPE acoustic materials.