Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14902 results about "Silicon nitride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon nitride is a chemical compound of the elements silicon and nitrogen. Si₃N₄ is the most thermodynamically stable of the silicon nitrides. Hence, Si₃N₄ is the most commercially important of the silicon nitrides and is generally understood as what is being referred to where the term "silicon nitride" is used. It is a white, high-melting-point solid that is relatively chemically inert, being attacked by dilute HF and hot H₂SO₄. It is very hard (8.5 on the mohs scale). It has a high thermal stability.

Memory cell incorporating a chalcogenide element and method of making same

Owner:ROUND ROCK RES LLC

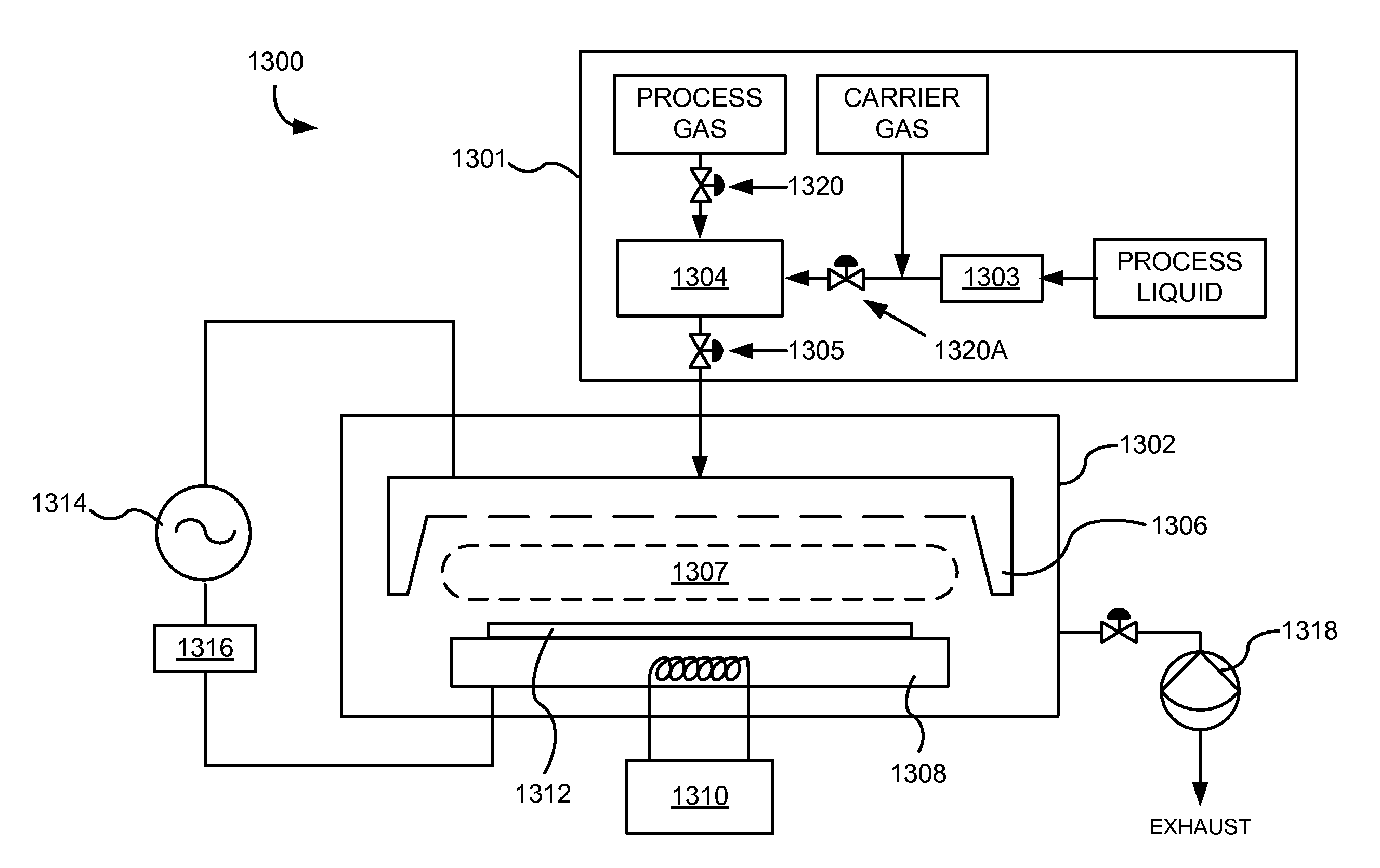

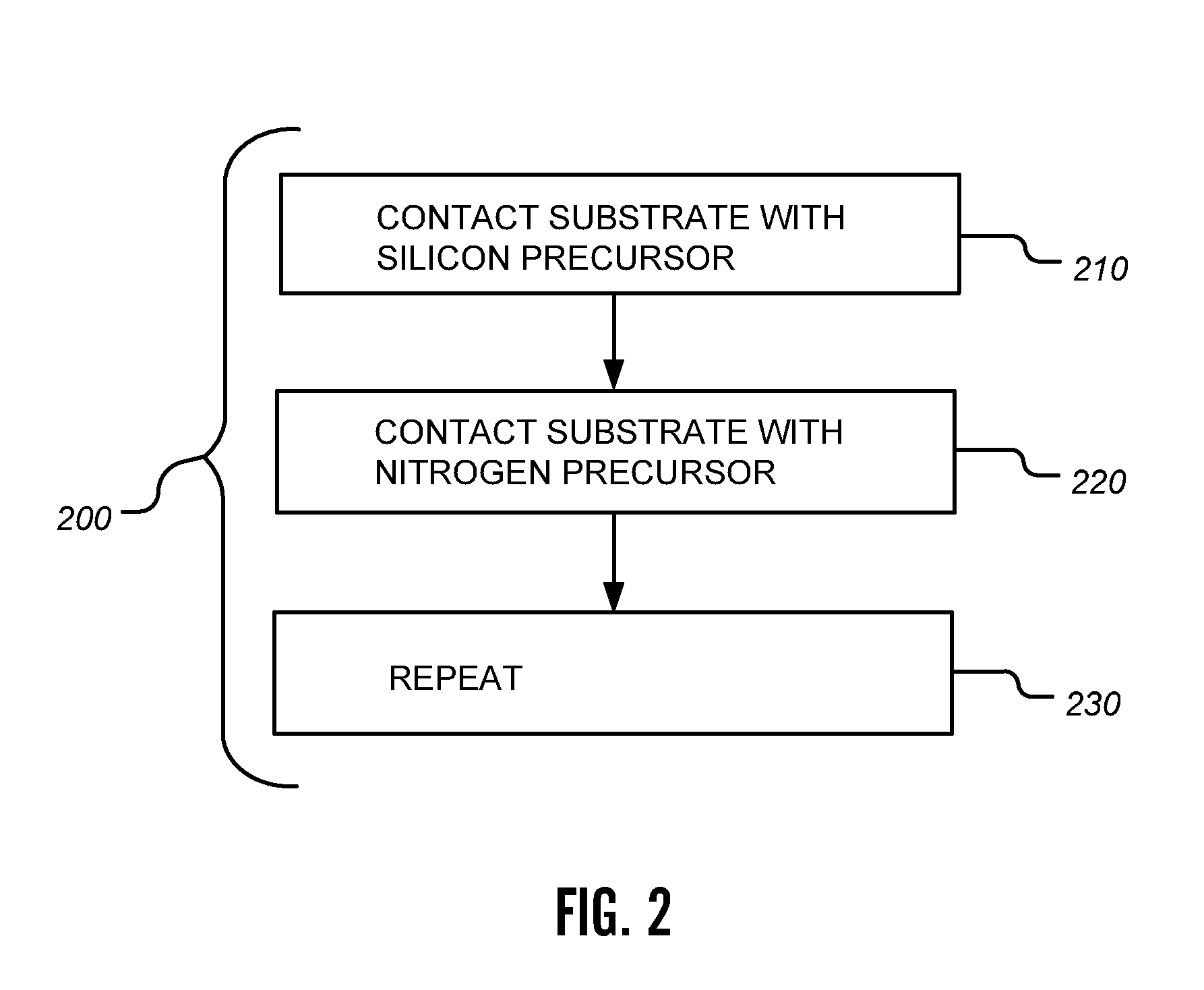

Silicon nitride films and methods

InactiveUS20110256734A1Reduce carbon contentSemiconductor/solid-state device manufacturingChemical vapor deposition coatingOptoelectronicsSemiconductor

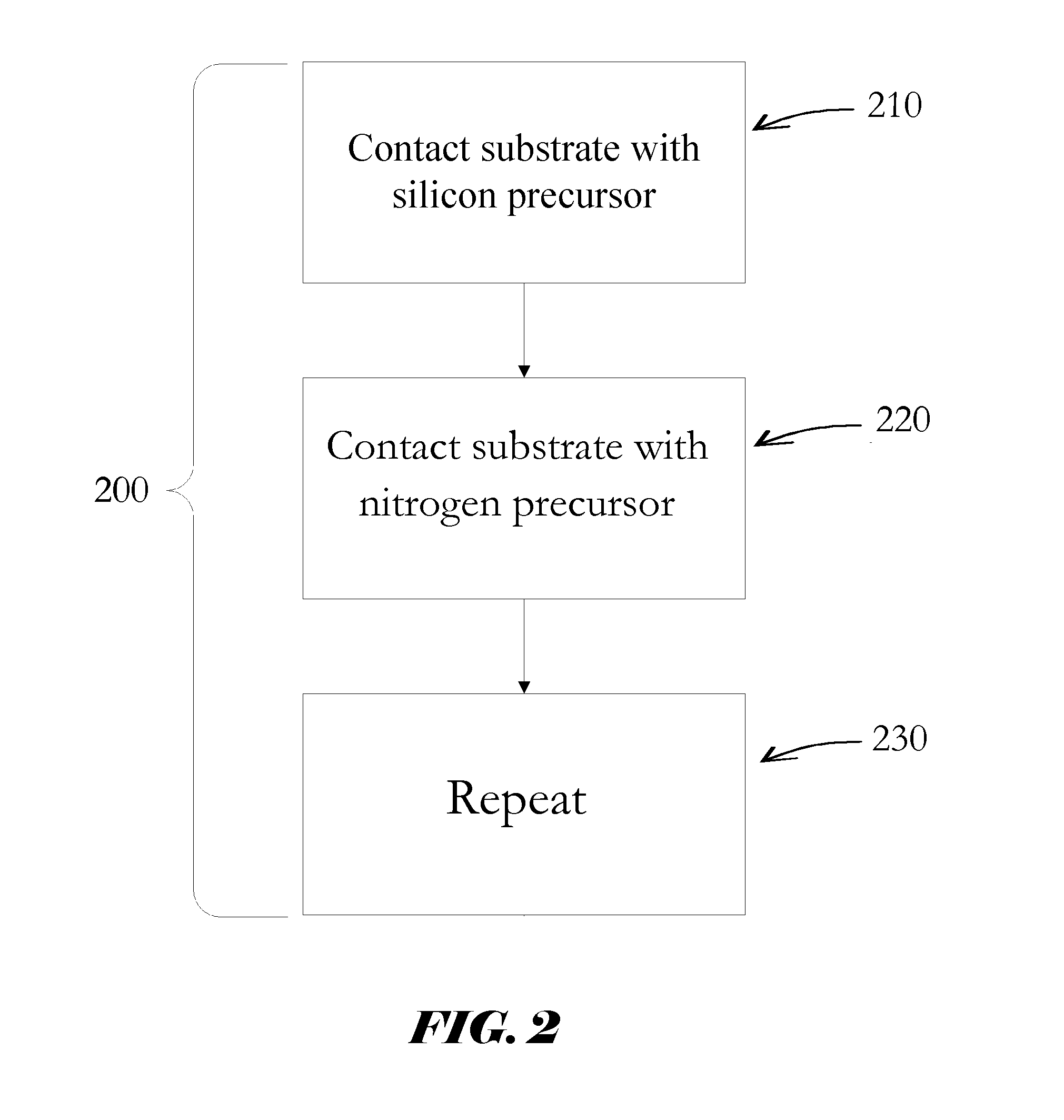

Described are methods of making SiN materials on substrates, particularly SiN thin films on semiconductor substrates. Improved SiN films made by the methods are also included.

Owner:NOVELLUS SYSTEMS

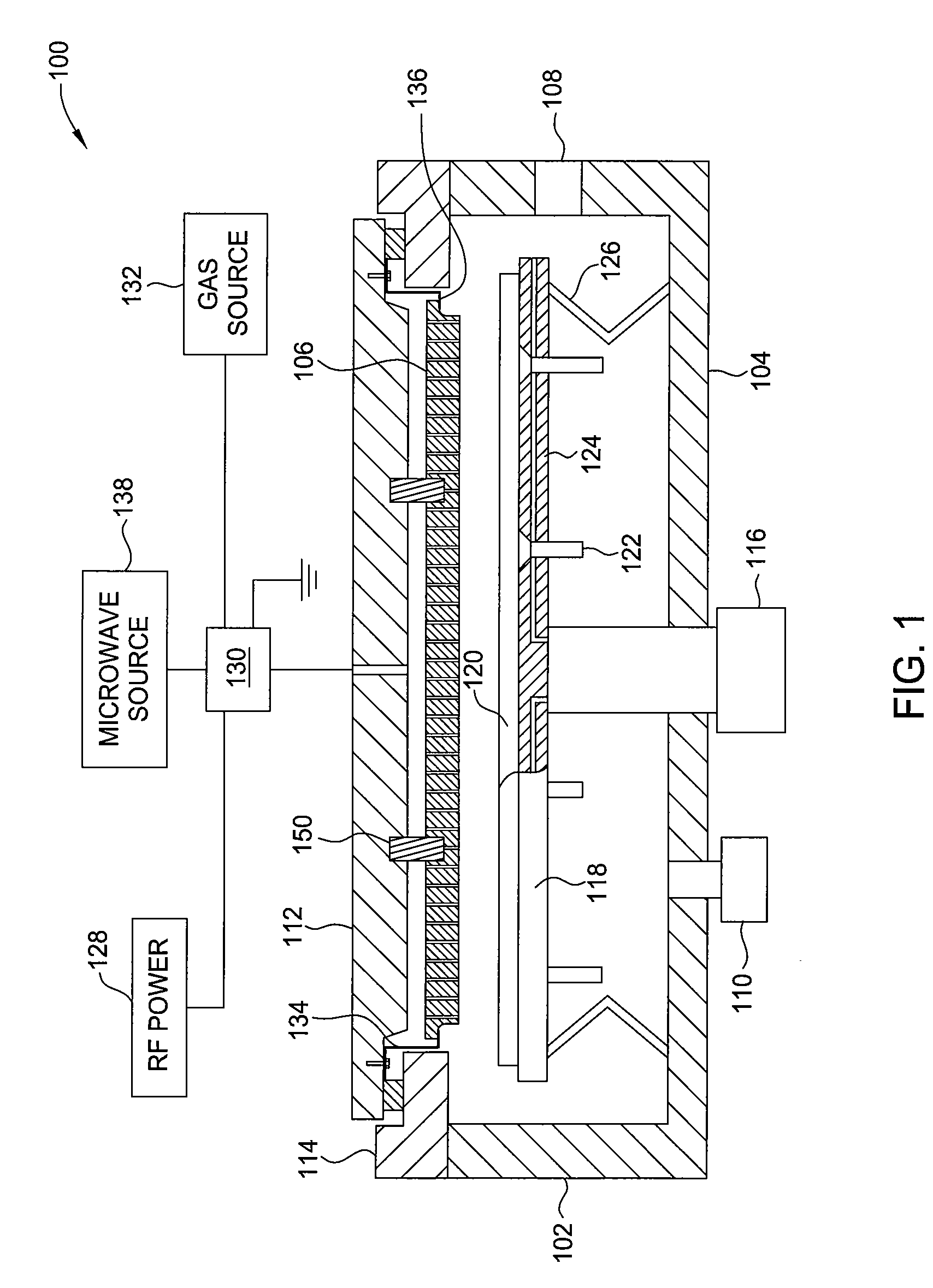

Method for forming strained silicon nitride films and a device containing such films

A method for forming a strained SiN film and a semiconductor device containing the strained SiN film. The method includes exposing the substrate to a gas including a silicon precursor, exposing the substrate to a gas containing a nitrogen precursor activated by a plasma source at a first level of plasma power and configured to react with the silicon precursor with a first reactivity characteristic, and exposing the substrate to a gas containing the nitrogen precursor activated by the plasma source at a second level of plasma power different from the first level and configured to react with the silicon precursor with a second reactivity characteristic such that a property of the silicon nitride film formed on the substrate changes to provide the strained silicon nitride film.

Owner:TOKYO ELECTRON LTD

High stress nitride film and method for formation thereof

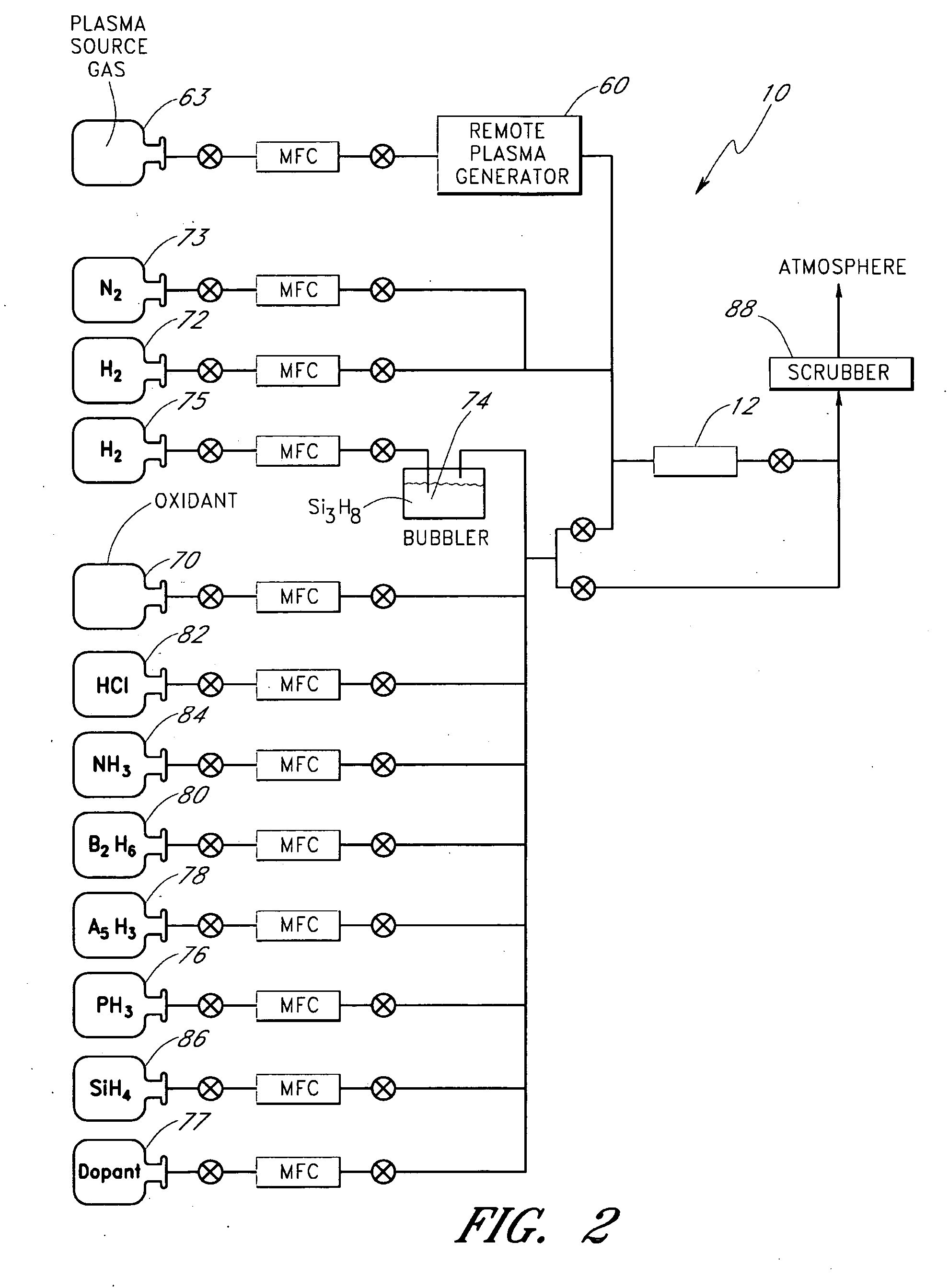

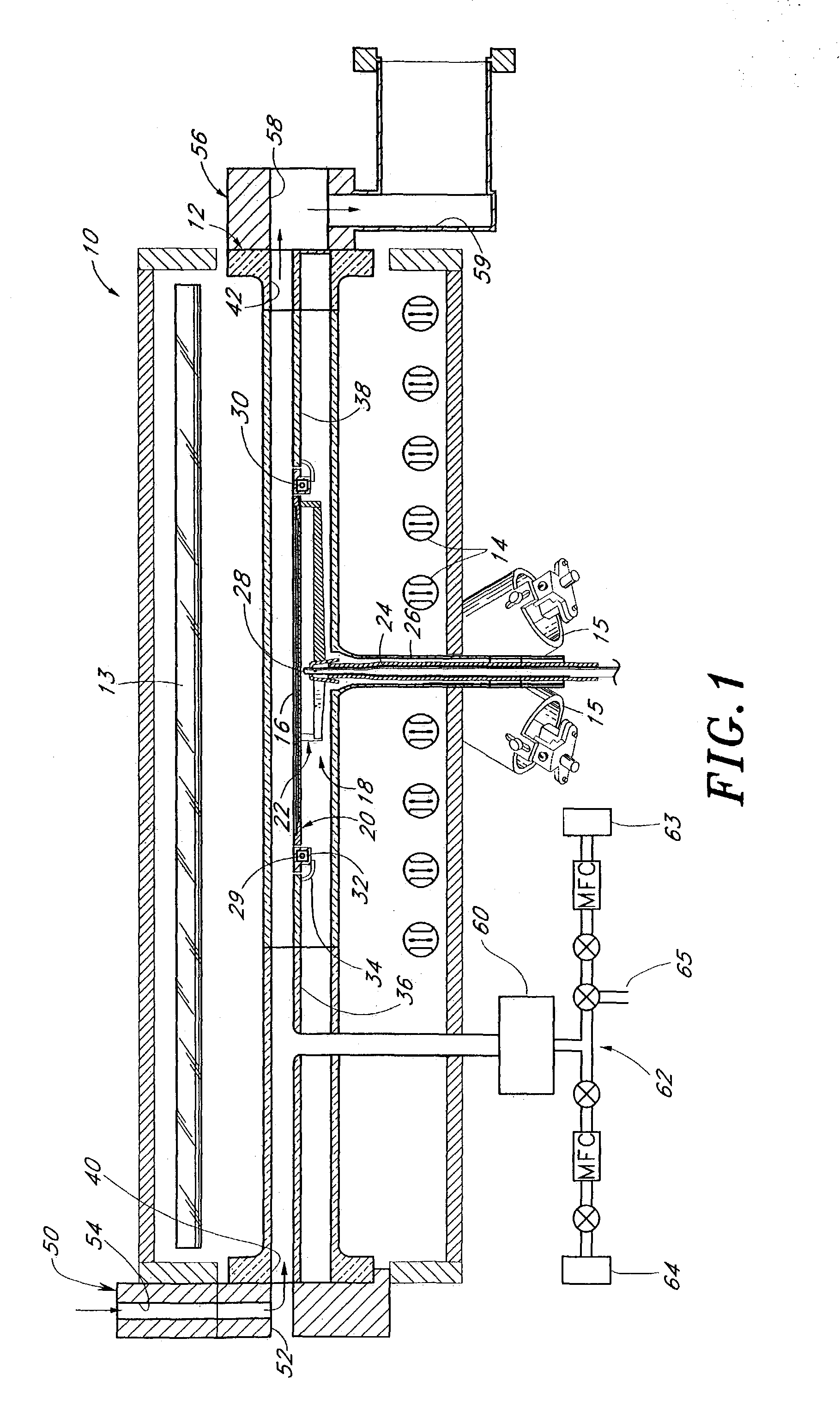

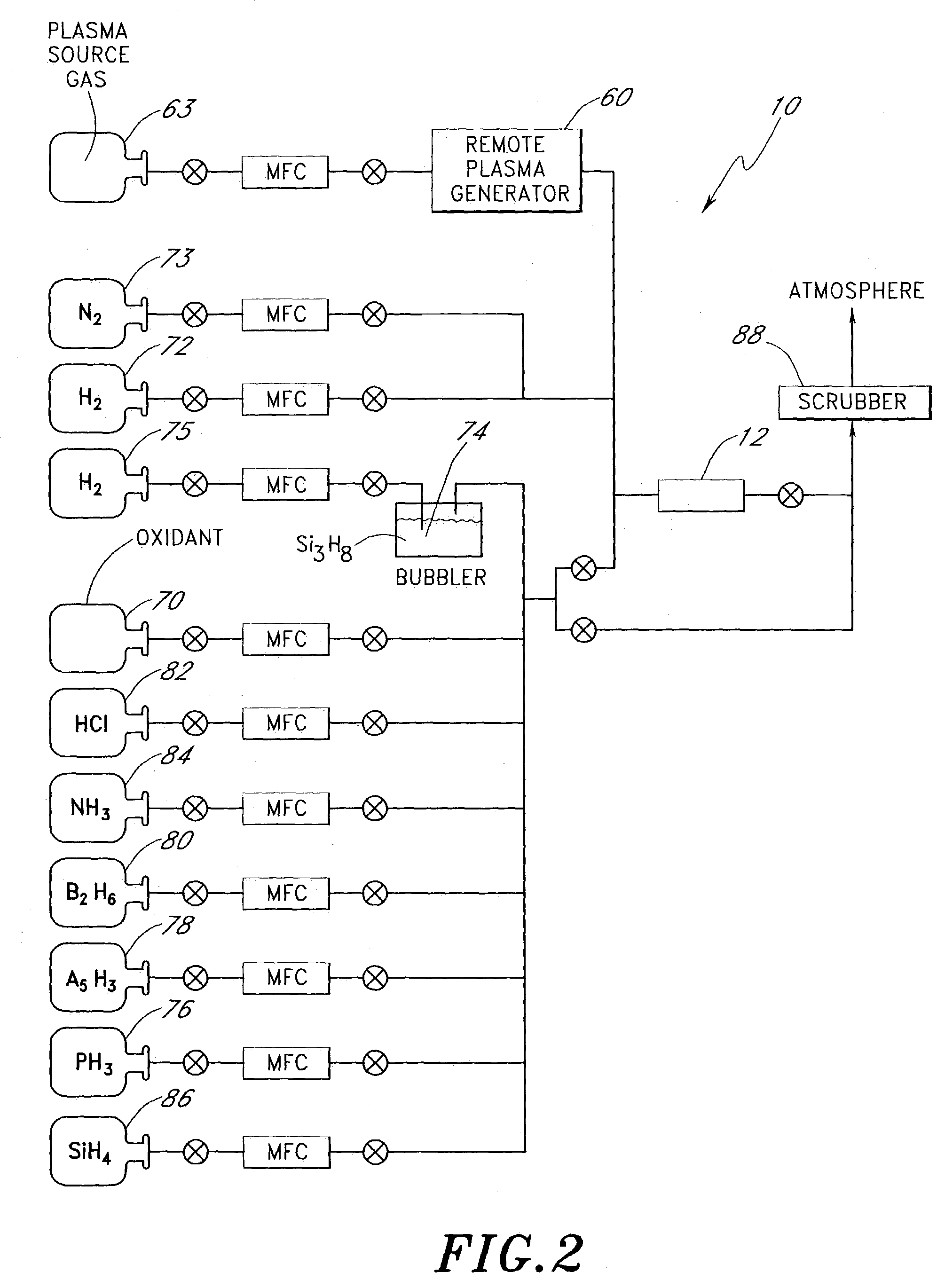

ActiveUS20060199357A1Increase the tensile stressSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDopantNitrogen

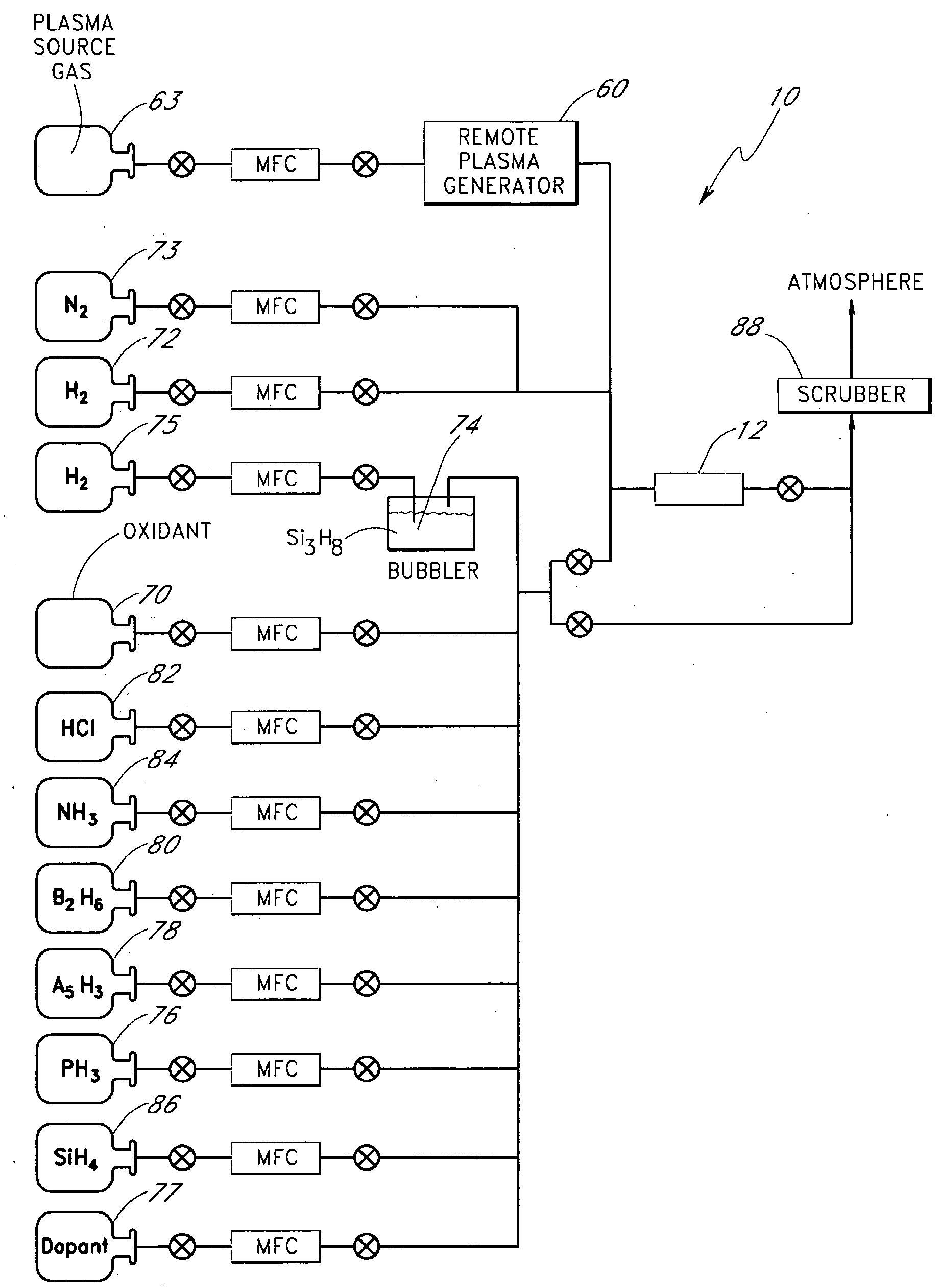

A silicon nitride film is formed on a substrate in a reaction chamber by introducing trisilane and a reactive nitrogen species into the chamber in separate pulses. A carbon precursor gas is also flowed into the chamber during introduction of the trisilane and / or during introduction of the reactive nitrogen species, or in pulses separate from the trisilane and reactive nitrogen species pulses. The carbon is used as a dopant in the silicon nitride film and advantageously allows a high stress silicon nitride film to be formed.

Owner:ASM INTERNATIONAL

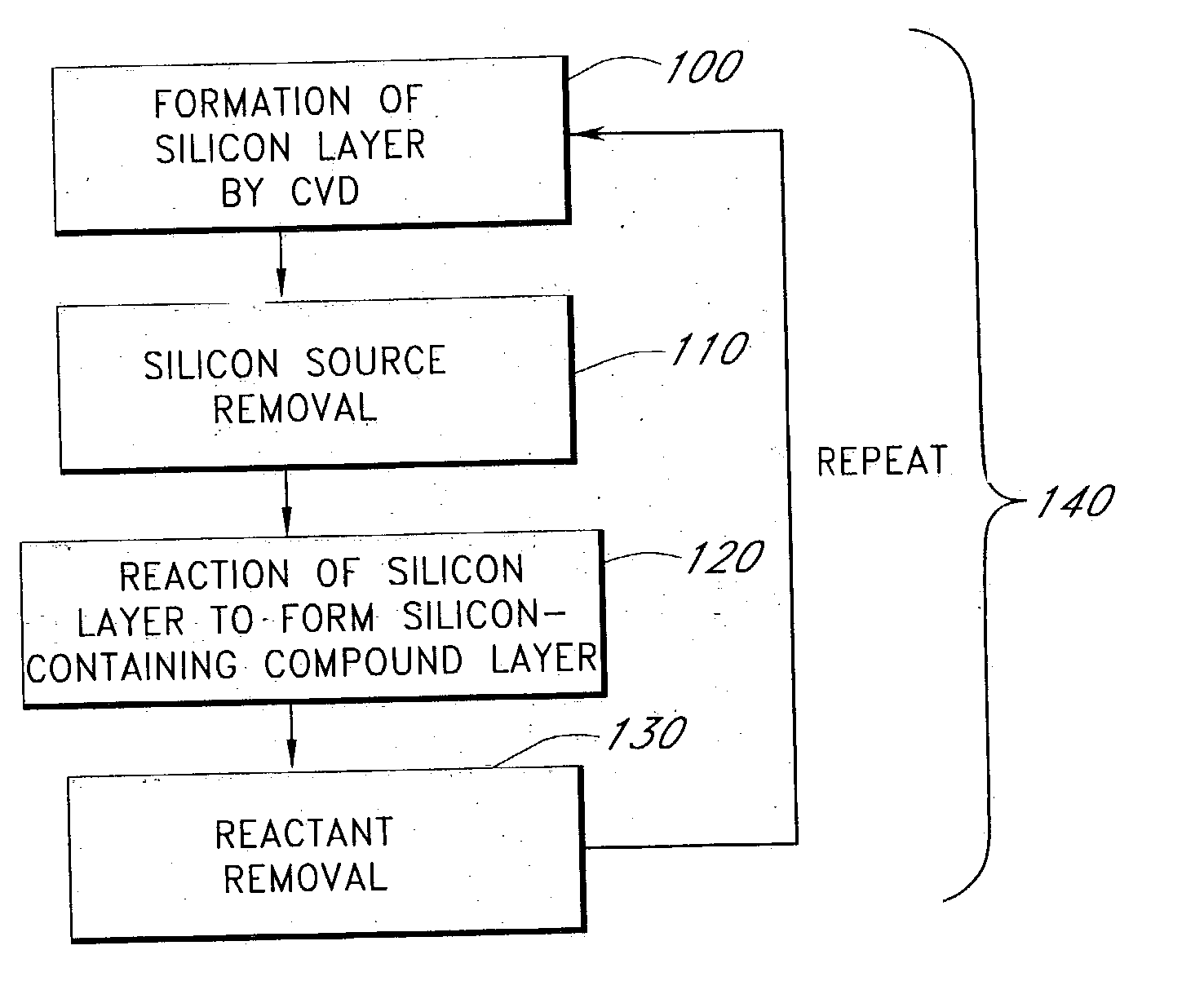

Method to form ultra high quality silicon-containing compound layers

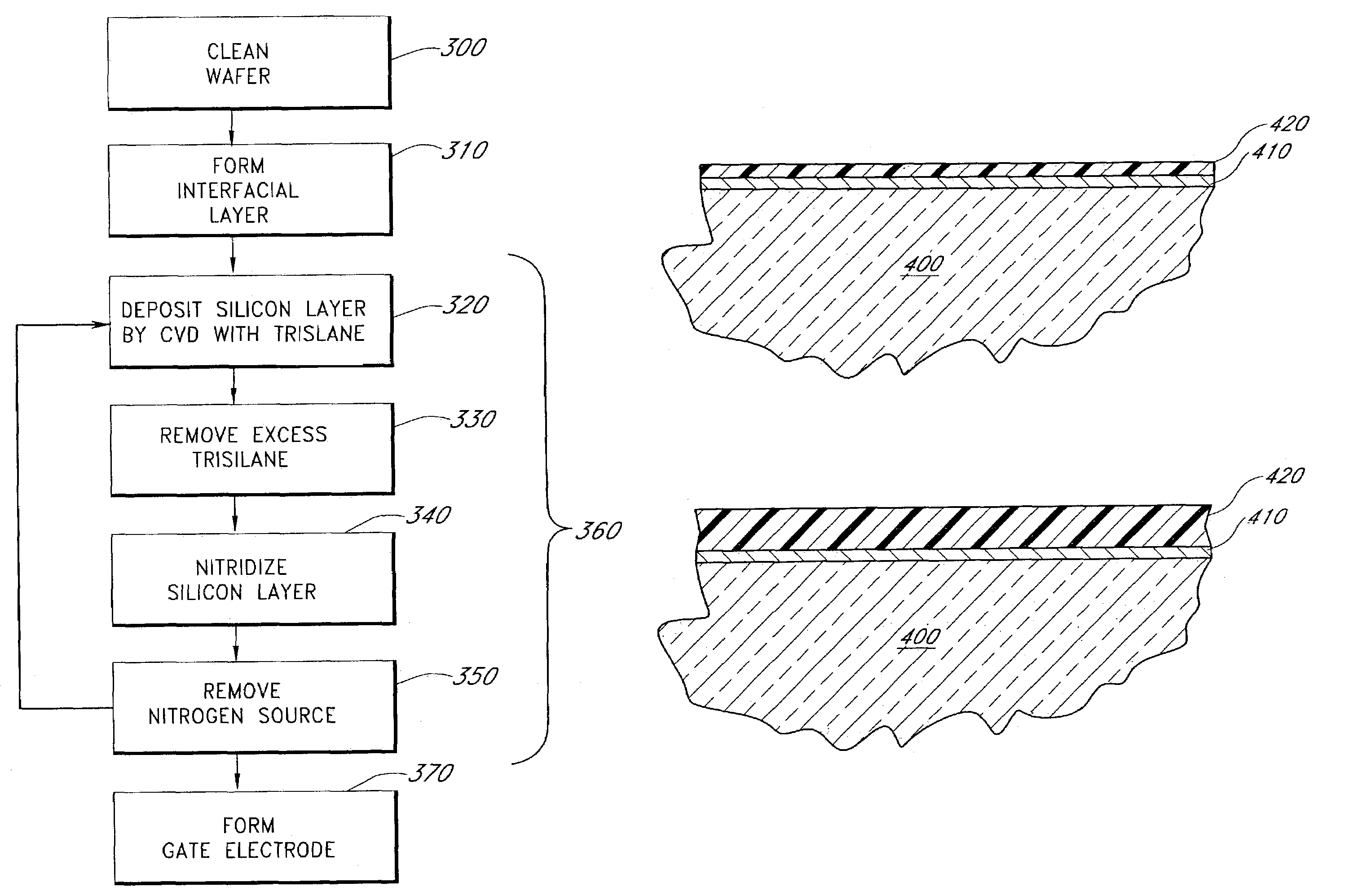

InactiveUS7297641B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTrisilaneReaction chamber

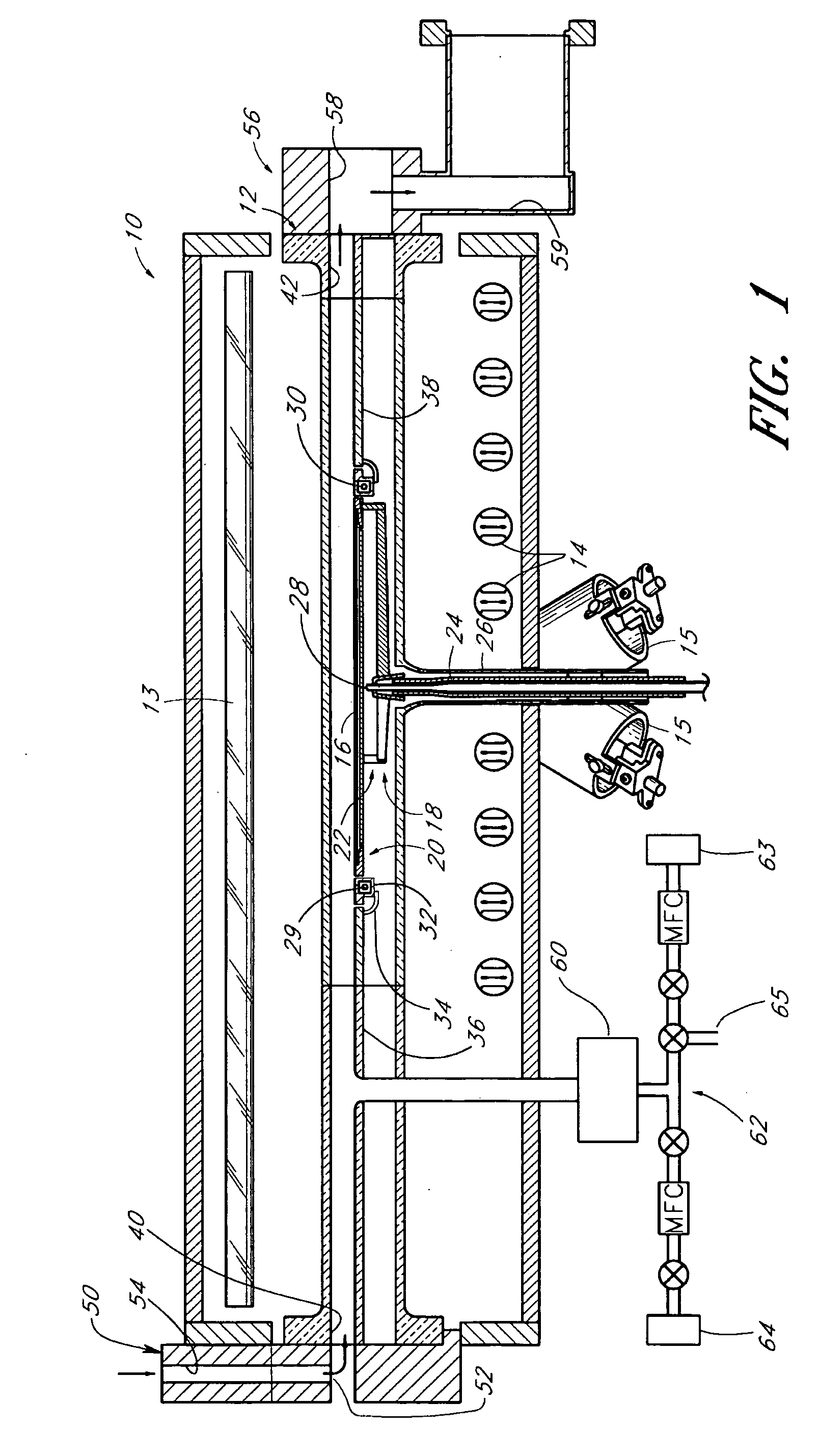

Multiple sequential processes are conducted in a reaction chamber to form ultra high quality silicon-containing compound layers, including silicon nitride layers. In a preferred embodiment, a silicon layer is deposited on a substrate using trisilane as the silicon precursor. A silicon nitride layer is then formed by nitriding the silicon layer. By repeating these steps, a silicon nitride layer of a desired thickness is formed.

Owner:ASM IP HLDG BV

Method to increase silicon nitride tensile stress using nitrogen plasma in-situ treatment and ex-situ UV cure

ActiveUS20080020591A1Improve performanceFilm stress is increasedTransistorSemiconductor/solid-state device manufacturingNitrogen plasmaUV curing

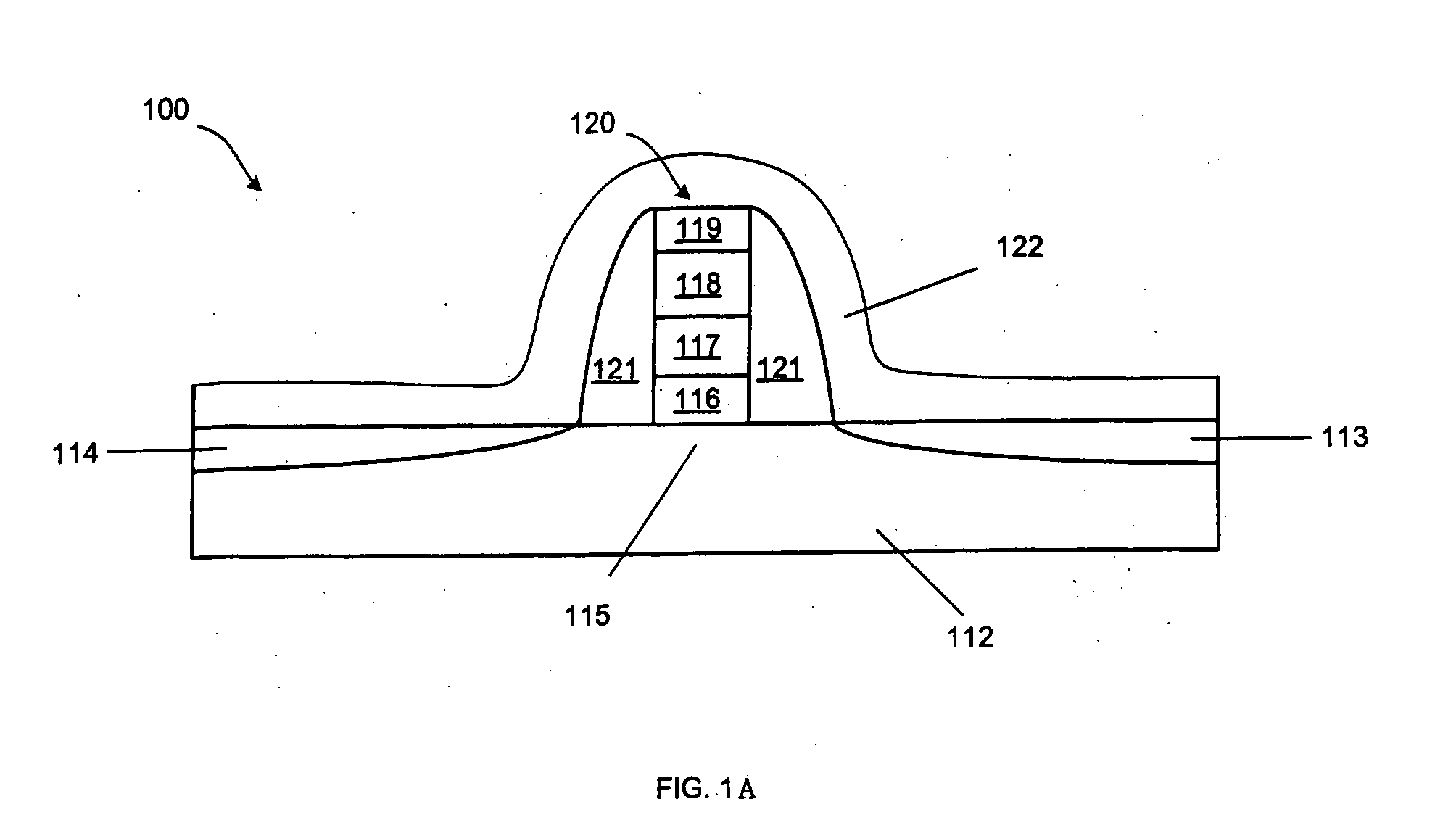

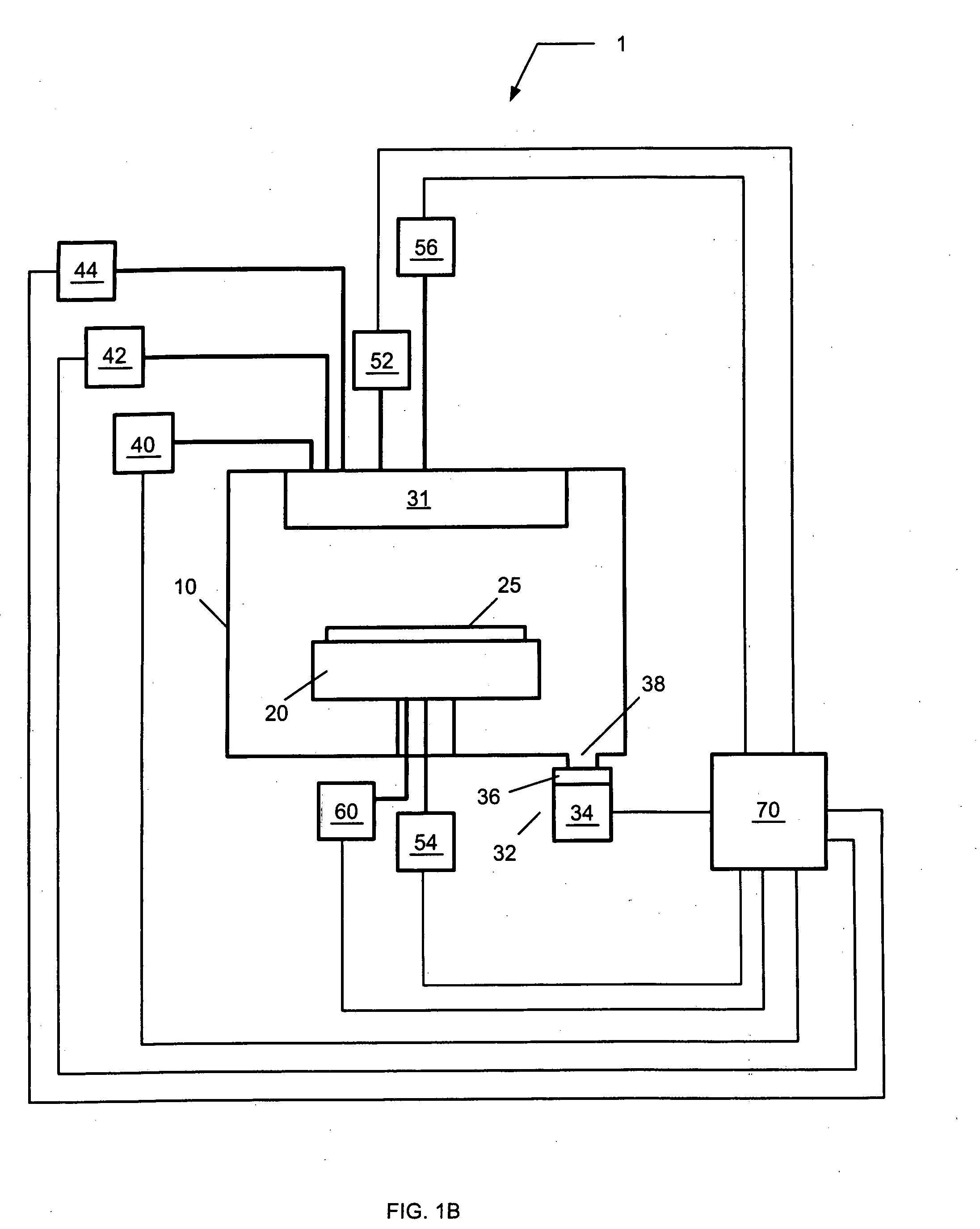

Stress of a silicon nitride layer may be enhanced by deposition at higher temperatures. Employing an apparatus that allows heating of a substrate to substantially greater than 400° C. (for example a heater made from ceramic rather than aluminum), the silicon nitride film as-deposited may exhibit enhanced stress allowing for improved performance of the underlying MOS transistor device. In accordance with alternative embodiments, a deposited silicon nitride film is exposed to curing with ultraviolet (UV) radiation at an elevated temperature, thereby helping remove hydrogen from the film and increasing film stress. In accordance with still other embodiments, a silicon nitride film is formed utilizing an integrated process employing a number of deposition / curing cycles to preserve integrity of the film at the sharp corner of the underlying raised feature. Adhesion between successive layers may be promoted by inclusion of a post-UV cure plasma treatment in each cycle.

Owner:APPLIED MATERIALS INC

Method to form ultra high quality silicon-containing compound layers

InactiveUS20050118837A1Semiconductor/solid-state device detailsSolid-state devicesMaterials scienceReaction chamber

Multiple sequential processes are conducted in a reaction chamber to form ultra high quality silicon-containing compound layers, including silicon nitride layers. In a preferred embodiment, a silicon layer is deposited on a substrate using trisilane as the silicon precursor. A silicon nitride layer is then formed by nitriding the silicon layer. By repeating these steps, a silicon nitride layer of a desired thickness is formed.

Owner:ASM IP HLDG BV

Thin films

InactiveUS20050181555A1Quality improvementHigh dielectric constantSolid-state devicesSemiconductor/solid-state device manufacturingGate dielectricSilicon oxide

Thin films are formed by formed by atomic layer deposition, whereby the composition of the film can be varied from monolayer to monolayer during cycles including alternating pulses of self-limiting chemistries. In the illustrated embodiments, varying amounts of impurity sources are introduced during the cyclical process. A graded gate dielectric is thereby provided, even for extremely thin layers. The gate dielectric as thin as 2 nm can be varied from pure silicon oxide to oxynitride to silicon nitride. Similarly, the gate dielectric can be varied from aluminum oxide to mixtures of aluminum oxide and a higher dielectric material (e.g., ZrO2) to pure high k material and back to aluminum oxide. In another embodiment, metal nitride (e.g., WN) is first formed as a barrier for lining dual damascene trenches and vias. During the alternating deposition process, copper can be introduced, e.g., in separate pulses, and the copper source pulses can gradually increase in frequency, forming a transition region, until pure copper is formed at the upper surface. Advantageously, graded compositions in these and a variety of other contexts help to avoid such problems as etch rate control, electromigration and non-ohmic electrical contact that can occur at sharp material interfaces. In some embodiments additional seed layers or additional transition layers are provided.

Owner:ASM INTERNATIONAL

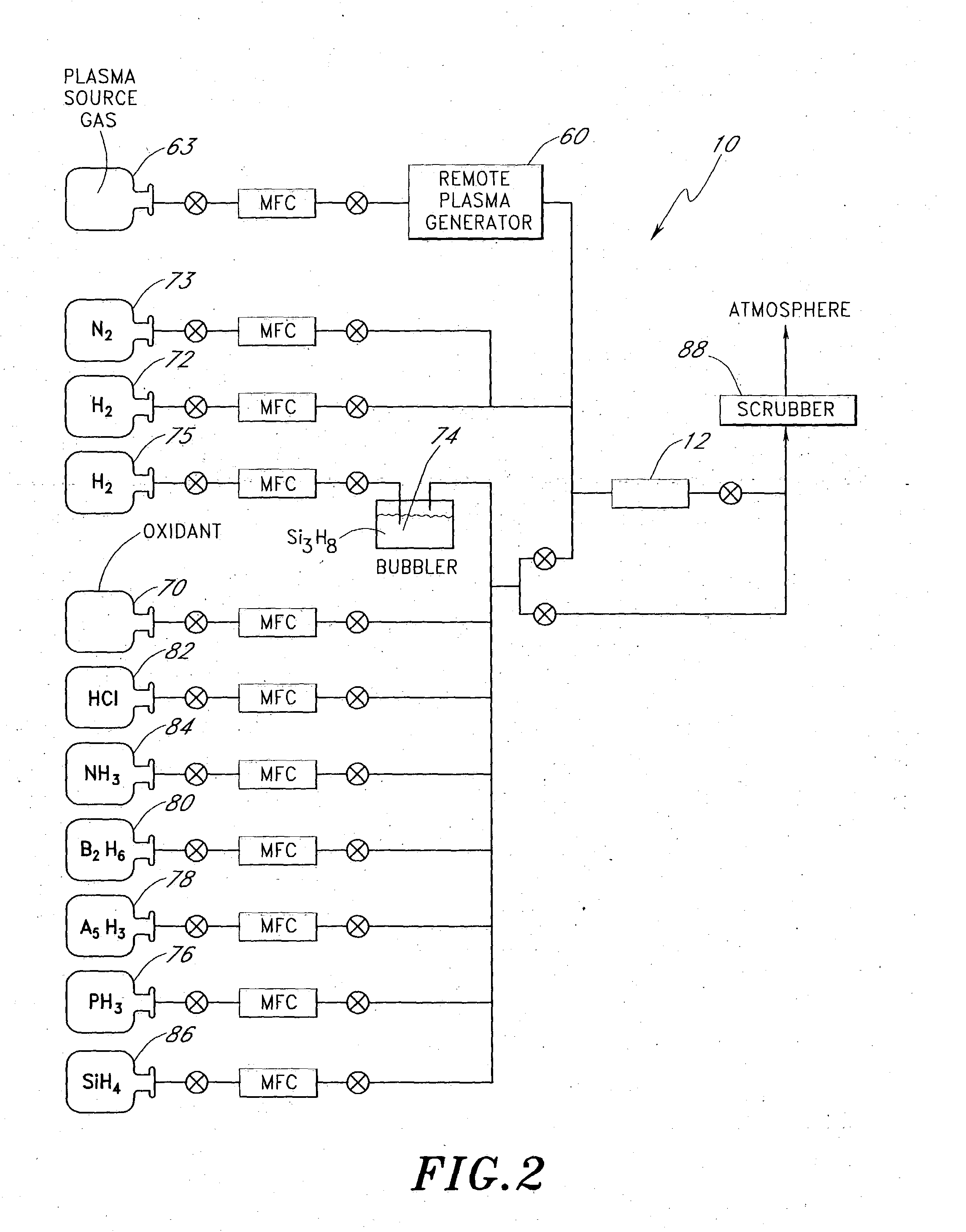

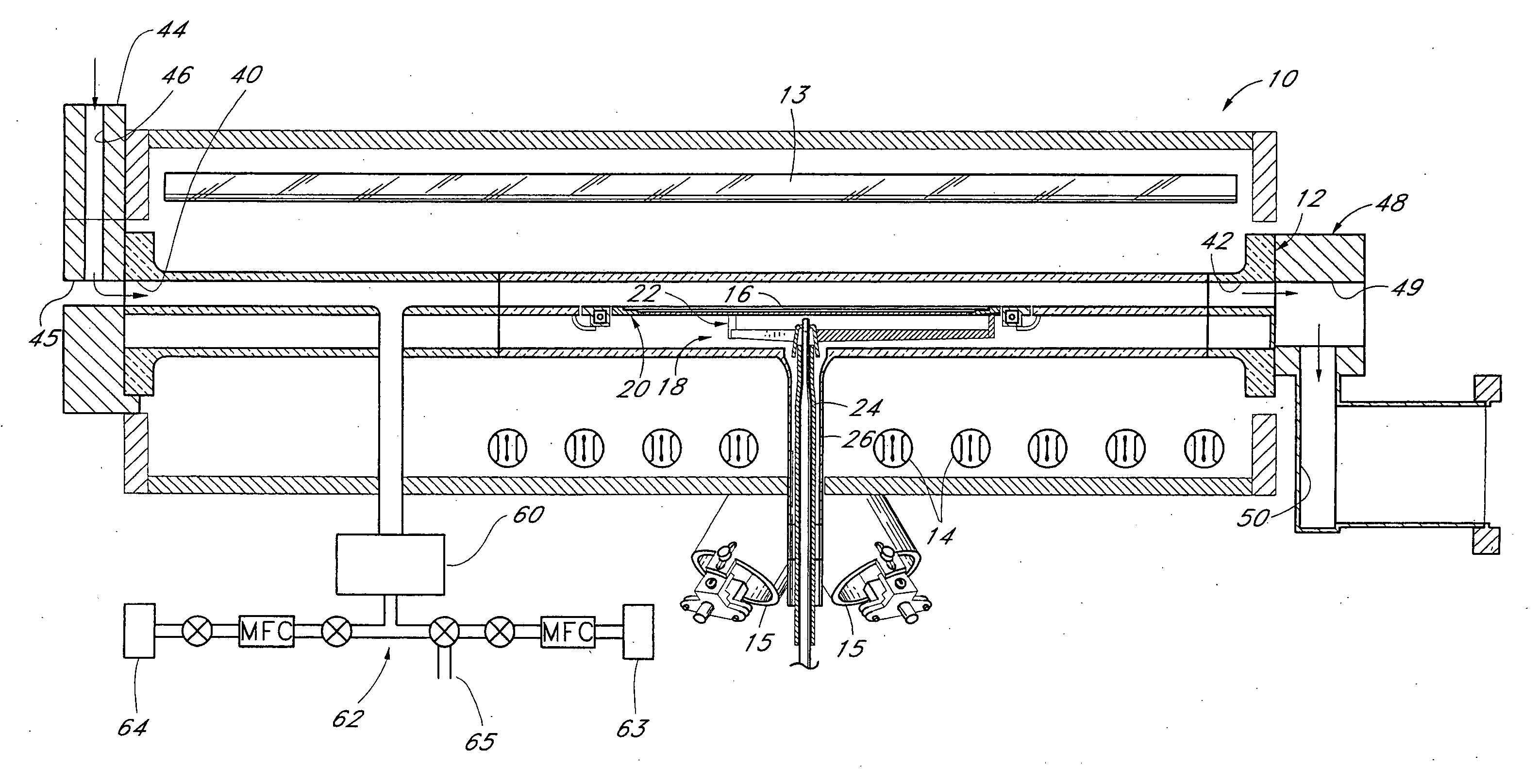

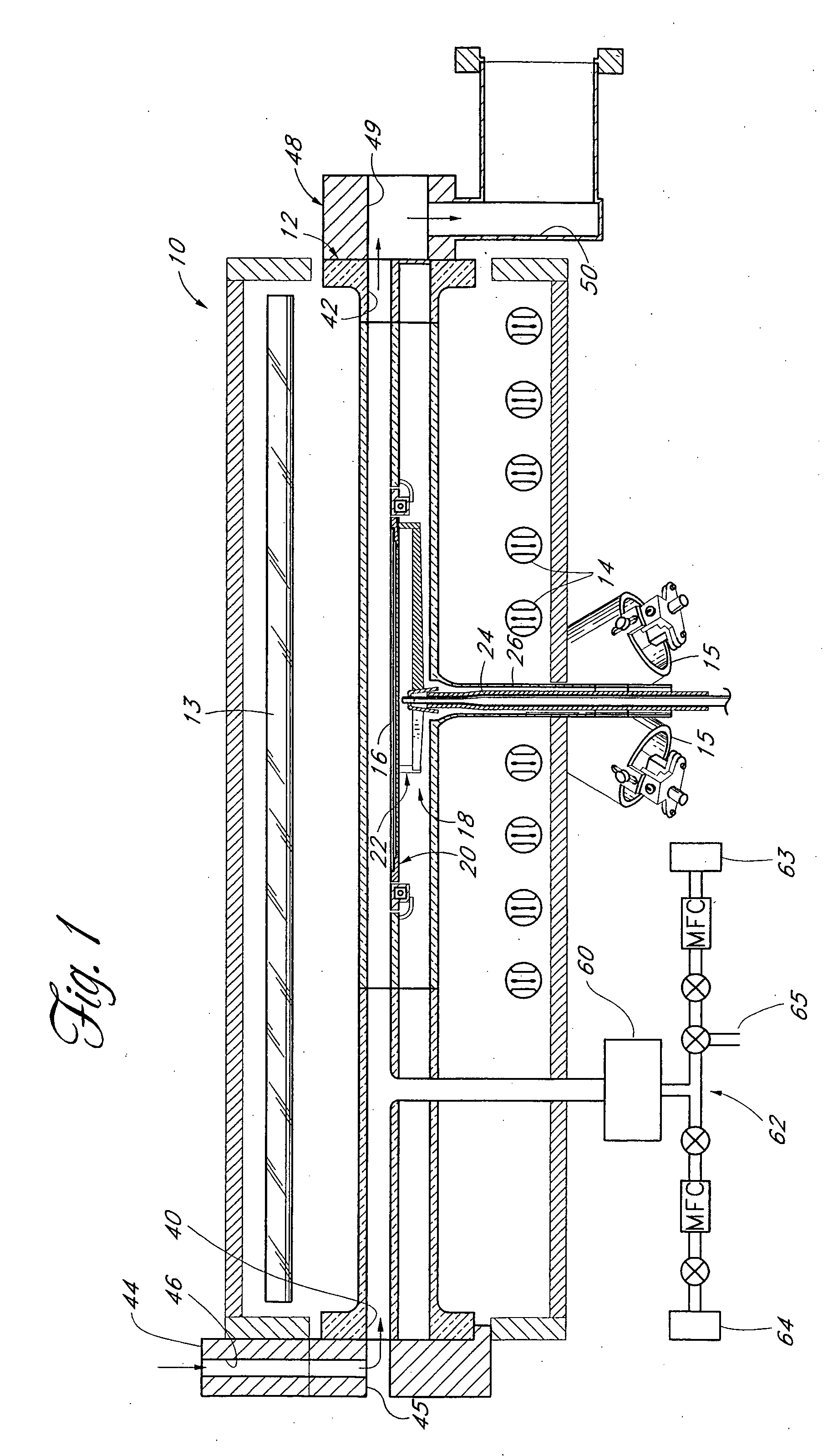

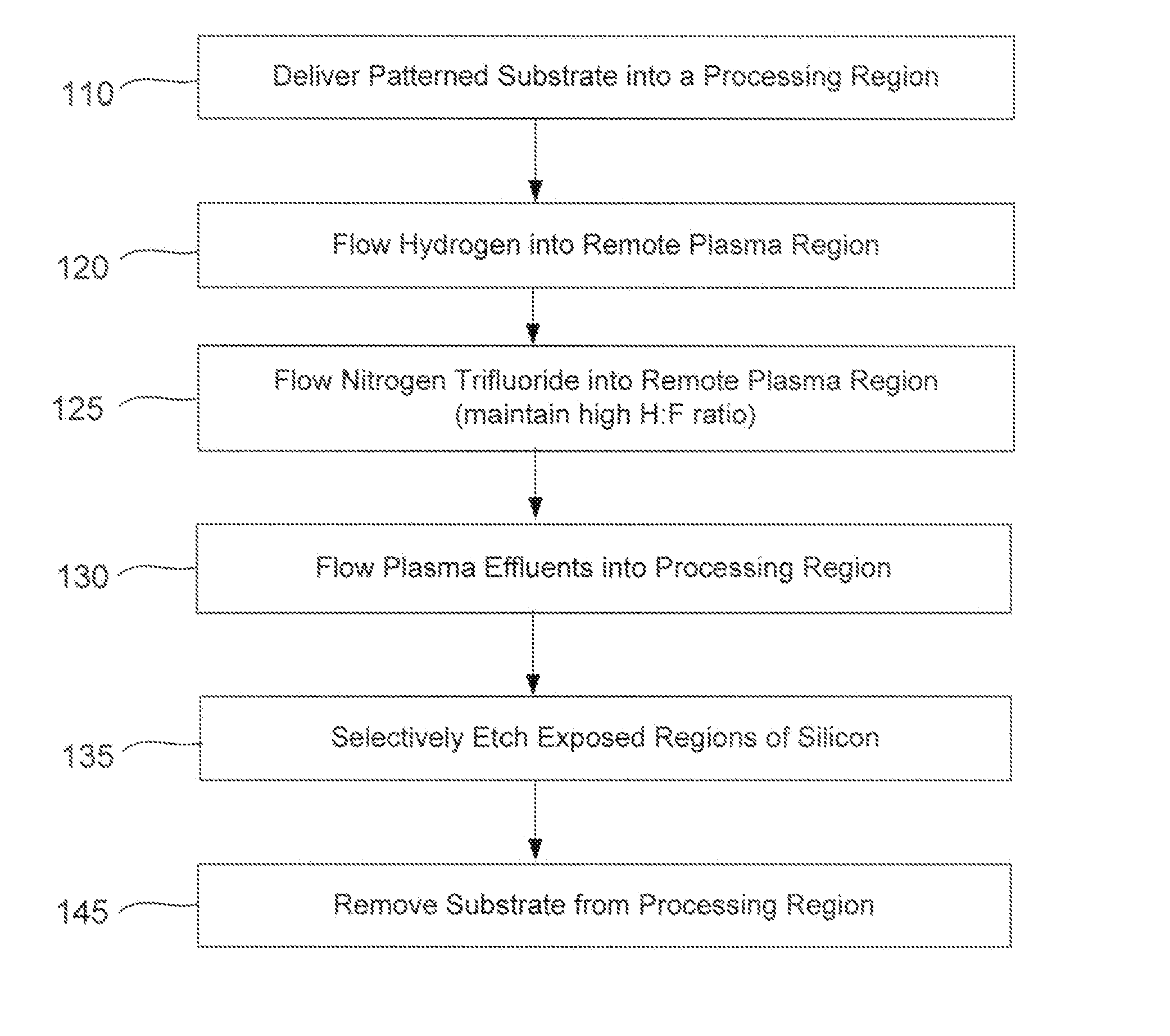

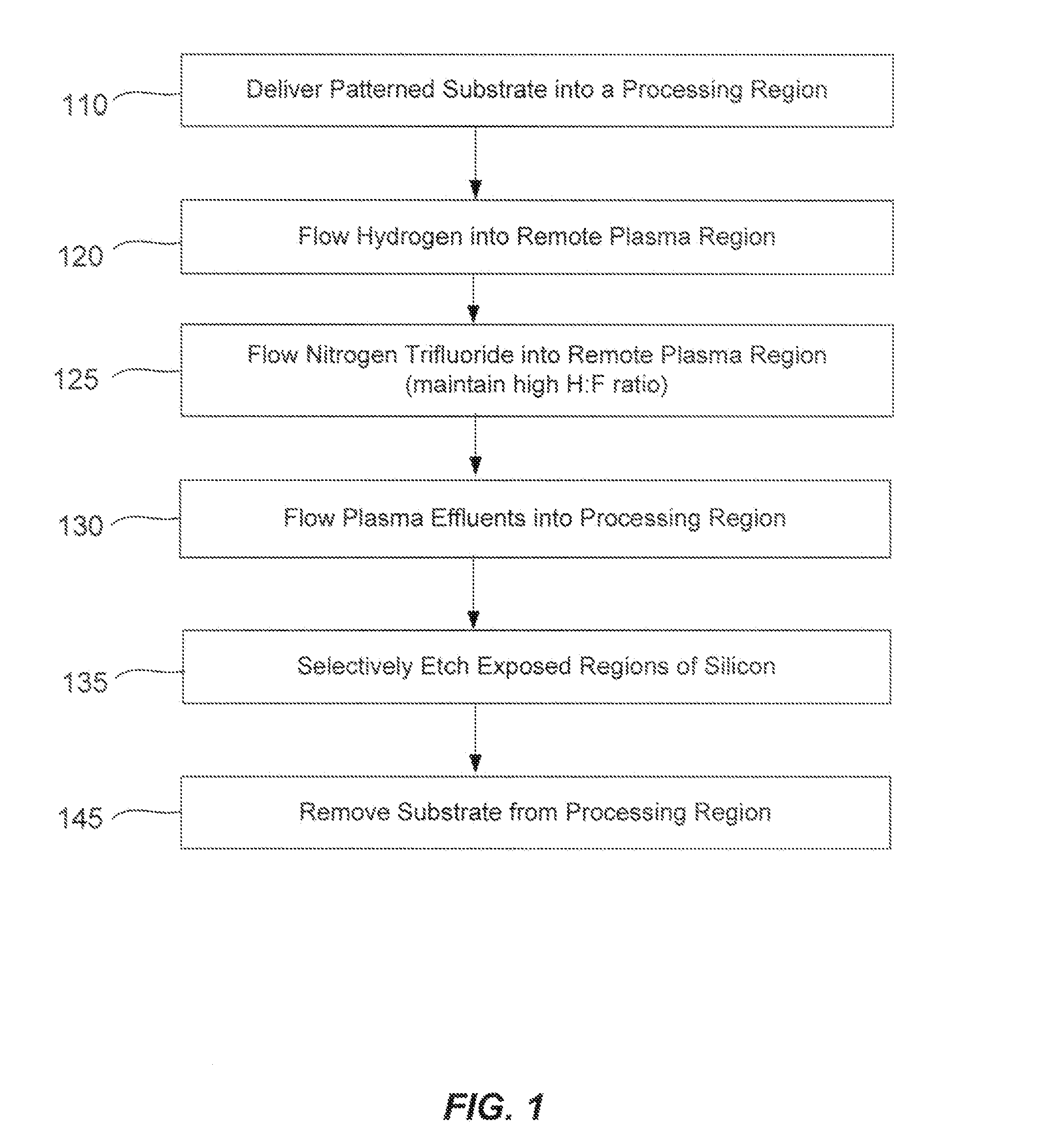

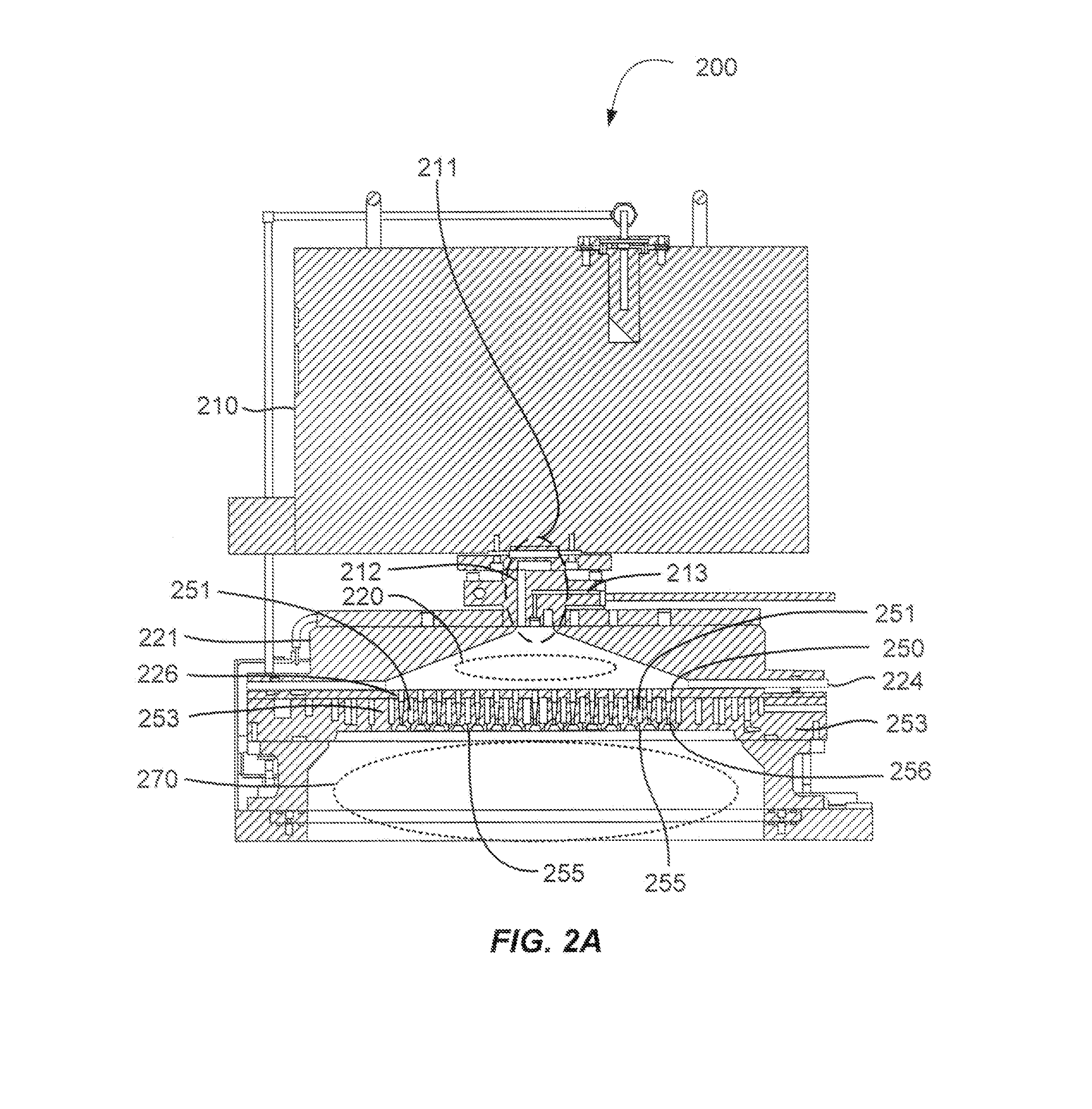

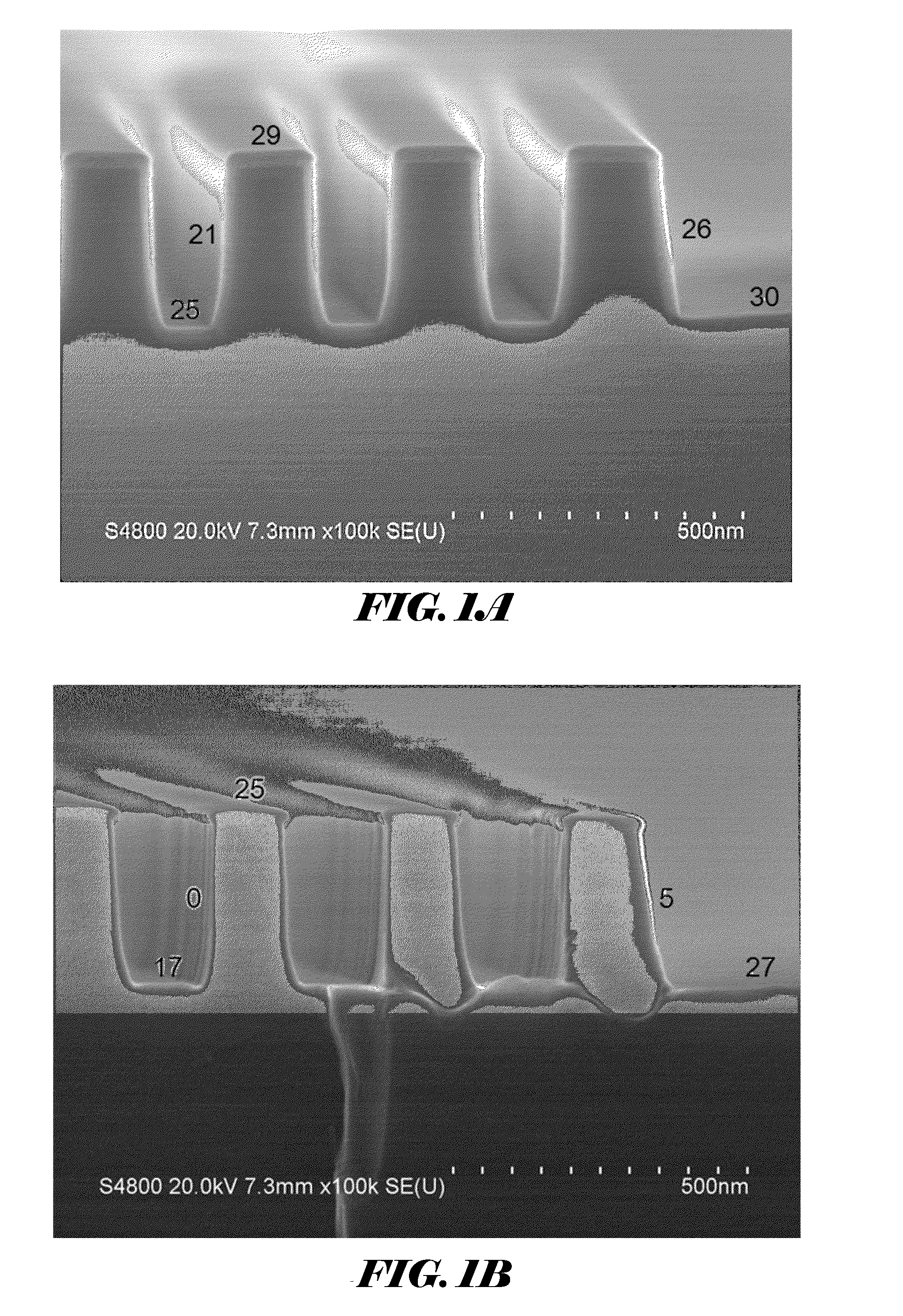

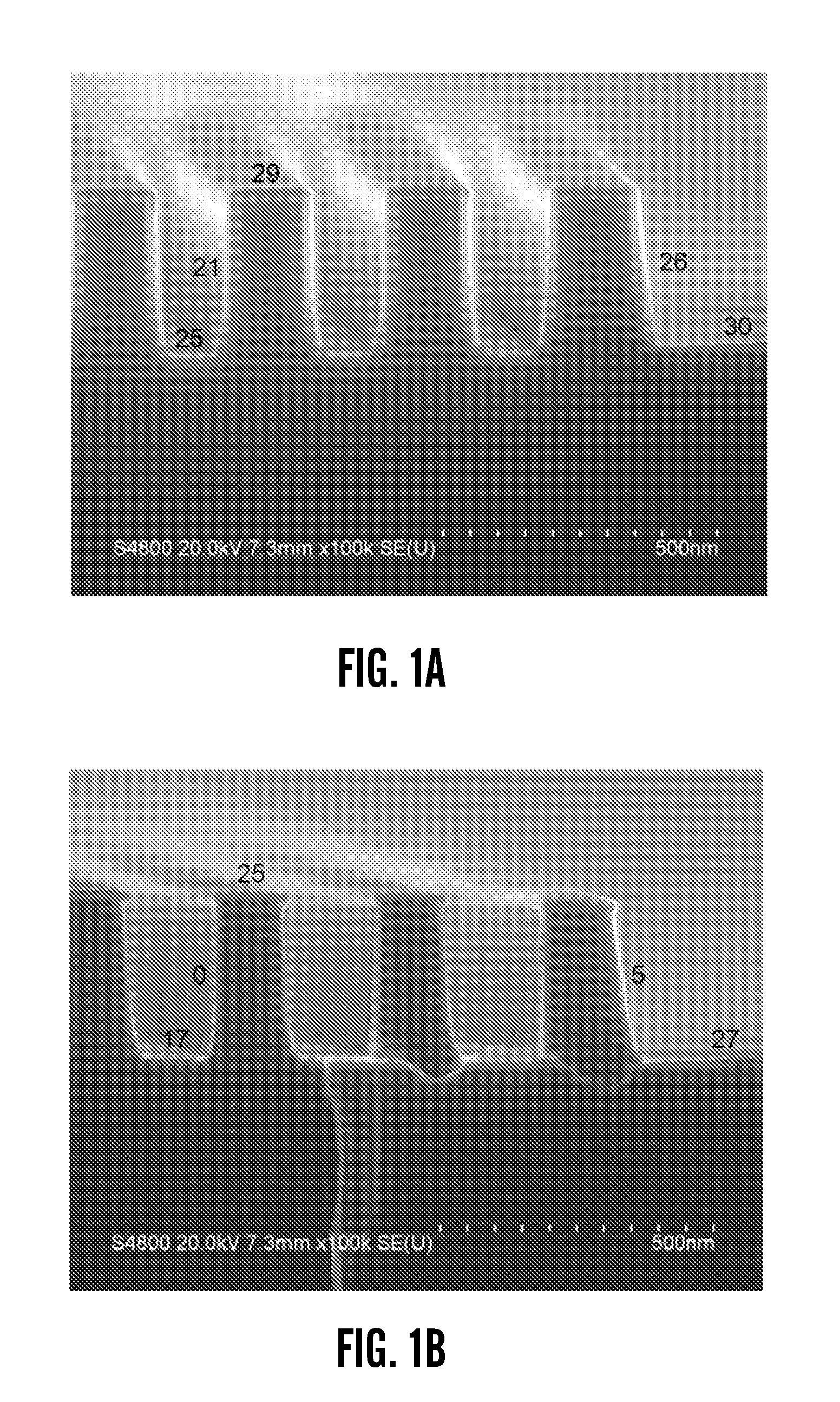

Selective etch of silicon by way of metastable hydrogen termination

ActiveUS20130089988A1Easy to disassembleReduces and substantially eliminates numberElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaHydrogen

Methods of etching exposed silicon on patterned heterogeneous structures is described and includes a remote plasma etch formed from a fluorine-containing precursor and a hydrogen-containing precursor. Plasma effluents from the remote plasma are flowed into a substrate processing region where the plasma effluents react with the exposed regions of silicon. The plasmas effluents react with the patterned heterogeneous structures to selectively remove silicon while very slowly removing other exposed materials. The silicon selectivity results, in part, from a preponderance of hydrogen-containing precursor in the remote plasma which hydrogen terminates surfaces on the patterned heterogeneous structures. A much lower flow of the fluorine-containing precursor progressively substitutes fluorine for hydrogen on the hydrogen-terminated silicon thereby selectively removing silicon from exposed regions of silicon. The methods may be used to selectively remove silicon far faster than silicon oxide, silicon nitride and a variety of metal-containing materials.

Owner:APPLIED MATERIALS INC

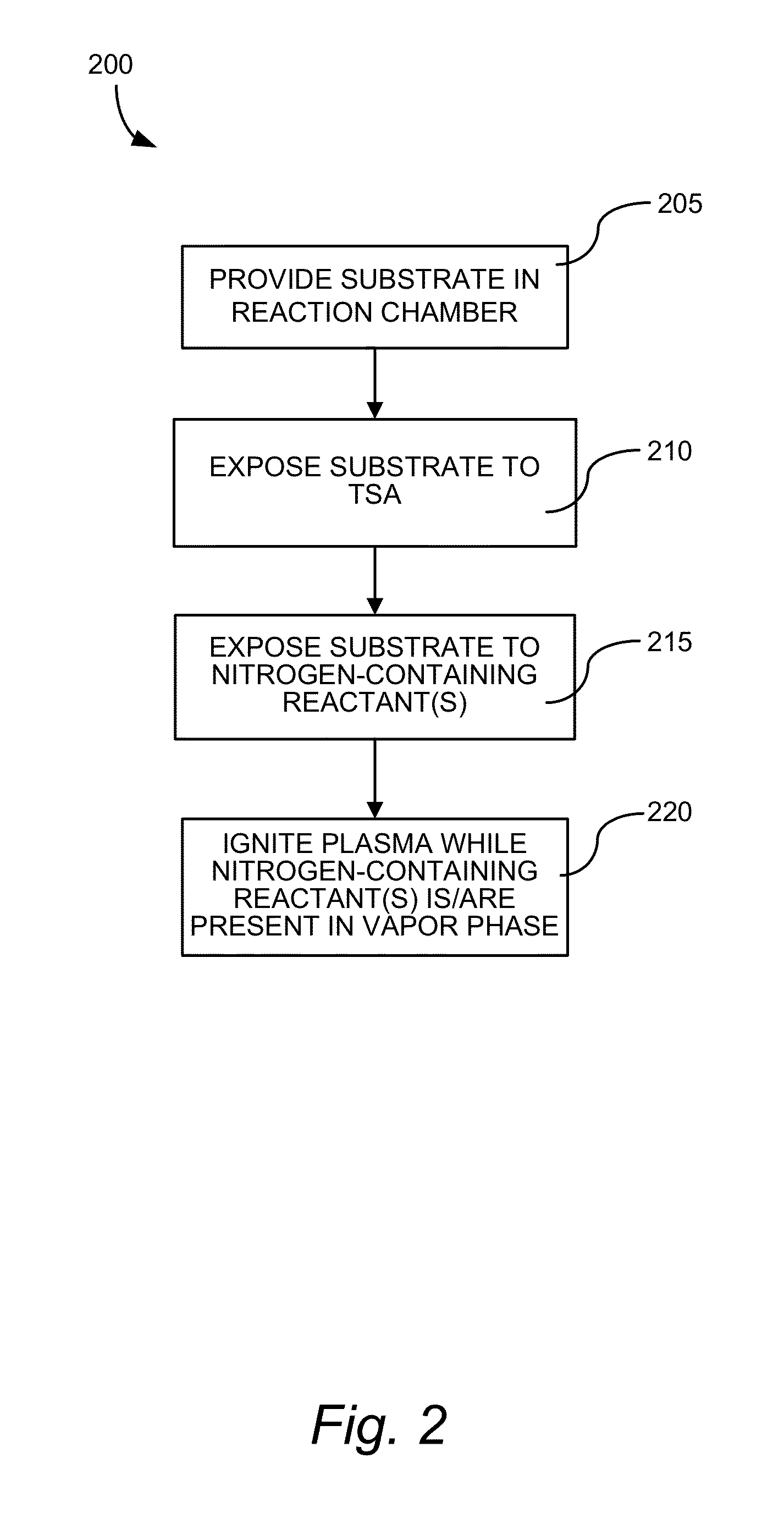

Method for depositing a chlorine-free conformal sin film

ActiveUS20130189854A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingChemistryEtching rate

Described are methods of making silicon nitride (SiN) materials on substrates. Improved SiN films made by the methods are also included. One aspect relates to depositing chlorine (Cl)-free conformal SiN films. In some embodiments, the SiN films are Cl-free and carbon (C)-free. Another aspect relates to methods of tuning the stress and / or wet etch rate of conformal SiN films. Another aspect relates to low-temperature methods of depositing high quality conformal SiN films. In some embodiments, the methods involve using trisilylamine (TSA) as a silicon-containing precursor.

Owner:NOVELLUS SYSTEMS

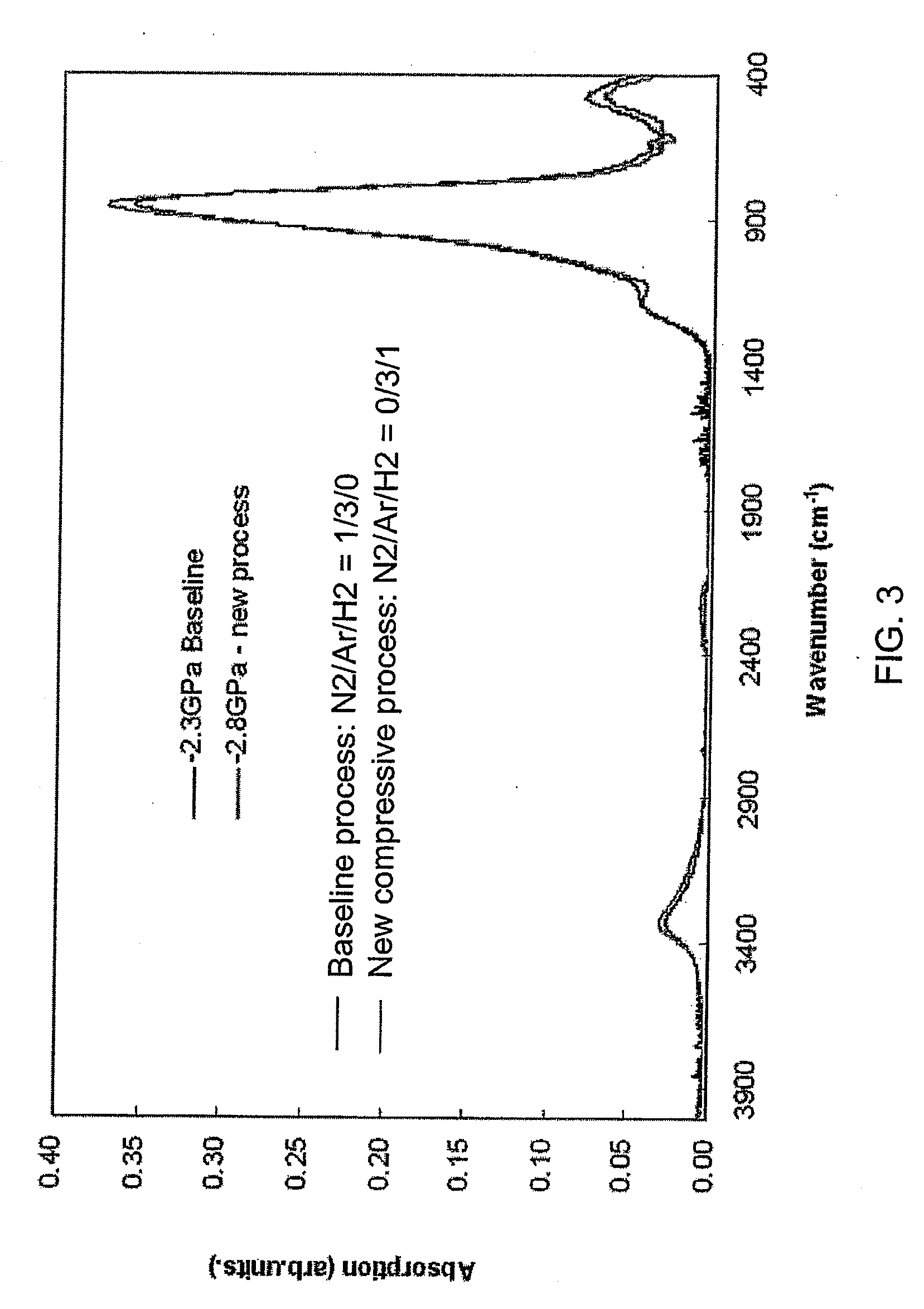

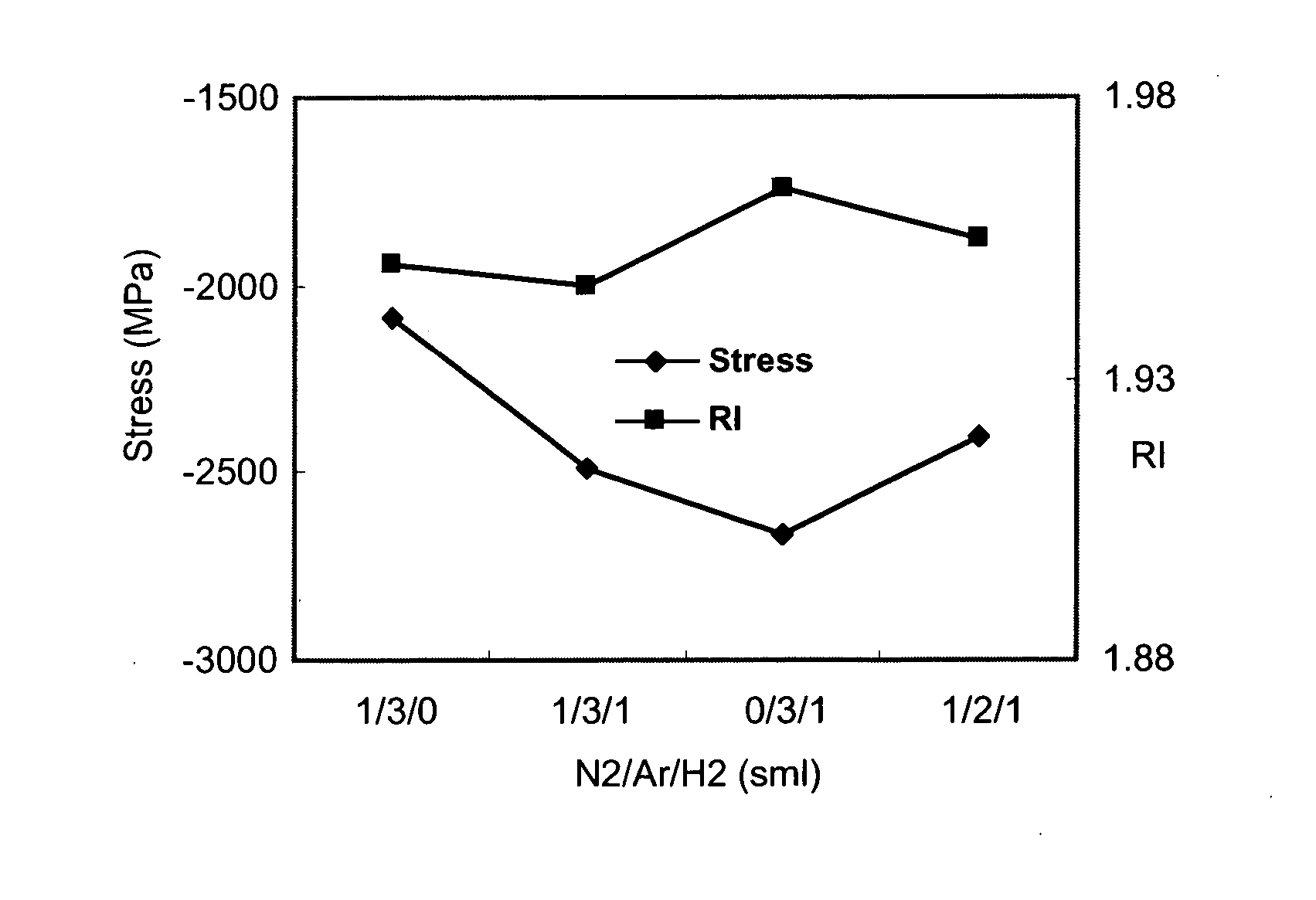

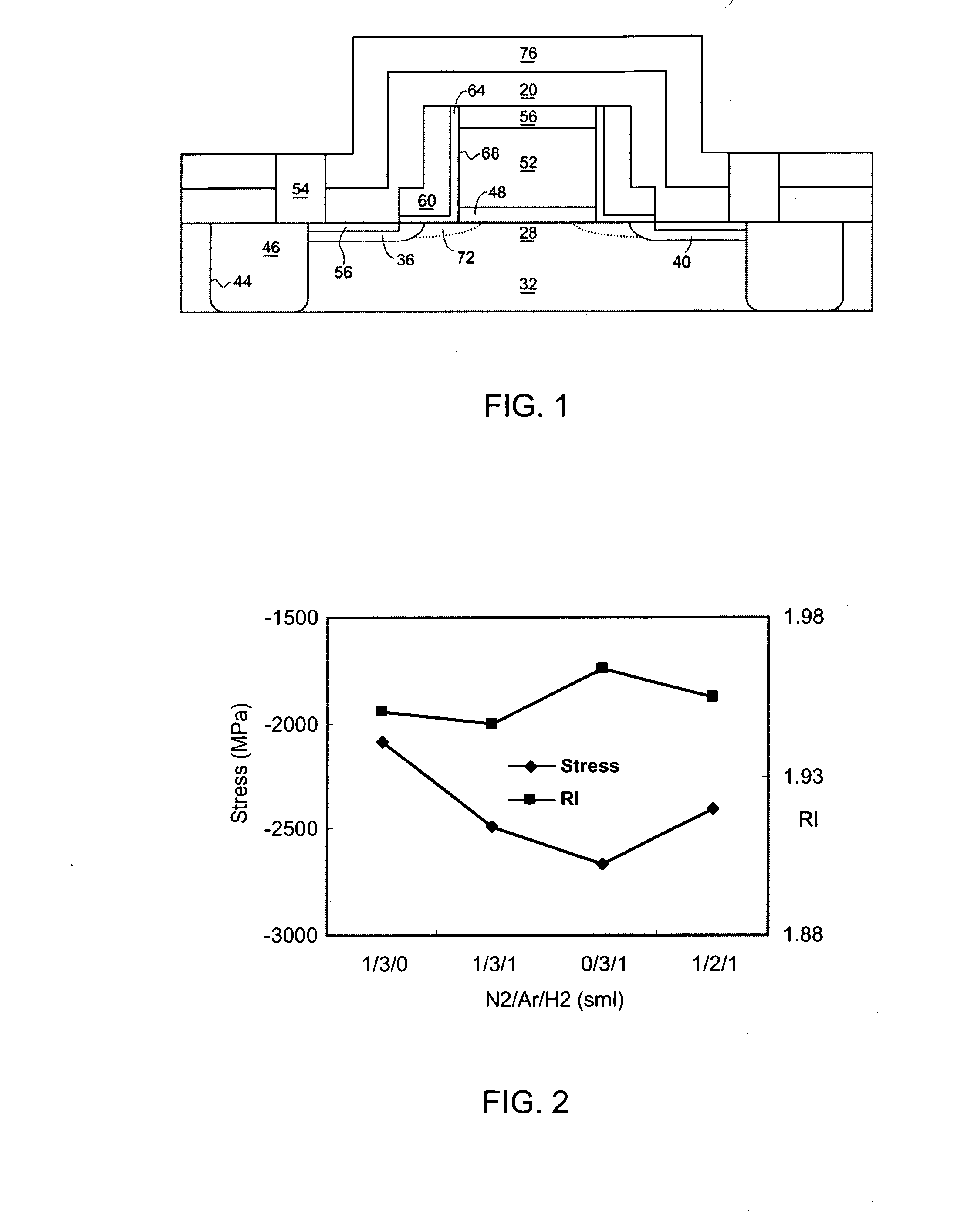

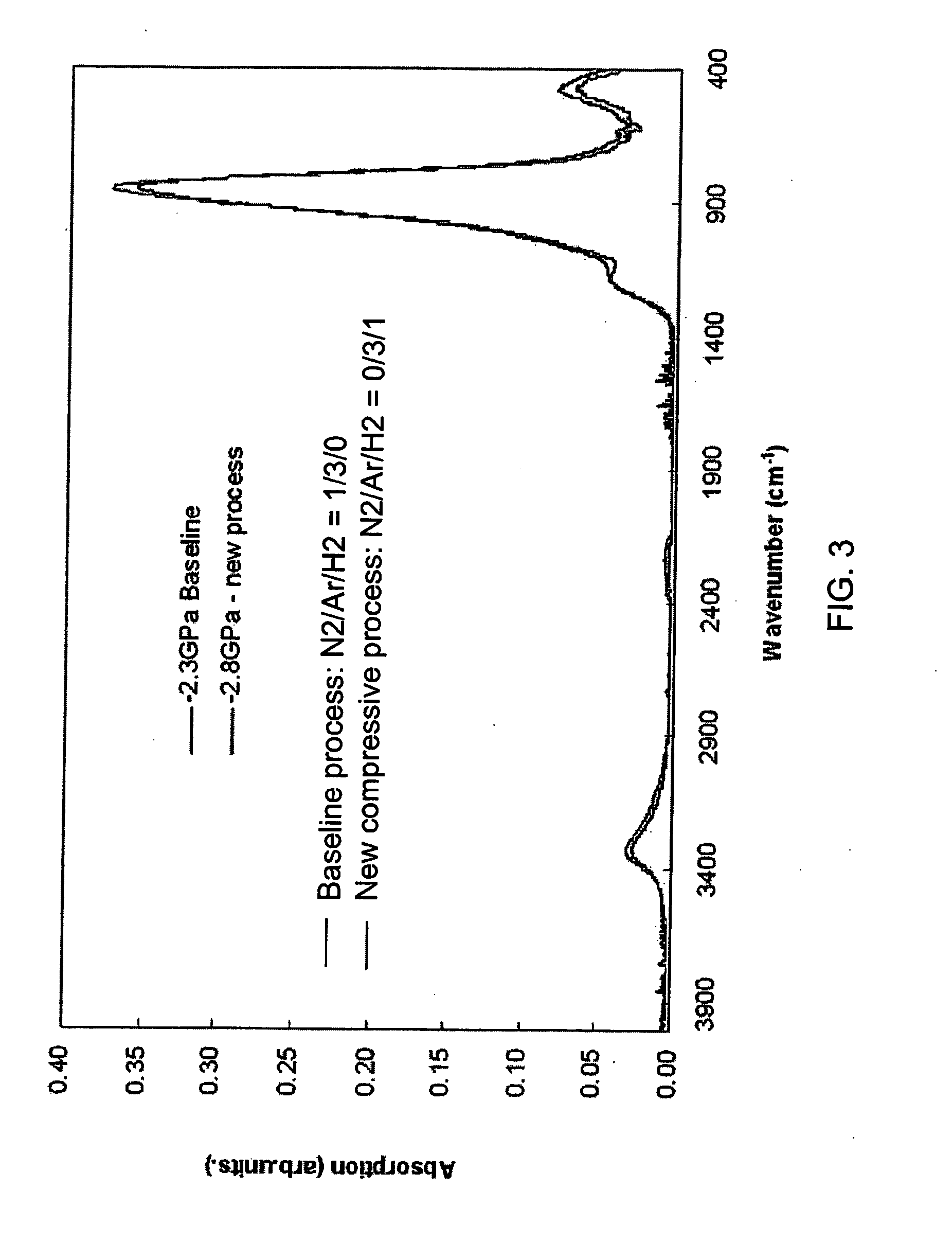

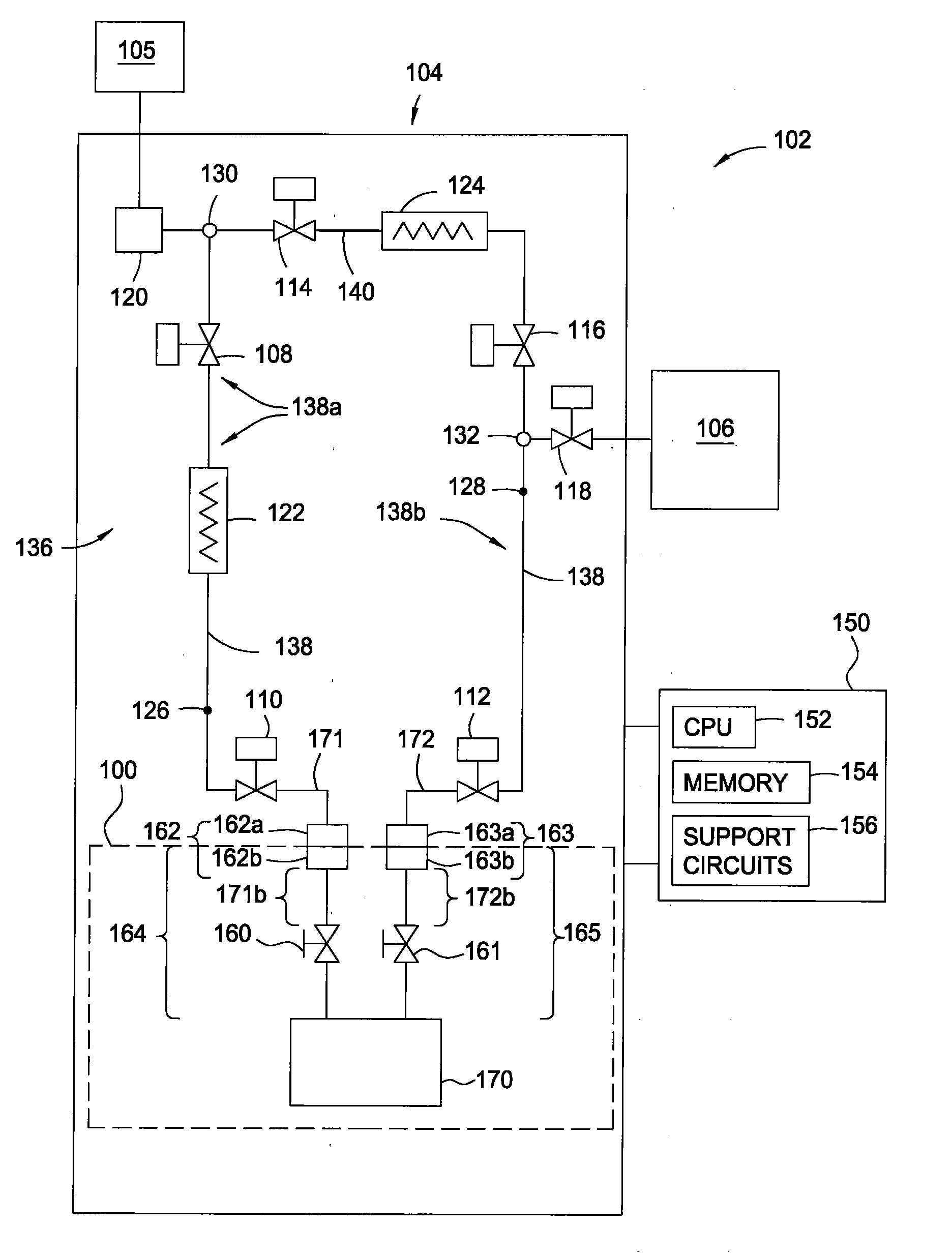

Method to increase the compressive stress of PECVD silicon nitride films

ActiveUS20060269692A1Increase silicon nitride compressive stressReduce defectsSemiconductor/solid-state device manufacturingElectrostatic cleaningHydrogenDevice material

Compressive stress in a film of a semiconductor device may be controlled utilizing one or more techniques, employed alone or in combination. A first set of embodiments increase silicon nitride compressive stress by adding hydrogen to the deposition chemistry, and reduce defects in a device fabricated with a high compressive stress silicon nitride film formed in the presence of hydrogen gas. A silicon nitride film may comprise an initiation layer formed in the absence of a hydrogen gas flow, underlying a high stress nitride layer formed in the presence of a hydrogen gas flow. A silicon nitride film formed in accordance with an embodiment of the present invention may exhibit a compressive stress of 2.8 GPa or higher.

Owner:APPLIED MATERIALS INC

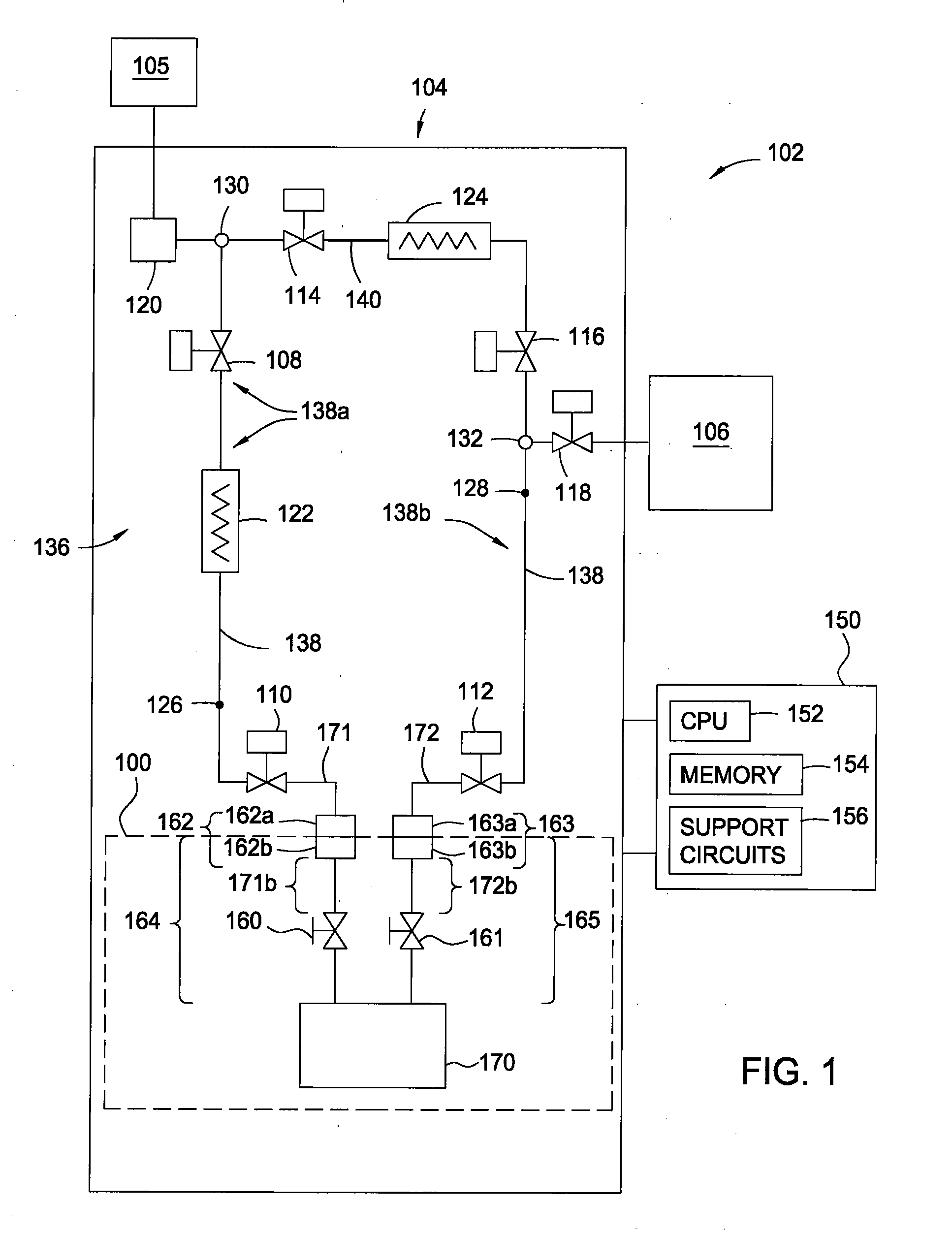

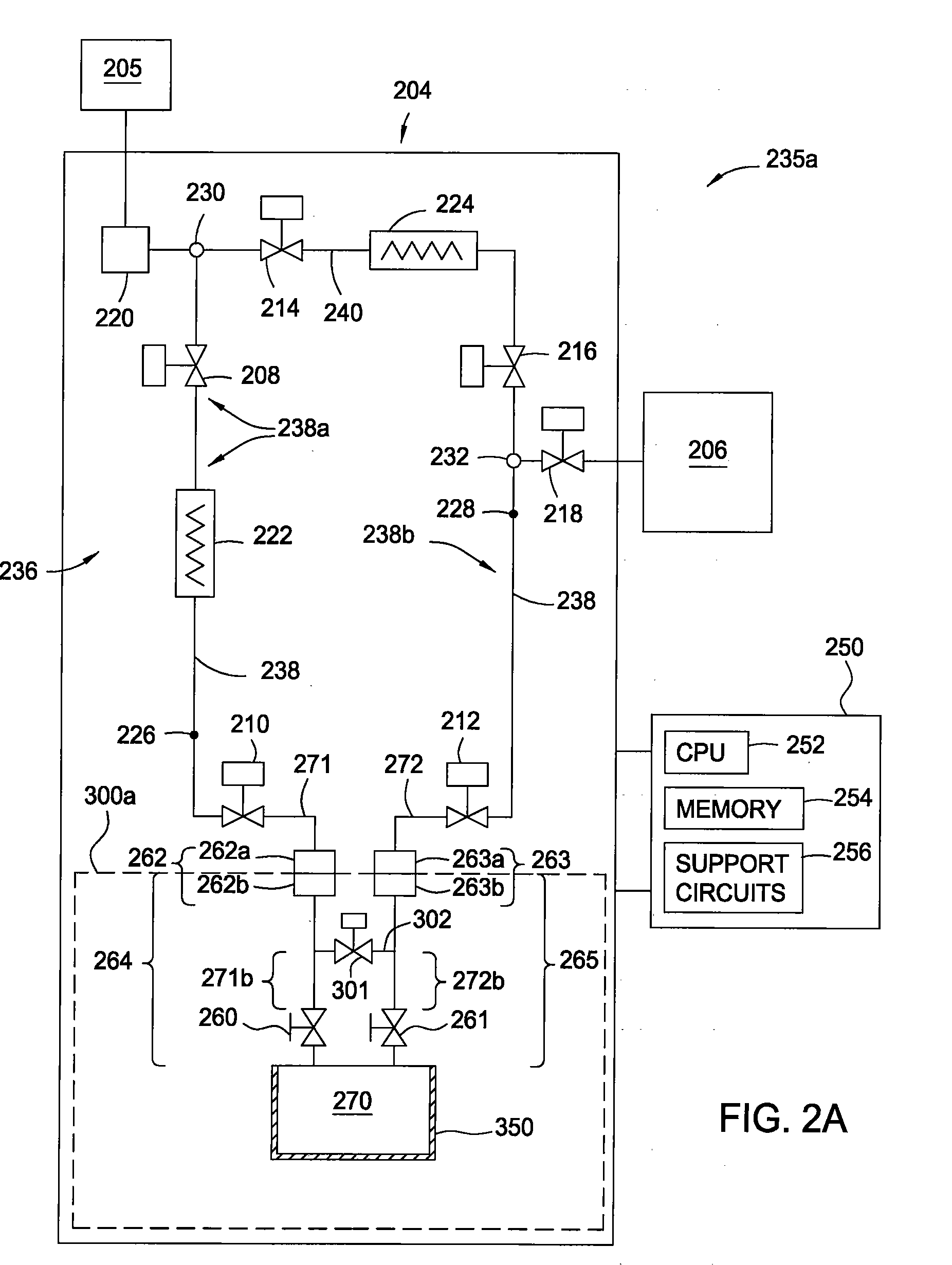

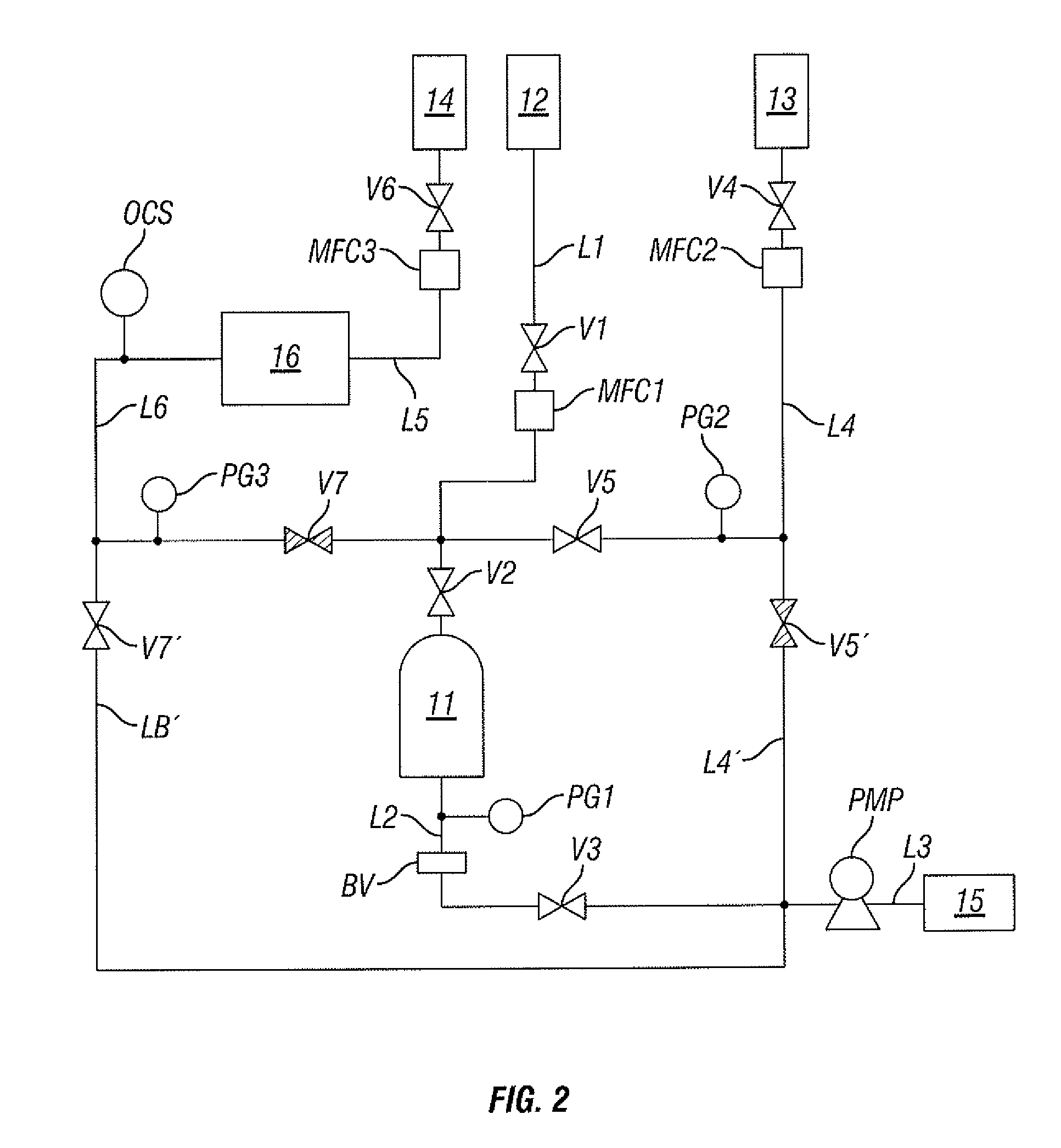

Ampoule with a thermally conductive coating

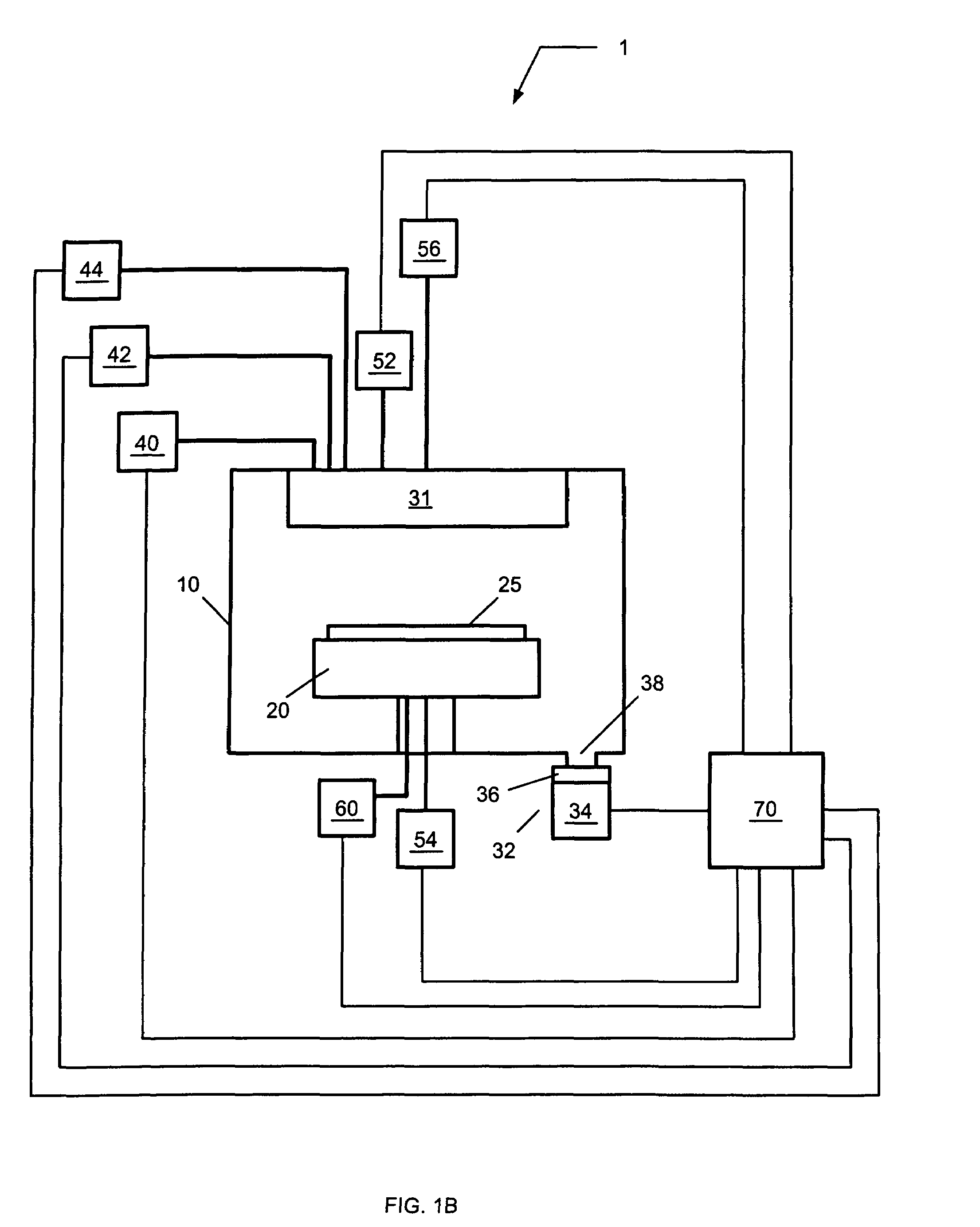

ActiveUS20080149031A1Improve temperature uniformityChemical vapor deposition coatingConductive coatingCompound (substance)

Embodiments of the invention provide an apparatus and a process for generating a chemical precursor used in a vapor deposition processing system. The apparatus includes a canister (e.g., ampoule) having a sidewall, a top, and a bottom encompassing an interior volume therein, inlet and outlet ports in fluid communication with the interior volume, and a thermally conductive coating disposed on or over the outside surface of the canister. The thermally conductive coating is more thermally conductive than the outside surface of the canister. The thermally conductive coating may contain aluminum, aluminum nitride, copper, brass, silver, titanium, silicon nitride, or alloys thereof. In some embodiments, an adhesion layer (e.g., titanium or tantalum) may be disposed between the outside surface of the canister and the thermally conductive coating. In other embodiments, the canister may contain a plurality of baffles or solid heat-transfer particles to help evenly heat a solid precursor therein.

Owner:APPLIED MATERIALS INC

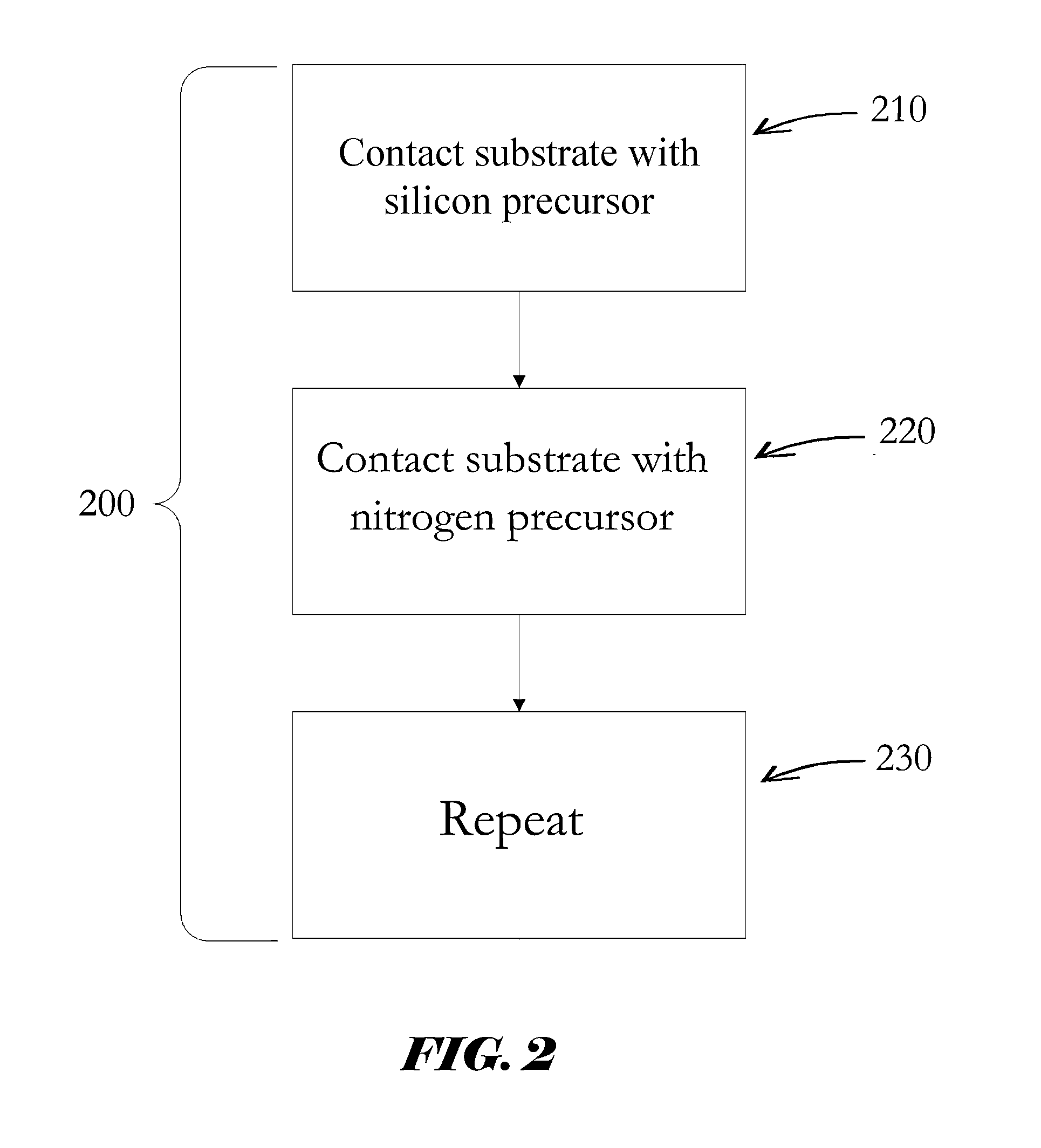

Si PRECURSORS FOR DEPOSITION OF SiN AT LOW TEMPERATURES

ActiveUS20140273528A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingMetallurgyAtomic layer deposition

Methods and precursors for depositing silicon nitride films by atomic layer deposition (ALD) are provided. In some embodiments the silicon precursors comprise an iodine ligand. The silicon nitride films may have a relatively uniform etch rate for both vertical and the horizontal portions when deposited onto three-dimensional structures such as FinFETS or other types of multiple gate FETs. In some embodiments, various silicon nitride films of the present disclosure have an etch rate of less than half the thermal oxide removal rate with diluted HF (0.5%).

Owner:ASM IP HLDG BV

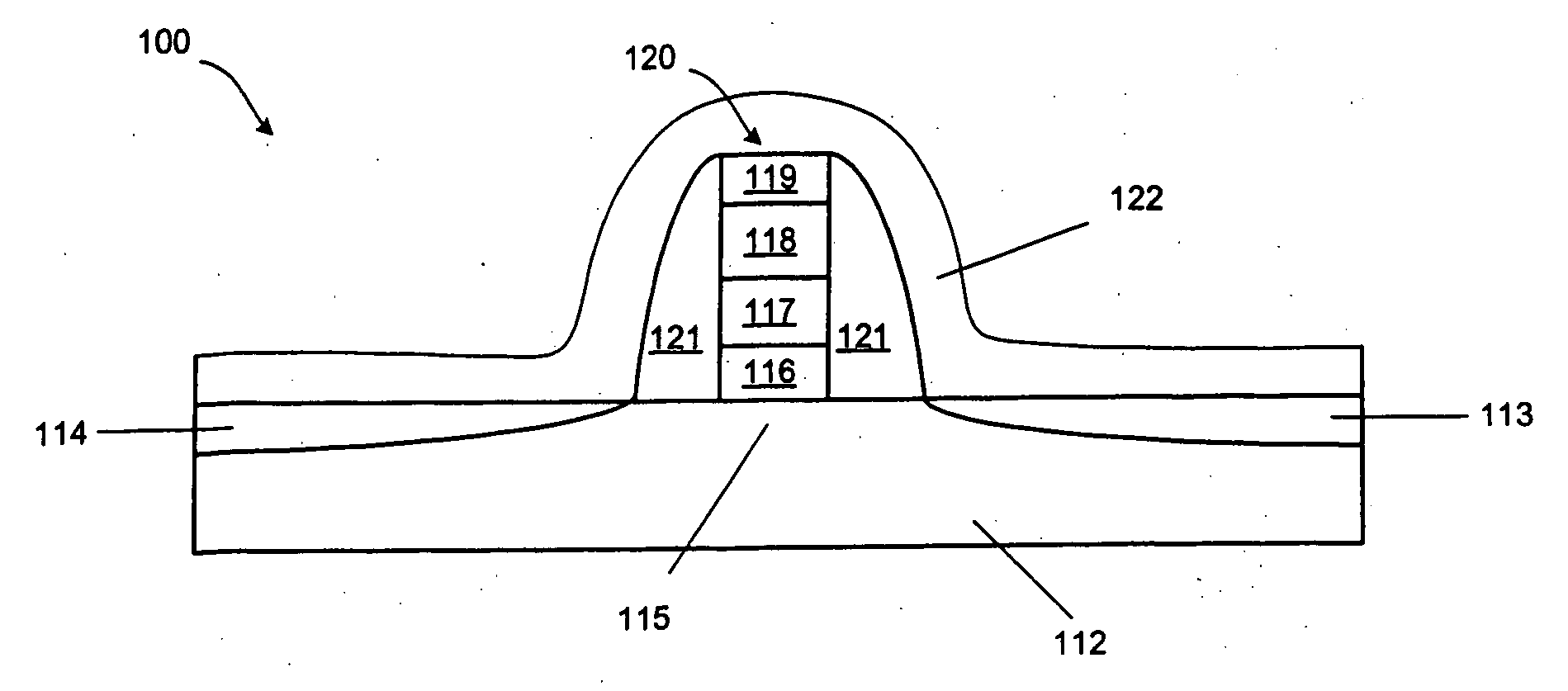

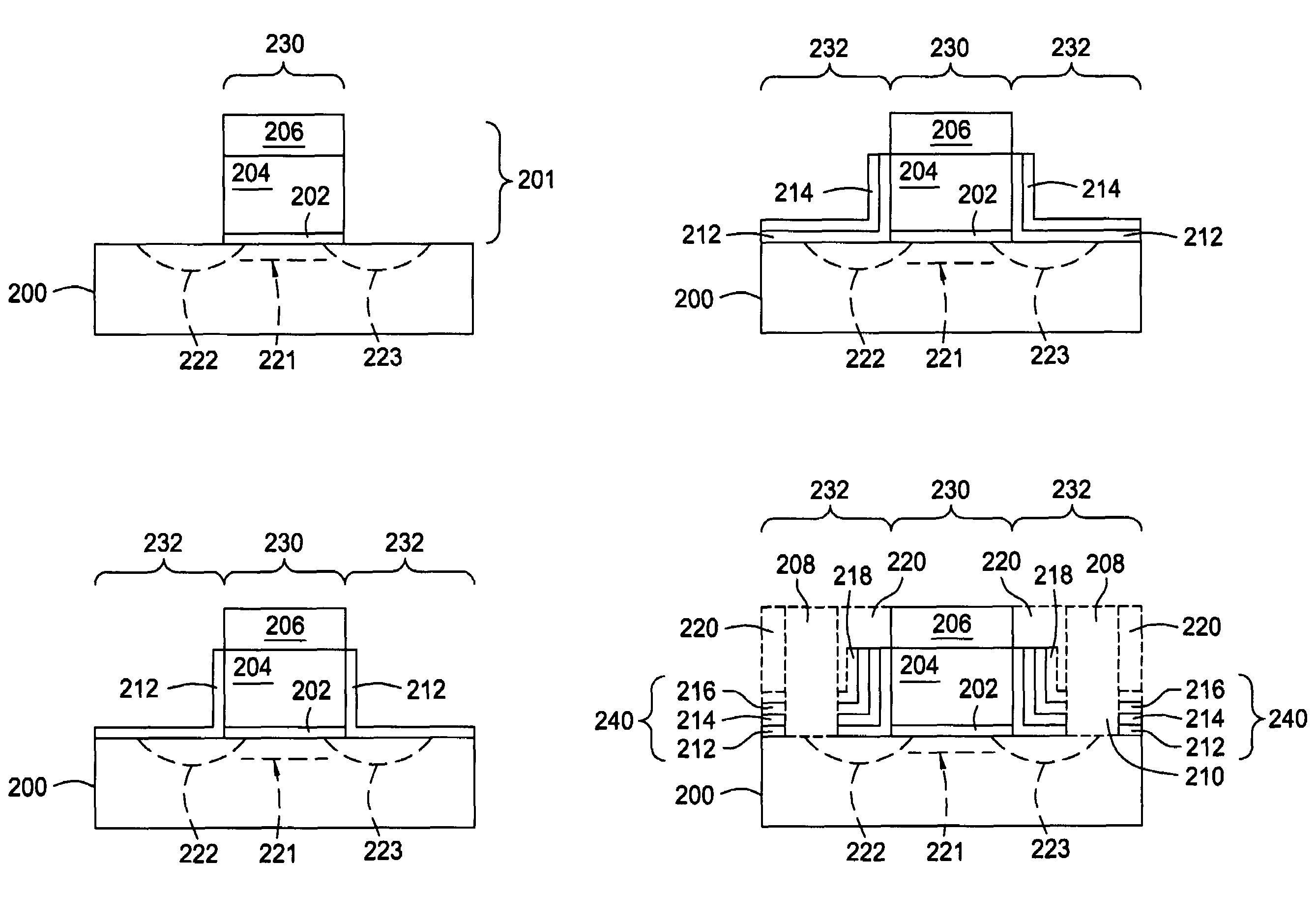

Method for fabricating silicon nitride spacer structures

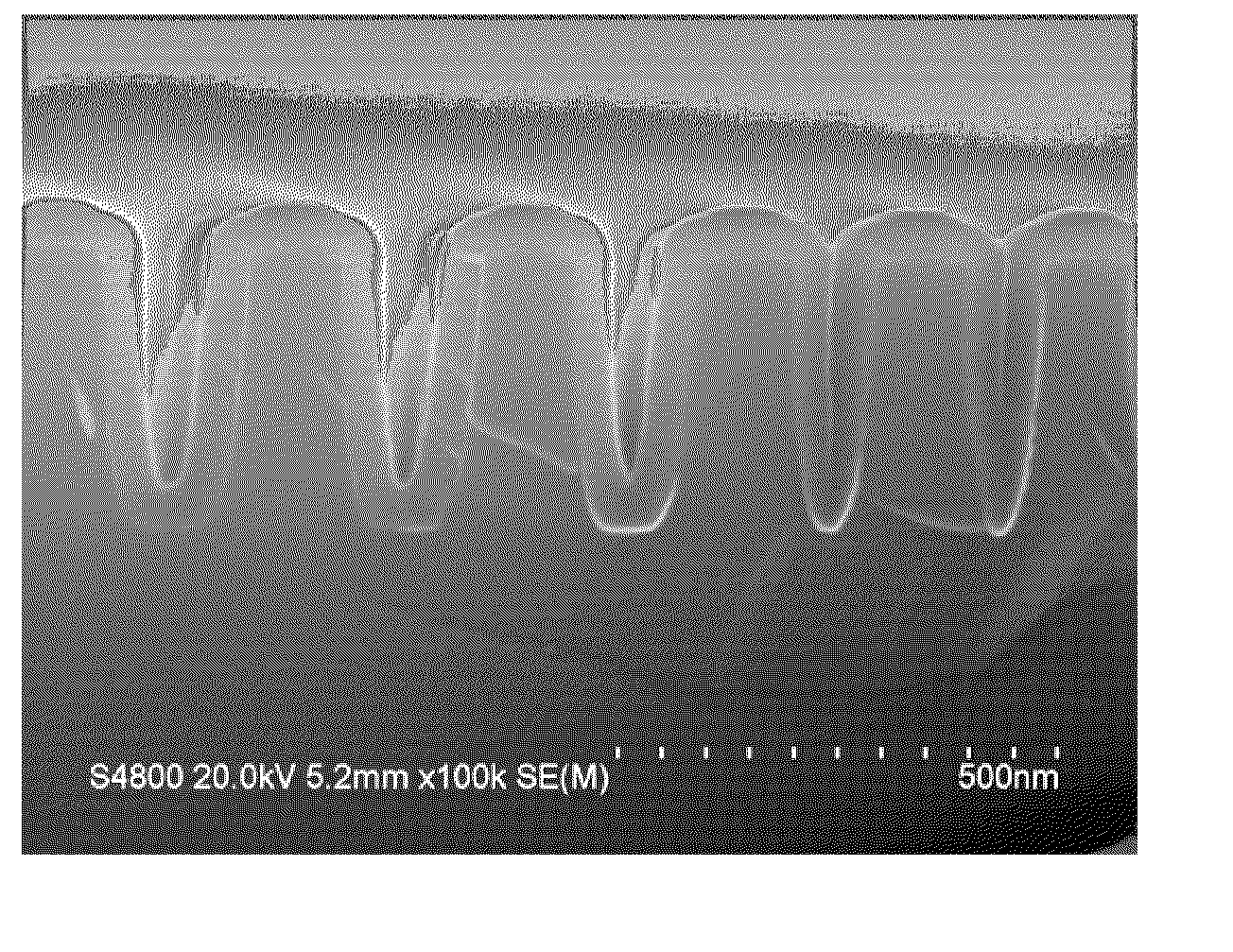

ActiveUS7294581B2Semiconductor/solid-state device manufacturingSemiconductor devicesDielectricSemiconductor

Embodiments of methods for fabricating a spacer structure on a semiconductor substrate are provided herein. In one embodiment, a method for fabricating a spacer structure on a semiconductor substrate includes providing a substrate containing a base structure over which the spacer structure is to be formed. The spacer structure may be formed over the base structure by depositing a first layer comprising silicon nitride on the base structure, depositing a second layer comprising a silicon-based dielectric material on the first layer, and depositing a third layer comprising silicon nitride on the second layer. The first, second, and third layers are deposited in a single processing reactor.

Owner:APPLIED MATERIALS INC

Organosilane compounds for modifying dielectrical properties of silicon oxide and silicon nitride films

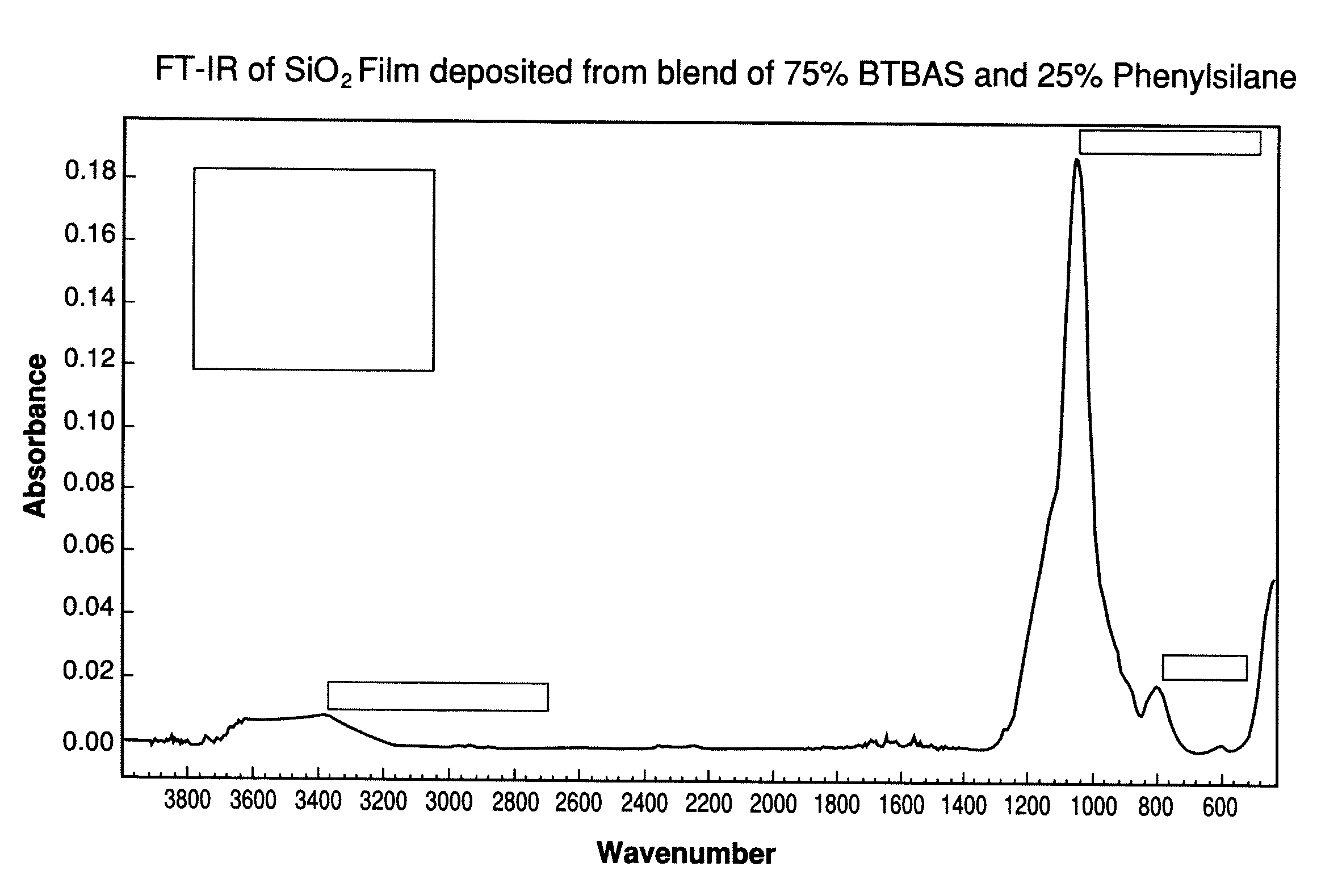

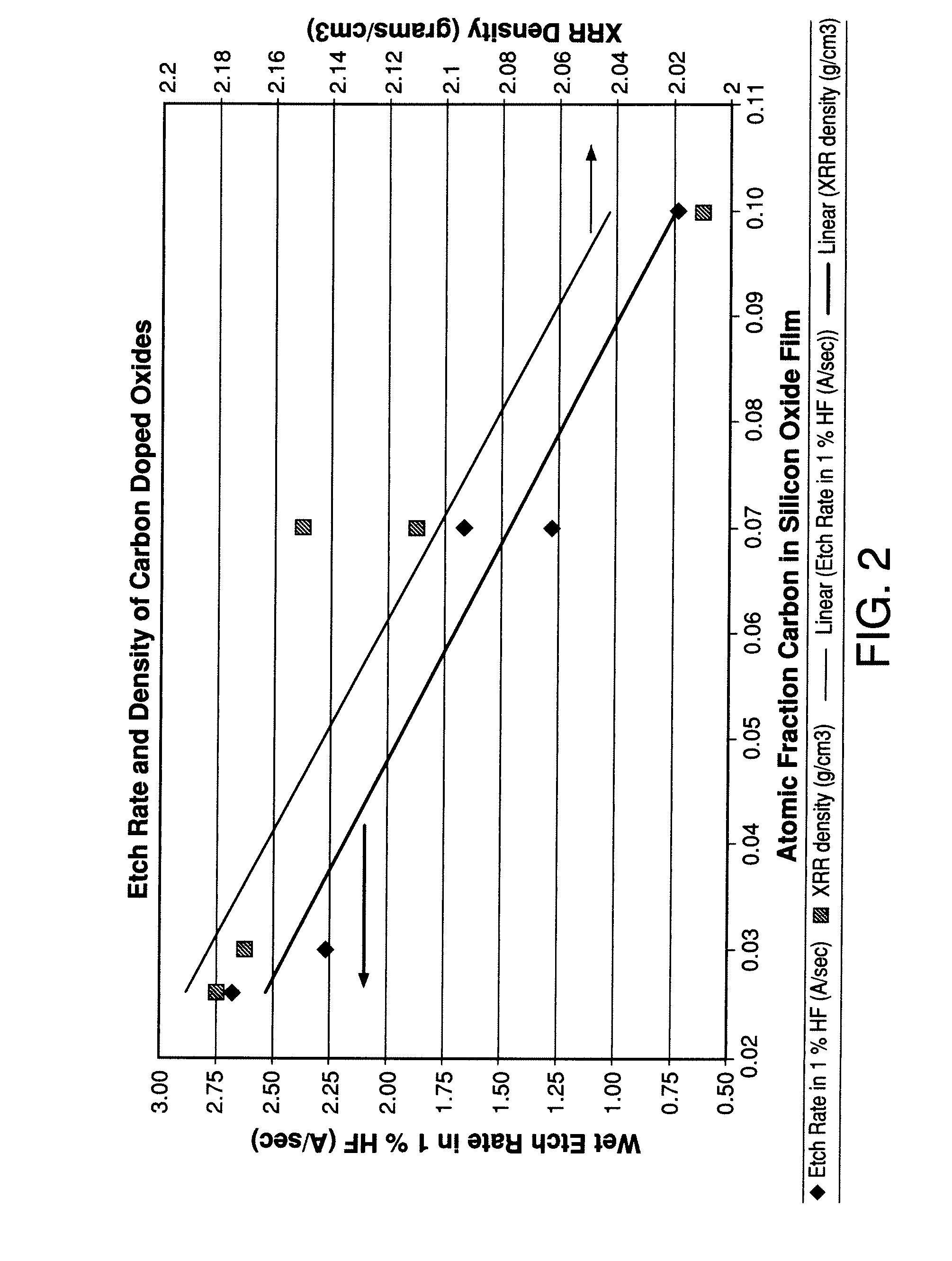

InactiveUS20080124946A1Excellent etch resistanceIncreasing flow ratioSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon oxideChemical Modifier

The present invention discloses a process for depositing a carbon containing silicon oxide film, or a carbon containing silicon nitride film having enhanced etch resistance. The process comprises using a silicon containing precursor, a carbon containing precursor and a chemical modifier. The present invention also discloses a process for depositing a silicon oxide film, or silicon nitride film having enhanced etch resistance comprising using an organosilane precursor and a chemical modifier.

Owner:VERSUM MATERIALS US LLC

Method for forming strained silicon nitride films and a device containing such films

ActiveUS7651961B2Vacuum evaporation coatingSemiconductor/solid-state device manufacturingNitrogenNitride

A method for forming a strained SiN film and a semiconductor device containing the strained SiN film. The method includes exposing the substrate to a gas including a silicon precursor, exposing the substrate to a gas containing a nitrogen precursor activated by a plasma source at a first level of plasma power and configured to react with the silicon precursor with a first reactivity characteristic, and exposing the substrate to a gas containing the nitrogen precursor activated by the plasma source at a second level of plasma power different from the first level and configured to react with the silicon precursor with a second reactivity characteristic such that a property of the silicon nitride film formed on the substrate changes to provide the strained silicon nitride film.

Owner:TOKYO ELECTRON LTD

Si PRECURSORS FOR DEPOSITION OF SiN AT LOW TEMPERATURES

ActiveUS20140273477A1Semiconductor/solid-state device manufacturingAtomic layer depositionThermal oxide

Methods and precursors for depositing silicon nitride films by atomic layer deposition (ALD) are provided. In some embodiments the silicon precursors comprise an iodine ligand. The silicon nitride films may have a relatively uniform etch rate for both vertical and the horizontal portions when deposited onto three-dimensional structures such as FinFETS or other types of multiple gate FETs. In some embodiments, various silicon nitride films of the present disclosure have an etch rate of less than half the thermal oxide removal rate with diluted HF (0.5%).

Owner:ASM IP HLDG BV

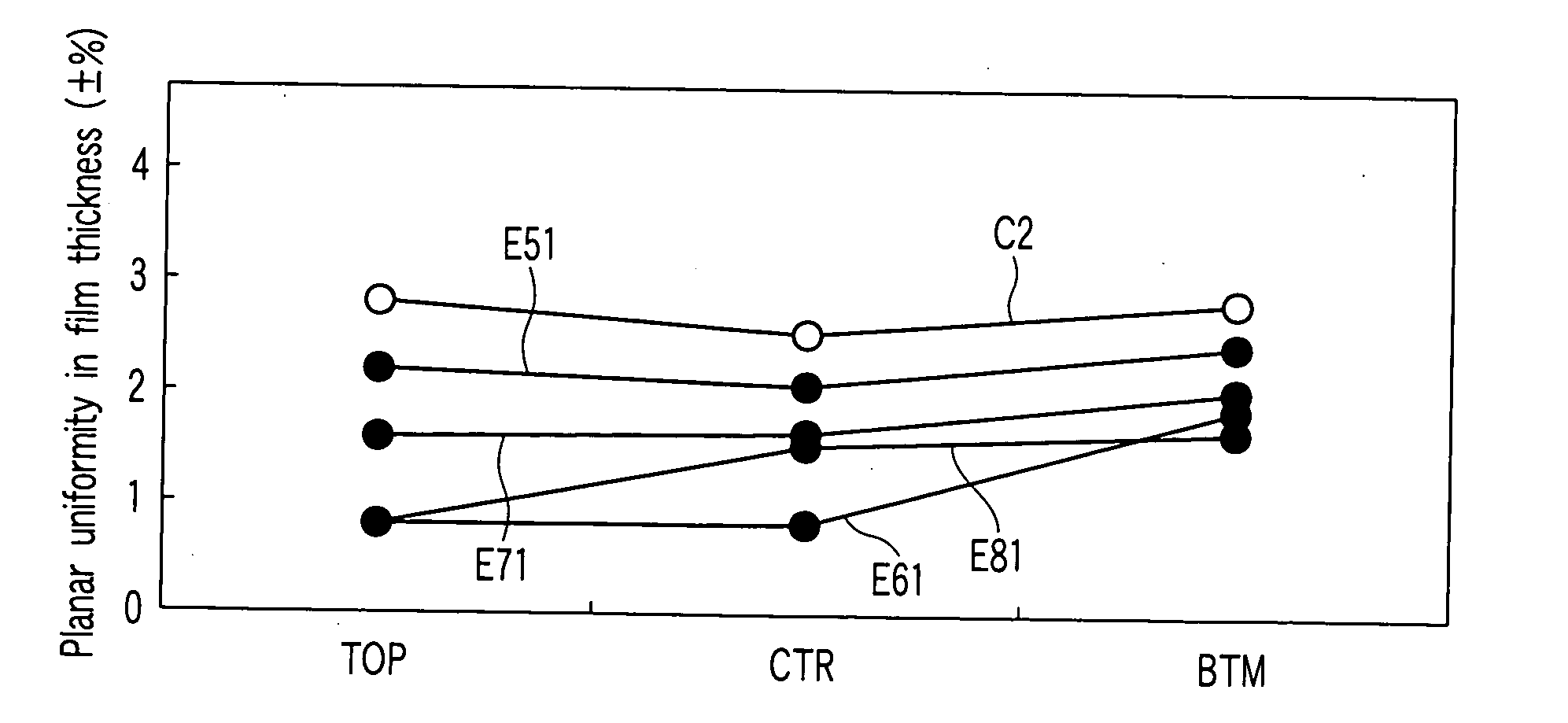

Low temperature thin film transistor process, device property, and device stability improvement

InactiveUS20090261331A1Low deposition rateIncrease deposition rateTransistorSemiconductor/solid-state device manufacturingDevice PropertiesHigh rate

A method and apparatus for forming a thin film transistor is provided. A gate dielectric layer is formed, which may be a bilayer, the first layer deposited at a low rate and the second deposited at a high rate. In some embodiments, the first dielectric layer is a silicon rich silicon nitride layer. An active layer is formed, which may also be a bilayer, the first active layer deposited at a low rate and the second at a high rate. The thin film transistors described herein have superior mobility and stability under stress.

Owner:APPLIED MATERIALS INC

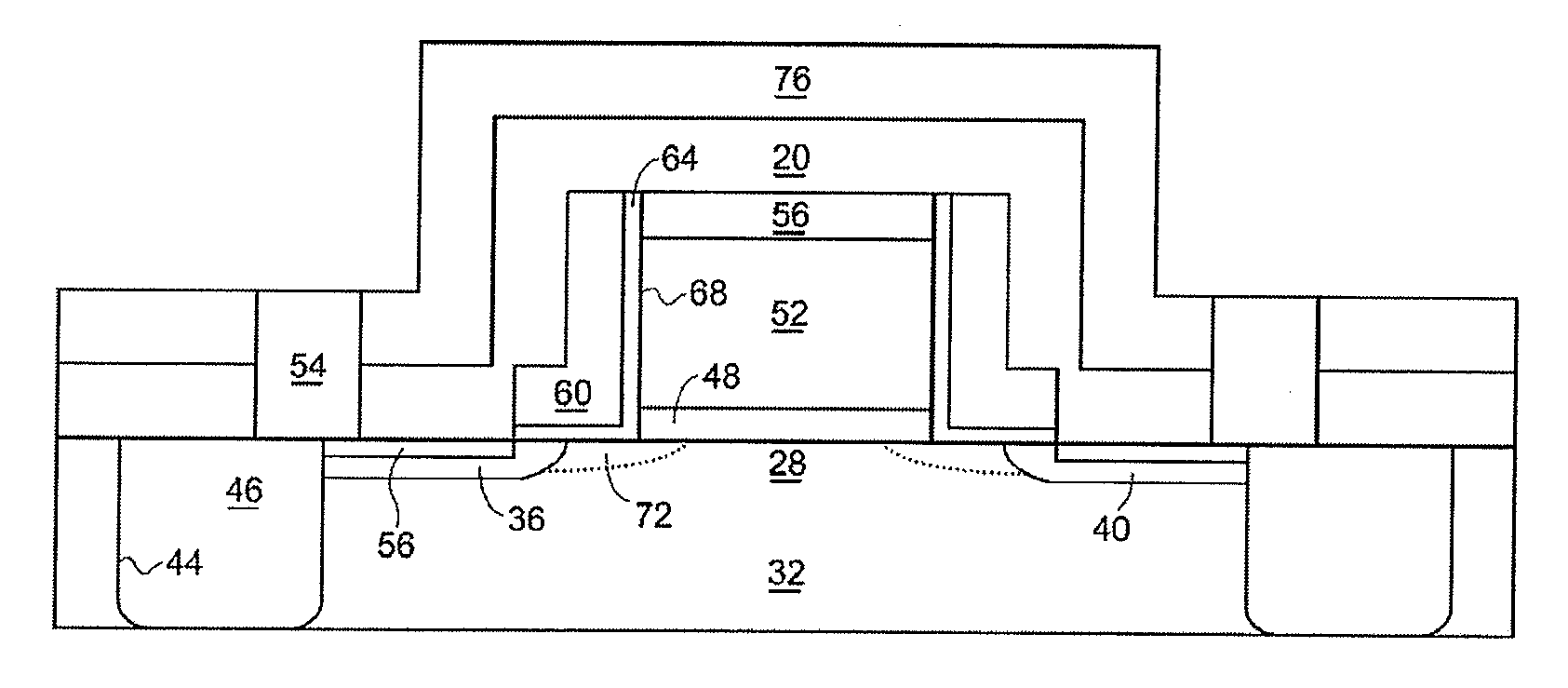

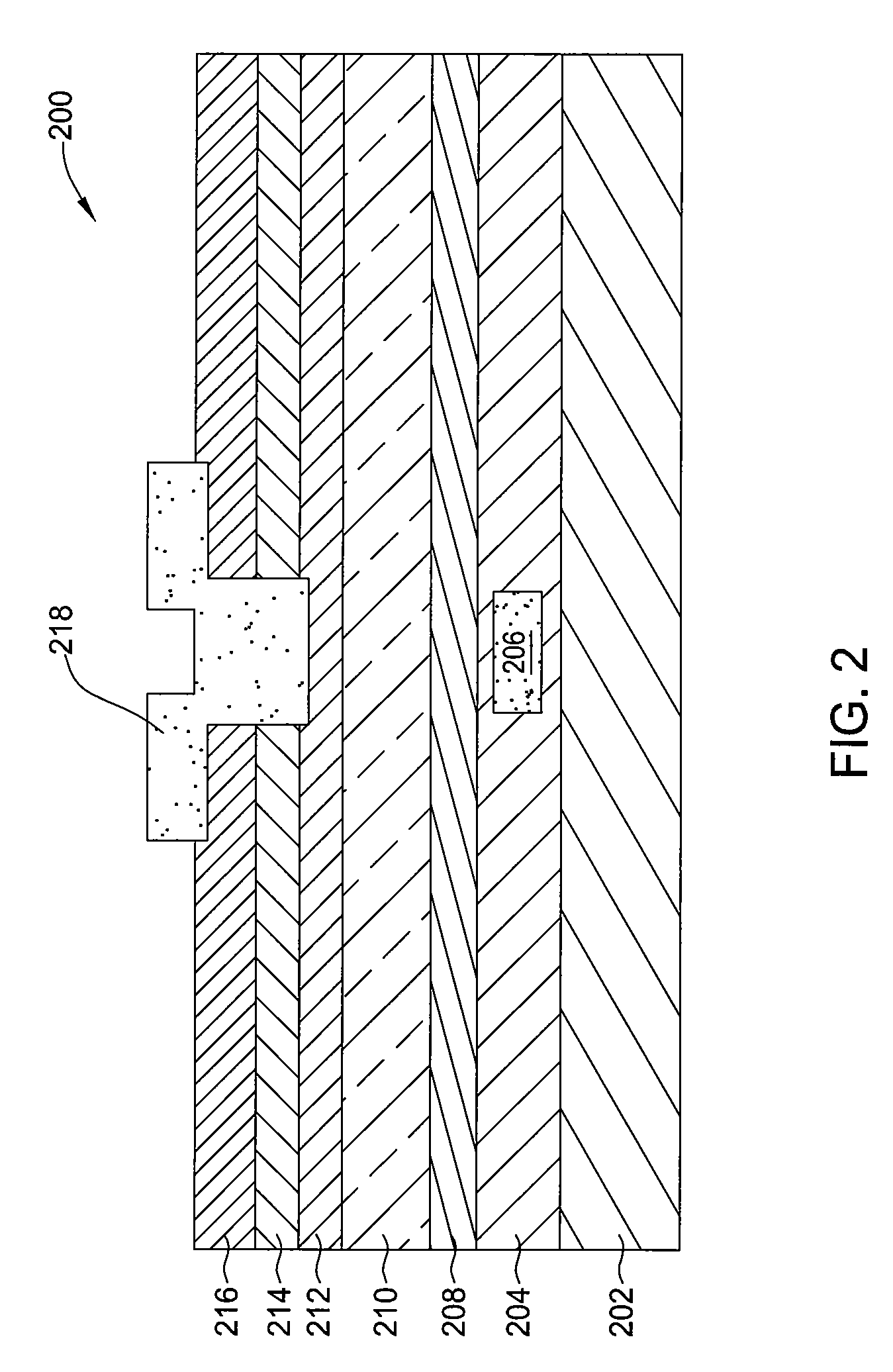

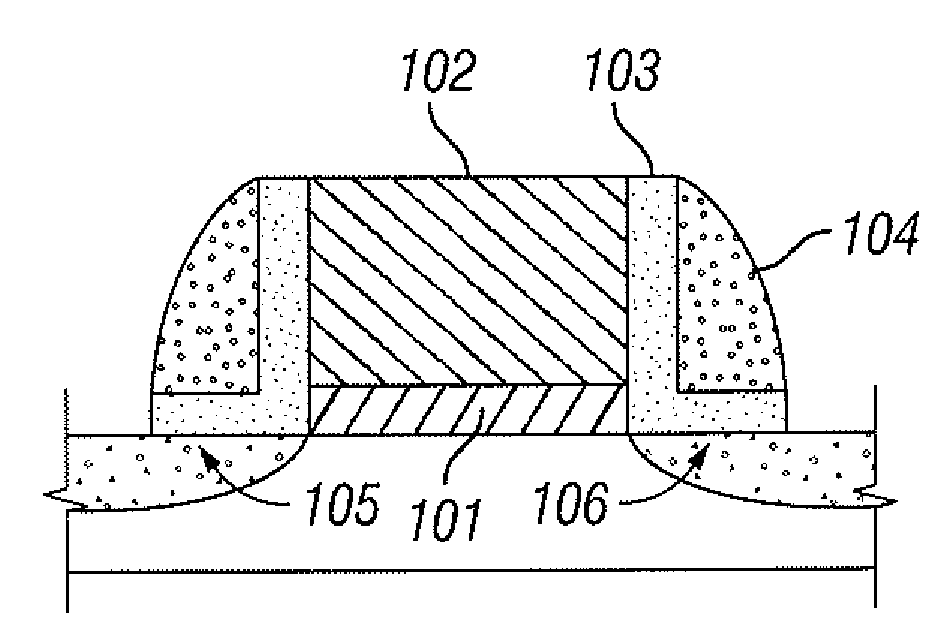

Memory cell incorporating a chalcogenide element

A memory cell incorporating a chalcogenide element and a method of making same is disclosed. In the method, a doped silicon substrate is provided with two or more polysilicon plugs to form an array of diode memory cells. A layer of silicon nitride is disposed over the plugs. Using a poly-spacer process, small pores are formed in the silicon nitride to expose a portion of the polysilicon plugs. A chalcogenide material is disposed in the pores by depositing a layer of chalcogenide material on the silicon nitride layer and planarizing the chalcogenide layer to the silicon nitride layer using CMP. A layer of TiN is next deposited over the plugs, followed by a metallization layer. The TiN and metallization layers are then masked and etched to define memory cell areas.

Owner:ROUND ROCK RES LLC

Si PRECURSORS FOR DEPOSITION OF SiN AT LOW TEMPERATURES

InactiveUS20140273531A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingAtomic layer depositionThermal oxide

Methods and precursors for depositing silicon nitride films by atomic layer deposition (ALD) are provided. In some embodiments the silicon precursors comprise an iodine ligand. The silicon nitride films may have a relatively uniform etch rate for both vertical and the horizontal portions when deposited onto three-dimensional structures such as FinFETS or other types of multiple gate FETs. In some embodiments, various silicon nitride films of the present disclosure have an etch rate of less than half the thermal oxide removal rate with diluted HF (0.5%).

Owner:ASM IP HLDG BV

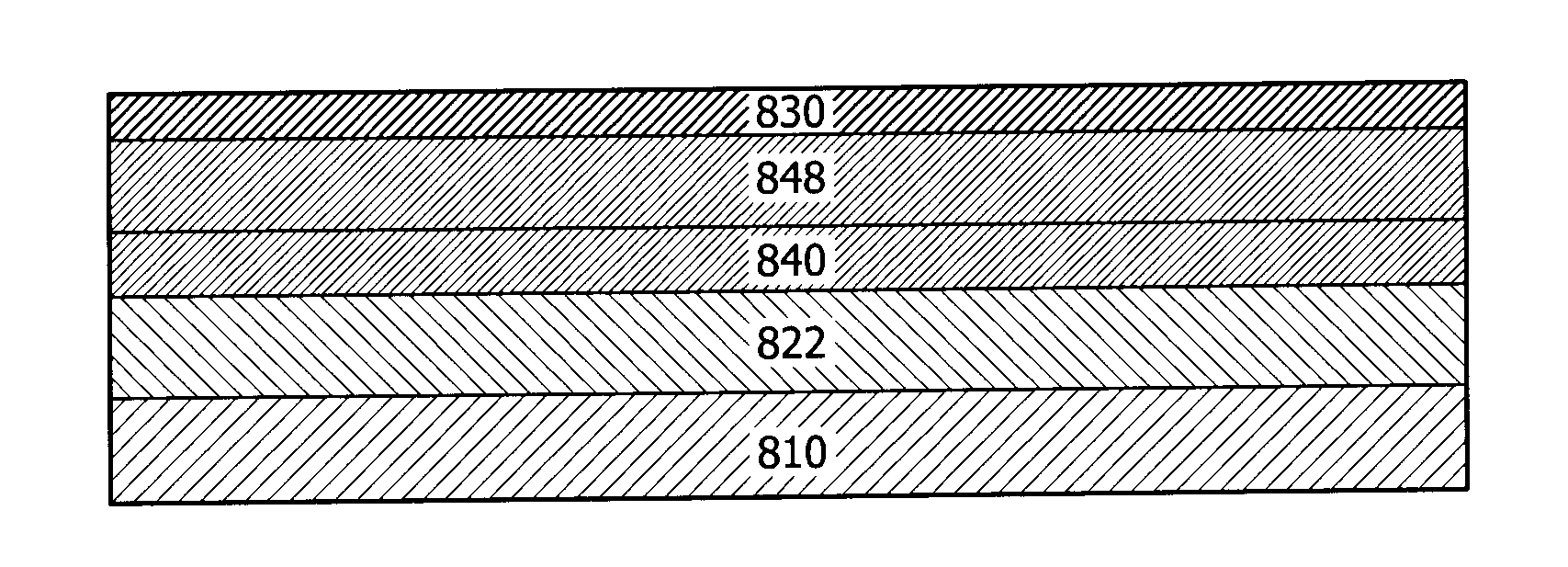

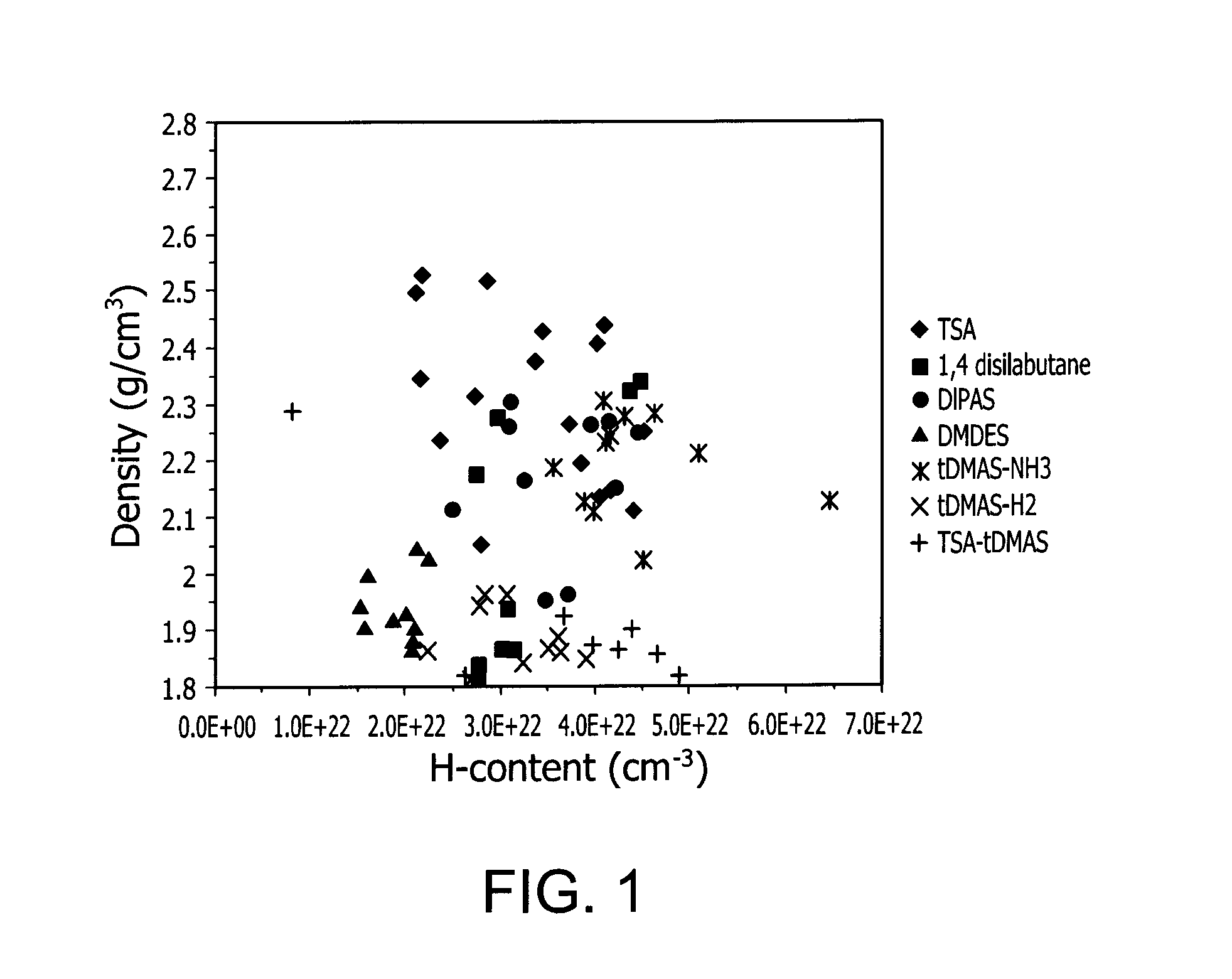

Barrier materials for display devices

ActiveUS20150021599A1TransistorSemiconductor/solid-state device manufacturingHydrogen contentDisplay device

Described herein are apparatus comprising one or more silicon-containing layers and a metal oxide layer. Also described herein are methods for forming one or more silicon-containing layers to be used, for example, as passivation layers in a display device. In one particular aspect, the apparatus comprises a transparent metal oxide layer, a silicon oxide layer and a silicon nitride layer. In this or other aspects, the apparatus is deposited at a temperature of 350° C. or below. The silicon-containing layers described herein comprise one or more of the following properties: a density of about 1.9 g / cm3 or greater; a hydrogen content of about 4×1022 cm−3 or less, and a transparency of about 90% or greater at 400-700 nm as measured by a UV-visible light spectrometer.

Owner:VERSUM MATERIALS US LLC

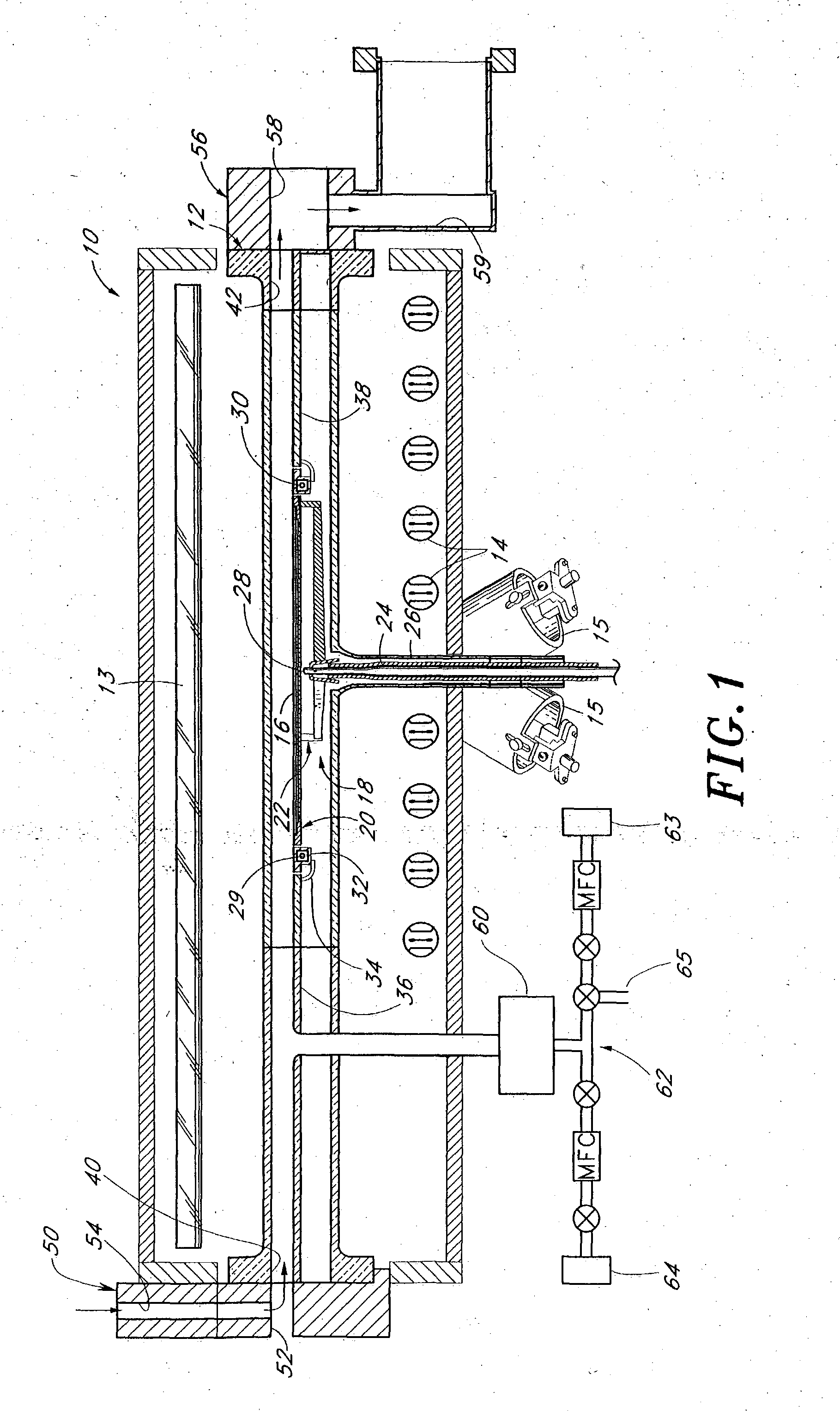

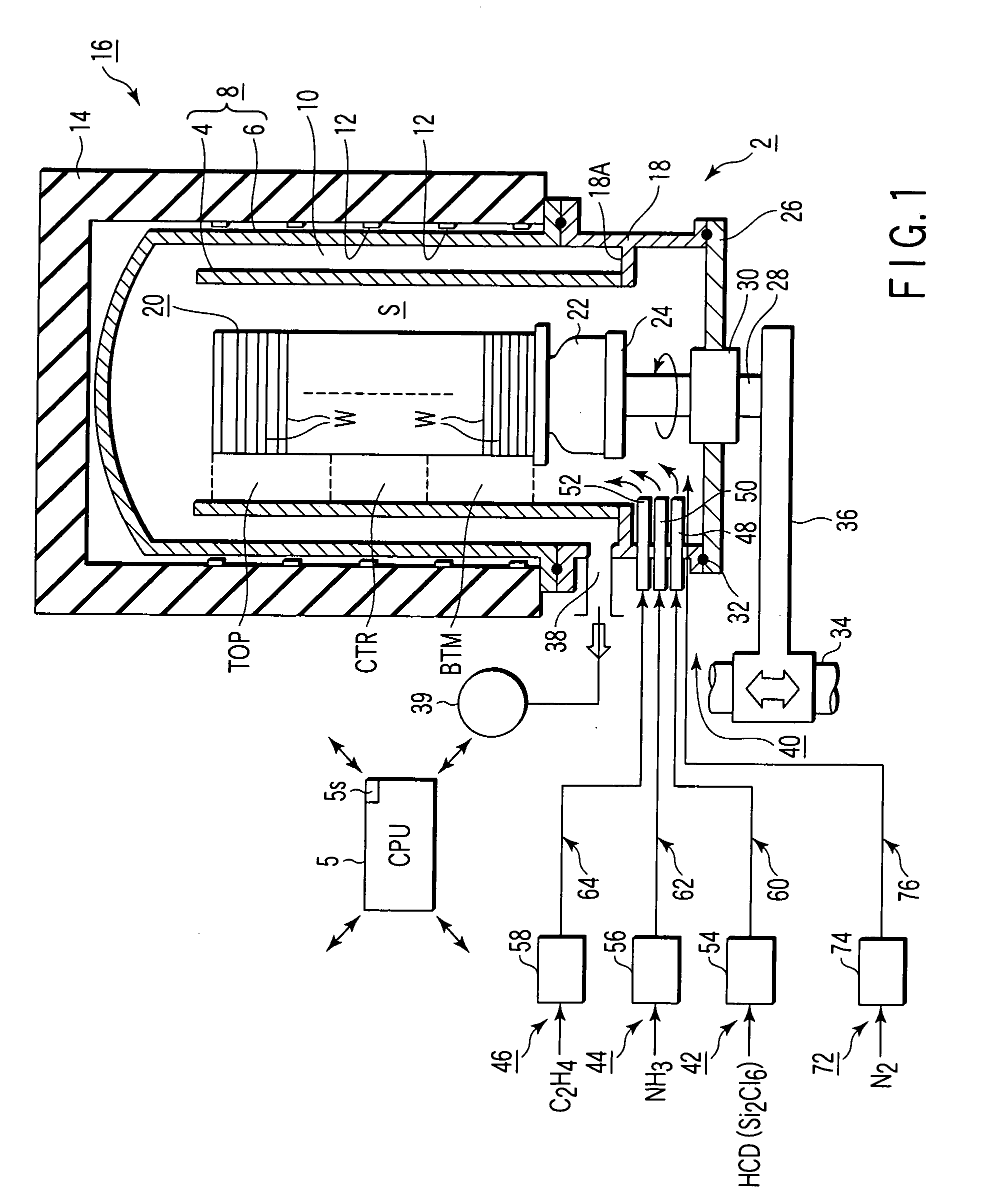

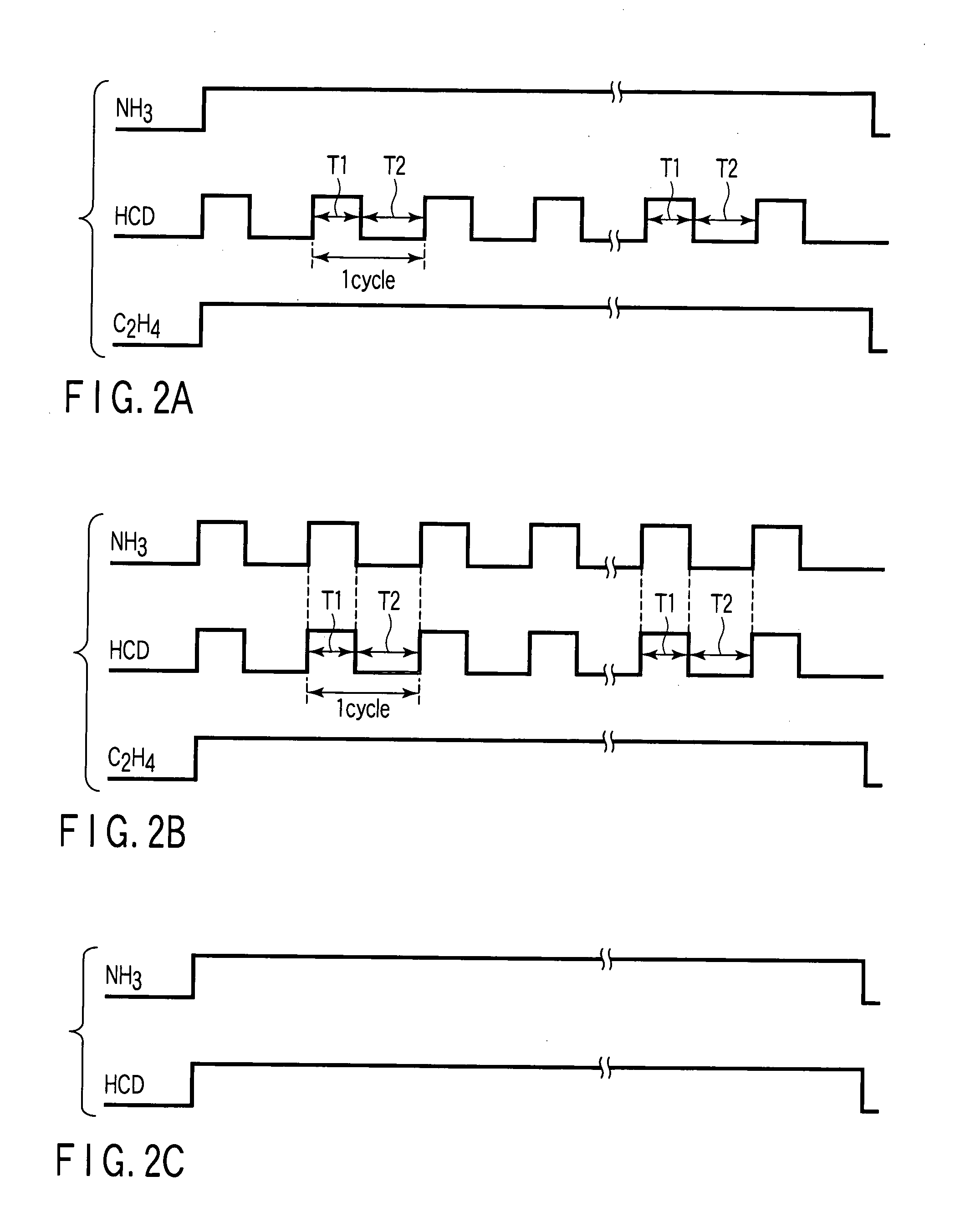

Cvd method for forming silicon nitride film

ActiveUS20060286817A1Low process temperatureImprove controllabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesAmmonia gas

A CVD method for forming a silicon nitride film includes exhausting a process chamber (8) that accommodates a target substrate (W), and supplying a silane family gas (HCD) and ammonia gas (NH3) into the process chamber, thereby forming a silicon nitride film on the target substrate by CVD. Said forming a silicon nitride film on the target substrate alternately includes a first period of performing supply of the silane family gas (HCD) into the process chamber (8), and a second period of stopping supply of the silane family gas.

Owner:TOKYO ELECTRON LTD

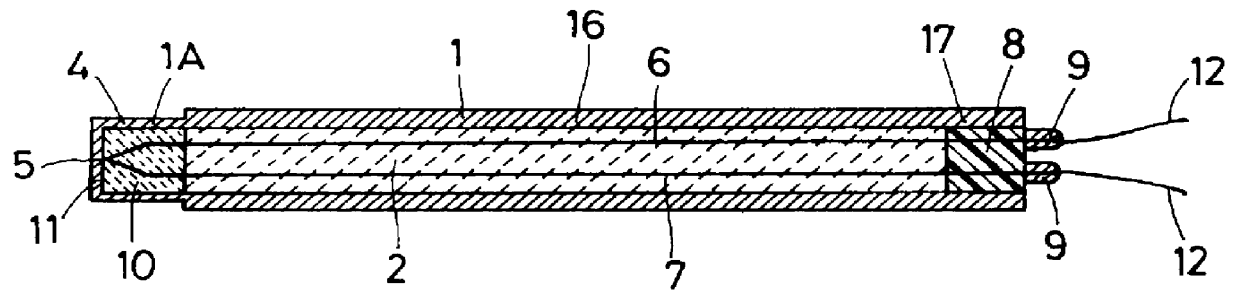

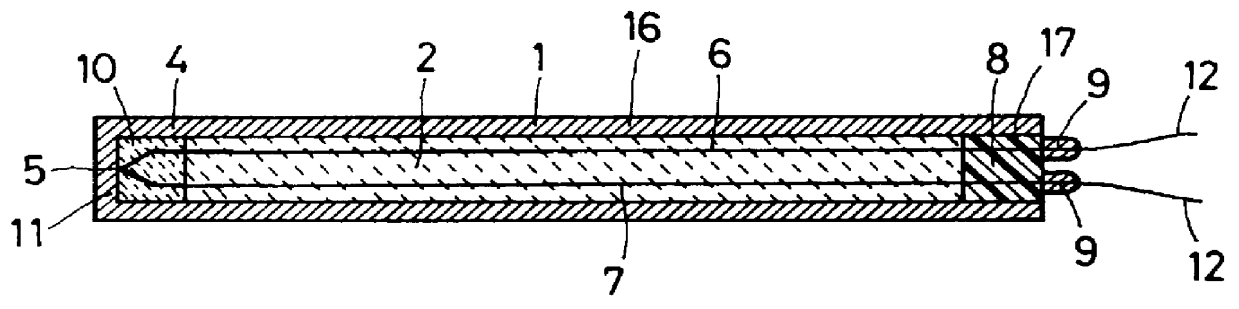

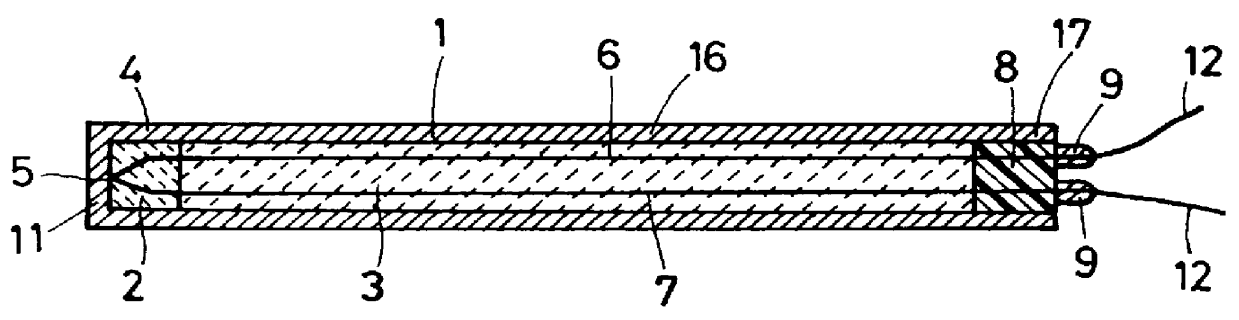

Ceramic sheath type thermocouple

InactiveUS6102565AThermometer detailsThermometers using electric/magnetic elementsHeat resistanceWhiskers

This ceramic sheath type thermocouple has a long service life, an improved temperature measuring responsibility and an improved temperature measuring precision, and enables repetitive use. The ceramic sheath type thermocouple has its protective tube 1 formed of a heat resisting ceramics selected from silicon nitride, sialon and silicon carbide. In the protective tube 1 are installed a pair of W-Re wires that are connected to form a joint portion constituting a temperature measuring point 5. A filler made of Si3N4 reaction-sintered ceramics is loaded into the front end portion of the protective tube to enclose the W-Re wires. Another filler made of SiC whisker with a heat conductivity smaller than that of the filler of the front end portion is loaded into the rear portion of the protective tube. An inert gas is sealed in the protective tube. Alternatively, the temperature measuring portion may be formed by exposing from the front end portion of the protective tube the joint portion where the ends of the W-Re wires are connected. The temperature measuring portion is coated with a cover film that is made of silicon carbide, silicon nitride or a composite of these, all having excellent heat resisting and corrosion resisting properties.

Owner:ISUZU MOTORS LTD

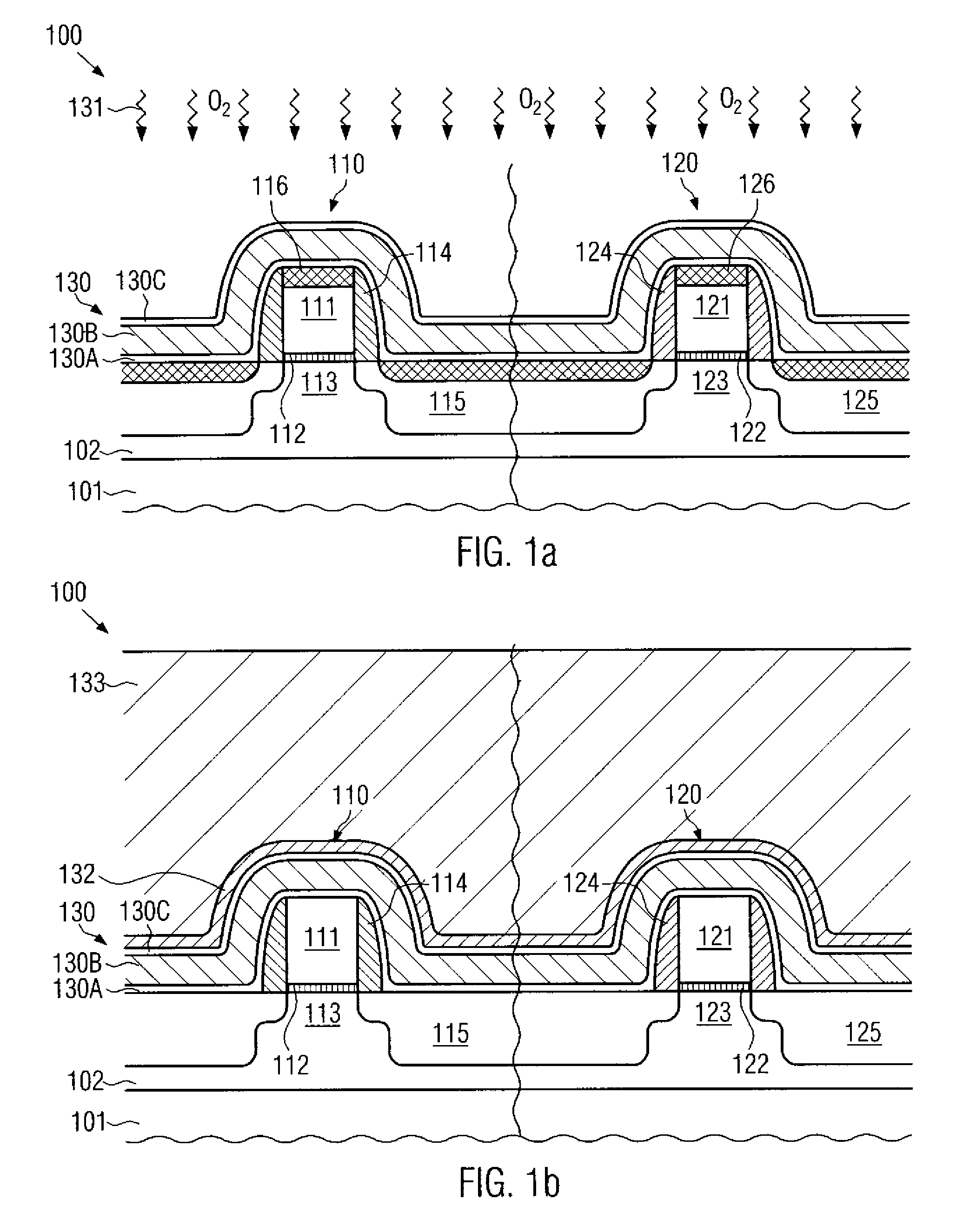

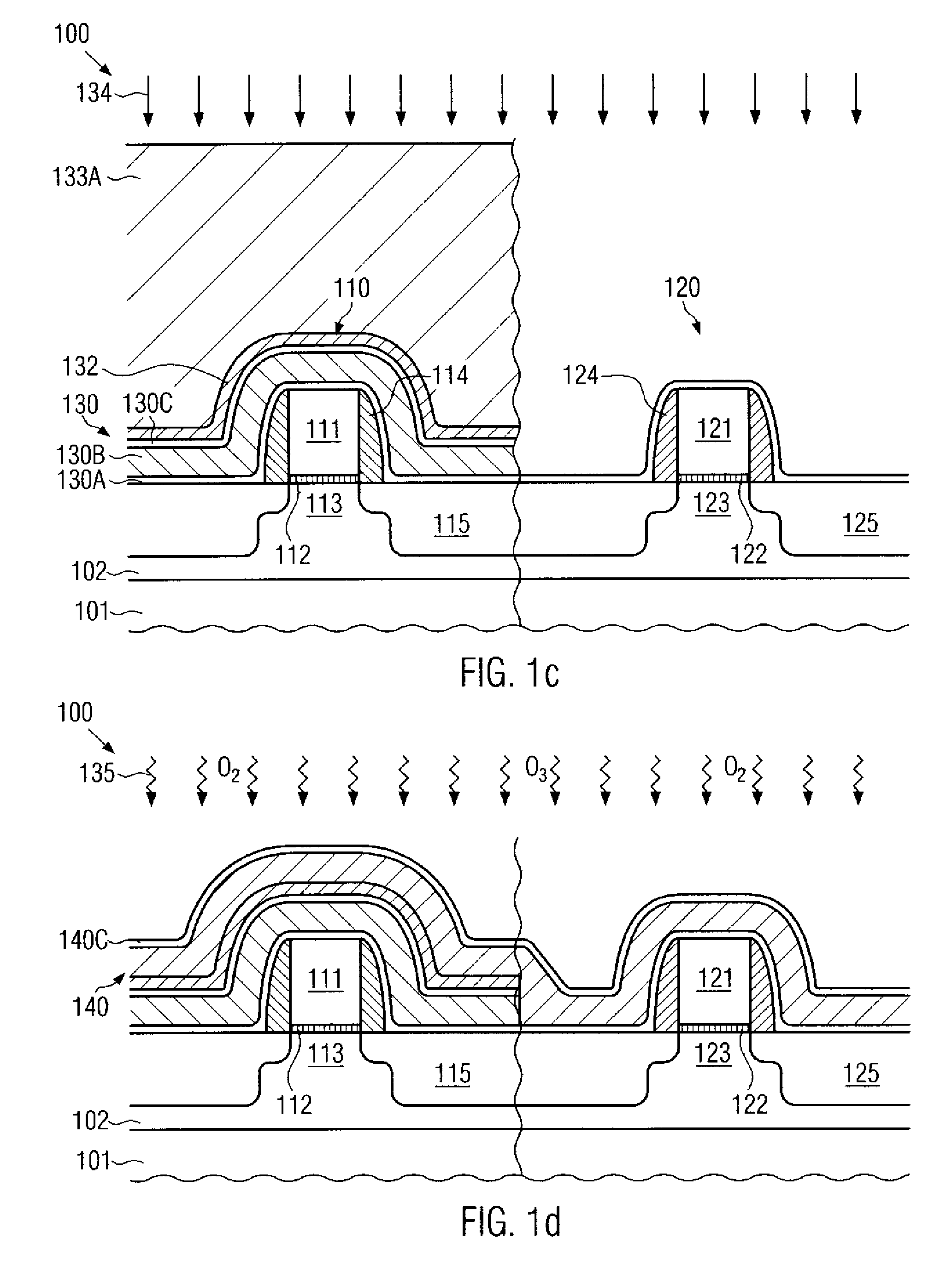

Method for reducing resist poisoning during patterning of silicon nitride layers in a semiconductor device

ActiveUS7550396B2Improve performanceReduce diffuseSemiconductor/solid-state device manufacturingSemiconductor devicesResistNitrogen

By performing a plasma treatment for efficiently sealing the surface of a stressed dielectric layer containing silicon nitride, an enhanced performance during the patterning of contact openings may be achieved, since nitrogen-induced resist poisoning may be significantly reduced during the selective patterning of stressed layers of different types of intrinsic stress.

Owner:TAIWAN SEMICON MFG CO LTD

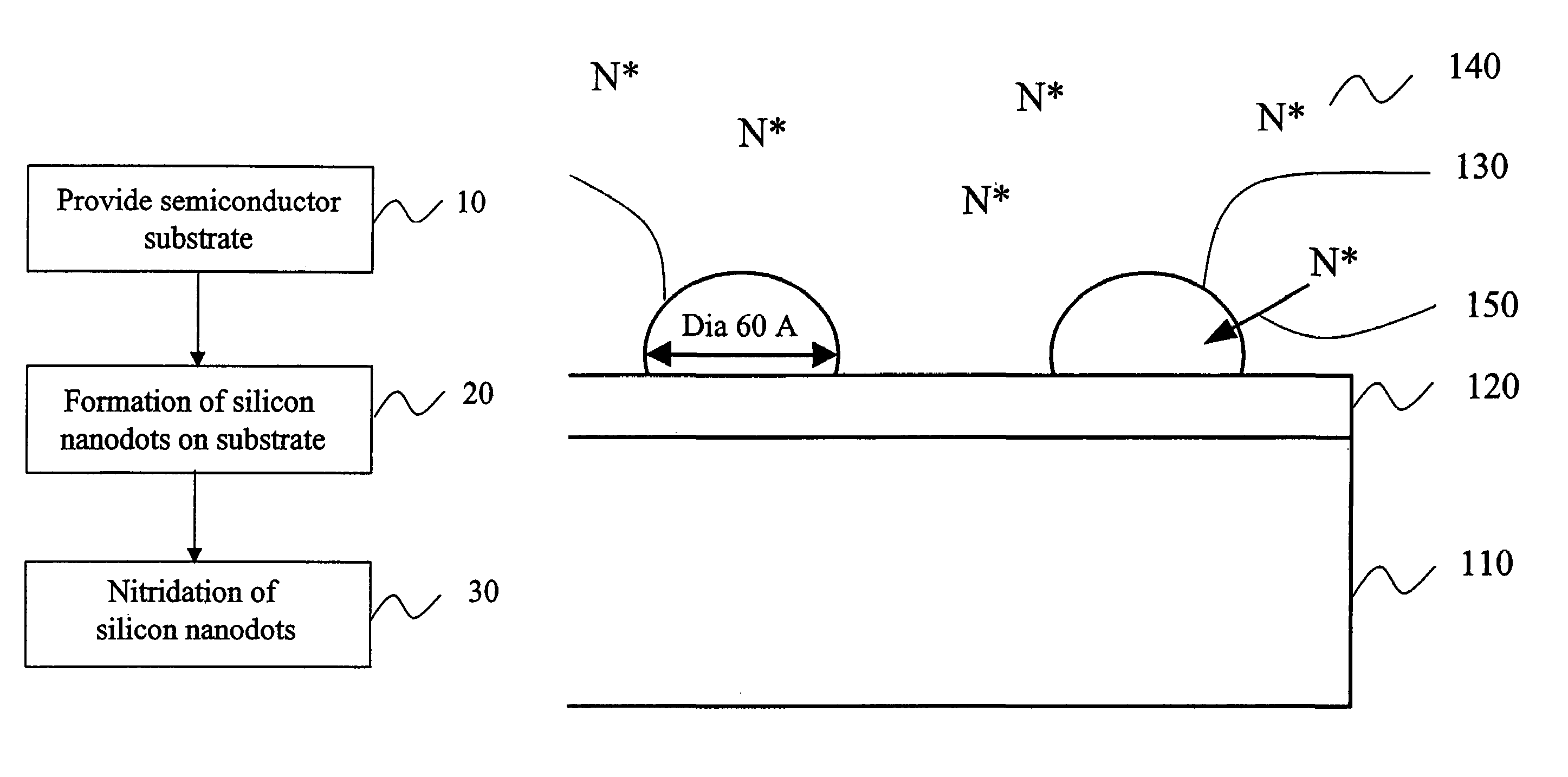

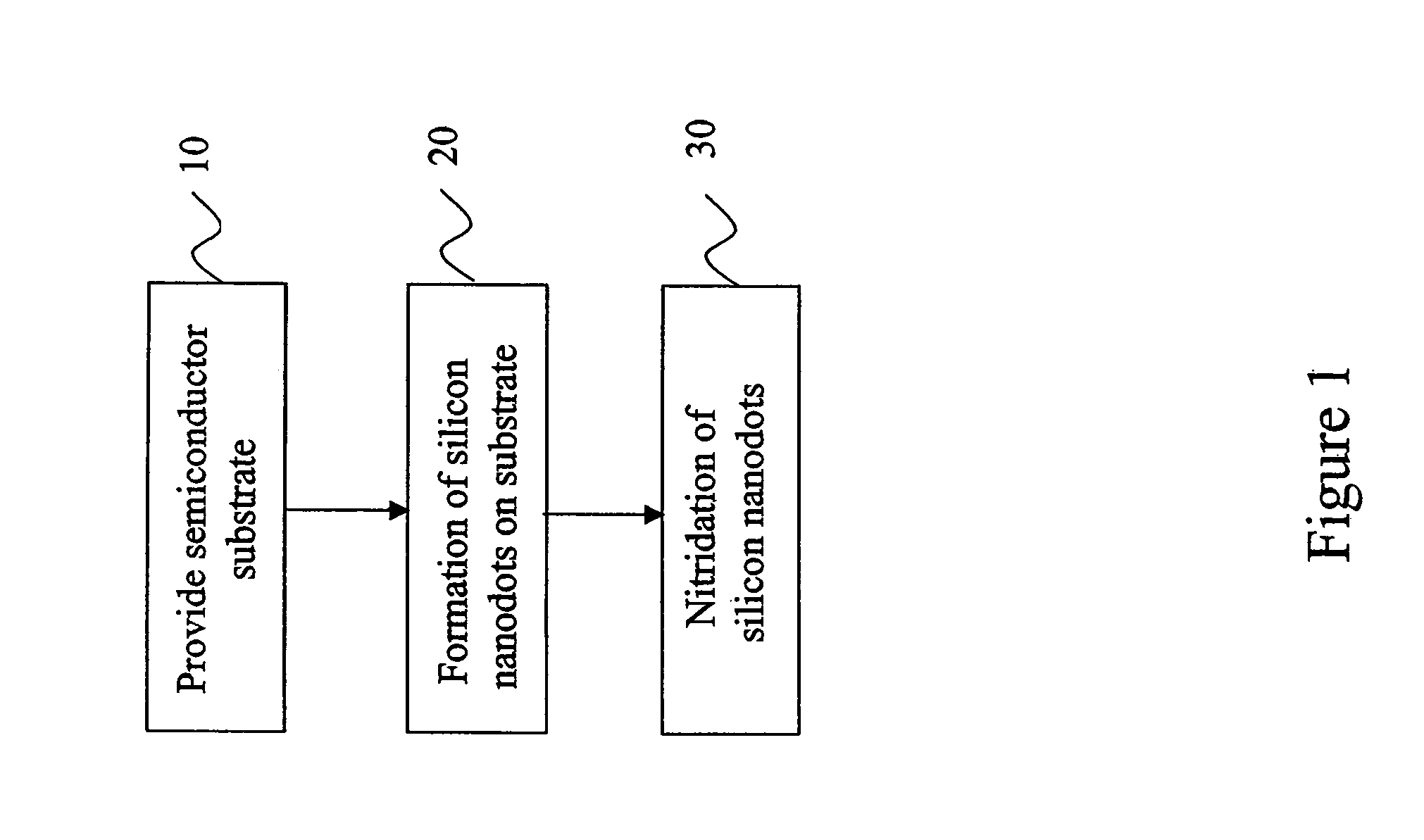

Method of fabricating silicon nitride nanodots

ActiveUS7092287B2Easily be in production environmentEasy to implementNanoinformaticsRead-only memoriesNanodotNitrogen

A method of forming silicon nitride nanodots that comprises the steps of forming silicon nanodots and then nitriding the silicon nanodots by exposing them to a nitrogen containing gas. Silicon nanodots were formed by low pressure chemical vapor deposition. Nitriding of the silicon nanodots was performed by exposing them to nitrogen radicals formed in a microwave radical generator, using N2 as the source gas.

Owner:ASM INTERNATIONAL

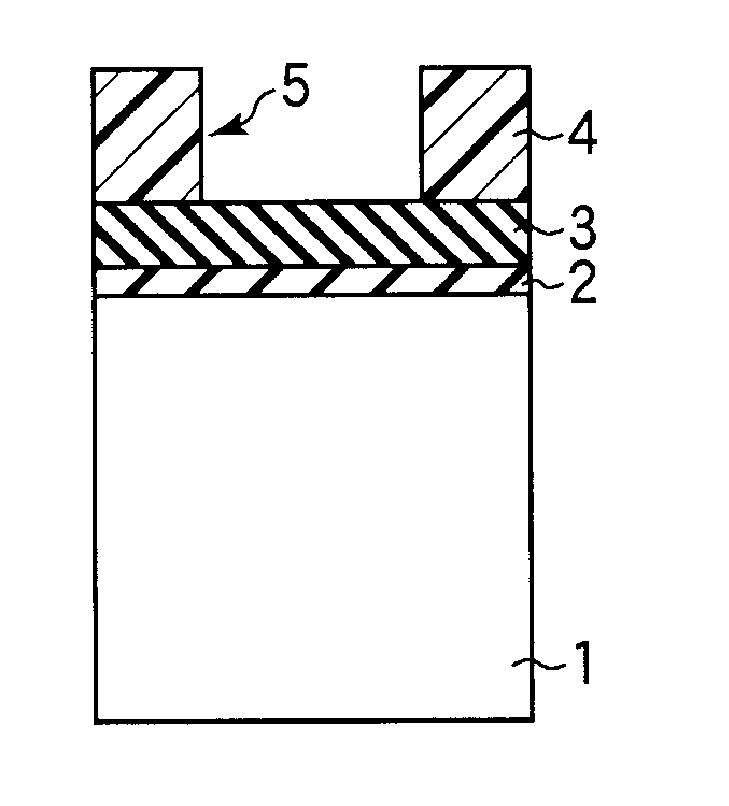

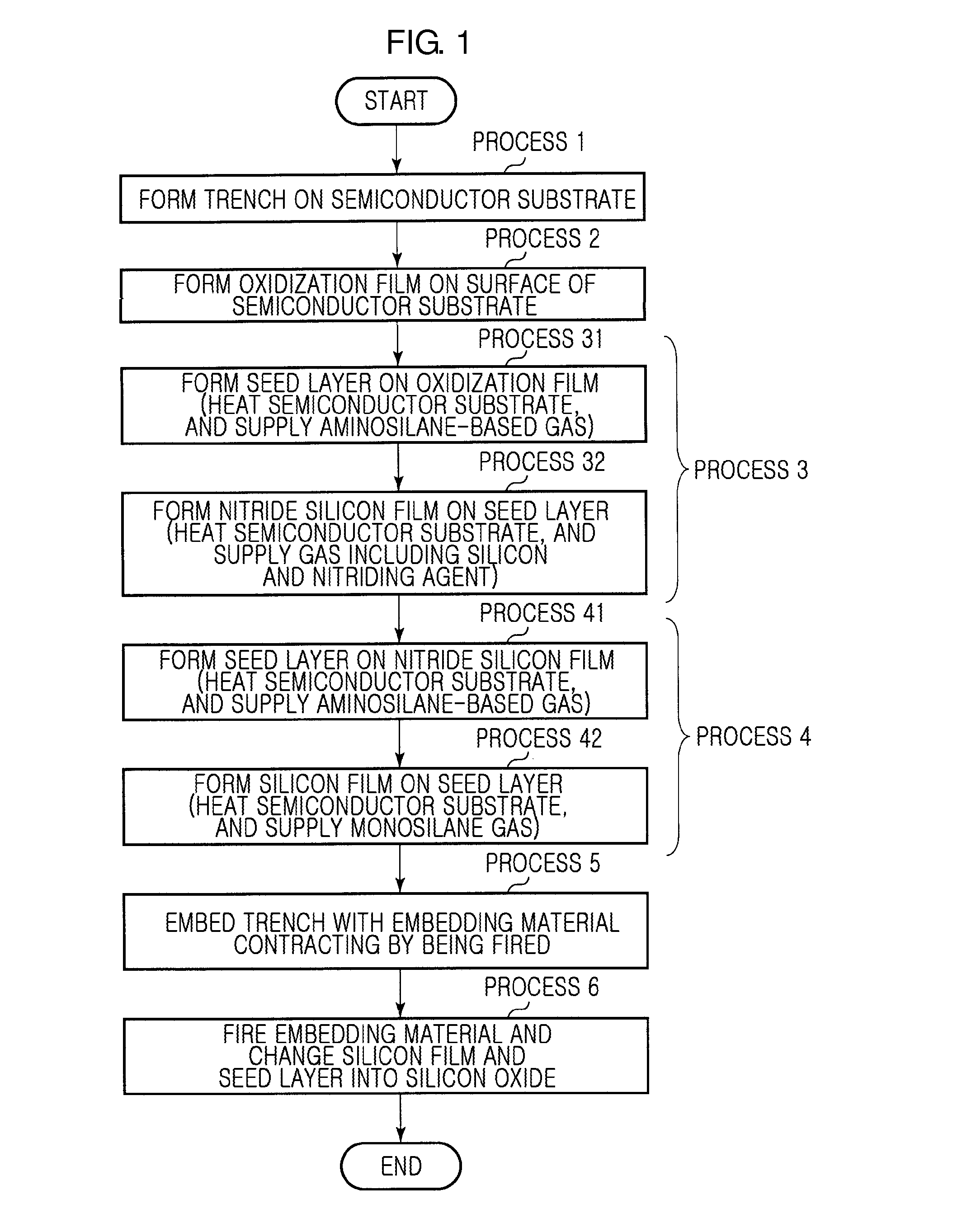

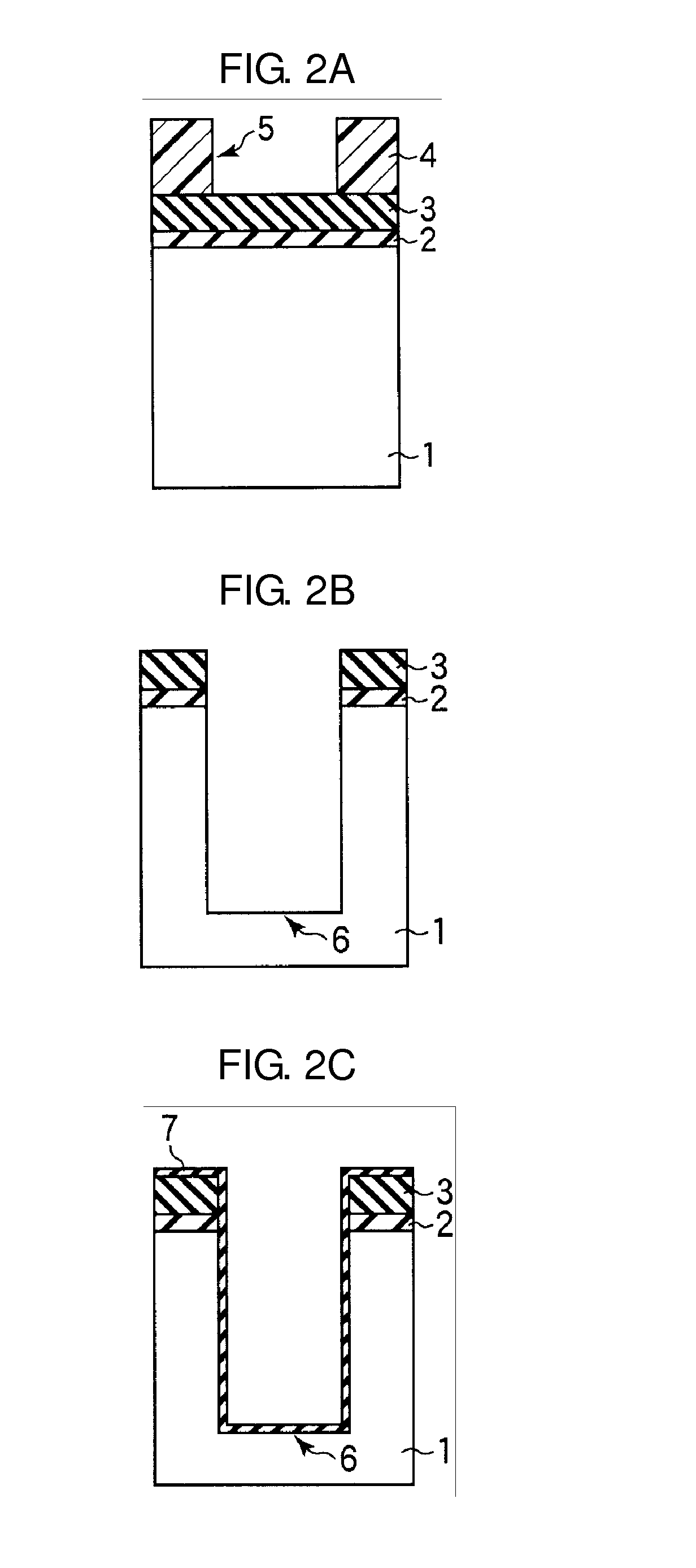

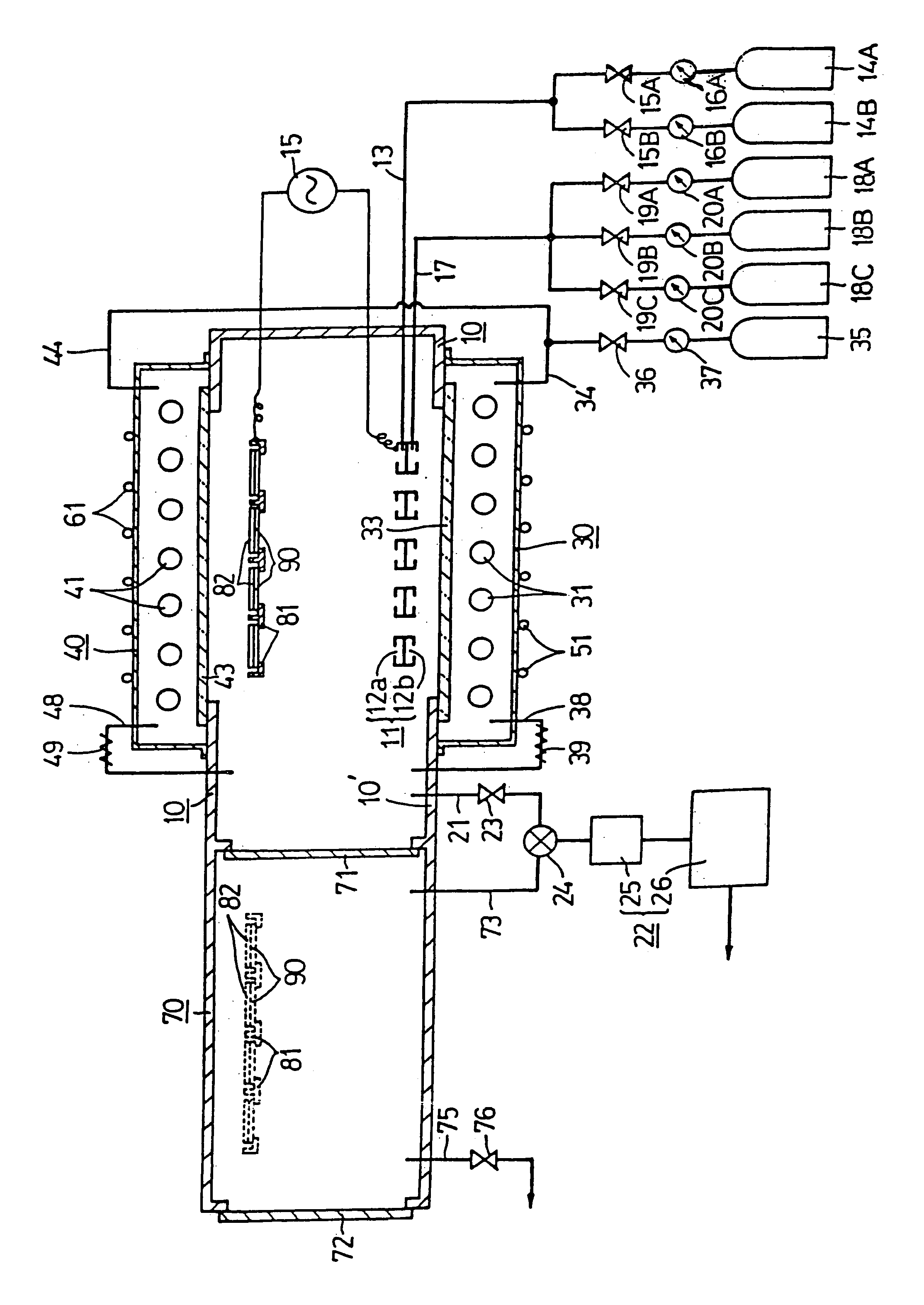

Trench embedding method and film-forming apparatus

ActiveUS20120164842A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon nitrideSilicon membrane

A trench embedding method includes forming an oxidization barrier film on a trench; forming an expandable film on the oxidization barrier film; embedding an embedding material that contracts by being fired on the trench; and firing the embedding material, wherein the forming of the oxidization barrier film includes: forming a first seed layer on the trench by supplying an aminosilane-based gas; and forming a silicon nitride film on the first seed layer, wherein the forming of the expandable film includes: forming a second seed layer on the silicon nitride film by supplying an aminosilane-based gas; and forming a silicon film on the second seed layer.

Owner:TOKYO ELECTRON LTD

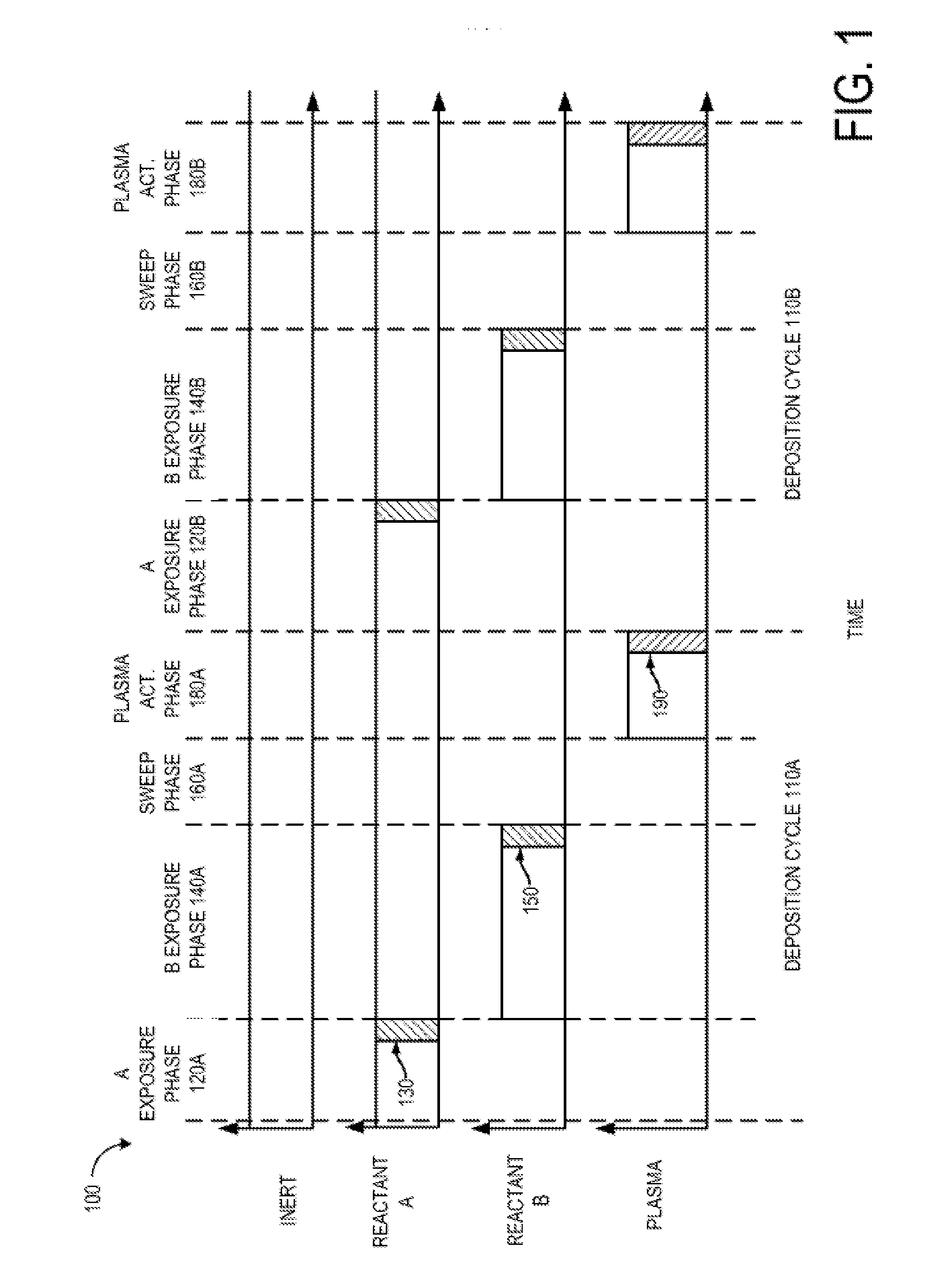

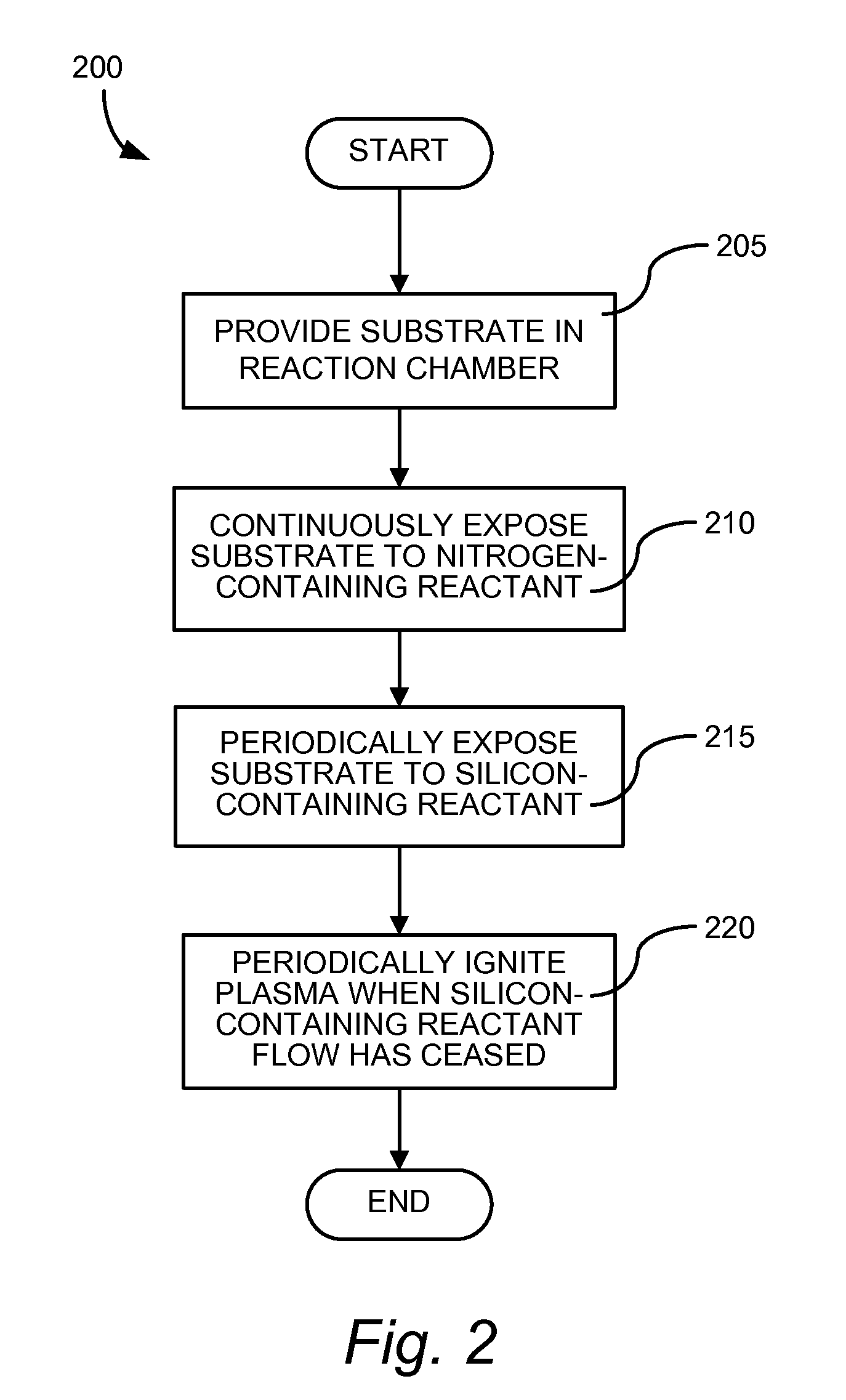

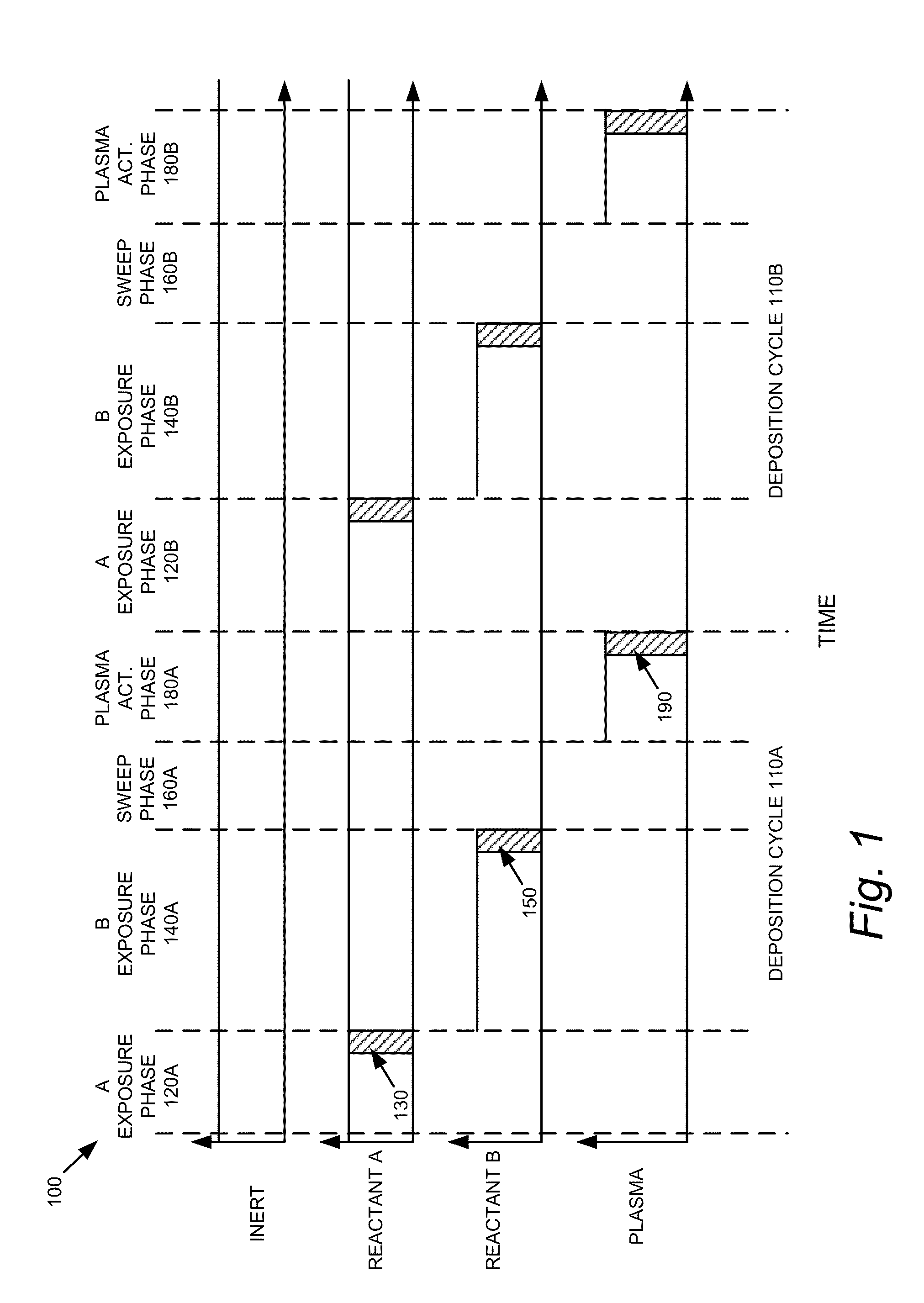

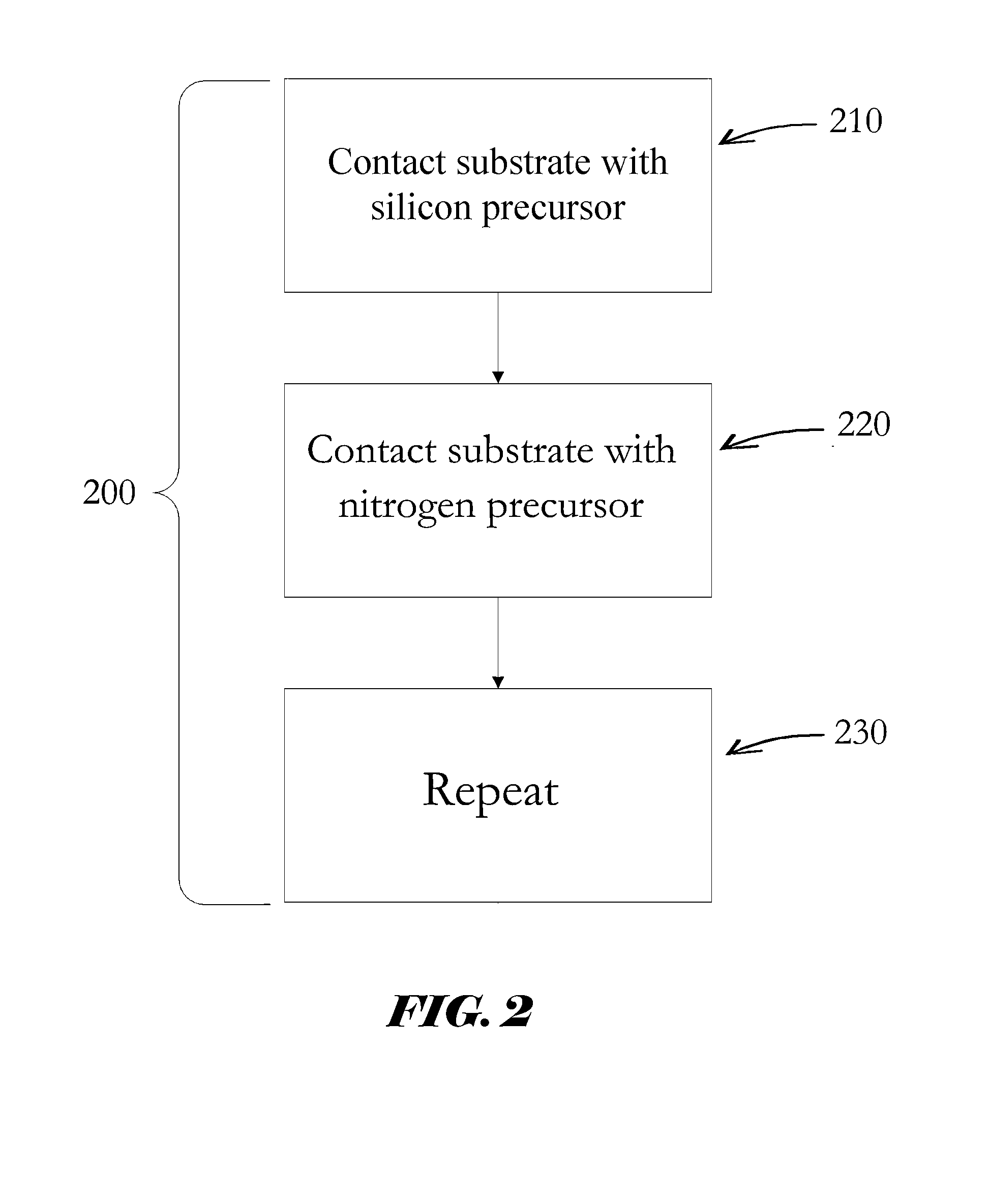

Deposition of SiN

ActiveUS20160079054A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogen plasmaAtomic layer deposition

Methods and precursors for forming silicon nitride films are provided. In some embodiments, silicon nitride can be deposited by atomic layer deposition (ALD), such as plasma enhanced ALD. In some embodiments, deposited silicon nitride can be treated with a plasma treatment. The plasma treatment can be a nitrogen plasma treatment. In some embodiments the silicon precursors for depositing the silicon nitride comprise an iodine ligand. The silicon nitride films may have a relatively uniform etch rate for both vertical and the horizontal portions when deposited onto three-dimensional structures such as FinFETS or other types of multiple gate FETs. In some embodiments, various silicon nitride films of the present disclosure have an etch rate of less than half the thermal oxide removal rate with diluted HF (0.5%). In some embodiments, a method for depositing silicon nitride films comprises a multi-step plasma treatment.

Owner:ASM IP HLDG BV

Method of forming silicon-containing films

A method of forming a silicon-containing film comprising providing a substrate in a reaction chamber, injecting into the reaction chamber at least one silicon-containing compound; injecting into the reaction chamber at least one co-reactant in the gaseous form; and reacting the substrate, silicon-containing compound, and co-reactant in the gaseous form at a temperature equal to or less than 550° C. to obtain a silicon-containing film deposited onto the substrate. A method of preparing a silicon nitride film comprising introducing a silicon wafer to a reaction chamber; introducing a silicon-containing compound to the reaction chamber; purging the reaction chamber with an inert gas; and introducing a nitrogen-containing co-reactant in gaseous form to the reaction chamber under conditions suitable for the formation of a monomolecular layer of a silicon nitride film on the silicon wafer.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Layer member forming method

InactiveUS6984595B1No damageShort timeSemiconductor/solid-state device manufacturingChemical vapor deposition coatingForming gasGas phase

A vapor reaction method including the steps of providing a pair of first and second electrodes within a reaction chamber where the pair of electrodes are arranged substantially parallel with each other. The method further includes the steps of placing a substrate in the reaction chamber where the substrate is held by said first electrode so that a first surface of the substrate faces toward the second electrode. A first film forming gas is introduced into the reaction chamber through the second electrode. The first film forming gas is excited to form a first insulating film by vapor deposition. The first insulating film may be silicon nitride. The method may also include the step of introducing a second film forming gas into the reaction chamber through the second electrode to ultimately form a second film. After removing the substrate from the reaction chamber, a cleaning gas may then be introduced through the second electrode to remove unnecessary layers from the inside of the reaction chamber.

Owner:SEMICON ENERGY LAB CO LTD

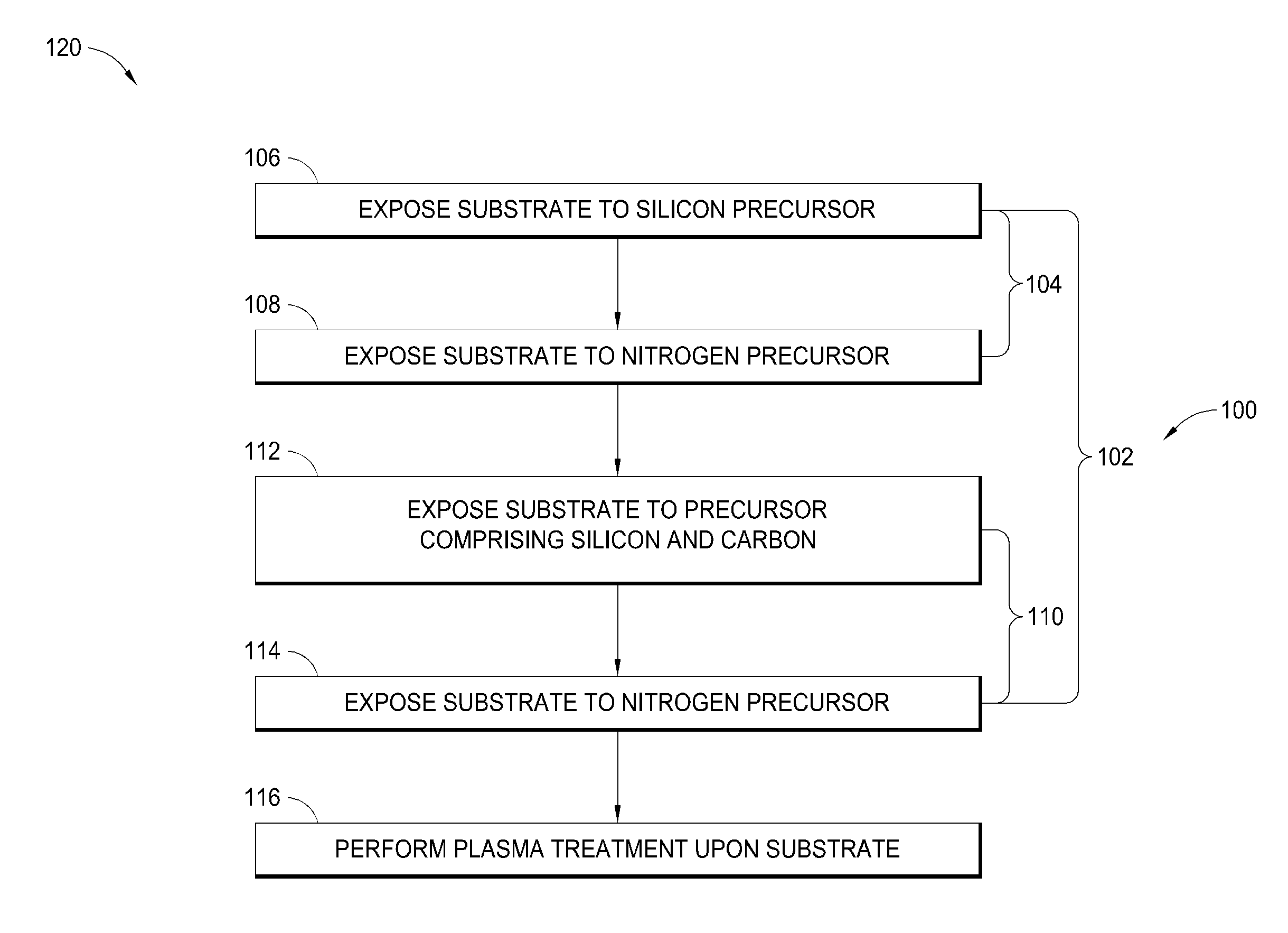

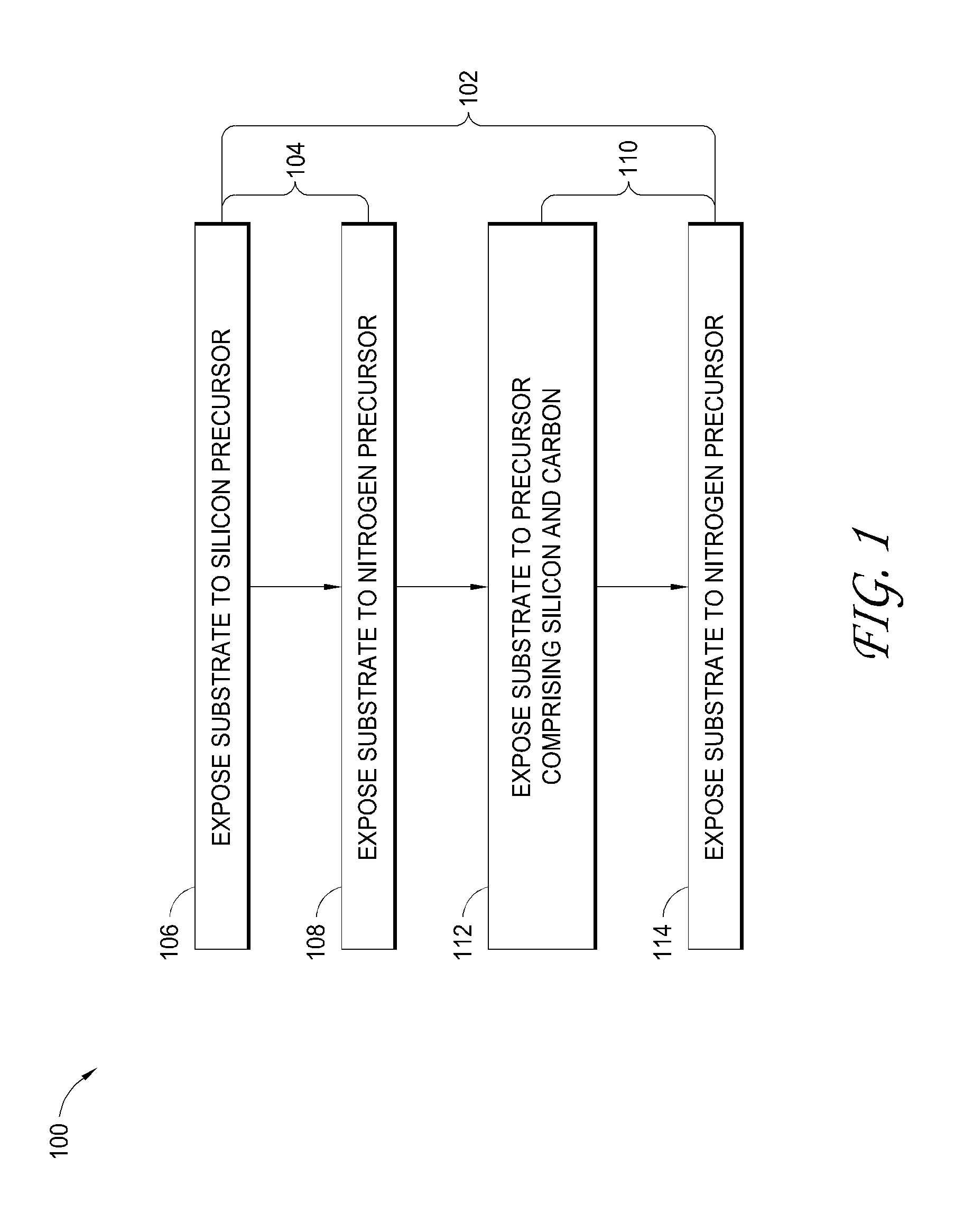

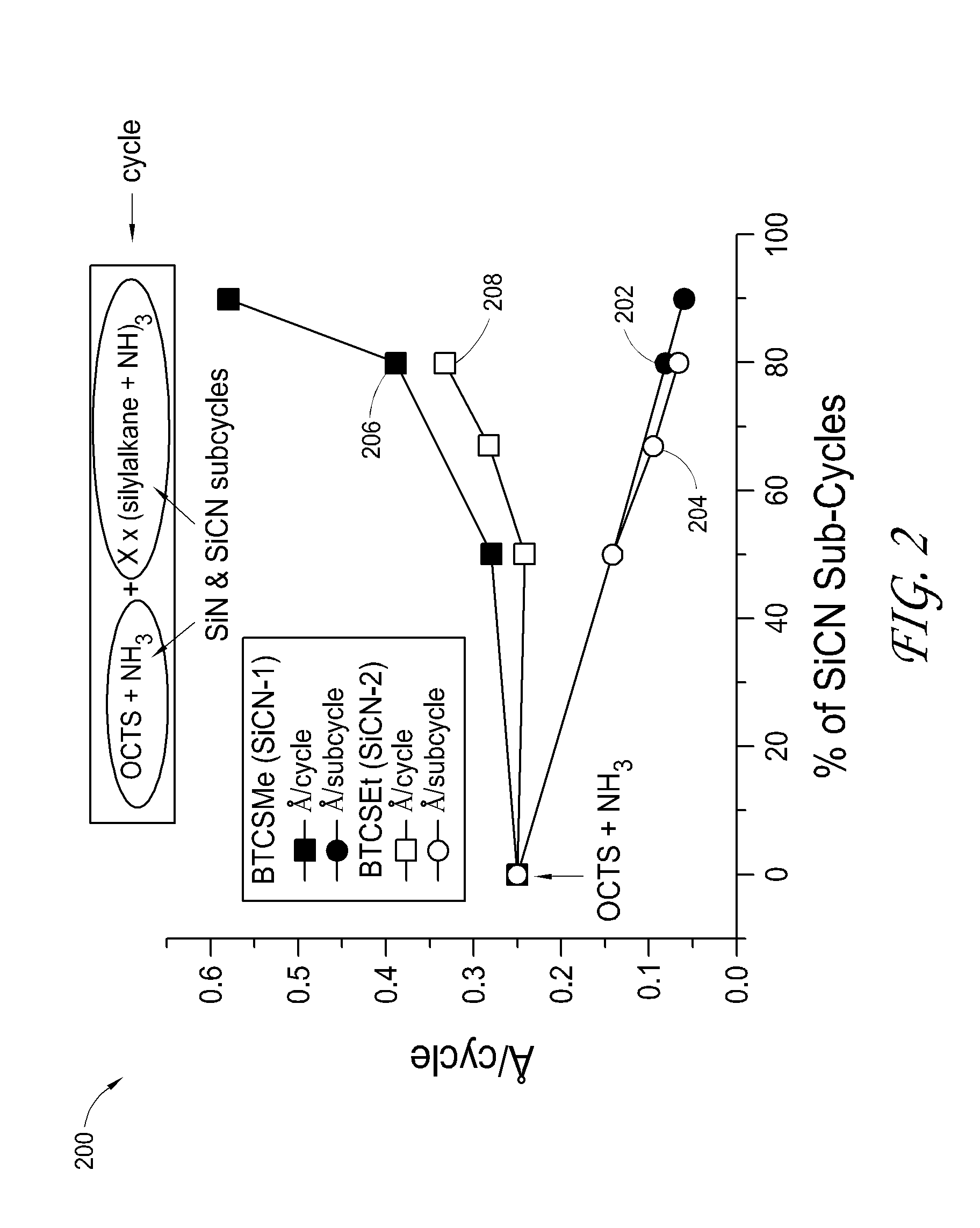

Atomic layer deposition of silicon carbon nitride based materials

ActiveUS20150162185A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingCarbon nitrideNitrogen

A process for depositing a silicon carbon nitride film on a substrate can include a plurality of complete deposition cycles, each complete deposition cycle having a SiN sub-cycle and a SiCN sub-cycle. The SiN sub-cycle can include alternately and sequentially contacting the substrate with a silicon precursor and a SiN sub-cycle nitrogen precursor. The SiCN sub-cycle can include alternately and sequentially contacting the substrate with carbon-containing precursor and a SiCN sub-cycle nitrogen precursor. The SiN sub-cycle and the SiCN sub-cycle can include atomic layer deposition (ALD). The process for depositing the silicon carbon nitride film can include a plasma treatment. The plasma treatment can follow a completed plurality of complete deposition cycles.

Owner:ASM IP HLDG BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com