HDPE Application Trends in Construction Industry

HDPE in Construction: Evolution and Objectives

High-density polyethylene (HDPE) has emerged as a versatile and increasingly popular material in the construction industry over the past few decades. Its journey from a niche product to a mainstream construction material reflects the evolving needs of the sector and advancements in polymer technology. Initially developed in the 1950s, HDPE found its first applications in the construction industry primarily in piping systems due to its excellent chemical resistance and durability.

The evolution of HDPE in construction has been driven by a combination of factors, including the need for more sustainable and long-lasting materials, improved performance in harsh environments, and cost-effectiveness. As the material properties of HDPE were refined and manufacturing processes improved, its applications expanded beyond piping to include geomembranes, insulation, and structural components.

In recent years, the construction industry has faced increasing pressure to adopt more environmentally friendly practices and materials. This has led to a renewed focus on HDPE, given its recyclability and lower carbon footprint compared to traditional materials like concrete and steel. The material's ability to be recycled multiple times without significant degradation in properties aligns well with the circular economy principles that are gaining traction in the construction sector.

The objectives for HDPE application in construction have evolved alongside technological advancements. Current goals include enhancing the material's strength-to-weight ratio, improving its resistance to UV radiation and extreme temperatures, and developing new composites that combine HDPE with other materials to create hybrid solutions with superior properties. There is also a growing emphasis on developing HDPE formulations that are specifically tailored for 3D printing applications in construction, potentially revolutionizing on-site manufacturing and custom component production.

Looking ahead, the construction industry aims to further integrate HDPE into smart building systems. This includes developing HDPE products with embedded sensors for real-time monitoring of structural integrity and environmental conditions. Additionally, there is ongoing research into improving the fire resistance of HDPE to expand its use in more critical building applications. The overarching goal is to position HDPE as a key material in creating more resilient, sustainable, and adaptable built environments that can meet the challenges of climate change and urbanization.

Market Analysis for HDPE in Construction

The HDPE (High-Density Polyethylene) market in the construction industry has experienced significant growth in recent years, driven by the material's unique properties and versatility. HDPE's resistance to corrosion, chemicals, and impact, coupled with its lightweight nature and durability, has made it an increasingly popular choice for various construction applications.

In the piping sector, HDPE has gained substantial market share, particularly in water and gas distribution systems. The material's flexibility and leak-resistant properties have led to its widespread adoption in underground piping networks, reducing installation costs and minimizing maintenance requirements. The global HDPE pipes market in construction is projected to grow at a steady rate, with emerging economies in Asia-Pacific and Latin America driving much of this expansion.

HDPE's application in geomembranes has also seen a surge in demand, especially in landfill liners, pond liners, and other containment systems. The material's impermeability and resistance to environmental stress cracking make it ideal for these applications, contributing to the growth of the geosynthetics market within the construction industry.

The use of HDPE in construction-related packaging, such as protective films and wraps, has increased due to its strength and moisture resistance. This segment has benefited from the overall growth in construction activities and the need for effective material protection during transportation and storage.

In the building materials sector, HDPE has found applications in insulation, vapor barriers, and moisture management systems. Its ability to provide effective moisture control while maintaining structural integrity has led to increased adoption in both residential and commercial construction projects.

The market for HDPE in construction has also been influenced by sustainability trends. The material's recyclability and long service life align with green building initiatives, driving its use in eco-friendly construction projects. This has opened up new market opportunities, particularly in regions with stringent environmental regulations.

Regionally, North America and Europe have mature HDPE markets in construction, with steady growth rates. However, the Asia-Pacific region, led by China and India, is expected to show the highest growth potential due to rapid urbanization and infrastructure development.

Despite the positive outlook, the HDPE market faces challenges from fluctuating raw material prices and competition from alternative materials. However, ongoing technological advancements in HDPE production and processing are expected to enhance its competitiveness and expand its applications in the construction industry.

HDPE Technical Challenges in Building Applications

High-density polyethylene (HDPE) has gained significant traction in the construction industry due to its unique properties and versatility. However, its application in building applications faces several technical challenges that need to be addressed for wider adoption.

One of the primary challenges is the thermal expansion and contraction of HDPE. The material's high coefficient of thermal expansion can lead to dimensional instability in building components, potentially causing warping, buckling, or gaps in structures. This issue is particularly problematic in regions with extreme temperature fluctuations, where the material's expansion and contraction can compromise the integrity of the building envelope.

Another significant challenge is the long-term durability and weathering resistance of HDPE in outdoor applications. While HDPE is known for its chemical resistance, prolonged exposure to UV radiation and environmental pollutants can lead to degradation over time. This degradation can manifest as discoloration, embrittlement, or loss of mechanical properties, potentially reducing the lifespan of HDPE-based building components.

The fire performance of HDPE is also a critical concern in building applications. HDPE is inherently combustible and can contribute to fire spread if not properly treated or protected. Developing effective fire-retardant additives or coatings that do not compromise the material's other desirable properties remains a technical challenge for researchers and manufacturers.

Joining and bonding HDPE components in construction applications present another set of challenges. Traditional fastening methods may not be suitable due to the material's low surface energy and chemical inertness. Developing reliable and durable joining techniques, such as specialized adhesives or welding processes, is crucial for ensuring the structural integrity of HDPE-based building systems.

The recyclability and end-of-life management of HDPE in building applications also pose technical challenges. While HDPE is recyclable, the presence of additives, coatings, or contamination from other building materials can complicate the recycling process. Developing effective separation and recycling technologies specific to HDPE building components is essential for promoting circular economy principles in construction.

Lastly, the integration of HDPE with other building materials and systems presents challenges in terms of compatibility and performance. Ensuring proper interfaces between HDPE and traditional construction materials, such as concrete, steel, or wood, requires careful consideration of thermal bridging, moisture management, and structural load transfer. Developing standardized design guidelines and testing protocols for HDPE-based building systems is crucial for their widespread acceptance in the construction industry.

Current HDPE Solutions in Construction

01 Composition and properties of HDPE

High-Density Polyethylene (HDPE) is a thermoplastic polymer with a high strength-to-density ratio. It is characterized by its long linear chains with minimal branching, resulting in higher tensile strength, stiffness, and chemical resistance compared to other polyethylene types. HDPE's properties make it suitable for various applications in packaging, construction, and automotive industries.- Composition and properties of HDPE: High-Density Polyethylene (HDPE) is a thermoplastic polymer with a high strength-to-density ratio. It is characterized by its long linear chains with minimal branching, resulting in higher tensile strength, stiffness, and chemical resistance compared to other polyethylene types. HDPE's properties make it suitable for various applications in packaging, construction, and automotive industries.

- HDPE blends and composites: HDPE can be blended with other materials or reinforced with fillers to enhance its properties. These blends and composites can improve mechanical strength, thermal stability, or specific functional characteristics. Common additives include other polymers, natural fibers, or inorganic particles, resulting in materials with tailored properties for specific applications.

- HDPE processing techniques: Various processing techniques are used to manufacture HDPE products, including injection molding, extrusion, and blow molding. These methods allow for the production of a wide range of HDPE items, from thin films to large containers. Advanced processing techniques can improve the material's performance or enable the creation of complex shapes and structures.

- Recycling and sustainability of HDPE: HDPE is widely recycled due to its thermoplastic nature, allowing it to be melted and reformed multiple times. Recycling processes for HDPE include mechanical recycling, chemical recycling, and energy recovery. Efforts are being made to improve recycling efficiency and develop more sustainable HDPE products, including the use of bio-based sources for HDPE production.

- HDPE applications in various industries: HDPE finds applications in numerous industries due to its versatile properties. It is commonly used in packaging for bottles, containers, and films. In construction, HDPE is used for pipes, geomembranes, and insulation. Other applications include automotive parts, toys, and medical devices. The material's durability, chemical resistance, and low cost contribute to its widespread use across different sectors.

02 HDPE blends and composites

HDPE can be blended with other materials or reinforced with fillers to enhance its properties. These blends and composites can improve mechanical strength, thermal stability, or specific functional characteristics. Common additives include other polymers, natural fibers, or inorganic particles, resulting in materials with tailored properties for specific applications.Expand Specific Solutions03 HDPE processing techniques

Various processing techniques are used to manufacture HDPE products, including injection molding, extrusion, blow molding, and rotational molding. Each method offers specific advantages and is suited for different product types. Advanced processing techniques can improve the material's performance or enable the production of complex shapes and structures.Expand Specific Solutions04 Recycling and sustainability of HDPE

HDPE is recyclable and can be reprocessed multiple times without significant loss of properties. Recycling processes for HDPE include mechanical recycling, chemical recycling, and energy recovery. Efforts are being made to improve recycling efficiency and develop more sustainable HDPE products, addressing environmental concerns associated with plastic waste.Expand Specific Solutions05 HDPE applications and innovations

HDPE finds applications in various industries due to its versatility. It is used in packaging, construction materials, automotive parts, and consumer goods. Ongoing research focuses on developing new HDPE grades with enhanced properties, such as improved barrier properties for packaging, increased durability for construction applications, or specialized formulations for 3D printing and other advanced manufacturing techniques.Expand Specific Solutions

Key HDPE Manufacturers and Suppliers

The HDPE application in the construction industry is experiencing significant growth, driven by increasing demand for durable and cost-effective materials. The market is in a mature stage but continues to expand, with a global market size expected to reach billions of dollars in the coming years. Major players like ExxonMobil Chemical Patents, Inc., Dow Global Technologies LLC, and SABIC Global Technologies BV are at the forefront of technological advancements. These companies, along with others such as Chevron Phillips Chemical Co. LP and PetroChina Co., Ltd., are investing heavily in R&D to improve HDPE properties for construction applications. The technology maturity is high, with ongoing innovations focusing on enhancing strength, durability, and sustainability of HDPE products for construction use.

Chevron Phillips Chemical Co. LP

China Petroleum & Chemical Corp.

Innovative HDPE Applications in Buildings

- The improved Innovene S low-pressure slurry process is used, using a double-loop reactor and an aluminum-modified supported chromium catalyst to copolymerize ethylene, hexene-1 and isobutane, and control the reaction conditions to produce low-density polyethylene geomembrane. Simplify the process and improve product softness and construction performance.

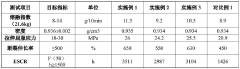

- A unimodal polyethylene composition with a density range of 0.935 to 0.975 g/cm³ and melt index of 0.1 to 1 g/10 min, exhibiting high Environmental Stress Crack Resistance (ESCR) values comparable to bimodal compositions, and featuring multiple distinct crystalline fractions, is developed. This composition is made in a single reactor with trace amounts of titanium and/or chromium, achieving a balance of properties typically associated with multimodal distributions at a lower cost.

Environmental Impact of HDPE in Construction

The environmental impact of HDPE in construction is a critical consideration as the industry increasingly adopts this versatile material. HDPE's durability and resistance to corrosion contribute to its long lifespan, potentially reducing the need for frequent replacements and associated environmental costs. This longevity can lead to decreased resource consumption and waste generation over time.

However, the production of HDPE involves energy-intensive processes and relies on fossil fuel resources, contributing to greenhouse gas emissions. The manufacturing process also generates pollutants and byproducts that require careful management to minimize environmental harm. Despite these concerns, advancements in production technologies are gradually improving the eco-efficiency of HDPE manufacturing.

In terms of waste management, HDPE presents both challenges and opportunities. While it is recyclable, the collection and processing of construction-grade HDPE can be complex due to contamination and the need for specialized recycling facilities. Improved recycling infrastructure and practices are essential to maximize the material's circularity and reduce its environmental footprint.

HDPE's resistance to biodegradation, while beneficial for durability, raises concerns about its persistence in the environment if not properly managed at the end of its life cycle. This has led to increased focus on developing biodegradable alternatives and enhancing recycling capabilities within the construction sector.

The material's lightweight nature compared to traditional construction materials like concrete or metal can result in reduced transportation emissions and easier on-site handling. This characteristic potentially lowers the overall carbon footprint of construction projects utilizing HDPE components.

HDPE's thermal insulation properties can contribute to improved energy efficiency in buildings, potentially reducing long-term energy consumption and associated environmental impacts. However, the full life-cycle assessment of HDPE in construction applications is complex and depends on factors such as specific usage, local climate, and disposal practices.

As the construction industry continues to prioritize sustainability, ongoing research and development efforts are focused on enhancing the environmental performance of HDPE. This includes exploring bio-based alternatives, improving recycling technologies, and optimizing production processes to reduce energy consumption and emissions. The future environmental impact of HDPE in construction will largely depend on these advancements and the industry's commitment to sustainable practices throughout the material's life cycle.

HDPE Standards and Regulations in Construction

The construction industry is subject to stringent regulations and standards to ensure safety, durability, and performance of materials used in building projects. High-Density Polyethylene (HDPE) applications in construction are no exception, and must adhere to a comprehensive set of standards and regulations.

In the United States, the American Society for Testing and Materials (ASTM) has developed several standards specifically for HDPE in construction. ASTM D3350 provides a cell classification system for HDPE materials, while ASTM F714 covers specifications for HDPE pipe based on outside diameter. These standards ensure consistency in material properties and performance across different manufacturers and applications.

The International Organization for Standardization (ISO) has also established global standards for HDPE in construction. ISO 4427 specifies requirements for HDPE piping systems for water supply, while ISO 8770 covers HDPE pipes for underground drainage and sewerage.

Regulatory bodies such as the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA) in the United States have set guidelines for the use of HDPE in specific applications. For instance, the EPA regulates the use of HDPE in potable water systems, while the FDA provides guidelines for HDPE in food-contact applications.

In Europe, the European Committee for Standardization (CEN) has developed harmonized standards for HDPE products used in construction. EN 12201 covers HDPE piping systems for water supply, and EN 1519 addresses HDPE pipes and fittings for soil and waste discharge within buildings.

Building codes in various countries also incorporate specific requirements for HDPE usage. The International Building Code (IBC) and the International Plumbing Code (IPC) in the United States include provisions for HDPE applications in construction, particularly in plumbing and drainage systems.

Certification programs, such as NSF International's certification for plastic piping systems, provide additional assurance of compliance with relevant standards and regulations. These certifications are often required by local building authorities and project specifications.

As sustainability becomes increasingly important in construction, new standards and regulations are emerging to address the environmental impact of HDPE applications. For example, the U.S. Green Building Council's LEED certification program includes credits for the use of recycled and recyclable materials, which can apply to certain HDPE products.

Compliance with these standards and regulations is crucial for manufacturers, contractors, and engineers working with HDPE in the construction industry. It ensures the safety, reliability, and performance of HDPE applications, while also facilitating trade and promoting innovation in the sector.