HDPE's Influence in Advancements in Sanitation Control

HDPE in Sanitation: Background and Objectives

High-density polyethylene (HDPE) has emerged as a pivotal material in advancing sanitation control, marking a significant milestone in public health and environmental management. The evolution of HDPE's role in sanitation can be traced back to the mid-20th century when plastic materials began to revolutionize various industries. Initially developed for industrial applications, HDPE's unique properties quickly garnered attention in the sanitation sector.

The journey of HDPE in sanitation control has been characterized by continuous innovation and adaptation to meet growing global challenges in waste management and public hygiene. From its early applications in simple containment solutions, HDPE has evolved to become an integral component in sophisticated sanitation systems, including advanced sewage networks, water treatment facilities, and waste management infrastructure.

The primary objective of incorporating HDPE in sanitation control is to enhance the efficiency, durability, and safety of sanitation systems while minimizing environmental impact. HDPE's resistance to chemicals, moisture, and microbial growth makes it an ideal material for containing and transporting waste and water. Its flexibility and strength allow for the creation of leak-proof systems that can withstand various environmental stresses, significantly reducing the risk of contamination.

As global awareness of environmental issues has increased, the focus on sustainable sanitation solutions has intensified. This shift has propelled HDPE to the forefront of sanitation technology, with researchers and engineers exploring new ways to leverage its properties. The material's recyclability and long lifespan align well with circular economy principles, making it a preferred choice in modern sanitation projects.

The technological trajectory of HDPE in sanitation control is closely linked to advancements in polymer science and manufacturing processes. Innovations in HDPE formulation have led to enhanced performance characteristics, such as improved UV resistance and increased structural integrity. These developments have expanded the material's applicability across diverse climatic conditions and challenging environments.

Looking ahead, the future of HDPE in sanitation control is poised for further growth and innovation. Emerging trends indicate a focus on smart sanitation systems that integrate HDPE components with sensor technologies and data analytics. This convergence aims to create more responsive and efficient sanitation infrastructure capable of addressing complex urban challenges and supporting sustainable development goals.

Market Analysis for HDPE Sanitation Solutions

The market for HDPE sanitation solutions has experienced significant growth in recent years, driven by increasing awareness of hygiene and sanitation issues globally. High-density polyethylene (HDPE) has emerged as a preferred material for various sanitation control applications due to its durability, chemical resistance, and cost-effectiveness.

In the water and wastewater treatment sector, HDPE pipes and fittings have gained substantial market share. The global HDPE pipes market, a significant portion of which is used in sanitation applications, was valued at approximately $17.5 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of over 5% from 2021 to 2028. This growth is primarily attributed to the increasing demand for clean water and efficient wastewater management systems in both developed and developing countries.

The sanitation products segment, including HDPE-based portable toilets, septic tanks, and waste containers, has also shown robust growth. The global portable toilet rental market, where HDPE is a dominant material, was valued at around $18 billion in 2020 and is expected to expand at a CAGR of over 7% from 2021 to 2028. This growth is fueled by increasing construction activities, outdoor events, and the need for improved sanitation facilities in remote areas.

In the healthcare sector, HDPE-based sanitation products such as medical waste containers and sharps disposal units have seen increased adoption. The global medical waste management market, where HDPE products play a crucial role, was valued at approximately $7 billion in 2020 and is projected to grow at a CAGR of over 5% from 2021 to 2028. This growth is driven by stringent regulations regarding medical waste disposal and the increasing volume of healthcare waste generated globally.

The agriculture sector has also contributed to the demand for HDPE sanitation solutions, particularly in irrigation systems and livestock waste management. The global agricultural films market, where HDPE is widely used, was valued at around $10 billion in 2020 and is expected to grow at a CAGR of over 6% from 2021 to 2028. This growth is attributed to the increasing adoption of modern farming techniques and the need for efficient water management in agriculture.

Geographically, Asia-Pacific is expected to be the fastest-growing market for HDPE sanitation solutions, driven by rapid urbanization, population growth, and increasing investments in infrastructure development. North America and Europe remain significant markets, with a focus on upgrading existing sanitation infrastructure and implementing advanced waste management systems.

HDPE Sanitation Technology: Current State and Challenges

High-density polyethylene (HDPE) has emerged as a pivotal material in advancing sanitation control technologies. The current state of HDPE sanitation technology is characterized by widespread adoption across various sectors, including water treatment, waste management, and healthcare facilities. HDPE's inherent properties, such as chemical resistance, durability, and impermeability, have positioned it as a preferred choice for sanitation applications.

In water treatment systems, HDPE pipes and containers are extensively used for their ability to maintain water quality and prevent contamination. The material's resistance to corrosion and chemical degradation ensures long-term reliability in water distribution networks. Additionally, HDPE's smooth interior surface reduces biofilm formation, contributing to improved water quality and reduced maintenance requirements.

The waste management sector has also benefited significantly from HDPE technology. HDPE-lined landfills have become standard practice, effectively containing leachate and preventing groundwater contamination. HDPE geomembranes are widely employed in constructing containment systems for hazardous waste, showcasing the material's versatility in environmental protection applications.

Healthcare facilities have increasingly incorporated HDPE in their sanitation protocols. HDPE-based medical waste containers and disposal systems have enhanced safety measures, reducing the risk of contamination and improving overall hygiene standards. The material's resistance to microbial growth has made it particularly valuable in maintaining sterile environments.

Despite these advancements, the HDPE sanitation technology sector faces several challenges. One primary concern is the environmental impact of HDPE production and disposal. While the material offers excellent durability, its non-biodegradable nature poses long-term environmental risks. The industry is grappling with the need to develop more sustainable production methods and improve recycling capabilities for HDPE products used in sanitation applications.

Another challenge lies in the optimization of HDPE properties for specific sanitation needs. While HDPE's general characteristics are beneficial, there is ongoing research to enhance its performance in targeted applications. For instance, improving HDPE's resistance to certain chemicals or increasing its thermal stability could expand its use in more demanding sanitation environments.

The integration of HDPE with smart technologies presents both opportunities and challenges. There is growing interest in developing HDPE products with embedded sensors or smart materials to enable real-time monitoring of sanitation systems. However, the implementation of such technologies while maintaining the integrity and cost-effectiveness of HDPE products remains a significant challenge.

Regulatory compliance and standardization across different regions also pose challenges to the HDPE sanitation technology sector. Ensuring that HDPE products meet diverse global standards for sanitation and safety requires ongoing efforts in research, testing, and certification processes.

Existing HDPE-based Sanitation Control Solutions

01 Antimicrobial additives for HDPE

Incorporating antimicrobial additives into HDPE materials to enhance sanitation control. These additives can inhibit the growth of bacteria, fungi, and other microorganisms on the surface of HDPE products, improving their hygiene and longevity in various applications.- Antimicrobial additives for HDPE: Incorporating antimicrobial agents into HDPE during the manufacturing process can enhance its sanitation control properties. These additives can inhibit the growth of bacteria, fungi, and other microorganisms on the surface of HDPE products, making them more hygienic and suitable for use in sanitary applications.

- Surface treatment techniques for HDPE: Various surface treatment methods can be applied to HDPE to improve its sanitation control capabilities. These techniques may include plasma treatment, corona discharge, or chemical etching, which can modify the surface properties of HDPE to make it more resistant to microbial growth and easier to clean.

- HDPE blends for enhanced sanitation: Blending HDPE with other polymers or materials can result in composites with improved sanitation control properties. These blends may offer better resistance to bacterial growth, enhanced cleanability, or increased durability in sanitary environments.

- Specialized HDPE formulations for medical applications: Developing specialized HDPE formulations for medical and healthcare applications can enhance sanitation control. These formulations may incorporate specific additives or undergo particular processing techniques to meet stringent hygiene requirements in medical settings.

- HDPE packaging solutions with improved sanitation: Innovative HDPE packaging designs and manufacturing processes can enhance sanitation control in food, pharmaceutical, and personal care industries. These solutions may include features such as antimicrobial coatings, easy-clean surfaces, or barrier properties to prevent contamination.

02 Surface treatment techniques for HDPE

Applying various surface treatment techniques to HDPE products to improve their sanitation properties. These methods may include plasma treatment, UV irradiation, or chemical modifications to enhance the material's resistance to microbial contamination and ease of cleaning.Expand Specific Solutions03 HDPE blends for improved sanitation

Developing HDPE blends with other materials or polymers to enhance sanitation control properties. These blends can combine the beneficial properties of HDPE with those of other materials to create products with superior hygiene characteristics and durability.Expand Specific Solutions04 Sanitation-focused HDPE product design

Designing HDPE products with specific features that facilitate better sanitation control. This may include incorporating smooth surfaces, minimizing joints and crevices, and creating easily cleanable structures to prevent the accumulation of contaminants and promote hygiene.Expand Specific Solutions05 Cleaning and maintenance protocols for HDPE

Developing specialized cleaning and maintenance protocols for HDPE products to ensure effective sanitation control. These protocols may include specific cleaning agents, techniques, and schedules tailored to the unique properties of HDPE materials in various applications.Expand Specific Solutions

Key Players in HDPE Sanitation Industry

The HDPE market in sanitation control is in a growth phase, driven by increasing demand for hygienic solutions. The market size is expanding, with a projected CAGR of 5.8% from 2021 to 2028. Technologically, HDPE applications are maturing, with companies like GOJO Industries, Ecolab USA, and Unilever leading innovations. China Petroleum & Chemical Corp. and Dow Global Technologies are advancing HDPE formulations, while universities such as Fuzhou University and The University of North Carolina at Charlotte contribute to research. The industry sees a mix of established players and emerging companies, indicating a competitive and evolving landscape with potential for further technological advancements in sanitation control applications.

GOJO Industries, Inc.

Ecolab USA, Inc.

Innovative HDPE Applications in Sanitation

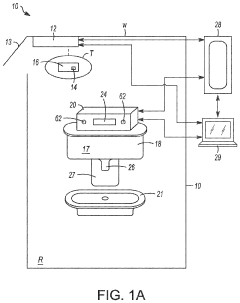

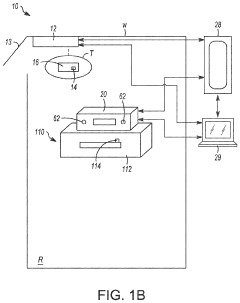

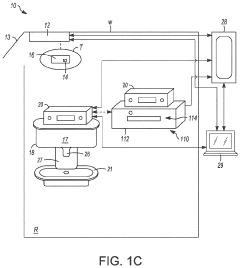

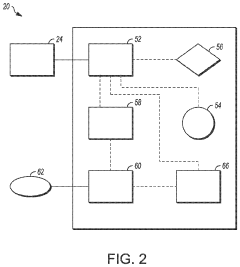

- A perimeter-based system comprising hand hygiene and glove dispensers with integrated control units, identity sensors, alarm indicators, and transmitters, which detect worker proximity and identity to enforce compliance by reminding and recording hand hygiene and gloving activities.

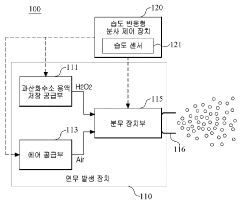

- An HPAE equipped with a humidity-responsive spray control device that intermittently controls the hydrogen peroxide aerosol spray based on humidity levels, using a humidity sensor to maintain concentrations below 100% humidity, preventing condensation and incorporating a plasma electrode for ionized aerosol generation.

Environmental Impact of HDPE in Sanitation

The environmental impact of High-Density Polyethylene (HDPE) in sanitation is a complex and multifaceted issue that requires careful consideration. HDPE has become a prevalent material in sanitation infrastructure due to its durability, chemical resistance, and cost-effectiveness. However, its widespread use also raises concerns about its long-term effects on the environment.

One of the primary environmental benefits of HDPE in sanitation systems is its longevity. HDPE pipes and containers can last for decades without degradation, reducing the need for frequent replacements and minimizing the environmental impact associated with manufacturing and installing new infrastructure. This durability also helps prevent leaks and contamination, protecting soil and water resources from pollution.

HDPE's resistance to corrosion and chemical degradation makes it an ideal material for handling various types of waste and chemicals used in sanitation processes. This resistance reduces the risk of environmental contamination due to material failure, which is particularly crucial in areas with aggressive soil conditions or high groundwater tables.

However, the production of HDPE relies heavily on fossil fuels, contributing to greenhouse gas emissions and climate change. The manufacturing process also involves the use of potentially harmful chemicals and the release of volatile organic compounds (VOCs). Efforts to reduce these impacts include the development of bio-based HDPE and more efficient production methods.

The end-of-life management of HDPE products in sanitation systems presents both challenges and opportunities. While HDPE is recyclable, the recycling process for sanitation-related products can be complicated due to contamination concerns. Proper collection and recycling systems are essential to maximize the material's lifecycle and minimize its environmental footprint.

HDPE's resistance to biodegradation, while beneficial for its longevity in use, becomes problematic when the material enters natural ecosystems. Improperly disposed HDPE products can persist in the environment for hundreds of years, potentially harming wildlife and ecosystems. This has led to increased focus on developing biodegradable alternatives and improving waste management practices.

The use of HDPE in sanitation systems also impacts water conservation efforts. The material's smooth interior surface reduces friction, allowing for more efficient water flow and potentially reducing the energy required for pumping. This efficiency can lead to lower water and energy consumption in sanitation processes, contributing to overall resource conservation.

As environmental concerns continue to grow, there is an increasing emphasis on life cycle assessments of HDPE in sanitation applications. These assessments consider the material's environmental impact from production through use and disposal, helping to inform more sustainable design and management practices in the sanitation sector.

Regulatory Framework for HDPE in Sanitation Control

The regulatory framework for HDPE in sanitation control has evolved significantly over the years, reflecting the growing importance of this material in ensuring public health and environmental safety. At the international level, organizations such as the World Health Organization (WHO) and the International Organization for Standardization (ISO) have established guidelines and standards for the use of HDPE in water and sanitation systems.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating the use of HDPE in sanitation control. The Safe Drinking Water Act (SDWA) and the Clean Water Act (CWA) provide the legislative foundation for these regulations. The EPA has established specific standards for HDPE pipes and fittings used in potable water systems, including requirements for material composition, performance, and testing protocols.

The National Sanitation Foundation (NSF) International, a non-governmental organization, has developed several standards that are widely recognized and adopted by regulatory bodies. NSF/ANSI 61, for instance, sets criteria for materials and products that come into contact with drinking water, including HDPE components. This standard ensures that these materials do not leach harmful contaminants into the water supply.

In Europe, the European Union has implemented the Drinking Water Directive, which sets quality standards for drinking water and indirectly influences the use of HDPE in water distribution systems. The European Committee for Standardization (CEN) has developed specific standards for plastic piping systems, including those made from HDPE, used in water supply and sanitation applications.

Many countries have adopted or adapted these international standards into their national regulatory frameworks. For example, Australia and New Zealand follow the AS/NZS 4130 standard for polyethylene pipes for pressure applications, which includes specifications for HDPE pipes used in water and sanitation systems.

In developing countries, the regulatory landscape for HDPE in sanitation control is often less comprehensive but is gradually improving. International development agencies and non-governmental organizations often play a significant role in promoting the adoption of standards and best practices in these regions.

The regulatory framework also extends to the manufacturing processes of HDPE products used in sanitation control. Good Manufacturing Practices (GMP) and quality management systems such as ISO 9001 are often required to ensure consistent product quality and safety. Additionally, environmental regulations increasingly focus on the lifecycle of HDPE products, including their production, use, and disposal, to minimize environmental impact and promote sustainability in sanitation control applications.