HDPE's Position in Global Plastic Reduction Strategies

HDPE Evolution and Objectives

High-density polyethylene (HDPE) has played a significant role in the global plastics industry since its commercial introduction in the 1950s. As a versatile and durable material, HDPE has found widespread applications across various sectors, including packaging, construction, and automotive industries. However, the increasing global focus on plastic reduction strategies has necessitated a reevaluation of HDPE's position and future trajectory.

The evolution of HDPE has been marked by continuous improvements in its properties and production processes. Initially developed as a more robust alternative to low-density polyethylene, HDPE has undergone numerous advancements in catalyst technology and manufacturing techniques. These developments have led to enhanced mechanical properties, improved processability, and increased cost-effectiveness, solidifying HDPE's position as a preferred material for many applications.

In recent years, the global plastic reduction movement has gained significant momentum, driven by growing environmental concerns and regulatory pressures. This shift has prompted the plastics industry, including HDPE manufacturers, to reassess their strategies and align with sustainability goals. The objectives for HDPE in this context are multifaceted, focusing on reducing environmental impact while maintaining its utility and economic viability.

One primary objective is to improve the recyclability of HDPE products. This involves enhancing collection and sorting systems, developing advanced recycling technologies, and increasing the use of recycled HDPE in new products. The aim is to create a more circular economy for HDPE, reducing the demand for virgin material and minimizing waste.

Another key objective is to explore bio-based alternatives to traditional petroleum-derived HDPE. Research efforts are focused on developing HDPE from renewable sources, such as plant-based feedstocks, without compromising the material's performance characteristics. This aligns with the broader goal of reducing the carbon footprint associated with HDPE production and use.

Furthermore, there is a growing emphasis on designing HDPE products for longevity and reusability. This approach aims to extend the lifecycle of HDPE products, thereby reducing overall plastic consumption. It involves innovations in product design, as well as shifts in consumer behavior and business models that prioritize durability over disposability.

As the plastics industry navigates the challenges posed by global plastic reduction strategies, the future of HDPE lies in its ability to adapt and innovate. The objectives set for HDPE encompass not only technological advancements but also systemic changes in how the material is produced, used, and managed at the end of its life cycle. By addressing these objectives, HDPE aims to maintain its relevance and utility while contributing to a more sustainable and environmentally responsible future.

Global Demand Analysis for HDPE

The global demand for High-Density Polyethylene (HDPE) continues to grow despite increasing environmental concerns and plastic reduction initiatives. This resilience in demand can be attributed to HDPE's versatility, durability, and recyclability, which make it a preferred choice in various industries.

In the packaging sector, HDPE remains a dominant material due to its excellent moisture barrier properties and chemical resistance. The food and beverage industry, in particular, relies heavily on HDPE for containers, bottles, and packaging films. The growing e-commerce sector has further boosted demand for HDPE packaging materials, as they provide protection during shipping and handling.

The construction industry represents another significant market for HDPE, with applications in pipes, fittings, and geomembranes. The material's resistance to corrosion and chemicals, coupled with its long lifespan, makes it ideal for water and sewage systems. As urbanization continues and infrastructure development accelerates in emerging economies, the demand for HDPE in construction is expected to rise.

In the automotive sector, HDPE is increasingly used in lightweight components to improve fuel efficiency and reduce emissions. This trend aligns with global efforts to decrease carbon footprints, positioning HDPE as a material that can contribute to sustainability goals while meeting performance requirements.

The agriculture industry also contributes to HDPE demand through its use in irrigation systems, greenhouse films, and storage containers. As global food production needs increase, the demand for efficient agricultural solutions incorporating HDPE is likely to grow.

Geographically, Asia-Pacific remains the largest consumer of HDPE, driven by rapid industrialization, population growth, and increasing disposable incomes. China and India are key markets within this region, with their expanding manufacturing sectors and growing middle-class populations fueling demand.

North America and Europe, while mature markets, continue to show steady demand for HDPE. In these regions, the focus is shifting towards recycled HDPE and bio-based alternatives, reflecting growing environmental consciousness and regulatory pressures.

The Middle East and Africa are emerging as significant growth markets for HDPE, particularly in infrastructure development and packaging applications. As these regions invest in modernizing their economies, the demand for HDPE is expected to increase substantially.

Despite the global push for plastic reduction, HDPE's market is projected to grow. This growth is supported by the material's recyclability and the development of more sustainable production methods. As recycling technologies advance and circular economy principles gain traction, HDPE is likely to maintain its position as a key plastic material in the global market.

HDPE Challenges in Plastic Reduction

High-density polyethylene (HDPE) faces significant challenges in the context of global plastic reduction strategies. Despite its widespread use and numerous advantages, HDPE's position in sustainability efforts is increasingly scrutinized. One of the primary challenges is its persistence in the environment. HDPE, like many plastics, takes hundreds of years to decompose naturally, contributing to long-term pollution in landfills and marine ecosystems.

Recycling HDPE presents another set of obstacles. While technically recyclable, the efficiency and effectiveness of HDPE recycling processes are often limited. Contamination from food residues, labels, and mixed plastic types can complicate recycling efforts, reducing the quality and usability of recycled HDPE. Additionally, the economic viability of HDPE recycling remains a concern, as the costs associated with collection, sorting, and processing can sometimes outweigh the value of the recycled material.

The production of HDPE also poses environmental challenges. The manufacturing process relies heavily on fossil fuels, contributing to greenhouse gas emissions and climate change. As global initiatives push for reduced carbon footprints, the HDPE industry faces pressure to adopt more sustainable production methods or find alternative materials.

Consumer perception and behavior present another hurdle for HDPE in plastic reduction strategies. While HDPE is valued for its durability and versatility, these same qualities contribute to its environmental impact when improperly disposed of. Changing consumer habits and encouraging responsible use and disposal of HDPE products is a complex challenge that requires education, incentives, and potentially regulatory intervention.

Policy and regulatory landscapes are evolving rapidly, posing both challenges and opportunities for HDPE. Many regions are implementing bans or restrictions on single-use plastics, which include some HDPE products. Adapting to these changing regulations while maintaining product functionality and market competitiveness is a significant challenge for manufacturers and users of HDPE.

The development of biodegradable alternatives to HDPE is gaining momentum, potentially threatening its market position. While these alternatives often cannot match HDPE's performance in all applications, they are increasingly seen as more environmentally friendly options. The HDPE industry must innovate to improve its environmental profile or risk losing market share to these emerging materials.

Lastly, the challenge of balancing performance with sustainability is paramount. HDPE's unique properties make it ideal for many applications, particularly in packaging and construction. Finding materials that can match its performance while offering improved environmental characteristics is a significant technological and economic challenge. This balance is crucial for maintaining HDPE's relevance in a world increasingly focused on sustainable materials and circular economy principles.

Current HDPE Reduction Strategies

01 HDPE in packaging applications

High-Density Polyethylene (HDPE) is widely used in packaging applications due to its excellent strength, durability, and chemical resistance. It is commonly employed in the production of bottles, containers, and films for various industries, including food, beverage, and personal care products. HDPE's position in packaging is reinforced by its ability to provide effective barrier properties and maintain product integrity.- HDPE in packaging applications: High-Density Polyethylene (HDPE) is widely used in packaging applications due to its excellent strength, durability, and chemical resistance. It is commonly employed in the production of bottles, containers, and films for various industries, including food, beverage, and personal care products. HDPE's position in packaging is reinforced by its ability to provide a moisture barrier and maintain product freshness.

- HDPE in construction and infrastructure: HDPE plays a significant role in construction and infrastructure projects. It is used in the manufacture of pipes for water supply, sewage systems, and gas distribution due to its corrosion resistance and long service life. HDPE is also utilized in geomembranes for landfill liners and in cable protection systems for underground utilities.

- HDPE in automotive applications: The automotive industry employs HDPE in various components due to its lightweight nature and impact resistance. It is used in fuel tanks, interior trim parts, and under-the-hood applications. HDPE's position in this sector is strengthened by its ability to reduce vehicle weight, thereby improving fuel efficiency and reducing emissions.

- HDPE in material blends and composites: HDPE is often used in blends and composites to enhance the properties of other materials. It can be combined with other polymers, fibers, or additives to create materials with improved strength, impact resistance, or specific functional characteristics. These blends and composites find applications in various industries, expanding HDPE's position across multiple sectors.

- HDPE in recycling and sustainability: HDPE's position in the circular economy is significant due to its recyclability. It can be recycled multiple times without significant loss of properties, making it a preferred material for sustainable packaging and products. The recycling of HDPE contributes to reducing plastic waste and conserving resources, aligning with global sustainability goals.

02 HDPE in construction and infrastructure

HDPE plays a significant role in construction and infrastructure projects. It is used in the manufacture of pipes for water supply, sewage systems, and gas distribution due to its corrosion resistance and long service life. HDPE is also utilized in geomembranes for landfill liners and in various construction materials, contributing to improved durability and reduced maintenance costs in infrastructure applications.Expand Specific Solutions03 HDPE in automotive applications

The automotive industry increasingly adopts HDPE for various components due to its lightweight properties and impact resistance. HDPE is used in fuel tanks, interior trim parts, and under-the-hood applications. Its position in this sector is strengthened by its ability to contribute to vehicle weight reduction, improved fuel efficiency, and enhanced safety features.Expand Specific Solutions04 HDPE in material blends and composites

HDPE is often used in blends and composites to enhance the properties of other materials or to create new materials with improved characteristics. It can be blended with other polymers or reinforced with fibers to produce materials with tailored properties for specific applications. This versatility expands HDPE's position across various industries and enables the development of innovative products.Expand Specific Solutions05 HDPE in recycling and sustainability

HDPE's position in the context of sustainability and circular economy is significant. It is one of the most widely recycled plastics, with established recycling streams in many countries. Recycled HDPE can be used in various applications, reducing the demand for virgin material and minimizing environmental impact. The recyclability of HDPE contributes to its continued importance in product design and material selection across industries.Expand Specific Solutions

Key HDPE Industry Players

The global plastic reduction strategies involving HDPE are in a transitional phase, with the market experiencing moderate growth despite environmental concerns. The HDPE market size is substantial, driven by its versatility and recyclability. Technologically, HDPE is mature, but innovation focuses on enhancing its sustainability profile. Companies like Dow Global Technologies LLC, DuPont de Nemours, Inc., and Chevron Phillips Chemical Co. LP are at the forefront of developing advanced HDPE formulations and recycling technologies. Academic institutions such as Cornell University and Oxford University Innovation Ltd. are contributing to research on HDPE's environmental impact and potential alternatives, indicating a collaborative approach to addressing plastic reduction challenges.

Procter & Gamble Co.

Dow Global Technologies LLC

HDPE Innovations for Sustainability

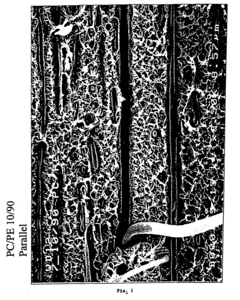

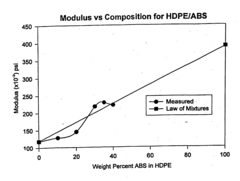

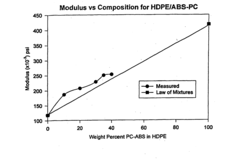

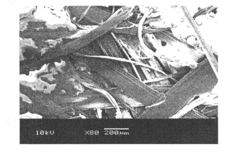

- An immiscible polymer blend of high-density polyethylene (HDPE) with acrylonitrile-butadiene-styrene (ABS) or polycarbonate (PC), or a mixture of both, with specific melt flow rates, is used to create a stiffer plastic composite, leveraging recycled materials for environmental and cost benefits, and incorporating reinforcing fillers for enhanced properties.

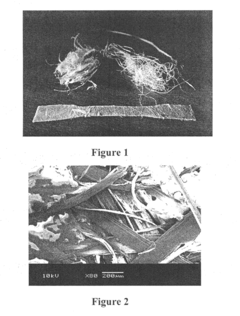

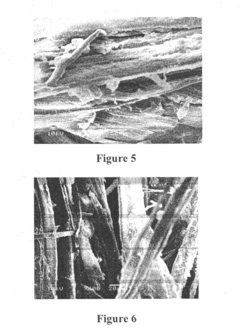

- Development of hemp fiber composites with a recycled HDPE matrix, where hemp fibers are treated with NaOH to enhance fiber-matrix adhesion, resulting in improved mechanical properties and resistance to moisture and insects, using processes like extrusion, pultrusion, and vacuum-assisted infusion.

Environmental Impact Assessment

The environmental impact assessment of HDPE (High-Density Polyethylene) in the context of global plastic reduction strategies reveals a complex interplay of factors. HDPE, while widely used for its durability and versatility, presents significant environmental challenges throughout its lifecycle.

In production, HDPE manufacturing processes contribute to greenhouse gas emissions and energy consumption. The extraction of raw materials, primarily derived from fossil fuels, further exacerbates its carbon footprint. However, compared to other plastics, HDPE's production is relatively less energy-intensive, offering a marginal advantage in terms of environmental impact during the manufacturing phase.

The use phase of HDPE products generally has a lower environmental impact due to their longevity and reusability. Many HDPE items, such as reusable shopping bags and durable containers, can replace single-use alternatives, potentially reducing overall plastic consumption. This aspect aligns with global plastic reduction strategies that emphasize reuse and longevity of products.

End-of-life management of HDPE presents both challenges and opportunities. While HDPE is recyclable, the actual recycling rates vary significantly across regions. In areas with well-established recycling infrastructure, HDPE can be effectively recycled multiple times, reducing the need for virgin material production. However, in regions lacking proper waste management systems, HDPE contributes to plastic pollution in terrestrial and marine environments.

The persistence of HDPE in the environment is a major concern. When improperly disposed of, it can take hundreds of years to decompose, leading to long-term ecological impacts. Microplastic pollution from degrading HDPE products poses risks to wildlife and potentially enters the food chain, affecting ecosystem health and biodiversity.

In the context of global plastic reduction strategies, HDPE's position is nuanced. Its recyclability and potential for reuse align with circular economy principles, supporting efforts to reduce plastic waste. However, its fossil fuel origin and persistence in the environment conflict with goals to reduce overall plastic production and environmental impact.

Innovations in bio-based HDPE and enhanced recycling technologies offer promising avenues for mitigating environmental impacts. These developments could potentially position HDPE more favorably within global plastic reduction frameworks, balancing its utility with environmental considerations.

Circular Economy Integration

The integration of HDPE into circular economy strategies is becoming increasingly crucial in global plastic reduction efforts. As a versatile and widely used plastic, HDPE presents both challenges and opportunities in the transition towards a more sustainable and circular plastics economy.

One of the key aspects of integrating HDPE into circular economy models is the development of efficient recycling systems. Advanced sorting technologies, such as near-infrared spectroscopy and artificial intelligence-driven systems, are being implemented to improve the identification and separation of HDPE from mixed plastic waste streams. This enhanced sorting capability significantly increases the quality and quantity of recyclable HDPE, making it more viable for reprocessing and reuse in various applications.

The chemical recycling of HDPE is gaining traction as a complementary approach to mechanical recycling. This process breaks down HDPE into its molecular components, allowing for the production of virgin-quality plastic. While still in its early stages, chemical recycling shows promise in addressing contamination issues and expanding the range of HDPE products that can be effectively recycled.

Design for recyclability is another critical factor in HDPE's circular economy integration. Manufacturers are increasingly adopting eco-design principles, creating HDPE products that are easier to recycle at the end of their life cycle. This includes using mono-material designs, avoiding problematic additives, and incorporating recycled content into new products.

The development of closed-loop systems for HDPE is emerging as a key strategy in various industries. For instance, in the packaging sector, companies are implementing take-back programs and collaborating with recyclers to ensure their HDPE packaging is collected, recycled, and reincorporated into new packaging or products. This approach not only reduces waste but also creates a more sustainable supply chain for HDPE.

Policy initiatives and regulatory frameworks play a crucial role in facilitating HDPE's integration into circular economy models. Extended Producer Responsibility (EPR) schemes, recycled content mandates, and plastic taxes are being implemented in various regions to incentivize the use of recycled HDPE and promote circular practices. These policies are driving innovation in HDPE recycling technologies and encouraging businesses to adopt more sustainable practices.

The shift towards a circular economy for HDPE also involves rethinking business models. Innovative approaches such as product-as-a-service models and reusable packaging systems are being explored to extend the lifespan of HDPE products and reduce single-use applications. These models not only minimize waste but also create new value streams and customer engagement opportunities.