Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82 results about "Nitrous acid ester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethyl nitrate is the ethyl ester of nitric acid and has the chemical formula C2H5NO3. It is a colourless, volatile, highly flammable liquid. It is used in organic synthesis and as an intermediate in the preparation of some drugs, dyes, and perfumes.

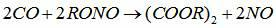

Preparation method for catalyst for synthesizing oxalic ester by gas-phase

ActiveCN101543784ALow costCatalyst activation/preparationPreparation by carbon monoxide or formate reactionGas phaseReaction temperature

The invention discloses a preparation method for a catalyst for synthesizing oxalic ester by gas-phase. The catalyst takes alpha-alumina as a carrier, palladium as an active component and 2 MOxes as an additive, M is magnesium, titanium, zirconium, vanadium, manganese, iron, nickel, copper, zinc, molybdenum or tungsten, and components of the catalyst (calculated by carrier mass) are: 0.01 to 0.75 percent of the palladium and 0.1 to 20 percent of MOxes. The preparation method comprises the following steps that: firstly, an additive metal salt solution is used to impregnate the carrier, and a palladium salt solution is used to impregnate the carrier to obtain the catalyst after the carrier is dried and roasted. Before the use, pure hydrogen or H2-N2 mixed gas is activated by the catalyst at a temperature of between 150 and 450 DEG C. The catalyst can be used for synthesizing oxalic ester by the carbonylation of CO and nitrous acid ester, the using reaction temperature of the catalyst is between 70 and 150 DEG C, and the reaction space velocity is between 500 and 9,000h<-1>. The catalyst has higher reaction activity and selectivity; and the catalyst has low cost.

Owner:HAISO TECH

Method for separating and purify dermatansulfate and low-molecular heparan sulfate from sodium heparan product

ActiveCN1850864AStable separationImprove solubilityOrganic active ingredientsDermatan sulfateSodium heparin

The invention relates to a method to separate and purify dermatan sulfate and low molecule heparan sulfate from sodium heparin by-product. It uses the by-product of producing sodium heparin as raw material taking fractional precipitation through alcohol to gain raw dermatan sulfate; uses nitrite and nitrous acid ester compounding as oxidant to degrade the heparan sulfate into low molecule heparan sulfate and taking fractional precipitation through alcohol to separate high purity dermatan sulfate and low molecule heparin sulfate.

Owner:NANJING KING FRIEND BIOCHEM PHARMA CO LTD

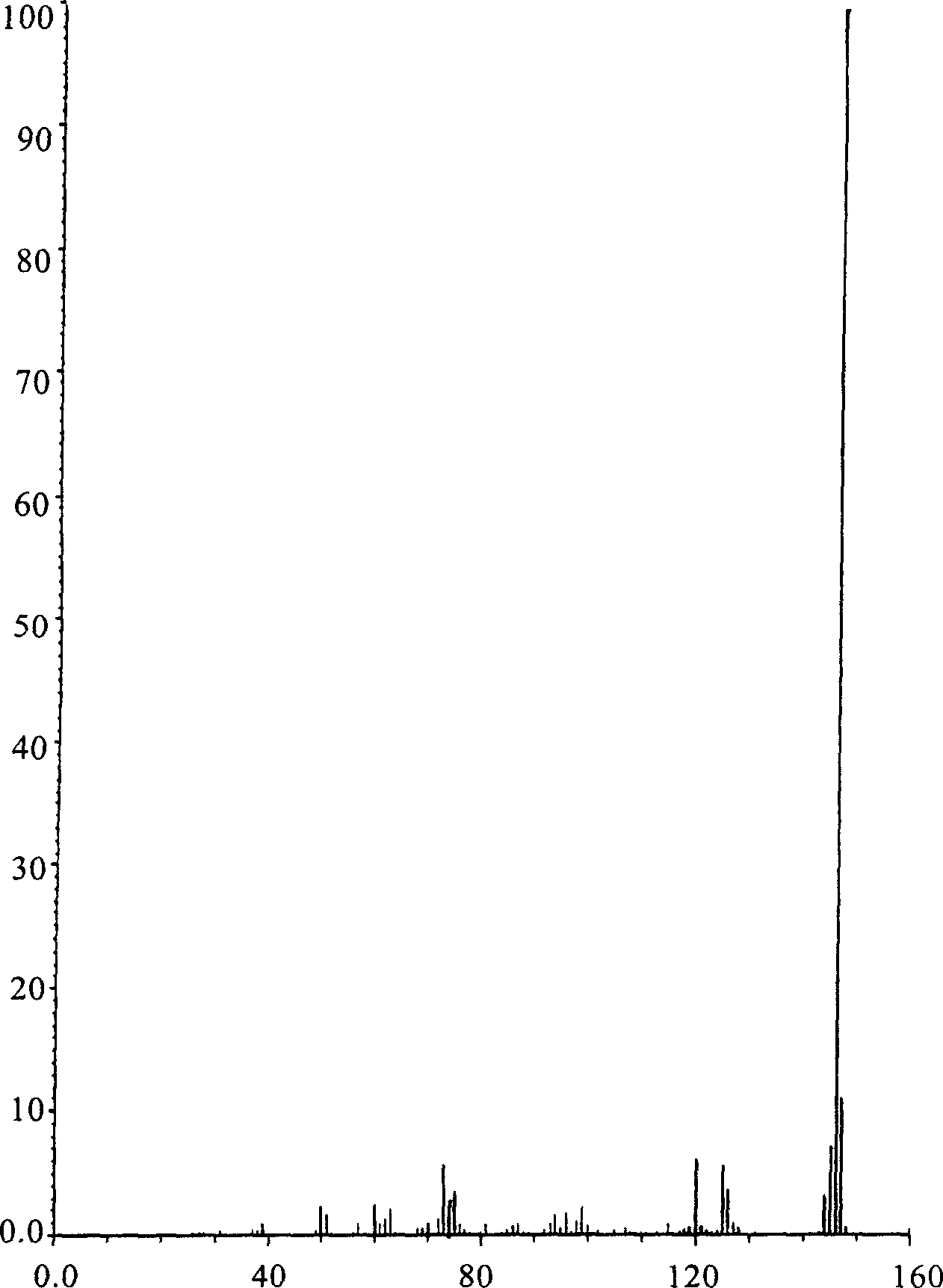

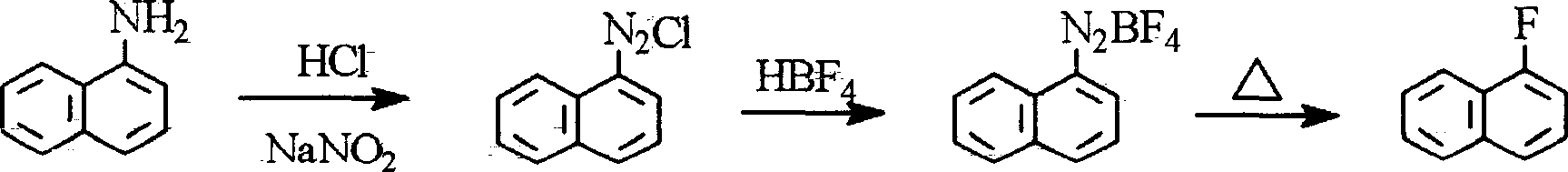

Prepn process of 1-fluoronaphthalene

ActiveCN1887833AShort synthetic routeMild conditionsHalogenated hydrocarbon preparationNitriteNitrous acid ester

The preparation process of 1-fluoronaphthalene includes the following steps: (1) reacting 1-naphthylamine with nitrous acid, nitrous acid ester or nitrite in acid medium to obtain diazo salt; (2) reacting the diazo salt with fluoroboric acid or its salt or fluorophosphoric acid or its salt to obtain diazo fluoroborate or diazo fluorophosphate; and (3) heating the diazo fluoroborate or diazo fluorophosphate to decompose to obtain 1-fluoronaphthalene. The process has short synthesis path, less side products, mild reaction condition, easy control, relatively low cost, great production capacity, high product purity and other advantages, and the product is used as medicine intermediate.

Owner:SHANGHAI CHEMSPEC CORP

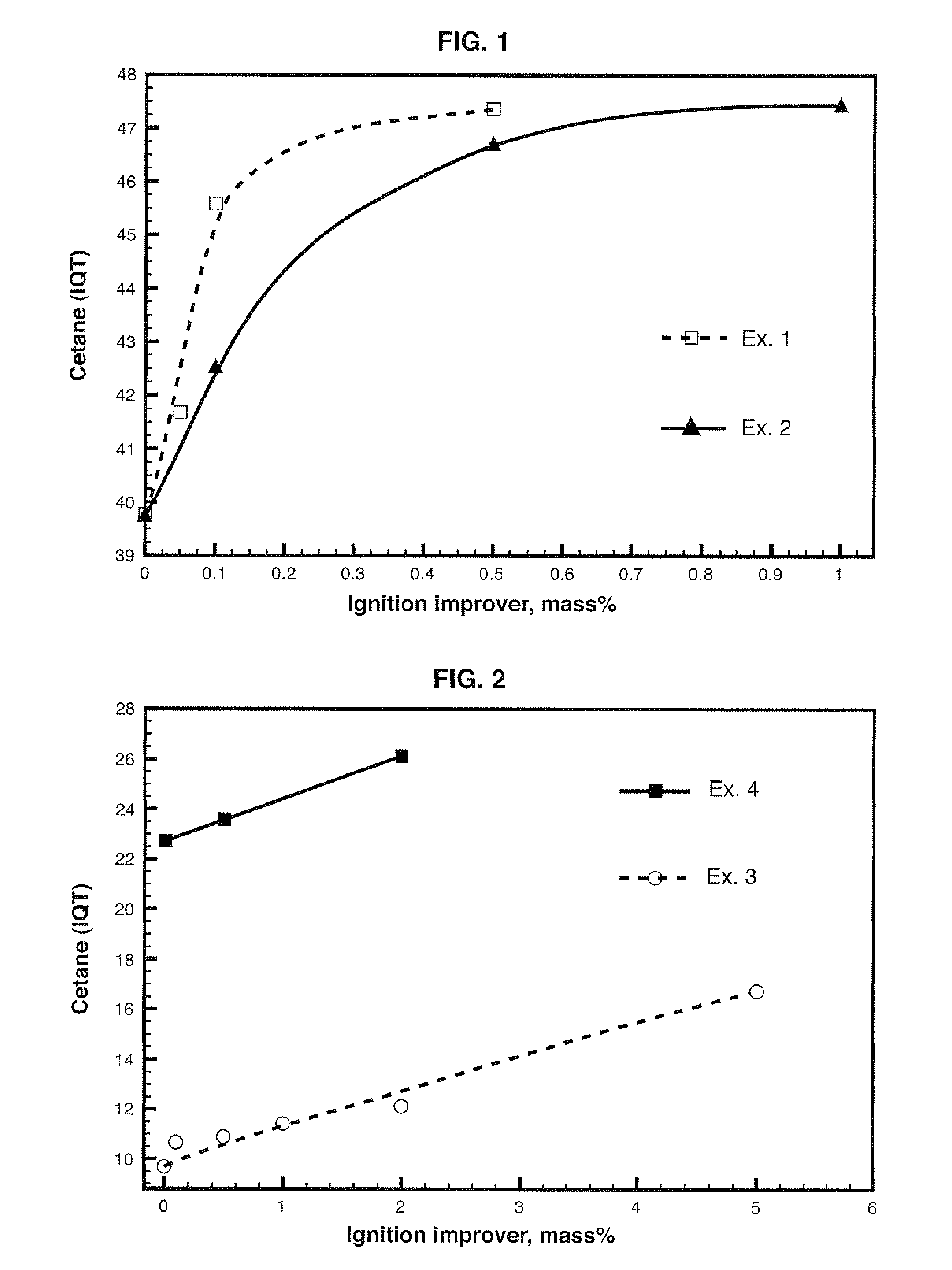

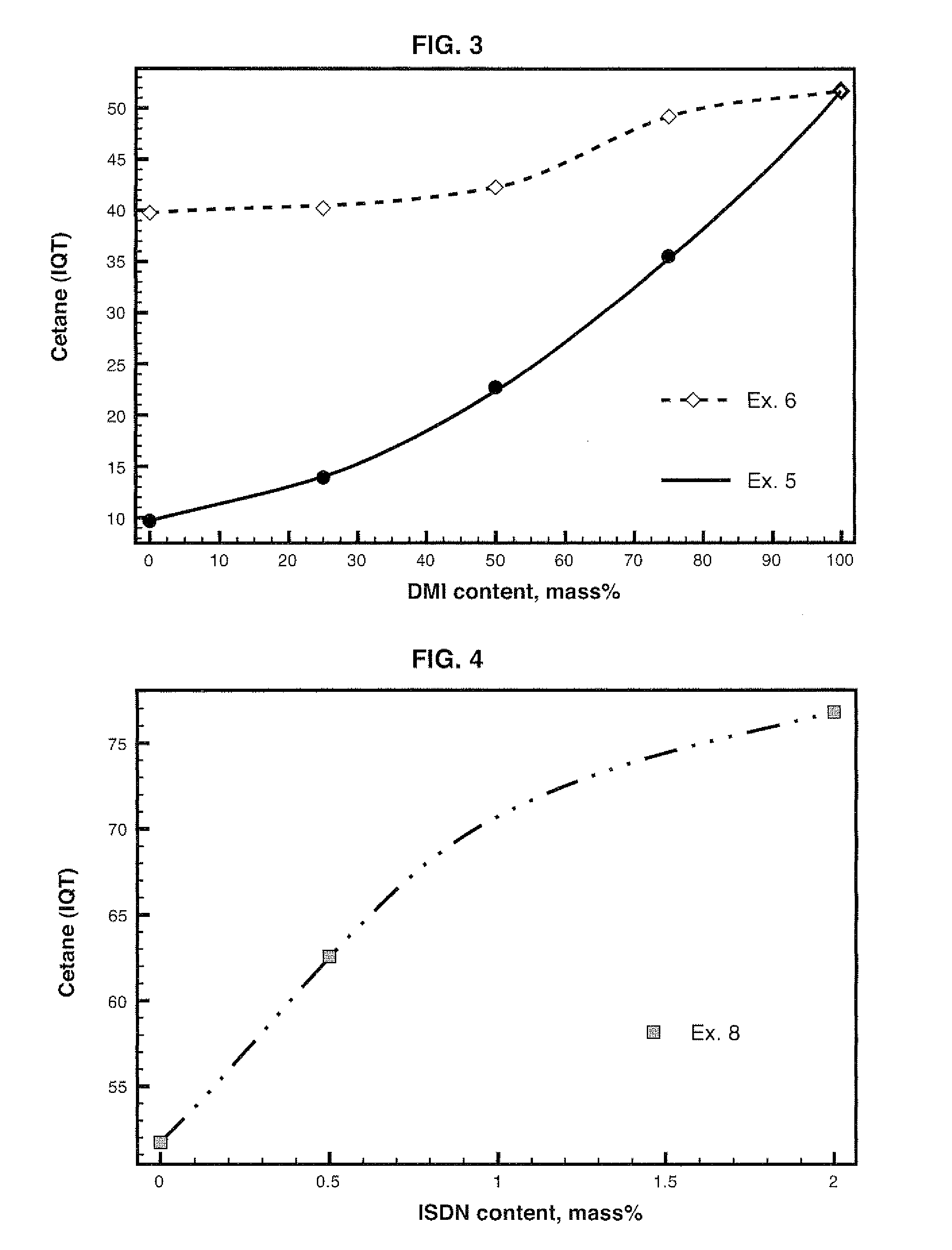

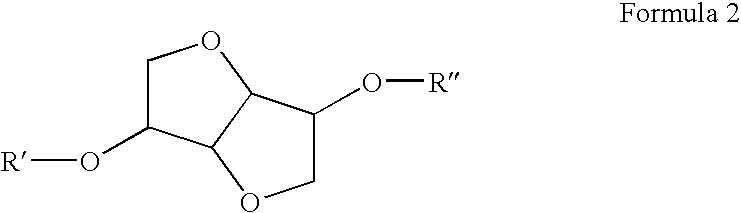

Diesel cycle fuel compositions containing dianhydrohexitols and related products

Diesel cycle fuel compositions are described containing at least one dianhydrohexitol compound according to the general formula 2 and / or itsderived hydrocarbyl ethers or nitric ethers compounds, where the R′ and R″ substituents are both H or one or both of R′ and R″ is alkyl, cycloalkyl or phenyl, or one or both are —NO2. A preferred fuel composition is that containing dimethyl isosorbide (DMI) added or not of isosorbide dinitrate (ISDN) as ignition improver. The dianhydrohexitols compounds form compositions with at least one of the components selected among petroleum-derived diesel fuel, biodiesel, ethanol and water. The mixture of DMI and ISDN has excellent cetane number (IQT). Still, the oxygenated nature of the dianhydrohexitols and related compounds of the fuel compositions inhibits soot formation upon burning of the said Diesel cycle fuel compositions.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

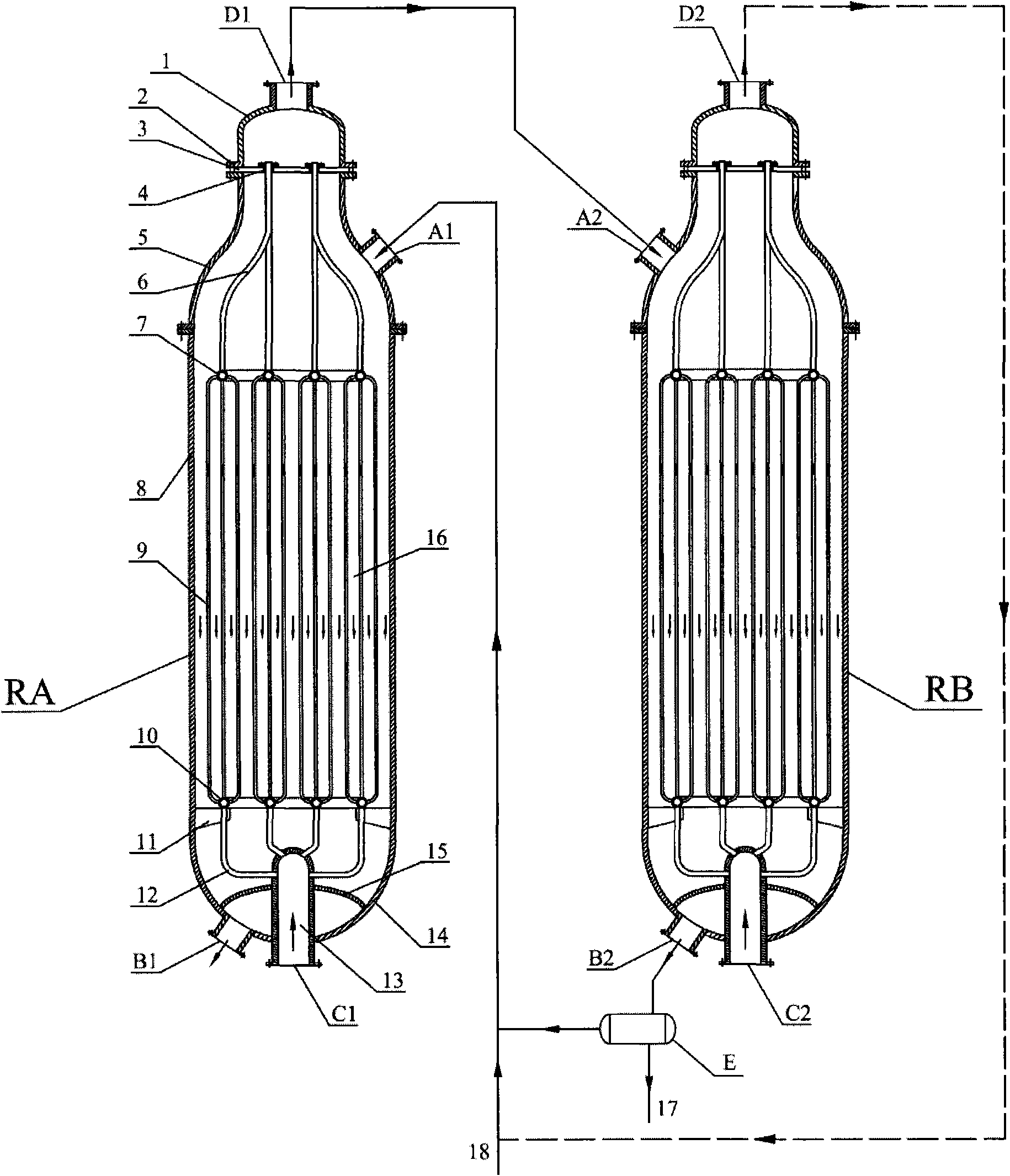

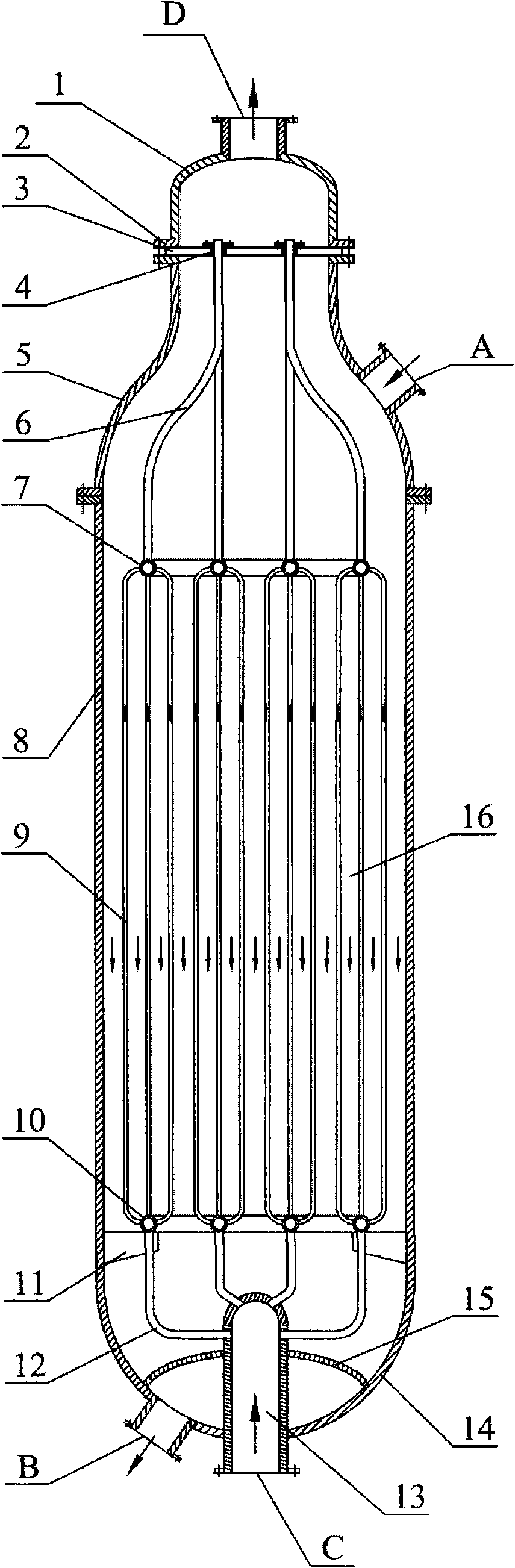

Method for producing oxalic ester by gas phase CO coupling

ActiveCN101993369AIncrease conversion rate per passHigh selectivityPreparation by carbon monoxide or formate reactionChemical/physical processesNitrous acid esterCoupling

The invention relates to a method for producing oxalic ester by gas phase CO coupling, which mainly solves the problems of low selectivity of the target product oxalic ester and low conversion per pass of the raw materials in the prior art. In the method, a technical scheme is adopted as follows: CO and nitrous acid ester in mol ratio of 1-5:1 are used as raw materials; a first batch of raw material as a cooling medium passes through tubes of a first tube-type fixed bed reactor, after heat exchange, enters a second fixed bed reactor, contacts with a palladium-containing catalyst II in a catalyst bed II in the reactor for reaction to generate a reaction effluent I containing the oxalic ester; and a gas phase effluent II containing CO is obtained by gas-liquid separation of the reaction effluent I, and is uniformly mixed with a second batch of raw material containing the fresh component nitrous acid ester, and the mixture is returned into the first tube-type fixed bed reactor, contacts with a palladium-containing catalyst I in a catalyst bed I outside the tubes for reaction to generate the reaction effluent containing the oxalic ester, wherein the total mol ratio of CO to nitrous acid ester in the raw material is 1-4:1, the mol ratio of the second batch of nitrous acid ester to the first batch of nitrous acid ester material is 0.2-5:1, and at least two reactors are connected in series. By using the method, the problems can be better solved and the method can be used in the industrial production for increasing the yield of the oxalic ester.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for oxalate ester synthetic reaction and preparation method of catalyst

ActiveCN103962130AHigh activityCatalyst carriersPreparation by carbon monoxide or formate reactionGas phaseNitric oxide

The invention discloses a catalyst for the oxalate ester synthetic reaction and a preparation method of the catalyst. The catalyst uses a zirconia-aluminium oxide composite oxide as a carrier, wherein the zirconia in the composite oxide mainly exists in a square crystal form, and the aluminium oxide in the composite oxide mainly exists in a delta-aluminium oxide form. After being subjected to hydro-thermal treatment by a urea solution, the carrier is subjected to active load in the next step. A main active component of the catalyst is palladium, and an assistant is selected from one of zinc, nickel and iron. Based on the weight of the carrier, the content of the palladium is 0.03-0.3%, and the content of the assistant is 0.01-0.5%. By the adoption of the method, the prepared catalyst is uniform in active component distribution, can show the advantages of good catalytic activity and high stability when being used in the oxalate ester synthetic reaction by using gas-phase carbonic oxide and nitrous acid ester, can resist influence of industrial raw material gas impurities such as nitric oxide and methyl alcohol steam, and is more suitable for an industrialized production process.

Owner:商丘国龙新材料有限公司

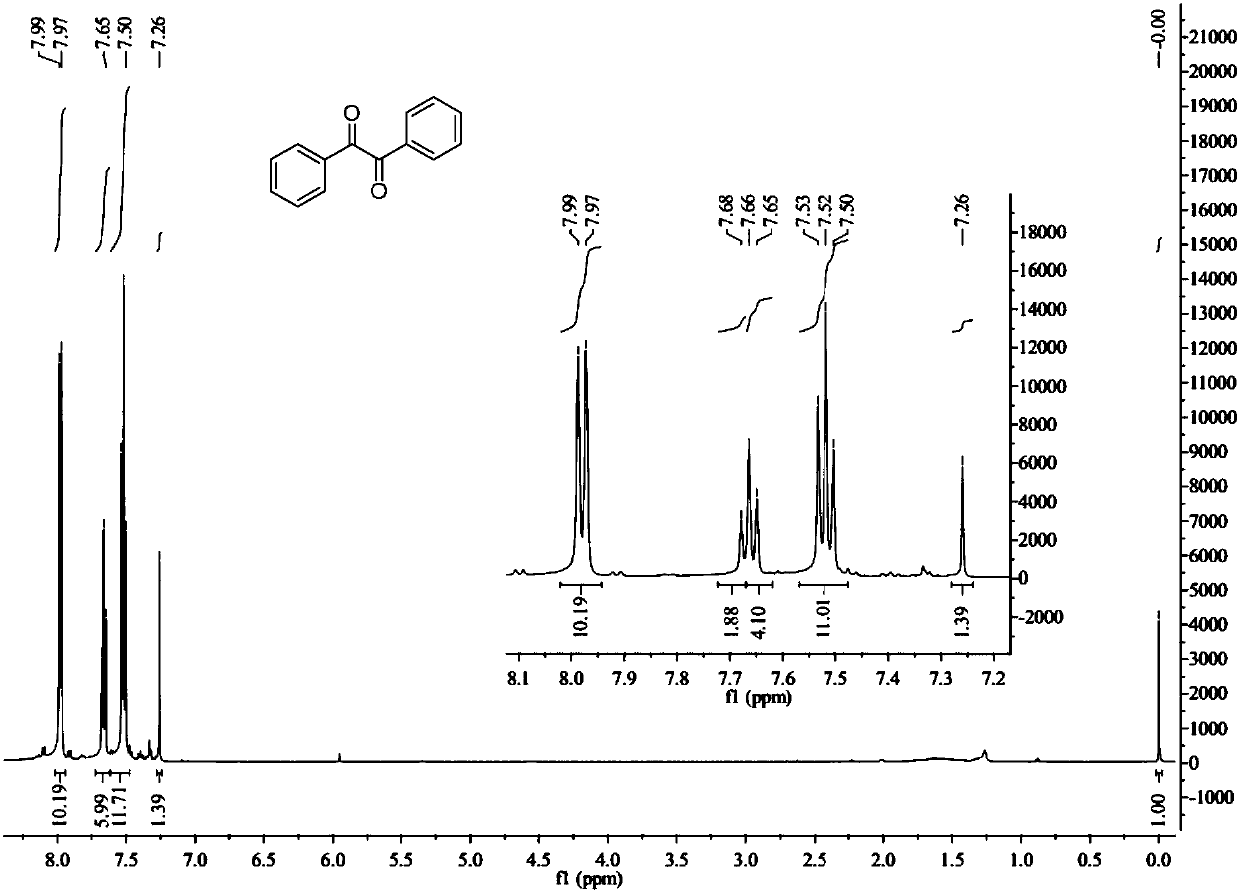

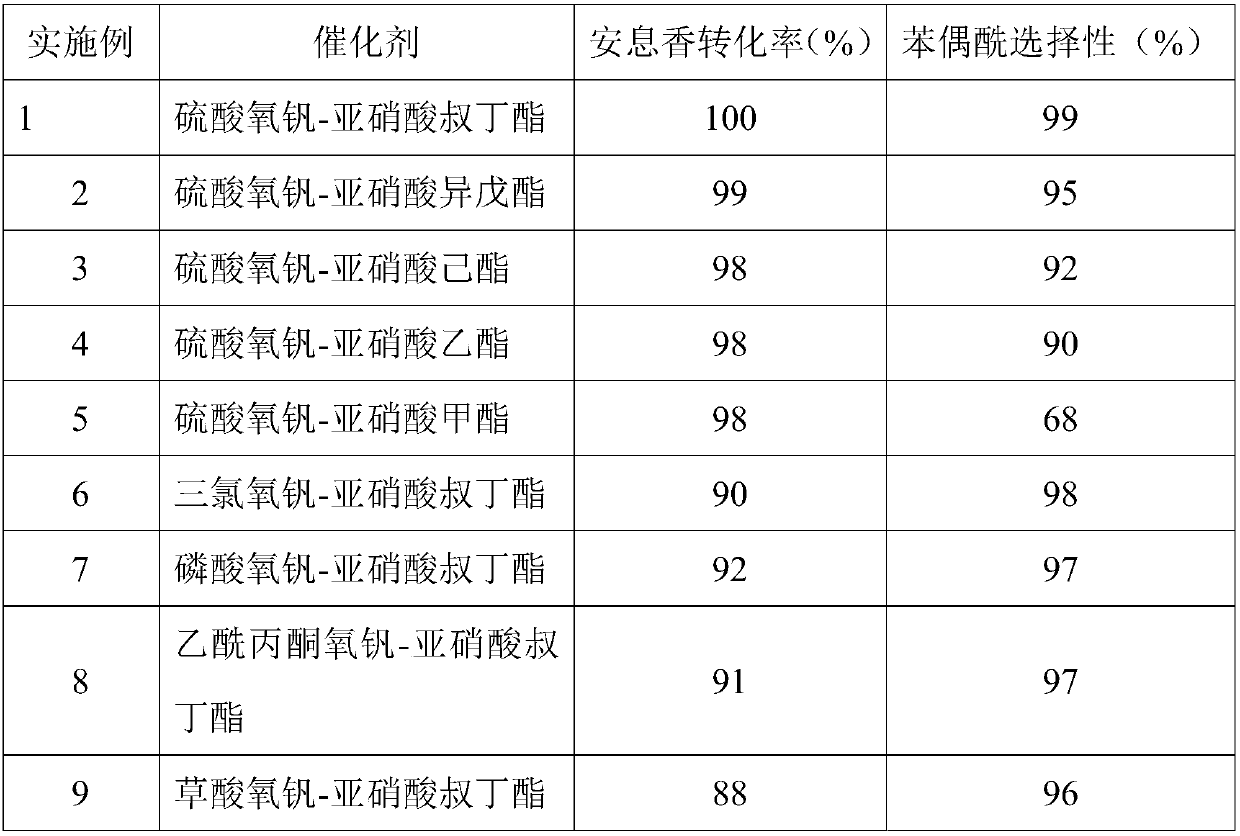

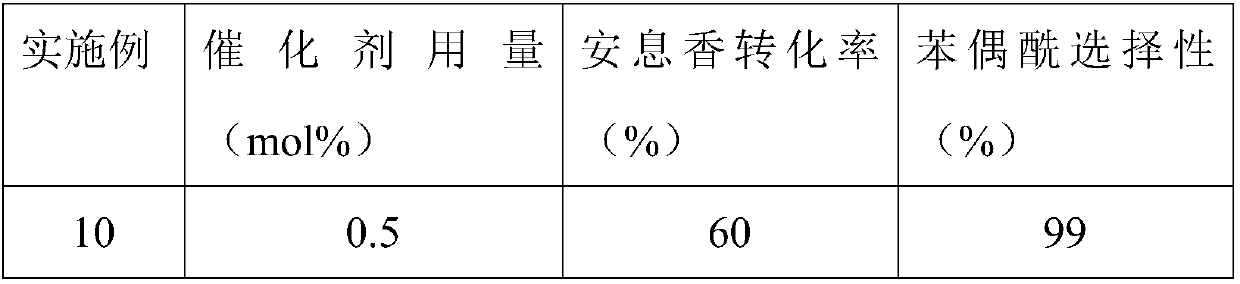

Method for preparing benzil by performing catalytic oxidation on benzoin

InactiveCN107903155AImprove conversion rateHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsNitrous acid esterCatalytic oxidation

The invention belongs to the technical field of preparation of benzyl and provides a method for preparing benzil by performing catalytic oxidation on benzoin. According to the method, oxygen or air serves as an oxidizing agent, a composite catalyst consists of two components, namely vanadium oxide and nitrous acid ester, and the benzyl is prepared by performing catalytic oxidation on the benzoin at 60 to 120 DEG C. Compared with the stoichiometric chemistry oxidation methods such as traditional chromate oxidation method, the nitric acid oxidation method and the permanganate oxidation method, the method has the following advantages: the reaction condition is mild, the catalyst is cheap and efficient, the reaction is green and environment-friendly, the conversion rate of the benzoin is high,the selectivity of the benzyl is high, and good application prospect and high practical value are achieved.

Owner:DALIAN UNIV OF TECH

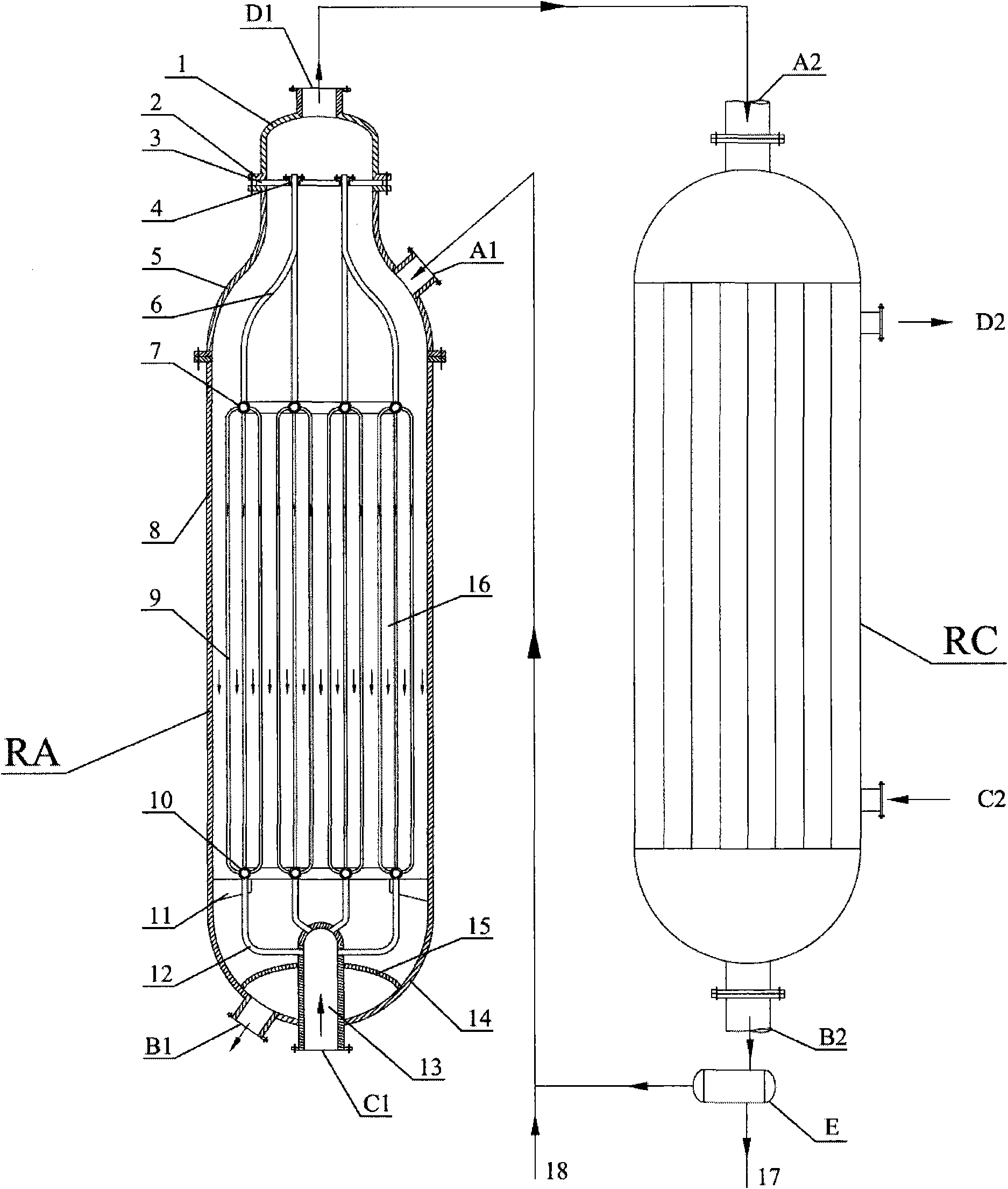

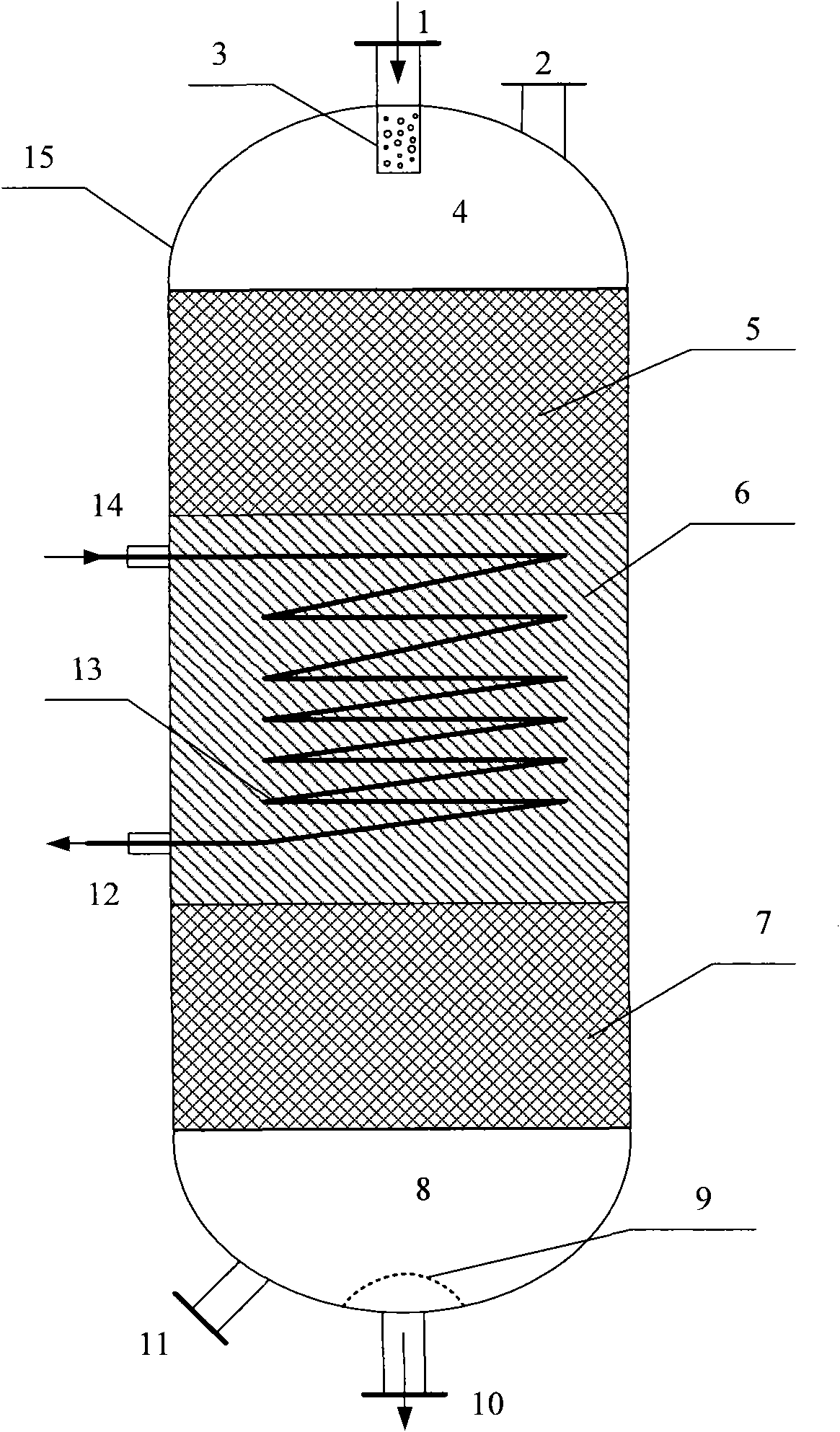

Method for synthesizing oxalic ester by CO coupling

ActiveCN101993368AIncrease conversion rate per passImprove technical effectPreparation by carbon monoxide or formate reactionChemical/physical processesNitrous acid esterContact time

The invention relates to a method for synthesizing oxalic ester by CO coupling, which mainly solves the problems that the temperature difference in a reactor is large, temperature runaway and inactivation of the catalyst can be caused easily, and the selectivity of the target product oxalic ester is low. The invention adopts the technical scheme of taking nitrous acid ester and CO as raw materials, wherein the mol ratio of the CO to the nitrous acid ester is 1-5:1, and taking at least one of the nitrous acid ester, the CO or water as a cooling medium, and comprising the following steps: underthe conditions that the reaction temperature is 60 DEG C-160 DEG C, the reaction pressure is 0-1.5MPa, and the contact time is 0.5-6 seconds, the cooling medium passes through tubes in a tube-type fixed bed reactor, a catalyst bed is positioned outside the tubes, and after raw gas enters the reactor, the raw gas contacts with the palladium catalyst outside the tubes and reacts to generate the oxalic ester, wherein the flow direction of the cooling medium is in the same or reverse direction of the flow direction of the raw gas. The technical scheme better solves the problems and can be used for the industrial production for increasing the yield of the oxalic ester.

Owner:CHINA PETROLEUM & CHEM CORP +1

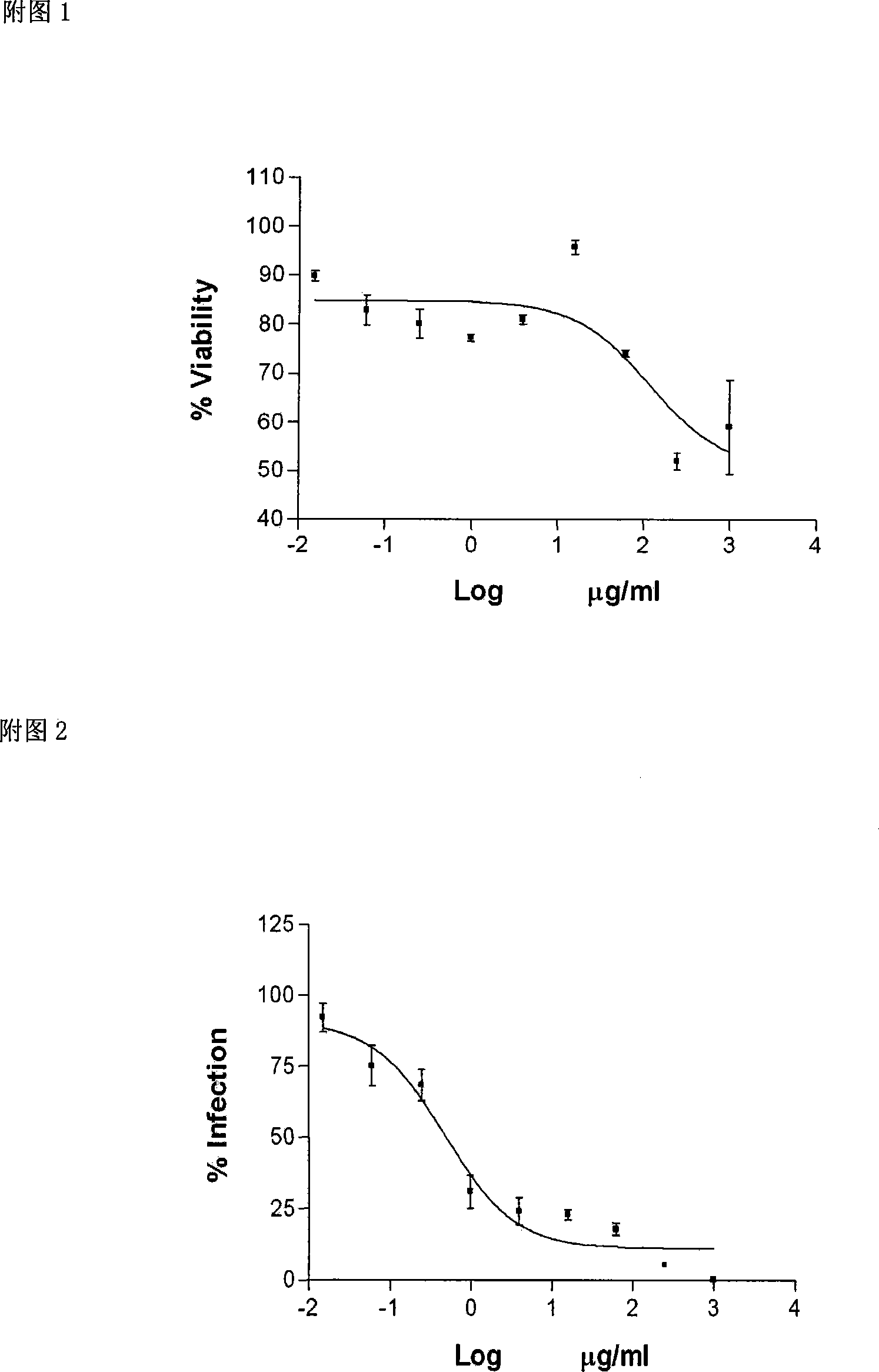

Preparation and application of sage polysaccharides and its esters

The invention relates to the preparation and application of Salvia polysaccharide and its esters. The sugar chain is sorbitol, rhamnose, and galactose linked through 1->6 (or non-reducing terminal), 1->4 and 1->3 glycosidic bond. The invention provided Salvia polysaccharide and its esters is prepared from Salvia as raw material or residues of Salvia after extracting fat-soluble effective ingredient or (and) water soluble phenolic acid by leaching with hot water, concentrating, precipitating with ethanol, deproteinizing to obtain Salvia polysaccharide, and esterizing to obtain Salvia polysaccharide ester (sulfate, phosphate ester, nitric ether and acetic ester).The invention obtained Salvia polysaccharide and its esters both have strong human immunodeficiency virus and herpes simplex virus resisting activity, has low toxicity to human cell, and can be used for preparing preparation for preventing or treating AIDS viral and herpes simplex viral infection.

Owner:陈朝银

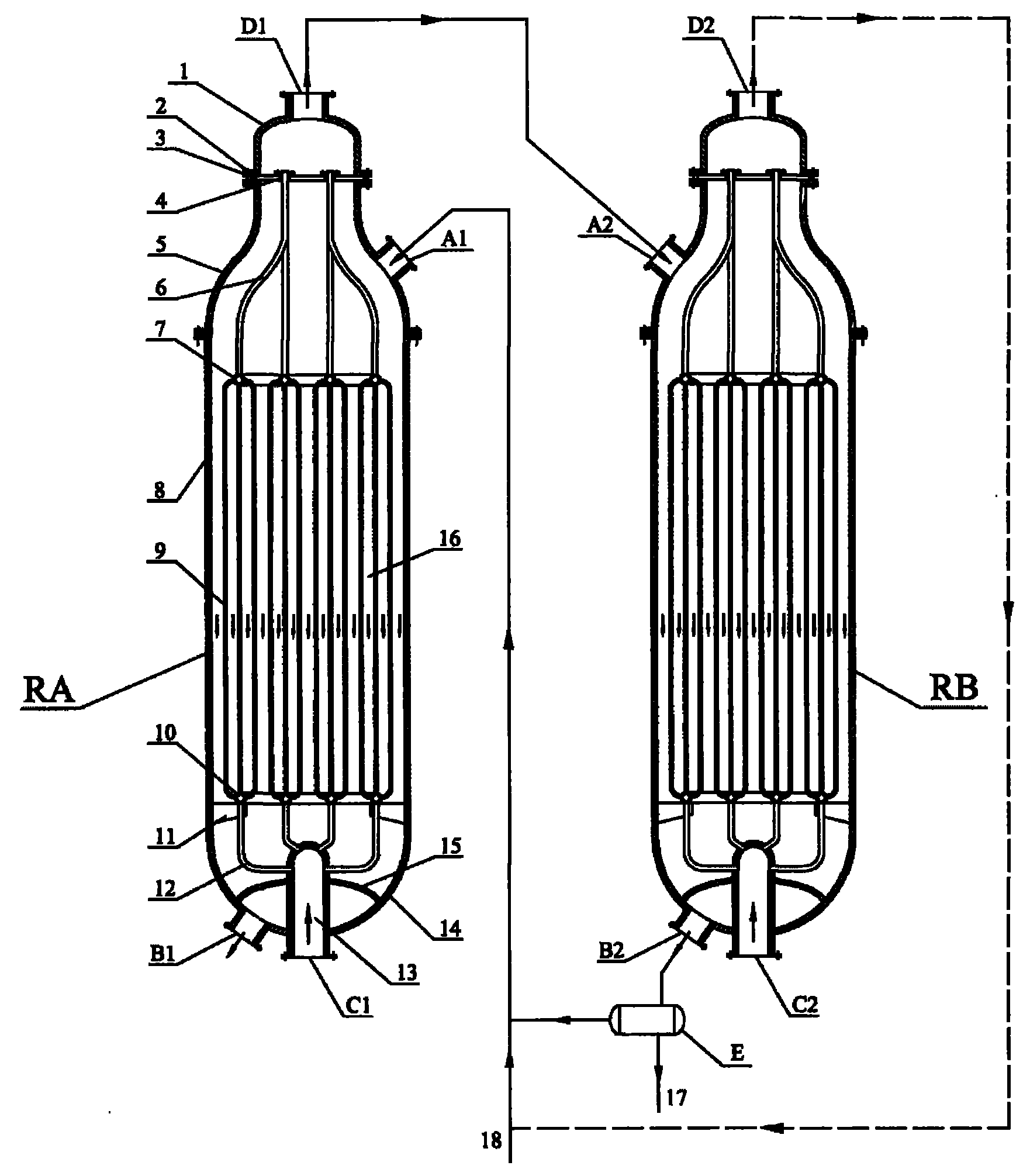

Method for preparing oxalate coupling reaction of CO

ActiveCN101475474AImprove conversion rateImprove technical effectPreparation by carbon monoxide or formate reactionNitrous acid esterCoupling

The invention relates to a method for preparing oxalic ester by CO coupling, which mainly solves the problems of low selectivity of target products in the prior art. The method adopts a technical proposal that: the method comprises the following steps that: (a) a first spout of raw materials of gases containing nitrous acid ester and CO enter a first reaction area first to contact a palladium-containing catalyst I to generate a first spout of reaction effluent containing the oxalic ester; and (b) gaseous phase components subjected to the gas-liquid separation or not subjected to separation of the first spout of the reaction effluent and a second spout of gases containing the nitrous acid ester directly enter at least one second reaction area and are contacted with a palladium-containing catalyst II to generate a second spout of reaction effluent containing the oxalic ester, wherein the mol ratio of the first spout of gases containing the nitrous acid ester to the second spout of the gases containing the nitrous acid ester is 0.1-10:1, and the mol ratio of the CO to the sum of the first spout of the nitrous acid ester and the second spout of the nitrous acid ester is 1-3:1. The method solves the problems well and can be used in industrial production for increasing the yield of the oxalic ester.

Owner:CHINA PETROLEUM & CHEM CORP +1

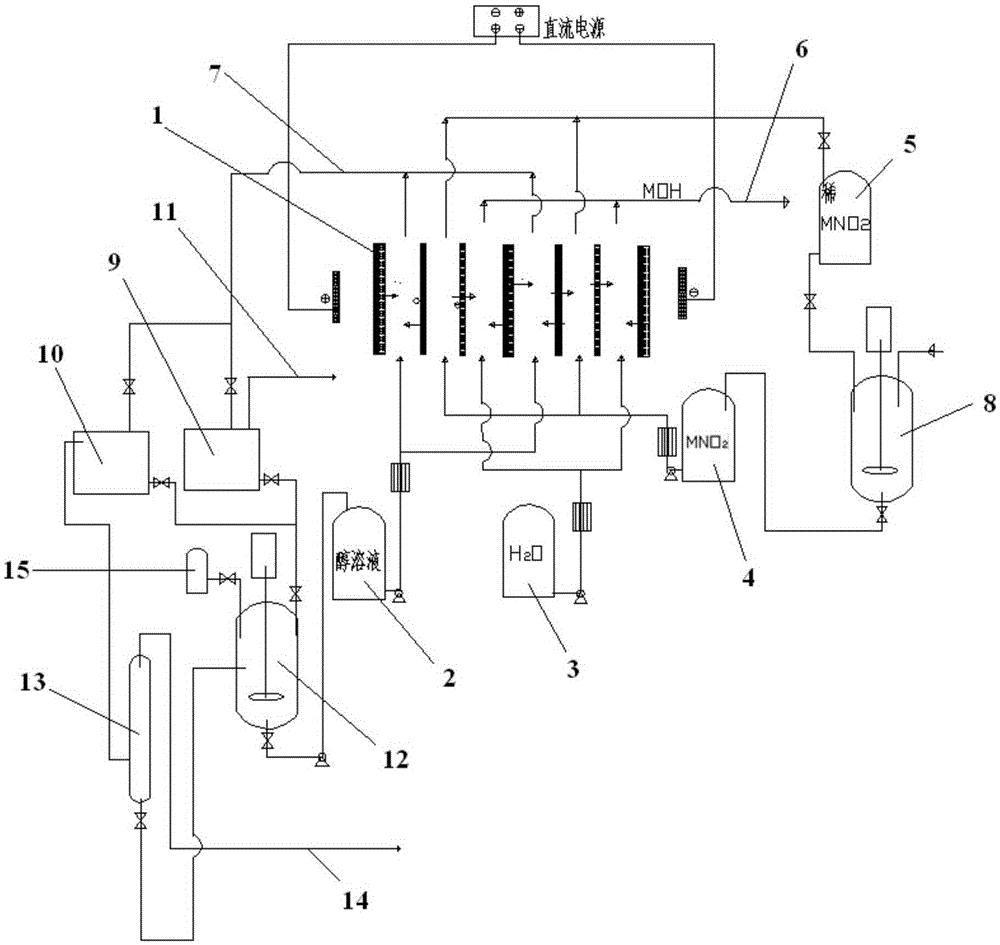

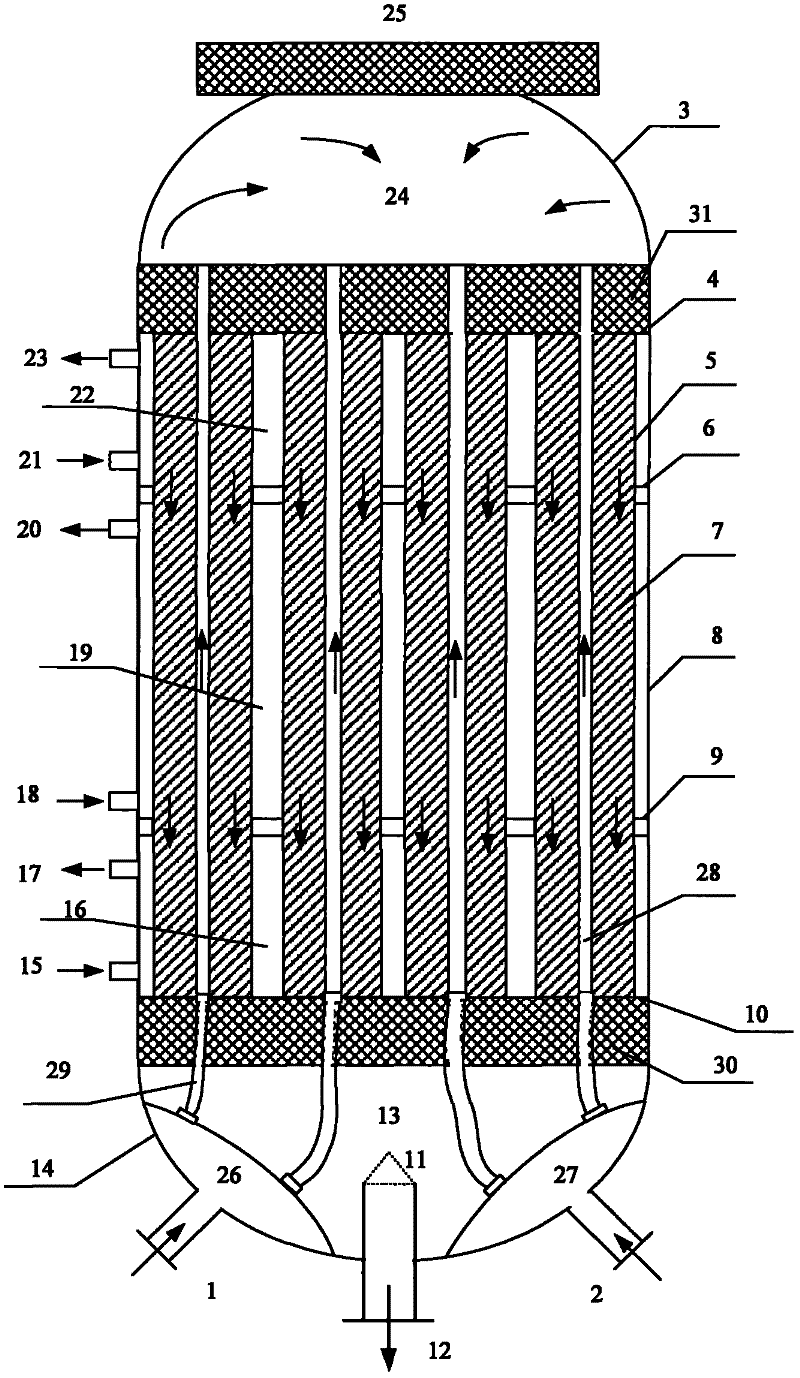

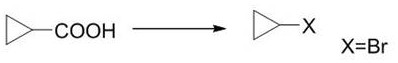

Method and device capable of continuously preparing nitrous acid ester

ActiveCN105237402AWon't happenProduction process is environmentally friendlyNitrous acid preparation ester preparationNitriteAlcohol

The invention provides a method and device capable of continuously preparing nitrous acid ester. The method comprises the following steps: taking a nitrite solution and an alcohol solution as the raw materials, individually introducing the nitrite solution and alcohol solution into a bipolar membrane electrodialysis device to carry out reactions to obtain three products: reaction mixed liquid containing nitrous acid ester, a residual nitrite solution, and an alkali solution; recovering the residual nitrite as raw materials for cycle use; recovering the alkali solution; making the reaction mixed liquid containing nitrous acid ester go through a gas-liquid separator or a liquid-liquid separator to obtain nitrous acid ester and an alcohol solution, collecting the target product namely nitrous acid ester, and recovering the alcohol solution as raw materials for cycle use. The provided method does not generate waste gas and waste liquid, the produced alkali liquid can be recovered for industrial production, the generated mother liquor can be completely recovered and reutilized in the reaction system, the production technology is environment-friendly, the reaction temperature is low, the reaction process is safe, and no safety hazard exists.

Owner:SHANDONG LANGHENG CHEM CO LTD +1

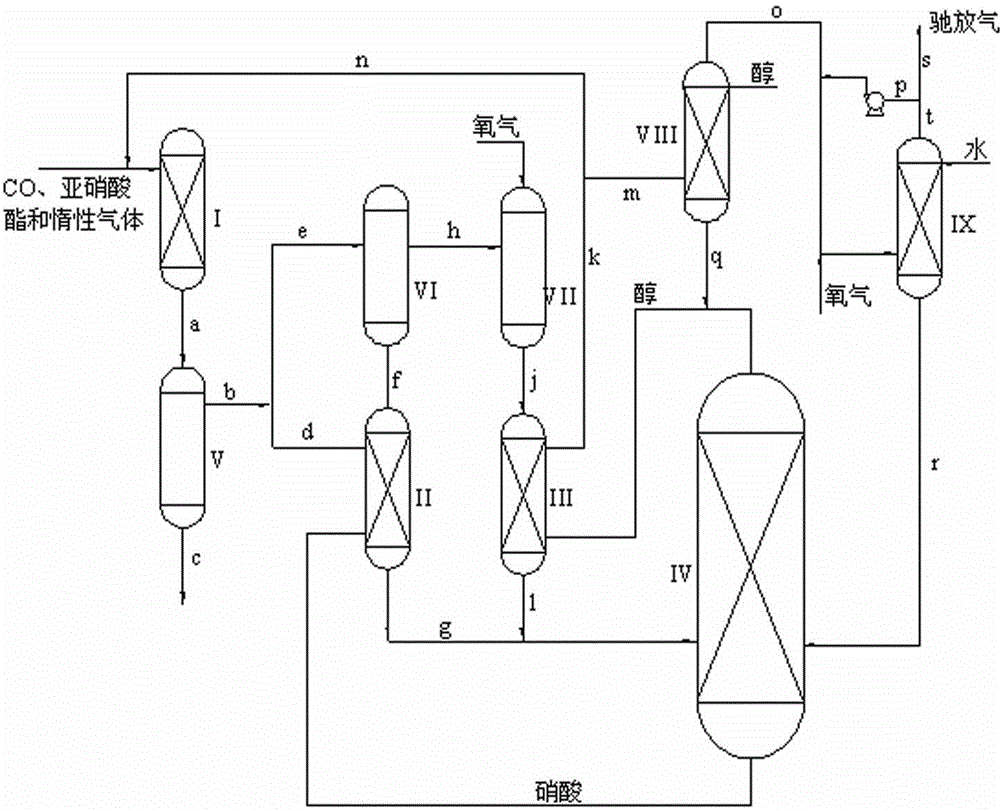

Method for recycling nitrogen oxide in tail gas by means of production of oxalate with CO

ActiveCN103599685AEmission reductionImprove utilization efficiencyDispersed particle separationOxalateNitrous acid ester

The invention discloses a method for recycling nitrogen oxide in a tail gas by means of production of oxalate with CO. The method comprises the following steps that nitrous acid ester in the tail gas is absorbed by alkyl alcohol, absorption liquid is recycled in a regeneration reactor, meanwhile, the tail gas absorbed by the alkyl alcohol is firstly contacted with O2 to convert NO in the tail gas into NO2, the NO2 is converted into nitric acid and NO in a water washing tower, the generated nitric acid can be concentrated in a nitric acid concentration tower to be recycled, the NO is returned to react with oxygen and is conveyed into the water washing tower to be circularly absorbed, the nitrogen oxide in the exhausted tail gas can be decreased to be less than 100 ppm after continuous oxidization and water washing absorption, and most nitrogen oxide is recycled at the same time, so that the nitrogen oxide and the nitrous acid ester in the tail gas are effectively recycled, the utilization rate of the nitrogen oxide is improved, the pollutant emission is greatly decreased, the environment is protected and the cost is saved.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

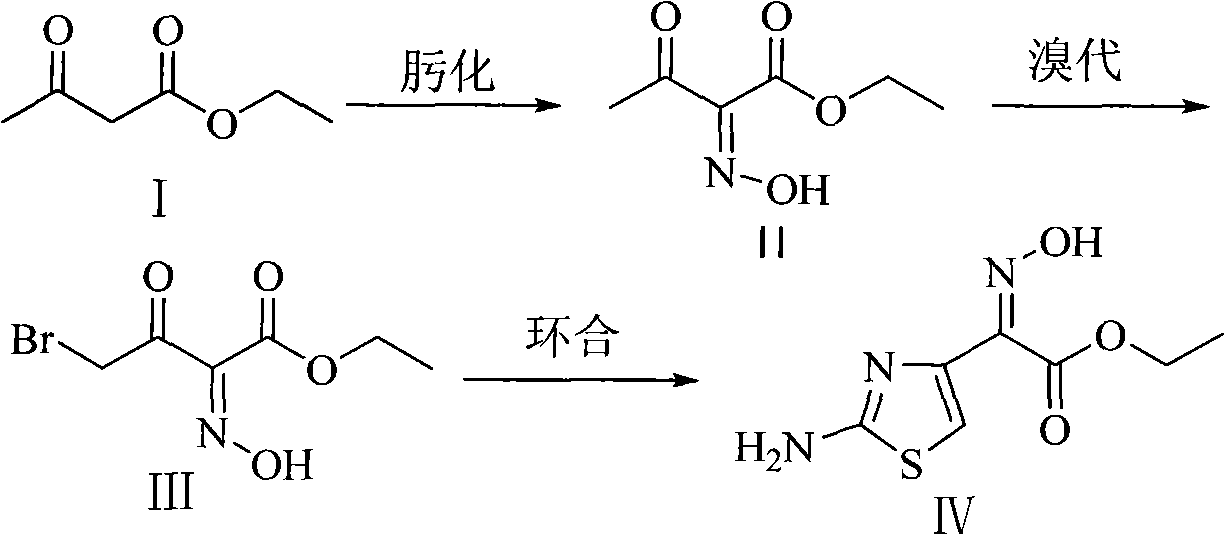

Method for preparing Ethyl 2-(2-aminothiazole-4-yl)-2-hydroxyiminoacetate

InactiveCN101337946ANo need for separation and purificationAvoid Competing Bromination ReactionsOrganic chemistryThioureaUnit operation

The invention relates to a method for preparing ethyl-demethy laminothiazolyloximate, which comprises the following steps: oximate is performed on acetylacetic ether by using nitrous acid ester in alcohol solvent, and then cyclization is performed between the solution and thiourea through bromination to prepare ethyl-demethy laminothiazolyloximate. The method mainly has the beneficial effects that both oximate and bromination intermediates need no separation and purification, and are used in the next reaction directly, so the operating steps are simplified, the route is advanced, the reaction condition is mild, the operating steps are simplified, the unit operation is avoided, the post-processing is simple, the manufacture cost is low, the yield is higher, the production of the three wastes is less, and more important implementary value and the social and economic benefits are realized.

Owner:ZHEJIANG UNIV OF TECH +1

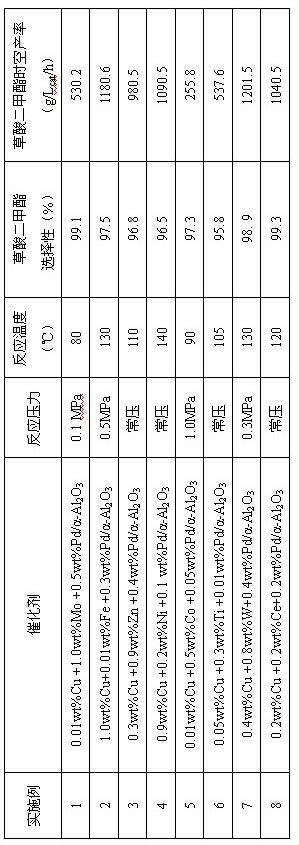

Catalyst used for gas-phase synthesis of oxalate ester and its preparation method

ActiveCN102441405AHigh selectivityUse less precious metalsPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsPtru catalystNitrous acid ester

Belonging to the technical field of oxalate ester preparation, the invention aims to provide a catalyst which has high activity and high selectivity and is used in a reaction between carbon monoxide and nitrous acid ester for gas-phase synthesis of oxalate ester as well as its preparation method. The catalyst takes alpha-Al2O3 as a carrier, adopts palladium as a main active component, and employs copper as a first auxiliary agent and M as a second auxiliary agent, wherein, M can be ferrum, nickel, zinc, cobalt, titanium, cerium, molybdenum or tungsten. In terms of the carrier mass, the catalyst is composed of: 0.01-0.5 wt% of palladium, 0.01-1.0 wt% of copper, and 0.01-1.0 wt% of M. Prepared by a deposition-precipitation method, the catalyst of the invention can be used for carbonylation of CO and nitrous acid ester so as to synthesize oxalate ester. And the catalyst is used at a reaction temperature of 80-140DEG C, a reaction pressure of normal pressure to 1.0Mpa, and a reaction space velocity of 500-9000h<-1>. The catalyst provided in the invention has high reaction activity and selectivity, good repeatability of reaction performance, low cost, and simple preparation method, thus being easy for large-scale production.

Owner:河南能源集团研究总院有限公司

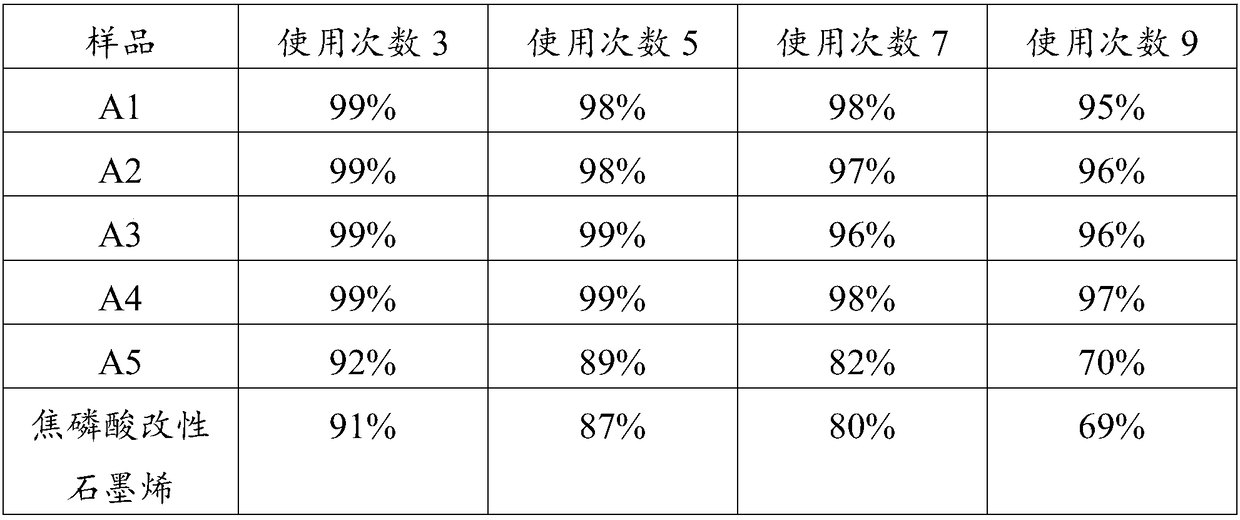

Preparation method for fatty amine modified graphene

ActiveCN109231191AHigh yieldEasy to separateOther chemical processesGrapheneNitrous acid esterFatty amine

The invention discloses a method for preparing amino modified graphene through fatty amine modified graphene, and belongs to the field of new materials. The method comprises the following steps that fatty amine and nitrous acid ester are firstly dissolved in a solvent separately, the temperature of a mixture of the graphene and the solvent is controlled, a small amount of acid is added into the graphene, the two reactants are added into the mixture, and reaction is carried out; and filtering and washing are carried out so as obtain the amino modified graphene. The method has the advantages ofbeing simple in technological process, mild in conditions, high in safety, low in cost, capable of improving the product stability and capable of providing the possibility for industrial production oflarge-scale preparation of the fatty amine modified graphene.

Owner:XINXIANG UNIV

Method for producing oxalic ester by gas phase CO coupling

ActiveCN101993364ALower conversion rateMeet the requirements of oxygen contentPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsMolecular sieveNitrous acid ester

The invention relates to a method for producing oxalic ester by gas phase CO coupling, which mainly solves the technical problems of low oxygen removal rate of raw materials, low selectivity of target products and low space-time yield of the oxalic ester in the prior art. The method comprises the following steps: (a) firstly, a CO gas raw material containing oxygen and NO gas enter a deoxidizing reactor and contact with a molecular sieve catalyst, and the oxygen in the raw material reacts with the NO to generate a gas phase effluent I containing NO2, unreacted NO and CO; (b) the gas phase effluent I and nitrous acid ester enter a coupling reactor and contact with a palladium-containing catalyst to react to generate an effluent II containing the oxalic ester; and (c) the effluent II of the oxalic ester is separated to obtain the oxalic ester product and a gas phase effluent III containing nitrogen oxides, wherein the mol ratio of the NO to oxygen in the CO gas raw material containing the oxygen in the step (a) is 4-100:1. By using the technical scheme, the problems are better solved and the method can be used for the industrial production for increasing the yield of the oxalic ester.

Owner:CHINA PETROLEUM & CHEM CORP +1

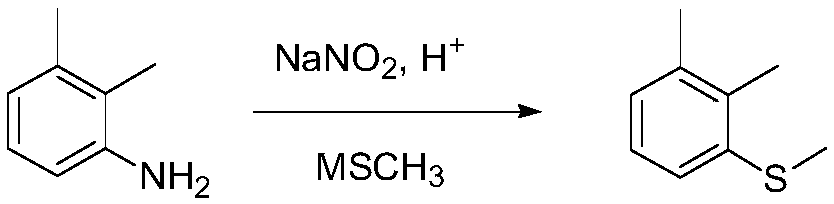

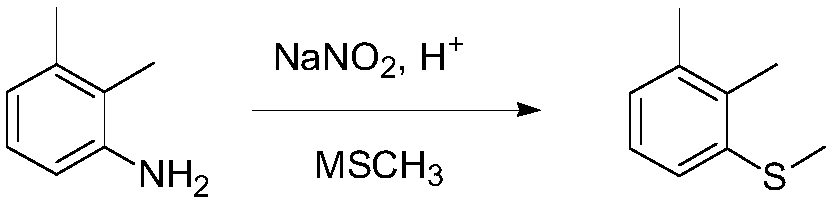

Synthetic method of topramezone intermediate 1,2-dimethyl-3-methylsulfanyl-benzene

The invention relates to the field of organic synthesis, in particular to a synthetic method of a topramezone intermediate 1,2-dimethyl-3-methylsulfanyl-benzene. The method comprises the following steps: (1) reacting 2,3-dimethylaniline or a salt thereof with sodium nitrite in an acidic environment to generate a corresponding diazonium salt; and (2) reacting the diazonium salt with a methyl mercaptide to generate the 1,2-dimethyl-3-methylsulfanyl-benzene. The synthetic method of the topramezone intermediate 1,2-dimethyl-3-methylsulfanyl-benzene provided by the invention has low costs and lessthree wastes (waste gas, waste water and industrial residue), uses the sodium nitrite to replace expensive nitrous acid ester, uses the methyl mercaptide to replace dimethyl sulfide with a strong smell, has good atom economy, avoids generation of methyl mercaptide with a smell difficult to control, and avoids the problems of solvent recovery and environmental problems in the recovery process caused by the use of a large amount of the dimethyl sulfide.

Owner:JIANGSU FLAG CHEM IND

Method for preparing 2-fluoro-4-nitrophenol

InactiveCN1850778ASimple preparation processHigh yieldOrganic chemistryOrganic compound preparationReaction temperature4-nitrosophenol

This invention relates to chemical product preparation method, especially 2- fluorin-4-nitrophenol preparation method. First is nitrosation reaction, 2-fluoropenol is material, it nitrosation generates 2-fluorin-4-nitrosophenol. Muriate acid concentration is 15-20 percent, first select 15 percent, nitrosation solvent is nitrous acid metal salt or nitrous acid ester, and sodium nitrate is first selected. The reaction temperature is -5-5 degrees centigrade, 0 degree centigrade is first selected. Second is oxidizing reaction, dilute nitric acid is used to oxidize 2-fluorin-4-nitrosophenol to make 2-fluorin-4-nitrophenol. The dilute nitric acid concentration is 15-55 percent, 30 percent is first selected. Its preparation technique is simple, very few isomers is generated during nitrosation, yield can reach 90 percent, its polishin is also easy, purity can reach more than 99.5 percent, cost is reduced.

Owner:YETAI FINE CHEM INST CHANGZHOU CITY

Method for separating and purify dermatansulfate and low-molecular heparan sulfate from sodium heparan product

ActiveCN100384884CStable separationImprove solubilityOrganic active ingredientsDermatan sulfateSodium heparin

The invention relates to a method to separate and purify dermatan sulfate and low molecule heparan sulfate from sodium heparin by-product. It uses the by-product of producing sodium heparin as raw material taking fractional precipitation through alcohol to gain raw dermatan sulfate; uses nitrite and nitrous acid ester compounding as oxidant to degrade the heparan sulfate into low molecule heparan sulfate and taking fractional precipitation through alcohol to separate high purity dermatan sulfate and low molecule heparin sulfate.

Owner:NANJING KING FRIEND BIOCHEM PHARMA CO LTD

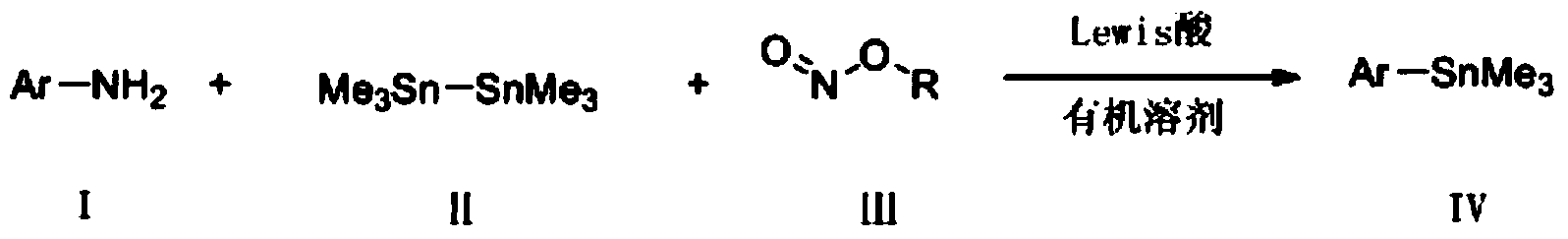

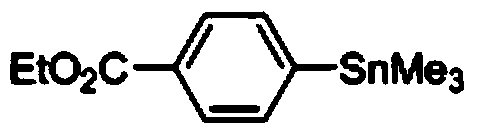

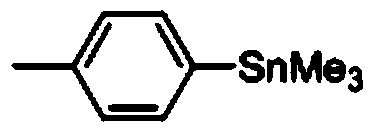

Preparation method for aryl tin compound

InactiveCN103665026AImprove reaction efficiencyLower reaction costTin organic compoundsArylNitrous acid ester

The invention discloses a preparation method for an aryl tin compound. The aryl tin compound is prepared from reaction of aromatic amine Ar-NH2, distannanes, alkyl nitrous acid ester and Lewis acid in an organic solution, wherein Ar represents a substitutional or non-substitutional benzene ring or an aromatic heterocyclic ring group, and the reaction is prominently quickened by the adopted Lewis acid. According to the invention, the preparation method enables a one-step conversion of the aromatic amine into the aryl tin compound under mild condition for the first time, and is high in reaction rate and low in reaction cost; the reaction involved in the method disclosed by the invention requires no strict water-free and oxygen-free conditions, occurs smoothly in the air and is easy to operate, and meanwhile has an excellent tolerance and universality for the functional group, therefore, the method can be widely used for the preparation of aryl tin compounds.

Owner:PEKING UNIV

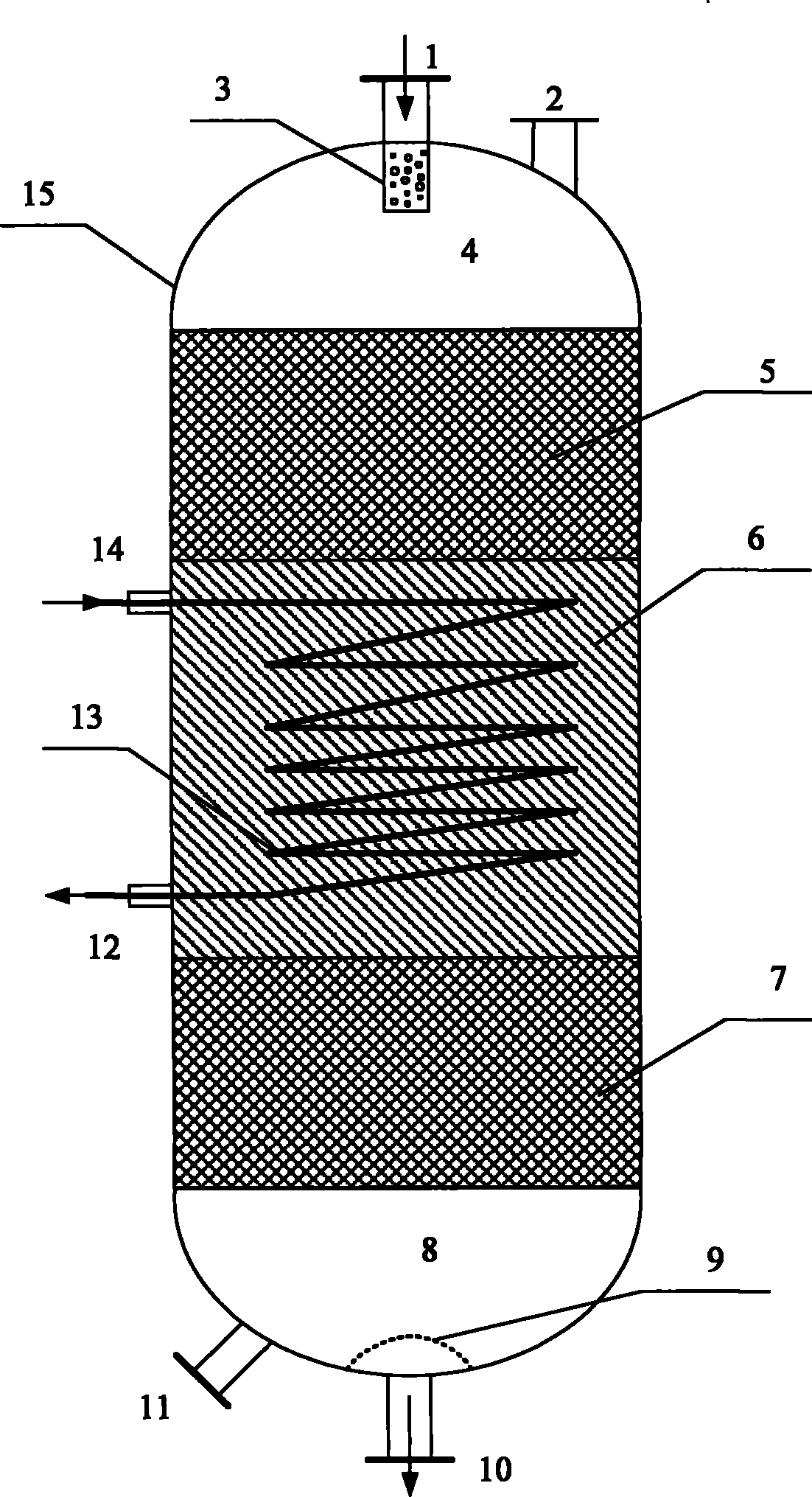

Method for preparing oxalate through CO catalytic coupling reaction

ActiveCN102649740AImprove technical effectPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureReactions stress

The invention relates to a method for preparing oxalate through CO catalytic coupling reaction. The technical problems of difficulty in temperature control and low selectivity of target product during the process of preparing oxalate through CO catalytic coupling reaction in the prior art are solved. The method comprises the following steps of: taking a mixed gas containing nitrous acid ester and CO as a raw material, and contacting the raw material with a noble metal catalyst in an upper heat-insulating catalytic bed, a heat-exchange catalytic bed and a lower heat-insulating catalytic bed in a heat-point distributed area enhanced heat-exchange combined reactor in turn, under the conditions of reaction temperature at 100-180 DEG C, volume hourly space velocity at 500-10000 per hour, reaction pressure at -0.08-1.5MPa and mole ratio of CO to nitrous acid ester being (1-5):1, thereby generating an effluent containing the oxalate by reacting. According to the technical scheme, the problem is more efficiently solved. The method is suitable for the industrial production for preparing oxalate through CO catalytic coupling.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing oxalic ester by CO coupling

ActiveCN101993363AImprove securityPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsNitrous acid esterAlcohol

The invention relates to a method for preparing oxalic ester by CO coupling, by which the main technical problems that in a system for preparing the oxalic ester by CO coupling in the prior art, the content of nitrous acid ester in gas components entering a cyclic compressor is high and the safety is poor are solved. The invention has the technical scheme comprising the following steps: (a) firstly, gas containing CO and nitrous acid ester enters a coupling reactor to contact with a palladium catalyst and react to generate an effluent I; (b) after gas-liquid separation of the reaction effluent I, a liquid phase reaction effluent II and a gas phase reaction effluent III are obtained, and the effluent III contacts with a C1-C9 alcoholic solution in an absorption tower to obtain a liquid phase effluent IV and a gas phase effluent V; and (c) after further gas-liquid separation is carried out on the gas phase effluent V by a condenser for removing the nitrous acid ester, a gaseous effluentVI of which the content of nitrous acid ester is less than 50ppm is obtained, and the gaseous effluent VI reenters a compressing system. The technical scheme better solves the problems and can be used for industrial production of the oxalic ester.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing oxalic ester by CO coupling

ActiveCN102219675AImprove conversion rateHigh selectivityPreparation by carbon monoxide or formate reactionNitrous acid esterCoupling

The invention relates a method for producing oxalic ester by CO coupling, mainly solving the technical problems of low objective product selectivity and low conversion per pass in the prior art. According to the technical scheme of the method, a raw material mixture containing nitrous acid ester and CO is in contact with a catalyst containing palladium under the conditions that the reaction temperature is 80 to 160 DEG C and the reaction pressure is 0.09 to 1.5MPa, then a reaction effluent containing oxalic ester is generated, wherein the catalyst containing palladium is fixed on a rotor of asuper gravity rotating bed reactor, the molar ratio of CO to nitrous acid ester in the raw material is (1-5):1. The problems are solved better by using the technical scheme of the method disclosed bythe invention. The method disclosed by the invention can be used in the industrial production of increase production of oxalic ester.

Owner:CHINA PETROLEUM & CHEM CORP +1

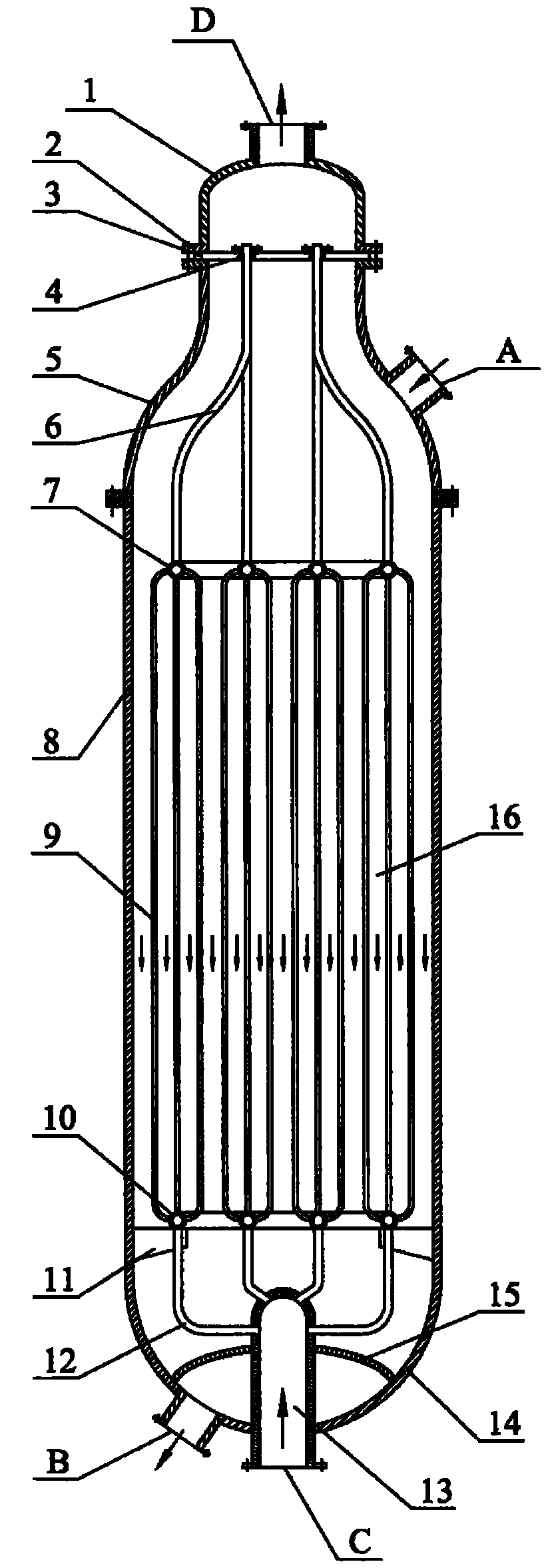

Method for producing oxalate through catalytic coupling reaction of carbon monoxide

ActiveCN102649734APreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureReactions stress

The invention relates to a method for producing oxalate through catalytic coupling reaction of carbon monoxide, and mainly solves the technical problems in the prior art that in the reaction process of producing oxalate through catalytic coupling of carbon monoxide, the temperature control is difficult and oxalate is low in selectivity. The method adopts a mixed gas of both nitrous acid ester and carbon monoxide as the raw material and comprises the step that under the conditions that the reaction temperature is 100-180 DEG C, the hourly space velocity is 500-10,000 hours<-1>, the reaction pressure is -0.08-1.5MPa and the carbon monoxide / nitrous acid ester molar ratio is 1-5:1, the raw material is in contact with a precious metal catalyst in a compound reactor adopting an inner-tube and outer-tube sleeve structure and a hotspot distribution area for heat transfer enhancement, so as to react to produce an effluent containing oxalate. By adopting the technical scheme, the problems are better solved, and the method provided by the invention can be used for industrial production of oxalate through catalytic coupling of carbon monoxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing oxalate through carbon monoxide coupling

ActiveCN102649730AImprove technical effectPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureLanthanum

The invention relates to a method for producing oxalate through carbon monoxide coupling, and mainly solves the technical problem in the prior art that the target product is low in selectivity. The method adopts a mixed gas containing both nitrous acid ester and carbon monoxide as the raw material, also adopts a fluidized bed reactor, and comprises the step that under the conditions that the reaction temperature is 100-180 DEG C, the hourly space velocity is 500-10,000 hours<-1> and the reaction pressure is -0.08-1.5MPa, the raw material is in contact with a palladium-containing precious metal catalyst in which lanthanum, praseodymium or bismuth is selected as the additive, so as to react to produce oxalate, wherein a catalyst carrier is spherical aluminum oxide with the average particle diameter of 20-300 microns. By adopting the technical scheme, the problem is better solved and the method provided by the invention can be used for industrial increase production of oxalate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing C1-C4 alkyl nitrous acid ester by catalytic reaction

The invention relates to a method for preparing C1-C4 alkyl nitrous acid ester by a catalytic reaction, which mainly solves the problem in the prior art that a product, namely nitrous acid ester is low in selectivity. The method comprises the following steps: (a), a nitrogen oxide and oxygen enter a reactor I at first and are in contact reaction with a catalyst I, so as to generate an effluence I containing NO2 and unreacted NO; (b), the effluence I and the C1-C4 alkanol enter a reactor II and are in contact reaction with a ZSM-5 molecular sieve catalyst so as to generate an effluence II containing nitrous acid ester; and (c), the nitrous acid ester is obtained through separating the effluence II containing the nitrous acid ester, wherein the reactor I is a fixed bed reactor, the reactor II is a revolving bed high-gravity field reactor, and a ZSM-5 molecular sieve catalyst layer is fixed on the rotor of the revolving bed high-gravity field reactor. According to the invention, the problem is better solved, and the method is suitable for the industrial production of C1-C4 alkyl nitrous acid ester.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for catalyst for synthesizing oxalic ester by gas-phase

ActiveCN101543784BLow costCatalyst activation/preparationPreparation by carbon monoxide or formate reactionGas phaseReaction temperature

The present invention discloses a preparation method for a catalyst for synthesizing oxalic ester by gas-phase. The catalyst takes alpha-alumina as a carrier, palladium as an active component and 2 MOxes as an additive, M is magnesium, titanium, zirconium, vanadium, manganese, iron, nickel, copper, zinc, molybdenum or tungsten, and components of the catalyst (calculated by carrier mass) are: 0.01 to 0.75percent of the palladium and 0.1 to 20 percent of MOxes. The preparation method comprises the following steps that: firstly, an additive metal salt solution is used to impregnate the carrier, and a palladium salt solution is used to impregnate the carrier to obtain the catalyst after the carrier is dried and roasted. Before the use, pure hydrogen or H2-N2 mixed gas is activated by the catalyst at a temperature of between 150 and 450 DEG C. The catalyst can be used for synthesizing oxalic ester by the carbonylation of CO and nitrous acid ester, the using reaction temperature of the catalyst is between 70 and 150 DEG C, and the reaction space velocity is between 500 and 9,000h<-1>. The catalyst has higher reaction activity and selectivity; and the catalyst has low cost.

Owner:HAISO TECH

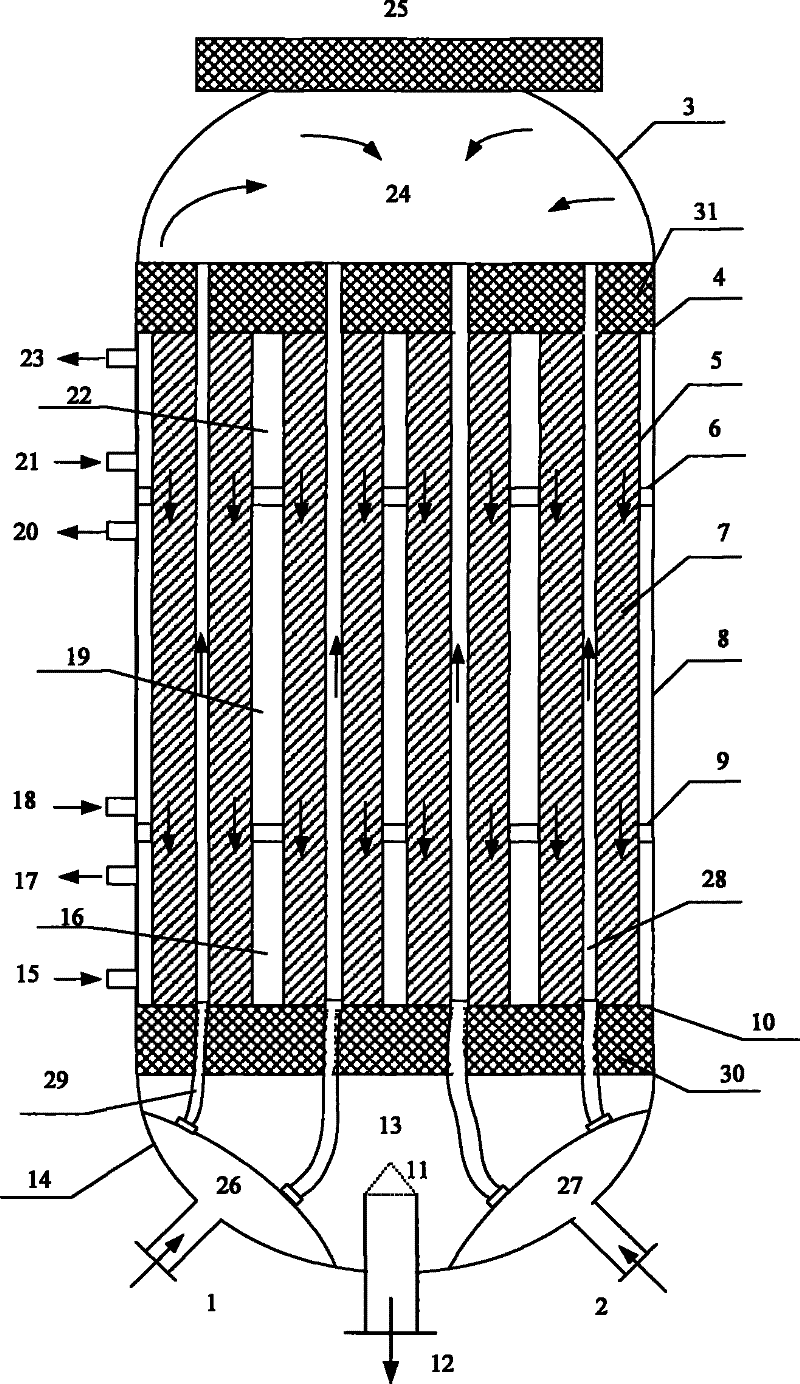

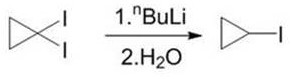

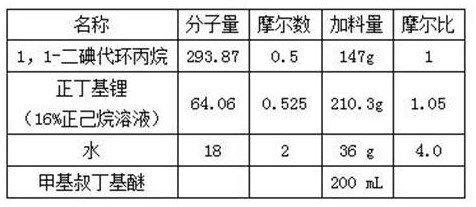

Synthetic method and process of halogenated cyclopropane

PendingCN112573992ALow priceEasy to getPreparation by dehalogenationNitrous acid esterBiochemical engineering

The invention discloses a synthetic method and process of halogenated cyclopropane. The synthesis method and process comprise the following two steps of: (1) reacting cyclopropylamine serving as a rawmaterial with halogenated metal salt in the presence of nitrosation reagents such as nitrous acid ester to obtain 1, 1-dihalogenated cyclopropane; and (2) carrying out metallization reaction on the 1, 1dihalogenated cyclopropane and an organic metal reagent, and hydrolyzing to obtain halogenated cyclopropane. The synthesis method and process have the advantages that toxic reagents causing environmental pollution are not used, the purity and yield of the obtained product are high, and the synthesis method and process are suitable for industrial production.

Owner:DALIAN RES & DESIGN INST OF CHEM IND

Method for producing oxalate through gas-phase reaction of carbon monoxide

ActiveCN102649728AMolecular sieve catalystsPreparation by carbon monoxide or formate reactionGas phaseReaction temperature

The invention relates to a method for producing oxalate through gas-phase reaction of carbon monoxide, and mainly solves the technical problem in the prior art that the target product is low in selectivity. The method adopts a mixed gas containing both nitrous acid ester and carbon monoxide as the raw material, and comprises the step that the raw material is in contact with a precious metal catalyst to produce oxalate under the conditions that the reaction temperature is 100-180 DEG C, the hourly space velocity is 500-10,000 hours <-1> and the reaction pressure is -0.08-1.5MPa, wherein the precious metal catalyst selects palladium as the active component, at least one of gallium or germanium as the additive and at least one of aluminum oxide, silicon oxide or molecular sieve as the carrier. By adopting the technical scheme, the problem is better solved and the method provided by the invention can be used for industrial increase production of oxalate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low load noble metal catalyst for dilute nitric acid reduction, preparation and application

ActiveCN109433200AReduce manufacturing costImprove adaptabilityMetal/metal-oxides/metal-hydroxide catalystsNitrous acid preparation ester preparationNitrous acid esterSaline solutions

The invention provides a low load noble metal catalyst for dilute nitric acid reduction and belongs to the technical field of dilute nitric acid catalysis. Calculated as per the total mass of the catalyst, the catalyst comprises the following ingredients by mass percentage: 0.02-0.25% of active ingredient, 0.5-5% of assistant and the balance of carrier, wherein the active ingredient is one or moreof noble metals Pd, Pt and Rh; the assistant is an alkali metal element K or Na; and the carrier is active carbon. The invention further provides a preparation method of the catalyst, which comprisesthe steps: 1) preparing an assistant saline solution and an active ingredient saline solution in proportion, 2) loading the prepared assistant saline solution onto the active carbon carrier, and drying and roasting to form a standby sample, and 3) loading the prepared active ingredient saline solution onto the standby sample, and drying and roasting to form the catalyst. The loading capacity of noble metals in the catalyst is only 0.02-0.25%; when cost is lowered, the dilute nitric acid reduction can be effectively catalyzed to generate nitrous acid ester; a nitric acid conversion rate reaches above 90%; and nitrous acid ester selectivity reaches 100%.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com