How to Differentiate HDPE Products Through Design?

HDPE Design Evolution

The evolution of High-Density Polyethylene (HDPE) product design has been a journey of continuous innovation and adaptation to meet changing market demands and technological advancements. Initially, HDPE products were primarily focused on basic functionality, with simple designs that emphasized durability and cost-effectiveness. As the material's properties became better understood, designers began to explore more complex shapes and structures, leveraging HDPE's flexibility and strength.

In the 1960s and 1970s, the introduction of blow molding techniques revolutionized HDPE product design, allowing for the creation of hollow objects with intricate shapes. This led to a proliferation of HDPE containers, bottles, and packaging solutions. The design focus shifted towards optimizing wall thickness, improving impact resistance, and enhancing barrier properties.

The 1980s and 1990s saw a growing emphasis on sustainability and recyclability in HDPE product design. Designers began incorporating features that facilitated easier recycling, such as removable labels and single-material construction. This period also witnessed the development of more sophisticated molding techniques, enabling the production of larger and more complex HDPE products, including automotive components and industrial containers.

The turn of the millennium brought about a new era in HDPE design, characterized by the integration of advanced technologies. Computer-aided design (CAD) and finite element analysis (FEA) tools allowed for more precise optimization of product geometry, leading to lighter yet stronger designs. This period also saw the rise of customization in HDPE products, with designers leveraging the material's versatility to create tailored solutions for specific industries and applications.

In recent years, the focus of HDPE product design has shifted towards enhancing aesthetics and user experience. Designers are now exploring ways to create visually appealing surfaces, incorporate textures, and even mimic the appearance of other materials. This has led to the development of HDPE products that not only perform well but also look and feel premium, expanding their use in consumer goods and high-end applications.

The latest frontier in HDPE design evolution is the incorporation of smart features and connectivity. Designers are experimenting with embedding sensors, RFID tags, and other electronic components into HDPE products, creating intelligent packaging solutions and IoT-enabled devices. This convergence of material science and digital technology is opening up new possibilities for HDPE product differentiation and value addition.

Throughout its evolution, HDPE product design has consistently pushed the boundaries of what's possible with this versatile material. From simple, functional designs to complex, smart products, the journey of HDPE design reflects broader trends in manufacturing, sustainability, and consumer preferences. As we look to the future, the continued evolution of HDPE design promises to deliver even more innovative and differentiated products that meet the ever-changing needs of various industries and consumers.

Market Demand Analysis

The market demand for differentiated HDPE products through design is driven by several key factors in the current industrial landscape. Firstly, there is a growing emphasis on sustainability and environmental consciousness among consumers and businesses alike. This has led to an increased demand for HDPE products that are not only recyclable but also designed with eco-friendly features, such as reduced material usage or improved end-of-life recyclability.

In the packaging sector, which is a major consumer of HDPE, there is a significant push for innovative designs that enhance product protection while minimizing material use. Companies are seeking HDPE packaging solutions that offer better stackability, improved barrier properties, and unique shapes that stand out on retail shelves. This demand is particularly strong in the food and beverage industry, where product differentiation through packaging design can significantly impact consumer choices.

The construction industry represents another substantial market for differentiated HDPE products. There is a rising demand for HDPE pipes and fittings with enhanced durability, chemical resistance, and ease of installation. Designers are challenged to create HDPE products that can withstand higher pressures and more extreme temperatures, expanding their applicability in various construction projects.

In the automotive sector, lightweight materials are highly sought after to improve fuel efficiency and reduce emissions. This has created a niche market for HDPE components designed to replace heavier materials without compromising on strength or performance. Innovative designs that allow for complex geometries and integrated functionalities are particularly valued in this sector.

The consumer goods market also presents significant opportunities for differentiated HDPE products. There is a growing demand for household items, toys, and personal care products made from HDPE that offer unique aesthetics, improved functionality, and enhanced durability. Designers are exploring ways to create HDPE products with premium looks and feels, challenging the perception of plastic as a low-value material.

Market analysis indicates that companies capable of offering customized HDPE product designs have a competitive edge. This includes the ability to produce small batches of specialized designs, which is particularly attractive to niche markets and for product testing phases. The demand for such flexibility is driving investments in advanced manufacturing technologies like 3D printing of HDPE.

Furthermore, there is a growing market for HDPE products designed with circular economy principles in mind. This includes designs that facilitate easy disassembly for recycling, products made from recycled HDPE, and those designed for multiple life cycles. Such innovations are not only meeting consumer demands but also aligning with increasingly stringent environmental regulations in various markets.

HDPE Design Challenges

High-density polyethylene (HDPE) is a versatile and widely used material in various industries, but designing products that stand out in a competitive market presents several challenges. One of the primary obstacles is the material's inherent limitations in terms of aesthetics and surface finish. HDPE typically has a matte, slightly waxy appearance that can be perceived as less premium compared to other plastics or materials.

Another significant challenge lies in the material's mechanical properties. While HDPE offers excellent chemical resistance and durability, it can be prone to creep and stress cracking under certain conditions. This necessitates careful consideration of design features, especially in load-bearing applications or products exposed to harsh environments.

Color consistency and stability pose additional hurdles in HDPE product design. The material's natural translucency can make achieving vibrant, consistent colors challenging, particularly for products with large surface areas or those exposed to UV radiation. Designers must work closely with material suppliers and colorants to develop solutions that maintain aesthetic appeal throughout the product's lifecycle.

Incorporating complex geometries or intricate details in HDPE products can be problematic due to the material's high shrinkage rate during cooling. This characteristic can lead to warping, sink marks, or dimensional inaccuracies, limiting the design possibilities and potentially affecting both form and function.

The recyclability of HDPE, while generally considered an advantage, can also present design challenges. Creating products that are easily recyclable without compromising on performance or aesthetics requires innovative thinking and may limit certain design choices, such as the use of multi-material components or certain additives.

Differentiation through tactile properties is another area where designers face difficulties. HDPE's natural feel can be perceived as less premium compared to other materials, making it challenging to create products with a distinct tactile experience that sets them apart from competitors.

Lastly, balancing cost-effectiveness with unique design features presents an ongoing challenge. While HDPE is relatively inexpensive, incorporating distinctive design elements or surface treatments to differentiate products can significantly impact production costs, potentially eroding the material's economic advantages.

Addressing these challenges requires a multifaceted approach, combining material science expertise, innovative design techniques, and a deep understanding of manufacturing processes. Designers must continuously explore new ways to push the boundaries of HDPE's capabilities while maintaining the material's core benefits of durability, chemical resistance, and cost-effectiveness.

Current Design Solutions

01 HDPE material composition and properties

High-density polyethylene (HDPE) is a versatile material used in product design. Its composition can be modified to enhance specific properties such as strength, durability, and chemical resistance. Various additives and processing techniques can be employed to tailor HDPE for different applications, improving its performance in areas like impact resistance and weatherability.- HDPE material composition and properties: The design of HDPE products often involves optimizing the material composition to enhance specific properties. This includes blending HDPE with other polymers or additives to improve strength, durability, and processability. Researchers focus on developing HDPE compositions that offer better resistance to environmental factors, increased flexibility, or improved thermal properties for various applications.

- Manufacturing processes for HDPE products: Various manufacturing techniques are employed in HDPE product design, including injection molding, extrusion, and blow molding. These processes are continually refined to improve efficiency, reduce waste, and enhance product quality. Innovations in manufacturing methods focus on achieving better surface finishes, reducing cycle times, and enabling the production of complex shapes and structures.

- Sustainable and eco-friendly HDPE product design: There is a growing emphasis on designing HDPE products with sustainability in mind. This includes incorporating recycled HDPE materials, developing biodegradable HDPE blends, and designing products for easy recyclability at the end of their lifecycle. Efforts are also made to reduce material usage through innovative design approaches and to minimize the environmental impact of HDPE product manufacturing processes.

- HDPE product design for specific applications: HDPE products are designed for a wide range of applications, each with unique requirements. This includes designing HDPE containers for food packaging, pipes for water distribution, automotive components, and medical devices. The design process involves considering factors such as chemical resistance, impact strength, and regulatory compliance specific to each application.

- Advanced testing and quality control in HDPE product design: To ensure the reliability and performance of HDPE products, advanced testing and quality control methods are integrated into the design process. This includes developing new testing protocols, implementing non-destructive evaluation techniques, and utilizing computer simulations to predict product behavior under various conditions. These methods help in optimizing designs and ensuring product safety and longevity.

02 HDPE product manufacturing processes

Different manufacturing processes are used for HDPE product design, including injection molding, blow molding, and extrusion. Each process has its advantages and is suitable for specific product types. Advanced techniques like rotational molding and compression molding can be employed for creating complex shapes or large-scale products. Process optimization is crucial for achieving desired product quality and efficiency.Expand Specific Solutions03 HDPE product design for specific applications

HDPE products are designed for various applications, including packaging, construction, automotive parts, and consumer goods. The design process involves considering factors such as product functionality, environmental conditions, and regulatory requirements. Specialized designs may incorporate features like reinforcement structures, interlocking mechanisms, or multi-layer constructions to meet specific performance criteria.Expand Specific Solutions04 Sustainability and recycling considerations in HDPE product design

Incorporating sustainability principles in HDPE product design is becoming increasingly important. This includes designing products for easy recycling, using recycled HDPE content, and minimizing material waste. Innovations in HDPE recycling technologies and the development of bio-based HDPE alternatives are also influencing product design approaches to reduce environmental impact.Expand Specific Solutions05 HDPE product testing and quality control

Rigorous testing and quality control measures are essential in HDPE product design to ensure performance, safety, and compliance with industry standards. This includes mechanical testing, chemical resistance evaluations, and accelerated aging tests. Advanced analytical techniques and simulation tools are used to predict product behavior under various conditions, helping to optimize designs before production.Expand Specific Solutions

Key HDPE Manufacturers

The differentiation of HDPE products through design is currently in a mature yet evolving stage, with a growing market driven by increasing demand for innovative packaging solutions. The global HDPE market size is substantial, expected to reach USD 84.79 billion by 2028. Technologically, the field is moderately mature, with companies like Dow Global Technologies LLC, ExxonMobil Chemical Patents, Inc., and SABIC Global Technologies BV leading in innovation. These firms are focusing on enhancing HDPE properties, such as improved barrier characteristics and recyclability, to meet evolving consumer and regulatory demands. Emerging players like Borealis AG and NOVA Chemicals Corp. are also contributing to advancements in HDPE design, particularly in sustainable solutions.

Dow Global Technologies LLC

NOVA Chemicals Corp.

Innovative HDPE Designs

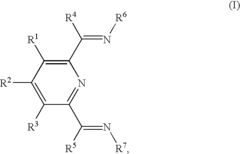

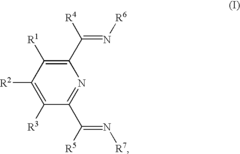

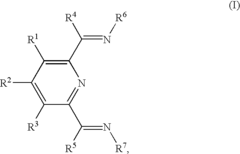

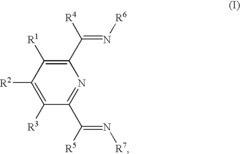

- HDPE is produced using polymerization catalysts comprising iron or cobalt complexes of specific compounds, such as those with aryl and substituted aryl groups, which significantly reduce water vapor and oxygen transmission rates, making them suitable for improved packaging.

- A method involving fluorination of polyolefin containers using a fluorination gas and a second gas, such as oxygen or halogens, in a controlled chamber environment to reduce extractable components and enhance barrier properties, specifically by exposing the containers to these gases for a controlled duration, then evacuating and returning to atmospheric conditions, resulting in treated containers with low perfluoroalkyl substances and maintaining weight integrity.

Sustainability Factors

Sustainability has become a crucial factor in differentiating HDPE products through design. As consumers and regulators increasingly prioritize environmental concerns, manufacturers are exploring innovative ways to enhance the sustainability of HDPE products. One key approach is the incorporation of recycled HDPE content into new products, reducing the demand for virgin materials and minimizing waste. This strategy not only appeals to environmentally conscious consumers but also aligns with circular economy principles.

Design for recyclability is another essential sustainability factor. HDPE products can be engineered to facilitate easier disassembly and separation of components, enabling more efficient recycling processes. This may involve using single-material designs or ensuring that different materials can be easily separated during the recycling process. Additionally, designers are focusing on reducing the overall material usage in HDPE products without compromising functionality, leading to lighter and more resource-efficient designs.

The durability and longevity of HDPE products also contribute to their sustainability profile. By designing products that are more resistant to wear, tear, and environmental factors, manufacturers can extend the lifespan of HDPE items, reducing the need for frequent replacements and ultimately decreasing waste generation. This approach not only benefits the environment but also enhances the value proposition for consumers seeking long-lasting products.

Energy efficiency in the production process is another critical sustainability factor. Manufacturers are exploring ways to optimize the molding and forming processes for HDPE products, reducing energy consumption and associated carbon emissions. This may involve the use of more efficient machinery, improved process controls, or the integration of renewable energy sources in manufacturing facilities.

Biodegradability and compostability are emerging areas of focus in HDPE product design. While traditional HDPE is not biodegradable, research is ongoing to develop additives or modified formulations that can enhance the material's ability to break down in natural environments without compromising its desirable properties. This approach aims to address concerns about plastic pollution, particularly in single-use applications.

Lastly, the use of bio-based HDPE derived from renewable resources is gaining traction as a sustainability differentiator. By sourcing HDPE from plant-based materials rather than fossil fuels, manufacturers can reduce the carbon footprint of their products and appeal to consumers seeking more environmentally friendly alternatives. However, careful consideration must be given to the overall lifecycle impact of bio-based HDPE, including land use and agricultural practices associated with feedstock production.

Regulatory Considerations

When differentiating HDPE products through design, regulatory considerations play a crucial role in ensuring compliance and market acceptance. The regulatory landscape for HDPE products varies depending on the intended application and geographical region. In the United States, the Food and Drug Administration (FDA) regulates HDPE products that come into contact with food or pharmaceuticals. Manufacturers must ensure their HDPE designs meet FDA requirements for food-contact substances, including specific additives and processing aids.

The European Union has its own set of regulations, such as the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) and the Restriction of Hazardous Substances (RoHS) directives. These regulations impact the design of HDPE products by limiting the use of certain chemicals and additives. Designers must carefully consider material selection and processing methods to comply with these stringent requirements.

Environmental regulations also significantly influence HDPE product design. Many countries have implemented plastic waste reduction policies, encouraging the use of recyclable or biodegradable materials. Designers must consider end-of-life scenarios for HDPE products, incorporating features that facilitate recycling or exploring bio-based HDPE alternatives to meet sustainability goals.

Safety standards are another critical regulatory aspect. For instance, HDPE products used in construction or automotive applications must adhere to specific fire safety and impact resistance standards. These requirements often necessitate the incorporation of flame retardants or reinforcing materials, which can affect the overall design and manufacturing process.

Labeling and packaging regulations also impact HDPE product design. Many jurisdictions require clear identification of plastic types to aid in recycling efforts. Designers may need to incorporate molded-in recycling symbols or ensure that product packaging includes appropriate recycling information.

Regulatory compliance can be a differentiating factor in itself. By designing HDPE products that not only meet but exceed regulatory requirements, manufacturers can gain a competitive edge in the market. This may involve developing innovative solutions that address emerging regulatory concerns or anticipating future regulatory changes.

As regulations continue to evolve, particularly in response to environmental concerns, HDPE product designers must stay informed and adaptable. Engaging with regulatory bodies, participating in industry associations, and investing in research and development can help companies navigate the complex regulatory landscape and create differentiated HDPE products that meet both market demands and regulatory requirements.